Precise positioning method for nano-displacement table based on partially coherent light

A technology of precise positioning and coherent light, which is applied in the field of flying precision engineering, can solve the problems of short coherent distance of coherent light, smaller measurement range, and measurement data processing, so as to avoid random noise and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

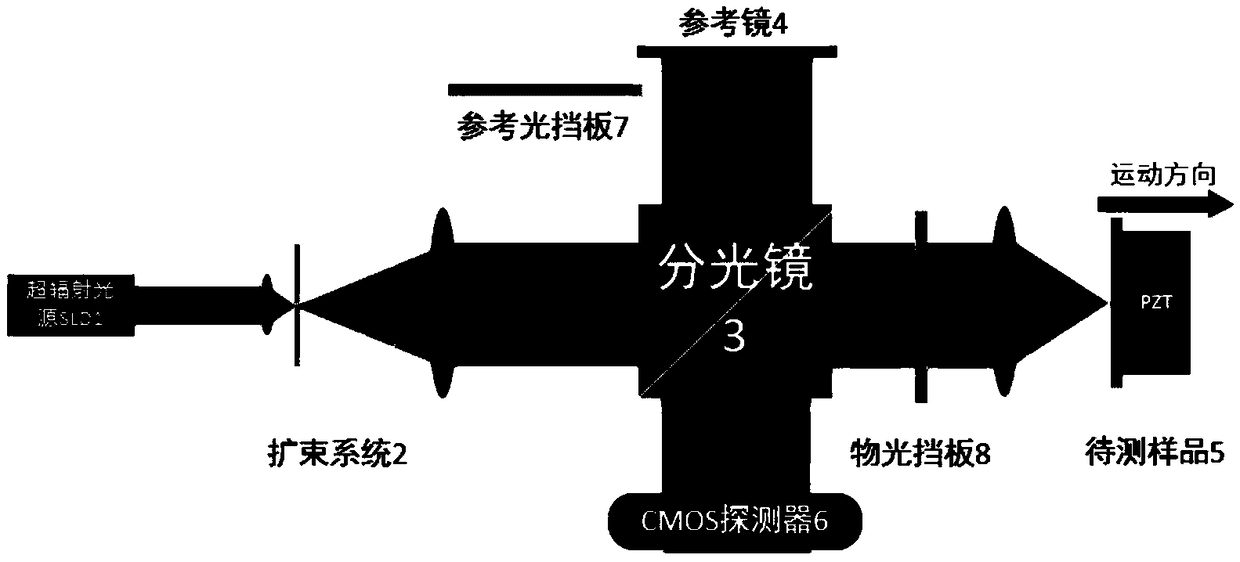

[0032] Embodiment 1: as figure 1 As shown, the dual-channel optical path consists of a superluminescent diode SLD light source, a beam expander system, a beam splitter, a reference mirror, a sample to be tested, a CMOS detector, a reference light baffle, and an object light baffle. Partially coherent light is emitted from the SLD and widened by the beam expander system, and then split into two beams by the beam splitter, reflected by the reference mirror and the sample to be tested, and then combined by the beam splitter to reach the CMOS detector. The reference light baffle is used for preliminary focusing and can block the beam passing through the reference mirror, and the object light baffle is used for light source calibration and will block the beam passing through the sample to be measured.

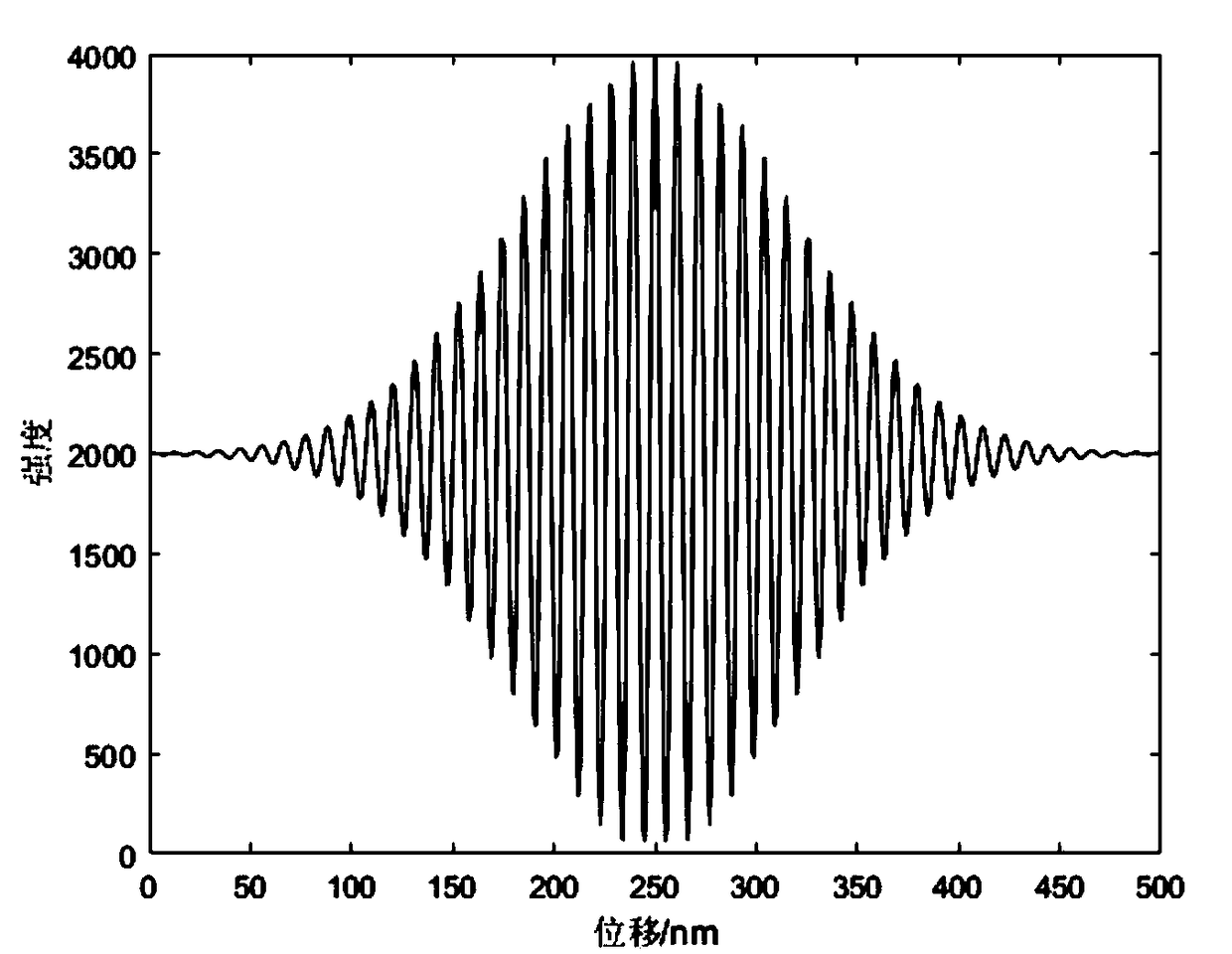

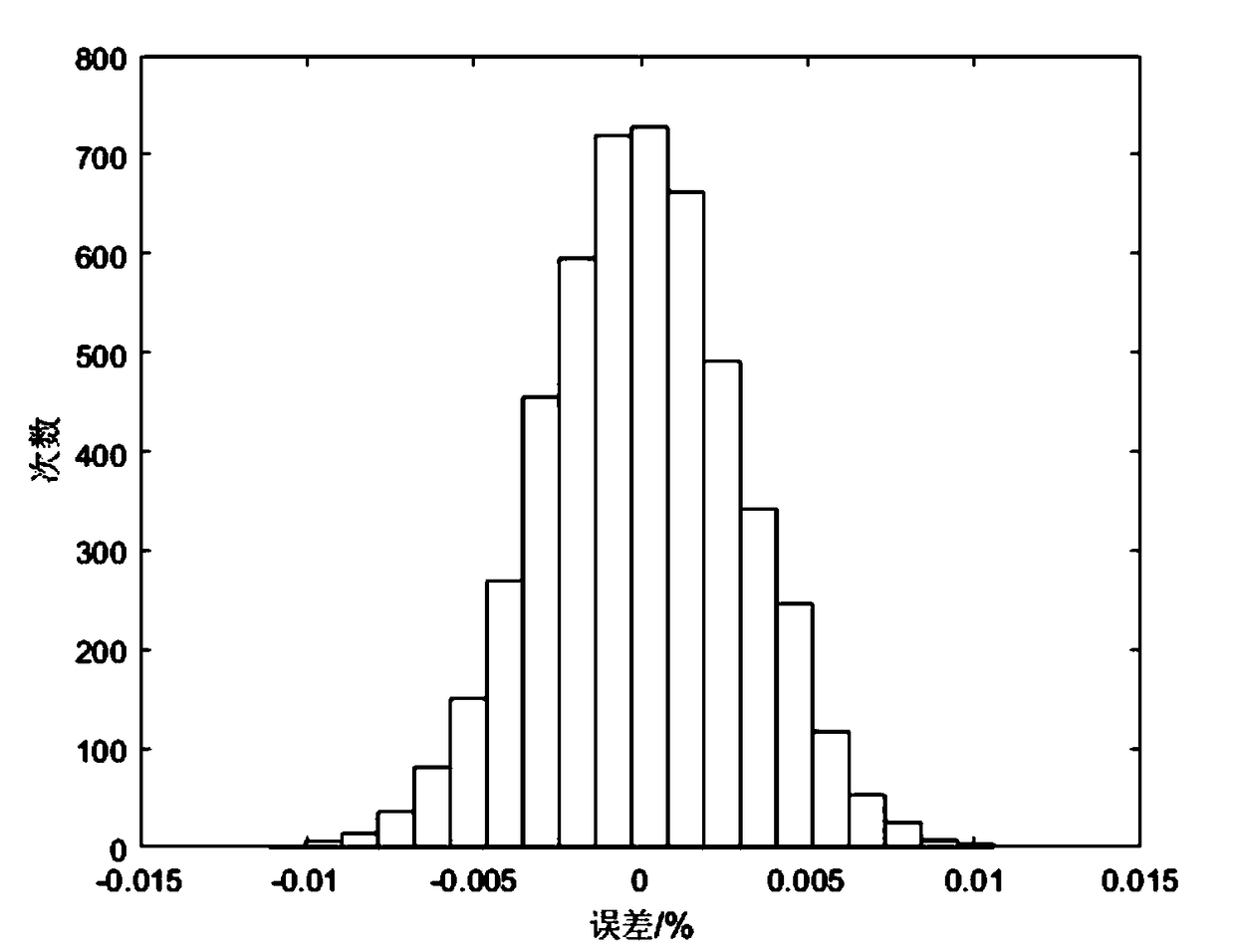

[0033] In the measurement process, after the optical path is built, the object light baffle is firstly added, and its intensity change is measured by CMOS, and the intensity distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com