Two-station machining unit with wheel dressing and grinding

A technology of grinding processing and dressing devices, which is applied to the parts of grinding machine tools, abrasive surface adjustment devices, metal processing equipment, etc., and can solve the problems of poor processing quality and surface accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

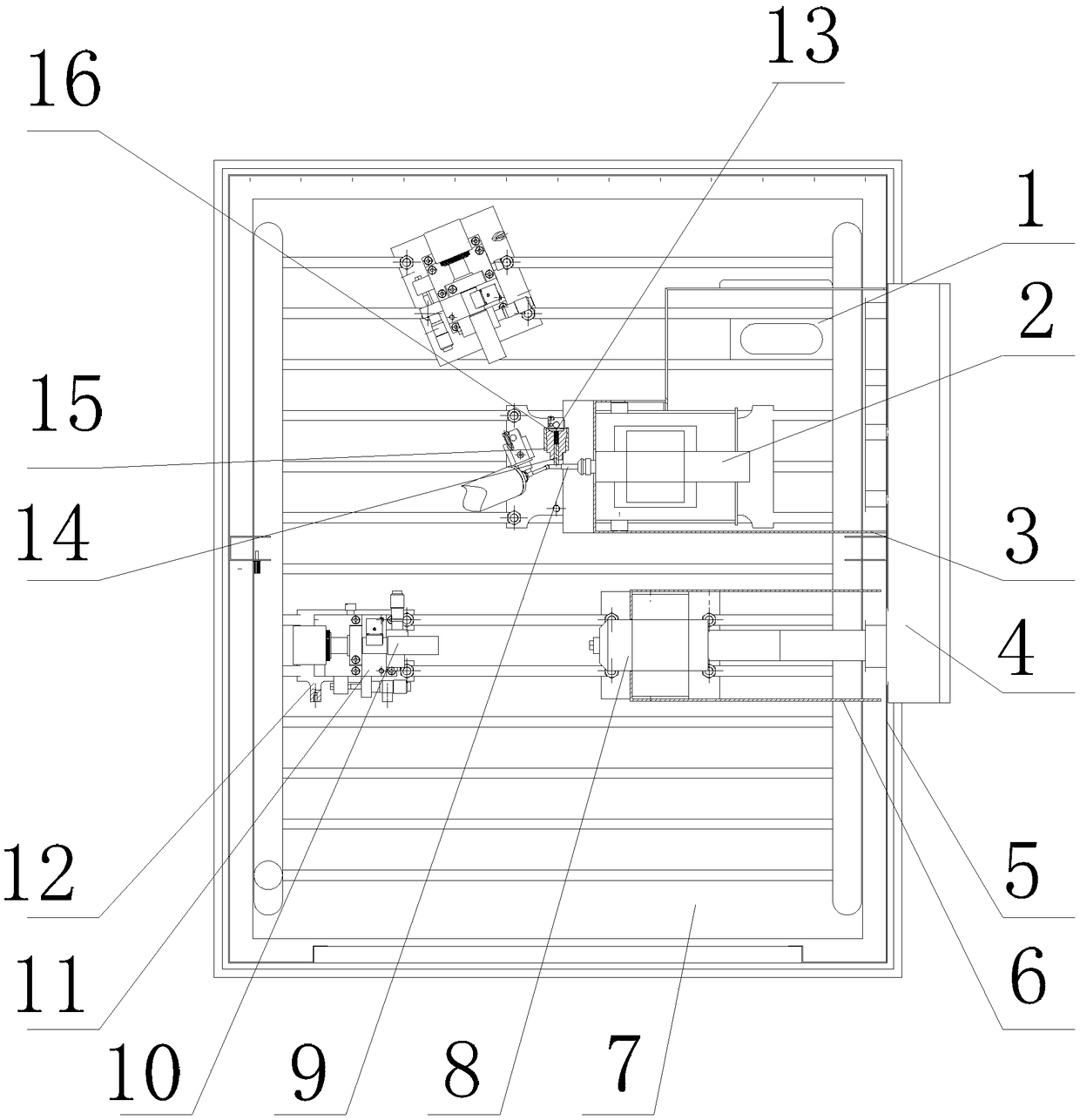

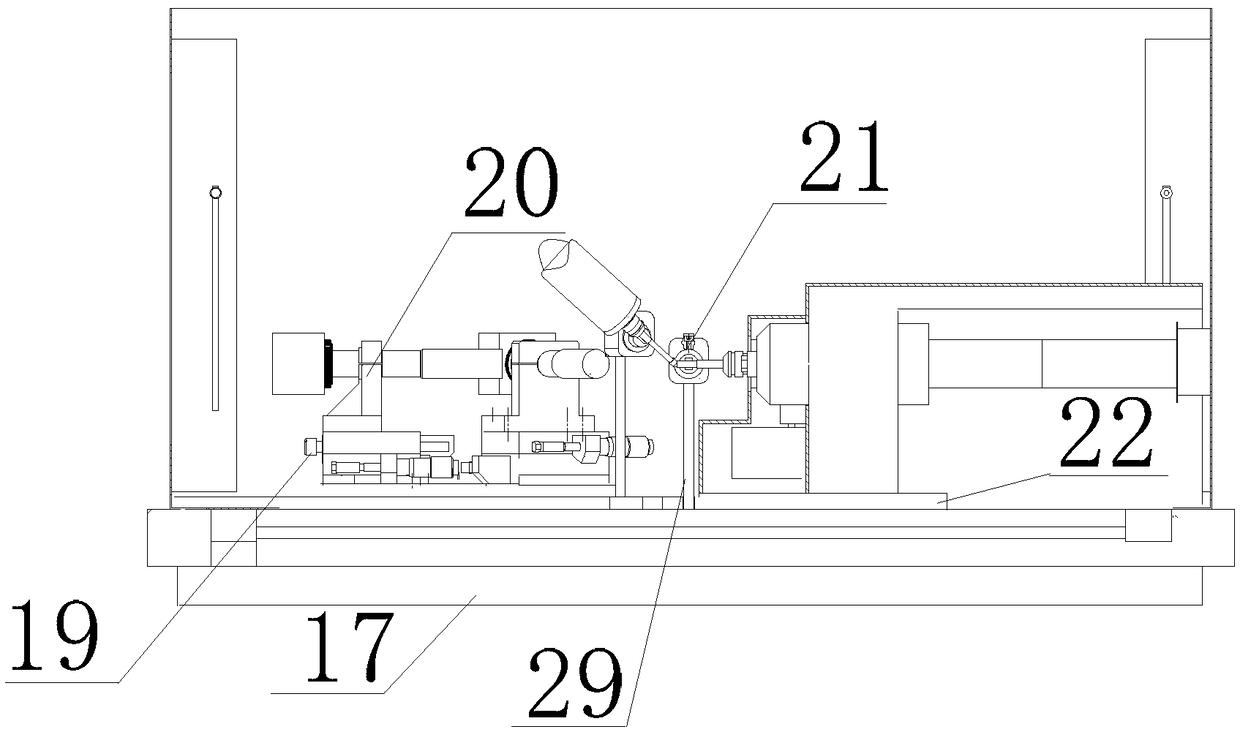

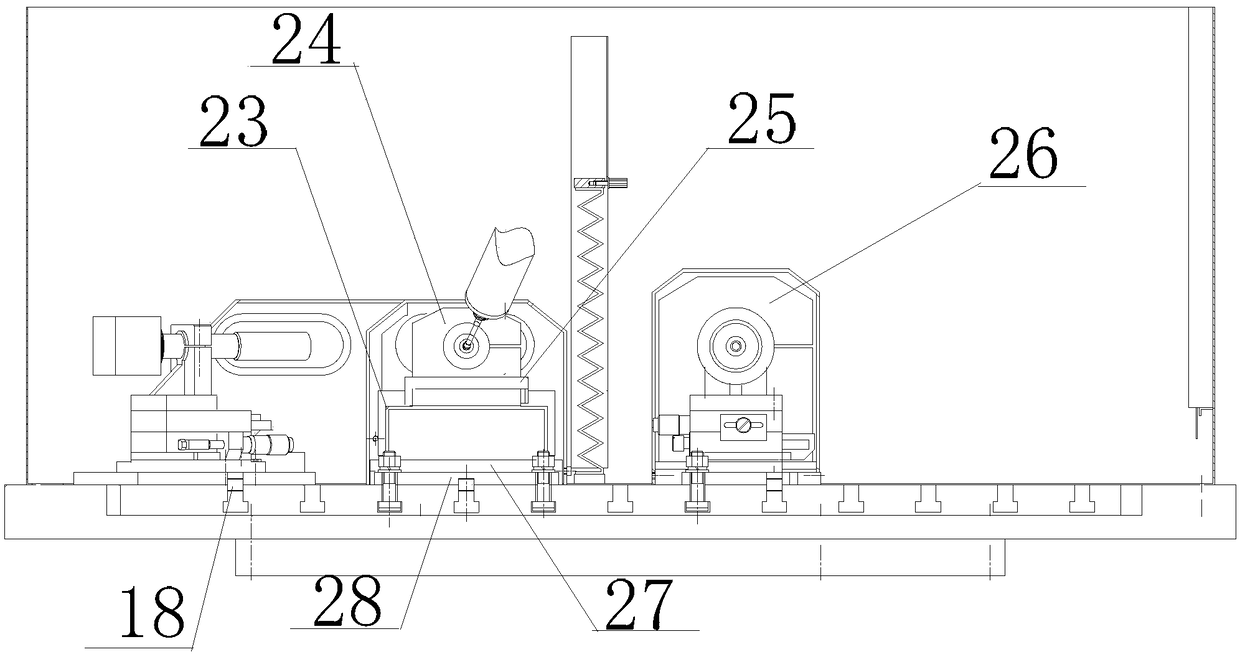

[0026] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this embodiment, the two-station processing device with grinding wheel dressing and grinding described in this embodiment, the device includes a dressing device protective cover 3, a worktable protective cover 5, a workpiece spindle device protective cover 6, and a worktable 7 , workpiece spindle 8, two CCD monitoring devices, EDM trimming device, workpiece spindle transition plate 22, precision positioning platform protective cover 23, protective device cover 25, workpiece spindle clamping piece 26, ultra-precision positioning platform 27, trimming device Transition plate 28, electrode support rod 29 and electrode cover plate 13;

[0027] The CCD monitoring device includes a two-dimensional micro-displacement platform 11, a CCD tool setting device connecting plate 12, a CCD camera 10, a CCD tool setting device positioning block 18, a two-dimensional micro-displacement platform connecting plate 1...

specific Embodiment approach 2

[0061] Specific Embodiment 2. This embodiment is a further description of the two-station processing device with grinding wheel dressing and grinding described in Specific Embodiment 1. It also includes a wire routing block 1 and a wire routing groove 4. The wiring trough 4 is fixedly installed on the outside of the workbench protective cover 5 by bolts; the wiring stopper 1 presses the sealing rubber pad on the workbench by screws.

[0062] The wiring block 1 of this embodiment presses the sealing rubber pad on the workbench with screws to prevent the working fluid from flowing into the lower part of the workbench.

specific Embodiment approach 3

[0063] Specific embodiment three. This embodiment is a further description of the two-station processing device with grinding wheel dressing and grinding described in specific embodiment one or two. It also includes a workbench transition plate 17, and the workbench transition A plate 17 is mounted on the underside of the table 7 .

[0064] Advantages of the present invention:

[0065] (1) The device is suitable for small-sized parts grinding and EDM dressing of ball-end grinding wheels with a diameter of less than 2mm. The accuracy of the ball-end grinding wheel after dressing is better than 2μm;

[0066] (2) The device can realize the CCD monitoring of the wear state of the grinding wheel at any time during the grinding process, and perform EDM dressing on the worn grinding wheel at any time to ensure the processing quality of the workpiece after grinding;

[0067] (3) The feed movement of the dressing device is realized by a high-precision positioning platform, which can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com