Patents

Literature

172results about How to "No mechanical friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

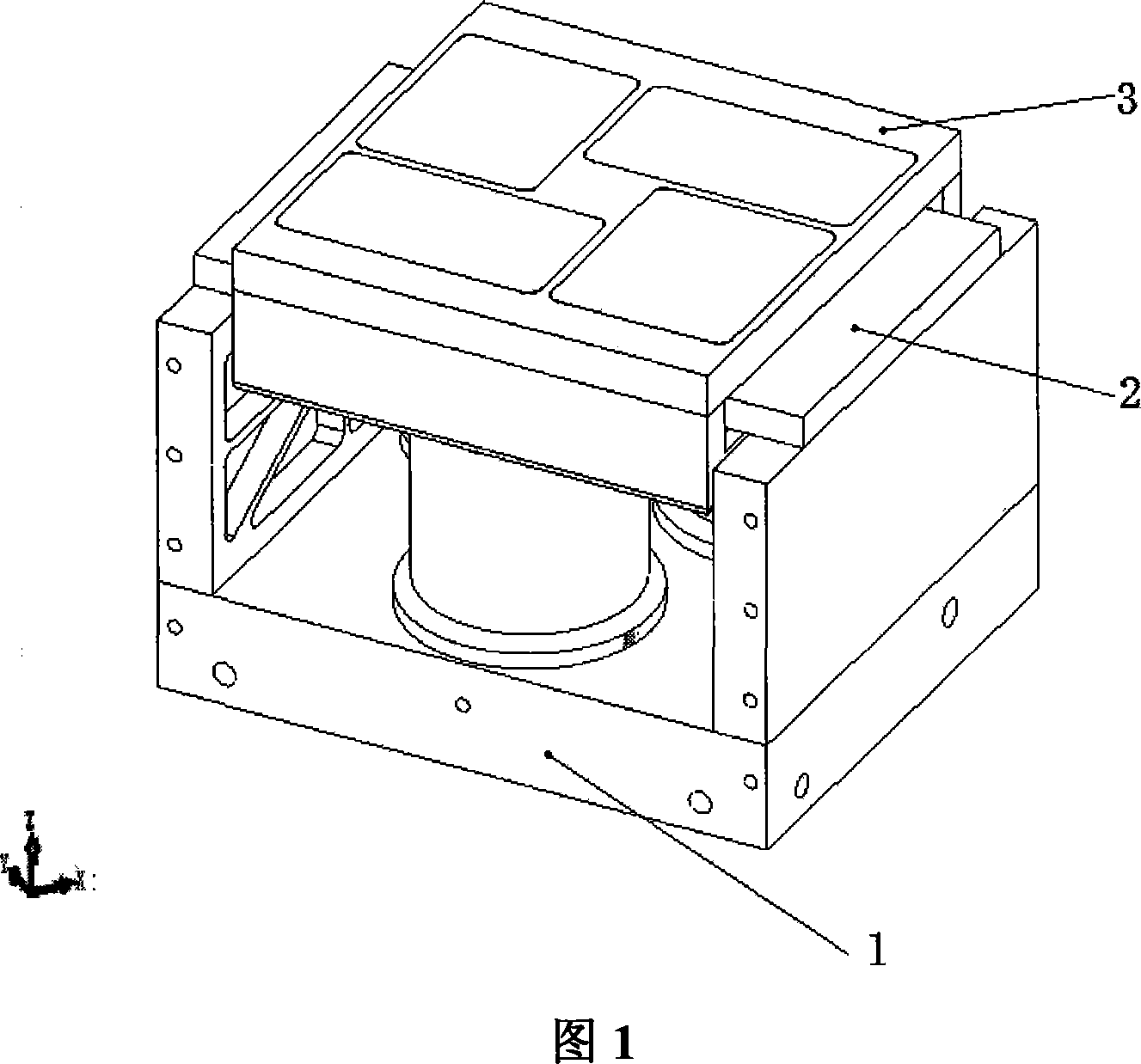

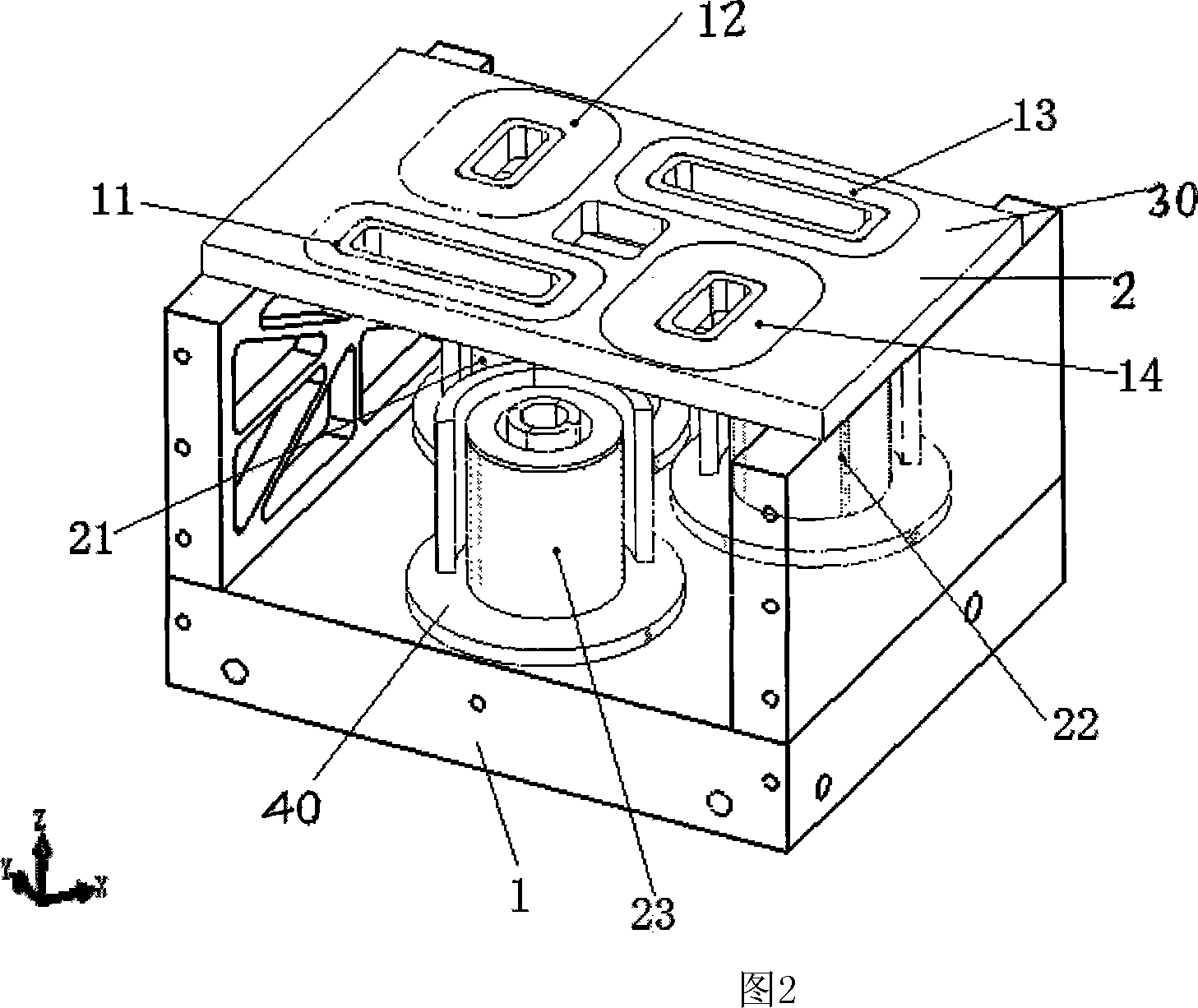

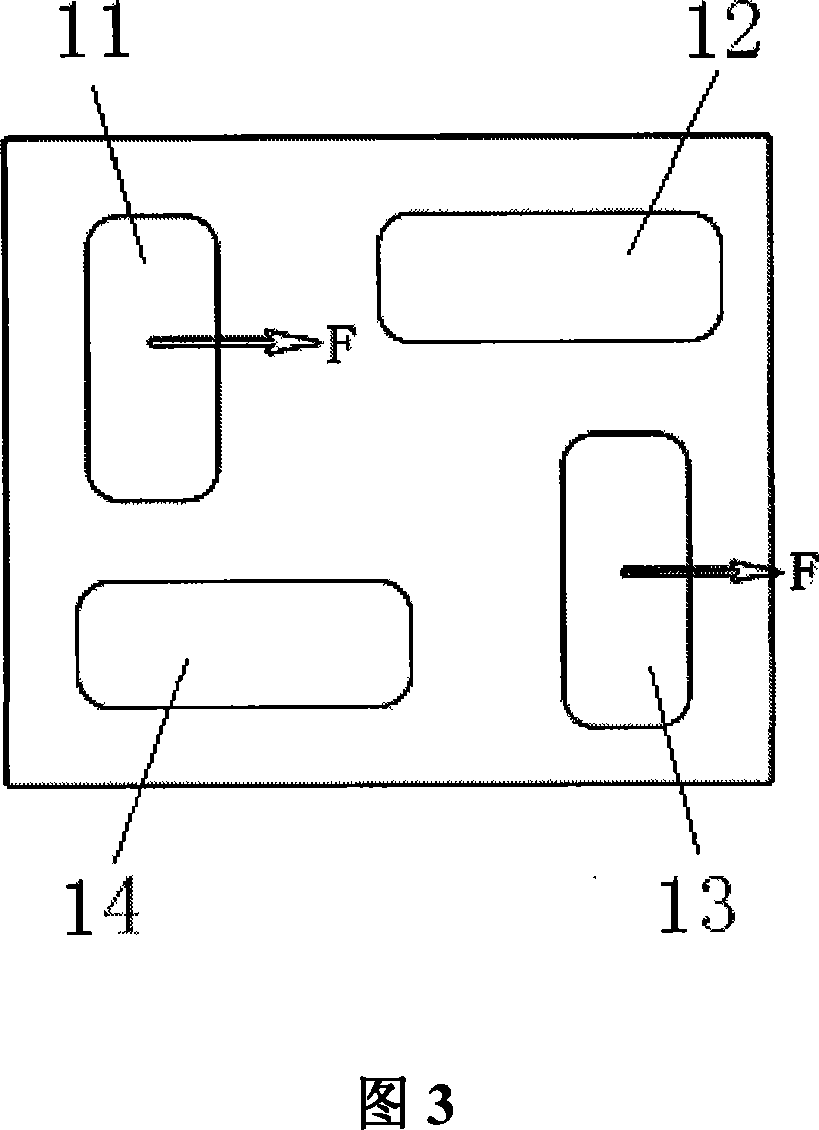

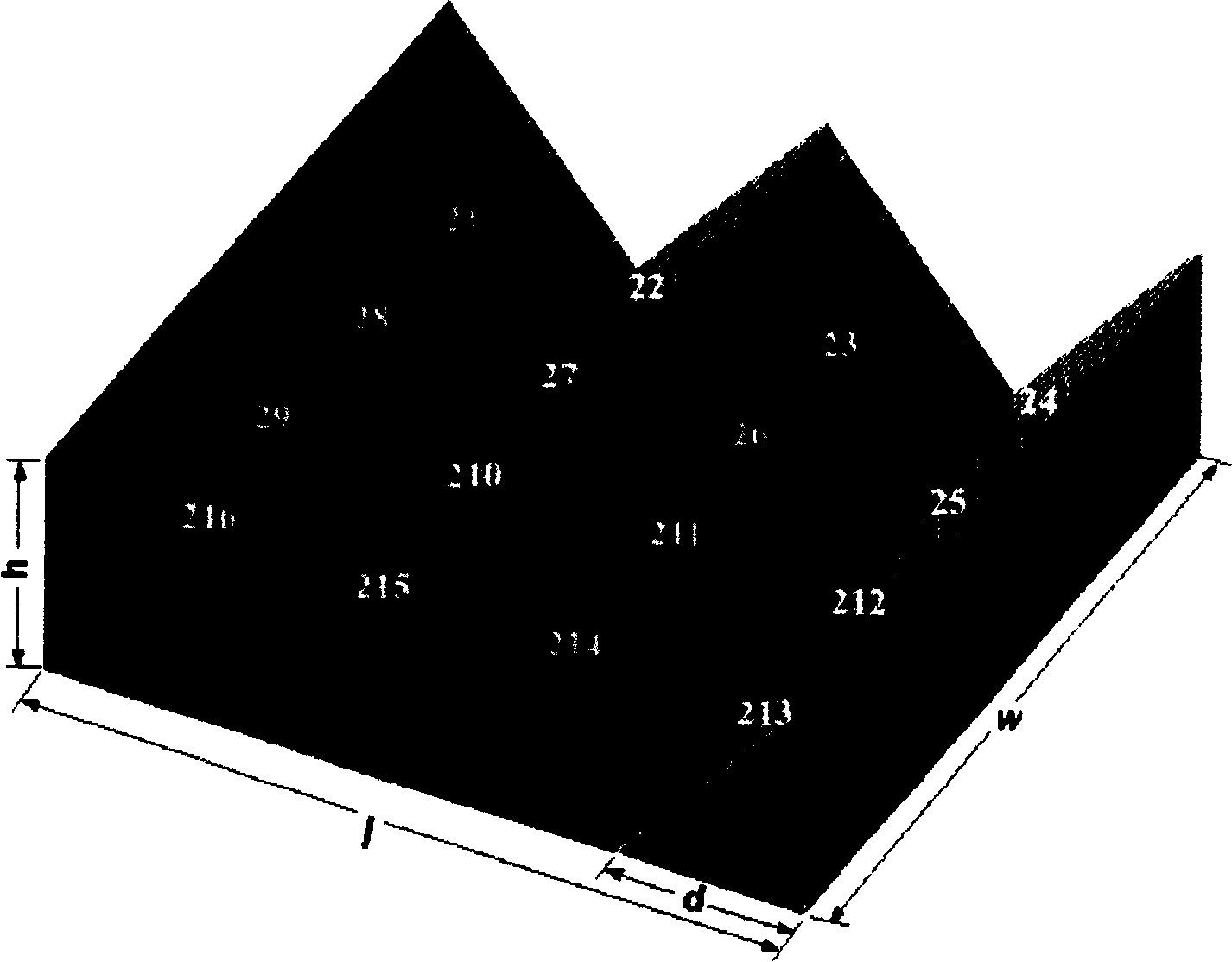

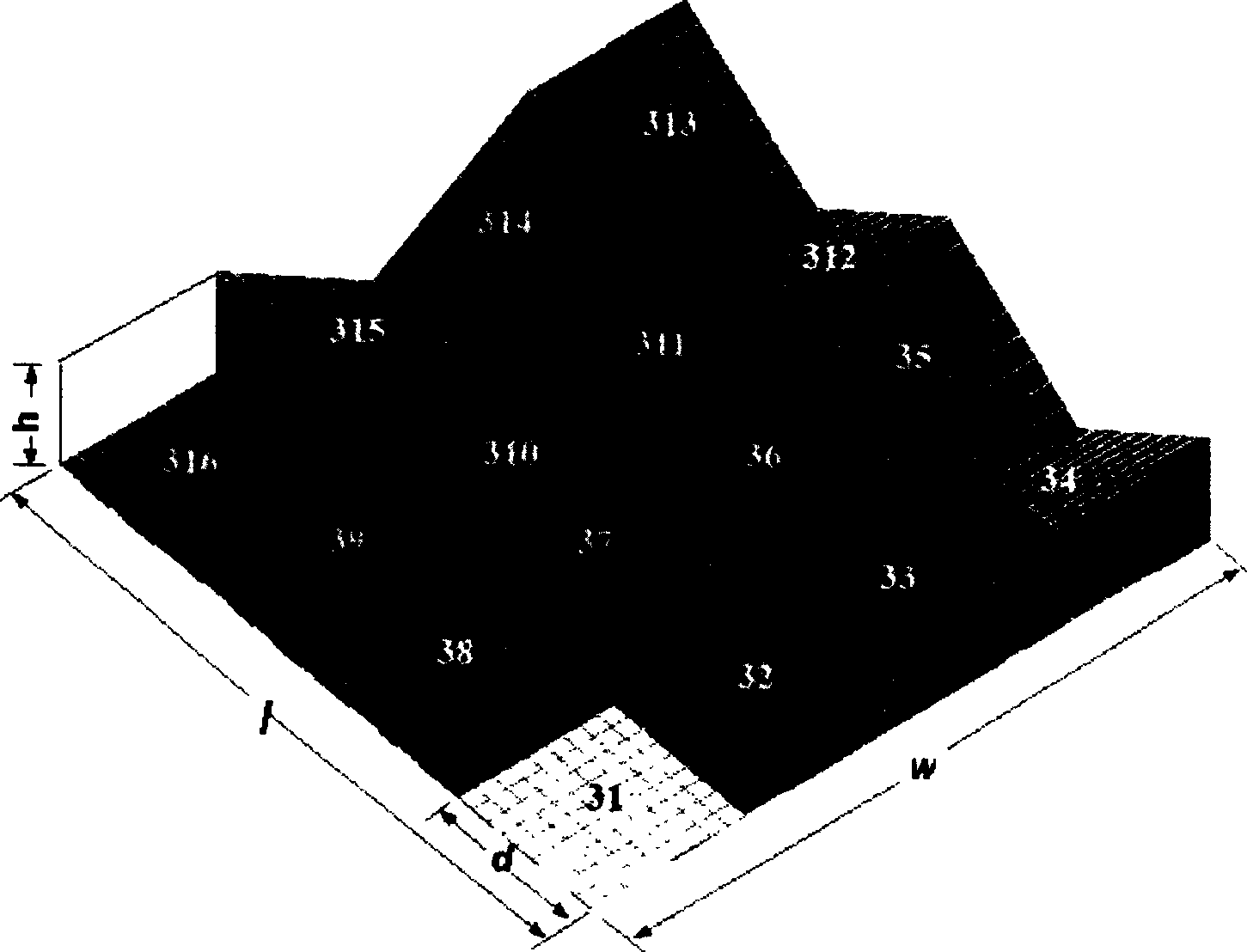

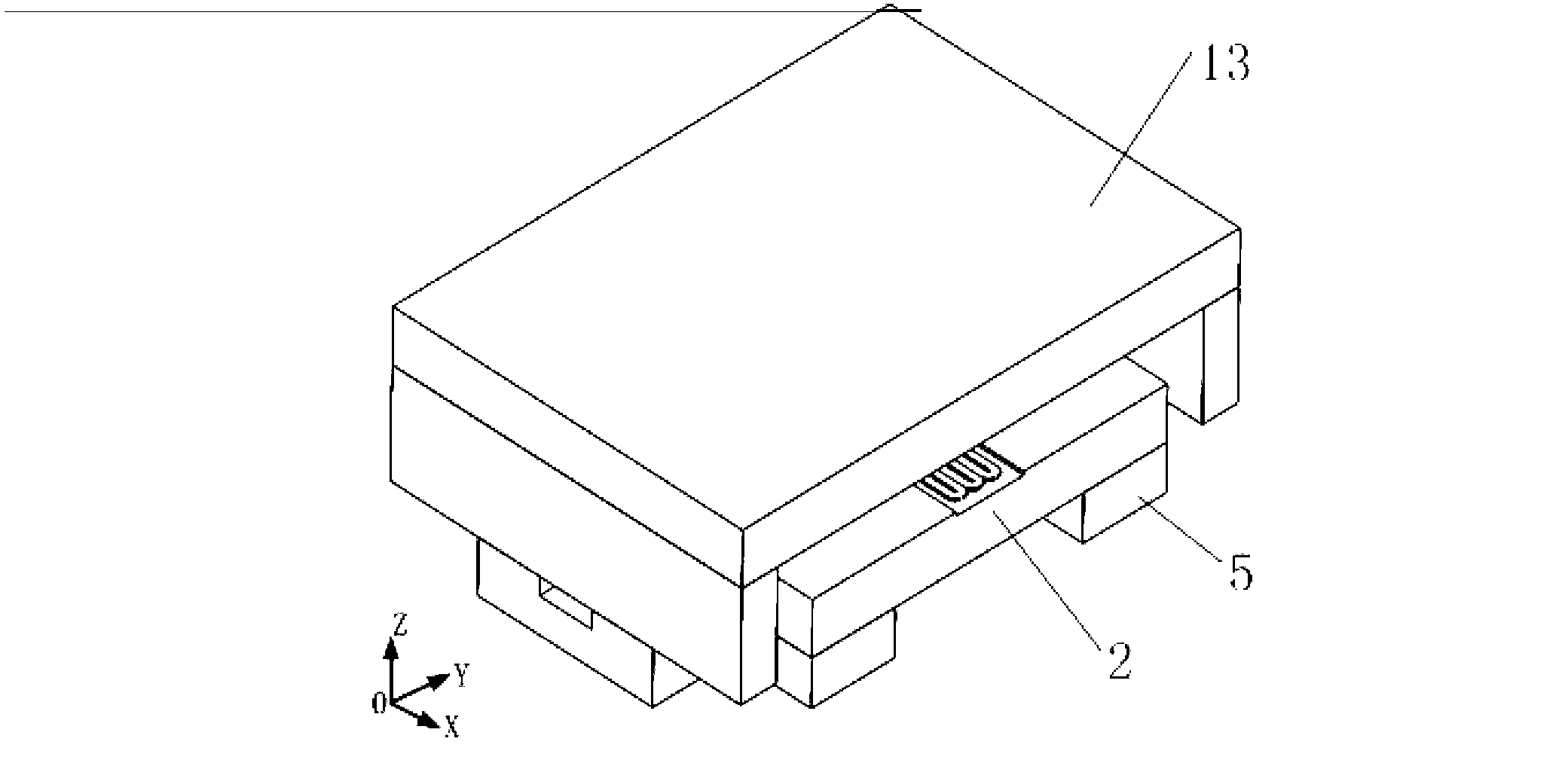

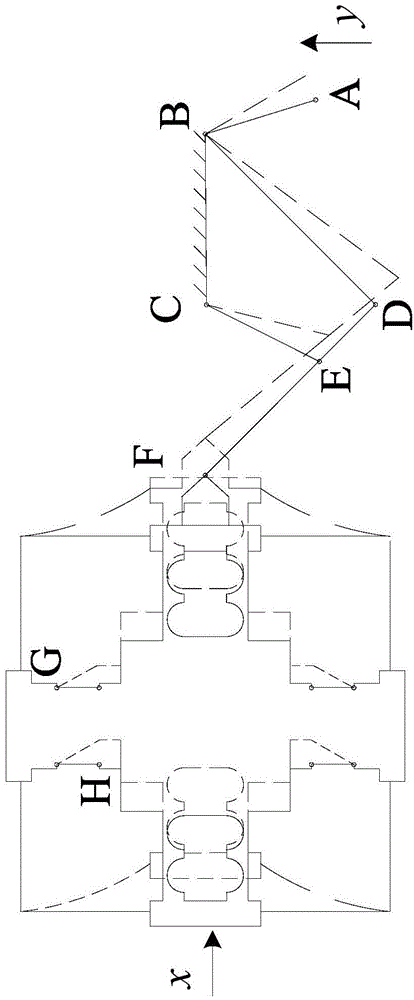

6 freedom degree micromotion operating platform

ActiveCN101078889ASimple structureCompact structurePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringDegrees of freedom

The invention discloses a 6 freedom degree micromotion bench in ultra precise processing and testing device technical domain, which is characterized by the following: possessing three groups of electromagnetic driving units; arranging in horizontal plane; driving the micromotion bench to X, Y, theta z3 freedom degree move in horizontal plane; arranging three electromagnetic driving units along vertical direction; driving the micromotion bench to Z, theta x and theta y3 freedom degree move. This invention possesses simple structure and higher displacement distinguishability, which can be used to realize 6 freedom degree motions for ultra precise process and check.

Owner:TSINGHUA UNIV +1

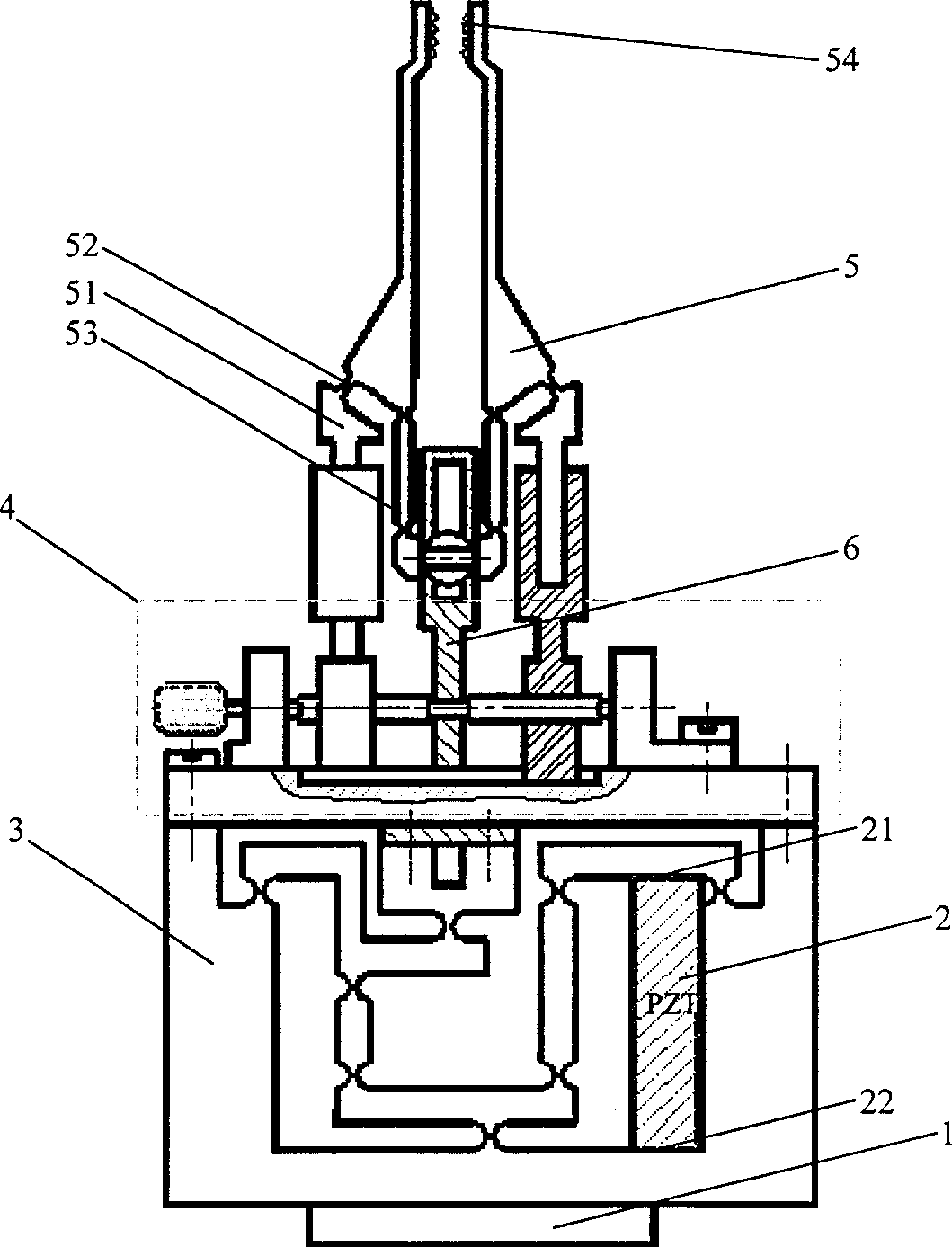

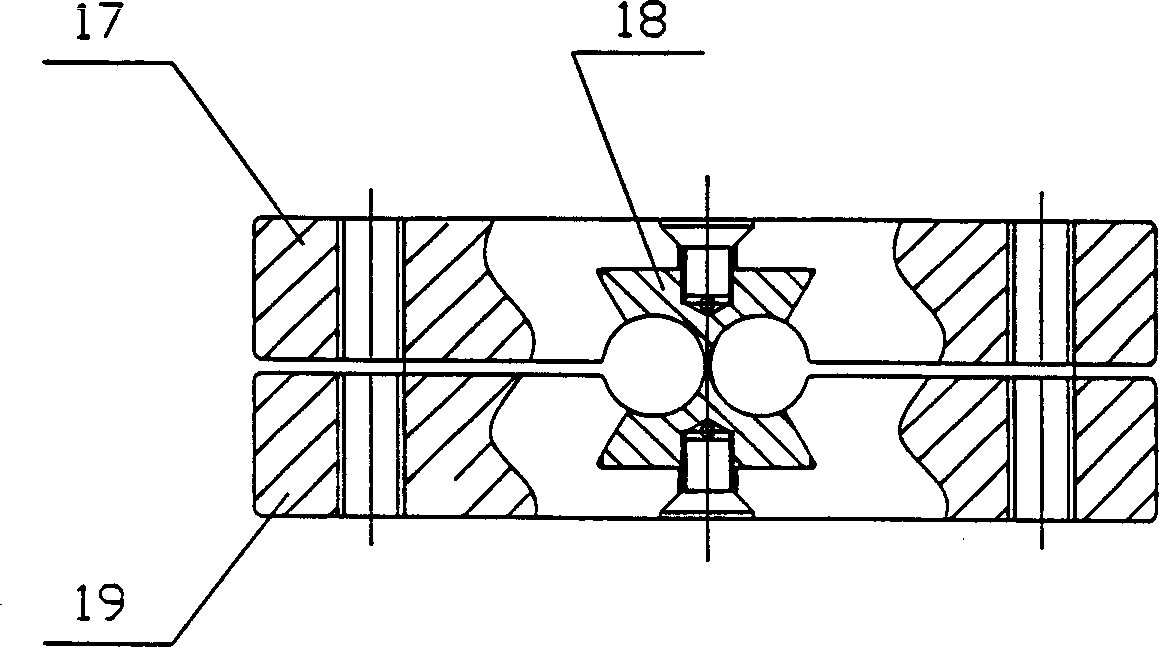

Flexible micro-positioning stage with two degrees of freedom

ActiveCN101738855AAvoid assemblyNo gapPhotomechanical apparatusFlexible MechanismsLithographic artist

The invention discloses a flexible micro-positioning stage with two degrees of freedom, the design of the flexible micro-positioning stage with two degrees of freedom comprises a flexible mechanism and an integral structure, two piezoelectric ceramic drivers are adopted in the structure, the tail part of each driver is connected with a base through a bolt, and the top end of each driver is connected with a spherical joint through a thread, thereby realizing Hertz contact. The flexible mechanism of the positioning stage mainly comprises three parts of the base, flexible branched chains with entirely consistent structures and a supporting movable platform thereof. Two displacement sensors are used for measuring actual output of the movable platform and respectively fixed between the base and the movable platform through an L-shaped support and a Z-shaped support. The flexible micro-positioning stage is characterized by high resolution and fast dynamic response speed, and can be taken as an auxiliary positioning platform of a nano-imprint lithography positioning system for realizing micro-feeding and precise positioning.

Owner:南通致远船舶设计有限公司

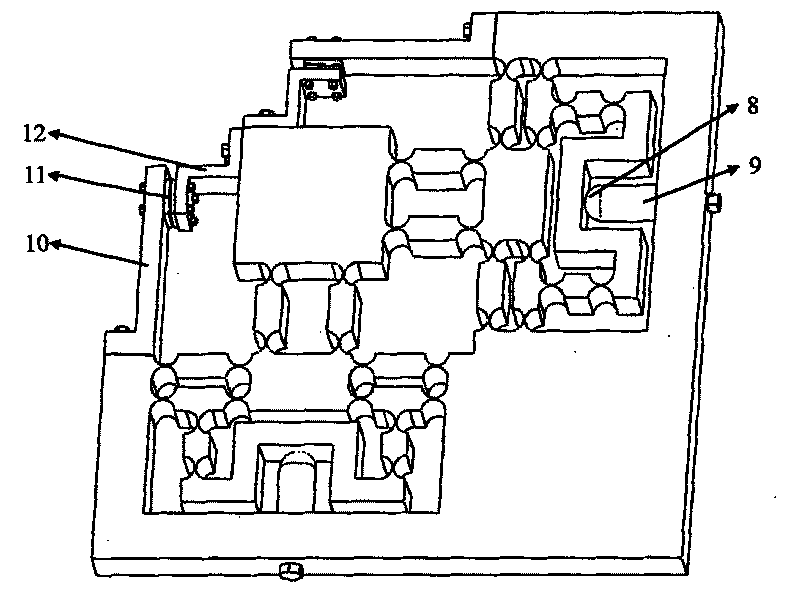

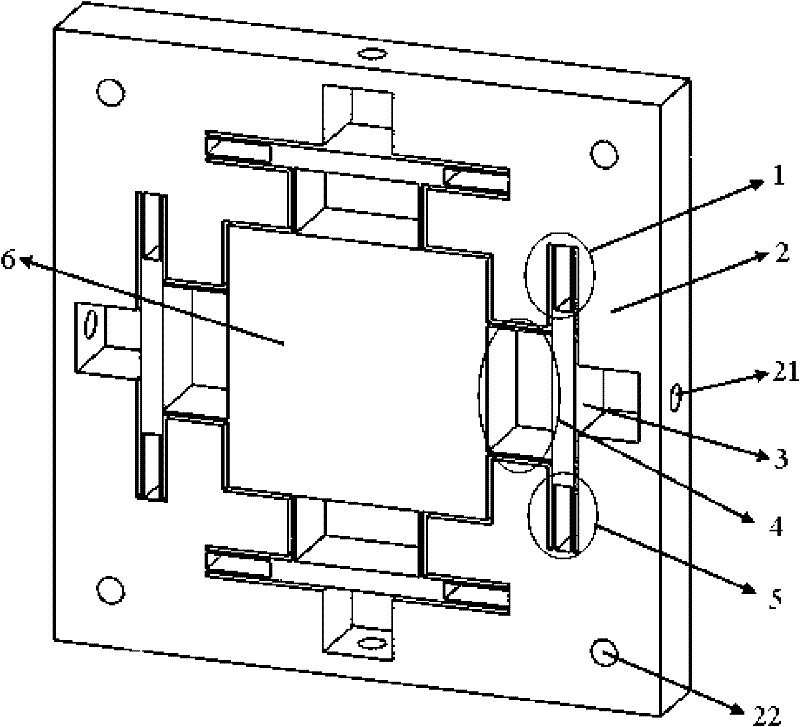

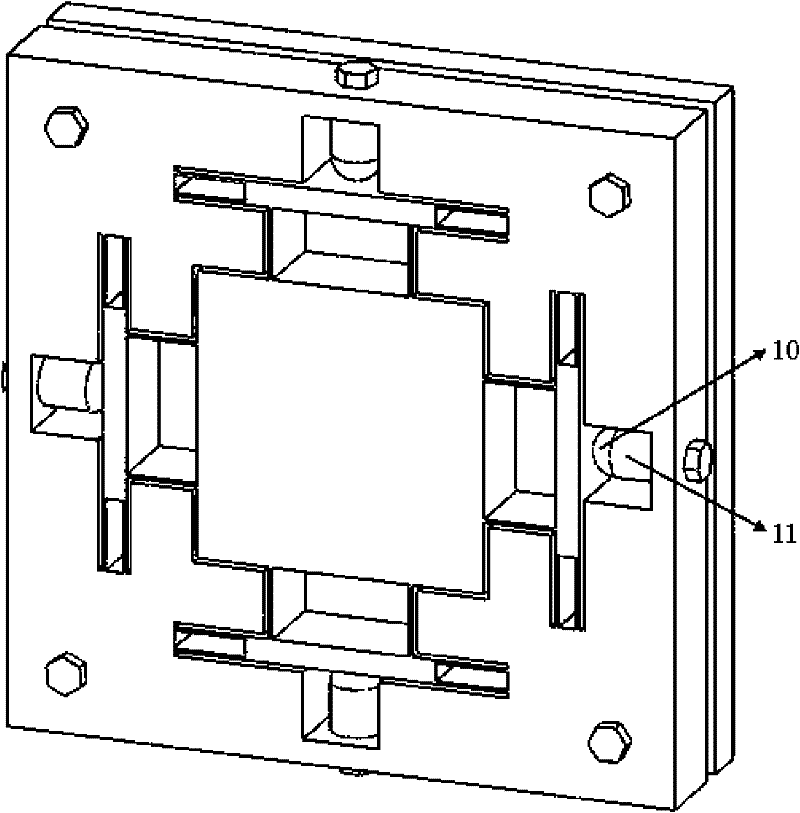

Three-degree of freedom flexible precision positioning workbench

InactiveCN101770182AAvoid assemblyNo gapPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistThree degrees of freedom

The invention discloses a three-degree of freedom flexible precision positioning workbench. In a structure of the workbench, six piezoelectric ceramic drivers are adopted, the tail of each driver is connected with a substrate through bolts, and the top end is in threaded connection with a ball joint to realize hertz contact; a flexible structure of the positioning workbench mainly comprises the substrate, six flexible branched chains with identical structures and a movable platform supported by the flexible branched chains; and three position sensors are used for measuring the actual output of the movable platform and are respectively fixed between a rigid support and the movable platform. The precision positioning workbench has the characteristics of high resolution ratio and high speed of dynamic response, and can be used as an assisted positioning platform of a nano-imprint lithography positioning system to realize microscale feeding and precision positioning.

Owner:TIANJIN UNIV

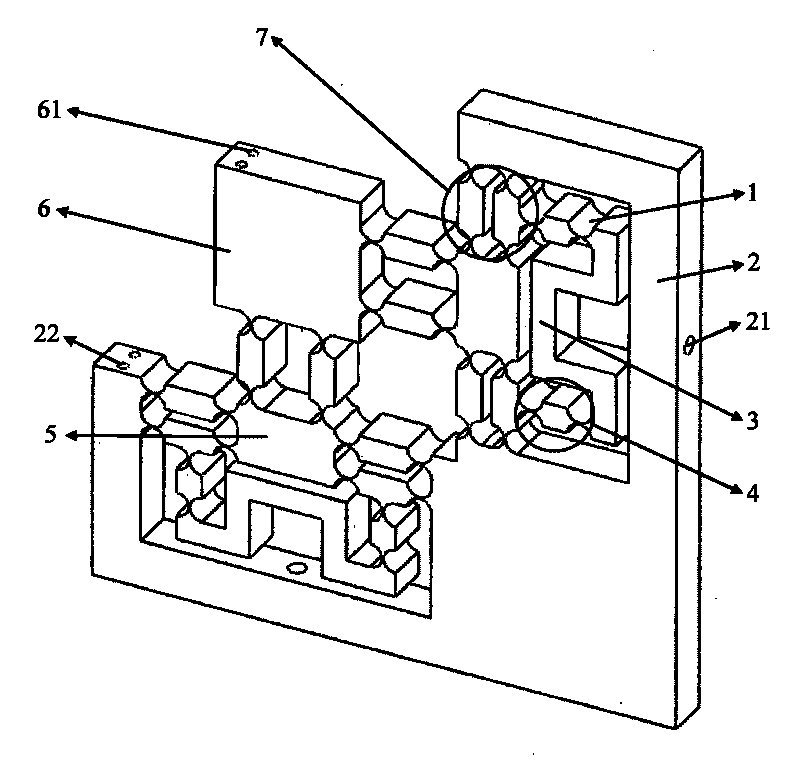

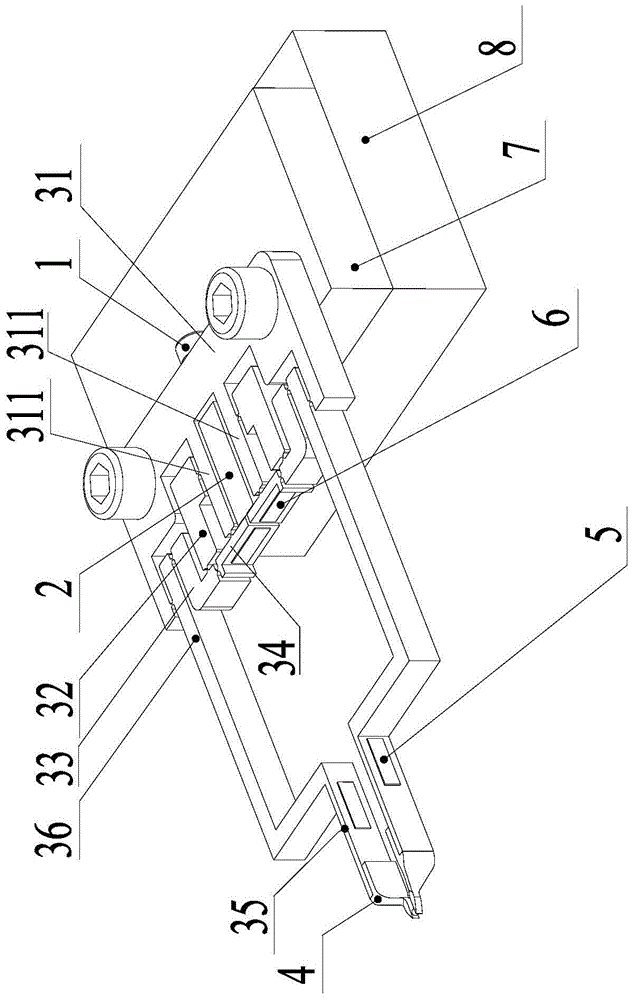

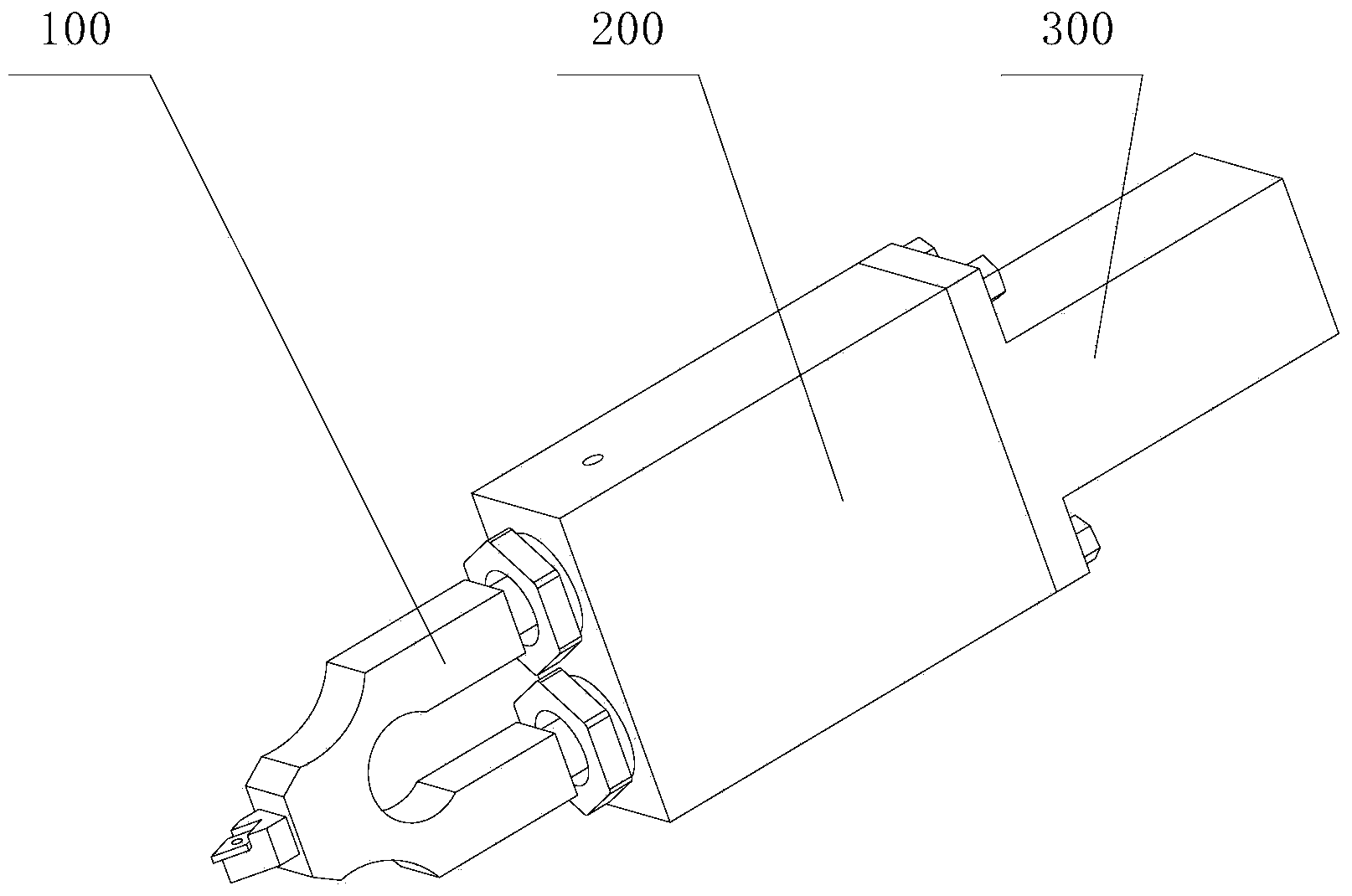

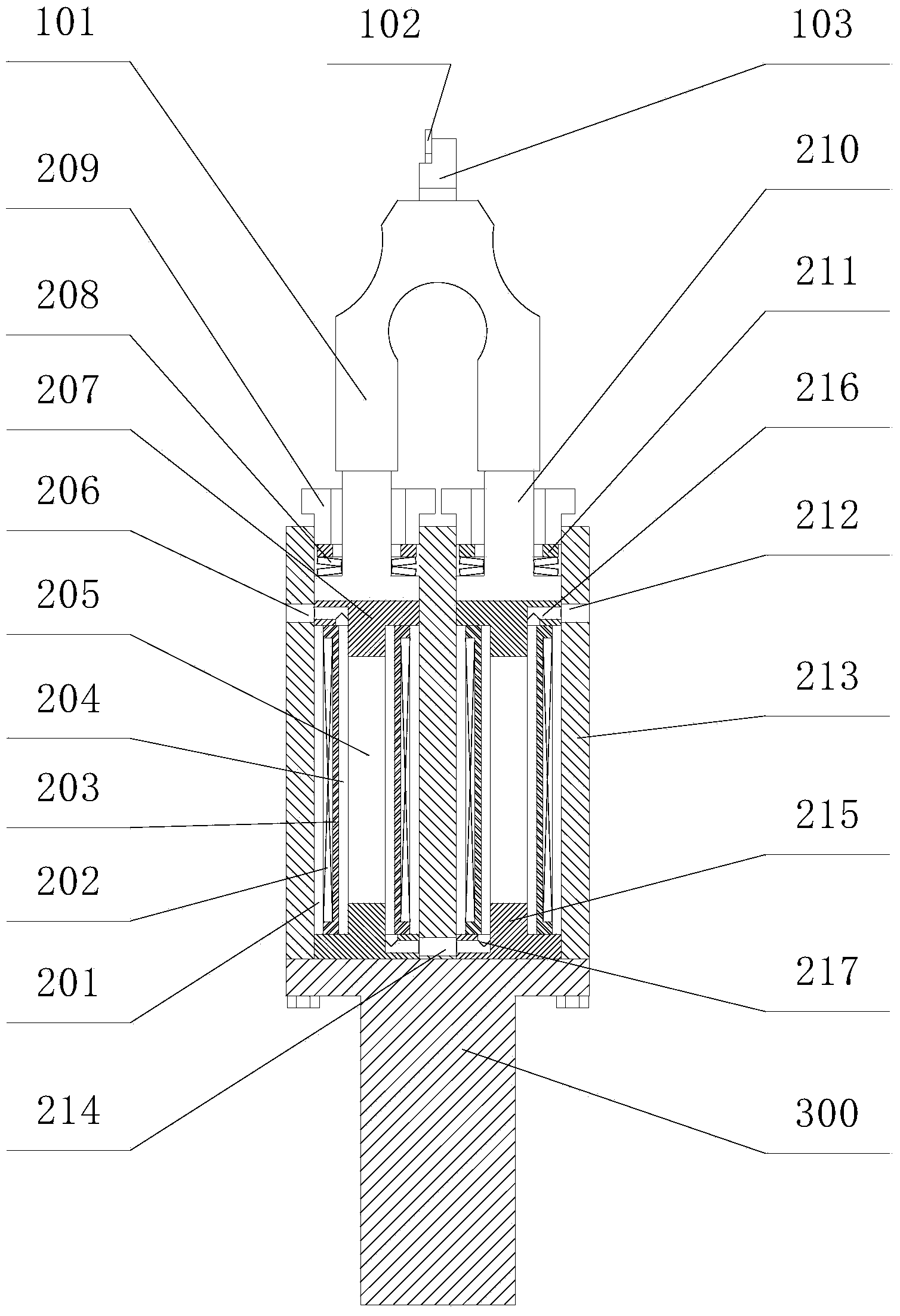

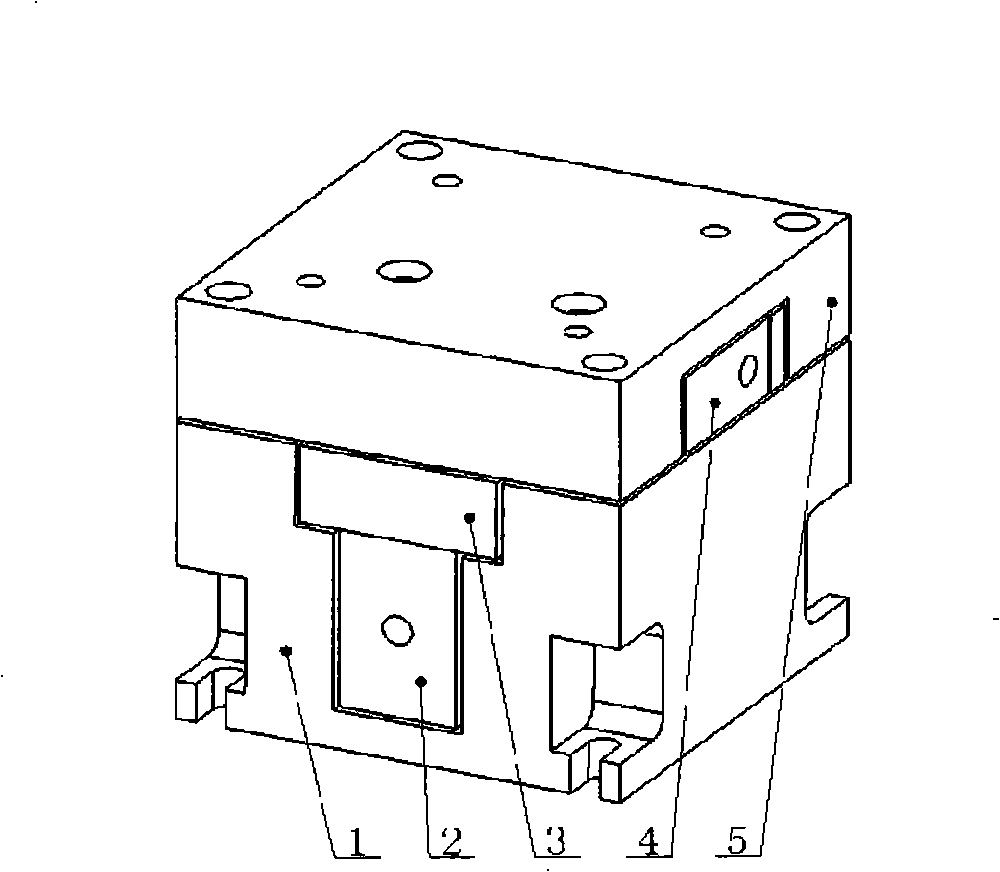

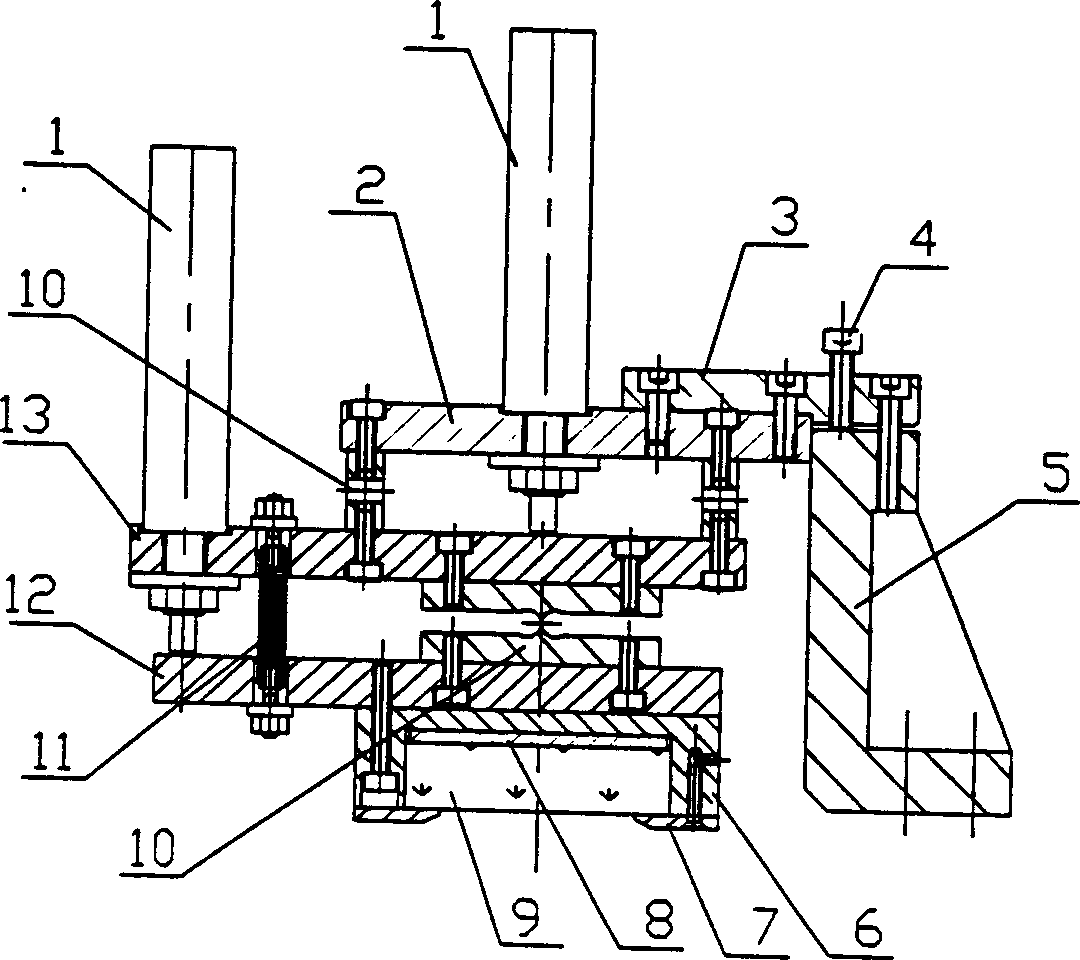

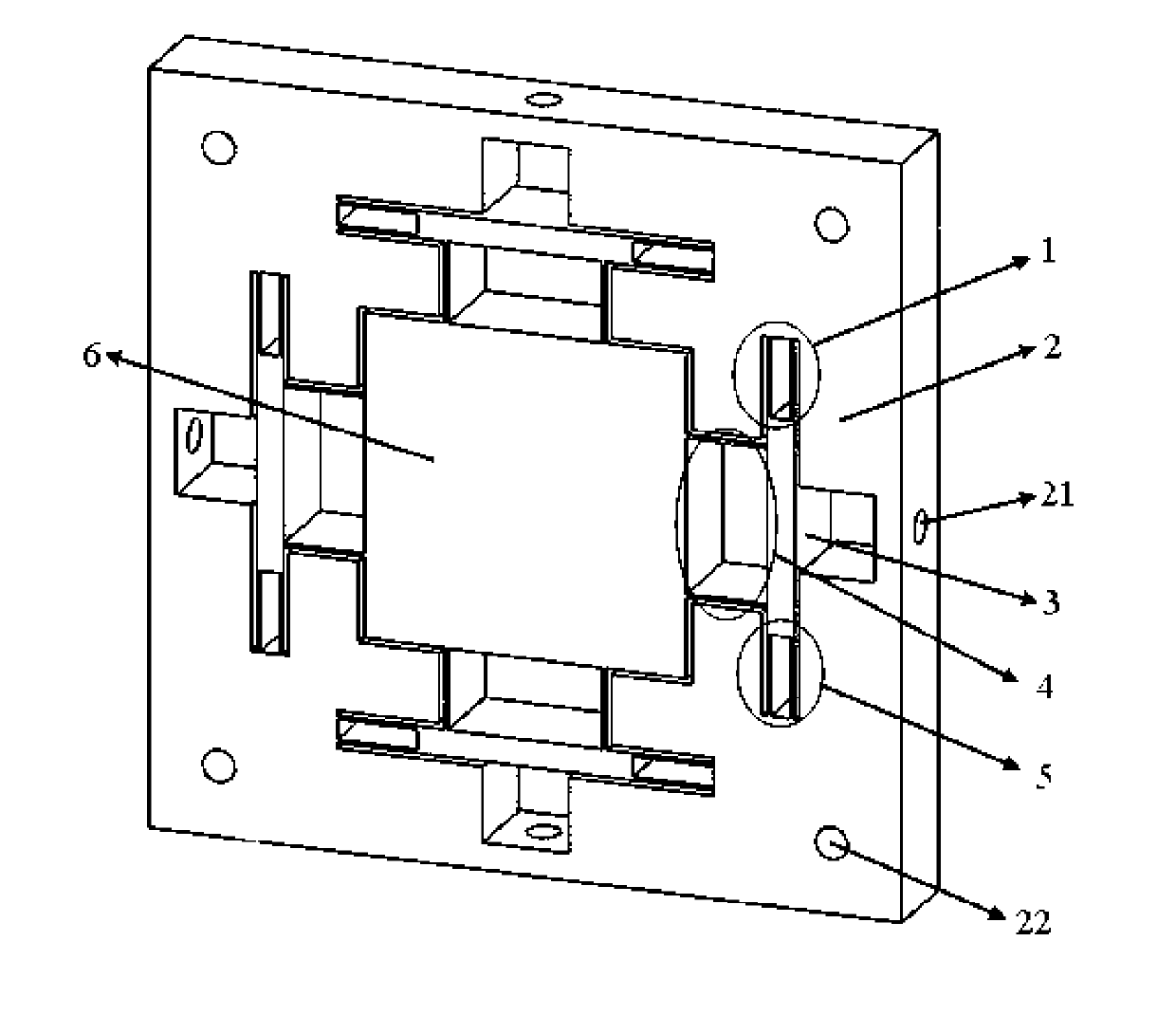

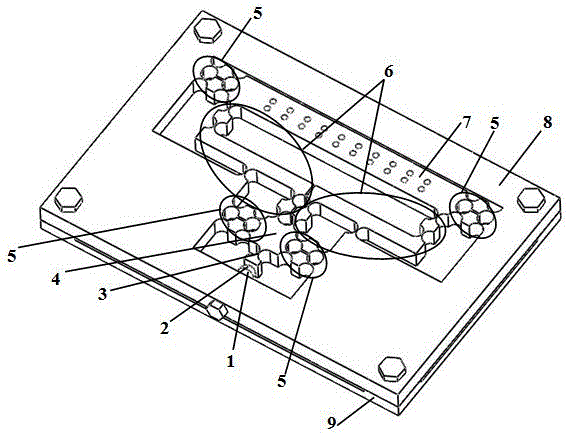

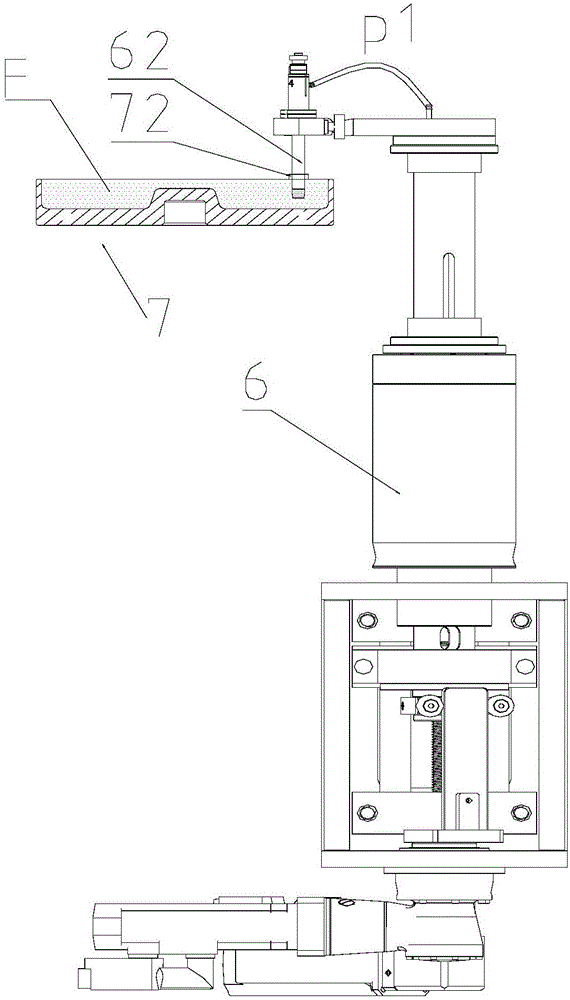

Flexible hinge amplification-based piezoelectric microgripper

InactiveCN104647347AReduce volumeNo mechanical frictionMicromanipulatorGripping headsElectricityEngineering

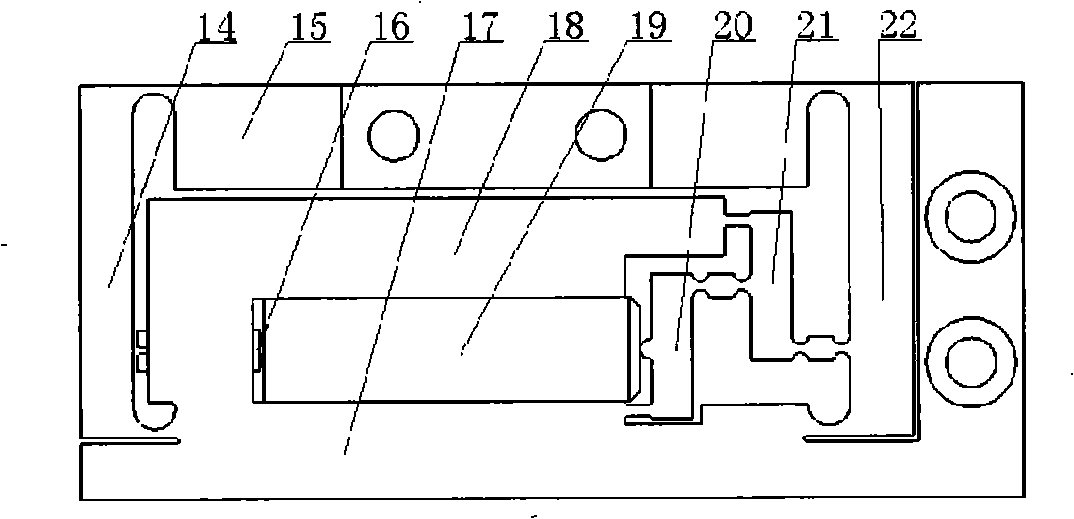

The invention discloses a flexible hinge amplification-based piezoelectric microgripper, which comprises a substrate, a rack, a piezoelectric stack driver, a pre-tightening screw, a motion transmission mechanism, a pair of clamping arms and a chuck; the deformation of the piezoelectric stack driver is converted into the displacement of the chuck by the motion transmission mechanism; the rack is provided with two pillars, and the piezoelectric stack driver is located between the two pillars; the motion transmission mechanism comprises a pair of double-rocker mechanisms and a pair of lever support arms; one end of an active rocker of each double-rocker mechanism is hinged with the corresponding pillar, and the other end of the active rocker is hinged with a corresponding connecting rod; each active rocker is provided with an extension section; the extension sections of the active rockers lean against the piezoelectric stack driver; the deformation of the piezoelectric stack driver serves as the driving force of each double-rocker mechanism; a position detection strain gage is adhered to the extension section of the corresponding active rocker; each clamping arm is provided with a clamping force detection strain gage. The flexible hinge amplification-based piezoelectric microgripper disclosed by the invention has the advantages that not only can the large stroke of the tail end of the microgripper be realized but also the clamping force detection and the position detection of the tail end of the microgripper can be integrated.

Owner:ZHEJIANG UNIV

Two-degree of freedom precise positioning work table

The invention discloses a two-degree of freedom precise positioning work table, which comprises a base, a moving platform, a rigid support which is connected with the bottom of the base, and four flexible branched chains which are connected between the moving platform and the base, wherein each flexible branched chain comprises a moving block and three groups of flexible plate spring structures; each flexible plate spring structure consists of two '-'-shaped flexible plate springs; a first group and a second group of the flexible plate spring structures are respectively positioned at the left side and the right side of the moving block; the lower ends of the two '-'-shaped flexible plate springs of a third group of the flexible plate spring structures are connected with the side wall of the upper end of the moving block, and the upper ends thereof are connected with the side wall of the moving platform; four piezoelectric ceramics driving devices are respectively horizontally arranged; a ball-shaped joint of each driving device is supported on the side wall of the lower end of the moving block; and conducting strips of two position sensors are respectively connected with the upper plane of the rigid support and the lower plane of the moving platform. The positioning work table can be taken as an auxiliary positioning platform of a nanometer embossing photoetching positioning system to realize the microscale feeding and the precise positioning.

Owner:TIANJIN UNIV

Miniature manipulate with piezoelectric-type flexible drive and adjustable range

InactiveCN1376631AReduce nonlinear errorHigh resolutionTelevision system detailsMicromanipulatorSpatial structureMicro robotics

A piezoelectric clamping micromanipulator with flexible drive and amplification and adjustable range is composed of microactuator, flexible multiplying mechanism, size pre-regulator, and clamping micromanipulator. Its advantages are compact structure, high reliability, and low non-linear error.

Owner:TSINGHUA UNIV

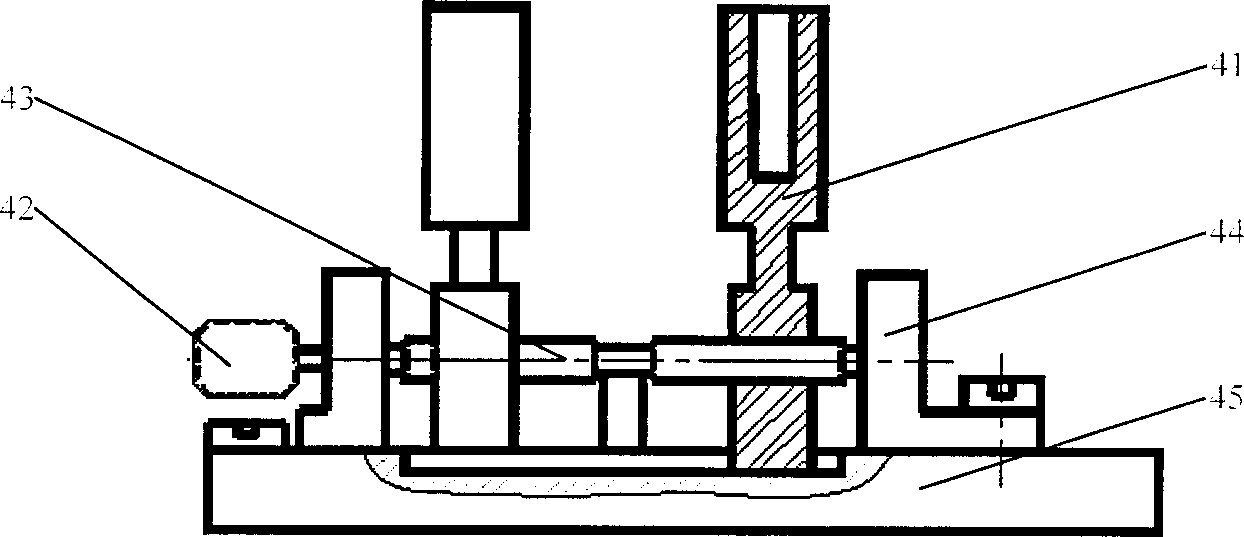

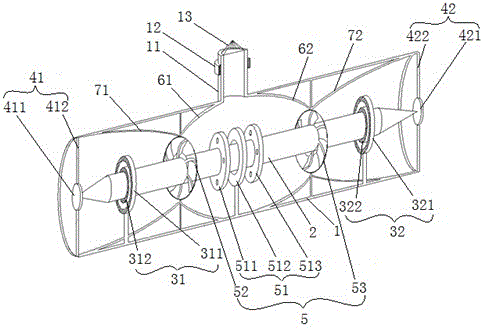

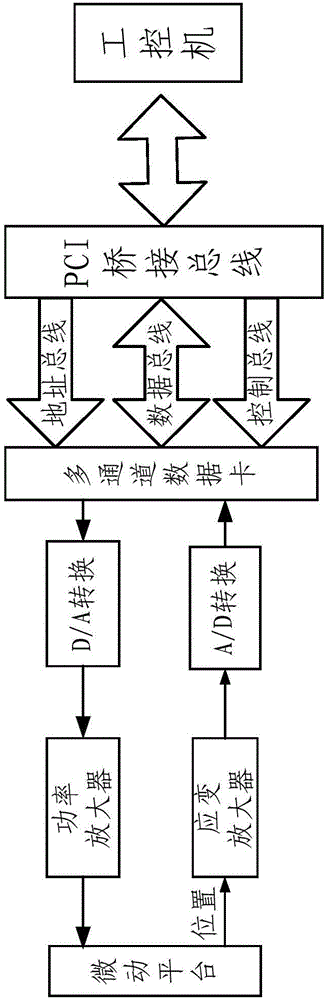

Double-stimulation ultrasonic elliptical vibration processing device

InactiveCN103586192ALarge magnetostrictive strainIncrease output powerMechanical vibrations separationSonificationTransducer

Provided is a double-stimulation ultrasonic elliptical vibration processing device. A giant magnetostrictive material is adopted to serve as a drive element, two sets of giant magnetostrictive transducers are arranged in parallel, large-area one-way water-cooling systems are arranged in the transducers, and flexible hinge connection is adopted at vibration output ends. The device has the advantages of being high in output power, loading capacity and energy conversion efficiency, wide in bandwidth, compact and reasonable in structure and the like, and can be widely applied to various ultrasonic elliptical vibration processing operating conditions.

Owner:HUAZHONG UNIV OF SCI & TECH

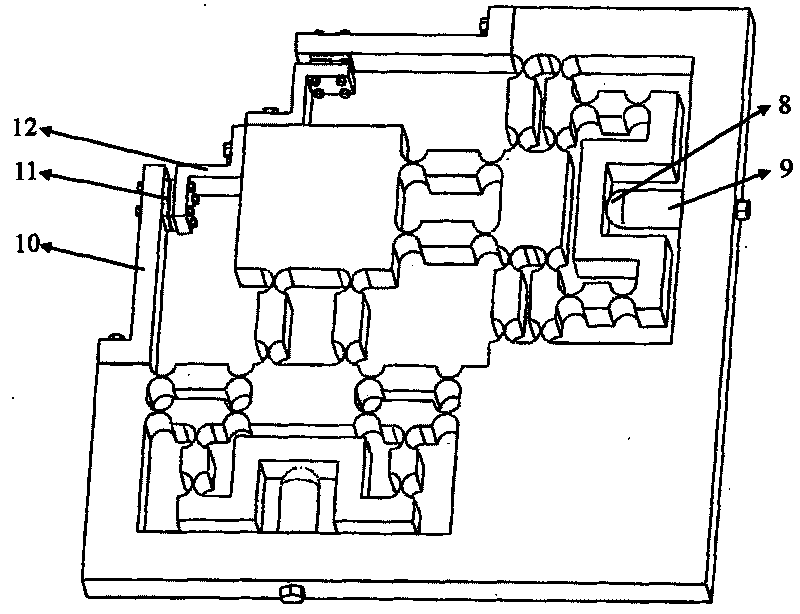

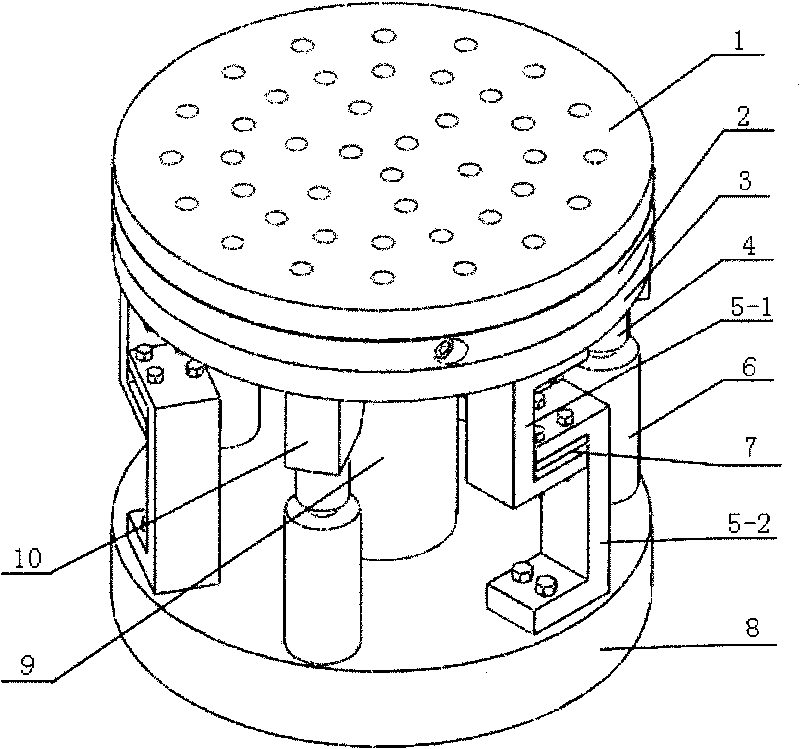

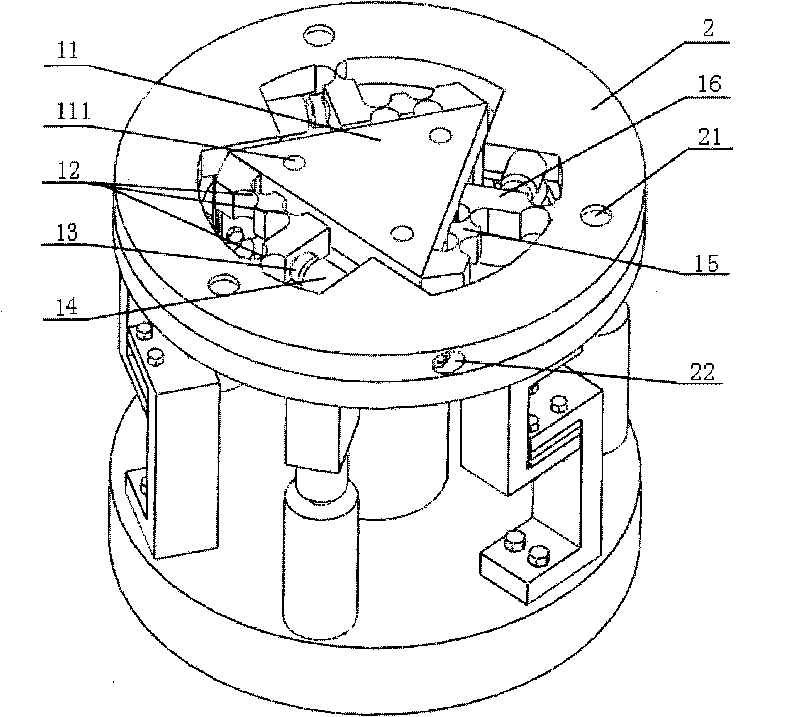

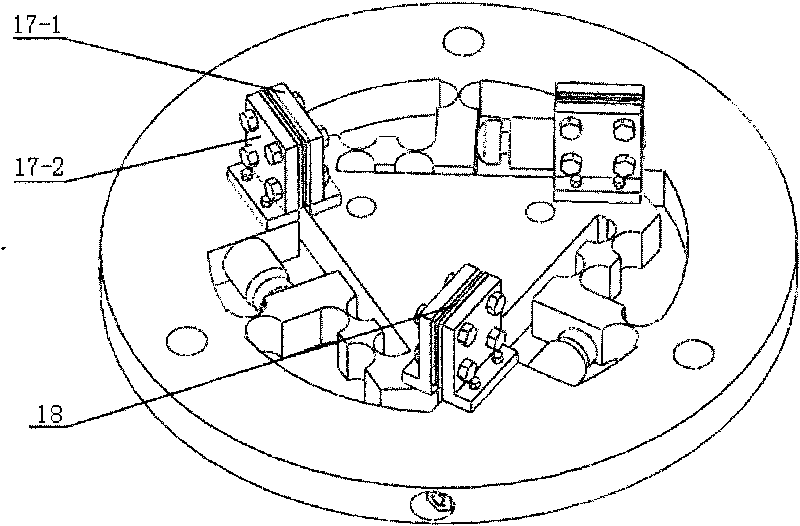

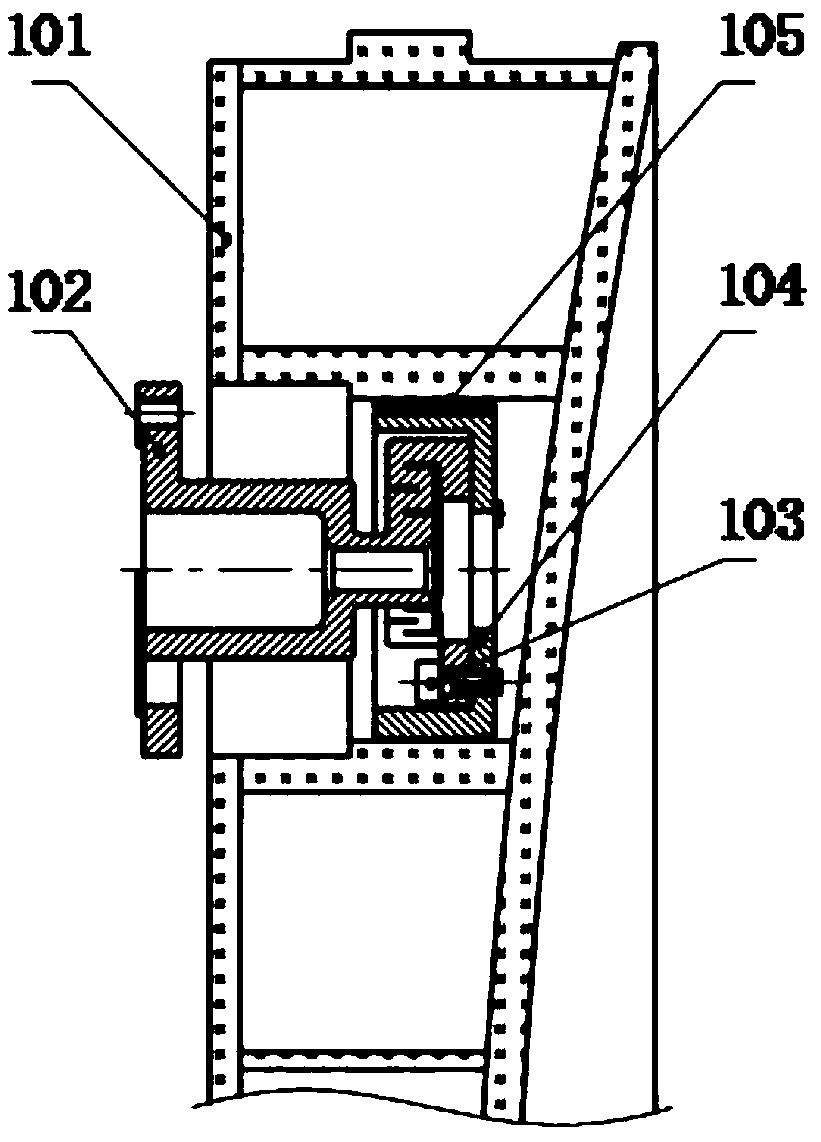

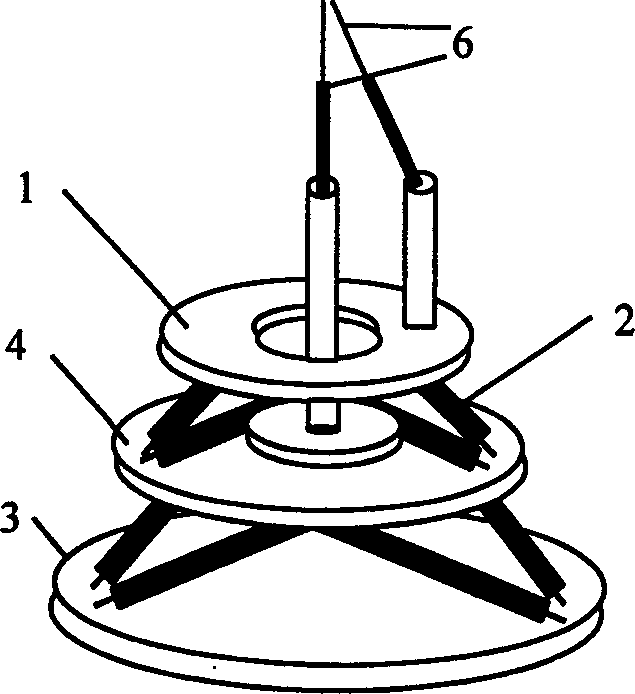

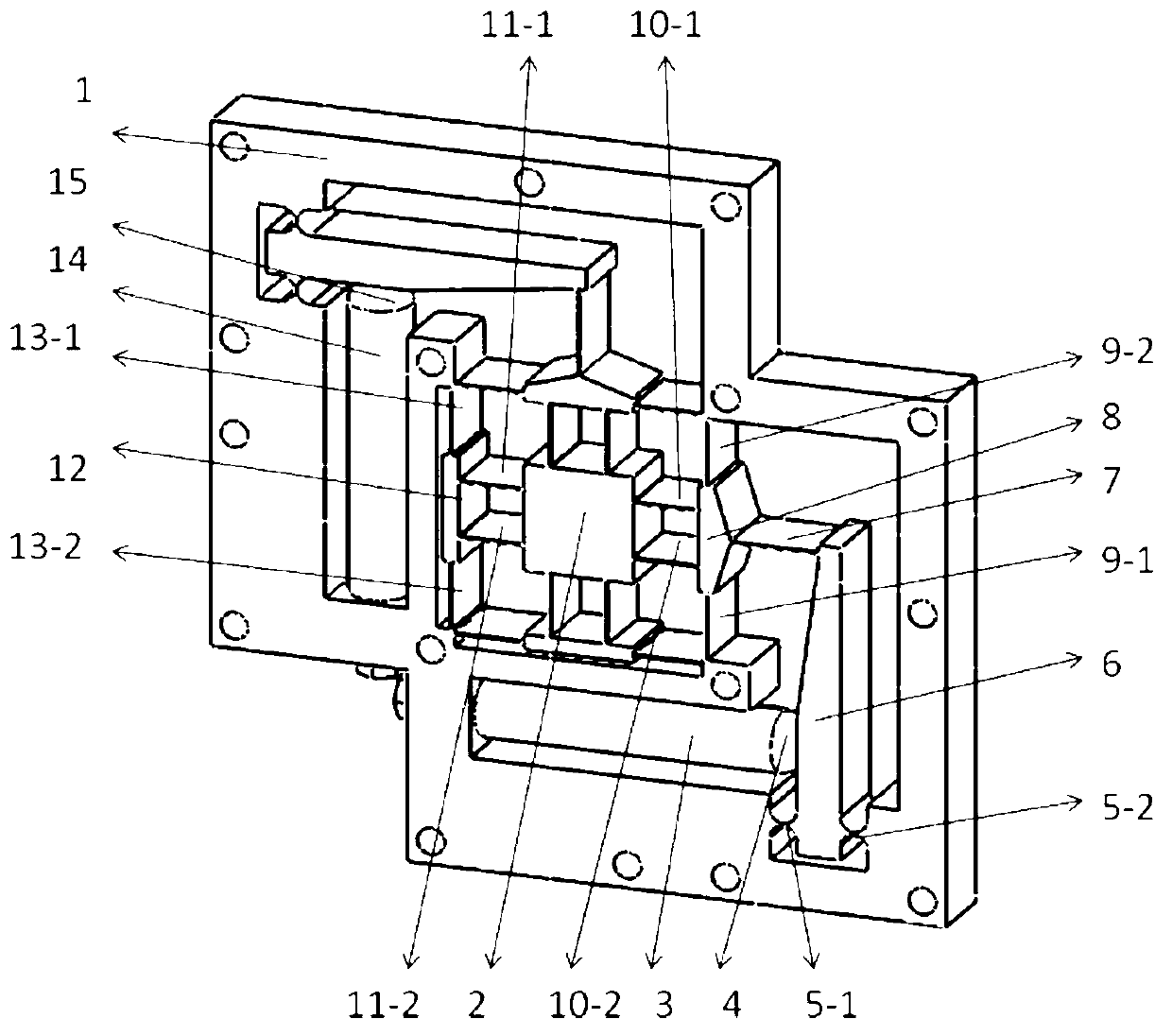

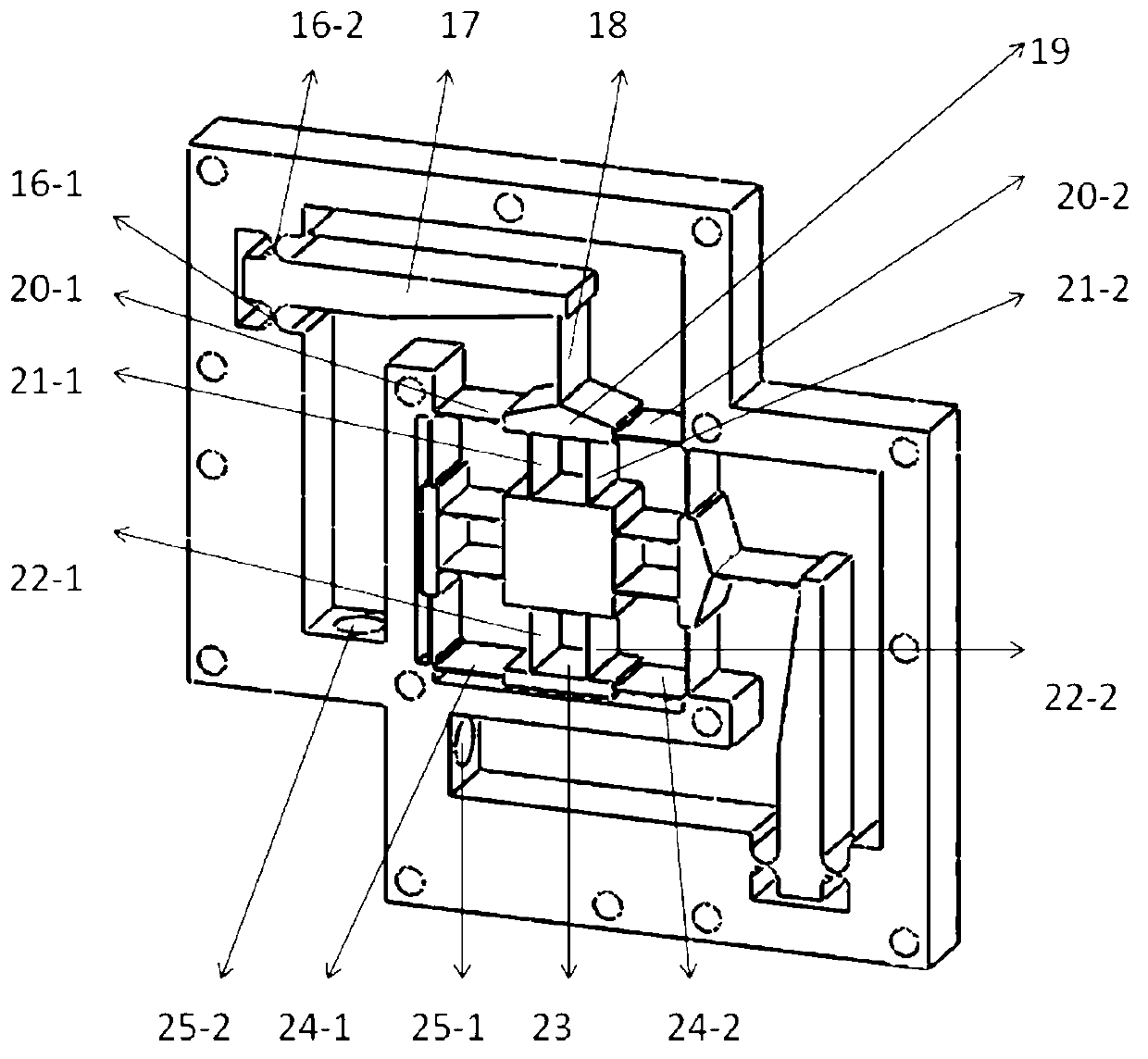

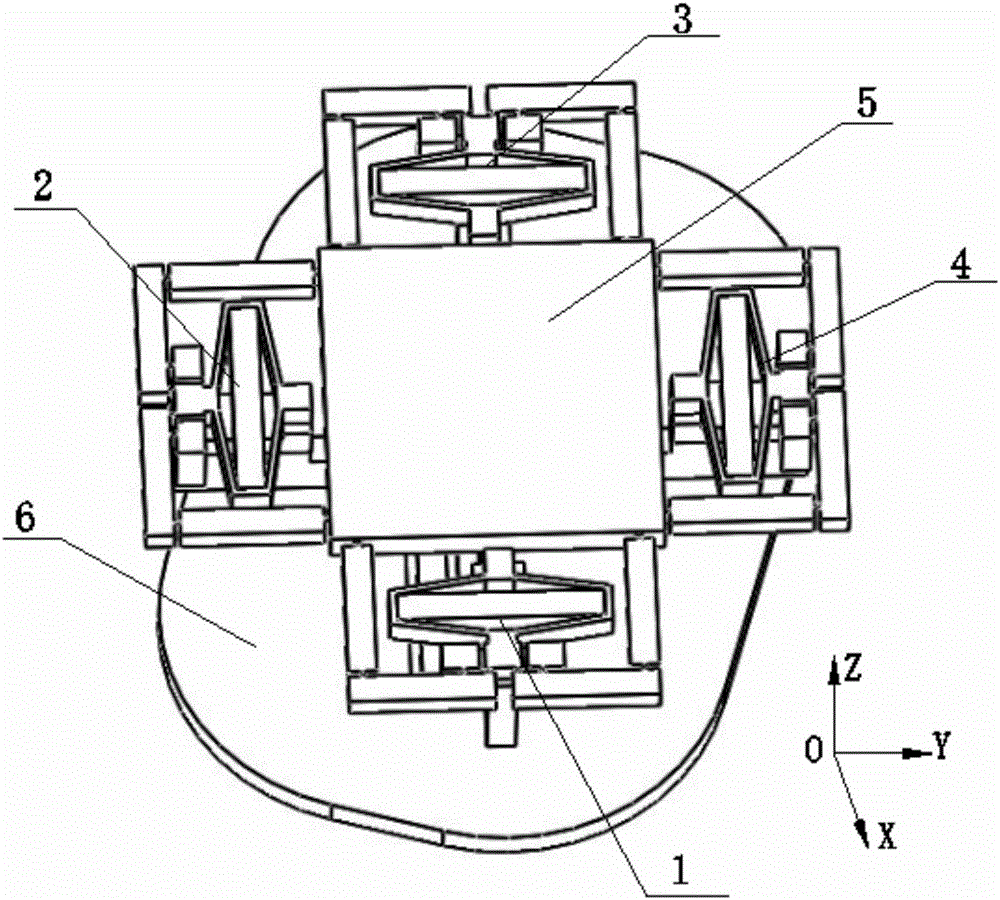

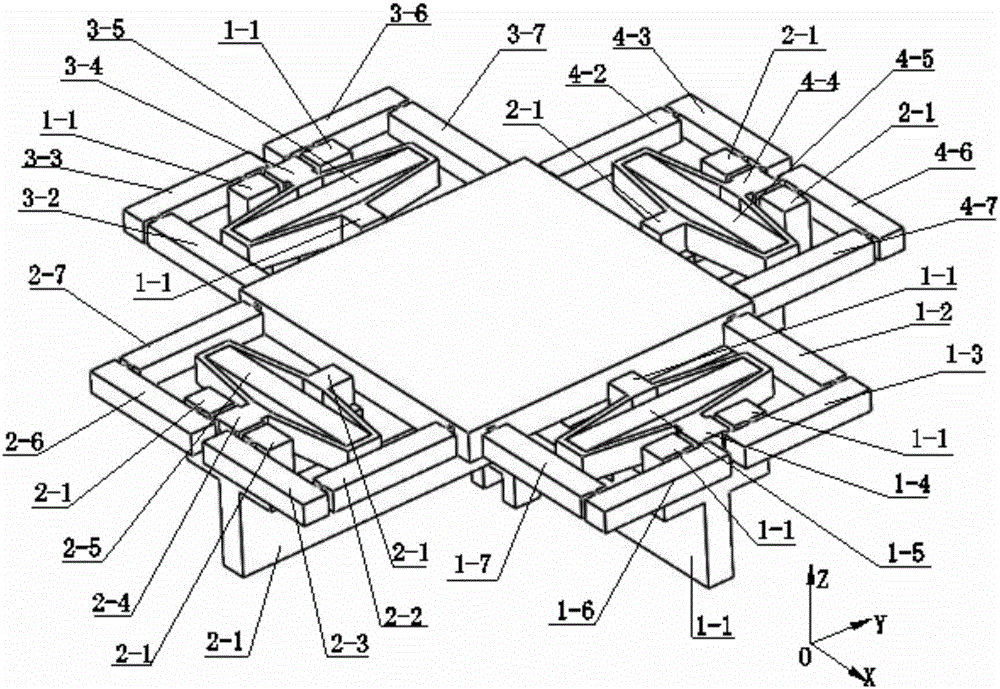

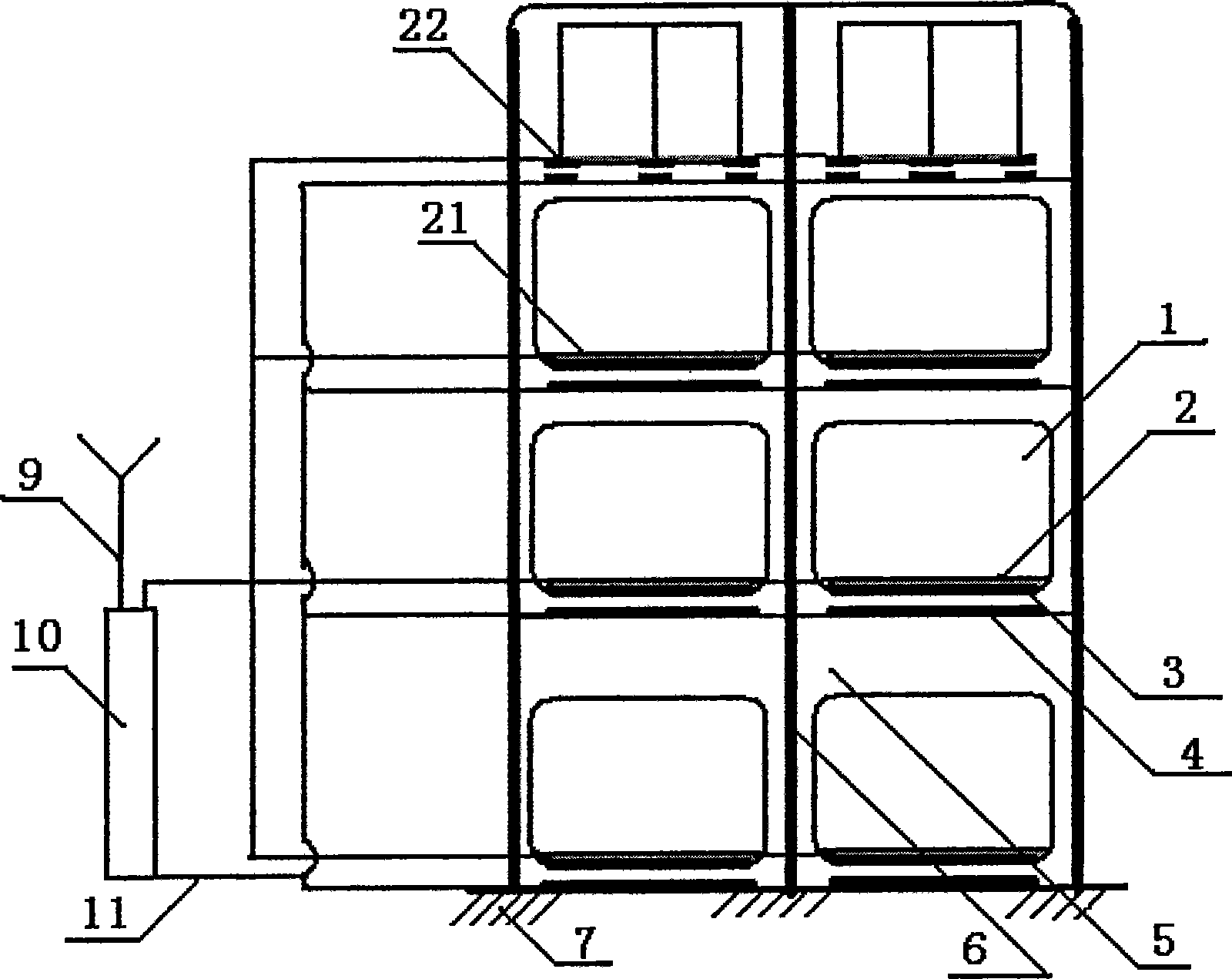

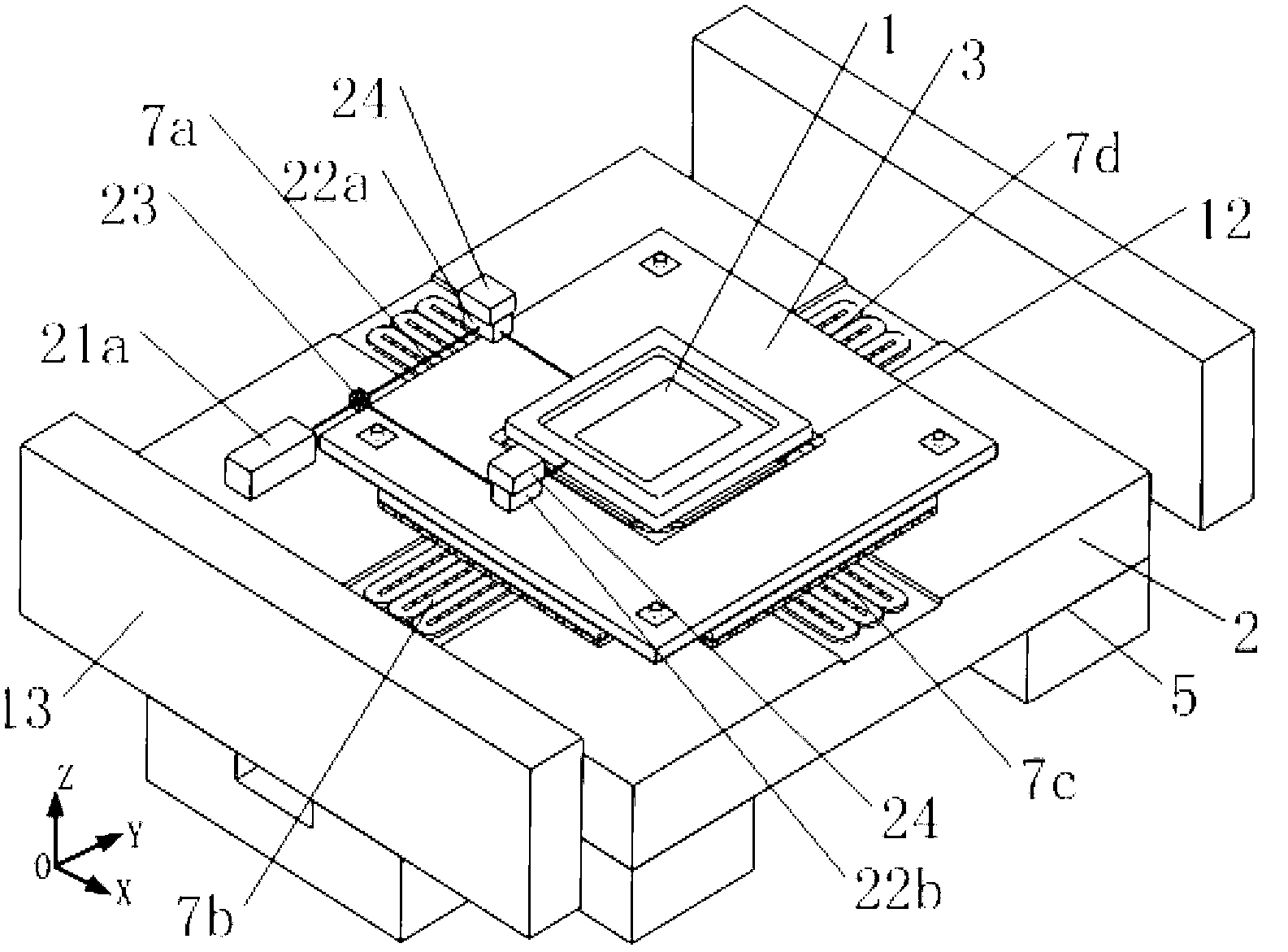

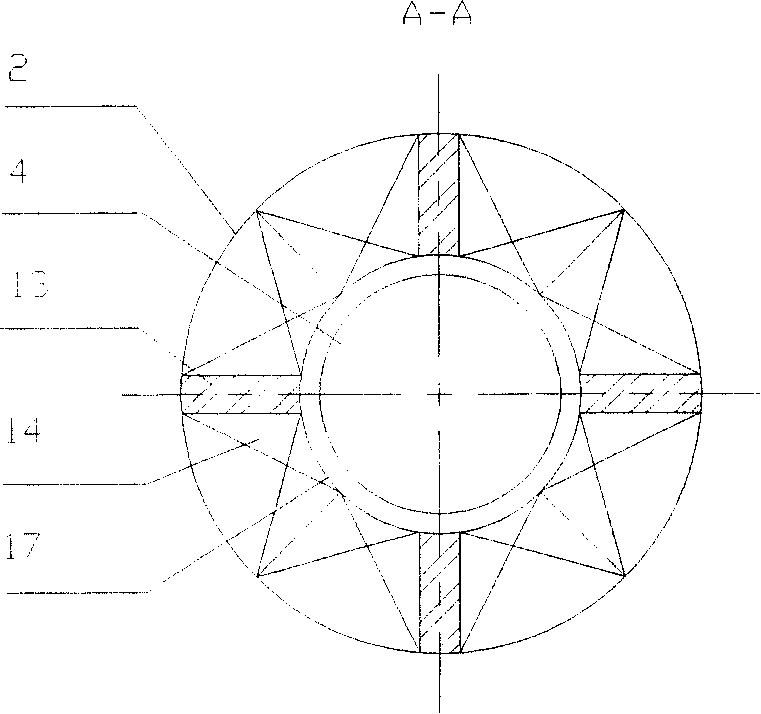

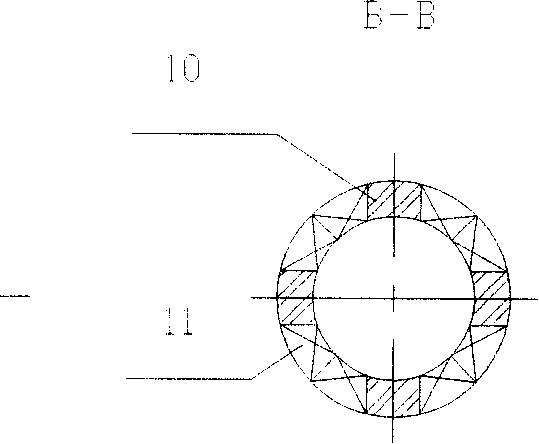

Six-freedom-degree precision positioning table for nano-imprint lithography system

ActiveCN101726997ACompact structureIncrease stiffnessPhotomechanical apparatusWork benchesElectricityImage resolution

The invention discloses a six-freedom-degree precision positioning table for a nano-imprint lithography system, wherein a spatial flexibility mechanism comprises a pre-tightening mechanism, three first displacement sensor and three first piezoelectric ceramic drivers, the pre-tightening mechanism comprises an elastic pre-tightening ring connected with a rigid ring, a base, a vertical column, three bottom elastic hinges and a first displacement sensor, the piezoelectric ceramic drivers are pushed on the elastic hinges; a plane flexibility mechanism comprises a rigid ring, a rigid supporting table, three flexible branched chains and three second piezoelectric ceramic drivers, each flexible branched chain comprises three top part elastic gemels, three second elastic gemels are connected by a driving connecting rod and a middle connecting rod, two second elastic gemels are respectively connected with the rigid ring and the rigid supporting table, the second piezoelectric ceramic drivers are pushed against on the driving connecting rod, three pairs of the supports are arranged, and each pair of the supports are connected with a second displacement sensor, and the rigid supporting table is connected with a movable platform; the working table has high resolution ratio and rapid dynamic response speed.

Owner:南通致远船舶设计有限公司

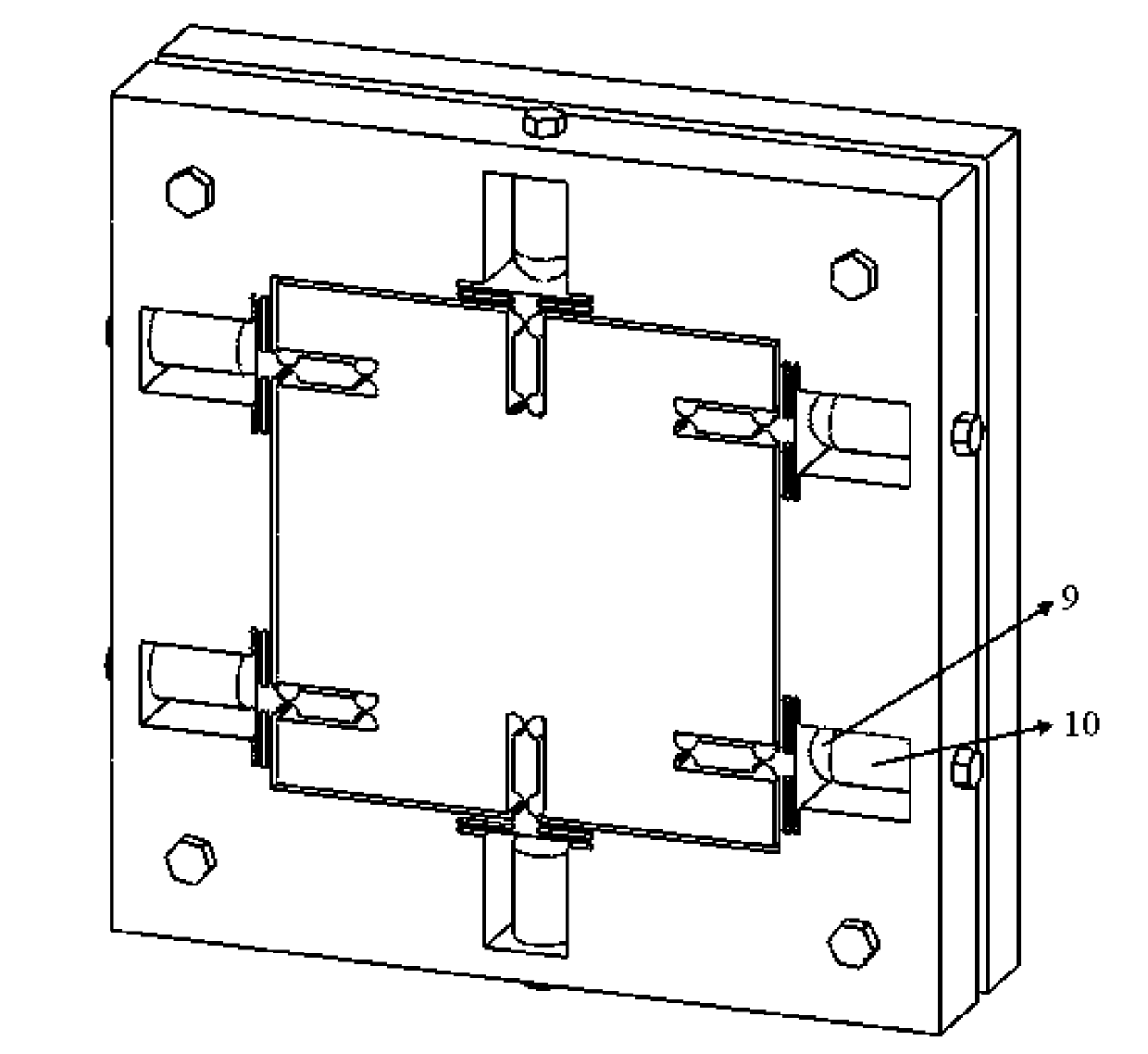

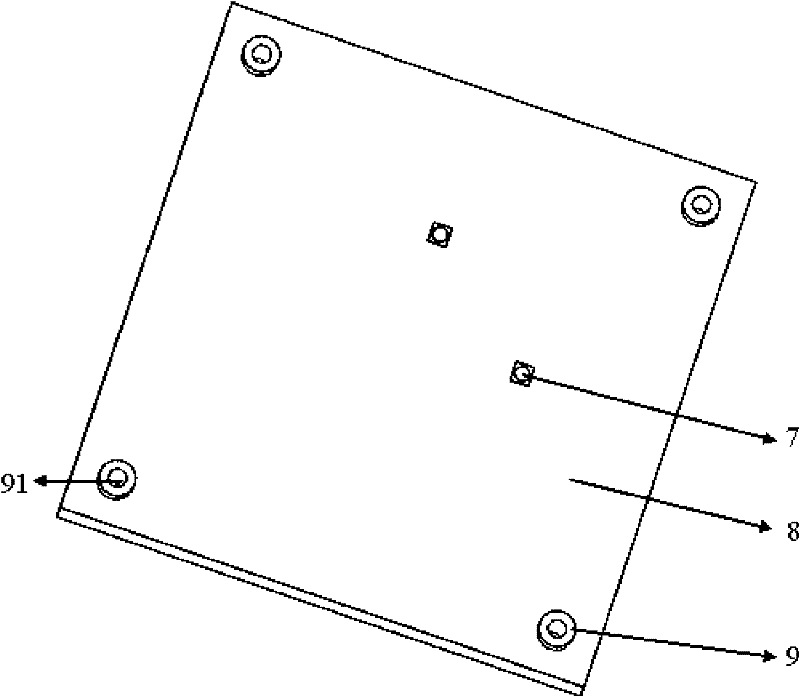

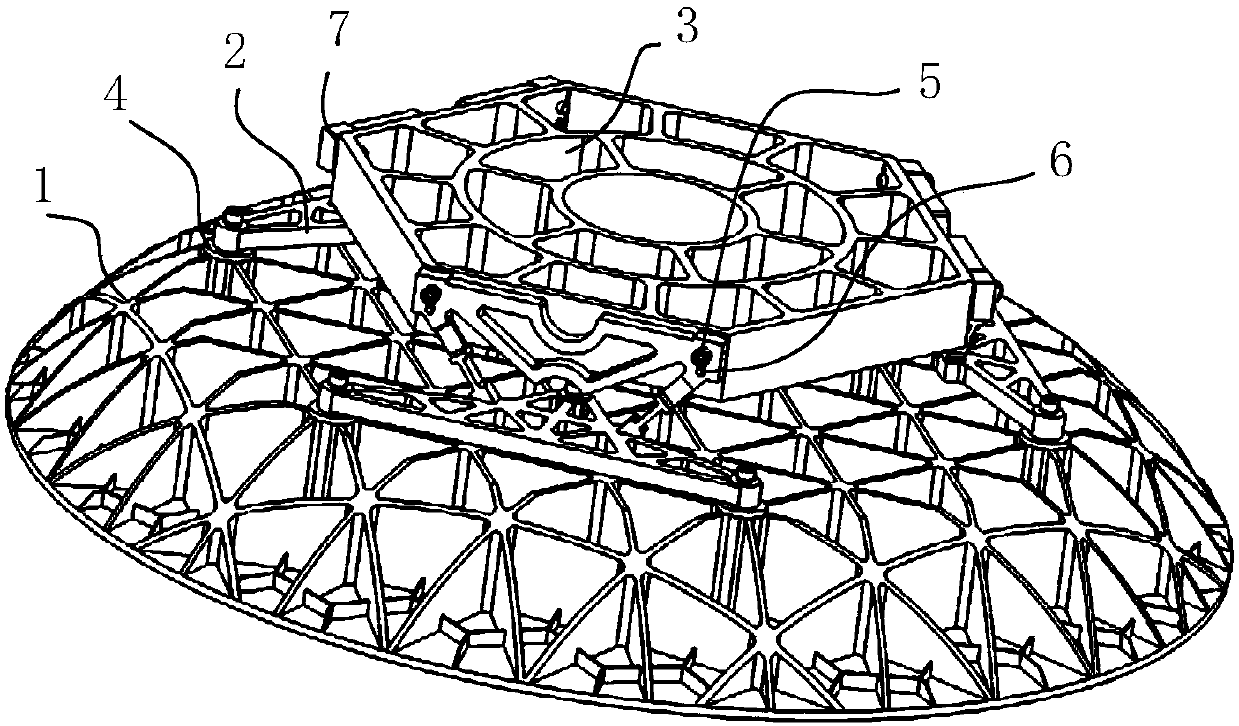

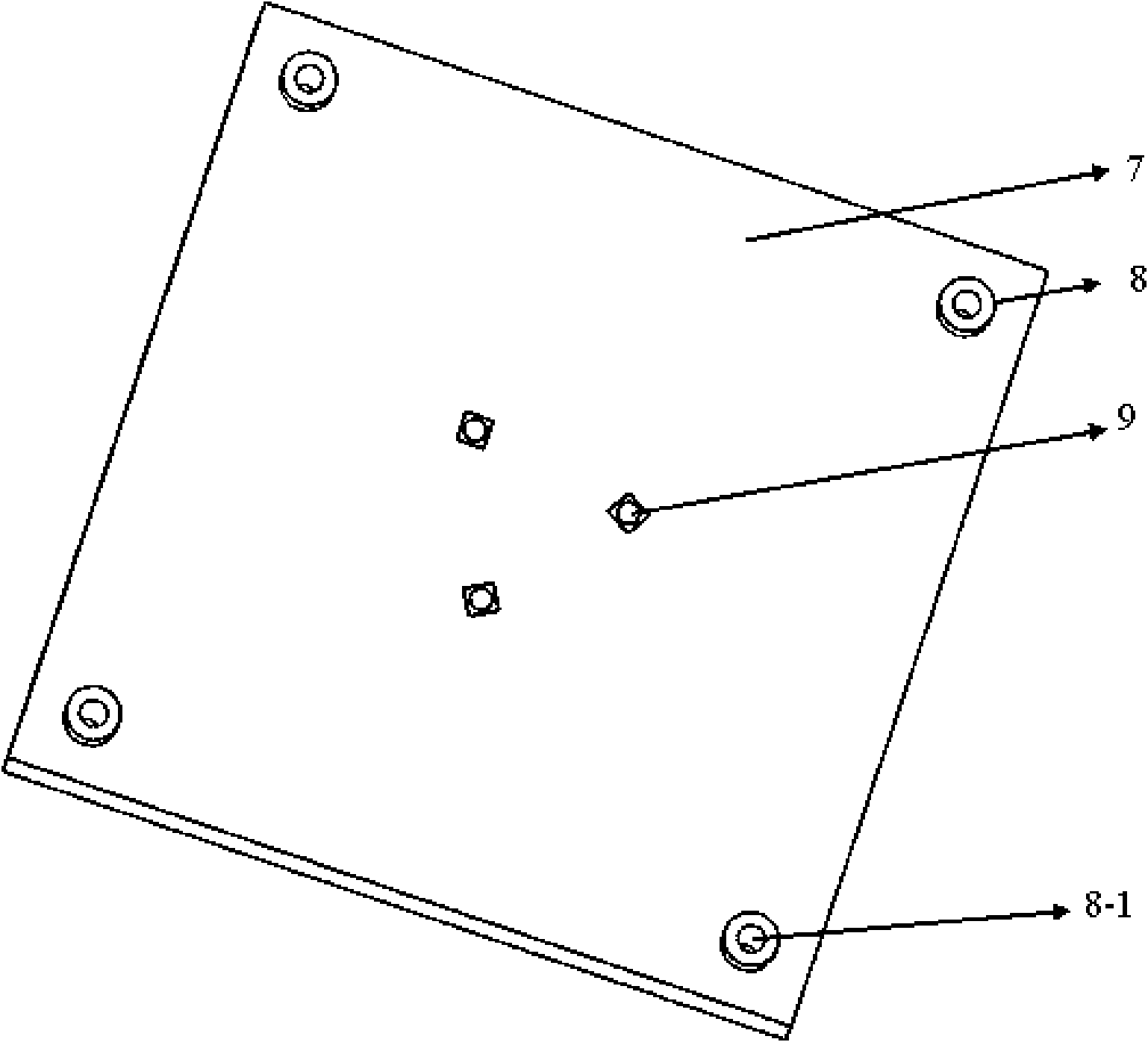

Large-caliber optical reflector with back flexible supporting structure

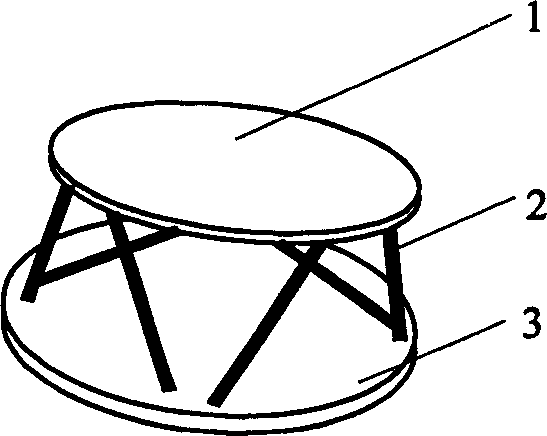

PendingCN109633859AImproved Gravity DeformationImplementation constraintsMountingsOptical reflectionEngineering

The invention relates to a large-caliber optical reflector with a back flexible supporting structure. The problems that too much supporting links exist, the assembling process is complex, the size andthe quality of the supporting back plate are too large in the existing large-caliber reflector back multi-point supporting technology, and the requirement for surface type precision is high under theworking conditions of gravity release and environment temperature change is difficult to be ensured at the same time are effectively solved. The reflector comprises a reflector mirror body, flexiblesupports and a supporting back plate, the number of the flexible supports is three, and the flexible supports are uniformly distributed between the reflector mirror body and the supporting back platein the circumferential direction; each flexible support comprises an isosceles triangular bottom frame and a trapezoid vertical frame which are perpendicular to each other; the three vertexes of the isosceles triangular bottom frame are connected with the back of the reflector mirror body; the top edge of the trapezoid vertical frame is connected with the isosceles triangle bottom frame, the bottom edge of the trapezoid vertical frame is connected with the side surface of the supporting back plate; and the bottom edge of the trapezoid vertical frame adopts a flexible hinge structure, and the two waist parts of the trapezoid vertical frame are correspondingly of a flexible reed structure.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

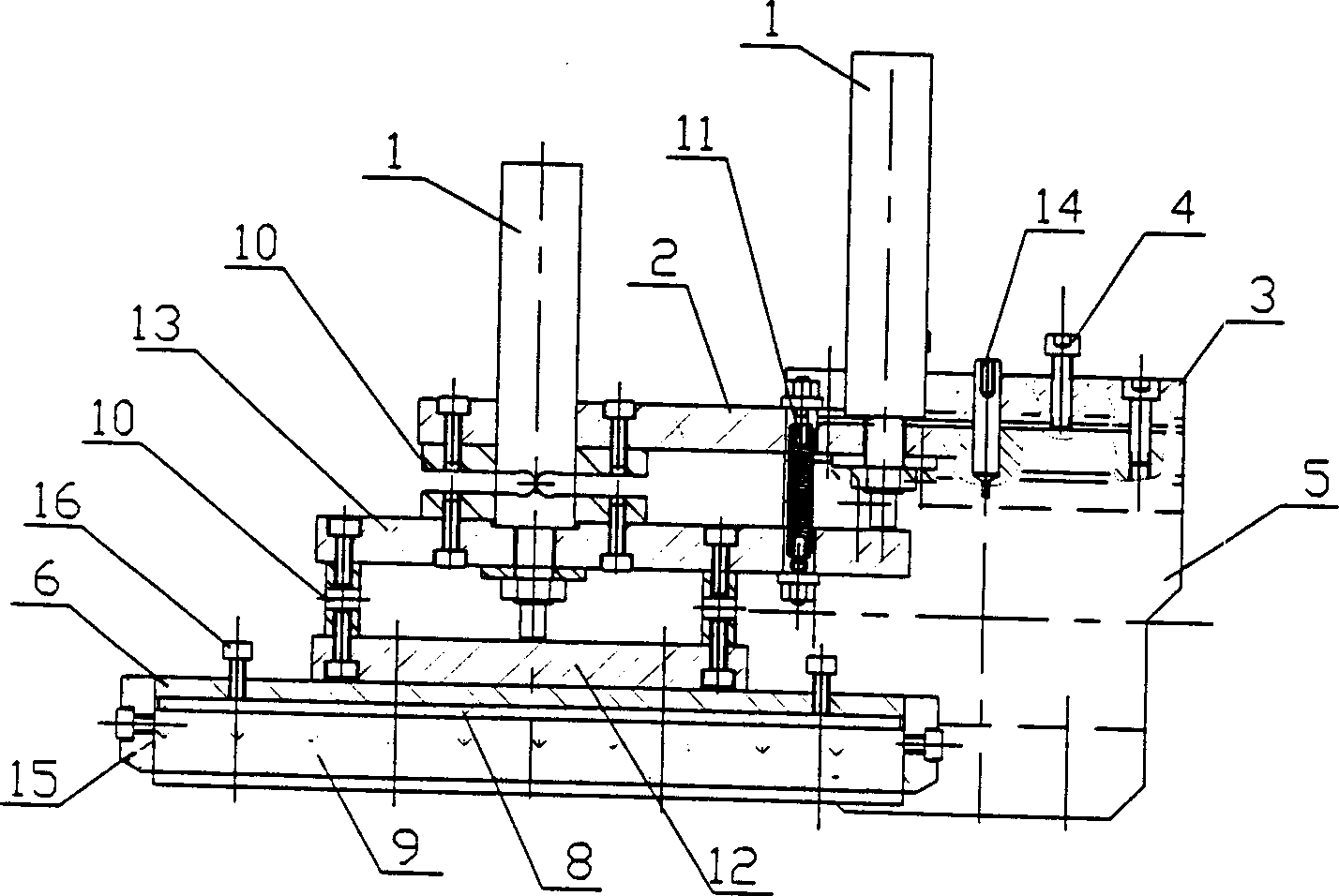

X-Y-Z three freedom degree tandem type nanometer grade microposition workstation

The invention discloses a serially-connected nano-scale micro positioning workbench which has X-Y-Z three-dimensional freedom degrees and comprises a base, a movable platform, an X-directional displacement amplifier, a Y-directional displacement amplifier and a Z-directional displacement amplifier; furthermore, the base, the Z-directional displacement amplifier, the Y-directional displacement amplifier, the X-directional displacement amplifier and the movable platform are sequentially connected into a serially-connected structure, and the displacements are respectively controlled between the freedom degrees; wherein, the X-directional displacement amplifier and the Y-directional displacement amplifier have the same structure. The serially-connected nano-scale micro positioning workbench has compact structure and large delivery stroke range, one point on the movable platform can reach any point in the delivery stroke range, and the serially-connected nano-scale micro positioning workbench can be applied to various occasions with strict space restriction and larger displacement requirement.

Owner:上海青客时尚生活服务股份有限公司

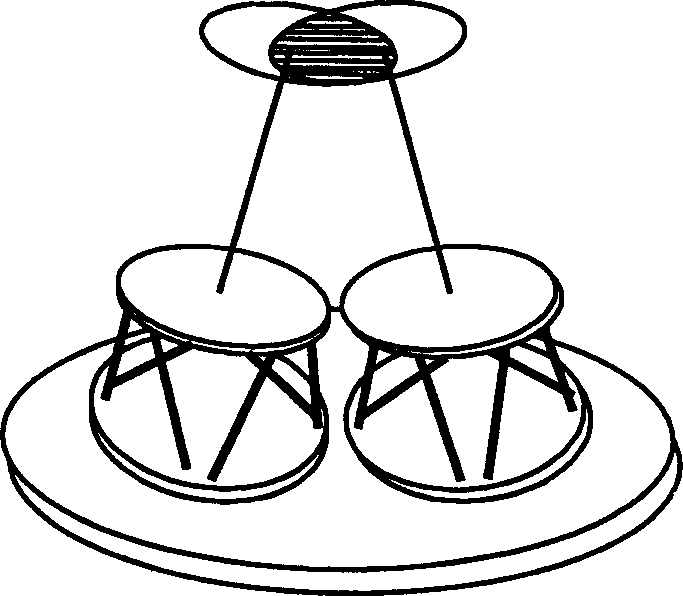

Series-parallel micro operation parallel-connection robot mechanical apparatus

InactiveCN1454753AReduce volumeGreat effortProgramme-controlled manipulatorComputer control systemMicro-operation

Disclosed is a parallel robot set to assemble diminutive machine. The robot comprises two same three-dimensional parallel frames which are in series. The parallel frame has three active links that comprise two Huke gemels and a micro displacement amplifier. The computer control system drives the displacement output of the piezoelectricity equipment. The undersides of the three active links are connected with the middle plate, and another side is connected with the work plate in a parallel frame group.In another group, the undersides of the three active links are connected with the underpan, and another side is connected with the middle plate. The middle plate is hung under the underpan. The two fingers of the robot are set on the work plate and the middle plate, which can work just like the human fingers.

Owner:BEIJING UNIV OF TECH

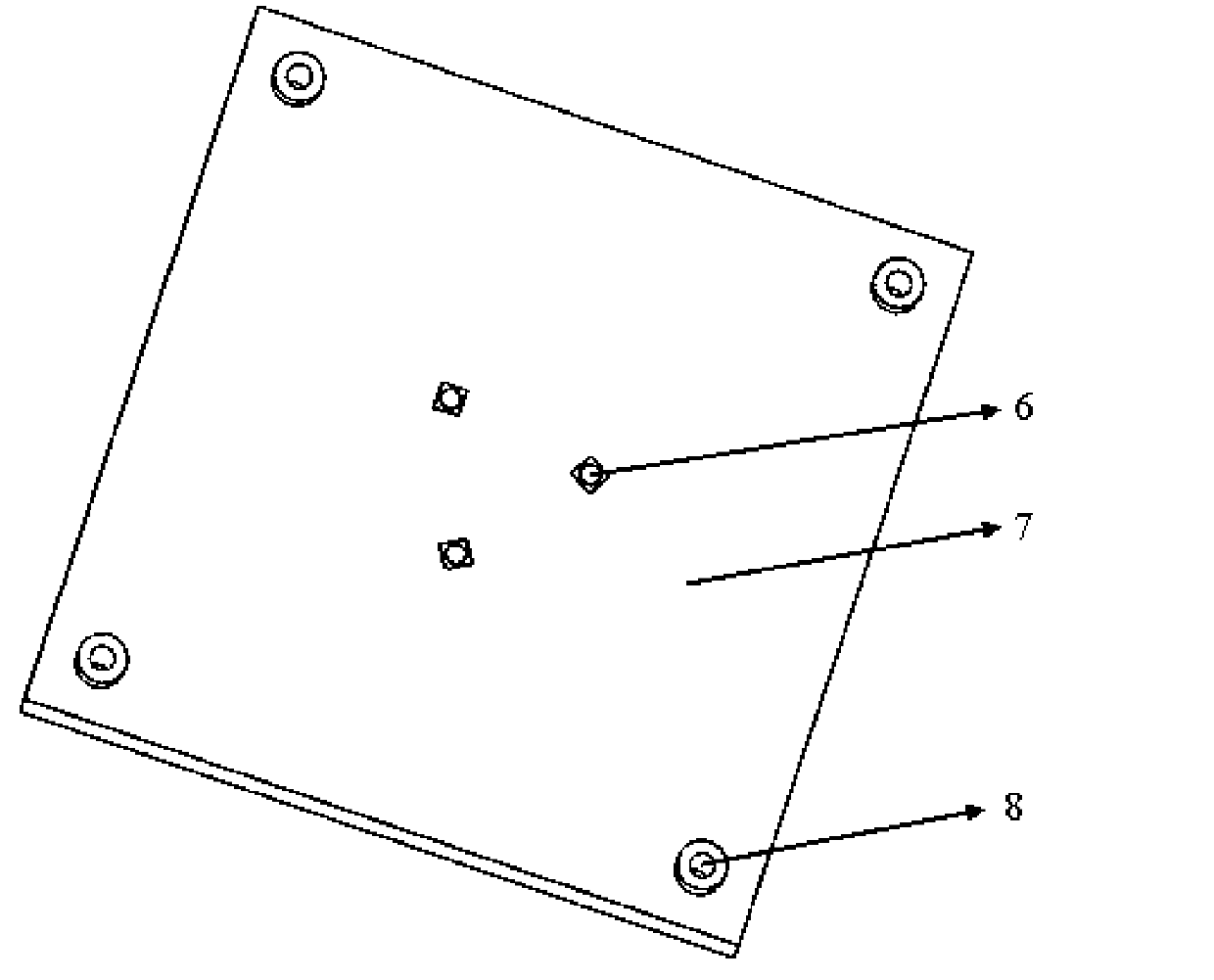

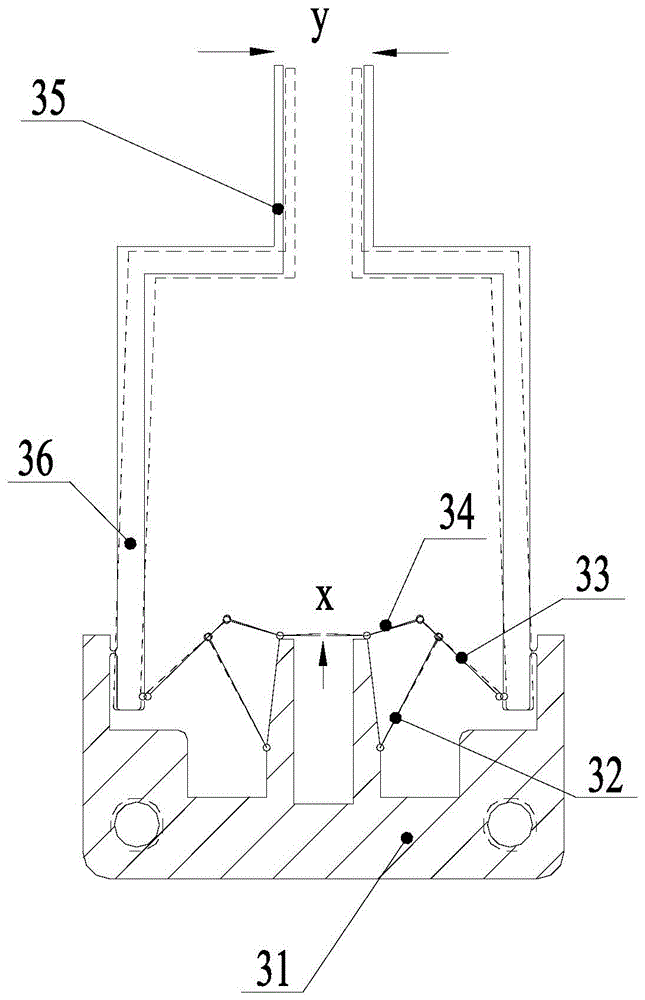

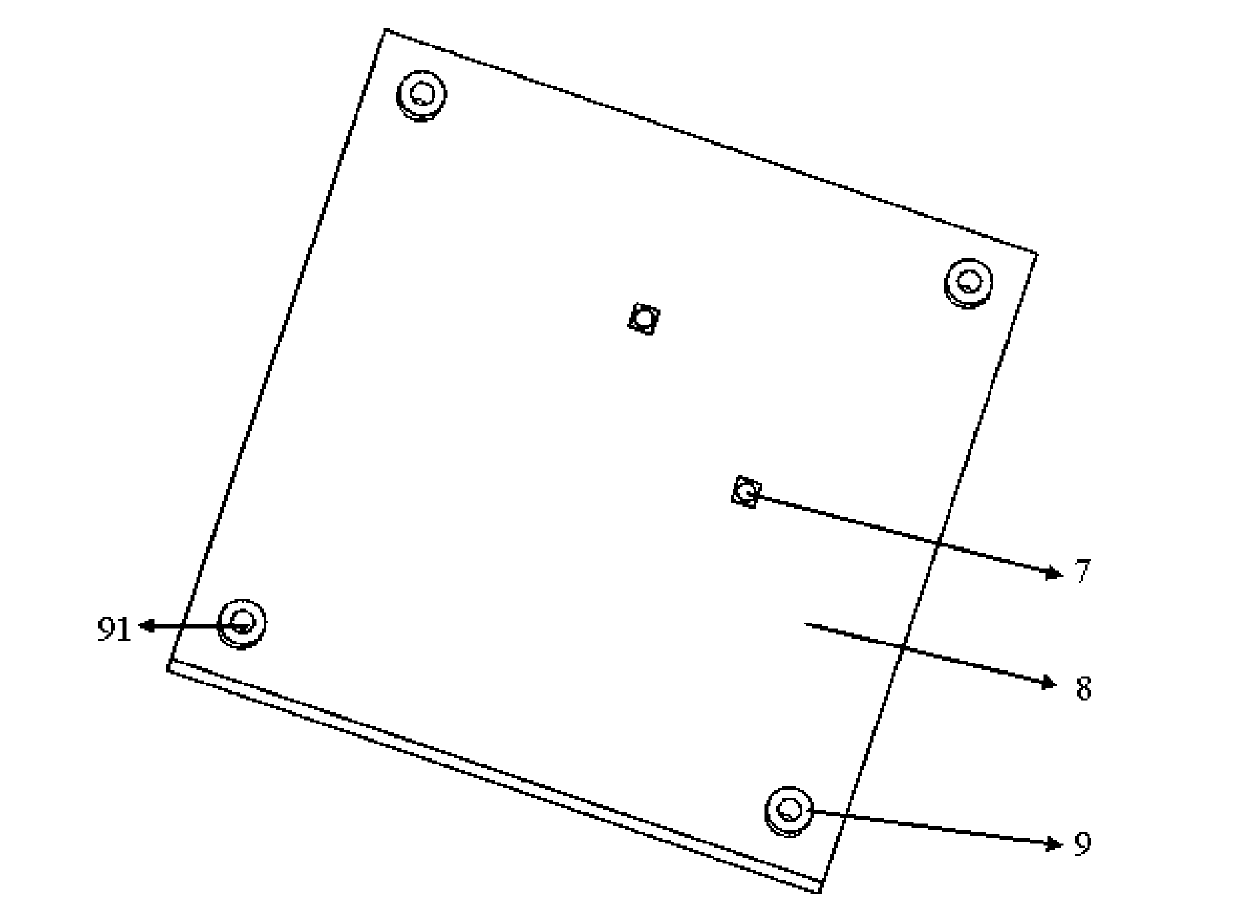

Two-degree-of-freedom nanometer positioning platform

InactiveCN102998899AWith active adjustmentRealize proactive adjustmentPhotomechanical apparatusElectricityLithographic artist

The invention discloses a two-degree-of-freedom nanometer positioning platform. The nanometer positioning platform comprises a movable platform and a base which are connected with each other through a flexible branched chain in an x-axis direction and a flexible branched chain in an y-axis direction. As adopting a flexible parallel connection structure, the nanometer positioning platform has the advantages of high rigidity, high precision, low inertia, compact structure, no error accumulation and the like; and as adopting a flexible plate spring as a transmission component, the nanometer positioning platform has the advantages of no mechanical friction and no gap. Furthermore, based on the elastic deformation of materials, the tiny deformation generated by the flexible plate spring and a tiny working space at the tail end of an actuator, the nanometer positioning platform can effectively eliminate the defects of non-linearity and the like of a parallel connection mechanism; and two piezoelectric ceramic drivers are used for respectively driving the two flexible branched chains, so that a relative position of a template and a substrate in an imprint lithography process can be initiatively adjusted. The two-degree-of-freedom nanometer positioning platform provided by the invention can be taken as an auxiliary positioning platform of a nanometer imprint lithography positioning system, and can implement micro-scale feeding and precise positioning.

Owner:TIANJIN UNIV

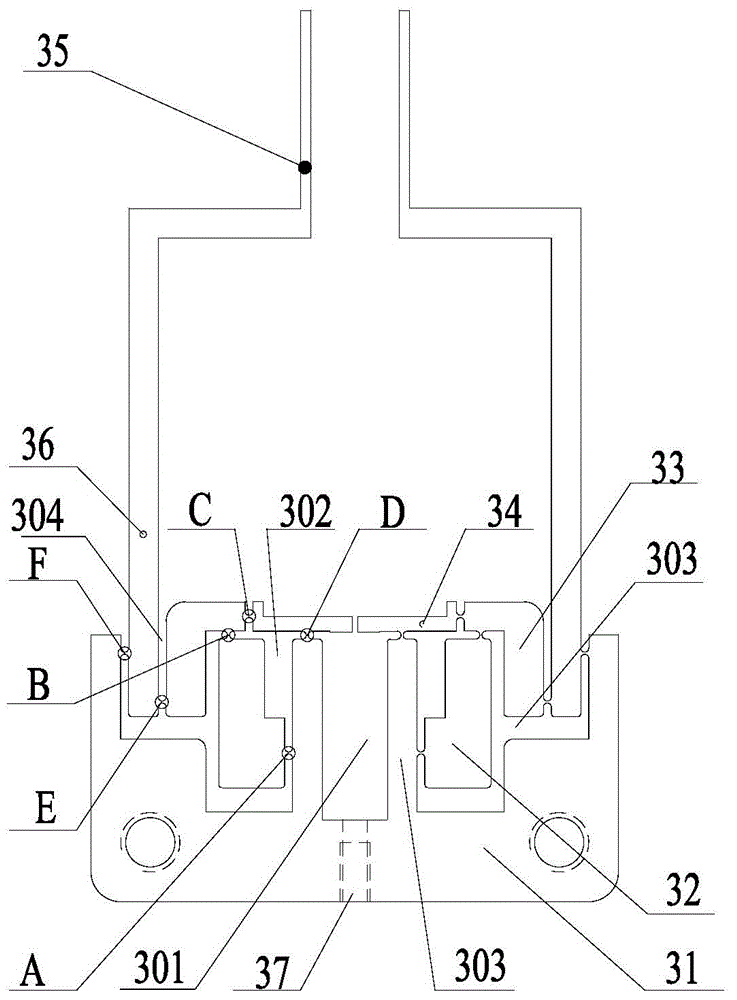

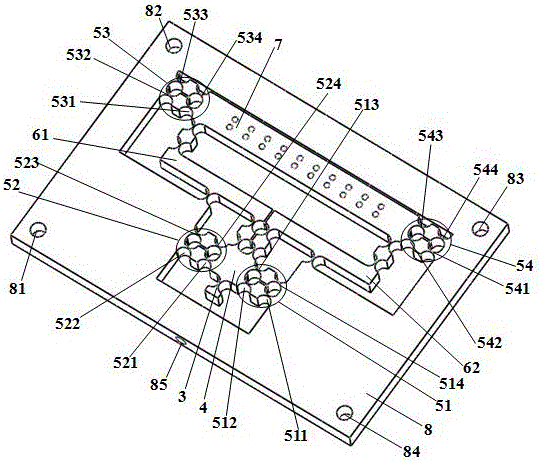

Three DOF micro-positioning workbench for nano-imprint lithography system

InactiveCN101776851AAvoid assemblyNo gapPhotomechanical exposure apparatusMicrolithography exposure apparatusFlexible MechanismsLithographic artist

The invention discloses a three DOF micro-positioning workbench for a nano-imprint lithography system, which comprises six piezoelectric ceramic drives; and each drive is connected with a base, and the top end is connected with a spherical connector by thread. The workbench also comprises six flexible fork chains of a flexible mechanism with totally consistent structure and a moving platform which is supported by the flexible fork chains; and three position sensors are used to measure the actual output of the moving platform, and are respectively fixed between a rigid support and the moving platform. The micro-positioning workbench is characterized by high resolution and high dynamic response speed, can serves as an auxiliary positioning platform of a nano-imprint lithography positioning system, and realize micro feeding and precise positioning.

Owner:TIANJIN UNIV

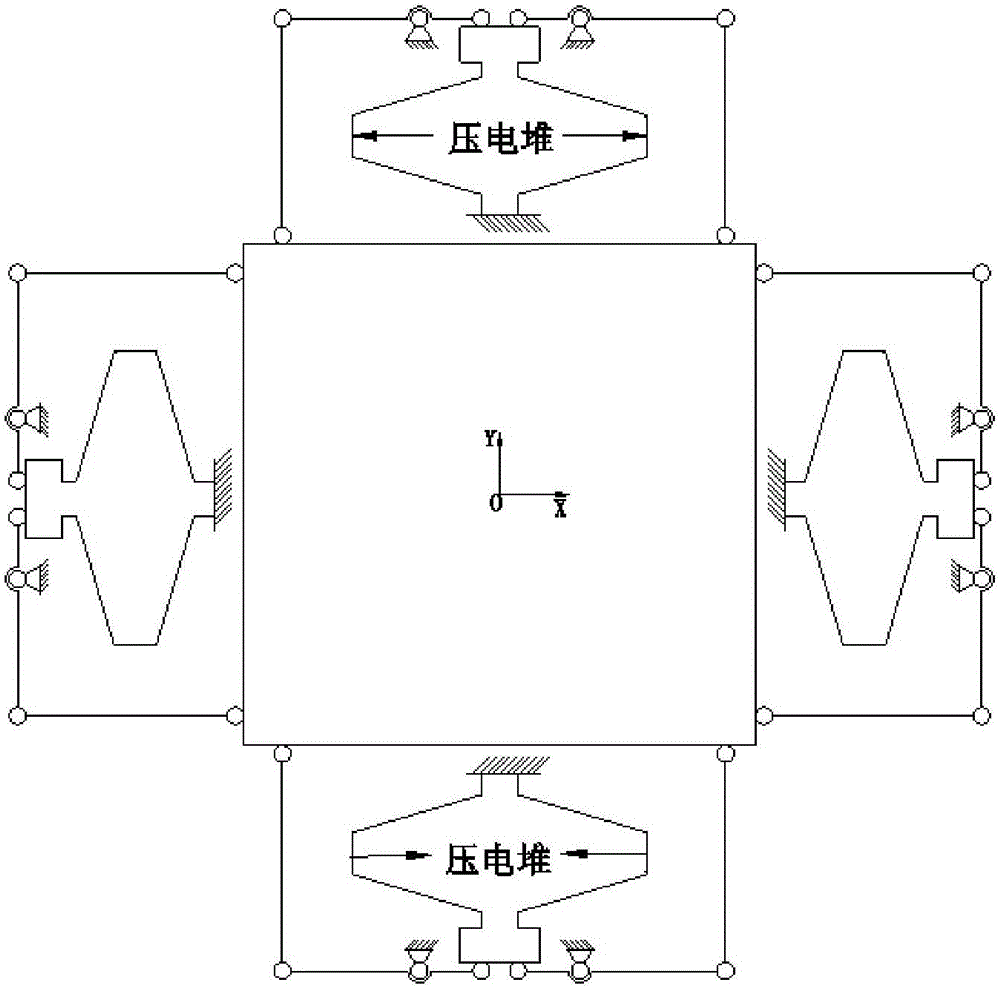

Translational and rotational 3-degree-of-freedom piezoelectric driving adjusting device and method

ActiveCN106737646ACompact structureReduce weightProgramme-controlled manipulatorElectricityEngineering

A translational and rotational 3-degree-of-freedom piezoelectric driving adjusting device and method are provided; the device comprises X-directional translation mechanisms, Y-directional translation mechanisms, a Z-directional deflection mechanism and a carrier platform; the X-directional translation mechanism and the Y-directional translation mechanism have similar principles and each comprise a diamond displacement amplifying mechanism, a lever displacement amplifying mechanism and a guide mechanism that are arranged in symmetry, and the X-directional translation mechanism and the Y-directional translation mechanism are vertically mounted through base cavities; when a pair of piezoelectric stacks in each X-directional translation mechanism are under voltages equal in magnitude and opposite in direction, the platform translates in X-direction; a pair of piezoelectric stacks in each Y-directional translation mechanism are under voltages equal in magnitude and opposite in direction, the platform translates in Y-direction; the Z-directional deflection mechanism positioned at the bottom is composed of a mounting baseplate and two piezoelectric stacks with precompression, and outputs Z-directional deflection when the piezoelectric stacks therein are under the voltages equal in magnitude and opposite in direction. Owing to the guide mechanism, the X-directional translation and Y-directional translation of the platform are decoupled; the whole device is free of mechanical friction, and can provide 3-degree-of-freedom high-precision independent adjustment.

Owner:XI AN JIAOTONG UNIV

Technical application of magnetic suspension in filed of vibration prevention of engineering structure

InactiveCN101545291AControllable and adjustable vibrationNo vibrationMagnetic holding devicesShock proofingElectrical polarityEngineering

The invention relates to buildings, and particularly belongs to technical application of magnetic suspension in the filed of vibration prevention of an engineering structure. The invention adopts the technical proposal that: a plurality of substructures are arranged in the engineering structure, the bottom layers of the substructure are provided with an electromagnet, the lower part of the electromagnet is provided with a corresponding structural electromagnet, the electromagnet and the structural electromagnet after being powered have the same electromagnetic polarity, and the electromagnet and the structural electromagnet are connected with an electromagnetic control device with an earthquake signal receiving device. The technical application has the advantages that: because the engineering structure applied with the magnetic suspension technology fully isolates the earthquake influence, the problems of various assumptions calculated by earthquake action, mutual influence of the earthquake and the structure, and the like disappear; and the structure is not influenced by the strength, properties and the like of the earthquake.

Owner:FUZHOU PLANNING DESIGN & RES INST

Two-dimensional precise angle trimmer for the second crystal of double-crystal monochromator

The two-dimensional precise angle timer for the second crystal of double crystal monochromator belongs to regulating mechanism. The upper support board is connected first to the positioning board and then to the frame, one linear stepped motor with coder is positioned via the head screws to the upper support board, one other linear stepped motor with coder is fixed to the middle support board via one tensile spring assembly and the head screws, the middle support board and the lower support board are connected via two flexible hinge assemblies, the second crystal is mounted onto the regulating board via one other tensils spring assembly, and the two crystal holding boards are connected to the lower support board.

Owner:SHANGHAI JIAO TONG UNIV

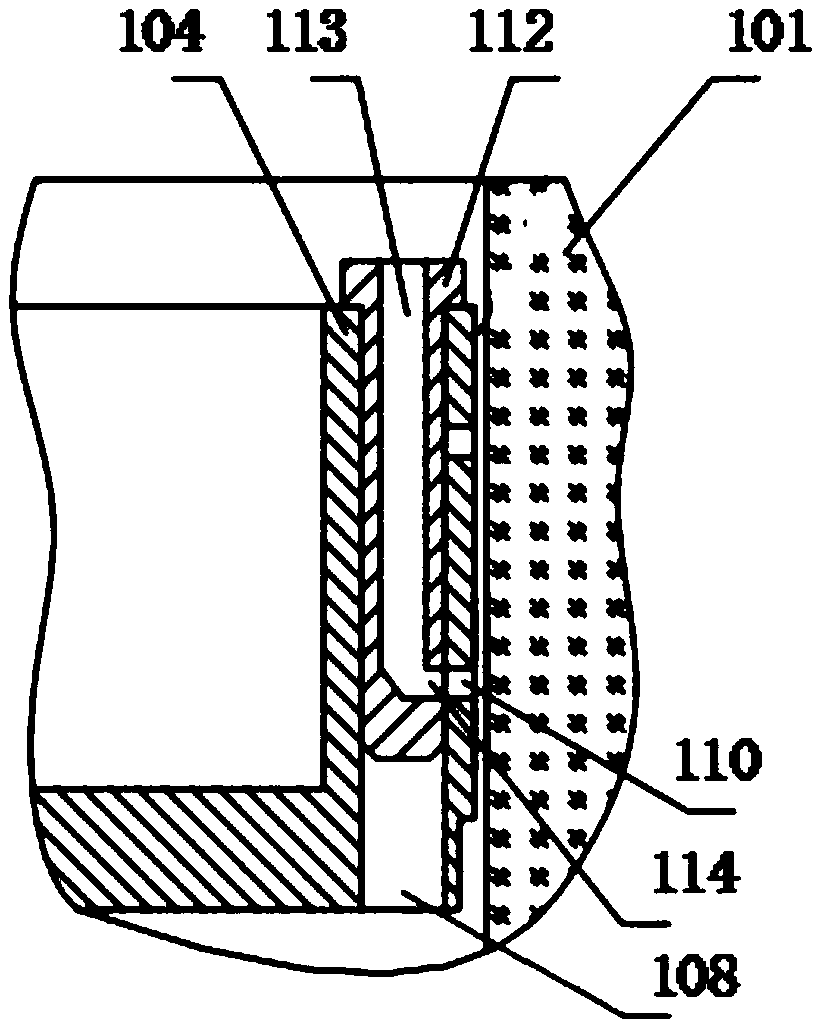

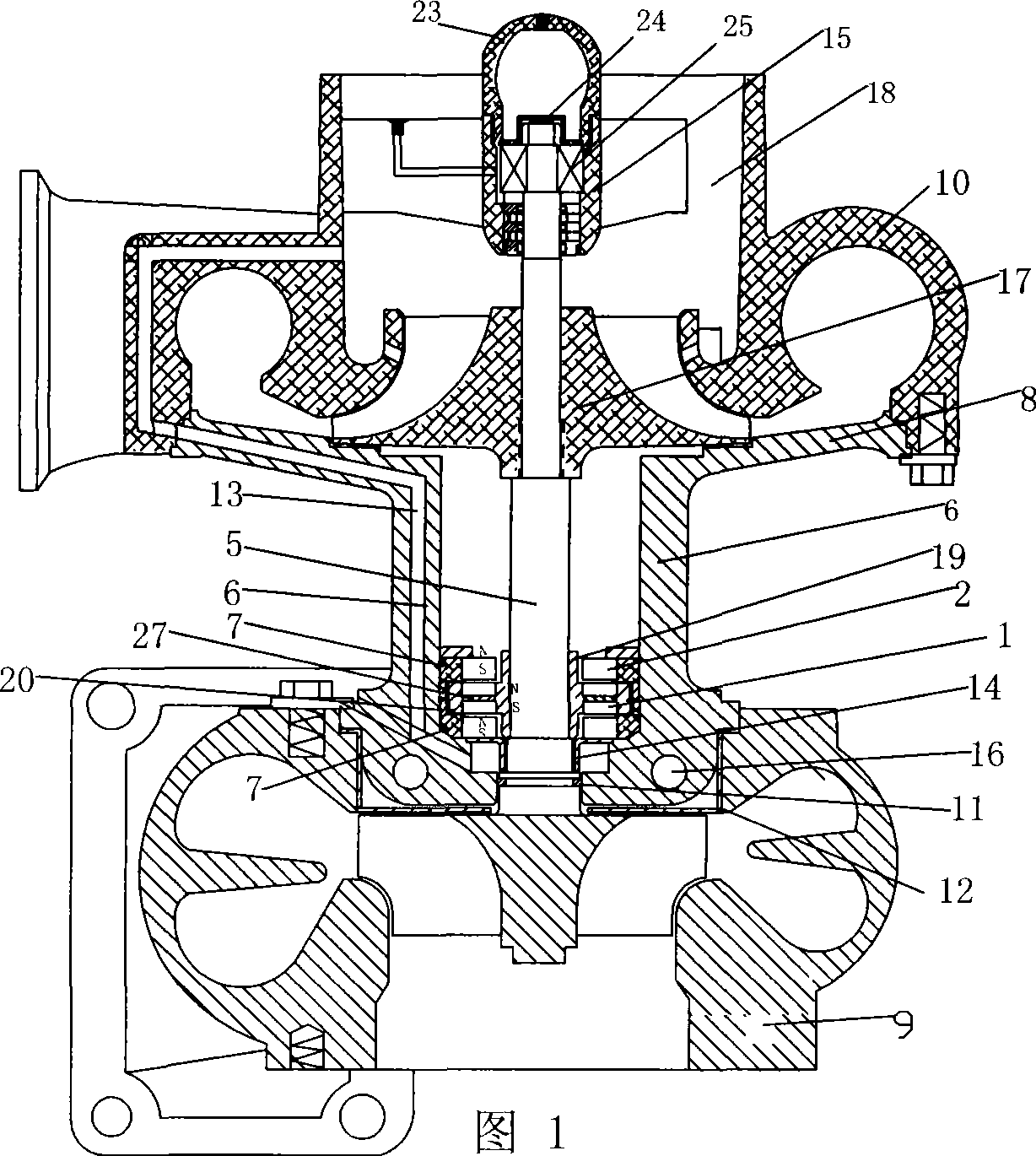

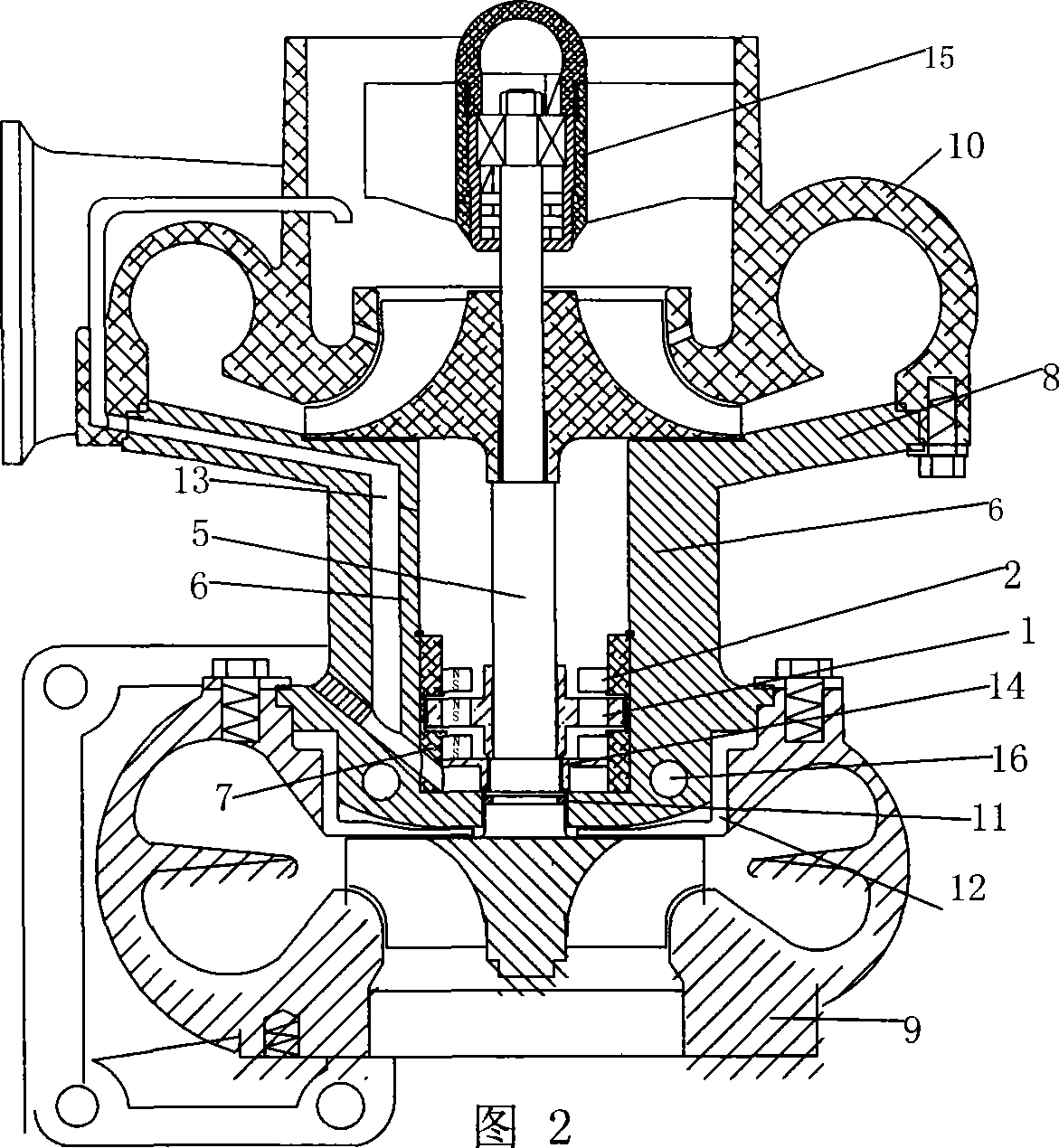

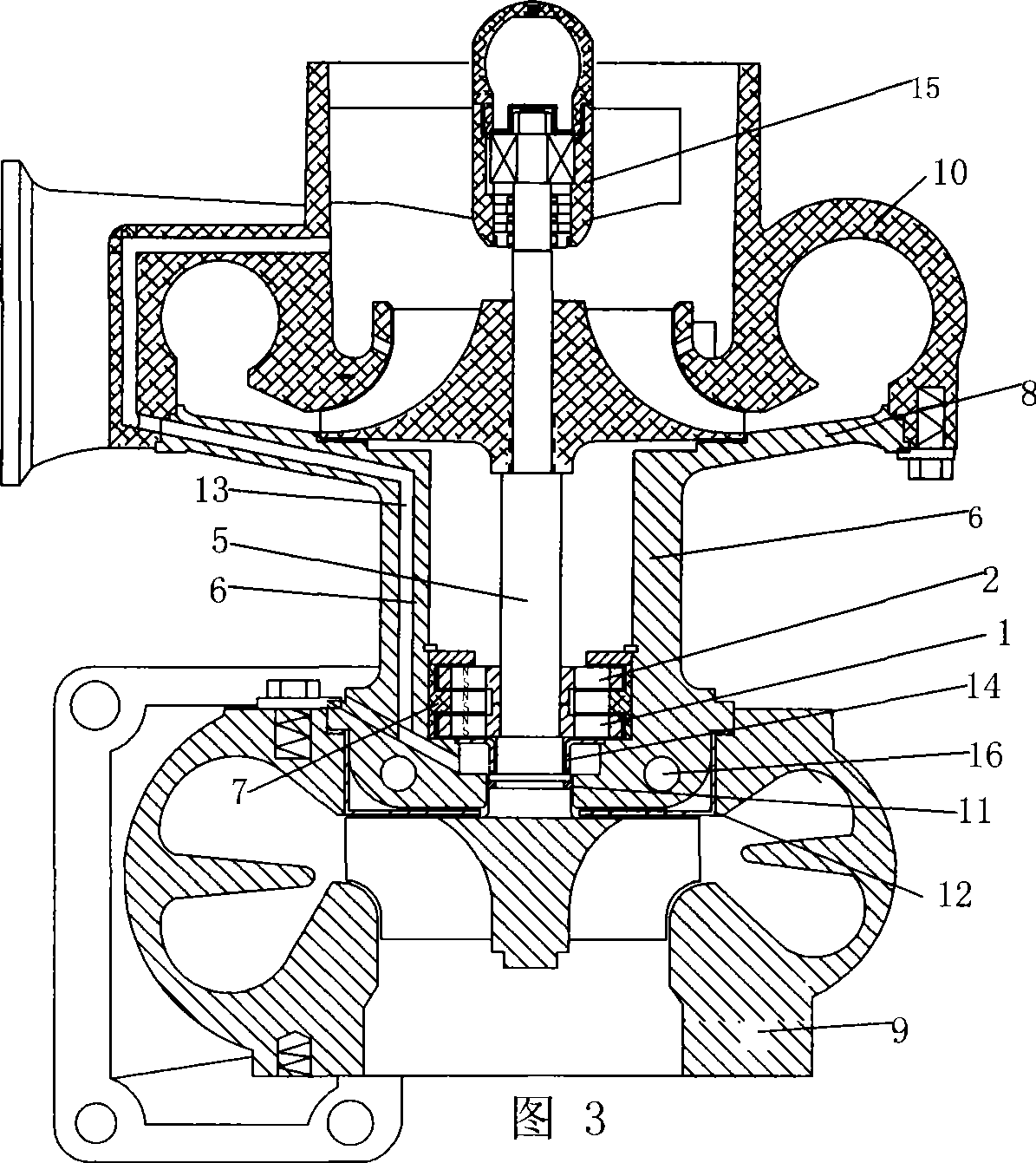

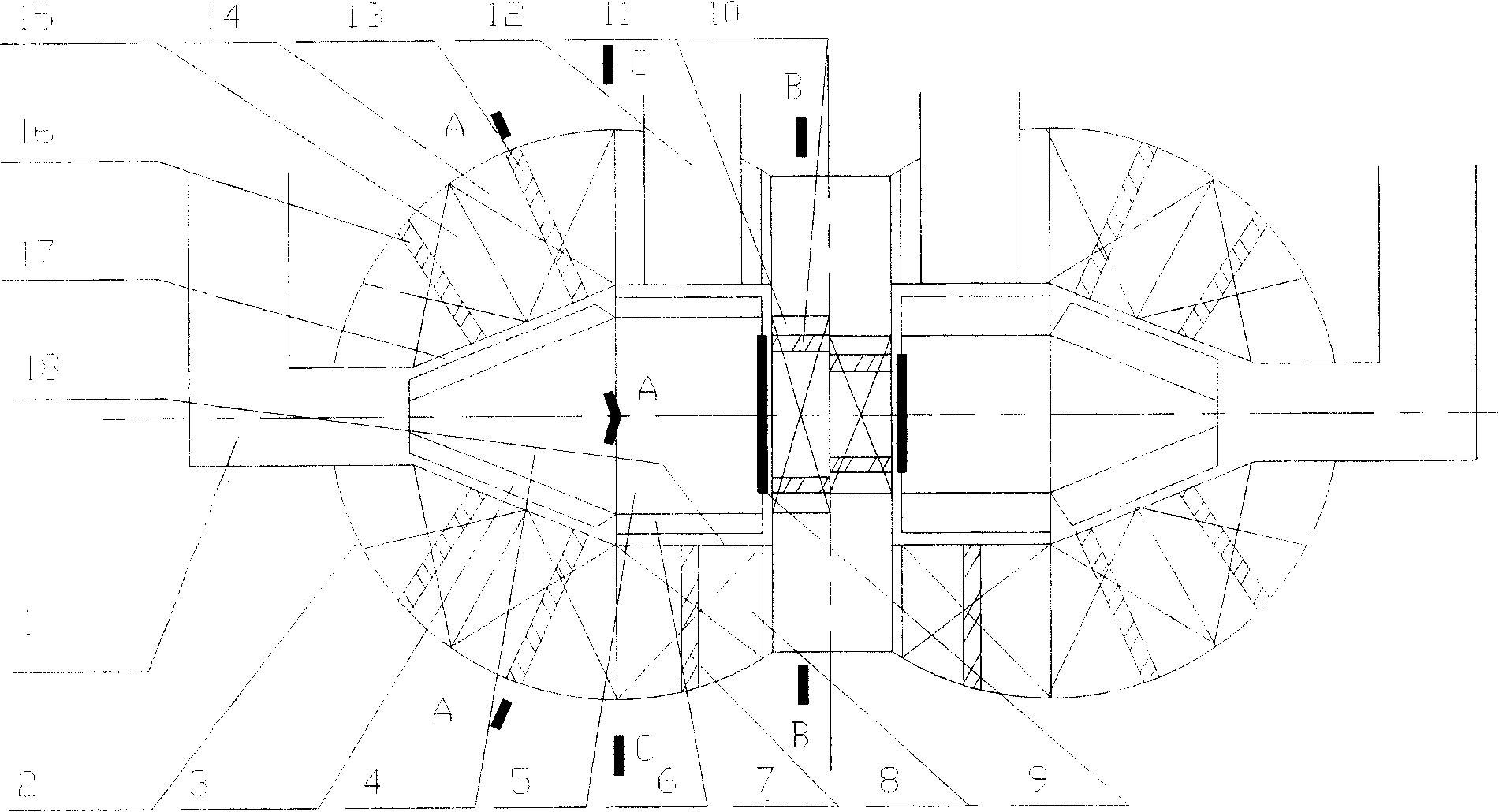

Turbocharger

InactiveCN101429878AImprove efficiencyNot vulnerableCombustion enginesGas turbine plantsImpellerTurbocharger

The invention discloses a turbocharger. The invention adopts a technical proposal that the turbocharger comprises a turbine rotor shaft assembly, an intermediate, a pressure housing, a diffusion plate fixedly connected with or integrally formed with the pressure housing, wherein the turbine rotor shaft assembly is at least provided with a set of permanent magnet rings matched with each other between a turbine and a compressor impeller. The permanent magnet rings comprise at least one permanent magnet dynamic ring and at least one permanent magnet static ring which are matched with each other to suspend a rotor shaft of the turbine rotor shaft assembly. The invention provides a friction-free turbocharger which uses permanent magnet rings to suspend the rotor shaft of the turbine. The turbocharger can solve the problems of susceptibility to damage, oil leakage and pollution, reduce response lags, and does not cause serious influence on the engine except for reduction in power when damaged. The turbocharger solves the problems of susceptibility to damage, oil leakage and pollution of the prior turbocharger and overcomes the drawbacks such as high price, large volume and complex structure of electromagnetic suspension bearing exhaust turbocharger.

Owner:南通通州江华纺织有限公司

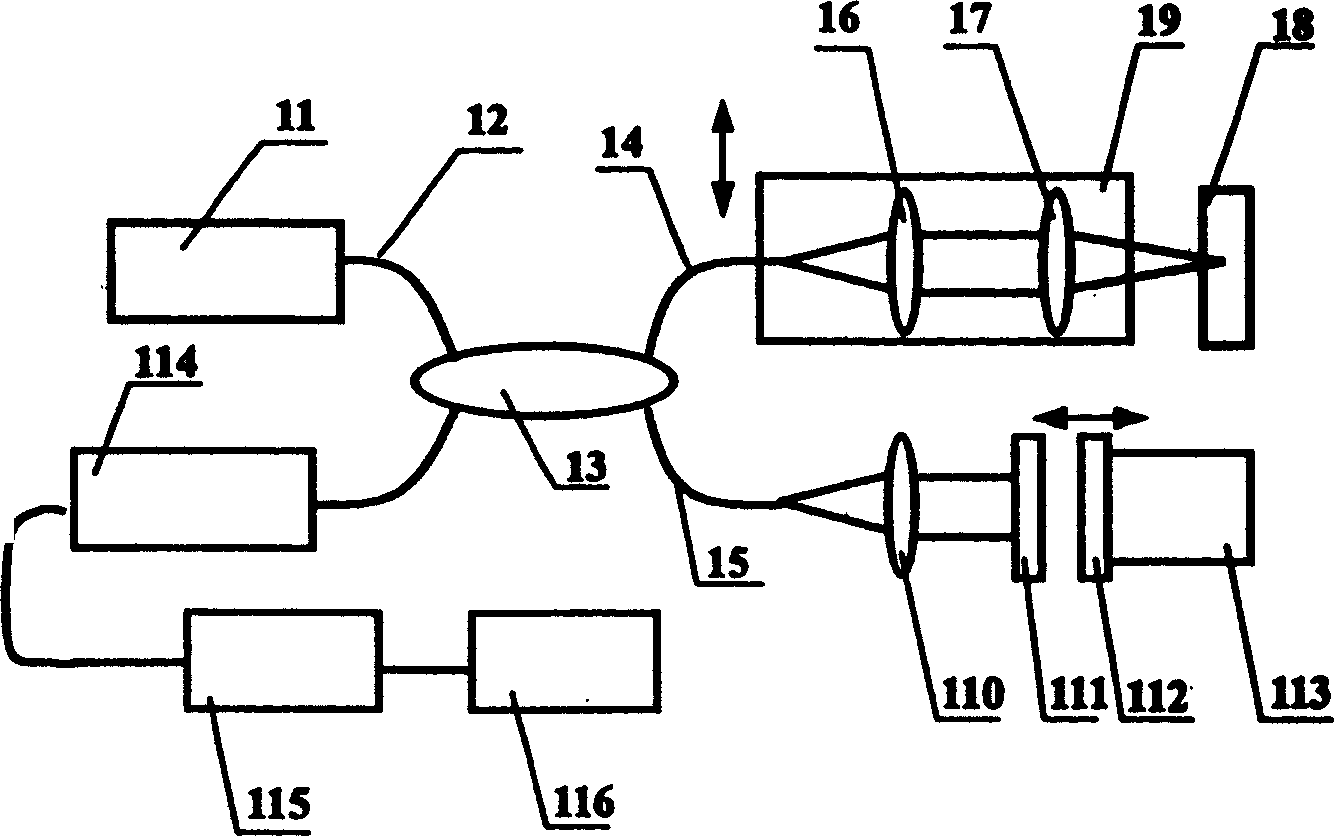

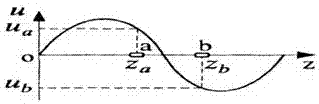

Longitudinal scanning method and device in optical image system of coherent faults

InactiveCN1539376AImprove machining accuracyQuick responseMaterial analysis by optical meansRadiation diagnosticsIt equipmentLight beam

A method for longitudinal scan in optically coherent tomographic imaging system features that a prism system composed of moving prism group and static prism group is used in a longitudinal scanner and a microshifting device is used to drive said moving prism group for realizing high-speed high-precision linear longitudinal scanning. Its equipment is composed of light source, optical fibre, optical fibre coupler, lens, said prism system and microshifting device.

Owner:SICHUAN UNIV

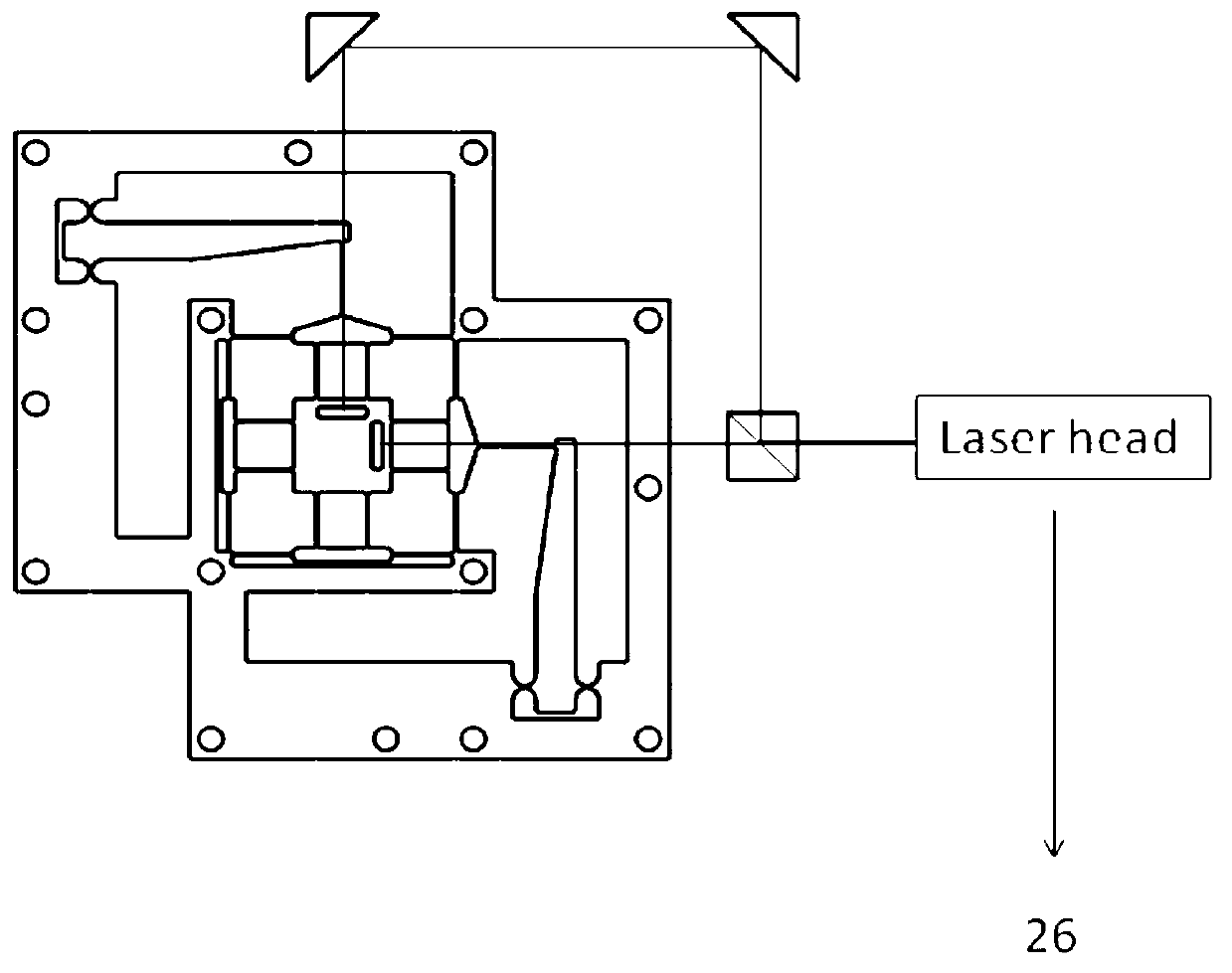

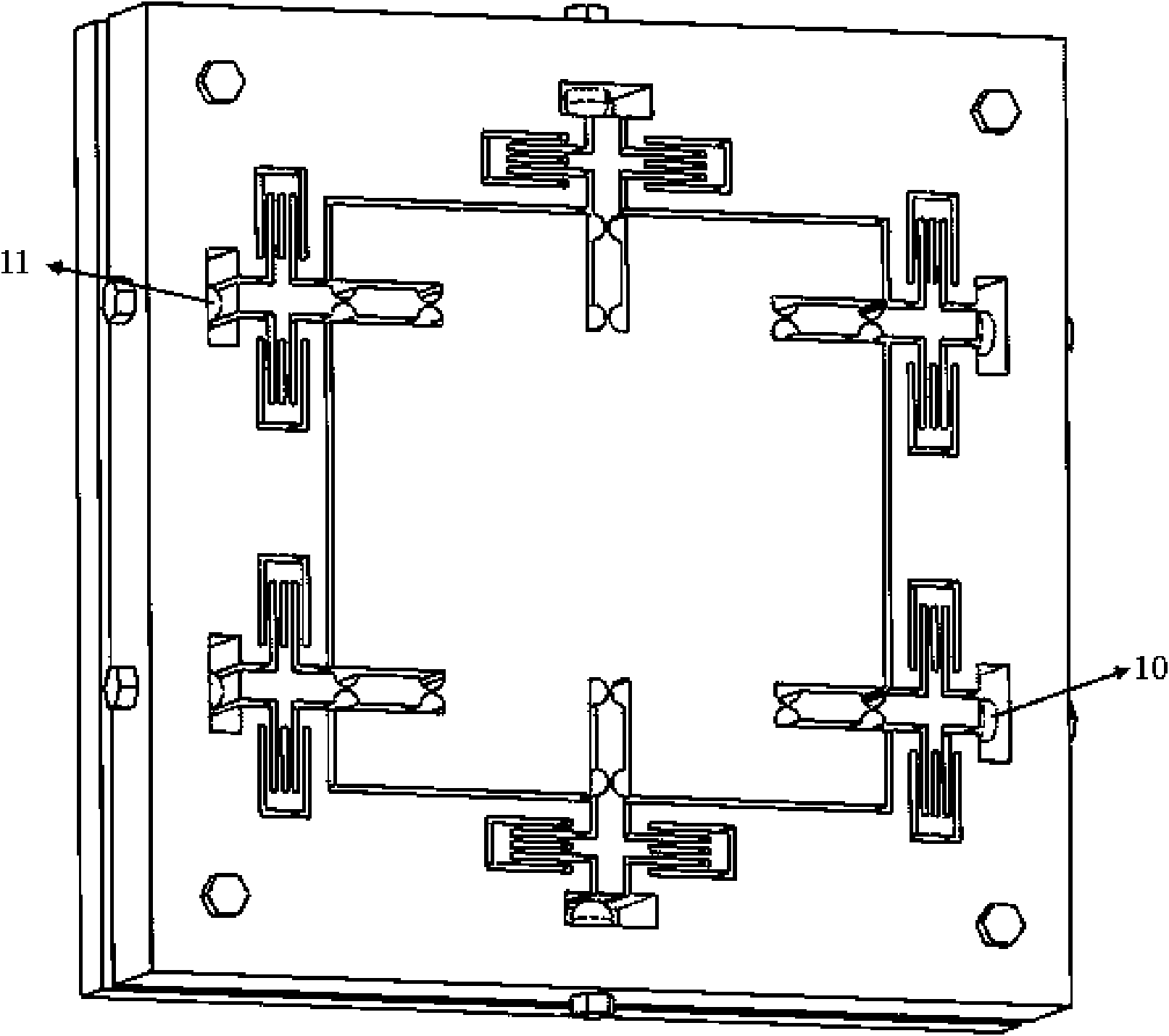

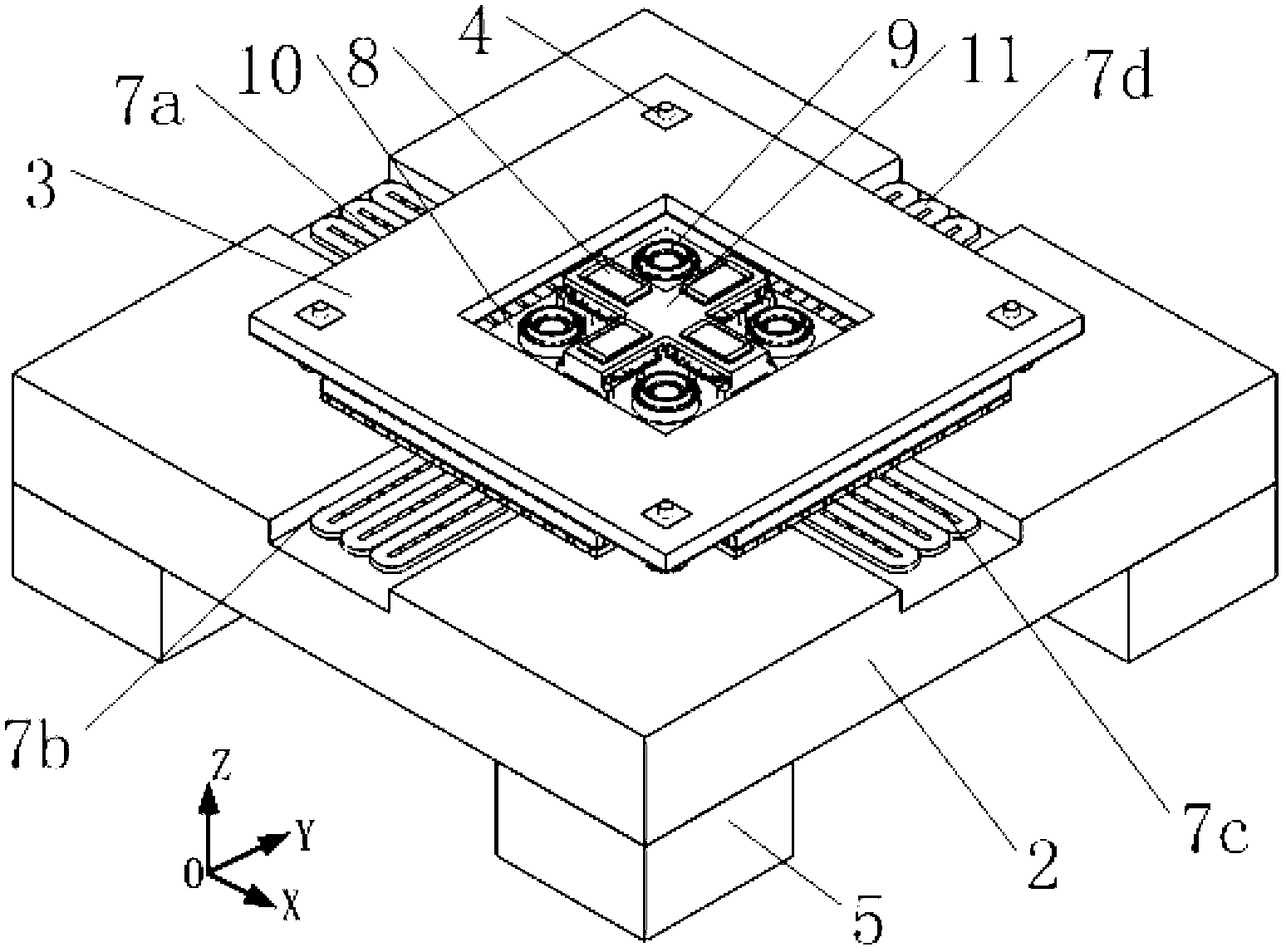

Rough-fine-movement laminated workbench with laser interferometer measurement

ActiveCN103226296AAvoid production difficultiesIncrease the itineraryUsing optical meansPhotomechanical exposure apparatusAir bearingLithographic artist

The invention relates to a rough-fine-movement laminated workbench with laser interferometer measurement. The workbench is mainly used in a lithography system. The laminated workbench comprises a fine movement bench, a rough movement bench, a balancing block, four vibration isolators, and a measuring frame. The rough movement bench comprises a rough movement bench frame, four moving iron electromagnetic driving modules, and four air bearings. The fine movement bench is arranged at the middle of the rough movement bench frame. The system also comprises a laser interferometer measurement assembly used in position feedback between a sheet bearing stage of a six degrees of freedom (DOF) positioning device and a pedestal. The laser interferometer measurement assembly is composed of a laser source, an optical path assembly, and a laser interferometer. With the laser interferometer measurement assembly, real-time six-DOF measurement can be carried out upon the movement part of the device. The workbench provided by the invention has a simple and compact structure. The mass of the movement parts is light. A rough movement bench driving motor adopts a lengthened rectangular coil group. On a basis that movement precision is not influenced, manufacturing difficulty of a large-scale halbach magnetic steel array is avoided, and driving motor stroke is increased, such that movement precision is improved.

Owner:TSINGHUA UNIV +1

Bearing free, engine free and axle free complete artificial heart pump

The invention provides a bearing free, engine free and axle free complete artificial heart blood pump, wherein the blood pump comprises two symmetrical cardiac sinus blood pumps with the same structure, which connects in sequence the blood intake port, the funnel type blood pump inner chamber, the cylinder type blood pump inner chamber with the blood flow exit. The interconnected awl blade wheel and the column blade wheel placed into the inner chamber of the funnel type blood pump inner chamber and the cylinder type blood pump inner chamber. The outer walls of the funnel type blood pump inner chamber and the cylinder type blood pump inner chamber are provided with a plurality groups of coils.

Owner:BEIJING UNIV OF TECH

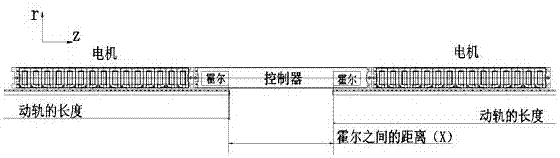

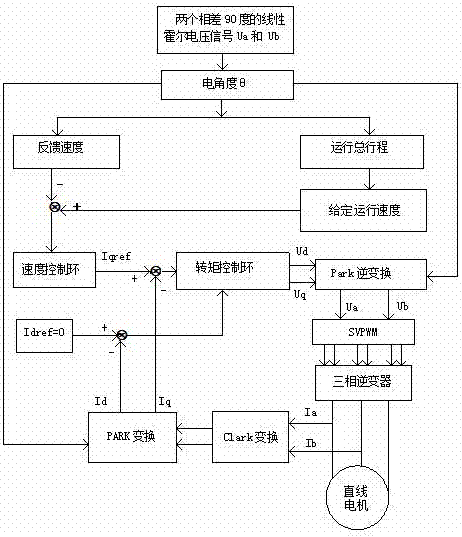

Method for straight line motor automatic door vector control based on linear Hall sensor

ActiveCN107465373AEasy to implementHigh precisionElectronic commutation motor controlAC motor controlProportional integral differentialControl vector

The invention discloses a method for straight line motor automatic door vector control based on linear Hall sensors. The method comprises the following steps: detecting counter electromotive force of a linear motor through two linear Hall sensors which differ from each other for 90 degrees, and performing vector control; according to the counter electromotive force, calculating an electric angle of the linear motor; according to difference feedback of the electric angle, calculating an operation speed of the linear motor and a total route to be operated; comparing the operation speed calculated according to the feedback of the linear motor with a given speed so as to obtain a speed difference, performing PID (Proportional Integral Differential) control of a speed control ring so as to obtain output torque current Iqref, enabling exciting current Idref to be 0, adopting the output torque current Iqref and the current Idref=0 as input of the torque control ring, generating voltage output expected by the linear motor through the torque control ring, and changing the operation speed of the linear motor along with change of the given speed. The method has the advantages of being high in precision, low in cost and easy in algorithm achievement.

Owner:谢文超

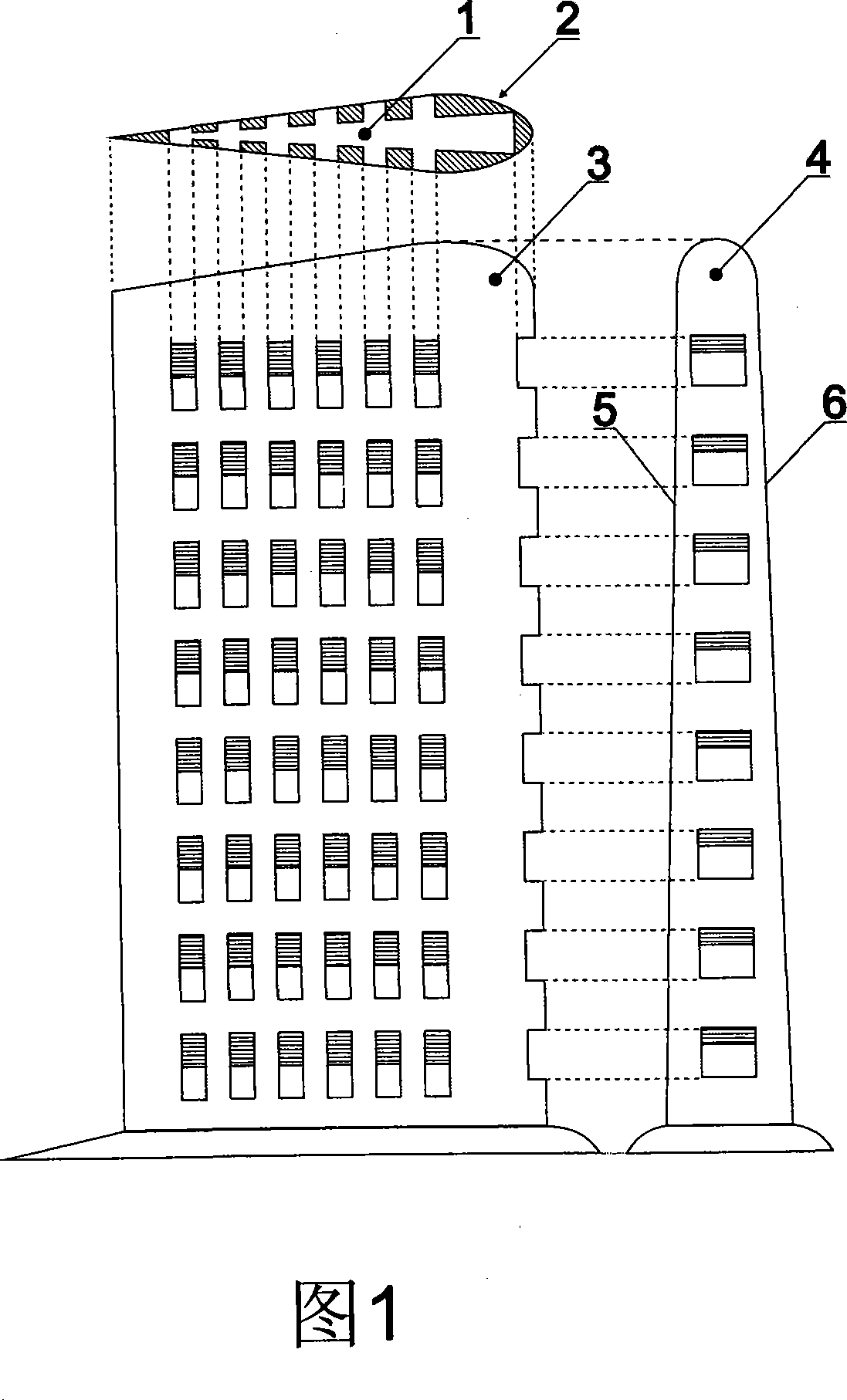

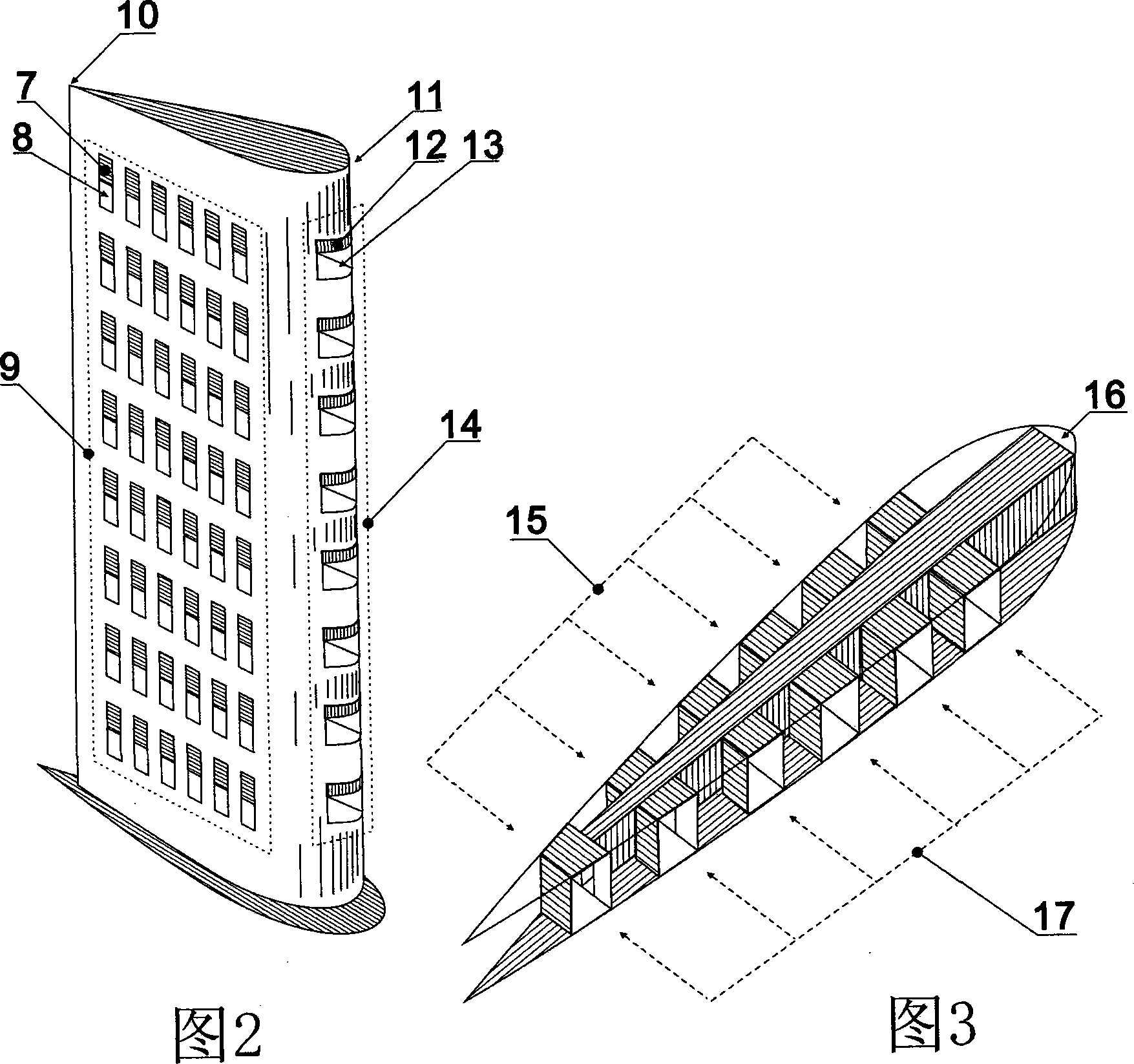

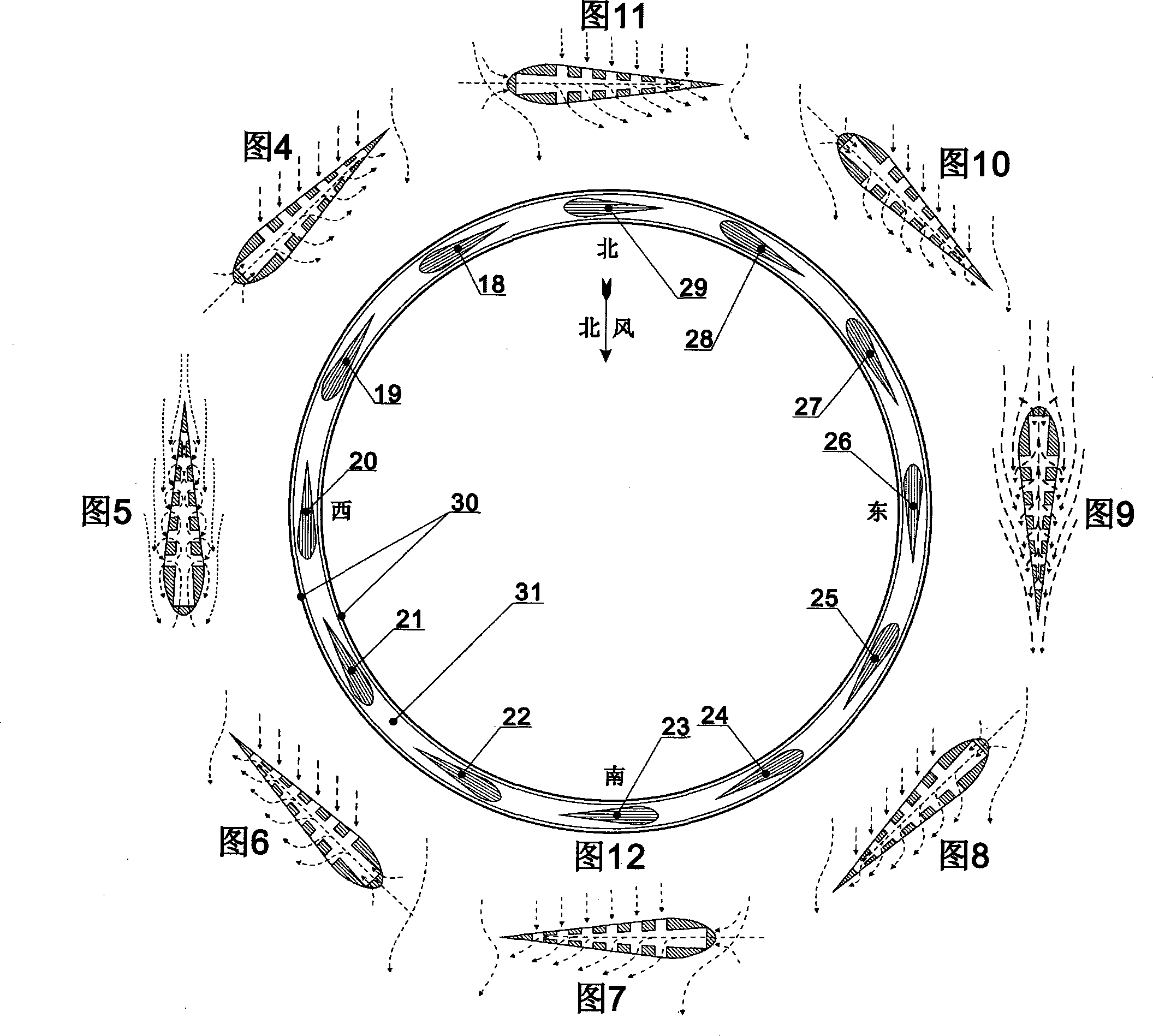

Magnetic levitation reinforced concrete built pressing jet type wing-shape sail wind power generator

InactiveCN101054950AIncrease power generationNo mechanical frictionWind motor controlFinal product manufactureReinforced concreteElectric control

The present invention relates to a stamping jet type wing shape wind sail wind generator made of magnetic suspension reinforced concrete. The generator changes the inner structure of the wind sail on the base of colligating the design idea of modern aerodynamics and retaining conventional wing shape wind sail. Because the generator adopts large area and the technology principle of the stamping jet type wing shape wind sail, it increases the area of practical wind arrest for the wind generator and also greatly improves the electricity generation efficiency for single wind generator. The present invention not only adopts the structure of the stamping jet type wing shape wind sail, but also combines the modern magnetic suspension groundsill track technology, machine-electric control technology and the conventional low cost and durable reinforced concrete structure producing technics. Thereby, the whole wind generator system not only is in favor for high efficiency big power electricity generation but also has no mechanical friction, no noise, no zoology pollution and long using life. Because the main structure of the stamping jet type wing shape wind sail wind generator is entirely made of reinforced concrete, thereby it omits complex mechanical machining and reduces the producing and manufacturing cost.

Owner:SHENZHEN WIND WATER WHEEL NEW ENERGY TECH

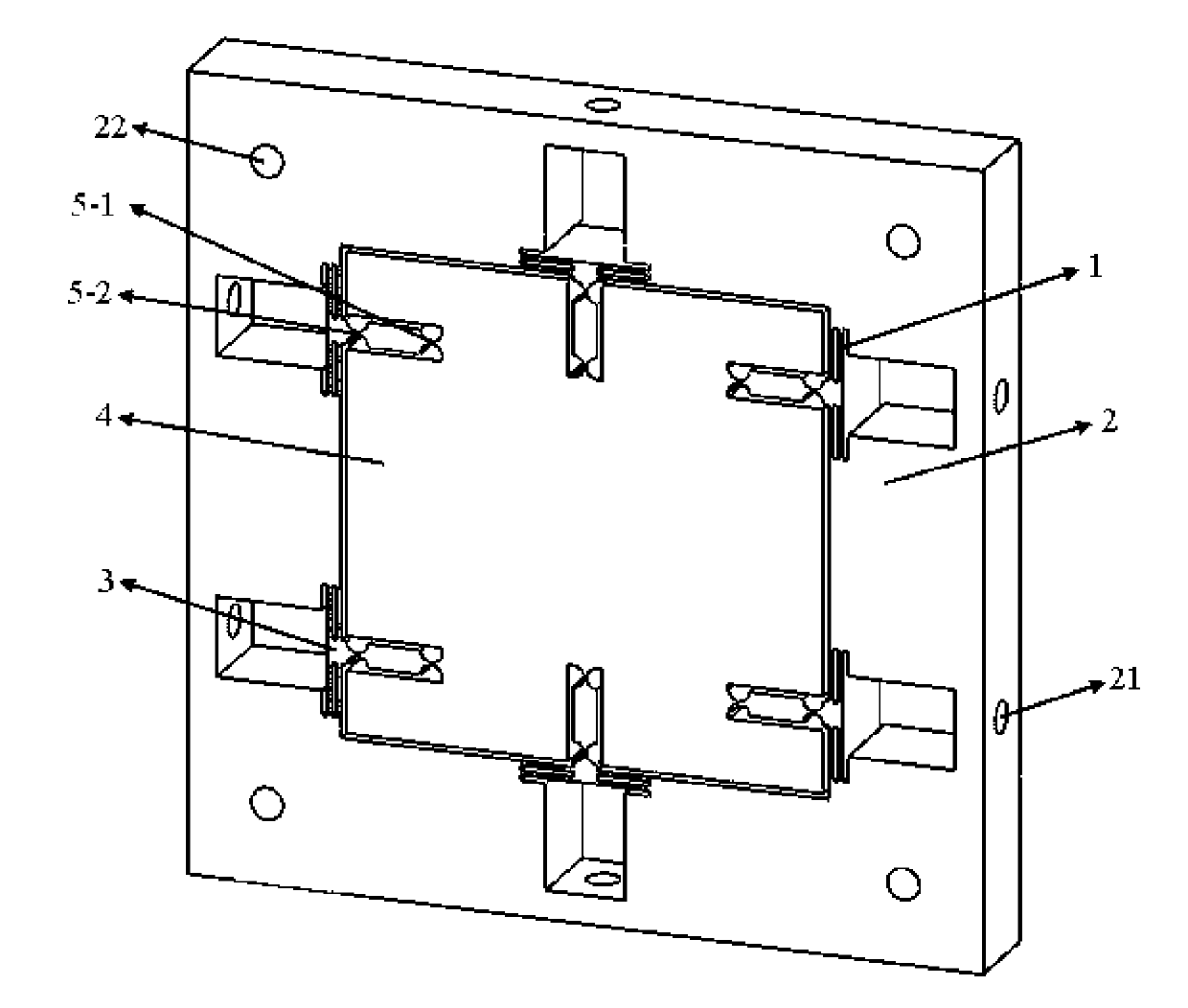

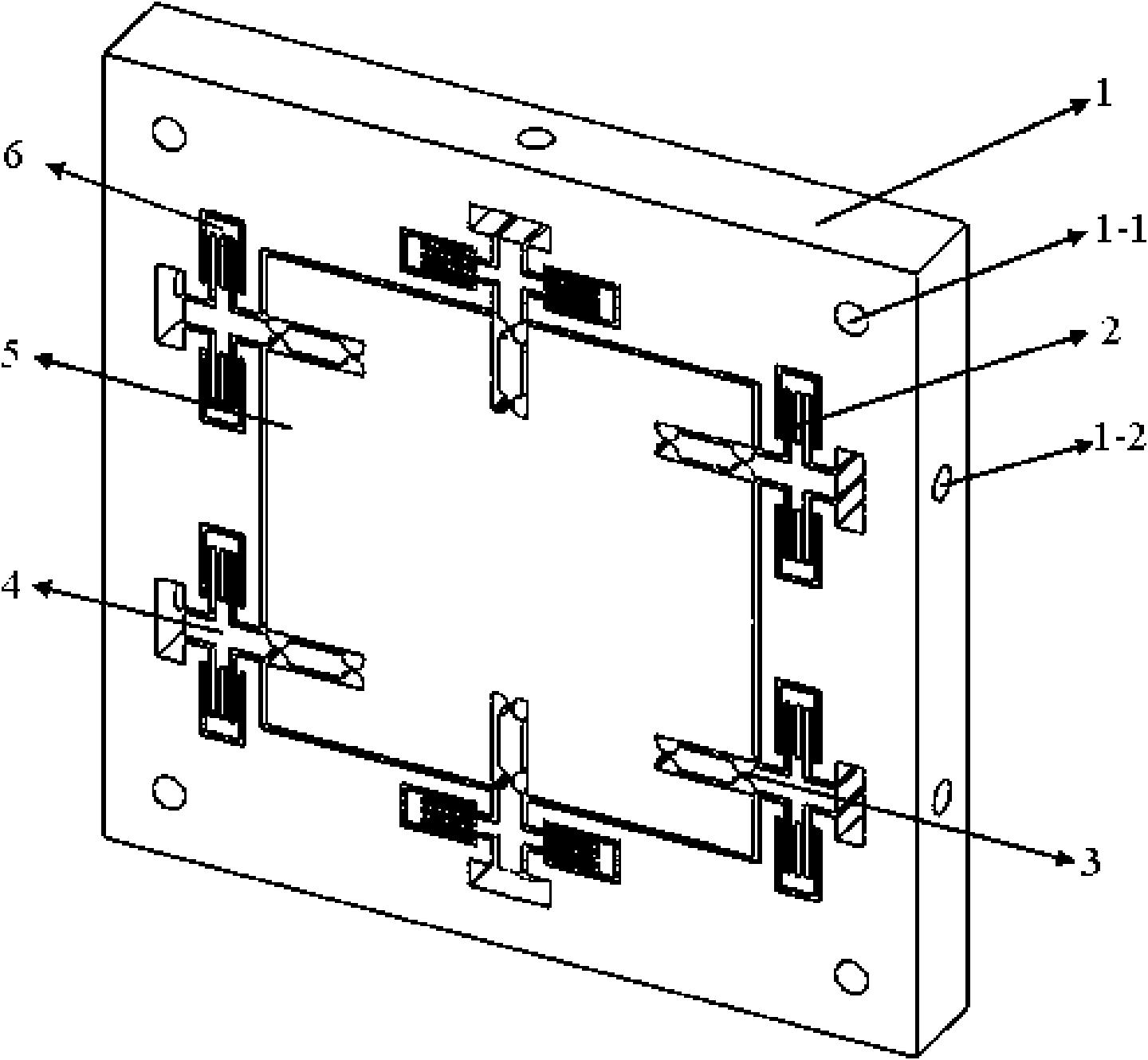

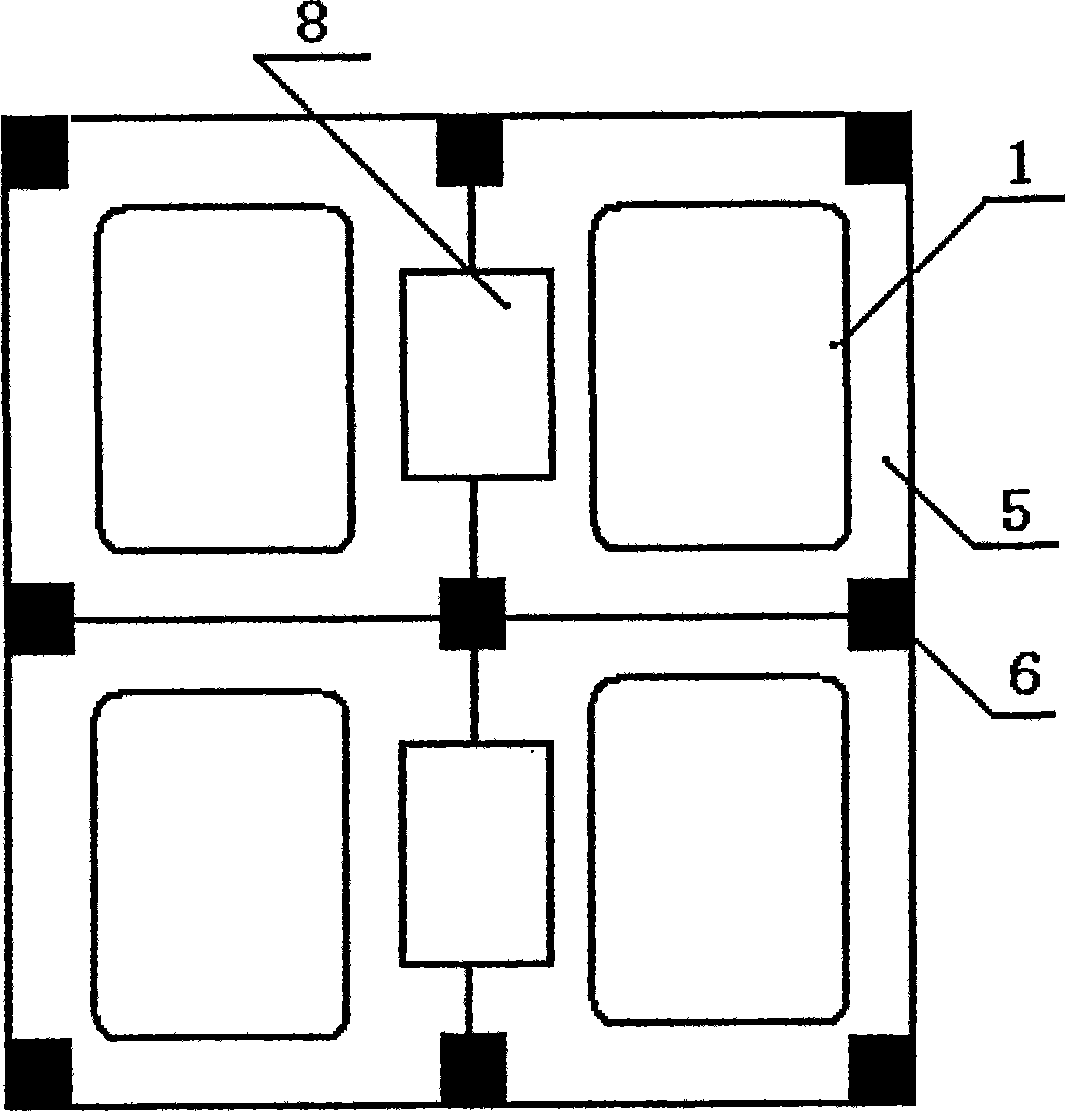

Two-translational-motion precision positioning working table for nano-imprint photoetching system

The invention discloses a two-freedom-degree precision positioning working table for a nano-imprint photoetching system, comprising a base, a movable platform, a rigid bracket connected to the bottom part of the base and four flexible branched chains connected between the movable platform and the base; in the structure, four piezoelectric ceramic drivers are adopted, the tail part of each driver is connected with the base by a bolt, and the top end thereof is connected with a ball joint by threads to realize Hertz contact; two position sensors are used for measuring practical output of the movable platform and are respectively fixed between the rigid bracket and the movable platform. The precision positioning working table has the characteristics of high resolution ratio and rapid dynamic response speed, and can be used as an auxiliary locating platform of the nano-imprint photoetching system for realizing micro feeding and precision location.

Owner:江苏金秋刺绣花边有限公司

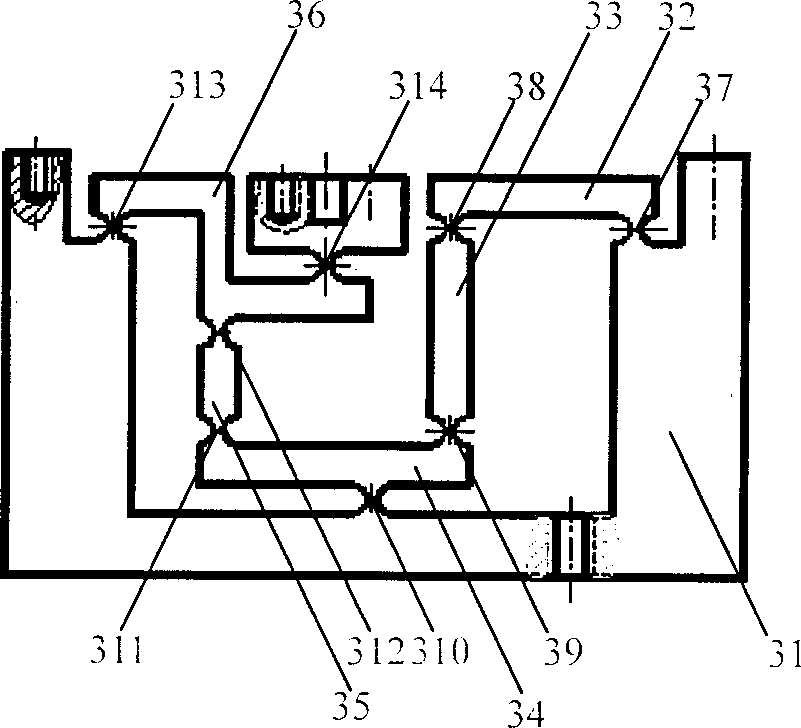

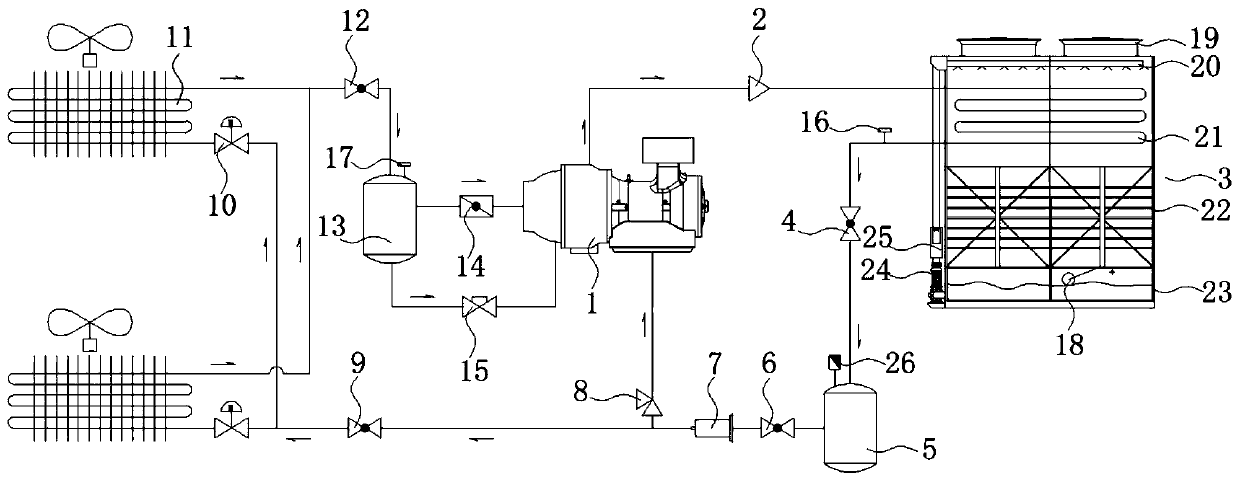

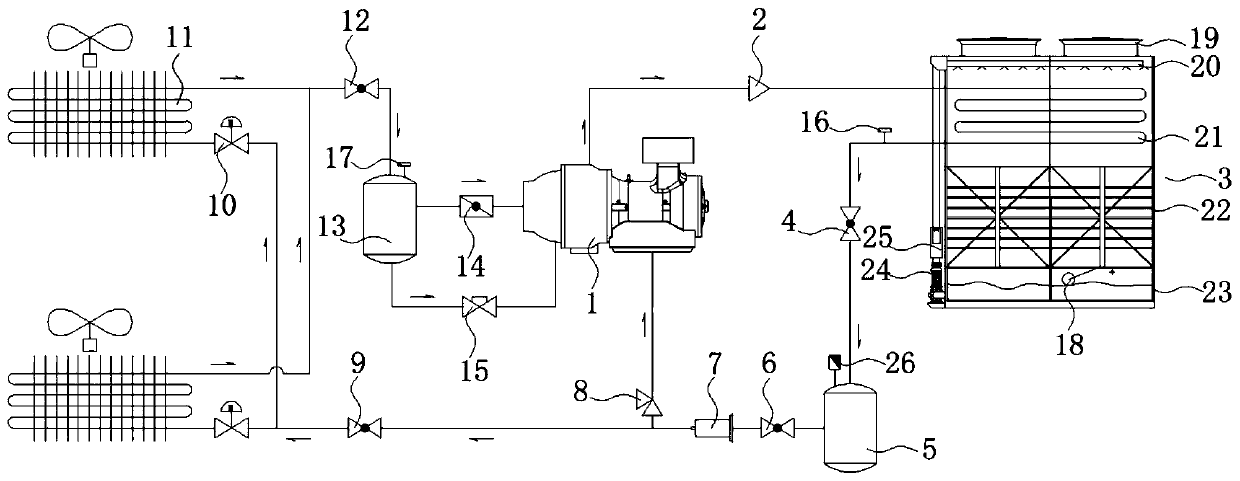

Wide-working-condition annual refrigeration type evaporative cooling magnetic suspension refrigerating unit and control method

PendingCN111141041ATo meet the changing needs of multiple working conditionsImprove operational efficiencyMechanical apparatusCompression machines with non-reversible cycleControl engineeringLiquid storage tank

The invention relates to a wide-working-condition annual refrigeration type evaporative cooling magnetic suspension refrigerating unit and a control method. The wide-working-condition annual refrigeration type evaporative cooling magnetic suspension refrigerating unit comprises a plurality of direct-expansion coils, the output ends of the plurality of direct-expansion coils are integrated into a pipeline through a plurality of pipelines and then connected with the inlet end of a vapor-liquid separator, an air outlet and an auxiliary air port of the vapor-liquid separator communicate with an air suction port and an air supplement port of a magnetic suspension compressor through the pipelines respectively, an exhaust port of the magnetic suspension compressor is connected with the inlet endof an evaporative cooling type condenser through the pipelines, the outlet end of the evaporative cooling type condenser is connected with the inlet end of a liquid storage tank through the pipelines,the outlet end of the liquid storage tank is connected with the inlet end of a dry filter, and the outlet end of the dry filter is connected with a liquid spraying connector of the magnetic suspension compressor and the inlet ends of the direct-expansion coils through the pipelines correspondingly. According to the wide-working-condition annual refrigeration type evaporative cooling magnetic suspension refrigerating unit and the control method, the evaporation temperature range of the unit can be adjusted within -5 DEG C to 18 DEG C, the requirement for multi-working-condition changes can bemet, the magnetic suspension compressor reduces mechanical friction of moving parts by utilizing the magnetic suspension technology, and the service life of the unit is greatly prolonged.

Owner:辽宁沣知稼农业科技发展有限公司

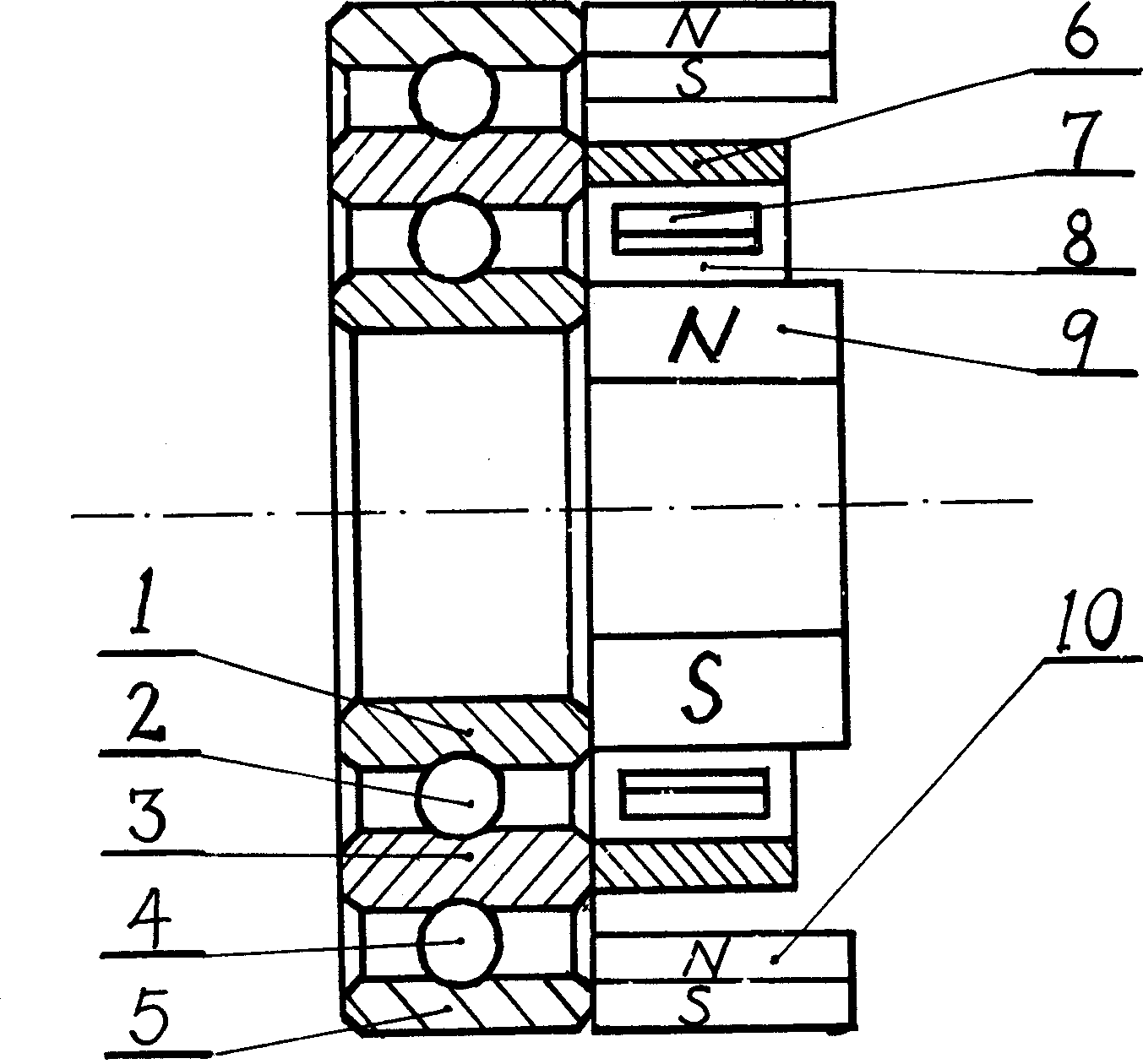

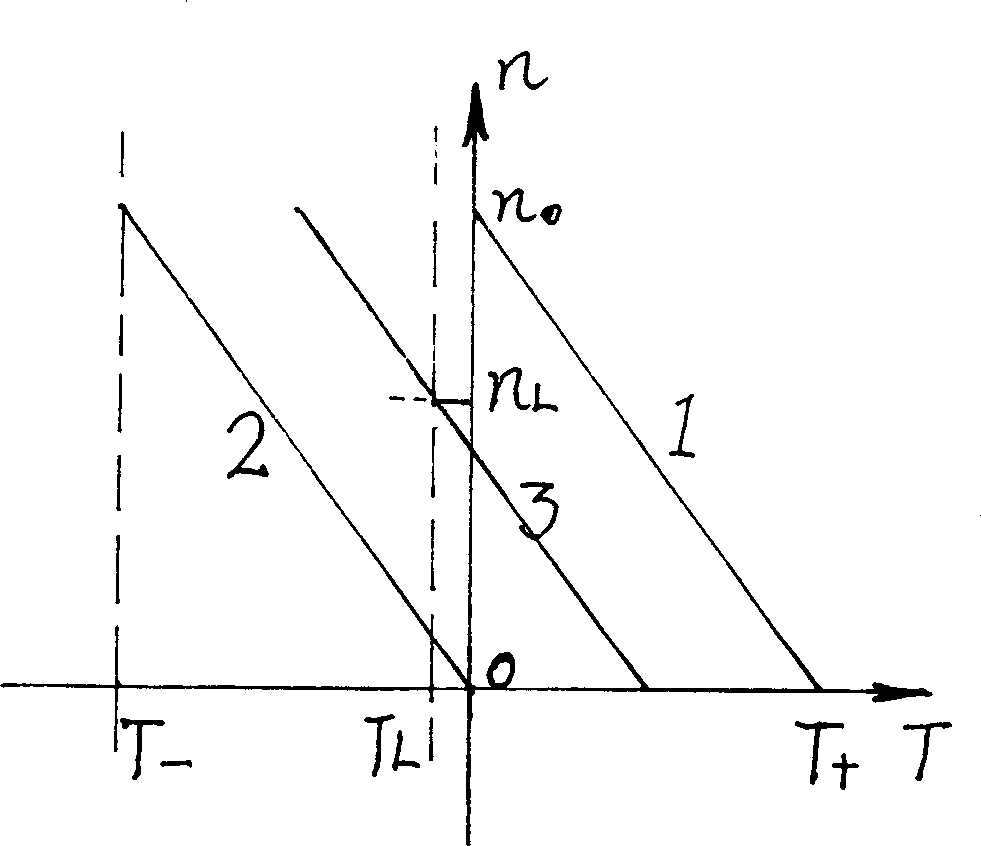

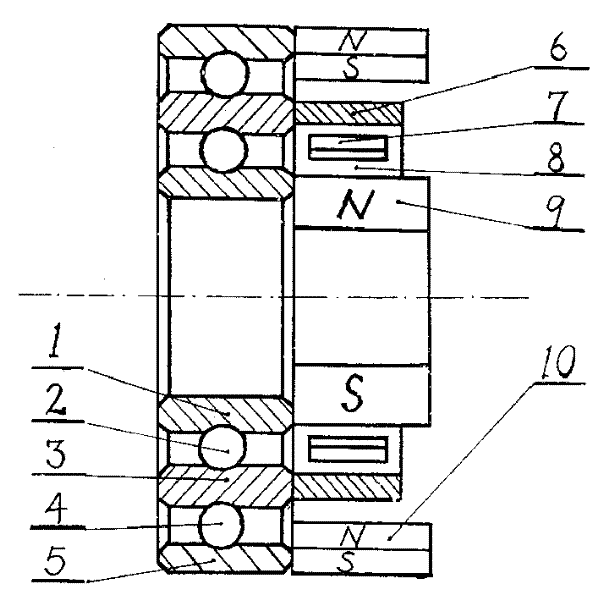

Secondary bearing with electromagnetic speed regulation in interelectrode

InactiveCN1490532AIncrease limit speedExtended service lifeRolling contact bearingsBearing componentsSingle stageEngineering

Owner:李军

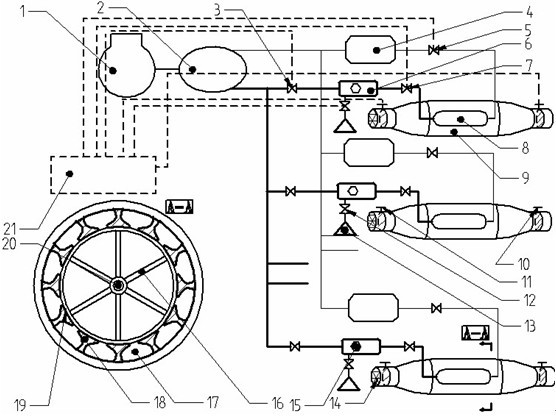

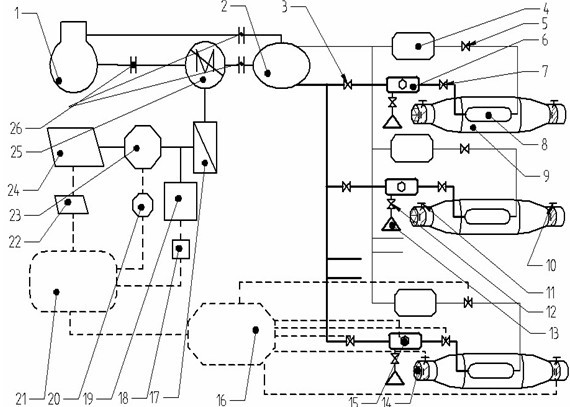

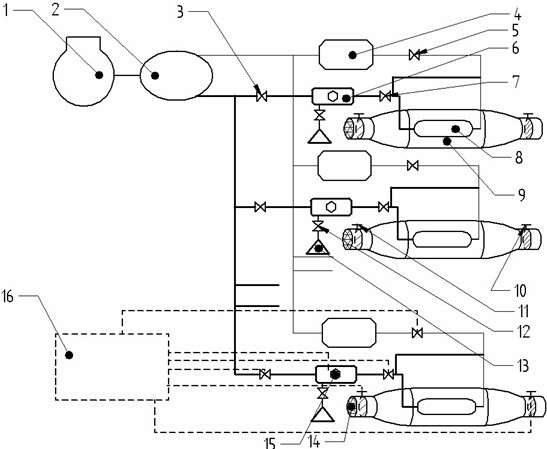

High-efficiency silencing water surface or underwater driving technology

InactiveCN102085908AStable speedImprove operational efficiencyMachines/enginesPropulsive elementsRamjetJet flow

The invention relates to a high-efficiency silencing water surface or underwater driving technology. An air compressor / high pressure steam generator generates high pressure gas / steam, the gas outlet of the air compressor or high pressure steam generator is connected with a high pressure gas holder in parallel, the gas inlet of the air compressor or high pressure steam generator is connected with a low pressure gas holder / condenser in parallel, the high pressure gas holder is respectively connected with a boosting gas bag and an additional water ramjet subsystem, the low pressure gas holder / condenser is connected with the boosting gas bag, and the boosting gas bag is arranged in a guide pipe. The communication between a plurality of boosting gas bags and the high pressure gas holders or the low pressure gas holder / condenser is controlled to control expansion and contraction of the gas bags, the boosting gas bag is expanded to extrude the water in the guide pipe out, so as to generate athrust and drive a ship to move; the boosting gas bag contracts and the guide pipe is filled with water to be ready for jet flow at the next time; the direction of inlet outlet water in the guide pipe can be determined by controlling the open and close of water inlet outlet valves at the two ends of the guide pipe; and the process can be repeated to drive the ship to do various movements.

Owner:SICHUAN UNIV

Axial flow magnetic suspension permanent magnet hydro-generator

InactiveCN105927454AExtended Service Life SuspensionLow costHydro energy generationReaction enginesMagnetic bearingMagnetic axis

The invention discloses an axial flow magnetic suspension permanent magnet hydro-generator. The axial flow magnetic suspension permanent magnet hydro-generator comprises a volute, a rotor shaft, a left suspension magnetic bearing, a right suspension magnetic bearing, a left limiting assembly, a right limiting assembly, a hydro-generator set, a first flow guiding assembly and a second flow guiding assembly, wherein the volute is provided with a water inlet; the rotor shaft is arranged in the volute and the rotor shaft and the volute are provided with the same axis; the left suspension magnetic bearing and the right suspension magnetic bearing are arranged in the volute and the left suspension magnetic bearing, the right suspension magnetic bearing and the volute are provided with the same axis; the left limiting assembly and the right limiting assembly are arranged at the two ends of the volute correspondingly and used for axially limiting the rotor shaft; the hydro-generator set is arranged on the rotor shaft; the first flow guiding assembly is arranged in the volute and used for guiding entered water to the hydro-generator set; and the second flow guiding assembly is used for guiding water in a cavity out of the two ends of the volute. The two ends of the rotor shaft are arranged in the left suspension magnetic bearing and the right suspension magnetic bearing in a penetrating mode correspondingly and always suspended on the axis of the volute and not eccentric under the radial repulsive force action of the left suspension magnetic bearing and the right suspension magnetic bearing. The two ends of the rotor shaft abut against the left limiting assembly and the right limiting assembly correspondingly. The axial flow magnetic suspension permanent magnet hydro-generator is simple in structure and high in power generating efficiency.

Owner:CHONGQING UNIV OF TECH

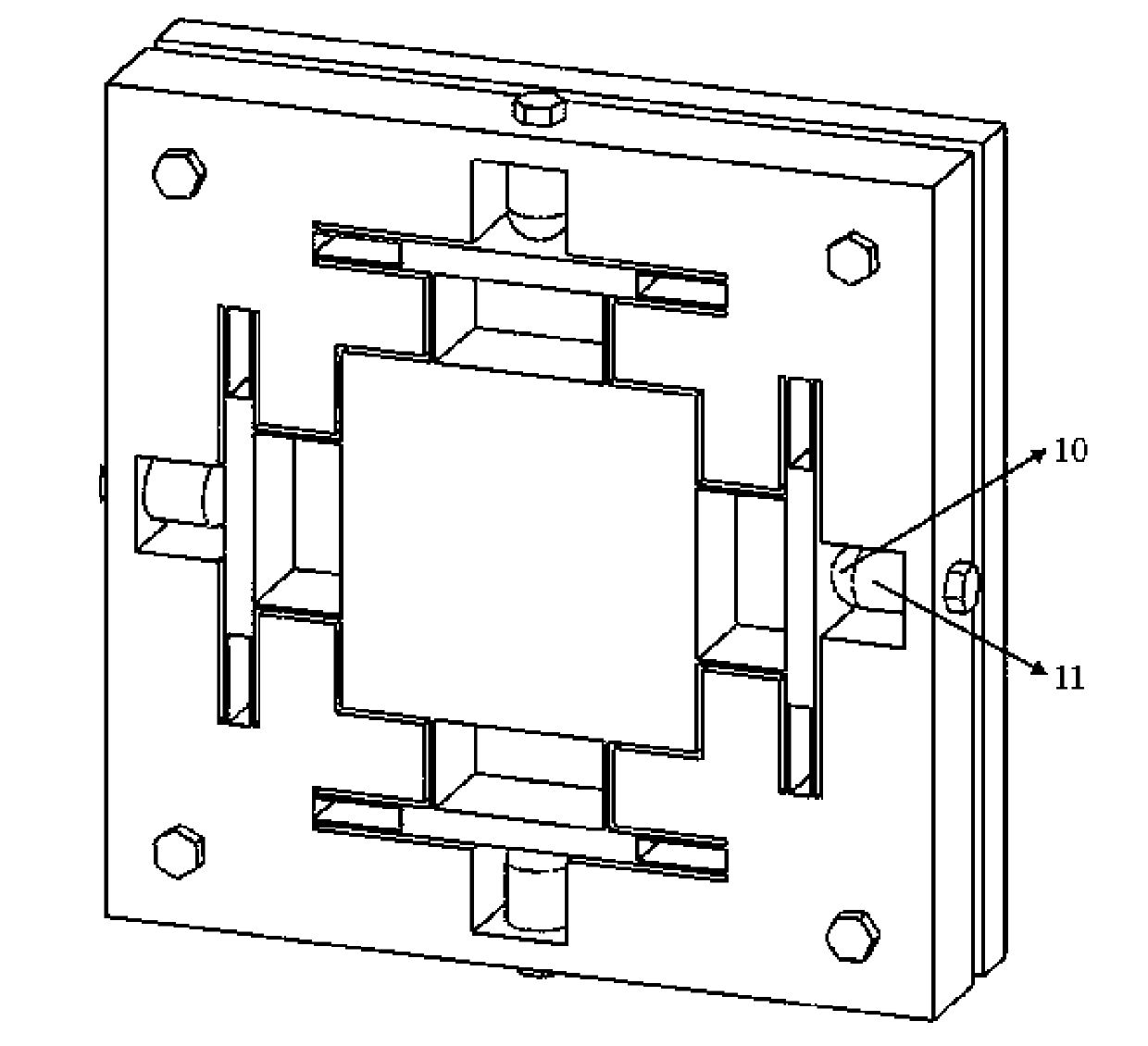

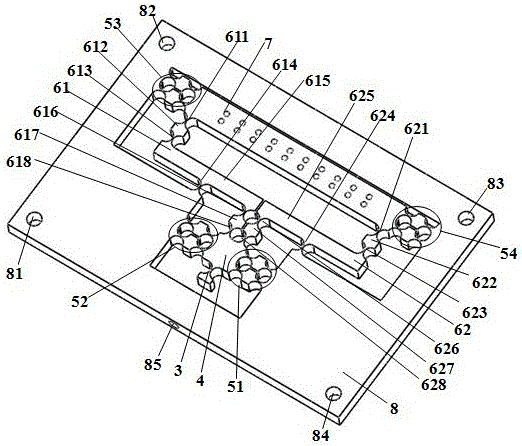

Symmetrical decoupling and single degree of freedom flexible operation mechanism

The invention discloses a symmetrical decoupling and single degree of freedom flexible operation mechanism. The symmetrical decoupling and single degree of freedom flexible operation mechanism is characterized in that the flexible operation mechanism comprises the following components connected and assembled according to design requirements: a piezoelectric ceramics driver, a spherical connector, a driving end flexible hinge, a rigid connecting block, four groups of flexible hinge combinations, two flexible chains, a rigid moving platform, a rigid support frame and a base. The mechanism adopting the flexible connecting structure, the single degree of freedom flexible hinges and the piezoelectric ceramics driver driving technology has one actuation terminal, can be applied to micro / nano operation mechanical systems, and has the advantages of being high in precision, low in inertia, compact in structure, free of error accumulation, free of mechanical friction, free of clearance, convenient to process, convenient to manufacture, convenient to industrially implement and the like.

Owner:HEBEI UNIV OF TECH

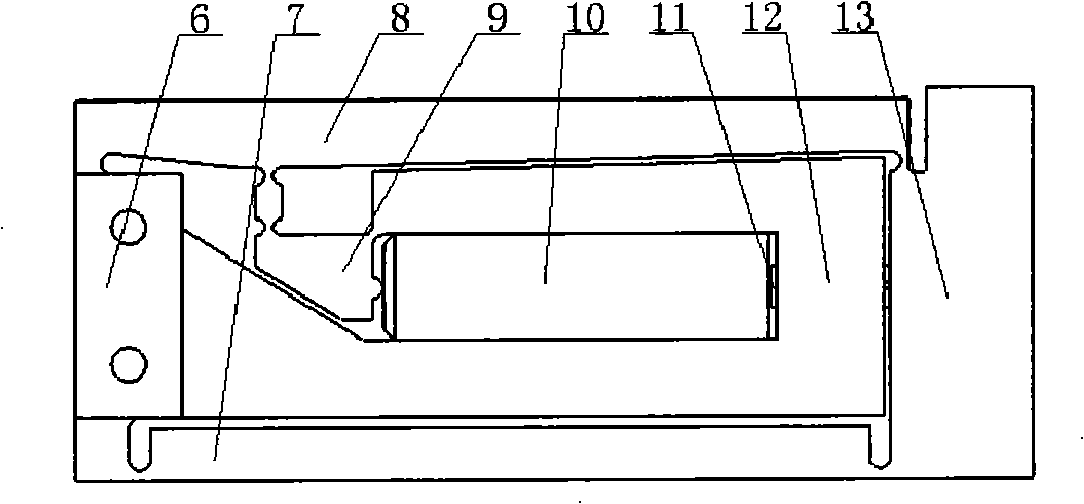

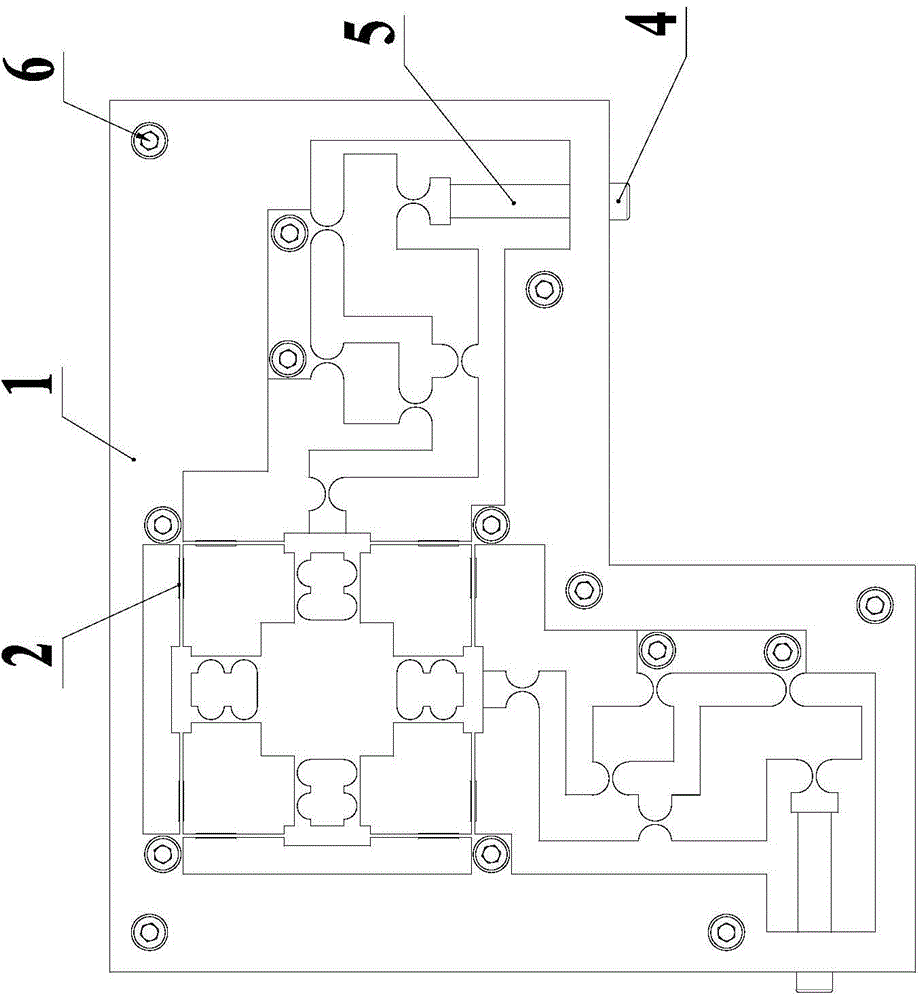

Piezoelectric micro-platform capable of amplifying based on flexible hinge

ActiveCN104925738AReduce volumeNo mechanical frictionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringHinge point

The invention discloses a piezoelectric micro-platform capable of amplifying based on a flexible hinge. The piezoelectric micro-platform comprises a frame and a carrier platform, wherein a micro-driver and an amplifying mechanism are arranged on the frame; the amplifying mechanism is a double-rocker mechanism; an extension section is arranged on one end, which is far away from a connecting rod, of a driving rocker of the double-rocker mechanism, and a free end of the extension section of the driving rocker supports the micro-driver; the driving rocker and the extension section thereof form an amplifying lever with a hinge point of the driving rocker and the frame as a pivot; an extension section is arranged on one end of the connecting rod, which is far away from the driving rocker; the carrier platform is connected to a decoupling mechanism, the decoupling mechanism is formed by at least one pair of decoupling units, and the two decoupling units are symmetrical around the center of the carrier platform; each decoupling unit is formed by a connecting arm and a pair of flexible arms, one end of each flexible arm is hinged to the frame, the other end of each flexible arm is hinged to the connecting arm, and the other end of the connecting arm is hinged to the carrier platform; the extension section of the connecting rod is hinged to any one decoupling unit. The piezoelectric micro-platform has the advantage that the driving displacement of the micro-driver can be amplified.

Owner:NINGBO UNIV

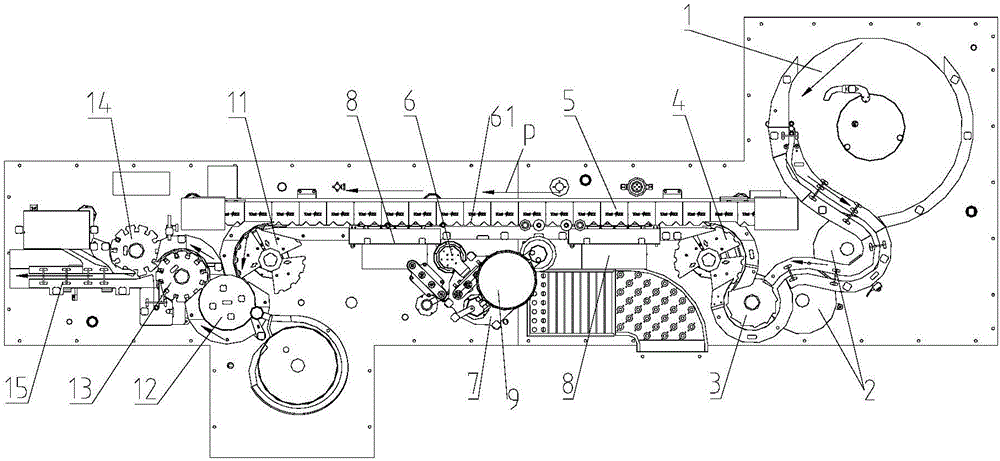

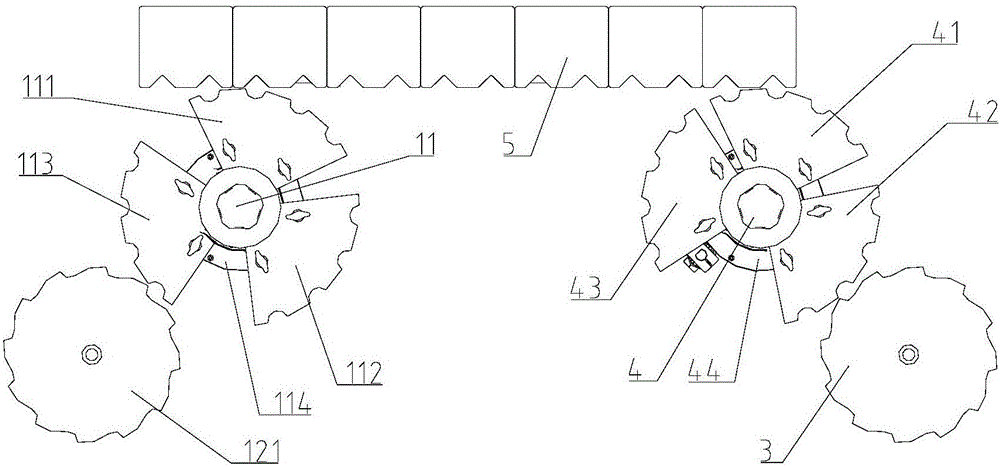

Gas flow insertion pipe type powder filling machine

ActiveCN106477081AQuality assuranceImprove cleanlinessConveyorsSolid materialIntermittent motionBottle

The invention discloses a gas flow insertion pipe type powder filling machine comprising a buffer rotary table, an acceleration rotary table receiving all penicillin bottles from the buffer rotary table, a feed star wheel receiving all the penicillin bottles from the acceleration rotary table, a feed fan-shaped star wheel, a conveying net belt, a powder plate, a filling mechanism, a discharge fan-shaped star wheel and a pressing and plugging mechanism. The feed fan-shaped star wheel equally divides all the penicillin bottles from the feed star wheel into three sets and converts the continuous movement of the three sets of penicillin bottles into intermittent movement. The conveying net belt conveys the three sets of penicillin bottles to filling stations in an intermittent movement manner correspondingly. The powder plate is installed beside the filling stations and contains medicine powder. The filing mechanism sucks the medicine powder in the powder plate and fills the medicine powder in all the penicillin bottles on the filling stations. The discharge fan-shaped star wheel divides all the penicillin bottles, where filling is completed, from the conveying net belt into three sets, and converts the intermittent movement of the three sets of penicillin bottles into continuous movement. The pressing and plugging mechanism continuously presses and plugs all the penicillin bottles from the discharge fan-shaped star wheel. The gas flow insertion pipe type powder filling machine can effectively avoid contamination and improve the filling precision.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com