A two-degree-of-freedom vibration suppression system for high-altitude construction robot work platforms

A technology for construction robots and work platforms, which is applied in mechanical equipment, springs/shock absorbers, vibration suppression adjustment, etc. Effects of space and dynamics, good structural parameters, small condition number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0018] This embodiment provides a two-dimensional vibration suppression mechanism for a high-altitude construction robot work platform;

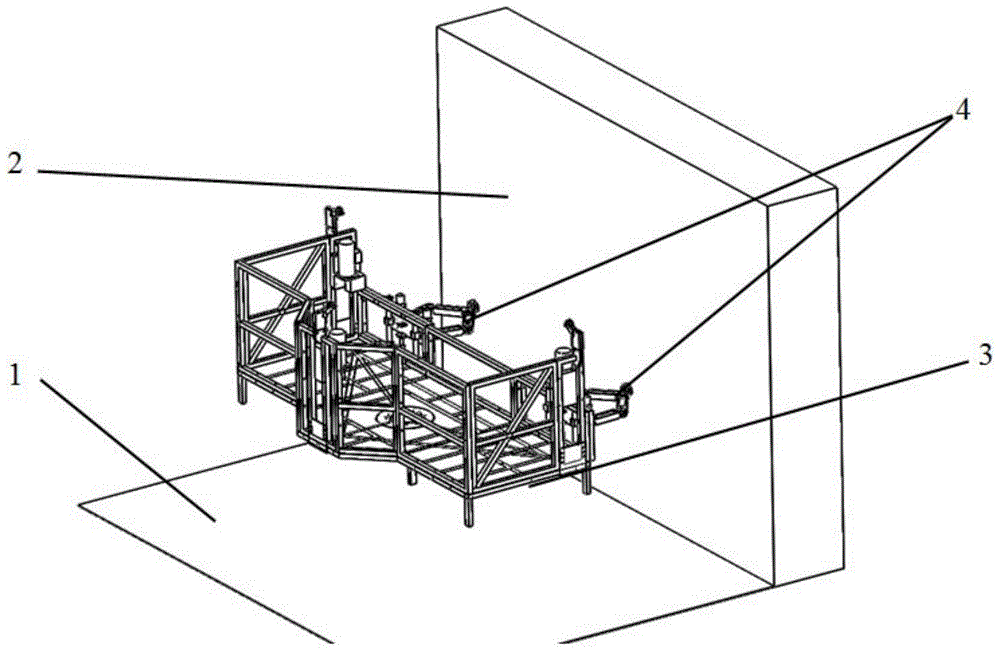

[0019] The working environment of the working platform 3 for the high-altitude construction robot includes the ground 1 and the working facade 2 parallel to the outer wall of the building. The overall assembly diagram of the two-dimensional vibration suppression mechanism and the working platform is as follows figure 1 shown;

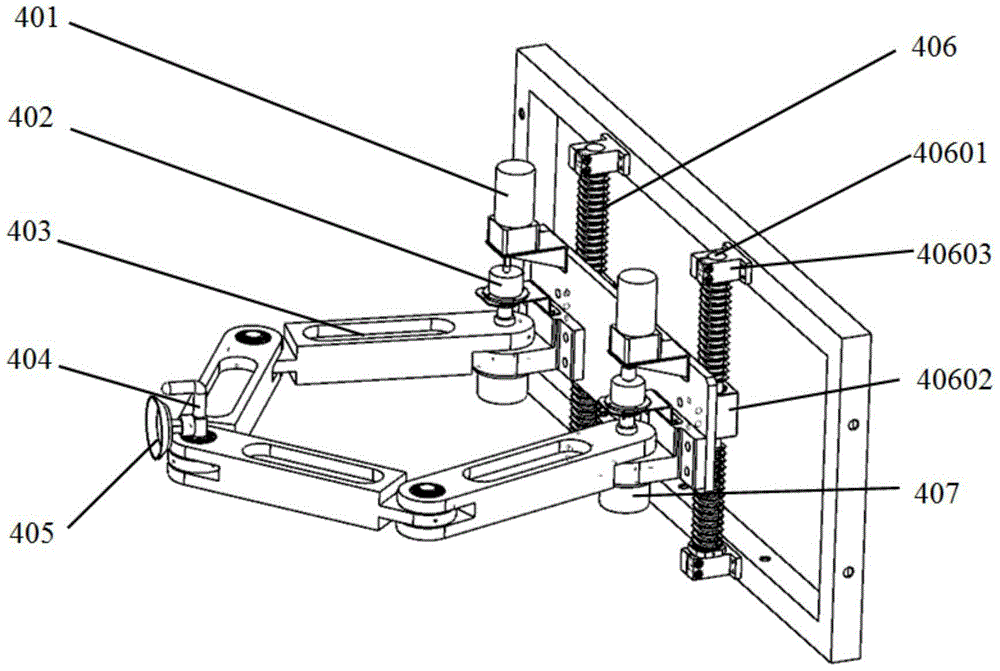

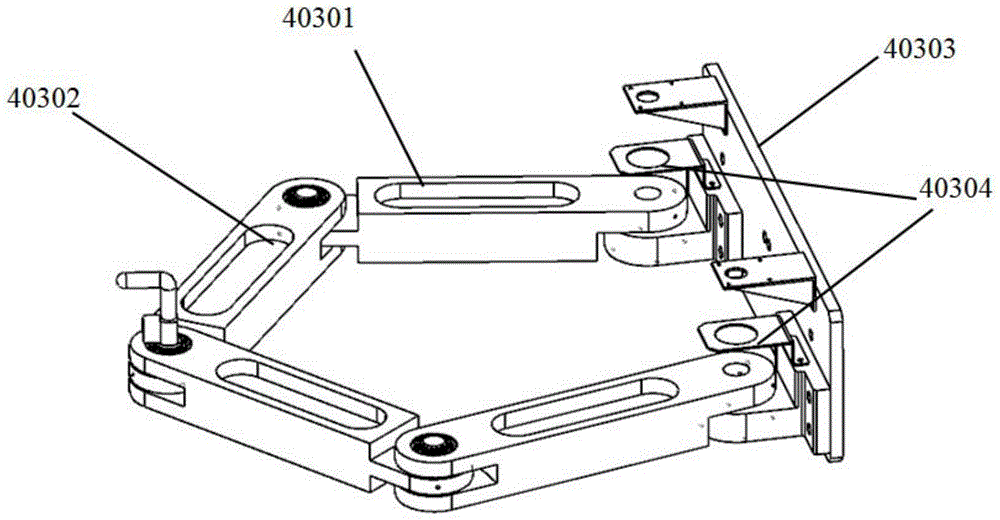

[0020] The two-dimensional vibration suppression mechanism 4 includes a force sensor 404, two equal-length active rods 40301, two equal-length driven rods 40302, a horizontal adjustment motor 401, a magnetic powder clutch 402, a rotary magneto-rheological damper 407, Mounting plate 40303, vertical damping mechanism 406, the inner surface of the mounting plate has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com