Patents

Literature

71 results about "Drill wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

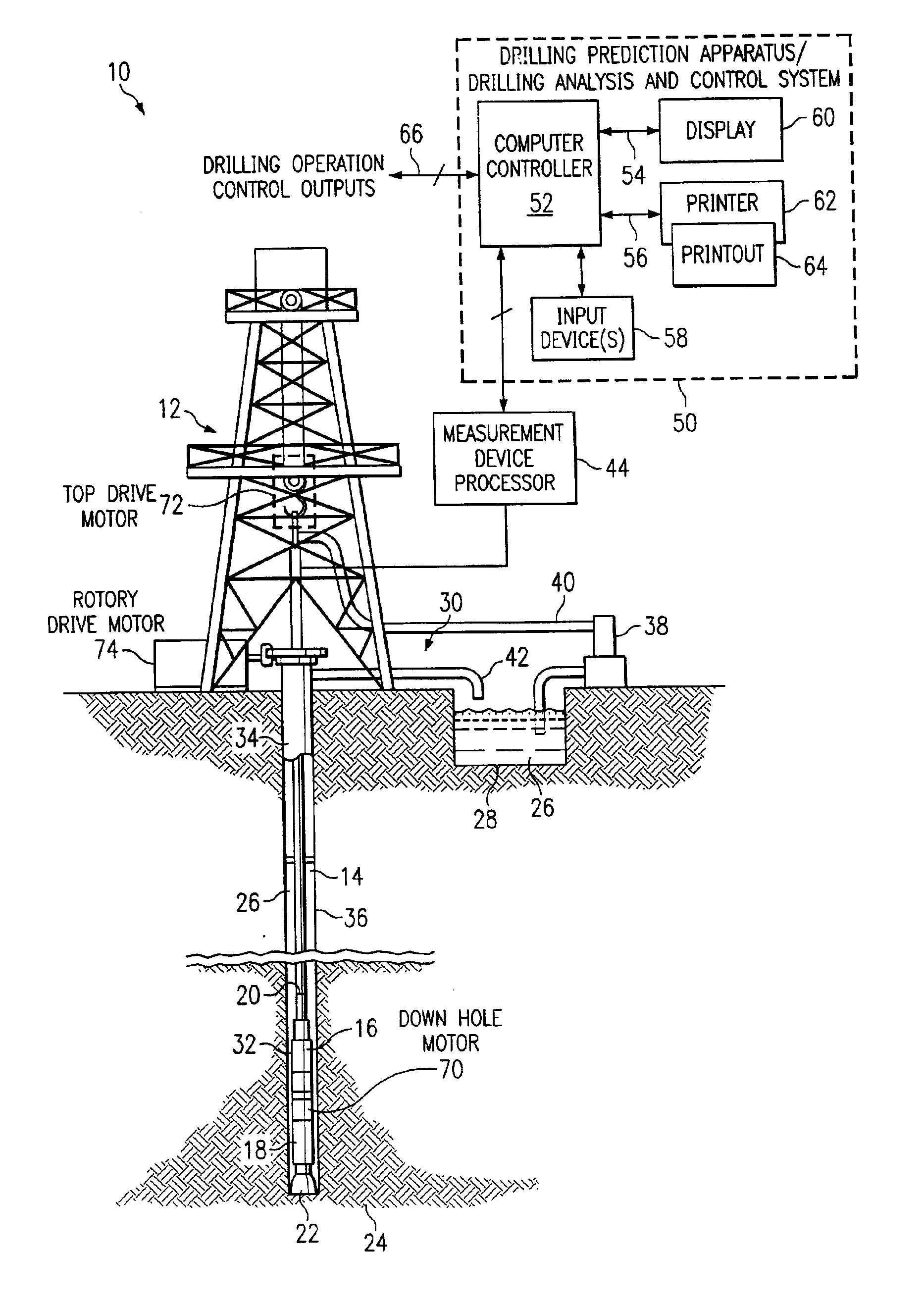

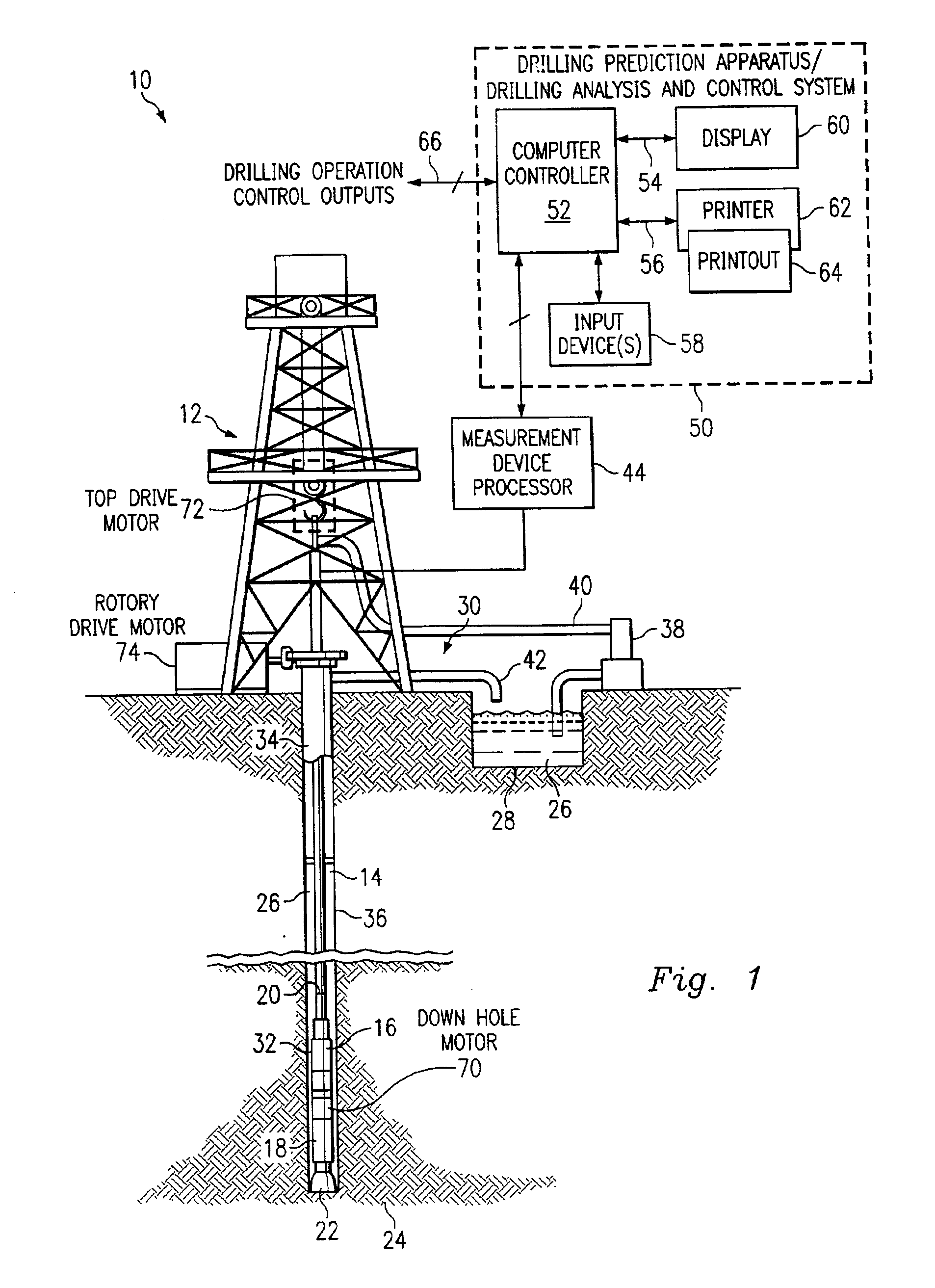

Method and system for predicting performance of a drilling system of a given formation

InactiveUS7032689B2Electric/magnetic detection for well-loggingEarth drilling toolsComputer printingDisplay device

A method and apparatus for predicting the performance of a drilling system for the drilling of a well bore in a given formation includes generating a geology characteristic of the formation per unit depth according to a prescribed geology model, obtaining specifications of proposed drilling equipment for use in the drilling of the well bore, and predicting a drilling mechanics in response to the specifications as a function of the geology characteristic per unit depth according to a prescribed drilling mechanics model. Responsive to a predicted-drilling mechanics, a controller controls a parameter in the drilling of the well bore. The geology characteristic includes at least rock strength. The specifications include at least a bit specification of a recommended drill bit. Lastly, the predicted drilling mechanics include at least one of bit wear, mechanical efficiency, power, and operating parameters. A display is provided for generating a display of the geology characteristic and predicted drilling mechanics per unit depth, including either a display monitor or a printer.

Owner:HALLIBURTON ENERGY SERVICES INC

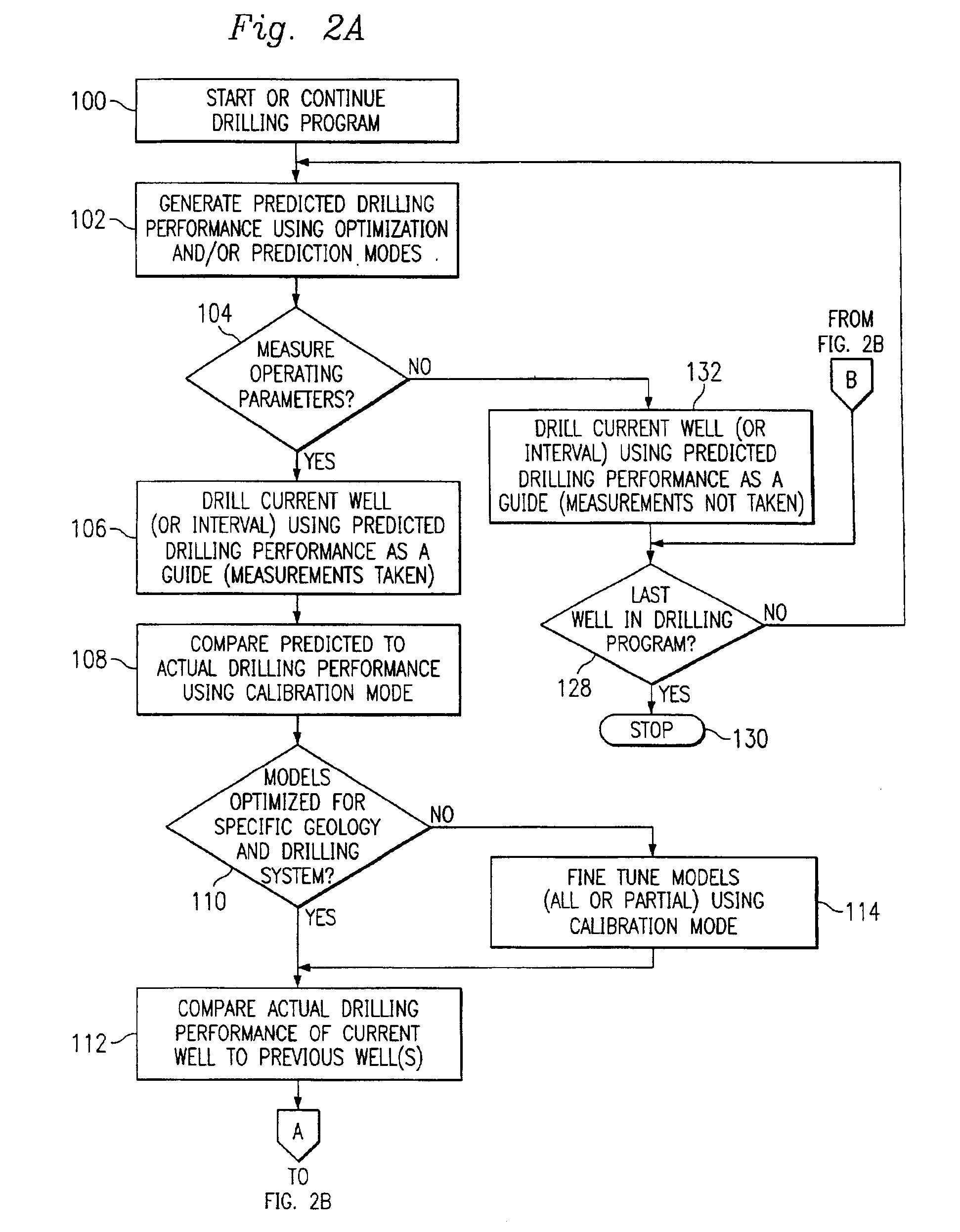

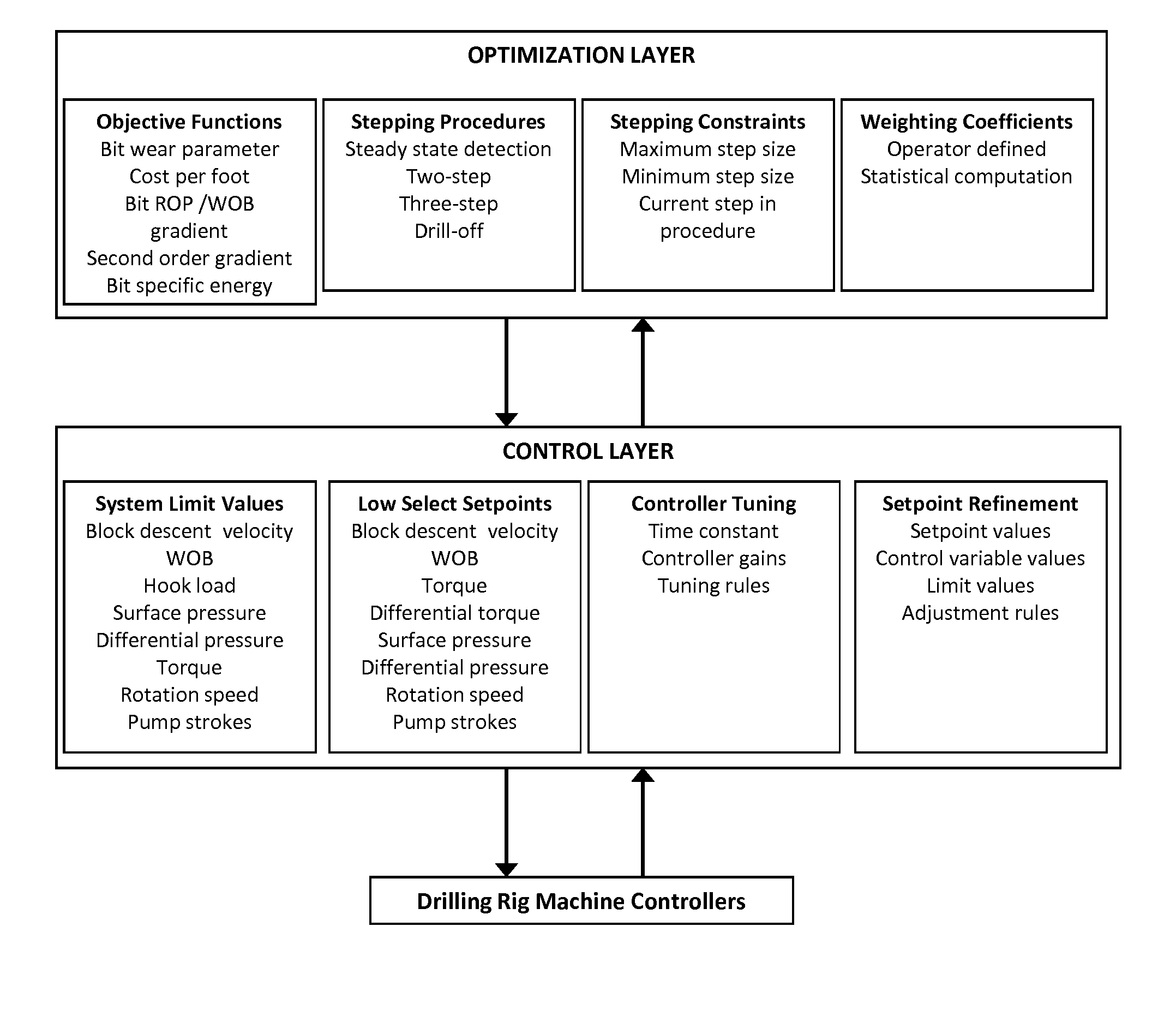

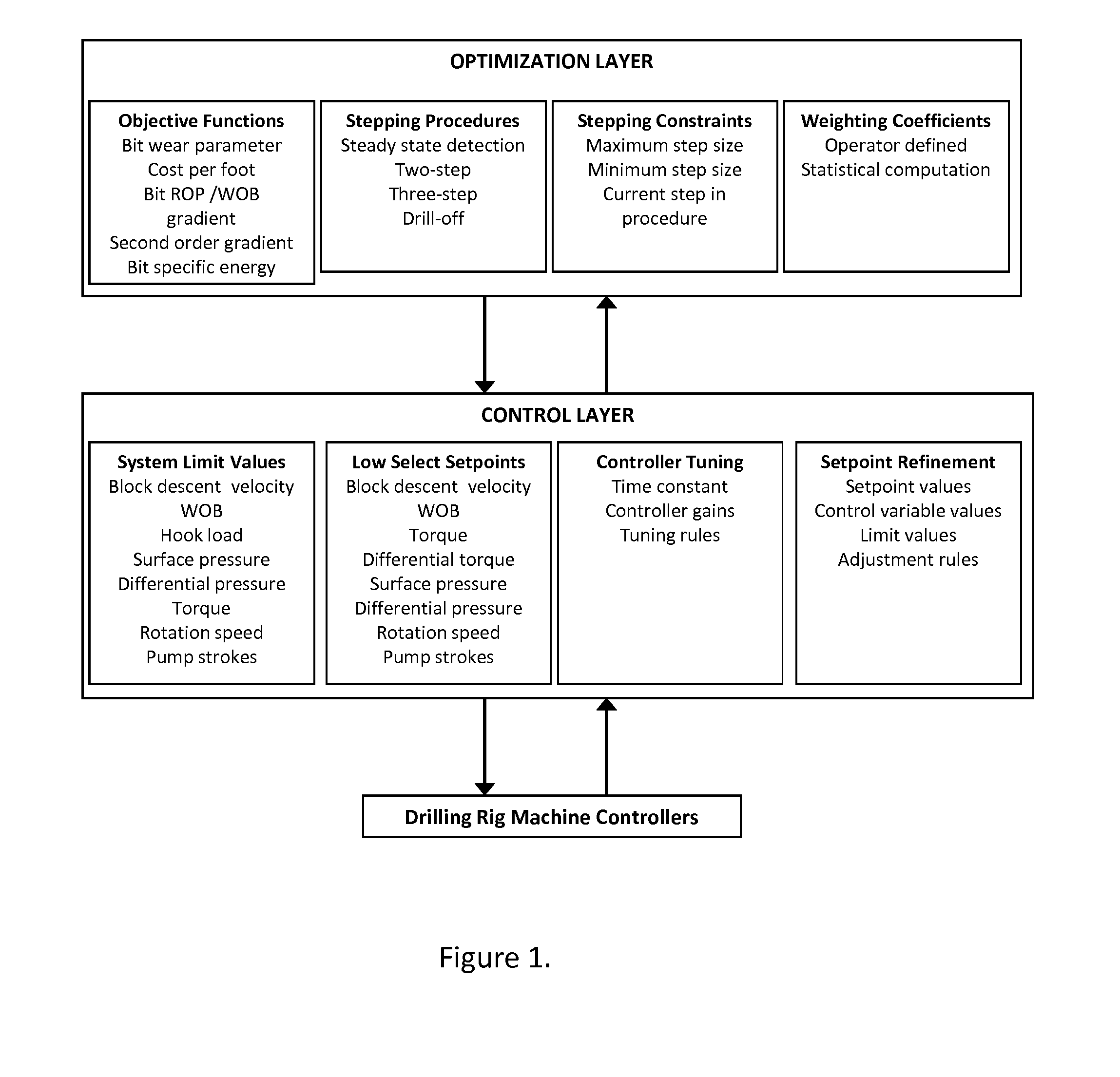

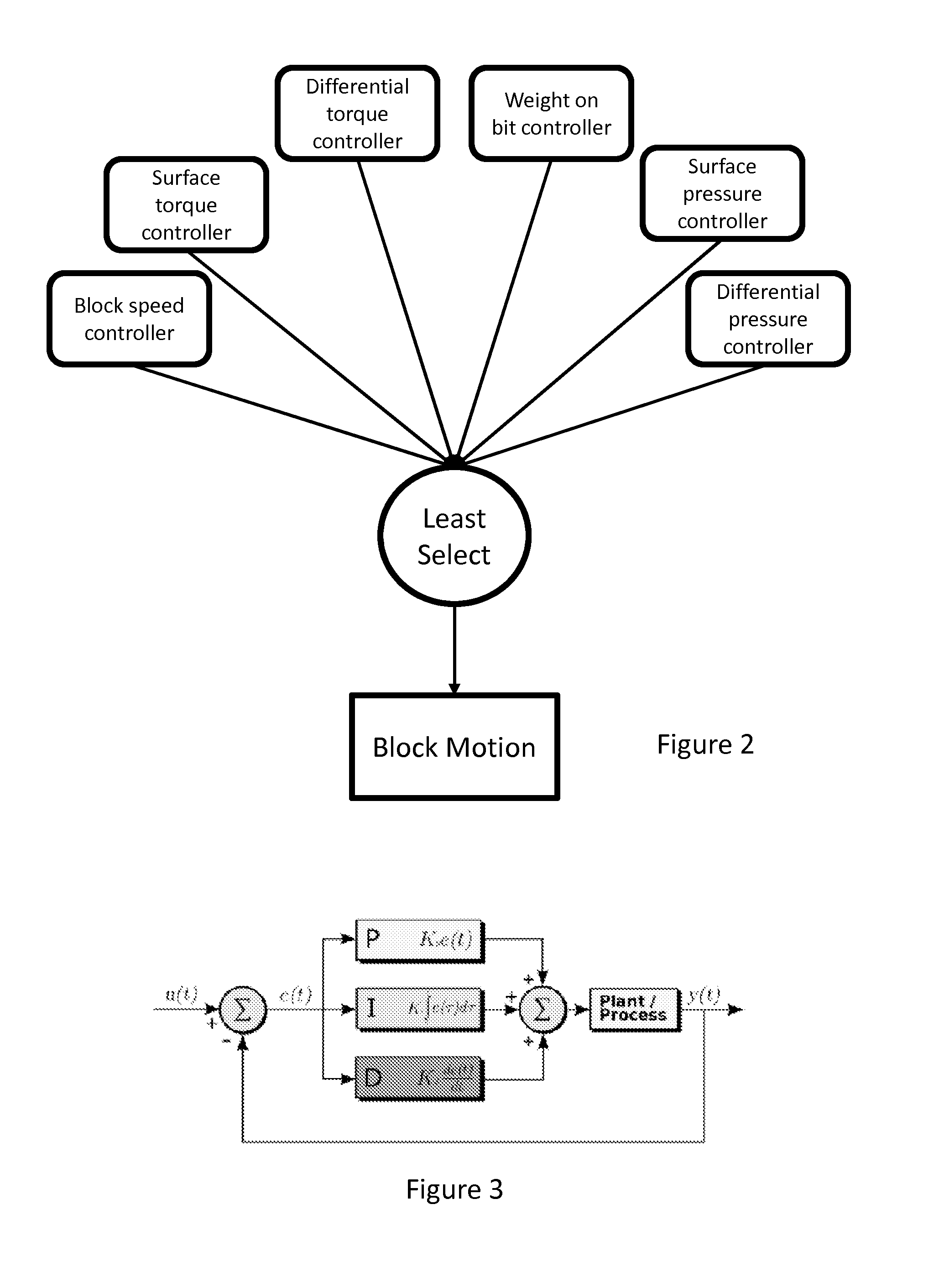

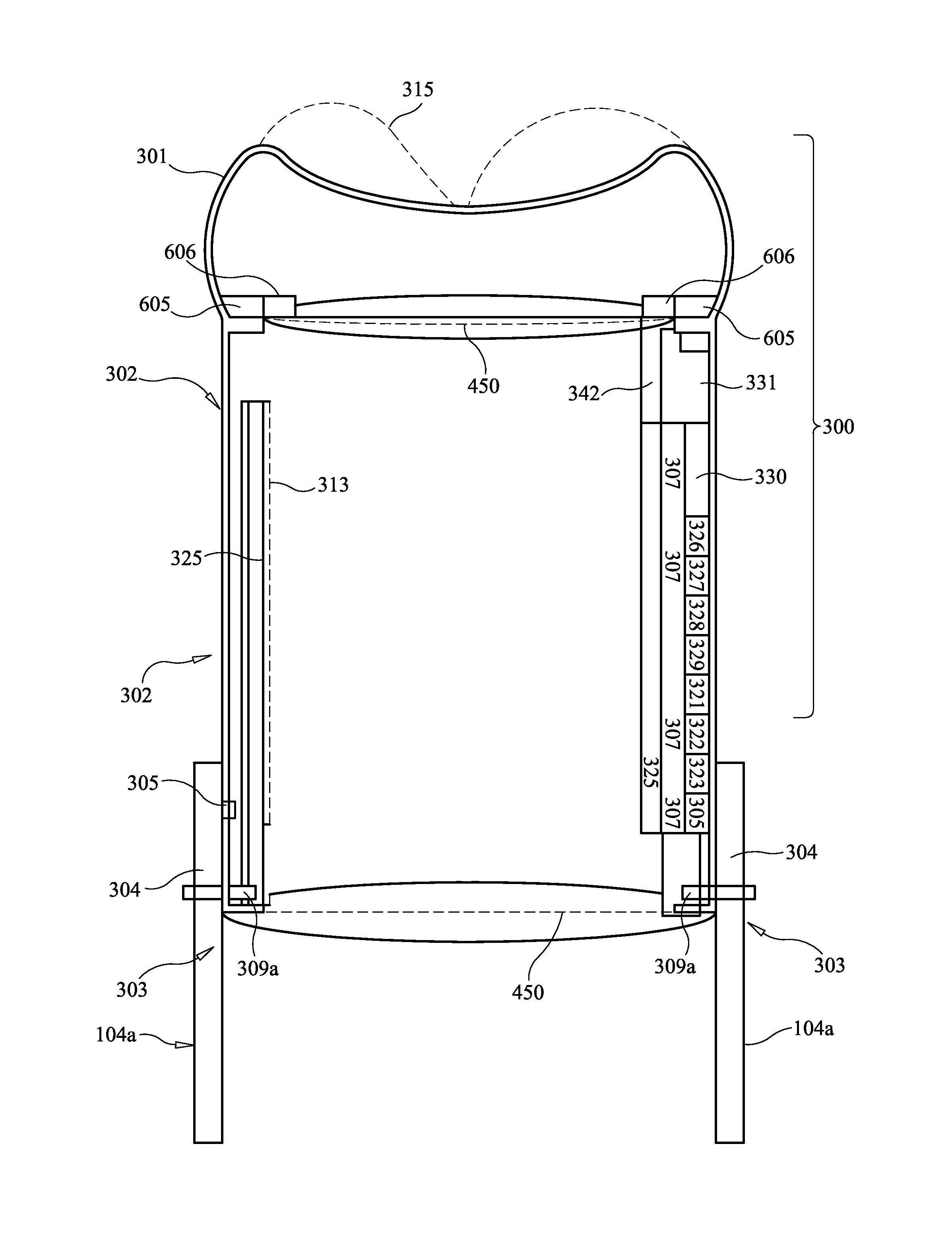

Optimizing performance of a drilling assembly

ActiveUS20150252664A1Improve performanceDrilling performance is continuouslySampled-variable control systemsComputer controlSelf-tuningSystem time

A system and method for optimized control of an assembly for drilling a borehole comprises a self-tuning, multivariable controller and an optimization engine that manipulates the setpoints of the controller such that drilling performance may be continuously optimized. The method includes evaluation of a characteristic system time constant, using this constant to compute bit ROP, using computed ROP to compute process gains, which are used to tune the multivariable controller, automatically refining controller setpoints based on controller performance, and using an optimization engine to systematically adjust controller setpoints such that drilling parameters are optimized based on any of several performance indicators, or a weighted combination of performance indicators. The method further comprises using at least one performance indicators which may be computed using estimated bit ROP: bit wear parameter; gradient of cost per foot; gradient of bit ROP versus WOB; simplified mechanical specific energy; and hydraulic specific energy.

Owner:SHELL USA INC

Drill bit and cylinder body device, assemblies, systems and methods

A drilling system includes a cylinder body and drill bit assembly. The drill bit includes a plurality of drill bit blades, each having at least one drill bit element. A cylinder body is connected to the drill bit. A plurality of transmitters are mounted on each drill bit element and transmit data characterizing a degree of wear of the drill bit to a data transmitter and receiver of the cylinder body that is in communication with the plurality of transmitters.

Owner:ZURN WILLIAM HARRISON

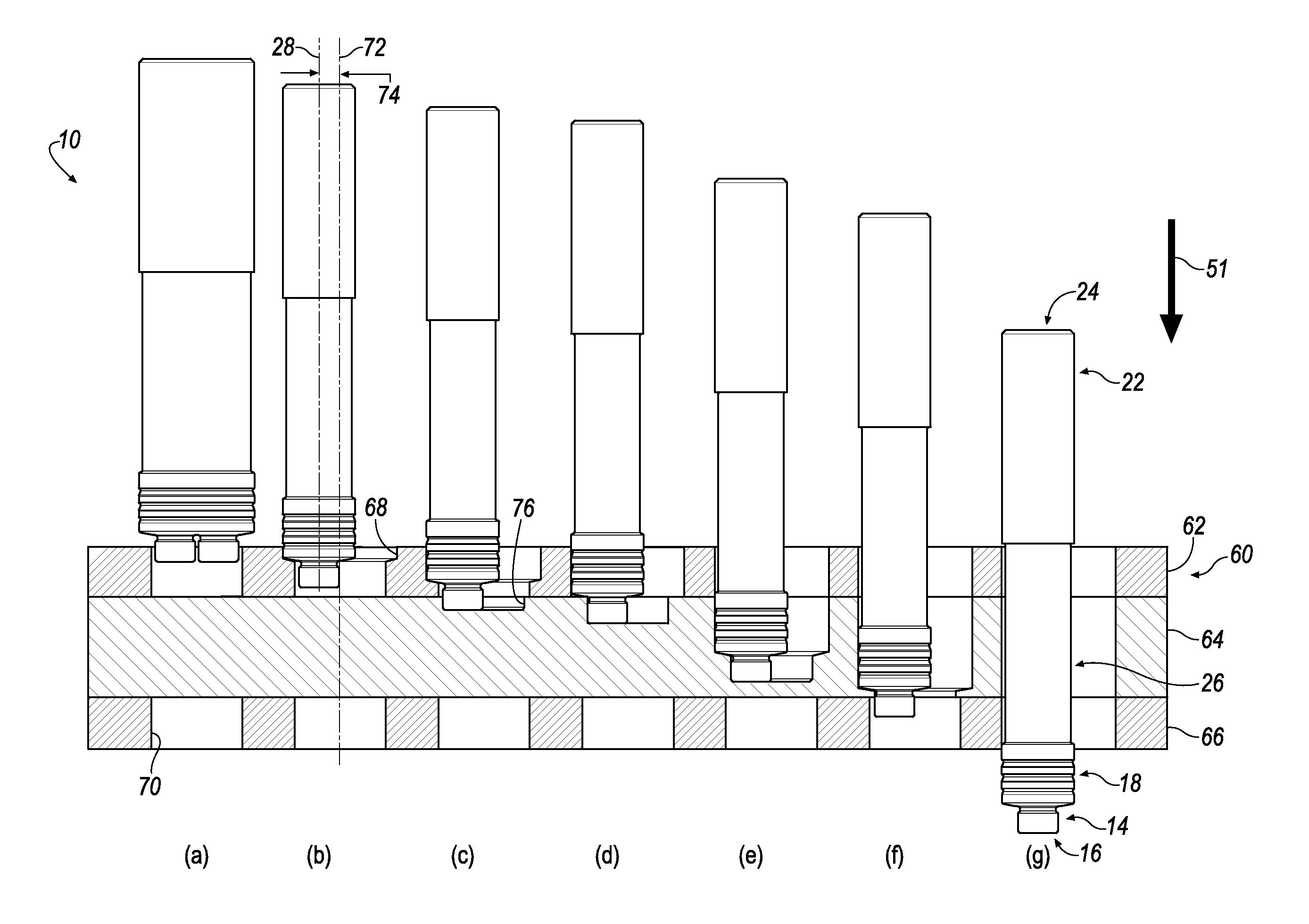

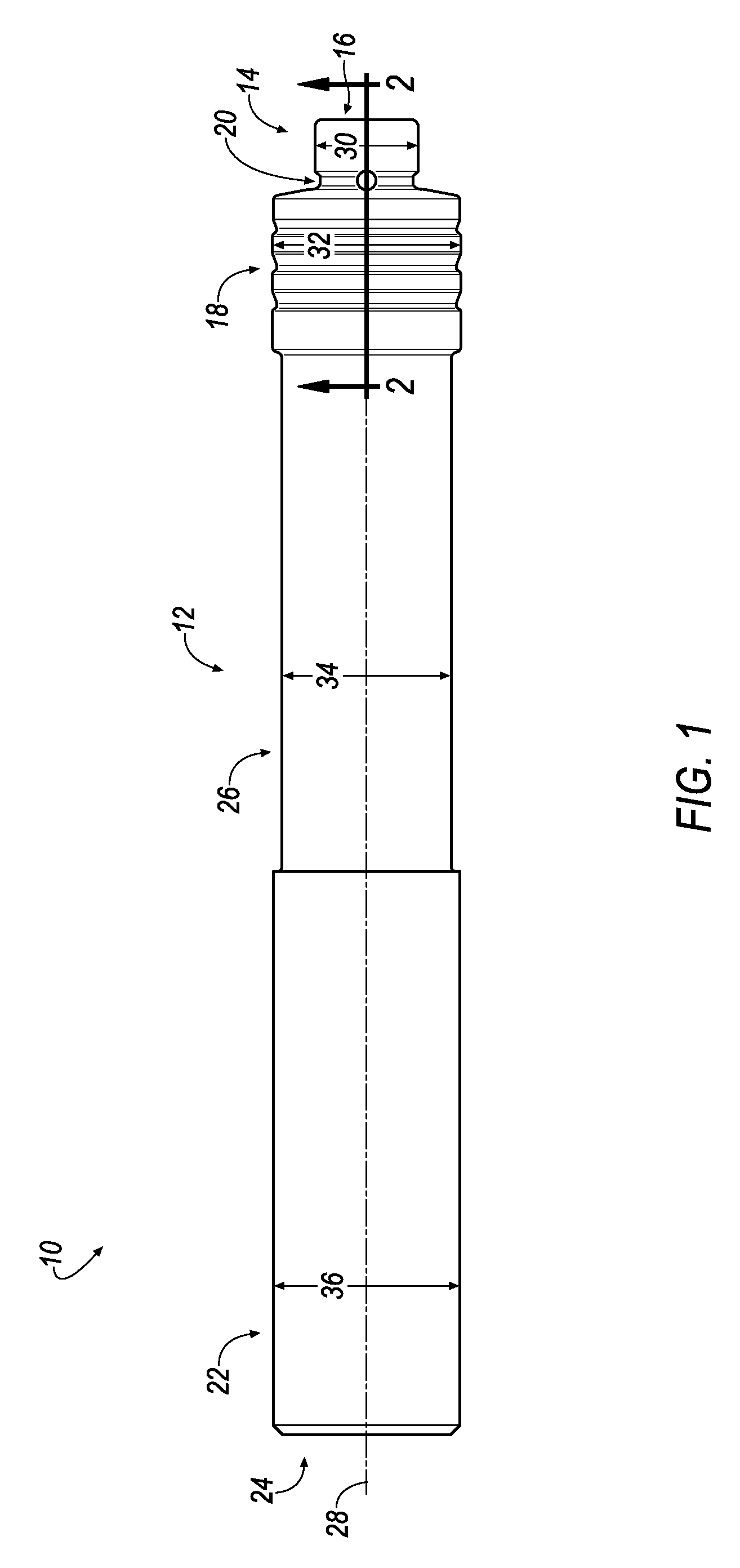

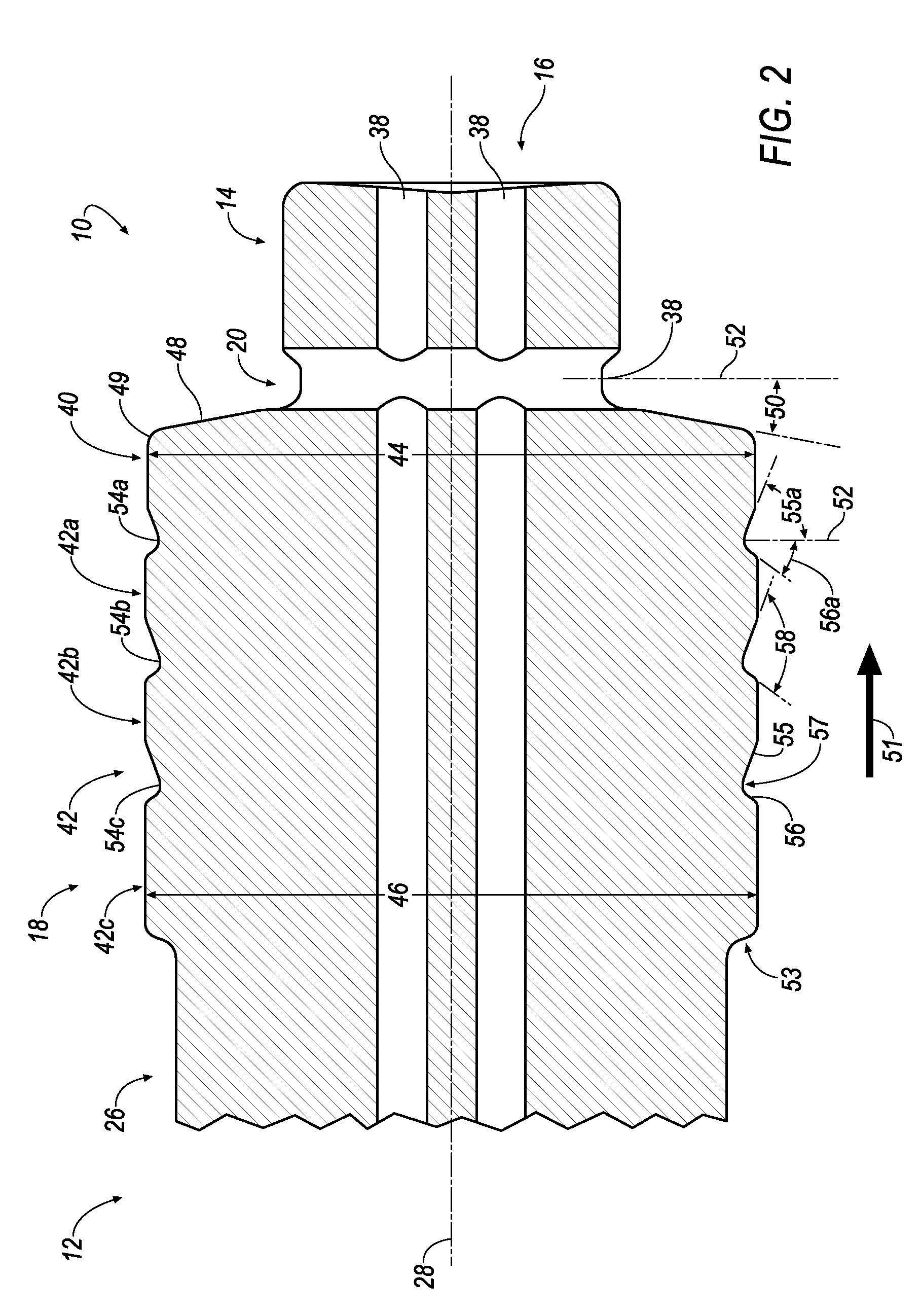

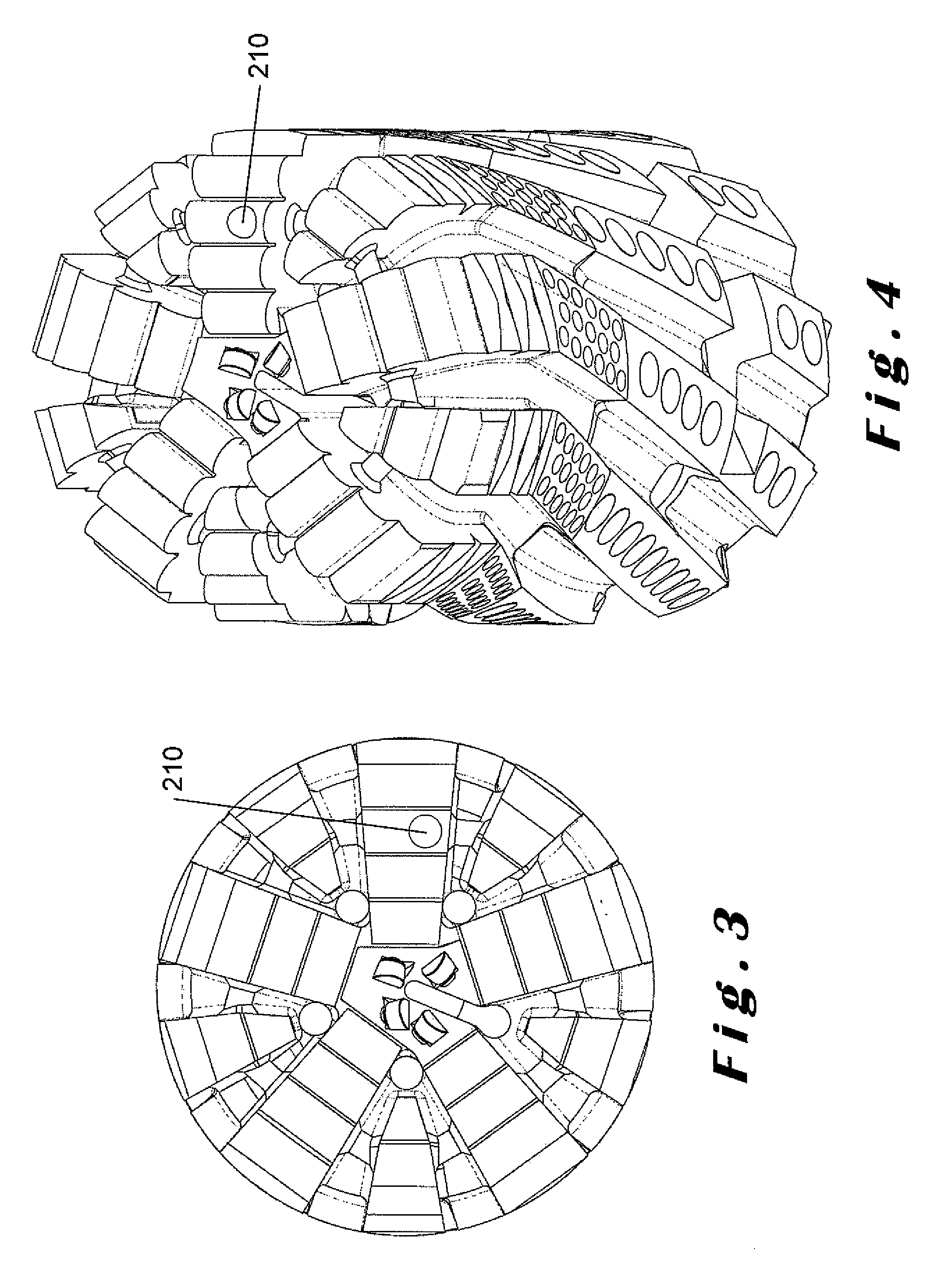

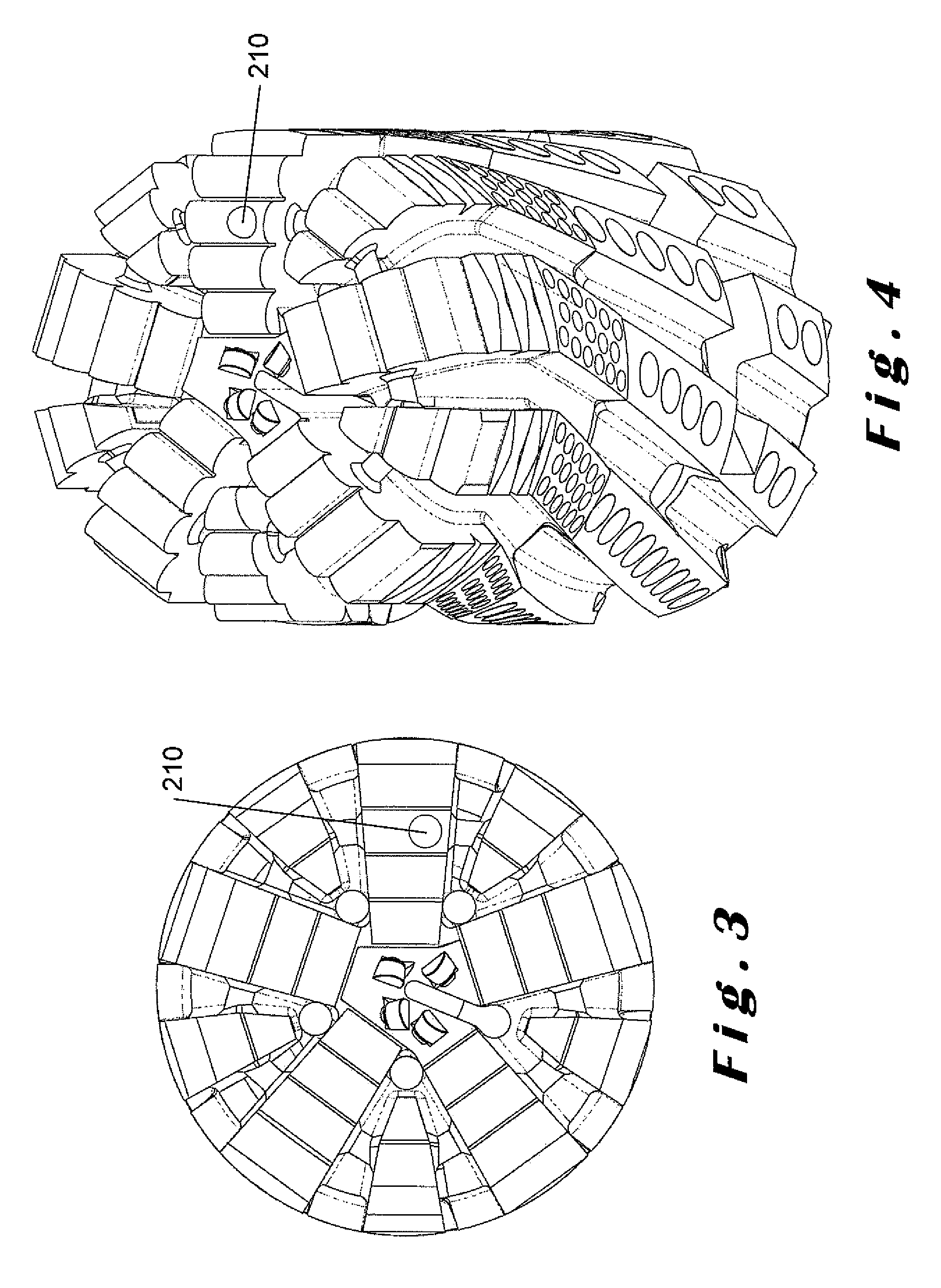

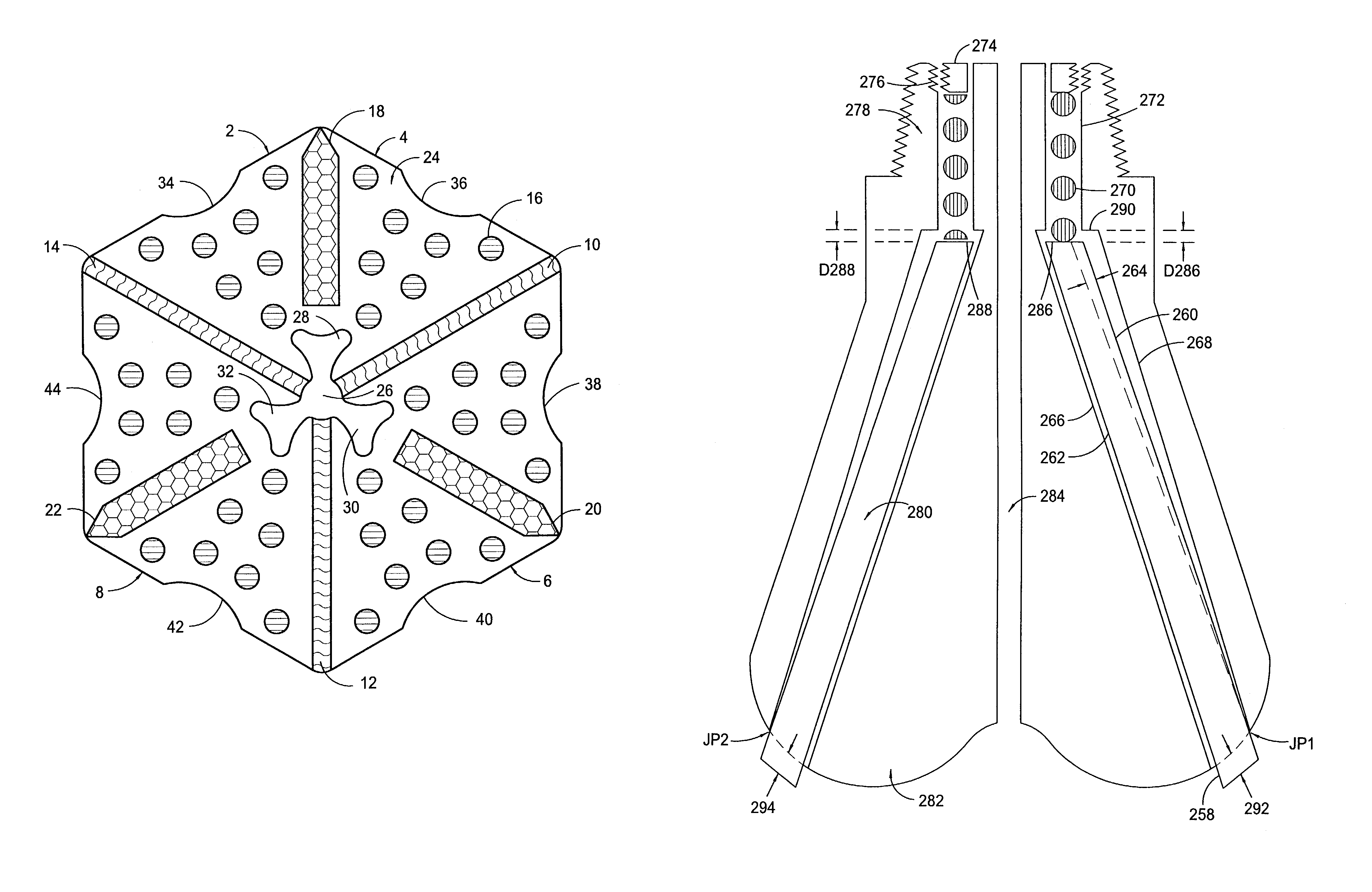

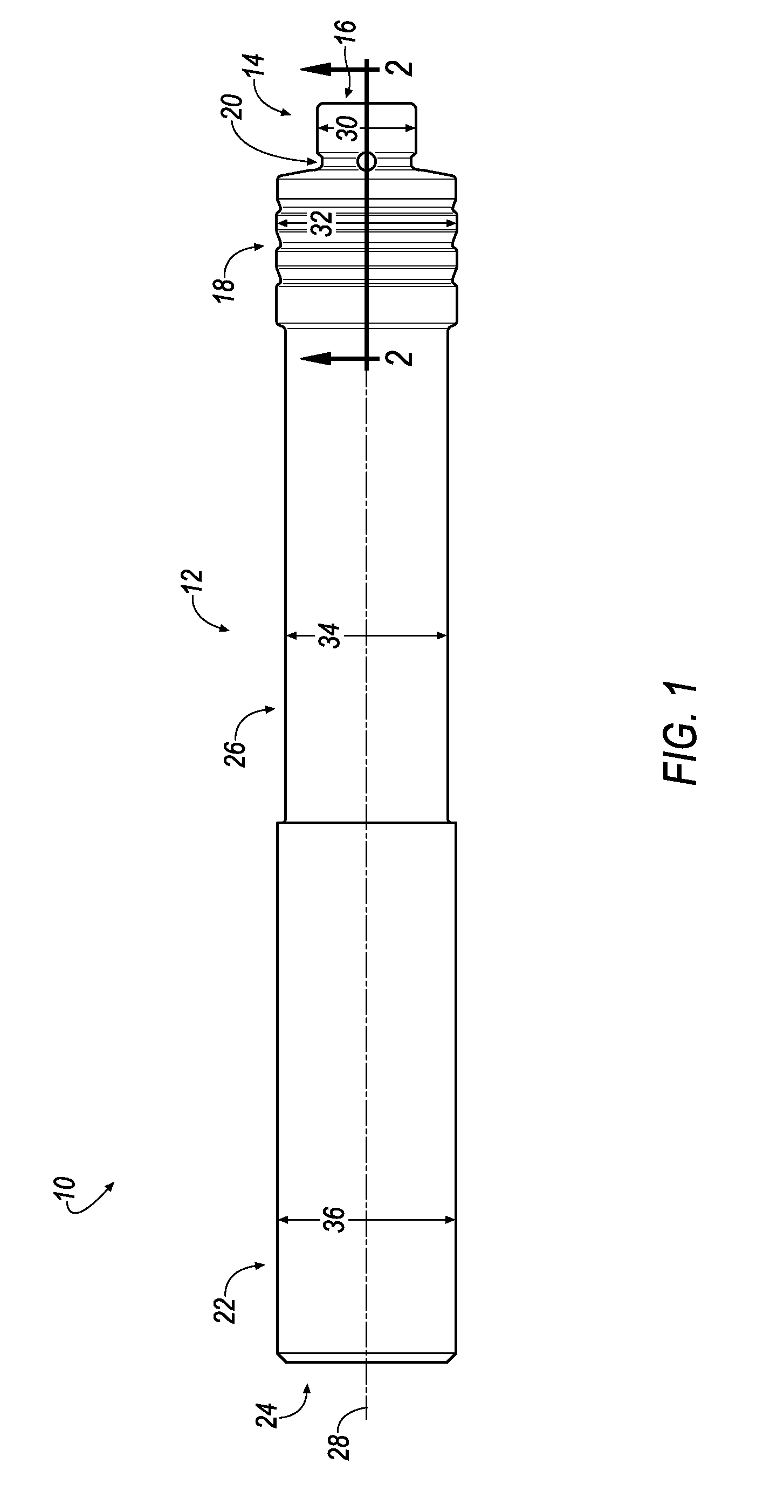

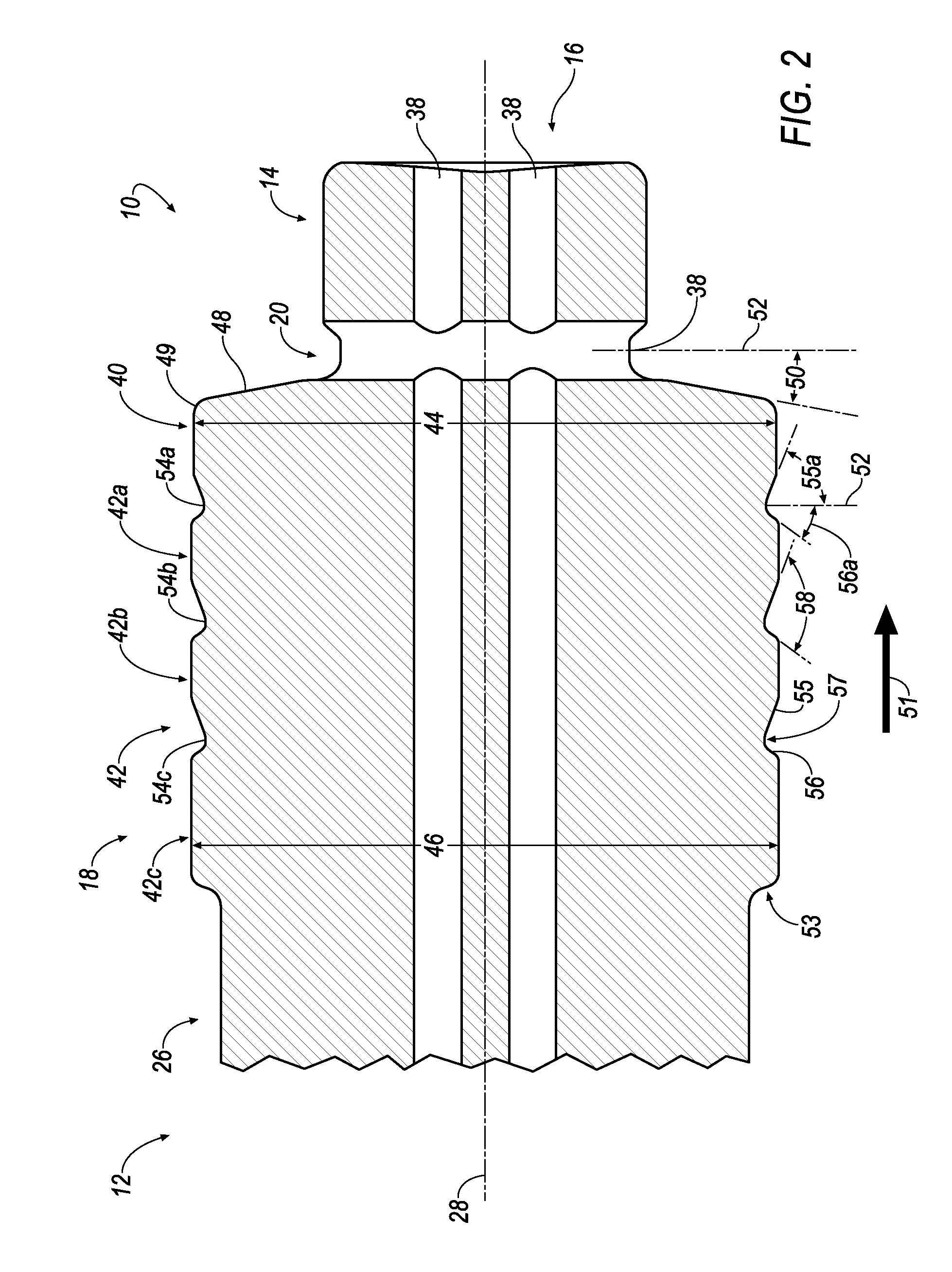

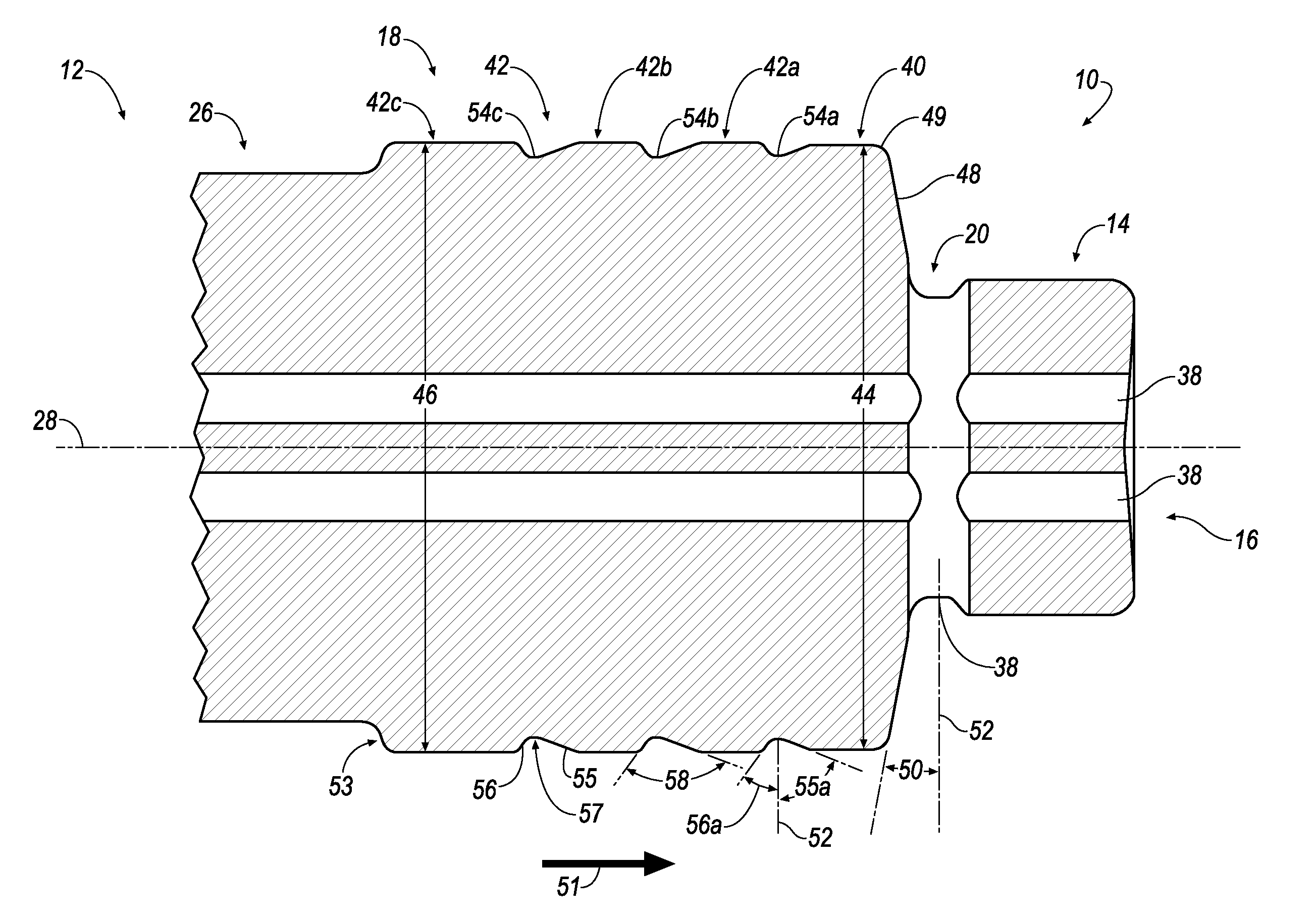

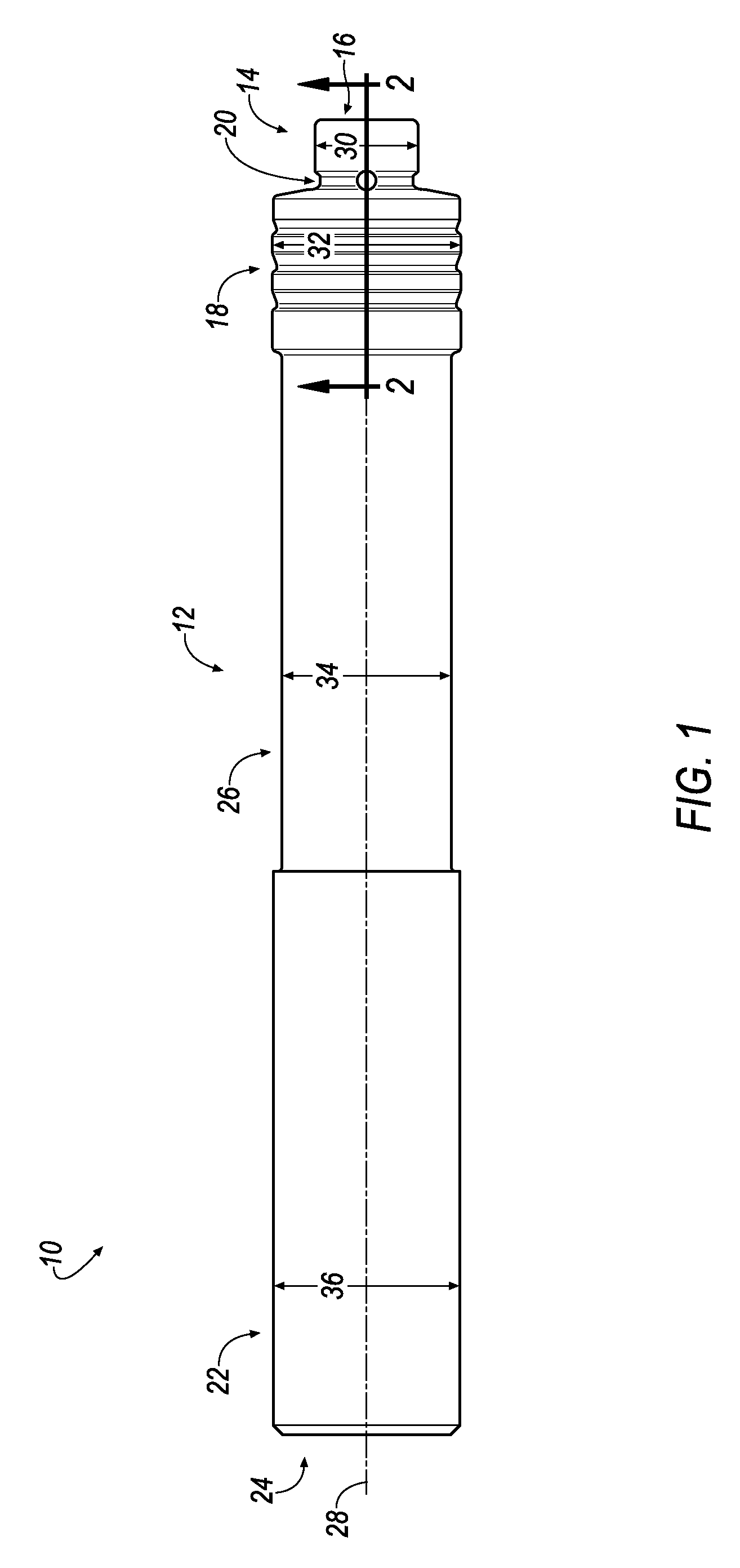

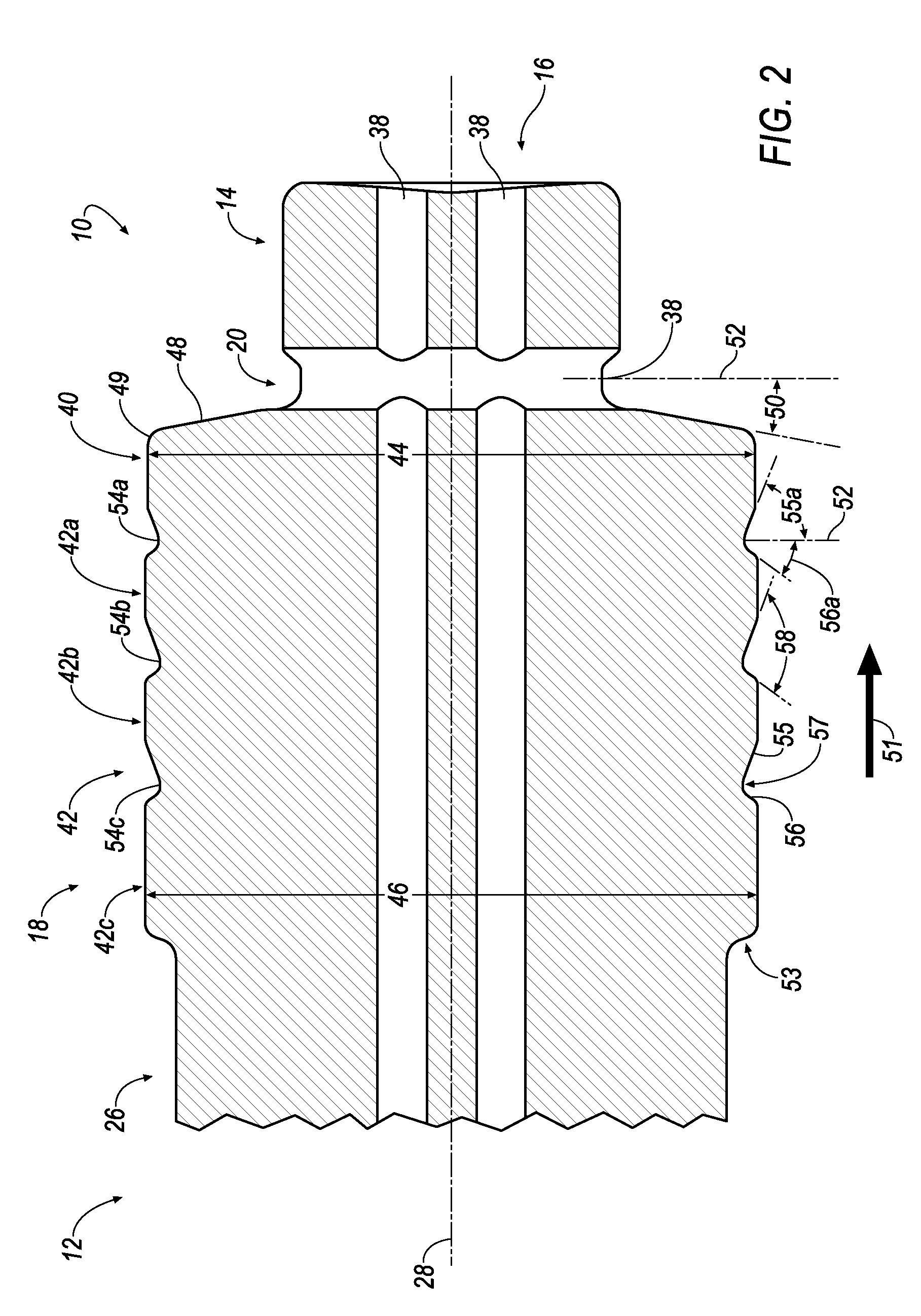

Segmented orbital drill

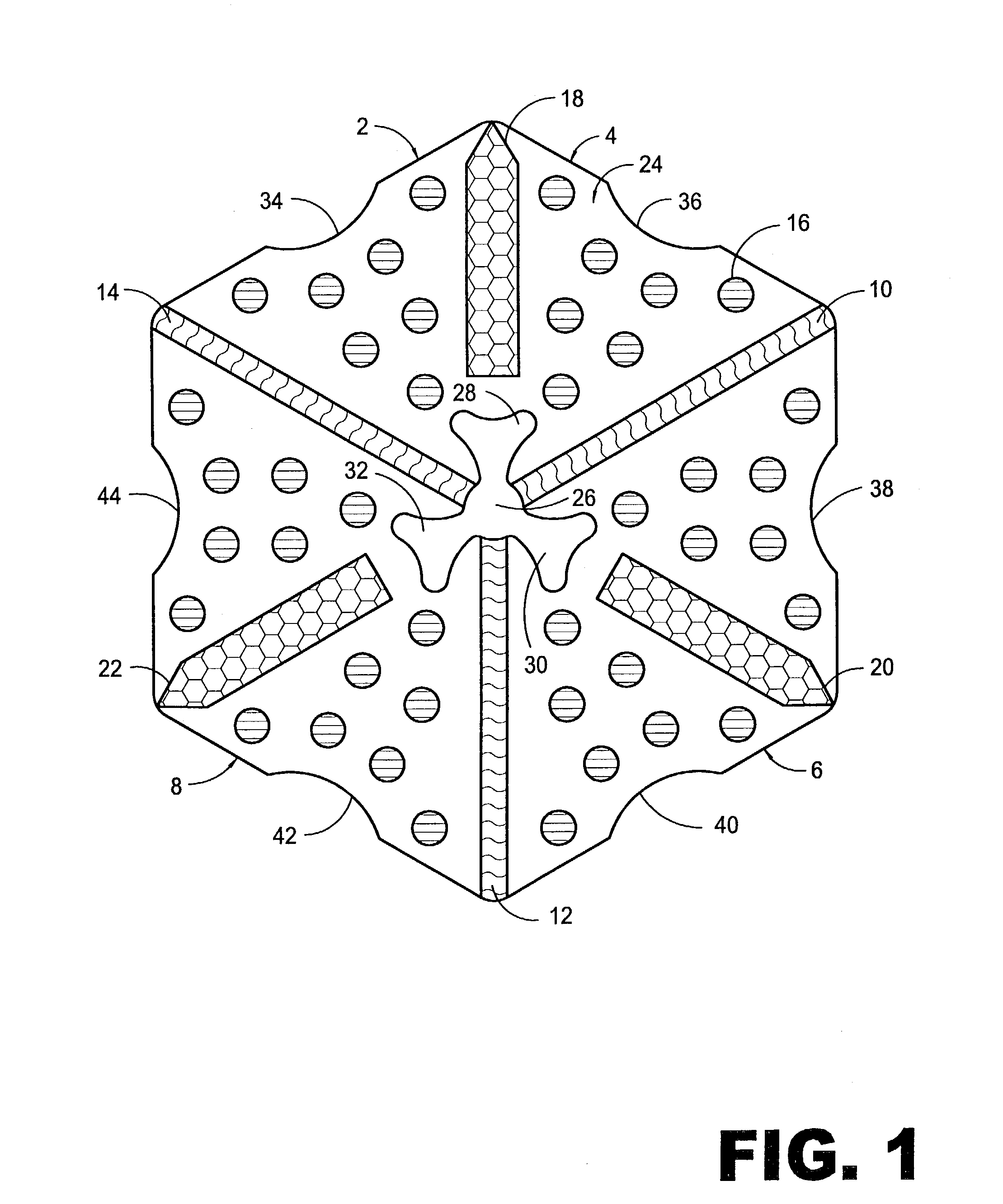

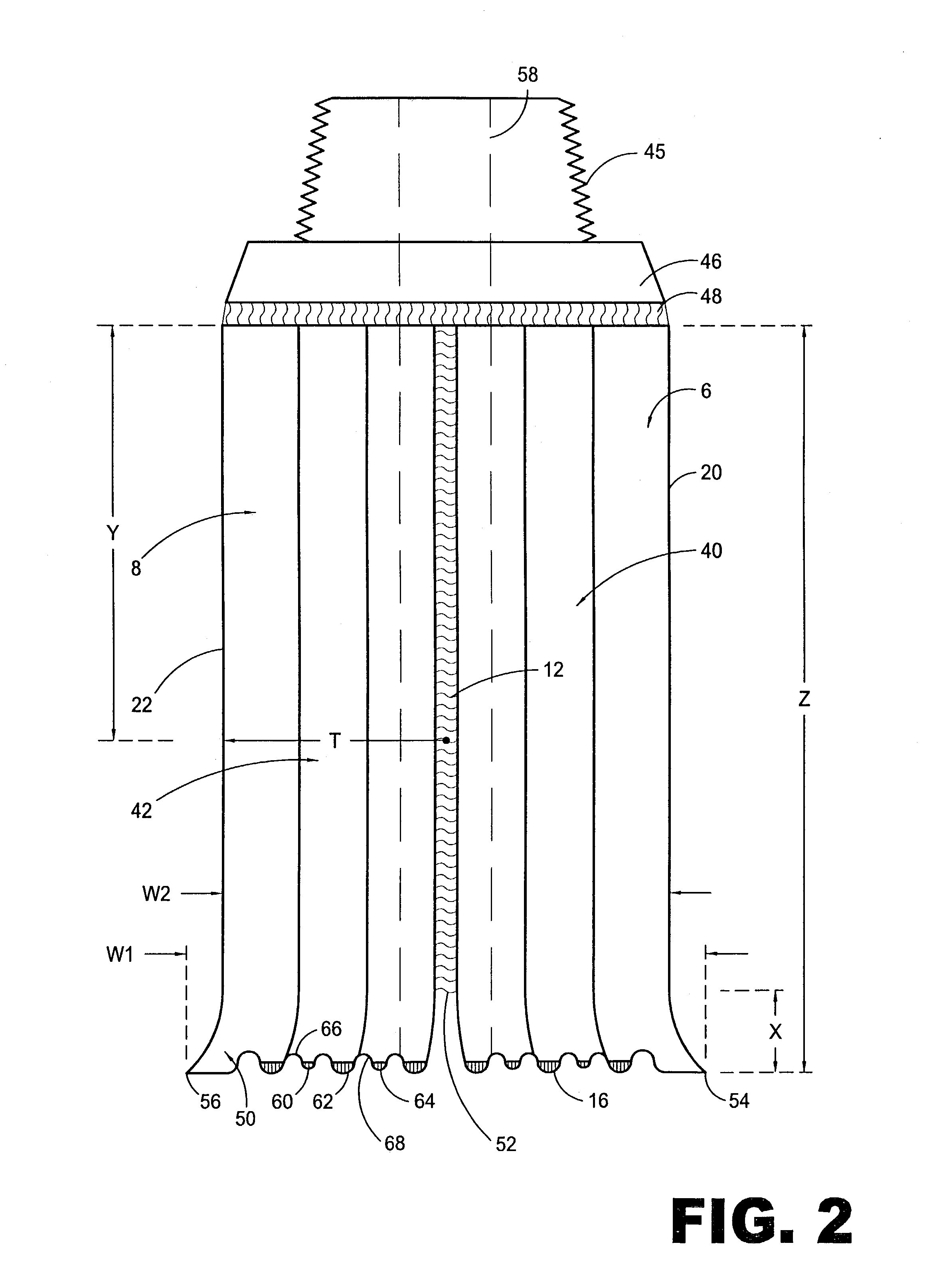

ActiveUS20120219371A1Improve tool lifeIncreased tool wearTransportation and packagingMilling cuttersClassical mechanicsStructural engineering

A segmented orbital drill includes a segmented portion with a semi-finishing cutting portion and a plurality of finishing cutting portions. The semi-finishing cutting portion and finishing cutting portions are separated by grooves formed by a front wall and a rear wall. The segmented portion allows for a fresh cutting edge (i.e., rear wall of the groove) to be revealed as the orbital drill wears in the axial direction. The segmented portion also causes less contact with the workpiece, which reduces power consumption and minimizes deflection of the orbital drill. The segmented orbital drill also includes an optional pilot at one end of the drill, and a clearance neck portion between a shank and the segmented portion. A method of machining a workpiece using the segmented orbital drill is also disclosed.

Owner:KENNAMETAL INC

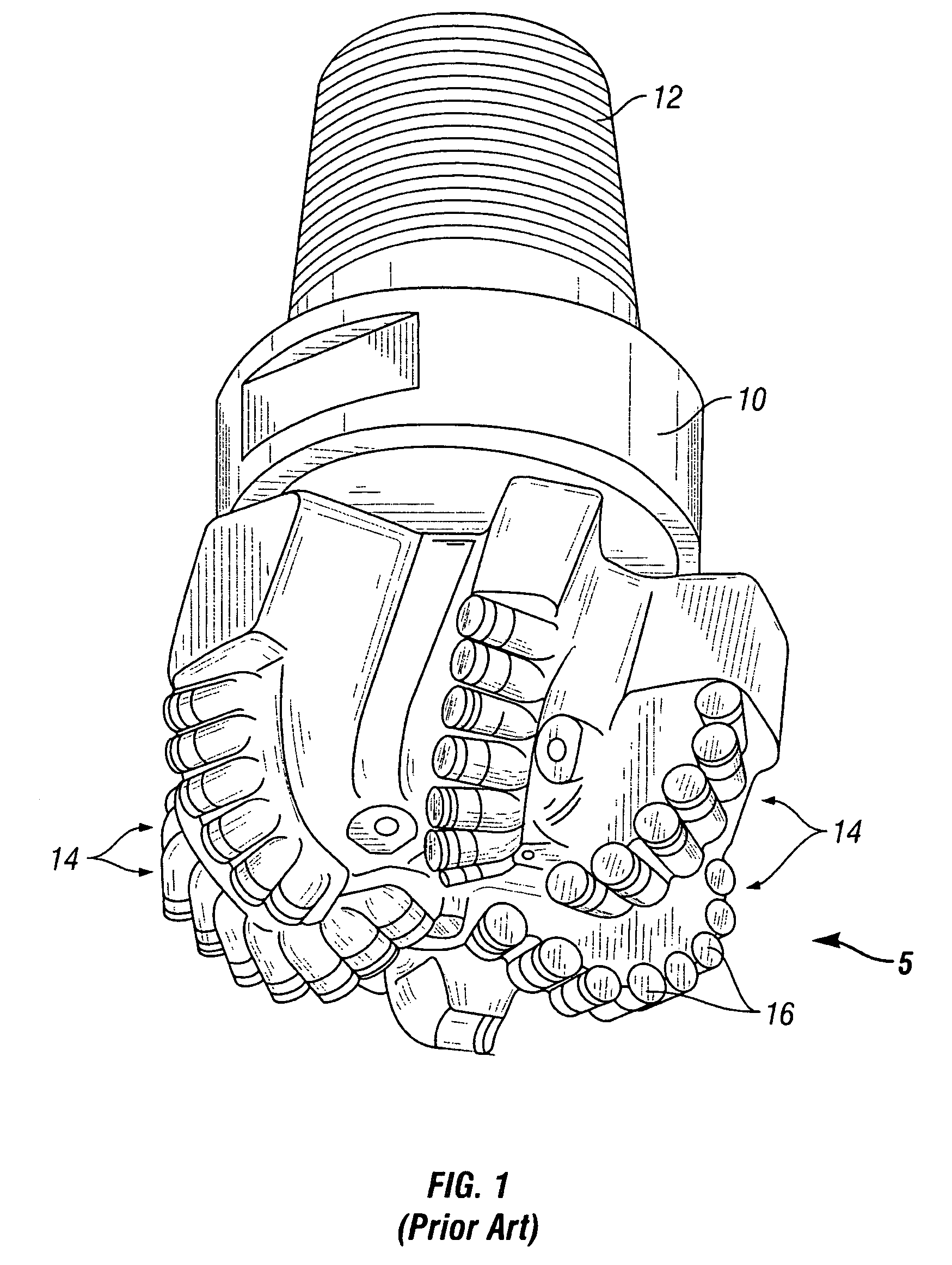

Fixed-head bit with stabilizing features

A fixed-head drill bit includes a bit body having a plurality of cutting elements and at least one wear knuckle disposed on the bit body. Each cutting element includes a cutting surface defining a swept cutting profile when the bit is rotated about an axis. The at least one wear knuckle is positioned at least partially within and extending at least partially outside a selected one or more of the swept cutting profiles, allowing the fixed-head drill bit to wear into a more stable configuration.

Owner:SMITH INT INC

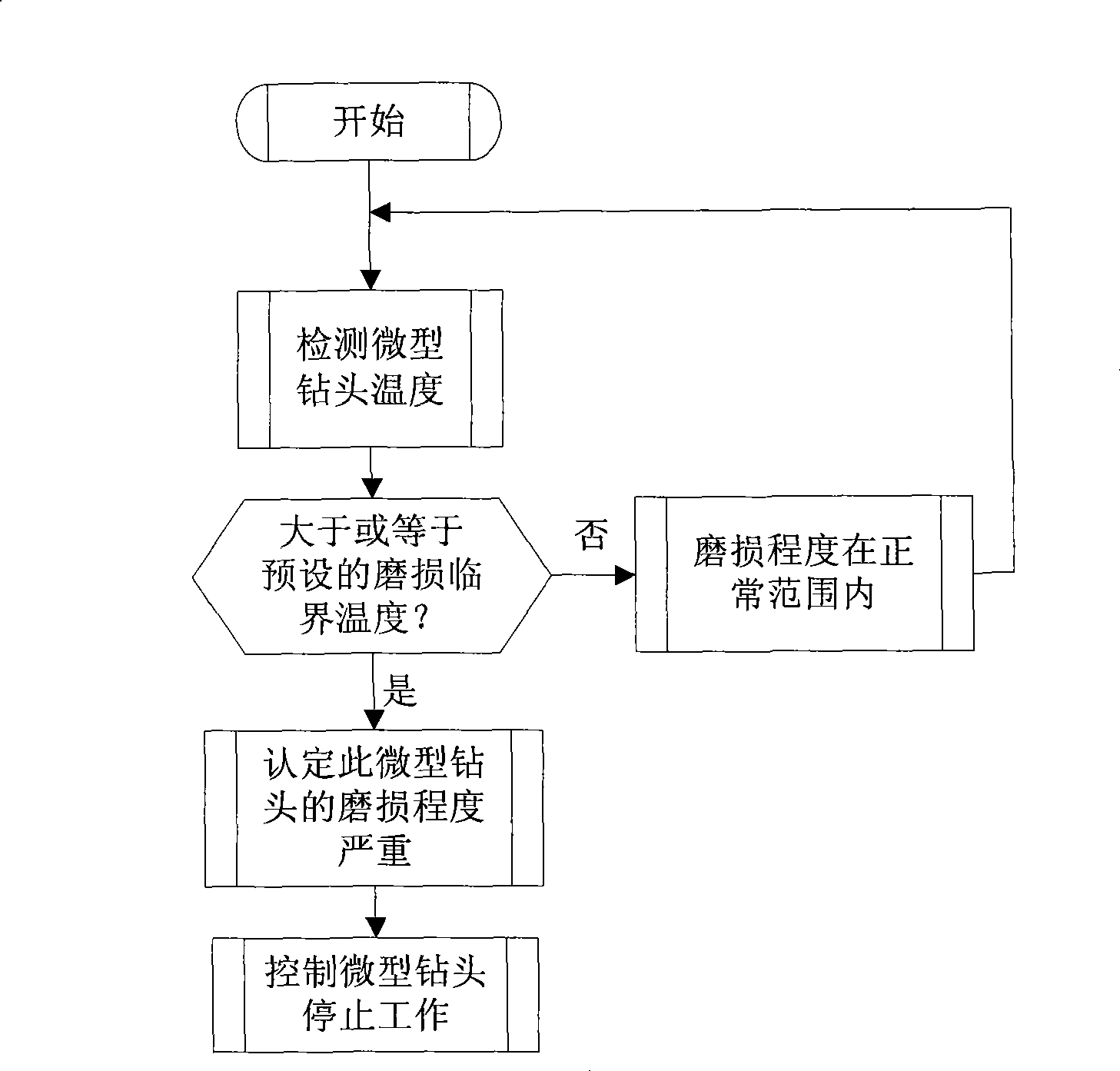

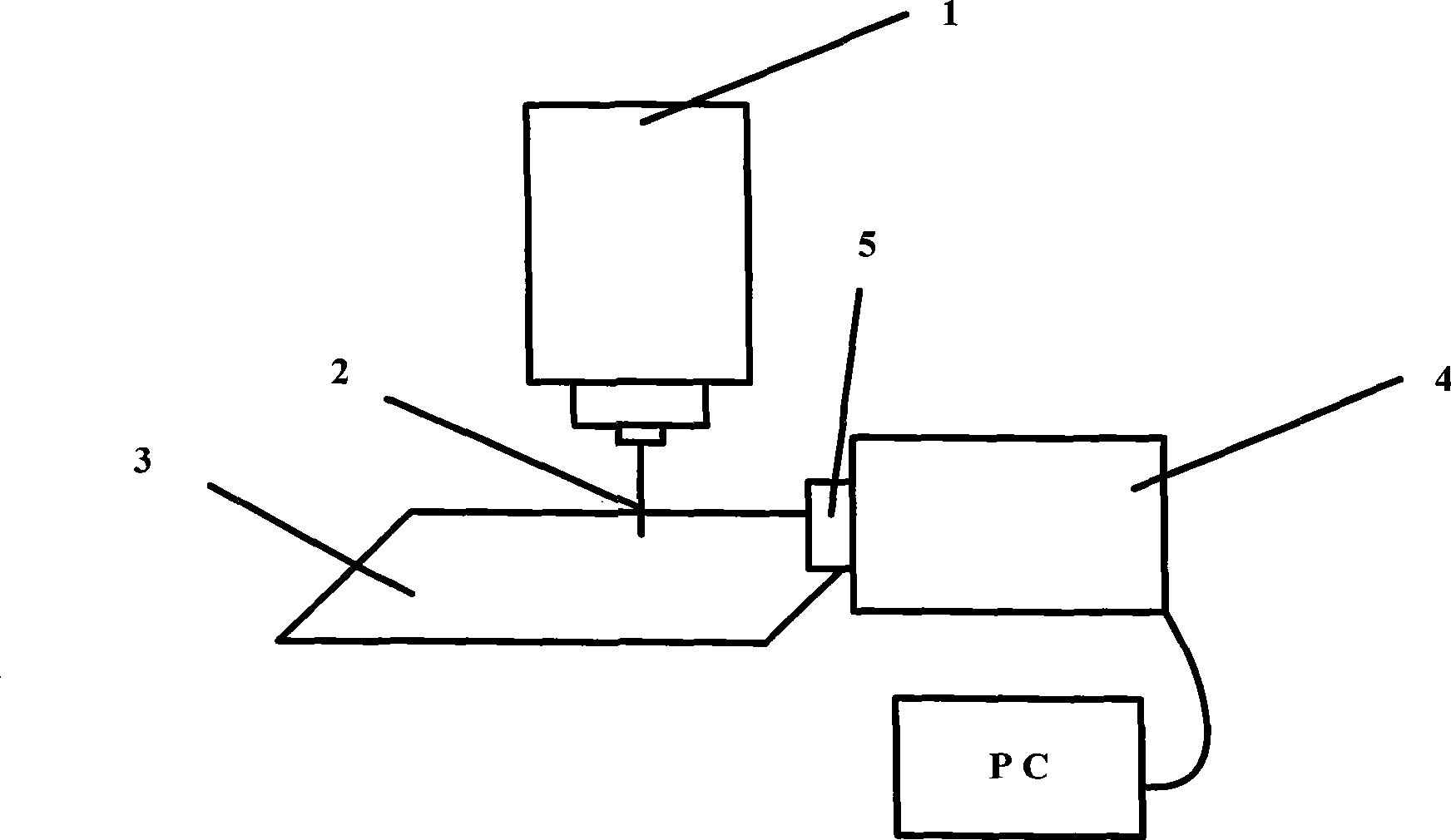

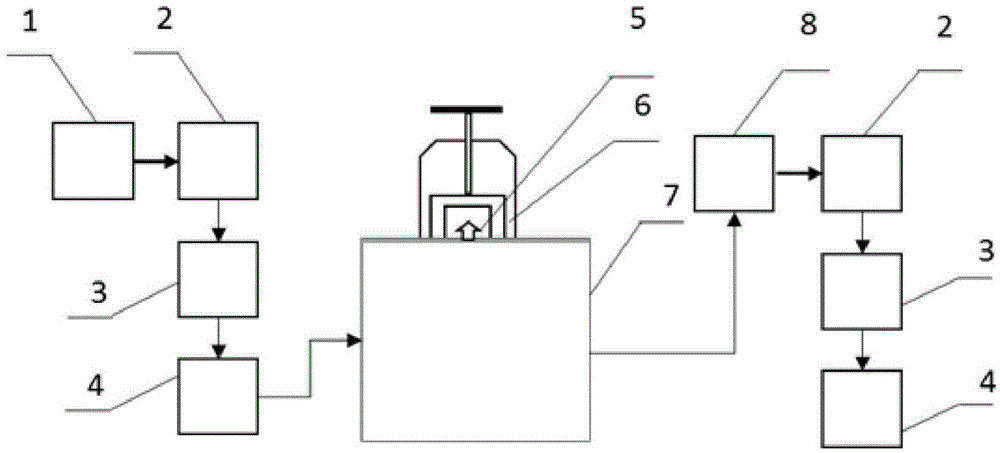

Method for detecting micro drill-bit wear degree, method using the said method and drilling device

ActiveCN101422825AEasy to detectDrilling/boring measurement devicesMeasurement/indication equipmentsBit wearEngineering

The invention discloses a method for detecting the wear degree of a microbit, a device and a drilling machine which use the method. The method for detecting the wear degree of the microbit comprises the following steps: A: the temperature of the microbit is detected; and B: the temperature which is detected in the step A is compared with preset wear critical temperature, if the temperature is higher than or equal to the preset wear critical temperature, the wear degree of the microbit is determined to be serious; and if the temperature is lower than the preset wear critical temperature, the wear degree of the microbit is determined to be within the normal range. The wear degree of the microbit is detected by detecting the temperature of the microbit, therefore, the wear degree of the microbit can be known without demounting the bit, and the detection is very convenient.

Owner:SHENZHEN JINZHOU PRECISION TECH

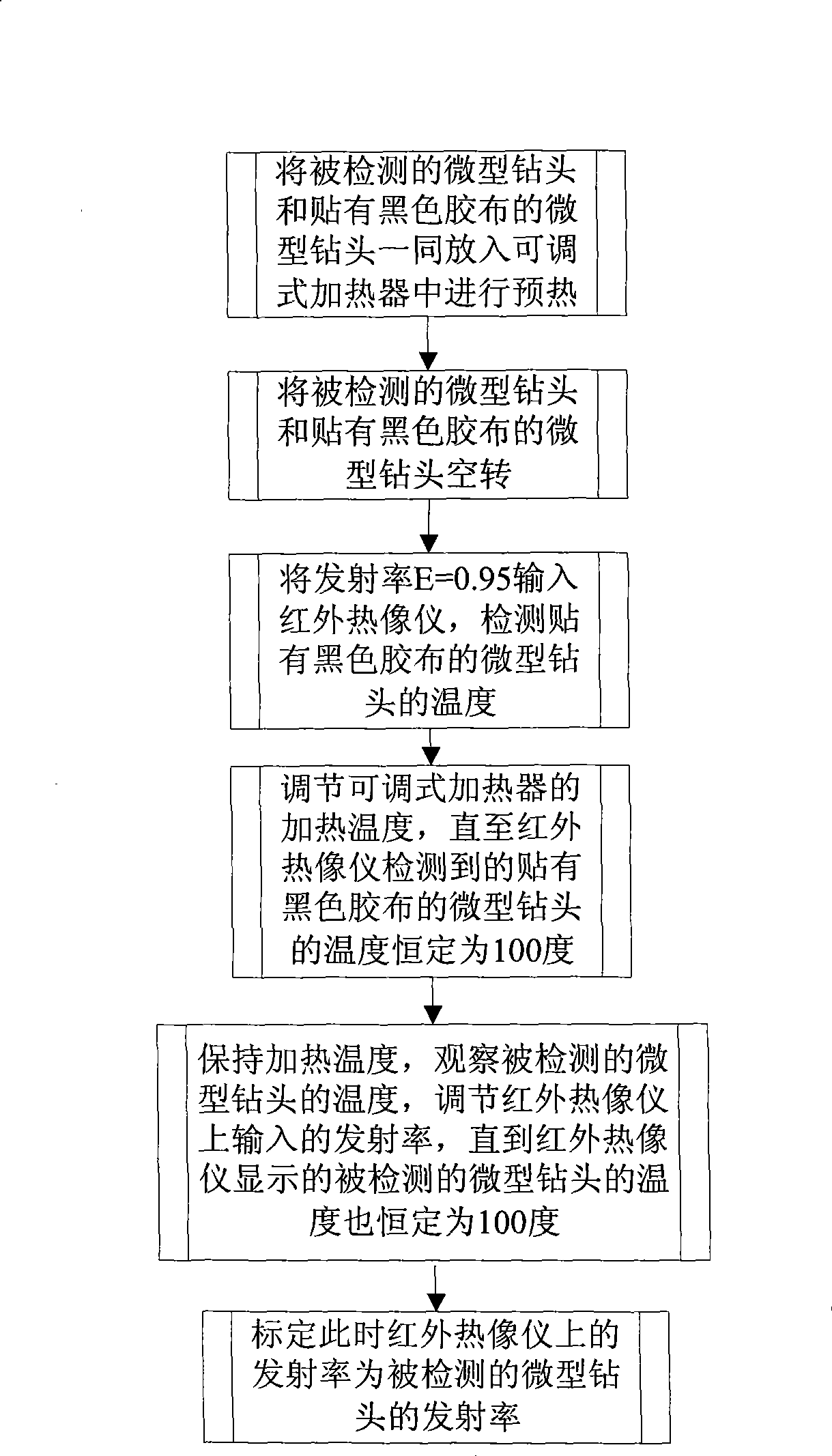

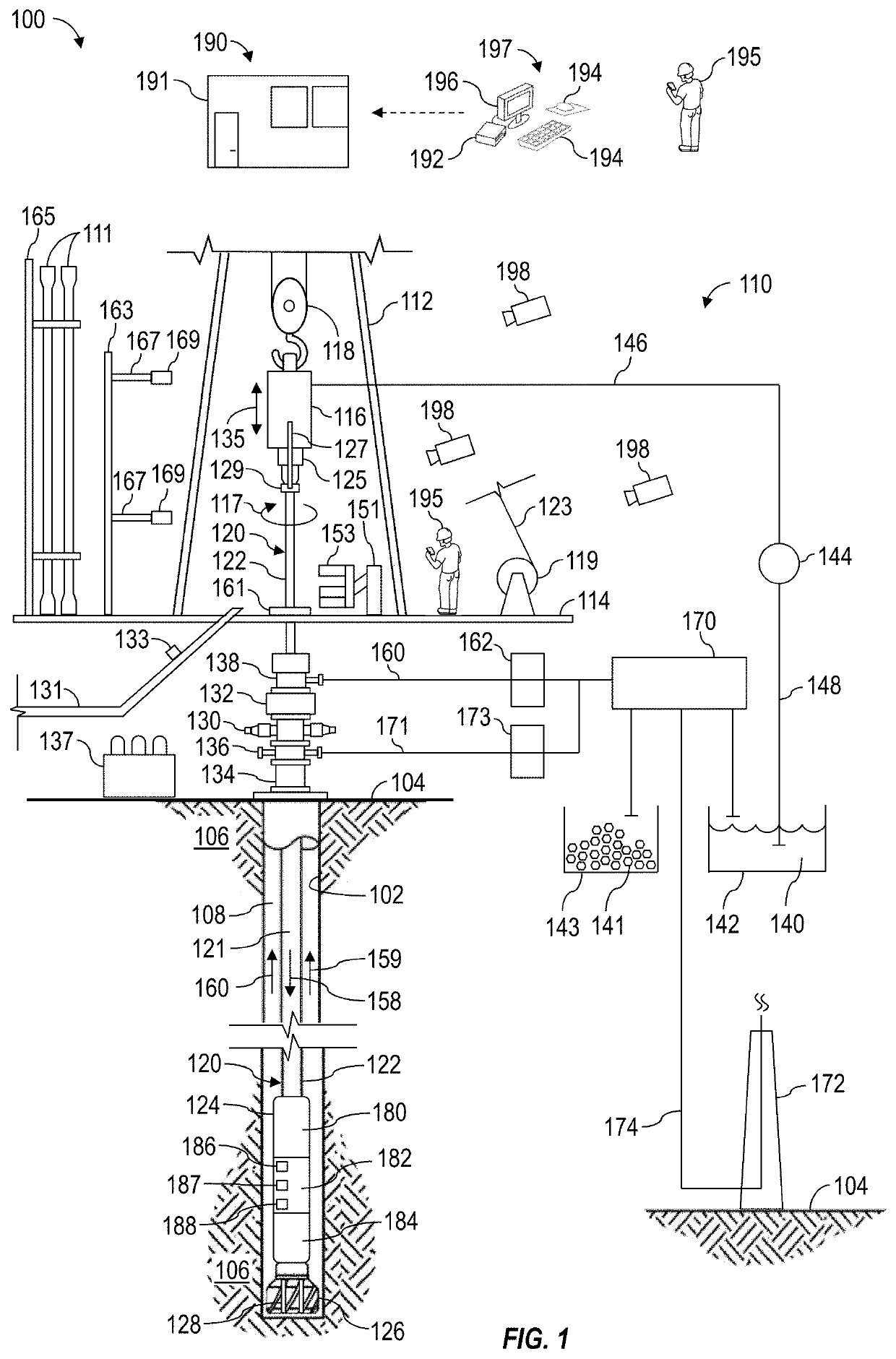

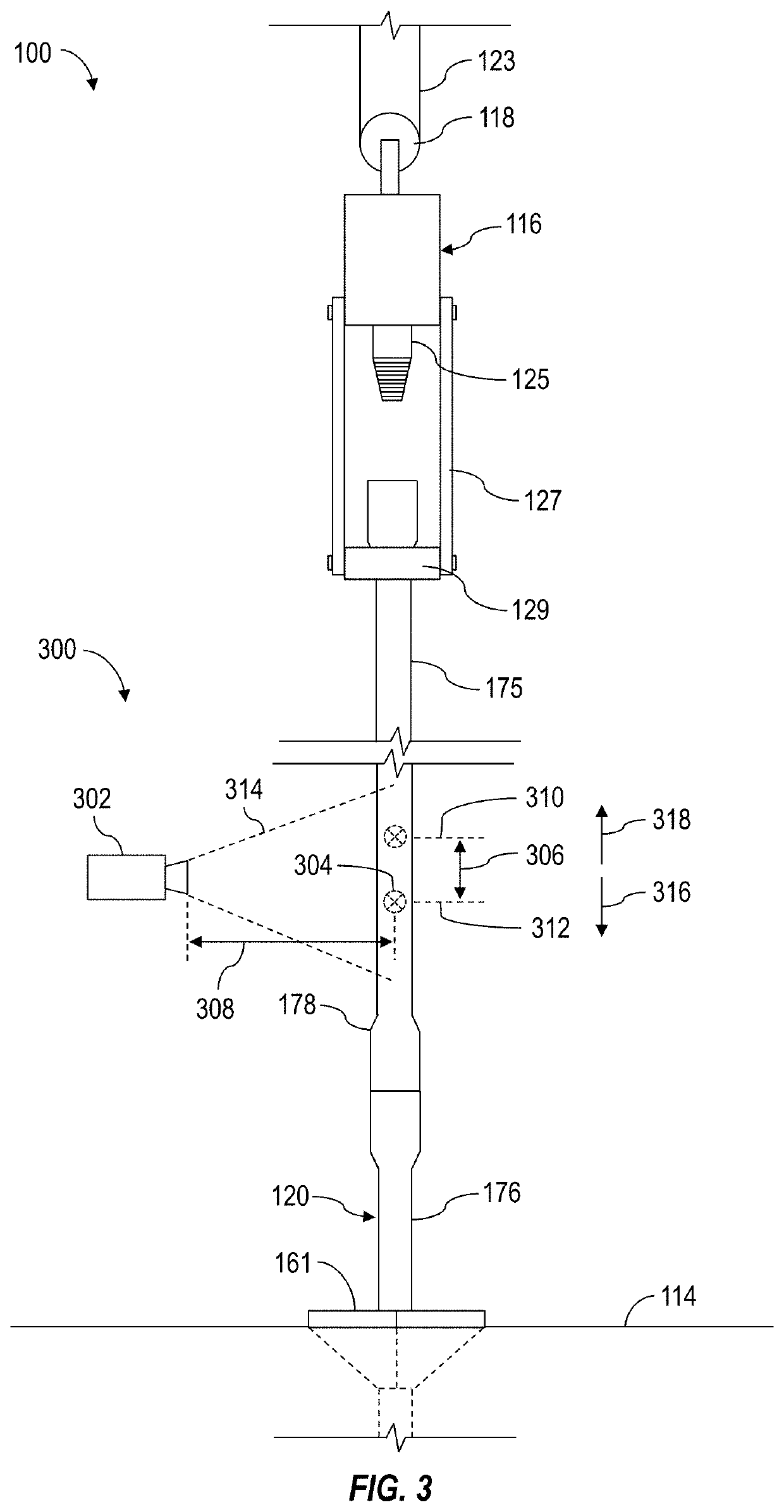

Utilizing Vision Systems at a Wellsite

Utilizing vision systems at a wellsite, which may include operating a video camera to generate a video signal comprising images of one or more pieces of equipment or components and receiving the video signal by a processing system, which may then process the images to monitor or determine physical and / or operational characteristics associated with the one or more pieces of equipment in the images. The physical and / or operational characteristics may include wear of a drill bit for drilling wellbores, alignment between pieces of equipment or components at the wellsite, and / or safety compliance at the wellsite.

Owner:SCHLUMBERGER TECH CORP

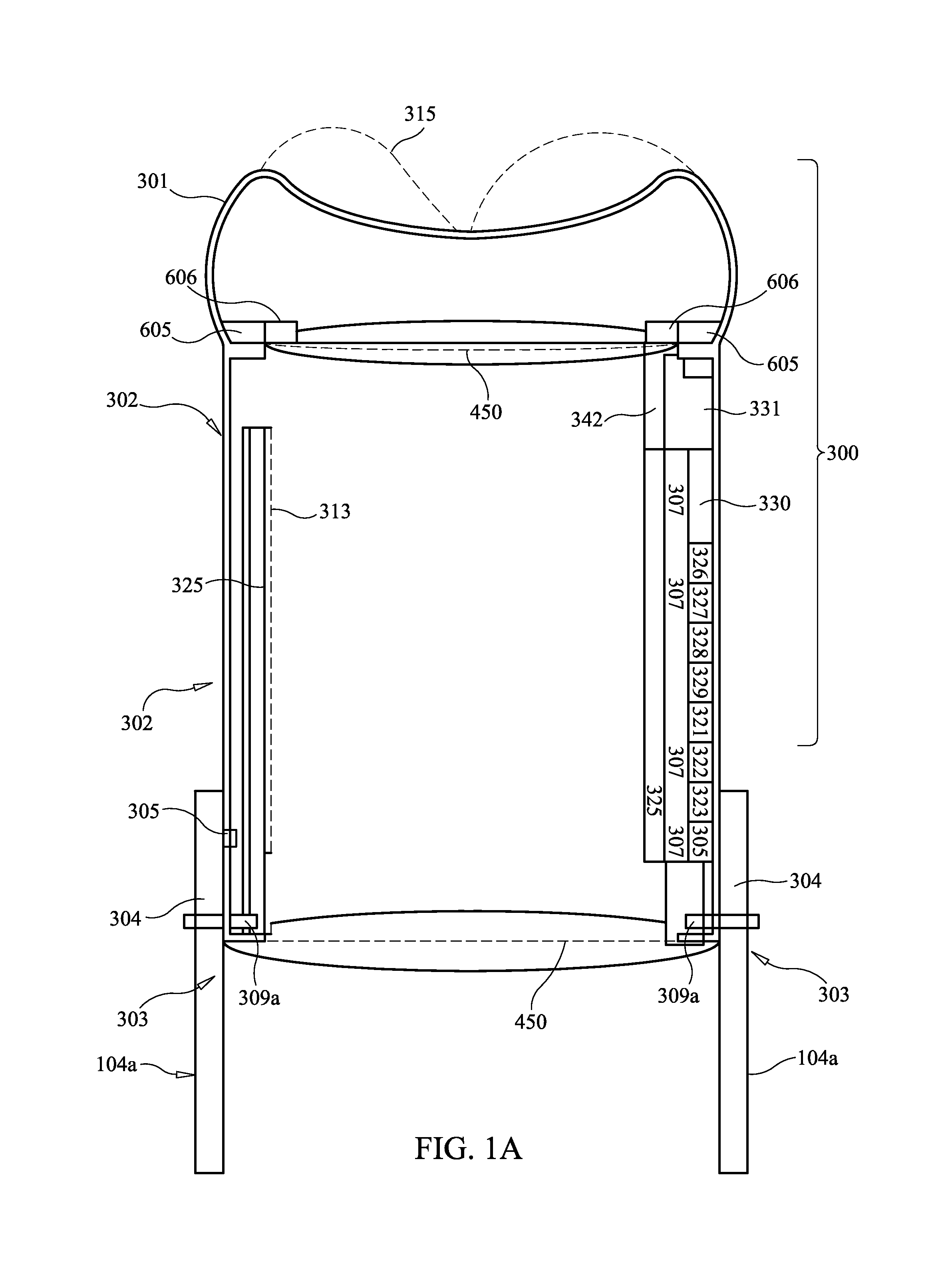

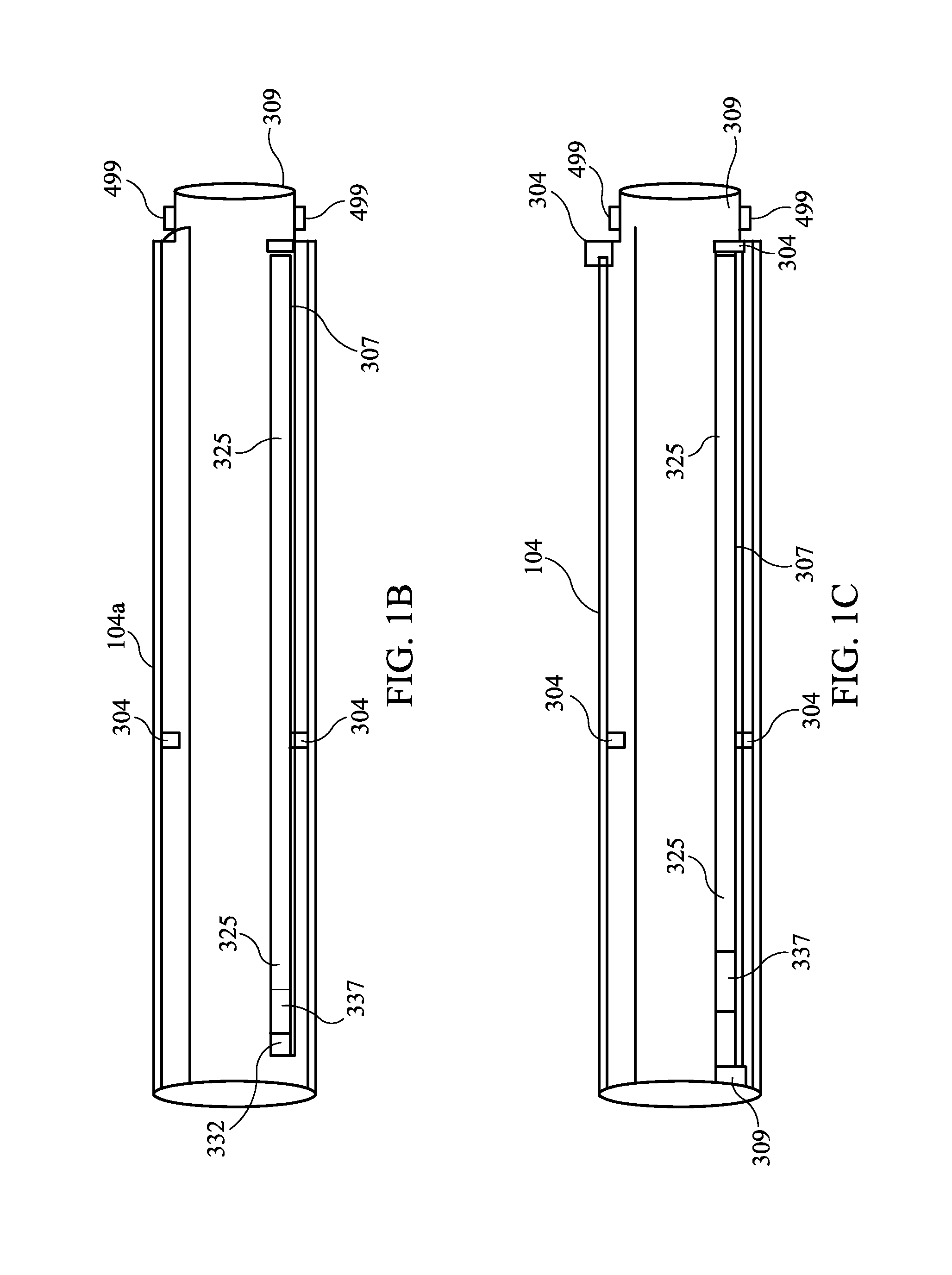

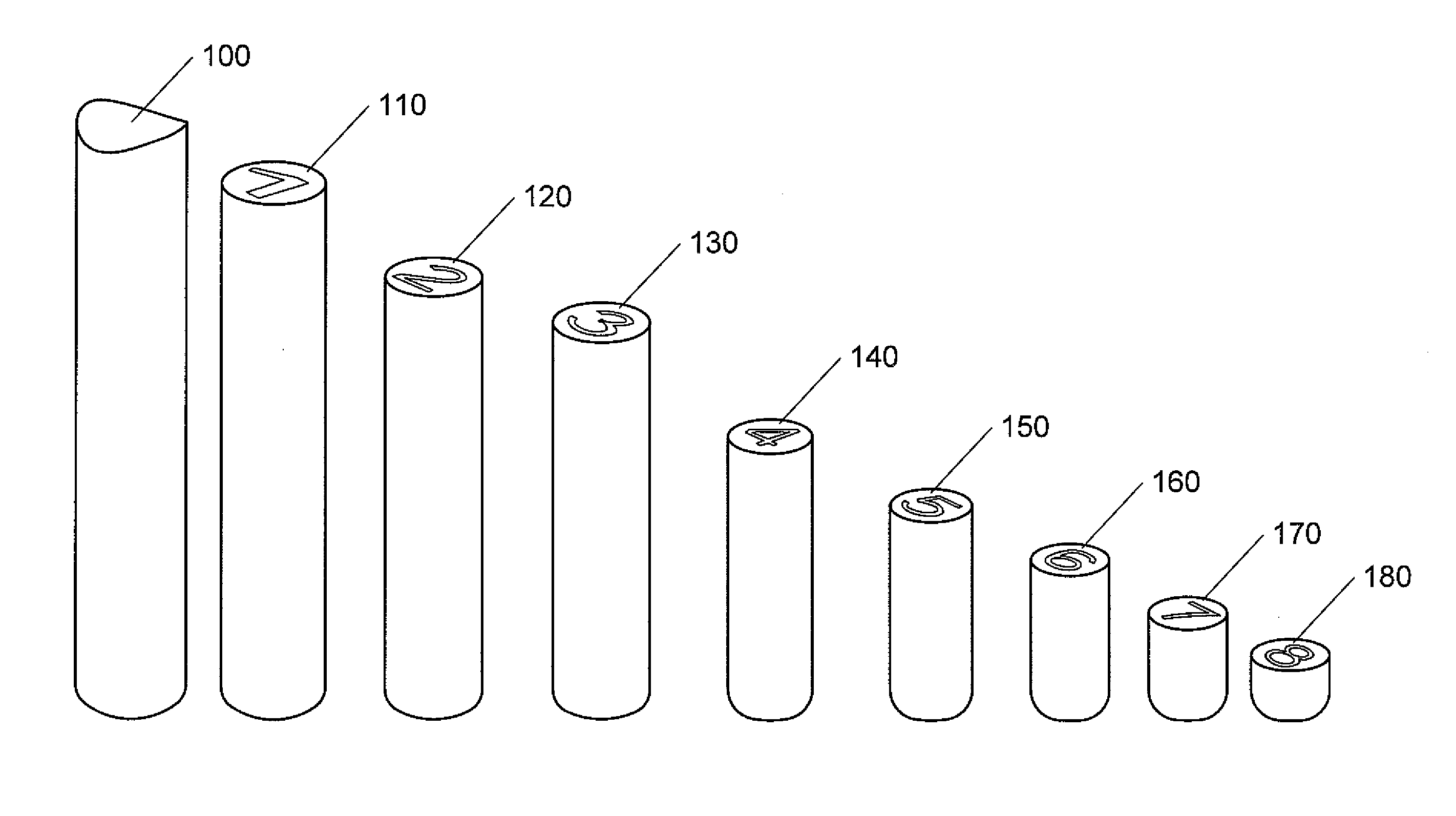

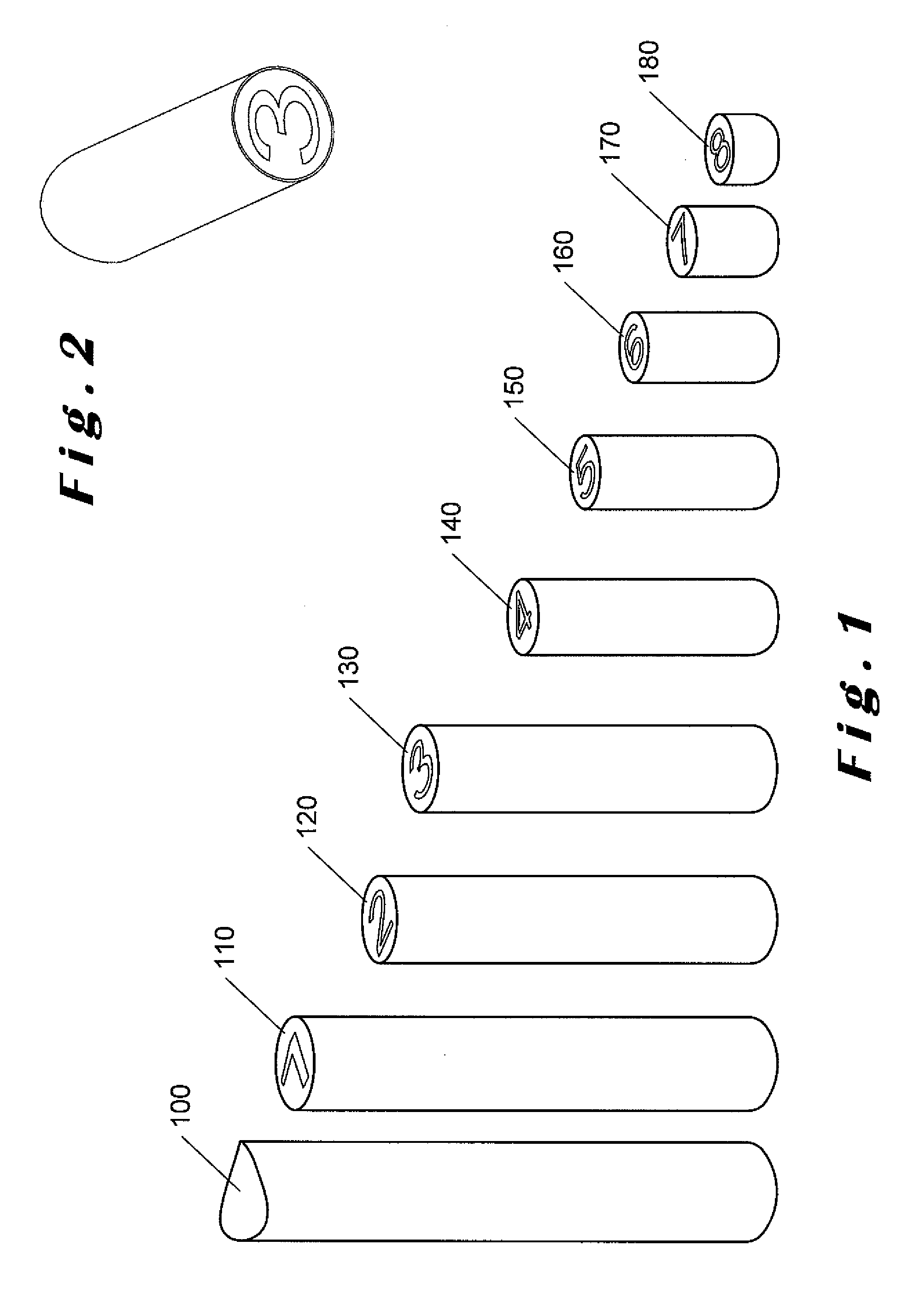

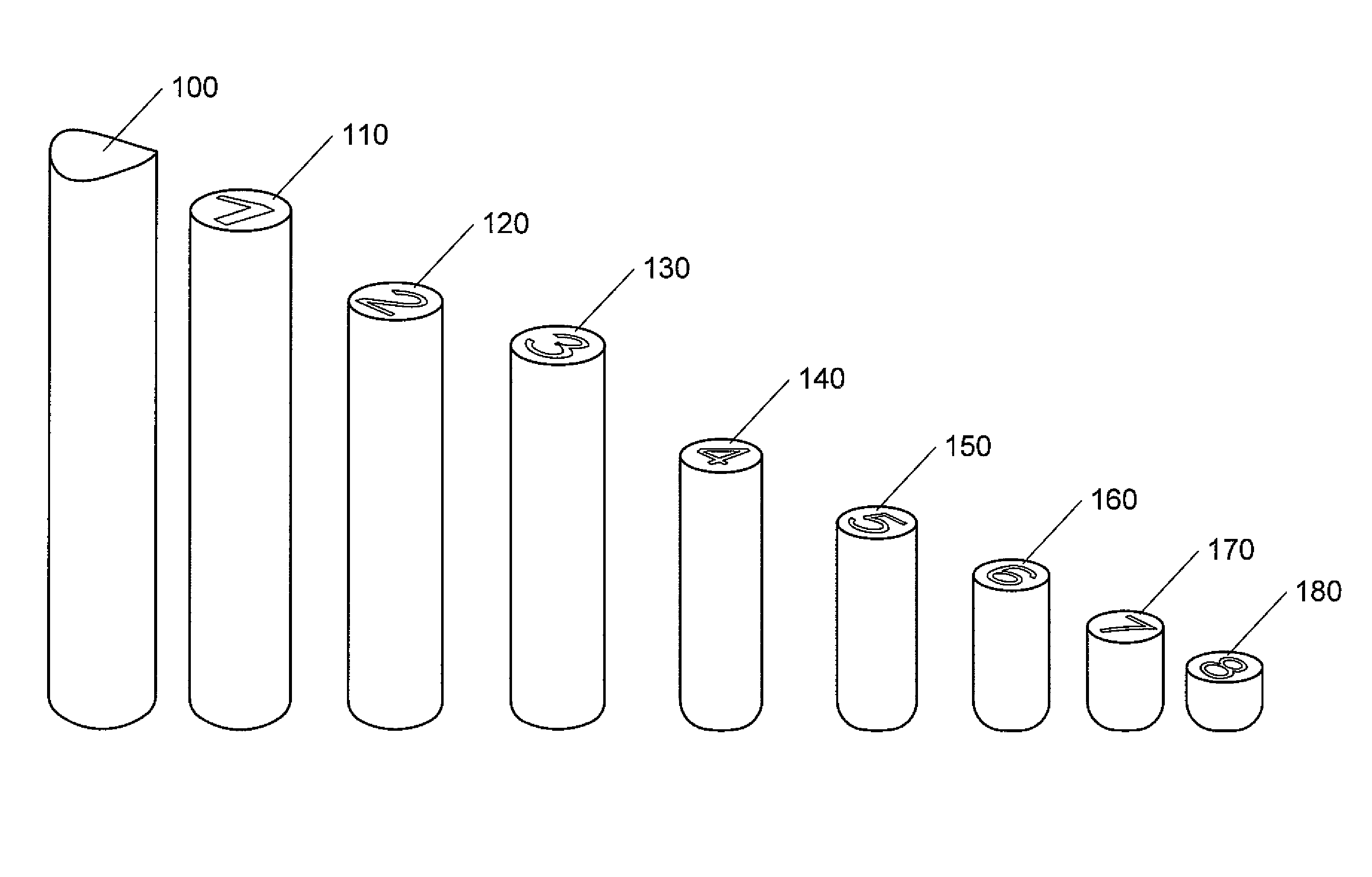

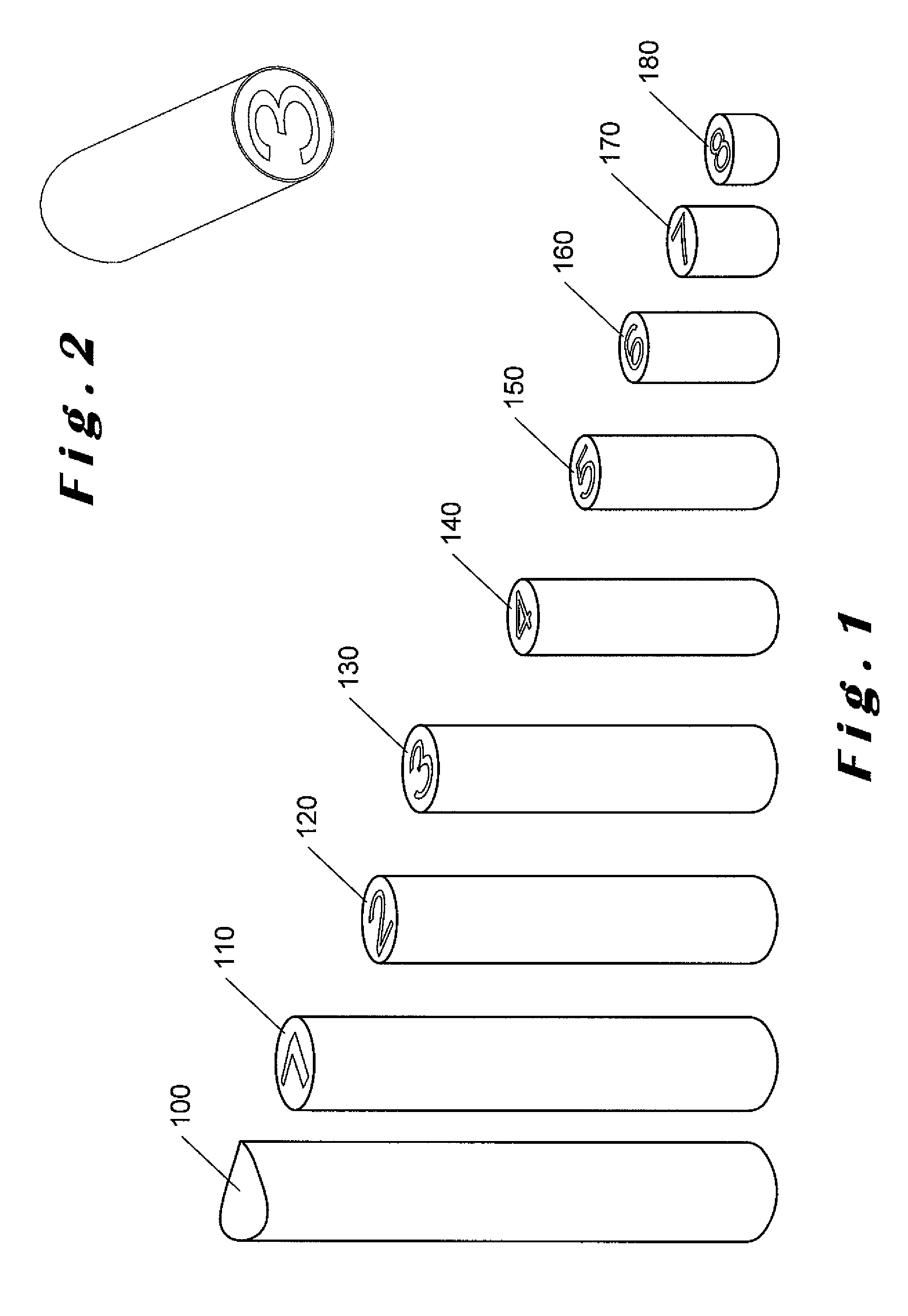

Wear Indicators for Drilling Equipment

InactiveUS20140102791A1Easy to identifySure easyEarth drilling toolsMeasurement devicesEngineeringGrade system

Described herein is a wear indicator (100) for use in a drill bit or a core head. The wear indicator (100) comprises an elongate element that forms part of the drill bit. The elongate element has a plurality of numbers (110, 120, 130, 140, 150, 160, 170, 180) formed along its length, each number (110, 120, 130, 140, 150, 160, 170, 180) being formed as a void and corresponds to a level of wear in accordance with the IADC dull grading system. As the drill becomes worn, the wear indicator (100) wears at the same rate to reveal one of the numbers (110, 120, 130, 140, 150, 160, 170, 180). The numbers range from “1” to “8” where the number “1” illustrates the least wear and the number “8” indicates the most wear. When unworn, none of the numbers are visible.

Owner:HALLIBURTON ENERGY SERVICES INC

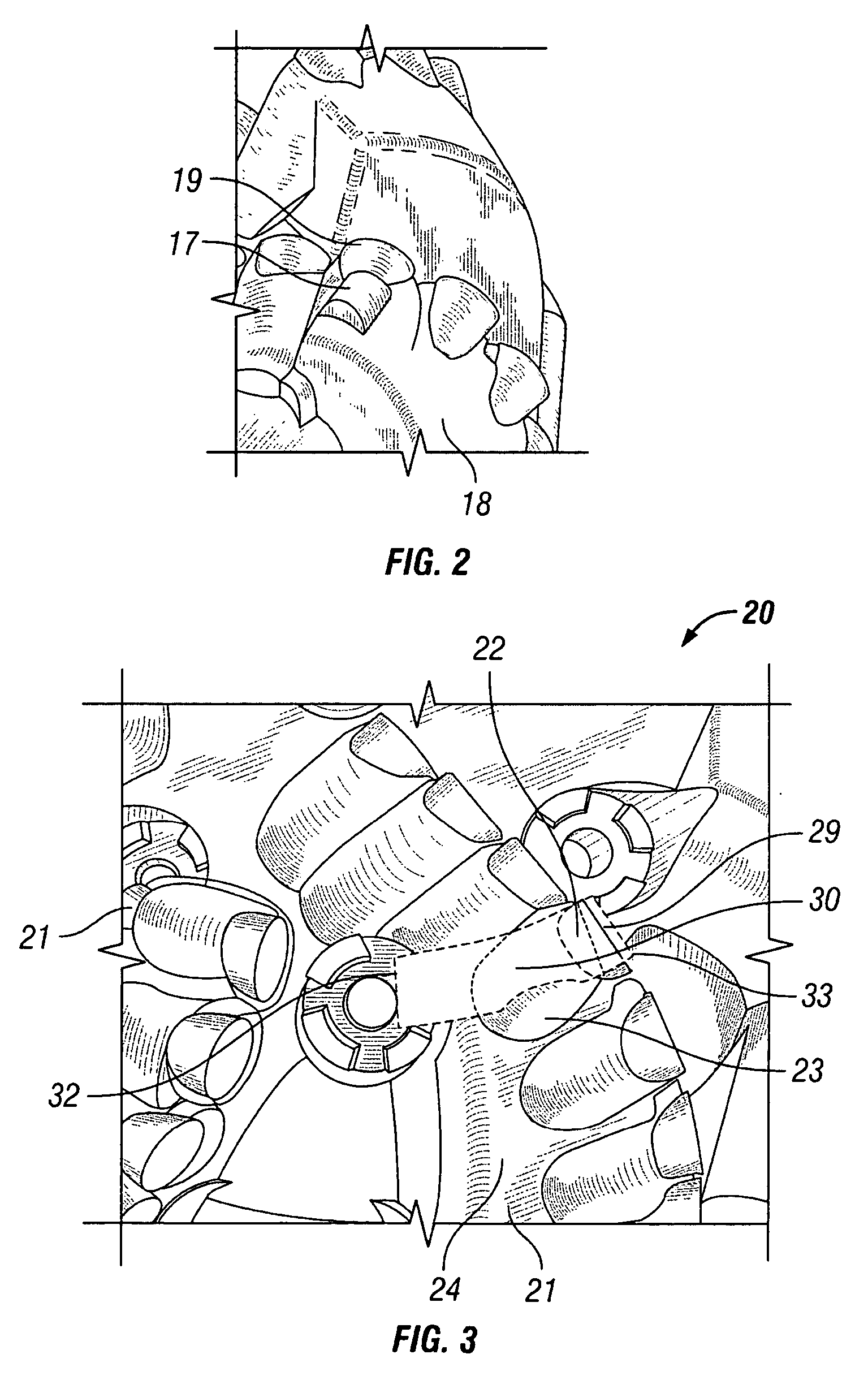

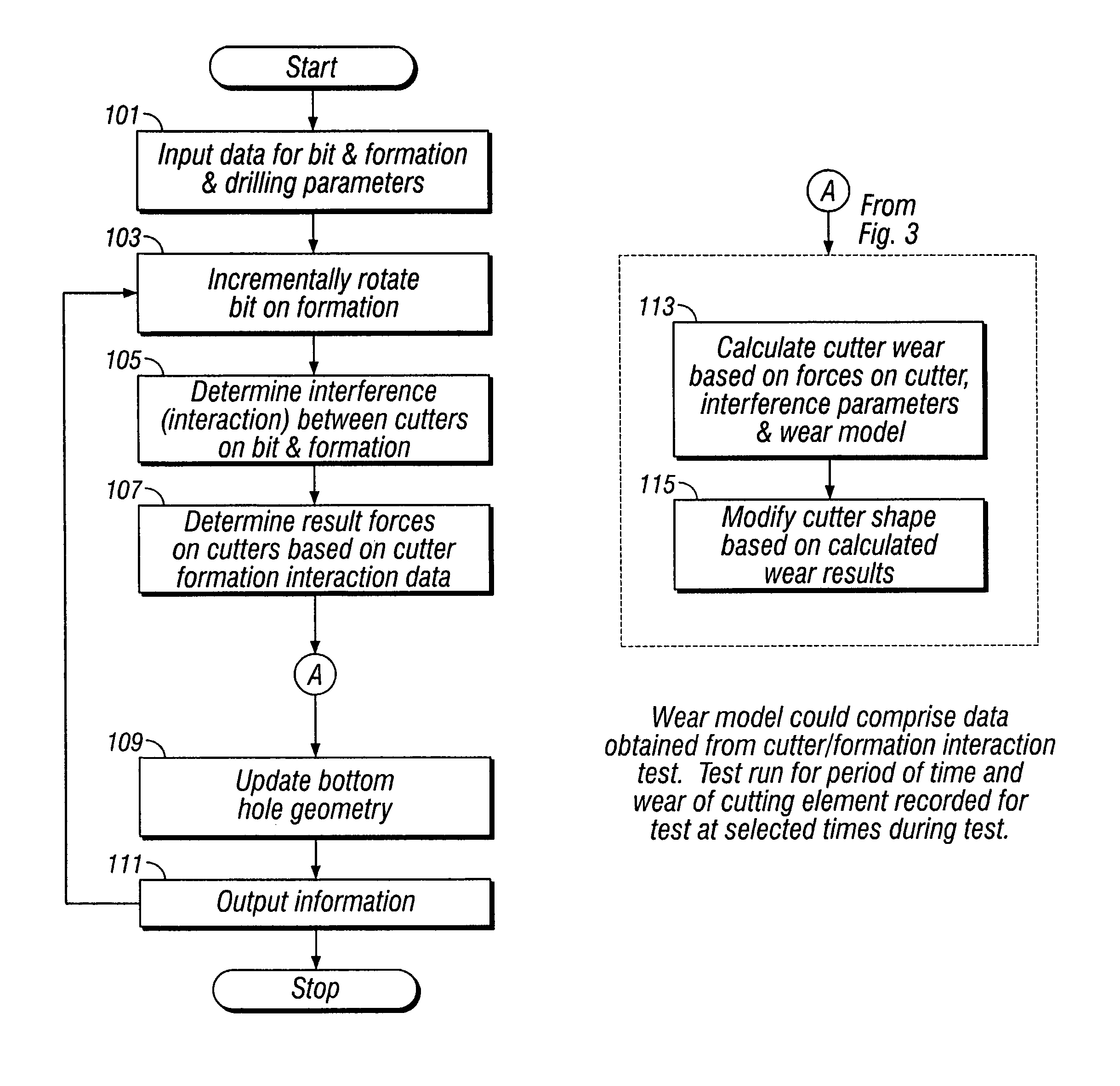

Methods for modeling wear of fixed cutter bits and for designing and optimizing fixed cutter bits

In one aspect, the invention provides a method for modeling the wear of a fixed cutter bit drilling earth formations. A method for determining wear of a fixed cutter drill bit includes simulating the fixed cutter drill bit drilling an earth formation; determining a cutter-formation interaction force and a relative sliding velocity of a selected area on a cutting surface on a cutter of the fixed cutter drill bit during the drilling; and calculating a wear rate of the selected area based on the cutter-formation interaction force and the relative sliding velocity.

Owner:SMITH INT INC

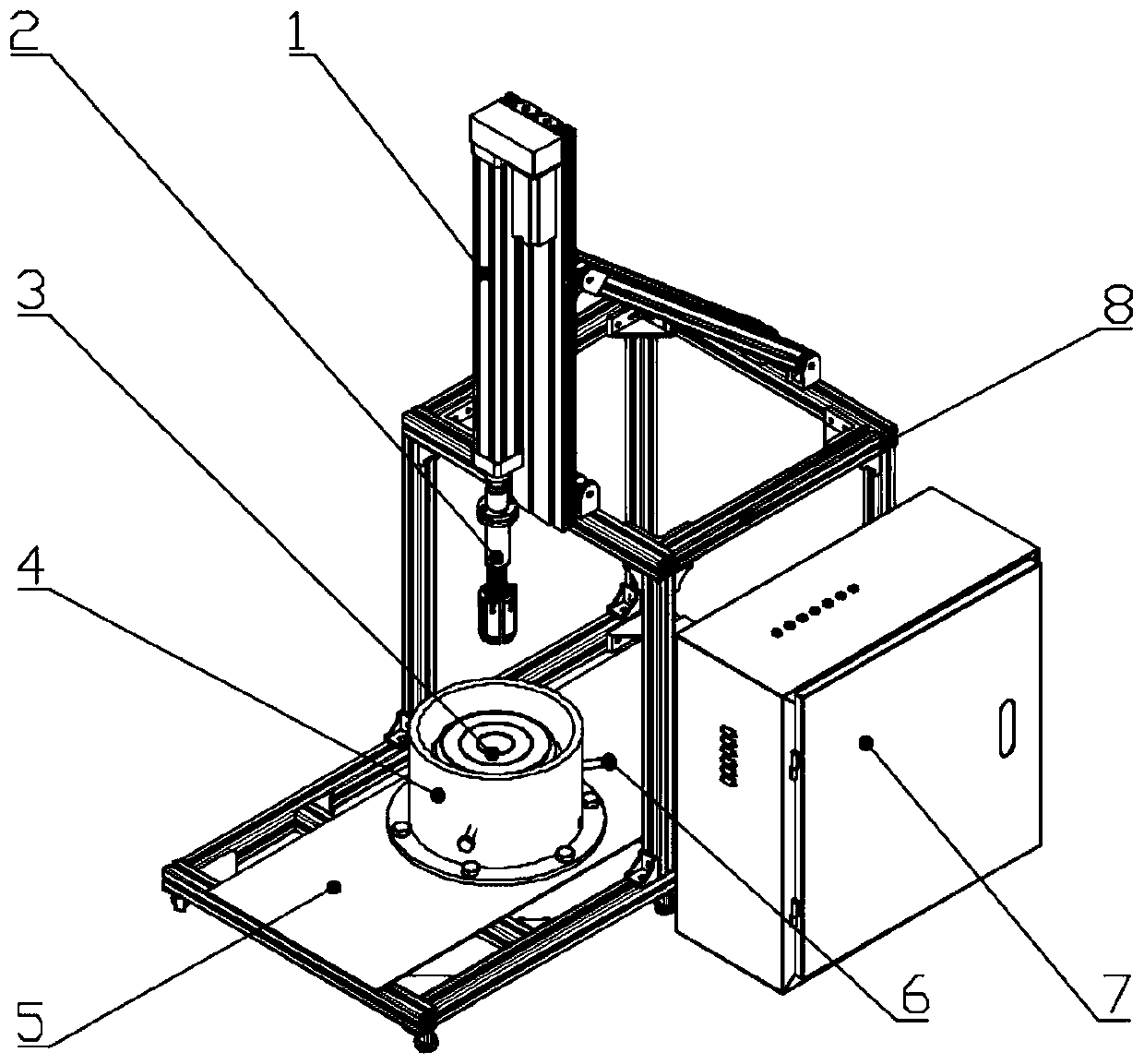

High-voltage pulse drill bit and rock breaking experimental facility

PendingCN111119739AHigh crushing drilling efficiencyQuality improvementMachine part testingDrill bitsVoltage pulseClassical mechanics

The invention provides a high-voltage pulse drill bit and a rock breaking experimental facility. The high-voltage pulse drill bit is located over a rock and comprises a plurality of negative electrodes, a negative electrode fixing sleeve for fixing the negative electrodes, a positive electrode, an insulating sleeve, a spring, an insulating handle and a cable. The positive electrode is divided intoa positive electrode upper half portion and a positive electrode lower half portion which are in threaded connection with each other. The rock breaking experimental facility comprises a servo electric cylinder, a control assembly, the high-voltage pulse drill bit, a high-voltage pulse power source, a material container assembly, an aluminum profile support and an aluminum base and is used for breaking the rock. The high-voltage pulse drill bit and the rock breaking experimental facility have the advantages that the rock breaking drilling efficiency is high, and the quality of the wall of a well is high; as for an irregular rock, the contact between the electrode and the rock is closer through adjustment of extending and retracting of the positive electrode, and thus the rock is broken more effectively; and the noise and vibration are reduced, the abrasion to the drill bit is small, and the energy consumption is small.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Wear indicators for drilling equipment

Described herein is a wear indicator (100) for use in a drill bit or a core head. The wear indicator (100) comprises an elongate element that forms part of the drill bit. The elongate element has a plurality of numbers (110, 120, 130, 140, 150, 160, 170, 180) formed along its length, each number (110, 120, 130, 140, 150, 160, 170, 180) being formed as a void and corresponds to a level of wear in accordance with the IADC dull grading system. As the drill becomes worn, the wear indicator (100) wears at the same rate to reveal one of the numbers (110, 120, 130, 140, 150, 160, 170, 180). The numbers range from “1” to “8” where the number “1” illustrates the least wear and the number “8” indicates the most wear. When unworn, none of the numbers are visible.

Owner:HALLIBURTON ENERGY SERVICES INC

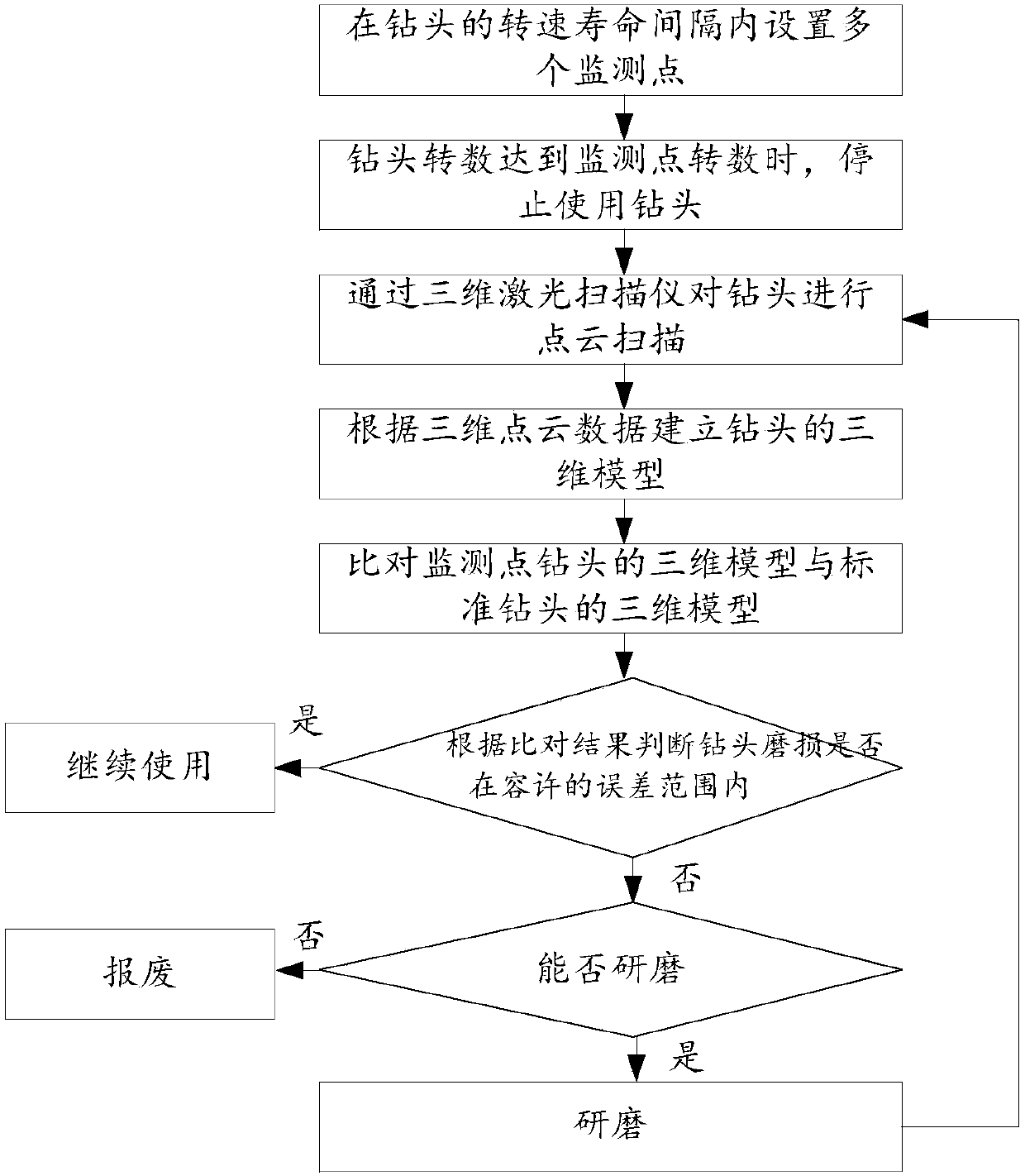

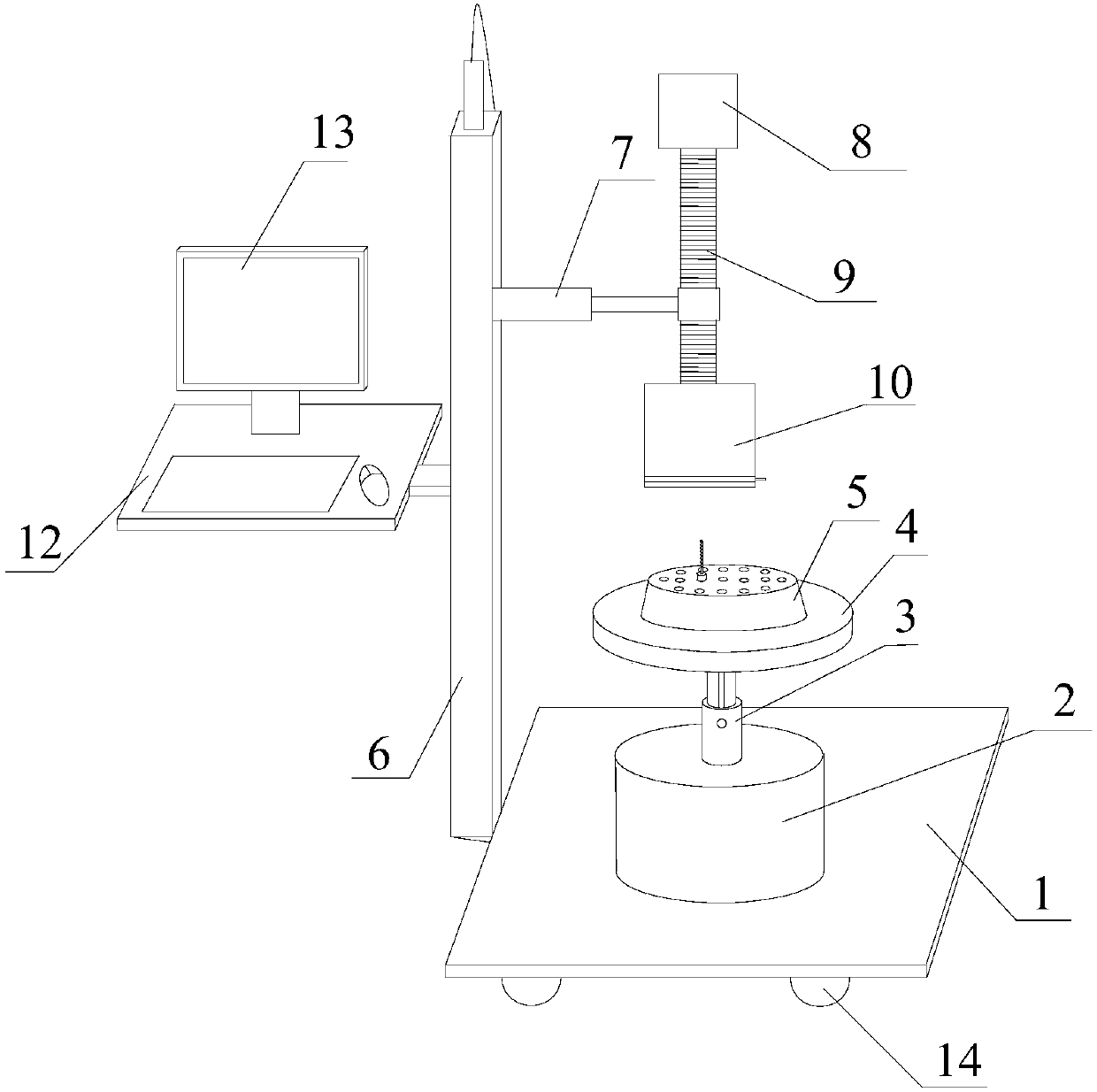

Drill bit wear monitoring method

The present invention belongs to the drill bit detection technical field and discloses a drill bit wear monitoring method. The method includes the following steps that: S1, a plurality of monitoring points are set at the intervals of the life span of the number of times of rotation of a drill bit; S2, when the rotation of the drill bit achieves the number of times of rotation of the monitoring points, the use of the drill bit is stopped; S3, point-cloud scanning is performed on the drill bit at the monitoring points through using a three-dimensional laser scanner, so that the three-dimensionalcloud data of the drill bit can be acquired; S4, the three-dimensional model of the drill bit at the monitoring points is built through modeling software according to the three-dimensional point cloud data of the drill bit; S5, the three-dimensional model of the drill bit at the monitoring points is compared with the three-dimensional model of a standard drill bit; S6, whether the wear of the drill bit at the monitoring points is within an allowable error range is judged, when the wear of the drill bit exceeds the allowable error range, the drill bit is ground or scrapped; and S7, after the drill bit is ground, S3 to S6 are executed. The drill bit wear monitoring method has high measurement accuracy and can detect some small defects, thereby improving the quality of the hole drilling of the drill bit.

Owner:JILIN TEACHERS INST OF ENG & TECH

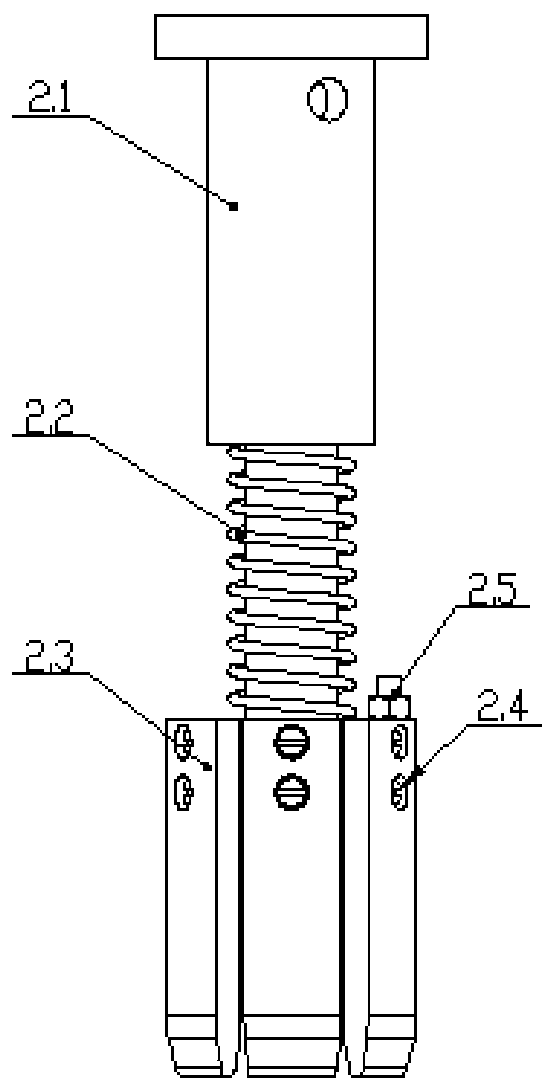

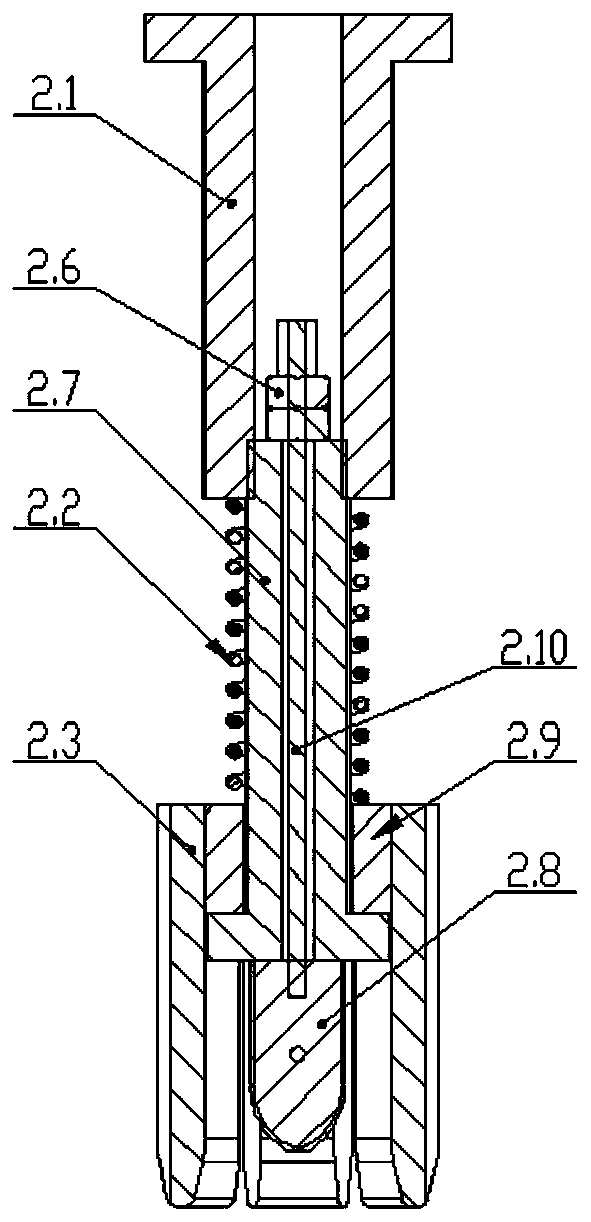

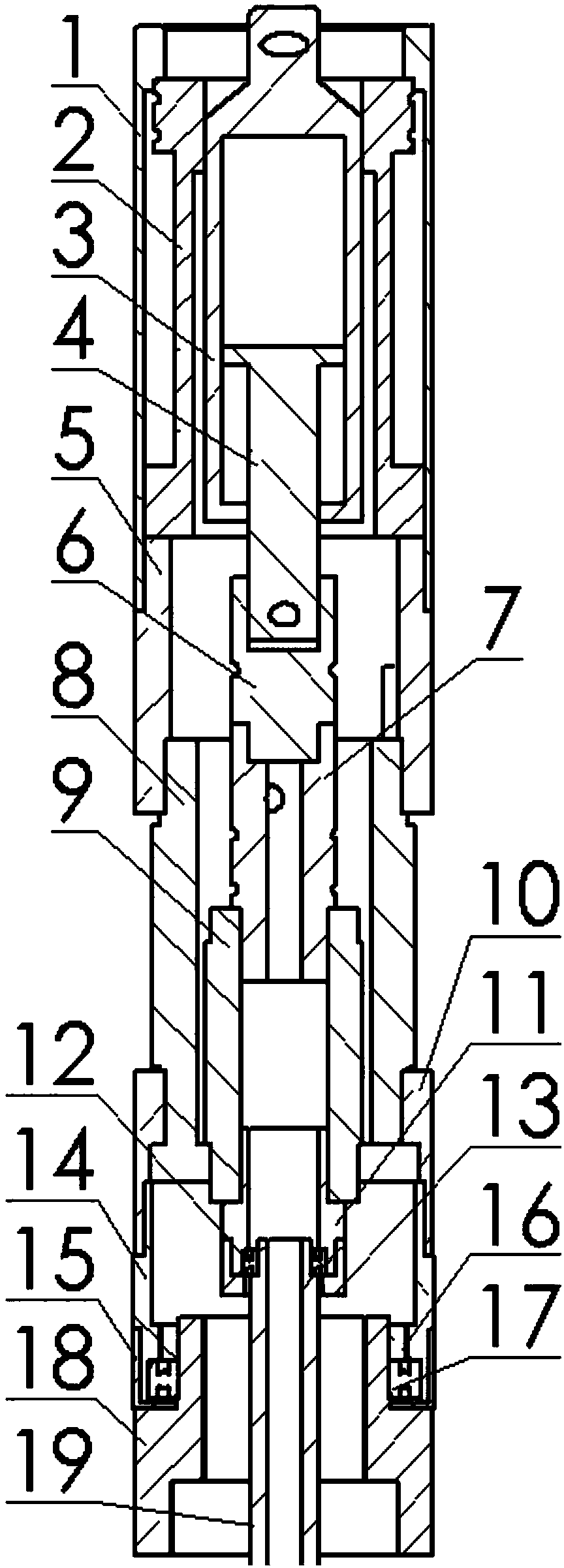

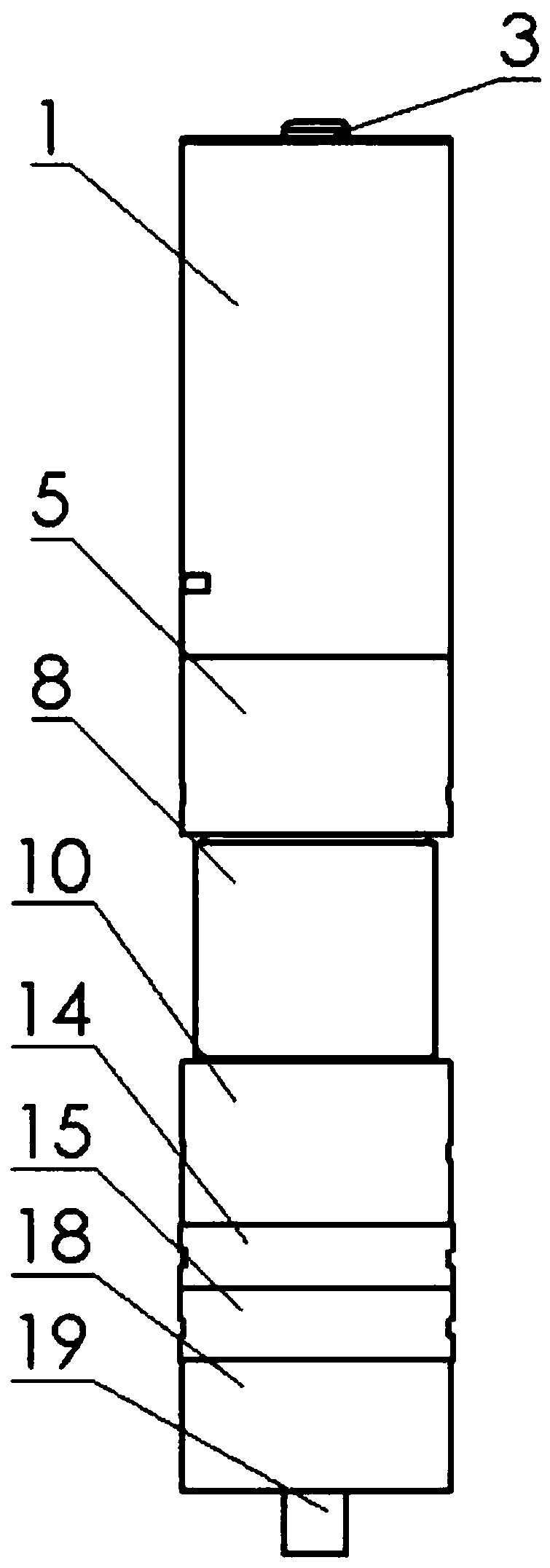

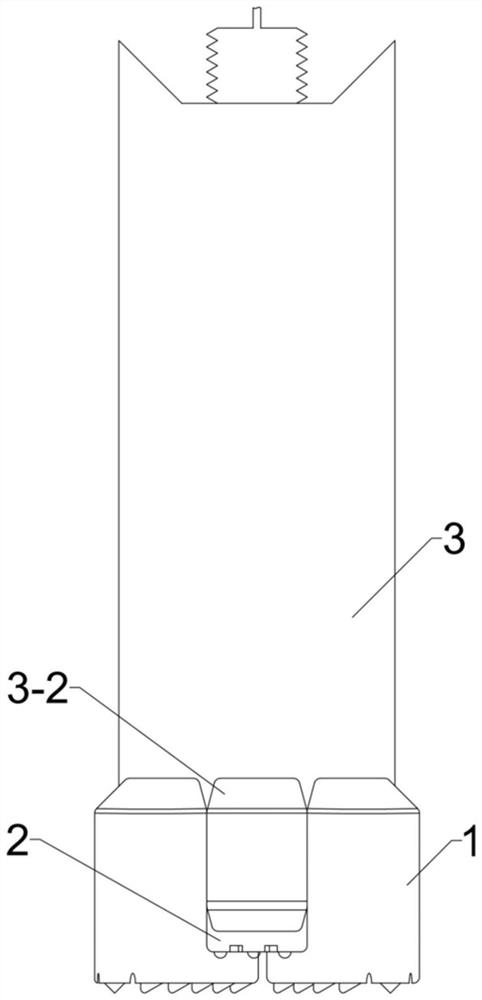

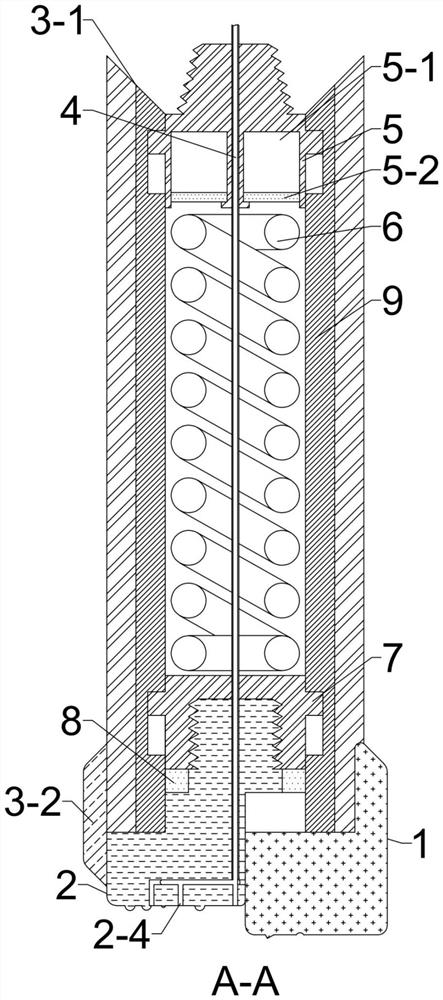

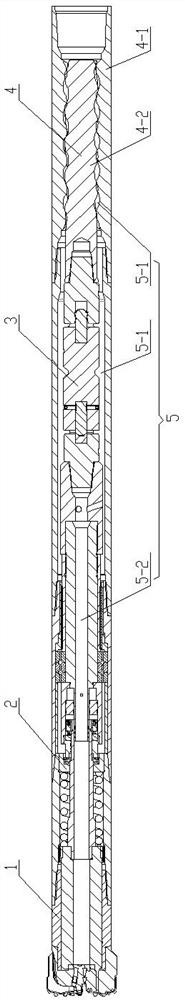

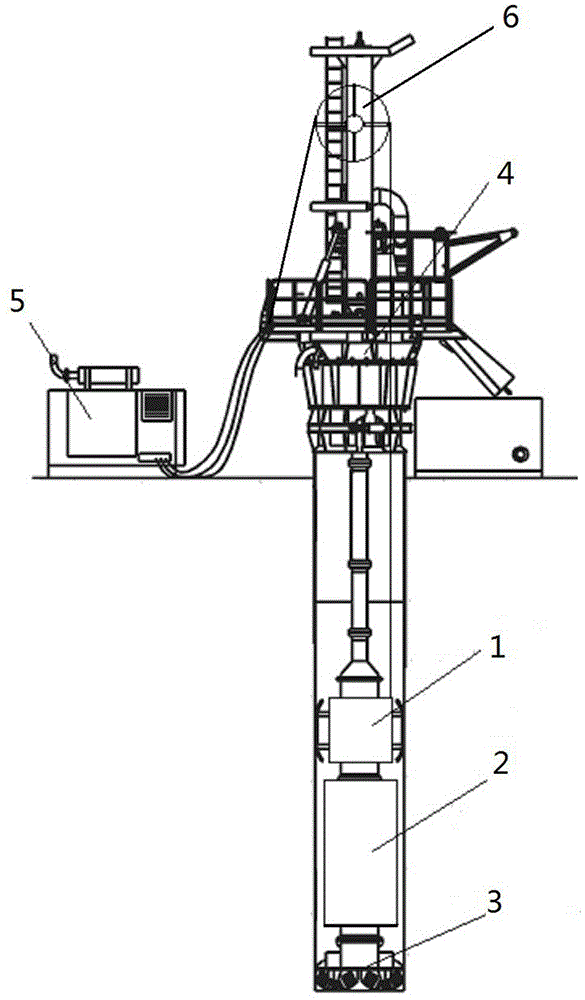

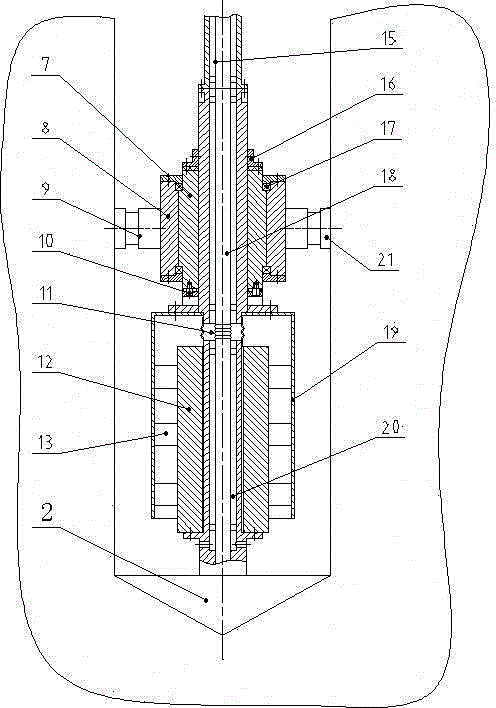

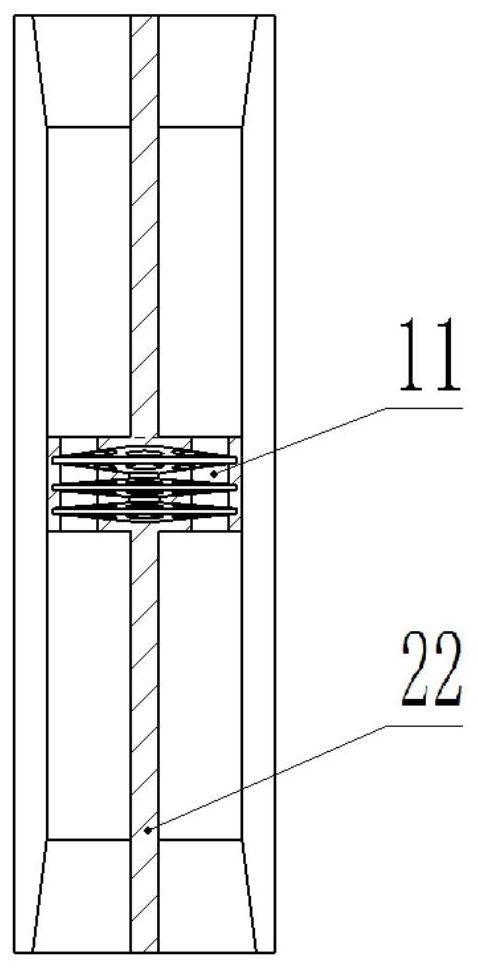

Double drill bit torque self-balancing pressure adjusting device

PendingCN107795273AImprove rock breaking efficiencyLower Drilling CostsBorehole drivesHardnessSynergy

The invention discloses a double drill bit torque self-balancing pressure adjusting device, and belongs to the field of well drilling and misering. The double drill bit torque self-balancing pressureadjusting device comprises an external drill bit pressure adjusting assembly, an inner drill bit pressure adjusting assembly and a pressure adjusting pushing rod assembly. According to the double drill bit torque self-balancing pressure adjusting device, characteristics of a pressure-transmitting bearing are utilized, the situation that the drilling pressure is transmitted from an upper static drilling tool to a lower rotary drilling tool is realized, no torque effect acts on the upper drilling tool, and static-dynamic conversion and pressure transmitting of the drilling tools are achieved; and meanwhile, when an inner drill bit and an outer drill bit drill and encounter stratums with different hardness, synergistic action of an internal pressure sensor, an external pressure sensor and a pressure adjusting pushing rod is utilized to realize automatic adjusting of the drilling pressure applied to the inner drill bit and the outer drill bit, the drilling pressure applied to the inner drill bit and the outer drill bit is dynamically distributed so that the inner drill bit and the outer drill bit can conduct synergistic action while working, the conditions of drilling bit jamming and different abrasion degrees of the inner drill bit and the outer drill bit due to uneven force applied to the inner drill bit and the outer drill bit when the inner drill bit and the outer drill bit drill and encounter different stratums are avoided, and the rock-breaking efficiency of the drill bits can be greatly improved.

Owner:JILIN UNIV

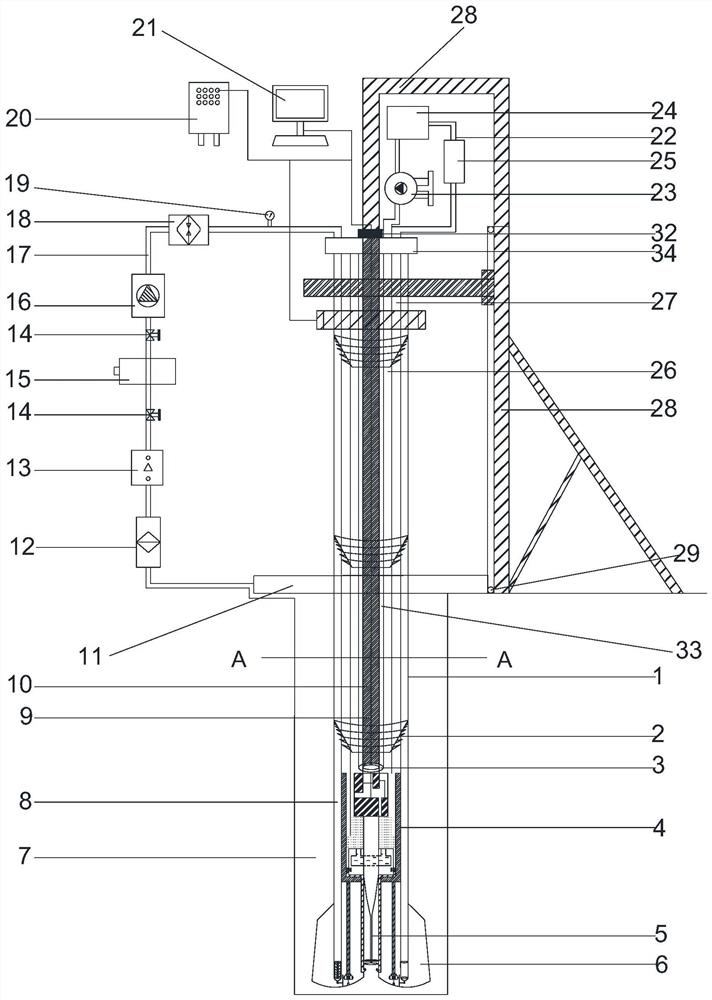

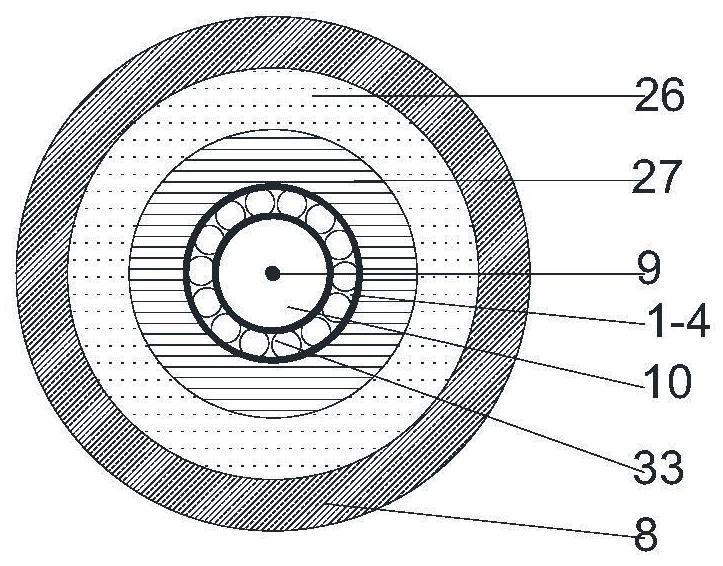

Microwave-assisted supercritical carbon dioxide jet drilling device and method

PendingCN112796664ALow tensile strengthImprove crushing efficiencyDrill bitsDrilling rodsEngineeringMicrowave irradiation

The invention relates to a microwave-assisted supercritical carbon dioxide jet drilling device and method. The problems that a drill bit is seriously abraded, the drill bit is frequently taken off and replaced, and the drilling aging is seriously affected in a traditional mechanical rock breaking method are solved. The drilling efficiency is improved through the process that two kinds of input energy of microwave irradiation and supercritical carbon dioxide jet are organically matched. The drilling device has the mode that rotary jet and direct jet alternately act to carry out erosion damage on rock. A jet fluid nozzle controls the jet speed through a ball valve, and the drilling efficiency is improved. The strength of the rock is effectively reduced through the permeation effect of supercritical carbon dioxide and the expansion effect of the supercritical carbon dioxide under microwave irradiation. Compared with a conventional drilling device, the drilling capacity of the device for rock masses with different strengths can be greatly improved, and the drilling efficiency is greatly improved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

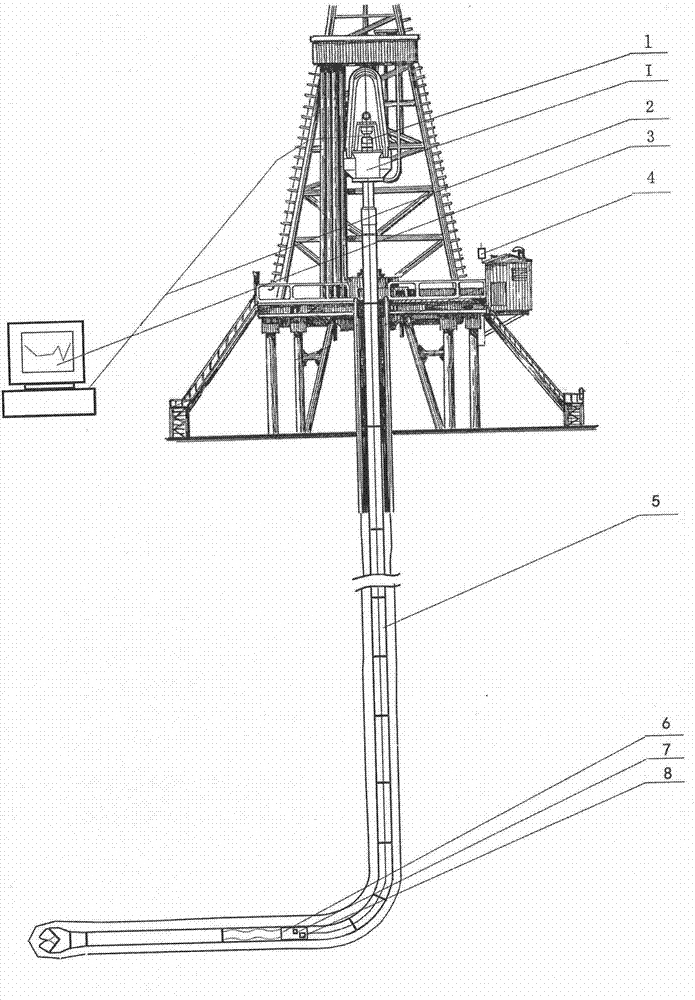

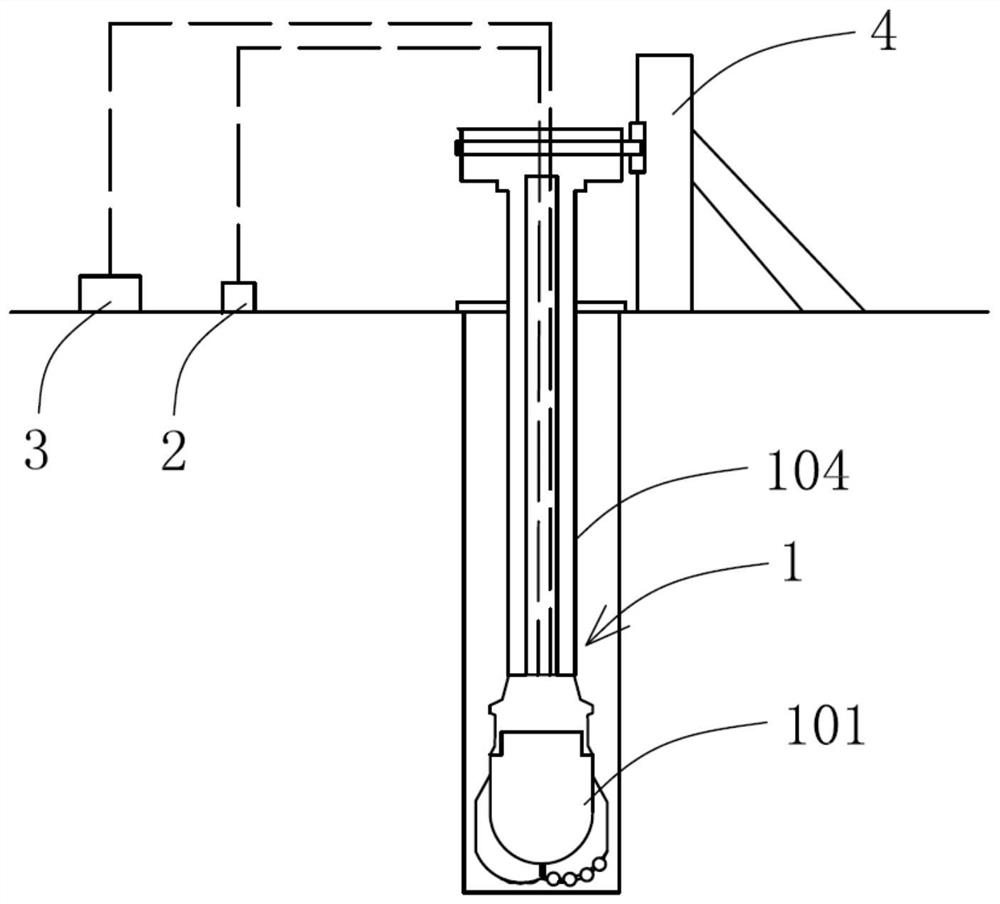

Intelligent drilling tool drilling wired data transmitting system

InactiveCN107130958AEnhanced overall recoveryOvercoming expensiveSurveyData acquisitionOil production

The invention relates to an intelligent drilling tool drilling wired data transmission system, which consists of a cable rotary joint, a signal cable, a control host, an alarm, an intelligent drilling tool, a drilling and geological parameter detector, a cable detector, and a serial port communication module. The composition solves the problem of difficult downhole data acquisition and transmission that has plagued the drilling industry for many years, and overcomes the problems of expensive wireless MWD equipment, low transmission rate, need to be equipped with expensive high-temperature batteries, short continuous working time, high requirements for drilling mud, and equipment Short maintenance period, complex construction process, large construction team and other disadvantages, after the wear resistance and corrosion resistance treatment of intelligent drilling tools, intelligent drilling tools can be reused, cable brings superior signal transmission performance, and can be equipped with more Advanced testing instruments can collect more drilling and geological parameters in real time, improve the accuracy and superiority of drilling well trajectory control, improve drilling exploration effects, and improve oil production efficiency.

Owner:张洪新

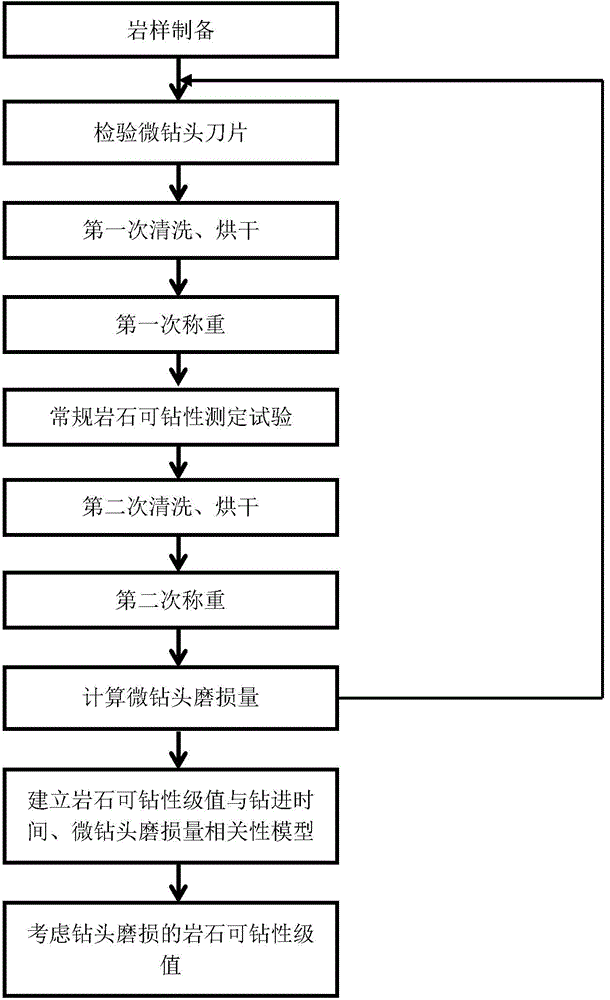

Rock drillability determining method capable of determining drill bit wear

Owner:SINOPEC SHENGLI PETROLEUM ENG CO LTD DRILLING TECH RES INST

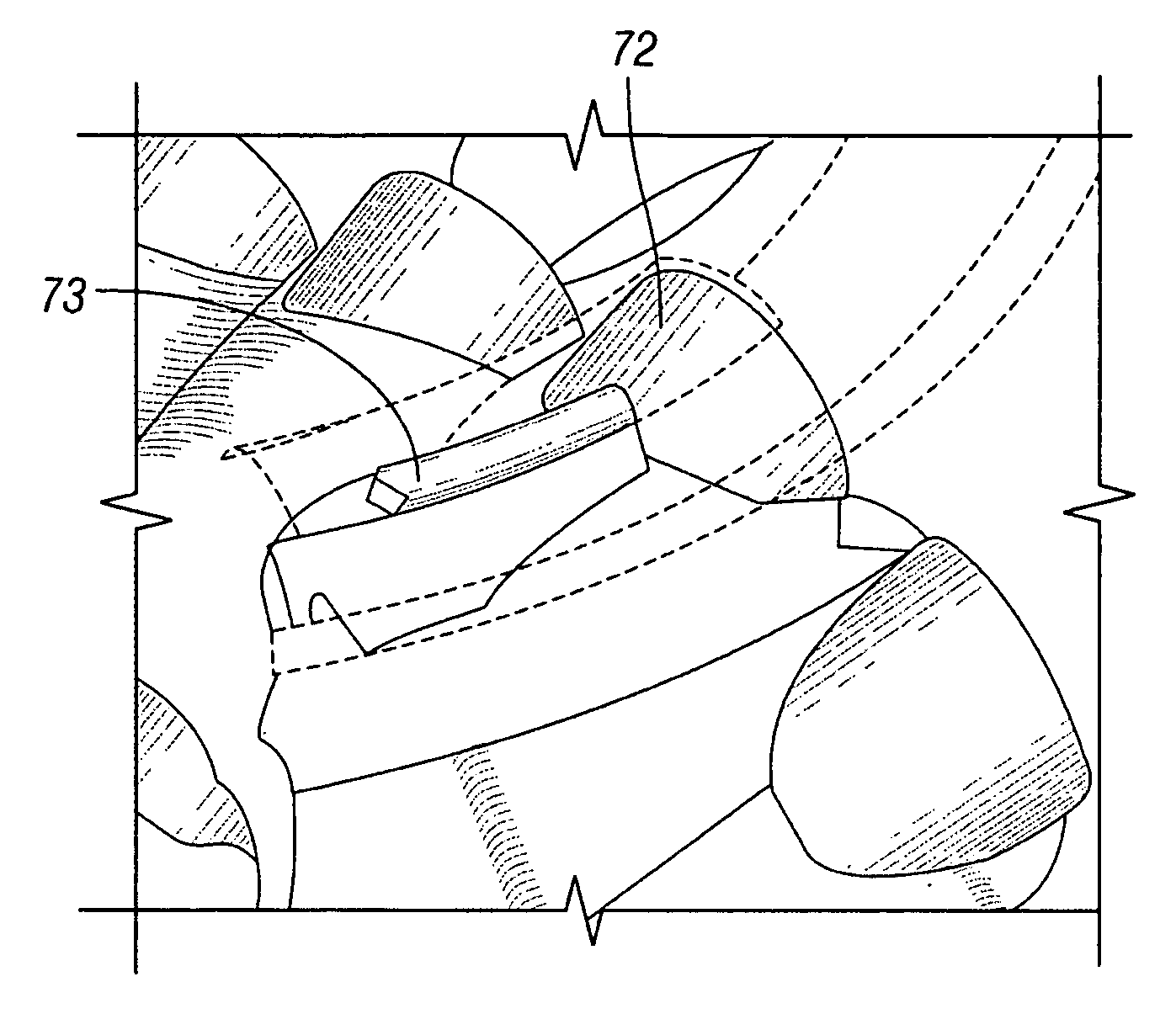

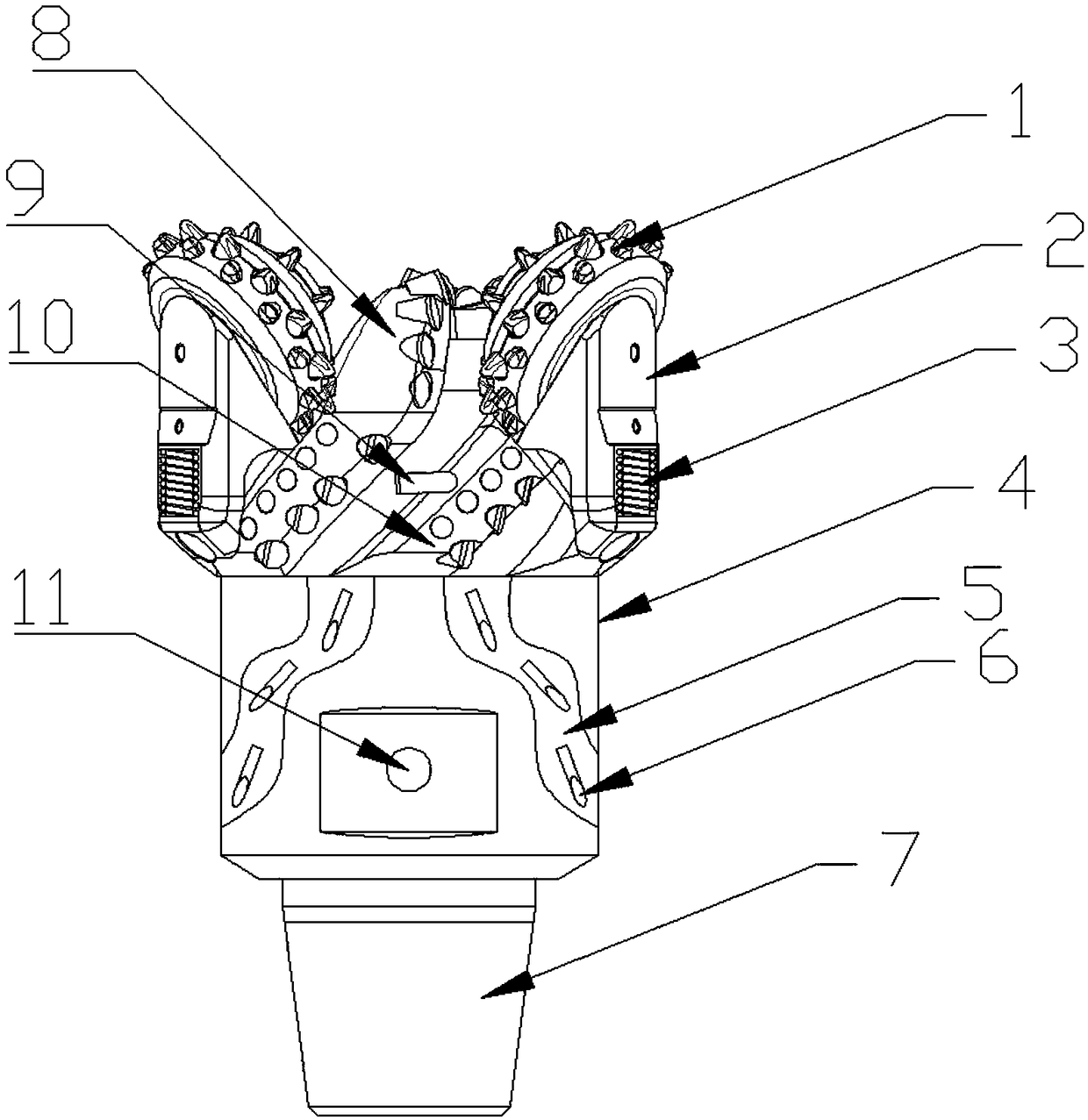

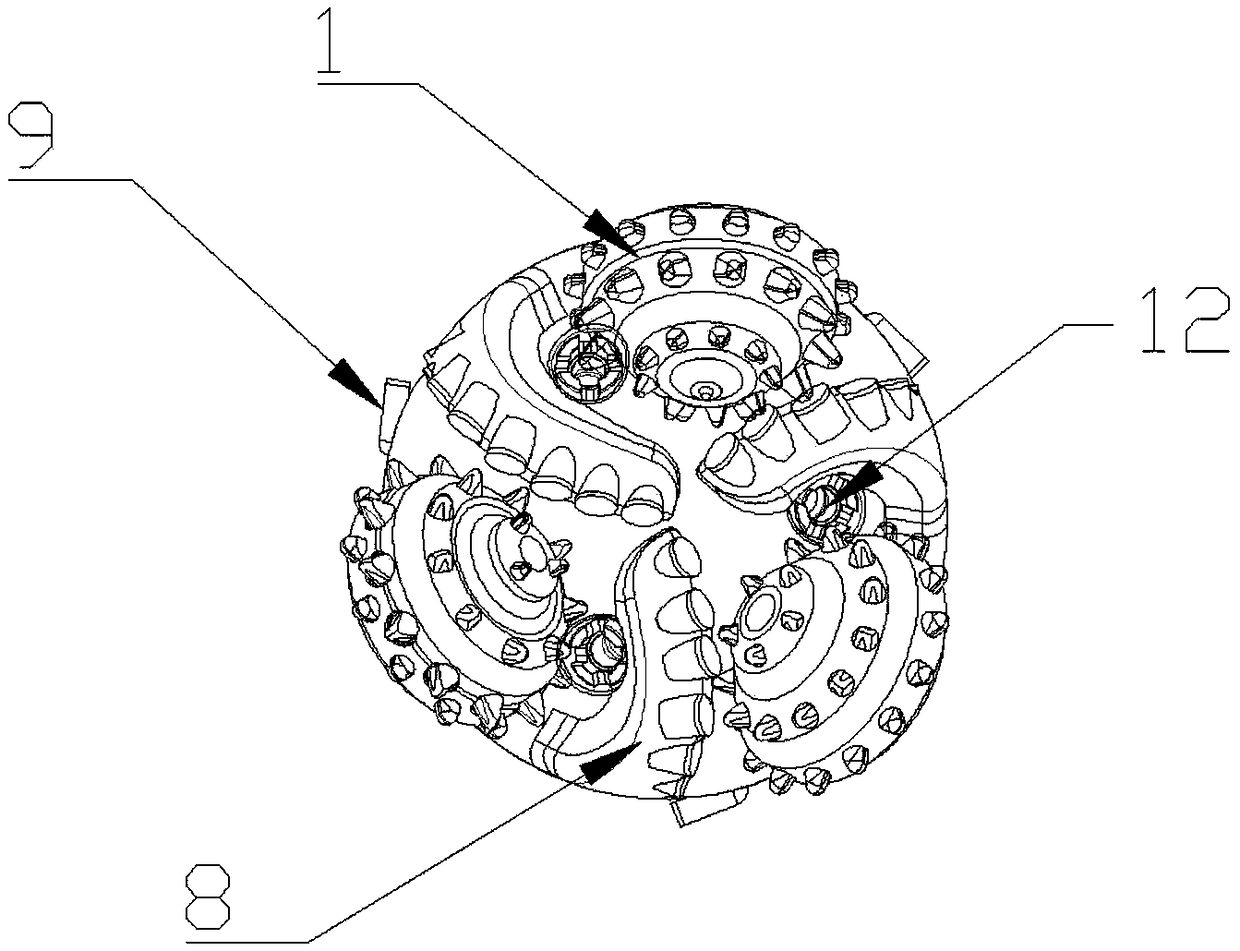

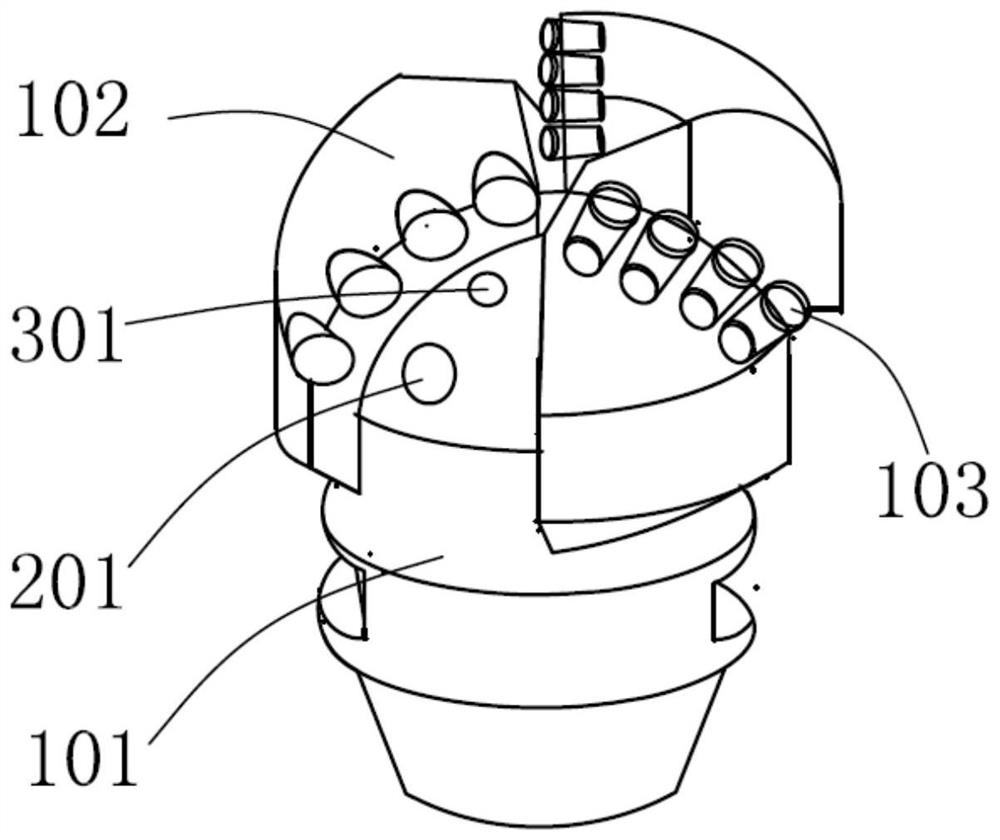

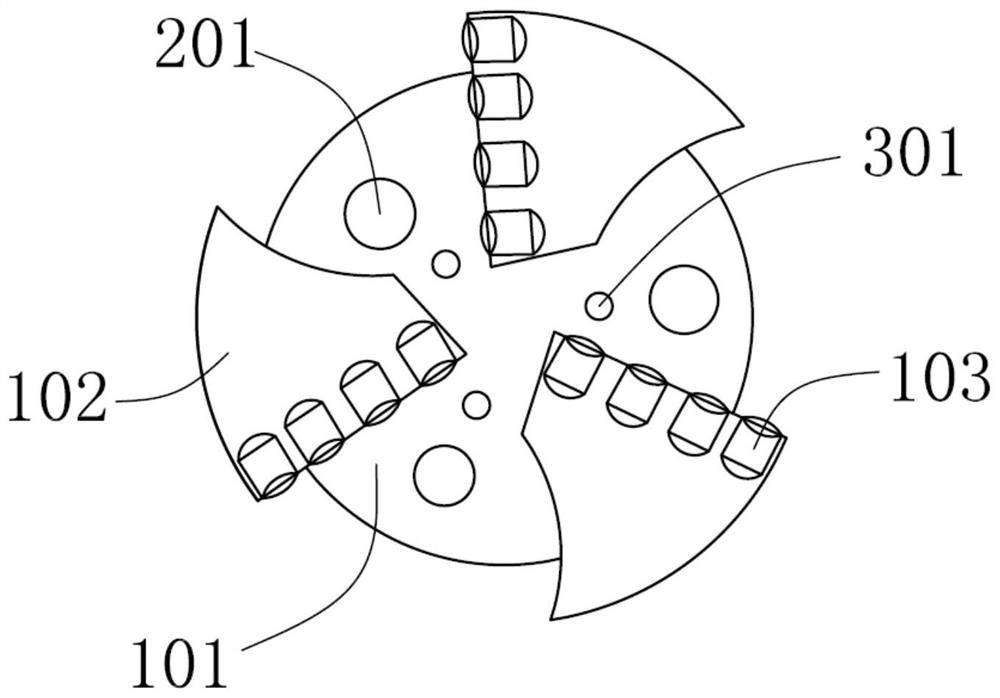

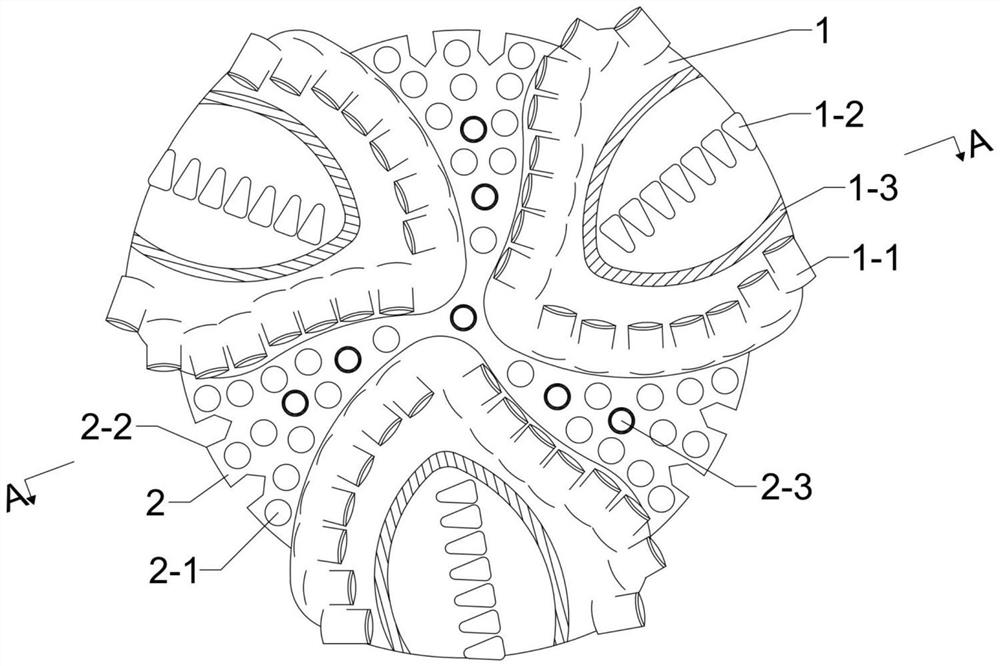

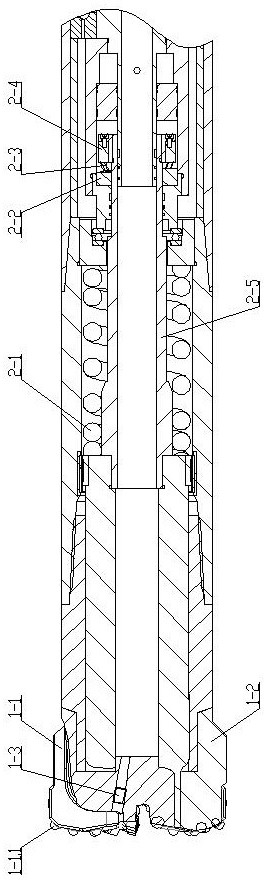

Three-blade PDC and tricone tooth combined drill bit

PendingCN109505521AReduce vibration intensityReduce vibrationDrill bitsConstructionsMedial axisWell drilling

The invention discloses a three-blade PDC and tricone tooth combined drill bit and belongs to the technical field of drill bits for petroleum drilling. The problem is solved that a combined drill bitin the prior art is instable and accordingly the service life is short. The three-blade PDC and tricone tooth combined drill bit comprises an installing portion, wherein the installing portion is provided with a thread and is connected with an intermediate shaft, the intermediate shaft is connected with joints, tooth palms are connected to the joints, compression springs are installed in the toothpalms, the upper ends of the compression springs are connected with the insides of the tooth palms, the lower ends of the compression springs are connected with the joints, the joints are welded andconnected with the tooth palms, empty groove for installing the compression springs are formed in the tooth palms, the tooth palms are provided with cones, the number of the tooth palms and the numberof the cones are both three, PDC blades are arranged among the cones, and the PDC blade positions on the side faces of the joints are all provided with side blades. The abrasion of the drill bit is effectively reduced, the service life is long, and a drilling effect is good.

Owner:CANGZHOU GREAT DRILL

Rotary drill bit compensating for changes in hardness of geological formations

InactiveUS6962217B1Minimize timePrevents sticking and jammingDrill bitsDrilling rodsWell drillingBit wear

A long lasting rotary drill bit for drilling a hole into variable hardness geological formations that has a self-actuating mechanism responsive to the hardness of the geological formation to minimize the time necessary to drill a borehole. A long lasting rotary drill bit for drilling a hole into variable hardness geological formations that has a mechanism controllable from the surface of the earth to change the mechanical configuration of the bit to minimize the time necessary to drill a borehole. A monolithic long lasting rotary drill bit for drilling a hole into a geological formation having hardened rods composed of hard material such as tungsten carbide that are cast into a relatively soft steel matrix material to make a rotary drill bit that compensates for wear on the bottom of the drill bit and that also compensates for lateral wear of the drill bit using passive, self-actuating mechanisms, triggered by bit wear to drill relatively constant diameter holes.

Owner:SMART DRILLING & COMPLETION

Microwave rock breaking drilling device

PendingCN112523685AReduce intensityImprove absorbing performanceDrill bitsDrilling machines and methodsMicrowave - actionWell drilling

The invention provides a microwave rock breaking drilling device. The microwave rock breaking drilling device comprises an integrated drill bit assembly, a microwave generation assembly and a water jetting dust removal assembly. The integrated drill bit assembly comprises a drill bit body, a cutter head and cutting teeth. The cutter head and the cutting teeth are arranged on the drill bit body. The microwave generation assembly comprises microwave emission holes, and the microwave emission holes are formed in the drill bit body and communicate with the outside. The water jetting dust removal assembly comprises water jetting holes, and the water jetting holes are formed in the drill bit body and communicate with the outside. On the one hand, when hard rock drilling is carried out, the microwave generation assembly is used for performing microwave action on rock, the rock temperature field is changed to soften the rock, the rock strength is reduced, drill bit abrasion is reduced, and therock breaking efficiency is improved; and on the other hand, the influence of mud, dust and the like on the microwave emission holes is effectively solved through a water jetting cleaning system, theeffect of reducing the temperature of the drill bit can be achieved, the rock wave absorbing capacity is enhanced, the microwave effect is improved, efficiency is improved, and losses are reduced.

Owner:SHENZHEN UNIV

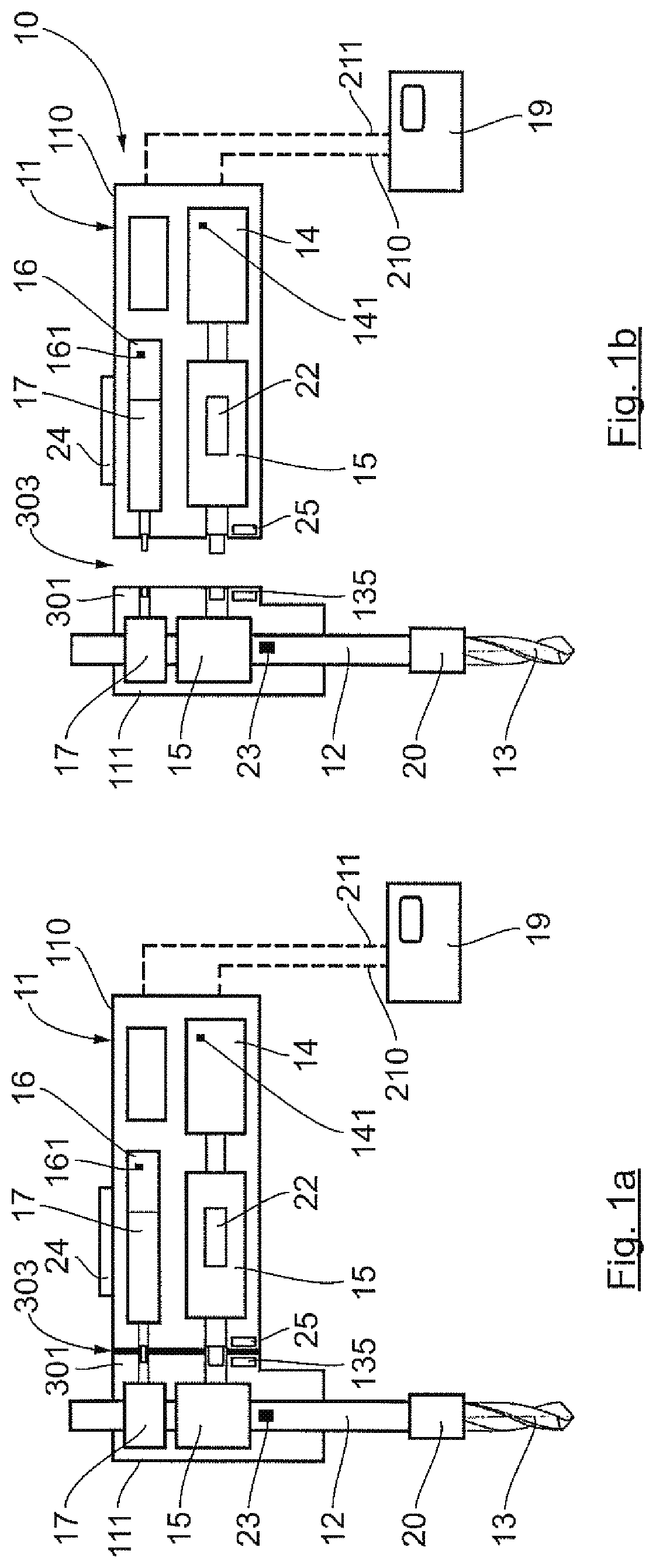

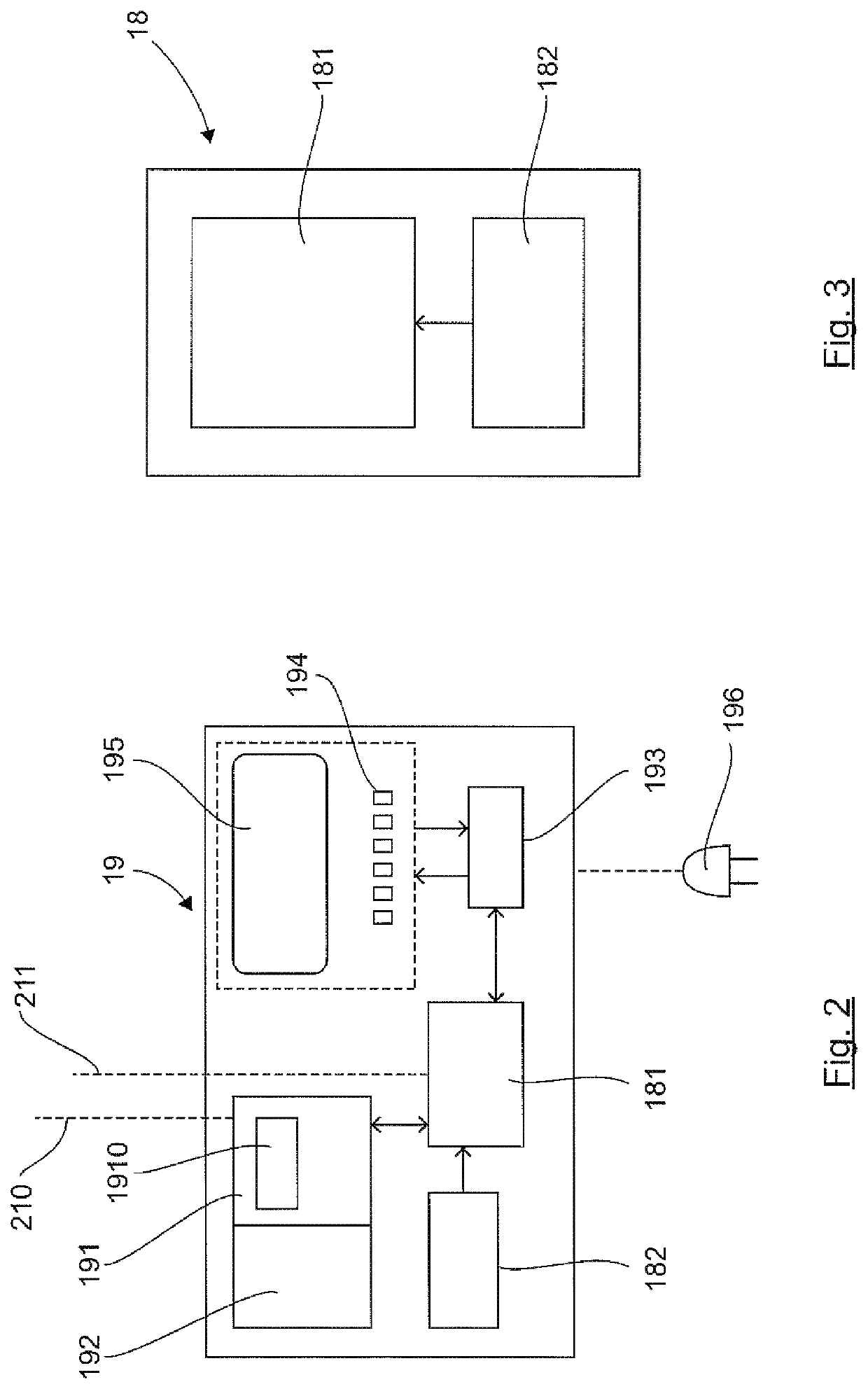

Method for determining the state of wear of a drill, and corresponding device

ActiveUS10953510B2Easily know right timeDeterioration of qualityProgramme controlDrilling/boring measurement devicesWell drillingClassical mechanics

A method is provided for assessing wear of a drill bit throughout its use for carrying out the drilling of elements to be drilled constituted by at least one layer and at least one material. The wear of the drill bit expresses its capacity to perform a drilling that meets at least one criterion of quality of a drilling. The method includes at least: measuring or detecting at least one parameter having an effect on the wear of the drill bit, the parameter being chosen from: the depth of drilling performed by the drill bit, and the entry of the drill bit into the element to be drilled; and determining at least one state of wear of the drill bit, each state of wear being determined as a function of one of the parameters and being characteristic of one of the criteria of quality of a drilling.

Owner:SETI TEC

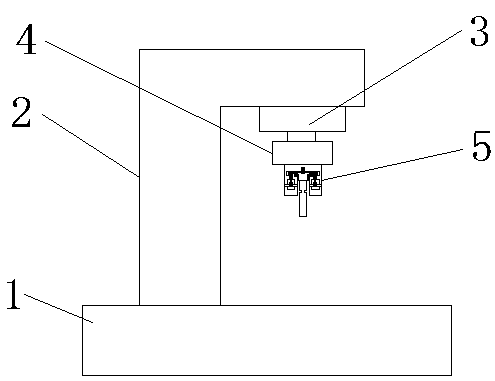

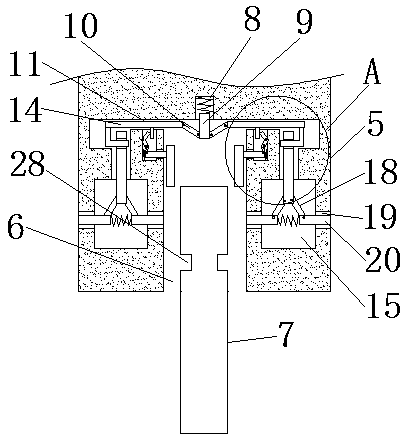

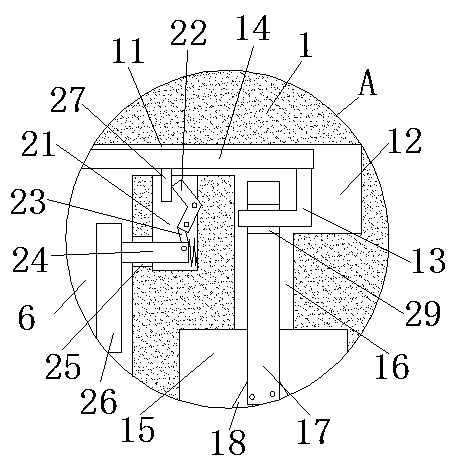

Perforating device for new material processing

InactiveCN110877364AEasy to disassembleEasy to installMetal working apparatusHydraulic cylinderCoupling

The invention discloses a perforating device for new material processing. The perforating device for new material processing comprises a base; an L-shaped post is fixedly mounted on the top side of the base; a telescopic hydraulic cylinder is fixedly mounted on the bottom side of the L-shaped post; a motor is fixedly mounted on a telescopic shaft of the telescopic hydraulic cylinder; a rotating shaft is fixedly mounted on an output shaft of the motor through a shaft coupling; a mounting groove is formed in the bottom end of the rotating shaft; a drill bit is arranged in the mounting groove; the bottom side of the drill bit extends out of the mounting groove; a groove is formed in the inner wall of the top side of the mounting groove; an ejector rod is movably mounted in the groove; the bottom end of the ejector rod extends into the mounting groove, and two rotating rods are rotatably mounted at the bottom end of the ejector rod; and the moving grooves which are symmetric based the drill bit are formed in the inner walls of the two sides of the mounting groove. The perforating device for new material processing is easy to operate; when the drill bit is worn or broken, the drill bitcan be taken out by pressing two clamping rods far from each other; the detachment of the drill bit is facilitated; a new drill bit can be fixed by vertically moving the new drill bit aligning with the mounting groove; the mounting of the new drill bit is facilitated; and the demands of people are met.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

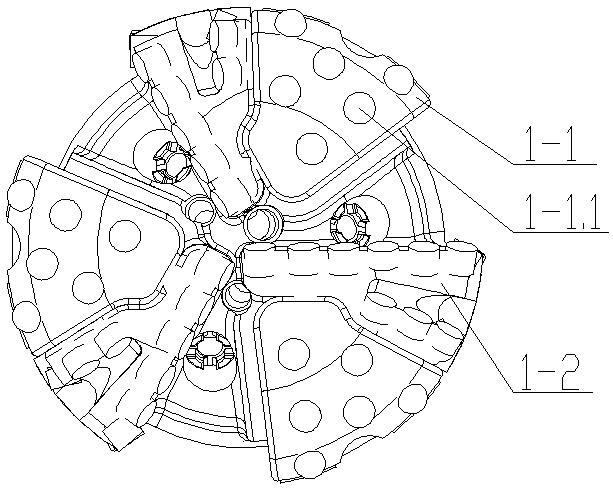

Dynamic tension shear tunneling drill bit and composite rock breaking method

ActiveCN114718465AImprove rock breaking efficiencyReduce wear rateDrill bitsConstructionsClassical mechanicsRock breaking

The invention discloses a dynamic tension shear tunneling drill bit and a composite rock breaking method. The drill bit head comprises a rotary drill bit, an impact drill bit and high-pressure nozzles, the high-pressure nozzles are distributed on the working face of the impact drill bit, the impact drill bit comprises a plurality of centrosymmetric impact structures, the rotary drill bit comprises a plurality of centrosymmetric rotary structures, and the number of the impact structures corresponds to that of the rotary structures. The impact structure of the impact drill bit and the rotating structure of the rotating drill bit are arranged in a spaced mode, and the impact structure and the rotating structure are connected in a sliding mode in the axial direction. The tunneling efficiency in the deep complex hard rock geological environment is improved, and drill bit abrasion is reduced.

Owner:CENT SOUTH UNIV

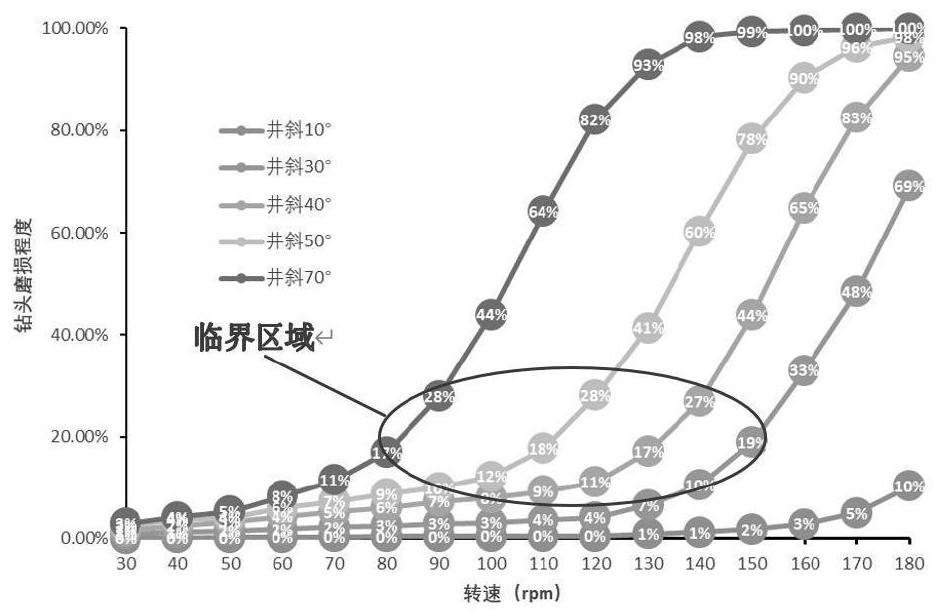

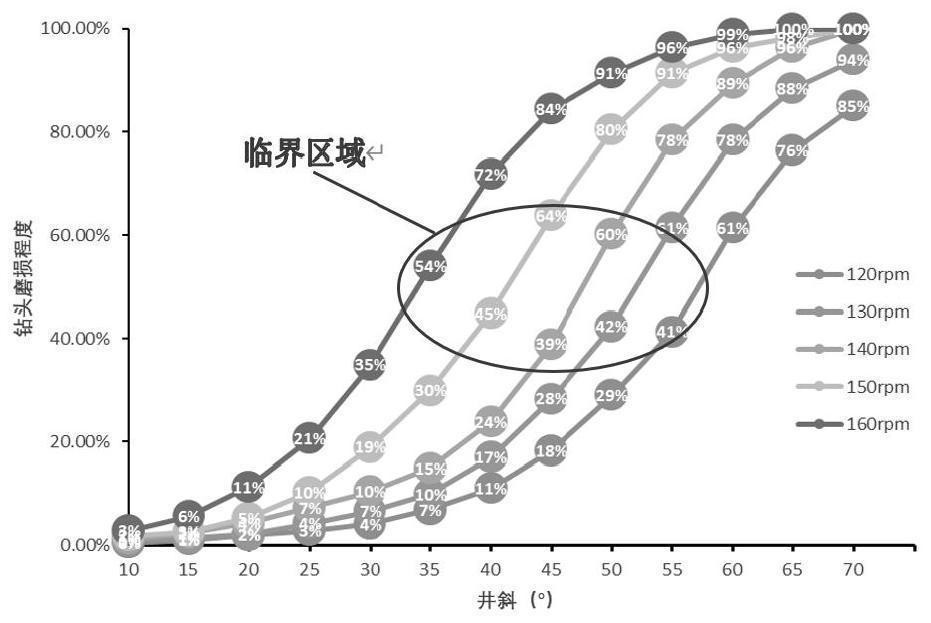

Drill bit wear quantitative evaluation method suitable for machine learning

PendingCN114021423ARealize the quantitative analysis of wear degree calculationSolve math problemsDesign optimisation/simulationUnivariate analysisStatistical analysis

The invention discloses a drill bit wear quantitative evaluation method suitable for machine learning. According to the invention, analysis is completed on the basis of statistical analysis of actual construction data of a completed well, and the analysis is actually statistical analysis; the change characteristics and rules of historical well data are analyzed, and the characteristics and rules of data reaction are actual reactions of actual engineering; according to the invention, the discrete drill bit wear degree representation is converted into the continuous numerical variable, so that the mathematical difficulty for a machine learning theory is solved. A drill bit abrasion degree calculation model is established in a data driving mode, and drill bit abrasion degree calculation quantitative analysis is achieved; through main influence factor univariate analysis, the method can achieve the effects that (1) the factor which has the largest influence on the abrasion degree of the drill bit is determined, drilling parameters are optimized, serious abrasion of the drill bit is avoided, and the service life of the drill bit is prolonged; and 2) the wear degree of the drill bit is quantitatively analyzed, and thus making a decision reference for drill bit replacement in tripping.

Owner:CNOOC ENERGY TECH & SERVICES

Drilling machine

ActiveCN111112686APrevent flying outPrevent fallingMaintainance and safety accessoriesBoring/drilling machinesThermodynamicsCentrifugal force

The invention discloses a drilling machine. The drilling machine structurally comprises a fixing seat, a connecting seat, a machining table, a drill bit connecting seat and a chipping collecting device, wherein the fixing seat is provided with the connecting seat, the connecting seat is fixedly connected with the machining table, the machining table is mechanically connected with the drill bit connecting seat, and the drill bit connecting seat is connected with the chipping collecting device. The drilling machine has the beneficial effects that chippings generated in the steel pipe drilling process are collected through arranging a chipping collecting groove, so that the chippings generated in the drilling process are prevented from falling off and blocking another drilling point; meanwhile, a solid balance weight layer is arranged at the end, close to a first plate, of a second plate so that the force application direction of the second plate can be always vertically downward, and when the chipping collecting groove rotates anticlockwise by 90 degrees, a second cavity is in a closed state; and when the chipping collecting groove is reset, the second cavity is opened, so that the chippings in a first cavity enters the second cavity and are prevented from flying out of the chipping collecting groove under the action of centrifugal force in the rotating process, and meanwhile theproblem that drill bit abrasion is aggravated due to the existence of the chipping can be effectively solved.

Owner:东莞市华盛精密模具配件有限公司

Punching and cutting combined drilling tool

ActiveCN113931576AImprove applicable working conditionsEasy to cut intoDrill bitsBorehole drivesPunchingMining engineering

The invention discloses a punching and cutting combined drilling tool, relates to the field of drilling equipment. The problems that the working efficiency is low and the wear rate of a drill bit is high when rocks are crushed only by rotating the drill bit are mainly solved. The punching and cutting combined drilling tool mainly structurally comprises a PDC drill bit body and a percussion drill bit body and is characterized by further comprising a percussion structure connected with the percussion drill bit body. The punching and cutting combined drilling tool is suitable for different stratums of various geological conditions, the construction efficiency is high, and drill bit abrasion is small.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

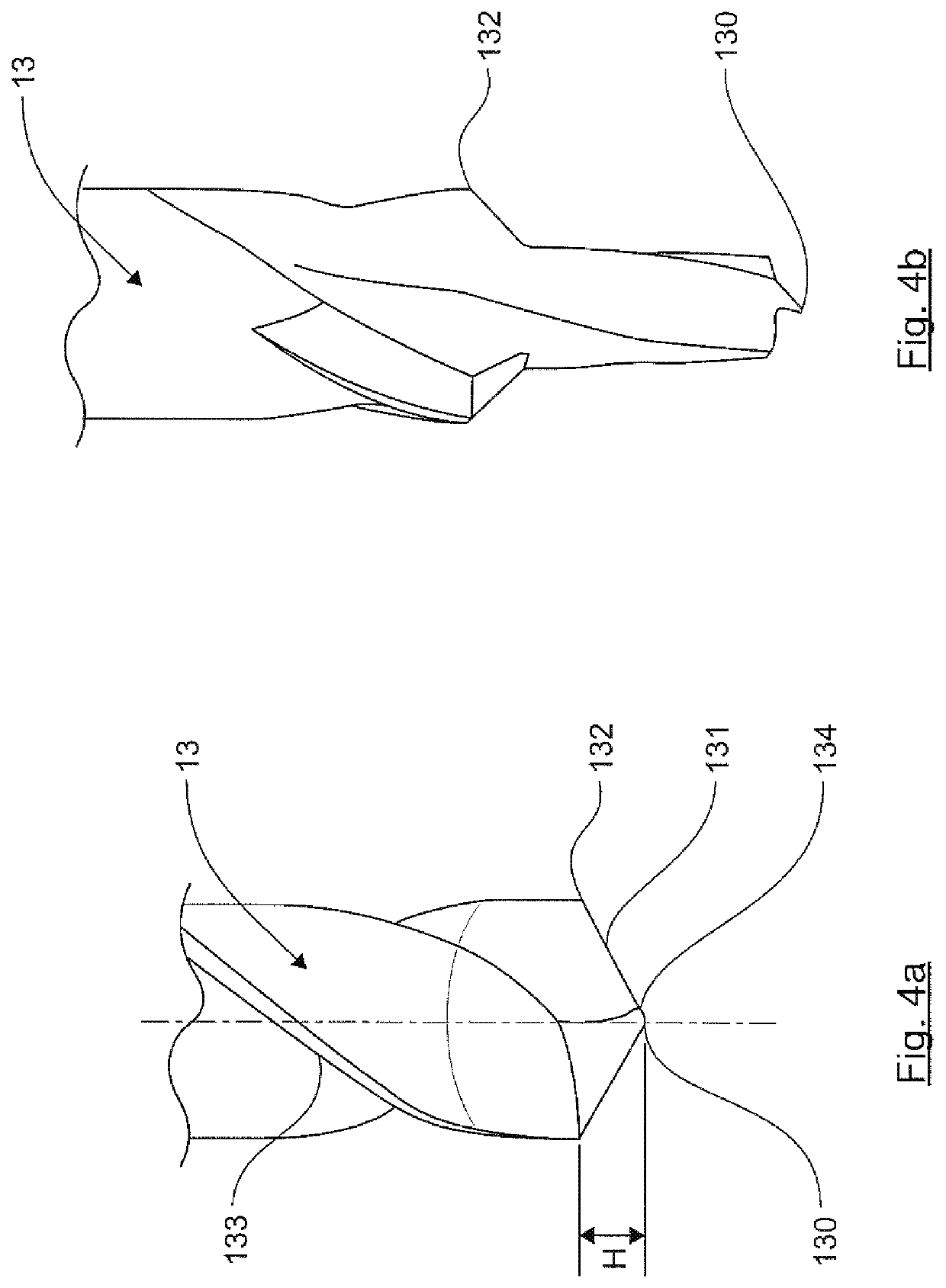

Segmented orbital drill

A segmented orbital drill includes a segmented portion with a semi-finishing cutting portion and a plurality of finishing cutting portions. The semi-finishing cutting portion and finishing cutting portions are separated by grooves formed by a front wall and a rear wall. The segmented portion allows for a fresh cutting edge (i.e., rear wall of the groove) to be revealed as the orbital drill wears in the axial direction. The segmented portion also causes less contact with the workpiece, which reduces power consumption and minimizes deflection of the orbital drill. The segmented orbital drill also includes an optional pilot at one end of the drill, and a clearance neck portion between a shank and the segmented portion. A method of machining a workpiece using the segmented orbital drill is also disclosed.

Owner:KENNAMETAL INC

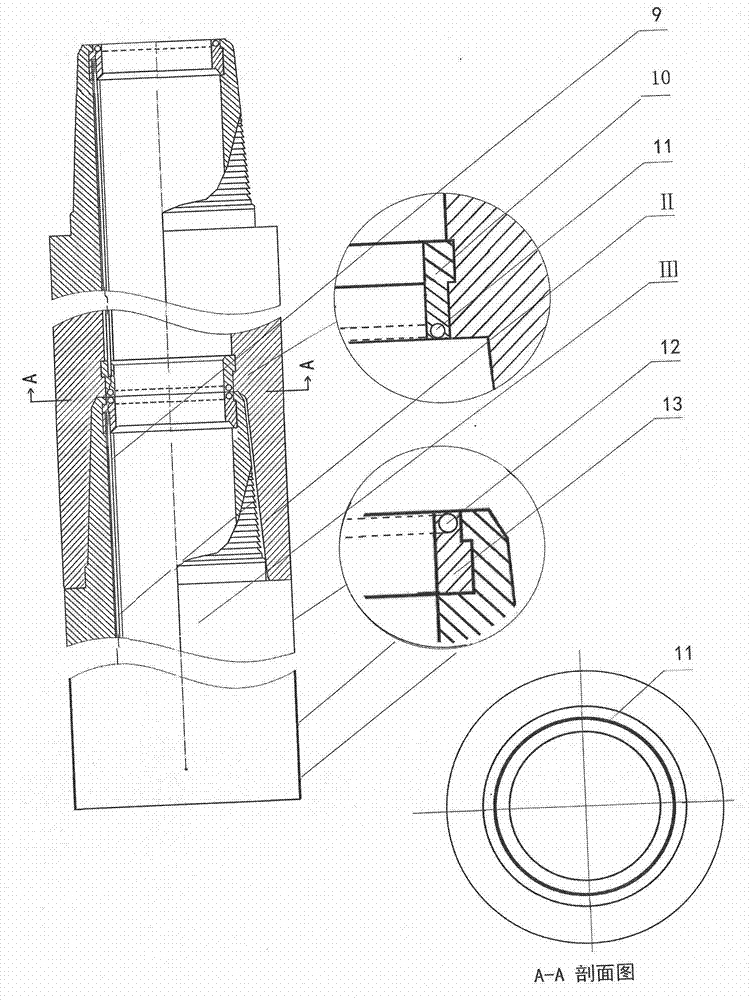

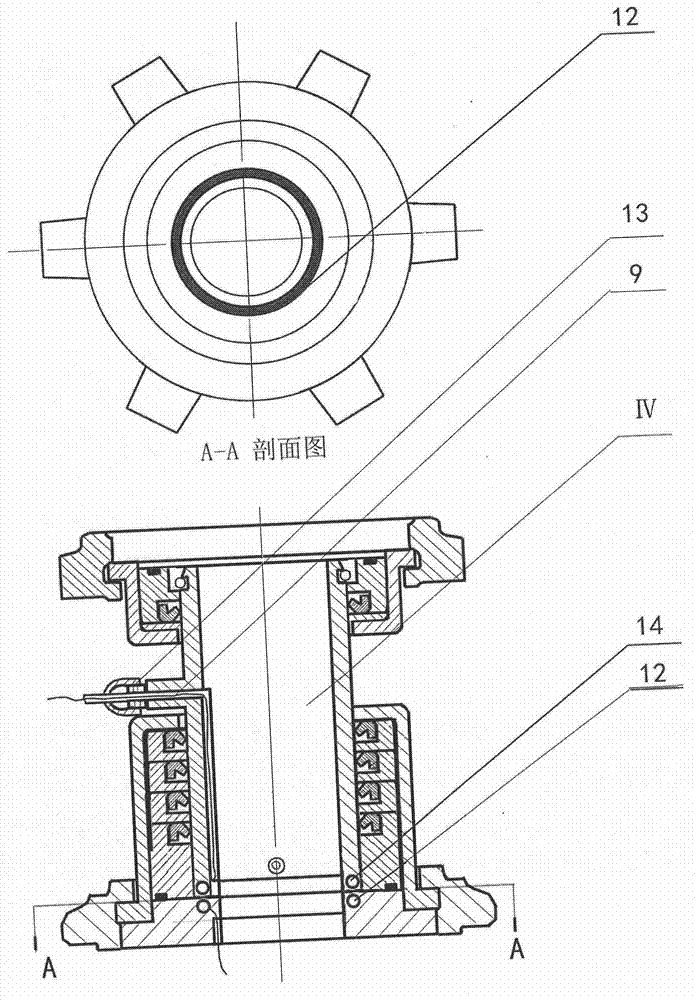

Downhole breaking rock-entering drill of hydraulic slewing drilling machine

InactiveCN106320974AQuick responseImprove anti-rotation effectBorehole drivesEngineeringDrilling machines

The invention provides a downhole breaking rock-entering drill of a hydraulic slewing drilling machine and relates to a rock breaking device applicable to a power head type full hydraulic slewing drilling machine. The problems that in the drilling process, once an existing power head type full hydraulic slewing drilling machine encounters a rock stratum, a drill bit cannot enter the rock easily, the drilling efficiency is low, one-time impact holing of a large-diameter pile hole cannot be achieved, continuous hole bottom slag discharge cannot be achieved, the rock entering speed is slow, the drill bit is severely abraded, and the cost is high are solved. An oil circuit rotating connector assembly is additionally arranged on a drill rod of the slewing drilling machine. A central shaft of the rotating connector assembly is connected with the drill rod through a flange. The lower end of the rotating connector assembly is connected with a gas lifting hard rock drill bit through a vibrator. In the drilling and rock entering processes, percussive drilling is adopted, the rock entering and drilling efficiency is improved, continuous gas lifting slag discharge of the drilling machine is not changed while the vibrator conducts vibrating striking to cooperate with drilling of a drill bit, and the functions of striking and drilling of the power head type full hydraulic slewing drilling machine are achieved.

Owner:XIANGYANG CHANGKAN INTELLIGENT MACHINERY

Segmented orbital drill

A segmented orbital drill includes a segmented portion with a semi-finishing cutting portion and a plurality of finishing cutting portions. The semi-finishing cutting portion and finishing cutting portions are separated by grooves formed by a front wall and a rear wall. The segmented portion allows for a fresh cutting edge (i.e., rear wall of the groove) to be revealed as the orbital drill wears in the axial direction. The segmented portion also causes less contact with the workpiece, which reduces power consumption and minimizes deflection of the orbital drill. The segmented orbital drill also includes an optional pilot at one end of the drill, and a clearance neck portion between a shank and the segmented portion. A method of machining a workpiece using the segmented orbital drill is also disclosed.

Owner:KENNAMETAL INC

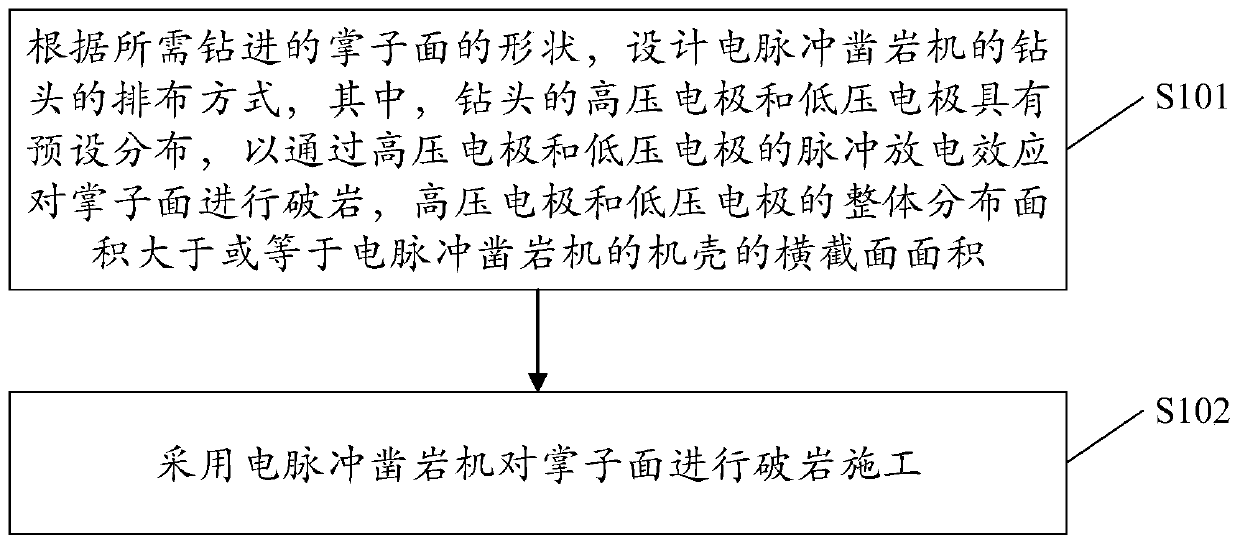

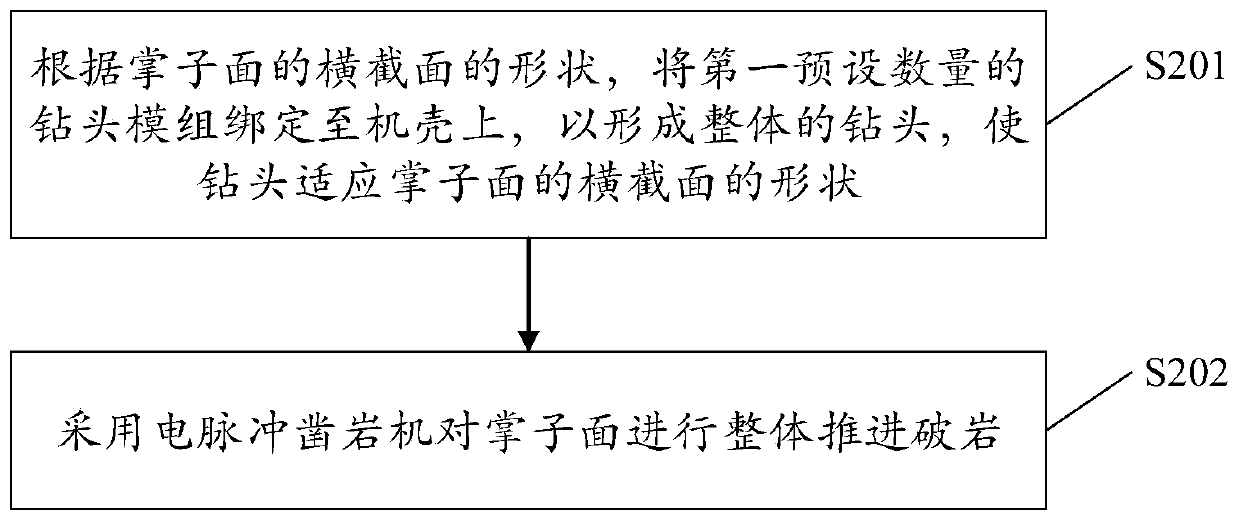

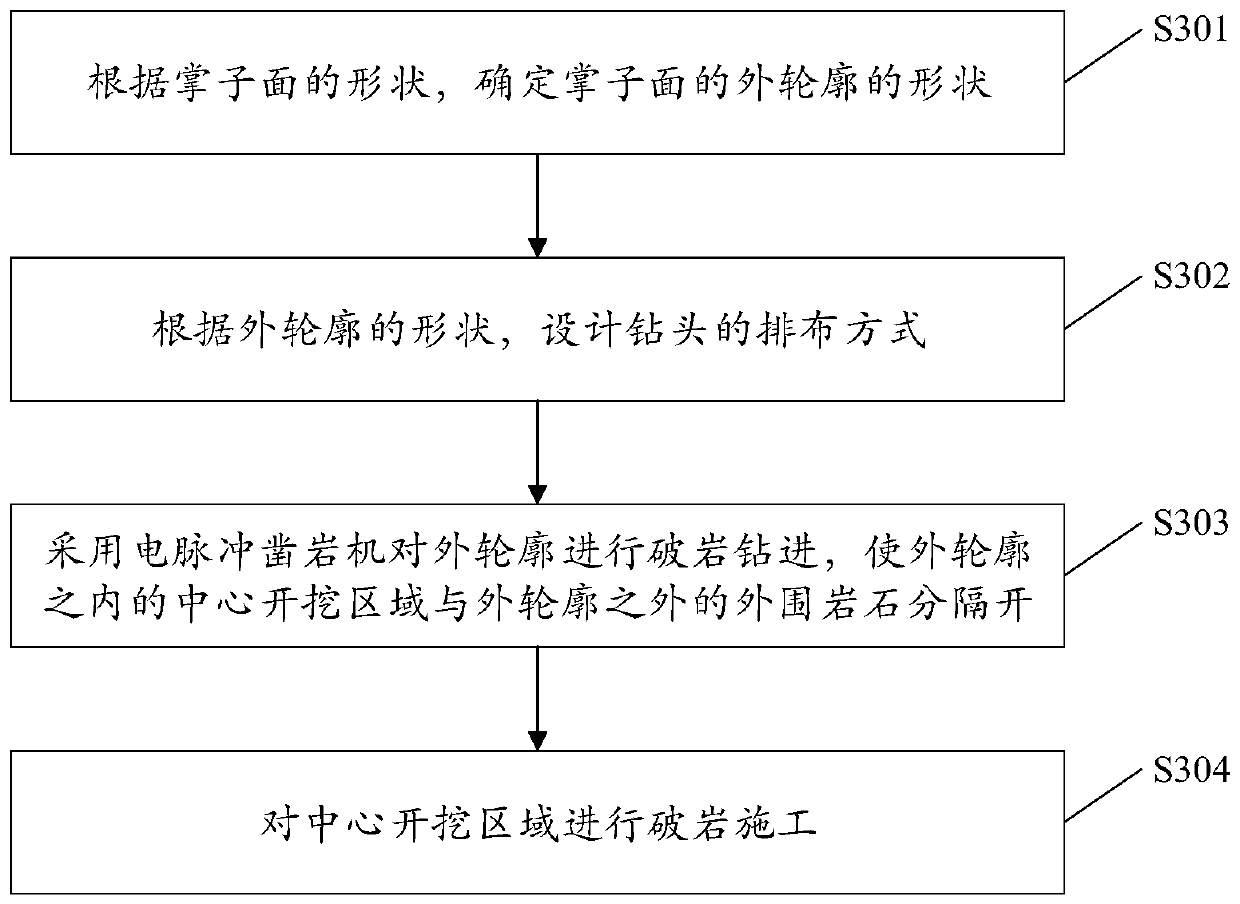

Hard rock tunnel construction method

InactiveCN110924972AGuaranteed stabilityTo achieve the purpose of excavating the face of the tunnelTunnelsLow voltageRock tunnel

The invention discloses a hard rock tunnel construction method. The hard rock tunnel construction method comprises the following steps that an arrangement mode of drill bits of an electric pulse rockdrill is designed according to the shape of a tunnel face needing to be drilled, wherein the high-voltage electrode and the low-voltage electrode of the drill bits have a preset distribution so as toperform rock break on the tunnel face through the pulse discharge effect of the high-voltage electrode and the low-voltage electrode, and the overall distribution area of the high-voltage electrode and the low-voltage electrode is larger than or equal to the cross-sectional area of a shell of the electric pulse rock drill; and the electric pulse rock drill is adopted to perform rock breaking construction on the tunnel face. When the tunnel face is subjected to rock breaking, outlines excavated by the drill bits can completely contain the shell of the electric pulse rock drill, thus over-breakand under-break can be avoided, and the stability of a tunnel supporting structure system is ensured. Meanwhile, due to the fact that the electric pulse rock drill performs rock breaking by utilizingthe pulse discharge effect, the drill bits do not need to rotate in the rock breaking process of the tunnel face, so that the wear amount of the drill bits is small, and the rock breaking efficiency is high.

Owner:CHINA RAILWAY CONSTR HEAVY IND

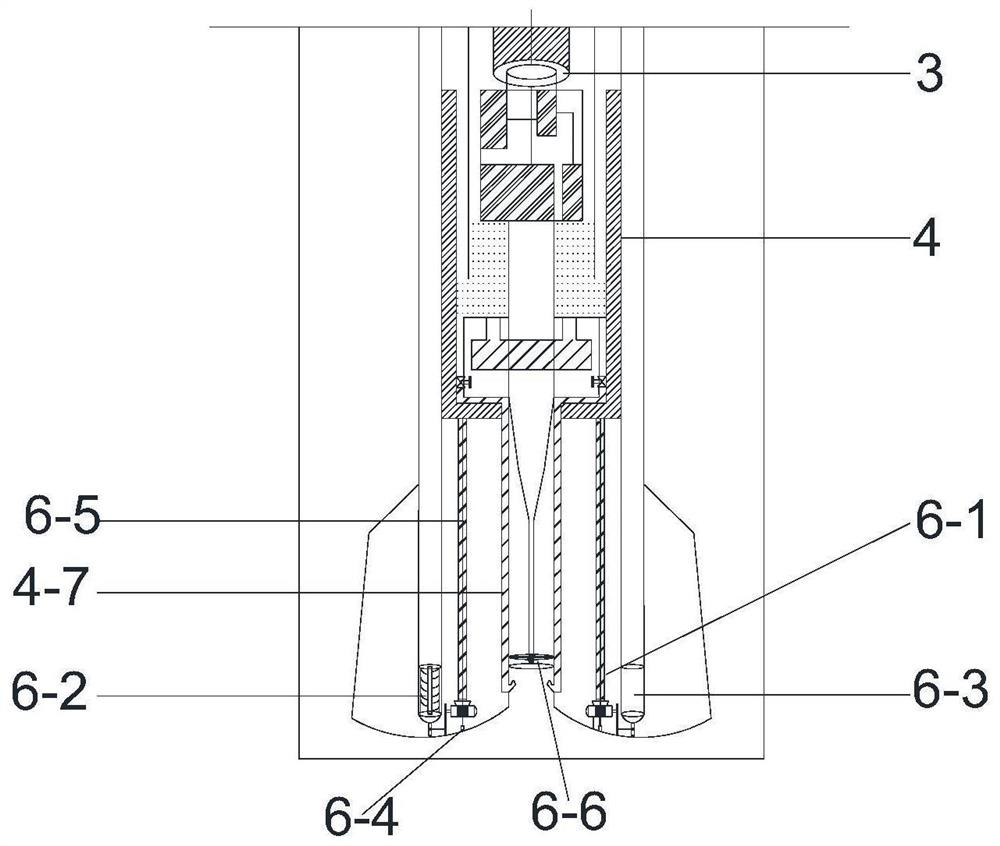

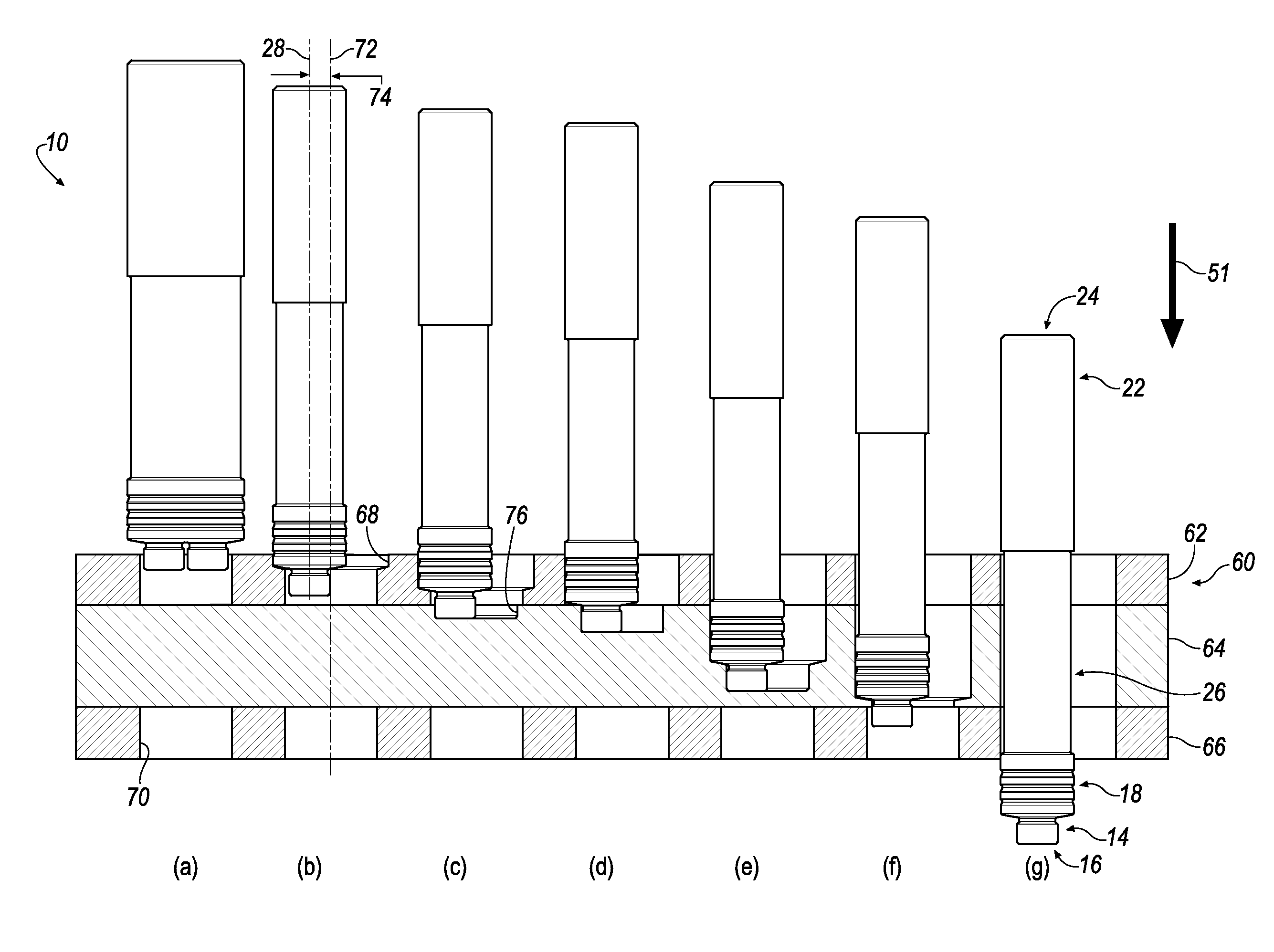

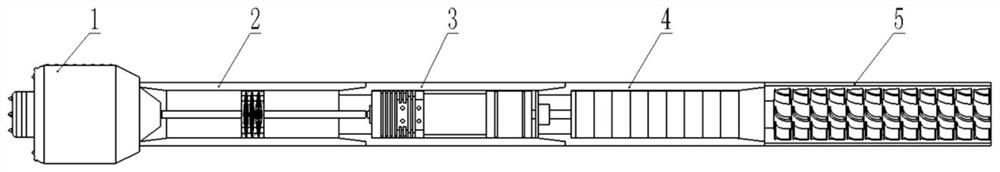

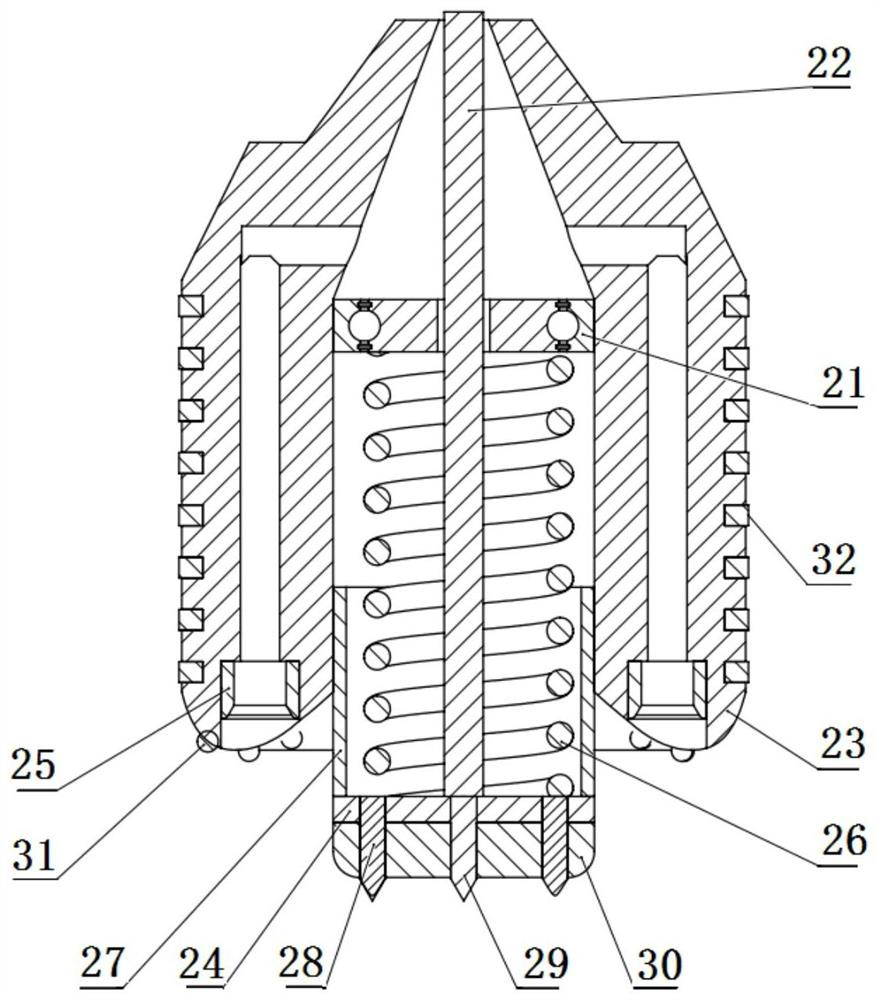

Impact voltage rock breaking combined drilling tool for improving mechanical drilling speed of hard stratum

InactiveCN112343500ANot easy to wearIn line with the trend of drilling developmentDrill bitsBorehole drivesVoltage generatorWell drilling

The invention provides an impact voltage rock breaking combined drilling tool for improving the mechanical drilling speed of a hard stratum. The problems that an existing drilling tool is low in drilling efficiency, large in drill bit abrasion and high in drilling cost are mainly solved. The impact voltage rock breaking combined drilling tool is characterized in that the upper end of an impact voltage rock breaking drill bit (1) is sequentially connected with a mud current sleeve (2), an impact voltage generator short circuit (3), a lithium battery short circuit (4) and an underground power generation short circuit (5) from bottom to top, wherein an insulating righting bearing (21) is arranged at the upper end of the interior of a drill bit shell (3), the lower end of the interior of the drill bit shell (3) is connected with a spring sleeve (27), the spring sleeve (27) is connected with an electrode holder (24), and the electrode holder (24) is connected with a low-voltage grounding electrode (28) and a high-voltage center electrode (29). The impact voltage rock breaking combined drilling tool for improving the mechanical drilling speed of the hard stratum can be used for impact voltage discharge rock breaking construction, the drilling efficiency is high, the cost is low, the drill bit is not prone to abrasion, and the impact voltage rock breaking combined drilling tool is suitable for drilling various types of wells.

Owner:DAQING PETROLEUM ADMINISTRATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com