Inchworm precision rotary micro-driver based on compliant mechanism

A compliant mechanism and micro-driver technology, applied in the field of precision micro-operation, can solve problems such as poor motion stability, low running speed, and small output load, and achieve the effect of large clamping force, fast motion speed, and large single-step output displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

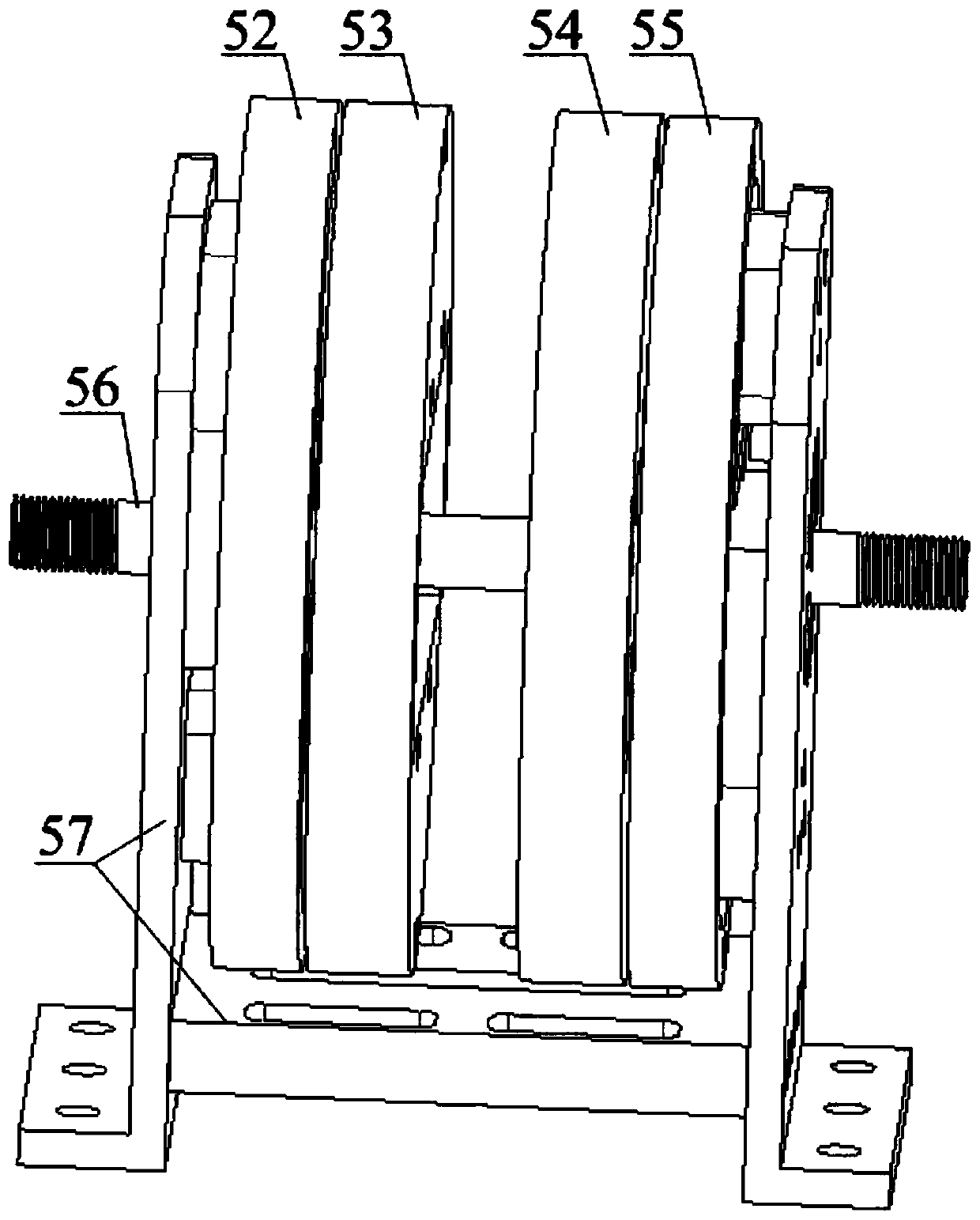

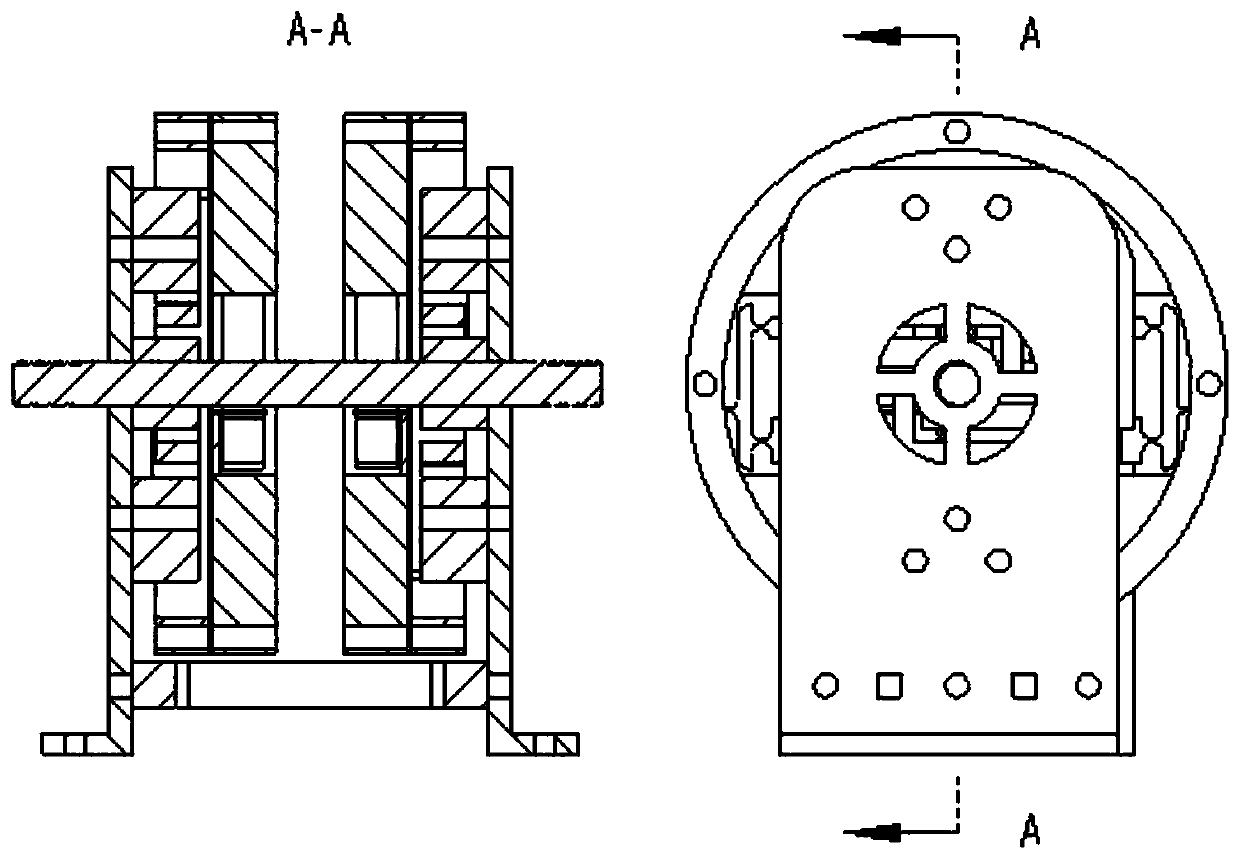

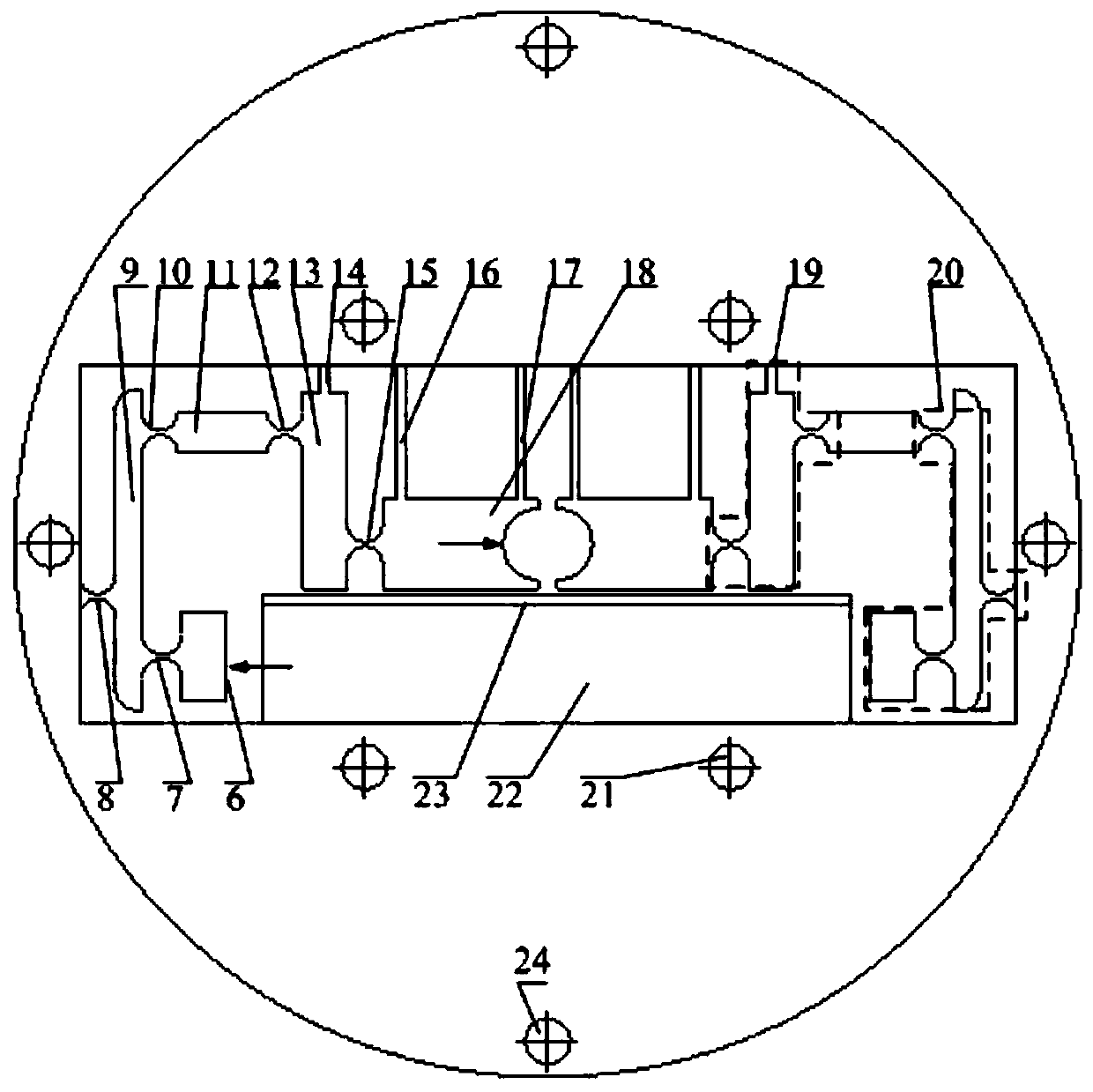

[0045] The design principle of an inchworm-type precision rotary micro-driver based on a compliant mechanism is as follows: Figure 9 As shown, the drive unit includes a first drive unit 1 and a second drive unit 3, which are respectively connected to the fixed bracket by bolts; the clamp unit includes a first clamp unit 2 and a second clamp unit 4, which are fixedly connected to the fixed bracket by bolts respectively. The first driving unit 1 and the second driving unit 3; the output unit 5 is matched with the clamping unit, the driving unit and the bracket by using round holes.

[0046] The working process of the above-mentioned structure imitating the law of motion of the inchworm is as follows:

[0047] Figure 9 (a) indicates that the rotary microdriver is in a non-working state; Figure 9 (b) indicates that the first clamping unit 2 is in the working state, and the unit clamps the output unit 5; Figure 9 (c) indicates that the first driving unit 1 is in the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com