Patents

Literature

38results about How to "Easy to cut into" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

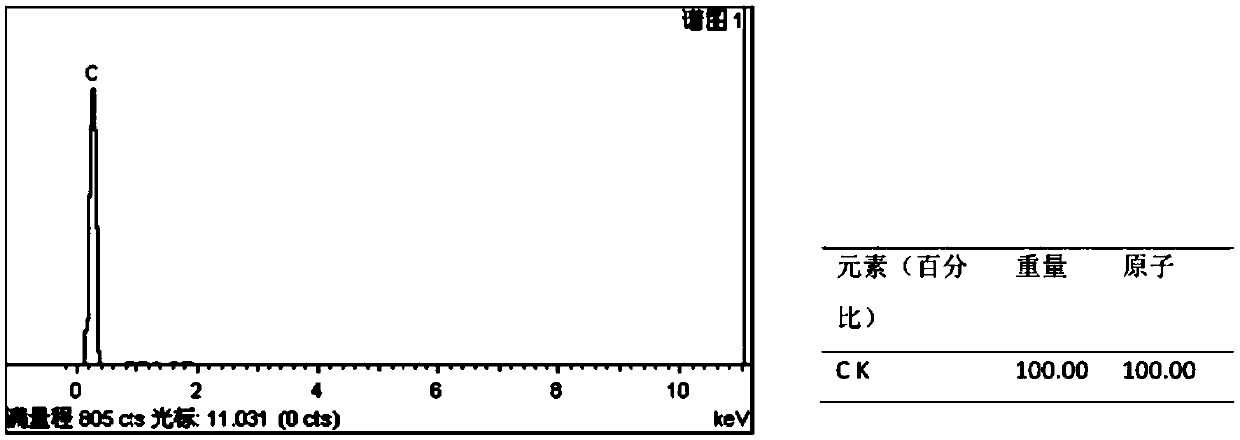

Diamond coating cutter, and preparation method and application thereof in high speed graphite processing

ActiveCN105563665AReduce cutting shock and vibrationAvoid breakingChemical vapor deposition coatingStone-like material working toolsHardnessLow friction

The invention discloses a diamond coating cutter, and a preparation method and the application thereof in high speed graphite processing. The diamond coating cutter comprises a cutter tip, a blade and a clamping cutter holder, wherein the clamping cutter holder is made of a hard alloy matrix, the cutter tip and the blade are coated with diamond coatings on matrix materials, the diamond coating cutter is characterized in that the end cutting edge front angle gamma o1 of the blade is 2 to 6 degrees, the end cutting edge rear angle alpha 1 is 5 to 13 degrees, the peripheral cutting edge front angle gamma o2 is 5 to 15 degrees, the peripheral cutting edge rear angle alpha 2 is 10 to 14 degrees, and the helical angle beta is 15 to 45 degrees. The diamond coating cutter provided by the invention has the characteristics of high hardness, wear resistance, low friction coefficient, good heat conduction and the like, is suitable for high speed graphite processing, can effectively overcome frictional wear caused by graphite dust to the surface of the cutter, and is classified as an ideal cutter for cutting graphite.

Owner:GUANGDONG UNIV OF TECH

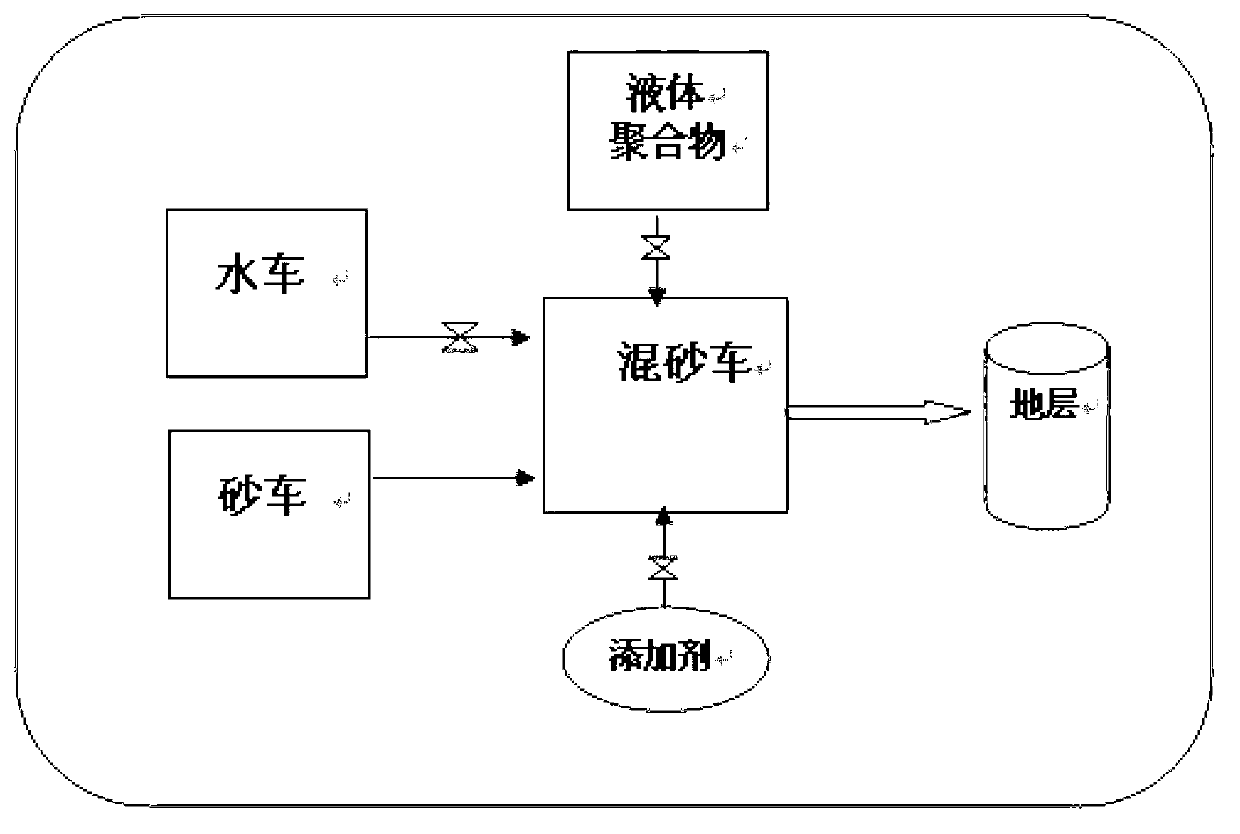

Fracturing process for online continuous preparation based on liquid polymer

InactiveCN102996107AQuality improvementReduce operating costsFluid removalDrilling compositionProcess engineeringMaterials science

The invention discloses a fracturing process for online continuous preparation based on a liquid polymer. The method comprises the steps of directly and proportionately pumping the high-content liquid polymer into a fracturing blender truck through a proportioning pump in an in-situ online adding manner; and adding water and propping agent into the liquid polymer, and mixing the water, the propping agent and a thickening polymer together proportionately under agitation of the fracturing blender truck, wherein the ratio of sand can be up to 15%-100% and even 250%. According to the method, the preparation does not need to be implemented in a liquid preparation station or a preparation pool, and the continuous preparation and construction can be achieved. The method closely combines preparation and construction, and truly fulfills the purposes of convenience in operation, reduction of construction costs, economization, environment protection, oil reservoir protection, yield increase, and efficiency enhancement.

Owner:SUNCOO PETROLEUM TECH

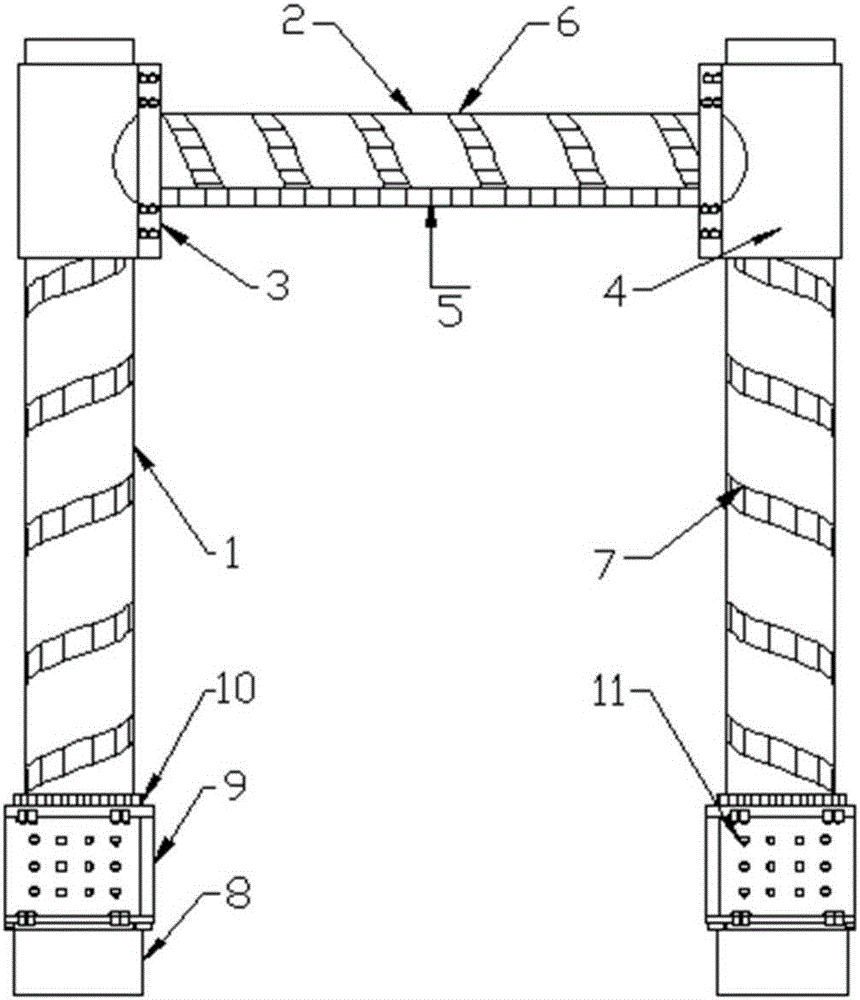

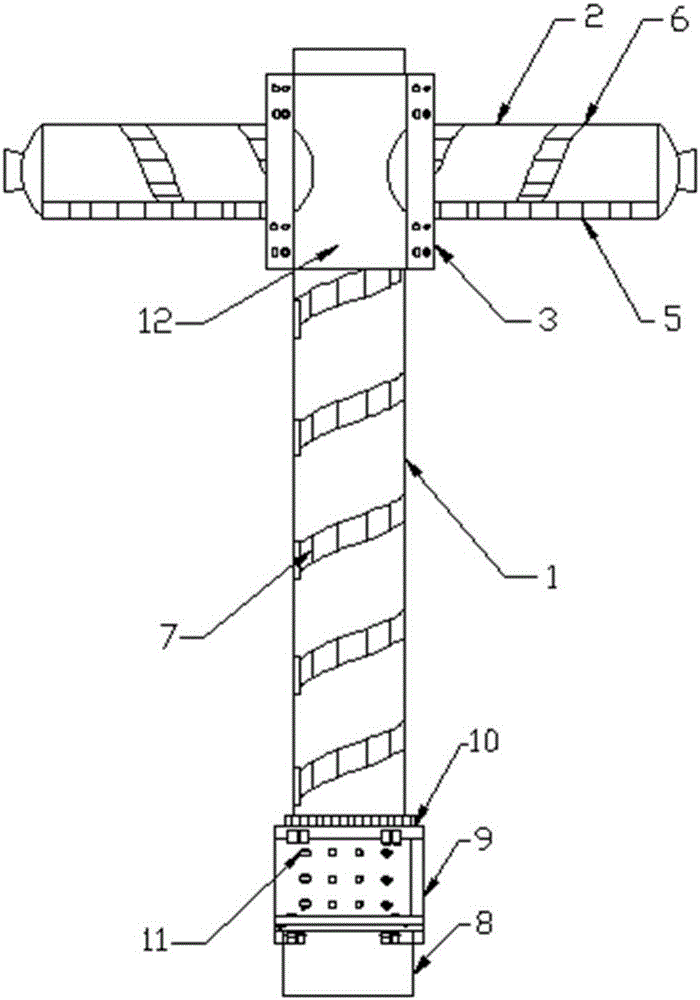

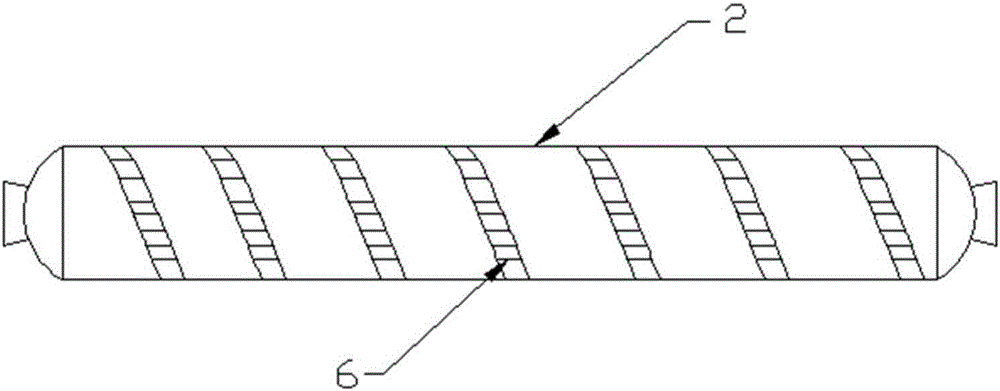

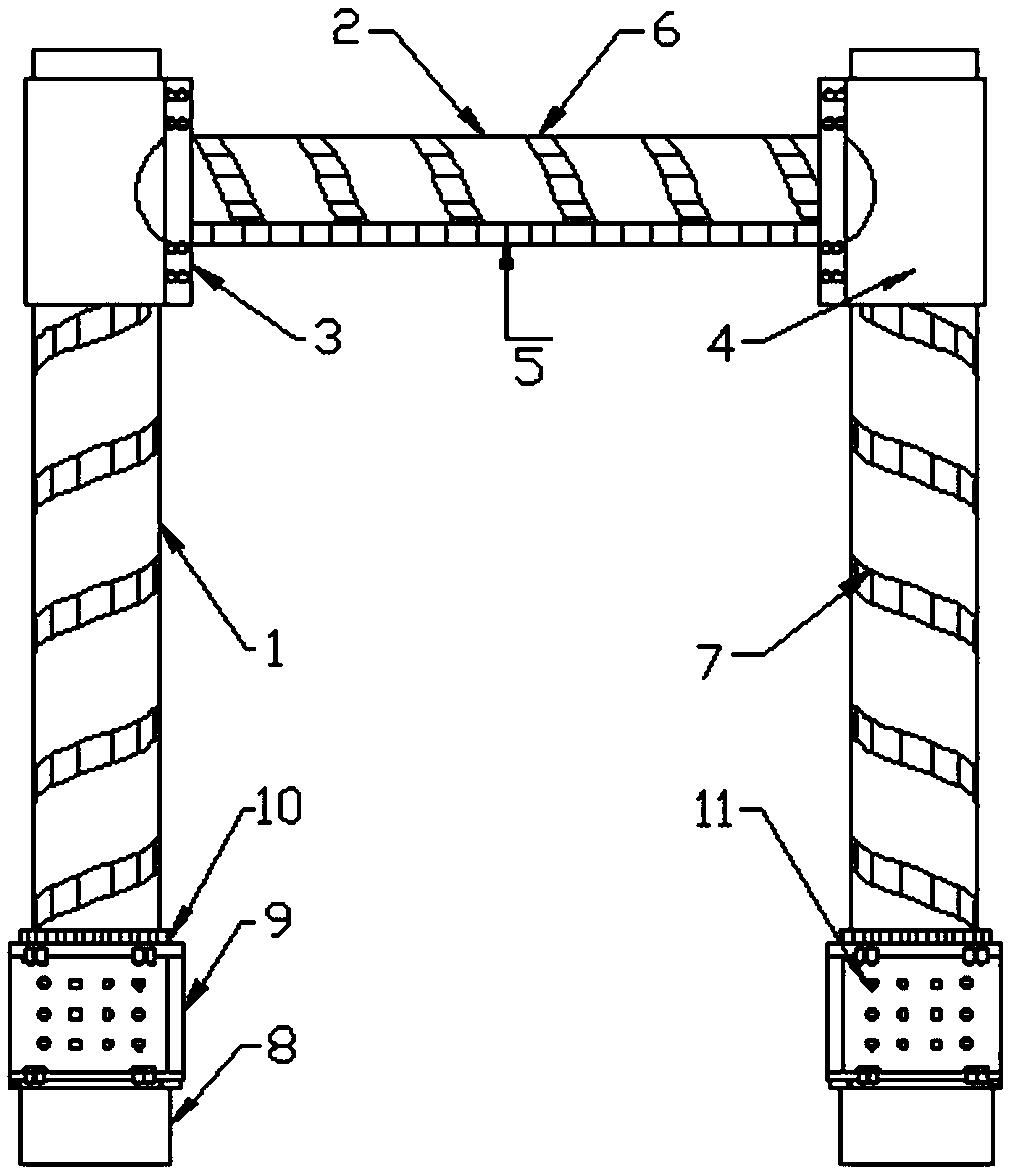

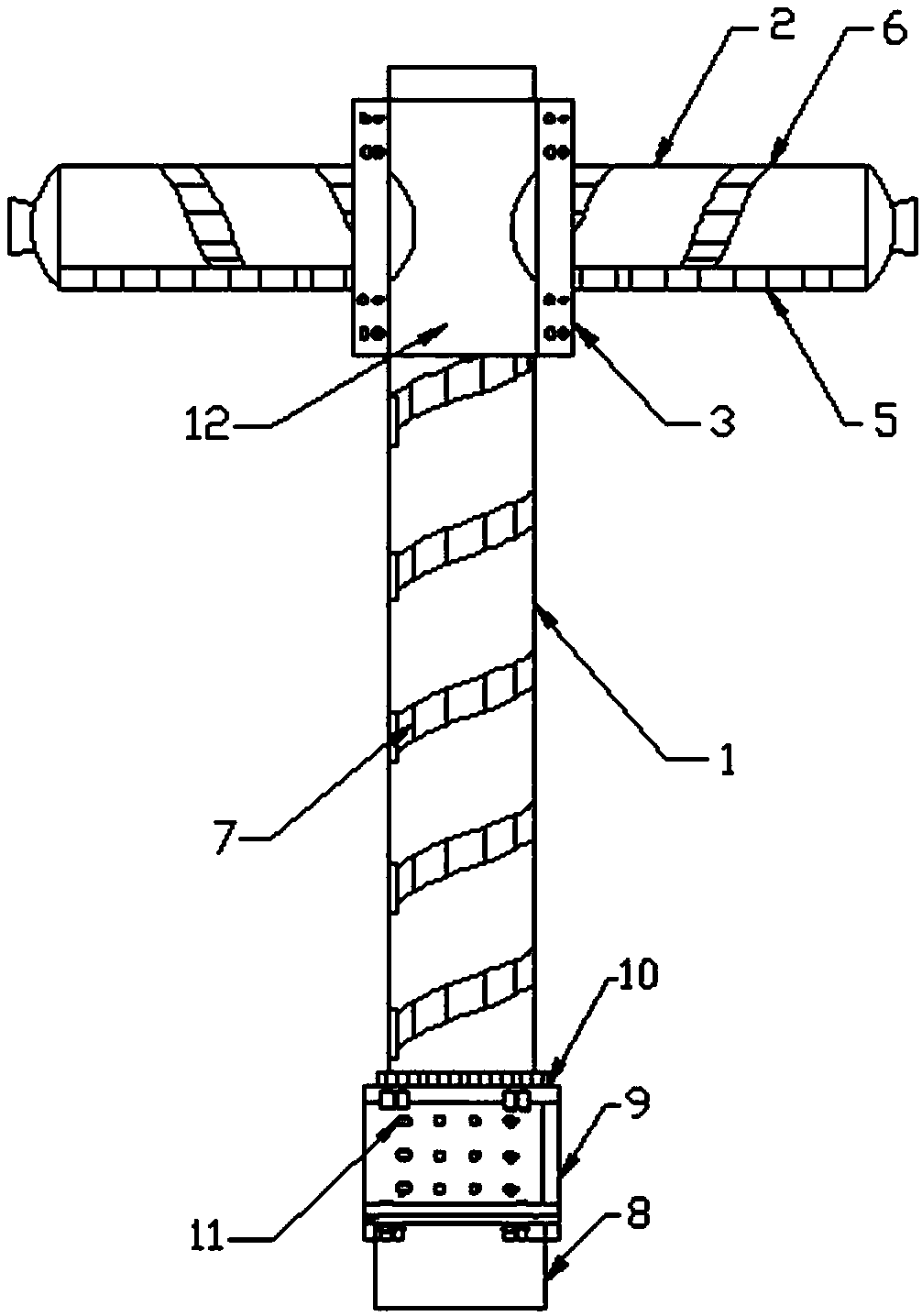

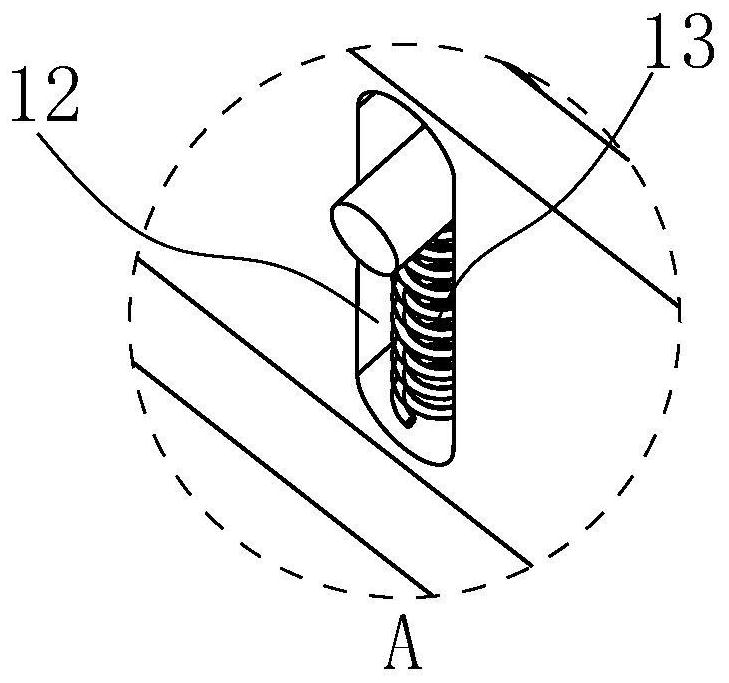

Historic building timberwork beam-column system house composite strengthening method

The invention discloses a historic building timberwork beam-column system house composite strengthening method. The method comprises the steps that wooden columns are included. After transverse fiber cloth extend and are wound on the wooden columns, spiral fiber cloth on pasting columns are hooped on the transverse fiber cloth, beam columns are connected into a beam-column system through mortises and tenons, mortise-tenon joints of the beam columns are strengthened through the transverse fiber cloth pasted to wooden beams and the wooden columns and single-opening iron parts or double-opening iron parts hooped on the wooden columns, and the transverse fiber cloth is compacted and anchored on the wooden beams through the spiral fiber cloth pasted to the wooden beams and the single-opening iron parts or the double-opening iron parts. The strengthening defects of existing historic timberwork systems are overcome, the connection reliability of the fiber cloth and the wooden beams is ensured, the bearing capacity of the beam-column components and connection joints can be effectively improved, meanwhile, the repair principles of restoration of the old as the old, restoration of the building original forms and reversibility are met, and the method can be widely used for repair and strengthening of historic building timberwork beam-column systems.

Owner:SOUTHWEAT UNIV OF SCI & TECH

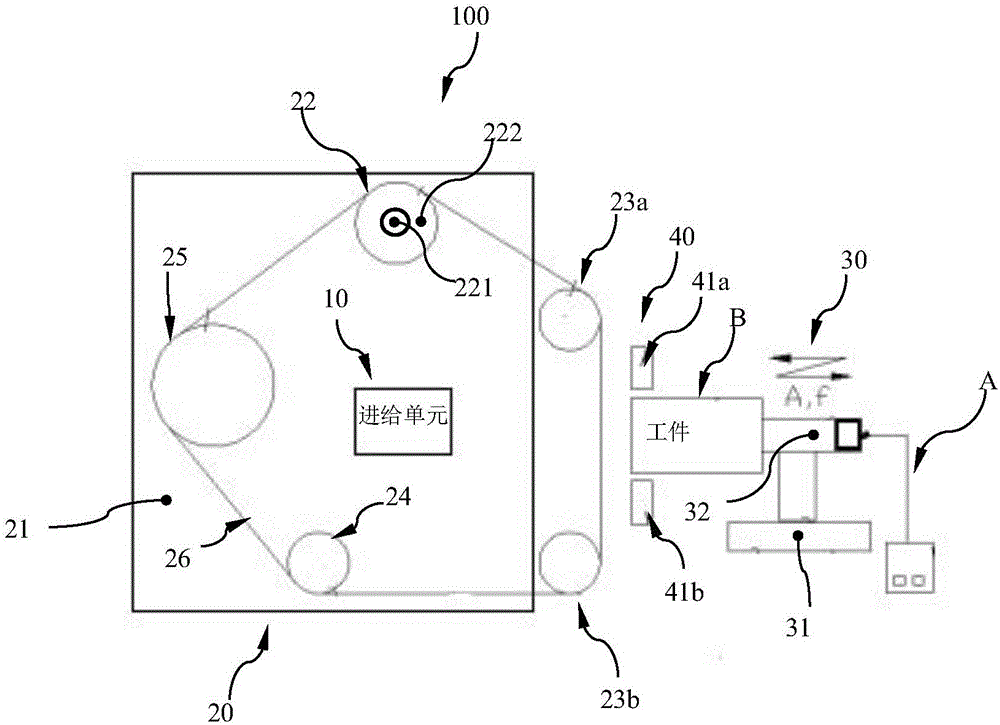

Ring type consolidated diamond scroll saw cutting device and workpiece cutting method

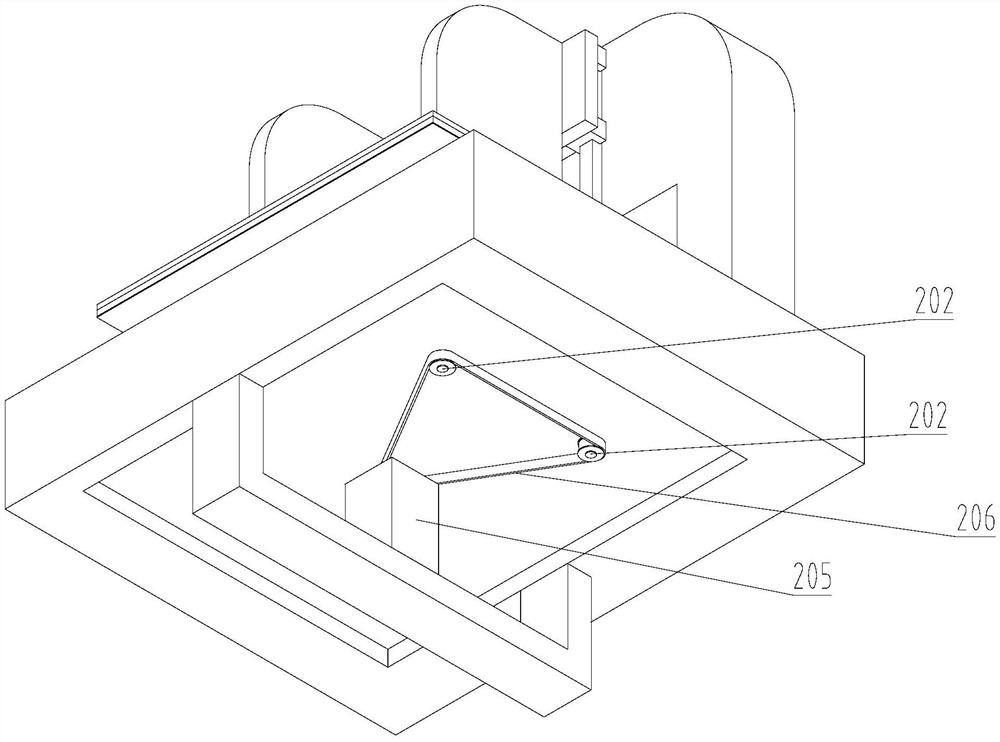

InactiveCN106042201ASustained impactReduce difficultyWorking accessoriesFine working devicesEngineeringUltrasonic vibration

A ring-type consolidated diamond wire saw cutting device, which is connected with an ultrasonic vibration device, includes: a wire saw unit with a drive mechanism, at least one guide wheel, and a wire saw wire that surrounds the drive mechanism and the guide wheel and forms a closed loop, and drives The mechanism drives the wire saw wire to make the main cutting movement; the feed unit is connected with the wire saw unit and is used to drive the wire saw wire to move along the direction perpendicular to the main cutting motion of the wire saw wire; the workpiece fixing unit is fixedly arranged on the feed unit In the moving direction, it is used to fix the workpiece. The workpiece fixing unit has: a fixed fixture; a horn arranged on the fixture and connected to the ultrasonic vibration device is used to amplify the high-frequency vibration input by the ultrasonic vibration device, and the fixture clamps the workpiece and is in contact with the horn. The horn connected with the ultrasonic vibration device applies vibration to the workpiece, causing the workpiece to vibrate ultrasonically, so that the workpiece has a continuous impact on the wire saw wire, which reduces the difficulty of the wire saw wire cutting into the workpiece, thereby improving processing efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

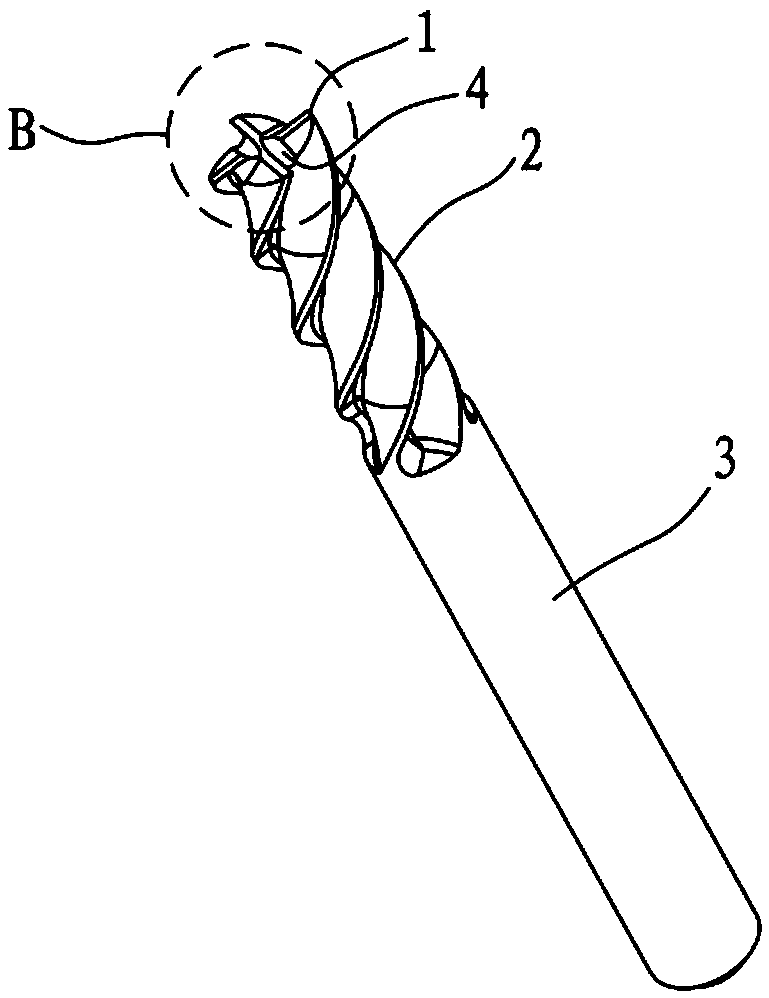

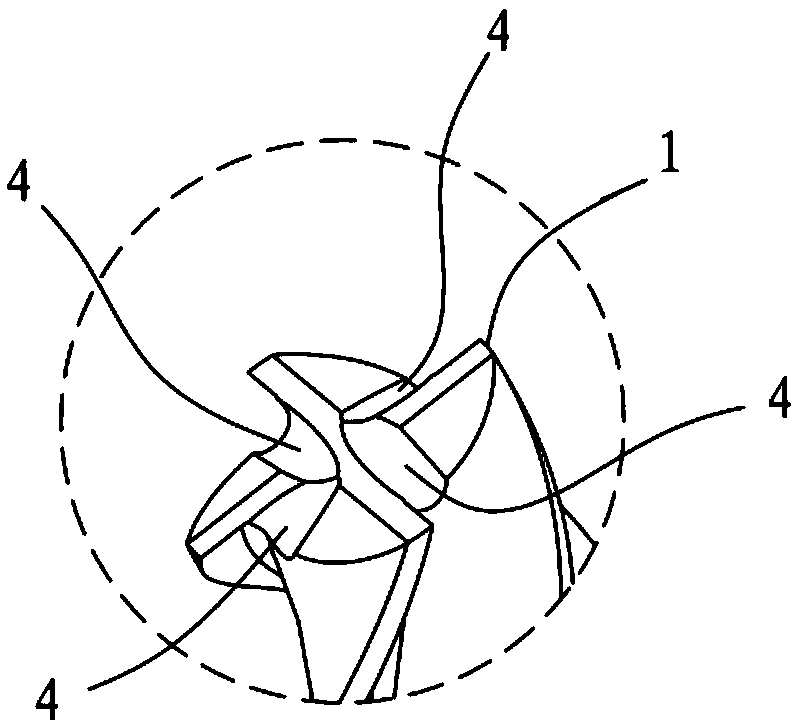

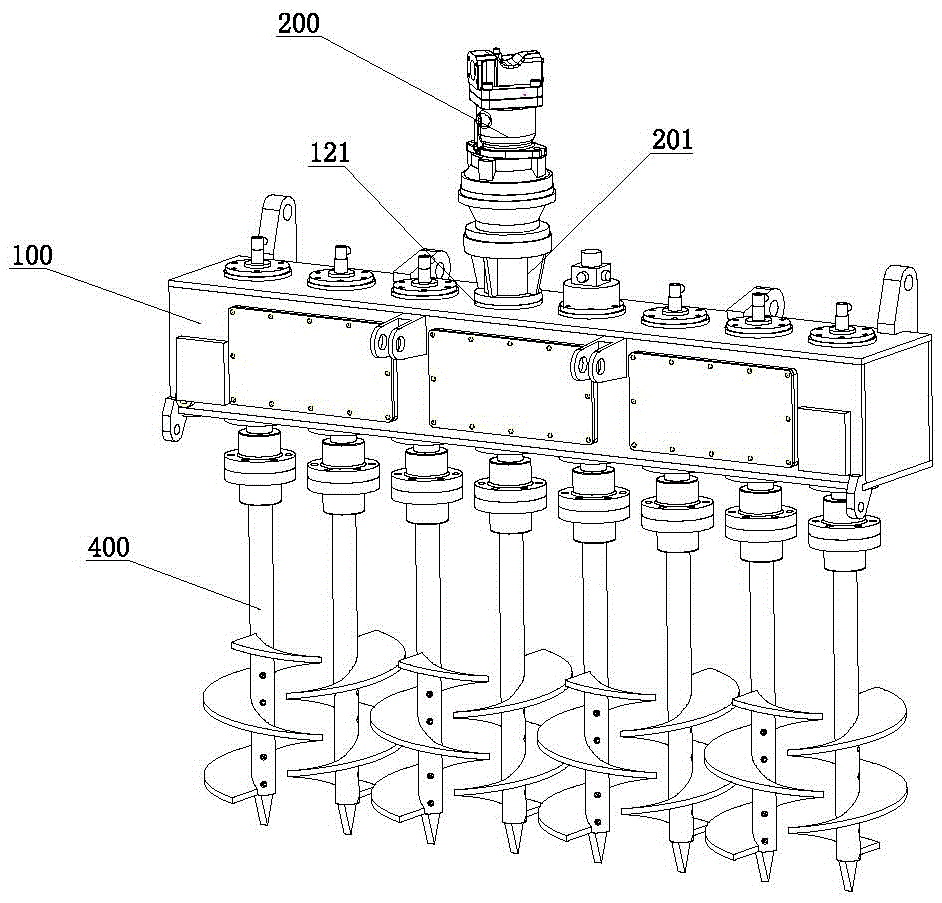

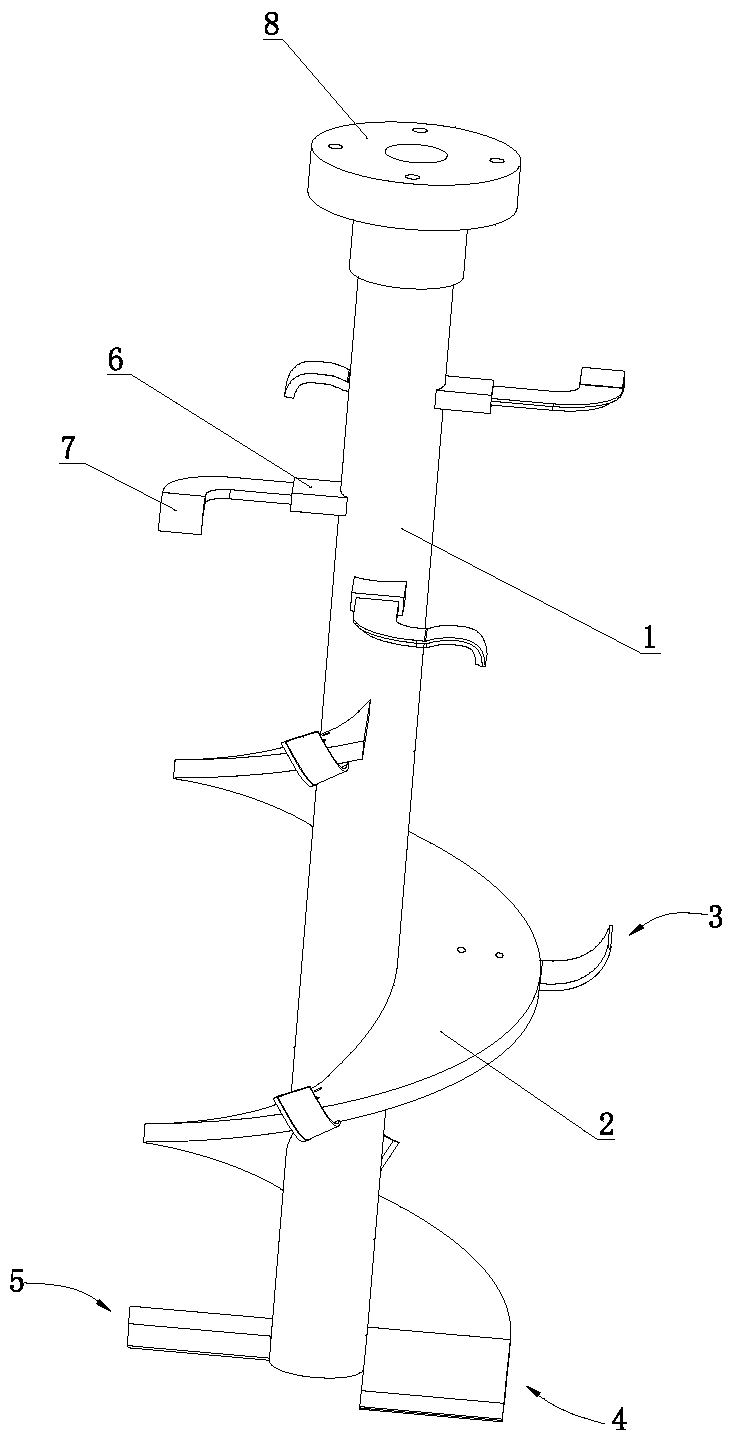

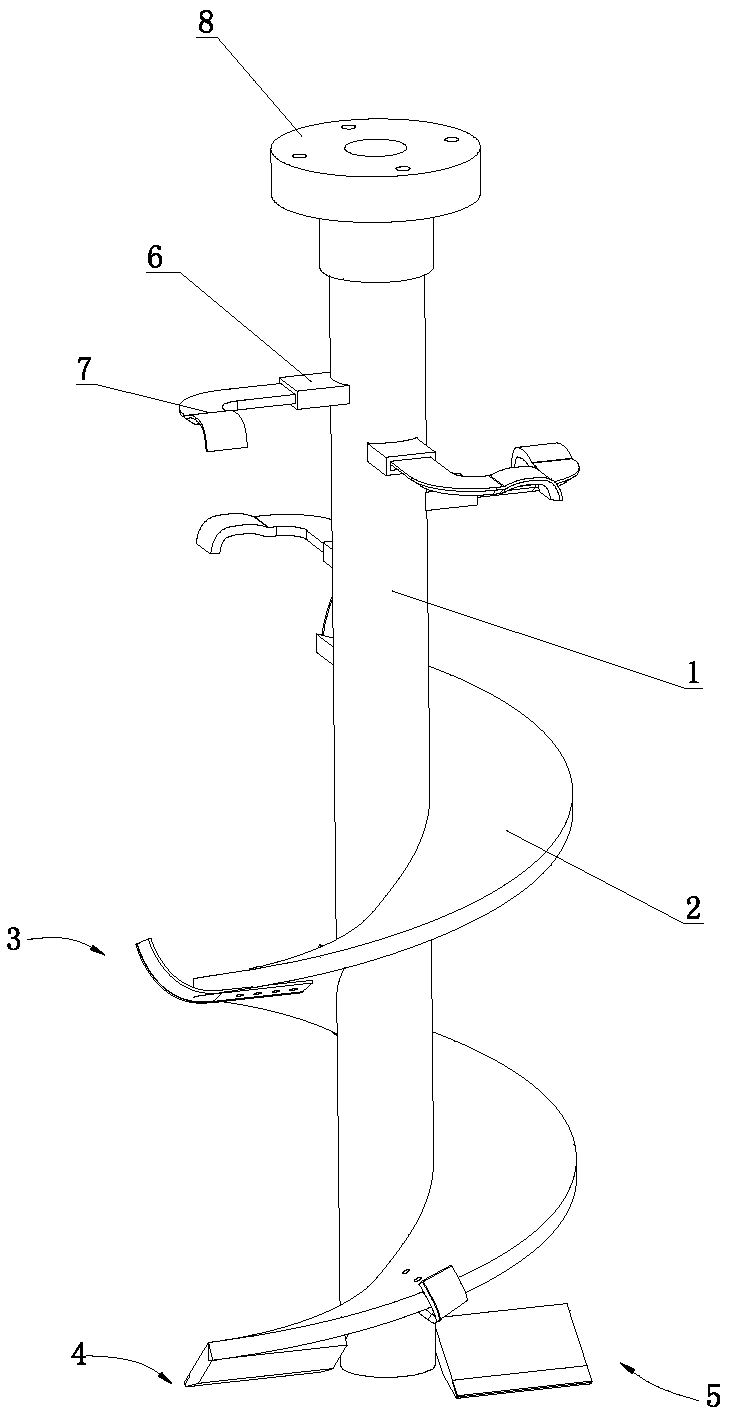

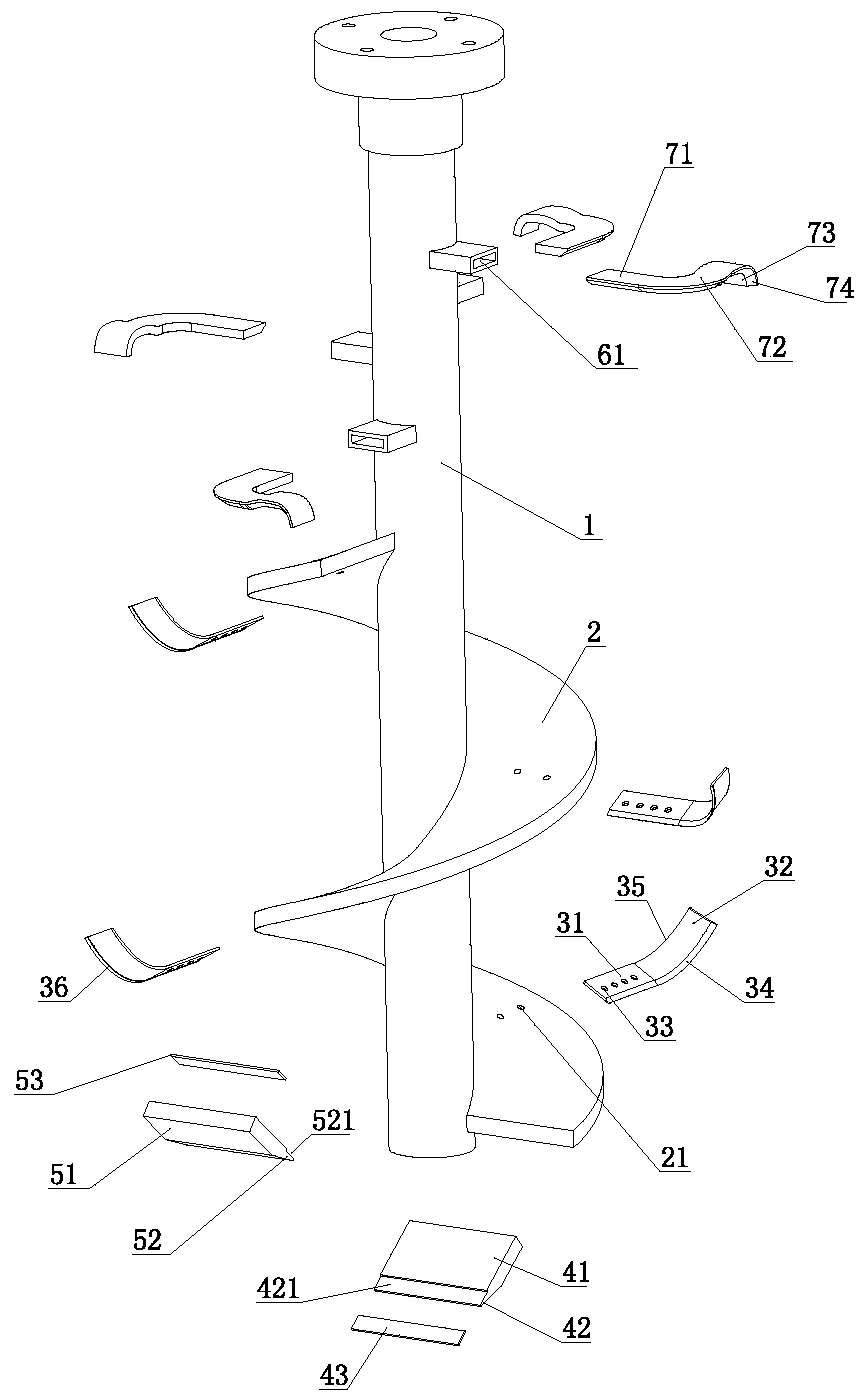

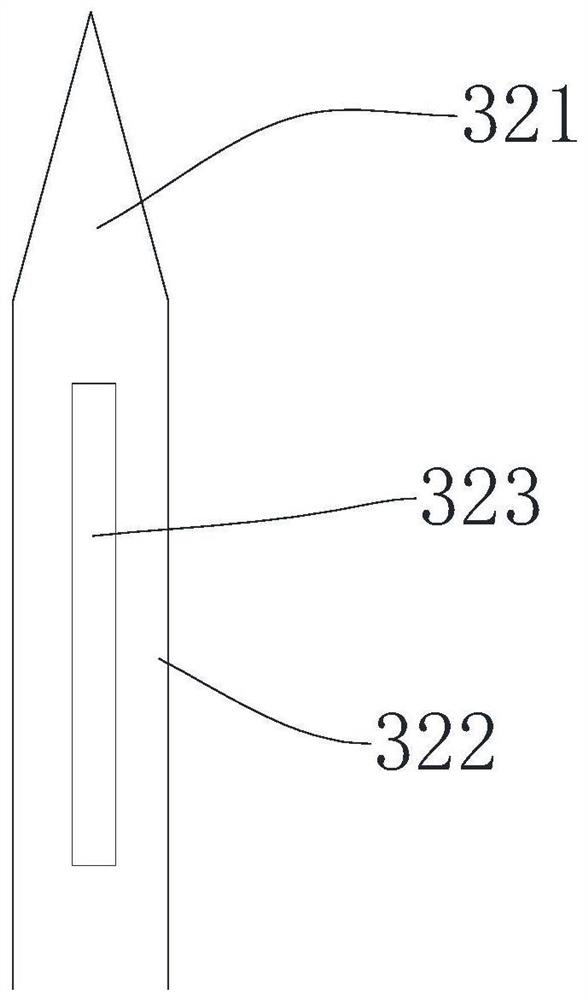

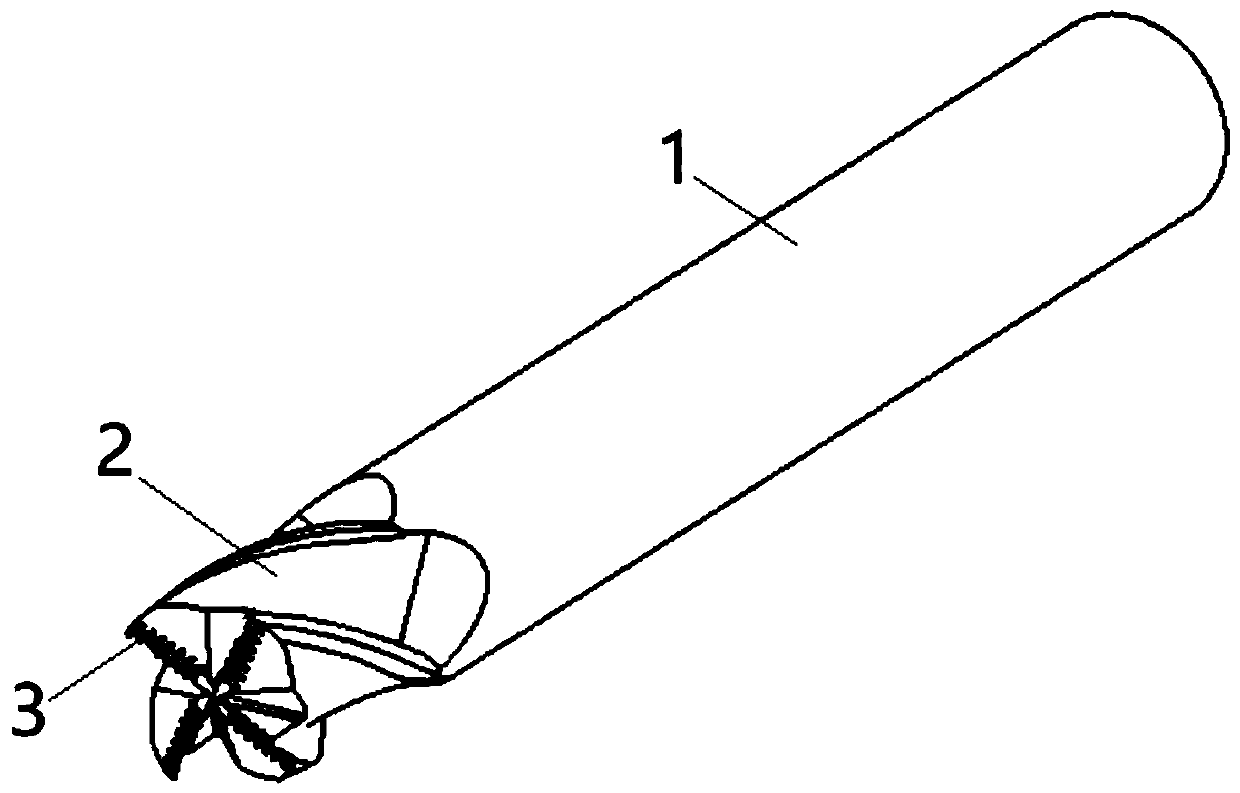

Subsoiling and tilling device

The invention discloses a subsoiling and tilling device. The subsoiling and tilling device comprises a transmission case, wherein more than one transmission shaft is arranged in the transmission case, one end of each transmission shaft extends out of the transmission case, and extending ends of the transmission shafts are connected with a subsoiling and tilling knife tool; the subsoiling and tilling knife tool comprises a knife carrier, a spiral sheet is fixed on the knife carrier, knife blades are mounted on the spiral sheet, a first soil piercing knife blade is fixed at the lower end of the spiral sheet, and a second soil piercing knife blade is fixed at the lower end of the knife carrier; and the lower ends of the first and second soil piercing knife blades are lower than the bottom face of the knife carrier, crushing and leveling knife blades are arranged at the upper end of the knife carrier in a staggered manner, and each crushing and leveling knife blade has an insertion part, a first bent part and a second bent part. According to the subsoiling and tilling device, due to the structure, the subsoiling and tilling knife tool can more easily pierce soil and is more uniformly stressed during soil piercing, and the fluffiness and crushing degrees of land in the vertical direction are different, so that the growth of plants is better facilitated, and leveling re-crushing for topsoil can be better carried out by using the knife tool.

Owner:GUANGXI WUFENG MACHINERY CO LTD

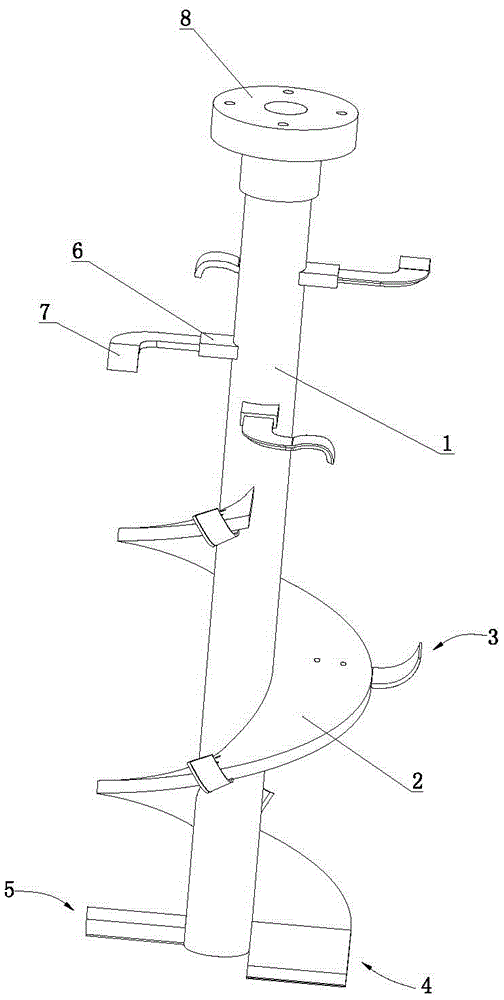

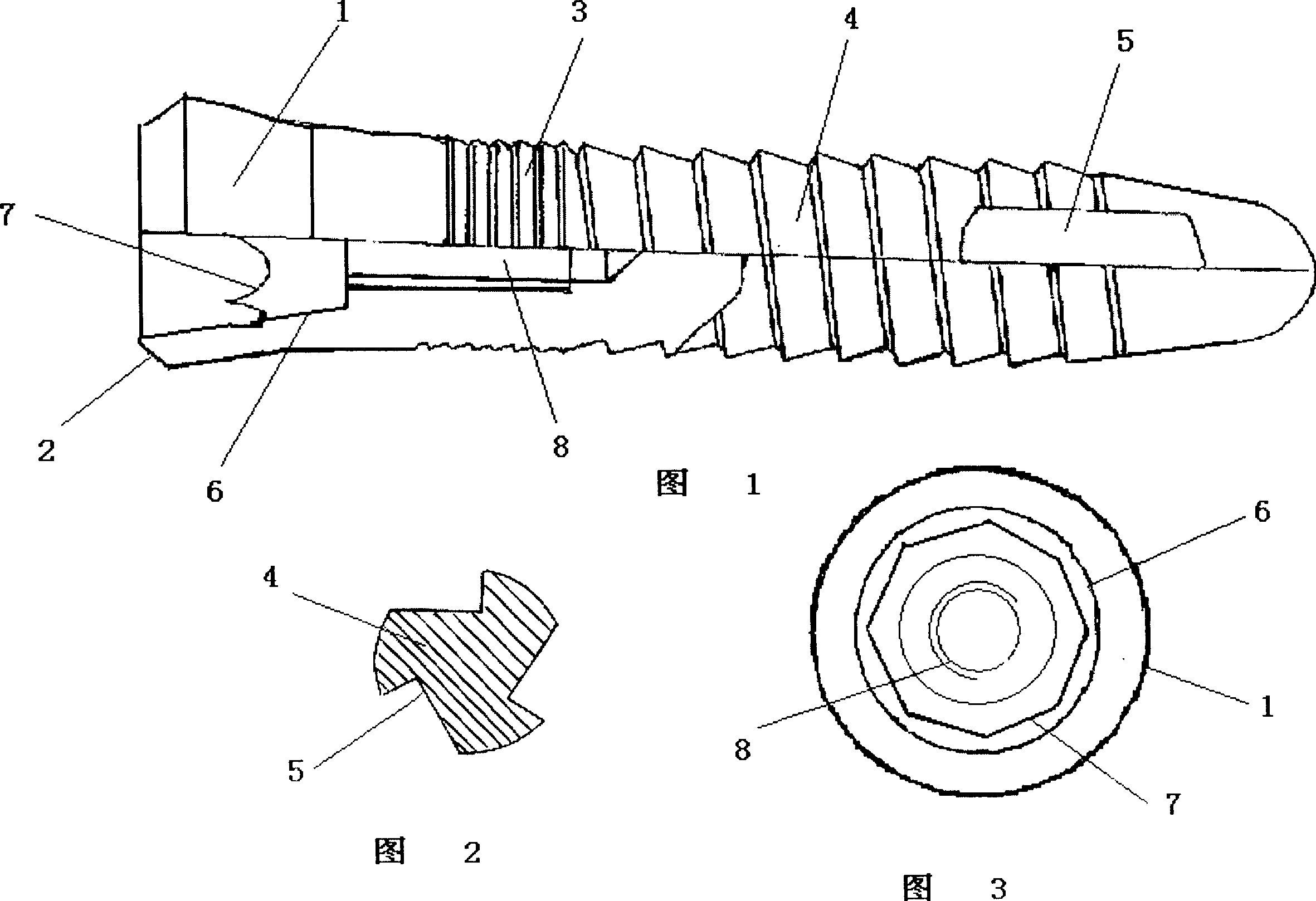

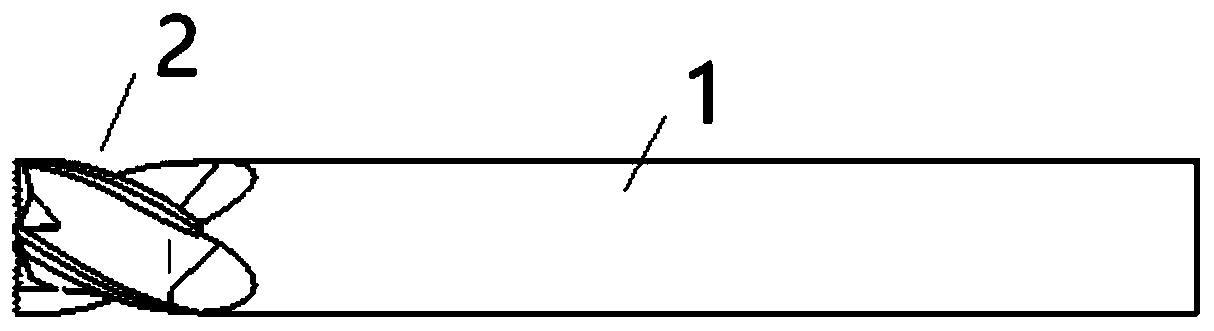

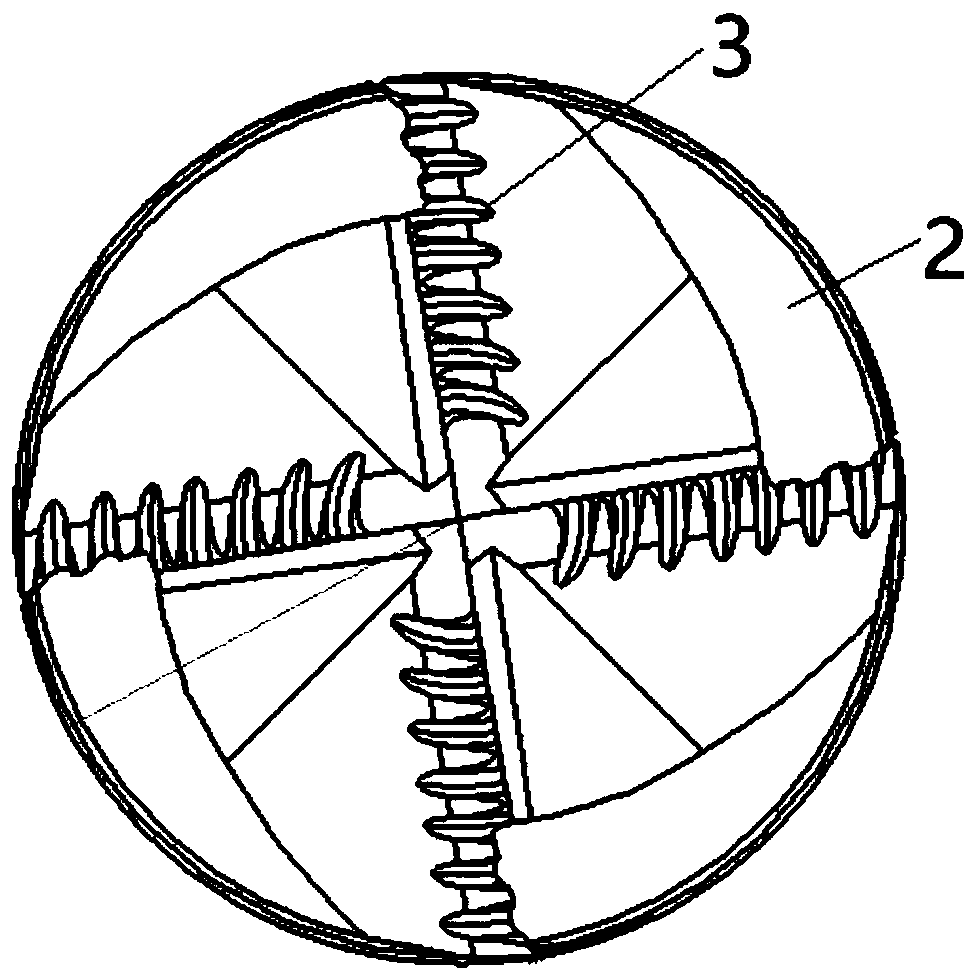

Micro thread implant

ActiveCN1931109ASolve the problem of insufficient neck strengthEasy to cut intoDental implantsJaw boneEngineering

The micro thread implant includes one conic top with larger upper part and smaller lower part, one conic hole including one octagonal middle part and one lower screw hole part and surface coating of hydroxyapatite. It features the neck with fine thread, the root part with self-tapping straight thread and the conic end, with both the fine thread and the straight thread being saw tooth threads. The present invention has high neck strength, capacity of preventing microbes from invading, easy integrating with bone, easy screwing into the jaw bone and self locking, and may be used in repair dental defection, especially false tooth implanting operation.

Owner:BEIJING LEIDEN BIOMATERIAL

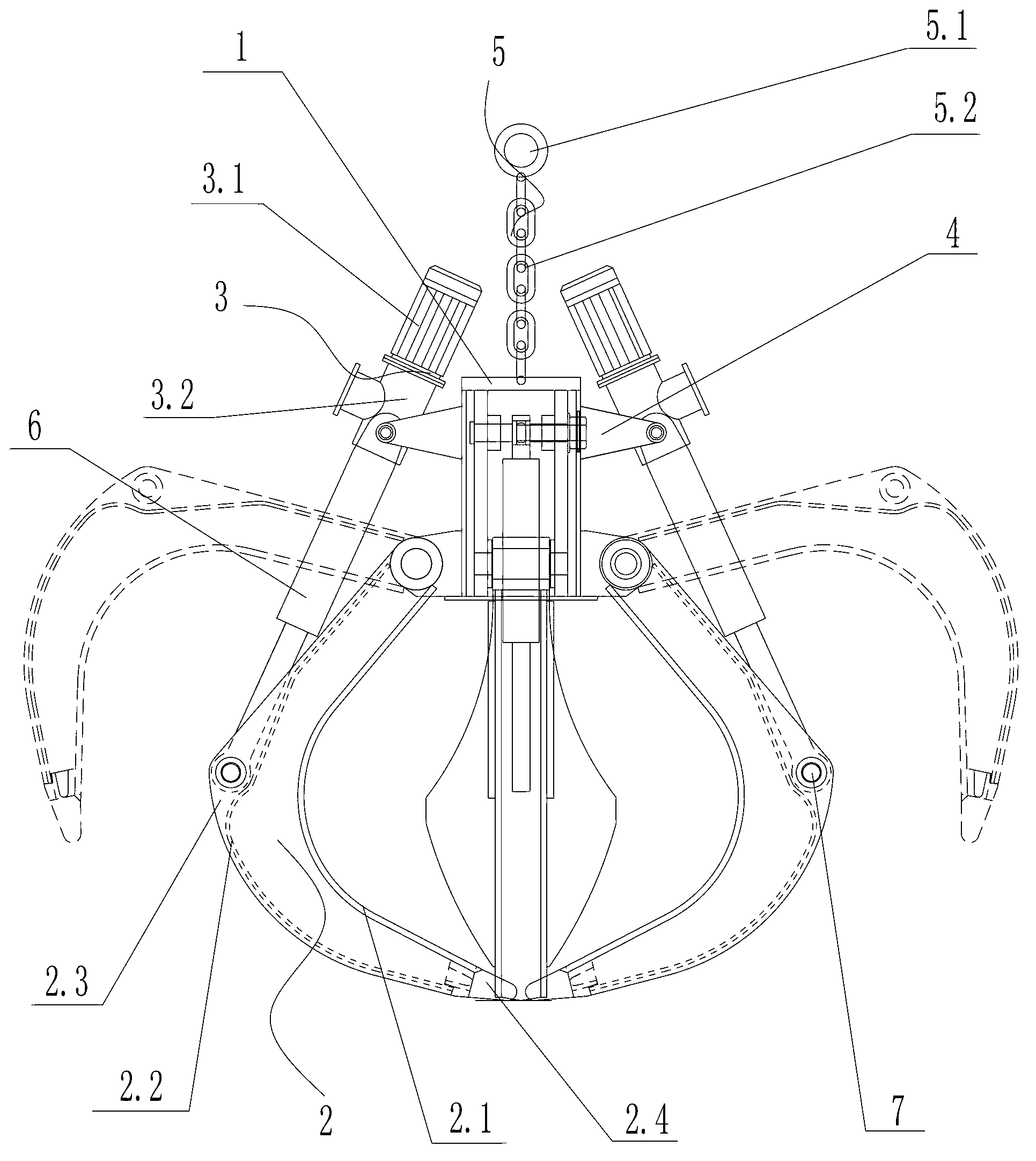

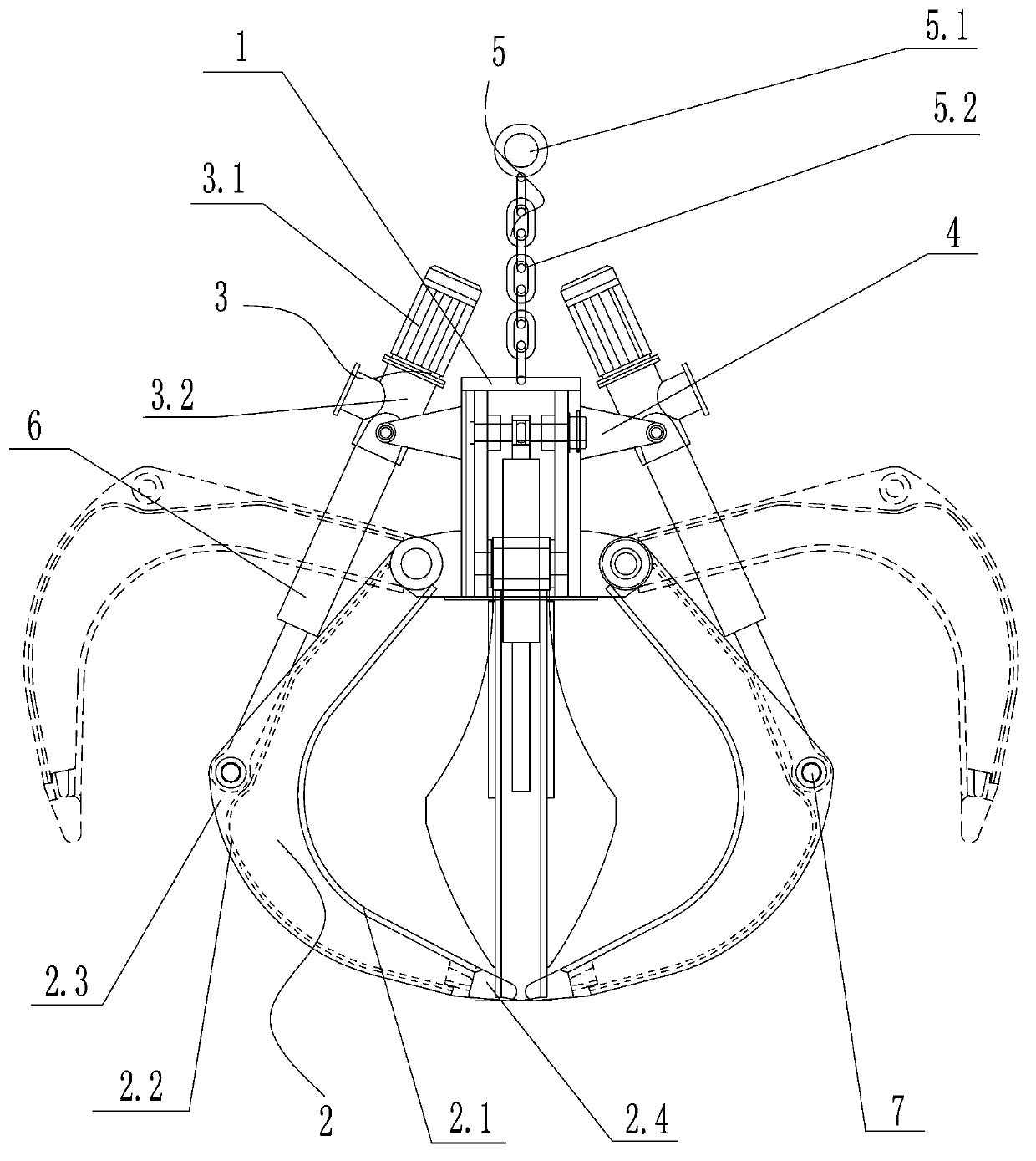

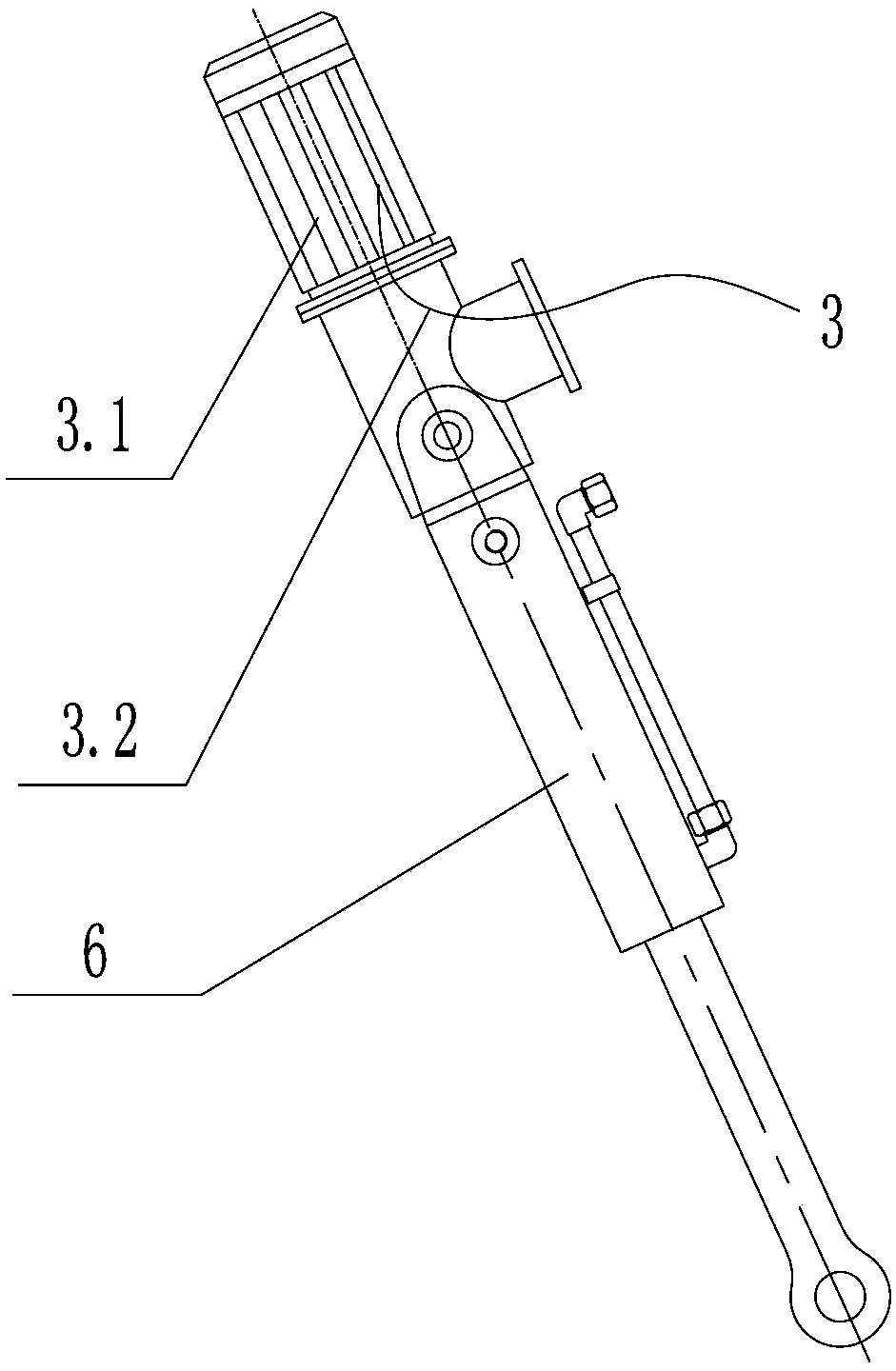

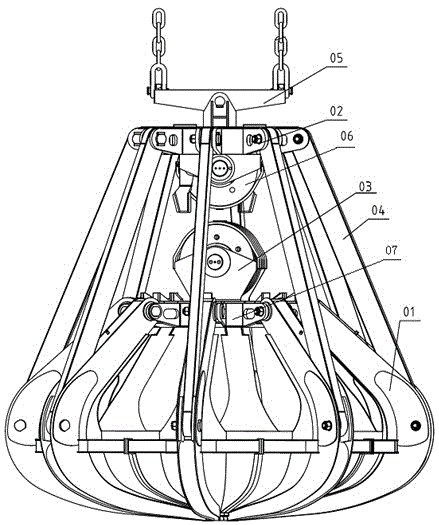

Garbage grab bucket

The invention discloses a garbage grab bucket, comprising a seat body (1), at least two grab bucket pedals (2) of which the upper ends are hinged with the seat body (1), a hydraulic cylinder (6) of which a free end of a piston rod is hinged with the grab bucket pedals (2), and a hoisting mechanism (5) which is fixedly connected with a crane or a travelling crane, wherein the hoisting mechanism (5) is fixedly connected with the seat body (1); a cylinder end of the hydraulic cylinder (6) is hinged with the seat body (1); the garbage grab bucket also comprises hydraulic drive mechanisms (3) of which the quantity is equal to that of the grab bucket pedals (2); the hydraulic drive mechanisms (3) are arranged outside the seat body (1); and the hydraulic drive mechanisms (3) are integrally connected with the cylinder body of the hydraulic cylinder (6). The garbage grab bucket is convenient to install and maintain, and excellent in stability and durability.

Owner:宁波泰来环保设备有限公司

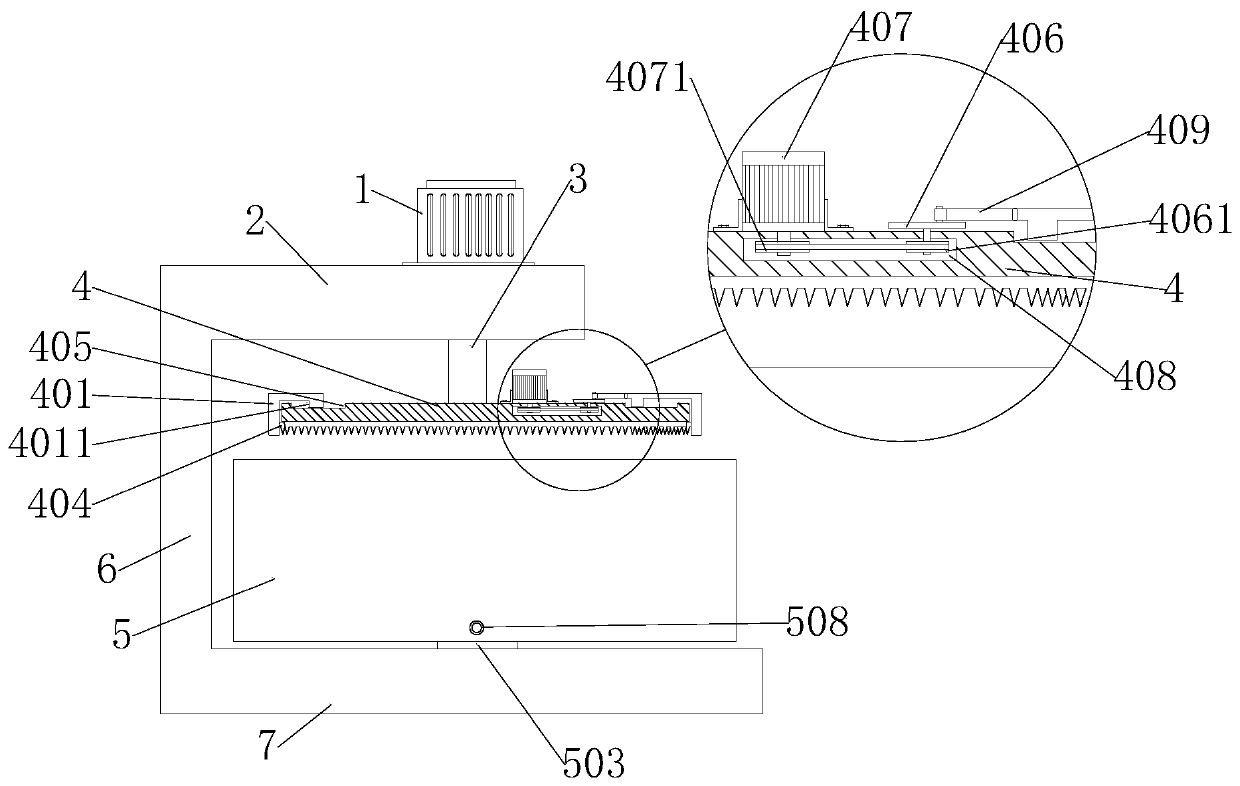

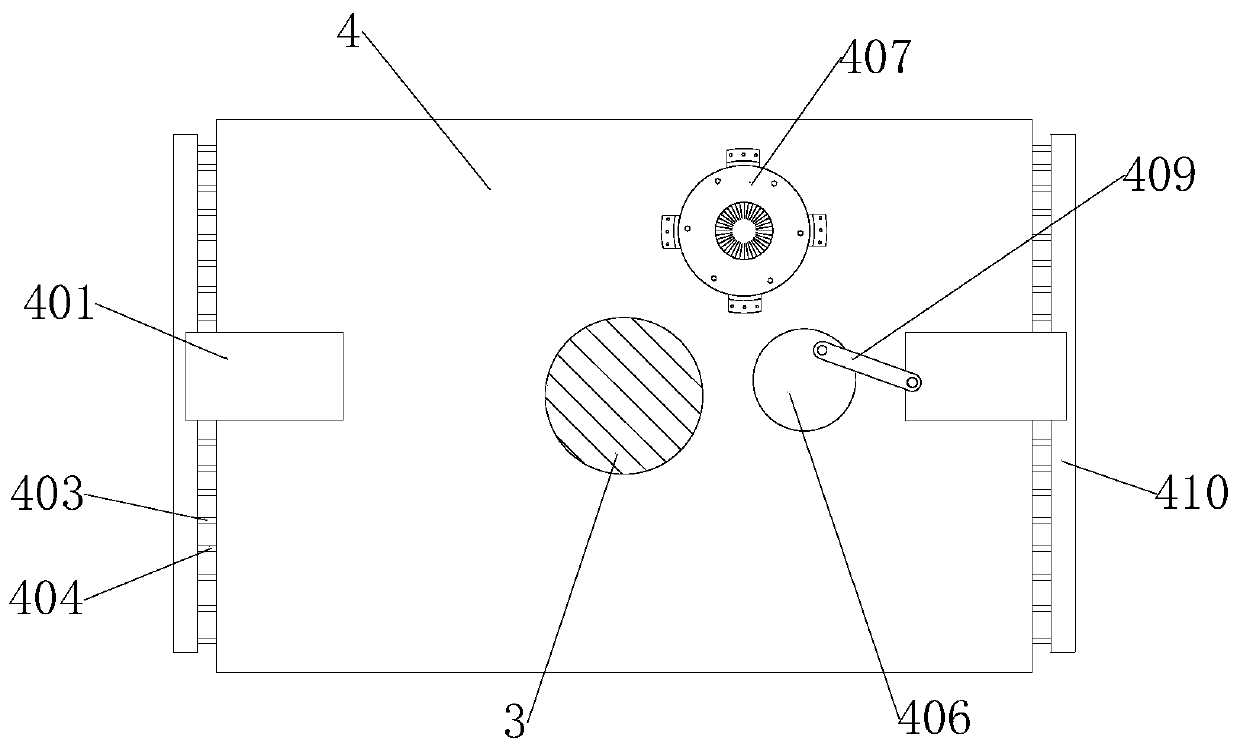

Self-adaptation controllable vibration metal cutting device and method based on super magnetostriction

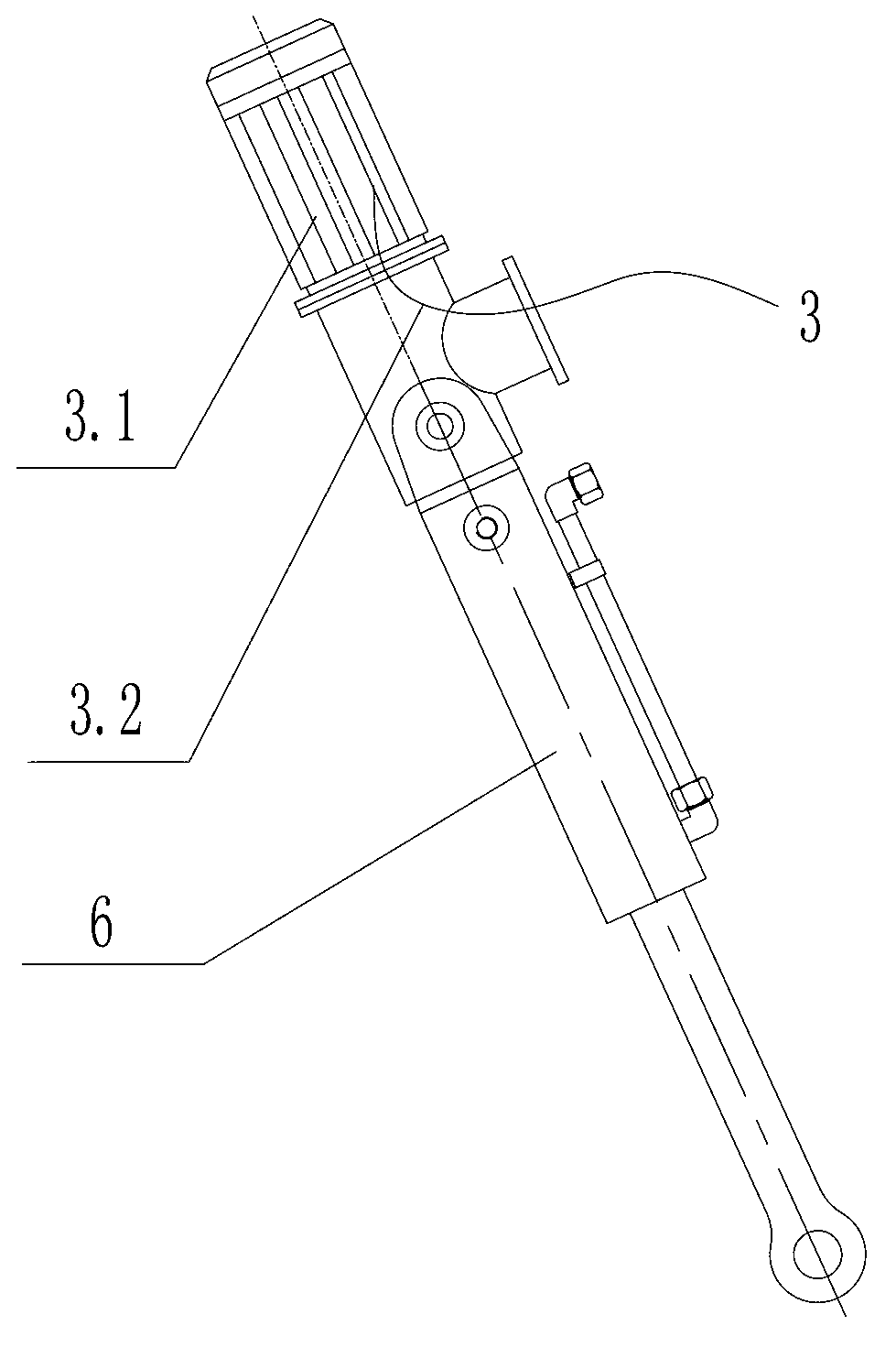

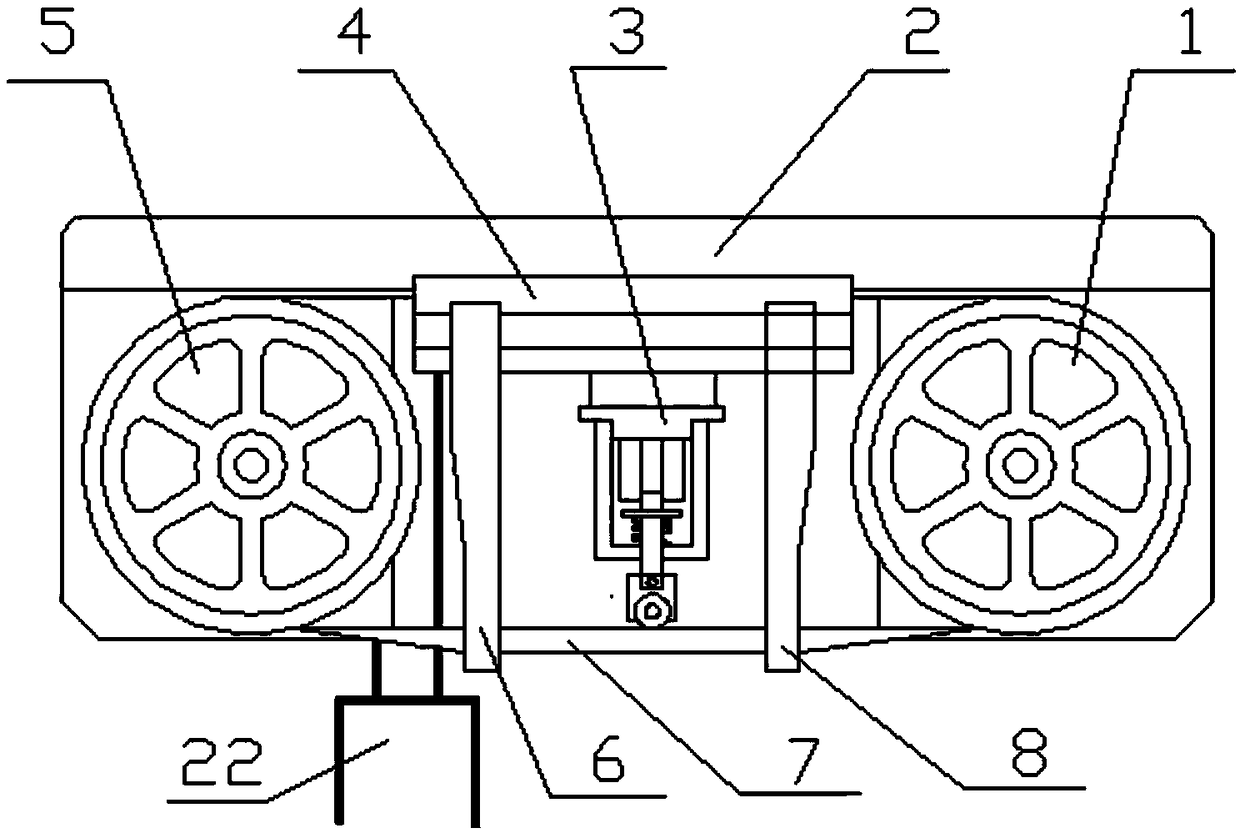

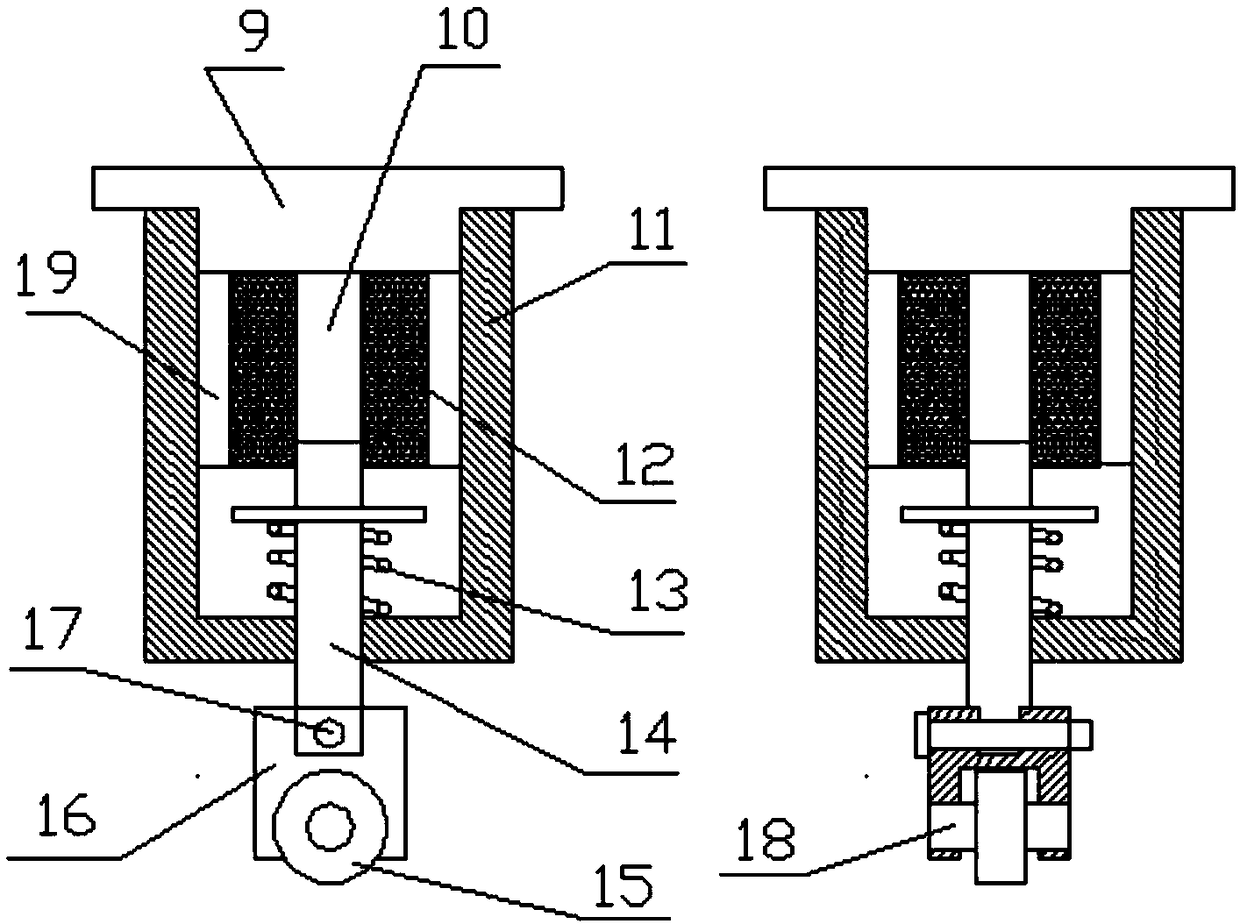

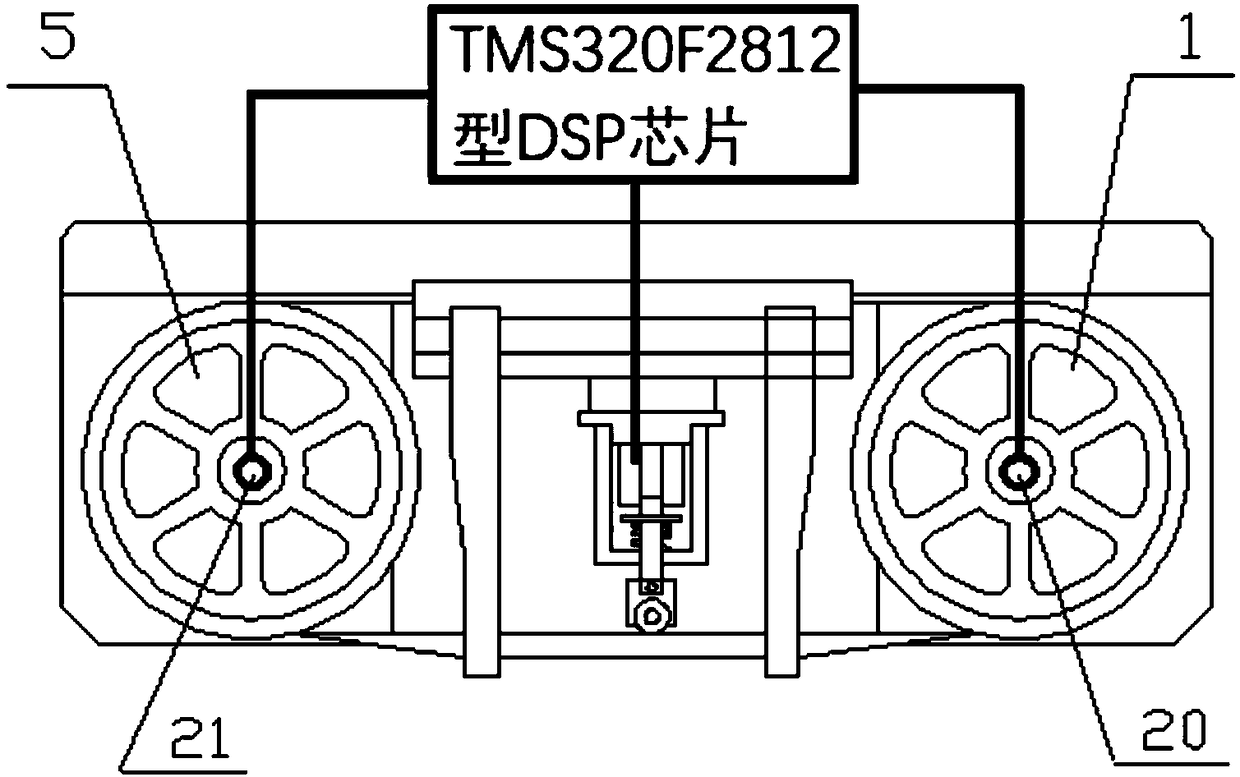

PendingCN109396550ALarge strain valueHigh controllable precisionMetal sawing devicesMetal sawing accessoriesHydraulic cylinderEngineering

The invention discloses a self-adaptation controllable vibration metal cutting device and method based on super magnetostriction. A saw frame, a vibration mechanism, a saw beam, a driving belt wheel,a driven belt wheel, a saw strip, a hydraulic cylinder and a DSP chip are included. The vibration mechanism is fixed to the lower end face of the saw beam. A left guiding arm and a right guiding arm are arranged on the two sides of the vibration mechanism correspondingly. The base is arranged at the opening position in the upper end of the shell. The lower end face of the base is connected with anamplitude changing rod through a super magnetostriction material. The amplitude changing rod penetrates through the bottom face of the shell and is connected with a bearing frame. The outer side faceof the super magnetostriction material is sequentially sleeved with an exciting coil and a permanent magnet. The driven belt wheel and the driving belt wheel are provided with a rotation speed sensorand a torque sensor correspondingly. The rotation speed sensor and the torque sensor are connected with the DSP chip. The DSP chip is connected with the vibration mechanism through a PLC. Through thesimple structure design, saw strip vibration cutting can be achieved, saw strip tooth tips can more easily cut into the materials, and cuttings can be more easily discharged.

Owner:LISHUI UNIV

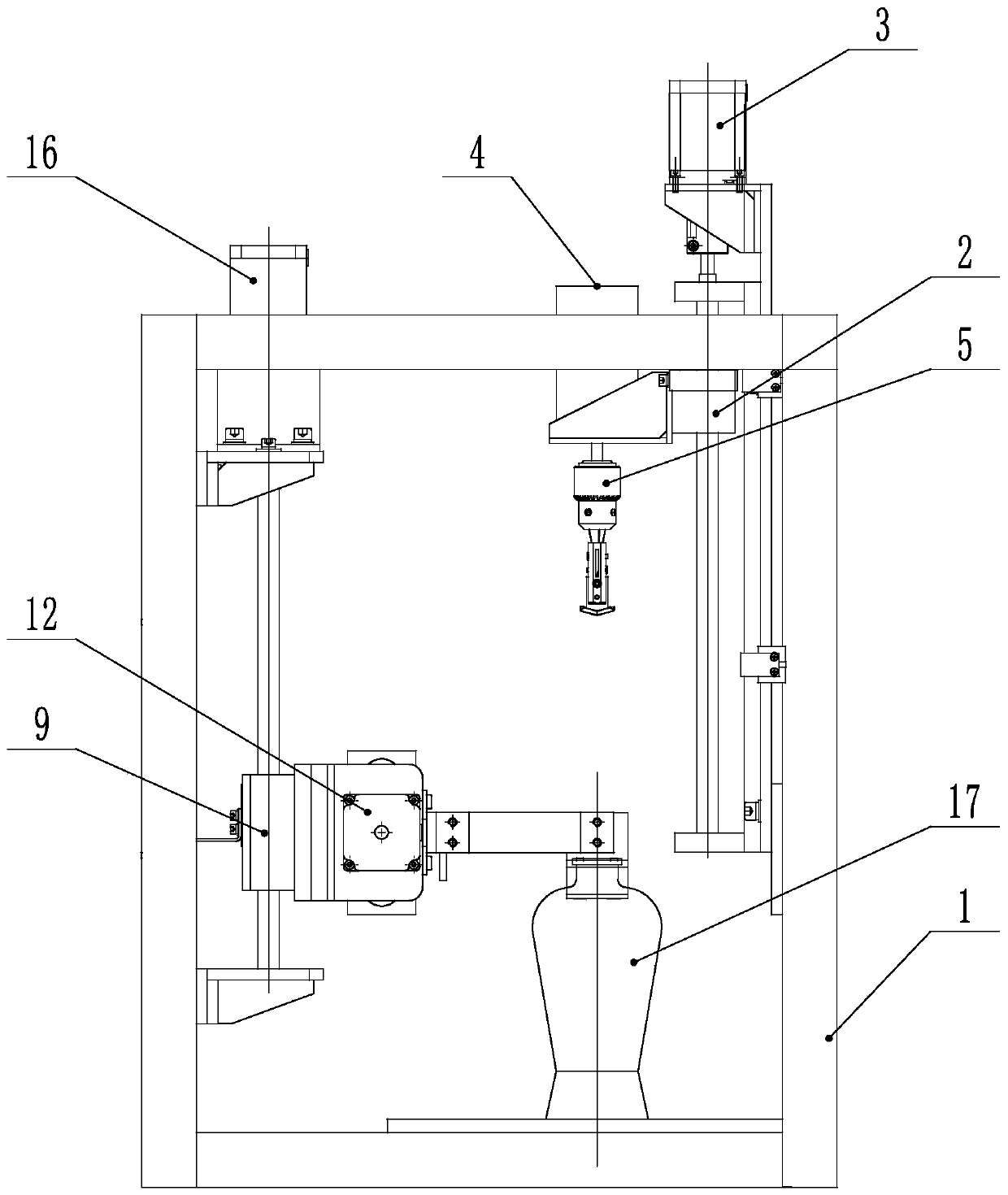

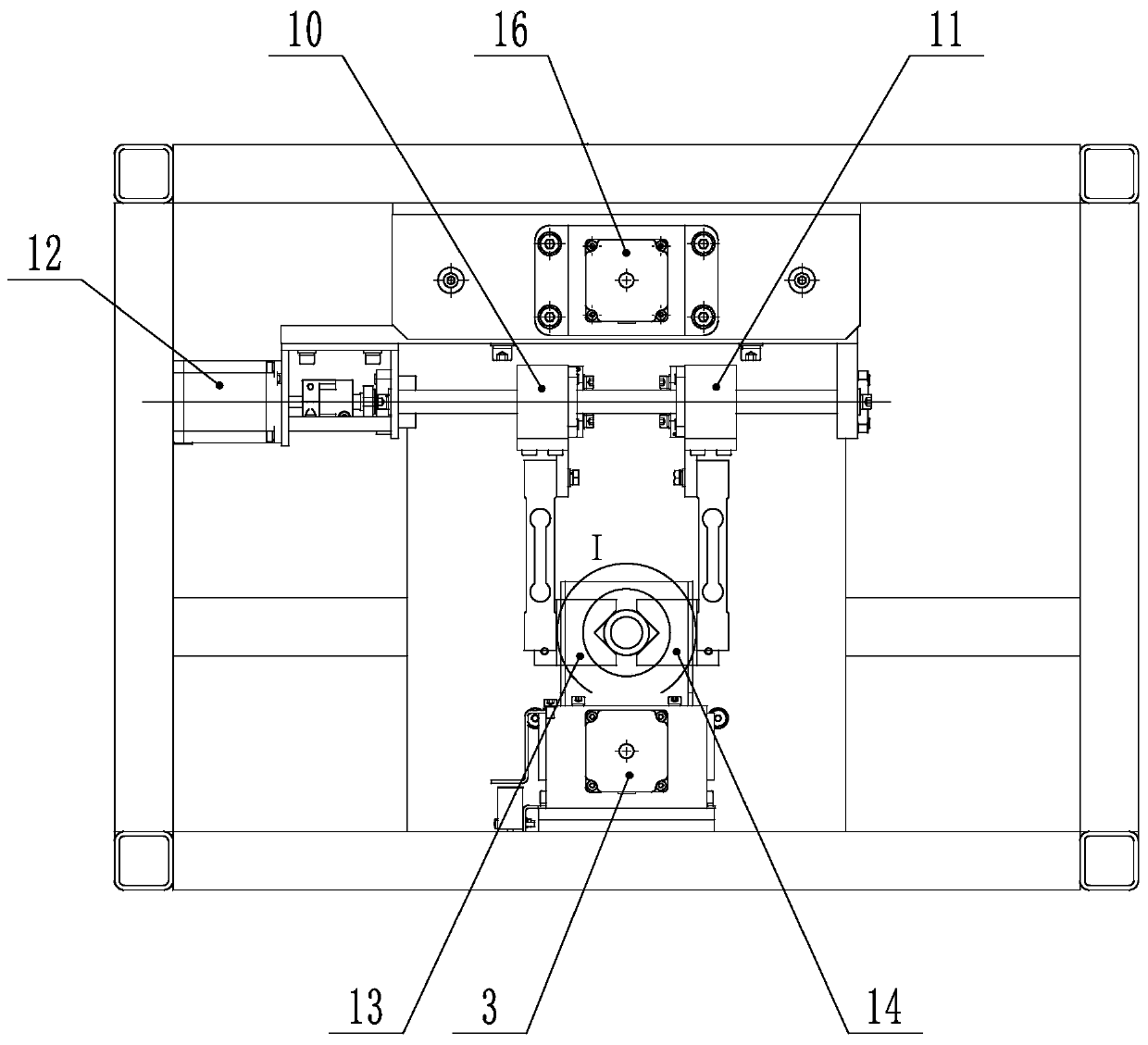

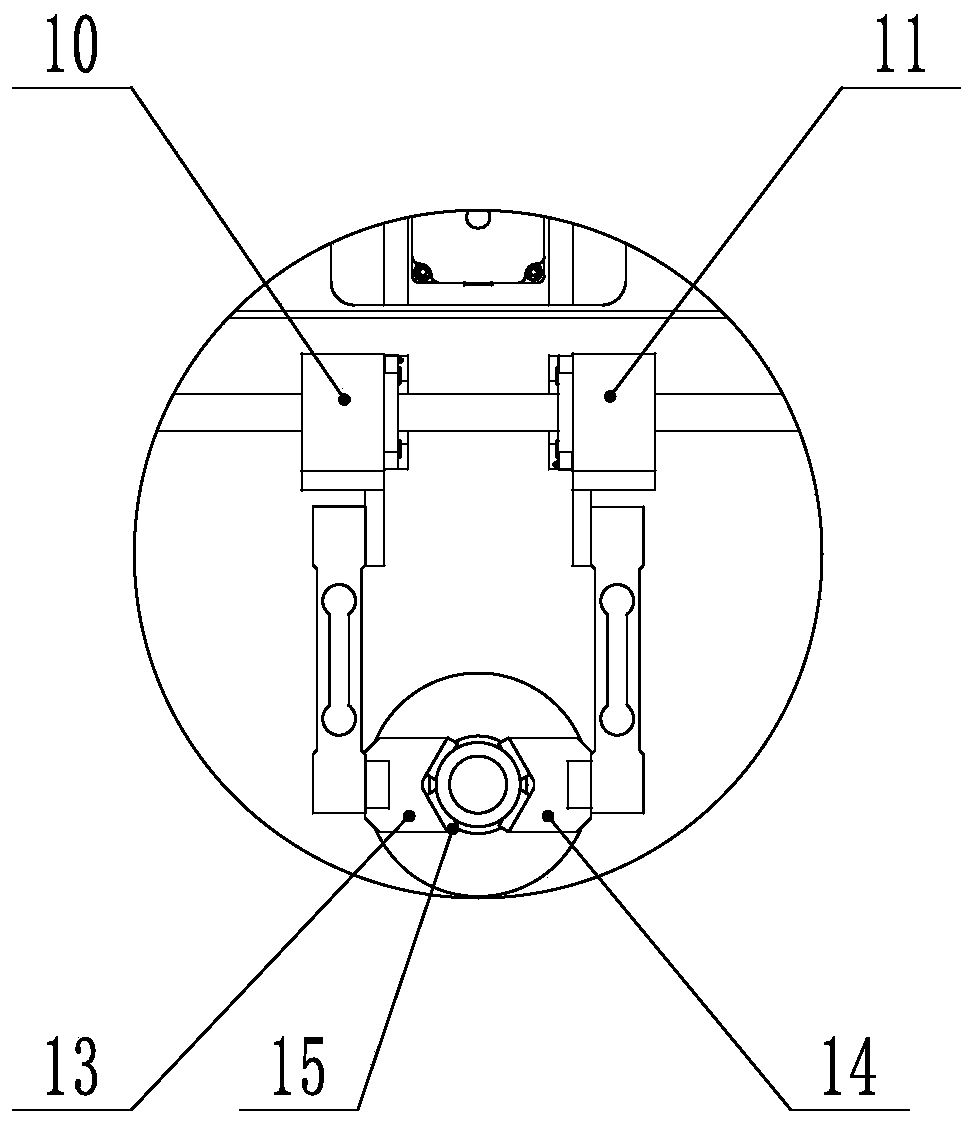

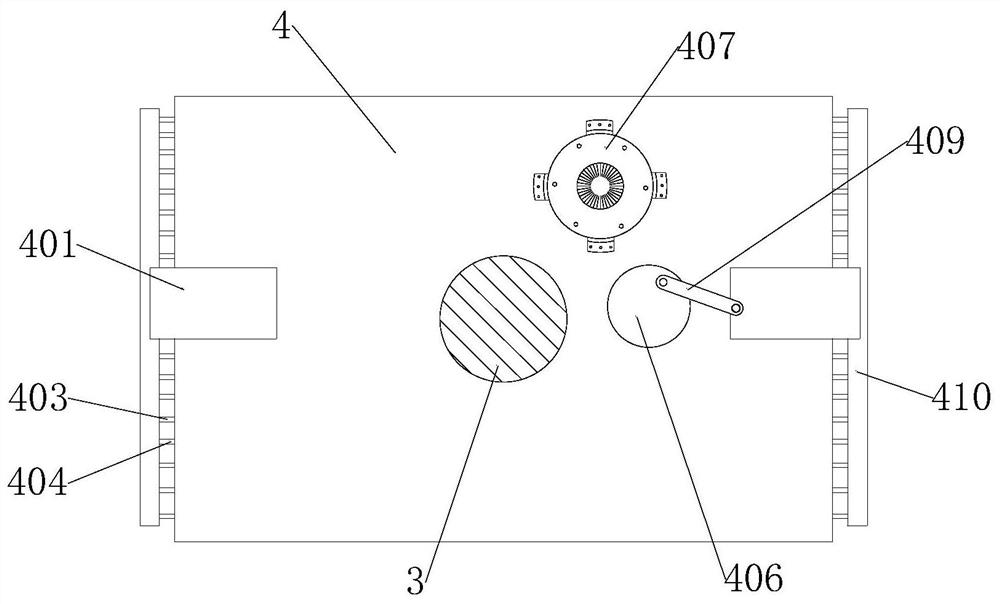

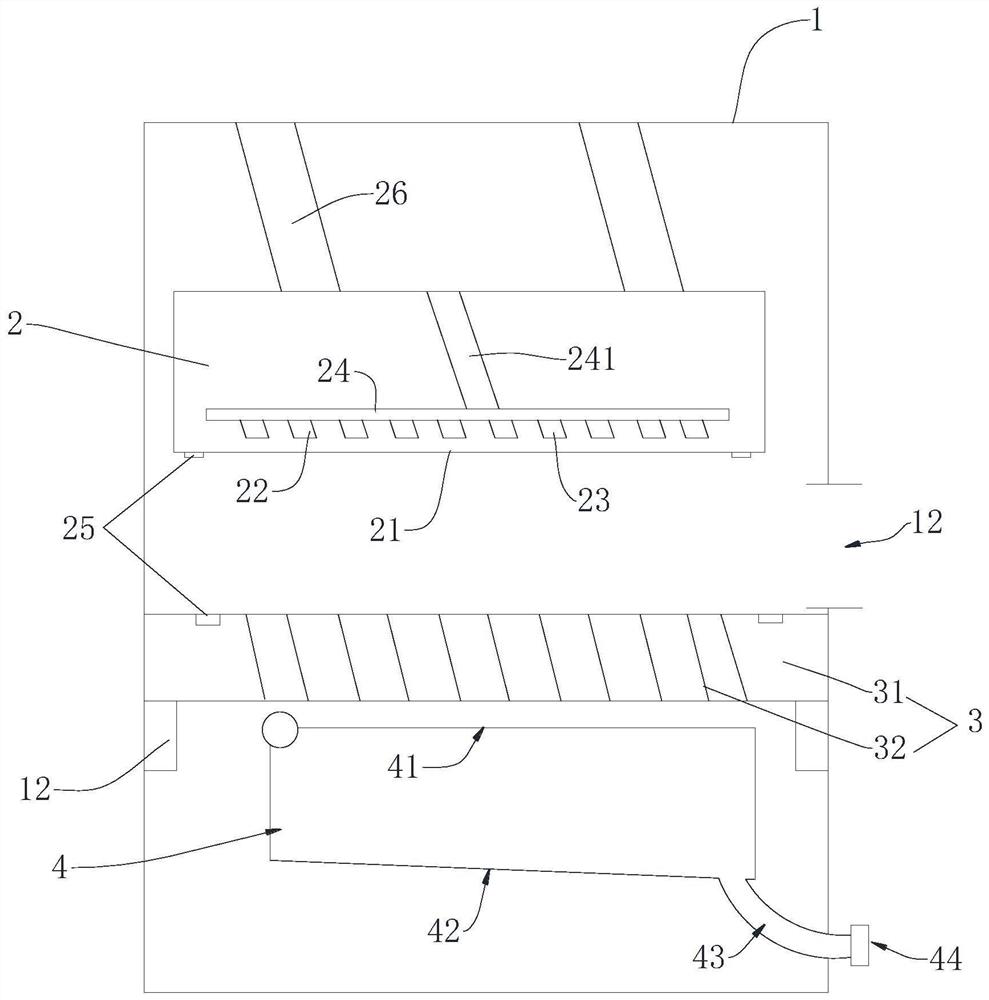

Mouth trimming device for grouting ceramic bottle

PendingCN109877952ASimple actionEasy to operateCeramic shaping apparatusNeck partsElectric machinery

The invention discloses a mouth trimming device for a grouting ceramic bottle. The mouth trimming device comprises a rack, wherein a clamping mechanism for clamping the neck part of the ceramic bottleis mounted on the rack; the clamping mechanism clamps the ceramic bottle on a mouth trimming station; a mouth trimming slide base is vertically mounted on a position, above the mouth trimming station, on the rack in a sliding mode; the mouth trimming slide base is driven by a mouth trimming lifting power device to lift; a rotary clamping head driven by a rotary motor is mounted on the mouth trimming slide base; a mouth trimming combined tool is mounted on the rotary clamping head; the mouth trimming combined tool comprises a tool shaft mounted on the rotary clamping head; the lower end of thetool shaft is equipped with a first blade which extends into the inner wall of the bottle mouth to repair the inner wall of the bottle mouth; and a second blade for repairing the upper end surface ofthe bottle mouth is fixedly arranged on a position, above the first blade, on the tool shaft. The mouth trimming device can automatically grind and repair the inner wall and the upper end surface ofthe bottle mouth, replaces labor power, and improves repair quality.

Owner:哈尔滨创博智能装备有限公司

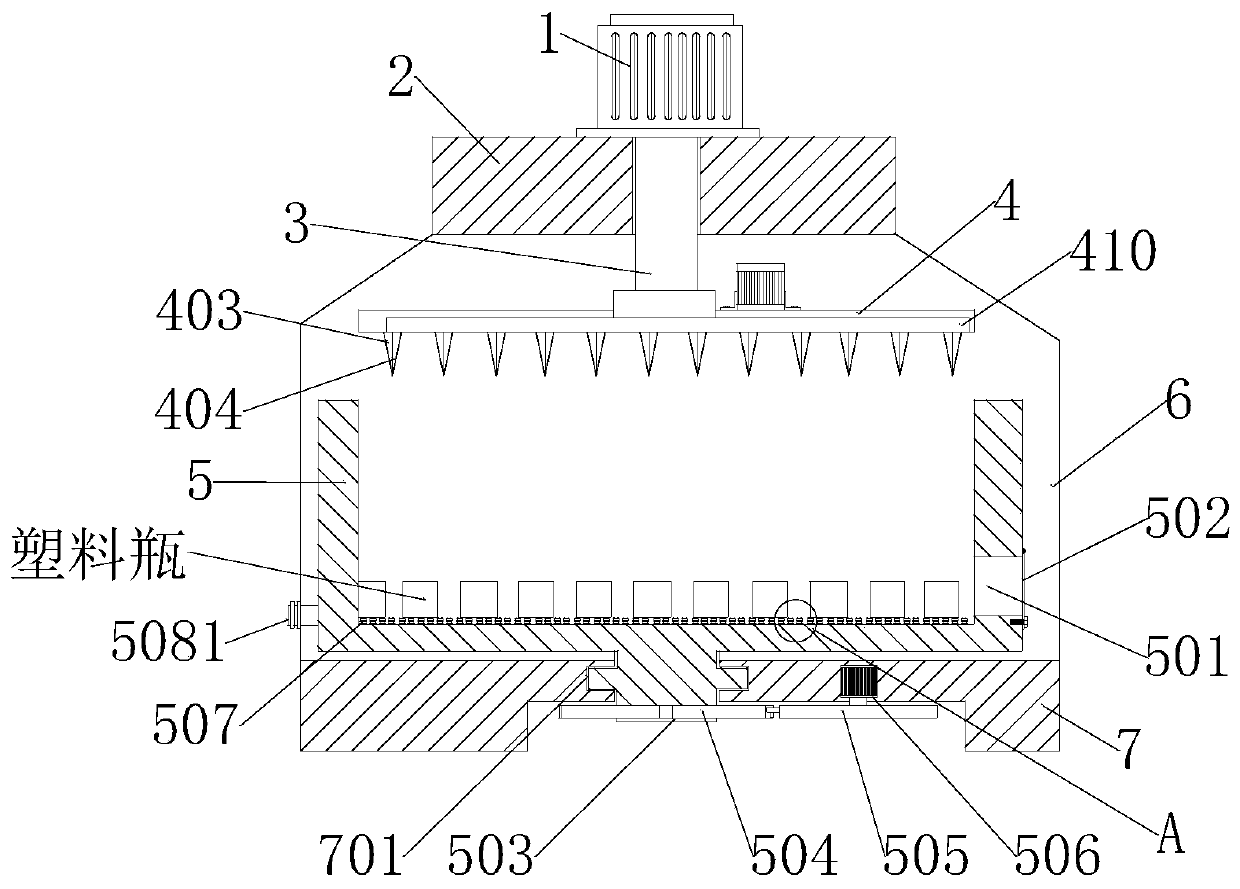

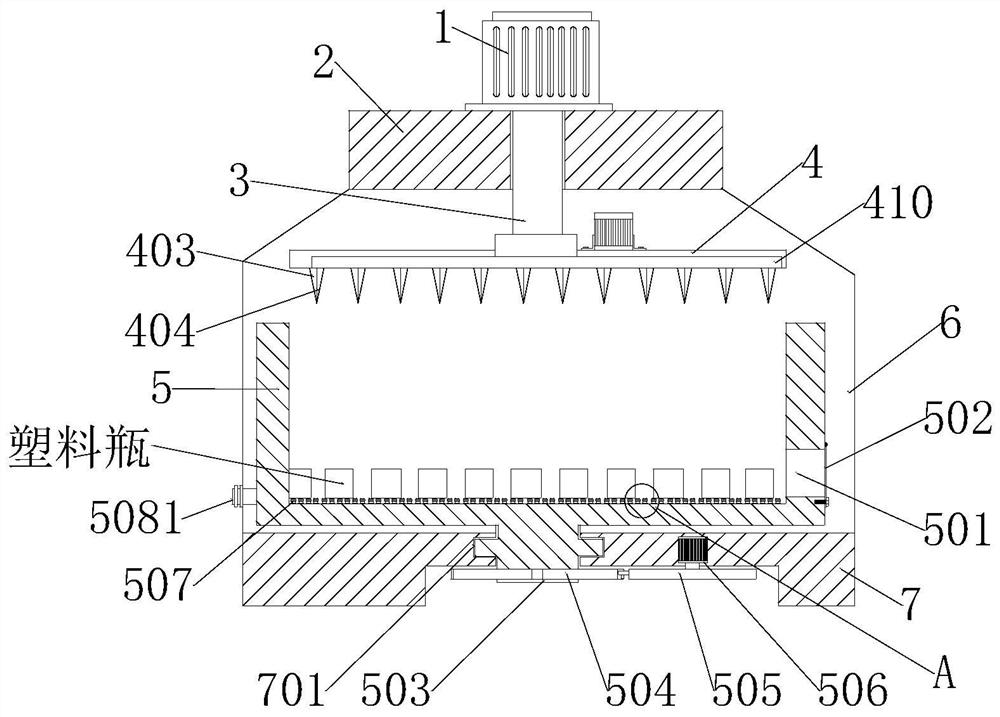

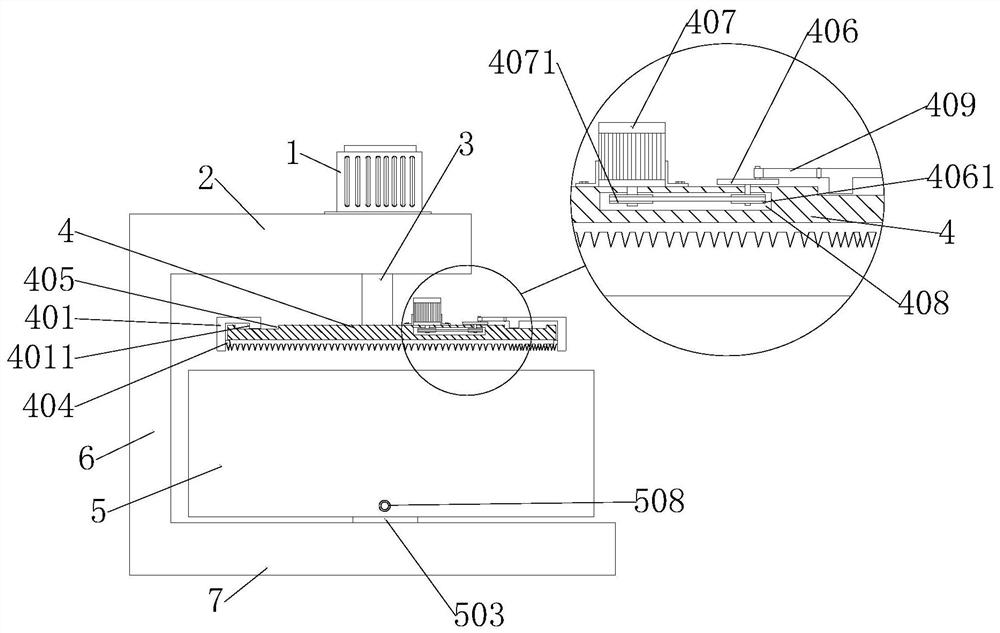

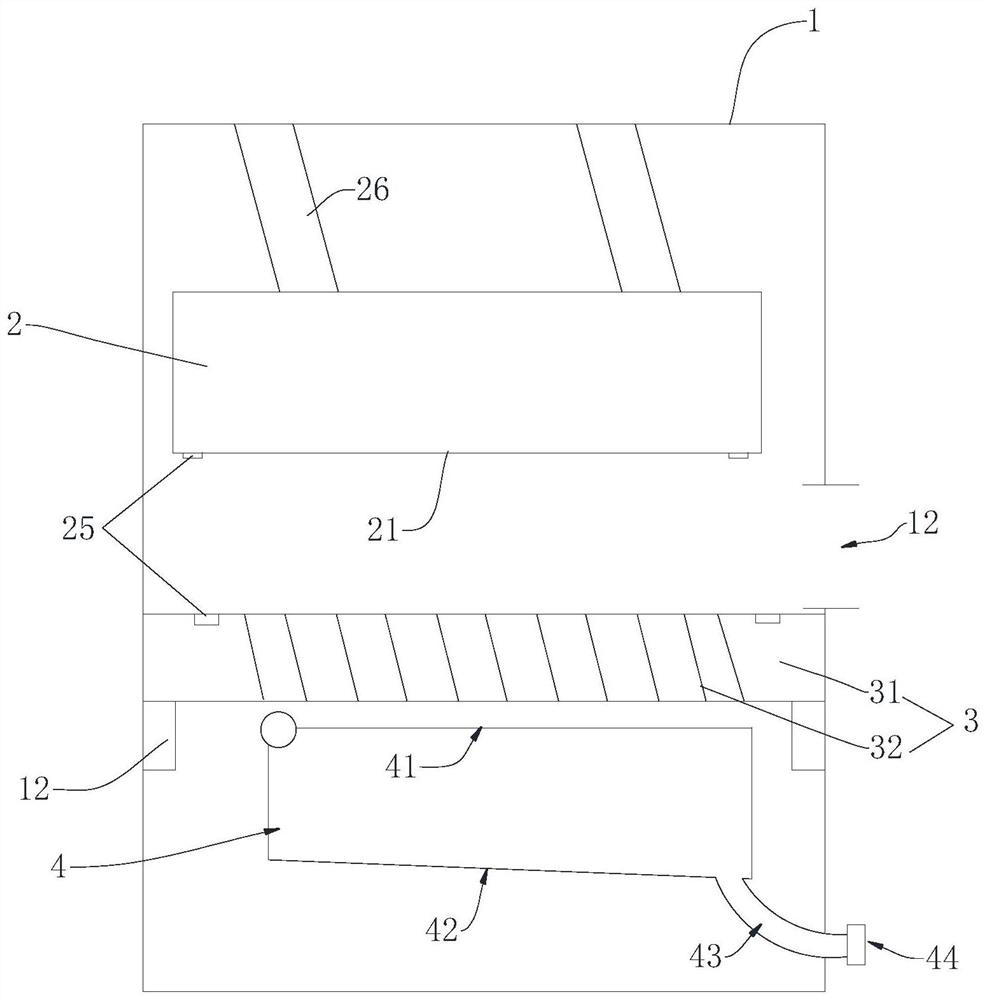

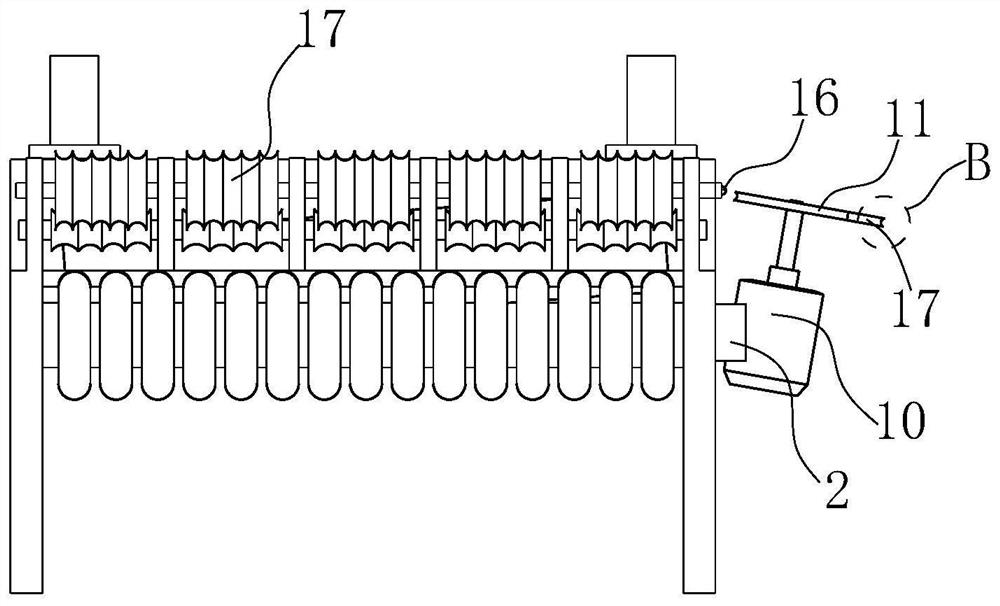

Plastic garbage slitting treatment system

ActiveCN111086127AEasy to cut intoEfficient cuttingPlastic recyclingGrain treatmentsHydraulic cylinderAirbag

The invention discloses a plastic garbage slitting treatment system, and relates to the technical field of garbage collection and machining. The plastic garbage slitting treatment system comprises a base, wherein a supporting plate which is vertically fixed to the top end of the base is arranged at the top end of the base, a horizontally arranged top plate is arranged at the top end of the supporting plate, a hydraulic cylinder is mounted at the top end of the top plate, the bottom end of the hydraulic cylinder extends downwards to be provided with a piston rod, the bottom end of the piston rod is fixed with a knife rest of a square plate structure, and the knife rest is horizontally fixed to the bottom end of the piston rod. According to the plastic garbage slitting treatment system, a shaft rod is arranged at the middle position of the bottom end of a garbage slitting box, groove wheels are driven by a second motor to drive the garbage slitting box to rotate, the groove wheels enablethe garbage slitting box to rotate by 90 degrees at a time, the knife rest downwards extends into a garbage slitting groove every time to cut plastic bottles and plastic airbag bags at different angles, the crushing efficiency of the plastic bottles and the plastic airbag bags is improved, and the fixed knife rest at the bottom end of the knife rest can effectively cut the plastic bottles and theplastic airbag bags.

Owner:福建泉州业德弗科技有限公司

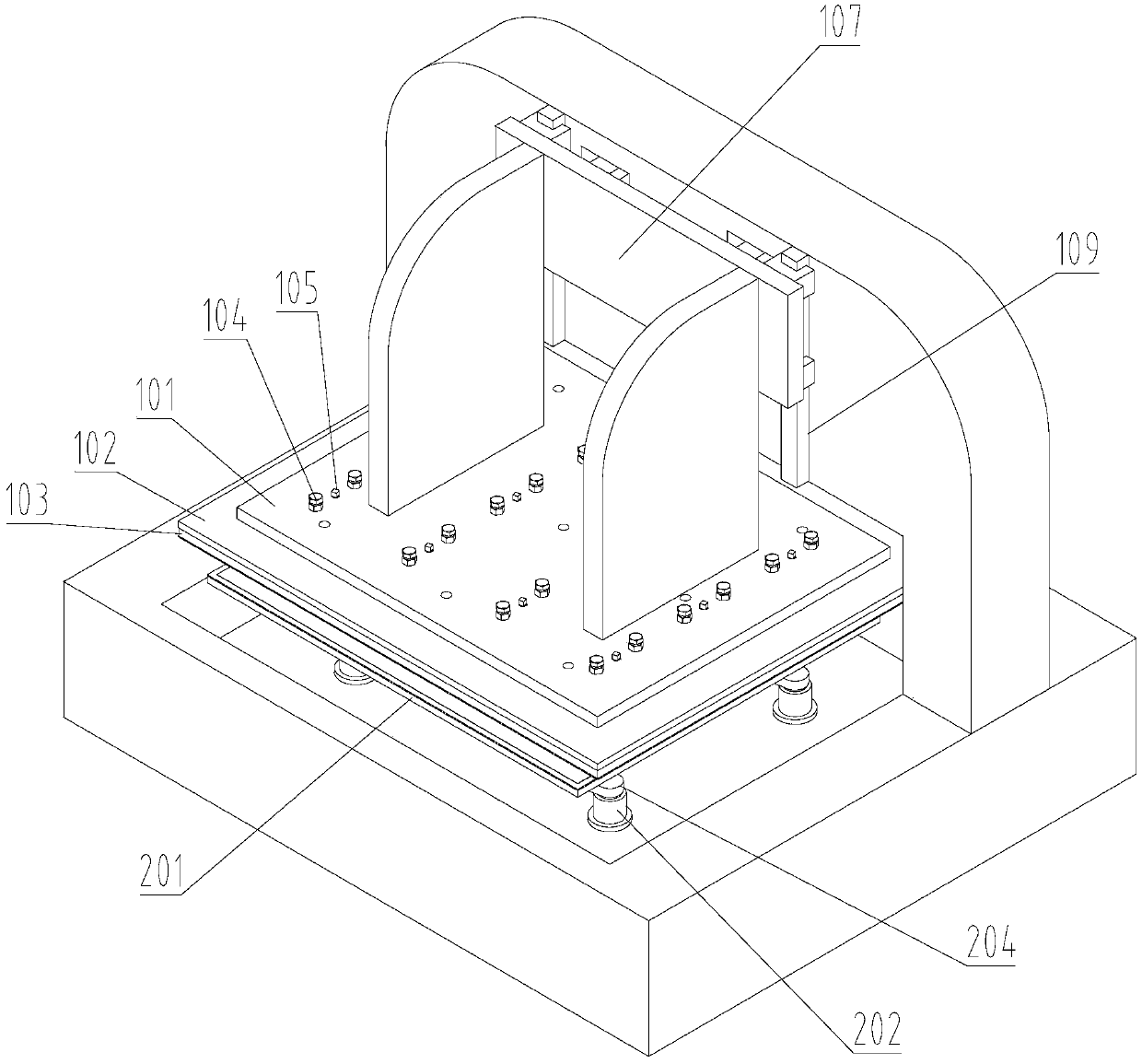

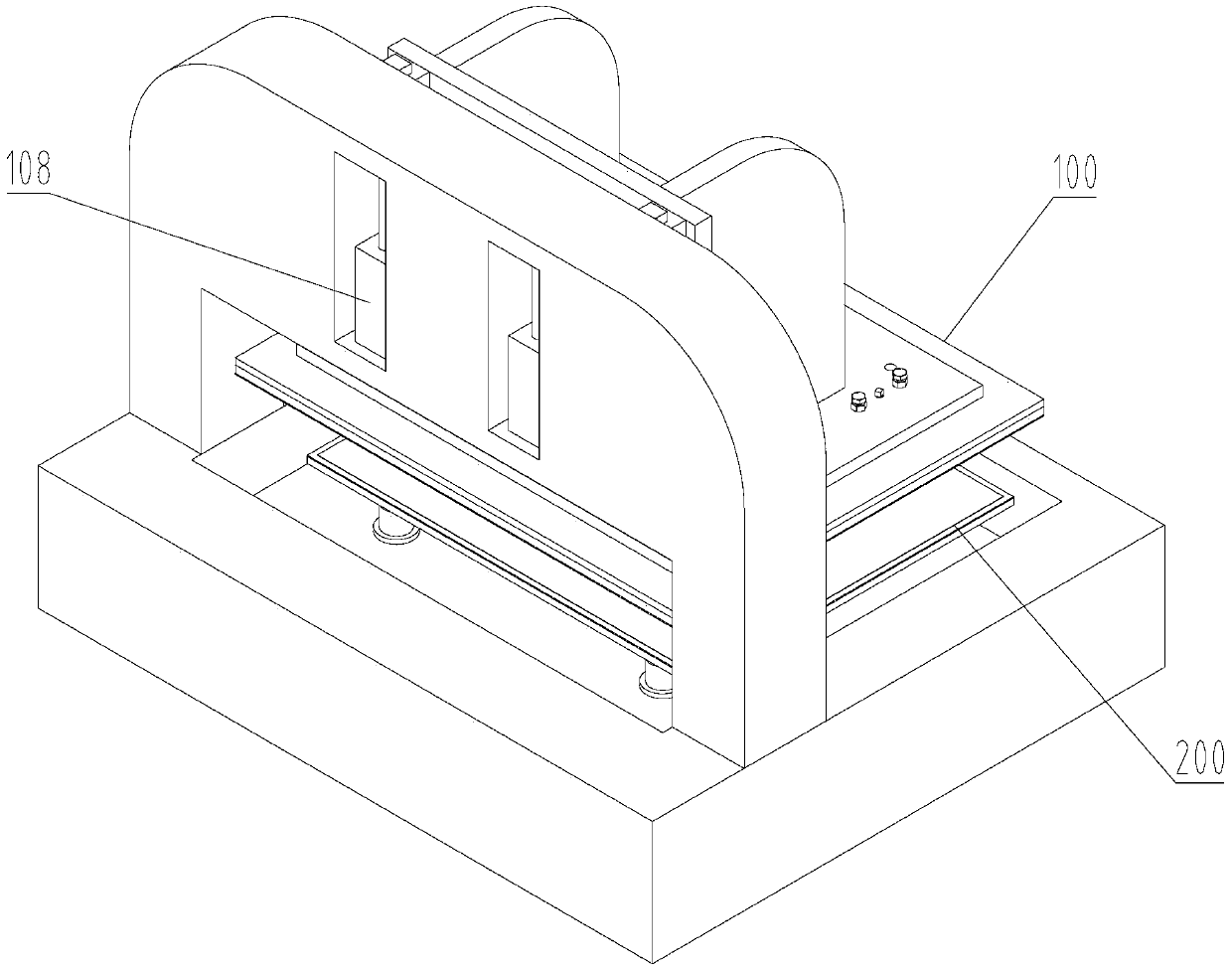

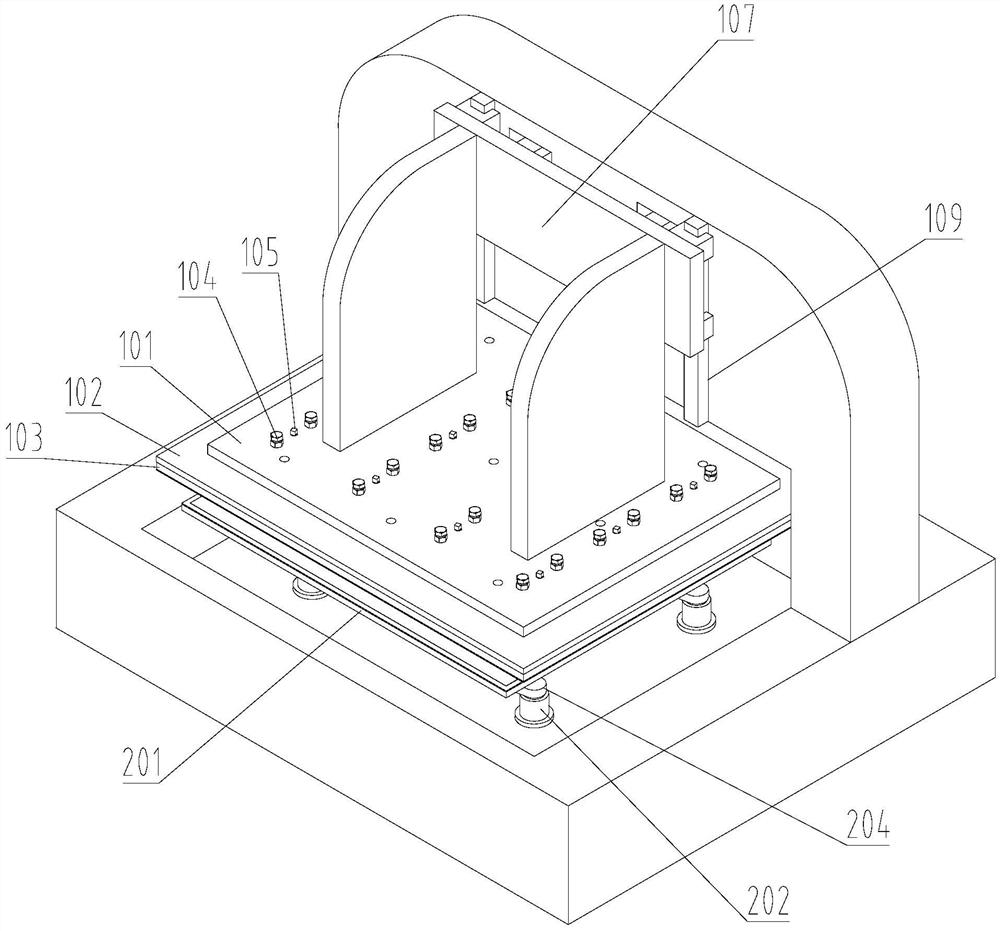

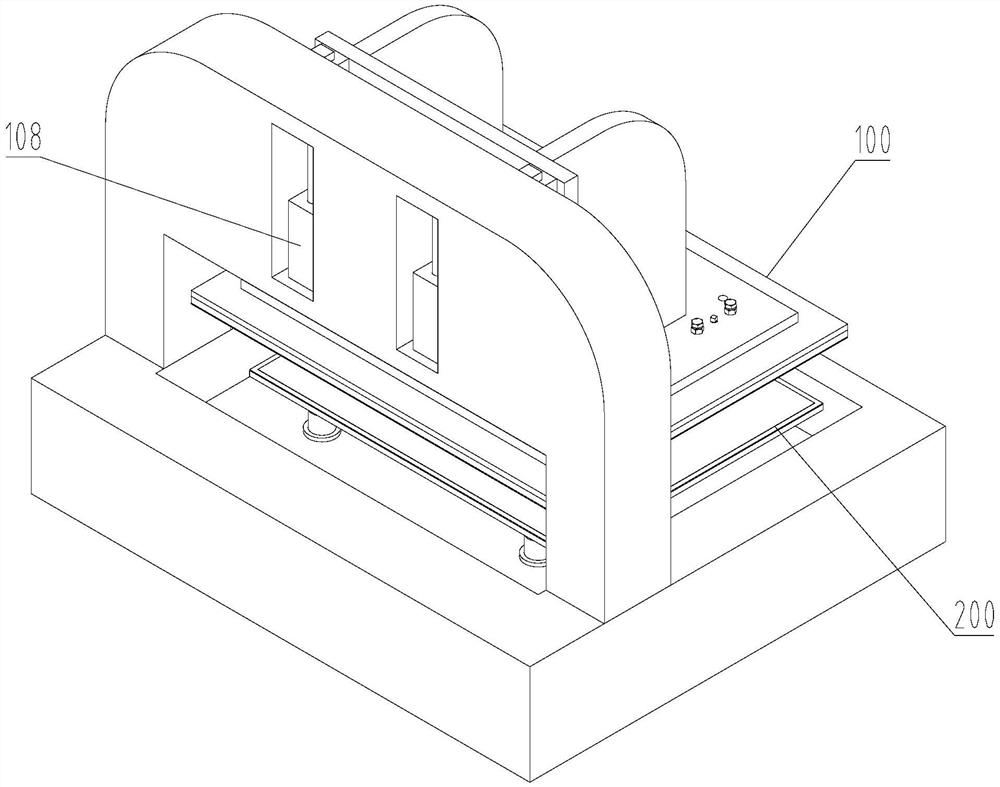

Polishing machine

ActiveCN110893576ATrim thicknessIncrease pressureGrinding carriagesPolishing machinesPolishingSlope angle

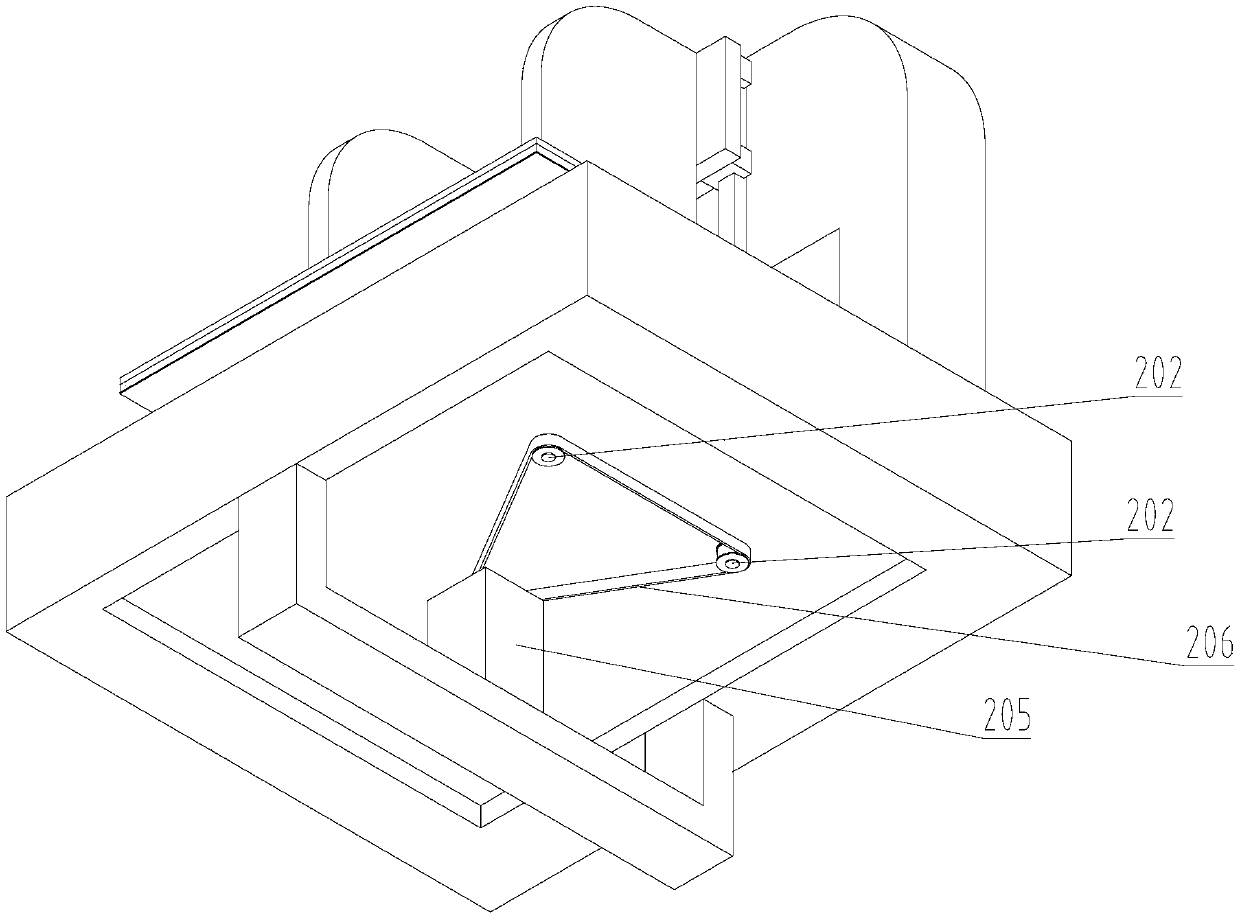

The invention discloses a polishing machine. The polishing machine comprises a polishing mechanism (100) and a bearing mechanism (200) which are arranged in the vertical direction, wherein the bearingmechanism (200) is configured to be capable of bearing glass to be polished and enabling the glass to be polished to move in a horizontal plane; the polishing mechanism (100) is arranged to be capable of trimming the thickness of the glass to be polished; the polishing mechanism (100) is provided with a supporting plate (101), a polishing disc and a plurality of adjusting assemblies; the supporting plate (101) is configured to be close to and far away from the glass to be polished; the polishing disc is installed on the supporting plate (101) through the plurality of adjusting assemblies; andthe plurality of adjusting assemblies are configured to be capable of adjusting the inclination angle of the polishing disc relative to the supporting plate (101) and enable the polishing disc to keep the inclination angle. According to the polishing machine, the thickness of glass can be finished when the glass is polished.

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

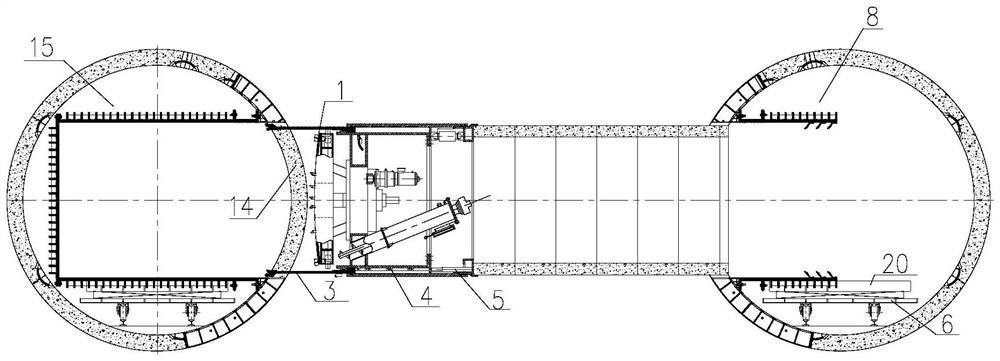

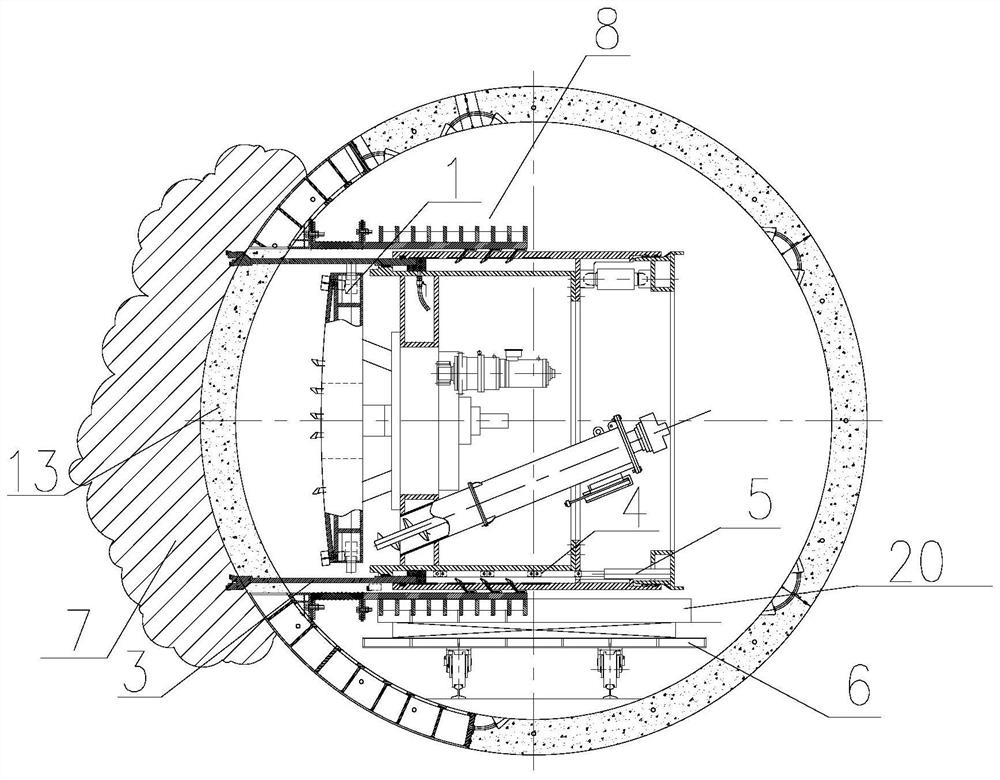

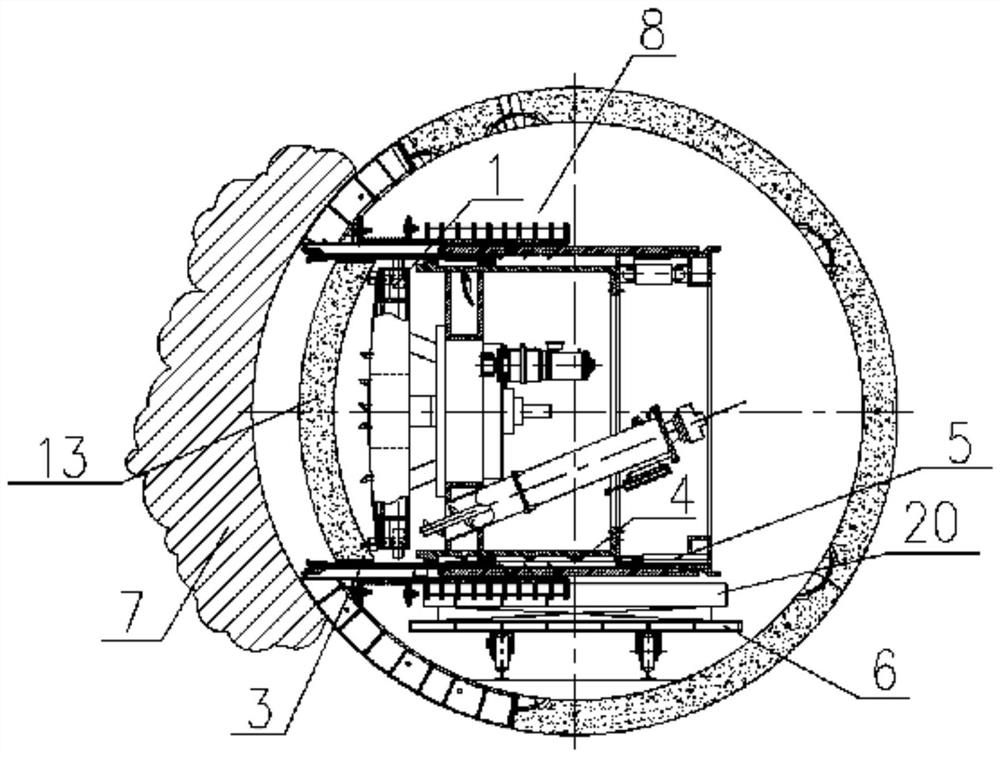

Tunnel contact channel tunneling device and method by means of flexible sleeve launching and receiving

PendingCN112746852AImprove adaptabilityAvoid damageUnderground chambersTunnel liningEngineeringMachine

The invention discloses a tunnel contact channel tunneling device and method by means of flexible sleeve launching and receiving. The tunneling device comprises a tunneling device, a supporting trolley, a flexible launching sleeve system, a flexible receiving sleeve system and a moving device, wherein the moving device is installed on the supporting trolley, supports the flexible launching sleeve system and the tunneling device and is used for making the flexible launching sleeve system and the tunneling device move front and back in the contact channel launching axis direction; and the flexible launching sleeve system and the flexible receiving sleeve system are correspondingly connected with main tunnel segments on the launching side and the receiving side. According to the method, the posture can be adjusted mainly through the adaptability of the flexible sleeve system according to launching and receiving of a tunneling machine, meanwhile, the flexible sleeve system is conveniently connected with the main tunnel segments and disconnected with the main tunnel segments, and cut tunnel portal segments are conveniently taken out. Compared with existing similar equipment and method, the device and method have the advantages of being high in adaptability, high in construction efficiency, completely controllable in construction risk and the like.

Owner:ZHONGYIFENG CONSTR GRP

Garbage grab bucket

Owner:宁波泰来环保设备有限公司

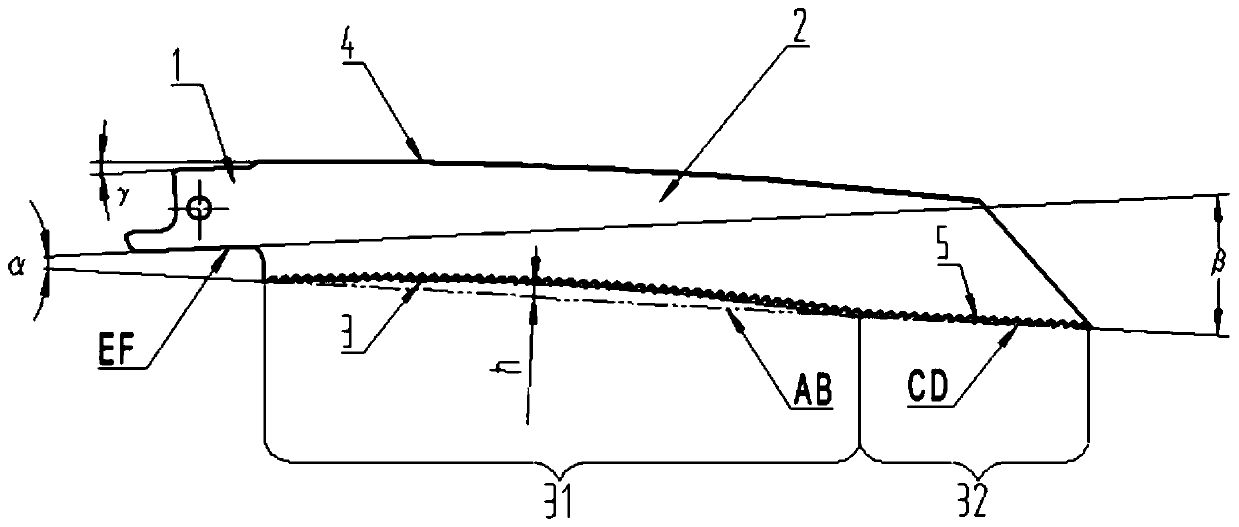

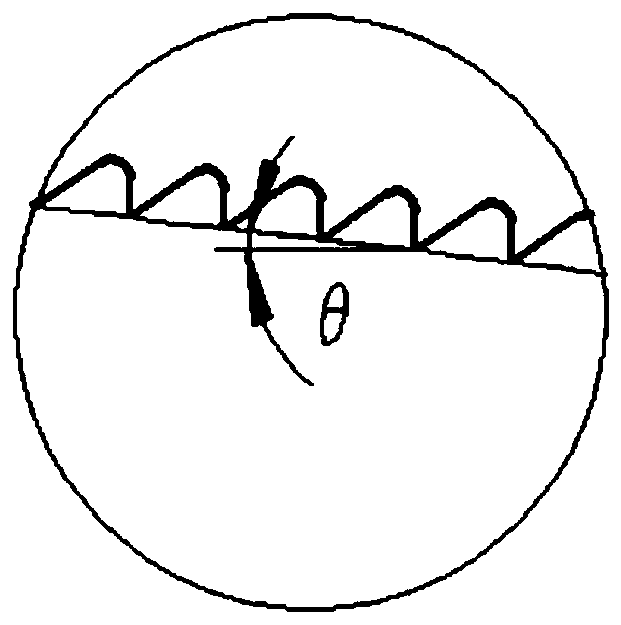

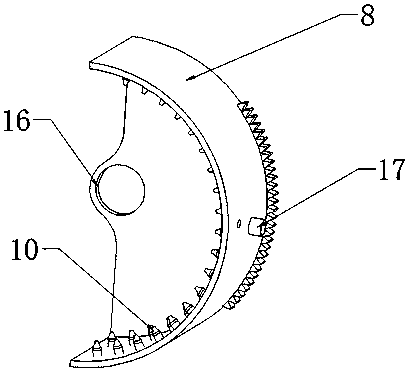

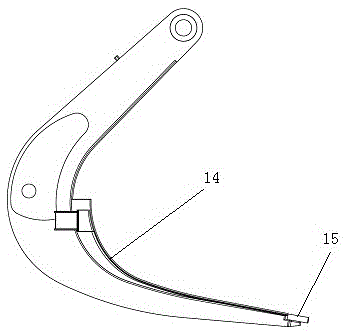

Novel arc-shaped reciprocating saw

The invention provides a novel arc-shaped reciprocating saw. The novel arc-shaped reciprocating saw comprises a saw body and a handle part for being connected with an electric reciprocating saw clamping device; a row of saw teeth are arranged at the cutting edge of the saw body; and the cutting edge comprises an arc-shaped curve part, and the back edge of the saw body is in an arc shape. Accordingto the technical scheme, the technical problem that an existing reciprocating saw is difficult to obtain a larger actual cutting angle is solved, and the actual cutting angle when the reciprocating saw is cutting is optimized, so that the actual cutting angle gradually increases with the arc-shaped curve, the reciprocating saw makes it easier to cut into a workpiece, the sawing depth in a singlestroke is increased, the cutting efficiency is improved, and thus efficient cutting is realized; and meanwhile, the vibration during cutting is reduced, and the comfort and safety of users are improved.

Owner:大连远东工具有限公司

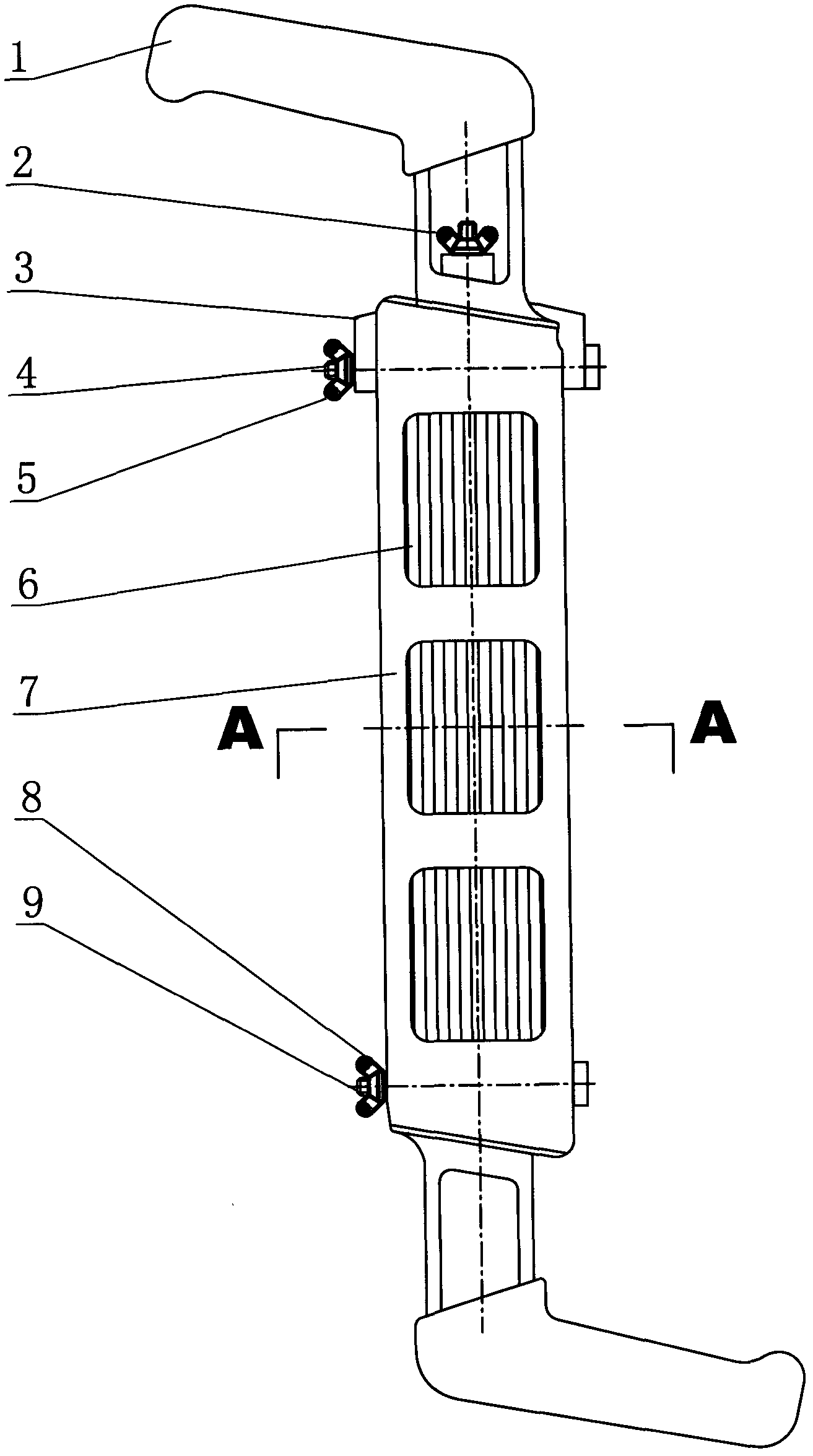

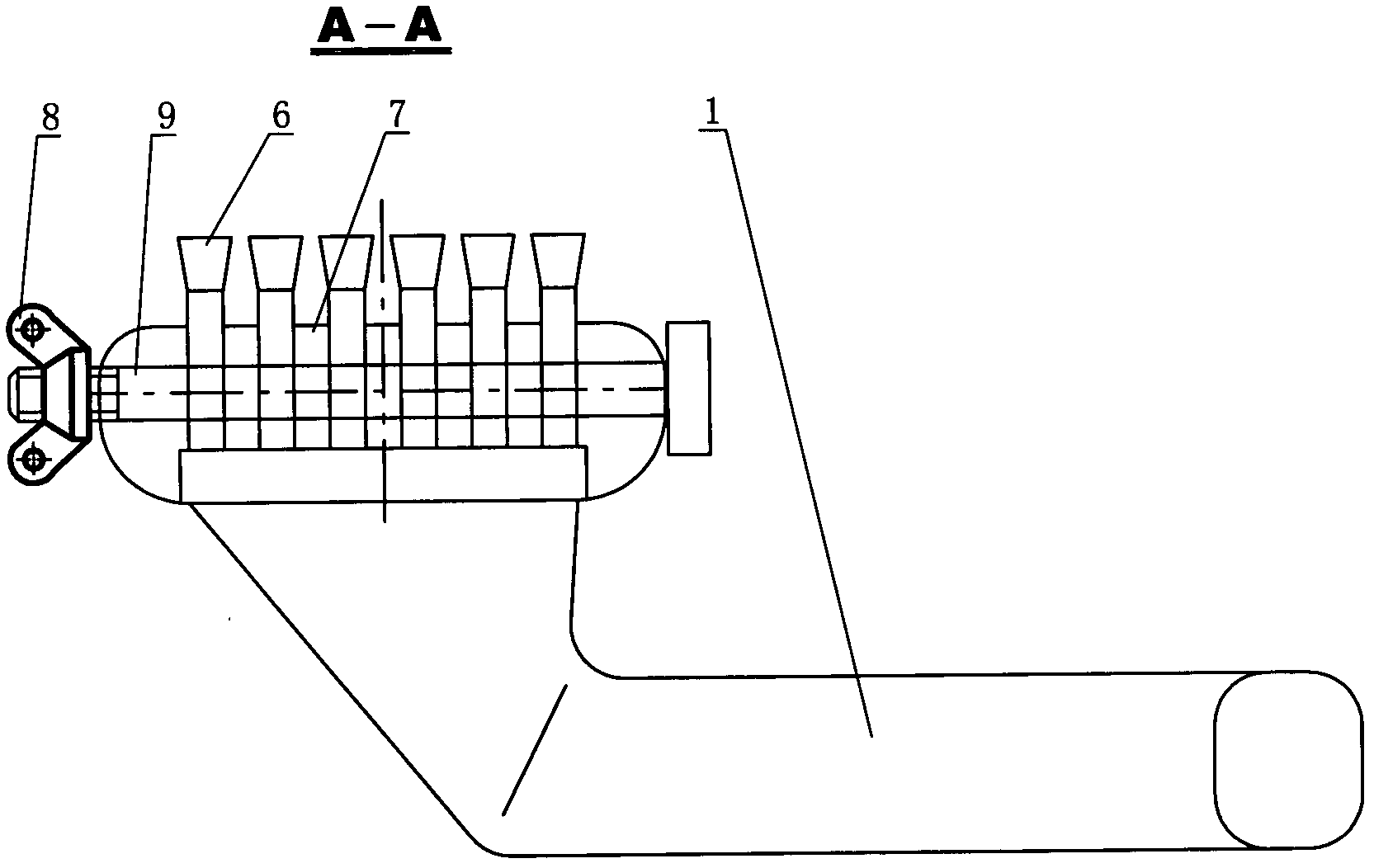

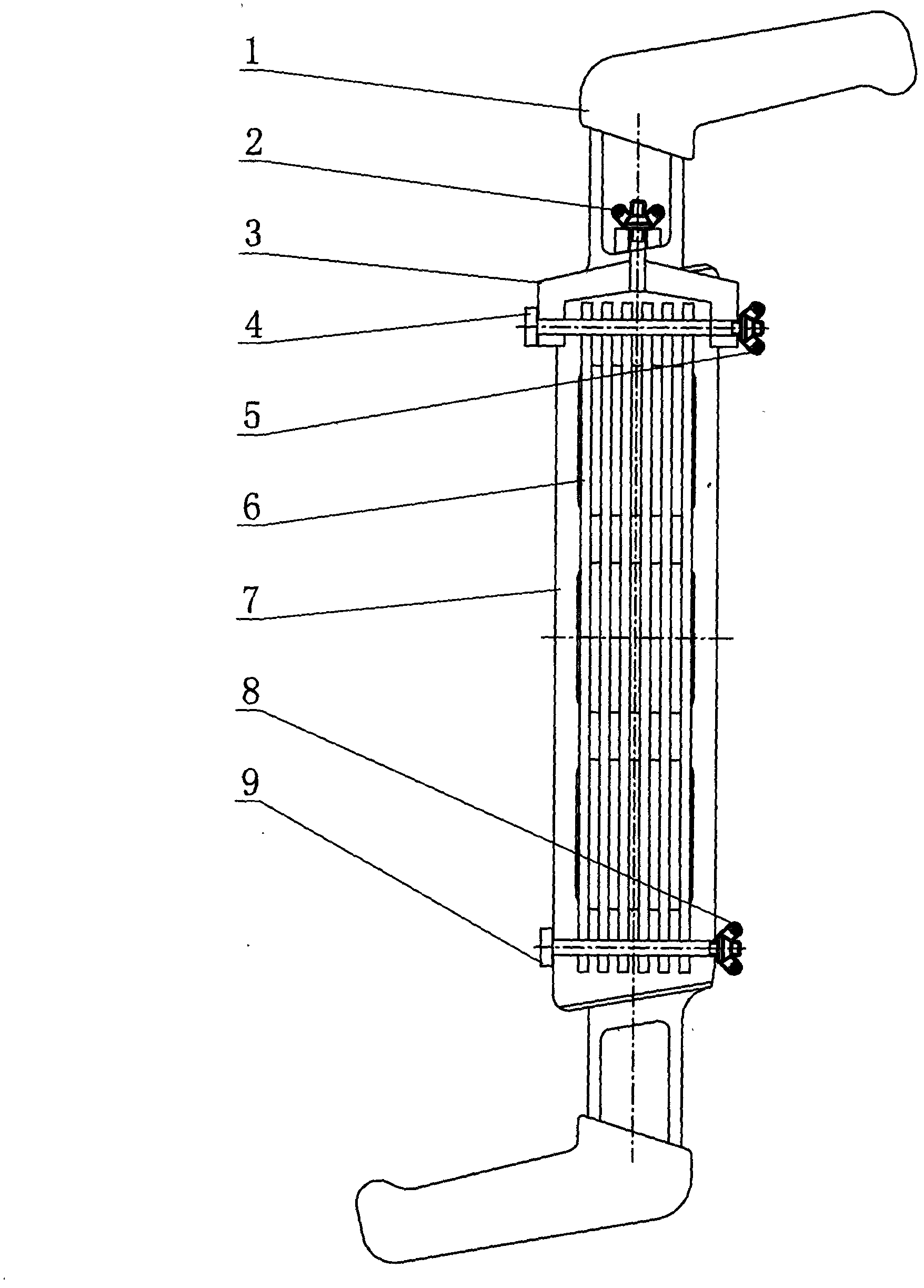

File for soft materials

InactiveCN103203500ADifficult to cut intoEasy to cut intoMetal sawing devicesFiling/rasping toolsSoft materialsCopper

The invention relates to a file used by a fitter for manual operation, in particular to a file which has a special structure, adopts the combination of saw blades and a main file body, and is capable of filing soft materials such as aluminum, copper and plastics. The file for soft materials consists of basic parts such as a file handle, an alary nut, a saw blade tightening slider, a saw blade tightening rod, saw blades and the main file body. According to the file for soft materials, the characteristic that a saw blade cannot be sticky to cuttings easily in the cutting process is utilized, a plurality of saw blades are arrayed in parallel and fixedly arranged in one manual fixture, so that a novel file for soft materials is constituted, the file for soft materials not only can be cut into a workpiece easily when cutting soft materials, but also can not be sticky to cuttings in the cutting process, so that the operation efficiency of manual filing is greatly improved. The saw blade tightening rod is inserted into holes in the two sides of the saw blade tightening slider, the saw blade tightening slider can pull the saw blade tightening rod outwards in the process of tightening the alary nut, so that the saw blades inserted into the rectangular empty slots of the main file body are tightened, and the workpiece can be filed conveniently.

Owner:SHANGHAI HANGXIANG HARDWARE FITTINGS

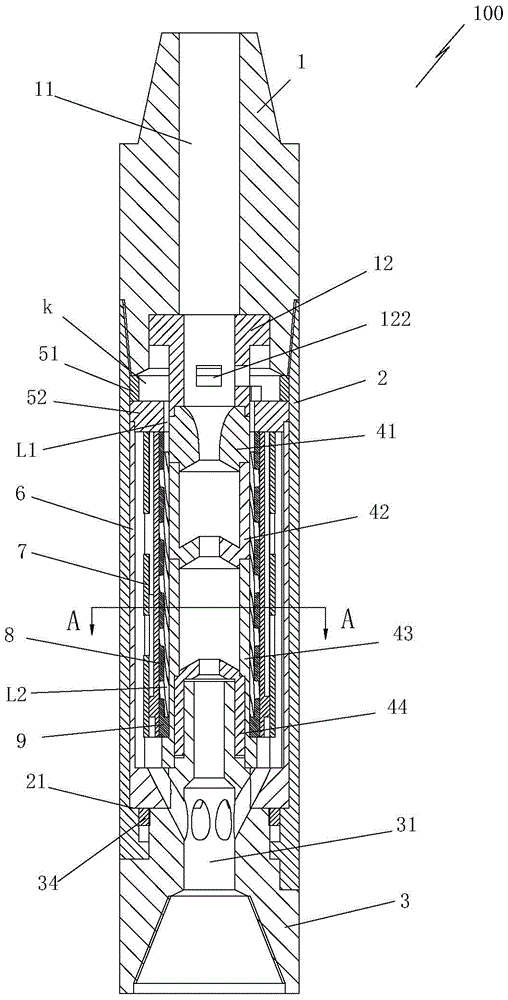

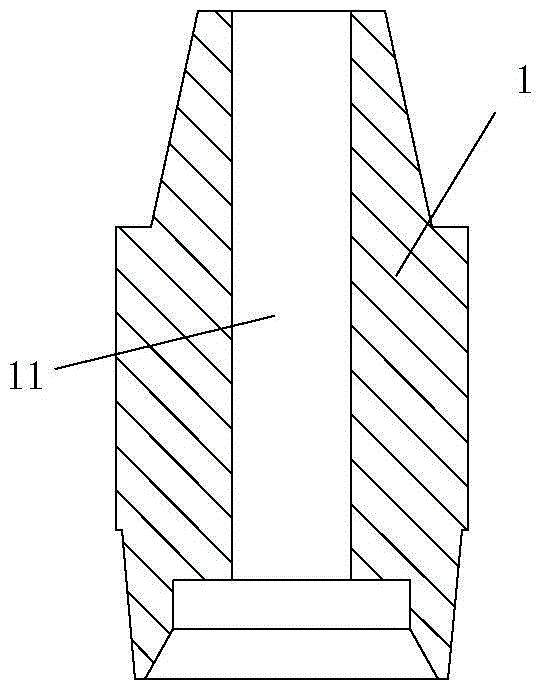

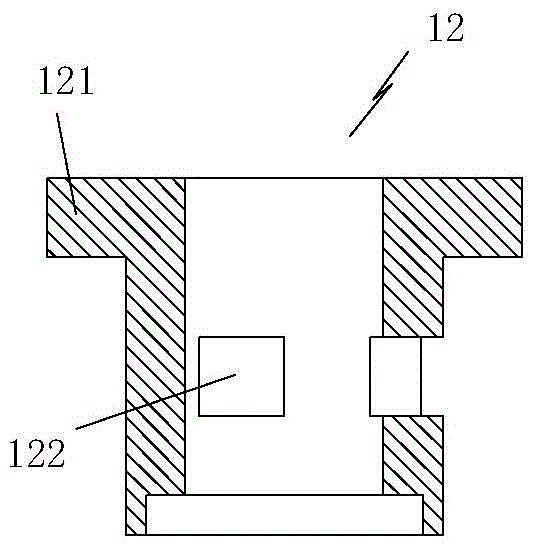

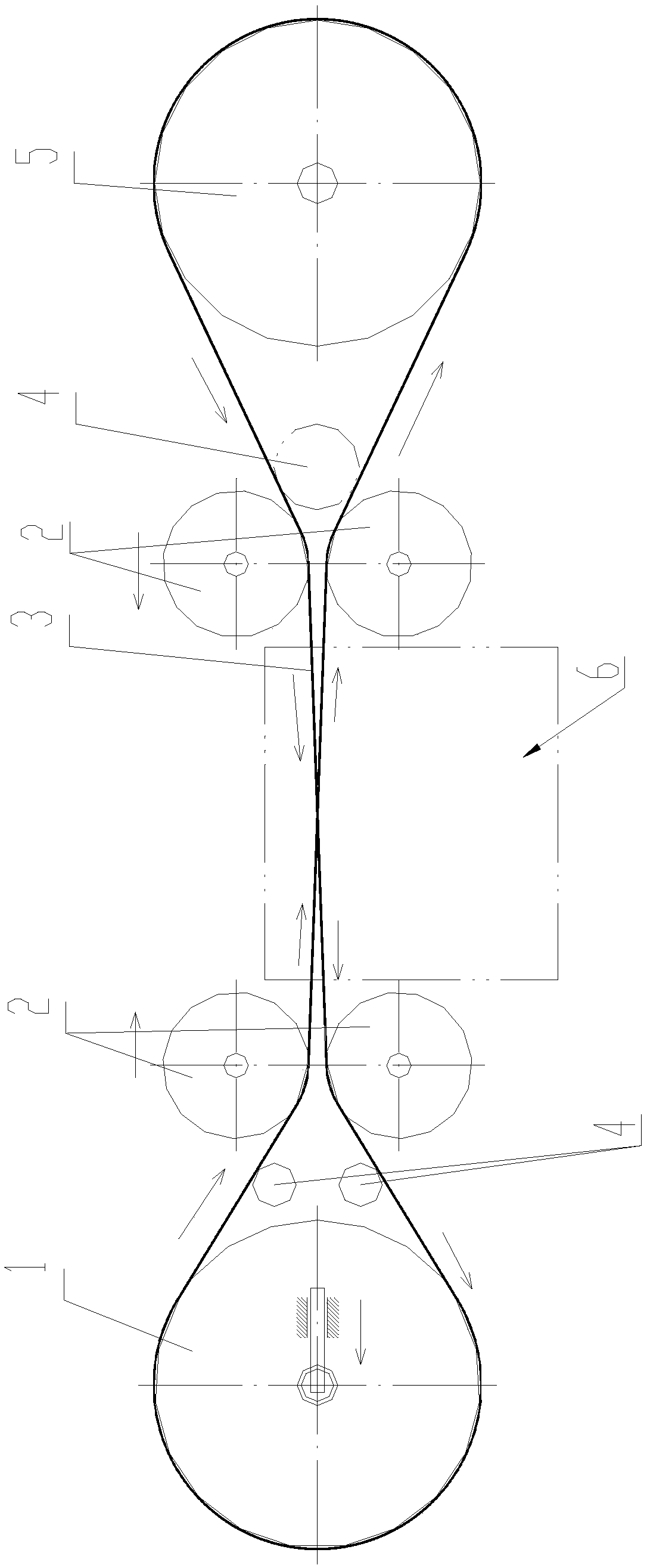

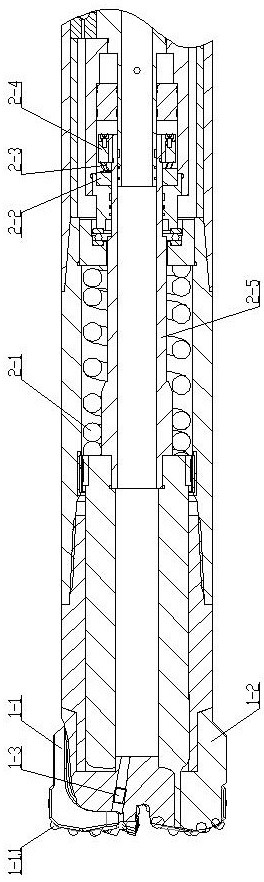

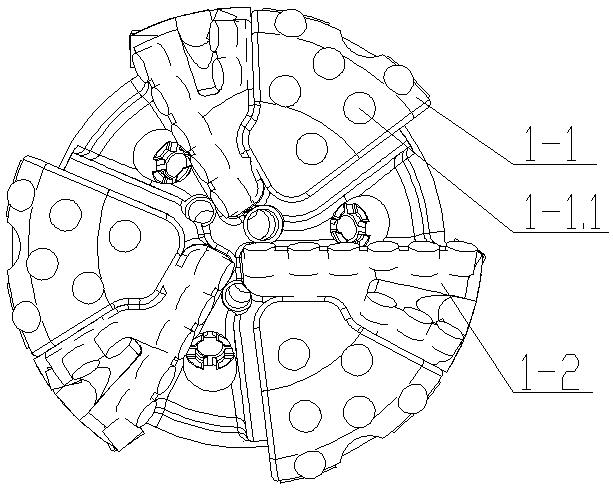

Compound Impact Drilling Tools

ActiveCN104563862BImprove stabilityExtended service lifeDrilling drivesBorehole drivesWell drillingSpray nozzle

The invention relates to a composite impact well drilling tool, which comprises an upper pup joint and a middle outer casing in fixed connection, wherein the bottom of the middle outer casing is provided with a drill bit seat in a hanging way, the lower end of the inner side of the upper pup joint is provided with a flow divider, the side wall of the flow divider is provided with a flow dividing passage, the lower end of the flow divider is sequentially and fixedly connected with an upper spray nozzle, an upper cavity and a lower cavity, the upper part of the drill bit seat is provided with a lower spray nozzle in a sleeving way, the lower spray nozzle is glidingly arranged in the lower cavity, a sleeve, an end cover and an impact tube which are fixed in the axial direction and the circumferential direction are sequentially arranged at the inner side of the middle outer casing and are positioned under the upper pup joint from top to bottom, and a pendulum bob and a reversing tube are coaxially arranged inside the impact tube. The well drilling tool has the advantages that high-frequency axial impact loads generated through the upper spray nozzle, the upper cavity, the lower cavity and the lower spray nozzle exert on rock, so that a drill bit can easily cut into the rock, the rock breaking efficiency is improved, meanwhile, the high-frequency circumferential impact loads are generated through continuous reciprocating swinging of the pendulum bob, and the drill bit is prevented from generating a stick slip phenomenon when the cutting-in depth is greater.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

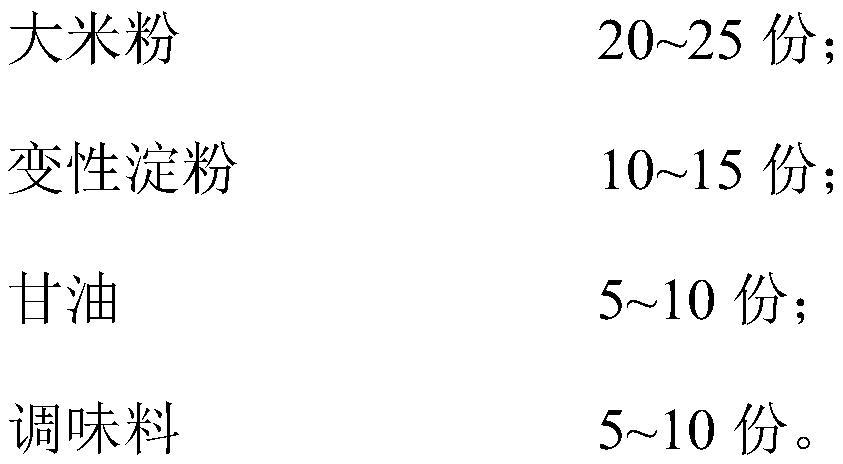

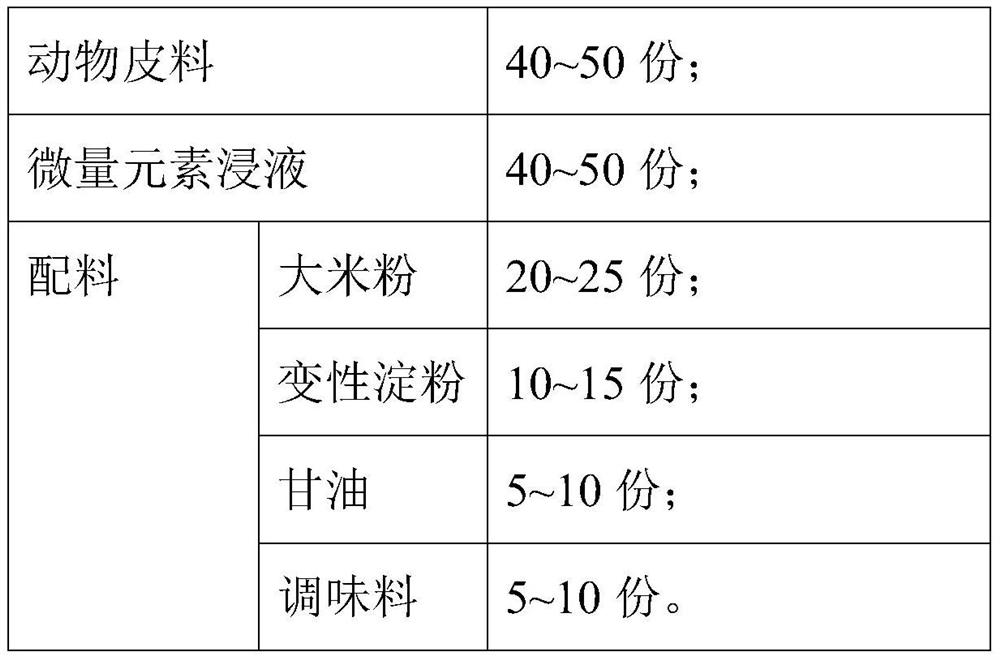

A kind of animal food made of leather and its preparation method

ActiveCN106578568BMolar reductionImprovement ingredientsAnimal feeding stuffAccessory food factorsBiotechnologyAnimal food

The invention discloses animal food made of leather and a production method thereof, wherein the animal food made of leather is made of the following ingredients in parts by weight: 40-50 parts of animal leather; 40-50 parts of trace element immersion solution 40-60 parts; its preparation method includes steps: 1) preparing animal leather: crushing animal leather into particles; 2) preparing trace element immersion liquid: dissolving trace element in a solvent to obtain trace element immersion 3) prefabrication: immerse the animal hide treated in step 1) in the trace element immersion solution obtained in step 2) to obtain prefabricated animal hide; 4) shaping: add the prefabricated animal hide obtained in step 3) 5) drying: drying the semi-finished product to obtain animal food made of leather; the animal food is added with trace elements to improve the nutrition of the animal food, and through Add leather to increase the flavor and unique taste.

Owner:SHANDONG HAICHUANG IND & TRADE CO LTD

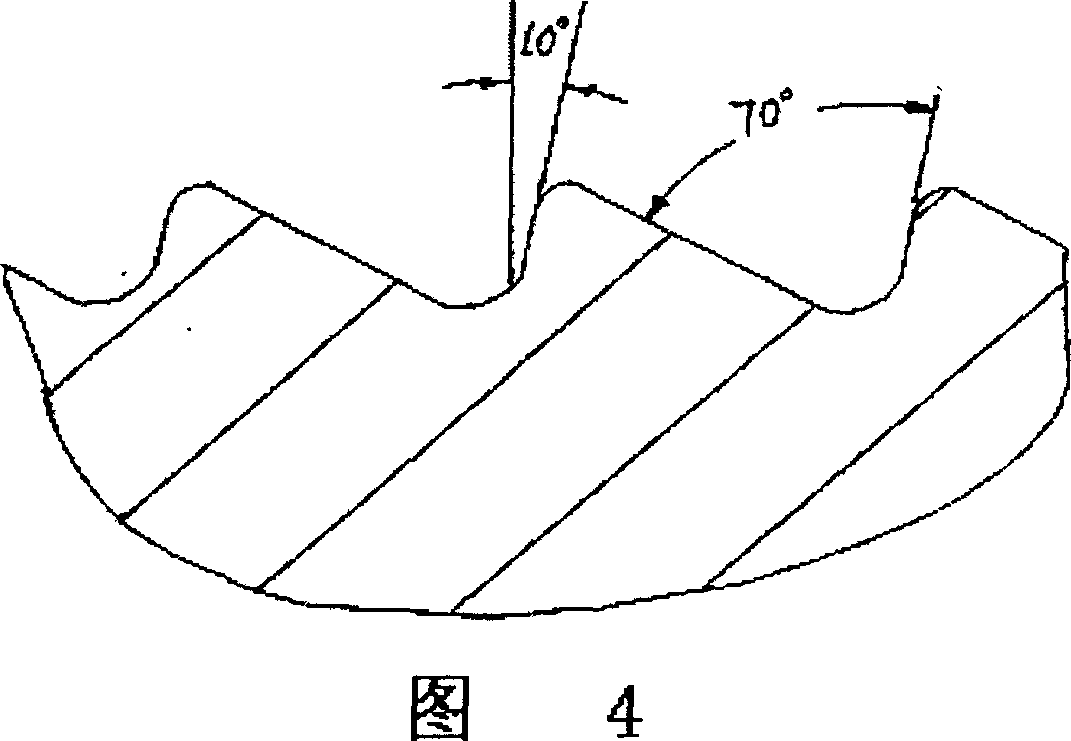

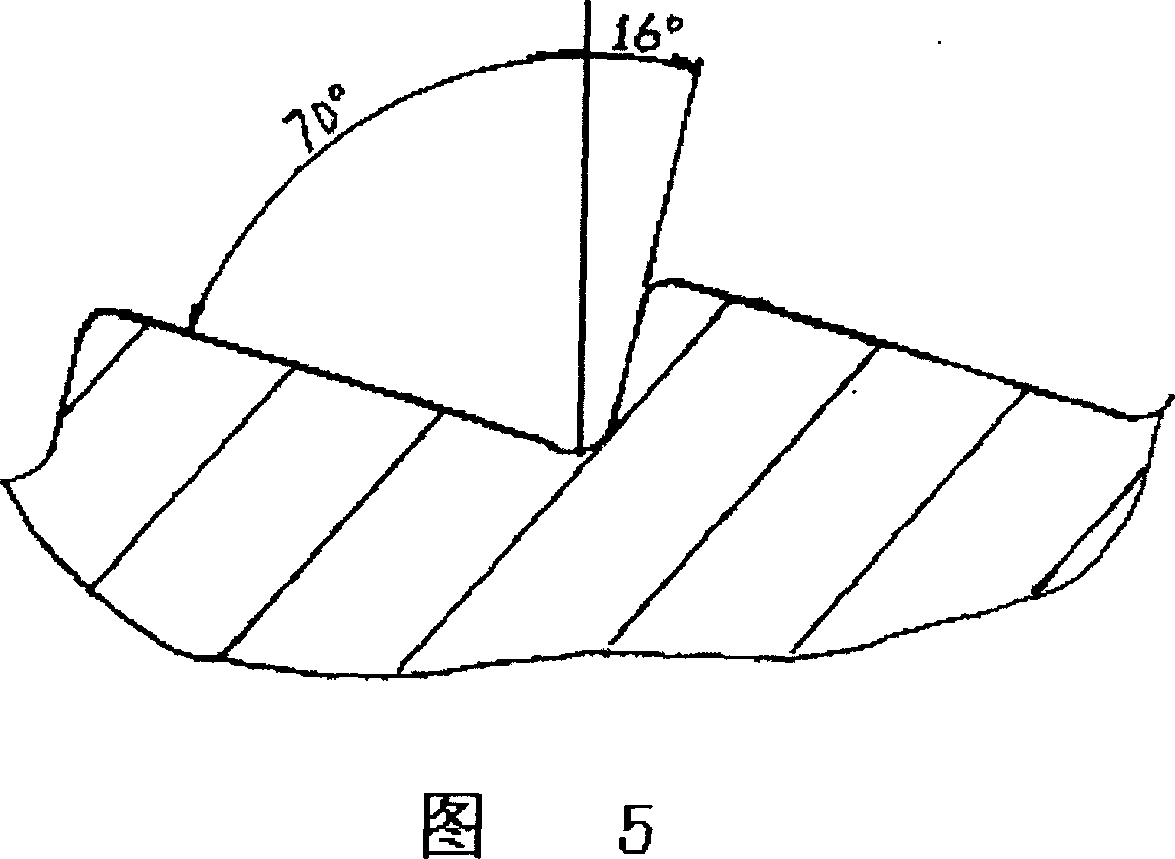

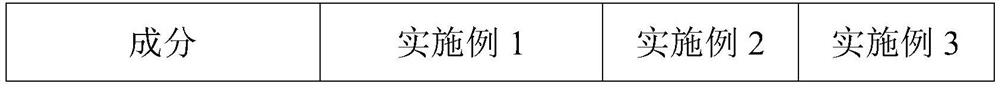

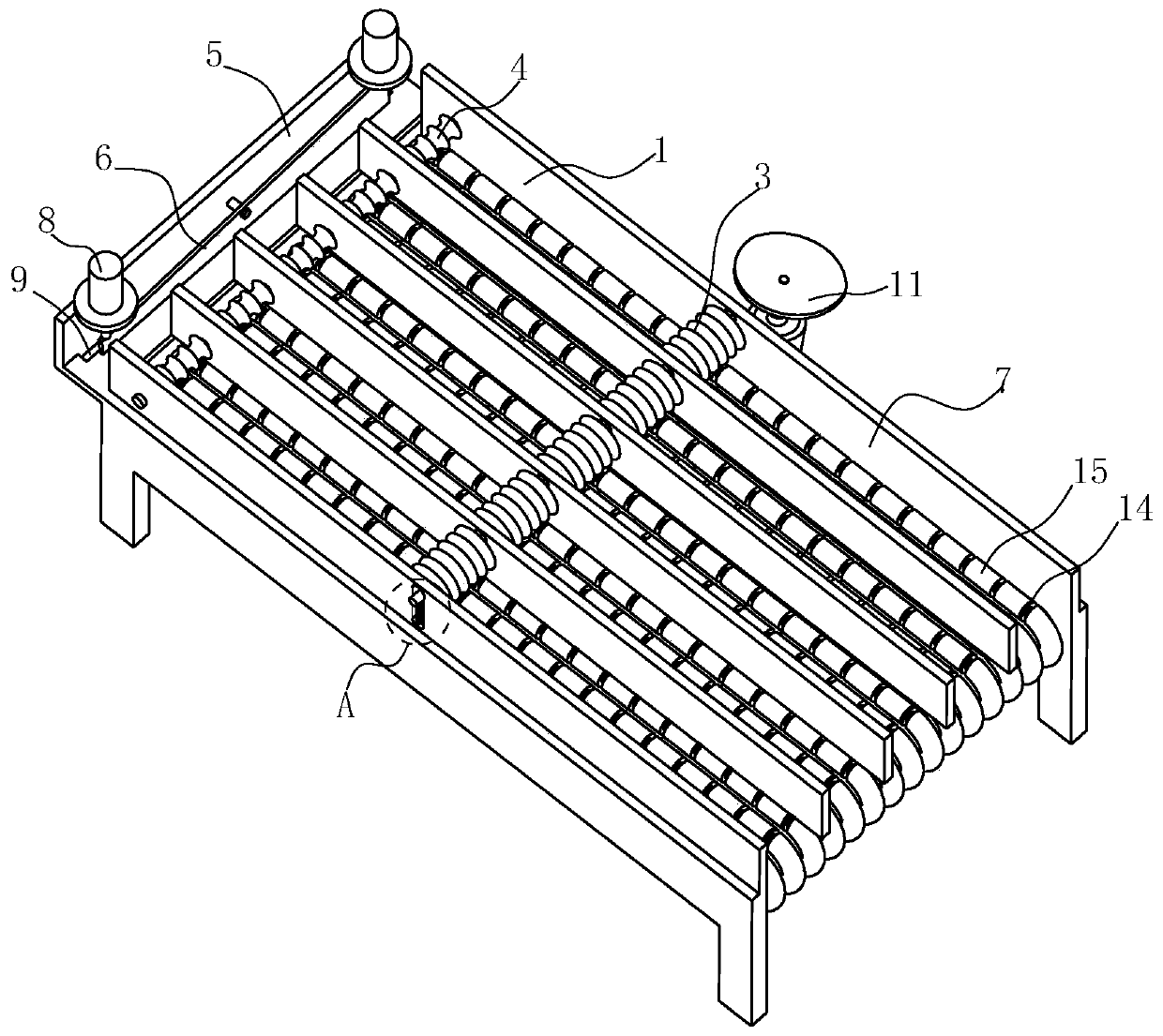

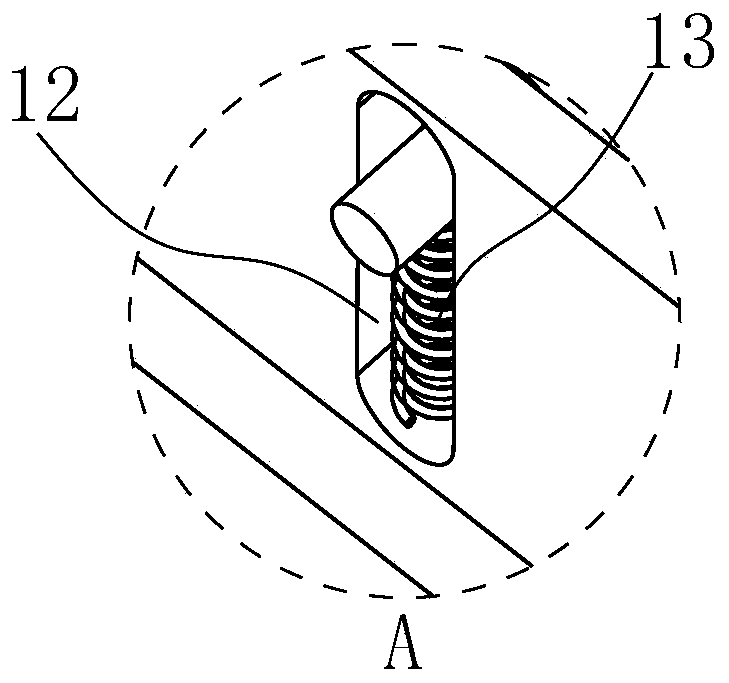

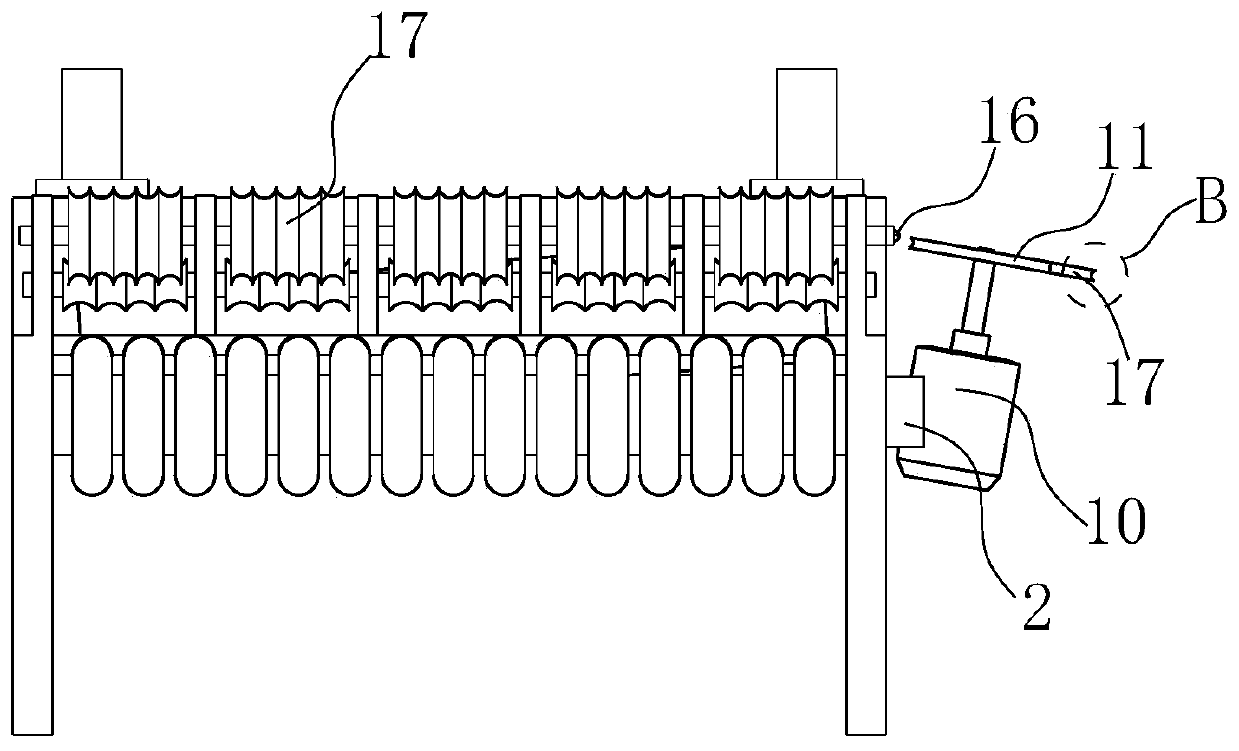

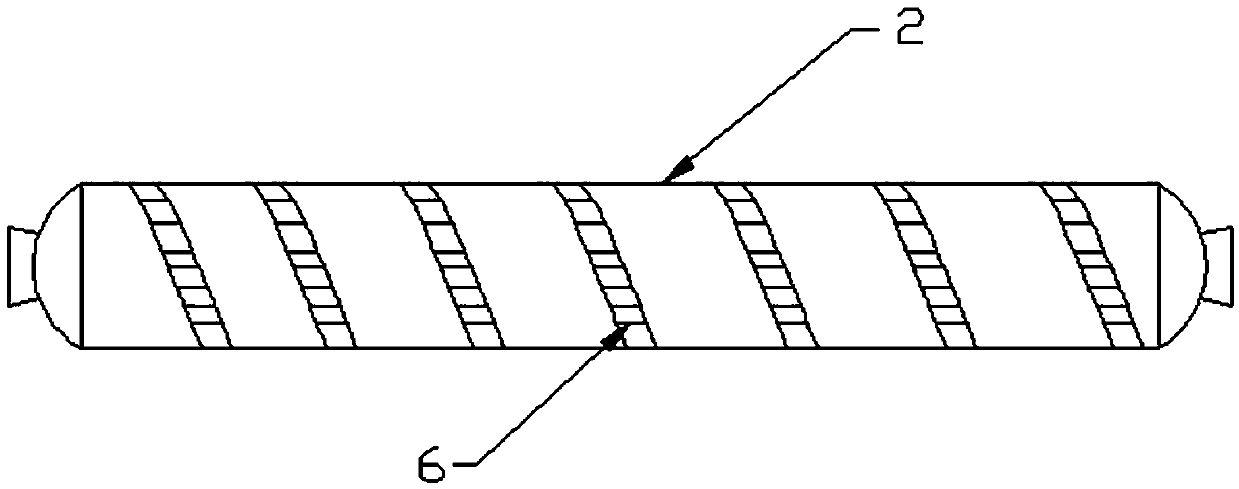

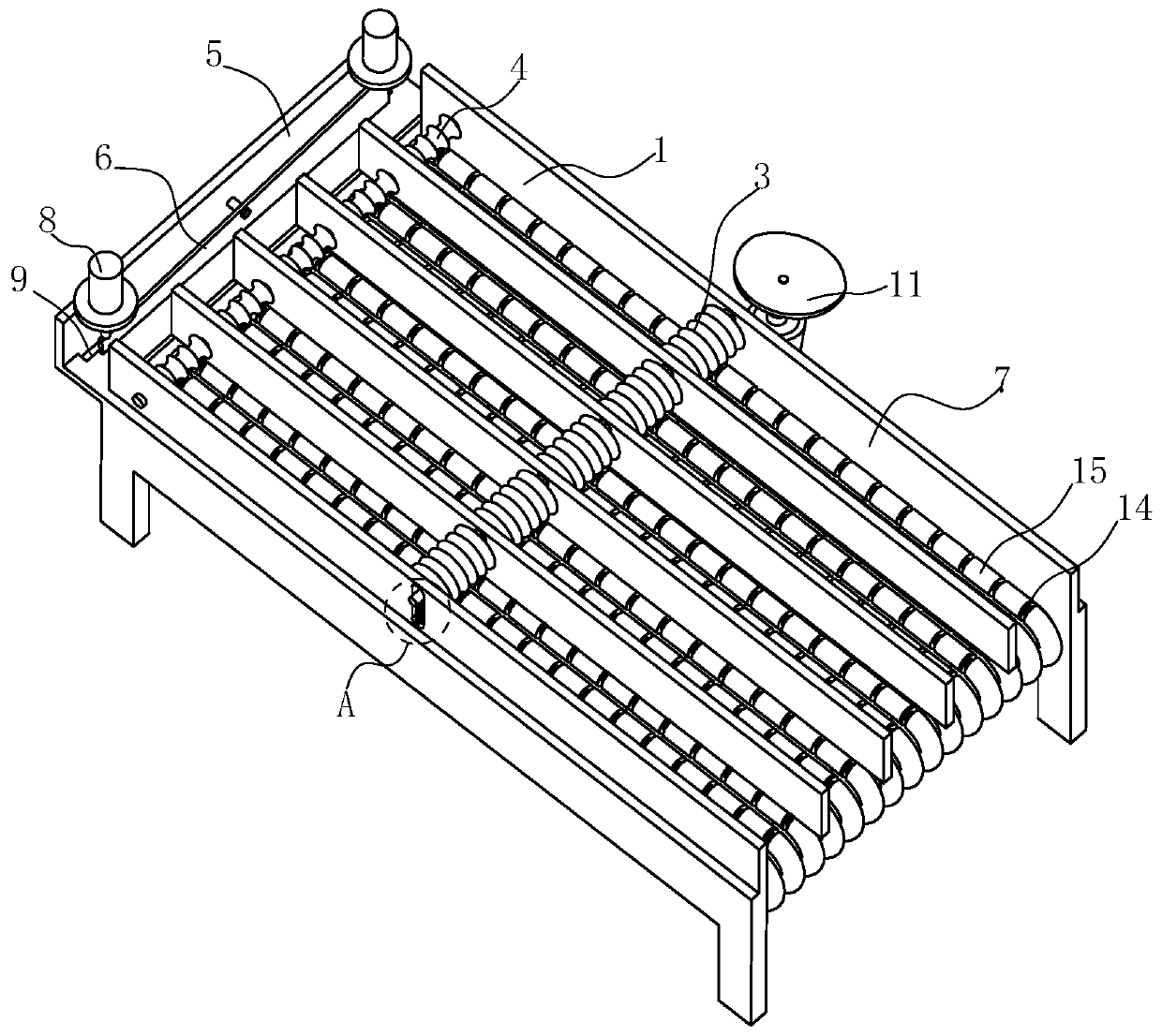

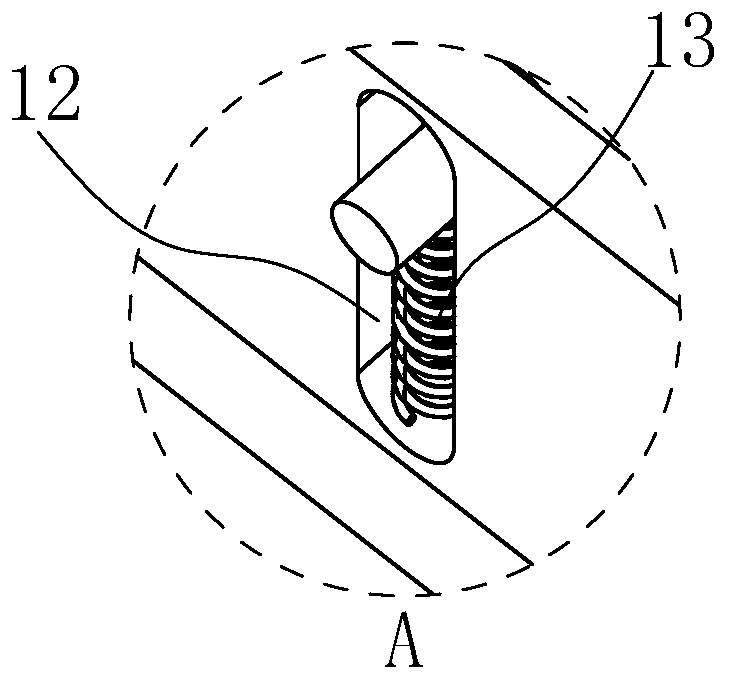

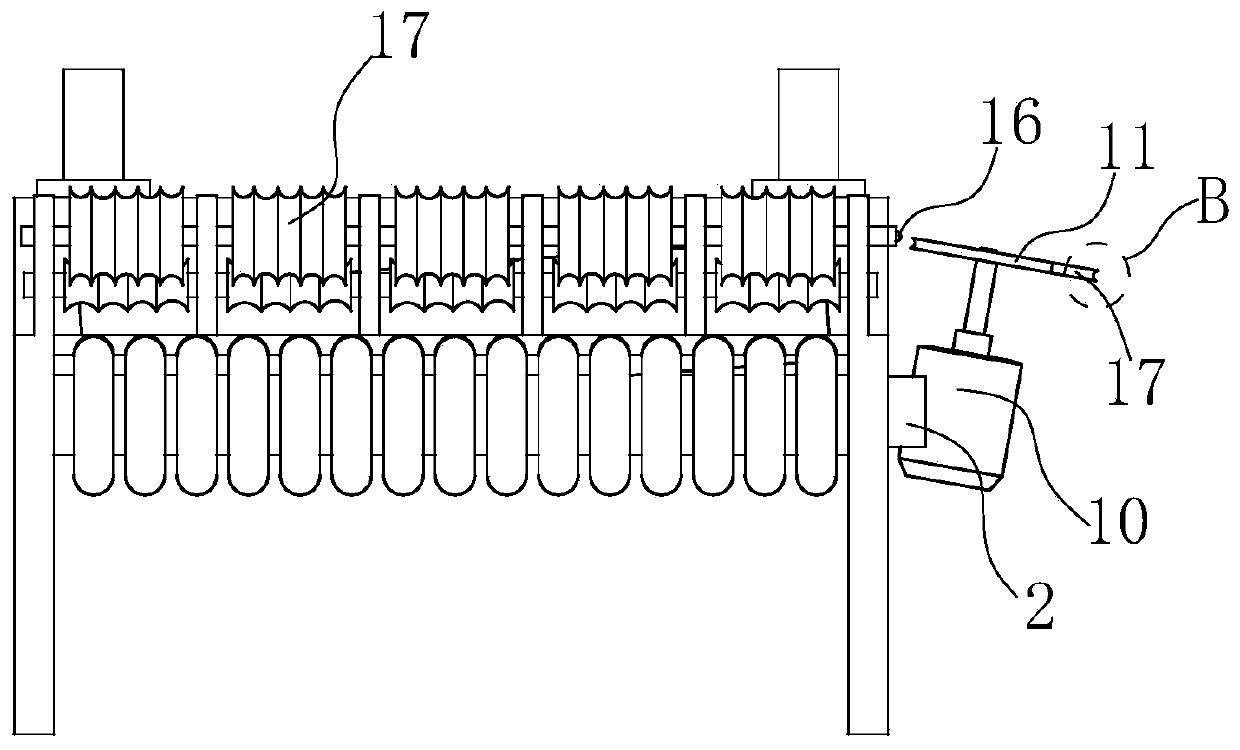

Multiple Diamond Beaded Wire Saw Machine and Its Cutting Process

InactiveCN106079106BReduce jitterAppropriate entry angleStone-like material working toolsDiamond wire sawEngineering

Owner:山东金瑞诺华兴机械有限公司

A punching and cutting compound drilling tool

ActiveCN113931576BImprove applicable working conditionsEasy to cut intoDrill bitsConstructionsPunchingMining engineering

The invention discloses a punching and cutting composite drilling tool, which relates to the field of drilling equipment and is mainly used to solve the problems of low working efficiency and high wear rate of the drill bit only relying on the rotation of the drill bit to break rocks. Its main structure includes a PDC drill bit and a percussion drill bit, and is characterized in that it also includes a percussion structure connected with the percussion drill bit. The punching and cutting composite drilling tool provided by the invention is suitable for various formations with different geological conditions, and has high construction efficiency and small wear of the drill bit.

Owner:SICHUAN DEEP & FAST OIL DRILLING TOOLS CO LTD

A plastic waste cutting and processing system

ActiveCN111086127BEasy to cut intoEfficient cuttingPlastic recyclingGrain treatmentsHydraulic cylinderPlastic waste

The invention discloses a plastic garbage cutting and processing system, which relates to the technical field of garbage recycling and processing, and comprises a base, the top of the base is provided with a support plate upright and fixed on the top of the base, and the top of the support plate is provided with a horizontally arranged Top plate, the top of the top plate is equipped with a hydraulic cylinder, the bottom end of the hydraulic cylinder protrudes downwards with a piston rod, the bottom end of the piston rod is fixed with a knife rest with a square plate structure, and the knife rest is horizontally fixed on bottom end of the piston rod. In the present invention, a shaft is arranged at the middle position of the bottom end of the garbage cutting box, and the second motor drives the groove wheel to drive the garbage cutting box to rotate, and the groove wheel makes the garbage cutting box rotate 90 degrees each time, so that the knife rest Extending down into the garbage cutting groove to cut plastic bottles and plastic airbags at different angles, improve the shredding efficiency of plastic bottles and plastic airbags, so that the fixed knife holder at the bottom of the knife holder can cut plastic bottles and plastic airbags produce effective cuts.

Owner:福建泉州业德弗科技有限公司

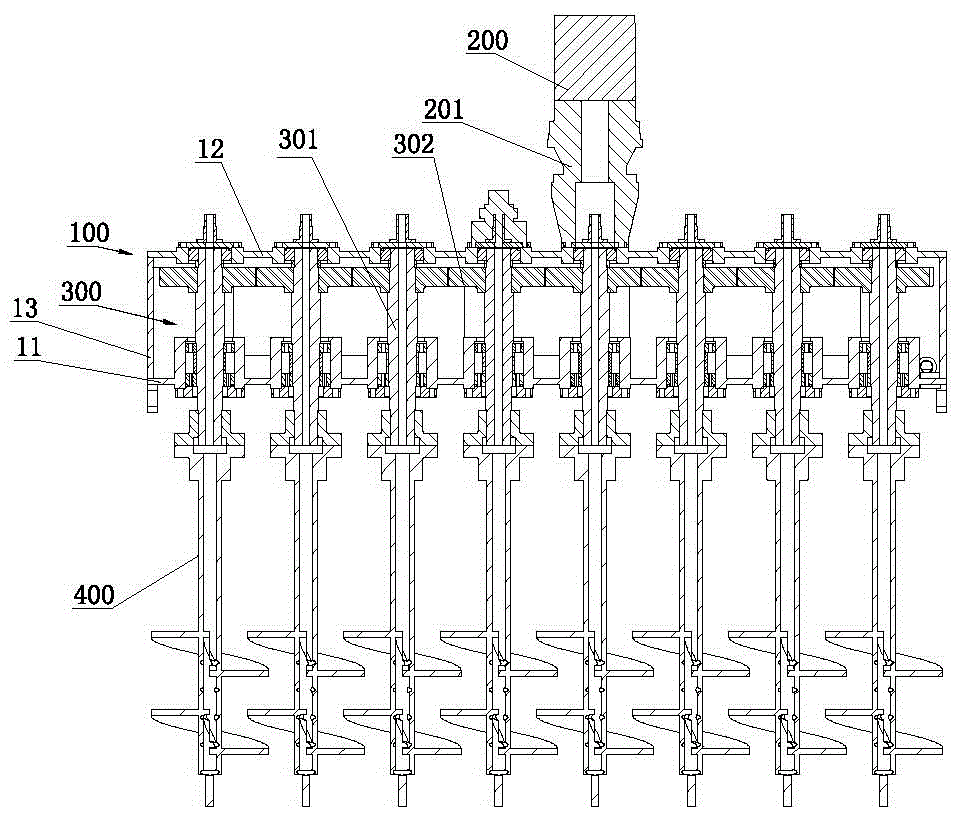

A plowing tool

The invention discloses a subsoiling and tilling knife tool. The subsoiling and tilling knife tool comprises a knife carrier, a spiral sheet is fixed on the knife carrier, knife blades are mounted on the spiral sheet, a first soil piercing knife blade is fixed at the lower end of the spiral sheet, and a second soil piercing knife blade is fixed at the lower end of the knife carrier; and the lower ends of the first and second soil piercing knife blades are lower than the bottom face of the knife carrier, an inclination angle of the first soil piercing knife blade and an inclination angle of the second soil piercing knife blade each is slightly greater than a spiral angle of the spiral sheet, crushing and leveling knife blades are arranged at the upper end of the knife carrier in a staggered manner, and each crushing and leveling knife blade has an insertion part, a first bent part and a second bent part. According to the subsoiling and tilling knife tool, due to the structure, the subsoiling and tilling knife tool can more easily pierce soil and is more uniformly stressed during soil piercing, so that leveling re-crushing for topsoil can be better carried out by using the knife tool.

Owner:GUANGXI WUFENG MACHINERY CO LTD

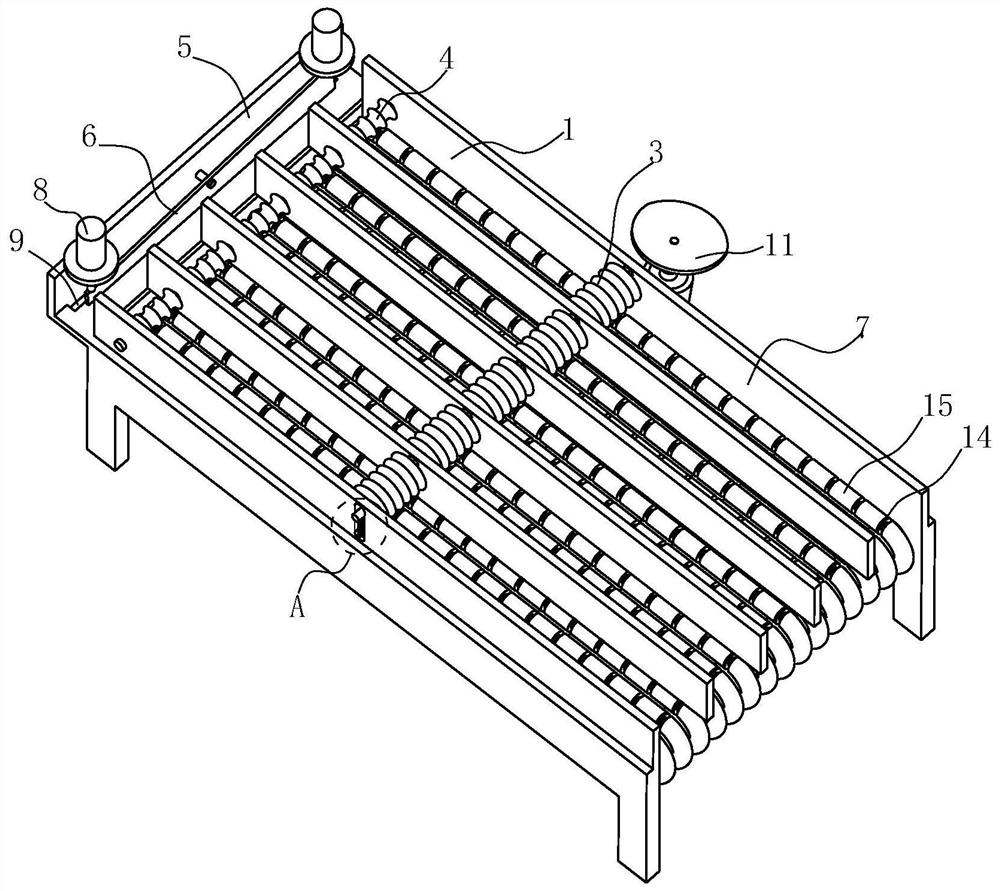

Evenly-spreading and slicing integrated equipment for cassia twigs and method

InactiveCN109702793AEasy to stagger each otherPave the wayMetal working apparatusCleaning processes and apparatusRolling resistanceEngineering

The invention relates to evenly-spreading and slicing integrated equipment for cassia twigs and a method, and belongs to the technical field of traditional Chinese medicine processing equipment. The equipment comprises a frame body; rollers are mounted on the frame body; pressing trimming wheels are mounted above the rollers; pressing wheels are mounted behind the pressing trimming wheels; a cutting platform is arranged at the back end of the frame body; a cutter is mounted on the cutting platform and is driven by driving components; ropes are wound around the outer sides of the rollers; rotatable rotating sleeves are strung on the ropes; side end plates are arranged on the left and right sides of the frame body; and both ends of the pressing trimming wheels and both ends of the pressing wheels are fixed to the side end plates on the corresponding sides. According to the equipment, the ropes are sleeved with the rotating sleeves, the rotating sleeves rotate under the lateral pressure of the cassia twigs, and the sliding friction force between the cassia twigs and the ropes is converted into the rolling friction force, so that the cassia twigs can be staggered easily under pressure,the cassia twigs making contact with the rotating sleeves are rotated to one side with relatively low stress, gaps are filled, and the cassia twigs are spread gradually.

Owner:亳州市爱开发网络科技有限公司

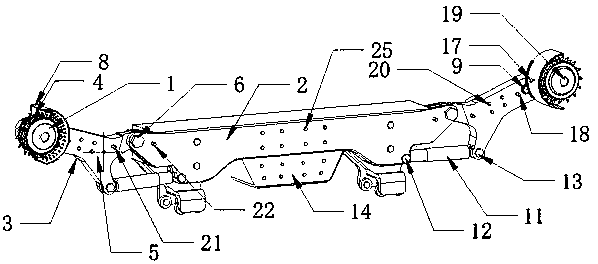

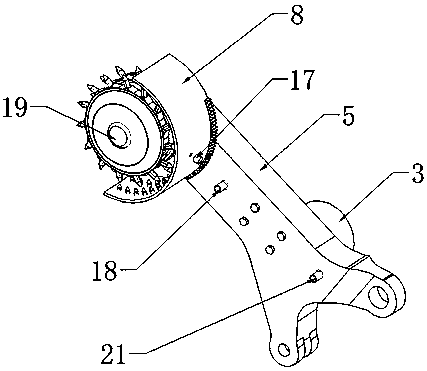

An Improved Coal Shearer

InactiveCN106089196BLower working temperatureExtended service lifeFluid-pressure actuator testingSlitting machinesHydraulic cylinderControl signal

The invention discloses an improved coal cutter. The improved coal cutter comprises rollers and a machine body. The rollers are located at the front end and the rear end of the machine body and connected to the machine body through supporting arms. The machine body is provided with hydraulic cylinders to control the lifting heights of the supporting arms. Force sensors are arranged in oil ways of the hydraulic cylinders and located in the machine body. Baffles are arranged between the rollers and the supporting arms. Blowholes are formed in the baffles. The baffles can swing in a certain angle range, and power is provided by gears located at the tail ends of stepping motors on the supporting arms. Driving motors at the tail ends of the supporting arms drive gearboxes to provide power for the rollers. A control cabinet and an air pump are arranged in the middle of the machine body. The control cabinet controls the operation process of the whole coal cutter and outputs control signals to motor achieving advancing and retracting. The coal cutter is reasonable in improvement.

Owner:南京同歌网络科技有限公司

Wax mould casting device and method

InactiveCN113275506AReduce resistanceReduce lossFoundry mouldsFoundry coresParaffin waxStructural engineering

The invention relates to a wax mold casting device and method. The wax mold casting device comprises a smelting chamber which comprises a feeding port, a mesh cutter arranged in the smelting chamber and a pressing block assembly; the mesh cutter comprises a plurality of blade units, the blade units are obliquely arranged, and a division gap is formed between every two adjacent blade units; and the pressing block assembly is arranged in the smelting chamber, a clamping space is formed between the pressing block assembly and the mesh cutter, the feeding port communicates with the clamping space, the face, facing the mesh cutter, of the pressing block assembly is a crushing pressing face, the pressing block assembly and the mesh cutter have a first state that the relative distance is gradually decreased and a second state that the relative distance is kept unchanged, and a movement path of the pressing block assembly and / or the mesh cutter is parallel to the blade units. Due to the fact that the blade units are obliquely arranged, the blade units can be more easily cut into paraffin plates, the resistance borne by the paraffin plates is reduced, the number of the paraffin plates attached to the mesh cutter is smaller, and therefore loss of the paraffin plates in the crushing process is reduced.

Owner:UNITED LASHING PRECISION CASTING

A Composite Reinforcement Method for Ancient Buildings with Wooden Structure Beam-column System

Owner:SOUTHWEAT UNIV OF SCI & TECH

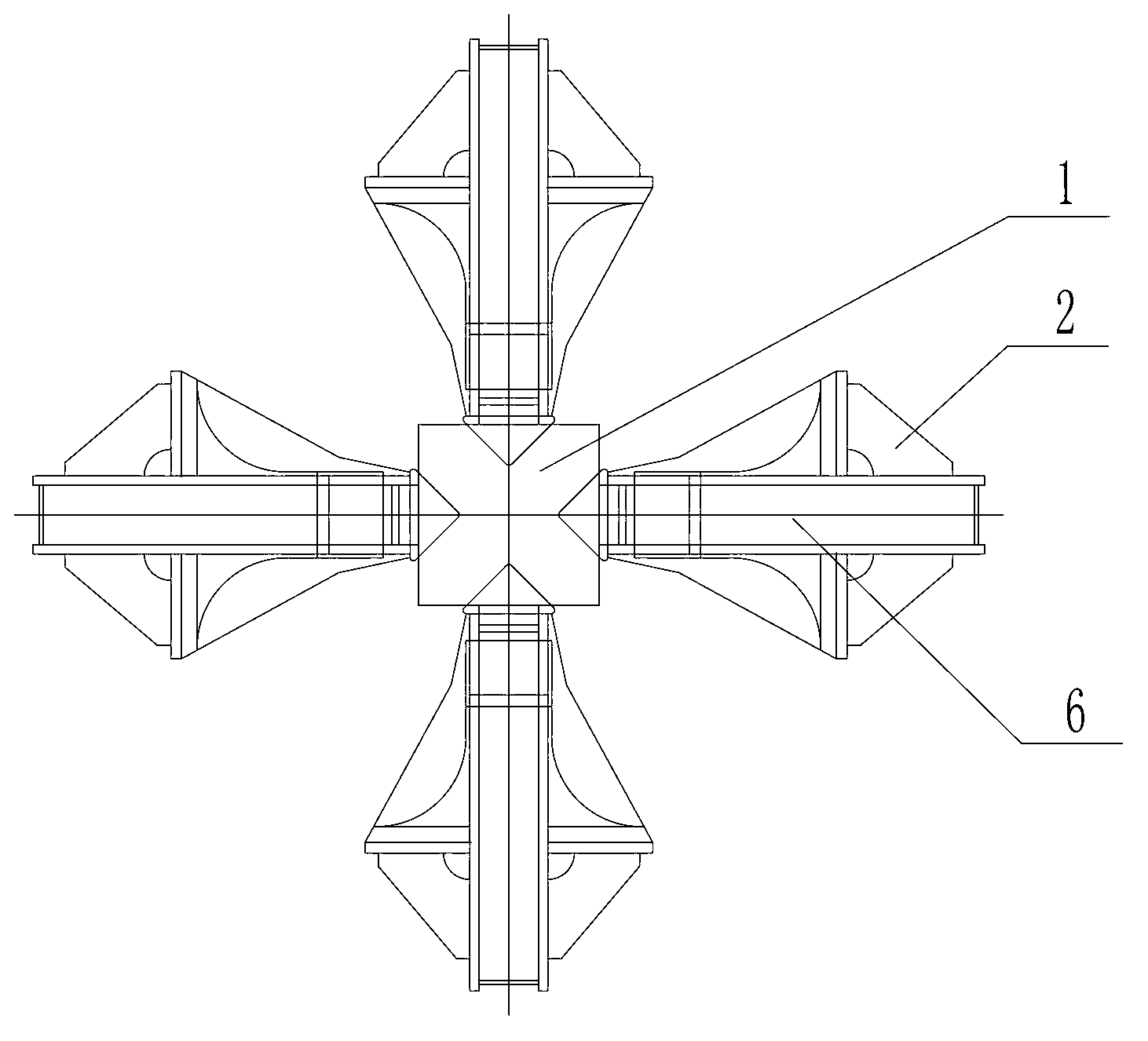

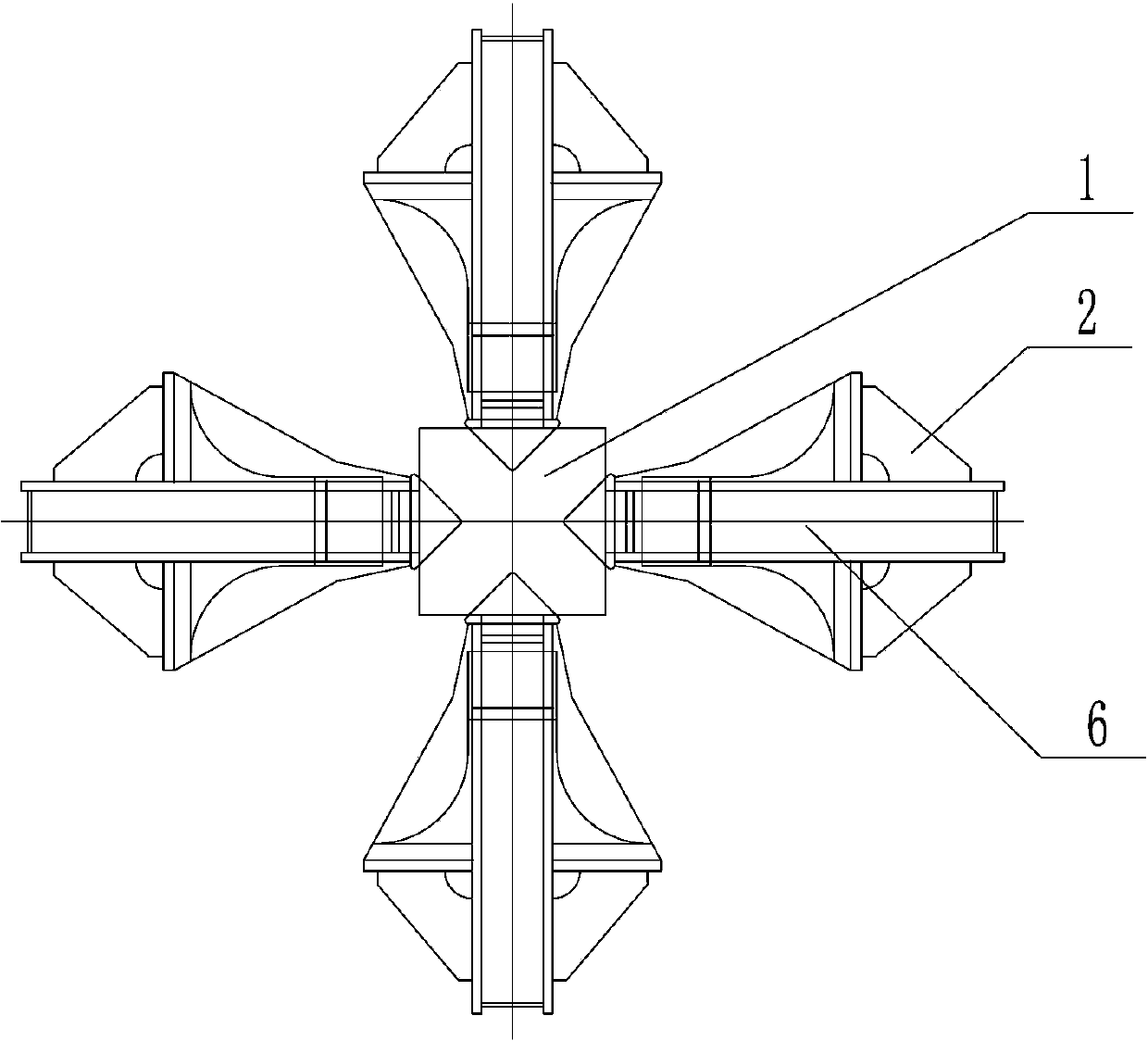

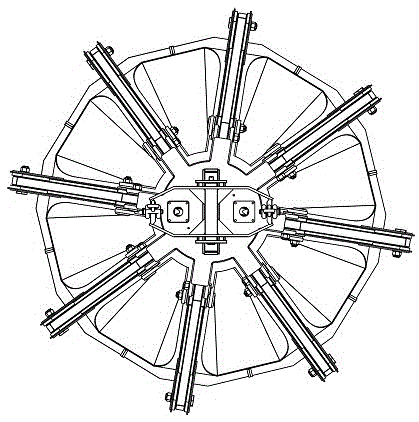

Four cables and eight petals nickel ore grab

The invention discloses a four-cable eight-piece nickel mineral grab bucket which comprises eight bucket flaps, wherein the bucket flaps are connected with support rods; the upper ends of the support rods are rotatably connected with an upper bearing beam through pin rolls; the upper bearing beam is arranged on a track cable balancing stand; a fixed pulley group is arranged on the upper bearing beam; the upper ends of the bucket flaps are hinged to a lower bearing beam; a movable block group is arranged on the lower bearing beam; the fixed pulley group is connected with the movable block group through a connecting component; the bucket flaps are combined to form a closable entirety; each bucket flap is connected with the upper bearing beam through a corresponding support rod, and is hinged to the lower bearing beam. According to the invention, the number of the bucket flaps is changed into eight, so that the stability of the entire grab bucket is higher, and the appearance is more symmetrical; according to the top view of the entire grab bucket, the bucket flap integrity is a hexadecagon and similar to a circle, so that the strength of a single bucket flap is increased, and the actual contact range between a material and each bucket flap is reduced so as to reduce the bucket flap bonding area.

Owner:上海佩纳沙士吉打机械有限公司

Integrated equipment and method for cassia twig evenly spreading and slicing

InactiveCN109702793BEasy to stagger each otherPave the wayMetal working apparatusCleaning processes and apparatusEngineeringMechanical engineering

The invention relates to an integrated equipment and method for cassia twig evenly spreading and slicing, and belongs to the technical field of traditional Chinese medicine processing equipment. Wheel, the rear end of the frame body is provided with a cutting table, a cutter is installed on the cutting table, and the cutter is driven by a driving part; a rope is wound on the outside of the roller, and a rotatable sleeve is strung on the rope; the frame body Side end plates are provided on the left and right sides of the wheel, and the two ends of the pressing wheel and the pressing wheel are respectively fixed on the side end plates on the corresponding sides. The present invention sets a rotary sleeve on the rope, and the rotary sleeve rotates when receiving the lateral pressure of the cassia twigs, and converts the sliding friction force between the cinnamon twigs and the rope into a rolling friction force, so that the cinnamon twigs can easily interact with each other when they are pressed. Stagger, turn the osmanthus twigs that are in contact with the rotating sleeve to the side where the force is less, fill the gaps, and gradually pave the osmanthus twigs flat.

Owner:亳州市爱开发网络科技有限公司

polisher

ActiveCN110893576BTrim thicknessIncrease pressureGrinding carriagesPolishing machinesPolishingEngineering

Owner:DONGXU OPTOELECTRONICS TECH CO LTD

A kind of wave edge end milling cutter

ActiveCN108723453BHigh strengthIncreased durabilityMilling cuttersMilling cutting insertsTool bitRough surface

The invention discloses a wave-edge end mill comprising a mill body. An end edge front mill surface is arranged at the end portion of a mill head, auxiliary cutting edges are formed by intersection ofthe end edge front mill surface and an end edge rear mill surface, the edge shape of the auxiliary cutting edges is a sine curve, and peaks and valleys of the adjacent auxiliary cutting edges are staggered. The mill head is provided with a mill point part which is provided with a mill point edge, and a mill body chamfer is arranged at the end portion of the mill body and is 45 degrees. A specialmill clamp is used for machining the end edge rear mill surface into a wavy surface, so that the end edge rear mill surface and the end edge front mill surface intersect to form the wavy auxiliary cutting edges; the mill point strength is high, the speed of cutting off workpiece blank machining allowance is increased, and on the premise that the mill rigidity and strength are ensured, the cuttingprocess is stable, cutting is fast, vibration is low, chip discharging is smooth, and the metal removing rate is high; and the wave-edge end mill is more suitable for rough milling machining and especially suitable for milling and gas cutting of steel plates and other workpieces with rough surfaces, so that large-feeding cutting is achieved.

Owner:西安昂达机电科技有限公司

Integrated equipment and method for cassia twig evenly spreading and slicing

ActiveCN107984525BEasy to stagger each otherPave the wayMetal working apparatusCleaning processes and apparatusRolling resistanceEngineering

The invention discloses a uniform laying and slicing integrated device for cassia twigs and a method and belongs to the technical field of traditional Chinese medicine processing devices. The device comprises a frame body which is provided with rolling wheels; pressing and trimming wheels are installed above the rolling wheels; pressing wheels are installed behind the pressing and trimming wheels;a cutting table is arranged at the rear end of the frame body, and is provided with a cutter; the cutter is driven by driving parts; ropes are wound on the outer sides of the rolling wheels, and rotatable rotating sleeves are arranged on the ropes in a stringing manner; the left side and the right side of the frame body are each provided with a side end plate; and the two ends of each pressing and trimming wheel and the two ends of each pressing wheel are both fixed to the side end plates on the corresponding sides. According to the uniform laying and slicing integrated device for the cassiatwigs, the ropes are sleeved with the rotating sleeves, the rotating sleeves rotate when bearing the lateral pressure of the cassia twigs, the sliding friction force between the cassia twigs and the ropes is converted into the rolling friction force, so that when the cassia twigs are pressed, the cassia twigs can be easily staggered from one another, the cassia twigs making contact with the rotating sleeves are rotated to the side where stress is small, filling is performed on gaps, and therefore the cassia twigs can be gradually laid flatly.

Owner:亳州市爱开发网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com