Method for monitoring wear state of shaft bottom drill bit during drilling

A wear state, drill bit technology, applied in the direction of measurement, drilling tools, drilling equipment, etc., can solve the problems of high misjudgment rate, high price, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

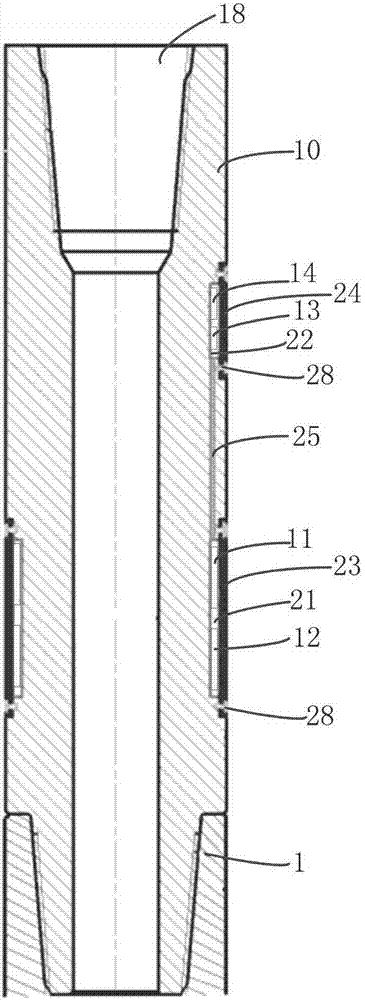

[0026] like figure 1 As shown, the present invention provides a device for monitoring the wear state of a downhole drill bit while drilling, comprising: a body 10, one end of which is used to be connected to the drill bit 1, and the other end is used to be connected to the drill collar; a first sensor 11, including a A plurality of first strain gauges on the outer peripheral surface of 10 are used to measure the torque that the drill bit 1 is subjected to; the second sensor 12 includes a plurality of second strain gauges arranged on the outer peripheral surface of the body, and is used to measure the axial torque that the drill bit 1 is subjected to. Force; the signal processing module 13 is connected with the first sensor 11 and the second sensor 12, and is used to convert the torque and axial force of the drill bit measured by the first sensor and the second sensor into digital signals; the central control module 14, It is connected with the signal processing module 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com