Patents

Literature

308results about How to "Low area cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

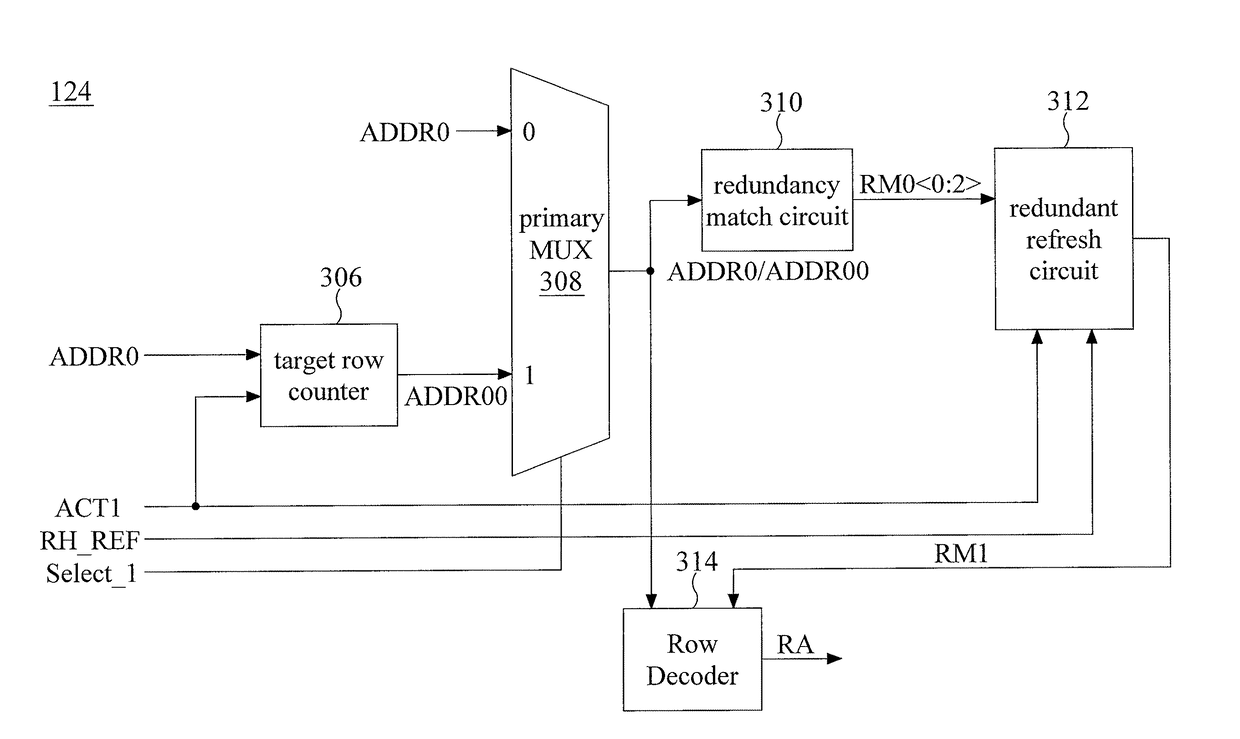

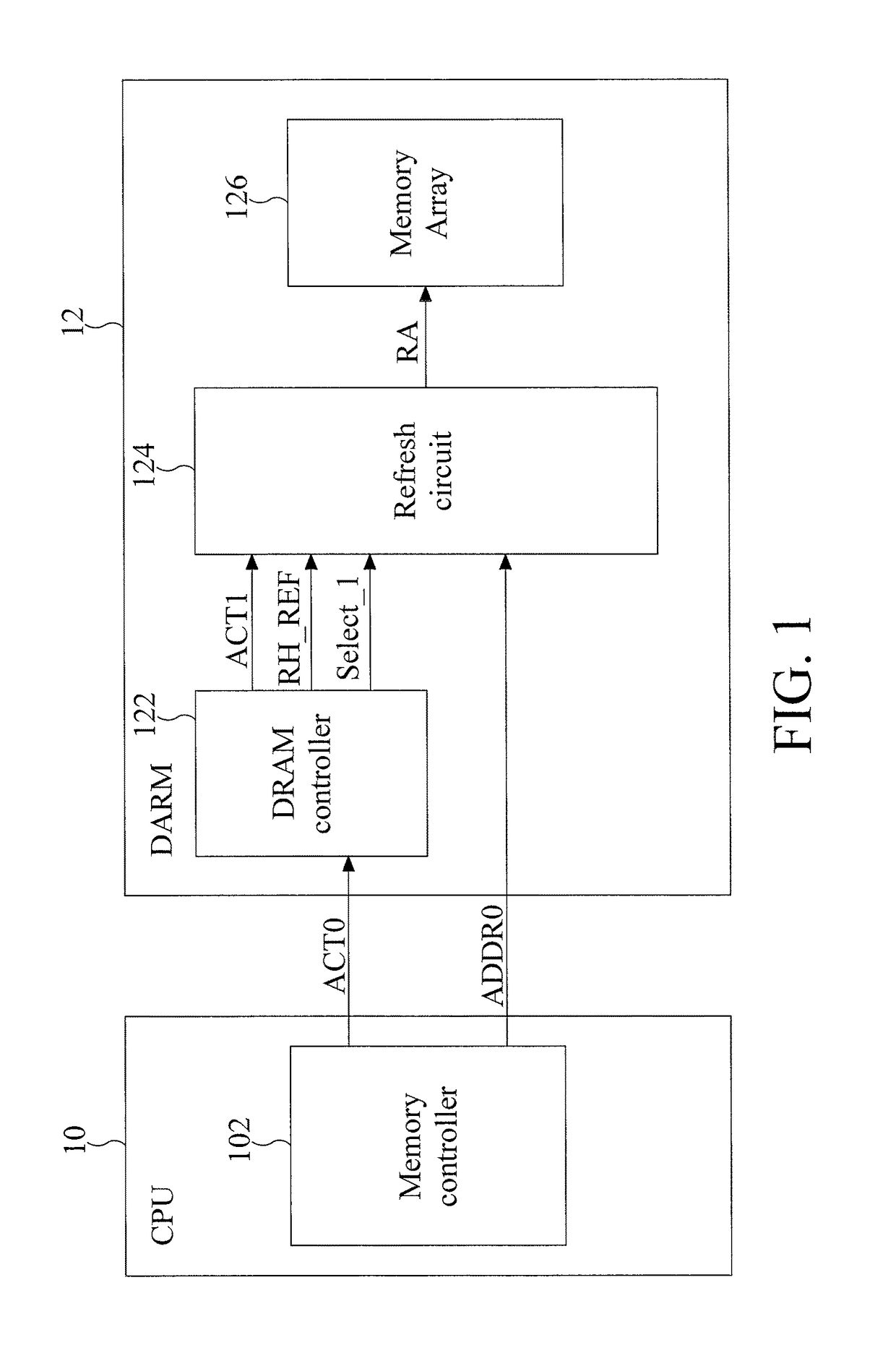

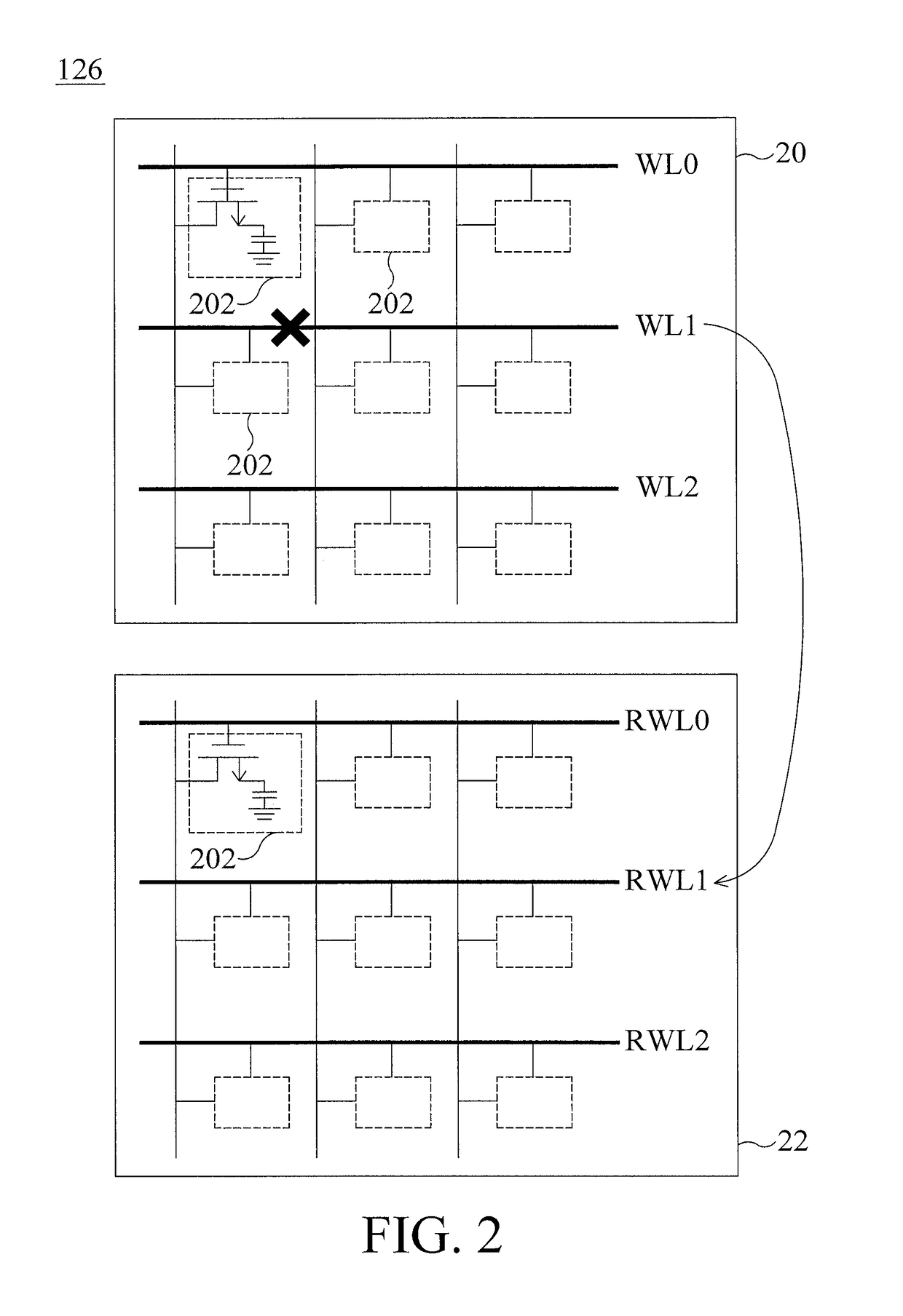

Dram circuit, redundant refresh circuit and refresh method

ActiveUS9799391B1Easy to useLow area costInput/output to record carriersDigital storageMemory controllerComputer science

A DRAM circuit includes an array having a normal word line, a first redundant word line and a second redundant word line immediately adjacent to the first redundant word line. The second redundant word line is activated if the normal word line is assigned, by a memory controller external to the DRAM circuit, to be activated. A redundant refresh circuit is configured to determine that the first redundant word line is required to be refreshed in response to the second redundant word line being activated; and a row decoder is configured to, according to the determination of the redundant refresh circuit, refresh the first redundant word line.

Owner:NAN YA TECH

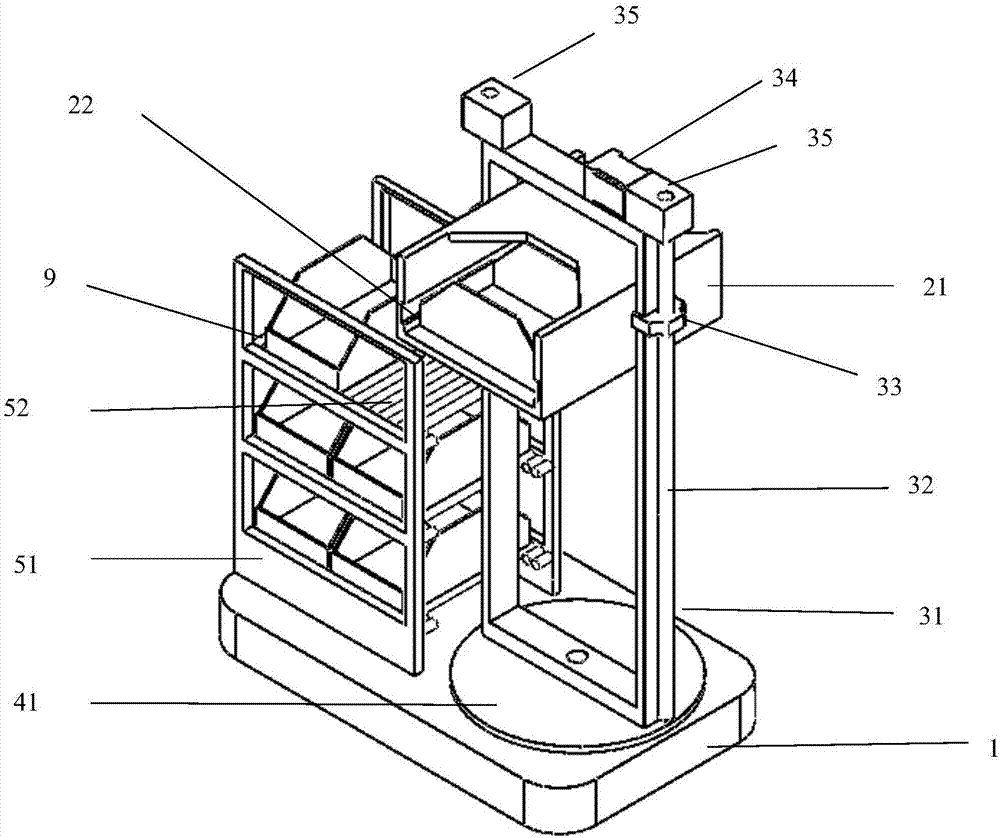

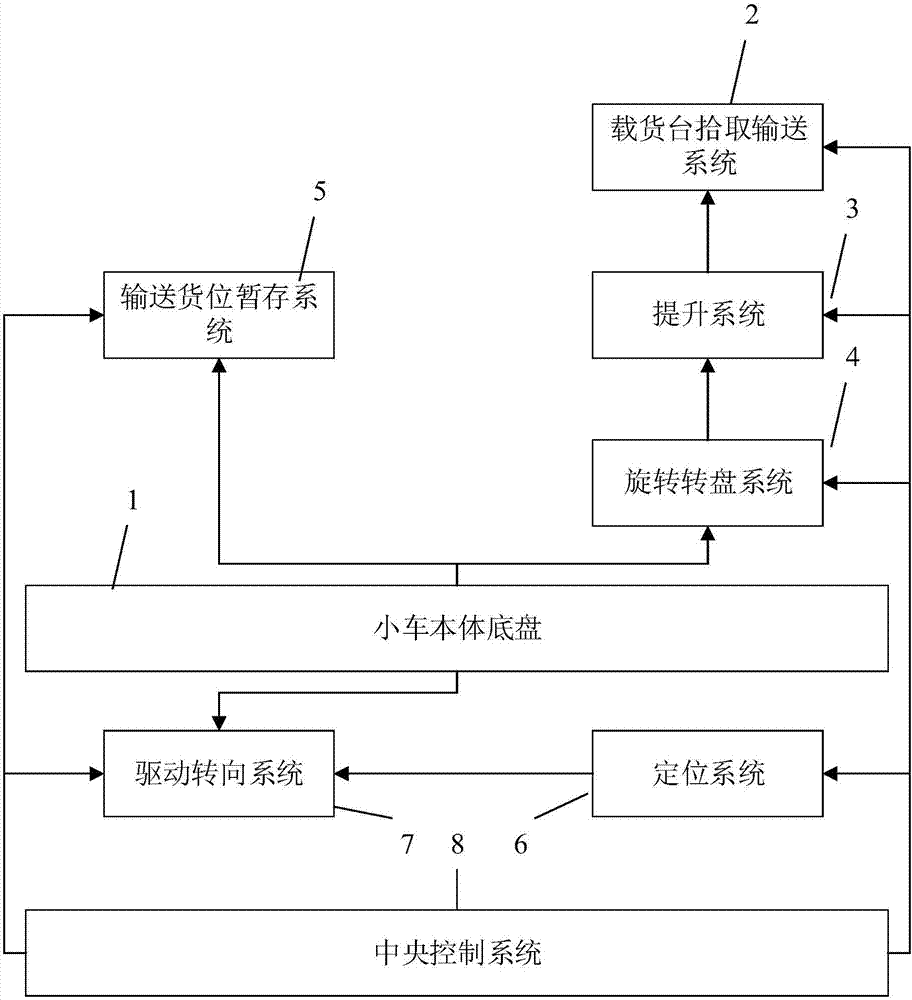

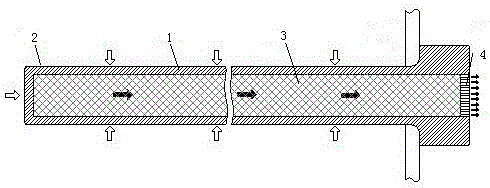

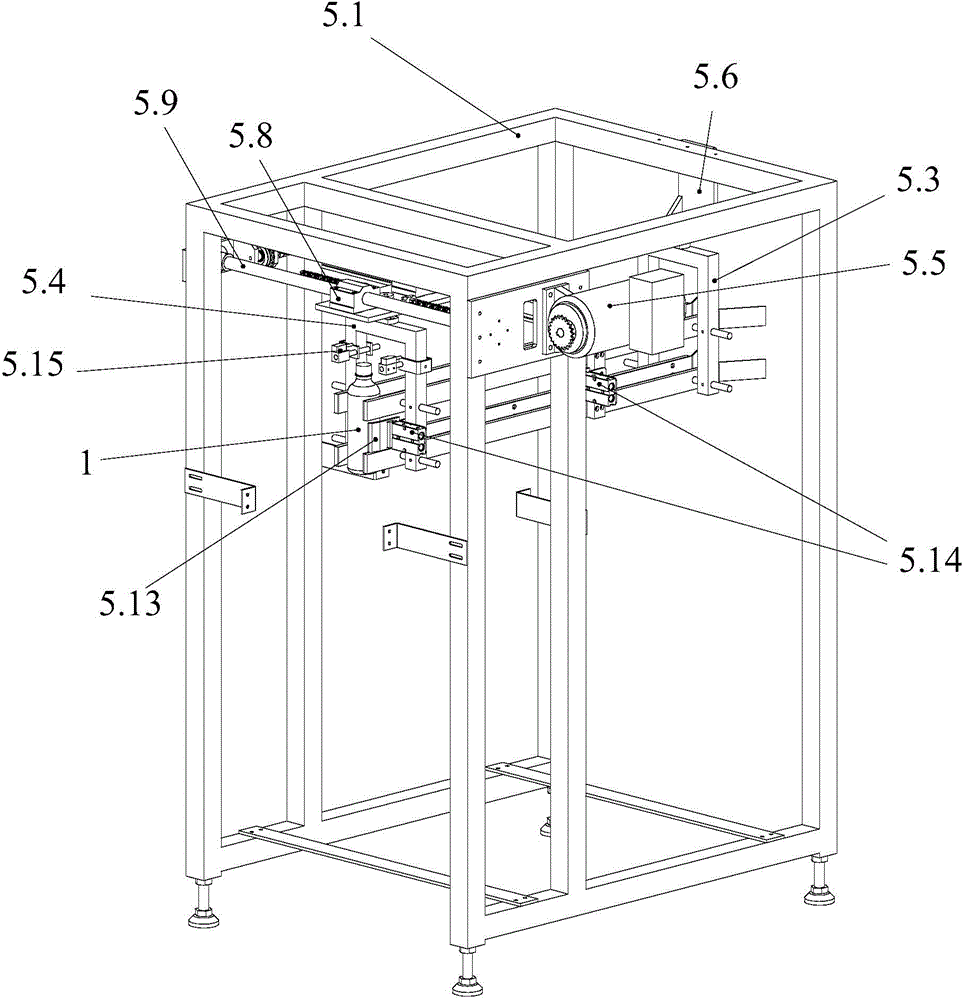

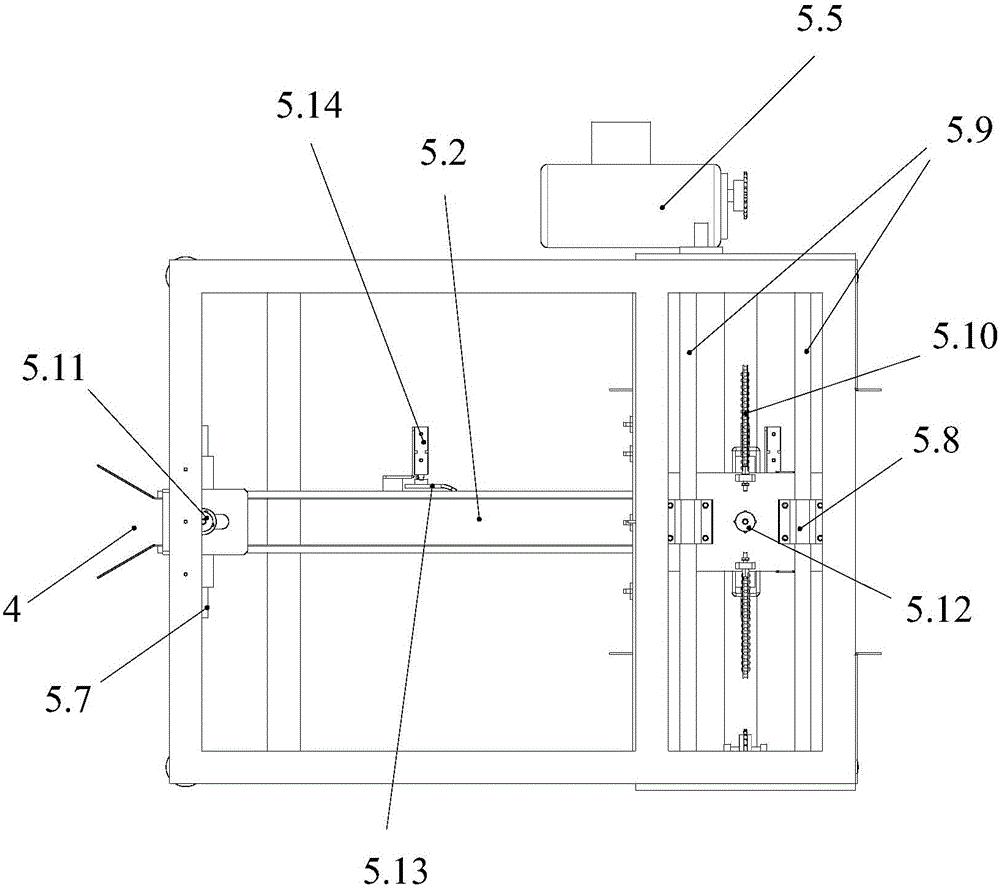

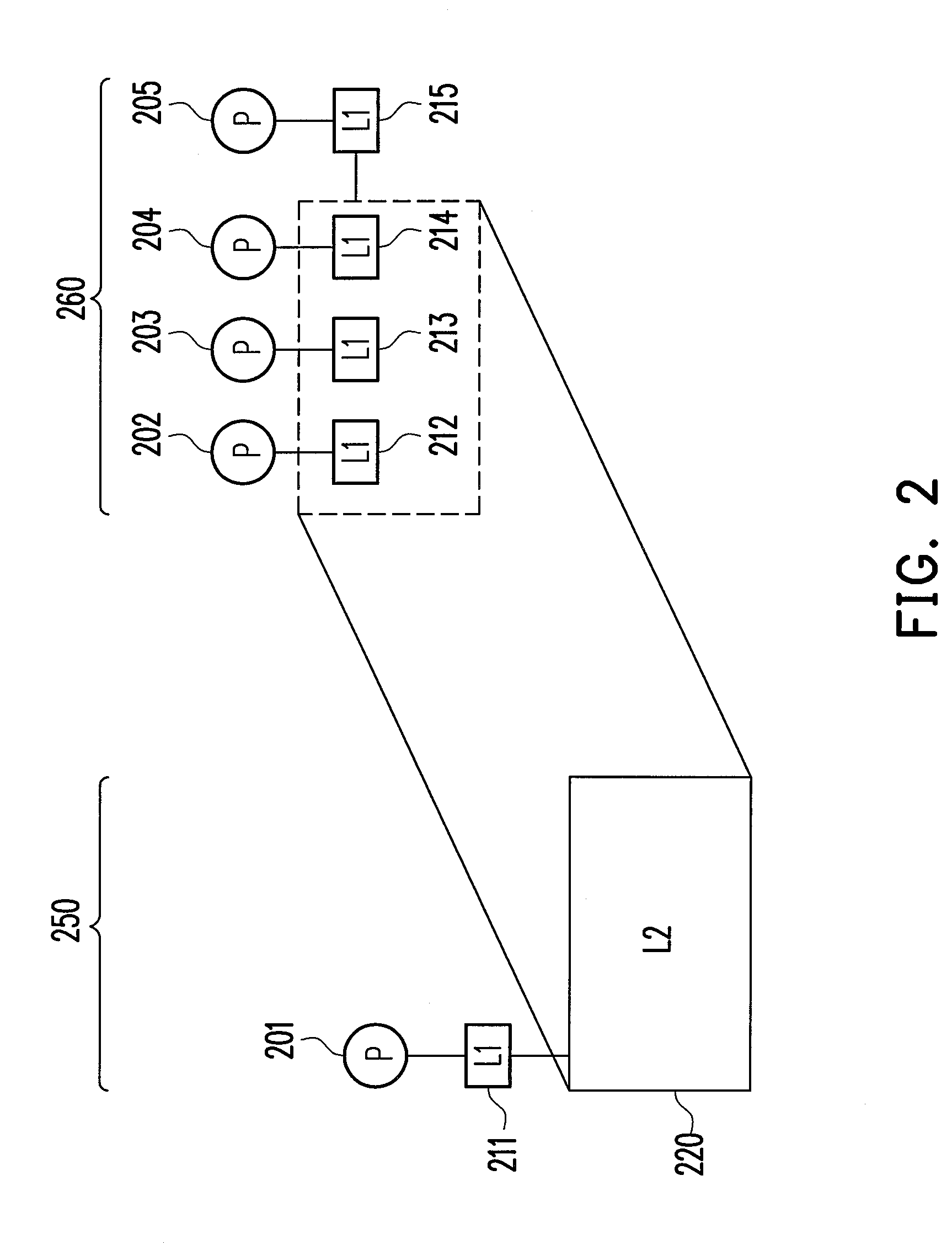

AGV (Automatic Guided Vehicle) and method

PendingCN107226310AImprove picking efficiencyImprove accuracyControl devices for conveyorsStorage devicesEngineeringTemporary storage

The invention discloses an AGV (Automatic Guided Vehicle) and a method. The AGV (Automatic Guided Vehicle) comprises a vehicle body chassis, a cargo bearing platform picking-up and conveying system, a lifting system, a rotary rotary-table system and a delivered cargo temporary storage system; the rotary rotary-table system and the delivered cargo temporary storage system are fixed to the two sides of the upper portion of the vehicle body chassis correspondingly; the lifting system is fixed to the upper portion of the rotary rotary-table system, and the control end of the lifting system is connected with the cargo bearing platform picking-up and conveying system; the delivered cargo temporary storage system comprises a plurality of layers of temporary storage racks, and each layer of the temporary storage racks is provided with a plurality of temporary storage cargo positions; and the lifting system is used for controlling the sliding height of the cargo bearing platform picking-up and conveying system, and the rotary rotary-table system is used for controlling the rotation angle of the lifting system. By means of the AGV (Automatic Guided Vehicle) and the method, operation of manual picking-up of workbins is omitted, manpower and time are saved, and meanwhile workbin picking-up efficiency and accuracy are also improved.

Owner:湖北九州云仓科技发展有限公司

Overlay mark for aligning different layers on a semiconductor wafer

ActiveUS7180593B2Prevent deviationLow area costSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

Owner:MACRONIX INT CO LTD

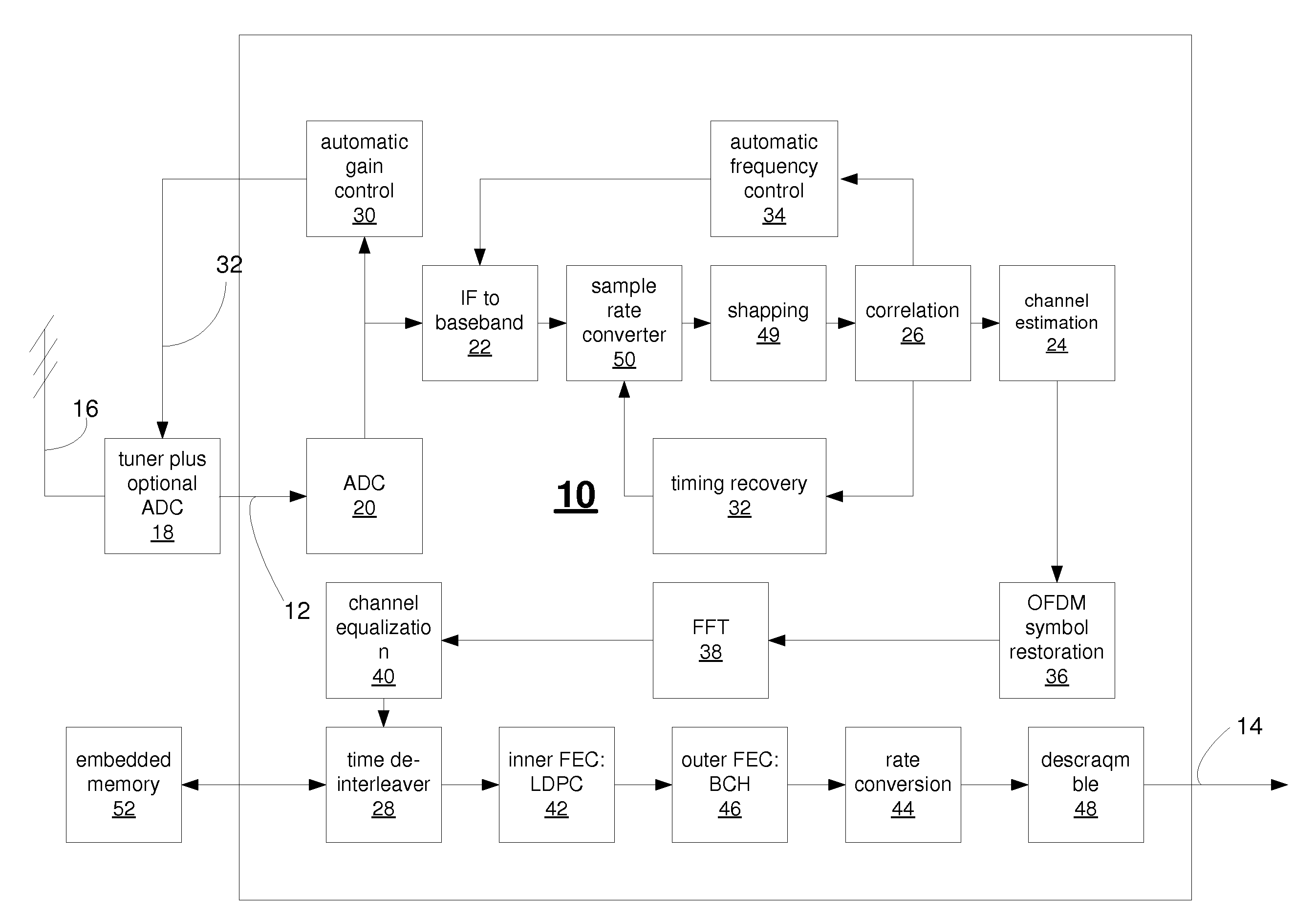

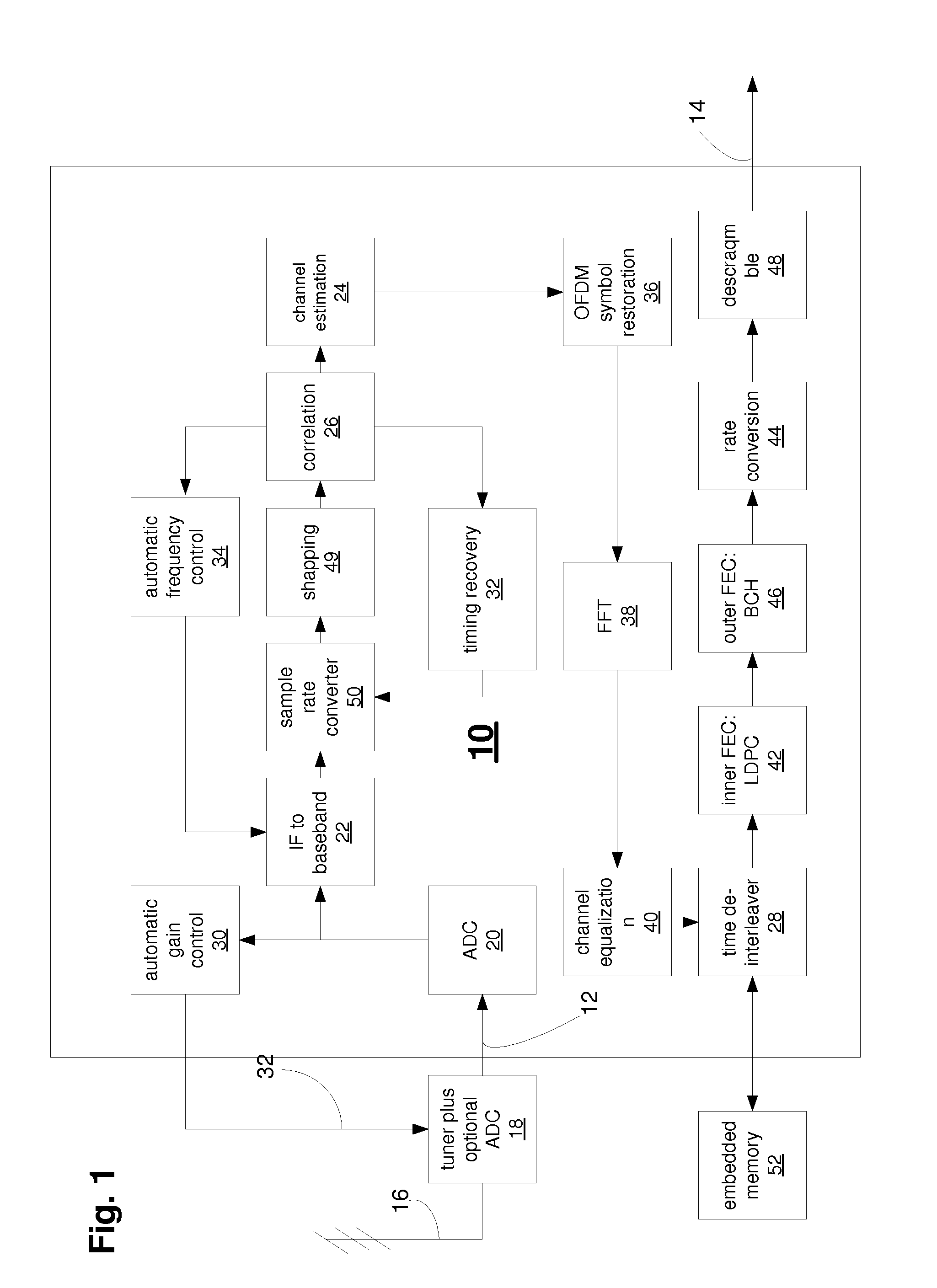

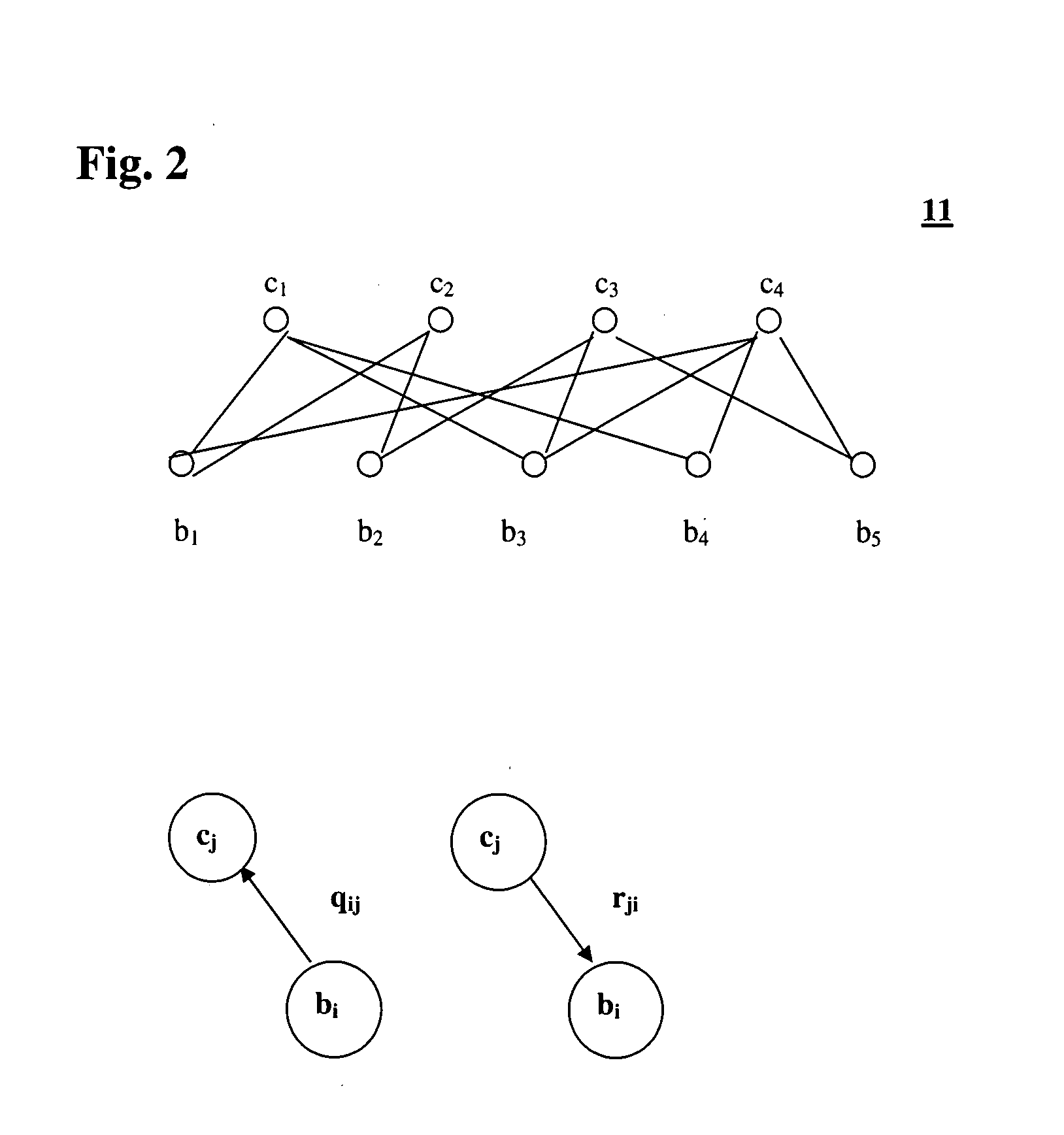

LDPC decoder with an improved llr update method using a set of relative values free from a shifting action

InactiveUS20090070659A1Reduce memory requirementsFast decodingModulated-carrier systemsError detection/correctionTheoretical computer scienceParity-check matrix

In a decoder having an improved LLR (log-likelihood-ratio) update method is provided. The method comprising the steps of: providing a parity check matrix; and using merely a set of parameters on a row of the parity check matrix instead of data of the whole non-zero elements of the parity check matrix free from at least one shifting action after each row updating; thereby saving memory space and process time.

Owner:LEGEND SILICON

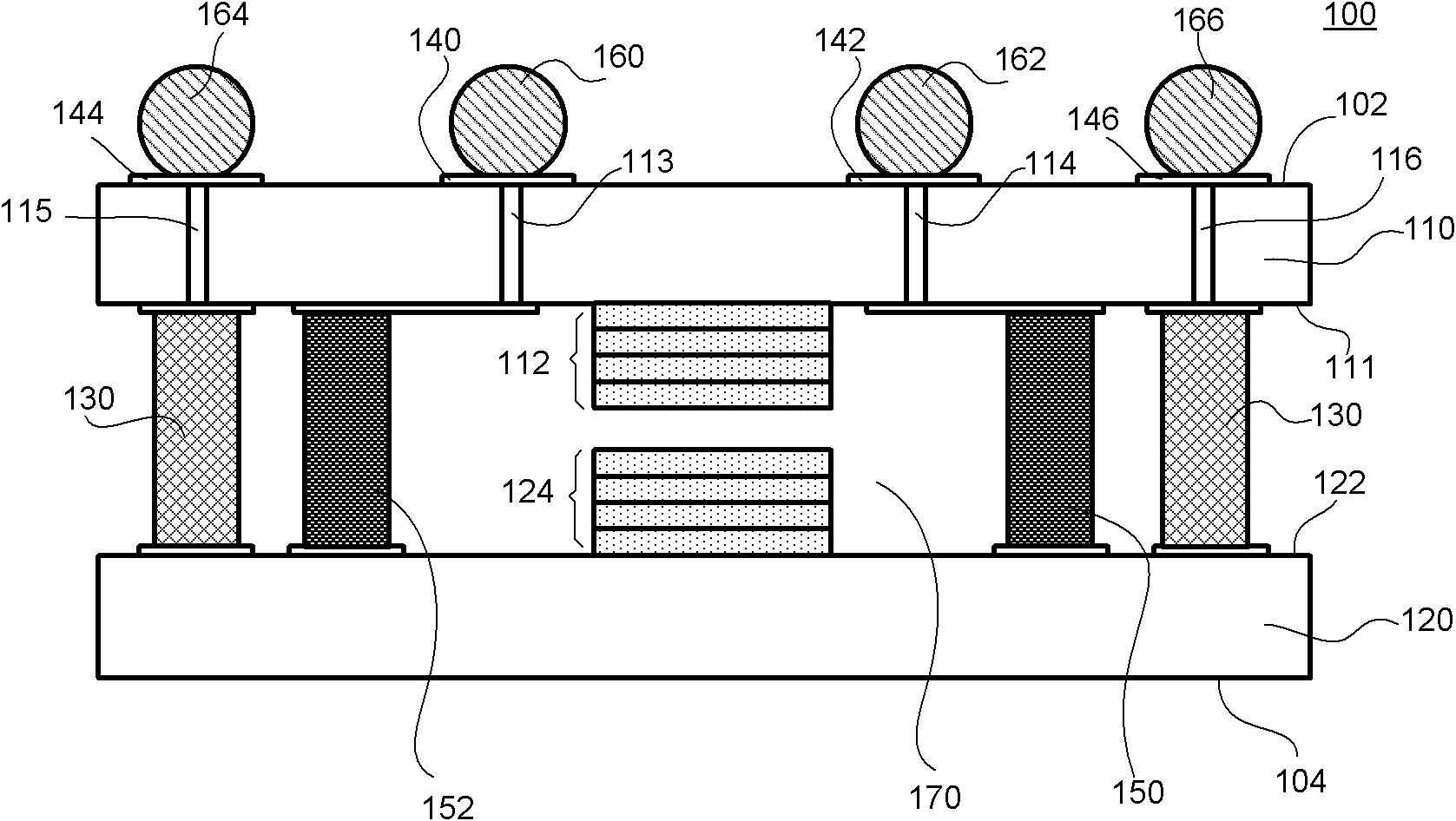

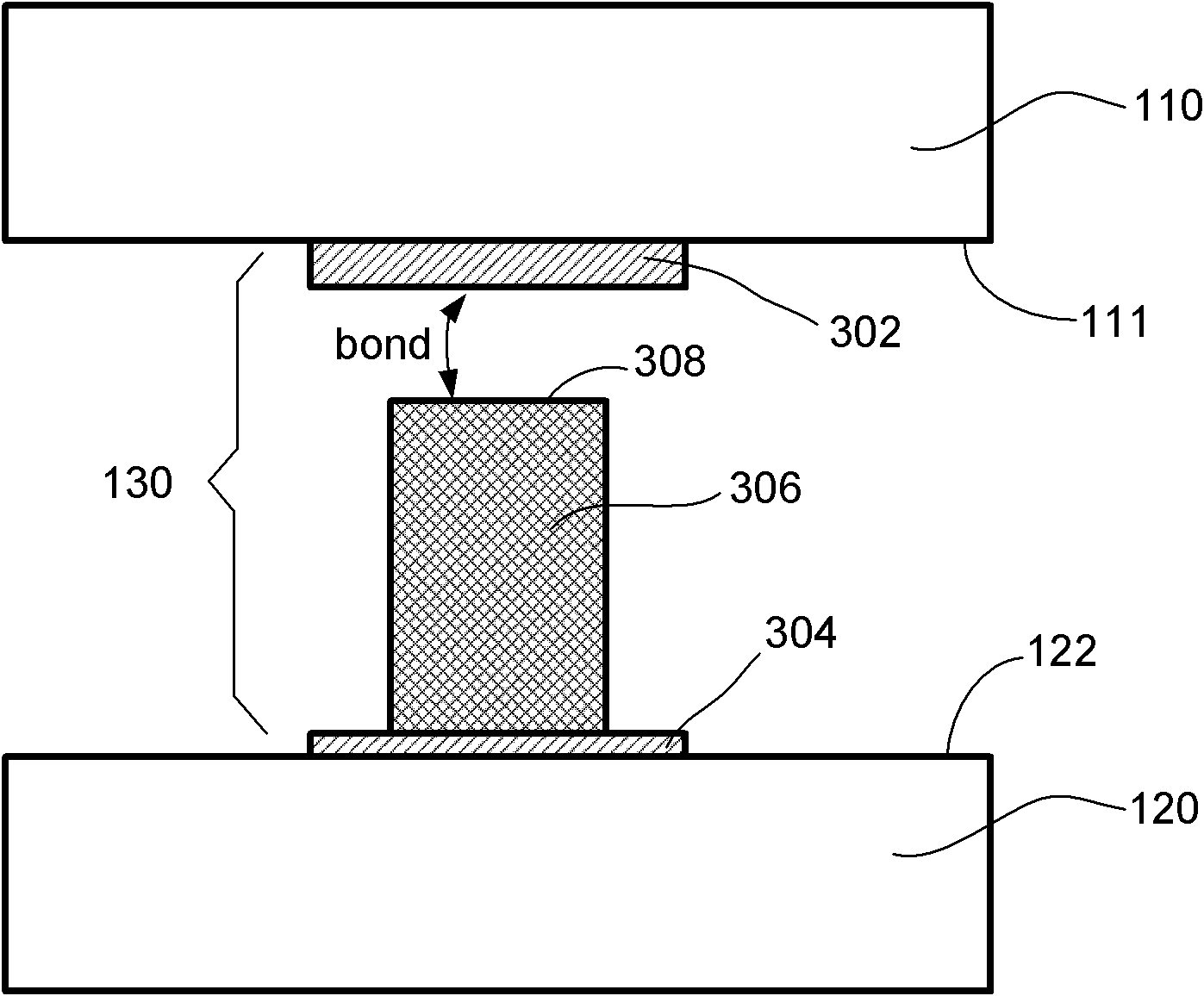

Integrated wafer level package

InactiveCN102111116ALow area costReduce manufacturing costImpedence networksFilter bankAcoustic wave

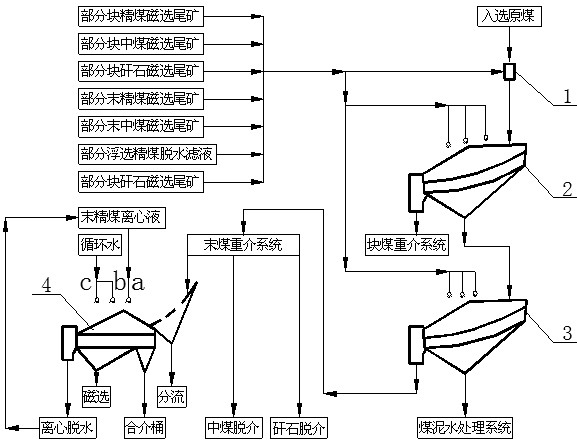

An integrated wafer level package comprises a first wafer provided with a first surface and a corresponding second surface, and a second wafer provided with a first surface and a corresponding second surface; a distance is kept between the two wafers; the second surface of the first wafer and the first surface of the second wafer are opposite to each other to form a first space; a first bulk acoustic wave filter is arranged on the second surface of the first wafer and a second bulk acoustic wave filter is arranged on the first surface of the second wafer, and the two bulk acoustic wave filters are directly opposite to each other to form a second space; a seal ring arranged between the two wafers circles the two bulk acoustic wave filters to form sealing, and the seal ring and the two bulk acoustic wave filters form a cavity; and at least an external electric connector is arranged and is in electric coupling with at least one of the two bulk acoustic wave filters. The integrated wafer level package has the advantages of lower manufacturing cost and high product quality; and by adopting the integrated wafer level package, two or more filter components can be packed into a wafer level package to prevent the filters from the environment pollution of ambient atmosphere.

Owner:张浩

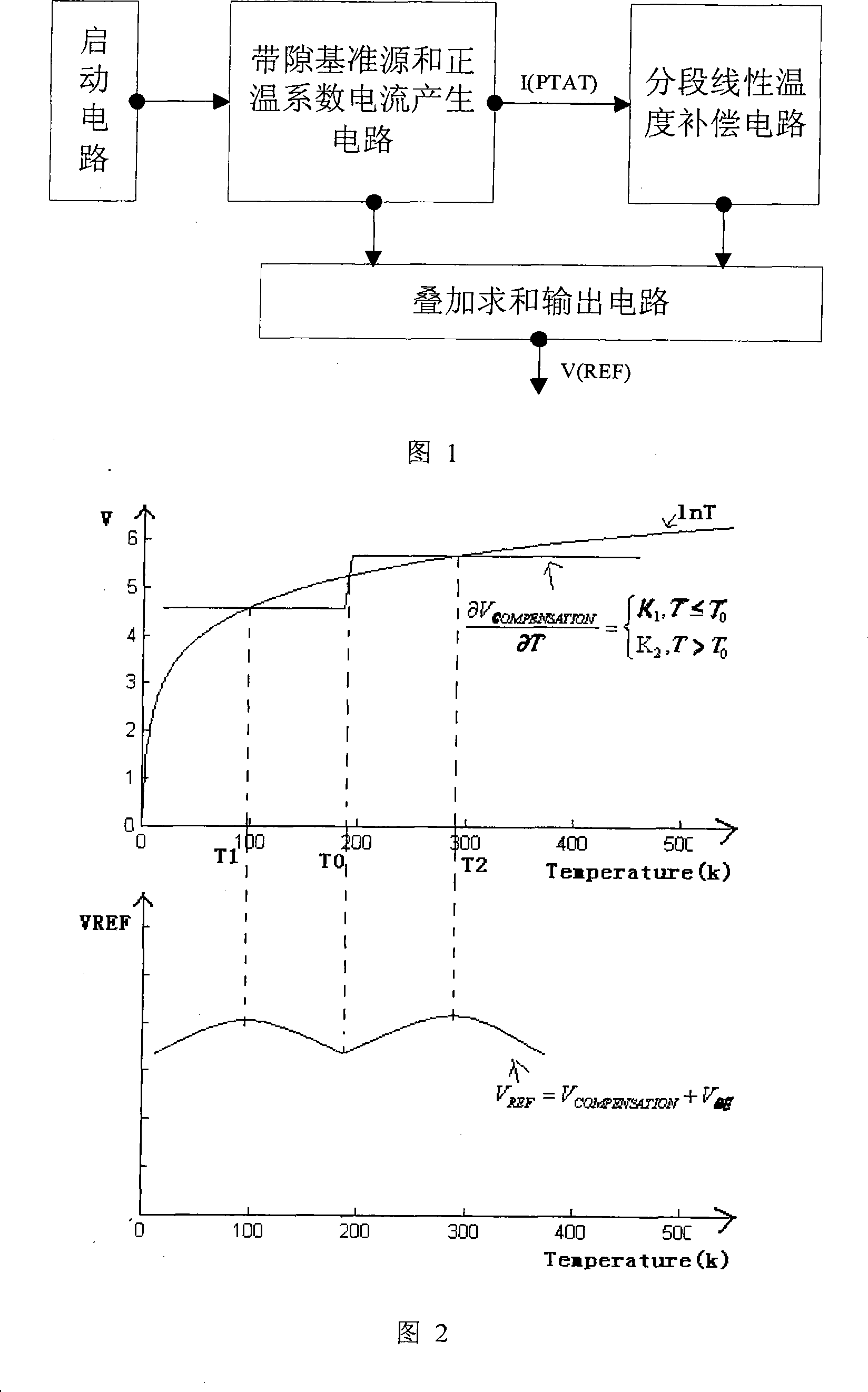

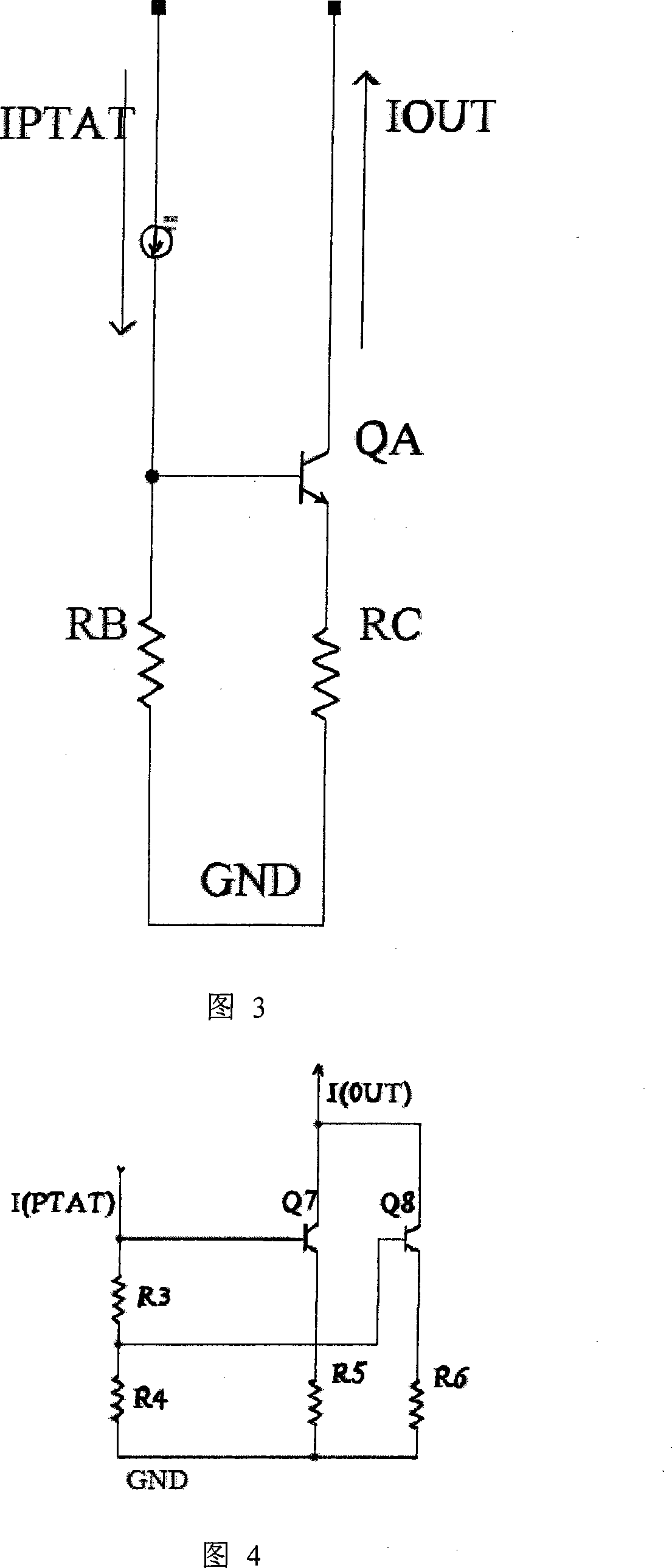

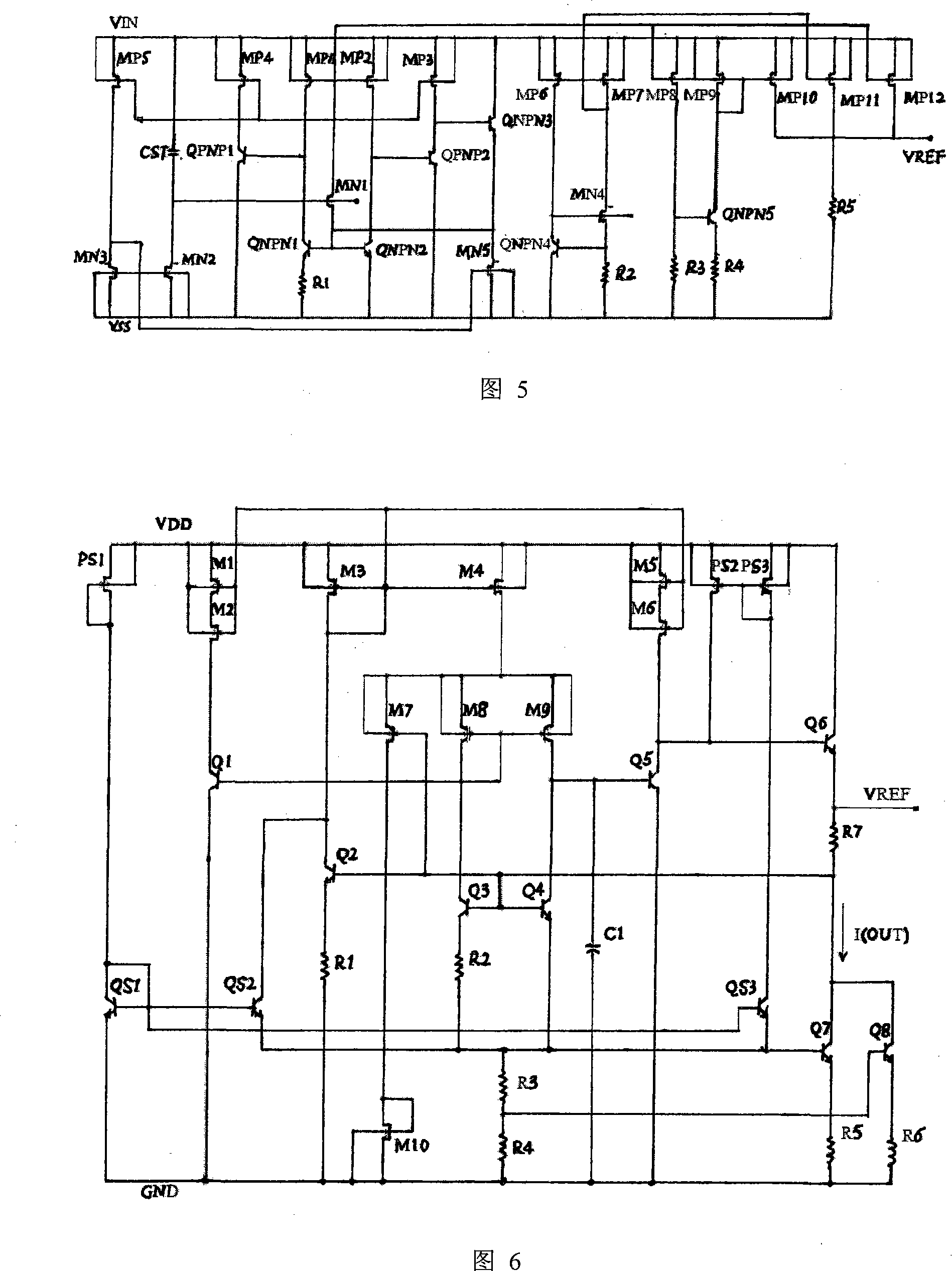

Piecewise linear temperature compensating circuit and temperature compensation voltage reference source

InactiveCN101216718AReduce the impactImprove temperature stabilityElectric variable regulationElectrical resistance and conductanceEngineering

The invention discloses a sectional linear temperature compensating circuit and a temperature compensating voltage reference source. The sectional linear temperature compensating circuit consists of resistances and a triode, wherein the number of resistances is at least two; the base electrode of the triode is connected with the input port to constitute an input end. One end of a first resistance is connected with the input port, and the other end is connected with a ground wire; the emitting electrode of the triode is connected with the ground wire through a second resistance, and the collector electrode of the triode constitutes an output end. In the voltage reference source, the band-gap reference source and the input end of a positive-temperature coefficient electric current generating circuit are connected with a summing output circuit and a sectional linear temperature compensation circuit respectively. The output end of the sectional linear temperature compensating circuit is connected with the summing output circuit. The invention reduces the impact of resistance temperature on the output amount and has good process compatibility and temperature stability.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

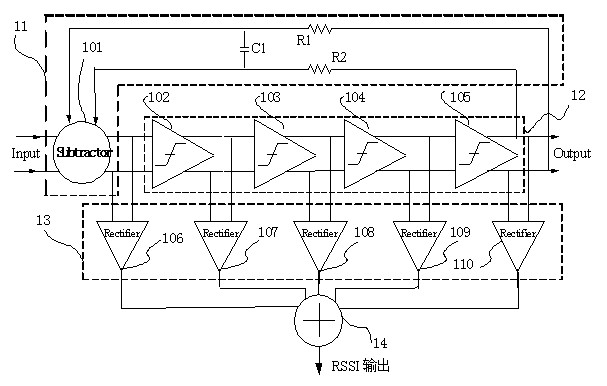

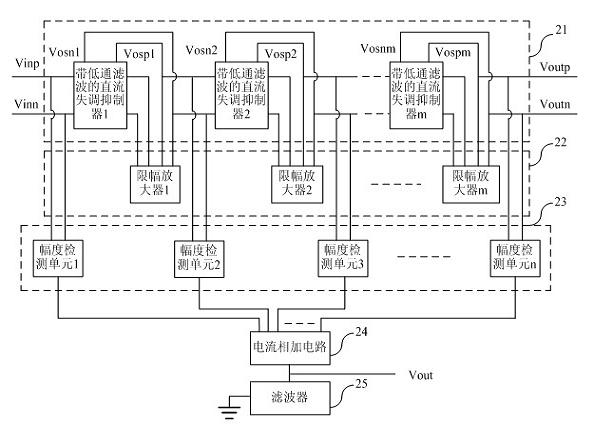

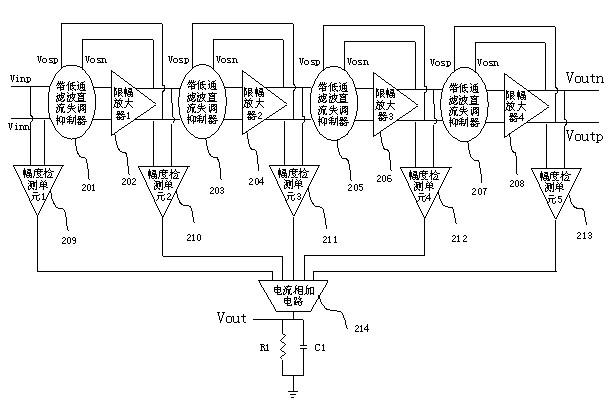

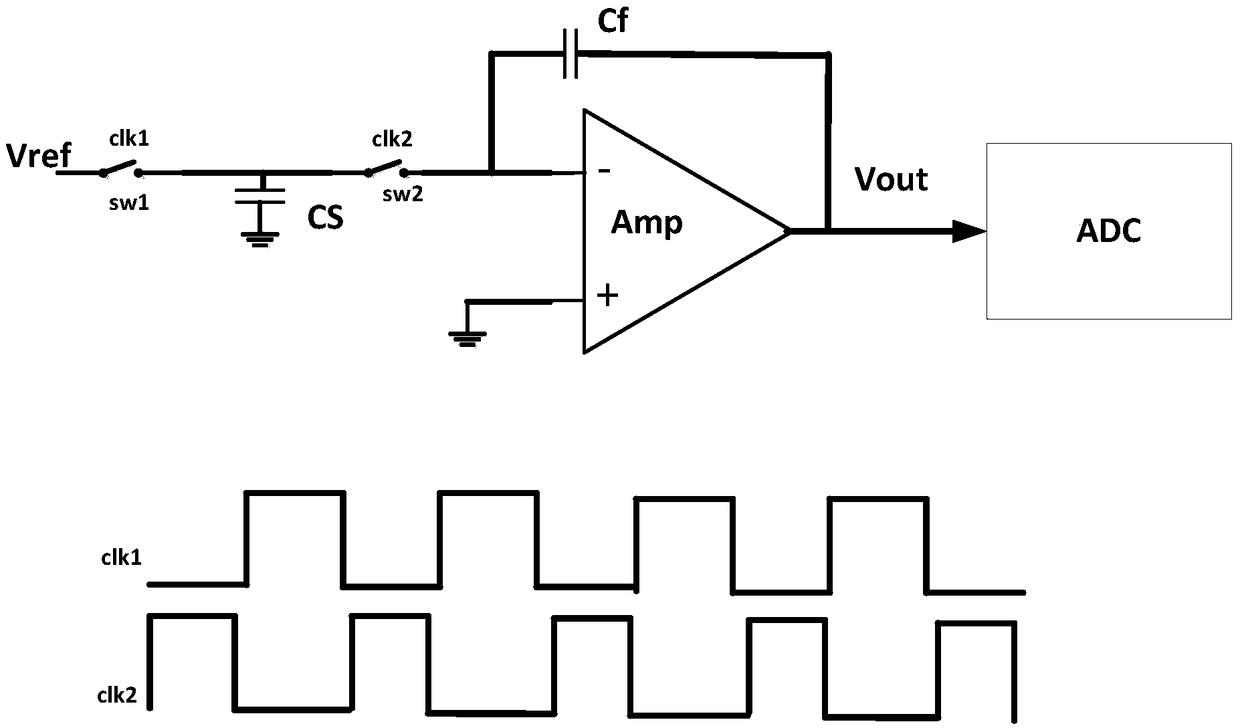

Amplitude detection circuit with direct current offset elimination function

ActiveCN102571227AOvercoming the inability to fully integrate on-chipGet over workReceivers monitoringIntermediate frequencySoftware engineering

The invention discloses an amplitude detection circuit with a direct current offset elimination function. The amplitude detection circuit has a differential structure, and consists of a direct current offset elimination circuit, an amplitude limiting amplification circuit, an amplitude detection circuit, a current addition circuit and a filtering circuit, wherein the direct current offset elimination circuit comprises a plurality of direct current offset suppressors with a low-pass filtering function; the amplitude limiting amplification circuit comprises a plurality of amplitude limiting amplifiers; and the amplitude detection circuit comprises a plurality of amplitude detection units. A differential radio frequency signal is amplified to be saturated by a plurality of stages of cascaded amplitude limiting amplifiers, the output of each stage of amplitude limiting amplifier is detected by the amplitude detection units, output detected amplitude values are transmitted to the current addition circuit for addition, and the sum is filtered by the low-pass filtering circuit to obtain output voltage related to the amplitude of the input signal. The circuit can be adapted to the requirements of high monolithic integration level of a radio frequency chip, and is applied to a high-integration level zero-intermediate frequency receiver with the requirement of signal amplitude detection.

Owner:杭州中科微电子有限公司

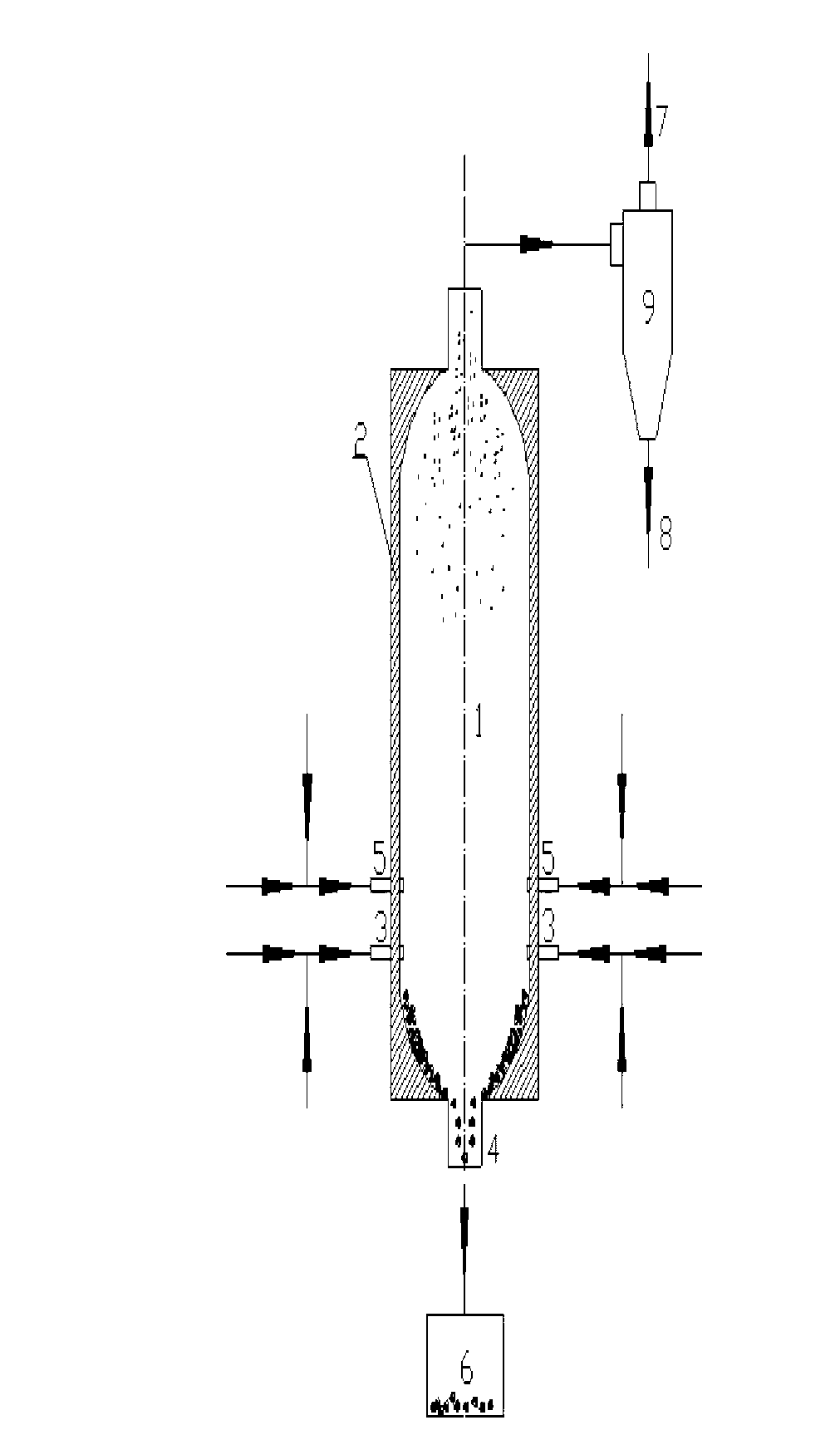

Process and device for quickly preparing powdered active coke for desulfurization by utilizing pulverized coal

ActiveCN103224235ASimple manufacturing processReduce manufacturing costCarbon compoundsOther chemical processesHigh concentrationResource utilization

The invention relates to a process and a device for quickly preparing powdered active coke for desulfurization by utilizing pulverized coal. The process and the device are used for producing a powdered active coke product with certain desulfurization performance and reducing combustible gas. According to the process, the powdered active coke for desulfurization and a byproduct reducing gas are prepared from the pulverized coal of 20 to 500 microns by remaining in an entrained-flow bed fast reaction furnace for 1 to 60 seconds. The process and the device has three characteristics that 1, the desulfurization active coke can be prepared by directly utilizing the pulverized coal for combustion of a boiler, so in-situ preparation of a desulfurizing agent of a coal-fired power plant can be realized, and the production cost and the transportation cost of the active coke are reduced; 2, the reducing combustible gas generated in the production process of the active coke can serve as a reburning fuel and is fed into the boiler, so the production quantity of nitric oxide during combustion of the pulverized coal is reduced and the energy efficiency of the whole process is improved; and 3, sulfur dioxide can be recovered and high-concentration sulfur dioxide can be reduced into elemental sulfur, so resource utilization of the sulfur dioxide can be realized.

Owner:SHANDONG UNIV

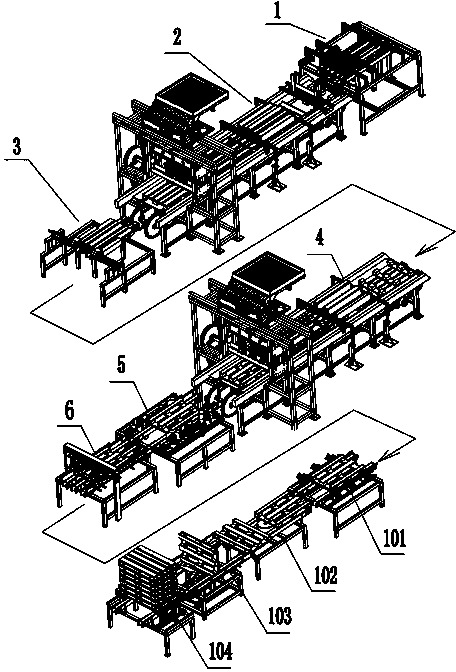

Automatic production line of wooden trays

ActiveCN103406965AImprove production efficiencyReduce labor costsWood working apparatusSurface plateNail device

The invention discloses an automatic production line of wooden trays, which can complete automatic laying for a bridging board, a surface board, and a bottom board, and automatically complete nailing operation. The automatic production line sequentially comprises a timber pier feeding device, a wooden tray front side component machining device, a turning device used for turning the wooden tray front side component, and a wooden tray back side component machining device, wherein the wooden tray front side component machining device comprises a front side component frame, and a first conveying device which is mounted on the front side component frame and can convey a plurality of timber piers in parallel; a bridging board blanking cabin used for accommodating the bridging board, a plurality of surface board blanking cabins, which are arranged in parallel and used for accommodating the surface board, and a nailing device are sequentially arranged on the front side component frame in the feeding direction of the first conveying device, and are all located above the first conveying device.

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

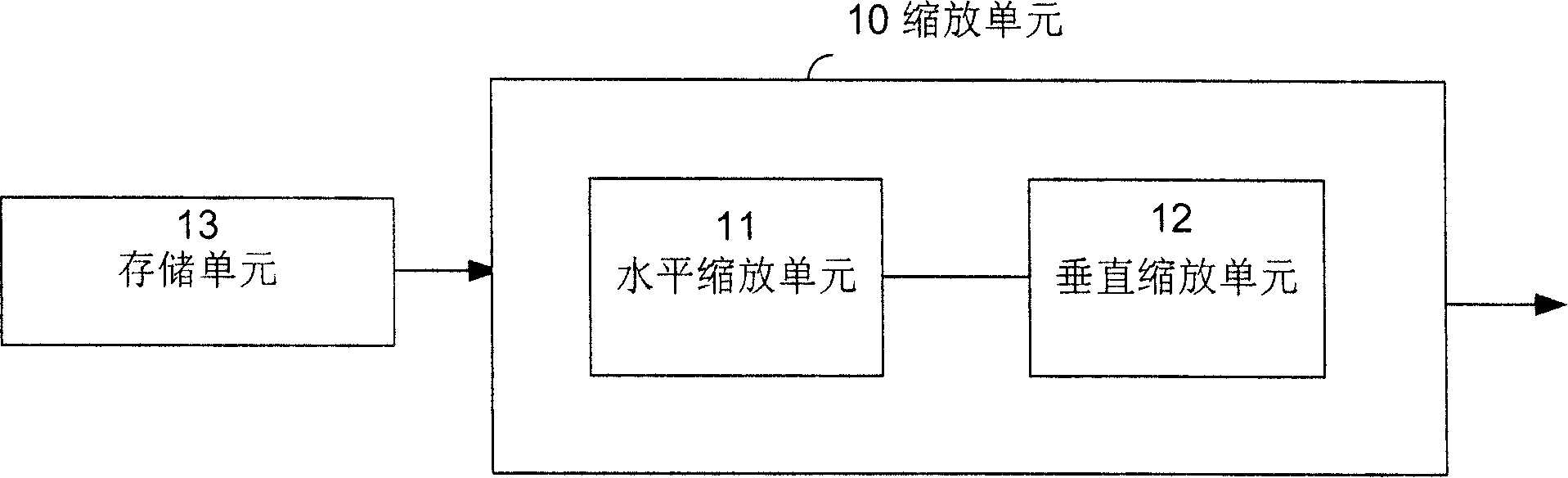

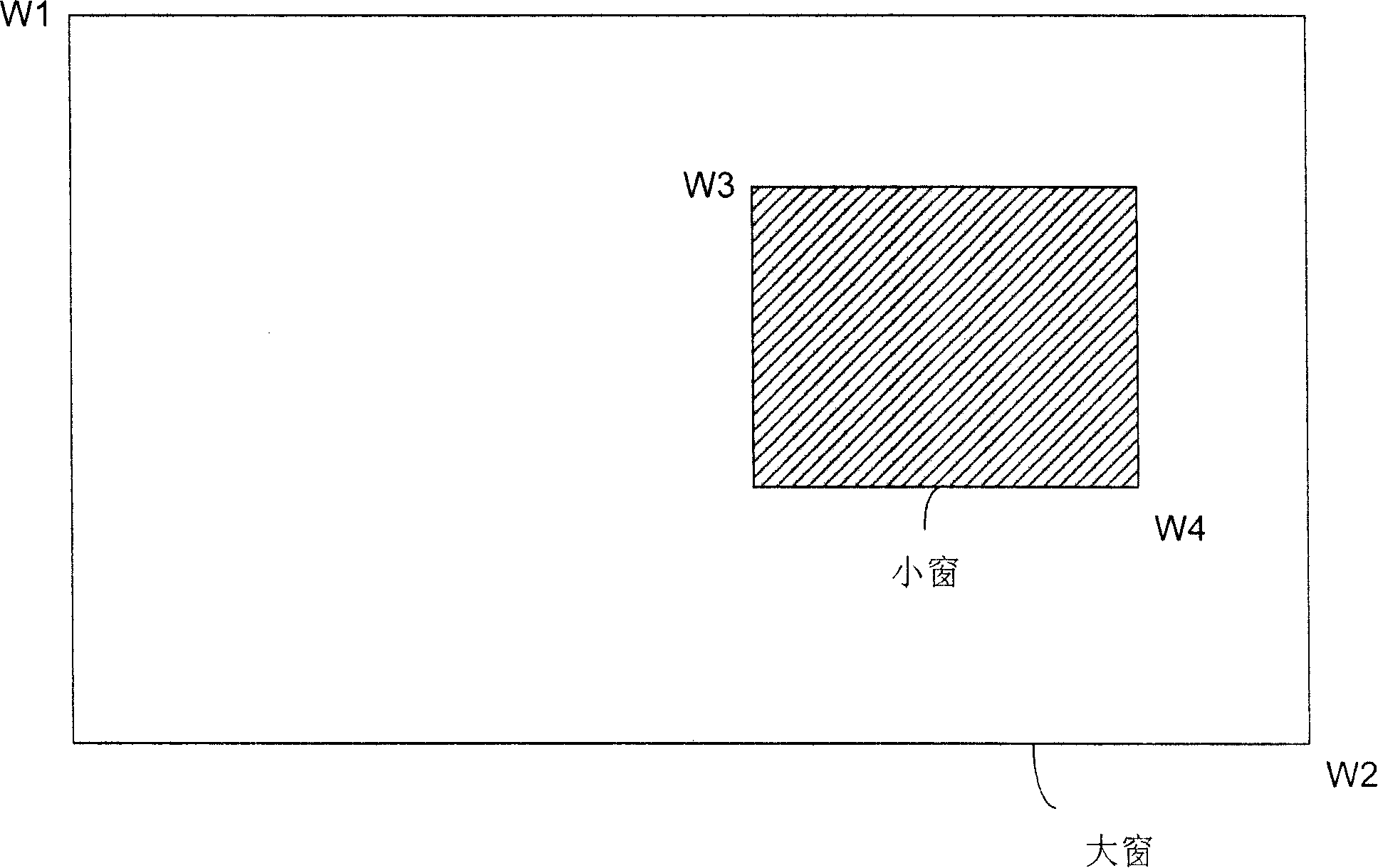

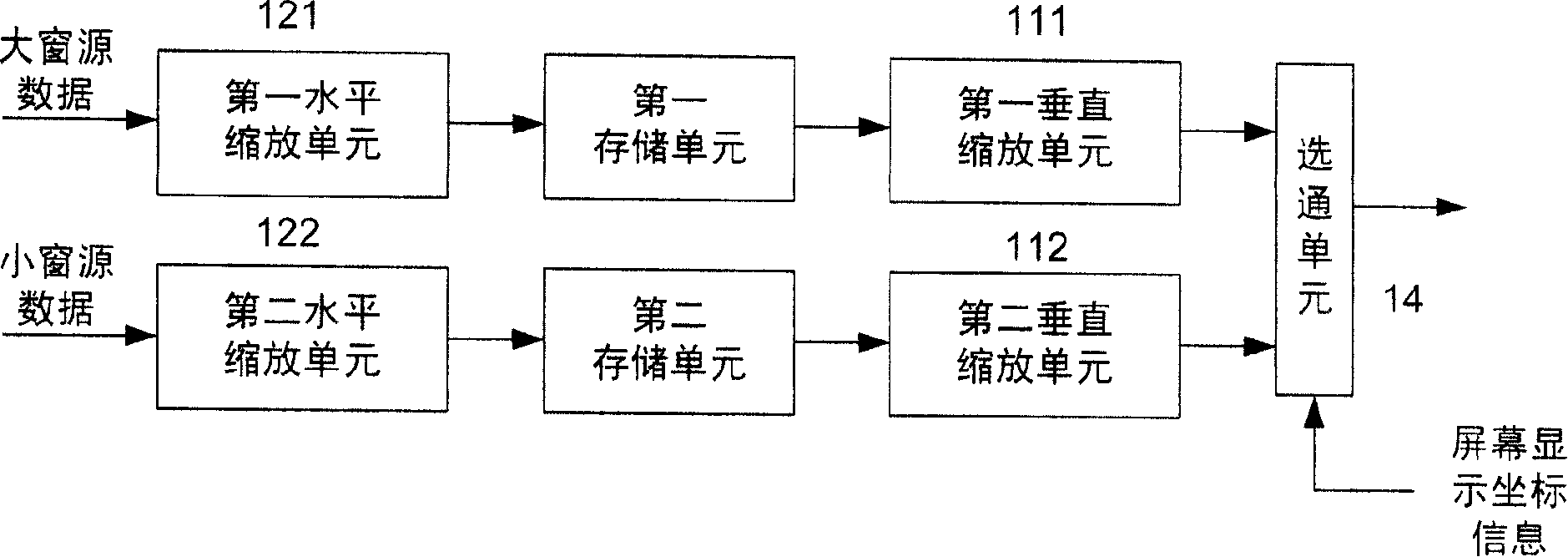

Image scaling device and image scaling method

InactiveCN101179671ASave resourcesLow area costTelevision system detailsGeometric image transformationScale unitImage scale

The invention provides an image scaling device and an image scaling method. The device includes: a horizontal scaling unit used for scaling operation in a horizontal direction for an image, a vertical scaling unit used for scaling operation in a vertical direction for the image, a memory cell that is arranged between the horizontal scaling unit and the vertical scaling unit and is used for temporarily saving image data in a horizontally displaying row, and a filtering unit used for selecting data within a coordinate scope of each window according to the superposition condition of each window which displays the image. The method includes the following steps: image data is scaled horizontally; the data within the coordinate scope of each window is selected according to the superposition condition of each window which displays the image; selected data within the coordinate scope of each window is saved temporarily; and the image data which is scaled horizontally within the coordinate scope of each window is picked up to conduct vertical scaling.

Owner:SHANGHAI MAGIMA DIGITAL INFORMATION

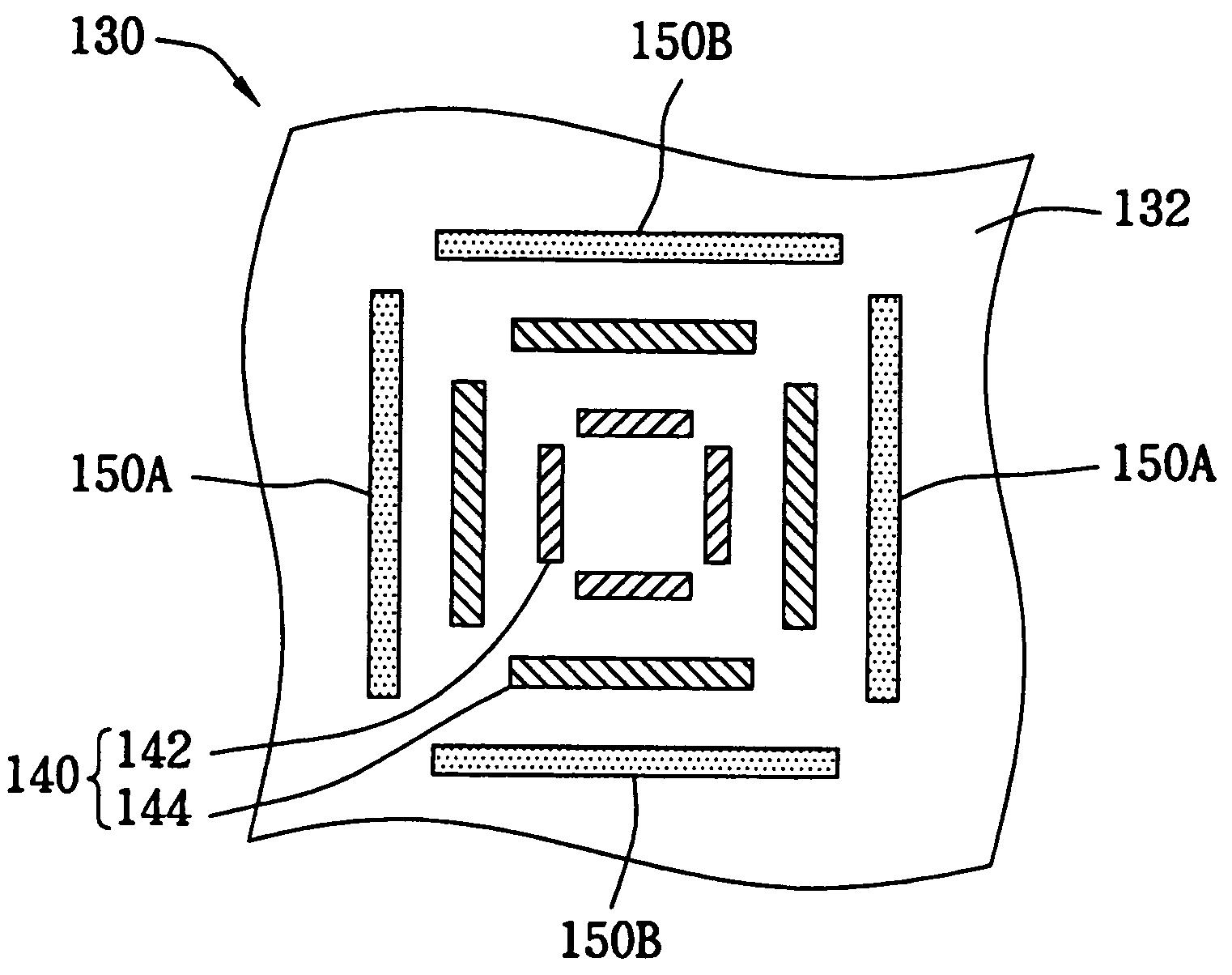

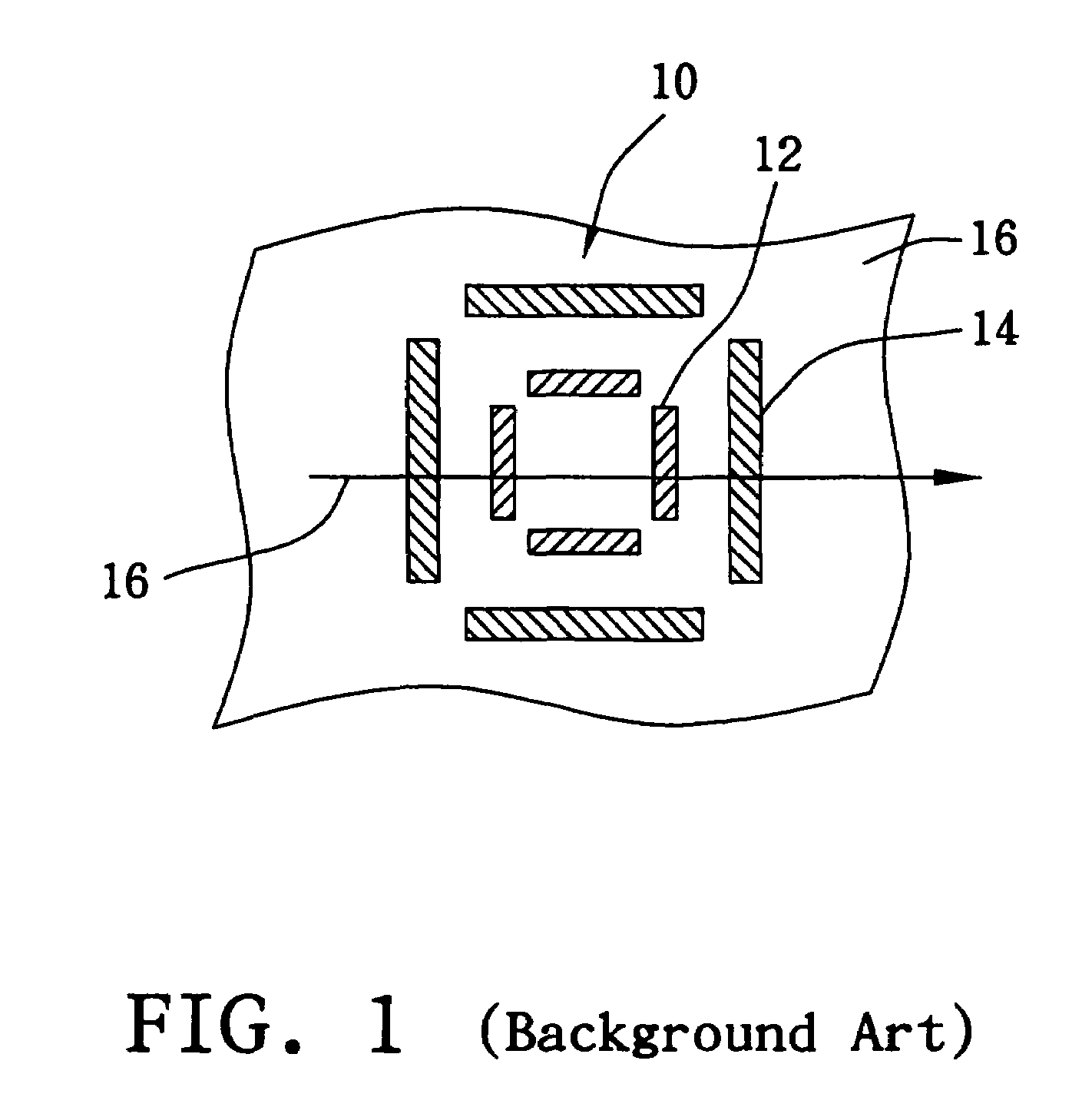

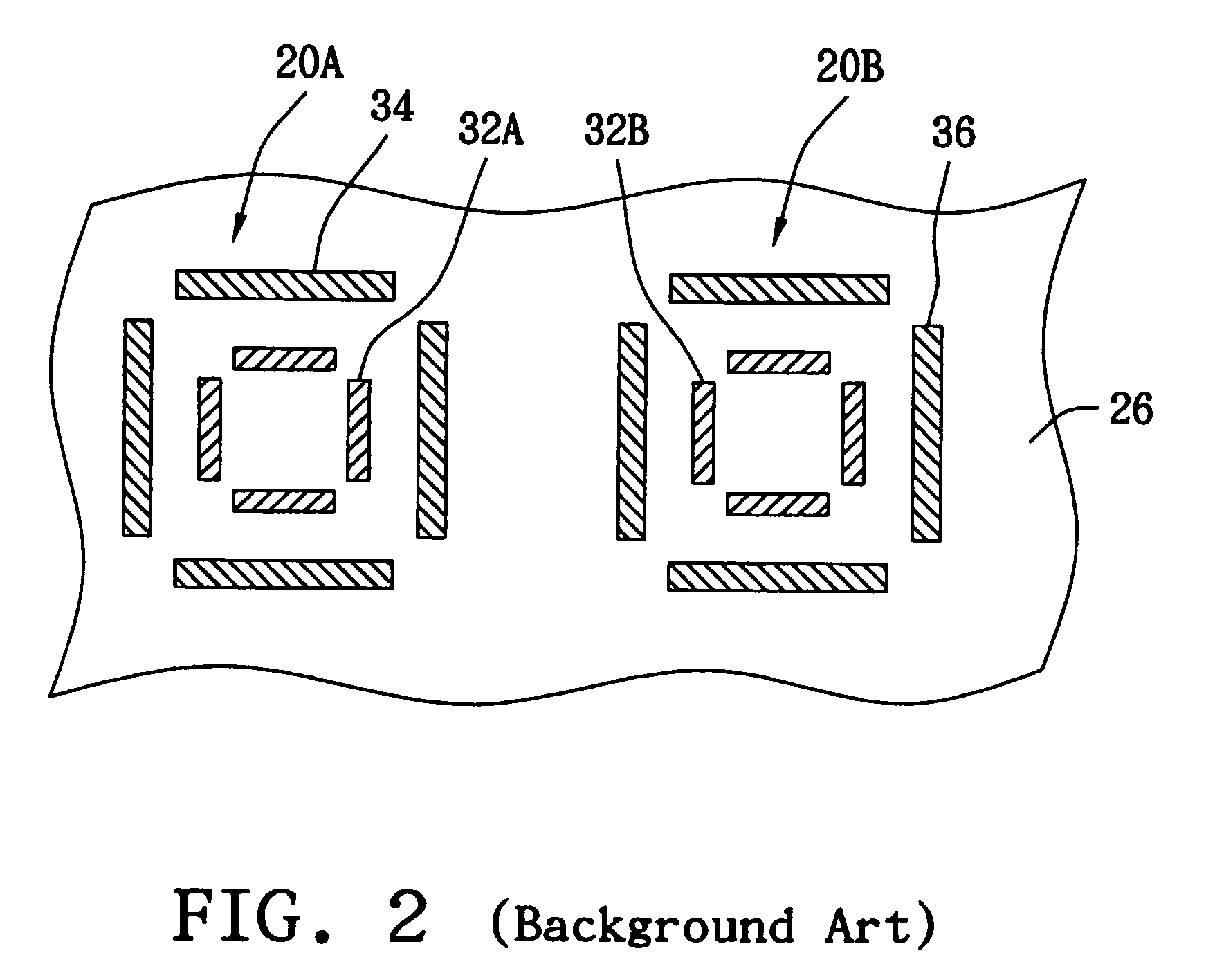

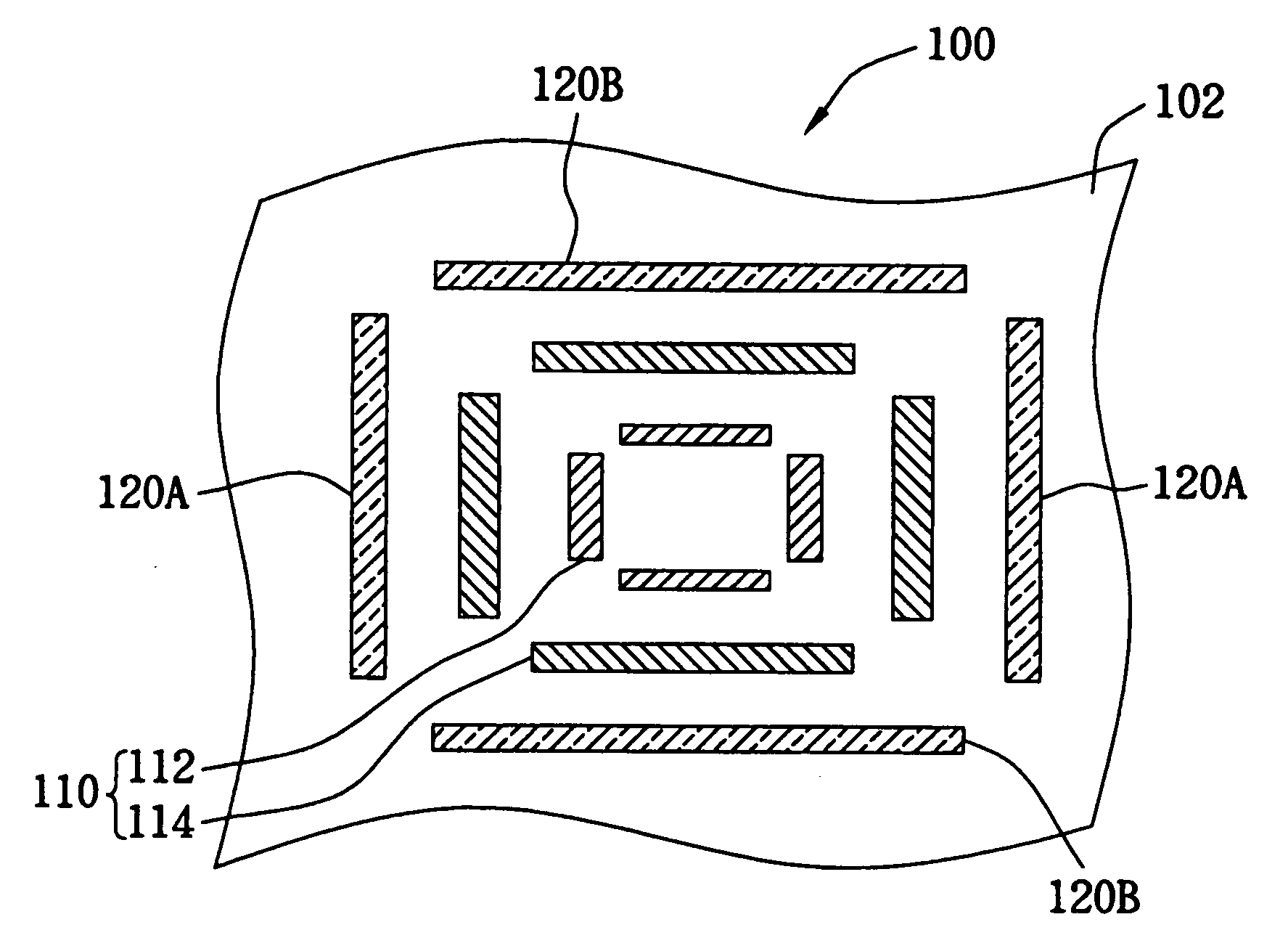

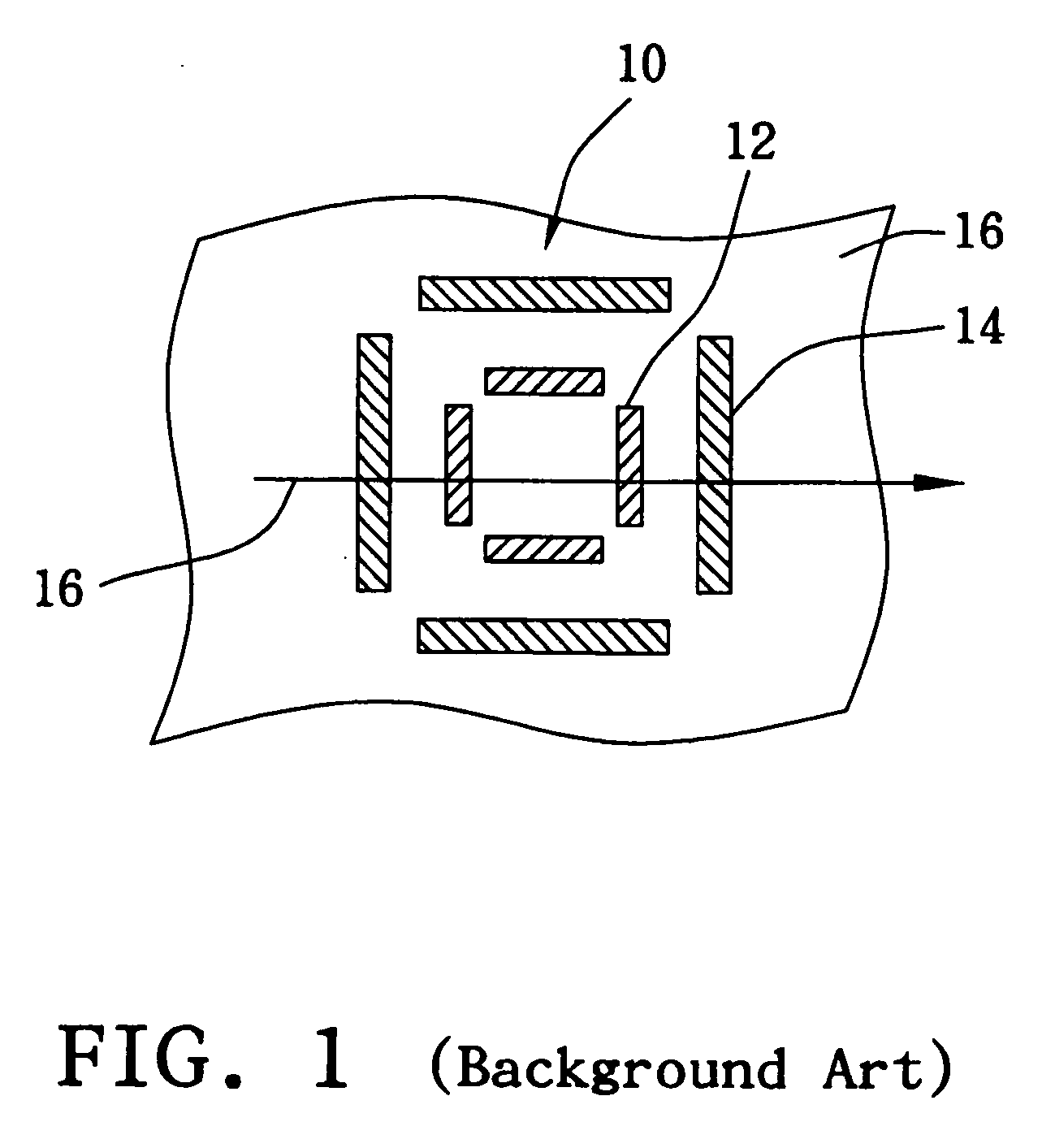

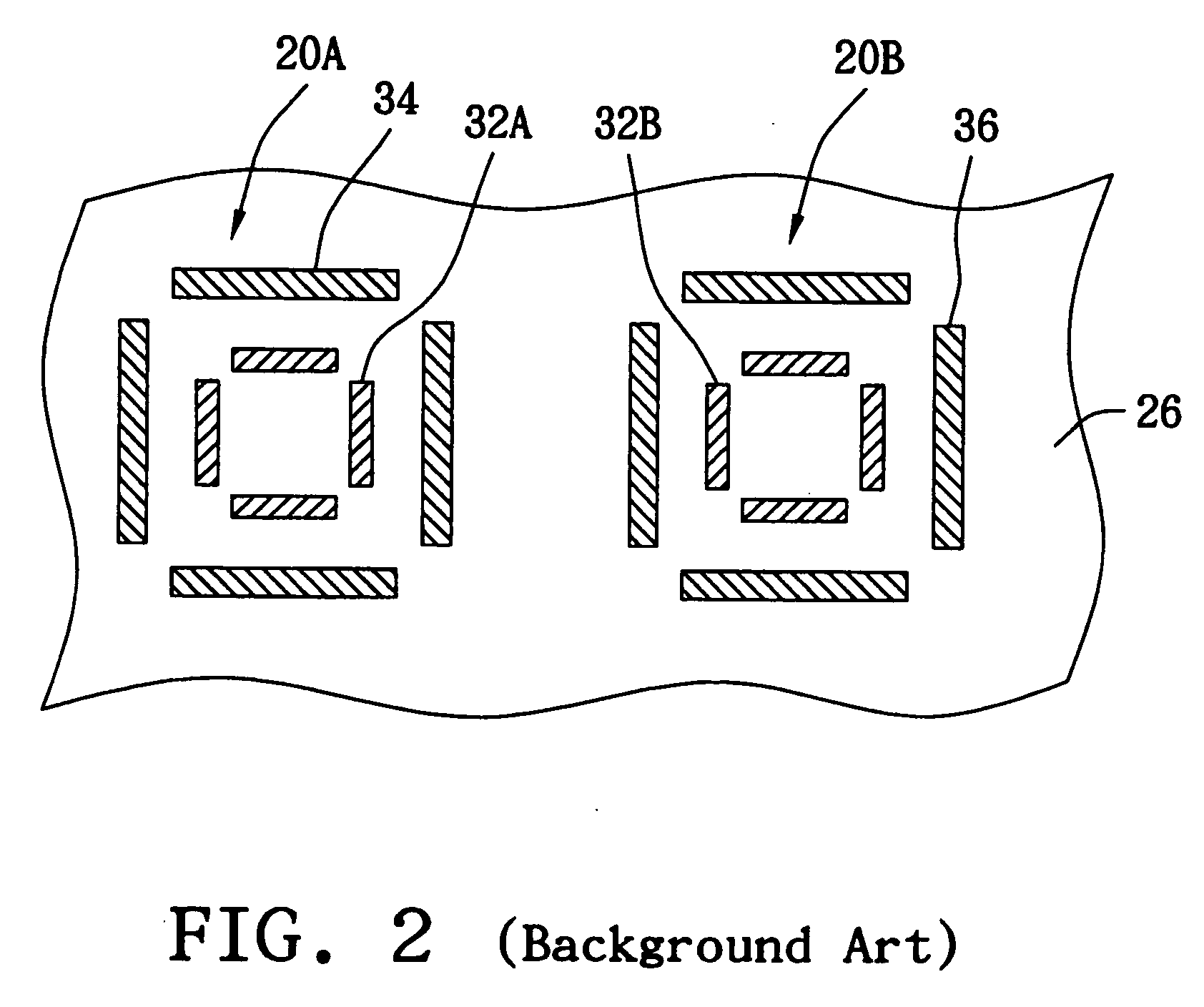

Overlay mark for aligning different layers on a semiconductor wafer

ActiveUS20050094145A1Low area costPrevent deviationSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The present invention provides an overlay mark for aligning different layers on a semiconductor wafer. The overlay mark comprises a bar-in-bar mark and two bar sets on the semiconductor wafer. The bar-in-bar mark comprises an inner bar mark positioned in one of the pre-layer and an outer bar mark positioned in the other pre-layer. The two bar sets are perpendicular to each other, and each of two bar sets comprises two parallel bars. The bars can be connected and the lengths of the bars can be the same or different.

Owner:MACRONIX INT CO LTD

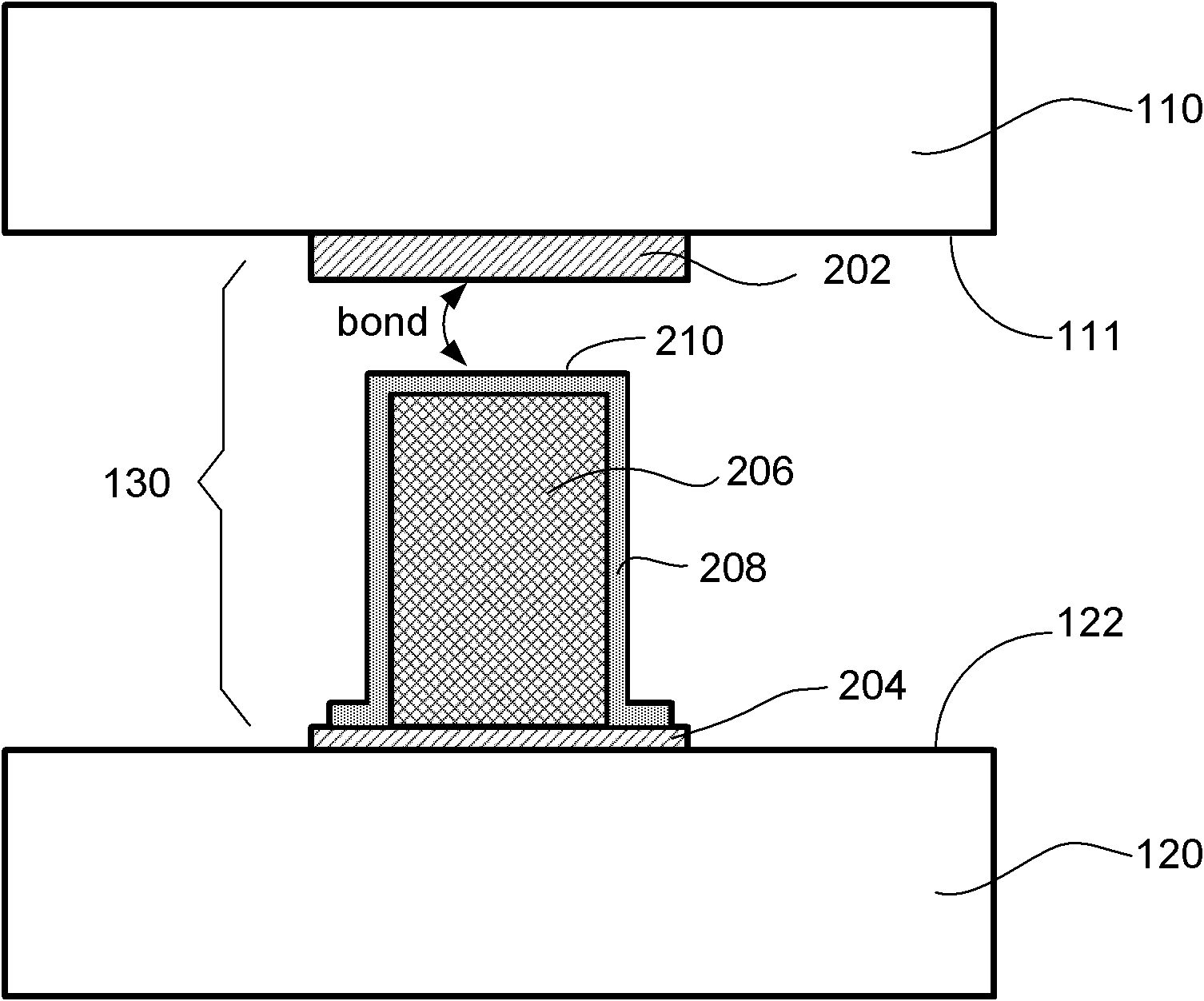

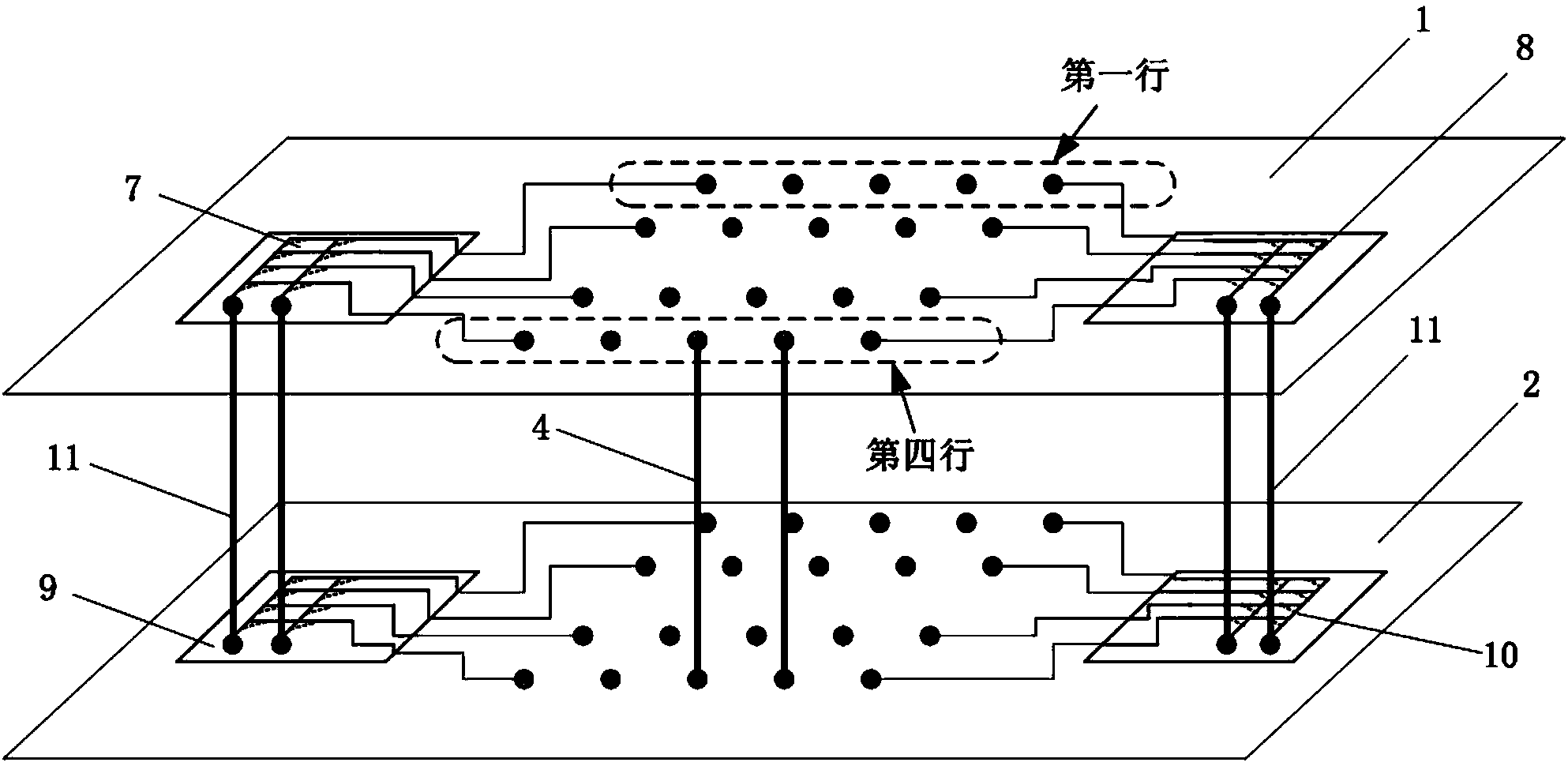

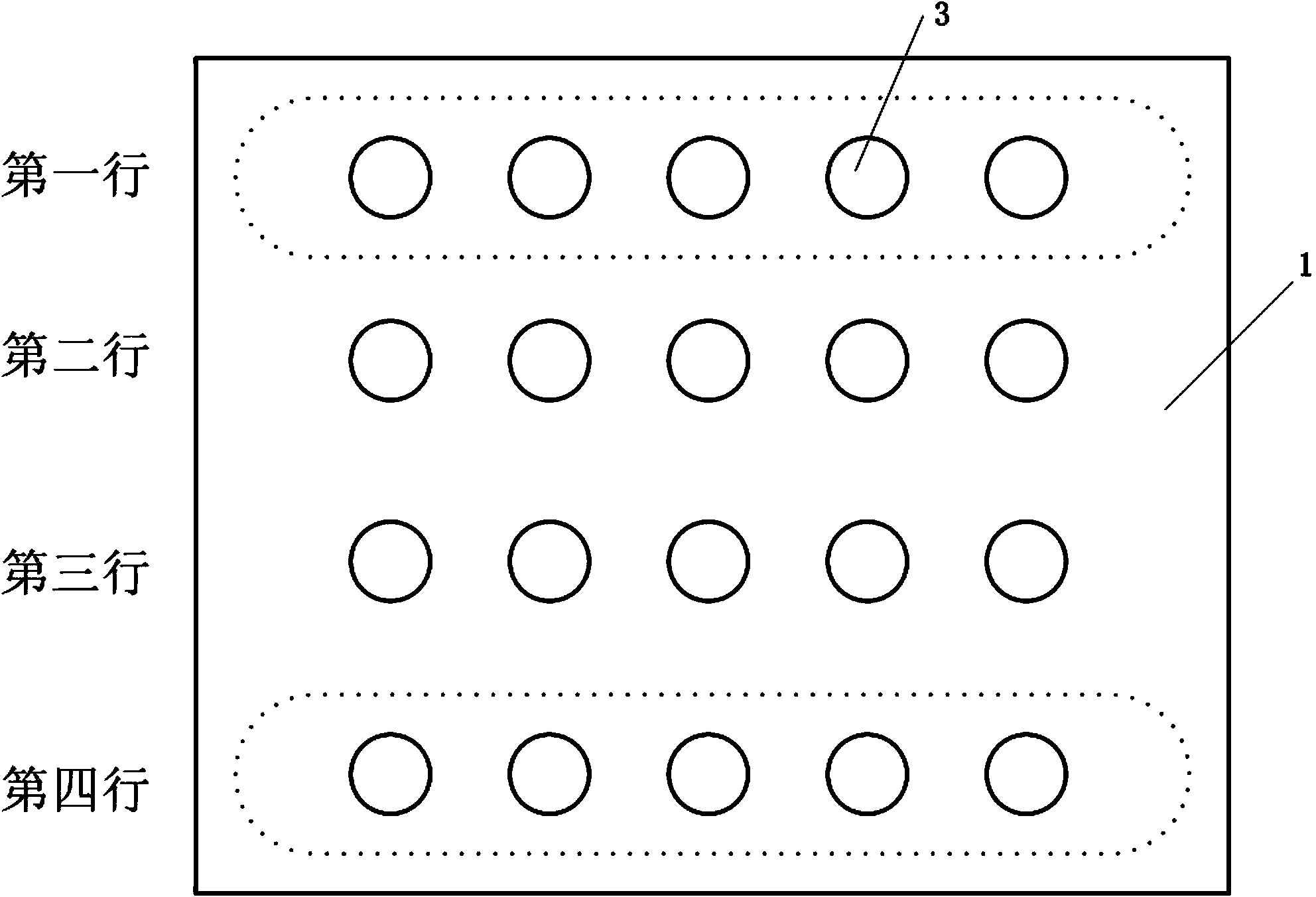

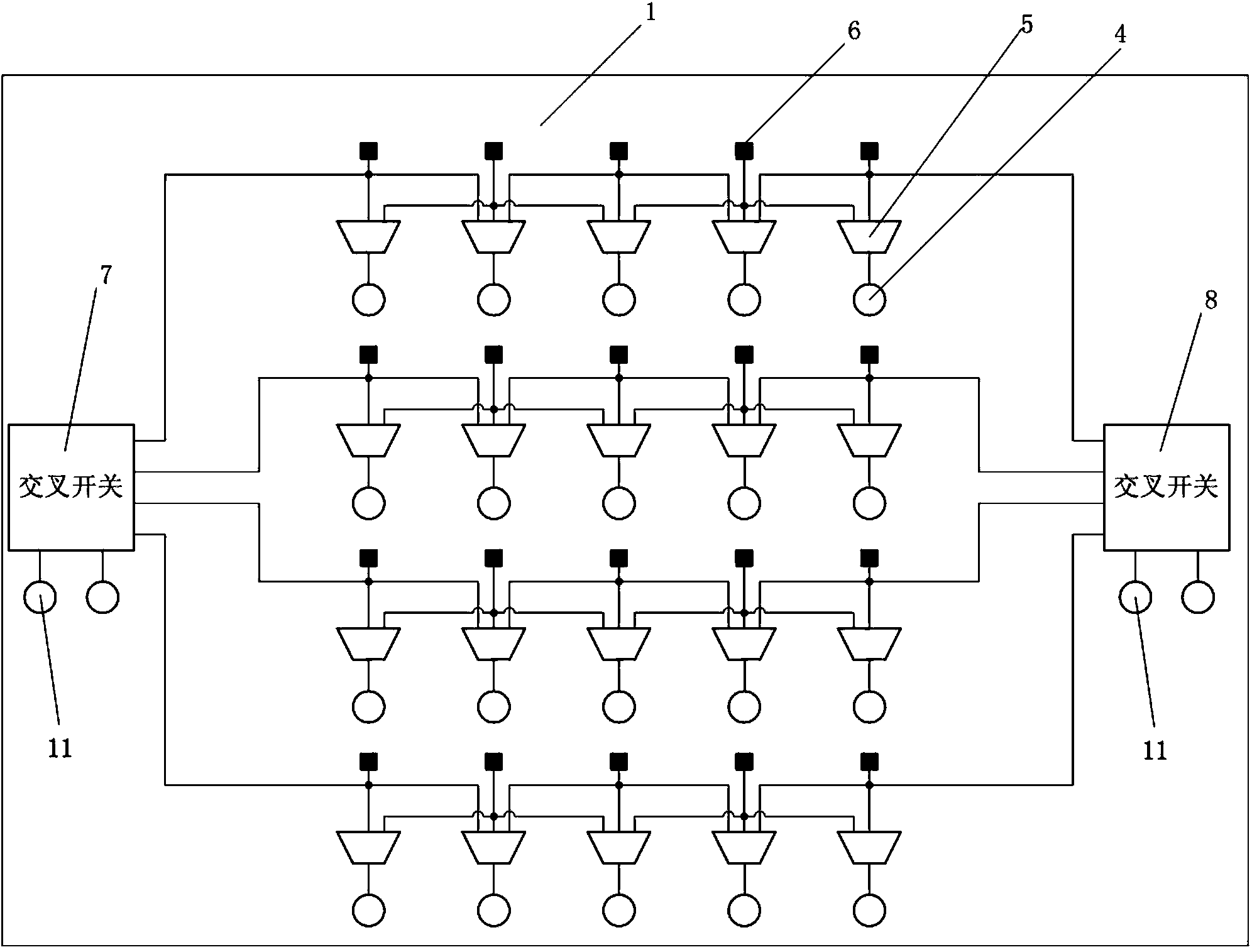

Three-dimensional chip redundant TSV fault-tolerant structure with function of transferring signal

InactiveCN103780243AImprove yieldLow costReliability increasing modificationsSemiconductor/solid-state device detailsCrossbar switch

The invention discloses a three-dimensional chip redundant TSV fault-tolerant structure with the function of transferring a signal. A three-dimensional chip comprises an upper-layer wafer and a lower-layer wafer. The upper-layer wafer and the lower-layer wafer are respectively provided with circular holes which are vertically and horizontally arrayed to form multiple rows and columns. Each circular hole in the upper-layer wafer and the corresponding circular hole in the lower-layer wafer are connected through a TSV. On the upper-layer wafer and the lower-layer wafer, the ends of all the TSVs are respectively connected with a signal transmission terminal through a multi-way selector. The upper-layer wafer and the lower-layer wafer are respectively provided with two crossbar switches, and all the crossbar switches are connected with the multi-way selectors. The crossbar switches of the upper-layer wafer are correspondingly connected with the crossbar switches of the lower-layer wafer through two redundant TSVs. The three-dimensional chip redundant TSV fault-tolerant structure has the advantages that the problem that a signal cannot be transmitted normally due to a TSV failure can be solved, the yield of the chip is effectively improved, hardware cost is low, the structure is simple, and the fault-tolerant capacity is high.

Owner:HEFEI UNIV OF TECH

Catalytic ceramic filter tube and preparation method

ActiveCN105107310AEfficient removalExtended service lifeSemi-permeable membranesDispersed particle filtrationActive componentElemental mercury

The invention provides a catalytic ceramic filter tube which is high in dust collection efficiency, can efficiently oxidize elemental mercury, can also efficiently reduce NOx, and achieves simultaneous dust removal and SCR denitration and a preparation method. The catalytic ceramic filter tube comprises a ceramic filter tube substrate, and a catalytic active component layer and a separation membrane which sequentially coat the ceramic filter tube substrate. The preparation method comprises the following steps: step 1. preparing the ceramic filter tube substrate by isostatic pressing molding; step 2. coating the ceramic filter tube substrate with a catalytic active component membrane to obtain a catalytic ceramic filter tube substrate; and step 3. preparing the separation membrane on the catalytic ceramic filter tube substrate. The catalytic ceramic filter tube provided by the invention can achieve integrated efficient removal of dust, NOx and elemental mercury in high-temperature flue gas (>300 DEG C), the service life of the catalyst can be prolonged through protection for the catalyst by the separation membrane and the substrate, and the structure arrangement of the ceramic filter tube can reduce the occupied area and running cost of equipment.

Owner:HUANENG POWER INTERNATIONAL +2

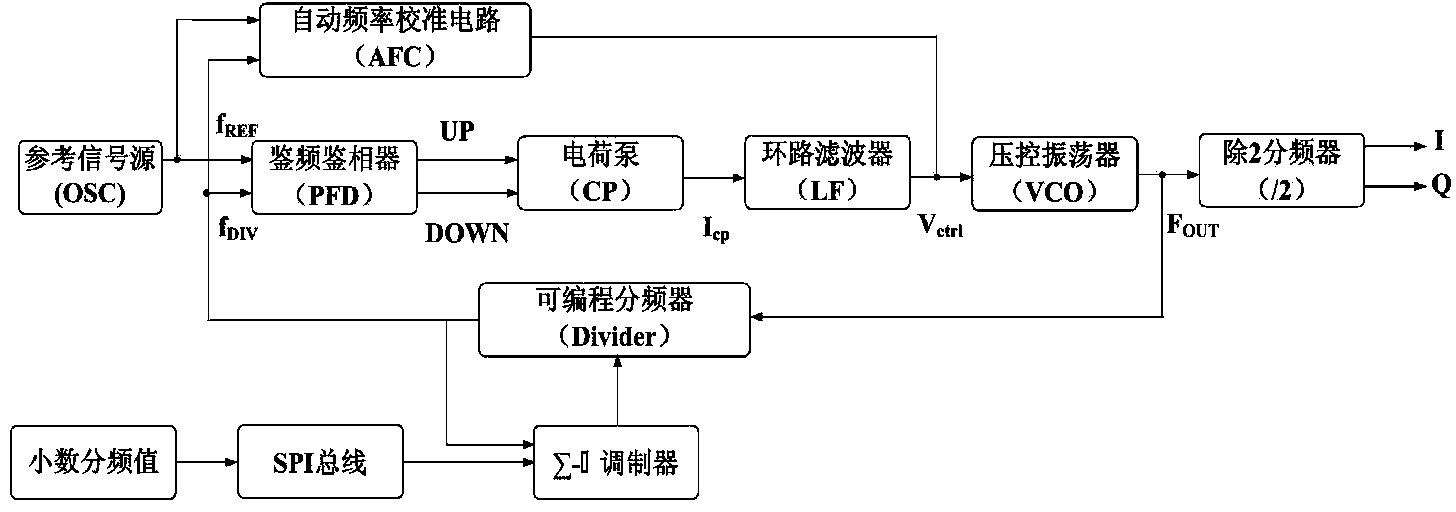

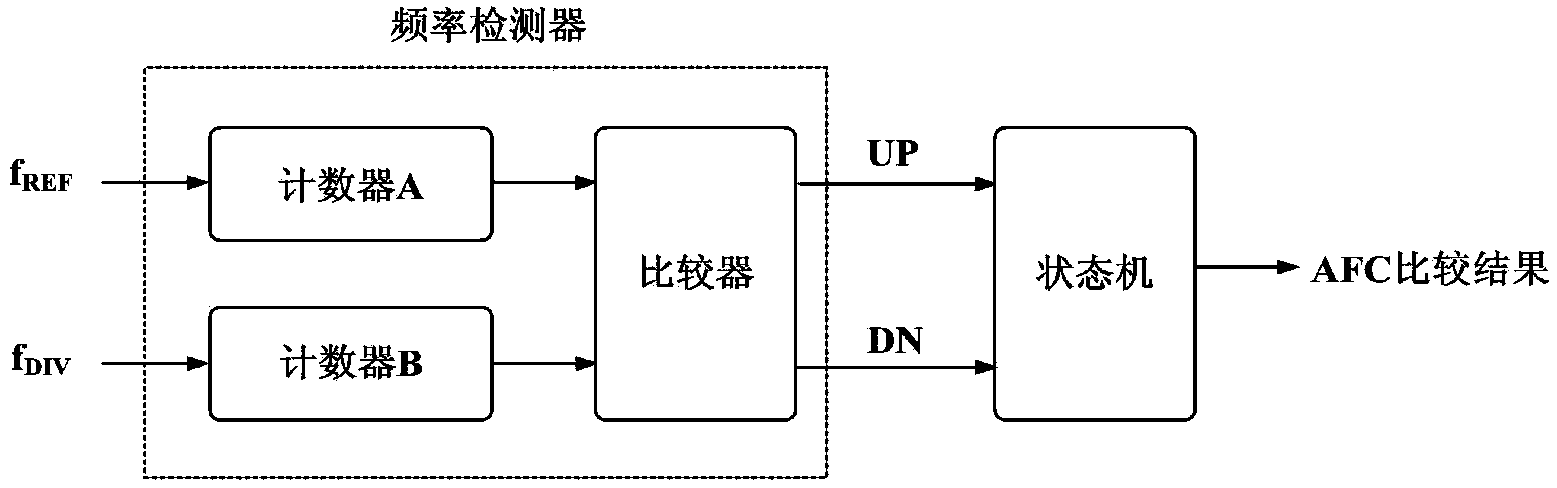

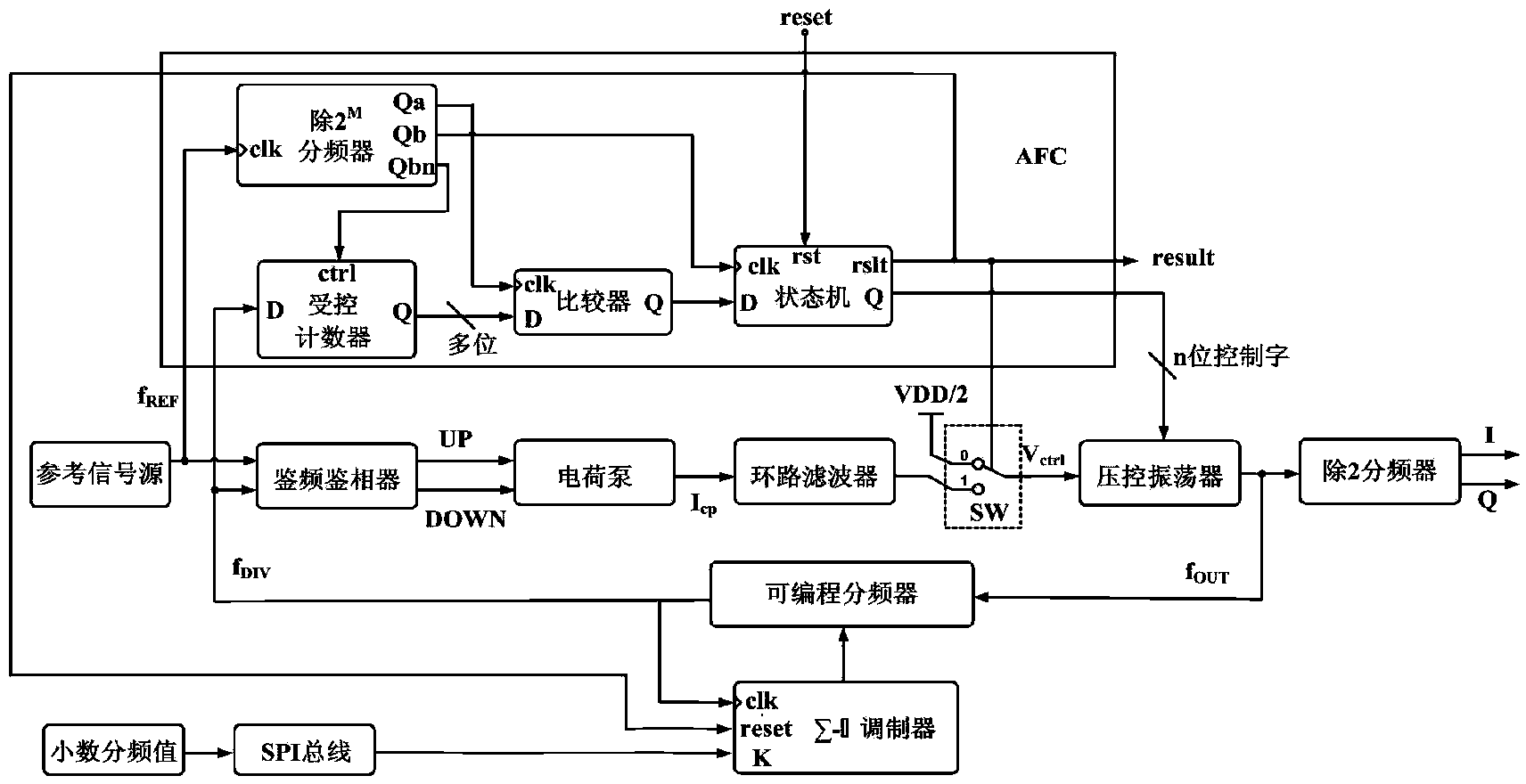

Automatic frequency calibration circuit for sigma-delta fractional frequency synthesizer

ActiveCN104038215AImprove reliabilityHigh precisionPulse automatic controlElectricityFrequency synthesizer

The invention discloses an automatic frequency calibration circuit for a sigma-delta fractional frequency synthesizer. The automatic frequency calibration circuit mainly comprises a 2M-divided frequency divider, a controlled counter, a comparator and a state machine, wherein the 2M-divided frequency synthesizer is used for controlling the running of the counter, the comparator and the state machine and the valid counting duration of the controlled counter, providing a sampling or working clock for the comparator and the state machine, and coordinating the time sequence relation between the comparator and the state machine; the comparator is used for comparing the reference of a frequency clock fREF and a feedback clock fDIV. The automatic frequency calibration circuit is at a rough calibration stage at a low level, and is at a fine calibration stage at a high level. At the rough calibration stage, the phase-locked loop of the frequency synthesizer is switched off, and the analog control end of a VCO (Voltage Control Oscillator) is connected with a fixed level. At the rough calibration stage, a result signal is at a low level, thus a sigma-delta decimal modulator is switched off, and the frequency error generated on the count value of the feedback clock fDIV by a decimal frequency dividing ratio part generated by the sigma-delta decimal modulator is lowered. At the fine calibration stage, the circuit runs normally.

Owner:NANJING UNIV OF POSTS & TELECOMM

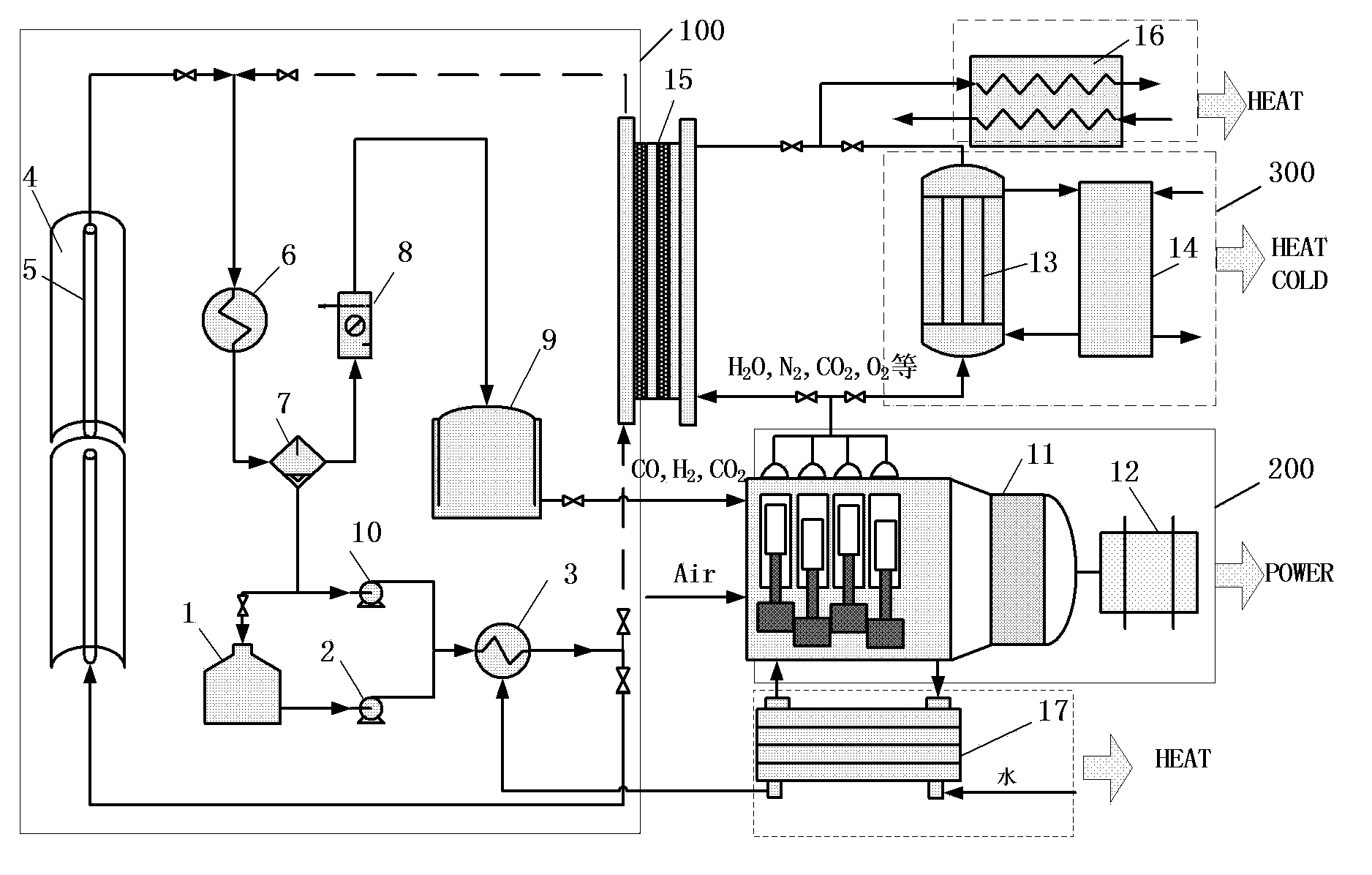

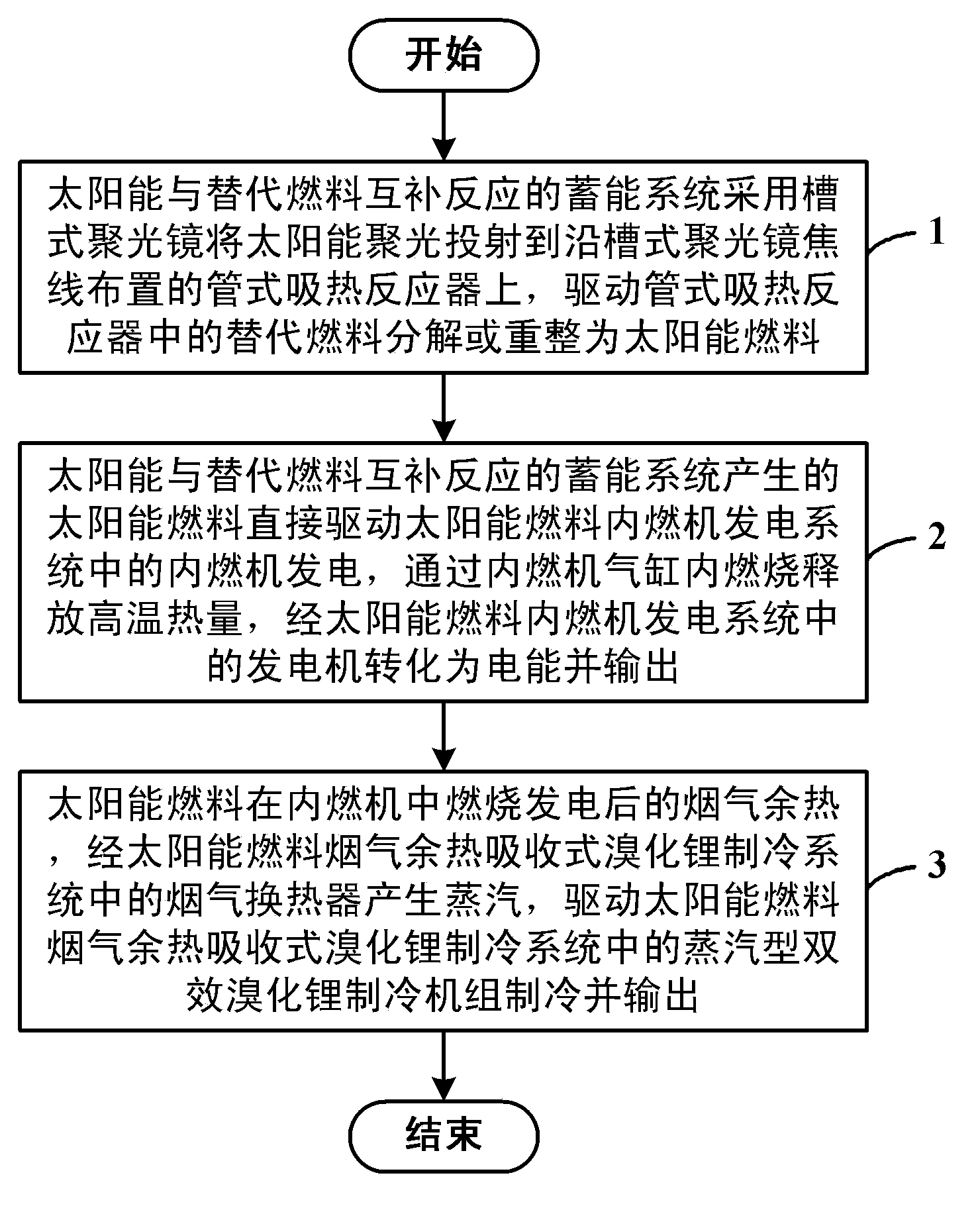

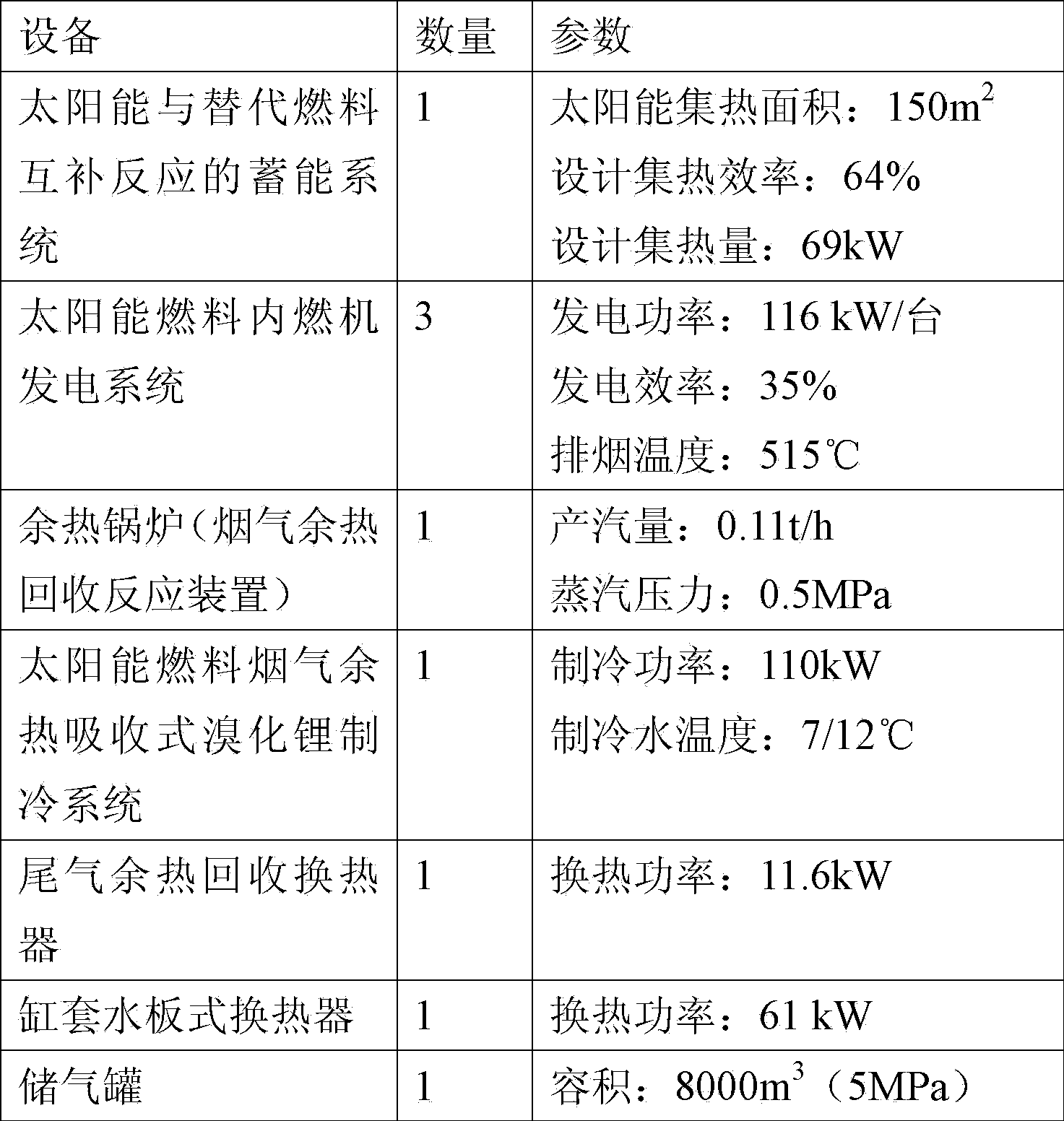

Solar energy and alternative fuel complementary distributed internal combustion engine cooling heating and power system and method

ActiveCN103807009ASmall volumeHigh energy storage densitySolar heating energyInternal combustion piston enginesAlternative fuelsHigh energy

The invention discloses a solar energy and alternative fuel complementary distributed internal combustion engine cooling heating and power system and method. The system comprises a solar energy and alternative fuel complementary reaction energy-accumulating system, a solar fuel internal combustion engine power generation system, a solar fuel flue gas residual heat absorptive lithium bromide refrigerating system, a flue gas residual heat recovery reaction device, a tail gas residual heat recovery heat exchanger and a cylinder jacket water plate heat exchanger. By adopting solar energy and alternative fuel in a complementary manner, conversion from solar energy to chemical energy of fuel is realized; light-converted synthetic gas fuel is stored and coupled with an internal combustion engine combined cooling heating and power system, so that high energy density is achieved, and the volume of an energy-storing device is reduced. Meanwhile, the aim of realizing multiple functions of combined solar cooling, heating and power at low cost and high efficiency is fulfilled, and separate solar cooling, heating and power at a high cost are avoided, so that the problems of difficulty in accumulating energy, high cost and low efficiency in the conventional solar heat utilization are solved effectively.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

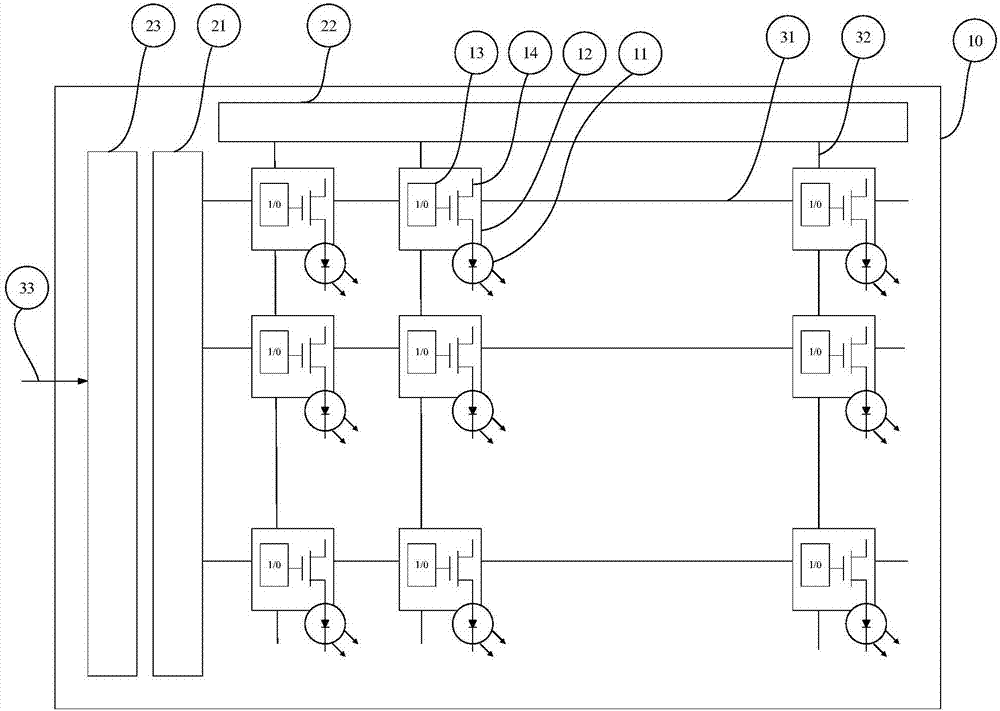

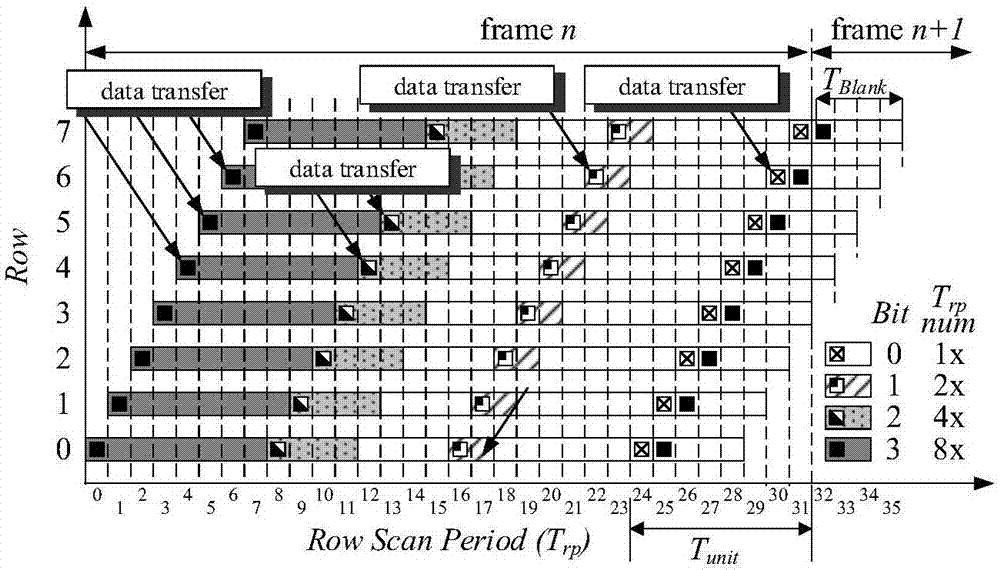

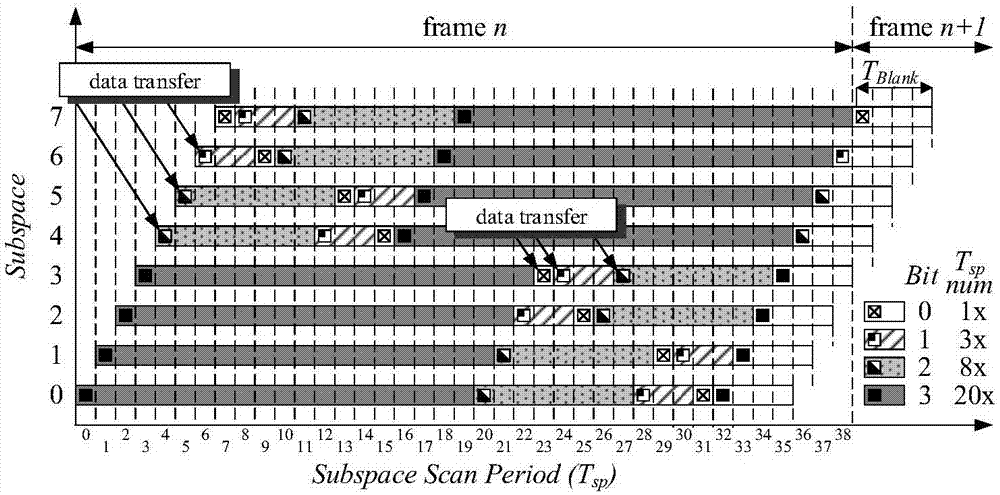

Digitally driven semiconductor display device

ActiveCN107038994AHigh speedIncrease refresh rateStatic indicating devicesDisplay deviceDigital storage

The invention discloses a digitally driven semiconductor display device which at least comprises a silicon substrate, and micro light emitting diodes that are manufactured on the silicon substrate and are arranged in an array. Furthermore each micro light emitting diode at least comprises a first electrode, a plurality of non-organic compound layers and a second electrode. The pixel circuit at least comprises a binary-value storage unit and a driving transistor. The driving transistor is an N-type or P-type metal-oxide semiconductor field effect transistor and only works in an on state or an off state. One end of the micro light emitting diode is connected with the source electrode or drain electrode of the driving transistor, and the other end is connected with a power supply, ground or a negative power supply. The light emitting brightness of the micro light emitting diode is in direct ratio with on time of the driving transistor in unit time. The gray scale generating mode of a display device is digital pulse width modulation. The digital pulse width modulation manner is subfield or subspace. The binary-value storage unit is arranged in a first voltage region, and the driving transistor is arranged in a second voltage region.

Owner:南京昀光科技有限公司

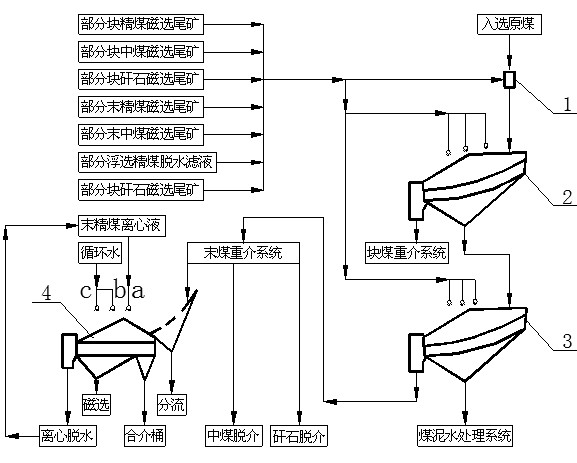

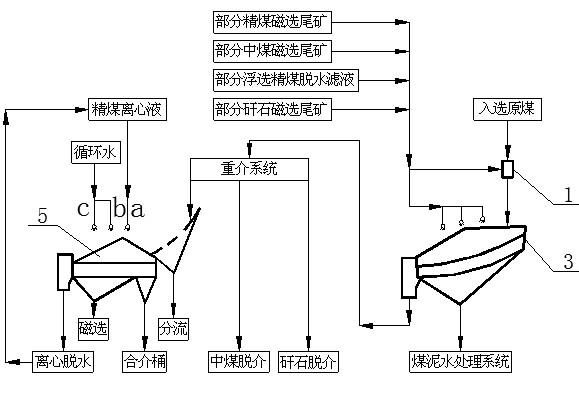

Coal slime treatment process for deslimed dense-medium coal separation

Disclosed is a coal slime treatment process for deslimed dense-medium coal separation. In the process, part of coal slime including magnetically separated clean coal tailings, magnetically separated middling coal tailings, magnetically separated gangue tailings and dehydrated filtrate of floatation separated clean coal is used as flush water for a wet-process classifying screen or a desliming screen and used as spray water for the same, and clean coal centrifugate is used as the primary spray water for a clean coal medium drainage screen. On the premise of guaranteeing feed concentration in floatation separation, work load of a concentrator can be lowered (by 20-40%), higher separation precision in gravity separation operation is maintained, better separation effect can be achieved in thecrude slime separation link and the fine slime flotation link, the recovery rate of crude particles in centrifugate is increased while medium consumption of coal separation plants is reduced, primaryinvestment, floor area and processing cost for deslimed dense-medium coal separation plants are decreased, product quality is improved, and higher economic benefit can be achieved.

Owner:CHINA UNIV OF MINING & TECH

Novel ceramic membrane tube with catalytic function and preparation method of novel ceramic membrane tube

ActiveCN106732641ALow running costThe preparation method is simple and controllableSemi-permeable membranesDispersed particle filtrationActive componentCatalytic function

The invention provides a novel ceramic membrane tube with a catalytic function and a preparation method of the novel ceramic membrane tube. The novel ceramic membrane tube comprises a support with one end open, a separation membrane coating the surface of the support, catalytic cotton filled in an inner cavity of the support and a honeycomb ceramic baffle which seals an opening of the support to be used for blocking and pressing the catalytic cotton. The novel ceramic membrane tube and the preparation method have the advantages that the method is novel and simple to implement, the original structure and the filtering function of the membrane tube are maintained, the catalyst function of the membrane tube is realized, the contact area of the catalytic active component and to-be-filtered gas is increased, the catalytic purification effect is improved, the catalytic component can be replaced or retreated after the ceramic membrane tube is used for a period of time due to the fact that the catalyst and the membrane tube can be separated, the service life of the membrane tube is prolonged, and the use cost is reduced.

Owner:江苏省陶瓷研究所有限公司 +1

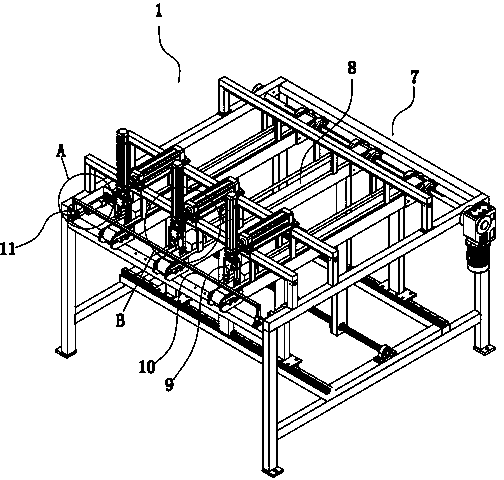

Automatic bottled product encasing device

ActiveCN104443499AHigh speedImprove efficiencyPackaging automatic controlPackaging bottlesMechanical engineeringFast speed

The invention provides an automatic bottled product encasing device. The automatic bottled product encasing device comprises a bottled product conveying mechanism, a shunting mechanism, an encasing mechanism, a box conveying mechanism and a controller. The bottled product conveying mechanism is provided with M conveying channels and used for arranging bottled products according to the preset number of rows / columns of the bottled products needing to be arranged in a box and guiding and conveying the bottled products. One end of the shunting mechanism is connected with a device inlet, the other end of the shunting mechanism is movably connected with the M conveying channels, and the shunting mechanism is used for movably shunting and guiding the bottled products conveyed from the single device inlet into the M conveying channels of the bottled product conveying mechanism. The encasing mechanism is connected with an outlet of the bottled product conveying mechanism and used for arranging the bottled products according to the preset number of rows / columns of the bottled products needing to be arranged in the box, after an array is formed, the whole array of the bottled products fall and are arranged in the box capable of being lifted. The box conveying mechanism is arranged on one side of the encasing mechanism. The encasing device is simple in structure, high in encasing speed and encasing stability, and capable of improving bottled product encasing efficiency and accuracy.

Owner:佛山市嘉荣智能机械有限公司

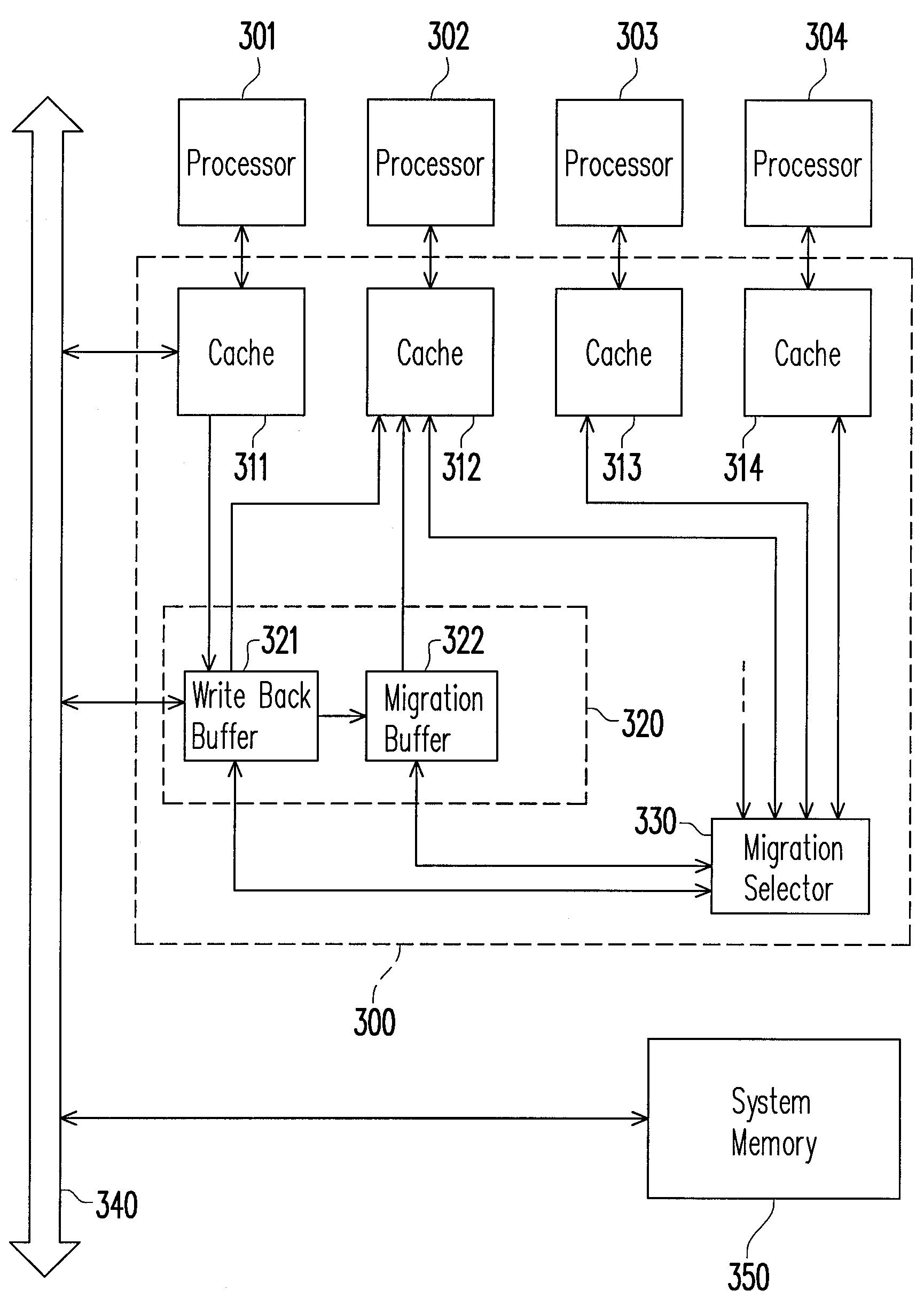

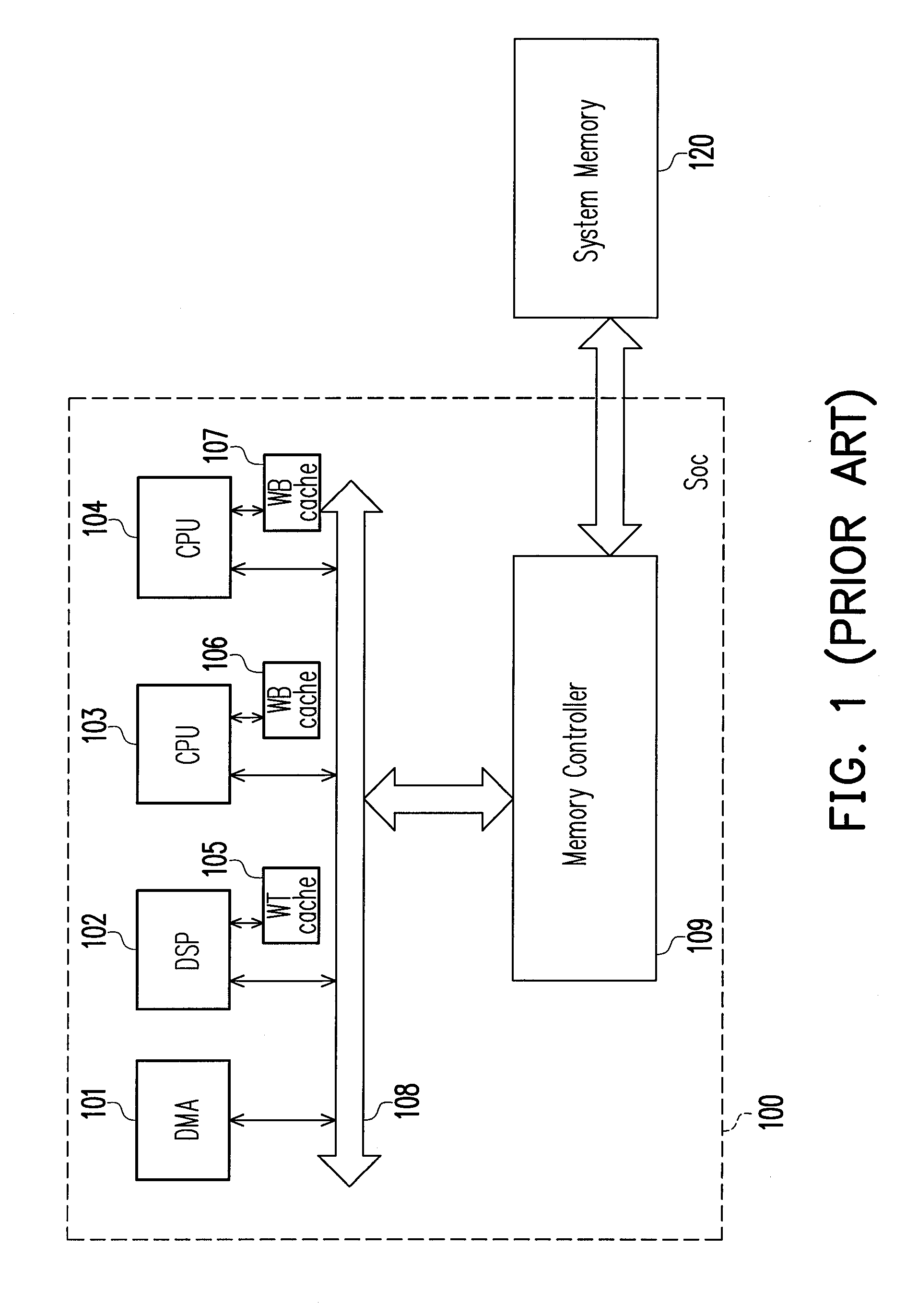

Cache system and controlling method thereof

InactiveUS20100281222A1Low area costReduce chip areaEnergy efficient ICTMemory adressing/allocation/relocationParallel computing

A cache system and a method for controlling the cache system are provided. The cache system includes a plurality of caches, a buffer module, and a migration selector. Each of the caches is accessed by a corresponding processor. Each of the caches includes a plurality of cache sets and each of the cache sets includes a plurality of cache lines. The buffer module is coupled to the caches for receiving and storing data evicted due to conflict miss from a source cache line of a source cache set of a source cache among the caches. The migration selector is coupled to the caches and the buffer module. The migration selector selects, from all the cache sets, a destination cache set of a destination cache among the caches according to a predetermined condition and causing the evicted data to be sent from the buffer module to the destination cache set.

Owner:FARADAY TECH CORP

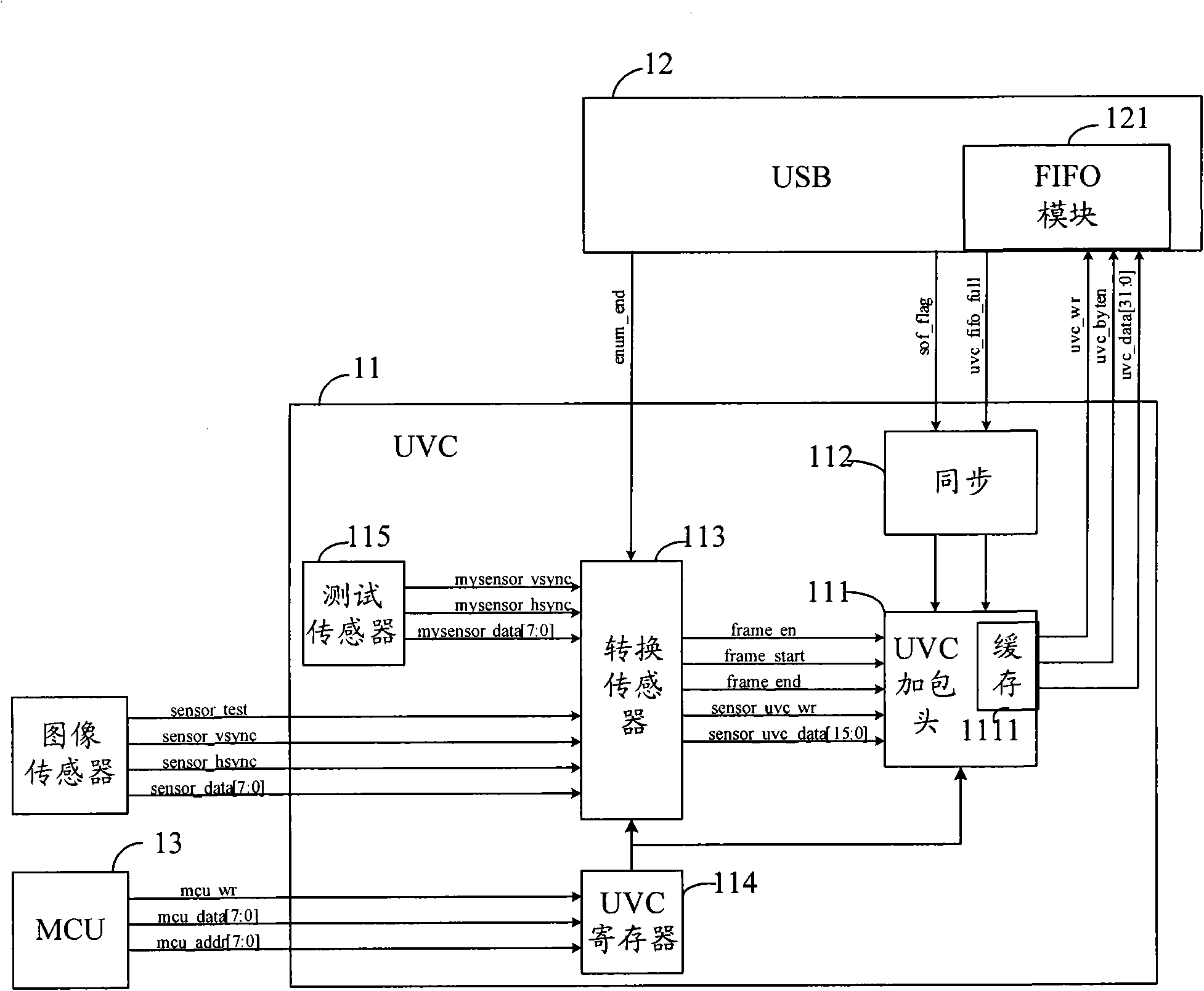

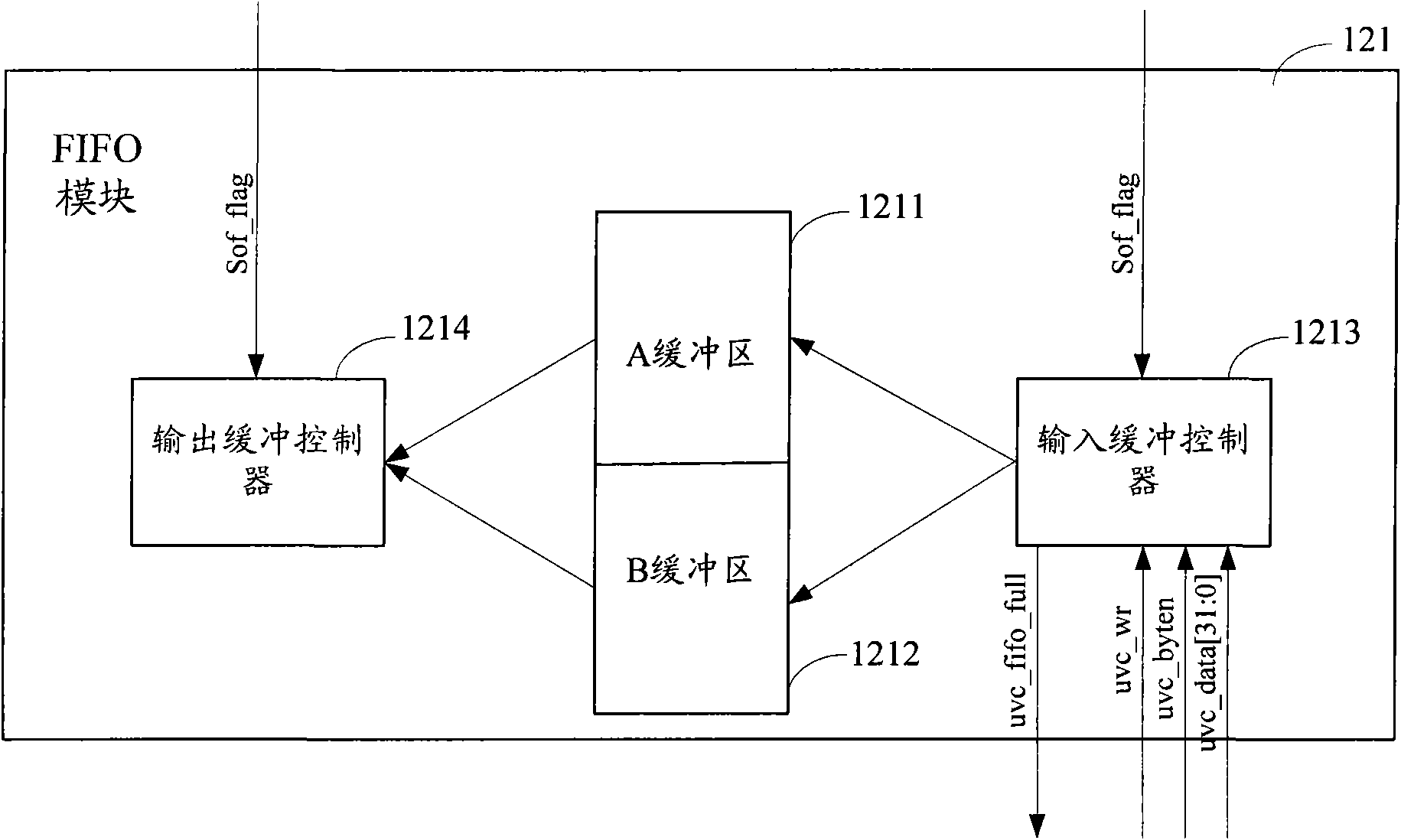

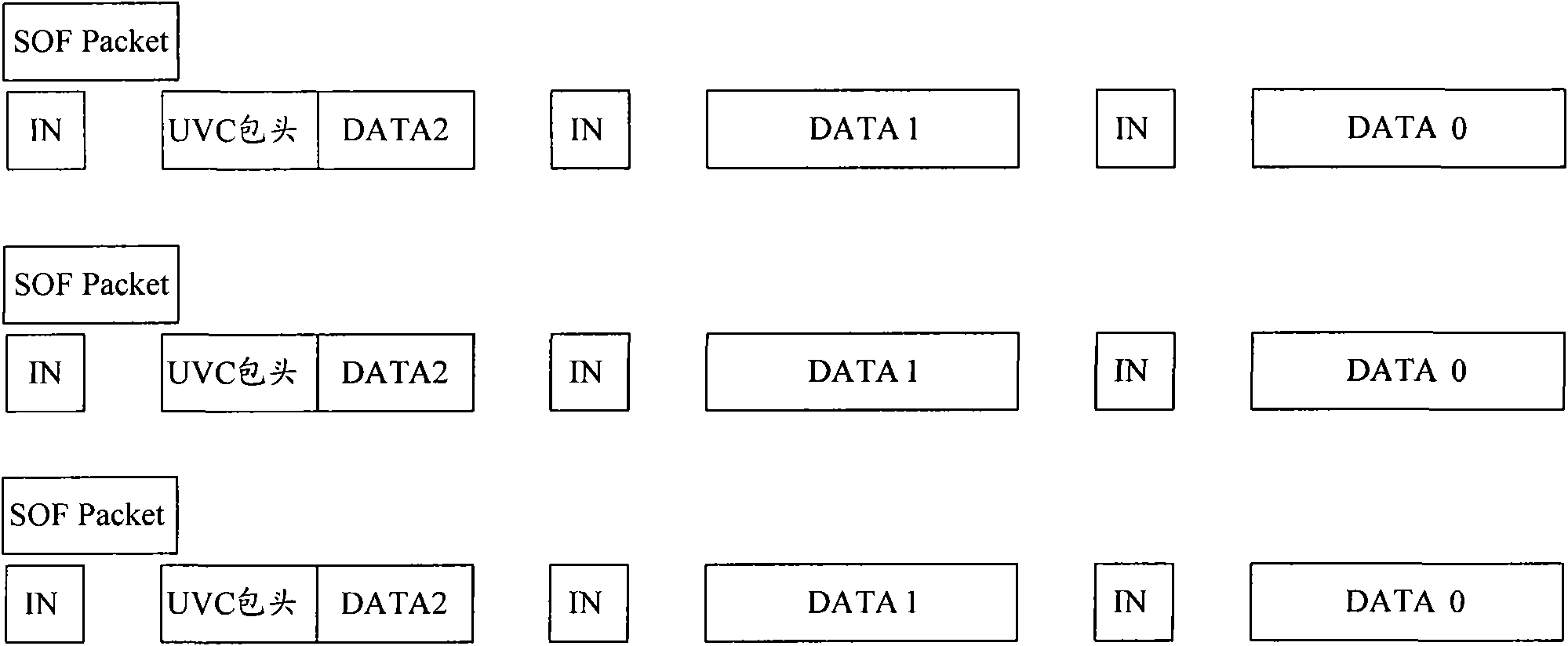

Device, USB equipment and method for realizing drive-free image data transmission

The invention discloses a device for realizing drive-free image data transmission. In a UVC unit, a transforming sensor module is arranged for judging a signal of an image frame. According to the signal and a published UVC protocol, a UVC packaging head module is arranged for performing the packaging head operation on the image data and then sending to a computer by a USB unit. The invention uses an FIFO module having a ping-pong operation in the USB unit so as to decrease the chip area and the manufacturing cost. A cache module is added in the UVC packaging head module so as to prevent the data from losing in the process of the ping-pong operation. The invention also discloses a piece of USB equipment and a method for realizing drive-free image data transmission. The operating system over the Windows XP SP2 supports the UVC protocol so applying the device, the USB equipment and the method of the invention to the image data transmission can realize directly using the USB image video equipment after being connected with a computer without driving.

Owner:BYD SEMICON CO LTD

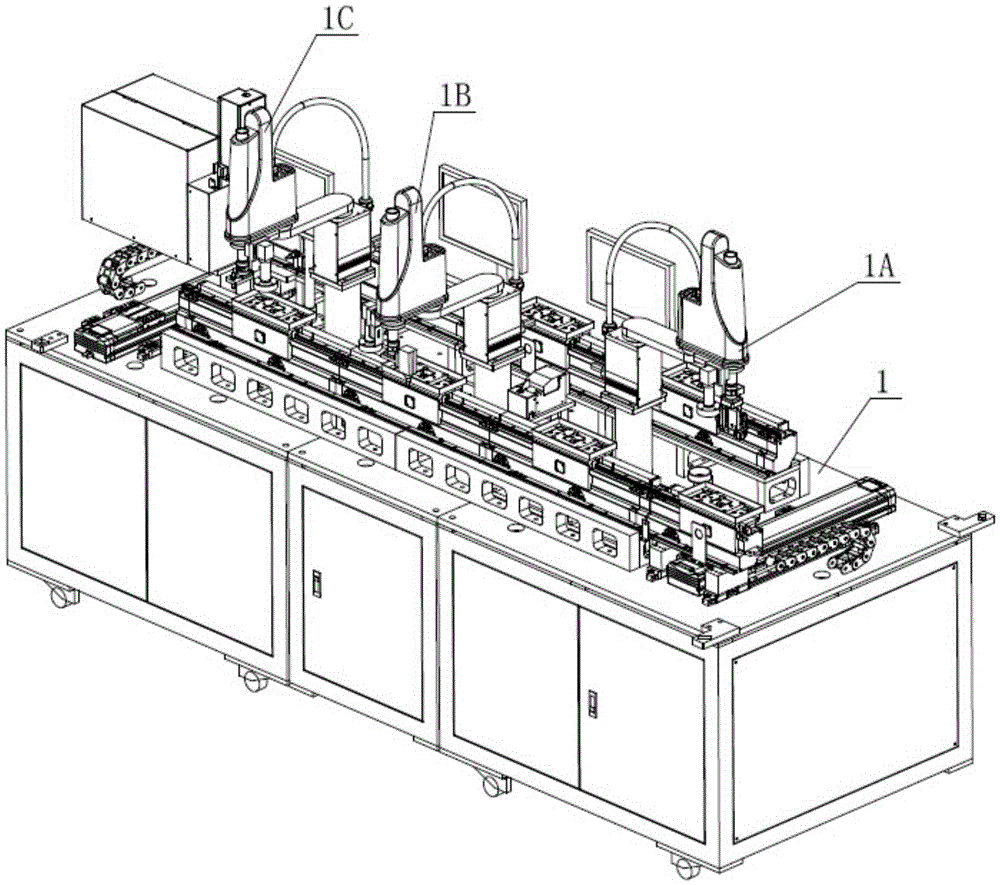

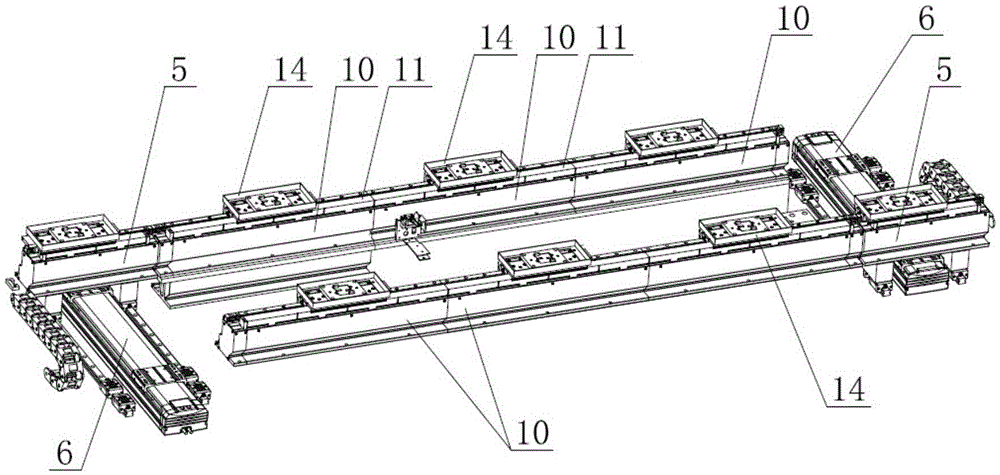

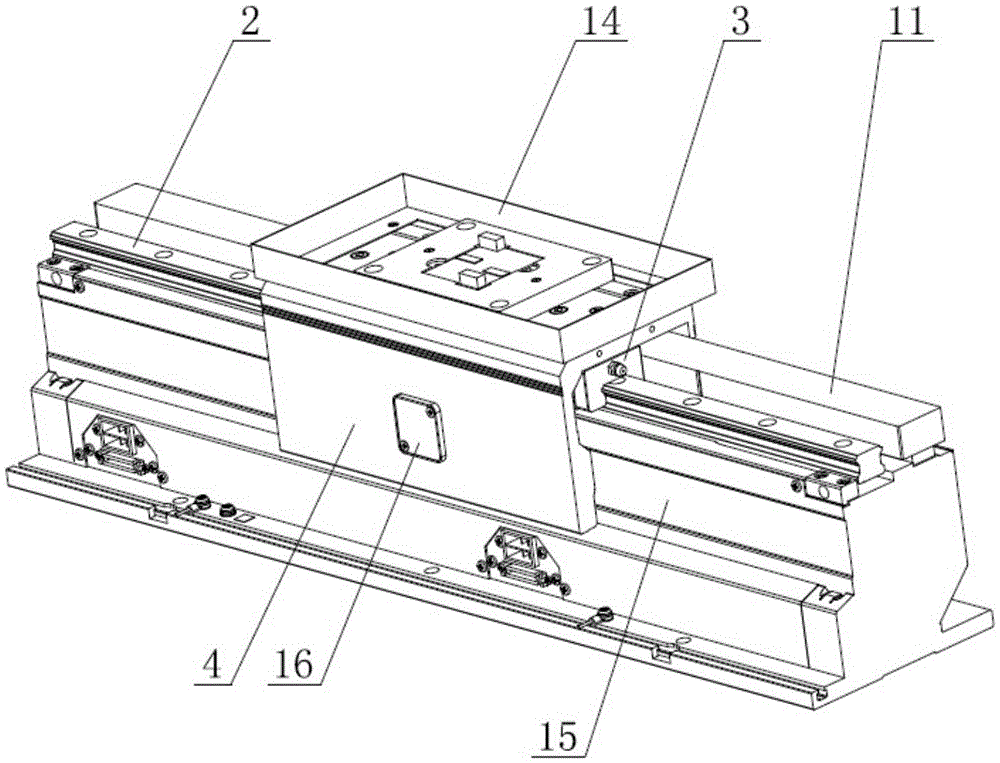

Linear sliding block type cyclic conveying production line

The invention relates to the technical field of automatic processing equipment, in particular to a linear sliding block type cyclic conveying production line. The linear sliding block type cyclic conveying production line comprises a machine frame, two fixed guide rail assemblies, sliding rails, sliding blocks and moving parts, wherein the two fixed guide rail assemblies are arranged on the machine frame in parallel; the sliding rails are mounted on the fixed guide rail assemblies; the sliding blocks are matched with the sliding rails; the moving parts are fixedly connected with the sliding blocks. The two ends of each fixed guide rail assembly are each provided with a movable guide rail seat and a rail exchanging driving mechanism used for driving the movable guide rail seat to move laterally. A feeding and discharging robot, a part plugging robot and a screwing robot are arranged on the machine frame and arranged on one side of fixed guide rail seats according to the processing sequence. By adopting the linear sliding block type cyclic conveying production line, the occupied area and investment cost of the production line can be greatly reduced, and the cost performance is higher.

Owner:DONGGUAN SUMIDA AUTOMATION CO LTD

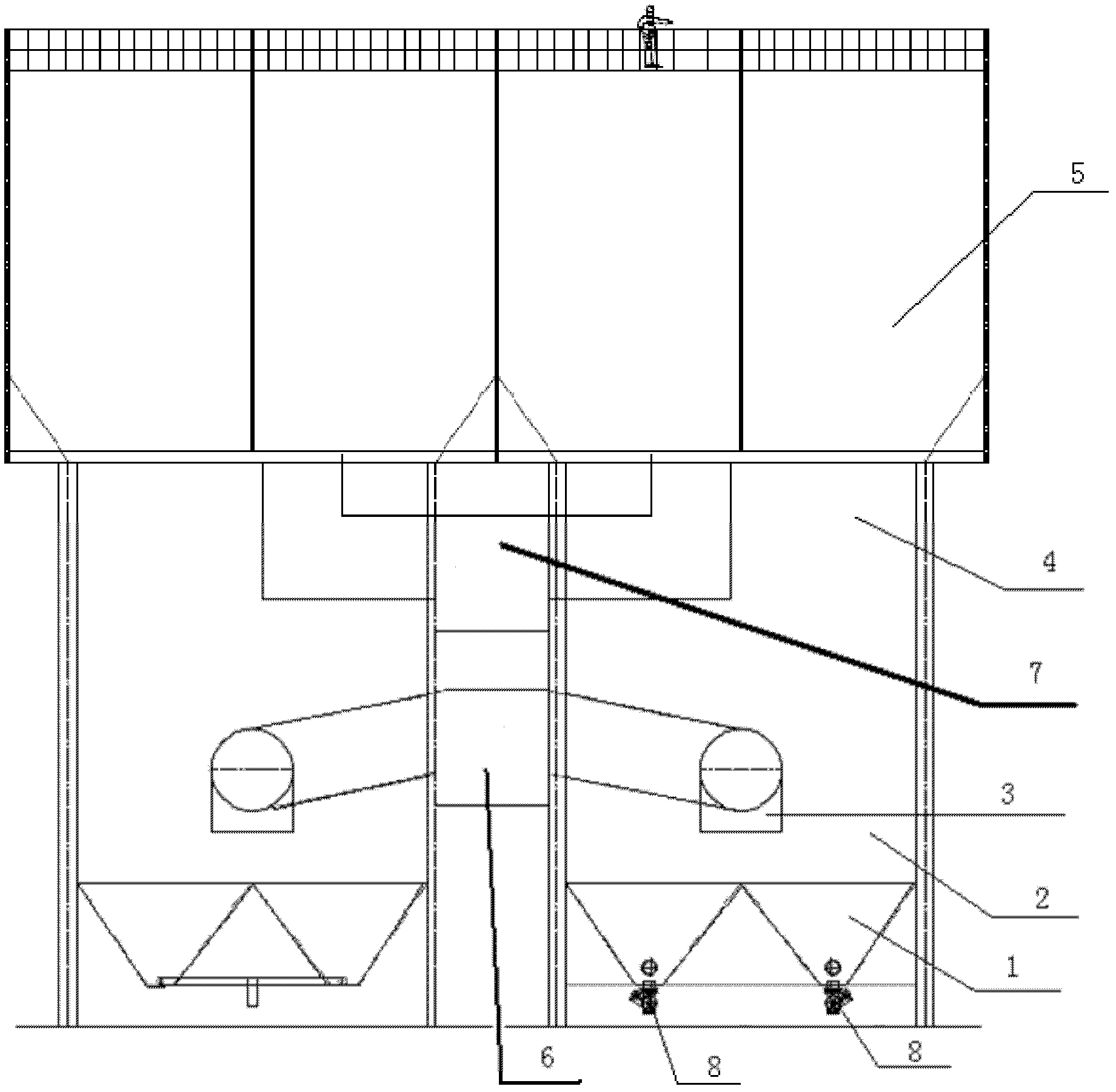

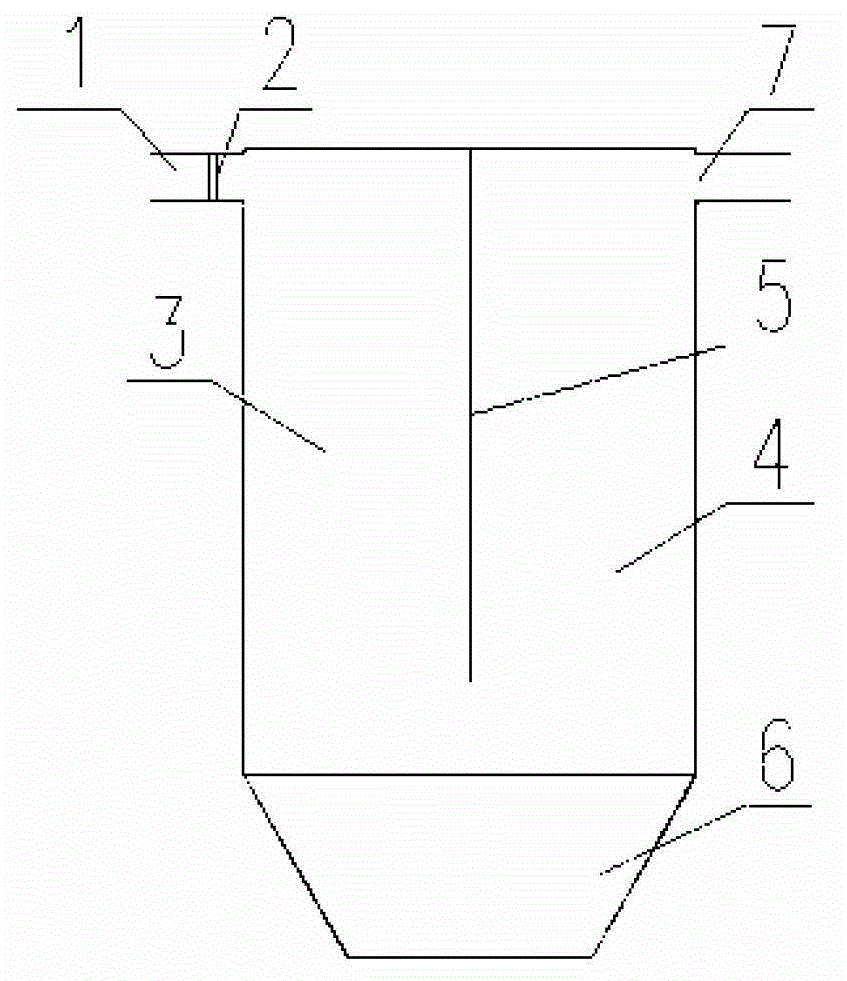

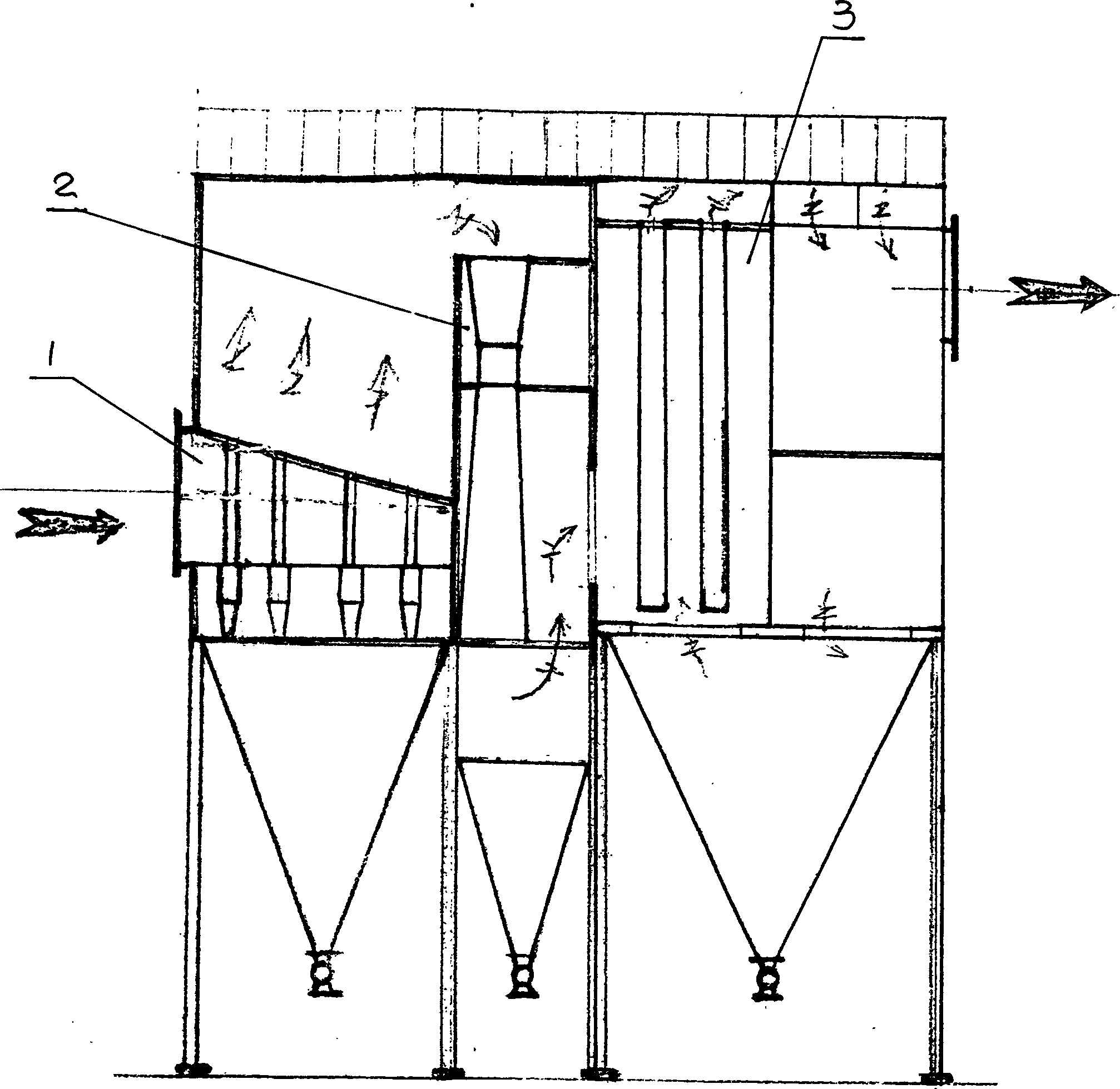

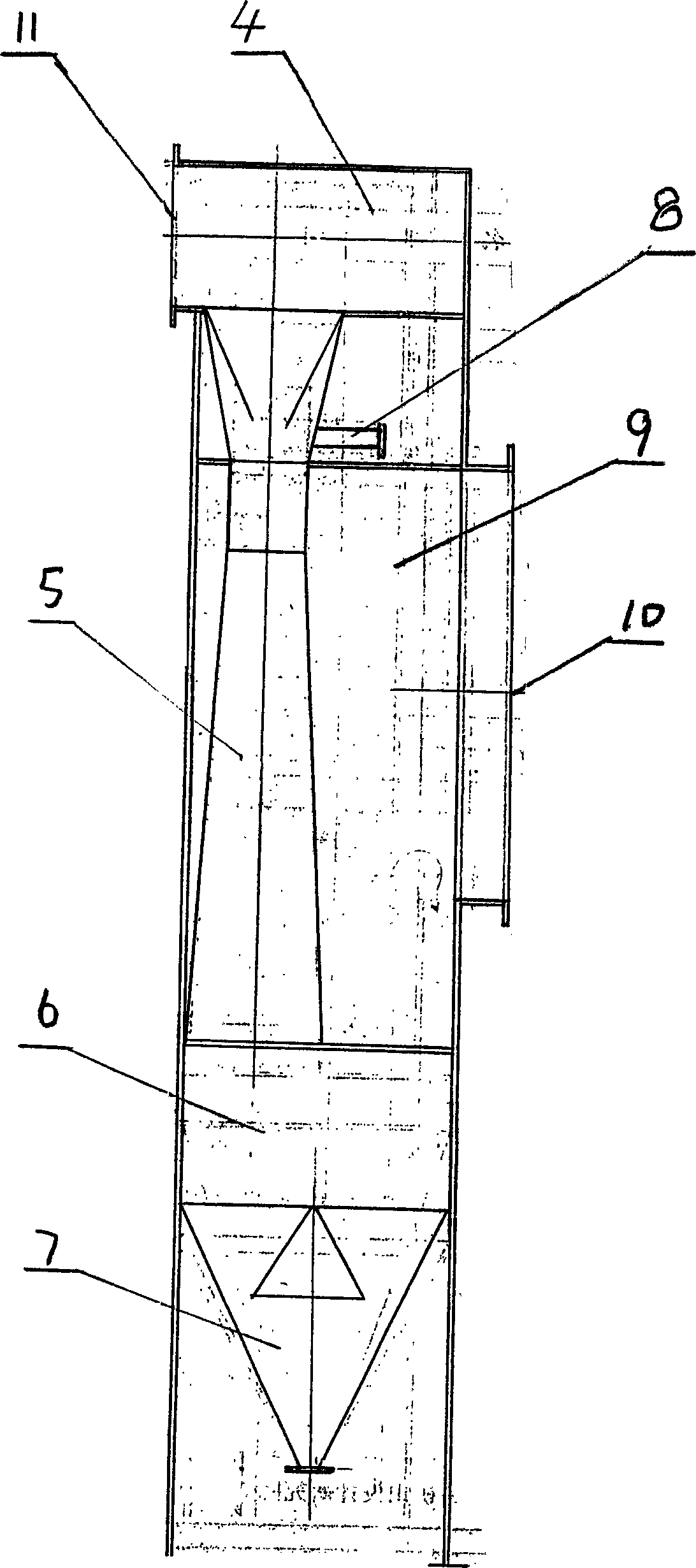

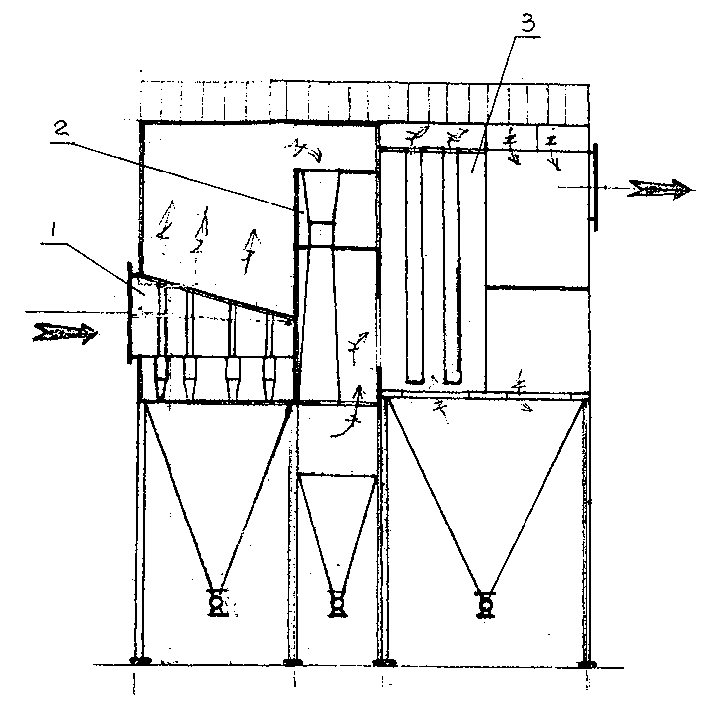

Semidry process fume desulfurizing and dedusting integrated device used for SO2

ActiveCN102210973AAvoid complexityAvoid energy consumptionDispersed particle separationEngineeringIntegrated devices

The invention belongs to the field of environmental engineering and relates to a semidry process fume desulfurizing and dedusting integrated device. the device comprises a fluidifying tank, a circulating fluidifying region, an injection orifice, a fine grain region, a separation region, a fume inlet, a fume outlet and a Roots blower, wherein the separation region is arranged at the top of the whole device, dust-containing fume is separated by virtue of the separation region, solid part is directly fallen into the fine grain region and the circulating fluidifying region to be continuously recycled; and the Roots blower is connected with the bottom of the fluidifying tank and provides fluidifying power for desulfurizer deposited at the bottom of the fluidigying tank and the whole circulating fluidifying region. In the semidry process fume desulfurizing and dedusting integrated device provided by the invention, a circulating ash conveying system is eliminated, and the integrated device can be used when the concentration of SO2 is lower than 1500mg / Nm<3>.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

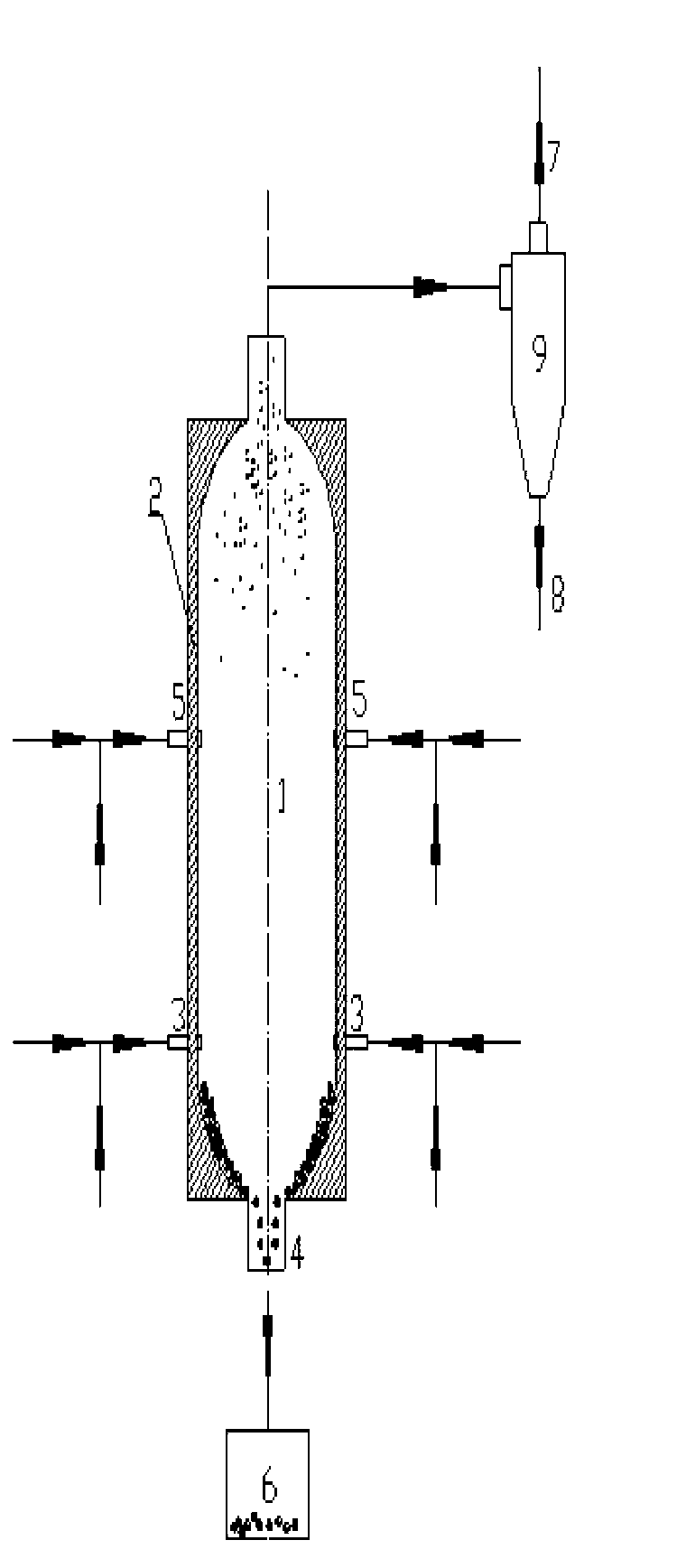

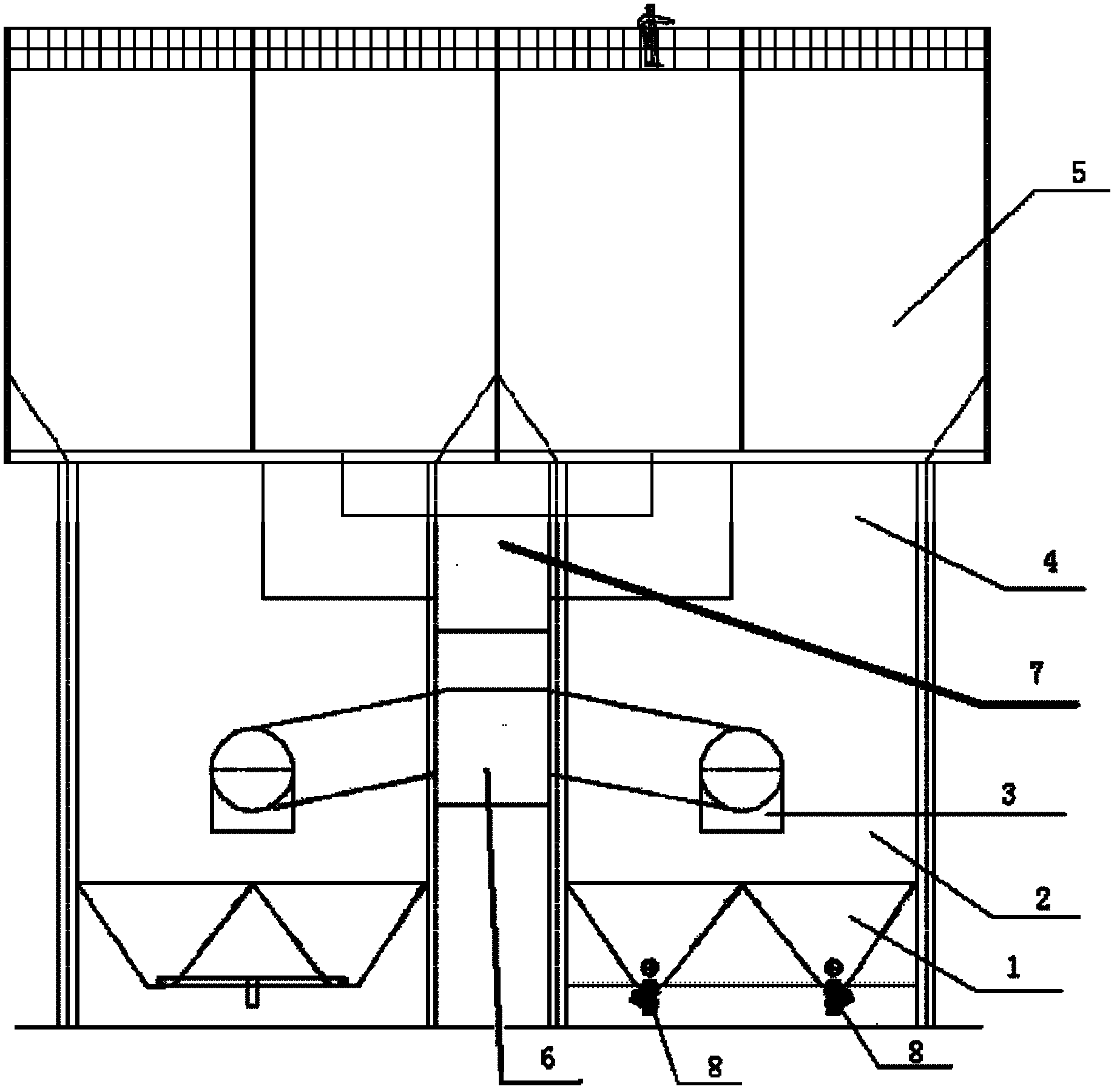

Semi-dry-process desulfurization apparatus

ActiveCN102872712AReduce loadExtended reaction timeDispersed particle separationThermodynamicsFlue gas

The invention belongs to the field of environmental engineering and relates to a semi-dry-process desulfurization apparatus. The apparatus comprises an inlet of an absorption tower, a guide plate, a dense phase chamber, a circulating fluidization chamber, a partition plate, an ash bucket and an outlet of the absorption tower, wherein the absorption tower is of a U-shaped design; the inlet of the absorption tower is arranged at the upper part of the left outer side of the whole apparatus; dust-containing flue gas enters the dense phase chamber from the inlet of the absorption tower via the guide plate; the flue gas and a desulfurizer are subjected to contact reaction in the dense phase chamber; large-grained circulating ash after reaction directly falls into the ash bucket at the bottom of the absorption tower, and fine-grained circulating ash enters the circulating fluidization chamber to be subjected to further reaction along with the flue gas; the desulfurized flue gas and part of the fine grains enter a subsequent dust remover from an outlet of a desulfurization tower; and the circulating ash at the bottom of the absorption tower and in the ash bucket of the dust remover is lifted to the inlet of the absorption tower in a medium-pressure delivery manner, thus finishing the whole cycle. According to the invention, the desulfurization reaction time is increased, the desulfurization efficiency is improved, the amount of the circulating ash is reduced, the load of the dust remover is lowered, the service life of the dust remover is prolonged, the energy is greatly saved, and the maintenance and repair frequency of the apparatus is reduced.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

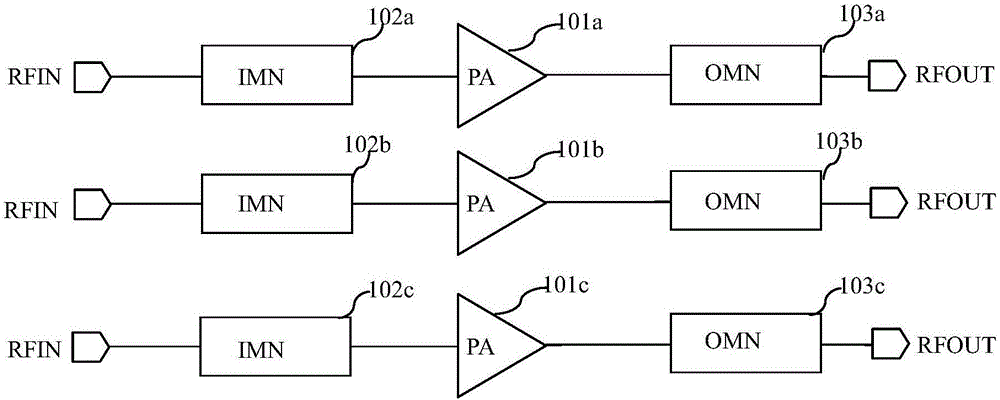

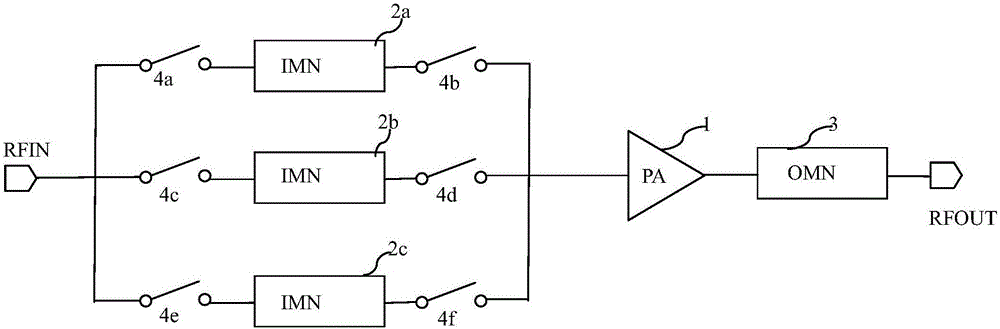

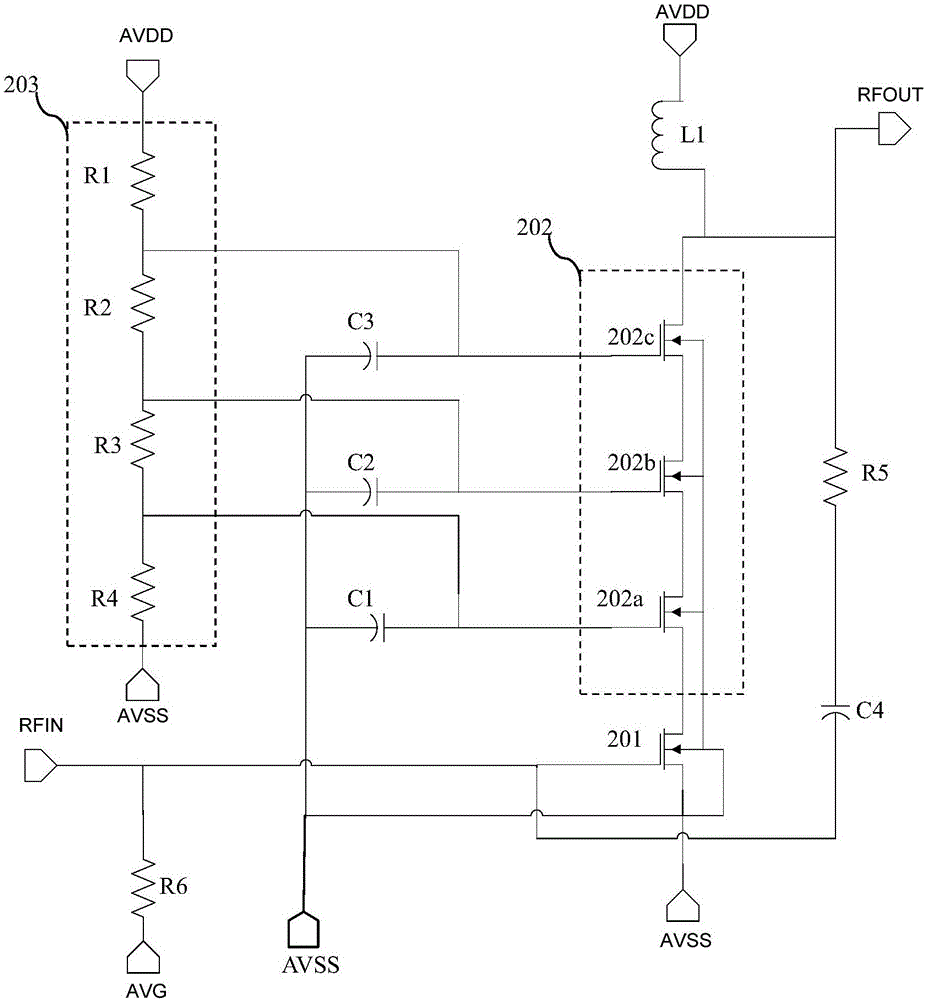

Multi-band radio frequency power amplifier

ActiveCN106253865AImprove withstand voltage and output powerReduce chip areaPower amplifiersRadio frequencyVIT signals

The invention discloses a multi-band radio frequency power amplifier, comprising multiple input matching network circuits, a radio frequency power amplifier circuit and an output matching network. The amplifier of the radio frequency power amplifier circuit is realized by employing an RFSOI technology, and through adoption of a mode of stacking MOS transistors, the withstand voltage and output power are improved. The input end of each input matching network is connected with a radio frequency input signal through a switch. The output end of each input matching circuit is connected with the input end of the radio frequency power amplifier circuit through a switch. Corresponding input matching networks are selected through the switches according to the difference of bands to which the frequency of the radio frequency input signals belong, thereby realizing input of multi-band radio frequency input signals. The output end of the radio frequency power amplifier circuit is connected with the input end of the output matching network. The output end of the output matching circuit outputs radio frequency output signals. According to the power amplifier, the chip area and usage cost can be greatly reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

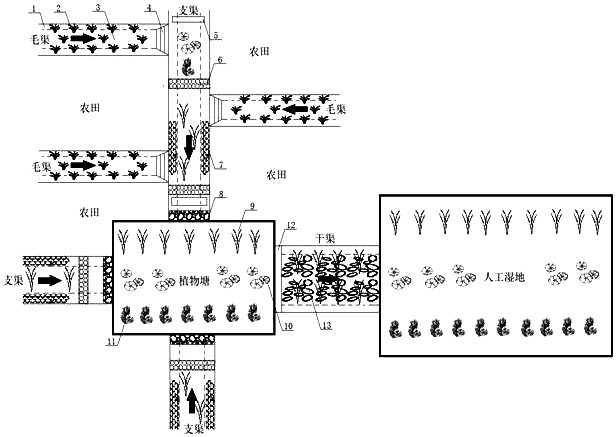

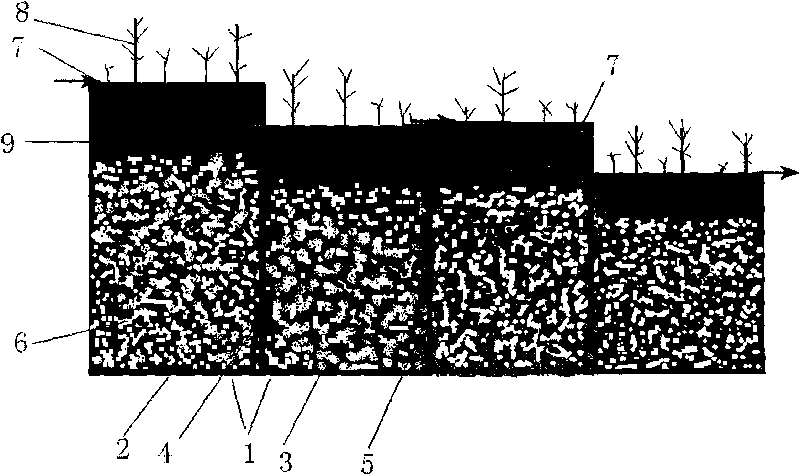

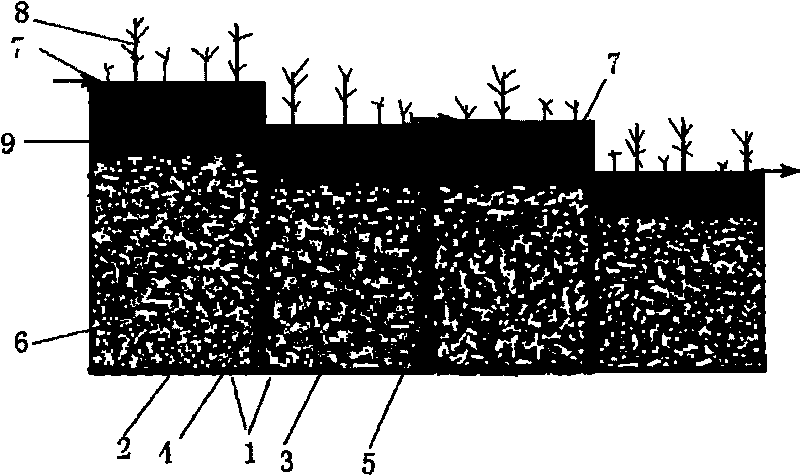

Composite ecological treatment method for intercepting farmland recession pollutants

InactiveCN112358053AEfficient removalGive full play to the purification abilityWater contaminantsTreatment with aerobic and anaerobic processesConstructed wetlandEnvironmental resource management

The invention discloses a composite ecological treatment method for intercepting farmland recession pollutants, relates to a farmland ecological treatment system, and provides an ecological ditch-plant pond-constructed wetland composite system for ecologically intercepting farmland recession pollutants and a construction method thereof. The method can relieve the continuous pressure of farmland recession on the natural water environment, overcome the technical defects of existing farmland recession treatment, effectively solve the problems that an artificial wetland purification system is single in function, the effluent quality cannot meet the specified requirements and the like, strengthen the removal effect on organic matter, nitrogen and phosphorus in water, reduce the occupied area ofthe wetland, reducing the wetland load, prevent wetland blockage, achieve the purposes of high efficiency and low consumption, and beautify the environmental landscape. The system is low in investment and operation cost, convenient to operate, free of electromechanical equipment and operation energy consumption and suitable for being applied to ecological interception treatment engineering of farmland returned water pollutants greatly affected by natural rainfall.

Owner:SHENYANG UNIV

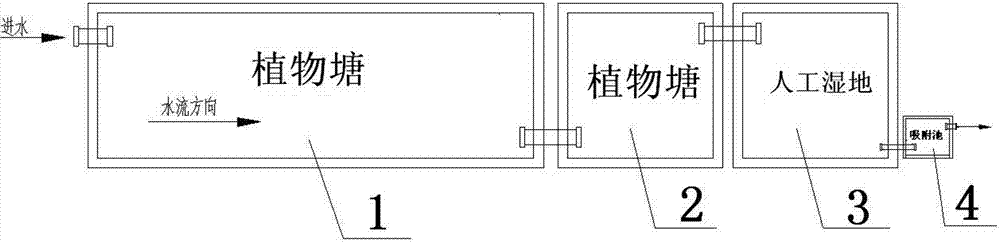

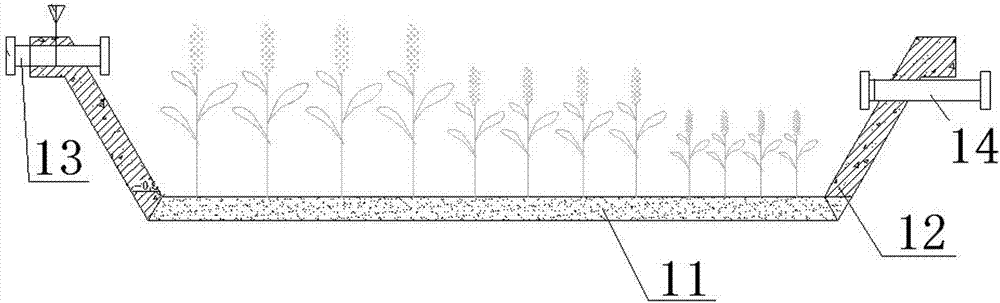

Method for efficient removal of heavy metals in farmland irrigation water by plant pond, constructed wetland and adsorption tank

InactiveCN106977062AFully absorbing capacityEnsuring full growthWater contaminantsWater/sewage treatmentConstructed wetlandWater flow

The invention discloses a method for efficient removal of heavy metals in farmland irrigation water by a plant pond, a constructed wetland and an adsorption tank. The method is mainly characterized in that farmland in which natural water inlet and outlet can be realized by difference of elevation is selected according to farmland irrigation ditch distribution conditions to form a 'plant pond, constructed wetland and adsorption tank' integrated purification process, aquatic plants such as typha and hydrilla are planted in the plant pond and the constructed wetland, and the adsorption tank is filled with industrial and agricultural wastes such as straws high in heavy metal adsorption capacity to purify heavy metal pollution in the farmland irrigation water. The aquatic plants can not only prevent short circuit of water flow but also improve purification efficiency; the adsorption tank can further improve purification efficiency to guarantee that heavy metals in the farmland irrigation water reach the standard. By adoption of the method, heavy metal pollution in the farmland irrigation water can be efficiently eliminated while pollution of N, P and the like can be cleared, and the heavy metal content of the farmland irrigation water can reach the standard all year round.

Owner:HUNAN AGRICULTURAL UNIV

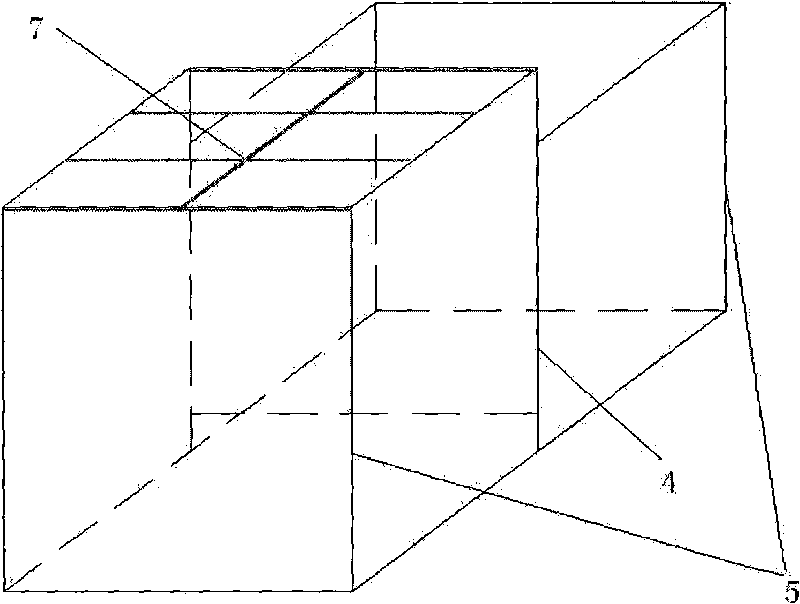

Stepped composite vertical flow artificial wetland sewage treatment device

InactiveCN101700932APracticalEven distribution of waterSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandSoil horizon

The invention relates to a stepped composite vertical flow artificial wetland sewage treatment device. The device comprises downflow tanks and upflow tanks, and the device is characterized in that the overall device is composed of a plurality of units, wherein each unit comprises a downflow tank and an upflow tank which are arranged next to each other, separated by a baffle plate and communicated with each other at the bottoms, the downflow tank is higher than the upflow tank to form a step; adjacent two units are separated by a baffle plate, the upflow tank of the previous unit and the downflow tank of the next unit are at the same level; matrix layers and soil layers are successively filled in the downflow tank and upflow tank of one unit from bottom to up, water pipes are paved on the soil layer of the downflow tank, and plants are planted in the soil layers of the downflow tank and upflow tank. The device has the advantages of wide application range, good restoration effect, low infrastructure cost, low management and maintenance cost, good appreciation and the like in the respect of restoring waterbody.

Owner:SHANGHAI UNIV

Combined two-stage flue gas desulfurization and dust-eliminating process

InactiveCN1454699ASimple processBest matchCombination devicesUsing liquid separation agentSulfurEngineering

The invention refers to a compound double-grade smoke desulfurizing and dust eliminating process which can desulfurize sulfur and eliminate dust effectively. It is made up of the first, the second and the third parts: the first part is ceramics multi-pipe dust catcher or electrostatic dust catcher, it carries on the first grade dust eliminating, it eliminates 90-99% dust in the smoke; the second part is venturi drying and absorbing tower, the sulfur in smoke reacts with desulfurizing liquid and is absorbed, realizes the first grade desulfurizing; the third part is bag desulfurizing and dust catcher, it eliminates the resultant in desulfurizing reaction and carries on secondary dust eliminating to the tiny particles in smoke.

Owner:樊金鑫

A touch screen and a mobile terminal

ActiveCN109375803ALow area costReduce manufacturing costElectronic switchingInput/output processes for data processingCapacitancePower flow

The present invention relates to the technical field of touch control, a touch screen is disclosed, a detection unit in the touch screen includes a voltage-current conversion module, a mixing module and a filter sampling module, an input terminal of the voltage-current conversion module is connected with a self-capacitor, the other input terminal is connected with a driving circuit, and the voltage-current conversion module samples the charge generated from the capacitor under the excitation of the excitation signal generated from the driving circuit, converts the charge generated from the capacitor into a current signal, and obtains the change data of the self-capacitance value by detecting the current signal. The embodiment of the invention discloses a touch screen and a mobile terminal,which reduces the area and cost of the touch screen detection circuit, improves the sampling efficiency, and thus improves the anti-interference ability of the detection circuit.

Owner:CHIPSEMI SEMICON (NINGBO) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com