Vacuum packaging container

A vacuum packaging and container technology, applied in packaging, packaging, transportation and packaging under vacuum/special atmosphere, etc., can solve the problems of easy blockage, difficulty, and inability to extract the opening at the end of the straw, and achieve low production precision, The effect of low cost and easy filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

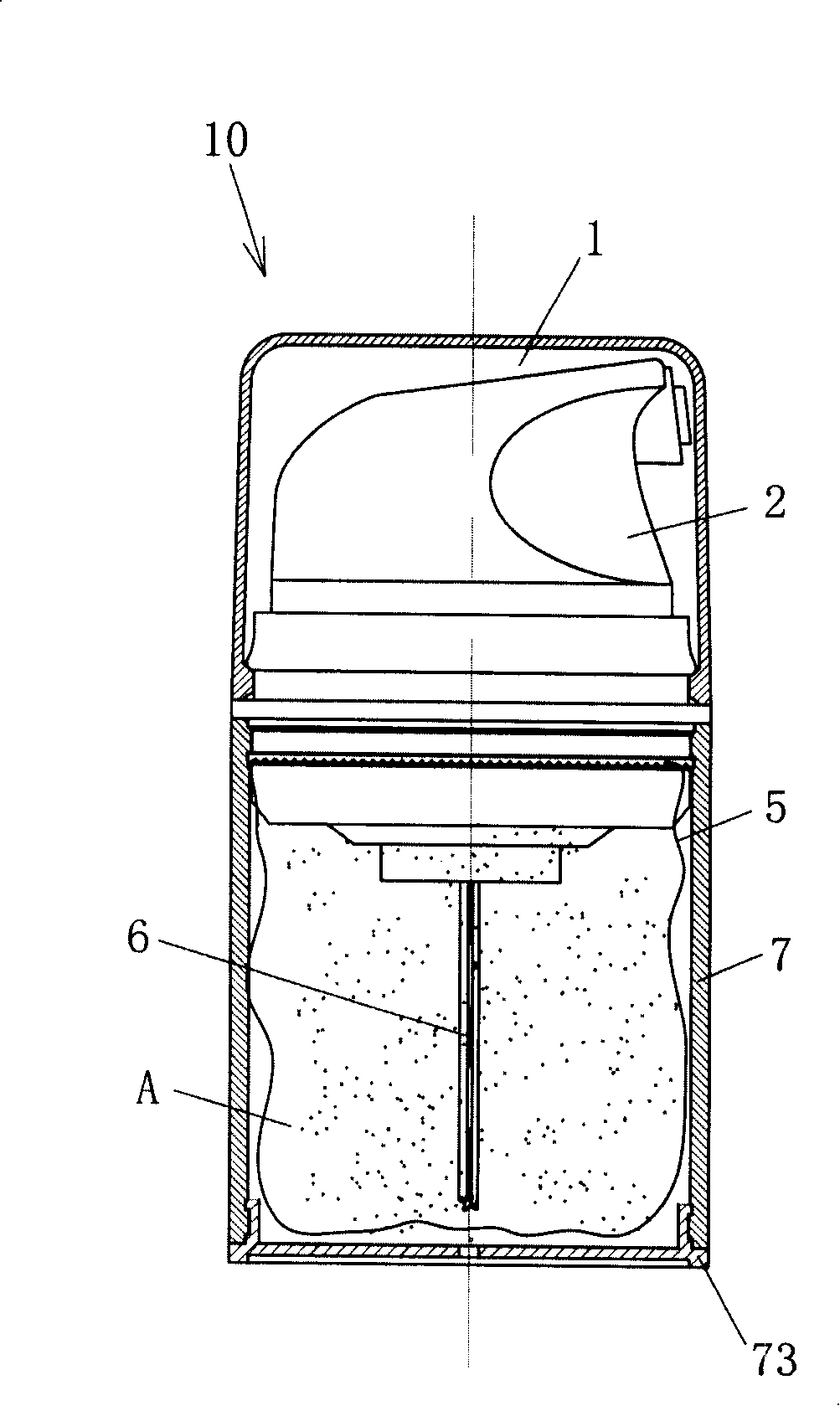

[0034] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the same reference numerals in each of the drawings indicate the same or similar components.

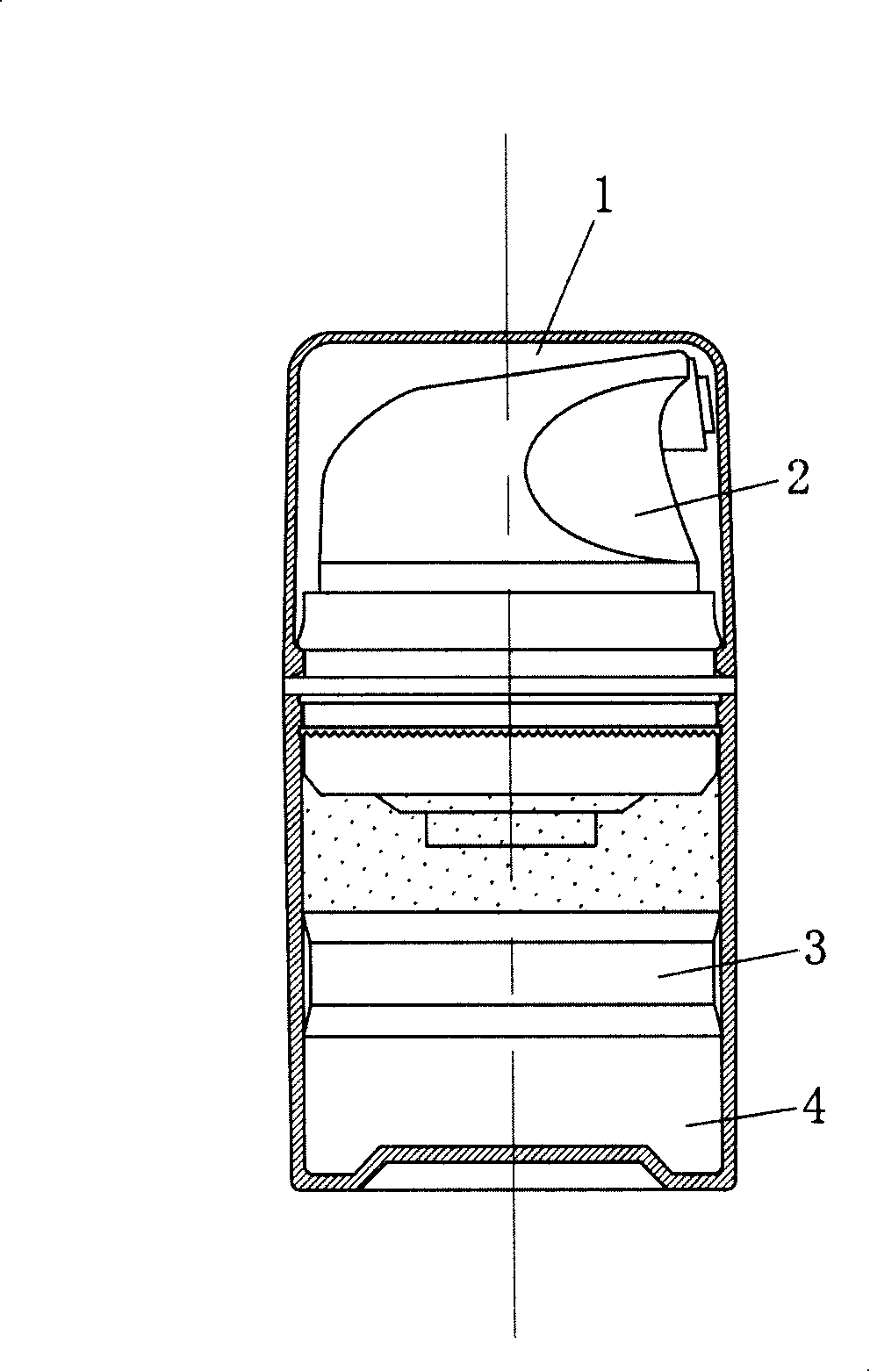

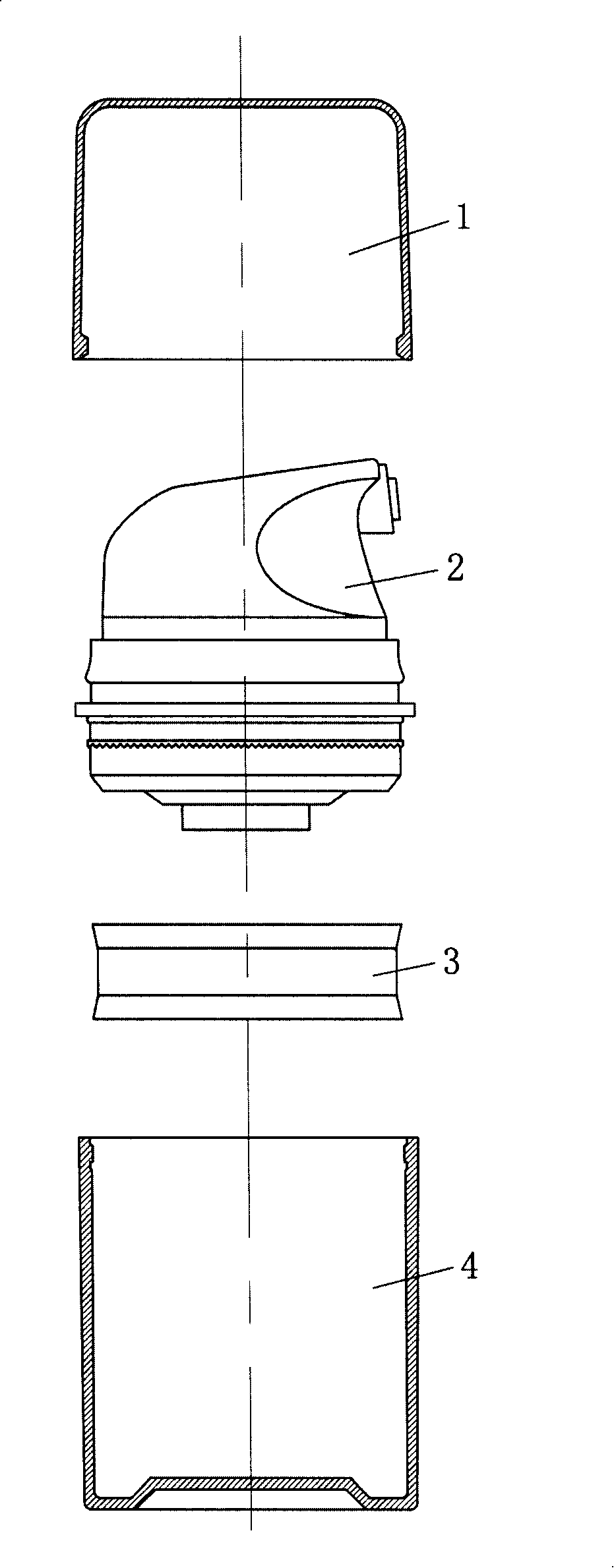

[0035] See Figure 2A-2C , which shows a vacuum-packed container 10 according to a first embodiment of the present invention. The vacuum packaging container 10 comprises: a bottle body 7, which has an open top 71 and a bottom 72, and is provided with a base 73 for closing the bottom, on which air holes are arranged; a lotion pump 2, which is installed on the top of the bottle body 7 71, and does not have the vent hole that balance air pressure is used; Cover cover 1, it is covered on the lotion pump 2; Sac bag 5, it has open first end 51 and the second end 52 of sealing, and its first end 51 Sealingly combined with the top 71 of the bottle body 7; and the guide strip 6, which is connected to the feeding port of the lotion pump 2 like a common straw.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com