Cutter wear state monitoring method based on deep gated cycle unit neural network

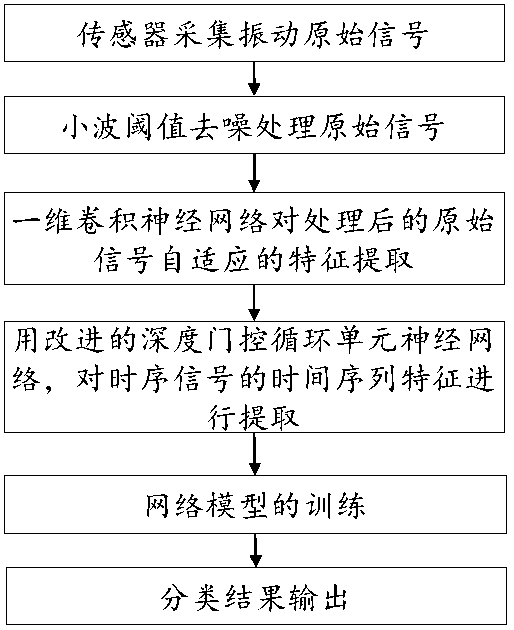

A cyclic unit and neural network technology is applied in the field of tool wear state monitoring based on a deep gated cyclic unit neural network, which can solve the problems of not taking into account correlation, prone to gradient dispersion, and insufficient convolution layers to grasp the overall situation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

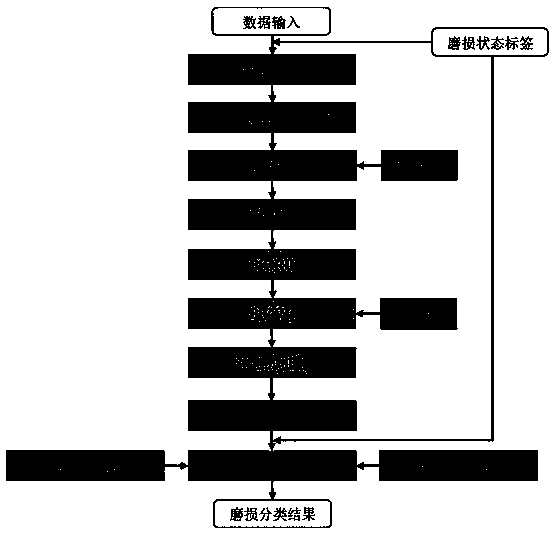

Method used

Image

Examples

Embodiment

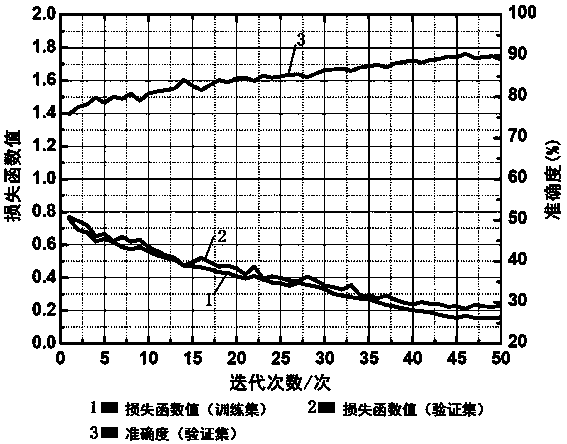

[0092] 1 Experimental design

[0093] (1) Status monitoring

[0094] In the experiment of the present invention, a high-precision numerical control vertical milling machine (model: VM600) is used for milling workpieces. No coolant is added during the milling process. The milling workpieces are die steel (S136), and the milling cutters use ultrafine particle tungsten carbide four-edged blades. Milling cutter with TiAIN coating on the cutting edge surface. Table 1 shows the cutting parameters of the milling experiment.

[0095] Table 1 Cutting parameters of milling experiments

[0096]

[0097] In the experiment, three acceleration sensors (model: INV9822) were used to magnetically adsorb on the machine tool fixture in the x, y, and z directions to collect the original vibration signals generated during tool processing in real time; The high-precision digital acquisition instrument (model: INV3018CT) processes the real-time signal and transmits it to the computer. The sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com