Patents

Literature

69 results about "Precision engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precision engineering is a subdiscipline of electrical engineering, software engineering, electronics engineering, mechanical engineering, and optical engineering concerned with designing machines, fixtures, and other structures that have exceptionally high tolerances, are repeatable, and are stable over time. These approaches have applications in machine tools, MEMS, NEMS, optoelectronics design, and many other fields.

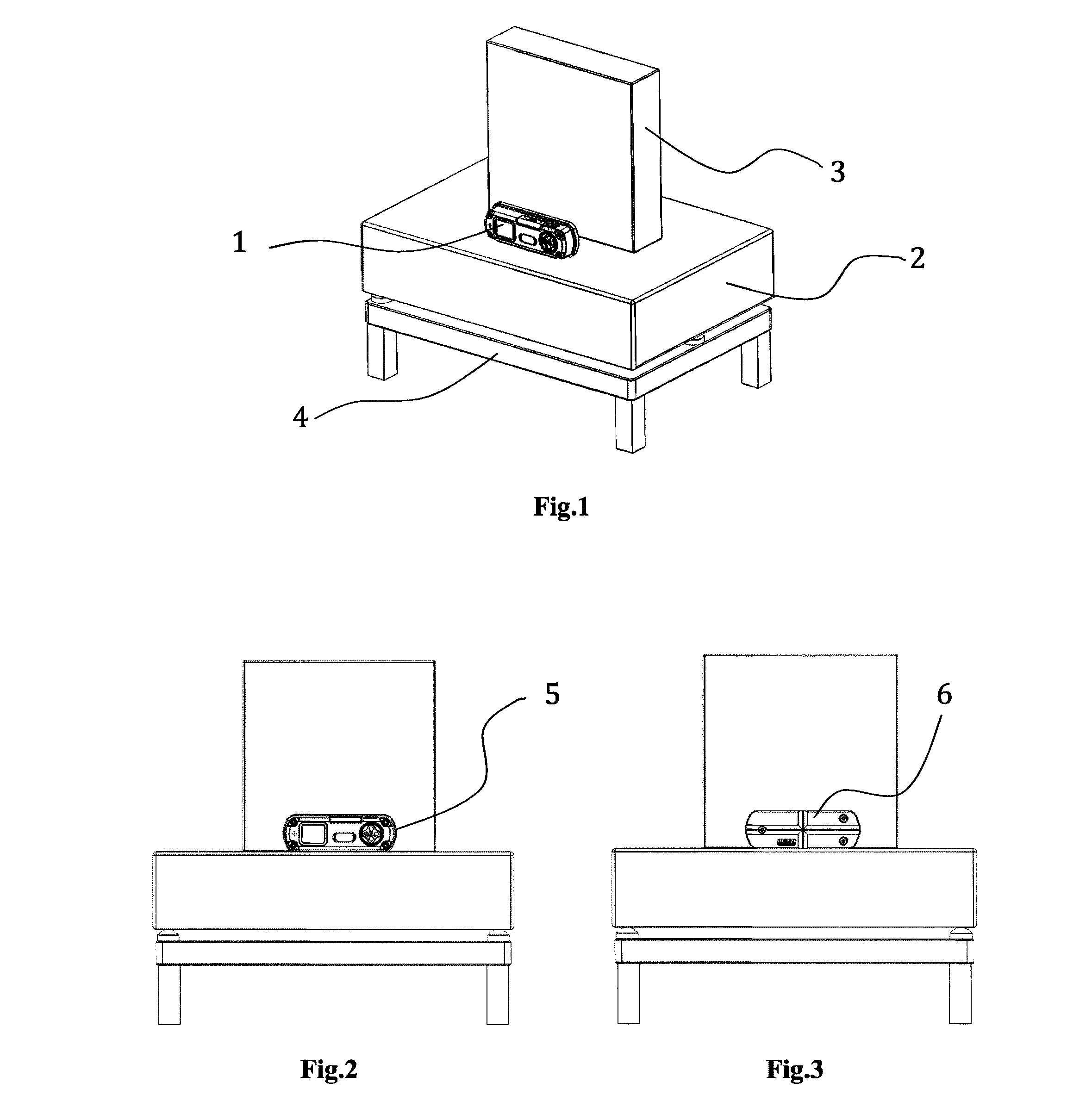

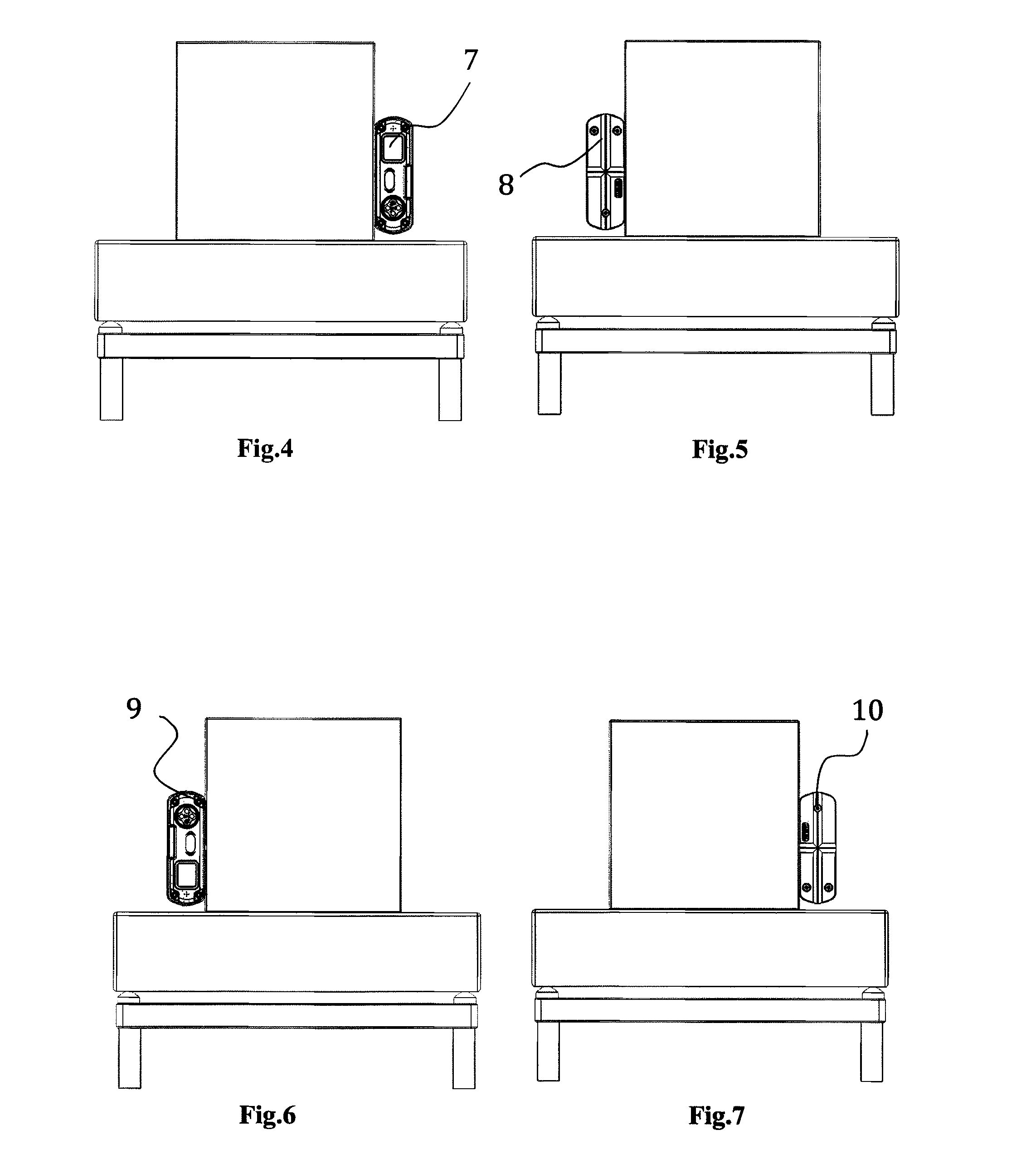

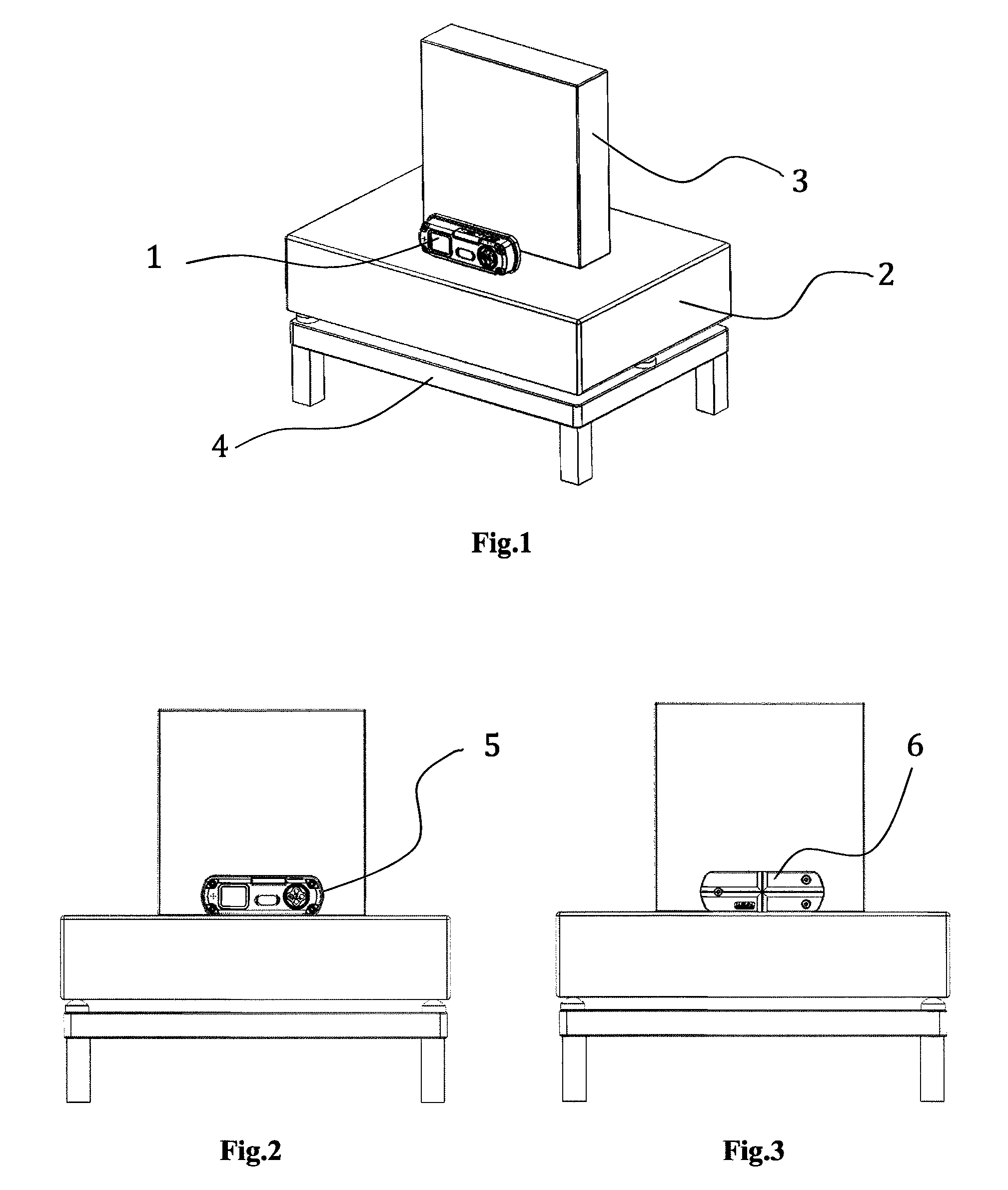

Angle measuring device and methods for calibration

ActiveUS20140350881A1High riskLower performance requirementsTesting/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsMeasurement devicePrecision engineering

The invention relates to a method for calibration of 2-axis high precision digital angle measurement device, particularly for initializing a planar angle measuring device and an apparatus to generate simultaneous two-dimensional resultant planar angles of full 360° rotation. The planar angle measurement device is, typically but not exclusively, used in concurrent two-dimensional angles leveling, setting and alignment tasks for precision machine setup in the fields of precision engineering and metrology applications.

Owner:DIGIPAS TECH INC

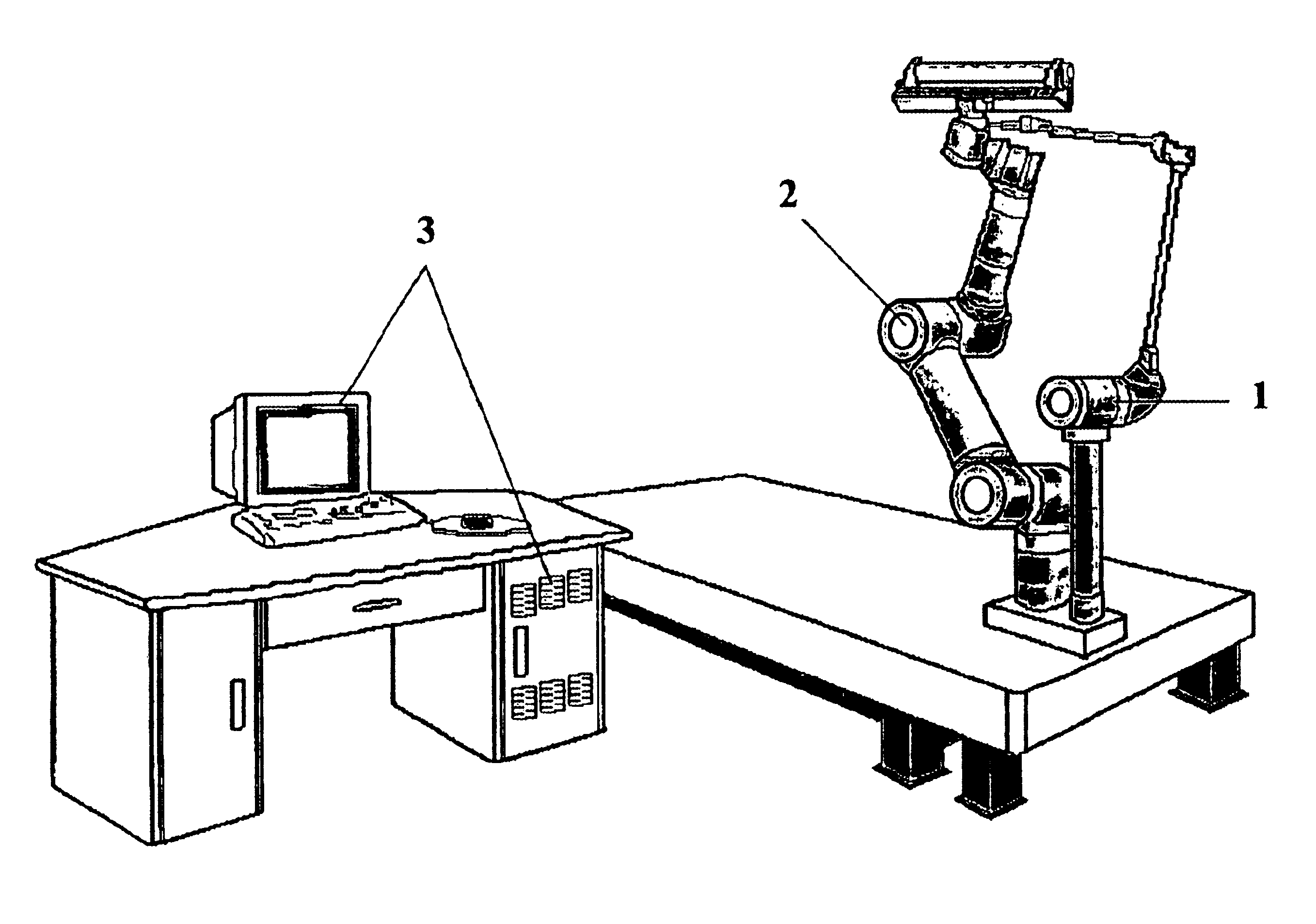

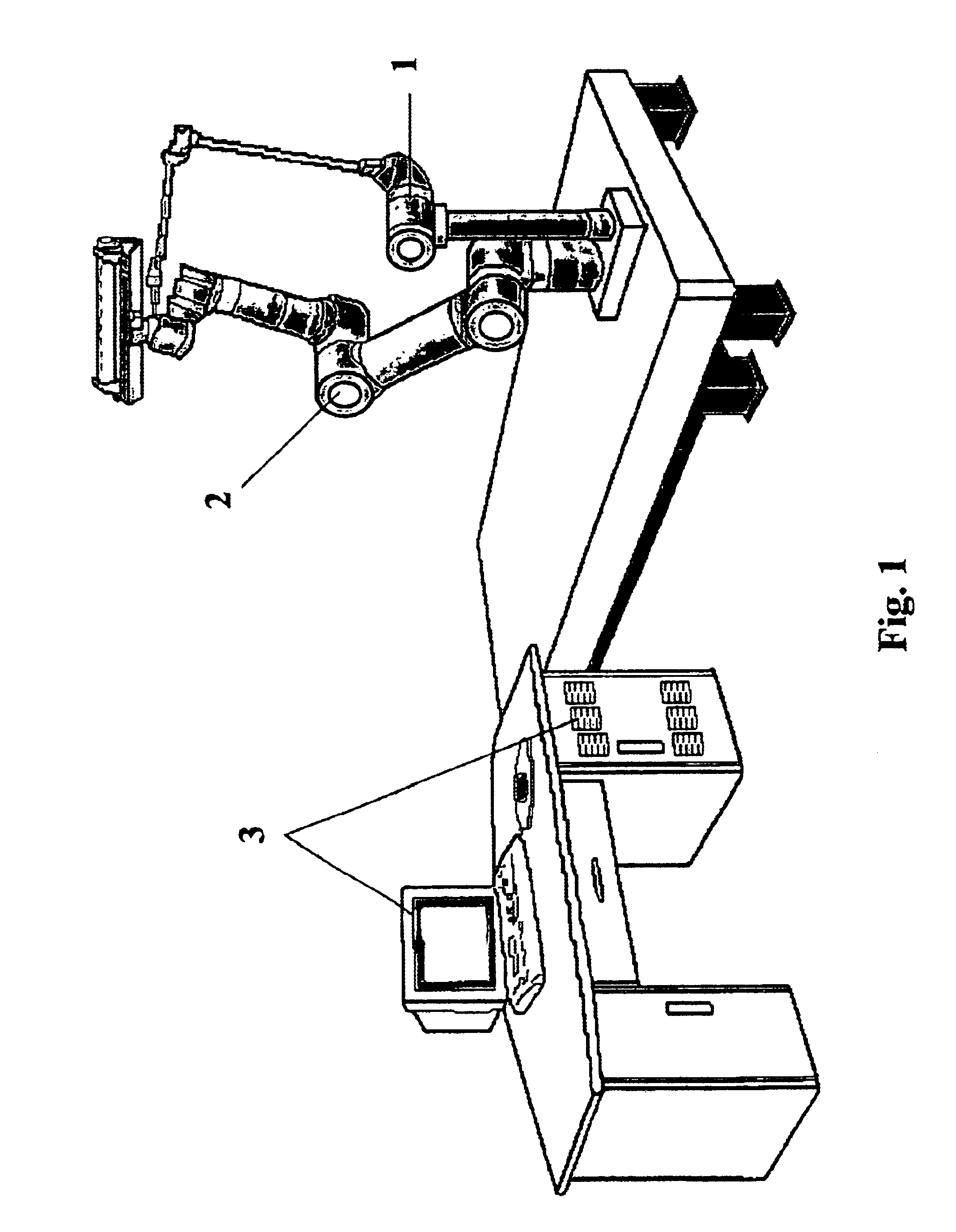

Ultra-precision robotic system

InactiveUS6882901B2Programme-controlled manipulatorDC motor speed/torque controlRoboticsRobotic systems

A multiple degree-of-freedom ultra-precision (DOF) robotic system yielding either rigid body guidance or large deformation analysis (LDRS, i.e. semi-flexible and flexible robotics) is developed based on the technology of integrating a multiple DOF ultra-precision shadow robotic measurement system with a multiple DOF robot for form a closed-loop linkage chain to establish a corresponding closed-loop feedback control of end-effecter of said robotic system without the use and limitation of any target or artificial marker in work-cell as the reference. In this way, the major degrading problems that greatly drag down the positioning accuracy of a robot have been fairly resolved. The embodiment conducts the details of the development of such a multiple DOF ultra-precision robotic system for the general applications in precision engineering.

Owner:GONG SHAO WEI

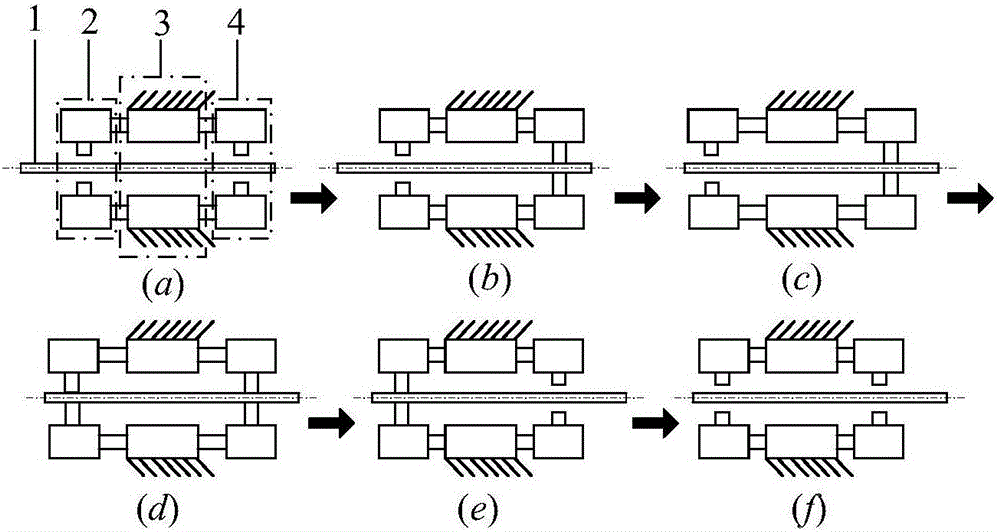

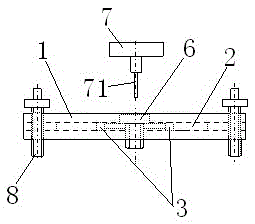

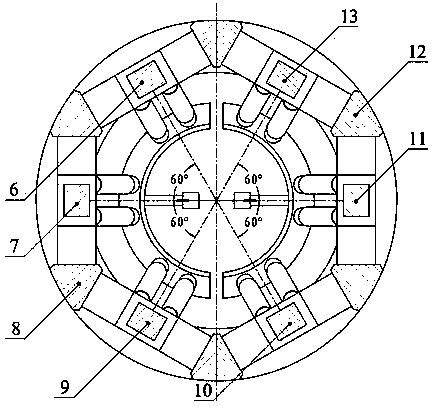

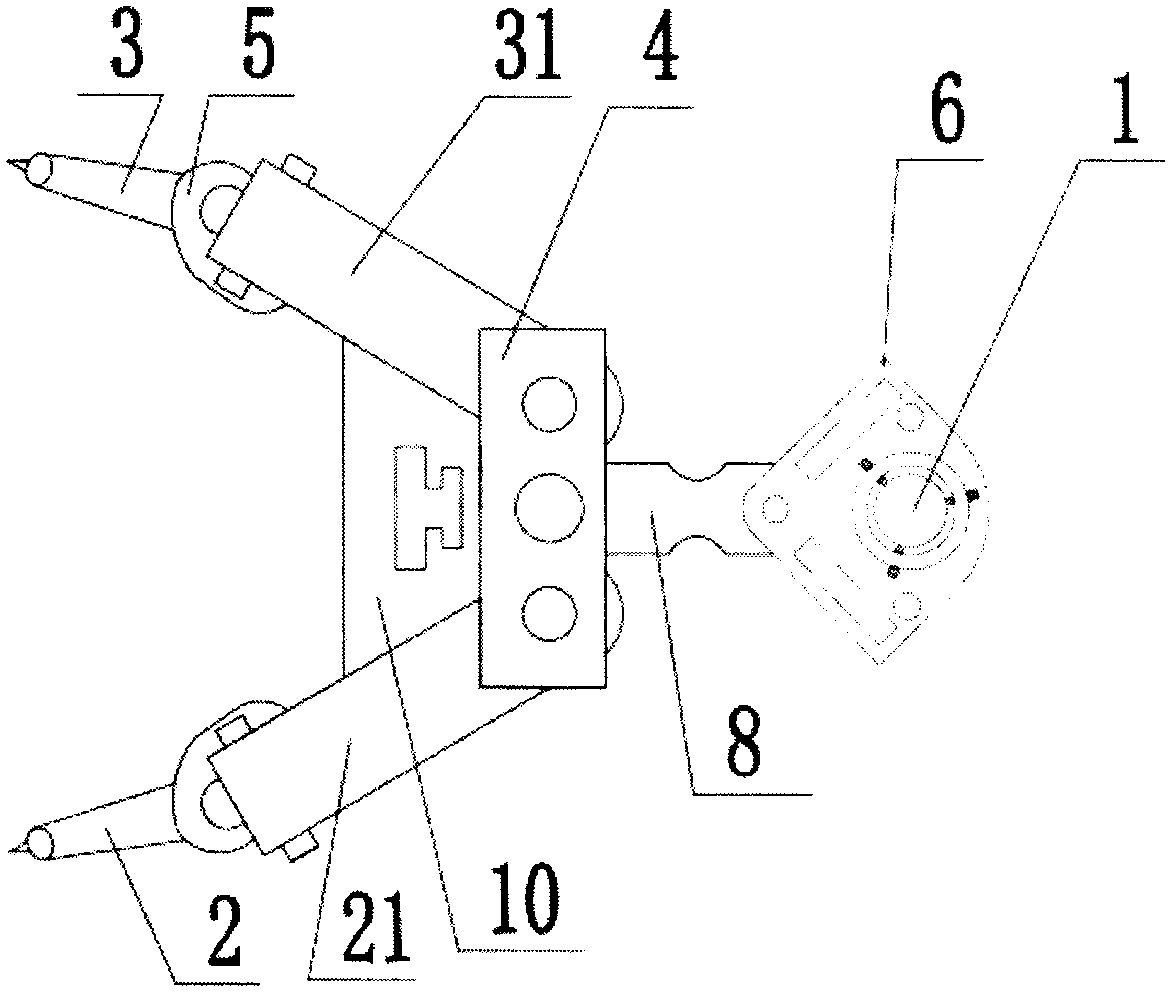

Inchworm-type precise linear micro-actuator based on complaint mechanism

ActiveCN106452165AHigh precisionLarge clamping forcePiezoelectric/electrostriction/magnetostriction machinesLinear motionMicro actuator

The invention discloses an inchworm-type precise linear micro-actuator based on a complaint mechanism. The inchworm-type precise linear micro-actuator comprises driving mechanisms, two clamping mechanisms and stators, wherein each driving mechanism consists of four symmetrically arranged driving branch chains and one pair of stators, each driving branch chain consists of two lever structures, the driving branch chains are connected to the stators by adopting flexible hinges, and reciprocating micromovement can be performed relative to the stators; each clamping mechanism consists of three pairs of flexible hinges, one pair of levers and one pair of clamping pieces which are symmetrically arranged, and the two clamping mechanisms are symmetrically connected to two ends of each driving mechanism through the levers; the stators are of long and thin cylinder-shaped structures, are arranged at the symmetrical center of the micro-actuator, are matched with the clamping mechanisms through holes, are matched with the driving mechanisms through through grooves, and can move in the holes and the through grooves. The clamping mechanisms are driven by the driving mechanisms to carry out reciprocating motion, and the stators are driven by the clamping mechanisms to perform a bionic inchworm motion law in the motion manner of linear motion. The disclosed micro-actuator can be used in the fields of ultra-precision machining, precision engineering, micro electro mechanical systems, bioengineering, semiconductor manufacturing and the like.

Owner:JIANGXI UNIV OF SCI & TECH

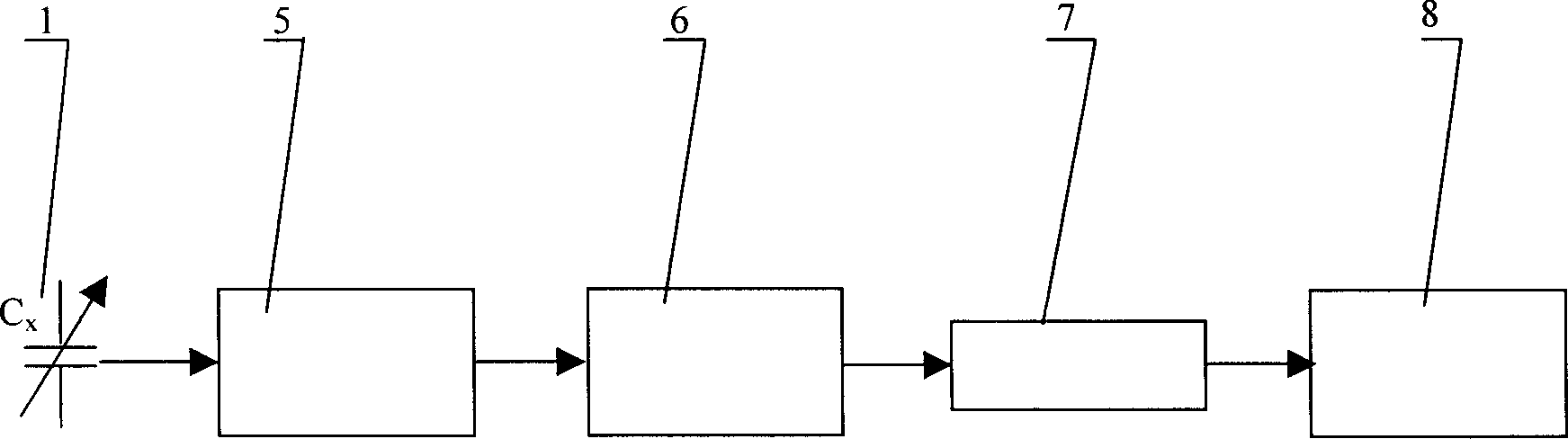

Electronic levelling instrument

InactiveCN1414342ASimple structureHigh measurement accuracyIncline measurementFrequency conversionPrecision engineering

An electronic level consists of a capacitive sensor and a measurement processor circuit. A sensor measuring circuit, an A / D conversion circuit, CPU and a LCD display are connected in series in the measurement processor circuit. A capacitance / frequency conversion circuit, the CPU and the LCD display are connected in series. The invention possesses the features as follows. (1) Capacitance is used as the sensor for measuring level, providing the high measuring accuracy with simple structure. (2) The measurement processor circuit with simple structure of the circuit is adopted, providing high sensitivity with cheap component. (3) The entire structure is simple so that the products are easy to be manufactured. The electronic level can be utilized in large-scale or precise engineering.

Owner:TIANJIN UNIV

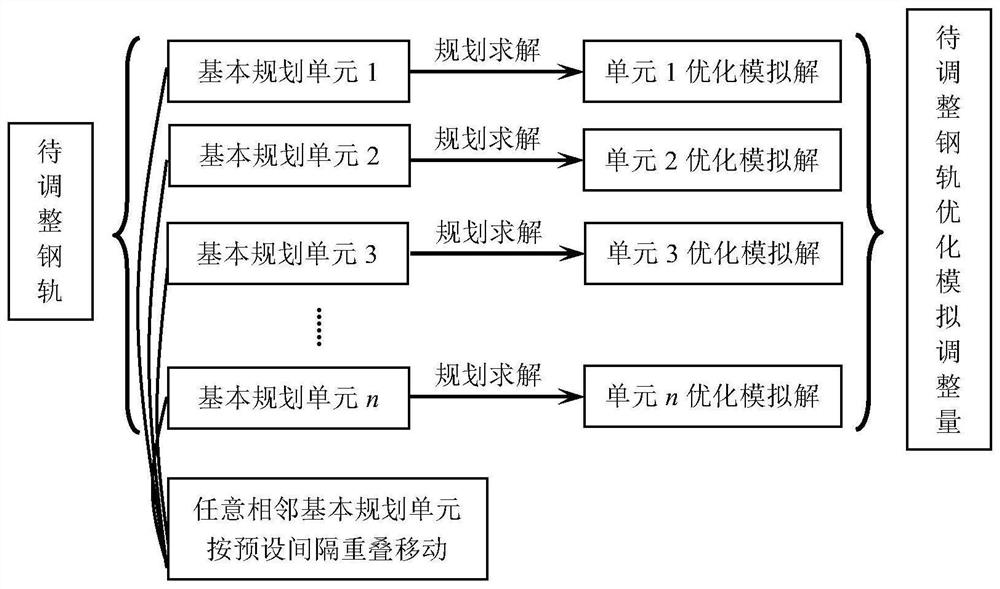

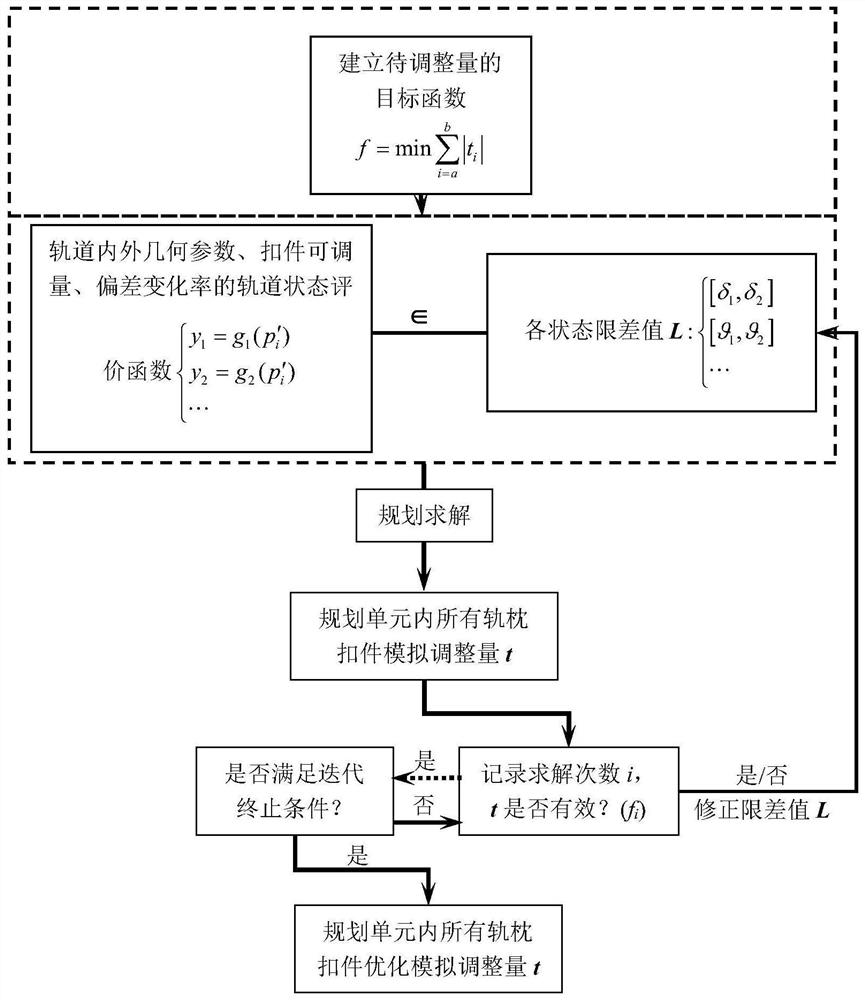

Track irregularity state optimization simulation fine adjustment method

The invention discloses a track irregularity state optimization simulation fine adjustment method, and belongs to the technical field of precision engineering measurement in the field of track traffic. The method comprises the following steps: segmenting a steel rail according to a preset length, and establishing a to-be-adjusted amount target function of a sleeper fastener in a segmentation planning unit; establishing an inequality constraint model based on the steel rail state evaluation function; solving the objective function and the inequality constraint model, and correcting a constant term of the inequality constraint model according to the solving result validity to reduce a constraint boundary value; and repeating the correction and solving processes until the end condition is met, and obtaining the fastener optimization simulation adjustment amount in the planning unit. According to the method, the dual goals of considering the track irregularity state optimization and the optimization simulation adjustment amount can be achieved, and the problems that a track fine adjustment scheme wastes time and labor, and the quality is uneven are solved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY +1

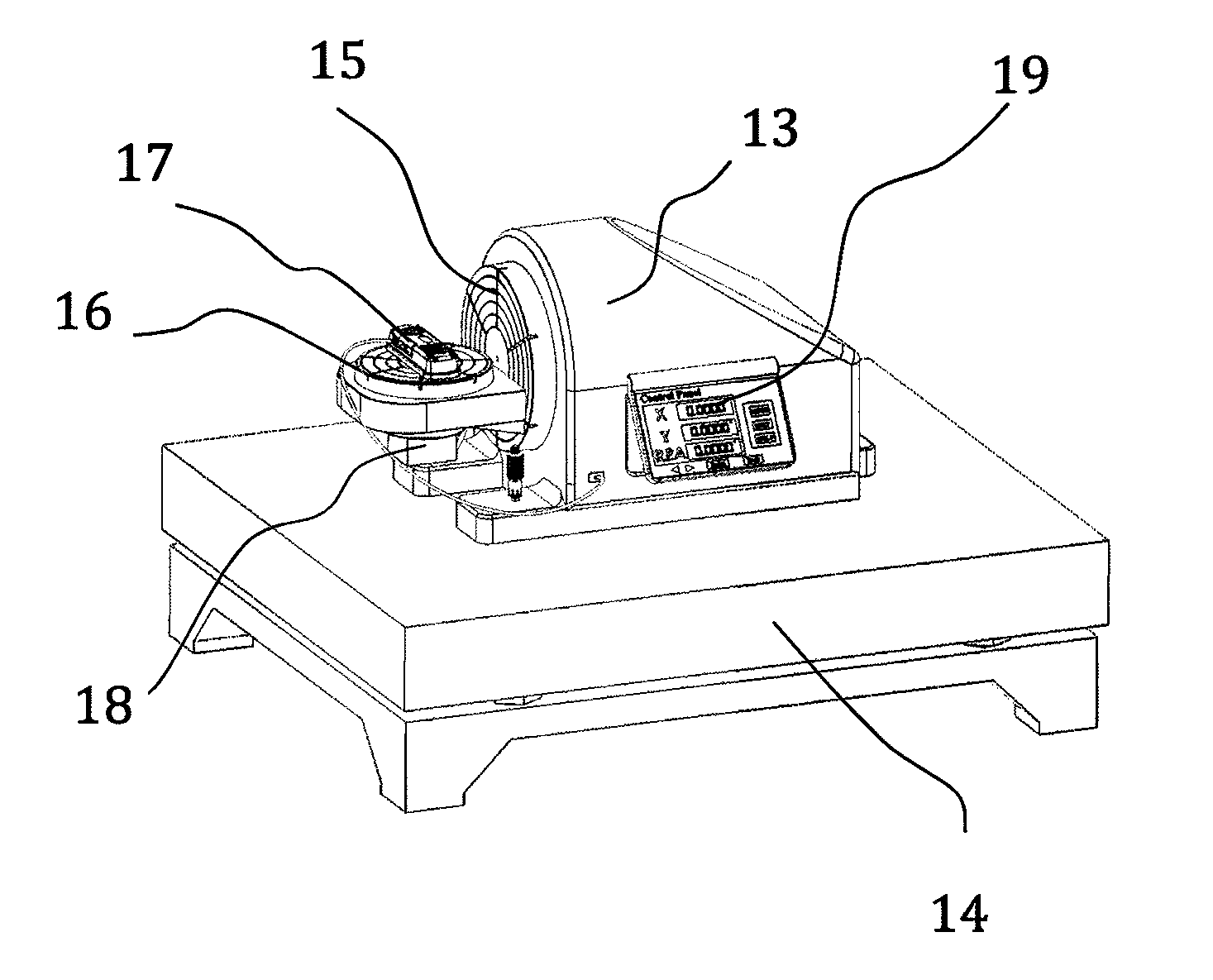

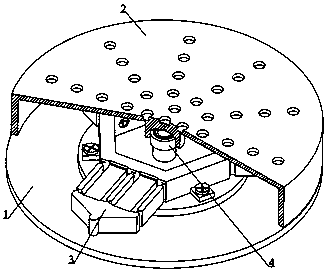

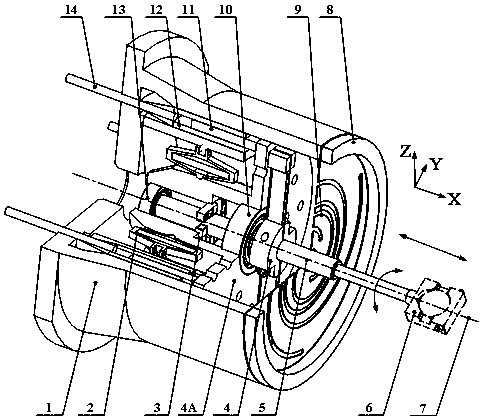

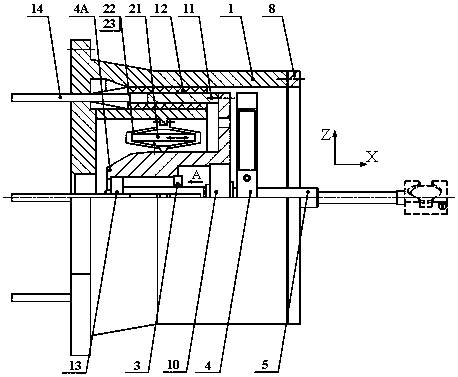

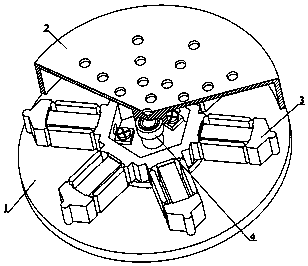

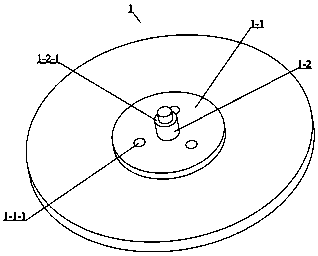

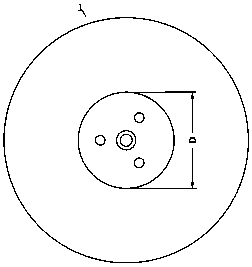

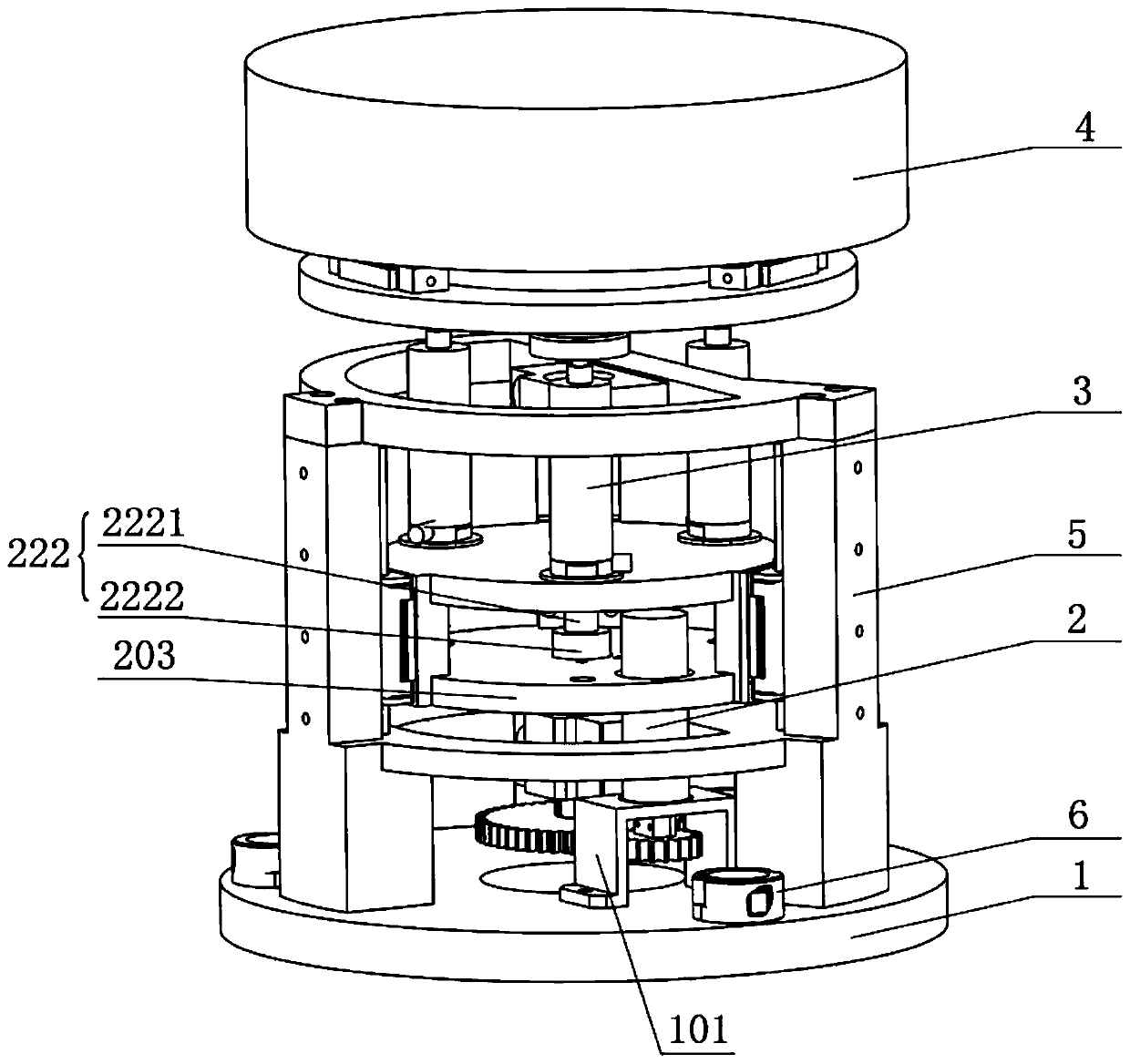

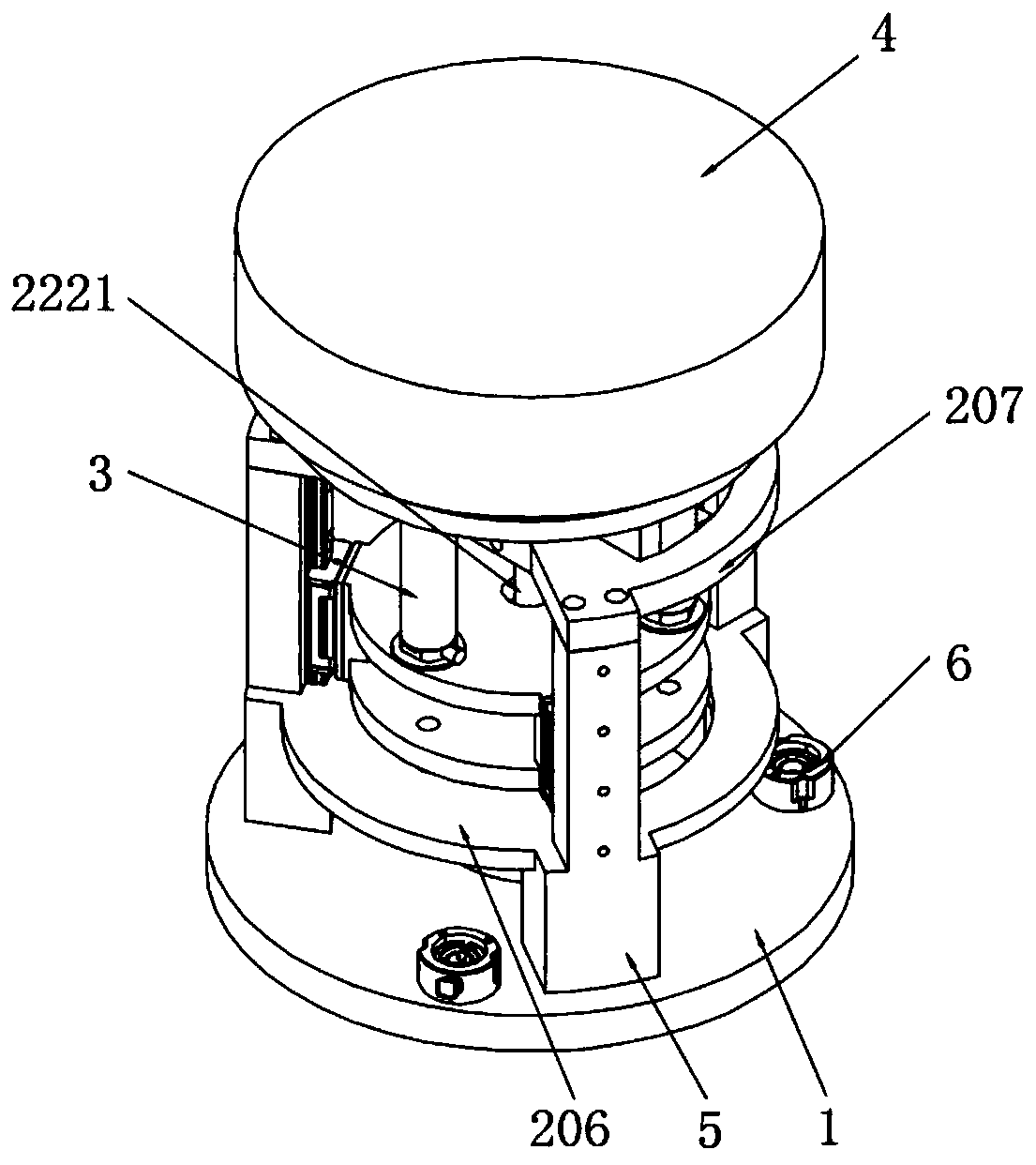

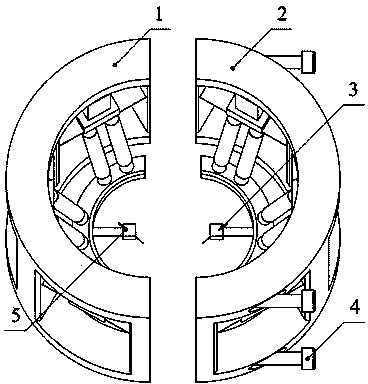

Bi-piezoelectric stack driving type precision rotary driving device

PendingCN107947629AHigh frequency responseReduce volumePiezoelectric/electrostriction/magnetostriction machinesInterference fitRotary stage

The invention relates to a bi-piezoelectric stack driving type precision rotary driving device, and belongs to the technical field of precision engineering. The bi-piezoelectric stack driving type precision rotary driving device comprises a support base, a rotary table, a stator assembly, a bearing and the like; the support base and the rotary table are connected through the bearing in a matched manner; the support base and the stator assembly are connected through a bolt; the rotary table and the stator assembly are contacted and matched through the front end of a driving foot; and the bearing, the support base and the rotary table are in interference fit. When an exciting electric signal acts on a stack type piezoelectric component, the stack type piezoelectric component performs axial elongation based on the inverse piezoelectric effect; therefore, the driving foot performs tangential displacement, so that the rotary table is driven to perform rotational motion; and the direction and the time sequence of driving voltage are changed, so that the rotary table can be controlled to perform forward rotation, inverse rotation and positioning stillness. The bi-piezoelectric stack driving type precision rotary driving device disclosed by the invention has the technical advantages of being simple in structure, high in positioning precision, large in stroke, rapid in response speed and the like, and has wide application prospect in the technical field of precision engineering.

Owner:JILIN UNIV

High-stability PA66 modified material and preparation method thereof

The invention discloses a high-stability PA66 modified material and a preparation method thereof. The modified material consists of the following components in percentage by weight: 65-76 percent of PA66 resin, 10-15 percent of PA6 resin, 2 percent of anti-wear agent, 1.5 percent of composite lubricating agent, 0.3 percent of antioxidant, 10-15 percent of wollastonite in powder, 0.1 percent of talc powder and 0.3 percent of coupling agent. The invention further provides a preparation method of the modified material. By blending the anti-wear agent and the wollastonite in powder and modifying PA66, the prepared nylon material has high mechanical property and high wear resistance, the defect of easy moisture absorption of nylon is overcome, and the size is stable. The high-stability PA66 modified material can be widely applied to the fields of gears, bearings, fan blades, bicycle parts, automobile industry parts, electronics and electrics, precision engineering products, mechanical treatment, sports apparatuses and the like.

Owner:徐东

Piezoelectric-electromagnetic hybrid driving multi-degree-of-freedom precision positioning device and control method

ActiveCN109980990AControl speedCompact structurePiezoelectric/electrostriction/magnetostriction machinesInterference fitElectricity

The invention relates to a piezoelectric-electromagnetic hybrid driving multi-degree-of-freedom precision positioning device and a control method, and belongs to the field of precision machinery and precision engineering. A piezoelectric inertial rotary positioning assembly is fixedly mounted in a connecting sleeve and ensures a clearance fit with an output shaft in the case of power outage. A piezoelectric bimorph rotary positioning assembly is installed in an interference fit with the output shaft. The output shaft is supported and guided by bearings I and II fixedly mounted in the connecting sleeve to ensure that the axis of a connecting assembly at the tail end of the output shaft is coaxial with an output axis. A clamping mechanism is fixedly connected to the flange of a body by a connecting bolt, is in close contact with the connecting sleeve by using a hemispherical contact member to realize self-locking, and is fixed to an external macro-adjustment positioning platform throughthe end portion of the body. The piezoelectric-electromagnetic hybrid driving multi-degree-of-freedom precision positioning device has compact structure, can achieve axial large-stroke linear positioning and macro-micro hybrid rotational positioning, can realize multi-degree-of-freedom motion output, and has good application prospects in the fields of precision optics, micromanipulation, aerospaceand precision instruments.

Owner:JILIN UNIV

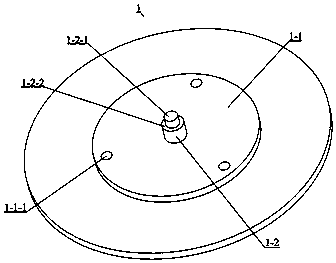

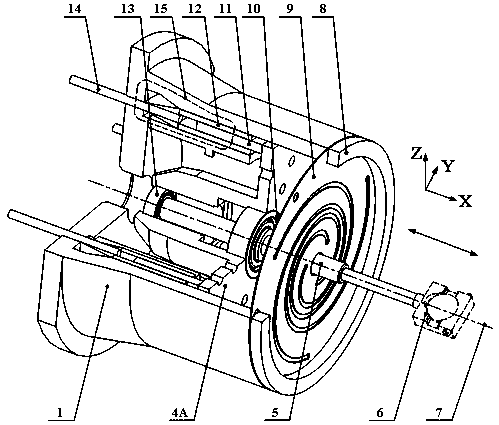

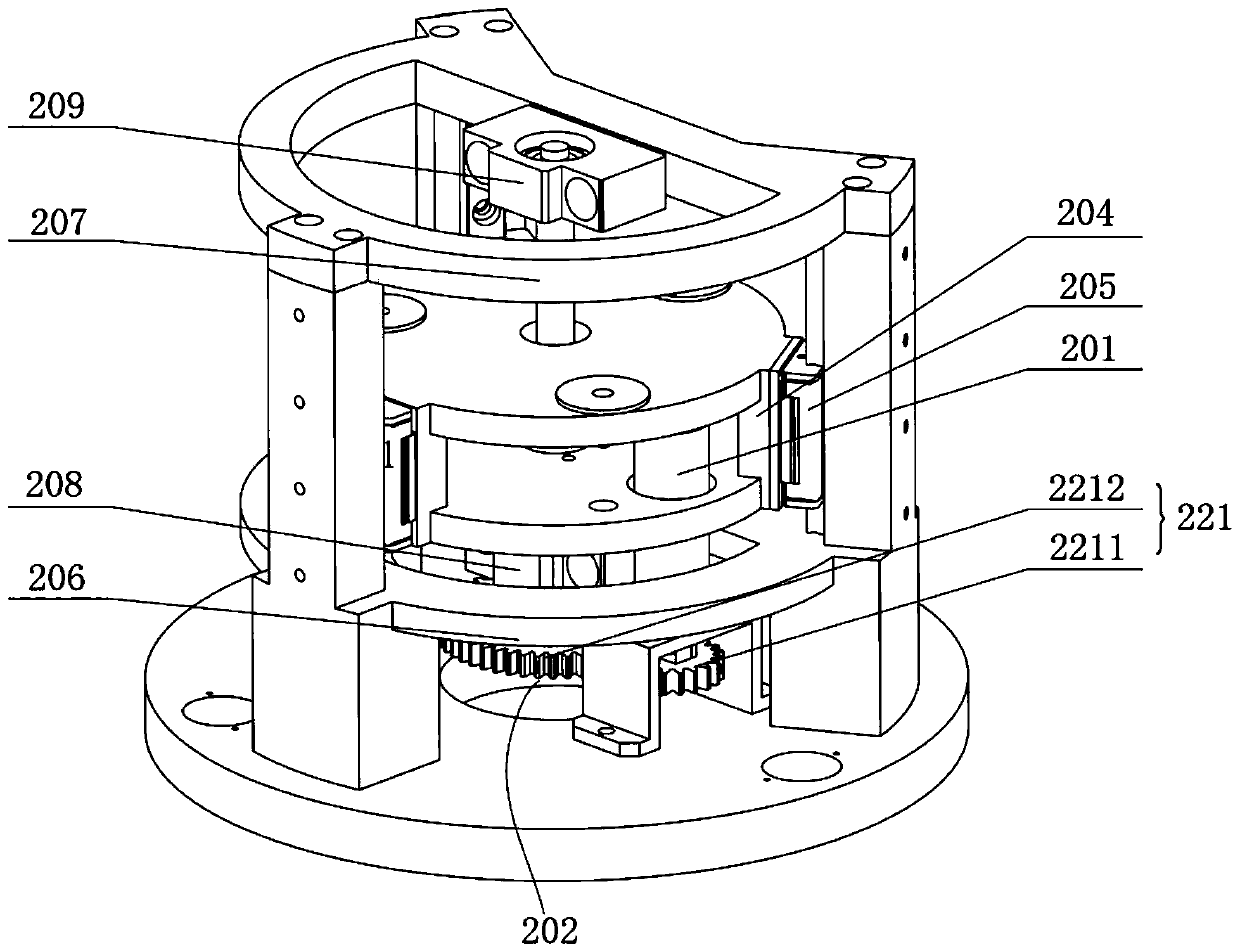

Piezoelectrically-driven precision rotation driving device using specially-shaped hinge transmission mechanism

PendingCN108233764AHigh frequency responseReduce volumePiezoelectric/electrostriction/magnetostriction machinesInterference fitEngineering

The invention relates to a piezoelectrically-driven precision rotation driving device using a specially-shaped hinge transmission mechanism, and belongs to the technical field of precision engineering. The piezoelectrically-driven precision rotation driving device using the specially-shaped hinge transmission mechanism comprises a base, a rotating table surface, a stator assembly, a bearing and other units, wherein the base and the rotating table surface are connected through the bearing; the base and the stator assembly are connected through bolts; the rotating table surface and the stator assembly are in contact fit through front ends of driving feet; the base and the rotating table surface are in interference fit with the bearing. When an excitation electric signal acts on a piezoelectric stack, the piezoelectric stack generates axial elongation based on an inverse piezoelectric effect, the driving feet generate tangential displacement to drive the rotating table surface to generateprecise rotating motion, and by changing the direction and the time sequence of driving voltage, the rotating table surface can be controlled to generate positive and reverse rotating motions and positioning can be achieved. The piezoelectrically-driven precision rotation driving device using the specially-shaped hinge transmission mechanism has many technical advantages such as simple structure, high positioning precision and high response speed, and has a wide application prospect in the technical field of precision engineering.

Owner:JILIN UNIV

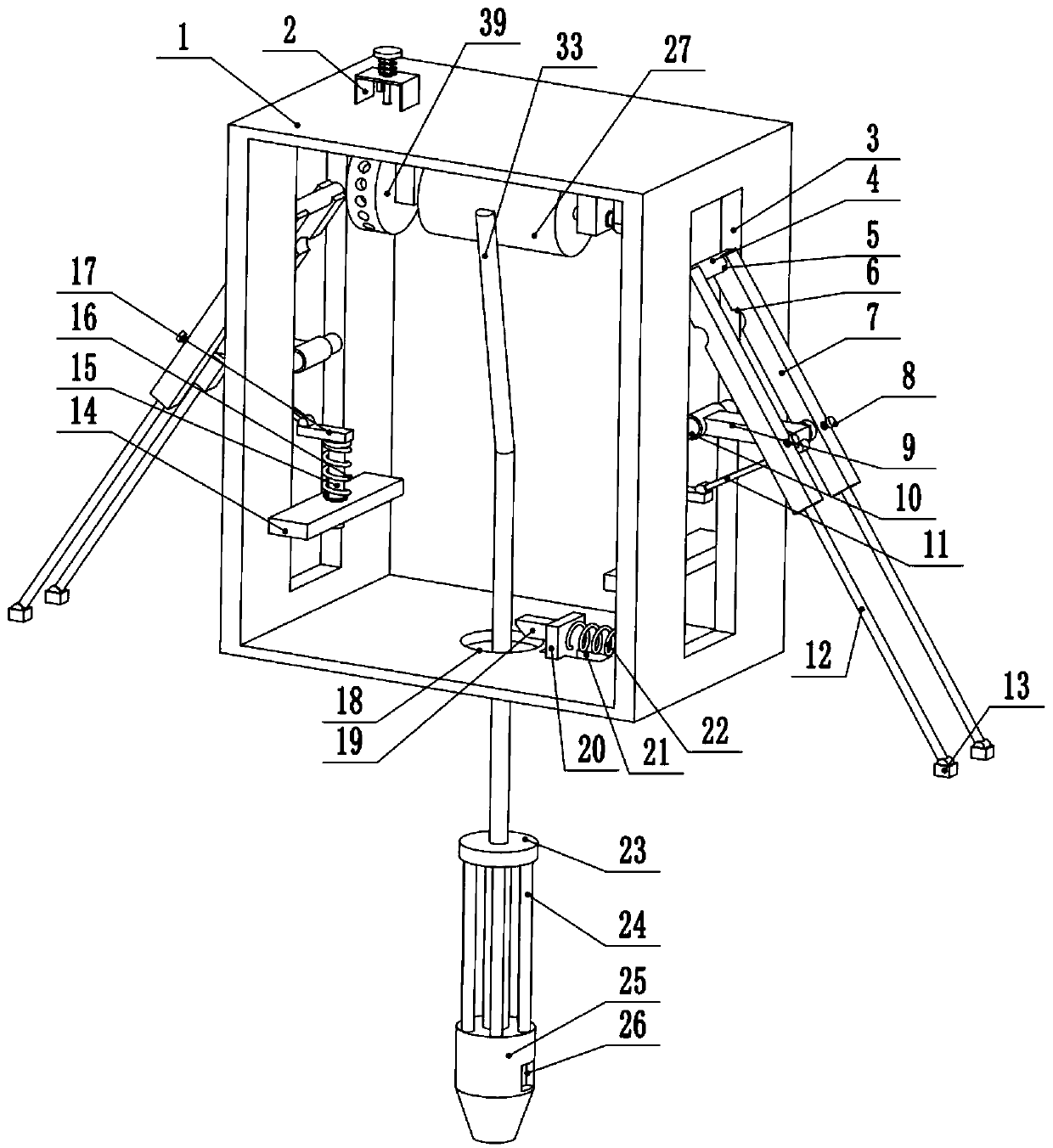

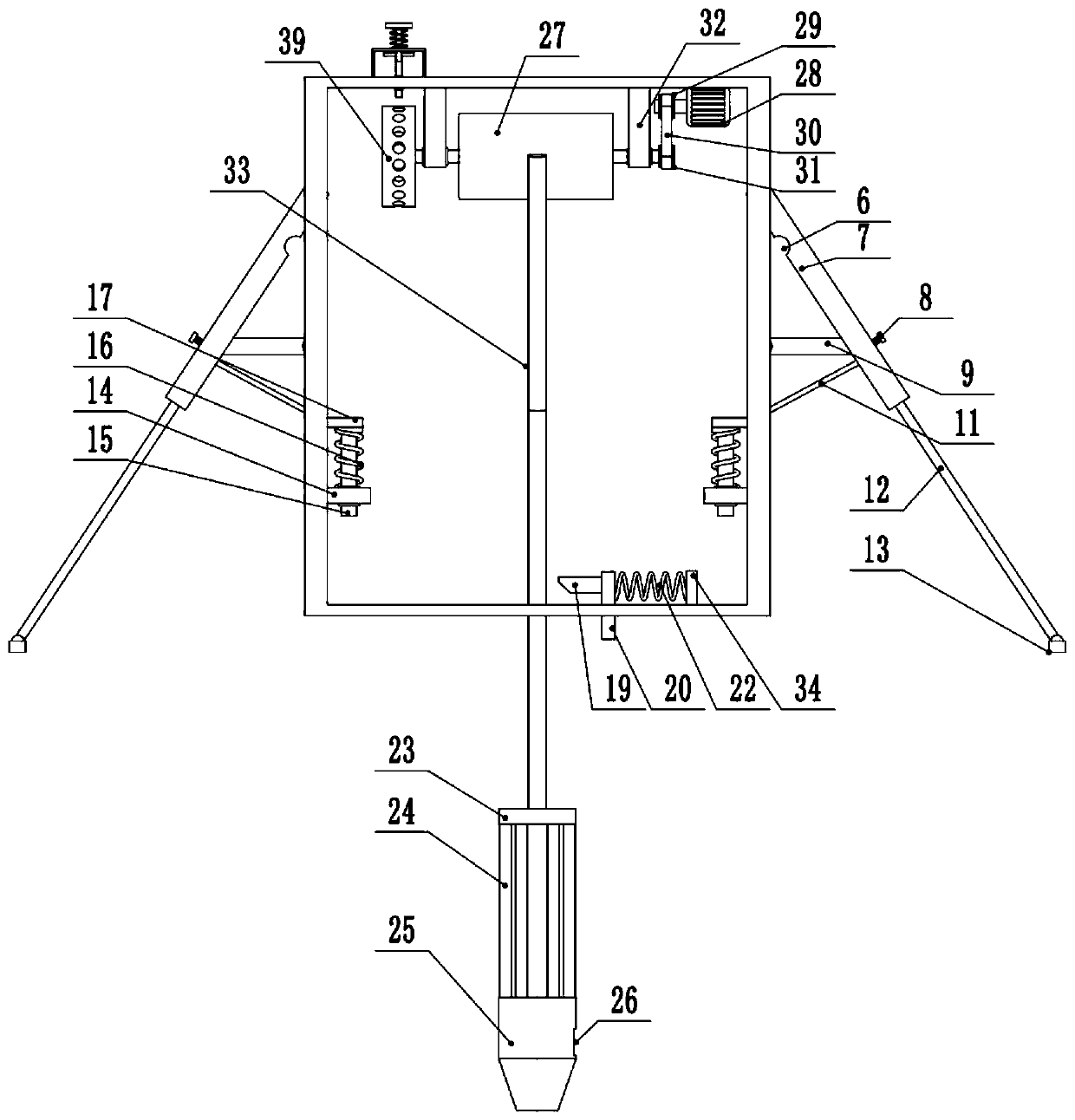

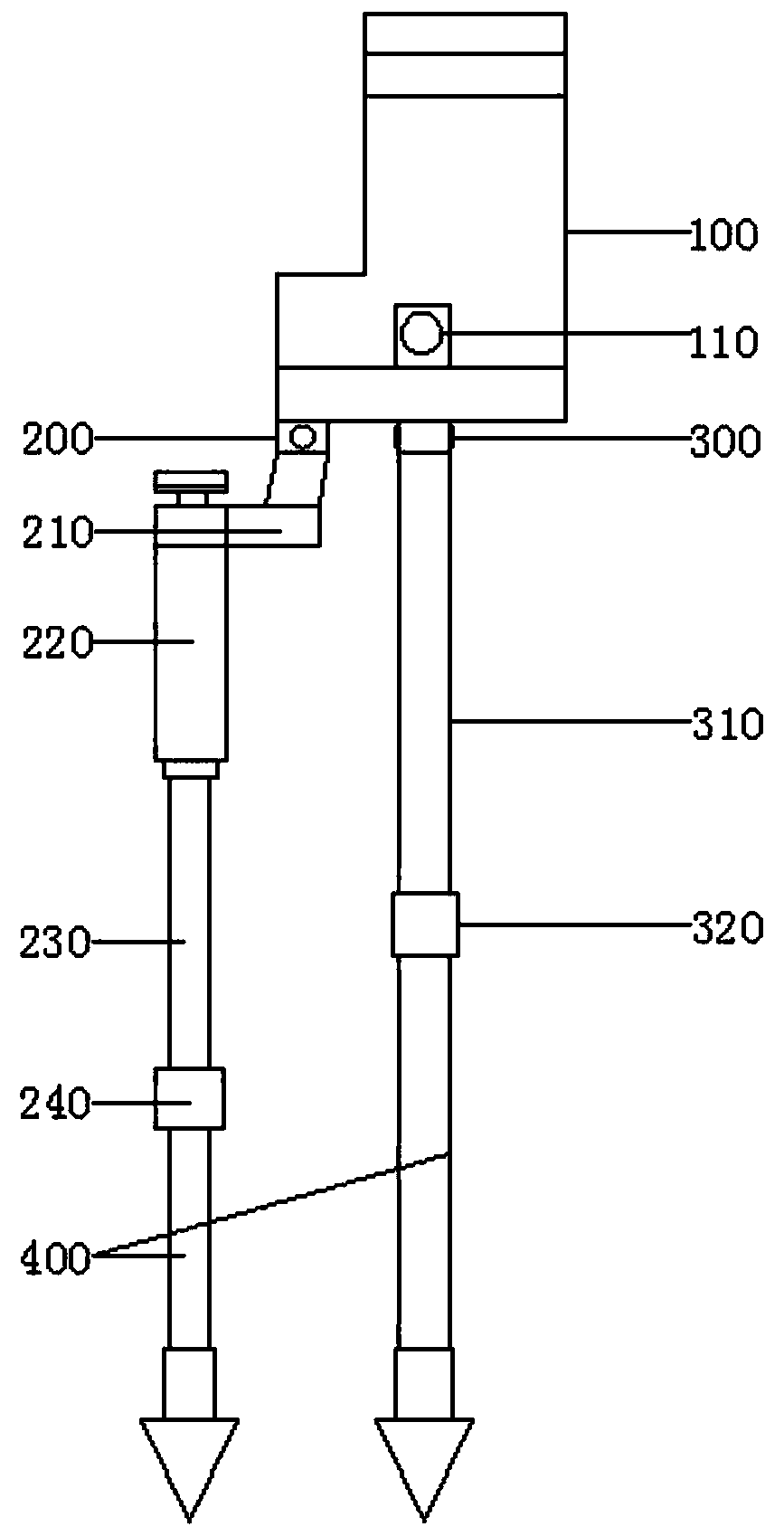

Novel multifunctional high-precision engineering surveying and mapping box staff

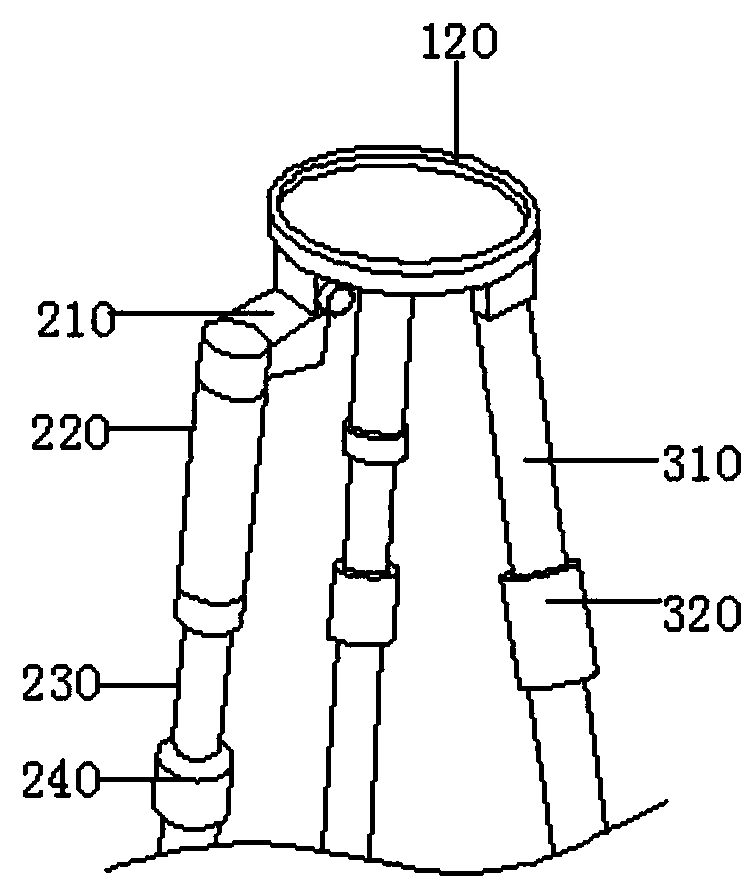

InactiveCN111550659AImprove portabilityHeight/levelling measurementStands/trestlesClassical mechanicsPrecision engineering

The invention relates to the technical field of engineering surveying and mapping, and discloses a novel multifunctional high-precision engineering surveying and mapping box staff. The novel multifunctional high-precision engineering surveying and mapping box staff comprises a main body. The top of the main body is provided with bearing seats rotatably connected with the left and right ends of a winding roller, the exterior of the winding roller is provided with a lifting rope, the lower end of the lifting rope is provided with a third fixing plate, and the lower portion of the third fixing plate is provided with a surveying and mapping head. The middle portions of the left and right side walls of the main body are provided with avoidance grooves, the middle portions of the avoidance grooves are provided with rotating shafts, the middle portions of the rotating shafts are rotatably connected with the ends, close to the center of the device, of ejecting rods, and the ends, away from thecenter of the device, of the ejecting rods are rotatably connected with the lower portions of sliding sleeves. According to the novel multifunctional high-precision engineering surveying and mappingbox staff, first limiting grooves and second limiting grooves are formed in the upper portions of the sliding sleeves and connected with stop rods in a clamping manner respectively, so that the wholedevice is supported by the sliding sleeves and sliding rods when in use; and the sliding sleeves, the ejecting rods and supporting rods are completely retracted into the avoidance grooves on the leftand right sides when the device is retracted, so that the portability of the device is improved.

Owner:吴汉涛 +2

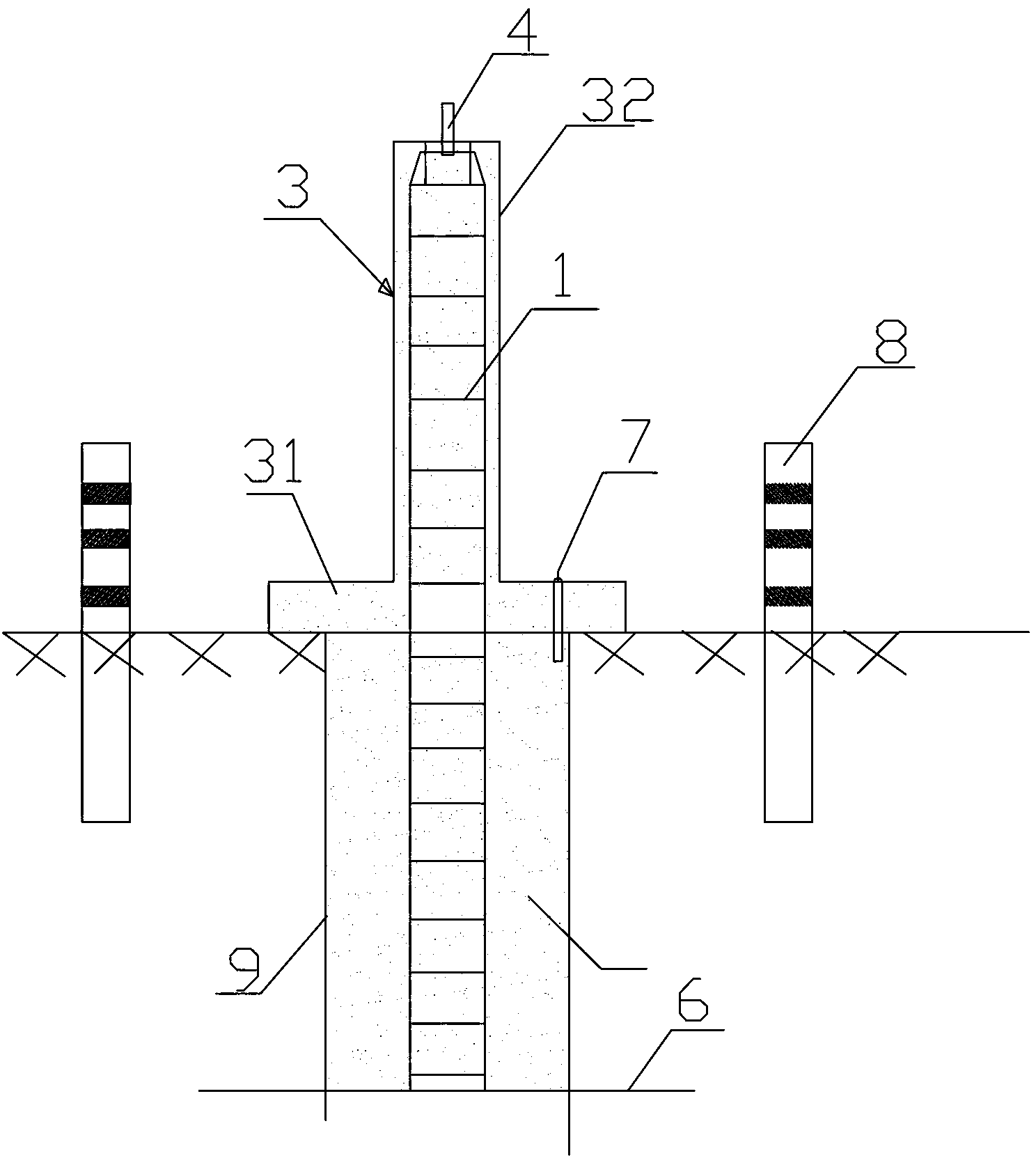

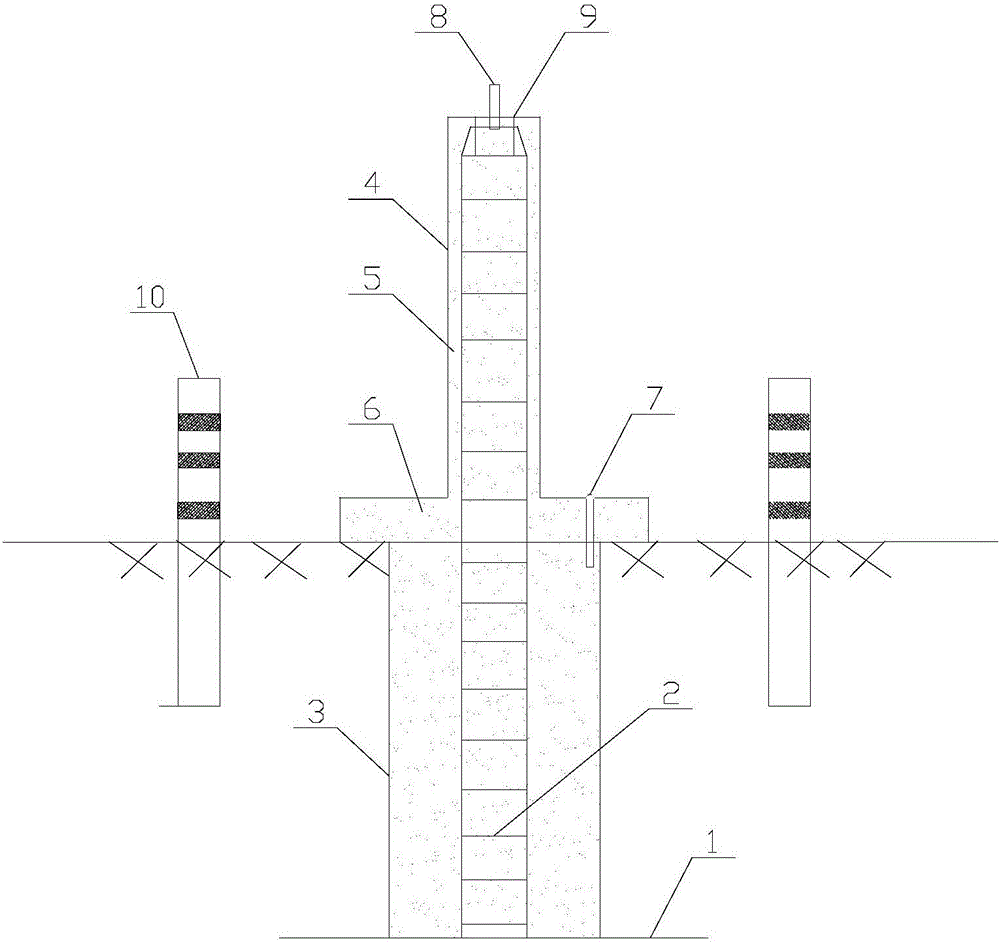

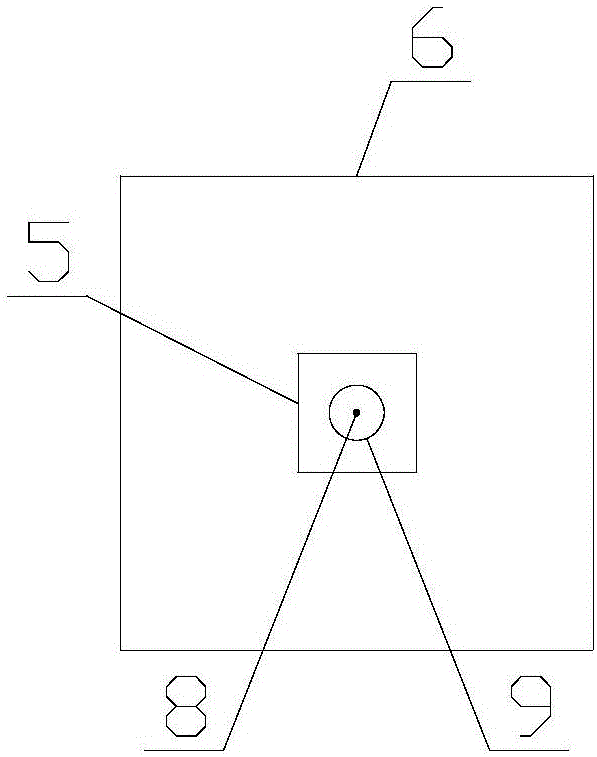

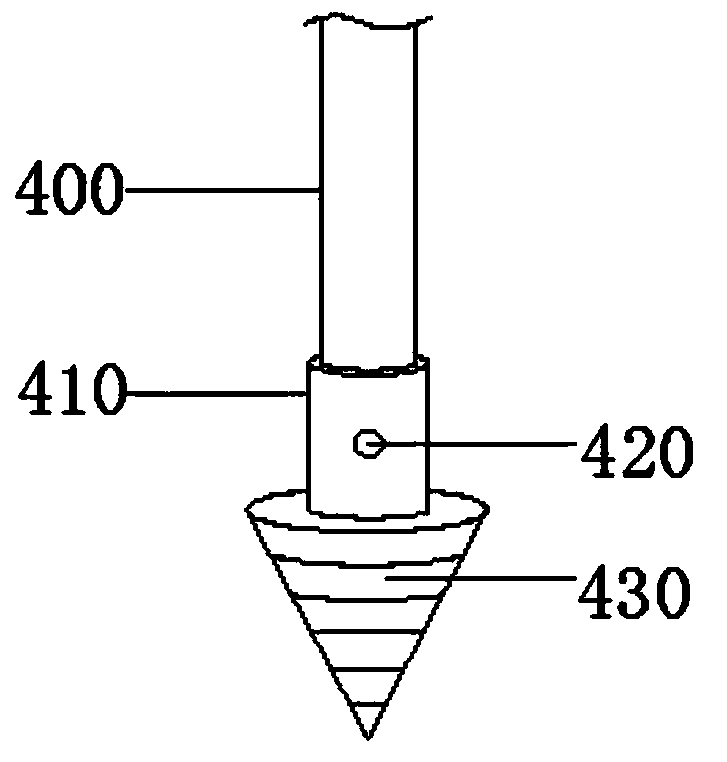

Fabrication method of forced centering observation pillar for precision engineering measurement and observation pillar

InactiveCN103076010ASimple processEasy to make embedding methodBulkheads/pilesPermanant marksPrecision engineeringEngineering

The invention discloses a fabrication method of a forced centering observation pillar for precision engineering measurement and the observation pillar. The fabrication method comprises the steps that a pile hole is dug manually and downward to a bed rock; a steel reinforcement cage is placed in the pile hole in a hanging manner; the bottom of the steel reinforcement cage is placed on the bed rock; the height-set steel reinforcement cage is reserved above the ground surface; an underground concrete pile is poured in the pile hole; after the underground concrete pile is solidified, a formwork is erected and an overground concrete column is poured on the steel reinforcement cage reserved above the ground surface; a forced centering bolt is embedded in the center of the top end of poured concrete; the diameter of the forced centering bolt is required to be matched with a bolt hole at the bottom of an instrument base; a forced centering disk is embedded at the top end of the concrete embedded with the forced centering bolt; and the forced centering bolt penetrates through the center of the forced centering disk. According to the fabrication method of the forced centering observation pillar for the precision engineering measurement and the observation pillar, the technology is simple; the fabrication and embedding method is simple; the pillar is easy to fabricate, and convenient to use, and is not damaged easily; an observation error can be reduced; the observation accuracy is reliable; and specified requirements of standards are met.

Owner:TIANJIN 20 CONSTR

High-performance modified polyamide composite material and preparation method thereof

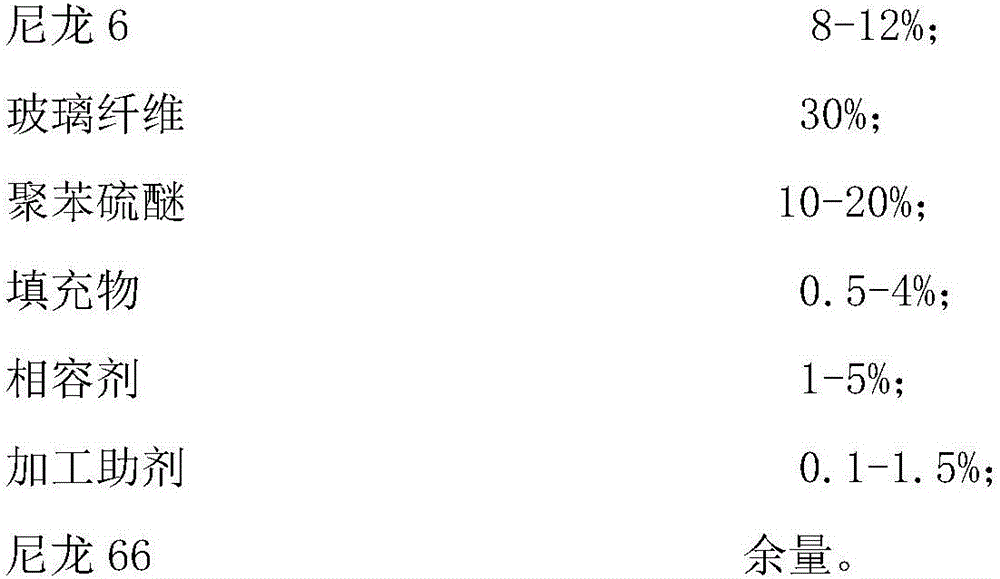

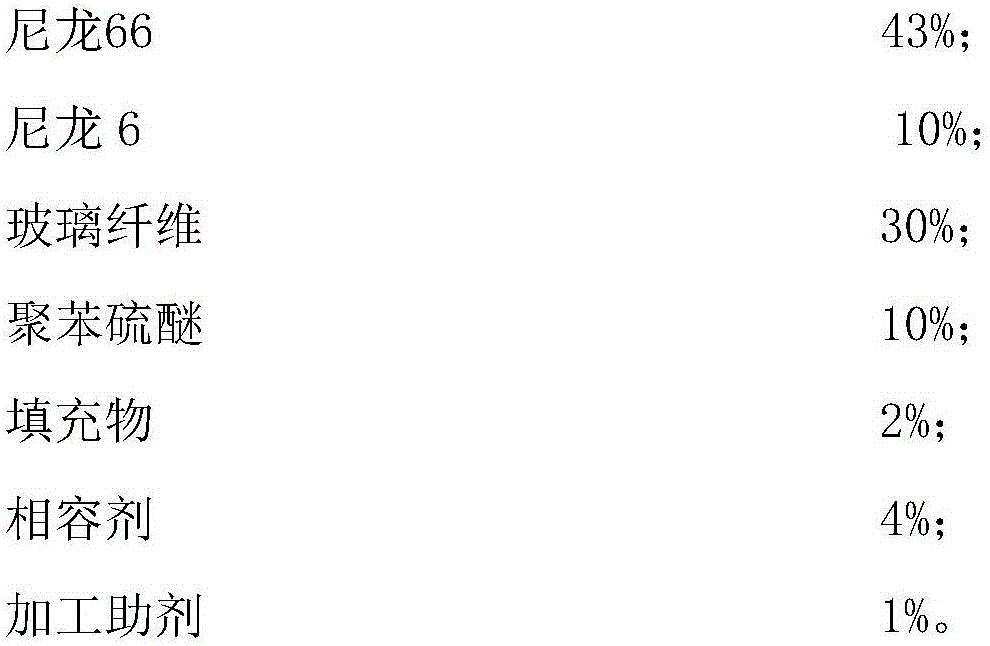

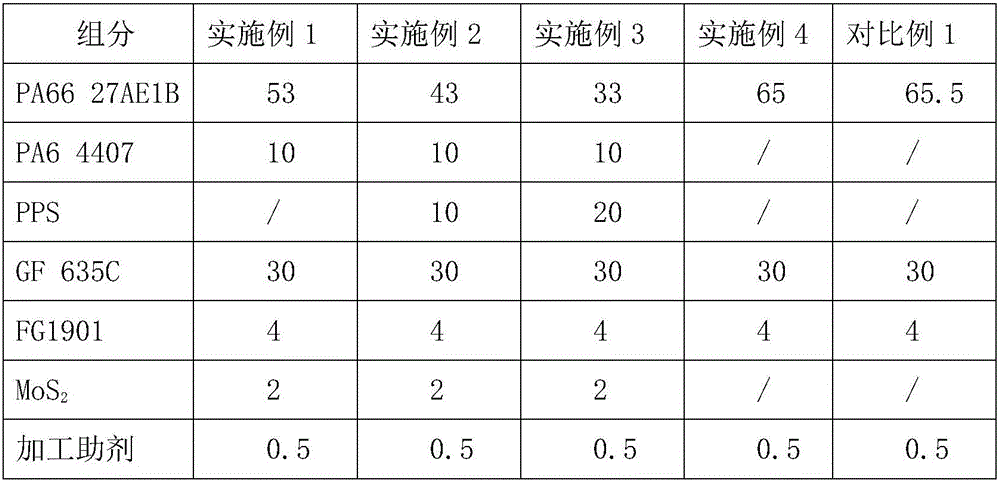

The invention provides a high-performance modified polyamide composite material. The high-performance modified polyamide composite material comprises, by weight, 8-12% of nylon 6, 30% of glass fibers, 10-20% of polyphenylene sulfide, 0.5-4% of a filler, 1-5% of a compatilizer, 0.1-0.5% of a processing auxiliary agent and the balance nylon 66. The invention also provides a preparation method of the high-performance modified polyamide composite material. The high-performance modified polyamide composite material can be used for machinery, apparatuses and instruments, automobile parts, electrical and electronic products, railway, household electrical appliance, communication, spinners, physical culture leisure articles, oil pipes, fuel tanks and precision engineering products.

Owner:SHANGHAI SHENGNAN COMPOSITE MATERIALS CO LTD

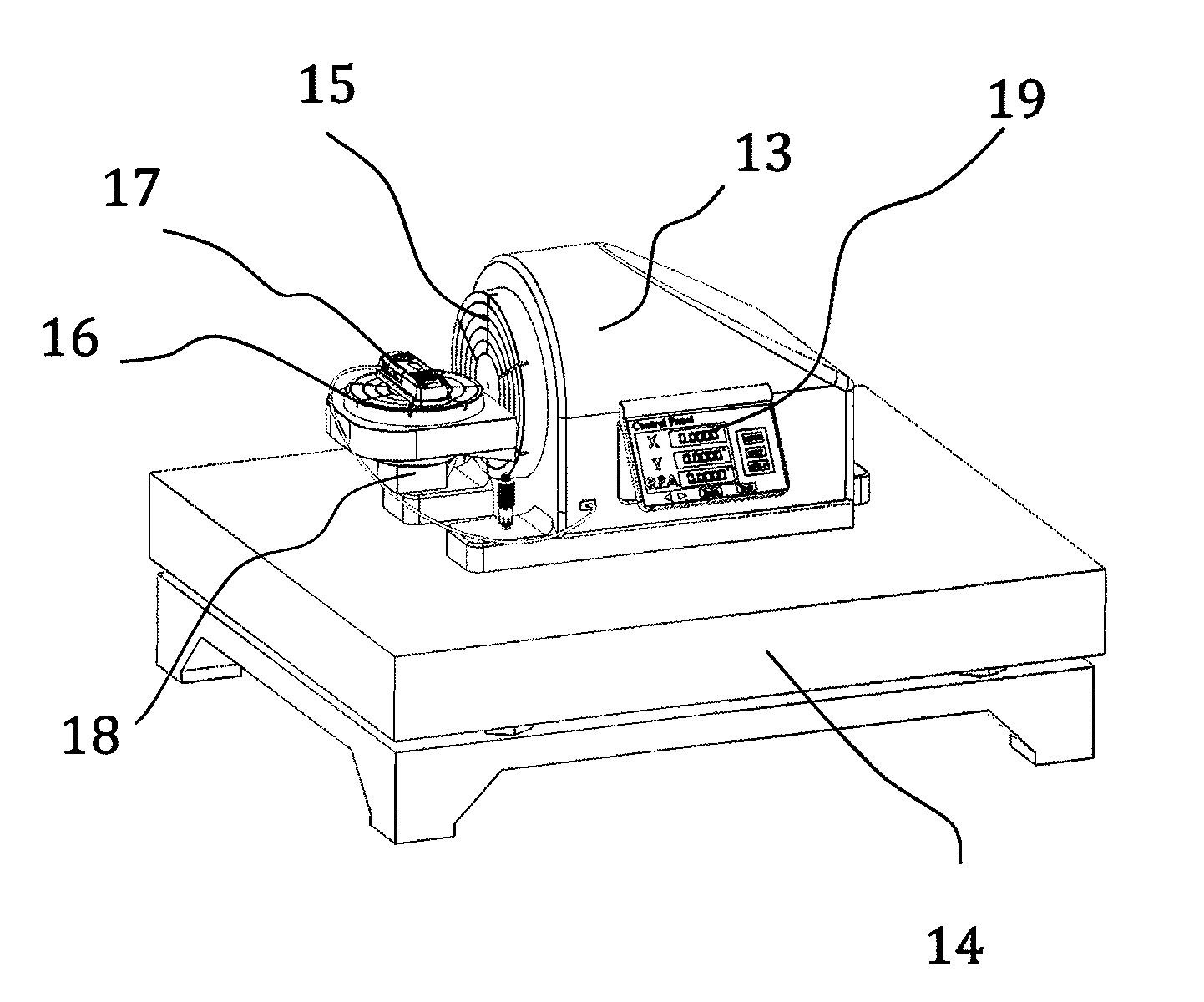

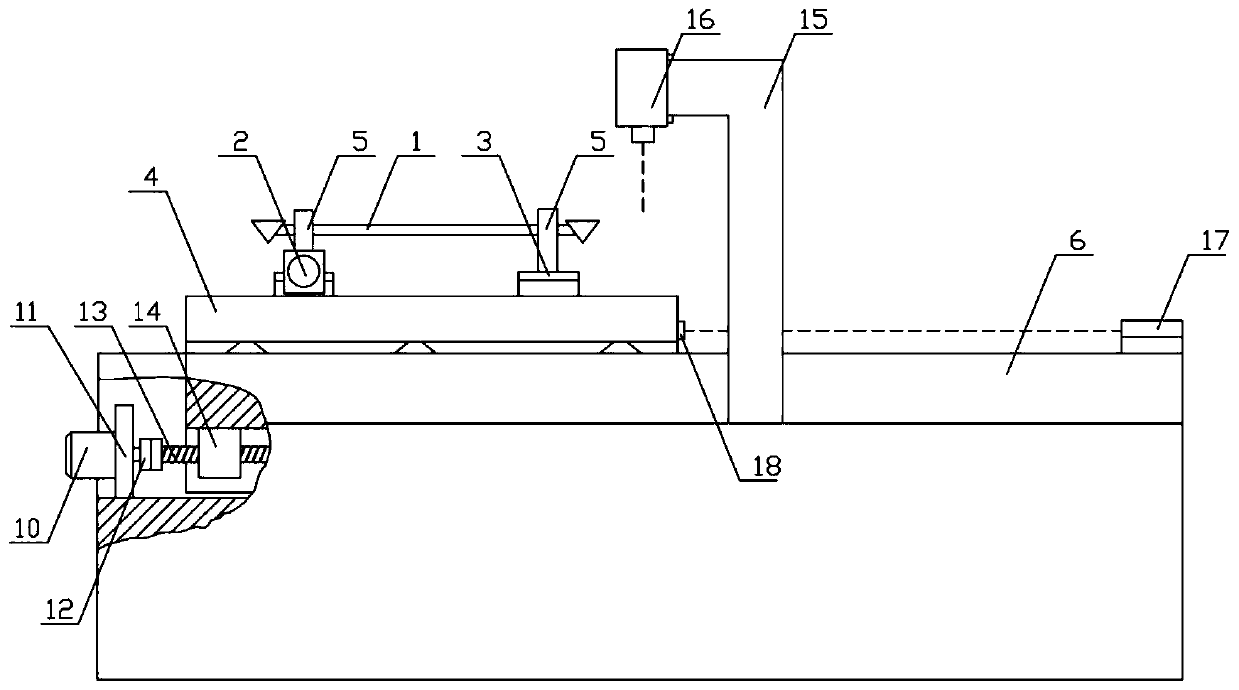

Regressive reflective ball length standard rod length measuring device and measuring method thereof

ActiveCN110207595AAccurate measurementSimple structureUsing optical meansGeometric properties/aberration measurementPrecision engineeringLength measurement

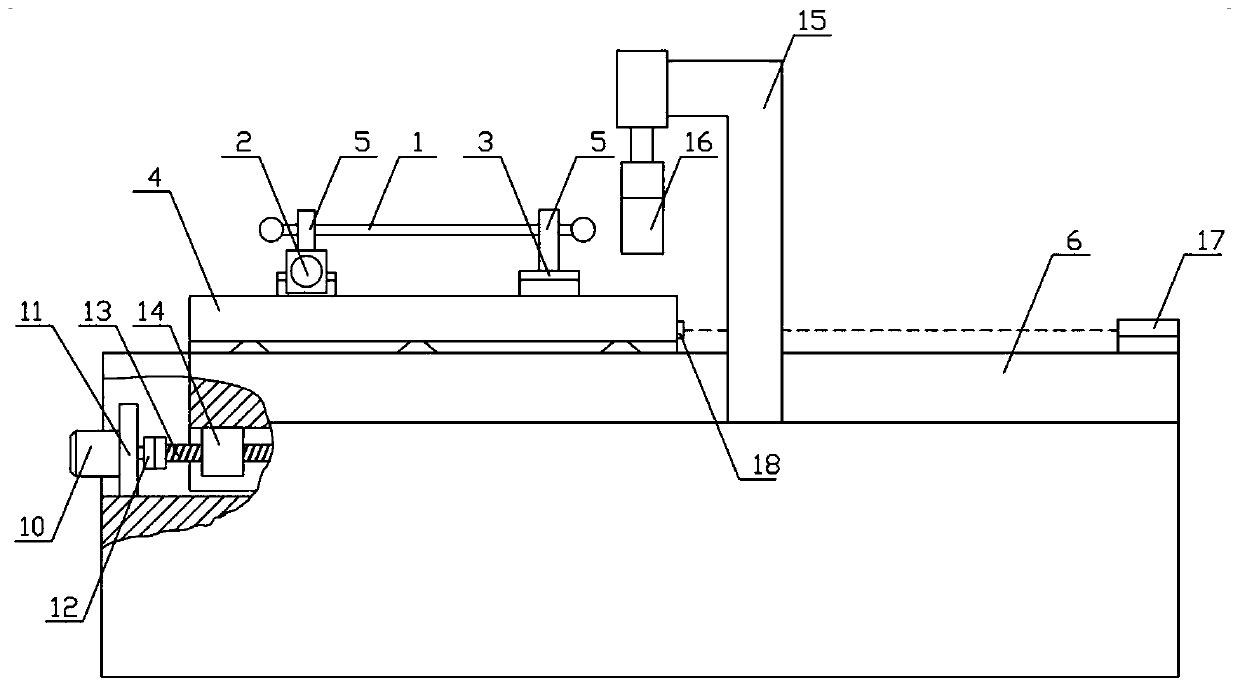

The invention relates to the technical field of precision engineering surveying, and provides a regressive reflective ball length standard rod length measuring device and a measuring method thereof. The regressive reflective ball length standard rod length measuring device comprises an optical sighting device, a calibration device, a directed sliding device and a distance measuring device; the optical sighting device is used for aiming optical centers of the regressive reflective balls at the two ends of the regressive reflective ball length standard rod; the calibration device is mounted on the directed sliding device, and a pre-calibrated regressive reflective ball length standard rod is placed on the calibration device; and the distance measuring device is used for detecting a sliding distance of the directed sliding device. The invention has the advantages of simple structure and convenient operation; and accurate measurement of the optical center spacing of the regressive reflective balls at both ends of the regressive reflective ball length standard rod is realized through using an indirect ranging method.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

Production method of forced centering observation mark stake for precision engineering measurement

InactiveCN106403996AImprove stabilityMeet the observation accuracy requirementsMeasurement devicesBedrockMeasuring instrument

The invention relates to a production method of a surveying control point mark stake, and discloses the production method of the force centering observation mark stake for precision engineering surveying. The method comprises the following steps: a stake hole is manually dug to a bedrock part; a steel reinforcement cage is hung in the stake hole, so that the bottom of the steel reinforcement cage is placed on the bedrock, and the a design height above the ground of the steel reinforcement cage is reserved; concrete is poured in the stake hole; after concrete below the ground is solidified, concrete is poured in a reserved steel reinforcement cage formwork above the ground; a forced centering bolt is embedded at a center position of the top of an overground part of the concrete stake, and the diameter of the bolt is matched with a bolt aperture at the bottom of a measuring instrument pedestal; a forced centering disc is embedded at the top of the overground part of the concrete stake, and the center of the disc passes through the forced centering bolt. Settlement and deviation are effectively avoided, damage is not easy, usage is convenient, observation errors are reduced, and observation precision is improved; during usage, a measuring instrument is directly screwed and connected to the forced centering bolt and leveled, interference factors are reduced and centering errors are reduced.

Owner:TIANJIN 20 CONSTR

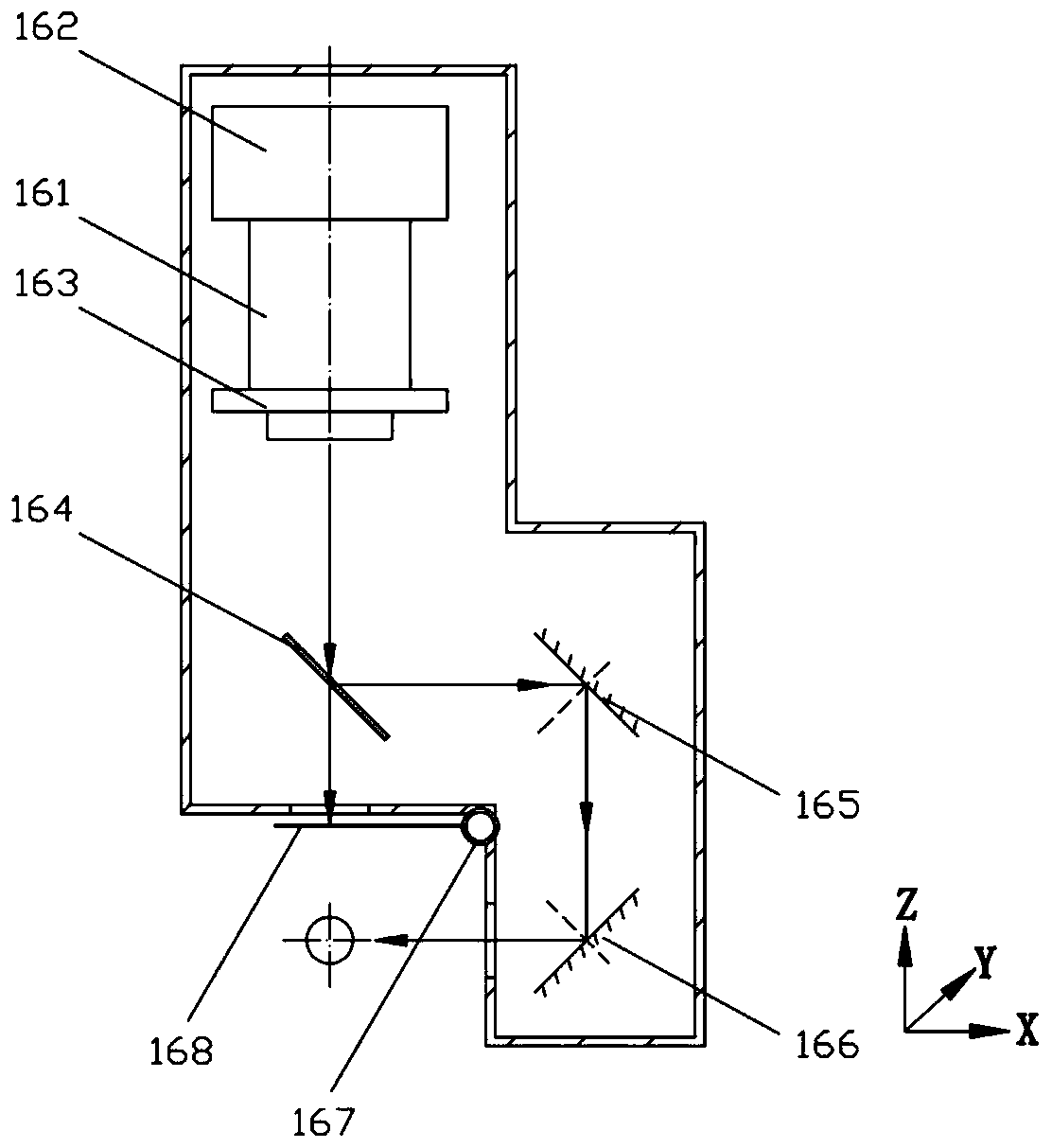

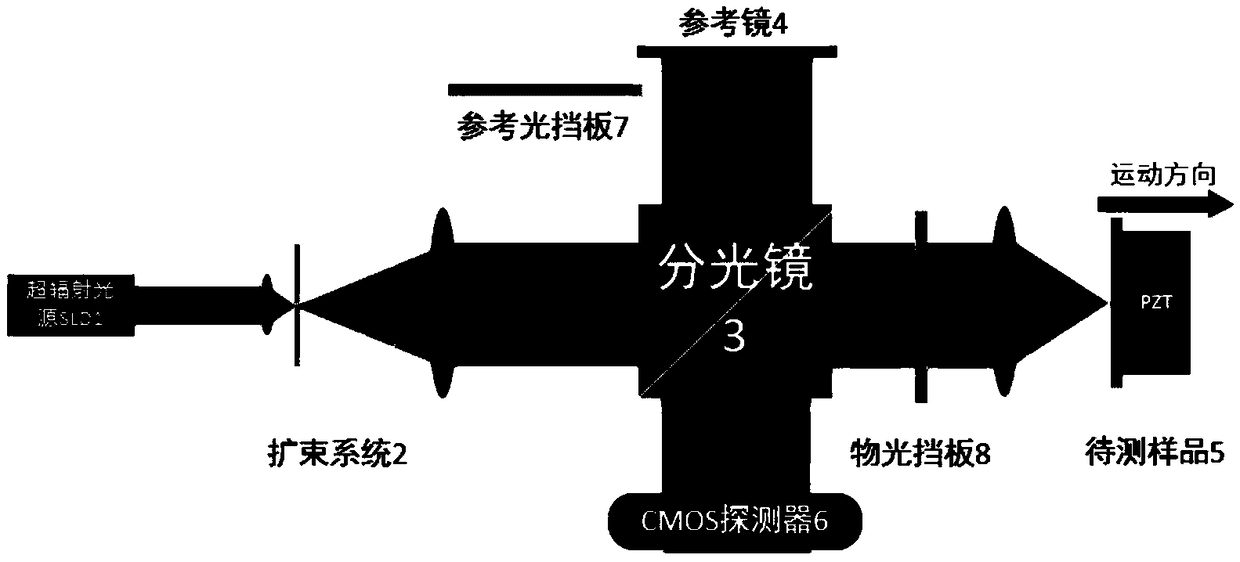

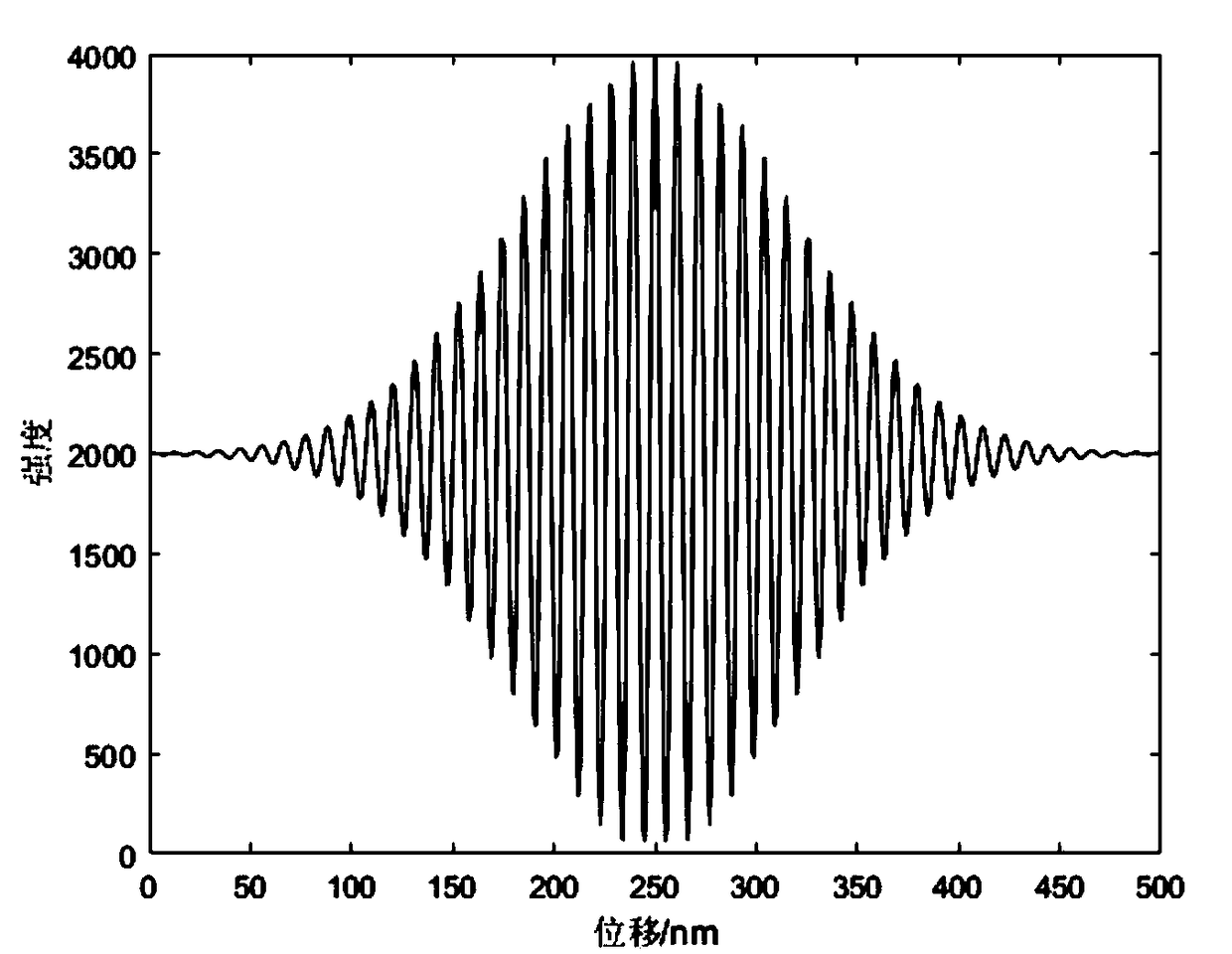

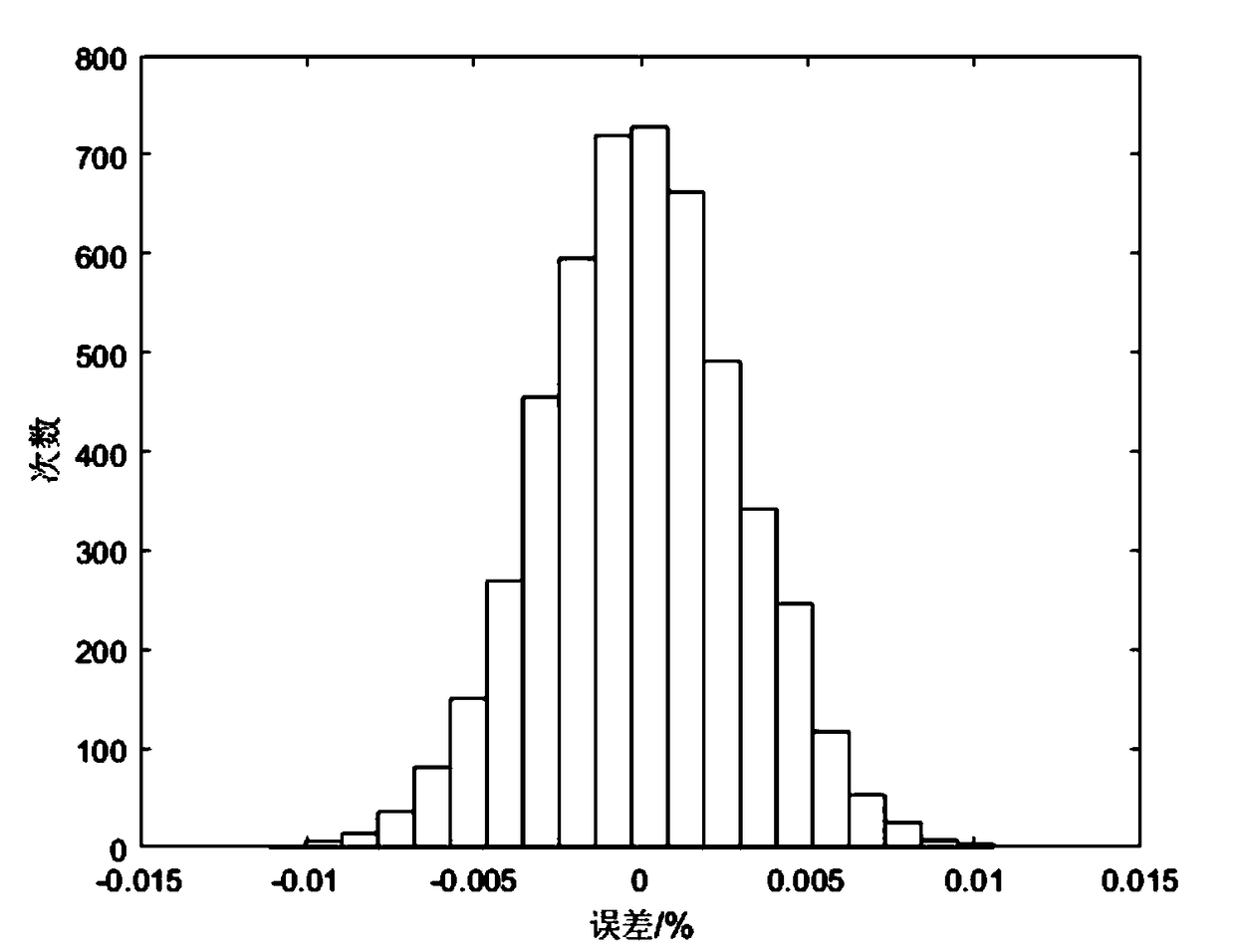

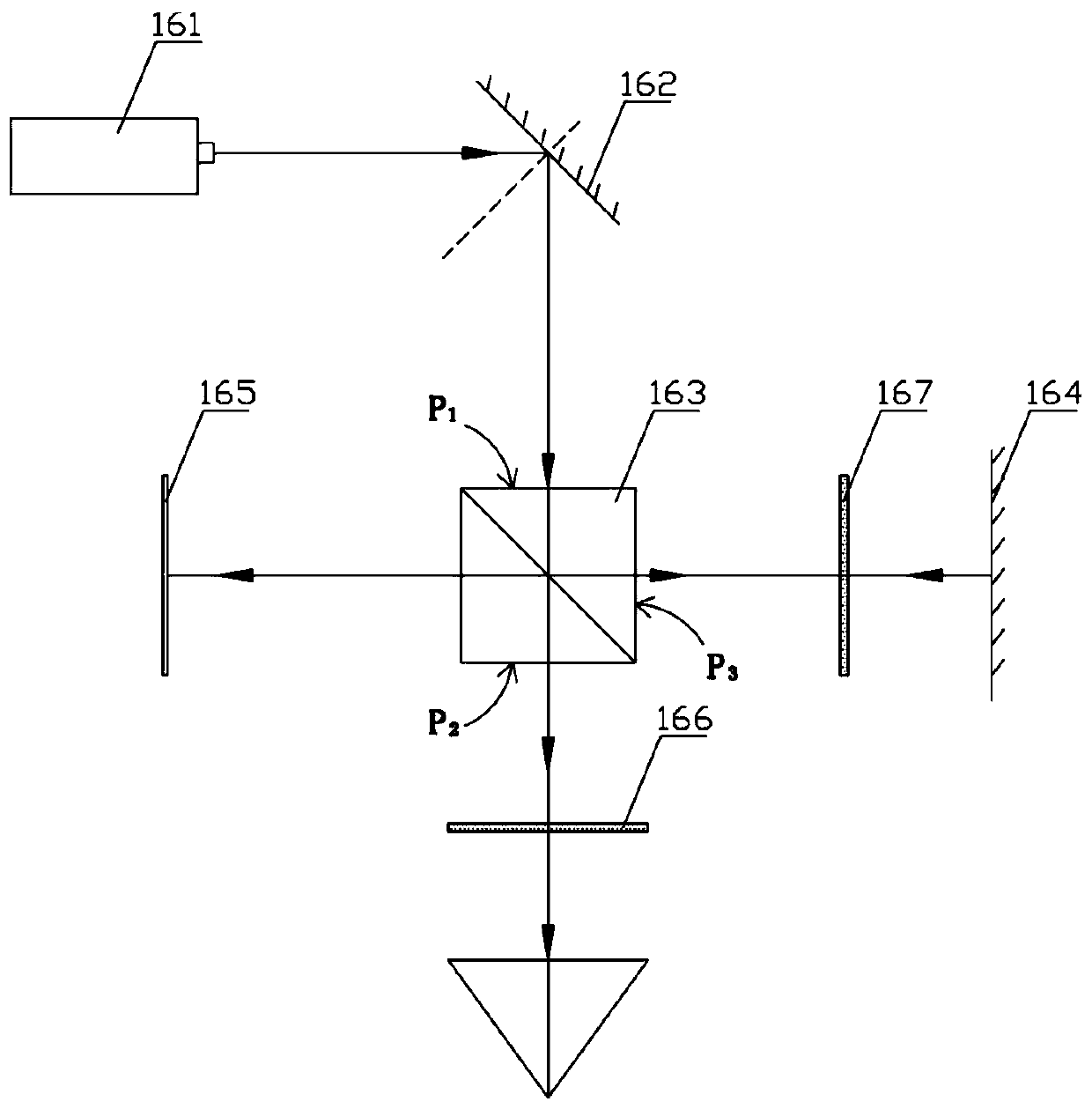

Precise positioning method for nano-displacement table based on partially coherent light

ActiveCN109358334AHigh precisionUsing optical meansElectromagnetic wave reradiationLight beamPrecision engineering

The invention belongs to the field of precision engineering, and particularly relates to a precise positioning method for a nano-displacement table based on partially coherent light. The method comprises the following steps of: employing a low-coherence light source, and using an interference light path to determine the optimal focusing position according to the contrast ratio of the interferenceimage; and recording the change in the interference fringes as the longitudinal movement of an objective lens, using the fitting algorithm in the invention to obtain the envelope curve of the interference intensity, calculating the physical parameters of the light beam, and determining the relative displacement through the phase relationship between the interference patterns. The algorithm takes into account the error effect, and is high in universality and anti-noise capability. The method has the advantages that the focusing and the displacement measurement can be achieved at the same time by adopting a partially coherent light source, and the higher repetition positioning precision can be obtained, and the method has important significance in improving the efficiency and the reliabilityof micro-nano machining.

Owner:FUDAN UNIV

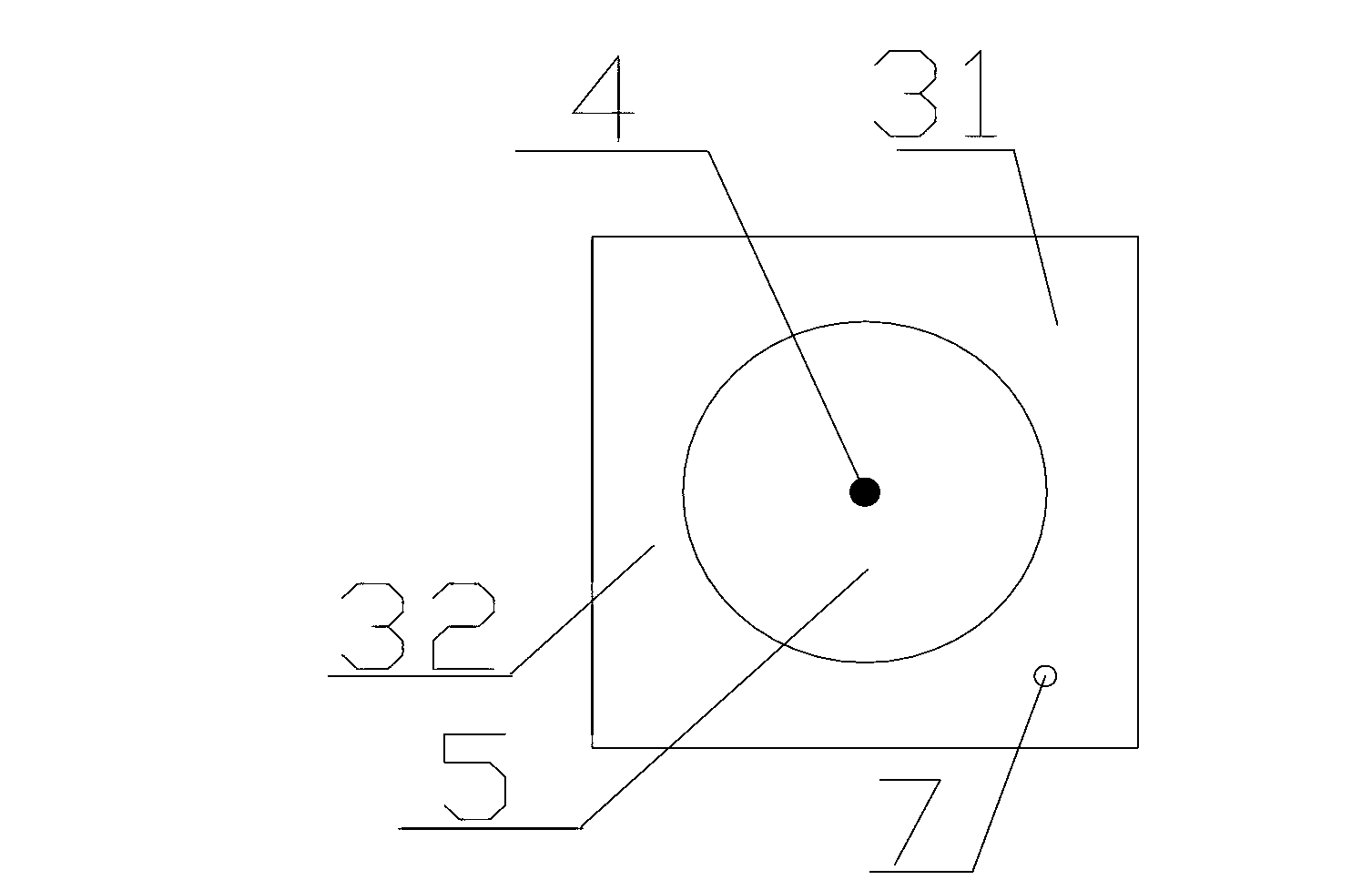

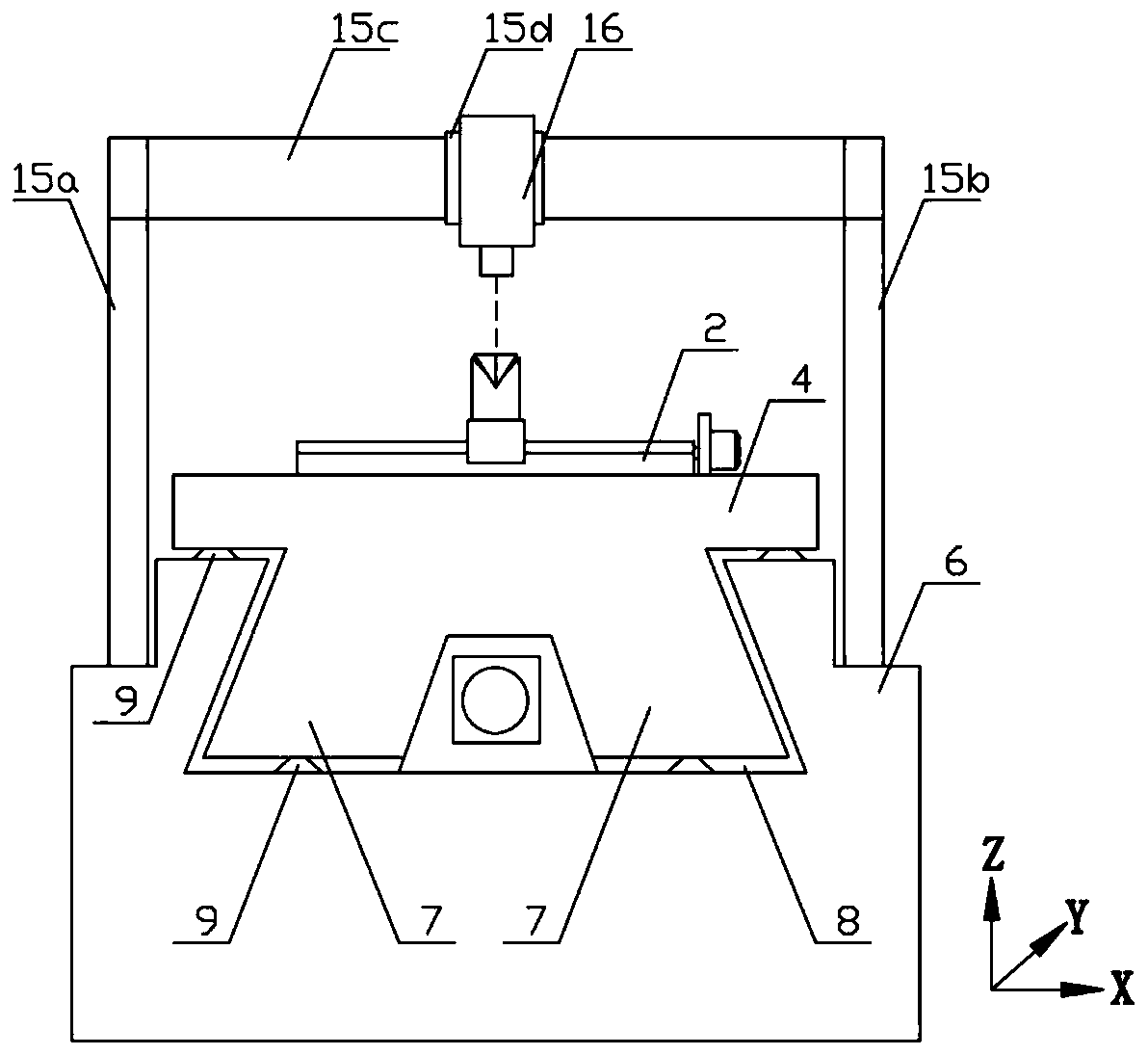

High-precision engineering measurement lofting discharge device and method

ActiveCN106840130AGuaranteed measurement accuracyImprove measurement efficiencySurveyor's staffsMovable markersPrecision engineeringTotal station

The invention discloses a high-precision engineering measurement lofting discharge device and method. An X-direction guide rail of the device is arranged in a lofting frame, a Y-direction guide rail is arranged on the X-direction guide rail, a target seat provided with an internal thread is arranged on the Y-direction guide rail, a lofting device is arranged on the target seat through threads, X-direction horizontal bubbles and Y-direction horizontal bubbles are arranged on the top surface of a lofting frame respectively, and elevation adjusting bolts are arranged at four corners of the lofting frame respectively. According to the method, the lofting frame is placed in an area needing a lofting point and is adjusted to a horizontal position; the target ball is placed on the target seat, and the plane coordinates of the target ball are measured and the distance between the target ball and the lofting point is calculated through a laser tracker or a total station; the target ball is moved to the lofting point and is fixed, a lofting device is used for replacing the target seat to implement discharge operation. The device and the method can be used for high-precision lofting discharge of production field engineering measurement, so that the defects of a traditional measurement mode are overcome, the measurement precision is guaranteed, the measurement efficiency is effectively improved, the measurement workload is reduced, and the cost of equipment maintenance and overhaul is reduced.

Owner:SHANGHAI JINYI INSPECTION TECH

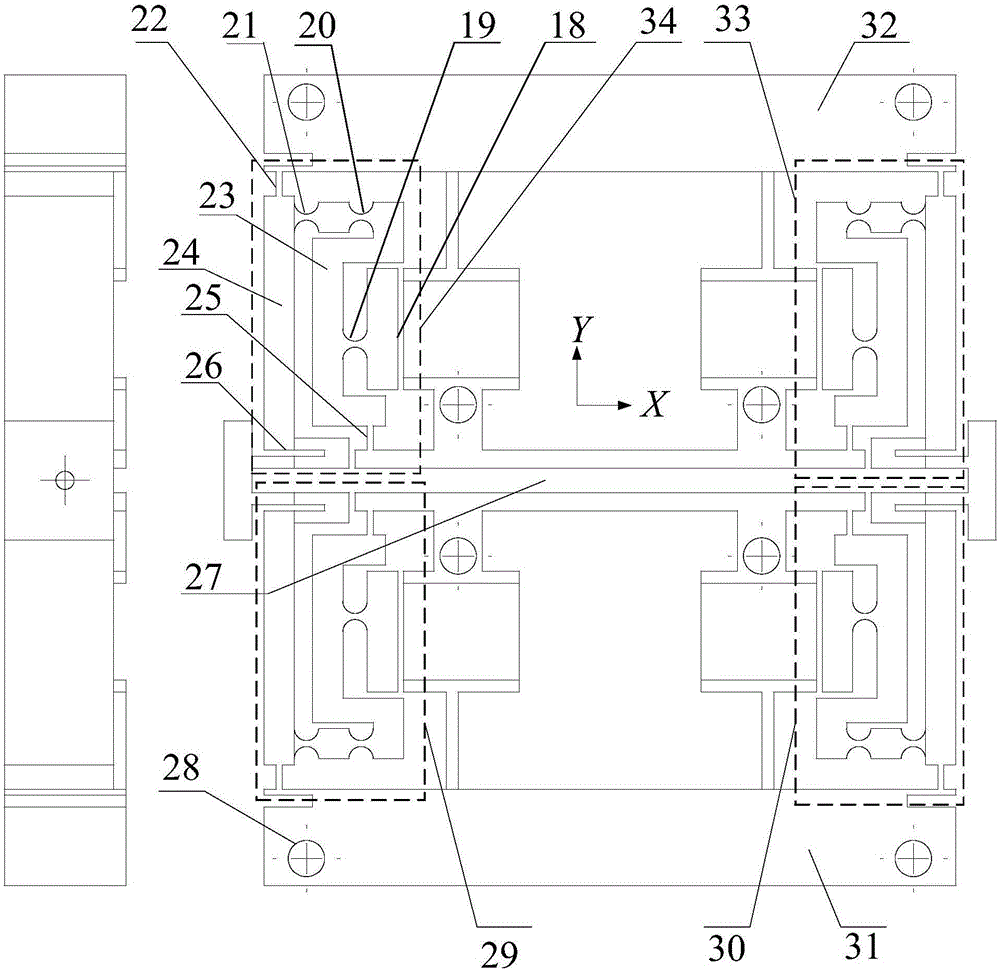

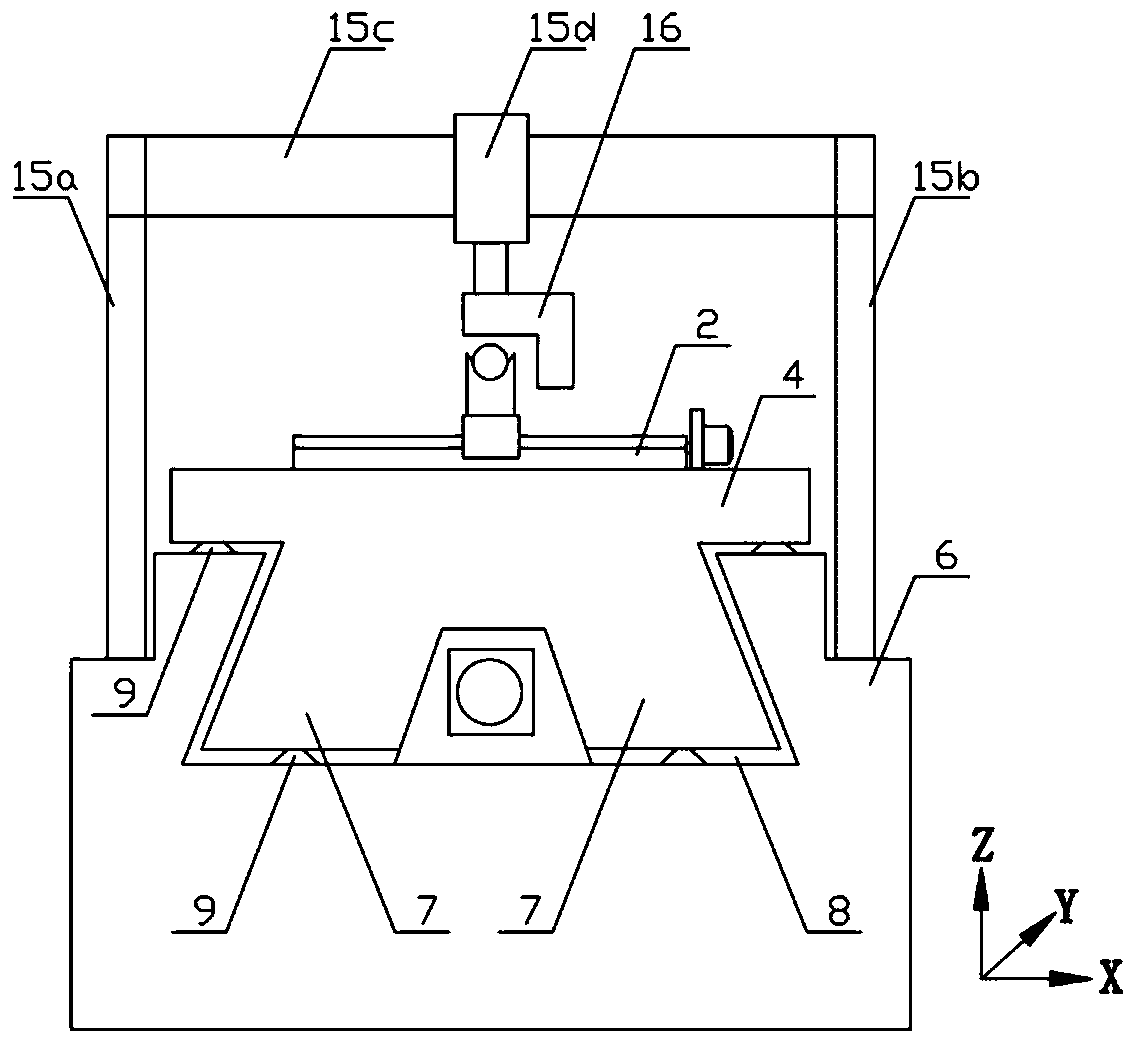

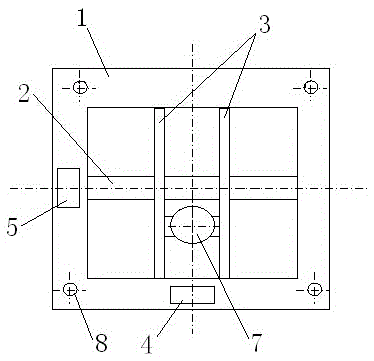

Plane linear displacement drive device and control method thereof

ActiveCN109940566ARealize high-precision displacement controlWork benchesElectricityPrecision engineering

The invention discloses a plane linear displacement drive device which comprises a support assembly, a large-stroke drive mechanism arranged on the support assembly, a micrometric displacement drive mechanism connected with the output end of the large-stroke drive mechanism, and an objective table connected with the output end of the micrometric displacement drive mechanism. The micrometric displacement drive mechanism is a piezoelectric ceramic driver; and the large-stroke drive mechanism comprises a torque output device and a transmission assembly connected with the output end of the torqueoutput device and used for converting rotation movement into linear movement; and the movement directions of the transmission assembly and the piezoelectric ceramic driver are the axial direction of the objective table. According to the plane linear displacement drive device provided by the invention, the control requirements on large stroke and high-precision displacement of workpiece displacement during the production and manufacturing process of high-precision engineering can be simultaneously met, and the processing efficiency and the processing precision are improved. The invention further discloses a control method of the plane linear displacement drive device which has the beneficial effects as mentioned above.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

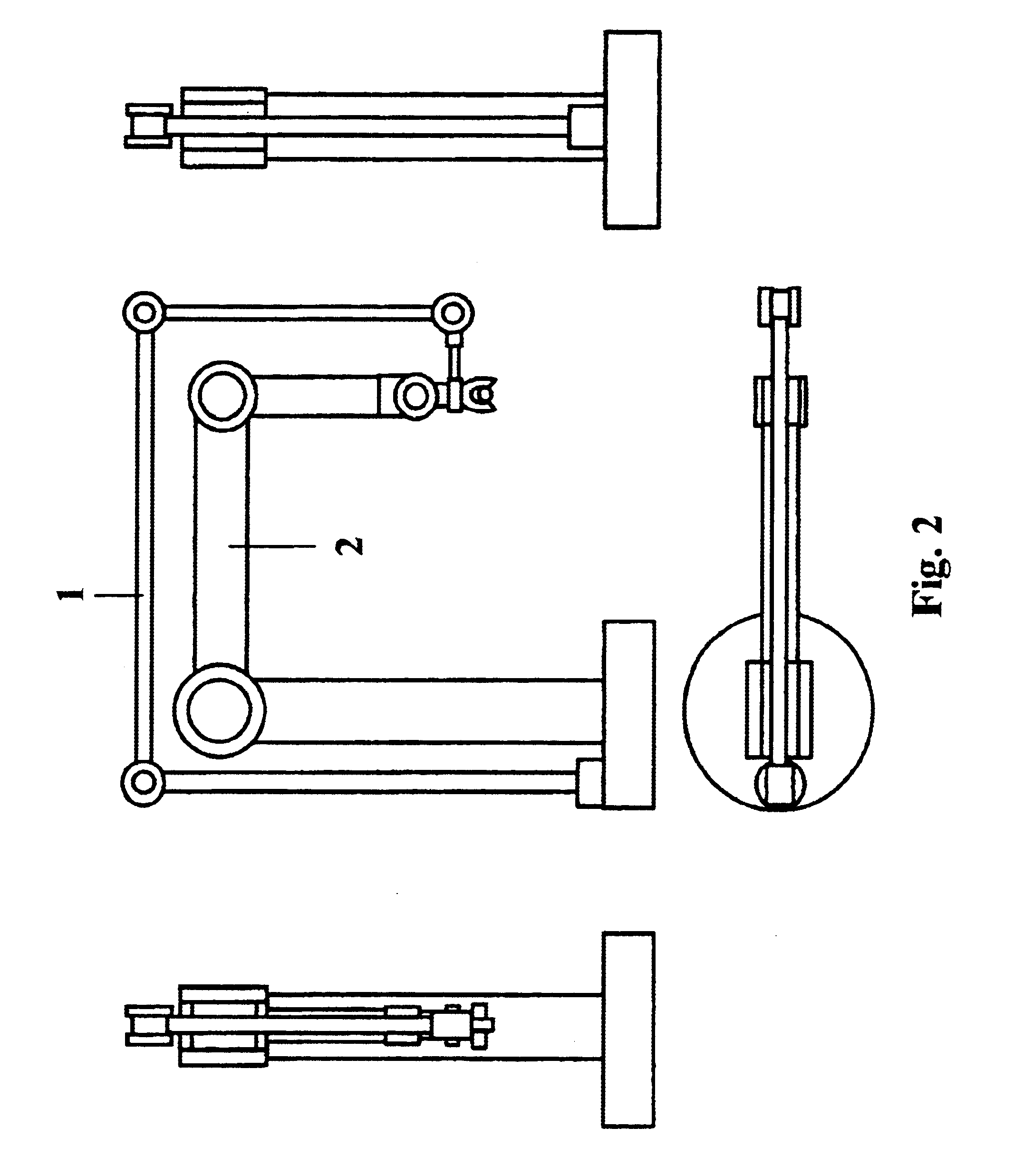

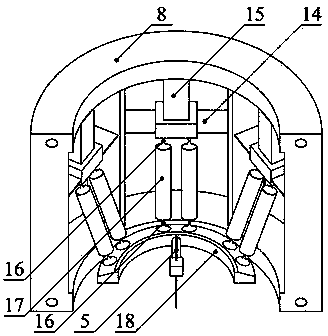

Parallel micromanipulation robot

InactiveCN103786151AHigh motion resolutionSmall moment of inertiaProgramme-controlled manipulatorMicro-operationControl engineering

A parallel micromanipulation robot comprises a left micromanipulation arm and a right micromanipulation arm, which are the same in structure and symmetrically arranged. Each of the left and right micromanipulation arms comprises a semi-cylindrical micromanipulation arm frame, three branch chains, a micromanipulation arm moving platform and a micromanipulation arm terminal tool. Each branch chain comprises a micro-displacement driver, a flexible prismatic pair and two branches the same in structure; one end of every branch is connected with the left micromanipulation arm moving platform, and the other end of each branch is connected with the corresponding flexible prismatic pair; the axes of the two branches are parallel to each other; the fixed end of the micro-displacement driver is connected with the left micromanipulation arm frame, and the drive end of the micro-displacement driver is connected with the flexible prismatic pair. The three branch chains forming each micromanipulator arm are evenly distributed in a semi-cylindrical space. The parallel micromanipulation robot allows for three-dimensional high-precision operation, is compact in overall structure with wide operating range and high resolution, and is widely applicable to the fields such as biomedical engineering and precision engineering.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

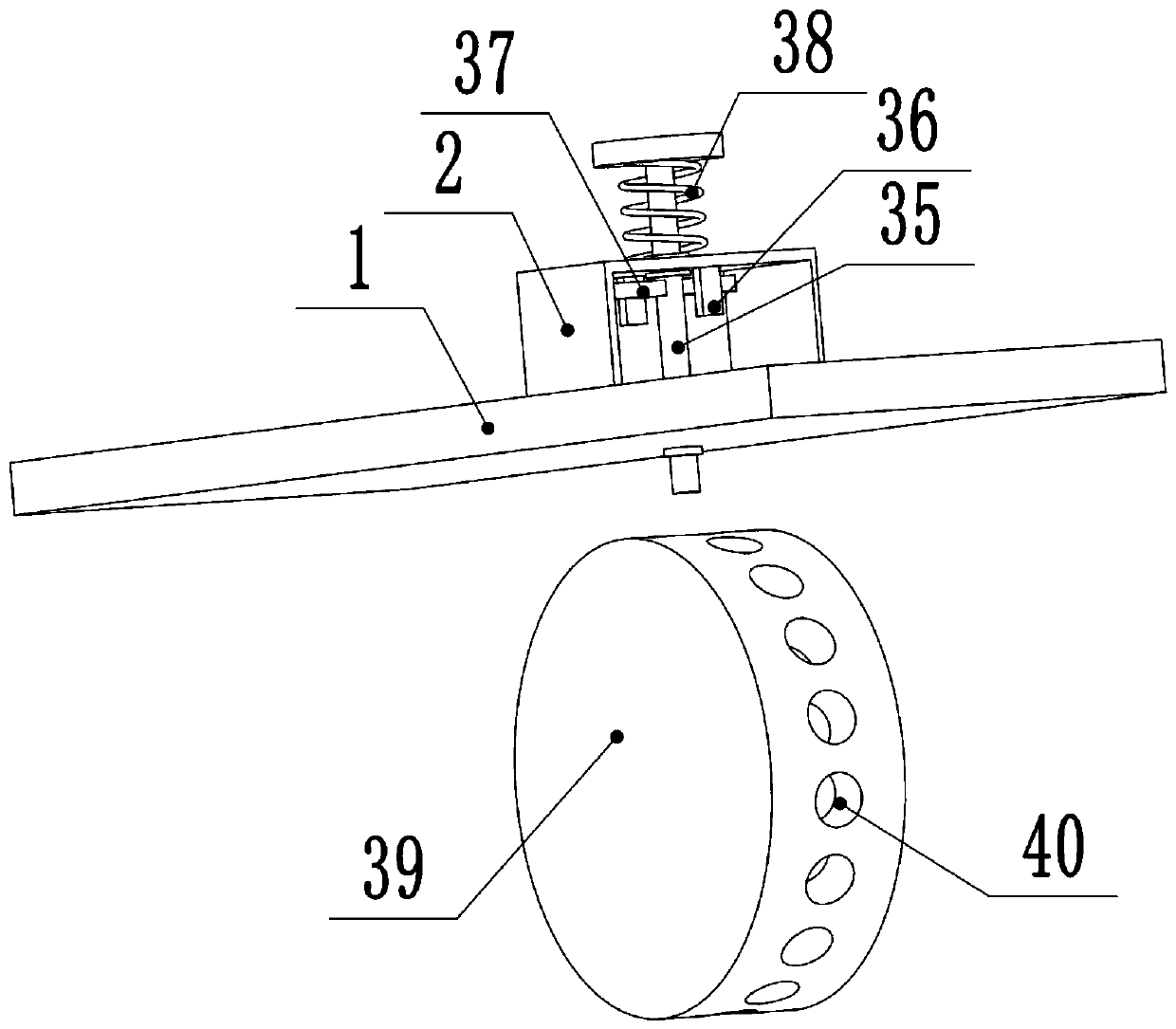

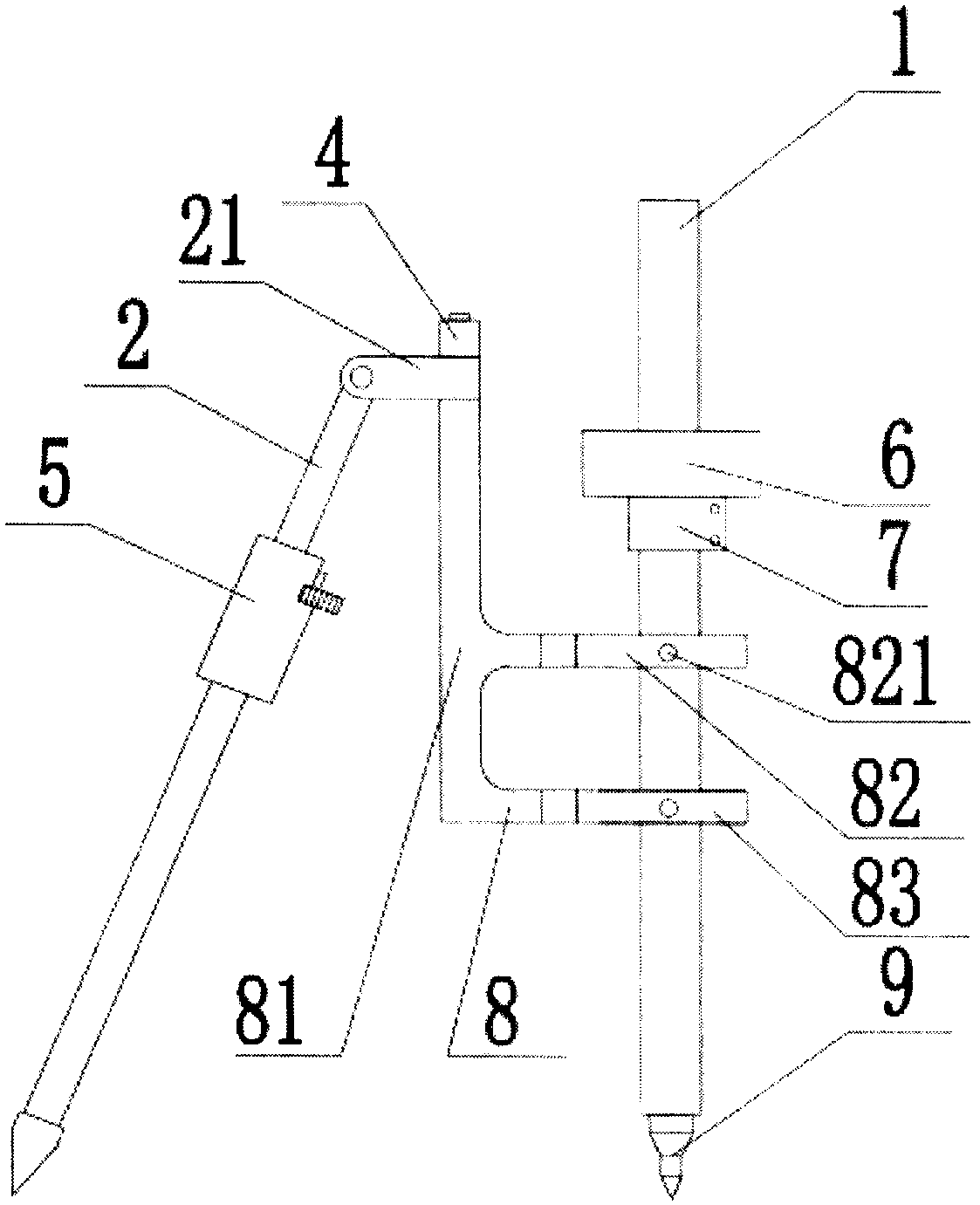

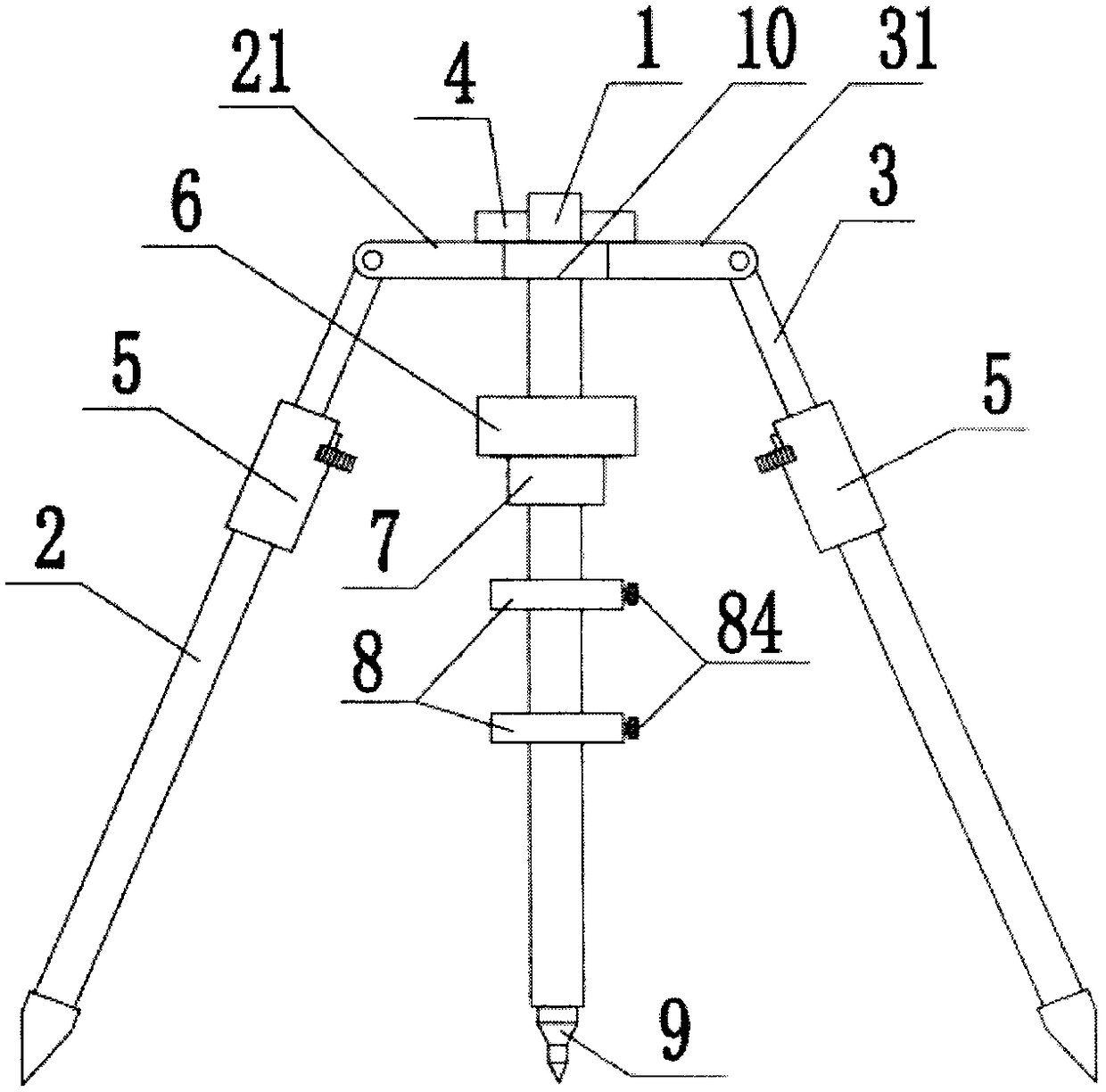

Centering rod device for high-precision engineering surveying

InactiveCN111121739AChange the disadvantages of not being able to lean forwardIncrease the effect of leaning forwardSurveying instrumentsPrecision engineeringEngineering

The invention, which belongs to the technical field of measuring devices, in particular relates to a centering rod device for high-precision engineering measurement. The device comprises a prism, a main combination frame, an auxiliary combination frame and induction frames. The bottom of the prism is fixedly connected with the main combination frame and the auxiliary combination frame. According to the invention, since a main connecting rod with a cross rod is arranged, a defect that a conventional triangle is fixed and cannot incline forwards is overcome, the effect that the triangle can incline forwards during fixation is improved, and combined fixation flexibility is improved; induction piles are combined on the three induction frames, an emitter is arranged on each induction pile and is used for carrying out infrared emission and receiving; when a height deviation occurs at a fixed angle, an infrared receiving module in an alarm device does not receive data or a vibration sensing module vibrates abnormally and a data analysis module carries out alarm working cooperatively, thereby improving the height uniformity of fixing pins, reducing the measurement error caused by the height difference, and guaranteeing the high precision of the measurement data.

Owner:深圳市长勘勘察设计有限公司

Angle measuring device and methods for calibration

ActiveUS9459121B2High riskLower performance requirementsMeasurement devicesMetrologyMeasurement device

The invention relates to a method for calibration of 2-axis high precision digital angle measurement device, particularly for initializing a planar angle measuring device and an apparatus to generate simultaneous two-dimensional resultant planar angles of full 360° rotation. The planar angle measurement device is, typically but not exclusively, used in concurrent two-dimensional angles leveling, setting and alignment tasks for precision machine setup in the fields of precision engineering and metrology applications.

Owner:DIGIPAS TECH INC

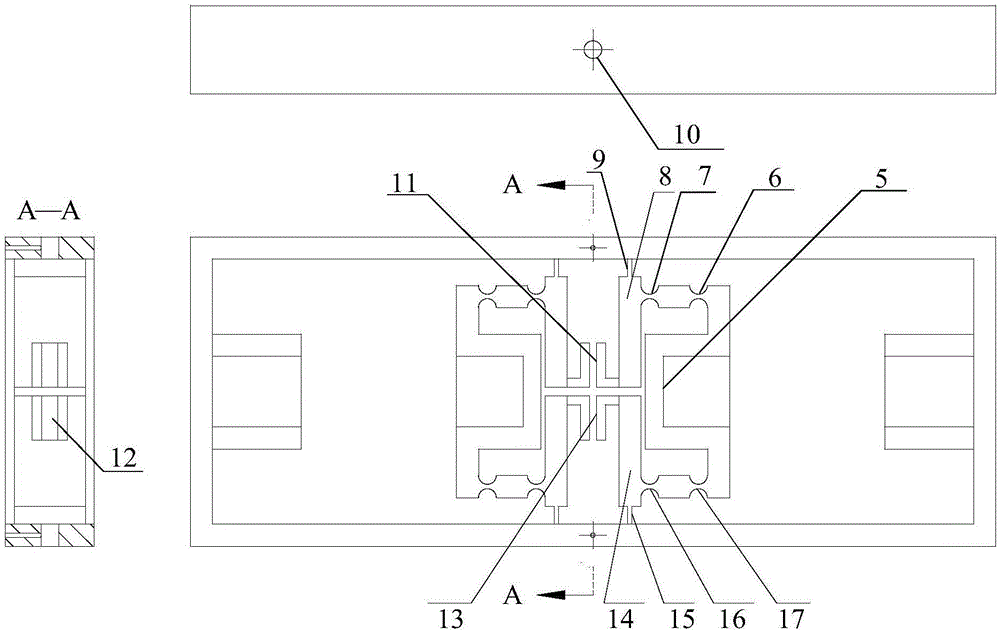

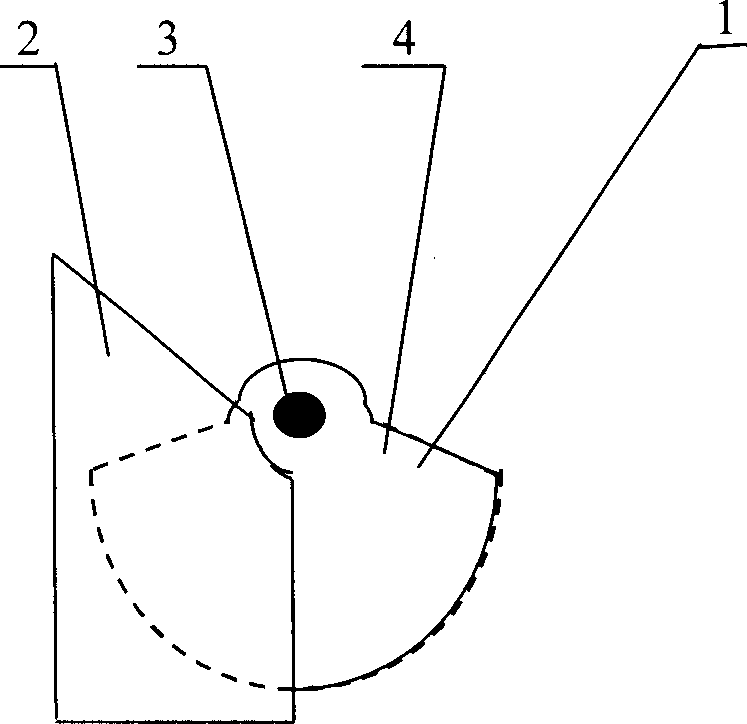

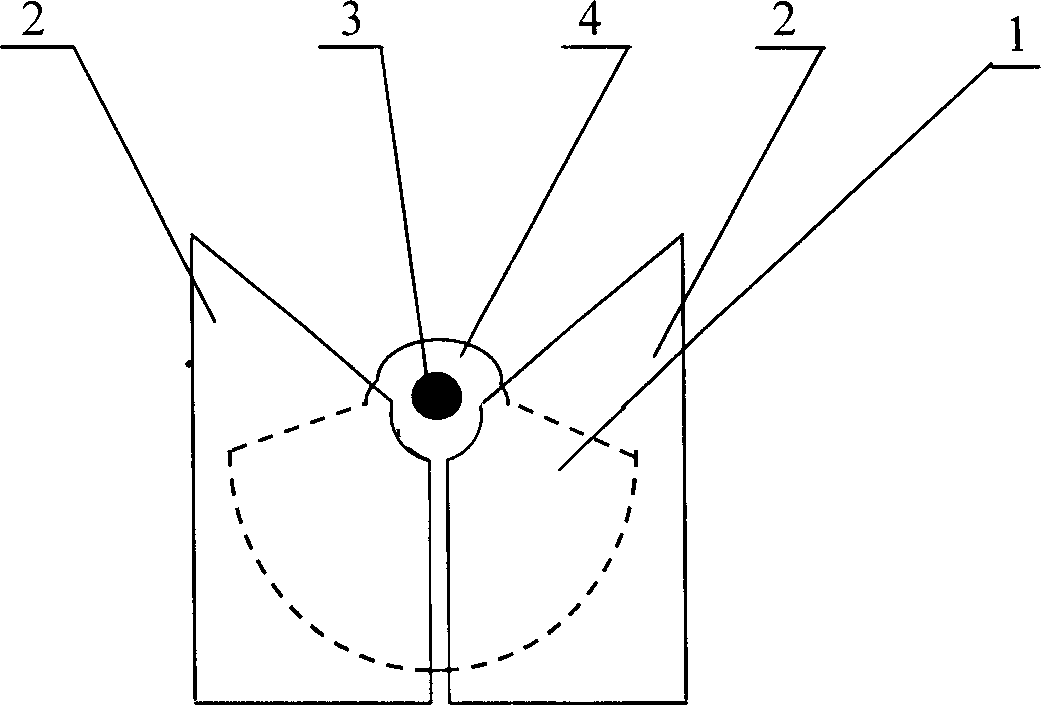

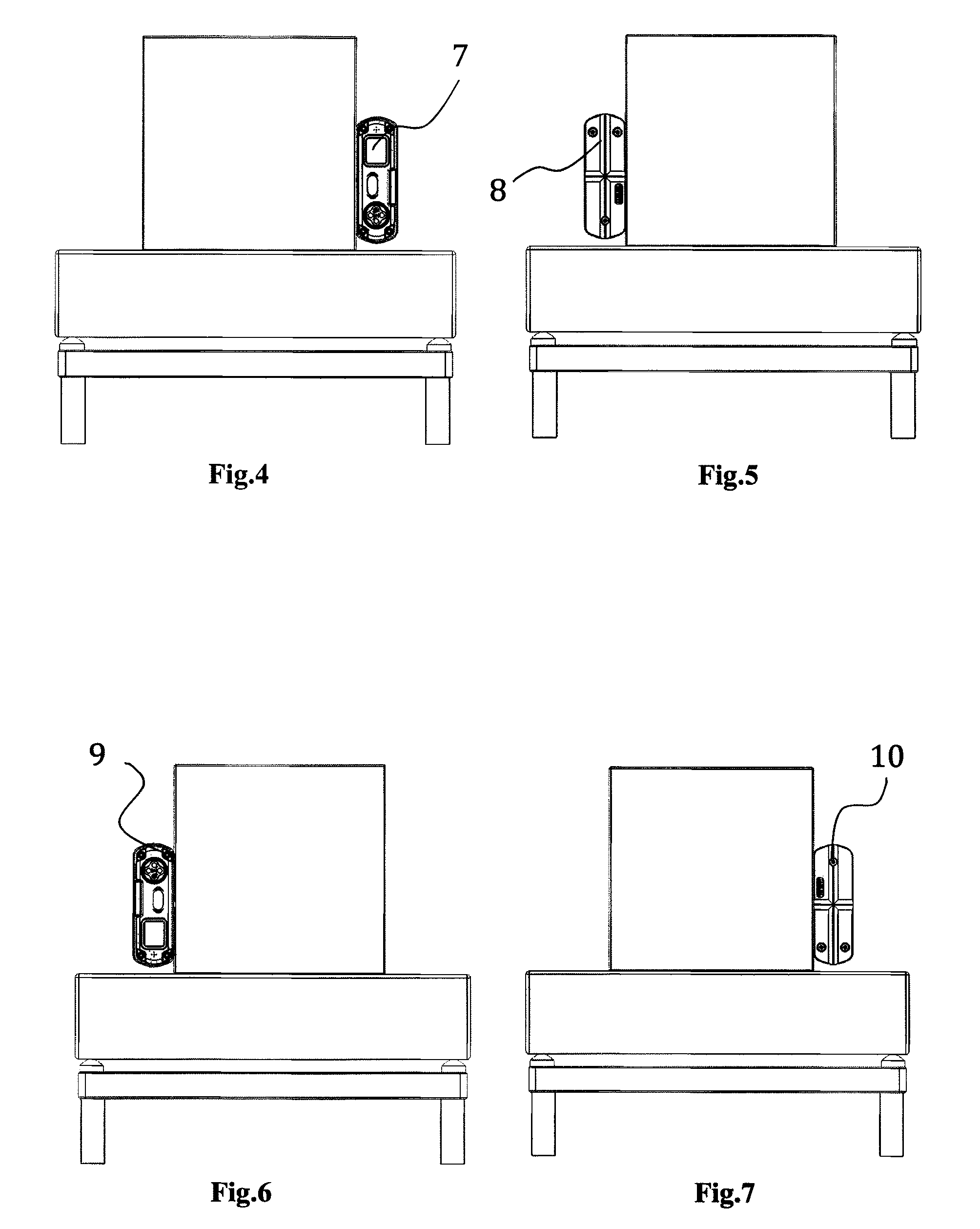

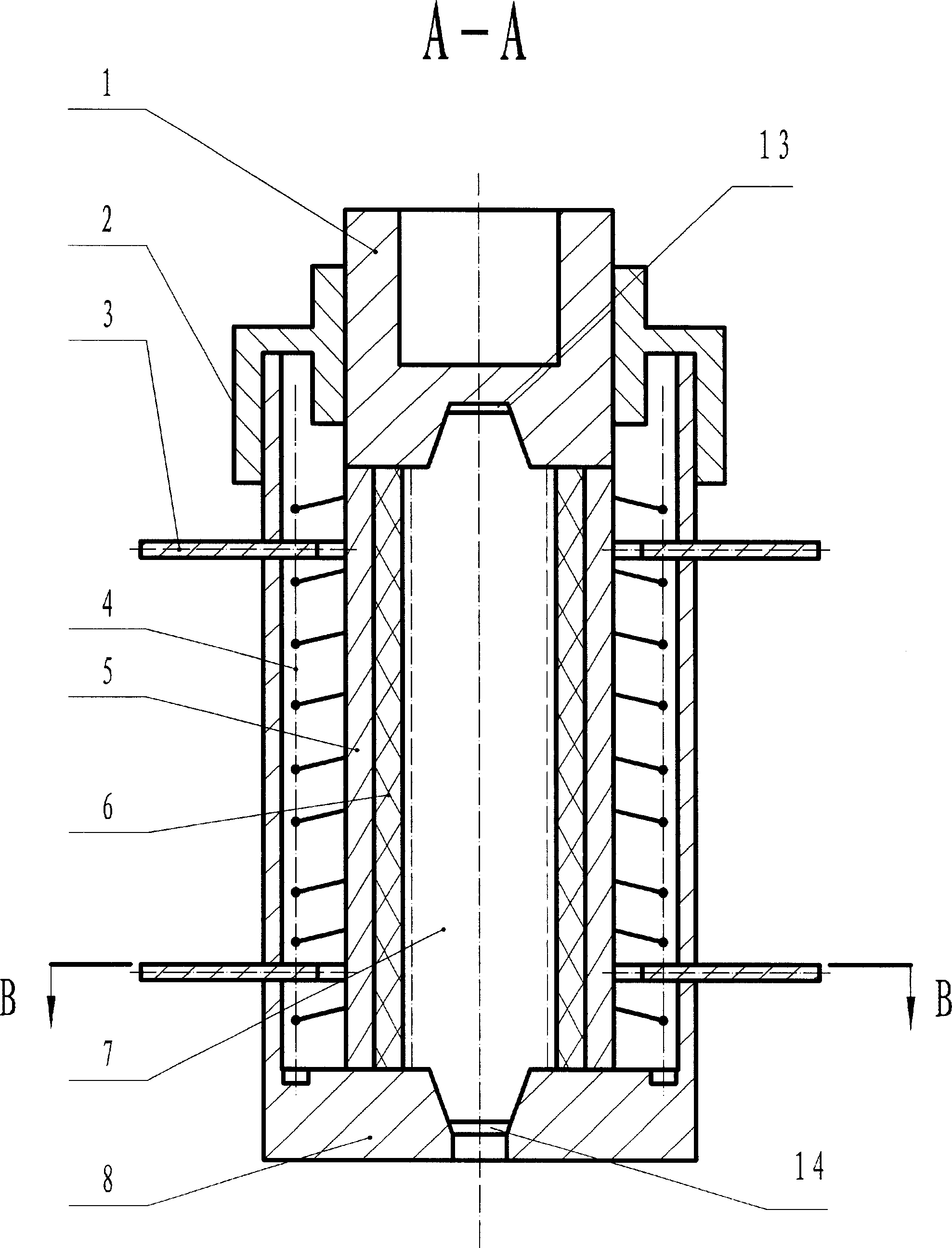

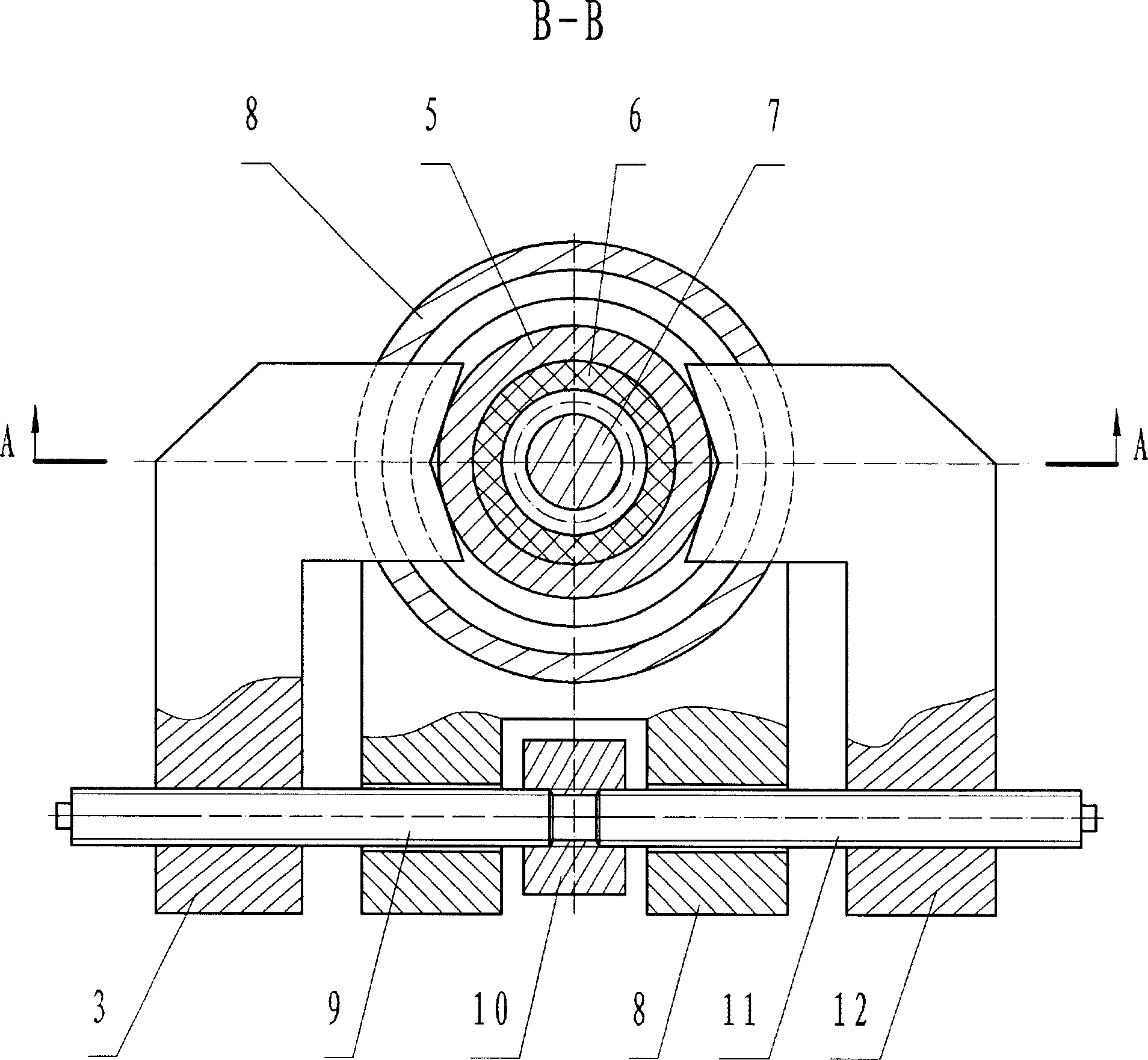

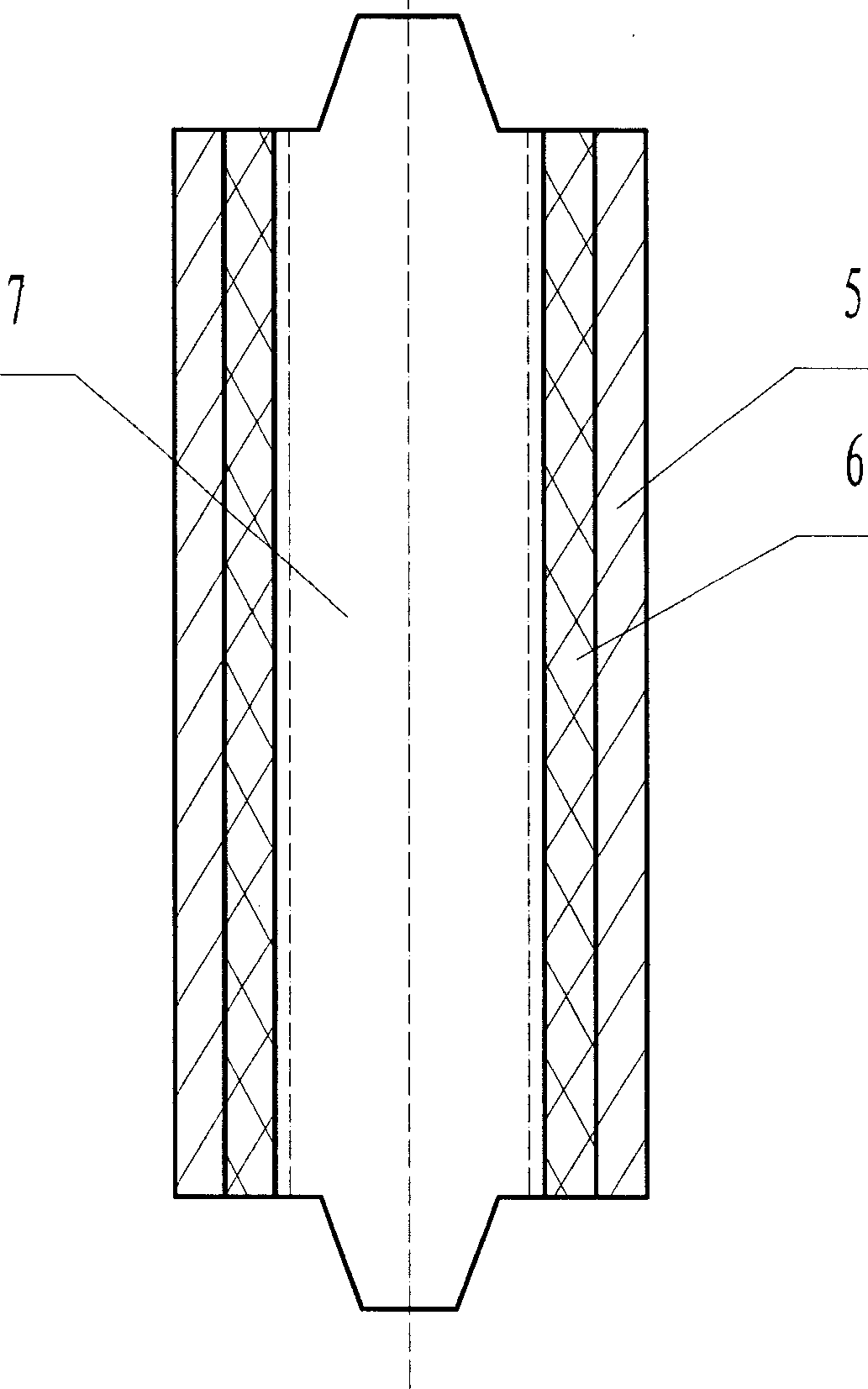

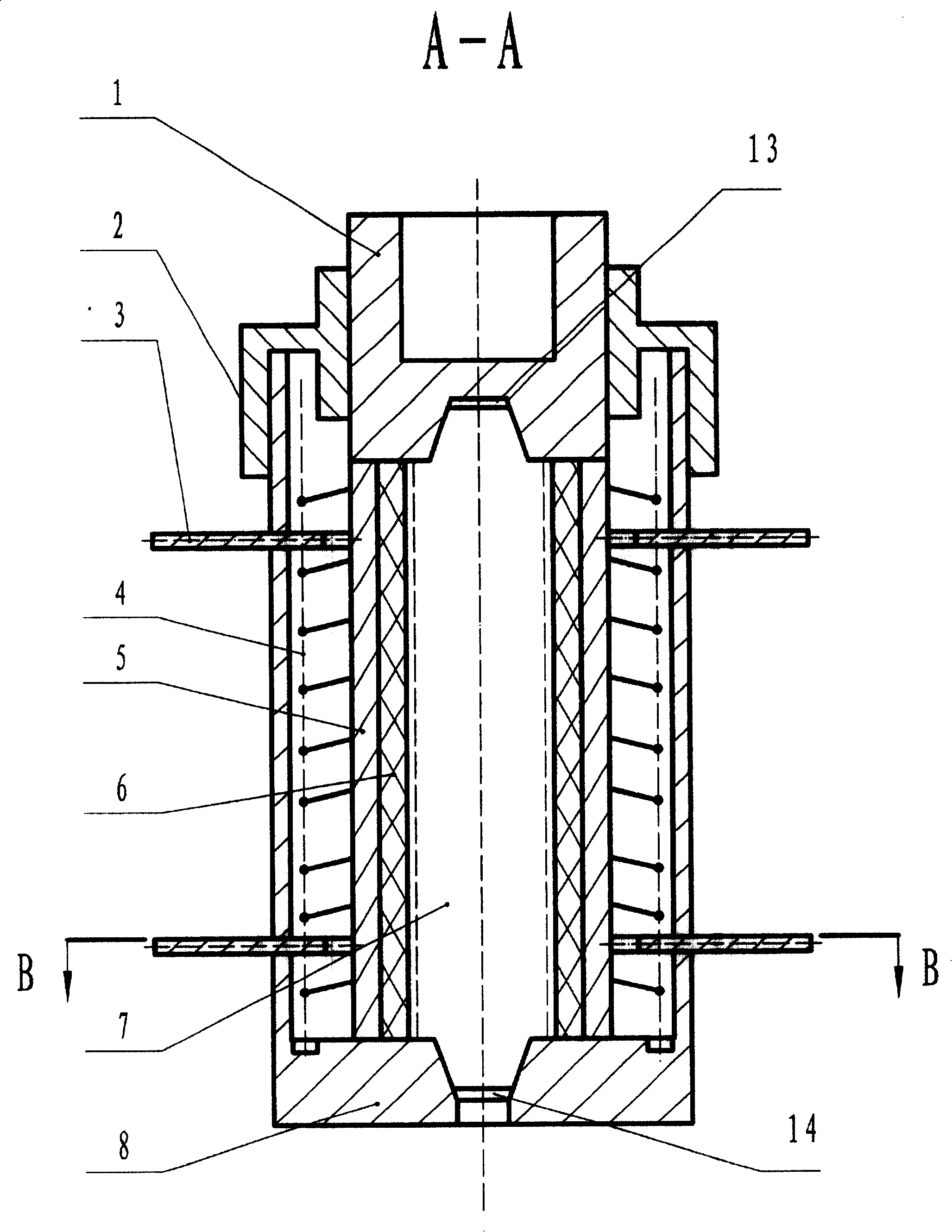

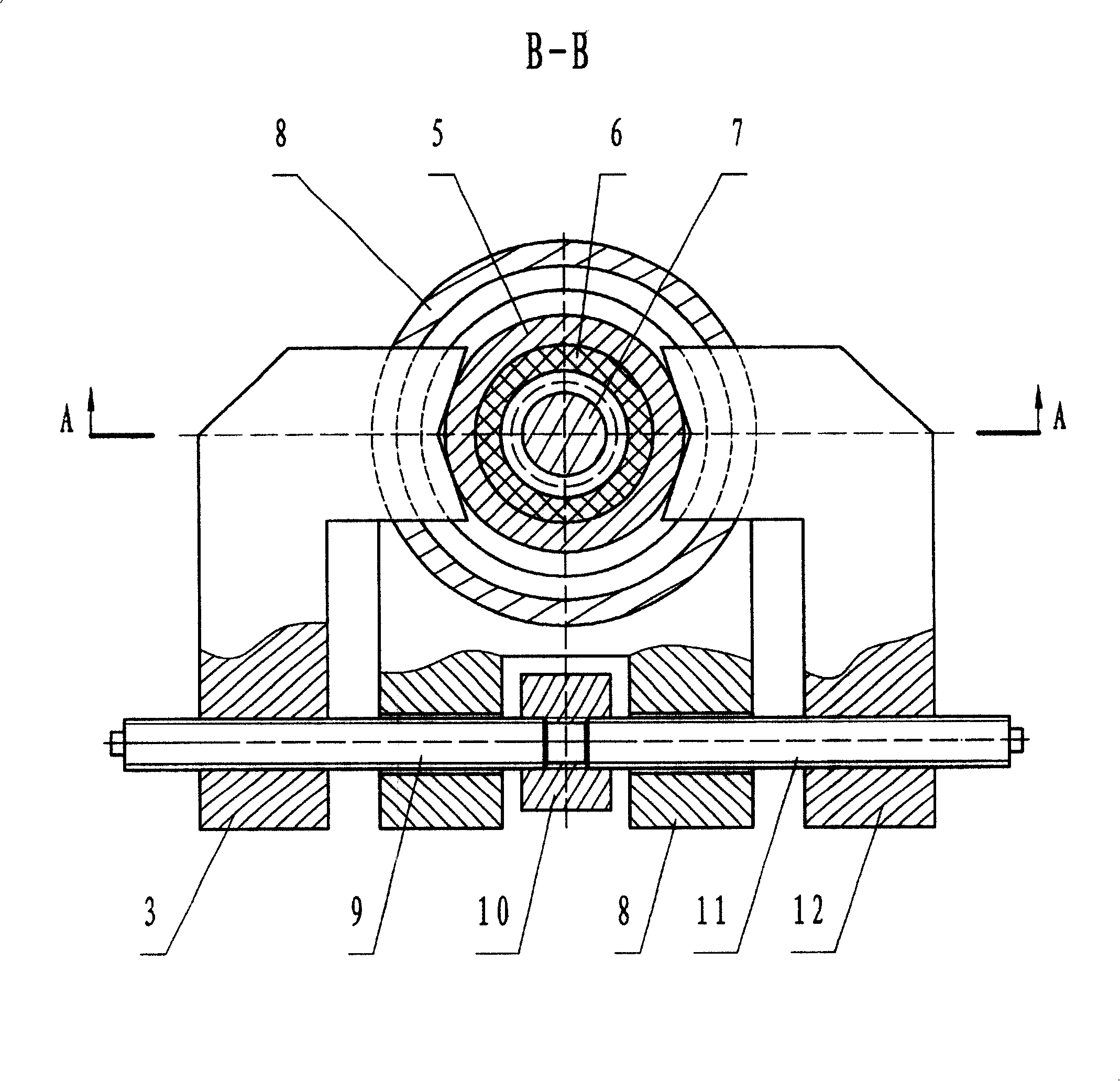

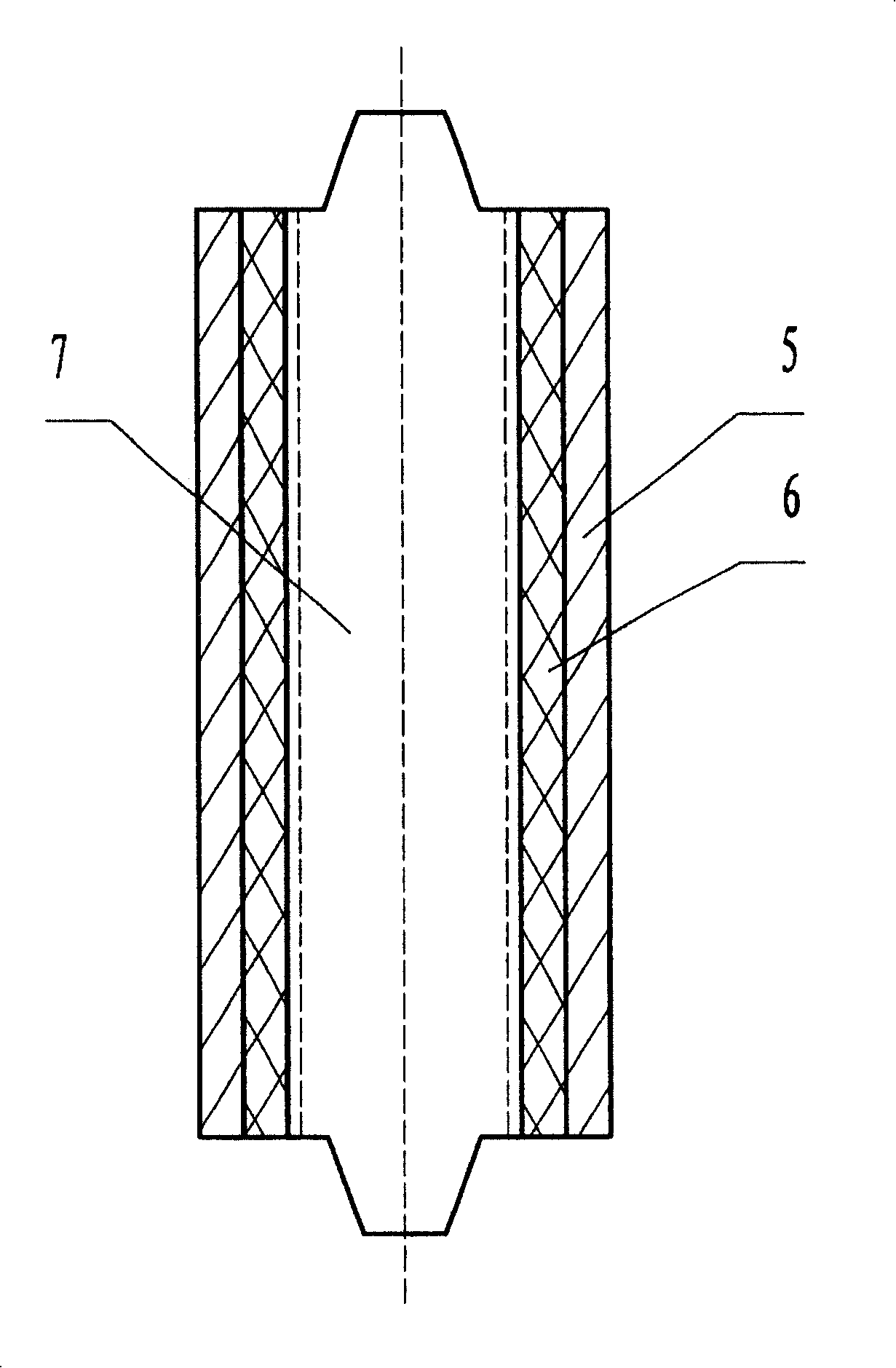

Inductive hot compacting dies for precision engineering plastic rubber products

InactiveCN1733446AEasy to assemble and disassemble the workpieceReduce lossesEngineering plasticPrecision engineering

The induced hot shaping mould for precise engineering plastic product comprises pressure head (1) that can slide up and down in guide cartridge (2) to fit work piece length, left clamp (3), induction coil (4) in main cartridge (8) to heat press evenly by high, middle and power frequency, mould core (7), left screw (9), coupling (10), right screw (11), and right clamp (12). This invention can fit to plastic products of a plurality of sizes, needs less energy, and fits particularly to process for new-type complex material.

Owner:CHONGQING UNIV

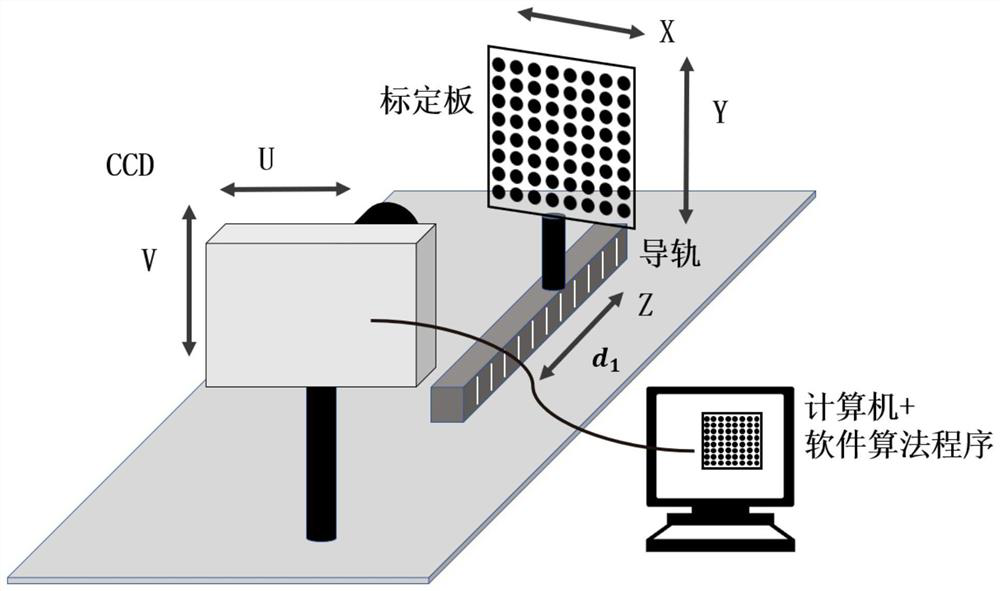

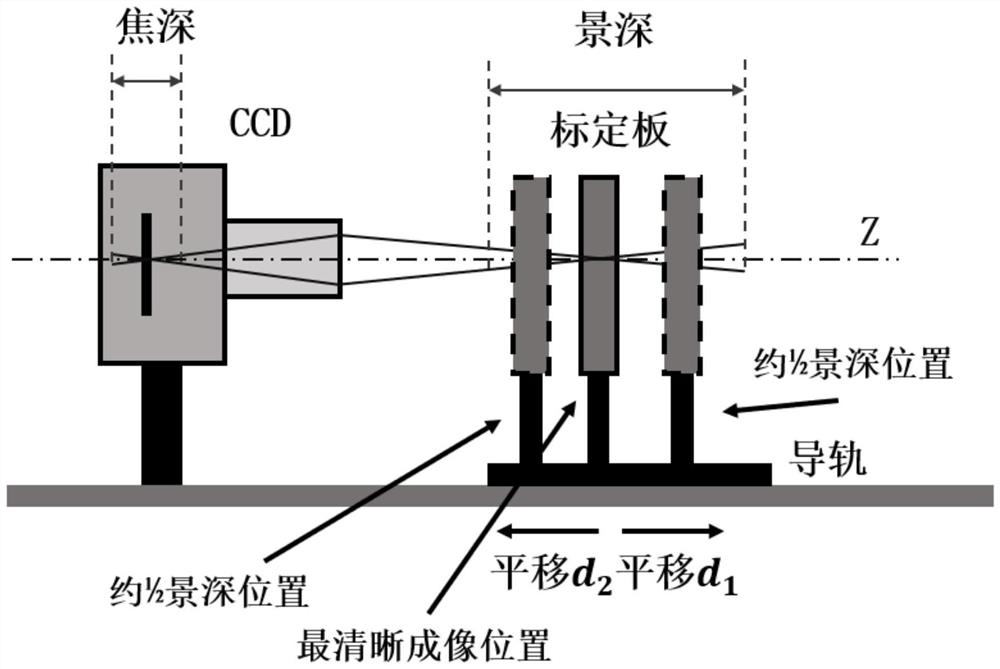

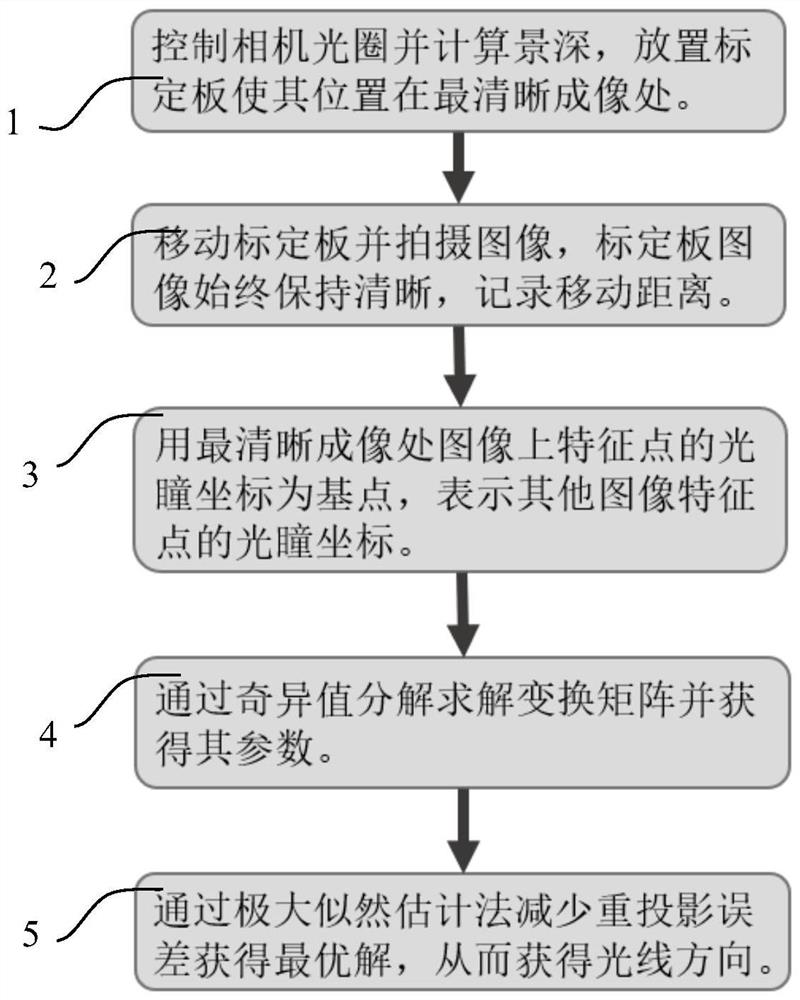

Camera calibration method for optical surface shape measurement and device for realizing method

PendingCN111862237AImprove accuracyImage analysisGeometric image transformationPrecision engineeringImaging Feature

The invention relates to the technical field of precision engineering, in particular to a camera calibration method in vision measurement and deflection. A camera calibration method for optical surface shape measurement is characterized in that a camera is arranged on a guide rail, a calibration plate containing round spot characteristics can move along the guide rail, and the method comprises thefollowing steps: respectively shooting corresponding position images at a focusing position and a plurality of front-back symmetrical positions; taking pupil coordinates of the feature points on theimage at the focusing position as base points, and performing linear interpolation through a triangular mesh method to represent pupil coordinates of other image feature points; constructing a corresponding equation between a pixel point and an actual object coordinate through affine transformation and a distortion item, and solving an object image transformation matrix parameter through singularvalue decomposition; and reducing reprojection errors through a maximum likelihood estimation method to obtain an optimal solution, and obtaining the light direction. Compared with an existing cameracalibration technology, the method has the advantages of being high in precision, wide in applicability, convenient to operate and the like.

Owner:FUDAN UNIV

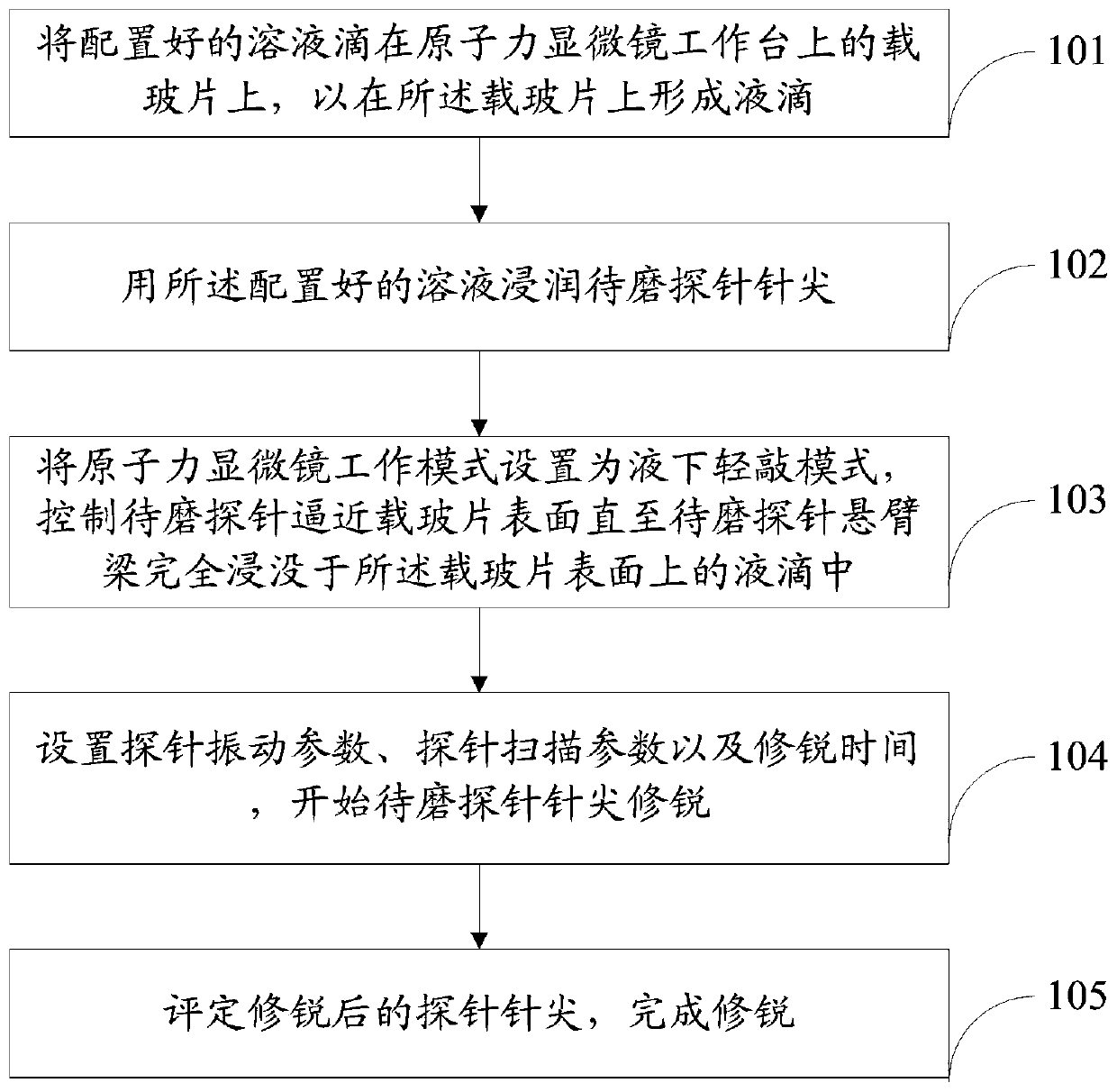

Sharpening method for probe tip of atomic force microscope

ActiveCN110531121ASimple methodEasy to implementScanning probe microscopyAtomic force microscopyMagnetic force microscope

The invention discloses a sharpening method for a probe tip of an atomic force microscope and relates to the technical field of precision engineering. The method comprises a step of dropping a prepared solution on a glass slide on an atomic force microscope workbench to form liquid drops on the glass slide, wherein a solute of the prepared solution is diamond powder, a step of infiltrating a tip of a probe to be ground with the prepared solution, a step of setting the working mode of the atomic force microscope as an under-liquid tapping mode and controlling the tip of the probe to be ground to approach a surface of the glass slide until a cantilever beam of the probe to be ground is completely immersed in the liquid drops on the surface of the glass slide, a step of setting probe vibration parameters, probe scanning parameters and a sharpening time and start to sharpen the tip of the probe to be sharpened, and a step of evaluating a sharpened probe tip to finish sharpening. Accordingto the method, the probe tip is sharpened through a self-excited oscillation probe tip and the grinding effect of diamond particles in the solution in an atomic force microscope under-liquid tapping mode, and the method is simple and effective and is easy to implement.

Owner:YANSHAN UNIV

Length measuring device for pyramid prism length standard rod and measuring method of length measuring device

ActiveCN110567377AAccurate measurementSimple structureUsing optical meansGeometric properties/aberration measurementPrecision engineeringLength measurement

The invention relates to the technical field of precision engineering measurement and provides a length measuring device for a pyramid prism length standard rod and a measuring method of the length measuring device. The length measuring device comprises a base, an optical sighting device, a calibration device, a directional sliding device and a distance measurement device, wherein the directionalsliding device is glidingly mounted on the base; the calibration device is mounted on the directional sliding device, and the pre-calibrated pyramid prism length standard rod is placed on the calibration device; the optical sighting device is mounted on the base and is oppositely arranged on one side of the directional sliding device; and the distance measurement device is used for detecting the sliding distance of the directional sliding device. The device is simple in structure and convenient to operate, and realizes accurate measurement of the distance between optical centers of pyramid prisms at two ends of the pyramid prism length standard rod.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH +1

Inductive hot compacting dies for precision engineering plastic rubber products

InactiveCN100404226CEasy to assemble and disassemble the workpieceReduce lossesEngineering plasticPrecision engineering

The induced hot shaping mould for precise engineering plastic product comprises pressure head (1) that can slide up and down in guide cartridge (2) to fit work piece length, left clamp (3), induction coil (4) in main cartridge (8) to heat press evenly by high, middle and power frequency, mould core (7), left screw (9), coupling (10), right screw (11), and right clamp (12). This invention can fit to plastic products of a plurality of sizes, needs less energy, and fits particularly to process for new-type complex material.

Owner:CHONGQING UNIV

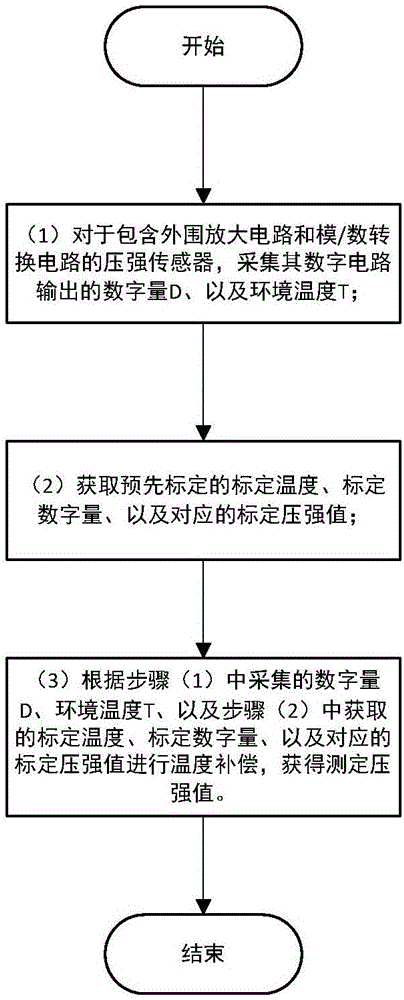

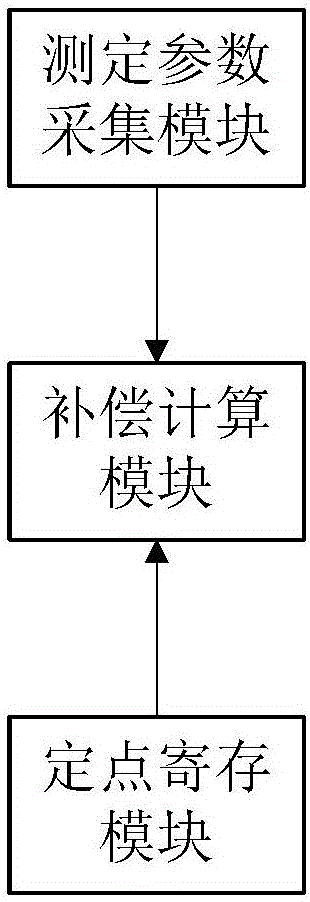

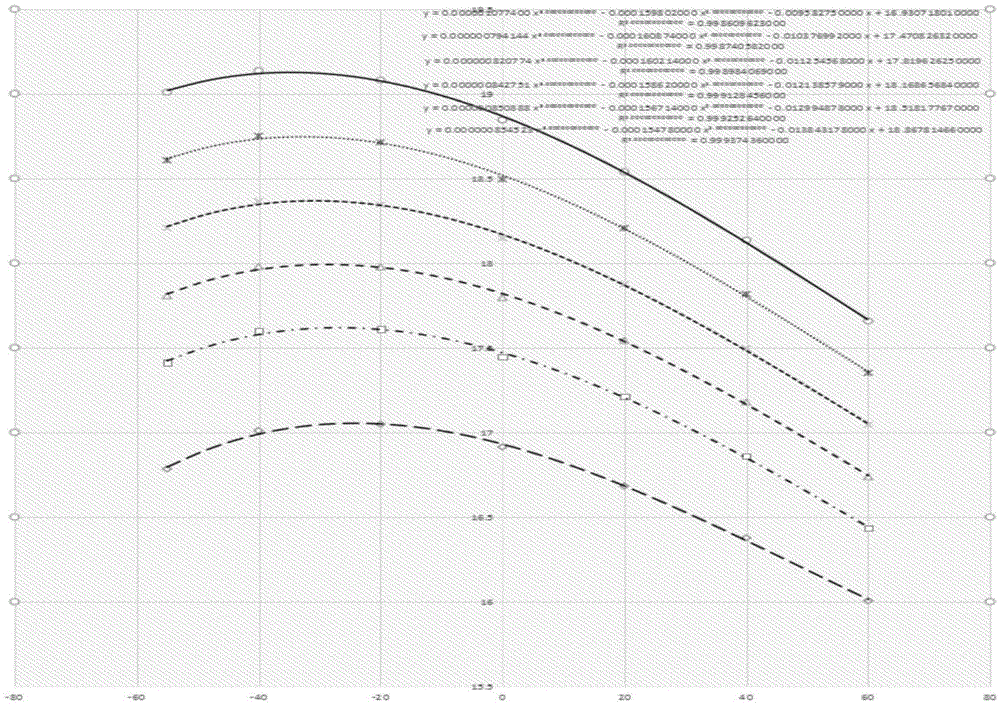

Pressure intensity value determination method and system

ActiveCN106644193AMeet measurement needsReduce measurement errorFluid pressure measurement using ohmic-resistance variationForce measurementPrecision engineeringEngineering

The present invention discloses a pressure intensity value determination method and system. The method comprises: (1) collecting the digital value D and the environment temperature T outputted by a digital circuit about the pressure intensity sensor including an amplification circuit and an analog-digital conversion circuit; (2) obtaining a calibration temperature, a calibration digital value and the corresponding calibration pressure intensity value calibrated in advance; and (3) performing temperature compensation according to the digital value D and the environment temperature T to obtain a determined pressure intensity value. The system comprises a determination parameter collection module, a fixed point register module and a compensation calculation module. The pressure intensity value determination method and system perform compensation calculation according to the relation between the digital value D outputted by the pressure intensity sensor according to the environment temperature and the actual pressure intensity value, and the obtained pressure intensity value error is controlled in the limitation of 1% through determination, the high-precision engineering measurement requirement can be satisfied, and the pressure intensity value determination method and system have wide application prospects and important application values in the aspects of the altitude calculation and the indoor navigation.

Owner:武汉立易方科技有限公司

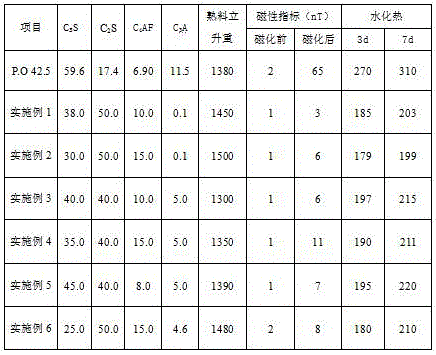

Low-magnetism cement and preparation method thereof

InactiveCN106746774AGuaranteed MagneticEasy to preparePrecision engineeringUltimate tensile strength

The invention discloses a low-magnetism cement and a preparation method thereof, and belongs to the technical field of cement. The cement comprises a low-magnetism cement clinker and gypsum, wherein the low-magnetism cement clinker comprises the following mineral components: 25-45% of C3S, 40-50% of C2S, 10-15% of C4AF, and 0.1-5% of C3A; the litre weight of the low-magnetism cement clinker is 1300-1500g / L; the magnetic field strength of the low-magnetism cement after magnetizing is less than 20nT. According to the low-magnetism cement, the blank of low-magnetism cement in the industry is filled; the low-magnetism cement is provided; the cement indexes are controlled, and the materials are strictly selected, so that the magnetism is controlled to be within 20nT range; the low-magnetism cement is widely applied to mass engineering construction, such as ocean engineering, national defense construction and precision engineering, and is of great significance.

Owner:JIAHUA SPECIAL CEMENT

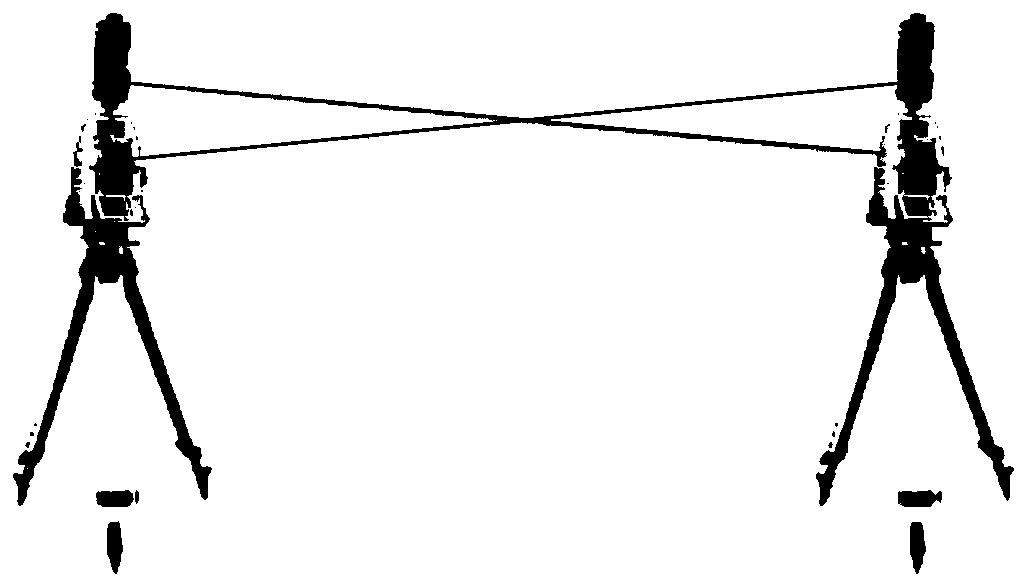

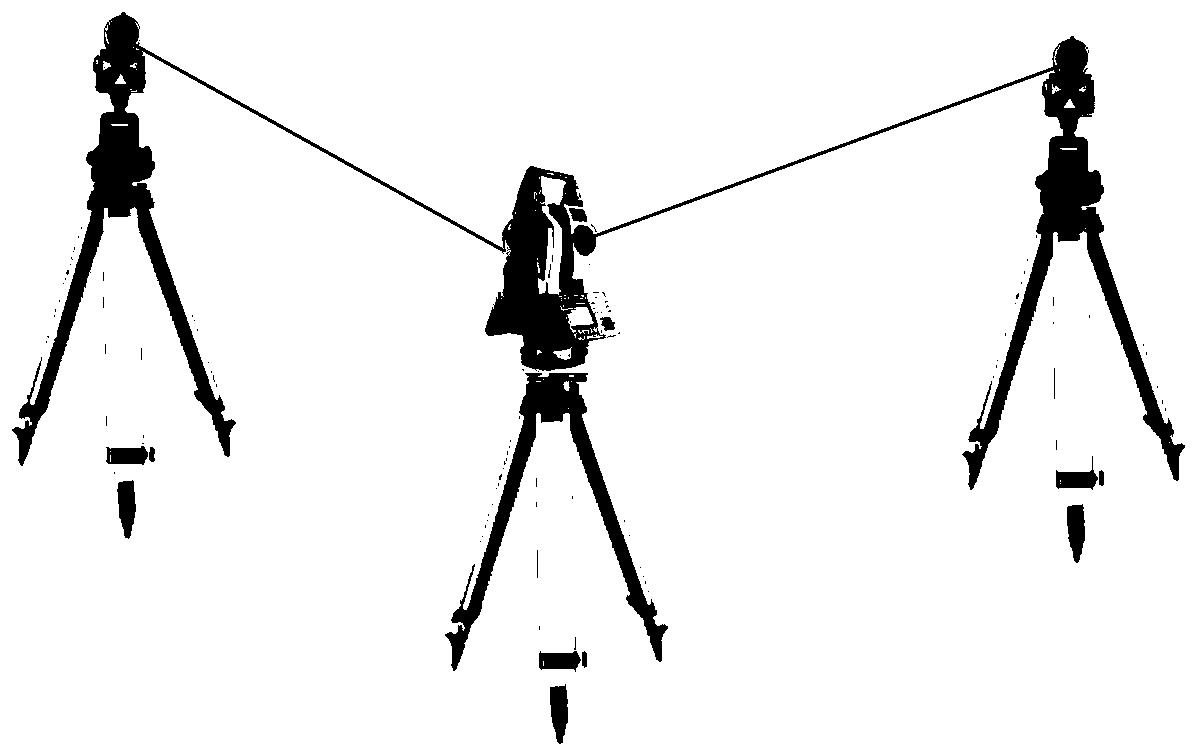

Three-dimensional precision control network measurement method

ActiveCN110779503AGuaranteed reliabilityReduce manual labor intensityAngle measurementSurveying instrumentsSimulationPrecision engineering

The invention, which belongs to the technical field of precision engineering measurement, relates to a three-dimensional precision control network measurement method. According to the method, three continuous adjacent wire points in a wire are used as a group of measurement objects; thee total stations are used for measuring each group of measurement objects in the wire; corresponding measurementdata of the next group of measurement objects are compared with measurement data of the previous group of same measurement objects; if the comparison result does not meet a set range, measurement is started again immediately by starting with a first group of measurement objects; and otherwise, measurement of the next group of measurement objects is carried out until all measurement points are measured completely. According to the measurement method provided by the invention, whether the measurement data are accurate or not can be compared in real time in the measurement process; and when the error of the measurement data of a certain group of measurement objects is large, measurement is started again directly from the first group of measurement points. The labor intensity of workers is relatively low; the measurement efficiency is high; the method is simple and efficient; and the high reliability of the measurement result can be guaranteed.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU +1

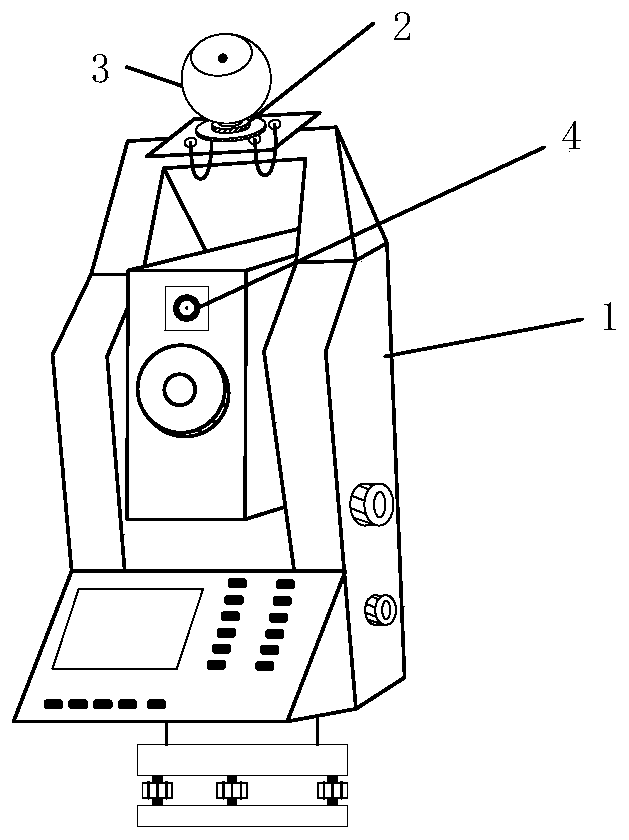

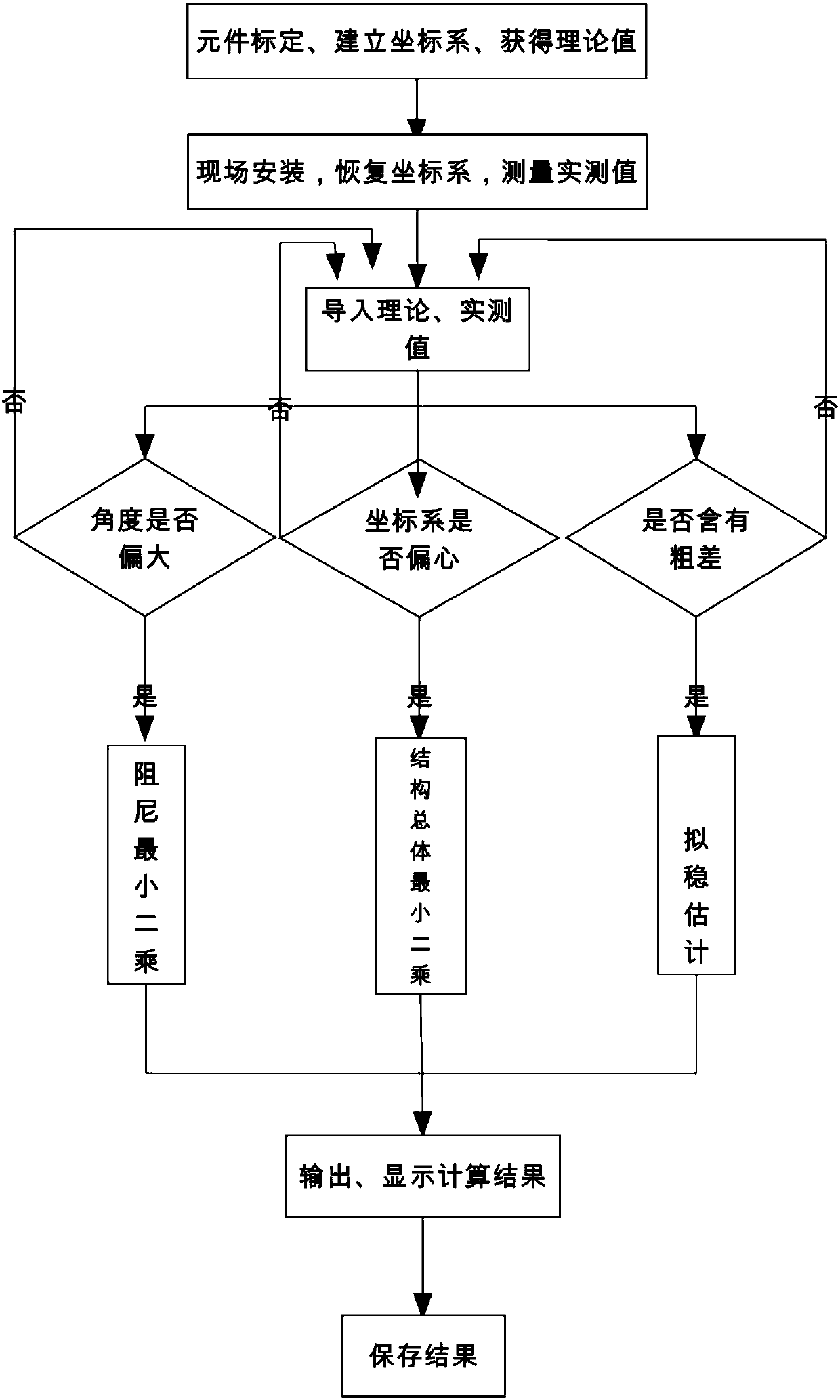

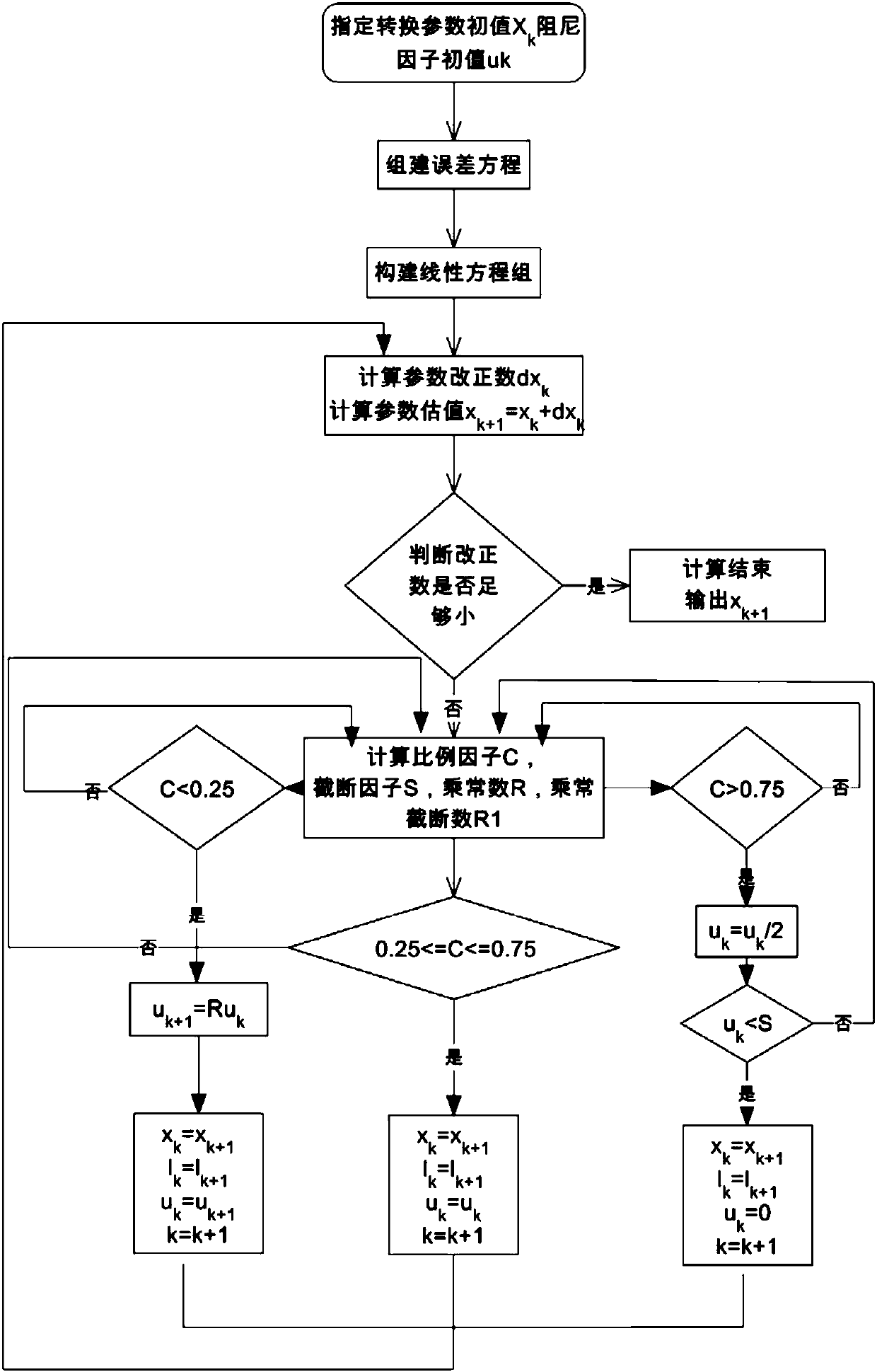

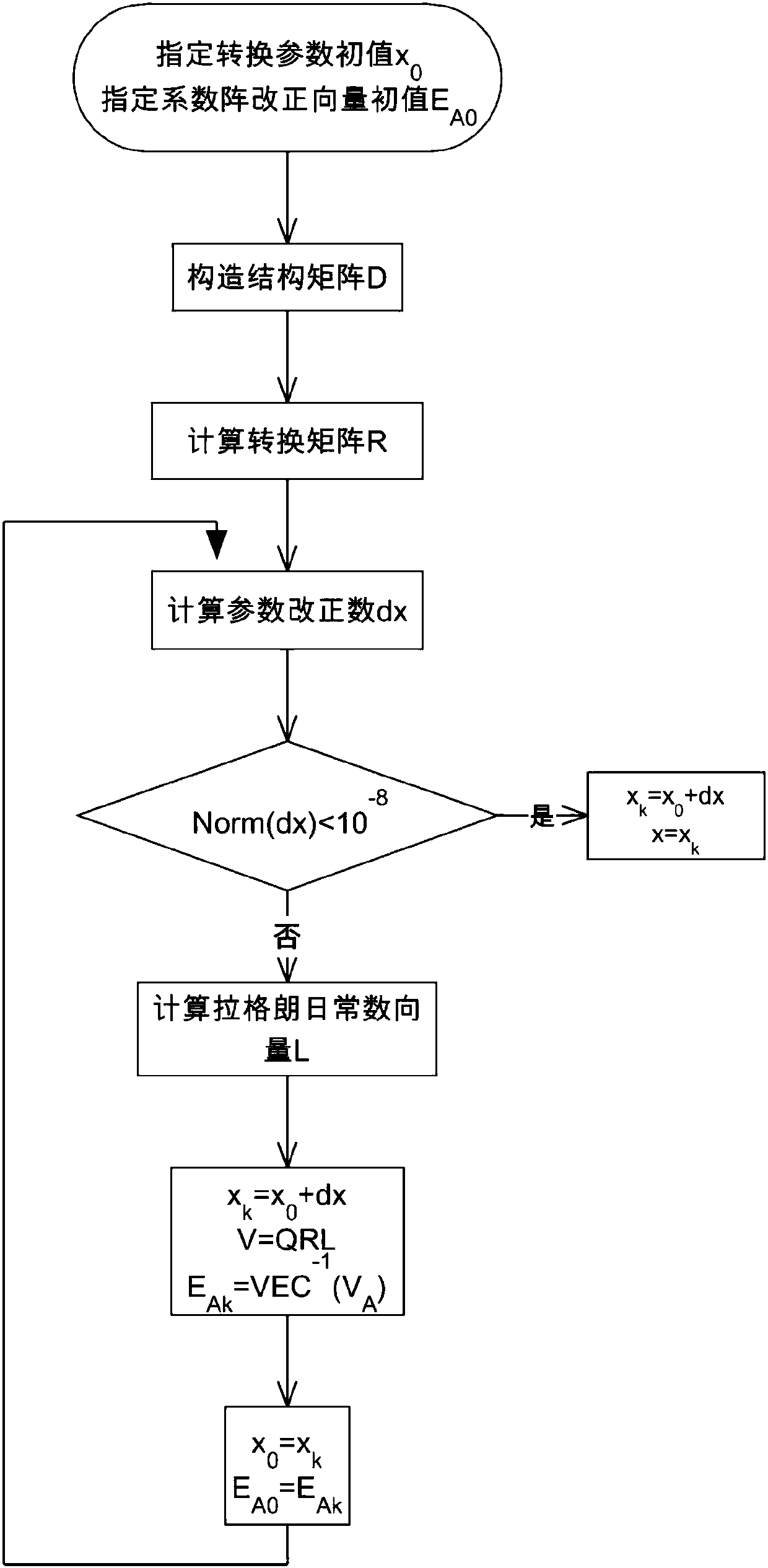

Method for measuring engineering collimation parameters of accelerator

ActiveCN108507502ASolve problemsNo loss of precisionUsing optical meansEstimation methodsTotal least squares

The invention relates to the technical field of precision engineering and industrial measurement, and particularly relates to a method for measuring engineering collimation parameters of an accelerator. The method is characterized in that a coordinate transformation relation between a calibration theoretical value and a measured installation value of mechanical equipment is established, and attitude parameters of the equipment are solved according to a singular value decomposition method, so that a problem of collimation parameter solving under the conditions of a large angle, eccentricity ofa coordinate system and existence of gross errors is solved by adopting a damped least squares method, a structured total least squares method and a quasi-stable estimation method. The method can be used by being matched with a laser tracker, a portable measuring arm or a total station instrument so as to complete the calculation of the calibration parameters; the collimation parameters can be calculated at any angles; the collimation parameters can be accurately calculated without moving a coordinate system when the coordinate system is eccentric; and the collimation parameters can be calculate without the loss of precision when there is a gross error. The method improves the calculation efficiency and precision and has robustness.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

High-precision engineering-measurement centering rod device

PendingCN108759805AEasy to adjustHigh measurement accuracySurveying instrumentsPipe waterArchitectural engineering

The invention discloses a high-precision engineering-measurement centering rod device. The high-precision engineering-measurement centering rod device comprises a centering rod, a limiting device, a detachable conical head arranged at the bottom end of the centering rod, a water level assembly fixedly connected on the centering rod, a left supporting assembly and a right supporting assembly, wherein the left supporting assembly and the right supporting assembly are symmetrically arranged on the two sides of the centering rod; a left connecting rod and a right connecting rod are fixedly connected with the top end of an F-shaped support separately, and the F-shaped support is fixedly connected with the centering rod; a fine adjustment assembly and a fast adjustment assembly which are capableof adjusting the length of the left supporting assembly and the length of the right supporting assembly are also arranged on the left supporting assembly and the right supporting assembly respectively; the water level assembly comprises a right pipe water level and a left pipe water level which are perpendicular to each other, and the two side edges of the limiting device are in contact cooperation with the left connecting rod and the right connecting rod respectively so that the left connecting rod and the right connecting rod can be parallel to the right pipe water level and the left pipe water level respectively. By means of the high-precision engineering-measurement centering rod device, the measurement precision of the centering rod can be effectively increased, adjustment of the water levels can be achieved through the fine adjustment assembly and the fast adjustment assembly, and different using requirements are met.

Owner:刘谦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com