Multiple Diamond Beaded Wire Saw Machine and Its Cutting Process

A technology of diamond beading and beading rope, applied in the field of cutting process and multiple diamond beaded wire saw machines, can solve the problems affecting the quality of the cutting plate and the life of the equipment, the poor rigidity of the independent tensioning wheel, and the large number of tensioning mechanisms. , to achieve the effect of improving the quality of the cutting board and the life of the equipment, improving the quality of the cutting board and improving the cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by specific embodiment and in conjunction with accompanying drawing, the present invention will be further described:

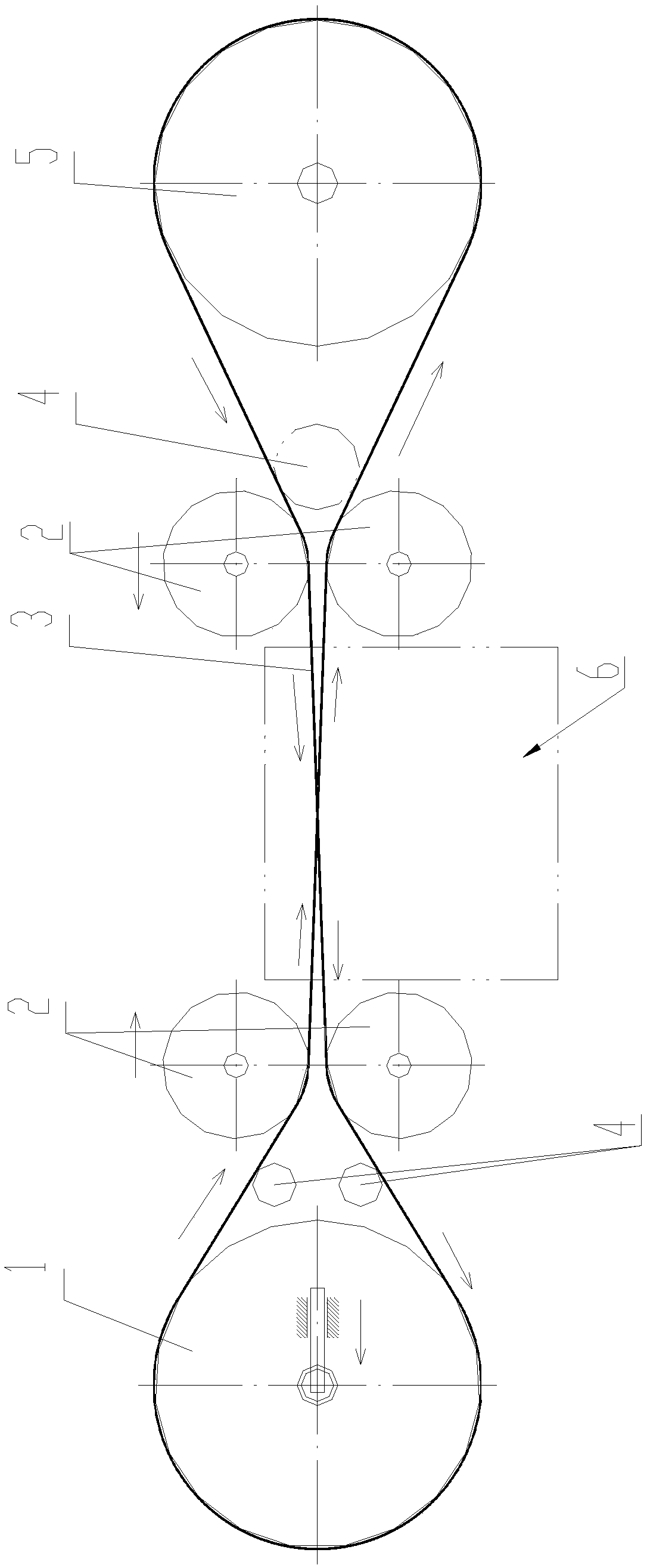

[0017] As shown in the figure, a multi-diamond beaded wire saw machine includes a driving wheel 5, a tensioner wheel 1, a plurality of closed ring-shaped diamond beaded wires 3, four positioning wheels 2, and several guide wheels 4. Wherein, the driving pulley 5 and the tension pulley 1 are respectively located at the outermost sides of the left and right sides. Each diamond beaded rope 3 is installed between the driving wheel 5 and the tensioning wheel 1 in a ∞ shape, that is, the saw rope on the driving wheel 5 bypasses from the bottom of the tensioning wheel 1 to the top of the tensioning wheel 1, Then reach the bottom of the driving pulley 5 from the top of the tensioning pulley 1 and walk around the driving pulley 5 to form a ∞ font. The four positioning wheels 2 are divided into two groups of left and right, each group has two positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com