Semidry process fume desulfurizing and dedusting integrated device used for SO2

A technology of desulfurization and dust removal and semi-dry method, which is applied in the field of environmental engineering, can solve the problems of waste of equipment resources, high energy consumption, and energy consumption of easy-to-collapse beds, so as to reduce floor space and operating costs, avoid high energy consumption, and reduce The effect of maintenance frequency and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

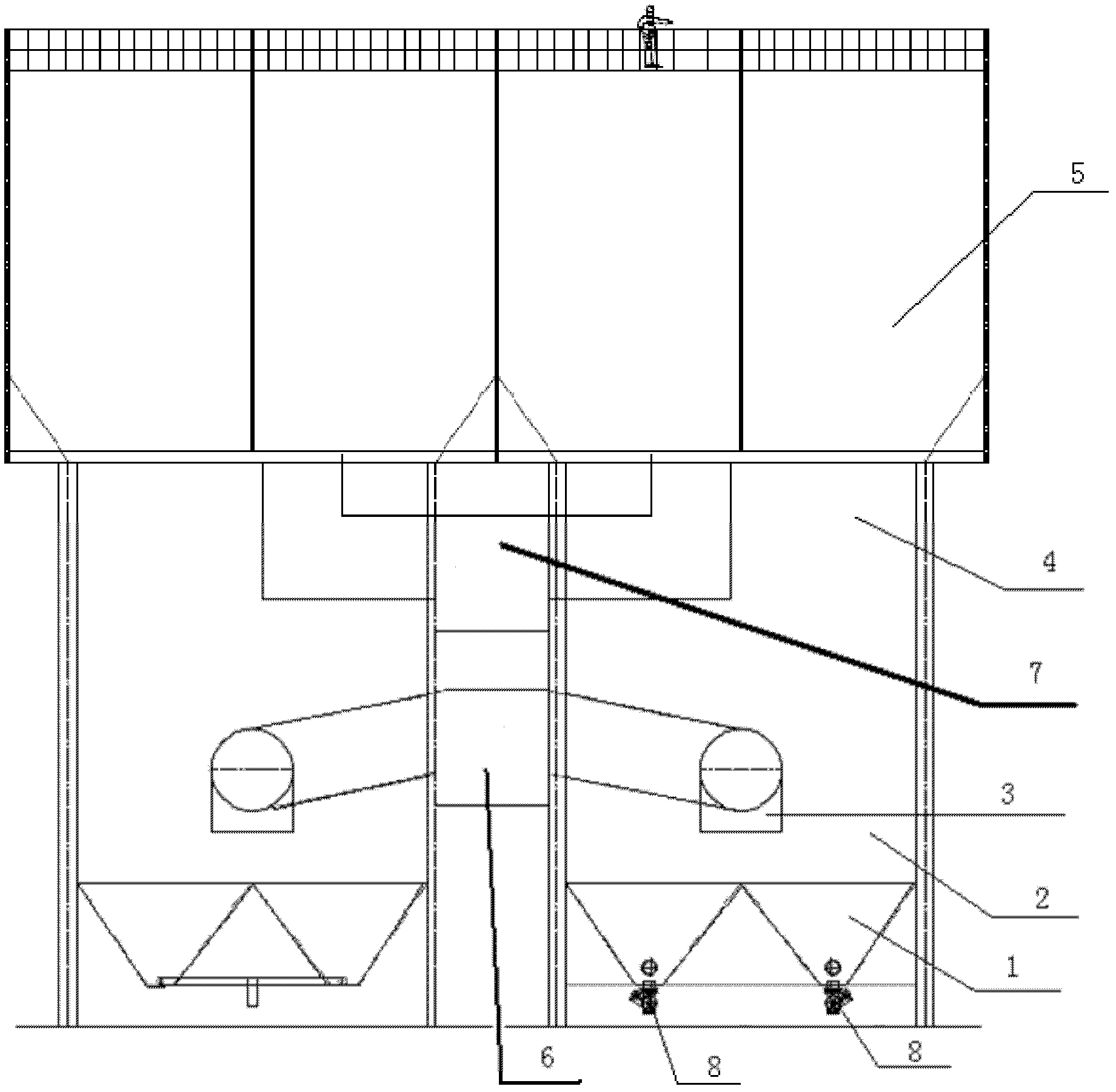

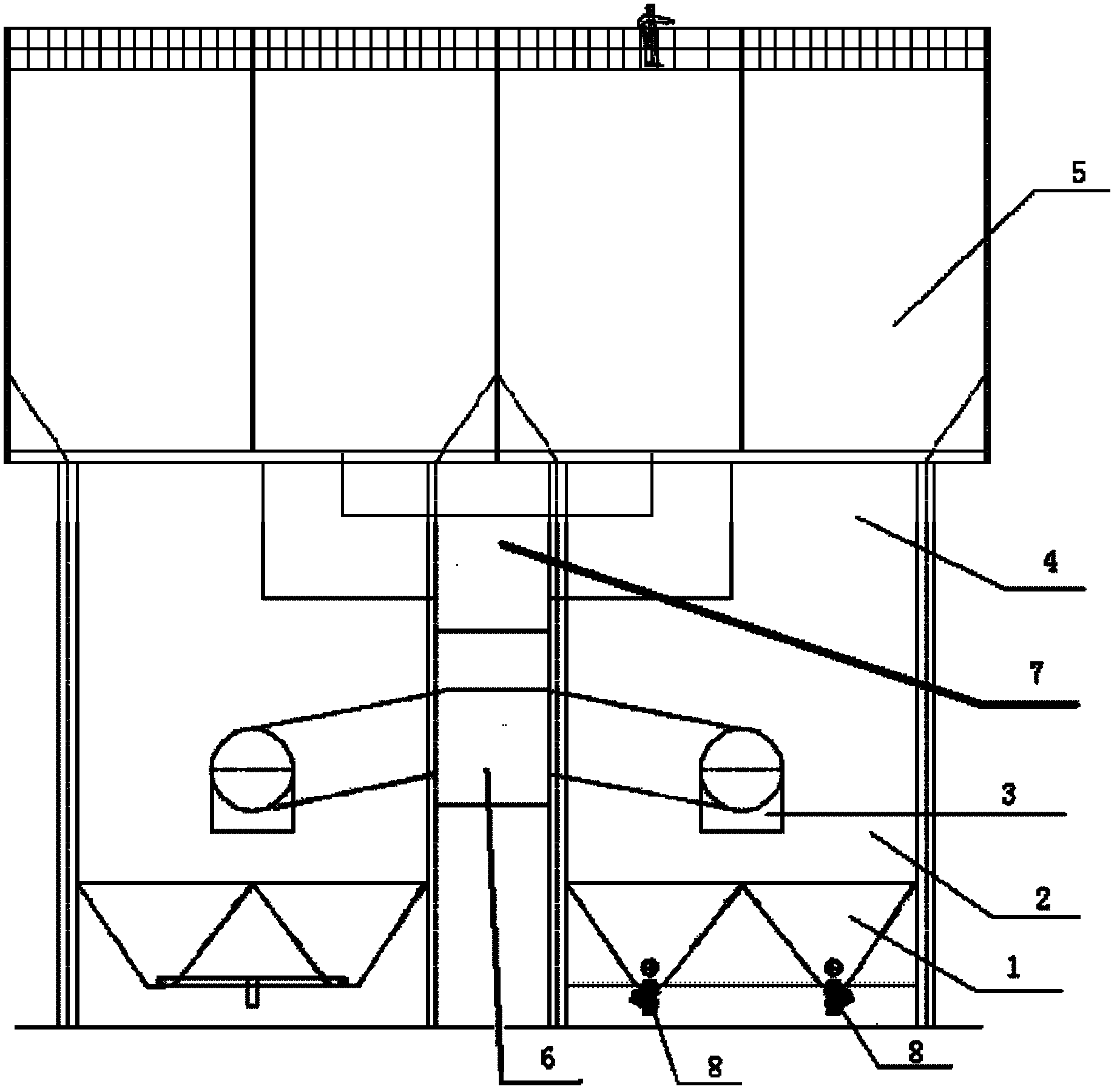

[0026] The present invention adopts the integrated design of desulfurization and dust removal, and saves the circulating ash conveying system and stirring device, greatly reduces the occupied area of the equipment without affecting the desulfurization rate, and saves power consumption and maintenance costs. The invention adds an injection port, which plays the role of uniform gas distribution and material distribution. After the flue gas and desulfurizer enter the desulfurization system, the flow field at the injection port changes to make it more uniform, and the contact and mixing of the flue gas and the desulfurizer is more efficient. Fully, the desulfurization rate is improved. After passing through the uniform flow field of the injection port, the flue gas enters the circulating fluidized zone along with the desulfurizing agent through the fluidized tank. The circulating fluidized zone is basically some coarse particles, and most of the fine particles enter the fine part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com