Novel multifunctional high-precision engineering surveying and mapping box staff

A multi-functional and high-precision technology, applied in the field of engineering surveying and mapping, can solve the problems of complicated operation and complicated folding of the support device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

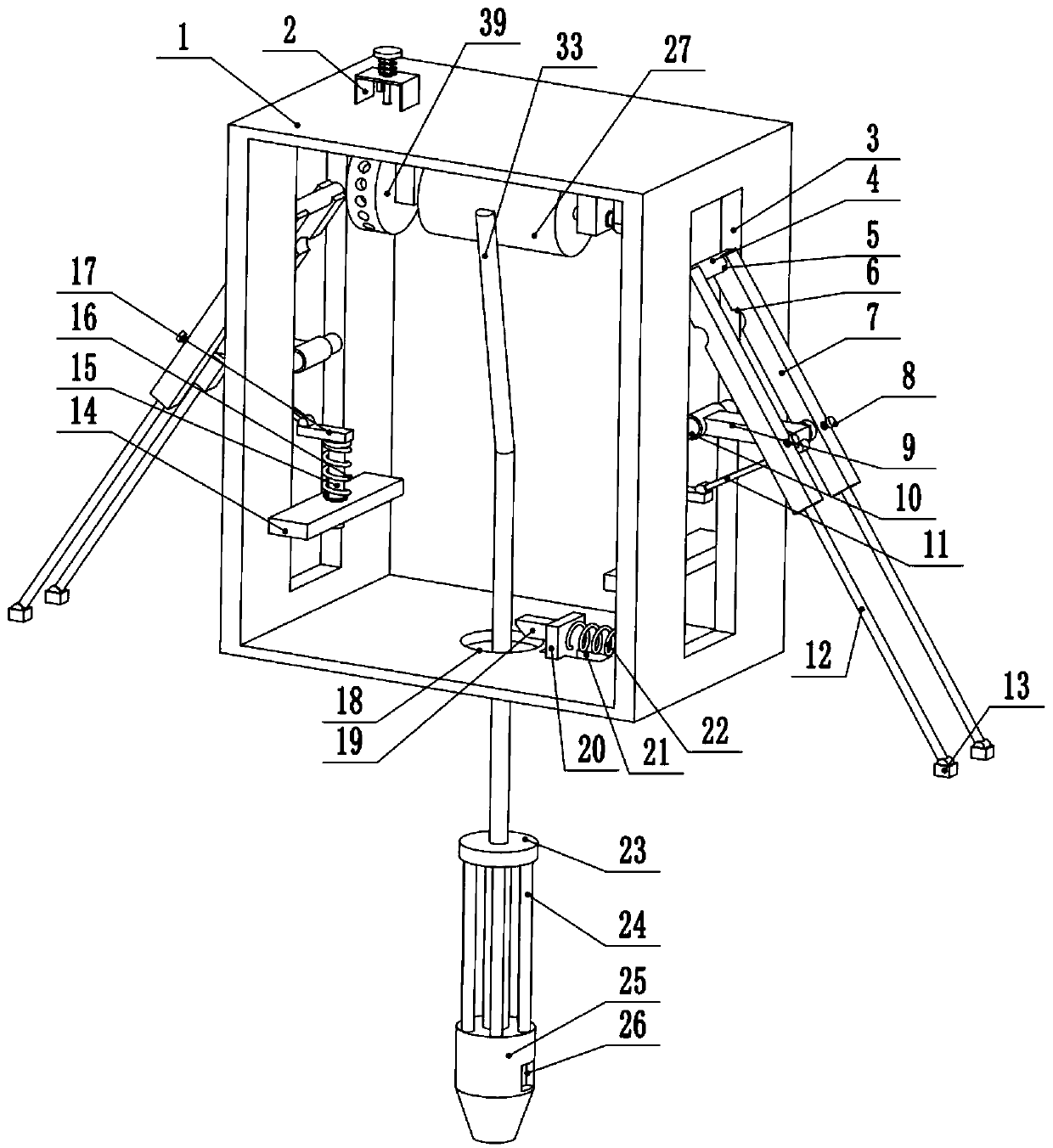

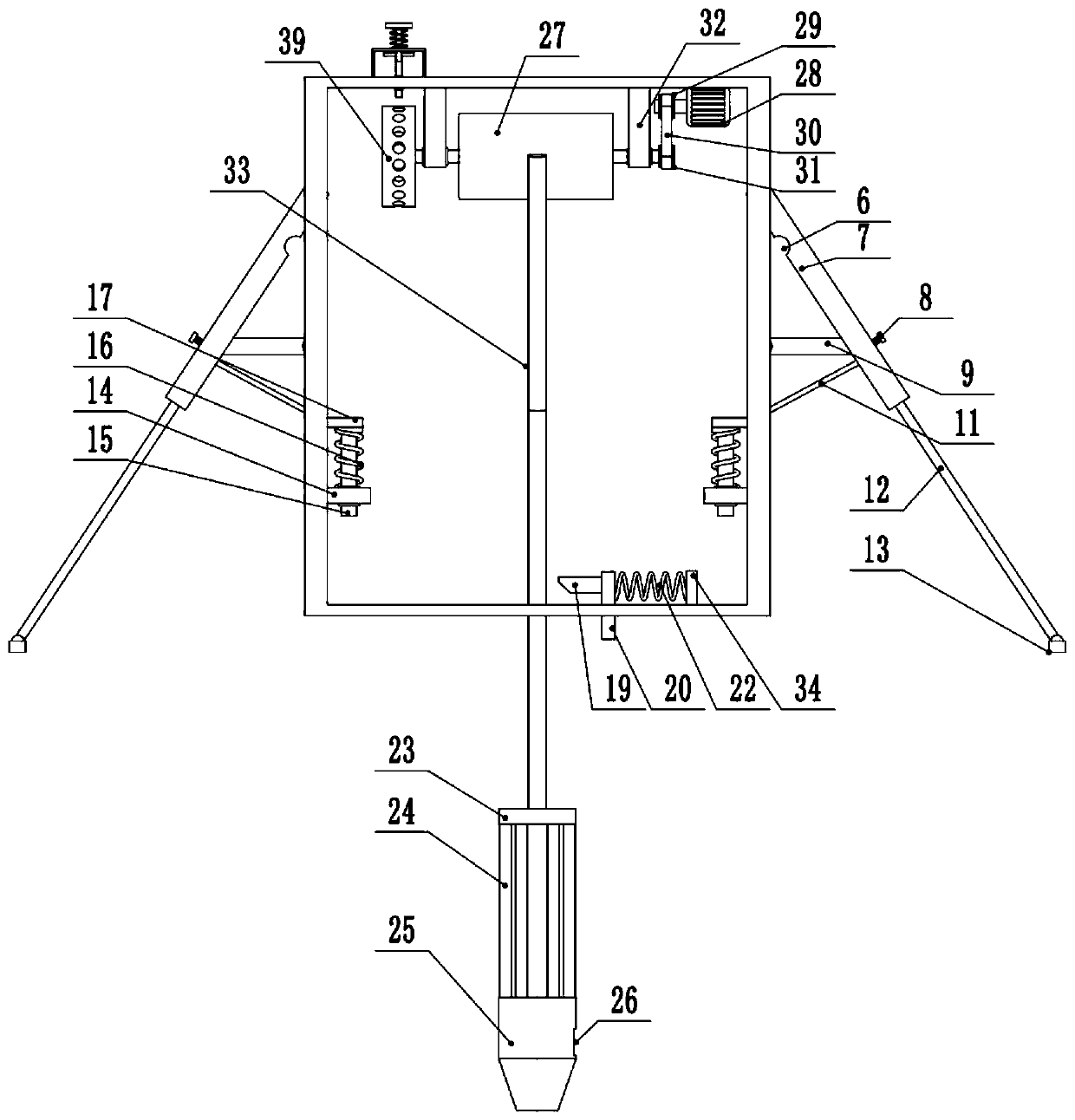

[0026] see figure 1 with figure 2 , a new type of multi-functional high-precision engineering surveying and mapping tower ruler, including a main body 1, the top of the main body 1 is provided with a bearing seat 32, the bearing seat 32 is rotatably connected to the left and right ends of the winding roller 27, and the upper right side of the main body 1 is provided with a drive Motor 28, the output shaft of drive motor 28 is fixedly connected first belt pulley 29, and first belt pulley 29 is connected second belt pulley 31 by belt 30, and second belt pulley 31 is fixedly connected the right end of winding roller 27, and winding roller 27 exteriors Hanging rope 33 is arranged, and the lower end of hanging rope 33 is provided with the 3rd fixed plate 23, and the bottom of the 3rd fixed plate 23 is provided with surveying head 25, and the middle part of the lower surface of main body 1 is provided with the relief hole 18, and the 3rd fixed plate 23 and Reinforcing ribs 24 are ...

Embodiment 2

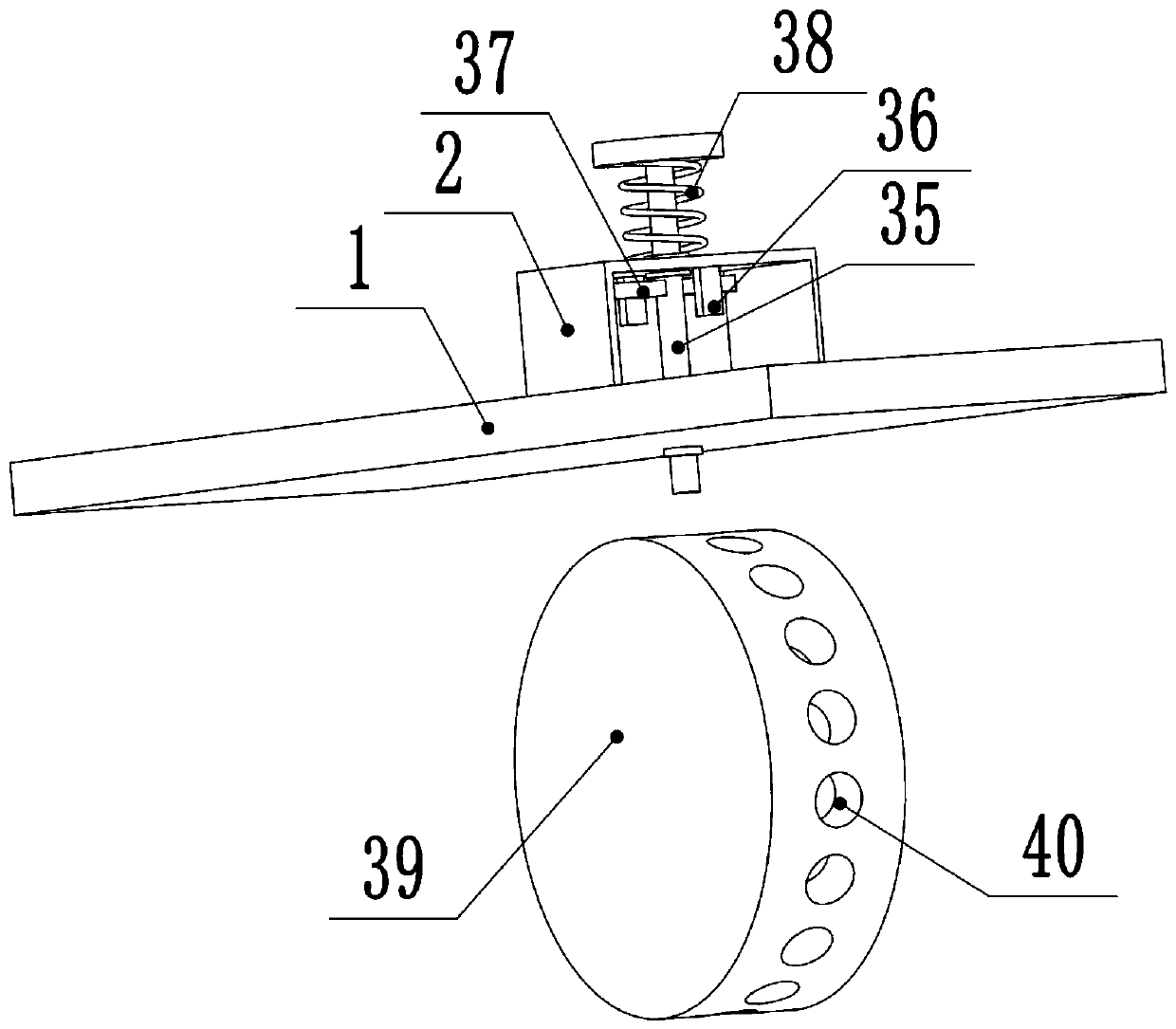

[0029] see image 3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the left end of the winding roller 27 is provided with a rotating wheel 39, the side wall of the rotating wheel 39 is provided with a limiting hole 40, the upper left of the main body 1 The side sliding connection is connected with the limit rod 35 that is matched with the limit hole 40, and the top of the limit rod 35 is slidably connected to the fixed frame 2, and a second spring 38 is arranged between the fixed frame 2 and the top of the limit rod 35, and the front and back of the fixed frame 2 Top blocks 36 are arranged on both sides, and top plates 37 are arranged on the left and right sides of the limit rod 35 . Because the winding roller 27 of the device is driven by the drive motor 28, yet the drive motor 28 may break down, in order to prevent the surveying head 25 from falling, a limit rod 35 and a limit hole 40 are set on the left side of the device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com