Macro and micro two-stage driving precision positioning mechanism

A technology of precision positioning and positioning pliers, applied in the direction of using feedback control, etc., can solve the problems of high manufacturing cost, complicated structure, and difficulty in manufacturing and installing two-stage guide rails, so as to eliminate backlash errors, reduce complexity, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

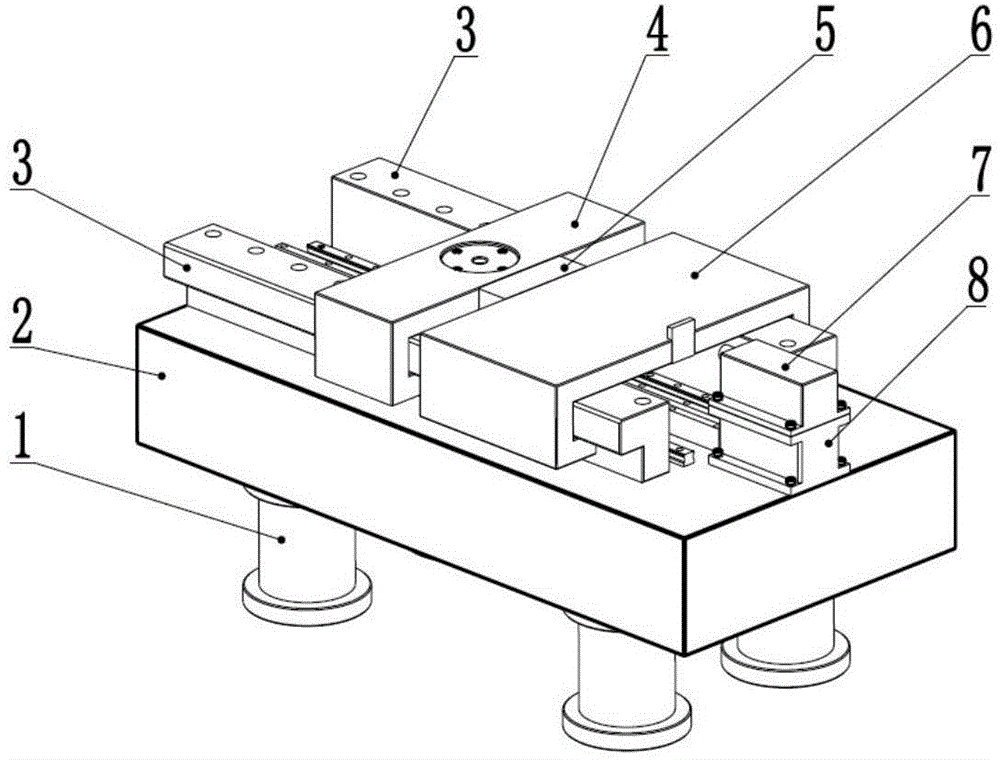

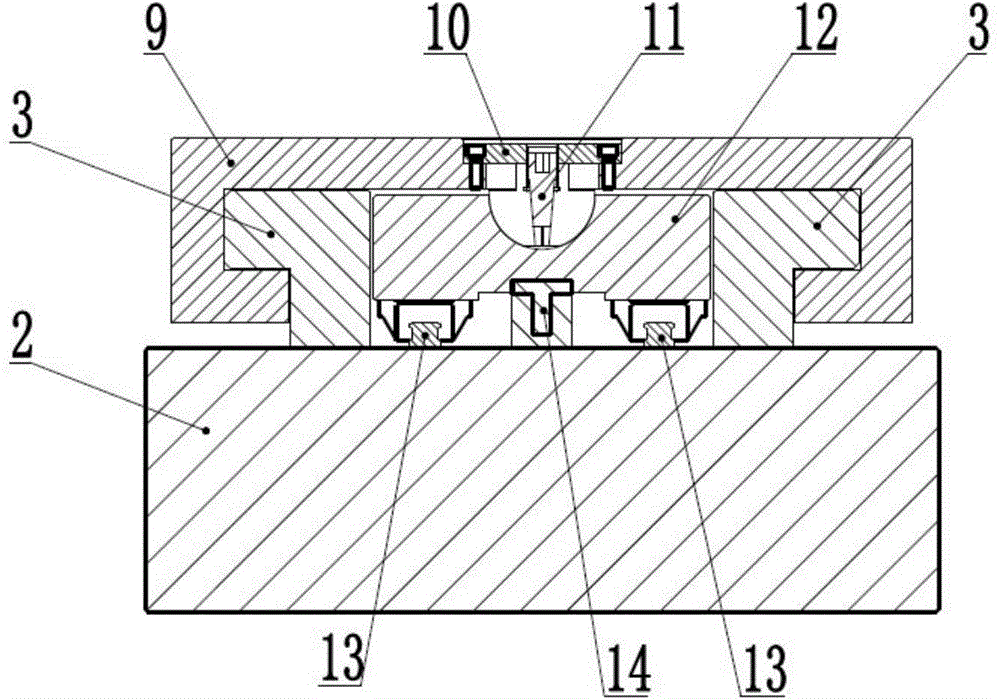

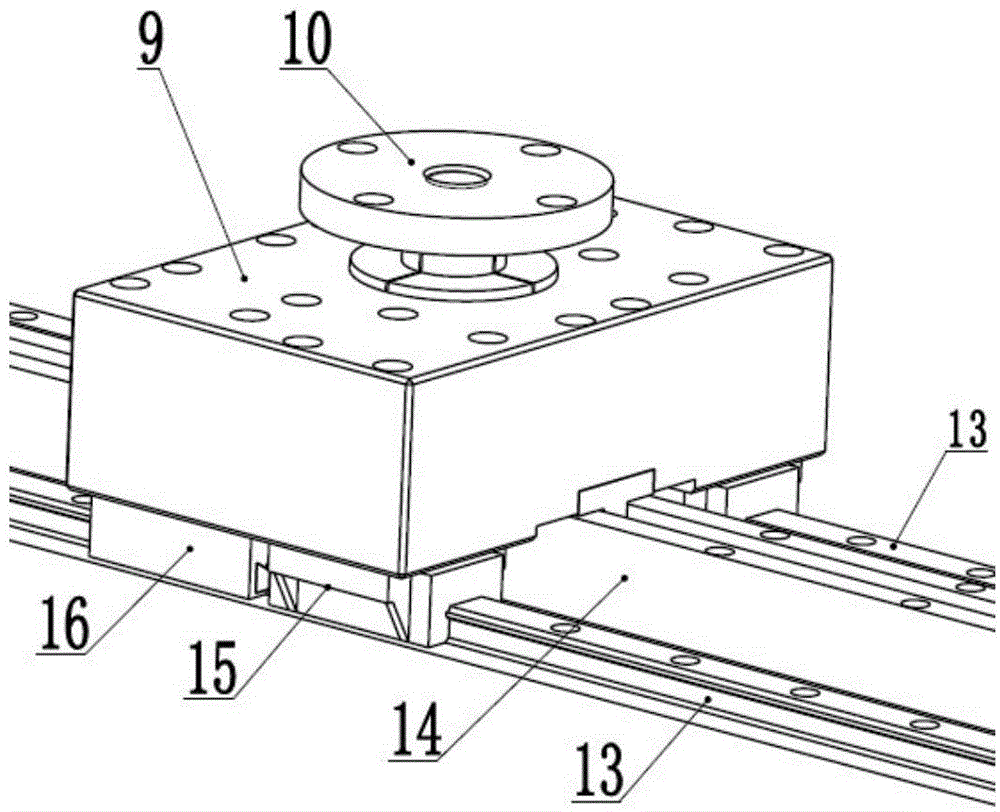

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0026] See attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Figure 6 And attached Figure 7 , a macro-micro two-stage driving precision positioning mechanism of the present invention includes a piezoelectric driver 5, a shock absorbing system 1, a base 2, an air bearing rail 3, a macro-positioning system 4, a micro-positioning slider 6, a bracket 8 and Laser interferometer 7;

[0027] The base 2 is fixedly connected to the upper end surface of the shock absorption system 1 by screws, the air bearing guide rail 3 is fixedly connected to one end of the installation plane of the base 2 by screws, and the bracket 8 is fixedly connected to the other end of the installation plane of the base 2 by screws , the laser interferometer is fixedly connected to the bracket 8 by screws, and the micro-movement pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com