Patents

Literature

271results about How to "Reduce manufacturing precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

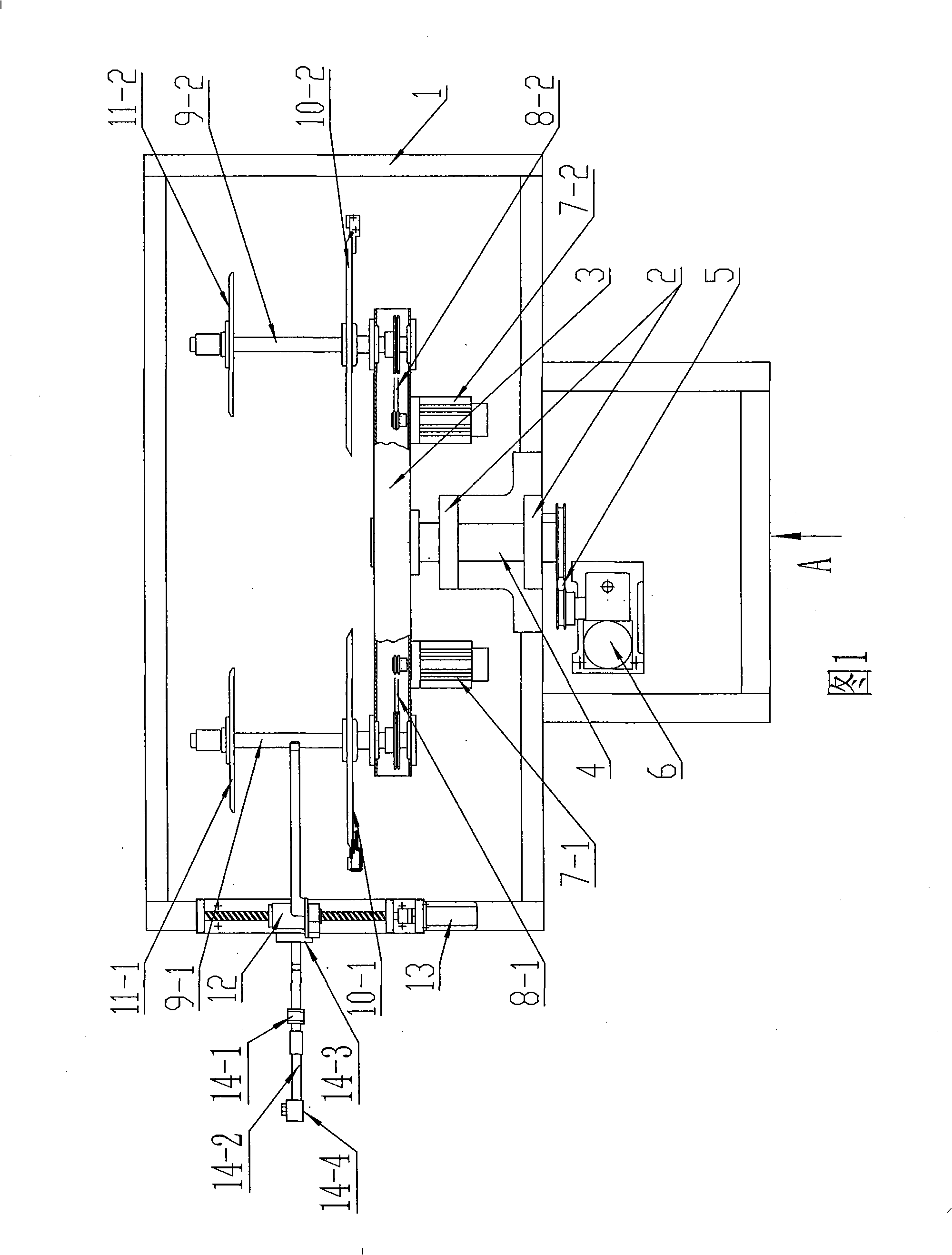

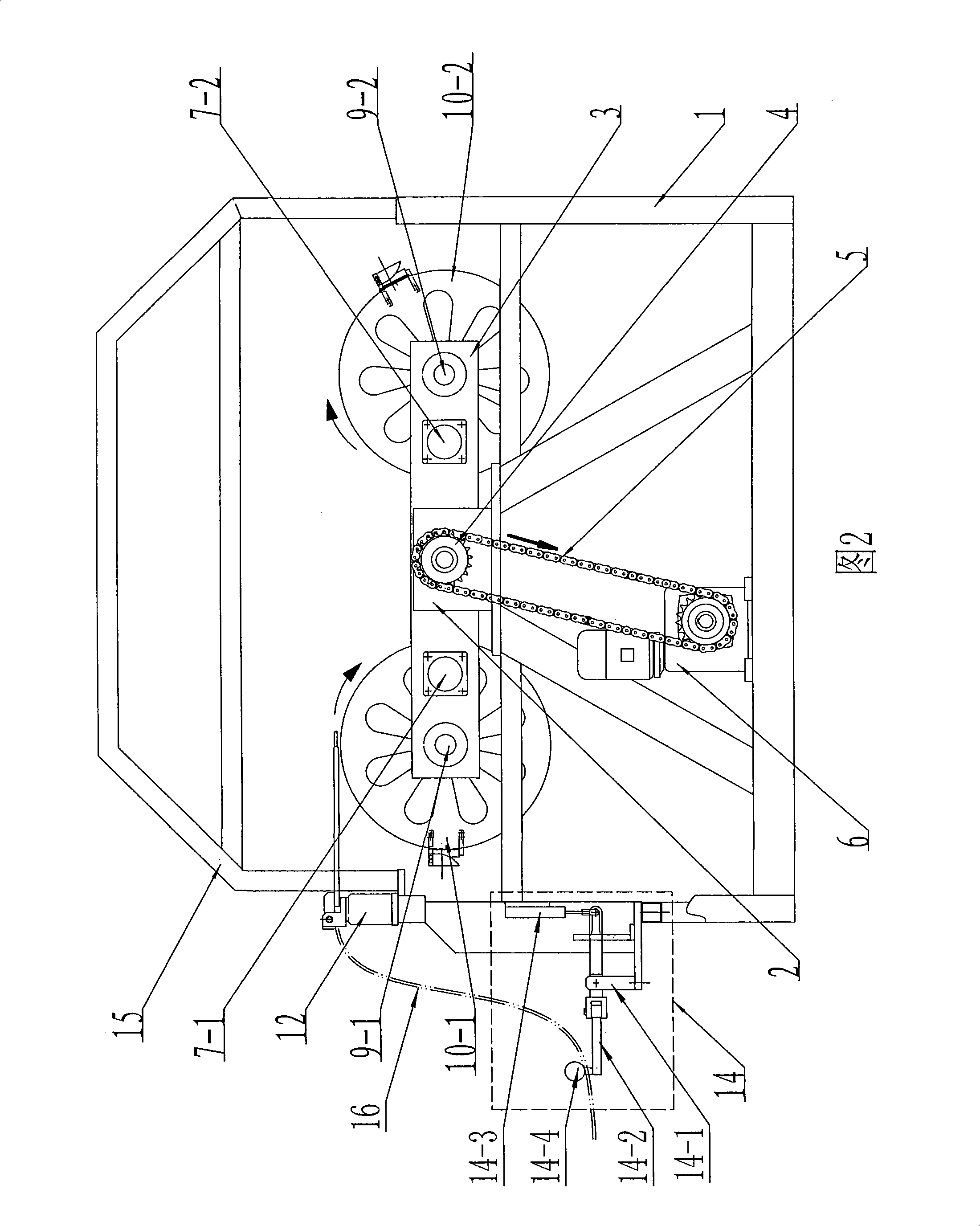

Full-automatic winding machine for winding plastic pipe

InactiveCN101301971AImprove work efficiencyGood automation effectFilament handlingWinding machineElectric machinery

The invention relates to a full-automatic winding machine used for winding plastic tubes, aiming at simplifying the complicated structure of the winding machine and comprising a main-machine base, a rotary big arm arranged on the main-machine base, a tube-distributing mechanism and a tension control mechanism, wherein, two winding disks are symmetrically arranged on the rotary big arm, and after improvement, two winding-disk driving motors are symmetrically arranged on the rotary big arm and respectively connected with the two winding disks in a transmission way. The invention adopts the design of configuring driving sources respectively for the two winding disks to overcome the defects of complicated winding disk supporting and jointing devices, etc. existing by sharing one driving source, and the improvement reduces parts and reduces the manufacturing accuracy of the parts so as to simplify action program and distinctly enhance the reliability of equipment. The full-automatic winding machine of the invention improves the automation capability of plastic hose winding, enhances winding efficiency and is suitable for the automatic manufacturing line of various plastic hoses.

Owner:武志生

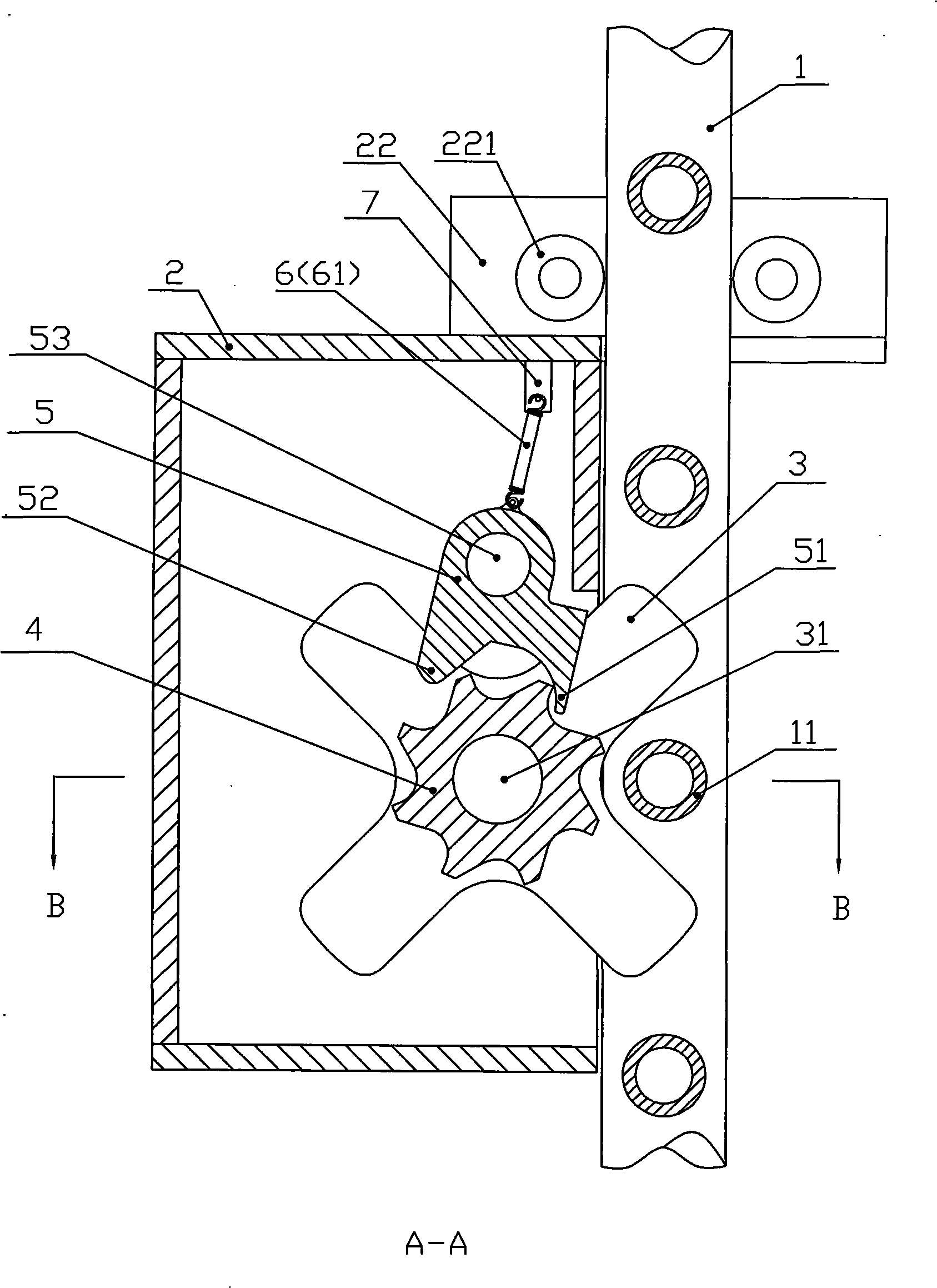

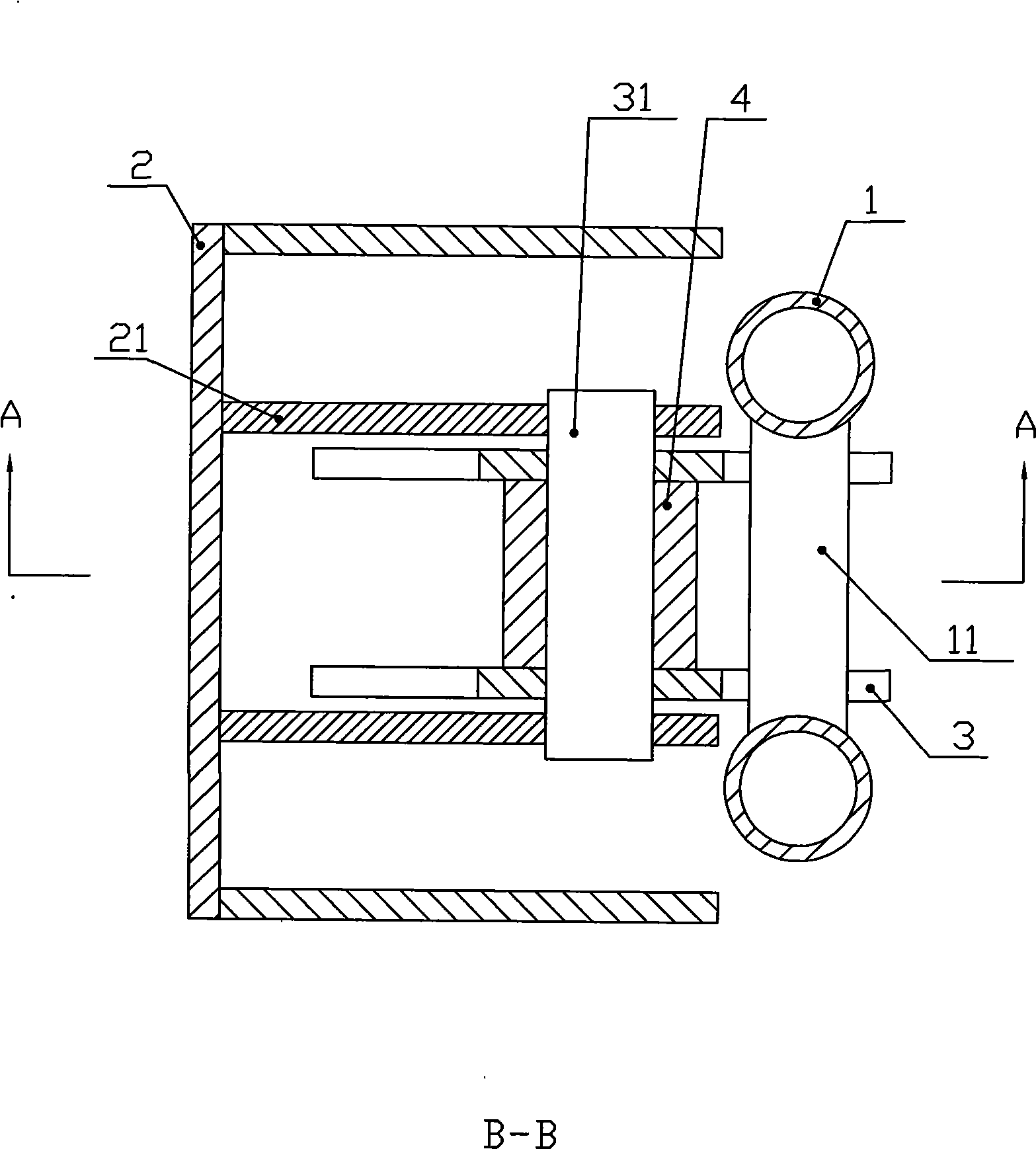

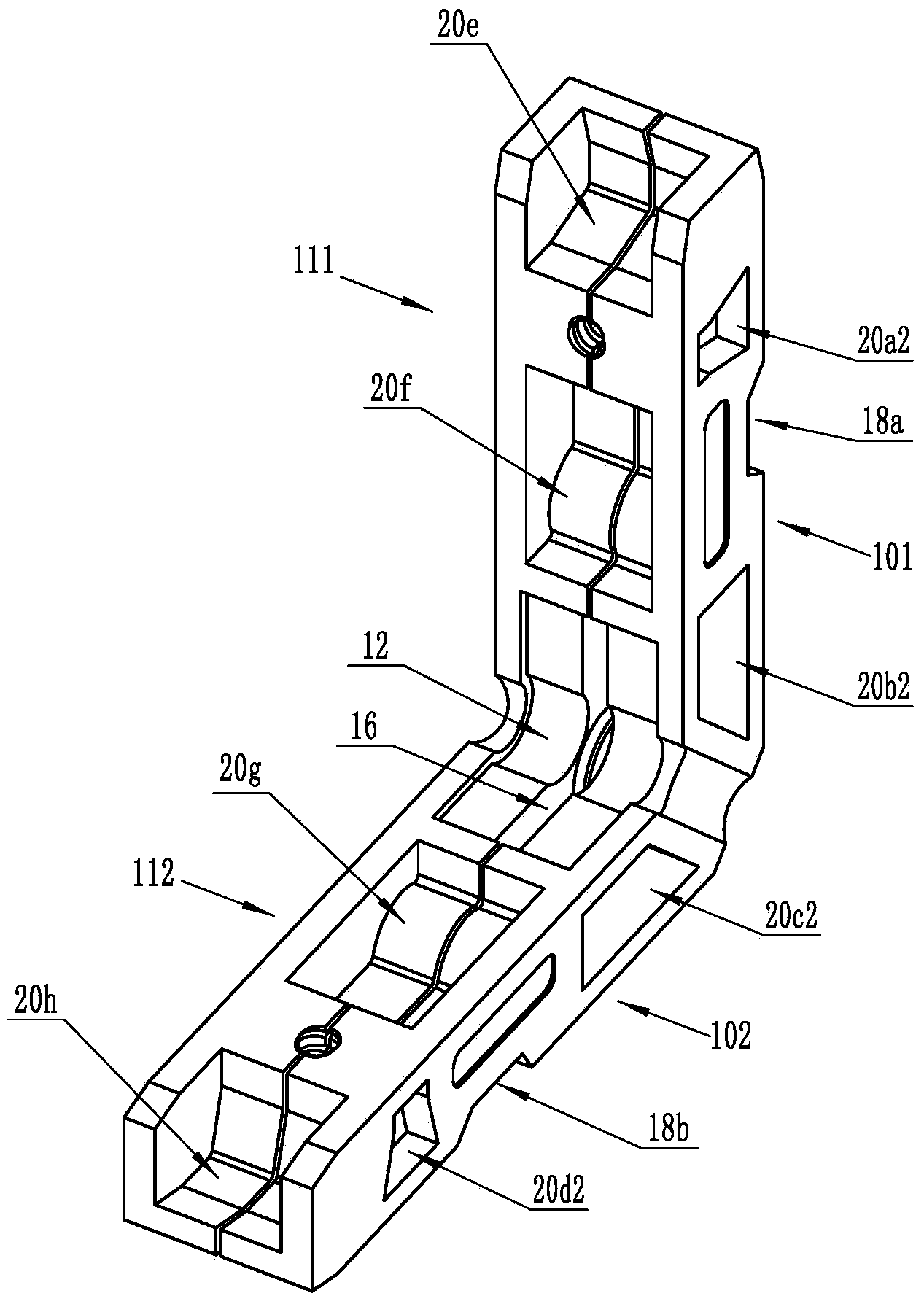

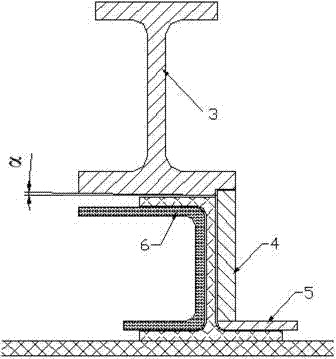

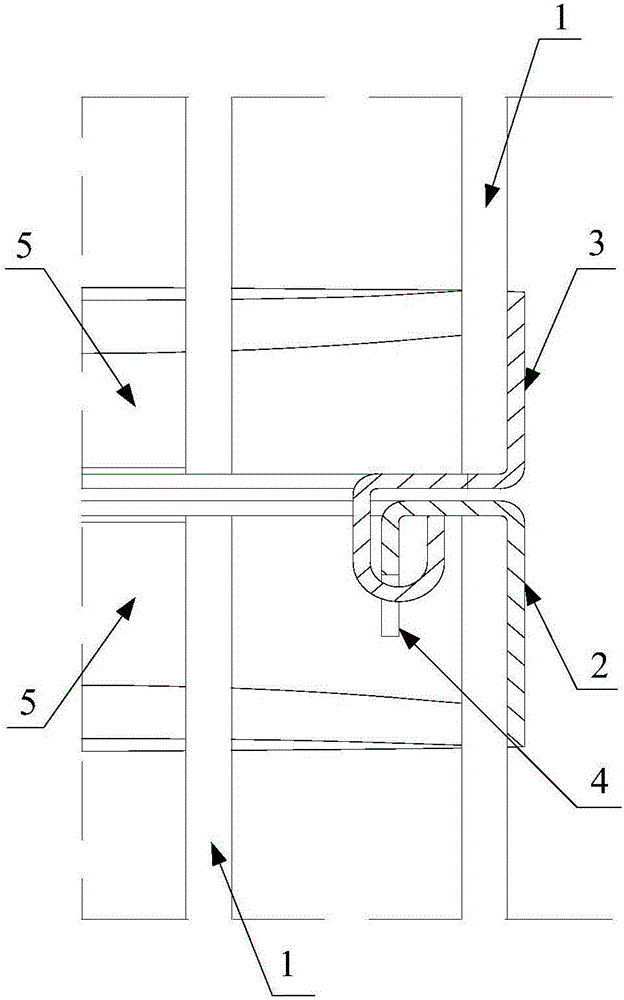

Rotating wheel falling prevention device of attachment type raise scaffold and working method thereof

InactiveCN101519910ANot affected by clearanceDoes not affect landingBuilding support scaffoldsEngineeringMechanical engineering

The invention provides a rotating wheel falling prevention device of an attachment type raise scaffold and a working method thereof. The rotating wheel falling prevention device is provided with a guide rail and a guide holder, wherein the guide holder is connected with a guide rail sliding sleeve, the guide rail is provided with spaced cross rods, the guide holder is provided with a rotating wheel which can be meshed with the cross rods in a transmission way, the rotating wheel is provided with a falling prevention clamping wheel, and a shaft seat of the rotating wheel is provided with swing needles by which the rotating wheel falling prevention device of the falling prevention clamping wheel, which reversely and fast rotates, can be braked; the falling prevention swing needles slowly swing and reset and the falling prevention clamping wheel slowly rotates during the slow raise and decline process of the scaffold so as to enable the raising or declining work of a scaffold body to be normally operated; when a scaffold body is suddenly declined, the rotating wheel generates high reverse rotation speed to enable the falling prevention swing needles not to be reset in time, thus the falling prevention swing needles clamp the falling prevention clamping wheel so as to enable the rotating wheel not to continuously reversely rotate, and the rotating wheel clamps the cross rods arranged on the guide rail so as to prevent the scaffold from continuously falling. The invention has the advantages of short braking distance, flexibility, reliability, difficult clamping, relative lower manufacturing accuracy and safe and reliable use.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

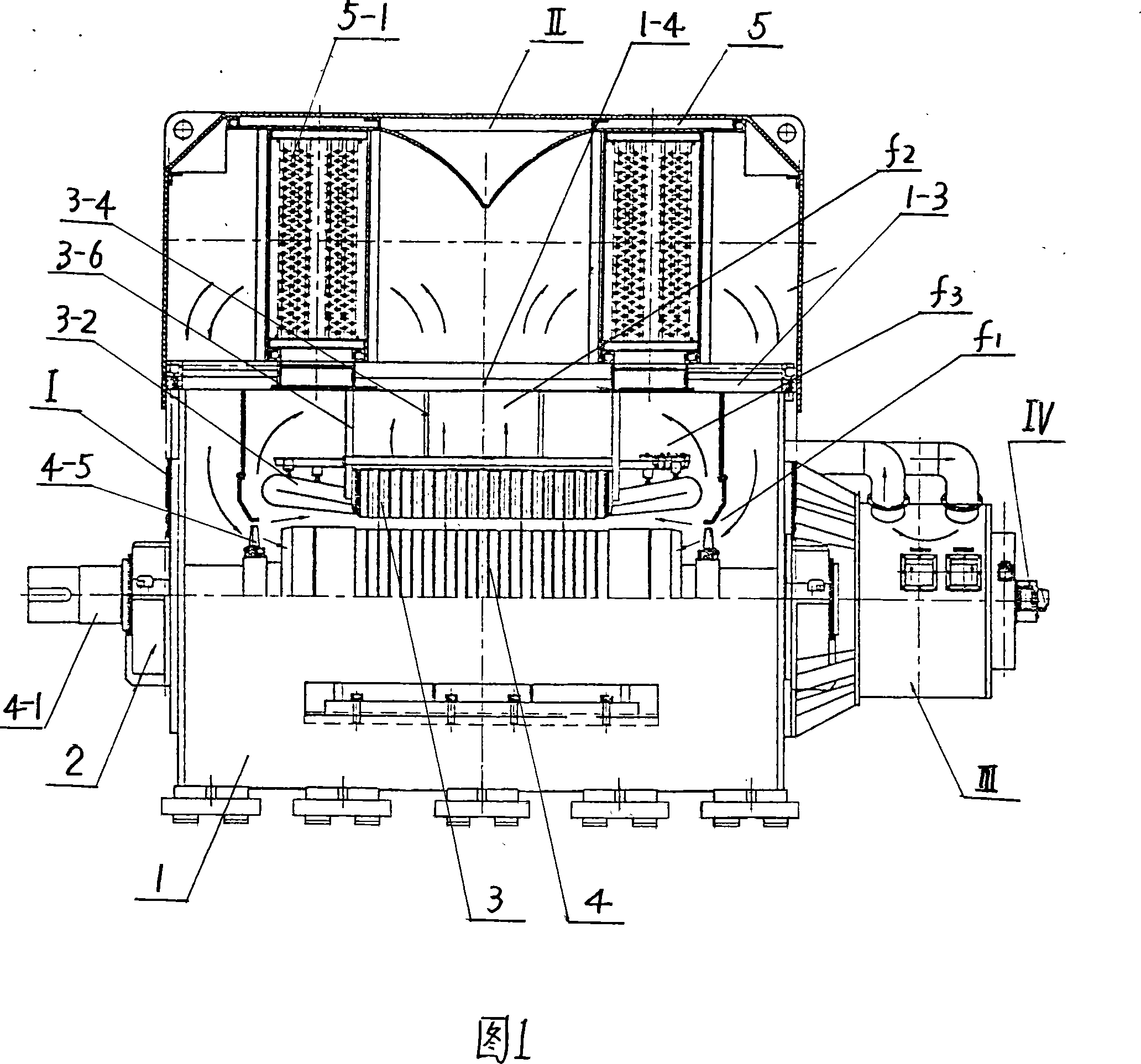

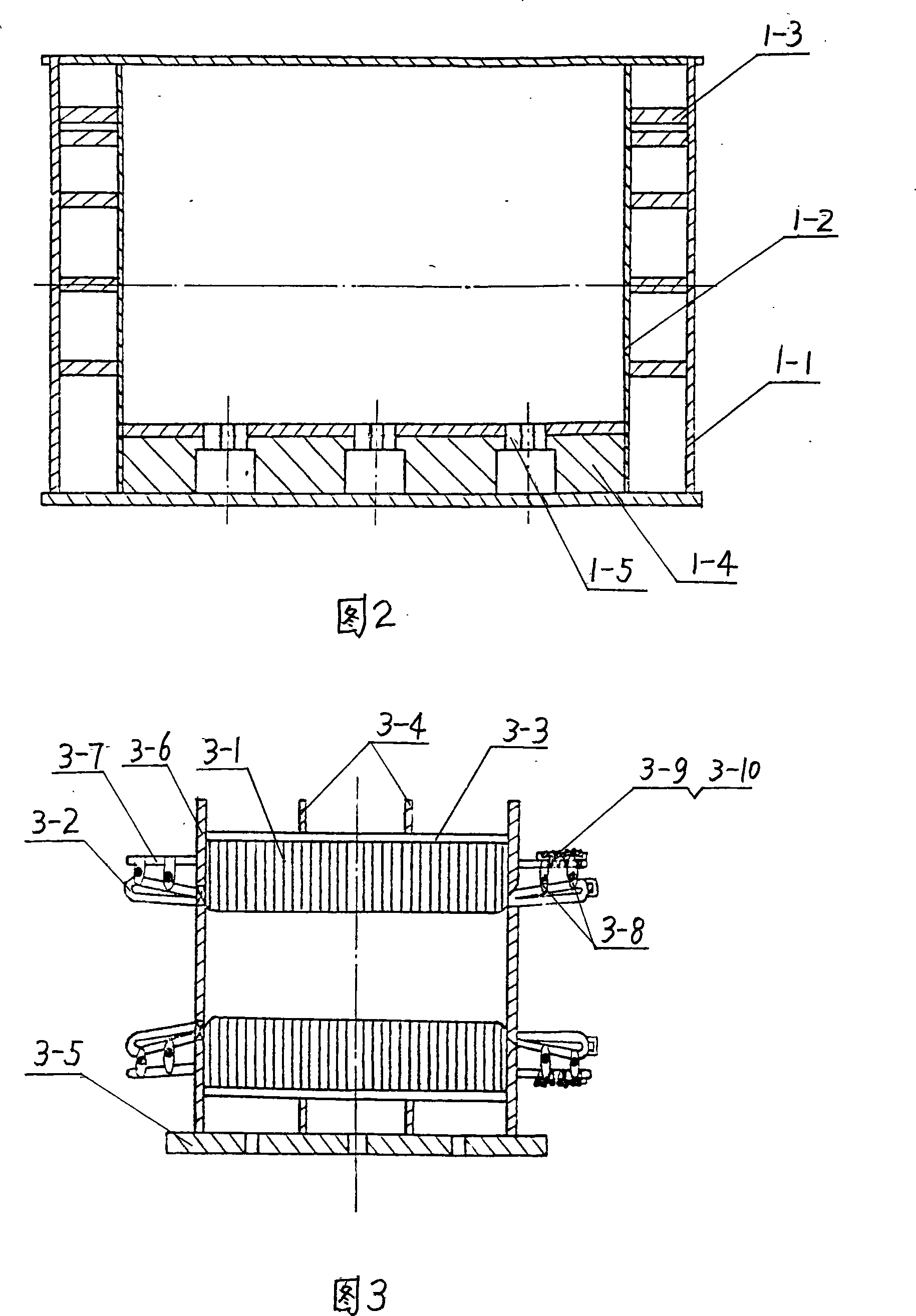

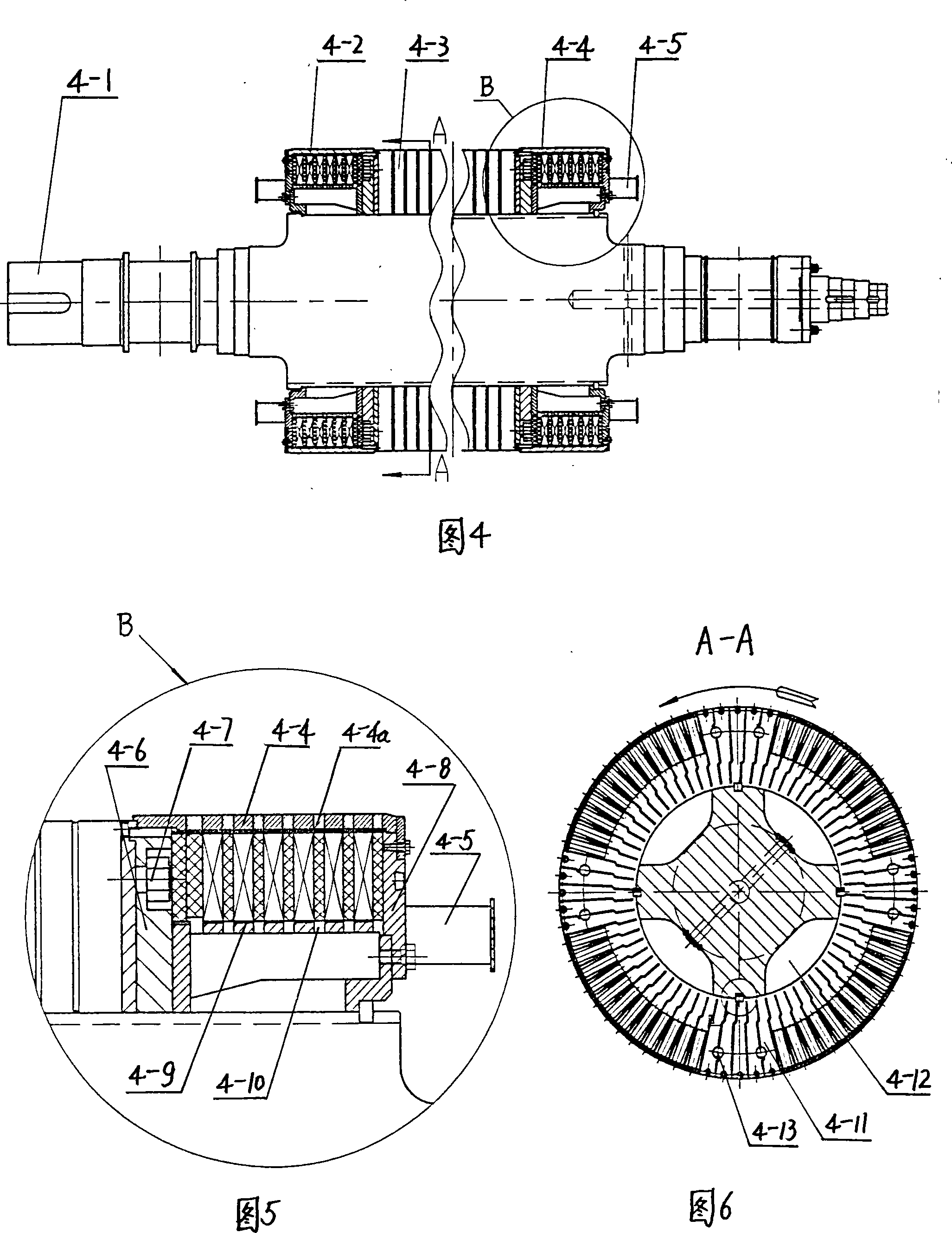

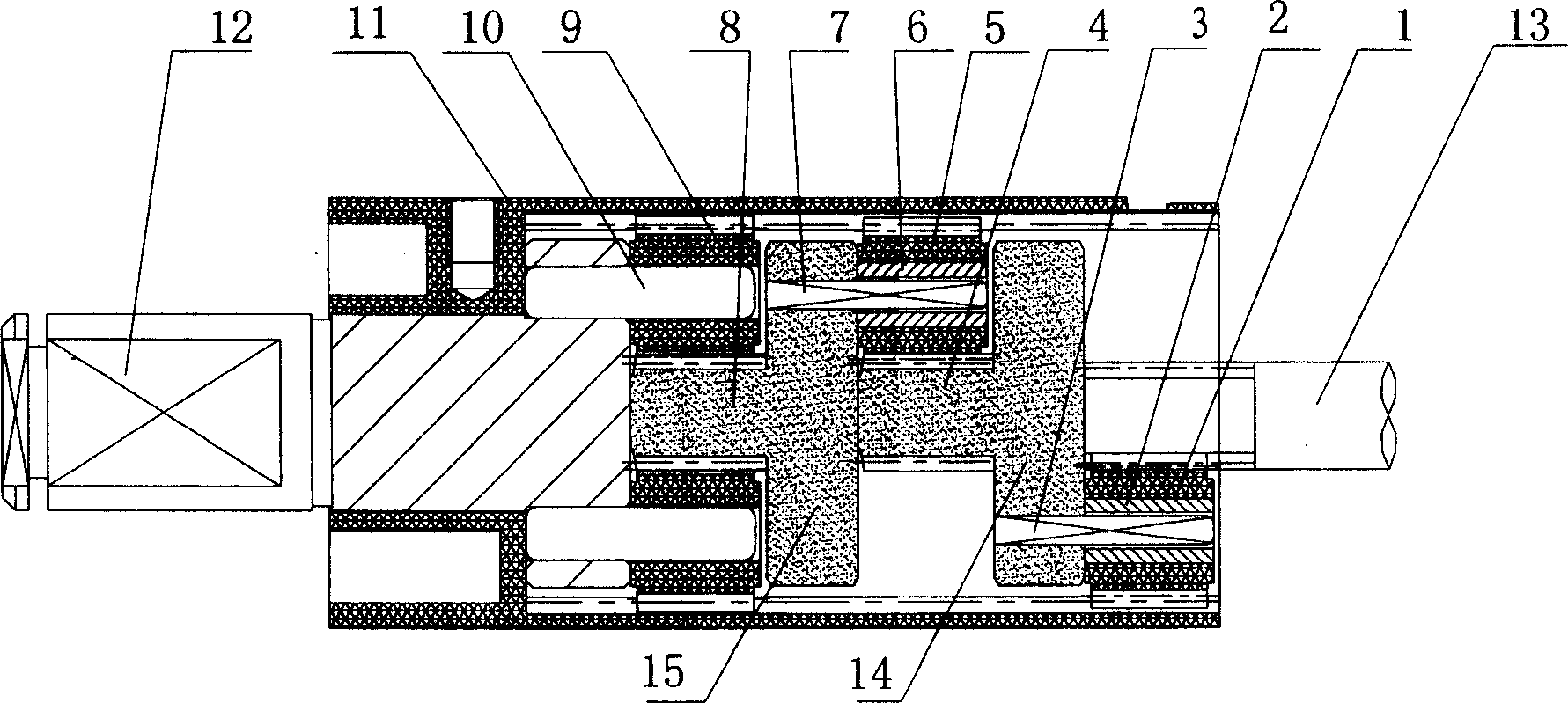

High-capacity non-salient pole nest plate type synchronous generator

ActiveCN101227129AEasy offlineGuaranteed accuracySynchronous generatorsMagnetic circuit rotating partsEngineeringDynamo

The invention relates to a large capacity non-salient pole plate fine type synchronous generator, which is characterized in that a main generator is provides with a stator which is sleeved with a motor base split unit and a rotor which is connected with a motor base through an end cover bearing, an exciting end of a rotor rotating shaft is provided with a brushless excitation system with a high pole number, the tail end of the system is provided with a grounding detecting device, and a cooling system comprises a cooling device which is positioned on the main generator, four ducted cooling paths which circulates in multiply return circuits and is formed by a stator ventilating circuit, a rotor ventilating circuit, an air gas ventilating circuit and an exciting dynamo ventilating circuit of the main generator. The generator has the advantages of reasonable design of the whole system, compact structure, complete function of each portion, convenient installation and maintenance, reliable operating property, high quality of voltage and electric current which are produced and the like, which saves manufacturing cost.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

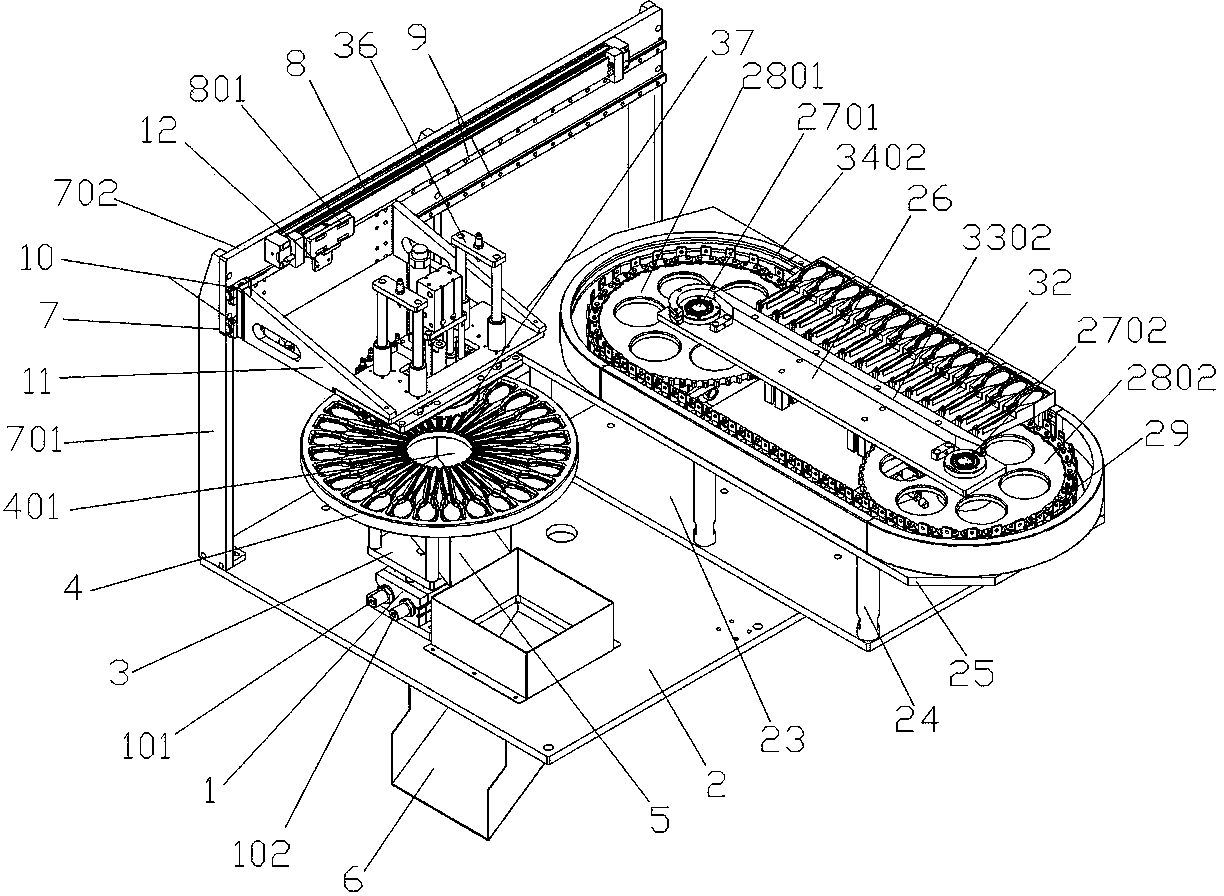

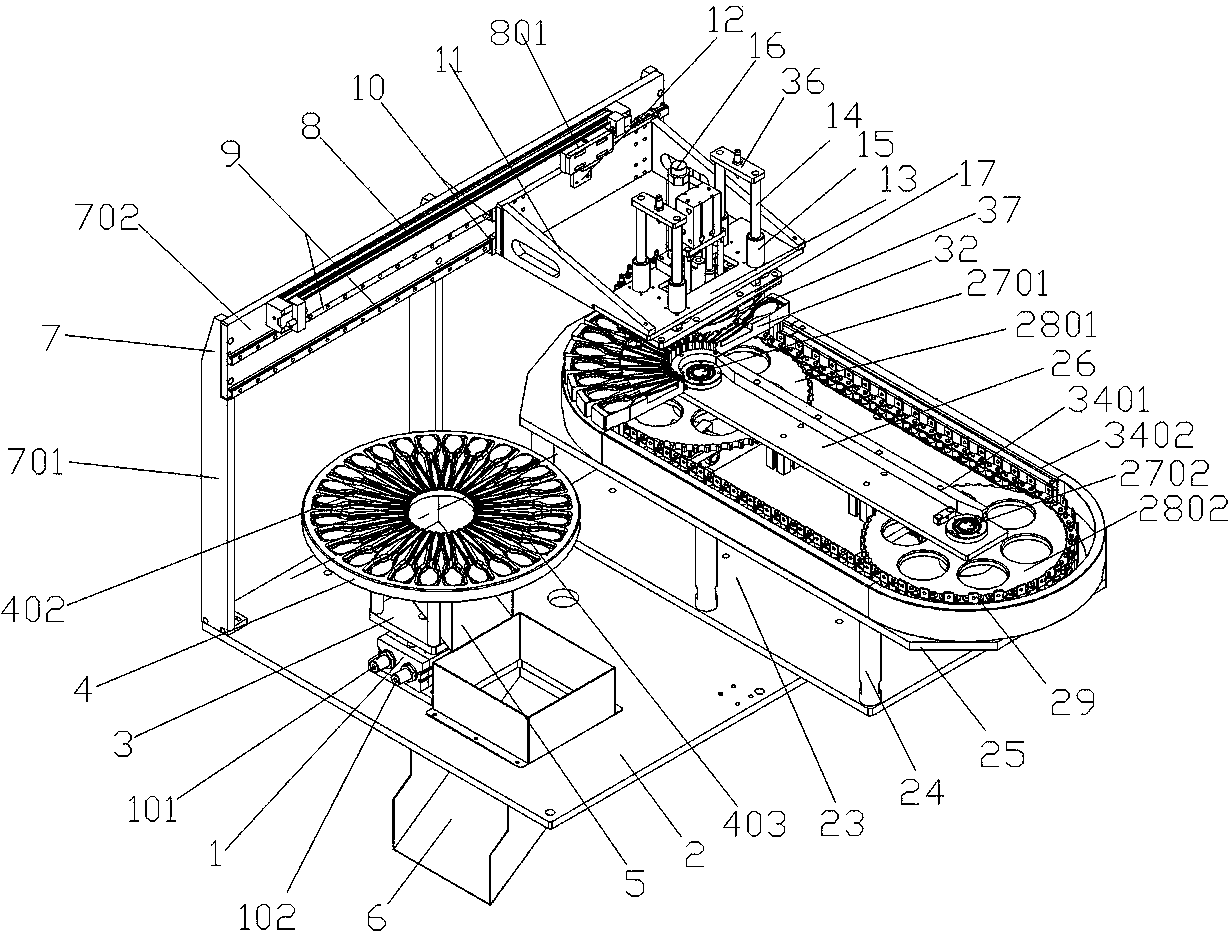

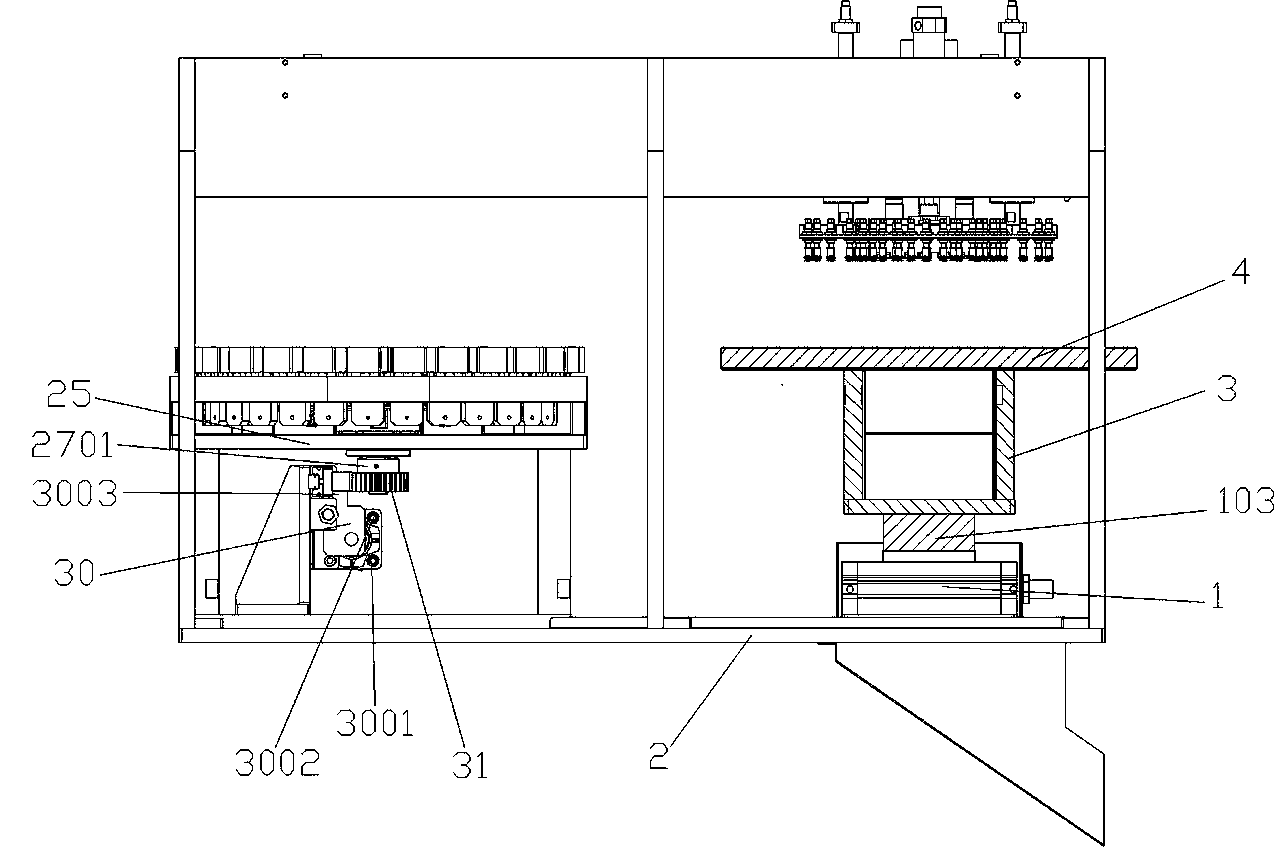

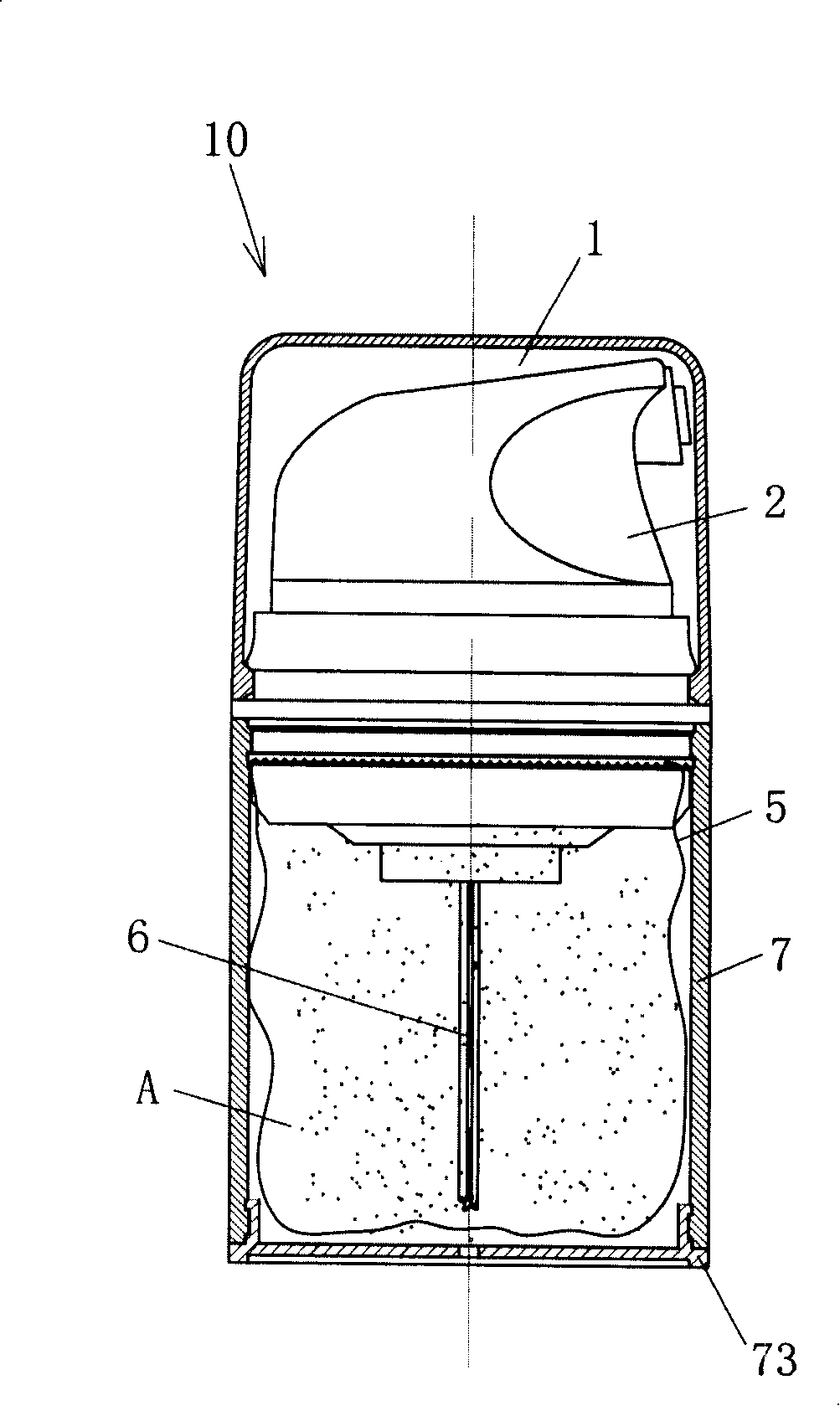

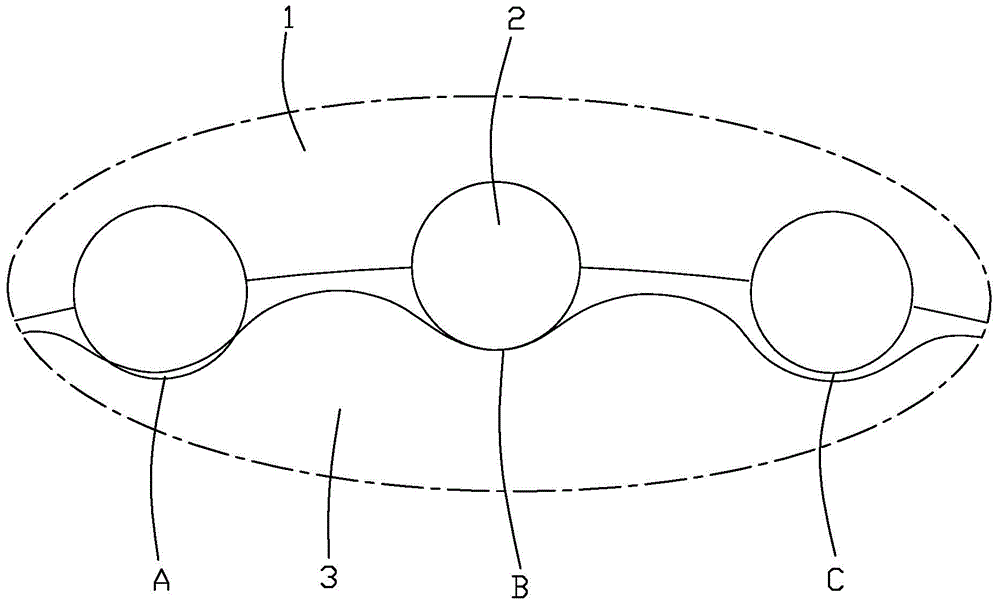

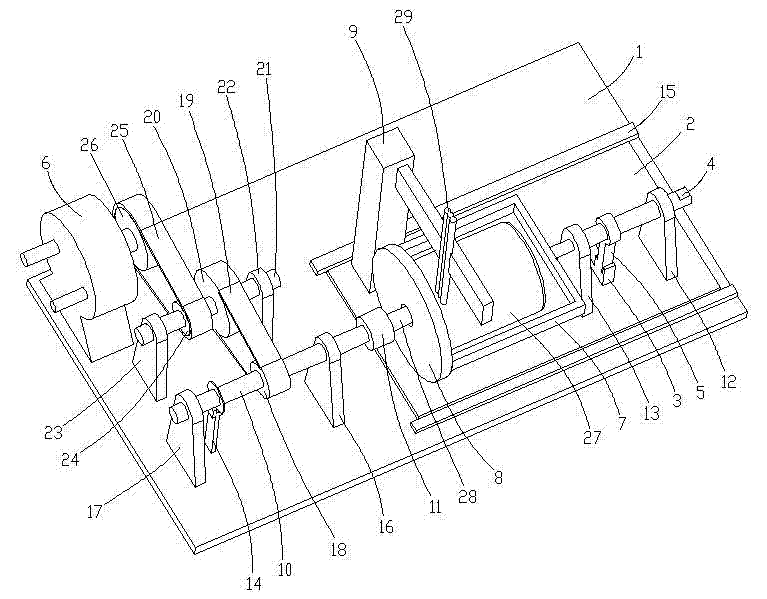

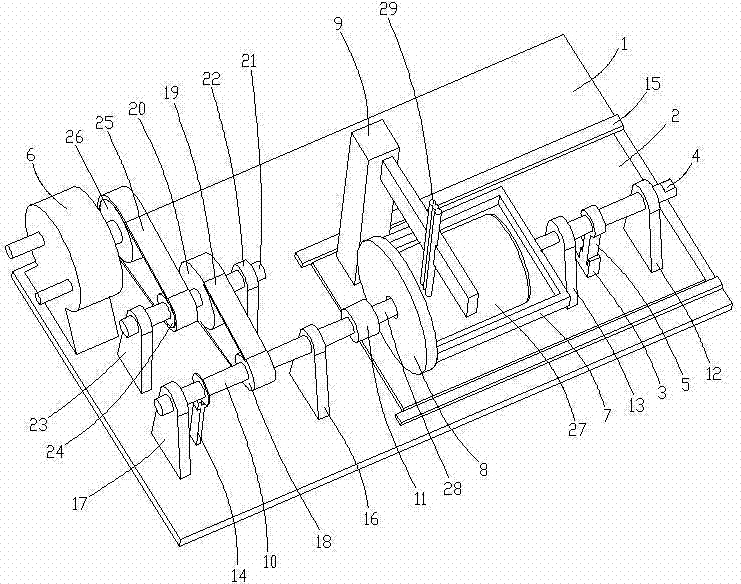

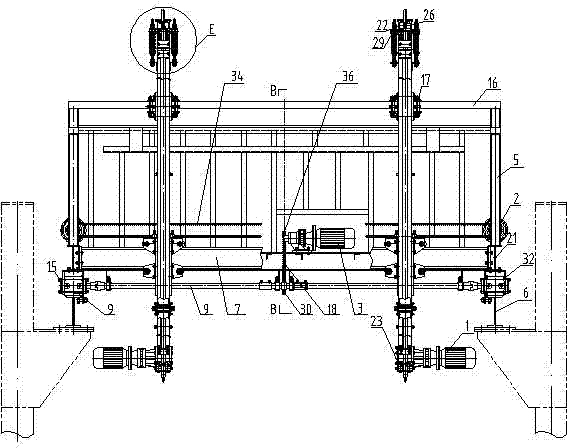

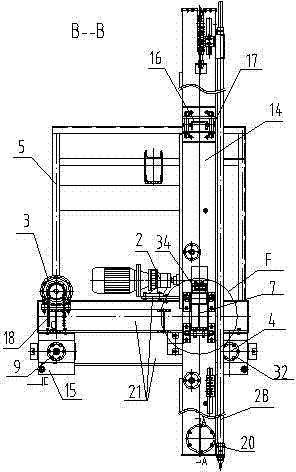

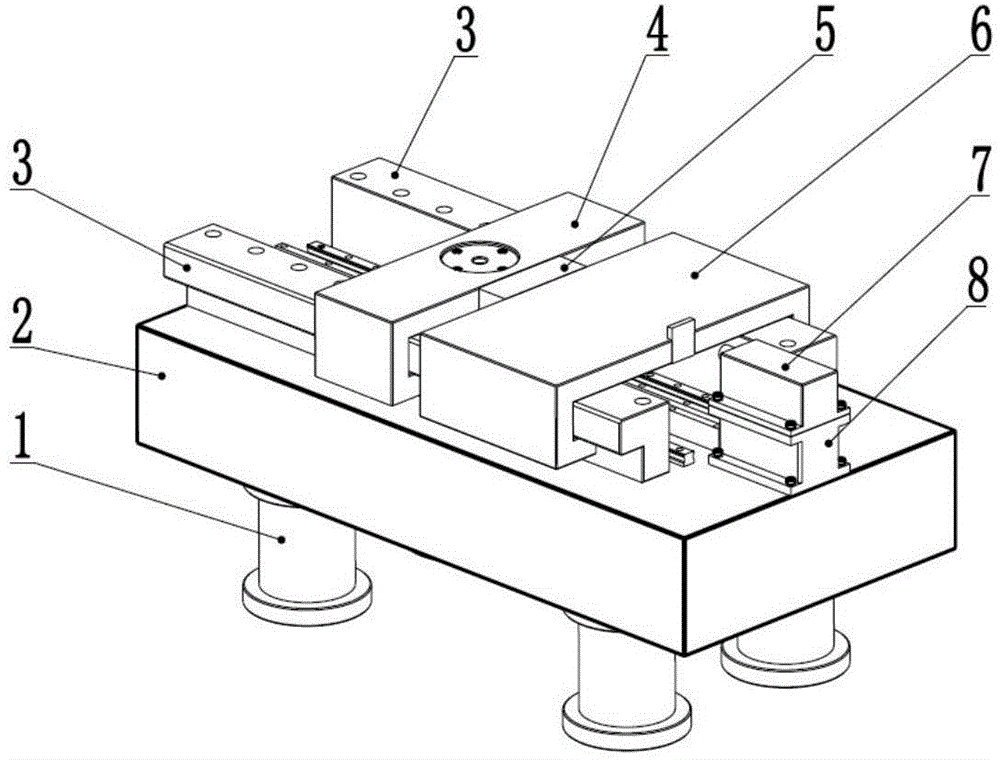

Turntable material collecting and transferring mechanism for injection molding product feeder

InactiveCN104044909AIncrease productivityReduce manufacturing precisionConveyor partsEngineeringTransfer mechanism

The invention relates to a material collecting and transferring mechanism for a feeder, in particular to a turntable material collecting and transferring mechanism for an injection molding product feeder. The material collecting and transferring mechanism comprises a disc collecting device, a material transferring device, a cutting head device and a turntable conversion device; the disc collecting device comprises a collecting disc; the material transferring device comprises a grabber structure, a lifting structure and a translation structure; the cutting head device comprises a cutter, a press ring, a second lifting cylinder and a material head guiding slot; the turntable conversion device comprises a turntable support, rotary shafts, product positioning parts, chain wheels, a chain and a second rotary part. By using the characteristics of two round ends, a linear middle part and the convertibility of the disc conversion device in the rotation process, injection molding products are converted to a linear arraying structure, capable of being taken away by a taking mechanism of the feeder, from the disc-like arraying structure, and the effect of connection between the conversion and the subsequent taking and distributing procedures is realized; the injection molding products with material heads can be transferred after the material heads are removed, and the manufacturing accuracy and manufacturing cost of an injection molding die can be reduced.

Owner:台州华曙机械有限公司

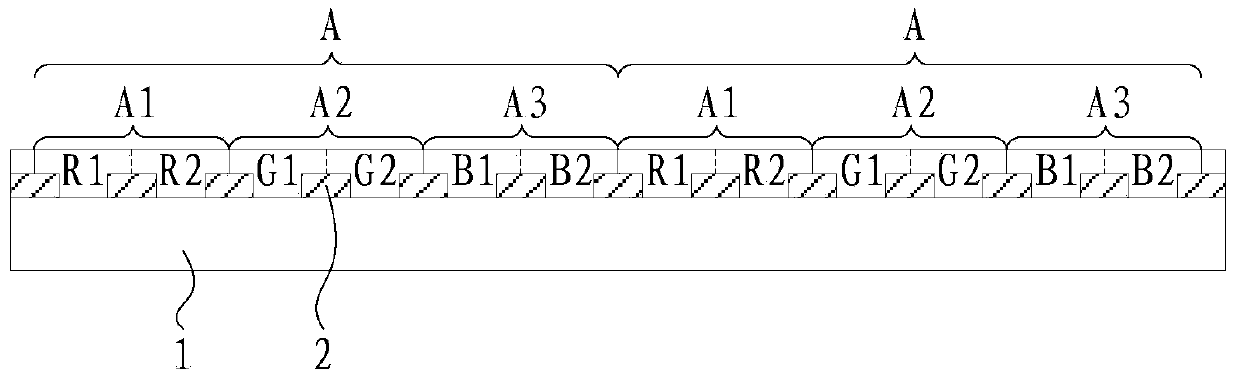

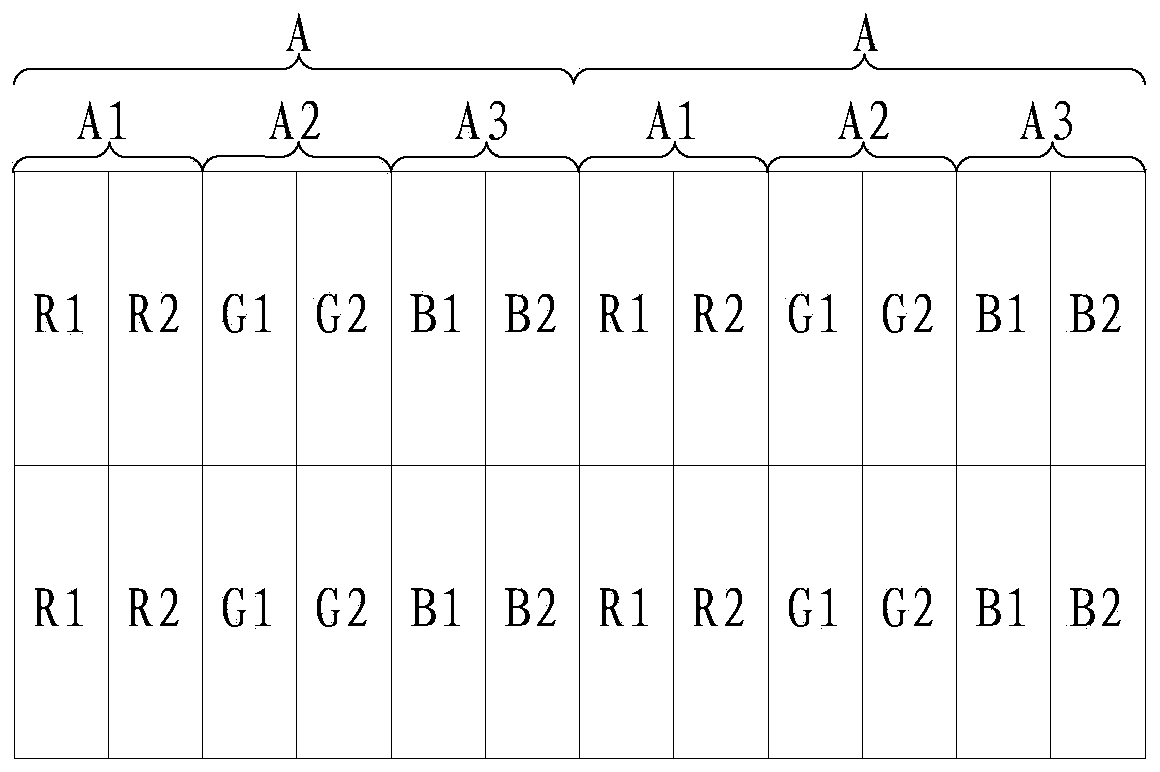

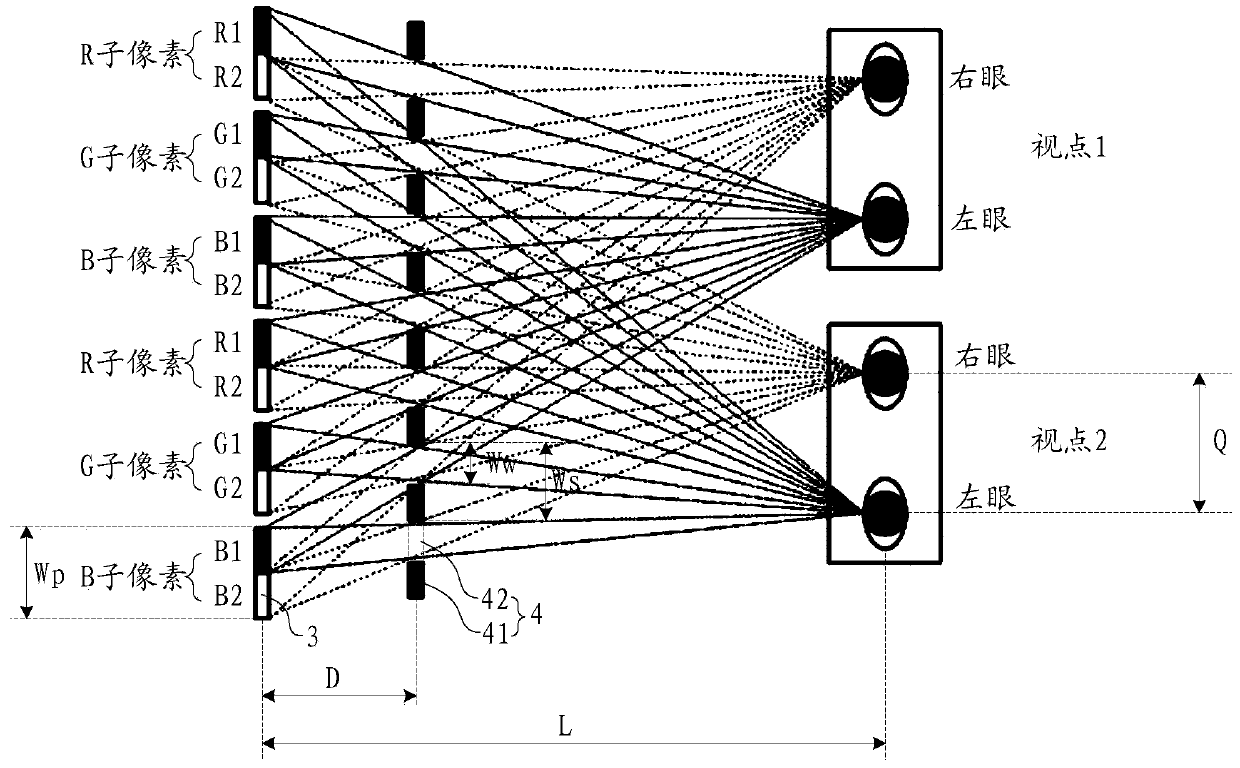

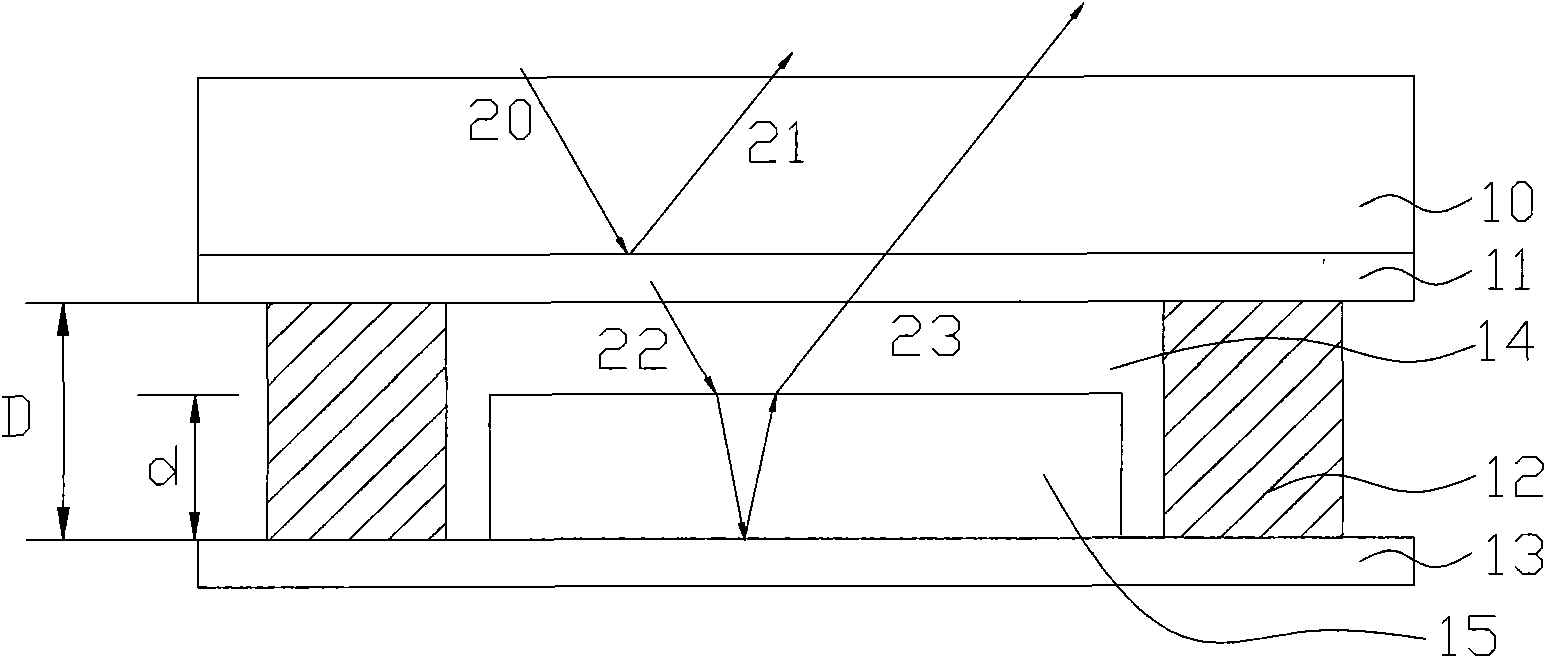

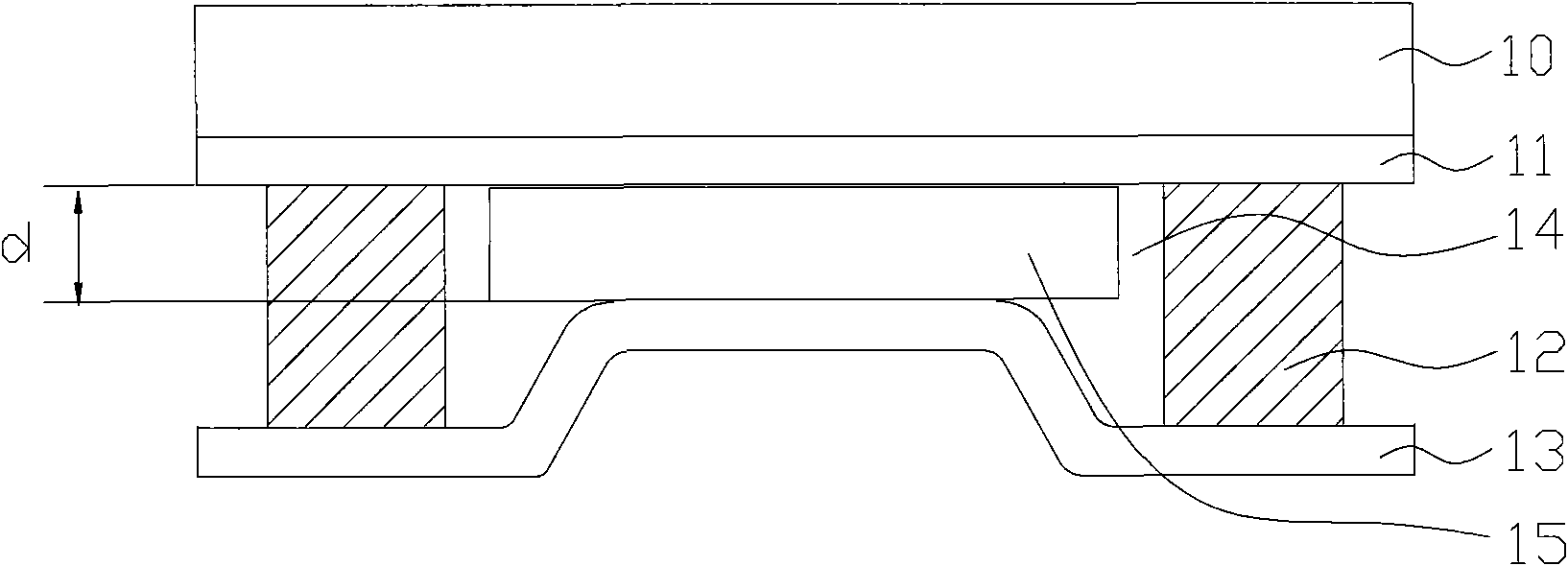

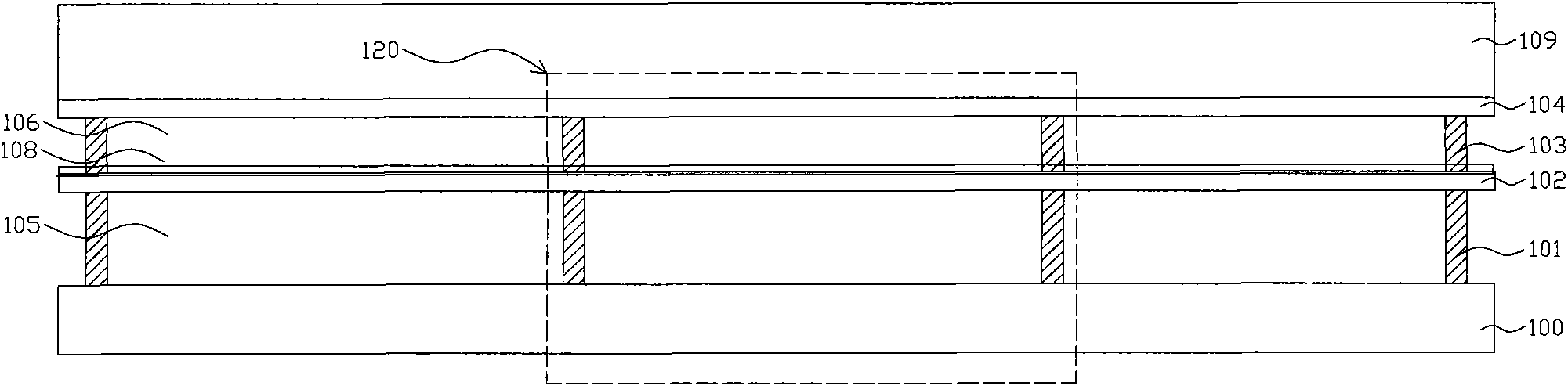

Color filter, color filter manufacturing method, display panel, display device and driving method

ActiveCN104297832AProduction accuracy and alignment accuracy decreaseReduce the difficulty of productionOptical filtersCathode-ray tube indicatorsComputer visionColor filter array

The invention provides a color filter, a color filter manufacturing method, a display panel, a display device and a driving method. The color filter comprises multiple colored color resistors and multiple pixel regions, wherein the multiple colored color resistors include the red color resistors, the green color resistors and the blue color resistors, the multiple pixel regions are arranged in a matrix mode, each pixel region comprises a red sub-pixel region, a green sub-pixel region and a blue sub-pixel region, each red sub-pixel region comprises red inferior sub-pixel regions, the number of the red inferior sub-pixel regions of each red sub-pixel region is an even number, one red color resistor is arranged in each red inferior sub-pixel region, each green sub-pixel region comprises green inferior sub-pixel regions, the number of the green inferior sub-pixel regions of each green sub-pixel region is an even number, one green color resistor is arranged in each green inferior sub-pixel region, each blue sub-pixel region comprises blue inferior sub-pixel regions, the number of the blue inferior sub-pixel regions of each blue sub-pixel region is an even number, and one blue color resistor is arranged in each blue inferior sub-pixel region. Compared with the prior art, the manufacturing precision of a mask plate required by the color filter is lowered, the alignment precision is lowered, and the manufacturing difficulty of the color filter is lowered.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Display panel, display method, display device and color rendition method thereof

InactiveCN101872579AChange widthControl wavelengthStatic indicating devicesIdentification meansDisplay deviceTransmittance

The invention provides a display panel, which comprises a base plate. The base plate has a first reflecting layer and a second reflecting layer with specific light transmittance. The first reflecting layer comprises a reflecting unit array. Each reflecting unit comprises a reflecting plate which can continuously move along a direction perpendicular to the first reflecting layer, and a supporting beam connected with the reflecting plate and a connecting part. The invention additionally provides a display method, a display device and a color rendition method thereof. The display panel synthesizes color through time sequence color without distinguishing pixel color, the manufacturing process is only one third of the manufacturing process of a traditional display panel manufacturing method, the structure is simple and the manufacturing cost is low. The display device can compensate color drift caused by manufacturing error, the task of accurately realizing color rendition is transferred to the peripheral circuit of the display panel from the manufacturing process, and thereby the requirement on the precision of the manufacturing process is reduced.

Owner:季中

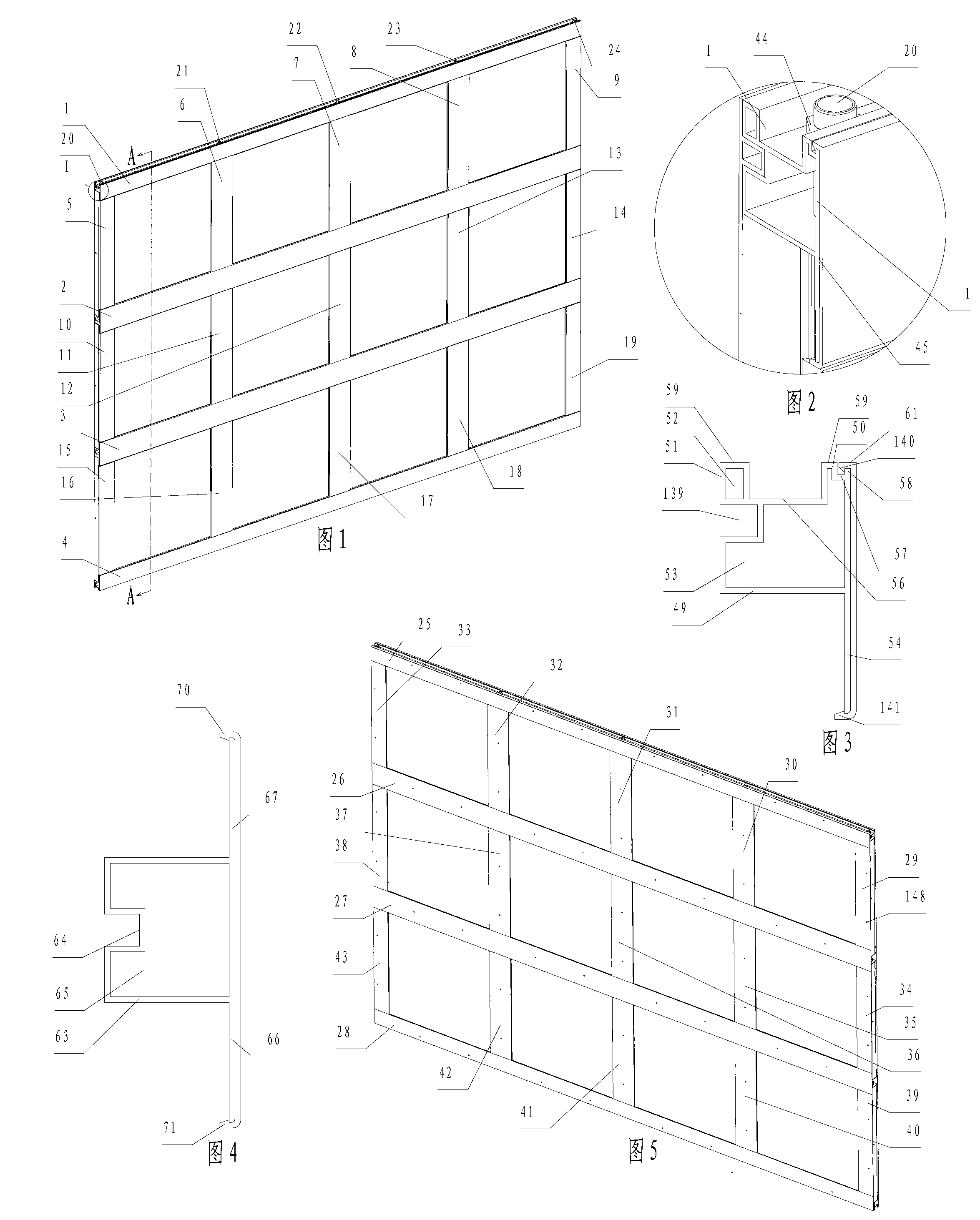

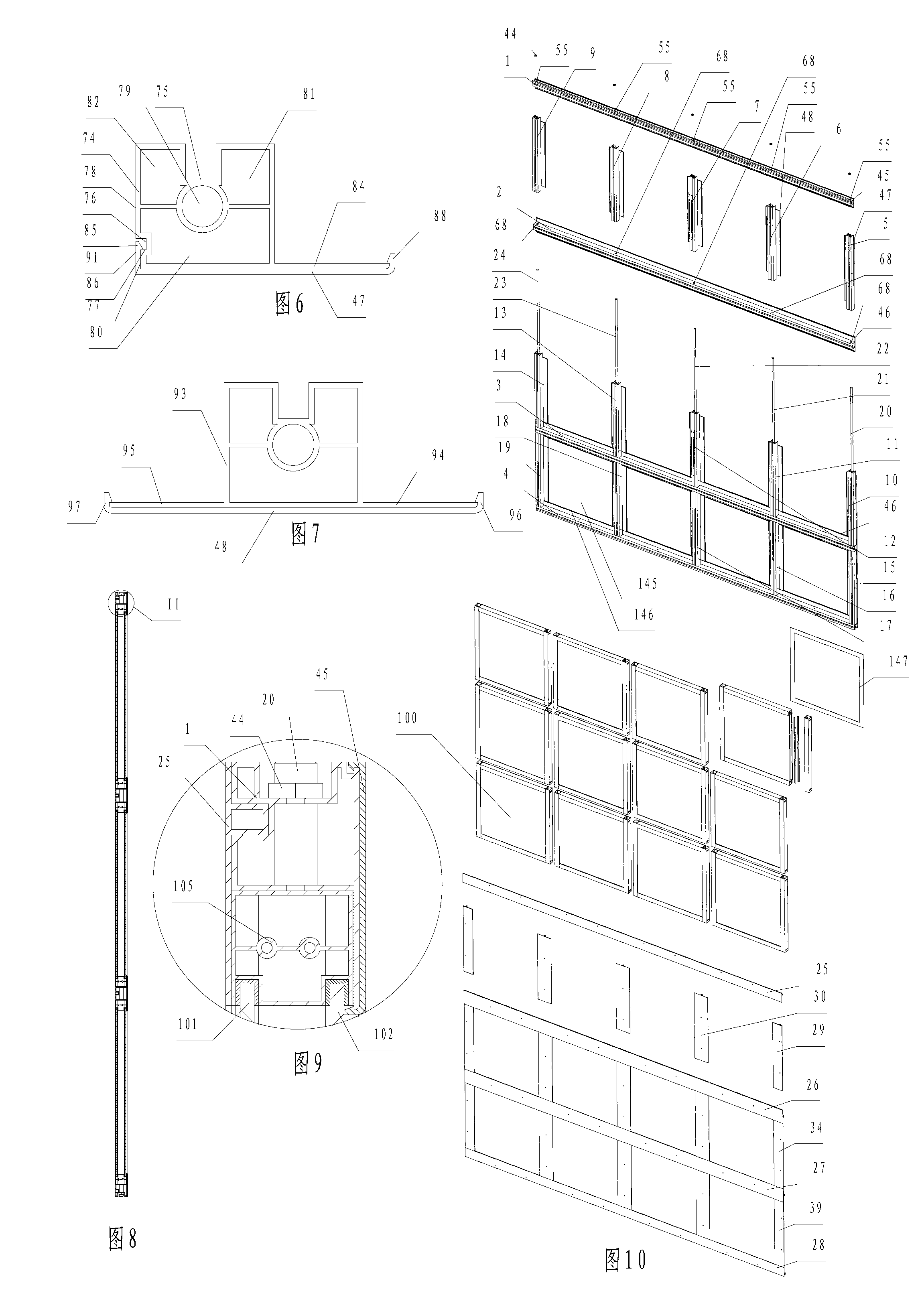

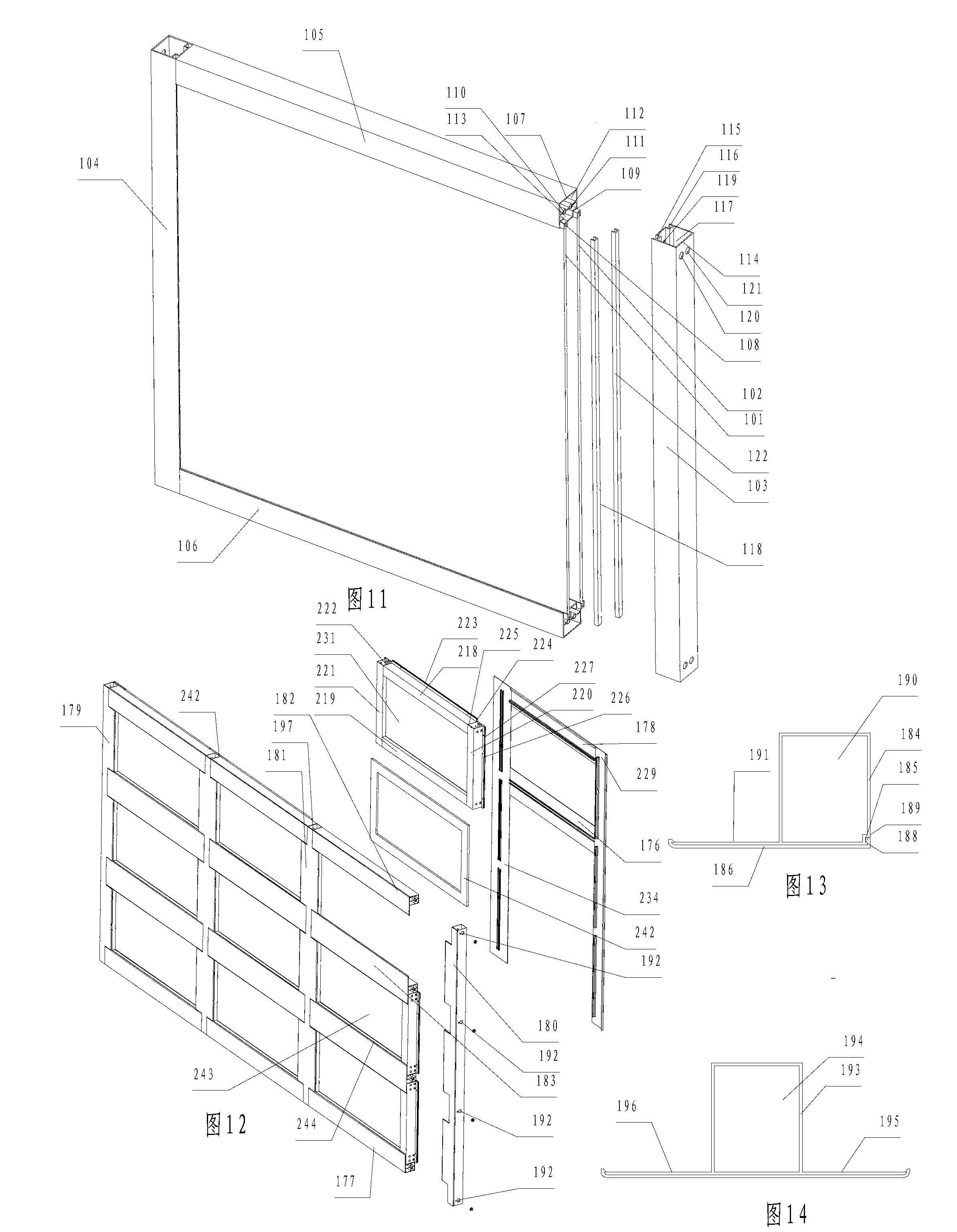

Combined construction structure

ActiveCN103075075AReduce aging speedEasy to replaceShutters/ movable grillesWallsIsolation effectKeel

The invention discloses a combined construction structure which comprises first keels, second keels and an interlayer module; the adjacent two first keels and the adjacent two second keels form a square frame for installing the interlayer module; flanges which are integrated with the corresponding first keels and second keels are arranged on four inner side surfaces opposite to the square frame; elastic buckle-type profile U-shaped first external spacer bars which are laterally buckled onto the first keels, and elastic buckled-type profile U-shaped second external spacer bars which are laterally buckled onto the second keels are also arranged; one of the two buckles of the first external spacer bar of the first keel on the outermost side is buckled on the related flange, and the other is buckled in a first slot; and one of the two buckles on the second external spacer of the second keel on the outermost side is buckled on the related flange, and the other is buckled on a second slot. The combined construction structure has the advantages of good heat isolation and sound isolation effects, convenience and quickness in installation, simple process, good strength and rigidity of main keels, and low cost.

Owner:深圳市华汇设计有限公司

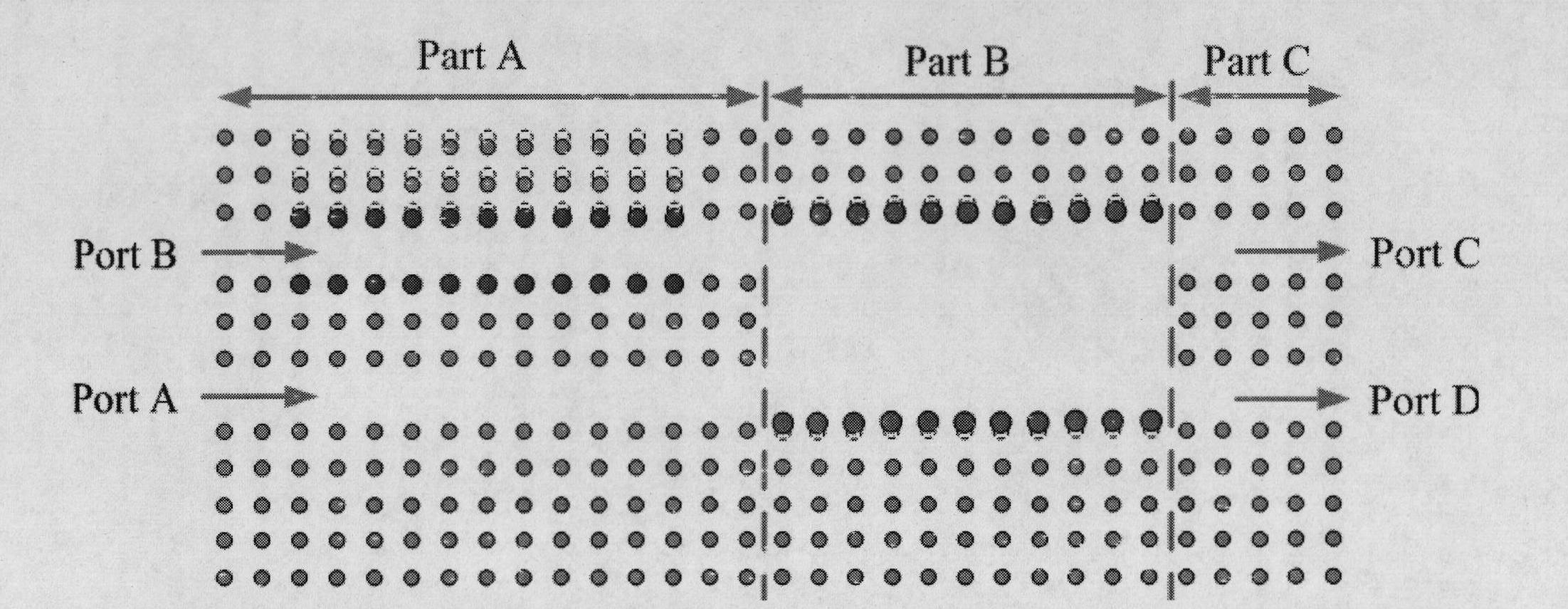

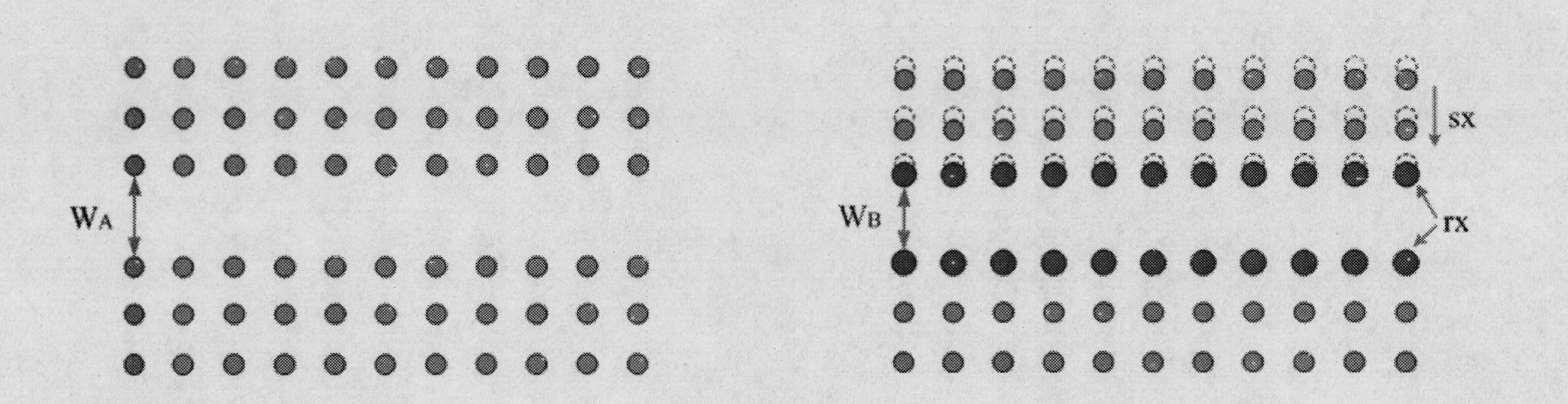

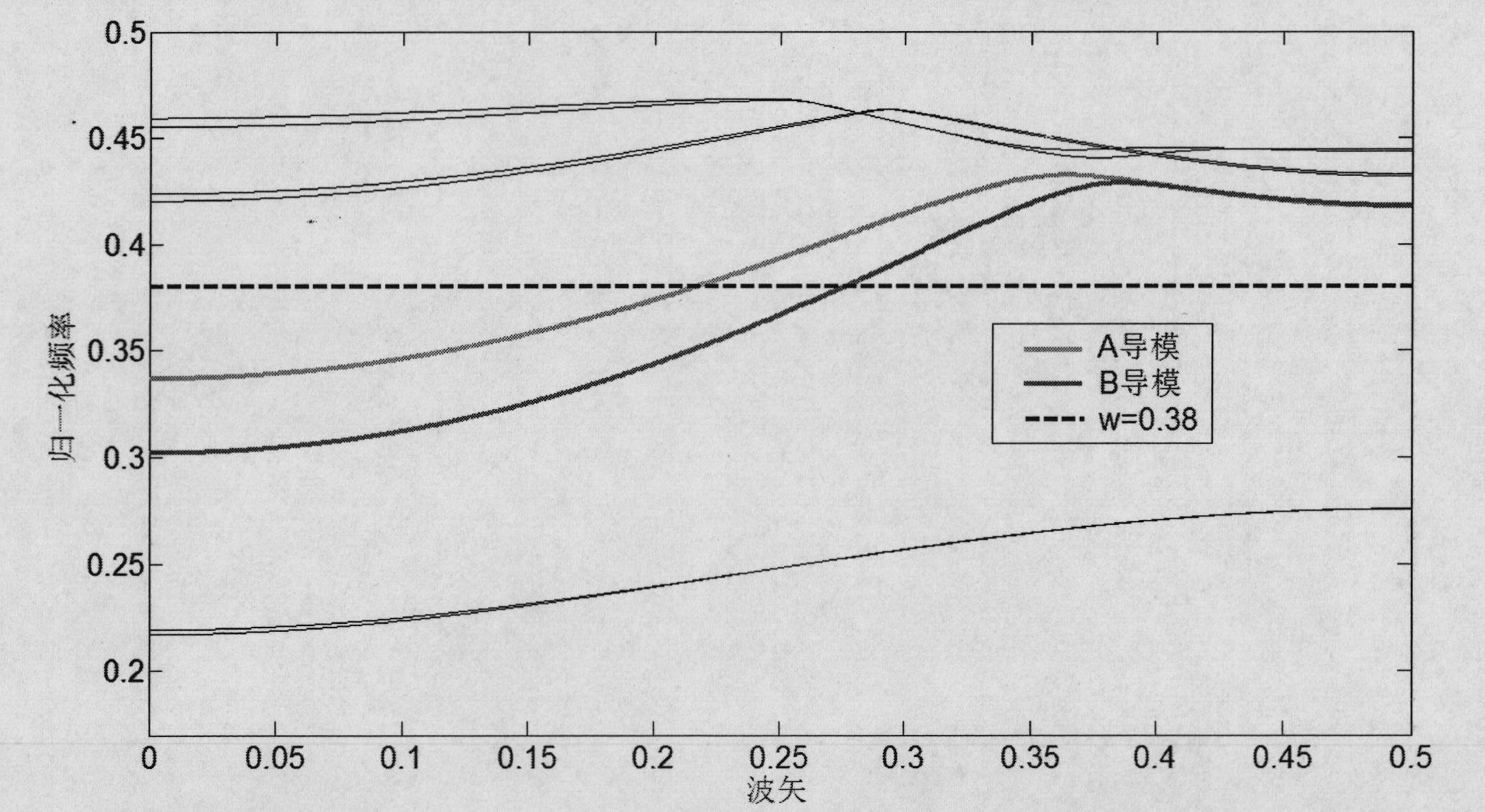

Photonic crystal all-optical exclusive-or logic gate structure based on interference principle

InactiveCN102323707AIntervention EfficientIncrease the apertureLogic circuits using opto-electronic devicesOptical light guidesCoupled mode theoryFully coupled

The invention relates to a photonic crystal all-optical exclusive-or logic gate structure based on an interference principle. In the photonic crystal all-optical exclusive-or logic gate structure based on the interference principle, by designing a special structure of an interference arm, a phase difference is generated between in-phase lights of different port input devices; the length of the interference arm is calculated by using a coupling mode theory, so the phase difference of input lights which pass through the interference arm is even times of Pi; and by designing the structure of a wave combining area, interference lights are fully coupled, and the logic exclusive-or operation of an output waveguide is realized. The photonic crystal all-optical exclusive-or logic gate structure based on the interference principle is made of a two-dimensional air background medium column square crystal lattice material, wherein the medium column material is crystalline silicon, and an index of refraction is 3.48; and by designing the unique structures of the interference arm and the wave combining area, the broadband exclusive-or operation of a window of 1,550 nm can be realized, and a new method is provided for miniature photonic integration.

Owner:BEIJING UNIV OF POSTS & TELECOMM

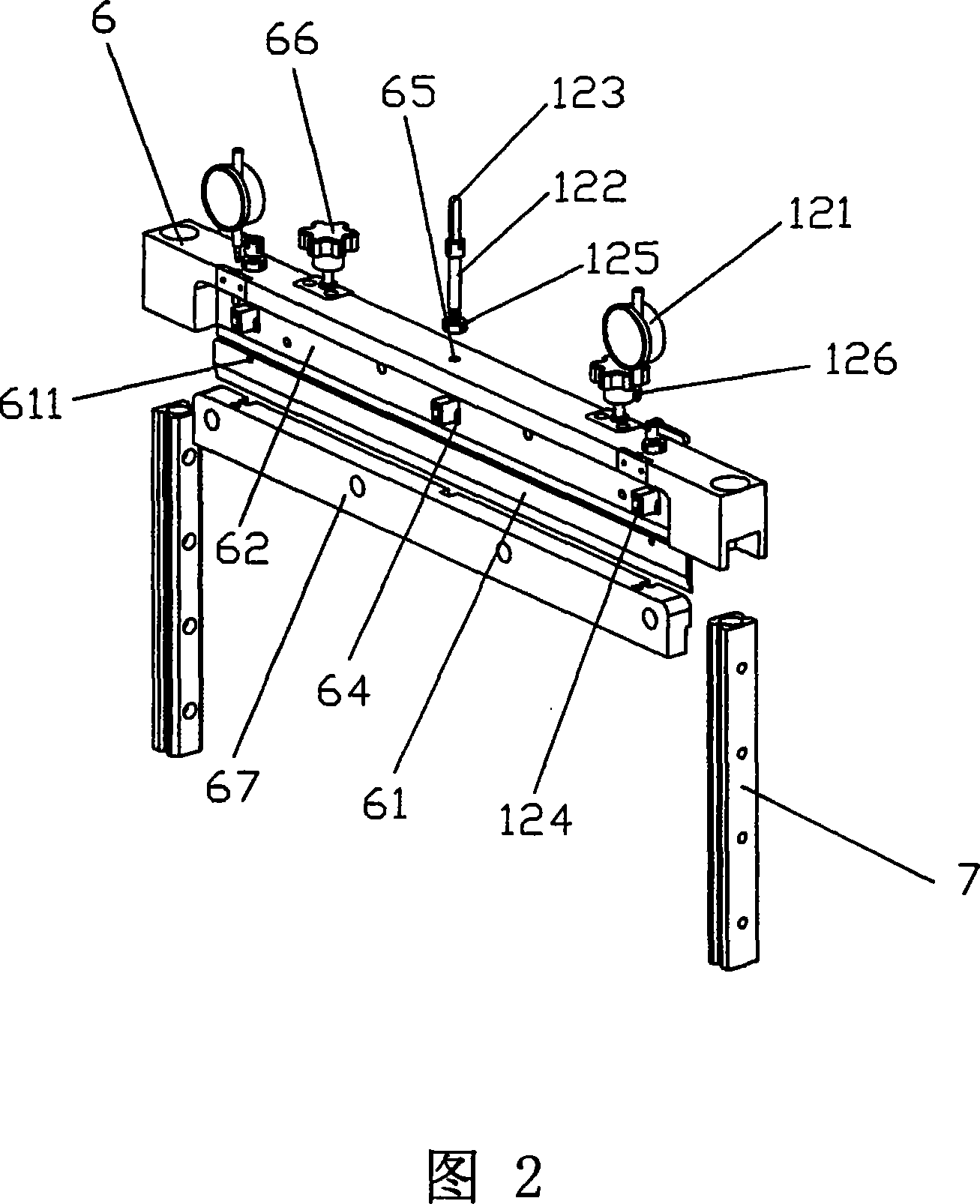

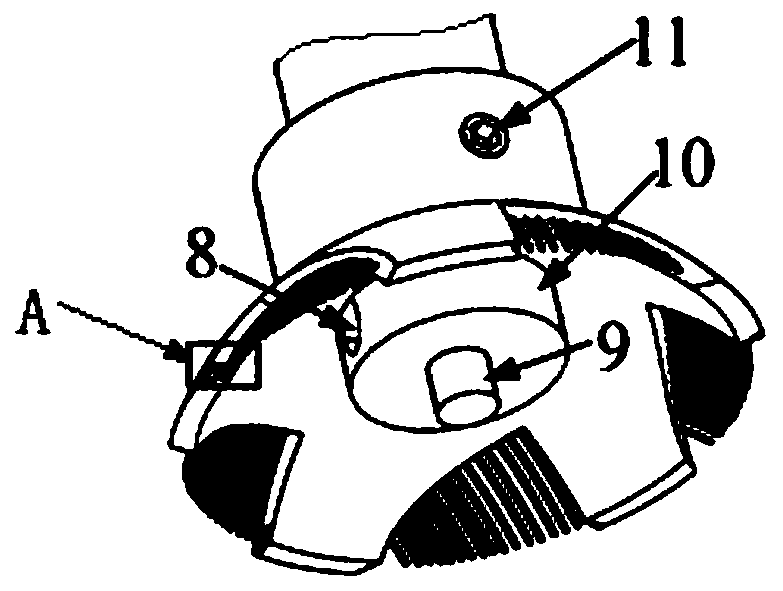

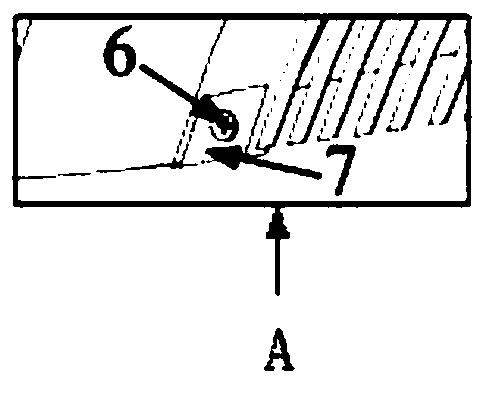

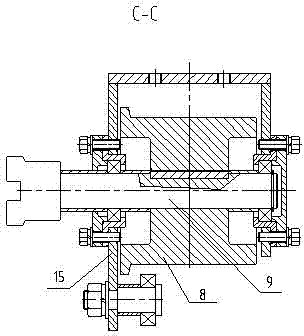

Cage pocket machining device

ActiveCN105127779AIncrease flexibilityReduce manufacturing precisionWork clamping meansPositioning apparatusMetallic materialsEngineering

The invention provides a cage pocket machining device which comprises a workpiece fixing shaft. A supporting sleeve is arranged on the periphery of the workpiece fixing shaft and used for being sleeved with a cage blank so as to conduct radial supporting on the cage blank. The supporting sleeve is made of nonmetal materials and achieves circumferential locking with the workpiece fixing shaft. According to the cage pocket machining device, because the cage blank is supported through the supporting sleeve made of the nonmetal materials, the situation that a cutting edge cracks when a drill bit drills through the cage blank and makes contact with the workpiece fixing shaft is avoided in the drilling process, and safety is high. Meanwhile, the drilling position has high flexibility and is not restrained by a hole which allows a drill bit to enter and is reserved in the workpiece fixing shaft, so that the tool manufacturing precision and the assembly difficulty are reduced.

Owner:LUOYANG BEARING RES INST CO LTD

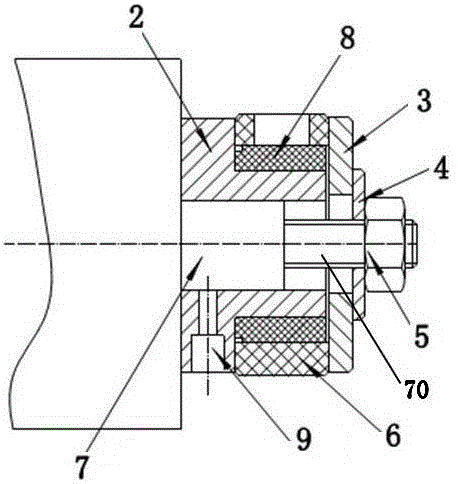

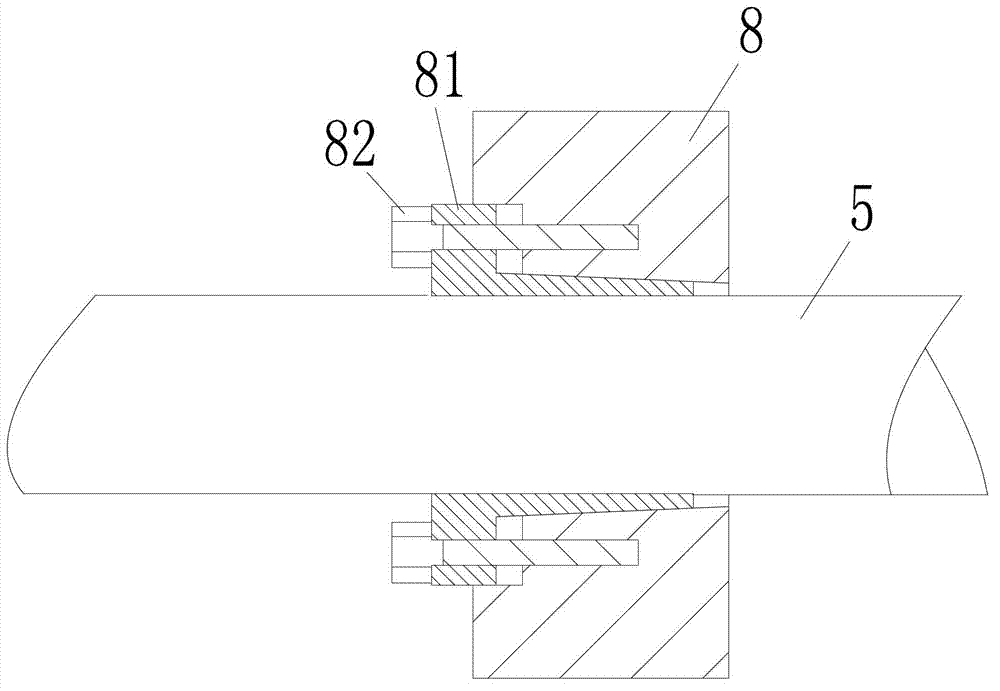

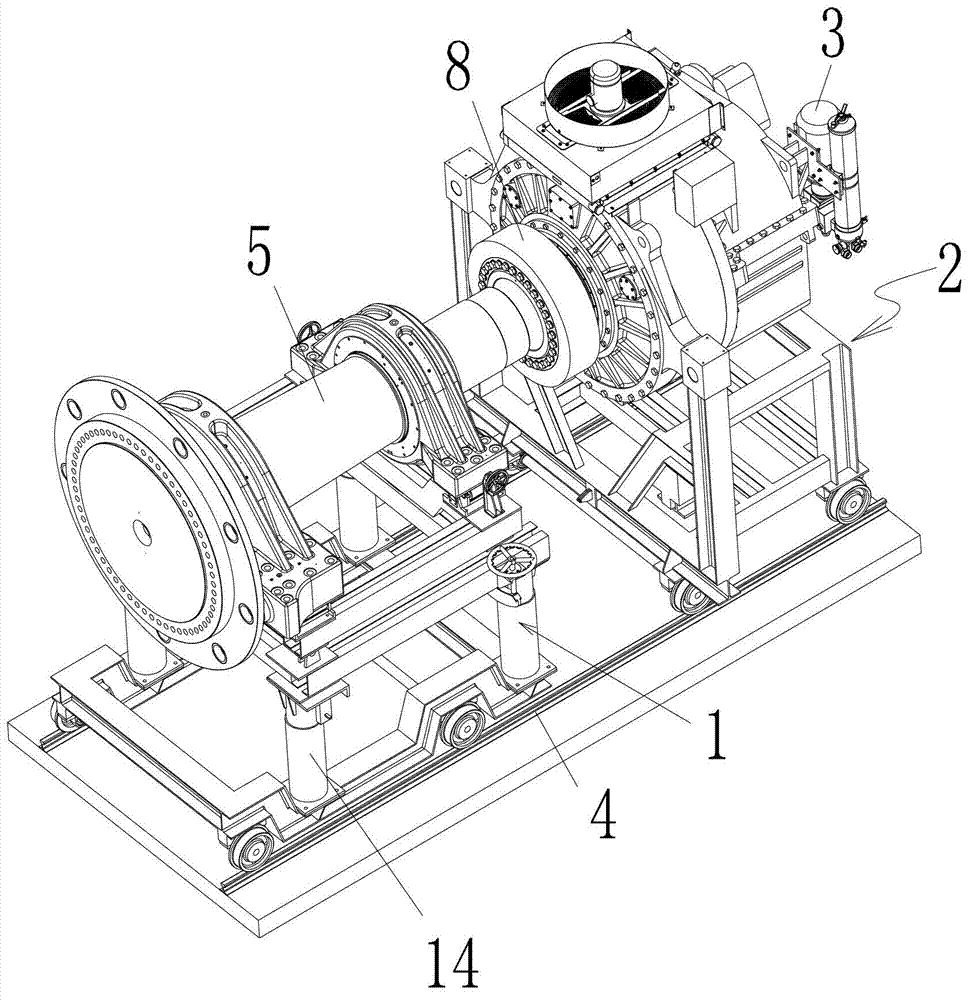

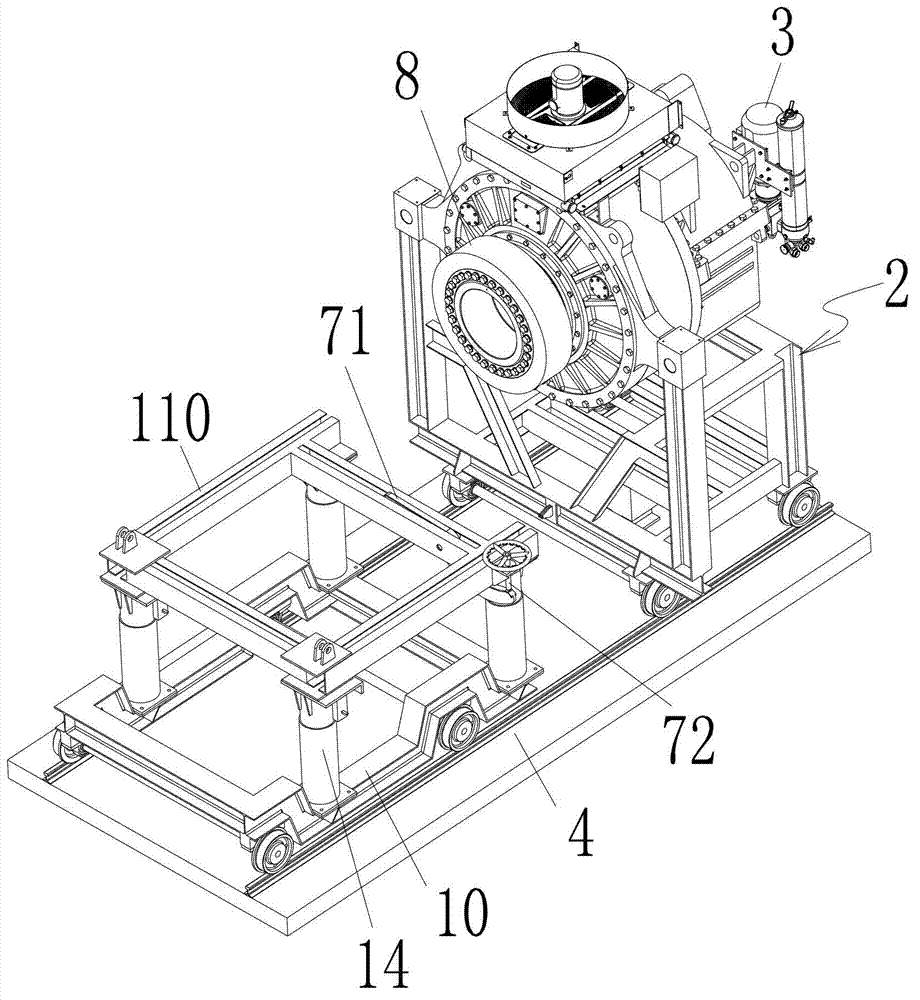

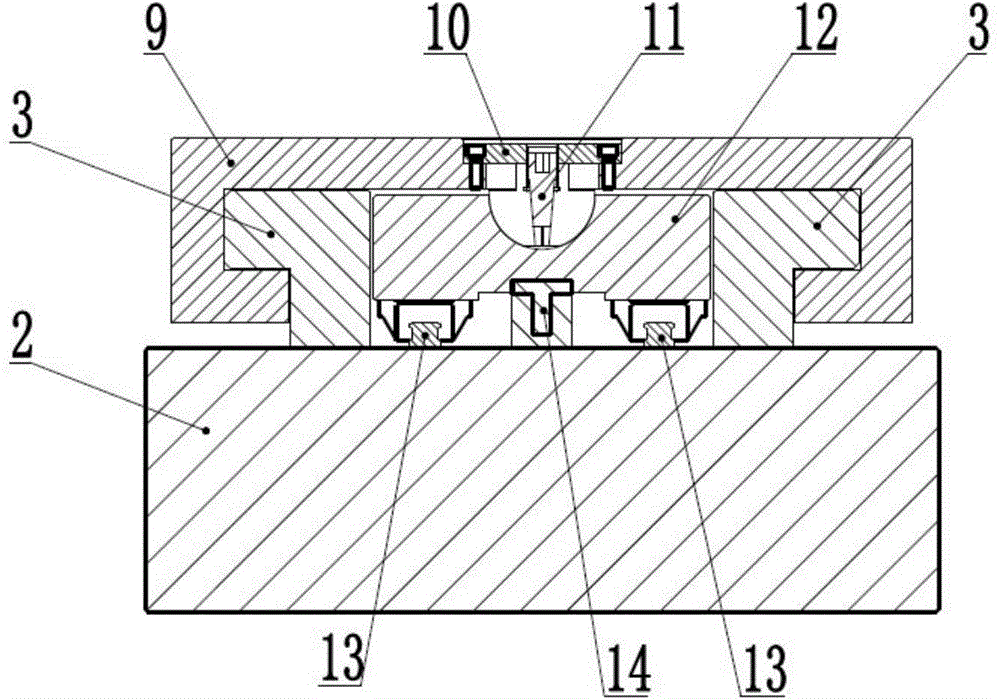

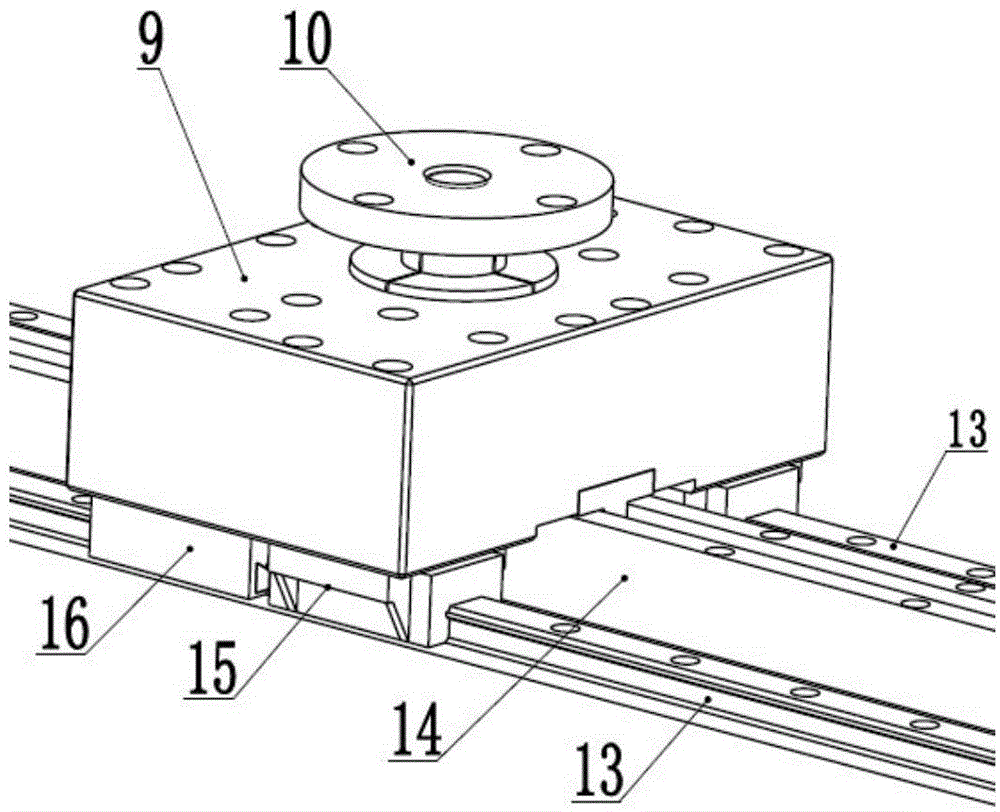

Device and method for centering wind power generator spindle and gearbox shaft expansion sleeve

ActiveCN103244363AAvoid Positioning ErrorsReduce manufacturing precisionWind energy generationWind motor componentsEngineeringWind force

The invention discloses a device and a method for centering a wind power generator spindle and a gearbox shaft expansion sleeve. The device comprises a wind power generator spindle support, a gearbox support and a tension machine, the wind power generator spindle support comprises a base and a floating rack in up-down arrangement, the floating rack comprises a mounting seat on an upper layer and a floating seat on a lower layer, a horizontal roller set supporting a wind power generator spindle assembly is mounted on the mounting seat and brings convenience to the wind power generator spindle to horizontally move, and a spring support between the base and the floating seat enables the wind power generator spindle assembly and the floating rack to be in a floating state in the vertical direction. The device and the method for centering the wind power generator spindle and the gearbox shaft expansion sleeve are high in centering accuracy, simple to operate and few in needed personnel.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

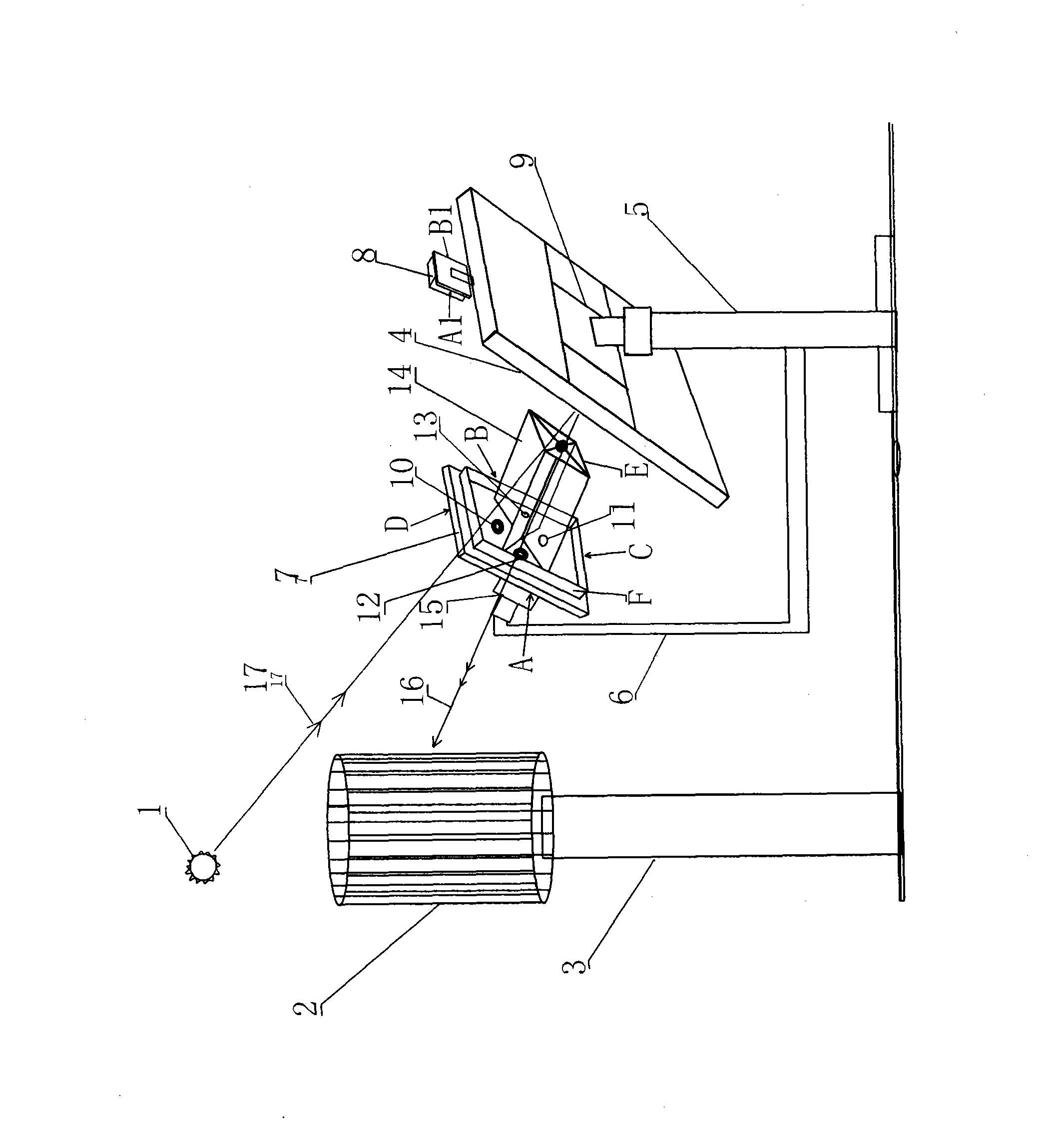

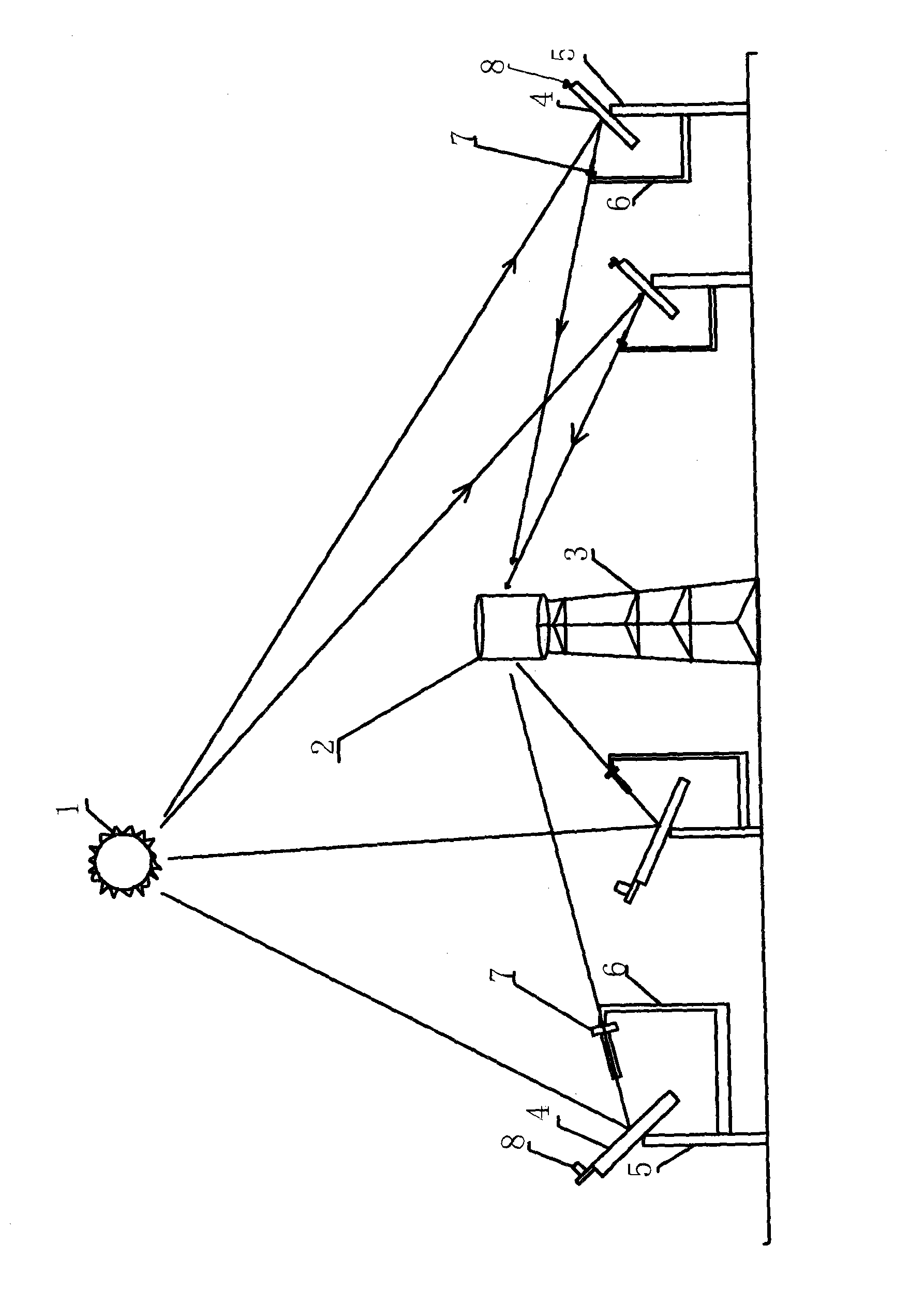

Tracking and aiming control method and device for heliostat

InactiveCN103309361AHigh cost and high stabilityImprove stabilityControl using feedbackComputer control systemMotor drive

The invention discloses a tracking and aiming control method and device for a heliostat. The traditional calculation method and the traditional computer control system are not adopted, while a new way is established. According to the tracking and aiming control method and device, a low-cost high-precision aiming sensor, a sun position recognition and tracking sensor and a three-point line tracking support aiming method are combined; accordingly, the heliostat is allowed to recognize the sun position and track the sun, and the light reflected to a specified target is fixed; the fact that a reflecting point of the heliostat, namely the heliostat, is permanently fixed at the specified target everywhere on earth for all seasons while the sun moves; the heliostat control method and device is implemented all by sensors. The system and structure of computers, software, programs, equations, longitude and latitude, linked control structure, laser aiming control, CCD aiming control, PLC control, large curved mirror reflection, and servo motor drive is not considered; stability and wind resistance are increased by several times; system cost and operation and maintenance cost are reduced by tens of times.

Owner:梁方民

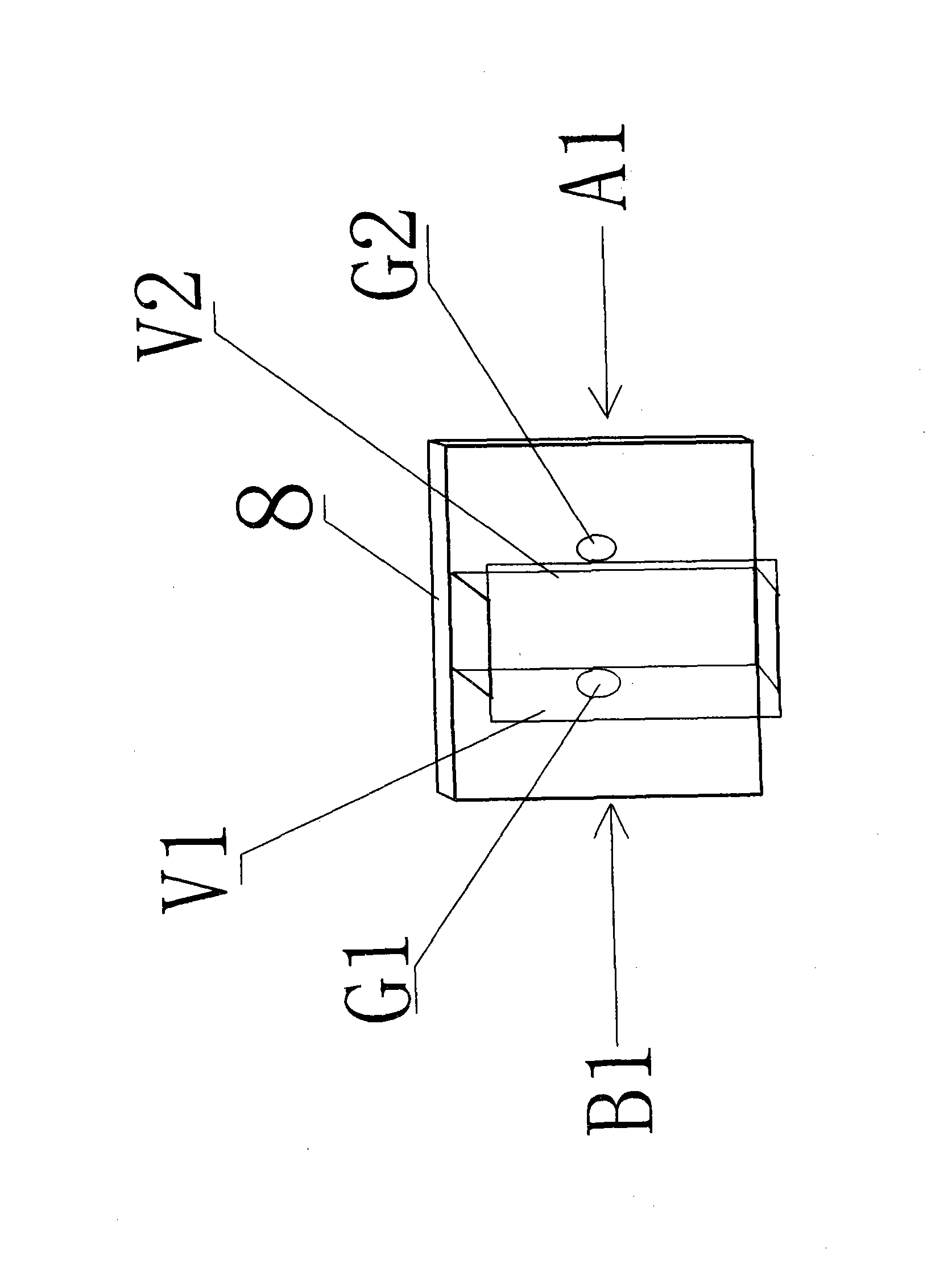

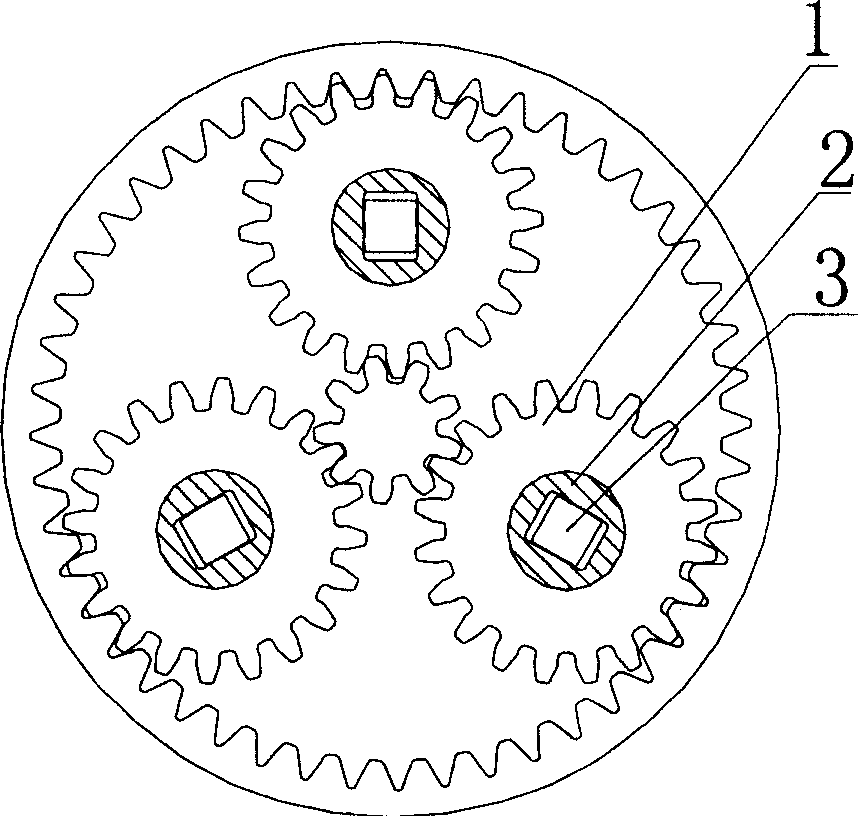

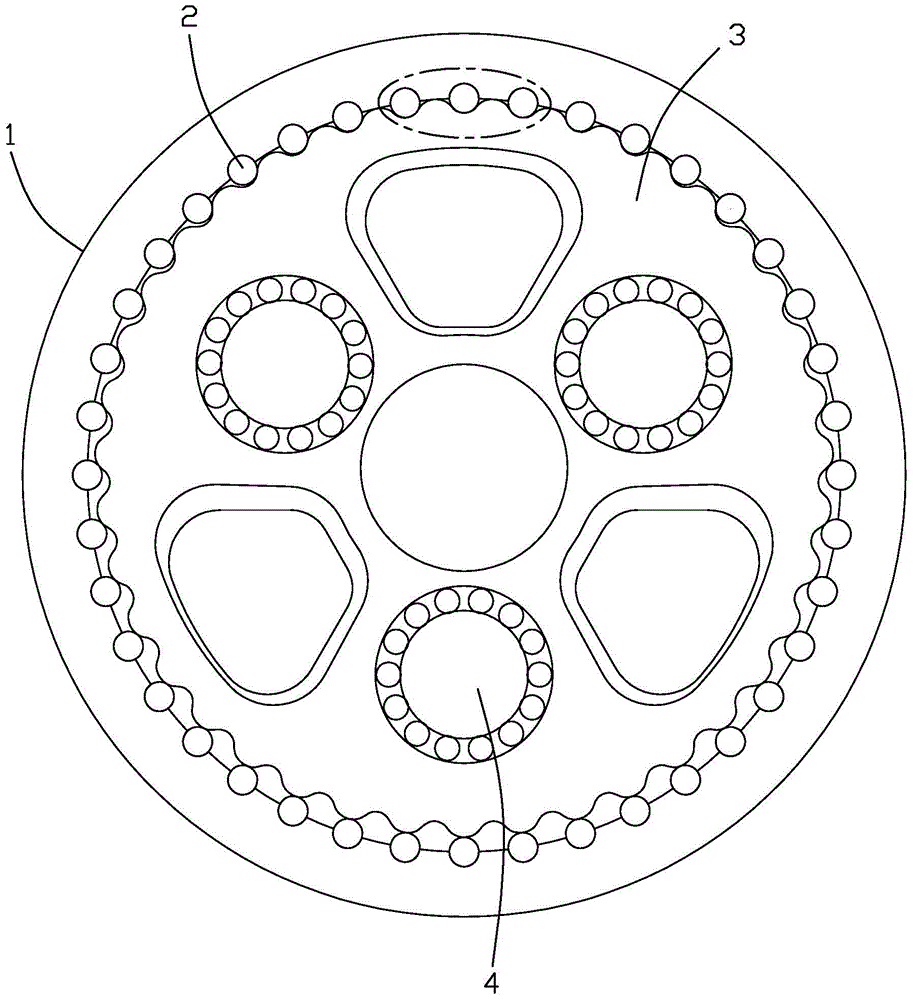

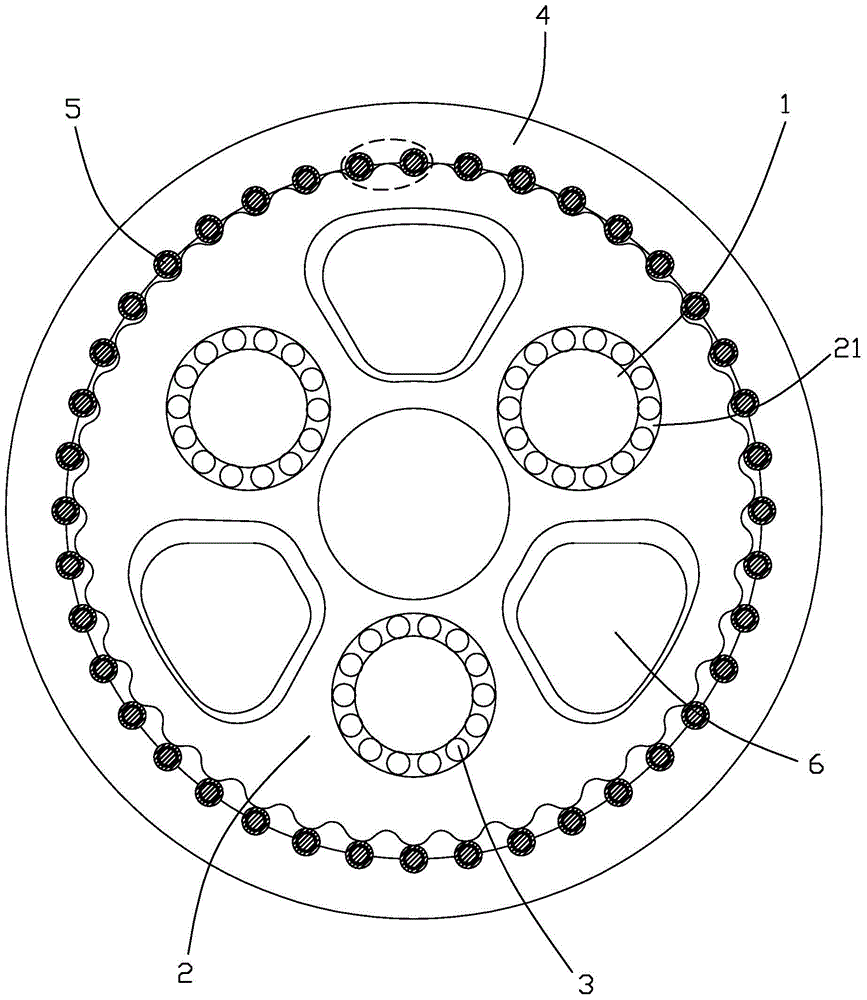

Floating load balancing mechanism for planet wheels and speed reducer thereof

InactiveCN1844703AExtend your lifeGood load balancing performanceToothed gearingsReduction driveGear wheel

The invention discloses a planet wheel float equal-load device and a speed reducer. Wherein, it has a inner tooth ring; the tooth of planet wheel is meshed to the outer tooth of sun wheel and the inner tooth of inner tooth wheel; the fixing axle is integrated with the planet support. It is characterized in that: the fixing axle and the planet wheel are float connected, while the fixing axle on the planet wheel support is a flat square axle mounted with a flat square sleeve; the inner hole of said sleeve can move along the axle of flat square axle but can not rotate; the planet wheel is mounted on the flat square sleeve, whose inner hole is movably matched with the outer circle of sleeve; the planet wheel can rotate on the outer circuit and move on the axle of flat square axle, to form a float equal load. The inventive speed reducer, via equal load, can improve the load strength of tooth surface, prolong the service life of gear wheel, confirm the transmission stability and reduce the noise.

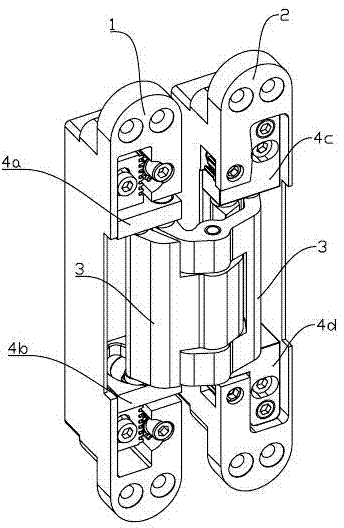

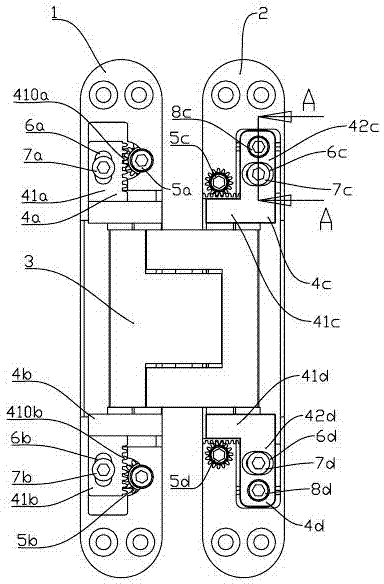

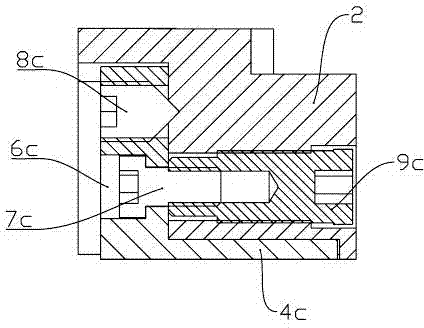

Adjustable door hinge

Owner:GUANGDONG ARCHIE HARDWARE

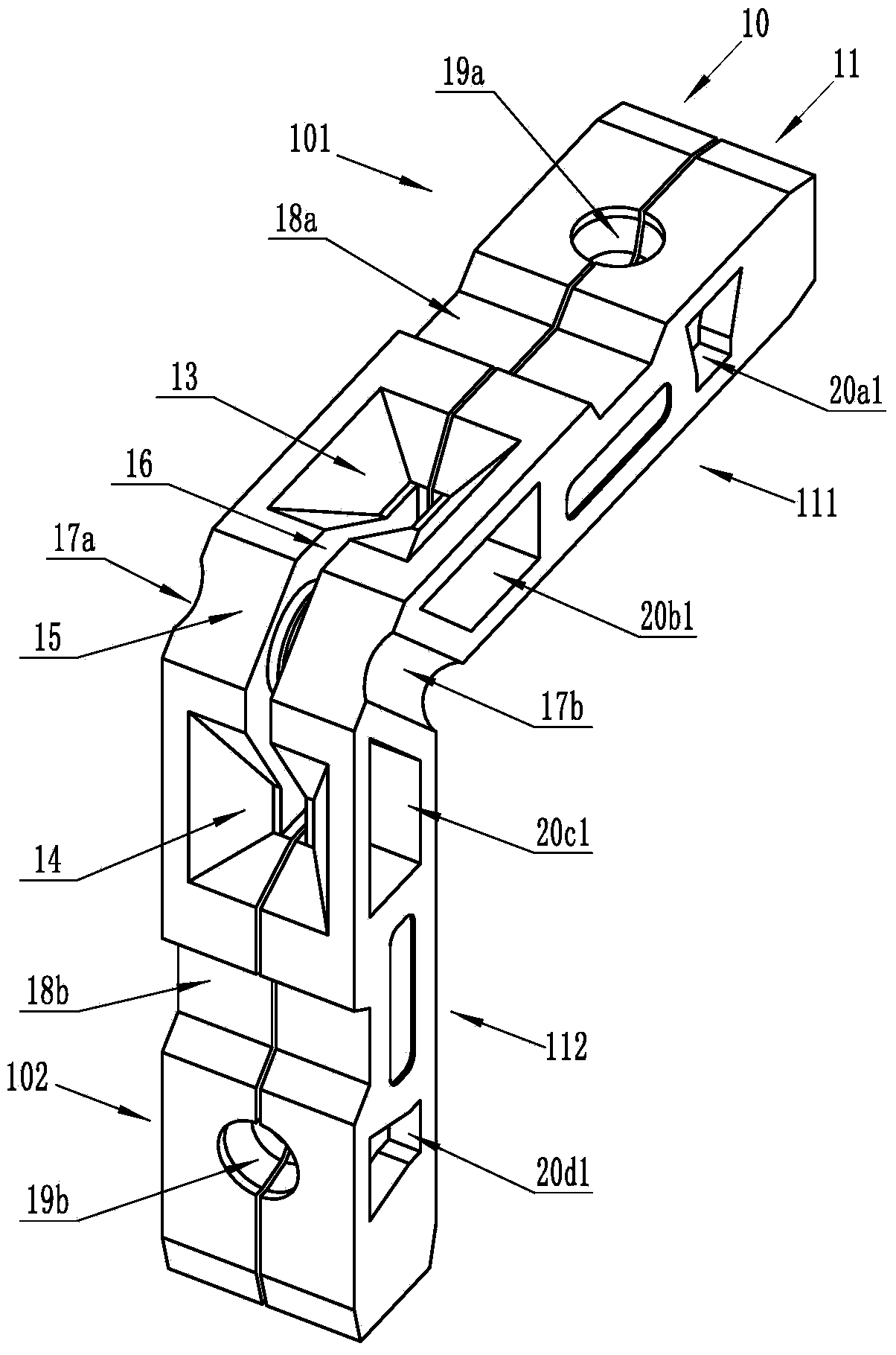

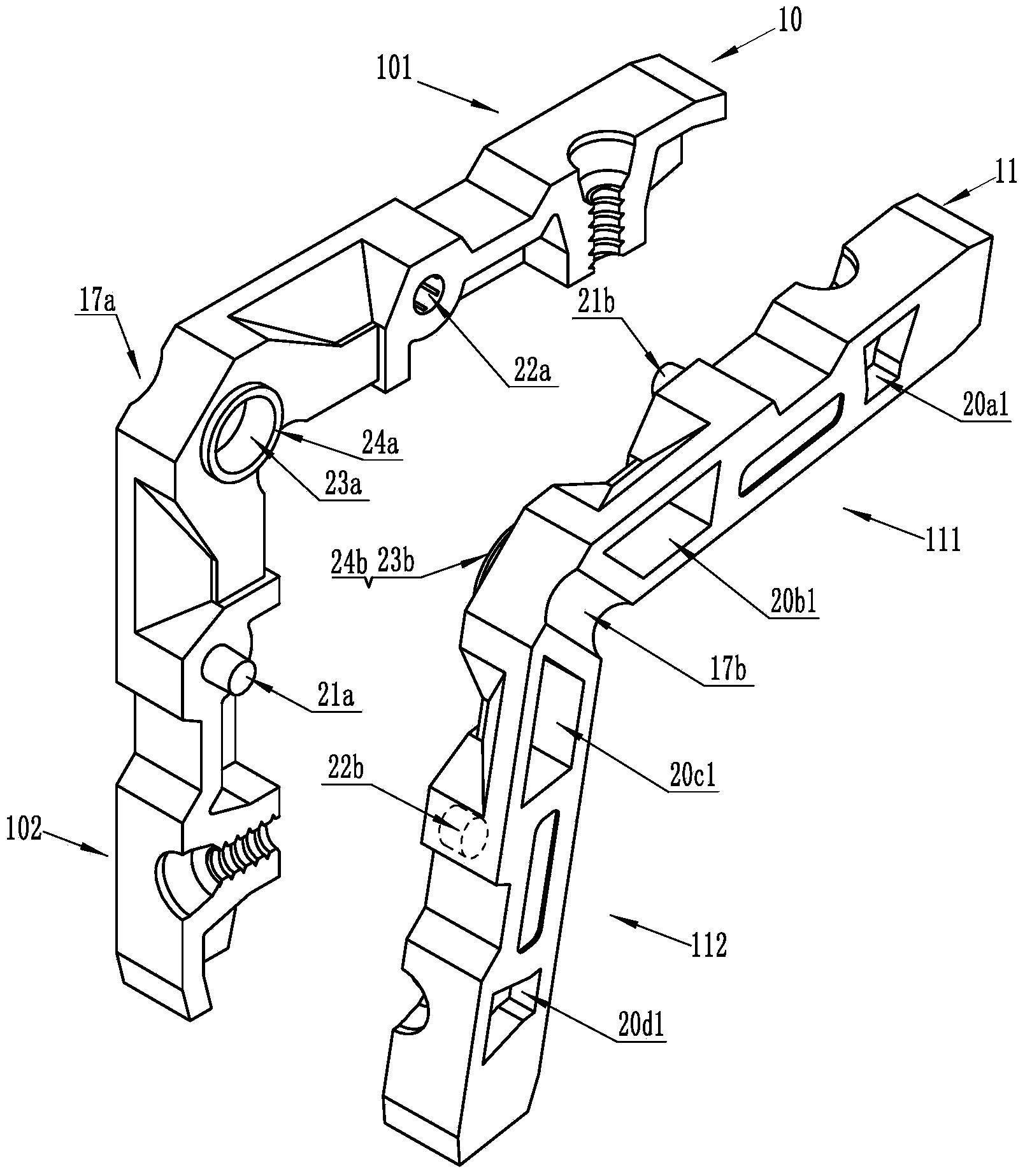

Compound angle code for corner combinations of profiles

Owner:SHANDONG HUAJIAN ALUMINUM GRP +1

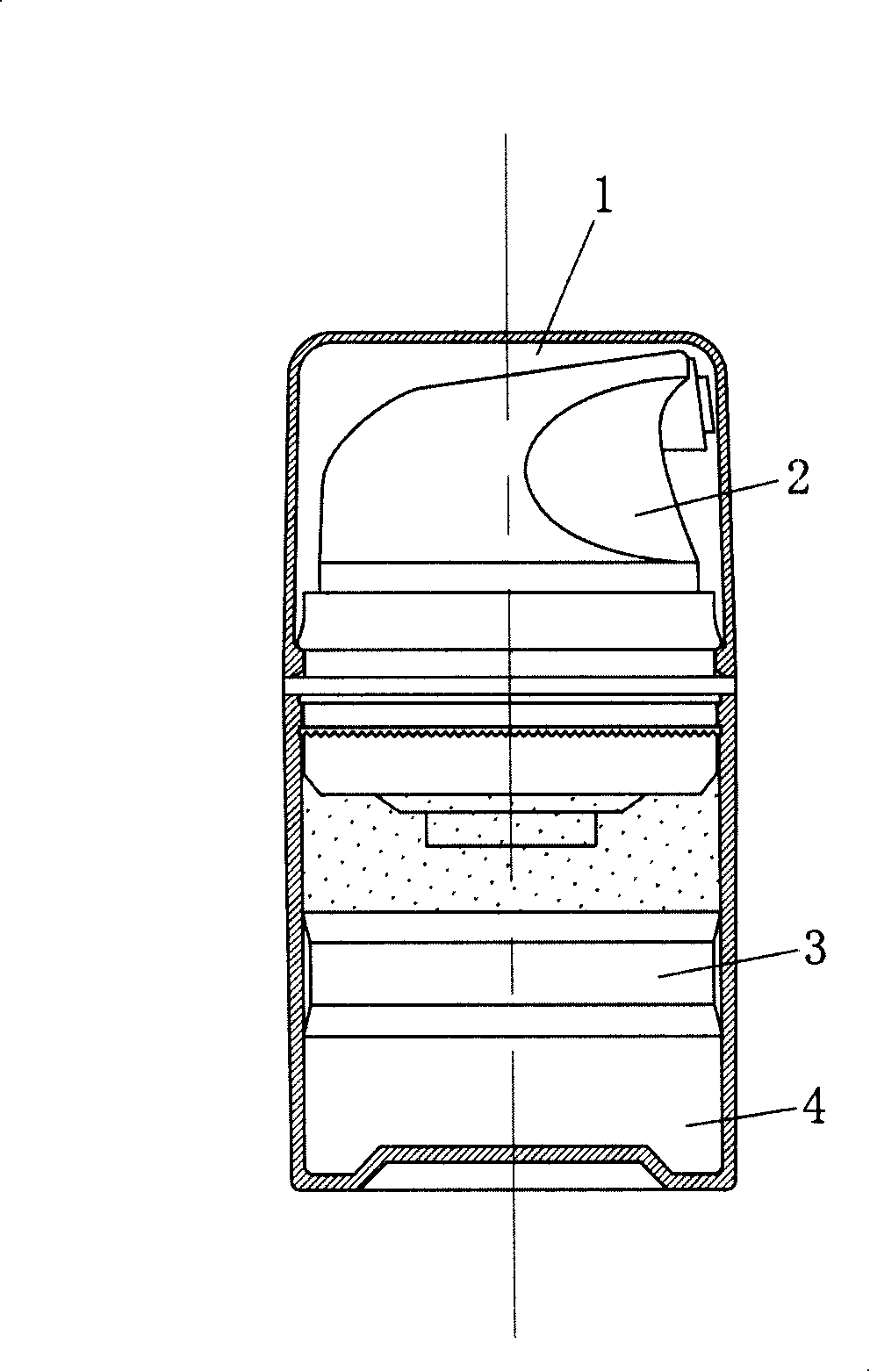

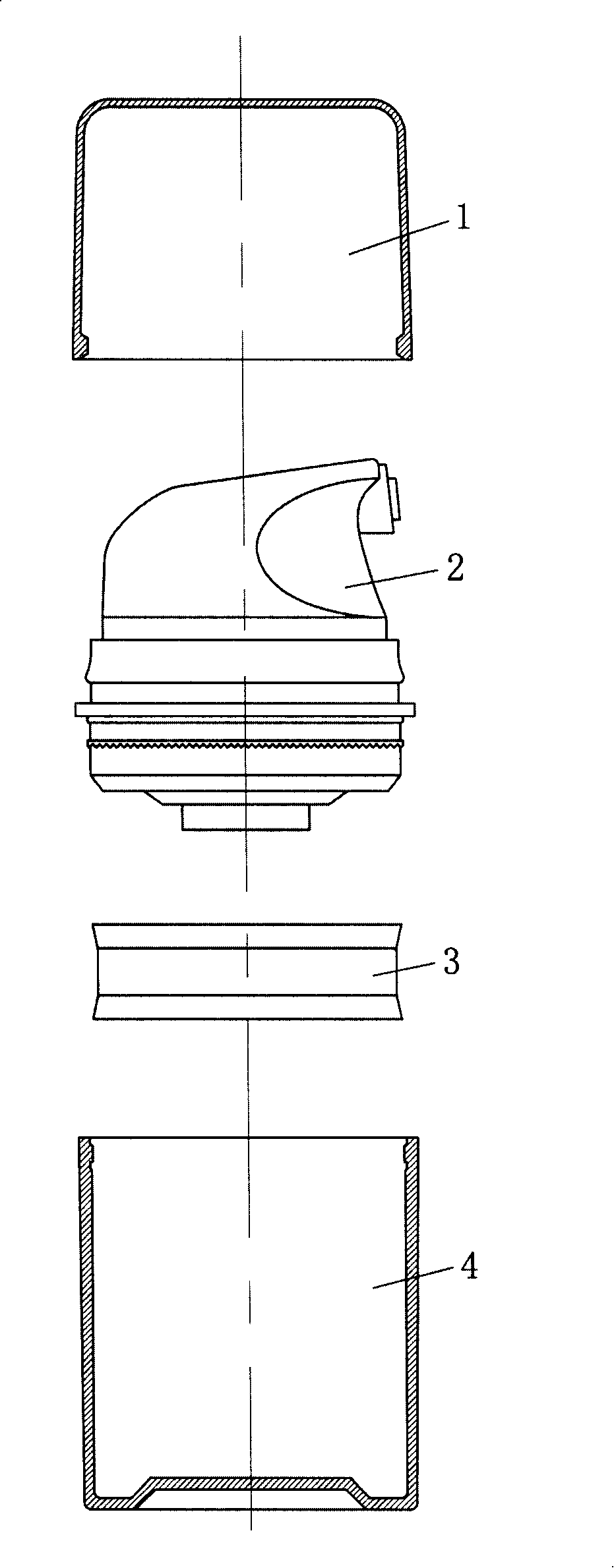

Vacuum packaging container

ActiveCN101214869AReduce manufacturing precisionLow costClosuresPackaging under vacuum/special atmosphereEmulsionSuction force

The invention provides a vacuum packaging container, including a bottle body which is equipped with a top part, a bottom part, a lateral wall, breather holes and an emulsion pump which is arranged on the top part of the bottle body. The invention is characterized in that the vacuum packaging container also includes at least one capsular bag, the periphery of which is combined with the inner wall of the bottle body in a way of sealing. Thus, one lateral of the capsular bag is in contact with the emulsion and the other lateral is communicated with the atmosphere. The vacuum packaging container also includes a guiding strip which is connected with the feed inlet of the emulsion pump. The guiding strip is shaped to be equipped with at least one opening guiding slot. With strong suction force, the vacuum packaging container of the invention can overcome the problem that the emulsion can not be suctioned out or is hard to be suctioned out completely. The vacuum packaging container of the invention also has the advantages of low manufacturing precision and low cost. In addition, the invention is equipped with the specific guiding strip, thereby ensuring that the feed inlet is not blocked under various conditions.

Owner:丁要武

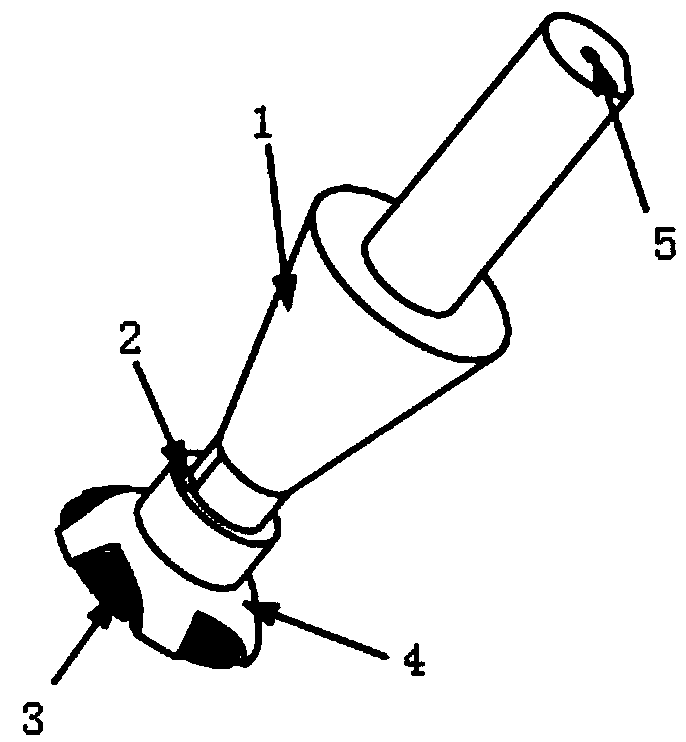

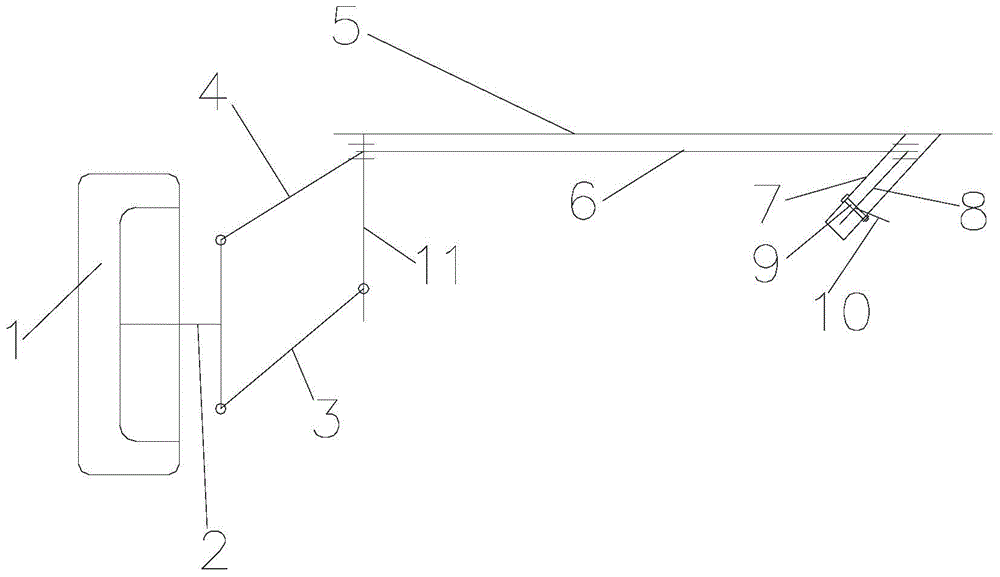

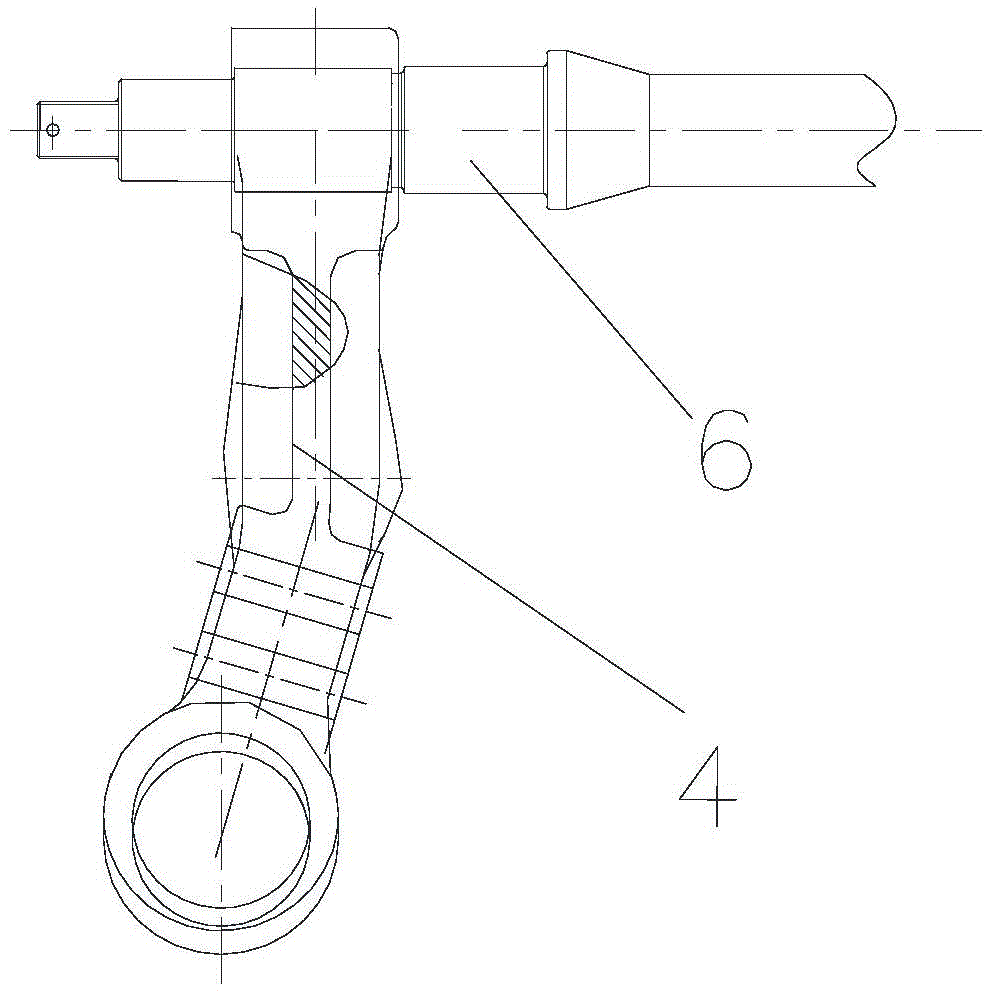

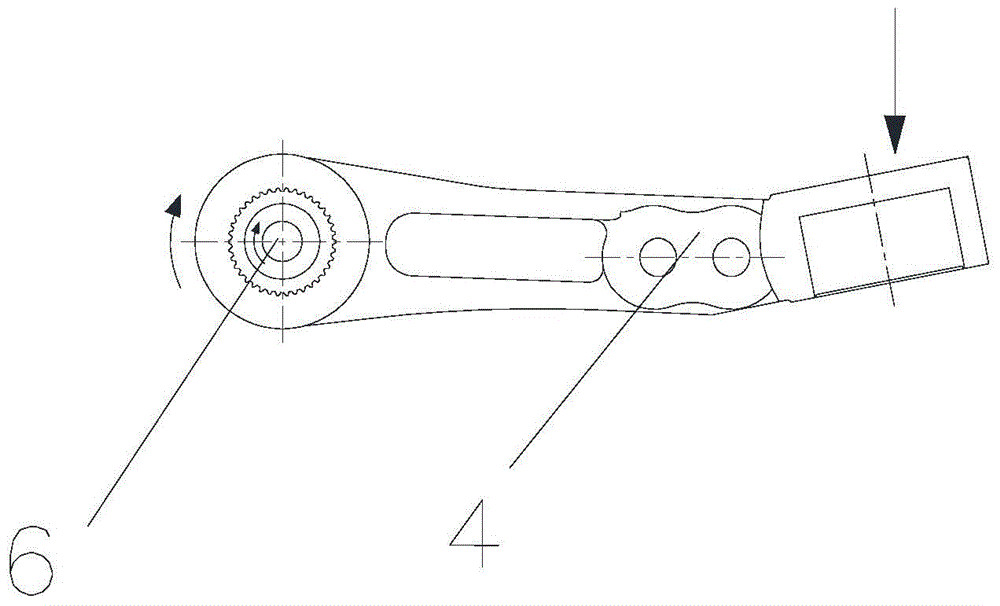

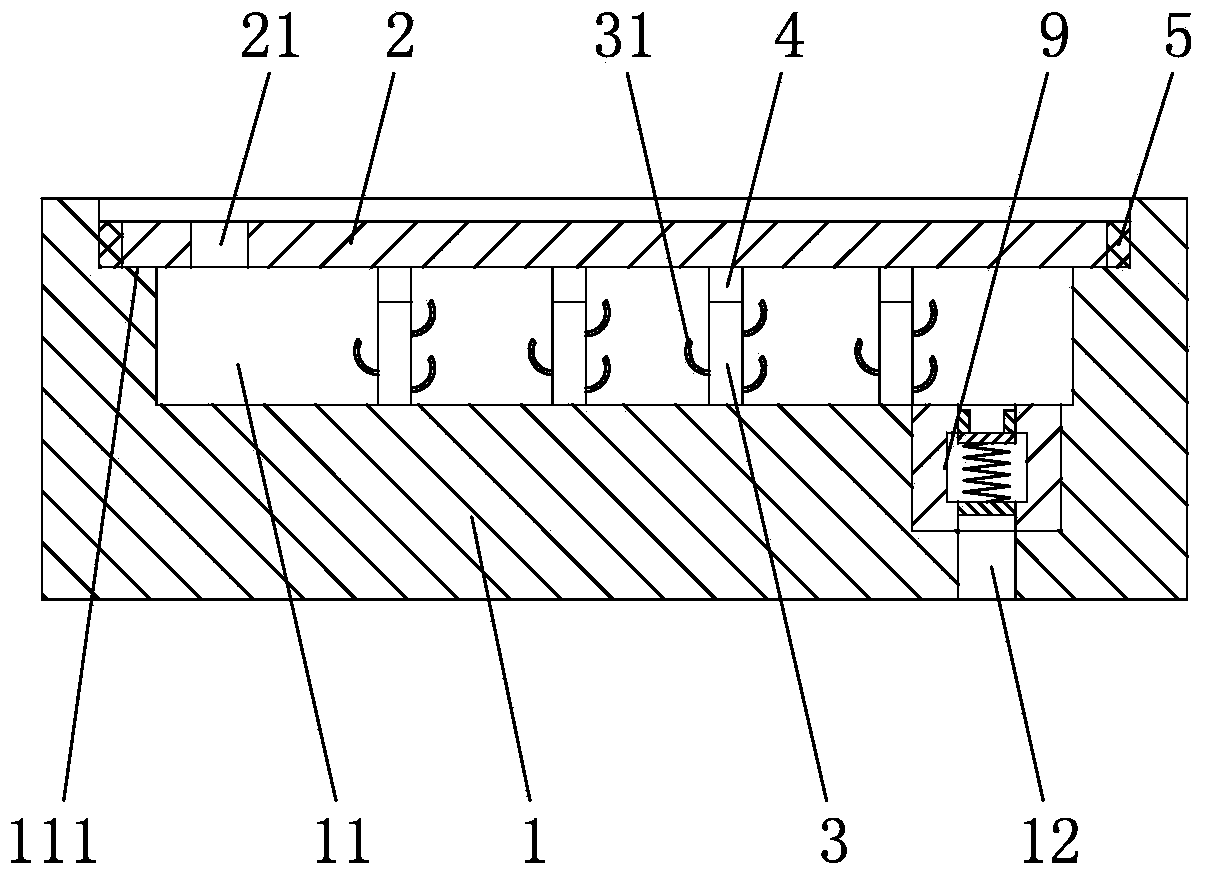

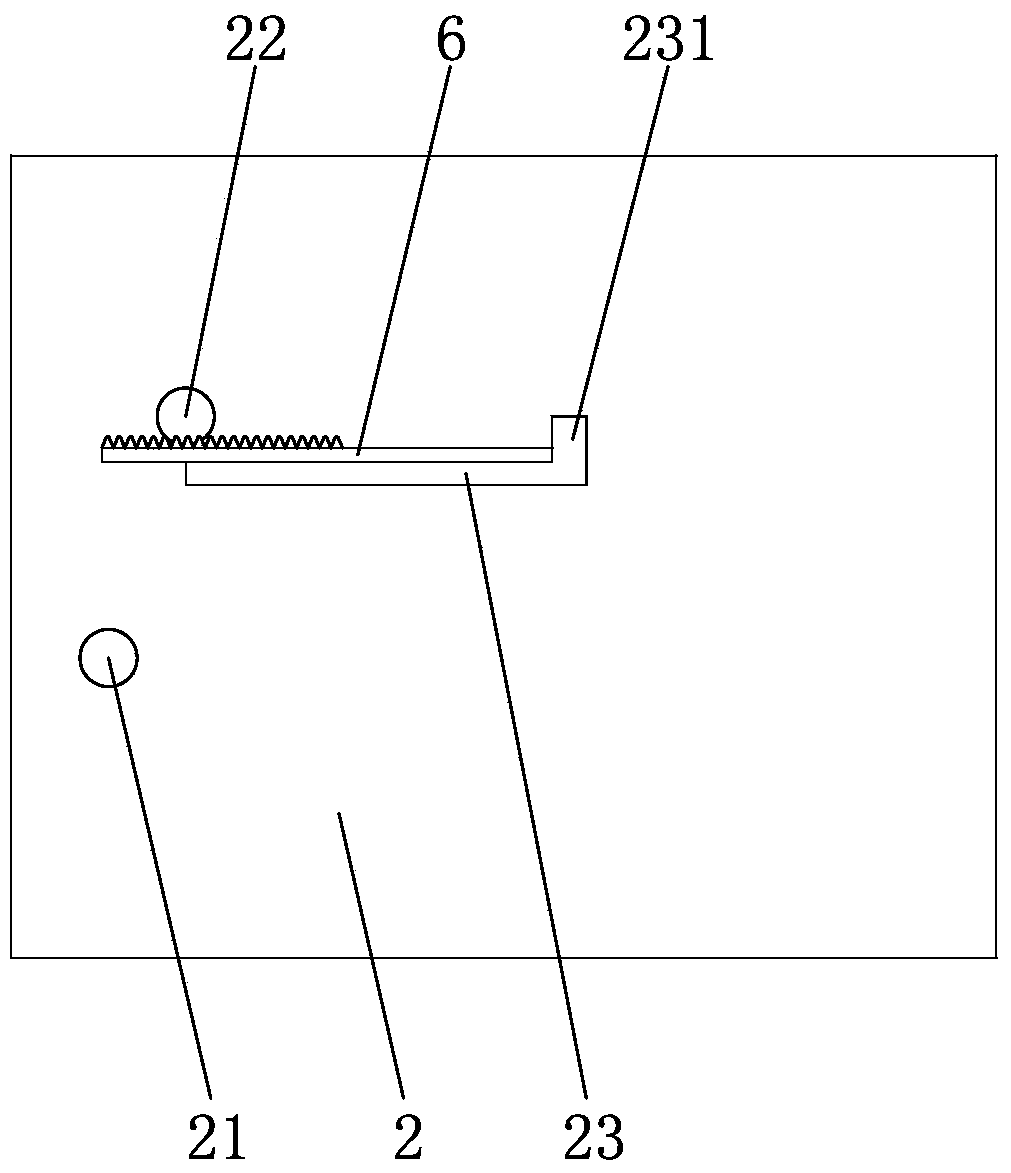

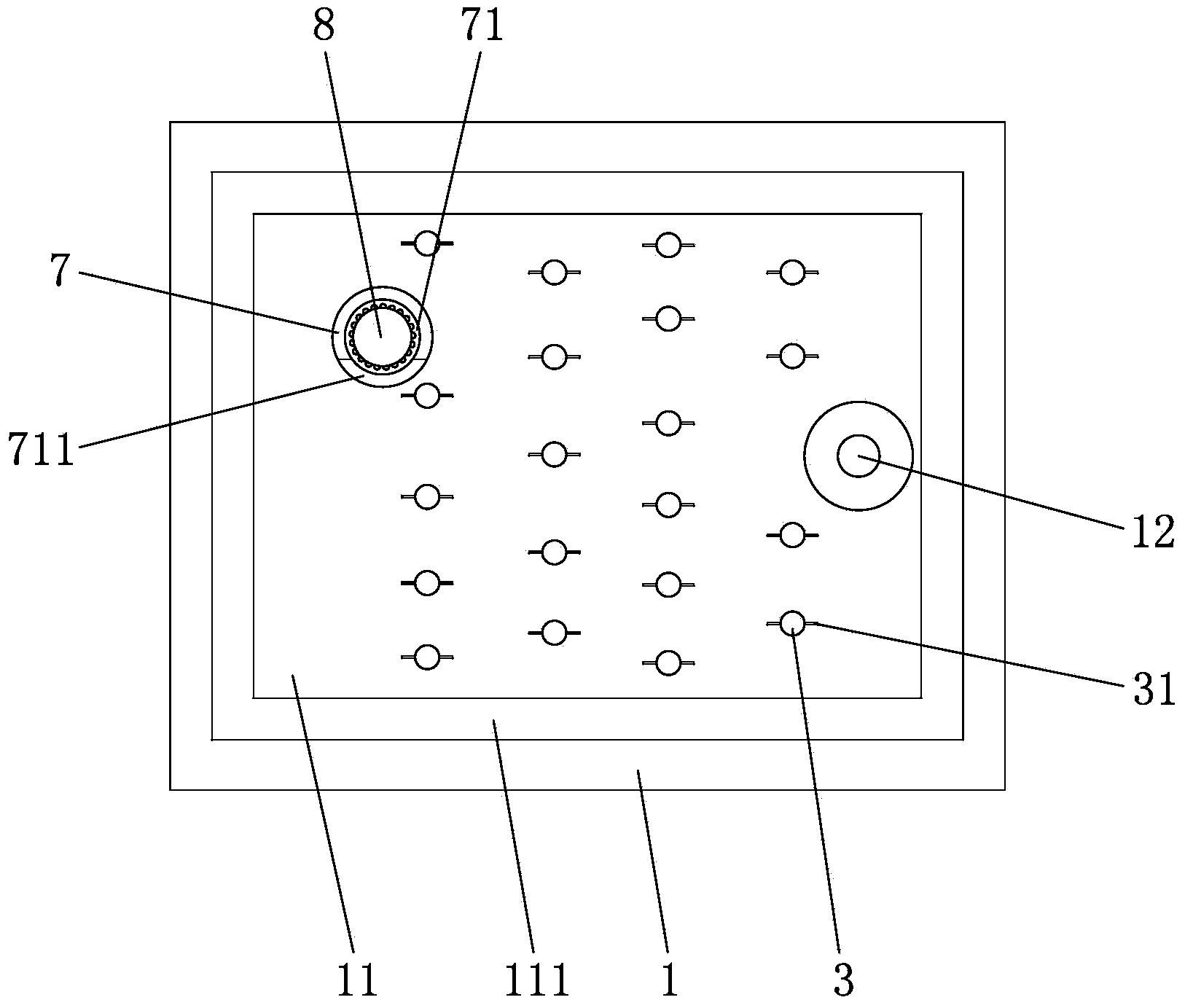

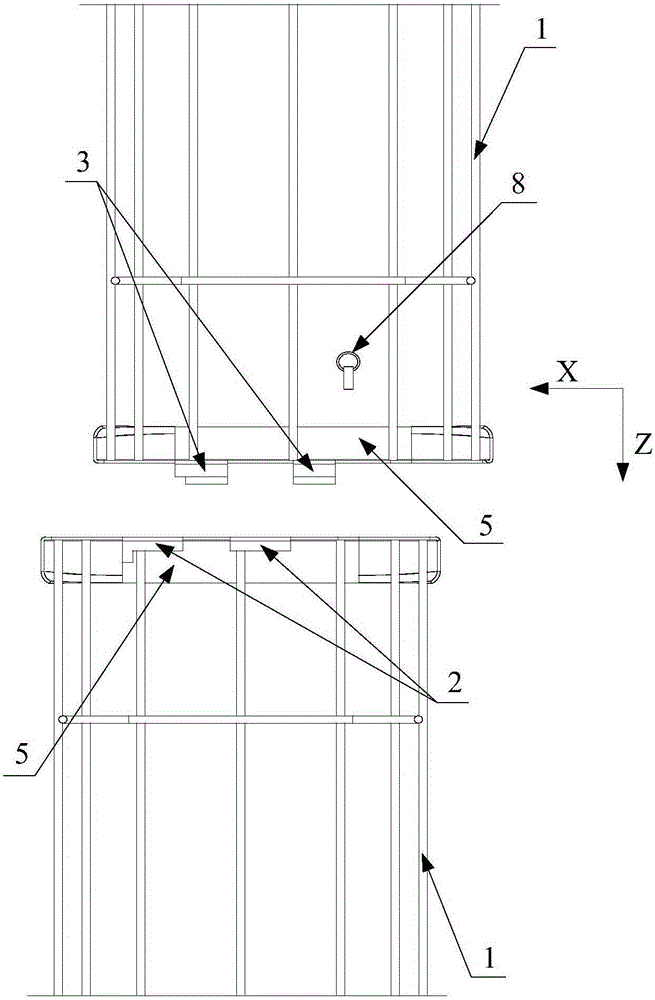

Mold for integrally molding J-shaped reinforced composite material wall plate

The invention belongs to a resin-based composite material molding technology, and relates to a mold for integrally molding a J-shaped reinforced composite material wall plate. The mold provided by the invention comprises an appearance mold 1, a positioning block 2, an upper flange forming mold 3, a limiting mold 4, a lower flange forming mold 5, and an auxiliary mold 6. According to the invention, the appearance mold 1 is adopted as a basis, and the positioning block 2, the upper flange forming mold 3 and the limiting mold 4 are positioned sequentially. Through the controlling over position precision of the assembled upper flange forming mold 3 and the assembled limiting mold 4, precision of the upper flange appearance surface of the J-shaped reinforcing rib and axis position precision of the reinforcing rib are ensured. Therefore, mold manufacturing cost is reduced, and manufacturing cycle is shortened.

Owner:AVIC COMPOSITES

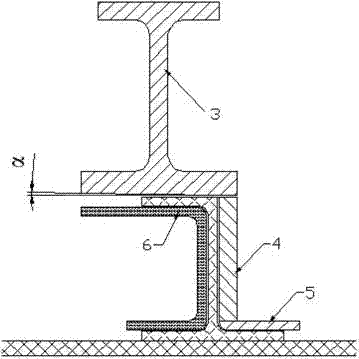

Machine for cutting material with one blade for two-purpose

InactiveCN101045306AReduce manufacturing precisionReduce manufacturing costMetal working apparatusEngineeringKnife holder

A material cutting machine with rolling cutter for cutting strips or cutting off is composed of a machine frame, a drive unit, a feeding frame, a rolling cutter, two straight guide tracks at both sides of said machine frame, an eccentric mechanism, a motor for driving said eccentric mechanism via drive rod, a cutter holder with a slot, a tool section in said slot and made of PVC, and a cutter trimming unit.

Owner:吕智雄

Elastic roller, pin-teeth cycloidal reducer and bearing

ActiveCN105134906APowerful overload shockHigh strengthBearing componentsInterference fitFlying height

The invention provides an elastic roller, a pin-teeth cycloidal reducer with the same and a bearing. The elastic roller comprises a hollow roller and a solid roller arranged inside the hollow roller, wherein a flying height for the hollow roller to generate elastic deformation is formed between the inner wall surface of the hollow roller and the outer wall surface of the solid roller. The elastic roller can provide a certain elastic deformation space for the hollow roller through the flying height, and further the sufficient elastic compensation ability can be realized during the selection and use of the interference fit; and meanwhile, the elastic roller can provide a certain support force through the inside solid roller, and can prevent the hollow roller from being flattened due to overlarge loading, so that the elastic roller can resist strong loading impact, has high strength and can not be damaged, thus reaching the aim of reliable elastic compensation, and further prolonging the service life of the elastic roller, pin-teeth cycloidal reducer and bearing provided by the invention.

Owner:QUANTA MACHINERY CO LTD

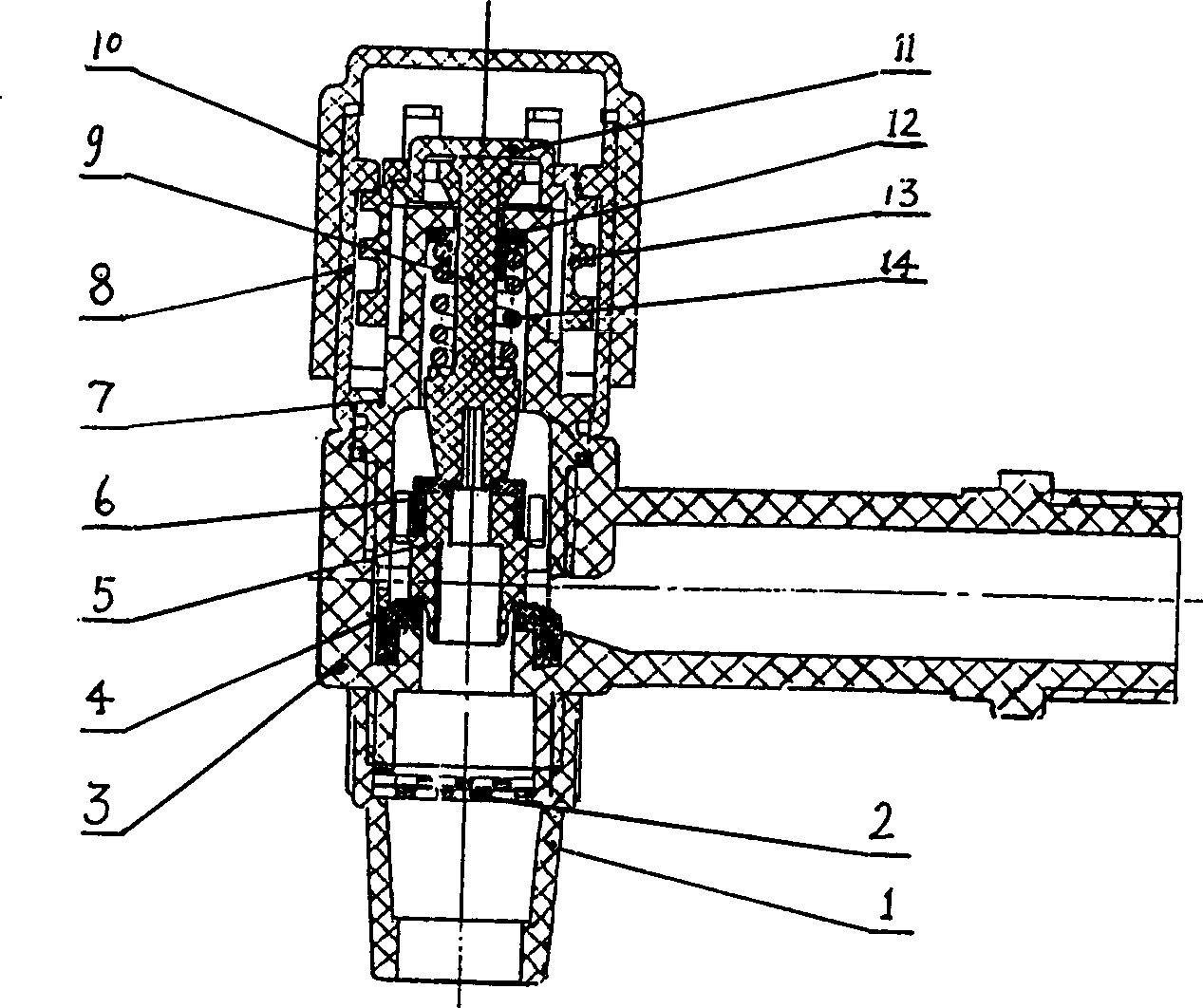

Water drop proof tap

InactiveCN1465876ASolve the dripping problemSolve the leakOperating means/releasing devices for valvesLift valveManufacturing cost reductionEngineering

The invention relates to the valve, especially valves with floating valve core in type of open and close by rotation. The valve is composed of the triple valve body, the floating valve core, the valve rod, the valve cap, the seal ring and the unit for controlling the valve rod. By taking full advantage of elasticity characteristics of the plastics, an erect claw is utilized to replace a cylinder.The circular bead is utilized to limit and lock the erect claw so as to reduce manufacturing accuracy needed as well as number of parts, material and cost. Since the steep fall structure of screw thread and the spring are used, the valve can return to closed position automatically when water quantity is low so as to solve the drip issue caused by not closing water faucet tightly or mild wear of seal ring. The stability of quality of the product is also raised.

Owner:蔡松城

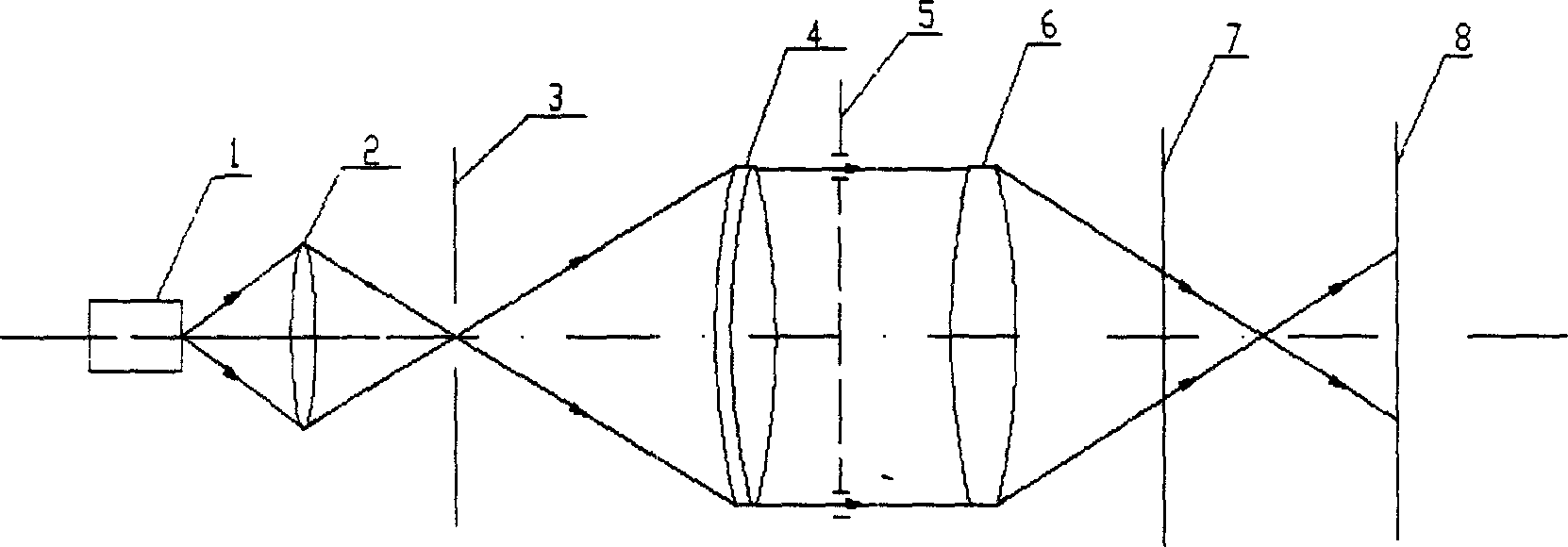

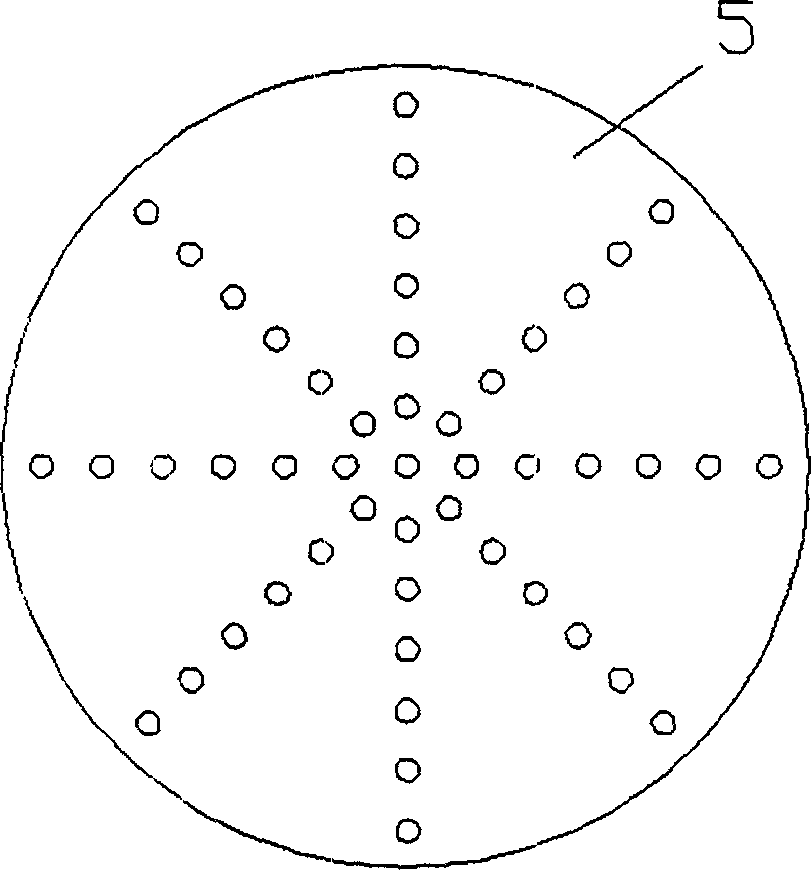

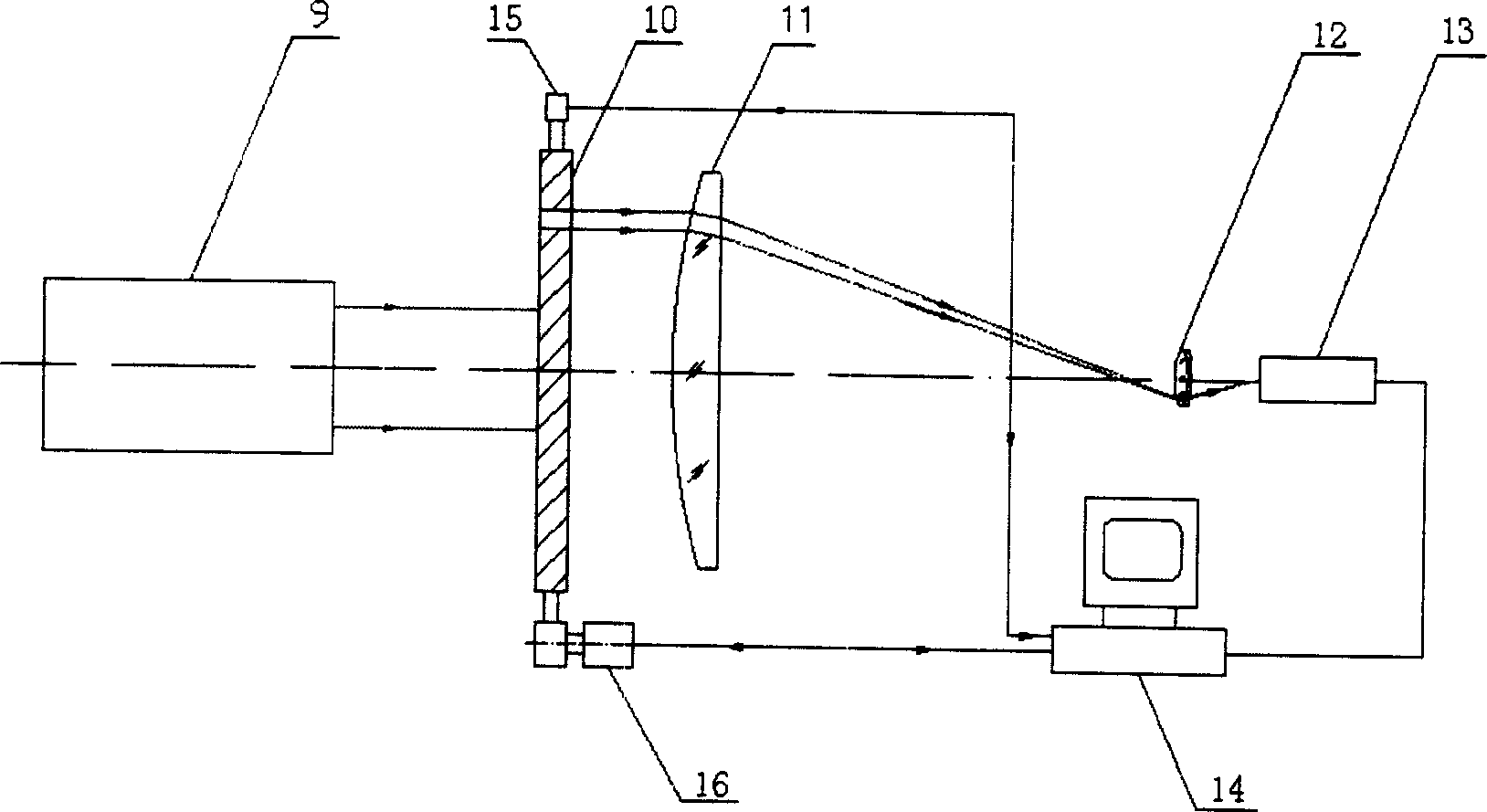

Multifunctional optical quality detector

InactiveCN1563943AReduce manufacturing precisionManufacturing precision requirements are lowMaterial analysis by optical meansStandard collimatorEngineering

The testing device includes standard collimator, scan type Hartmann diaphragm, focusing mirror, and CCD camera. The Hartmann diaphragm is installed on diaphragm bracket. Encoder is fixed on upper part of the bracket, and step motor and computer are installed on lower part of the bracket. Under control of computer, step motor drives scan type Hartmann diaphragm to rotate around optical axis, and computer receives image output from CCD camera and position information of scan type Hartmann diaphragm from encoder, and carries out data process for image. The invention can be applied for guiding fabricating optical elements, adjustment of optical path, evaluating qualities of incident beam and focal spot, possessing advantages of high testing precision, quick speed, and multiple functions.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Friction stir welding stirring tool system capable of achieving trailing intensive cooling and flash removing

ActiveCN110653618ASmall sizeReduce the amount of millingOther manufacturing equipments/toolsNon-electric welding apparatusBristleMilling cutter

A friction stir welding stirring tool system capable of achieving trailing intensive cooling and flash removing comprises a knife rest. The knife rest is composed of a circular connecting end and a hemispherical end, and the circular connecting end and the hemispherical end are of an integrally-formed structure. The knife rest is coaxially arranged at the work end of a stirring head in a sleevingmanner through the circular connecting end. Radial rotation of the stirring head and the knife rest is limited through a flat key, and the stirring head and the knife rest are fixed through a first jackscrew. An axial cooling hole is machined in the axis direction of the stirring head. A radial cooling hole communicating with the axial cooling hole is machined in a shaft shoulder of the stirring head in the radial direction. A stirring needle is mounted on the end face of the shaft shoulder of the stirring head. Grooves are evenly formed at the hemispherical end of the knife rest in the circumferential direction, a milling cutter is mounted on the edge of one end face of each groove, and bristles are evenly arranged on the other end face of each groove. By means of the system, the sizes offlashes can be greatly reduced, and the bearing capacity of a weld seam is also improved; and a cooling medium in the stirring head enters from the axial cooling hole of the stirring head through gravity and inflation pressure, manufacturing precision is greatly reduced, and cost is saved.

Owner:SHENYANG AEROSPACE UNIVERSITY

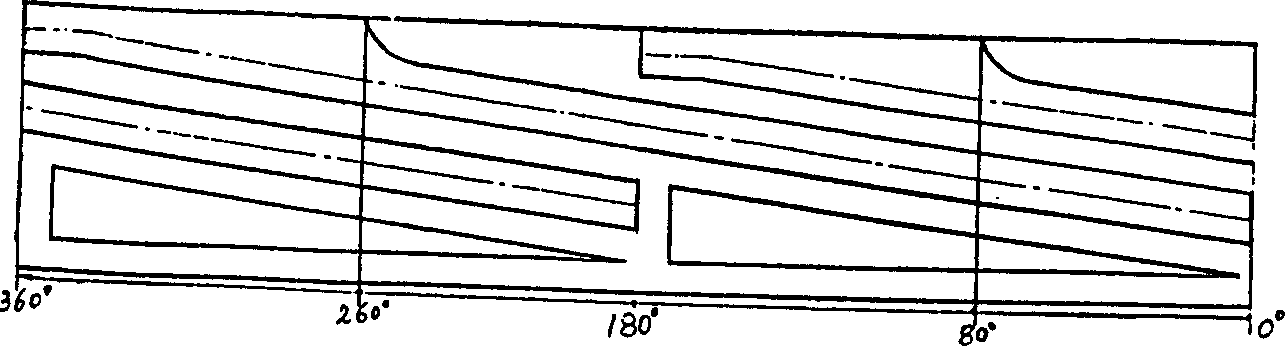

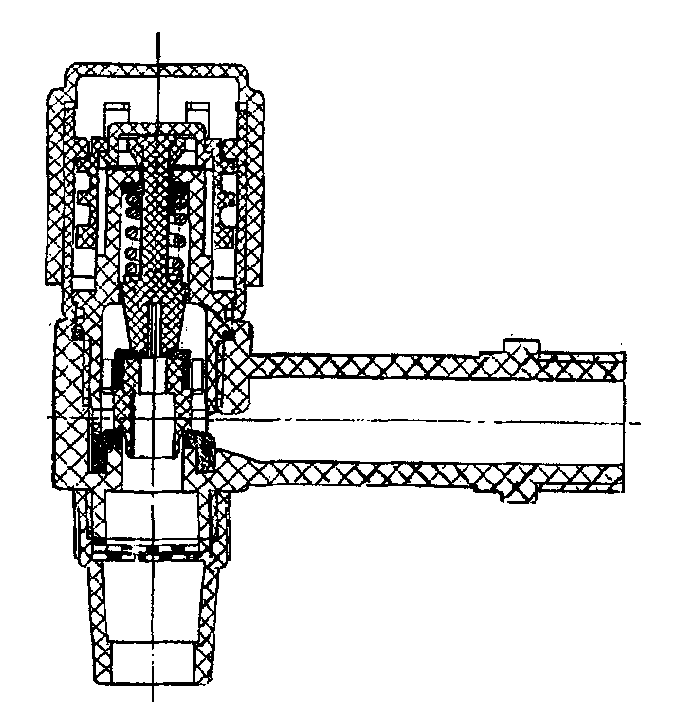

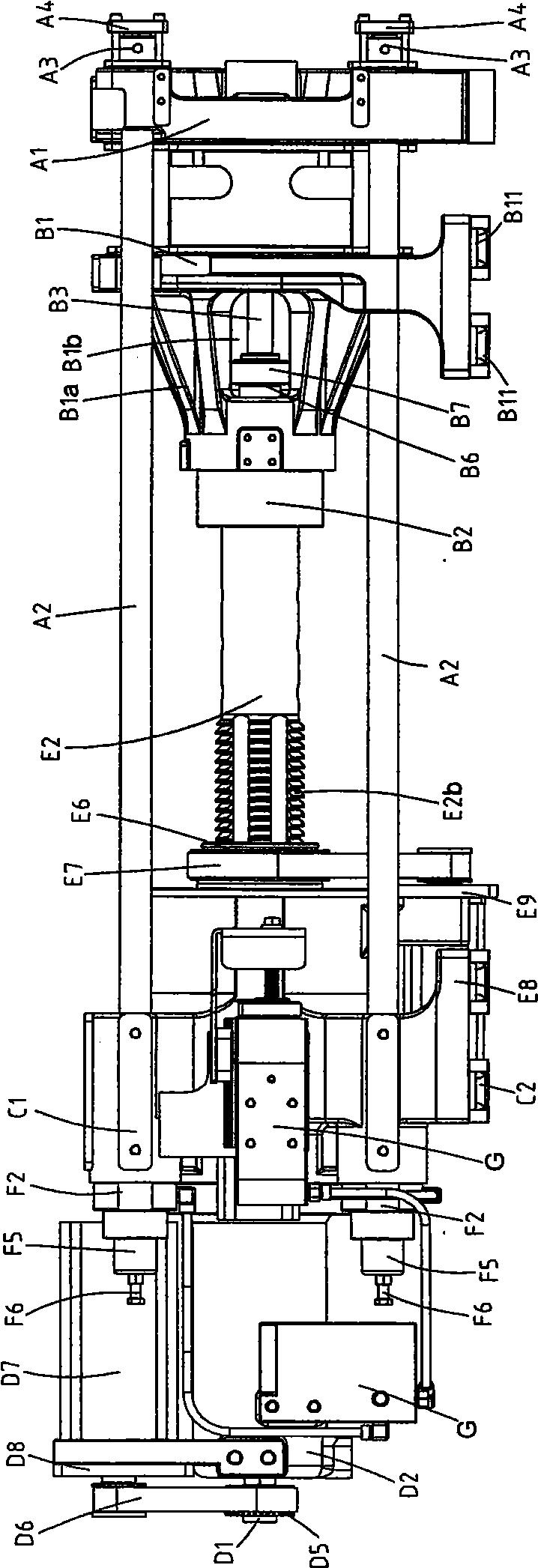

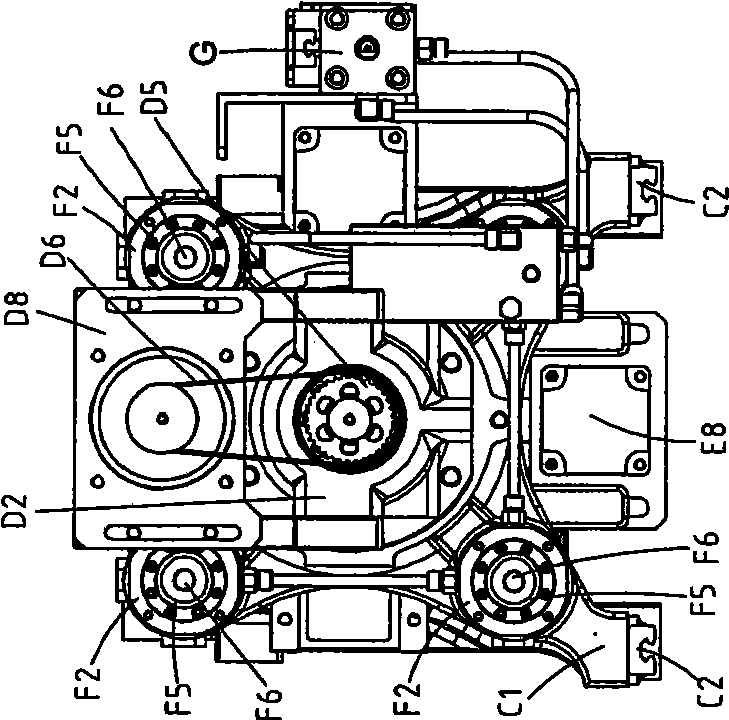

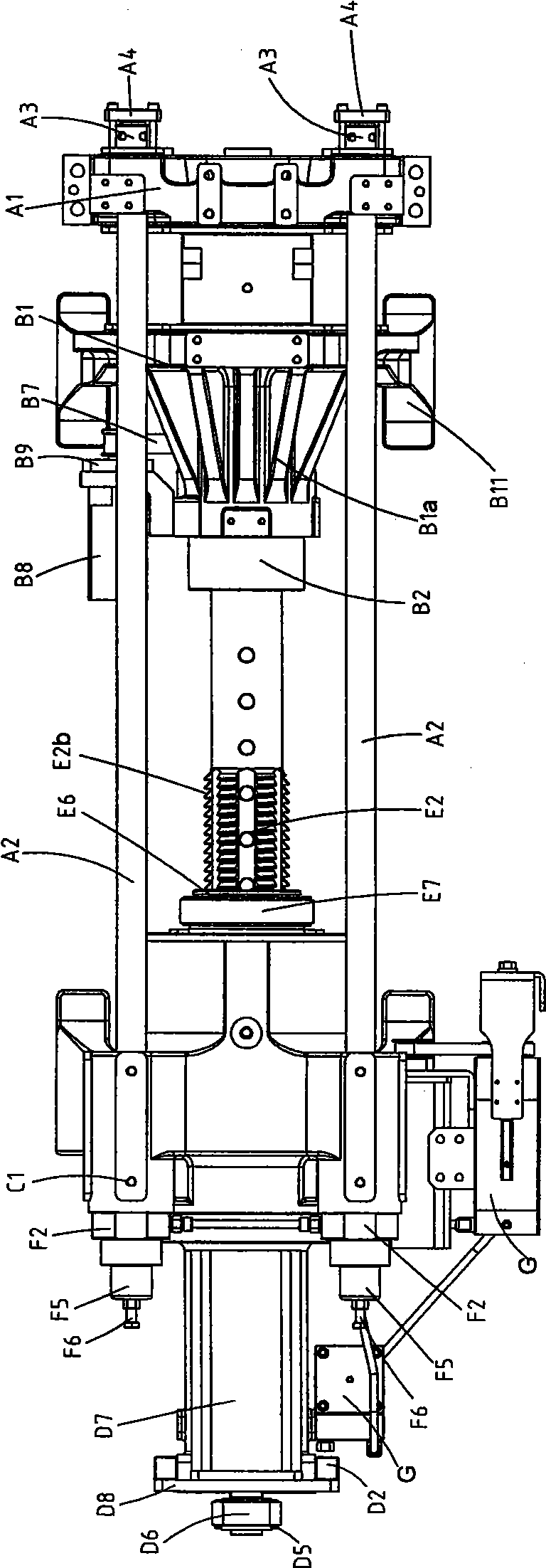

Mode locking mechanism of electric plastic injection machine

The invention discloses a mould locking device for an electric injection molding machine, which comprises a front moulding plate, a middle moulding plate and a back moulding plate which are arranged sequentially from front to back in parallel, wherein four pull rods are arranged between the front moulding plate and the back moulding plate, and the front ends of the pull rods are fixedly connected with the front moulding plate. The tail ends of the pull rods are connected with a mould locking piston, and an outer ring of the mould locking piston is glidingly matched with a mould locking oil cylinder which is fixedly connected with the back moulding plate. The back moulding plate is matched with at least one set of hydraulic jacks, and controls the movement of the mould locking piston. A mould moving motor which is matched on the back moulding plate is connected with a mould moving roll ball screw rod which is positioned in the center of the back moulding plate by driving. The front end of the mould moving roll ball screw rod is fixedly connected with the back end of the middle moulding plate through a main shaft, wherein the back end of the middle moulding plate adopts a horn-shaped structure, and the middle stressing and force transferring effect is uniform. The back moulding plate is provided with a mould adjusting component, a mould locking component and a quick mould moving component integrally, and the structure is compact. The mould moving roll ball screw rod and the main shaft adopt a thread pitch multi-head roll ball screw rod structure, and the mould moving speed is high.

Owner:NINGBO HAIXING MACHINERY MFG

Whole automobile attitude adjusting mechanism based on stepless adjusting and automobile chassis

ActiveCN103978863AReduce manufacturing precisionManufacturing precision requirements are lowResilient suspensionsPivoted suspension armsVehicle frameIndependent suspension

The invention discloses a whole automobile attitude adjusting mechanism based on stepless adjusting. The adjusting mechanism comprises a torsion bar spring, wherein the torsion bar spring is arranged under an automobile frame, the front end of the torsion bar spring is connected with a swing arm mechanism which is connected with automobile wheels, the back end of the torsion bar spring is connected with the automobile frame through a torsion bar mounting frame, the torsion bar mounting frame is provided with a driving mechanism, the driving mechanism is used for driving the torsion bar spring to do initial torsion, the torsion bar spring transfers the torque generated by the driving mechanism to the swing arm mechanism, the downward action force generated by the free end of the swing arm mechanism is transferred to the ground through the automobile wheels, and the reaction force generated by the ground is received and reversely transferred to the automobile frame, so as to adjust the height of the automobile frame. An automobile chassis comprises the automobile frame, the automobile wheels, a suspension system and the whole automobile attitude adjusting mechanism, wherein the whole automobile attitude adjusting mechanism is connected with the automobile wheels through the suspension system. The whole automobile attitude adjusting mechanism has the advantages that the calibrating qualified rate of the whole automobile is effectively increased, the manufacturing precision of relevant component parts of the independent suspension is reduced, and the cost is also reduced.

Owner:湖南易通星桥汽车零部件有限公司

Small-power motor power testing apparatus with power loss-free and wide measuring range properties

ActiveCN102226728AAccurately measure the output powerNo lossWork measurementTorque measurementDynamometerControl theory

The invention discloses a power testing apparatus for a small-power motor and the apparatus has power loss-free and wide measuring range properties. According to the invention, a front supporting seat is fixed on an active plate; a half axle is supported on the front supporting seat by a bearing; a moment rod is fixed on the axle body of the half axle; and a lower end of the moment rod is inserted into a testing position of a torque sensor. A rear end of the half axle and a center of a front end of a frame are fixed to each other; a rear end of the frame is fixed on an installation disk; a power shaft is arranged on the rear of the installation disk and is connected with a rear supporting seat through a bearing; the power shaft is connected with an input shaft of a dynamometer directly or by a speed change mechanism; and a rotating speed sensor is installed on the power shaft. According to the invention, a principle of a moment balance equation of Newton's third law is employed, wherein the equation is characterized in that sigma M is equal to an absolute value of-M, so that an equal corresponding relationship between a turning moment output by an output shaft of the motor and a counter turning moment that a housing of the motor is subjected to is obtained. And then the static counter torque, which is measured, is a torque output by the motor. The testing apparatus is free of losses and has a wide range; besides, an actual parameter value of the motor can be accurately tested by utilizing the testing apparatus.

Owner:重庆麦田普偌科技有限公司

Automatic grain sampler

InactiveCN102305726AGuaranteed uptimeAvoid out of syncWithdrawing sample devicesMotor driveDrive shaft

The invention discloses an automatic grain sampler. The automatic grain sampler comprises a longitudinal traveling cart which is arranged on longitudinal traveling tracks, two transverse traveling trolleys which are arranged on transverse traveling tracks of the longitudinal traveling cart, and fiche chain transmission lifting mechanisms which are arranged on the transverse traveling trolleys. The automatic grain sampler is characterized in that: a longitudinal traveling cart reducing motor drives a driving shaft of the cart by a chain wheel, and traveling wheels of the cart which are positioned at both ends of the driving shaft and a driven shaft of the cart are arranged on the longitudinal traveling tracks; the two transverse traveling trolleys have the same structure, a driving sprocket of a transverse traveling reducing motor shaft of one trolley is connected with a driven sprocket of a transverse traveling reducing motor shaft of the other trolley through a trolley chain, and moving rollers of the trolleys are arranged on the transverse traveling tracks; and driving sprockets of fiche lifting reducing motor shafts of the fiche chain transmission lifting mechanisms are connected with driven sprockets of sprocket adjustment shafts of the trolleys through fiche chains, and the fiche chains are fixedly connected with fiches. The automatic grain sampler has the advantages of simple structure, high manufacturing and assembly processability, low cost, high performance-price ratio and the like, and can be operated stably.

Owner:吉林三豪自动化机械有限责任公司

Deodorant shower room base

InactiveCN104295123ASolve the problem of pervasive odorAvoid tiltingFatty/oily/floating substances removal devicesSewerage structuresDeodorantEngineering

The invention relates to a deodorant shower room base and belongs to the field of shower rooms. The deodorant shower room base solves the problem that odor pervades a shower room. The deodorant shower room base comprises a base body, the base body is provided with a gutter channel, a drain hole is formed in the bottom wall of the gutter channel, a boss and supporting pillars are arranged on a bottom plate of the gutter channel, a groove is formed in the top end face of the boss, a gear matched with the groove is arranged in the groove, a notch is formed in the side wall of the groove, teeth of the gear penetrate through the notch and extent to the outside of the groove, hooks are arranged on the side wall of each supporting pillar, the side wall of the gutter channel is provided with a locking groove and an annular step, a mounting plate is arranged on the annular step and provided with a through hole and a water inlet hole, the water inlet hole and the drain hole are staggered, the through hole corresponds to the groove, sealing elements are arranged on the periphery of the mounting plate, and the mounting plate is connected with the annular step through the sealing elements in a sealed mode.

Owner:周伟

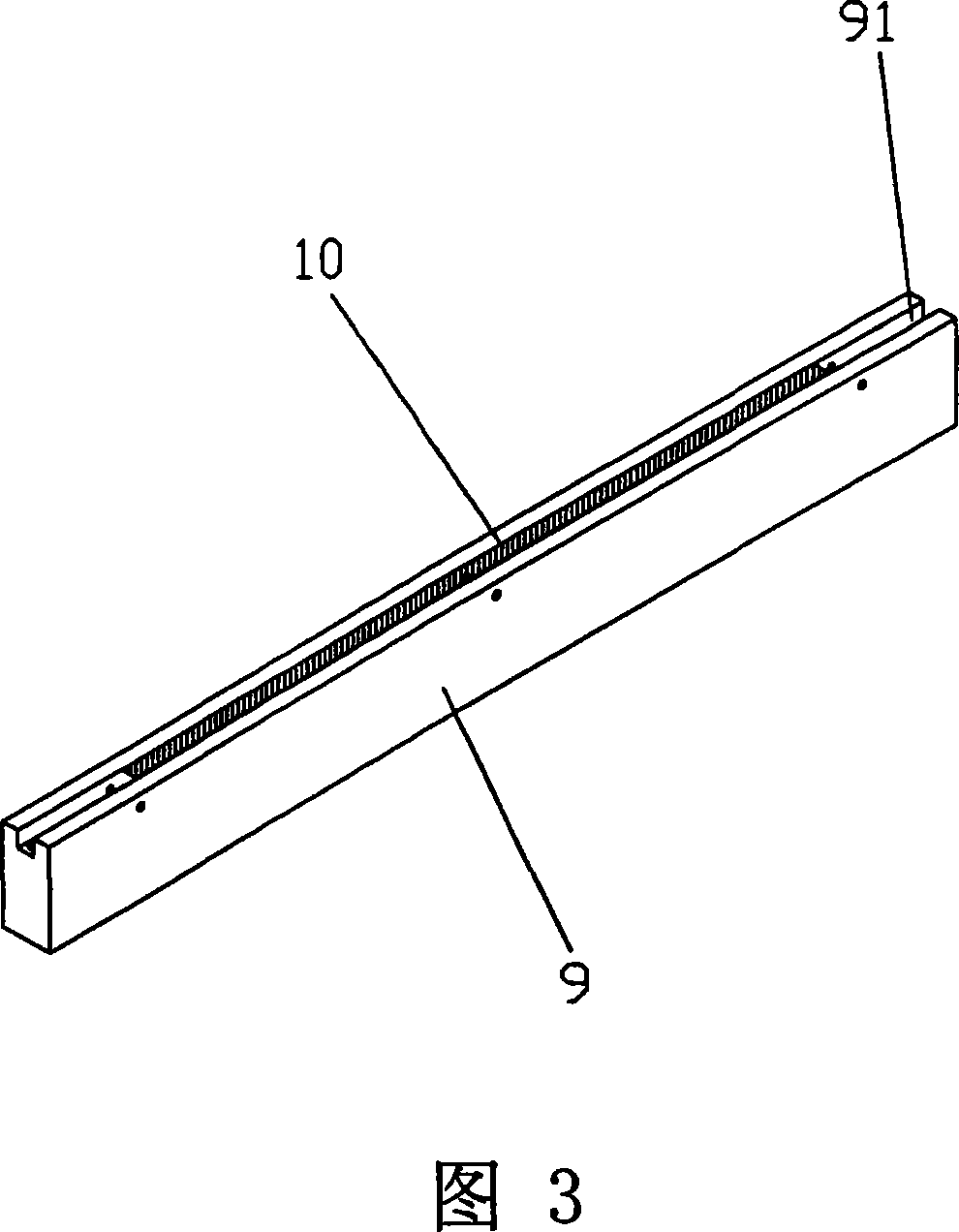

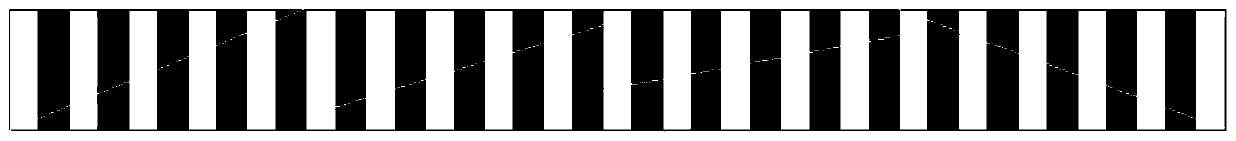

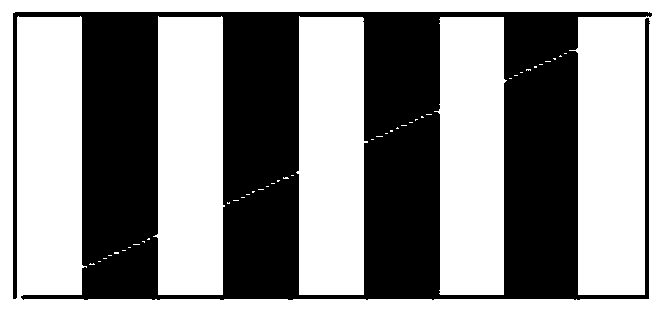

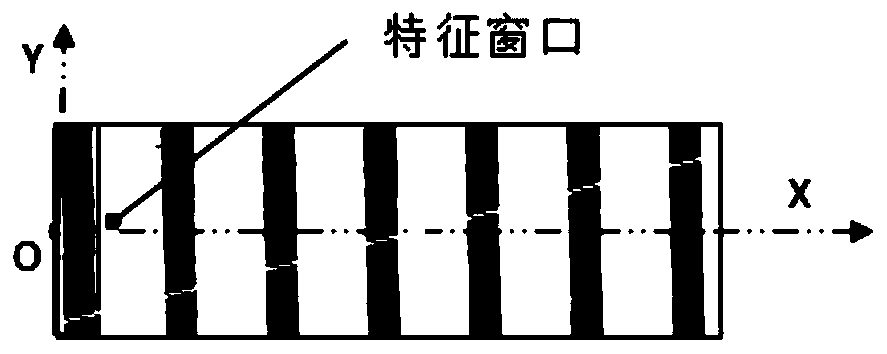

Incremental absolute grating ruler-based absolute displacement detection method

ActiveCN110260795AOvercoming limitations in manufacturing precisionFast operationUsing optical meansGratingAlgorithm

The invention discloses an incremental absolute grating ruler-based absolute displacement detection method. The method included the following steps that: an incremental type grating ruler is marked, so that the incremental type grating ruler can be converted into an incremental absolute grating ruler, and the uniqueness of each grid line is guaranteed; grating images are collected and de-noised, and the grid lines of the grating ruler are extracted, a neural network model for deep learning is established, each grid line is trained, and the trained neural network model is stored; a mathematical model for displacement detection is established, the image of a grating ruler to be subjected to displacement detection is collected, and the trained neural network model is used for carrying out grid line recognition, and a recognized grid line number is fed back to the mathematical model, so that a displacement detection value can be calculated. According to the method of the invention, the incremental type grating ruler is converted into the incremental absolute grating ruler; the functions of the absolute grating ruler are realized through an incremental mode; and the manufacturing precision of the grating ruler is greatly reduced.

Owner:FOSHAN HUADAO SUPER PRECISION TECH CO LTD

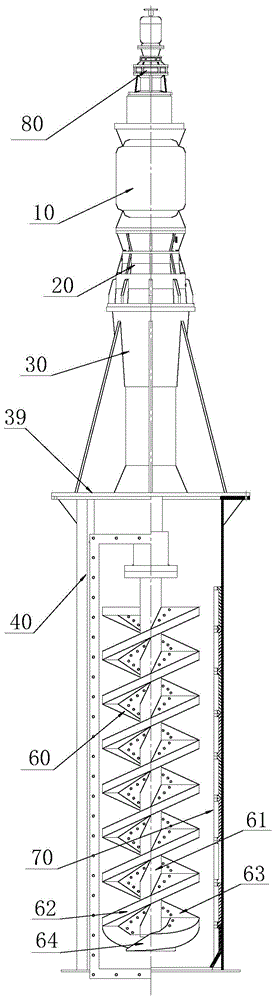

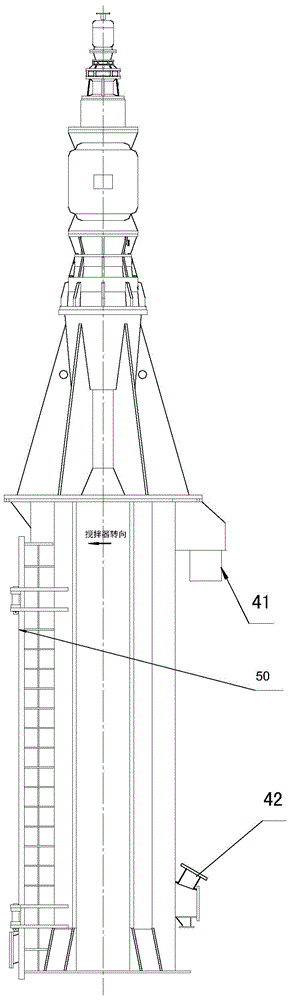

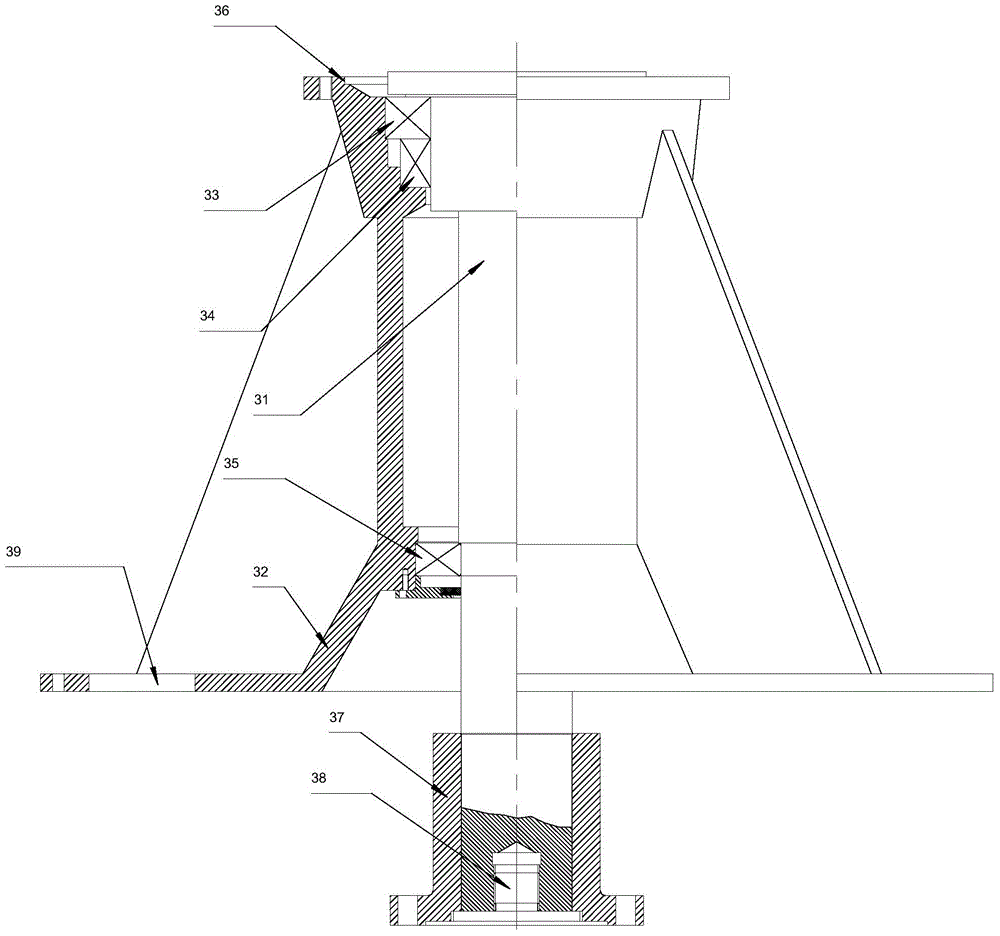

Tower mill

The invention discloses a tower mill. A technical scheme adopted by the tower mill is that the tower mill comprises a main motor, a speed reducing device, a supporting system, a cylinder, a door, a spiral stirrer and protective lining plates, wherein the main motor is connected with the speed reducing device, the speed reducing device is arranged on the supporting system, the supporting system is a completely-closed structure, a driving shaft is arranged in the supporting system, the upper end of the driving shaft is connected with the speed reducing device, and the lower end of the driving shaft is connected with a screw rod shaft of the spiral stirrer by virtue of a shaft sleeve; the protective lining plates are arranged on the inner walls of the cylinder and the door; the bottom end of a first spiral blade group and the bottom end of a second spiral blade group are connected with a double-head material picking blade which is fixedly arranged on the screw rod shaft; a discharge opening and a feed opening are formed in the cylinder; and the door is movably connected with the cylinder. By adopting the tower mill disclosed by the invention, the grinding efficiency of the tower mill can be significantly improved, the service life of wear-out parts can be prolonged, the loss of a grinding medium can be reduced, the assembly and use of the tower mill can be facilitated, the mechanical efficiency of the tower mill can be improved, and the manufacturing cost of the tower mill can be reduced.

Owner:任茂福

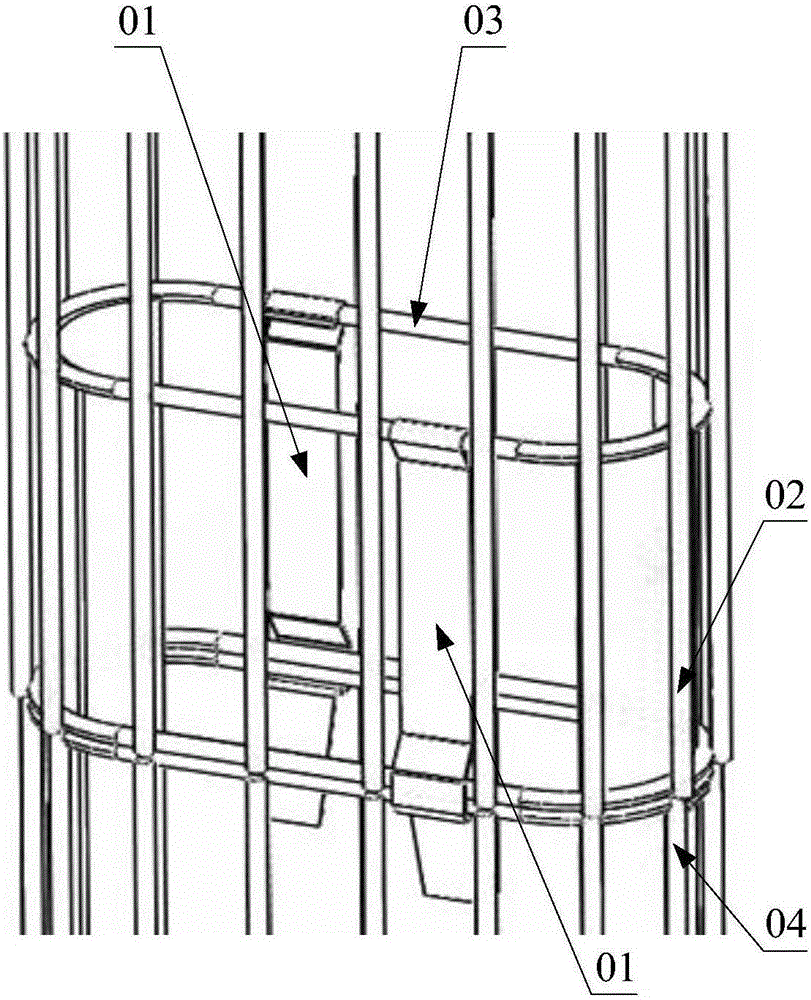

Bag type dust collector and sectioned bag cage thereof

InactiveCN105214398AGuaranteed to workNormal work relaxationDispersed particle filtrationEngineeringDust collector

The invention discloses a sectioned bag cage which comprises multiple connected bag cage sections. A clamping groove is formed in one of any two adjacent bag cage sections, and a clamping hook which can extend into the clamping groove to be clamped with the clamping groove so as to achieve connection of the two bag cage sections is arranged on the other of the two adjacent bag cage sections. In the sectioned bag cage, hook-groove structures are adopted replace elastic clamps so as to achieve connection of the bag cage sections, the phenomenon of filter bag puncture caused by drop of the elastic clamps is fundamentally avoided, and normal work of the sectioned bag cage is ensured. In addition, in the mode that the bag cage sections are connected by adopting the hook-groove structures, the accuracy requirement for matching sizes of the connecting positions of the upper and lower bag cage sections is greatly loosened, the manufacturing accuracy of connecting members is also reduced, the clamping grooves and the clamping hooks are both fixed to the bag cage sections, integration of the bag cage sections and the connecting members is achieved, and the connecting stability can be better. Furthermore, free-hand installation can be also achieved without special installing tools, and mounting and dismounting operation are more convenient. The invention further provides a bag type dust collector provided with the sectioned bag cage.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD

Macro and micro two-stage driving precision positioning mechanism

ActiveCN104656682AHigh linearity accuracyReduce complexityControl using feedbackLaser interferenceStator

The invention relates to a macro and micro two-stage driving precision positioning mechanism, belongs to the technical field of precision positioning and solves the technical problems of big manufacturing and mounting difficulty, complicated structure and high manufacturing cost of a two-stage guide rail in the prior art. The macro and micro two-stage driving precision positioning mechanism comprises a piezoelectric actuator, a vibration absorption system, a base, an air flotation guide rail, a macro-moving positioning system, a micro-moving positioning slide block, a support frame and a laser interference measurement instrument, wherein the base is fixedly connected with the upper end surface of the vibration absorption system through a screw; the air flotation guide rail is connected with one end of the base through a screw; the support frame is connected onto the other end of the base through a screw; the laser interference measurement instrument is connected with the support frame through a screw; the micro-moving positioning slide block is in clearance fit with the air flotation guide rail; a rotor of a linear motor is fixedly connected with a macro-moving positioning and clamping slide block; a stator of the linear motor is connected with the base through a screw; two clamping guide rails are connected with the base through screws; one end of the piezoelectric actuator is fixedly connected with the micro-moving positioning slide block, and the other end of the piezoelectric actuator is fixedly connected with the macro-moving positioning and clamping slide block.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com