Punching and cutting combined drilling tool

A compound drill and percussion drill technology, which is applied to drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of high drill bit wear rate and low work efficiency, and achieve the effects of improving applicable working conditions, convenient maintenance, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

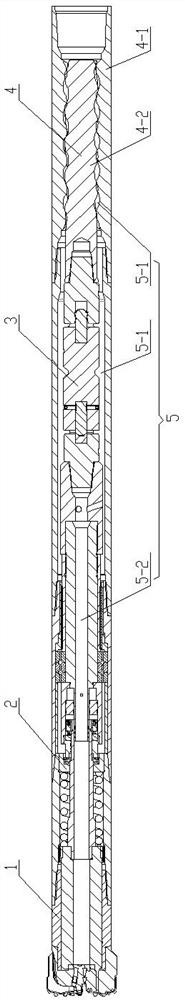

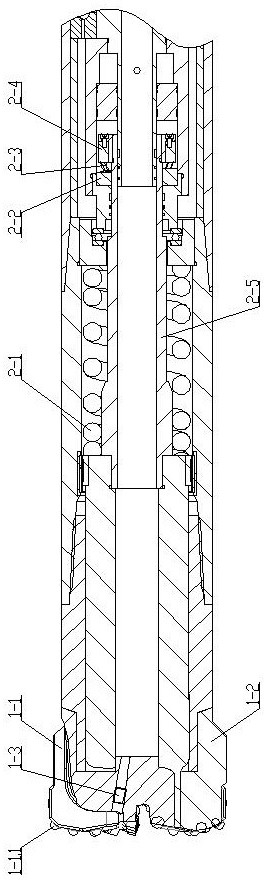

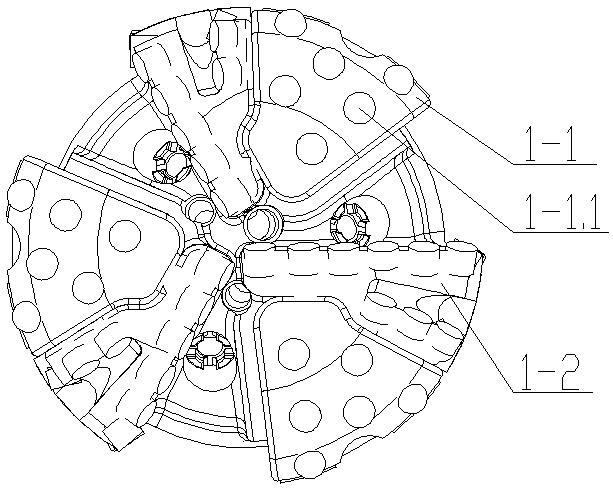

[0030] figure 1 and image 3 Shown is a punching and cutting composite drilling tool provided by the present invention, including a drill bit 1 , an impact structure 2 , a transmission structure 3 and a hydraulic motor 4 . The drill bit 1 includes a percussion drill 1-1 and a PDC drill 1-2, the PDC drill 1-2 and the percussion drill 1-1 are arranged at intervals, and the percussion teeth 1-1.1 set on the percussion drill 1-1 are connected with the percussion drill 1-1. The drill bit body is brazed, which is convenient to replace the impact teeth 1-1.1 of different shapes according to different geological conditions; the impact drill bit 1-1 is connected to the impact structure 2, and the impact structure 2 includes a rotary part, a top extension part and an axial force transmission part, and the rotary part Connect the power unit. The rotary part includes a cam 2-2, the protruding part includes a roller 2-3 and a roller seat 2-4, the axial force transmission part is a transm...

Embodiment 2

[0034] The scope of protection of the present invention is not limited to the mechanism mentioned in Embodiment 1. When the rotary part in Embodiment 1 is an annular boss with smooth ends, and the protruding part is a cam roller and a roller seat, when the annular boss rotates , the friction drives the cam roller to roll, because the radius of the cam roller changes, it drives the axial movement of the roller seat, and the axial force is transmitted to the impact drill through the axial transmission part, and the axial impact movement of the impact drill can also be realized .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com