Large plastic plate matching structure based on cantilever buckles

A cantilever buckle and matching structure technology, which is applied in the direction of thin plate connection, connecting components, mechanical equipment, etc., can solve the problems of low support rigidity, poor assembly stability, assembly deformation, etc., to improve support rigidity and shorten flanging Length, effect of reducing the processed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The embodiments are not intended to limit the scope of protection of the invention. Obviously, those skilled in the art can obtain other embodiments without having to pay creative work. Belong to the protection scope of the present invention.

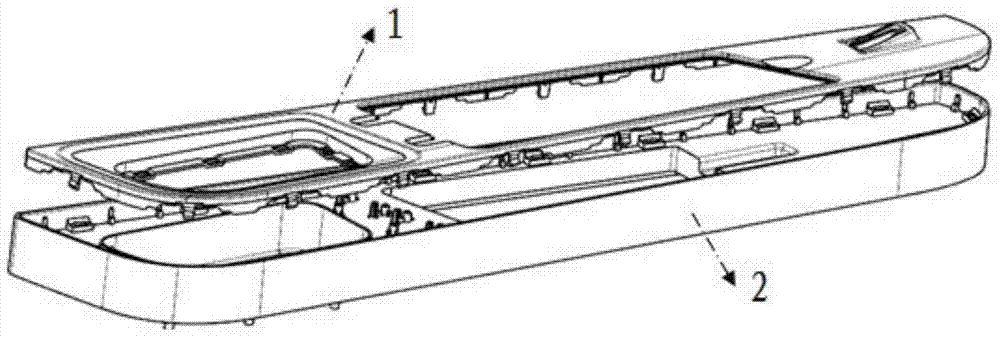

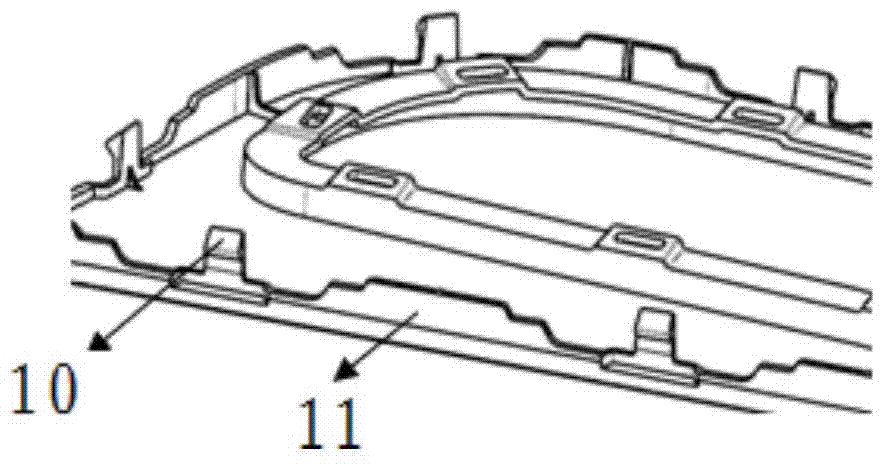

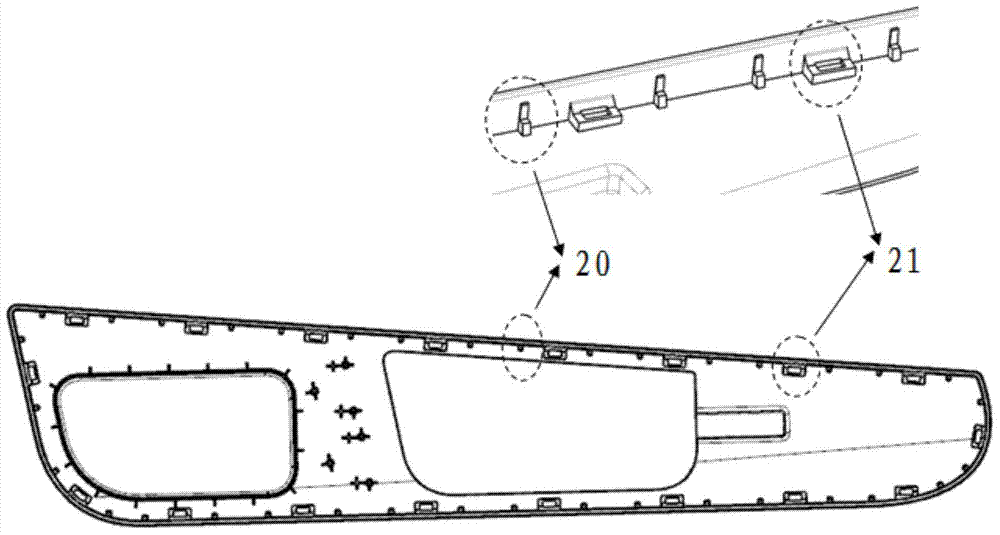

[0029] combine Figure 1 to Figure 7 As shown, a large-scale plastic plate fitting structure based on cantilever buckles includes a cover plate 1 and a base plate 2, and buckles 10 and cover plate flanges 11 are arranged at intervals along the periphery of the cover plate. The inner wall is provided with a card groove boss 21 matched with the buckle and a limit boss 20 for supporting the flanging of the cover plate. When the flanging of the cover plate is folded onto the side wall of the base plate, The lower end surface presses against the top surface of the limiting boss.

[0030] combine Figure 8 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com