Ring type consolidated diamond scroll saw cutting device and workpiece cutting method

A technology of diamond wire saws and cutting devices, which is applied in the direction of working accessories, stone processing equipment, fine working devices, etc., can solve the problems of wire saw wire instability, processing efficiency and processing quality decline, etc., to reduce difficulty and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

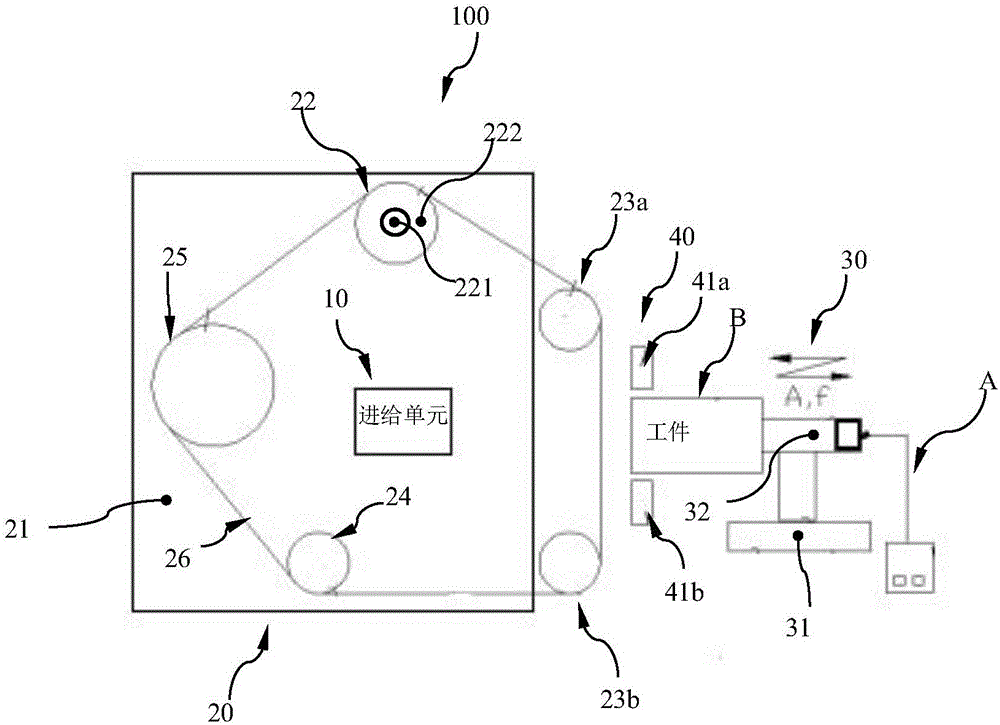

[0031] figure 1 It is a schematic structural diagram of a ring-type consolidated diamond wire saw cutting device according to an embodiment of the present invention.

[0032] The ring-type consolidated diamond wire saw cutting device 100 includes a mounting base (not shown in the figure), a feeding unit 10 , a wire saw unit 20 , a workpiece fixing unit 30 , a magnetic force unit 40 and a control unit.

[0033] The feeding unit 10 is arranged on the installation base, and is used to drive the wire saw unit 10 to move for feeding movement. In this embodiment, an existing X-Y moving platform is selected, and the X-Y moving platform has a movable part.

[0034] The wire saw unit 20 has a frame 21, a driving mechanism 22, two guide wheels 23a and 23b, a tension wheel 24, a wire storage drum 25, and a wire saw wire 26 surrounding the above components and forming a closed loop.

[0035] The frame 21 is fixed on the moving part of the X-Y moving platform by bolts.

[0036] The drivi...

Embodiment 2

[0055] Workpiece cutting method

[0056] Here we take a general wire saw to cut silicon crystal as an example for illustration. It consists of the following two steps:

[0057] Step 1: After connecting the silicon crystal workpiece with the horn, fix the horn on the workbench of the wire saw through the clamp, and connect the horn with the ultrasonic vibration device. In this embodiment, the workpiece is made of silicon crystal, and it can also be other Hard and brittle materials include gemstones, glass, silicon crystals, ceramics, etc.

[0058] Step 2: Set the relative position between the wire saw and the workpiece, fix the two electromagnets of the magnetic unit to the outlet and inlet ends of the wire saw wire cutting part, turn on the ultrasonic vibration device and the wire saw, and adjust the electromagnets respectively The distance from the wire saw wire and the position of the electromagnet, and the frequency and amplitude parameters of the appropriate ultrasonic v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com