Method for intelligently monitoring wear states of easily-worn parts of power plant coal mill based on MSET

A wear state, intelligent power plant technology, applied in the direction of grain processing, etc., can solve the problems of difficult online monitoring of the wearable parts of the coal mill, difficult online monitoring, and easy wear of the coal mill, so as to facilitate timely adjustment and prevent waste of resources , Improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

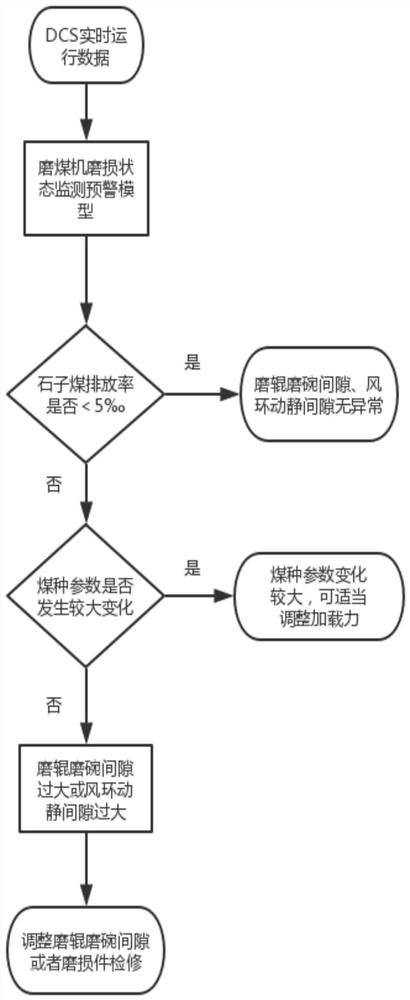

[0047] Embodiment 1 of the present application provides a method such as figure 1The MSET-based monitoring method for wear status of wearable parts of coal mills in smart power plants:

[0048] Step 1. Obtain the historical data of the measuring points of the wear state of the wearable parts of the coal mill under different working conditions;

[0049] Step 1.1. Select the modeling parameters from the monitoring parameters of the HP type medium-speed coal mill in Table 1; or expand the dimension of the monitoring parameters of the coal mill to obtain the modeling parameters; the monitoring parameters of the coal mill include the influence of stones Parameters of coal discharge rate, characteristic parameters of coal type, characteristic parameters of roller and bowl gap and dynamic and static gap of air ring; modeling parameters are shown in Table 2;

[0050] Table 1 Main monitoring parameters of HP type medium-speed coal pulverizer

[0051] parameter name unit ...

Embodiment 2

[0078] On the basis of the first embodiment, the second embodiment of the present application provides the application of the MSET-based monitoring method for the wear state of the wearing parts of the intelligent power plant coal mill in the first embodiment in actual situations:

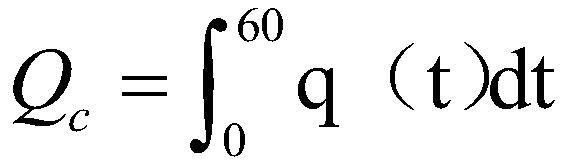

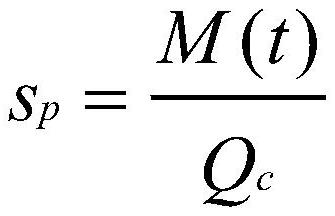

[0079] One model HP1203 coal mill, the pebble coal weighing and measuring device is fixed on the ground under the pebble coal operation box of the coal mill. The pebble coal weighing and measuring device has the function of accumulative pebble coal weight measurement, which is realized by a microcomputer device Display of the real-time weight m of pebble coal in the current operation box and the display of the hourly cumulative weight M(t) and related query functions.

[0080] The wear state monitoring method of the wearable parts of the coal mill based on the amount of pebble coal is as follows:

[0081] (a) First, adjust the HP1203 coal mill with the grinding rollers, bowl lining, air ring, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com