Automatic gearbox and assembling method thereof

A technology of automatic gearbox and assembly method, which is applied in the direction of transmission box, transmission parts, components with teeth, etc., can solve the problems of reducing work efficiency, time-consuming and laborious assembly of gearbox, troublesome secondary assembly and disassembly, etc., and achieves improvement Efficiency in assembly, ease of mass production, and effects of improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

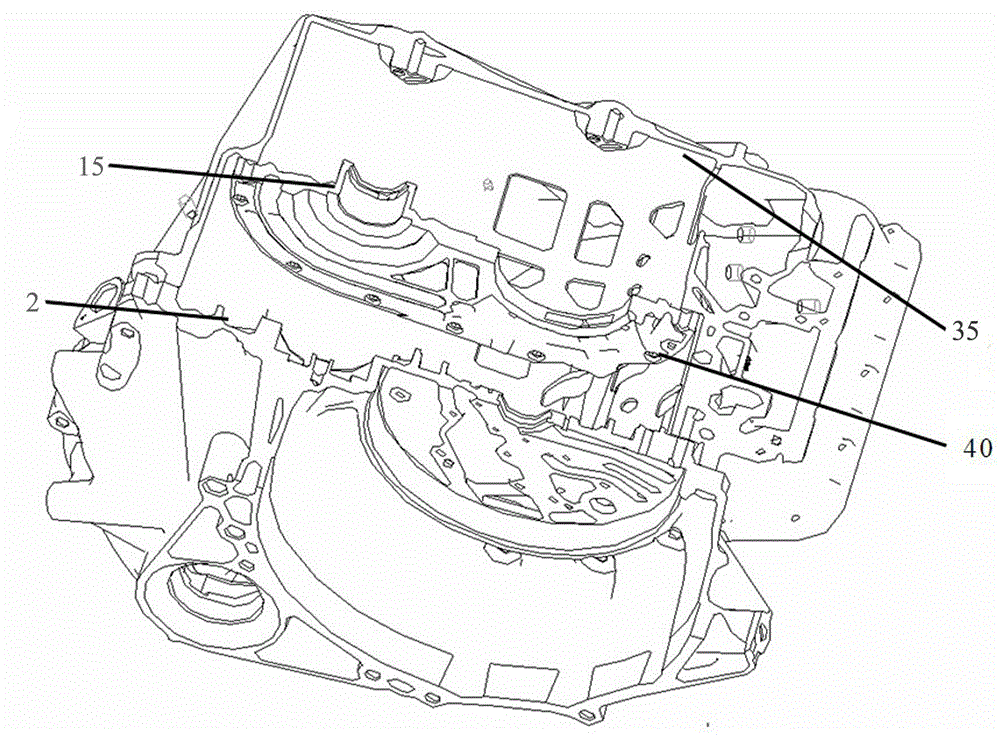

[0047] Examples such as figure 1 As shown, an automatic transmission includes a casing, and transmission components are arranged in the casing, and the casing includes a main casing 2 and a torque converter casing 35, and between the main casing 2 and the torque converter casing 35 A middle partition 15 is provided, and the middle partition 15 is in the shape of an oval plate, and the middle partition 15 is fixedly connected with the main casing 2 through bolts 40 .

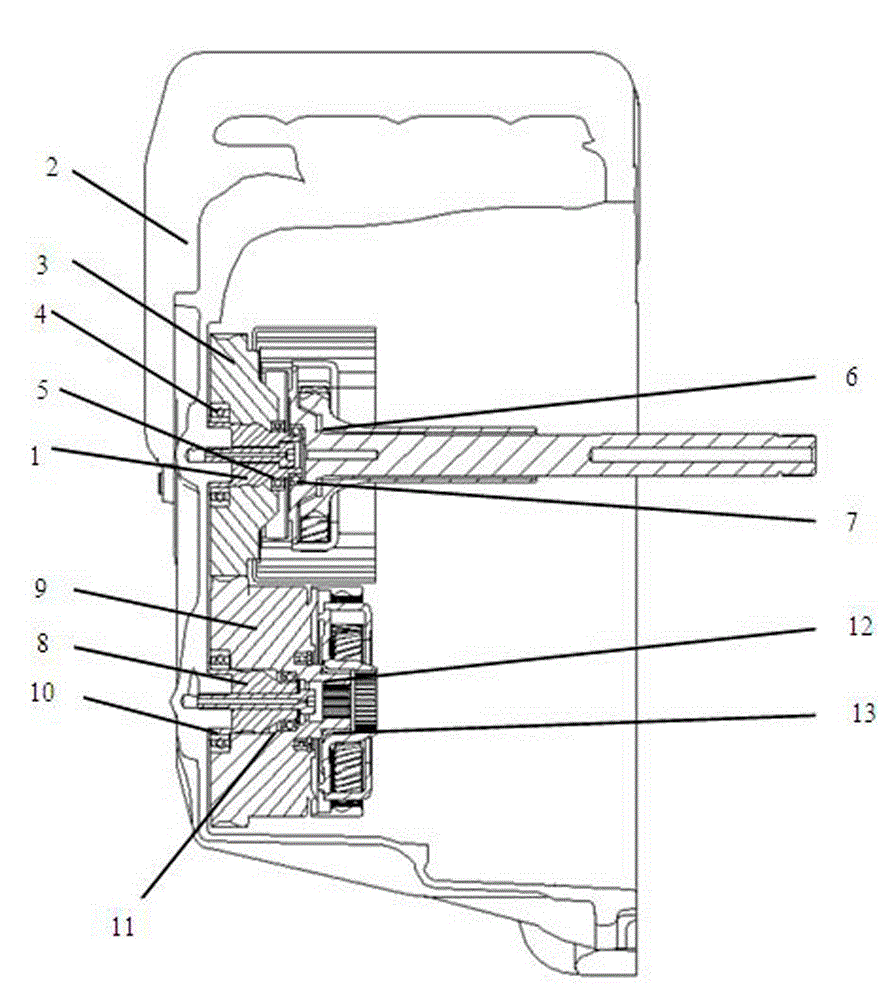

[0048] like figure 2As shown, the main housing 2 is connected with a main housing assembly, and the main housing assembly includes an input transmission assembly and an output transmission assembly.

[0049] The input transmission assembly includes an input shaft support seat 1, the input shaft support seat 1 is fixedly arranged on the main housing 2, the fifth gear transmission assembly 3 is set on the input shaft support seat 1, the fifth gear transmission assembly 3 and the input shaft support seat 1 are ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com