Patents

Literature

558results about How to "Improve support rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

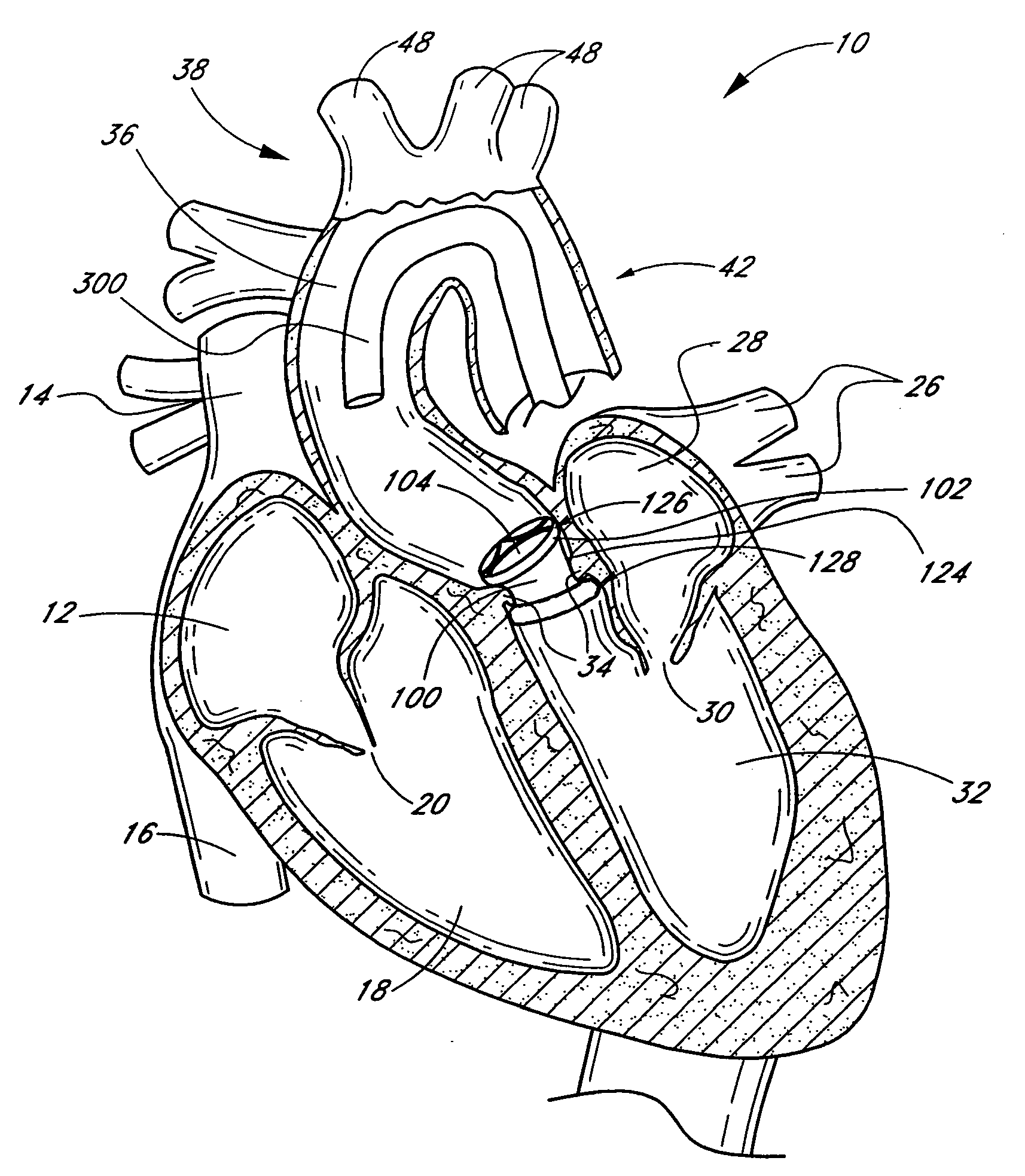

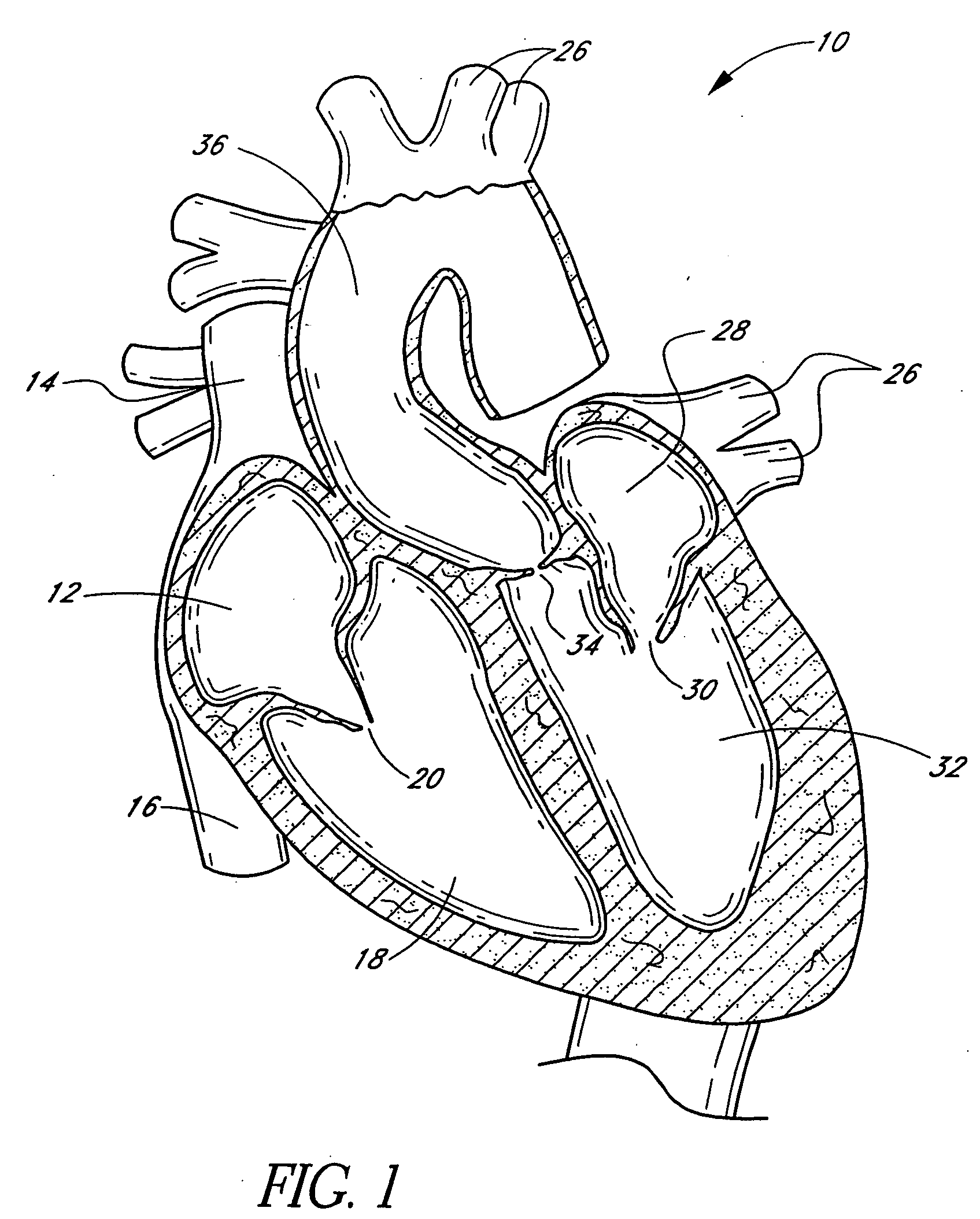

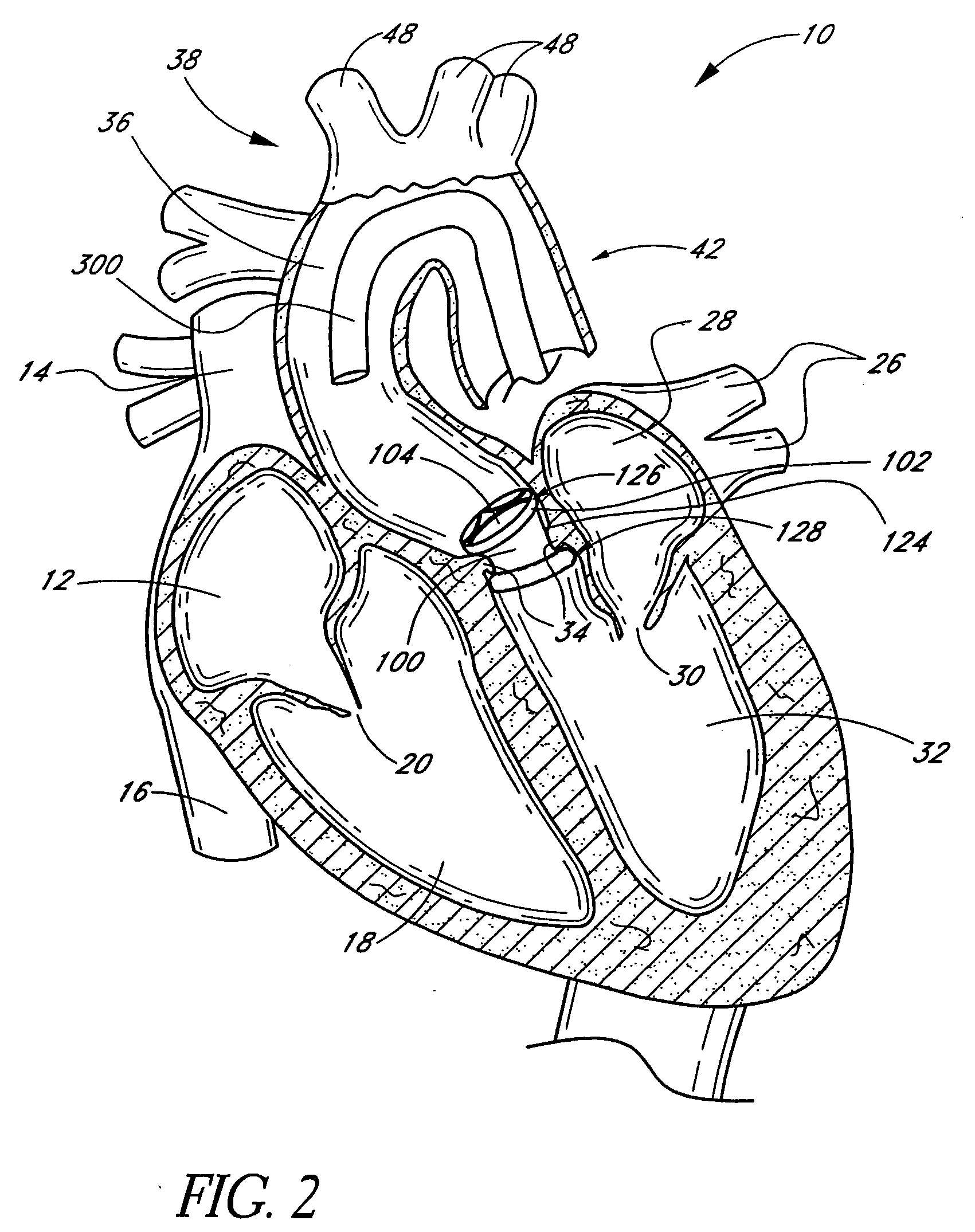

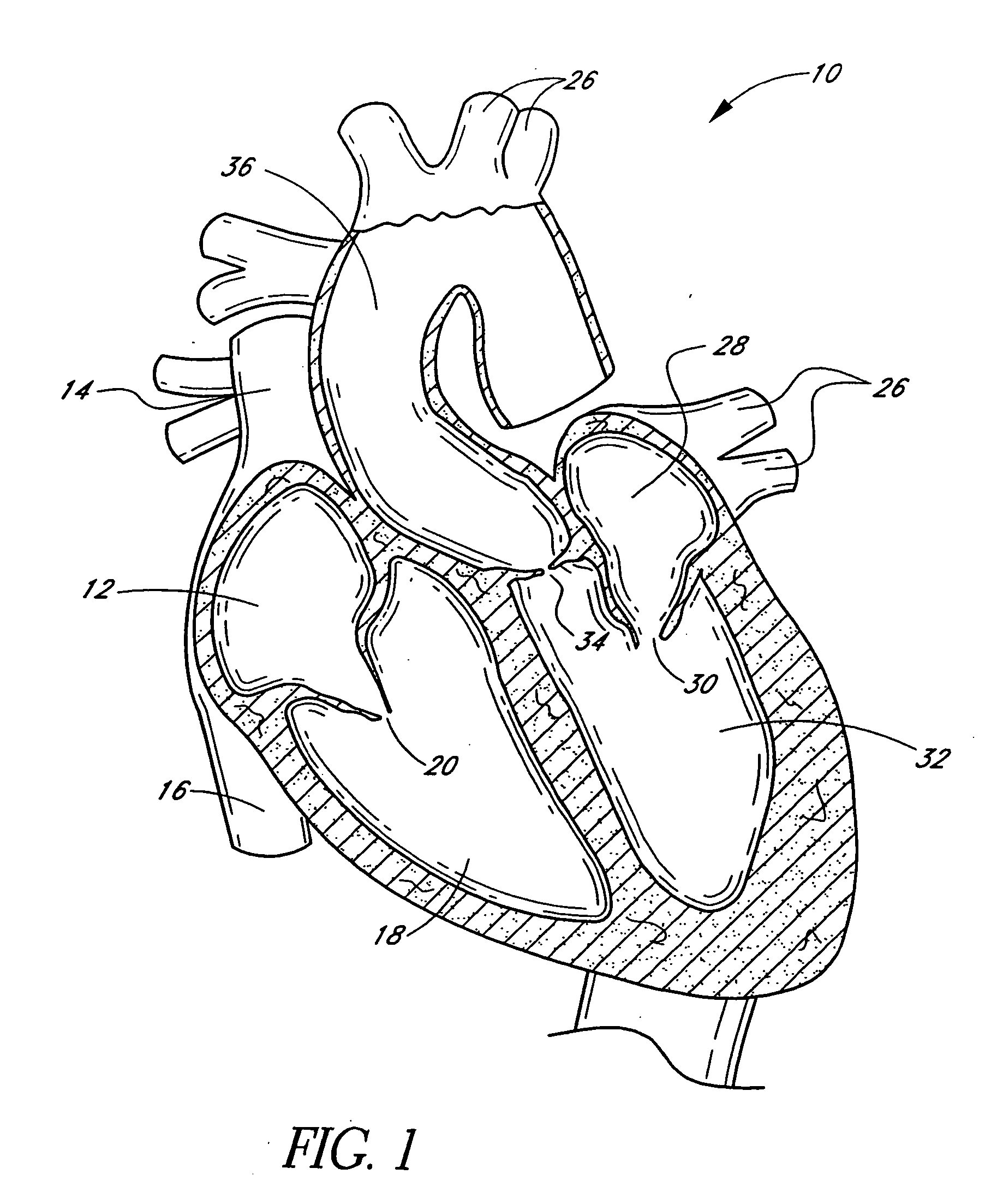

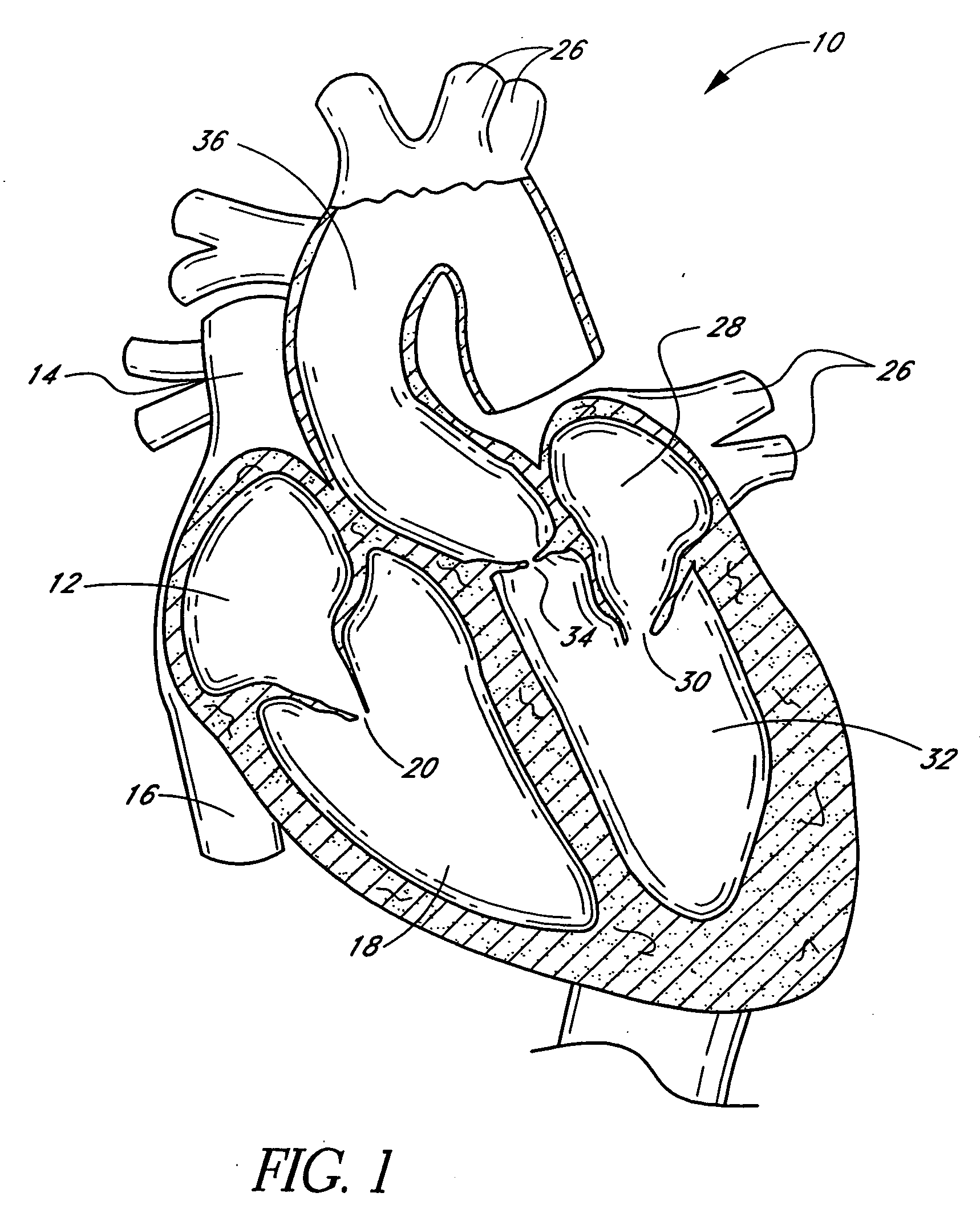

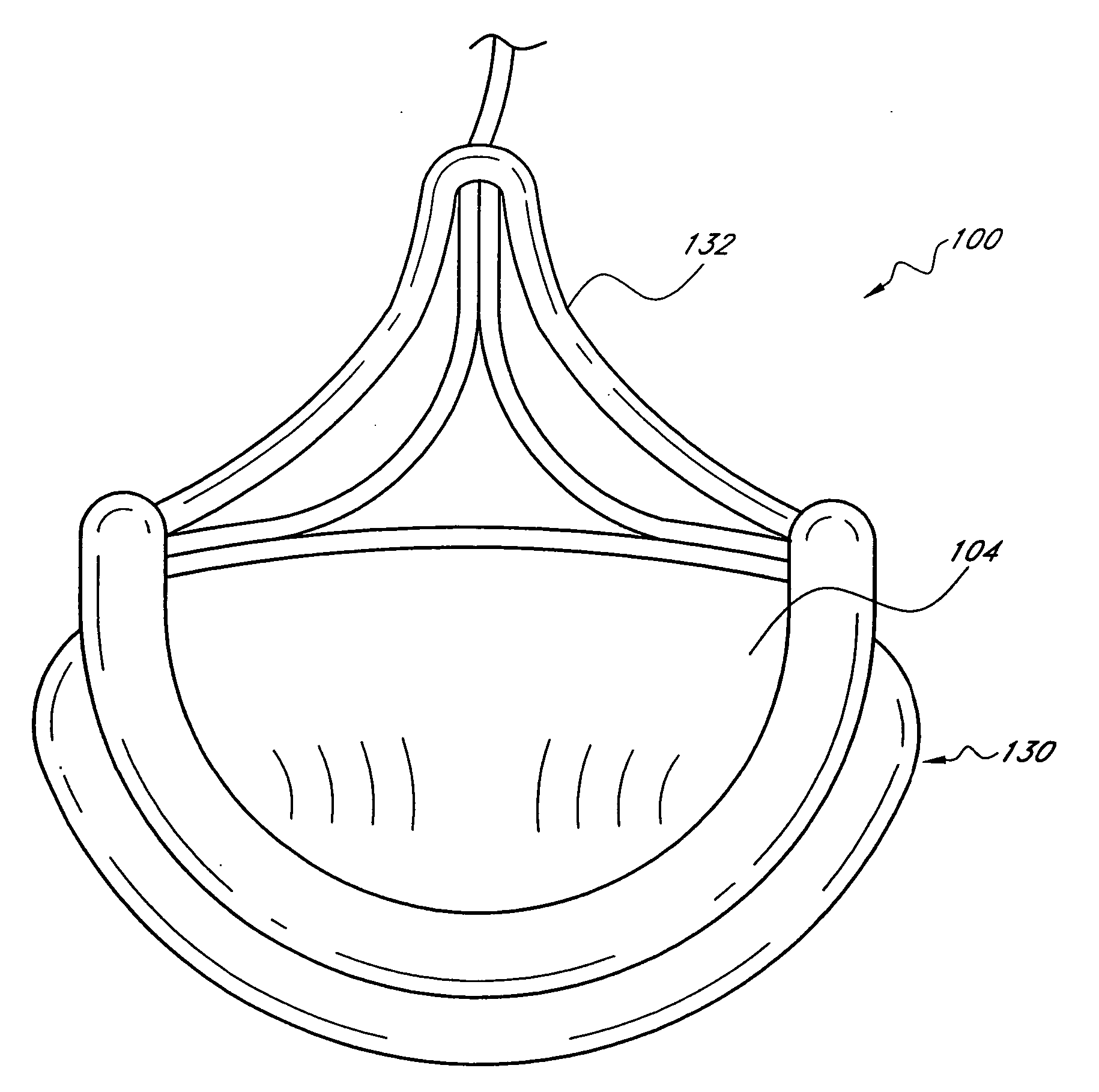

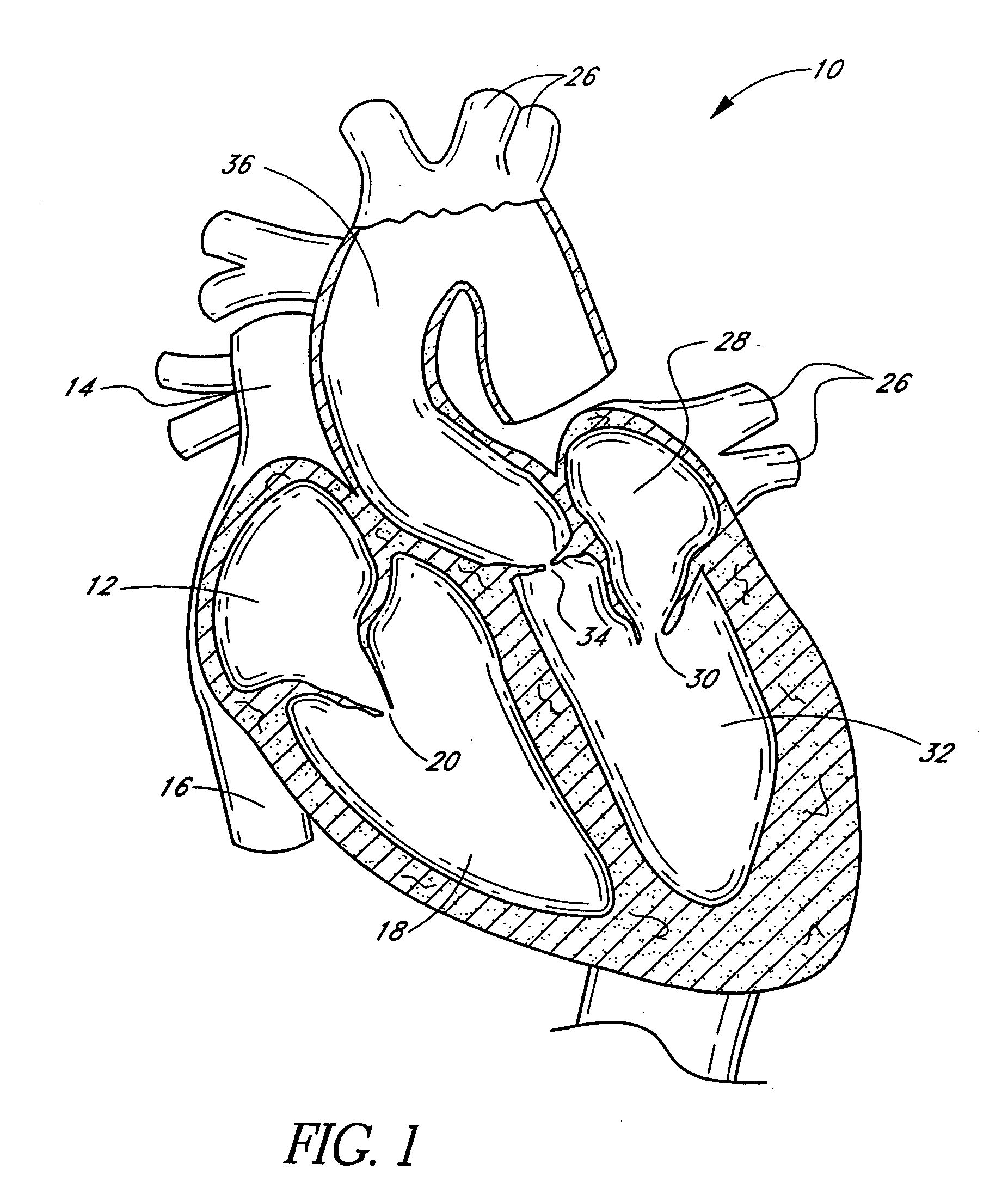

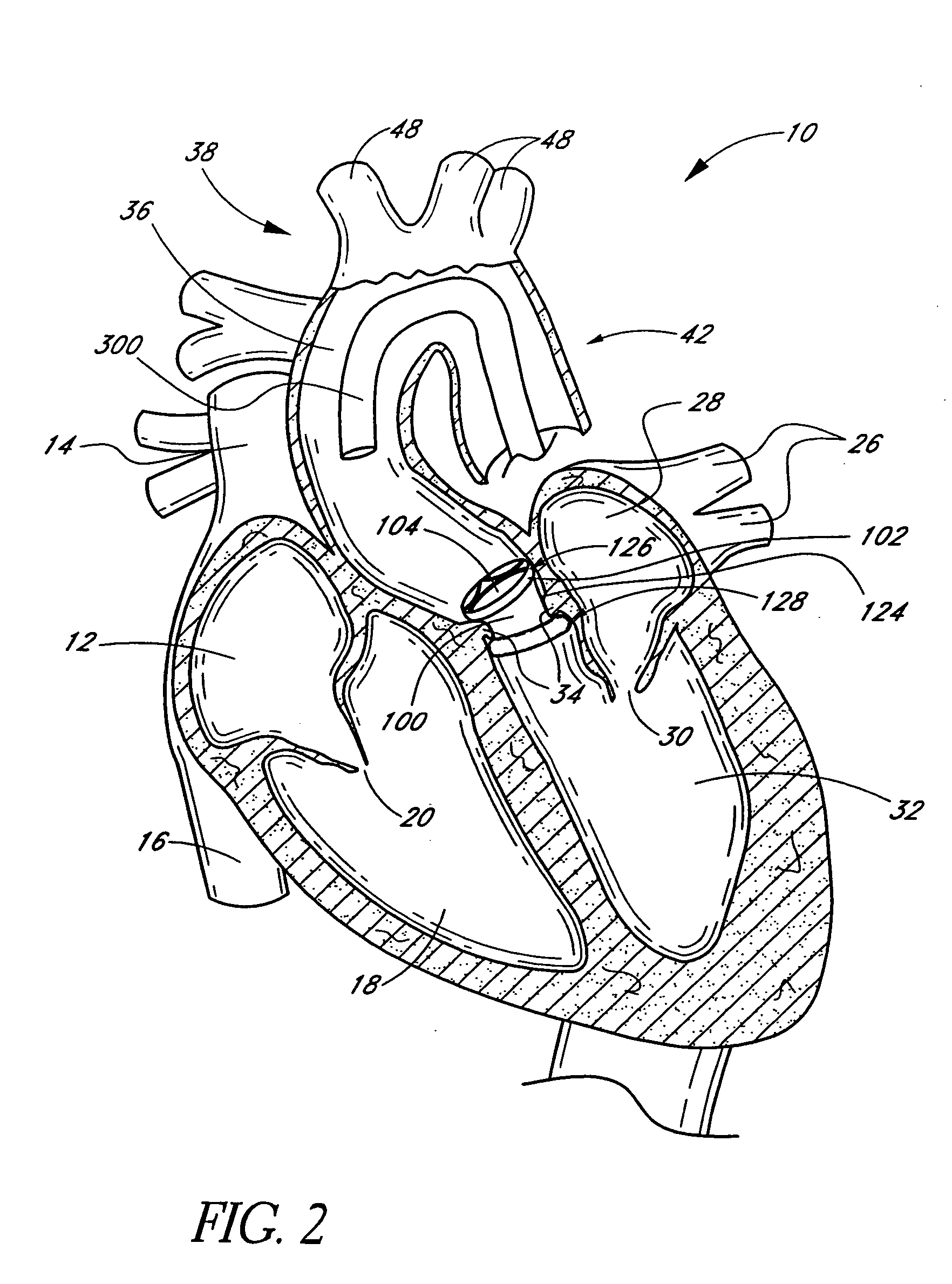

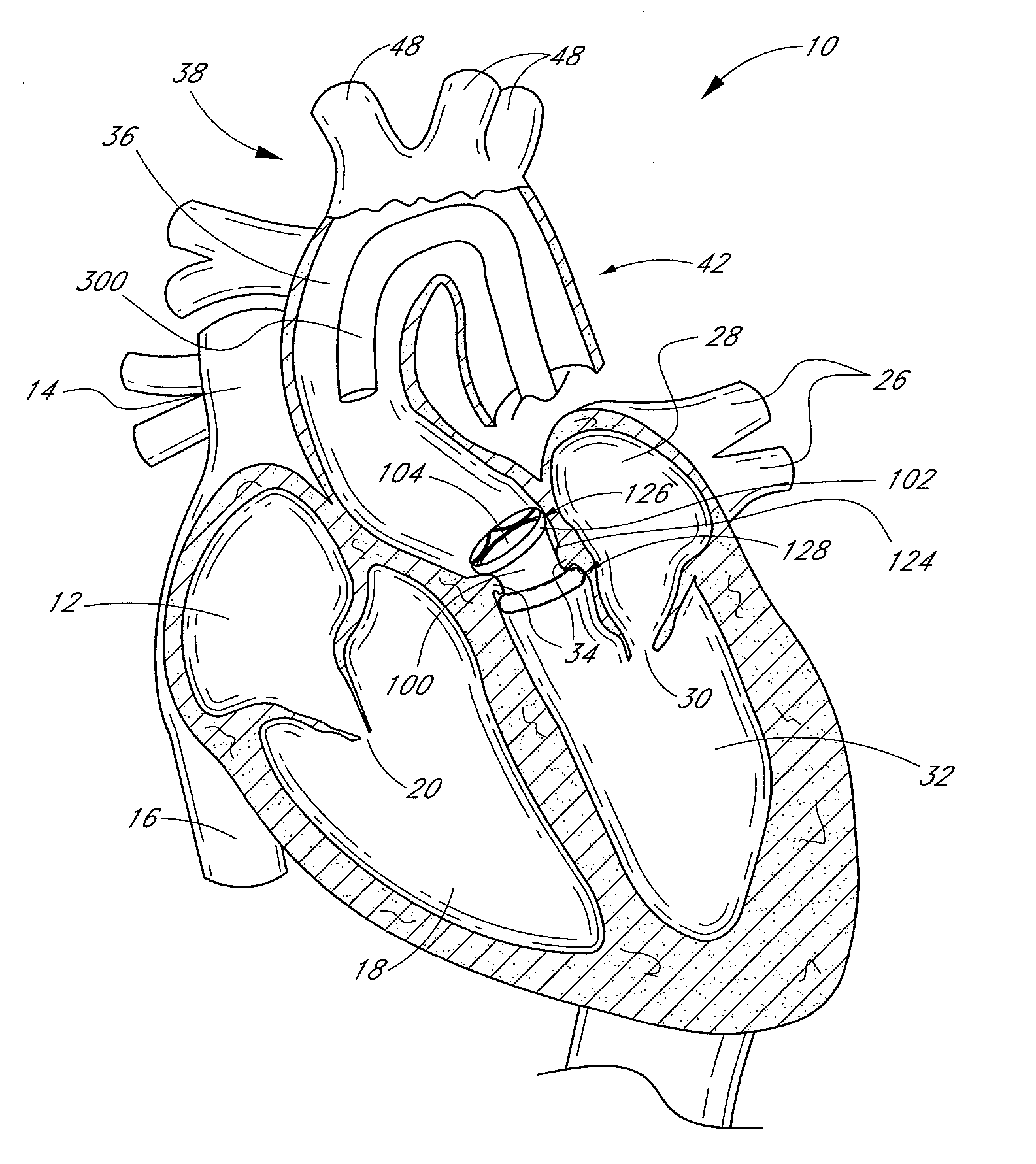

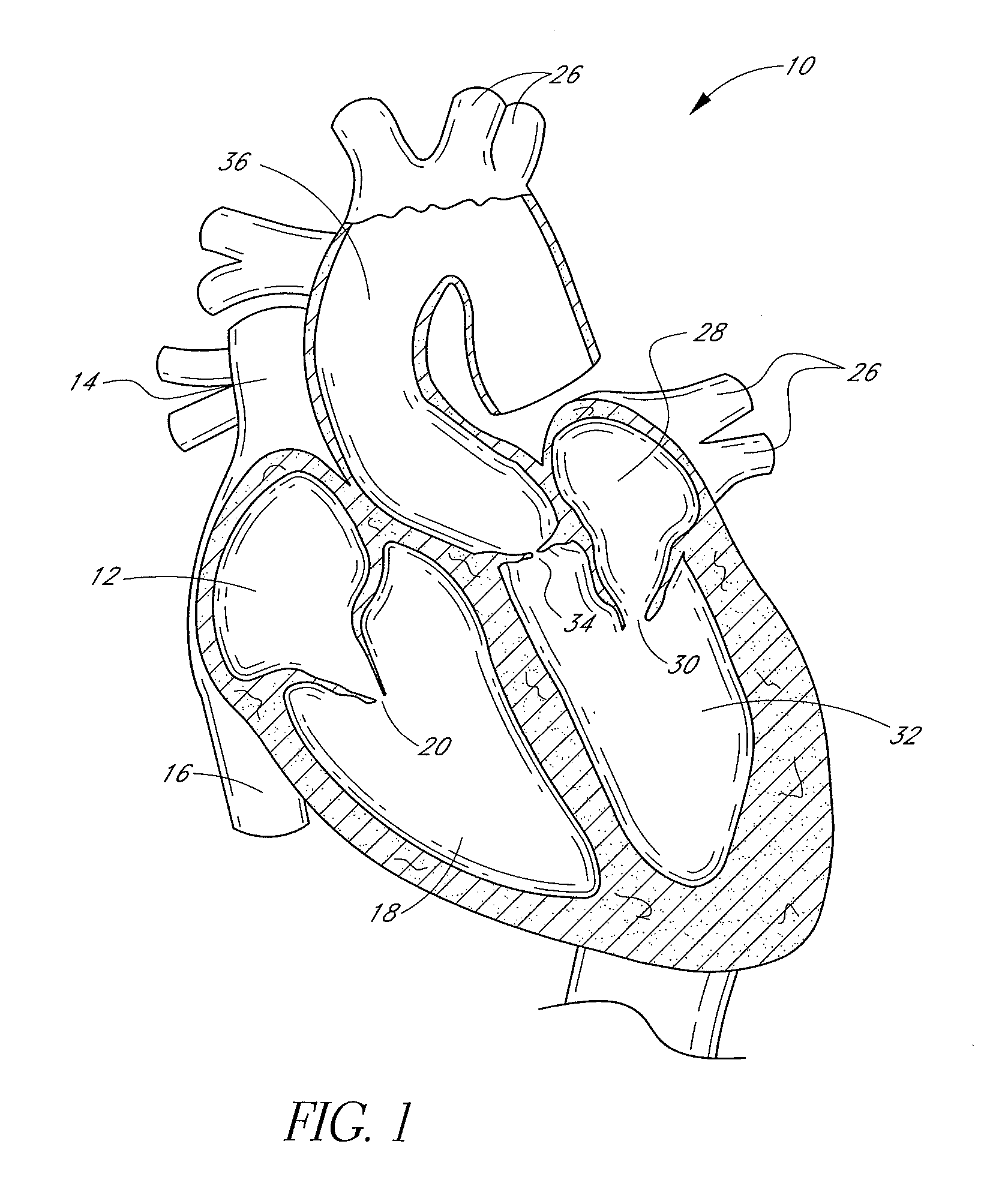

Nonstented heart valves with formed in situ support

InactiveUS20060020327A1Improve support rigidityMinimally invasive procedureSuture equipmentsHeart valvesProsthetic valveProsthesis

An implantable prosthetic valve having an in situ formable support structure and methods of deploying such a valve are disclosed. In one arrangement, the valve has a base and at least one flow occluder. A first flexible component which is incapable of retaining the valve at a functional site in the arterial vasculature extends proximally of the base of the valve. A second flexible component which is incapable of retaining the valve at a functional site in the arterial vasculature extends distally of the base of the valve. At least one rigidity component combines with at least one of the first and second flexible components to impart sufficient rigidity to the first or second components to retain the valve at the site.

Owner:DIRECT FLOW MEDICAL INC

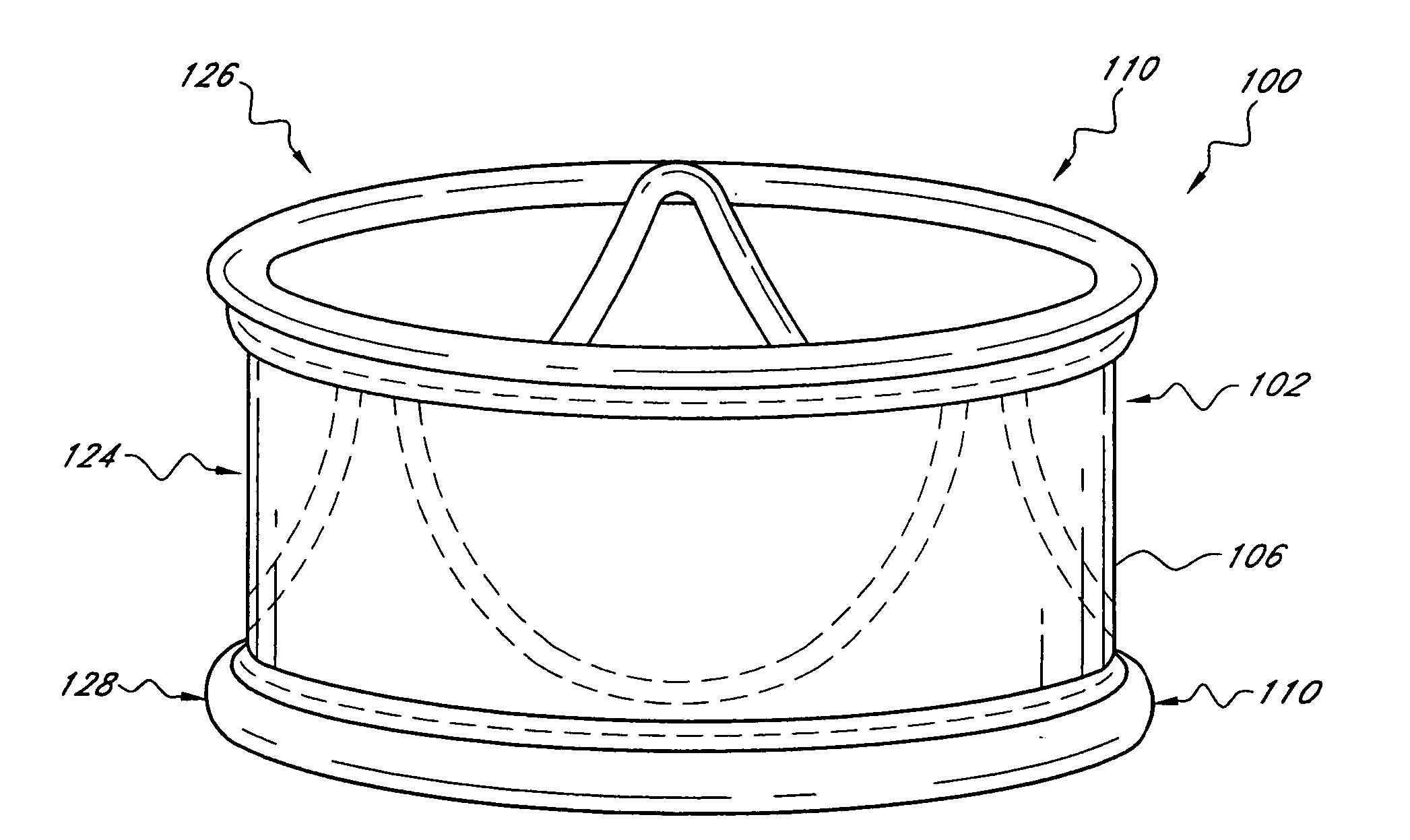

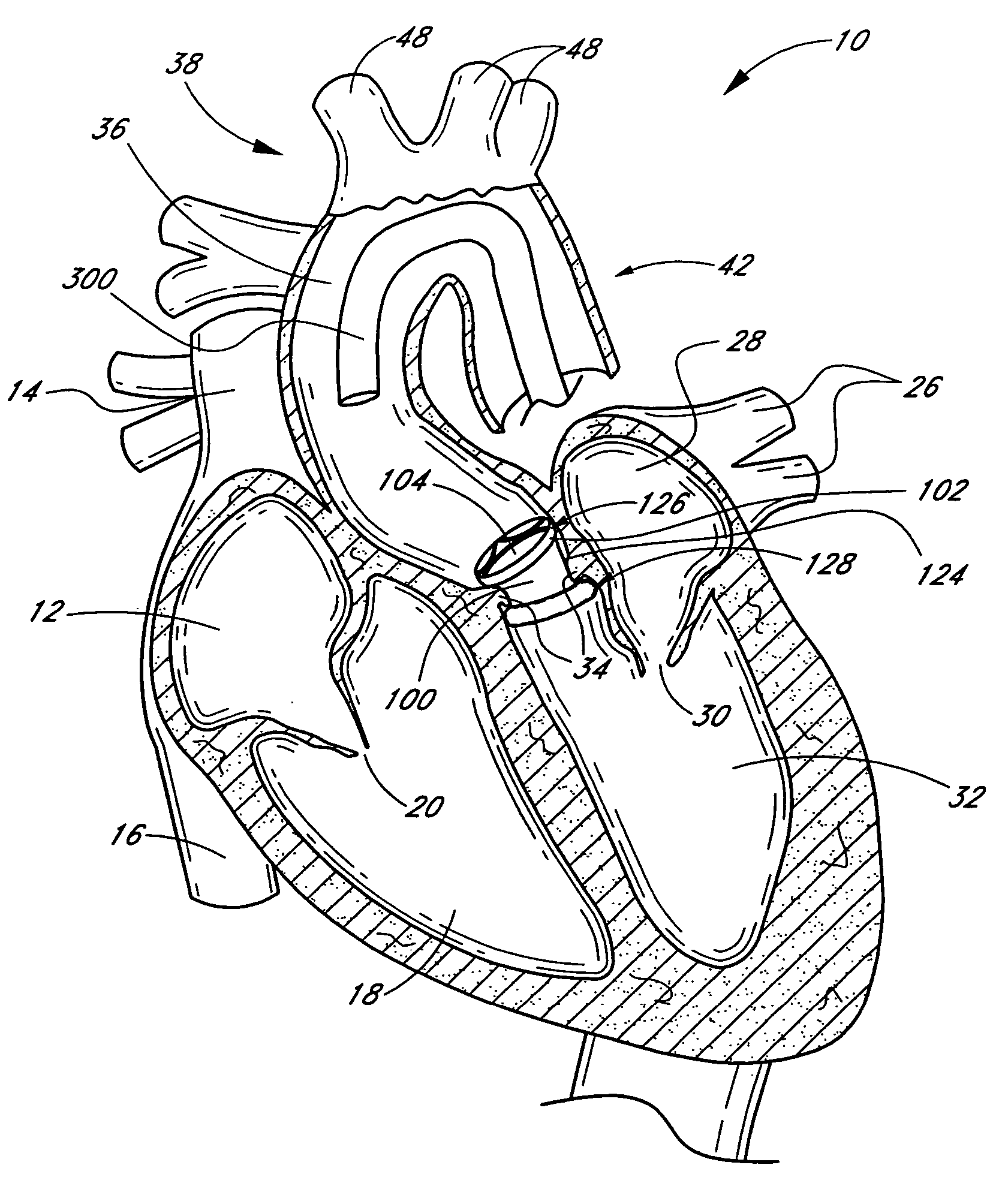

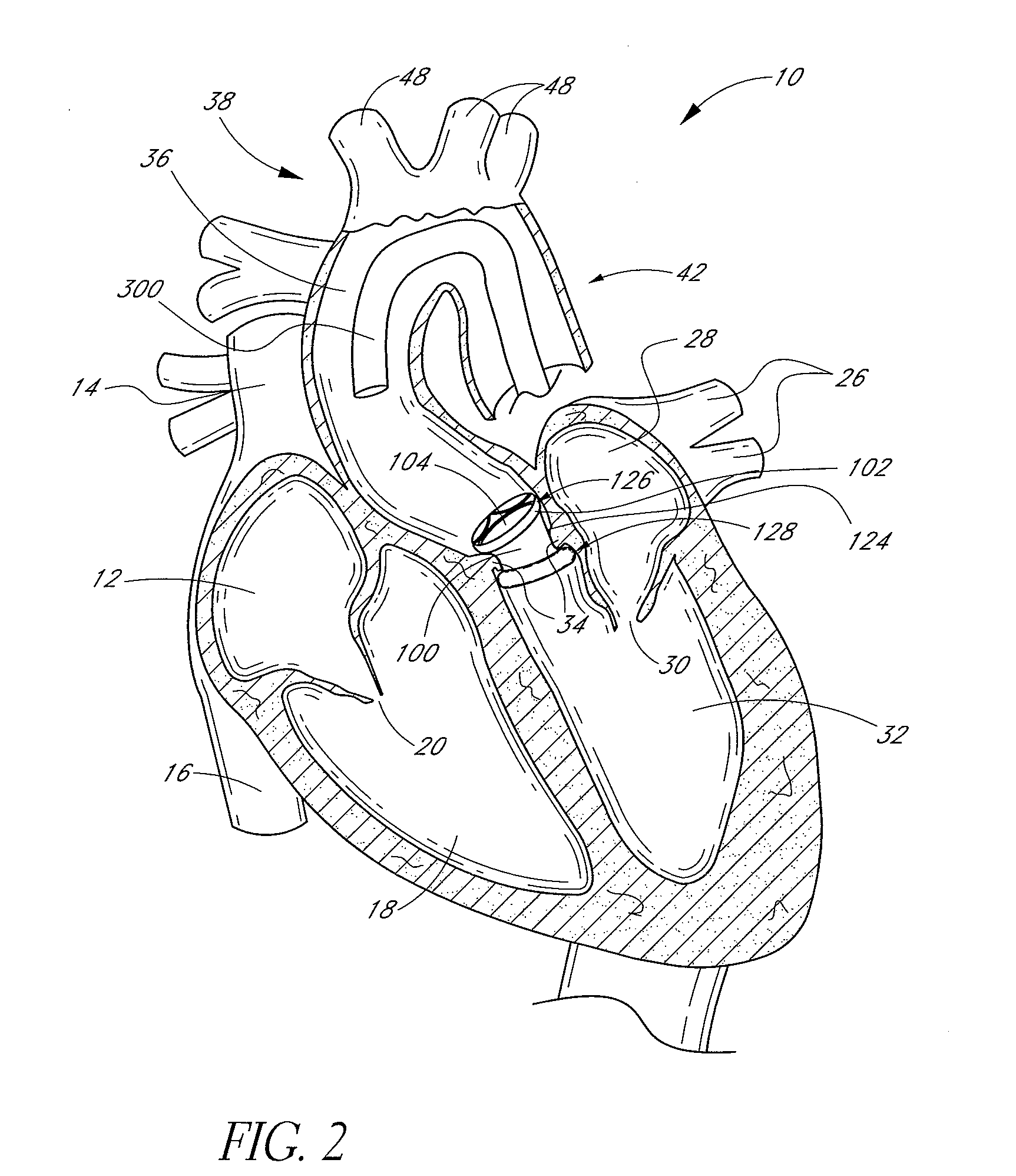

Translumenally implantable heart valve with multiple chamber formed in place support

InactiveUS20060025855A1Minimally invasive procedurePrevent disengagementSuture equipmentsHeart valvesProsthetic valveEngineering

A cardiovascular prosthetic valve comprises an inflatable body that has at least a first inflatable chamber and a second inflatable chamber that is not in fluid communication with the first inflatable chamber. The inflatable body is configured to form, at least in part, a generally annular ring. A valve is coupled to the inflatable body. The valve is configured to permit flow in a first axial direction and to inhibit flow in a second axial direction opposite to the first axial direction. A first inflation port is in communication with the first inflatable chamber. A second inflation port in communication with the second inflatable chamber.

Owner:DIRECT FLOW MEDICAL INC

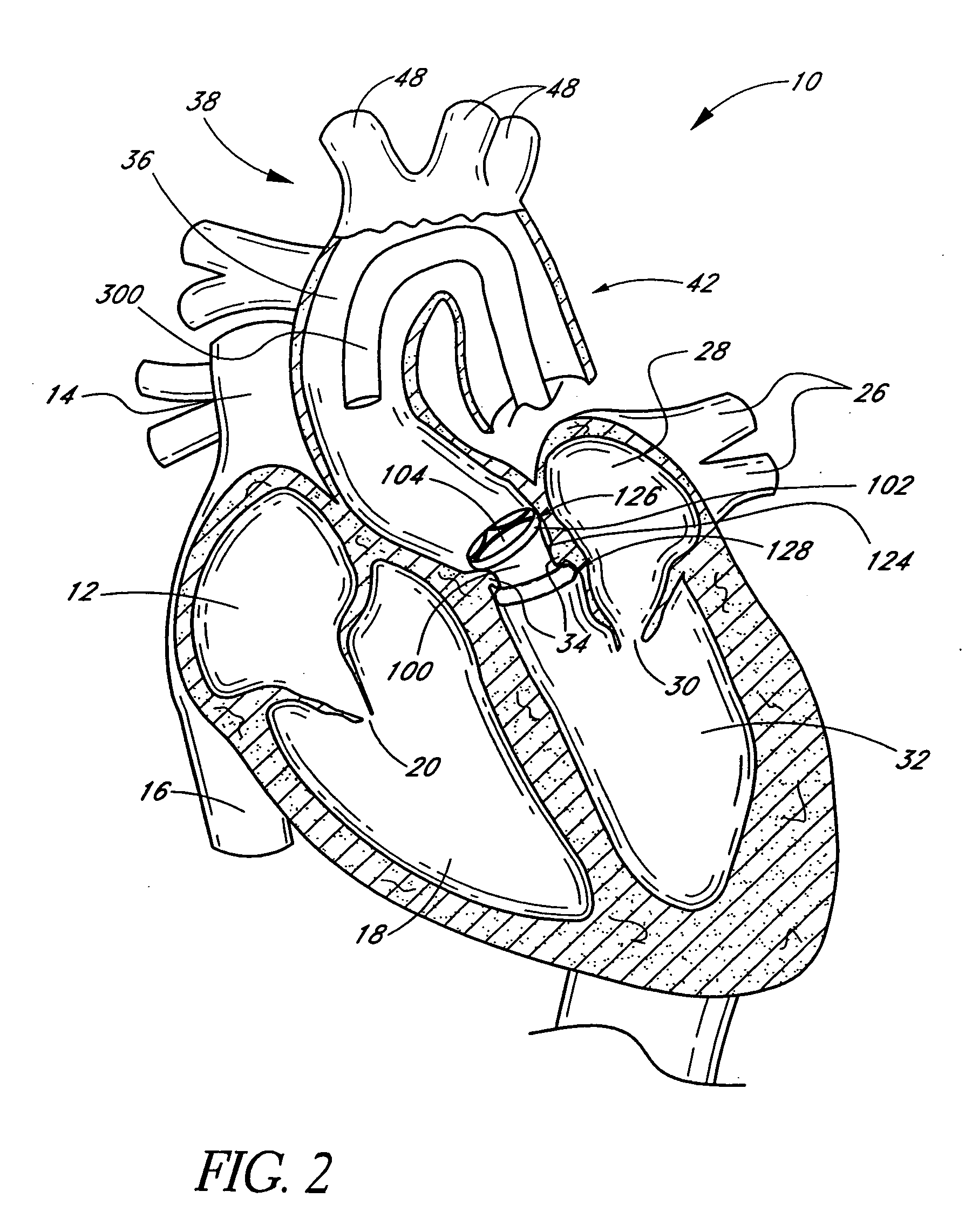

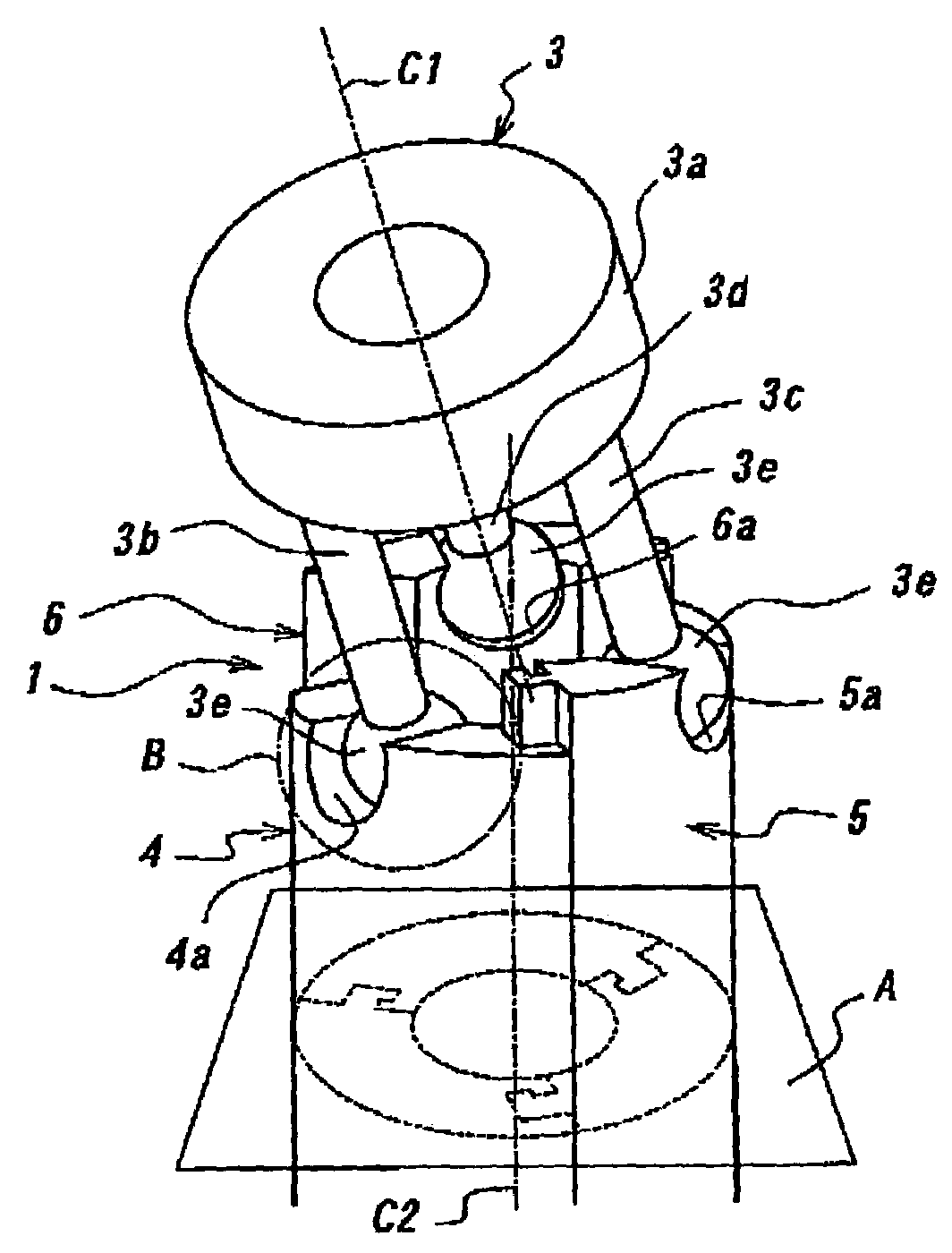

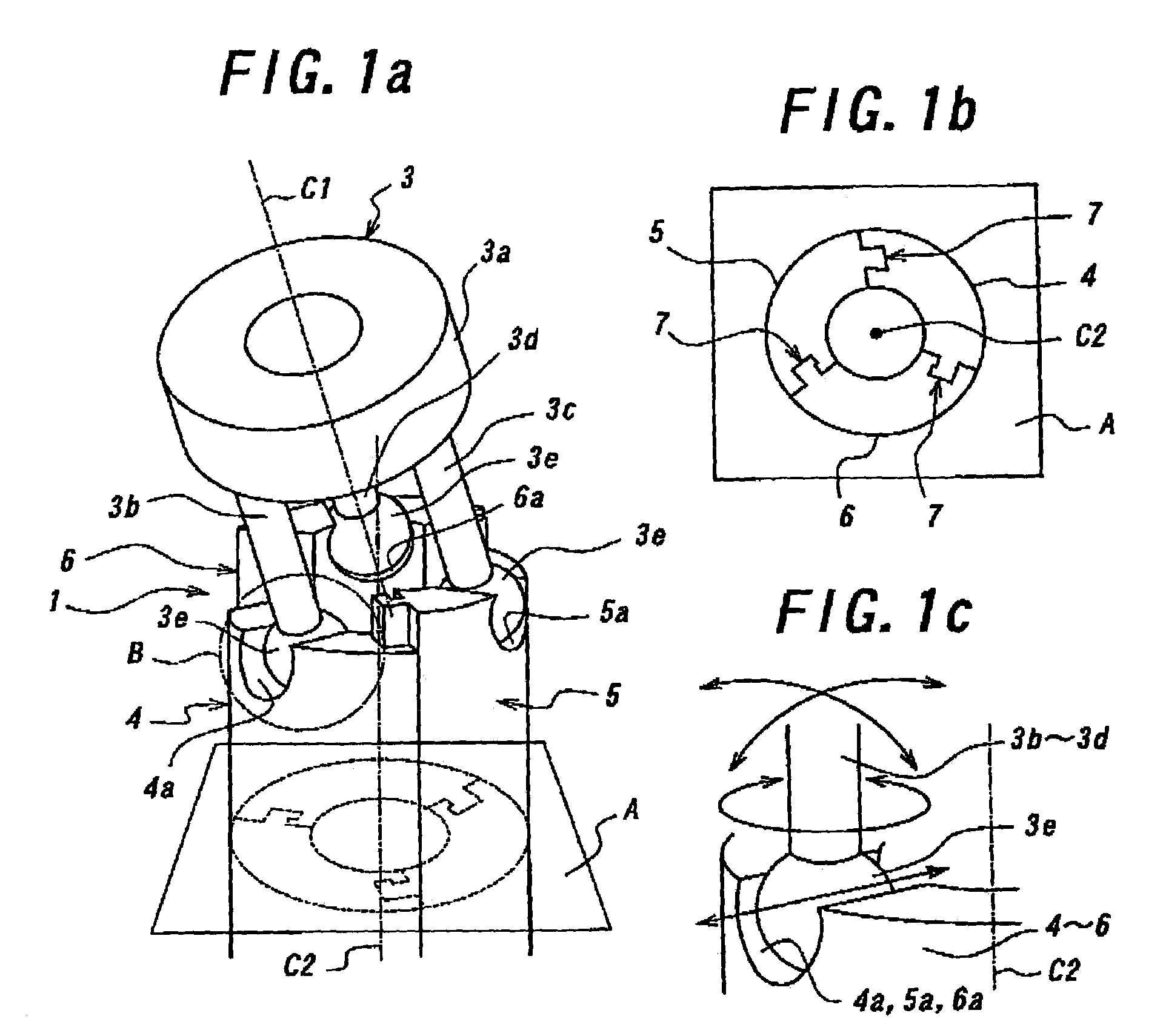

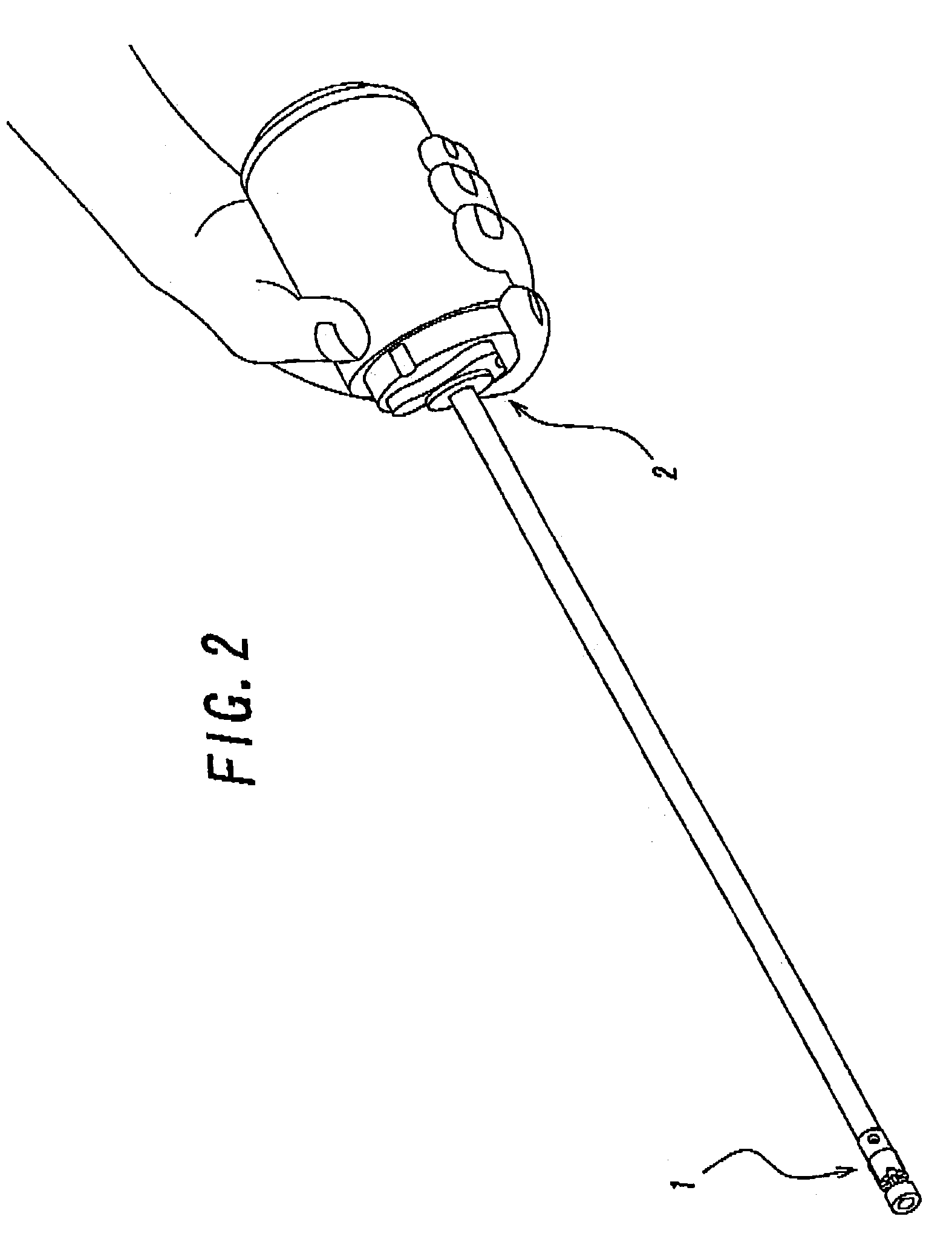

High-rigidity forceps tip assembly for active forceps and active forceps equipped with the same

InactiveUS7273488B2Efficiently transmitHigh rigidityMechanical apparatusJointsLaparoscopic surgeryForceps

Provided is a forceps tip assembly capable of supporting a forceps tip with high rigidity in order to realize a laparoscopic surgery requiring a significant power with the forceps tip, such as an organ removal surgery which has been heretofore difficult to be performed by a robot for medical use. The forceps tip assembly includes: a forceps tip supporting member which has a supporting part for supporting a forceps tip and three leg parts which are disposed at even intervals in a circumferential direction around a central axis line C1 and fixed to the supporting part so as to protrude backward from the supporting part; and three back-and-forth moving members which are disposed at even intervals in a circumferential direction around a predetermined central axis line C2 extending in a front-to-rear direction, which have their front end portions coupled with the three leg pads swingably and slidably in a direction orthogonal to the predetermined central axis line C2 and which are mutually coupled together as relatively movable in the extending direction of central axis line C2.

Owner:THE UNIV OF TOKYO

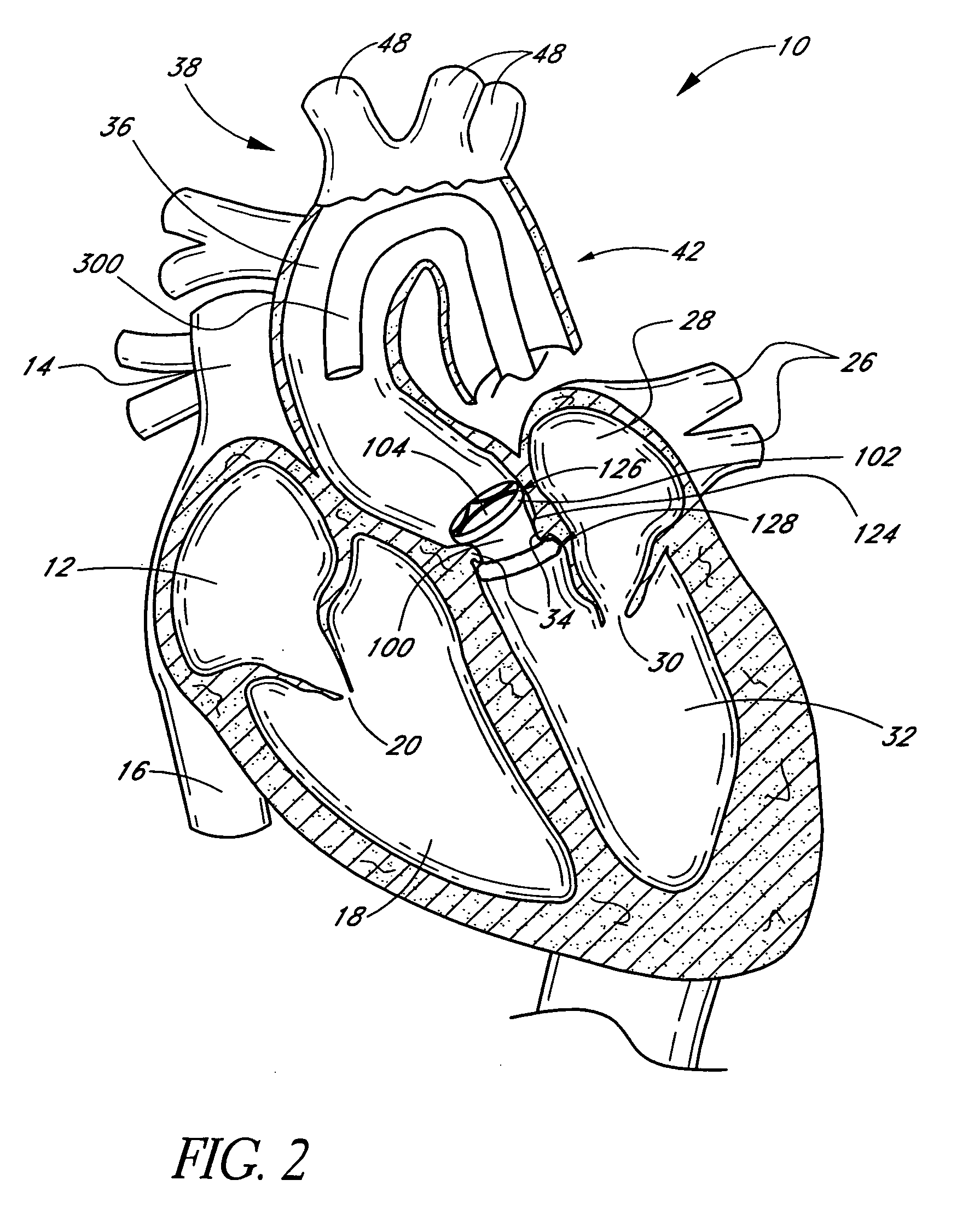

Methods of cardiac valve replacement using nonstented prosthetic valve

InactiveUS20060020334A1Minimally invasive procedurePrevent disengagementSuture equipmentsHeart valvesProximateProsthesis

A method of implanting a prosthetic valve within a heart comprises translumenally advancing a prosthetic valve comprising an inflatable structure to a position proximate a native valve of the heart. A portion of the inflatable structure that is distal to the native valve is inflated. A portion of the inflatable structure that is proximal to the native annular valve is inflated.

Owner:DIRECT FLOW MEDICAL INC

Translumenally implantable heart valve with formed in place support

InactiveUS20060025854A1Minimally invasive procedurePrevent disengagementSuture equipmentsHeart valvesProsthetic valveCuff

Owner:DIRECT FLOW MEDICAL INC

Method of in situ formation of translumenally deployable heart valve support

InactiveUS20080015687A1Minimally invasive procedurePrevent disengagementSuture equipmentsHeart valvesProximateProsthesis

A method of implanting a prosthetic valve within the heart comprises translumenally advancing a prosthetic valve comprising an inflatable structure to a position proximate a native valve of the heart. A first chamber of the inflatable structure is inflated and then, independently, a second chamber of the inflatable structure is inflated.

Owner:DIRECT FLOW MEDICAL INC

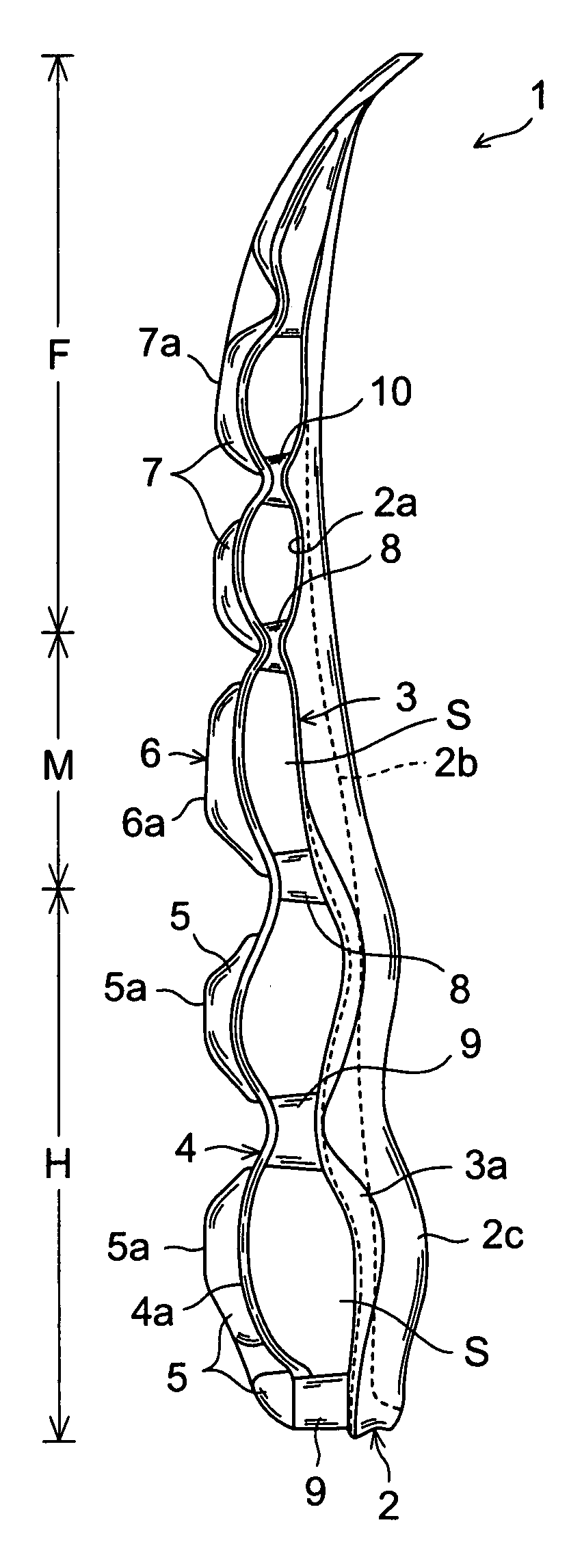

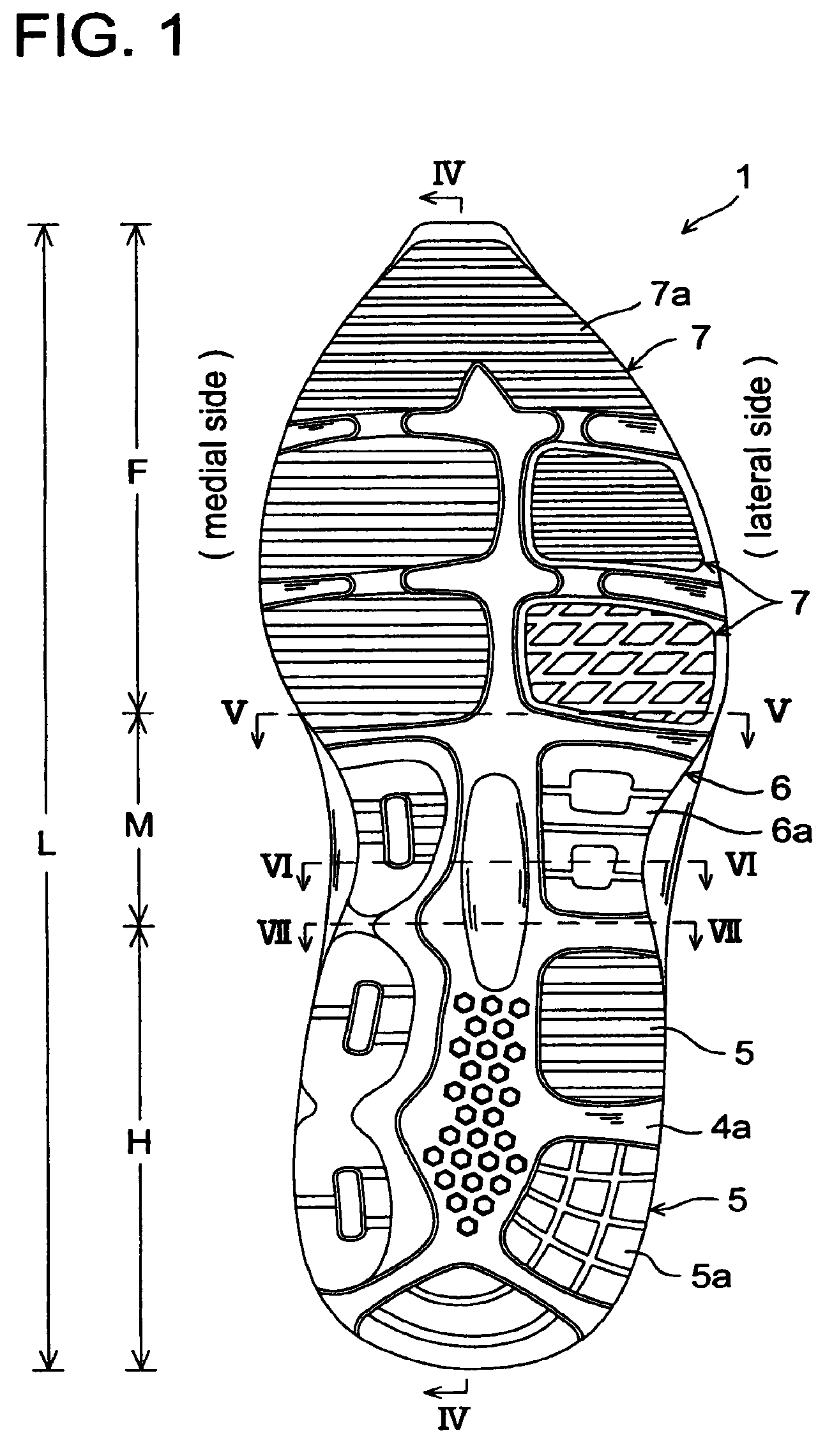

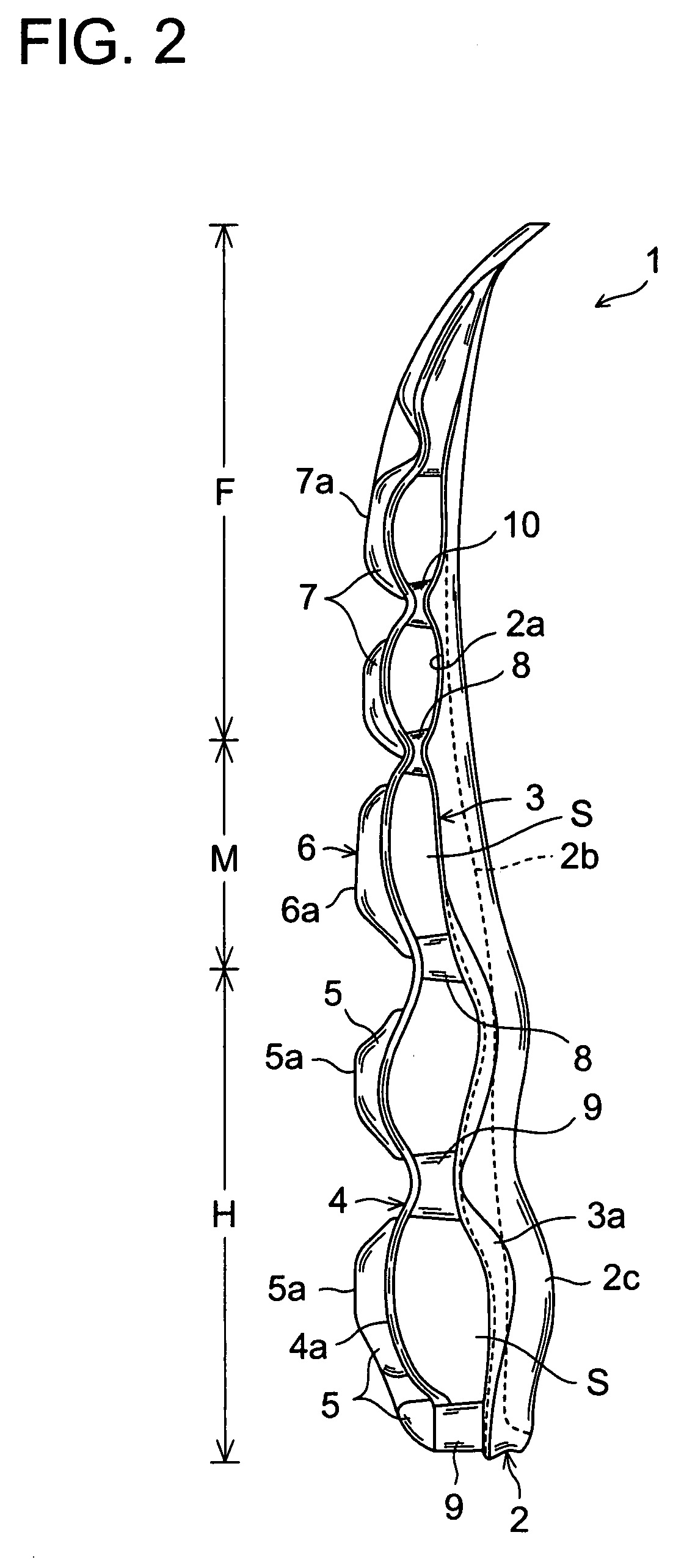

Midfoot structure of a sole assembly for a shoe

ActiveUS7886461B2Smooth transferRide feeling during running can be improvedSolesGround contactCurve shape

A midsole structure of a sole assembly for a shoe improves a ride feeling and stability of the midfoot portion of the sole assembly during running. The sole assembly 1 of the shoe includes an upper plate 3 disposed on an upper side of a midfoot portion M and formed of a hard elastic member, a lower plate 4 disposed under the upper plate 3, wherein the lower plate is formed of a hard elastic member and has a downwardly convexedly curved shape that forms a void S relative to the upper plate, a midfoot outsole 6 attached on a bottom surface 4a of the lower plate 4, having a ground contact surface 6a, and provided discretely in the longitudinal direction from an outsole 5 of a heel portion H and an outsole 7 of a forefoot portion F of the sole assembly 1, and connections 8, 9 provided on front and rear ends of the midfoot portion M and interconnecting the upper plate 3 with the lower plate 4 in the vertical direction.

Owner:MIZUNO CORPORATION

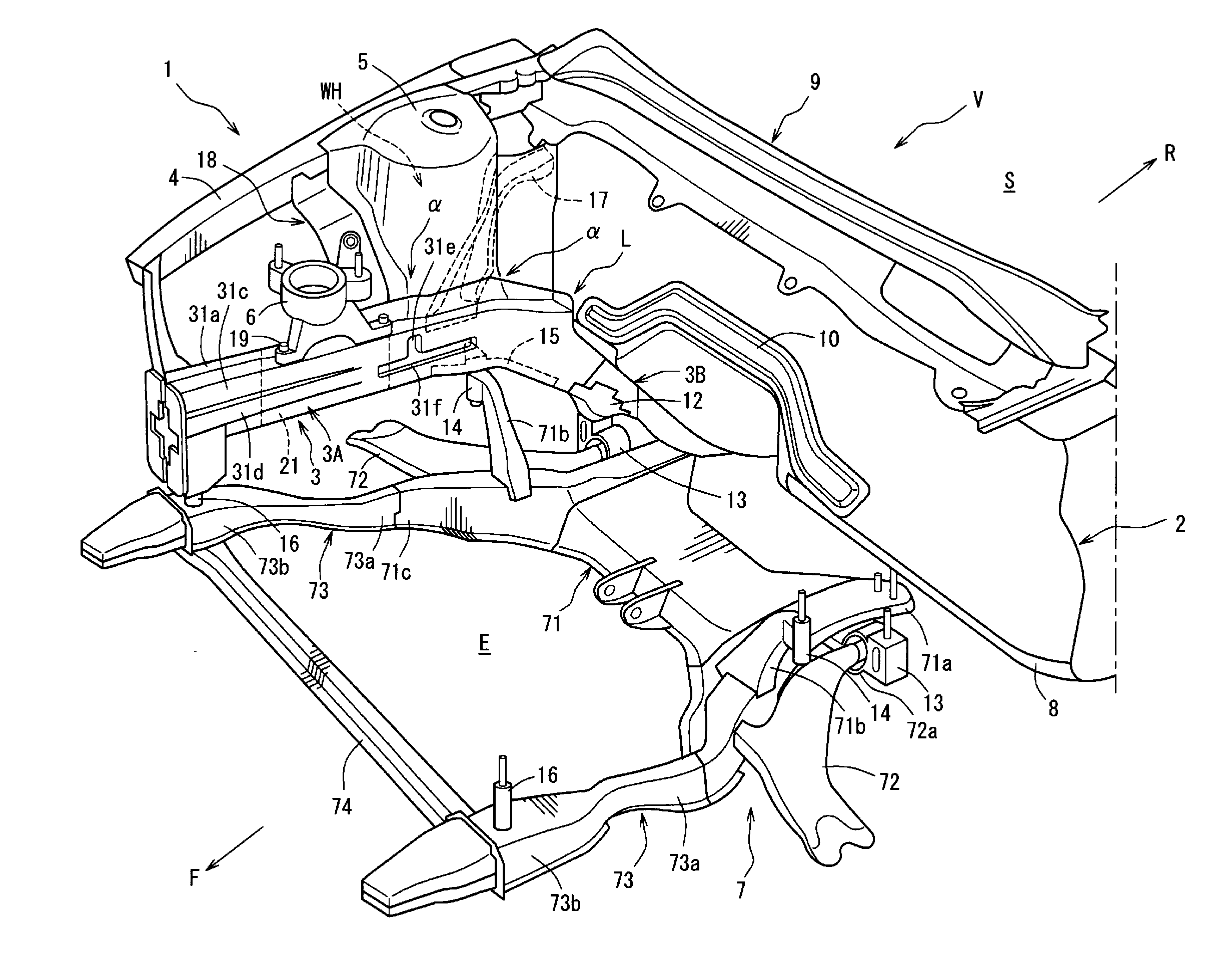

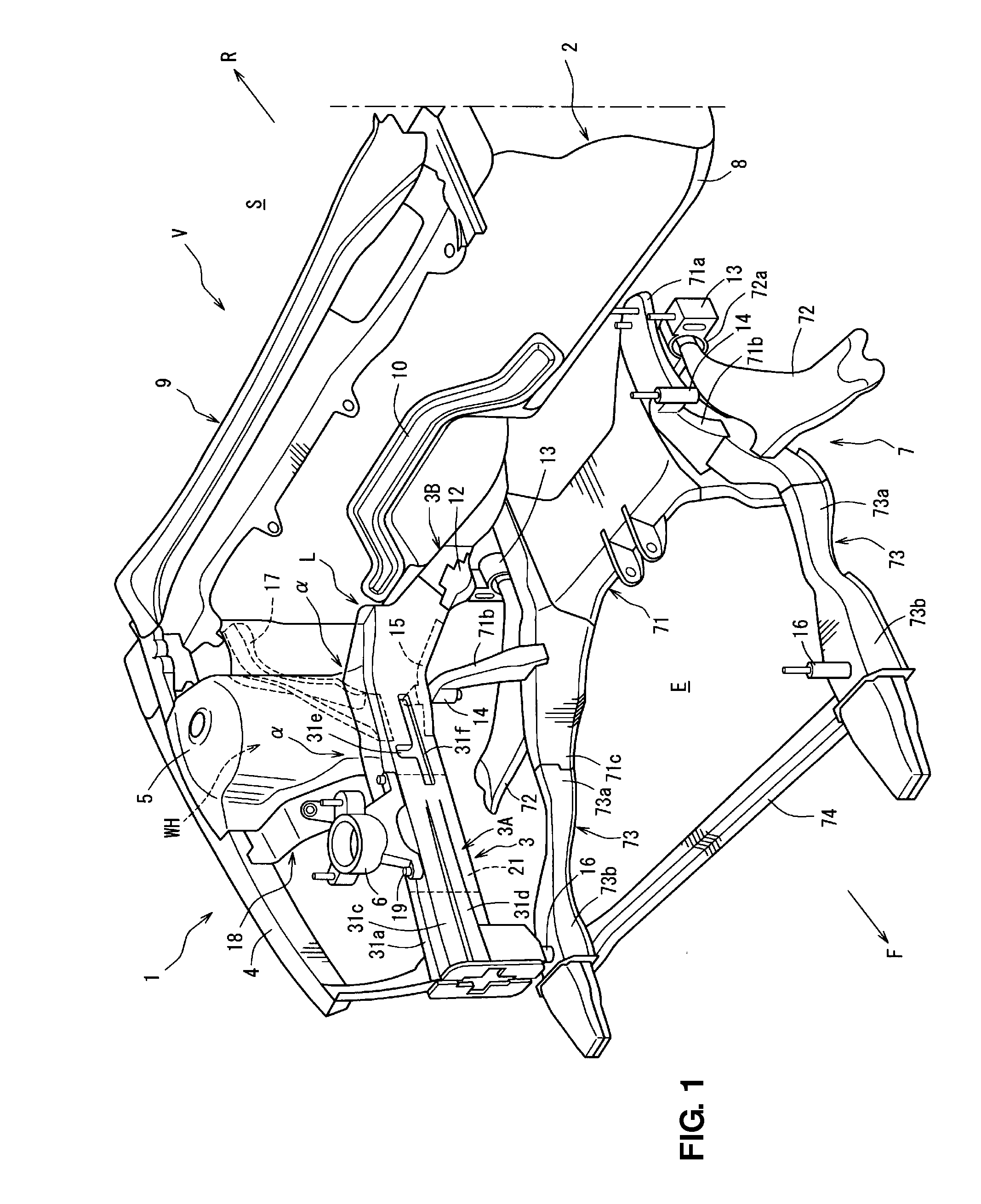

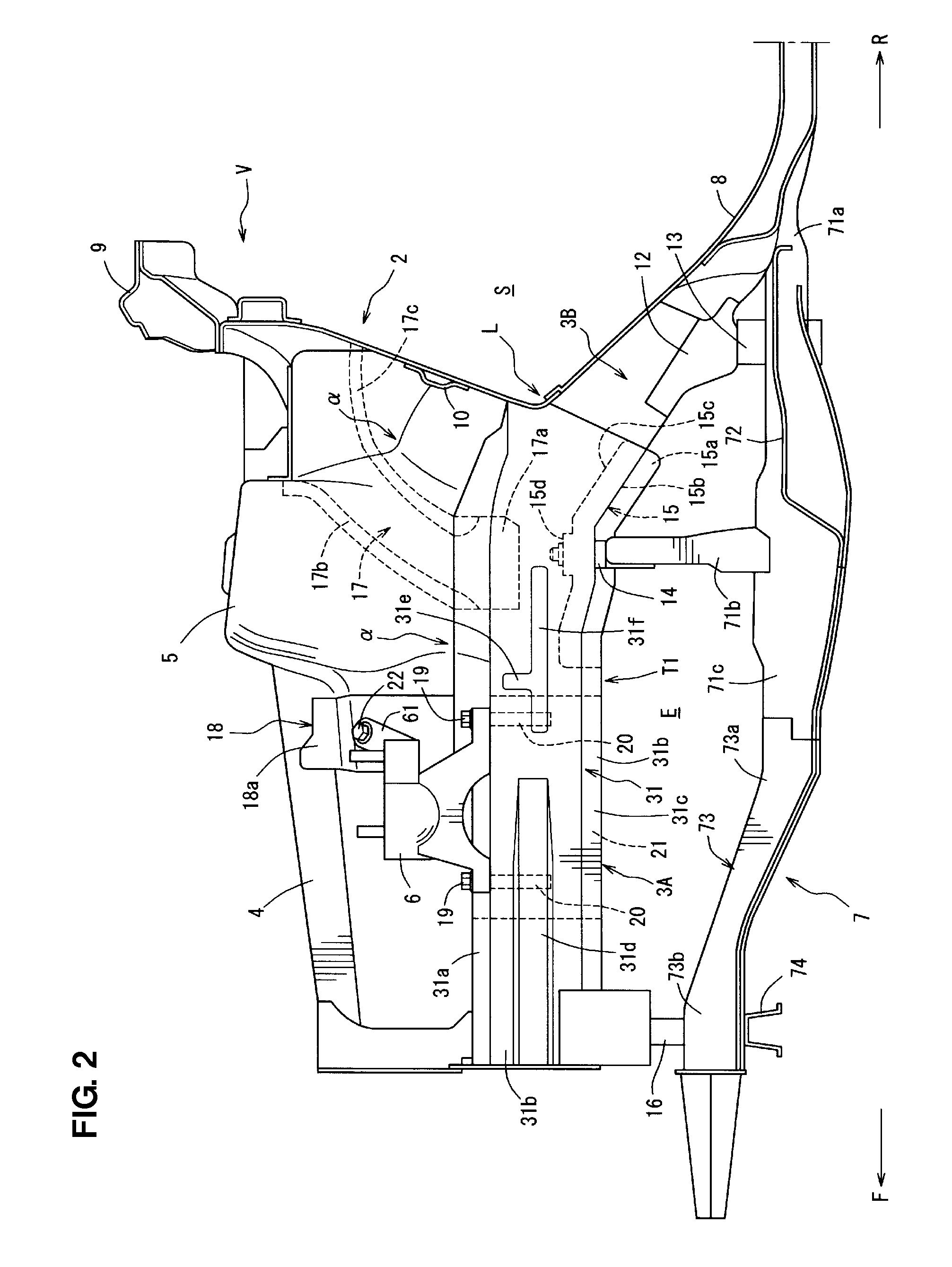

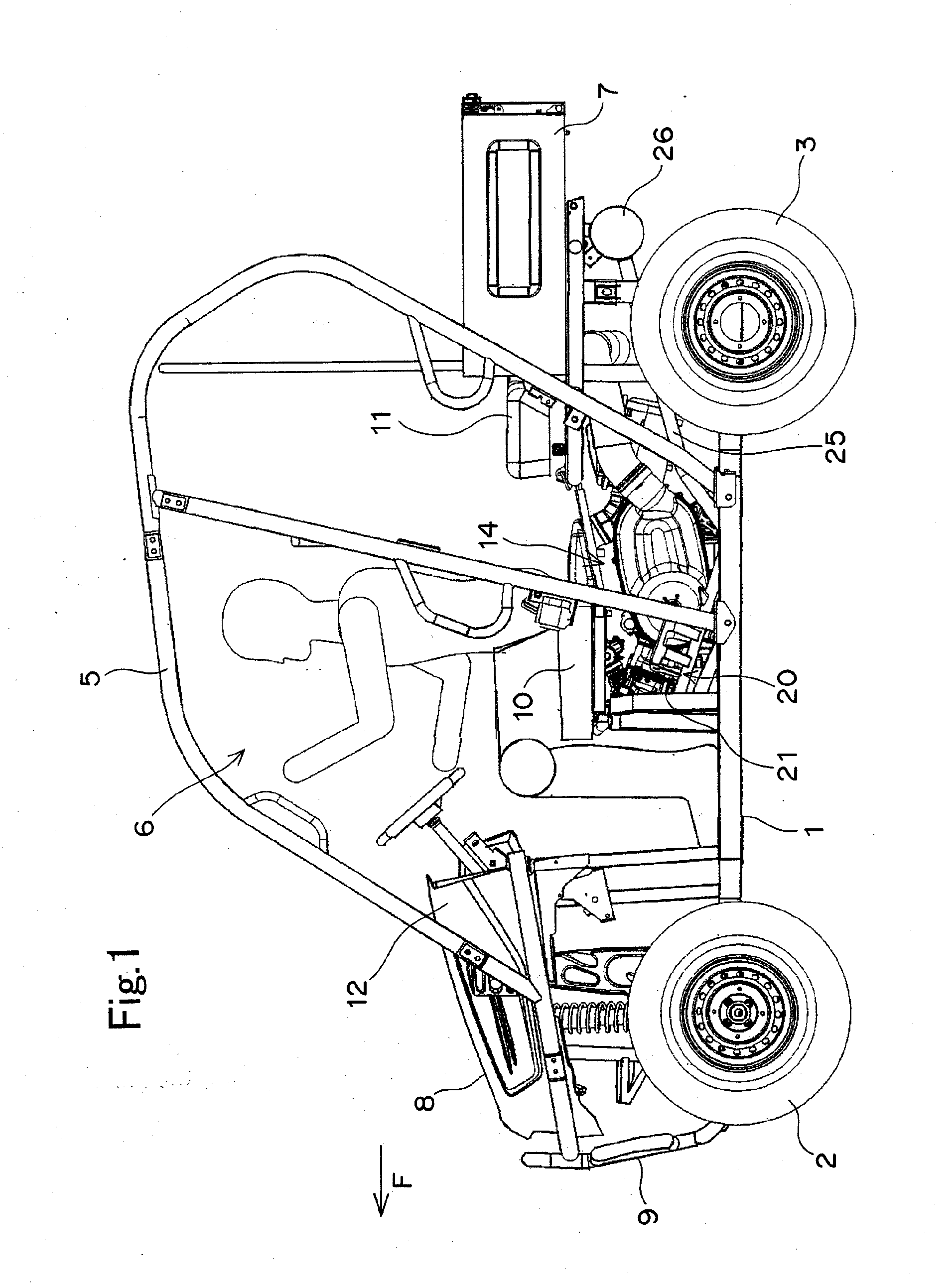

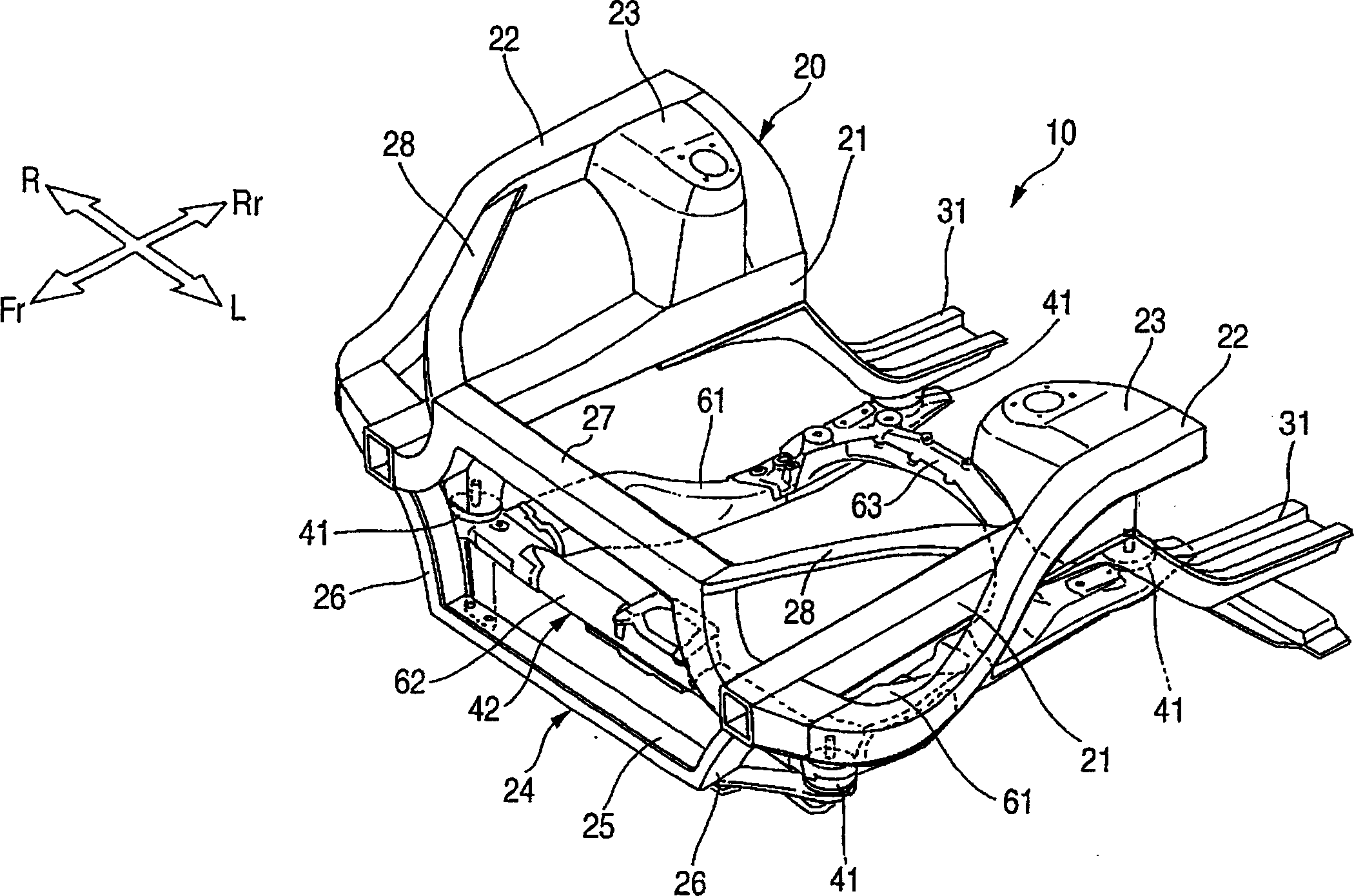

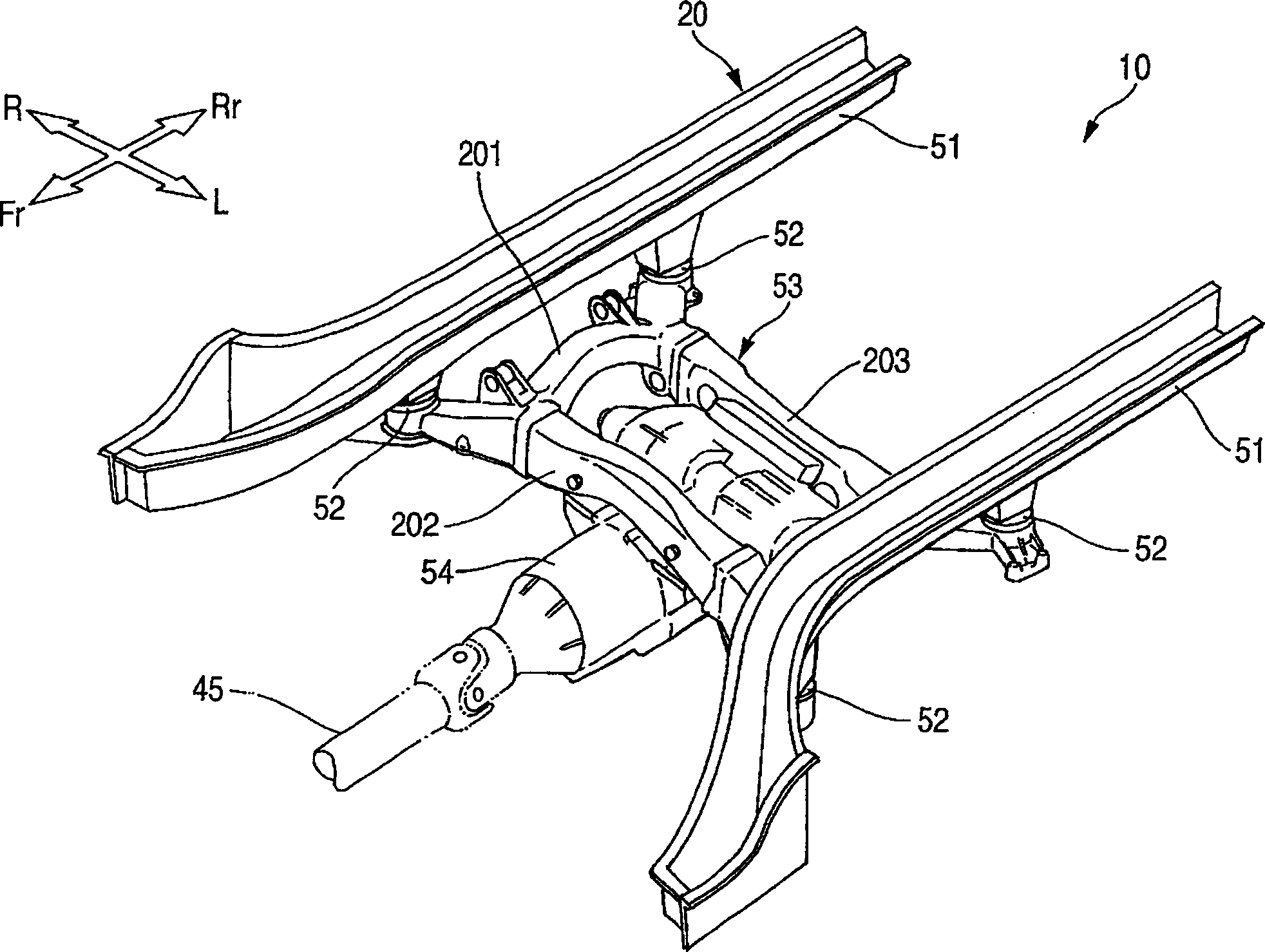

Front vehicle-body structure of vehicle

InactiveUS20110095568A1Reduce crash loadPrecise bendingVehicle seatsUnderstructuresEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

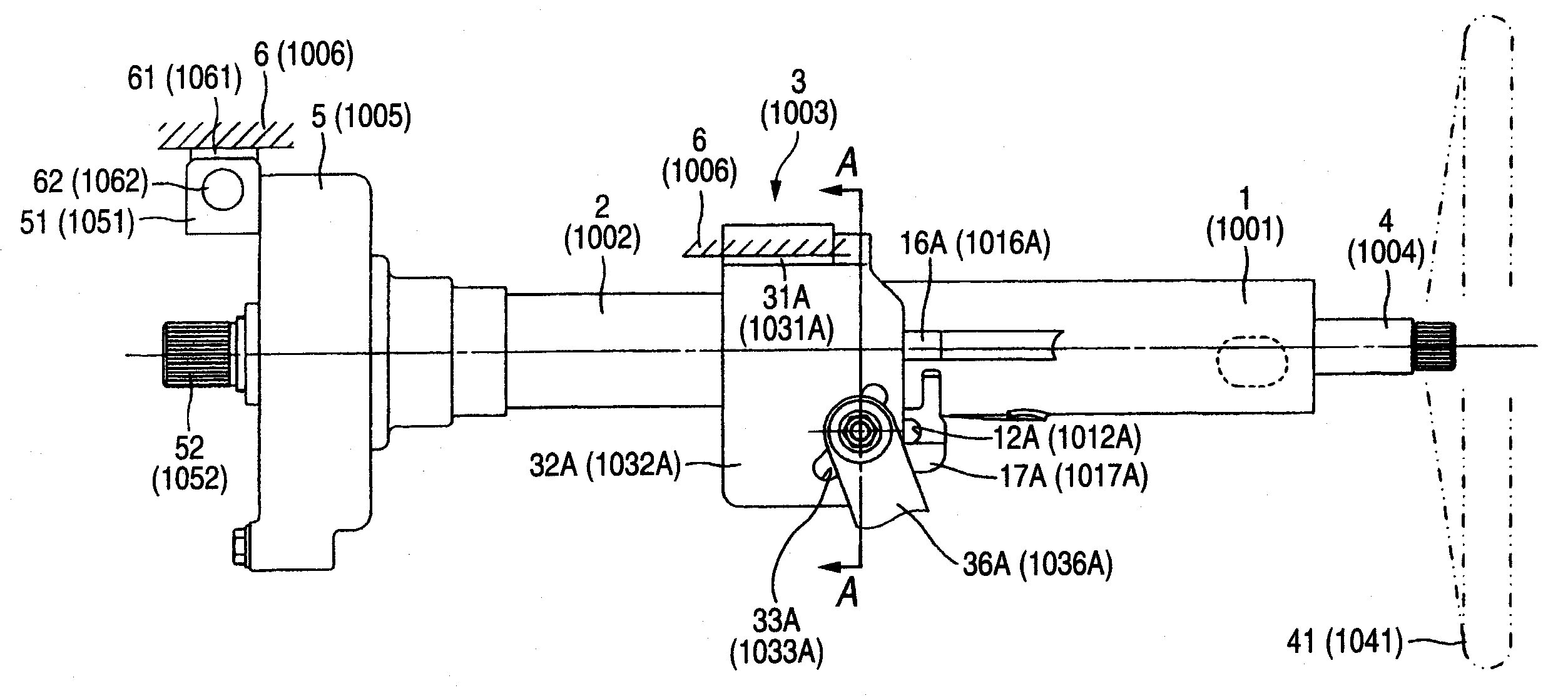

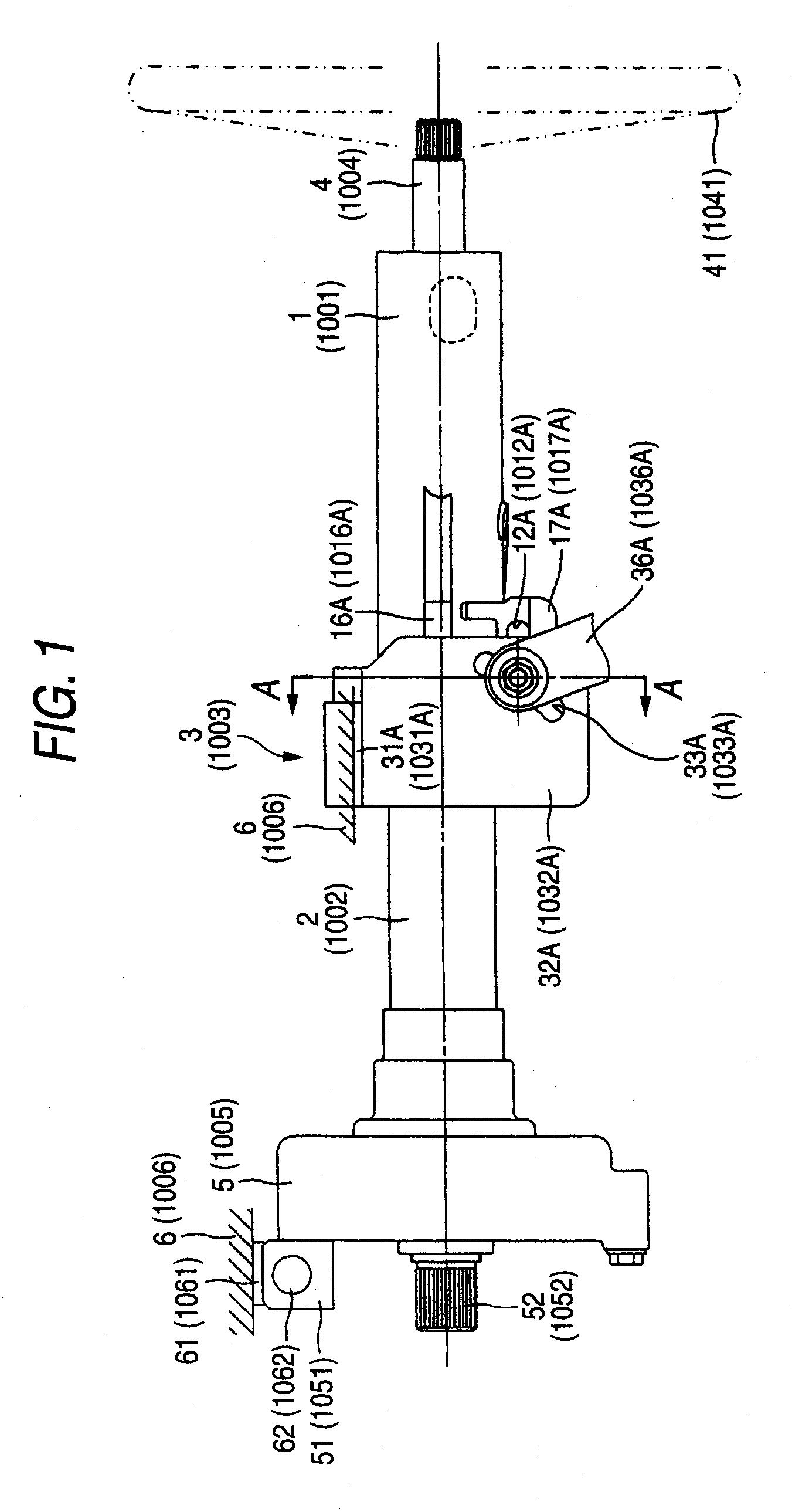

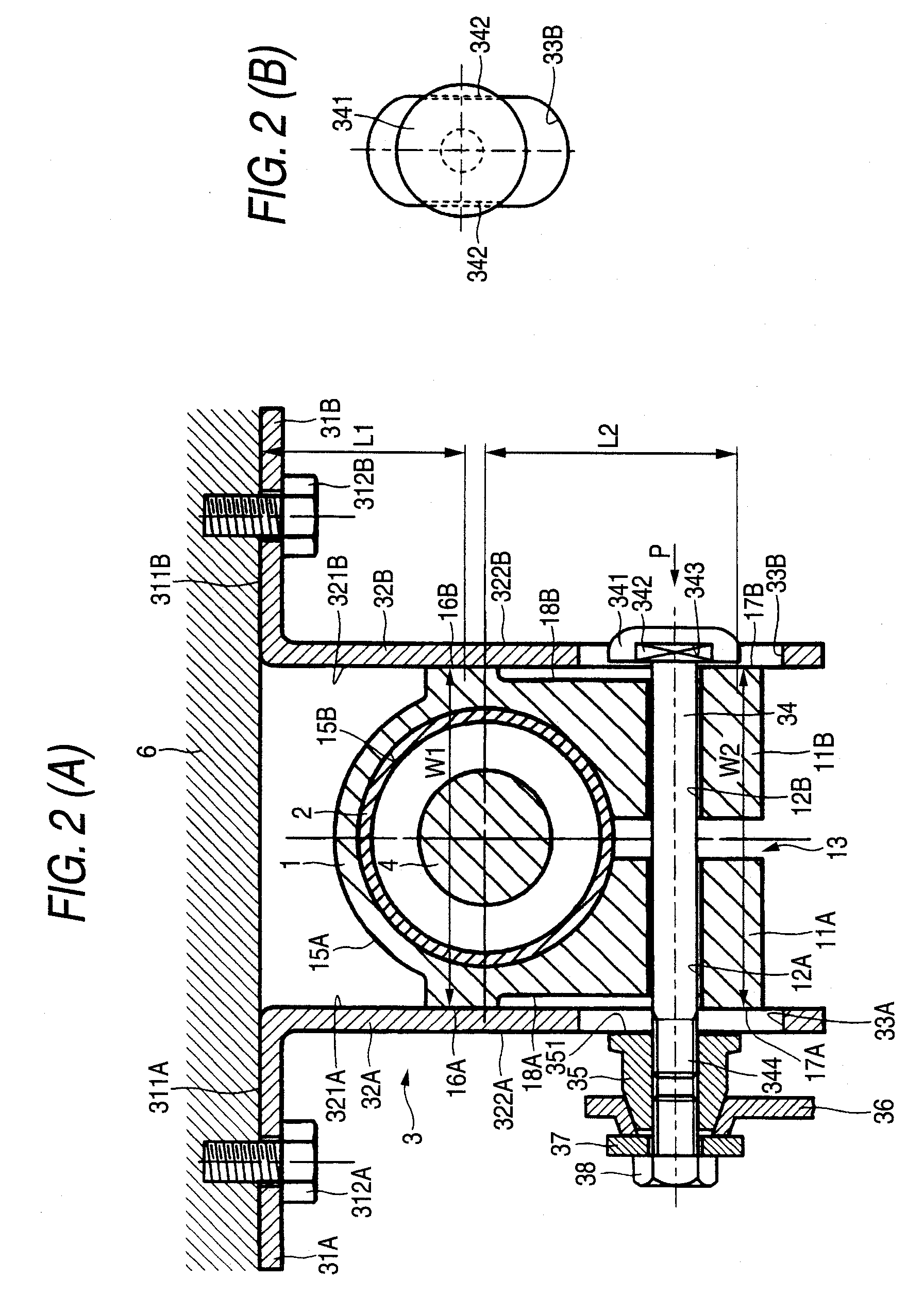

Steering Device

A steering device including a column rotatably supporting a steering shaft on which a steering wheel is mounted; a vehicle body attaching bracket that is attachable to a vehicle body and has a pair of right and left side plates for holding right and left side surfaces of the column therebetween; a fastening rod spaced from the axis of the column and inserted into the side plates of the vehicle body attaching bracket and the column; and fastening members arranged at both ends of the fastening rod to fasten the inner surfaces of the side plates to the side surfaces of the column, wherein contact surfaces of the right and left side surface of the column and the inner surfaces of the side plates are formed in two parts including a part near the axis of the fastening rod and a part spaced from the axis of the fastening rod.

Owner:NSK LTD

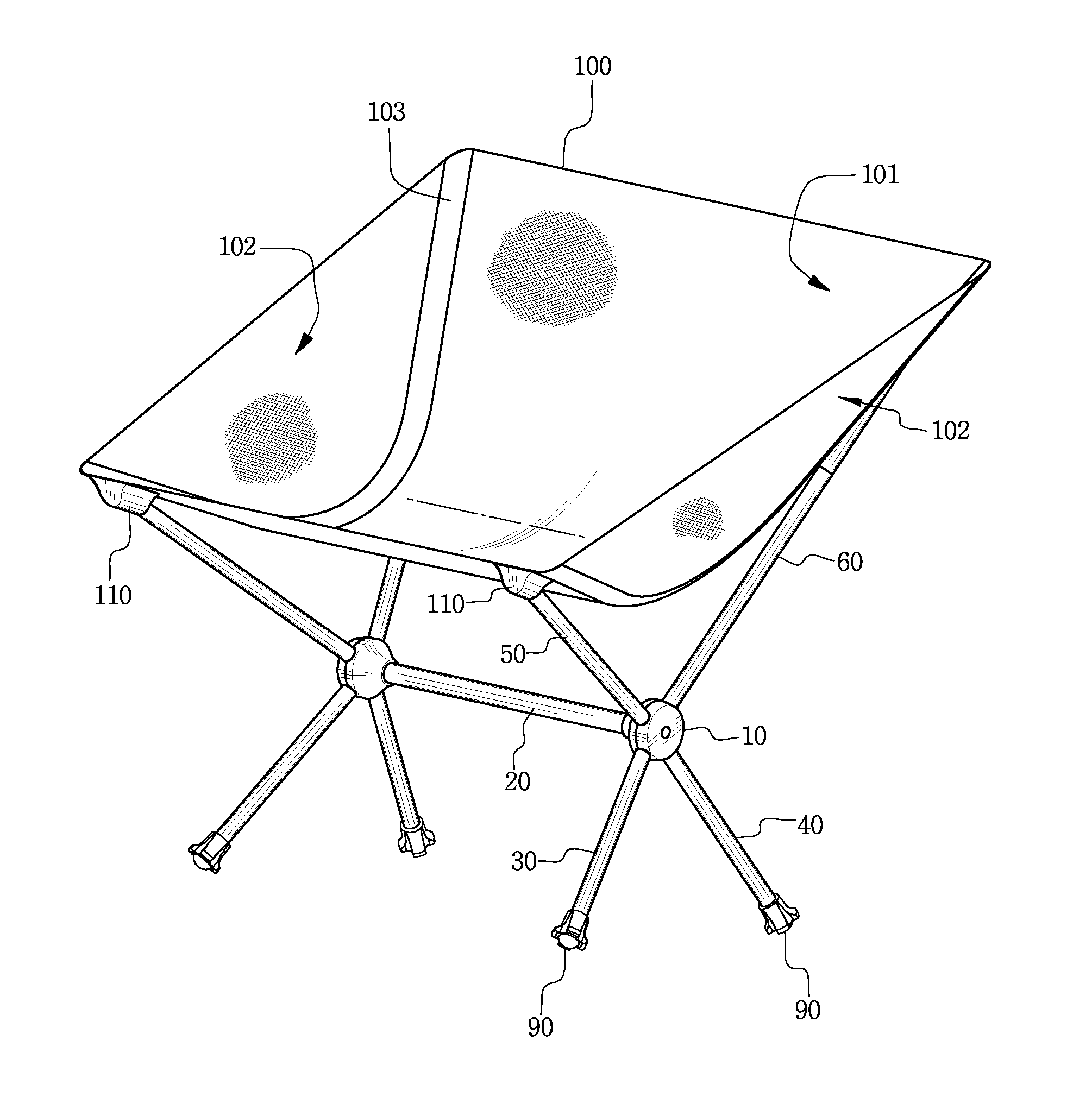

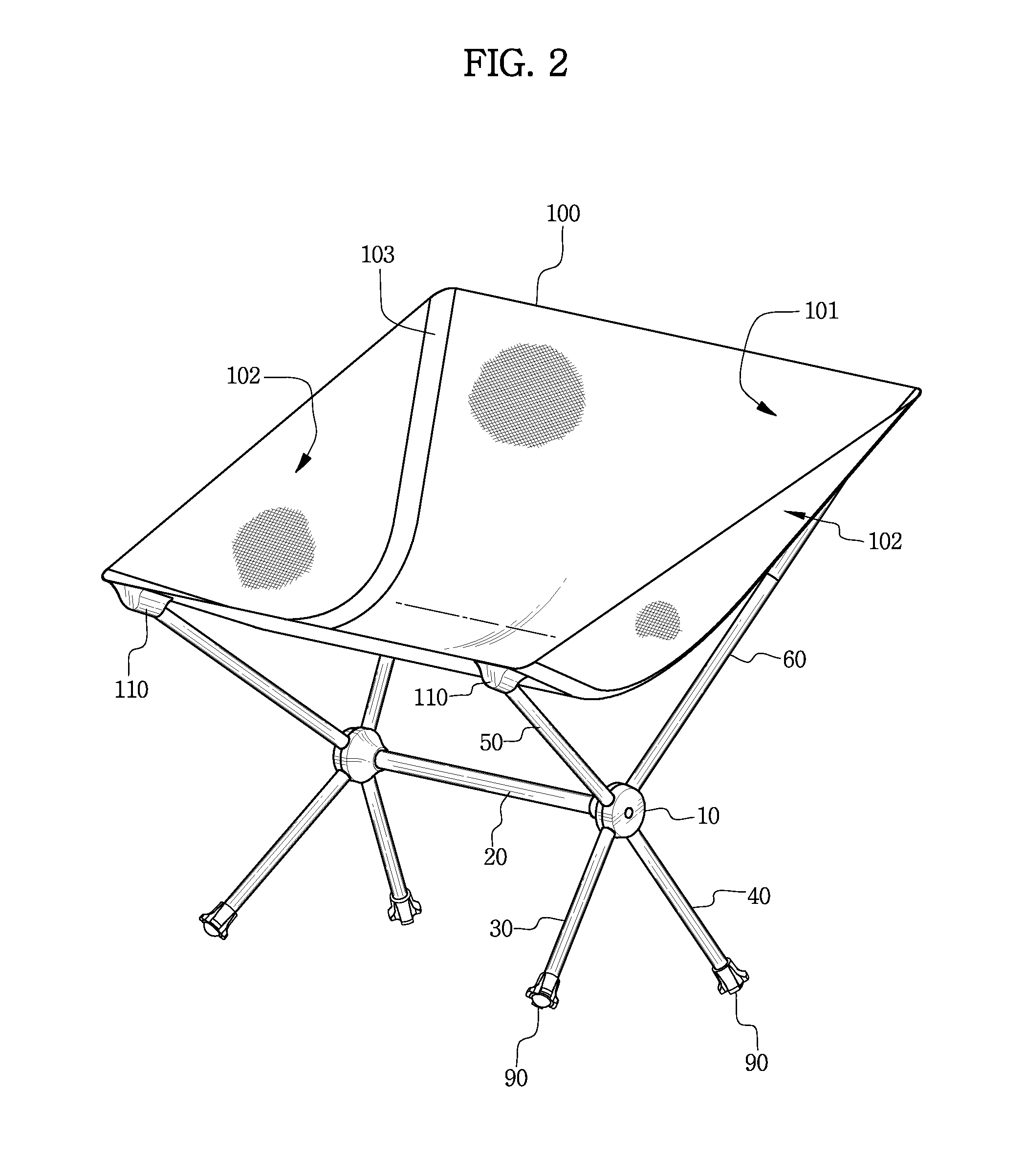

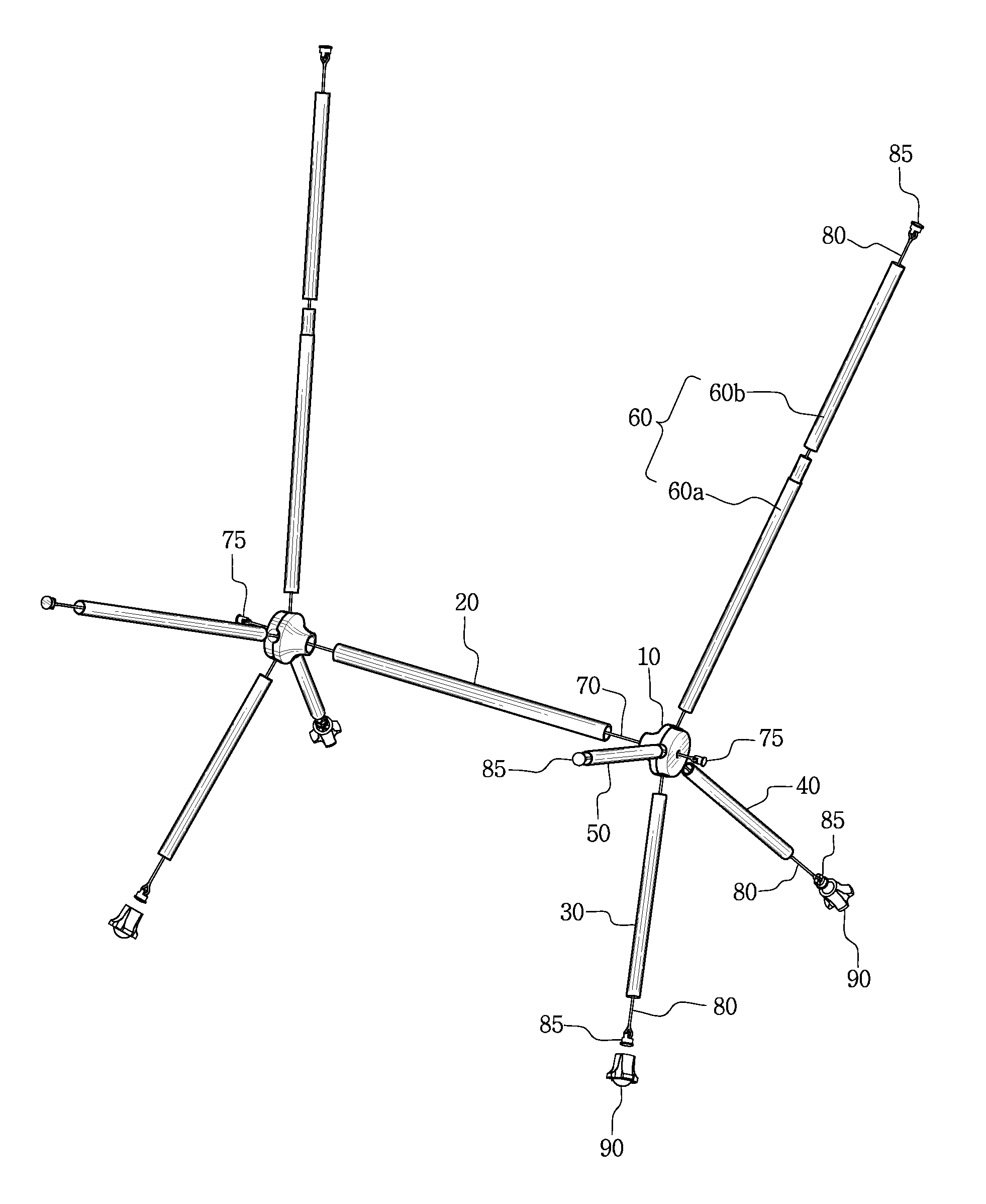

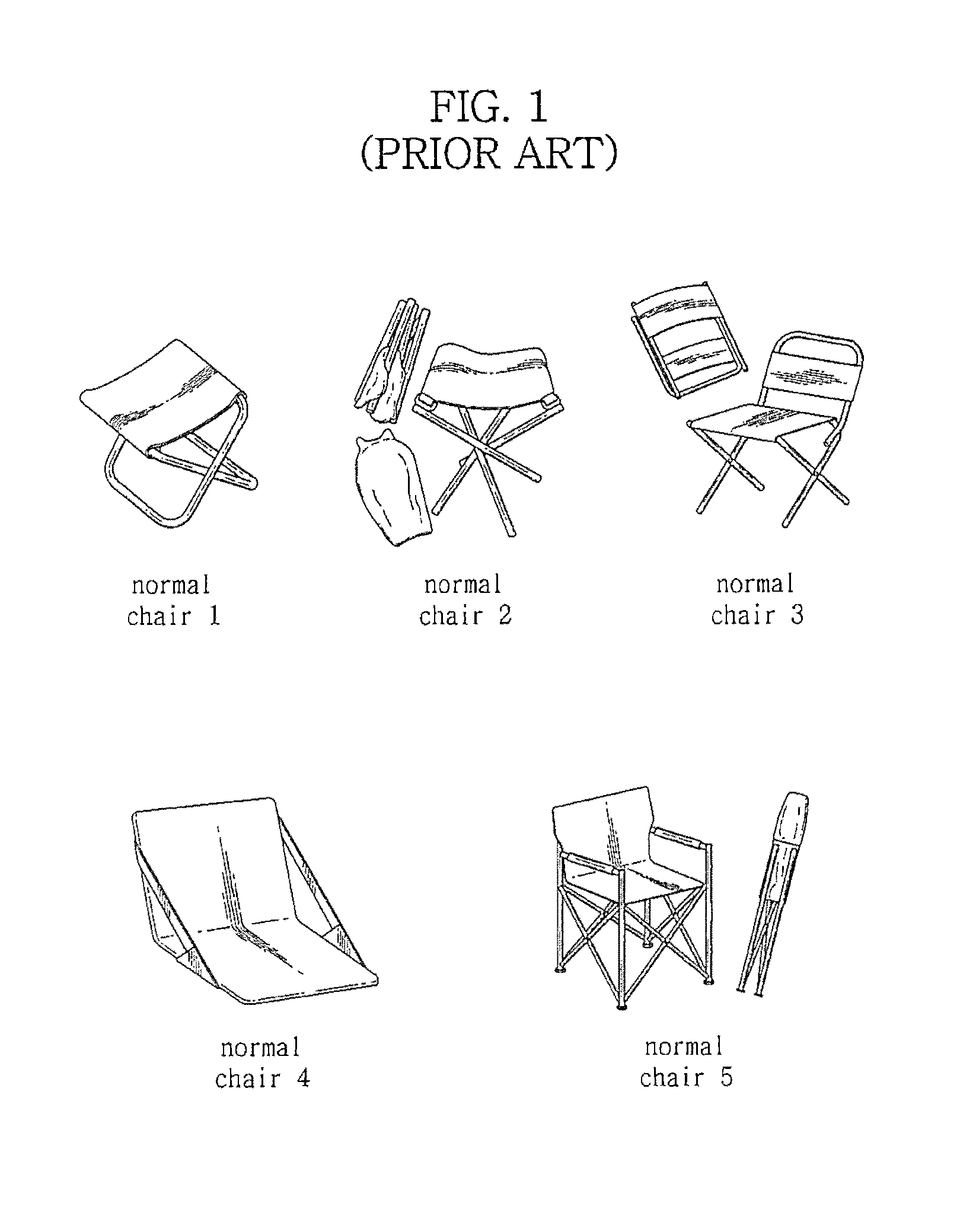

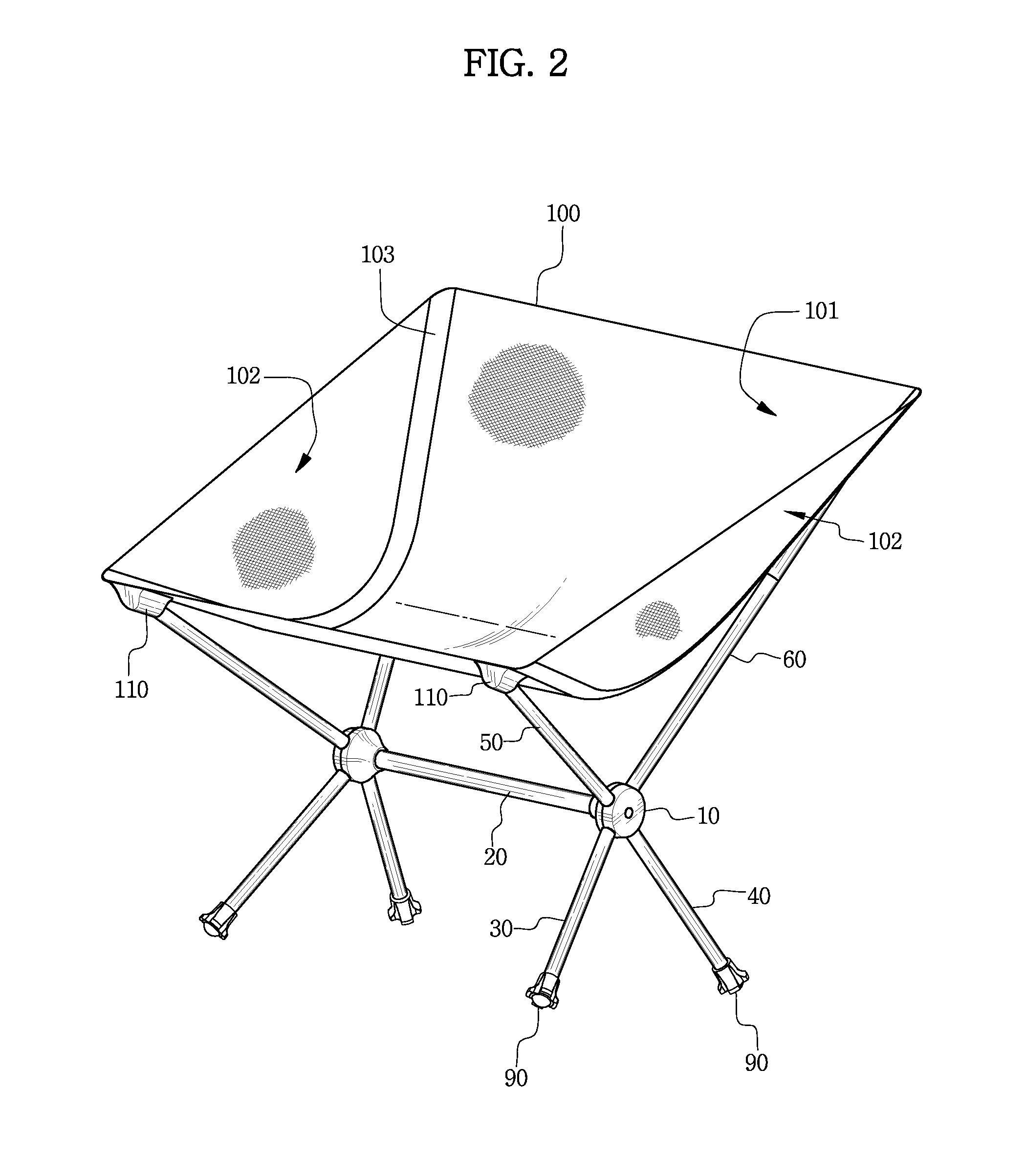

Portable chair

ActiveUS20120104805A1StrengthEasy to unfoldFoldable chairDismountable chairsEngineeringMechanical engineering

The portable chair of the disclosure includes: hubs respectively installed at both left and right sides of the chair; a central support frame connecting both left and right hubs; front and rear leg frames respectively having base ends separably coupled to the lower front and rear outer peripheral surfaces of the respective hubs and respectively having free ends disposed in a manner of radially extending toward the ground surface; front and rear pole frames respectively having base ends separably coupled to the upper front and rear outer peripheral surfaces of the respective hubs and respectively having free ends disposed in a manner of radially extending toward the sky; and a fabric sheet coupled to the free ends of the front and rear pole frames. The structural rigidity is excellent, and the chair may land on the ground surface in a stable posture.

Owner:LAH JEH KUN

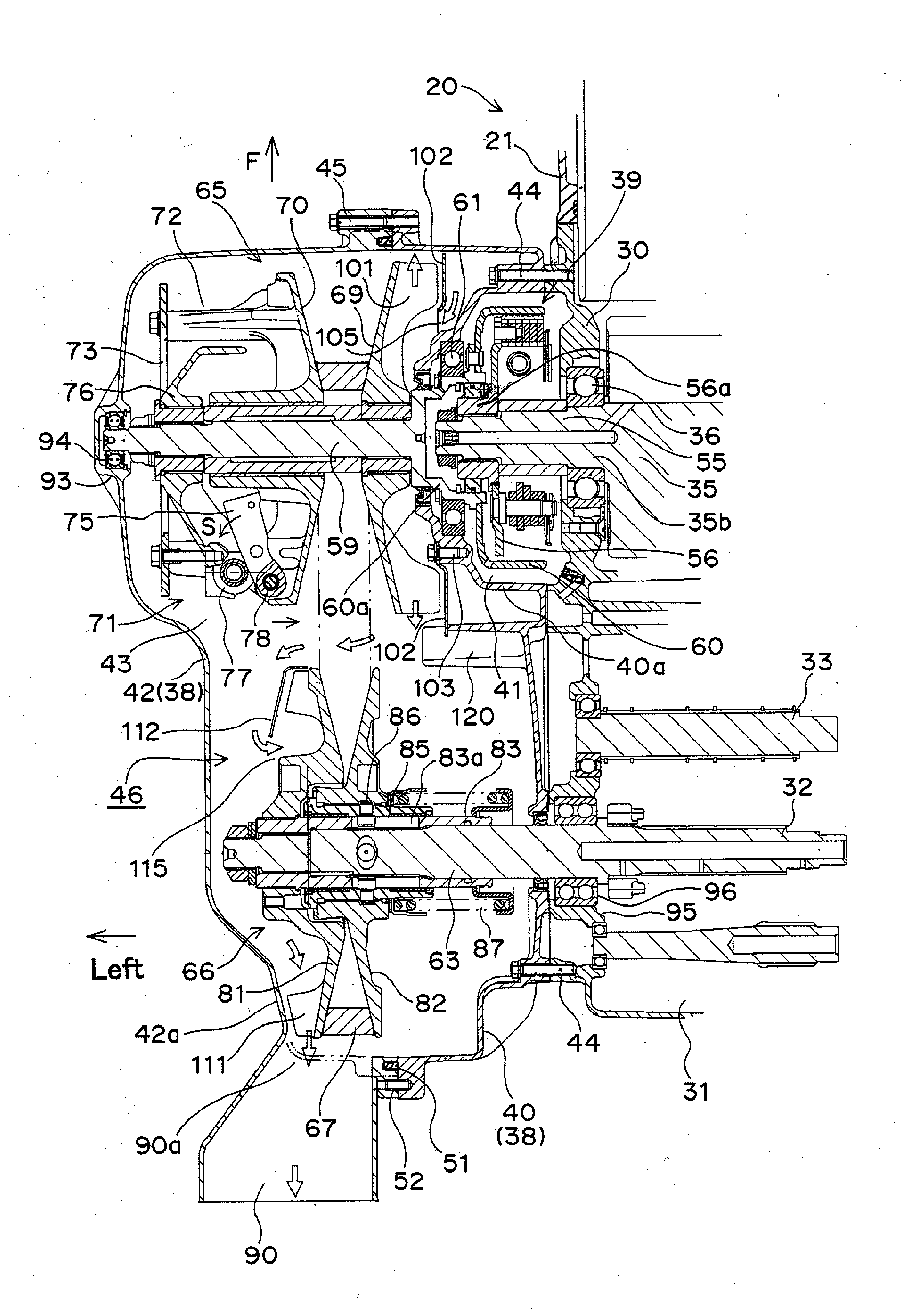

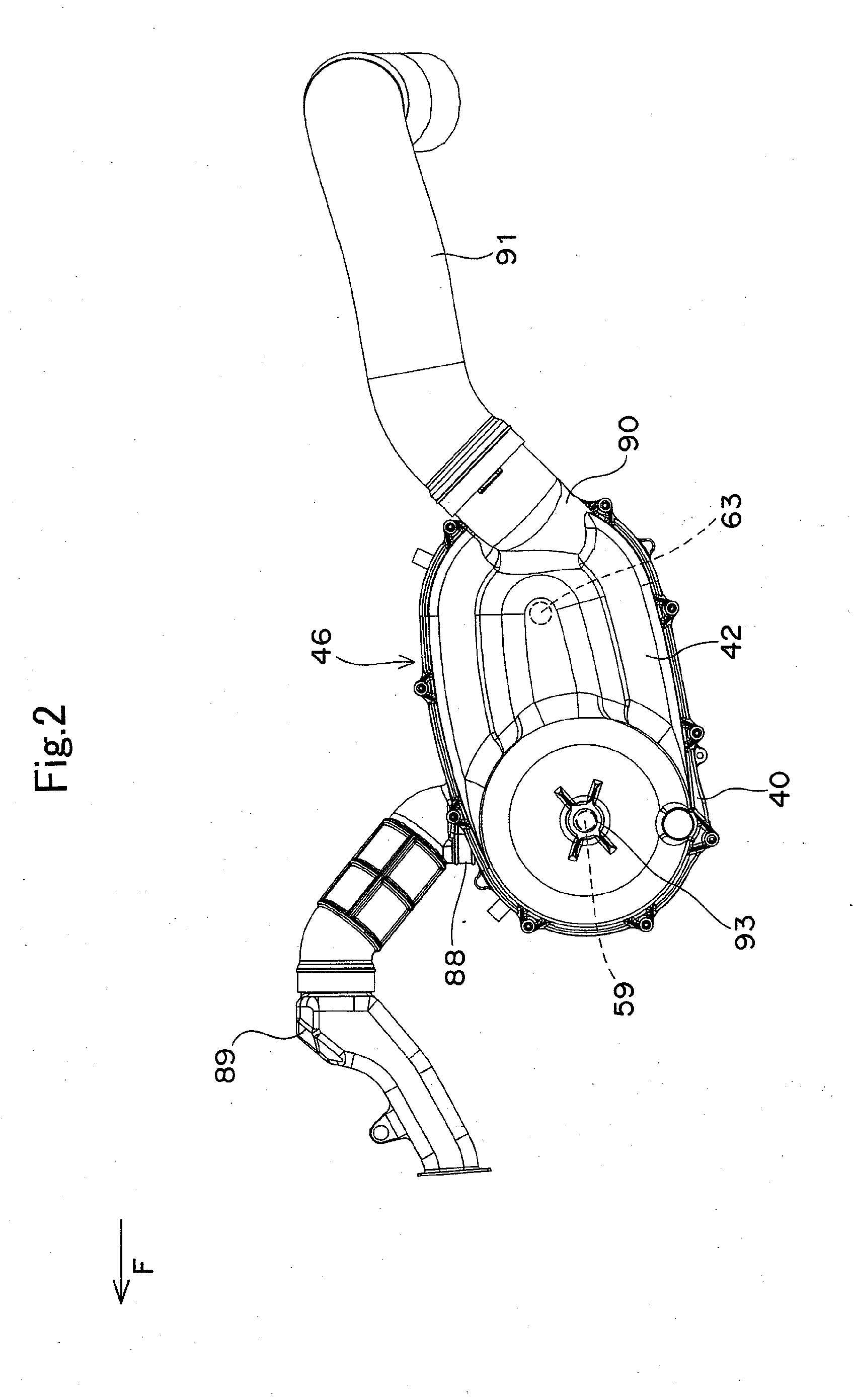

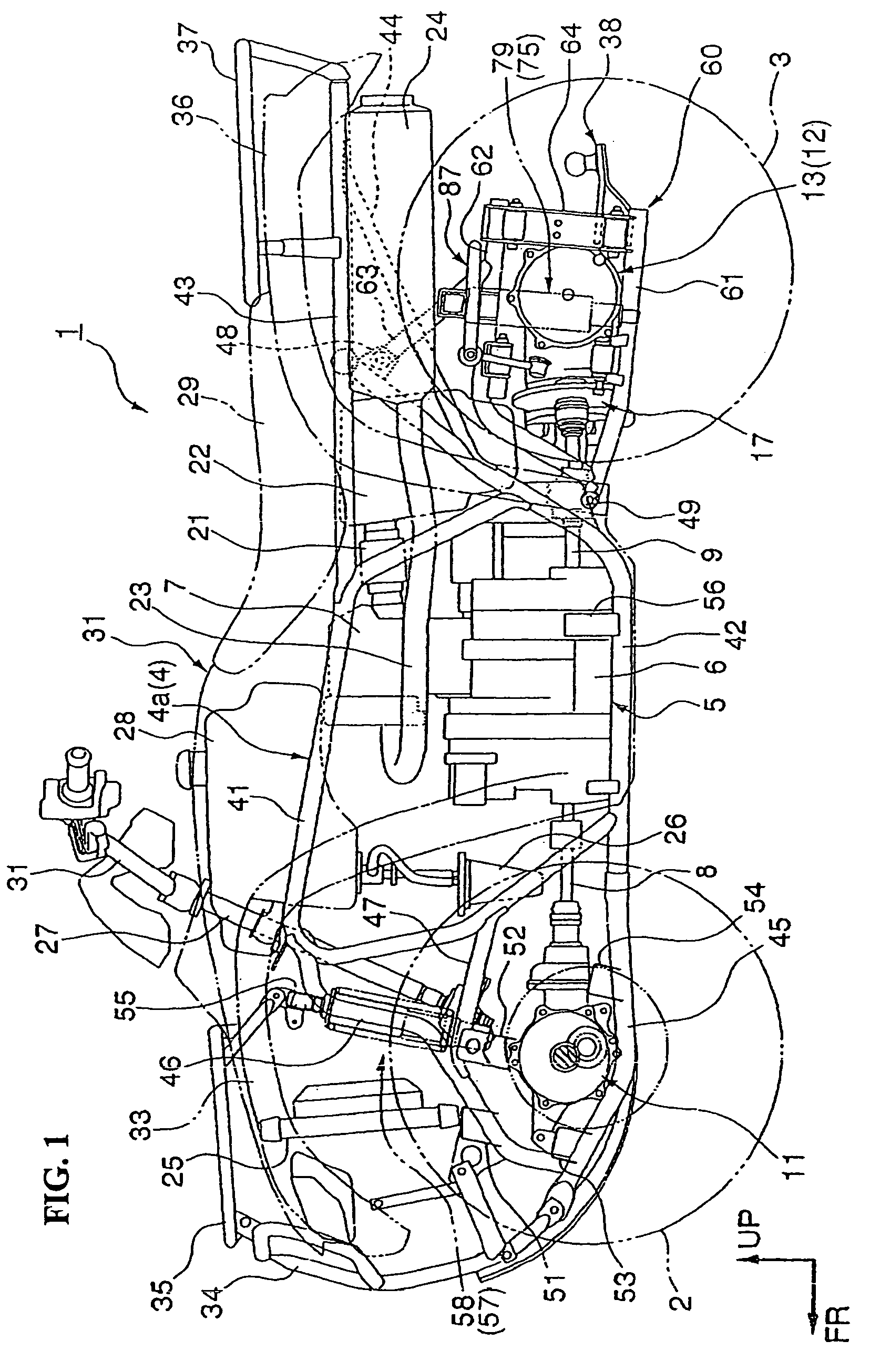

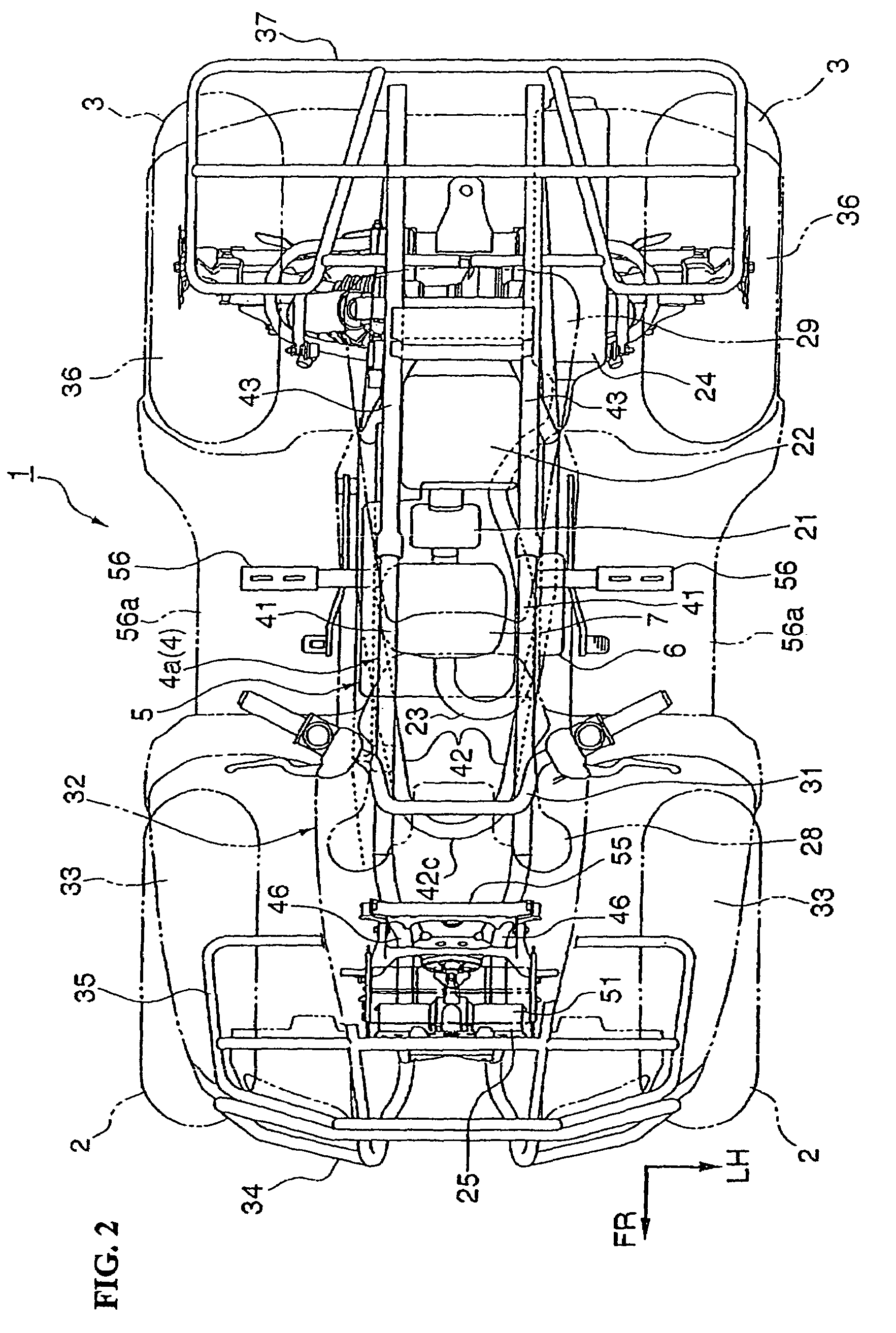

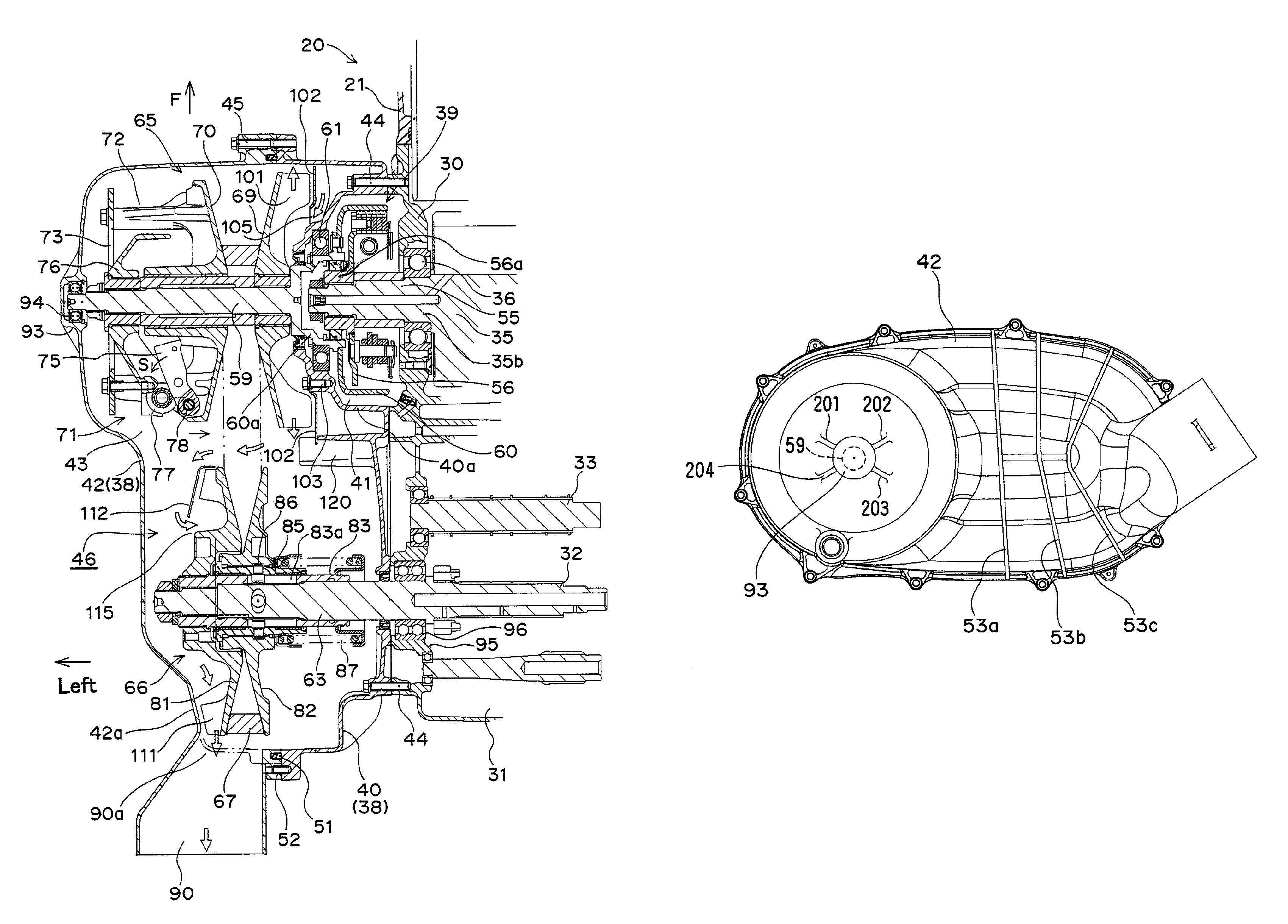

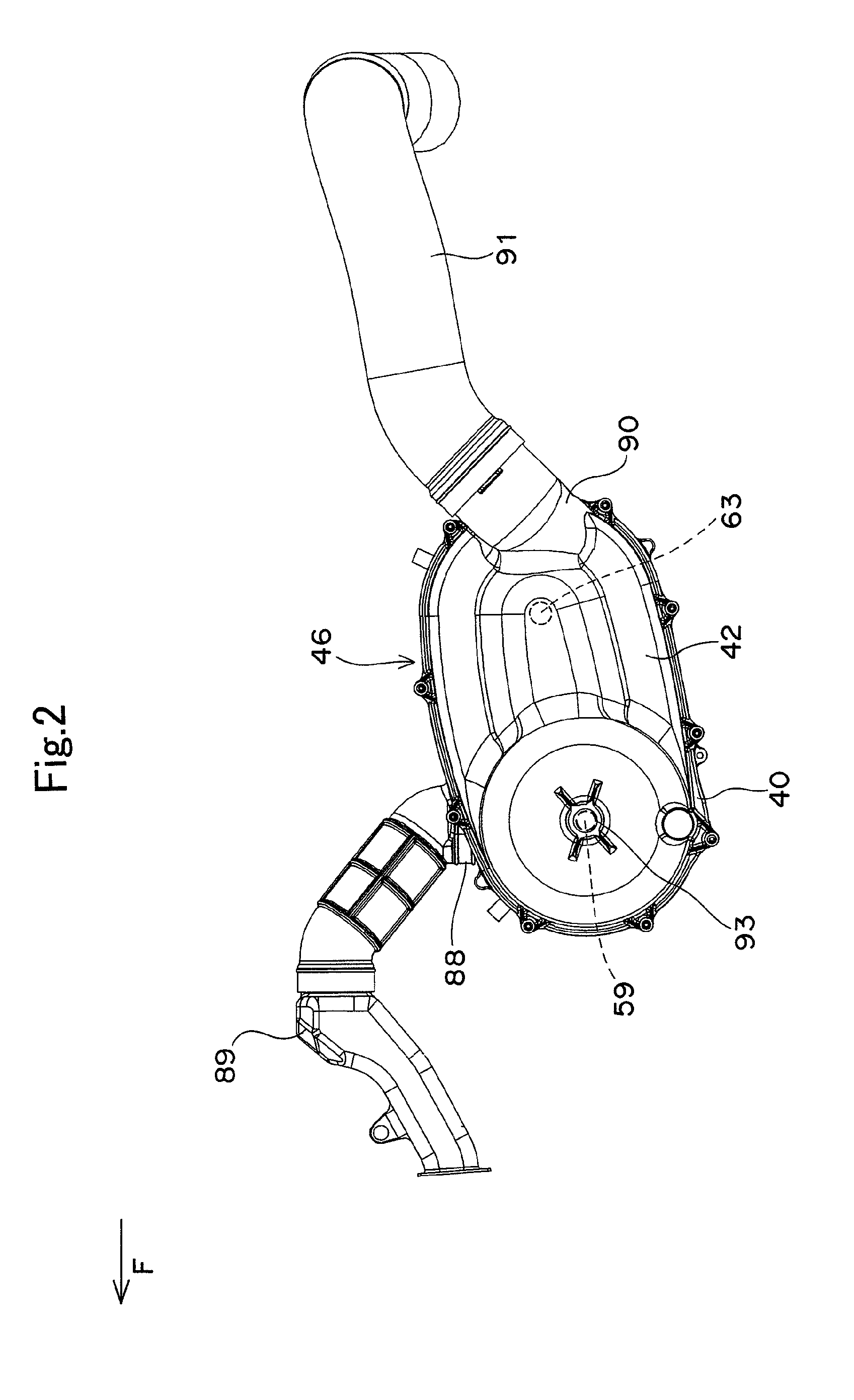

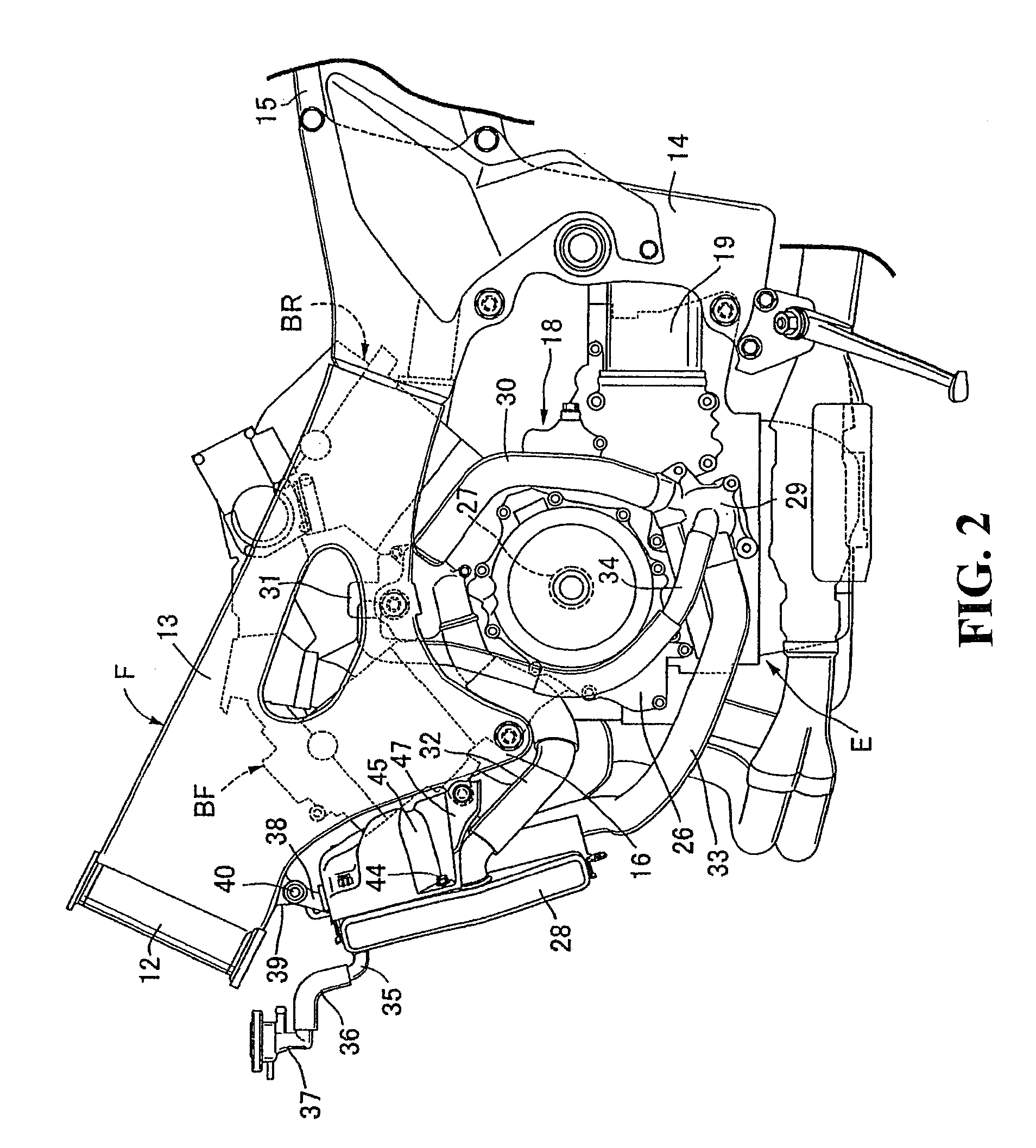

V-belt type continuously variable transmission

A V-belt type continuously variable transmission according to the present invention includes a drive pulley assembly provided in a drive shaft, a driven pulley assembly provided in a driven shaft, a V-belt looped over both the pulley assemblies, and a transmission case assembly housing both the pulley assemblies and the V-belt. One end of the drive shaft in the shaft direction is coupled to an output side rotation member of a centrifugal clutch, and the other end of the drive shaft is rotatably supported on a boss portion formed in the transmission case assembly.

Owner:KAWASAKI HEAVY IND LTD

Ultra centrifuge

InactiveCN102974474AImprove integrityGuaranteed uptimeMagnetic circuit rotating partsDynamo-electric gearsUltracentrifugeElectric machine

The invention discloses an ultra centrifuge. The ultra centrifuge solves the two major problems of development of high-speed motors and development of high-speed vacuum sealing devices, air floatation and air floatation hybrid bearing technology is adopted in the design of the high-speed motors, and bearing stiffiness and bearing stability are enhanced greatly; a large interference shrink fit method is adopted in the design of protective sleeves, and completeness of rotors is protected effectively; the rotors are of a three-section structure; a stator core is of a relatively eclectic 12-groove structure, and a winding utilizes a ring-type winding; and the cooling method is a force-air cooling method, and reliable and stable operation of an ultra centrifuge driving device is guaranteed. High-speed vacuum sealing utilizes a magnetic drive vacuum dynamic sealing connection method, and non-contact transmission of motive power is achieved through magnetic transmission between an inner magnet rotor and an outer magnet rotor. The successful development of the ultra centrifuge changes the passive situation that out country completely relies on import in an ultra centrifuge market, and the ultra centrifuge has wide market prospects and great social benefits.

Owner:HUNAN AEROSPACE ELECTROMECHANICAL EQUIP & SPECIAL MATERIAL INST

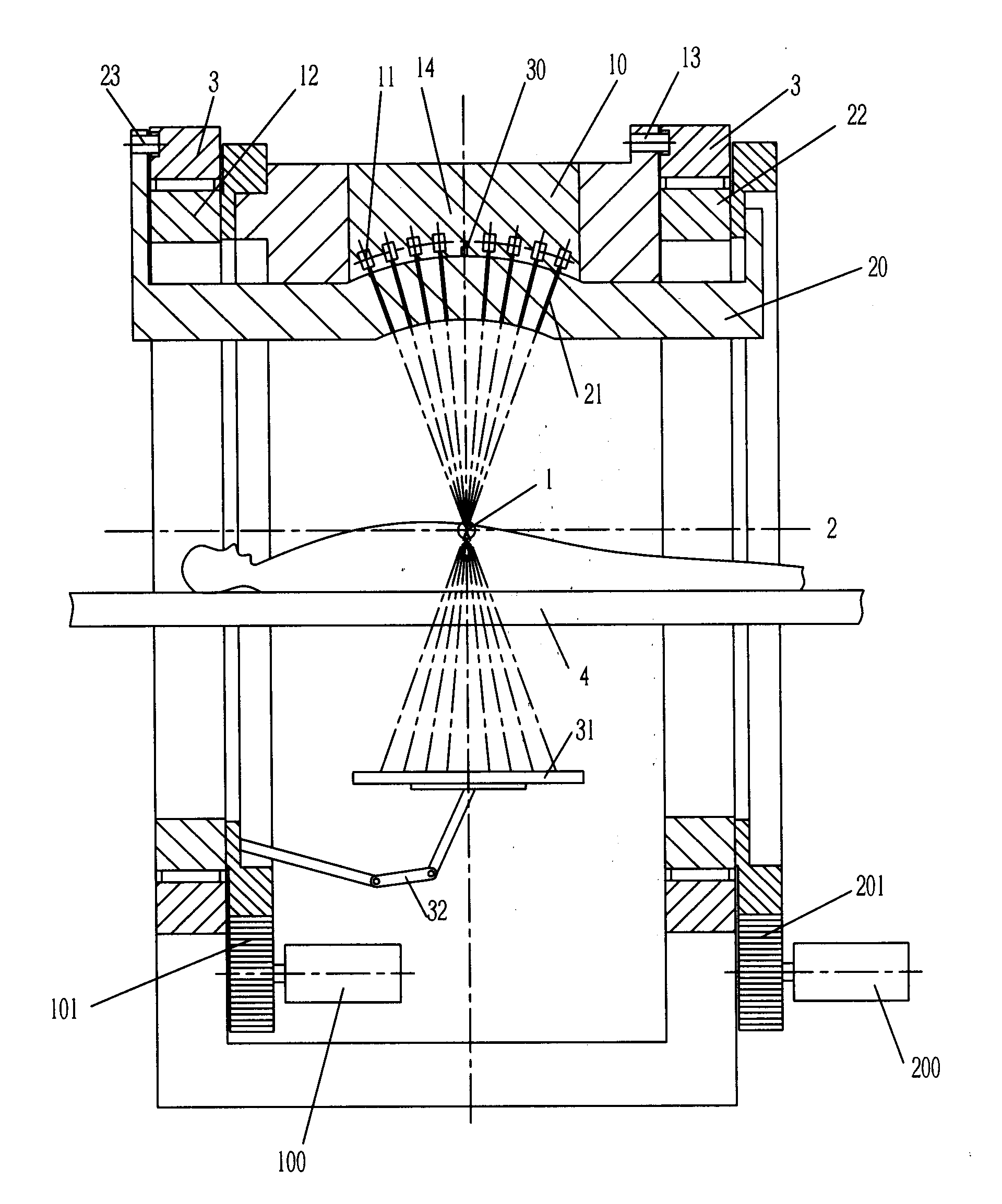

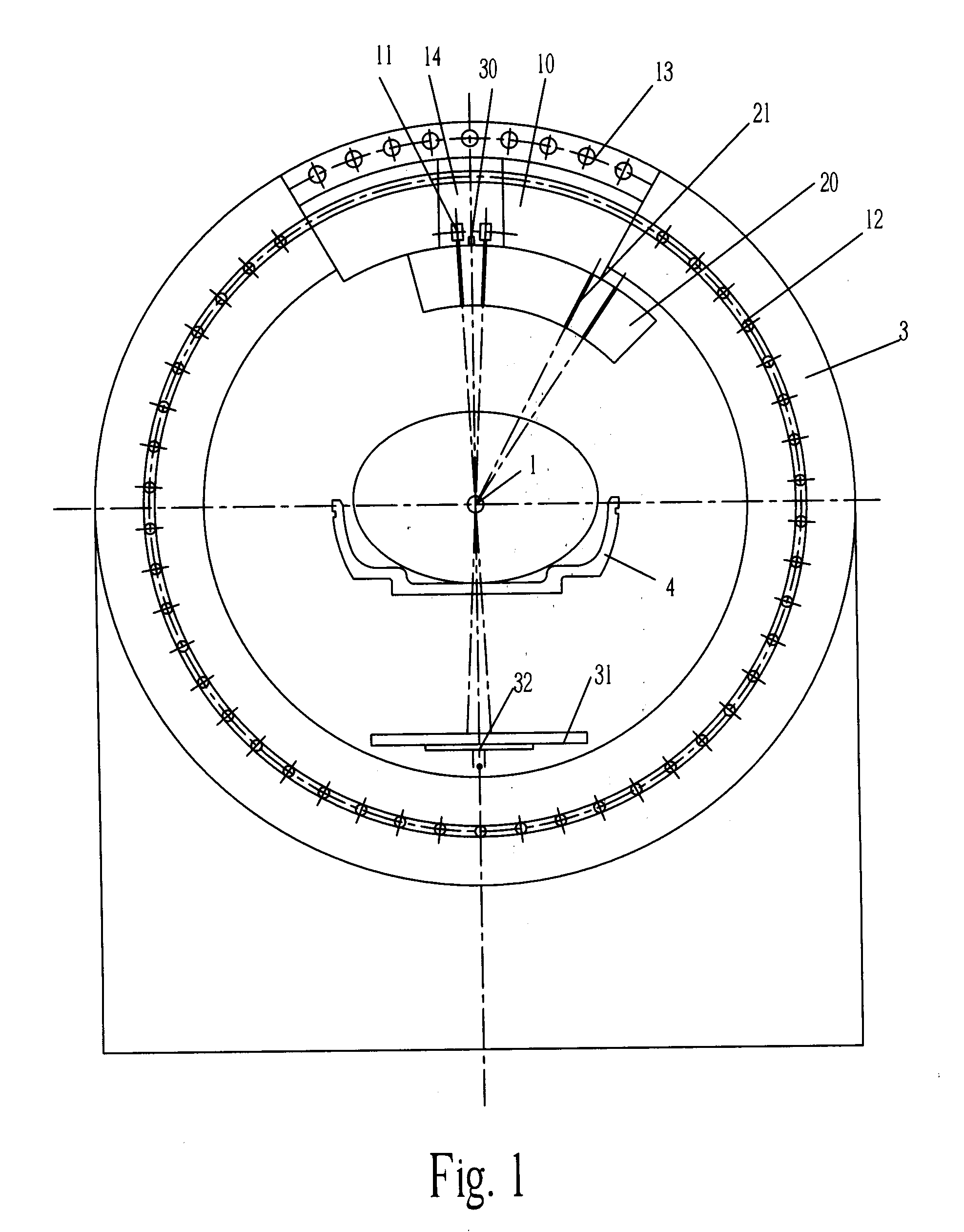

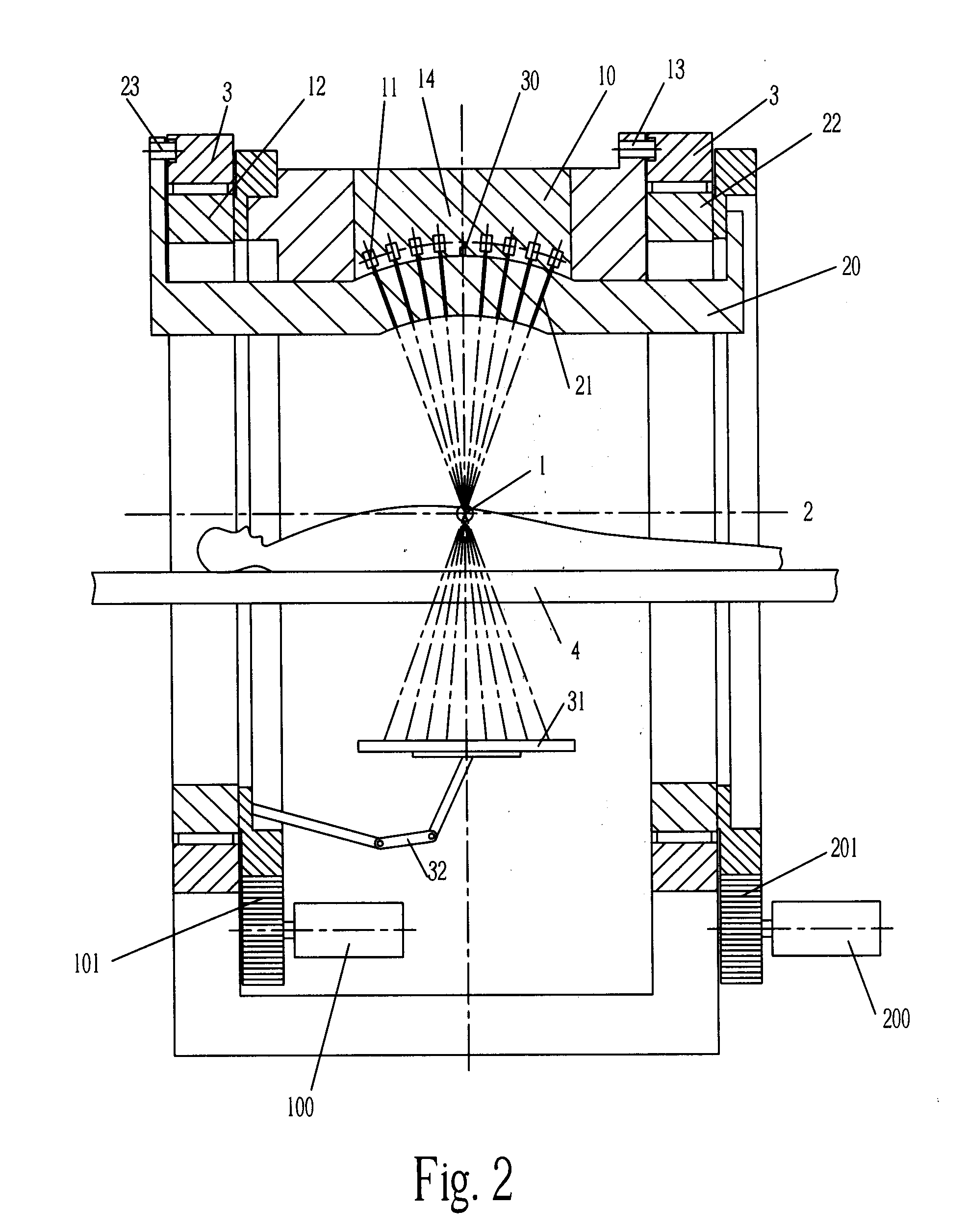

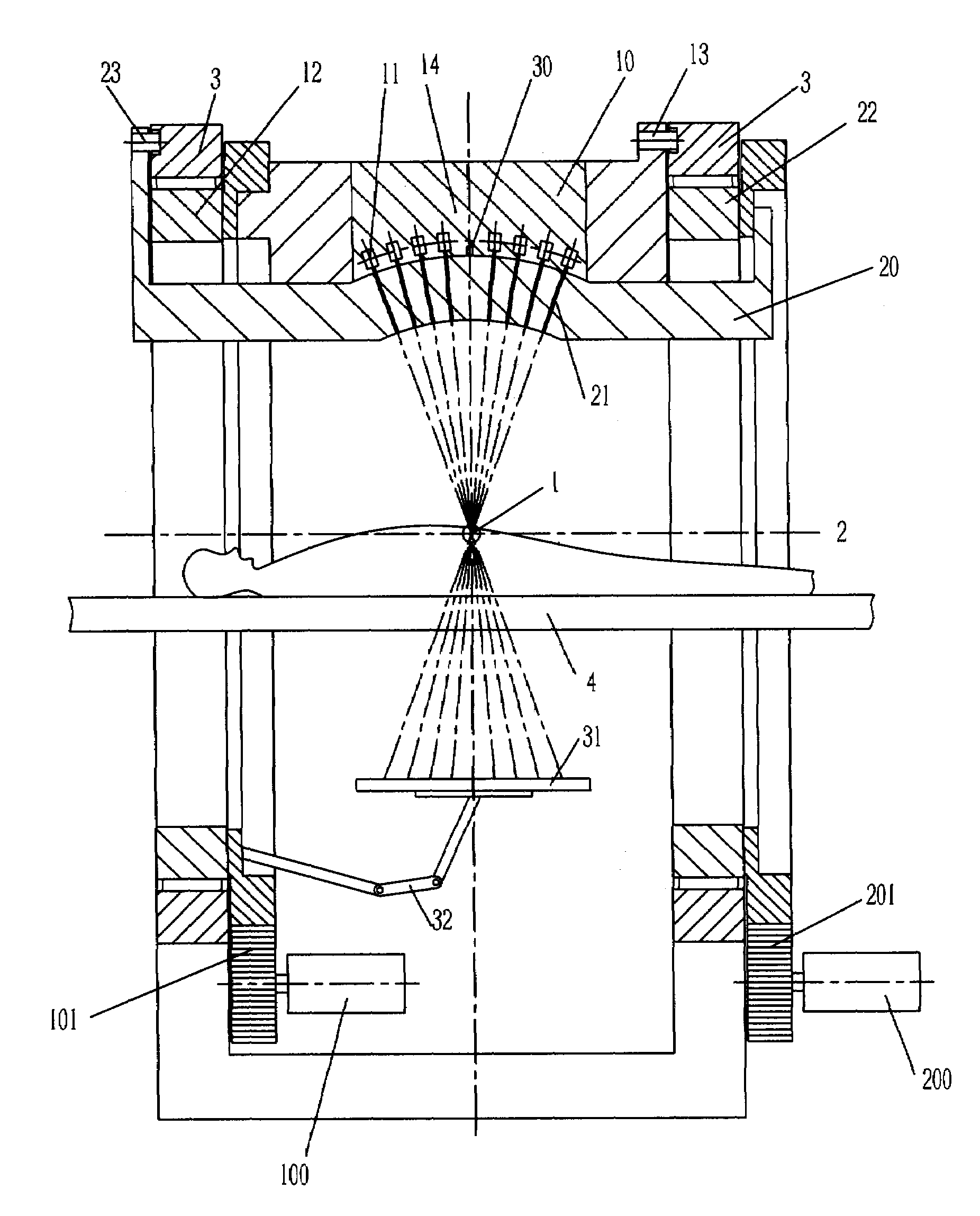

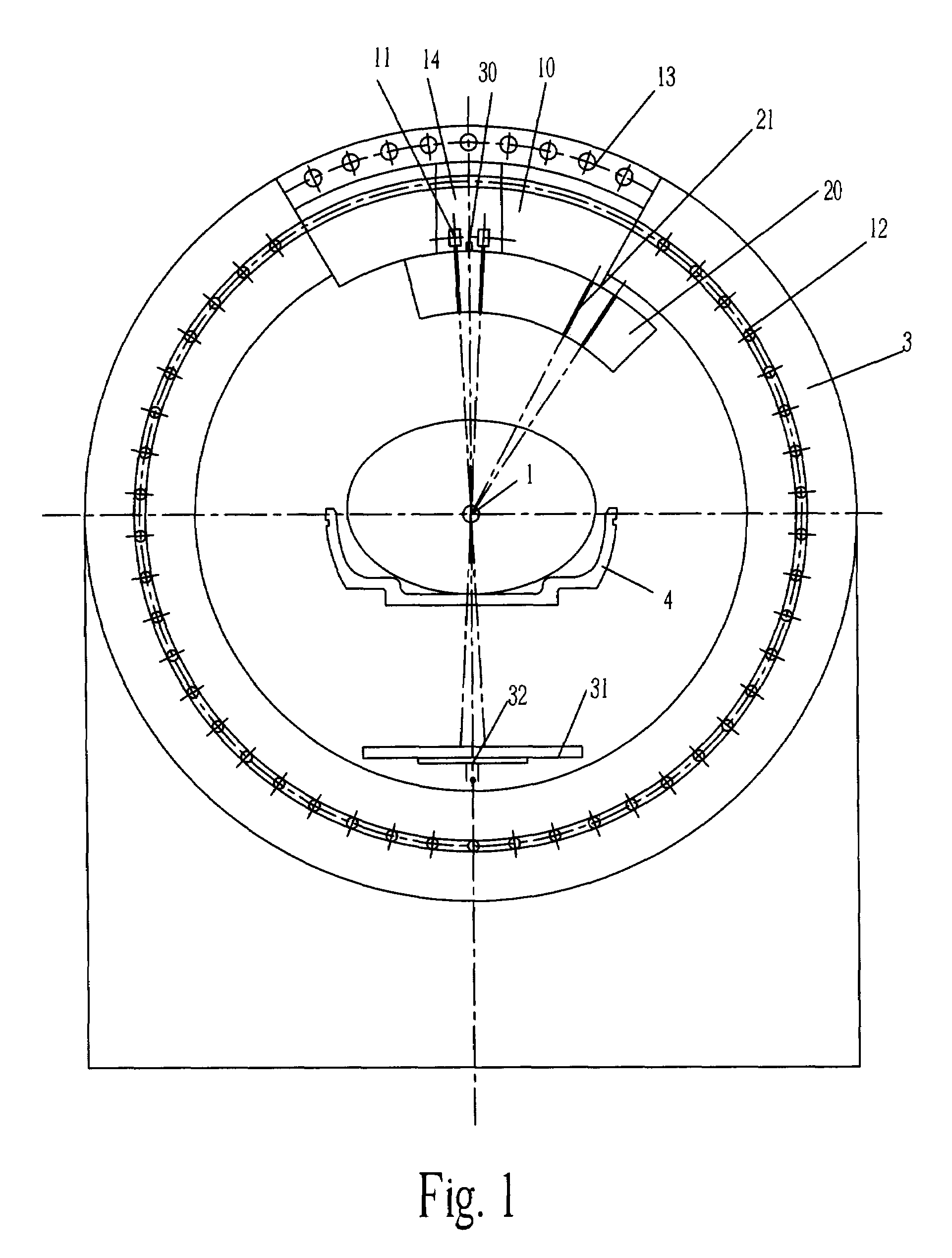

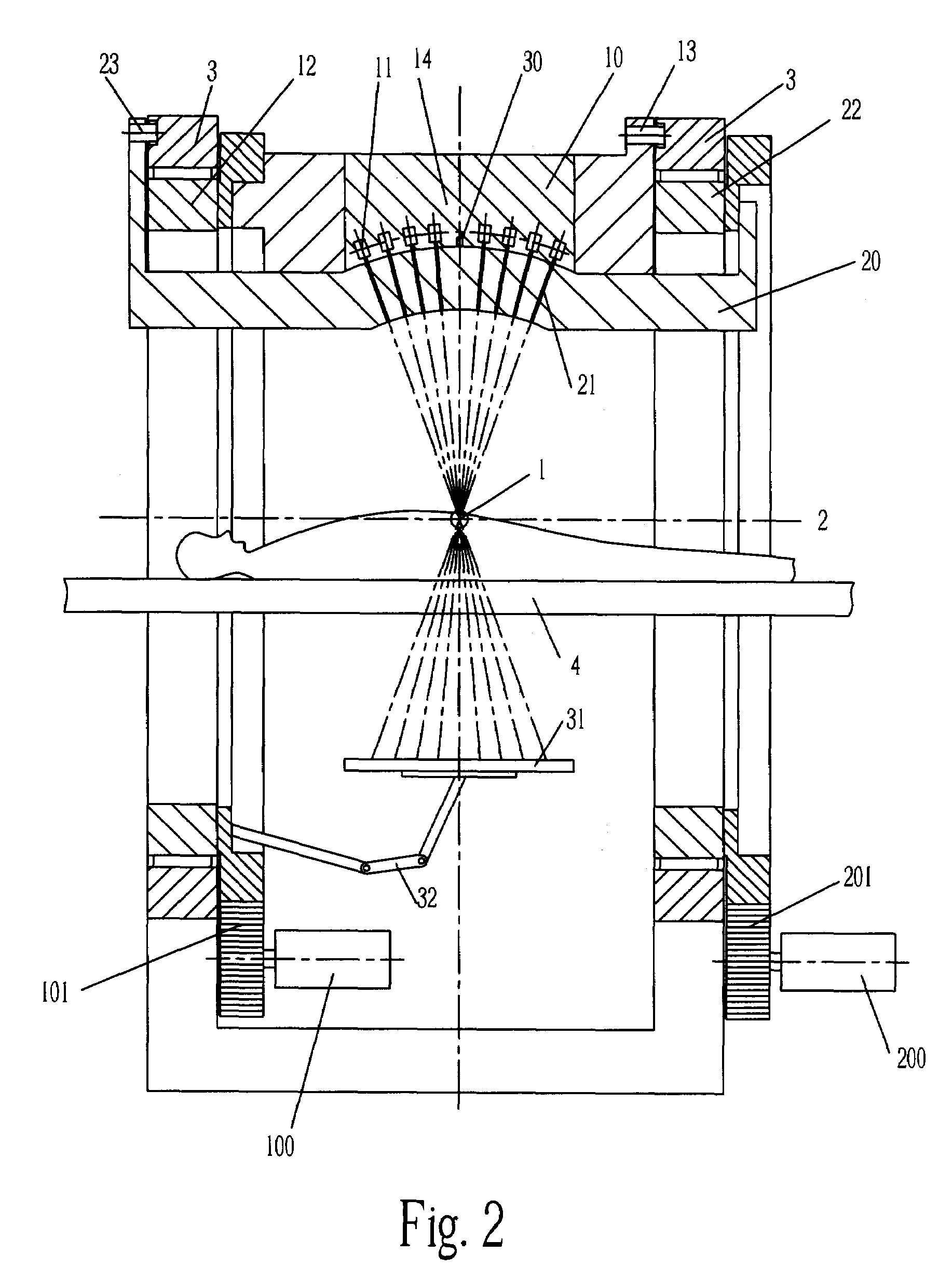

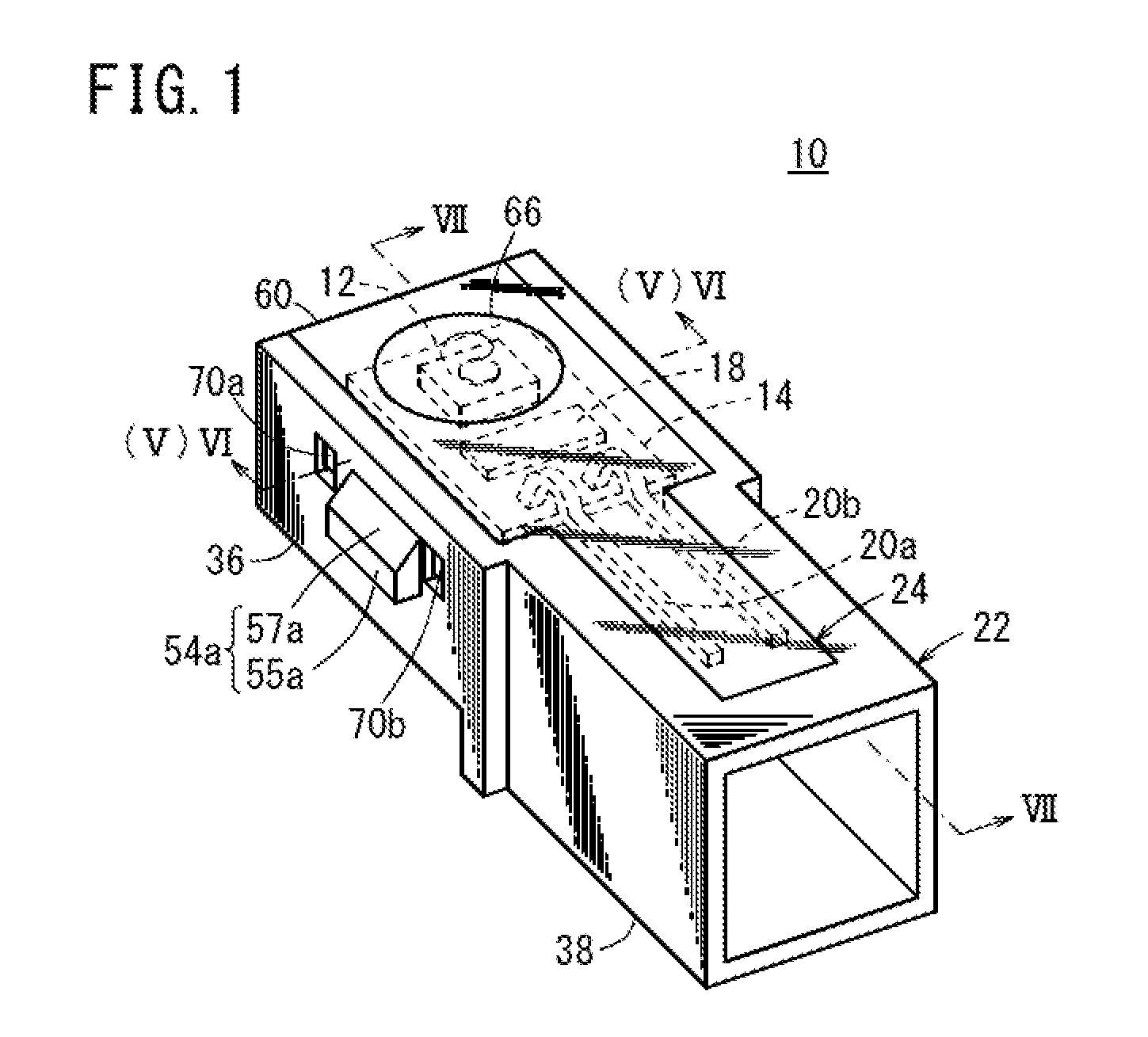

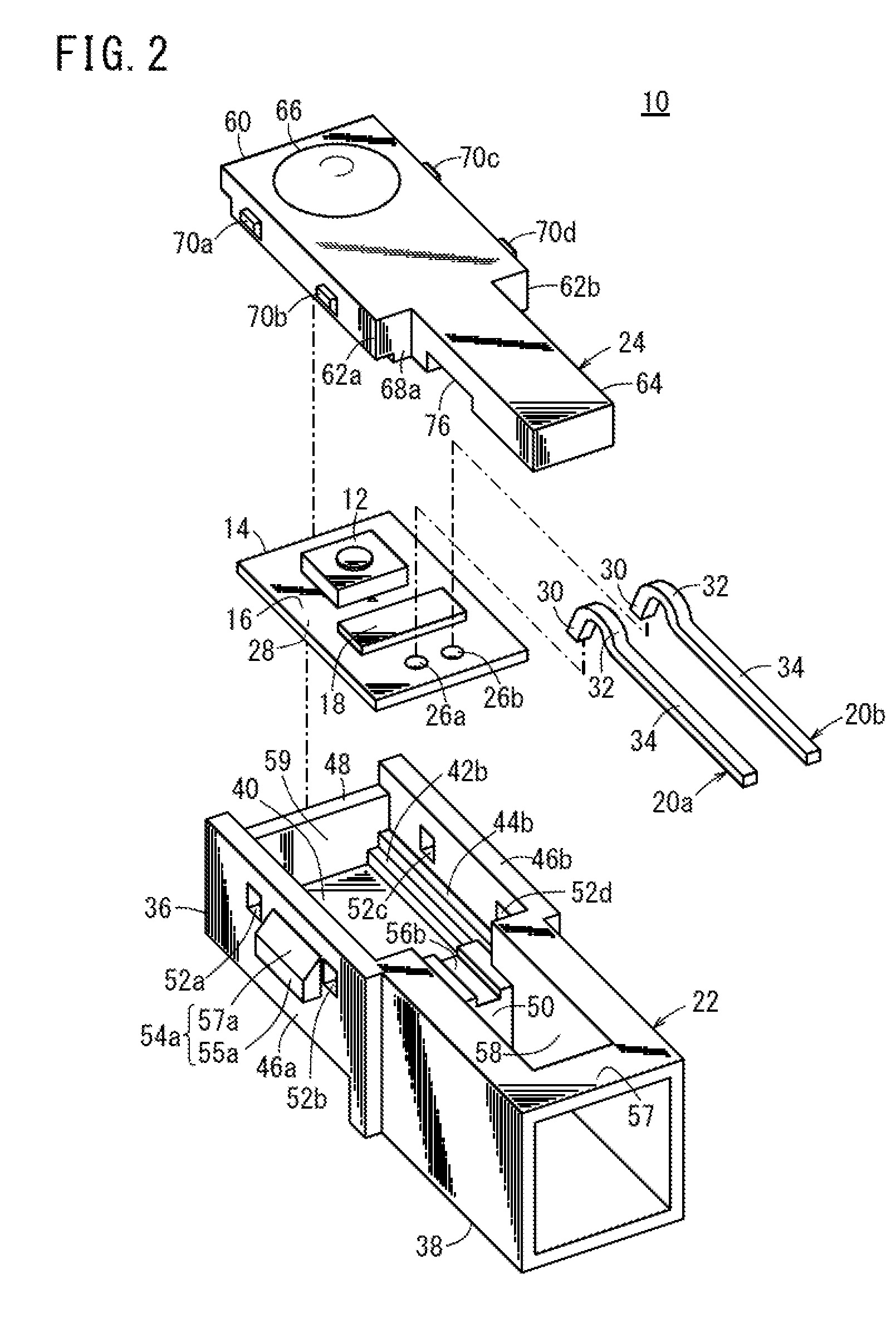

Radiotherapy Device

ActiveUS20090086909A1Expand the treatment spaceLow costHandling using diaphragms/collimetersX-ray apparatusRotational axisLight beam

The invention involves a rotary focused gamma-ray radiotherapy device. The invention includes a frame, a rotary ring positioned at the frame, and a source carrier and a collimator carrier that can rotate around a rotary axis respectively. The source carrier is equipped inside with multiple radiation sources. The collimator carrier is equipped inside with a corresponding beam channel to the radiation sources, which focus at a shared focus of the rotary axis through the beam channel. The source carrier and the collimator carrier are connected at both ends with the rotary ring and the frame, respectively. The single-layer and double-support structure of the source carrier and the collimator carrier adopted in the invention enlarges the treatment space, lowers manufacturing cost and difficulty, simplifies the mechanical structure, increases support rigidity of the source carrier and the collimator carrier, ensuring long-lasting and steady coaxial rotation of source carrier and collimator carrier, as well as position accuracy of the focusing center in the therapeutic system. Therefore, a precision radiotherapy is realized with improved radiotherapy effect.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

Radiotherapy device

ActiveUS7656999B2Expand the treatment spaceLow costHandling using diaphragms/collimetersX-ray apparatusRotational axisLight beam

The invention involves a rotary focused gamma-ray radiotherapy device. The invention includes a frame, a rotary ring positioned at the frame, and a source carrier and a collimator carrier that can rotate around a rotary axis respectively. The source carrier is equipped inside with multiple radiation sources. The collimator carrier is equipped inside with a corresponding beam channel to the radiation sources, which focus at a shared focus of the rotary axis through the beam channel. The source carrier and the collimator carrier are connected at both ends with the rotary ring and the frame, respectively. The single-layer and double-support structure of the source carrier and the collimator carrier adopted in the invention enlarges the treatment space, lowers manufacturing cost and difficulty, simplifies the mechanical structure, increases support rigidity of the source carrier and the collimator carrier, ensuring long-lasting and steady coaxial rotation of source carrier and collimator carrier, as well as position accuracy of the focusing center in the therapeutic system. Therefore, a precision radiotherapy is realized with improved radiotherapy effect.

Owner:SHEN ZHEN HYPER TECH SHENZHEN

Portable chair

The portable chair of the disclosure includes: hubs respectively installed at both left and right sides of the chair; a central support frame connecting both left and right hubs; front and rear leg frames respectively having base ends separably coupled to the lower front and rear outer peripheral surfaces of the respective hubs and respectively having free ends disposed in a manner of radially extending toward the ground surface; front and rear pole frames respectively having base ends separably coupled to the upper front and rear outer peripheral surfaces of the respective hubs and respectively having free ends disposed in a manner of radially extending toward the sky; and a fabric sheet coupled to the free ends of the front and rear pole frames. The structural rigidity is excellent, and the chair may land on the ground surface in a stable posture.

Owner:LAH JEH KUN

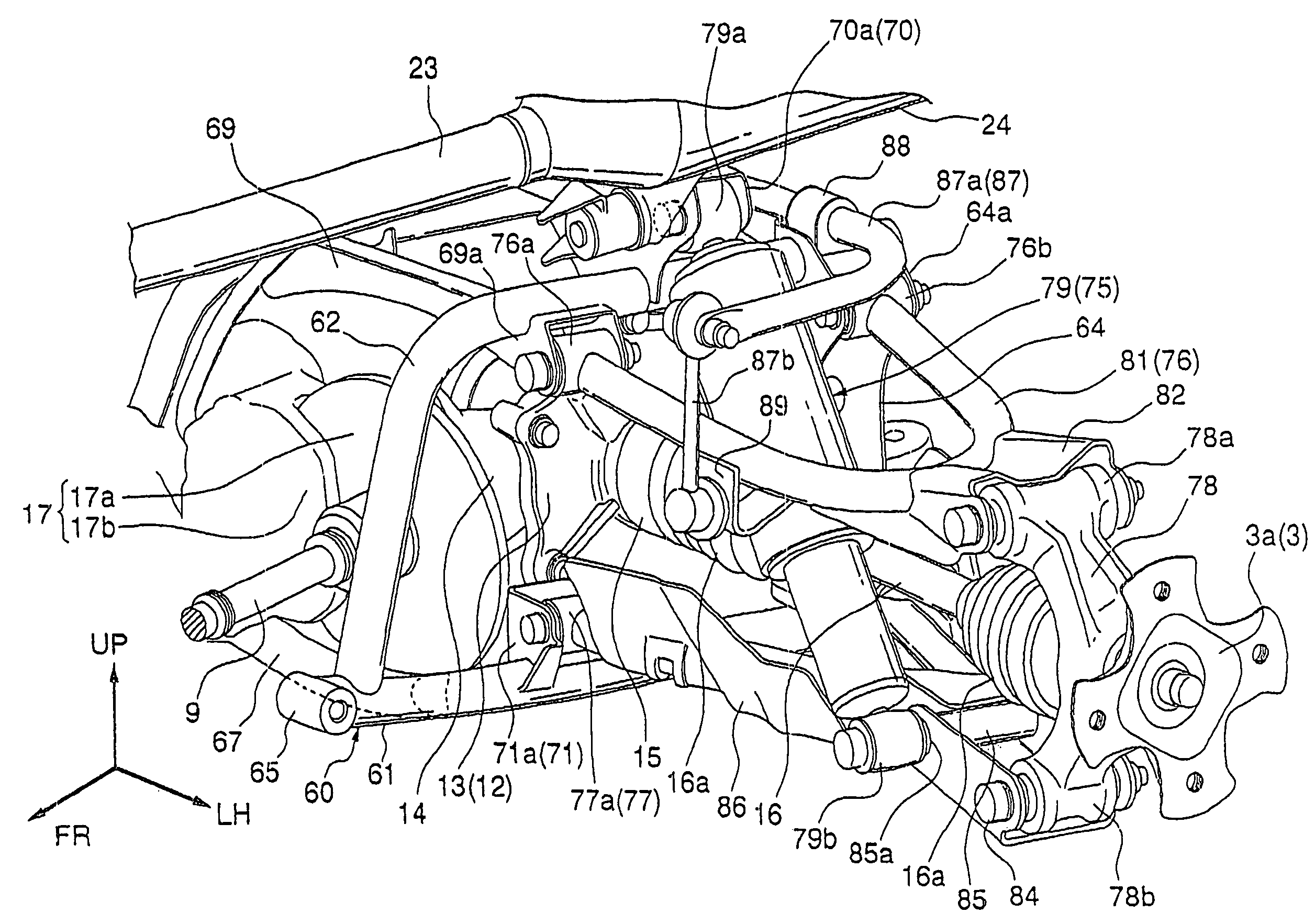

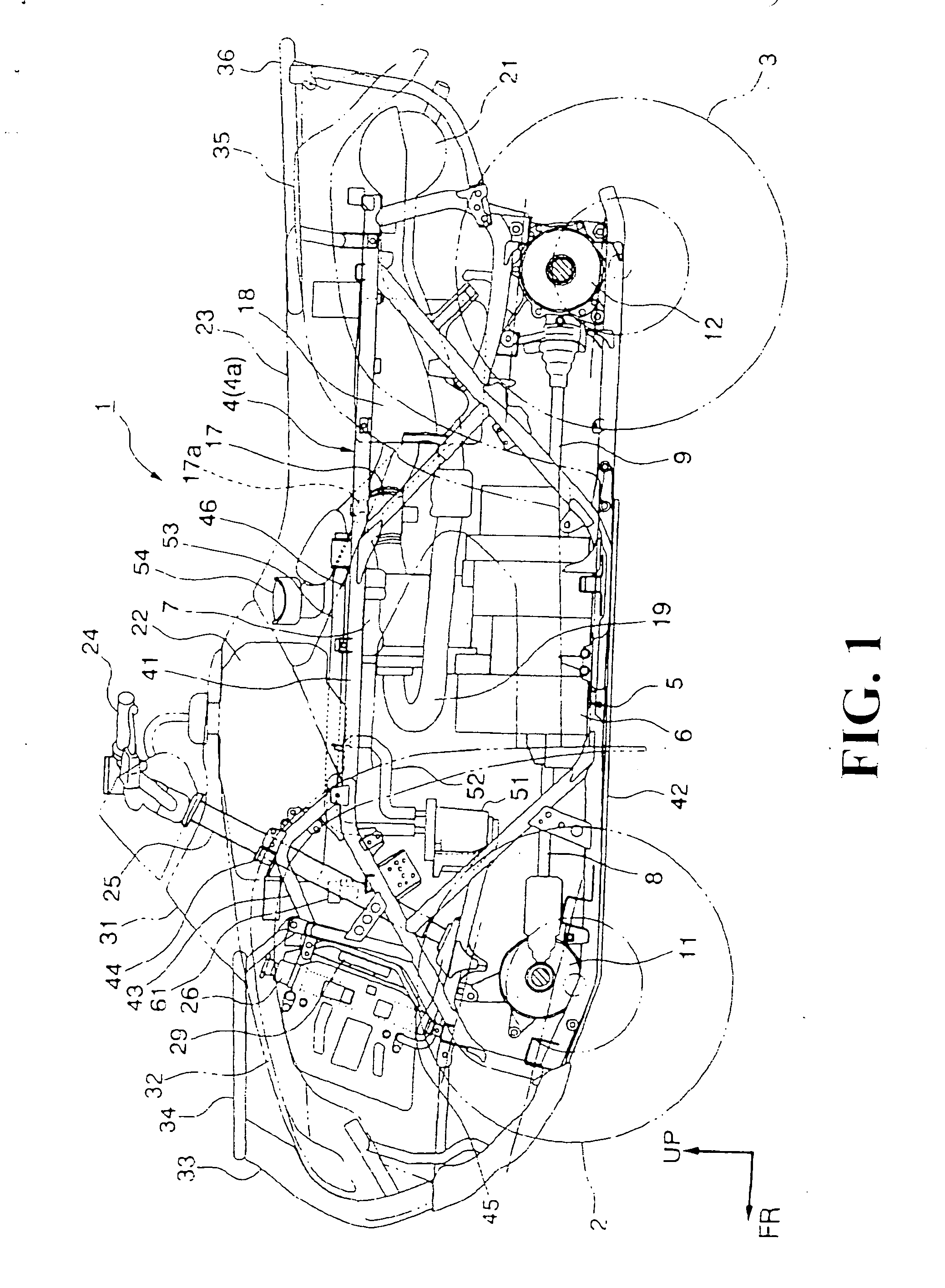

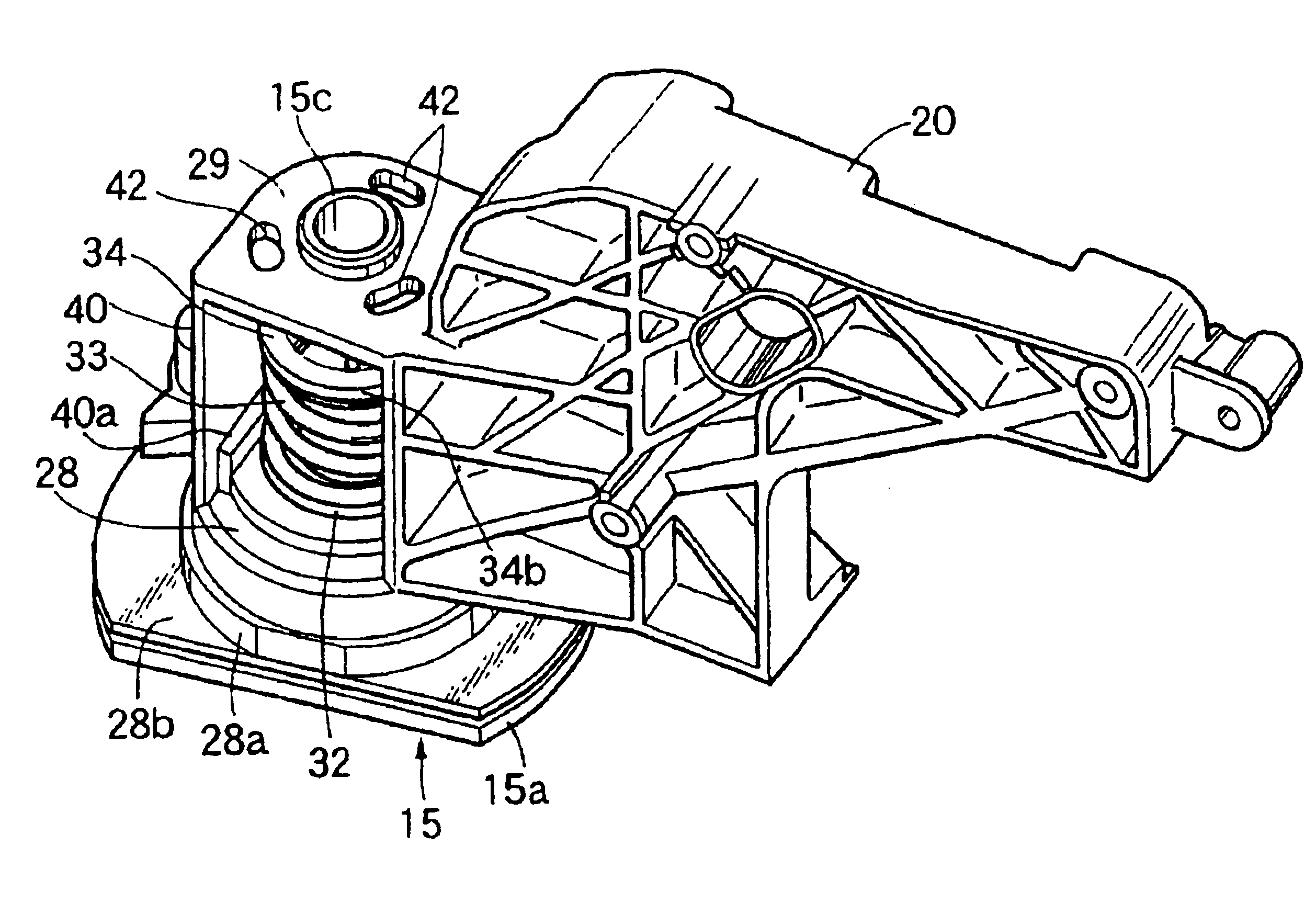

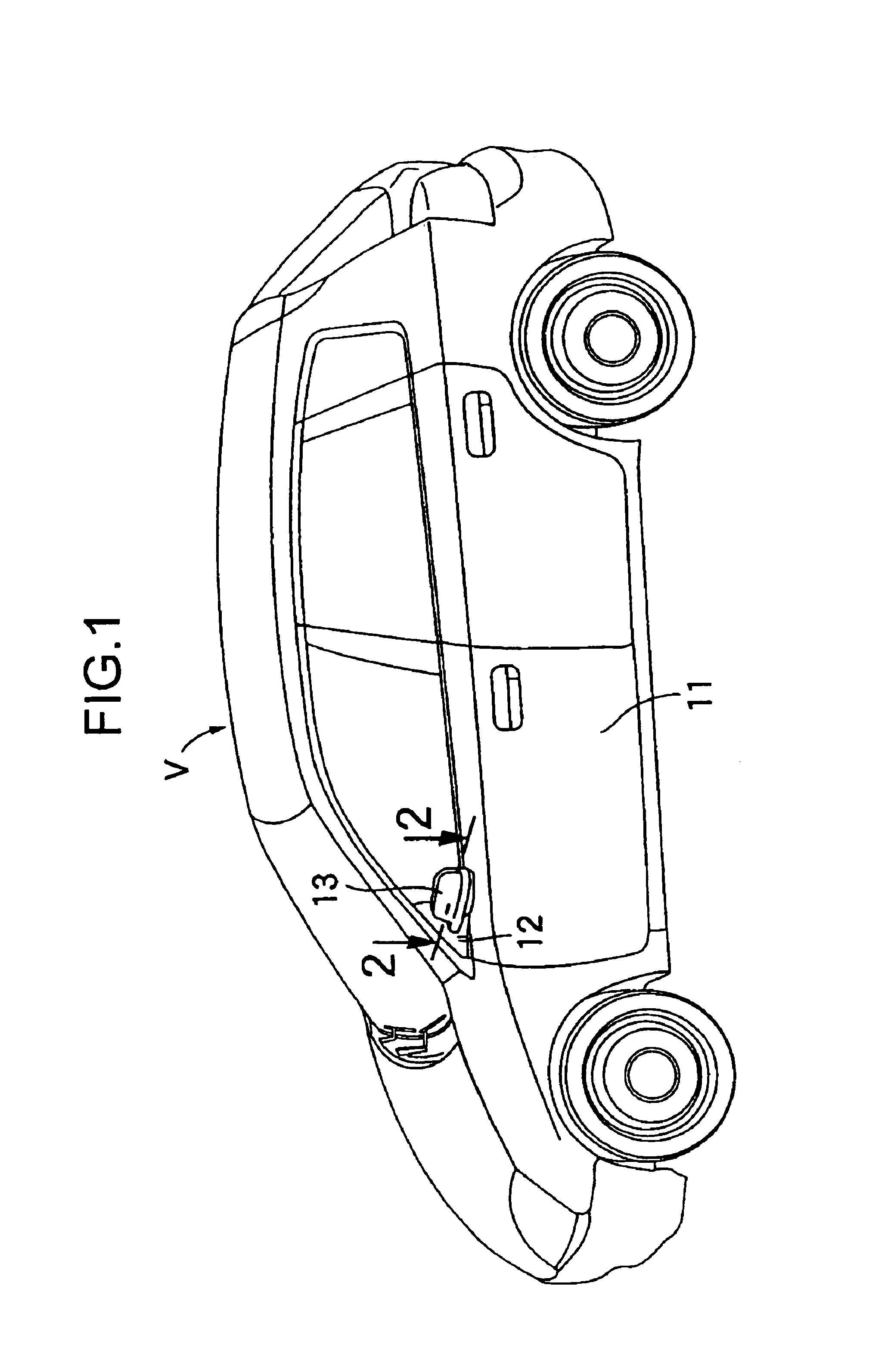

Suspension structure with improved shock absorber arrangement, and vehicle incorporating same

InactiveUS7690661B2Increase flexibilityIncreased shock absorber strokeInterconnection systemsResilient suspensionsVehicle frameEngineering

A suspension structure is configured to ensure a large stroke of a shock absorber in a suspension device without moving an upper end supporting position of a damper upward relative to a conventional mounting position. The suspension structure includes a rear suspension for suspending left and right rear wheels. The rear suspension includes left and right lower arms for supporting the left and right rear wheels by way of knuckles, and left and right rear shock absorbers interposed between the respective lower arms and a sub-frame of a vehicle body frame. A lower end connecting portion of the rear shock absorber is cantilevered to a front side of the lower arm.

Owner:HONDA MOTOR CO LTD

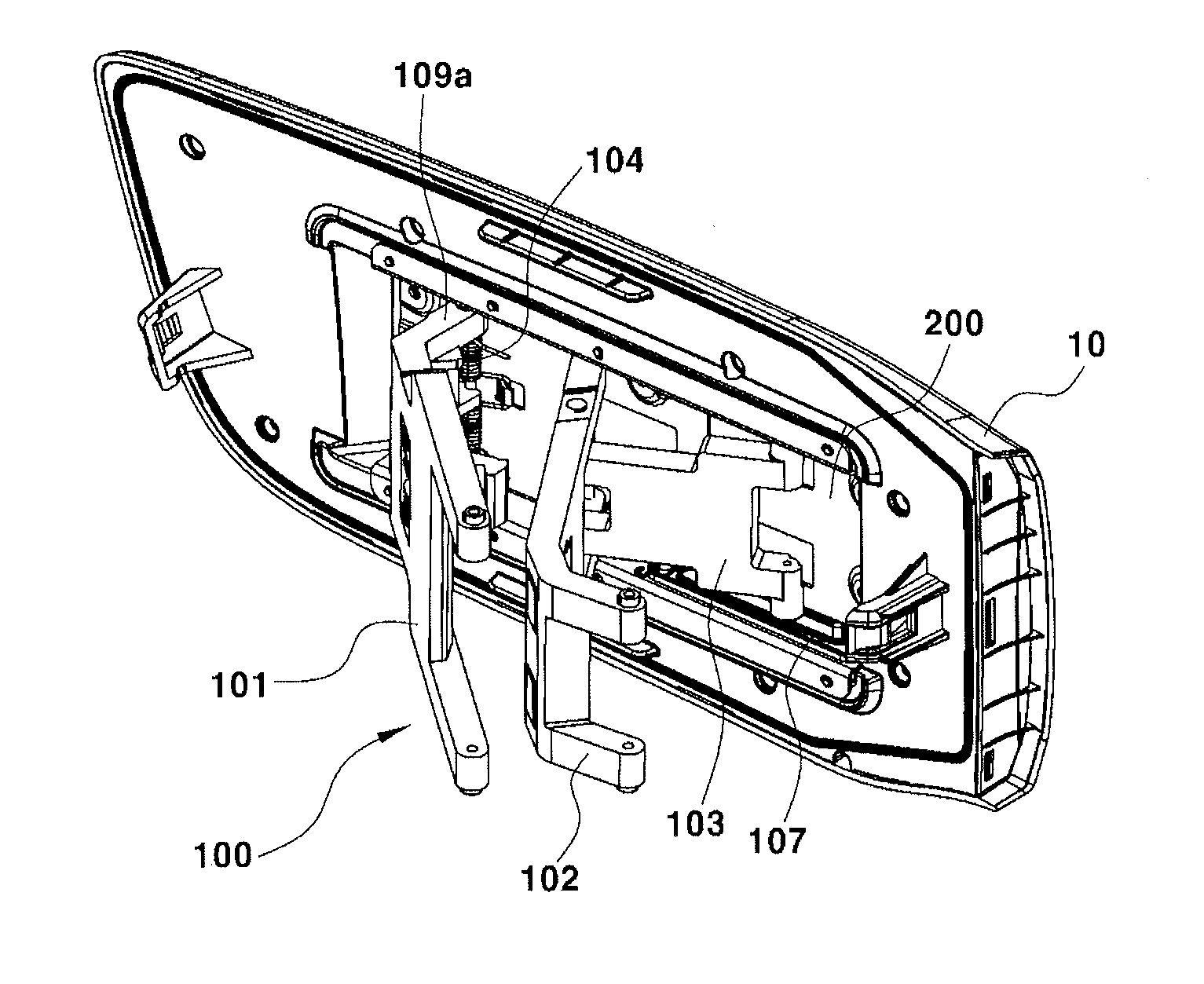

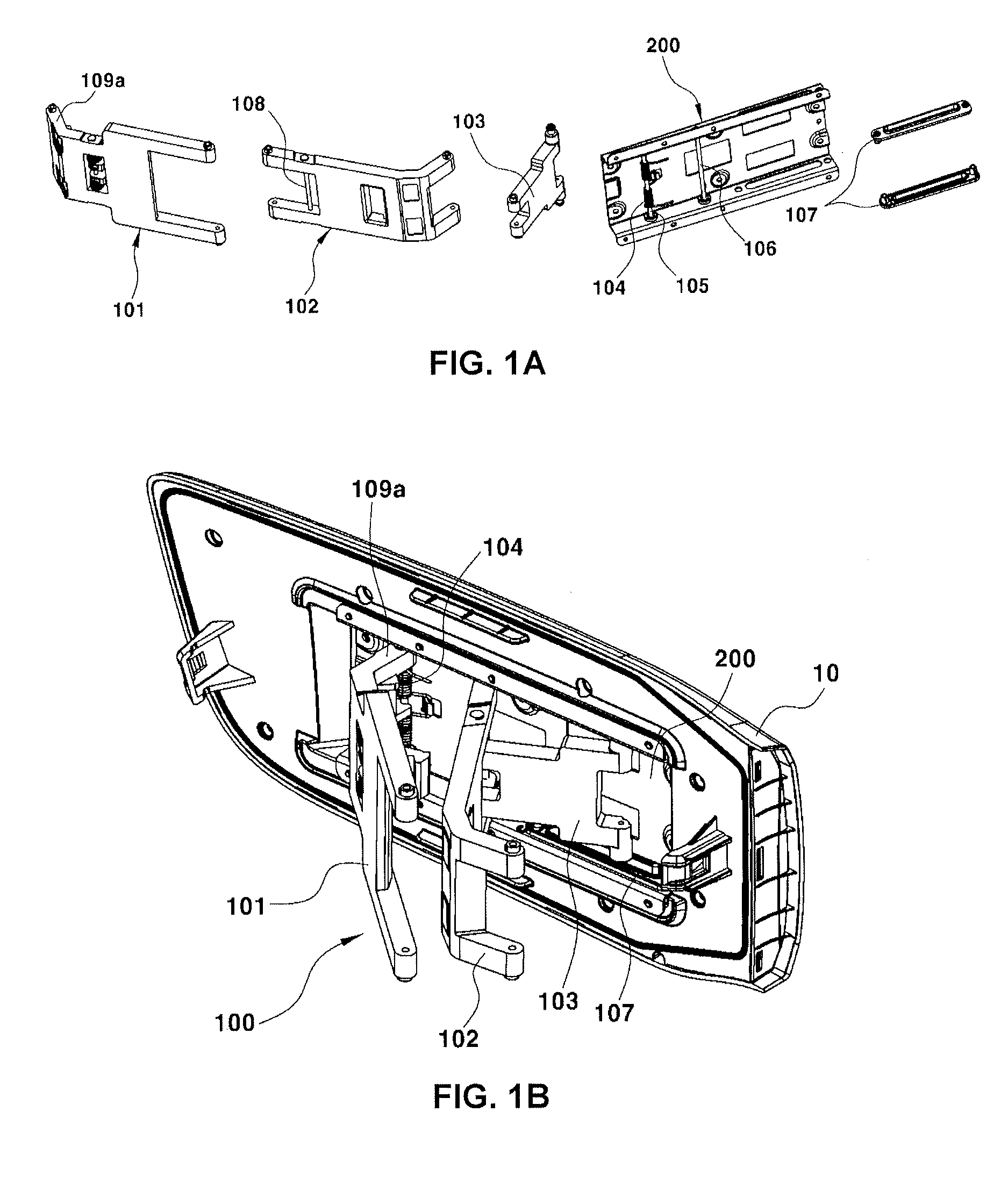

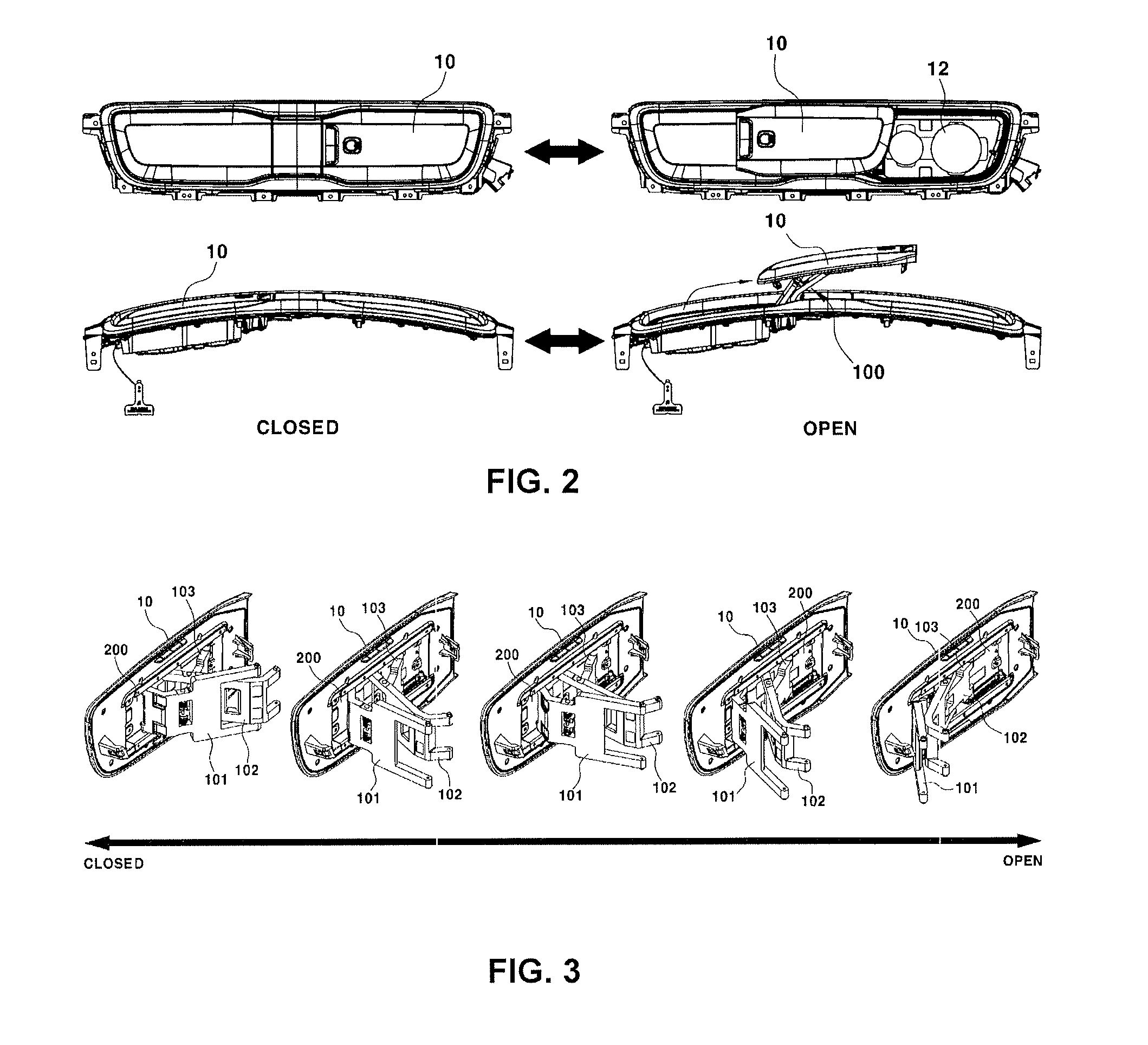

Door assembly for charging port of electric vehicle

ActiveUS20150375630A1Quantity minimizationAvoid interferenceCharging stationsElectric propulsion mountingElectric vehicleMinimum distance

A door assembly for a charging port for an electric vehicle may include a link assembly mounted to a back of a charging port door to perform a swing operation, in which the door is mounted in a structure capable of being kept at a minimum distance between the door and a vehicle body when the door is open according to the swing operation.

Owner:KIA MOTORS CORP +2

V-belt type continuously variable transmission

A V-belt type continuously variable transmission includes a drive pulley assembly provided on a drive shaft, a driven pulley assembly provided on a driven shaft, a V-belt looped over both the pulley assemblies, and a transmission case assembly housing both the pulley assemblies and the V-belt. One end of the drive shaft in the shaft direction is coupled to an output side rotation member of a centrifugal clutch, and the other end of the drive shaft is rotatably supported on a boss portion formed in the transmission case assembly.

Owner:KAWASAKI HEAVY IND LTD

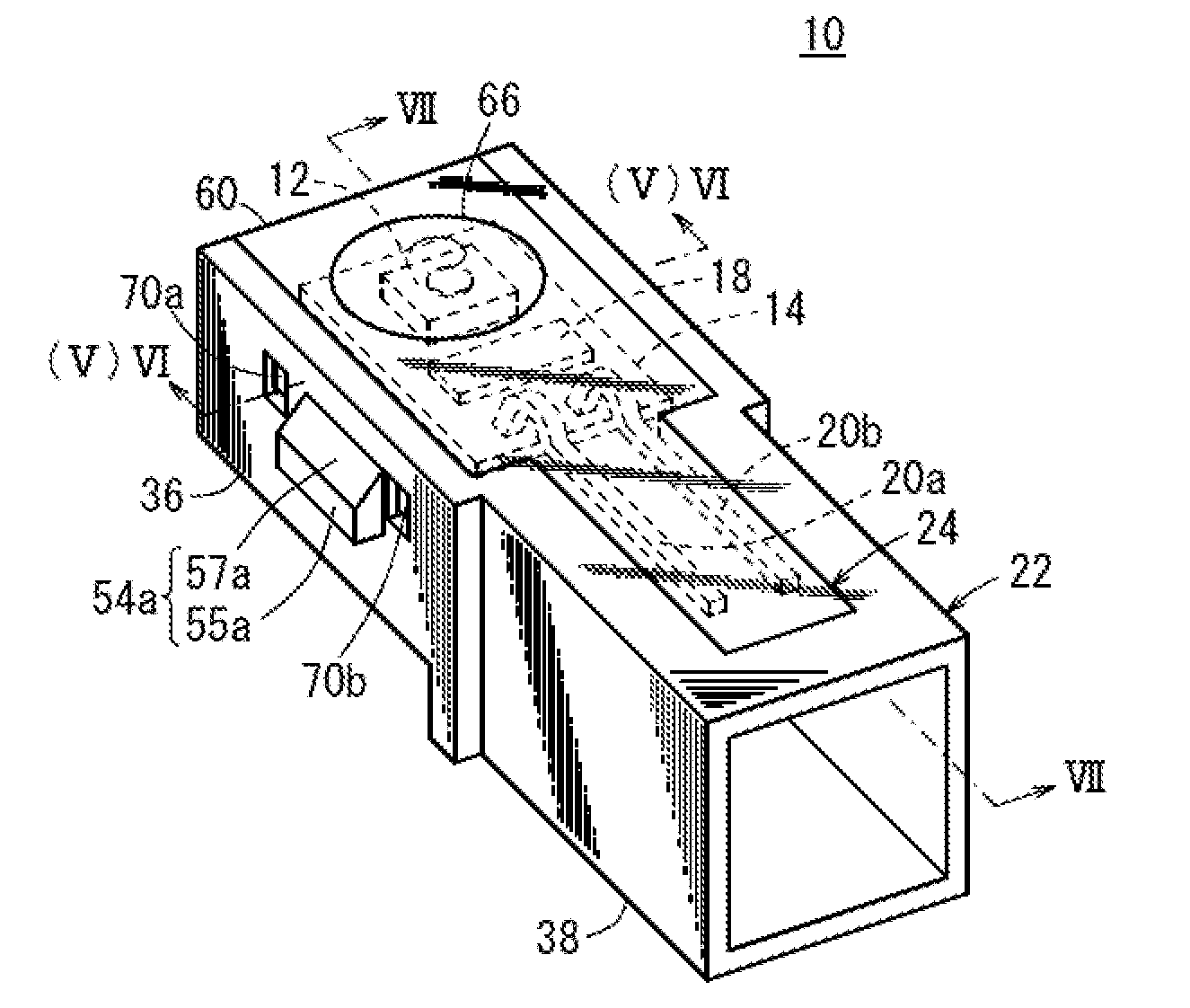

Structure of air cleaner box

ActiveUS20060230728A1Easy to operateImprove support rigidityCombination devicesDispersed particle filtrationElectrical and Electronics engineeringAir cleaners

An air cleaner box structured to facilitate the attaching and detaching operation of an air cleaner element While enhancing the support rigidity thereof. The air cleaner box includes a casing having a case body and the openable and closable case cover. The air cleaner element and the element holder to support the air cleaner element are contained in the casing. The element holder has an extended U-shape in cross section, and has end sections that are supported by the case body and the case cover respectively. The element holder pivots on the bottom face rear ends of the holder lower protrusions in an inclinable manner.

Owner:HONDA MOTOR CO LTD

Light-emitting device

ActiveUS20150146433A1Add supportAvoid displacementMechanical apparatusLighting circuitsLight guideEngineering

A light-emitting device comprises: a substrate that holds one end of connection terminals and on which is mounted an electronic component; a light-emitting element that is mounted on one face of the substrate; a support member on which the substrate is mounted; and a cover section that positionally locates and holds the substrate, by mounting on the support member in a condition abutting one face of the substrate. The cover section has a cover section body that covers one face of the substrate; on the cover section body, a light guide is provided, through which passes the light that is emitted from the light emitting element, in a condition in which movement thereof is restricted along directions on either side of the substrate.

Owner:TS TECH CO LTD

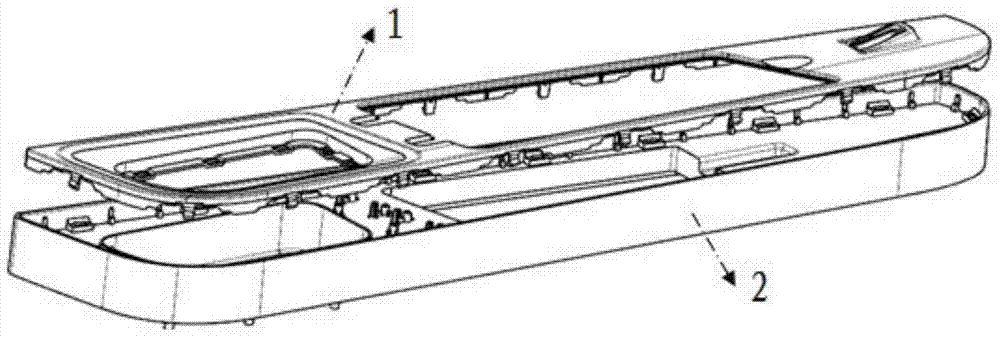

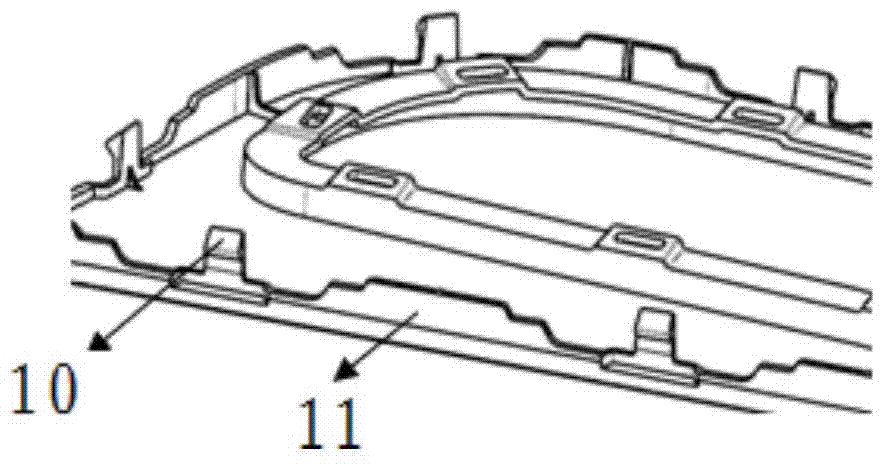

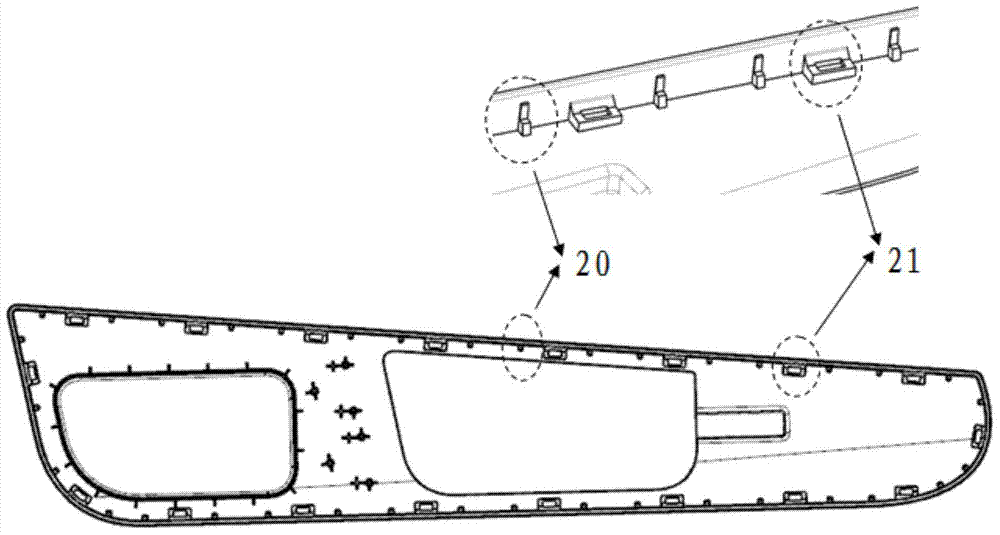

Large plastic plate matching structure based on cantilever buckles

The invention relates to a large plastic plate matching structure based on cantilever buckles. The large plastic plate matching structure comprises a cover plate (1) and a basal plate (2), the buckles (10) and cover plate turning edges (11) are arranged on the periphery of the cover plate at intervals, and the inner side wall of the basal plate is provided with clamping groove bosses (21) matched with the buckles and limiting bosses (20) used for supporting the cover plate turning edges. When the cover plate turning edges are turned to the upper portion of the side wall of the basal plate, the lower end faces of the cover plate turning edges abut against the top surfaces of the limiting bosses. Each clamping groove boss comprises a rectangular cavity (210) extending in the Z direction, the top surface of each limiting boss is a vertical limiting surface (201), and circumferential direction limiting surfaces (202) perpendicular to the vertical limiting surfaces are arranged at the upper ends of the vertical limiting surfaces. The limiting bosses are utilized, the clamping groove bosses are matched with the cover plate turning edges, and the buckles are used for multi-point horizontal surface matching; compared with an existing method that cover plate turning edges and grooves in the side wall of the basal plate are directly buckled and the turning edges directly abut against the bottom surface of the basal plate, better assembly stability is achieved.

Owner:BAOSTEEL DEV CO LTD

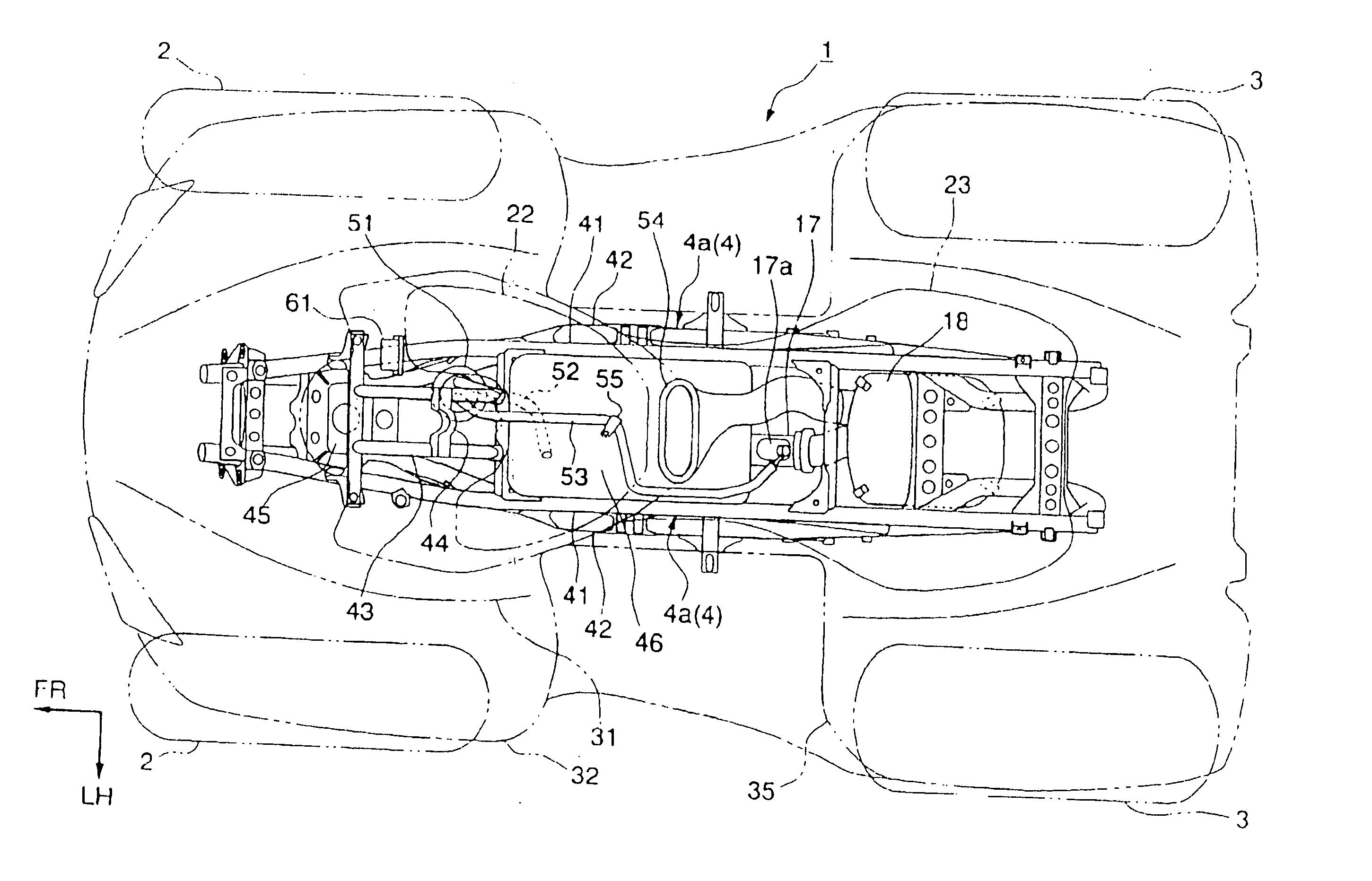

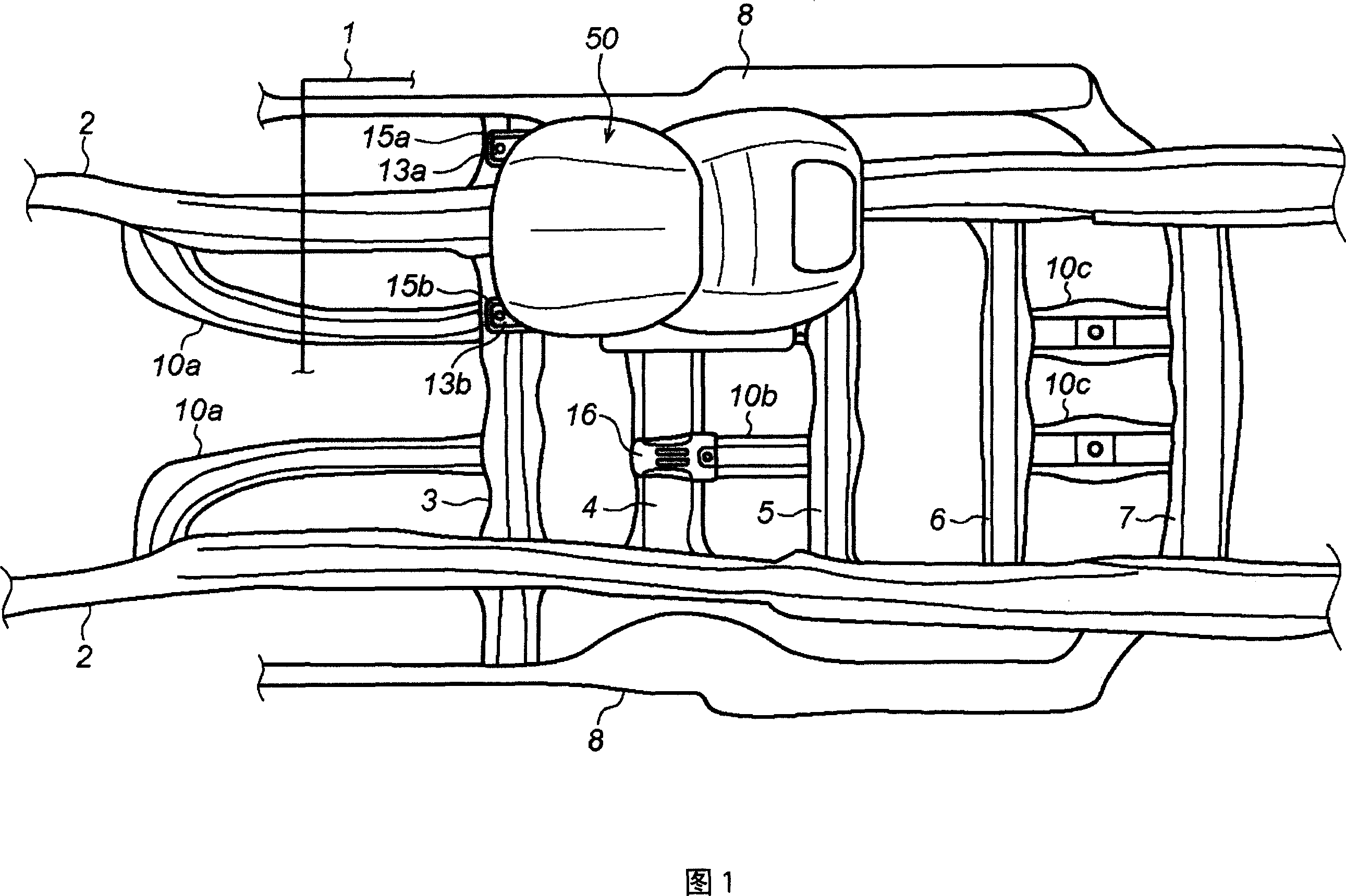

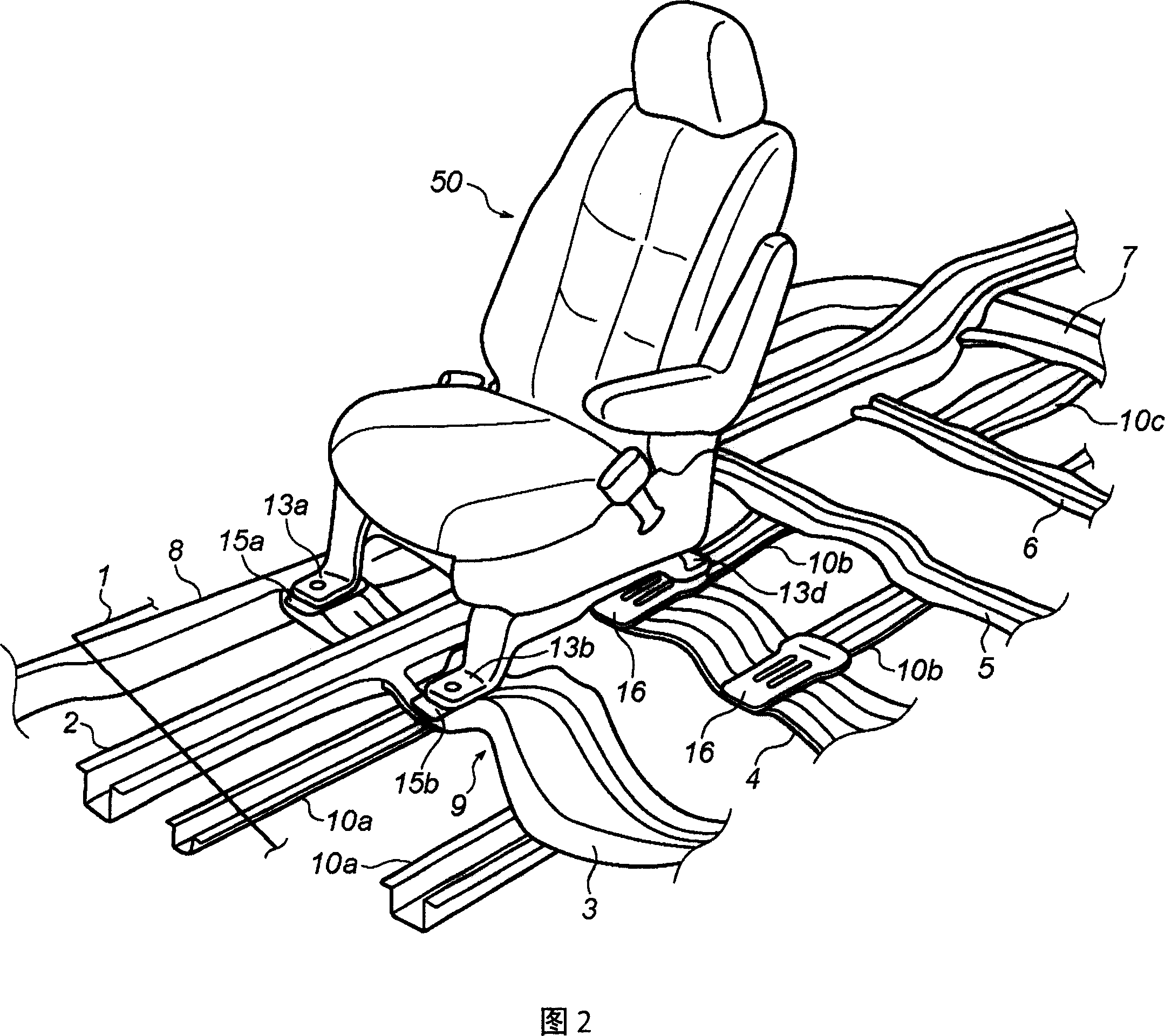

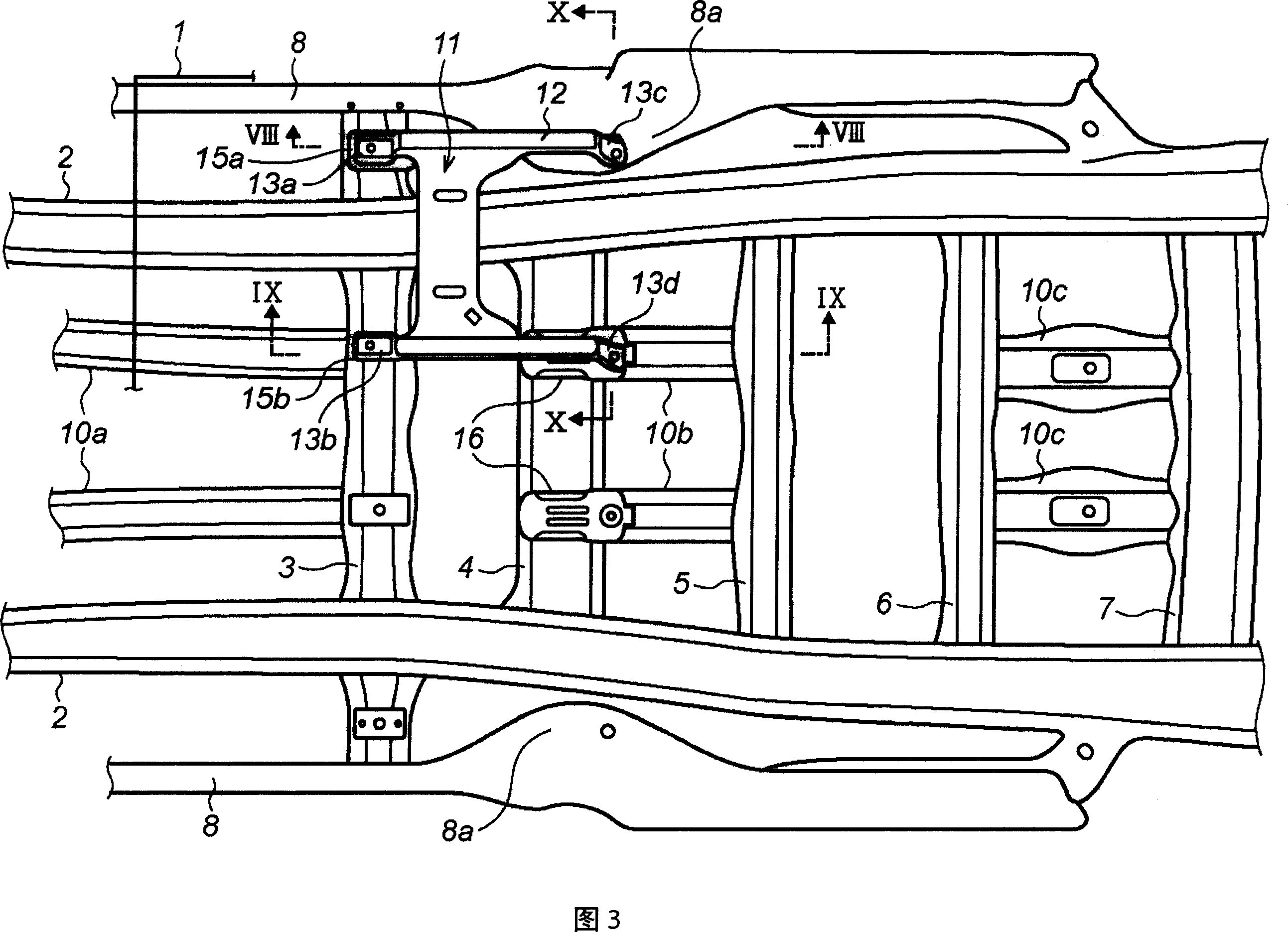

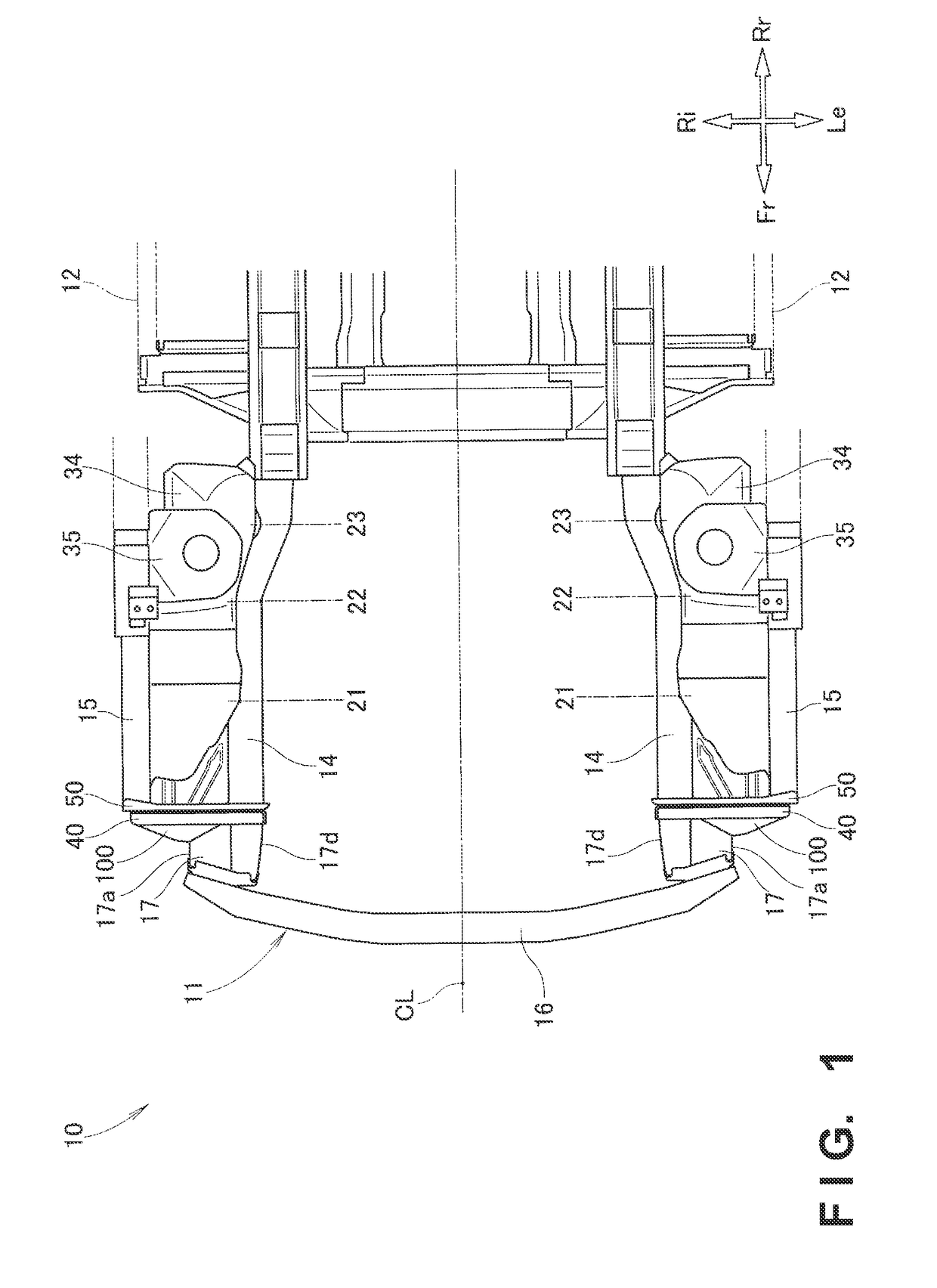

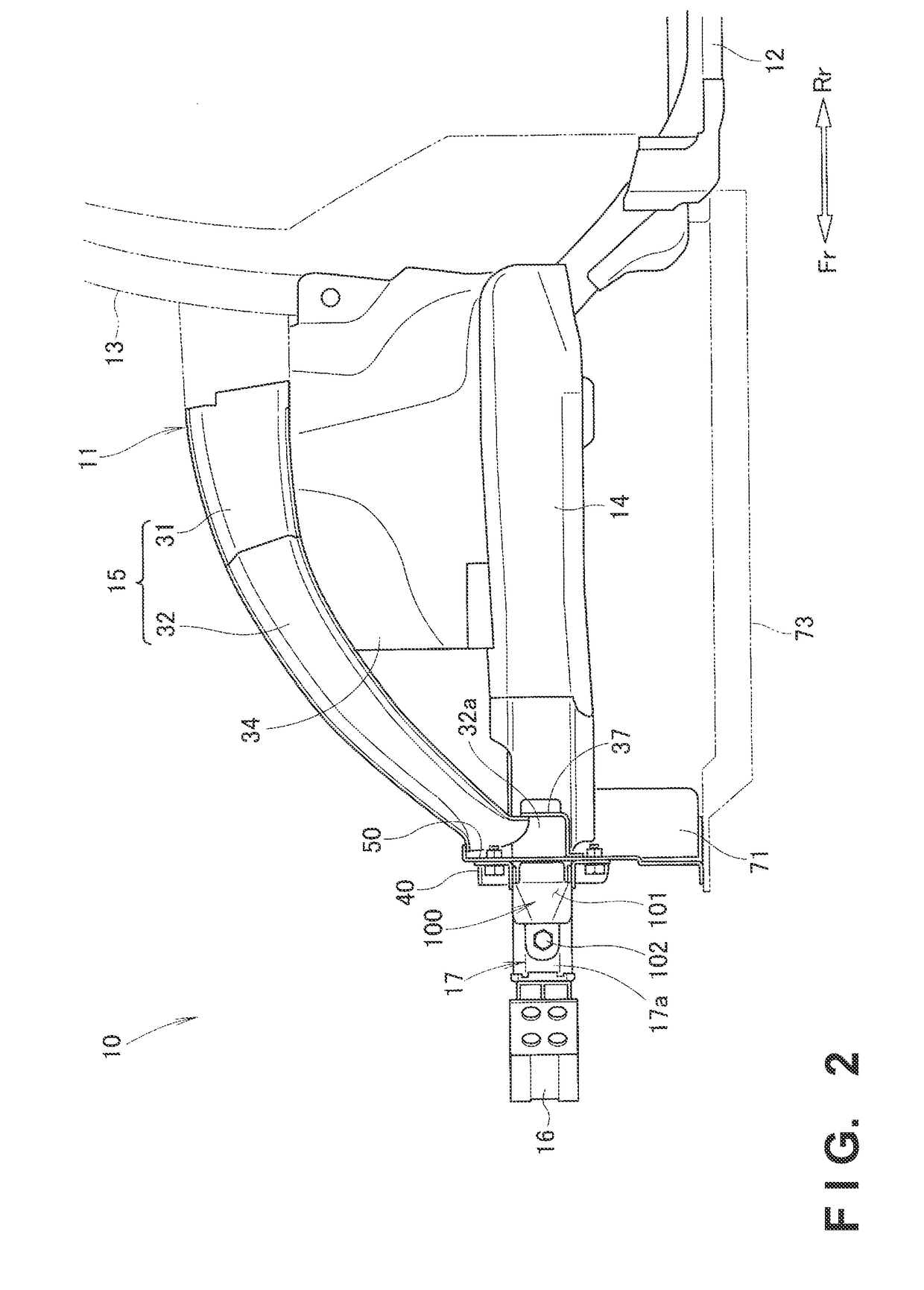

Lower vehicle body structure

InactiveCN1935581AImprove support rigidityVehicle seatsUnderstructuresEngineeringMechanical engineering

Owner:MAZDA MOTOR CORP

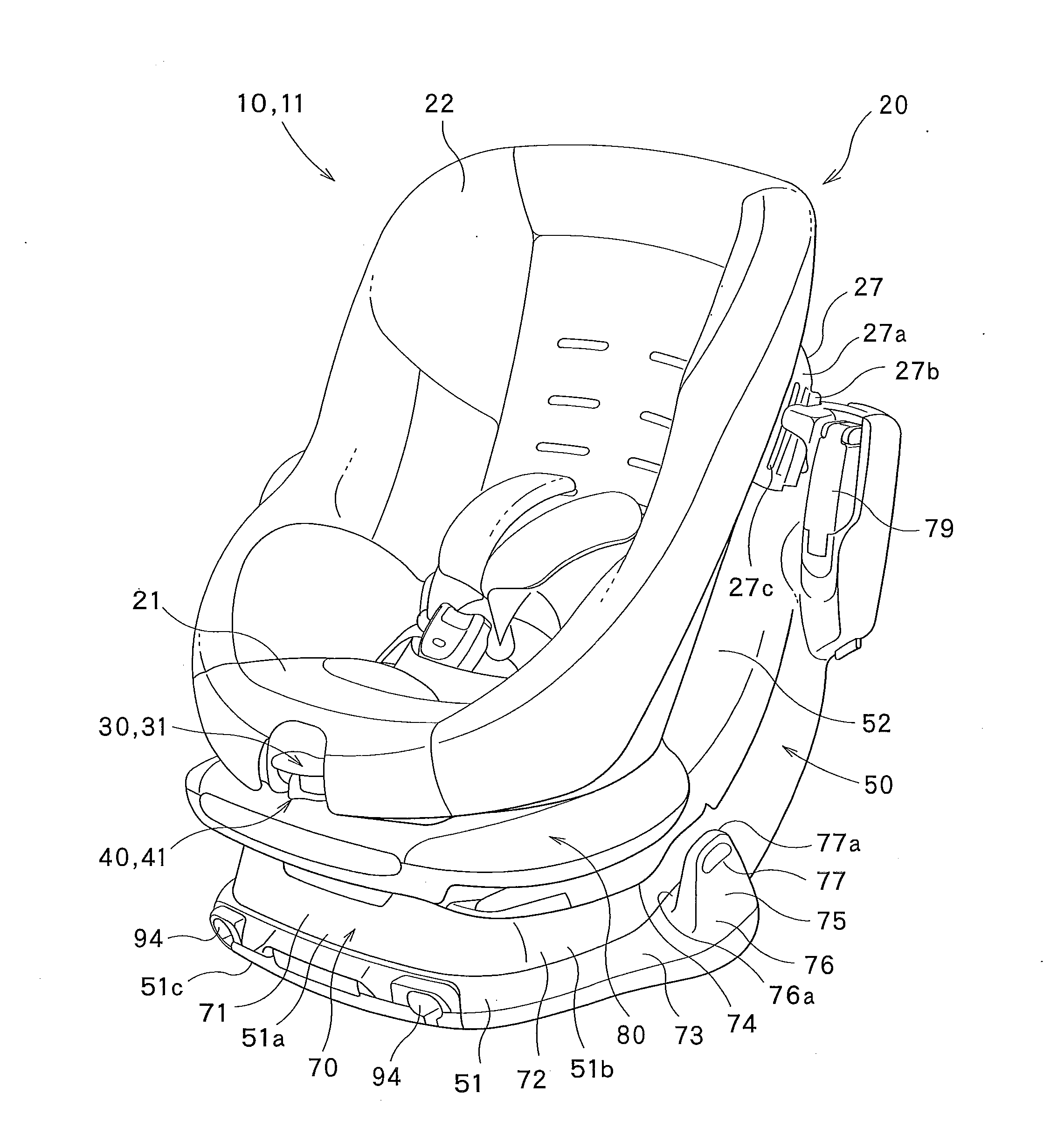

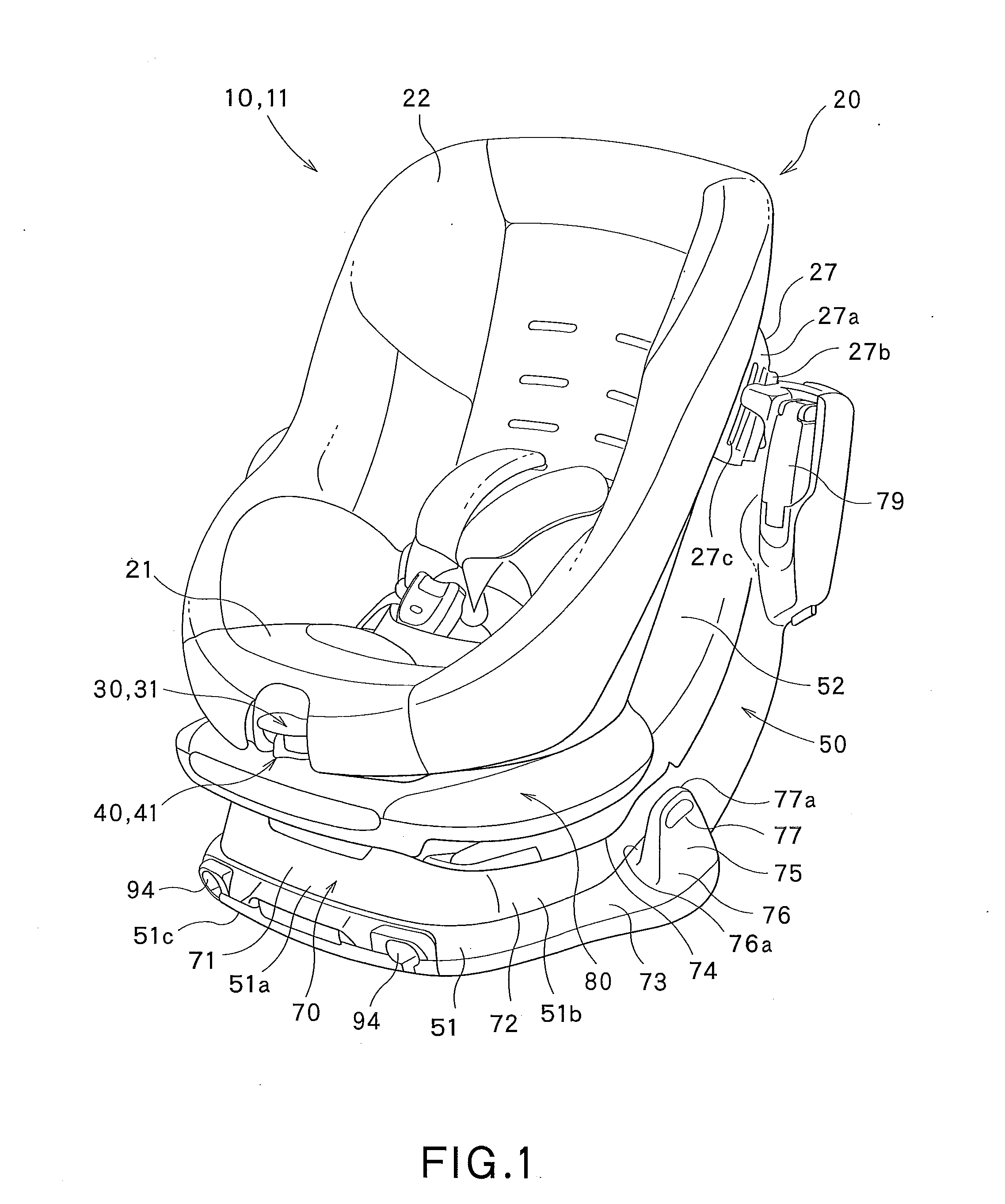

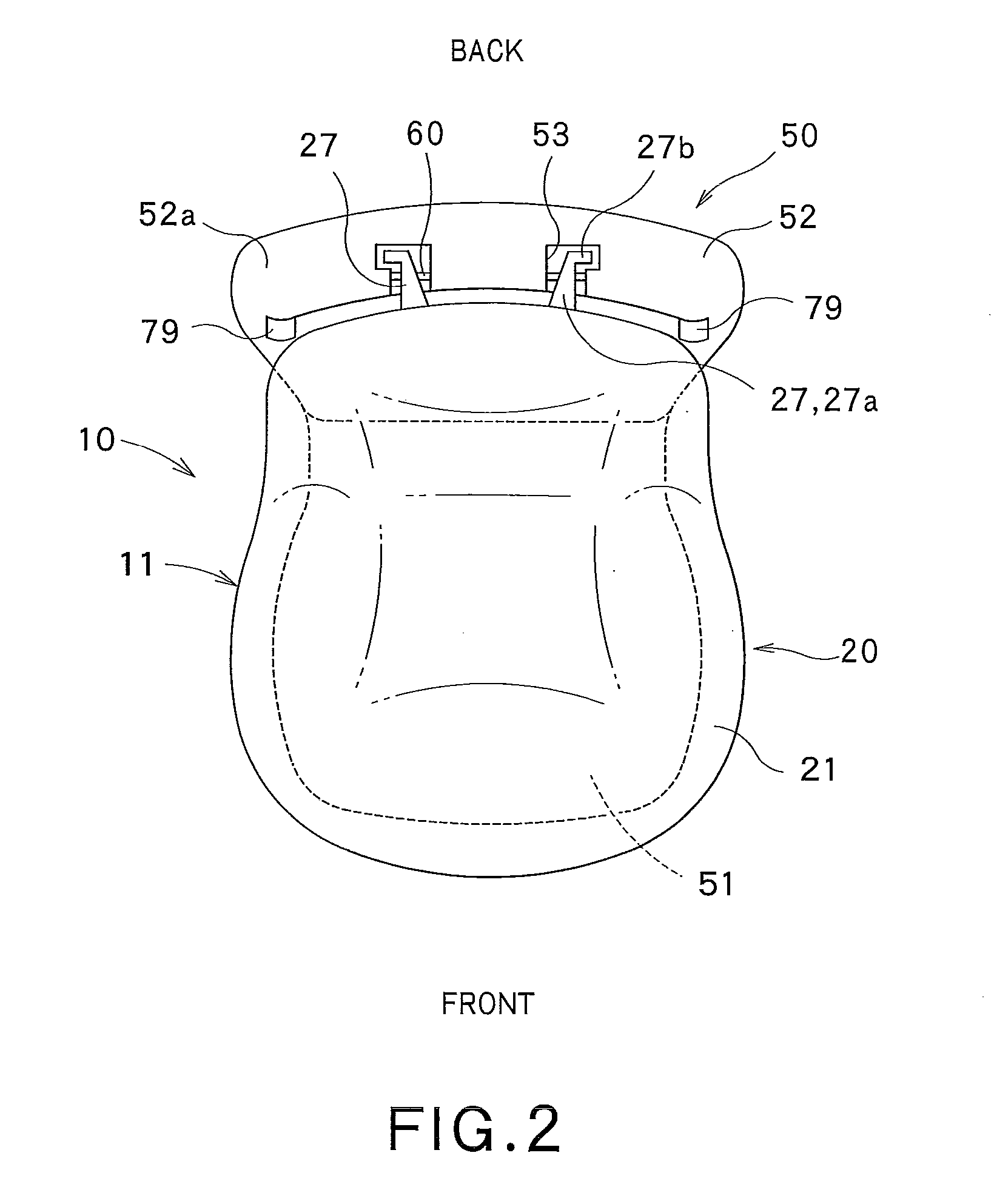

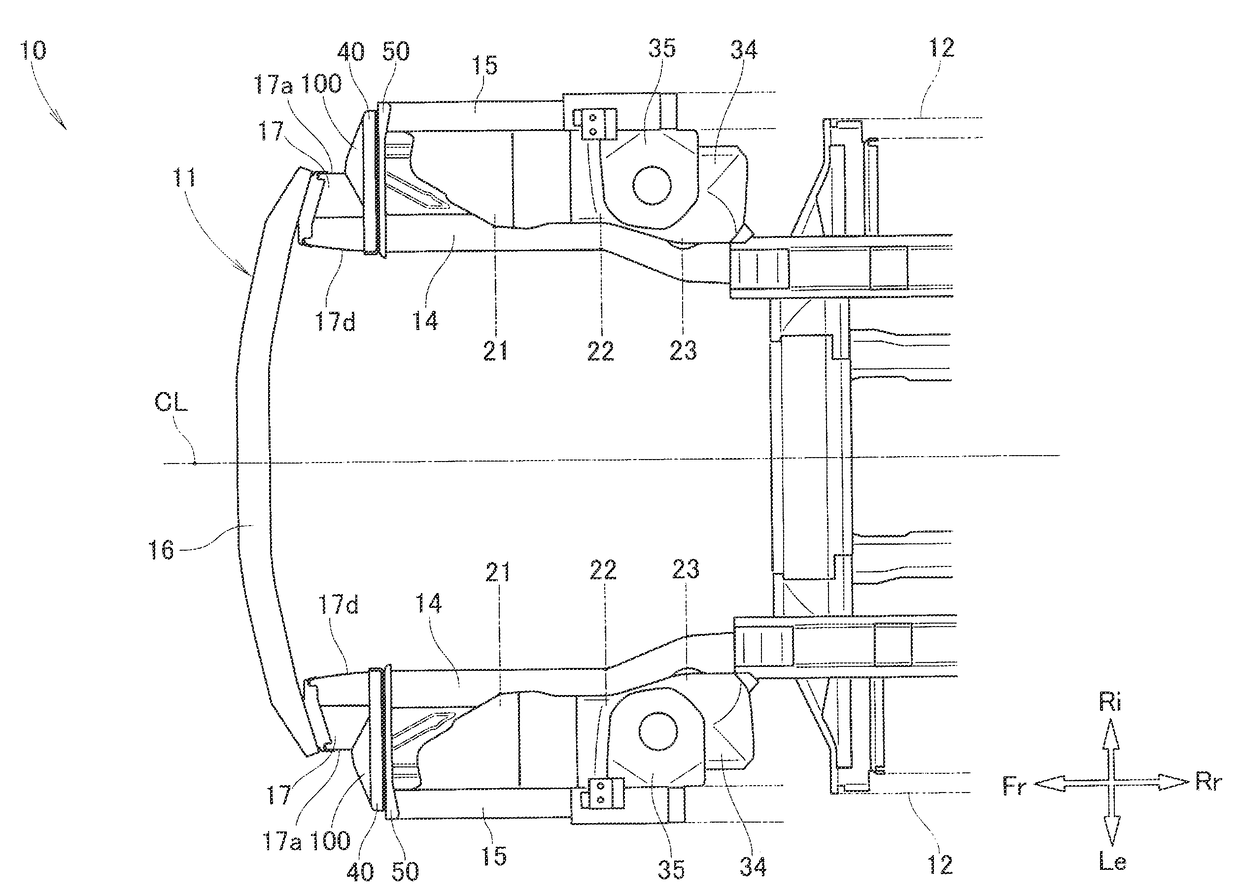

Child car seat

InactiveUS20110109138A1Reduce supportImprove support rigidityKids chairsChild seatsCar seatEngineering

There is provided a child car seat capable of preventing a seat body from being unintentionally moved to a turning position. The child car seat includes a pedestal and a seat body that can be slid with respect to the pedestal. A plurality of reclining positions and a turning position are included in a range within which the seat body can be slid. The seat body includes a retractable projecting member projecting toward the pedestal, and an operation member connected to the projecting member. The seat body can be held in the respective positions when the projecting member is engaged with the pedestal. An operation amount of the operation member, which is required for sliding the seat body between the reclining positions, is smaller than an operation amount of the operation member, which is required for sliding the seat body from the reclining position to the turning position.

Owner:COMBI CORP

Vehicle body front structure

ActiveUS20170113735A1Improve performanceIncrease vibrationVehicle sub-unit featuresUnderstructuresEngineeringFlange

Owner:HONDA MOTOR CO LTD

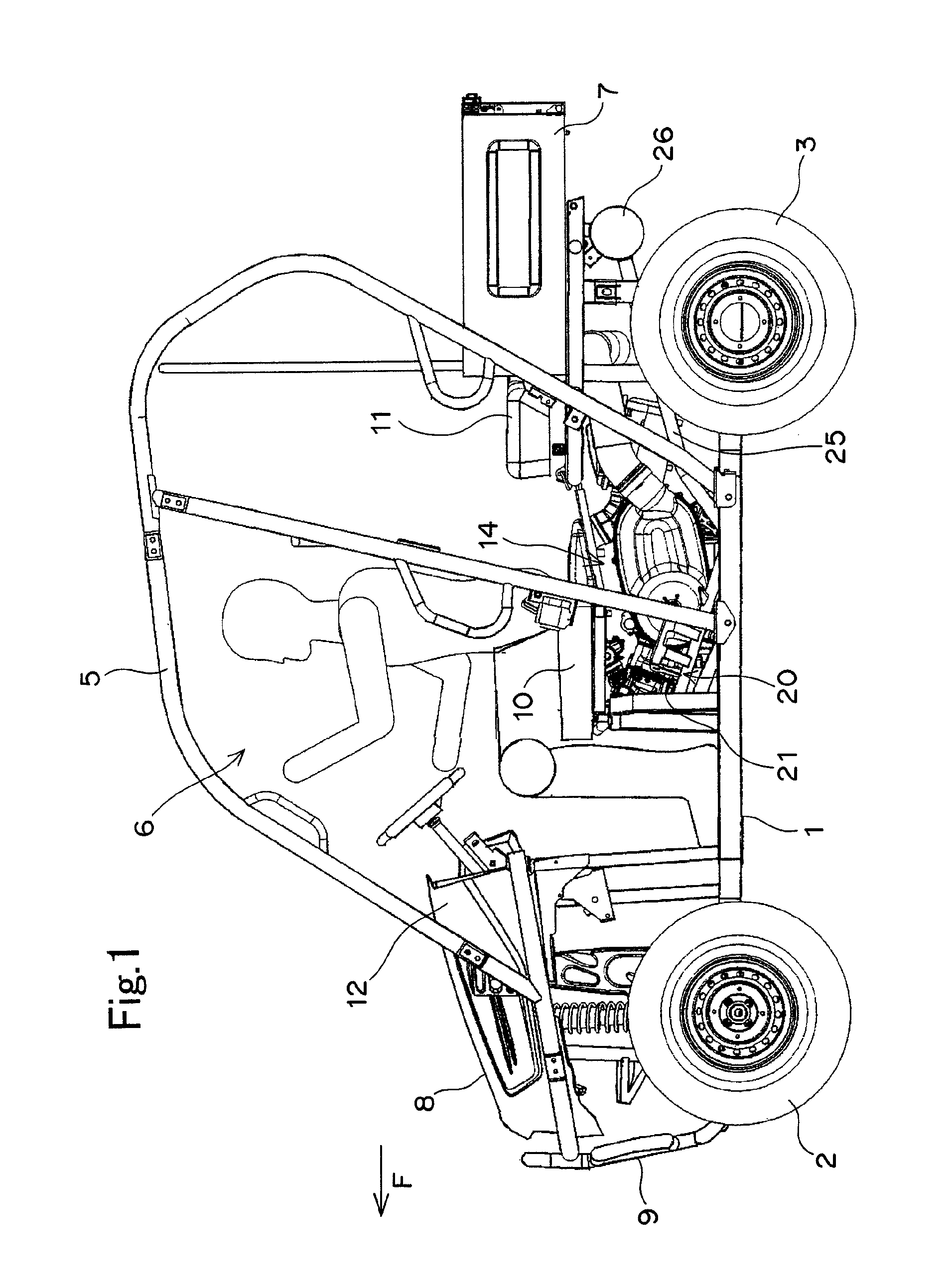

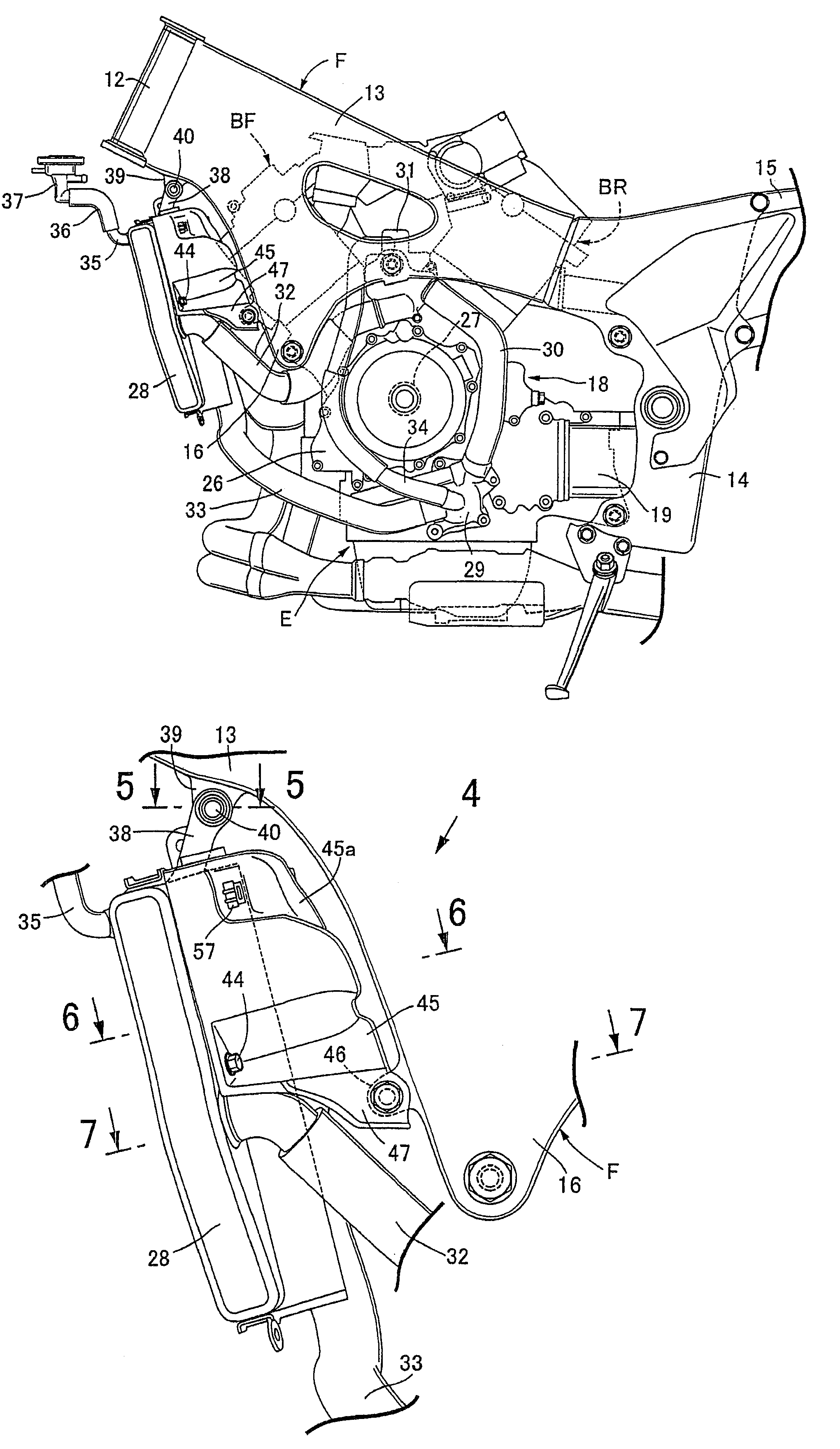

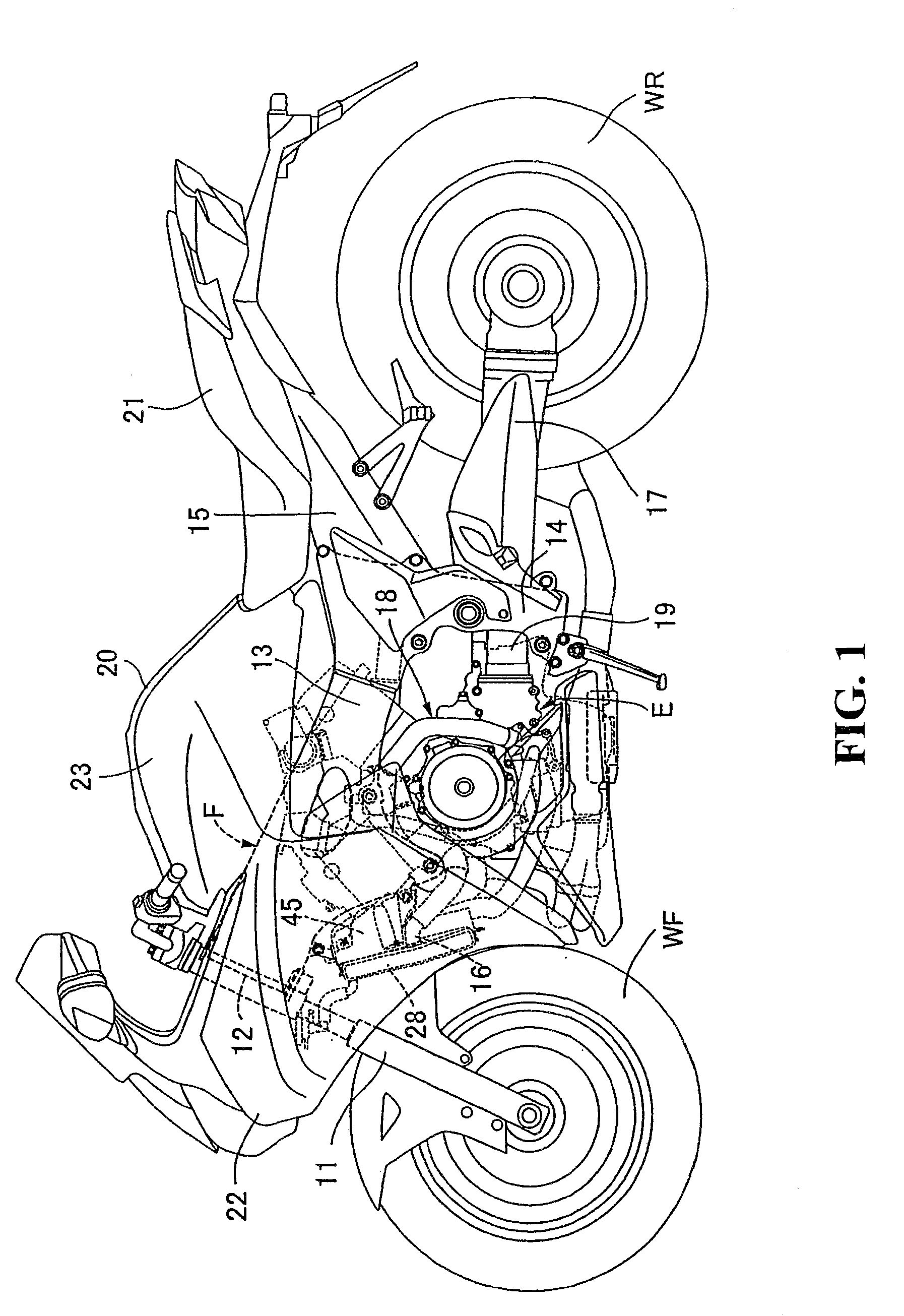

Radiator mounting structure for motorcycle

ActiveUS20100078242A1Increase the number ofReliable supportMotorcyclesPropulsion coolingWater coolingEngine mount

A radiator mounting structure for motorcycle, in which a radiator is disposed forward of a water-cooled engine mounted on a body frame and an upper portion of the radiator is attached to the body frame, in which running-air that passes the radiator is not directed to a rider. The radiator is reliably supported so as not to be affected by heat from the engine with an increase in the number of parts avoided. A shroud for covering the radiator from behind is attached the radiator and has at an upper portion thereof attachment arm portions attached to a body frame. Attachment portions fastened to stays provided on the body frame are provided at a rear lower portion of the shroud.

Owner:HONDA MOTOR CO LTD

Cylindrical roller bearing

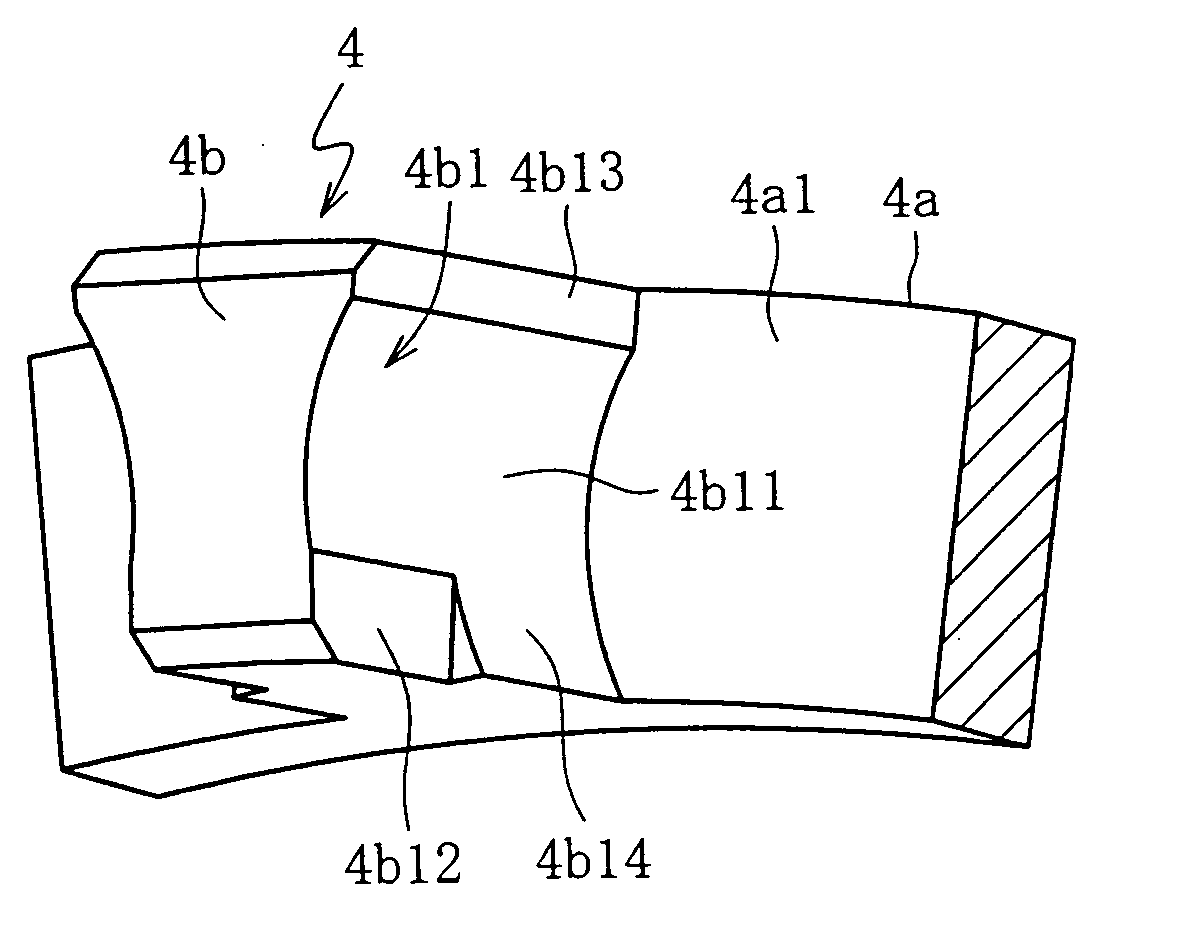

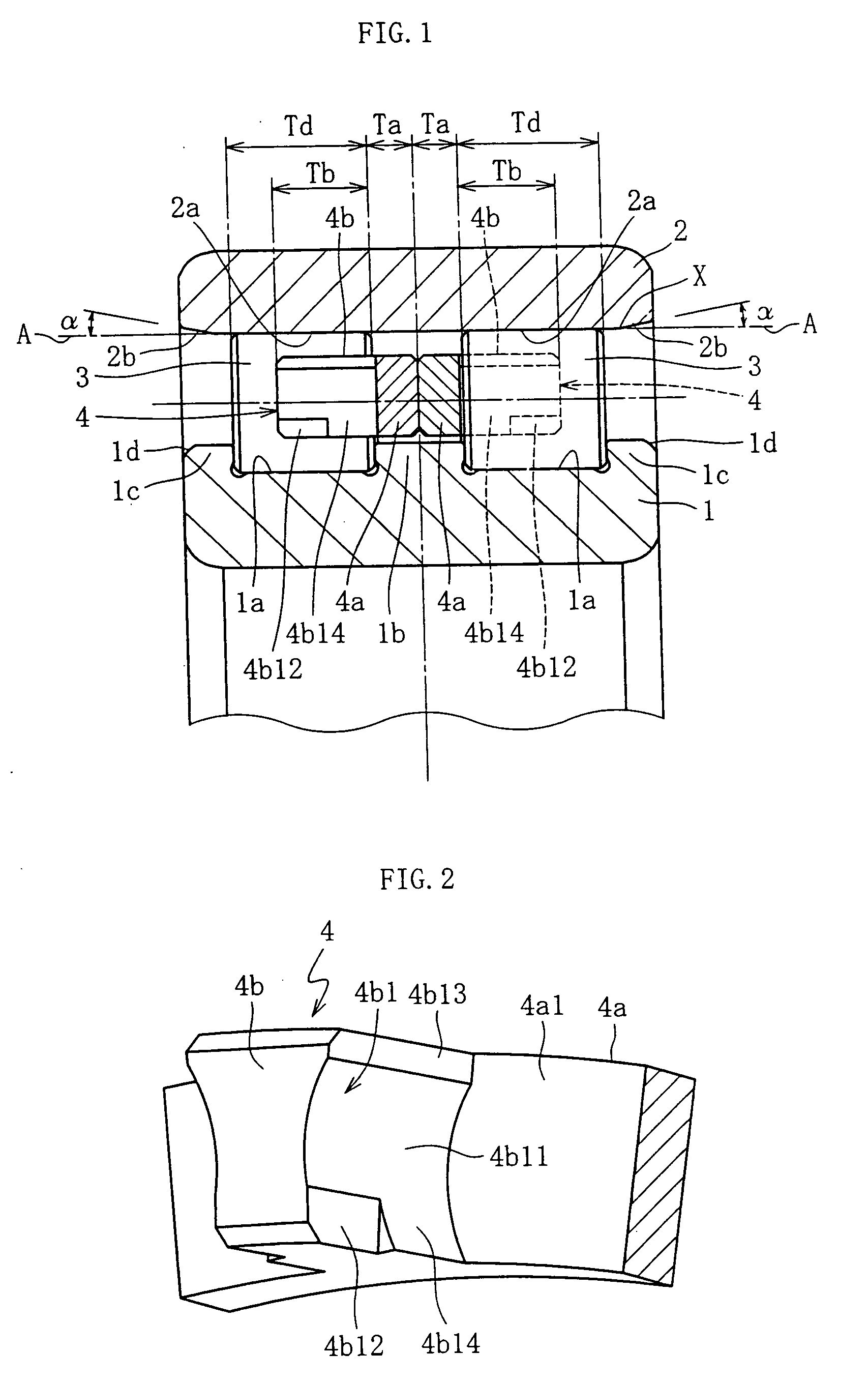

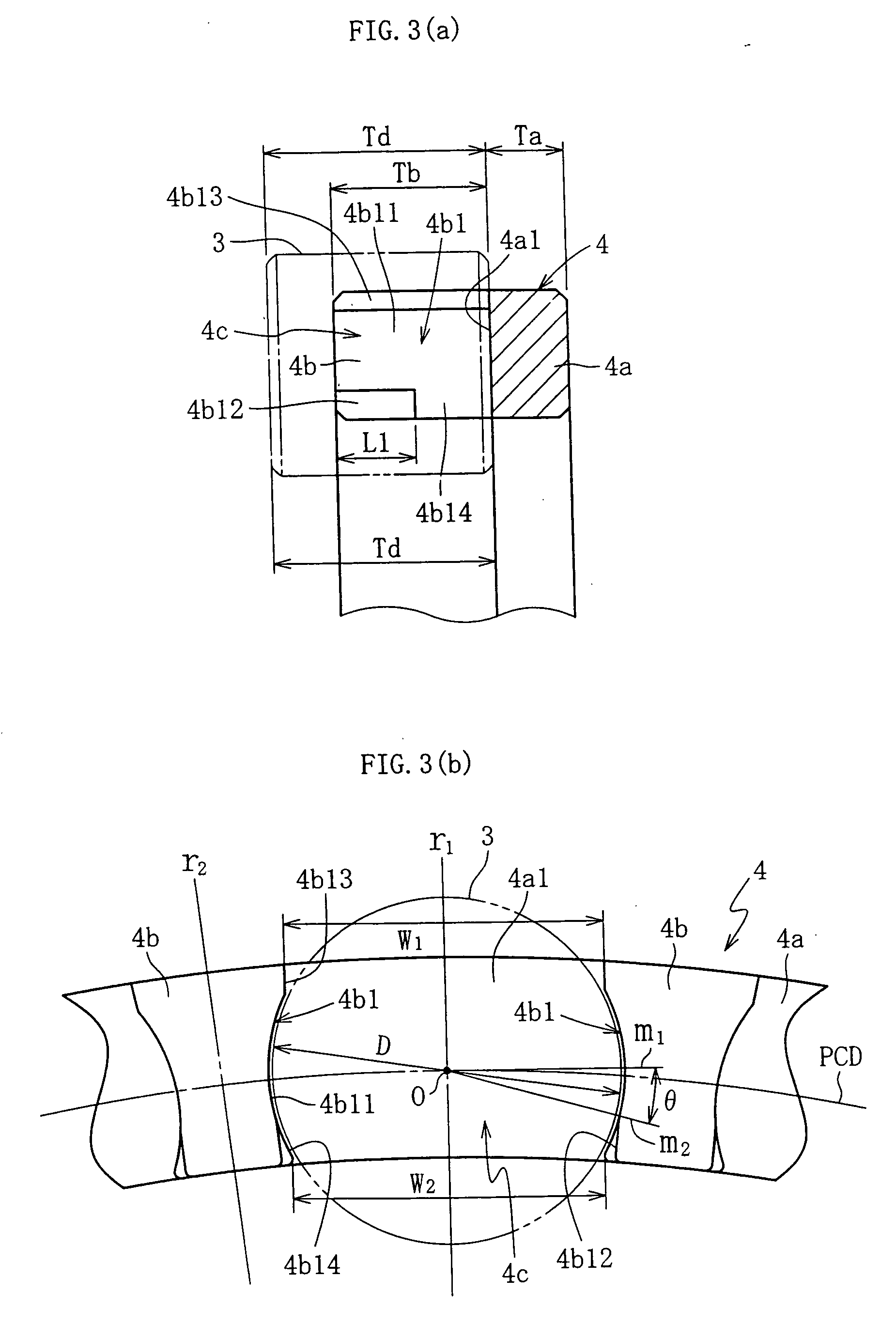

ActiveUS20050069239A1Reduce bearing temperatureAvoid abnormal wearRoller bearingsBearing componentsFree rotationEngineering

A cage of a cylindrical roller bearing includes an annular section, a plurality of pillars that extend axially in an integrated, continuous manner from the inside surface of the annular section, and a plurality of pockets, which are formed between the inner circumferential direction side faces of adjacent pillars, and hold the cylindrical rollers in a freely rotatable manner. The circumferential direction side faces of the pillars incorporate a circular arc surface formed in both the inside and outside diameter directions from the pocket PCD which passes through the pocket center of the pocket, and a roll-off section (lubricant reservoir) provided at the tip end inner circumferential section.

Owner:NTN CORP

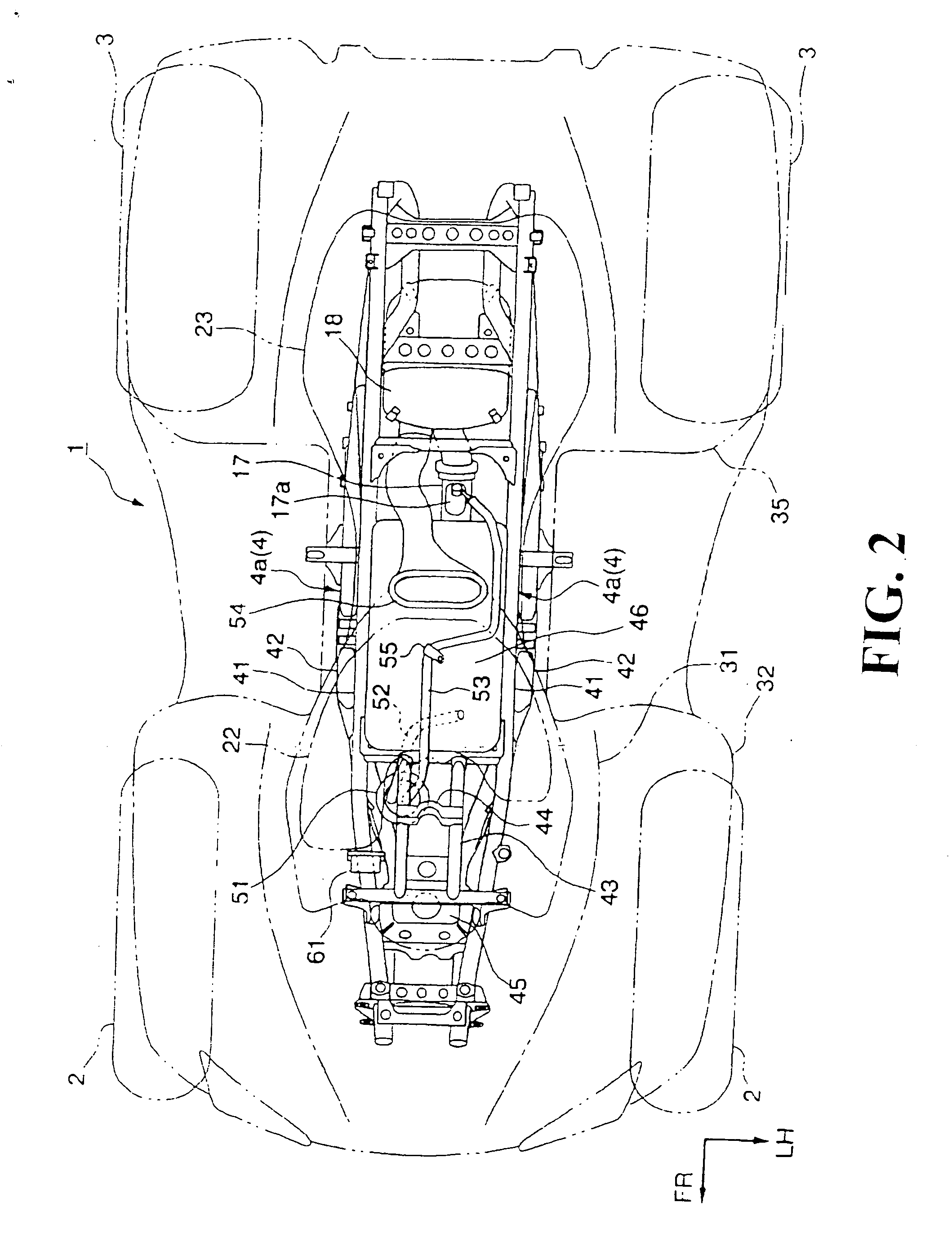

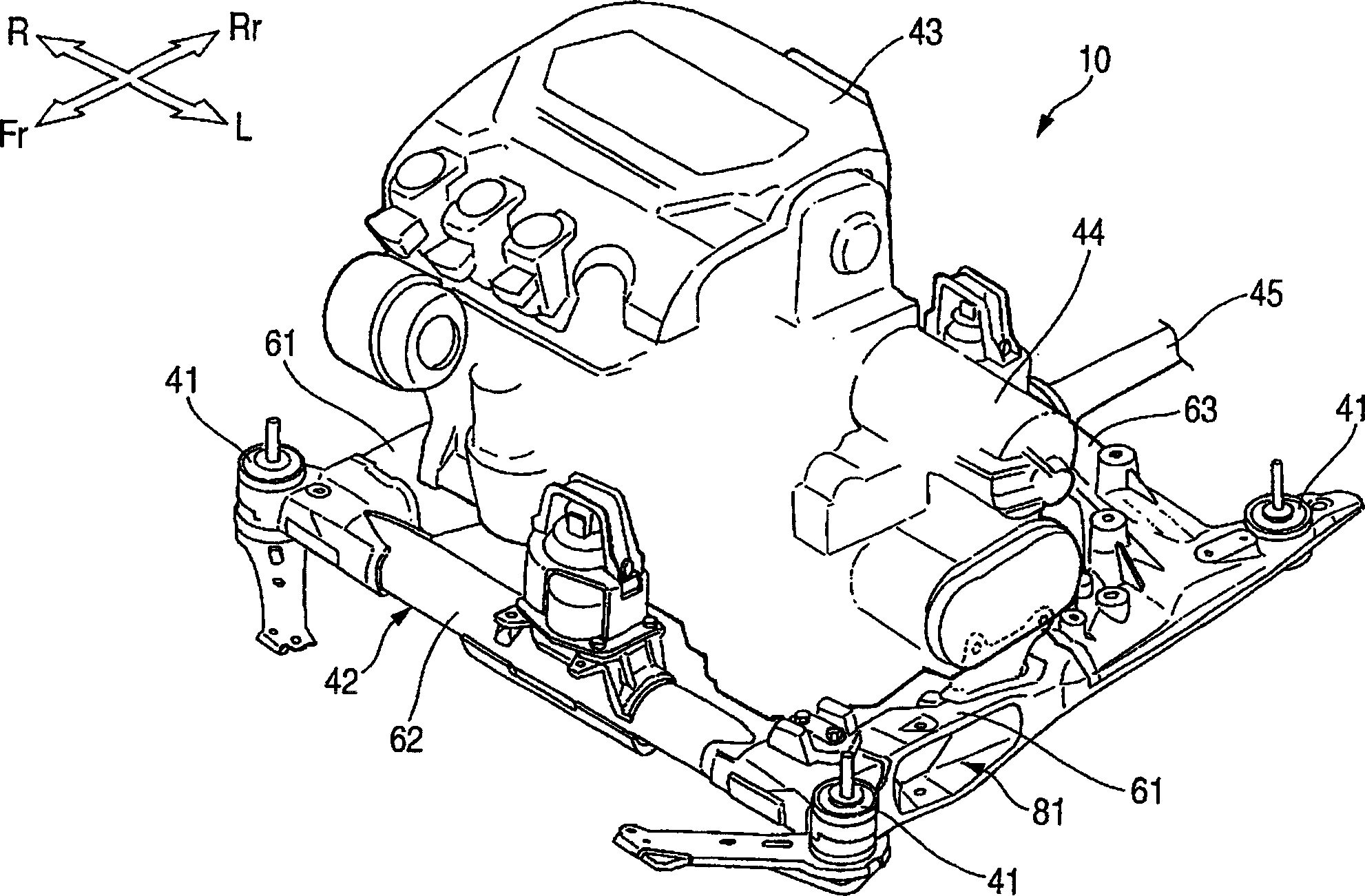

Subframe for vehicle and bush attaching structure

InactiveCN1842459AHigh strengthImprove installation strengthUnderstructuresPivoted suspension armsVehicle frameEngineering

A front cross member 202 of a rear subframe 53 has a recessed portion 221 which is recessed continuously over a longitudinal direction thereof. The recessed portion 221 is formed at a lower portion of the cross member 202 and is recessed upwardly, and an elastic bush 240 is fitted in a resulting recess. The elastic bush 240 has an elastic element 243 which connects together an inner tube 241 and an outer tube 242 which surrounds the inner tube 231 and is mounted on the rear subframe 53 at the recessed portion 221 as a bracket. The bracket 221 has bracket plate portions 263a, 263b which each have a plane which is brought into contact with an end face of the inner tube and folded-back portions 235, 235. The bracket 221 is disposed in such a manner as to hold therein both ends of the inner tube 241 and is configured such that the elastic bush 240 is mounted thereon by passing a bolt 224 through the inner tube 241.

Owner:HONDA MOTOR CO LTD

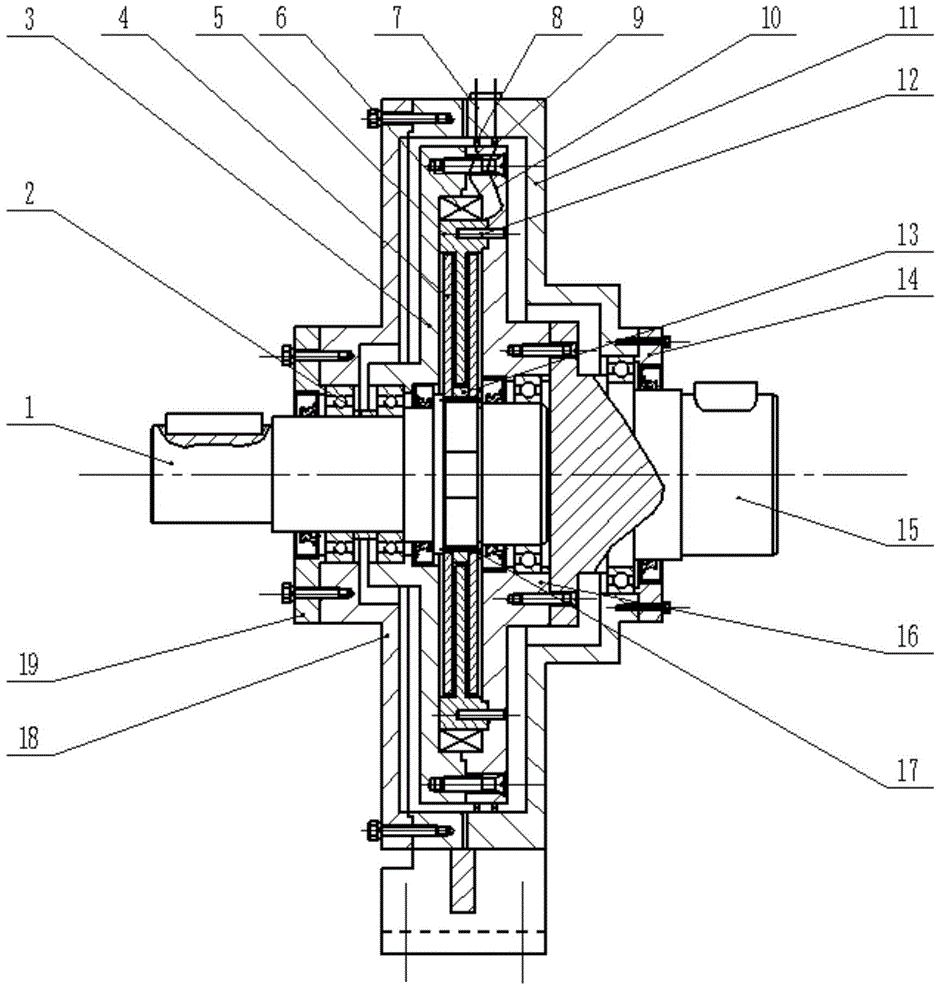

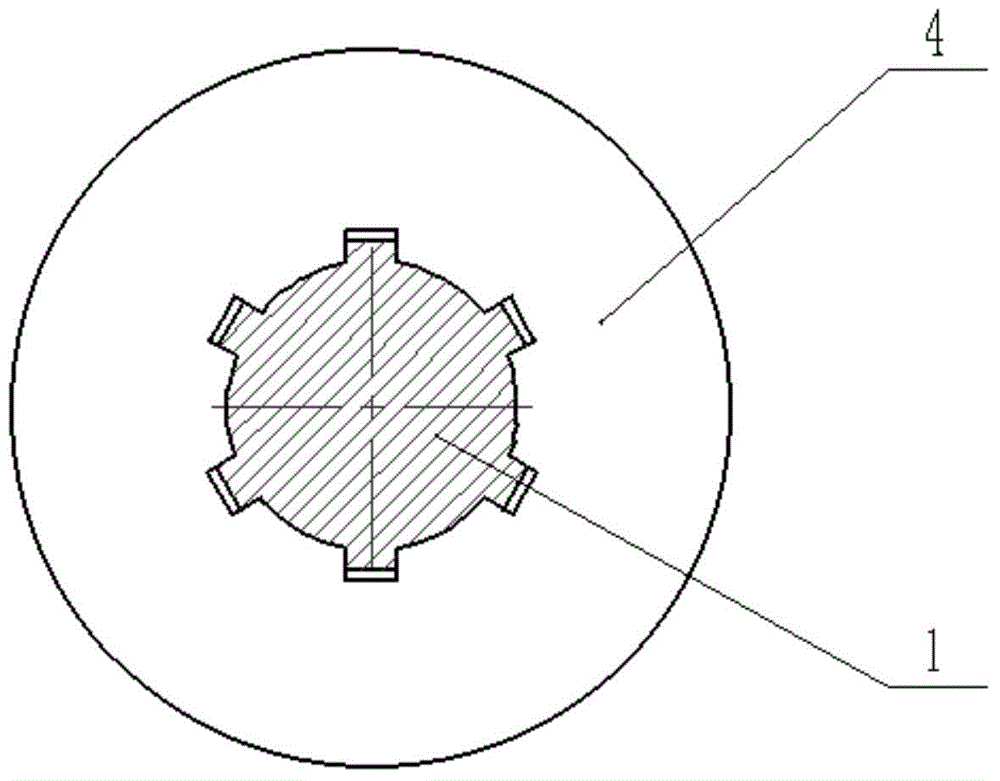

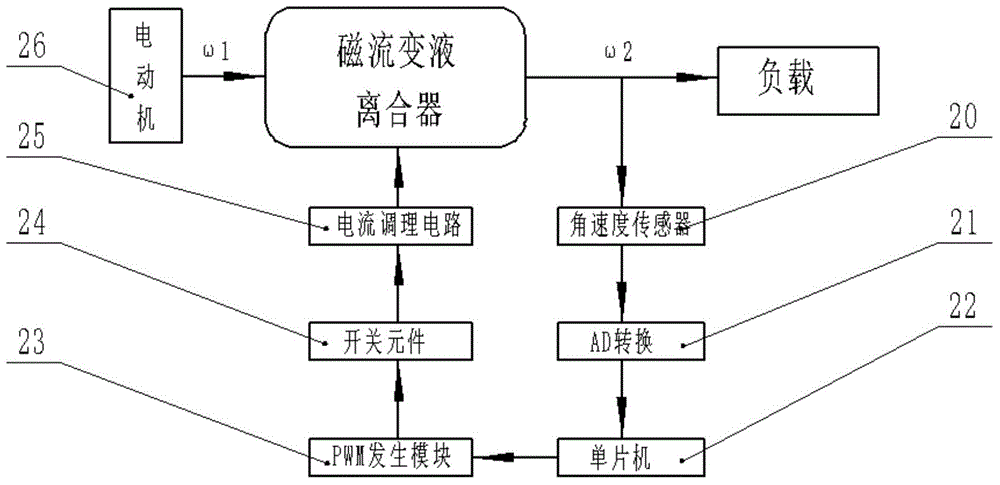

Multi-piece magnetorheological fluid electromagnetic clutch

InactiveCN103603891ACompact structureEasy to install and adjustNon-mechanical actuated clutchesPower flowAutomatic control

The invention discloses a multi-piece magnetorheological fluid electromagnetic clutch which is in a multi-piece structure. A plurality of gaps between drive and driven friction plates are filled with magnetorheological fluid serving as medium, a plurality of magnetorheological fluid operating ring surfaces are formed, magnetic field intensity of the gaps is high, distribution of the gaps is reasonable, high torque can be transmitted, high transmission power can be controlled with low excitation current, automatic control is easy to implement, and engaging and disengaging can be stabilized. Input and output shafts, both provided with end bearings, and a housing form a whole installed inside a frame. The multi-piece magnetorheological fluid electromagnetic clutch is compact in structure, high in rigidity, convenient to mount and maintain, simple in structure, high in reliability, stable in transmission, and applicable to various small- and medium-sized automatic devices and servo drivers.

Owner:NANJING UNIV OF SCI & TECH

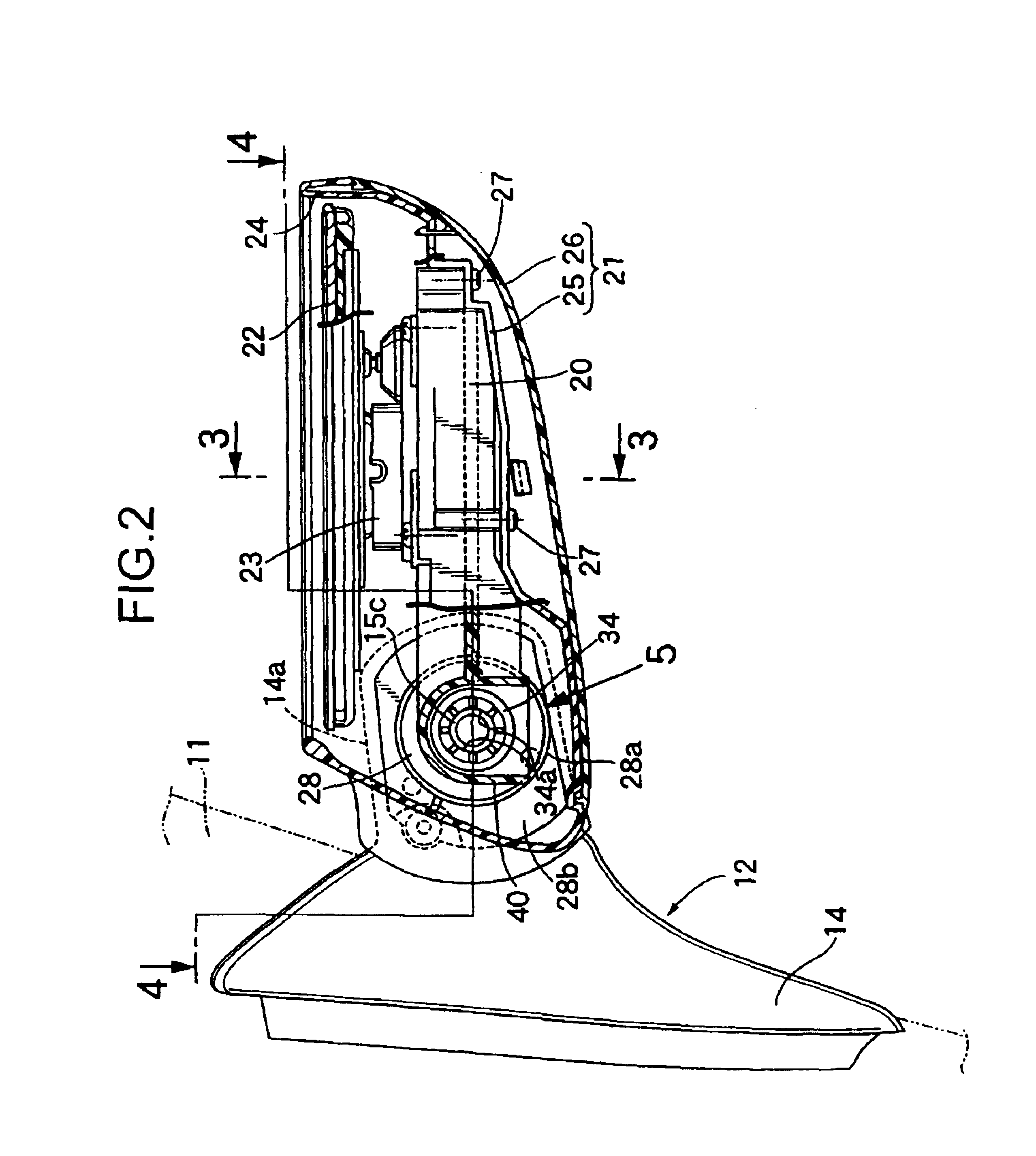

Door mirror

A door mirror including mirror-supporting therewith bracket supported by a bearing portion disposed integrally to a base of a support shaft, and a coil spring located under compression between a resilient receptacle and the bearing portion for urging the bearing portion toward the support seat. One bearing portion supported to the base end of the support and another bearing portion spaced apart from the bearing portion and supported rotationally on the top end of the support shaft are provided integrally to the bracket. The resilient receptacle is secured to a predetermined position of the support shaft so as to sandwich the coil spring that is compressed to a set load after passage of the support shaft through the coil spring located between both of the bearing portions between one of the bearing portions situated on the side of the support seat and the receptacle.

Owner:HONDA LOCK MFG CO LTD

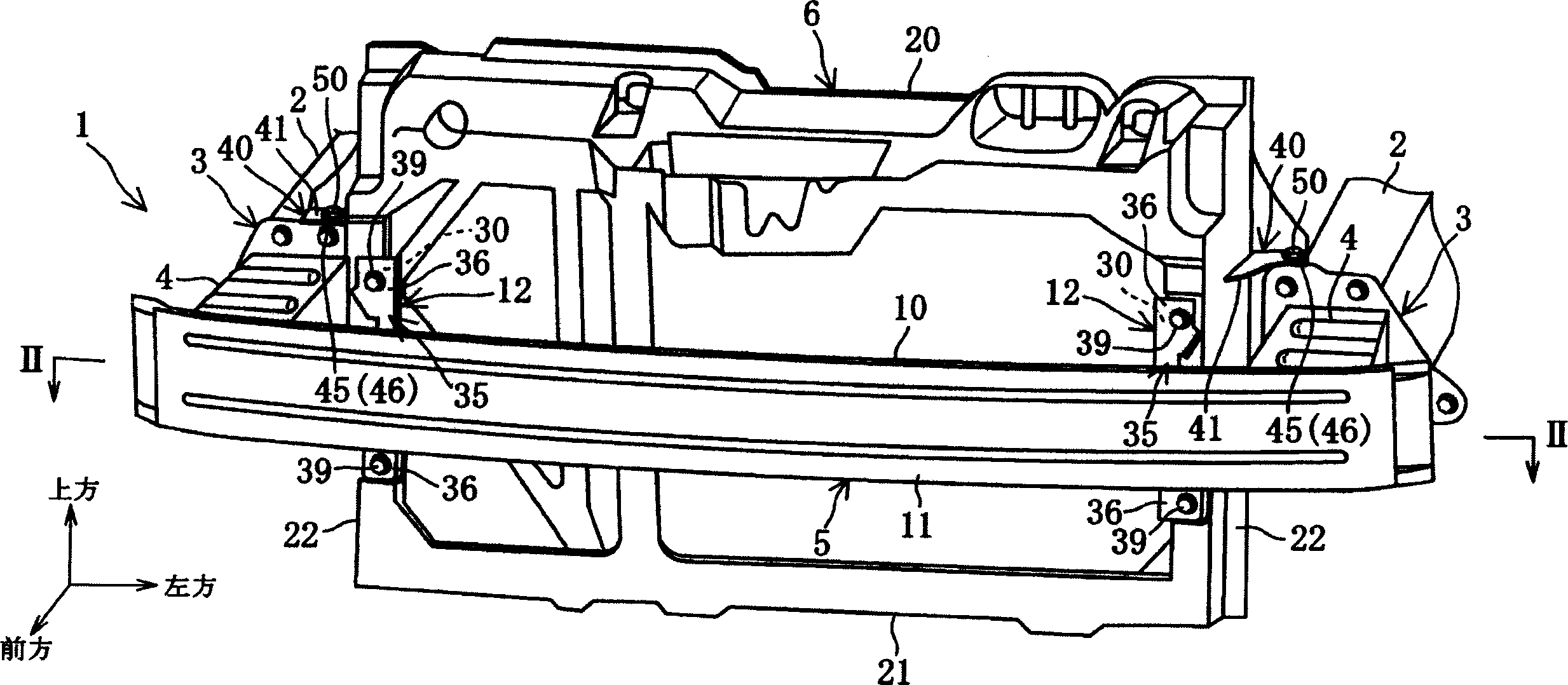

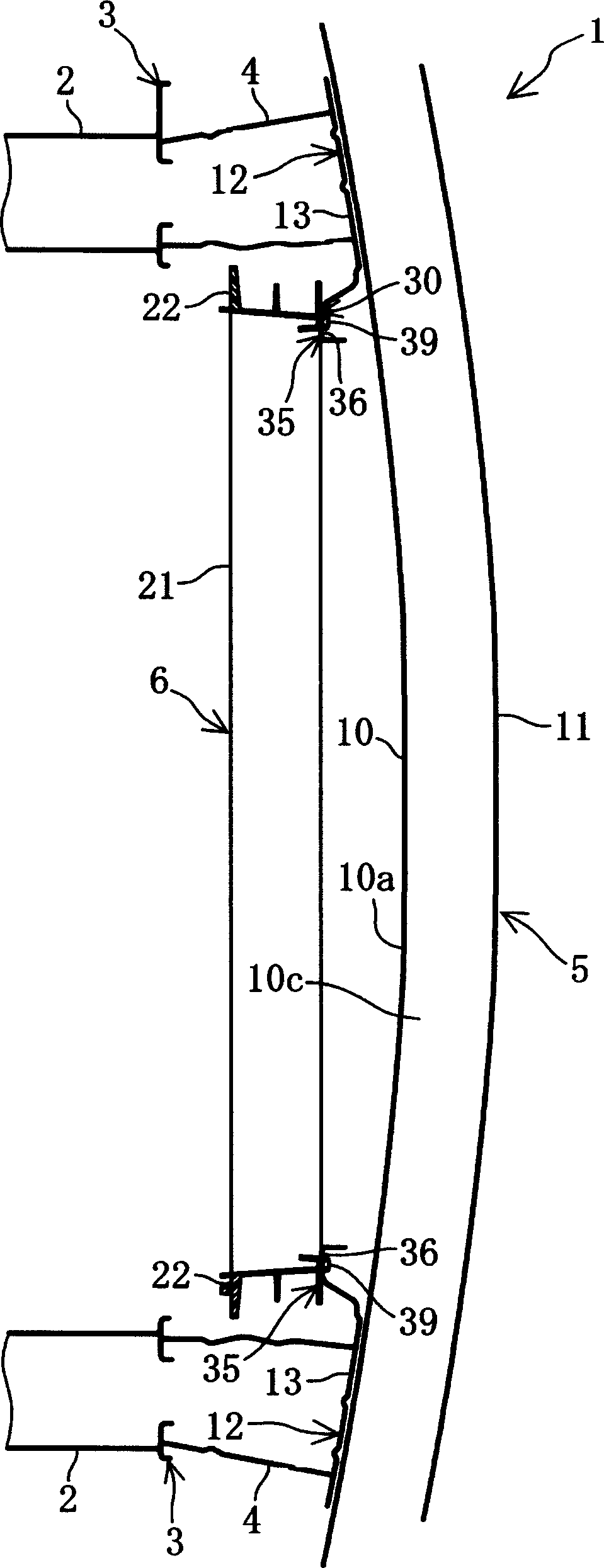

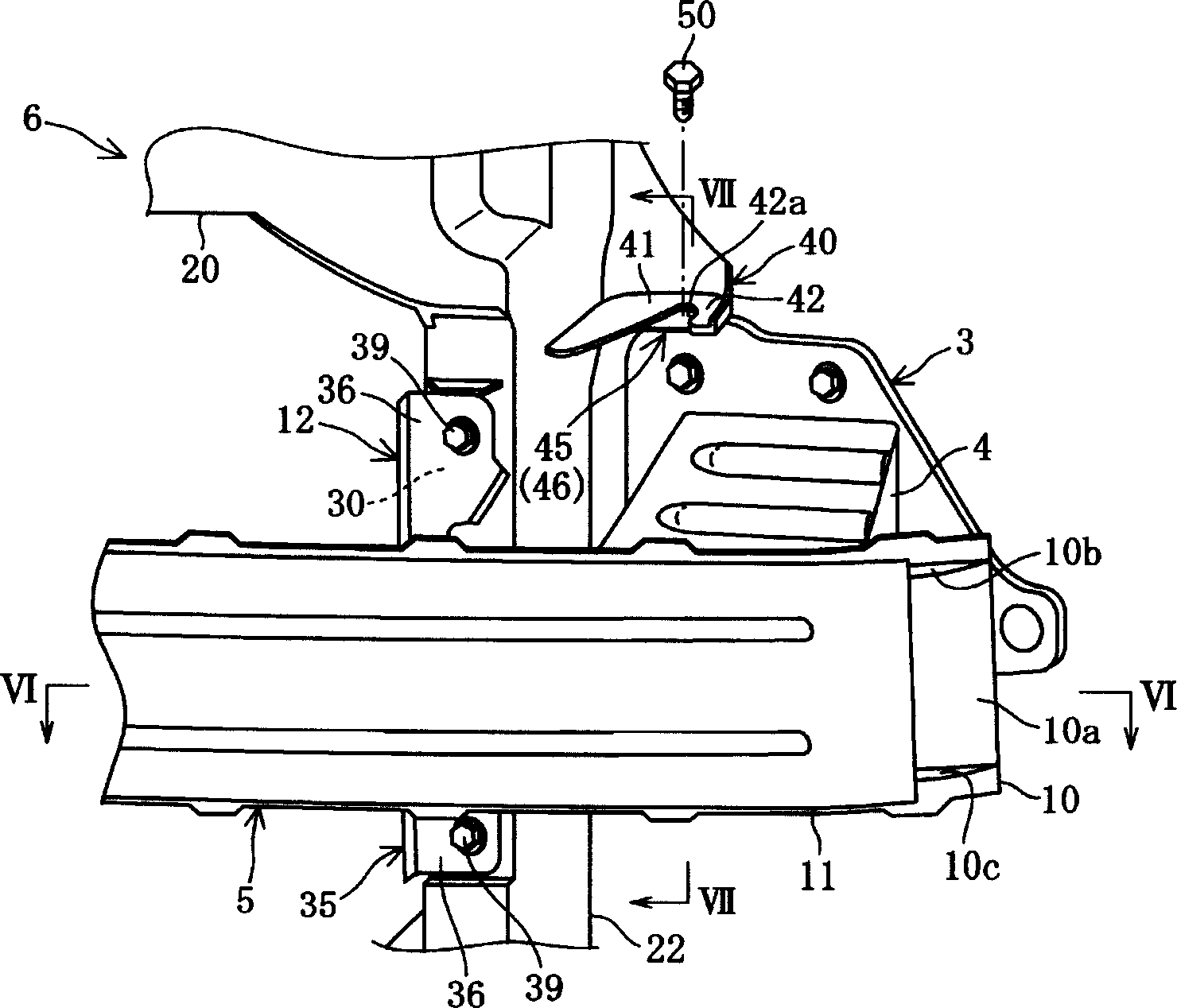

Auto heat radiator frame support structure

InactiveCN1876423AImprove support rigidityImprove the installation effectPropulsion coolingEngineeringFlange

The invention discloses a radiator bracket supporting structure which comprises left and right flange components (3) equipped with extending part (46); a security bar enhancing component (5) with a first supporting part (35) for the first part (30) constituted by the radiator bracket (6) and side bracket part (22), a second supporting part (45) constituted by the flange components (3) and the extending part (46) for supporting the second part (40) except for first part (30).

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com