Patents

Literature

35results about How to "High motion resolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Series-parallel micro operation parallel-connection robot mechanical apparatus

InactiveCN1454753AReduce volumeGreat effortProgramme-controlled manipulatorComputer control systemMicro-operation

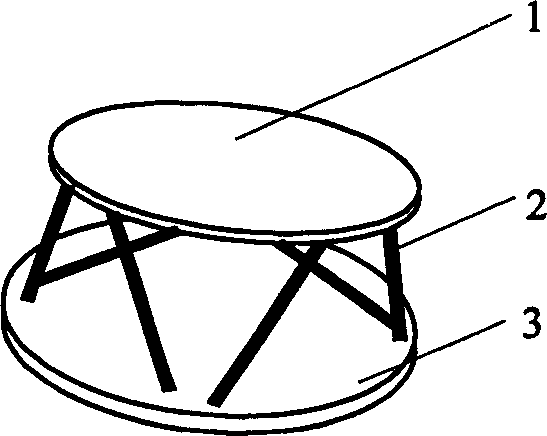

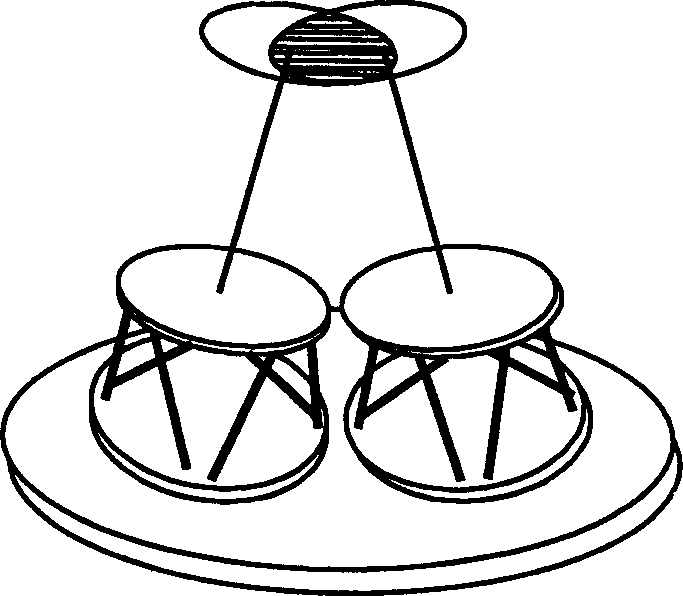

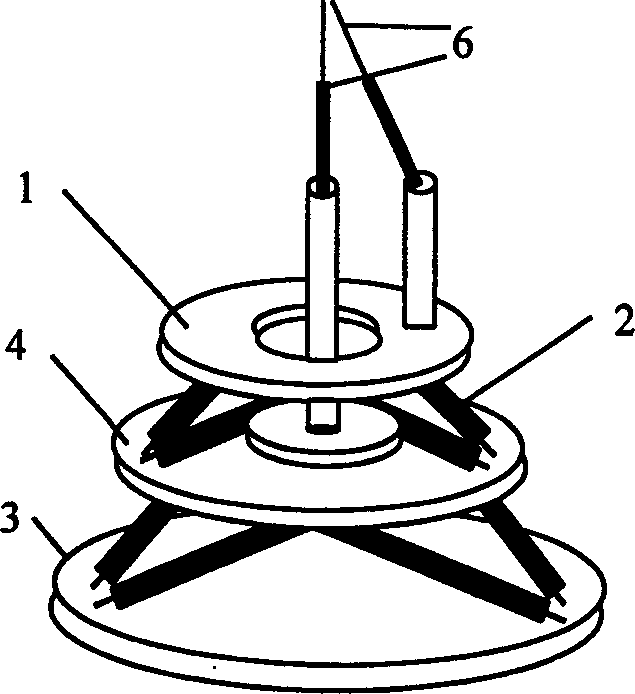

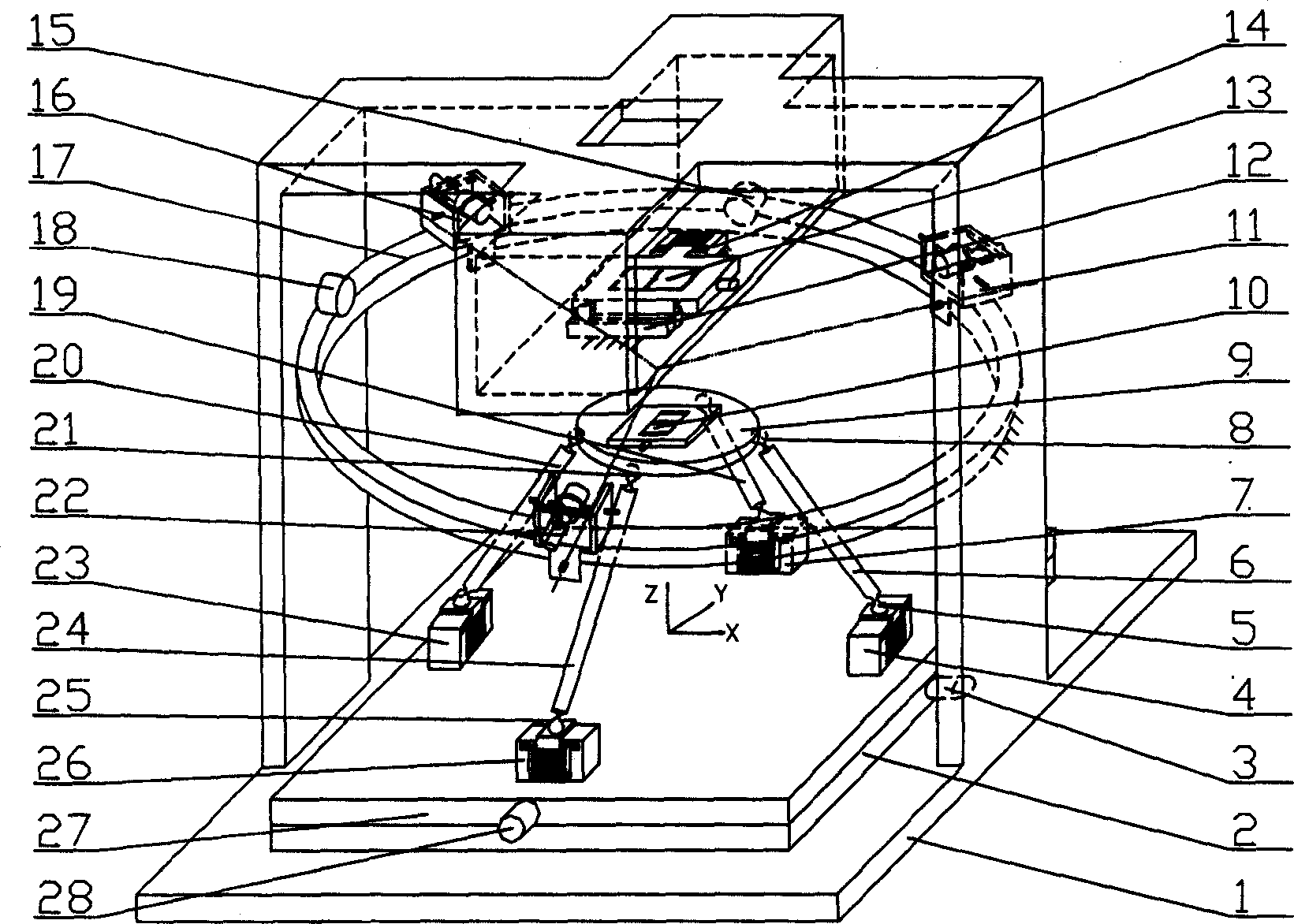

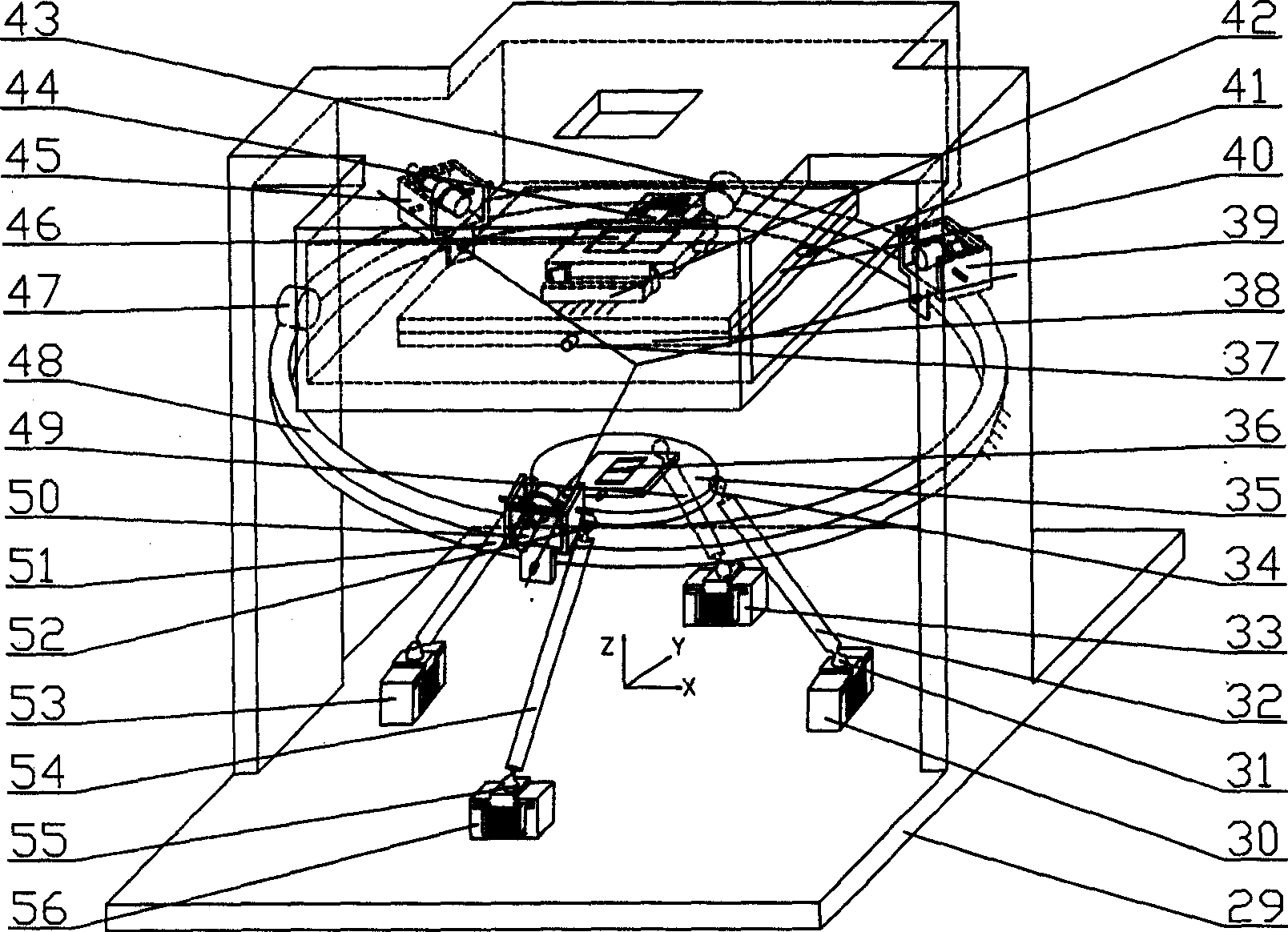

Disclosed is a parallel robot set to assemble diminutive machine. The robot comprises two same three-dimensional parallel frames which are in series. The parallel frame has three active links that comprise two Huke gemels and a micro displacement amplifier. The computer control system drives the displacement output of the piezoelectricity equipment. The undersides of the three active links are connected with the middle plate, and another side is connected with the work plate in a parallel frame group.In another group, the undersides of the three active links are connected with the underpan, and another side is connected with the middle plate. The middle plate is hung under the underpan. The two fingers of the robot are set on the work plate and the middle plate, which can work just like the human fingers.

Owner:BEIJING UNIV OF TECH

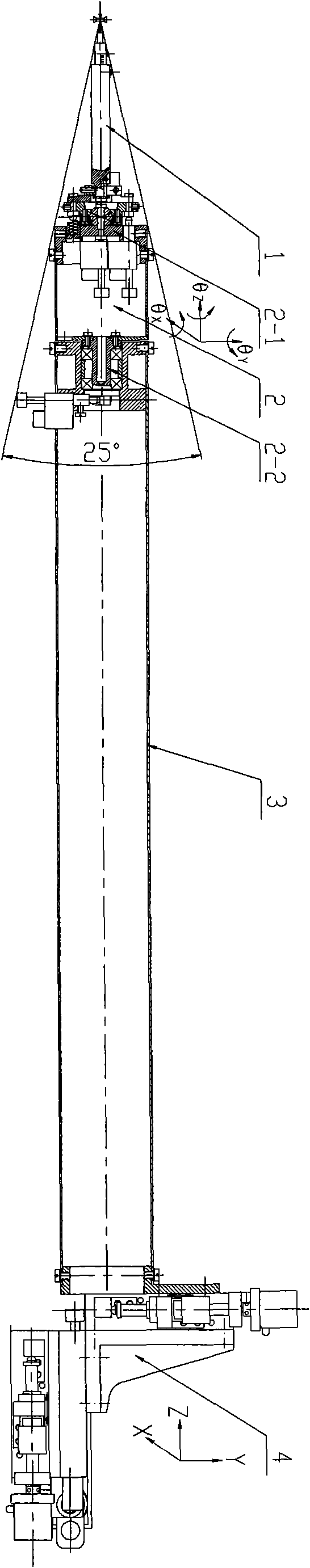

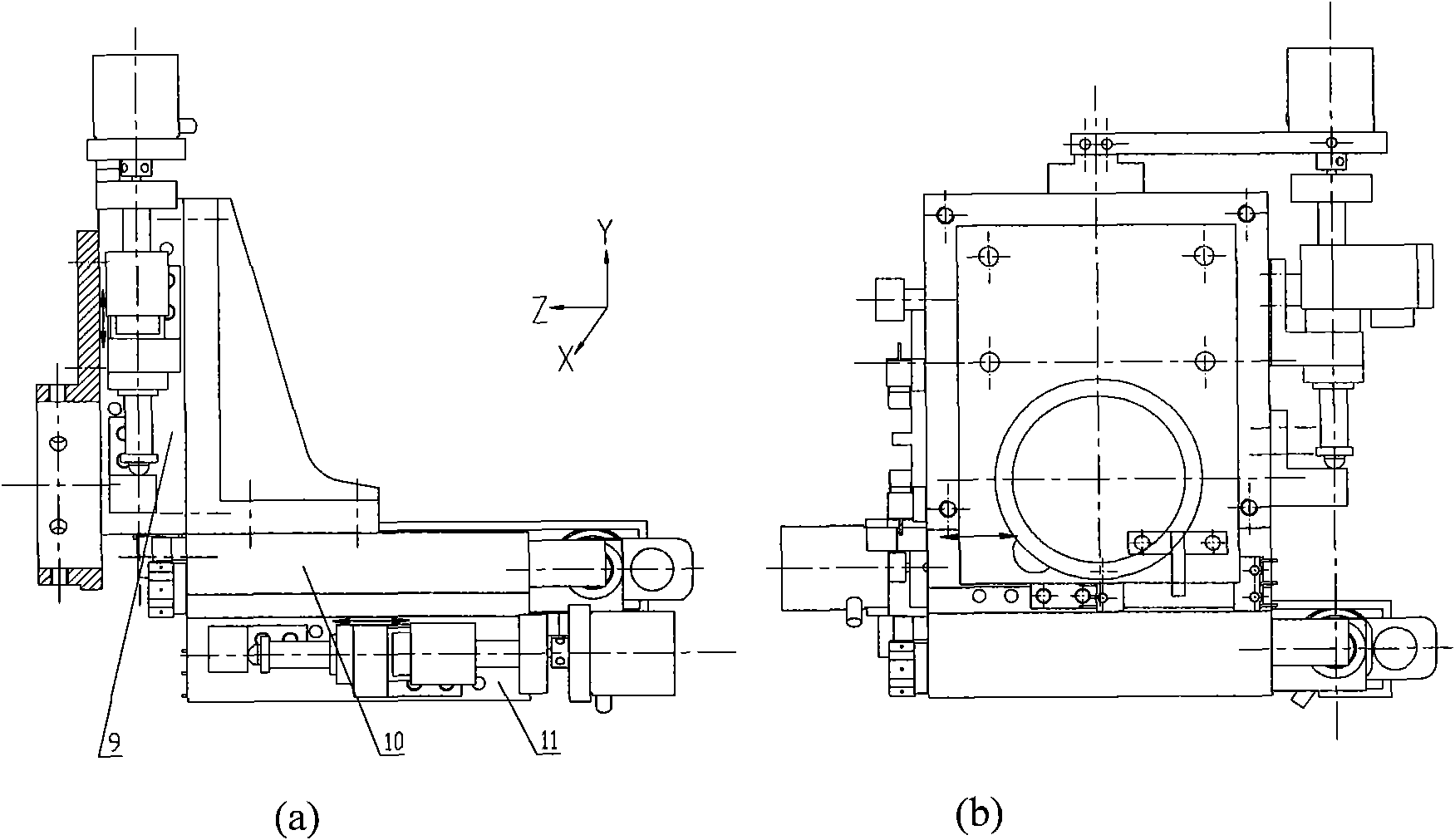

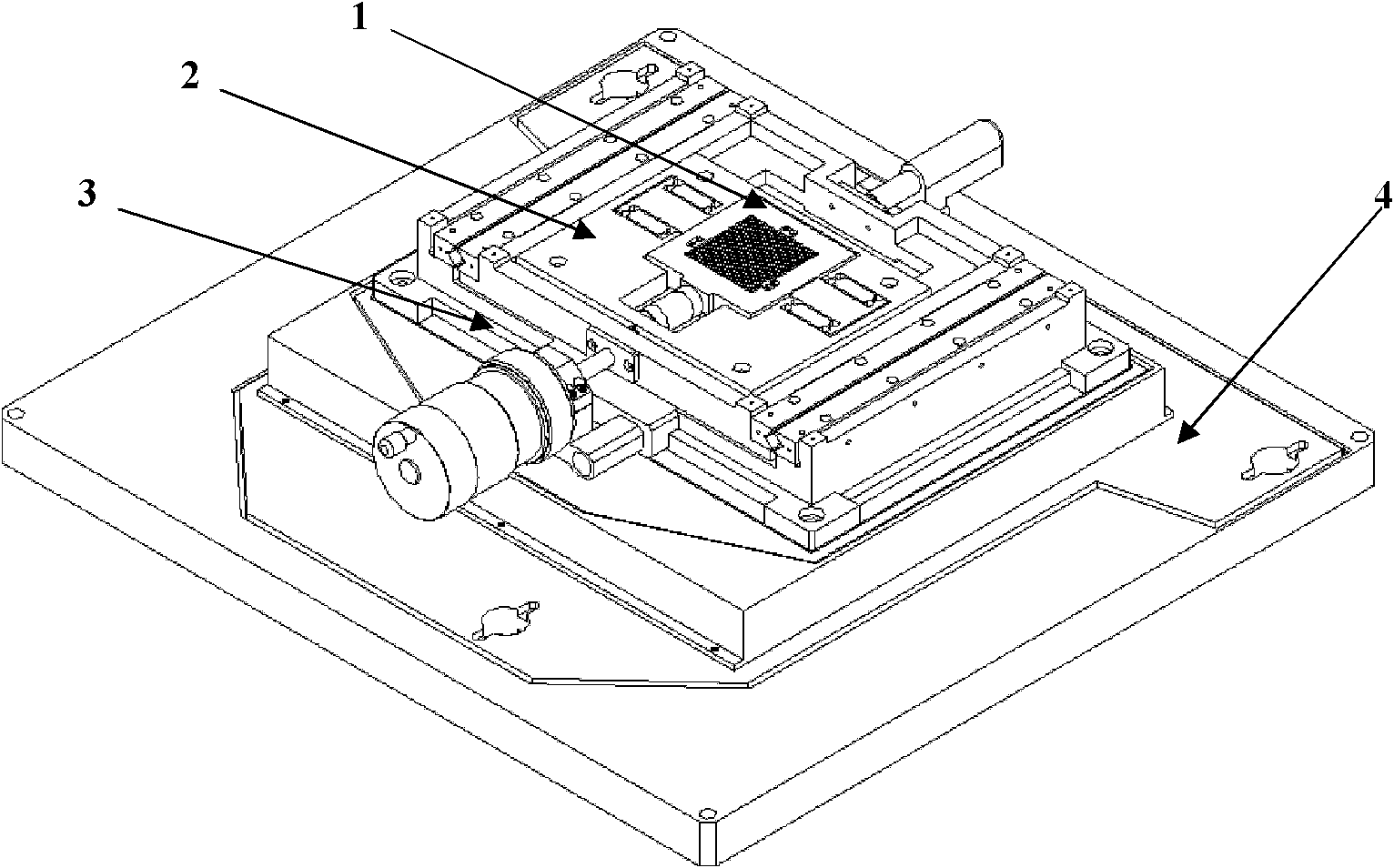

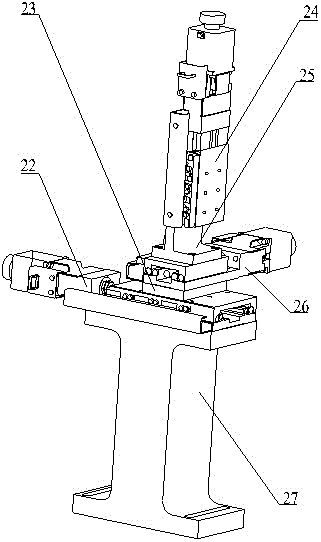

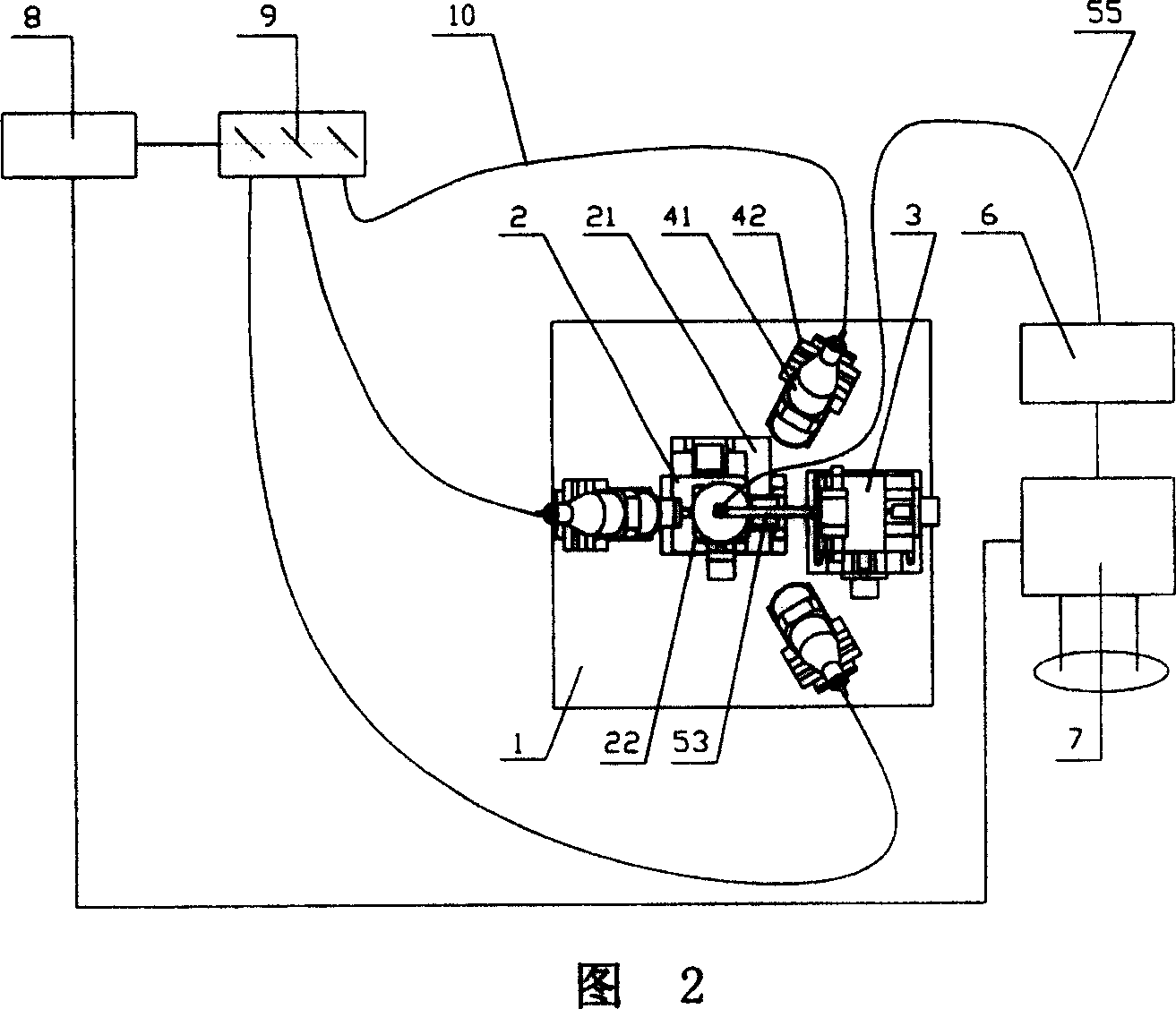

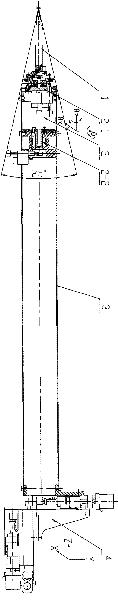

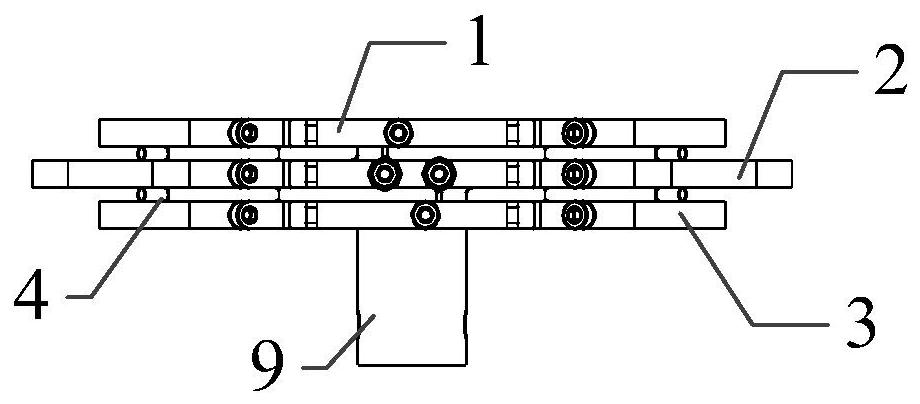

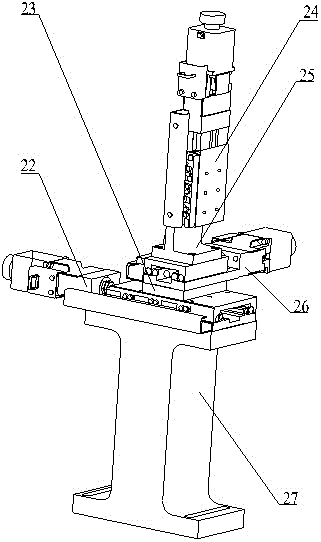

Six-degree-of-freedom series-connected robot with target positioning

InactiveCN101850547ACompact structureSmall duty cycleProgramme-controlled manipulatorImage resolutionEngineering

The invention relates to a six-degree-of-freedom series-connected robot with target positioning applied to inertial confinement fusion. By using a form of a series-connected mechanism for separating translation and rotation, and the six-degree-of-freedom series-connected robot with target positioning consists of a set of three-dimension translation work table and a set of three-dimension rotary robot. The translation and the rotation of each direction are both driven by a vacuum special motor actuator, each movement is relatively independent, and the precision movement of six freedom degrees can be finished in the space. By constructing a precise vacuum positioning mechanism with the six-degree-of-freedom in the space, the invention has the advantages of compact structure, small duty ratio angle, high motion resolution, easy control and precise positioning.

Owner:SHANGHAI UNIV

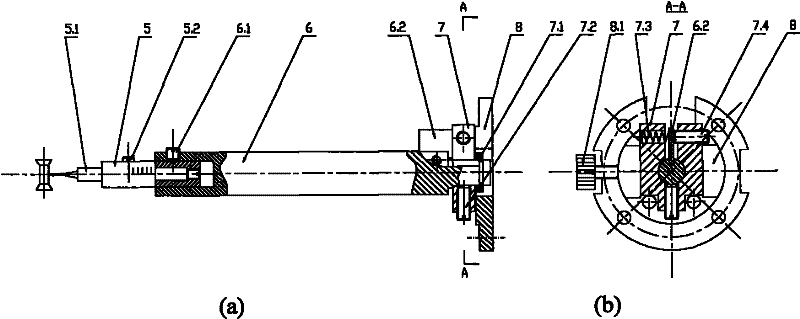

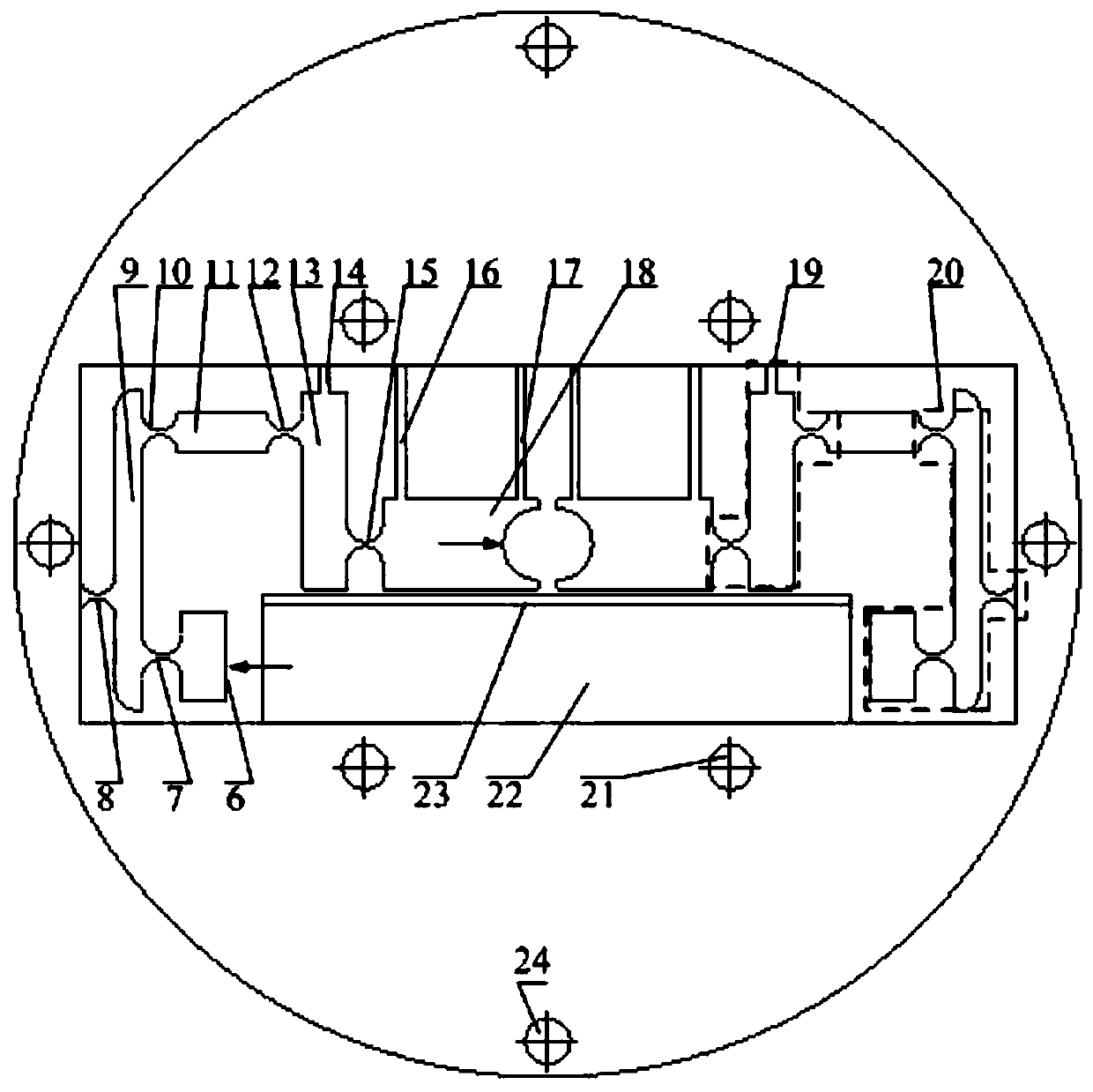

Inchworm-type precise linear micro-actuator based on complaint mechanism

ActiveCN106452165AHigh precisionLarge clamping forcePiezoelectric/electrostriction/magnetostriction machinesLinear motionMicro actuator

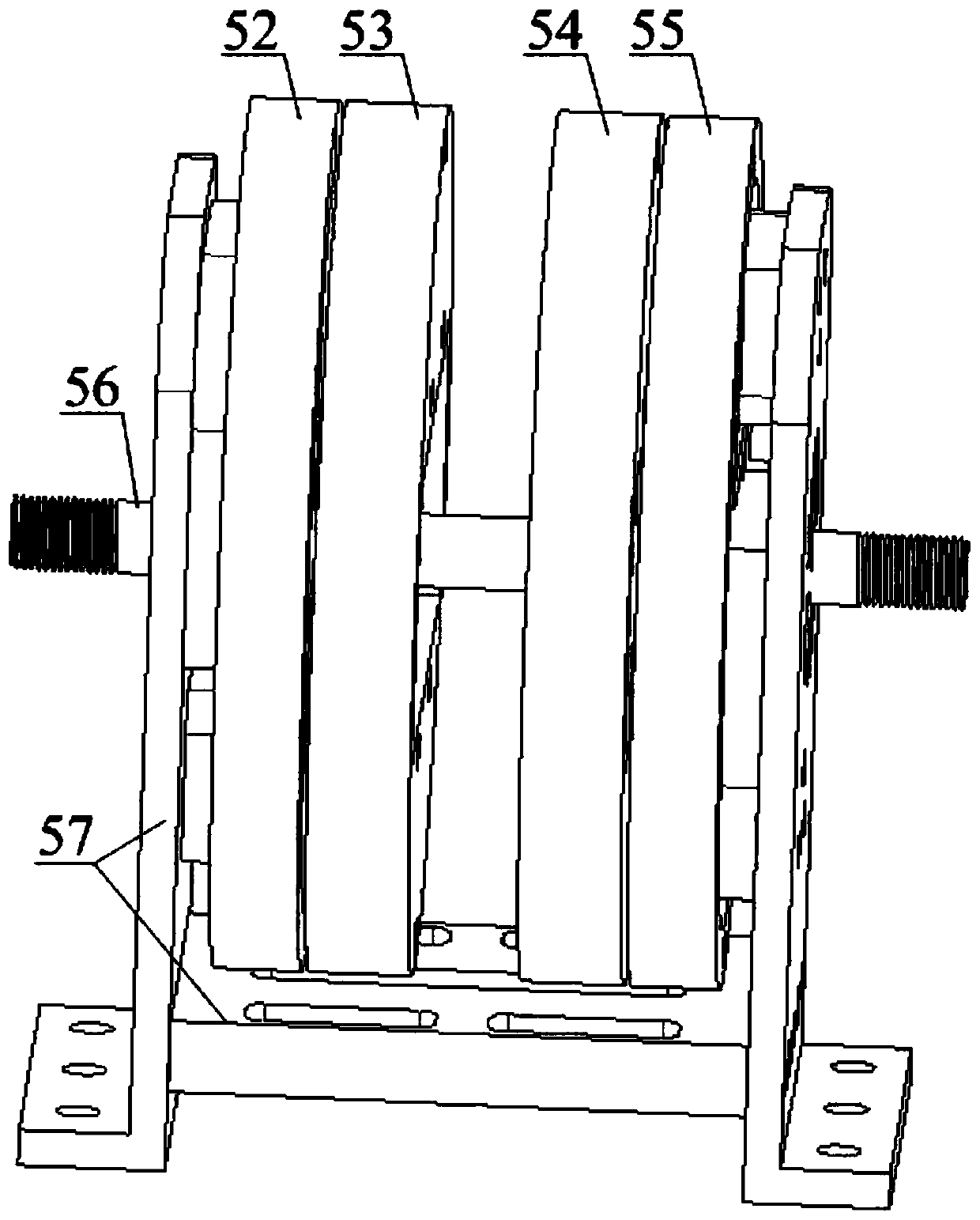

The invention discloses an inchworm-type precise linear micro-actuator based on a complaint mechanism. The inchworm-type precise linear micro-actuator comprises driving mechanisms, two clamping mechanisms and stators, wherein each driving mechanism consists of four symmetrically arranged driving branch chains and one pair of stators, each driving branch chain consists of two lever structures, the driving branch chains are connected to the stators by adopting flexible hinges, and reciprocating micromovement can be performed relative to the stators; each clamping mechanism consists of three pairs of flexible hinges, one pair of levers and one pair of clamping pieces which are symmetrically arranged, and the two clamping mechanisms are symmetrically connected to two ends of each driving mechanism through the levers; the stators are of long and thin cylinder-shaped structures, are arranged at the symmetrical center of the micro-actuator, are matched with the clamping mechanisms through holes, are matched with the driving mechanisms through through grooves, and can move in the holes and the through grooves. The clamping mechanisms are driven by the driving mechanisms to carry out reciprocating motion, and the stators are driven by the clamping mechanisms to perform a bionic inchworm motion law in the motion manner of linear motion. The disclosed micro-actuator can be used in the fields of ultra-precision machining, precision engineering, micro electro mechanical systems, bioengineering, semiconductor manufacturing and the like.

Owner:JIANGXI UNIV OF SCI & TECH

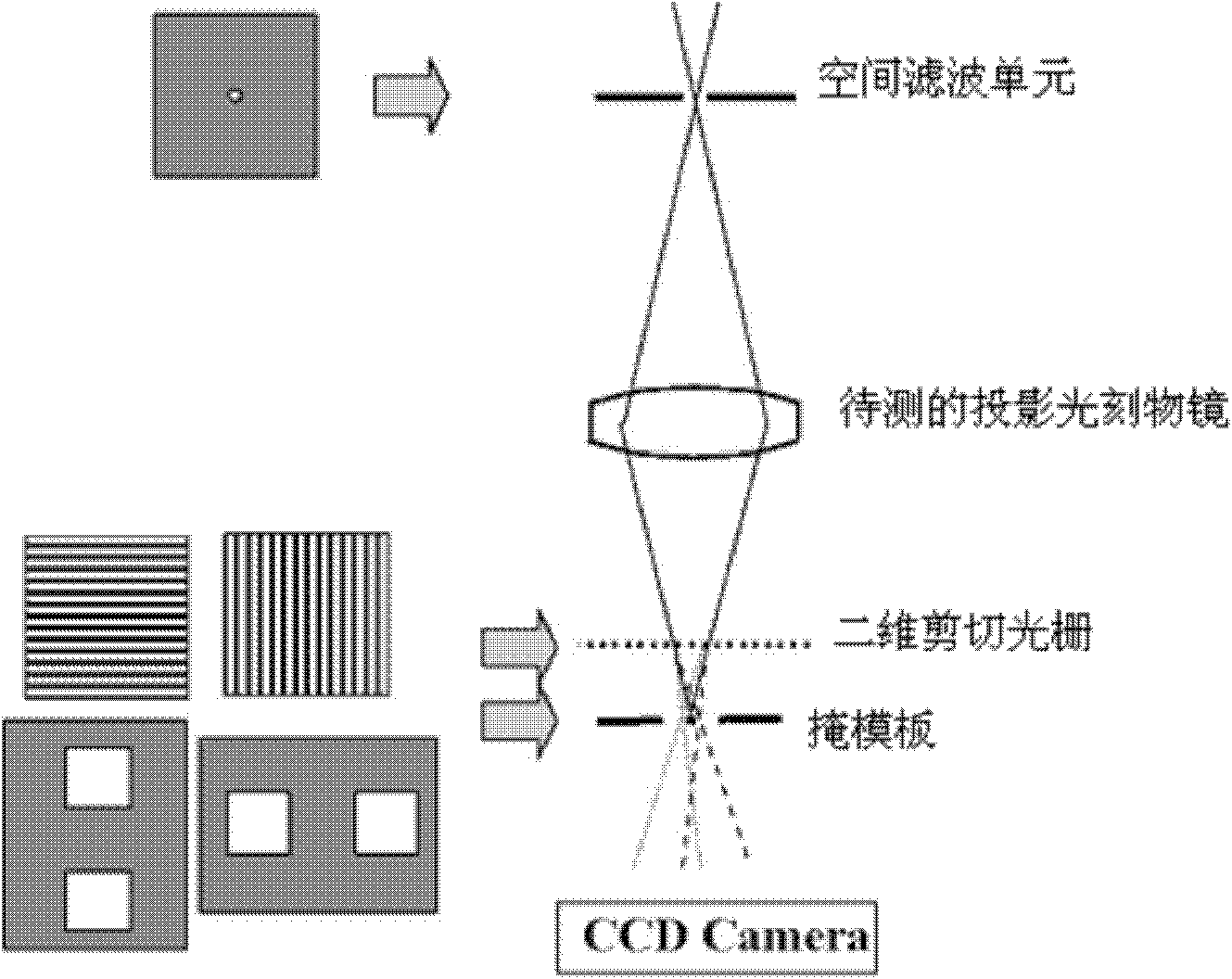

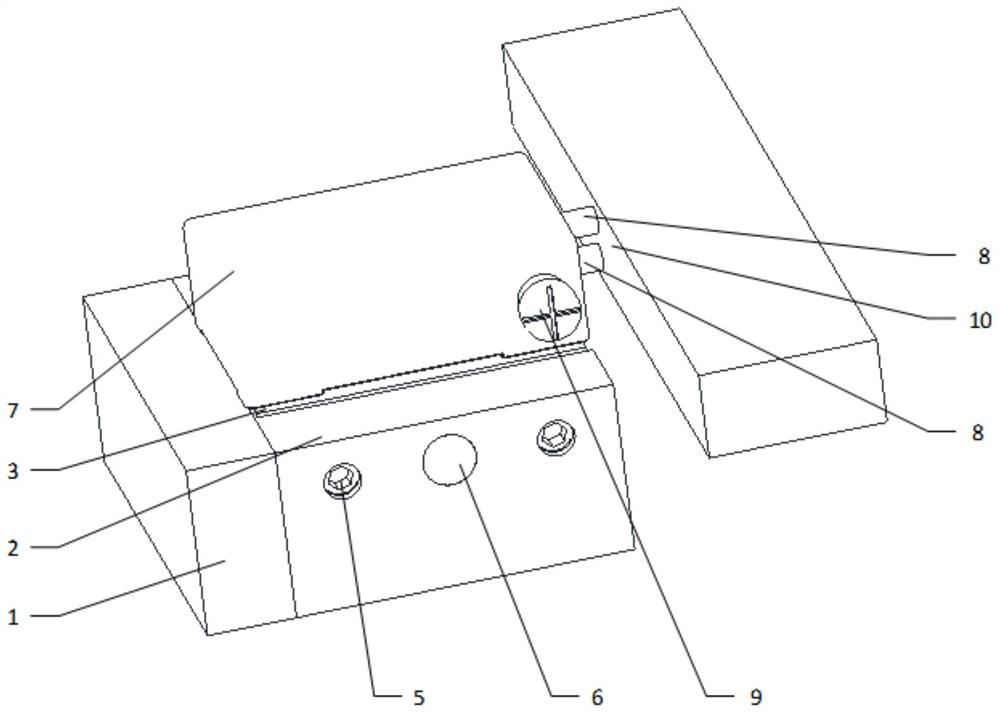

High-precision phase shift device of lateral shear interferometer

InactiveCN102519610AHigh motion resolutionFast dynamic responseOptical measurementsPhase shiftedGrating

The invention relates to a high-precision phase shift device of a lateral shear interferometer, which comprises a shear grating, a mask assembly, a base, a one-dimensional small travel high resolution displacement assembly, a one-dimensional big travel high resolution displacement assembly and a phase shifter leveling assembly. The shear grating is located in and fixed on the one-dimensional small travel high resolution displacement assembly, the mask assembly is fixed at the bottom of the one-dimensional small travel high resolution displacement assembly and keeps to be relative static with the one-dimensional small travel high resolution displacement assembly fixed on the one-dimensional big travel high resolution displacement assembly which is fixed on the base, and the phase shifter leveling assembly is connected with the bottom of the base. The high-precision phase shift device has the advantages of being ultrahigh in movement resolution, big in movement travel, high in dynamic response, capable of conducting high-precision fine tuning position in a relative large travel range, and compact in axial size simultaneously.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

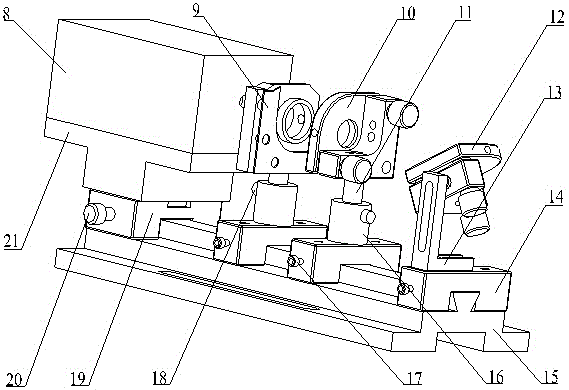

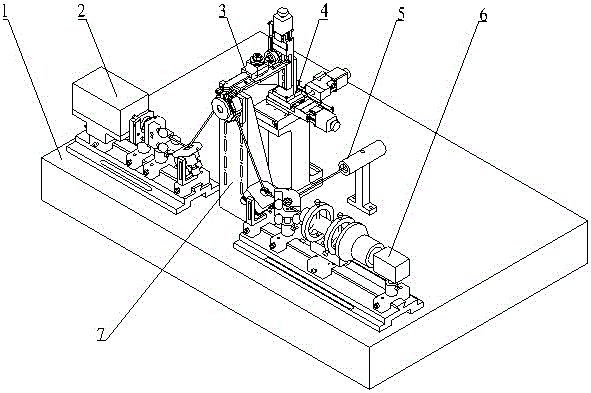

Optical glass automatic installing device for triangular laser gyroscope

InactiveCN103949881ASignificant technological progressImprove assembly efficiencyAssembly machinesGyroscopePlane mirror

The invention relates to an optical glass automatic installing device for a triangular laser gyroscope. The optical glass automatic installing device consists of an incidence laser obtaining system, a glass clamping mechanical arm with a force sensor, an optical glass position automatic regulation unit, an photoelectric detection unit, a facula image detection unit and a laser gyroscope cavity location unit, and is used for finishing the automatic installation of plane mirrors without coating films and spherical mirrors of the triangular laser gyroscope under the monitoring of multiple sensors. According to the optical glass automatic installing device for the triangular laser gyroscope, manual operation is replaced by an automatic device, the structure is simple, the motion resolution is high, the installation consistency is good, and the efficiency is high.

Owner:SHANGHAI UNIV

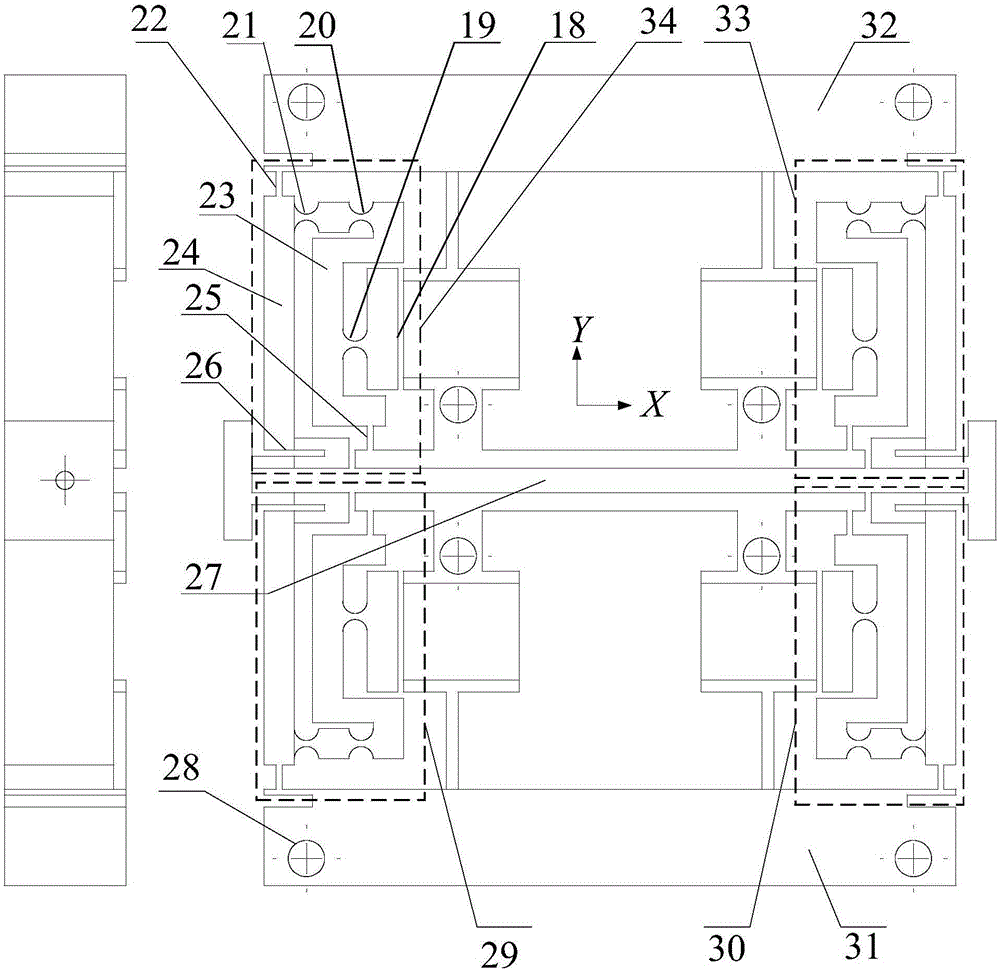

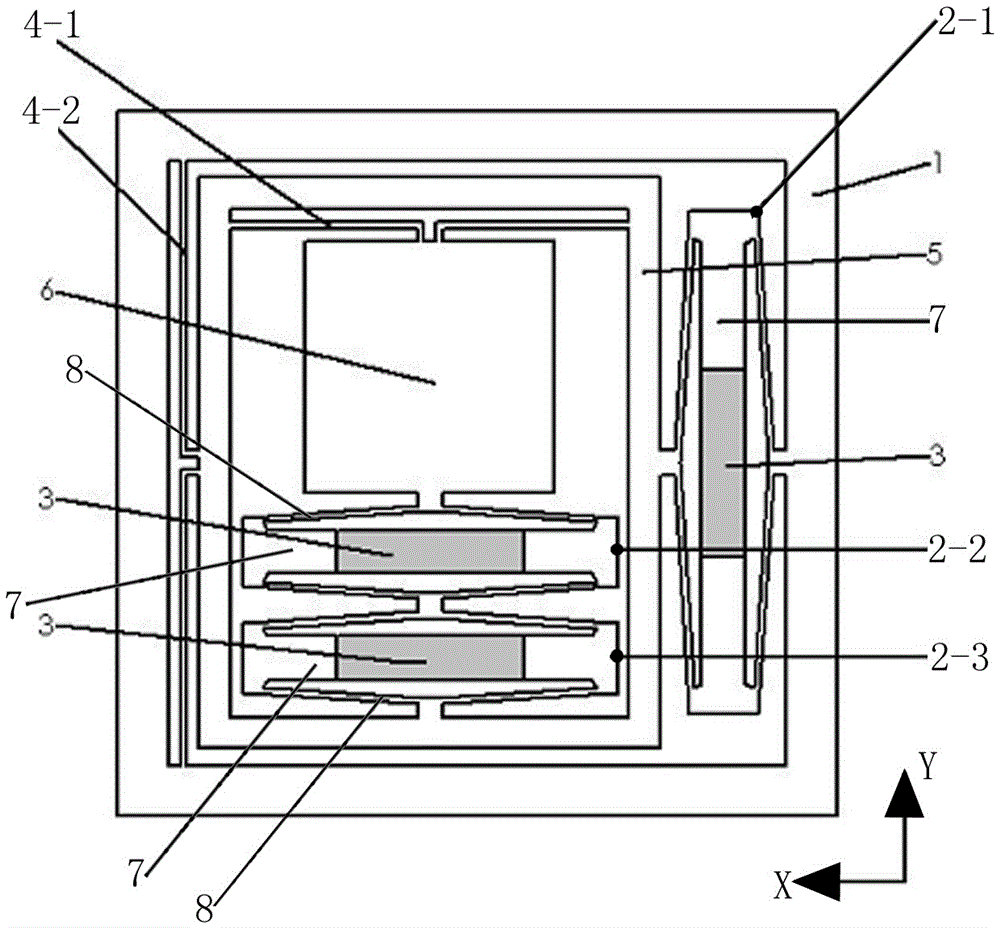

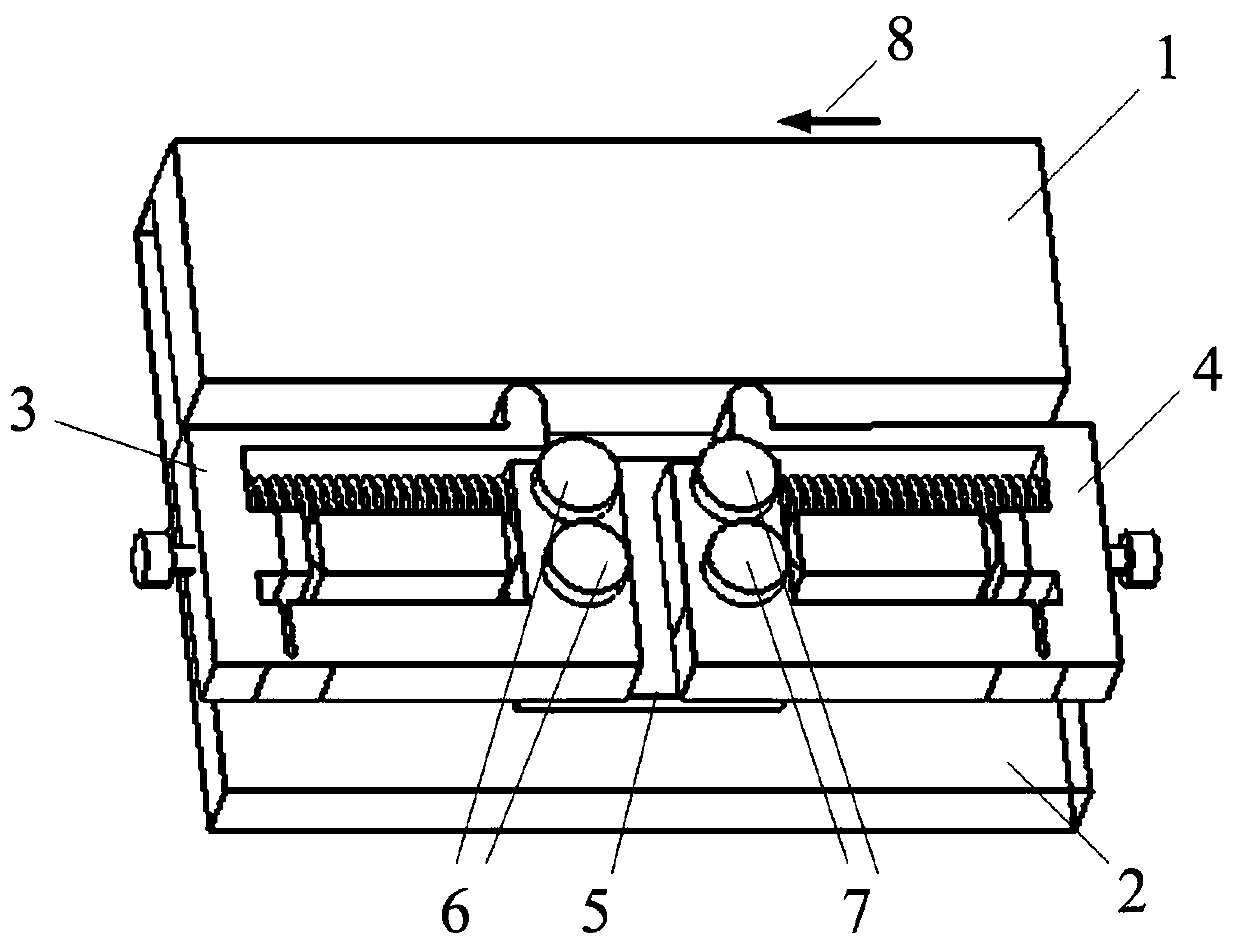

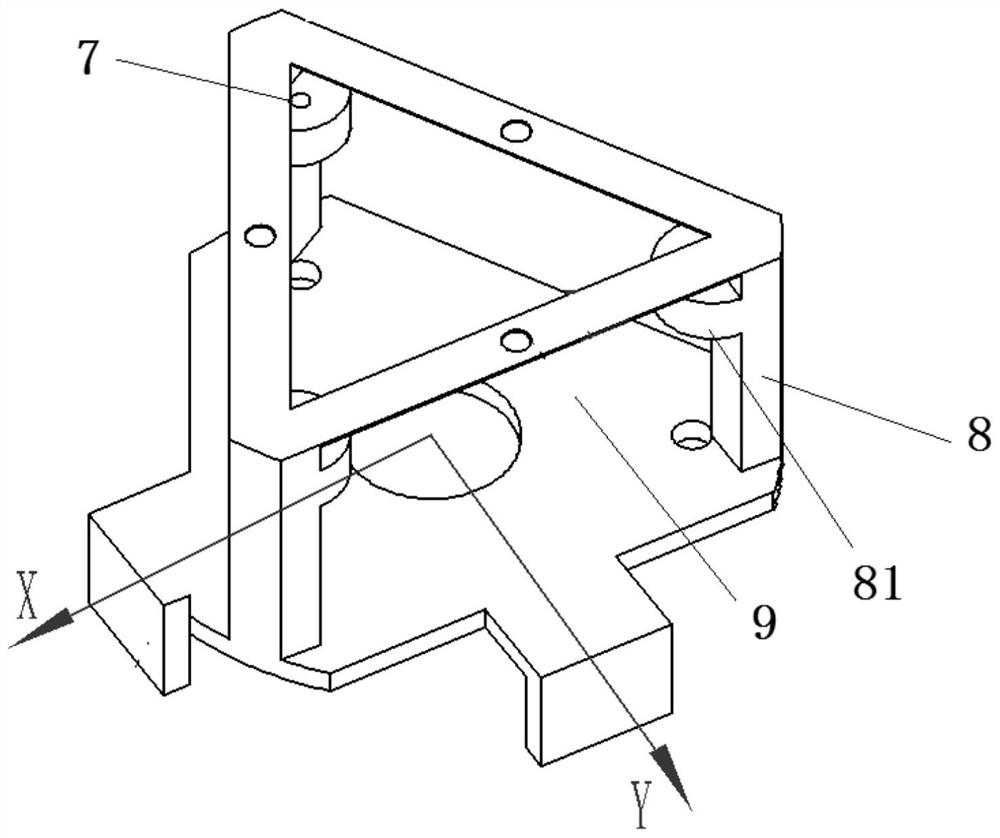

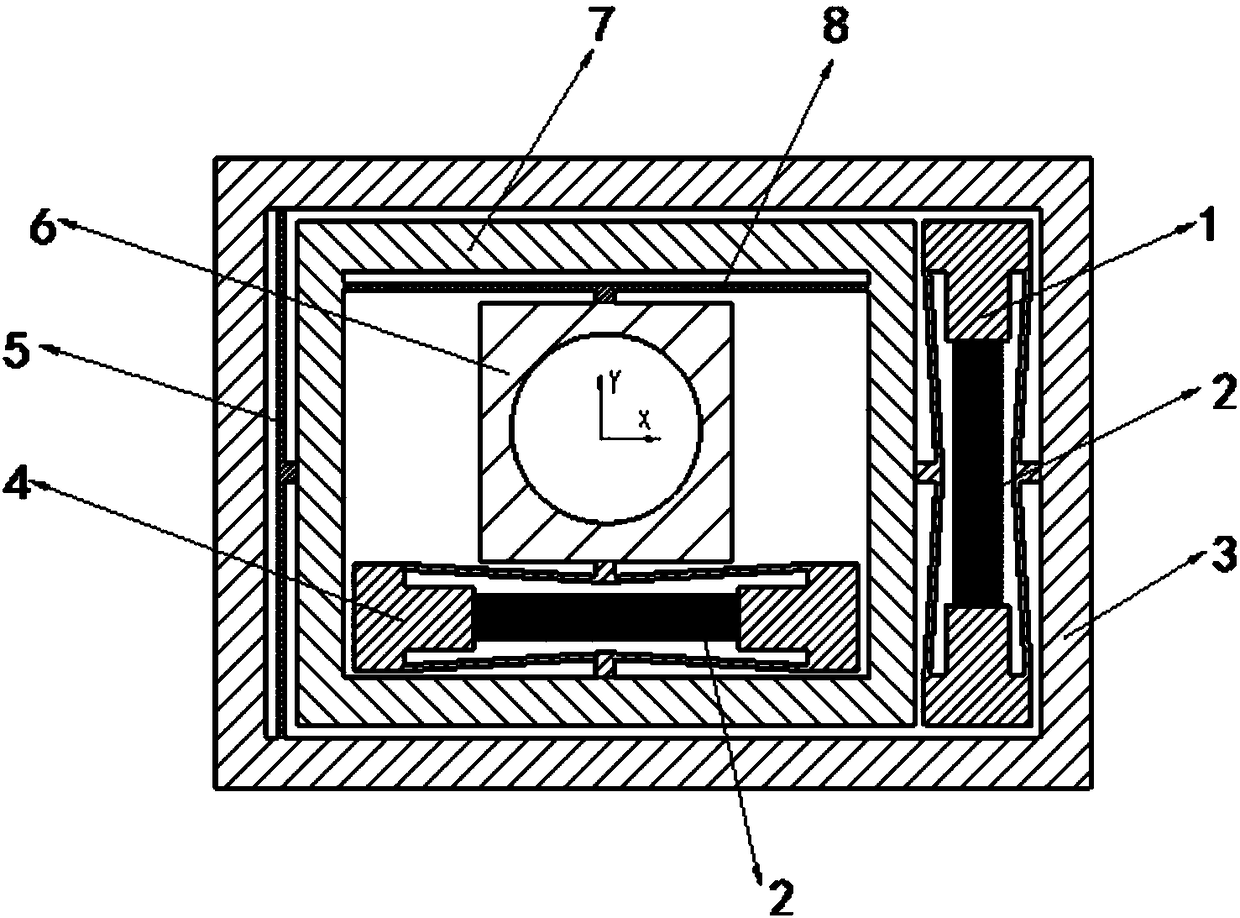

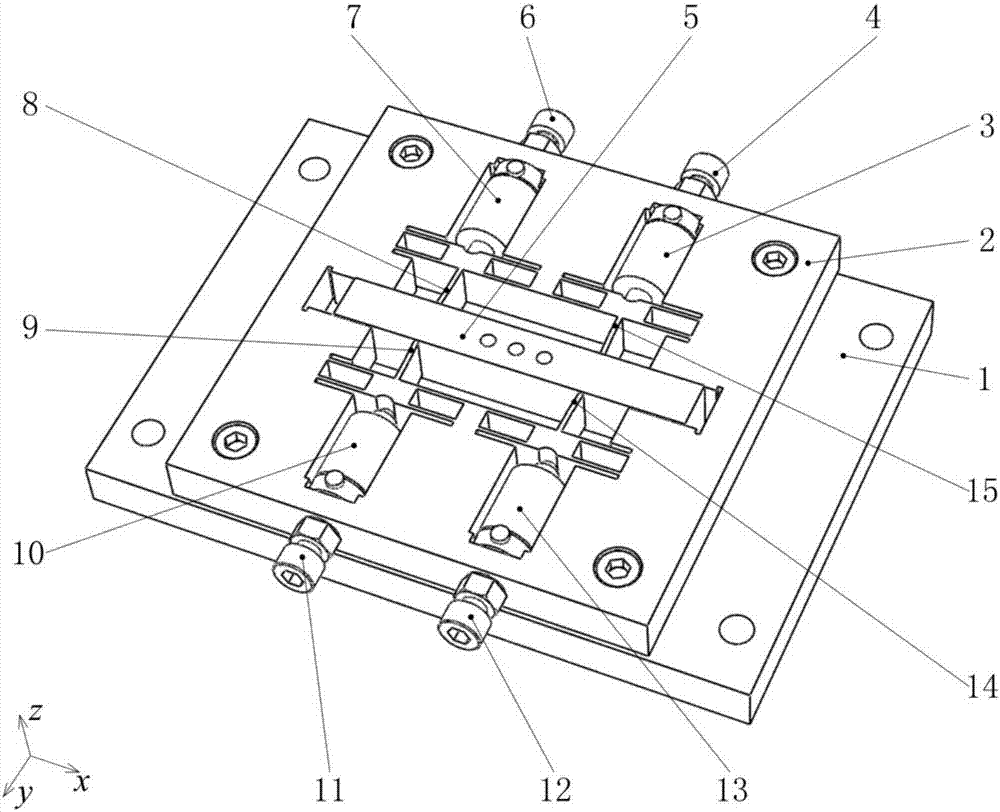

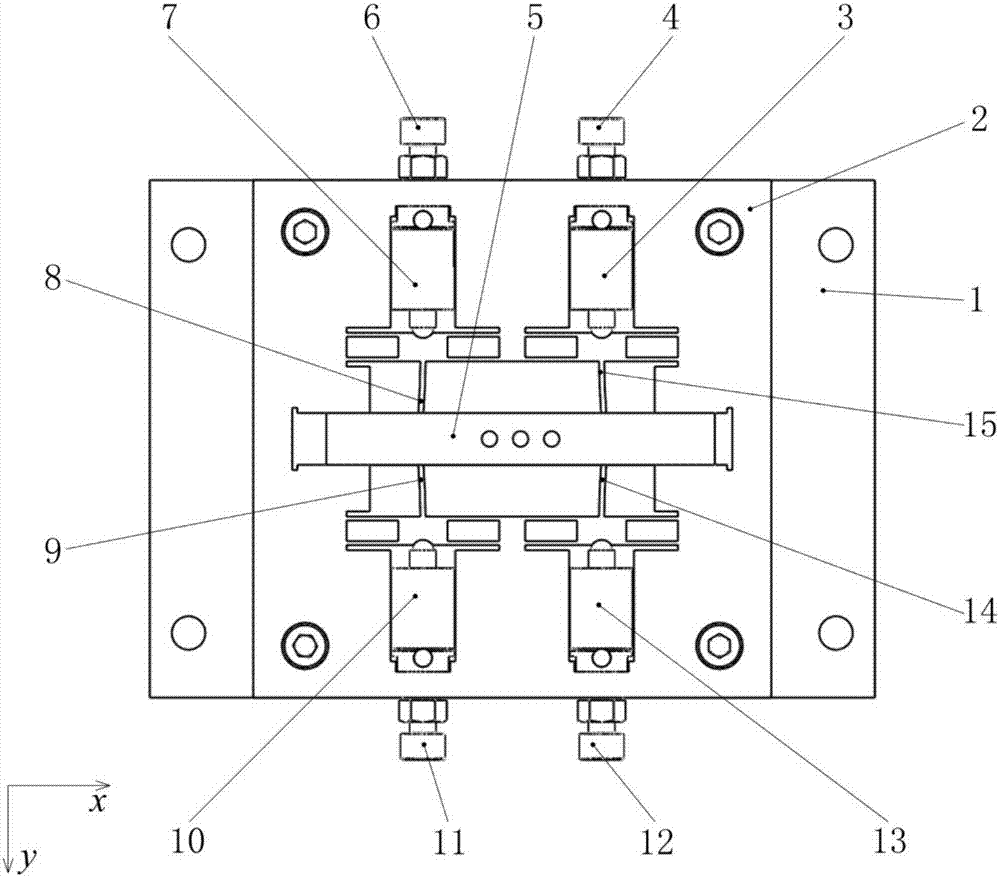

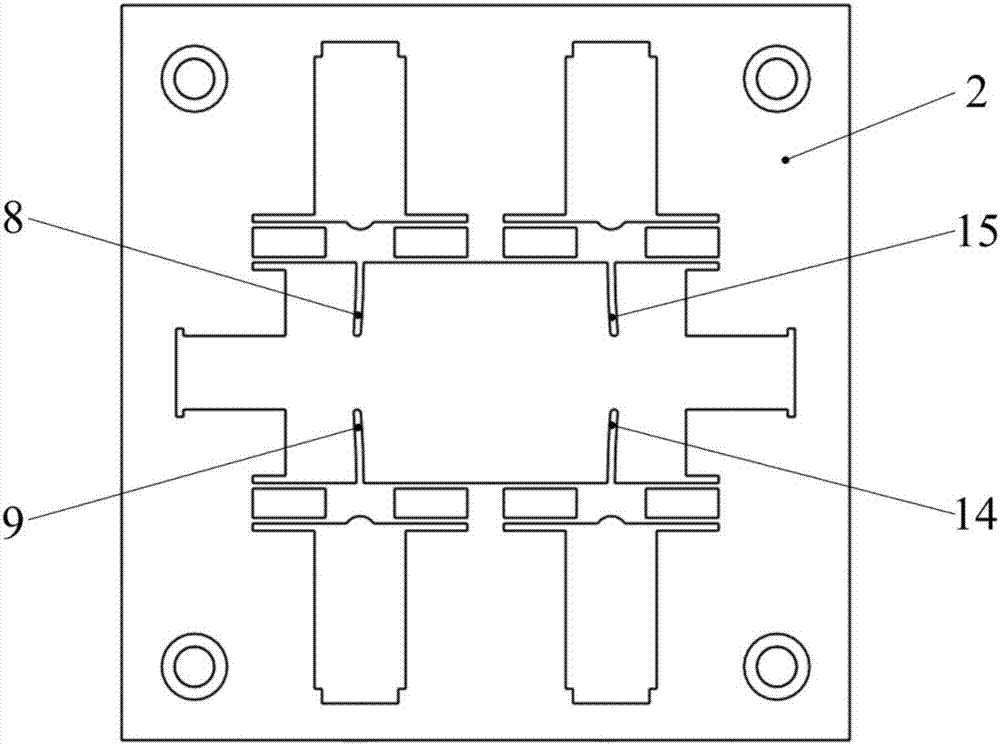

Piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform

InactiveCN106373617ASolve the problem of small output displacementImprove working precisionInstrumental componentsIndependent motionImage resolution

Disclosed is a piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform. The piezoelectric driving large-stroke no-coupling two-dimensional precise micro locating platform is characterize in that the platform comprises an outer layer support seat, a rhombus displacement magnifying mechanism, a piezoelectric ceramic actuator, symmetrical long arm hinges, an inner layer base plate and a workbench; and compared with the prior art, the platform has the advantages that 1, X-direction and Y-direction independent motion can be achieved, and X-direction and Y-direction simultaneous motion can also be achieved; 2, the maximum displacement output quantities in the X direction and the Y direction are close; 3, displacement quantity can be increased, coupling is eliminated, and error is reduced; and 4, the platform has the advantages that mechanical friction, delaying and clearance are avoided, lubrication is not needed, heat and noise are not produced, and the motion resolution is high.

Owner:SHENYANG POLYTECHNIC UNIV

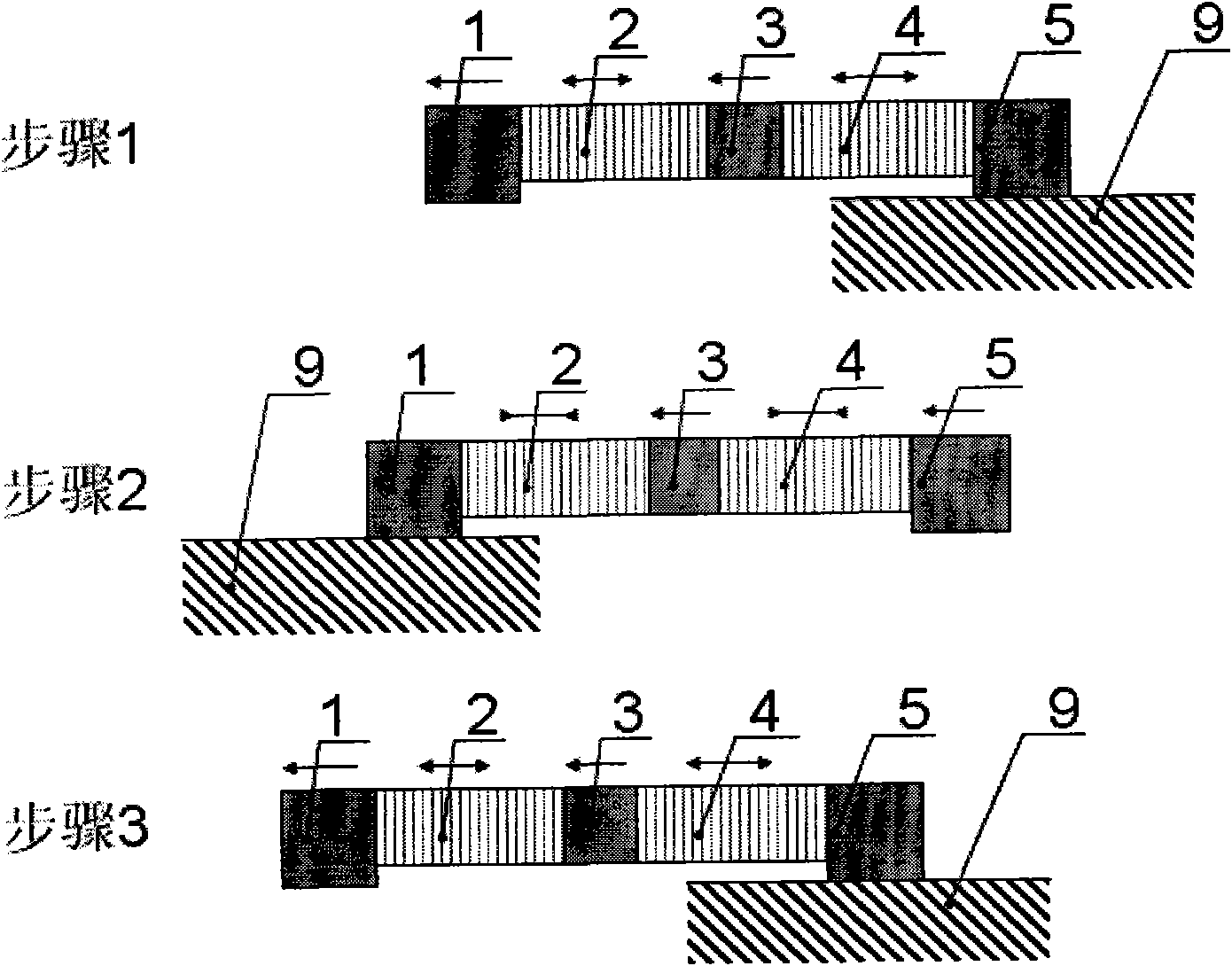

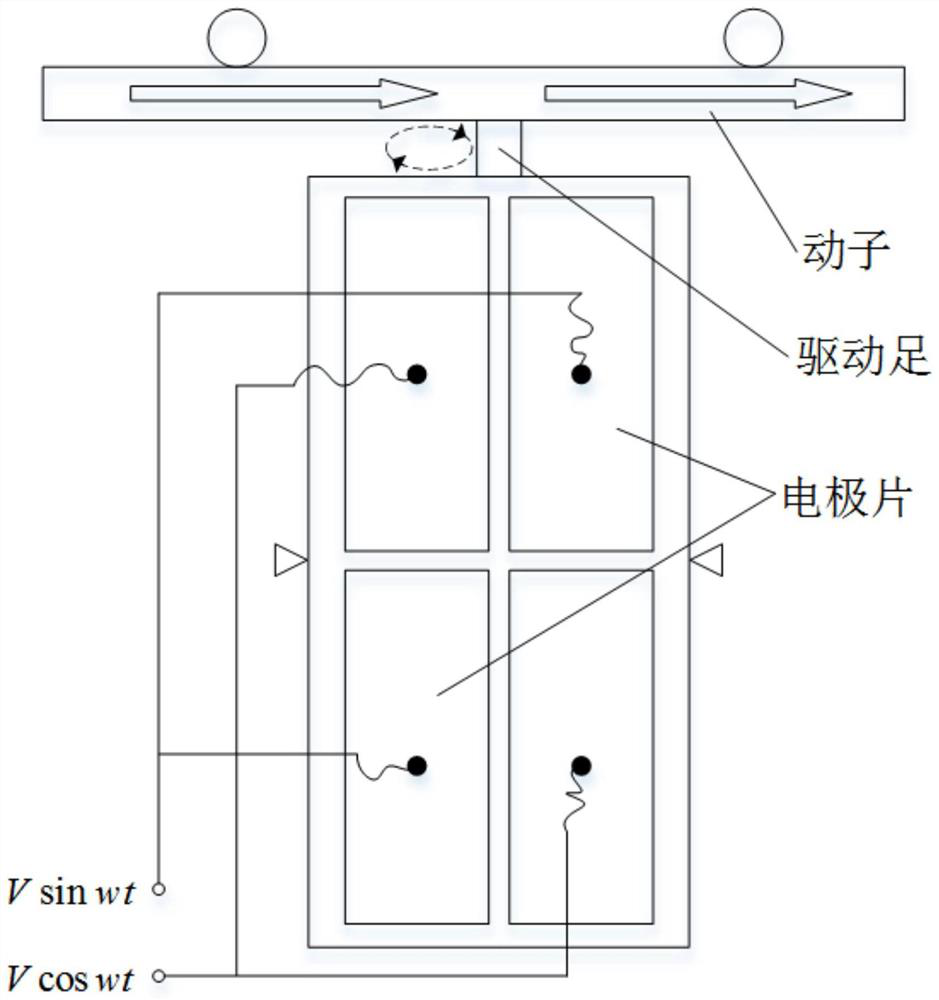

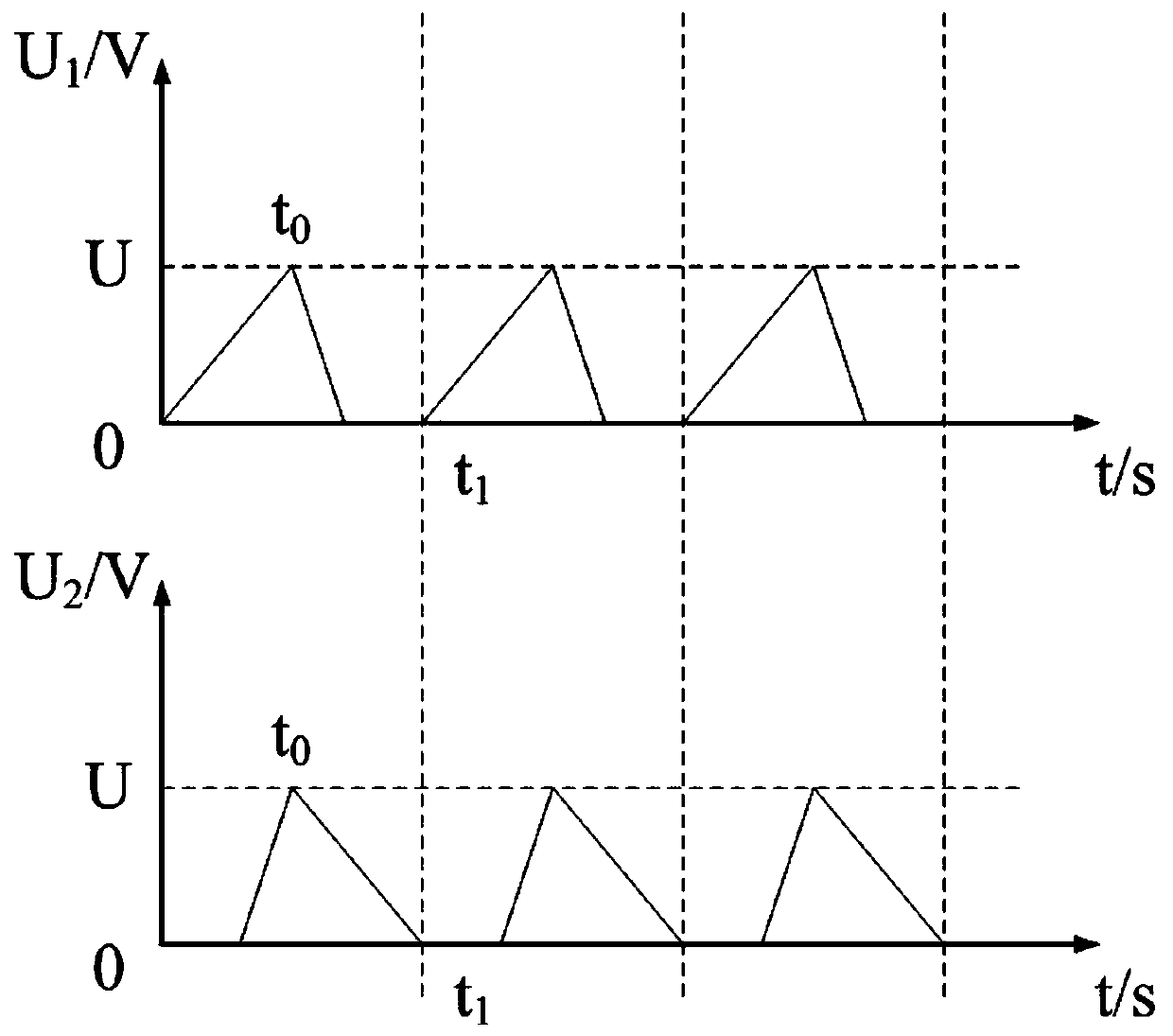

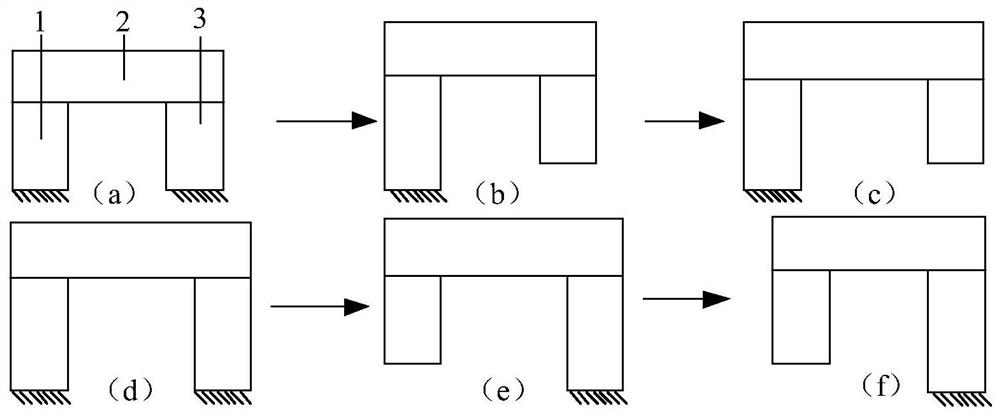

Inertial non-resonant biped piezoelectric linear actuator and working method

InactiveCN106787935AOvercome vulnerability to environmental factorsGuaranteed uptimePiezoelectric/electrostriction/magnetostriction machinesControl theoryLinear actuator

The invention discloses an inertial non-resonant biped piezoelectric linear actuator, which comprises a base, wherein a guide rail is arranged at the upper part of the base; a stator assembly is also arranged at the upper part of the base and is axisymmetrically distributed left driving foot of the stator assembly and right driving foot of the stator assembly; left laminated piezoelectric ceramic and right laminated piezoelectric ceramic are arranged in the left driving foot of the stator assembly and the right driving foot of the stator assembly respectively; and protruding parts of the driving feet of the stator assembly are in contact with one side of the guide rail. The invention further provides a working method of the inertial non-resonant biped piezoelectric linear actuator. Voltage slow-rising and fast-dropping and fast-rising and slow-dropping same-frequency sawtooth wave voltage signals are applied to the left laminated piezoelectric ceramic and the right laminated piezoelectric ceramic in two symmetrically arranged driving foot mechanisms respectively, so that stable continuous straight motion can be achieved, and the inertial non-resonant biped piezoelectric linear actuator has the advantages of being simple in structure, stable in operation, accurate in positioning, high in motion resolution and relatively low in cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Precise motion driving device based on bionics principle

InactiveCN102122901ASimple structureLow calorific valuePiezoelectric/electrostriction/magnetostriction machinesElectricityLow speed

The invention relates to a precise motion driving device based on a bionics principle and belongs to the technical field of geometric quantity measurement. The precise motion driving device comprises a front sucker, a front piezoelectric ceramics micrometric displacement driving element, a motion output supporting point, a back piezoelectric ceramics micrometric displacement driving element, and a back sucker, wherein an iron soft magnetic conductive panel used for fixing the driving device is used as the peripheral equipment of the driving device; and the motion output supporting point is driven to realize the nanometer precise positioning driving in a large motion scope by coordinating the suction actions of the front and back suckers and the stretching actions of the front and back piezoelectric ceramics micrometric displacement driving elements and pushing. The precise motion driving device based on a bionics principle has simple structure, low heat productivity, no pause in motion process, high motion resolution ratio and large motion scope which is only limited by the size of the iron soft magnetic conductive panel. The precise motion driving device can realize the precise motion and is suitable for the occasions requiring low-speed running.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

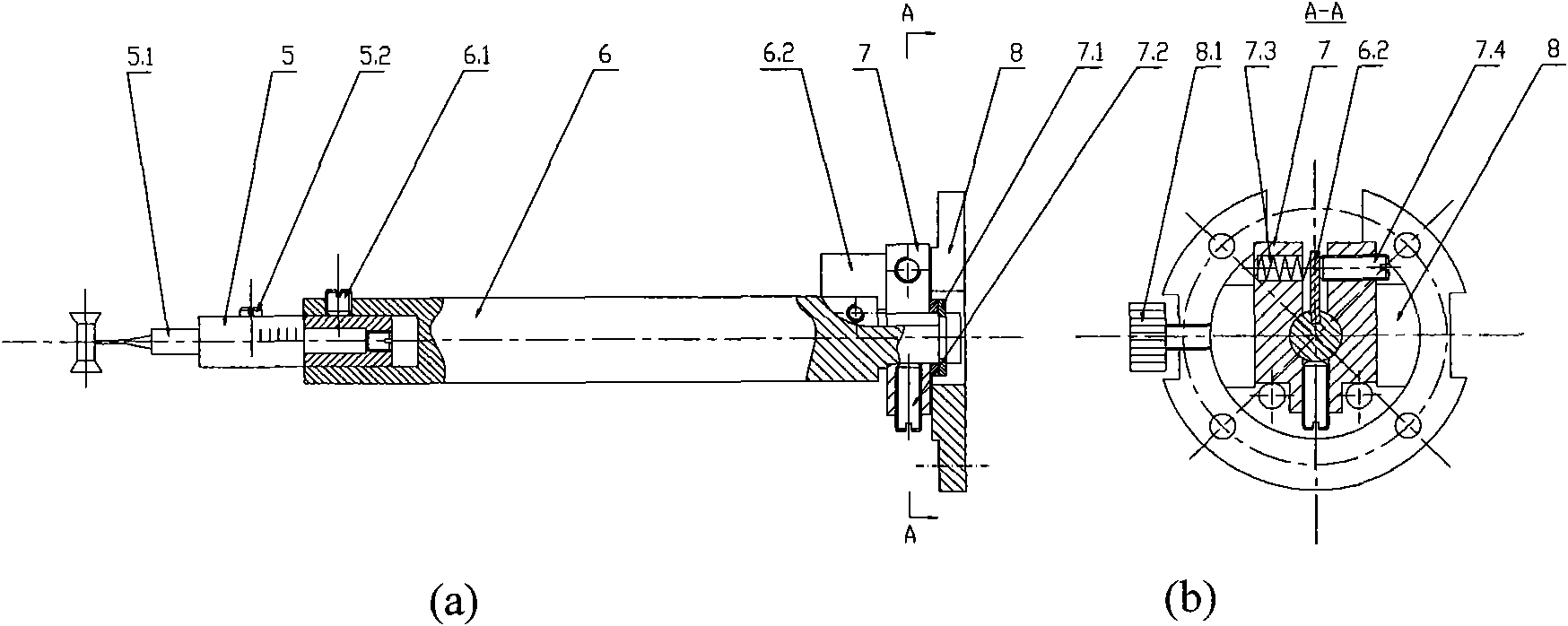

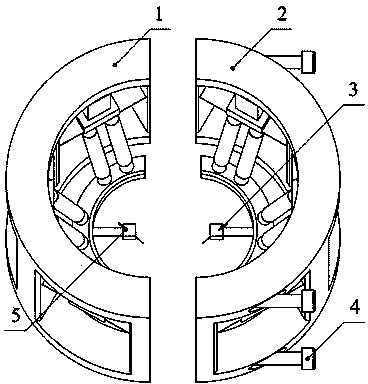

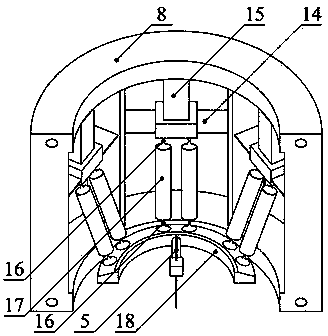

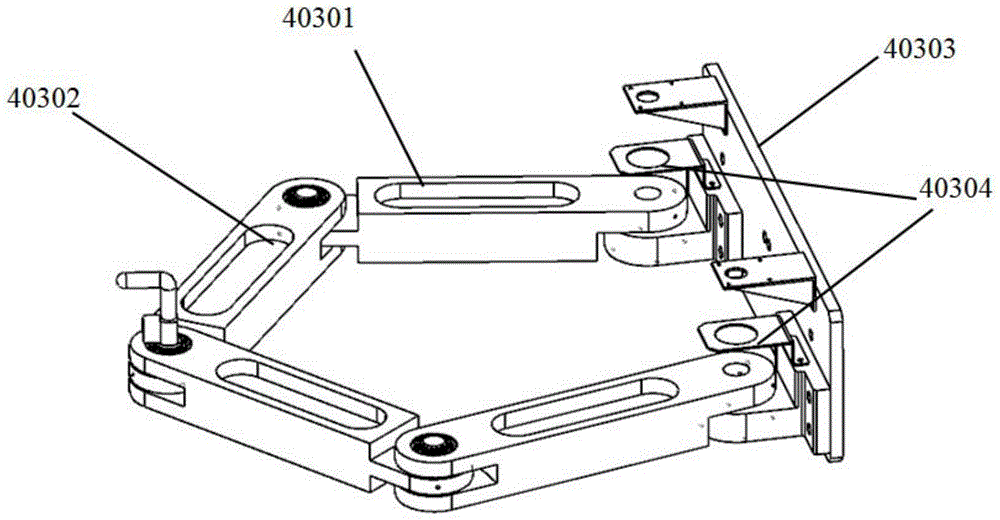

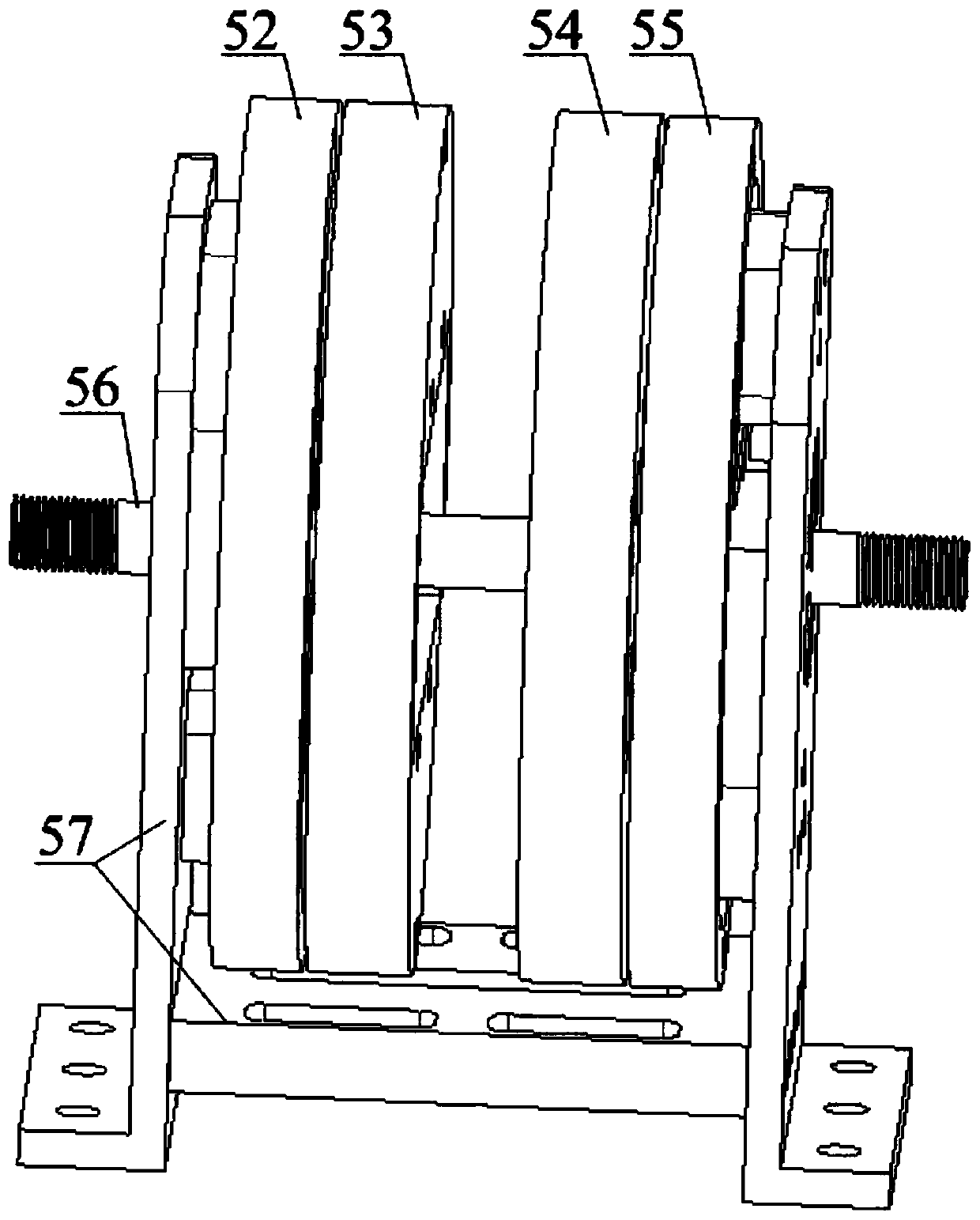

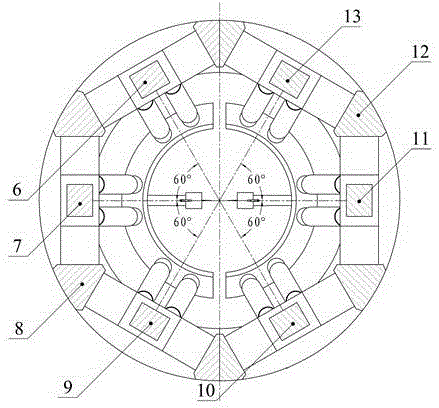

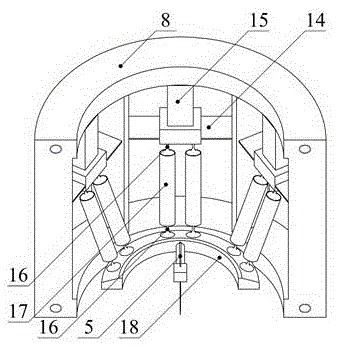

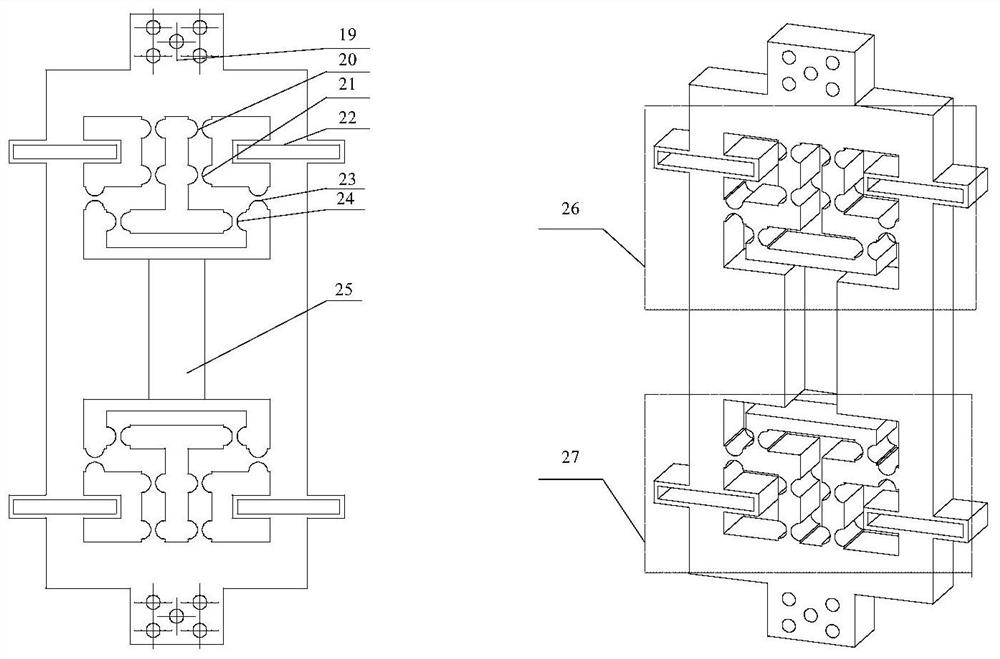

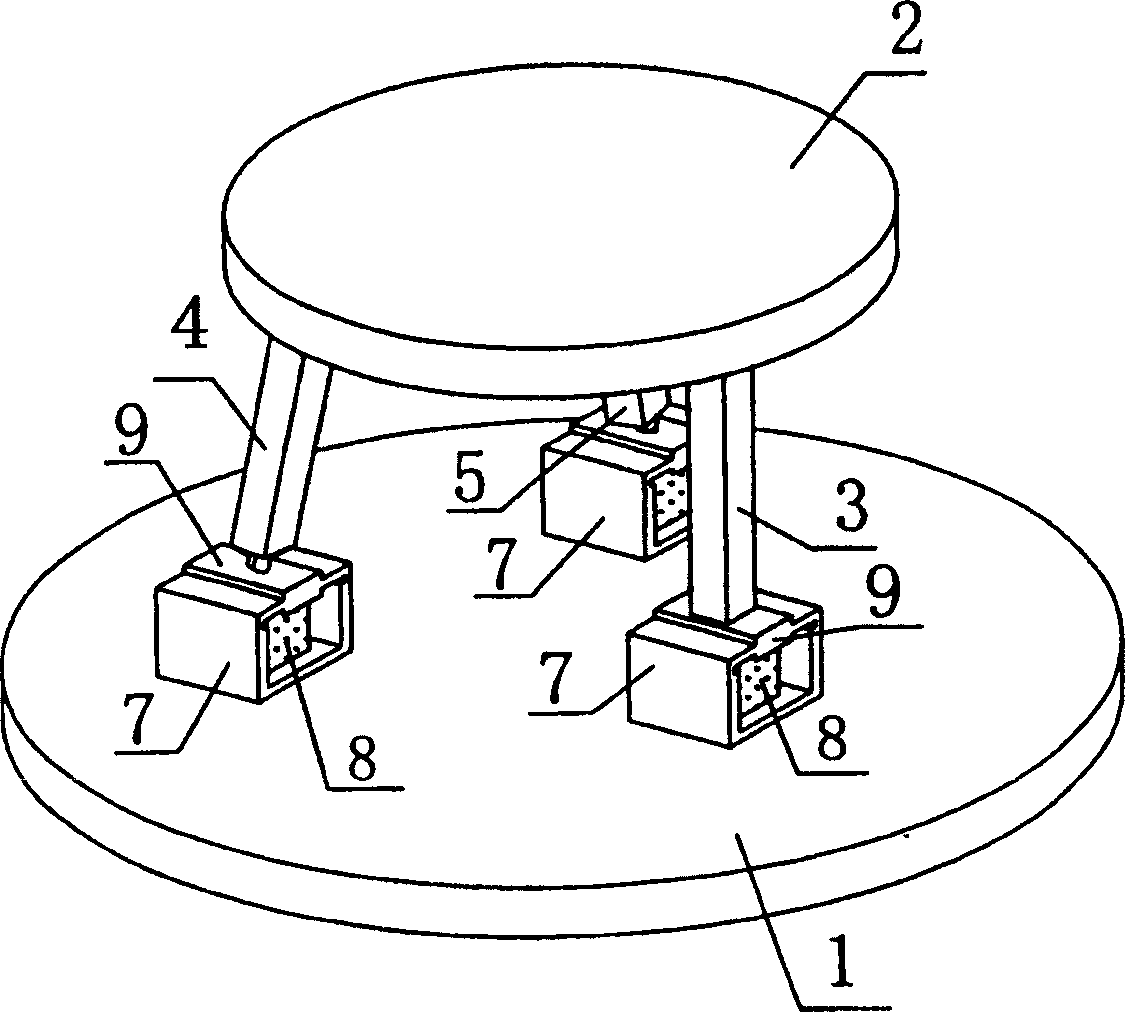

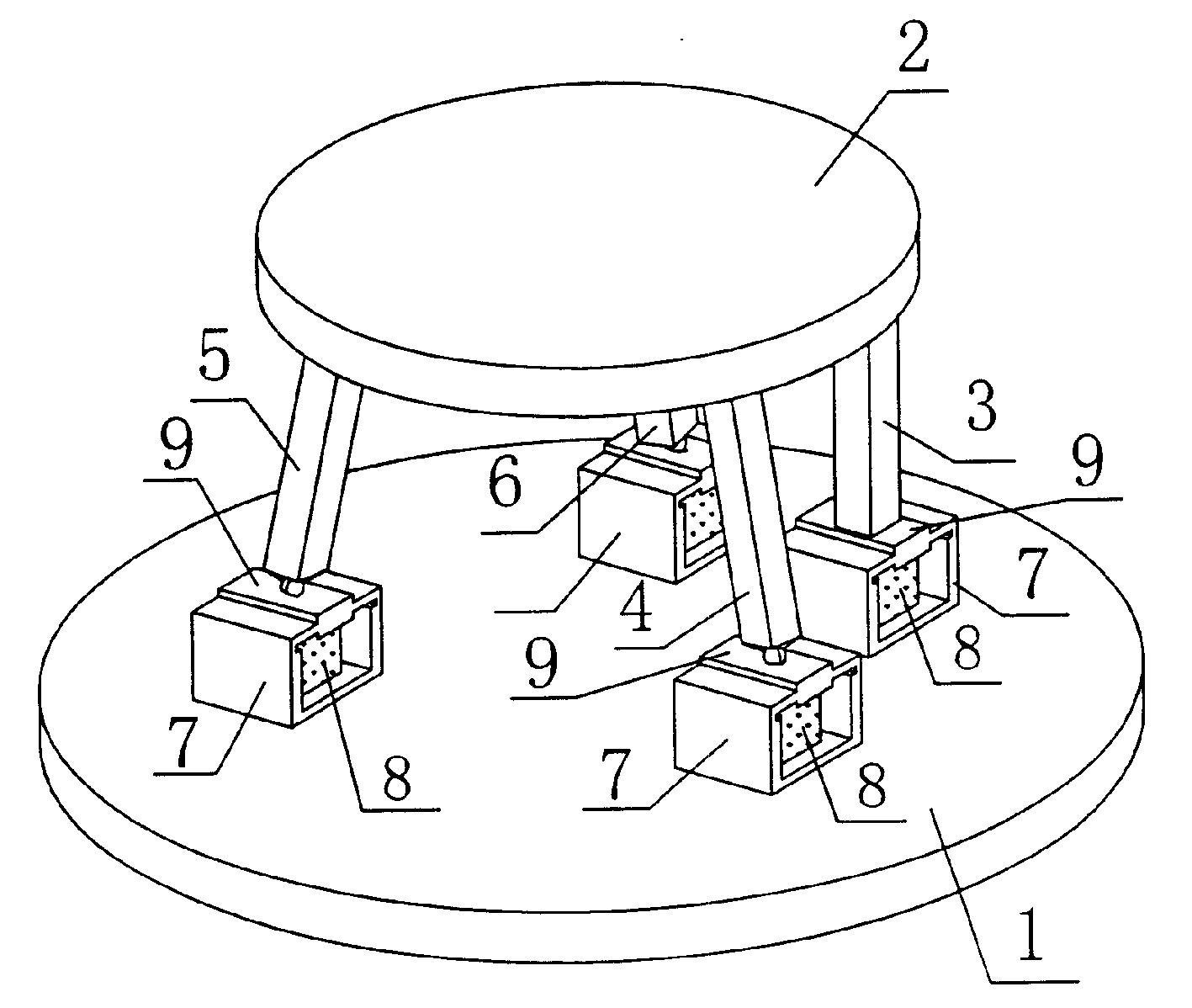

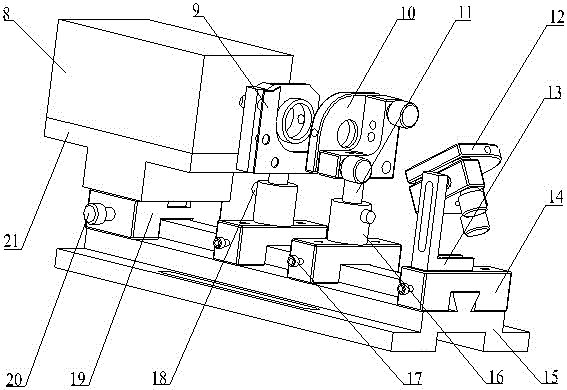

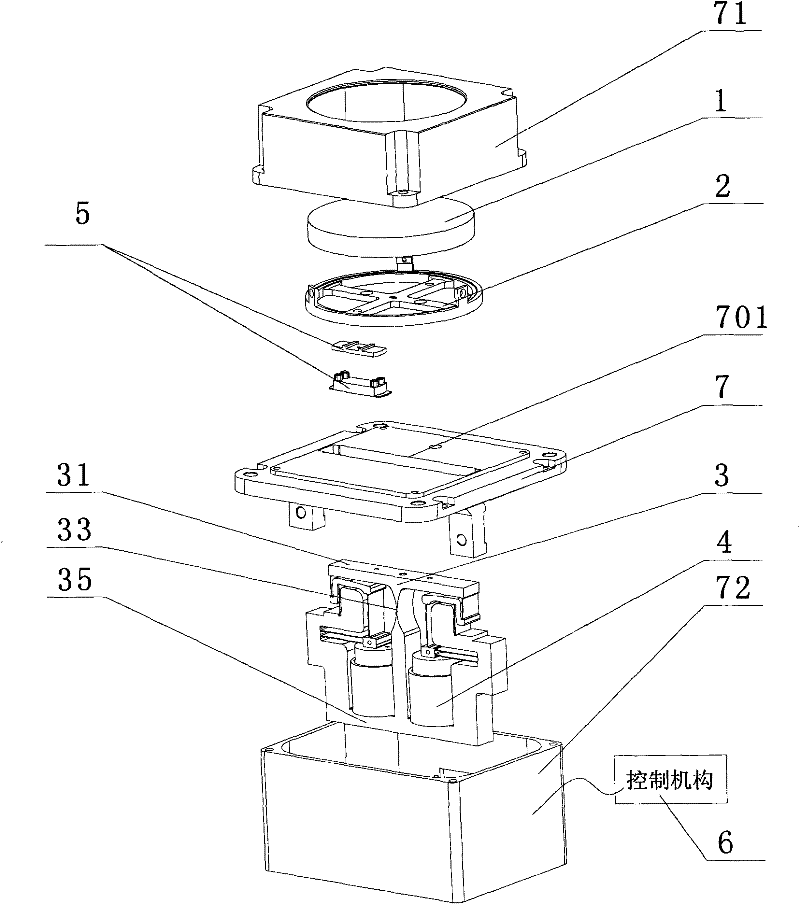

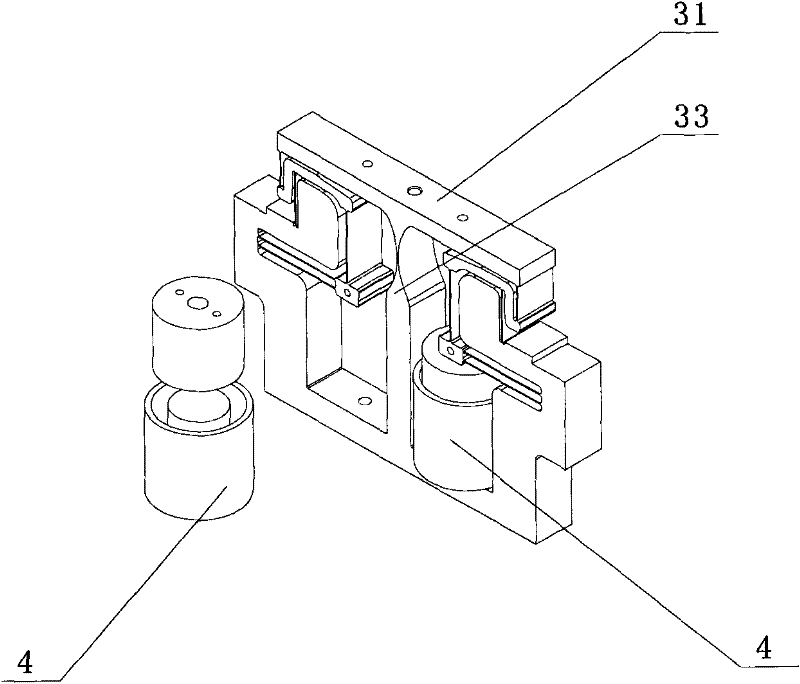

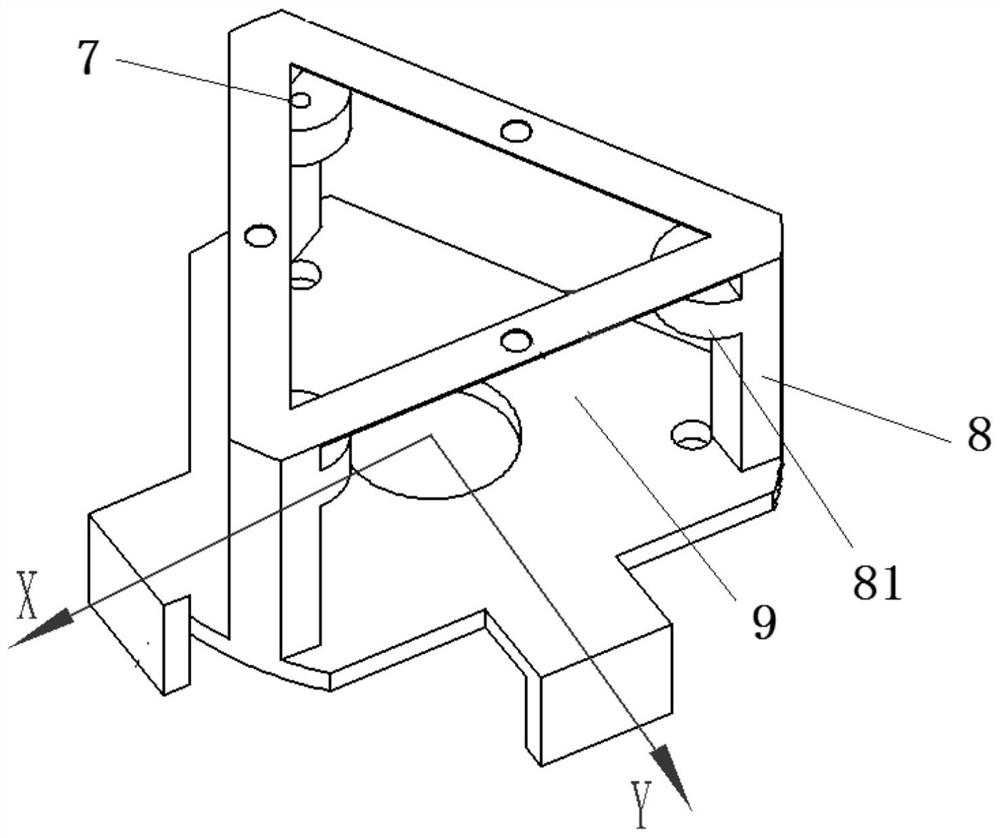

Parallel micromanipulation robot

InactiveCN103786151AHigh motion resolutionSmall moment of inertiaProgramme-controlled manipulatorMicro-operationControl engineering

A parallel micromanipulation robot comprises a left micromanipulation arm and a right micromanipulation arm, which are the same in structure and symmetrically arranged. Each of the left and right micromanipulation arms comprises a semi-cylindrical micromanipulation arm frame, three branch chains, a micromanipulation arm moving platform and a micromanipulation arm terminal tool. Each branch chain comprises a micro-displacement driver, a flexible prismatic pair and two branches the same in structure; one end of every branch is connected with the left micromanipulation arm moving platform, and the other end of each branch is connected with the corresponding flexible prismatic pair; the axes of the two branches are parallel to each other; the fixed end of the micro-displacement driver is connected with the left micromanipulation arm frame, and the drive end of the micro-displacement driver is connected with the flexible prismatic pair. The three branch chains forming each micromanipulator arm are evenly distributed in a semi-cylindrical space. The parallel micromanipulation robot allows for three-dimensional high-precision operation, is compact in overall structure with wide operating range and high resolution, and is widely applicable to the fields such as biomedical engineering and precision engineering.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

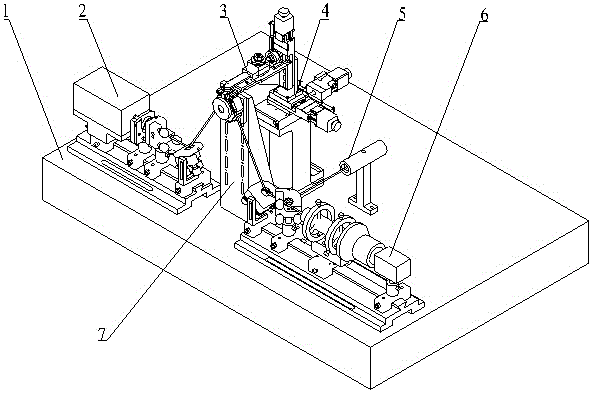

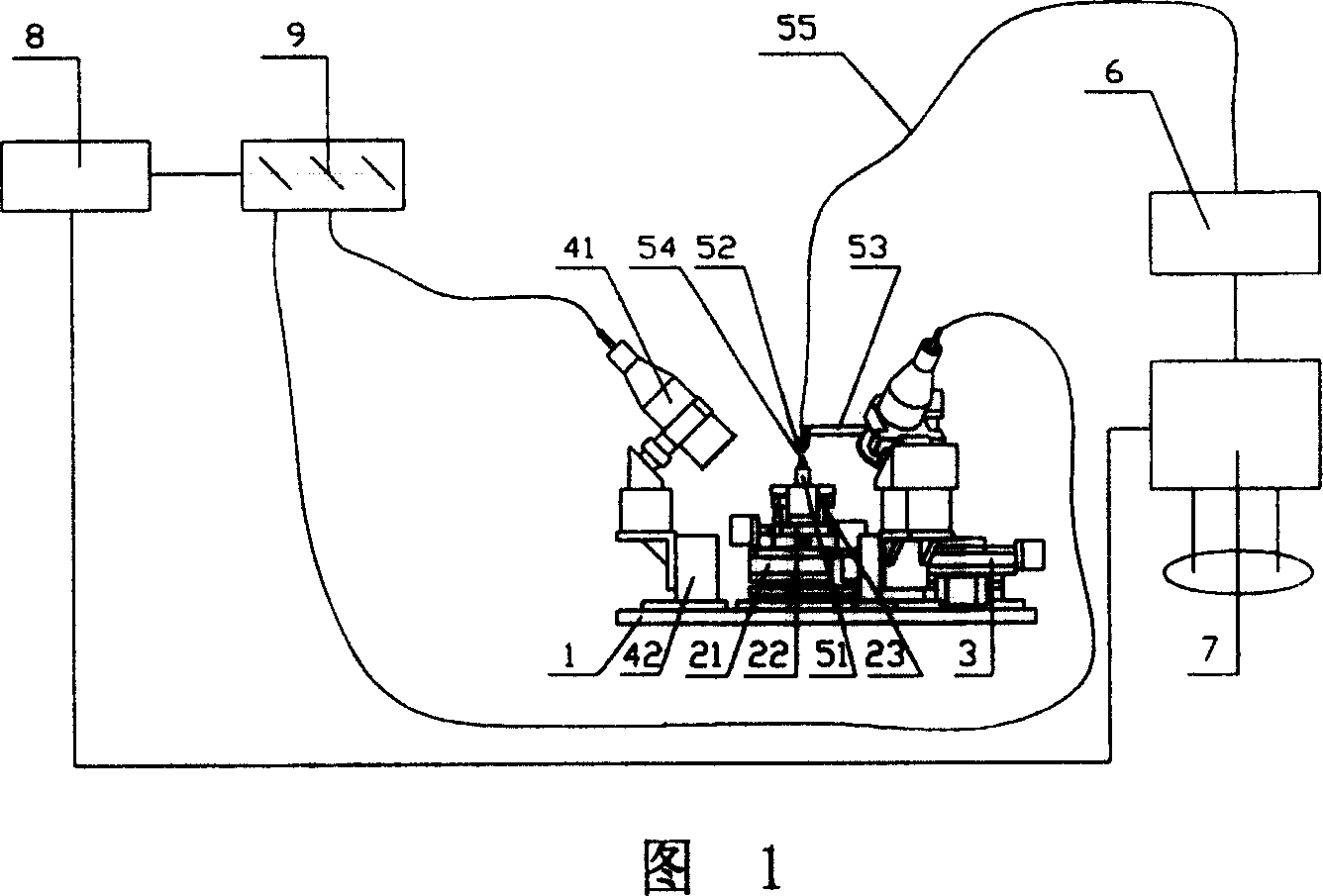

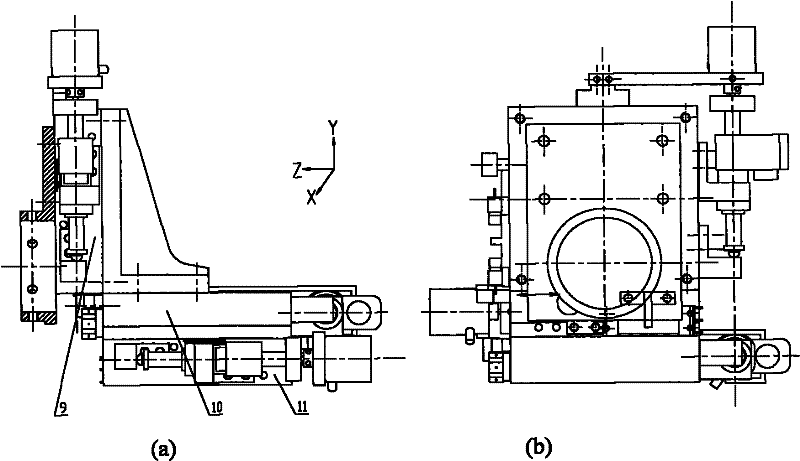

Automatic laser welding device for fibre-optical active component

InactiveCN100351033CAdaptableIncrease flexibilityLaser beam welding apparatusFiberOptical power meter

The automatic laser welding apparatus for active fiber device includes a work table, a control unit, a laser welding mechanism and a precise butt jointing mechanism, and the laser welding mechanism and the precise butt jointing mechanism are installed on the work table. The precise butt jointing mechanism includes a fiber position regulating mechanism and a light source device position regulating mechanism, the fiber position regulating mechanism includes three successively superposed 1D translation stages and one fiber device fixture on the stages, and the light source device position regulating mechanism includes one 2D inclined stage and two orthogonal micro platforms in the same structure and on the inclined stage. The control unit includes one host control computer and one light power meter and is connected via cables to other mechanisms. The present invention has the advantages of simple structure, simple control, low cost, great stroke, high resolution, etc.

Owner:NAT UNIV OF DEFENSE TECH

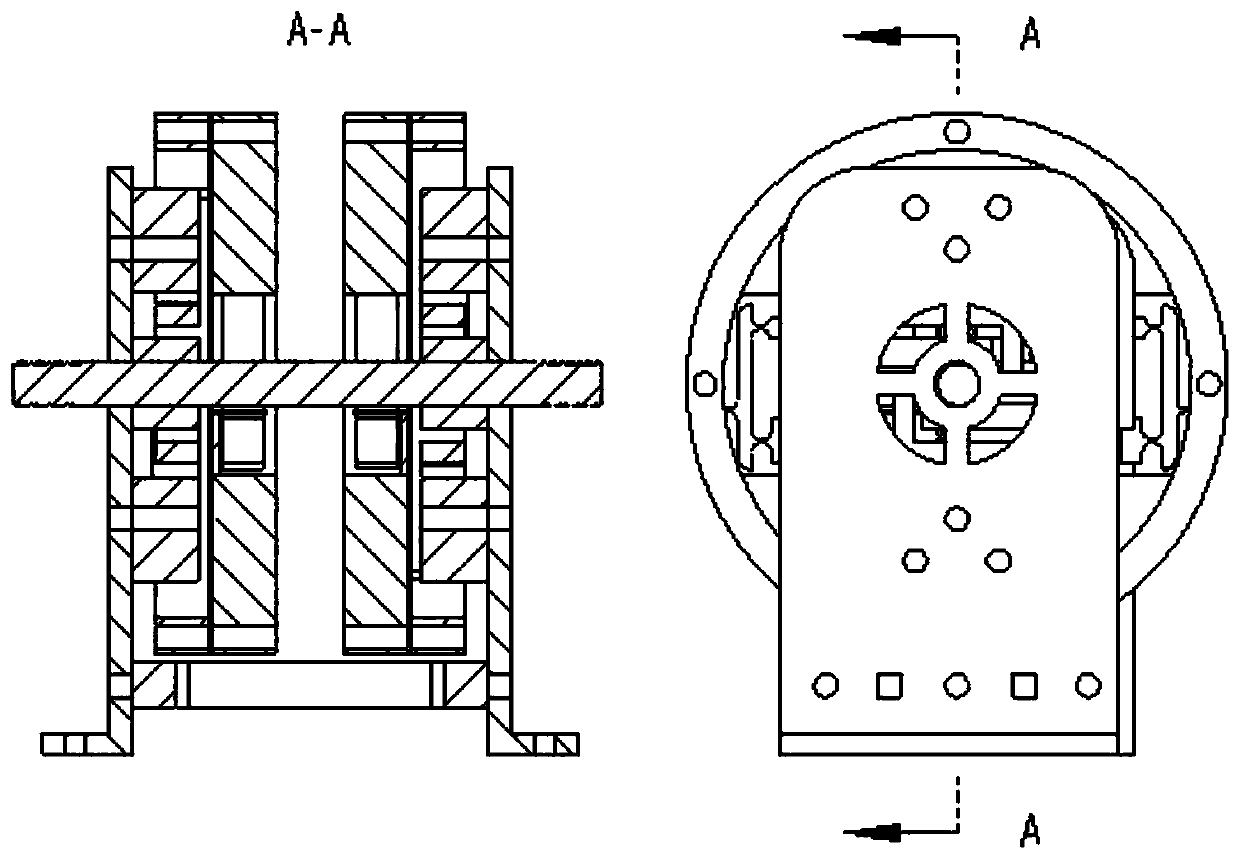

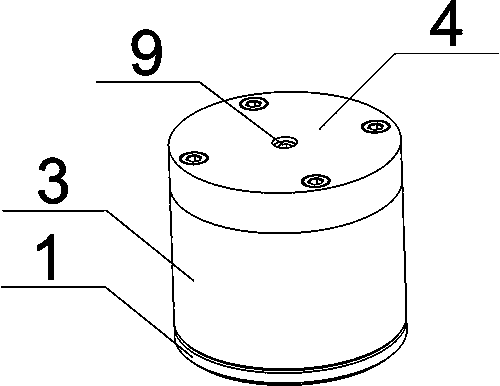

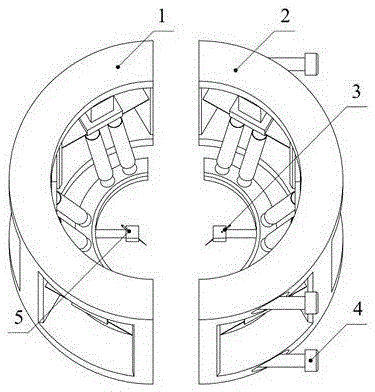

Inchworm precision rotary micro-driver based on compliant mechanism

ActiveCN110086374AHigh precisionRealize the clamping effectPiezoelectric/electrostriction/magnetostriction machinesCompliant mechanismHigh resolution

The invention discloses an inchworm precision rotary micro-driver based on a compliant mechanism, which comprises two driving mechanisms, two clamping mechanisms, a mover and a bracket, wherein the two driving mechanisms, namely, the first driving mechanism and the second driving mechanism, are the same in structure; the two clamping mechanisms, namely, the first clamping mechanism and the secondclamping mechanism, are the same in structure; the two driving mechanisms are respectively located at two sides, and the two clamping mechanisms are located between the two driving mechanisms; the mover is located on the bracket and placed at the symmetry center of the rotary micro-driver and mutually cooperated with the mechanisms through an output hole; the clamping mechanisms can clamp or release the mover; when the clamping mechanisms clamp the mover, the mover rotates along with the clamping mechanisms; and when the clamping mechanisms release the mover, the mover moves freely. The micro-driver provided by the invention has the advantages of large travel, high resolution, large output load, bidirectional movement and the like.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

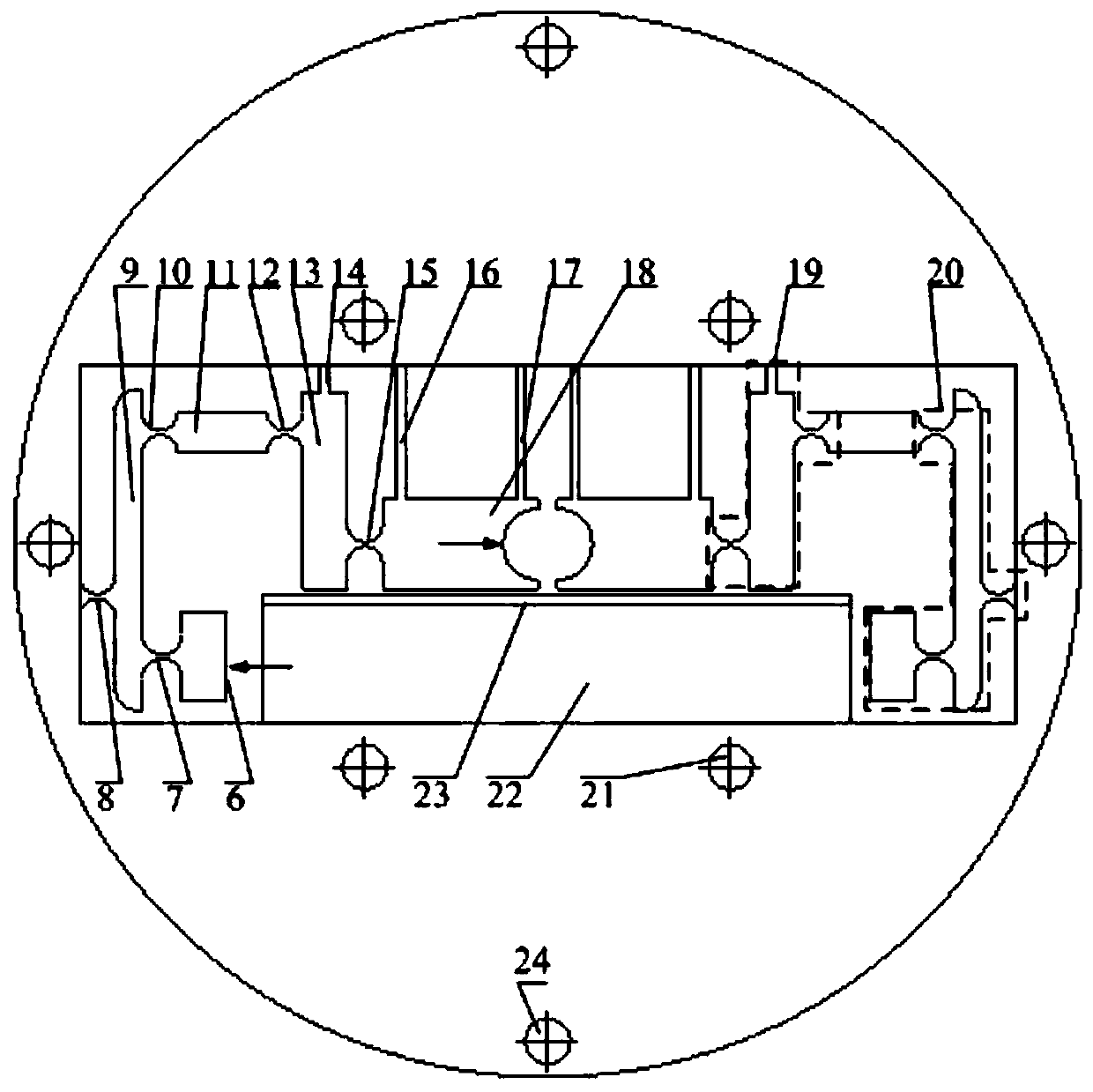

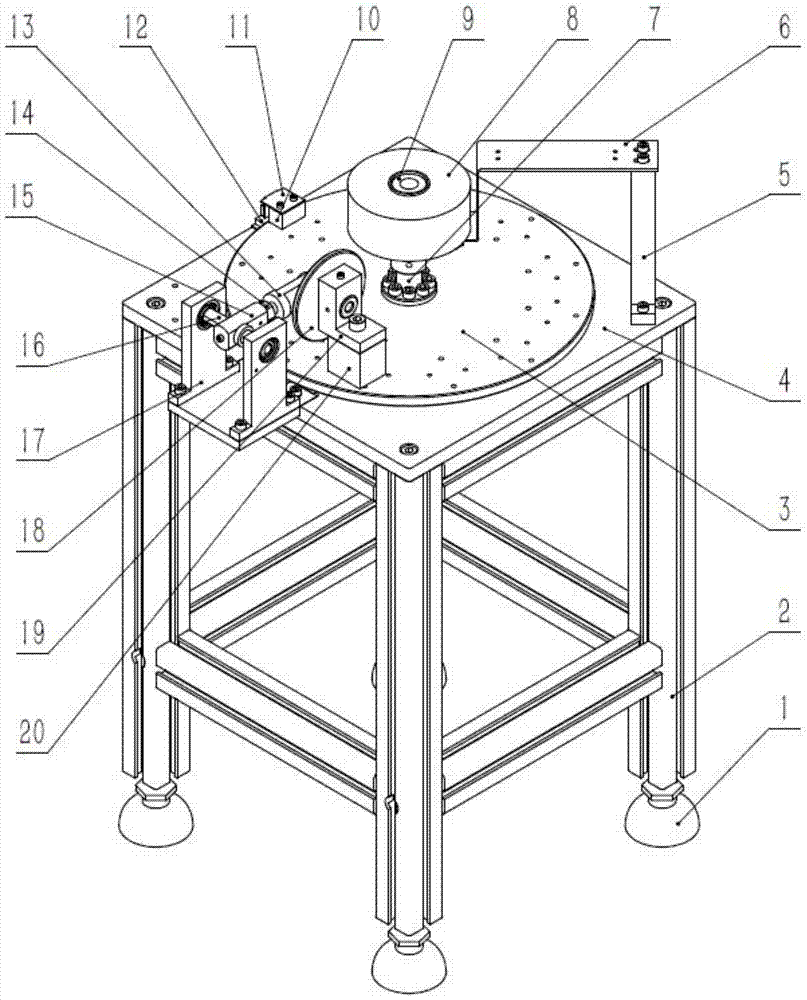

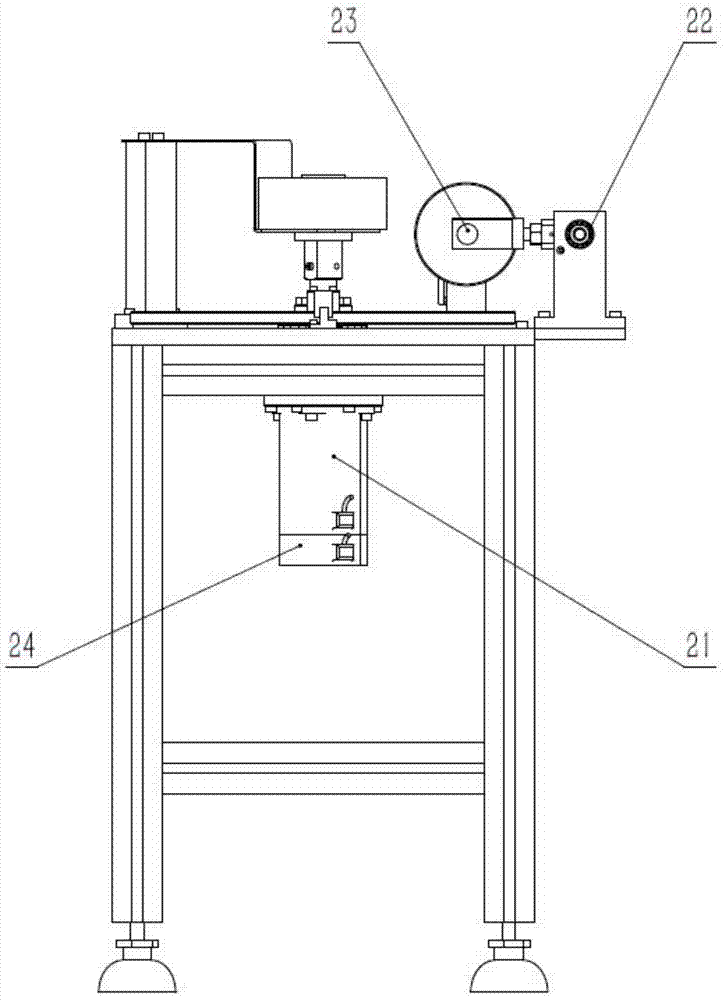

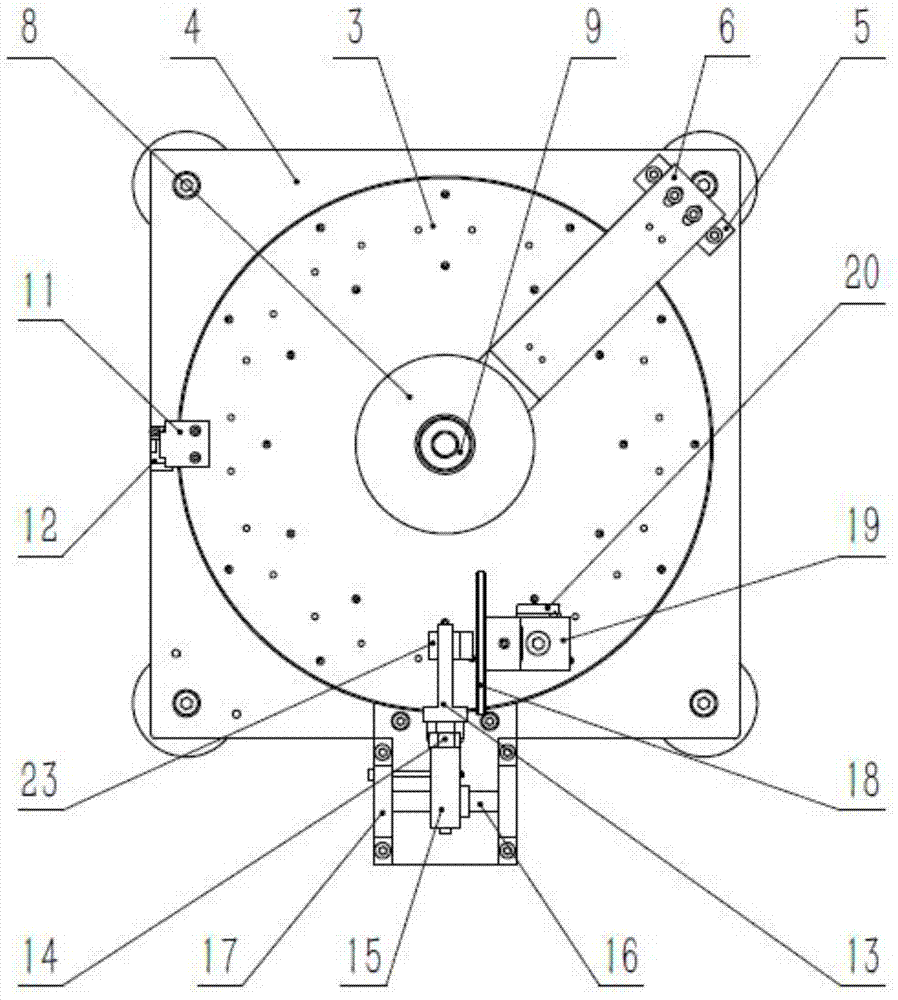

Servo-type multi-position turntable and its precision characteristic testing device

ActiveCN104942775BSmall transmission errorHigh positioning accuracyAutomatic control devicesMeasurement/indication equipmentsEngineeringReducer

The invention discloses a servo-type multi-station rotary table and a precision property testing device thereof. The rotary table comprises a rack and a fixed disc arranged on the rack, a multi-station rotary disc is installed on the fixed disc, a servo motor is installed on the rack, and the servo motor is in transmission connection with the multi-station rotary disc through a harmonic speed reducer; a photoelectric switch is installed between the multi-station rotary disc and the fixed disc, a motor encoder is installed on an output shaft of the servo motor, and an original point reset device is formed by the photoelectric switch and the motor encoder. The testing device comprises an angle encoder testing device and an eddy current displacement sensor testing device. According to the servo-type multi-station rotary table and the precision property testing device thereof, by means of the rotary table, the intermittent movement of the multi-station rotary disc under different numbers of divisions, different movement-static rates, different movement directions and different accelerating and decelerating control modes can be achieved; by means of the precision testing device, measurement of parameters such as fine division errors, dynamic division errors and repetitive errors of the multi-station rotary disc can be achieved.

Owner:SOUTHEAST UNIV

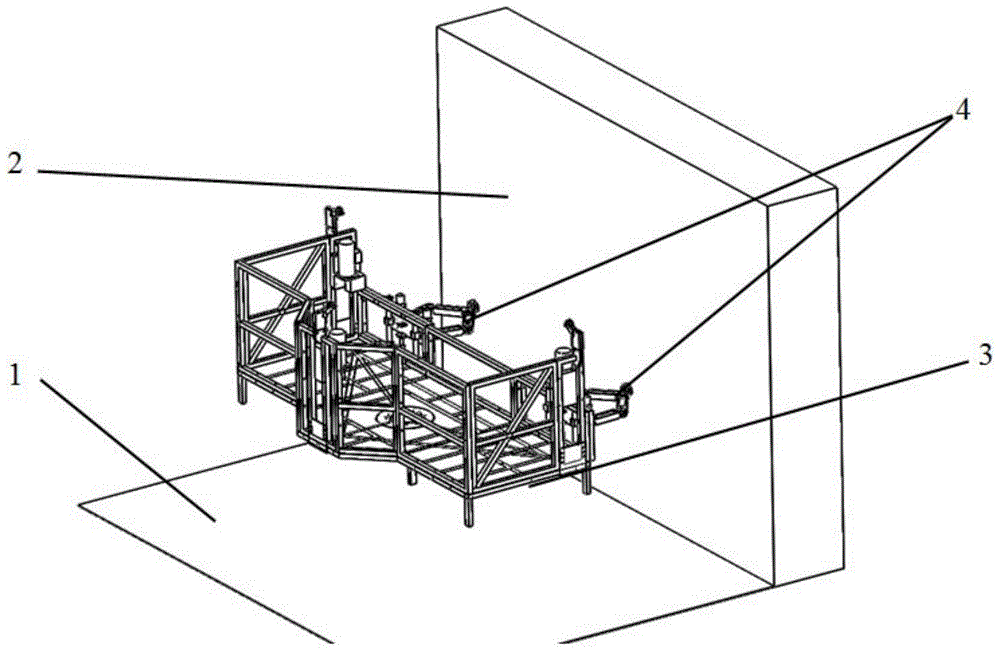

A two-degree-of-freedom vibration suppression system for high-altitude construction robot work platforms

ActiveCN105090339BHigh motion resolutionSmall motion resolutionNon-rotating vibration suppressionVertical vibrationMagneto rheological damper

A two-freedom-degree vibration restraining system applied to a high-altitude building robot operating platform comprises a force sensor, two driving rods with the same length, two driven rods with the same length, a horizontal adjusting motor, a magnetic powder clutch, a rotary type magneto-rheological damper, an installing plate and a vertical vibration reducing mechanism. The two-freedom-degree vibration restraining system is characterized in that two installing seat area arranged on the inner surface of the installing plate; each installing seat is connected with the front end of one driving rod through a driving rod controlling shaft, the tail end of each driving rod is connected with the front end of one driven rod, and the tail ends of the two driven rods are connected together; the installing plate, the driving rods and the driven rods form a planar five-connecting-rod mechanism; and the planar five-connecting-rod mechanism can move in a plane perpendicular to the inner surface of the installing plate and has two freedom degrees. The vertical vibration reducing mechanism is arranged on the outer surface of the installing plate.

Owner:HEBEI UNIV OF TECH

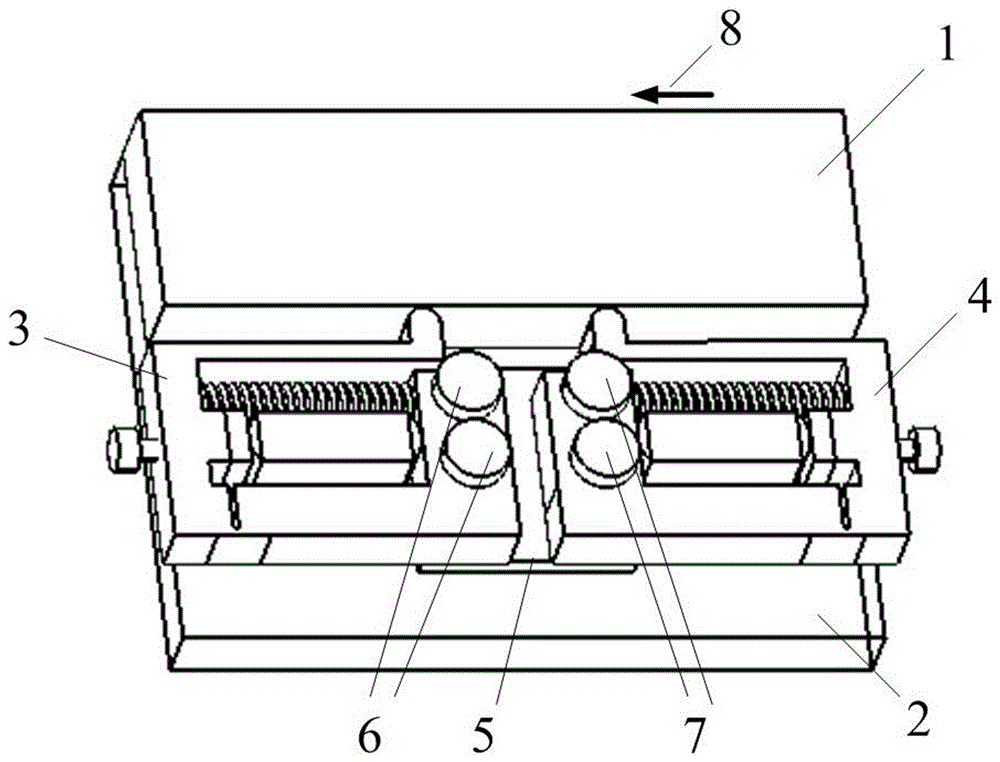

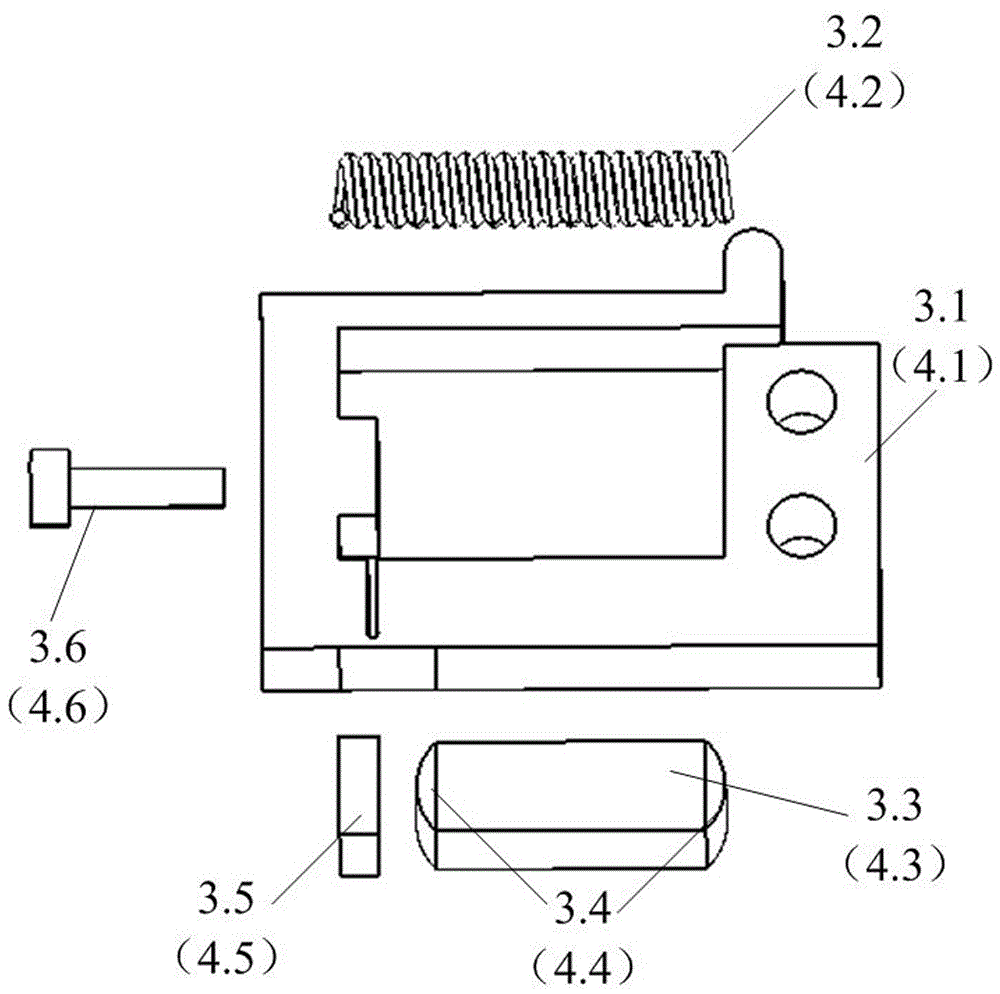

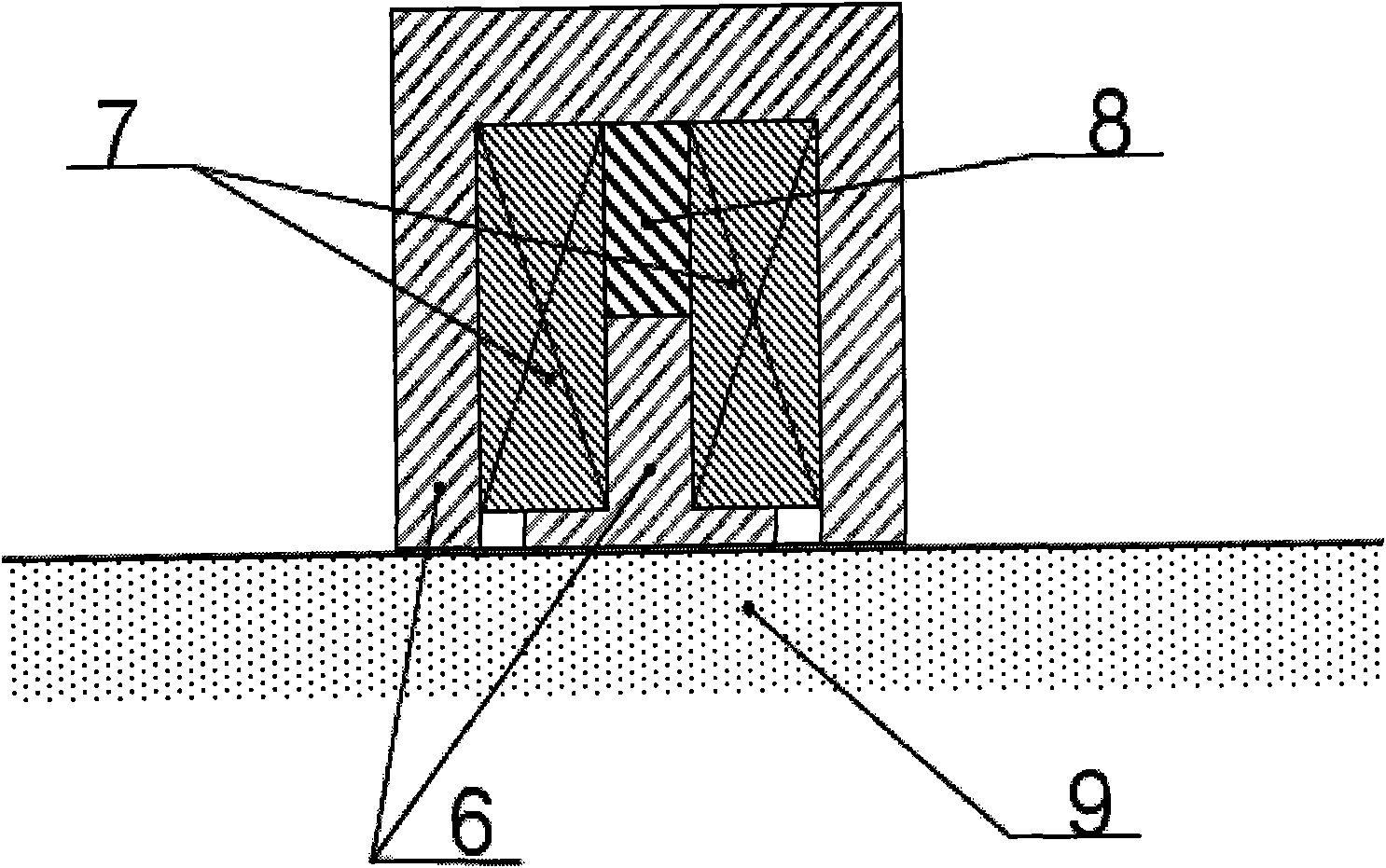

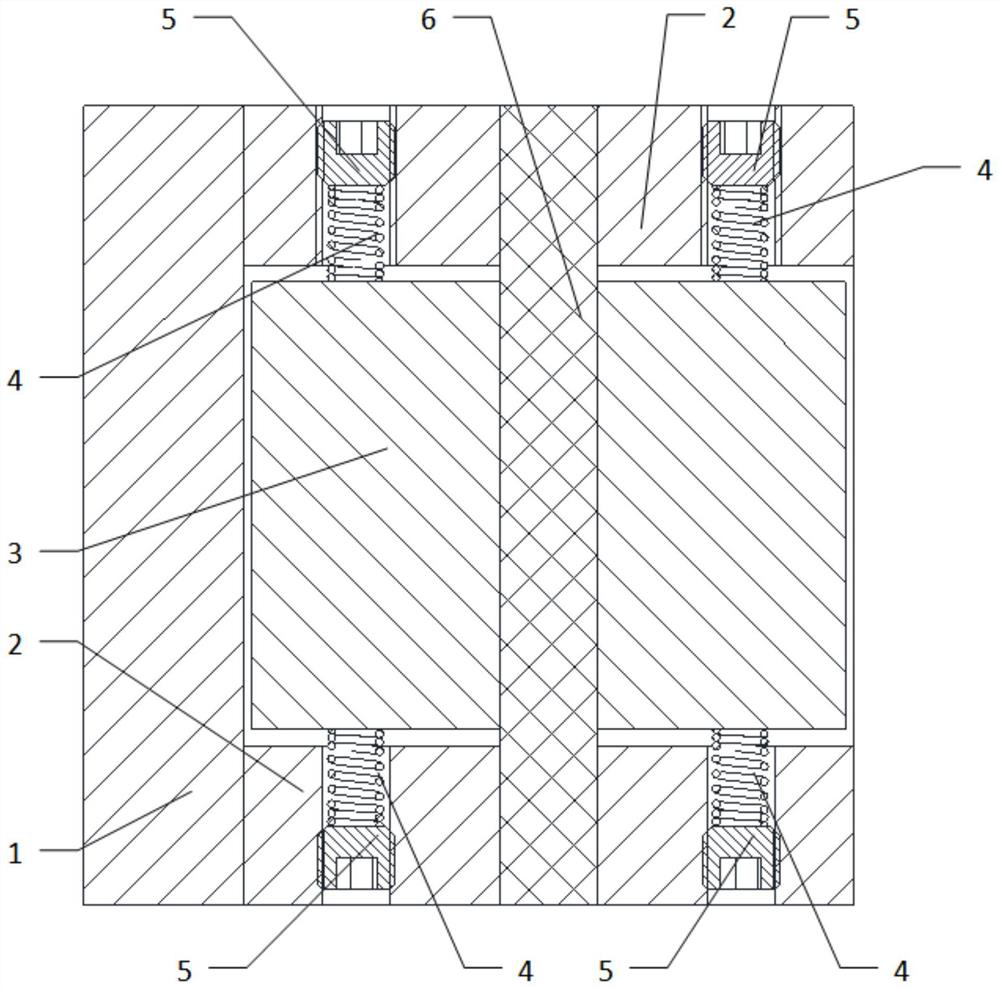

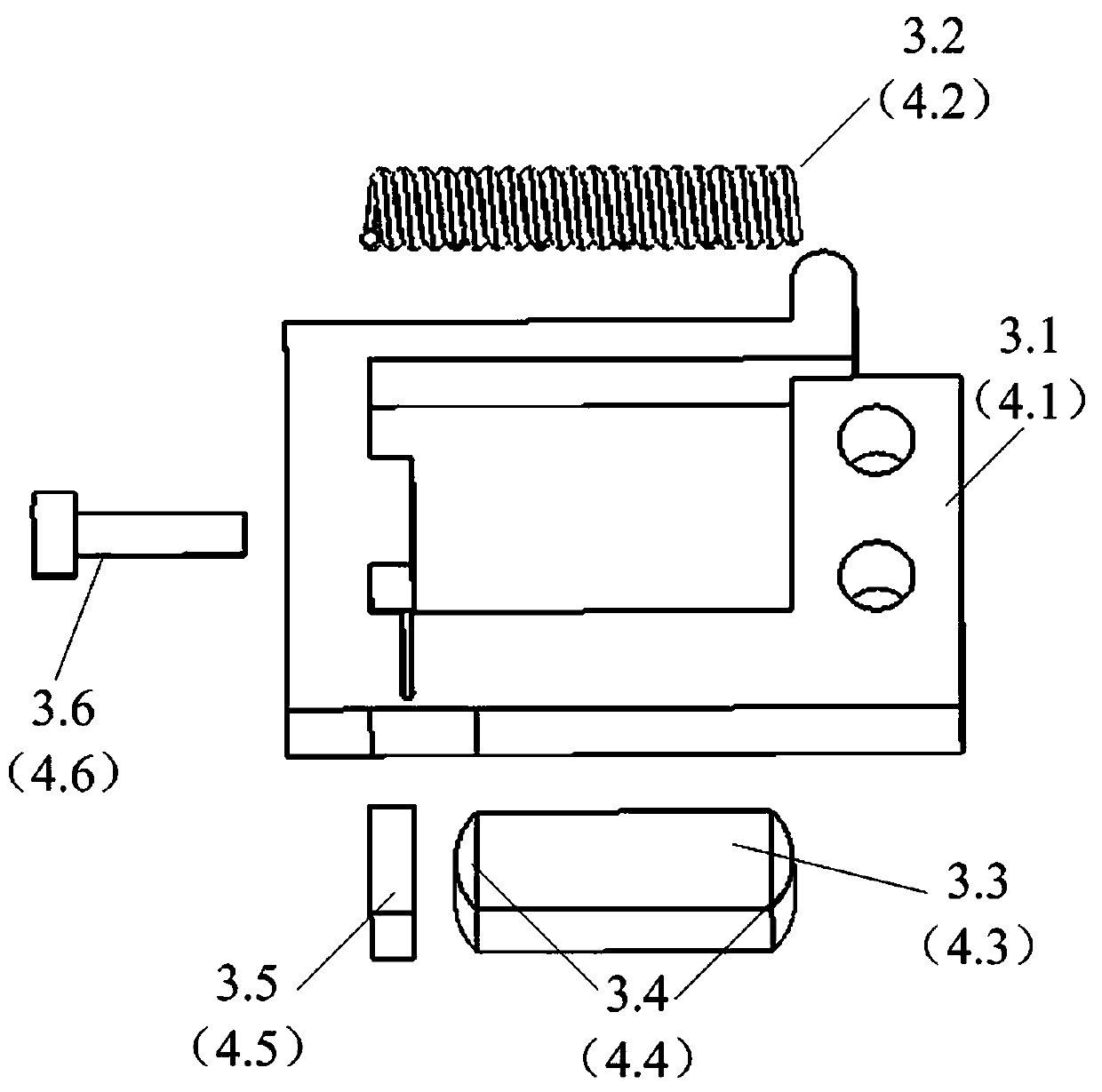

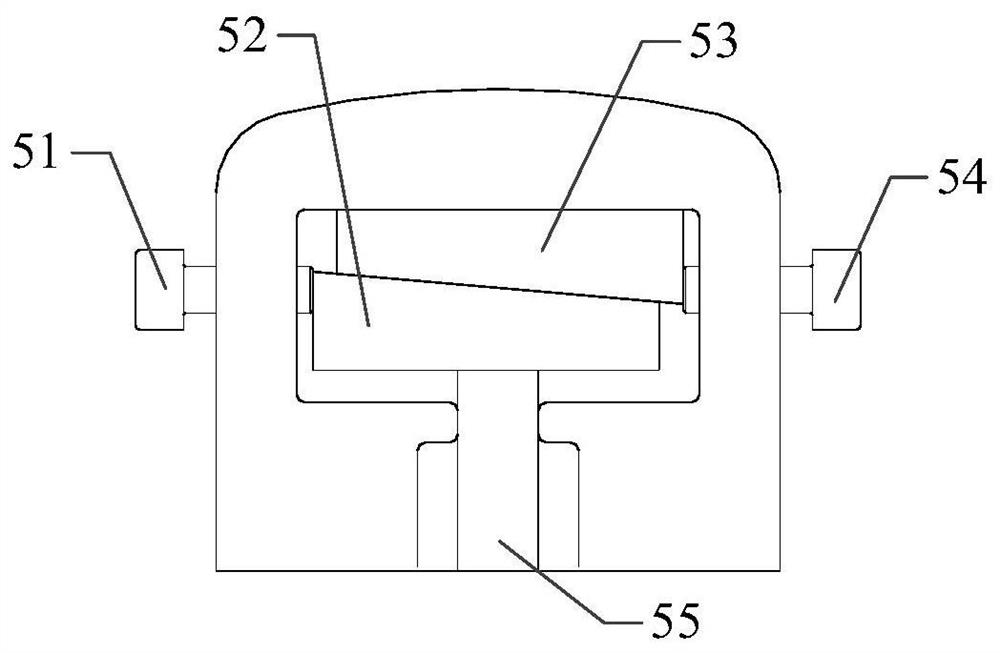

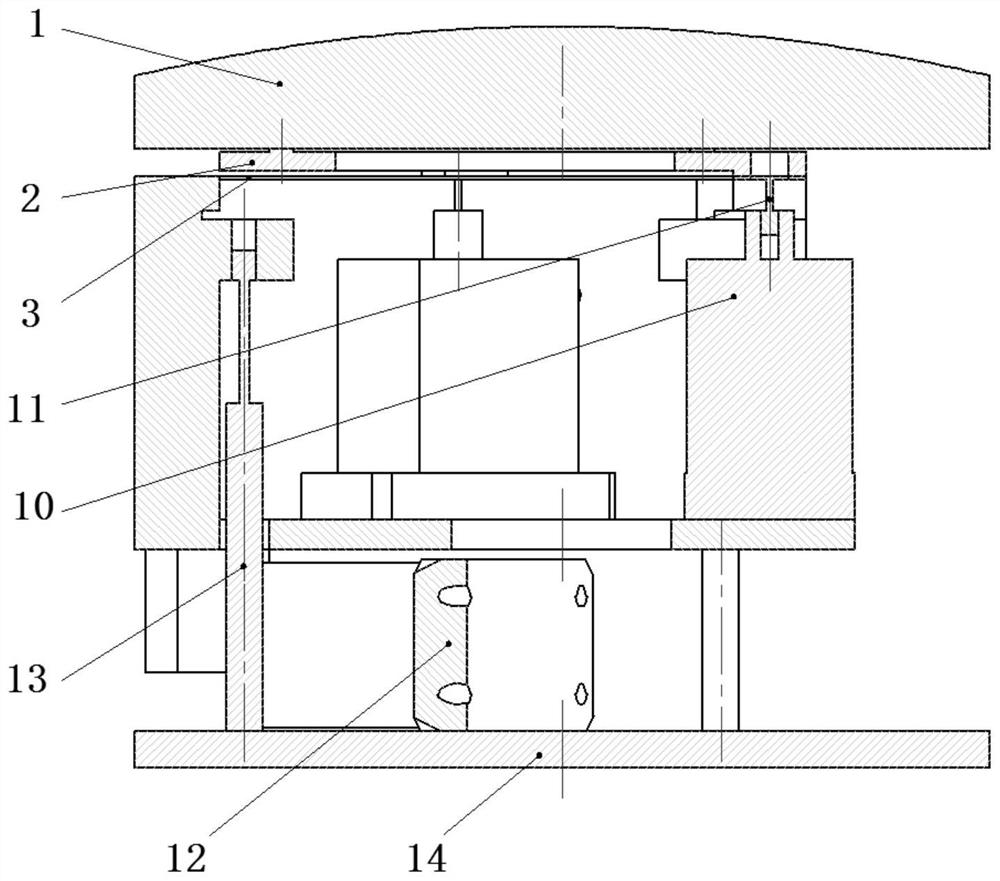

Device and method for improving motion resolution of standing wave type piezoelectric ultrasonic motor

ActiveCN113630036AImplement installation adjustmentsHigh motion resolutionPiezoelectric/electrostriction/magnetostriction machinesElectric machineryEngineering

The invention discloses a device and method for improving the motion resolution of a standing wave type piezoelectric ultrasonic motor. The device comprises a mode switching device; the mode switching device comprises a clamping device, a base, a sliding seat and a guide pin; the base is fixedly installed on a stable structure, the guide pin is fixedly connected into the base, and the sliding seat is installed in the base and can freely move in the axial direction of the guide pin; the piezoelectric ultrasonic motor is mounted on the sliding seat; and the clamping device is used for fixing and releasing the sliding seat, so that the motion state switching of the piezoelectric ultrasonic motor is realized, and the motion resolution of the piezoelectric ultrasonic motor is improved. According to the invention, the resolution switching device is introduced, so the coarse positioning and fine positioning motion mode conversion of the standing wave type piezoelectric ultrasonic motor is realized, and the motion resolution of the system is effectively improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

Six-degree-of-freedom series-connected robot with target positioning

InactiveCN101850547BPrecise positioningCompact structureProgramme-controlled manipulatorImage resolutionEngineering

The invention relates to a six-degree-of-freedom series-connected robot with target positioning applied to inertial confinement fusion. By using a form of a series-connected mechanism for separating translation and rotation, and the six-degree-of-freedom series-connected robot with target positioning consists of a set of three-dimension translation work table and a set of three-dimension rotary robot. The translation and the rotation of each direction are both driven by a vacuum special motor actuator, each movement is relatively independent, and the precision movement of six freedom degrees can be finished in the space. By constructing a precise vacuum positioning mechanism with the six-degree-of-freedom in the space, the invention has the advantages of compact structure, small duty ratio angle, high motion resolution, easy control and precise positioning.

Owner:SHANGHAI UNIV

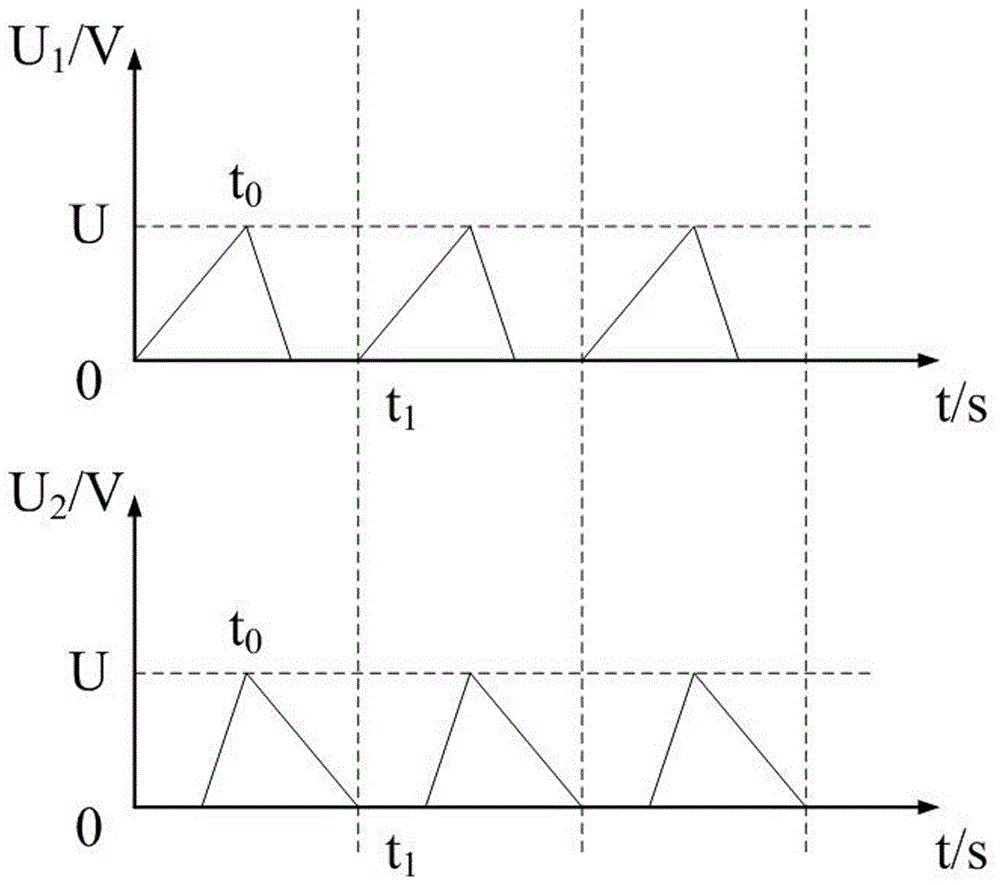

An inertial non-resonant bipedal piezoelectric linear actuator

InactiveCN106787935BOvercome vulnerability to environmental factorsGuaranteed uptimePiezoelectric/electrostriction/magnetostriction machinesElectricityLinear actuator

The invention discloses an inertial non-resonant biped piezoelectric linear actuator, which comprises a base, wherein a guide rail is arranged at the upper part of the base; a stator assembly is also arranged at the upper part of the base and is axisymmetrically distributed left driving foot of the stator assembly and right driving foot of the stator assembly; left laminated piezoelectric ceramic and right laminated piezoelectric ceramic are arranged in the left driving foot of the stator assembly and the right driving foot of the stator assembly respectively; and protruding parts of the driving feet of the stator assembly are in contact with one side of the guide rail. The invention further provides a working method of the inertial non-resonant biped piezoelectric linear actuator. Voltage slow-rising and fast-dropping and fast-rising and slow-dropping same-frequency sawtooth wave voltage signals are applied to the left laminated piezoelectric ceramic and the right laminated piezoelectric ceramic in two symmetrically arranged driving foot mechanisms respectively, so that stable continuous straight motion can be achieved, and the inertial non-resonant biped piezoelectric linear actuator has the advantages of being simple in structure, stable in operation, accurate in positioning, high in motion resolution and relatively low in cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

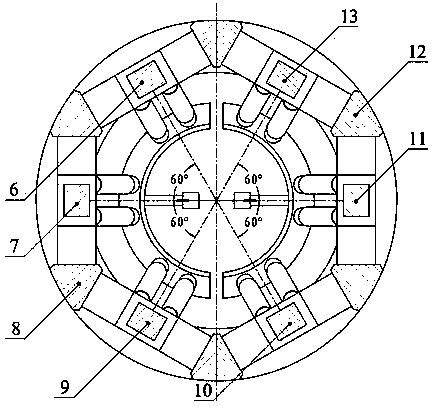

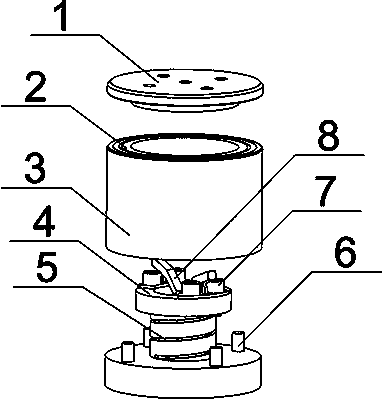

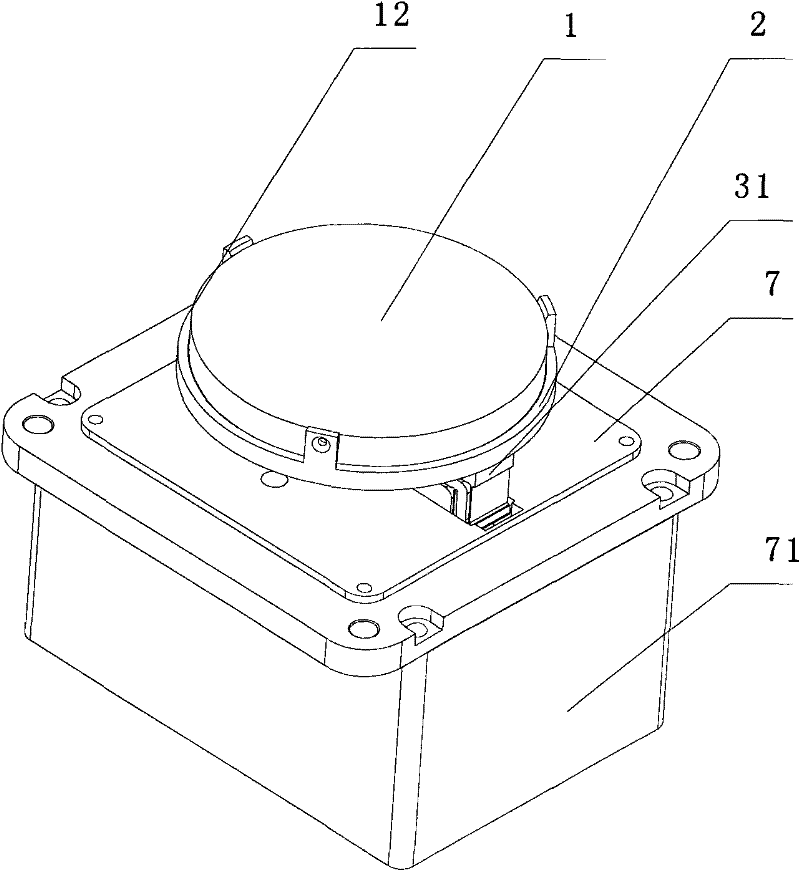

Piezoelectric driving rotary table based on spiral hinge mode conversion principle

InactiveCN111092565AHigh motion resolutionIncrease radial output forcePiezoelectric/electrostriction/magnetostriction machinesRotary stageEngineering

The invention discloses a piezoelectric driving rotary table based on a spiral hinge mode conversion principle, which aims to solve the technical problems of complex structural design, low motion resolution and the like of a current micro-nano rotary table. The piezoelectric driving rotary table is composed of a rotary table, a shaft ring, a supporting cylinder, a spiral hinge base, a piezoelectric stack, a supporting cylinder connecting bolt, a driving lever mounting bolt, a driving lever and a pre-tightening screw. The deformation characteristic of the spiral hinge is utilized to convert thelinear motion of the piezoelectric stack into the rotary motion of the rotary table, so that the structural design complexity of the rotary platform is reduced, and the motion resolution of the rotary table is improved; meanwhile, the radial output force of the rotary table is increased through the lever transmission mechanism, and the output efficiency of the rotary table is improved; and the rotary table is connected with the supporting cylinder through the shaft ring, so that the load capacity of the rotary table is increased. The piezoelectric driving rotary table has the advantages of being simple in structure, high in positioning precision, large in load capacity and the like, and has good development potential and application value in the field of precision driving and positioning.

Owner:CHANGCHUN UNIV OF TECH

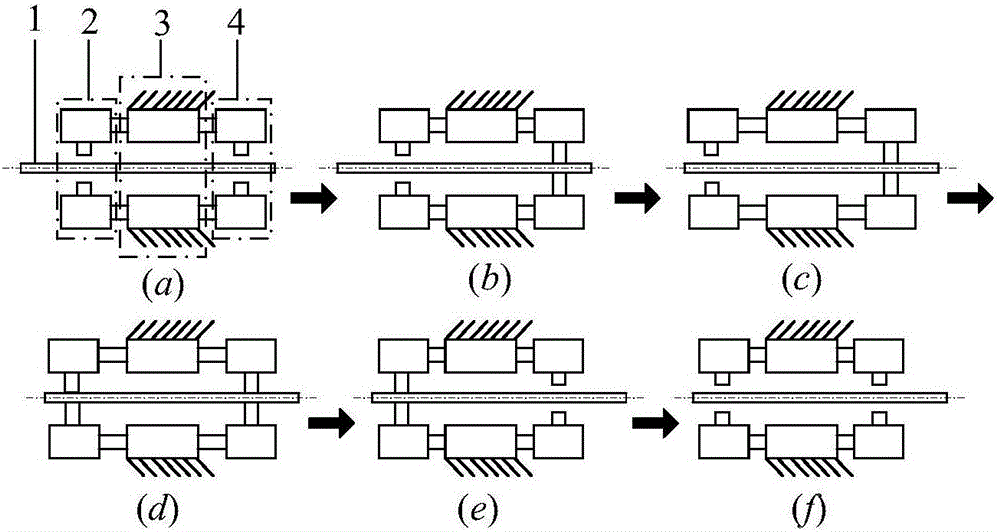

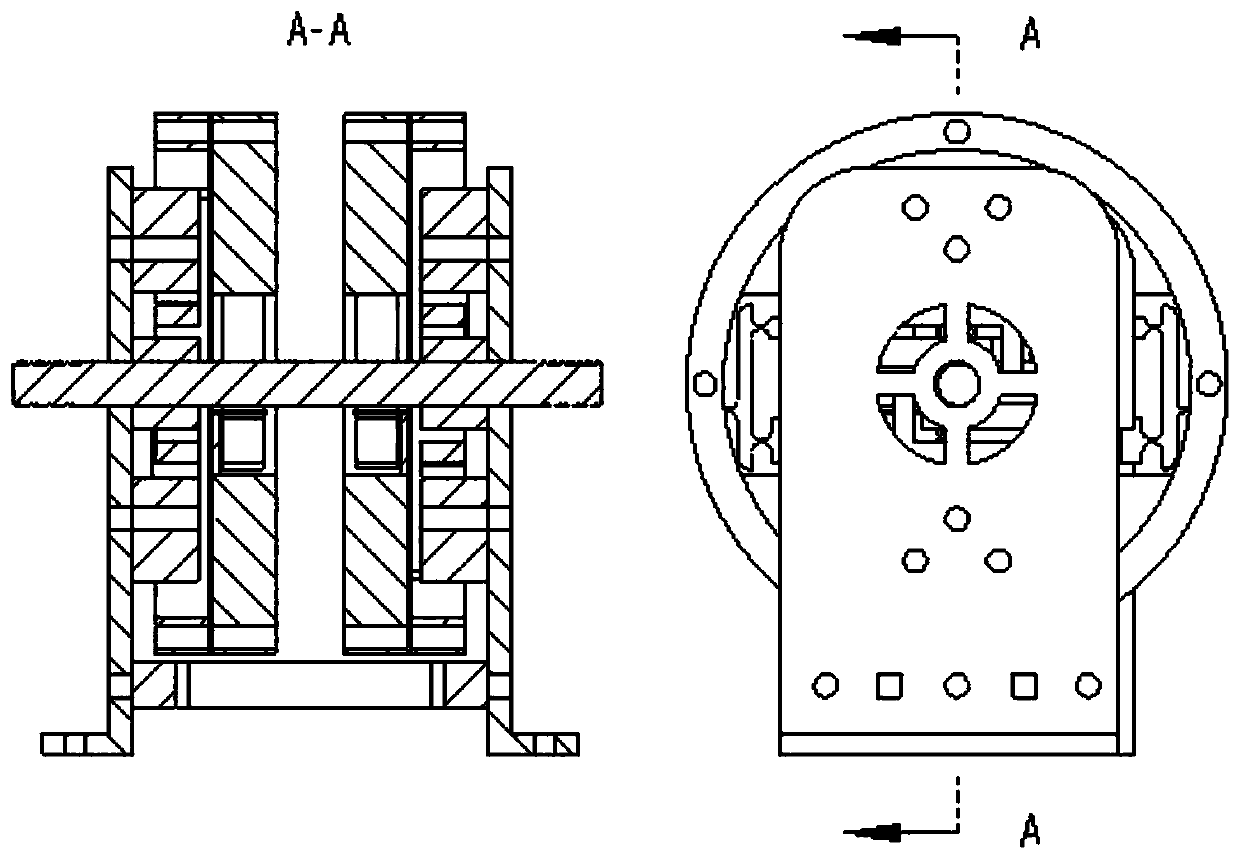

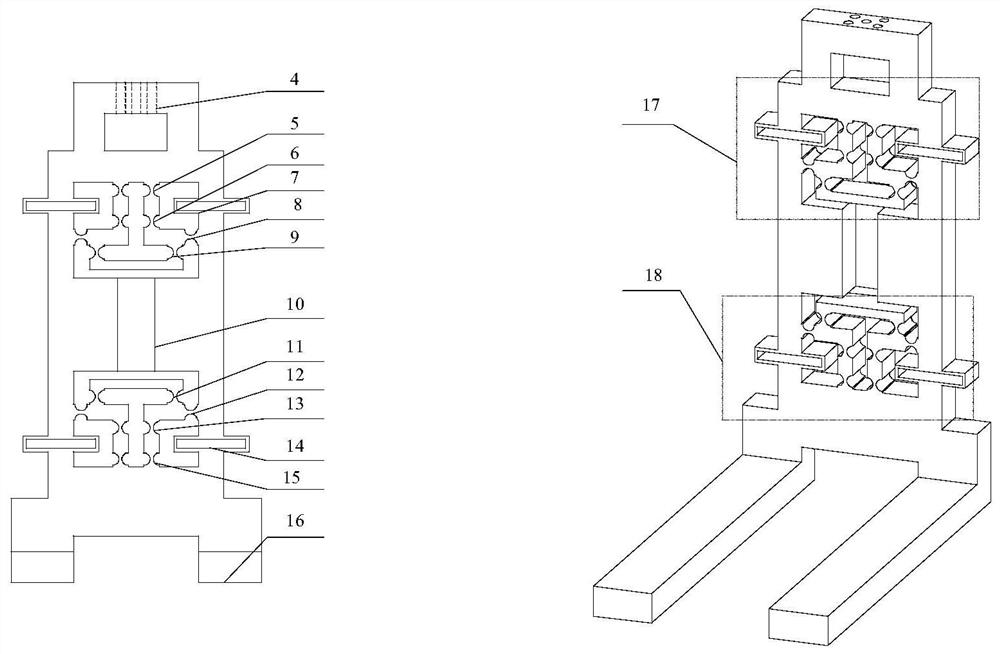

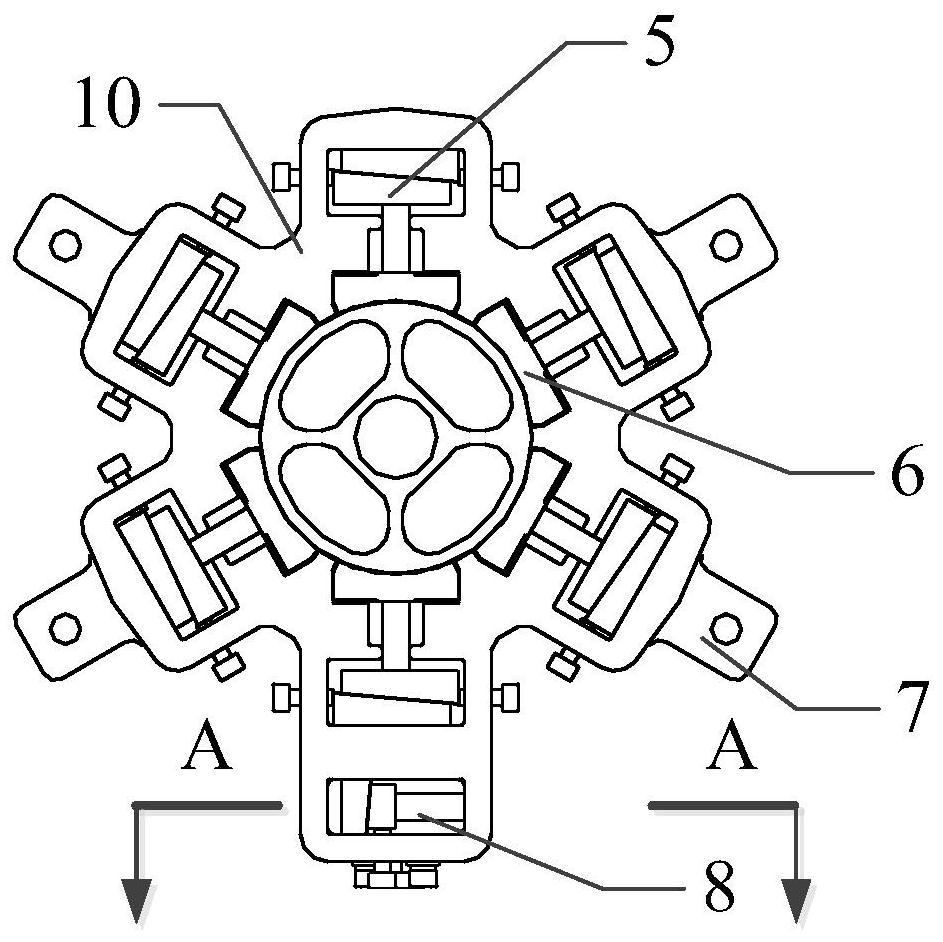

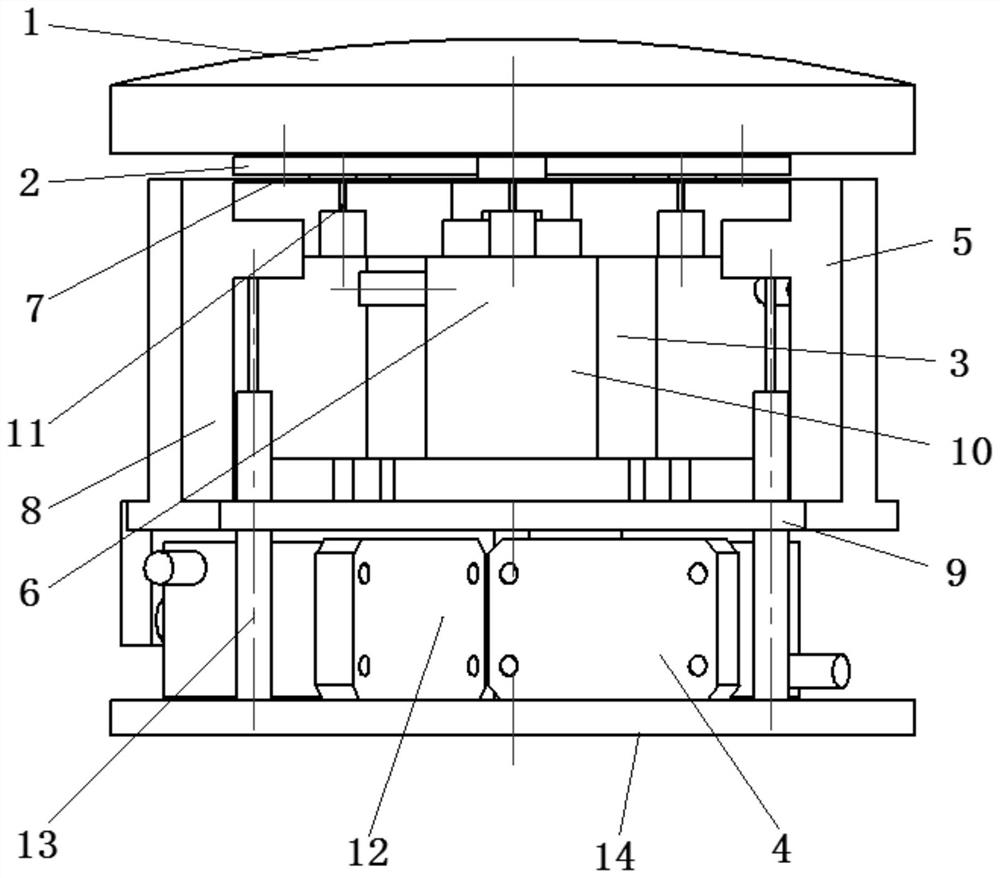

Device and method for improving motion resolution of standing wave type piezoelectric motor

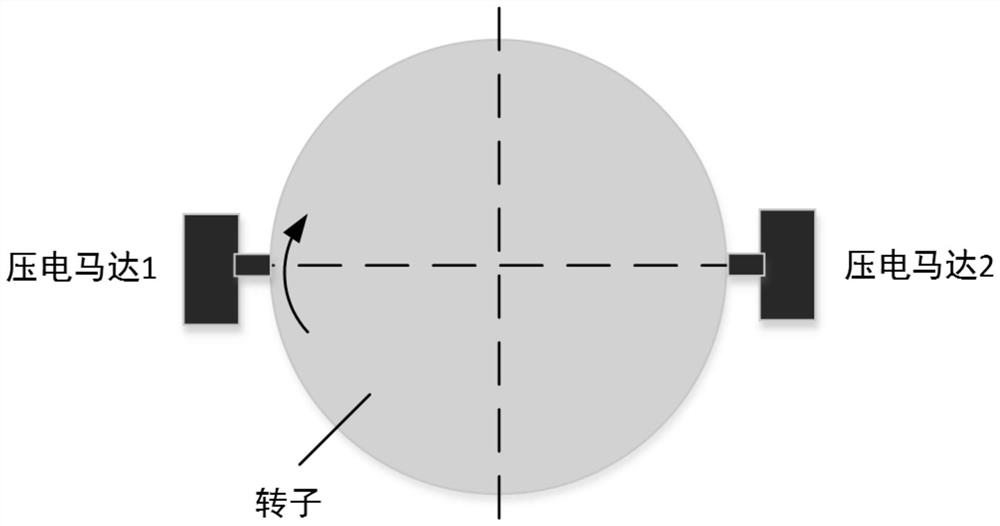

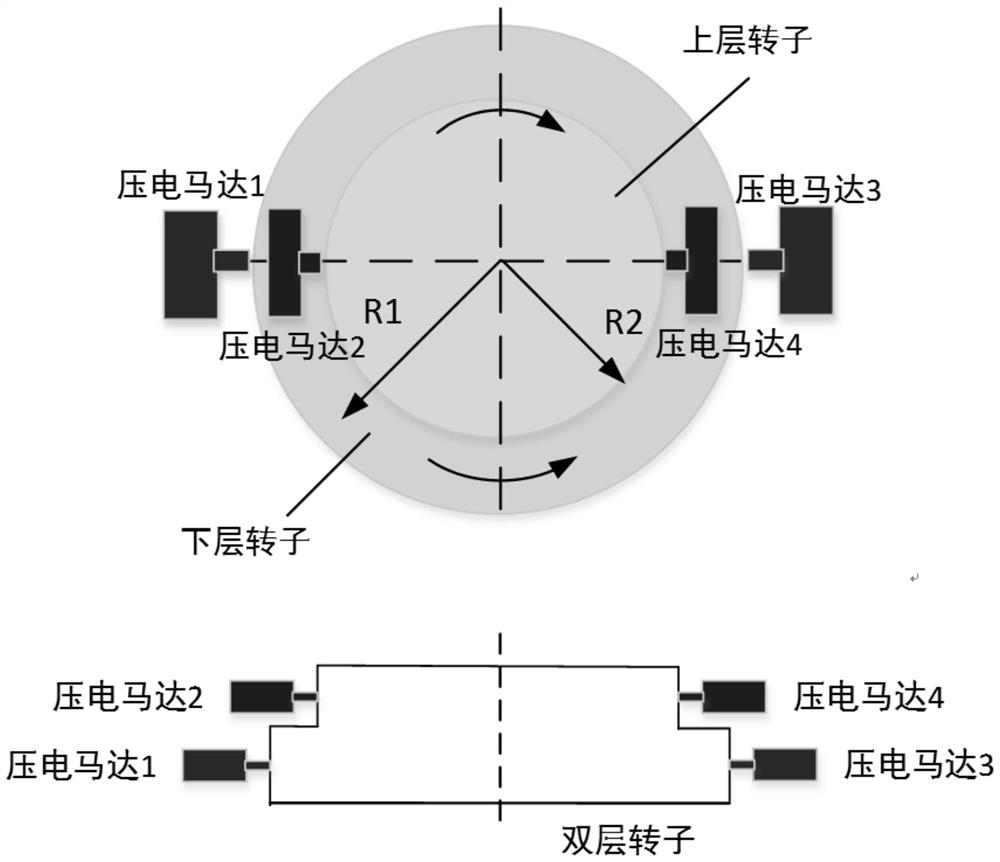

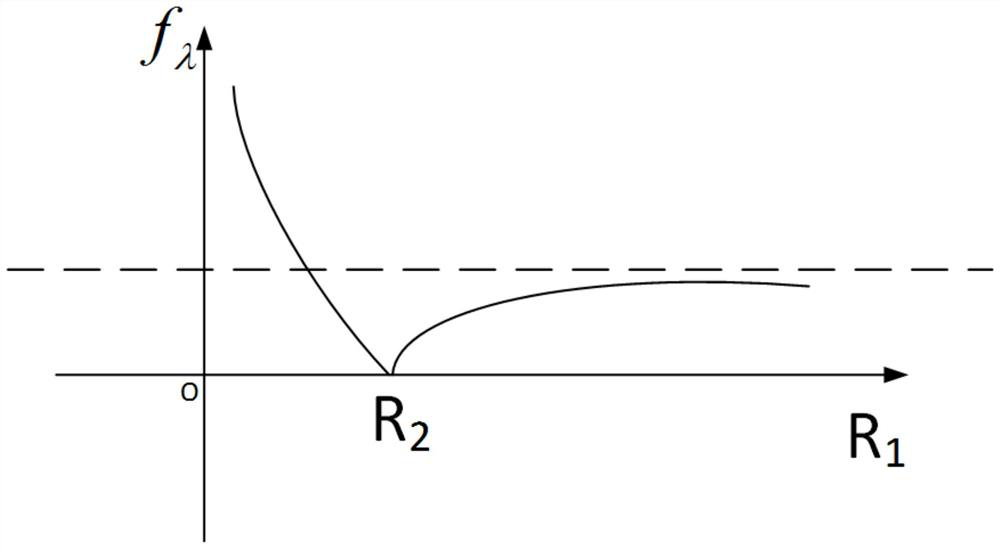

ActiveCN113630037AHigh motion resolutionPiezoelectric/electrostriction/magnetostriction machinesEngineeringRotor (electric)

The invention discloses a device and a method for improving the motion resolution of a standing wave type piezoelectric motor. The device comprises an upper-layer driving structure and a lower-layer driving structure; the upper-layer driving structure comprises an upper-layer rotor and upper-layer piezoelectric motor groups which are symmetrically arranged on the circumferential side of the upper-layer rotor along the circle center of the upper-layer rotor; the lower-layer driving structure comprises a lower-layer rotor and lower-layer piezoelectric motor groups which are symmetrically arranged on the circumferential side of the lower-layer rotor along the circle center of the lower-layer rotor, and each of the upper-layer piezoelectric motor group and the lower-layer piezoelectric motor group comprises N piezoelectric motors; the upper layer rotor and the lower layer rotor are coaxially arranged, the upper layer rotor is driven by the upper layer piezoelectric motor group to rotate in the clockwise direction, and the lower layer rotor is driven by the lower layer piezoelectric motor group to rotate in the anticlockwise direction. According to the invention, two groups of piezoelectric motors distributed on different driving radiuses move in opposite directions to form differential displacement, so the motion resolution is improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

An inchworm precision rotary micro-actuator based on a compliant mechanism

ActiveCN110086374BHigh precisionRealize the clamping effectPiezoelectric/electrostriction/magnetostriction machinesCompliant mechanismActuator

The invention discloses an inchworm precision rotary micro-driver based on a compliant mechanism, which comprises two driving mechanisms, two clamping mechanisms, a mover and a bracket, wherein the two driving mechanisms, namely, the first driving mechanism and the second driving mechanism, are the same in structure; the two clamping mechanisms, namely, the first clamping mechanism and the secondclamping mechanism, are the same in structure; the two driving mechanisms are respectively located at two sides, and the two clamping mechanisms are located between the two driving mechanisms; the mover is located on the bracket and placed at the symmetry center of the rotary micro-driver and mutually cooperated with the mechanisms through an output hole; the clamping mechanisms can clamp or release the mover; when the clamping mechanisms clamp the mover, the mover rotates along with the clamping mechanisms; and when the clamping mechanisms release the mover, the mover moves freely. The micro-driver provided by the invention has the advantages of large travel, high resolution, large output load, bidirectional movement and the like.

Owner:江苏康耐特精密机械有限公司

A parallel micro-manipulation robot

InactiveCN103786151BSmall moment of inertiaEasy to installProgramme-controlled manipulatorMicro-operationControl engineering

A novel parallel micro-manipulator robot includes left and right micro-manipulators with the same structure and arranged symmetrically. The left micro-manipulator or the right micro-manipulator includes a semi-cylindrical micro-manipulator mobile phone holder, three branch chains, a micro-manipulator manual platform and a micro-manipulator end tool; each branch chain includes a micro-displacement driver, a flexible The mobile pair and two branches with the same structure, each branch is composed of two flexible ball joints and a rigid connecting rod, one end of each branch is connected with the left micro-manipulation manual platform, and the other end is connected with the flexible mobile pair, and the two The axes of the branches are parallel to each other, the fixed end of the micro-displacement driver is connected with the left micro-manipulation mobile phone frame, and the driving end is connected with the flexible moving pair. The three branch chains constituting each micromanipulator are evenly distributed in the semi-cylindrical space. The invention can realize three-dimensional high-precision operation, has a compact overall structure and has a large operating range and high resolution, and can be widely used in fields such as biomedical engineering and precision engineering.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

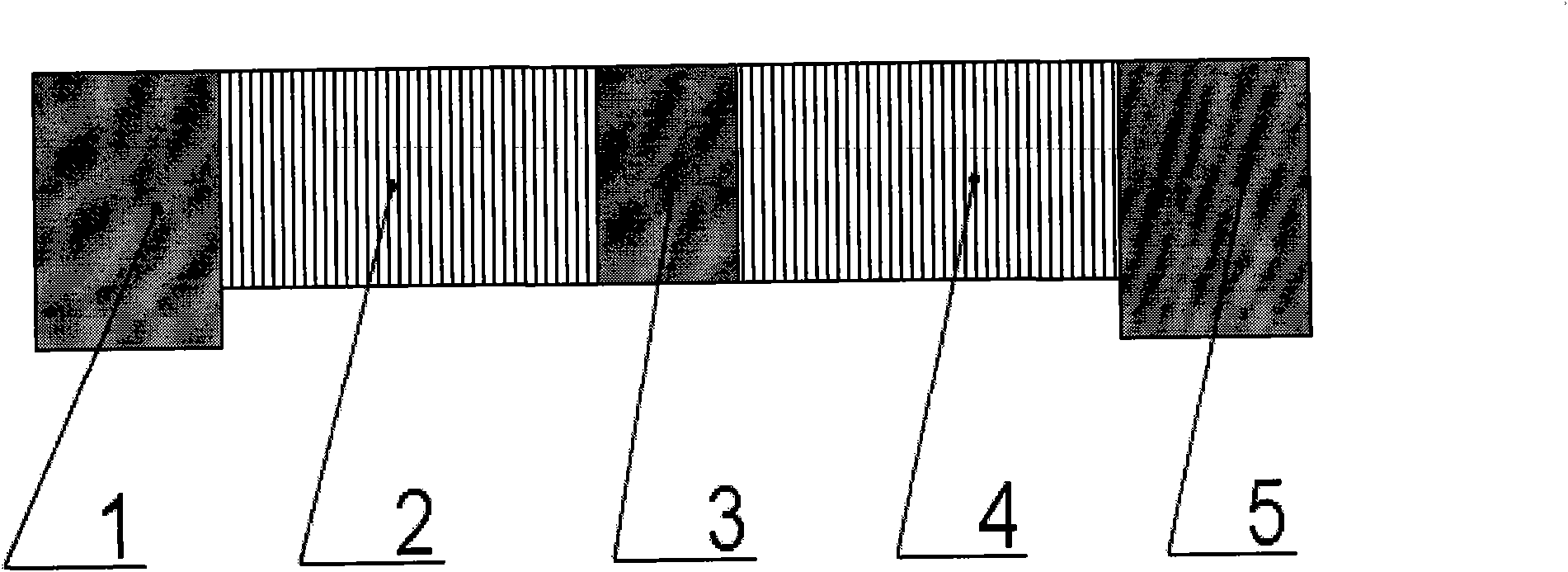

An inchworm-type micro-moving walking robot

The invention discloses an inchworm-type micro-movement walking robot. The robot is composed of two clamping units and one driving unit, wherein the driving unit is composed of two symmetrically arranged driving branch chains and two pairs of right-angle flexible hinges. The branch chain is composed of two lever structures, the drive unit and the two clamp units are connected by bolts, and the drive unit can perform reciprocating micro-displacement movement relative to the clamp unit; the clamp unit consists of two symmetrically arranged drive branch chains and Composed of 2 pairs of right-angle flexible hinges and a base plate, 2 clamping units are symmetrically connected to both ends of the drive unit through bolt holes. One end of the clamping unit is driven and its base is fixed, the driving structure is extended and the other clamping unit is driven to move in a straight line, imitating the law of motion of the bionic inchworm. The present invention adopts three piezoelectric stacks, utilizes the friction effect between the clamp unit and the ground to realize clamping, and can convert the action displacement of the piezoelectric stacks into an effective driving displacement.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

A Rotary Drive Device Based on Piezoelectric Stack

ActiveCN112713805BRealize forward and reverse rotationAchieve rotationPiezoelectric/electrostriction/magnetostriction machinesDrive shaftControl theory

Owner:中国空气动力研究与发展中心设备设计及测试技术研究所

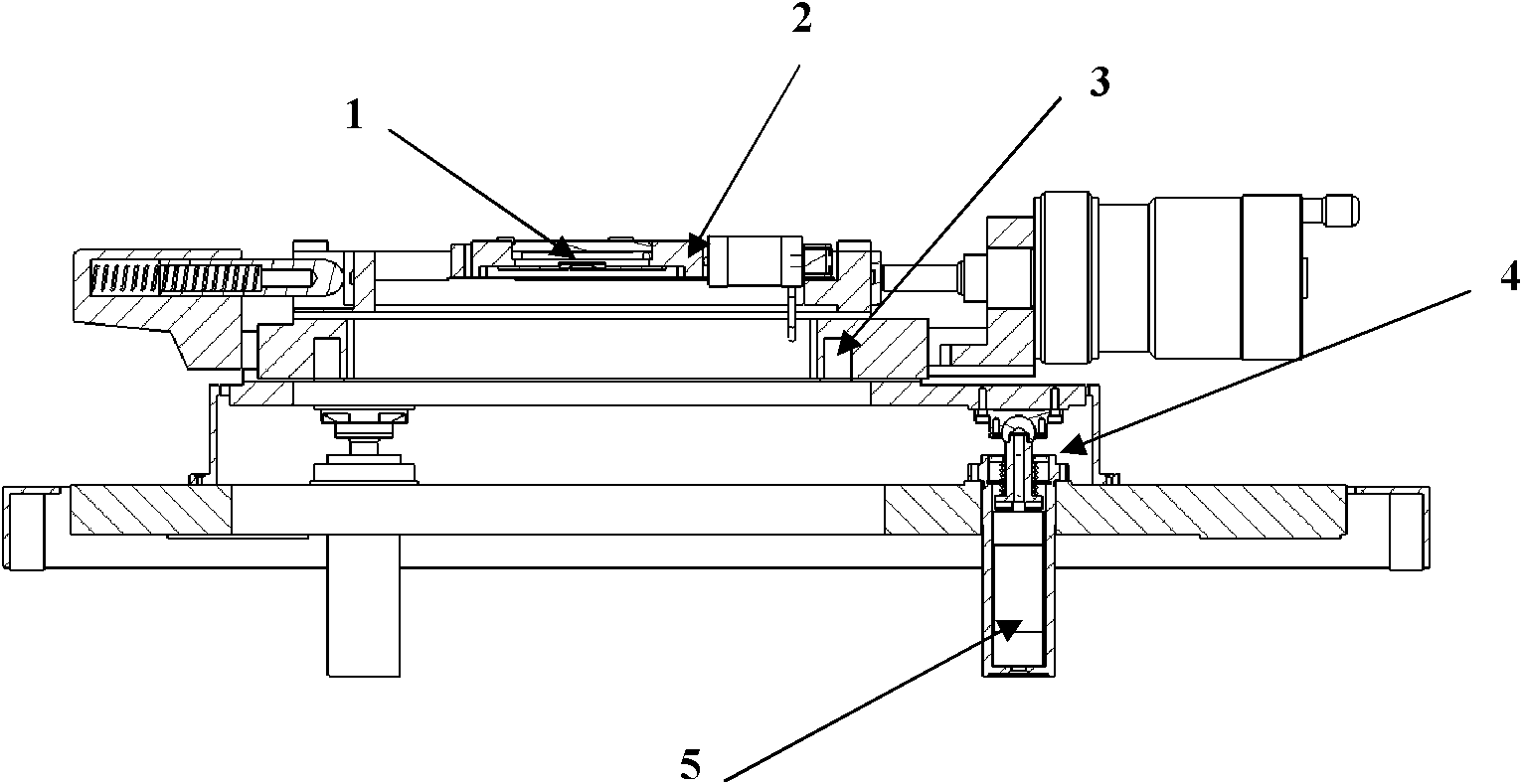

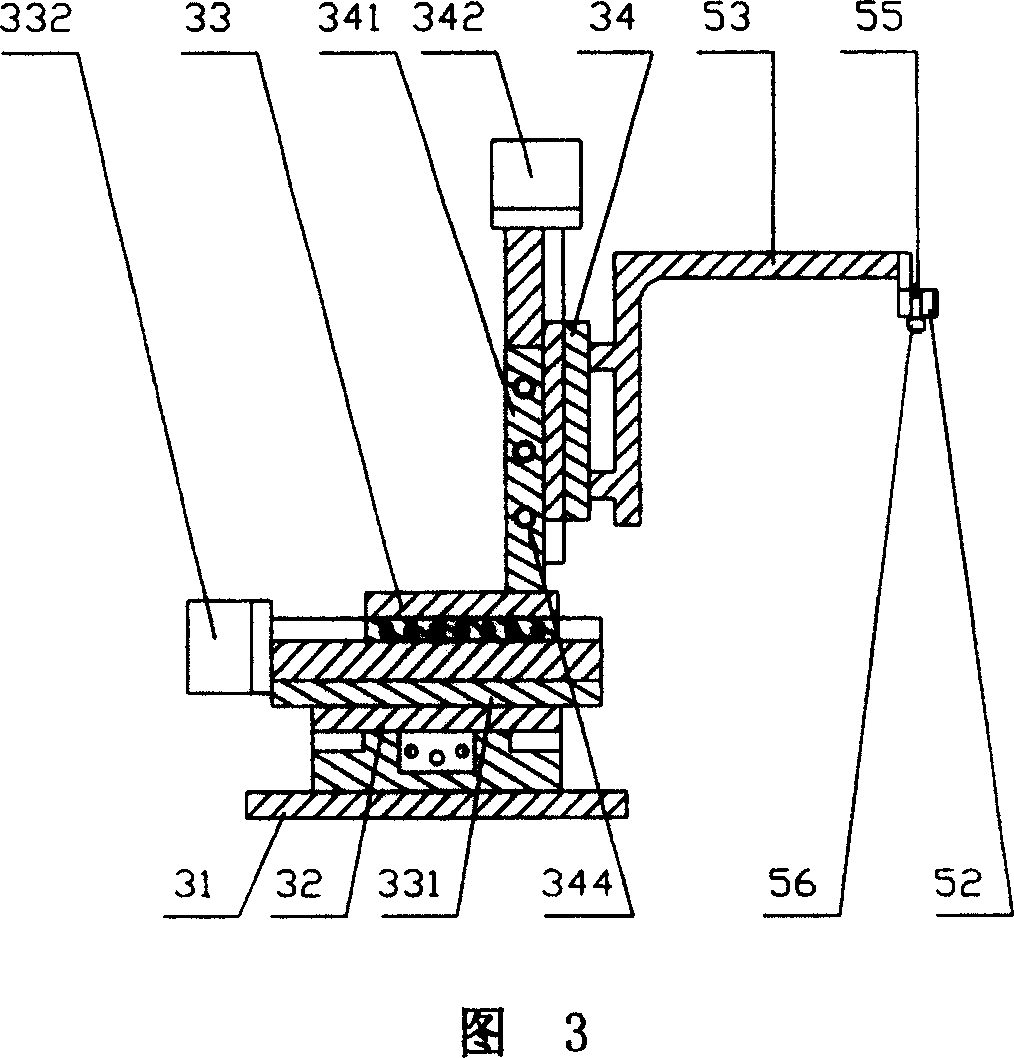

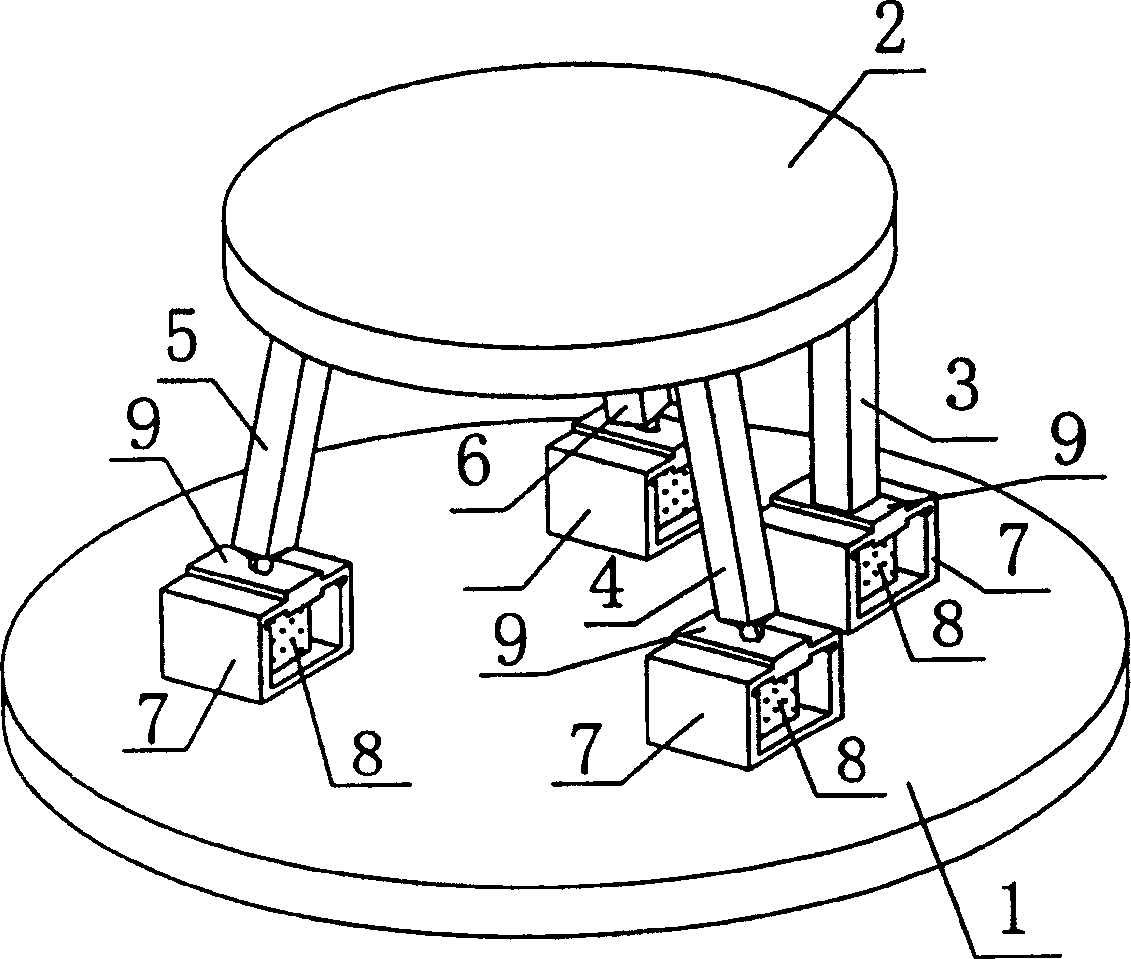

Precisively butting apparatus for photoelectric device package

InactiveCN1298030CHigh movement precisionHigh motion resolutionSemi-permeable membranesSemiconductor/solid-state device manufacturingEngineeringElectron

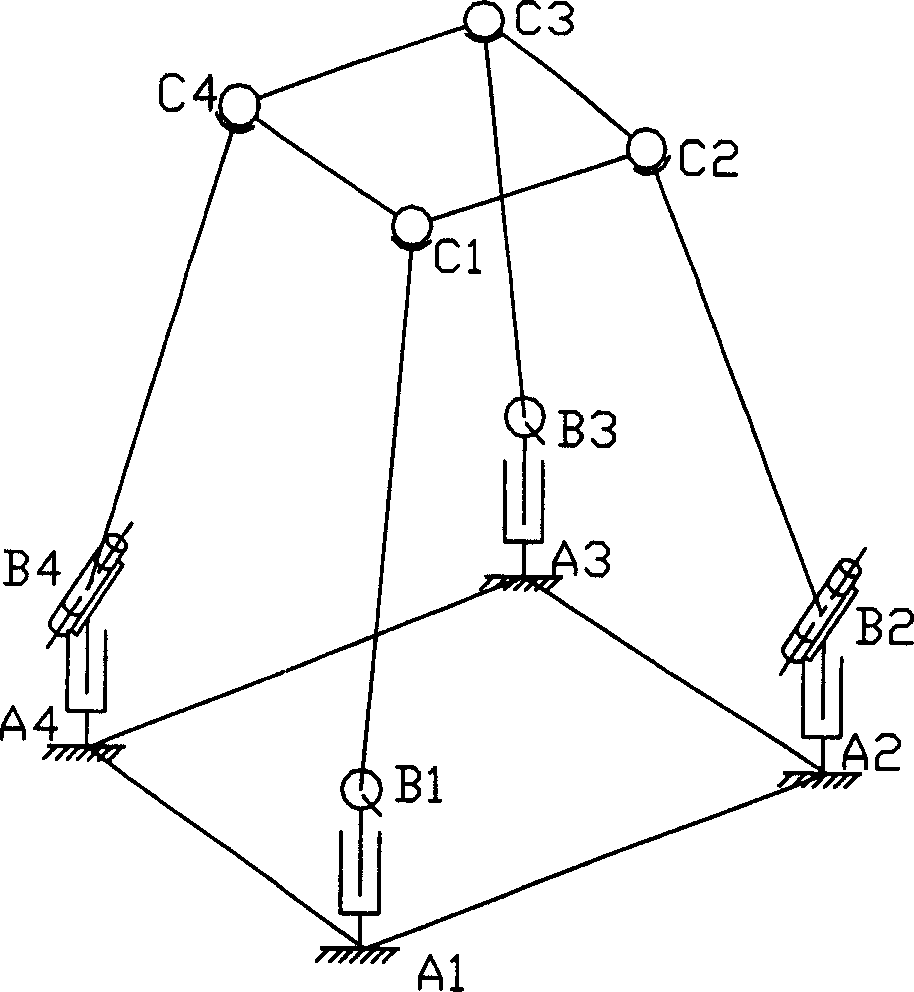

The invention consists of a base, a two-way translational platform, four locating beds, an actuated platform, a length control bar, a top optical fiber champing device and a bottom optical fiber champing device. The one end of length control bar is connected with the actuated platform through ball pivot and the other end of length control bar is connected with two locating beds through revolving joint. The length control bar is connected with another two locating beds through hooke articulation or ball pivot to form parallel space closed chain device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

New type series-parallel connection jogging robot

The invention belongs to the field of micro-movement robots. The main points of the structure of the present invention are: the base and the workbench are connected by 3 or 4 fixed-length rods, one end of which is connected to the base through a parallel plate flexible moving pair directly processed on the positioning seat. The other end is connected to the workbench through a ball joint or a Hooke hinge, and one end of the other fixed-length rod is directly processed on the positioning seat rigidly fixed on the base through a Hooke hinge or a ball joint. The other end is connected with the workbench through a ball joint, and the end of the fixed length rod connected with the base is provided with a micro-displacement driver. The invention can realize frictionless, gapless and high-resolution fretting operation.

Owner:SICHUAN UNIV

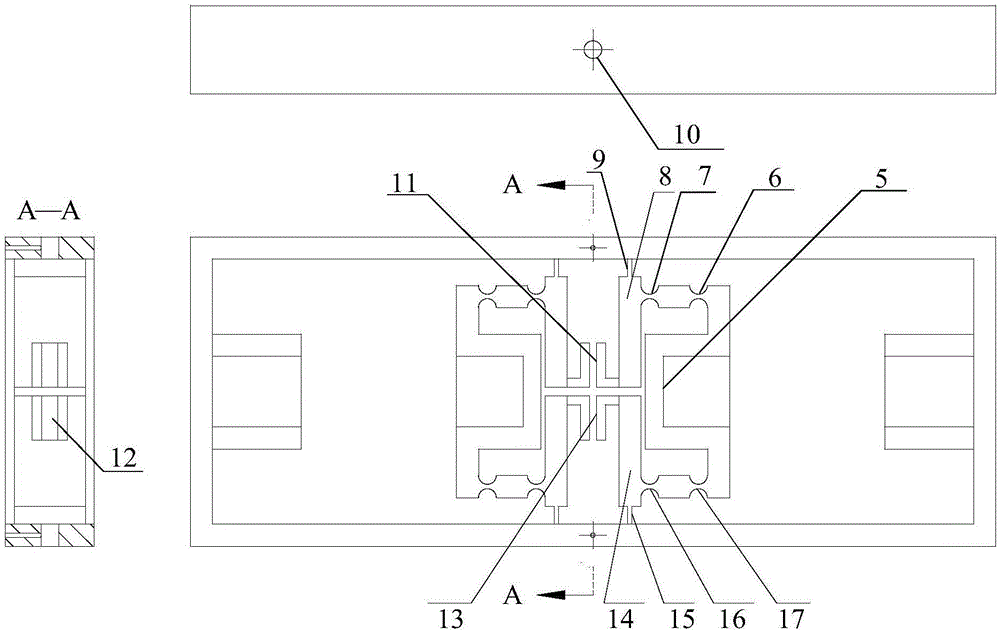

Series-parallel coupled multi-degree-of-freedom optical element precision adjustment platform

The invention discloses a series-parallel coupled multi-degree-of-freedom optical element precision adjustment platform, and solves the problems that a traditional optical element adjustment platform cannot give consideration to multi-degree-of-freedom precision adjustment at the same time, and the adjustment platform is low in complexity and high in reliability. The platform comprises a supporting seat, a first-stage adjustment mechanism and a second-stage adjustment mechanism; an optical element can be driven to translate in the Z direction and rotate in the X direction and the Y direction through a first micro-nano driving assembly in the first-stage adjustment mechanism, the optical element can be driven to translate in the X direction and the Y direction through a second micro-nano driving assembly in the second-stage adjustment mechanism, and therefore multi-dimensional high-precision adjustment of the spatial position of the optical element in the optical system is achieved, and the performance index of the optical system is improved.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

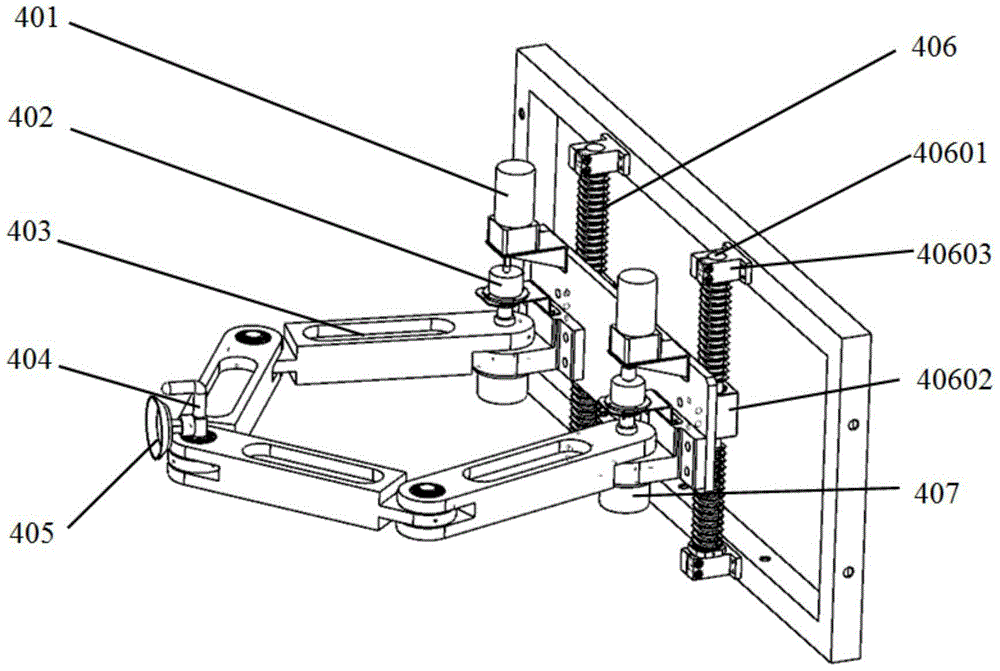

Triangular laser gyro optical lens automatic assembly device

InactiveCN103949881BSignificant technological progressImprove assembly efficiencyAssembly machinesGyroscopePlane mirror

The invention relates to an optical glass automatic installing device for a triangular laser gyroscope. The optical glass automatic installing device consists of an incidence laser obtaining system, a glass clamping mechanical arm with a force sensor, an optical glass position automatic regulation unit, an photoelectric detection unit, a facula image detection unit and a laser gyroscope cavity location unit, and is used for finishing the automatic installation of plane mirrors without coating films and spherical mirrors of the triangular laser gyroscope under the monitoring of multiple sensors. According to the optical glass automatic installing device for the triangular laser gyroscope, manual operation is replaced by an automatic device, the structure is simple, the motion resolution is high, the installation consistency is good, and the efficiency is high.

Owner:SHANGHAI UNIV

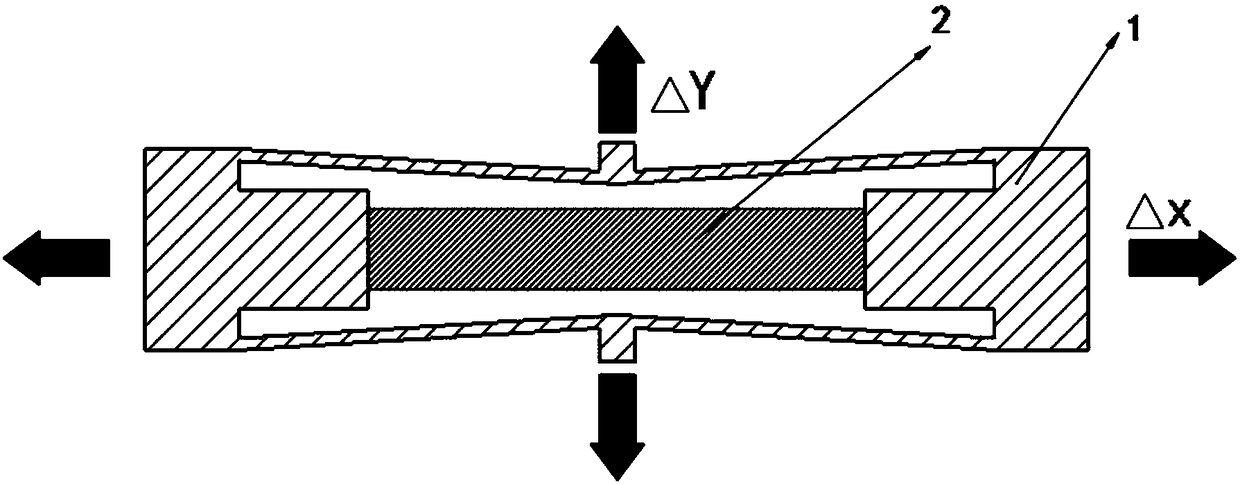

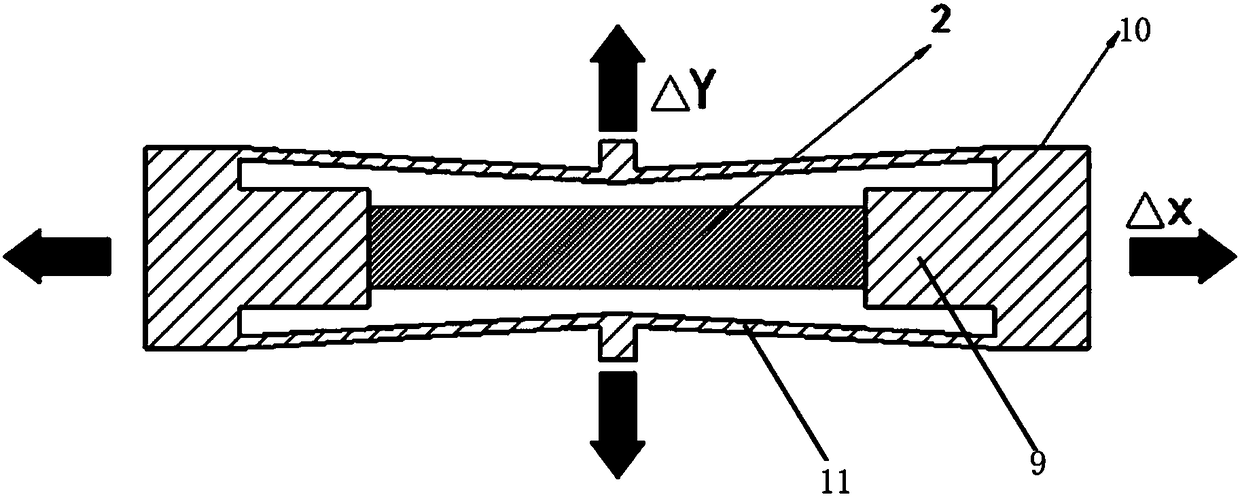

Piezoelectric driven micro-positioning platform based on hourglass displacement amplifier mechanism

InactiveCN108199610ASolve the problem of small output displacementHigh positioning accuracyPiezoelectric/electrostriction/magnetostriction machinesElectricityEngineering

The invention provides a piezoelectric driven micro-positioning platform based on an hourglass displacement amplifier mechanism. The platform comprises an outer-layer support (3), the hourglass displacement amplifier mechanism, a piezoelectric ceramic actuator (2), symmetrical long arm hinges, a workbench (6) and an inner-layer substrate (7). The hourglass displacement amplifier mechanism comprises an x-direction hourglass displacement amplifier mechanism (1) and a Y-direction hourglass displacement amplifier mechanism (4). The symmetrical long arm hinges comprise x-direction symmetrical longarm hinges (5) and Y-direction symmetrical long arm hinges (8). The piezoelectric driven micro-positioning platform based on the hourglass displacement amplifier mechanism can realize large-stroke motion of the workbench. Certainly, implementation of any product or method of the invention does not necessarily require all the advantages described above to be achieved simultaneously.

Owner:SHENYANG POLYTECHNIC UNIV

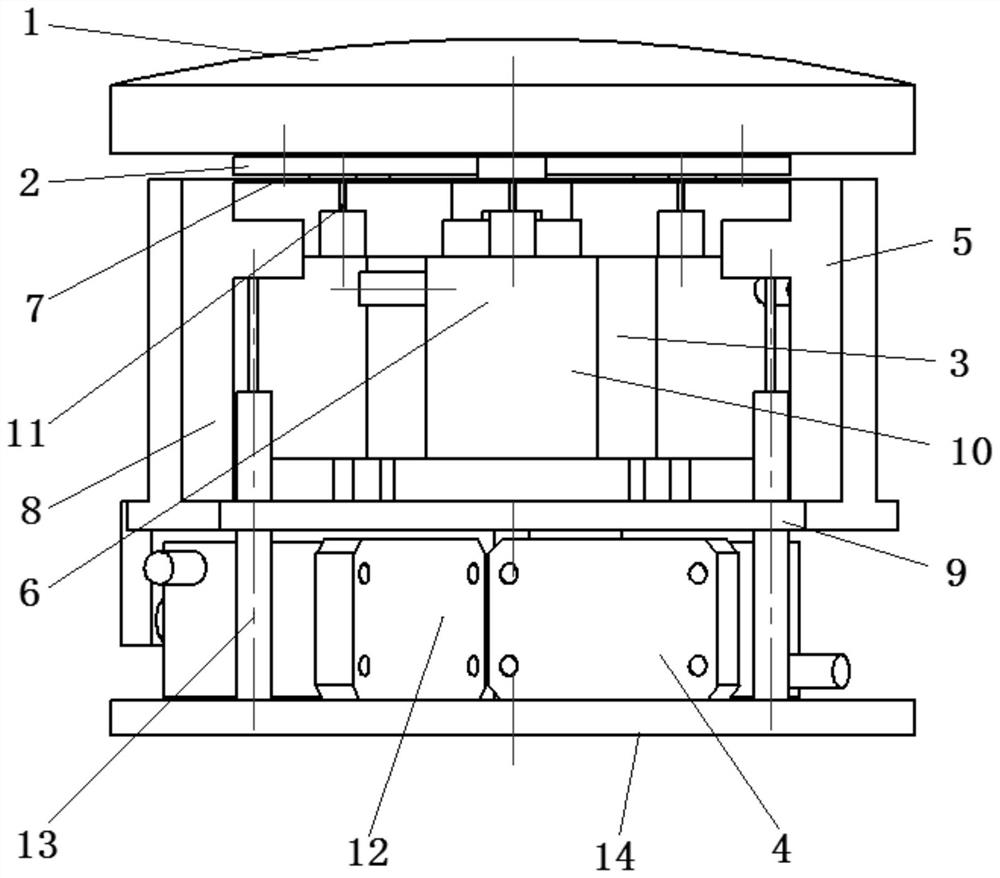

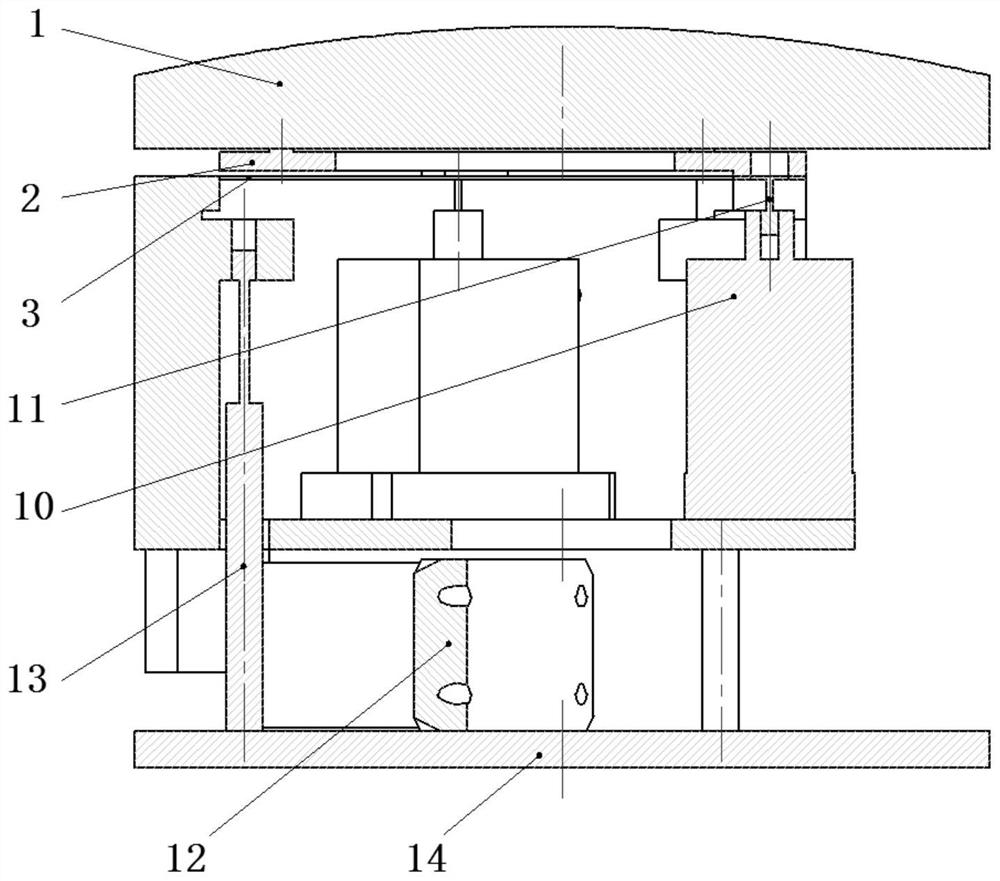

Light beam precision pointing device based on resolution multiplied compliant mechanism

ActiveCN101794020BCompact structureNo friction lossOptical elementsCompliant mechanismImage resolution

The invention discloses a light beam precision pointing device based on a resolution multiplied compliant mechanism, comprising a mirror bracket component, a driving mechanism and a control mechanism. The mirror bracket component is connected with the driving mechanism through the resolution multiplied compliant mechanism, the resolution multiplied compliant mechanism comprises a base and a flexible hinge fixed on the base and the mirror bracket component is fixed at the top of the flexible hinge; the driving mechanism comprises two drive motors used for pushing the flexible hinge and fixed on the base and the two drive motors are symmetrically arranged at two sides of the lower part of the flexible hinge. The invention has the advantages of compact structure, convenient processing, simple assembling, no friction loss, no movement clearance, no need for lubrication, high locating precision, network control, simple and convenient use, high reliability, strong adaptability and wide application range.

Owner:NAT UNIV OF DEFENSE TECH

A series-parallel coupled multi-degree-of-freedom optical element precision adjustment platform

The invention discloses a series-parallel coupled multi-degree-of-freedom optical element precision adjustment platform, which solves the problems that the traditional optical element adjustment platform cannot simultaneously take into account the multi-degree-of-freedom precision adjustment, and the adjustment platform itself has low complexity and high reliability. , the platform includes a support base, a first-level adjustment mechanism and a second-level adjustment mechanism; the optical element can be driven to translate along the Z direction and rotate around the X and Y directions through the first micro-nano-level driving component in the first-level adjustment mechanism. The second micro-nano-level driving component in the secondary adjustment mechanism can drive the optical element to translate along the X and Y directions, so as to realize the multi-dimensional and high-precision adjustment of the spatial position of the optical element in the optical system, thereby improving the performance index of the optical system.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com