Tower mill

A tower mill and main motor technology, applied in grain processing, etc., can solve problems such as difficult installation and adjustment methods, difficult maintenance, strong randomness, etc., and achieve the effects of convenient addition of grinding media, convenient installation, and high mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Example tower mill

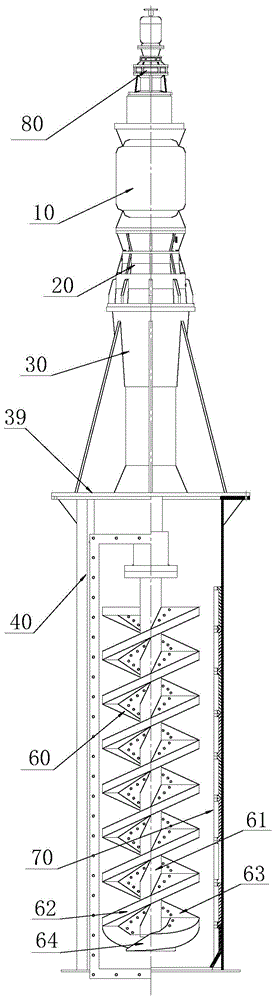

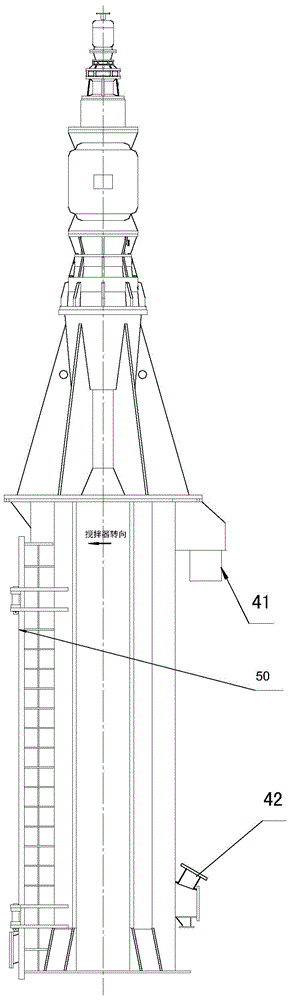

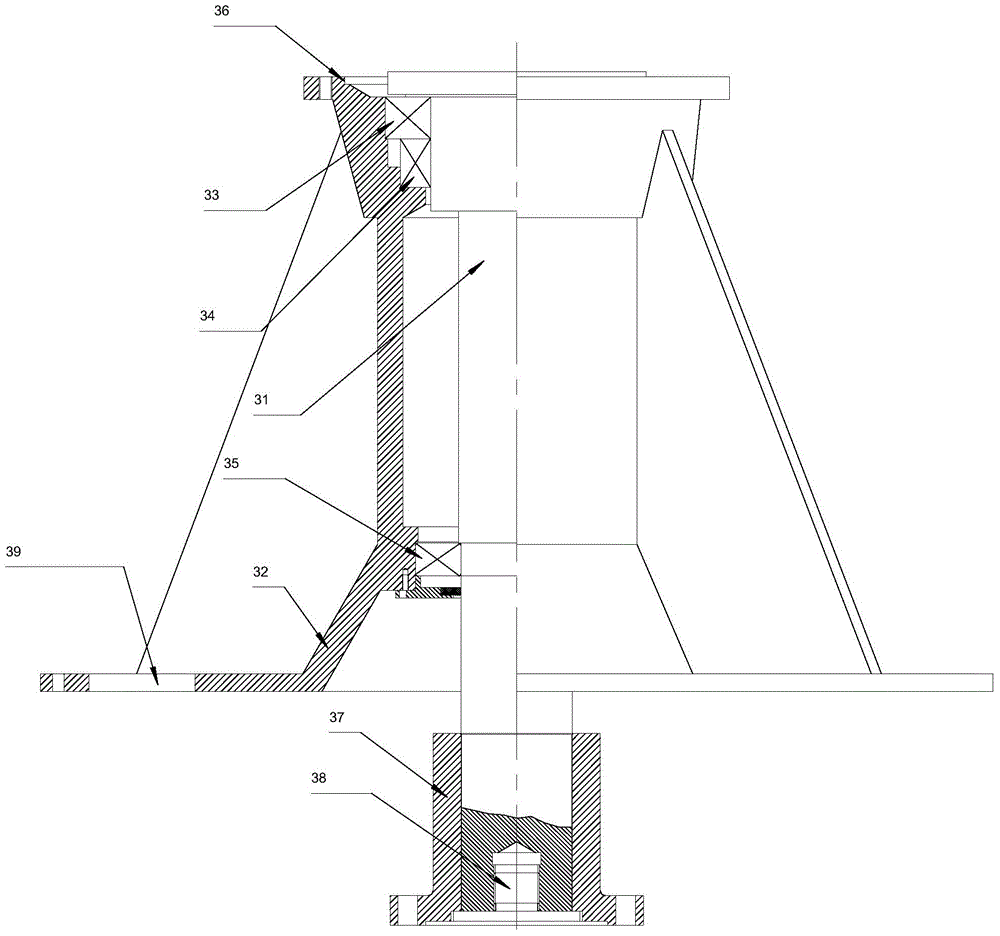

[0034] like Figure 1-Figure 8 Shown, a kind of tower mill is made up of main motor (10), reduction gear (20), support system (30), cylinder (40), door (50), helical agitator (60), protective liner ( 70) and slow start device (80) form.

[0035] The helical agitator (60) installed in the barrel (40) is composed of a screw shaft (61), a first helical blade group (62), a second helical blade group (63) and double-headed material taking blades (64). At the bottom of the spiral agitator (60), the bottom end of the first helical blade group (62) and the bottom end of the second helical blade group (63) form a double-headed helix symmetrical structure and are connected with the double-headed feeding blades (64). The head takes material blade (64) and fixes with the threaded surface of bolt and screw shaft (61) by the installation area (64-1) on the installation surface.

[0036] The double-head reclaiming blade (64) blade is helical, and its helical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com