Patents

Literature

477 results about "Annectant gyrus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

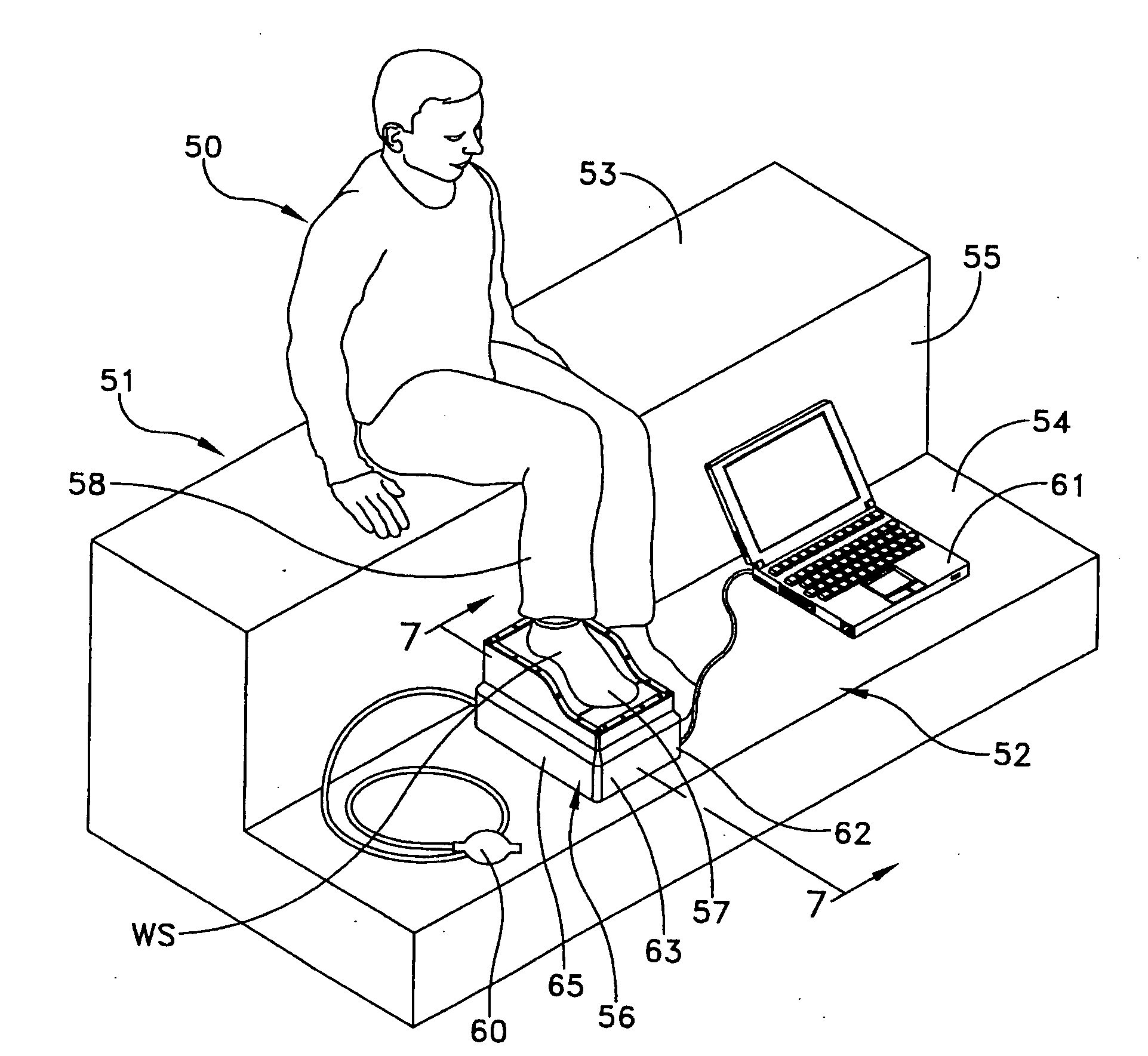

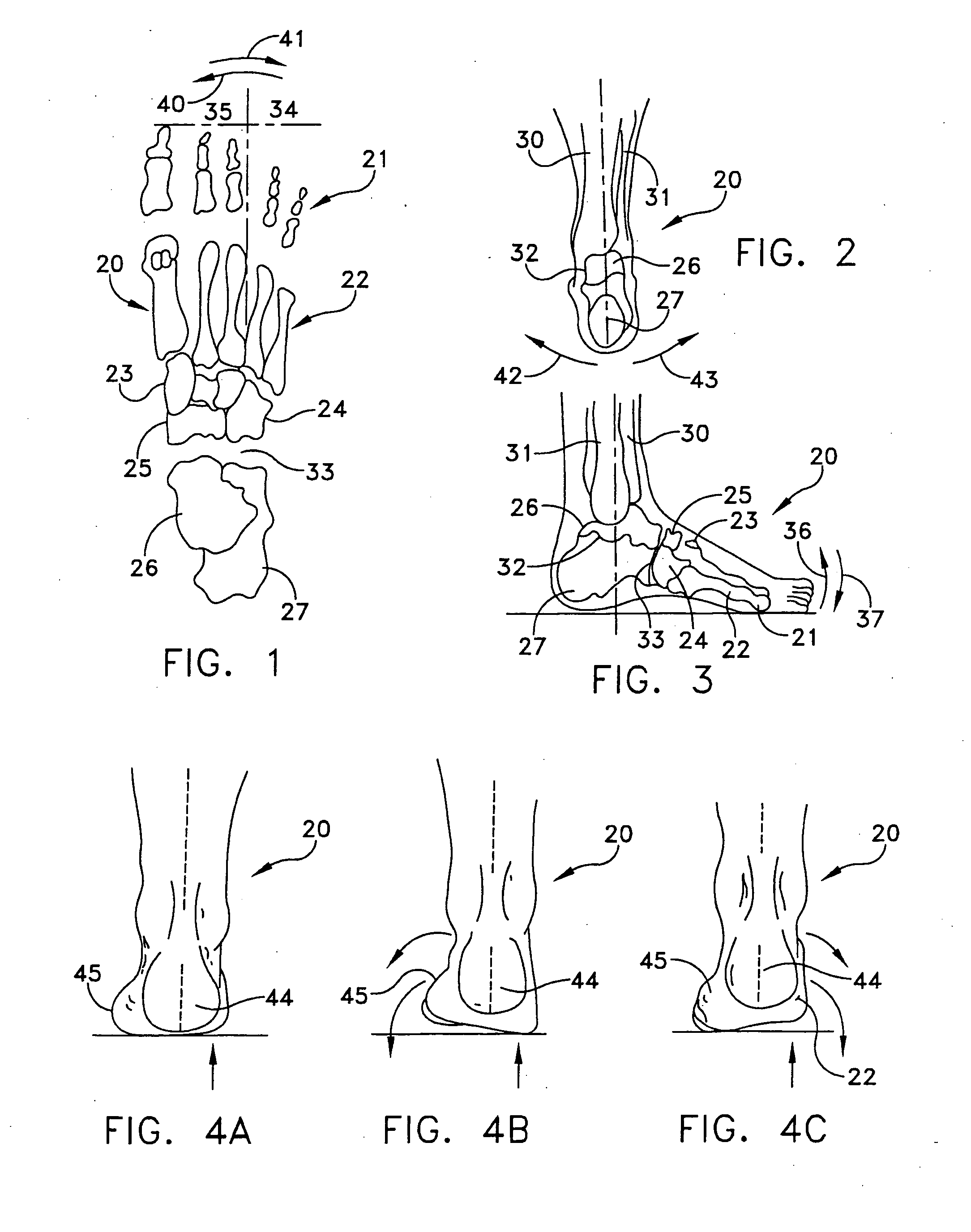

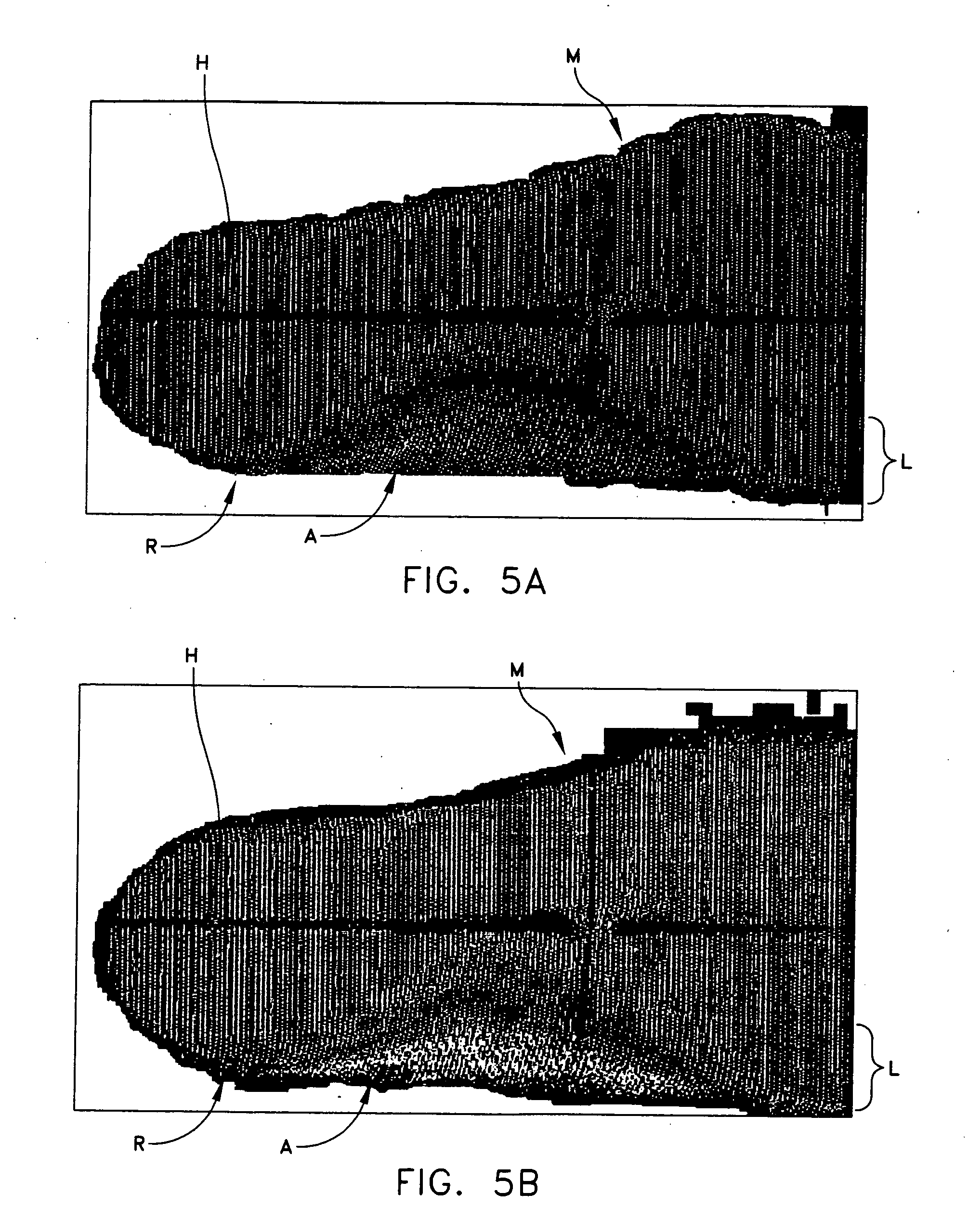

Method and apparatus for manufacturing custom orthotic footbeds

InactiveUS20060283243A1Promote generationUse minimizedFoot measurement devicesStructural/machines measurementNumerical controlOrthopedic inserts

A method and apparatus for providing a topographical map of the bottom of a patient's rear foot with the foot in a semi-weight bearing condition and in the neutral position. A flexible membrane defines the top of an air cushion that captures the patient's foot in the neutral position when the air pillow is inflated. The membrane also conforms to the bottom of the foot. A three-dimensional scanner located below the membrane measures the distances to the bottom of the membrane over an array of positions. A manufacturing facility converts these measurements into information by which computer numerical controlled equipment machines an orthotic insert for the patient's footwear.

Owner:ESOLES LLC

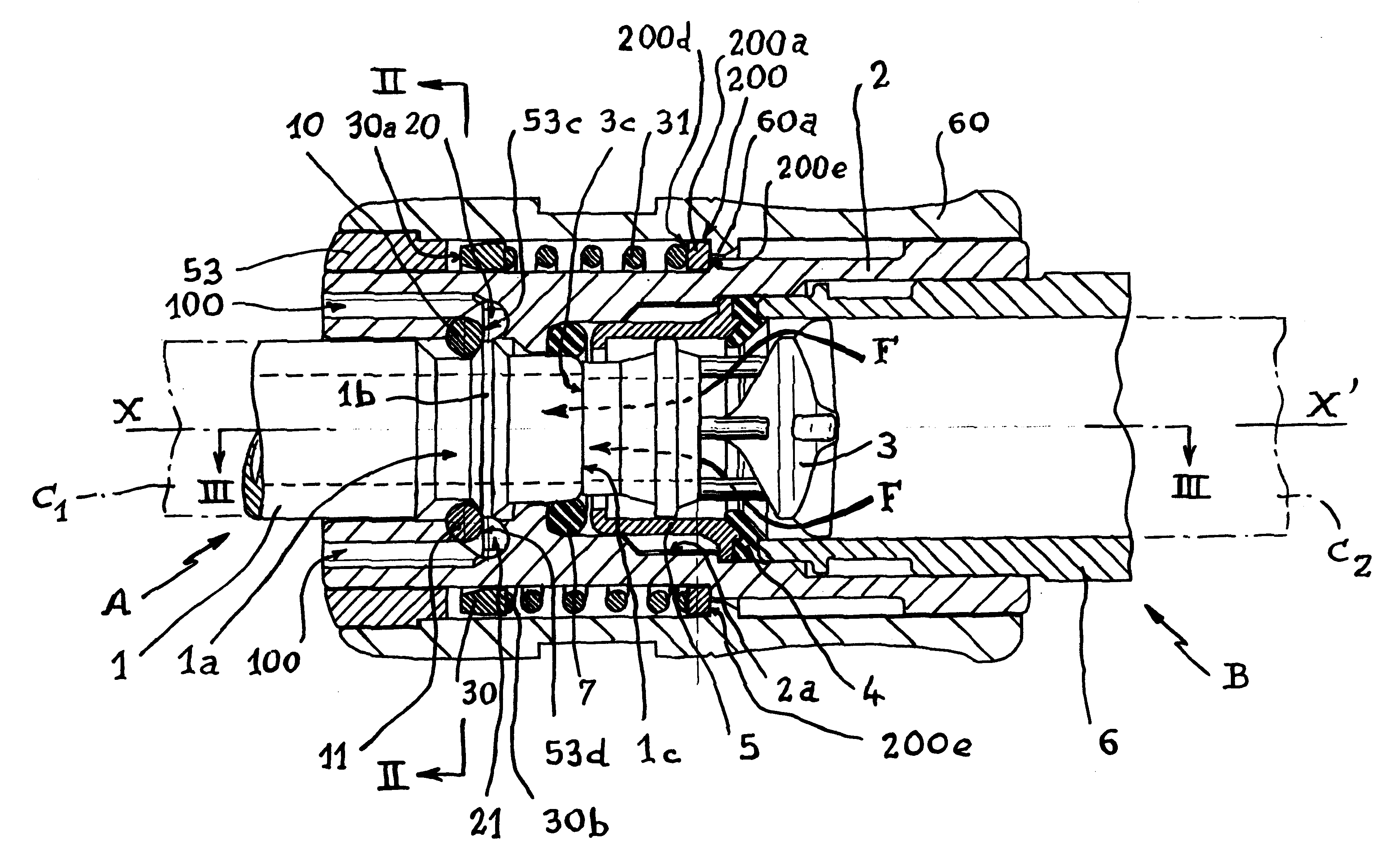

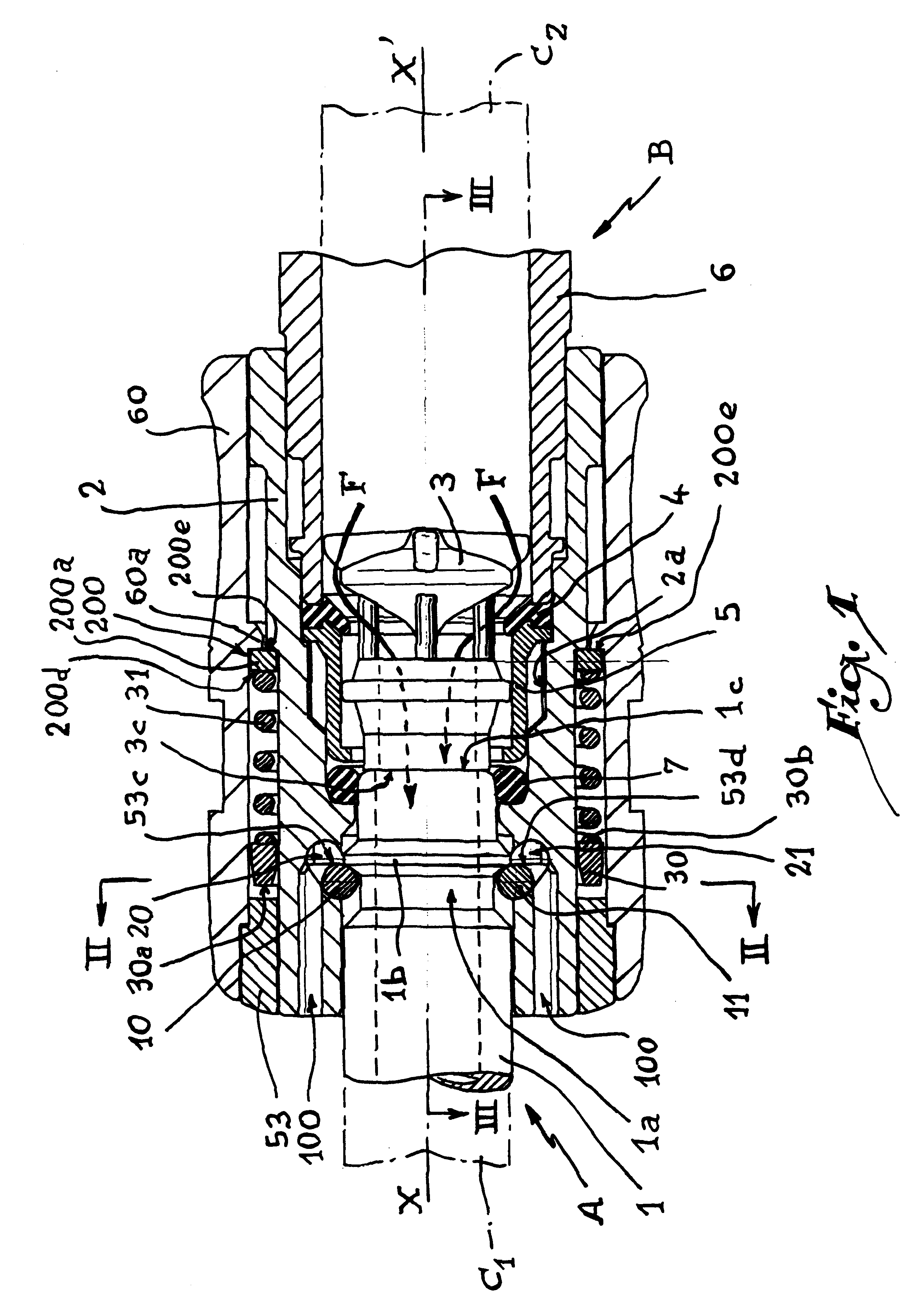

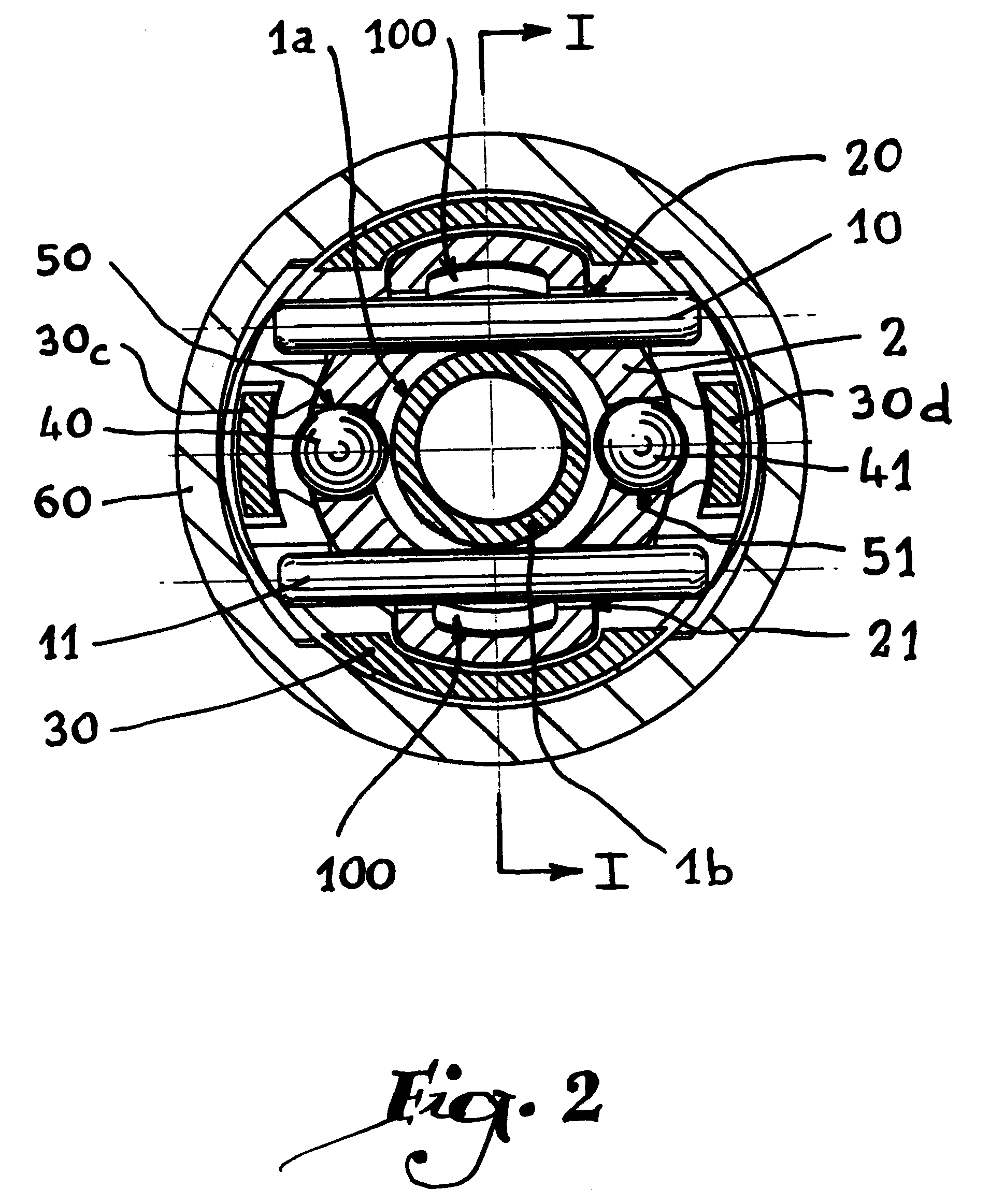

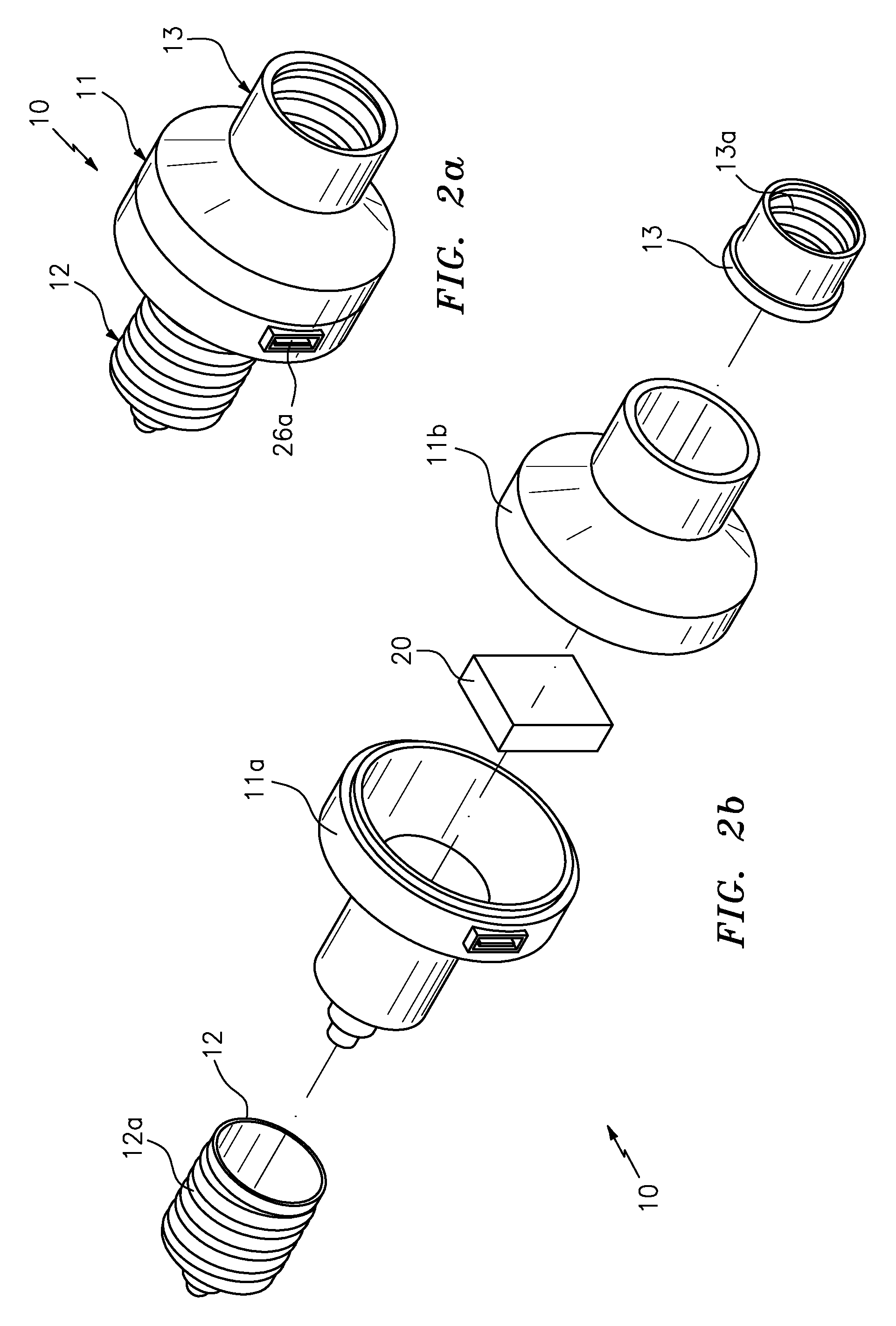

Quick safety connection for removably joining pipes

InactiveUS6412828B1Restrict movementIncrease pressureEngine sealsPipe elementsLocking mechanismEngineering

A quick safety connection for the removable joining of pipes, comprising a male connector and a female element adapted to fit and to be locked inside one another. A controlled locking mechanism is adapted to immobilized the male connector axially in a position of connection, while at least one retention member is provided to immobilize the male connector, after release of the connector by said locking mechanism, in an intermediate position of discharge of the pipe connection. The locking mechanism and retention member are controlled by a sleeve sliding around the female element. Vents and safety stops are provided to limit the movement of the sleeve under the effect of the pressure prevailing due to the discharge of the connection in the intermediate position between the female element and the sleeve.

Owner:STAUBLI FAVERGES SA

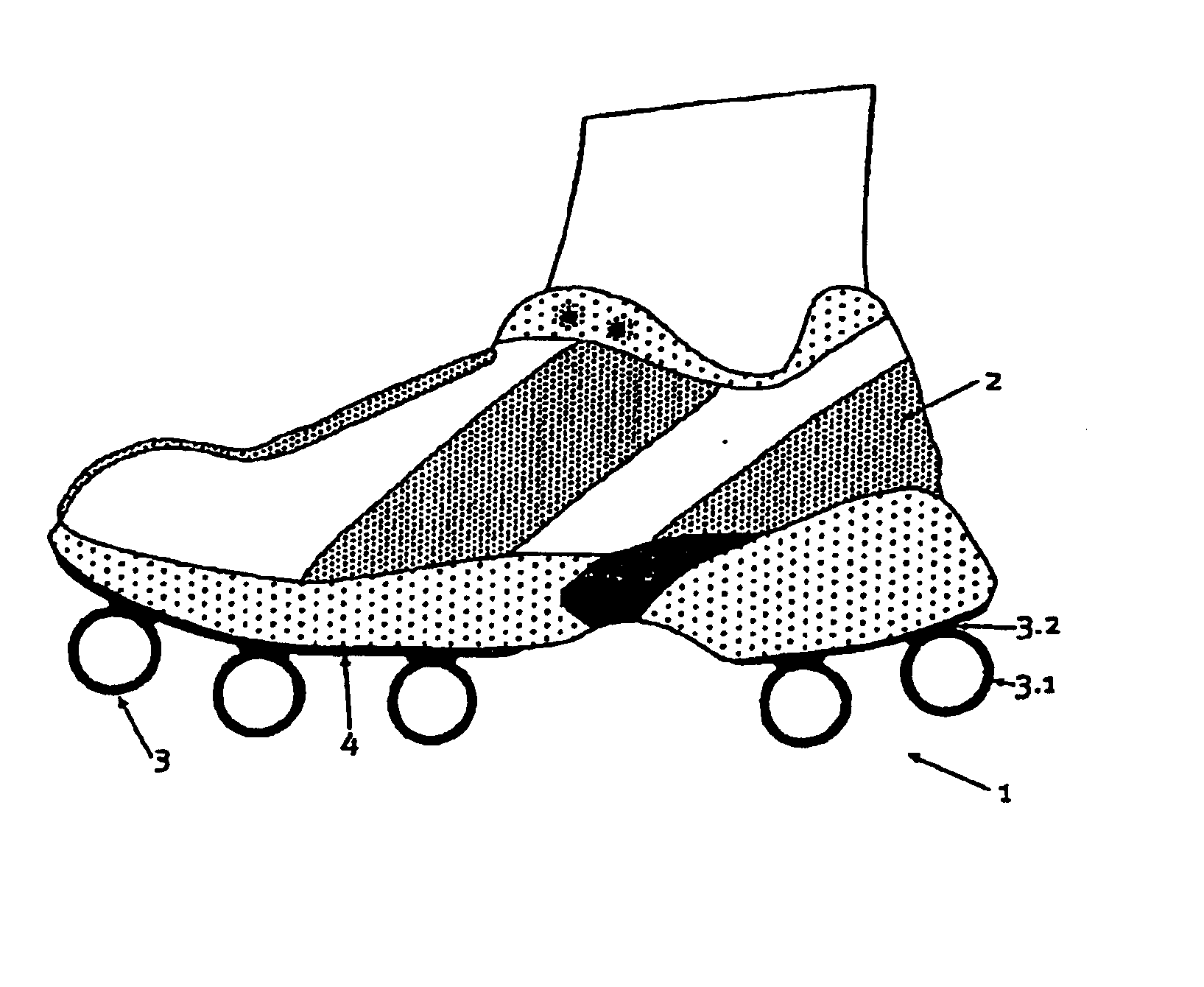

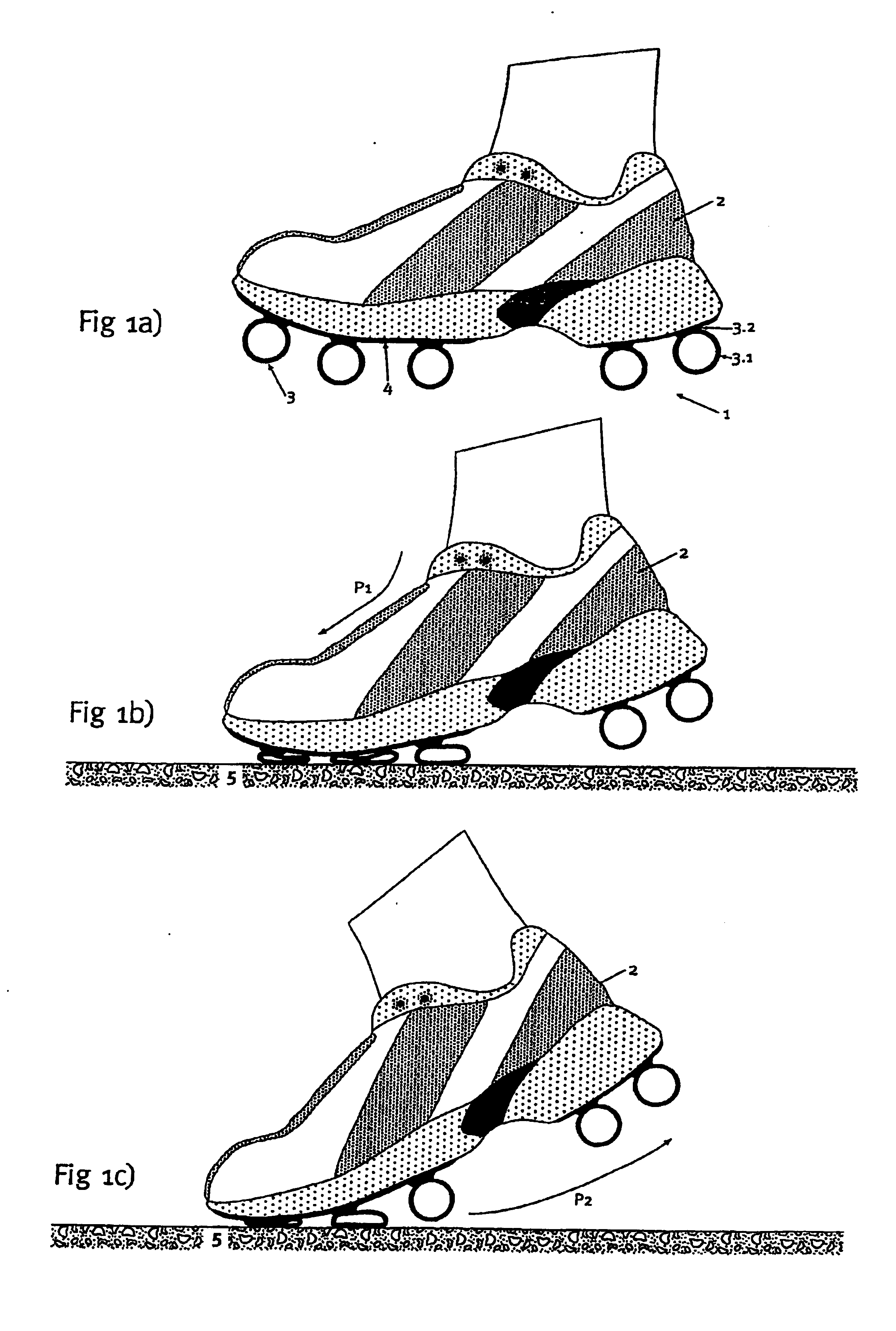

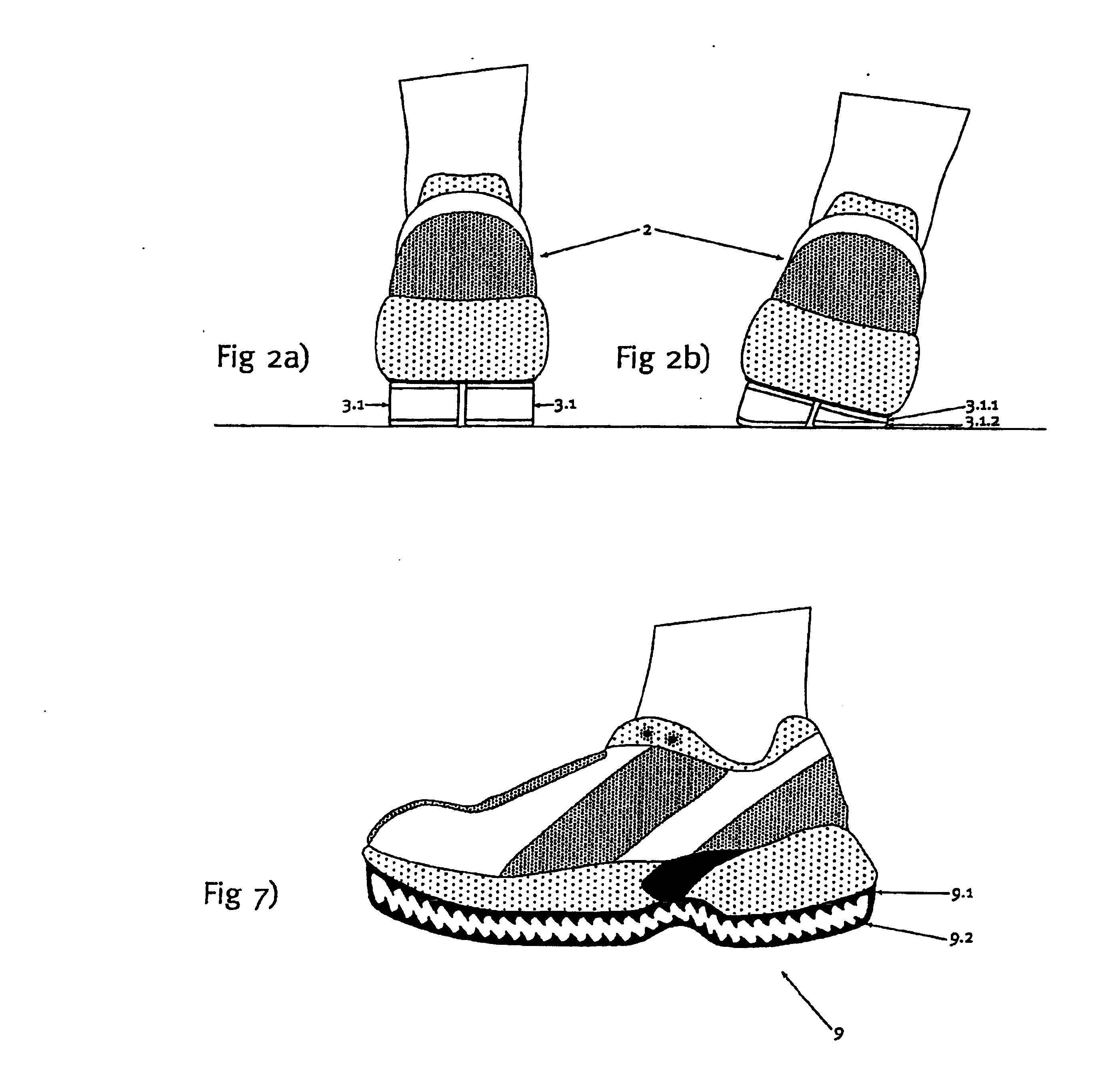

Outsole

An outsole (1, 3), in particular, for athletic shoes (2) can be realized with a significant elastic deformability in the tangential direction so as to also achieve a superior shock-absorption when the foot contacts the ground obliquely and with a slight propulsive force. According to the invention, the sole (1) essentially is only rigid to a tangential deformation beyond at least one critical point of deformation in the region that is deformed to this critical point. This results in a correspondingly increased stability for the runner in the respective point of contact or load application. The runner is also able to push off from the point of load application without any loss in distance. A floating effect on the sole is prevented. The sole can be affixed, as a whole or in a plurality of parts, also detachably to an intermediate sole (4) of the shoe (2).

Owner:GLIDEN LOCK

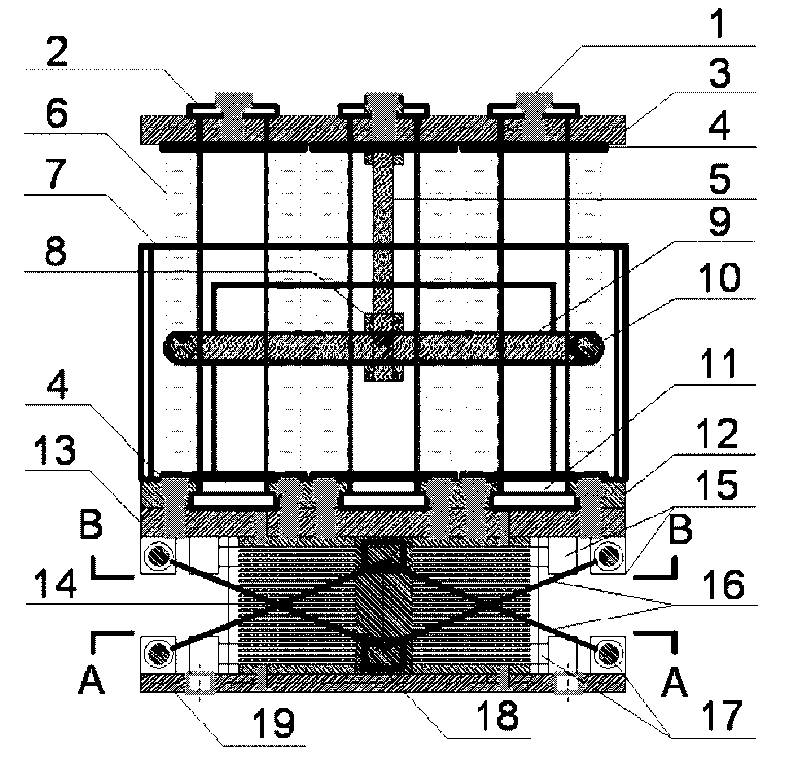

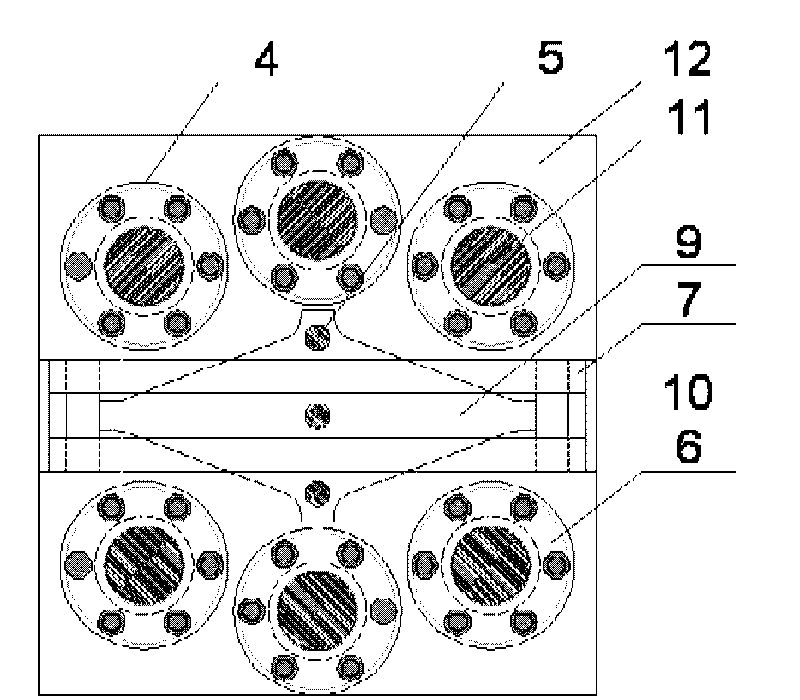

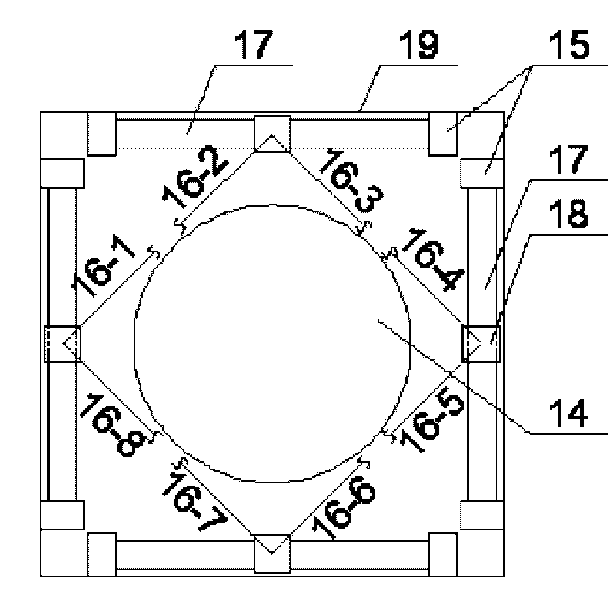

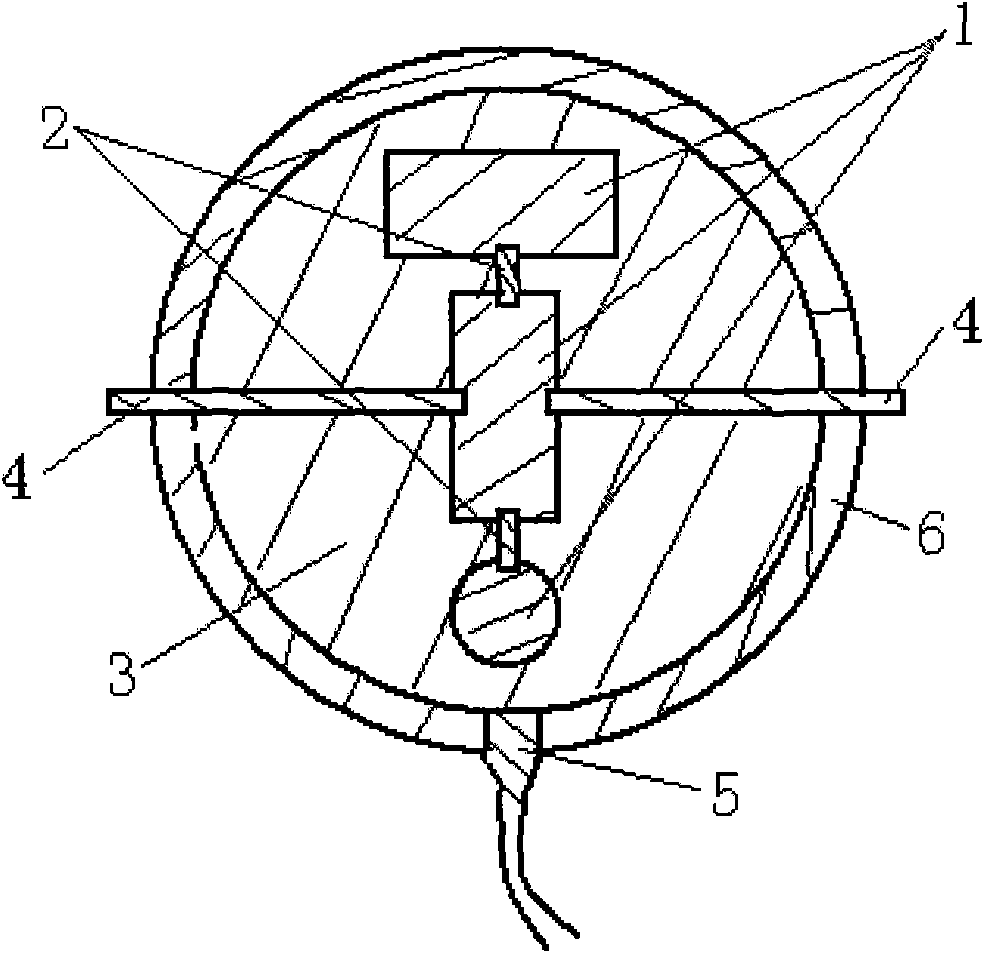

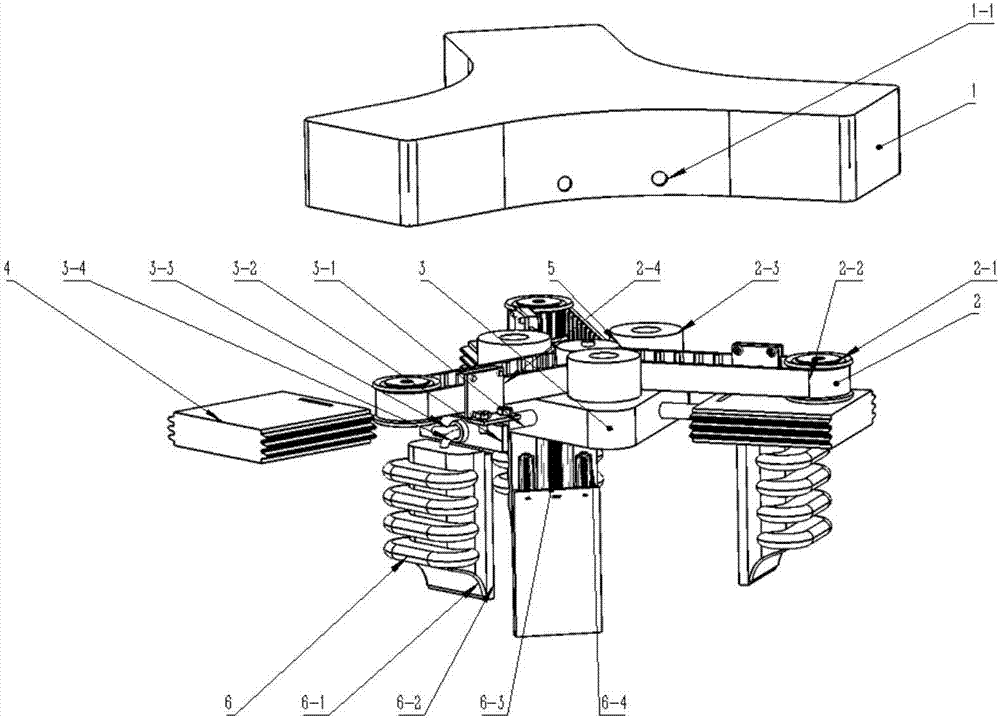

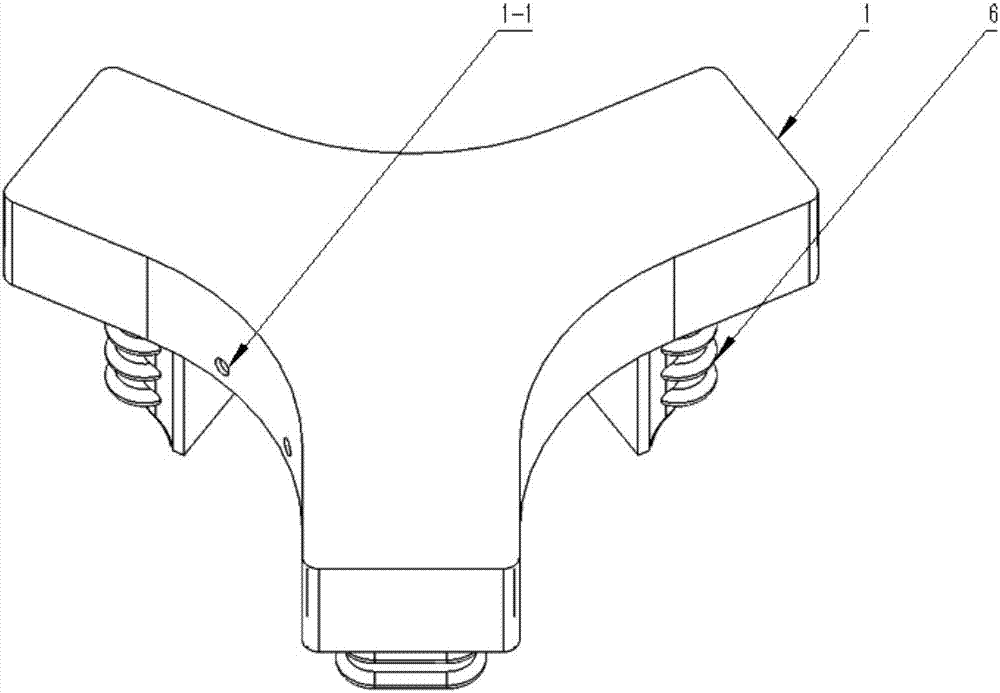

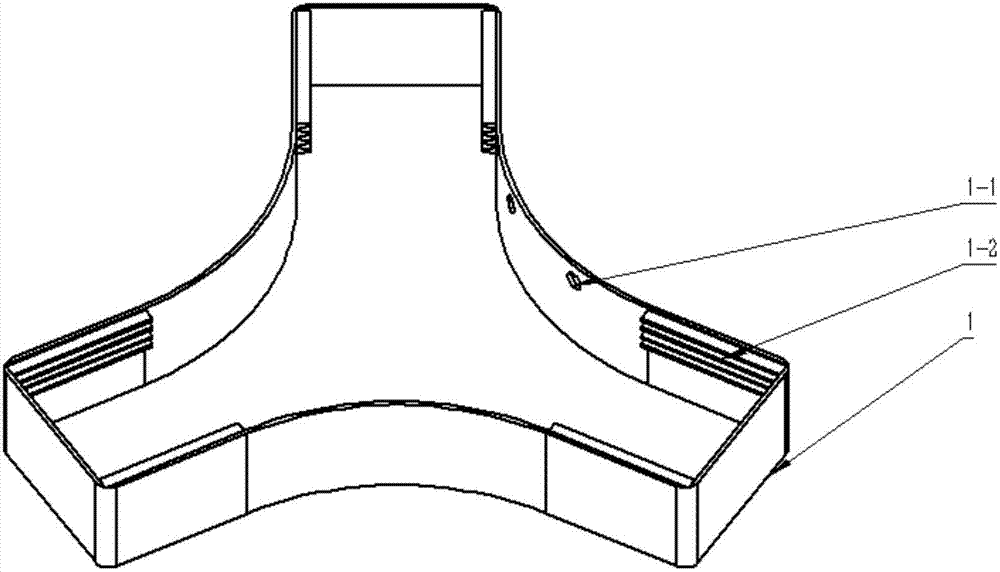

Three-dimensional isolation device

InactiveCN101761147ASufficient vertical bearing capacityAppropriate vertical load capacityShock proofingVibration controlUpper joint

The invention provides a three-dimensional isolation device, which belongs to the field of the vibration control of a civil engineering structure. The three-dimensional isolation device is characterized by mainly comprising a lead-laminated rubber shock isolator, a combined disc spring, a guiding shaft of the combined disc spring, a diamond steel plate damper and the like, wherein the lead-laminated rubber shock isolator is positioned at the lower part of the device, and a lower joint plate and a middle joint plate of the device are both fixed with a slide guide, a slide block and a crossed high-strength cable respectively; a fixed steel plate at the lower end of the guiding shaft of the disc spring is fixed on the middle joint plate by a bolt, the compound combined disc spring is sleeved on the guide shaft and the top end of the guide shaft is provided with an anti-pull baffle and an anti-pull bolt; and the diamond steel plate damper is positioned horizontally, and the two ends thereof are supported on a steel plate support bracket which is fixed on a fixed steel plate of the guiding shaft of the disc spring, and the middle of the diamond steel plate is fixed on an upper joint plate of the three-dimensional isolation device by a screw and a nut. The three-dimensional isolation device has enough vertical bearing force and provides proper vertical and horizontal rigidity and dampness; and key parts are connected reliably and horizontal limiting and vertical anti-pull measurements are provided.

Owner:DALIAN UNIV OF TECH

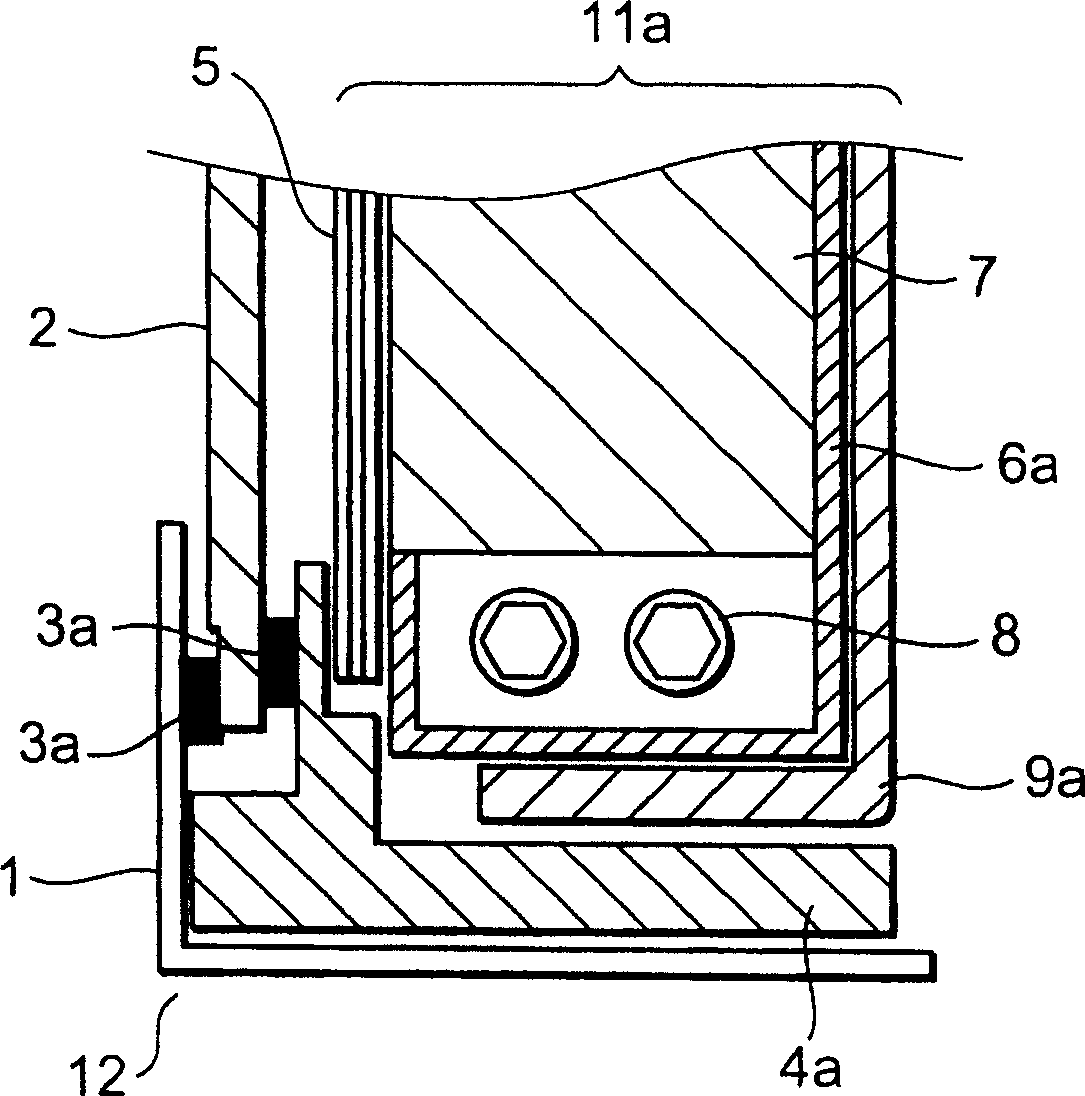

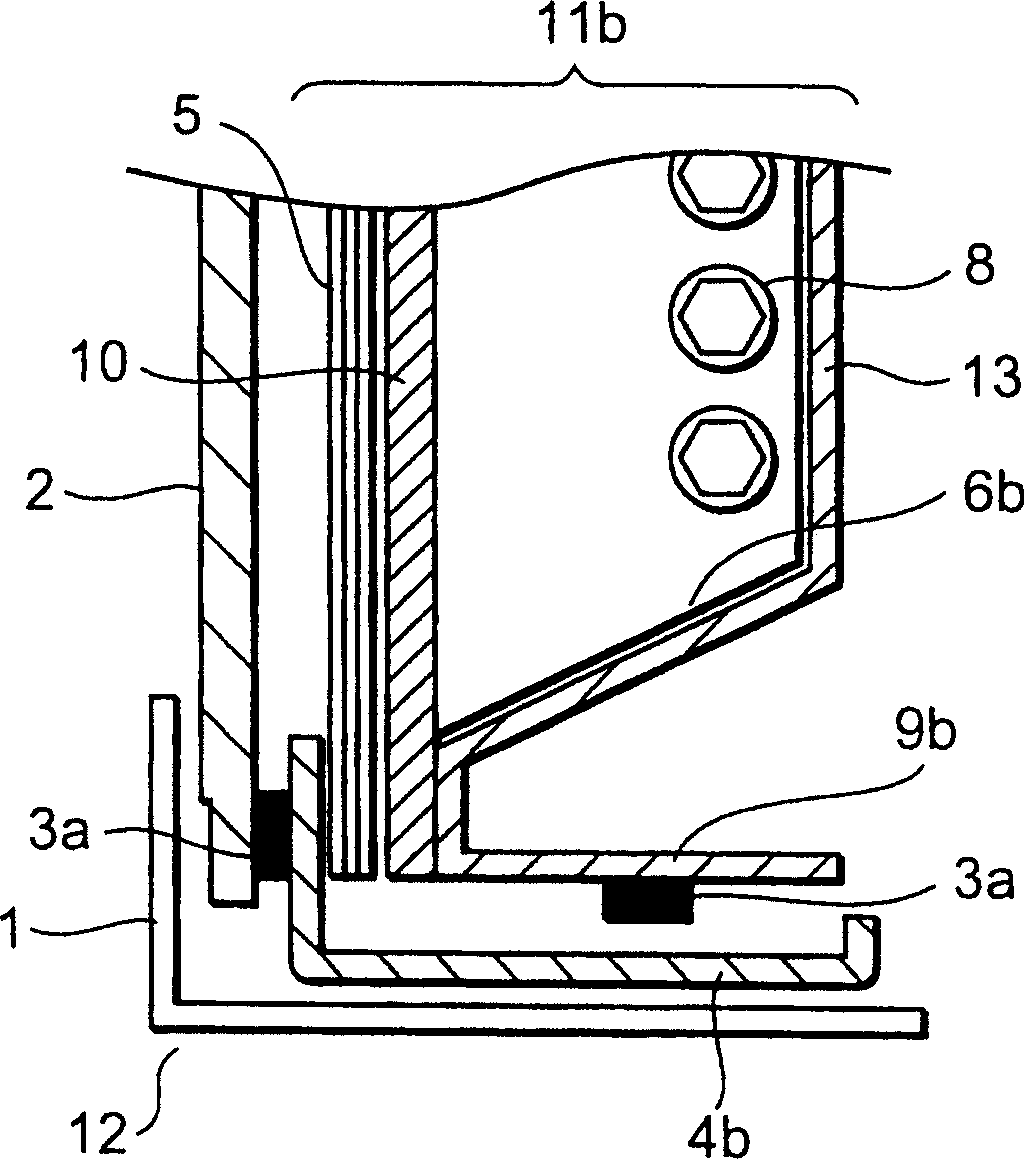

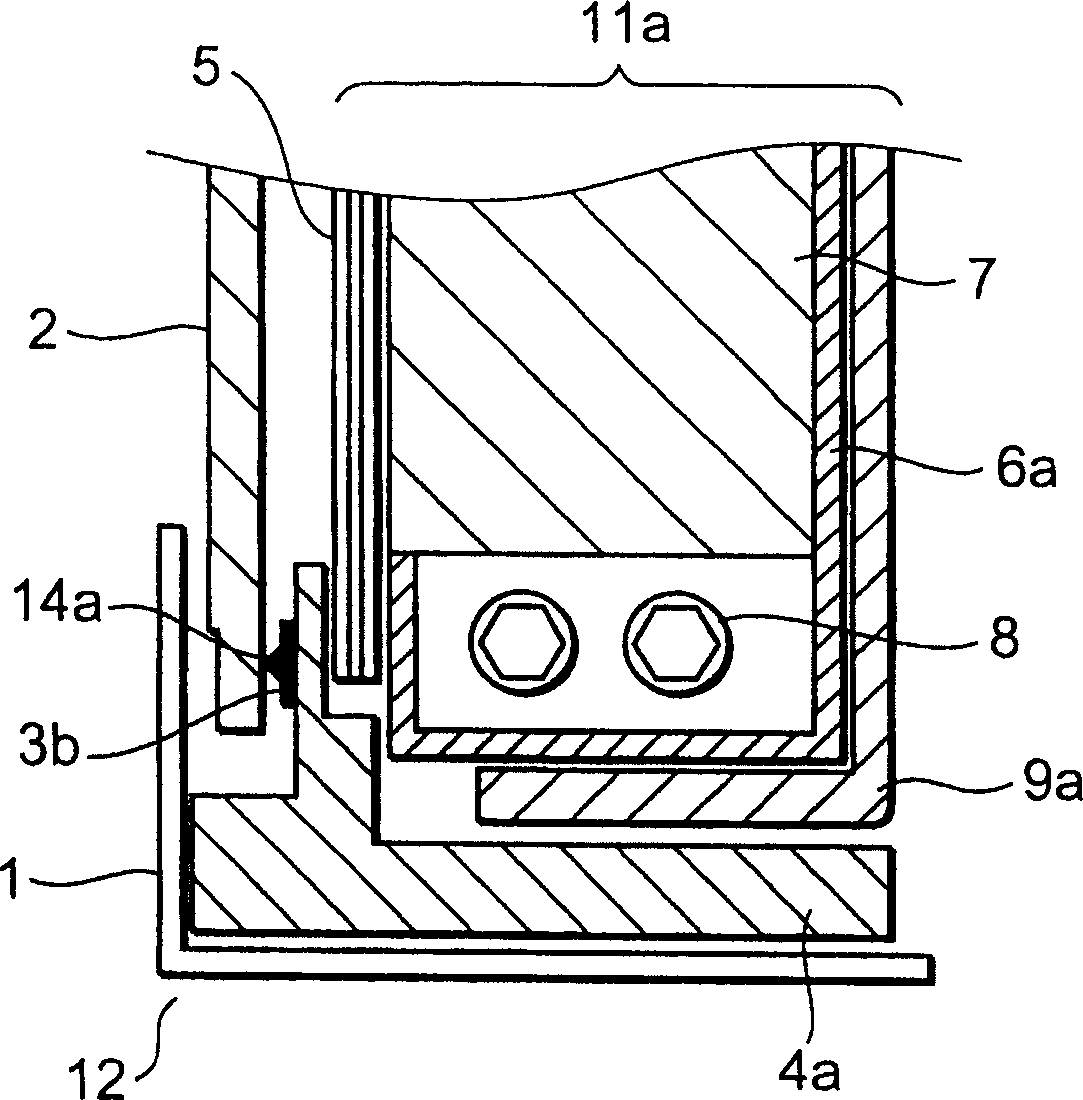

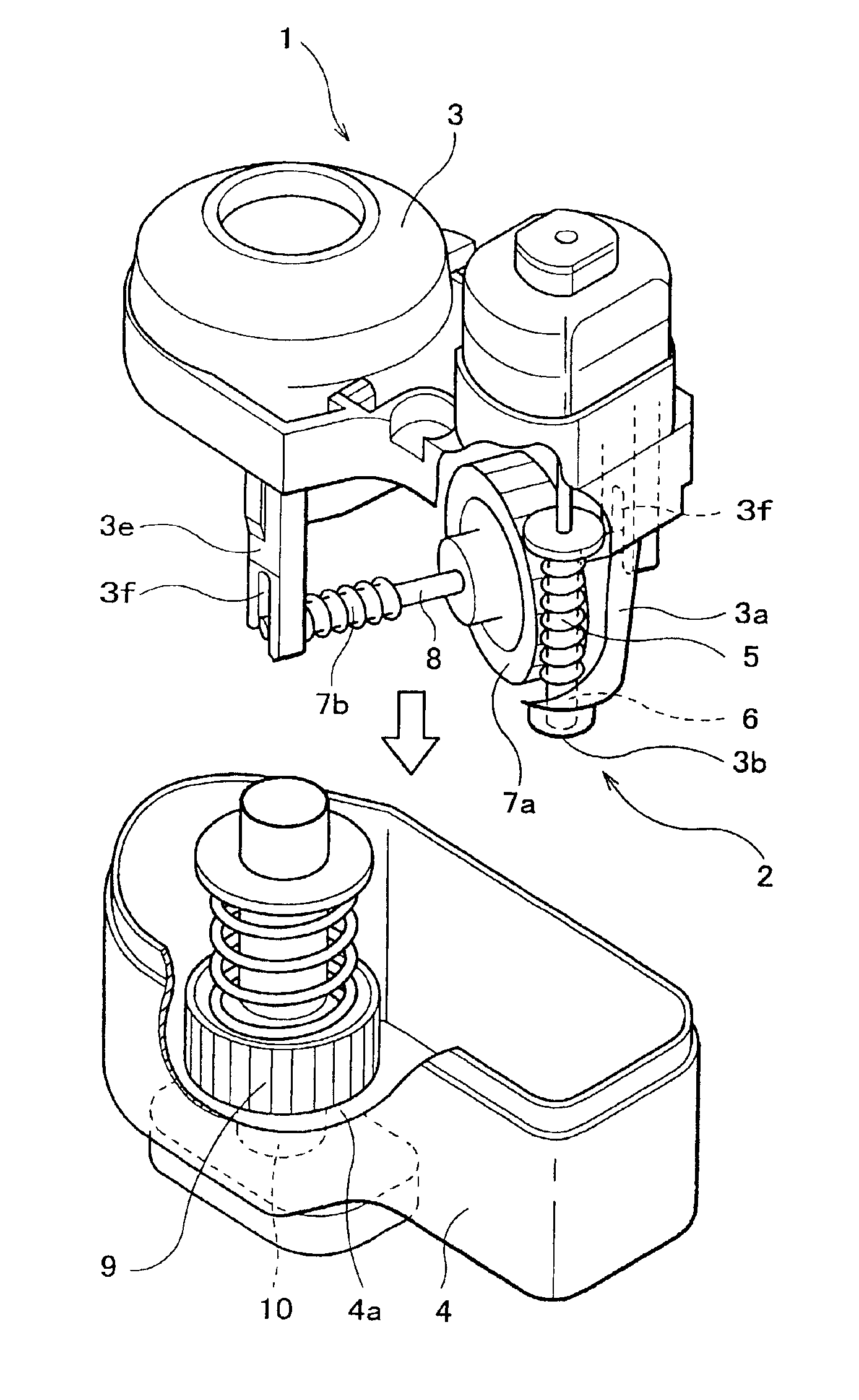

Liquid crystal display module and back light for the same

ActiveCN1673832AImprove reliabilityEasy to replaceStatic indicating devicesElongate light sourcesLiquid-crystal displayComputer module

An elastic member ( 3 b) is fixed to a space between a front surface of an intermediate frame ( 4 a) and a rear surface of a liquid crystal panel ( 2 ) constituting a liquid crystal display module ( 12 ), or a space between a rear surface of an upper frame ( 1 ) and the rear surface of the liquid crystal panel ( 2 ) constituting the liquid crystal display module ( 12 ). Alternatively, the elastic members ( 3 b) are fixed to both of the spaces. A peak portion ( 14 a) of the elastic member ( 3 b) is formed to possess a flexible structure. The liquid crystal display module is configured to hermetically seal the space between a back light ( 11 a) and the liquid crystal panel ( 2 ), the space between the upper frame ( 1 ) and the liquid crystal panel ( 2 ), or both of the spaces.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD

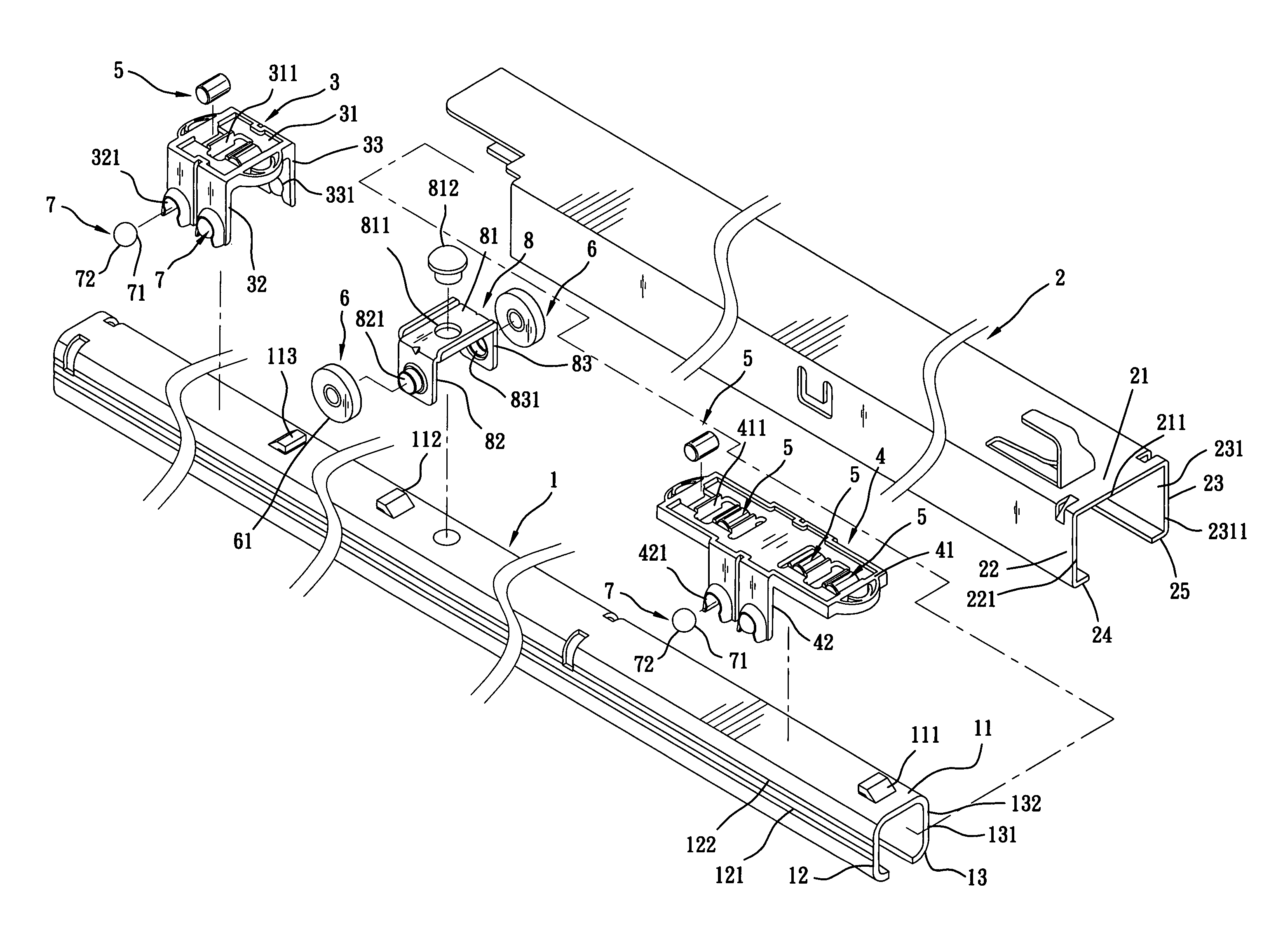

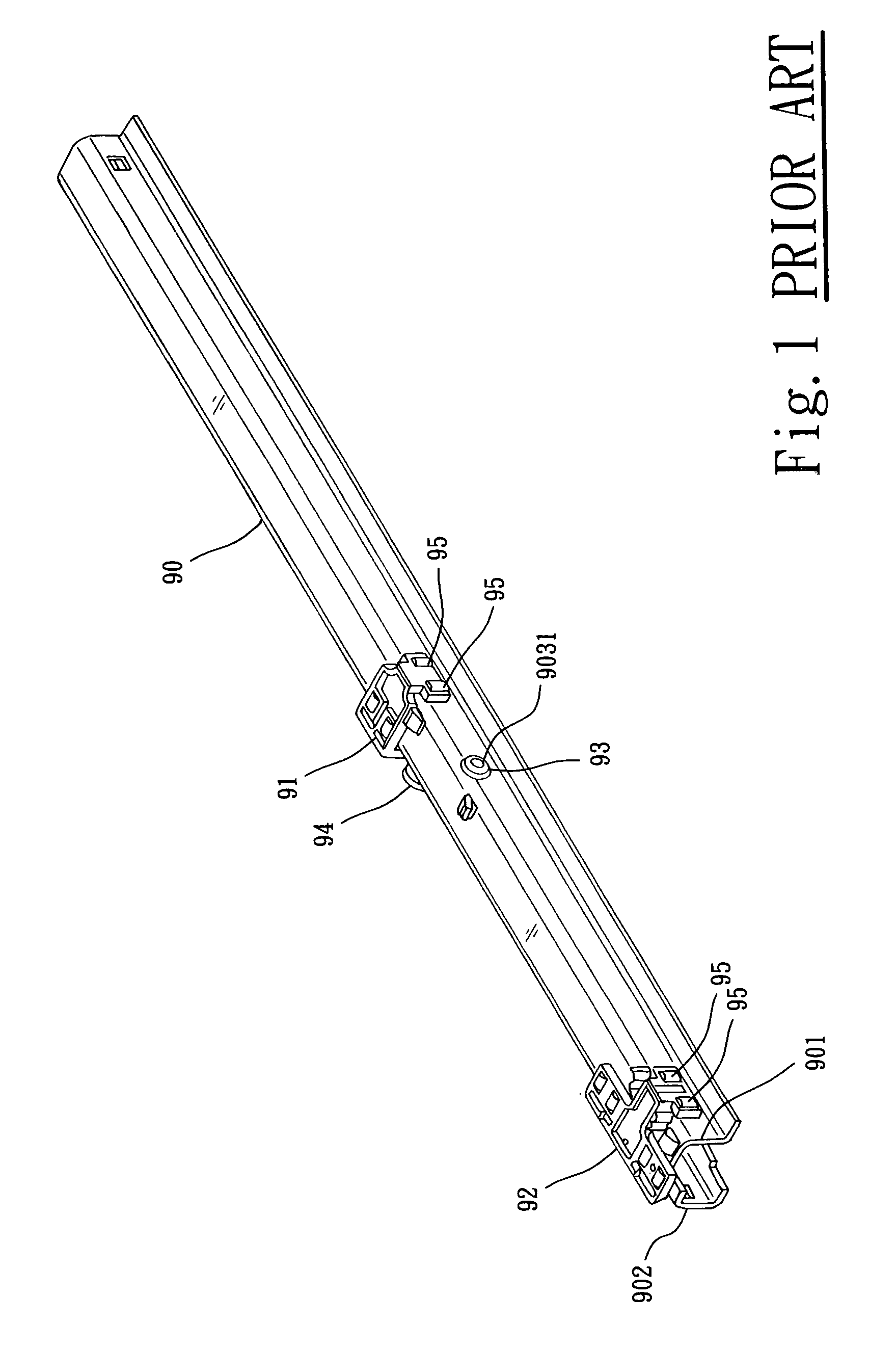

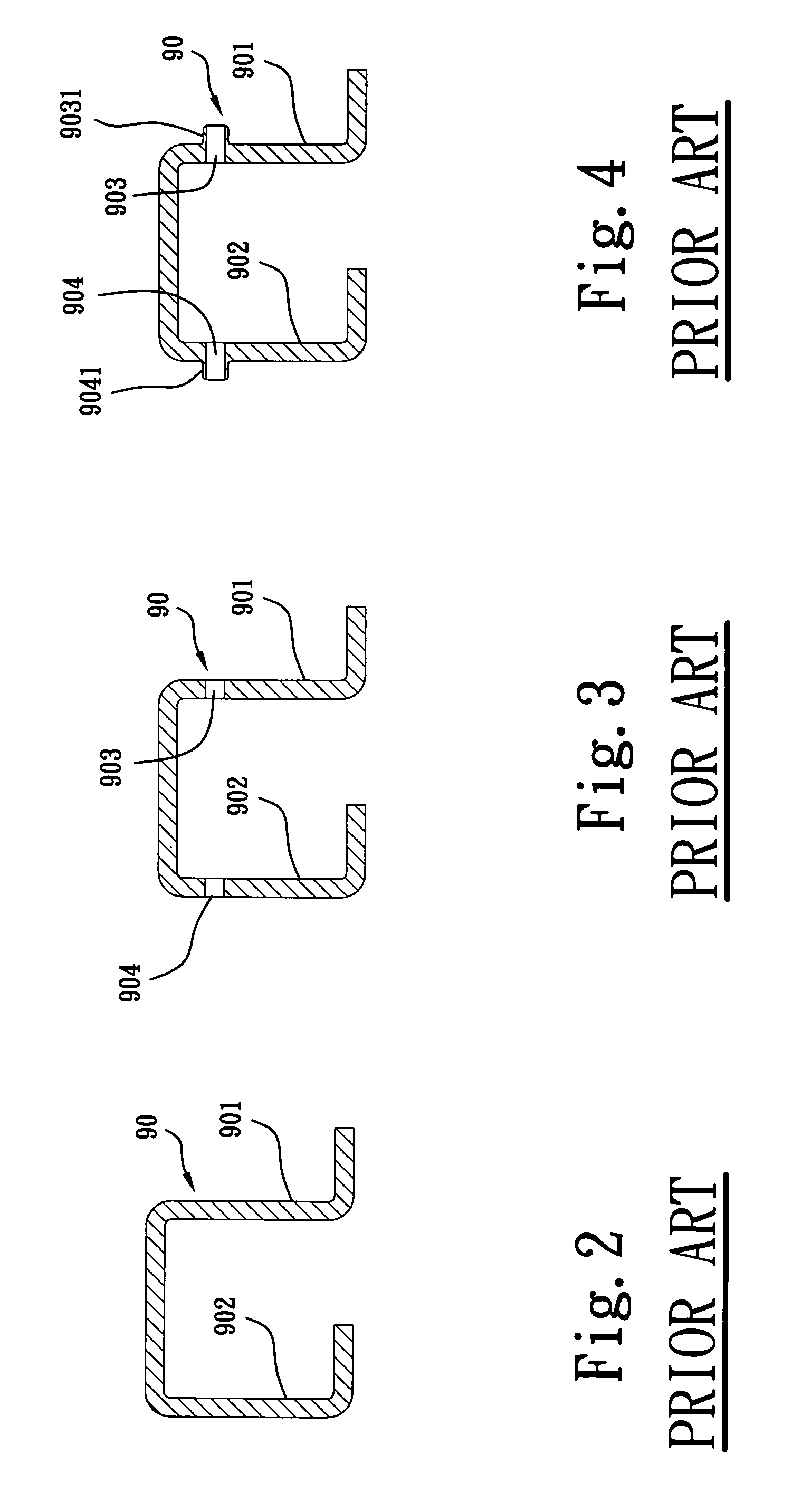

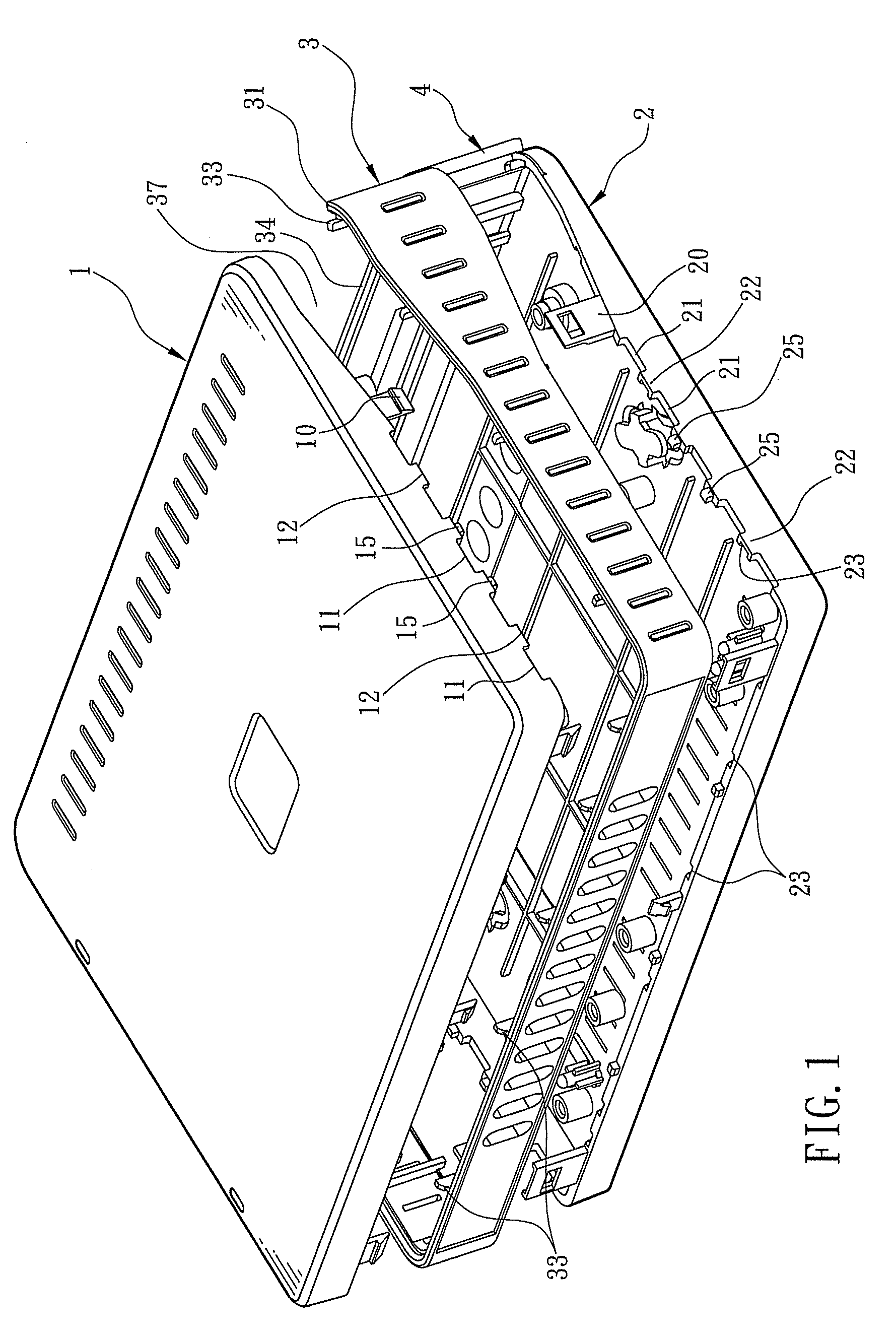

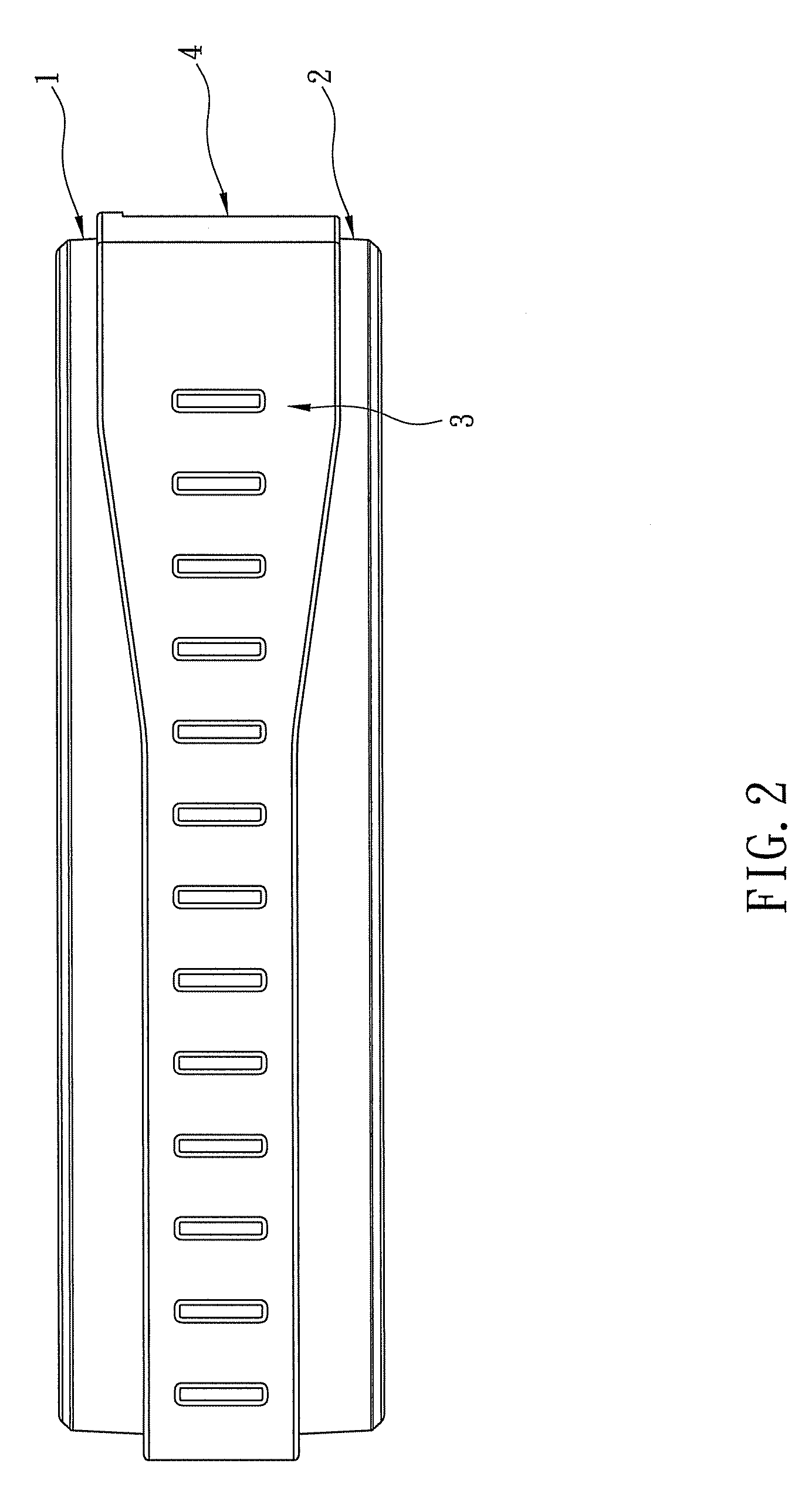

Sliding rail coupling structure for hidden sliding track assembly

A sliding rail coupling structure includes an outer rail, an intermediate sliding rail slidable in and out of the outer rail and having two longitudinal sliding grooves at two sides, sliding bearing bushes coupled to and movable along the intermediate sliding rail, each sliding bearing bush holding a plurality of roller cylinders that are kept in contact between the top wall of the intermediate sliding rail and the top wall of the outer sliding rail and a plurality of rolling balls that are respectively kept in contact between the longitudinal sliding grooves of the intermediate sliding rail and the sidewalls of the outer sliding rail, a roller holder affixed to the intermediate sliding rail to support two support rollers that are respectively in contact with two bottom flanges of the outer sliding rail.

Owner:GSLIDE

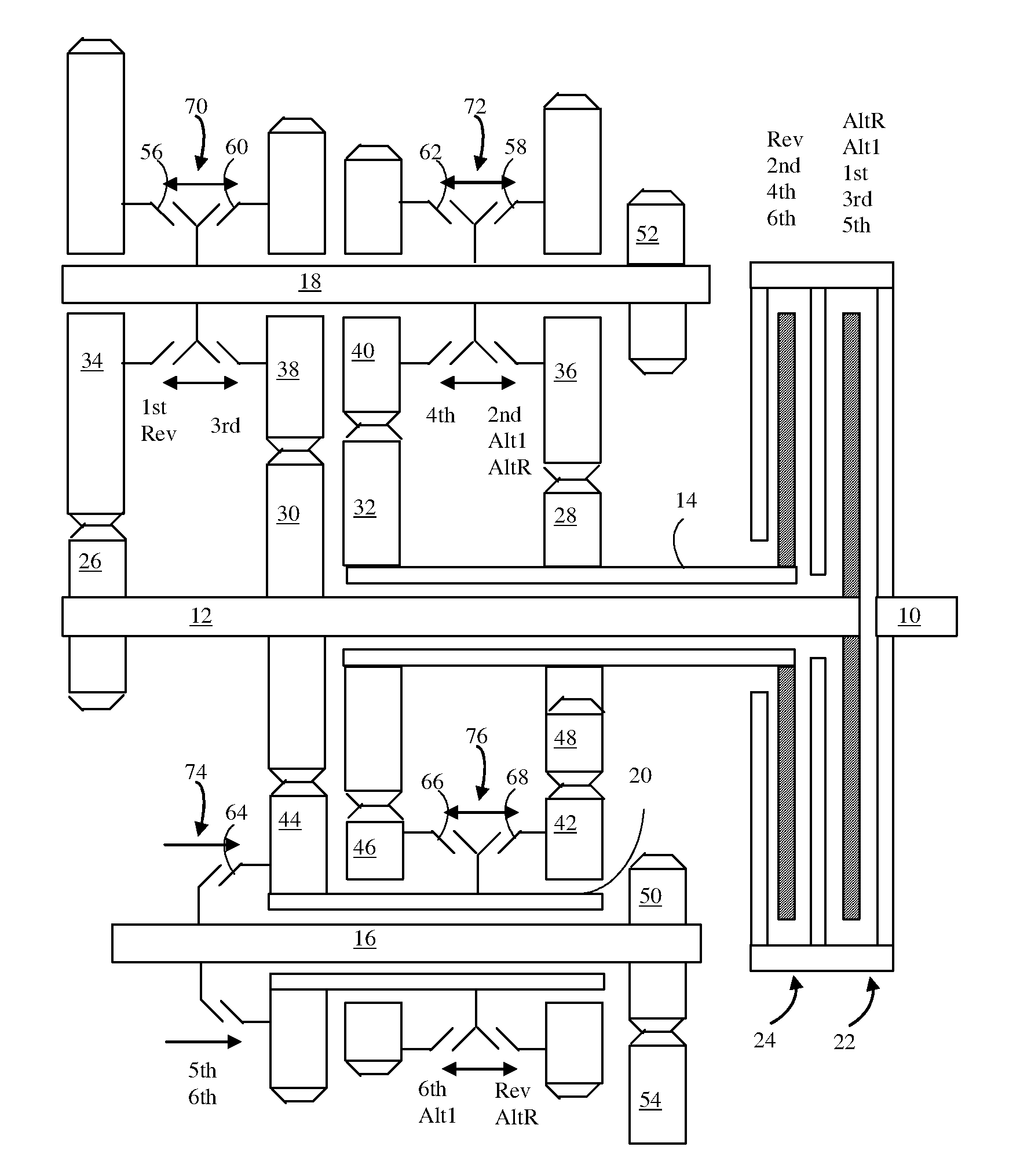

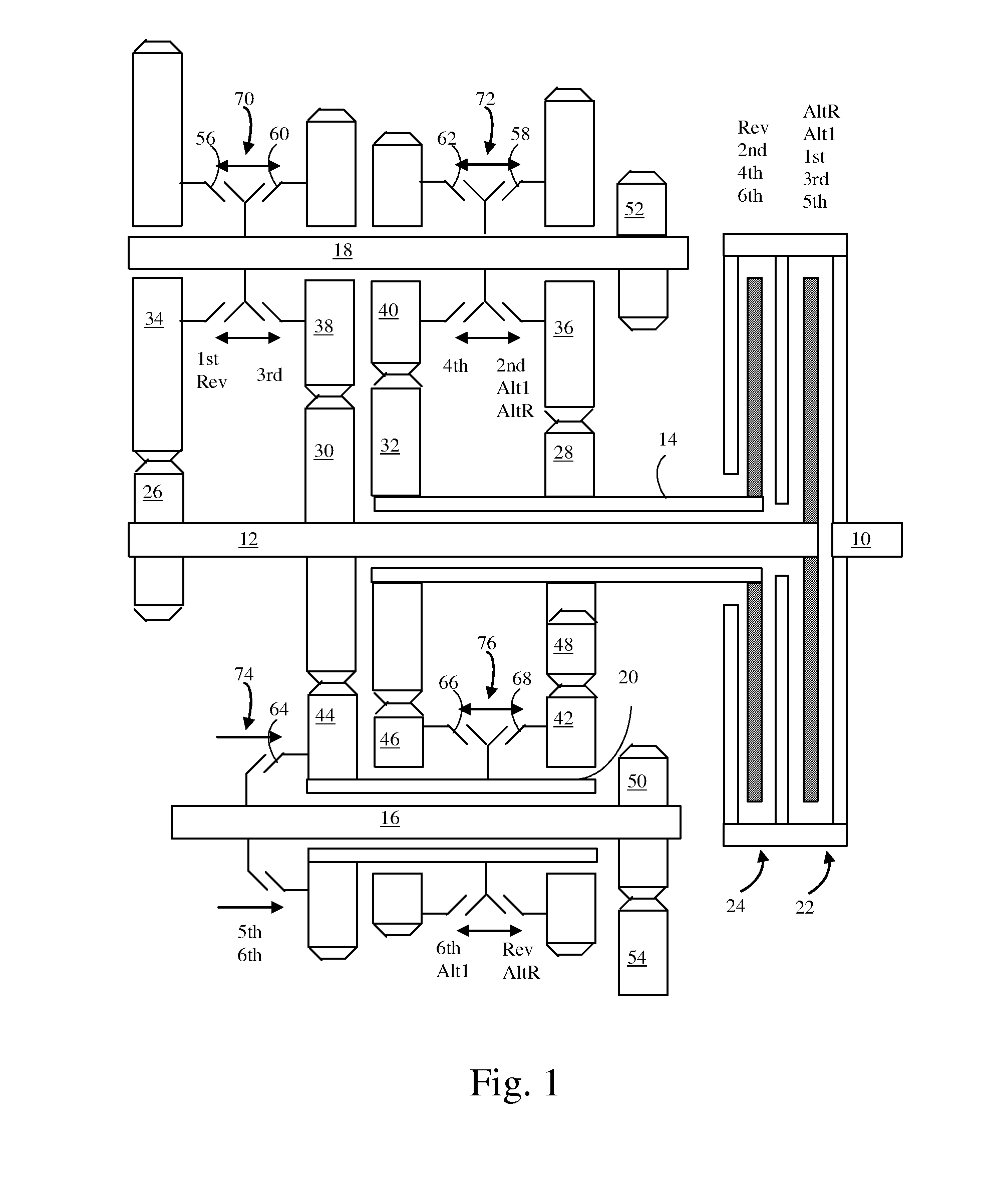

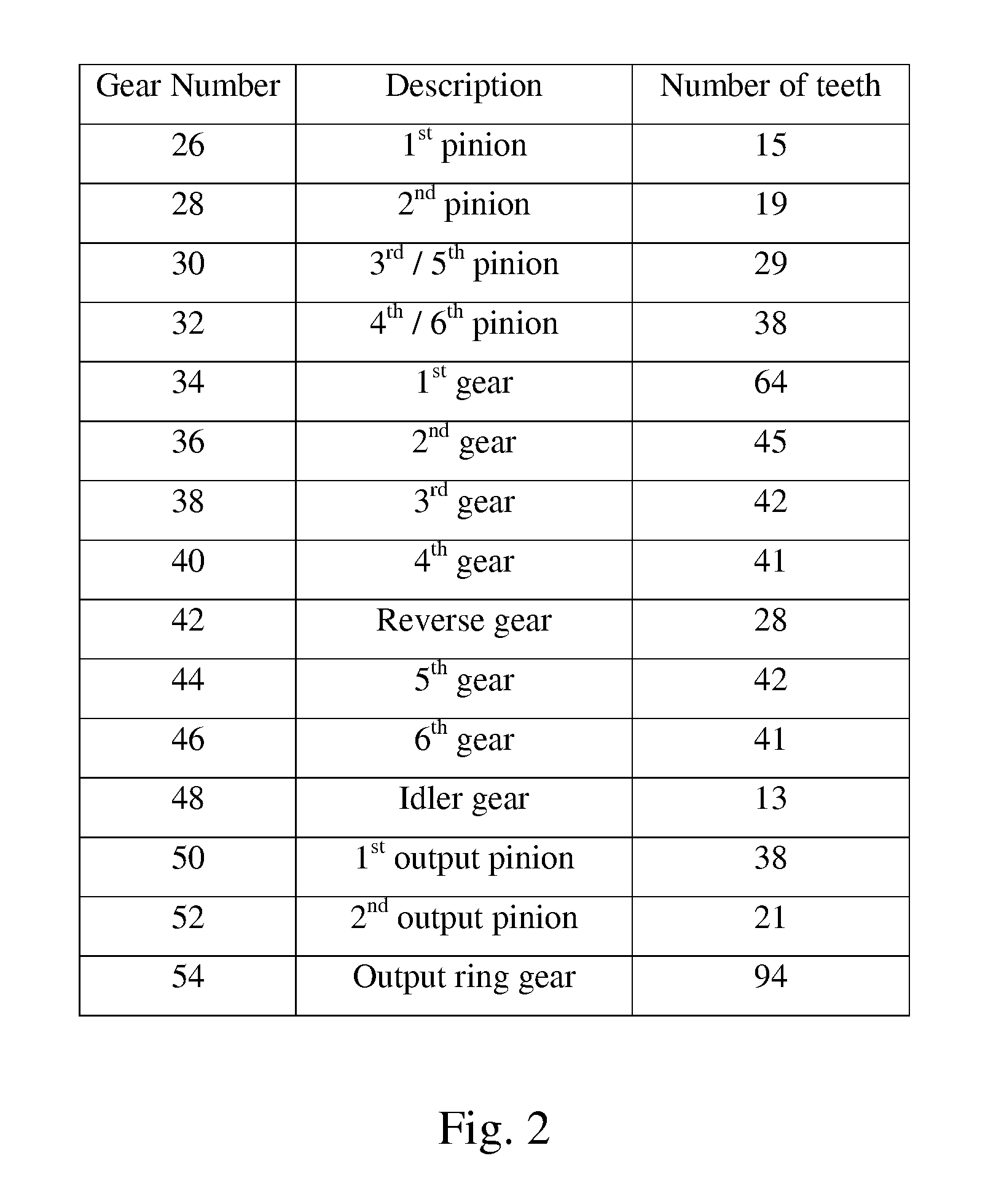

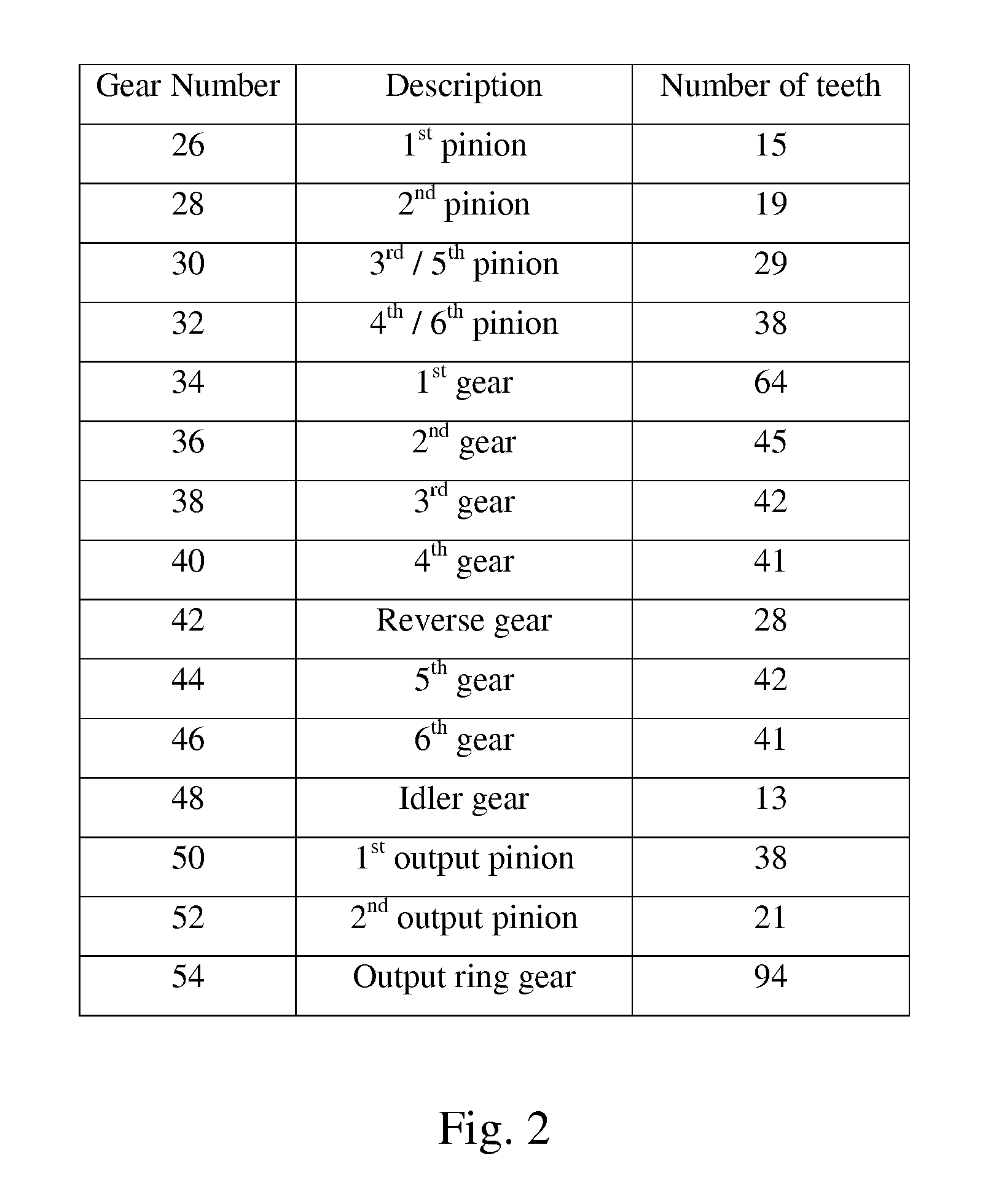

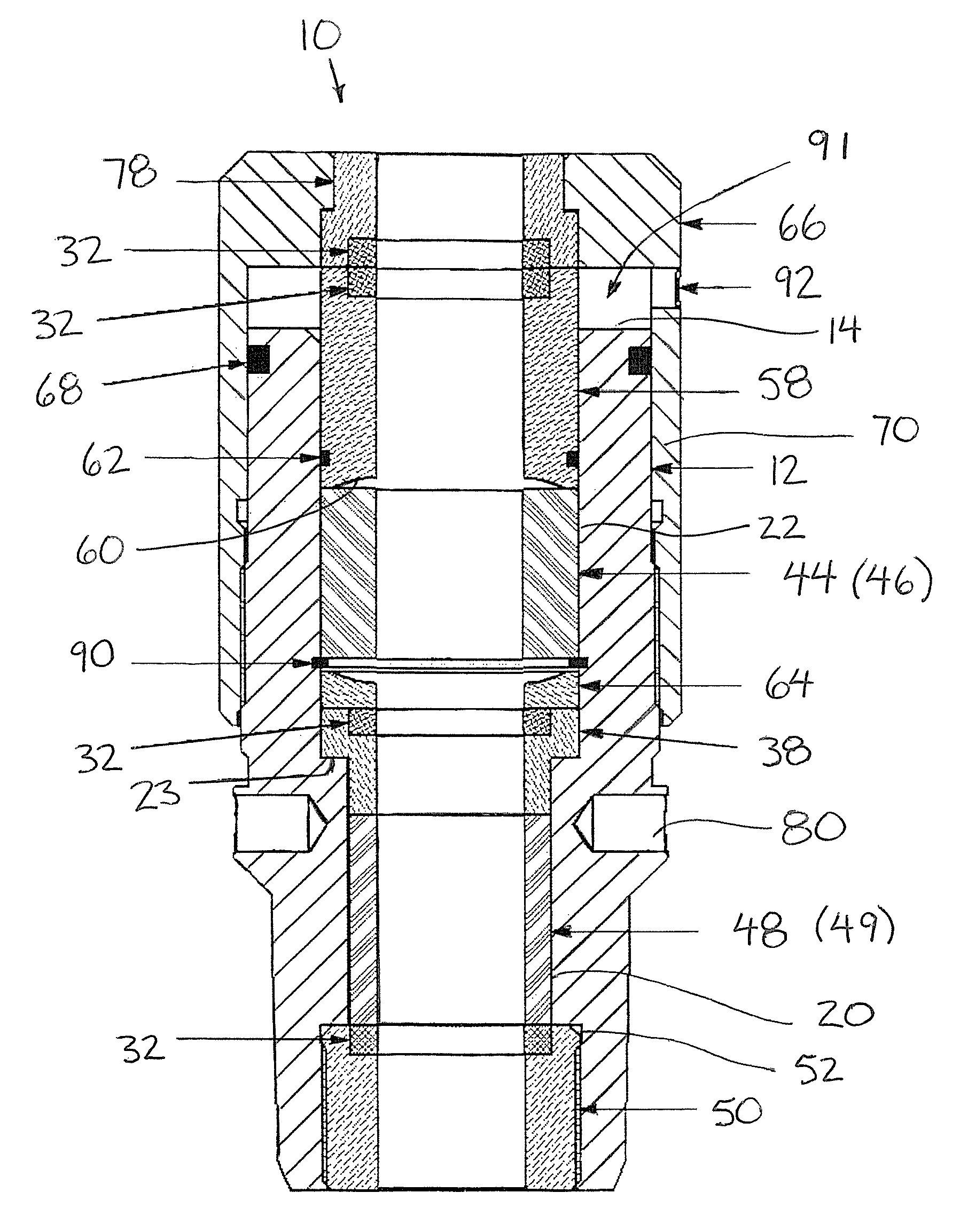

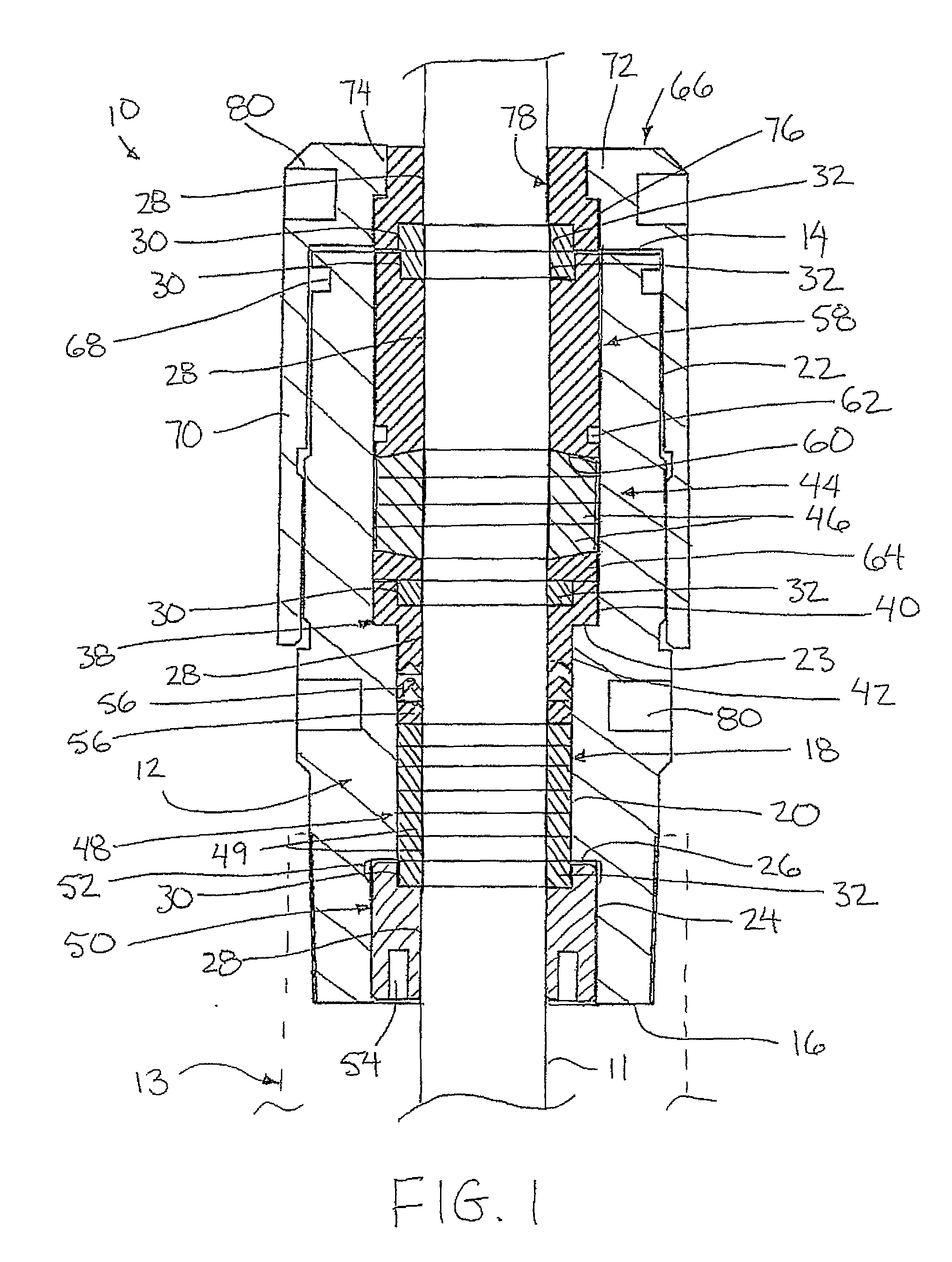

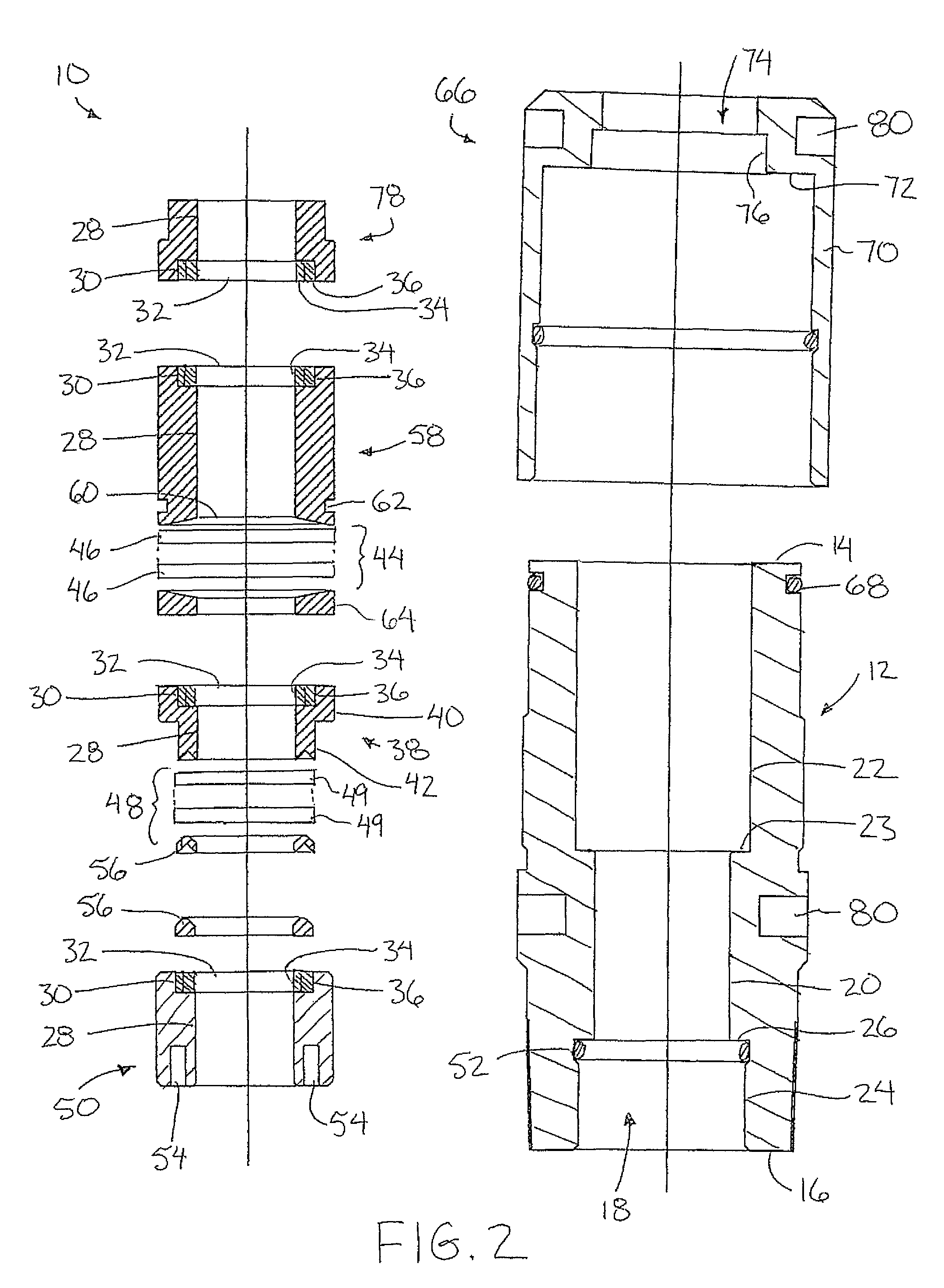

Dual clutch transmission having reduced axial length

ActiveUS20080245166A1Shorten the lengthToothed gearingsTransmission elementsElectric power transmissionPinion

A multiple speed power transmission comprises: an input; an output; first and second input shafts releasably coupled to the input by first and second friction clutches, respectively; a countershaft disposed parallel to the first and second input shafts; an output pinion fixed to the countershaft; an output ring gear fixed to the output and meshing with the output pinion; an intermediate shaft disposed coaxially with the countershaft; a first input pinion fixed to the first input shaft and meshing with a first gear fixed to the intermediate shaft; a second input pinion fixed to the second input shaft; a second gear disposed coaxially with the intermediate shaft; an idler gear meshing with the second input pinion and the second gear; a first coupler for releasably coupling the first countershaft to the intermediate shaft; and a second coupler for releasably coupling the intermediate shaft to the second gear.

Owner:FORD GLOBAL TECH LLC

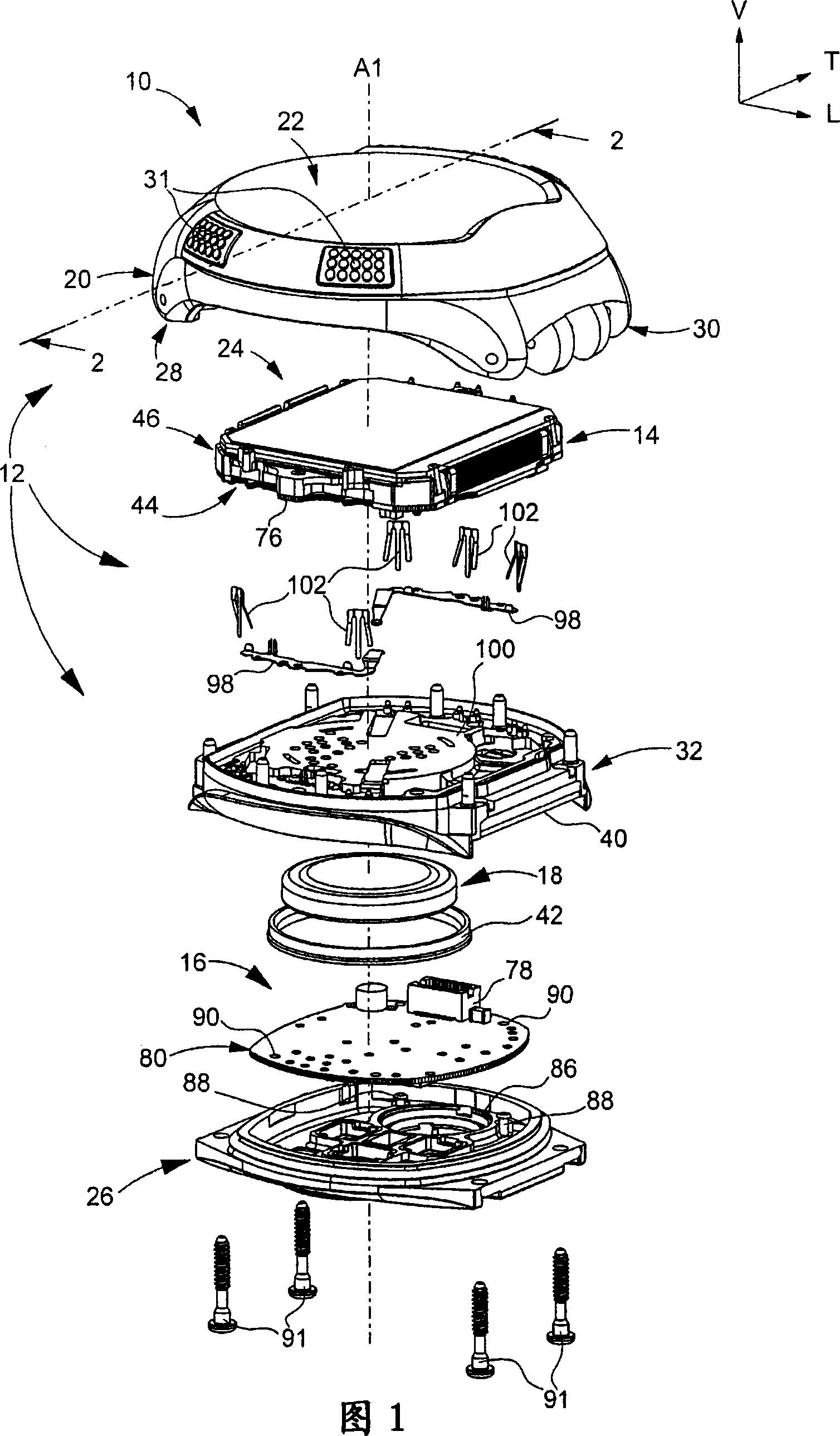

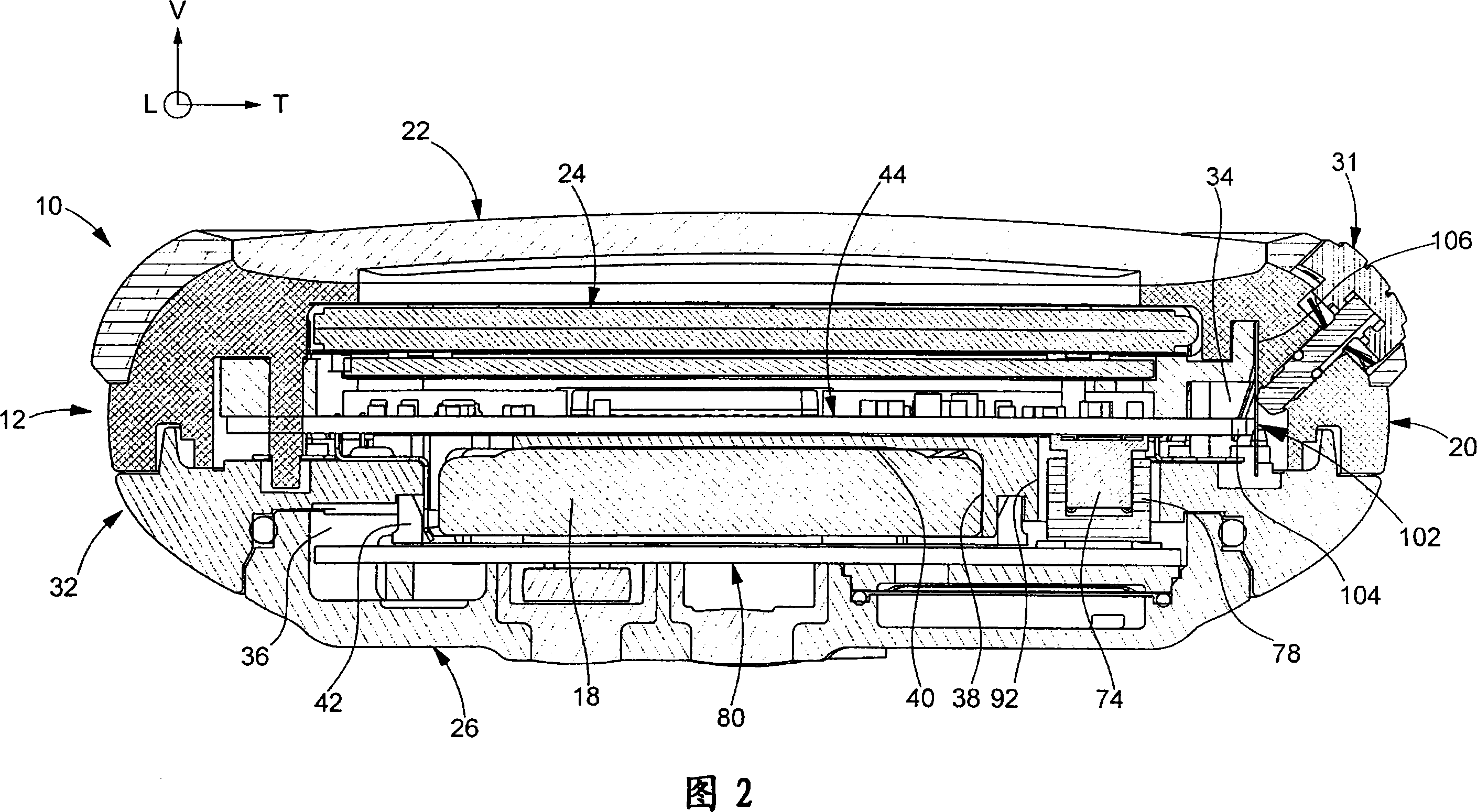

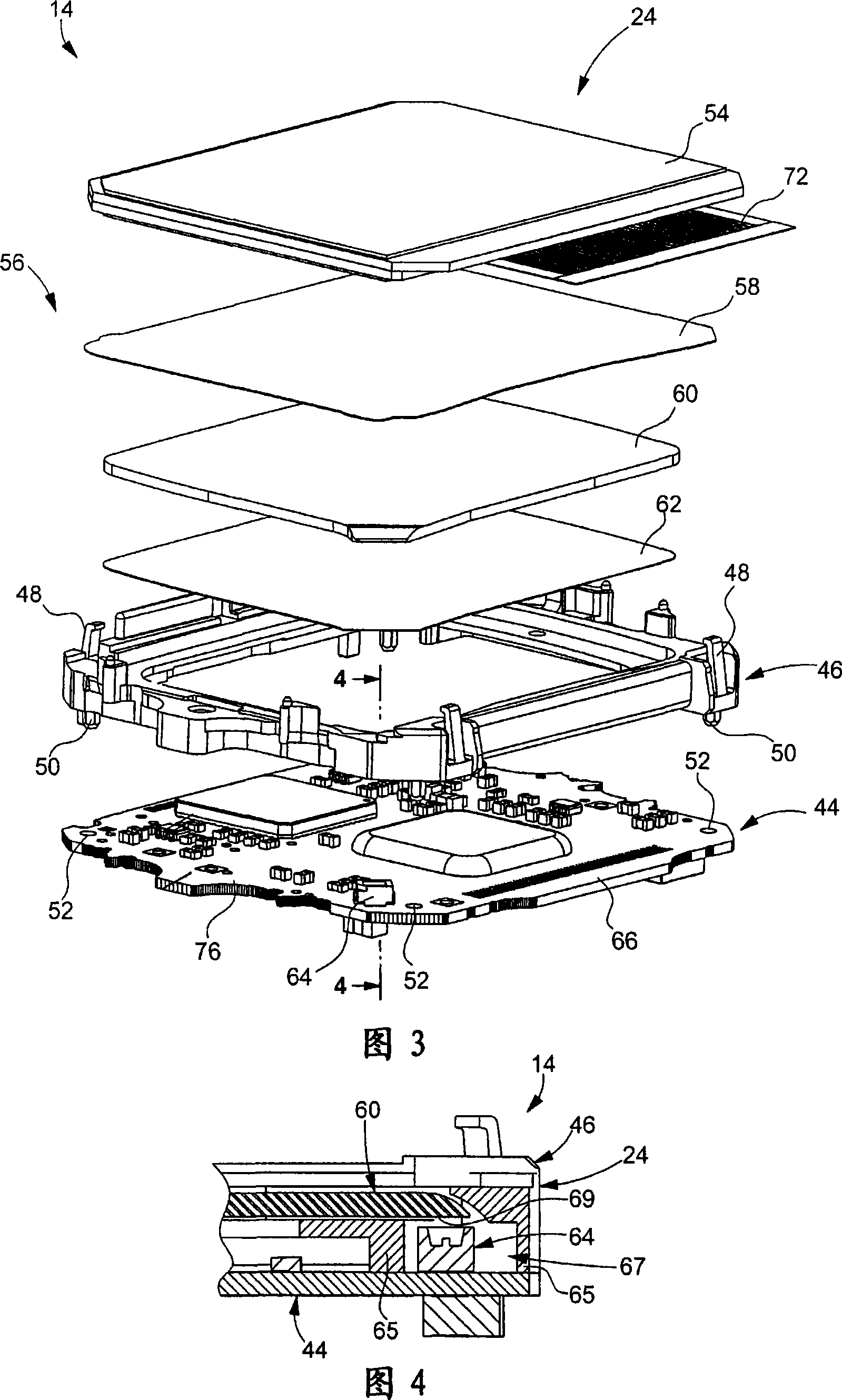

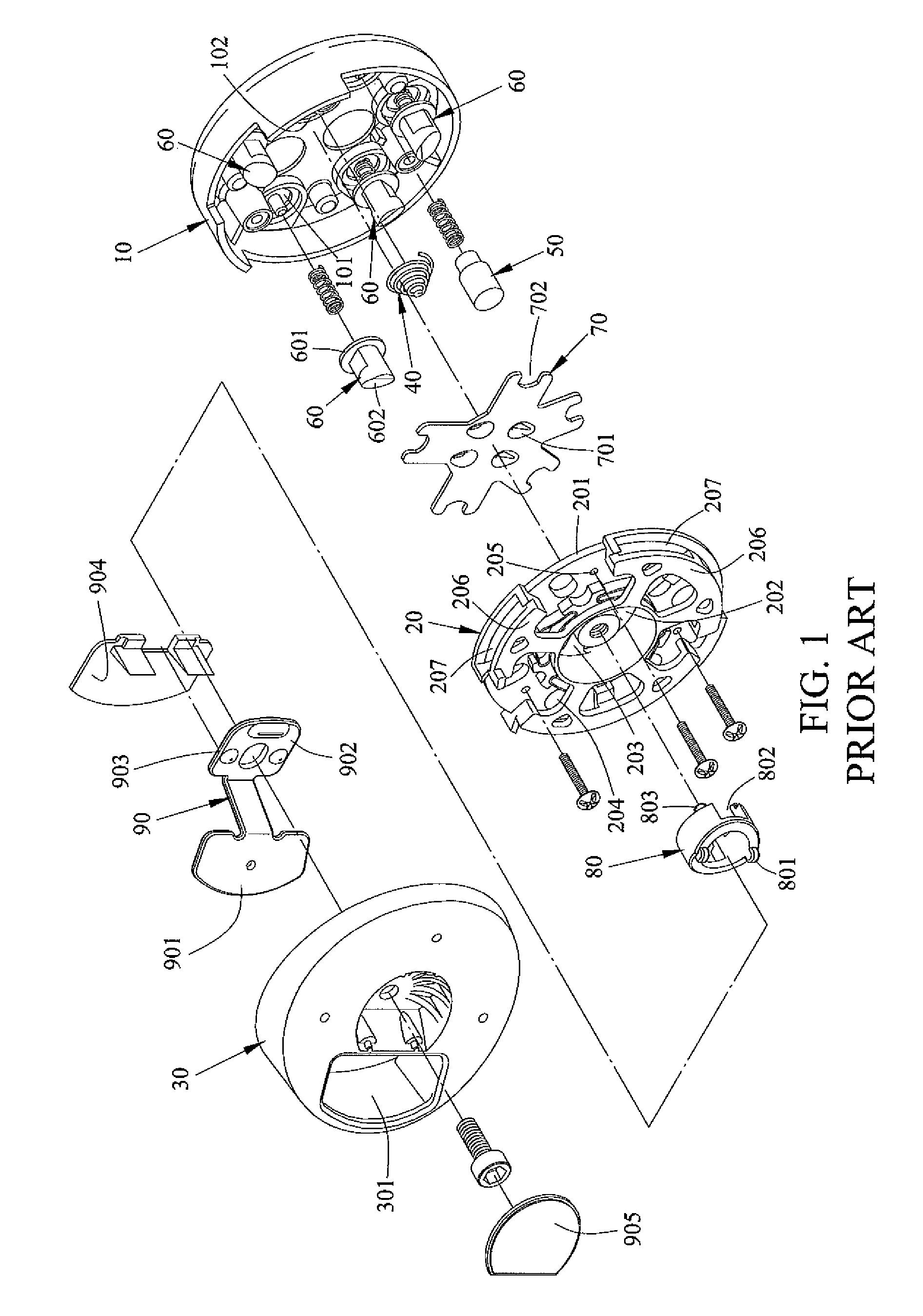

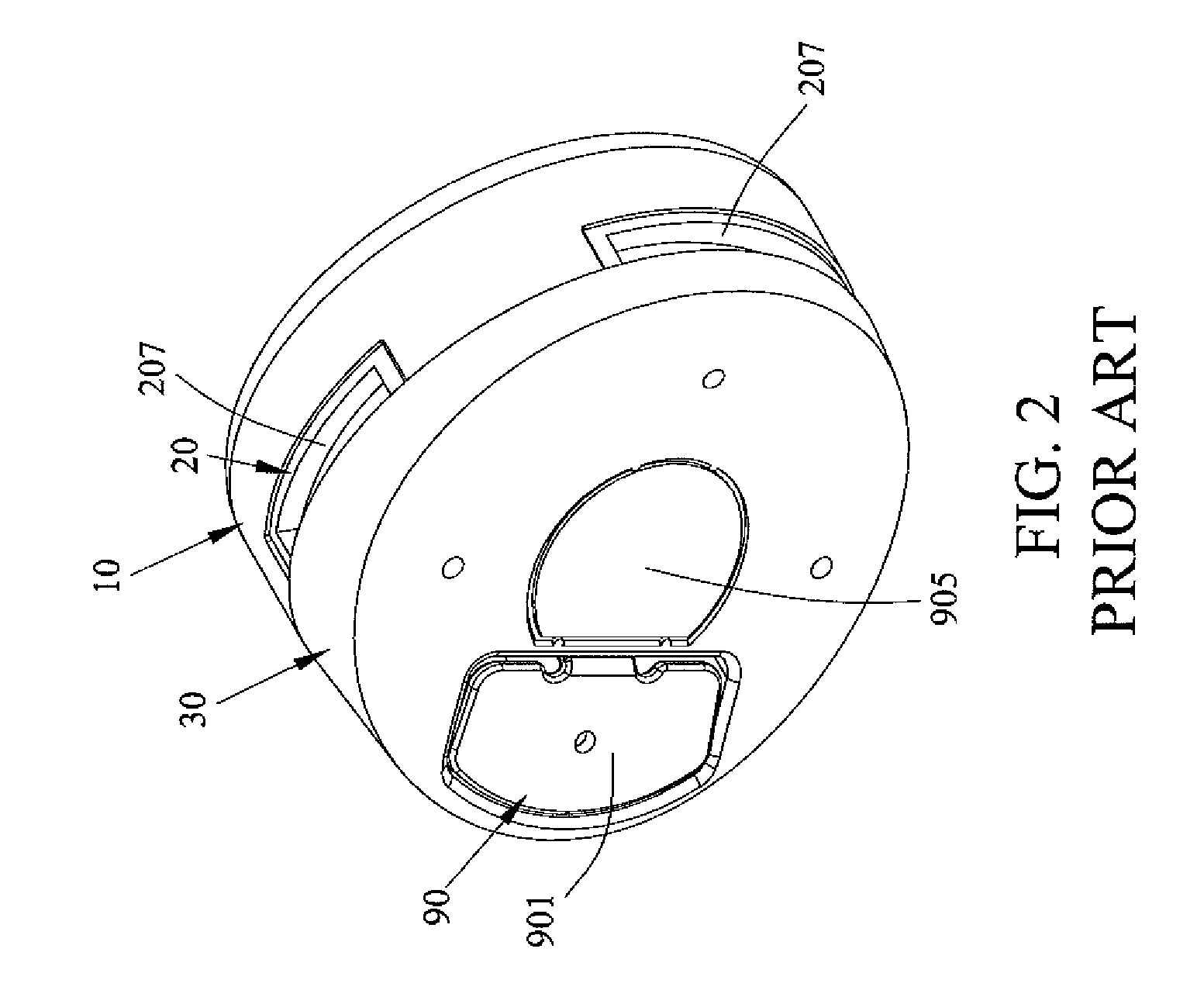

Electronic timepiece including an added partition and associated assembly method

InactiveCN101109928AElectronic time-piece structural detailsElectric windingDisplay deviceEngineering

Owner:ETA SA MFG HORLOGERE SUISSE

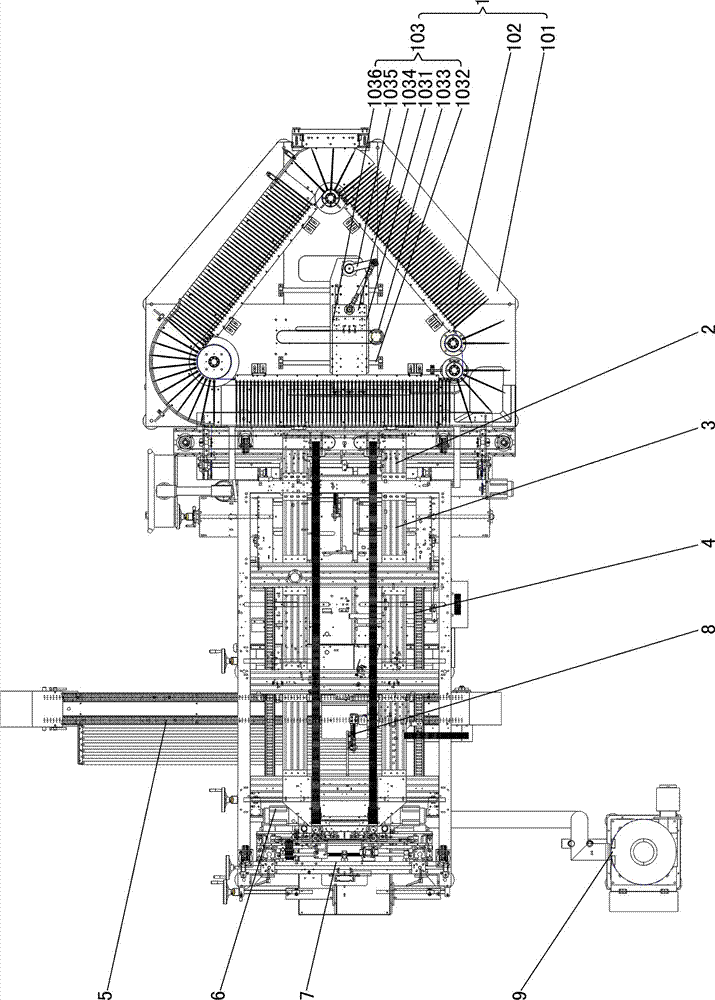

Full-automatic paper diaper packaging production line

ActiveCN104843248APrecise feedingAvoid getting stuckIndividual articlesStack machineCompression device

The invention relates to a full-automatic paper diaper packaging production line which comprises a stacking machine, pre-compression device, a transition mechanism, a secondary compression device, a bag feeding device, a bag opening device, a packaging, sealing and cutting-off device, a pushing mechanism and an offcut collecting device. The pre-compression device comprises a support, a support plate, a left compression mechanism, a right compression mechanism and a push out mechanism, wherein each of the left compression mechanism and the right compression mechanism comprises a compression translation mechanism, an upper push block and a lower push block, the upper push block and the lower push block are respectively connected with the power output end of the compression translation mechanism, and the upper push block is located above the lower push block. The full-automatic paper diaper packaging production line has the advantages that the upper push blocks and the lower push blocks are respectively driven by independent compression translation mechanisms and are fixed in the middle to perform pre-compression, paper diapers are prevented from being deviated and stuck, production smoothness is increased, and production efficiency is increased; the upper push blocks are separated from the lower push blocks, the friction between the paper diapers and the upper push blocks and the lower push blocks is reduced, and abrasion and scratch of the paper diapers are avoided.

Owner:孙少光

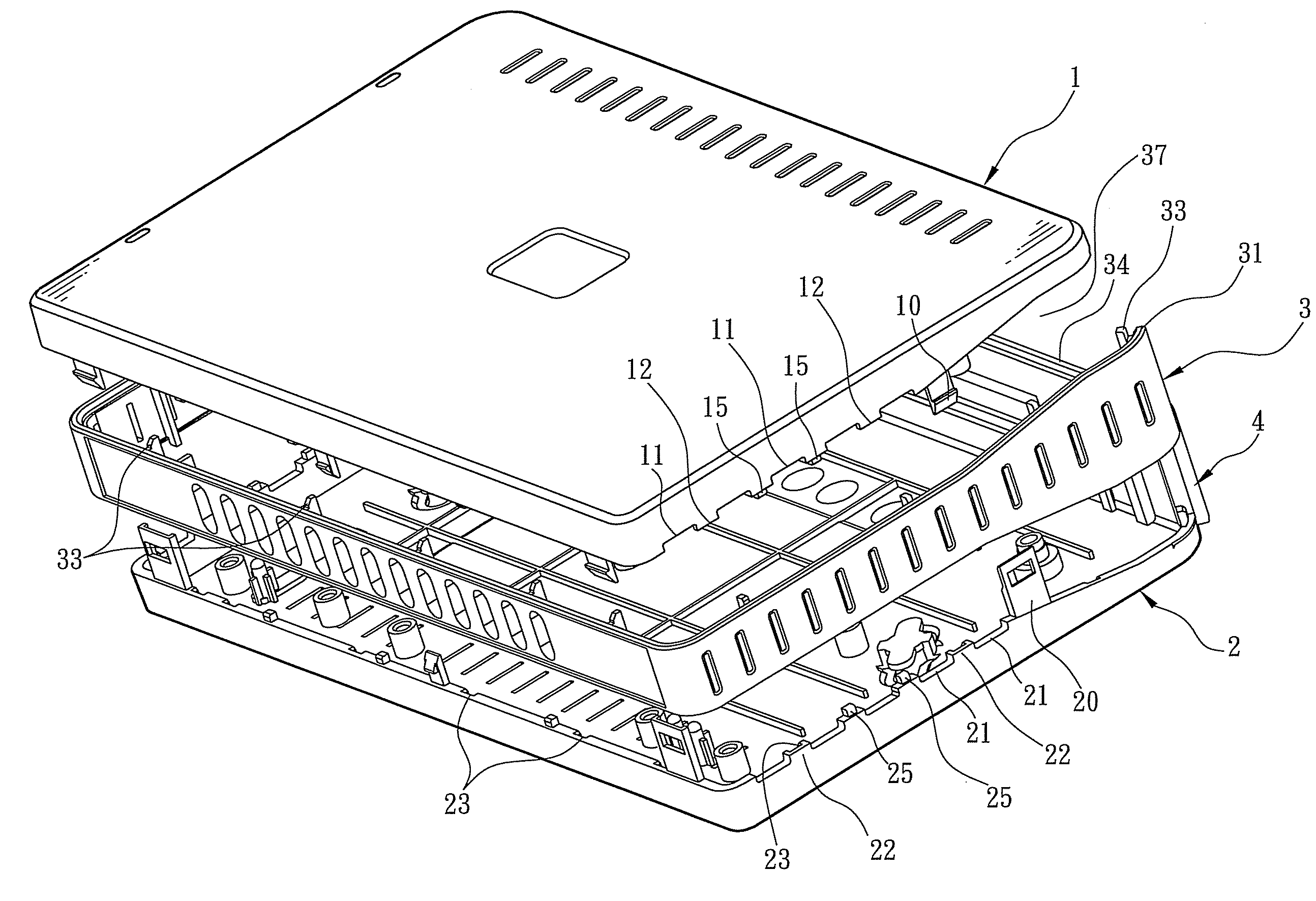

Housing with hidden ventilation holes

ActiveUS7712621B2Maintain structural strengthRigid containersElectrical apparatus casings/cabinets/drawersEngineeringFlange

The present invention is to provide a housing of an electronic device having a plurality of hidden ventilation holes, which comprises an intermediate frame, an upper shell and a lower shell, wherein the intermediate frame comprises an upright flange along the outer edges thereof, the upper shell and the lower shell respectively have its edge secured to an inner edge inside the flange of the intermediate frame, the upper shell and the lower shell both comprise a plurality of spaced cavities formed along the edge of the upper shell and the lower shell, and both the cavities are concealed behind the flange when the intermediate frame is assembled with the upper shell and the lower shell respectively, so as to maintain a structural strength of the housing and to be looked aesthetic.

Owner:D-LINK

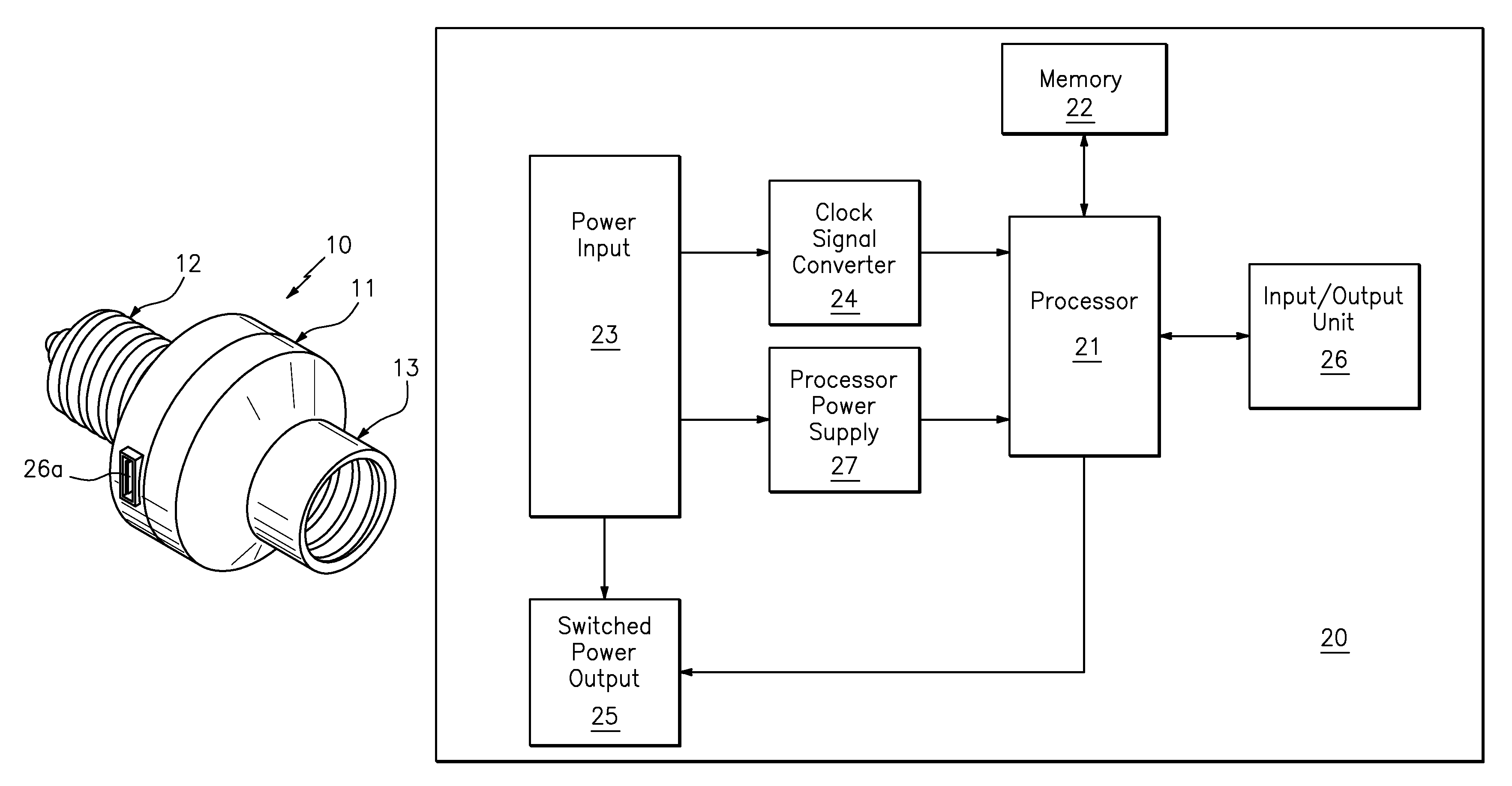

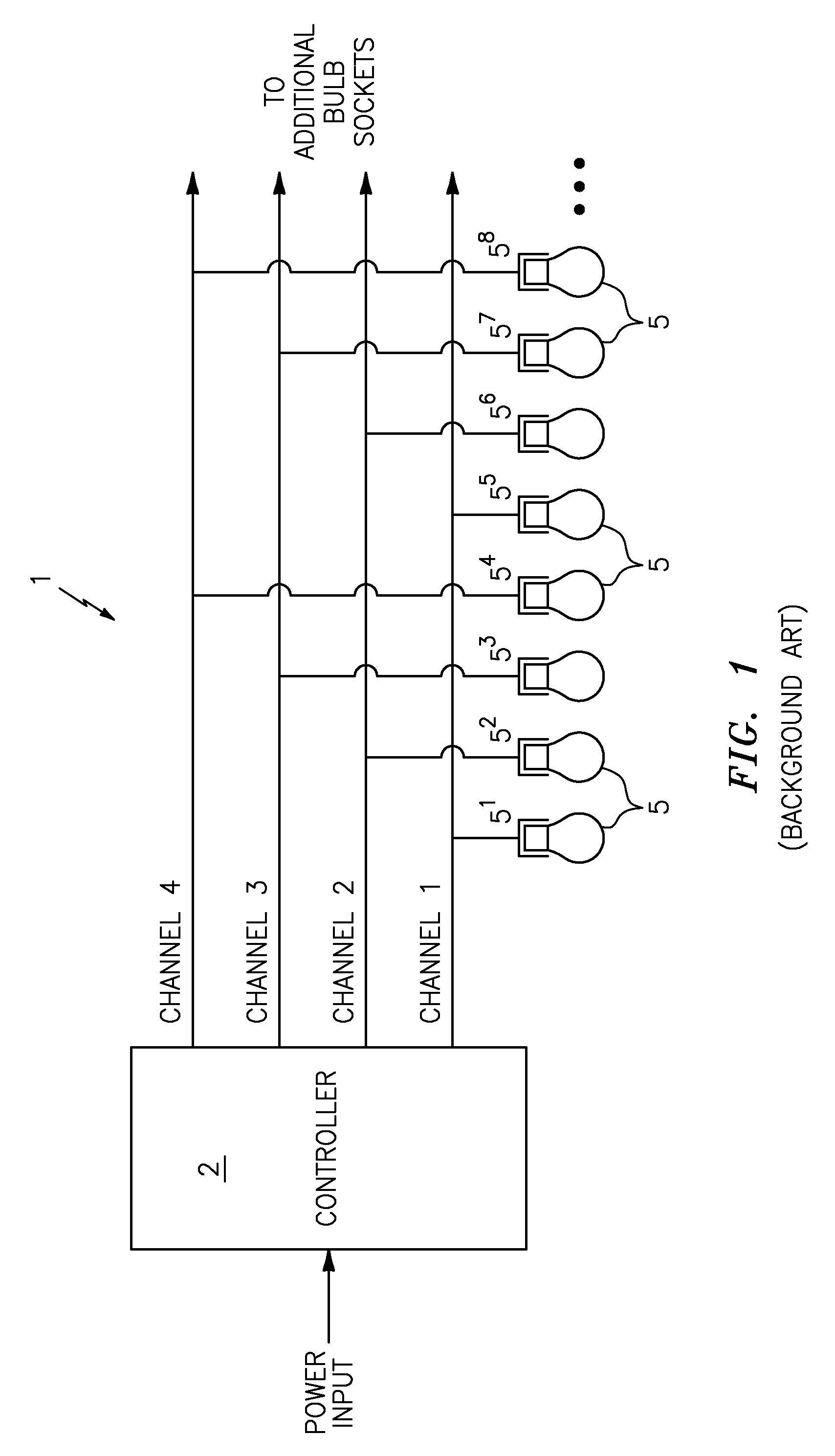

Programmable lighting effect device and system

A programmable lighting effect device and system includes a main body having a plug secured to the first end, a socket secured to the second end, and a controller secured within a middle portion. The controller utilizes the alternating current frequency of the supplied electricity as a common clock and further instructs a light bulb installed within the socket to perform a predetermined illumination effect based on stored operating instructions.

Owner:GILLIO LEE

Suction valve

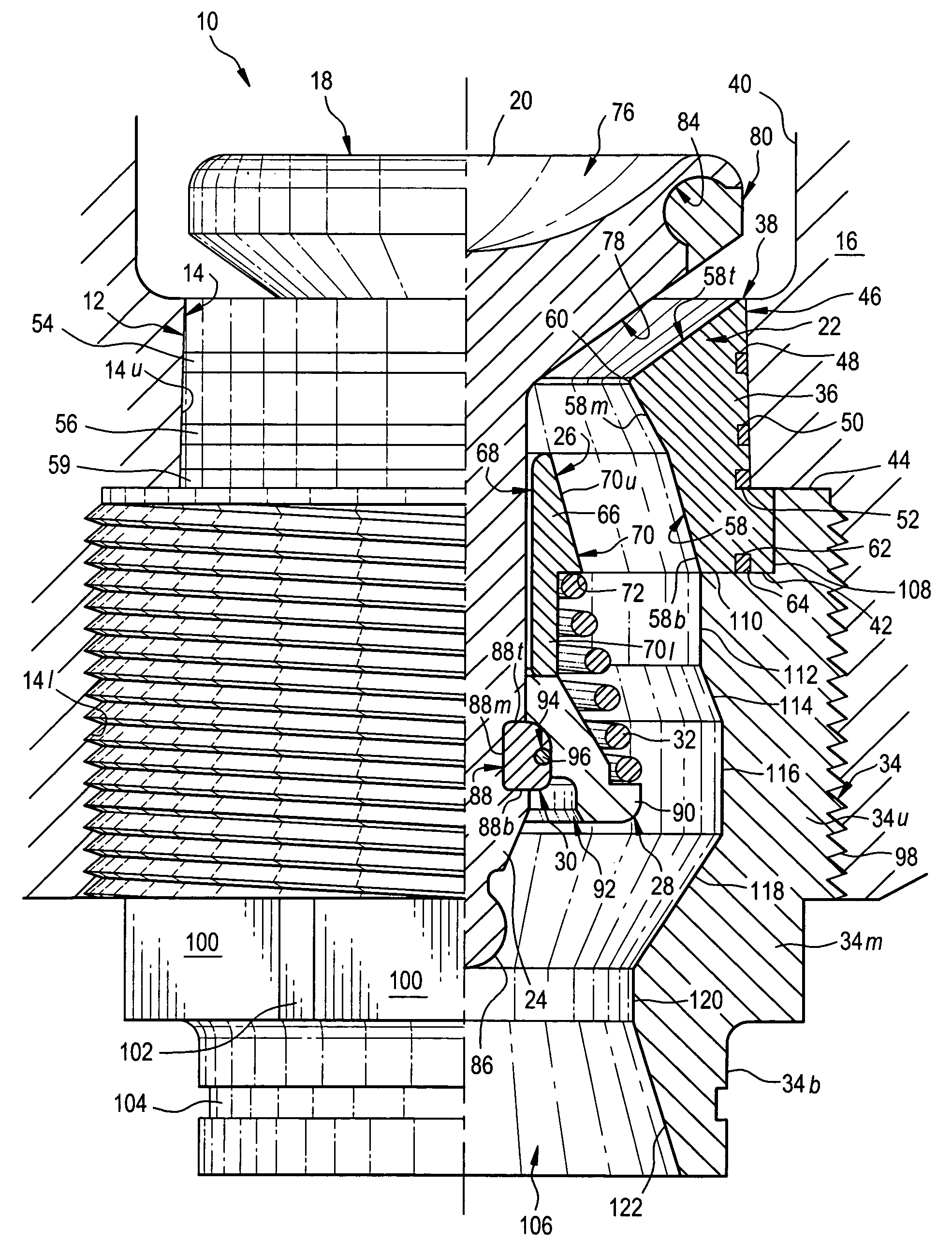

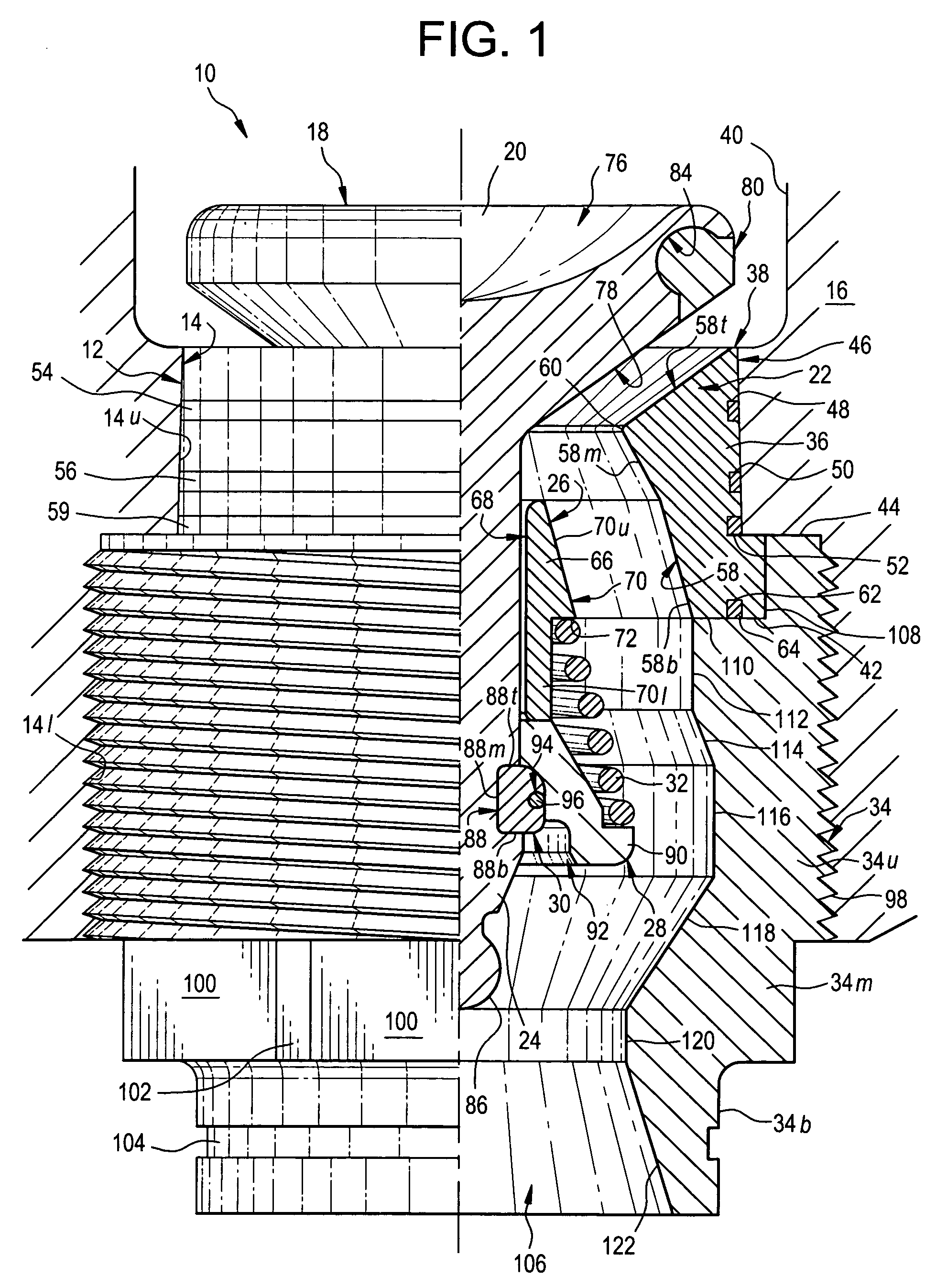

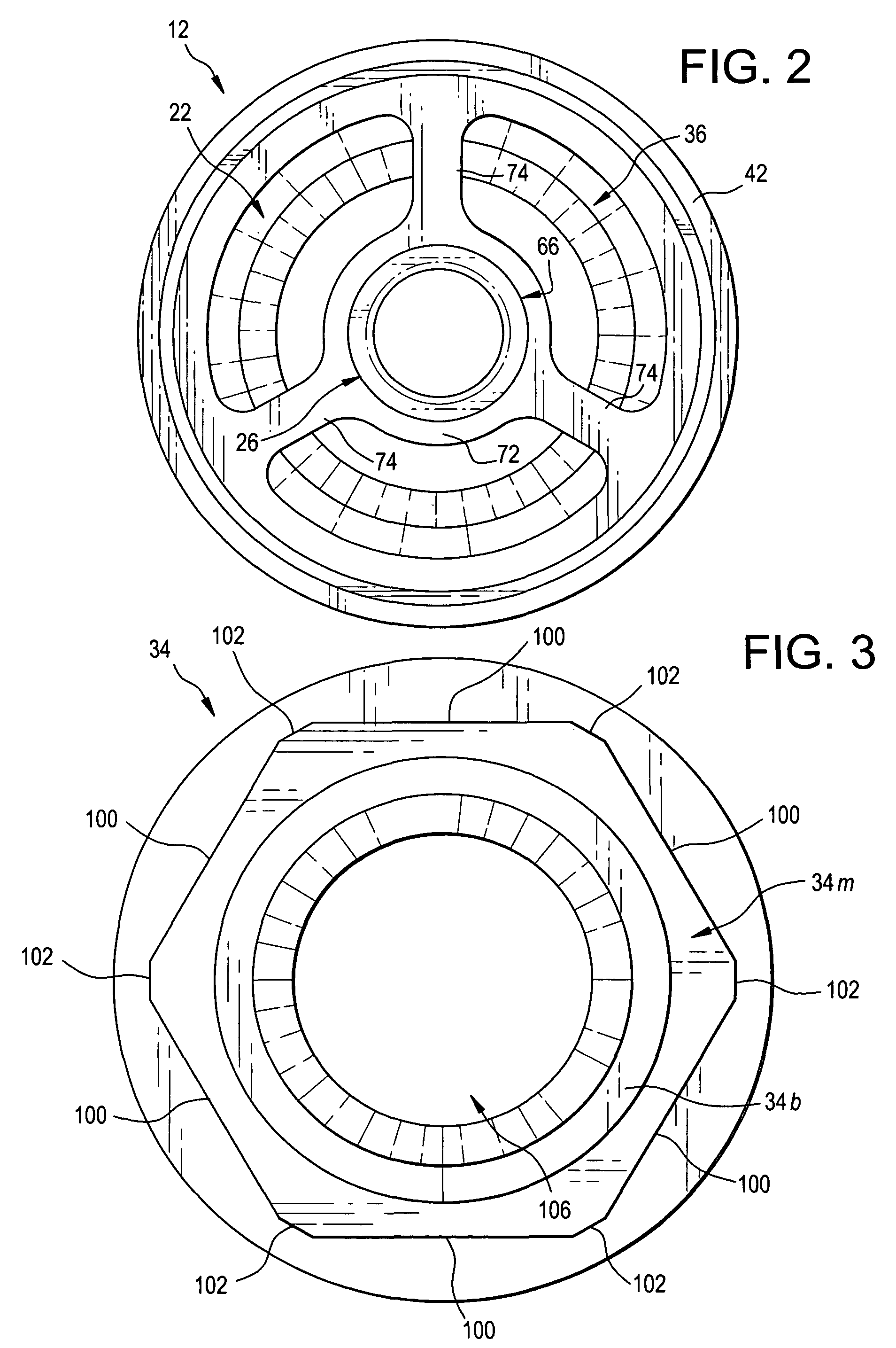

InactiveUS7891374B2Minimize the possibilityLow costCheck valvesEqualizing valvesEngineeringScrew thread

A suction valve seat and guide assembly has an outer ring and a peripheral flange projecting outwardly from the bottom of the outer ring, and an inner surface with a top part sloping downwardly and inwardly toward the center of the outer ring. The outer ring has an outer surface that slopes upwardly and inwardly from the flange. The guide has an inner ring positioned within the outer ring and a number of spaced-apart fins connecting the inner ring to the outer ring. A retainer has an internal passageway, an externally threaded, upper segment within the top of which is fitted the peripheral flange of the seat; a middle segment that is affixed to the bottom of the upper segment and has a polygonal cross section for easy gripping by a wrench; and, a bottom segment that is affixed to the bottom of the middle segment.

Owner:FORUM US

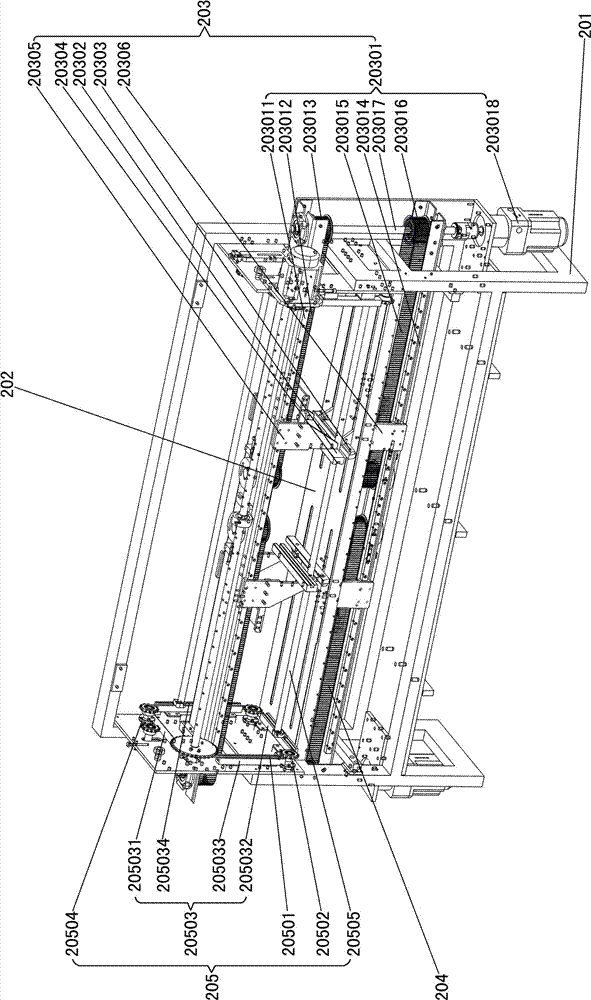

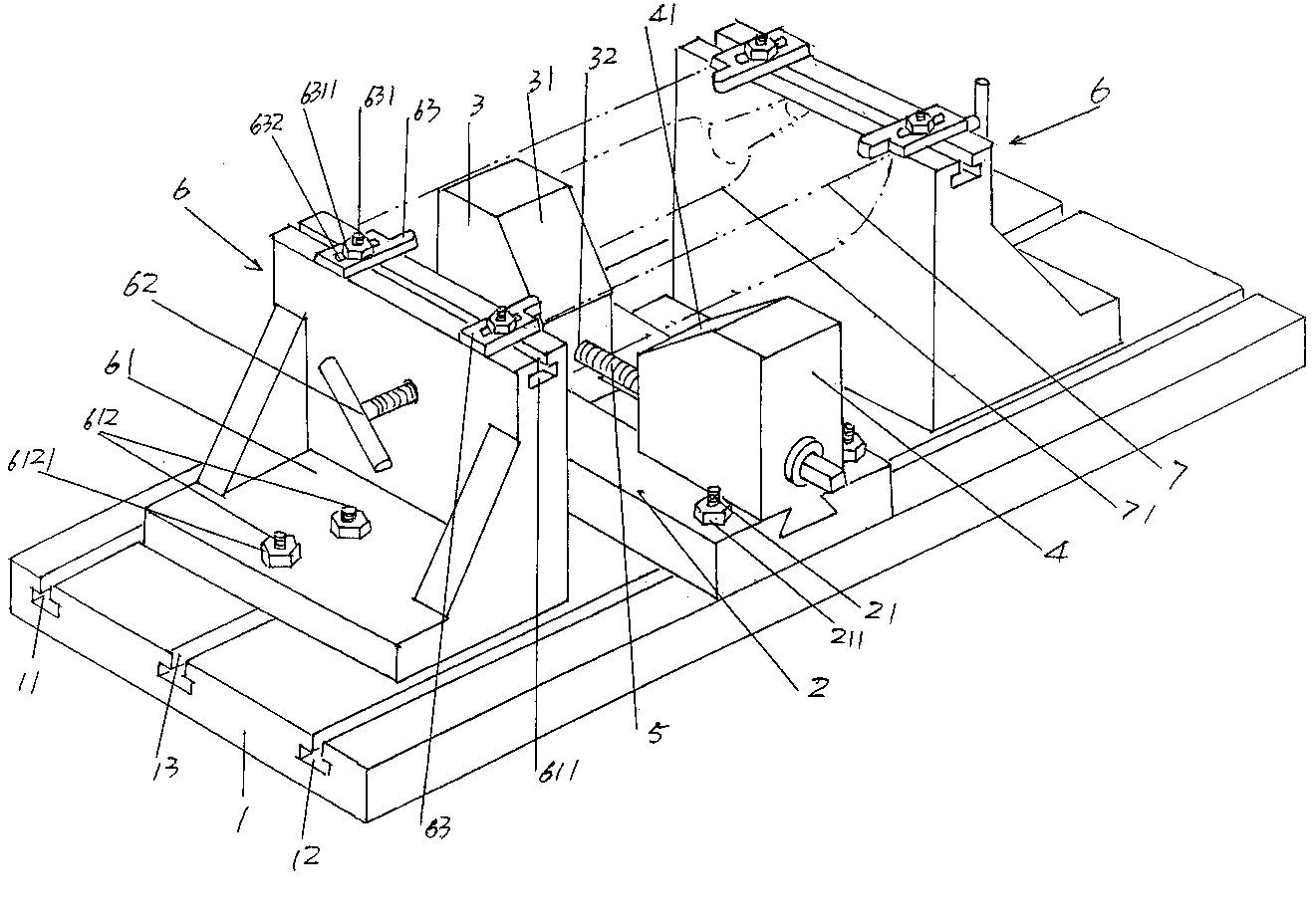

Work fixture for machining inner cavities and joint closing surfaces of glass molds

ActiveCN103056693AReduce the numberSimple structurePositioning apparatusMetal-working holdersLocking mechanismMachining

The invention discloses a work fixture for machining inner cavities and joint closing surfaces of glass molds, and belongs to the technical field of work fixtures. The work fixture comprises a bottom seat plate, a middle seat plate, a movable seat, a fixed seat, a traction screw of the movable seat and mold clamping mechanisms; a first adjusting groove, a second adjusting groove and a third adjusting groove are arranged on one side of the bottom seat plate; the middle seat plate is positioned in the center of the bottom seat plate, one end of the middle seat plate is fixed to the first adjusting groove, and the other end of the middle seat plate is fixed to the second adjusting groove; the movable seat is arranged at one end of the middle seat plate, the fixed seat is fixed to the other end of the middle seat plate, an inclined plane of the movable seat is formed on one side of the movable seat, an inclined plane of the fixed seat is formed on one side of the fixed seat, and the inclined plane of the movable seat and the inclined plane of the fixed seat form a V shape; one end of the traction screw of the movable seat is connected with the movable seat, and the other end of the traction screw of the movable seat is supported on the fixed seat; and one mold locking mechanism is positioned on one side of the middle seat plate, the other mold locking mechanism is positioned on the other side of the middle seat plate, and the mold locking mechanisms are respectively fixed to the third adjusting groove. The work fixture has the advantages that the work fixture is simple in structure, convenient to manufacture, quick in operation and good in clamping effect, and tends to be maintenance-free, and loosening is prevented during machining.

Owner:ORI MOLD TECH SUZHOU

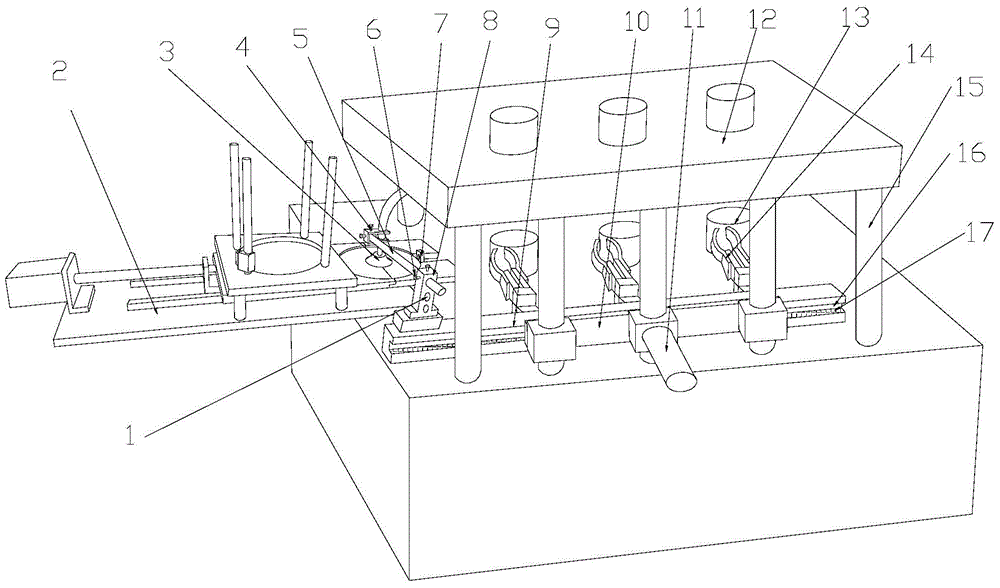

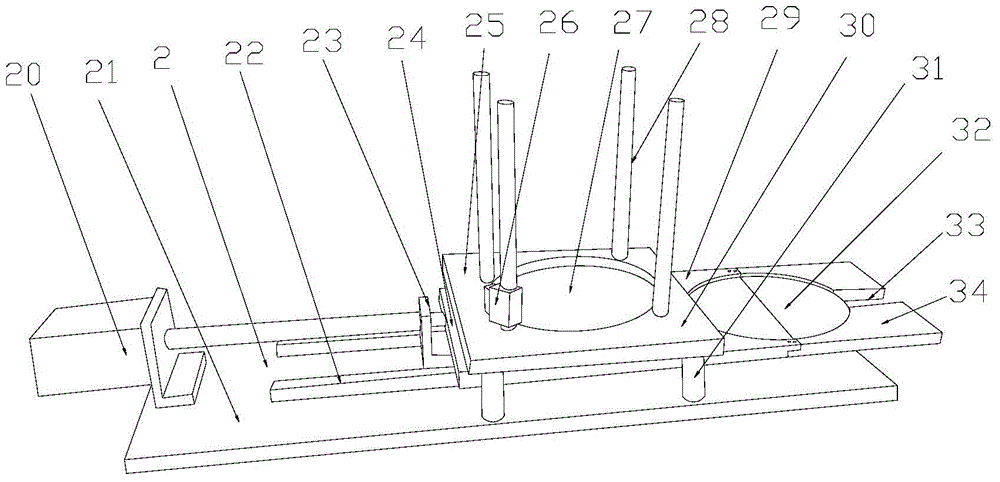

Automatic production equipment for ignition coil housing

InactiveCN104308034AGuaranteed uptimeSolve manual feedingMetal-working feeding devicesEngine componentsIgnition coilEngineering

The invention provides automatic production equipment for an ignition coil housing. The automatic production equipment comprises a stamping machine, three sets of stamping dies arranged on the stamping machine, five sets of guide rods symmetrically arranged on the two sides of the stamping machine, a feeding device arranged at the feeding end of the stamping machine, and a carrying mechanism arranged on the guide rod on one side of the stamping machine, wherein the carrying mechanism comprises a movable base, a drive motor which is fixed to a guide rod in the middle and used for driving the movable base to move left and right, three carrying devices which are arranged on the movable base and used with the stamping dies for carrying the manufactured raw materials of the ignition coil housing, and a feeding mechanism which is arranged at the feeding end of the movable base and used with the feeding device for extracting the manufactured raw materials of the ignition coil housing. According to the automatic production equipment, the materials can be automatically fed, discharged and carried in a stamping process, so that the problems of manual feeding, carrying and stamping are effectively solved, the material deficiency can be effectively reminded in time, idle running of the equipment can be effectively avoided, and the product surface cannot be influenced in a production process.

Owner:海盐爱建股份有限公司

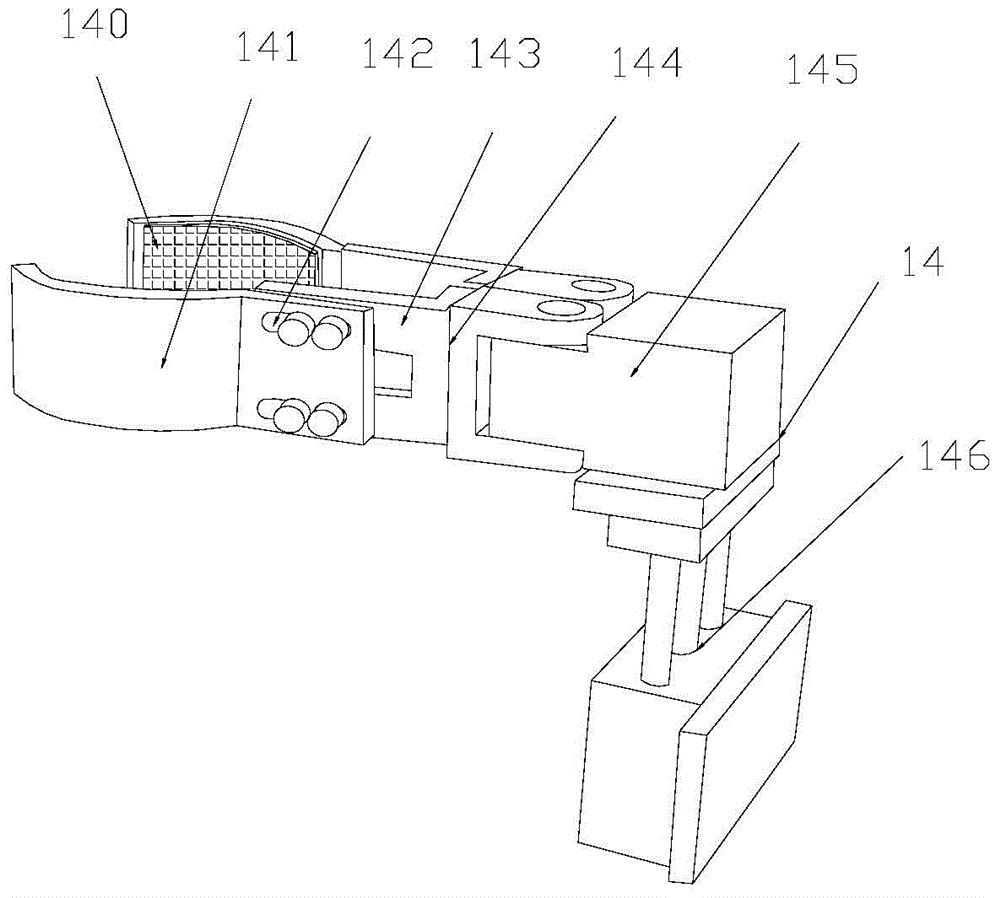

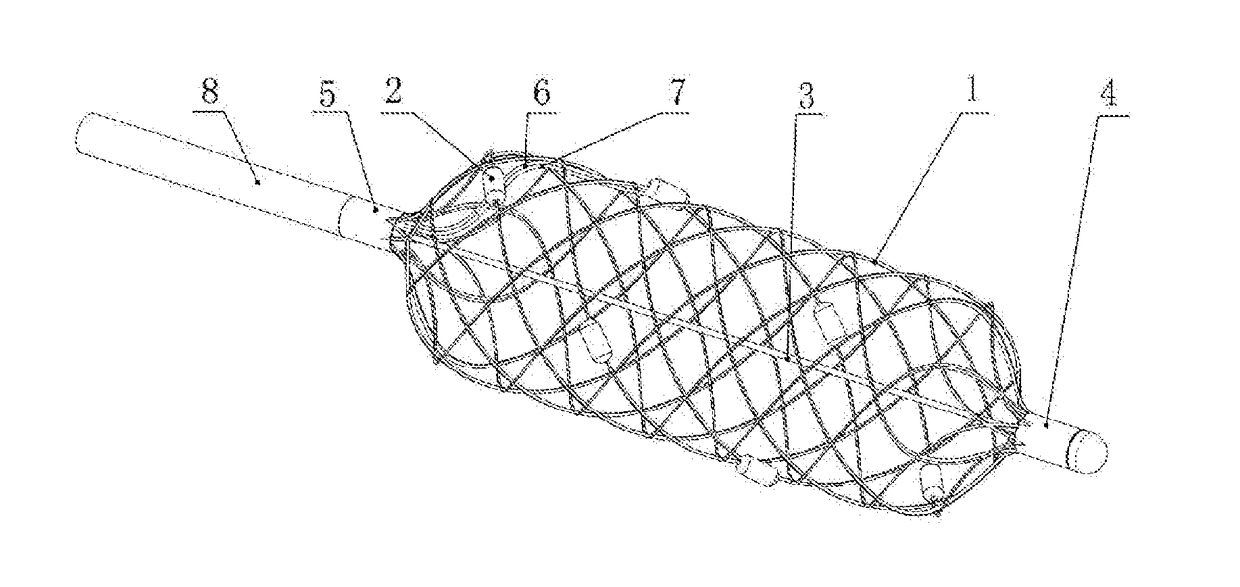

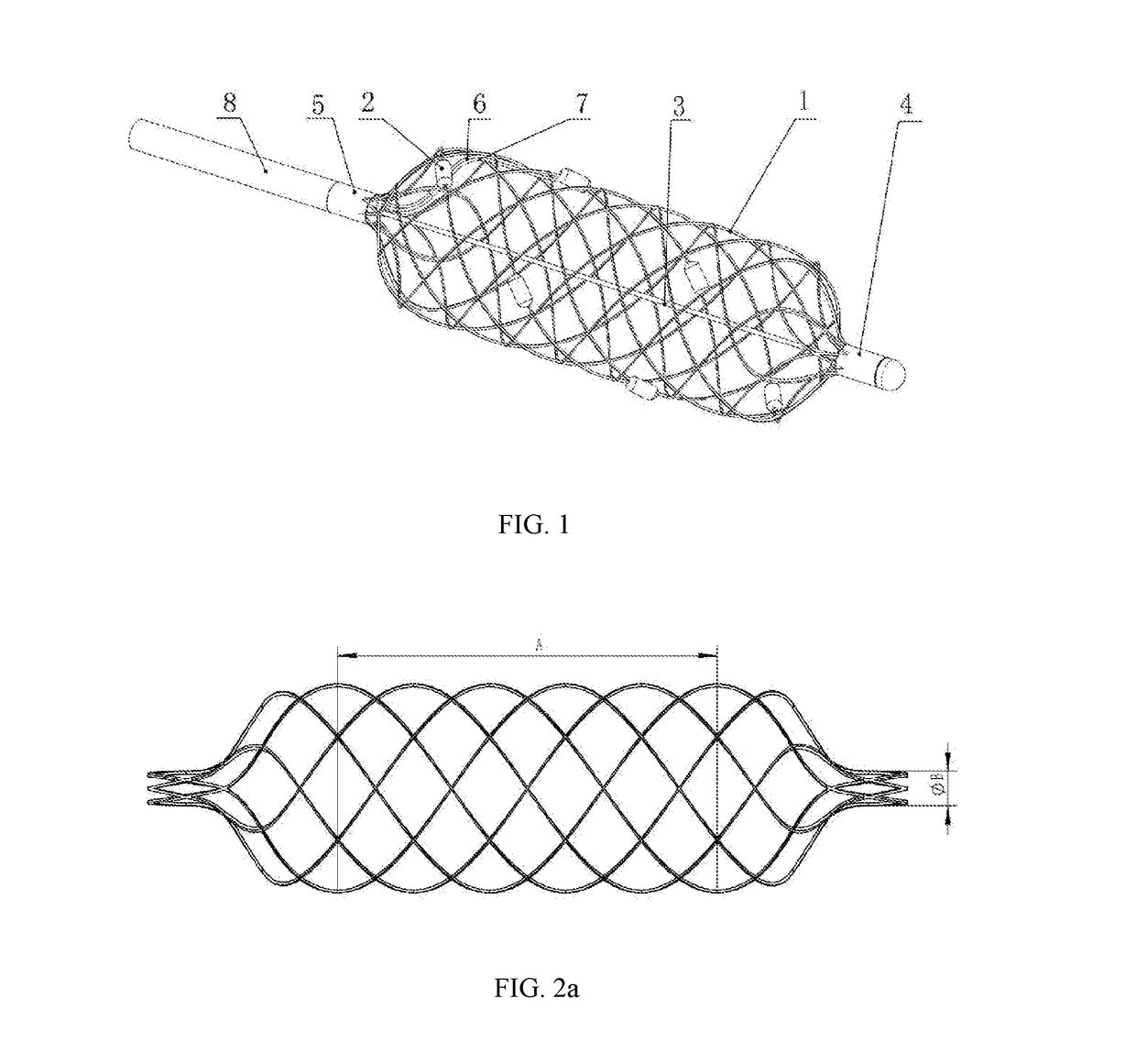

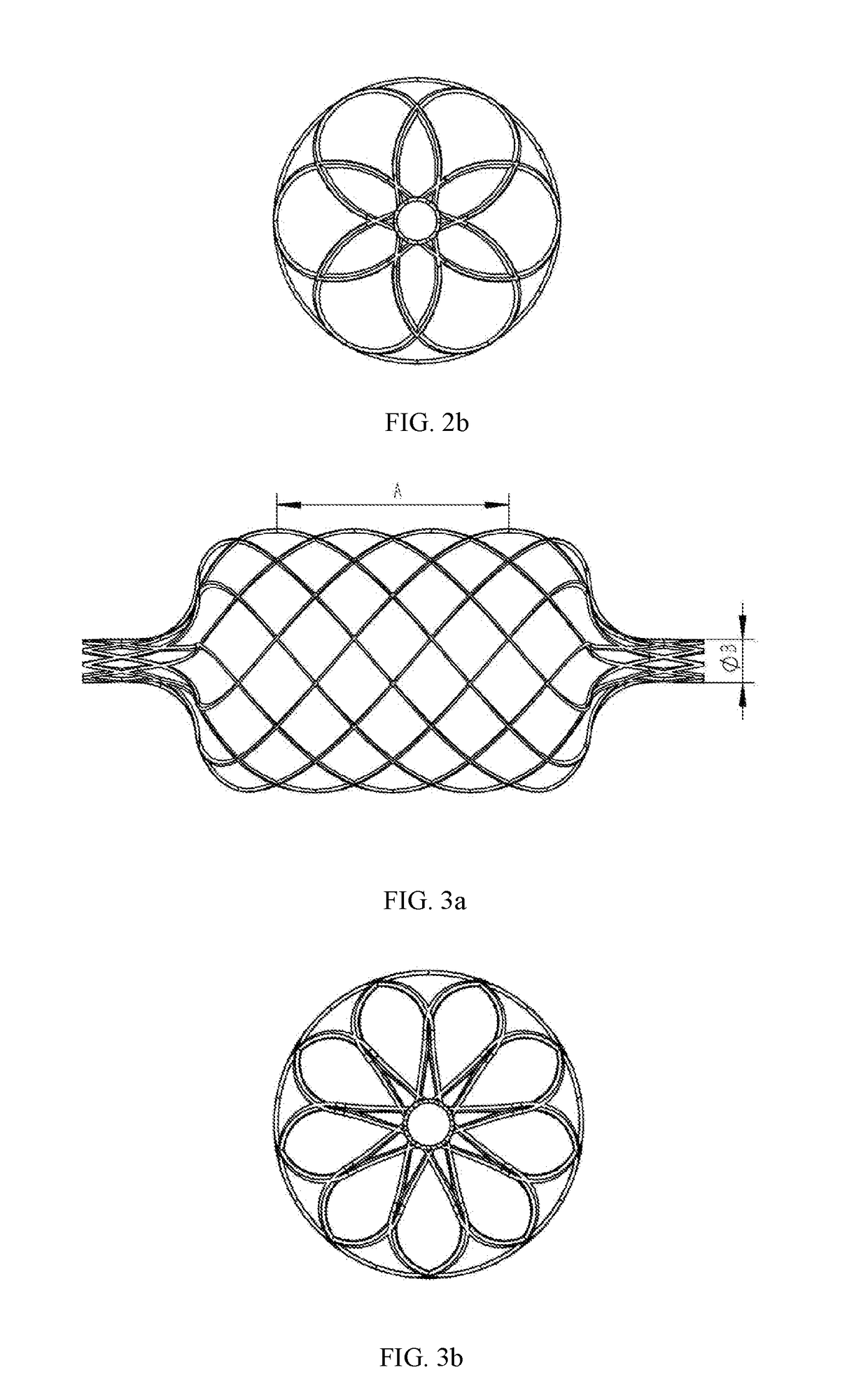

Radiofrequency ablation catheter having meshed tubular stent structure and an apparatus thereof

InactiveUS20170224415A1Good flexibilityNot causing excessive ablationSurgical instruments for heatingMedicineInsertion stent

A radiofrequency ablation catheter having a meshed tubular stent structure and an apparatus thereof, include a meshed tubular stent disposed at a front end of the catheter. The meshed tubular stent comprises and including a meshed tube (1). Both ends of the meshed tube are tapered to form a distal end and a proximal end of the meshed tubular stent. The intermediate segment of the meshed tubular stent has a contracted state and an expanded state. One or more electrodes (2) are fixed onto the intermediate segment. The radiofrequency ablation catheter has improved flexibility and provides great coverage for the blood vessels with different thicknesses and curves. When the meshed tubular stent expands in the blood vessels having different thicknesses of 4-12 mm, all of the electrodes (2) contact the walls. Moreover, when the meshed tubular stent expands in the curved blood vessels, all of the electrodes are ensured to contact the walls.

Owner:SHANGHAI GOLDEN LEAF MED TEC

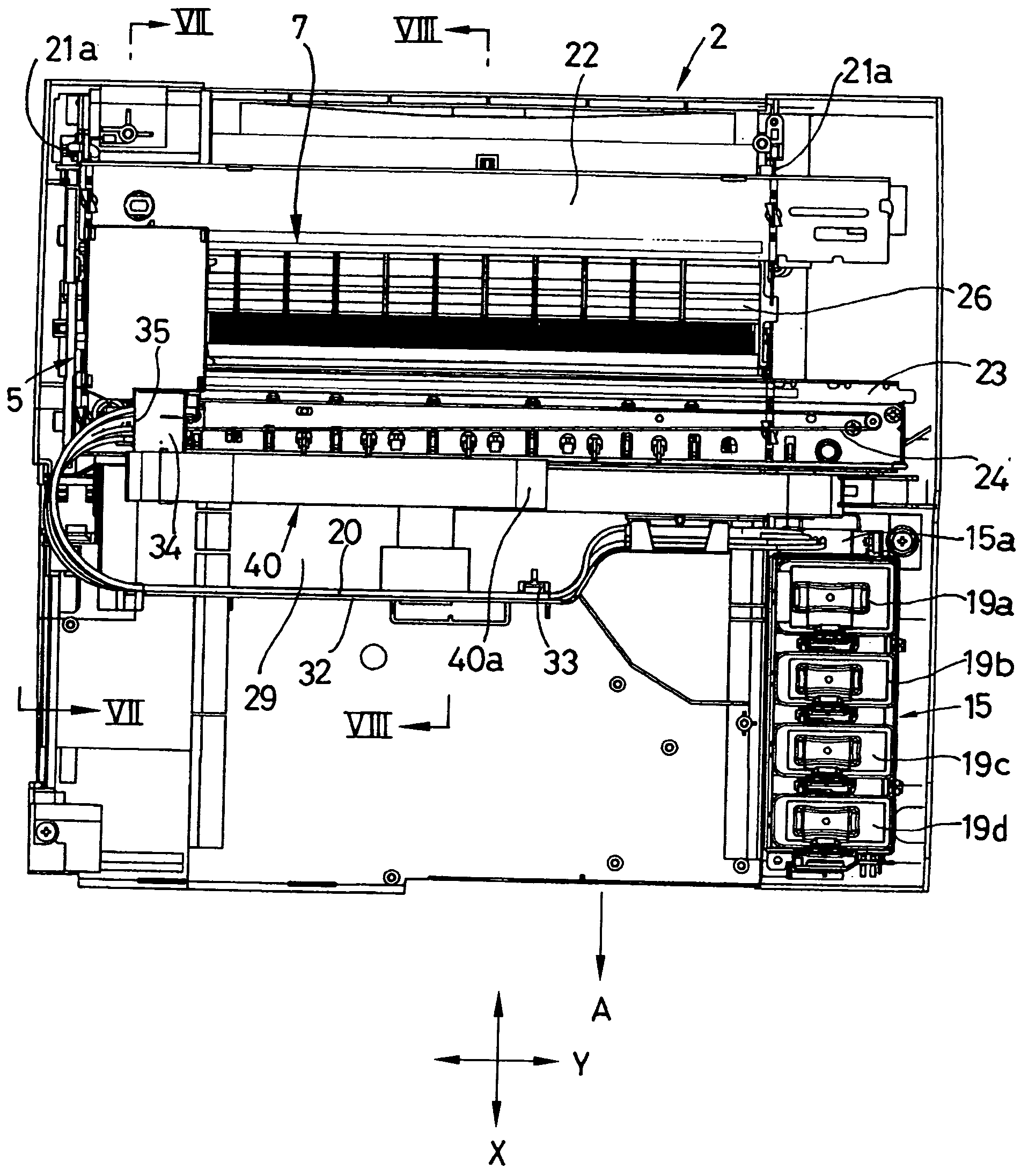

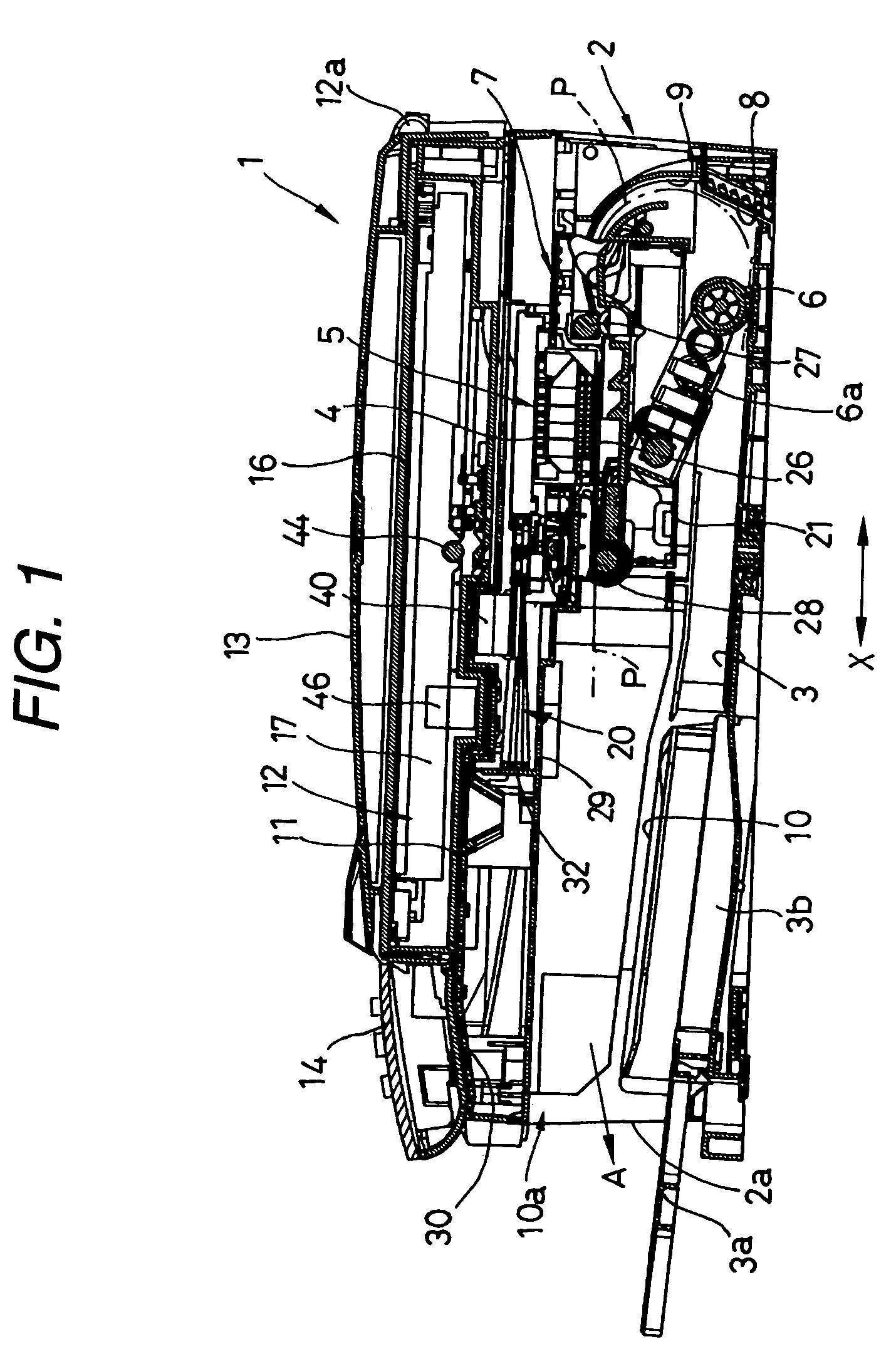

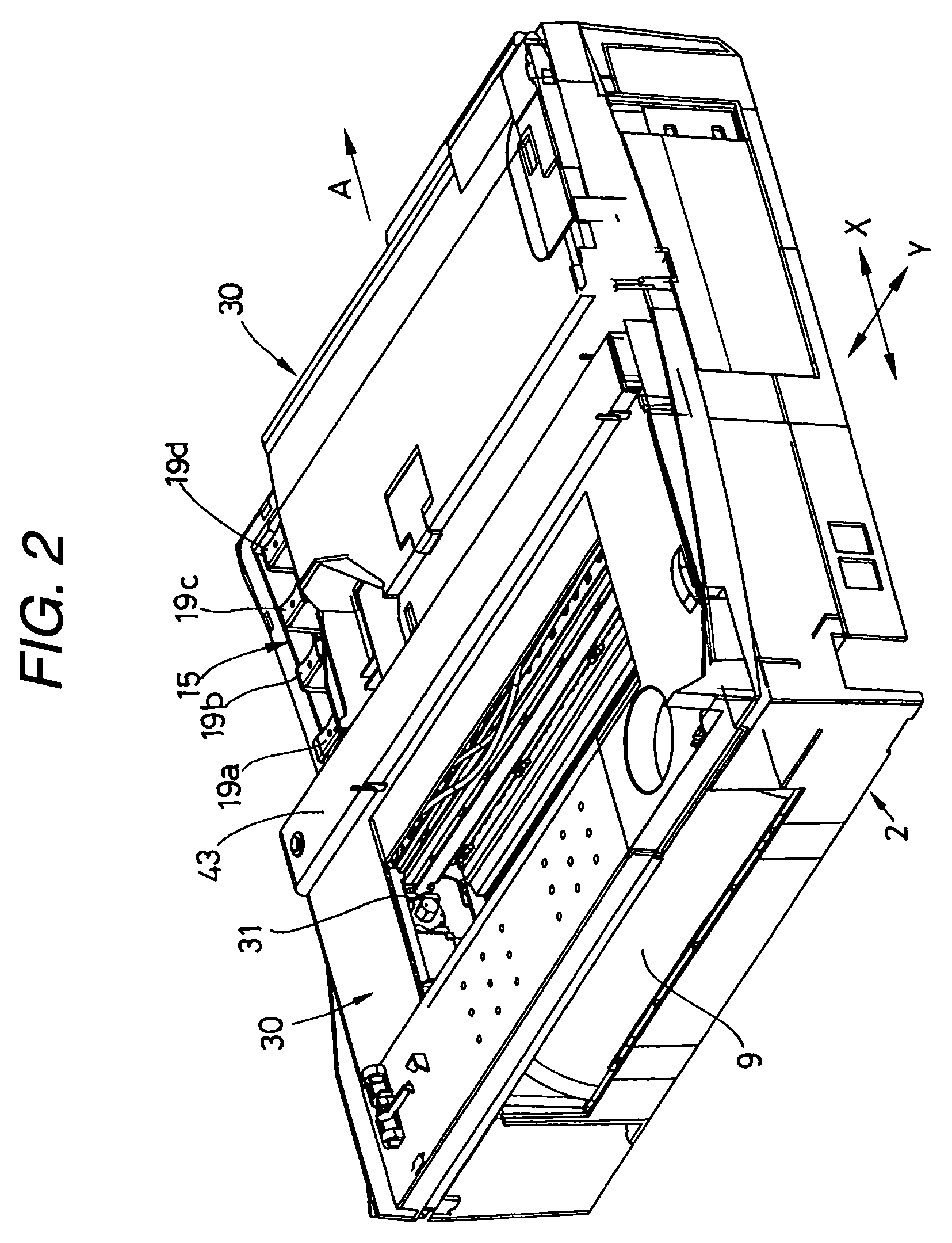

Image recording apparatus

An image recording apparatus includes a recording apparatus body, a carriage having joint portions, a recording head mounted on the carriage, an ink storage disposed in the recording apparatus body in a stationary state, an intermediate fixing portion provided in the recording apparatus body between the ink storage and the carriage, and ink supply tubes for supplying ink from the ink storage to the recording head. The ink supply tubes are fixed to the intermediate fixing portion and independently disposed between the intermediate fixing portion and the carriage. Midsections of the ink supply tubes are bent between a route of the carriage and the intermediate fixing portion. A direction of arrangement of the tubes at the midsections thereof extending toward the intermediate fixing portion and a direction of arrangement of the tubes at the midsections thereof extending toward the joint portions of the carriage are differentiated.

Owner:BROTHER KOGYO KK

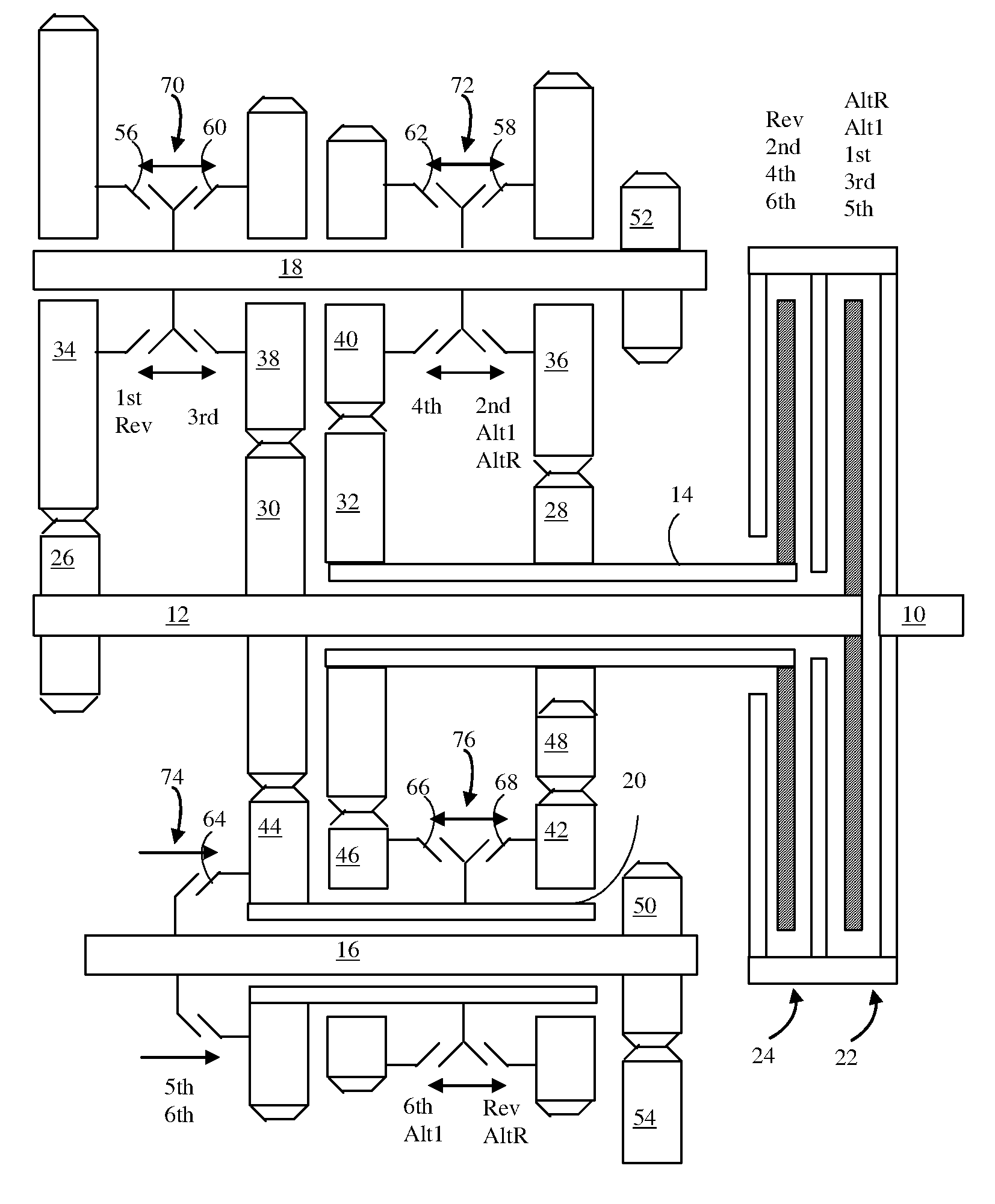

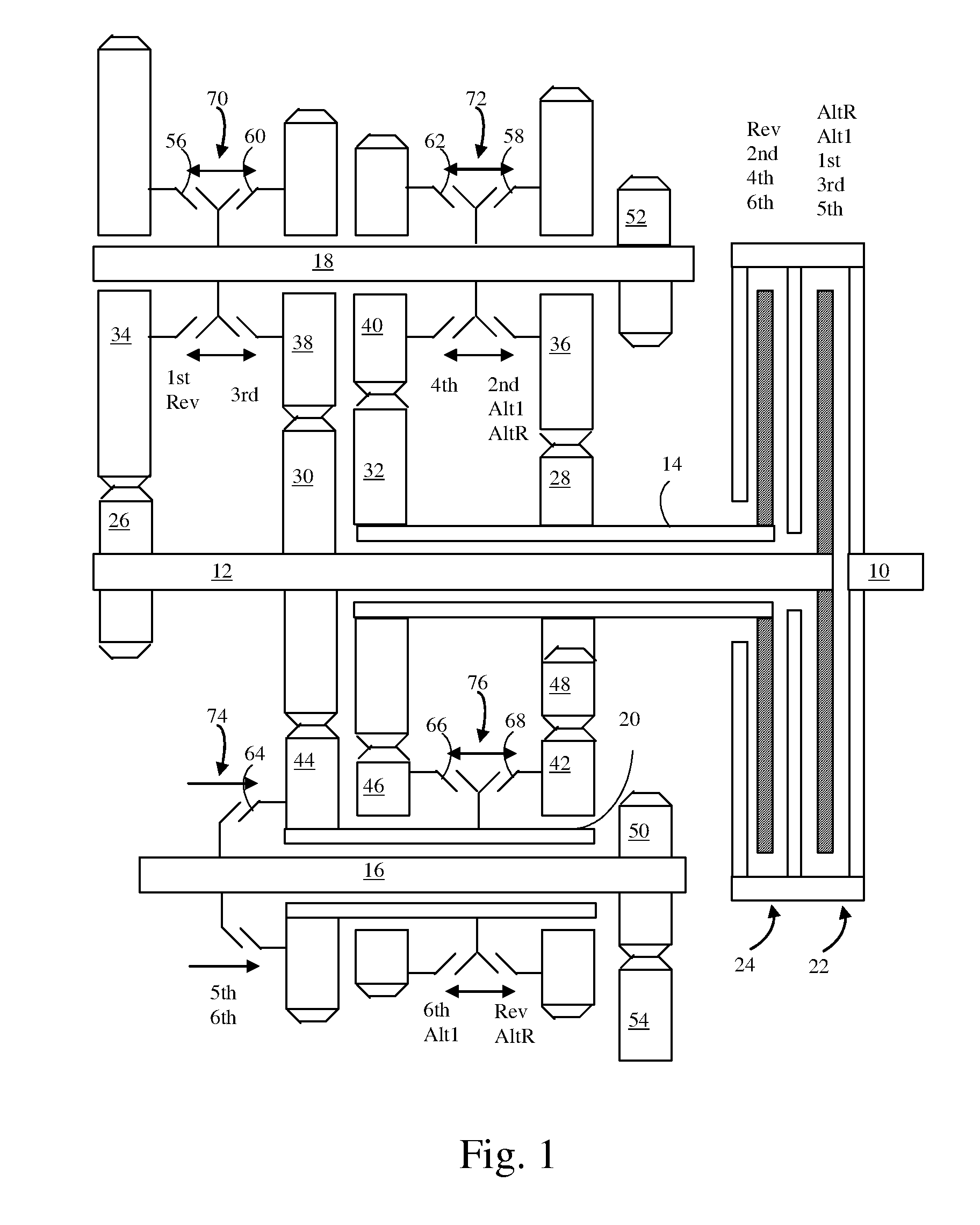

Dual clutch transmission having reduced axial length

ActiveUS7748286B2Shorten the lengthToothed gearingsTransmission elementsElectric power transmissionPinion

A multiple speed power transmission comprises: an input; an output; first and second input shafts releasably coupled to the input by first and second friction clutches, respectively; a countershaft disposed parallel to the first and second input shafts; an output pinion fixed to the countershaft; an output ring gear fixed to the output and meshing with the output pinion; an intermediate shaft disposed coaxially with the countershaft; a first input pinion fixed to the first input shaft and meshing with a first gear fixed to the intermediate shaft; a second input pinion fixed to the second input shaft; a second gear disposed coaxially with the intermediate shaft; an idler gear meshing with the second input pinion and the second gear; a first coupler for releasably coupling the first countershaft to the intermediate shaft; and a second coupler for releasably coupling the intermediate shaft to the second gear.

Owner:FORD GLOBAL TECH LLC

Stuffing box apparatus

A stuffing box apparatus for sealing between a polish rod in a hydrocarbon production well comprises a tubular housing arranged for connection to the well which has a bore therethrough to receive the polish rod. Sealing members are supported in the bore of the housing in an upper stack and a lower stack of smaller outer diameter separated by an intermediate bushing. An upper bushing compresses the upper stack against the intermediate bushing. The lower bushing fixes the lower stack against the bottom of the intermediate bushing. Each of the bushings includes a counter bore formed at one end which receives a wiper member arranged for sealing engagement between the bushing and the polish rod.

Owner:KK TOPCON

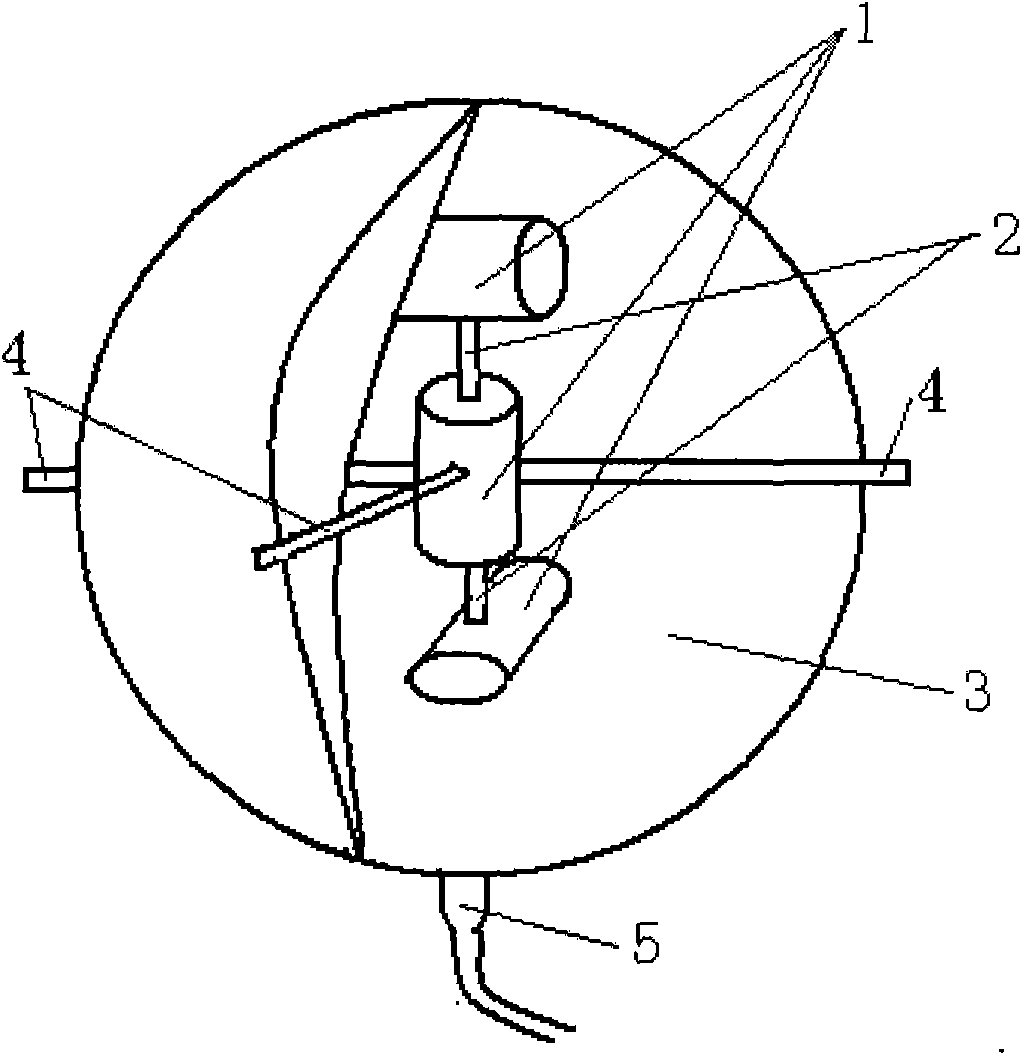

Trivector hydrophone based on piezoelectric velocity sensor

InactiveCN101561313AMeet the design requirementsSimple structureWave based measurement systemsSubsonic/sonic/ultrasonic wave measurementLow noiseHydrophone

The invention provides a trivector hydrophone based on a piezoelectric velocity sensor, which comprises a spheroid, and hanging elements, a velocity sensor and a multi-core output tape cable all arranged in the spheroid, wherein the velocity sensor comprises three piezoelectric velocity sensors which are connected in sequence through connecting rods; one end of the four hanging elements is fixed on the middle piezoelectric velocity sensor, while the other end extends out of the spheroid; and the spheroid is a solid sphere. The average density of the vector hydrophone approximates to the water medium density; the channel sensitivity is high in a working frequency band below 2,000 hz and is irrelevant to the frequency; the vector hydrophone has good cosine directivity; and the vector hydrophone is not limited by an obliquity during working. The vector hydrophone can be widely used in various fields of hydroacoustics, such as sonobuoys, low noise motion target measurement, target orientation and the like.

Owner:HARBIN ENG UNIV

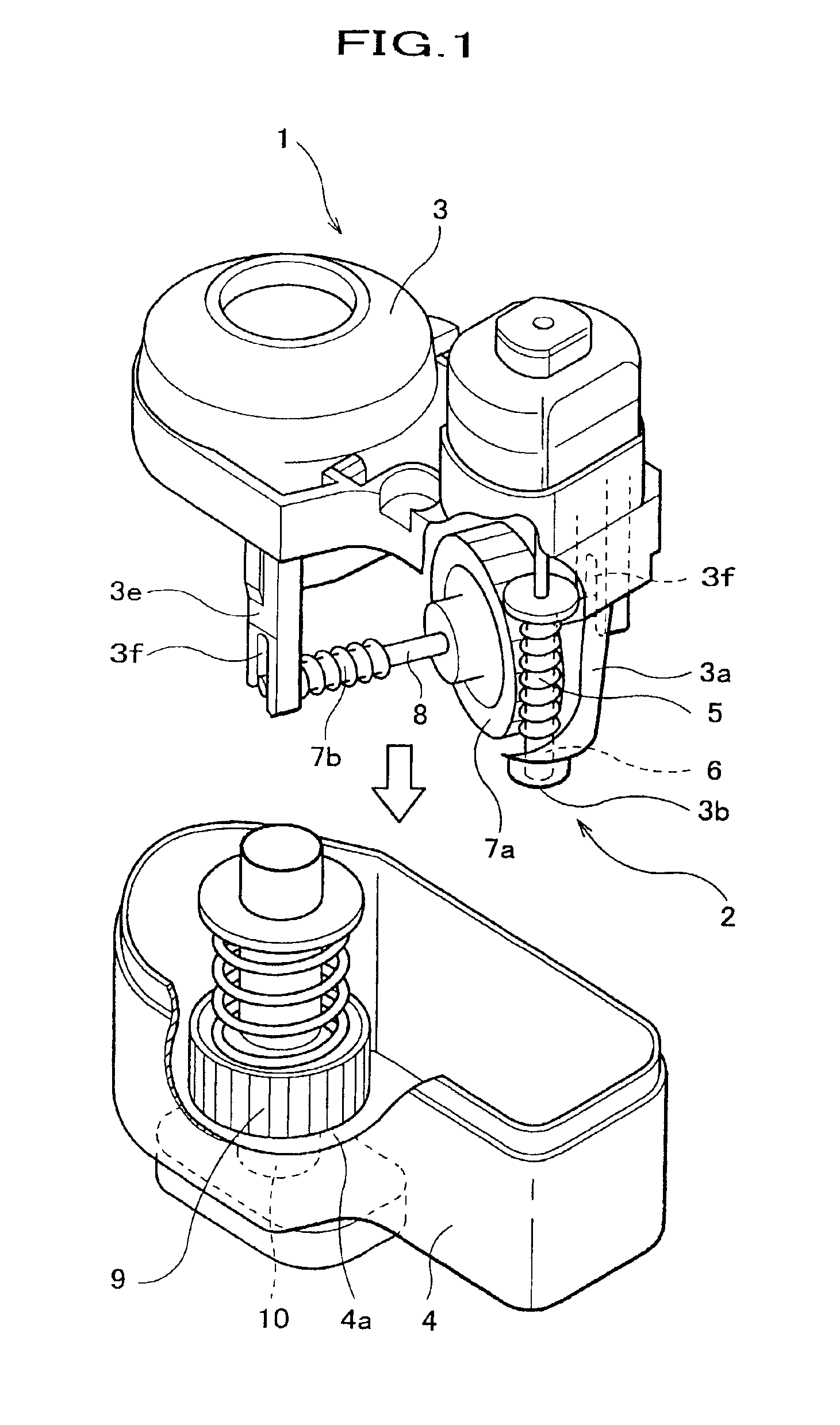

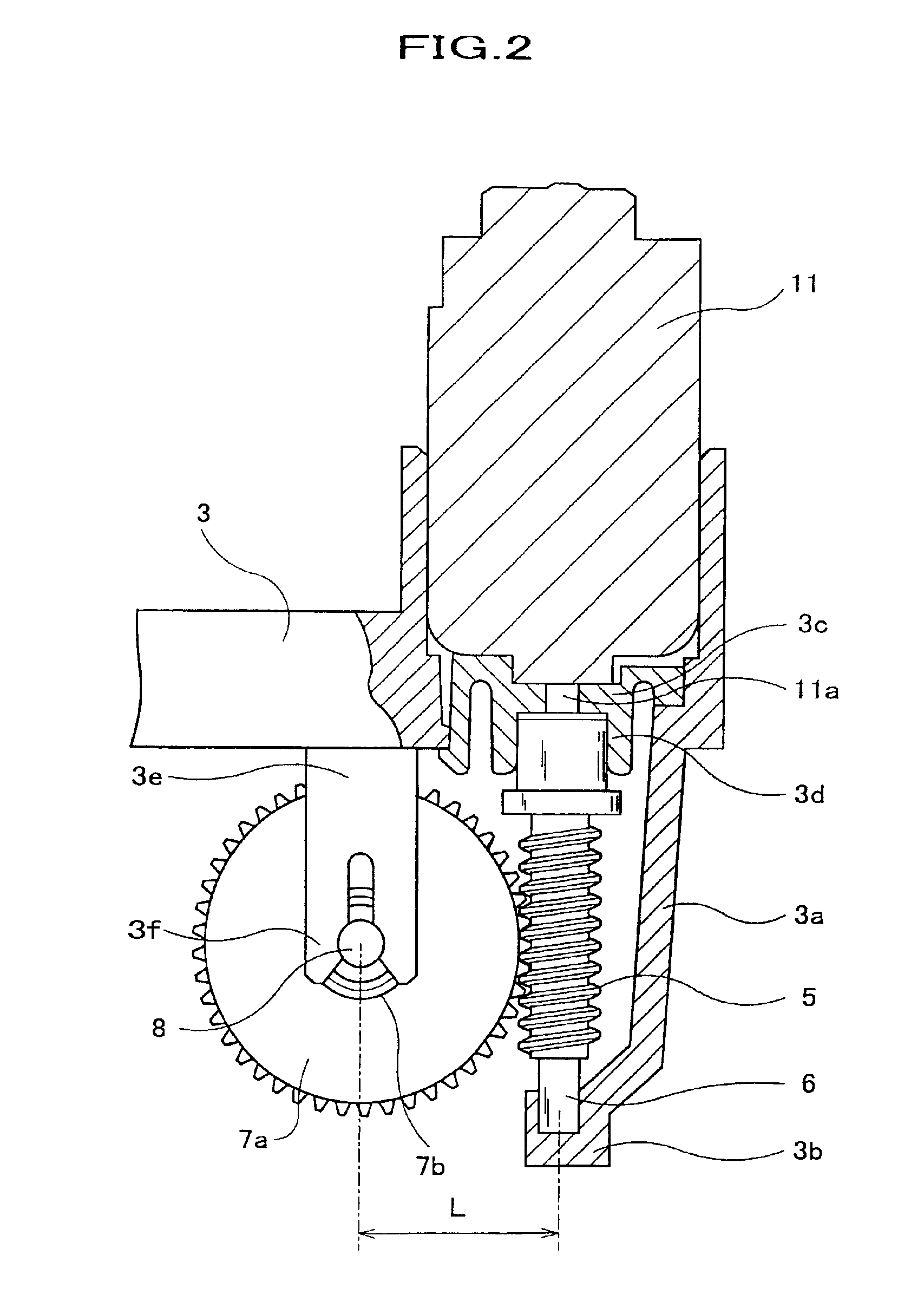

Speed reducer and electric retractable rearview mirror equipped with the speed reducer

InactiveUS6871969B2Steadily and smoothly transmittingReduce abrasionMirrorsToothed gearingsRear-view mirrorAnnectant gyrus

A speed reducer including a gear box having a first frame and a second frame combined together, an input gear fixed on an input shaft being rotated by a driving force, an output gear fixed on an output shaft, an intermediate shaft, intermediate gears fixed on the intermediate shaft to reduce a speed of rotation of the input gear for being transmitted to said output gear, wherein the input shaft and the intermediate shaft are rotatably supported by the first frame for always maintaining the length between each core of the input shaft and the intermediate shaft as a predetermined length.

Owner:MURAKAMI CORP

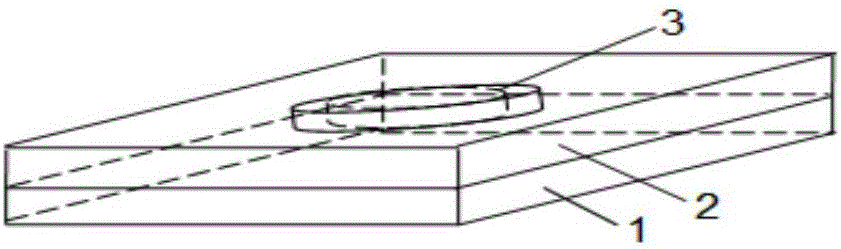

Three-dimensional fully-polarized super-surface invisible cloak

ActiveCN105823378AReduce thicknessFlexible designCamouflage devicesProtective buildings/sheltersPhase shiftedClassical mechanics

The invention discloses a three-dimensional fully-polarized super-surface invisible cloak. The three-dimensional fully-polarized super-surface invisible cloak is formed by seamlessly splicing phase-shift resonant units, wherein each phase-shift resonant unit is composed of an upper-layer medium, a middle-layer medium and a lower-layer medium, the dimensions of each contour line of each phase-shift resonant unit are less than a wavelength of a working electromagnetic wave, the upper-layer medium is a resonant structure with a full-polarization function, the upper-layer medium is fixed on the upper surface of the middle-layer medium, the middle-layer medium is a non-metal layer, the lower-layer medium is a metal layer, and the upper surface of the lower-layer medium and the lower surface of the middle-layer medium are tightly bonded and completely fitted; and a changed reflected wave phase of each phase-shift resonant unit meets the condition defined in the description, wherein delta is the changed reflected wave phase, theta is the complementary angle of an included angle between the working electromagnetic wave of the invisible cloak and a horizontal plane, h is a height of the geometric centre of each phase-shift resonant unit from the ground, and kb is a wave number of the working electromagnetic wave of the invisible cloak. The super-surface invisible cloak disclosed by the invention is insensitive to a polarization direction of the working electromagnetic wave, and suitable for all electromagnetic wave frequency bands.

Owner:ZHEJIANG UNIV

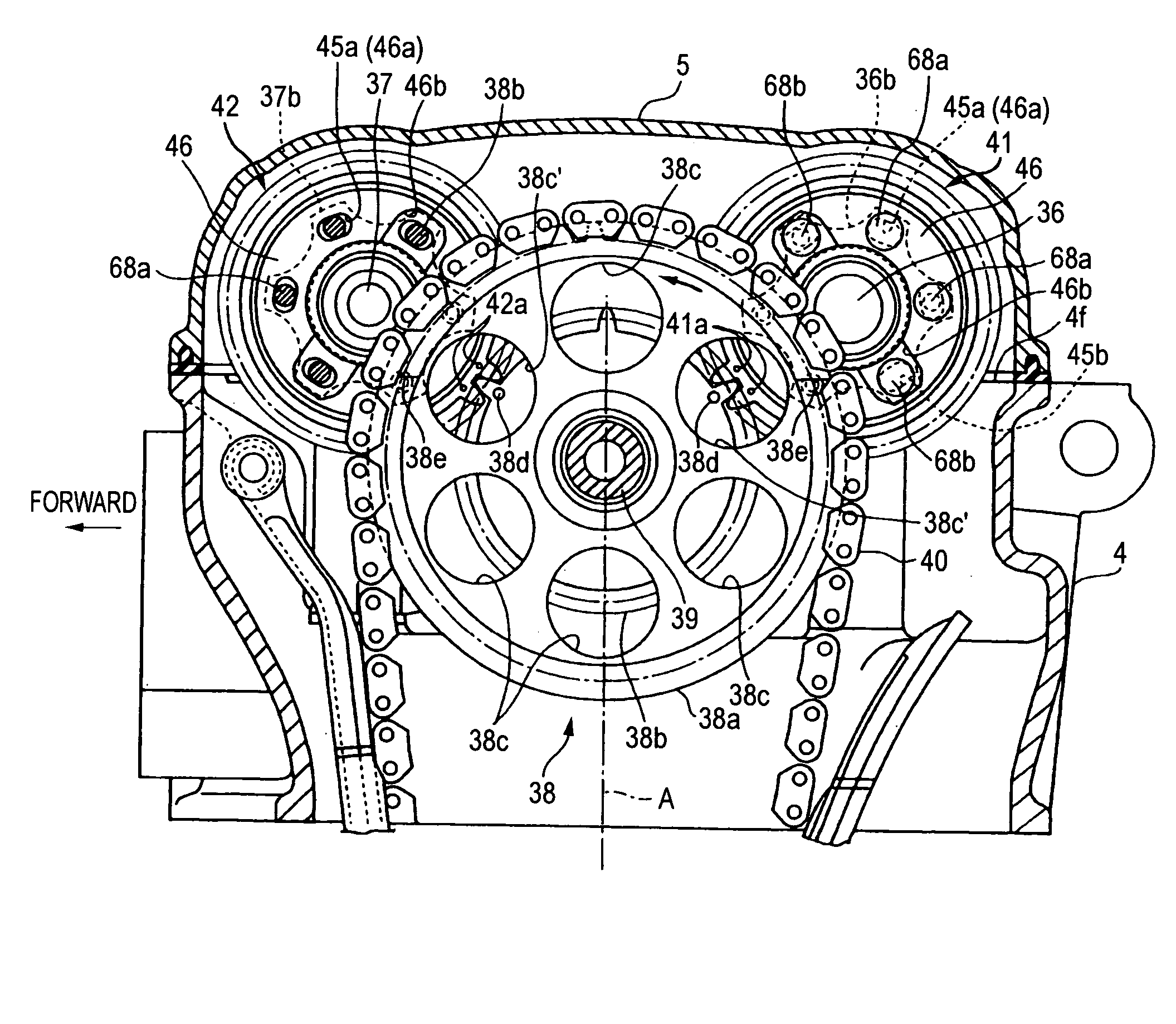

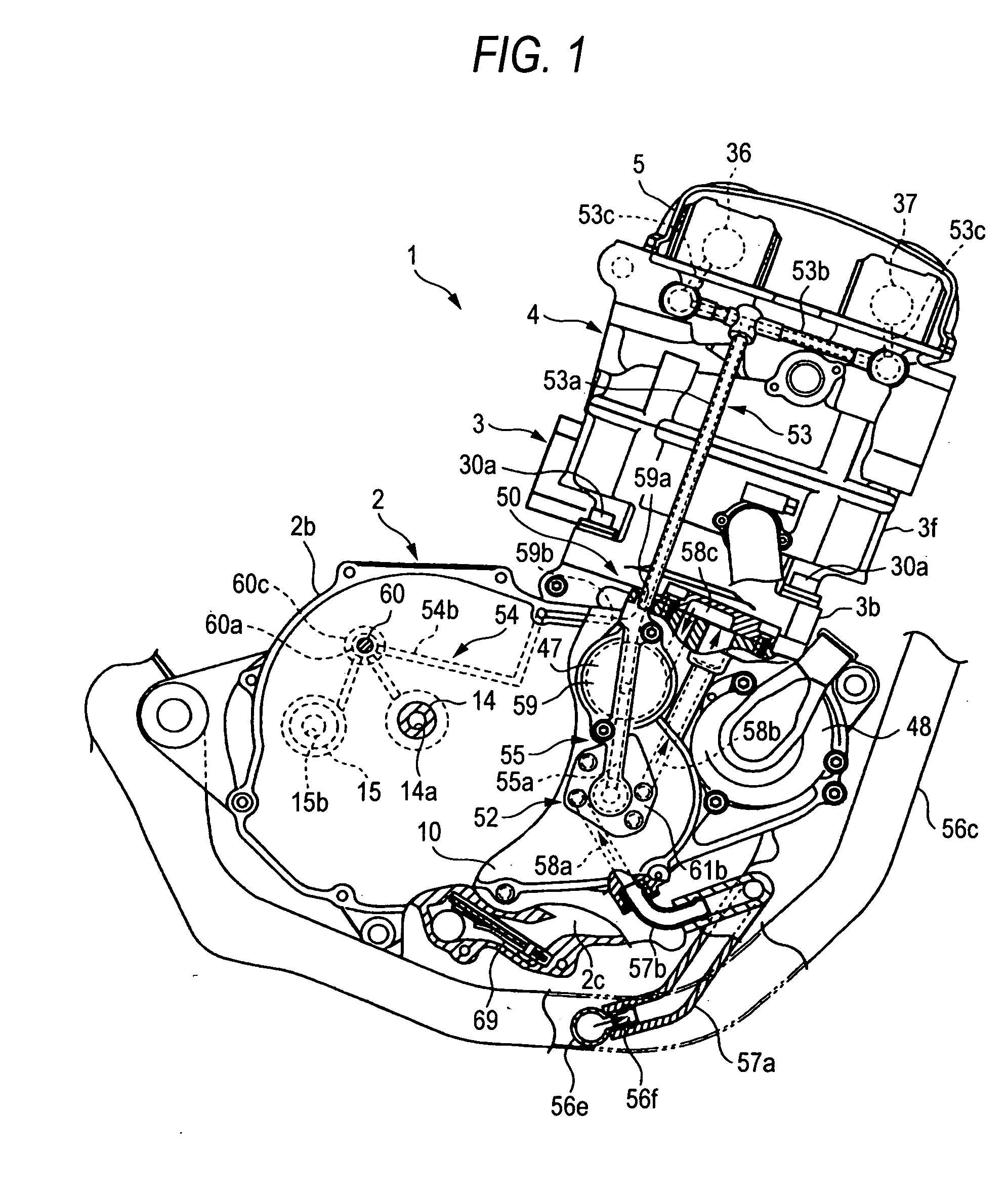

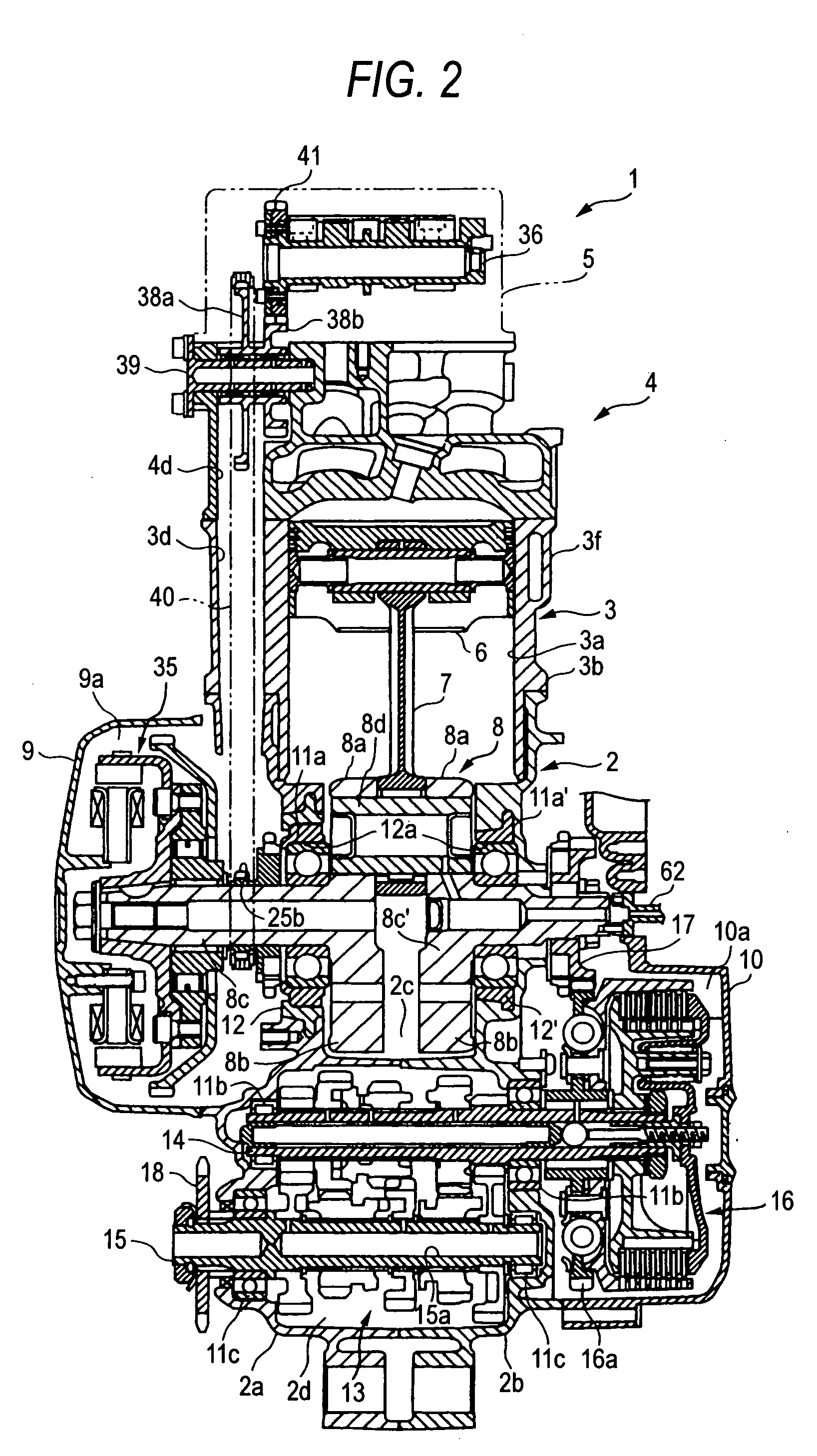

Engine valve moving device

In an engine valve train device in which a crankshaft sprocket 25b provided on a crankshaft 8 and an intermediate sprocket 38a disposed in the vicinity of camshafts 36, 37 are connected by means of a timing chain 40 and an intermediate gear 38b fixed to the intermediate sprocket 38a is made to mesh with camshaft gears 41, 42 fixed to the camshafts, the intermediate gear 38b is made smaller in diameter than the intermediate sprocket 38a and is disposed behind the intermediate sprocket 38, and furthermore, an inspection hole 38c′ is formed in the intermediate sprocket 38a for visualizing the meshing portion between the intermediate gear 38b and the camshafts gears 41, 42.

Owner:YAMAHA MOTOR CO LTD

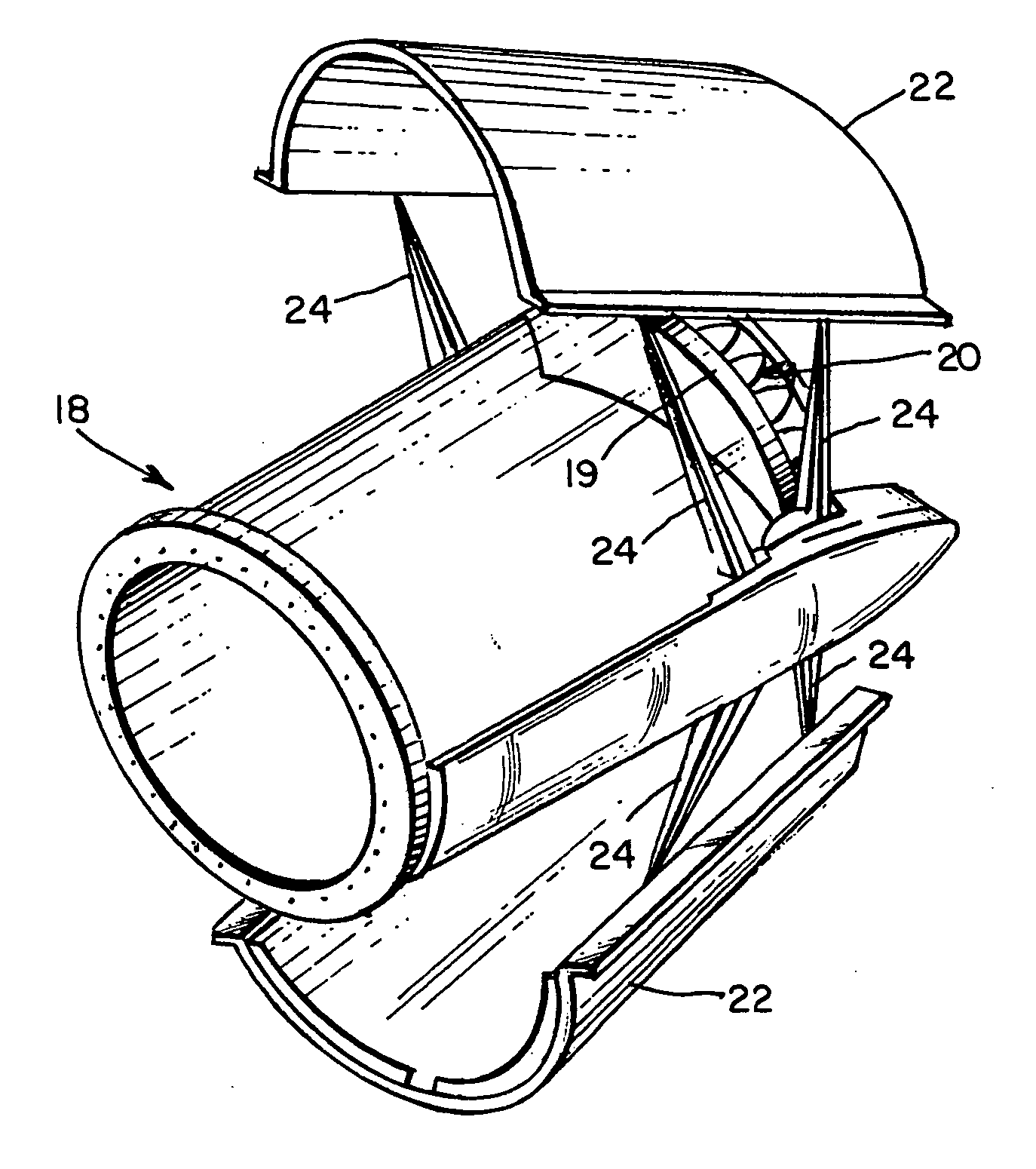

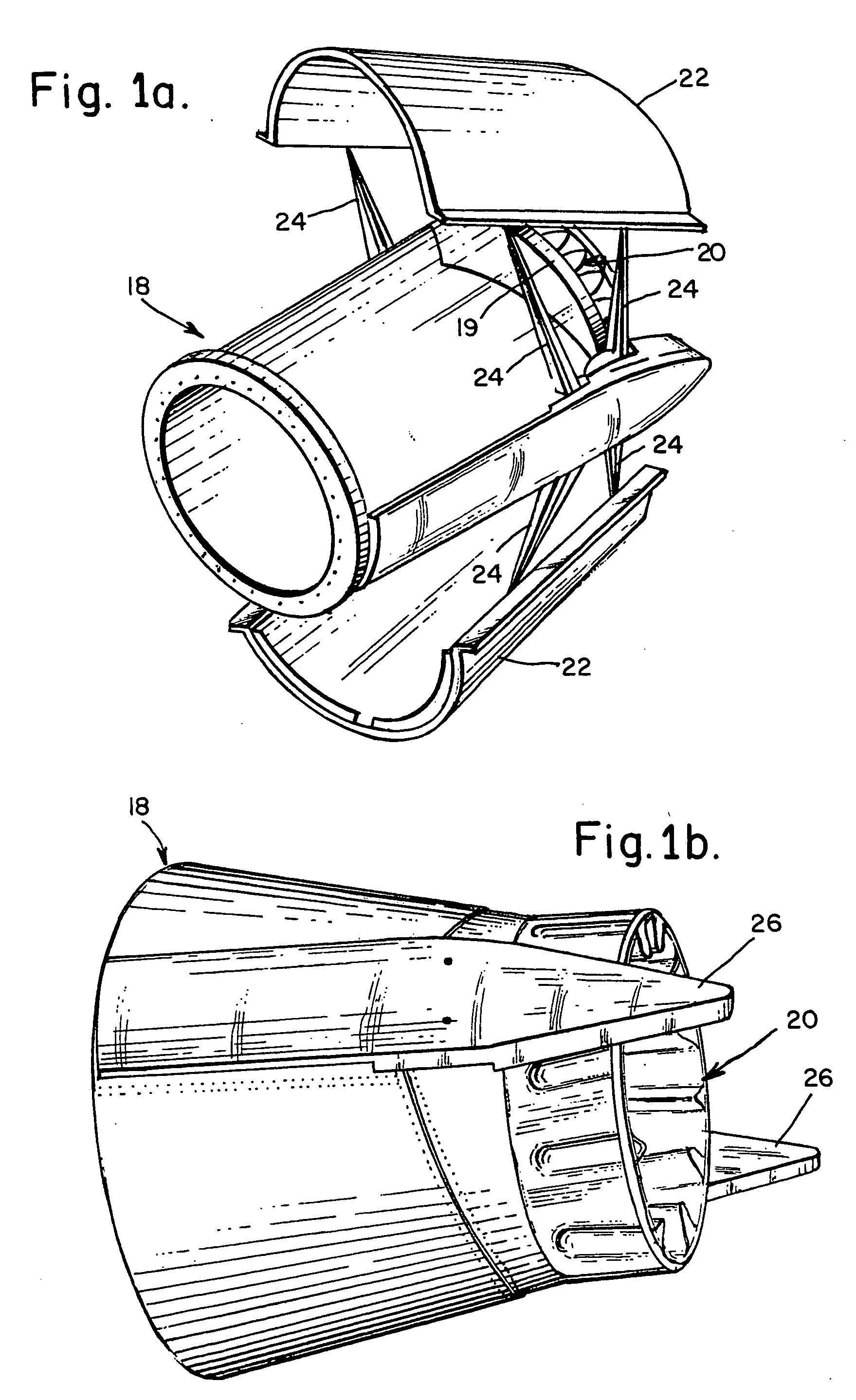

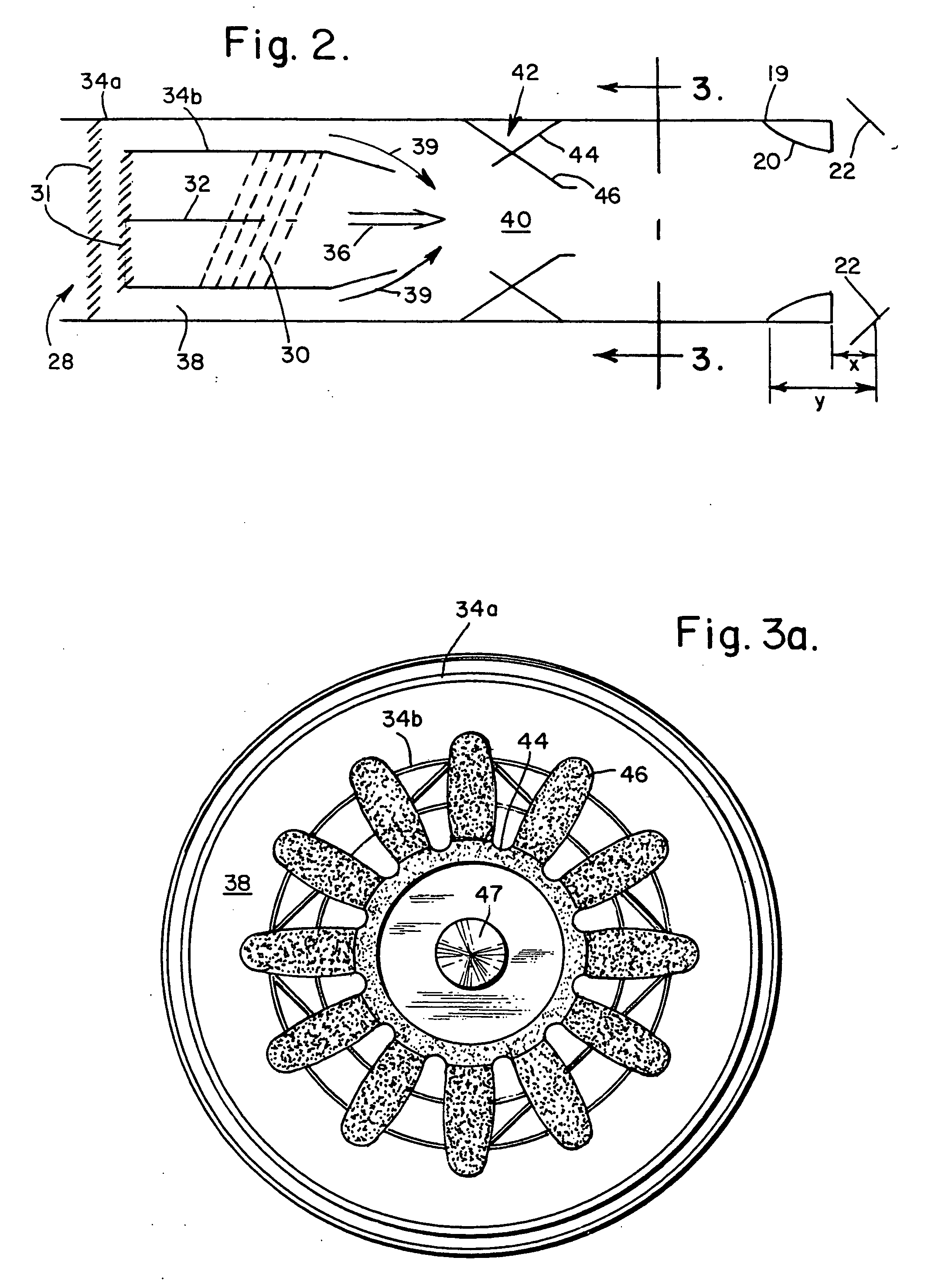

Jet nozzle mixer

A tailcone mixer for an engine, as well as a jet engine assembly, an airplane, and methods of repairing, improving operation, and retrofitting an engine. The tailcone mixer may include a main body and a plurality of lobes. The main body may include a wider forward end and a more narrow rear end and a mid-portion extending between the forward end and the rear end. The forward end is structured and arranged for attachment to an inner duct case. The rear end is closed, and the mid-portion has a first sloping contour from the forward end to the rear end. The lobes are rigidly secured to the mid-portion. Each of the lobes has an inner section and an outer section that extend from a forward section, with the forward section being adjacent the mid-portion of the main body and the inner section extending from the forward section towards the rear end of the main body while substantially following the first sloping contour of the mid-portion of the main body. The outer section extends rearwardly from the forward section and has a second sloping contour that gradually diverges from the first sloping contour of the mid-portion.

Owner:ANDERSON JACK H

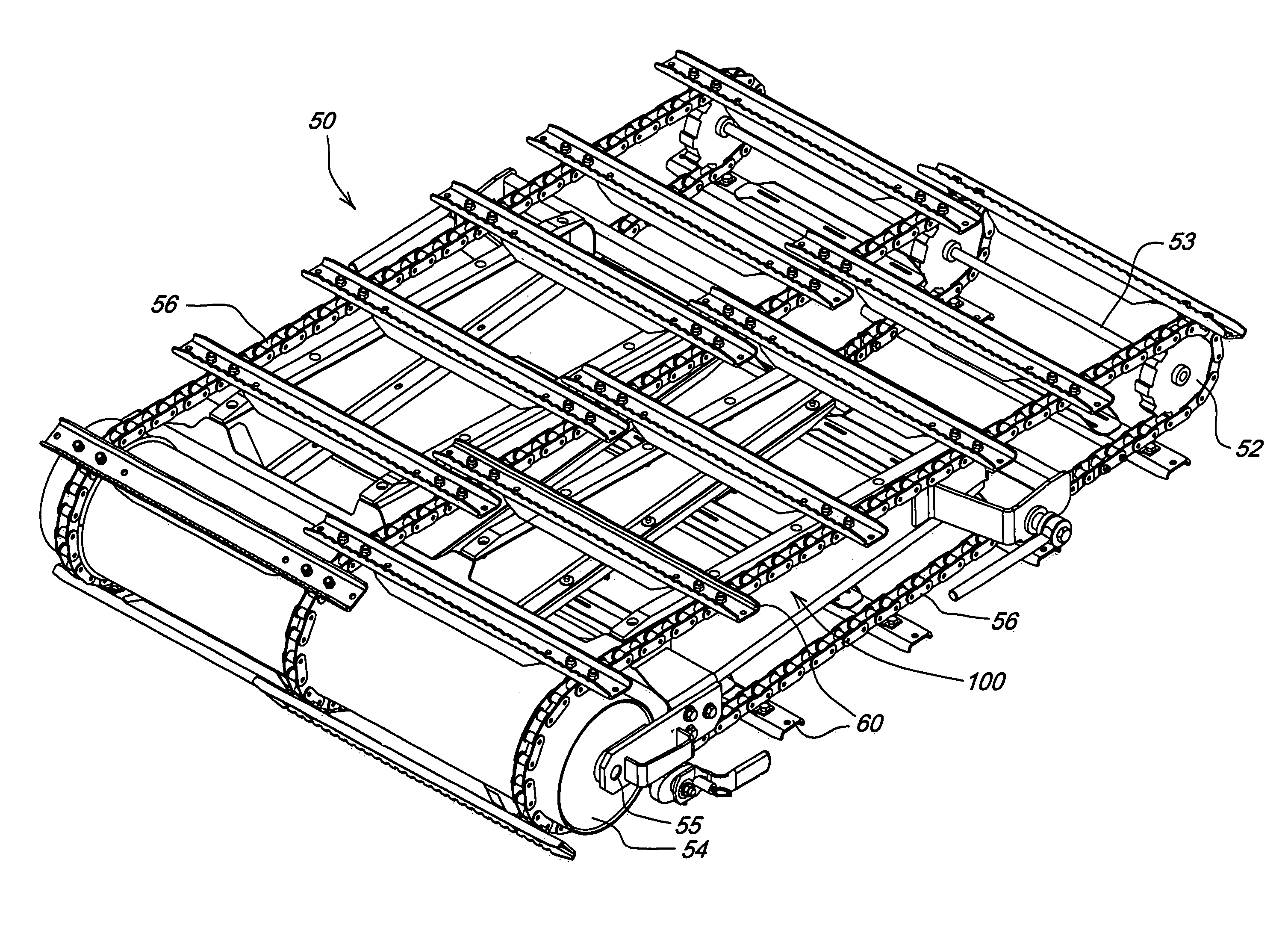

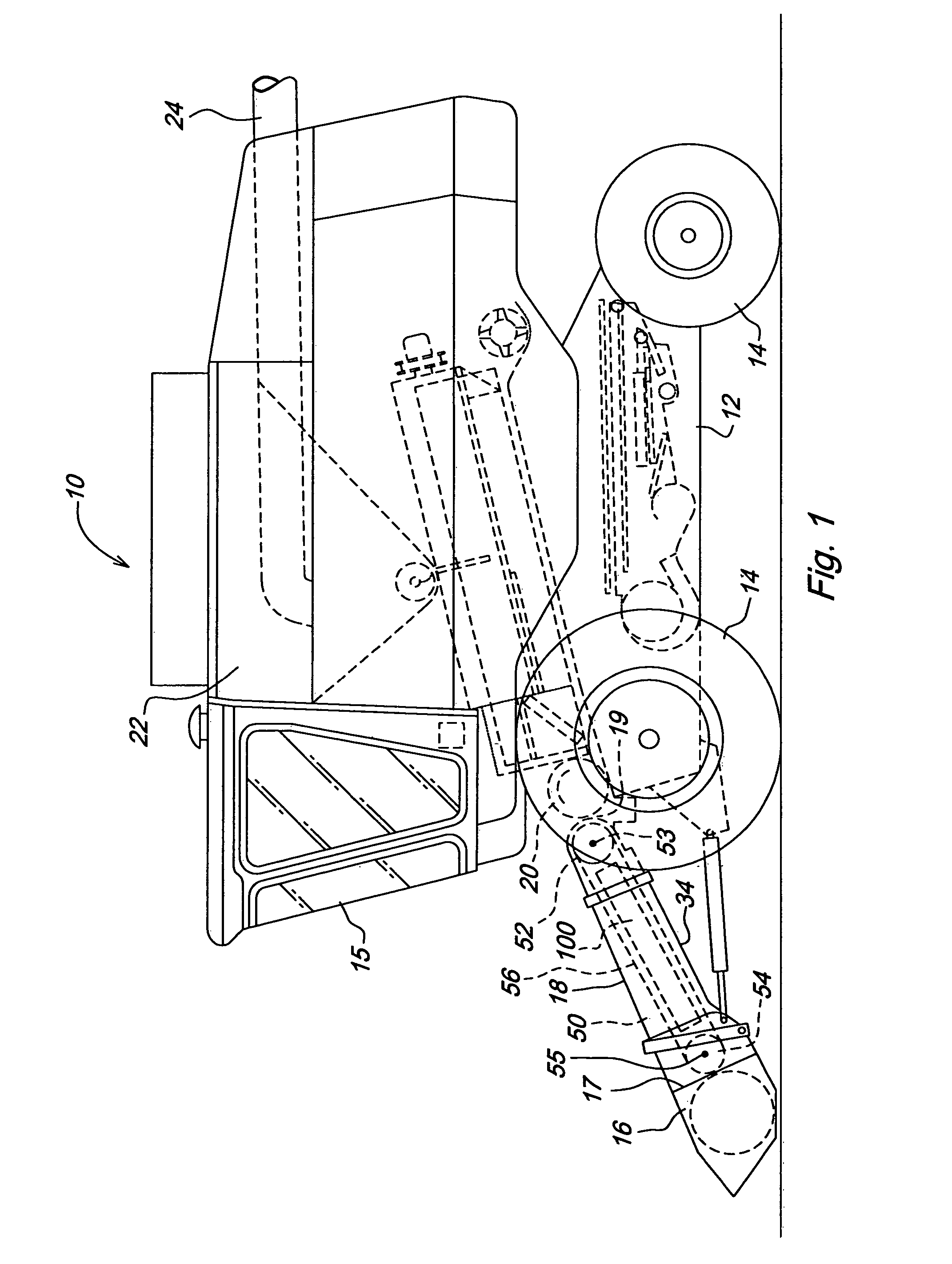

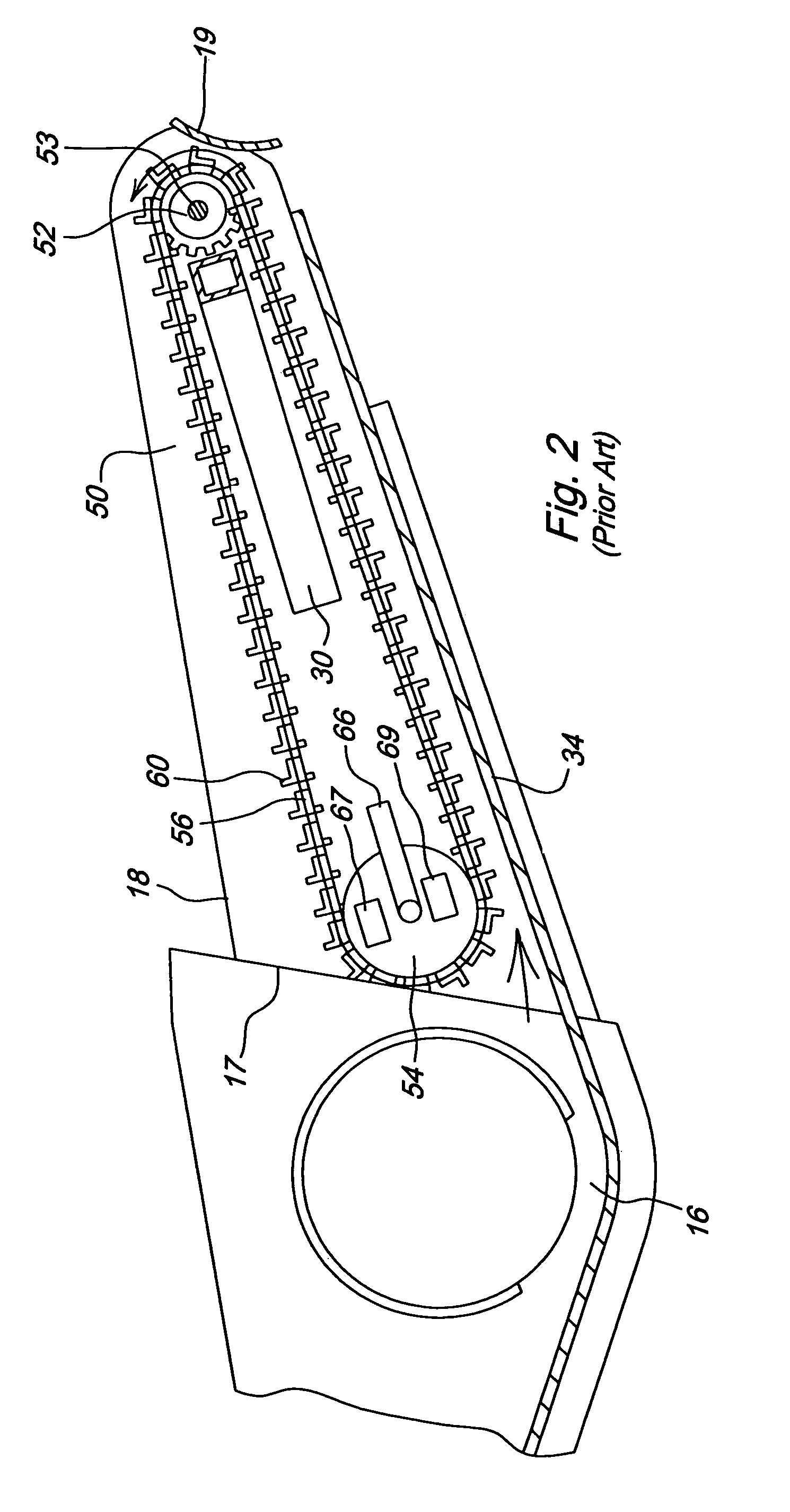

Conveyor chain support for feeder house

Owner:DEERE & CO

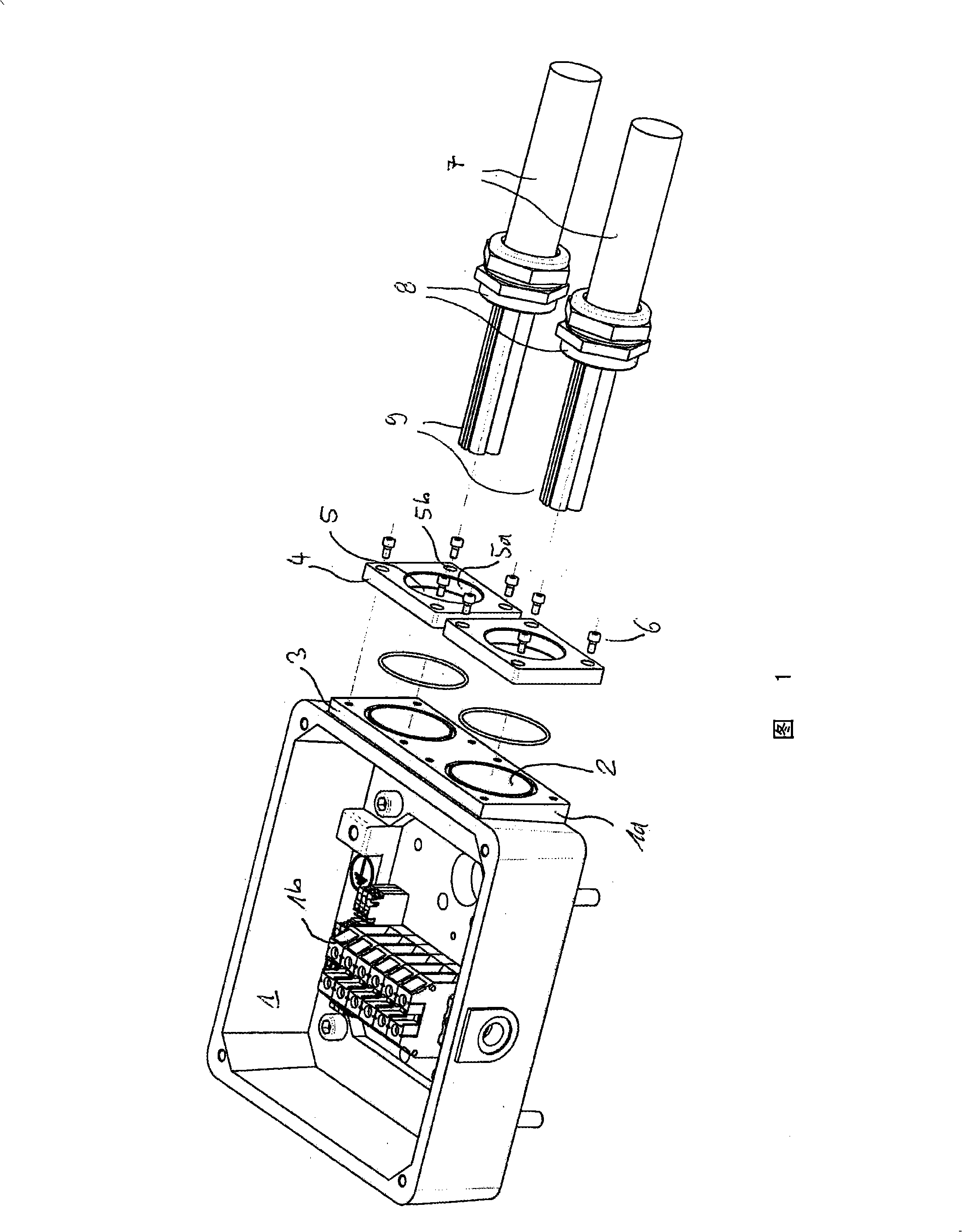

Terminal board for terminal box

InactiveCN101335446AQuick installationSimplify the installation processCasings/cabinets/drawers detailsCable terminationsElectric machineEngineering

The present invention relates to a terminal board used for terminal box. The terminal box used for electric machine electric machine according to the invention is provided with at least one opening for the terminal box. The terminal box comprises an intermediate piece comprising an opening and detachably arranged on the outer wall of the terminal box via fixing mechanisms, so that a terminal box inner space is accessible from outside the terminal box by the opening of the intermediate piece. The intermediate piece comprises a mechanism used for fastening a cable to the intermediate piece in order to cause the cable to pass through the opening of the intermediate piece. The invention also relates to a method, wherein the cable is guided into the opening of the intermediate piece released by the terminal box in a first step, and the intermediate piece and the cable fixed on the intermediate piece are arranged on the terminal box in a second step, preferably by means of a thread fastener or rail type guiding mechanism. The invention can assemble prefab cable on the terminal box or disassemble the cable from the terminal box without any problem at any moment.

Owner:ROBERT BOSCH GMBH

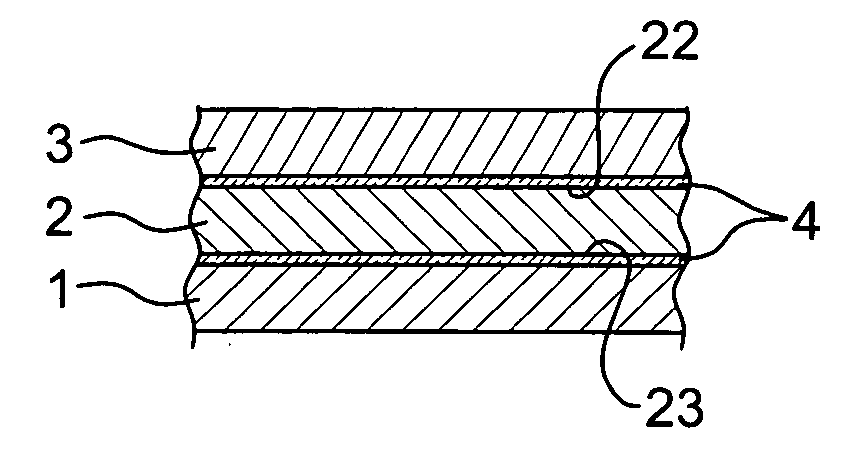

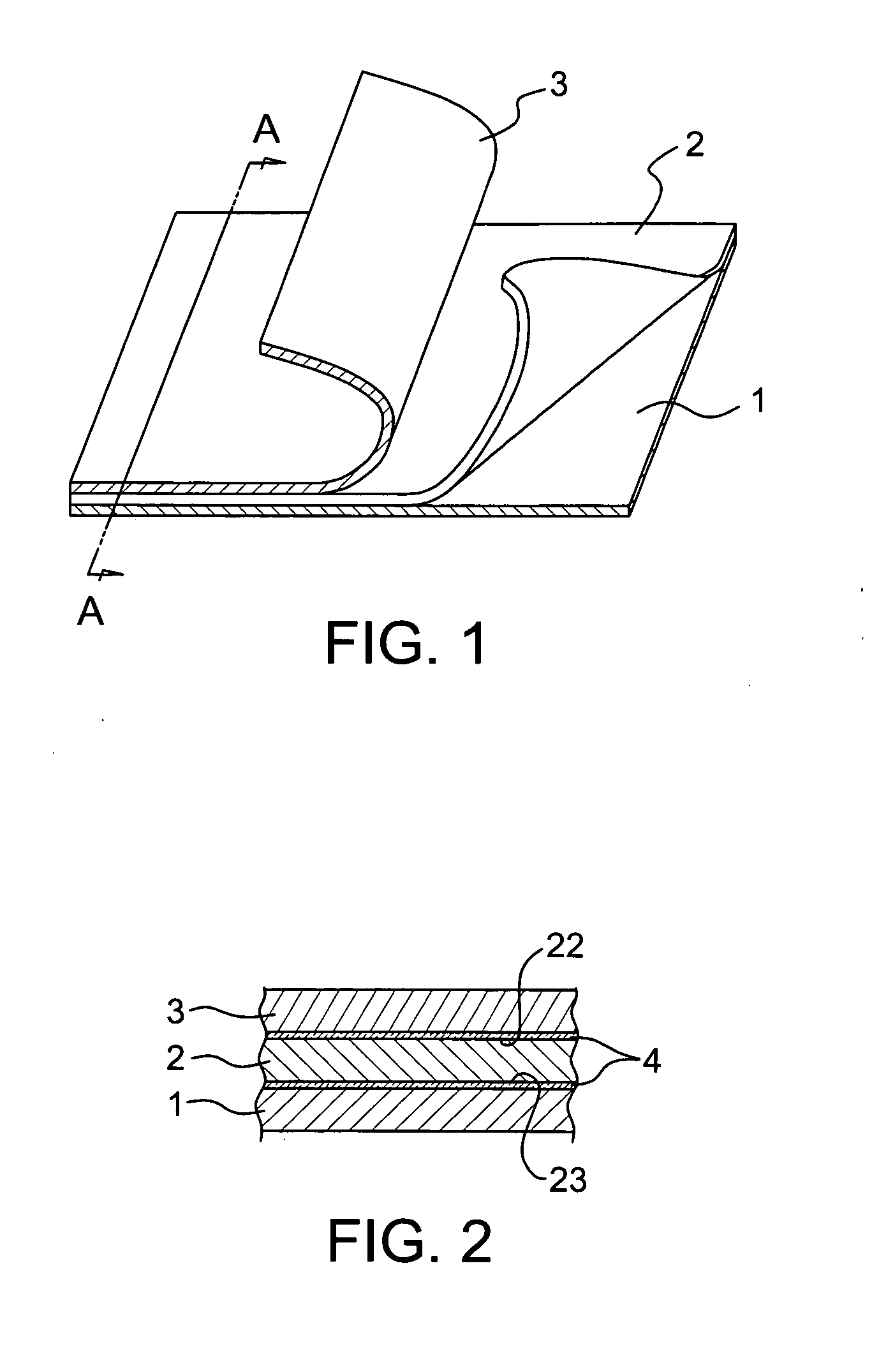

Antibacterial, waterproof, and absorbent composite cloth

InactiveUS20090081911A1Inhibit migrationCovering/liningsSynthetic resin layered productsInter layerSurgical Gowns

An antibacterial, waterproof and absorbent composite clothe for making special disposable clothing such as surgical gowns. The composite cloth mainly contains a three-layer flexible laminate, namely a middle layer, an outer layer and an inner layer. The middle layer is substantially waterproof and air breathable. The middle layer has an inner side and an outer side on opposite sides thereof. The outer layer is made of antibacterial non-woven fabric to prevent bacteria from migrating through the cloth and is secured to the outer side of the middle layer. The inner layer is made of absorbent non-woven fabric to absorb sweat and is secured to the inner side of the middle layer.

Owner:YANG GARY KERYI

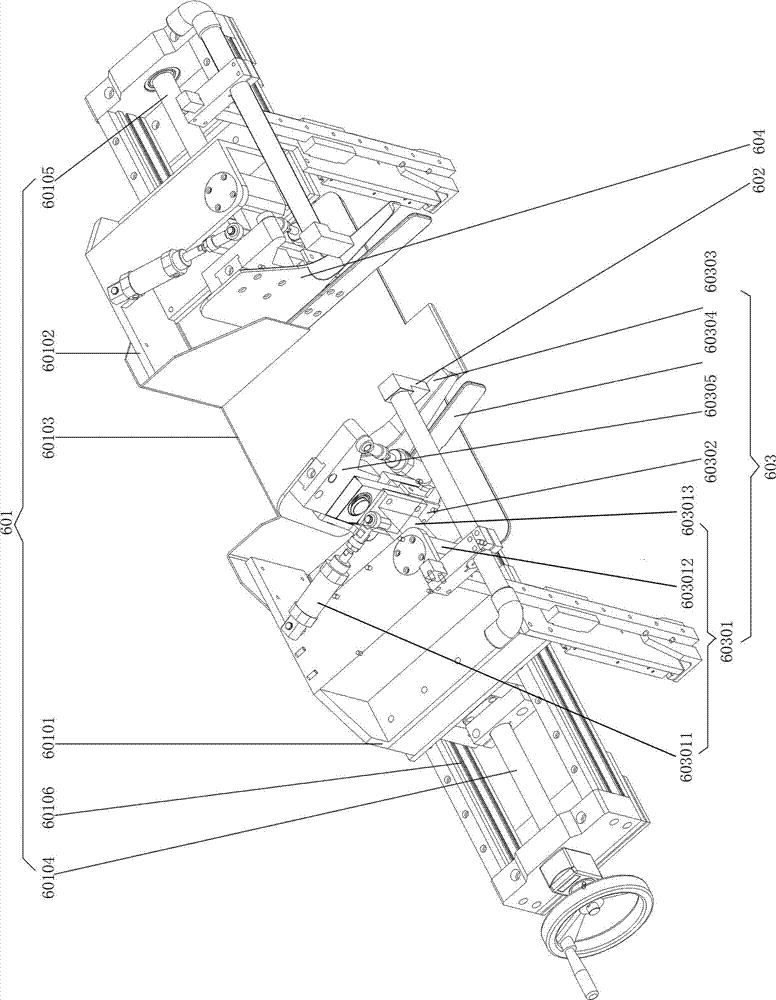

Flexible pneumatic gripper with force feedback and stroke

ActiveCN107081783AWith self-locking functionWith travel functionGripping headsEngineeringMechanical engineering

The invention relates to a flexible pneumatic gripper with force feedback and stroke. The flexible pneumatic gripper comprises a top shell, sliding blocks, a synchronous belt unit, a middle air cavity, a tension sensor, fingers and air conveying pipes, wherein connectors which communicate with an air source are formed in the top shell; a sliding groove is formed in the top shell; the sliding blocks are of hollow structures inside; a notch is formed in one surface of each sliding block; the sliding blocks are arranged on the sliding groove in a sliding manner; one end of the tension sensor is fixed to the top shell; the other end of the tension sensor is fixed to the top of the middle air cavity; air ends of the fingers are connected with the notches of the sliding blocks; one-way air valves are arranged in the air conveying pipes; one ends of the air conveying pipes are connected with the middle air cavity; the other end of each air conveying pipe is divided into two air pipes; the first air pipes enter the sliding blocks and communicate with the air ends of the fingers; and the second air pipes are arranged in the hollow structures in the sliding blocks and communicate with the hollow structures of the sliding blocks. The flexible pneumatic gripper is good in reliability, high in safety, high in control dimension and high in adaptability, and can better adapt to modern factories.

Owner:SUZHOU XINYOUHUA INVESTMENT ADVISOR CO LTD

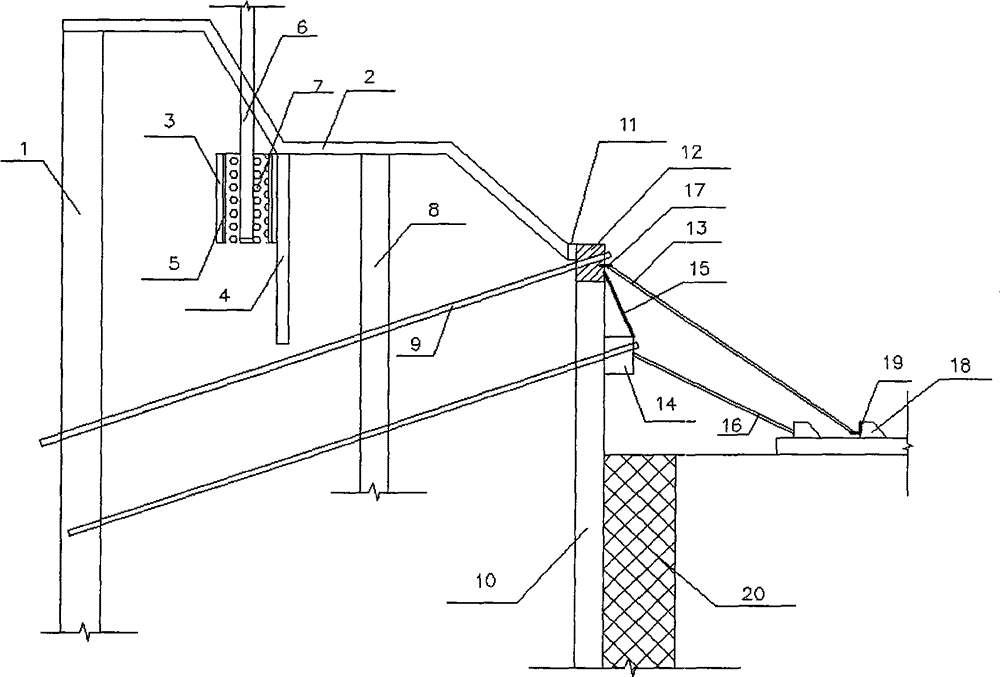

Basement supporting structure in soft soil area

ActiveCN104947686AReduce construction costsShort construction periodArtificial islandsExcavationsButtressBasement

The invention discloses a basement supporting structure in a soft soil area. The basement supporting structure is characterized by being provided with two side slopes; concrete slabs are laid at the top of the first side slope and the top of the second side slope, a water stop curtain is arranged at the end of the outer side of the first side slope, a U-steel weir is arranged at the corner of the first side slope, a concrete tube is arranged on the outer side of the U-steel weir, a drainage pipe is arranged in the middle of the concrete tube, the gap between the drainage pipe and the concrete tube is filled with pebbles, a negative pressure well is arranged in the middle of the horizontal segment of the second side slope, a coping beam is arranged at the top of a slope protection pile, a first anchor rod is fixed to the coping beam through an anchor device, an embedded steel plate is buried in the coping beam, an upper inclined strut is welded to the embedded steel plate and fixed to angle steel after being tensioned by a jack, the angle steel is welded to a steel plate embedded in a concrete buttress, a second anchor rod is fixed to an intermediate beam through an anchor device, and a passive soil reinforcement area is arranged on the inner side of the slope protection pile. The basement supporting structure is low in construction cost and short in construction period.

Owner:海南万泰建筑工程有限公司

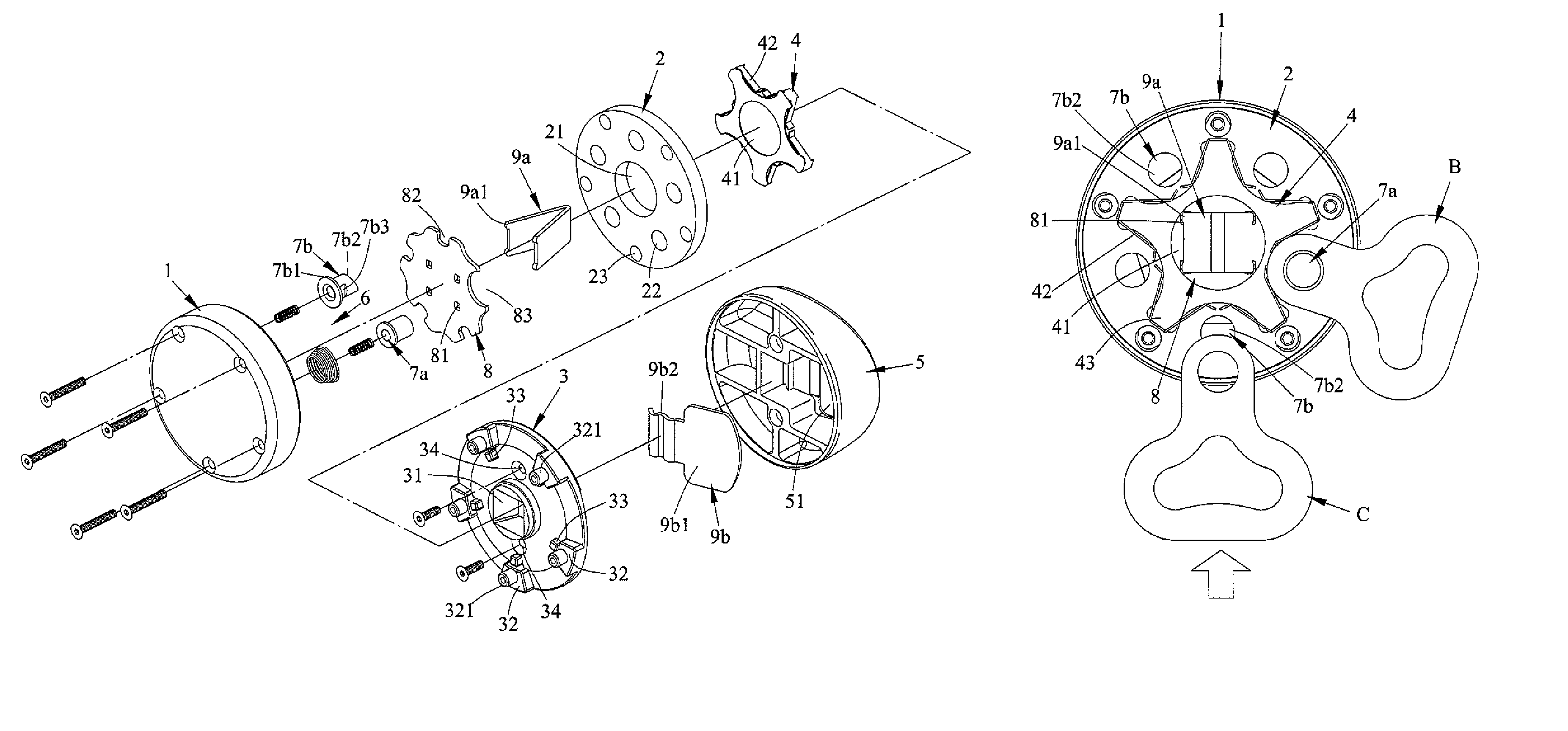

Seatbelt buckle for use in vehicle

InactiveUS7716794B2Simple structureLow production costSnap fastenersBelt control systemsIn vehicleWave shape

A seatbelt buckle for use in vehicle comprises a base, an intermediate loop, a fixed disc, an elastic member, an upper cover, a fixed post, four movable posts, an actuation member, a biasing element and a pressing element, wherein the intermediate loop and the fixed disc are screwed onto the base, the elastic member is secured between the intermediate loop and the fixed disc, and a plurality of snap-on recesses form between the intermediate loop and the fixed disc for the insertion of engaging members of the seatbelt, the pressing element is constructed in the form of a sheet, and one end thereof extends outwardly and includes a wave-shaped abutting segment arranged thereon, thereby lowering the production cost and saving force during unbuckling the seatbelt.

Owner:WU WEN YUAN

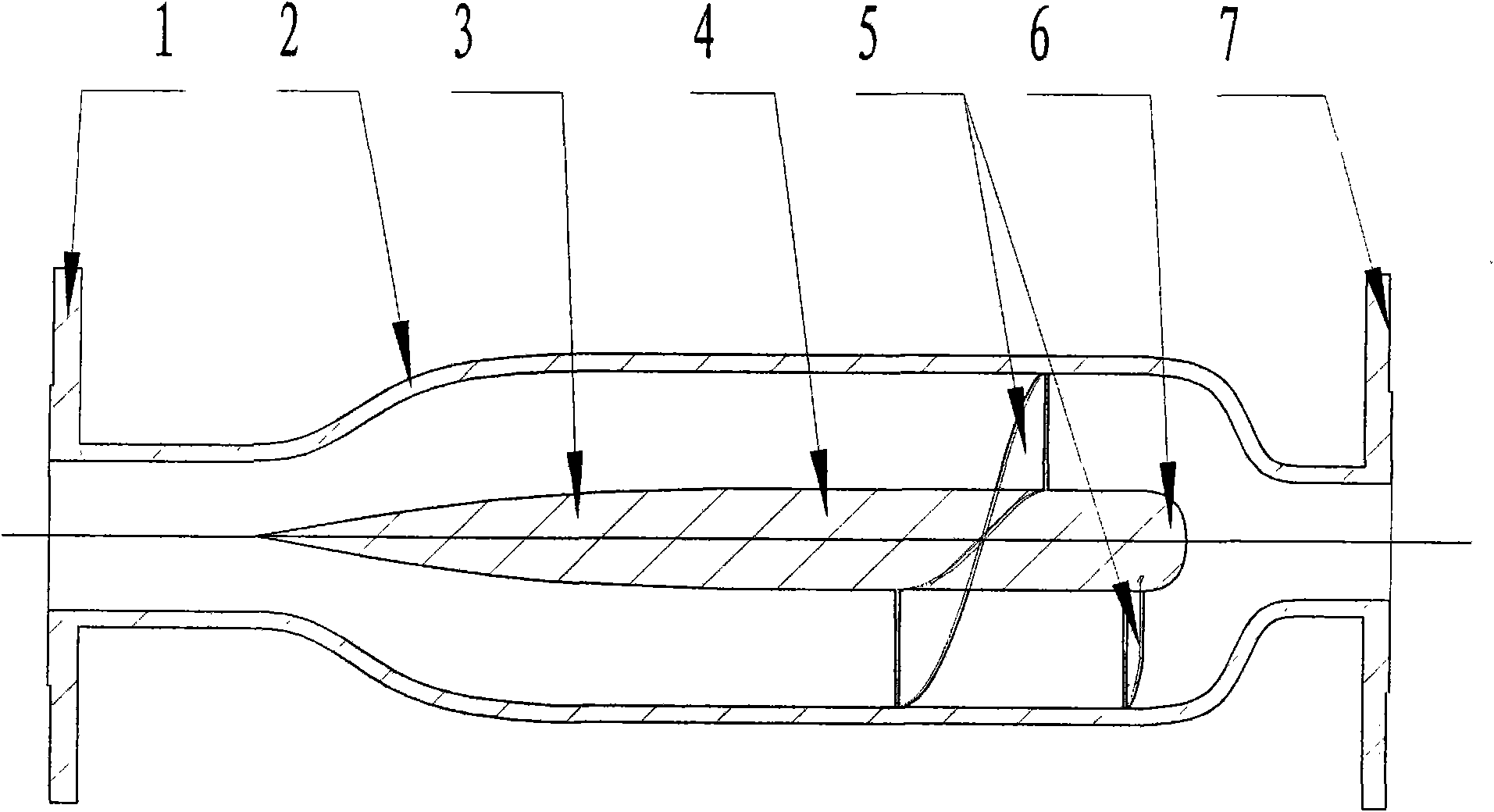

Axial-flow fluid vortex generator used on oil and gas pipeline

InactiveCN101603628AReduce workloadReduce transmission kinetic energy lossPipeline systemsWaxDevice form

The invention relates to a conveying device for the fluid of the mixture of oil and gas. The axial-flow fluid vortex generator used on oil and gas pipelines is formed by connecting an inlet end, a housing and an outlet end; a group of devices formed by connecting an inlet flow guiding cone, a helicallobe, a midbody and an outlet flow guiding cone are arranged in the housing; an inner end of the helicallobe is fixed on the midbody, and an outer end thereof is fixed on the housing. The invention ensures that the mixture fluid can flow in a pipeline in the modes of spiral and layering, so that compared with the traditional pure axial transmission, the deposition amount of paraffin and encrustment transmitted by the pipeline is decreased by more than 90%; meanwhile, the workload on cleaning paraffin precipitation sediment incrustation is reduced, the transmission kinetic energy loss is reduced, the transmission efficiency is improved, and the transmission cost is reduced. Meanwhile, the invention is also suitable for transmitting the mixture fluid in the fields of chemical engineering, medicine, food and the like.

Owner:XIAN HUAYANG ENERGY TECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com