Patents

Literature

39results about How to "Reduce heat treatment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

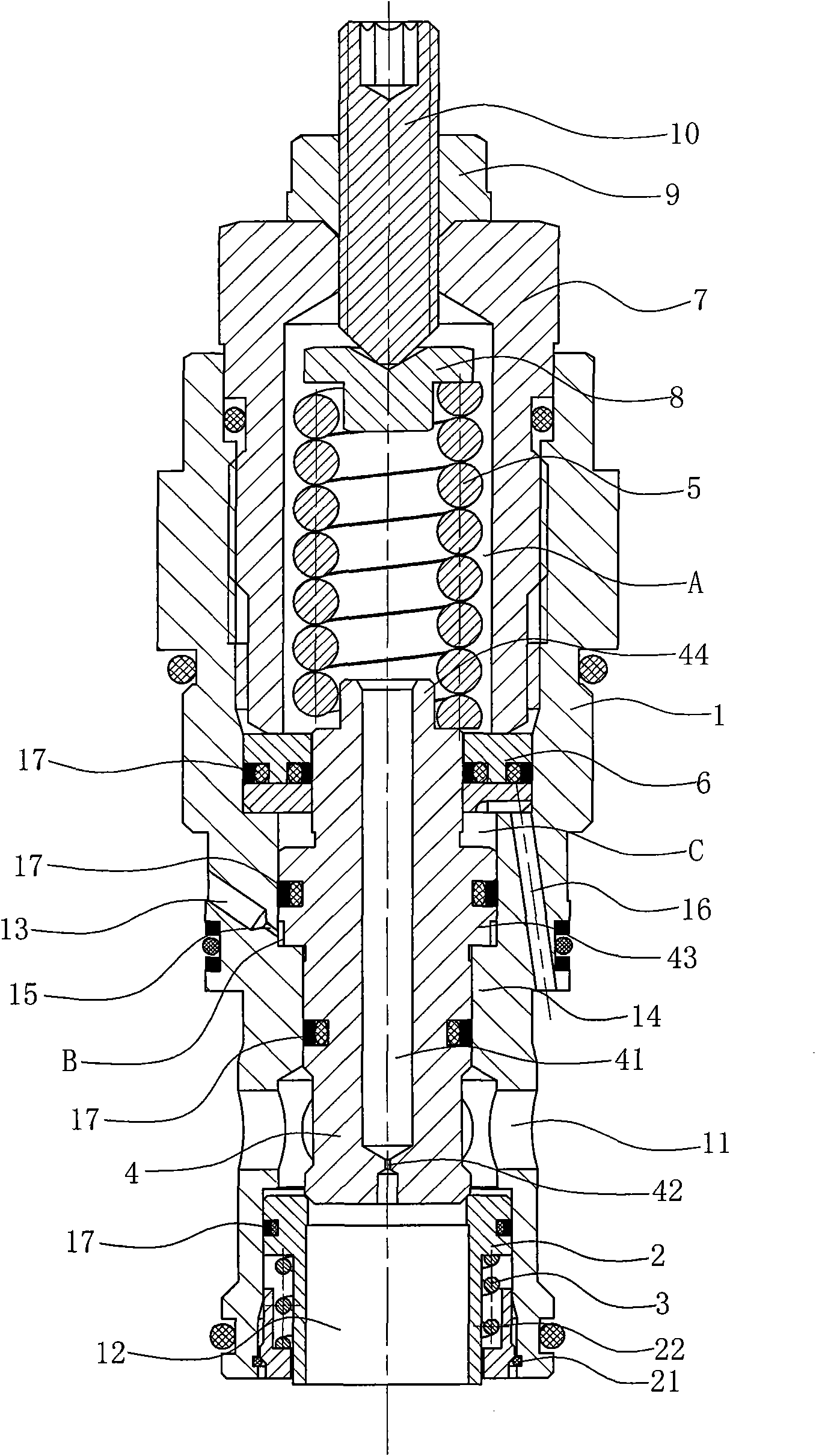

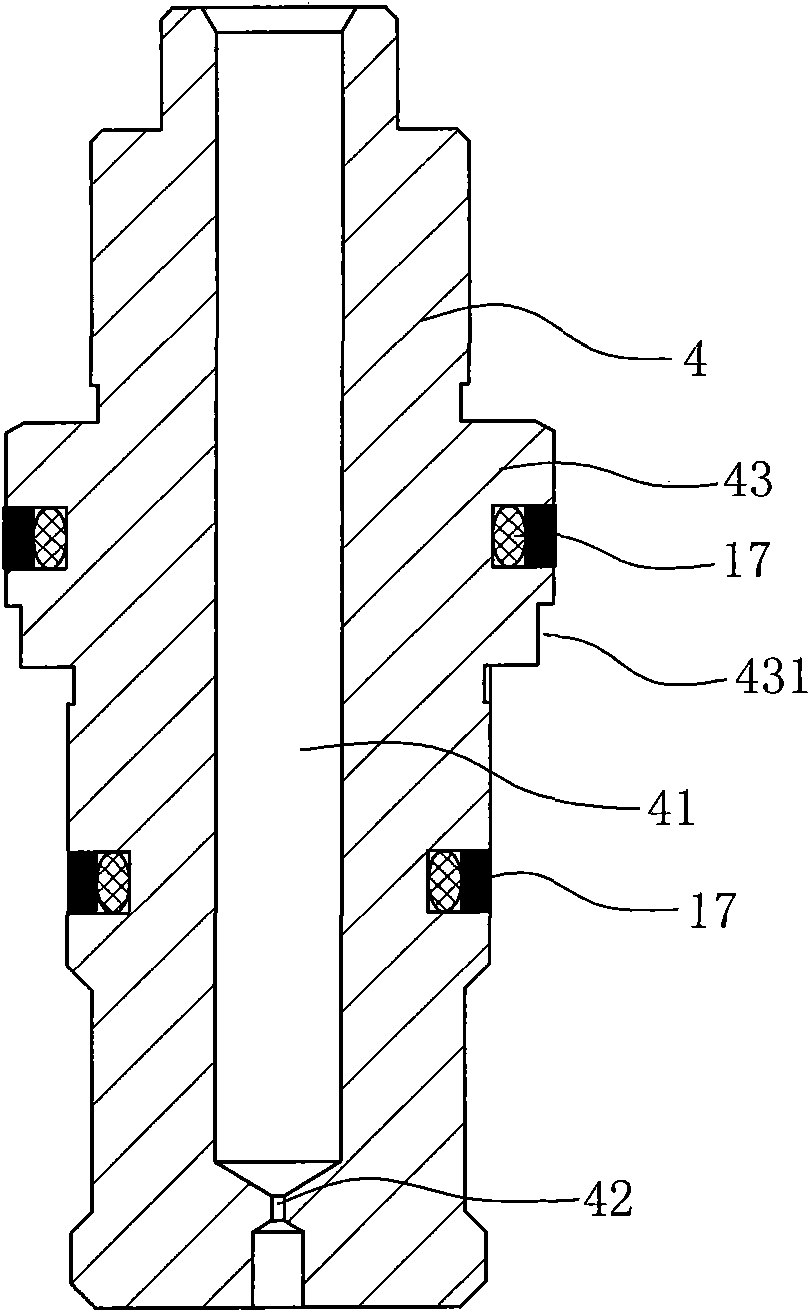

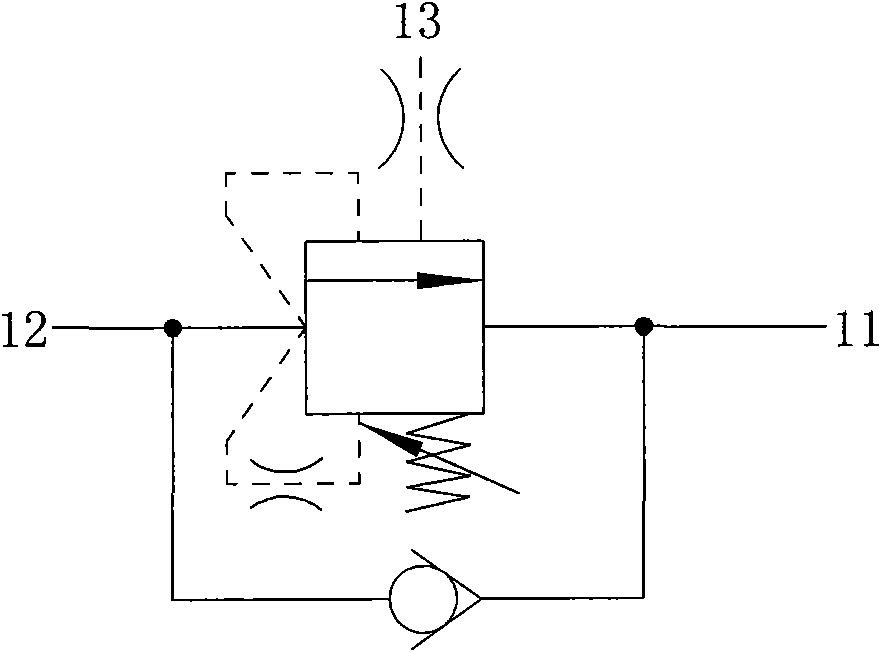

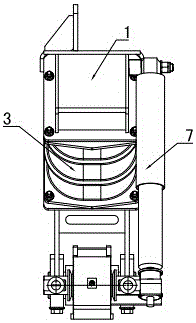

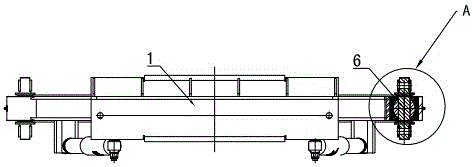

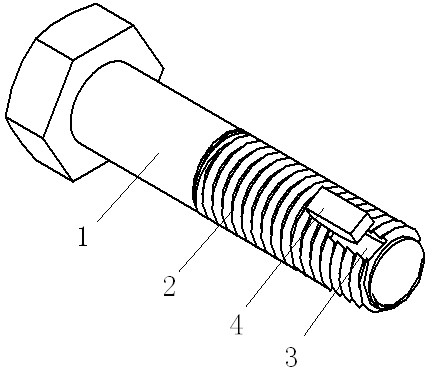

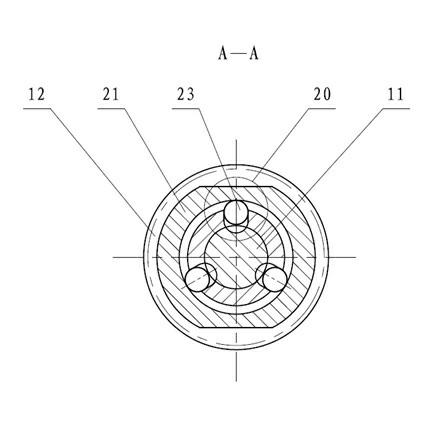

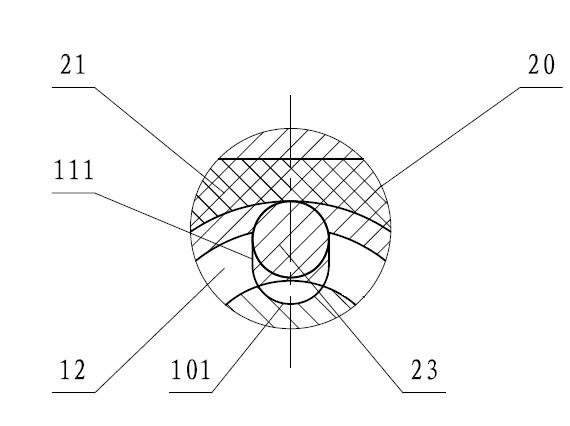

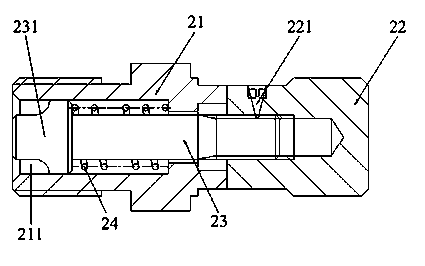

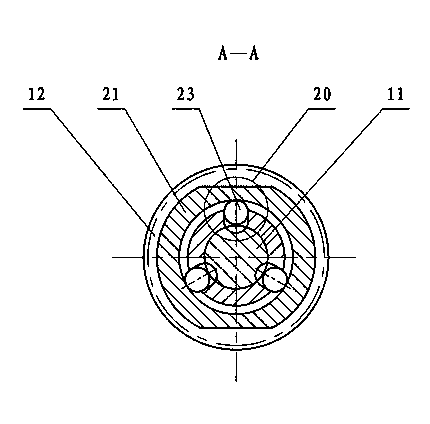

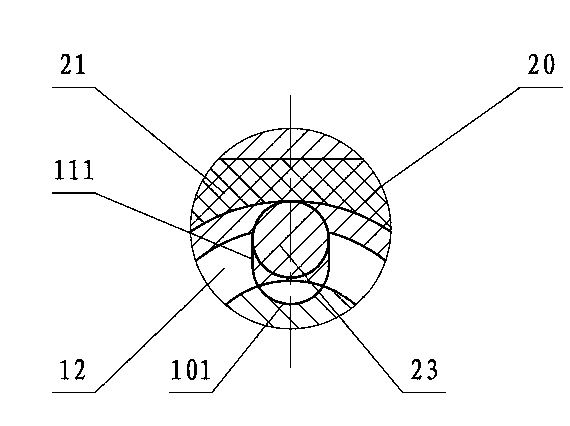

Plug-in type balance valve

InactiveCN101634317AReduce heat treatment requirementsReduce material requirementsServomotor componentsShoulder BladesThermal treatment

The invention relates to a plug-in type balance valve which comprises a valve body, a one-way valve core and a balance valve core, wherein a first oil opening, a second oil opening and a third oil opening are arranged on the valve body; the one-way valve core is arranged at the second oil opening and pushed by a first spring to maintain the trend of axial upward shift; the balance valve core is installed in the valve body and can be matched with a valve opening of the one-way valve core, and a second spring is arranged in a spring cavity of the valve body; the upper part in the balance valve core is provided with an axial passage and a first damping hole; the middle position of the balance valve core is provided with an axial convex shoulder; an annular notch is arranged on the periphery surface of the axial convex shoulder; the inner wall of the valve body is provided with an annular inner shoulder blade; an oil inlet cavity is formed among the annular notch, the inner wall of the valve body and the annular inner shoulder blade; and the third oil opening is communicated with the oil inlet cavity by a second damping hole on the side wall of the valve wall. The balance valve core and the one-way valve core are in an integral structure, and the structure is simple; the balance valve core and the one-way valve core are relatively independent on the relative position relationship, the assembly is convenient, and the requirements on heat treatment and materials of the balance valve core are lowered.

Owner:NINGBO HANSHANG HYDRAULIC

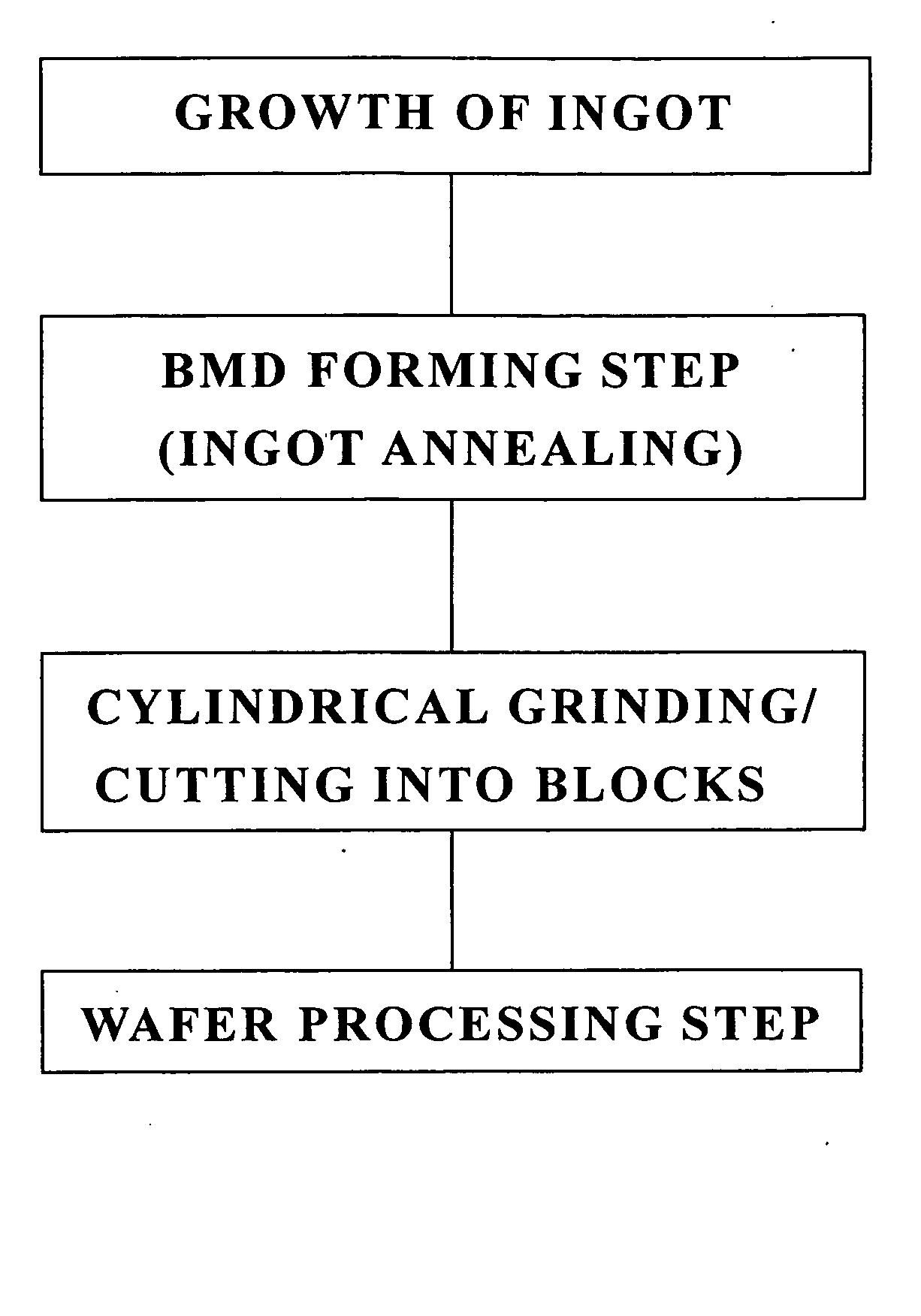

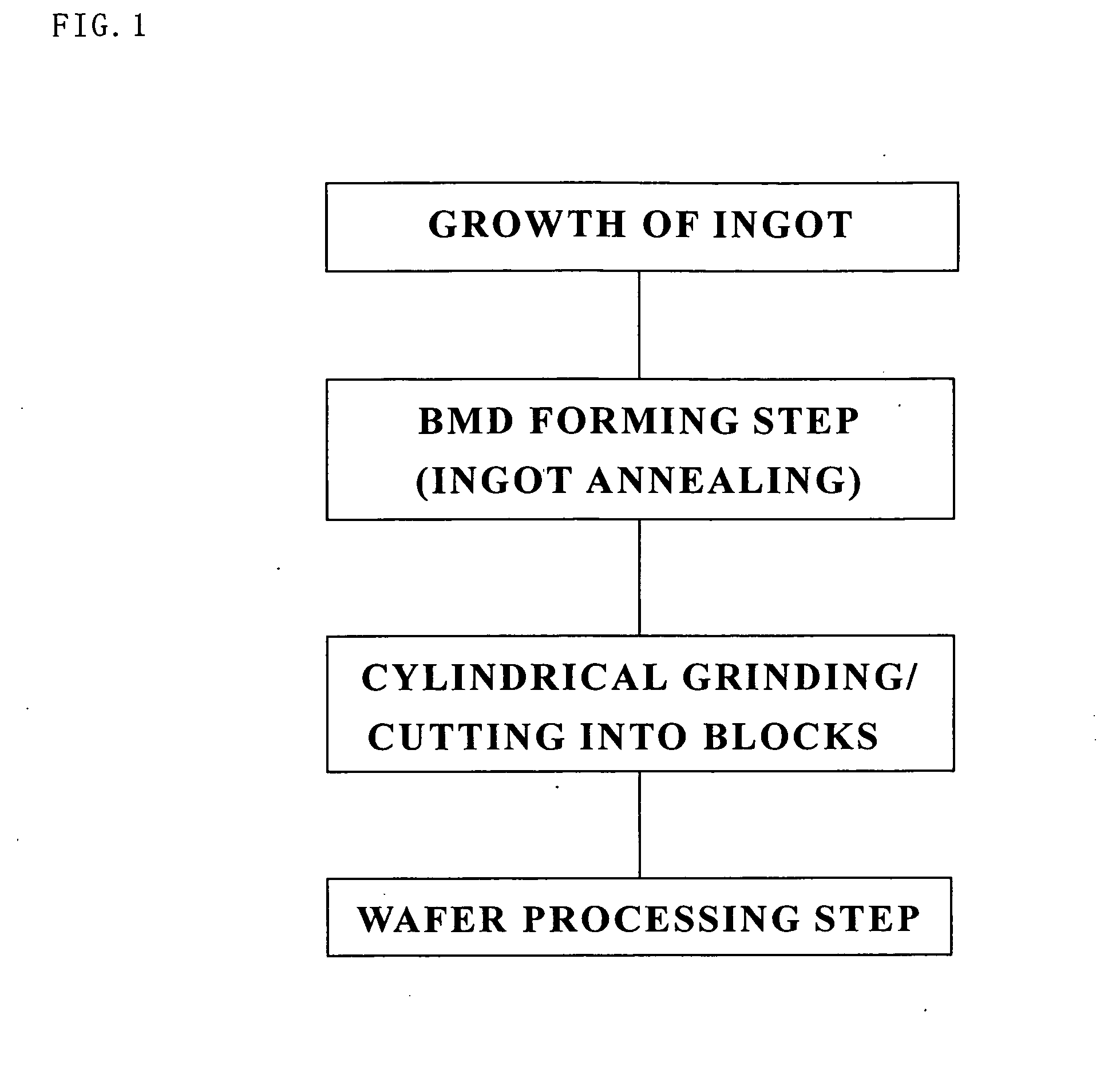

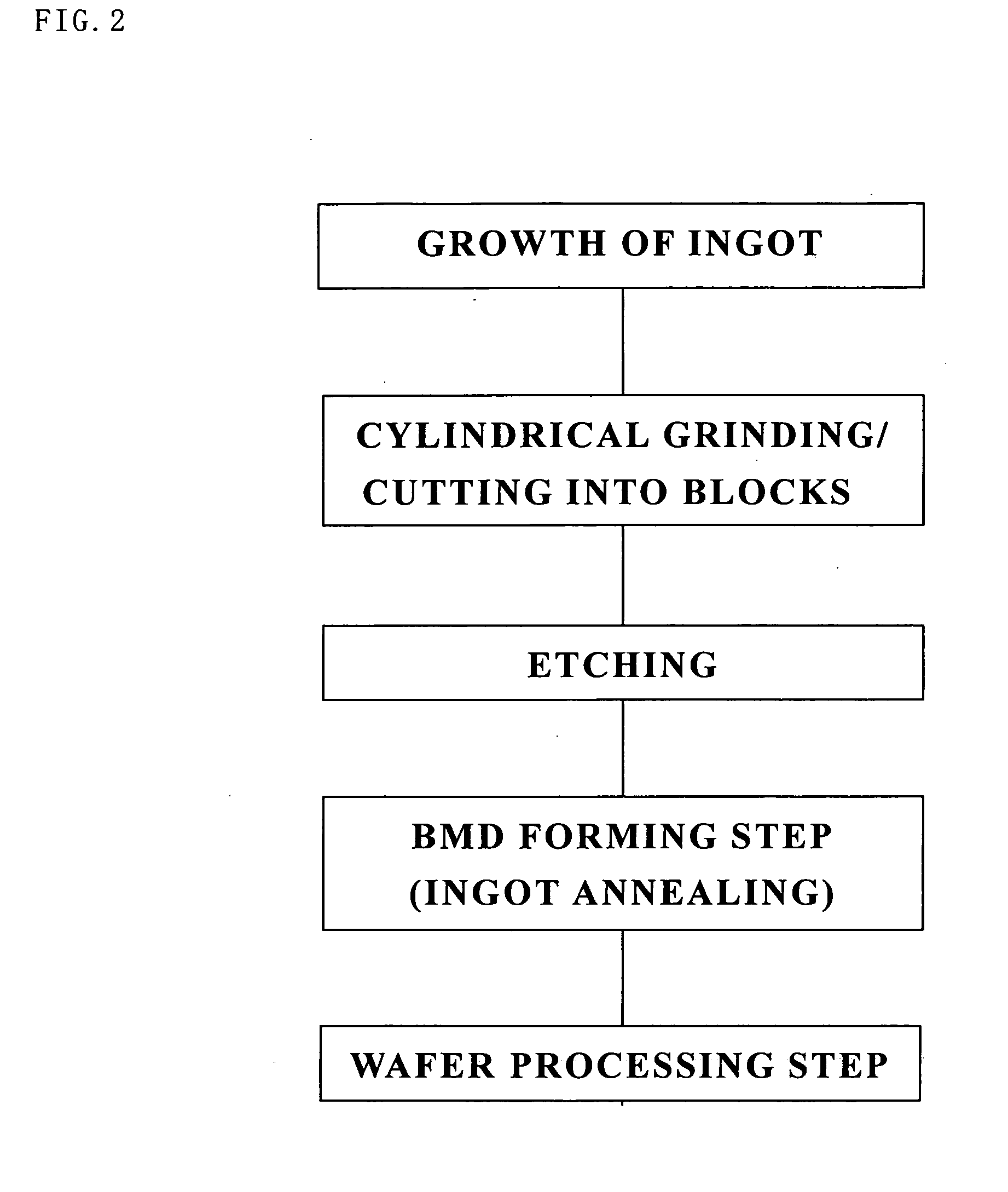

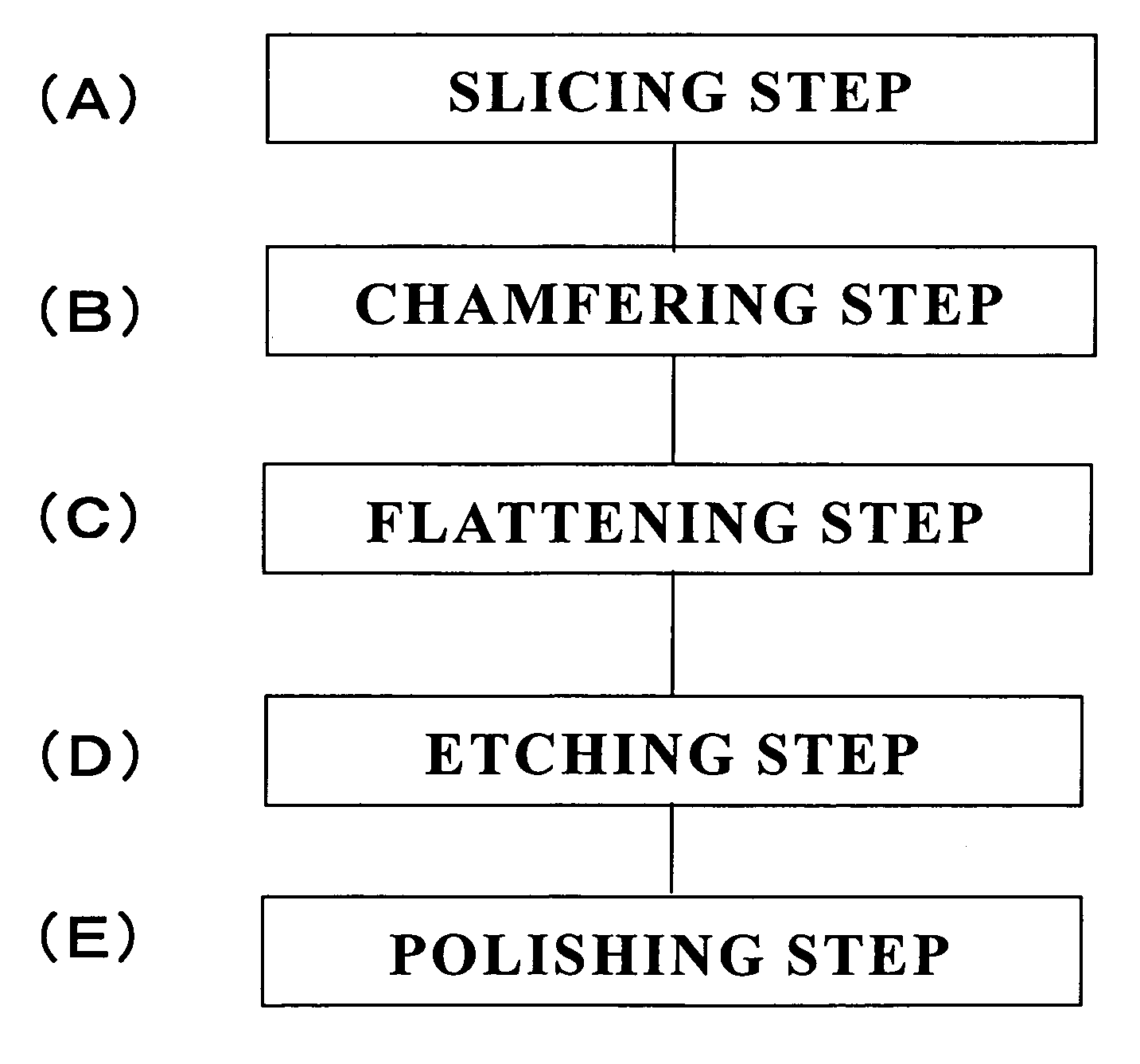

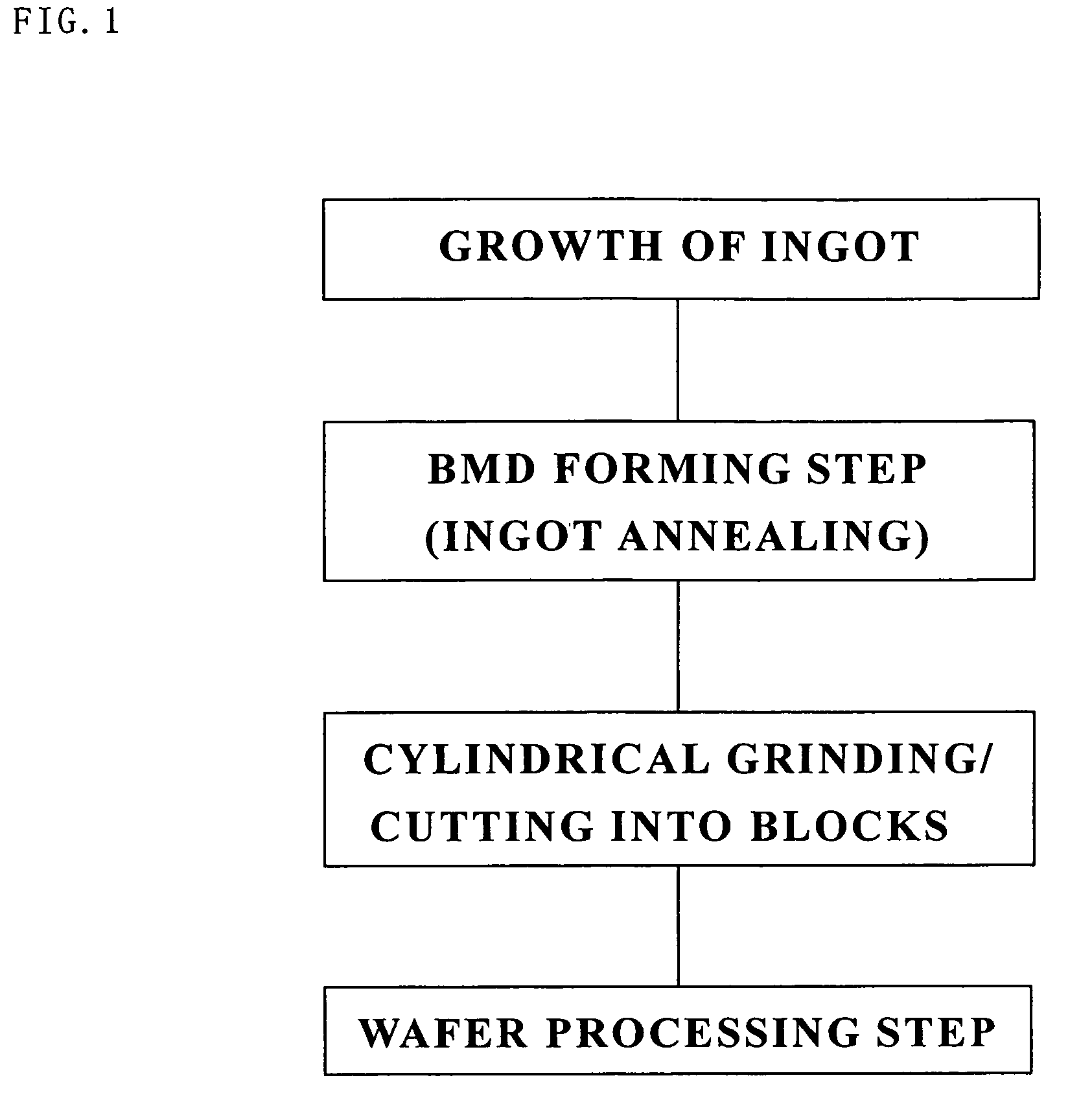

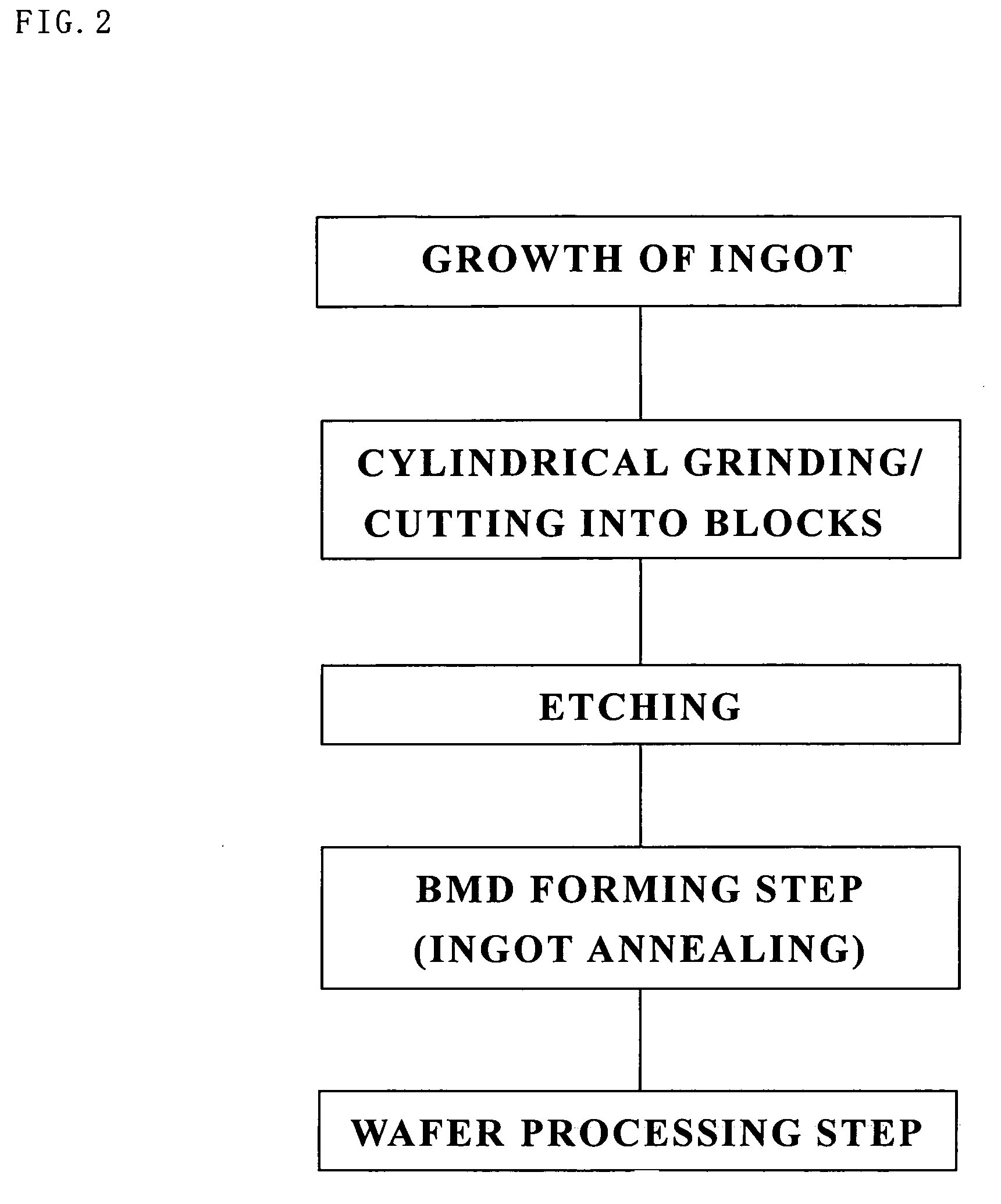

Method for producing a wafer

InactiveUS20060150894A1Improve abilitiesAvoid small quantitiesPolycrystalline material growthAfter-treatment detailsProduction rateWafering

The present invention is a method for producing a wafer comprising, at least, a BMD forming step of subjecting a silicon single crystal in a state of an ingot to heat treatment thereby to form bulk micro defects (BMDs) inside, and a wafer processing step of processing the ingot in which the bulk micro defects (BMDs) was formed into wafers. Thereby, there can be provided a method for producing a wafer, wherein heat treatment for providing IG capability in production of wafer can be shortened and wafers with high IG capability can be produced in large quantity. Also, the present invention can further comprise a wafer heat-treating step of subjecting the processed wafer to heat treatment, or an epitaxial growth step of forming an epitaxial layer on the wafer. Thereby, there is improved productivity of annealed wafers or epitaxial wafers that are excellent in gettering capability.

Owner:SHIN-ETSU HANDOTAI CO LTD

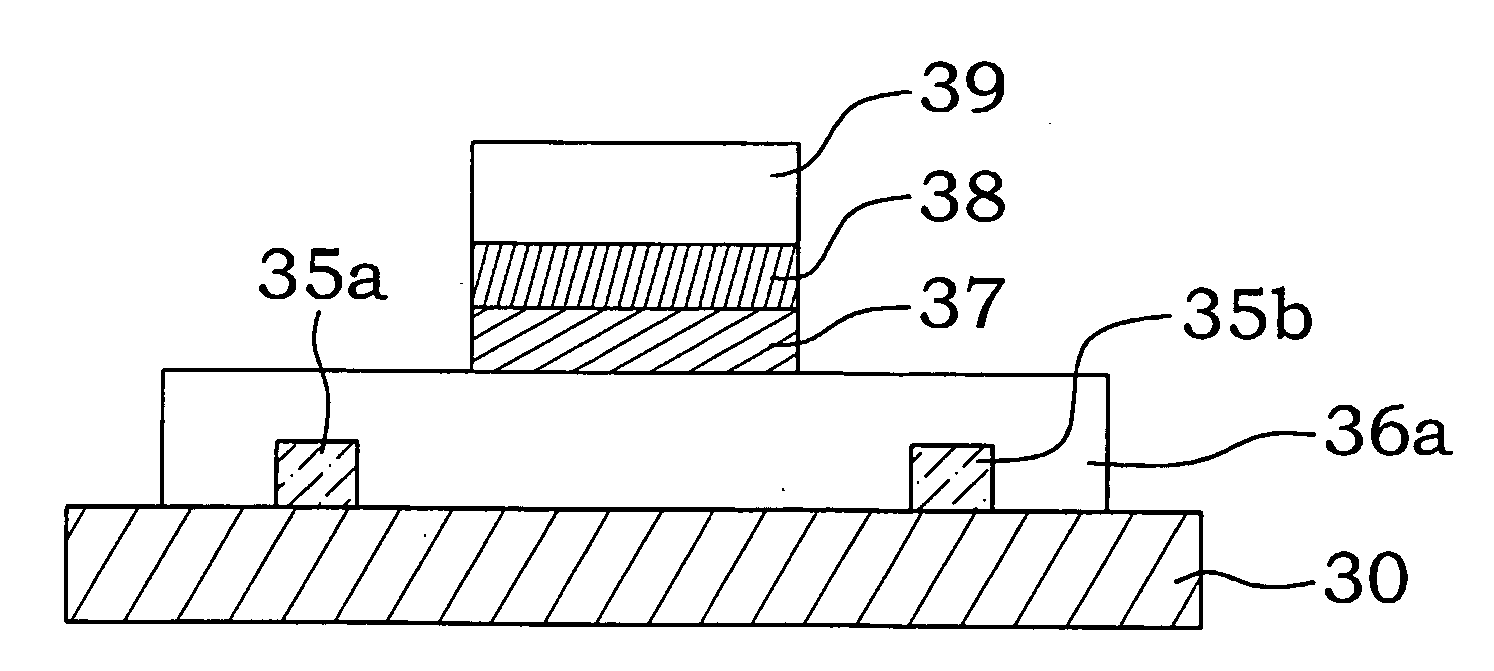

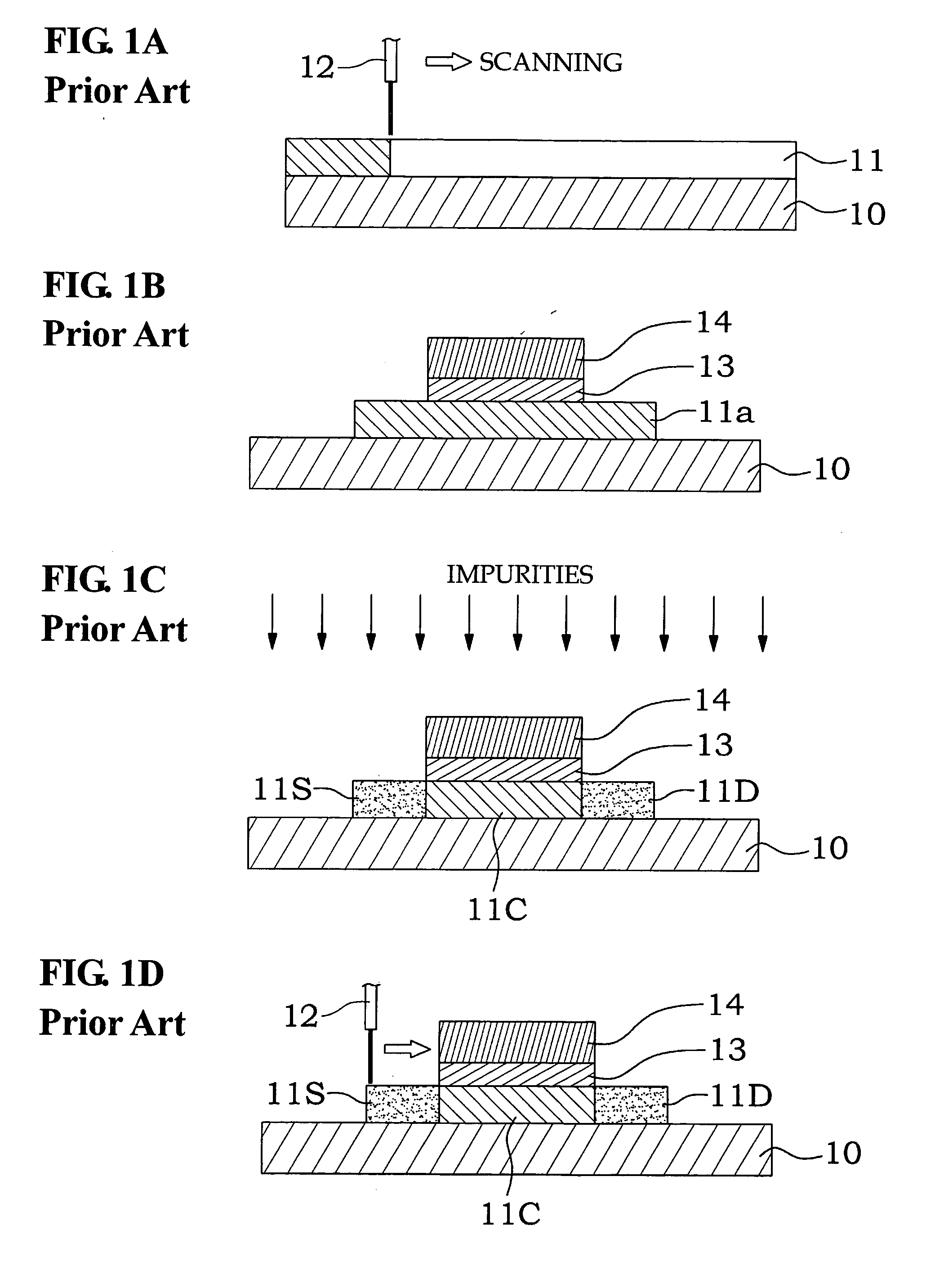

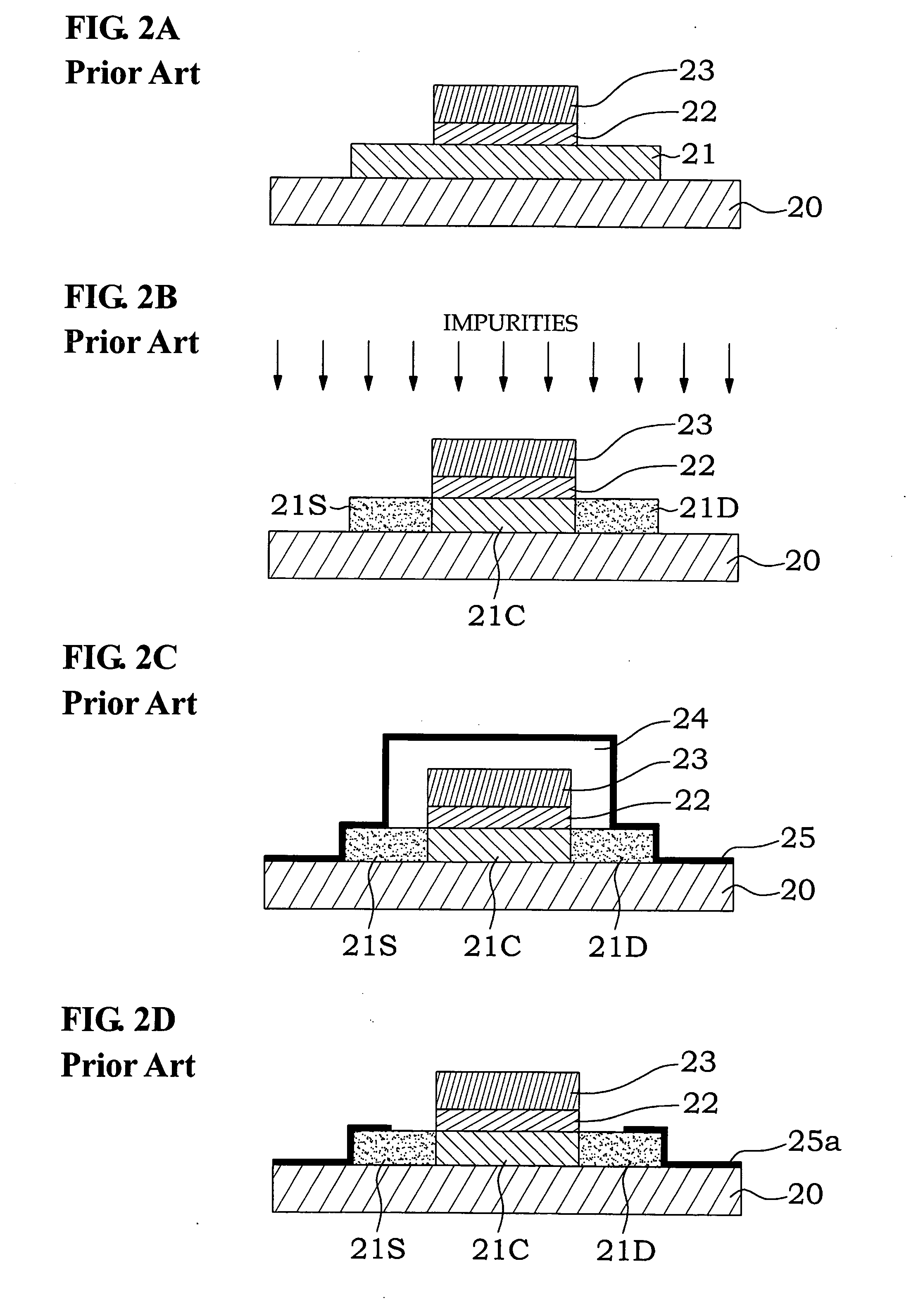

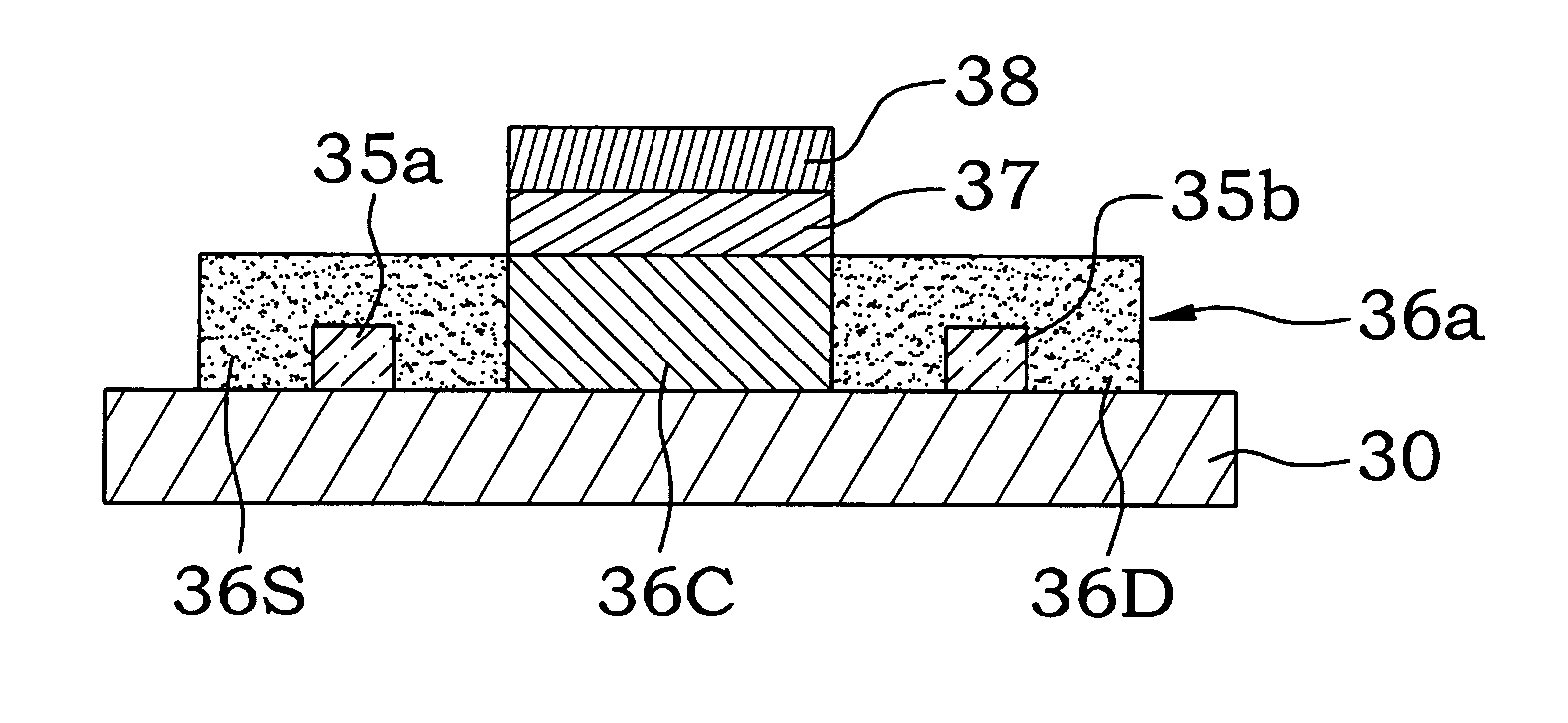

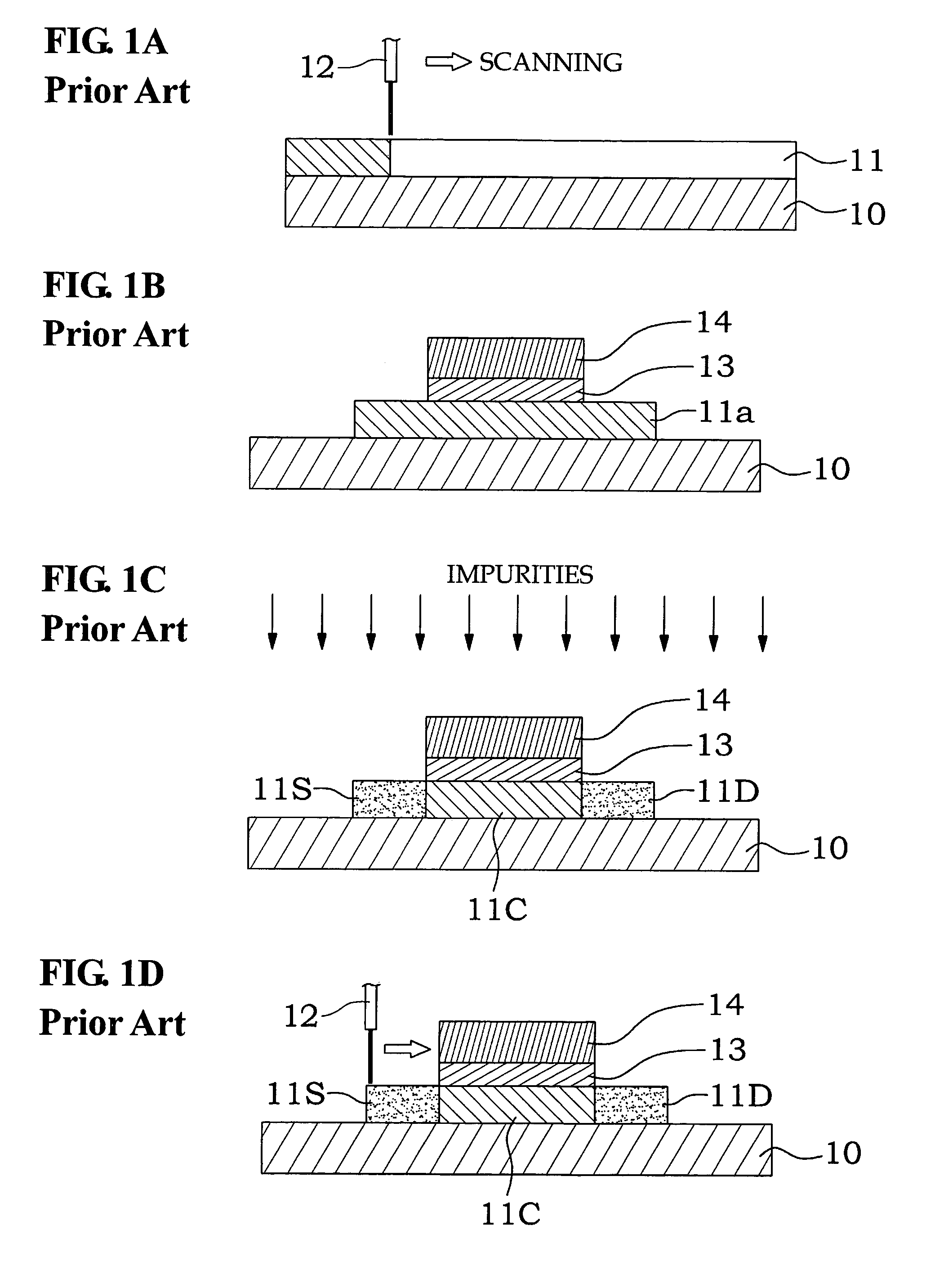

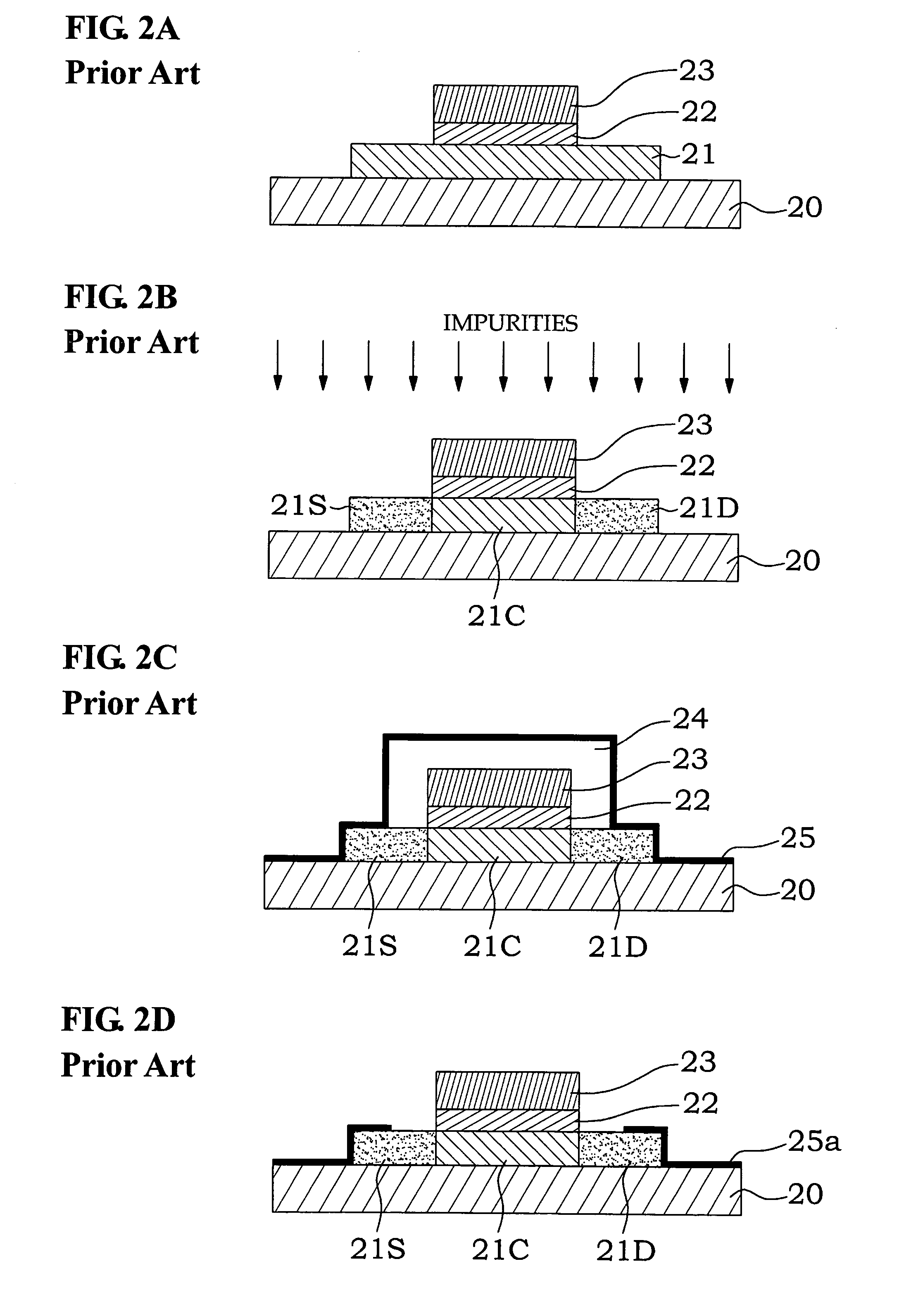

Method for crystallizing amorphous semiconductor thin film by epitaxial growth using non-metal seed and method for fabricating poly-crystalline thin film transistor using the same

InactiveUS20060270129A1Improve featuresEliminate pollutionSolid-state devicesSemiconductor/solid-state device manufacturingSeed crystalSemiconductor thin films

A method for crystallizing an amorphous semiconductor thin film using a non-metal seed epitaxial growth (NSEG) is provided. The method includes the steps of: forming a pair of non-metal seeds for inducing a crystallization of an amorphous semiconductor thin film at a predetermined distance on a transparent insulation substrate; depositing the amorphous semiconductor thin film on the insulation substrate; and heat-treating the insulation substrate to thereby epitaxially grow a poly-crystalline semiconductor thin film from the non-metal seeds, and to thus crystallize the amorphous semiconductor thin film. In the crystallization method, non-metal seeds are used instead of using crystallization induced metal to thereby epitaxially grow the poly-crystalline semiconductor thin film and to thus realize the amorphous semiconductor thin film without having metal pollution.

Owner:PAIK WOON SUH

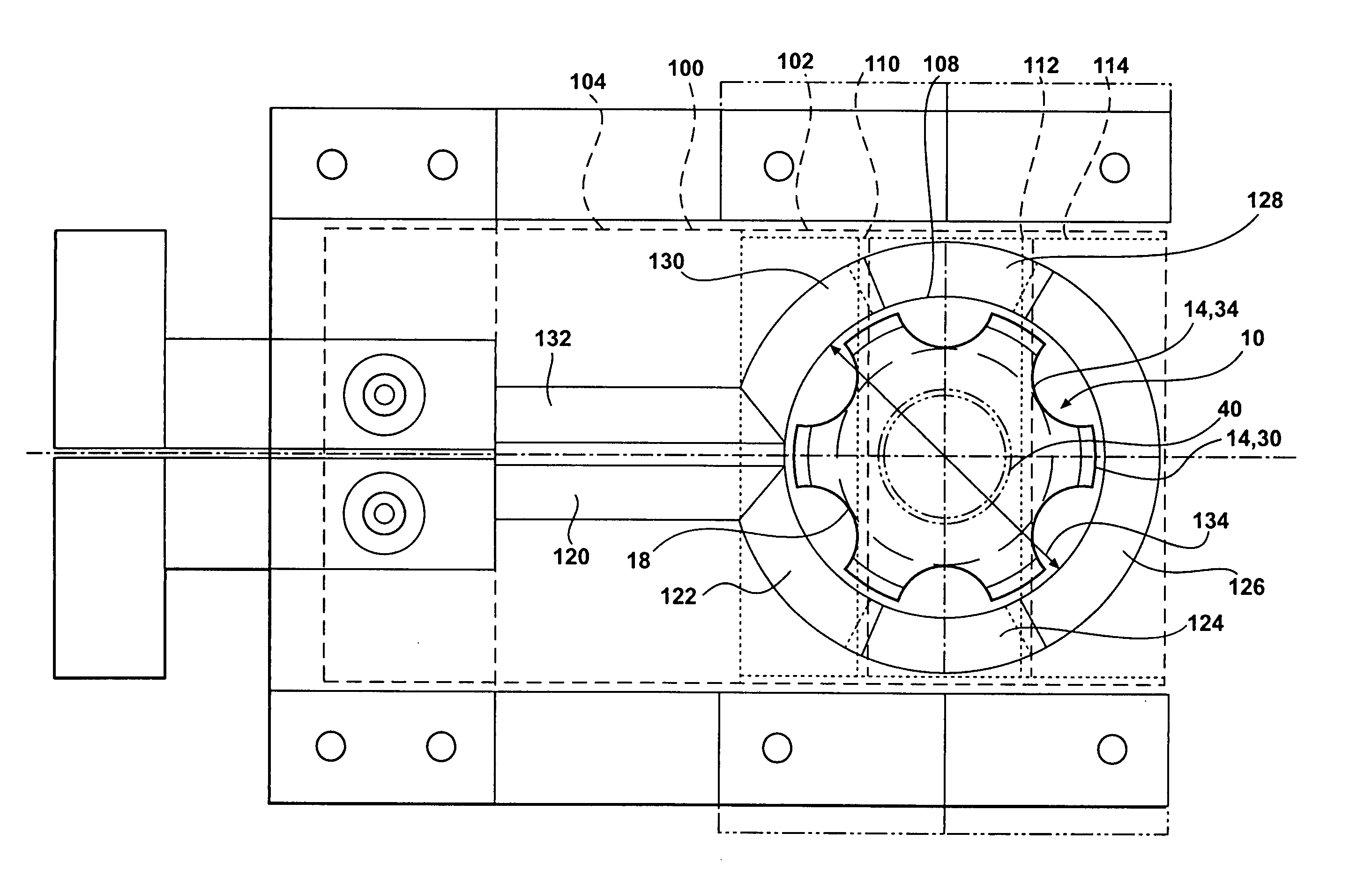

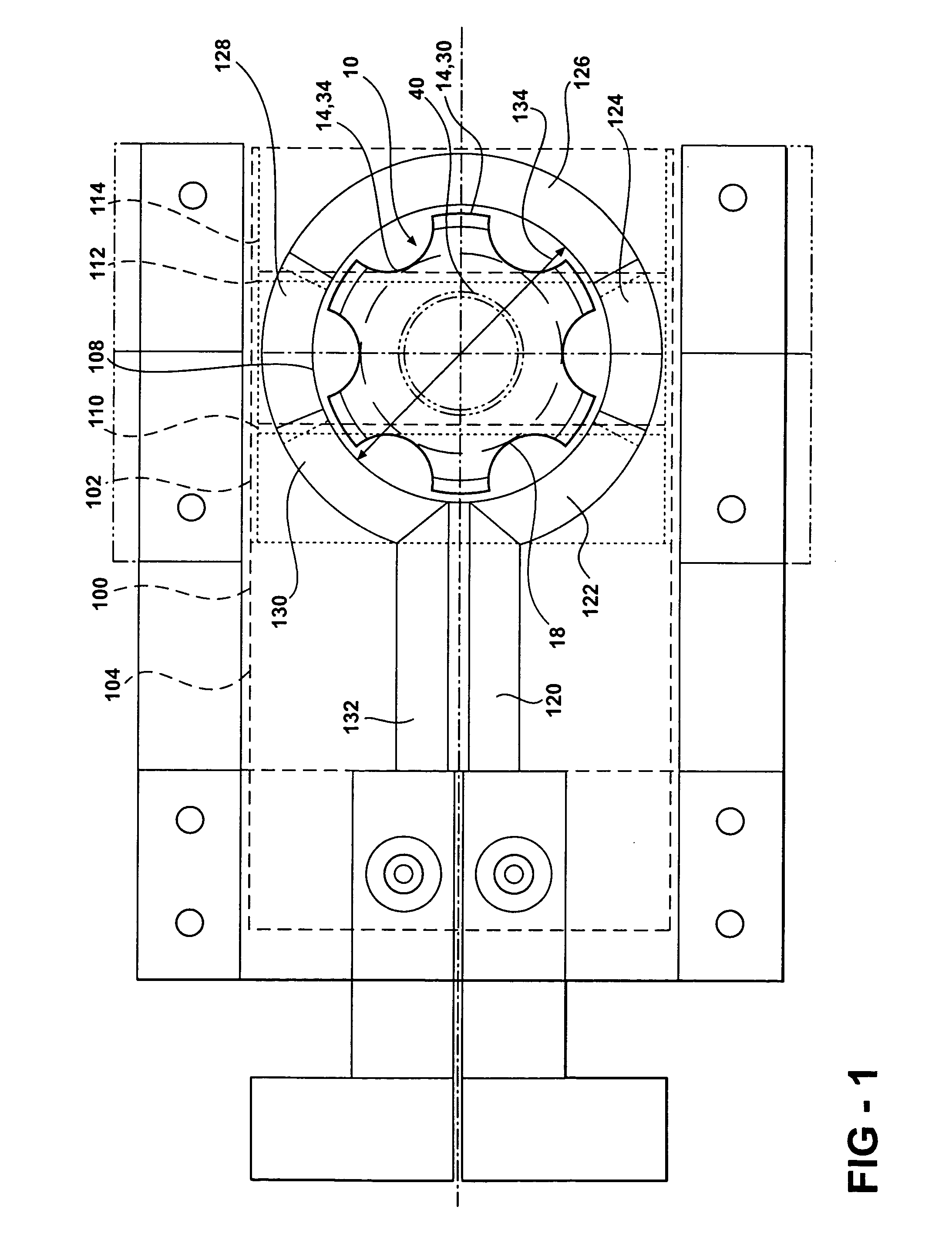

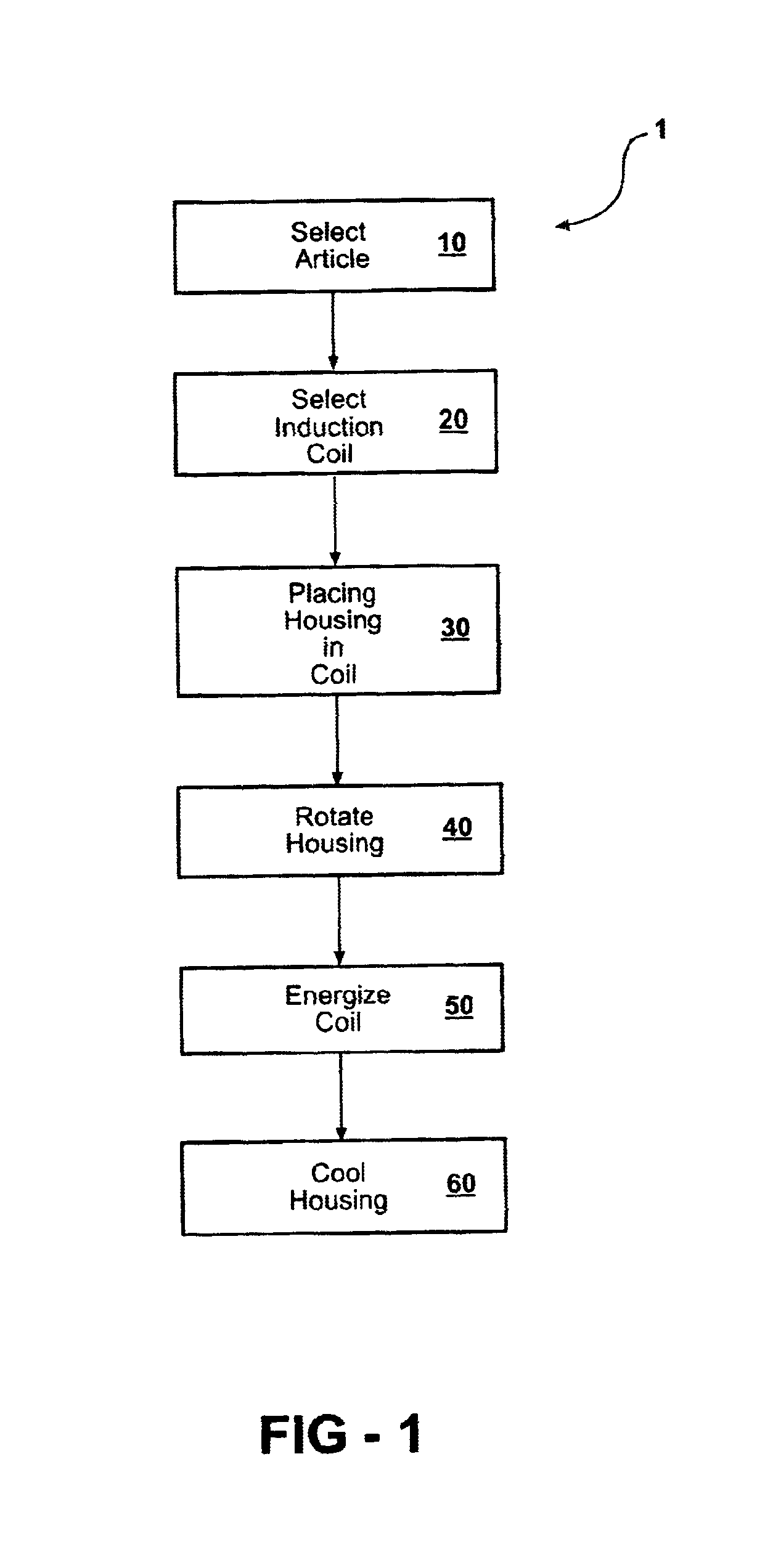

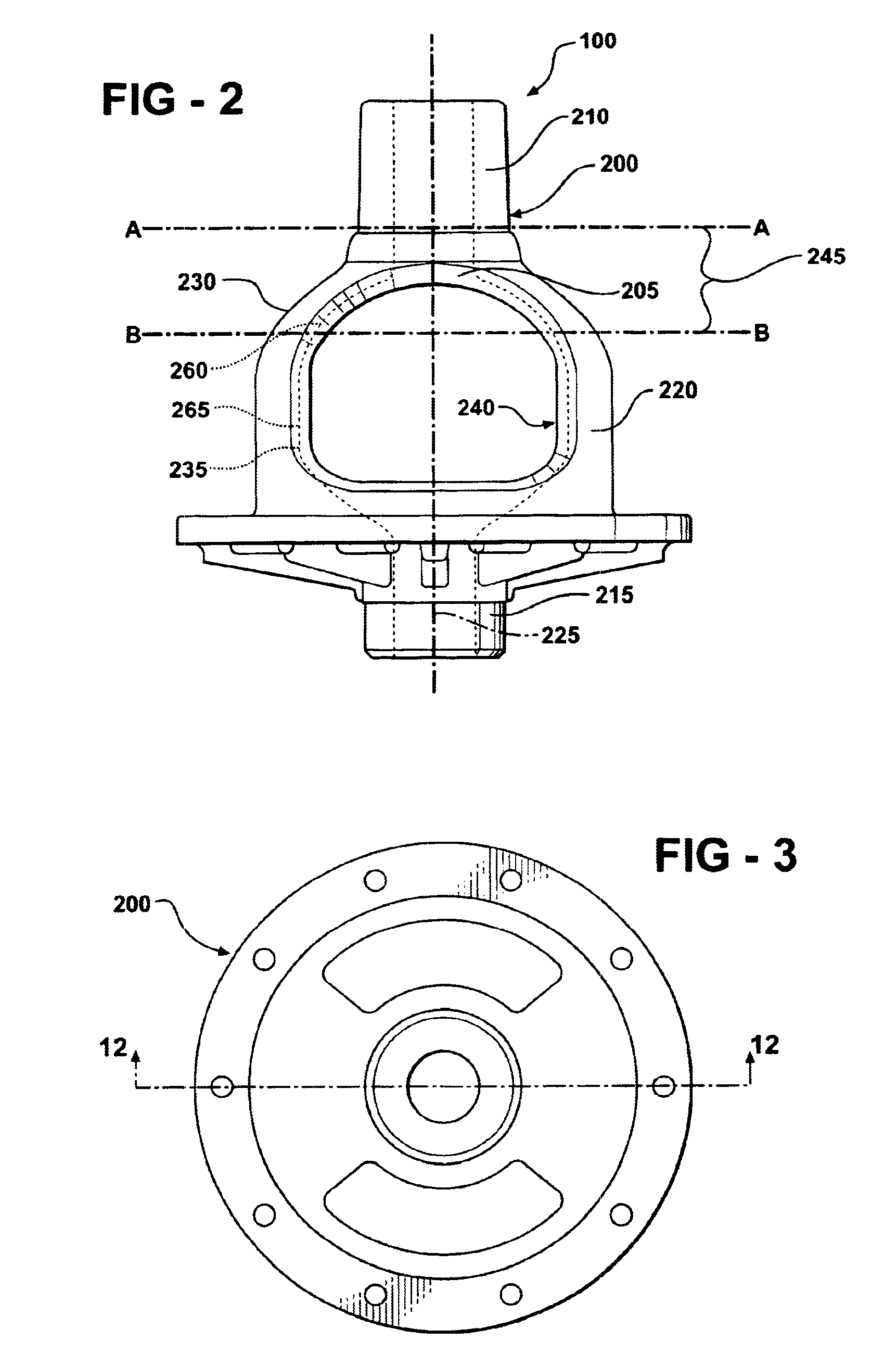

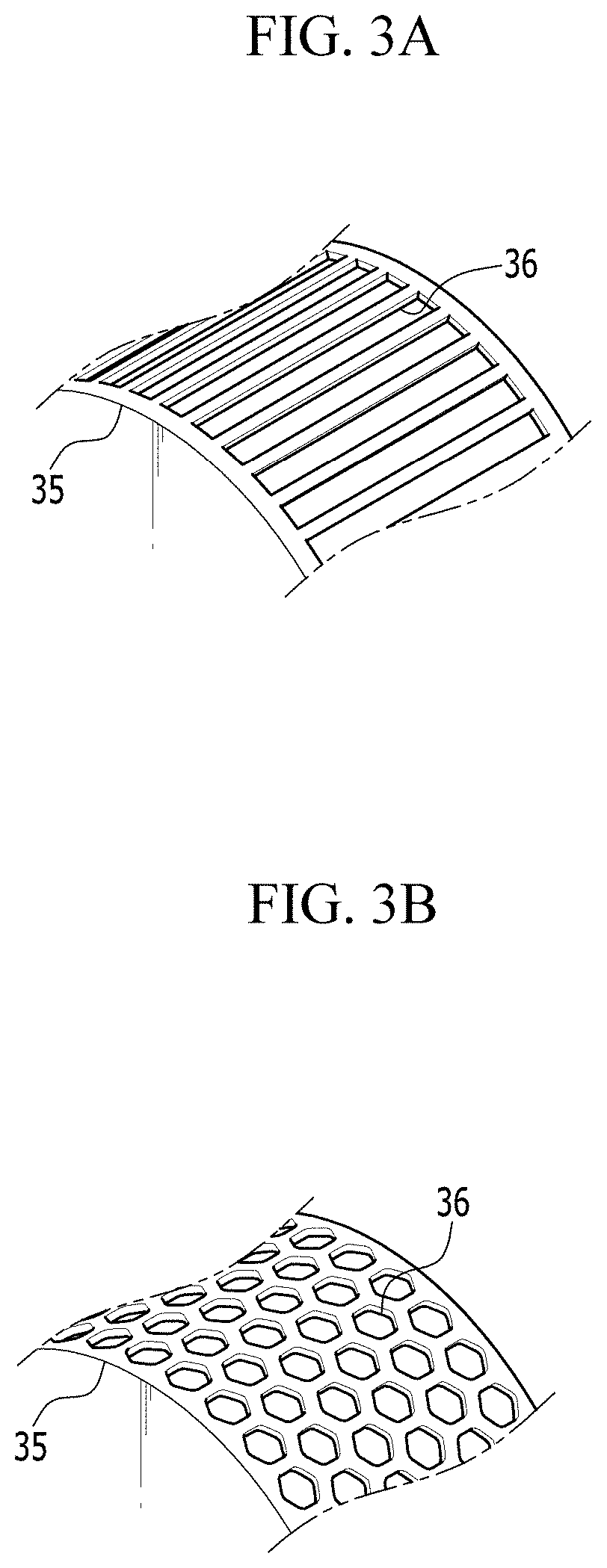

Induction heat treatment method and coil and article treated thereby

InactiveUS20050039830A1Additional componentEasy to controlCoil arrangementsFurnace typesInduction hardeningMaterials science

A method of induction heat treating the outer surface of articles having an irregular surface shape. The method employs an induction coil that provides a non-planar magnetic field that is adapted to the irregular shape of the article, such that distinct sections of the induction coil produce distinct magnetic fields that are adapted to induce currents in, and thereby provide heat to, distinct sections of the outer surface of the article. The method and induction coil are particularly adapted to provide an induction hardening heat treatment for the outer surfaces of the inner races of Rzeppa-type constant velocity joints.

Owner:FORD MOTOR CO

Method for crystallizing amorphous semiconductor thin film by epitaxial growth using non-metal seed and method for fabricating poly-crystalline thin film transistor using the same

InactiveUS7390705B2Function increaseReduce heat treatment requirementsPolycrystalline material growthSolid-state devicesOptoelectronicsSeed crystal

A method for crystallizing an amorphous semiconductor thin film using a non-metal seed epitaxial growth (NSEG) is provided. The method includes the steps of: forming a pair of non-metal seeds for inducing a crystallization of an amorphous semiconductor thin film at a predetermined distance on a transparent insulation substrate; depositing the amorphous semiconductor thin film on the insulation substrate; and heat-treating the insulation substrate to thereby epitaxially grow a poly-crystalline semiconductor thin film from the non-metal seeds, and to thus crystallize the amorphous semiconductor thin film. In the crystallization method, non-metal seeds are used instead of using crystallization induced metal to thereby epitaxially grow the poly-crystalline semiconductor thin film and to thus realize the amorphous semiconductor thin film without having metal pollution.

Owner:PAIK WOON SUH

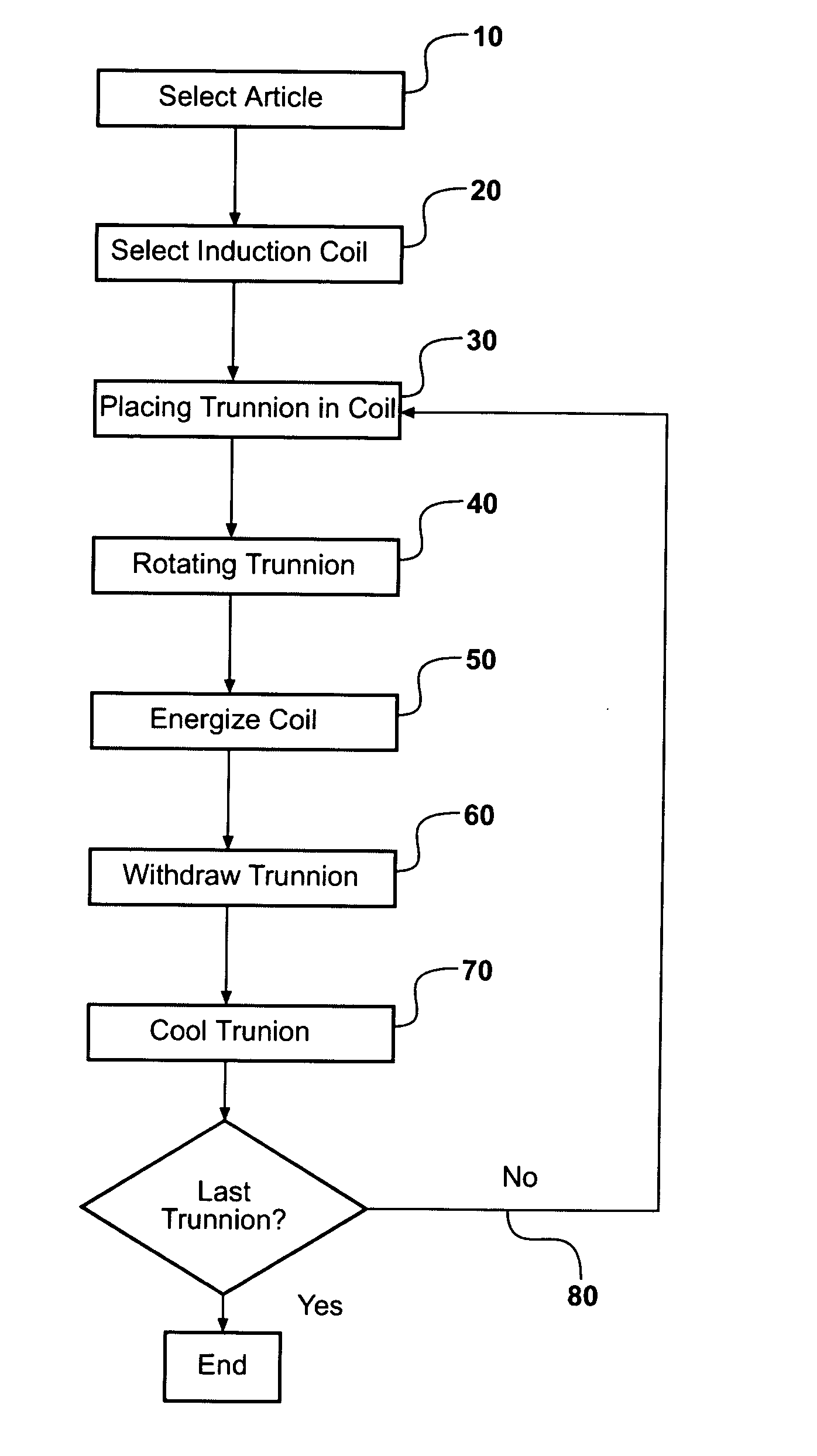

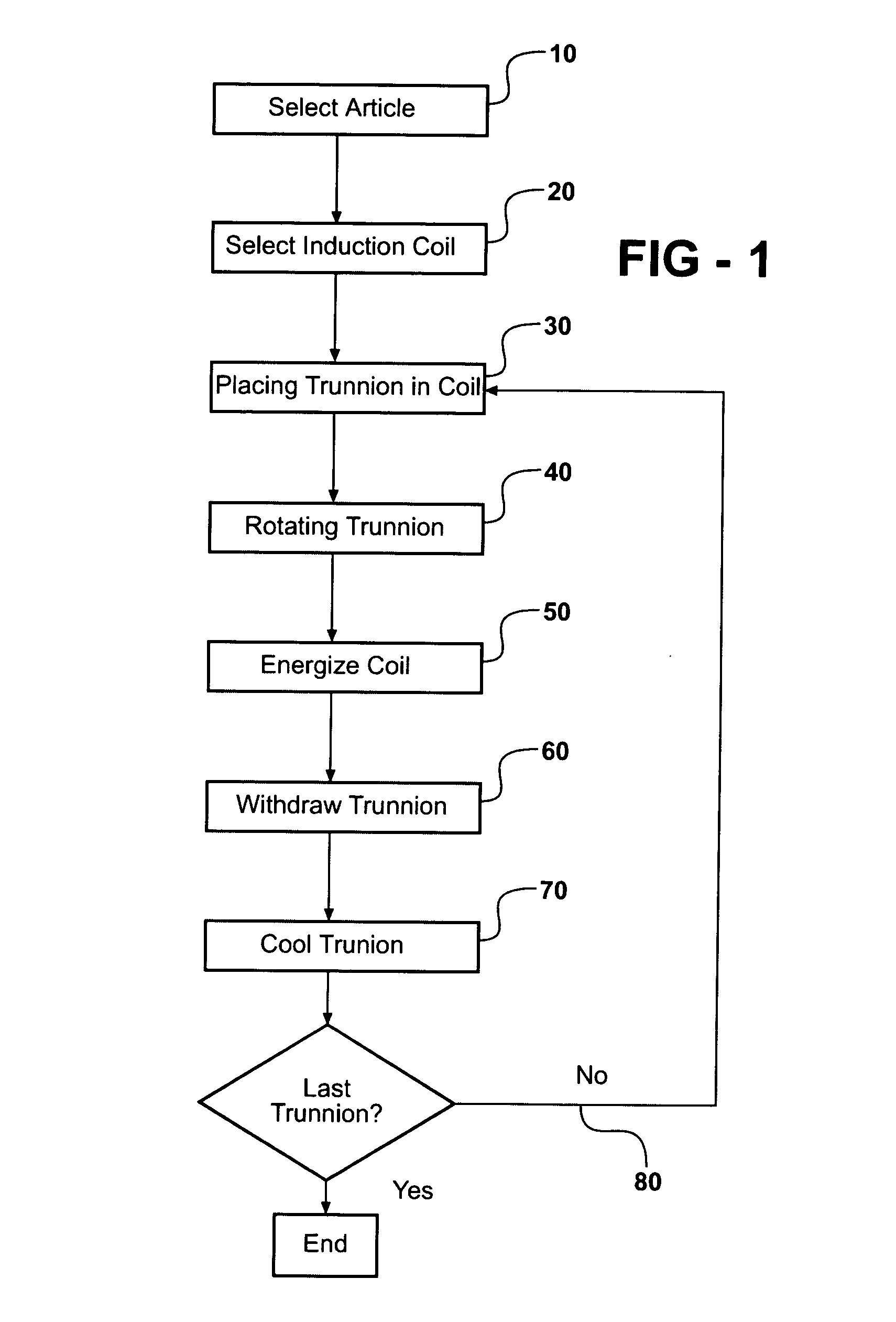

Induction heat treatment method and article treated thereby

InactiveUS20050039829A1Increase productionGood control over hardening processYielding couplingIncreasing energy efficiencyEngineeringInduction hardening

A method of induction heat-treating certain surfaces of an article comprising a hub and a plurality of trunnions or shafts extending therefrom, wherein the surfaces to be heat-treated comprise the surfaces of the trunnions. The method employs an induction coil that provides a planar magnetic field that is adapted to the irregular shape of the article, such that the induction coil produces magnetic fields that are adapted to induce currents in, and thereby heat, the trunnion surfaces of the article. The method and induction coil are particularly adapted to provide an induction hardening heat treatment for trunnion surfaces of trunnions used in steel spiders of spider or tripod-type constant velocity joints.

Owner:AUTOMOTIVE COMPONENTS HOLDINGS

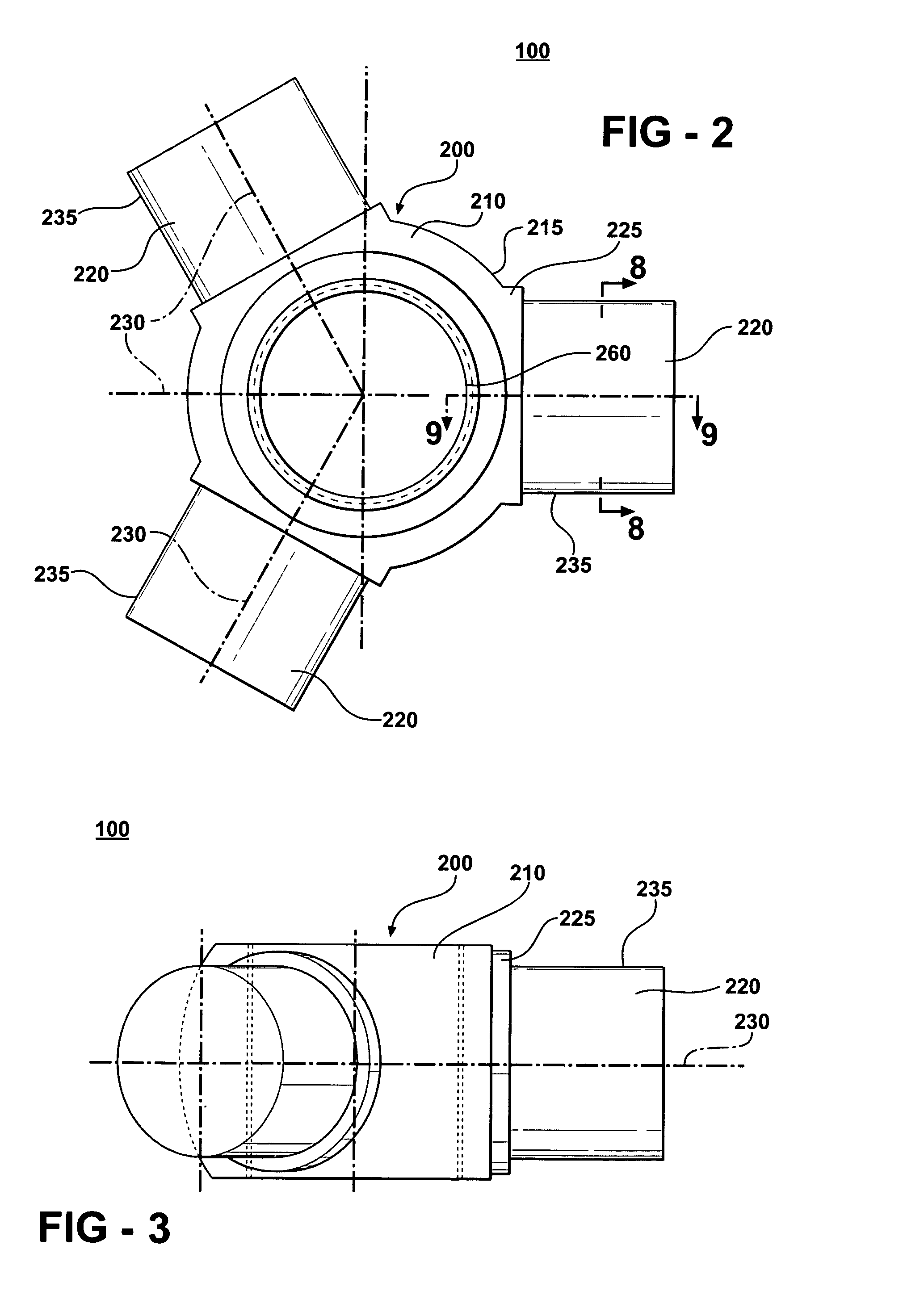

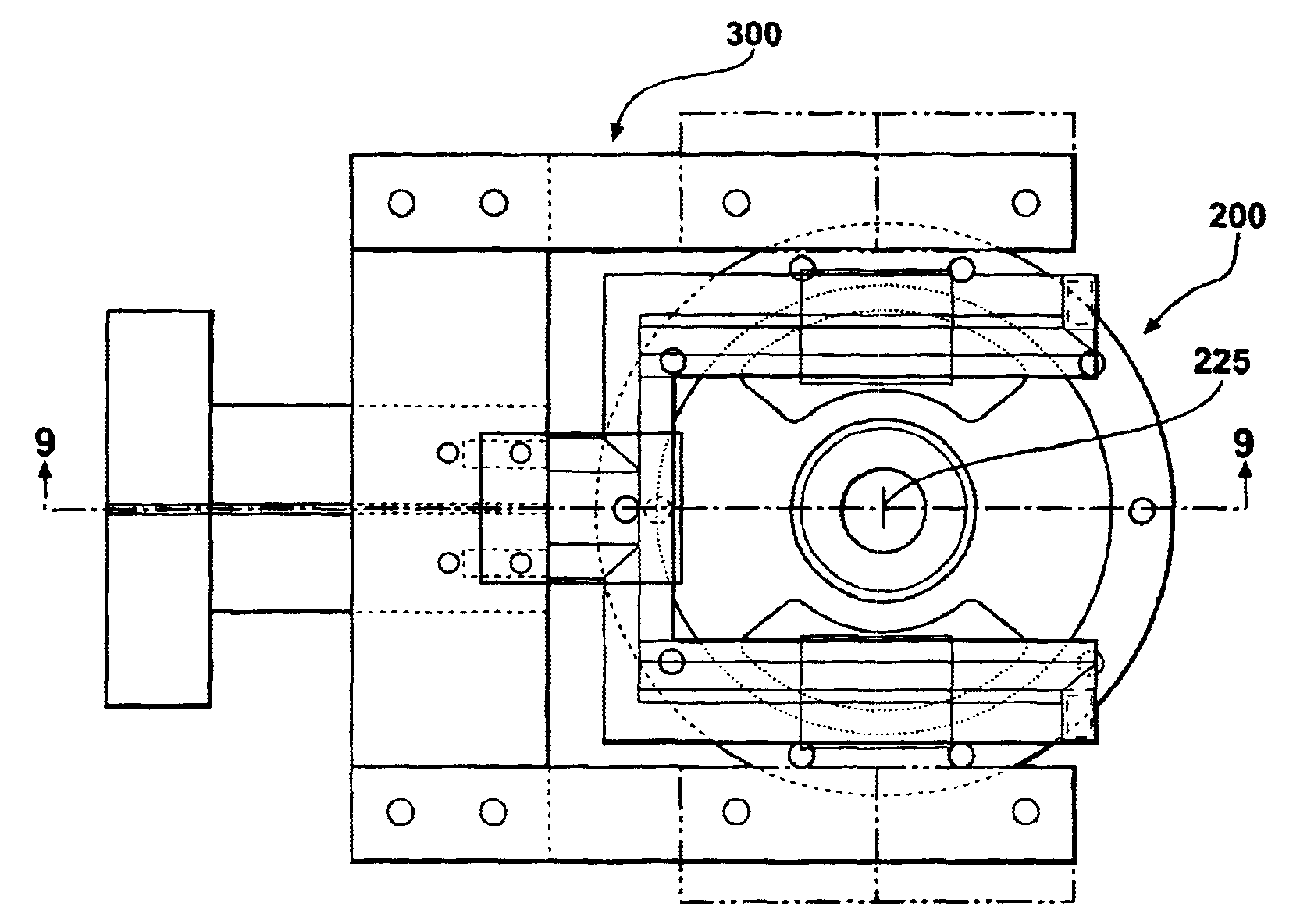

Induction heat treatment method and coil and article treated thereby

InactiveUS6940056B2High strengthMinimize distortionFurnaces without endless coreCoil arrangementsMartensite transformationEngineering

A method of induction heat treatment of articles having curved outer surfaces, such as differential housings. The method employs a semi-rectangular induction coil that is adapted to provide a plurality of lateral magnetic fields that are used to induce currents in, and thereby provide heat to, a portion of the curved section of the article. The method and induction coil are particularly adapted to provide an induction hardening heat treatment of a curved heat treatment portion of a differential housing. The differential housing was cast from nodular iron. The induction-hardening heat treatment comprised heating the heat treatment portion of the differential housing above the austenite transition temperature and quenching to below the martensite transformation temperature.

Owner:FORD GLOBAL TECH LLC

Process for the production of high-quality activated carbons as well as activated carbons produced according to the process

InactiveUS20160038913A1Increase contactReduce heat treatment requirementsCarbon compoundsOther chemical processesActivated carbonPotassium hydroxide

A process for the production of high-quality activated carbons from carbonized, self-regenerating, carbon-containing biomasses selects the carbonized biomasses from HTC carbon from fruit stones and HTC carbon from nut shells. The carbonized biomasses together with potassium hydroxide, sodium hydroxide or a mixture of both hydroxides as activator are subjected to a heat treatment at temperatures at which the activator exists in the form of a melt. The activator and the carbonized biomasses are present in a weight ratio of 0.5:1 to 6:1 at the beginning of the heat treatment.

Owner:AVA CO2 SCHWEIZ

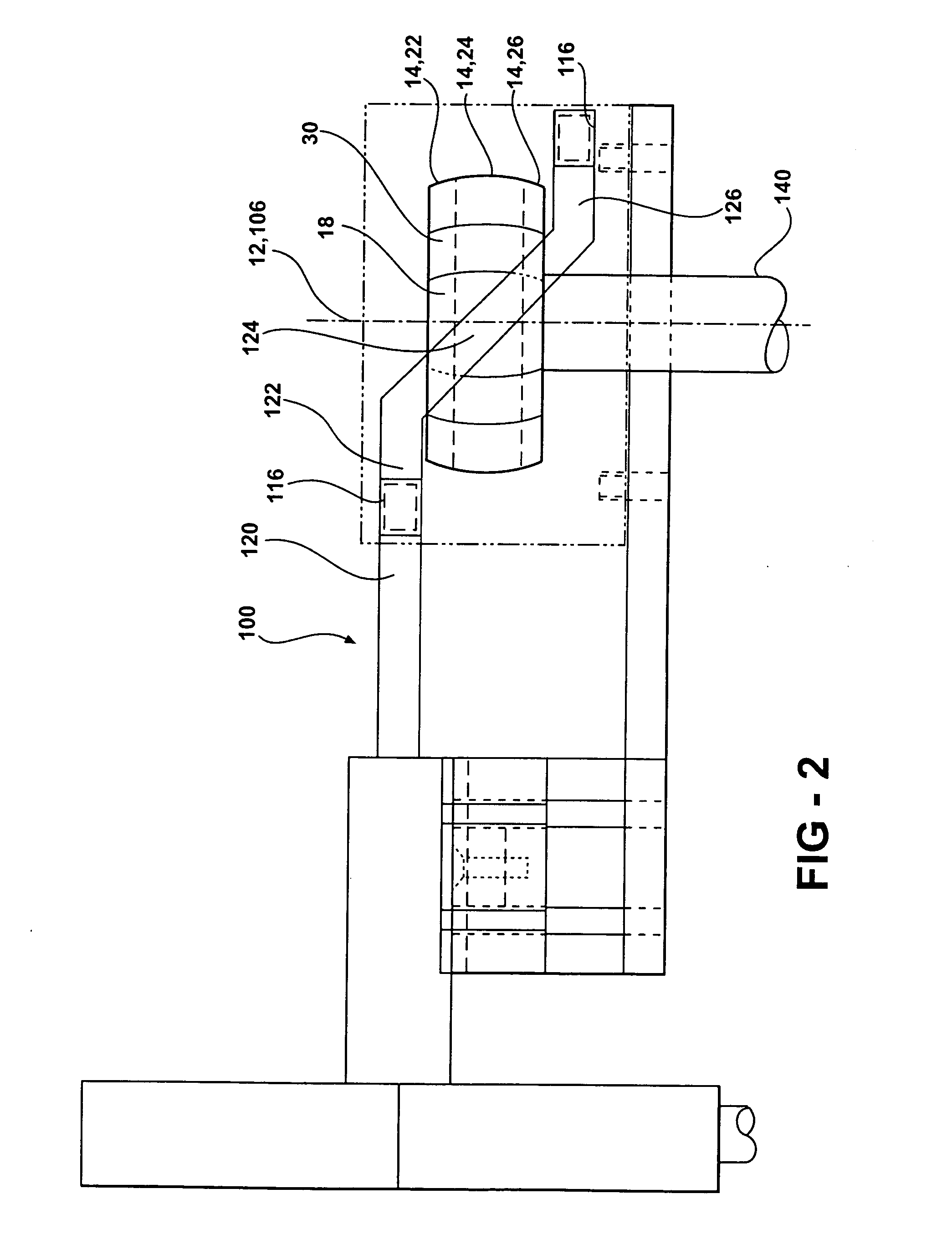

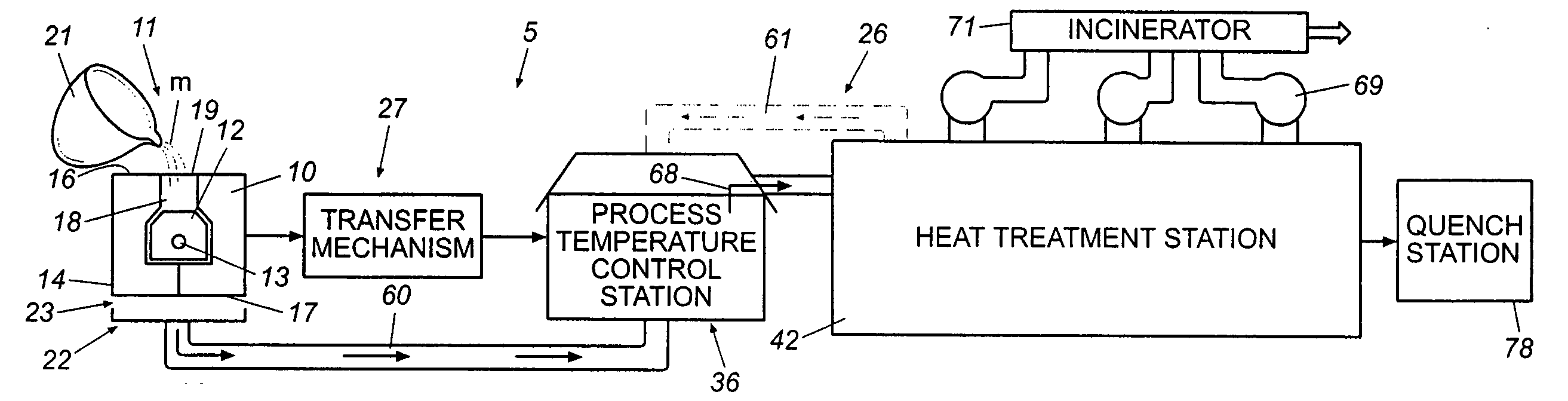

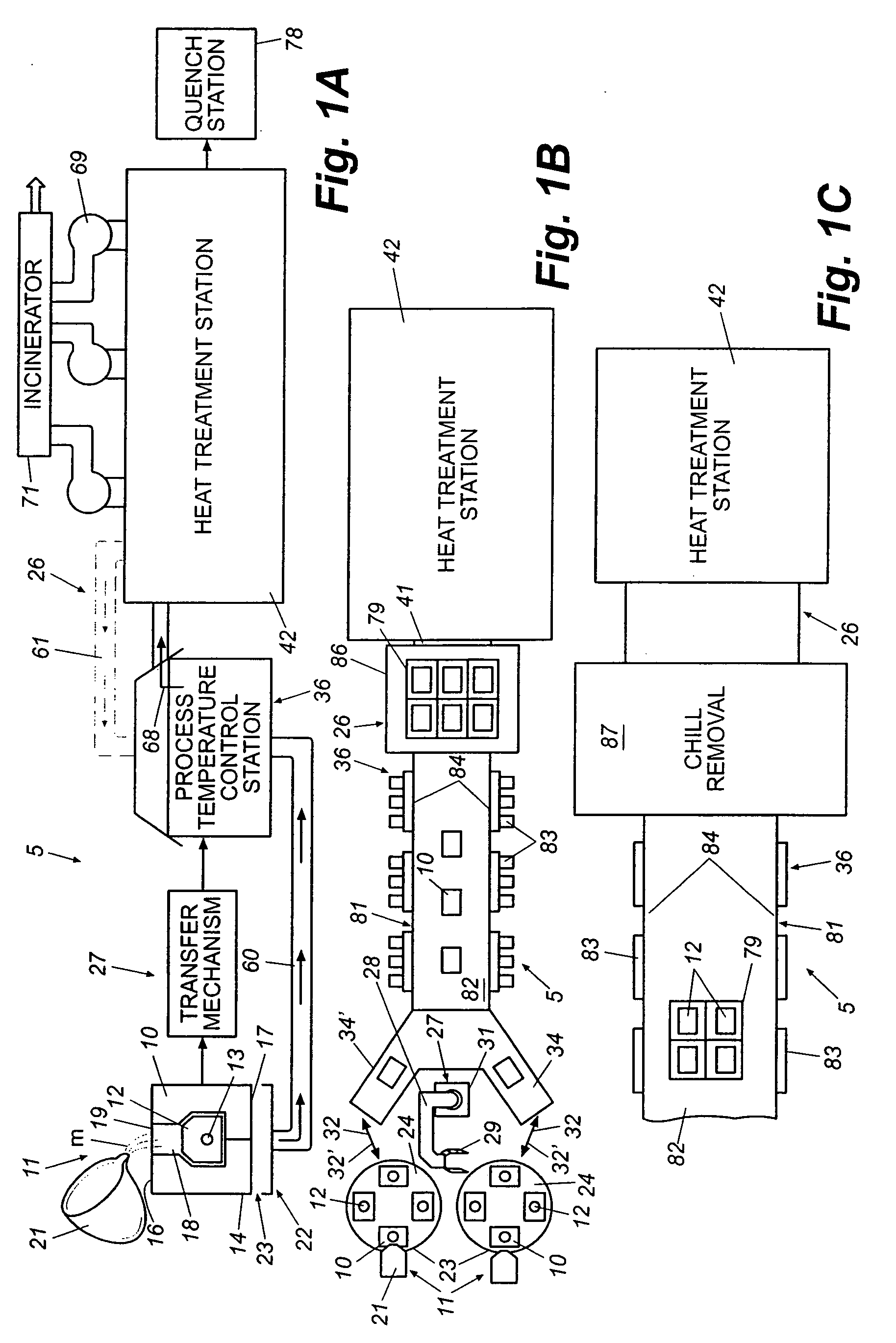

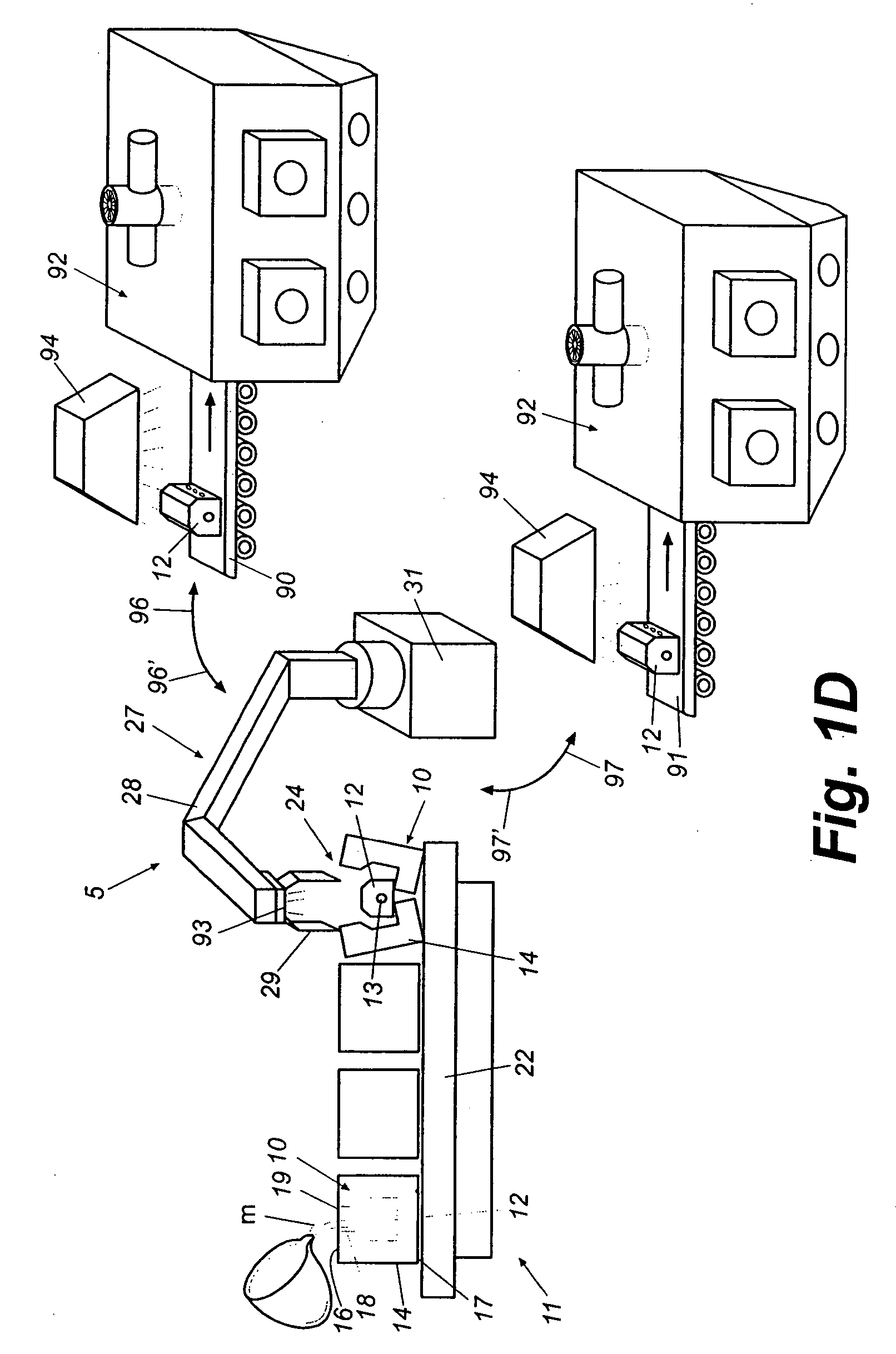

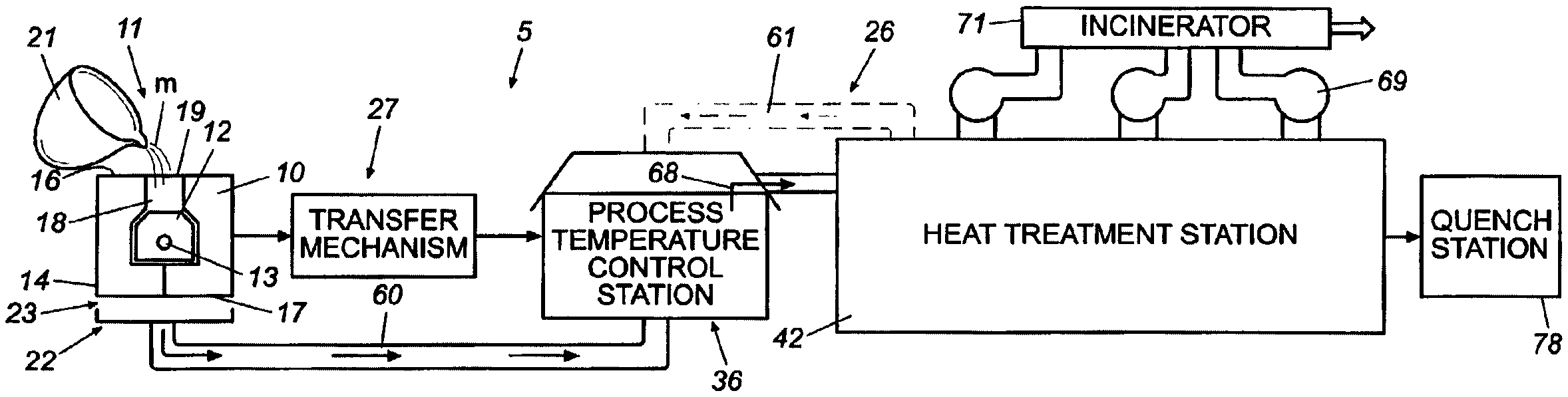

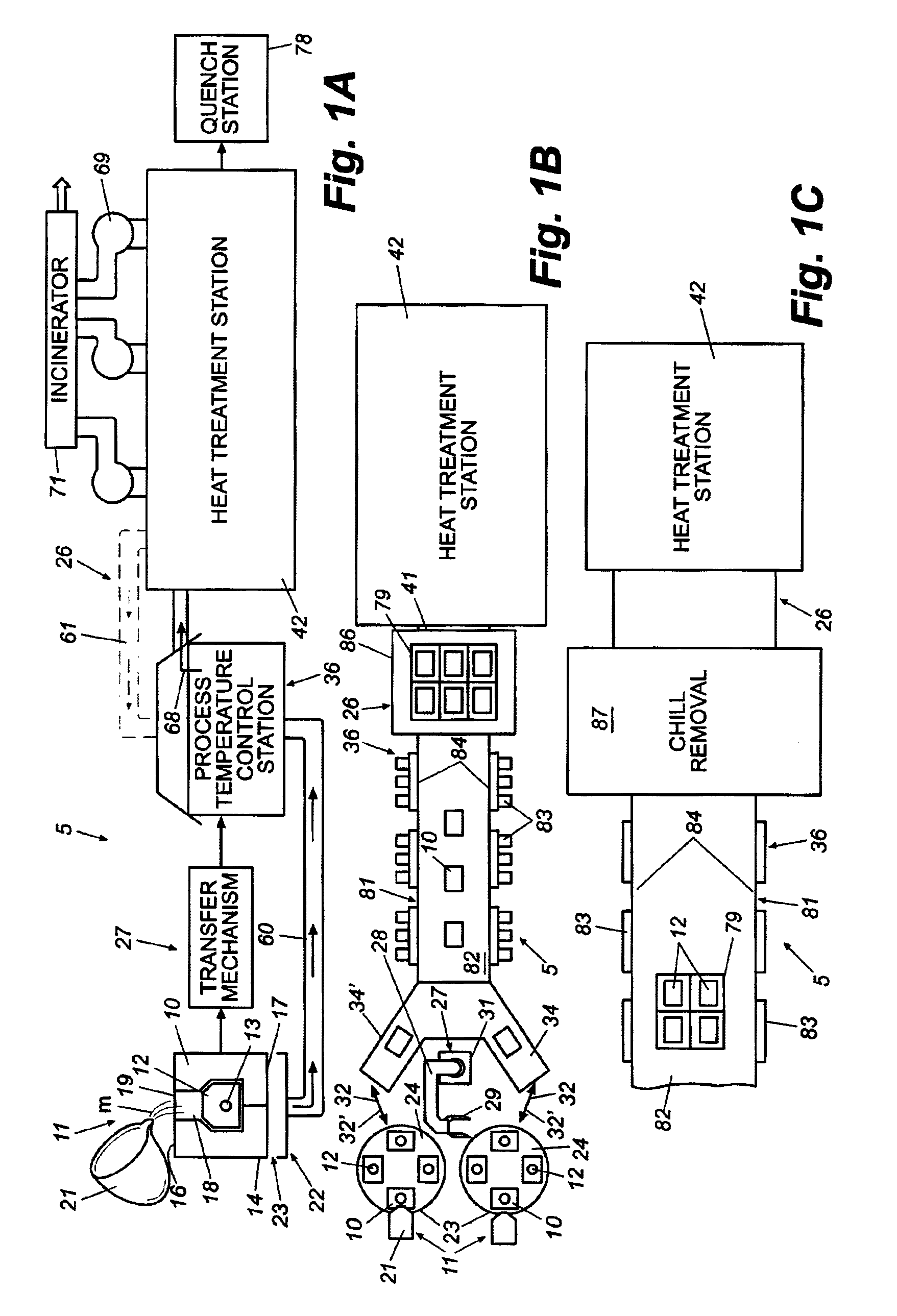

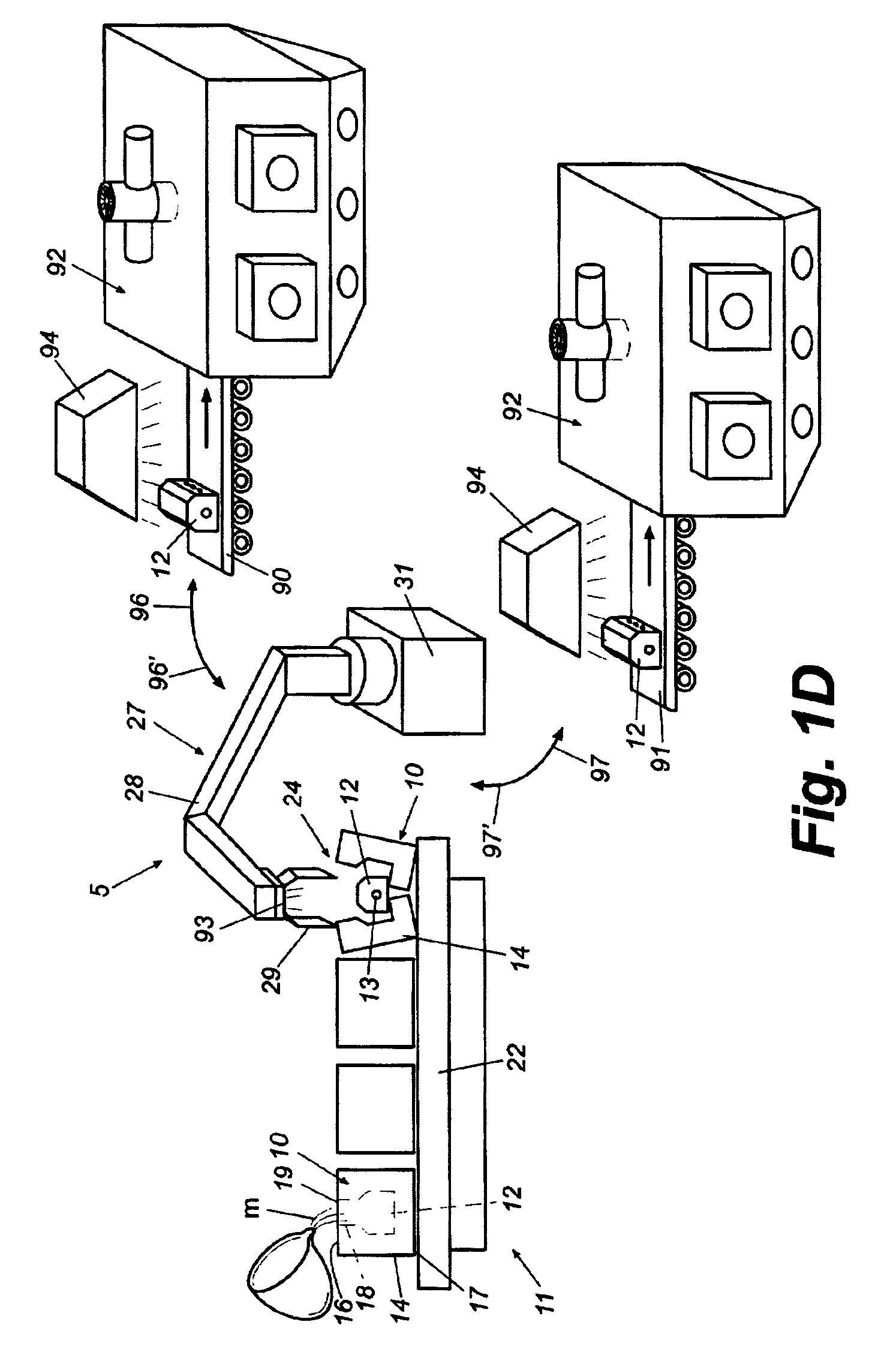

Integrated metal processing facility

InactiveUS20050257858A1Reduce heat treatment requirementsProcessing and heat treatment time can be enhanced and reducedCasting plantsFurnace typesMetalworkingMolten metal

An integrated metal processing facility in which molten metal is poured into a series of molds at a pouring station to form metal castings, which are then transferred to a heat treatment line. Prior to introduction of the castings into a heat treatment station of the heat treatment line, the castings are subjected to heating sufficient to arrest cooling of the castings at or above a process control temperature for the metal thereof.

Owner:CONSOL ENG

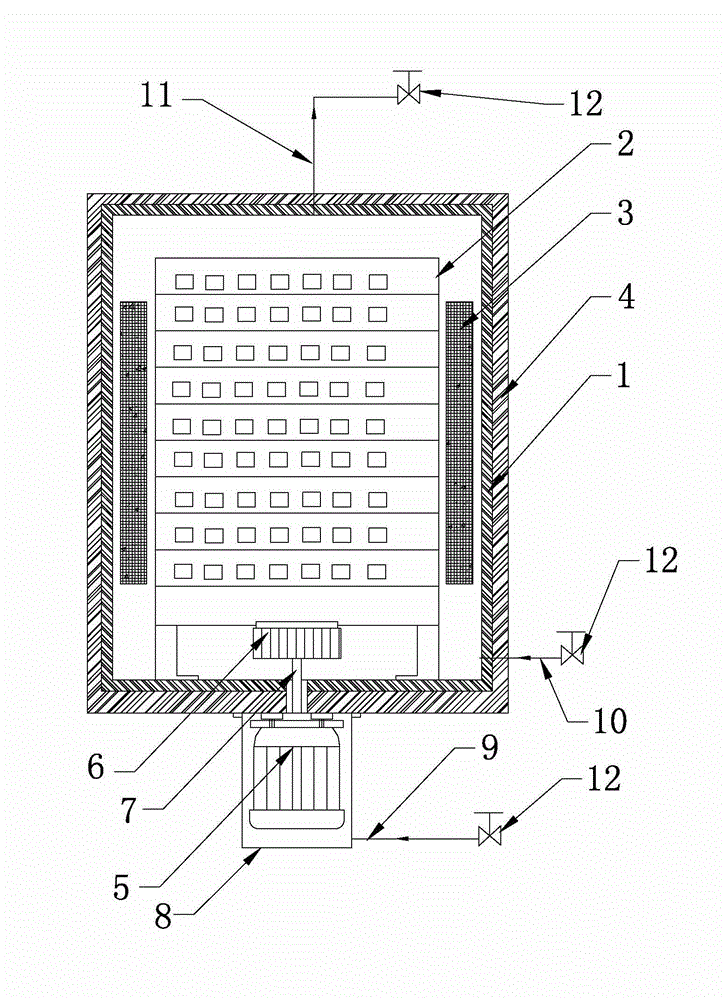

Upright normal pressure amorphous iron core heat treatment furnace

InactiveCN103555901AIncrease the number of stacksLower manufacturing requirementsFurnace typesHeat treatment furnacesBiochemical engineeringExhaust pipe

The invention relates to an upright normal pressure amorphous iron core heat treatment furnace. The heat treatment furnace comprises a tank body, a pile support, heating rods and an insulating layer, wherein the insulating layer is arranged outside the tank body; the pile support is arranged in the tank body. The heat treatment furnace is characterized by also comprising a motor, a fan, a rotating shaft, a seal cover, a first gas pipe, a second gas pipe and an exhaust pipe; the heating rods are arranged inside the tank body or between the insulating layer and the tank body; the motor is arranged outside the insulating layer; the fan is arranged in the tank body; one end of the rotating shaft is connected with the motor and the other end of the rotating shaft is connected with the fan after passing through the insulating layer and the tank body; the seal cover is arranged on the insulating layer and covers the motor; the first and second gas pipes are used for inputting gases into the tank body; the exhaust pipe is used for exhausting gases out of the tank body. The heat treatment furnace has the advantages that the heat treatment furnace can achieve heat treatment of amorphous iron cores in a normal pressure state and has good uniformity of heating temperatures.

Owner:江阴市晶磁电子有限公司

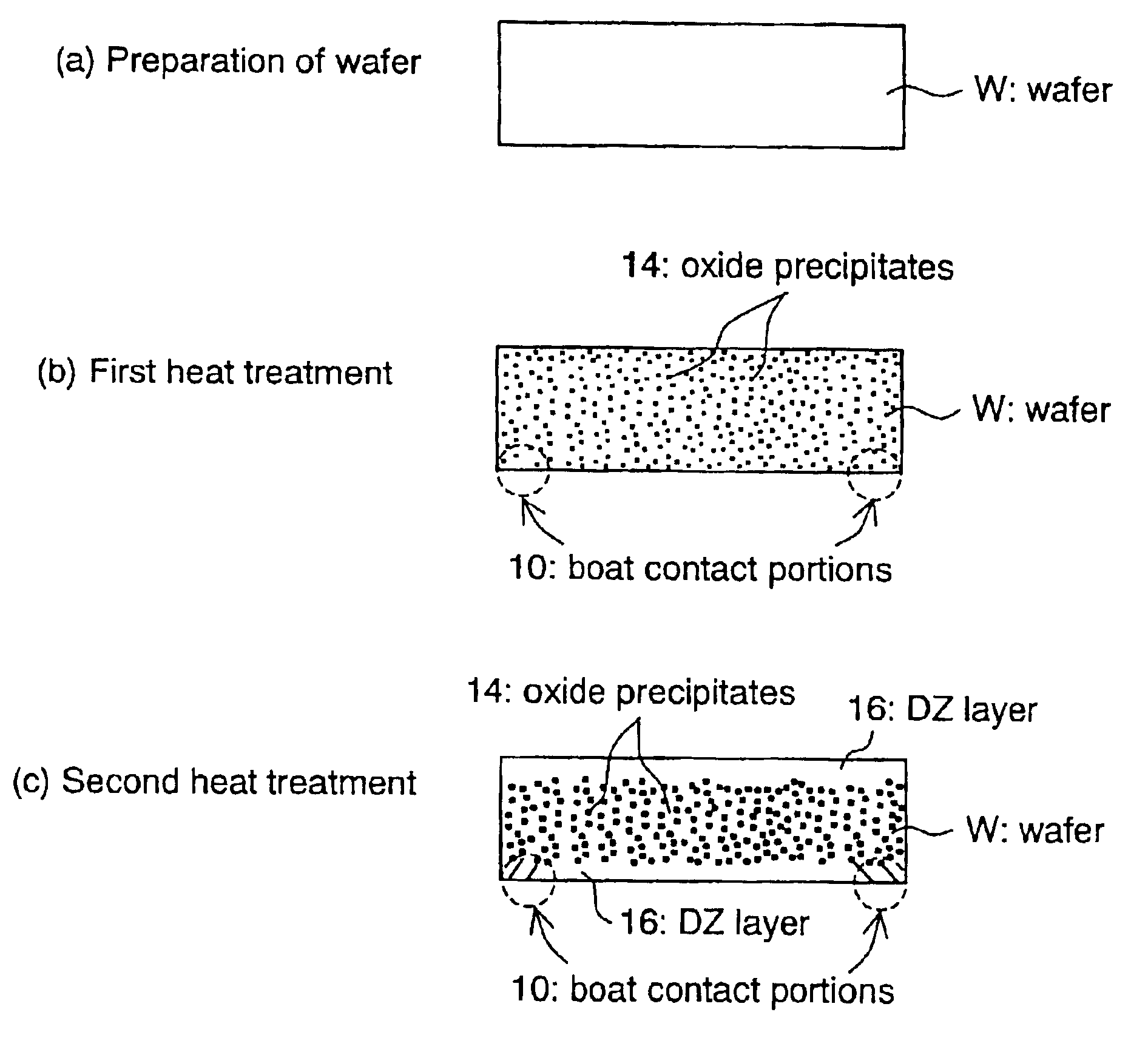

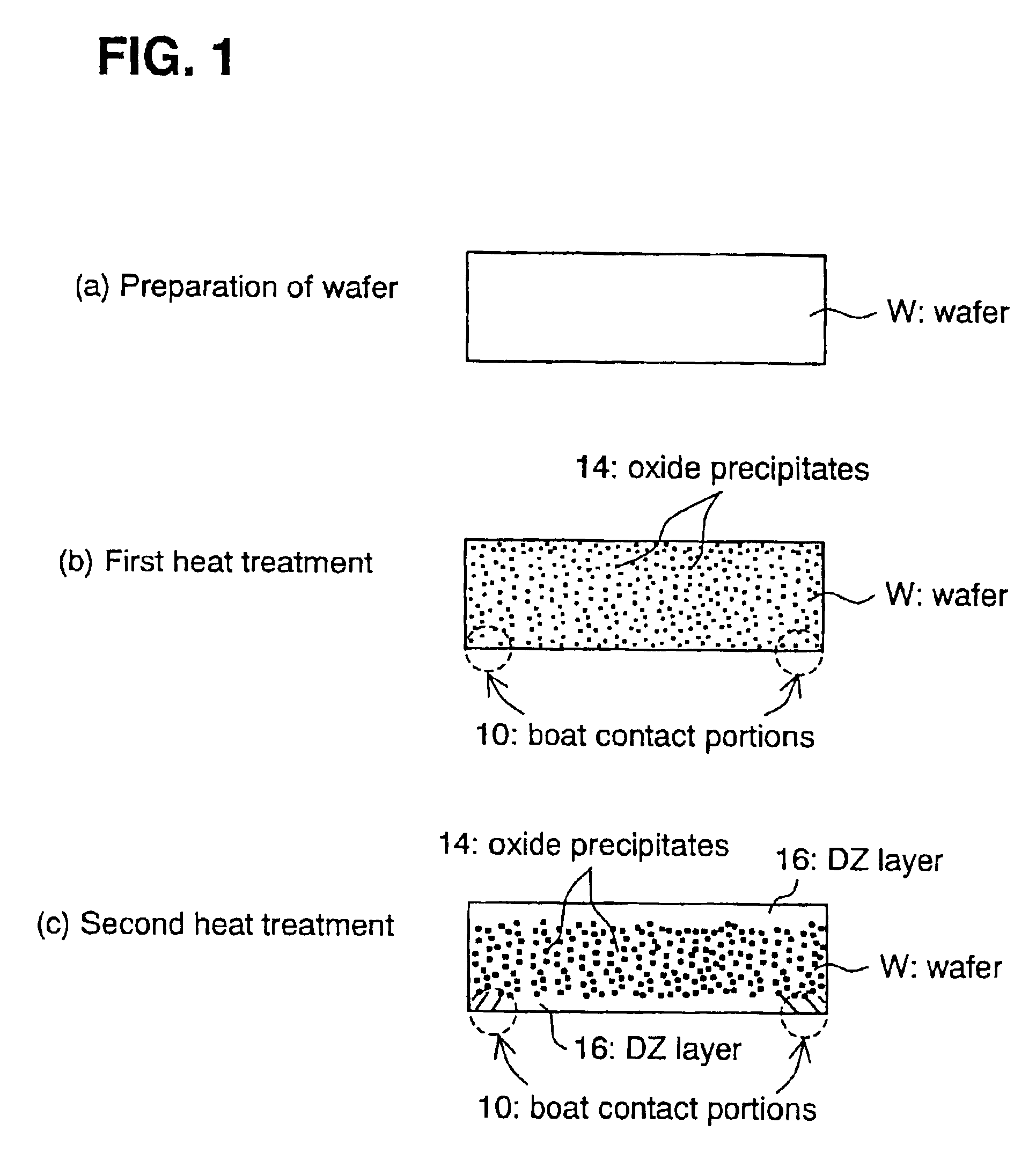

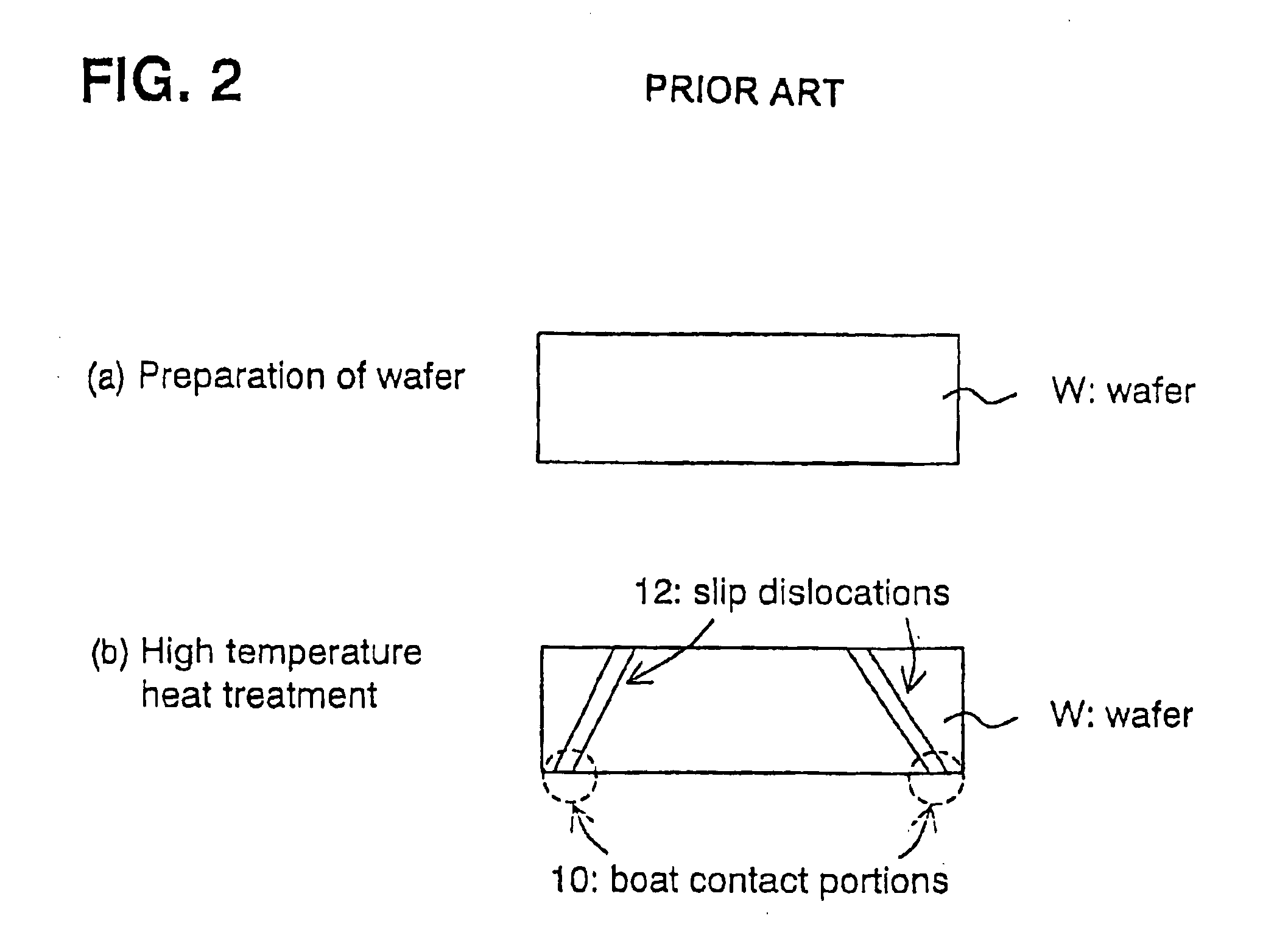

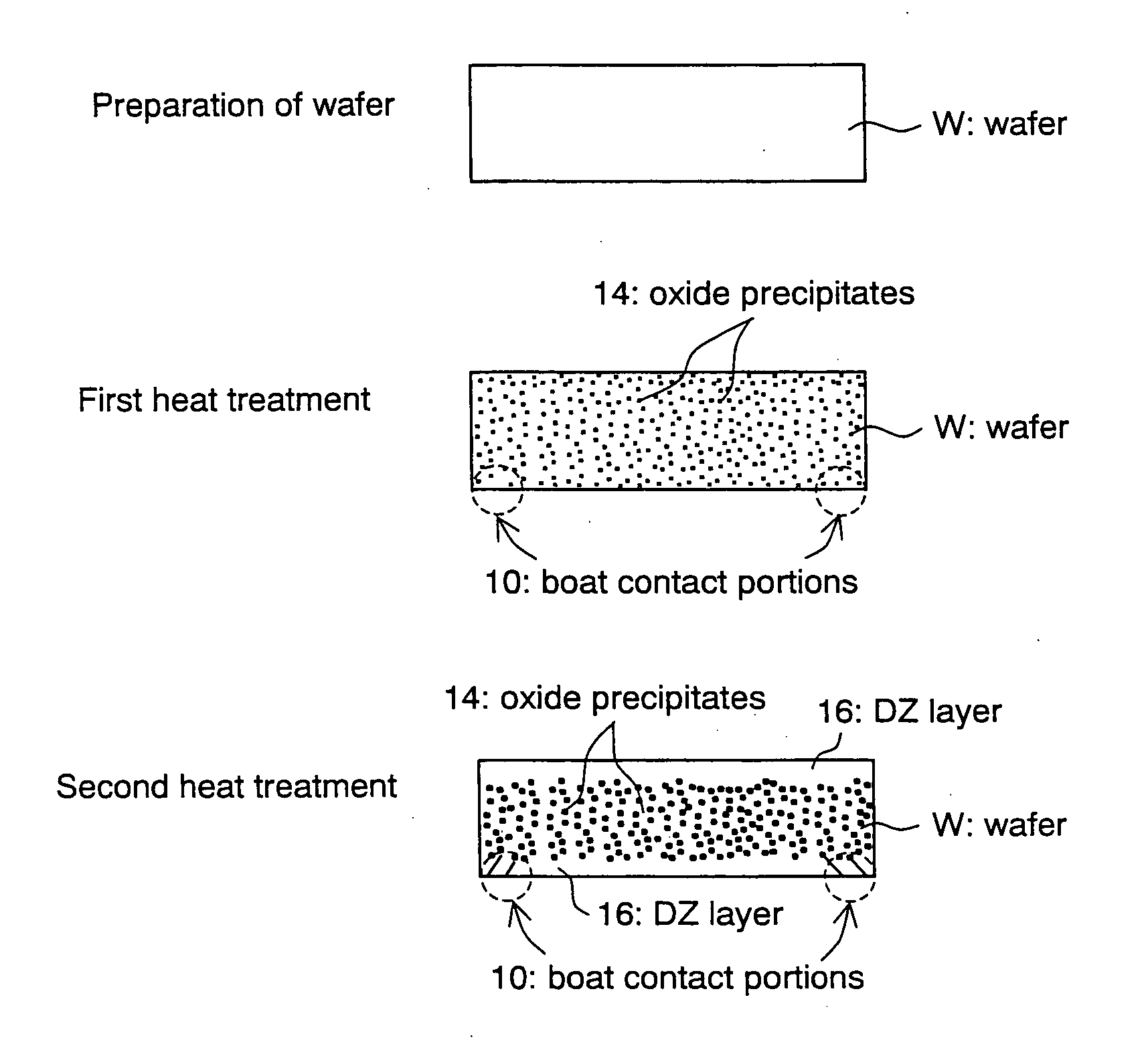

Manufacturing process for annealed wafer and annealed wafer

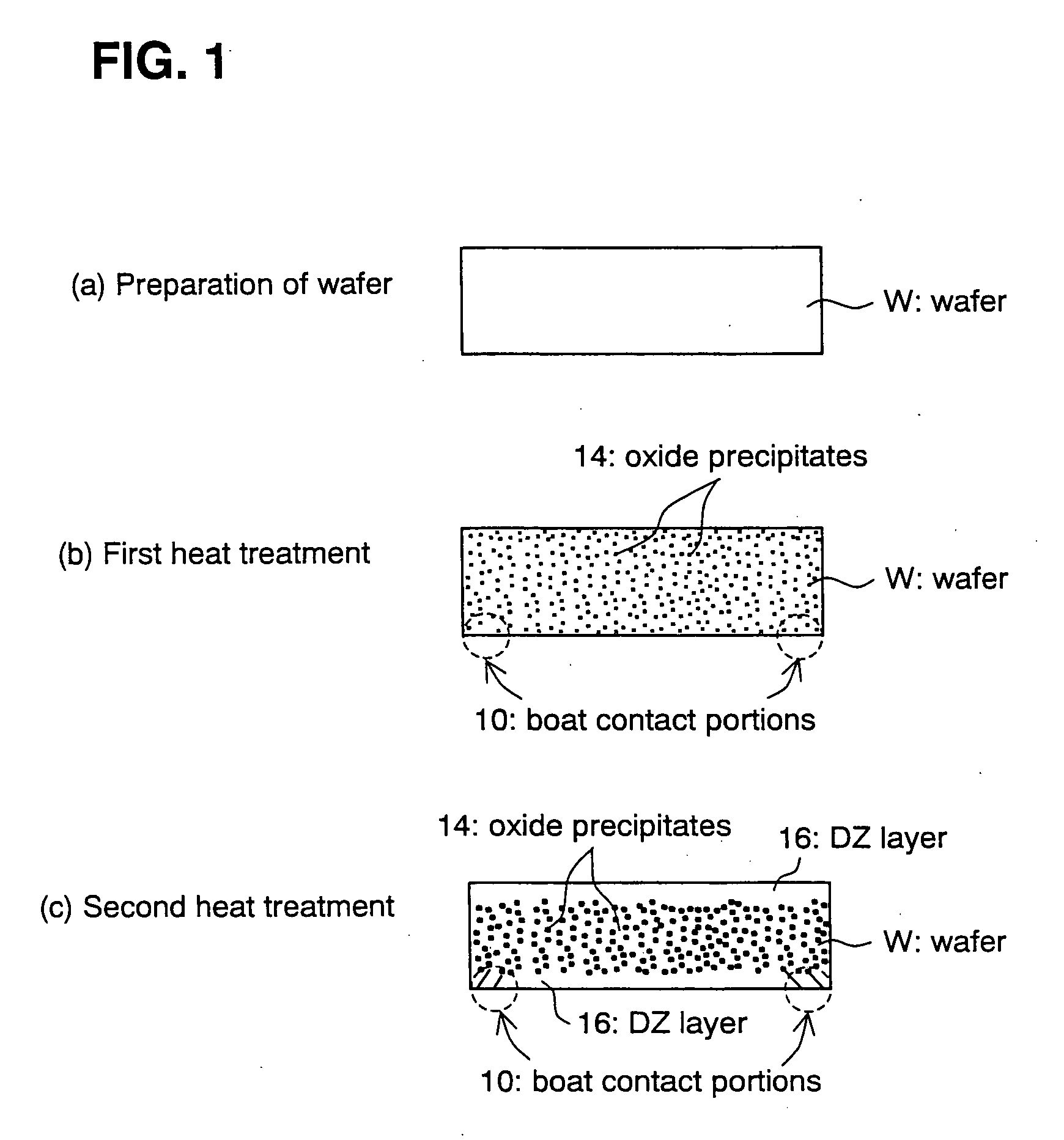

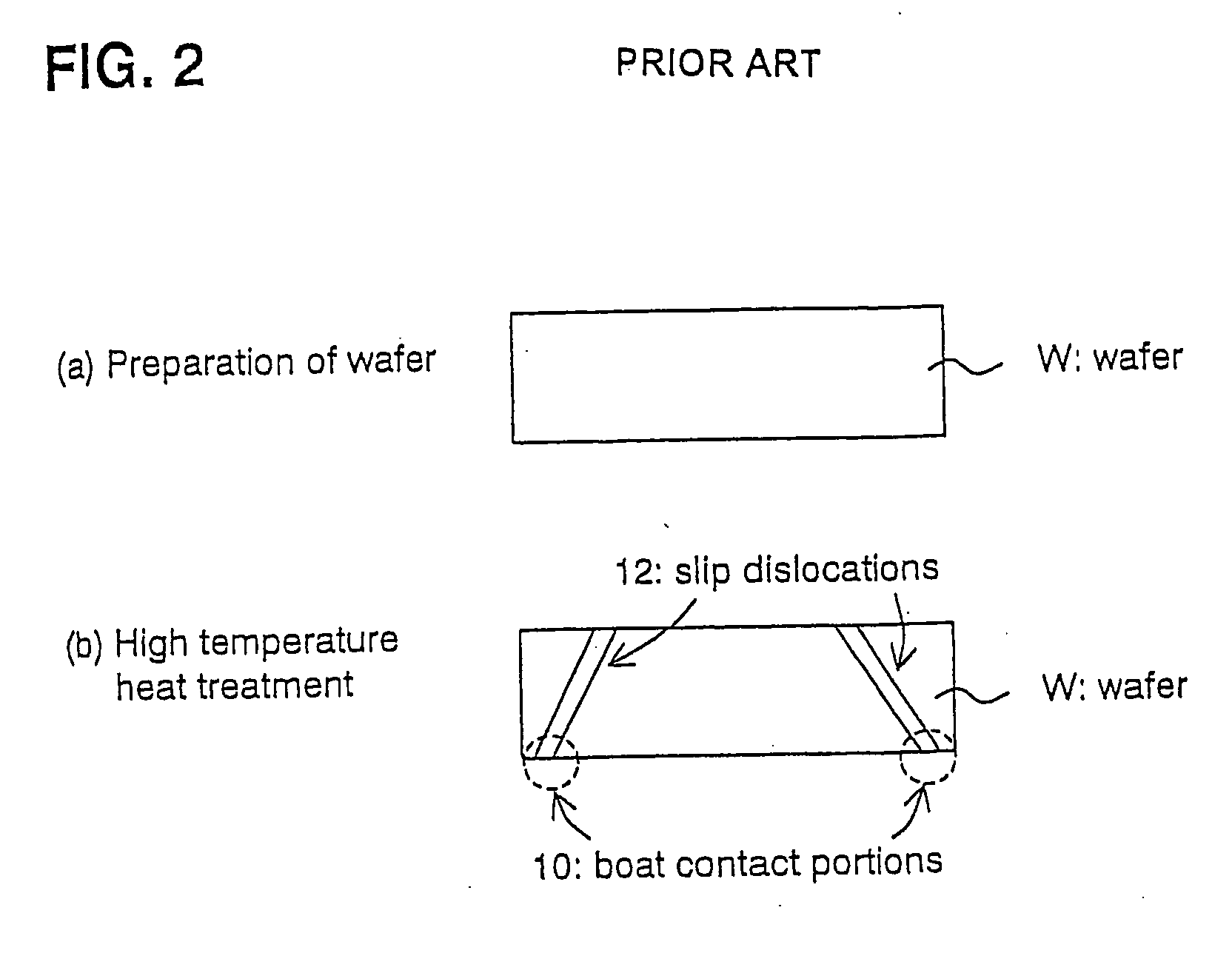

InactiveUS7081422B2Weight optimizationIncrease the diameterPolycrystalline material growthSemiconductor/solid-state device manufacturingWaferingHigh density

There are provided a heat-treating method capable of suppressing generation of slip in a CZ silicon single crystal wafer having a diameter of mainly 300 mm or more even under high temperature heat treatment to annihilate grown-in defects in the vicinity of a surface of the wafer, and an annealed wafer having a DZ layer in a surface layer of the wafer and oxide precipitates in the bulk thereof at a high density which exert a high gettering effect. First heat treatment of a silicon single crystal wafer manufactured from a silicon single crystal ingot pulled by means of a Czochralski method is performed at a temperature in the range of 600 to 1100° C. to form oxide precipitates in the bulk of the wafer, and thereafter, second heat treatment is performed at a temperature in the range of 1150 to 1300° C.

Owner:SHIN-ETSU HANDOTAI CO LTD

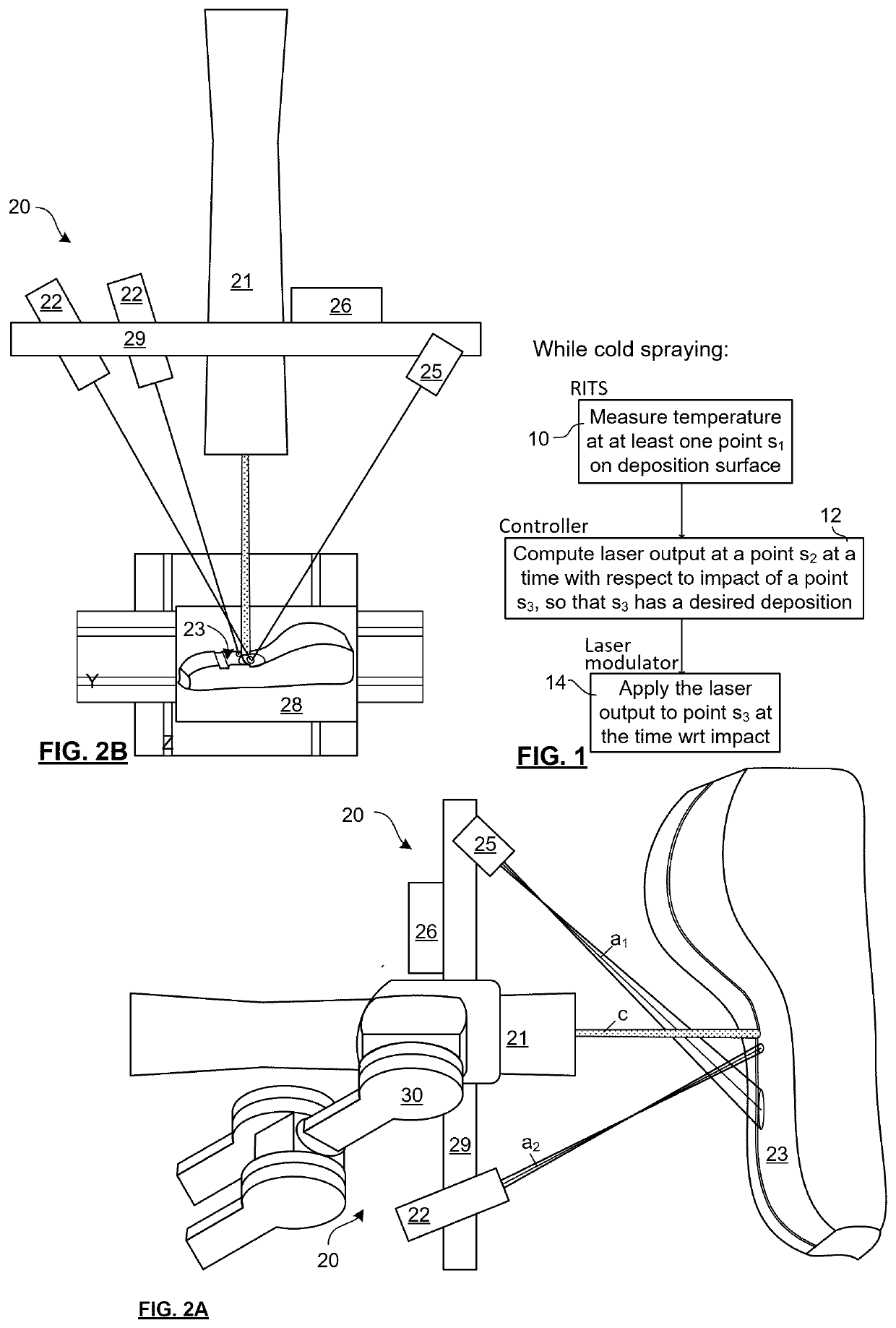

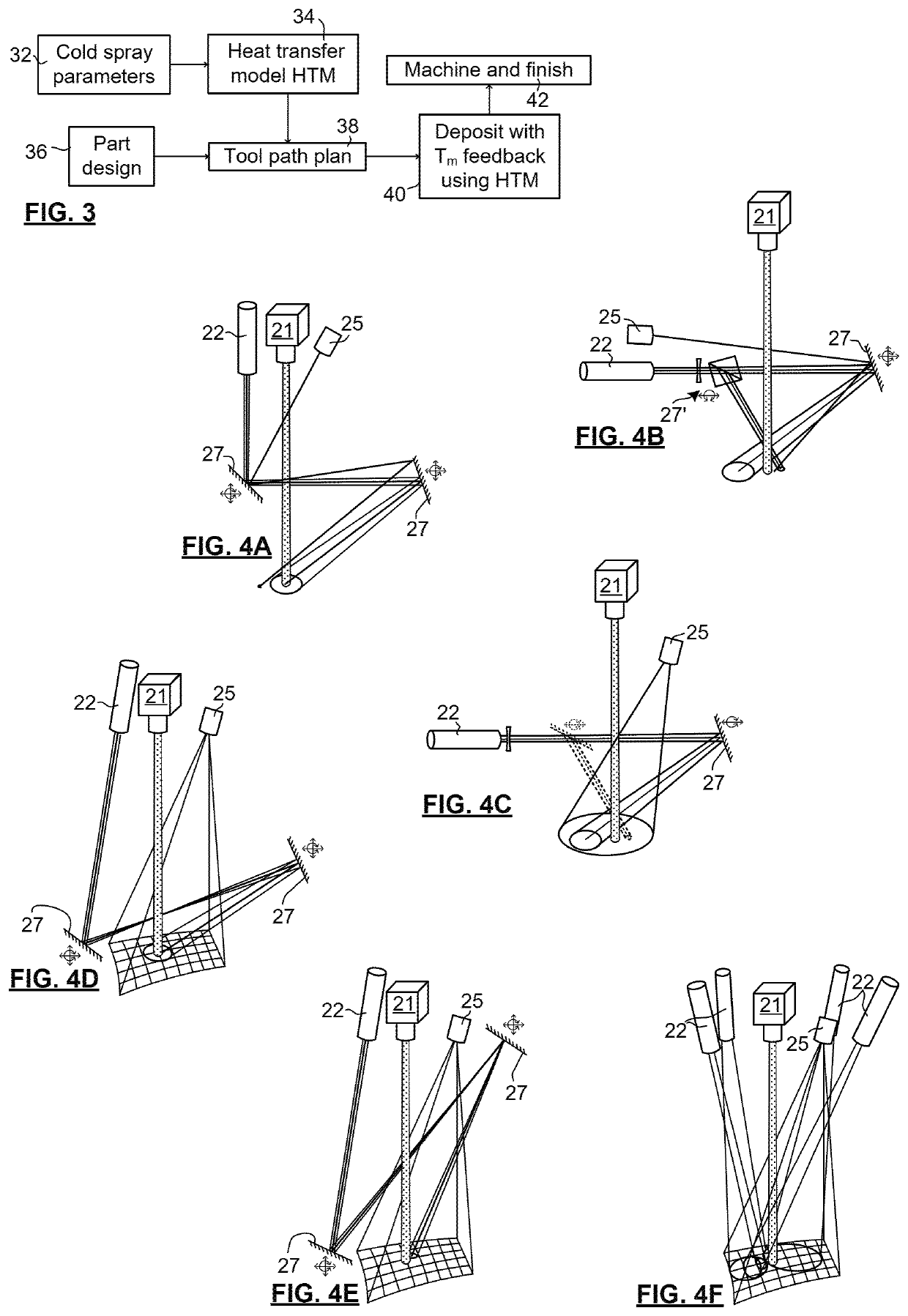

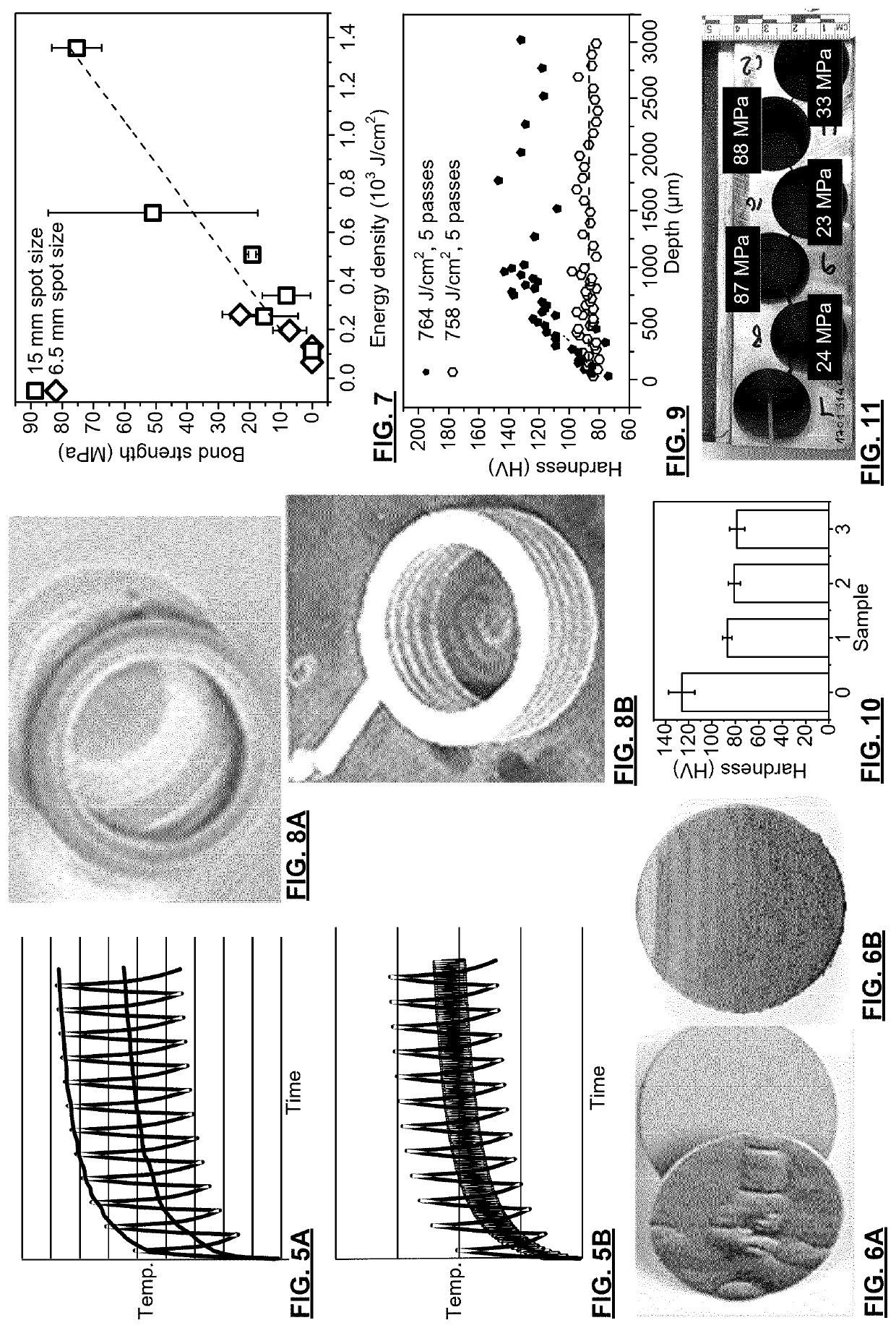

Apparatus and method for temperature controlled cold spray

PendingUS20210187618A1Good control over deposition propertyEasy temperature controlAdditive manufacturing apparatusIncreasing energy efficiencyTemperature controlFeedback controller

A technique for improving cold spray deposition conditions for cold spray additive manufacture of parts involves providing an in-situ temperature feedback controller with a remote instantaneous temperature sensor supplying surface temperature measurements of the deposition surface, and a (preferably long pulse) laser for heating. Temperature feedback allows for control over deposition conditions yielding predictable deposition properties.

Owner:NAT RES COUNCIL OF CANADA

Special chilled cast iron roller for wire rod bar finishing mill rack and production process thereof

The invention relates to a roller and a production process thereof, in particular to the special chilled cast iron roller for a wire rod bar finishing mill rack and the production process thereof. Theroller is prepared from chemical components of an outer layer and a core part. The outer layer is prepared from the chemical components: 3.0 to 3.2 percent of C, 0.4 to 0.60 percent of Si, 0.3 to 0.5percent of Mn, less than or equal to 0.05 percent of P, less than or equal to 0.03 percent of S, 1.25 to 1.45 percent of Cr, 0.3 to 0.5 percent of Mo, 3.0 to 3.5 percent of Ni, 0.1 to 0.3 percent ofV, 0.06 to 0.15 percent of Re, and 0.2 to 0.4 percent of Nb; and the core part is prepared from the chemical components: 3.0 to 3.5 percent of C, 2.2 to 2.60 percent of Si, 0.40 to 0.60 percent of Mn,less than or equal to 0.05 percent of P, less than or equal to 0.03 percent of S, 0.8 to 1.2 percent of Cu, larger than or equal to 0.05 percent of Mg, and the balance Fe and a small amount of residual elements. According to the special chilled cast iron roller for a wire rod bar finishing mill rack and the production process thereof provided by the invention, a traditional advantage of the chilled cast iron roller is fully played, and a carbide morphology and a roller microstructure are improved through optimized component preparation and improvement of a heat treatment process, so that a precious alloy resource is saved, a comprehensive performance of the roller is improved, and a production requirement of a steel rolling enterprise is met with a reasonable cost performance; and the on-machine rolling quantity of the roller is improved by 1.7 times compared with bainite made of a traditional material, and the roller price is only half of the price of high-speed steel.

Owner:湖州中杭轧辊有限公司

Process for the production of high-quality activated carbons as well as activated carbons produced according to the process

InactiveUS20170007980A1Reduce and prevent oxidationUniform supplyOther chemical processesCarbon compoundsActivated carbonPotassium hydroxide

A process for the production of high-quality activated carbons from carbonized, self-regenerating, carbon-containing biomasses selects the carbonized biomasses from HTC carbon from fruit stones and HTC carbon from nut shells. The carbonized biomasses together with potassium hydroxide, sodium hydroxide or a mixture of both hydroxides as activator are subjected to a heat treatment at temperatures at which the activator exists in the form of a melt. The activator and the carbonized biomasses are present in a weight ratio of 0.5:1 to 6:1 at the beginning of the heat treatment.

Owner:AVA CO2 SCHWEIZ

Method for producing a wafer

InactiveUS7211141B2High IG capabilityAvoid small quantitiesPolycrystalline material growthAfter-treatment detailsProduction rateWafering

The present invention is a method for producing a wafer comprising, at least, a BMD forming step of subjecting a silicon single crystal in a state of an ingot to heat treatment thereby to form bulk micro defects (BMDs) inside, and a wafer processing step of processing the ingot in which the bulk micro defects (BMDs) was formed into wafers. Thereby, there can be provided a method for producing a wafer, wherein heat treatment for providing IG capability in production of wafer can be shortened and wafers with high IG capability can be produced in large quantity. Also, the present invention can further comprise a wafer heat-treating step of subjecting the processed wafer to heat treatment, or an epitaxial growth step of forming an epitaxial layer on the wafer. Thereby, there is improved productivity of annealed wafers or epitaxial wafers that are excellent in gettering capability.

Owner:SHIN-ETSU HANDOTAI CO LTD

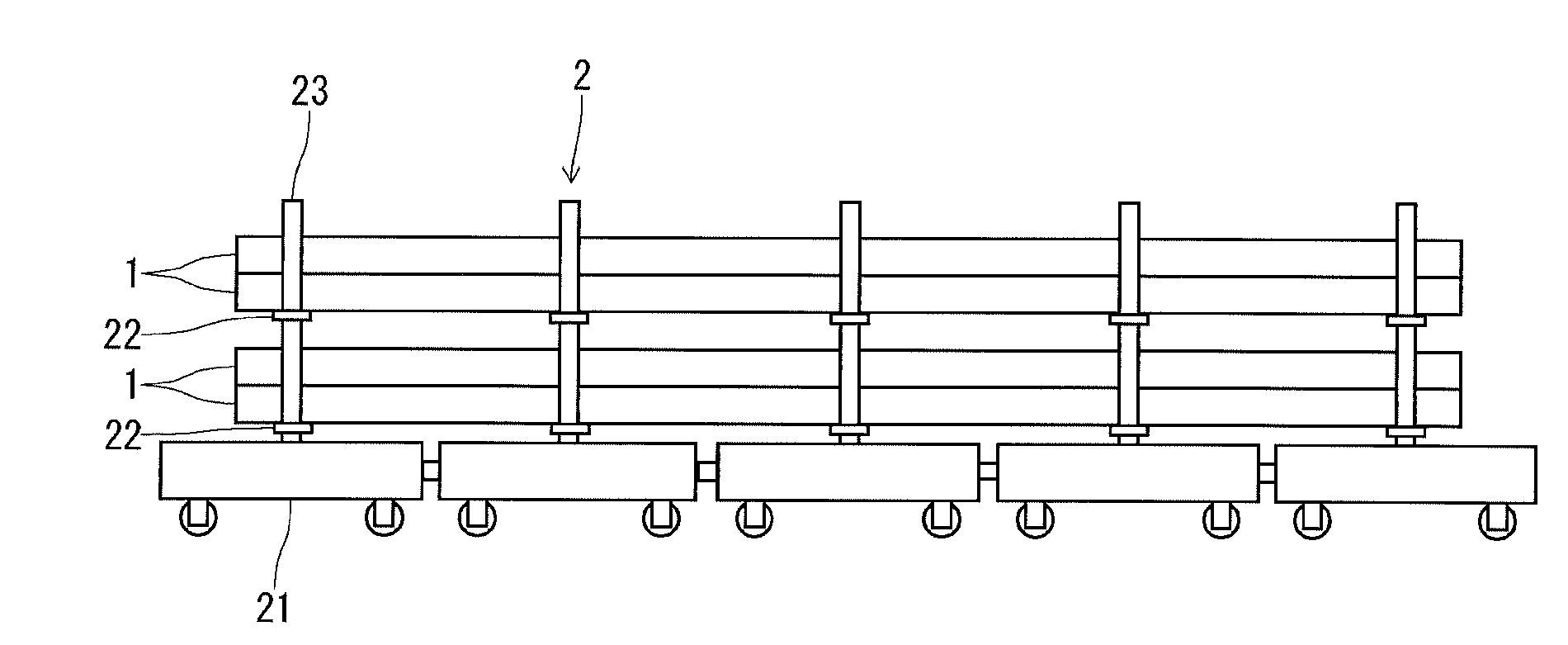

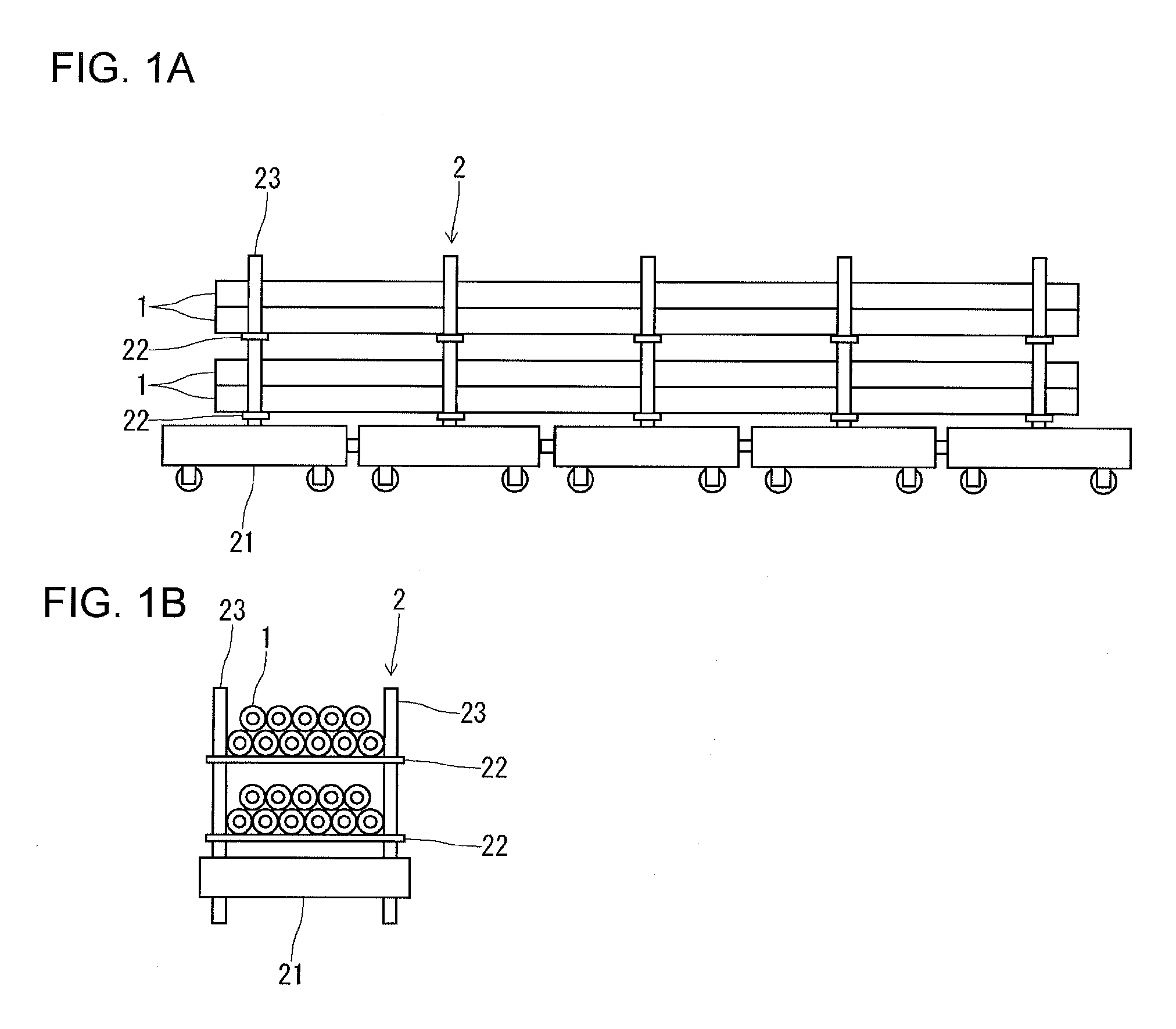

Method for heat-treating metal tubes or pipes for nuclear power plant, batch-type vacuum heat treatment furnace used therefor, and metal tubes or pipes for nuclear power plant heat-treated by the same

InactiveUS20120285577A1Remarkable effectReduce discolorationNuclear energy generationReactors manufactureIndirect contactNuclear power plant

In a method for heat treating a metal tube or pipe for a nuclear power plant, the tube or pipe being accommodated in a batch-type vacuum heat treatment furnace, when the tube or pipe is laid down on and is subjected to heat treatment on a plurality of metal cross beams arranged along a longitudinal direction of the tube or pipe, it is possible to suppress scratches to be formed on the outer surface of the tube or pipe and attributable to heat treatment, and to reduce the discoloration on the outer surface of the tube or pipe by holding the tube or pipe and the metal cross beams in indirect contact with each other by virtue of a heat resistant fabric having a thickness of 0.1 to 1.2 mm interposed in between.

Owner:NIPPON STEEL CORP

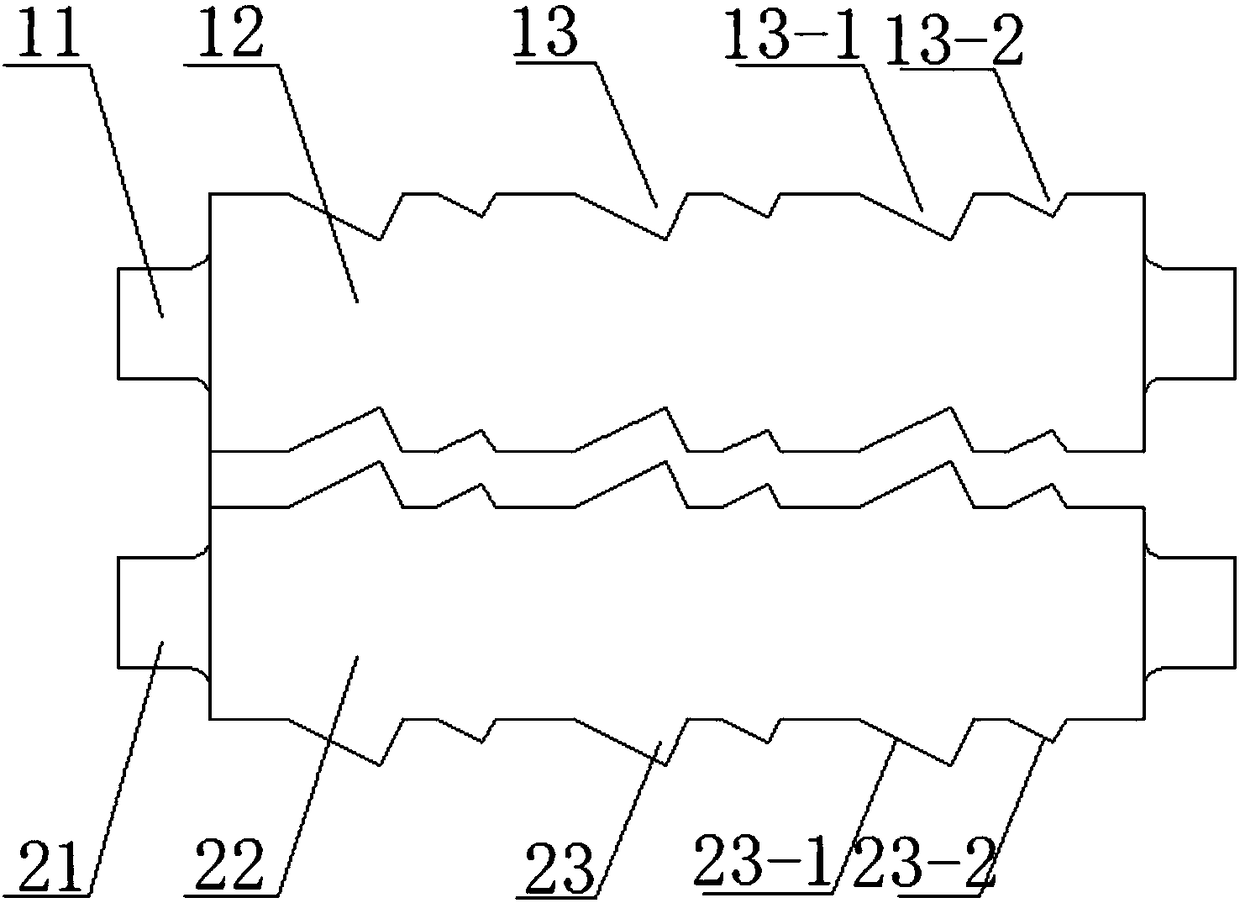

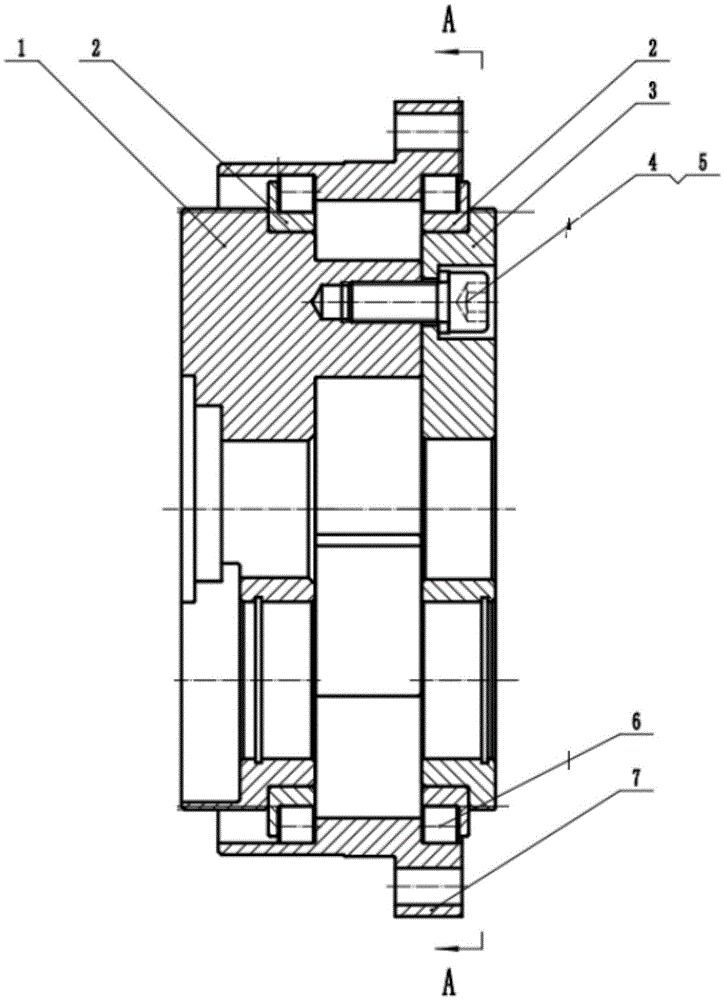

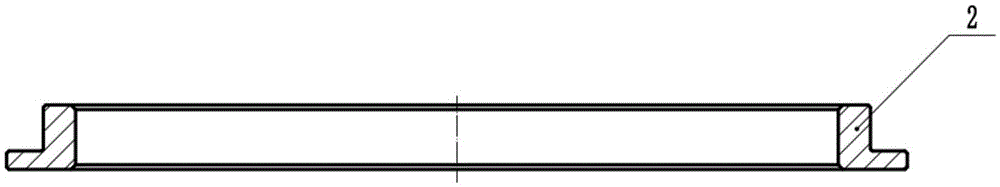

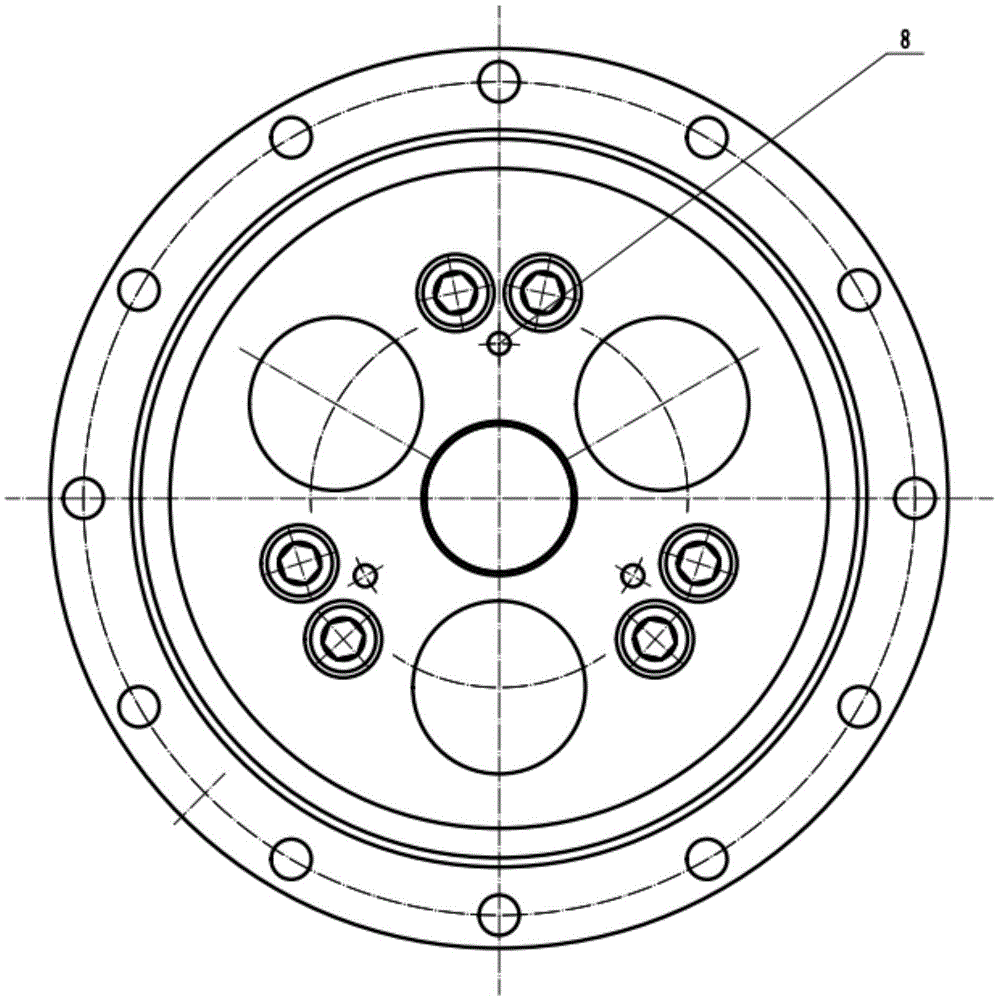

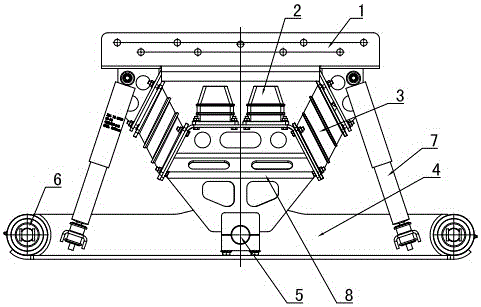

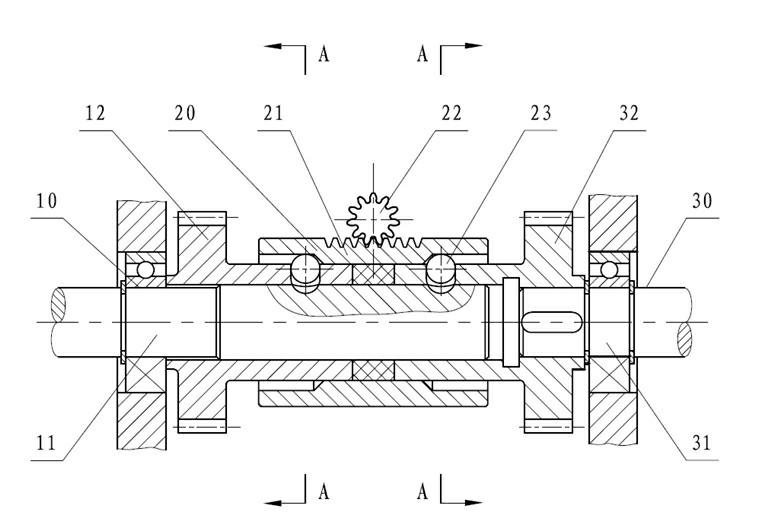

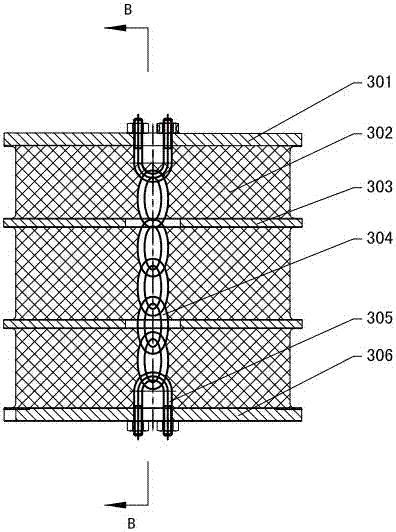

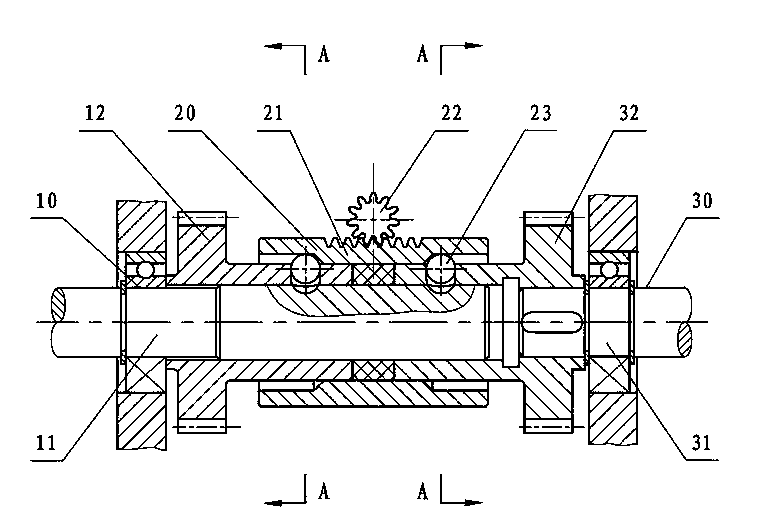

Simple supporting mechanism provided with two discs and machining method of simple supporting mechanism

ActiveCN105422744AImprove carrying capacityReduce heat treatment requirements and processing difficultyToothed gearingsGearing detailsBending momentEngineering

The invention discloses a simple supporting mechanism provided with two discs. The simple supporting mechanism comprises an inner gear, the left supporting disc and the right supporting disc, wherein the left supporting disc and the right supporting disc are arranged in a center hole of the inner gear and coaxially and fixedly connected. A left supporting bearing and a right supporting bearing are arranged between the left supporting disc and the center hole of the inner gear ring and between the right supporting disc and the center hole of the inner gear ring respectively. A roller of the left supporting bearing and a roller of the right supporting bearing are directly matched with the inner wall of the center hole of the inner gear. The simple supporting mechanism provided with the two discs can bear a large bending moment and a large axial load, the requirement of a precise speed reducer is met, the machining difficulty is lowered, and the manufacturing cost is reduced.

Owner:CHONGQING UNIV +1

Integrated metal processing facility

InactiveUS7258755B2Reduce heat treatment requirementsProcessing and heat treatment time can be enhanced and reducedCasting plantsFurnace typesMetalworkingMolten metal

An integrated metal processing facility in which molten metal is poured into a series of molds at a pouring station to form metal castings, which are then transferred to a heat treatment line. Prior to introduction of the castings into a heat treatment station of the heat treatment line, the castings are subjected to heating sufficient to arrest cooling of the castings at or above a process control temperature for the metal thereof.

Owner:CONSOL ENG

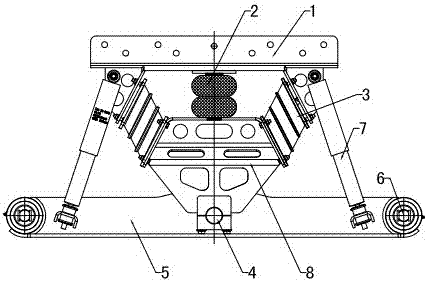

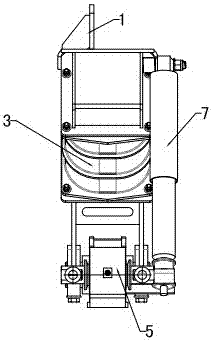

Novel rubber suspension assembly

ActiveCN105109296AHigh hardnessImprove integrityResilient suspensionsManufacturing technologyEngineering

The invention discloses a novel rubber suspension assembly, and belongs to the technical field of manufacture of vehicle parts. The novel rubber suspension assembly is characterized by comprising a rubber suspension fixing and welding plate (1) and a rubber suspension main welding and balancing beam (4) which are mutually arranged in parallel, wherein a rubber suspension main spring (3) is mounted between the rubber suspension fixing and welding plate (1) and the rubber suspension main welding and balancing beam (4); a supporting frame is arranged on the left side of the upper part of the rubber suspension main spring (3), a supporting frame is arranged on the right side of the upper part of the rubber suspension main spring (3), the two supporting frames are connected with two end parts of the rubber suspension fixing and welding plate (1) respectively, and a rubber suspension auxiliary spring (2) is vertically arranged at the middle position of the corresponding supporting frame; the lower part of the rubber suspension main spring (3) is connected to the middle position of the rubber suspension main welding and balancing beam (4).The novel rubber suspension assembly is light in structure, long in service life and convenient to maintain and preserve, and the novel rubber suspension assembly conforms to light weight requirements.

Owner:山东安博机械科技股份有限公司

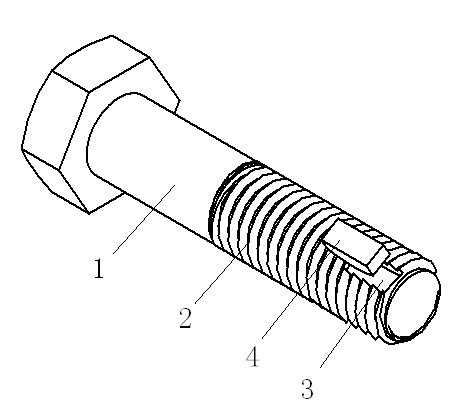

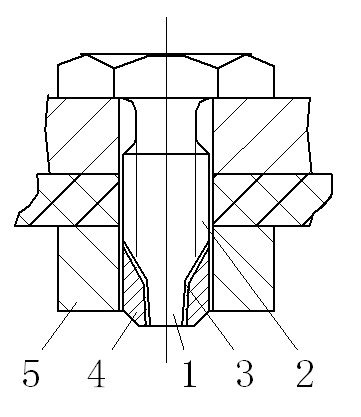

Method for preventing lock bolt from loosening and lock bolt assembly

InactiveCN102588418APrevent looseningAchieve self-locking functionNutsKey type connectionsScrew threadEmbedded system

The invention discloses a method for preventing a lock bolt from loosening and a lock bolt assembly. According to the invention, at least one key slot is made on the thread section of a bolt, and a key block is inserted into the key slot, then the bolt is screwed into a nut, thread teeth on the nut are used for extruding the key block to be deformed, a thread in closely matched with the nut is extruded on the key block, and then the thread of the nut can be tightly matched with the thread extruded on the key block to generate a locking force, so as to achieve the aim of preventing the lock bolt from loosening. The method for preventing the lock bolt from loosening and the lock bolt assembly not only have the advantages of being reliable in self-locking, good in strength and light in weight, but also has the advantages of being low in requirements on heat treatment, easy to product, low in production cost, convenient to use and the like.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

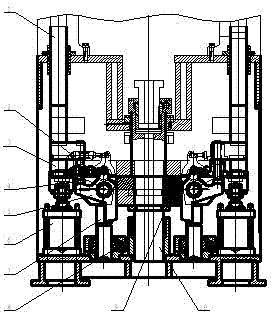

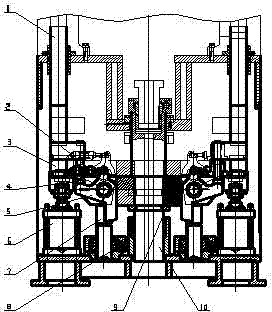

Double-support pressurizing mechanism

InactiveCN102441669ALower requirementReduce heat treatment requirementsEngineeringSymmetric structure

The invention relates to a double-support pressurizing mechanism, which comprises two symmetric ejector rods connected to two ends of an upper punch. The lower portion of each ejector rod drives a rotatable shifting fork stopper through a cylinder, equal-height support adjusting screw rods are arranged below the shifting fork stoppers, an open rod capable of contacting with each shifting fork stopper is arranged between each cylinder and the shifting fork stopper, and a mechanism for preventing a female die from descending is formed when the two shifting fork stoppers are supported on the support adjusting screw rods. By the aid of a two-side symmetric structure of the double-support pressurizing mechanism, pressure is evenly distributed on the double support adjusting screw rods, main pressing force is decomposed into component force, a pressure stress on the mechanism is decomposed into two smaller pressure stresses, the requirements of part materials and heat treatment are lowered on the premise of meeting functional requirements, and the functions of a single large-sized structure are realized by a structure of a smaller size.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

Manufacturing process for annealed wafer and annealed wafer

InactiveUS20060121291A1Weight optimizationIncrease the diameterPolycrystalline material growthSemiconductor/solid-state device manufacturingSurface layerHigh density

There are provided a heat-treating method capable of suppressing generation of slip in a CZ silicon single crystal wafer having a diameter of mainly 300 mm or more even under high temperature heat treatment to annihilate grown-in defects in the vicinity of a surface of the wafer, and an annealed wafer having a DZ layer in a surface layer of the wafer and oxide precipitates in the bulk thereof at a high density which exert a high gettering effect. First heat treatment of a silicon single crystal wafer manufactured from a silicon single crystal ingot pulled by means of a Czochralski method is performed at a temperature in the range of 600 to 1100° C. to form oxide precipitates in the bulk of the wafer, and thereafter, second heat treatment is performed at a temperature in the range of 1150 to 1300° C.

Owner:SHIN-ETSU HANDOTAI CO LTD

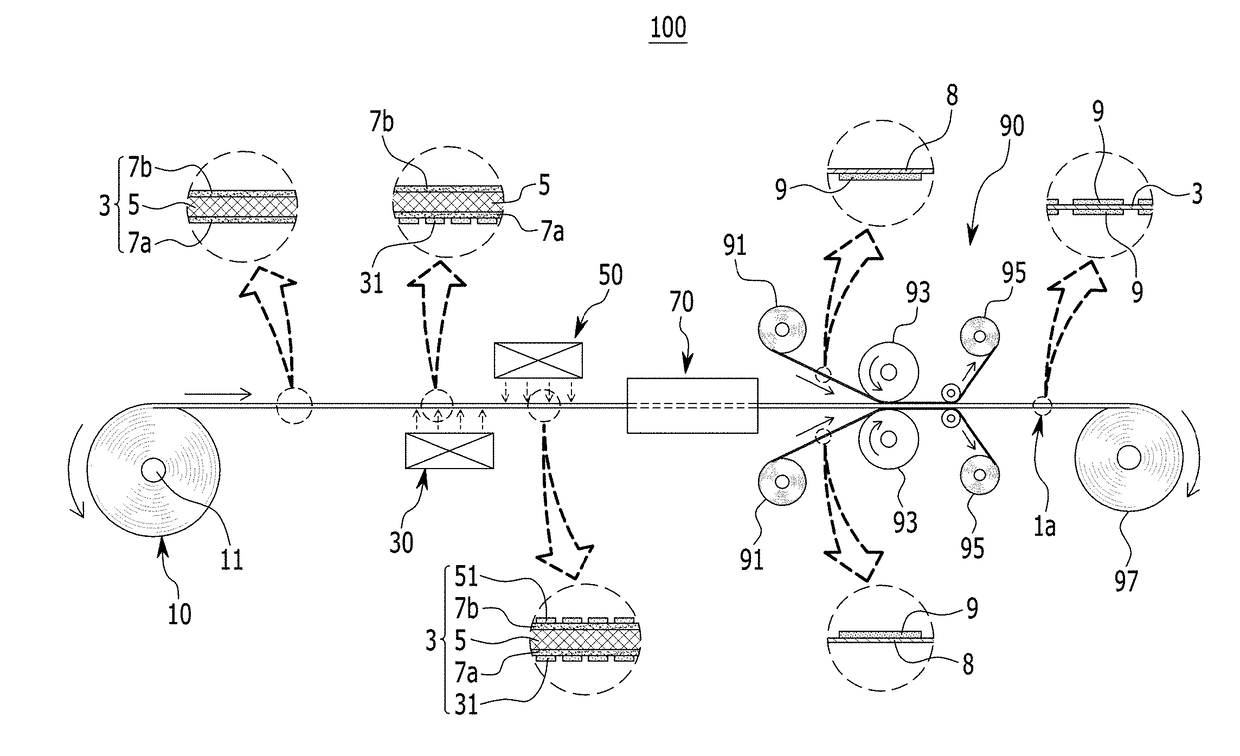

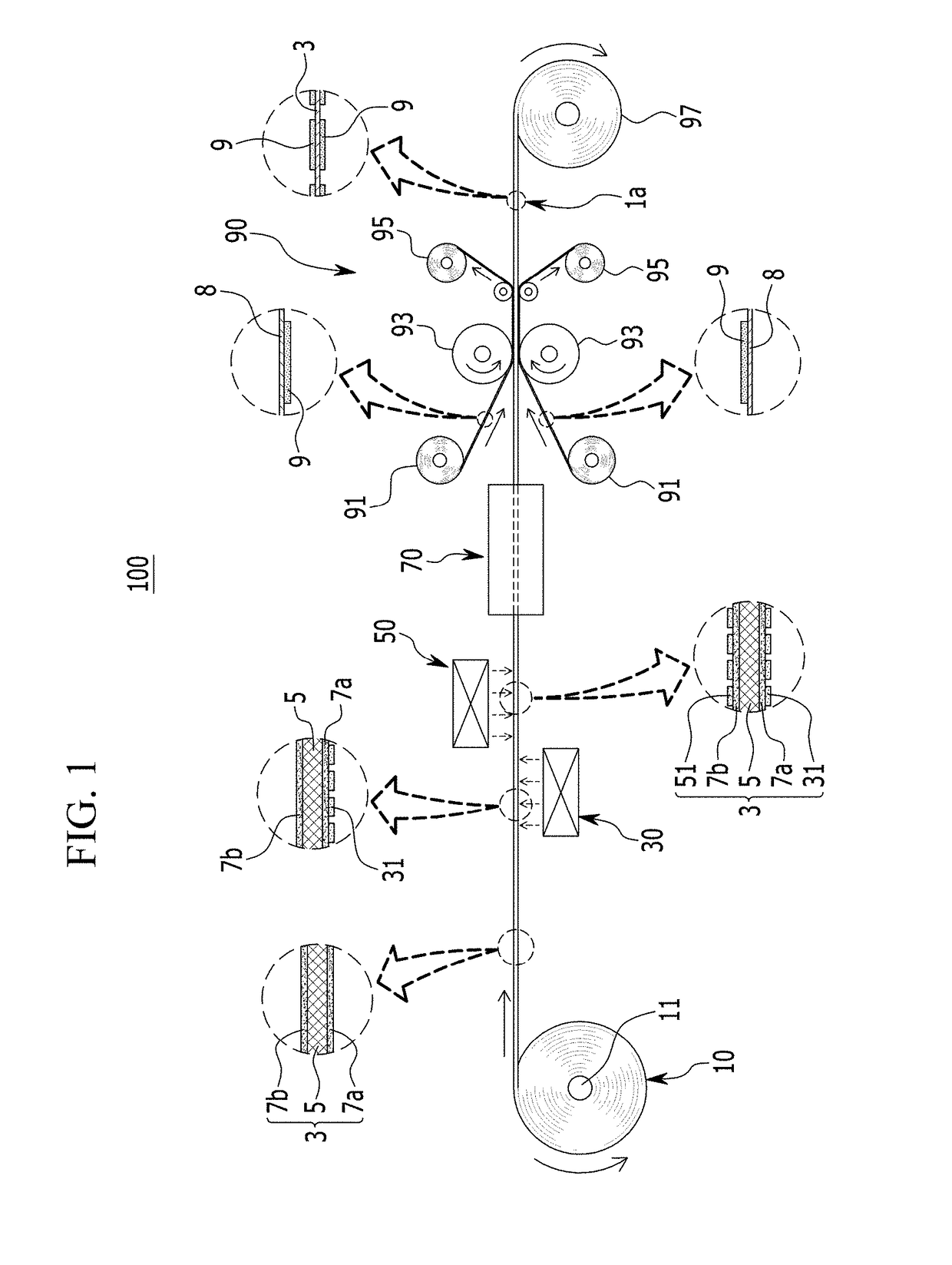

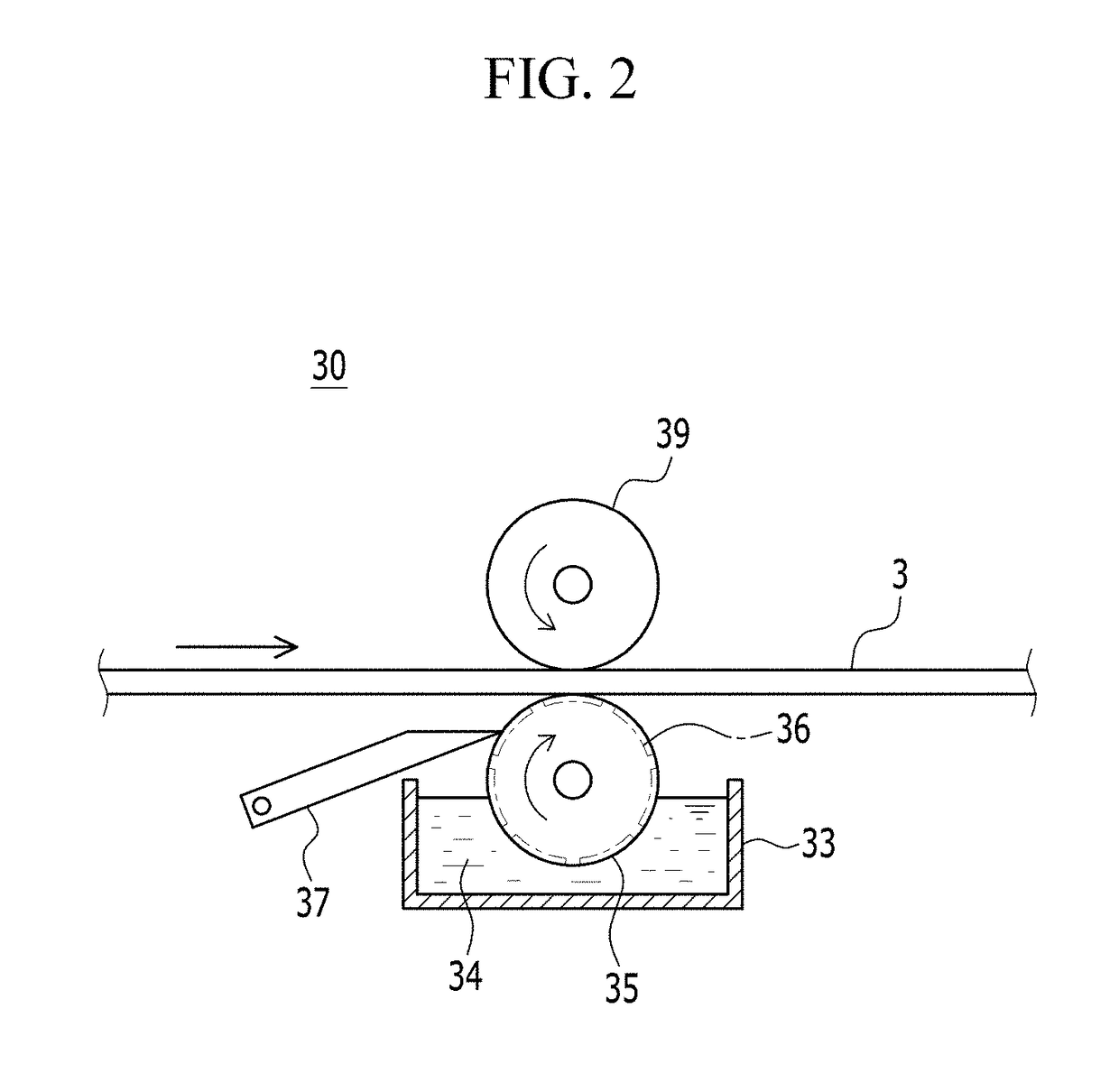

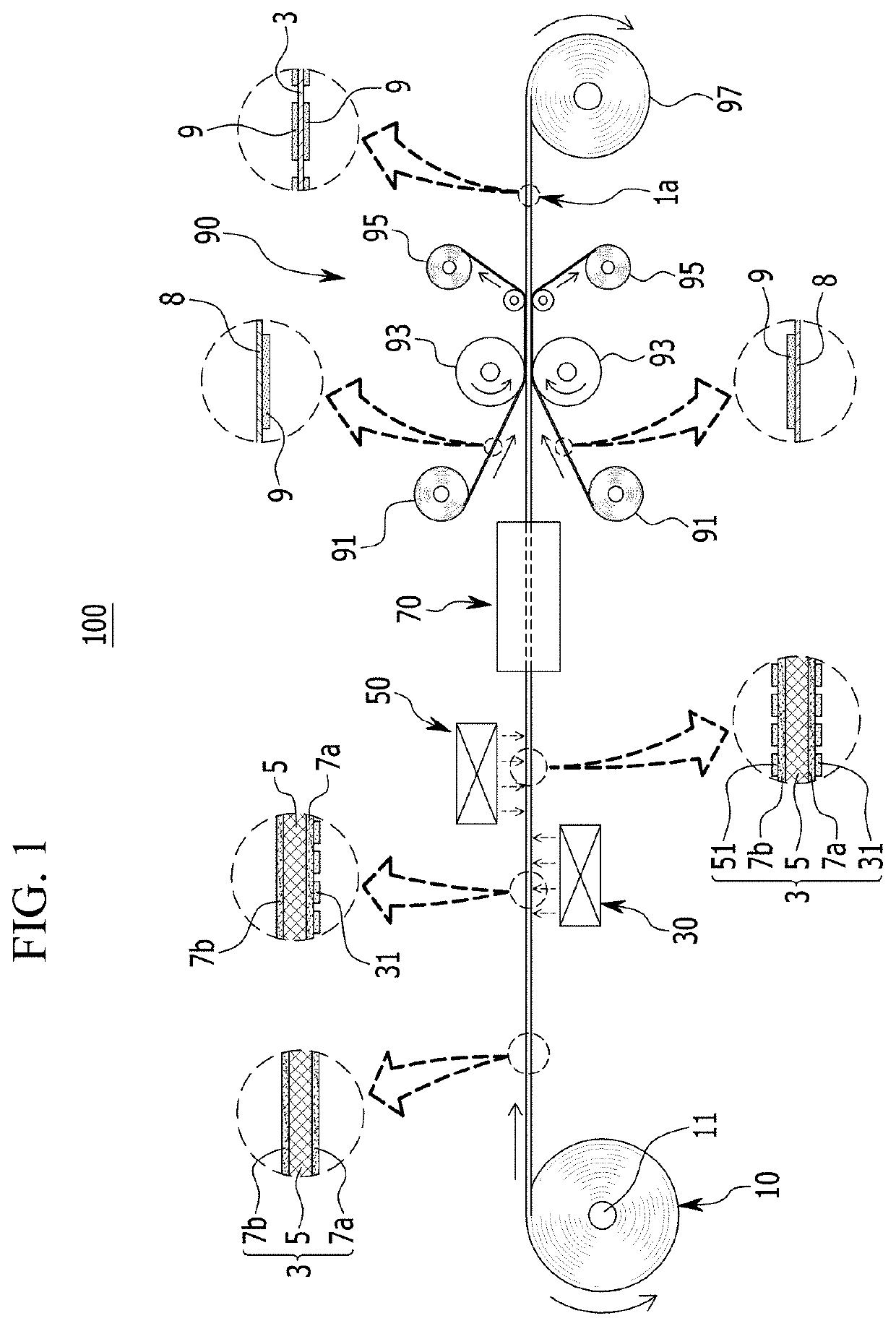

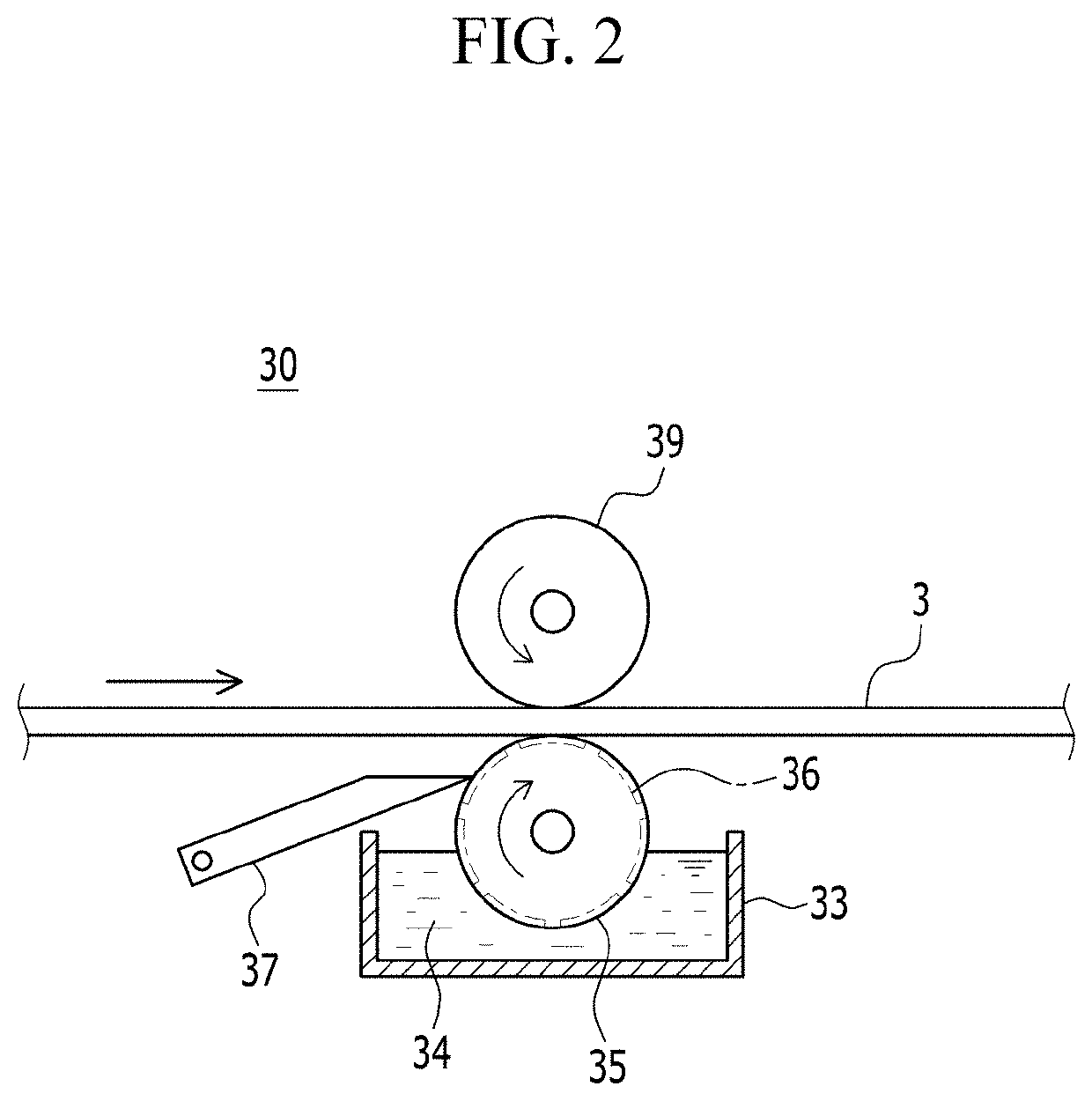

Device and method for manufacturing membrane-electrode assembly of fuel cell

ActiveUS20180331380A1Reduce heat treatment requirementsImprove productivityLamination ancillary operationsCell electrodesIonomerFuel cells

A manufacturing device of a membrane-electrode assembly for a fuel cell is provided. The manufacturing device includes an electrolyte membrane feeding unit forming a first and second ionomer bases impregnated at both surfaces of a reinforcing layer and unwinding an electrolyte membrane wound in a roll type supplied in a predetermined transporting path. A first patterning unit is disposed at a rear side of the electrolyte membrane feeding unit and patterns a first ionomer protrusion pattern layer on the first ionomer base and a second patterning unit is disposed at the rear side of the first patterning unit and patterns a second ionomer protrusion pattern layer on the second ionomer base. A transfer unit is disposed at the rear side of the second patterning unit and couples a catalyst electrode layer on the first and second ionomer protrusion pattern layers by a roll laminating method.

Owner:HYUNDAI MOTOR CO LTD +1

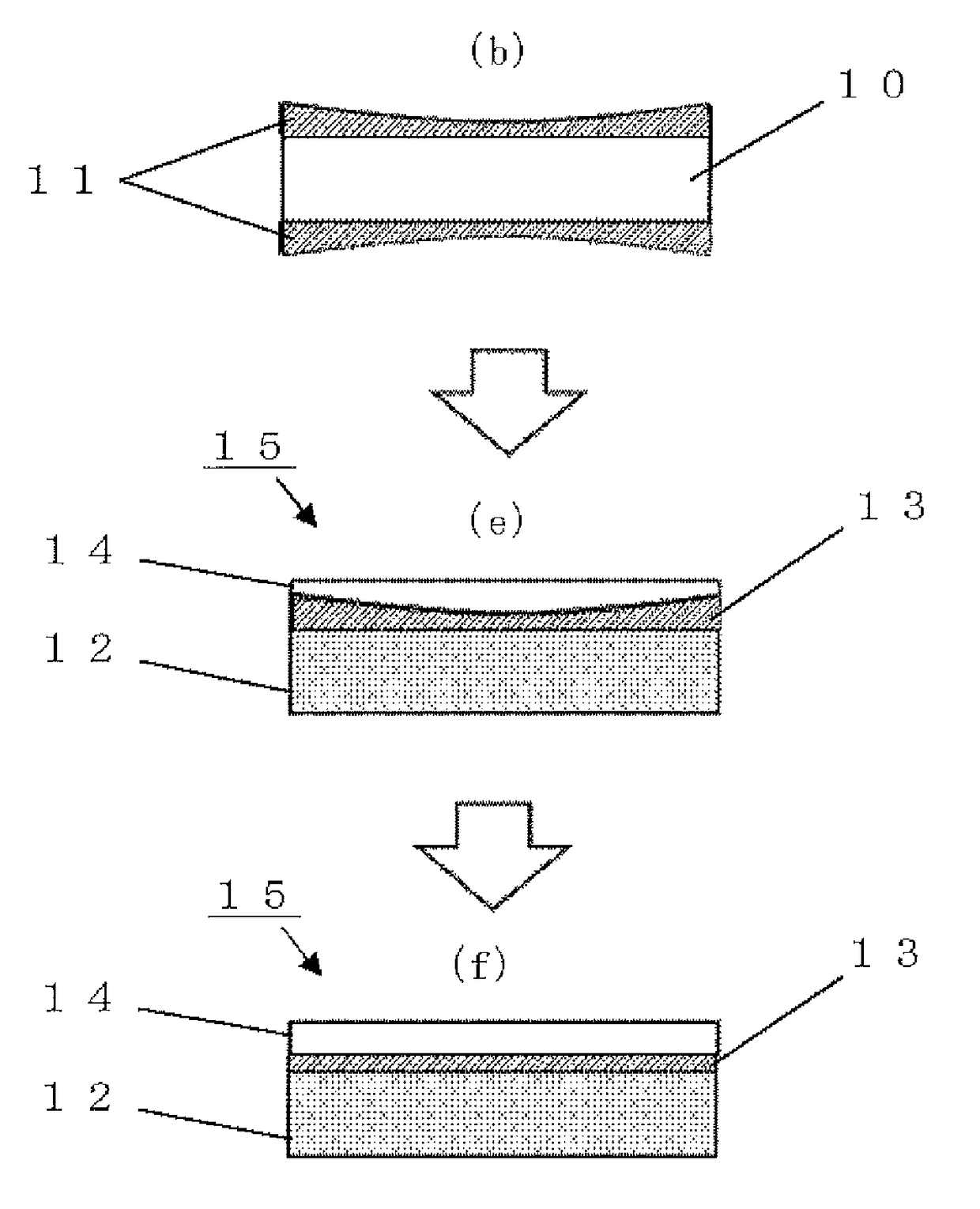

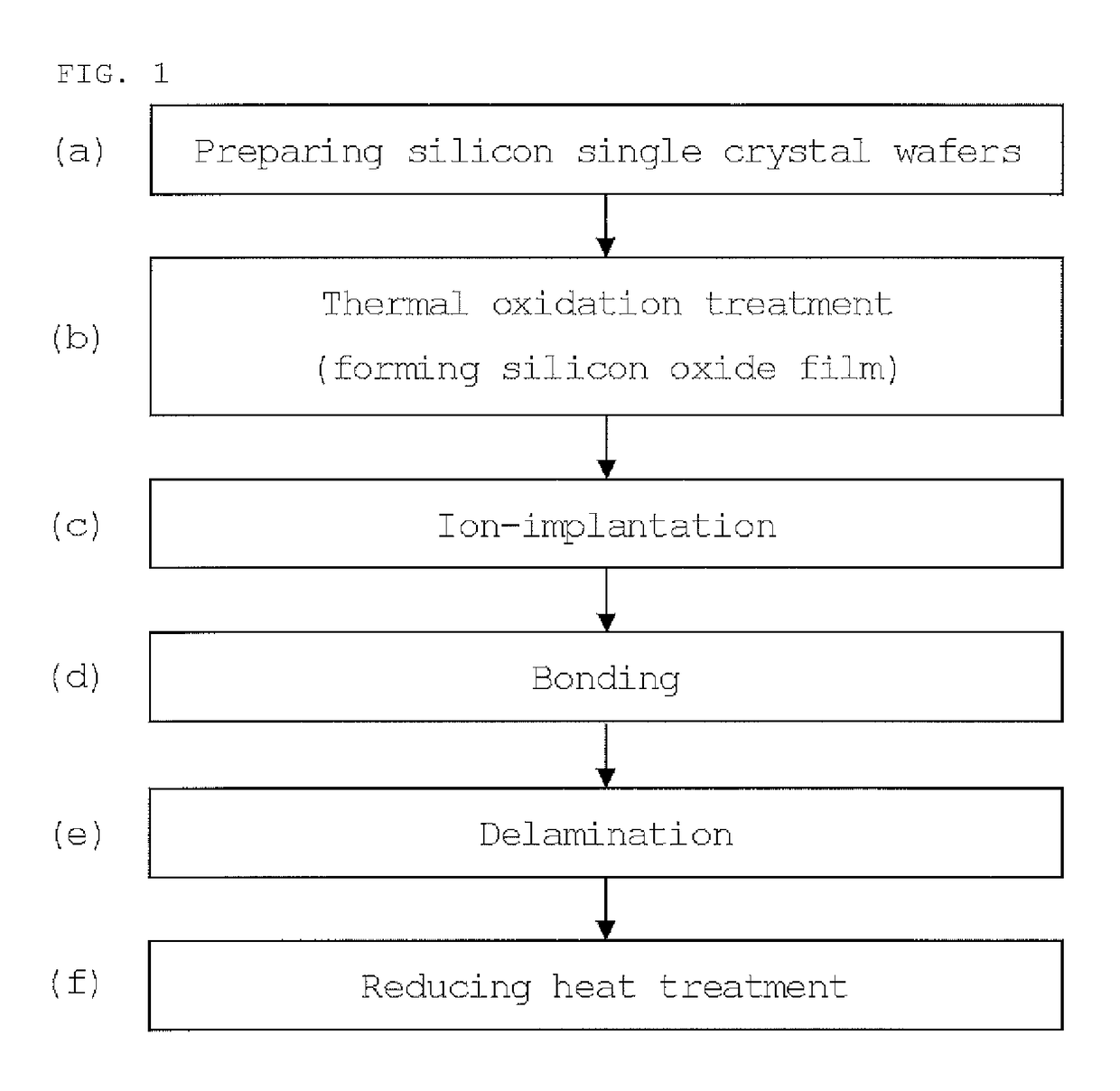

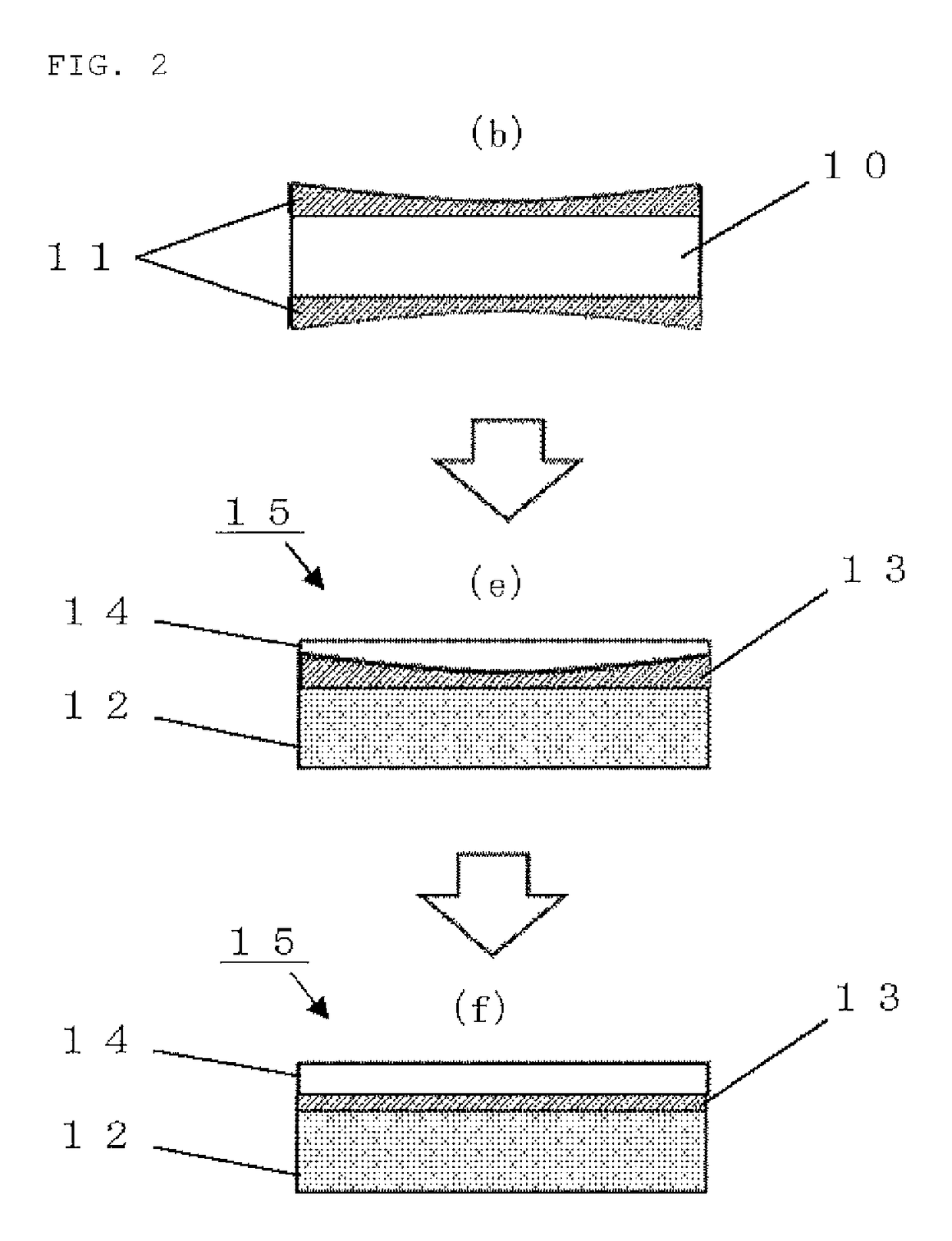

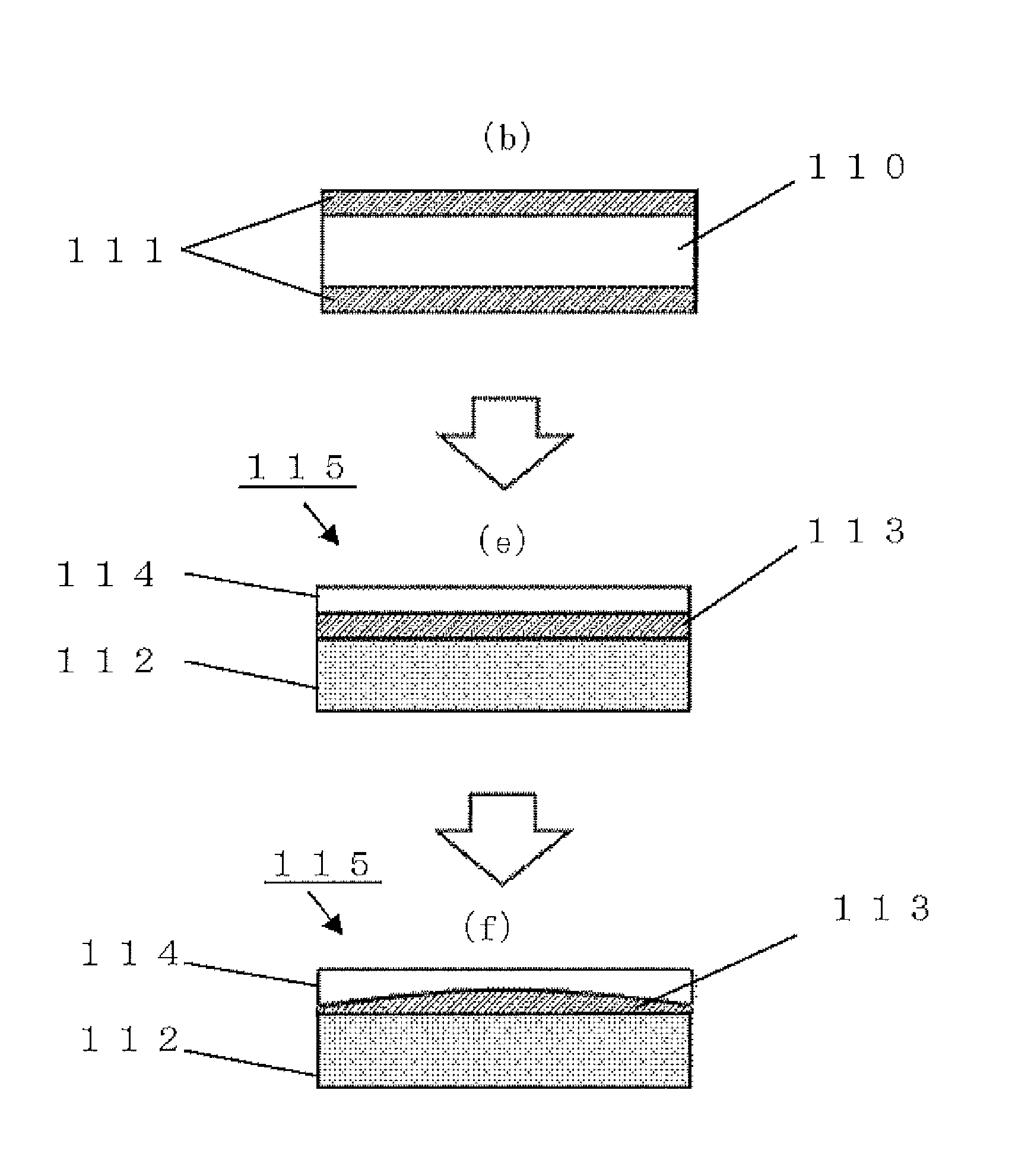

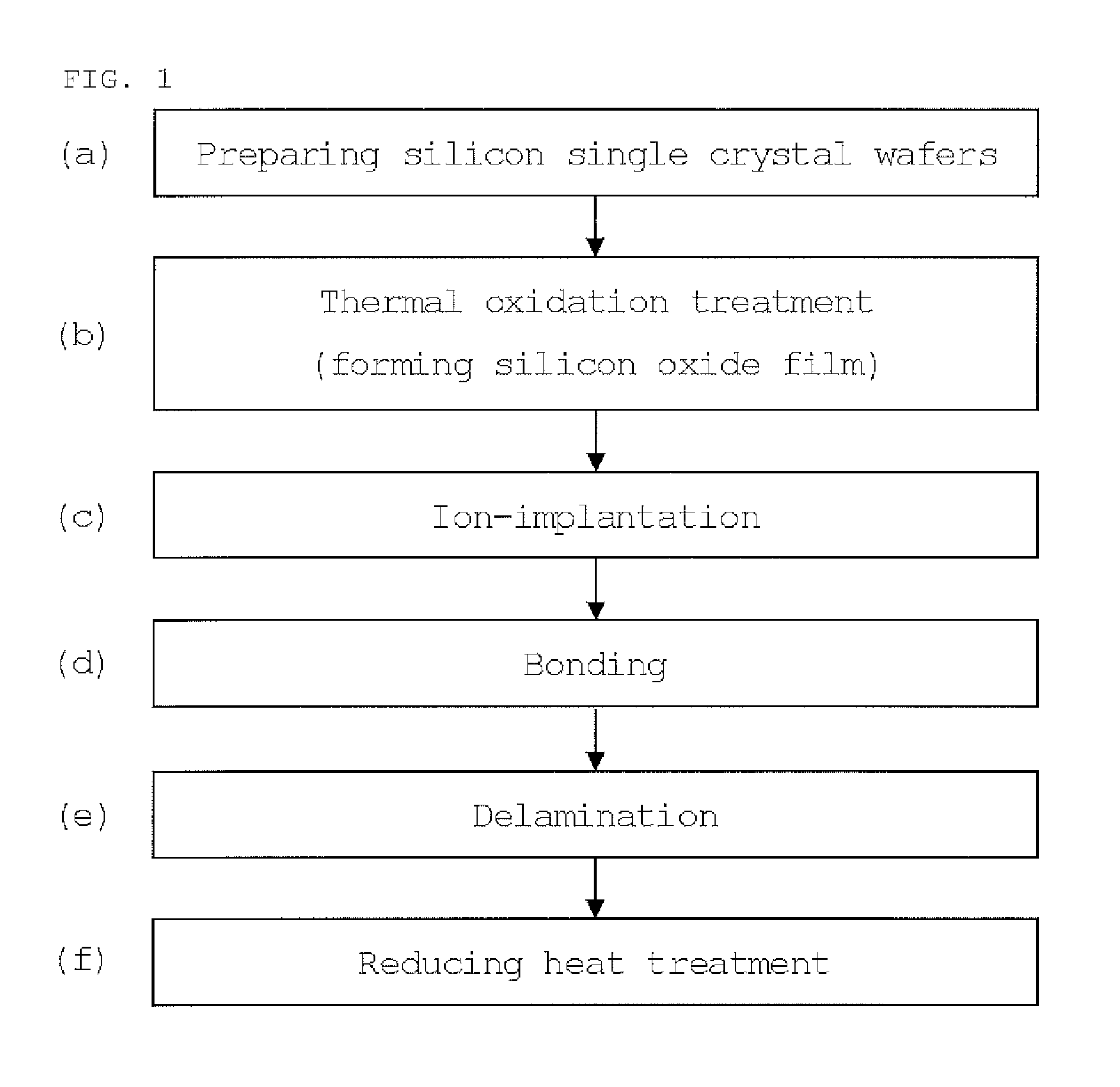

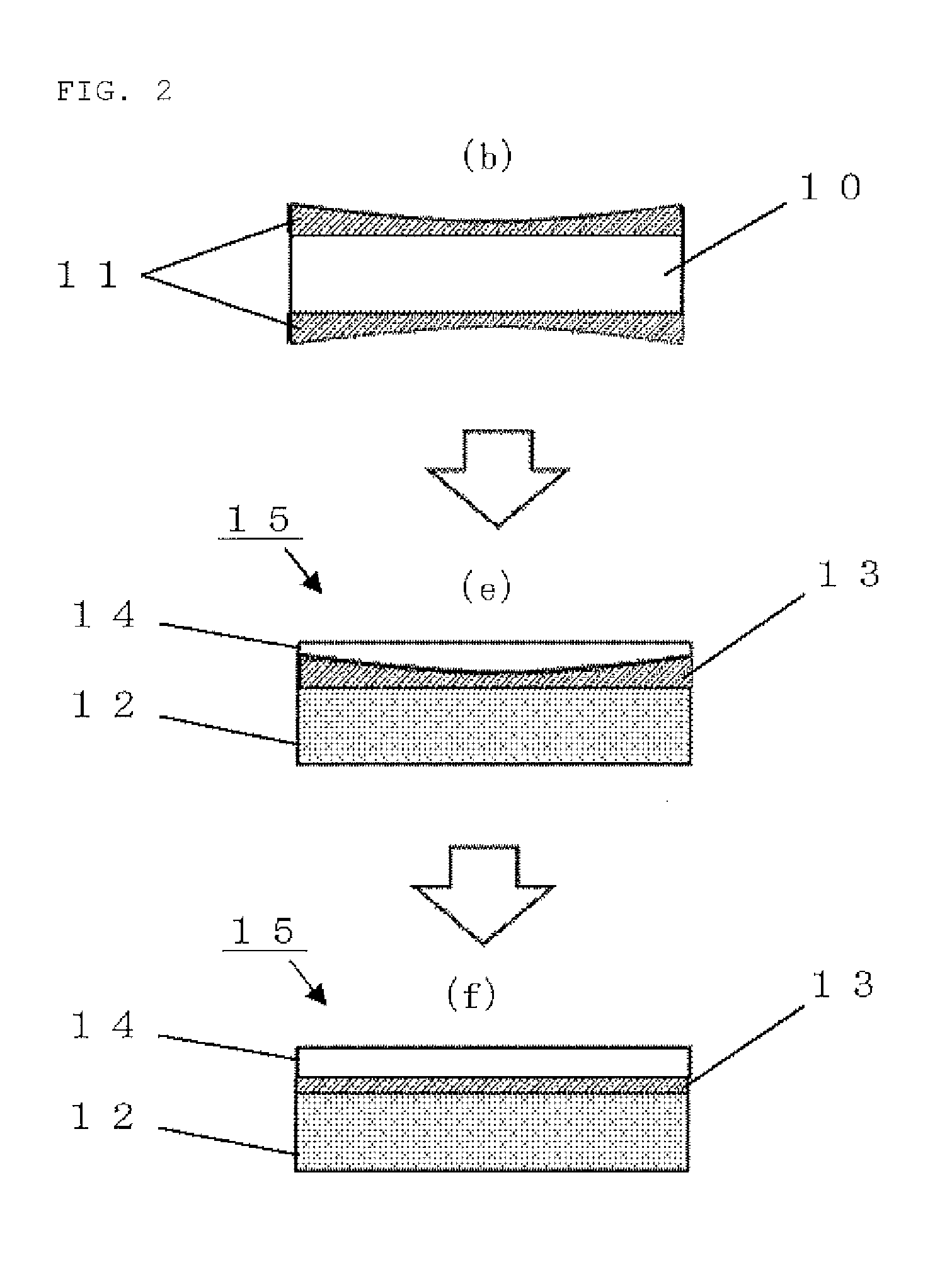

Method for manufacturing bonded SOI wafer

ActiveUS9793154B2Suppress mutationReduce heat treatment requirementsSemiconductor/solid-state device manufacturingOptoelectronicsSilicon oxide

The present invention is a method for manufacturing a bonded SOI wafer including: performing a thermal oxidation treatment including at least one of a thermal oxidation during temperature-rising and a thermal oxidation during temperature-falling with the use of a batch type heat treatment furnace, thereby forming a silicon oxide film in such a way that the oxide film buried in the delaminated bonded SOI wafer has a concentric oxide film thickness distribution, and subjecting the bonded SOI wafer after delaminating a bond wafer to a reducing heat treatment to make a film thickness range of the buried oxide film being smaller than a film thickness range before the reducing heat treatment. This provides a method for manufacturing a bonded SOI wafer which can suppress a variation of a radial distribution of a buried oxide film thickness caused by a reducing heat treatment performed after delaminating the SOI layer.

Owner:SHIN-ETSU HANDOTAI CO LTD

Method for manufacturing bonded soi wafer

ActiveUS20160372363A1Suppress mutationReduce heat treatment requirementsSemiconductor/solid-state device manufacturingOptoelectronicsSilicon oxide

The present invention is a method for manufacturing a bonded SOI wafer including: performing a thermal oxidation treatment including at least one of a thermal oxidation during temperature-rising and a thermal oxidation during temperature-falling with the use of a batch type heat treatment furnace, thereby forming a silicon oxide film in such a way that the oxide film buried in the delaminated bonded SOI wafer has a concentric oxide film thickness distribution, and subjecting the bonded SOI wafer after delaminating a bond wafer to a reducing heat treatment to make a film thickness range of the buried oxide film being smaller than a film thickness range before the reducing heat treatment. This provides a method for manufacturing a bonded SOT wafer which can suppress a variation of a radial distribution of a buried oxide film thickness caused by a reducing heat treatment performed after delaminating the SOI layer.

Owner:SHIN-ETSU HANDOTAI CO LTD

Clutch and reversing device

ActiveCN102606698AImprove transmission efficiencyReduce material requirementsGearingSteel ballEngineering

The invention discloses a clutch and reversing device comprising an input shaft part, a clutch and reversing part, an output shaft part, etc. The clutch and reversing device is characterized in that when a clutch slippage sleeve is arranged between an input shaft gear and an output shaft gear, steel balls in drill holes radially and uniformly distributed in sleeves of the input shaft gear and the output shaft gear are all positioned in countersink sections of an inner hole of the slippage sleeve, when an input shaft rotates, the steel balls are extruded out of input shaft ball sockets, and the input (or output) gear idles on the input shaft so as to realize the separation of a clutch. When the slippage sleeve moves towards the right side, transition inclined planes between the inner hole and countersinks of the slippage sleeve are gradually pressed down by the steel balls, then the steel balls are pressed and enter a circle of radially and uniformly distributed ball sockets at the right side of the input shaft, the input shaft and the output shaft gear are wedged into a whole, and an output shaft rotates along with the input shaft in the same direction; and the output shaft can rotate reversely when the slippage sleeve moves towards the left side. The clutch and reversing device can realize separation and reversion under the work condition of high rotation difference.

Owner:徐彬

Device and method for manufacturing membrane-electrode assembly of fuel cell

ActiveUS10673086B2Reduce heat treatment requirementsImprove productivityLamination ancillary operationsCell electrodesIonomerFuel cells

A manufacturing device of a membrane-electrode assembly for a fuel cell is provided. The manufacturing device includes an electrolyte membrane feeding unit forming a first and second ionomer bases impregnated at both surfaces of a reinforcing layer and unwinding an electrolyte membrane wound in a roll type supplied in a predetermined transporting path. A first patterning unit is disposed at a rear side of the electrolyte membrane feeding unit and patterns a first ionomer protrusion pattern layer on the first ionomer base and a second patterning unit is disposed at the rear side of the first patterning unit and patterns a second ionomer protrusion pattern layer on the second ionomer base. A transfer unit is disposed at the rear side of the second patterning unit and couples a catalyst electrode layer on the first and second ionomer protrusion pattern layers by a roll laminating method.

Owner:HYUNDAI MOTOR CO LTD +1

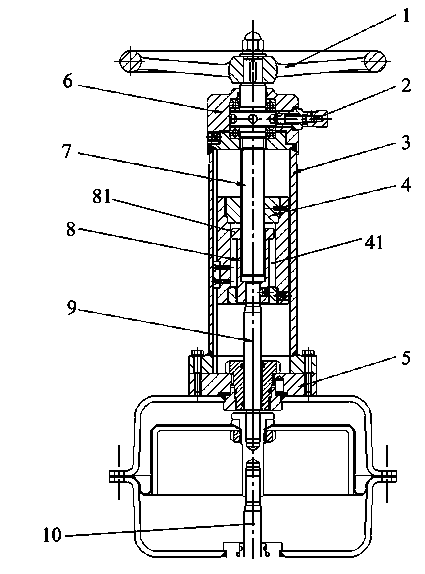

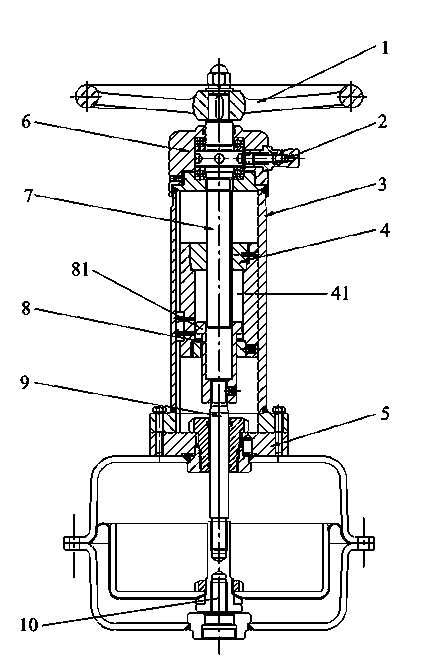

Top mounted hand wheel mechanism

ActiveCN102494179BNot easy to rustReduce heat treatment requirementsOperating means/releasing devices for valvesDrive shaftEngineering

Owner:ZHEJIANG SUPCON FLUID TECH

A New Type of Heavy Truck Air Suspension

ActiveCN105109297BReduce weightImprove performanceResilient suspensionsCushioningManufacturing technology

A new type of heavy truck air suspension belongs to the technical field of automobile parts manufacturing. It is characterized in that it comprises an upper rubber suspension main mounting plate (1) and a lower rubber suspension main welding equalizing beam (5), and a rubber spring base (8) is provided on the upper side of the rubber suspension main welding equalizing beam (5). ), the rubber suspension main springs (3) are respectively fixed between the two ends of the rubber spring base (8) and the rubber suspension main mounting plate (1). A rubber air spring (2) is also arranged between the two rubber suspension main springs (3). The new heavy truck air suspension is light in weight, good in variable stiffness performance and cushioning performance, strong in shock absorption, and improves usability and maintenance.

Owner:山东安博机械科技股份有限公司

Clutch and reversing device

ActiveCN102606698BImprove transmission efficiencyReduce material requirementsGearingEngineeringSteel ball

The invention discloses a clutch and reversing device comprising an input shaft part, a clutch and reversing part, an output shaft part, etc. The clutch and reversing device is characterized in that when a clutch slippage sleeve is arranged between an input shaft gear and an output shaft gear, steel balls in drill holes radially and uniformly distributed in sleeves of the input shaft gear and the output shaft gear are all positioned in countersink sections of an inner hole of the slippage sleeve, when an input shaft rotates, the steel balls are extruded out of input shaft ball sockets, and the input (or output) gear idles on the input shaft so as to realize the separation of a clutch. When the slippage sleeve moves towards the right side, transition inclined planes between the inner hole and countersinks of the slippage sleeve are gradually pressed down by the steel balls, then the steel balls are pressed and enter a circle of radially and uniformly distributed ball sockets at the right side of the input shaft, the input shaft and the output shaft gear are wedged into a whole, and an output shaft rotates along with the input shaft in the same direction; and the output shaft can rotate reversely when the slippage sleeve moves towards the left side. The clutch and reversing device can realize separation and reversion under the work condition of high rotation difference.

Owner:徐彬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com