Patents

Literature

184results about How to "Increase limit speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

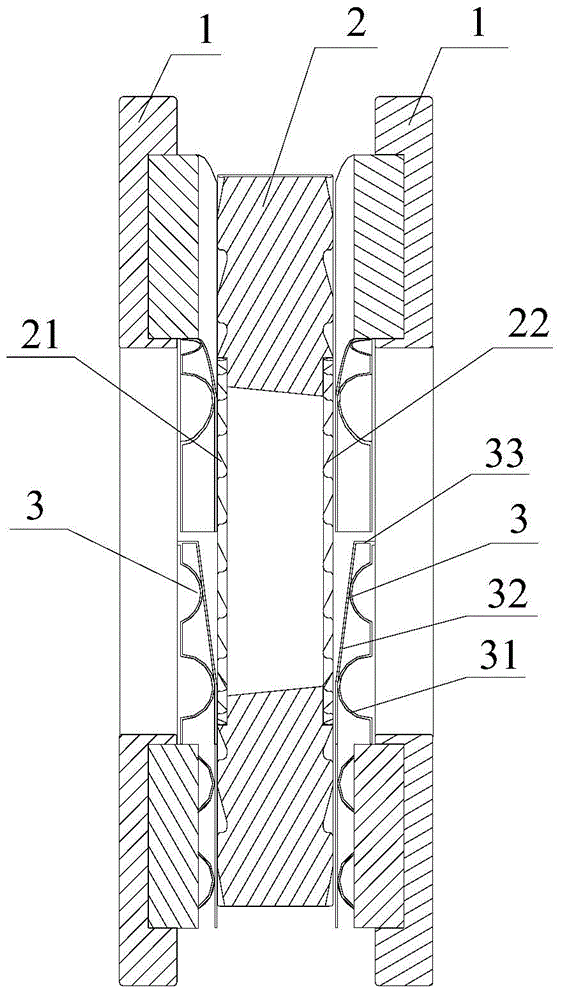

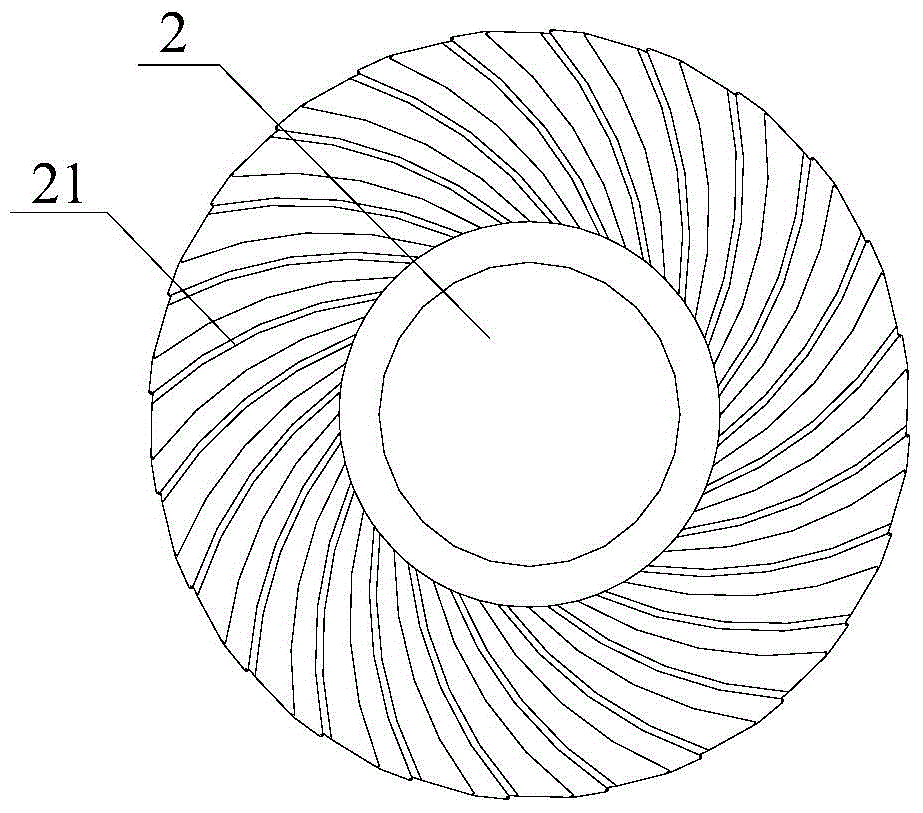

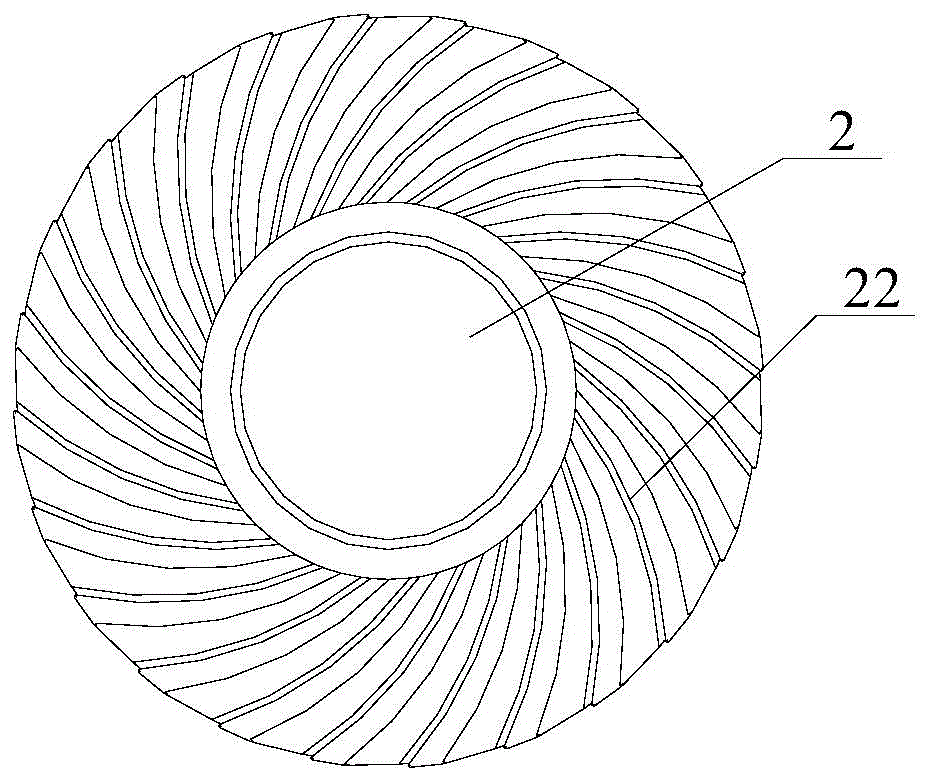

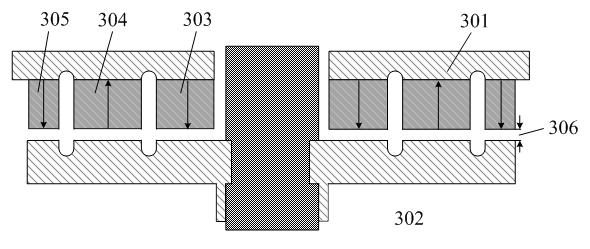

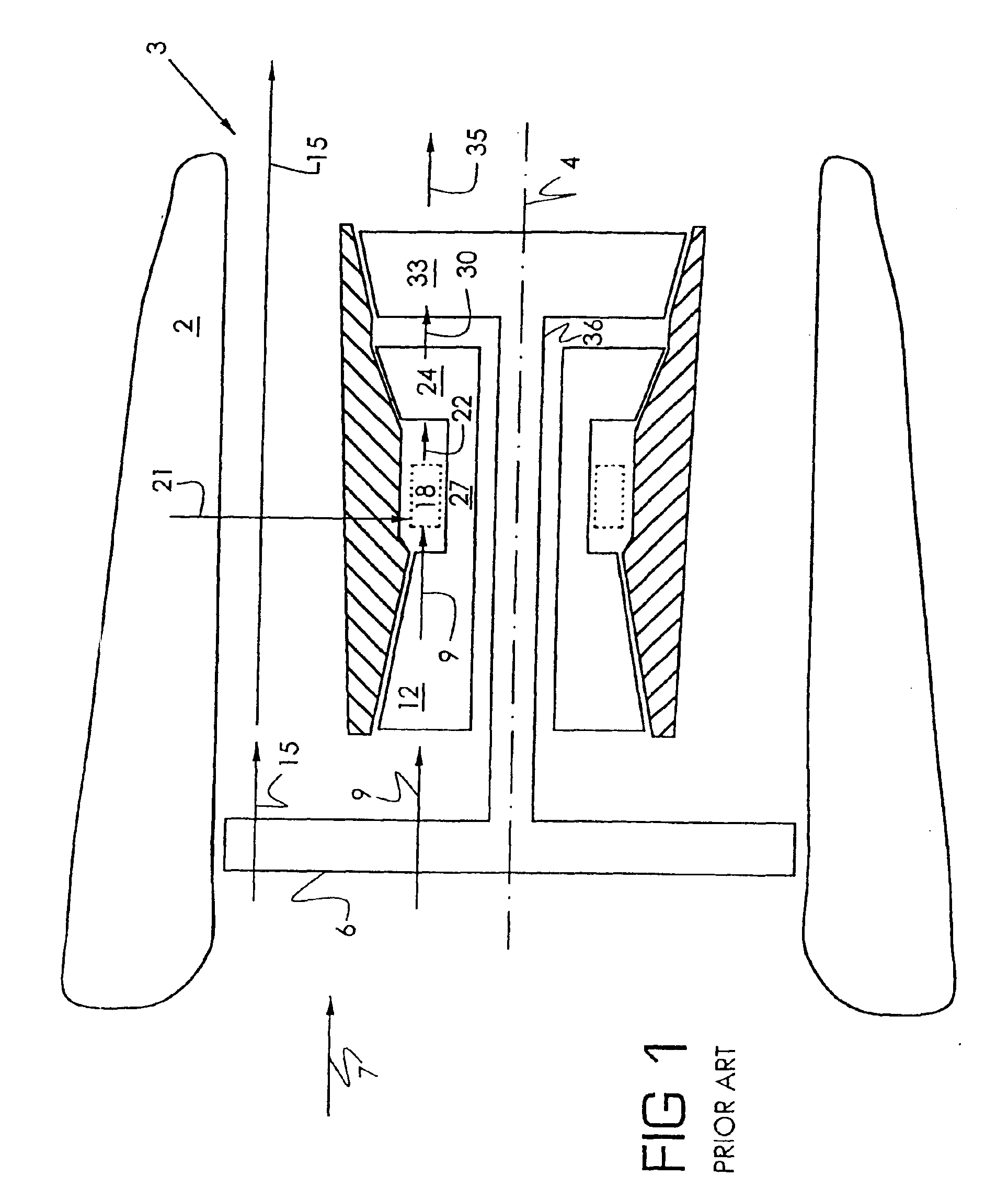

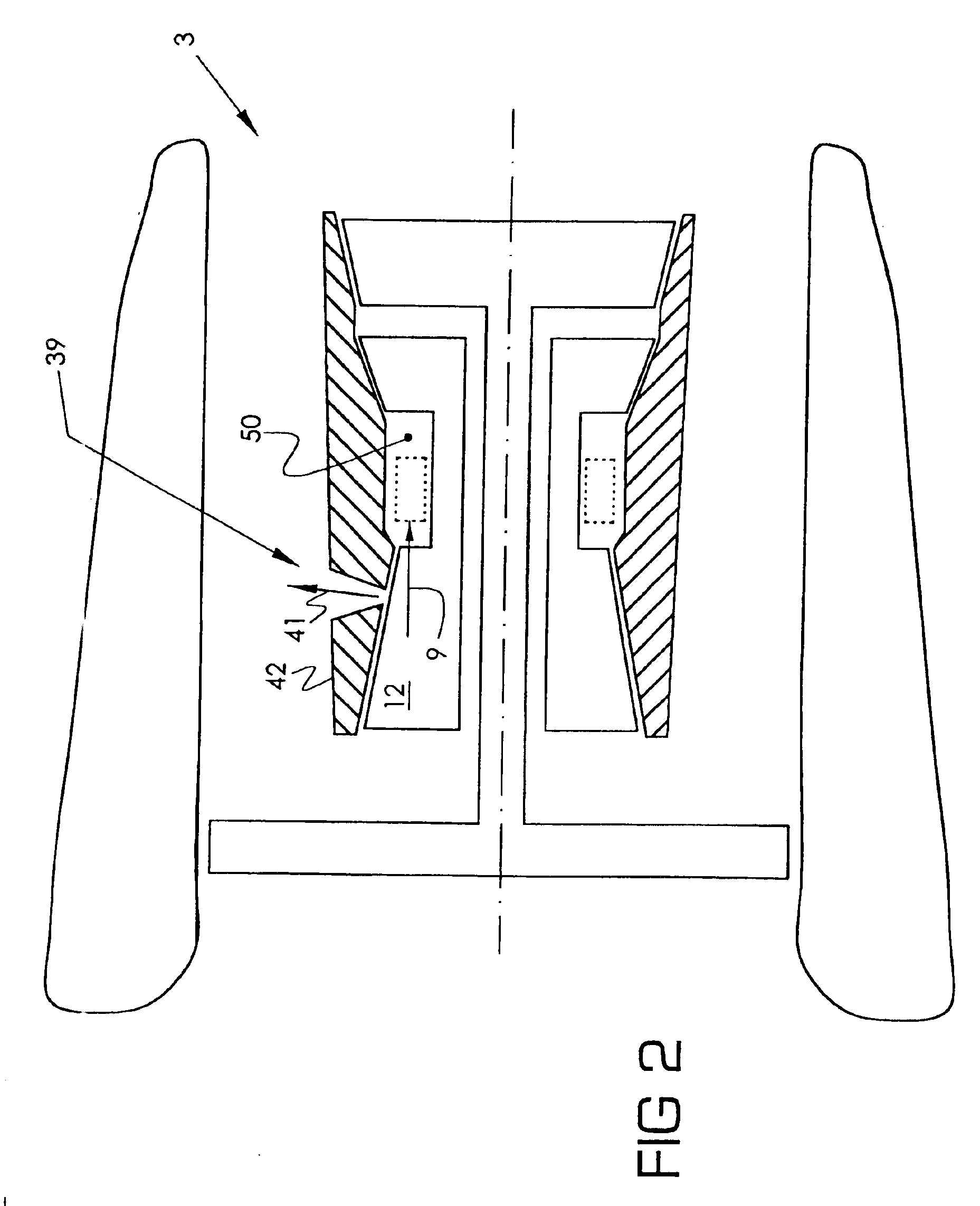

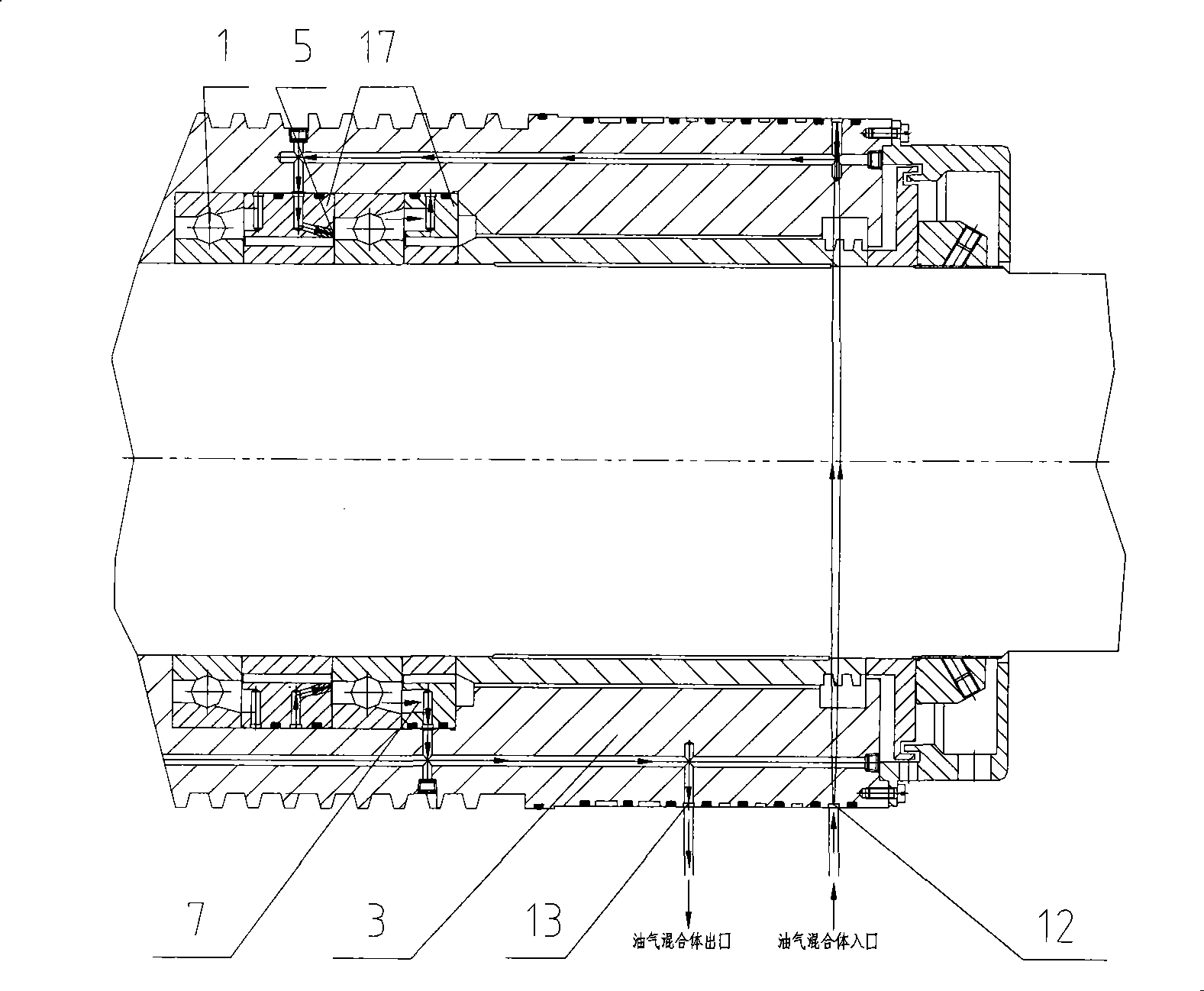

Hybrid type dynamic-pressure gas thrust bearing

InactiveCN104895917AIncrease limit speedImprove impact resistanceBearing componentsSliding contact bearingsHybrid typeUltra high speed

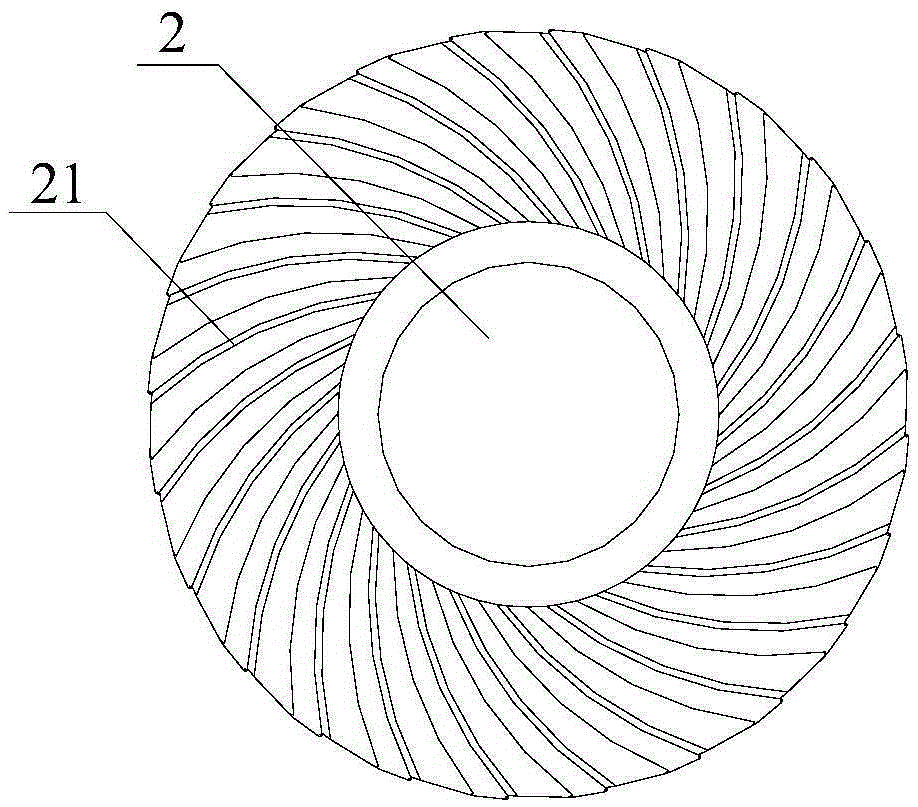

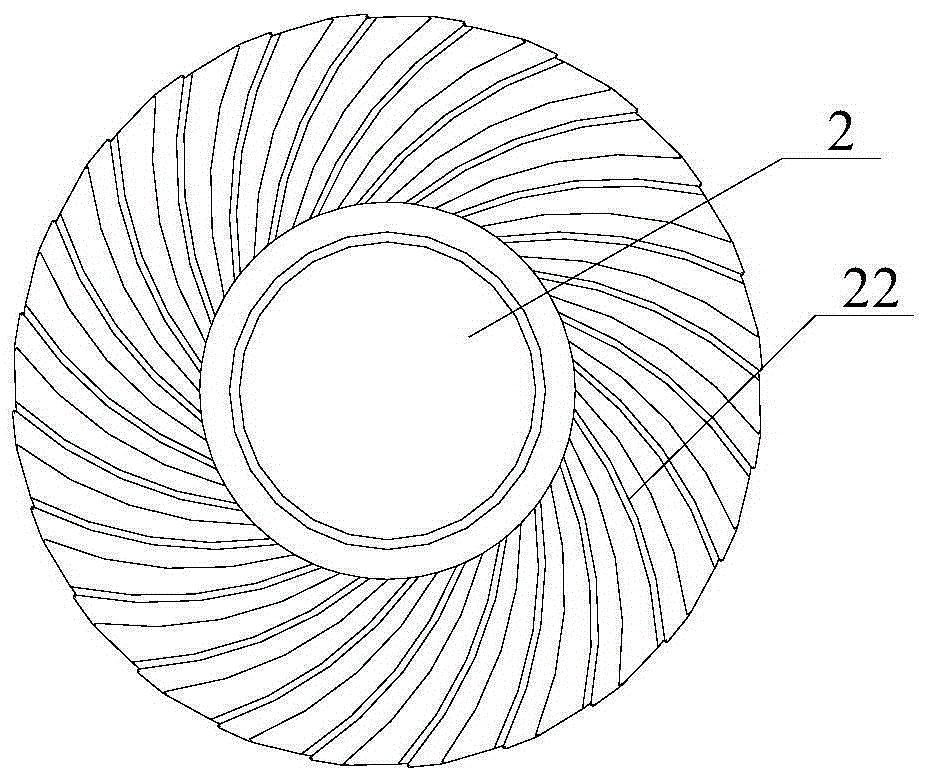

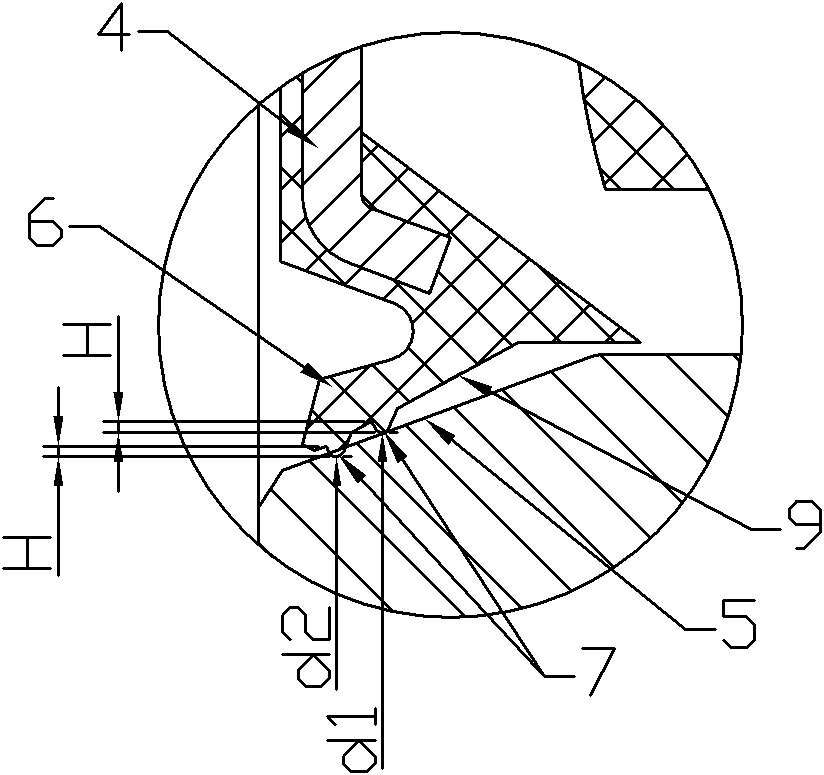

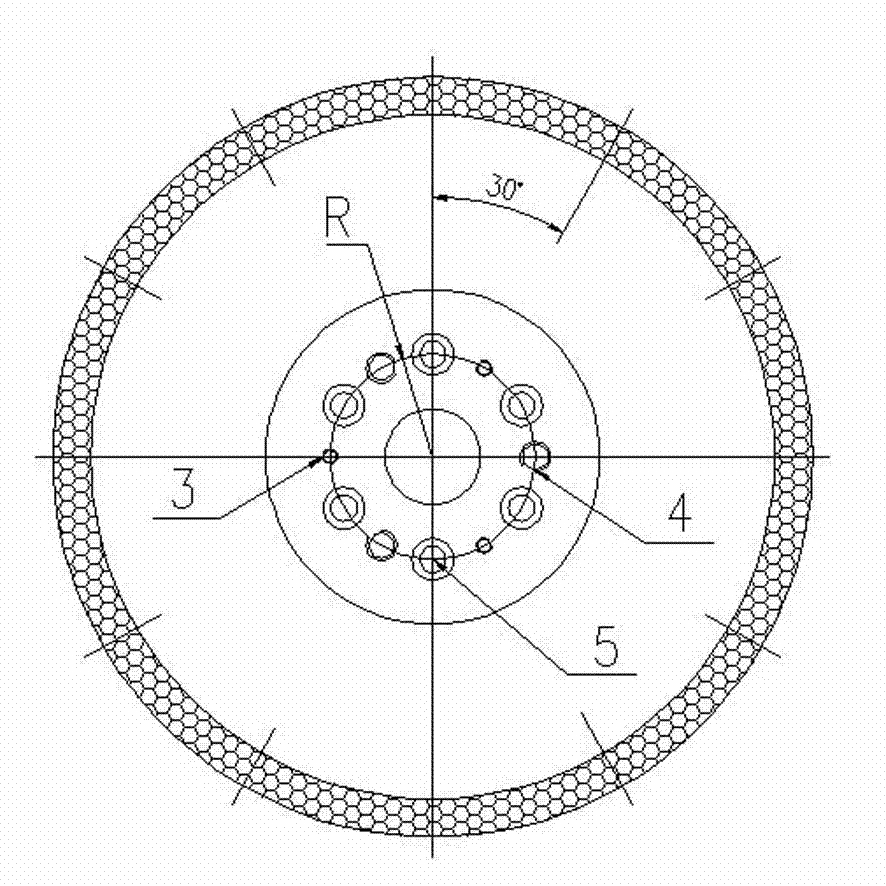

The invention discloses a hybrid type dynamic-pressure gas thrust bearing. The hybrid type dynamic-pressure gas thrust bearing comprises two outer plates, wherein an inner plate is clamped between the two outer plates; a foil type elastic part is arranged between each outer plate and the inner plate; groove type patterns with regular shapes are arranged on the two end surfaces of the inner plate; and the groove type patterns on one end surface and the groove type patterns on the other end surface form mirror symmetry. The hybrid type dynamic-pressure gas thrust bearing provided by the invention not only has rigid characteristics of high-limit rotation speed of a groove type dynamic-pressure gas thrust bearing, but also has flexible characteristics of high impact resistance and high loading capacity of a foil piece type dynamic-pressure gas thrust bearing, so that the application, in the ultra-high speed field under relatively large load, of the dynamic-pressure gas thrust bearing can be satisfied.

Owner:罗立峰

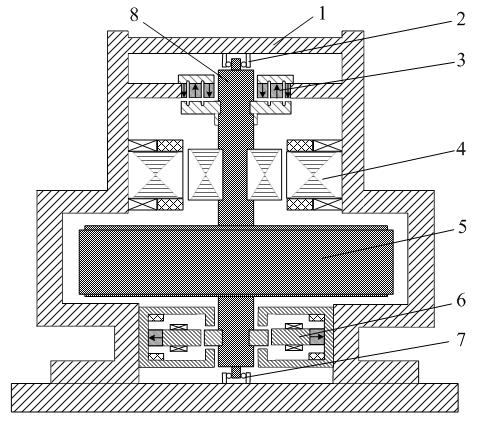

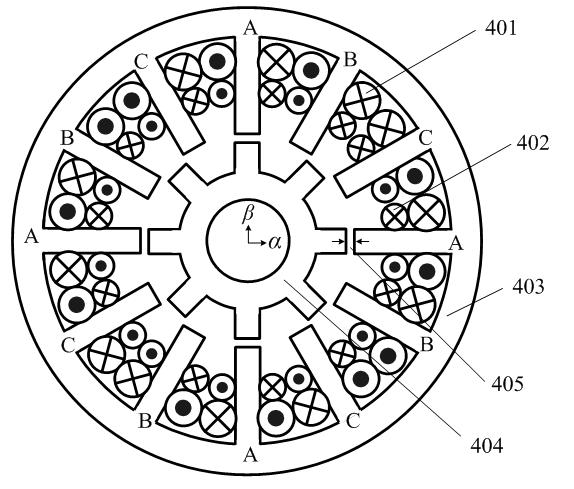

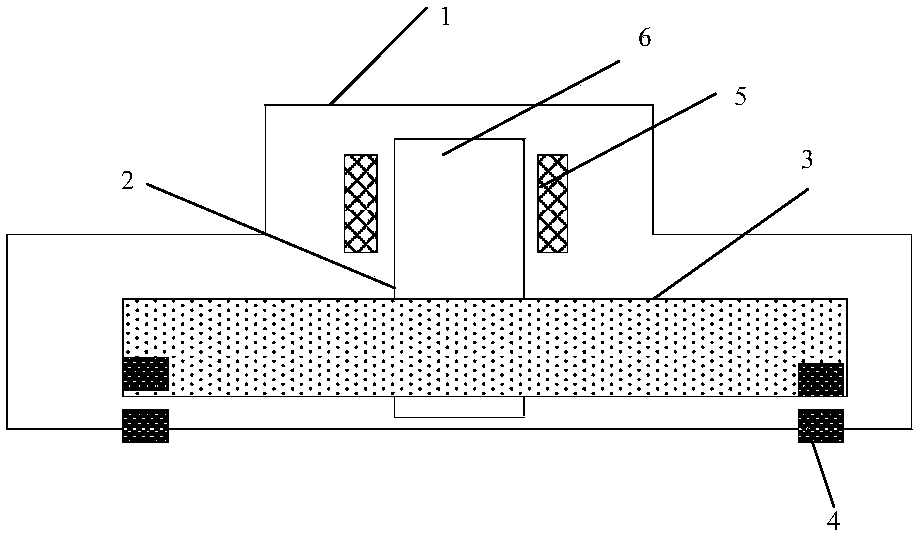

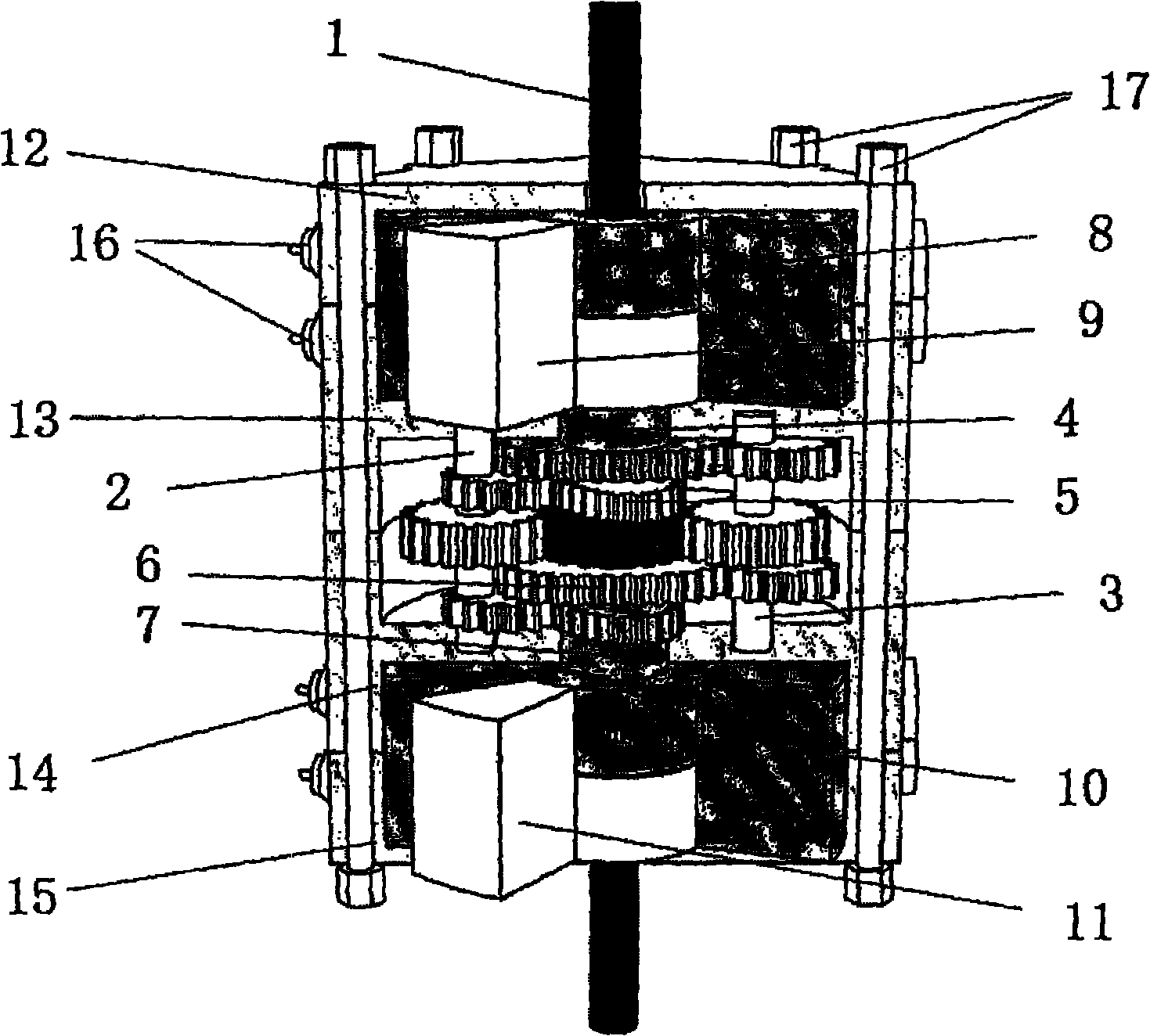

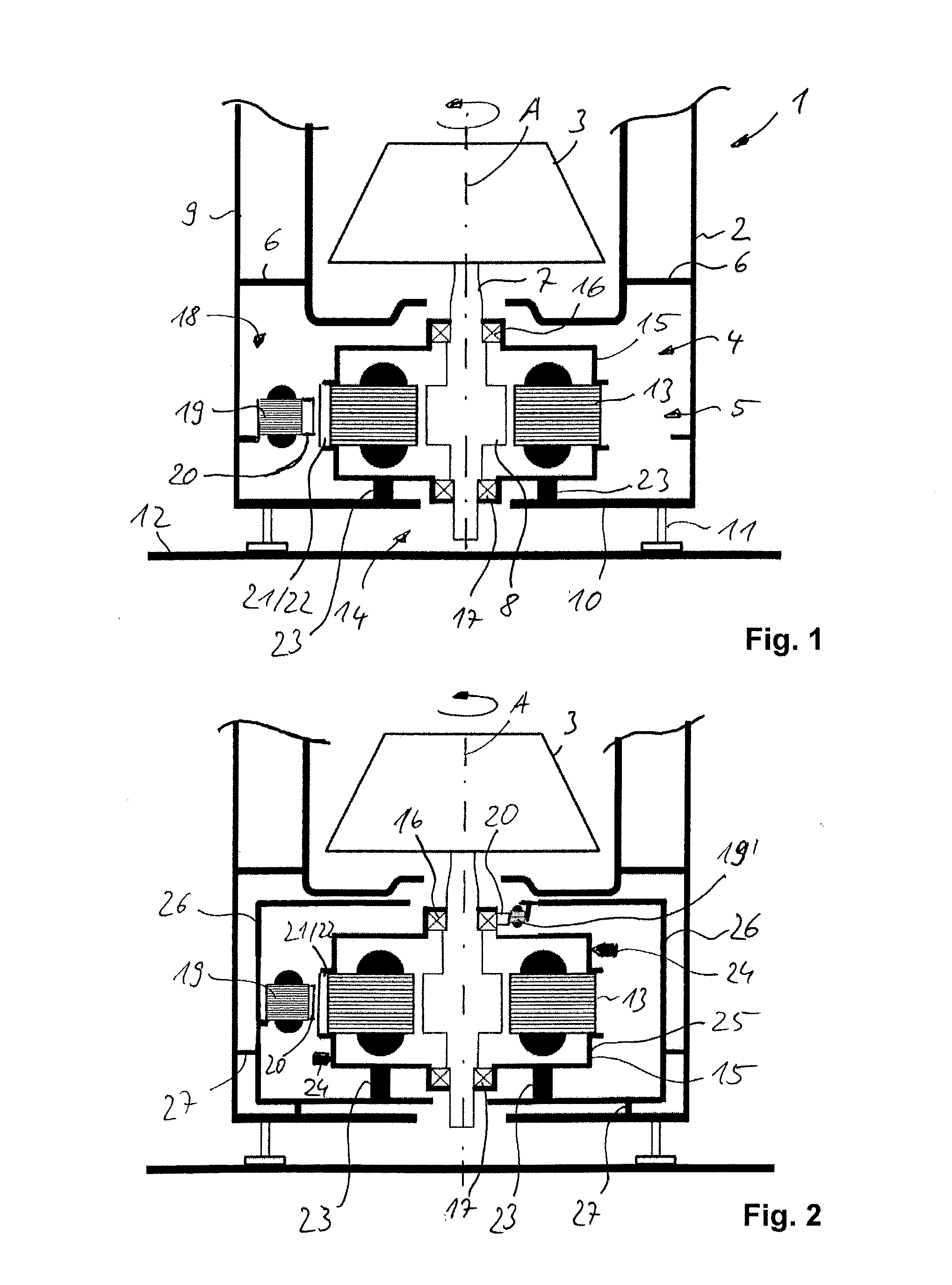

Flywheel energy storage device adopting bearingless switched reluctance motor

InactiveCN102684365AShorten the axial lengthIncrease the critical speedMechanical energy handlingMagnetic holding devicesMagnetic bearingFlywheel energy storage

The invention discloses a flywheel energy storage device adopting a bearingless switched reluctance motor. A permanent magnetic unloading bearing, a bearingless switched reluctance motor, a flywheel rotor and a mixed magnetic bearing are sequentially sleeved between the upper end and the lower end of a flywheel rotating shaft, wherein the permanent magnetic unloading flywheel carries the axial weight of the flywheel rotating shaft; the mixed magnetic bearing on the lower end overcomes the residual weight and the dynamic load of the flywheel rotating shaft, so that the flywheel rotating shaft is guaranteed to be stably suspended in the axial direction, simultaneously two-degree-of-freedom suspension bearing in the radial direction is provided for the flywheel rotating shaft, and the other two-degree-of-freedom suspension and electric function / power generation function in the axial direction are completed by the bearingless switched reluctance motor; and by adopting the high-speed electromotion / power generation running advantage and the self-suspension function of the bearingless switched reluctance motor, the strong unloading characteristic and the controllable suspension characteristic of the permanent magnetic unloading bearing and the mixed magnetic bearing are reasonably combined, so that the five-degree-of-freedom suspension of a flywheel with low loss and high reliability is realized, the running speed of the flywheel is improved, and the system power consumption and the size are reduced.

Owner:JIANGSU UNIV

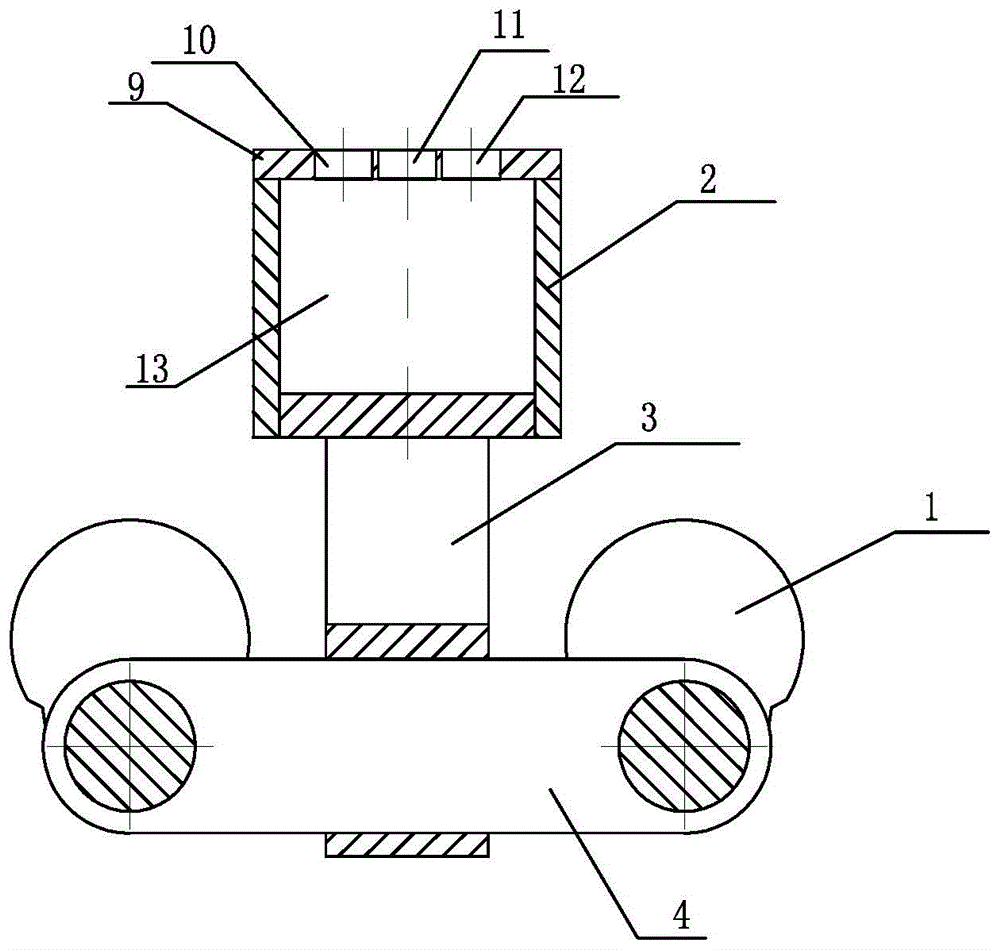

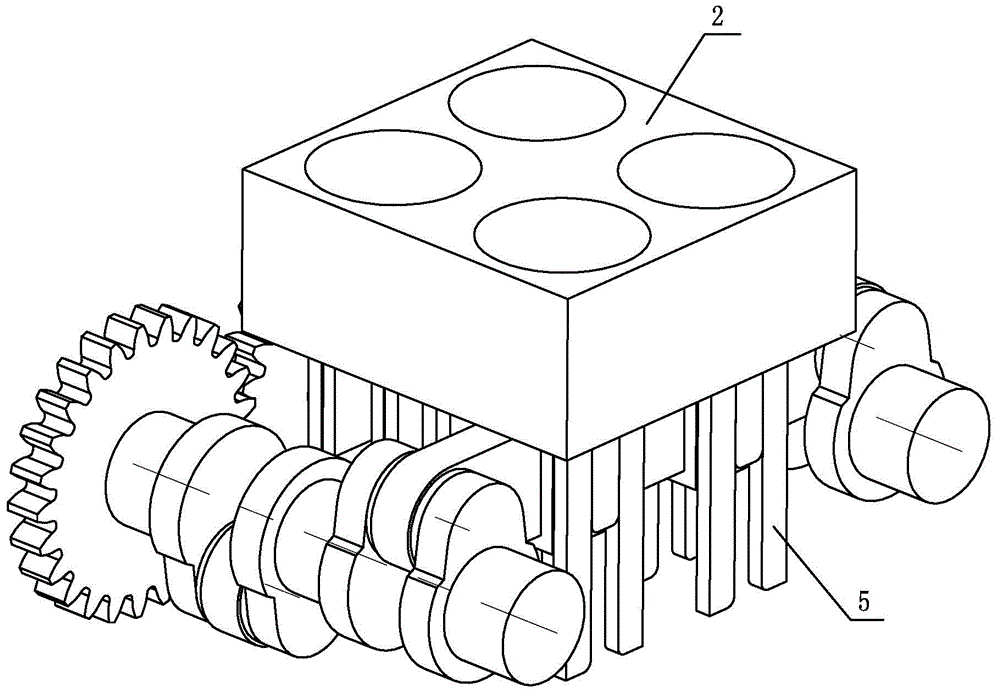

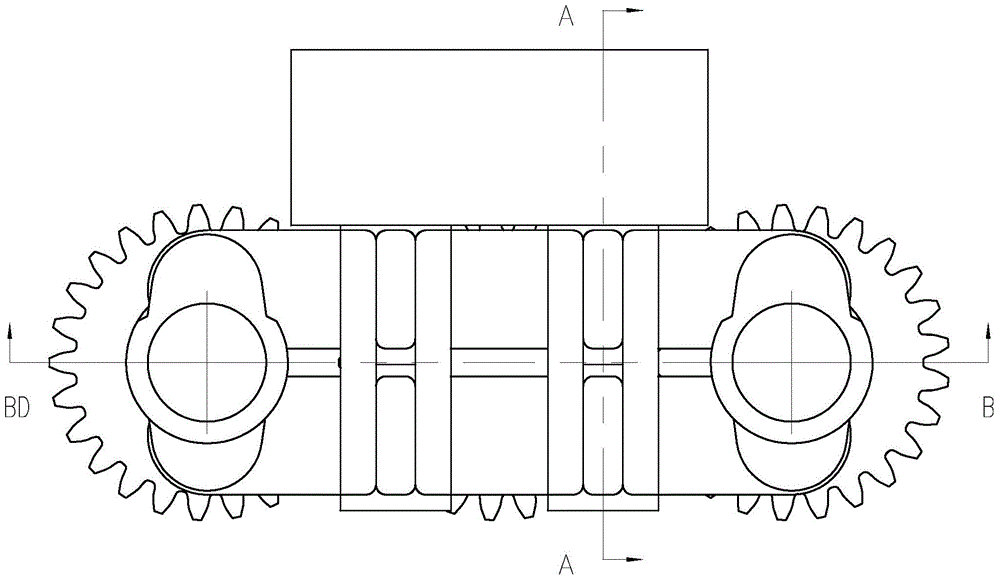

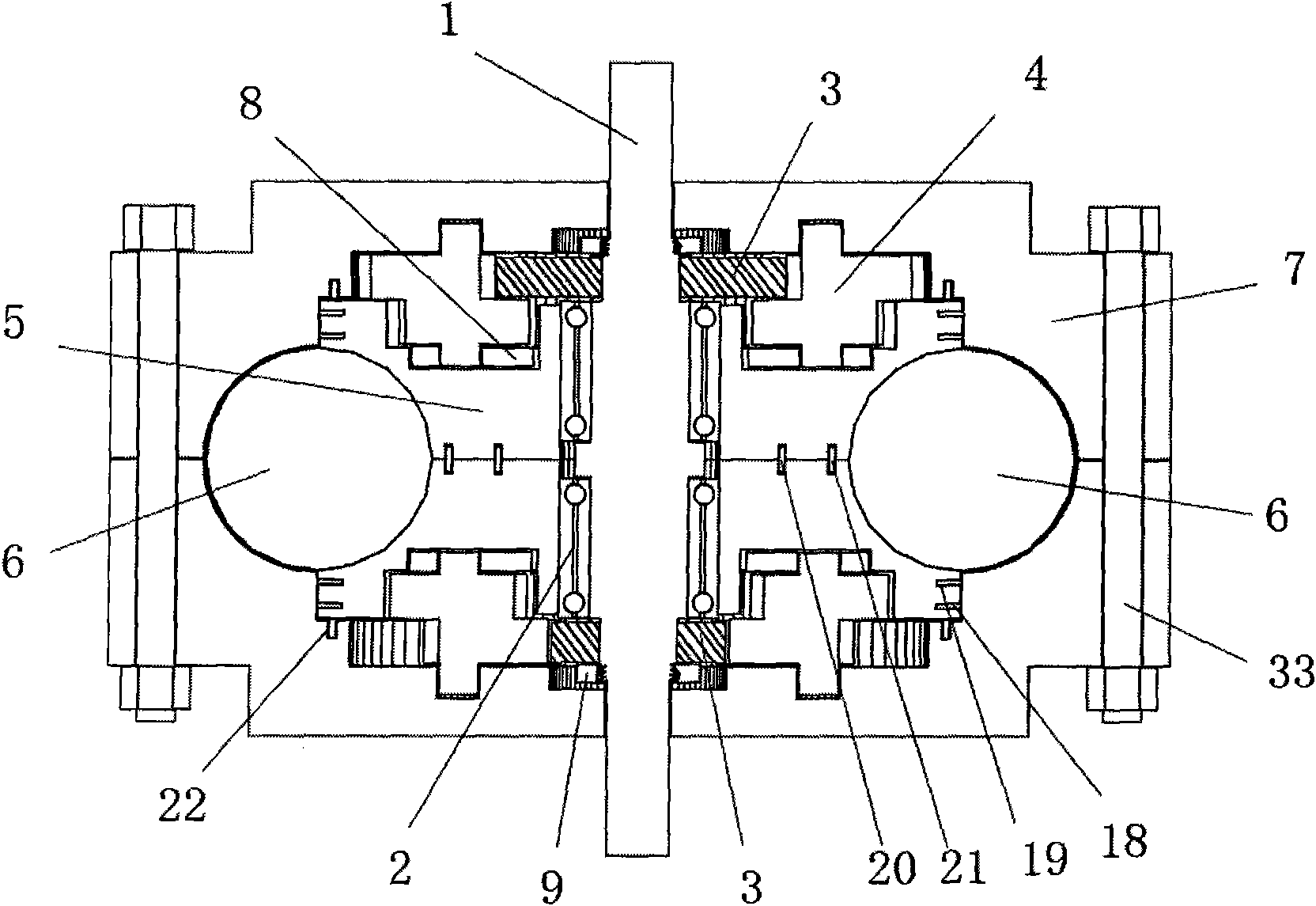

Double-crank mechanism engine

ActiveCN104481689AReduce toughnessReduce manufacturing costCylinder headsCylindersGas cylinderReciprocating motion

The invention discloses a double-crank mechanism engine, belonging to the technical field of engines. The double-crank mechanism engine comprises a gas cylinder and a piston capable of performing straight reciprocating motion in the gas cylinder, wherein two parallel crankshafts are arranged at the two sides of the gas cylinder; a connecting rod is hinged between corresponding crankshaft pins of the two crankshafts to form a double-crank mechanism; a connecting rod insertion slot and a slide block are arranged on a piston rod on the rear end of the piston, the connecting rod is inserted to the connecting rod insertion slot in a sliding manner, a guide block is fixed in the engine; a guide rail for sliding the slide block is formed on the guide block; the slide block is inserted to the guide rail; transmission gears are arranged on the end parts of the crankshafts; an output gear is engaged between the two transmission gears; and an output shaft is arranged on the output gear. The double-crank mechanism engine can be used for effectively lowering the abrasion and the impact of the piston and a cylinder sleeve, improving the reliability of the ceramic material applied to the engine and improving the practical heating efficiency.

Owner:王蓬波

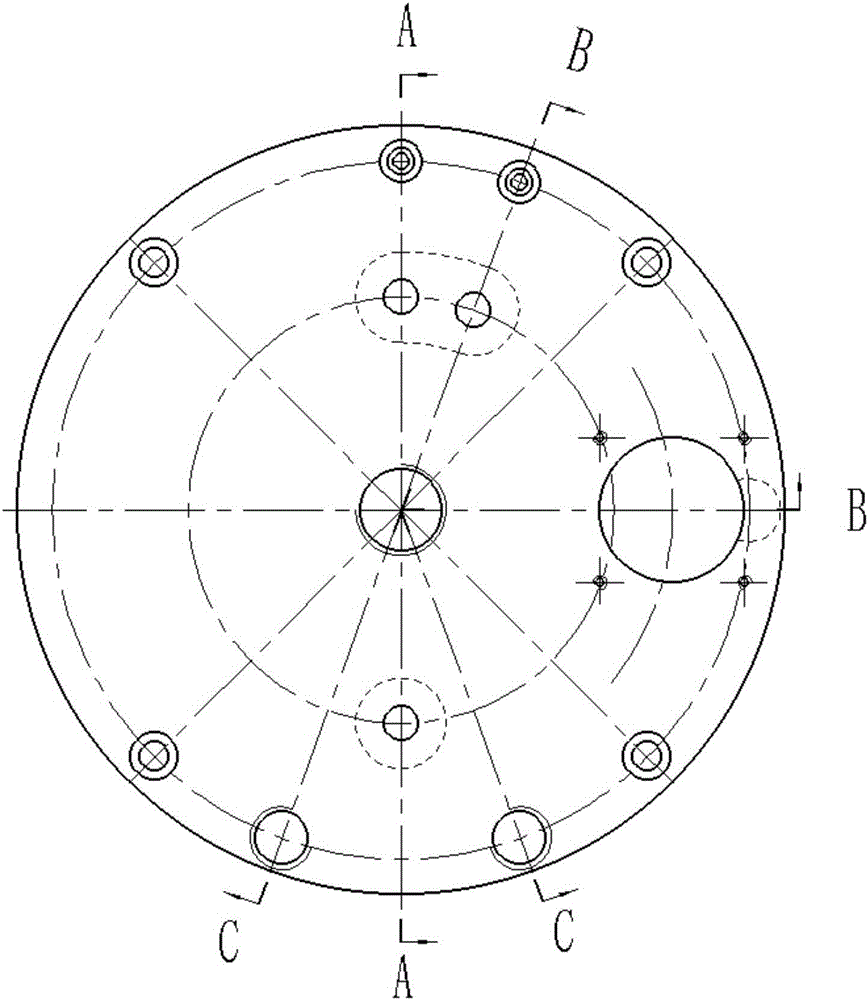

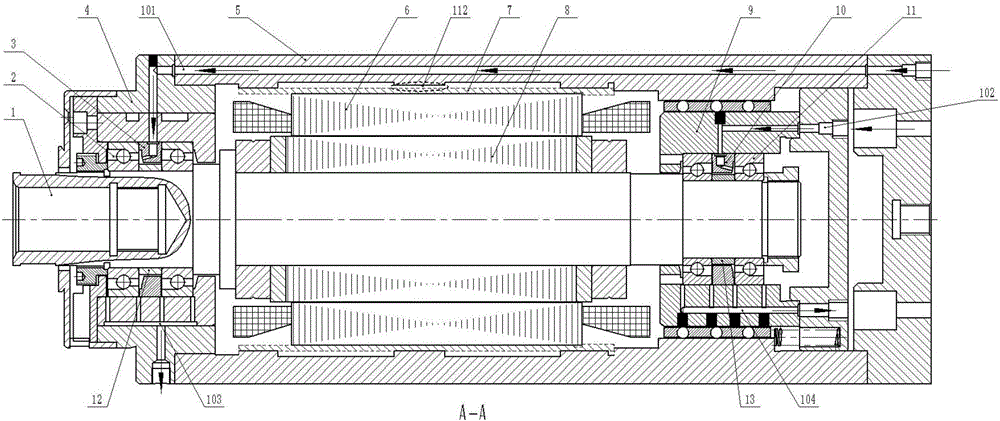

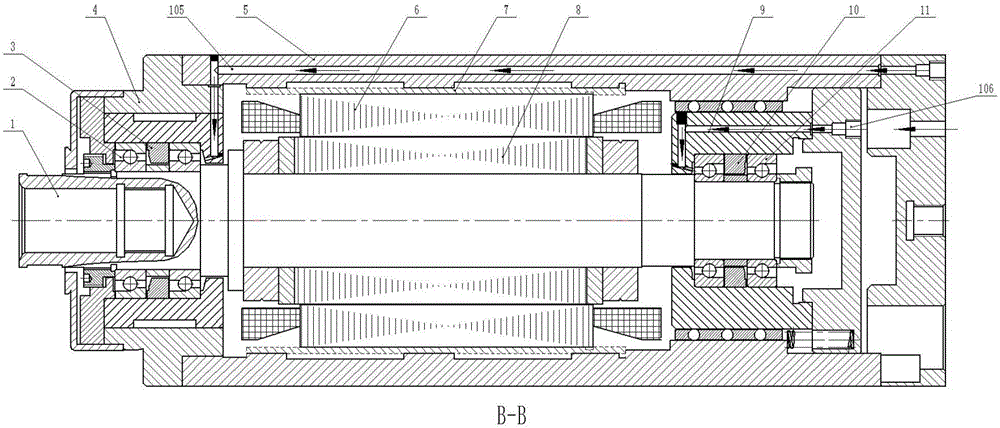

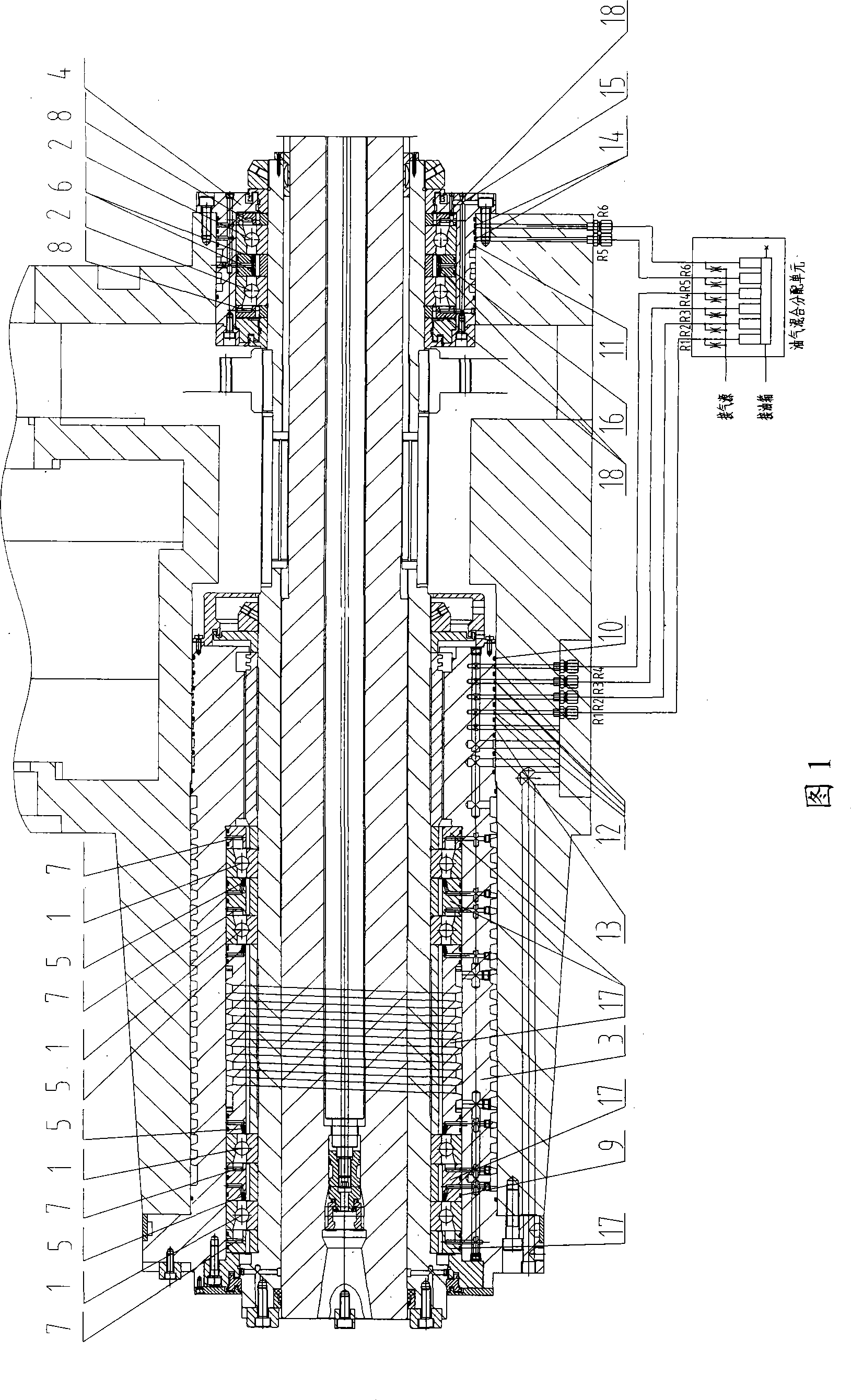

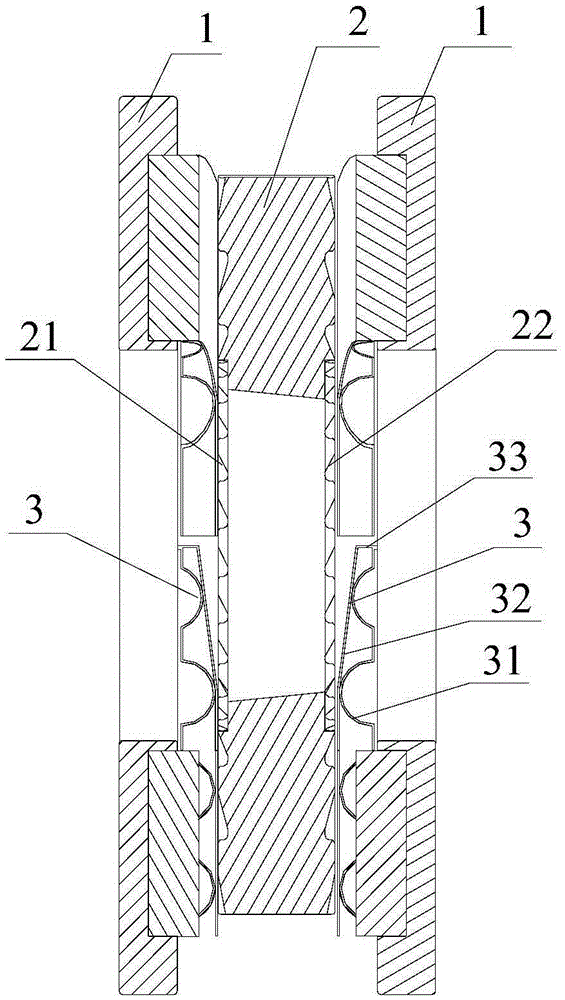

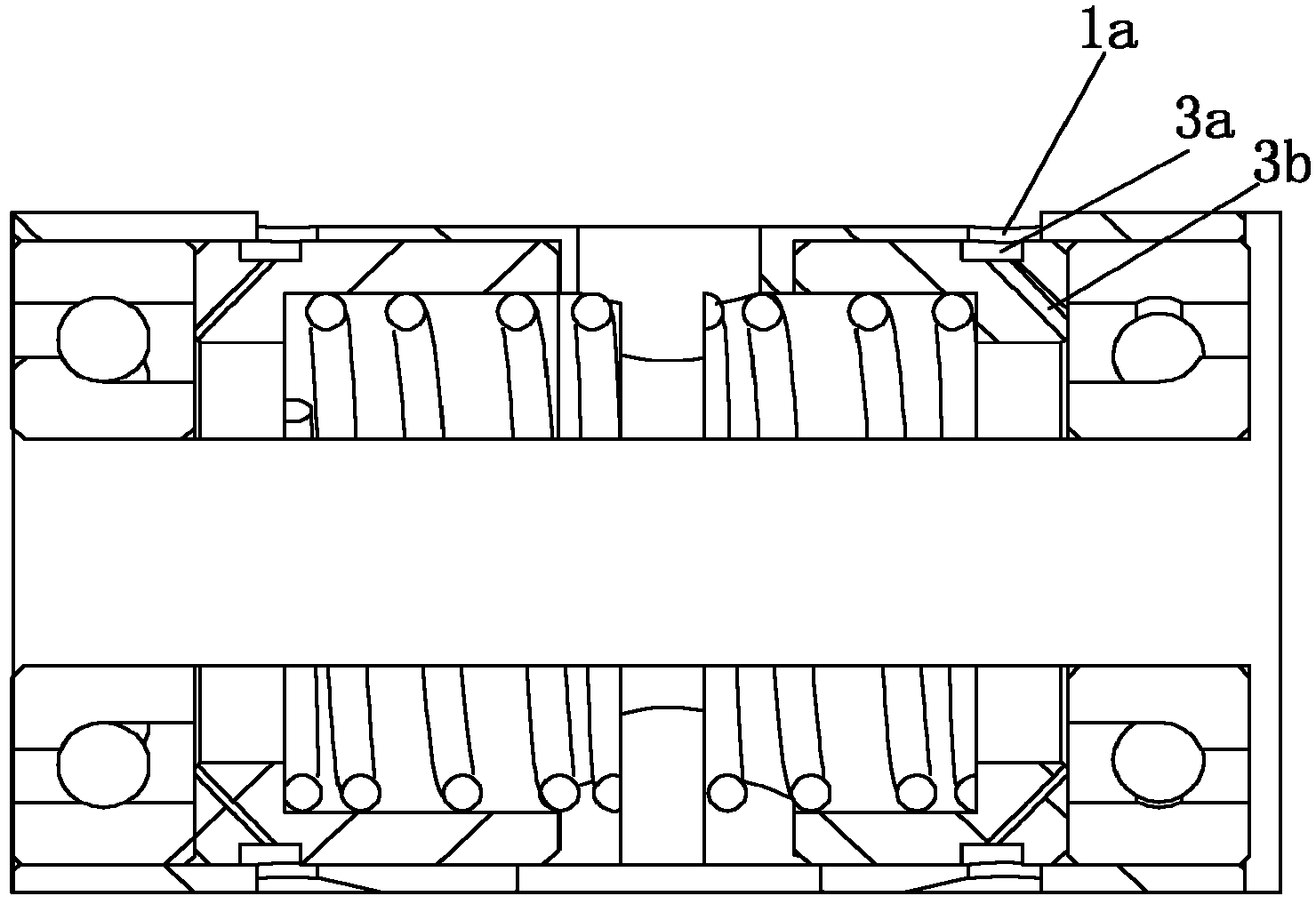

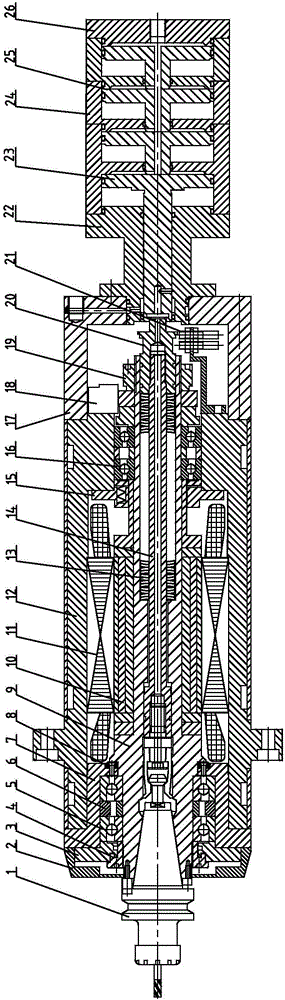

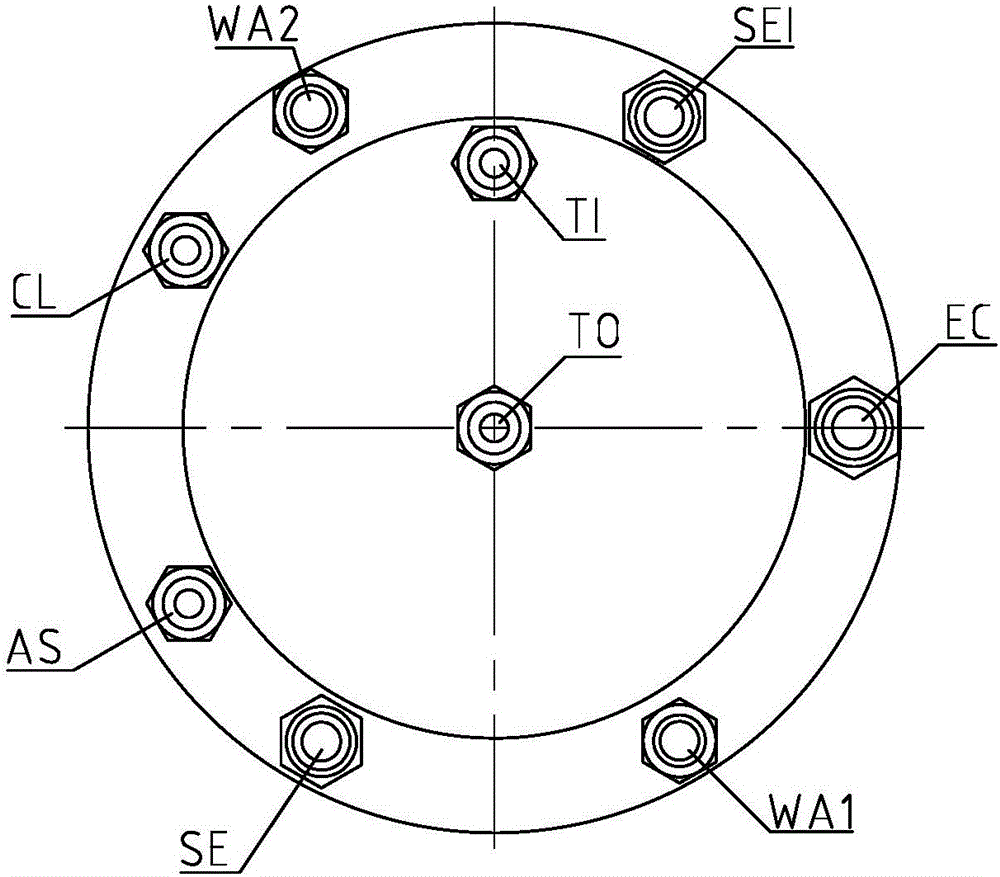

High-speed oil-gas lubrication electric spindle achieving precise oil supplying

ActiveCN106735335AGuaranteed accuracyAchieve reliabilityLarge fixed membersMaintainance and safety accessoriesGas lubricationCentral spindle

The invention discloses a high-speed oil-gas lubrication electric spindle achieving precise oil supplying, and belongs to the technical field of electric spindles. The overall electric spindle comprises a shell, and a stator is fixed in the shell; a front bearing chamber and a back bearing chamber are connected to the two ends of the shell respectively, and two bearings are connected in series in each bearing chamber, wherein the two bearings are separated through an inner bearing isolation pad and an outer bearing isolation pad; a central spindle is supported by the front bearings and the back bearings and provided with a rotor matched with the stator; each bearing is provided with an oil-gas lubrication oil line; annular cooling grooves are formed in the front bearing chamber and the shell respectively; the bearing shell is provided with oil-gas inlets and an oil-gas outlet, an oil-gas pipeline penetrates through the shell, the bearing chambers and the outer bearing isolation pads, the tail end of the pipeline is provided with an oil-gas nozzle, and each bearing is provided with an independent oil delivery line, an independent nozzle and an independent oil return line. Accordingly, by designing the independent oil-gas lubrication oil lines, nozzles and oil return lines, precise control over oil-gas lubrication parameters of the bearings is achieved, the lubricating effect of the bearings is improved, and the performance of the electric spindle is enhanced.

Owner:泰安海纳轴研科技有限公司

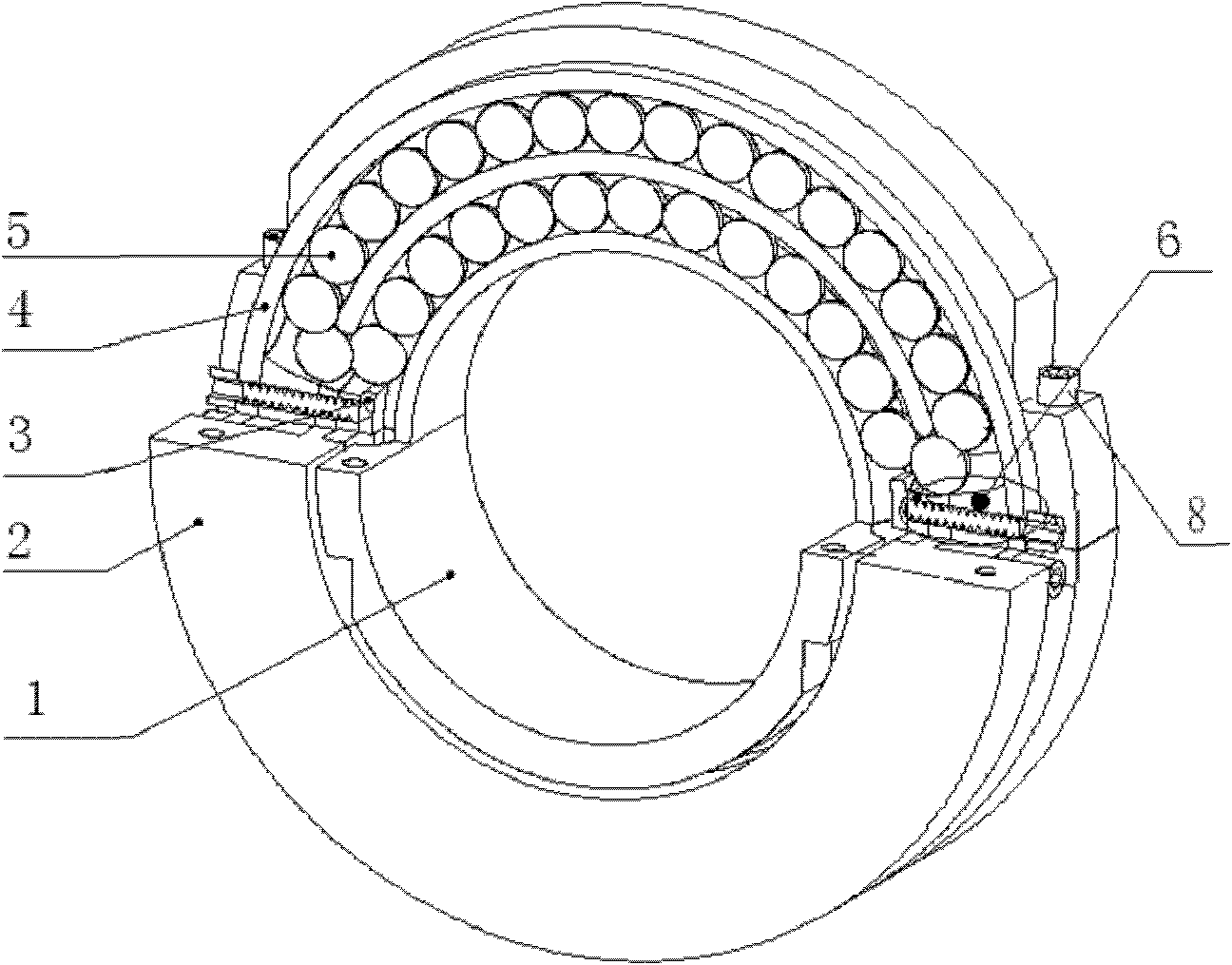

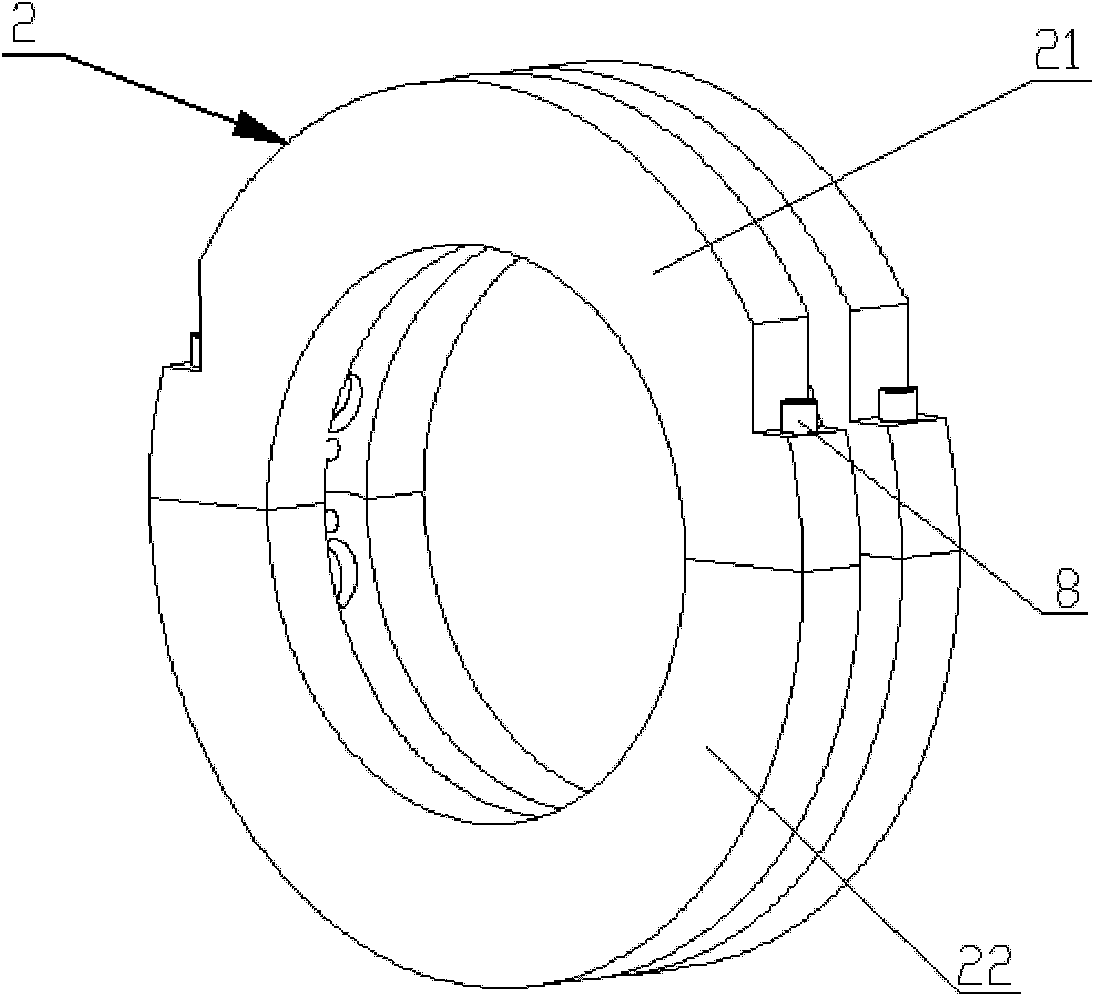

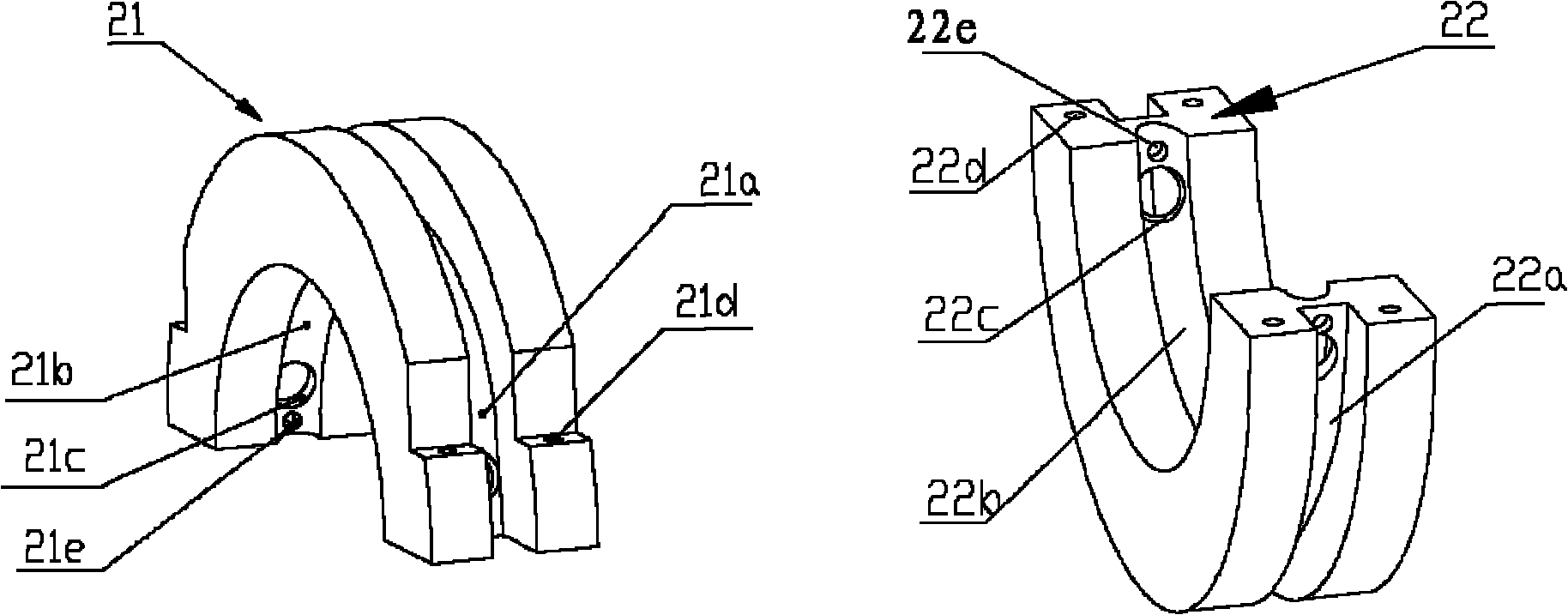

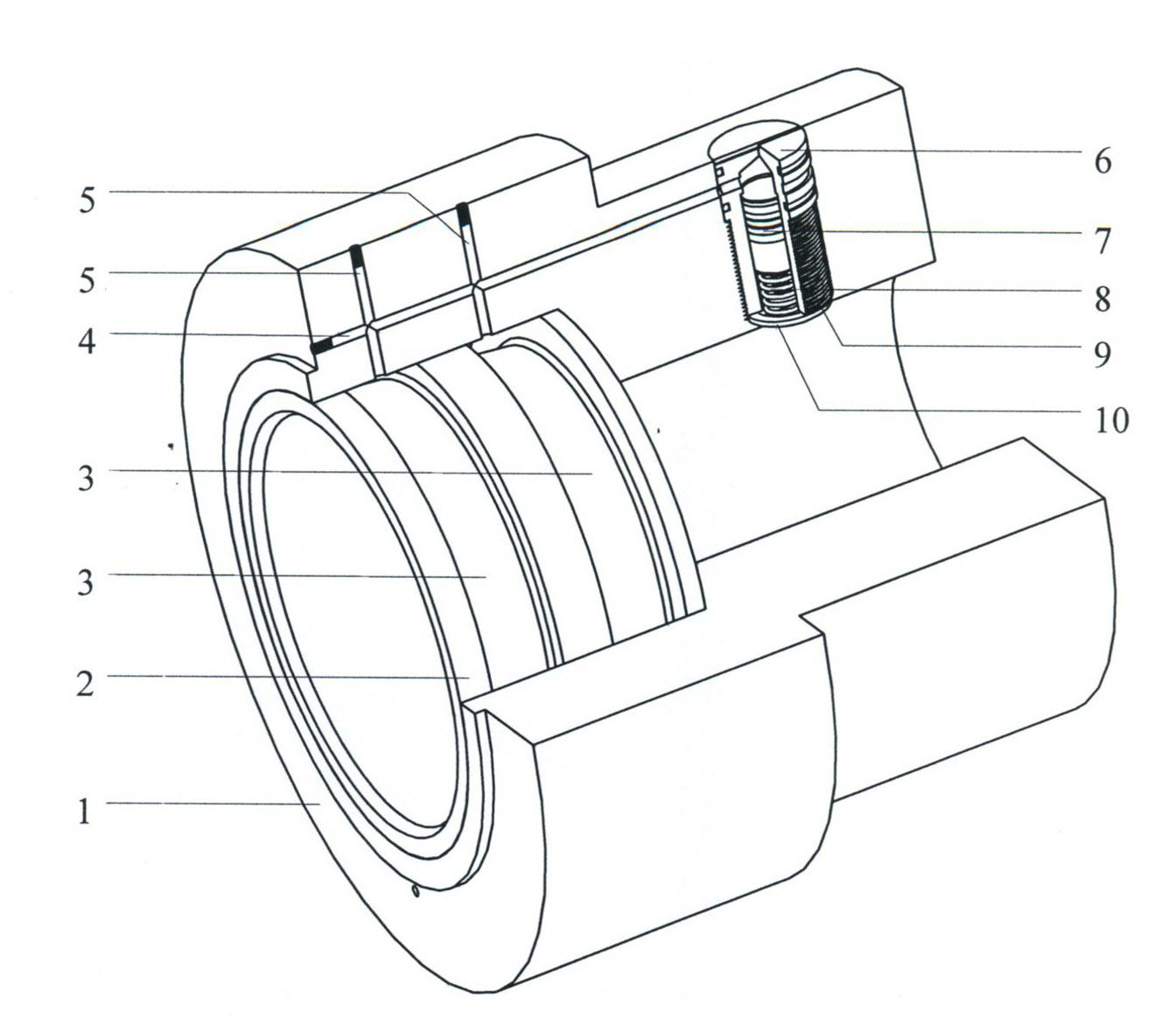

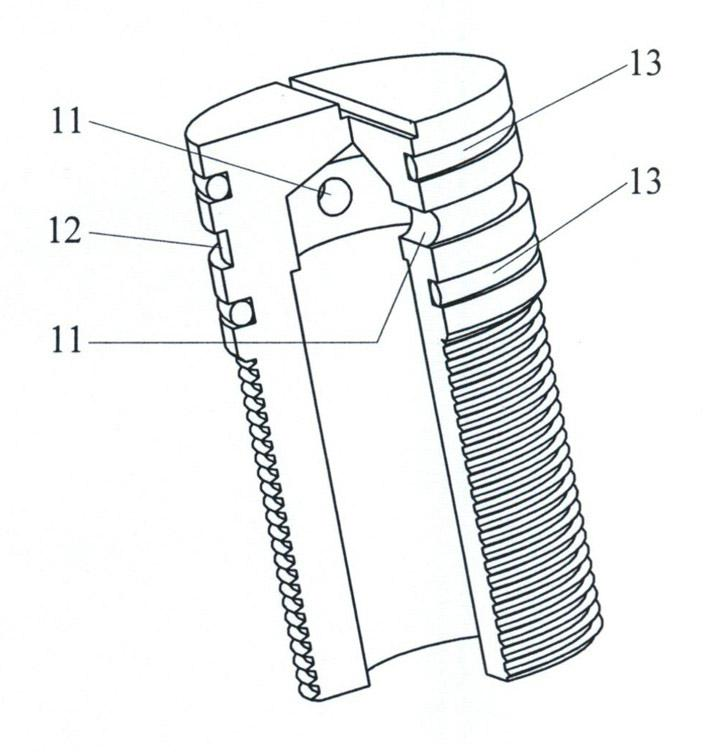

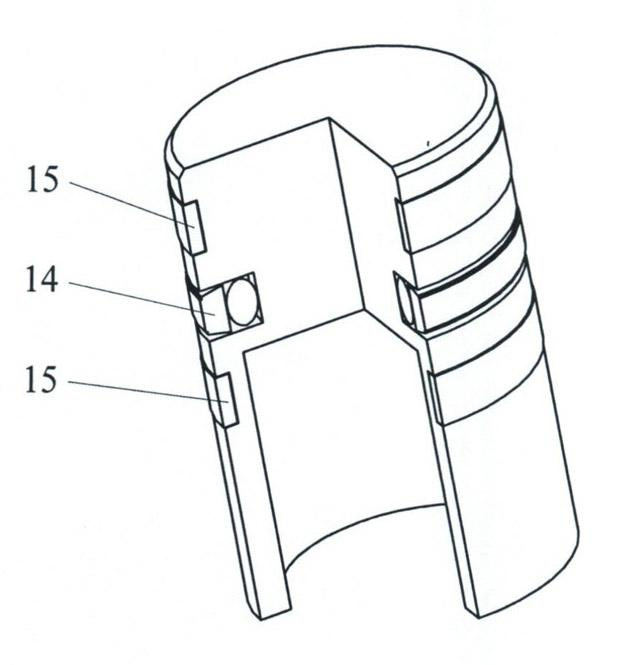

Circulating roller split bearing

InactiveCN101852246AImprove carrying capacityIncrease limit speedRoller bearingsShaftsEngineeringSingle row

The invention discloses a circulating roller split bearing, which comprises bearing bodies, outer rings, rolling bodies, inner check rings, inner rings, reversers, articulation hole bolts and articulation hole screws, the bearing bodies are provided with circular outer grooves and circular inner grooves, the inner check rings, the outer rings and the inner rings are semi-circular, each reverser comprises a screw, an outer check block and an inner check block, and the inner grooves, both through holes and outer grooves of the bearing bodies, the inner rings, the inner check rings, the outer rings and the reversers are formed into a double-layered through hollow frame in which the rolling bodies can directionally and circularly move. Positioning is accurate, the cage is dispensed with, the structure is simple, the number of bearing force points is large, the limit speed and the bearing capability are increased, the service life of the bearing is prolonged, and the circulating rolling bodies can be arranged in a single row or a plurality of rows, and can be balls, cylindrical rollers or tapered rollers.

Owner:武汉华瑞阳光新能源科技有限公司

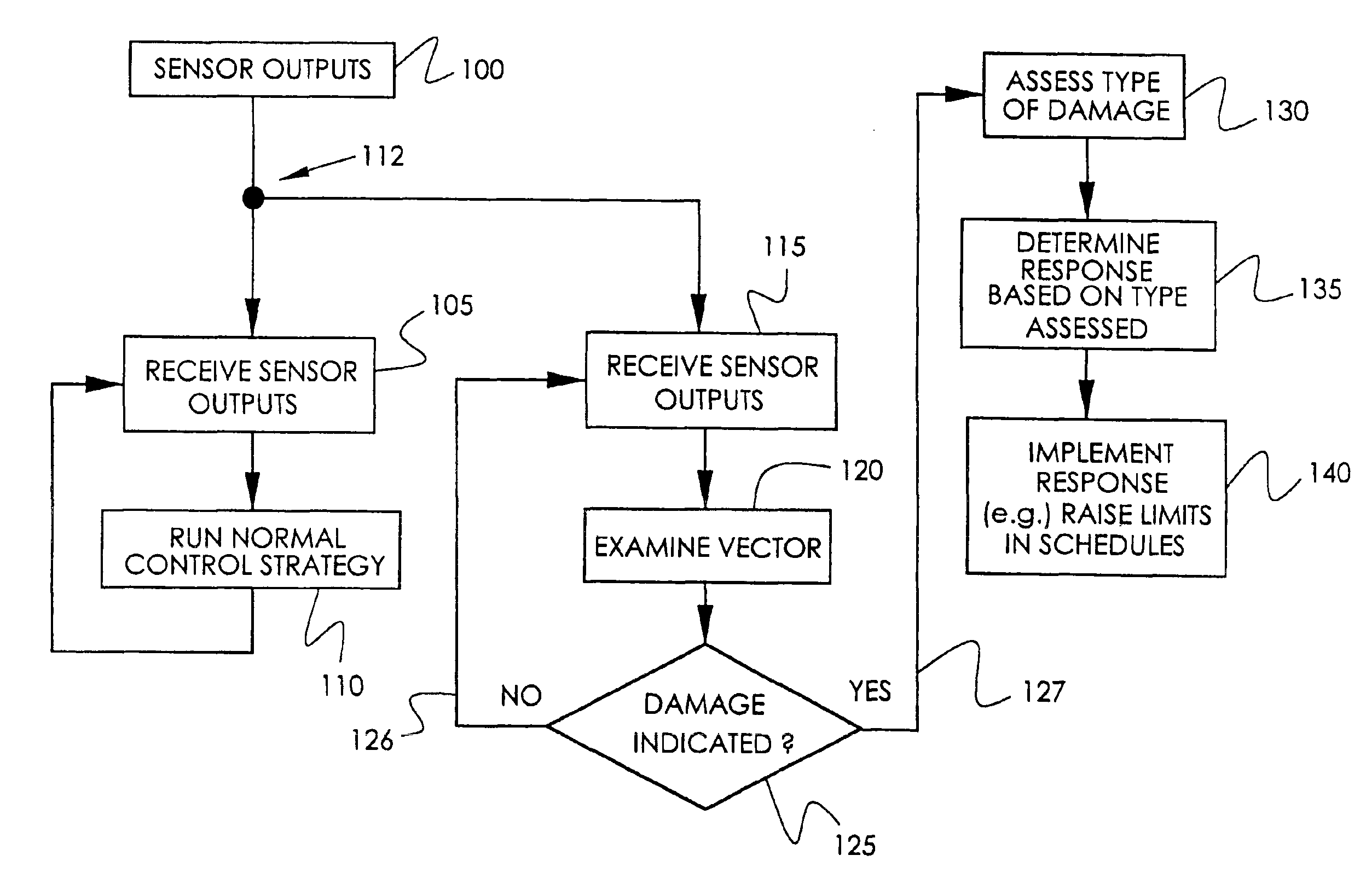

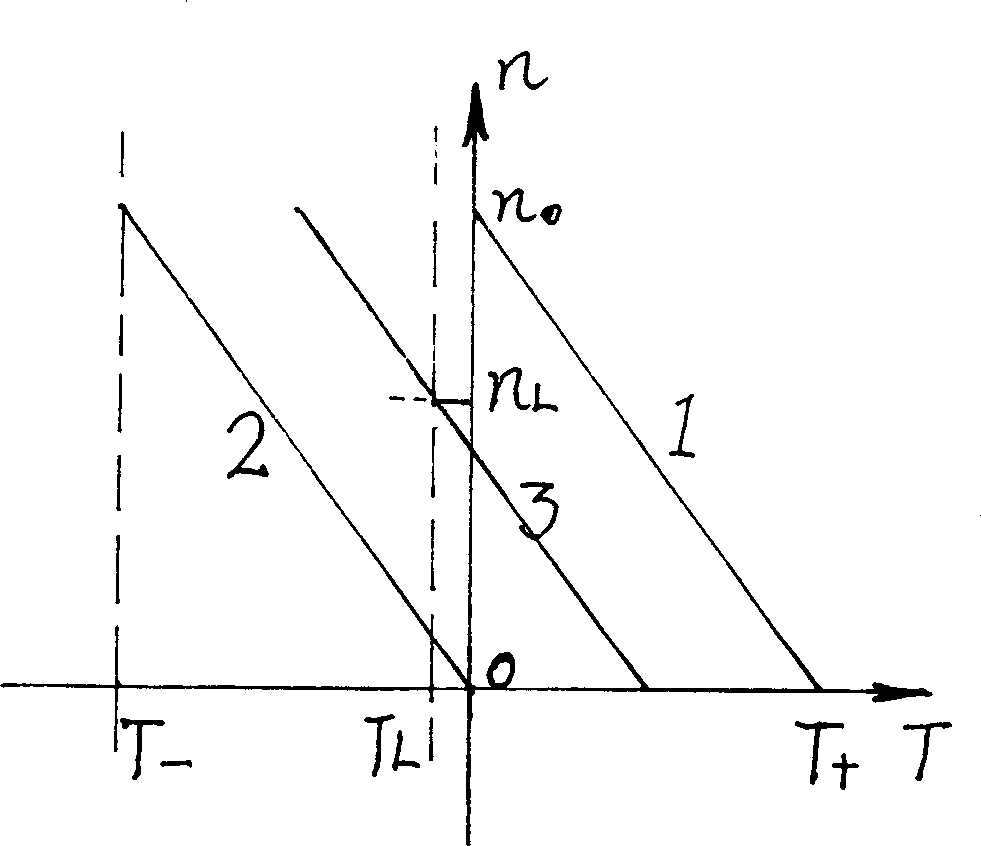

Control strategy for gas turbine engine

InactiveUS6860712B2Increase limit speedLifetime can be consumedWind motor controlPump componentsTurbineGas turbines

A control strategy for a gas turbine engine which exchanges future lifetime of the engine for present thrust. Gas turbine engines, such as those used in aircraft, sometimes incur damage, as when they ingest birds, or are struck with ballistic objects fired by an enemy. The invention detects the damage, and invokes a control strategy wherein the engine is operated in a more harsh manner, thereby sacrificing a significant part of the remaining lifetime of the engine, in order to obtain thrust currently.

Owner:GENERAL ELECTRIC CO

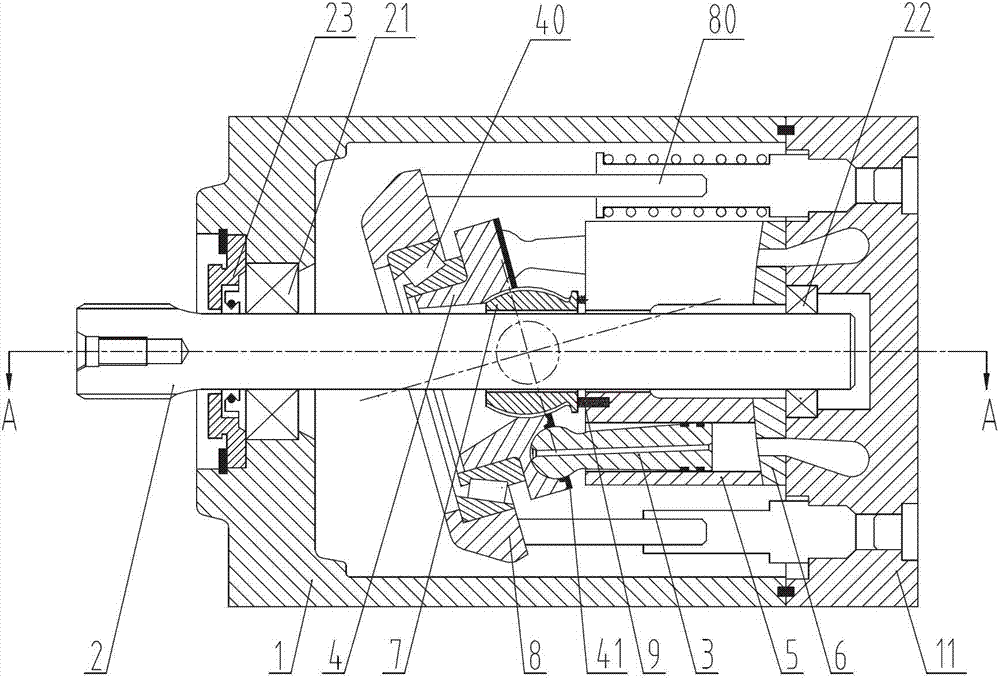

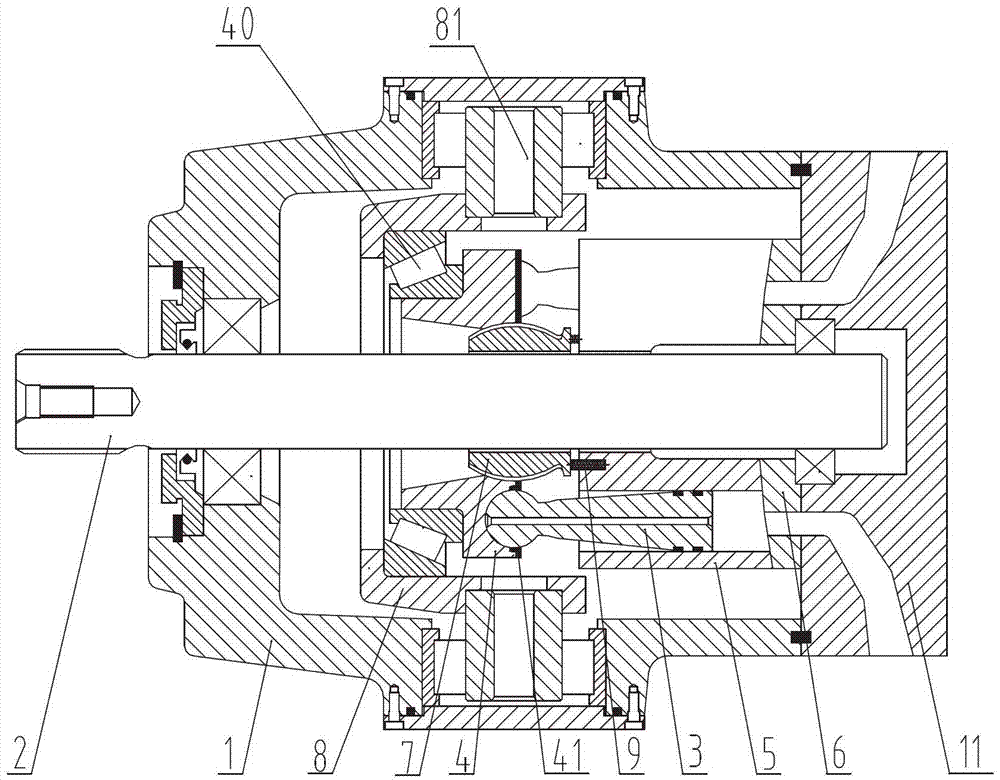

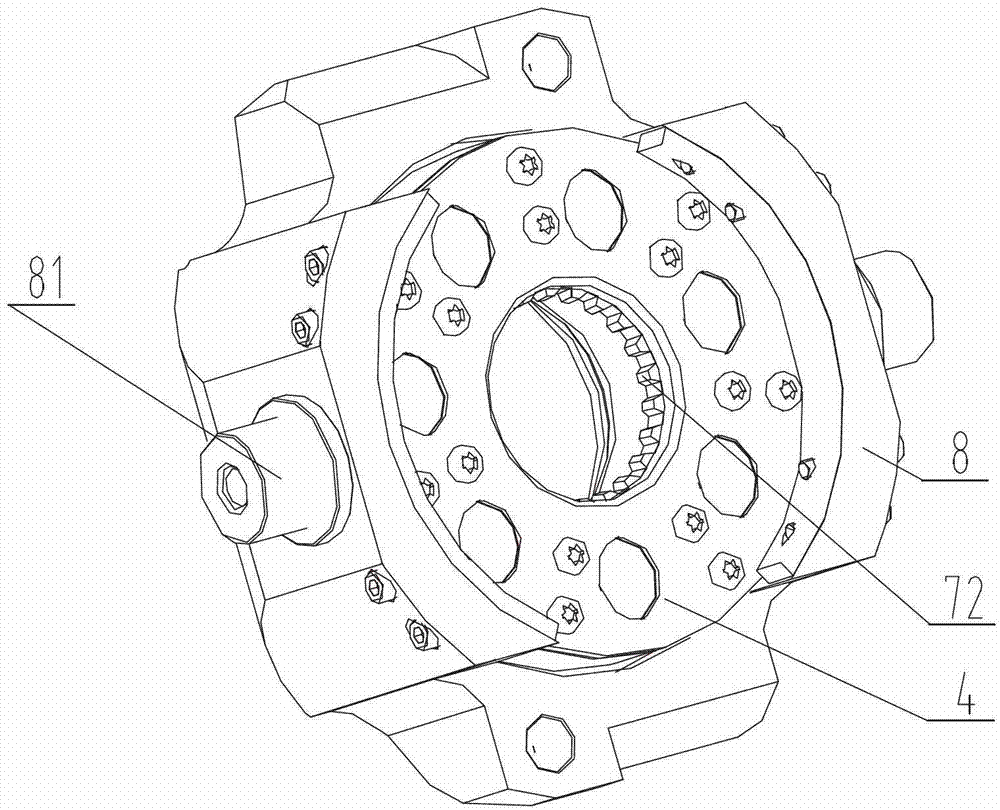

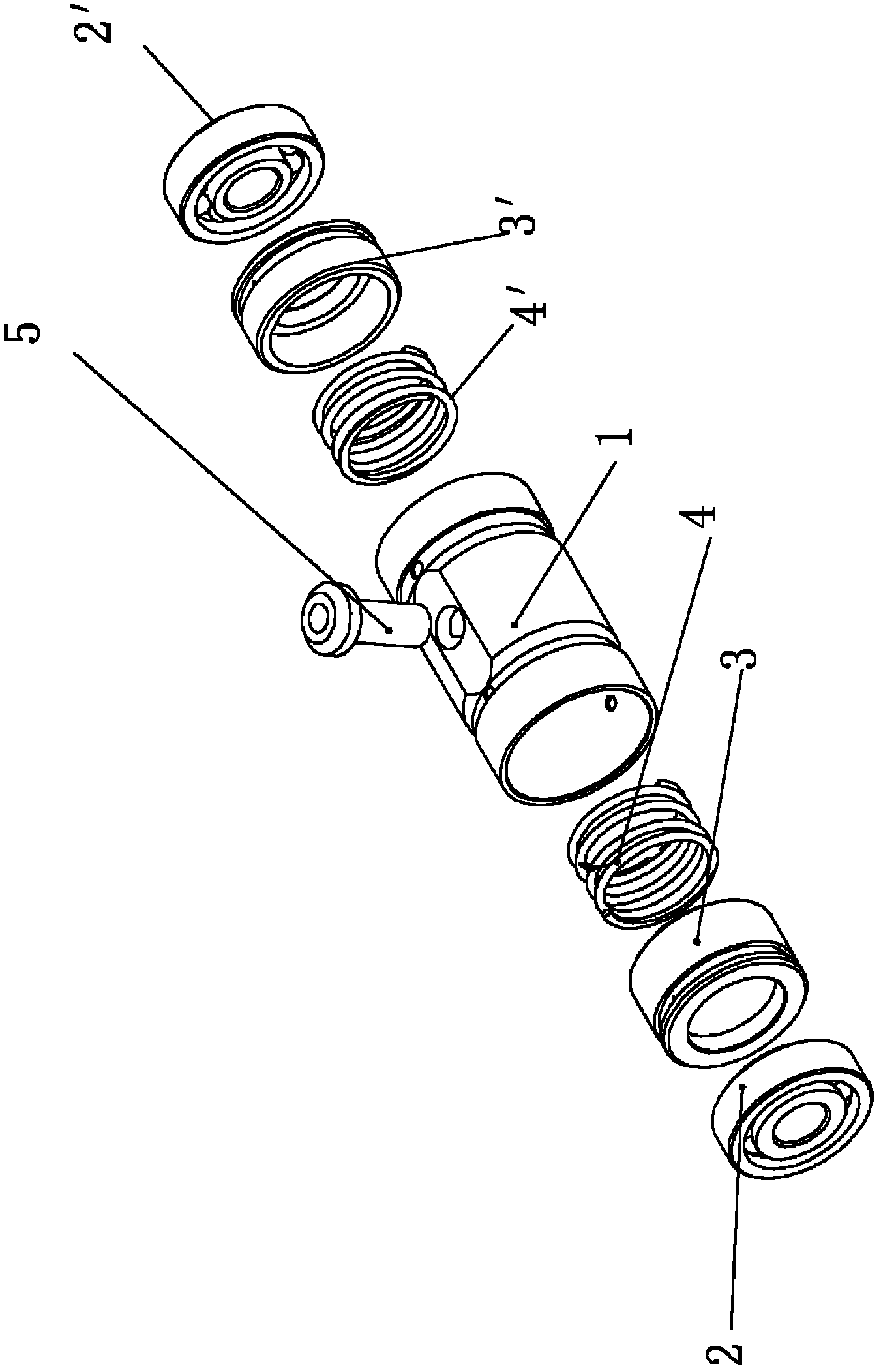

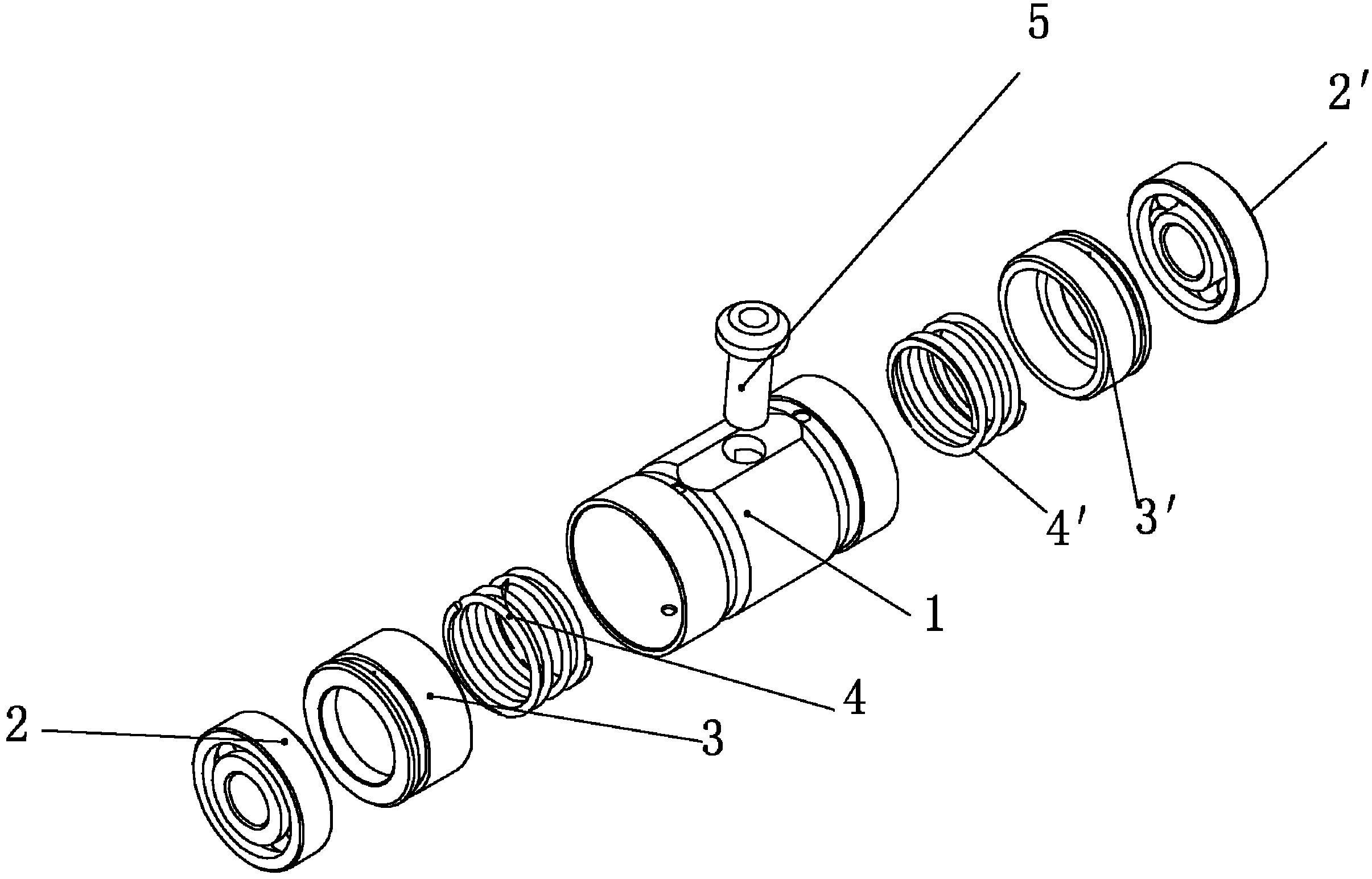

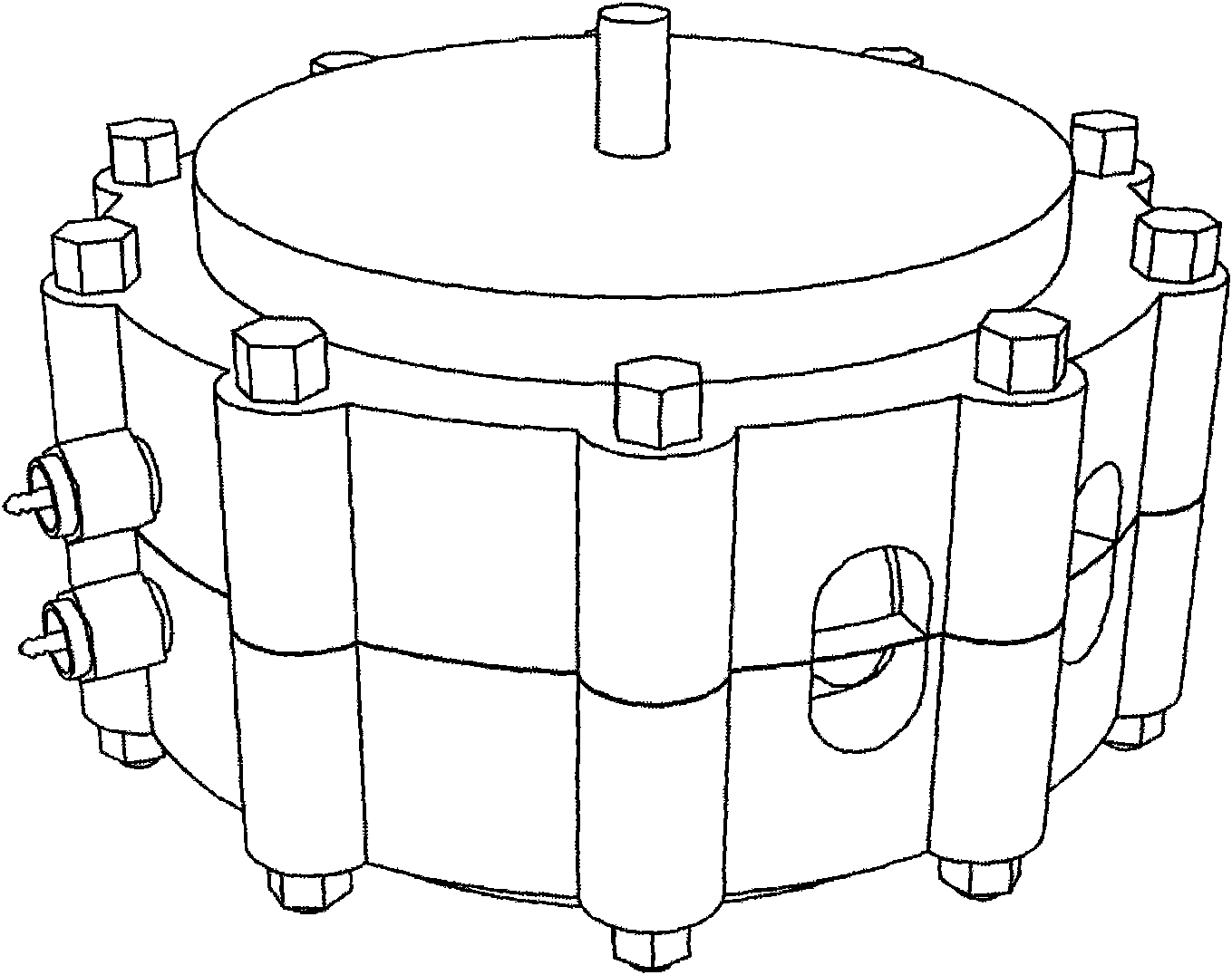

Swash plate type axial piston pump or motor

ActiveCN102926959AReduce Assembly MatesRequirements for lower machining accuracyPositive-displacement liquid enginesMulti-cylinder pumpsPlunger pumpTransmission line

The invention provides a swash plate type axial piston pump or a motor, which comprises a shell, a main shaft, a plurality of piston components, a swash plate, a cylinder, a distributive flow disk and a connecting part, wherein the connecting part comprises a first part and a second part which relatively swing, the first part is combined with the main shaft and synchronously rotates with the main shat, the swash plate is combined with the second part and synchronously rotates with the second part, a cylindrical inner hole is arranged on the center of the cylinder, the main shaft stretches into the cylindrical inner hole, the main shaft and the cylindrical inner hole are matched, and when the main shat rotates, the cylinder is driven by the piston components to rotate. The main shaft and the cylinder of the swash plate type axial piston pump can form clearance fit, the transmission line of the swash plate type axial piston pump is the main shaft, the connecting part, the swash plate, the piston components and the cylinder, and the swash plate type axial piston pump has the advantages of excellent assembly, high total efficiency and small lateral force, and can achieve the advantages of coaxial or through-shaft connection and the like.

Owner:SANY HEAVY IND CO LTD (CN)

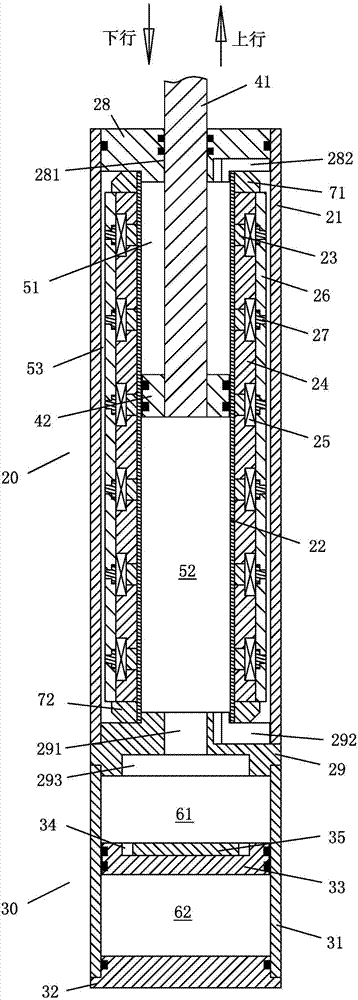

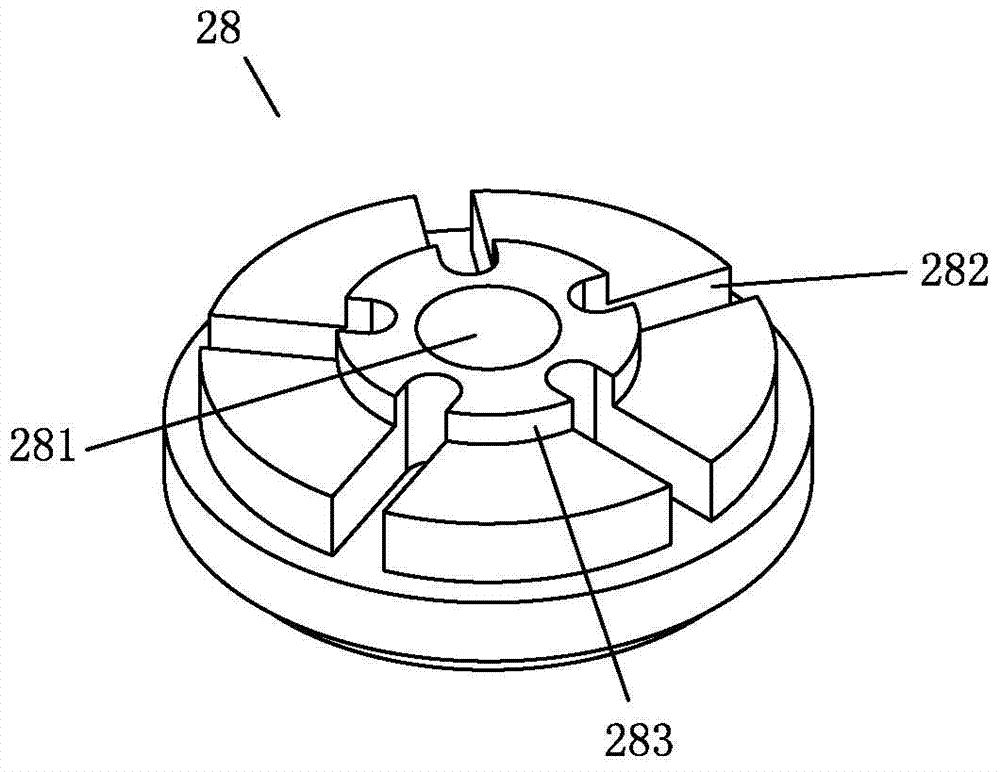

Magneto-rheological damper

ActiveCN104747649AIncrease limit speedExtended dwell timeSpringsNon-rotating vibration suppressionMagnetActive control

The invention discloses a magneto-rheological damper. The magneto-rheological damper comprises a damping cylinder and a compensating cylinder which are connected vertically. The damping cylinder comprises an outer cylinder, wherein an inner cylinder is arranged in the outer cylinder, the outer wall of the inner cylinder is alternatively sleeved with magnet yoke rings and a permanent magnet ring; a magnet exciting coil winds in an annular groove formed by adjacent magnet yoke rings and the permanent magnet ring between them; the magnet yoke rings and the magnet exciting coil are externally and alternatively sleeved with flux sleeve rings and magnet isolating sleeve rings; an annular damping channel is formed among the flux sleeve rings, the magnet isolating sleeve rings, and the inner wall of the outer cylinder; the upper and lower end openings of the outer cylinder are equipped with upper and lower end covers, and the inner cylinder is provided with a damping piston for dividing a damping cavity inside into upper and lower cavities; the upper and lower cavities are interconnected with the damping channel. The compensating cylinder comprises a cylinder body, wherein the upper end opening of the cylinder body is connected with the lower end cover, and the lower end opening of the cylinder body is equipped with the end cover; a compensating cavity forms in the cylinder body, and the cylinder body is provided with a floating piston for dividing the compensating cavity into fluid and gas cavities; the fluid cavity is interconnected with the lower cavity. The magneto-rheological damper solves the contradiction of adjustable damping force and adjustable multiple of the existing magneto-rheological damper, and is especially applicable to half-active control of an impact vibrating system.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

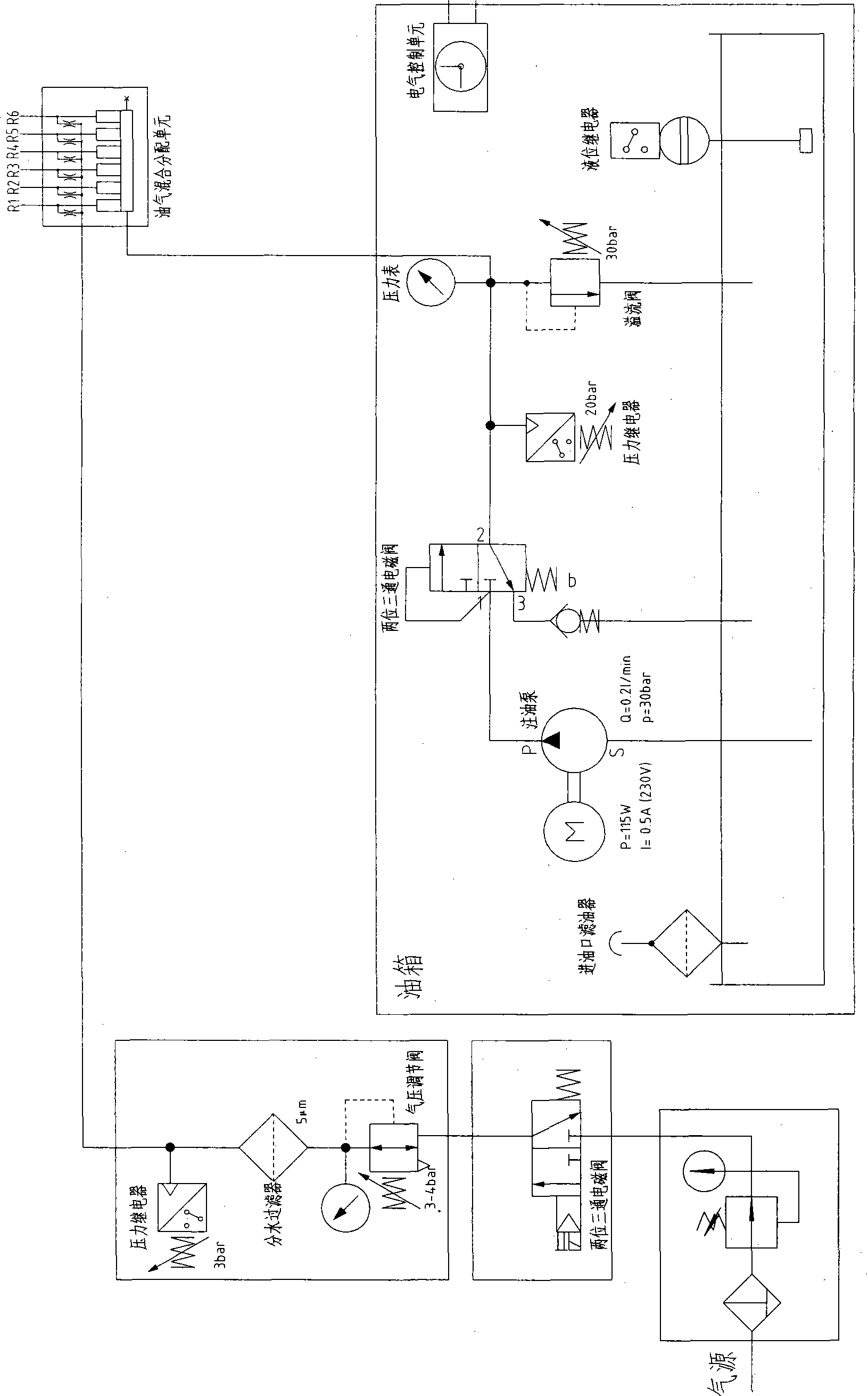

Large-size horizontal machining-center high-speed main-axle oil gas lubricating system

InactiveCN101362300ALow calorific valueSlow heatingMaintainance and safety accessoriesGas lubricationControl signal

The invention relates to an oil-gas lubrication system for a high speed main shaft in a large scale horizontal machining center. The oil-gas lubrication is adopted for the high speed main shaft with the diameter of large than 160 mm, and an external gas source and an external oil tank are arranged. The oil-gas lubrication system is characterized in that the system is composed of an oil-gas generating device and an oil-gas delivery mechanism, wherein, the lubrication circulation and the operation of an oil-filling pump are controlled through the program of an electric control unit inside the oil-gas generating device, the electric control unit is connected with the control system of a machining center through a connecting terminal, and the output of a control signal and the remote control of the oil-gas lubrication are realized; the gas source pipeline of the oil-gas generating device and the oil tank are respectively provided with an inductor and a pressure valve, and the pump is communicated with an oil-gas mixing and distribution unit inside the oil-gas generating device; a plurality of delivery pipelines of the oil-gas mixing and distribution unit are respectively connected with an oil-gas connector arranged at the bottom of a main shaft box, the oil-gas connector is communicated with an oil-gas channel on the bearing sleeve of the main shaft and the oil-gas channel on an annular outer sleeve gasket, and an oil-gas circulation delivery channel from entering the main shaft to being discharged out of the main shaft is formed. The friction coefficient between the inner / outer sleeve gasket and balls of the bearing system can be as low as 0.001 or even lower, simultaneously, the bearing of the main shaft is ensured to run in the required temperature range, the self control design can also ensure that once the running of the lubrication system is abnormal, the automatic shutdown of the machine tool can be implemented.

Owner:ZHONGJIE MACHINE TOOL

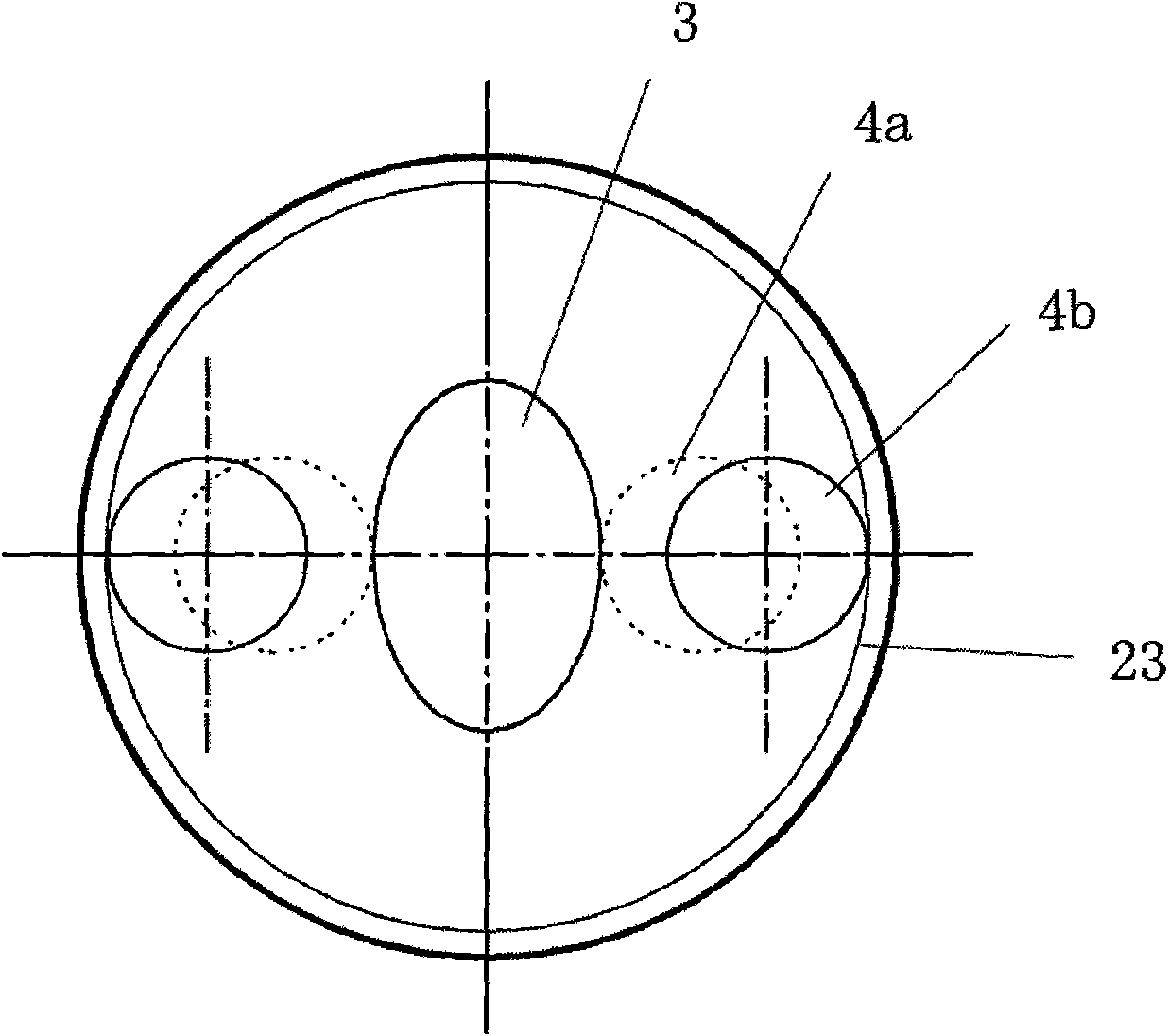

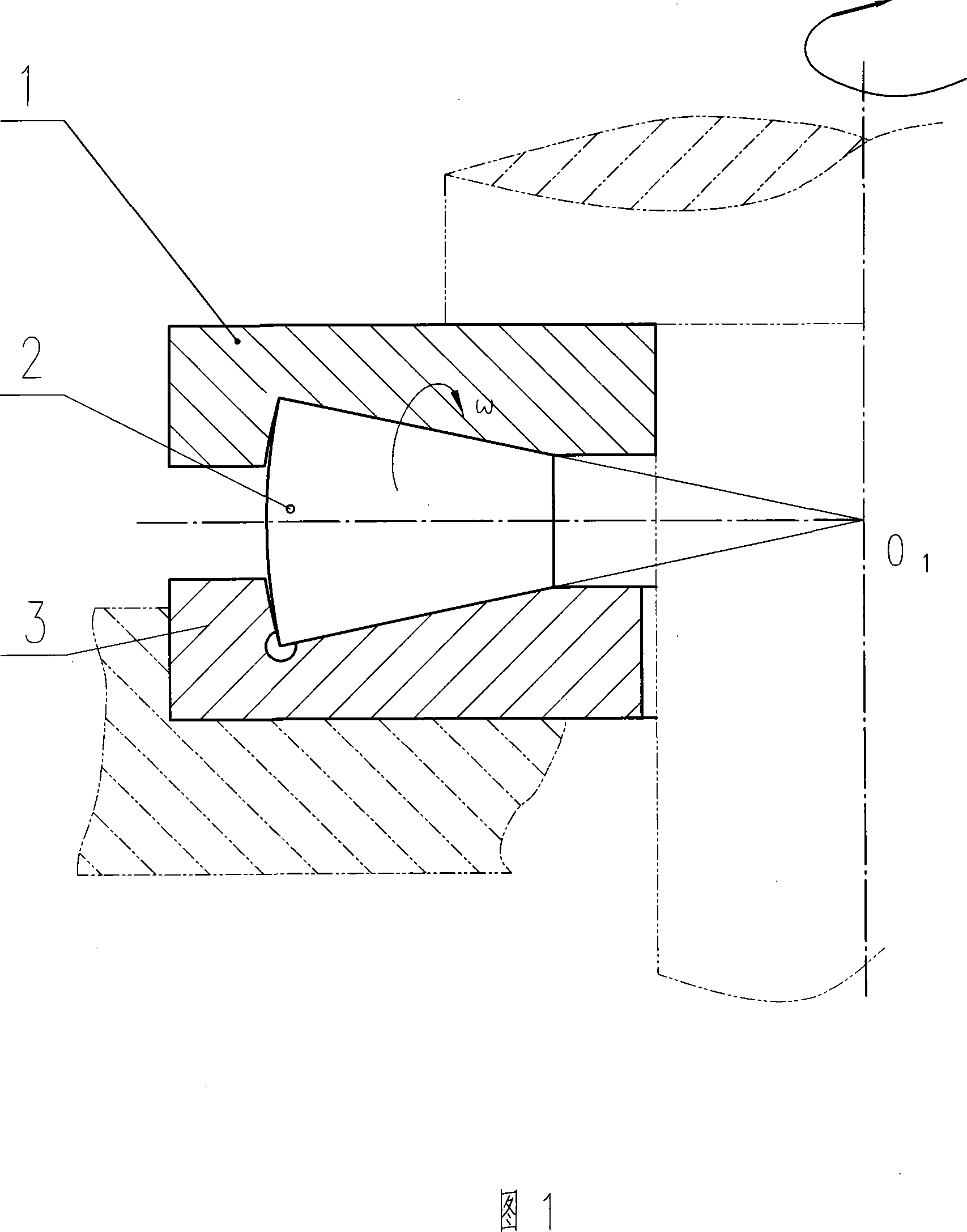

Hybrid type dynamic pressure gas thrust bearing

The invention discloses a hybrid type dynamic pressure gas thrust bearing. The hybrid type dynamic pressure gas thrust bearing comprises two outer plates. An inner plate is arranged between the two outer plates in a clamped mode. A foil type elastic piece is arranged between each outer plate and the inner plate. The two end faces of the inner plate are each provided with groove type patterns of the regular shapes. The groove type patterns on one end face are in mirror symmetry with the groove type patterns on the other end face. The hybrid type dynamic pressure gas thrust bearing has the rigid characteristic of the high limit speed of a groove type dynamic pressure gas journal bearing and has the flexible characteristics of the high impact resistance and the high loading capacity of a foil type dynamic pressure gas journal bearing, and the hybrid type dynamic pressure gas journal bearing can be applied in the ultrahigh-speed field of large loads.

Owner:罗立峰

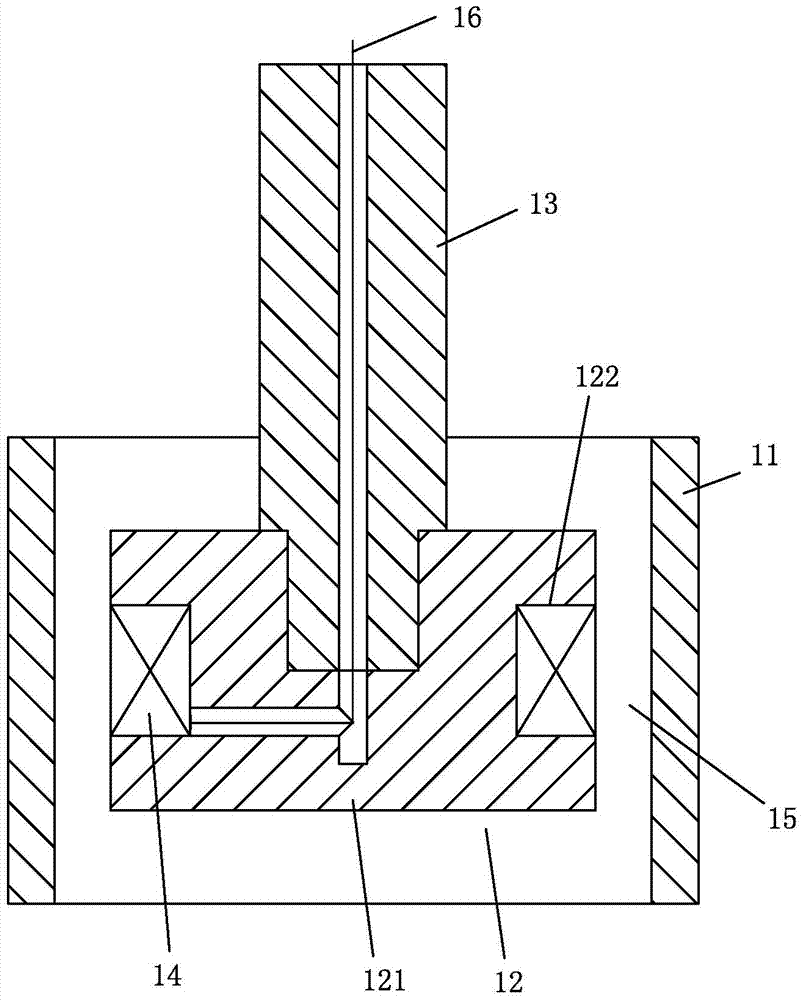

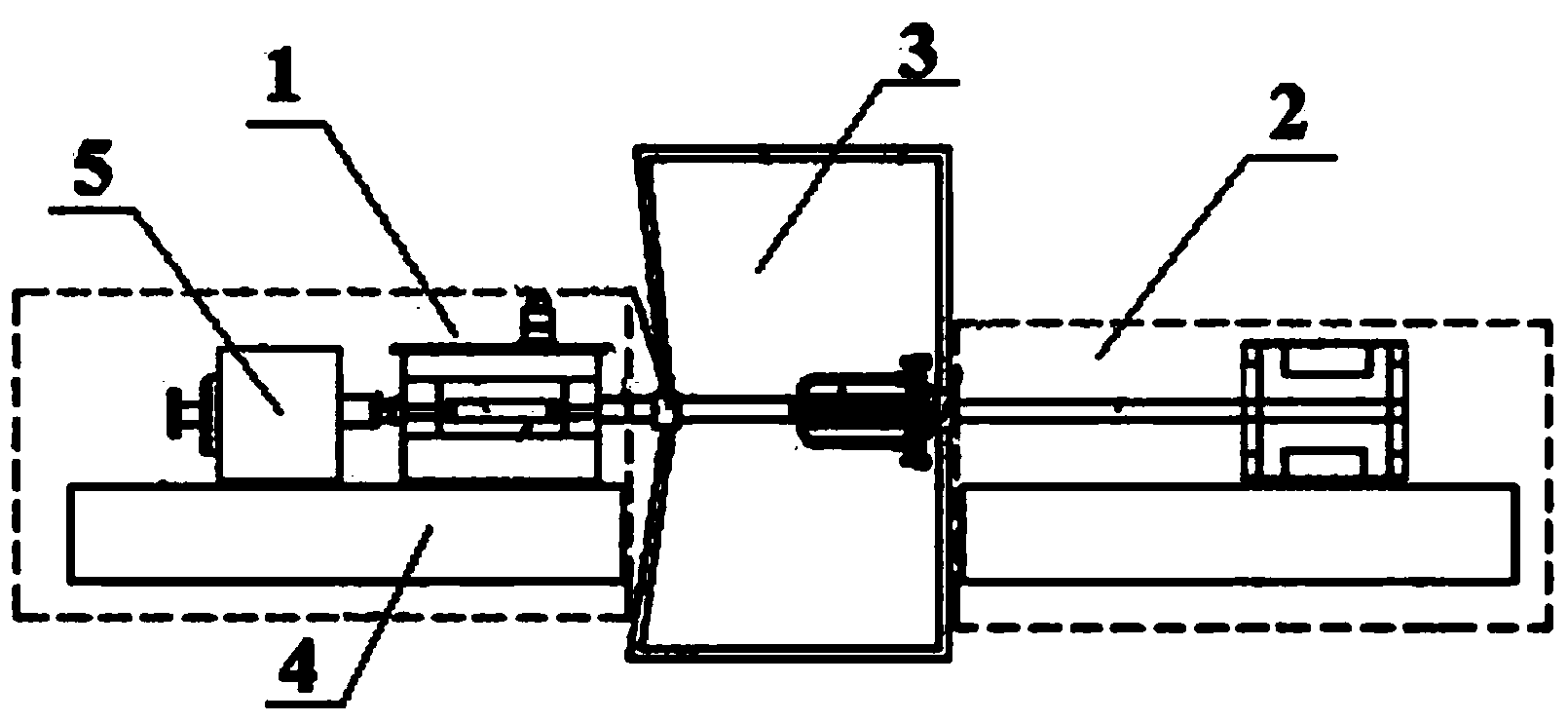

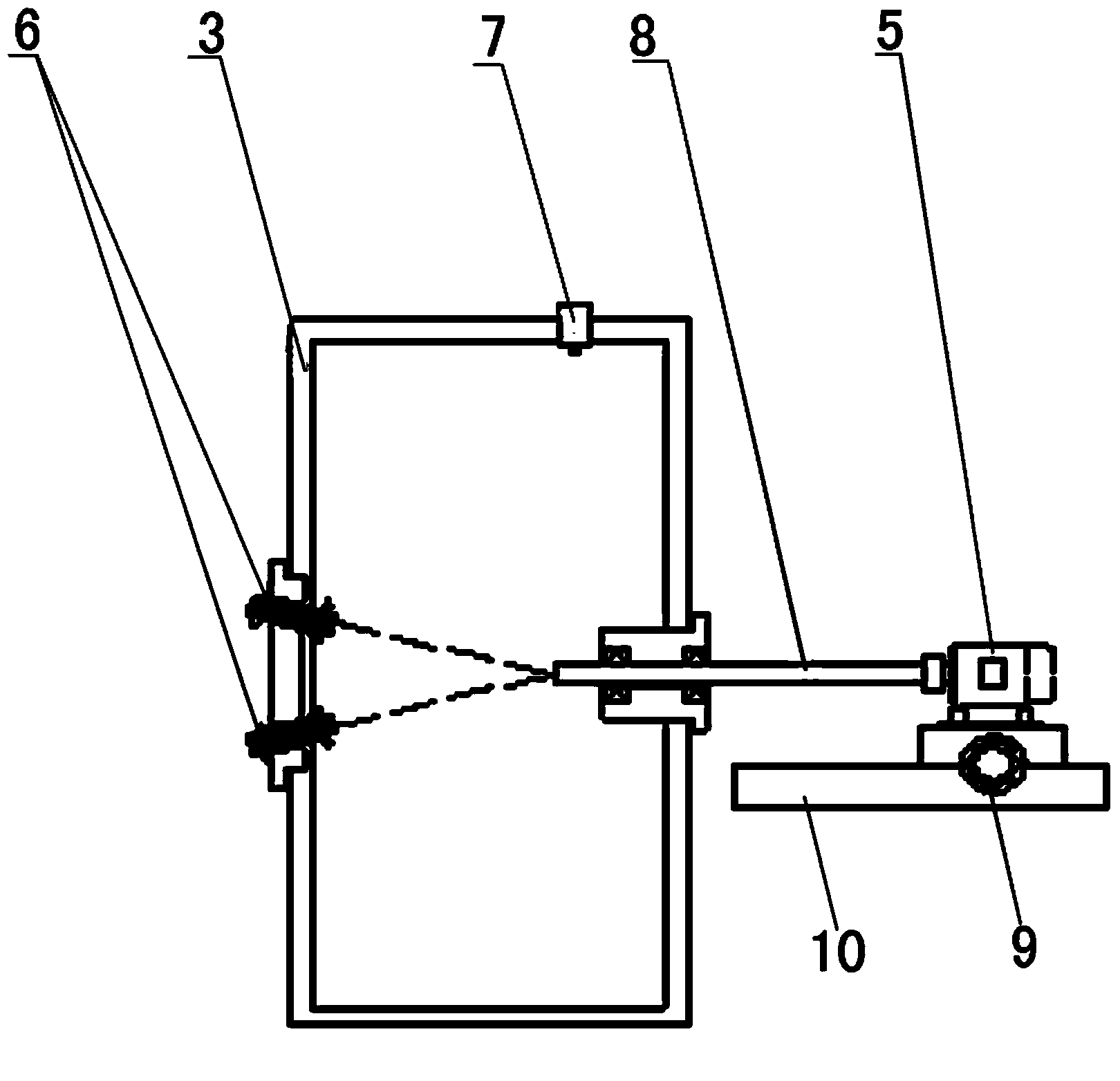

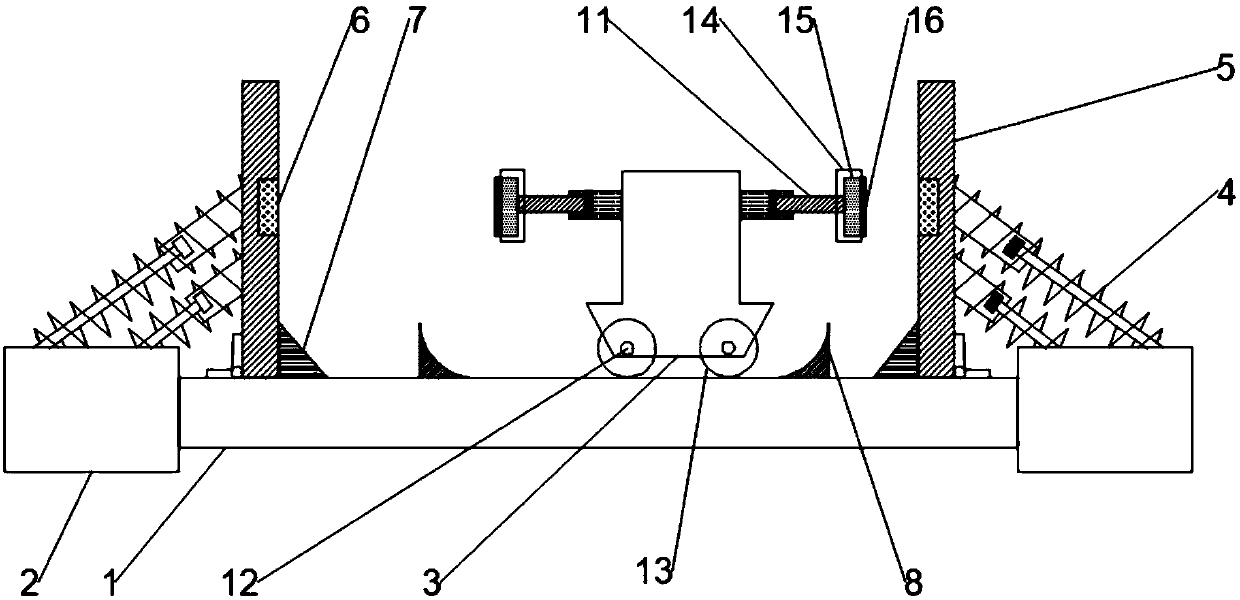

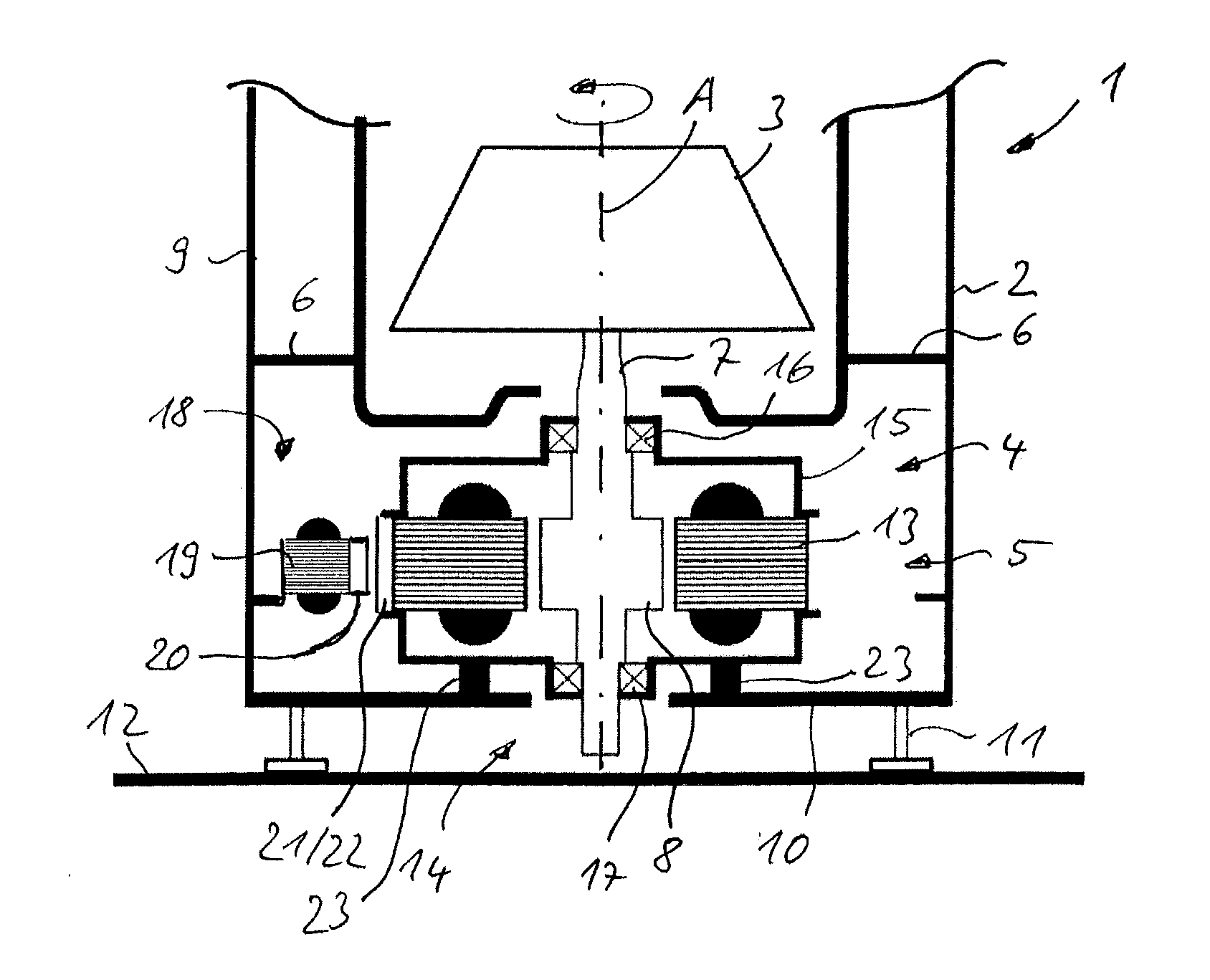

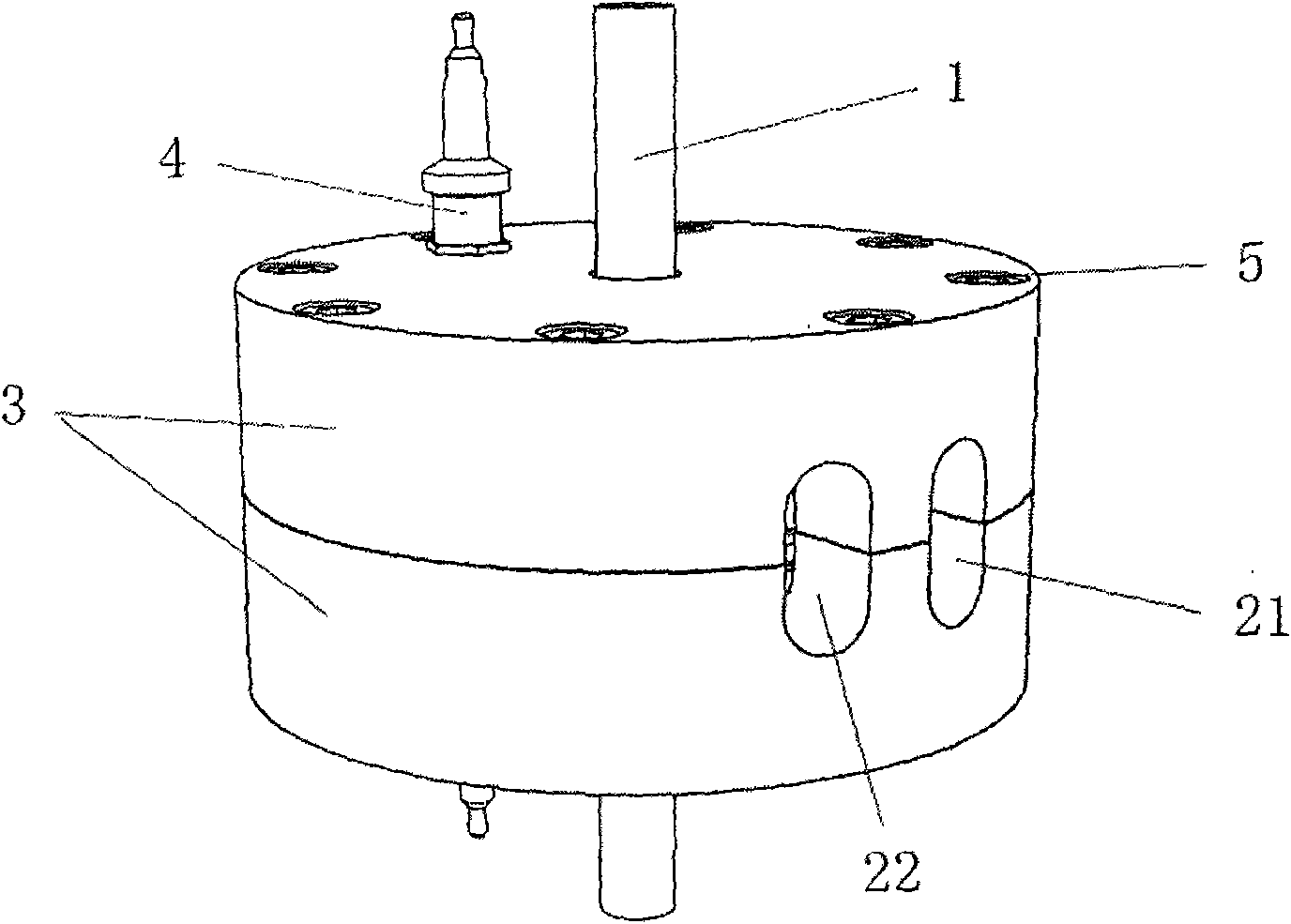

Laser heating rotating atomization method and device used for manufacturing metal or alloy powder

The invention relates to a laser heating rotating atomization method and device used for manufacturing metal or alloy powder. A traditional plasma gun is replaced by a single high-power laser (6) or a plurality of high-power lasers (6) focusing in different angles, a bar material is rotated at a high speed through a high-speed motor (5), and the bar material is automatically fed through a material pushing motor (9). Through the structures, a complex connecting mechanism of a traditional carbon brush and a copper electrode is omitted. Using limit of the carbon brush in a plasma rotating atomization device is eliminated, the metal and alloy powder can be manufactured in a carbon brush-free mode, the phenomena of frictional heating of the carbon brush and wear to the carbon brush are eliminated, and therefore the limit speed of the bar material is effectively increased, dust and noise pollution is greatly reduced, device stability is enhanced remarkably, and work efficiency is improved. The method and device can be applied to the field of manufacturing the metal or alloy powder through an atomization method.

Owner:ADVANCED FOR MATERIALS & EQUIP

Precise ceramic bearing and machining process thereof

InactiveCN102635635AExtended service lifeReduce coefficient of frictionBearing componentsBall bearingVolumetric Mass Density

The invention relates to a ceramic ball bearing, particularly relates to a precise ceramic bearing and a machining process thereof and belongs to the field of bearings and machining thereof. According to the precise ceramic bearing and the machining process thereof, a rolling body utilizes a silicon nitride ceramic material, the density is reduced, the centrifugal force is reduced by more than 40%, the limited rotating speed is improved by more than 30% and the service life of the bearing is prolonged by more than 50%. Meanwhile, the silicon nitride ceramic material has the advantages of small friction coefficient, strong self-lubricating capability, wear resistance, high-temperature resistance and the like. Furthermore, a sleeve ring machining process adopts cold rolling and the effect of the cold rolling procedure reduces a lathing procedure, shortens the production cycle, improves the production efficiency and reduces the consumption of raw materials. If the precise ceramic bearing is manufactured by a common cutting machining process, the utilization rate of materials is commonly 40-50%, but if the precise ceramic bearing is manufactured by a cold rolling method, the material utilization rate can reach 70-80%.

Owner:李东炬

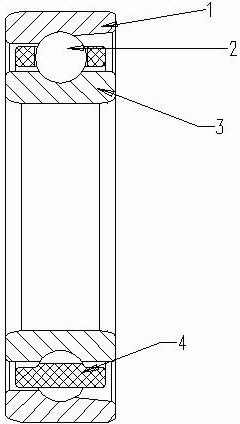

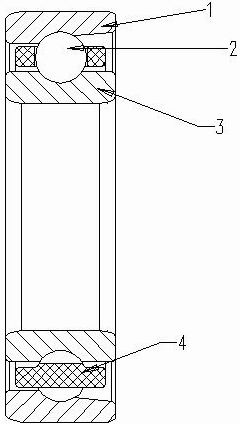

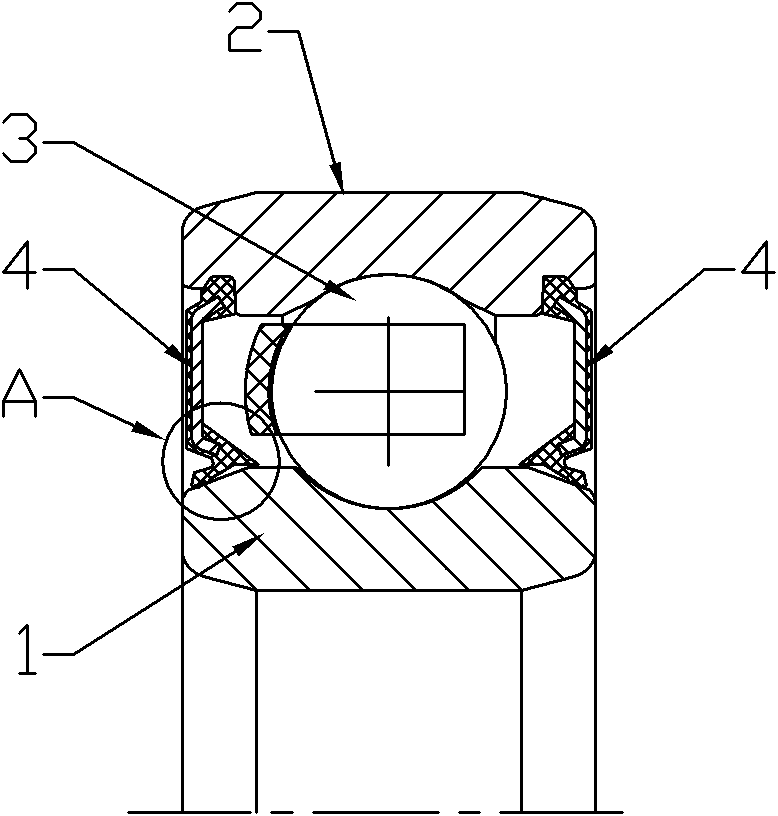

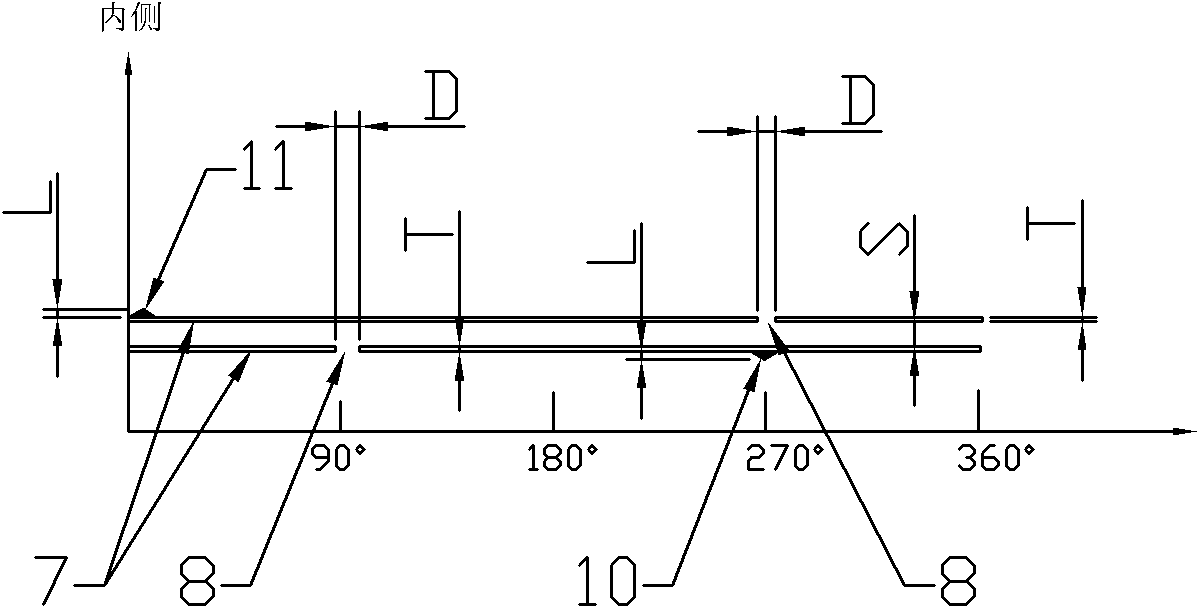

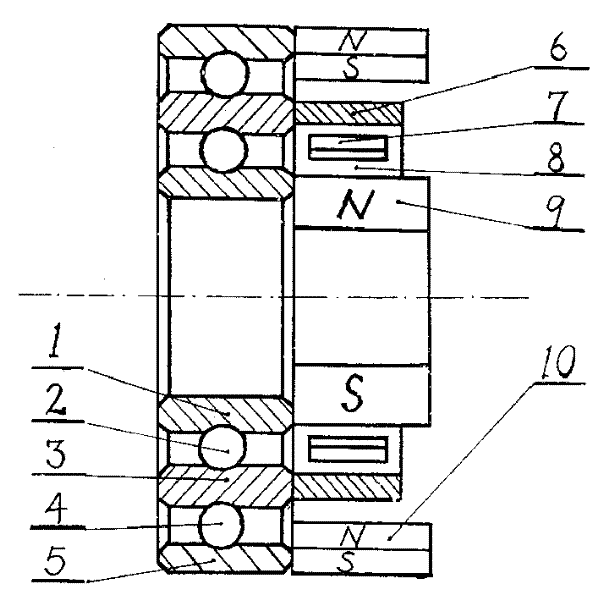

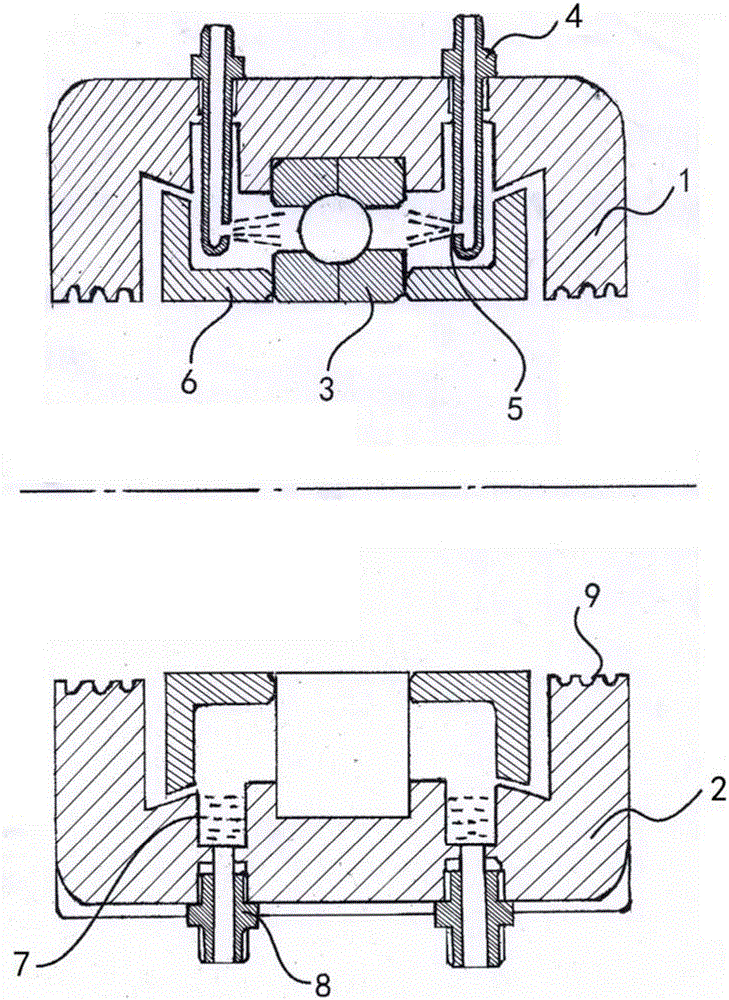

Rolling bearing sealing element and rolling bearing sealing structure

InactiveCN102003467AReduce wearReduce temperature riseEngine sealsBall bearingsRolling-element bearingEngineering

The invention discloses a rolling bearing sealing structure, belonging to a rolling bearing. Aiming at the disadvantage of difficult manufacture of the existing sealing element, the structure of the invention is characterized in that at least one end of the two ends of an inner ring is provided with an exposed inclined surface; the inner edge of the sealing element forms at least two parallel annular sealing bulged ribs; each sealing bulged rib is provided with at least a notch; the notches on the two adjacent sealing bulged ribs are staggered at a certain angle on the circumference; and the annular sealing bulged ribs contact with the exposed inclined surface so that the sealing match of the sealing element and the inner ring is realized. The invention has the advantages that the dimension of the annular sealing bulged ribs is small; the requirements of low operation friction, low abrasion, low temperature rise, high limit rotating speed and good sealing property are realized; the notches on the two adjacent sealing bulged ribs are staggered at a certain angle on the circumference, thus the routes of the dust entry and the grease leakage are prolonged and the reliable sealing is realized; and the sealing element structure that the notches are formed on the sealing bulged ribs is conveniently manufactured through a mould.

Owner:陈炳顺

Rotor Support Mechanism of Rolling Bearing Turbocharger

InactiveCN102278154ASolve Vibration ProblemsImprove support rigidityRolling contact bearingsInternal combustion piston enginesTurbochargerThrust bearing

The invention belongs to the field of turbochargers for internal combustion engines, in particular to a rotor supporting mechanism of a rolling bearing turbocharger. It includes a bearing sleeve and two springs, two thrust sleeves and two bearings in the bearing sleeve. The two springs are symmetrically arranged in the bearing sleeve and connected to each other. Put the spring into the thrust sleeve and apply pre-tightening force. Two bearings are respectively arranged on the end face of the thrust sleeve. Both bearings are angular contact rolling bearings. The advantage of the present invention is that ceramic rolling bearings are used instead of ordinary floating bearings, which improves the mechanical efficiency and transient response capability of the turbocharger, solves the vibration problem of the rolling bearing turbocharger, and improves the steady-state performance and performance of the turbocharger. The service life of the rolling bearing is improved, the support rigidity of the rolling bearing is improved, the limit speed of the rolling bearing is increased, the requirement of high-speed operation of the turbocharger is met, the lubrication problem of the turbocharger is solved, the reliability of the rolling bearing supercharger is improved, and the balanced transmission The force system meets the requirements for the normal operation of the rolling bearing turbocharger.

Owner:CHANGZHOU E&E TURBO POWER

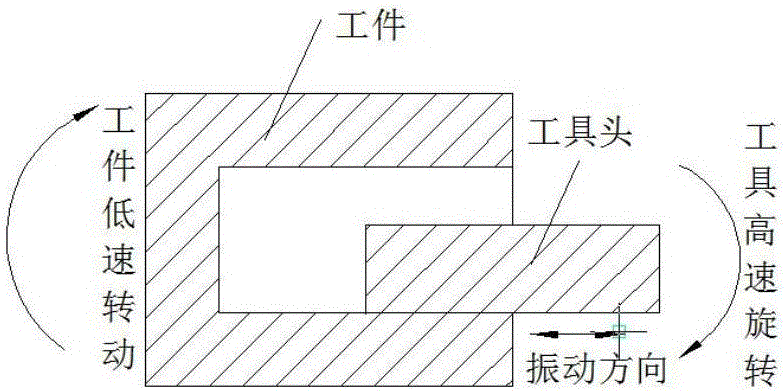

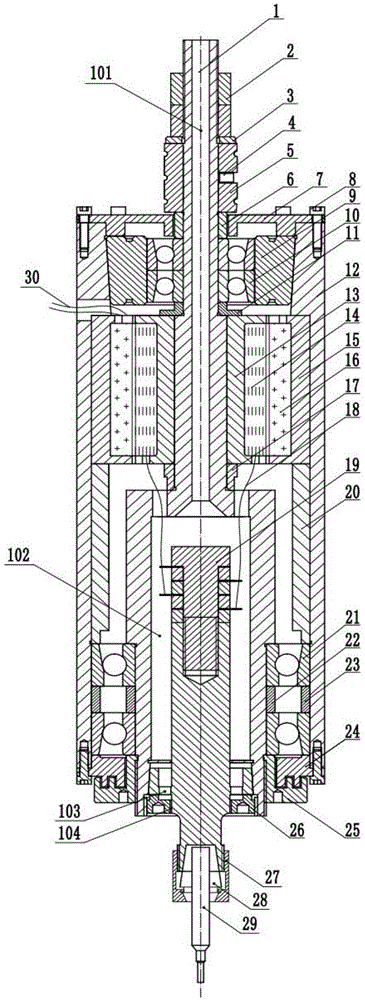

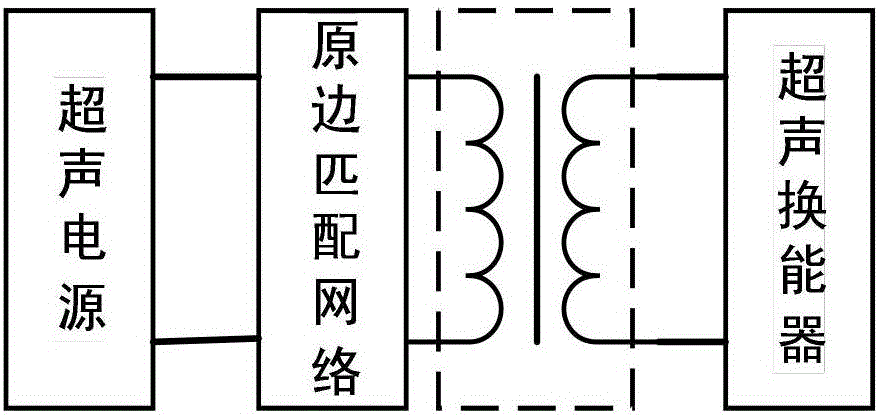

High-speed rotation ultrasonic grinding main shaft

ActiveCN107175543AHigh precisionImprove reliabilityGrinding spindlesGrinding/polishing safety devicesElectricityUltrasonic sensor

The invention provides a high-speed rotation ultrasonic grinding main shaft. A high-coaxiality conical hole is used for positioning, and the centering precision is improved. Through the design of a flange in the shape like the Arabic number 7, the contact distance is lengthened, one-time machining is conducted, and the installing reliability of an ultrasonic transducer is improved. No mechanical contact exists between a primary coil and a secondary coil, and no abrasion exists. A closed space is formed by an aluminum shell, and magnetic field leakage is obstructed. Cold nitrogen makes direct contact with a heating piezoelectric ceramic piece in a main shaft cavity, a large amount of heat is brought away, and the heat dissipation efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

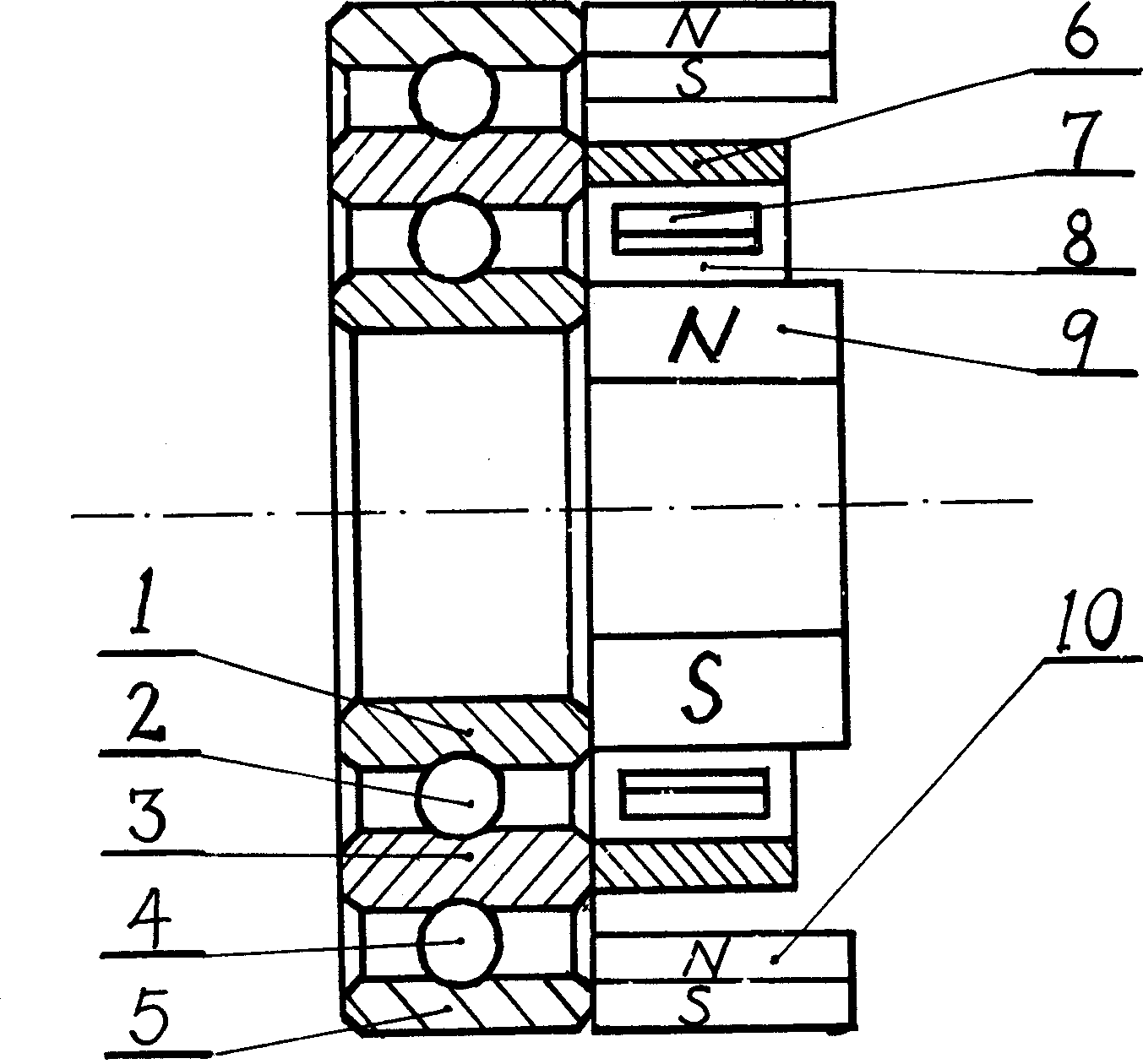

Secondary bearing with electromagnetic speed regulation in interelectrode

InactiveCN1490532AIncrease limit speedExtended service lifeRolling contact bearingsBearing componentsSingle stageEngineering

Owner:李军

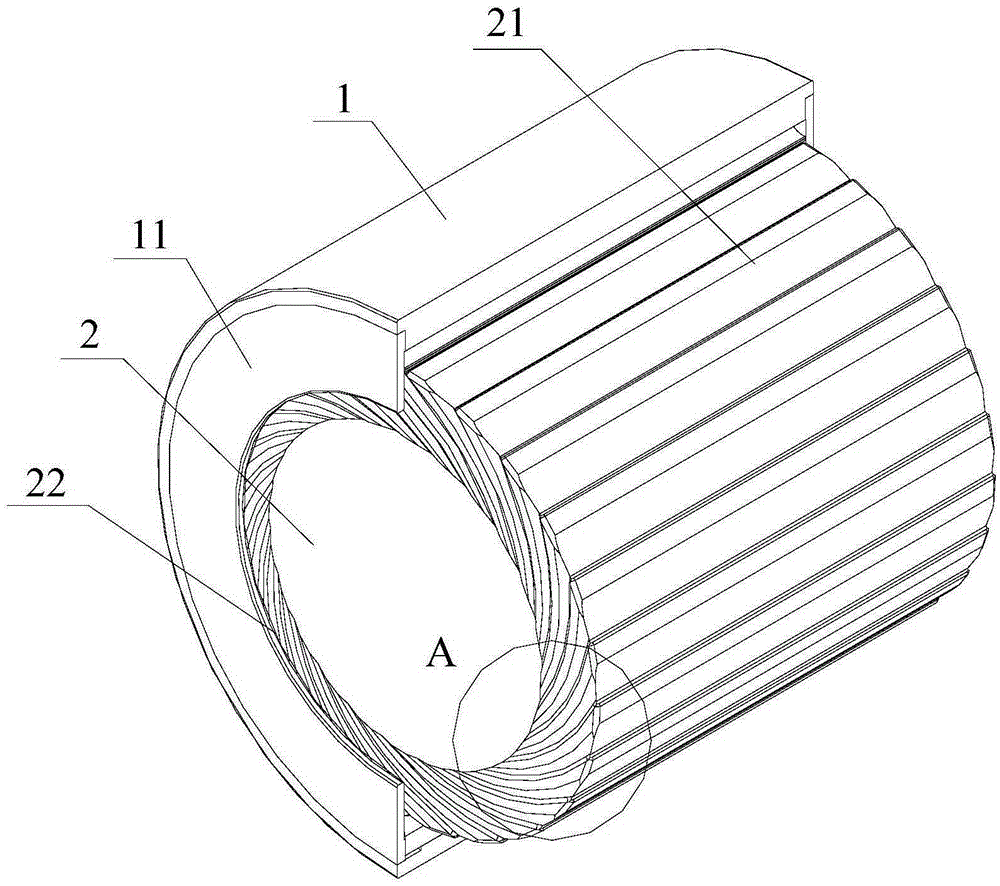

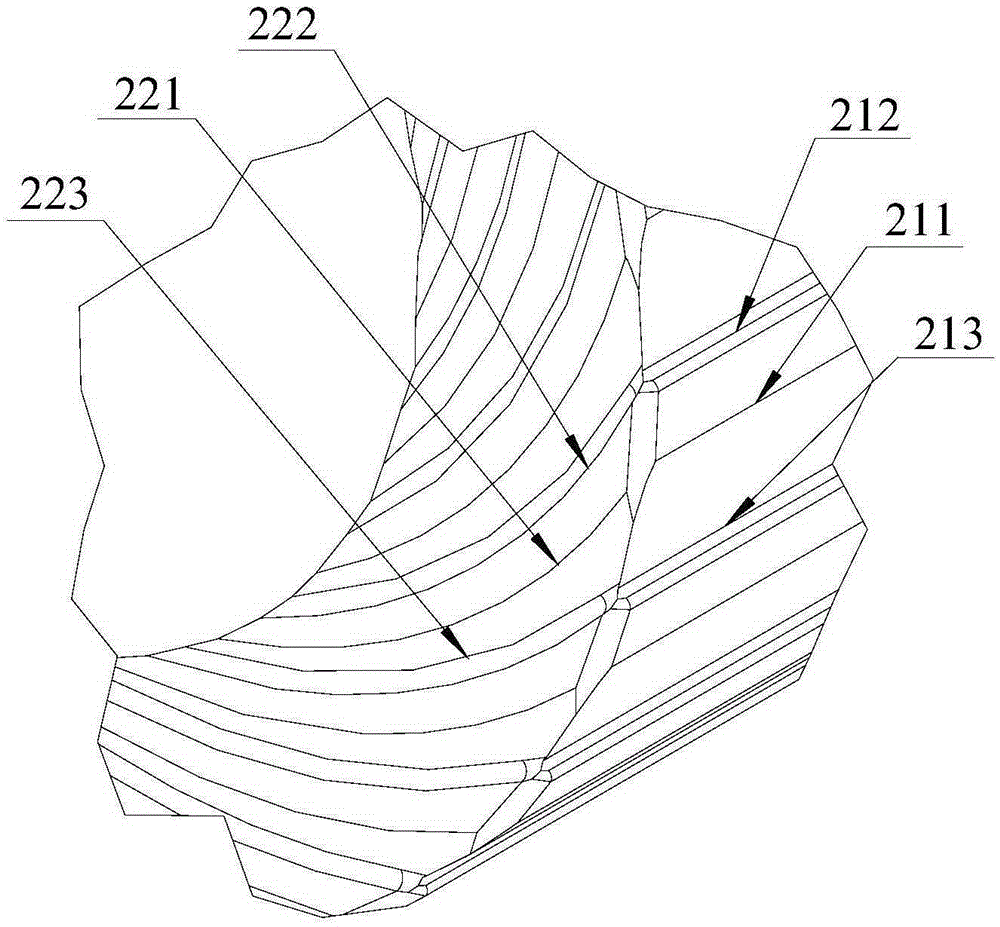

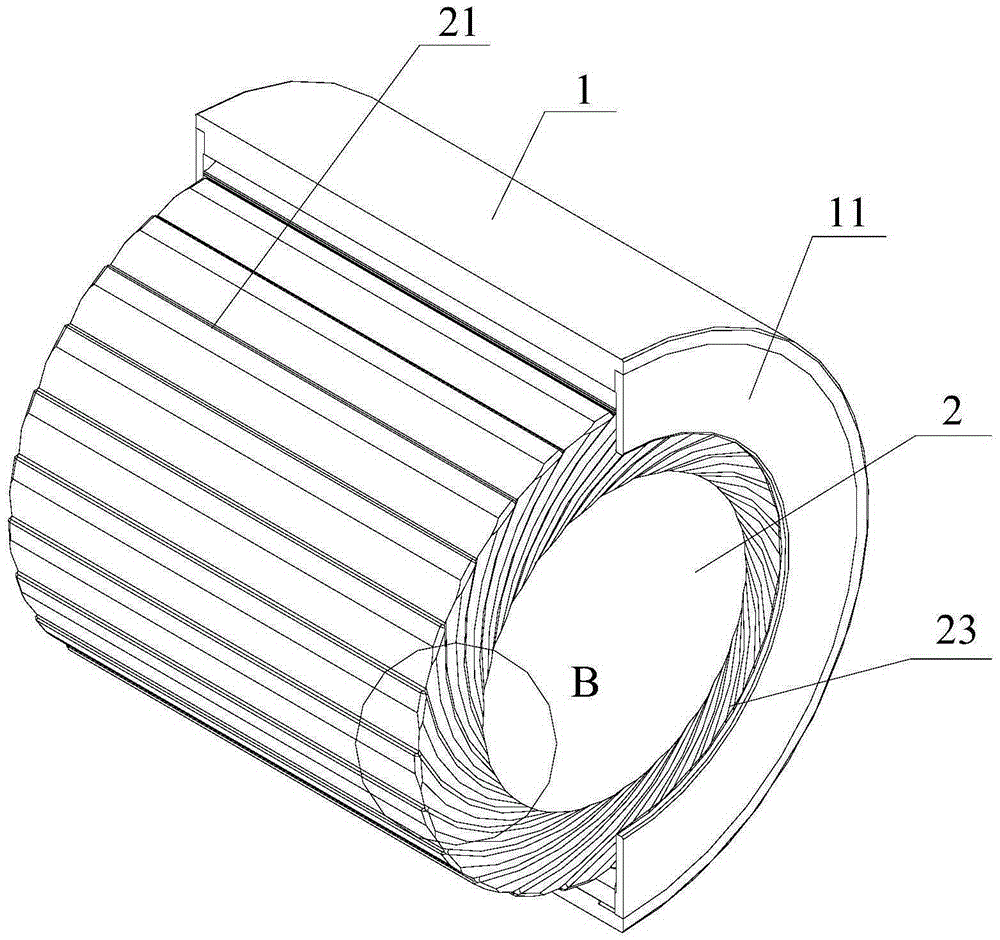

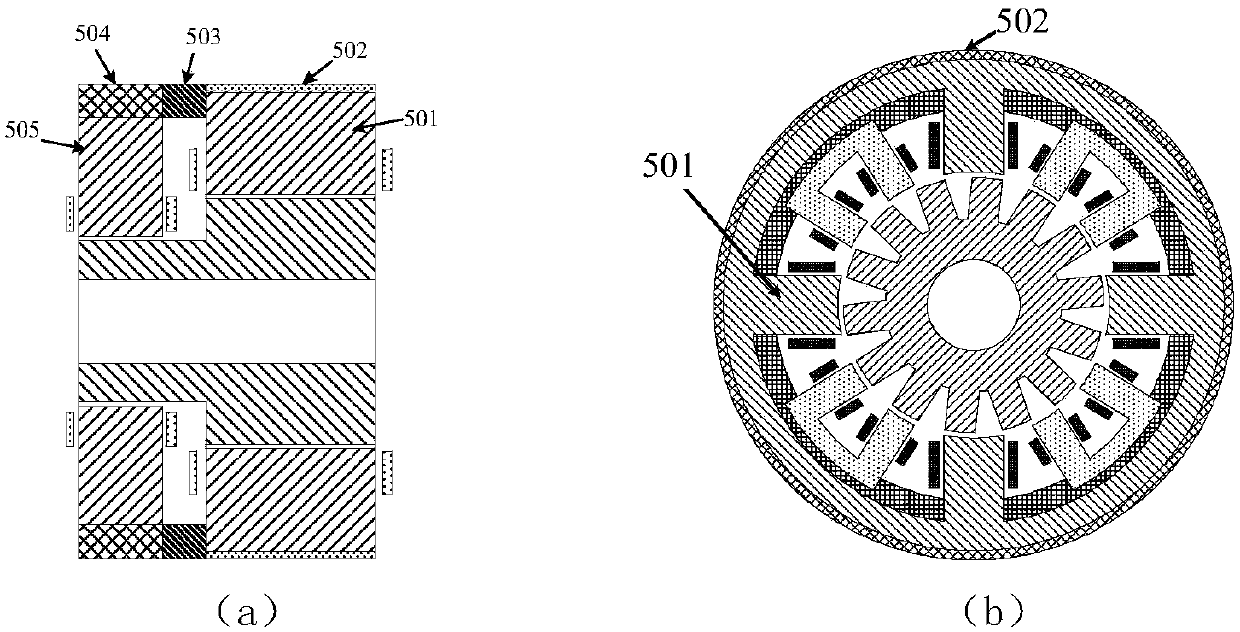

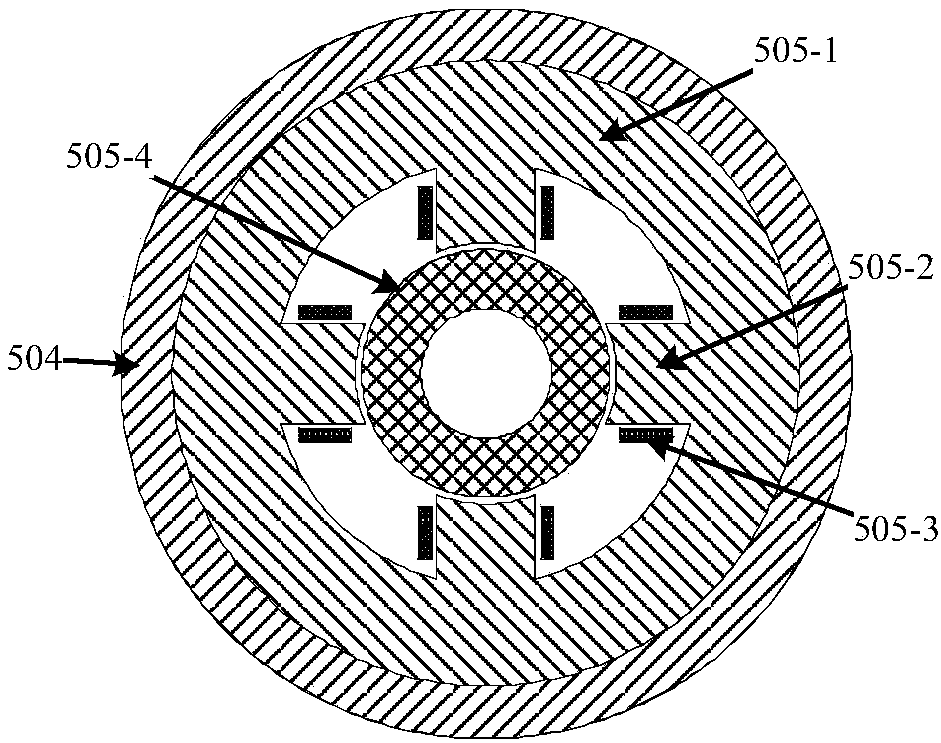

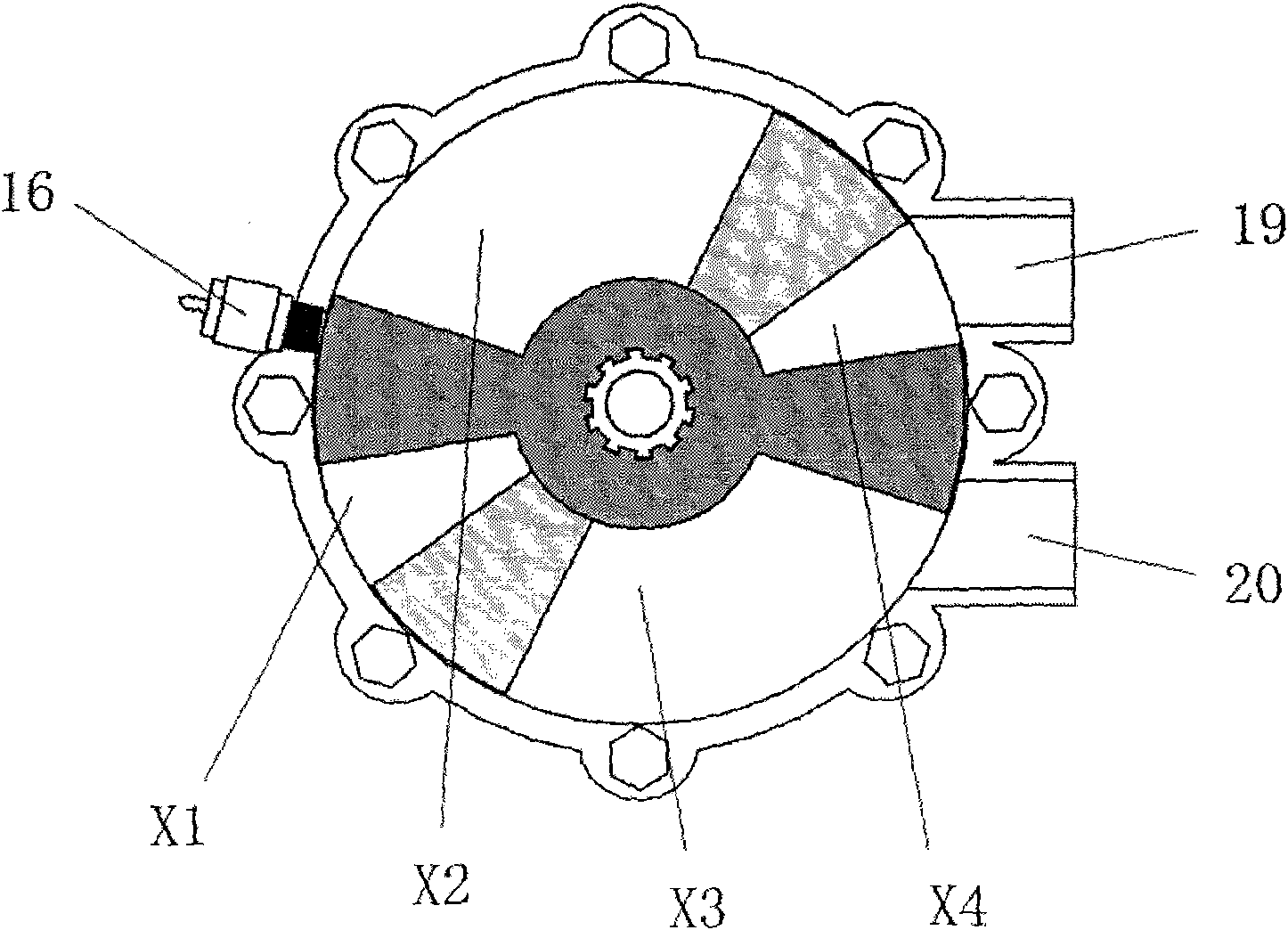

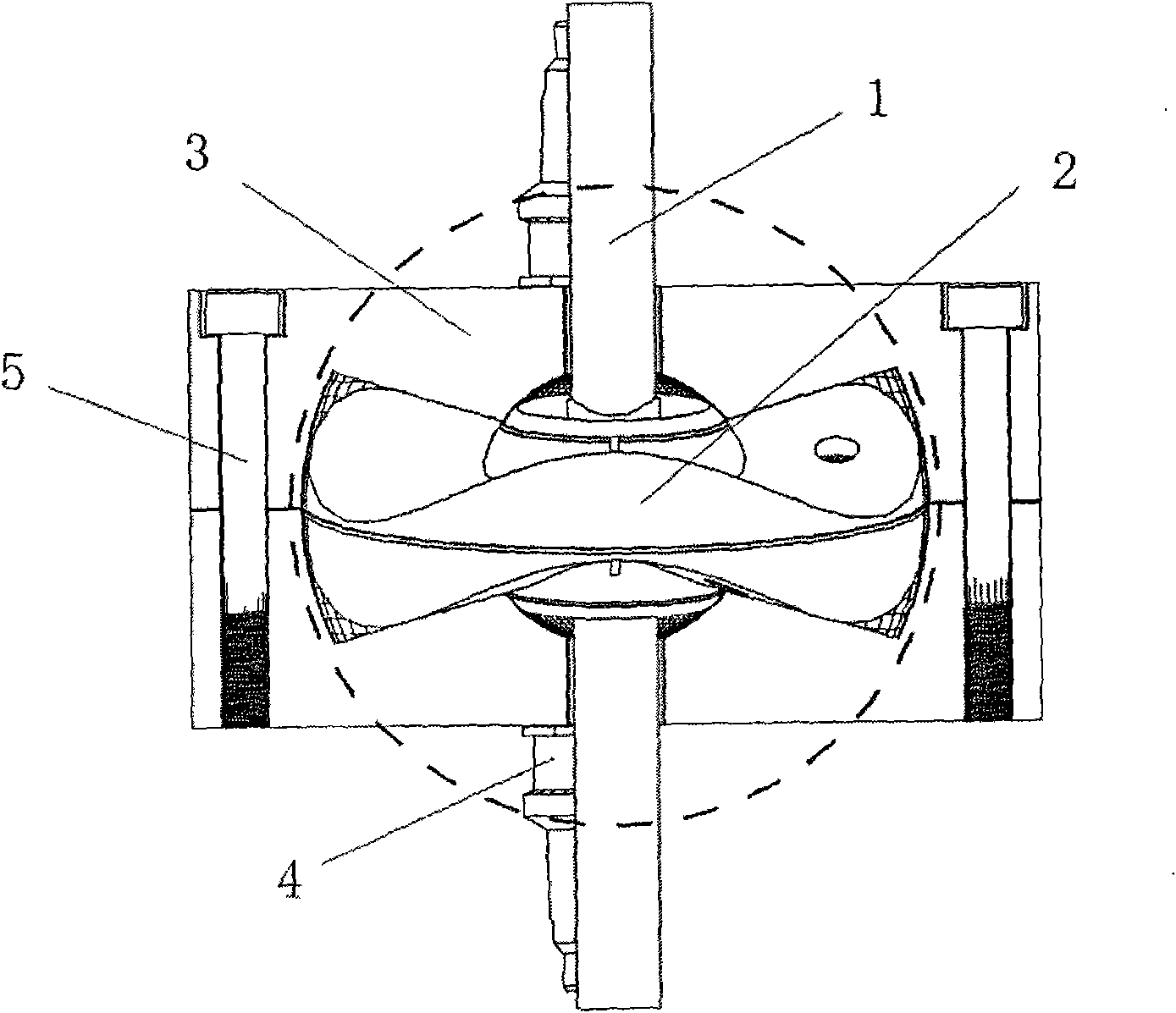

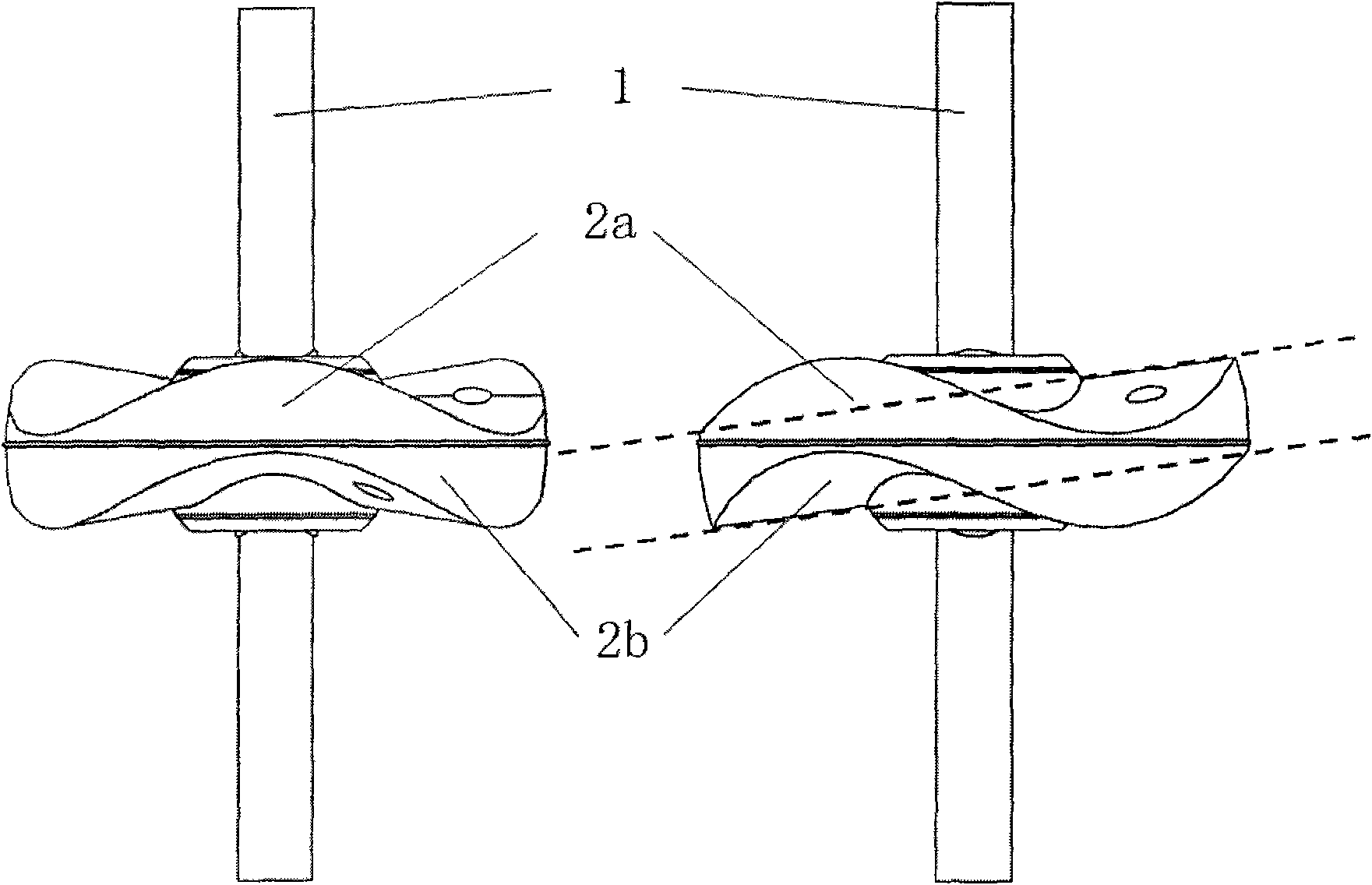

Hybrid type dynamic pressure gas journal bearing

ActiveCN105202018AImprove impact resistanceIncrease loading capacitySliding contact bearingsHybrid typeDynamic pressure

The invention discloses a hybrid type dynamic pressure gas journal bearing. The hybrid type dynamic pressure gas journal bearing comprises a bearing outer cover, an inner cover and a foil type elastic piece arranged between the bearing outer cover and the inner cover. The outer circumferential face and the two end faces of the inner sleeve of the bearing are each provided with groove type patterns of the regular shapes. The groove type patterns of one end face are in mirror symmetry with the groove type patterns on the other end face. The axial contour lines of the groove type patterns on the outer circumferential face correspond to the radial contour lines of the groove type patterns on the two end faces one to one. The axial contour lines and the radial contour lines are connected. The hybrid type dynamic pressure gas journal bearing has the rigid characteristic of the high limit speed of a groove type dynamic pressure gas journal bearing and has the flexible characteristics of the high impact resistance and the high loading capacity of a foil type dynamic pressure gas journal bearing, and the hybrid type dynamic pressure gas journal bearing can be applied in the ultrahigh-speed field of large loads.

Owner:罗立峰

Five-degree-of-freedom magnetic levitation flywheel energy storage device

ActiveCN107070072AShorten the axial lengthCompact structureMechanical energy handlingMagnetic holding devicesMagnetic bearingFlywheel energy storage

The invention relates to a five-degree-of-freedom magnetic levitation flywheel energy storage device. A rotating shaft, a flywheel, a permanent magnet unloading bearing, and a four-degree-of-freedom magnetic levitation support and transmission system are disposed in a vacuum vessel for reducing energy loss caused by wind resistance. The flywheel is installed on the lower end of the rotating shaft and the permanent magnet unloading bearing is fixedly connected with the flywheel and vacuum vessel. The top end of the flywheel energy storage device is provided with the four-degree-of-freedom magnetic levitation support and transmission system. The four-degree-of-freedom magnetic levitation support and transmission system consists of a magnetic levitation switch reluctance motor, a permanent magnet, a magnetic conductive plate and a magnetic bearing. The permanent magnet provides the magnetic levitation switch reluctance motor and the magnetic bearing with bias magnetic fields for generating required suspension force under the effect of the magnetic conductive plate. A redundant coil for generating a biased magnetic axis is eliminated so as to achieve low loss and compact system structure. The magnetic levitation switch reluctance motor uses torque / suspension self-decoupling structure to improve the stability and reliability of the system.

Owner:JIANGSU UNIV

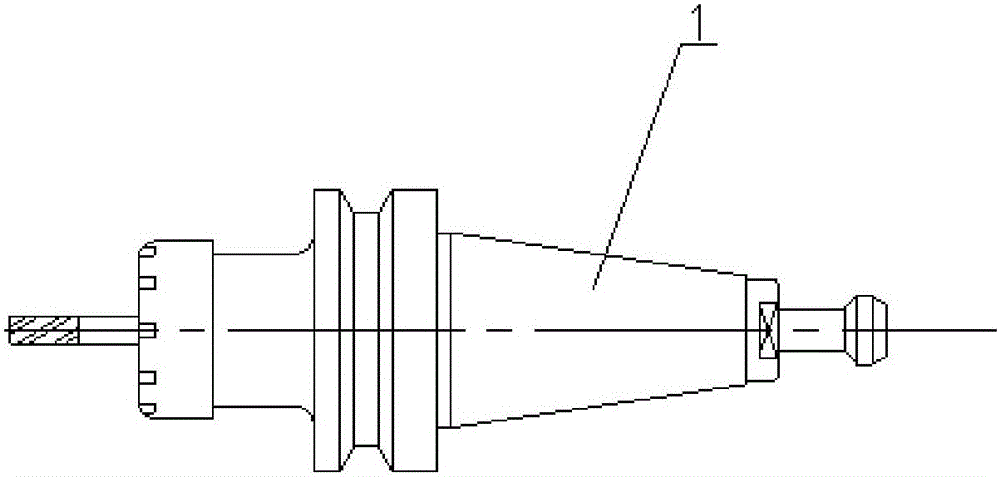

High-speed spindle with tapered hole capable of being automatically locked

InactiveCN102513553AImprove joint stiffnessGuaranteed stiffnessMetal-working apparatusInterference fitHydraulic cylinder

The invention provides a high-speed spindle with tapered hole capable of being automatically locked. The high-speed spindle comprises a spindle, an expansion wall, hydraulic cylinders and an oil path and is characterized in that: an inner hole at the shaft end of the spindle is fixedly linked with the expansion wall with the tapered hole through interference fit; two oil cavities are disposed on the outer surface of the expansion wall; a liquid medium is filled in the oil cavities; two sets of the hydraulic cylinders consisting of a cylinder body component and a piston are symmetrically arranged on the spindle with respect to the axis of the spindle; the cylinder body components are communicated with the oil cavities through the oil path; and a spring is arranged at the bottom of each piston. The high-speed spindle disclosed by the invention has the advantages that: the magnitude of the interference fit between the tapered surface of the knife handle and the tapered hole of the spindle is subjected to automatic compensation. Furthermore, the compensation amount is increased when a rotation speed is increased. The linkage rigidness and the positioning precision of the knife handle and the spindle are ensured at any rotation speed, and the limit rotation speed is improved. The deformation coaxiality generated by the expansion wall is very high, so that the good radial position precision can be ensured. The liquid medium can supply great damping, the power absorbers consist of the piston and the spring, so that the two have vibration absorption effects on the spindle.

Owner:YANSHAN UNIV

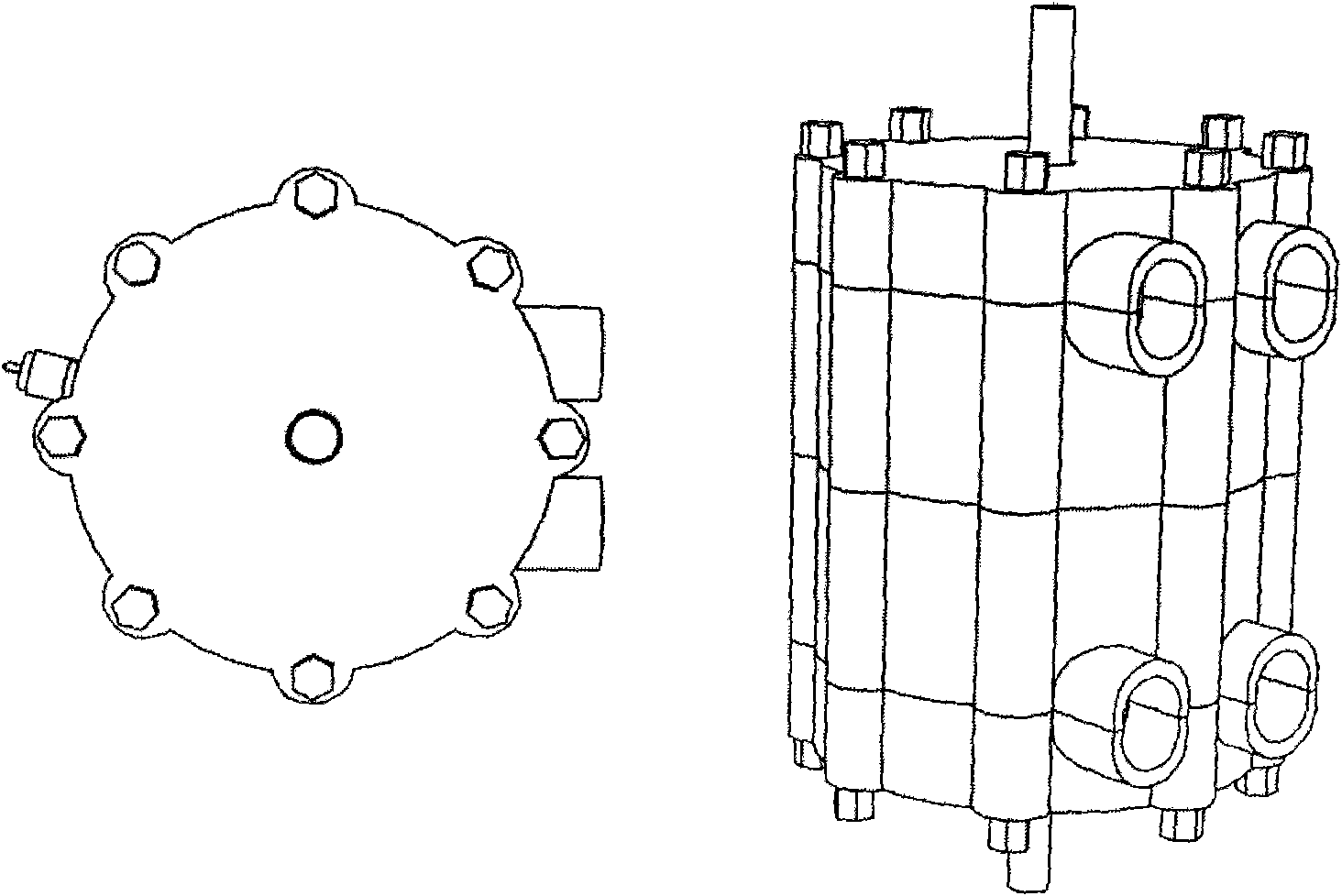

Interdigitated rotor engine

InactiveCN101852122AReduce manufacturing costEasy to produceInternal combustion piston enginesEngineeringContinuous operation

The invention relates to an interdigitated rotor engine. The complete machine comprises four shell components which are arranged side by side and fixed through bolts; in the three cavities of the inside of the rotor engine, the upper and lower cavities are used to hold a rotor assembly, and the middle cavity is used to hold a transmission system composed of an output shaft, an inner sleeve, an outer sleeve and a multiplex gear. By using the interdigitated rotor engine, power transmission can be realized and the alternate transposition and rotation of rotors can be realized so that the volumes of a plurality of cylinders composed of two interdigitated double-vane or four-vane rotors and the shell can change periodically. A gas port on one side of the rotor cavity is used for air admission and air exhaust, a spark plug on the other side is used for ignition, and the engine capable of performing continuous operation can be realized through four strokes.

Owner:谢坤

Trolley limiting buffer device of bridge crane

InactiveCN107555314ARealize double limitSimple structureRunwaysSafety gearVehicle frameOverhead crane

Owner:SHAOGUAN TAILI CRANE

Low-speed high-torque and permanent-magnet synchronous high-speed automatic tool-changing electric spindle

ActiveCN106041130ARealize automatic replacementEasy tool changePositioning apparatusMaintainance and safety accessoriesElectricityLow speed

The invention discloses a low-speed high-torque and permanent-magnet synchronous high-speed automatic tool-changing electric spindle. The electric spindle comprises a motor body, and a stator, a rotor, a rotor shaft, a spring pre-tightening mechanism, a front bearing and a rear bearing are arranged inside the motor body. The electric spindle further comprises a connection base fixed to the rear end of the motor body, a connector fixedly connected to the connection base, a steam cylinder assembly fixedly connected to the connector, a rear cover arranged at the end of the steam cylinder assembly and a front end cover connected to the front end of the motor body. A tool loosening and pulling mechanism is arranged in the center of the rotor shaft, a pulling claw is arranged at the front end of the tool loosening and pulling mechanism, a disc spring assembly is installed in the middle of the tool loosening and pulling mechanism, a high-performance sensor is adopted together, and therefore automatic tool changing is more convenient and accurate and rapider. A magneto-electric coder is adopted at the rear end, so that low-speed torque output is more balanced. Compressed air is adopted for non-contact air sealing so that higher rotation speed can be obtained. The electric spindle is simple and compact in structure and powerful in function, is smaller than common electric spindles with the same power in size, has the advantages that the speed is low and the torque is high and can be widely applied to high-speed and low-speed precision machining of various materials.

Owner:江苏华雕机械有限公司

Device for dynamic balancing of a rotating component

InactiveUS20130002063A1Gap of airEfficient use ofCentrifugesMechanical energy handlingRotational axisDynamic balance

A device for limiting an unbalance in inside a centrifugal, with an electric motor to drive a rotating component disposed in an enclosure around a rotational axis, wherein a rotor of the electric motor is non-rotatably connected to the rotating component, a bearing assembly for the rotor and the stator to be arranged in, and a stabilizer unit which generates as a function of a disturbing force acting on the rotating component a balancing force that is adapted to compensate said latter, the bearing assembly including support means such as to make the stator radially movable, and the stabilizer arranged radially outside and / or inside said stator and / or support means of the bearing assembly and having stabilizing means whereby in aggregate a radial balancing force can be generated.

Owner:HANNING ELECTRO WERKE GMBH & CO KG

Two-way elliptic gear engine

InactiveCN101852131ANo vibrationImprove conversion efficiencyMachines/enginesCombustion chamberGear wheel

The invention relates to a two-way elliptic gear engine which is integrally in a cylindrical shape. In the two-way elliptic gear engine, an output shaft, a bearing, a disk member, a plurality of pistons and an elliptic gear form a cylindrical rotor; two shells which are arranged oppositely, an inlet valve, an outlet valve, a plurality of hot fire heads, a gear frame and a plurality of duplex eccentric gears form a stator; the space between the rotor and the stator forms an annular combustion chamber, and the plurality of pistons rotate in the annular chamber and divide the combustion chamber into a plurality of cylinders; and the elliptic gear, the duplex eccentric gears and a disk inner gear form a transmission system for carrying out one-way differential transposition rotation among the pistons, so that the volume among the cylinders is changed to realize the purpose of forming the engine by four strokes.

Owner:谢坤

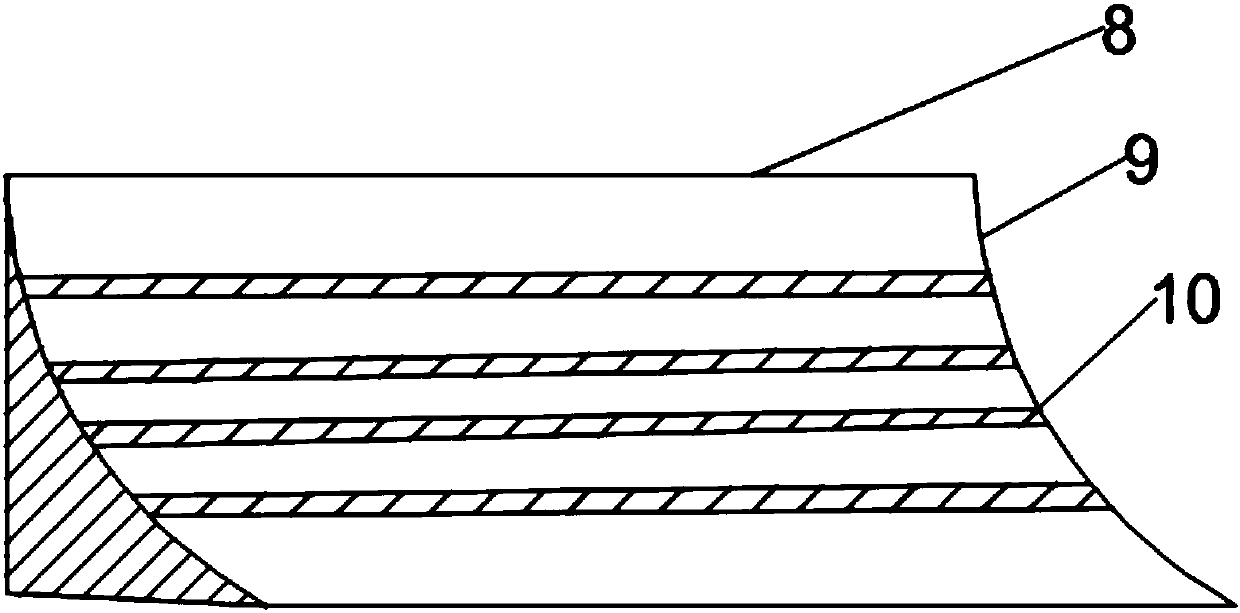

Splitting-type thin oil lubricating bearing seat

ActiveCN105003548AReduce the temperatureIncrease limit speedEngine lubricationBearing unit rigid supportOil canNozzle

The invention provides a splitting-type thin oil lubricating bearing seat. The splitting-type thin oil lubricating bearing seat comprises an upper cover and a base. After the upper cover is fixed to the base in a jointing mode, an annular groove used for installing of a bearing is formed. The outer ring of the bearing is arranged in the annular groove in an embedded mode. The portions, arranged on the two sides of the annular groove, on the top of the upper cover are axially provided with radial through holes respectively. An oil nozzle is arranged in each radial through hole. The portions, close to the lower ends, on the sides of the oil nozzles are provided with nozzle holes which face the bearing. According to the splitting-type thin oil lubricating bearing seat, oil can be supplied continuously through a hydraulic station by lubricating oil, it is not needed that oil supplying is carried out by manpower in a timing mode, the lubricating oil is returned back to an oil tank of the hydraulic station for being recycled, oil retainers are utilized, it is guaranteed that the lubricating oil cannot be leaked, and the leakage phenomenon does not exist. Meanwhile, a part of ball friction heat is taken away by the lubricating oil, the temperature of the bearing seat is far lower than the temperature of a lubricating grease lubricating bearing seat, the limit speed of the bearing can be improved by 20%, the temperature of the bearing is lowered, the service life of the bearing is prolonged, and maintaining of the bearing is lowered.

Owner:JIANGSU HENGLIANG CENTRIFUGE MFG

Precession rotary engine

InactiveCN101852124AEasy to processEasy to installInternal combustion piston enginesRotary piston pumpsCircular discPrecession

The invention relates to a precession rotary engine. The precession rotary engine comprises a rotor assembly composed of a disc rotor member and an output shaft member and a cylindrical stator composed of an upper case and a lower case which are opposite, wherein rotors rotate in the stators in the rotation-precession ratio of 1:3 so that the volumes of six cylinders formed between the rotors andthe stators change periodically; a pair of gas ports on one side of the circumference of the entire case are used to realize air admission and exhaust and a spark plug on the other side of the case is used to strike a light, thus the four-stroke principle can be realized and the six-cylinder engine with very large power-weight ratio can be formed.

Owner:谢坤

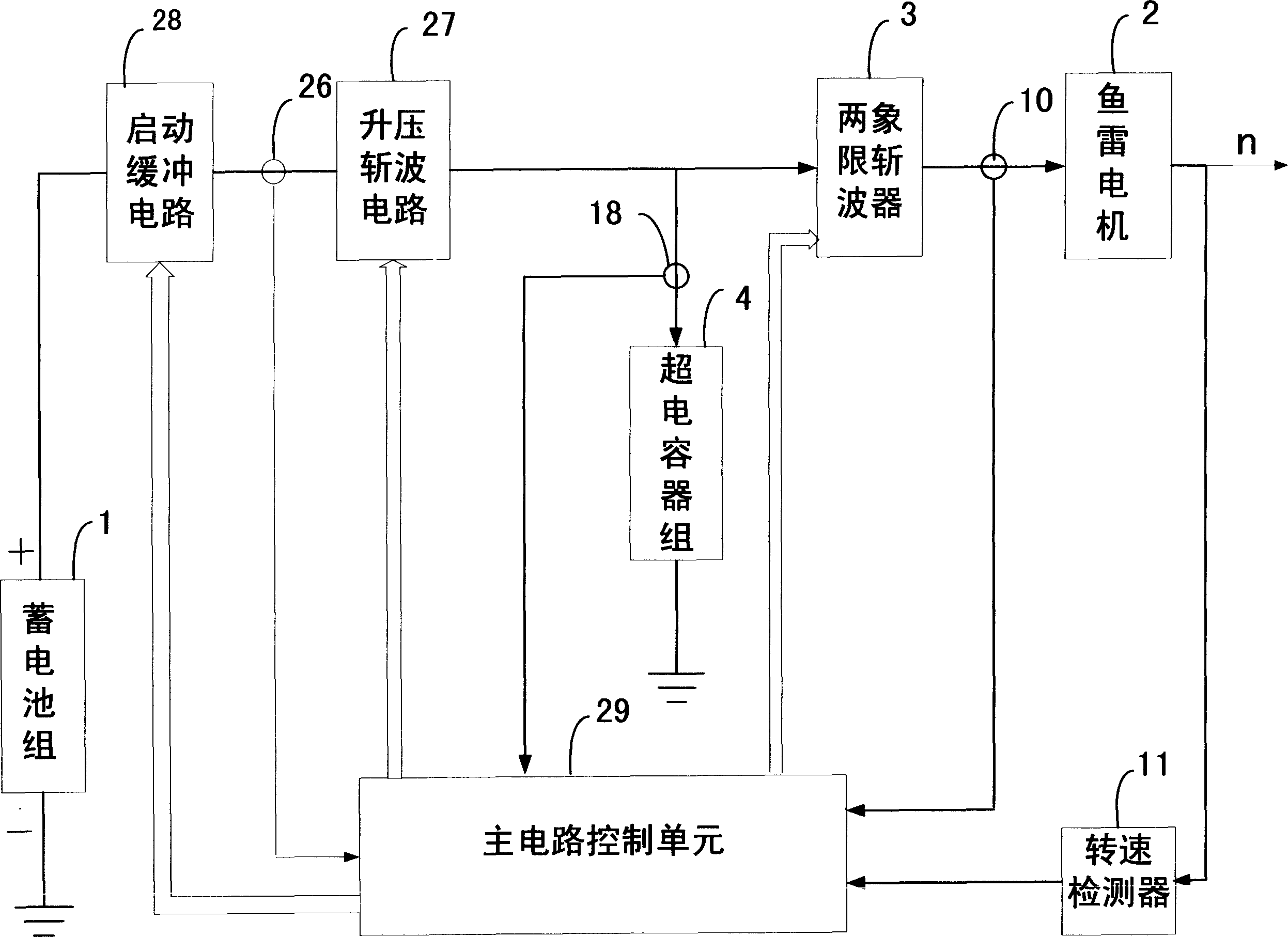

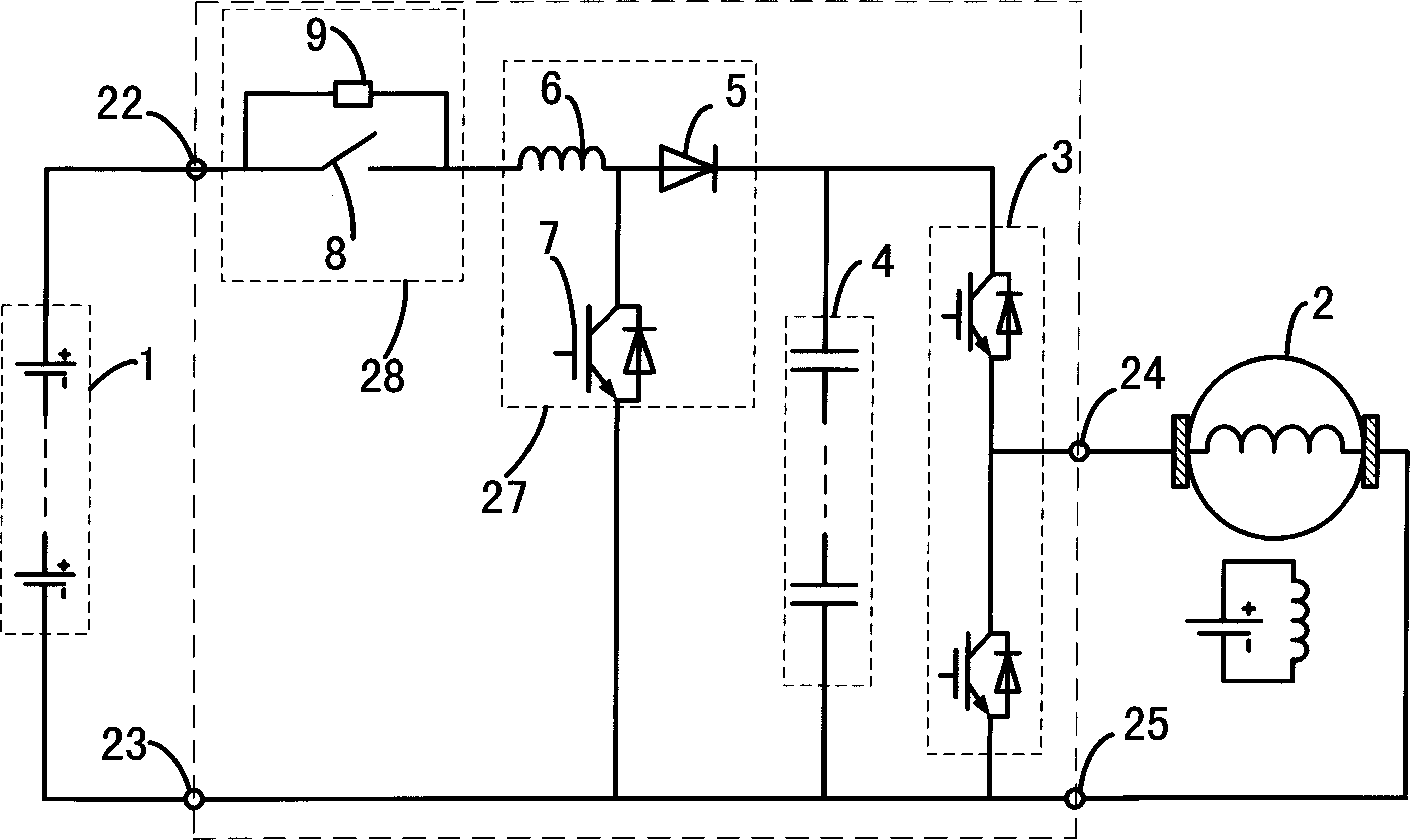

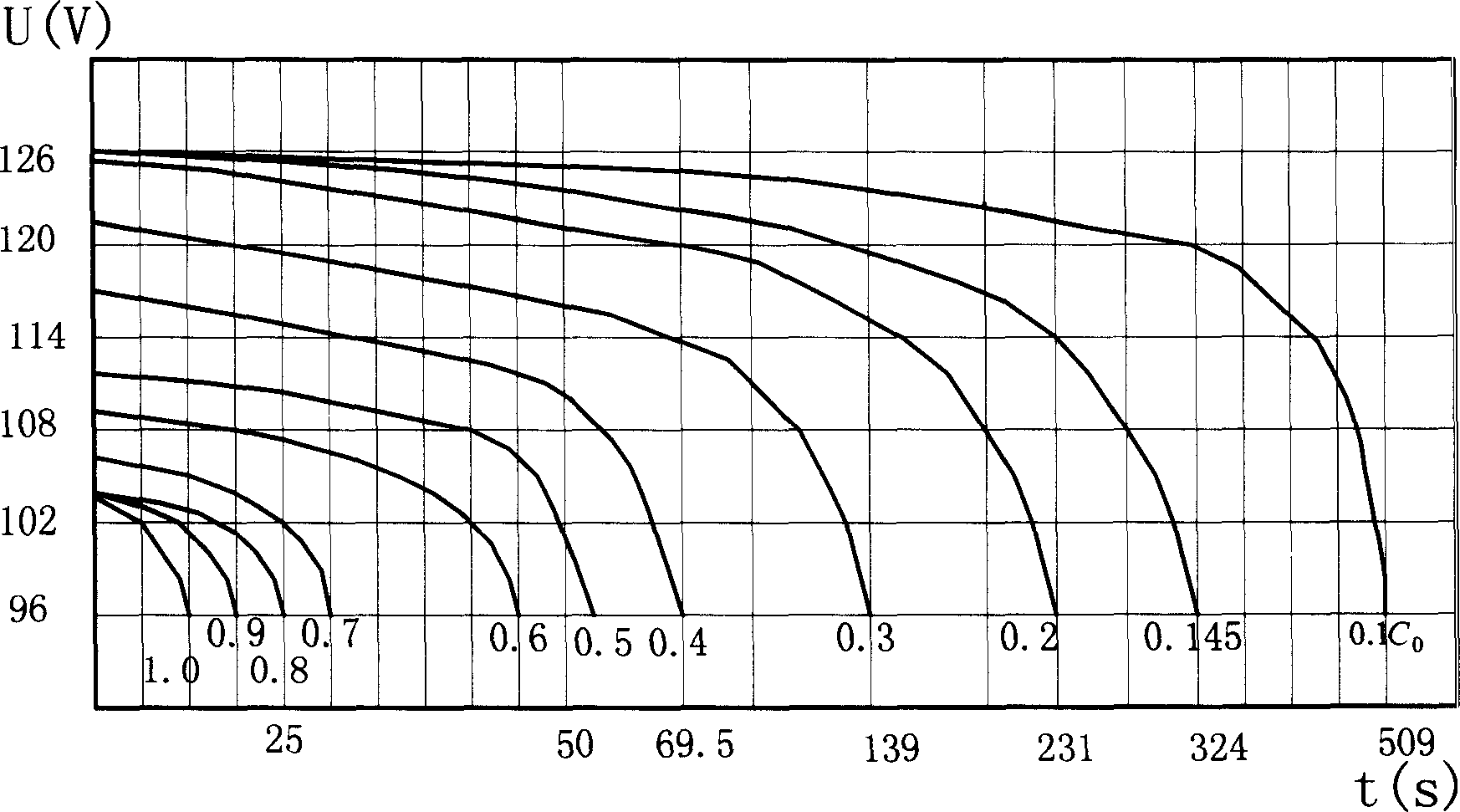

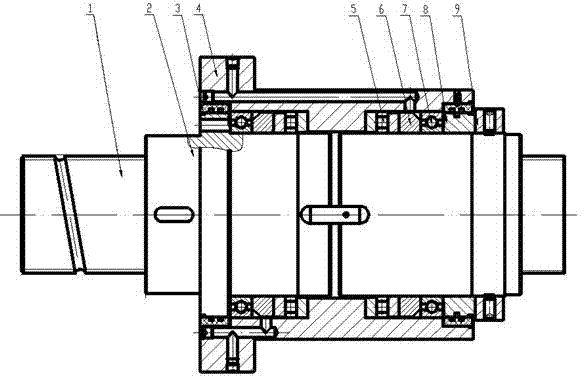

Combined torpedo propelling device with super capacitance and DC chopper speed control circuit

InactiveCN1800772AIncrease limit speedAvoid shockMarine torpedoesField or armature current controlCapacitancePre-charge

The invention relates to a combined direct current chopper adjuster for pushing fish torpedo, which comprises a dual-quadrant direct current copper (3), a direct current motor for pushing fish torpedo; a super capacity group (4) for supplying the electric energy of limited navigation speed of fish torpedo and filtering the wave of bus voltage; a ascending direct current copper (27) for lifting the supplying voltage of said dual-quadrant direct copper and the direct current motor; and a pre-charging device (28) for limiting discharge current of accumulator group, the ascending copper circuit can improve the output voltage of said fish torpedo direct current pushing system, increase the instant output powder of motor, and lift the instant limited speed of fish torpedo, while in limited speed, the copper can control the accumulator group in constant-current discharge mode to effectively confirm the discharge ability of accumulator group. The invention can adjust the speed of fish torpedo in large range with improved shot range.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Swivel nut combination unit

The invention relates to a ball screen pair, in particular to a swivel nut combination unit applied to the field of long-range high-speed heavy load. The swivel nut combination unit comprises a ball screw, a ball nut, a ball bearing and a shell. The ball nut is connected with the ball screw in a threaded manner. The shell covers the ball nut through the ball bearing. When the ball screw rotates, the ball nut drives the shell to axially and linearly move along the ball screw. The bearing is directly mounted outside the ball nut pair, the design of a transition sleeve is omitted, and the radial size is reduced greatly; the ball screw is immobilized; a drive motor drives the ball nut pair to rotate and linearly move along a raceway so that the shell is driven to linearly move; the screw is fixed, rotational inertia of a mechanical motion system is reduced greatly, and limit speed of the system is increased; the swivel nut combination unit is easy for high speed transmission and most applicable to the field of long-range high speed motion.

Owner:NANJING TECHN EQUIP MFG

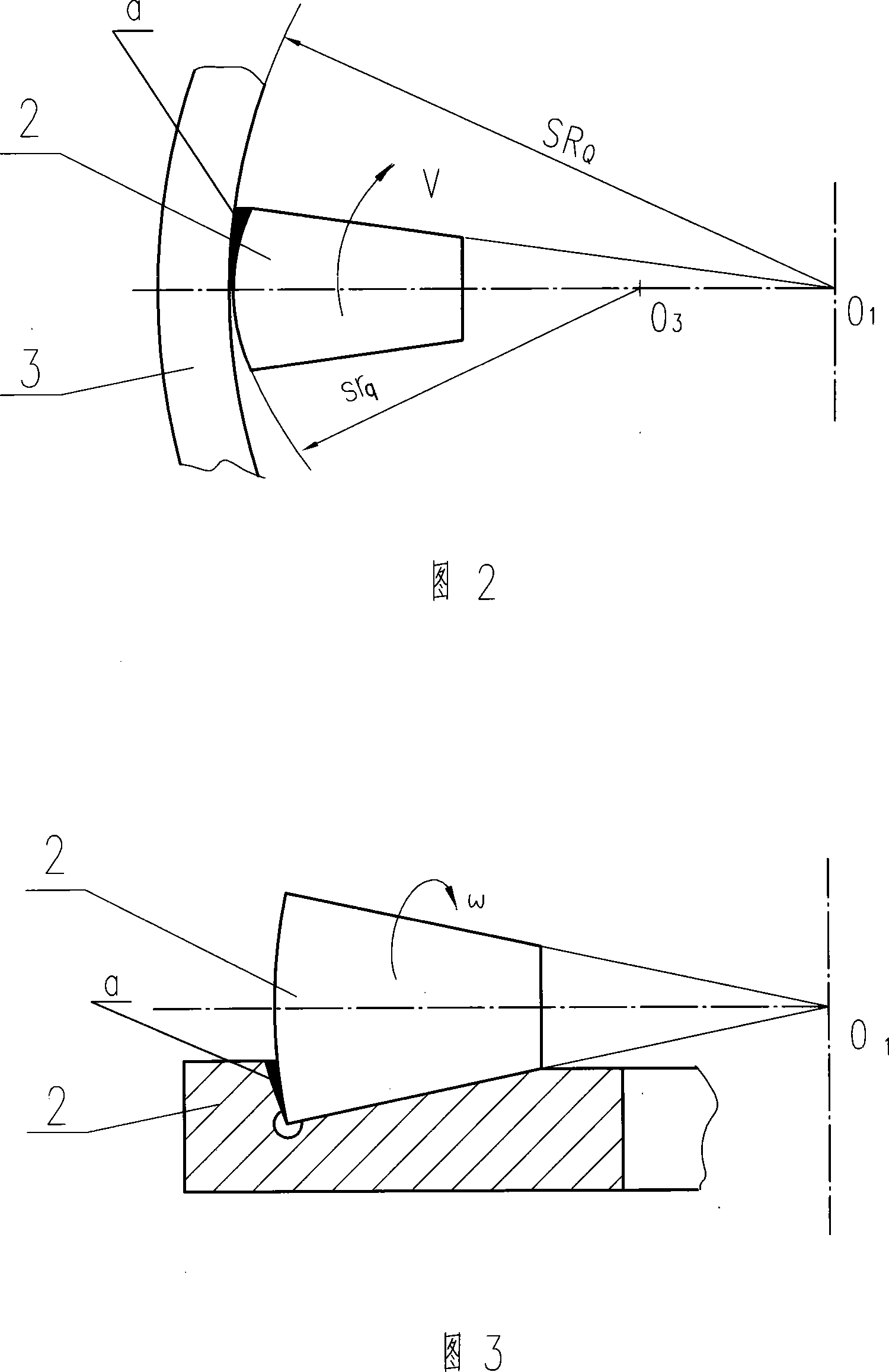

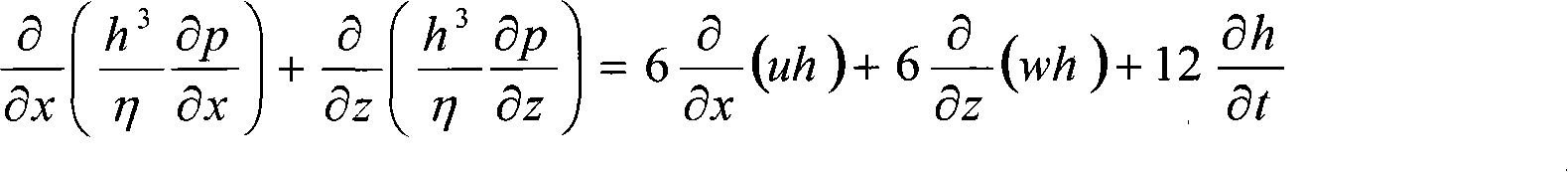

Oil film lubrication method between large-end face of taperroller and capped edge of housing washer in thrush bearing

InactiveCN101092992AImprove performanceRich design methodBearing componentsRolling-element bearingThrust bearing

This invention discloses a film lubrication method for thrust bearing roller cone races and ribs, which forms a wedge clearance between the large end surface of a roller and inside wall of a ring rib and fills it with lubrication oil, when the shape, size of the clearance and axial load, glide speed and viscosity of the oil are matched to each other, a dynamic pressure film is formed between the two surfaces, in which the wedge clearance is formed by cone roller spherical large end surface and the ring rib spherical ring, so it's easy to form a dynamic pressure film by selecting race SRQ of the inner surface of the race and axis ring and srq of the cone large end surface reasonably.

Owner:郭溪泉

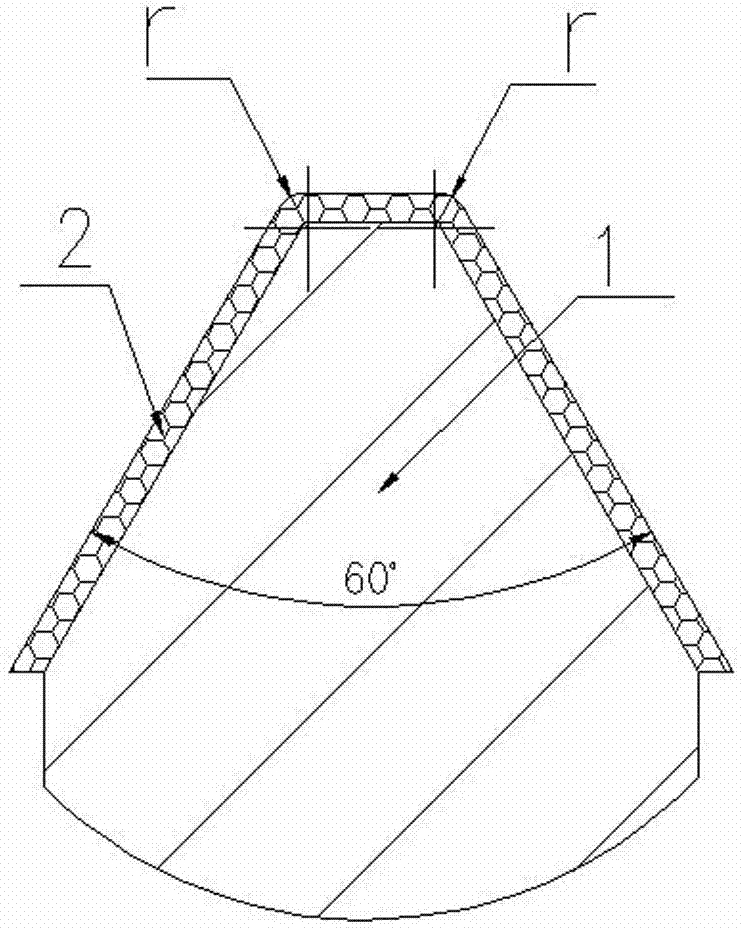

Electroplating CBN grinding wheel for efficient and precise gear profile grinding and manufacturing method of electroplating CBN grinding wheel for efficient and precise gear profile grinding

ActiveCN103878705AImprove mass distributionIncrease limit speedBonded abrasive wheelsIsosceles trapezoidAdsorptive membrane

The invention relates to an electroplating CBN grinding wheel for efficient and precise gear profile grinding. The electroplating CBN grinding wheel comprises a dish-shaped base body and a material grinding area at the edge of the dish-shaped base body, the mass of the material grinding area is 4%-15% of the total mass of the base body, the cross-section of a material grinding layer on the material grinding area is in an isosceles trapezoid shape, and the upper bottom and the two lateral edges are chamfered. A manufacturing method of the electroplating CBN grinding wheel includes the steps of firstly machining the base body of the grinding wheel, and then sequentially conducting negative and positive pole alternative electrochemistry oil removing, clamp and electrostatic adsorption film insulation assembling, negative and positive pole alternative electrolytic treatment, ballistic method preplating, grinding material assembling, thickening and grinding wheel electroplating on the base body of the grinding wheel. The using linear velocity of the electroplating CBN grinding wheel can achieve 250 m / s, and the grinding feeding amount achieves 4 m / min-10 m / min and is much higher than that of a common grinding wheel. The roughness Ra can achieve 0.4 micrometers, the surface quality requirement of a workpiece can be met, and gear efficient and precise gear profile grinding can be successfully achieved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com