Simple supporting mechanism provided with two discs and machining method of simple supporting mechanism

A double disc and disc technology, applied in the field of design and processing of the output support mechanism of the planetary reducer with small tooth difference, can solve the problems of not being able to bear the large bending moment axial load, processing difficulty, high heat treatment requirements, etc., to improve the bearing capacity ability, reduce manufacturing accuracy, and reduce the effects of transmission error loss links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

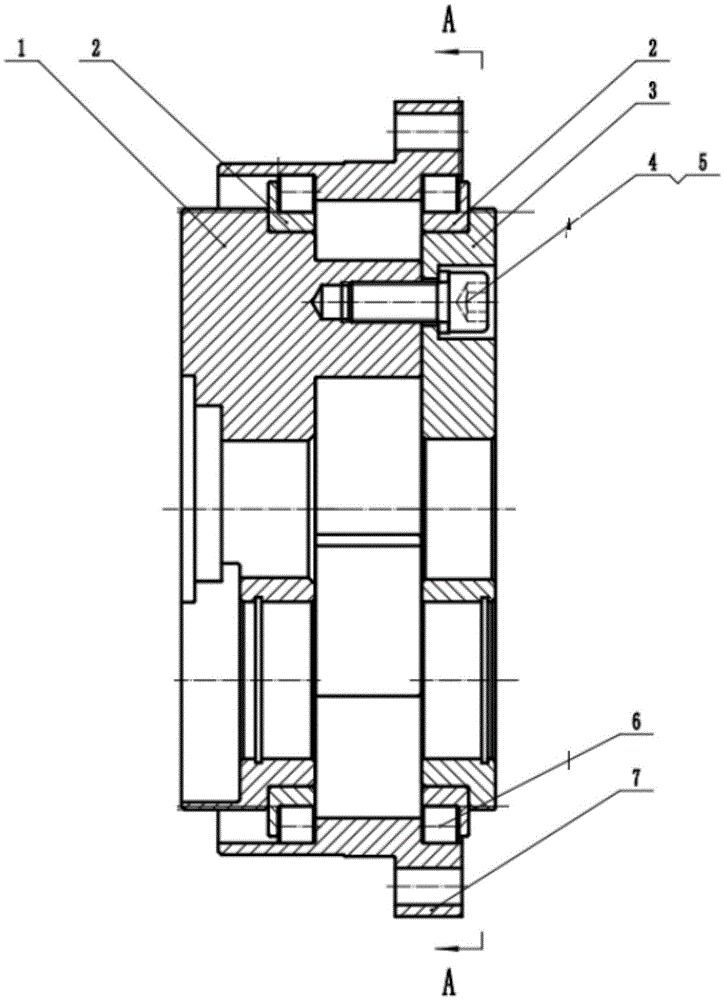

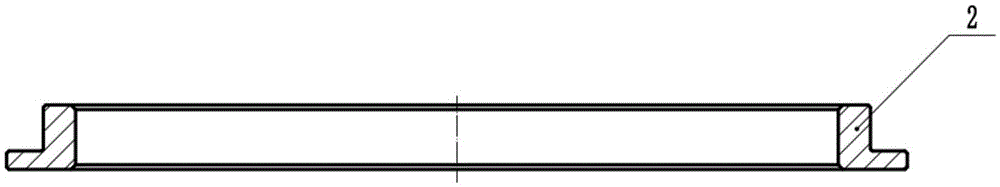

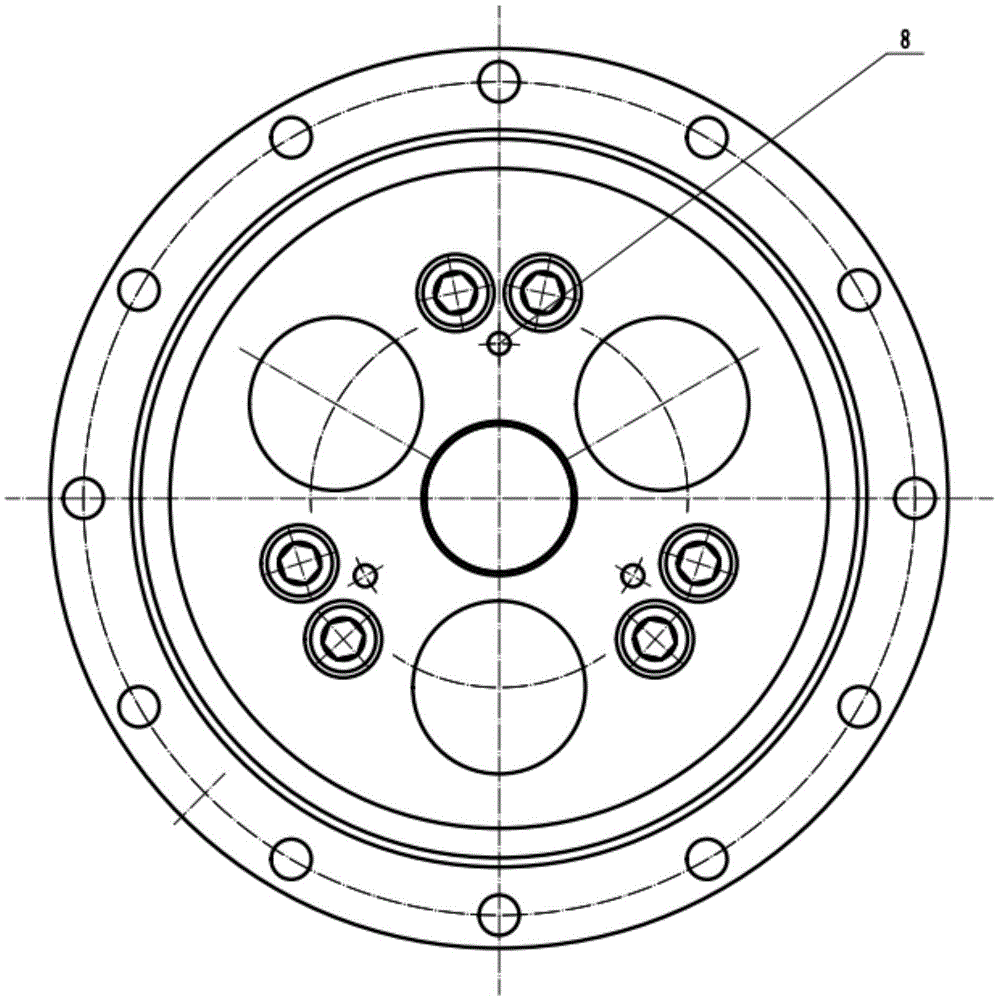

[0029] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a structural schematic diagram of the bearing inner pipeline 2 of the present invention; image 3 It is the A-A sectional view of the present invention; the double disc simple support mechanism of the present embodiment includes an internal gear 7 and a left support disc 1 and a right support circle which are arranged in the center hole of the internal gear 7 and are coaxially fixedly connected Disc 3; a left support bearing and a right support bearing are respectively provided between the left support disc 1 and the right support disc 3 and the center hole of the internal gear 7, and the rollers 6 of the left support bearing and the right support bearing It directly cooperates with the inner wall of the center hole of the inner gear 7, so that the outer raceway of the bearing is integrated on the center hole of the supporting inner gear 7 to control the radial and axial clearance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com