Patents

Literature

127results about How to "Maintain structural strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microstructured Surface

InactiveUS20170014111A1Improve pressure distributionIncrease surface areaFouling preventionSurgeryPolymerMaterials science

Owner:BVW HLDG +1

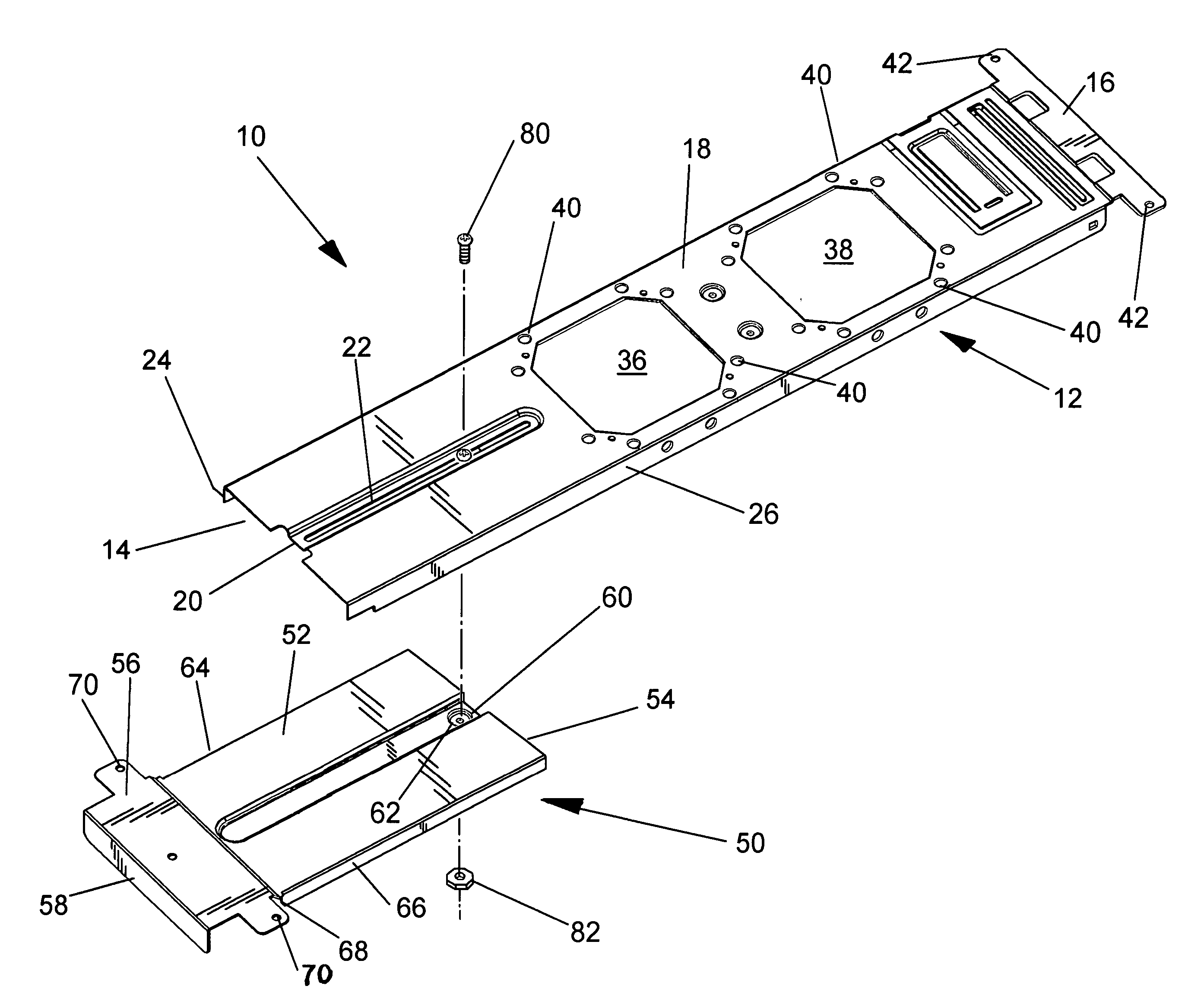

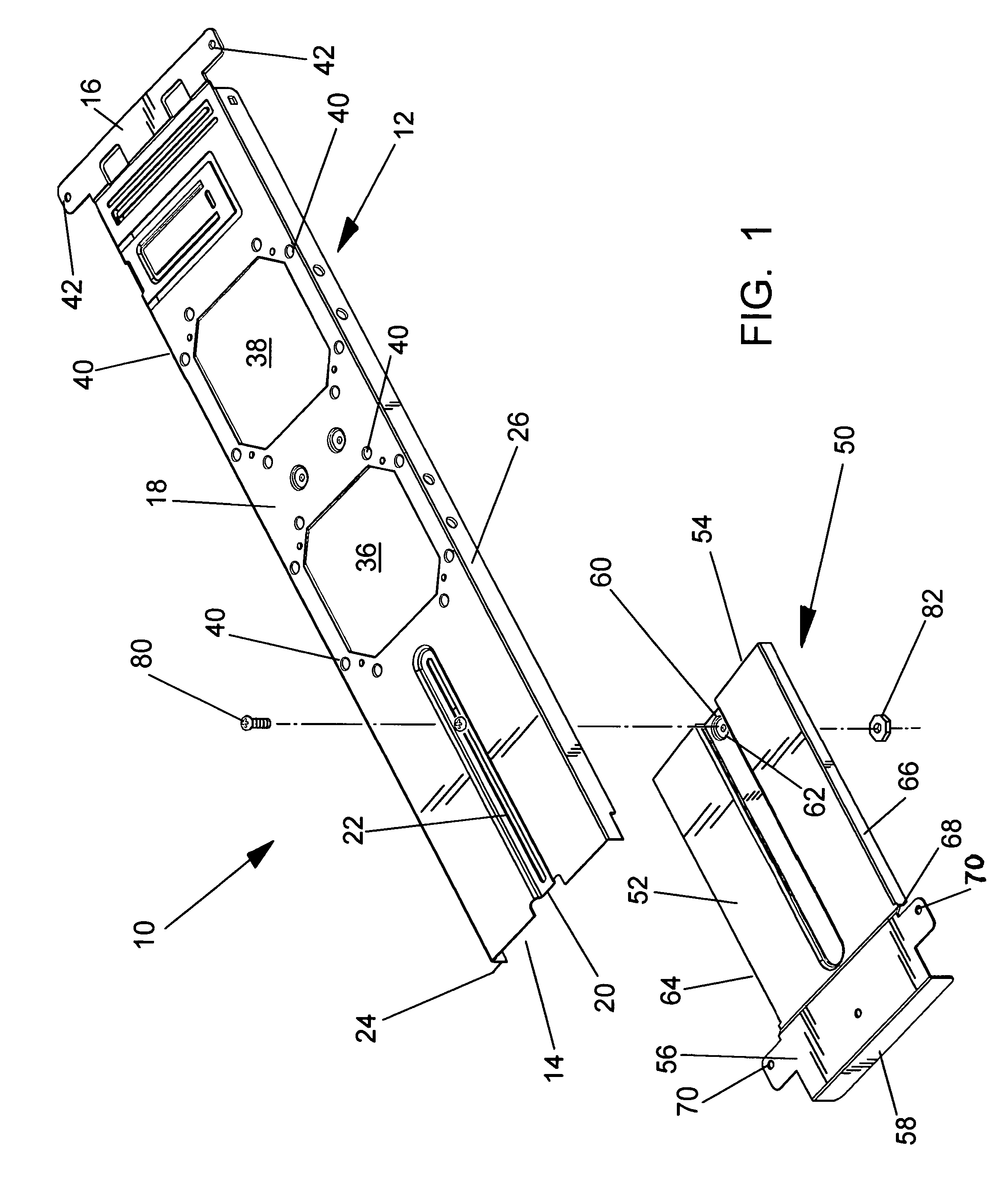

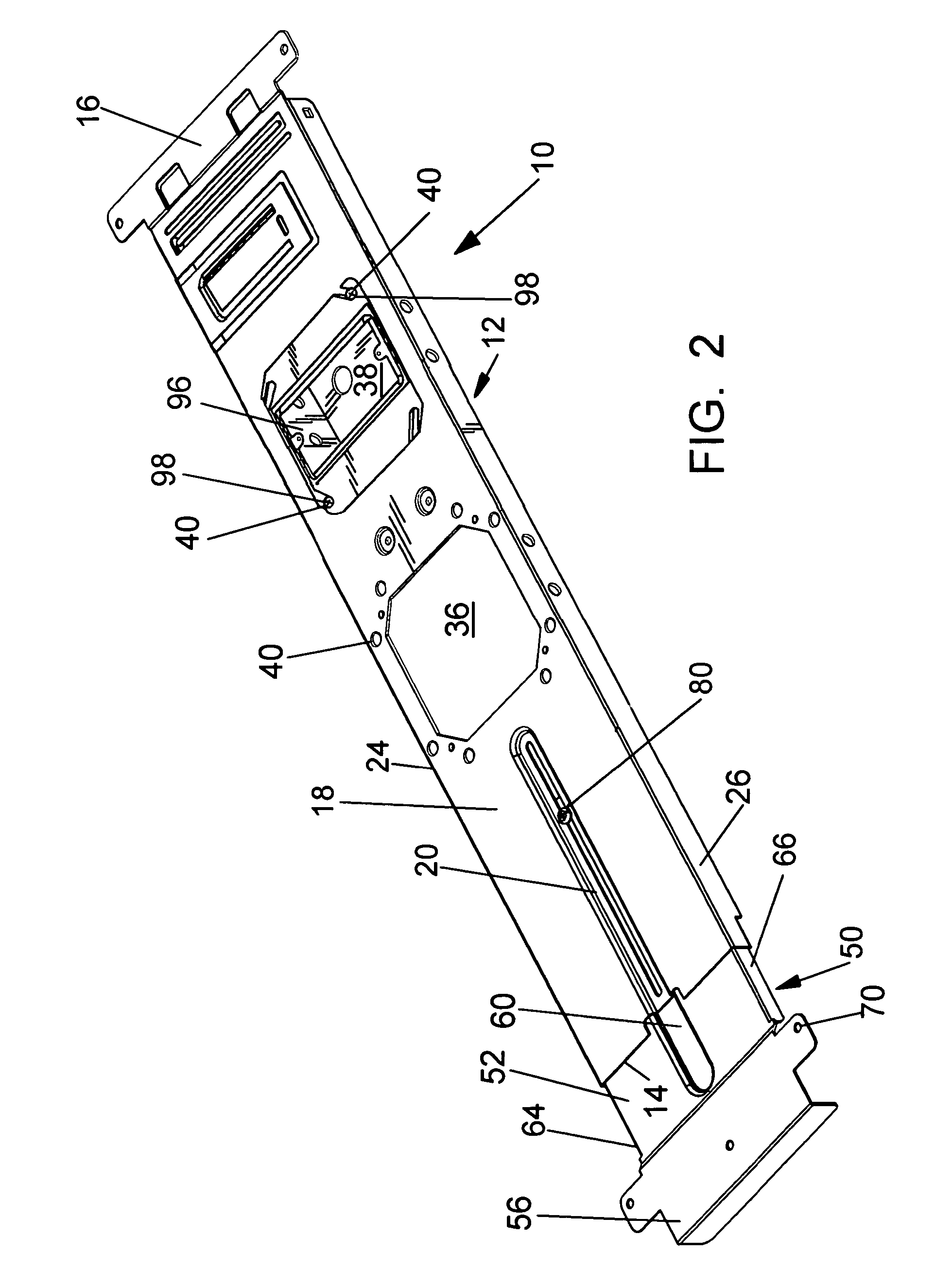

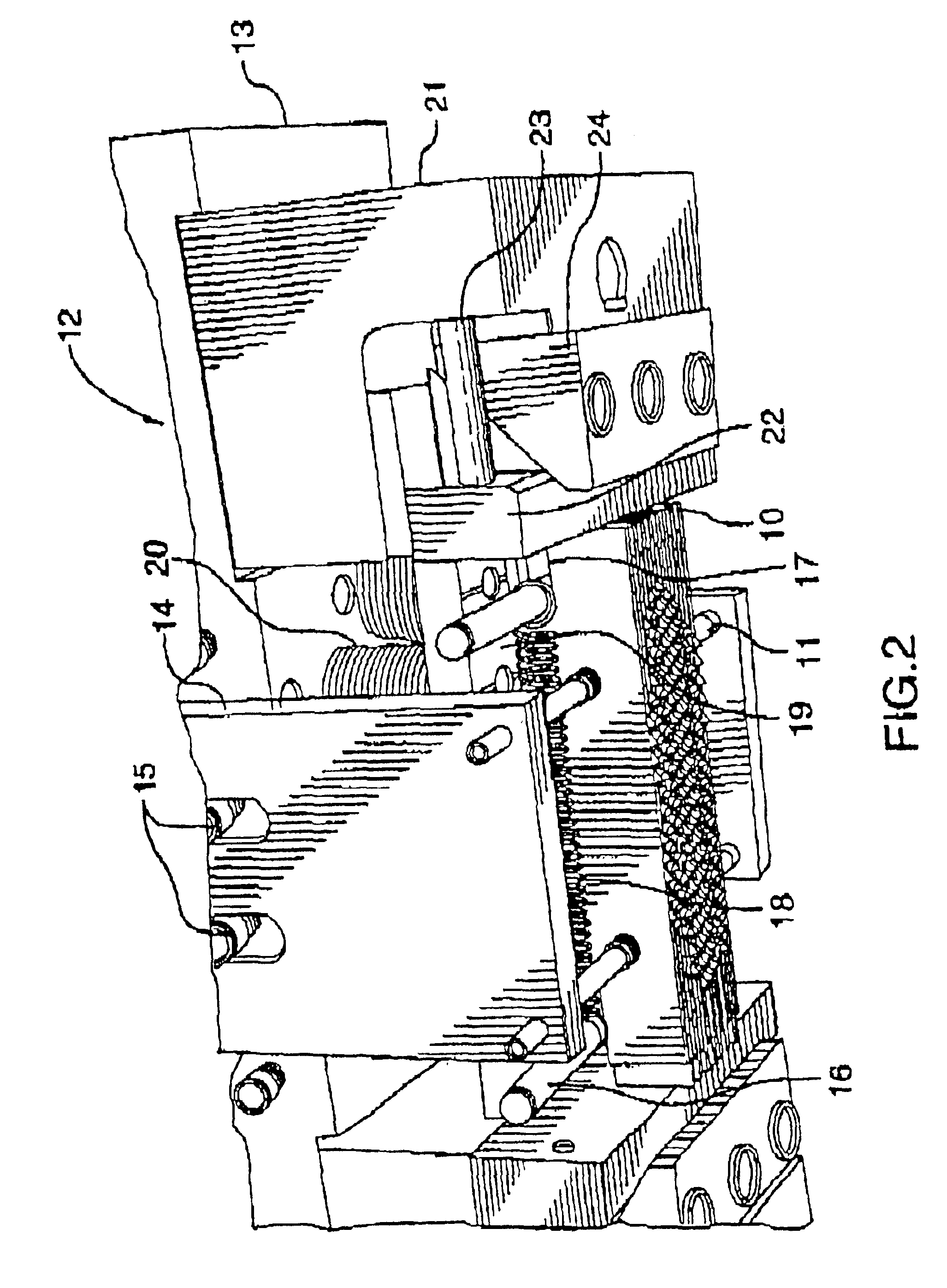

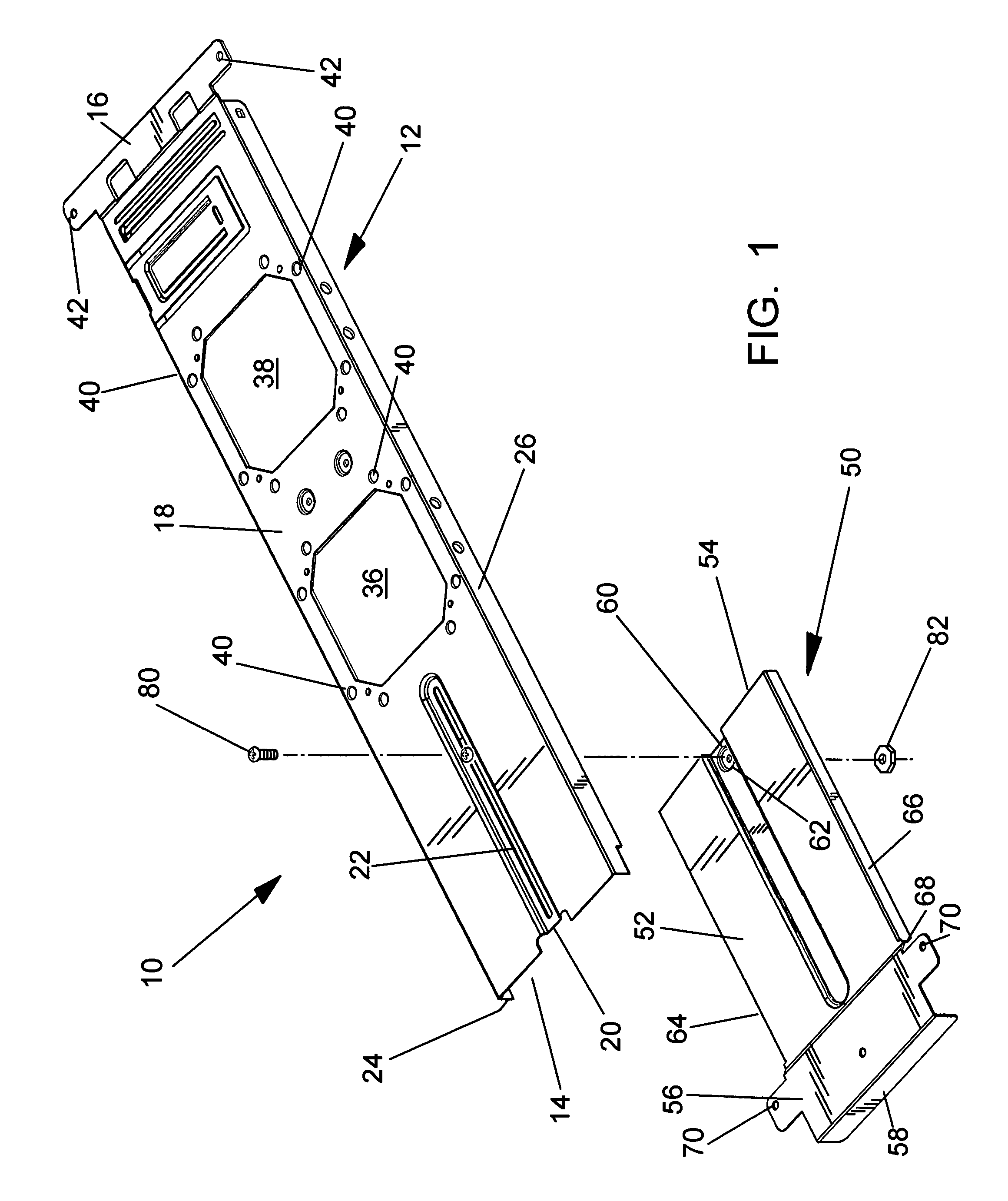

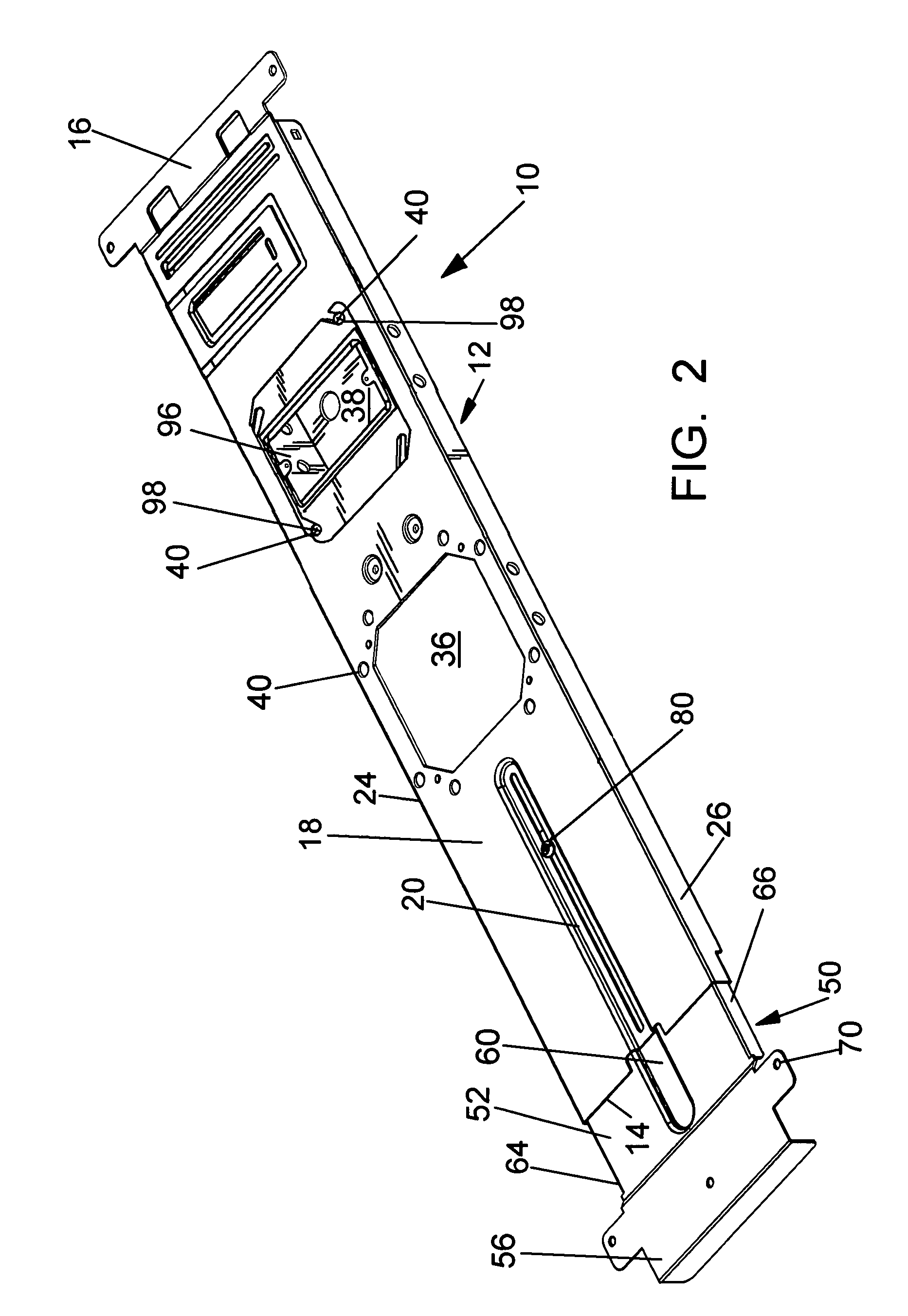

Adjustable mounting bracket assembly for mounting an electrical box

ActiveUS7271336B2Improve structural strengthMaintain structural strengthMachine supportsCouplings bases/casesEngineeringFastener

An adjustable mounting bracket assembly for mounting an electrical box that includes: (a) a mounting bracket that includes a mounting plate having a first opening for receiving an electrical box and a rail having a first aperture; a mounting bracket attaching end; a mounting bracket mating end; a first pair of side walls and a pair of tabs; (b) an adapter plate that includes: a base plate having a track with a second aperture; an adapter plate attaching end; an adapter plate mating end; and a second pair of side walls; and (c) a fastener. The mounting bracket mating end slidably receives the adapter plate mating end and the first aperture in the rail aligns with the second aperture in the track. The fastener is inserted in the first and second apertures and tightened to secure the mounting bracket to the adapter plate.

Owner:THOMAS & BETTS INT INC

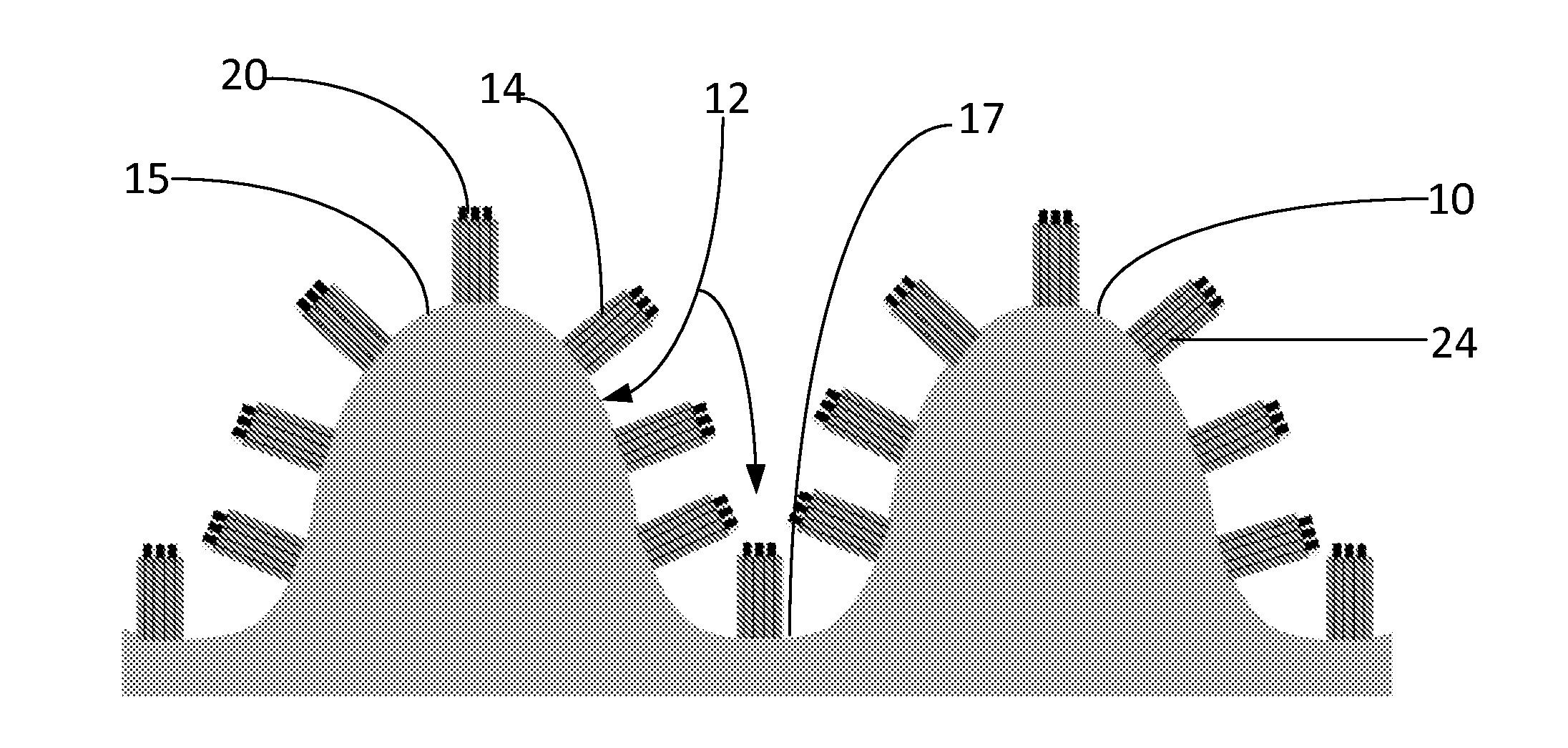

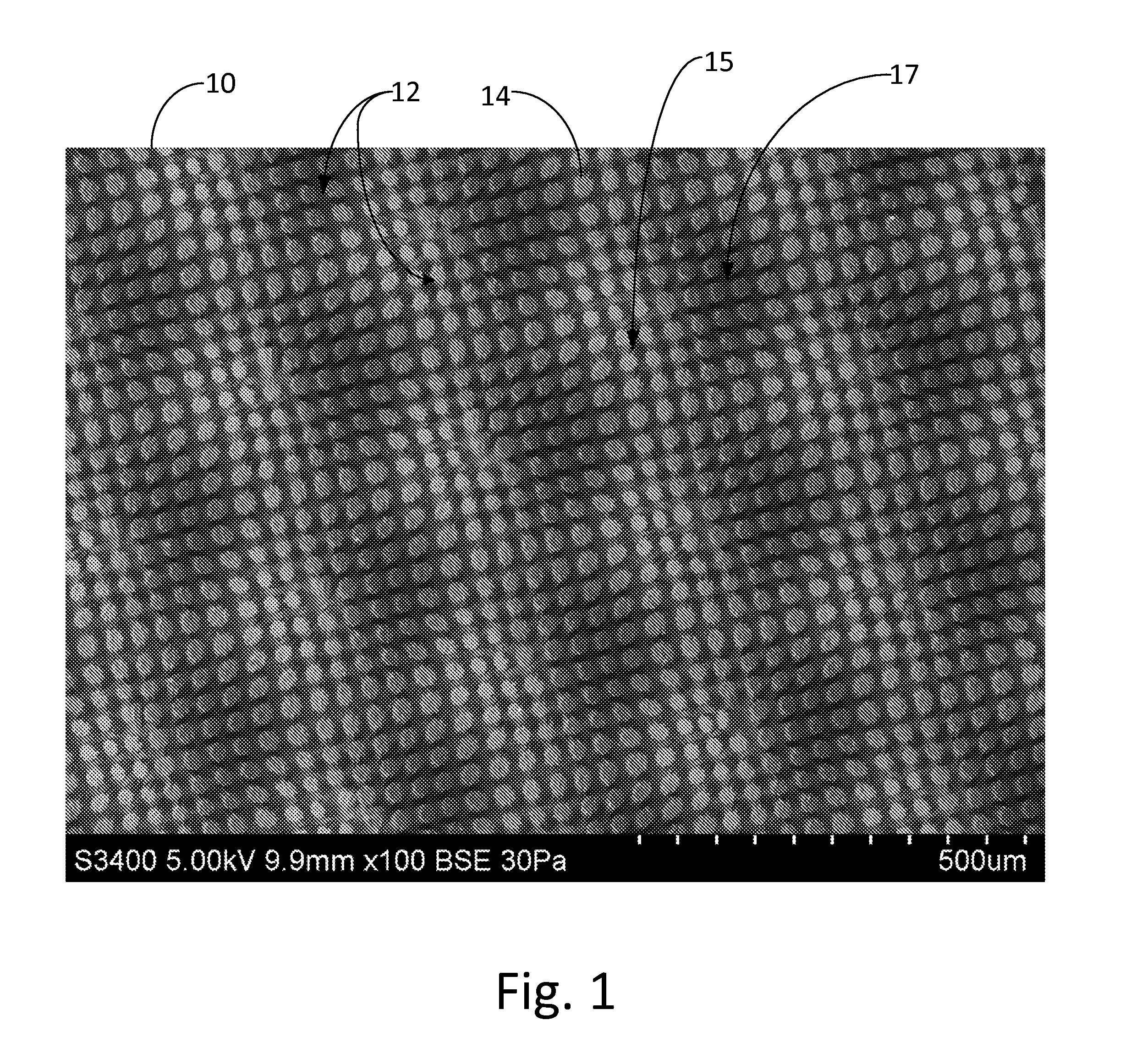

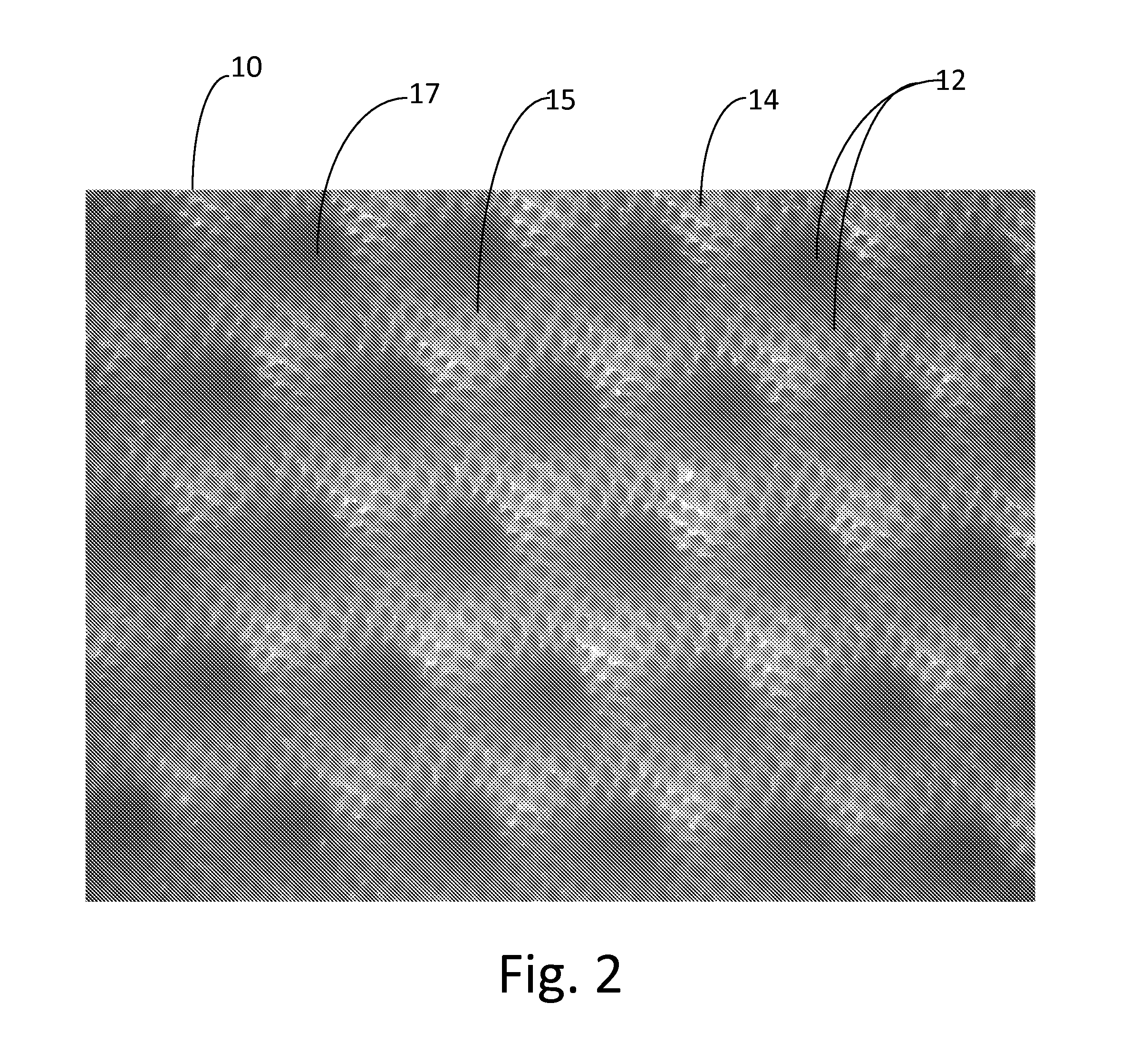

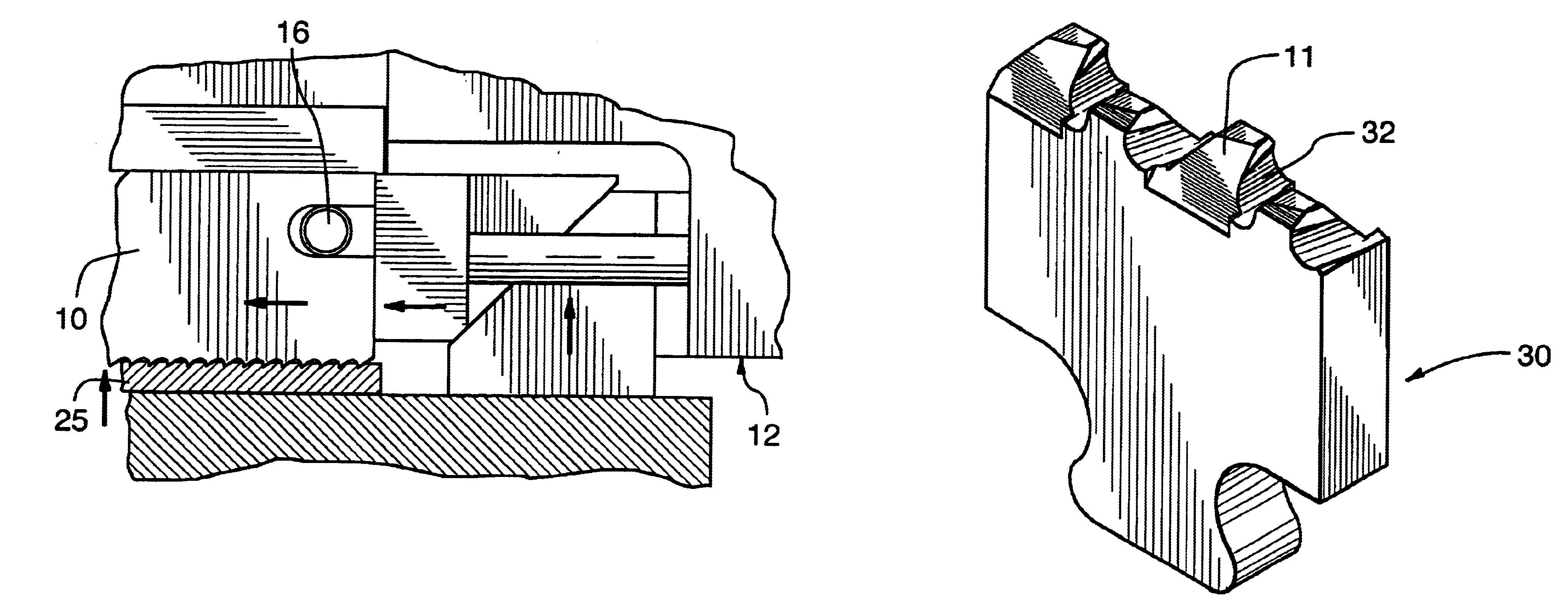

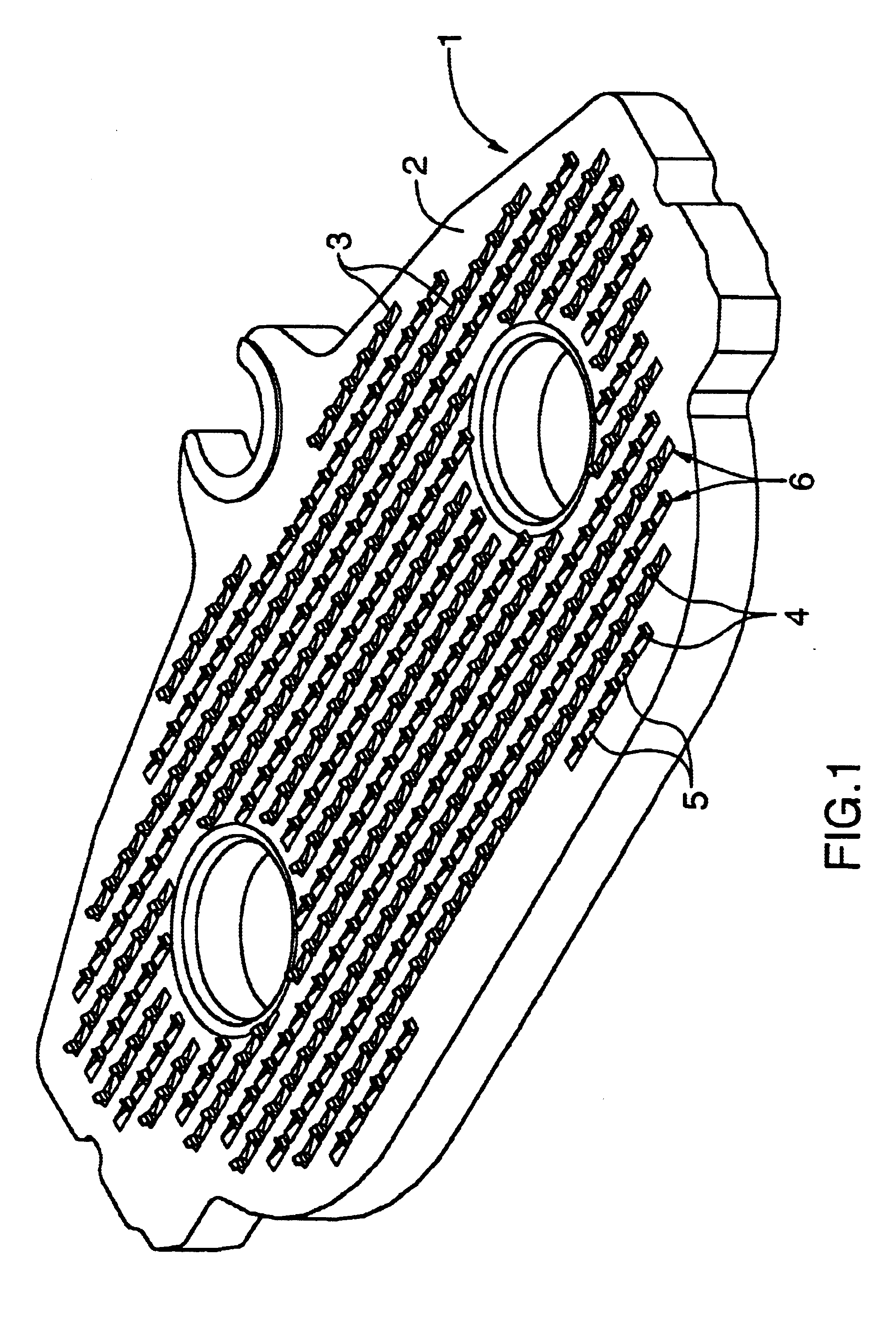

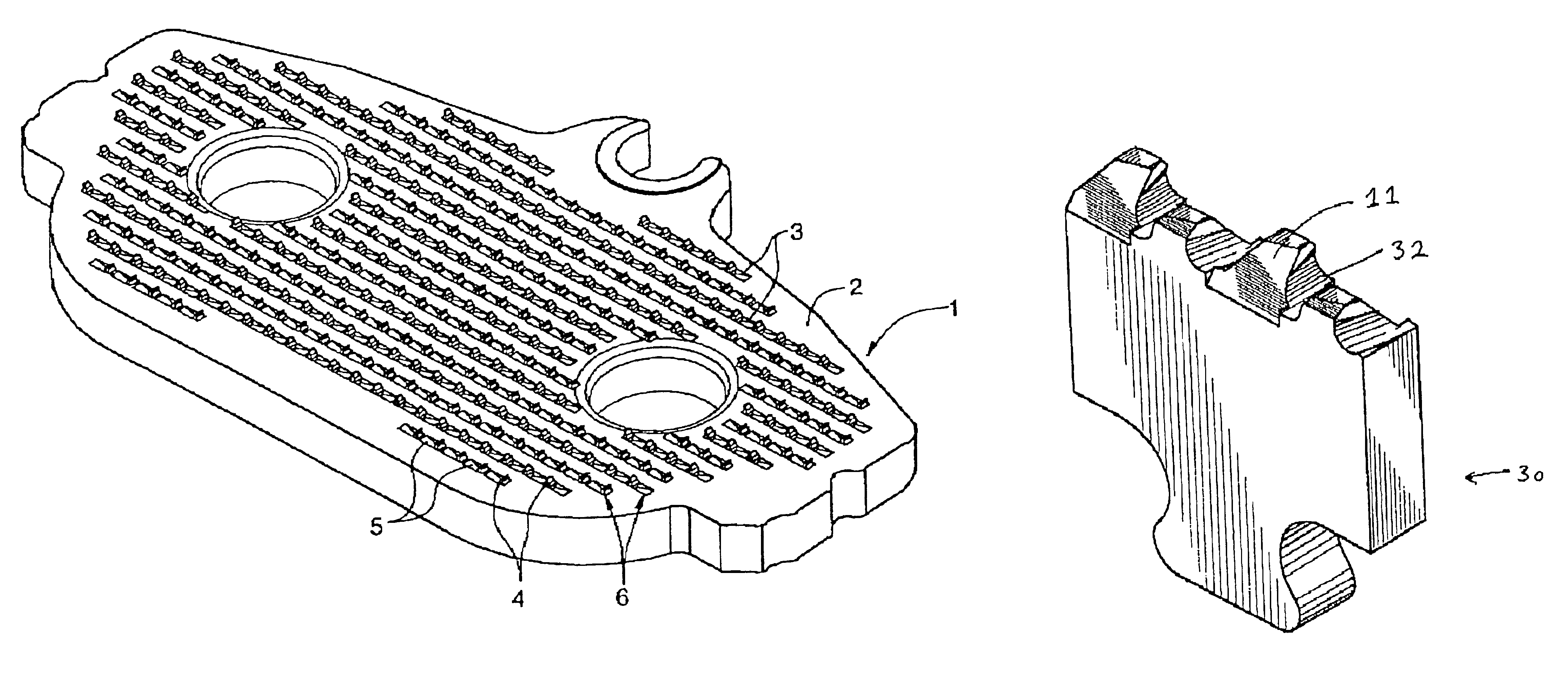

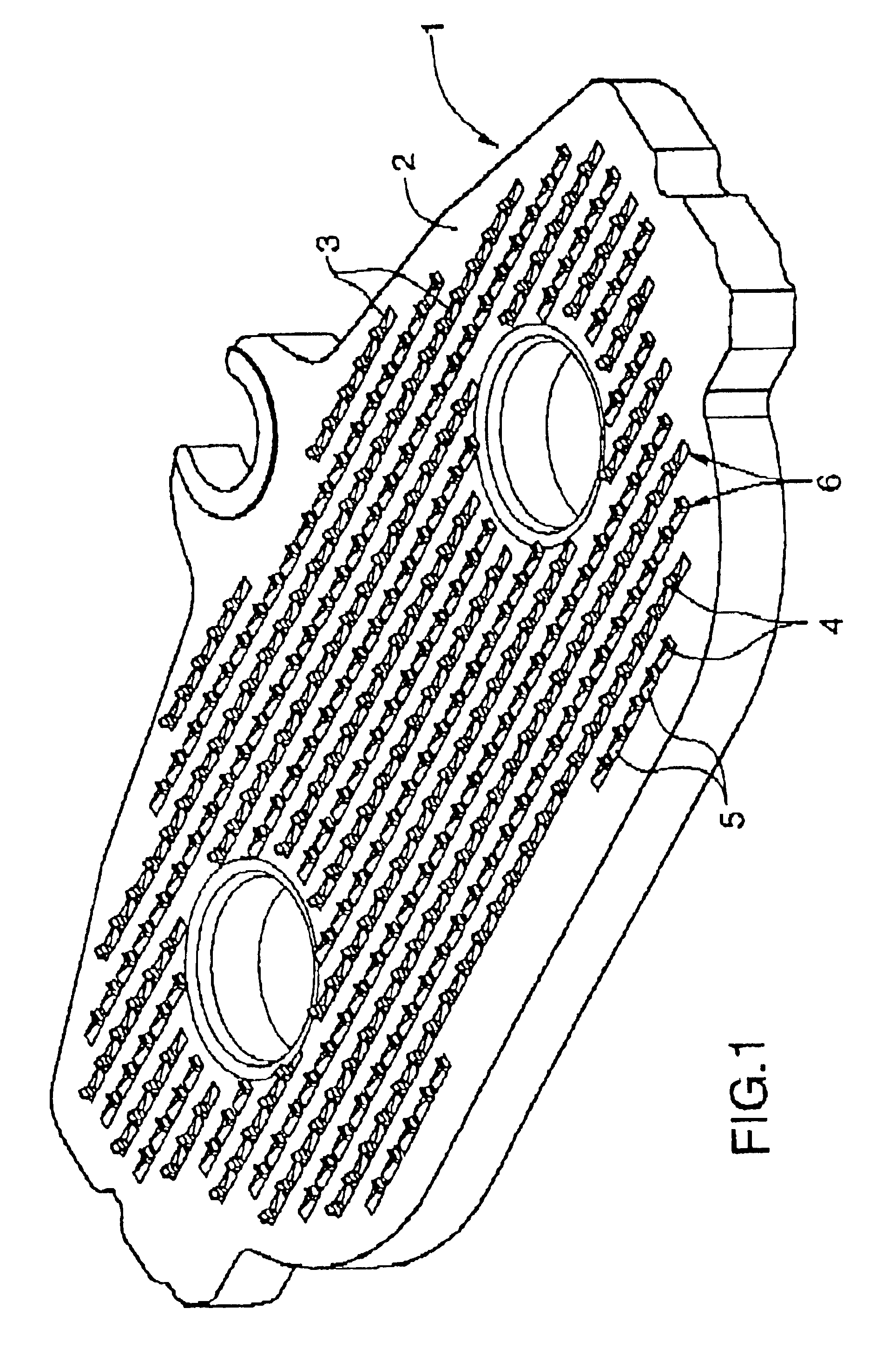

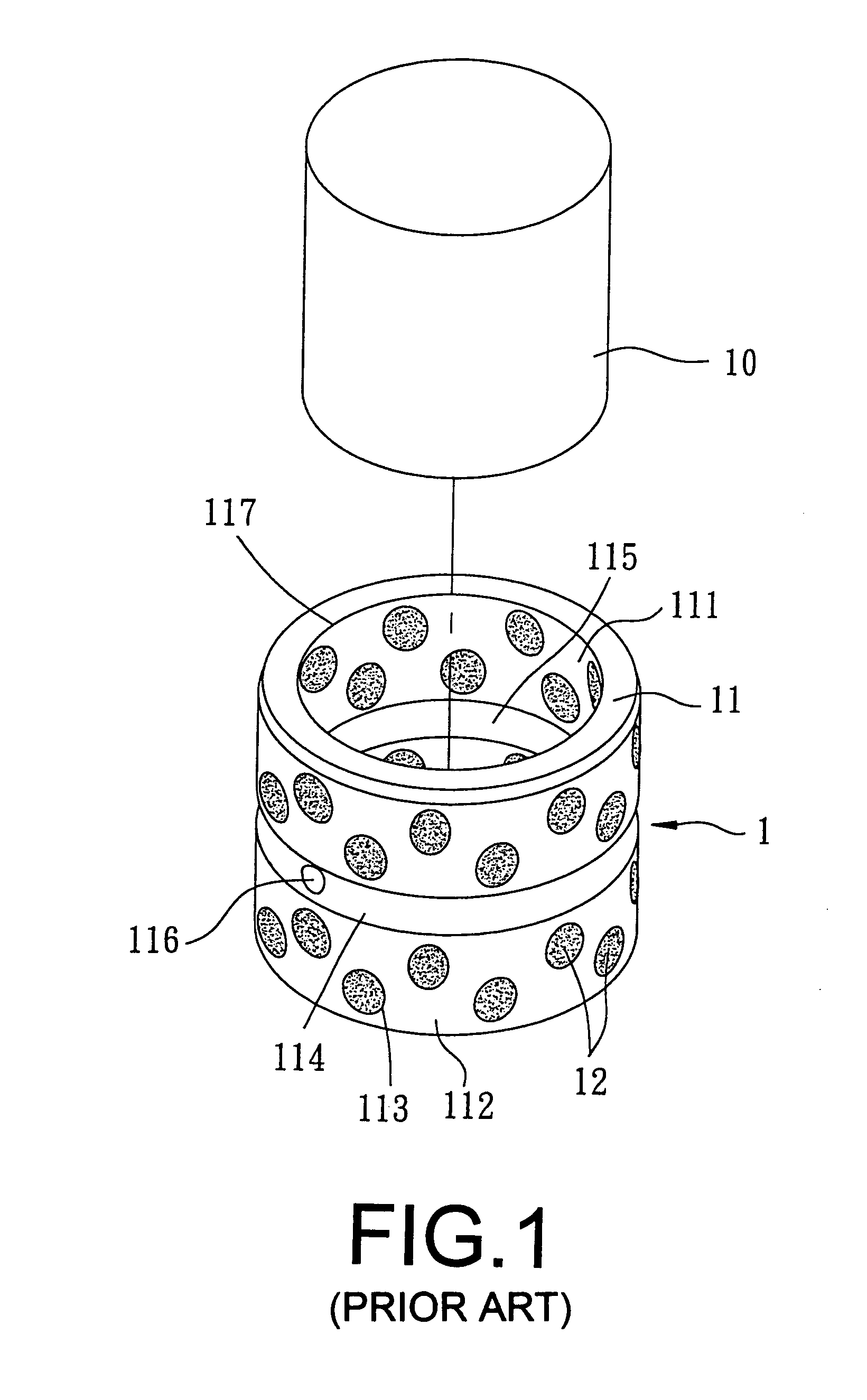

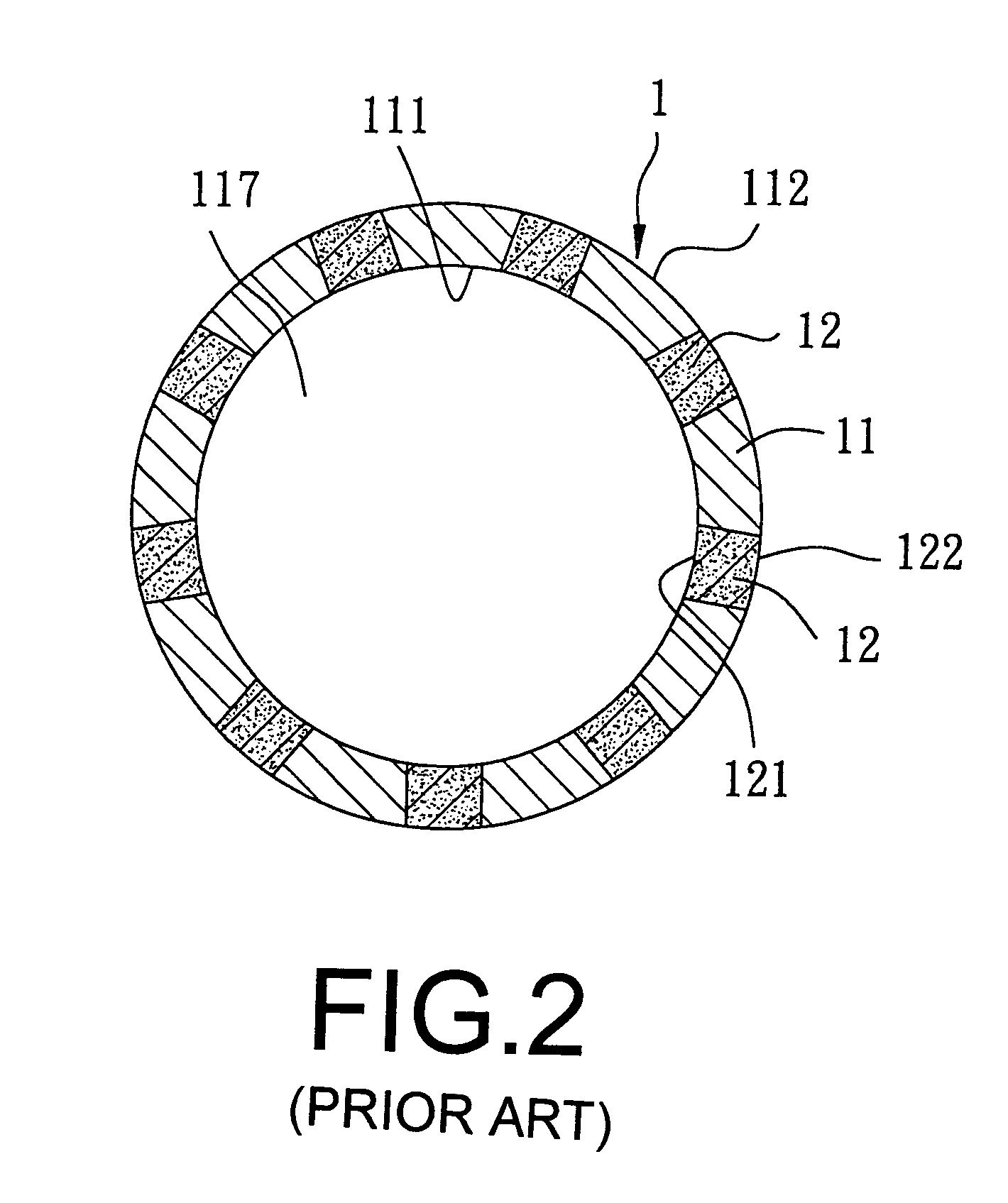

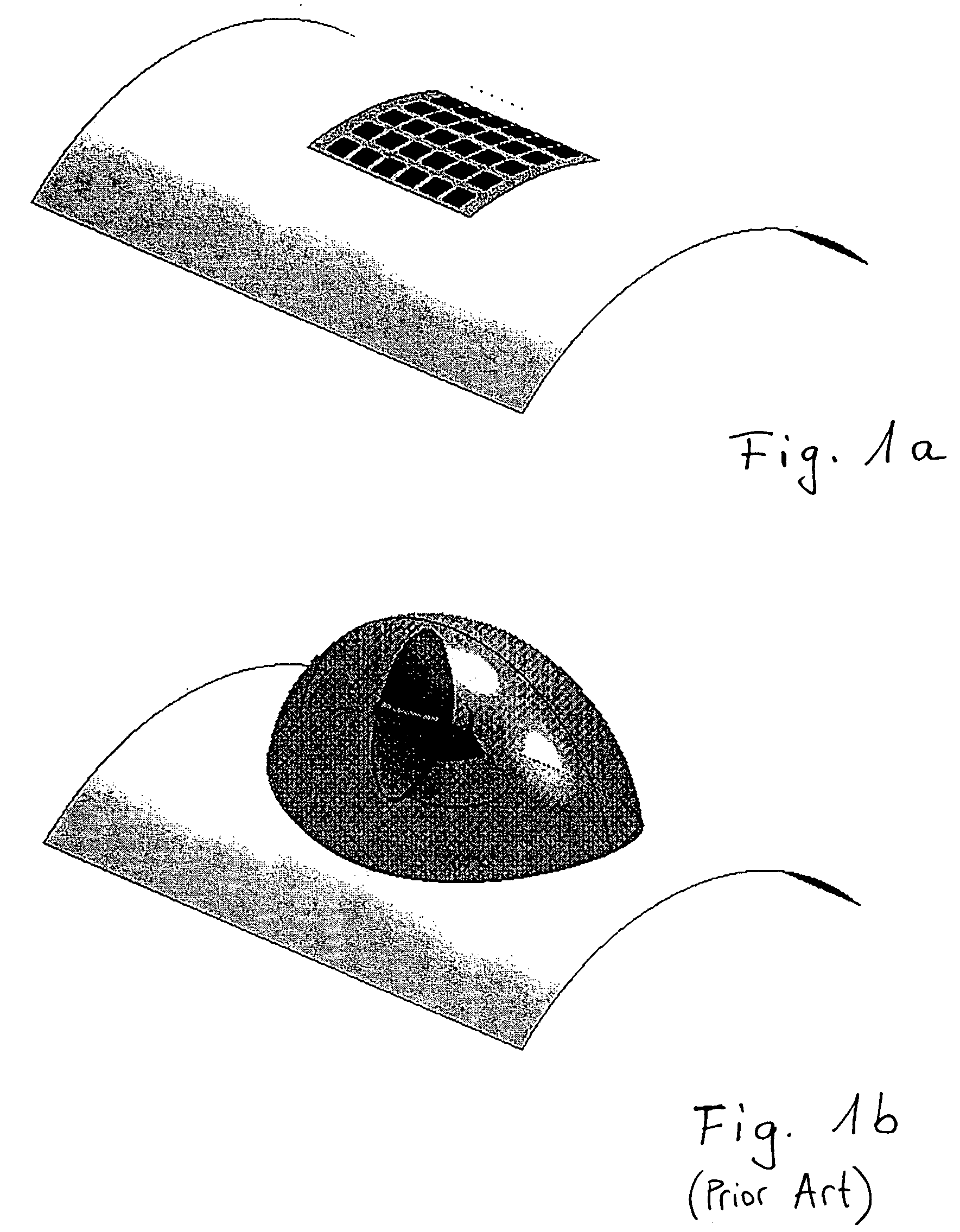

Apparatus for manufacturing a brake plate

InactiveUS6843095B2Improve bindingImprove structural strengthSpringsPlaning/slotting machinesBiomedical engineering

The invention is a plate for holding a friction material in a brake assembly. The plate preferably comprises a contact surface for attaching the friction material to the plate, a second surface opposing the contact surface; and a plurality of retaining structures formed on the contact surface, each retaining structure comprising a projecting member extending from a point between the contact surface and the second surface, so that the member extends outwardly from the contact surface for engagement with the friction material.

Owner:NUCAP IND

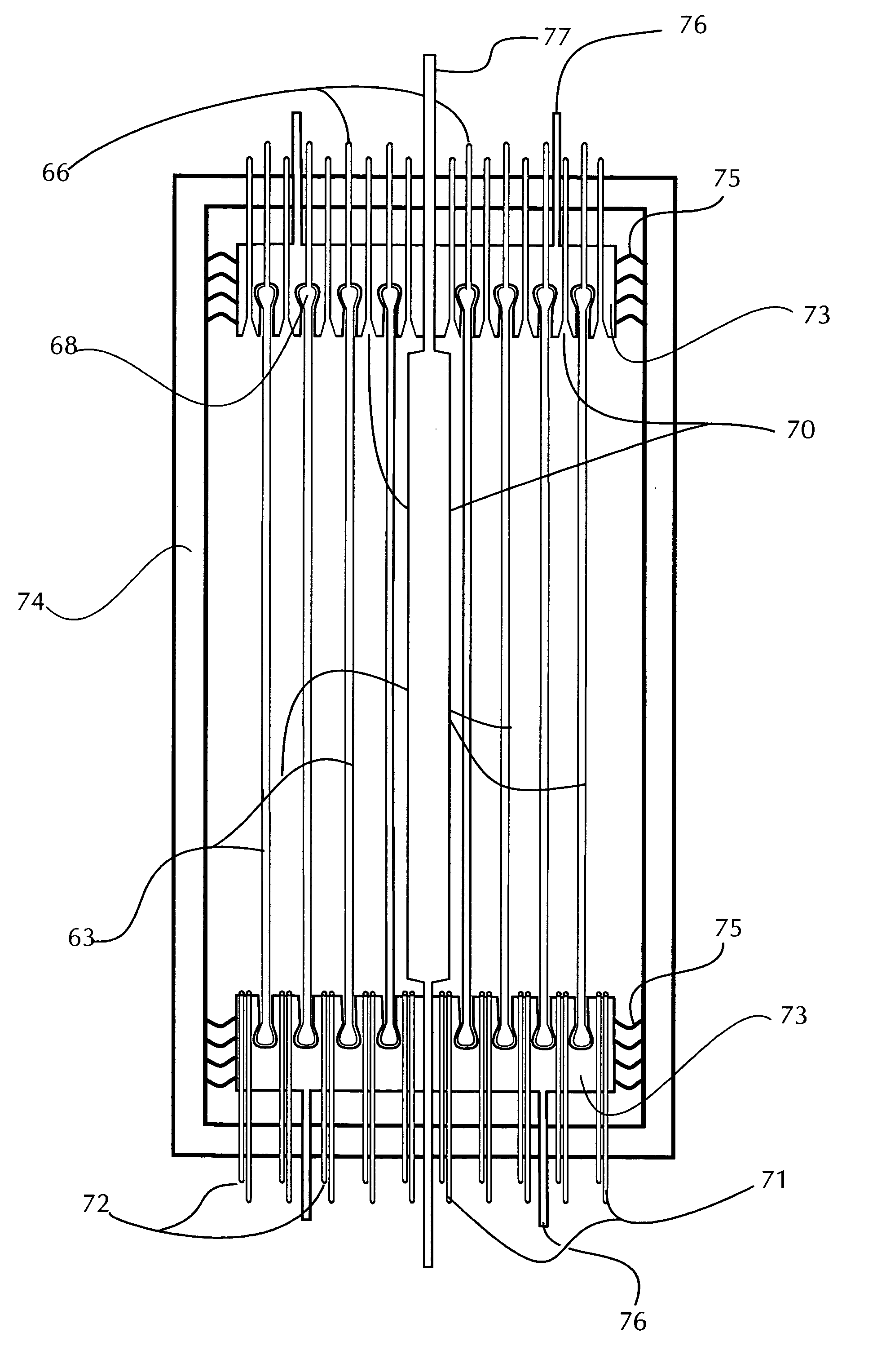

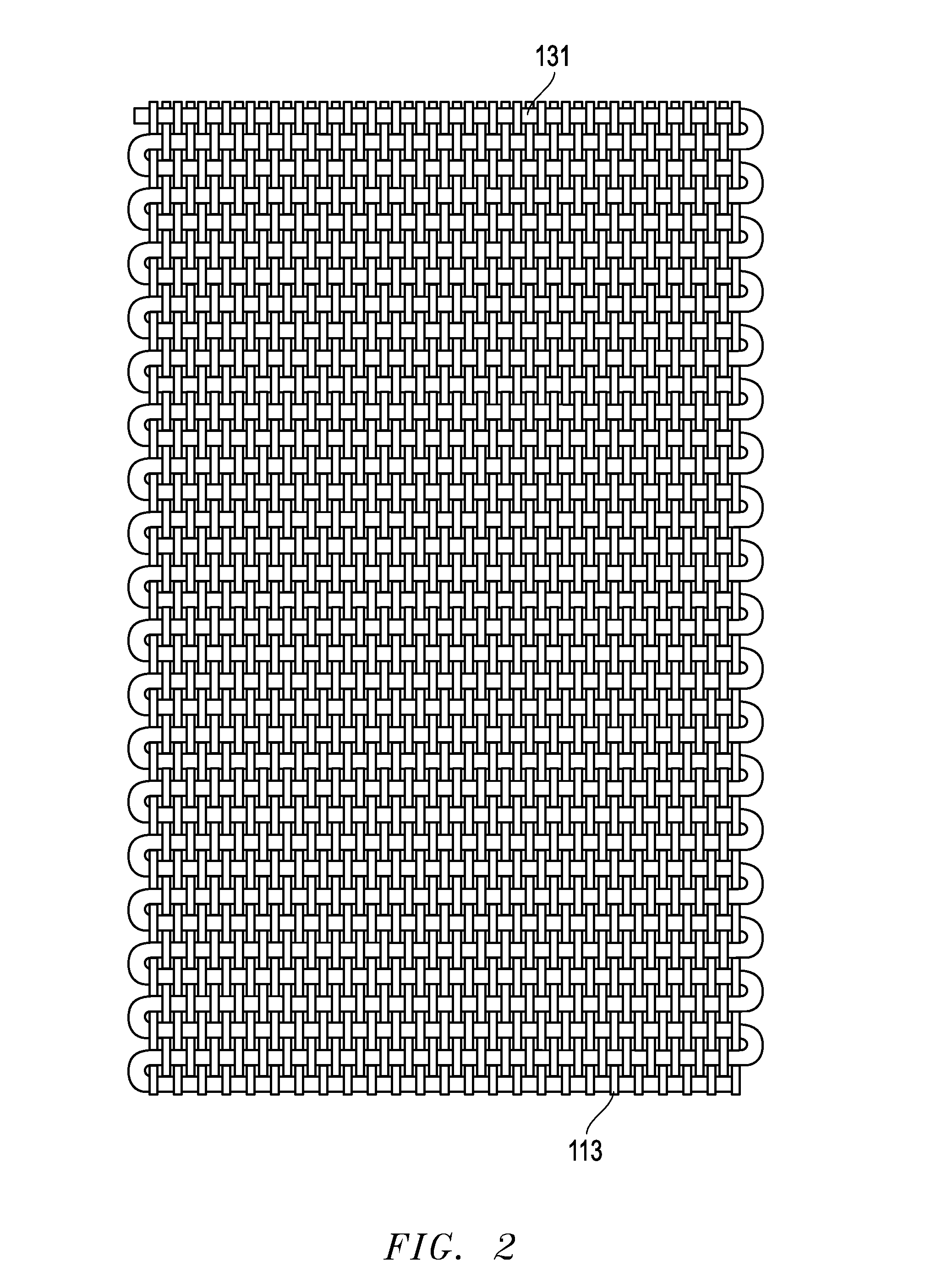

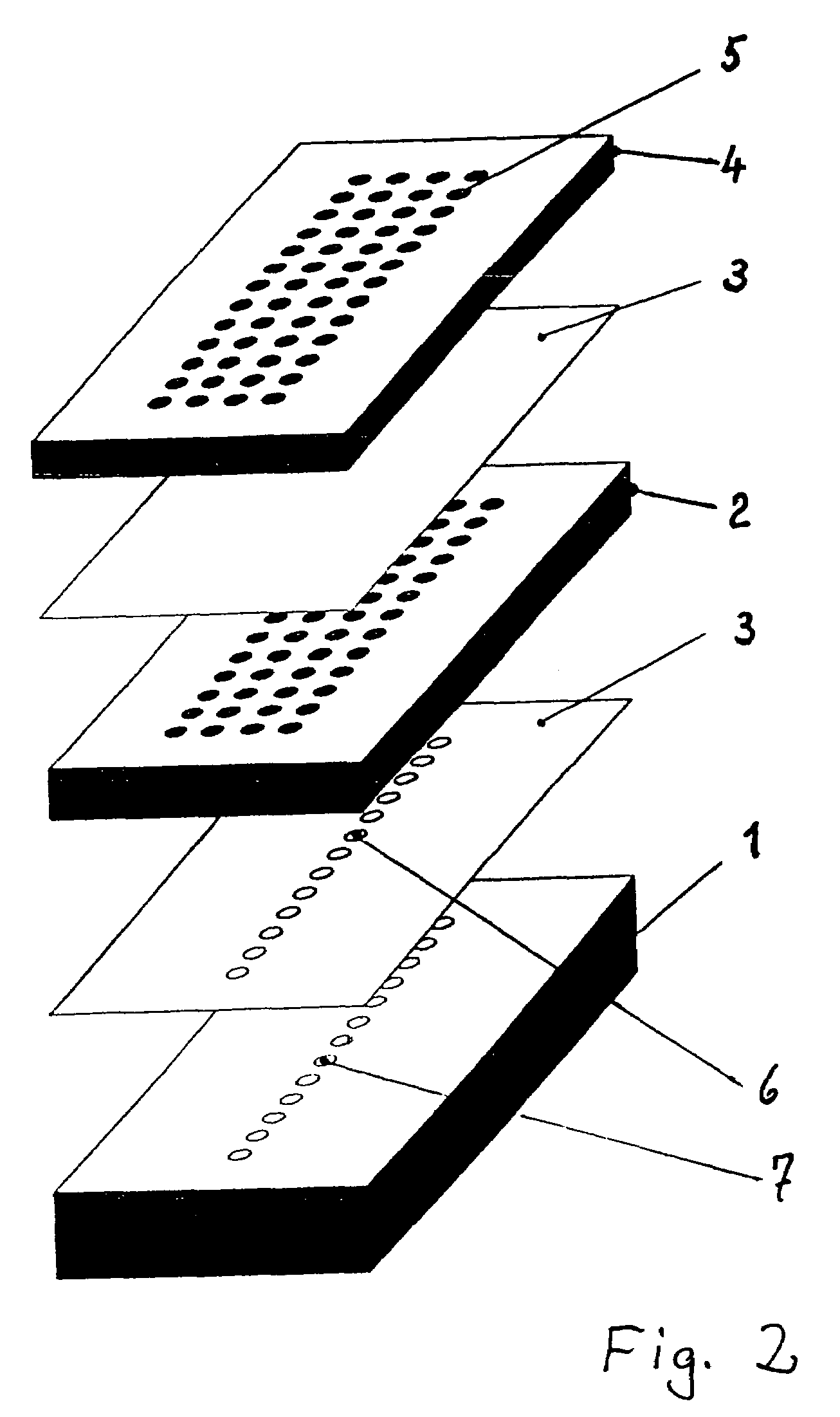

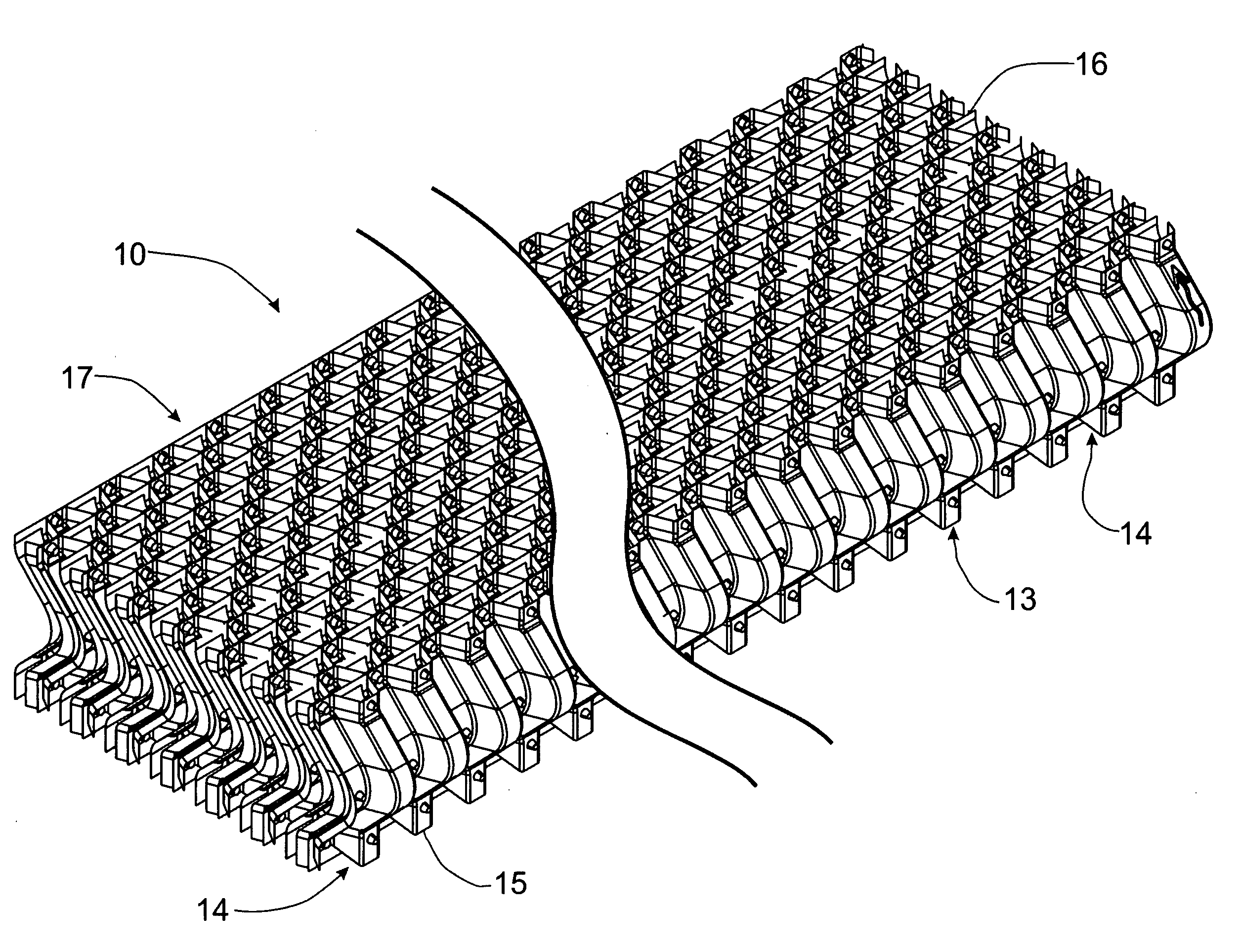

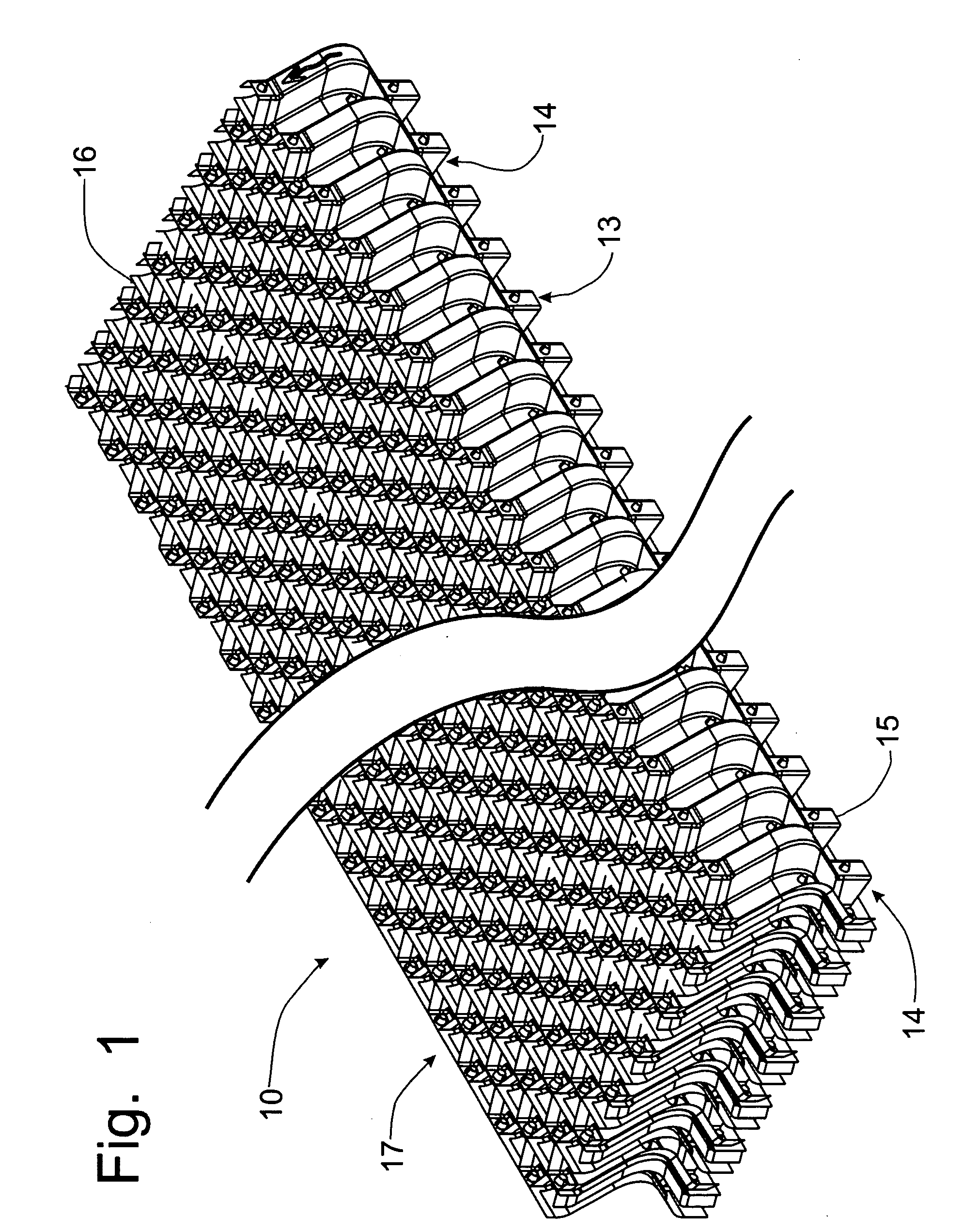

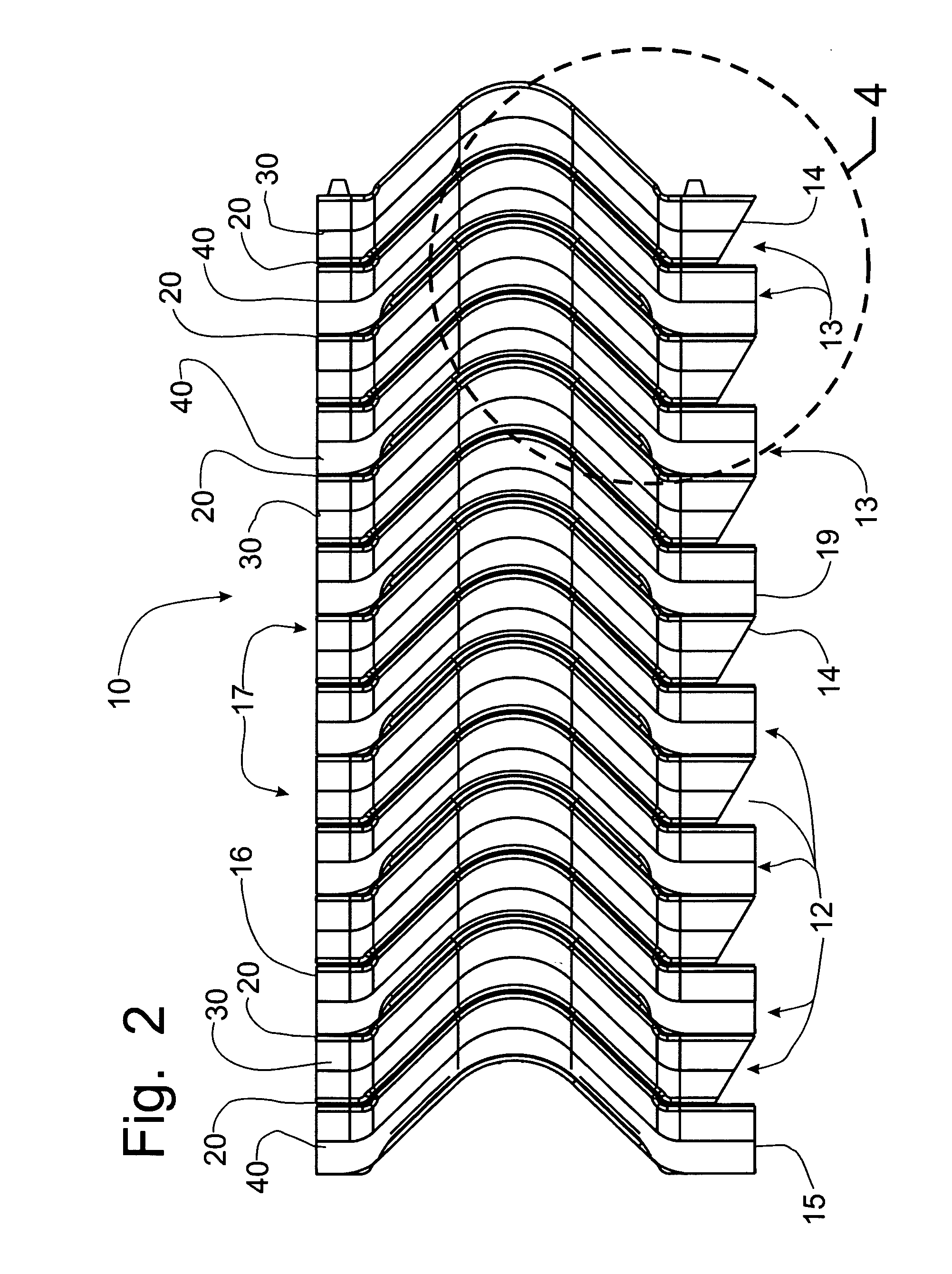

Filtration system and dynamic fluid separation method

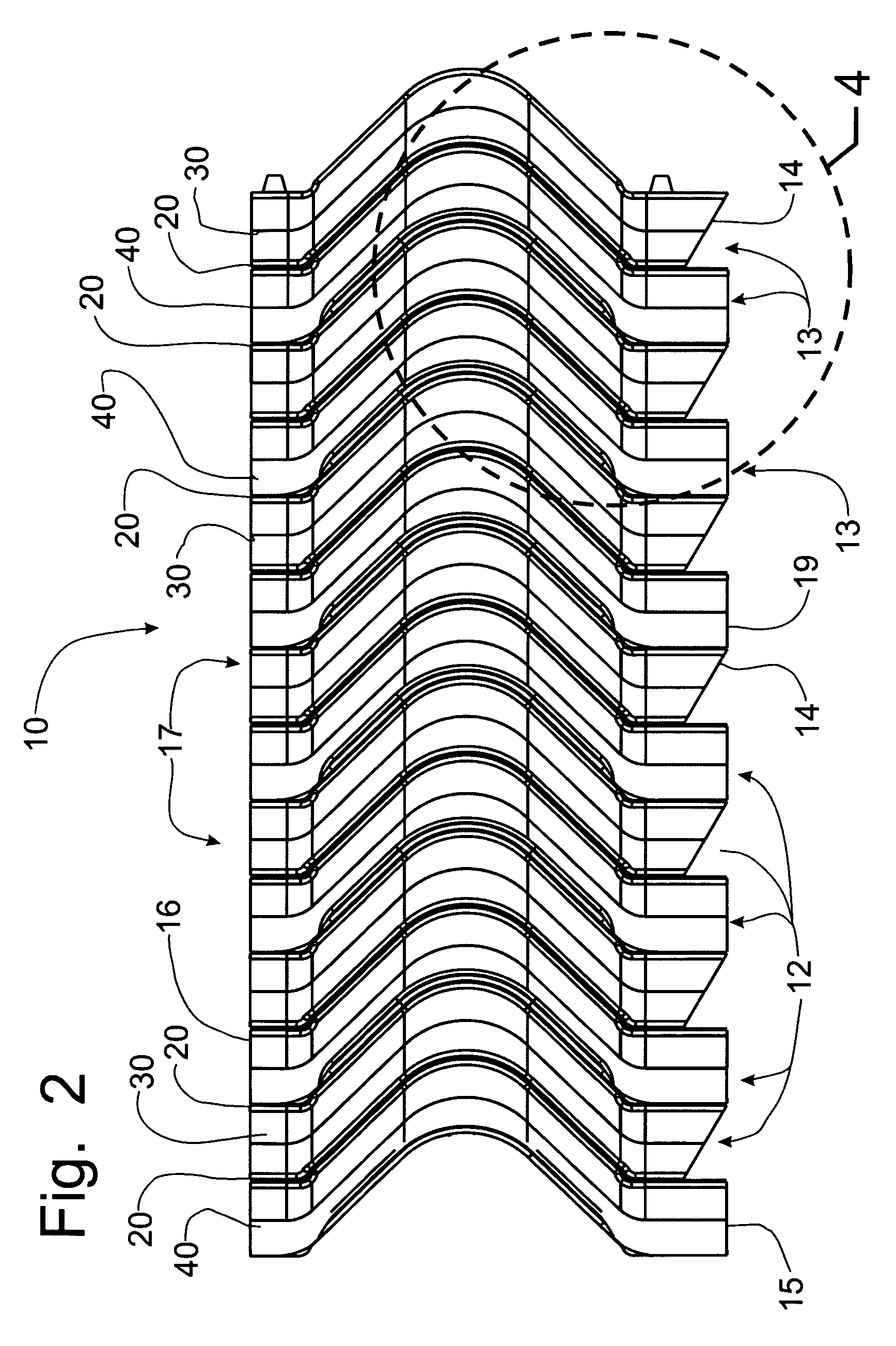

InactiveUS20050023207A1Maintain structural strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPorous membraneMembrane configuration

A filtration system is provided with filter media operable to remove solids, particulate and colloidal matter from a process fluid. The filtration system may include one or more porous membranes which are anchored or secured on their periphery with a large open work area operable to remove selected components from the process fluid. The filter media may include an envelope formed from two membrane sheets with a spacer element disposed there between. A chamber or collection zone may be formed within the envelope to receive clarified fluid separated from the process fluid. Alternatively, the filter media may be multiple layers of spiral wound membranes or a roll of membranes.

Owner:PHASE

Brake plate and method and apparatus for manufacturing same

InactiveUS6910255B2Improve bindingImprove structural strengthSpringsMetal rolling stand detailsEngineeringMechanical engineering

The invention is a plate for holding a friction material in a brake assembly. The plate preferably comprises a contact surface for attaching the friction material to the plate, a second surface opposing the contact surface; and a plurality of retaining structures formed on the contact surface, each retaining structure comprising a projecting member extending from a point between the contact surface and the second surface, so that the member extends outwardly from the contact surface for engagement with the friction material.

Owner:NUCAP IND

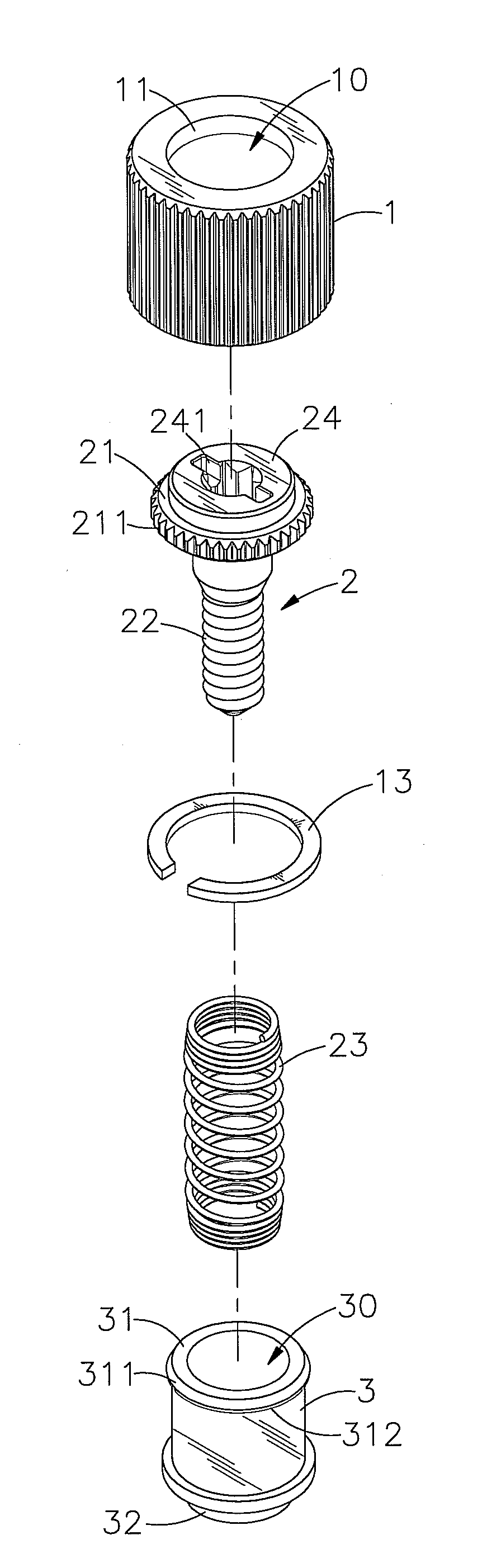

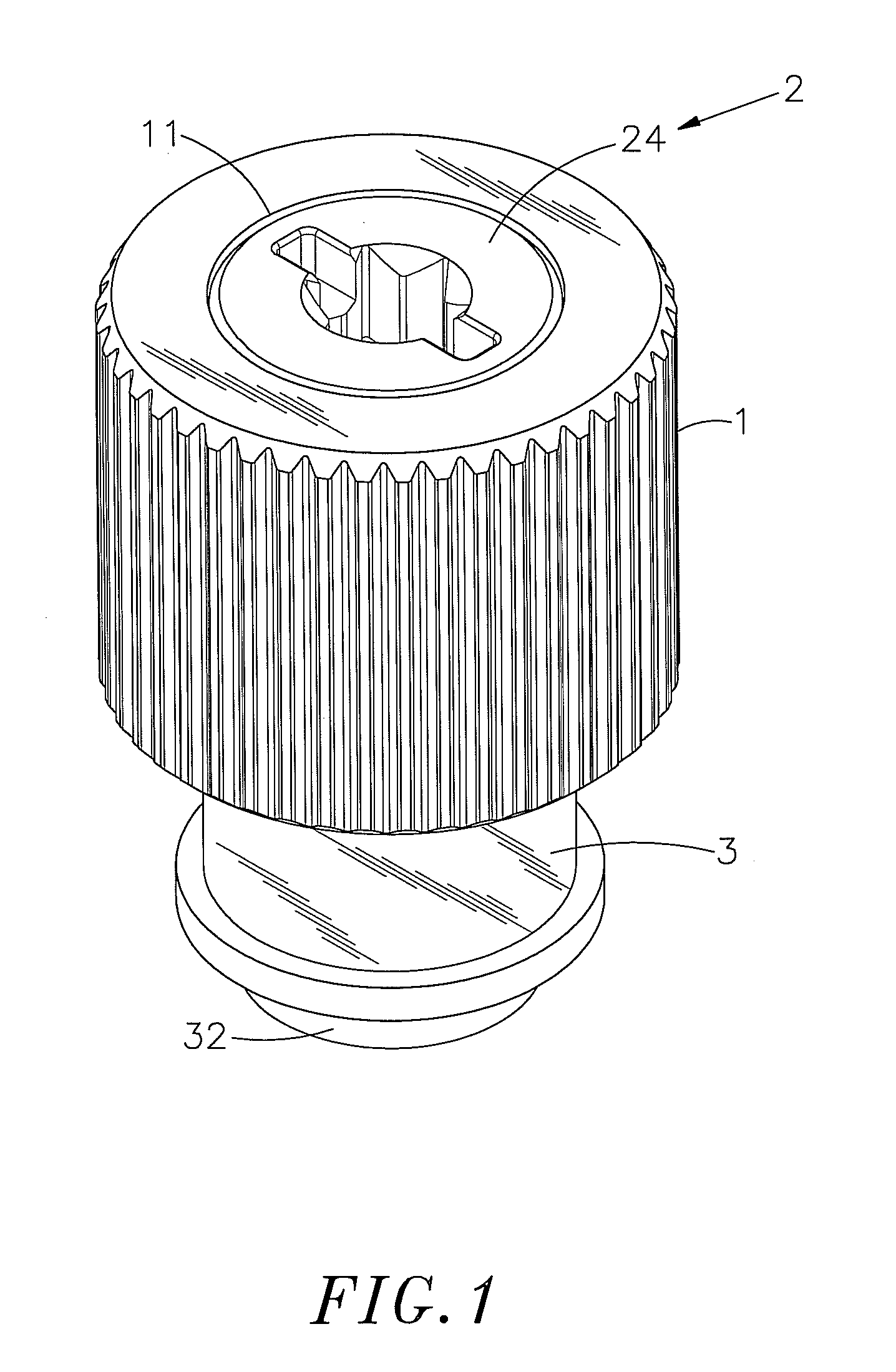

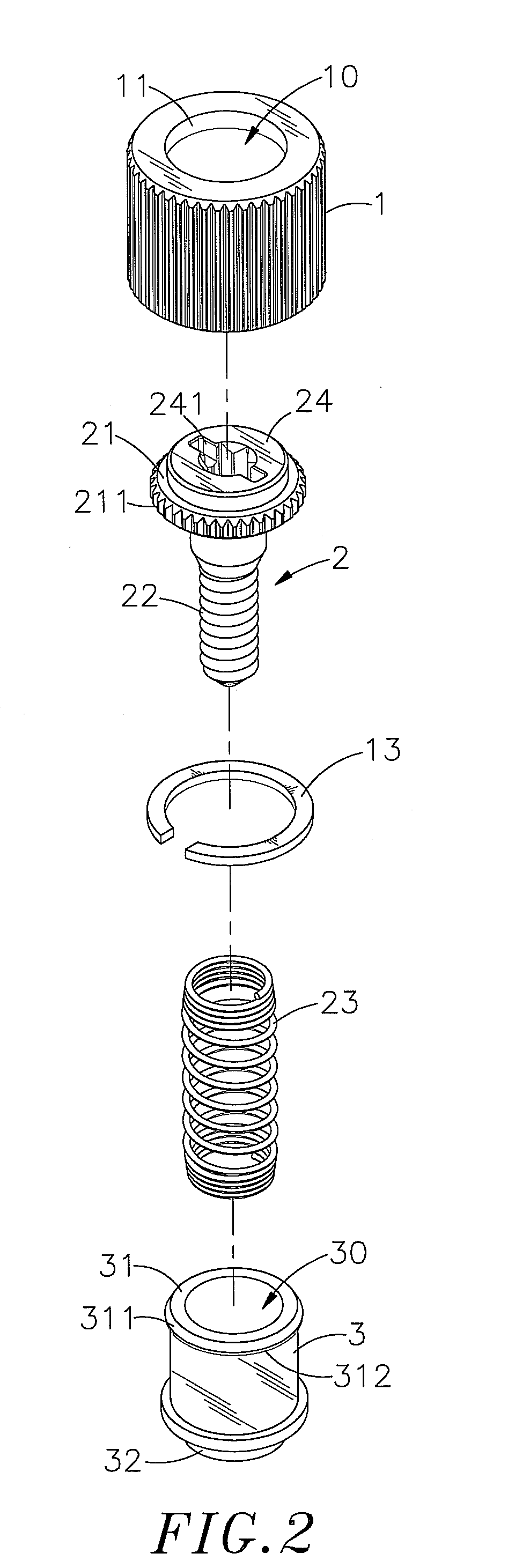

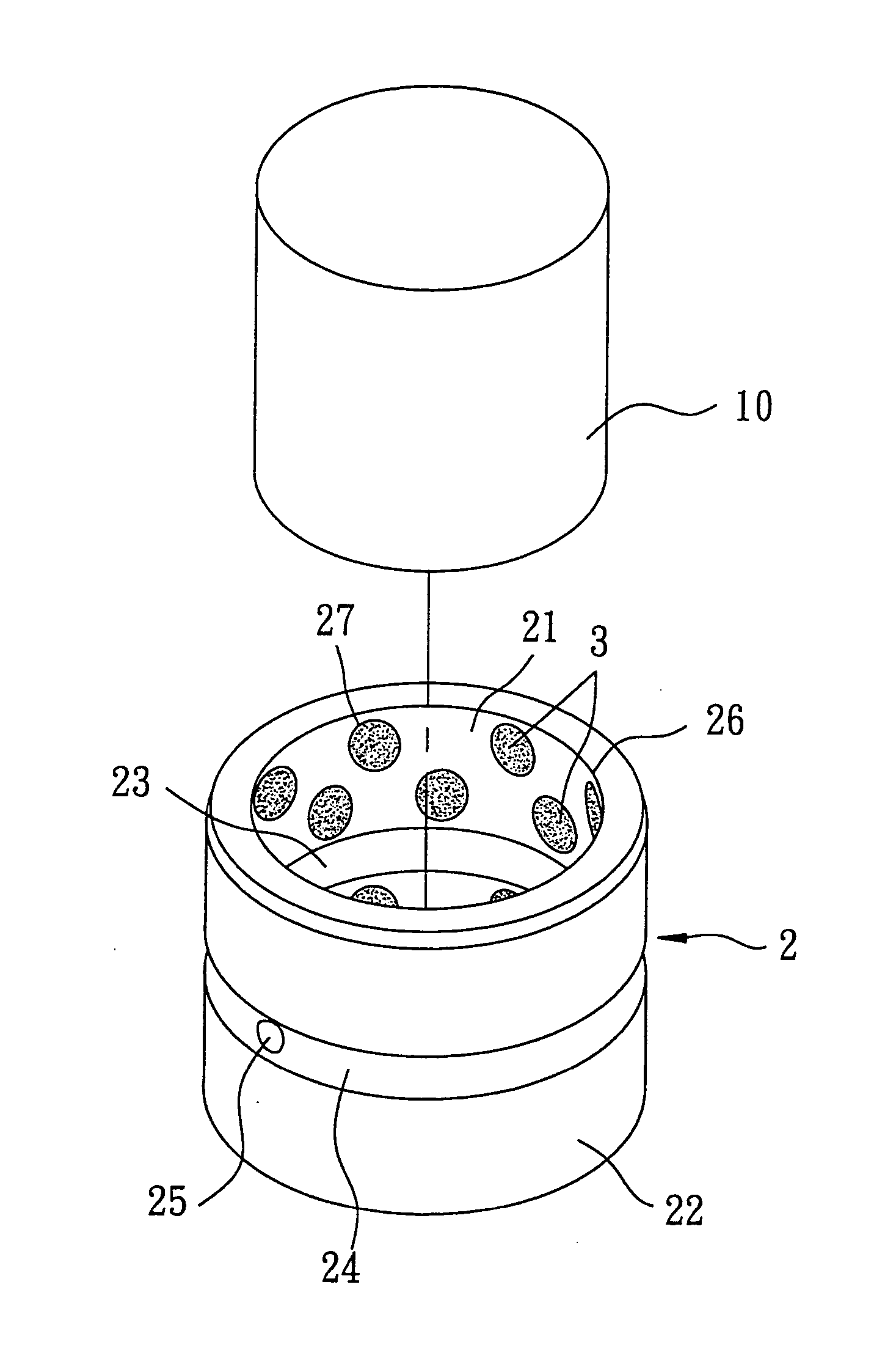

Floating fastener

A floating fastener includes a mounting socket bonded to a first plate member and having a beveled top mounting flange, a cap member axially slidably coupled to the mounting socket, an expandable stop ring mounted in a locating groove in the bottom side of the cap member to facilitate coupling of the cap member to the mounting socket and to prohibit the cap member from moving upwardly over the top mounting flange of the mounting socket, a locking member affixed to the cap member for fastening to a second plate member to lock the first and second plate members together, and a spring member sleeved onto the locking member and stopped between the head of the locking member and a shoulder in the mounting socket.

Owner:HANWIT PRECISION IND LTD

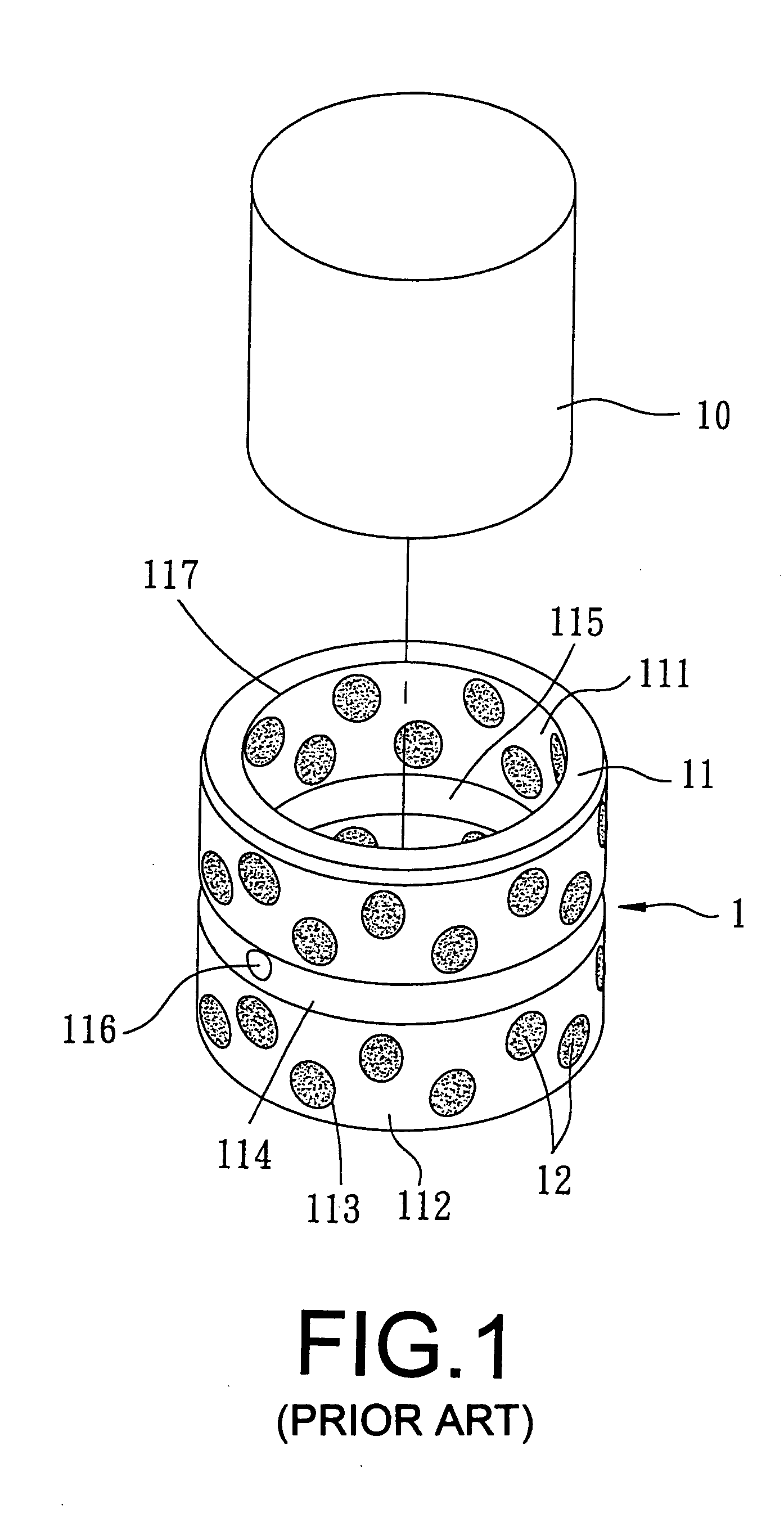

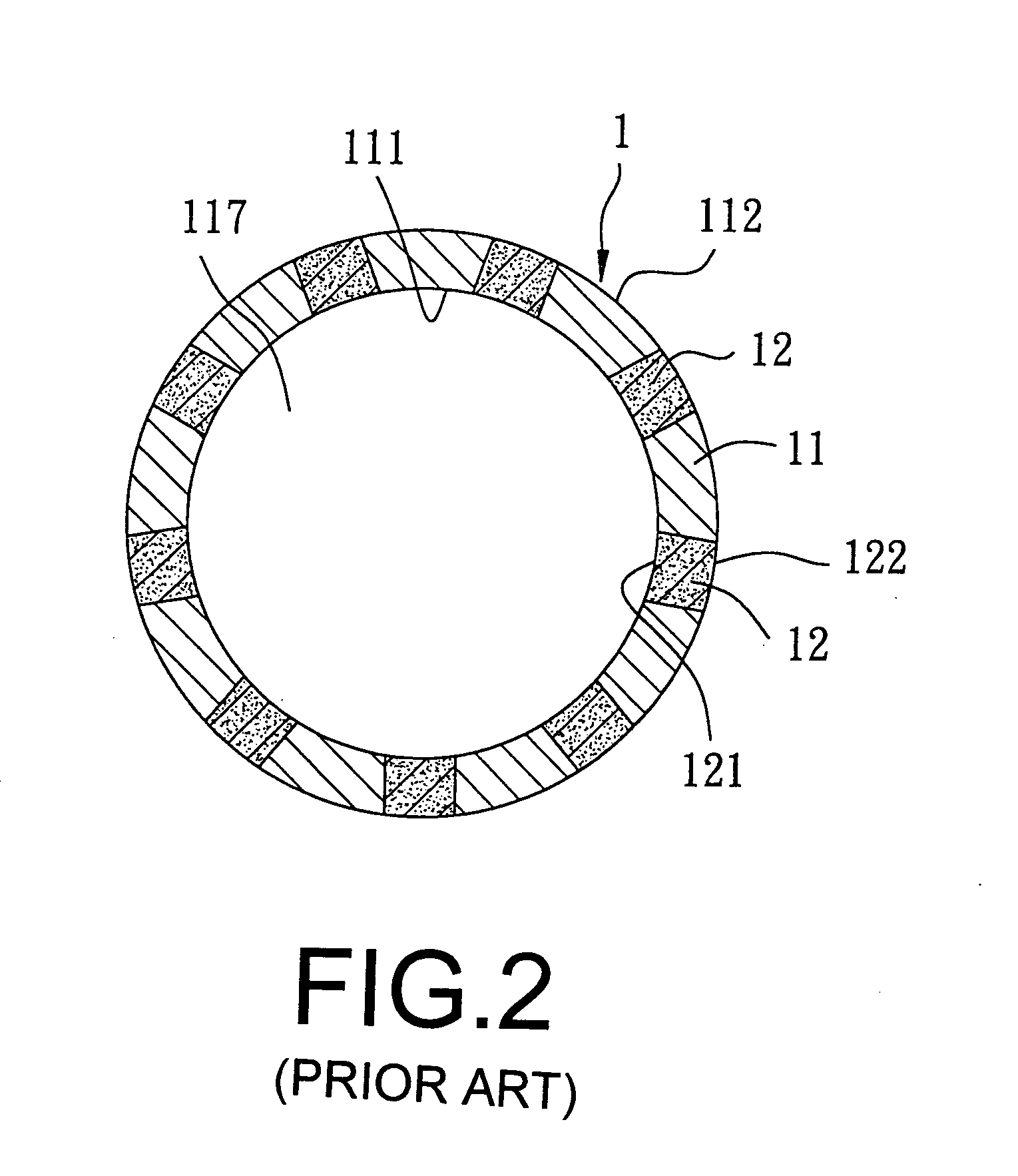

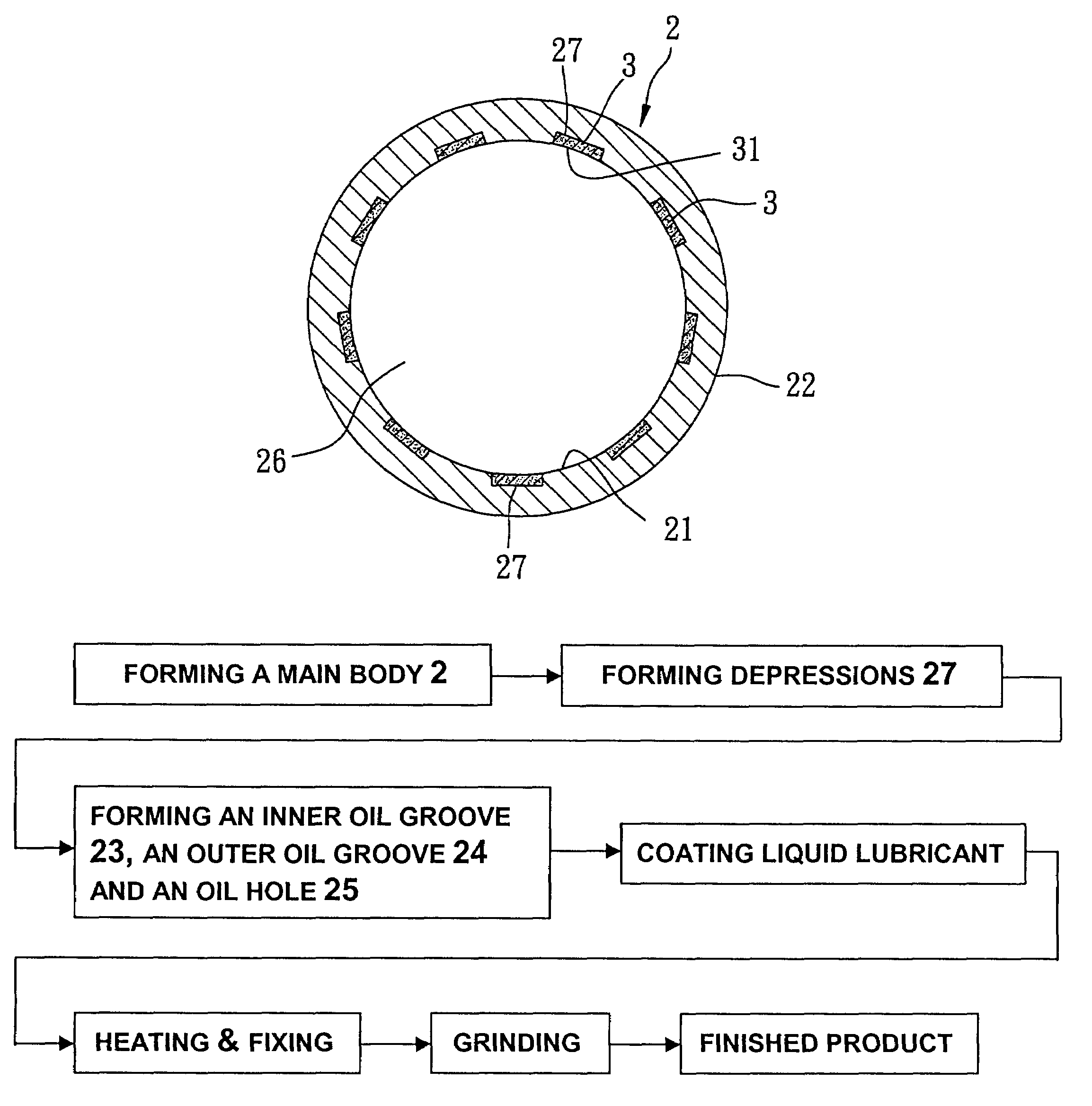

Self-lubricating bearing and method of producing the same

This invention relates to a self-lubricating bearing and a method of producing the same. The self-lubricating bearing includes a main body and a plurality of solid lubricant pieces. The main body has an inner annular wall surface, an outer annular wall surface, and a through hole defined by the inner annular wall surface. The solid lubricant pieces are embedded in a plurality of depressions of the inner annular wall surface by coating and grinding and each has a radial inside annular surface in a curve conforming to that of the inner annular wall surface. The forming of the depressions without radially penetrating through the outer annular wall surface to make the solid lubricant pieces embedded into the depressions with less amount by coating and grinding allows the self-lubricating bearing to reduce the material cost, and keep its structural strength and lubricating effect simultaneously.

Owner:LEE HU I LONG

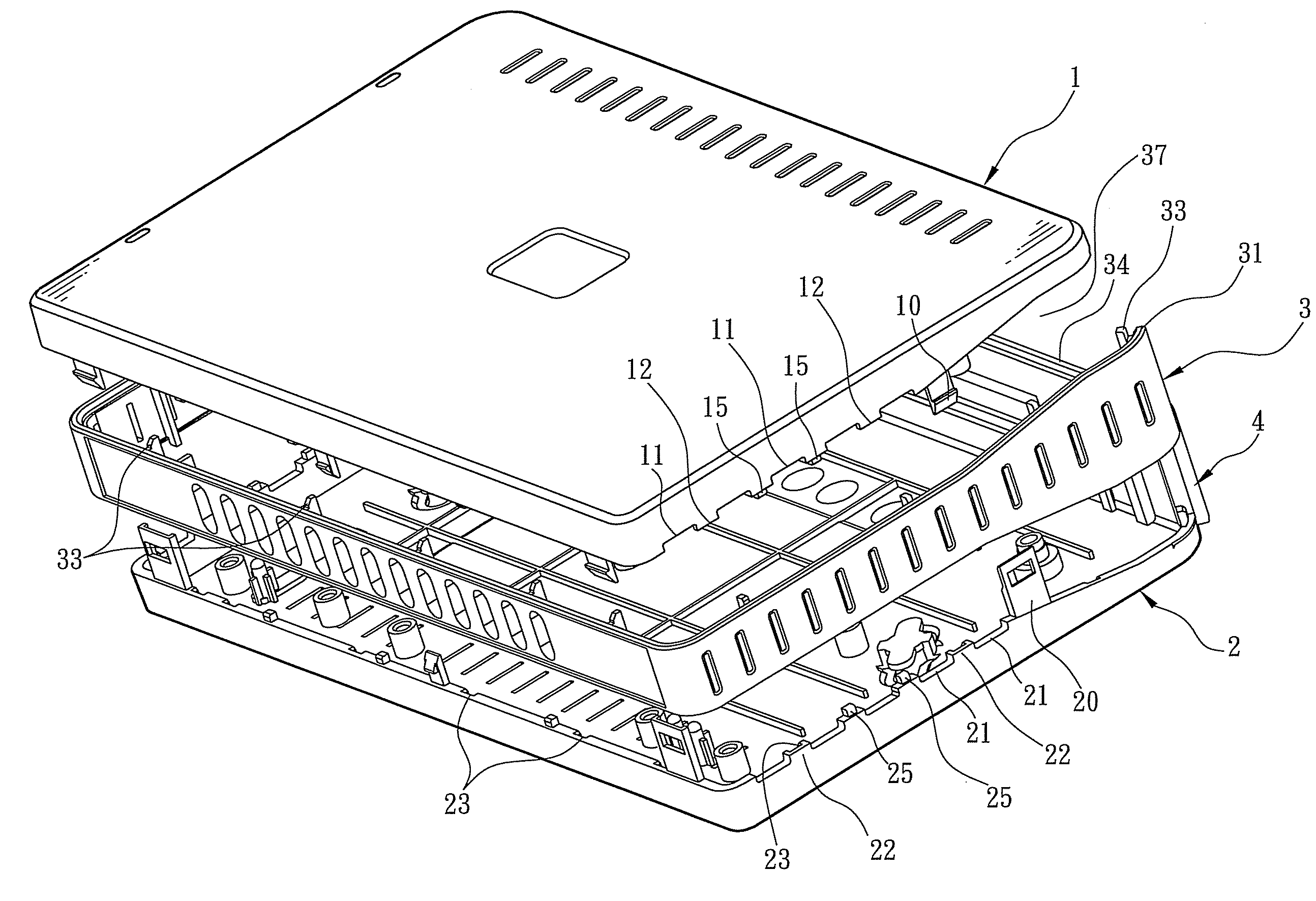

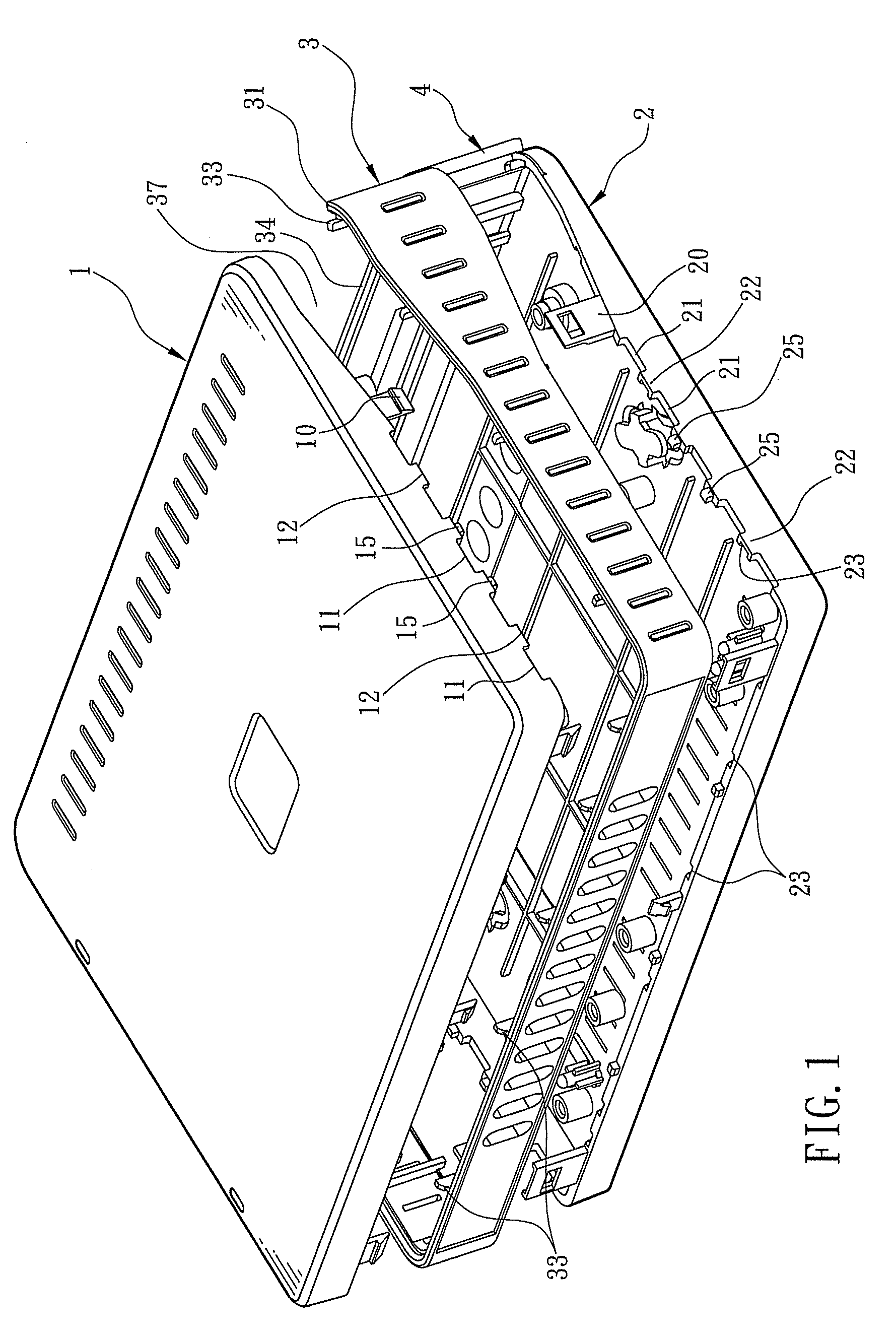

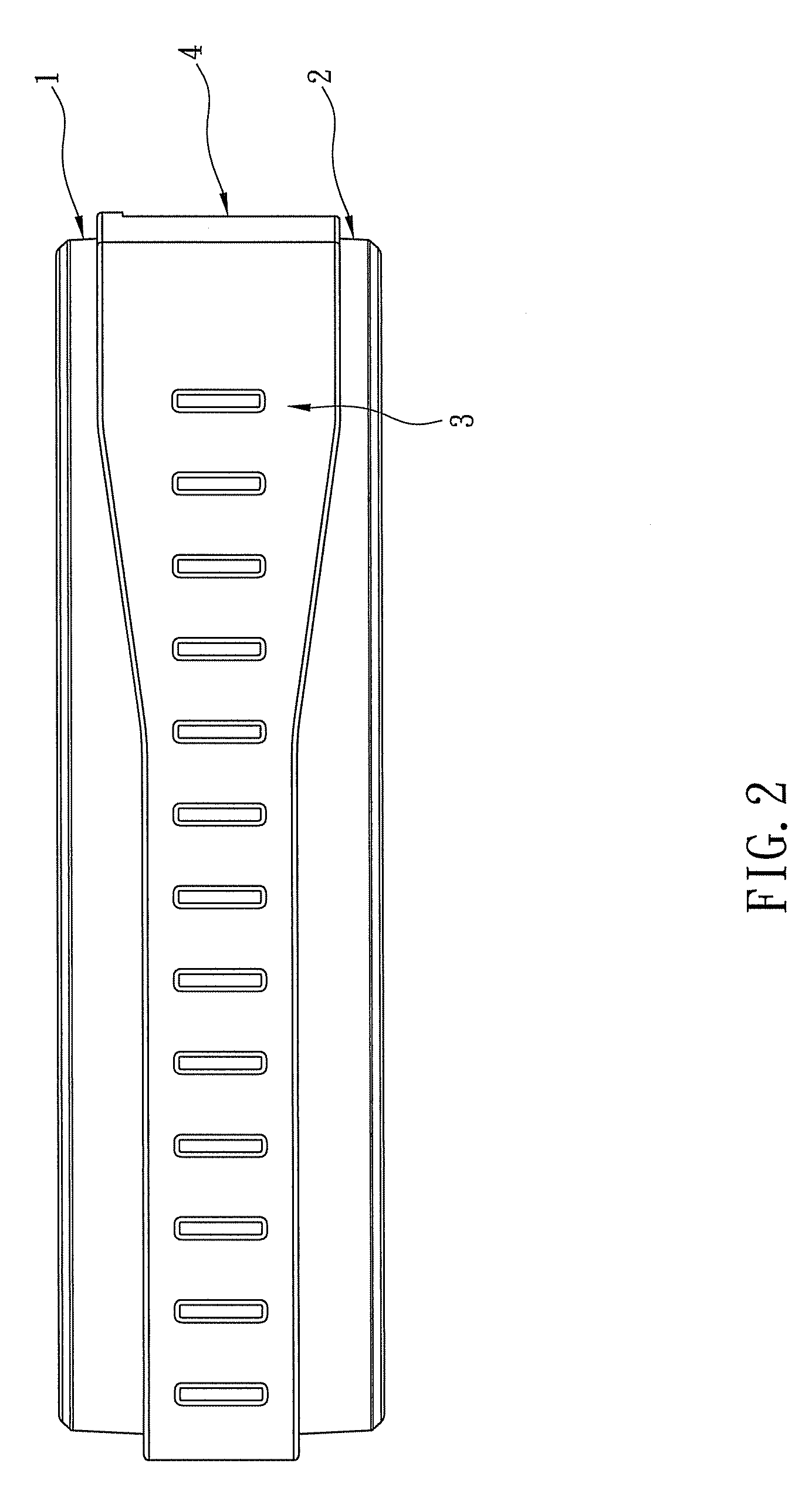

Housing with hidden ventilation holes

ActiveUS7712621B2Maintain structural strengthRigid containersElectrical apparatus casings/cabinets/drawersEngineeringFlange

The present invention is to provide a housing of an electronic device having a plurality of hidden ventilation holes, which comprises an intermediate frame, an upper shell and a lower shell, wherein the intermediate frame comprises an upright flange along the outer edges thereof, the upper shell and the lower shell respectively have its edge secured to an inner edge inside the flange of the intermediate frame, the upper shell and the lower shell both comprise a plurality of spaced cavities formed along the edge of the upper shell and the lower shell, and both the cavities are concealed behind the flange when the intermediate frame is assembled with the upper shell and the lower shell respectively, so as to maintain a structural strength of the housing and to be looked aesthetic.

Owner:D-LINK

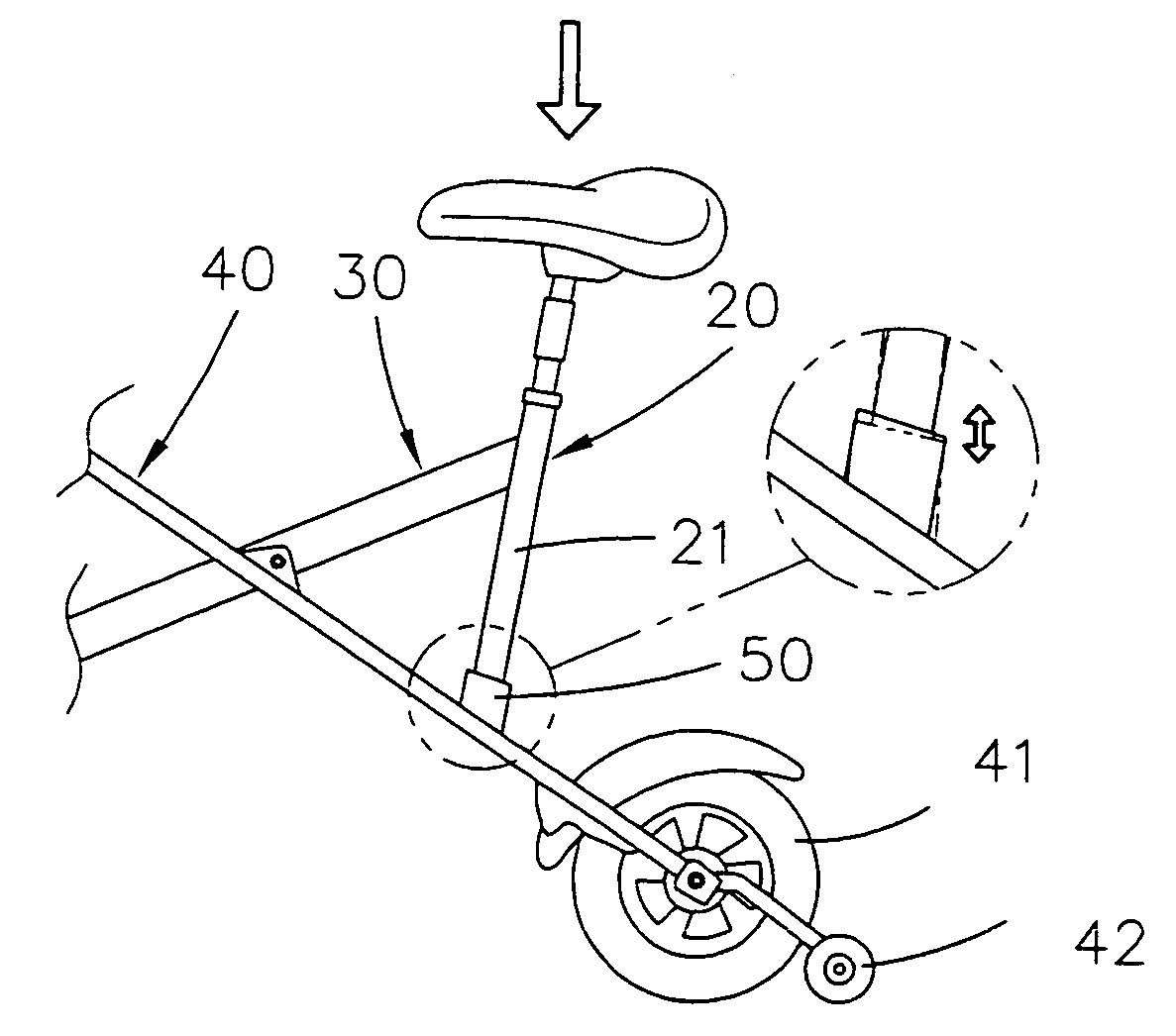

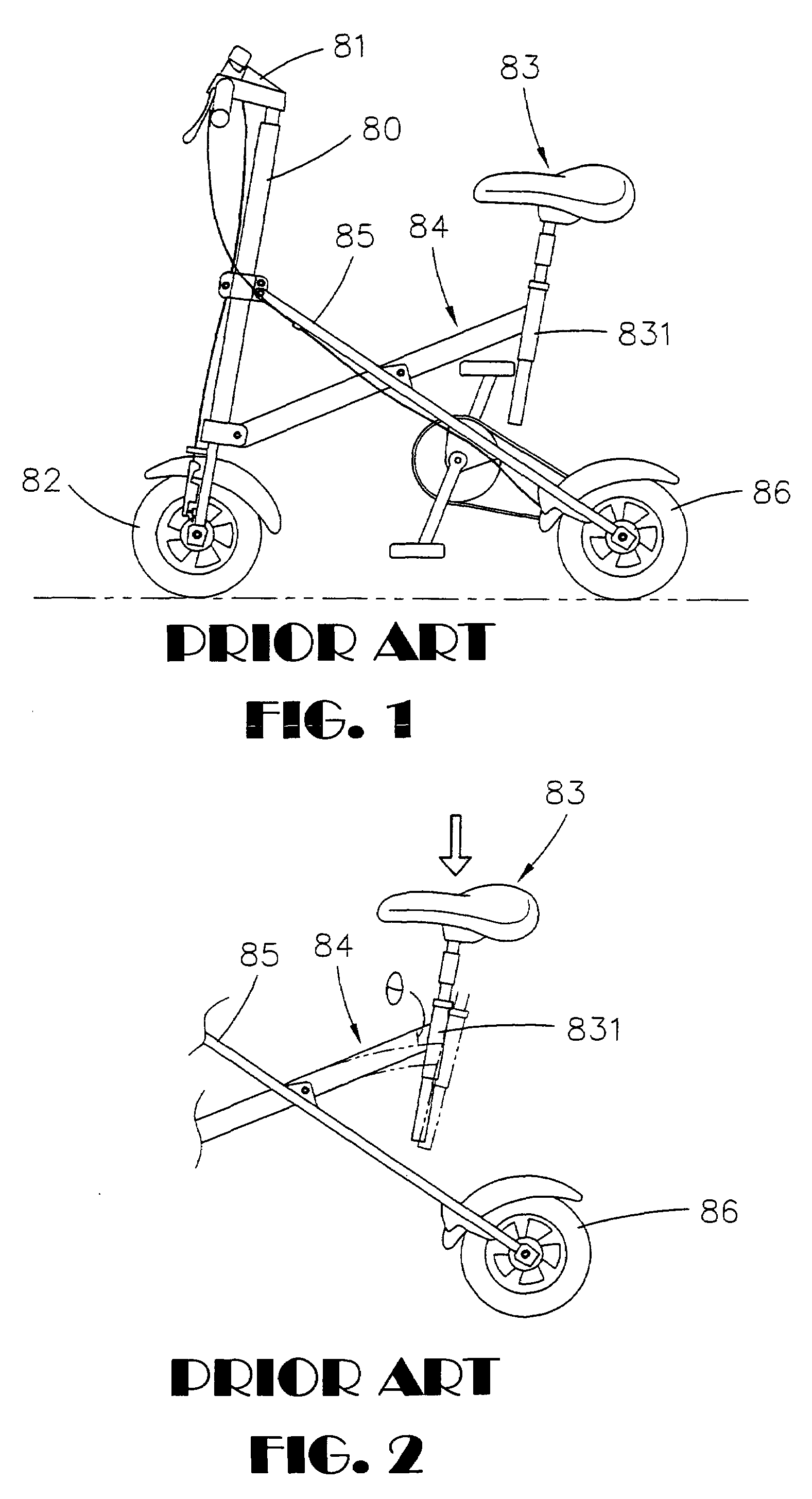

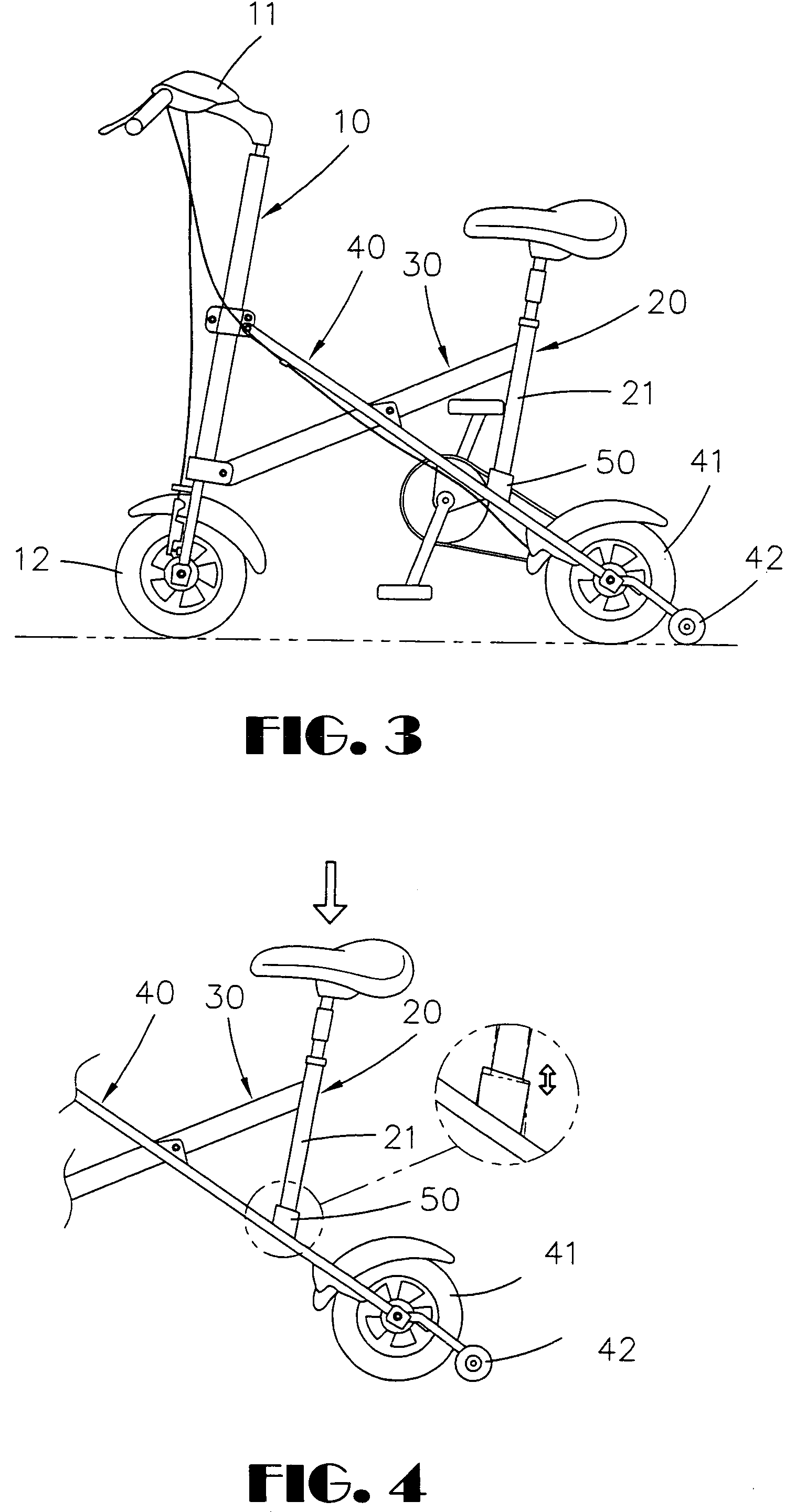

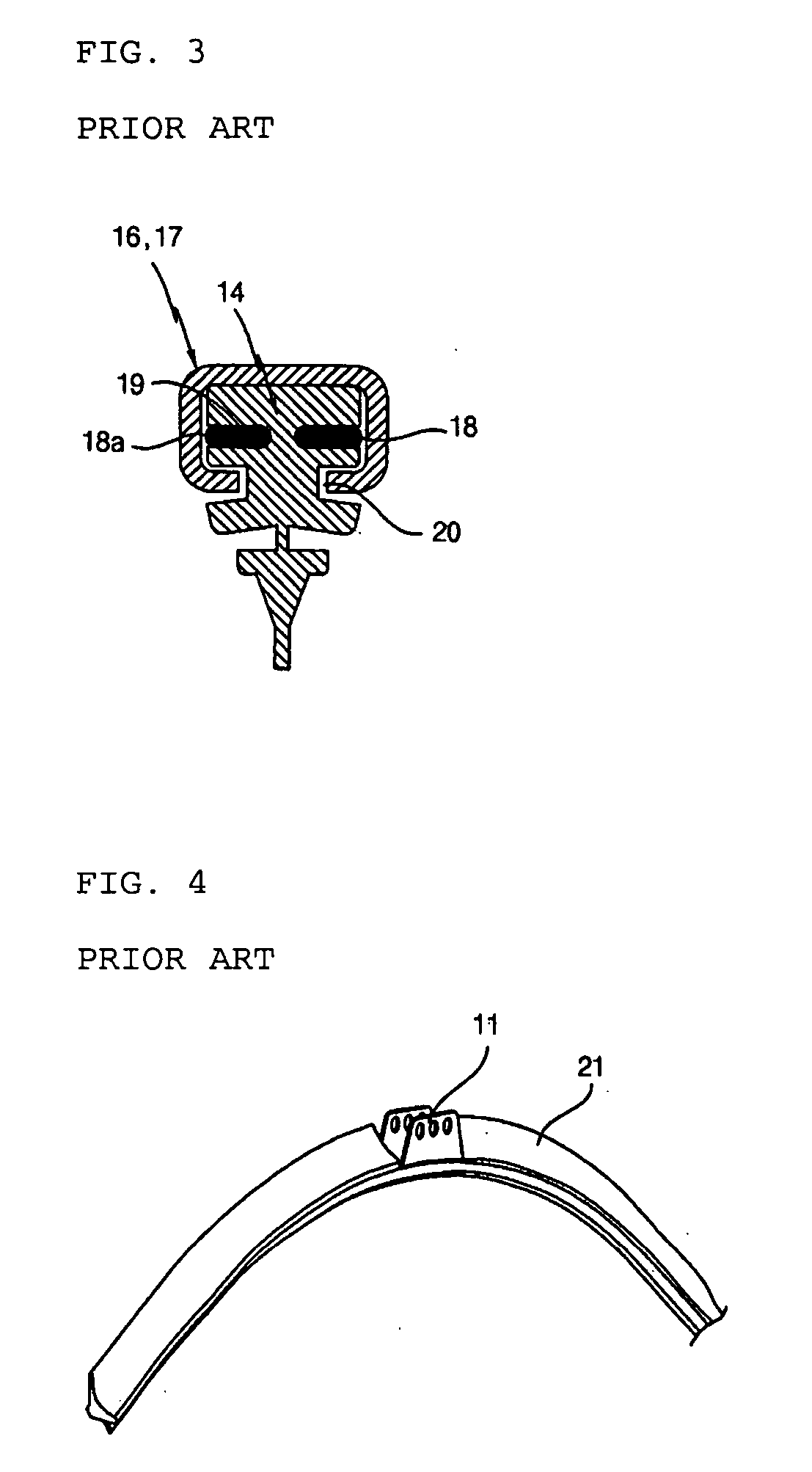

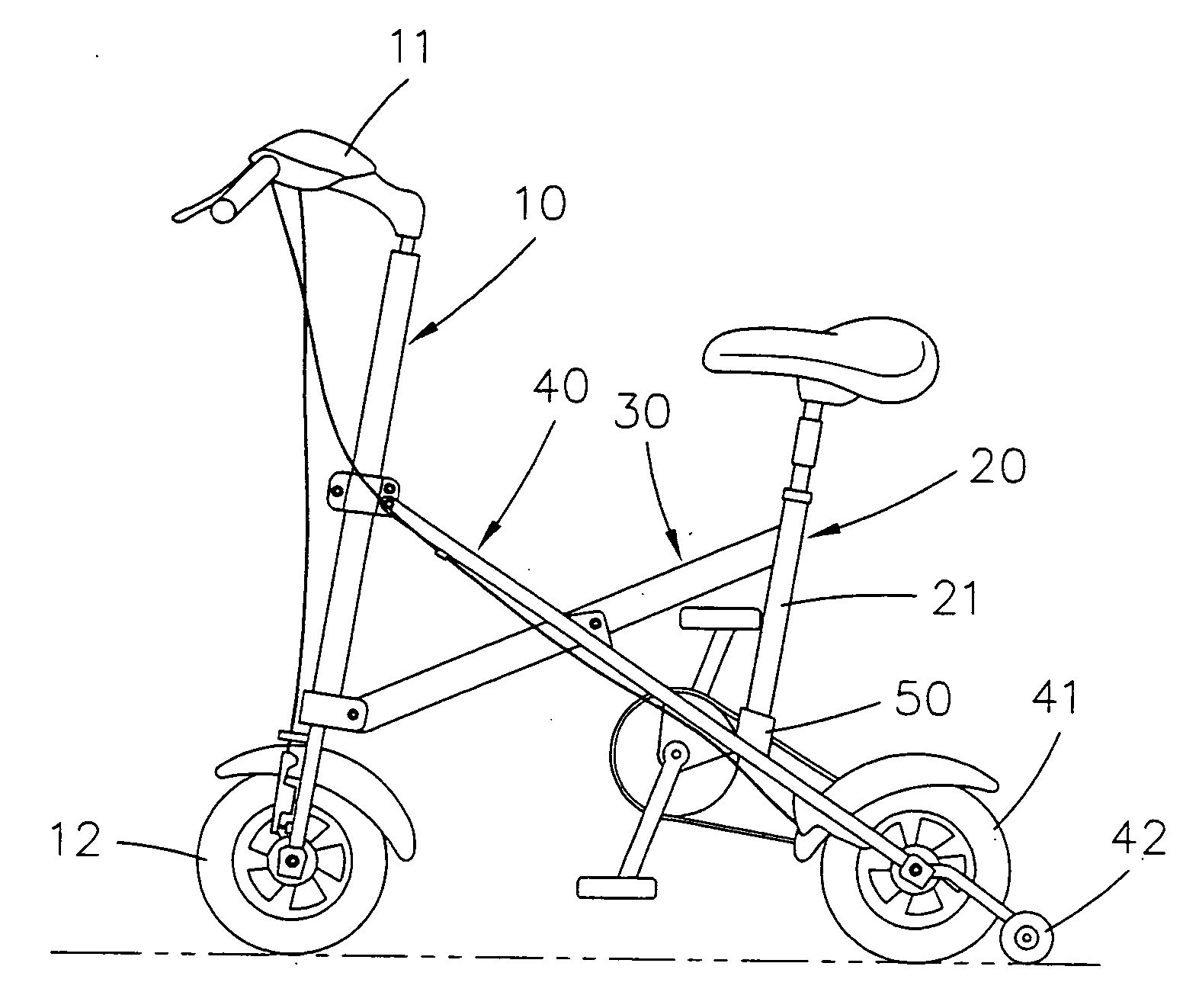

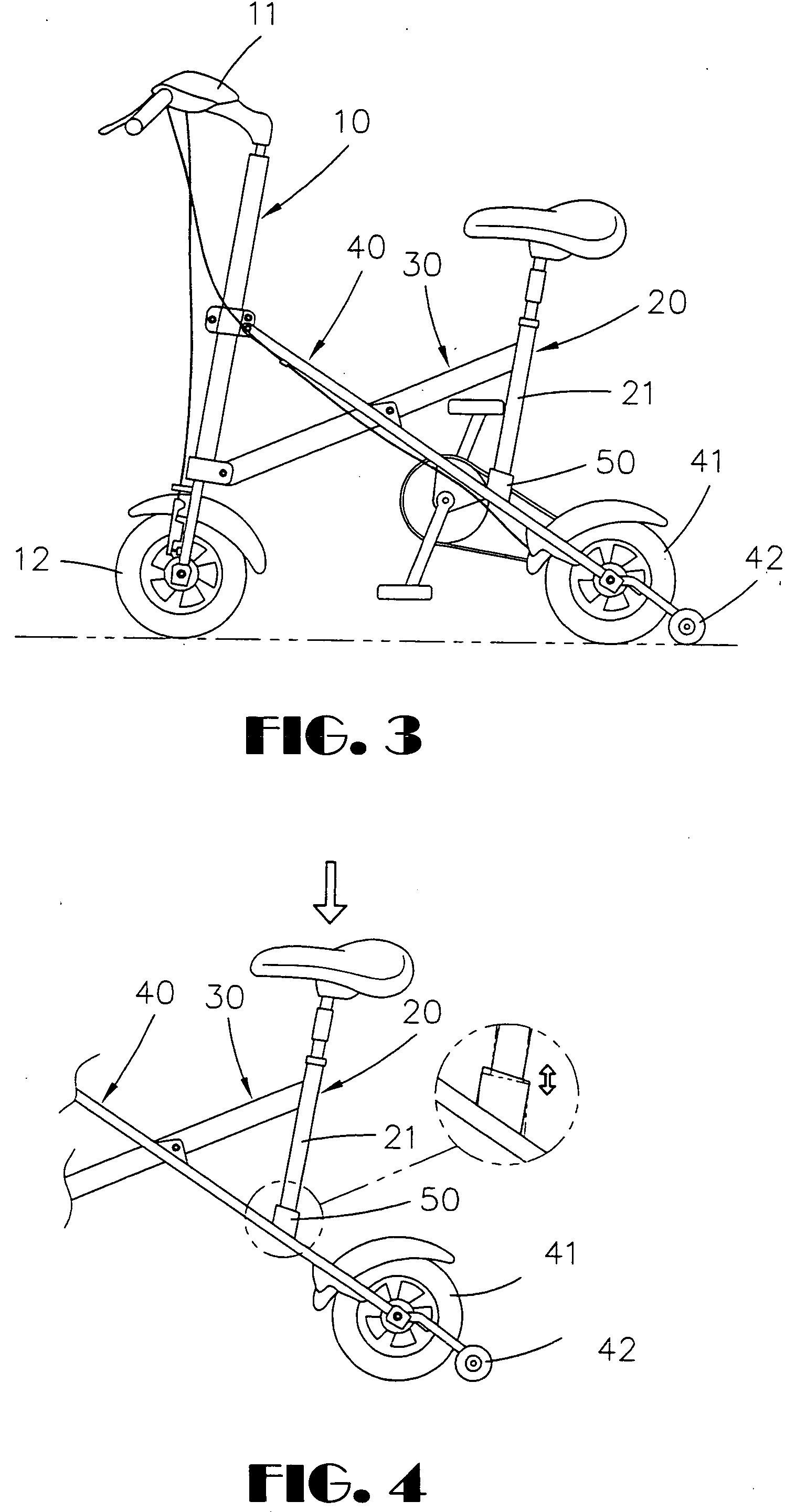

Folding bicycle

InactiveUS7314226B2Maintain structural strengthImprove balancePassenger cyclesWheel based transmissionMechanical engineering

Provided is a folding bicycle comprising two auxiliary rear wheels at both sides of a rear wheel; a seat including a seat tube extended downward; a first crossbar having a front end pivotably connected to a lower portion of a handle above a front wheel, and a rear end fixedly connected to an intermediate portion of the seat tube; a pair of second crossbars having two front ends pivotably connected to an intermediate portion of the handle, and two rear ends fixedly connected to both ends of an hub of the rear wheel. The first crossbar passes an intermediate portion of the second crossbar and is pivotably connected thereto. A flexible shock absorbing means is provided at a joining portion of the seat tube and the second crossbars. The shock absorbing means is adapted to elastically deform when a downward force is exerted on the seat.

Owner:HSU YU TU

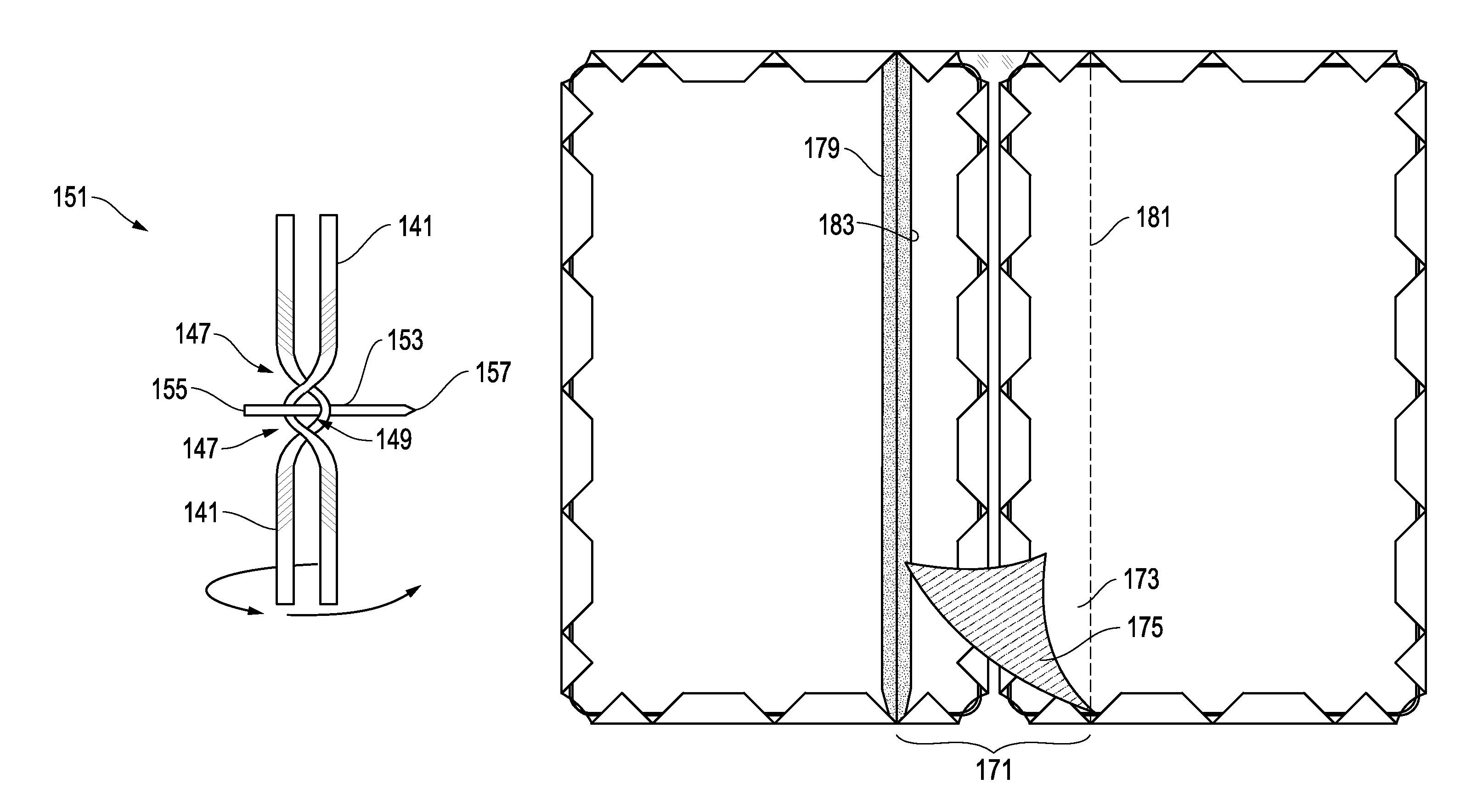

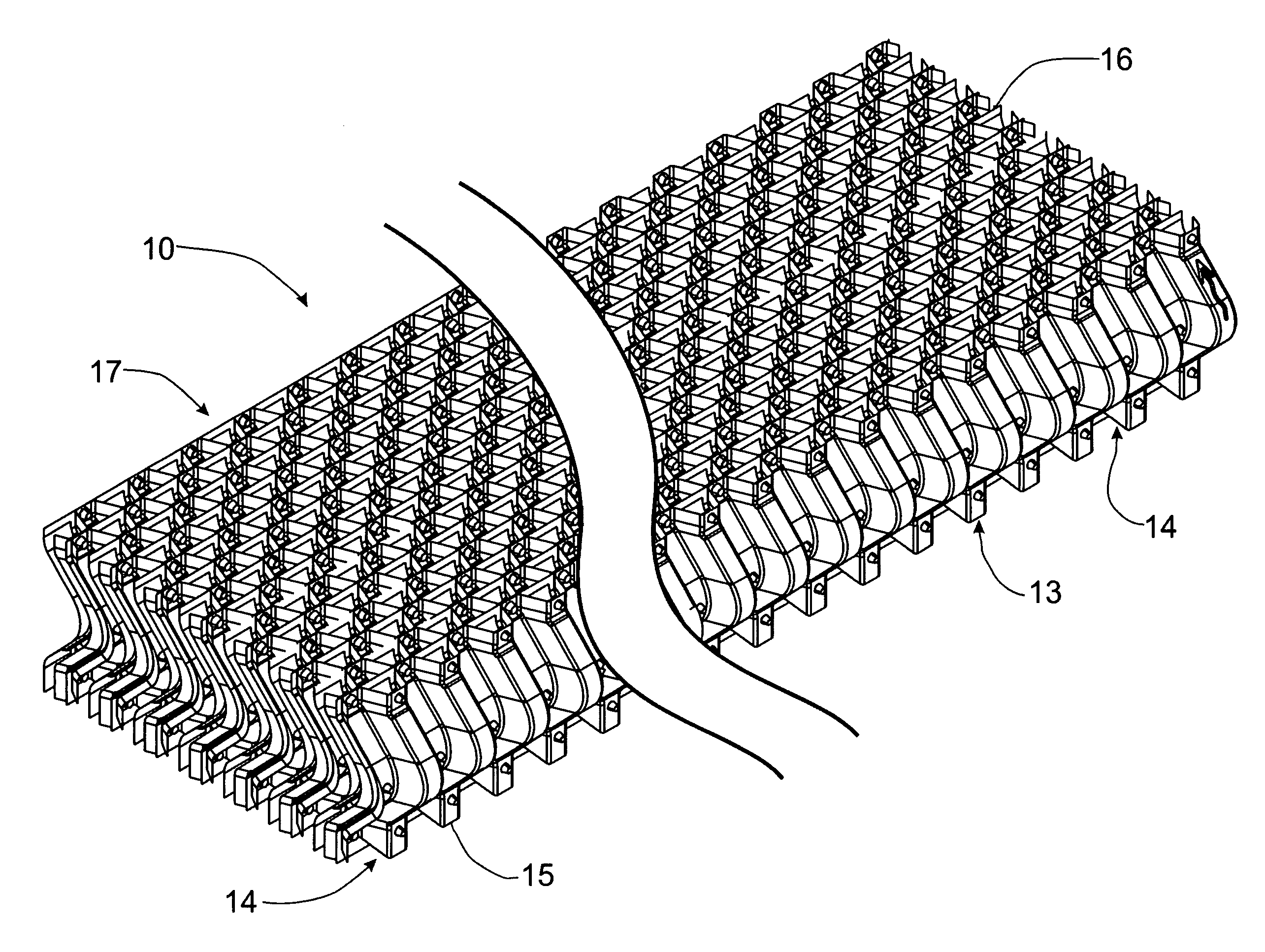

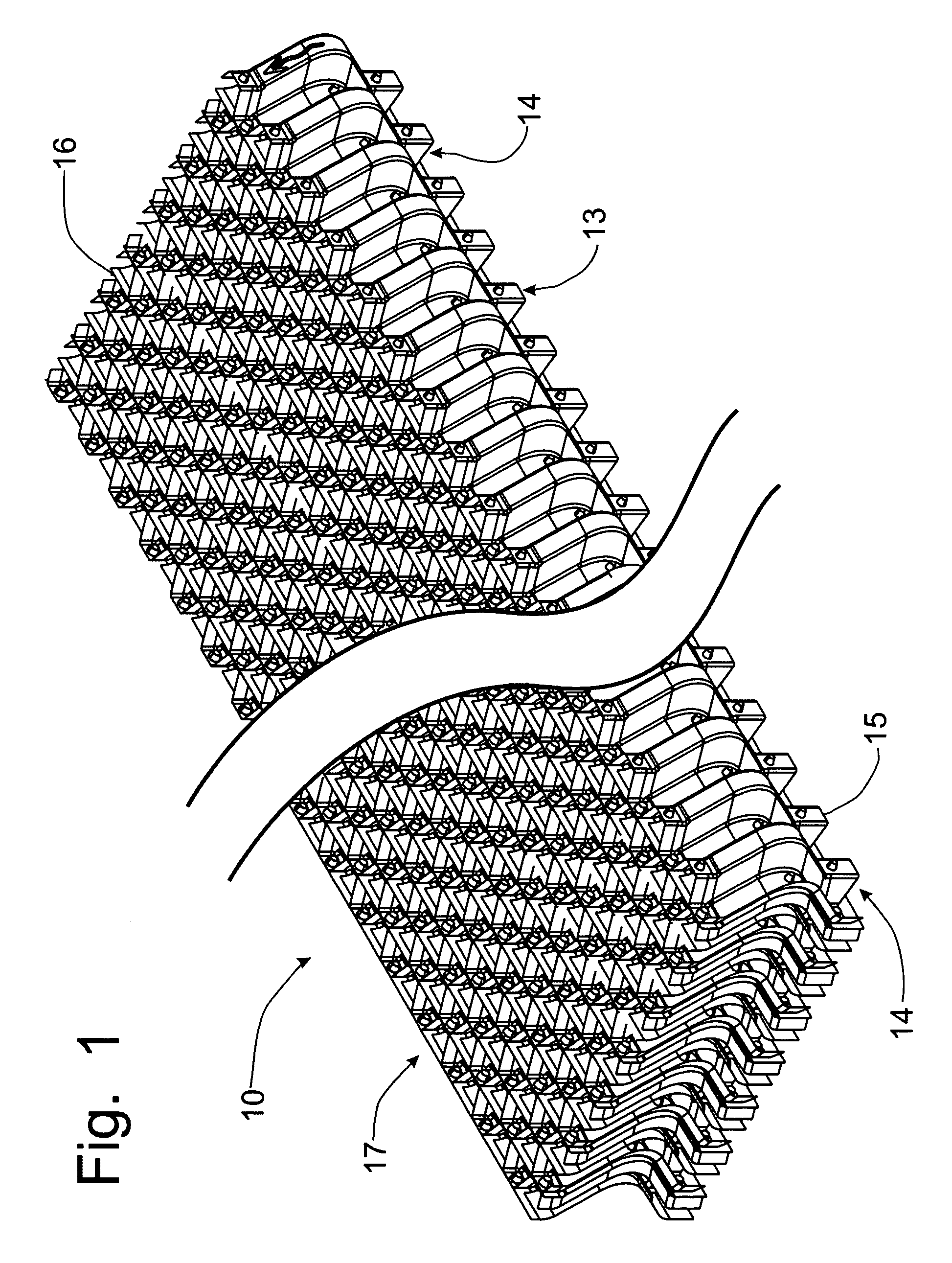

Blast control blanket

ActiveUS8573125B1Maximum protectionEasy to modifyReactive armourDynamic armourControl systemLocking mechanism

A relatively lightweight, modular, blast control system utilizes a plurality of fabric panels that may be joined to form a matrix or blanket to protect or control the blast. The panels are preferably made from layers of auxetic woven fabric, with each successive fabric layer oriented between 0-90 degrees from the previous layer. The panels may be connected together via a locking mechanism or assembly comprising a cable which runs the length of the perimeter of each fabric panel, and a torque pin rotated about two adjoining cables to form an interlocking connection. The panels connected in this manner form the fully assembled blast control blanket.

Owner:BLAST CONTROL SYST L L C

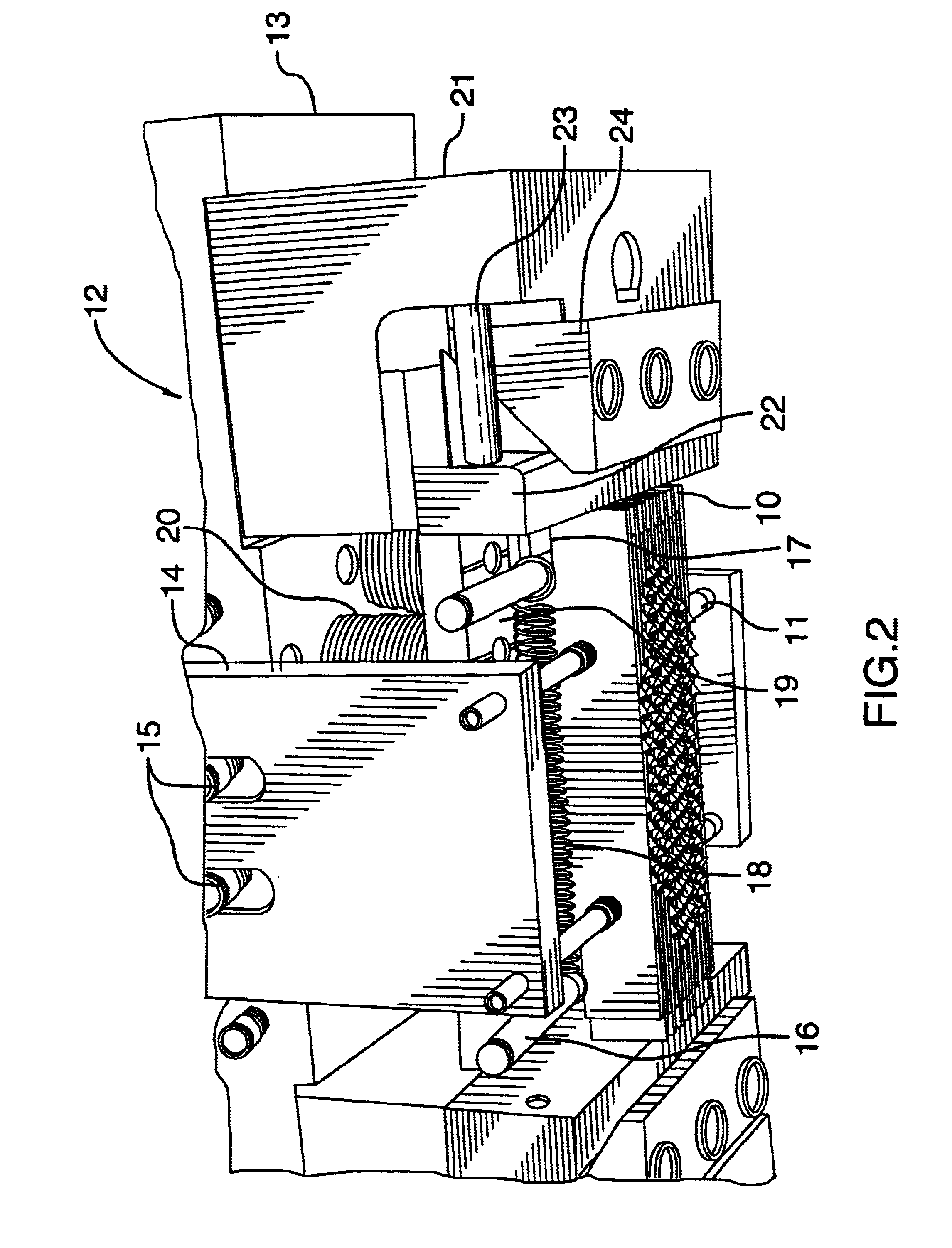

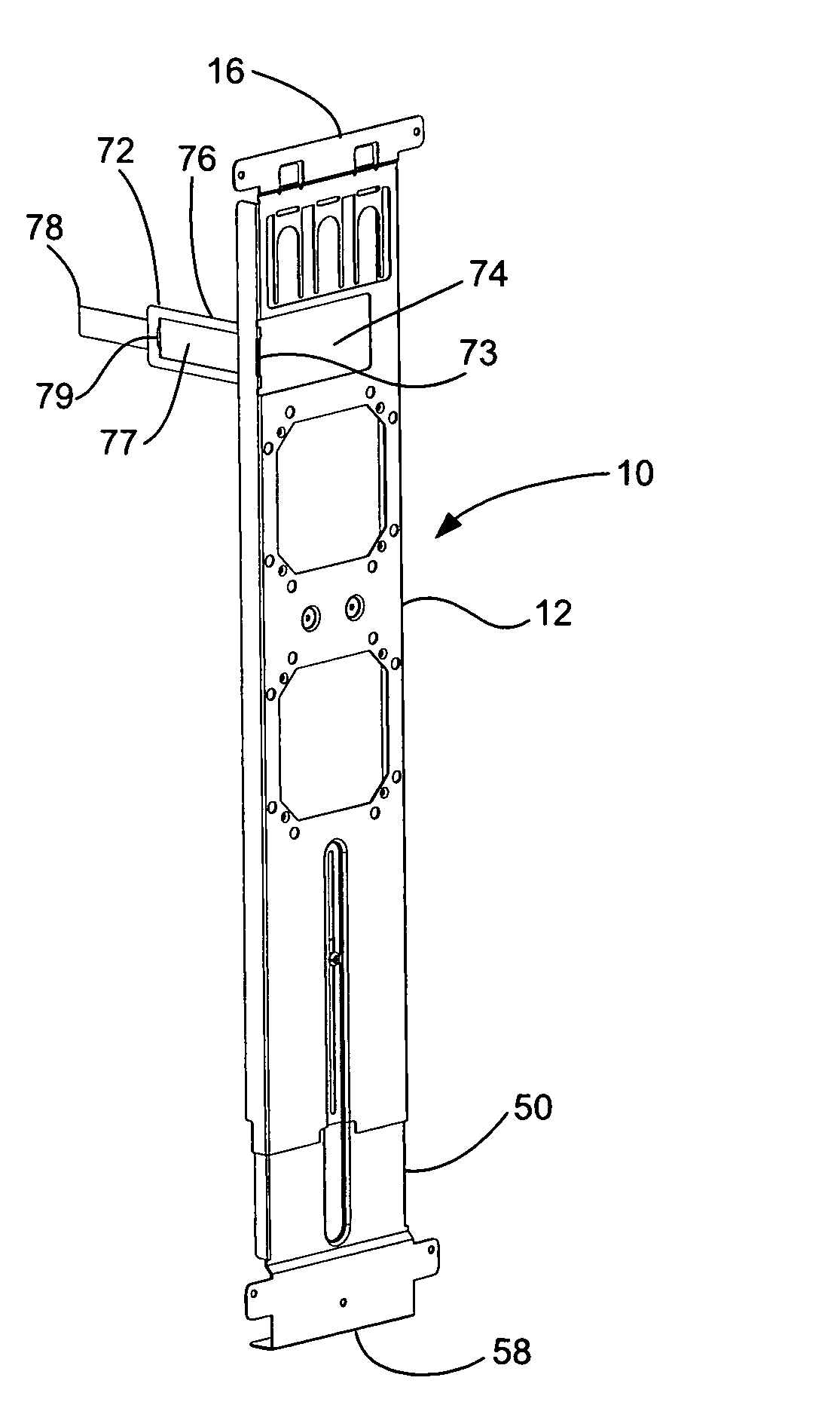

Far-side support for brackets

ActiveUS7521631B2Improve structural strengthMaintain structural strengthSubstation/switching arrangement detailsMachine supportsEngineeringMechanical engineering

A mounting bracket assembly for mounting an electrical box having one or more far-side supports, which fold out and contact the structure behind the bracket to provide additional stability and support. The mounting bracket assembly includes: a mounting plate having a pair of opposing sides, an opening for receiving an electrical box and a far-side support; and a mounting bracket attaching end. The far-side support has a first end, a second end and a pair of sides and includes a first section and a second section. The far-side support foldably extends from the mounting plate and the second section foldably extends from the first section. The first end of the far-side support is connected to the mounting plate and the far-side support can include a support bending aperture at the first end. The second section can include a first end, a second end and a pair of sides and the first end of the second section can have an extender bending aperture and can connect to the second end of the first section. The pair of sides of the first section are substantially parallel to the pair of sides of the second section.

Owner:THOMAS & BETTS INT INC

Self-lubricating bearing and method of producing the same

This invention relates to a self-lubricating bearing and a method of producing the same. The self-lubricating bearing includes a main body and a plurality of solid lubricant pieces. The main body has an inner annular wall surface, an outer annular wall surface, and a through hole defined by the inner annular wall surface. The solid lubricant pieces are embedded in a plurality of depressions of the inner annular wall surface by coating and grinding and each has a radial inside annular surface in a curve conforming to that of the inner annular wall surface. The forming of the depressions without radially penetrating through the outer annular wall surface to make the solid lubricant pieces embedded into the depressions with less amount by coating and grinding allows the self-lubricating bearing to reduce the material cost, and keep its structural strength and lubricating effect simultaneously.

Owner:LEE HU I LONG

Outside structure conformal antenna in a supporting structure of a vehicle

ActiveUS7253777B2Maintain structural strengthLarge volumeSimultaneous aerial operationsAntenna adaptation in movable bodiesSupporting systemConformal antenna

An antenna mounted on a supporting system primary structure of a vehicle, in which the supporting system primary structure has an indentation. The antenna includes an EM functional core incorporated into the indentation of the supporting system primary structure, and a cover plate forming one of an upper and outer cover of the EM functional core that is structured and arranged as a conformal outside. Furthermore, boundary areas of the cover plate are connected with the supporting system primary structure. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:AIRBUS DEFENCE & SPACE

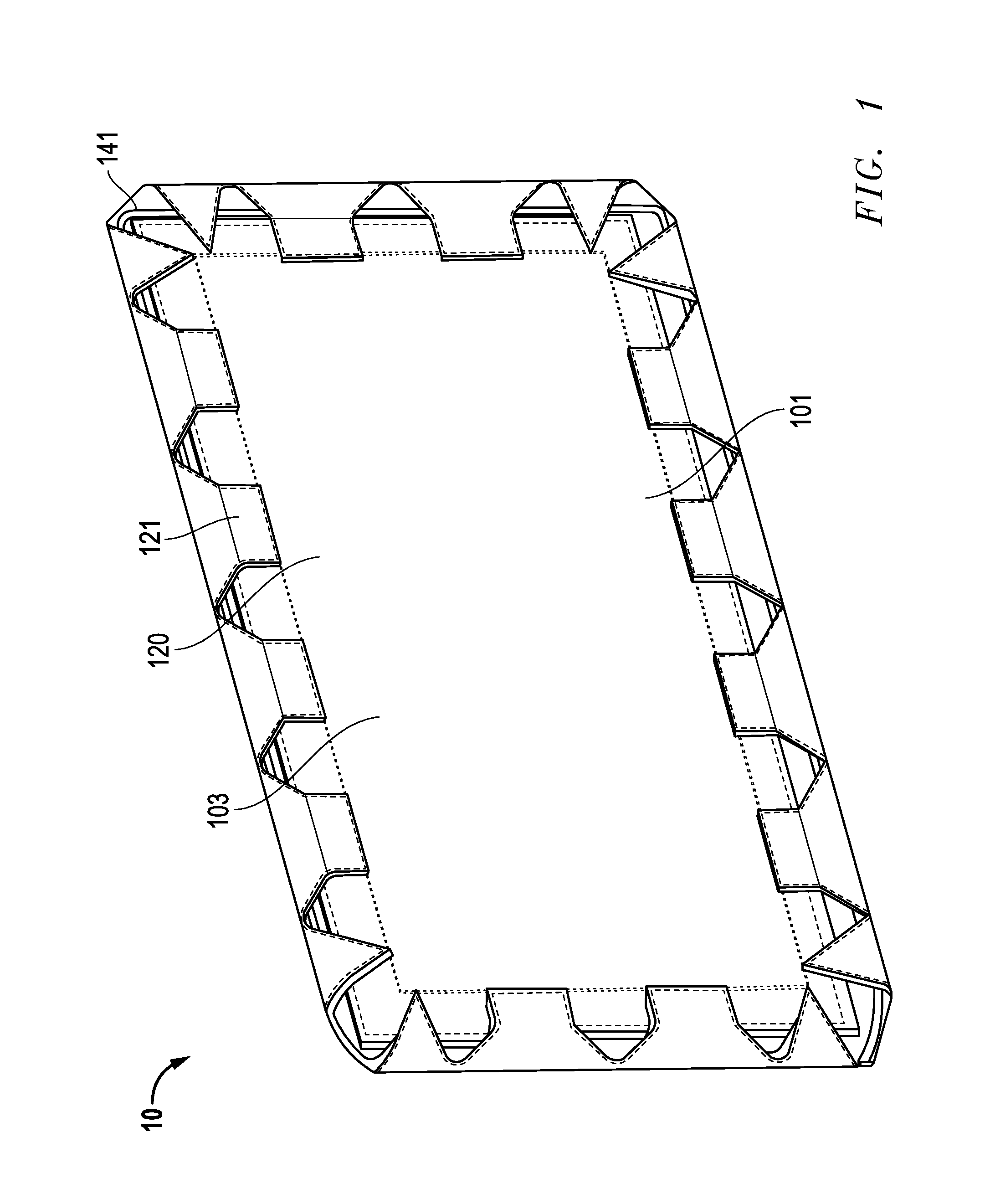

Drift eliminator with formed beveled tip

ActiveUS7674304B2Avoid formingMaintain structural strengthCarburetting airCombination devicesEngineeringMechanical engineering

A drift eliminator is formed from alternating curved spacers and corrugated spacer members to define tube-like passageways for the flow of air through an evaporative cooling apparatus. The formation of the corrugated blade member with beveled side walls places the back walls of the channels in a different plane than the front walls, with the lower edge of the front walls of the channels being positioned in a common plane along with the lower edge of the blade members. The angled side walls impede the formation of a film of water across the inlet opening into the channel, which requires an increase in horsepower for the fan to push air through the drift eliminator. Mechanical fastening devices molded into the respective members connects the corrugated spacer members and the blade members. A method of forming the corrugated spacer members to provide the angled side walls is also provided.

Owner:BRENTWOOD INDS

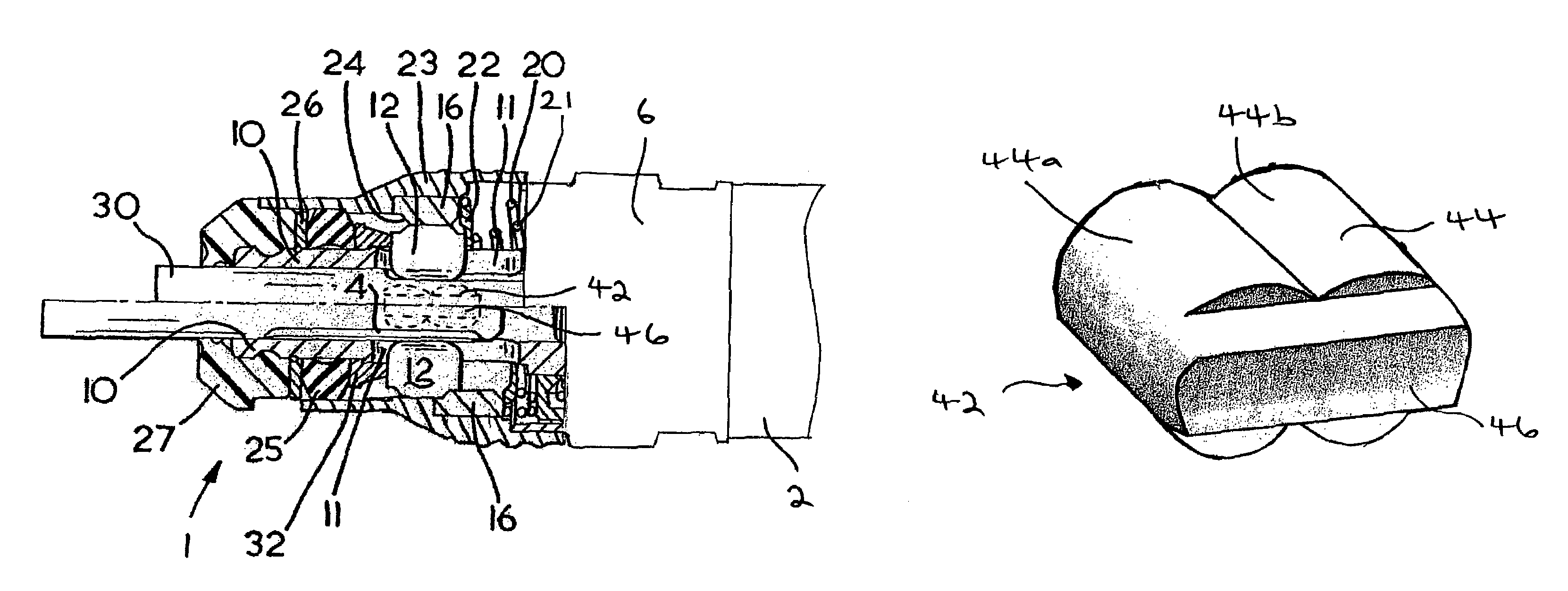

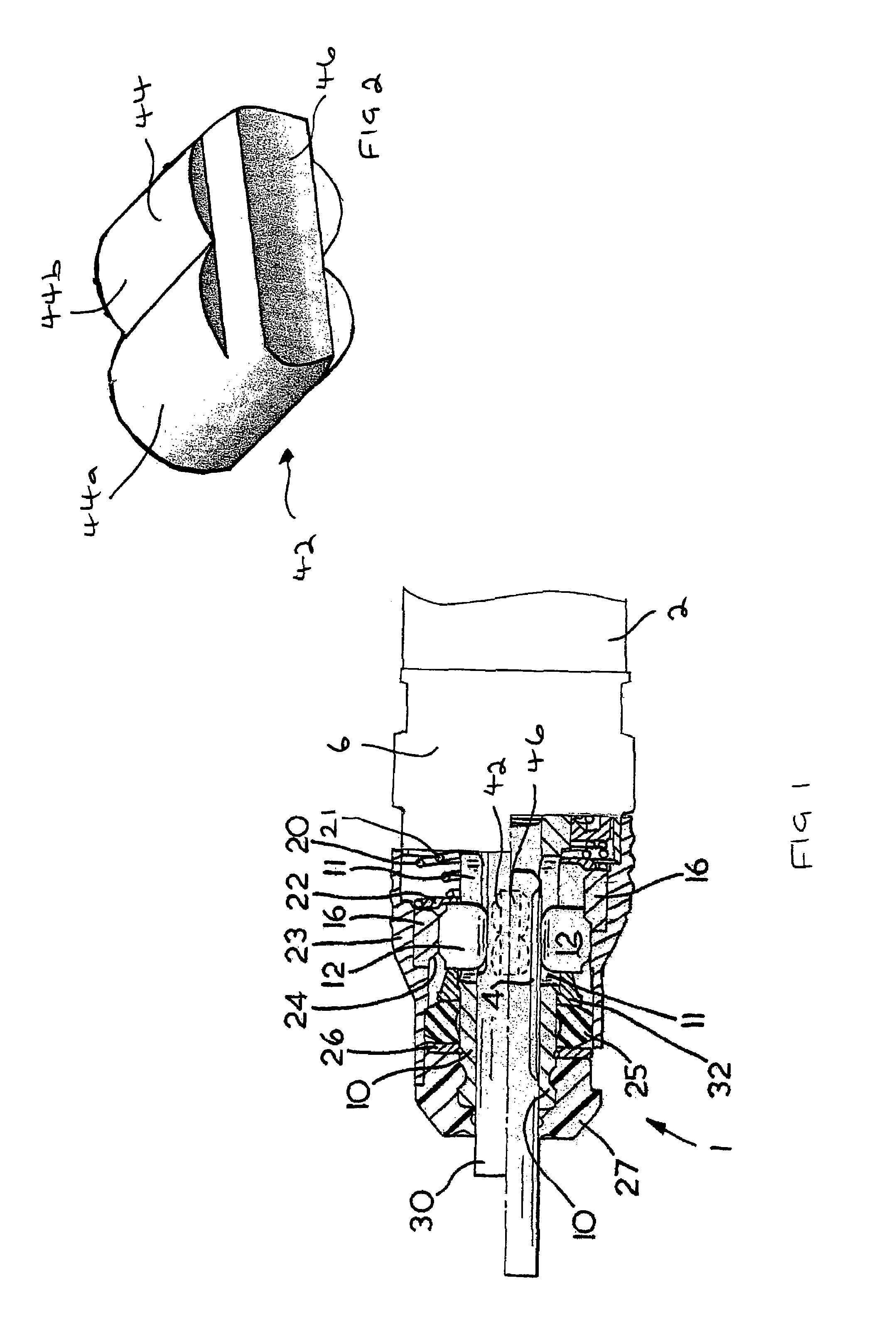

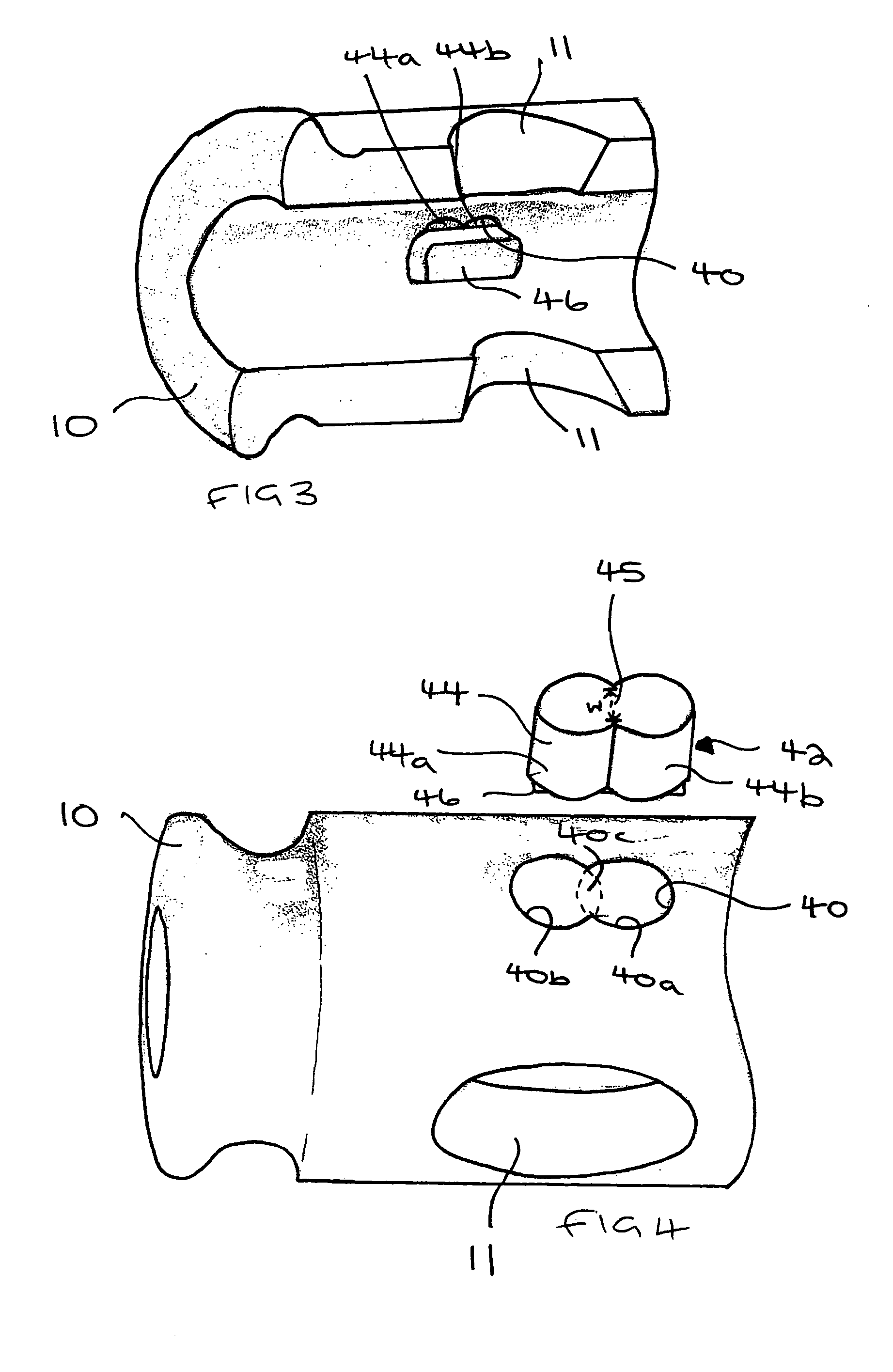

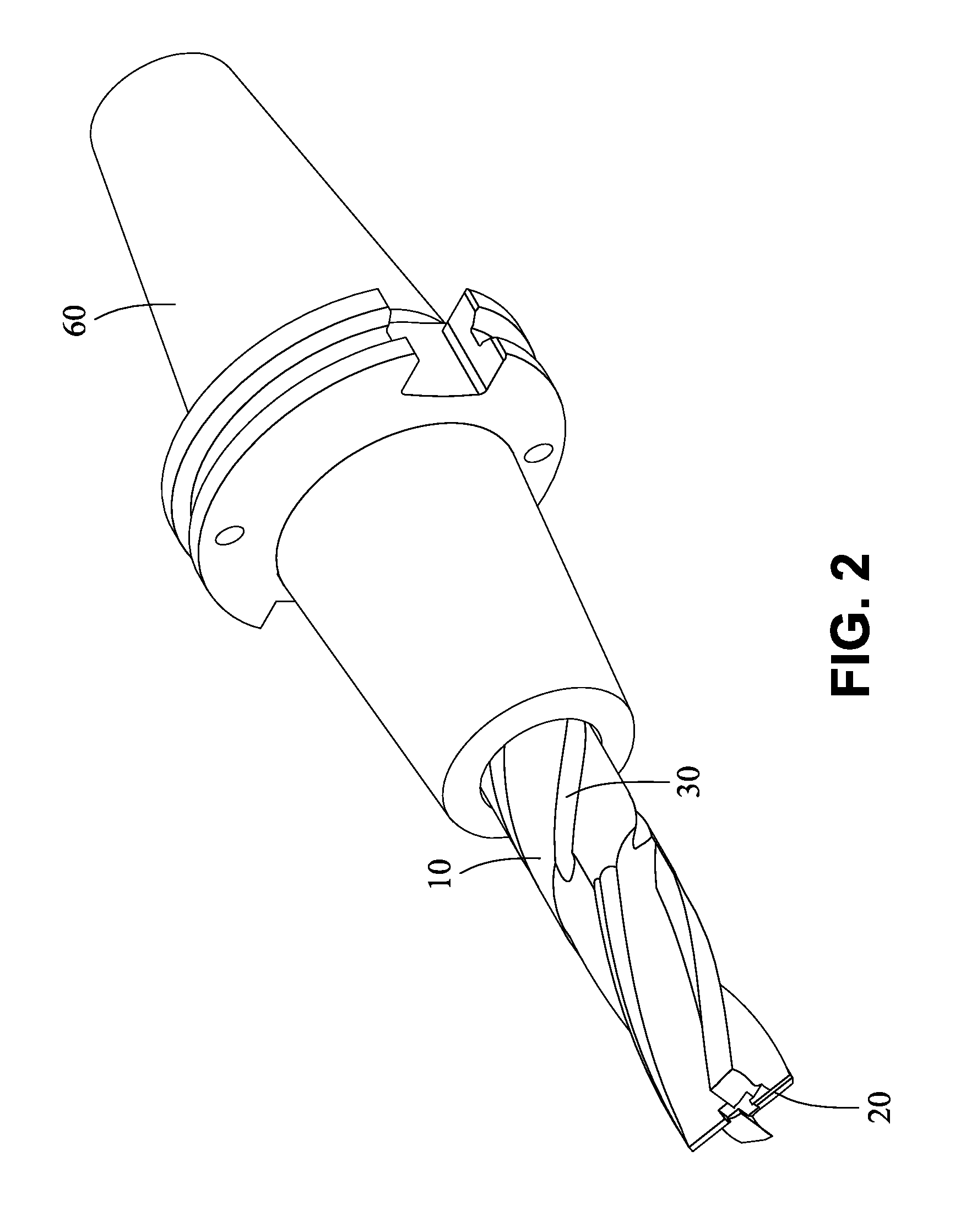

Tool holder for a rotary hammer

InactiveUS7338051B2Easy constructionMinimise circumferenceSleeve/socket jointsPortable percussive toolsEngineeringDrill bit

Owner:BLACK & DECKER INC

Substrate-free flip chip light emitting diode and manufacturing method thereof

InactiveUS20060278884A1Low costImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingProtection layerLight-emitting diode

A substrate-free LED device is provided. The LED device comprises a substrate, an epitaxial layer disposed on the substrate, a first electrode disposed on a portion of the epitaxial layer, a second electrode disposed on another portion of the epitaxial layer, and a protection layer, disposed over the epitaxial layer. It is noted that in the LED device, the substrate comprises, for example but not limited to, high heat-sink substrate, and the protection layer comprises, for example but not limited to, high heat-sink, high transparent material.

Owner:CHUNGHWA PICTURE TUBES LTD

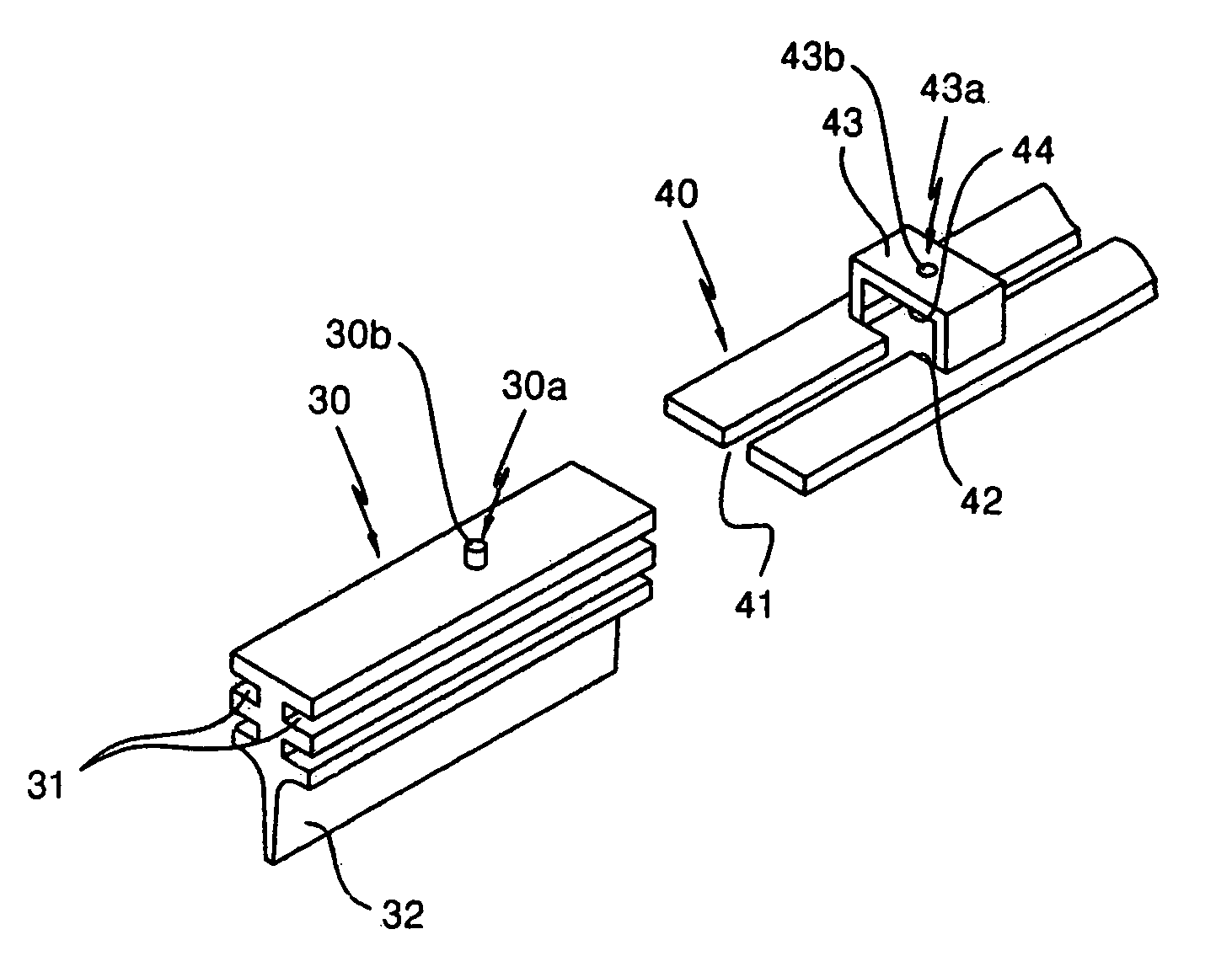

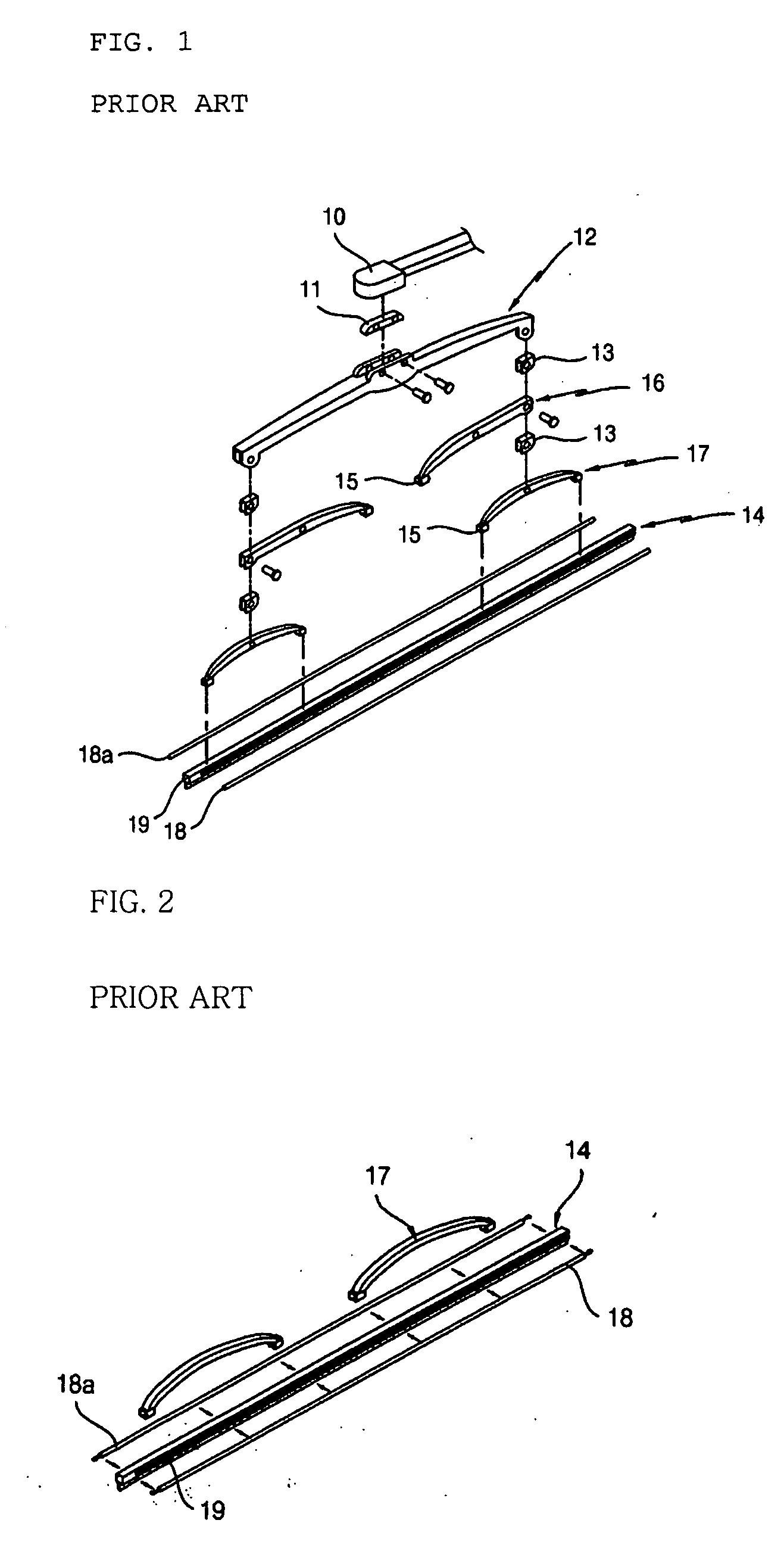

Automotive wiper

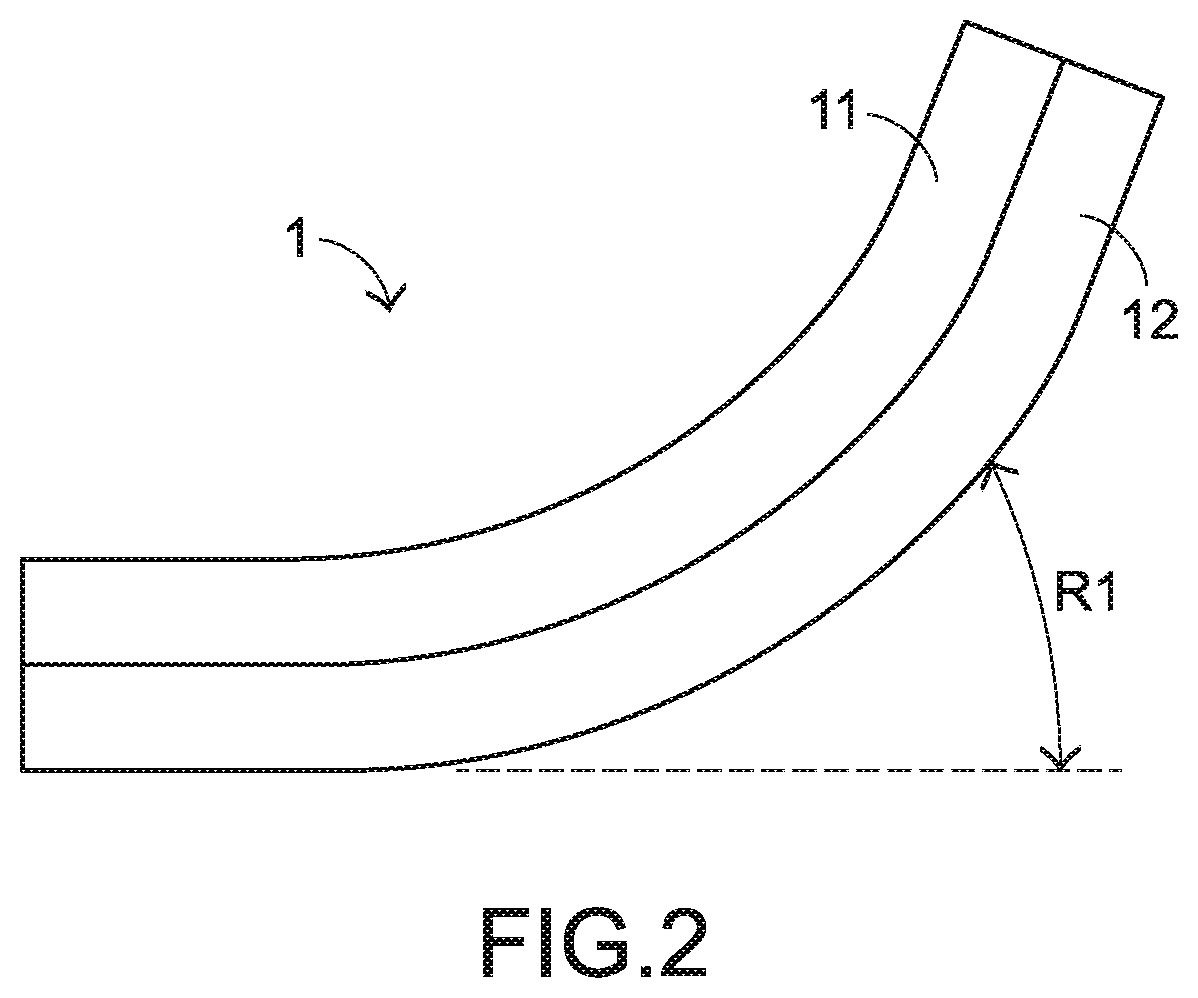

InactiveUS20060064840A1Maintain structural strengthEasy to assembleWindow cleanersVehicle cleaningCouplingEngineering

Provided is an automotive wiper that has a frame, which supports a rubber blade, is formed in one piece with a tension spring, and is easily assembled with the blade. A tensile member (40) symmetrically extends in one piece from a center of the wiper in opposite directions to form both a single-piece tension spring and skeletal frame. A slot (41) is centrally cut along a length of the tensile member to insert the blade (30) therein. A blade mounting receptacle (42) is formed at a center of the slot to insert the blade for its assembly. A guiding member (43) is formed above the mounting receptacle. An assembly guide (43a) is formed on the guiding member to center the blade for assembly. A coupling positioner (30a) is centrally disposed on a surface of the blade to position the blade for assembly with respect to the assembly guide formed on the guiding member.

Owner:PARK LTD

Folding bicycle

InactiveUS20070024023A1Maintain structural strengthImprove balancePassenger cyclesWheel based transmissionMechanical engineering

Provided is a folding bicycle comprising two auxiliary rear wheels at both sides of a rear wheel; a seat including a seat tube extended downward; a first crossbar having a front end pivotably connected to a lower portion of a handle above a front wheel, and a rear end fixedly connected to an intermediate portion of the seat tube; a pair of second crossbars having two front ends pivotably connected to an intermediate portion of the handle, and two rear ends fixedly connected to both ends of an hub of the rear wheel. The first crossbar passes an intermediate portion of the second crossbar and is pivotably connected thereto. A flexible shock absorbing means is provided at a joining portion of the seat tube and the second crossbars. The shock absorbing means is adapted to elastically deform when a downward force is exerted on the seat.

Owner:HSU YU TU

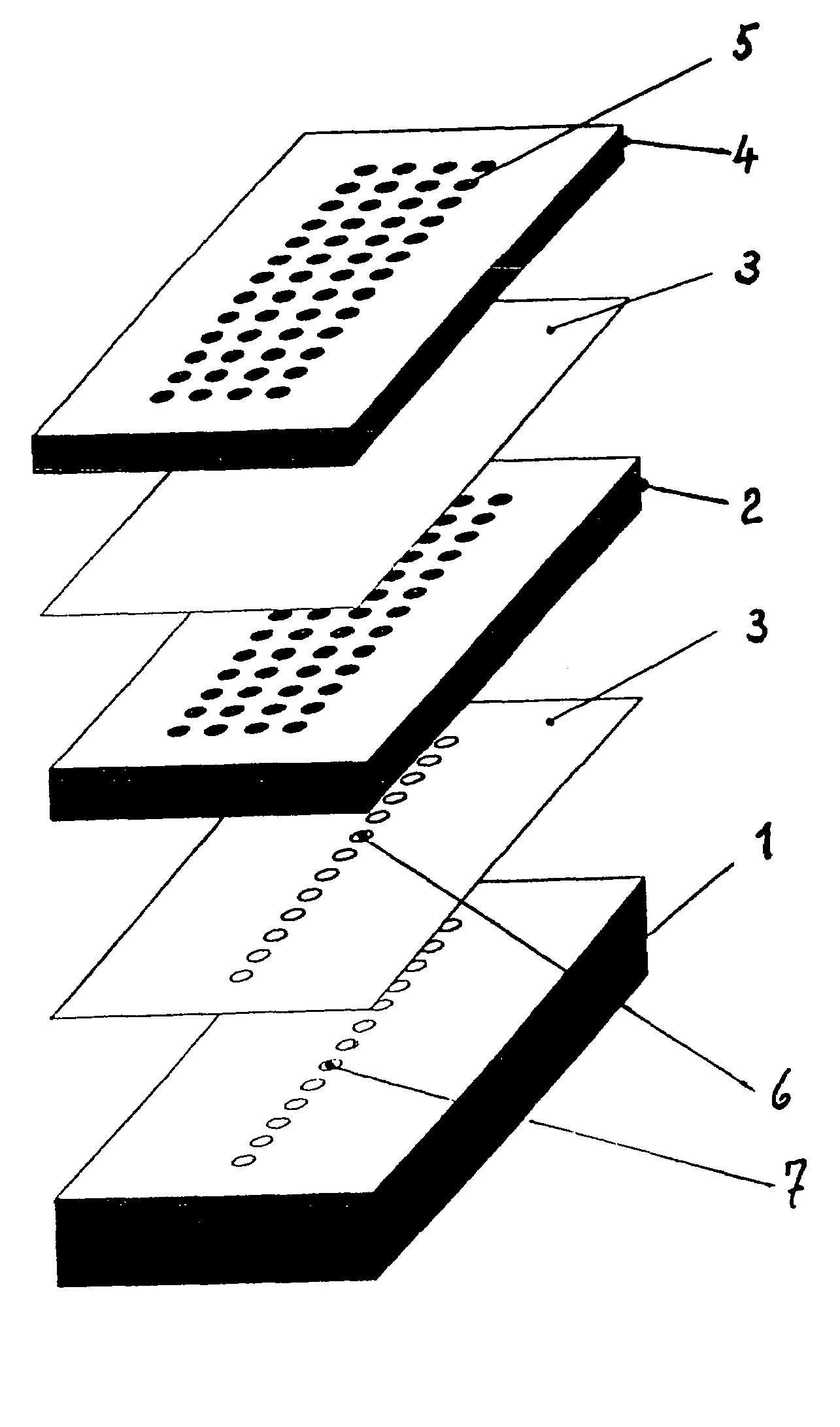

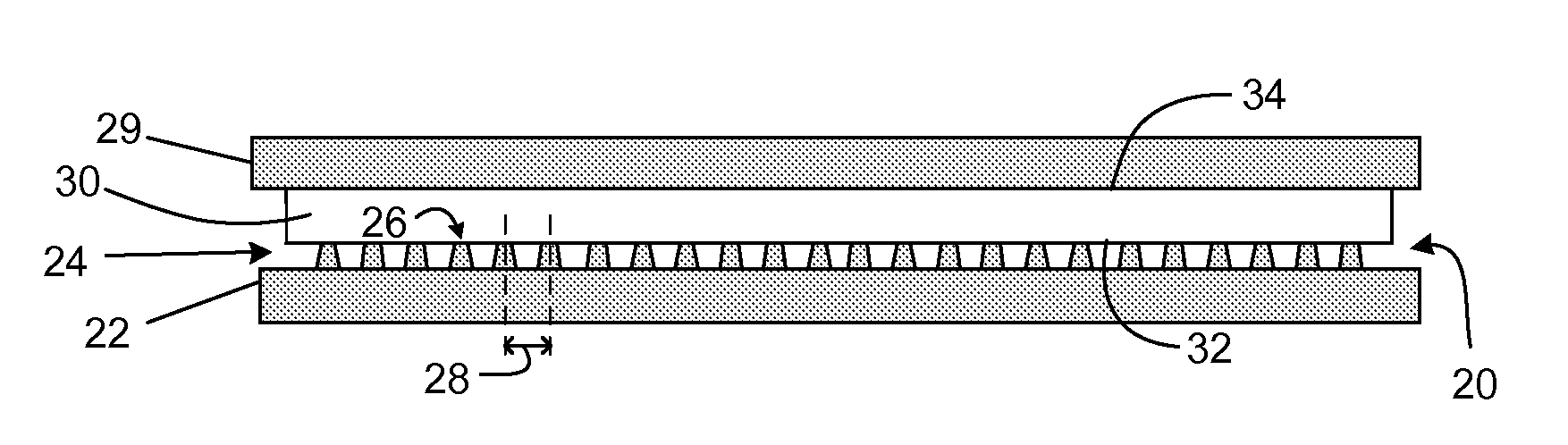

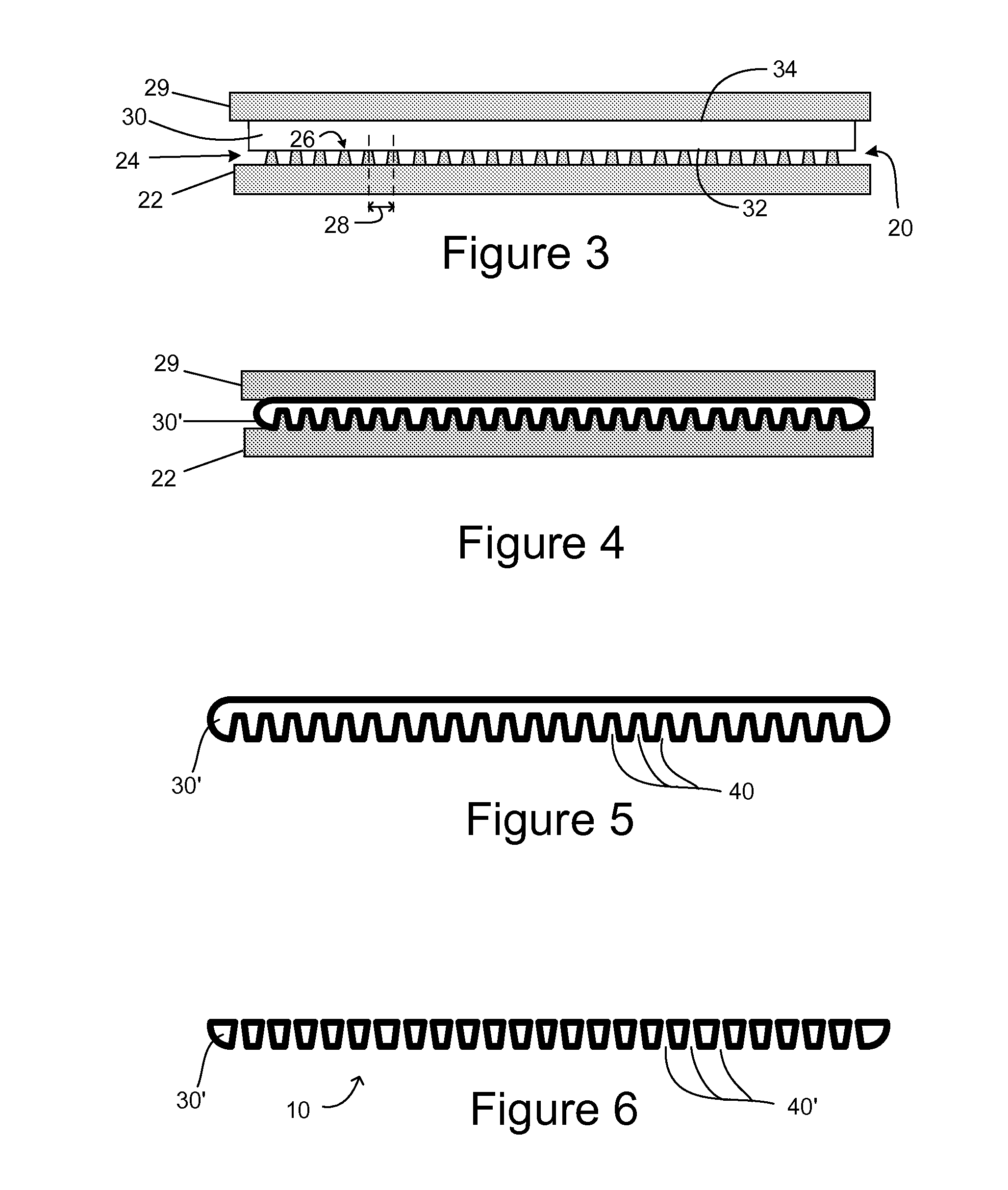

Methods of forming a glass wiring board substrate

InactiveUS20130239617A1Low CTEWell-matchedSolid-state devicesGlass reforming apparatusMicrometerIntegrated circuit

Disclosed is a method or process for forming a glass wiring board substrate for integrated circuit wiring boards, including providing a first molding surface (20) positioned on a first mold (22) having truncated conical pins (24) protruding therefrom, the pins (24) having a diameter at the top end (26) thereof of 150 micrometers or less, and a minimum pitch (28) of 400 micrometers or less, providing a glass sheet (30) having first and second surfaces (32,34) on opposite major sides thereof, pressing the first surface (32) of the glass sheet against the molding surface (20), heating the glass sheet (30) and the first molding surface (20) together to a temperature sufficient to soften a glass of which the glass sheet (30) is comprised, such that the pattern of the first molding (20) surface is replicated in the first surface (32) of the glass sheet (30), thereby producing a formed glass sheet (30′) having an array of holes (40) therein, cooling the formed glass sheet (30′) and the molding surface (20) together to a temperature below the softening point of said glass, and separating the formed glass sheet (30) from the molding surface (20). The forming may press the glass sheet using one mold surface or two mold surfaces simultaneously. For embodiments using a single mold, the holes may be blind holes after pressing, and may then be opened to form through-holes by back side lapping. Alternatively, the glass is pressed up to through-hole formation, avoiding the need of back side lapping.

Owner:CORNING INC

Grouting method for blast furnace

InactiveCN101649365APrecise positioningReasonable particle size compositionLinings repairBlast furnace componentsDrill bitMaterials science

The invention relates to a grouting method for a blast furnace, aiming to enhance the grouting success rate of the blast furnace. In the invention, the temperature of a furnace shell of the blast furnace is measured by using infrared imaging scanning and an infrared temperature measuring instrument to find out the position with relative high temperature; the position is taken as a datum point, holes are bored at vertical or transverse interface parts between two cooling walls or among three cooling walls which are adjacently installed at the upper side, the lower side, the left side and the right side; a hollow drill is used to drill through the furnace shell firstly, then drill through fillers between the furnace shell and the cooling wall, continuously drill a hole forwards to drill through the cooling wall, and then drill through unshaped ramming materials or pouring materials between a brick lining and the cooling wall; a drilling channel is cleaned; a grouting channel is dredged,lubricated and preheated; and an amount upper limit value of grouting is controlled to be 60 kg to 120 kg; proper grouting pressure is ensured, when the brick size of the brick lining is small and isnot provided with a brick locking groove, the grouting pressure is relative low to be generally controlled to be 1.0 MPa-1.5 MPa, and when the brick size of the brick lining is large and is provided with the brick locking groove, the grouting pressure is relative high to be generally controlled to be 1.0-3.0 MPa.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

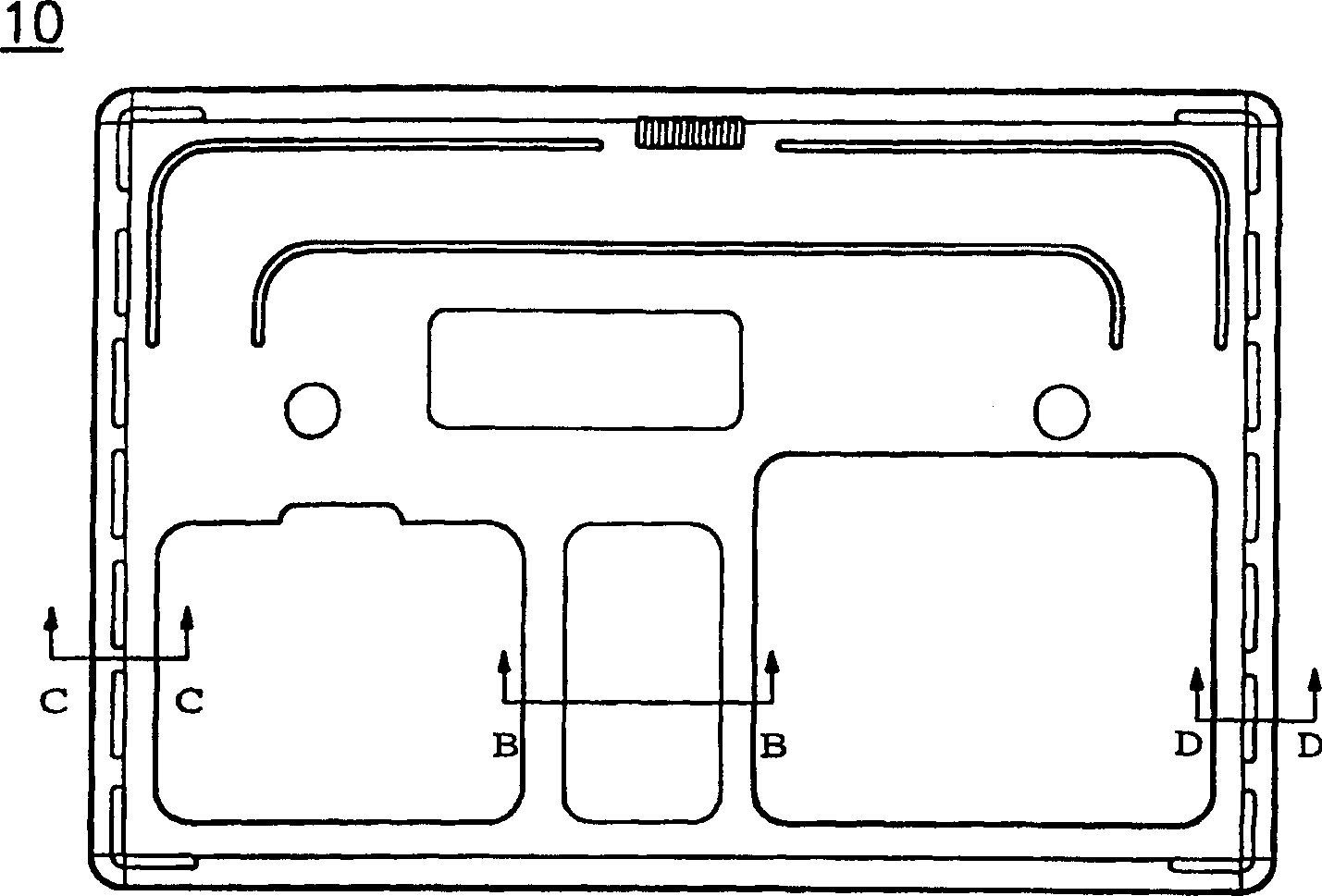

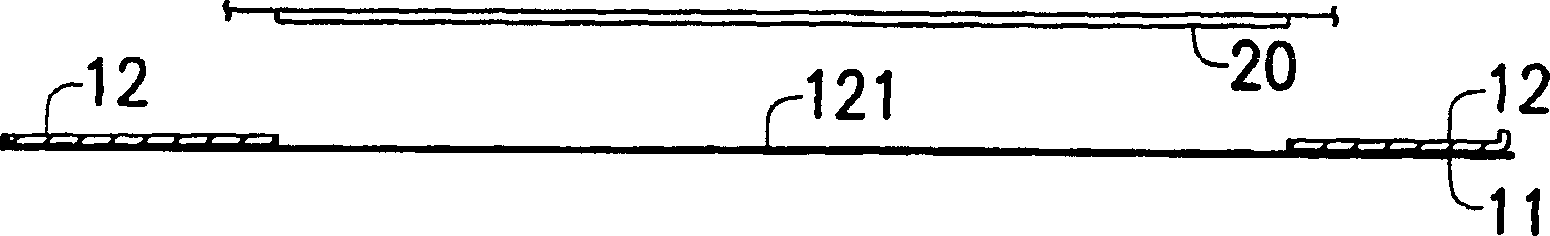

Cases of electronic devices and mfg. methods

InactiveCN1431861AMaintain structural strengthMetal casingsMetallic materialsElectrical and Electronics engineering

The invention relates to the method for mfg. cases of electronic devices. The electronic device contains at least one element. The method includes following steps. First, using the first metal material to form the first component. Then, using the second metal material to form the second component. At least one sectional difference part is formed on the second component. Finally, with the manner of the second component going closer to the element and the sectional difference part corresponding to the element, the first component and the second component are assembled as the case of the electronic device. The method makes cases meet the requirement of lightweight, thin short and small, meanwhile the structure intensity is maintained.

Owner:QUANTA COMPUTER INC +2

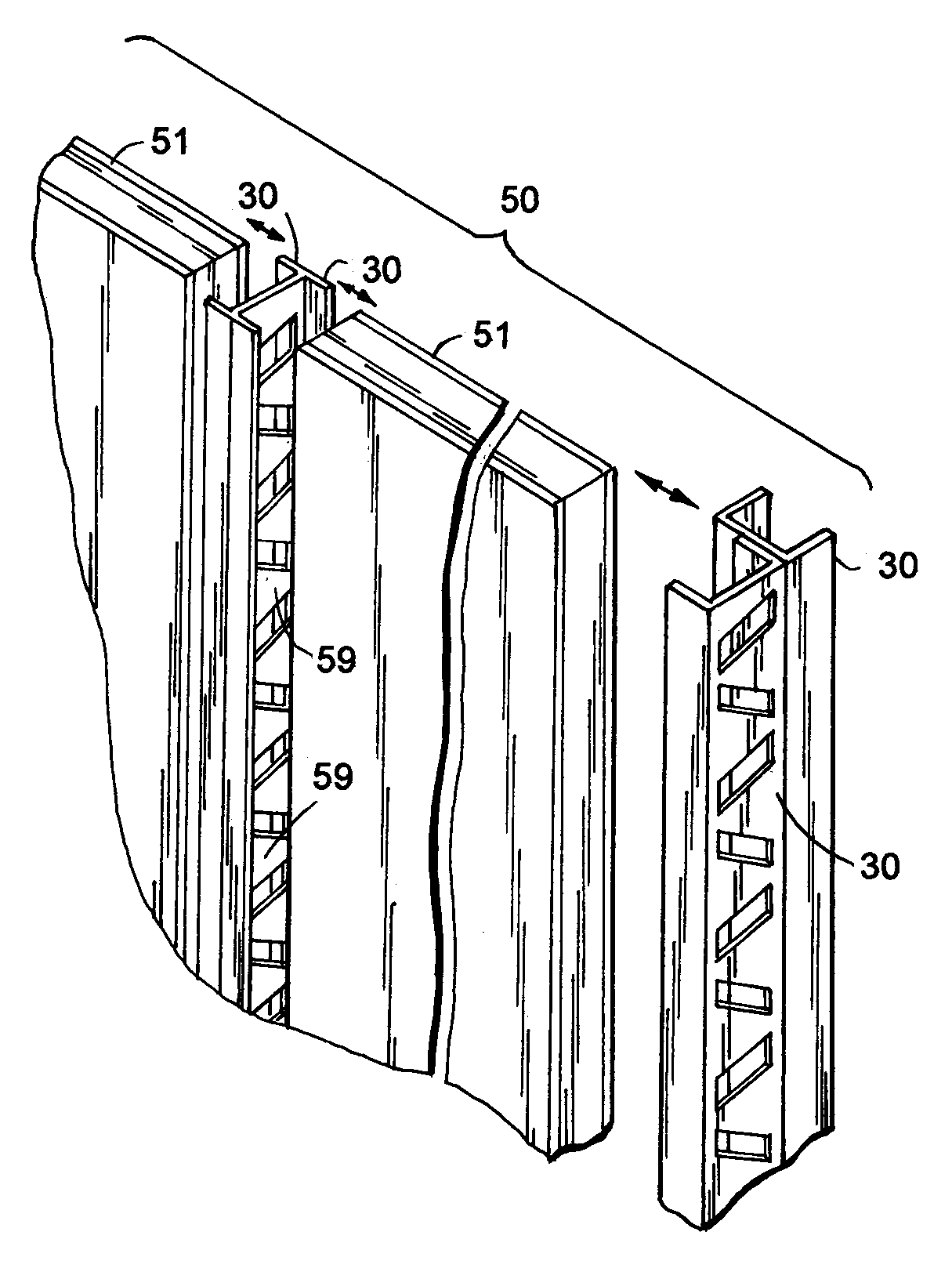

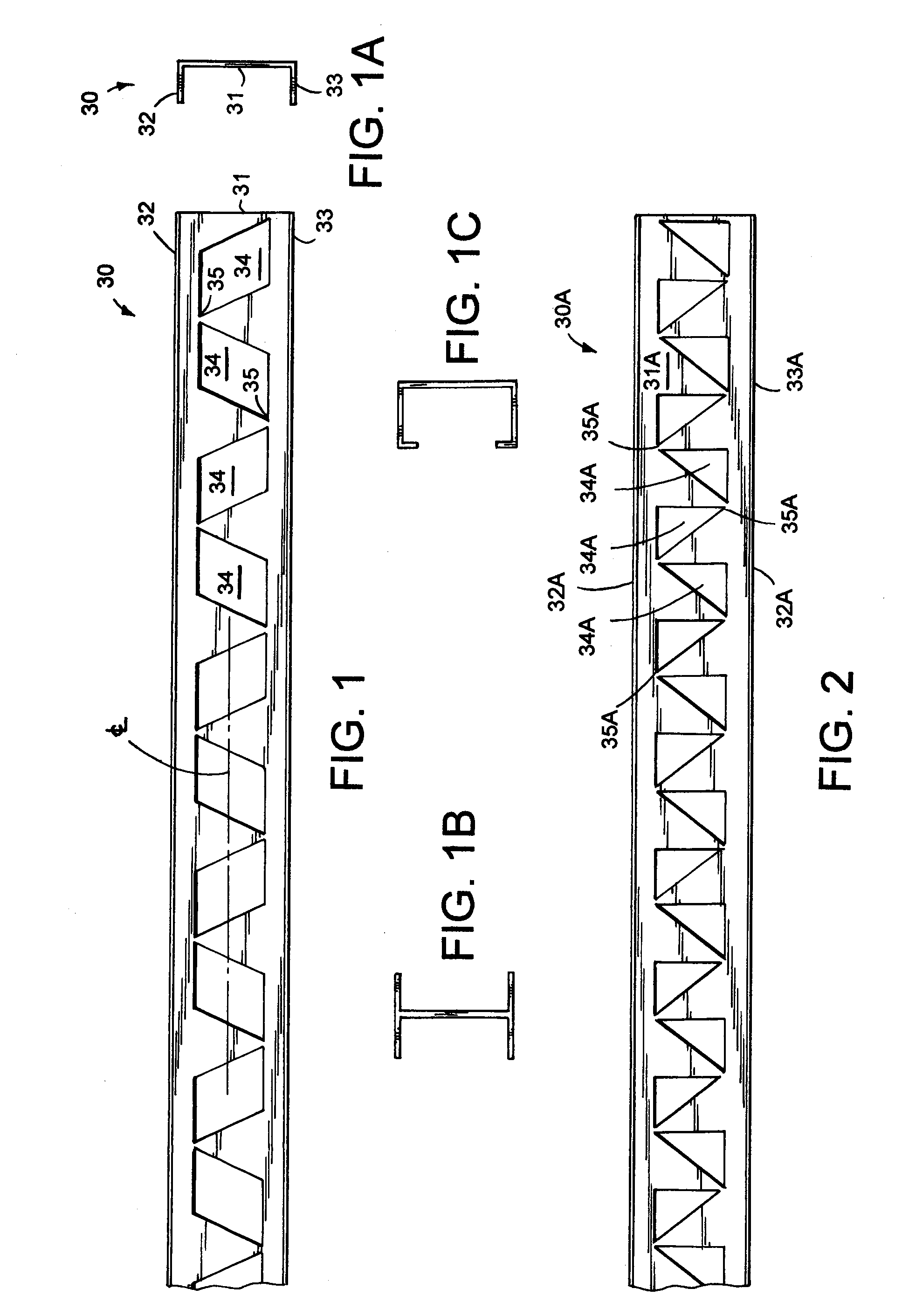

Thermal stud or plate for building wall

InactiveUS20090165416A1Improved thermal insulation valueMinimizes thermal conductivityWallsLoad-supporting elementsEngineeringUltimate tensile strength

A metal thermal stud / plate has a center web with geometrically-shaped apertures spaced longitudinally along its centerline. The apertures define alternatingly-positioned narrow necks of material therebetween near ends of the center web. The narrow necks minimize thermal conductivity between the spaced flanges, but adjacent ones of the narrow necks are longitudinally misaligned due to their alternating positions to thus prevent forming a weak longitudinally-extending fold line in the stud / plate, thus maintaining its strength. In one form, the narrow necks are at most about 0.100 inches wide without substantially degrading the strength of the studs / plates, or can be a ratio of neck width to center web of as low as 0.09:4 down to 0.03:4. A building wall frame includes a plurality of the metal studs / plates and foam insulated panels with edges engaging the center webs of adjacent studs / plates to thus stabilize the metal studs / plates.

Owner:PORTER WILLIAM H

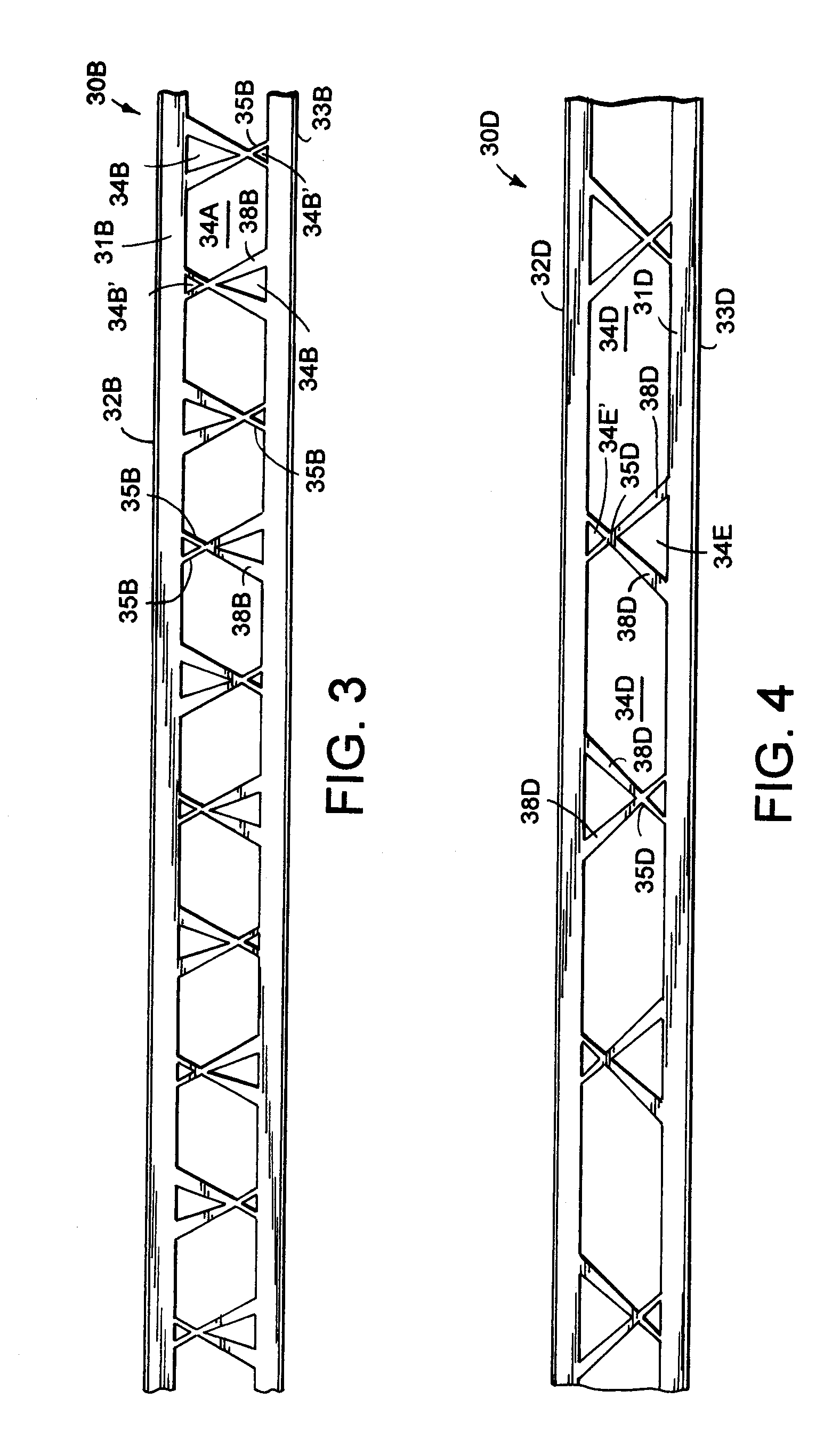

Blade fastening device having cuttign fluid guide grooves on a blade

InactiveUS20160207122A1Reduce the temperatureEasy to cutTransportation and packagingMilling cuttersEngineeringUltimate tensile strength

A blade for a blade fastening device is provided with a body having a first end fastened in a blade seat and a second end extending out of the blade seat; a machining point formed at the second end of the body for machining an object being machined; and at least one cutting fluid groove formed on a surface of the body and extending from the second end of the body to the machining point. The blade can guide cutting fluid to an object being machined via the at least one groove so as to clear swarf left at a cutting site and decrease temperature at the cutting site. Further, the structural strength of the blade can be maintained.

Owner:XPOLE PRECISION TOOLS

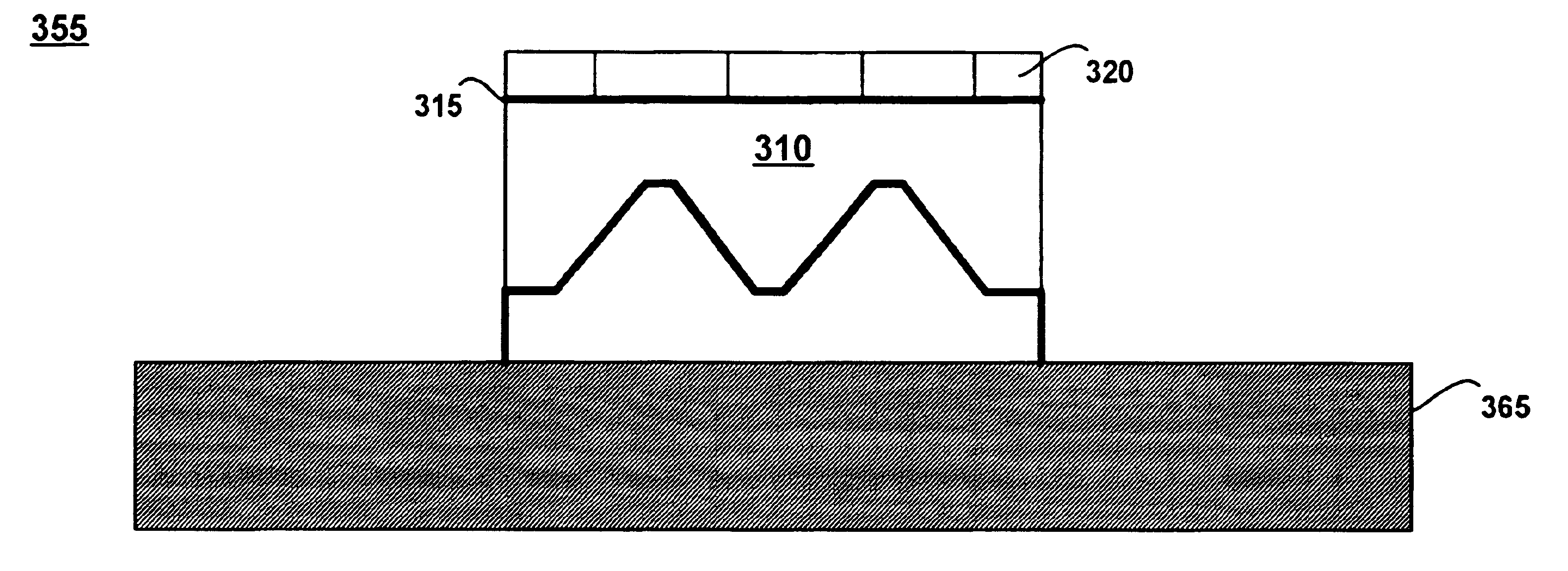

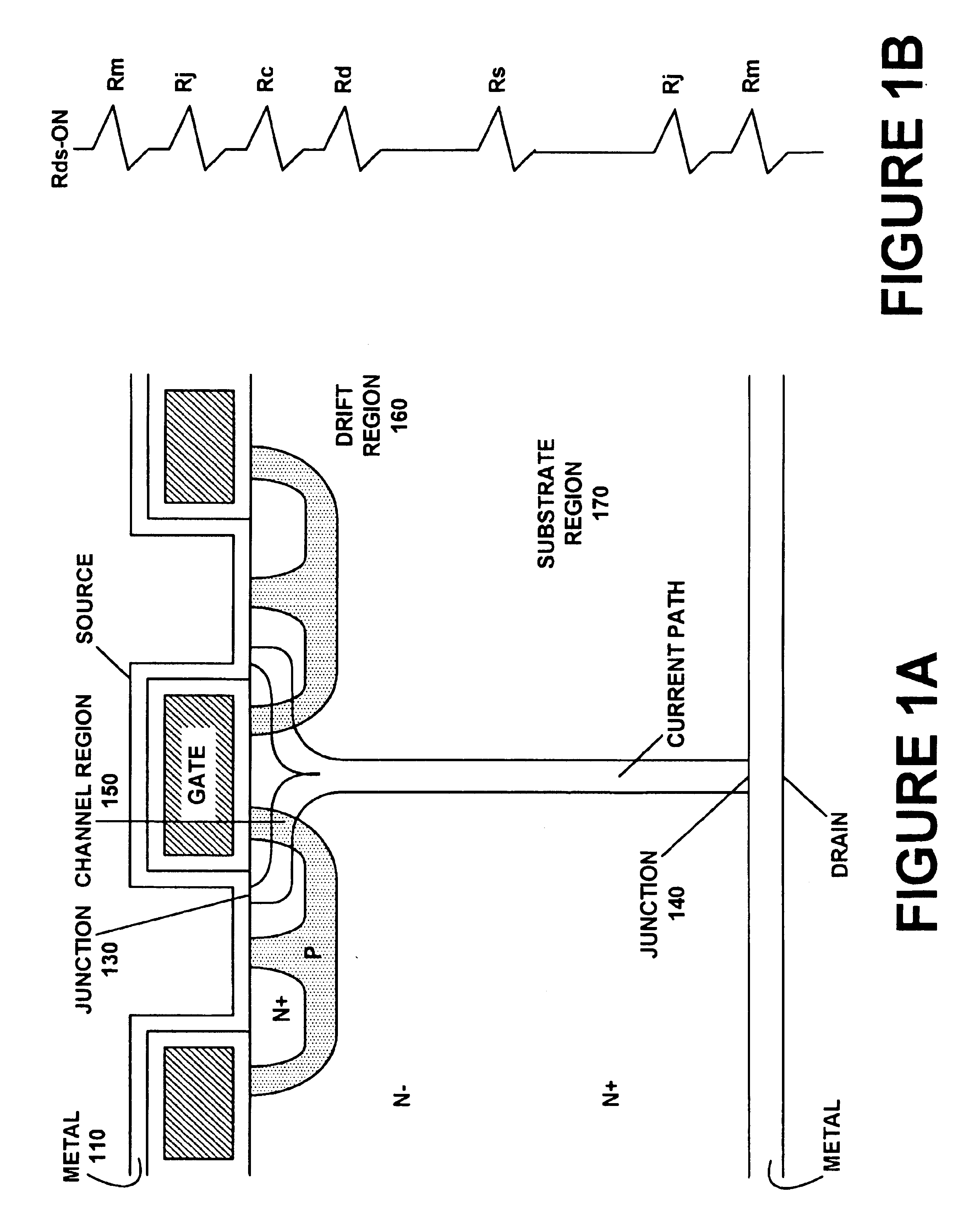

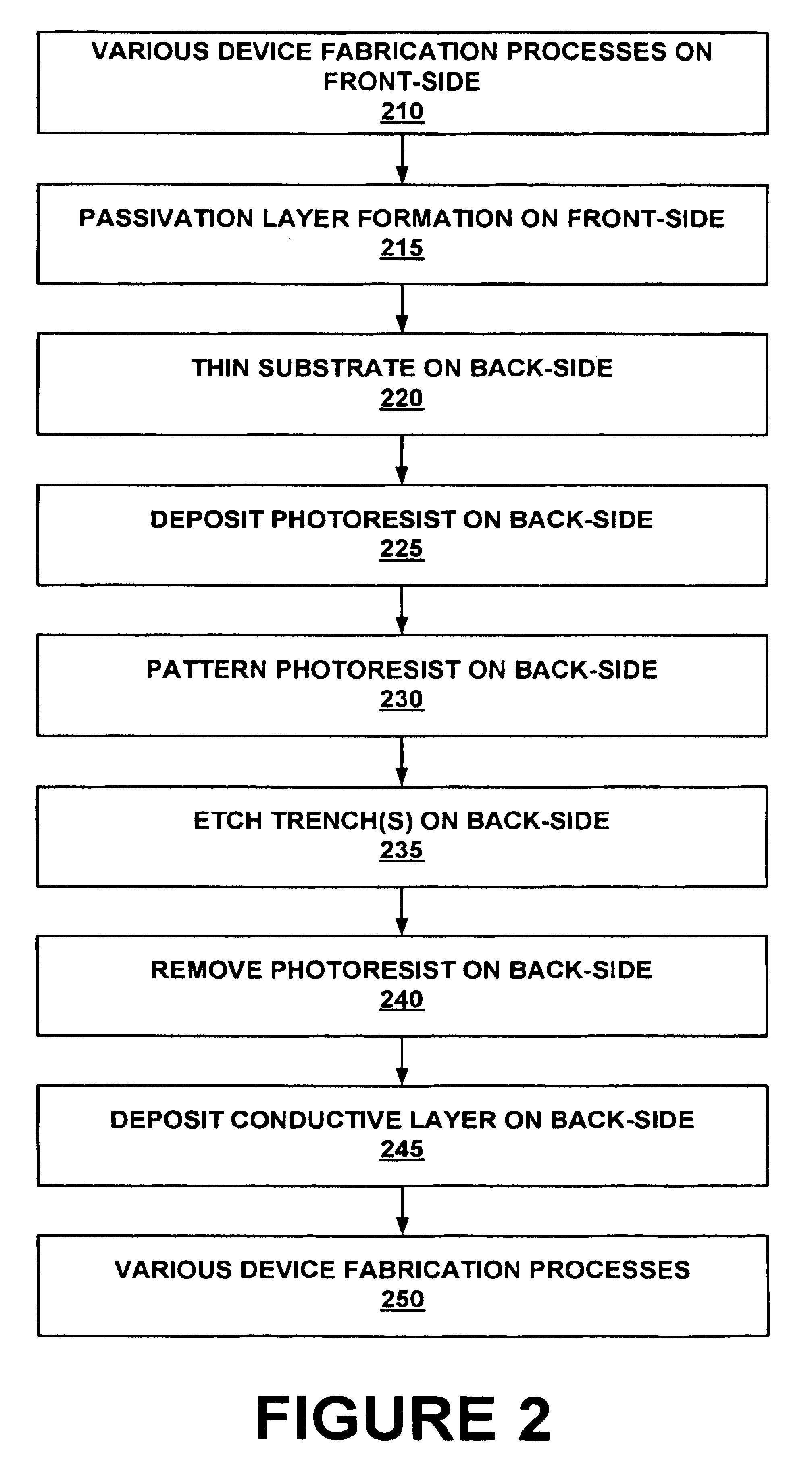

Semiconductor substrate with trenches for reducing substrate resistance

InactiveUS6858471B1Lowering substrate resistanceAssure mechanical stiffnessRelieving strain on wire connectionSolid-state devicesElectrical resistance and conductanceConductive materials

In one embodiment of the present invention, a method for fabricating semiconductor devices comprises forming an active region about a front-side of a substrate. A plurality of trenches are then formed about a back-side of the substrate. A grid of banks separates the trenches. A conductive material is then applied to the back-side of the substrate. The trenches and the conductive material act to reduce the on-state resistance of the substrate and enhance thermal conductivity, while the grid of banks maintains the structural strength of the wafer.

Owner:VISHAY SILICONIX LLC

Drift Eliminator with Formed Beveled Tip

ActiveUS20090320689A1Avoid formingMaintain structural strengthCarburetting airCombination devicesEngineeringKnife blades

A drift eliminator is formed from alternating curved spacers and corrugated spacer members to define tube-like passageways for the flow of air through an evaporative cooling apparatus. The formation of the corrugated blade member with beveled side walls places the back walls of the channels in a different plane than the front walls, with the lower edge of the front walls of the channels being positioned in a common plane along with the lower edge of the blade members. The angled side walls impede the formation of a film of water across the inlet opening into the channel, which requires an increase in horsepower for the fan to push air through the drift eliminator. Mechanical fastening devices molded into the respective members connects the corrugated spacer members and the blade members. A method of forming the corrugated spacer members to provide the angled side walls is also provided.

Owner:BRENTWOOD INDS

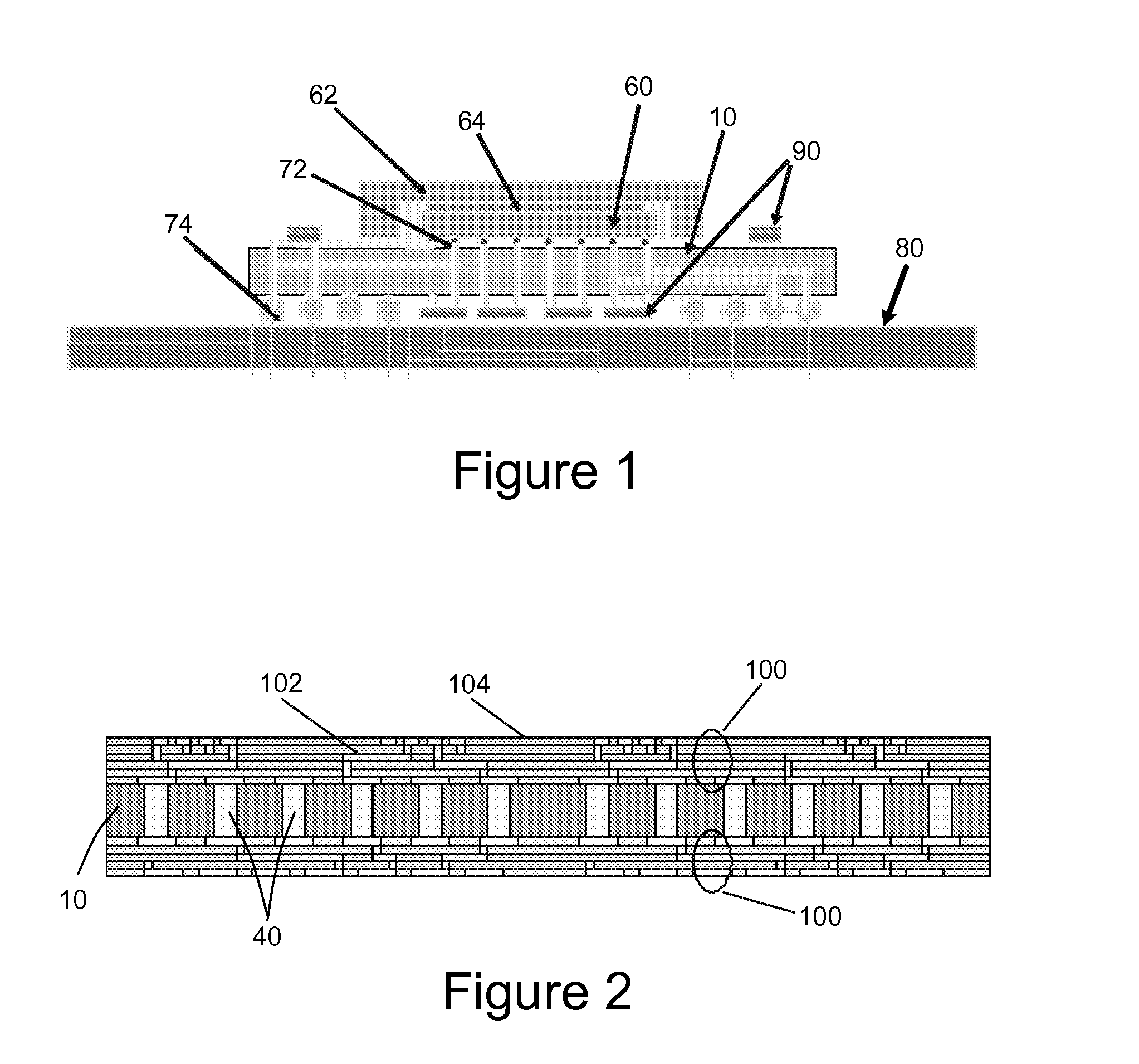

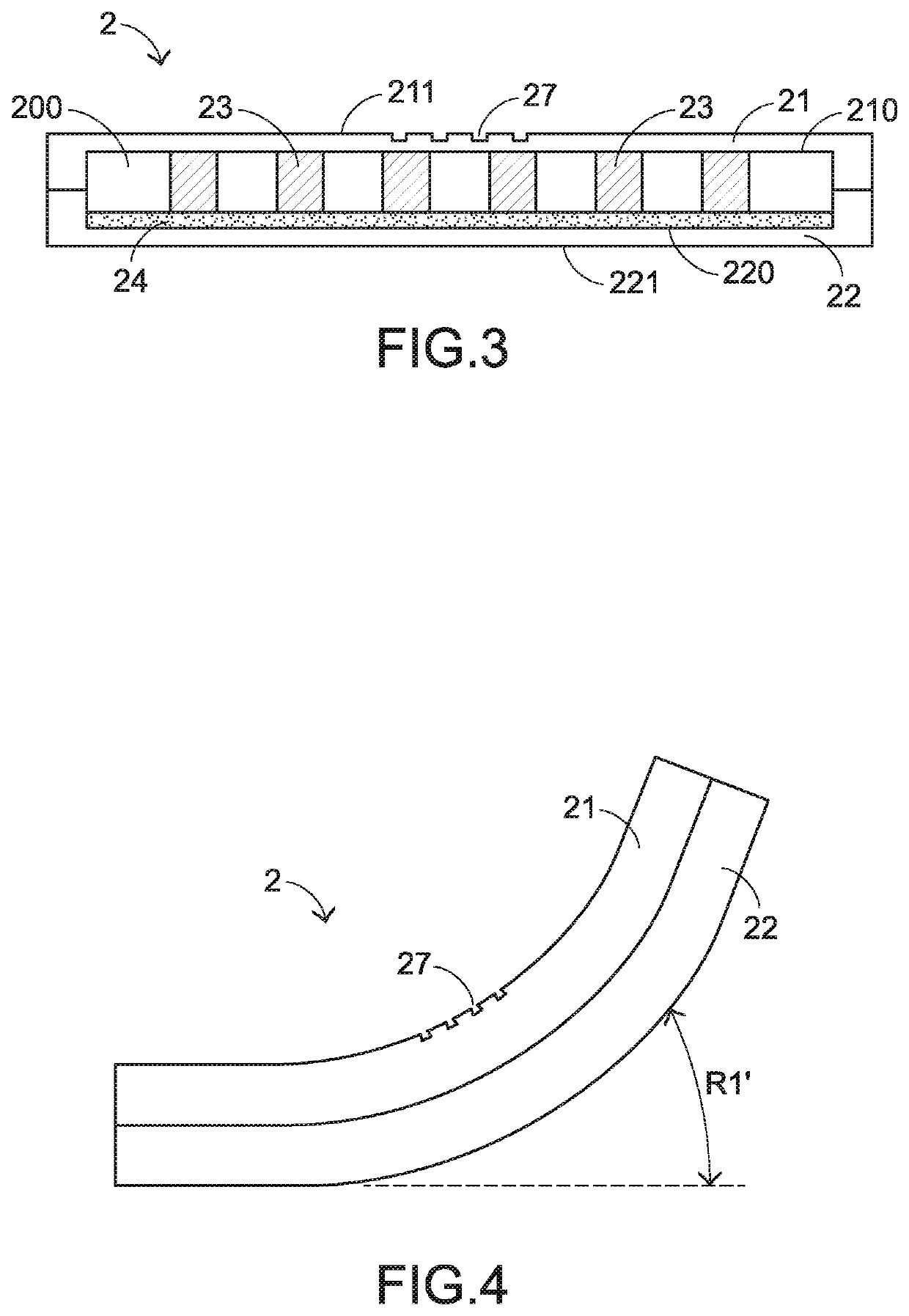

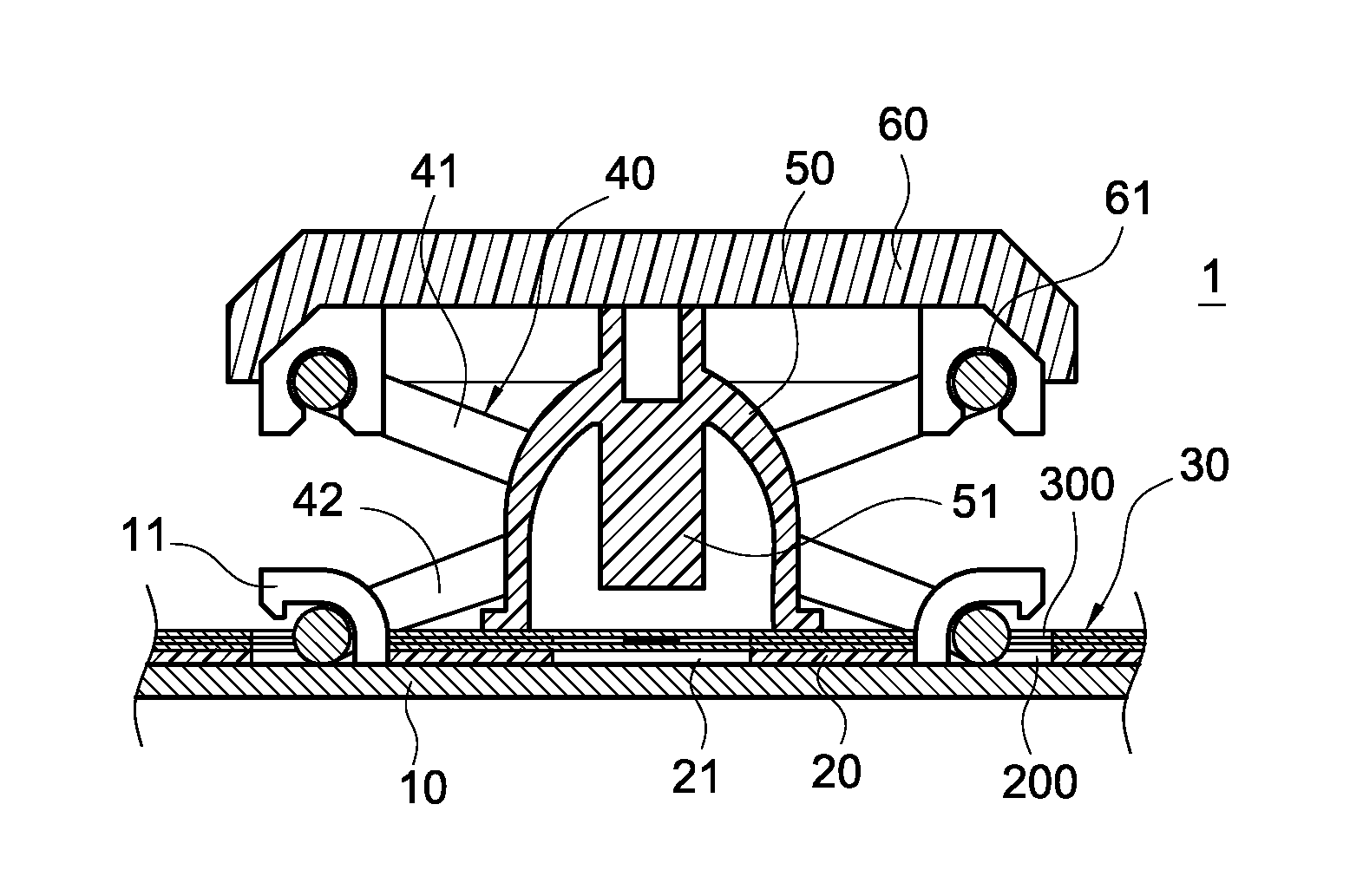

Flexible vapor chamber

InactiveUS20200326134A1Maintain structural strengthPrevent crashSpacing meansReinforcing meansEngineeringMechanical engineering

A flexible vapor chamber for an electronic device includes an upper cover, a lower cover, an accommodation space, a capillary structure, plural support structures and a working fluid. The upper cover is made of a first flexible material. The lower cover is made of a second flexible material. The accommodation space is arranged between the upper cover and the lower cover. The capillary structure is disposed on the lower cover and accommodated within the accommodation space. The plural support structures are disposed on the upper cover and accommodated within the accommodation space. The plural support structures are contacted with the capillary structure. The working fluid is accommodated within the accommodation space. The flexible vapor chamber is permitted to be subjected to a flexural action in a flexible range. Consequently, the installation of the flexible vapor chamber complies with a shape of the electronic device.

Owner:AURAS TECH

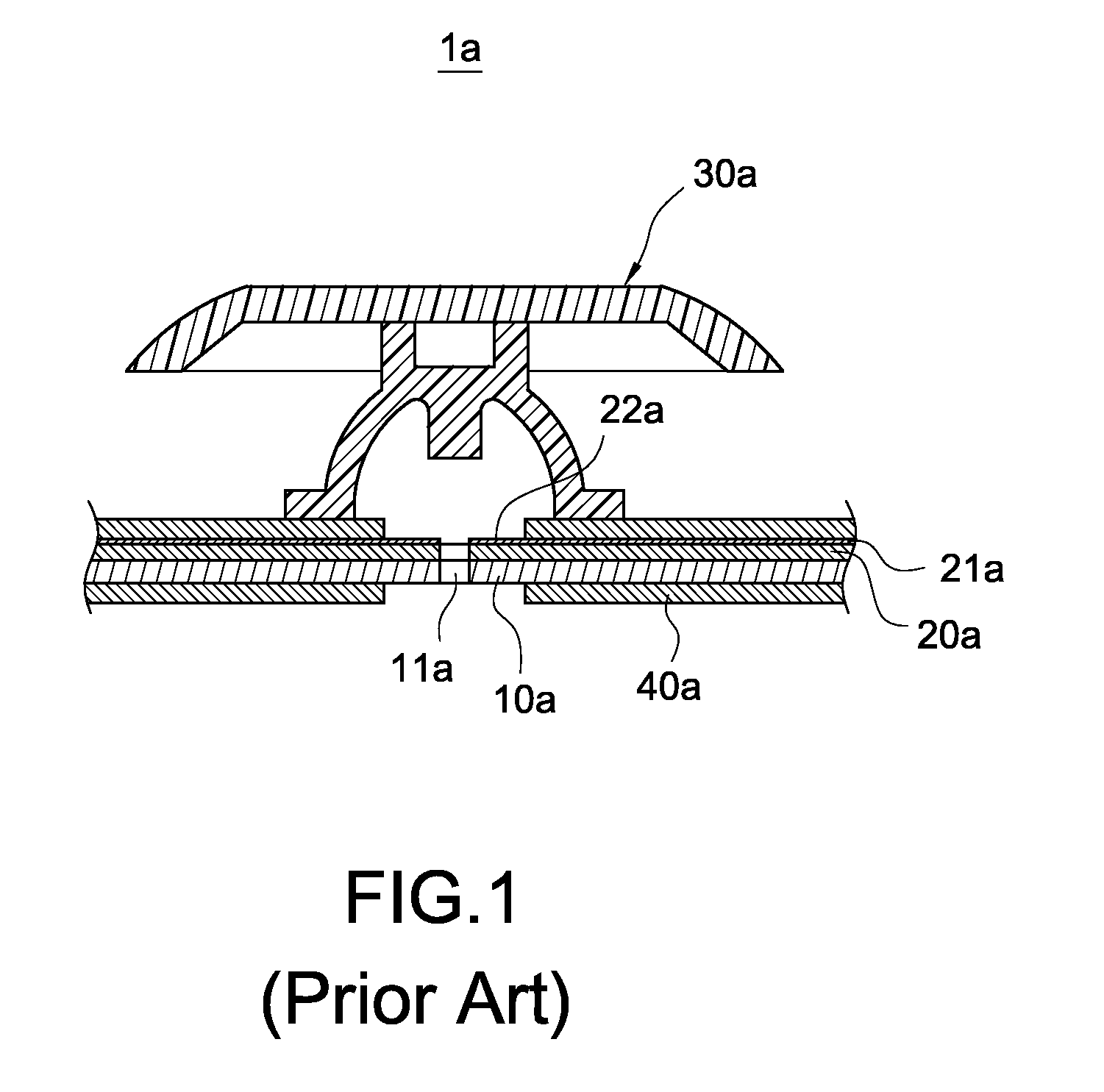

Dustproof press key structure

InactiveUS20110297525A1Thin thicknessMaintain structural strengthContact mechanismsContact surface shape/structureKey pressingMembrane switch

A press key structure includes a bottom board, an insulating plate, a thin film circuit board, an elastic trigger element, and a keycap covered onto the elastic trigger element, and the insulating plate is installed on the bottom board and includes a penetrating hole, and the thin film circuit board is covered onto the insulating plate, and the thin film circuit board and the bottom board are enclosed to define a containing space at a position corresponding to the penetrating hole, and the thin film circuit board includes a thin film switch disposed above the containing space, and the elastic trigger element is installed above the thin film circuit board, such that external dusts can be prevented from entering into the press key structure from the penetrating hole, and the adverse effect of the dusts on the electric connection and the press path of the press key can be avoided.

Owner:CHICONY ELECTRONICS

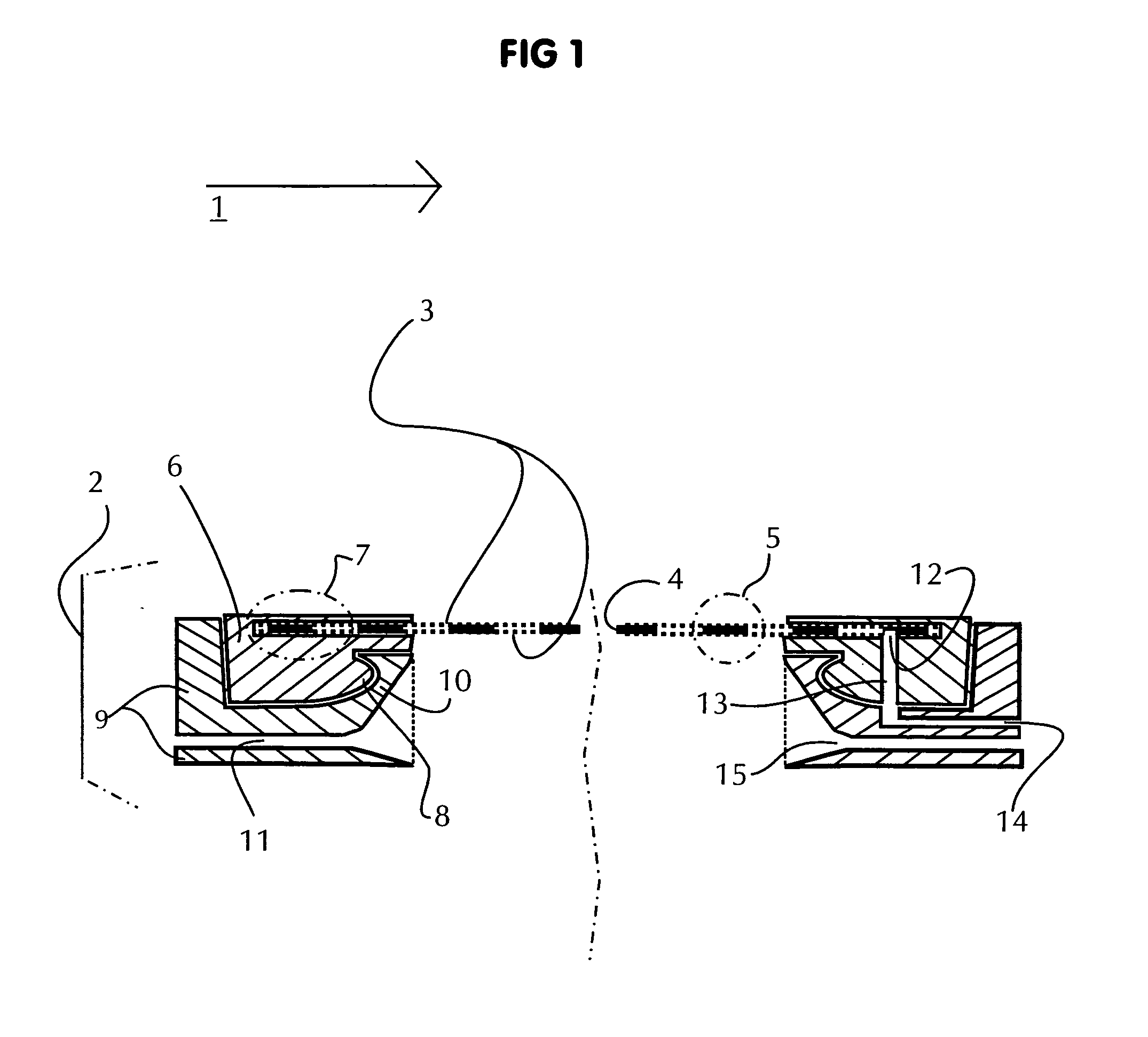

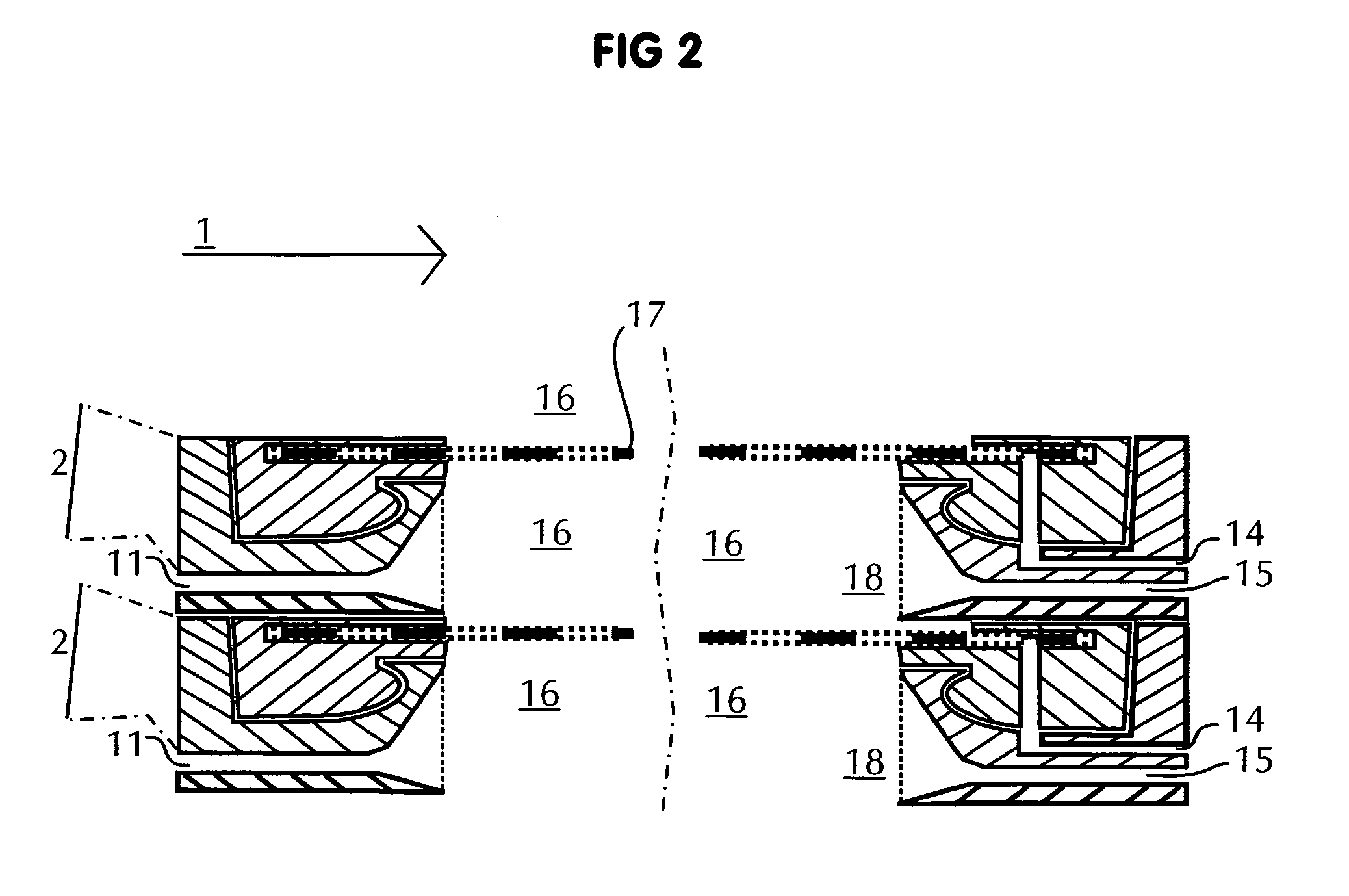

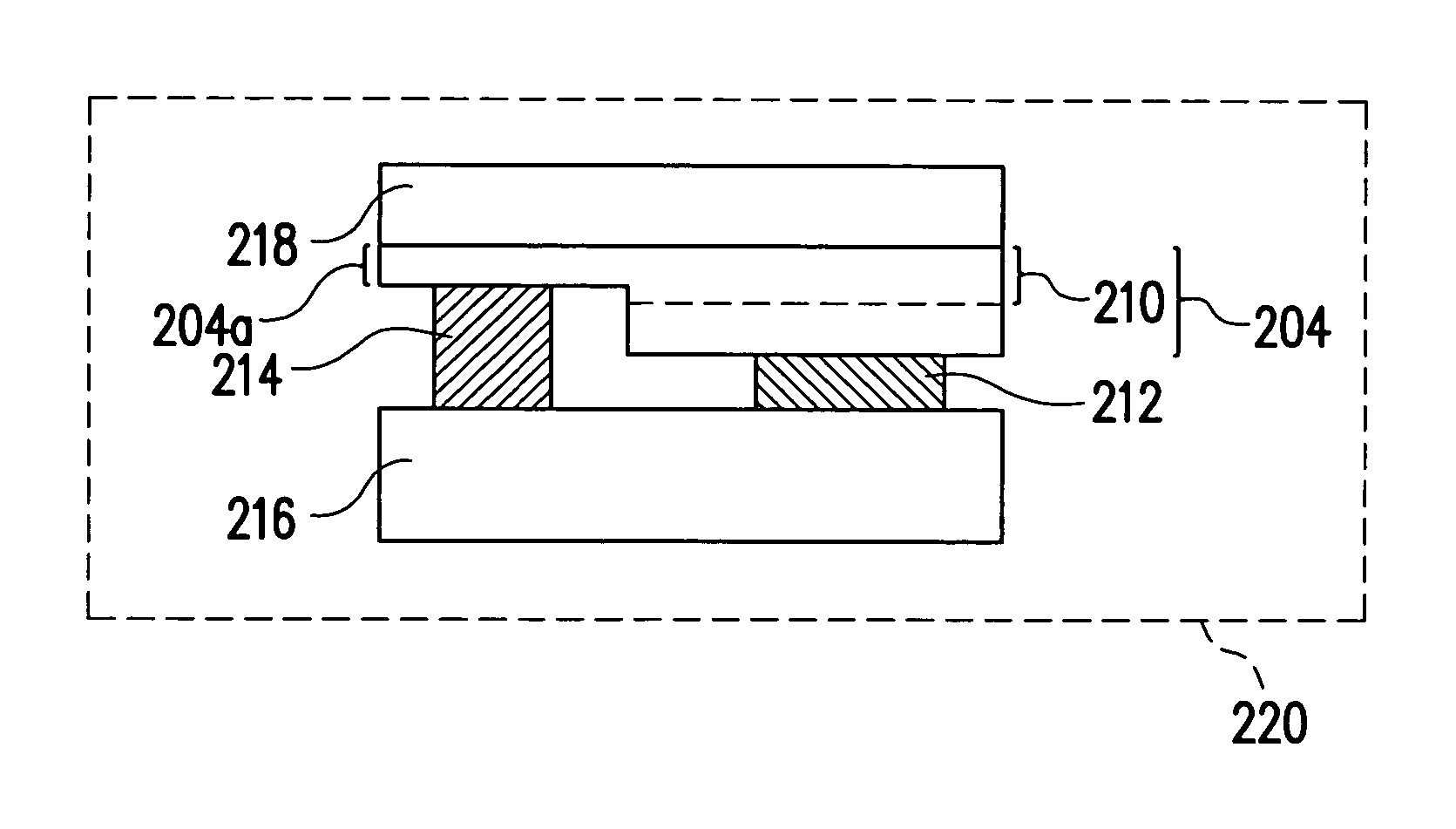

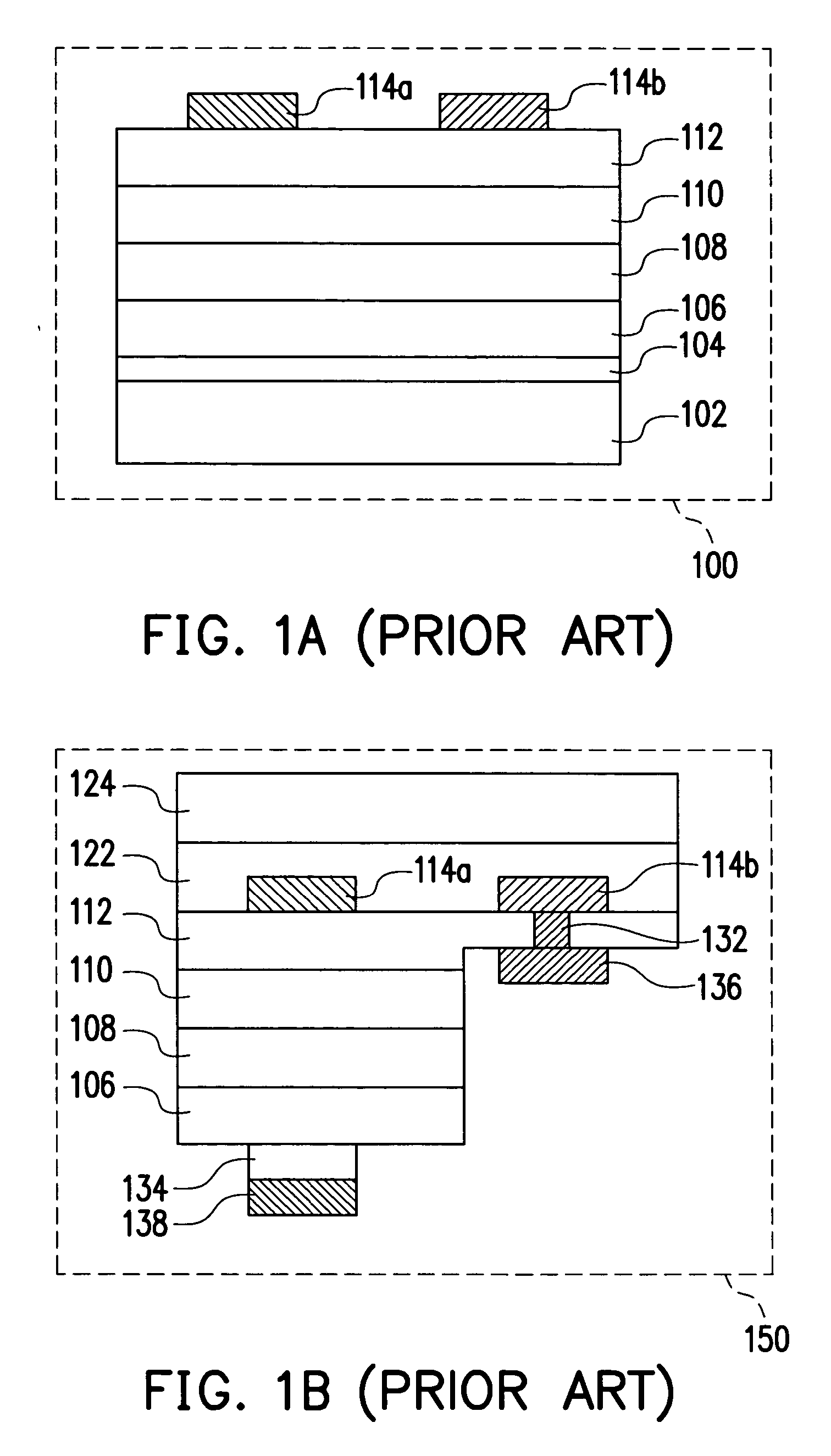

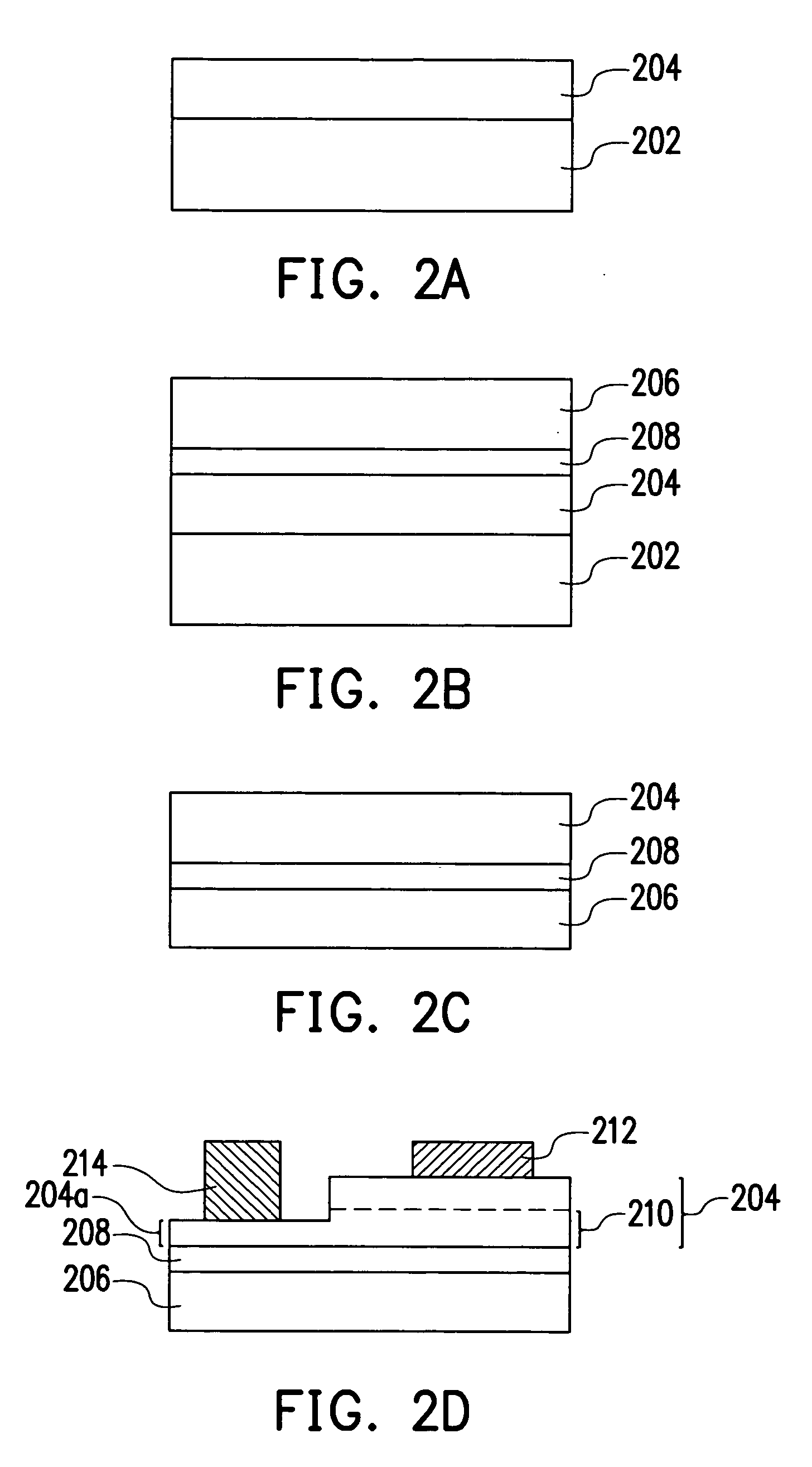

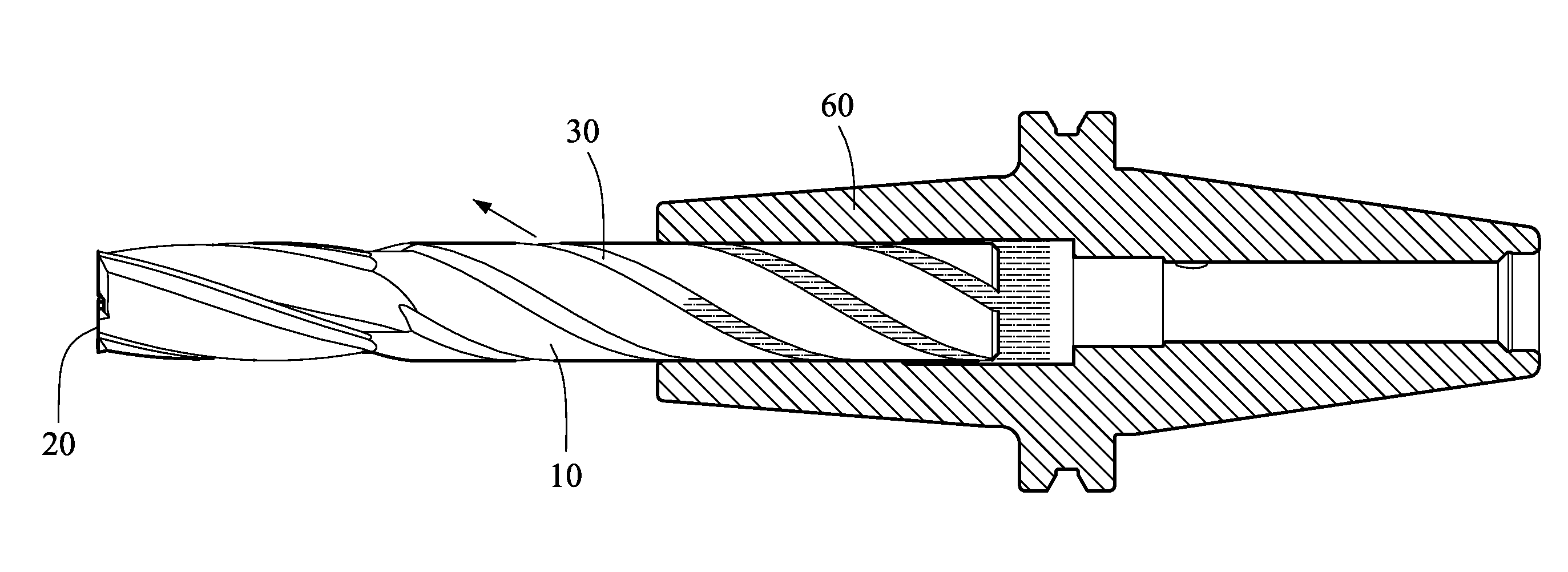

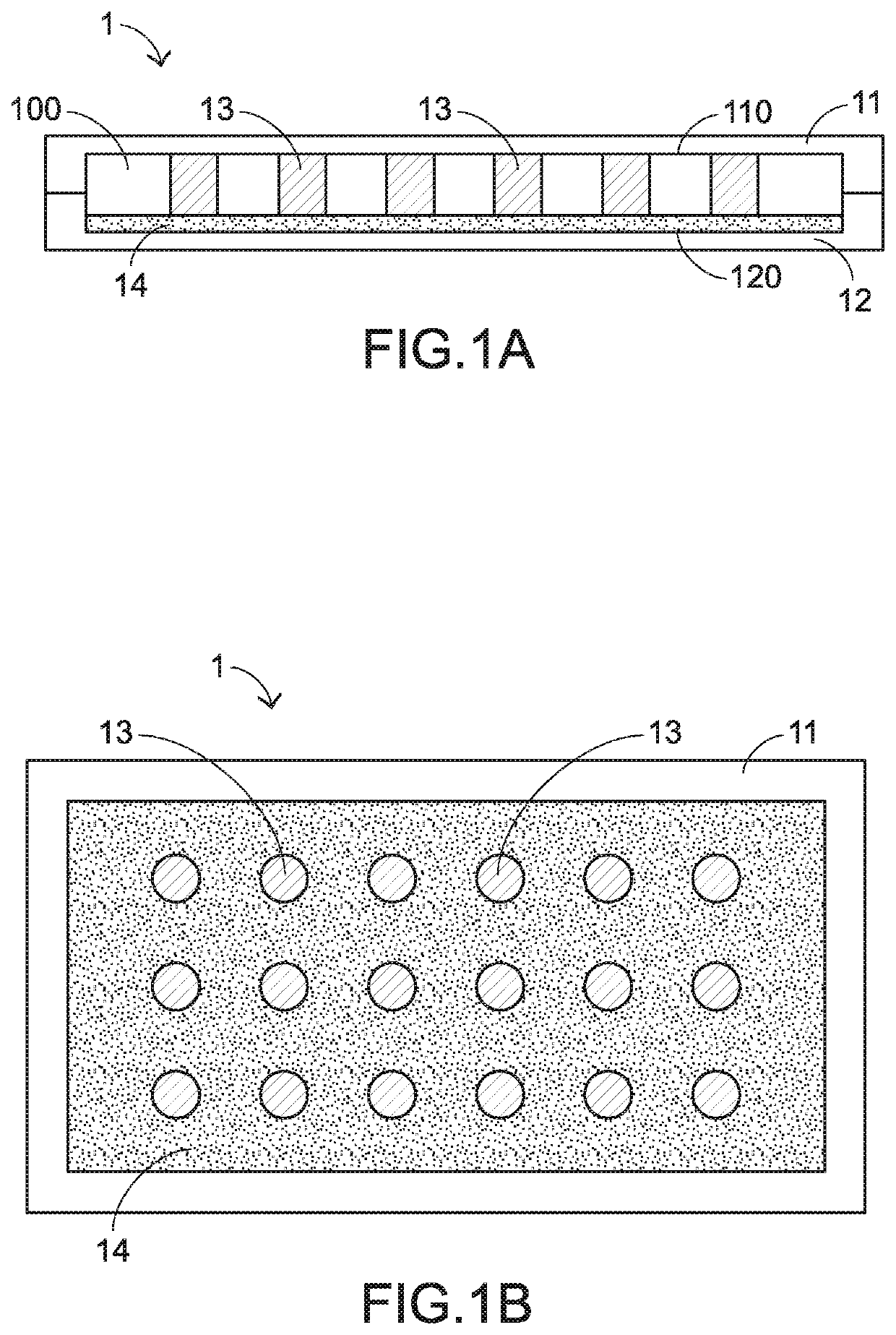

Method of fabricating flip chip ball grid array package

ActiveUS7041531B2Reduce thicknessAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

A method of fabricating a flip chip ball grid array (FC-BGA) package is provided. First, a substrate including a first surface and a second surface is provided, wherein the first surface includes a plurality of cavities. Then, a plurality of flip chips is adhered in the cavities of the substrate. Thereafter, an underfill filling step is performed to fill an underfill between the substrate the flip chips. Then, a ball placement step is performed to attach a plurality of solder balls to a second surface of the substrate. Thereafter, the substrate is divided to separate a portion of the substrate adhering to the flip chips from a sidewall of the cavities.

Owner:ADVANCED SEMICON ENG INC

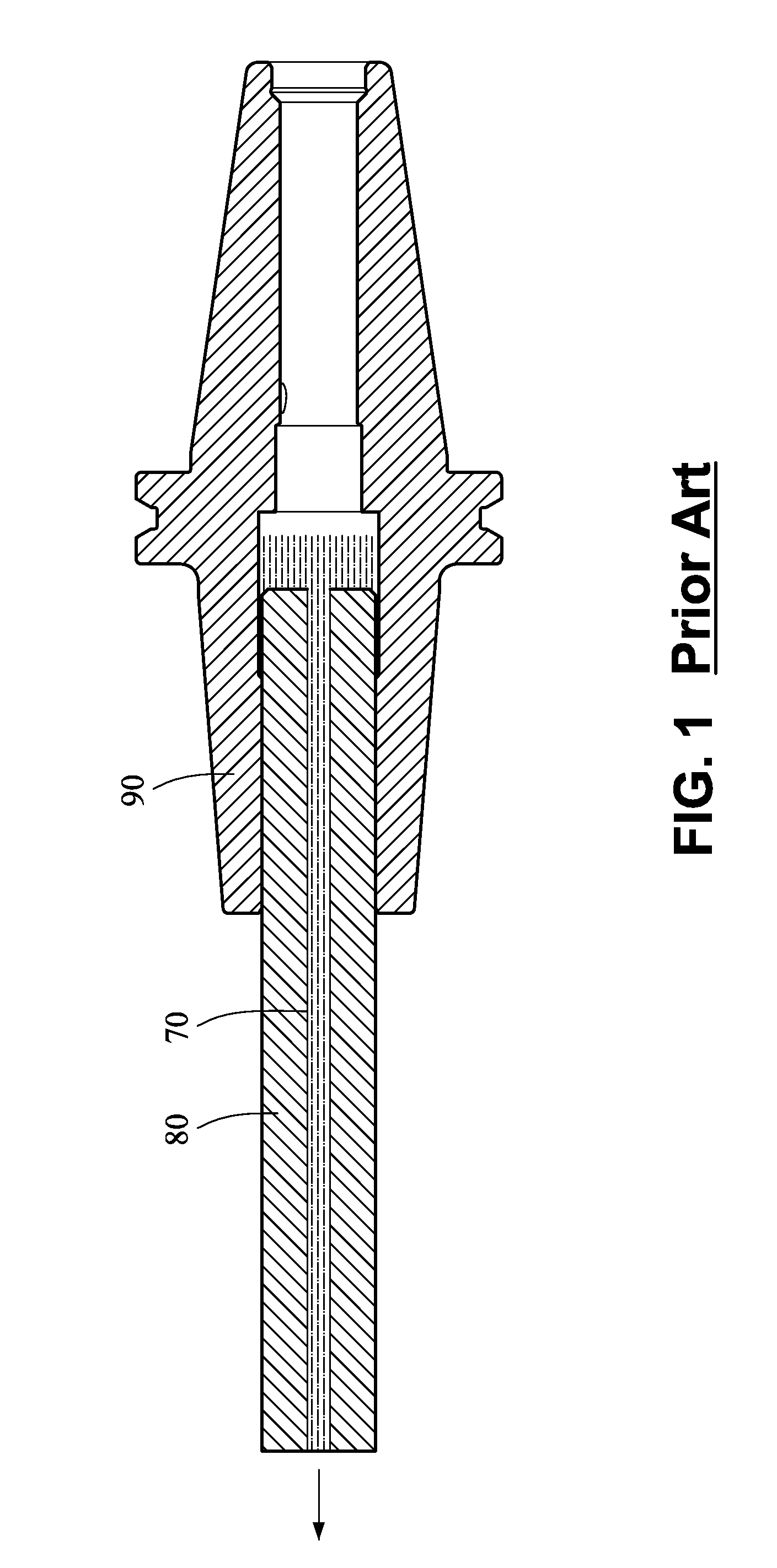

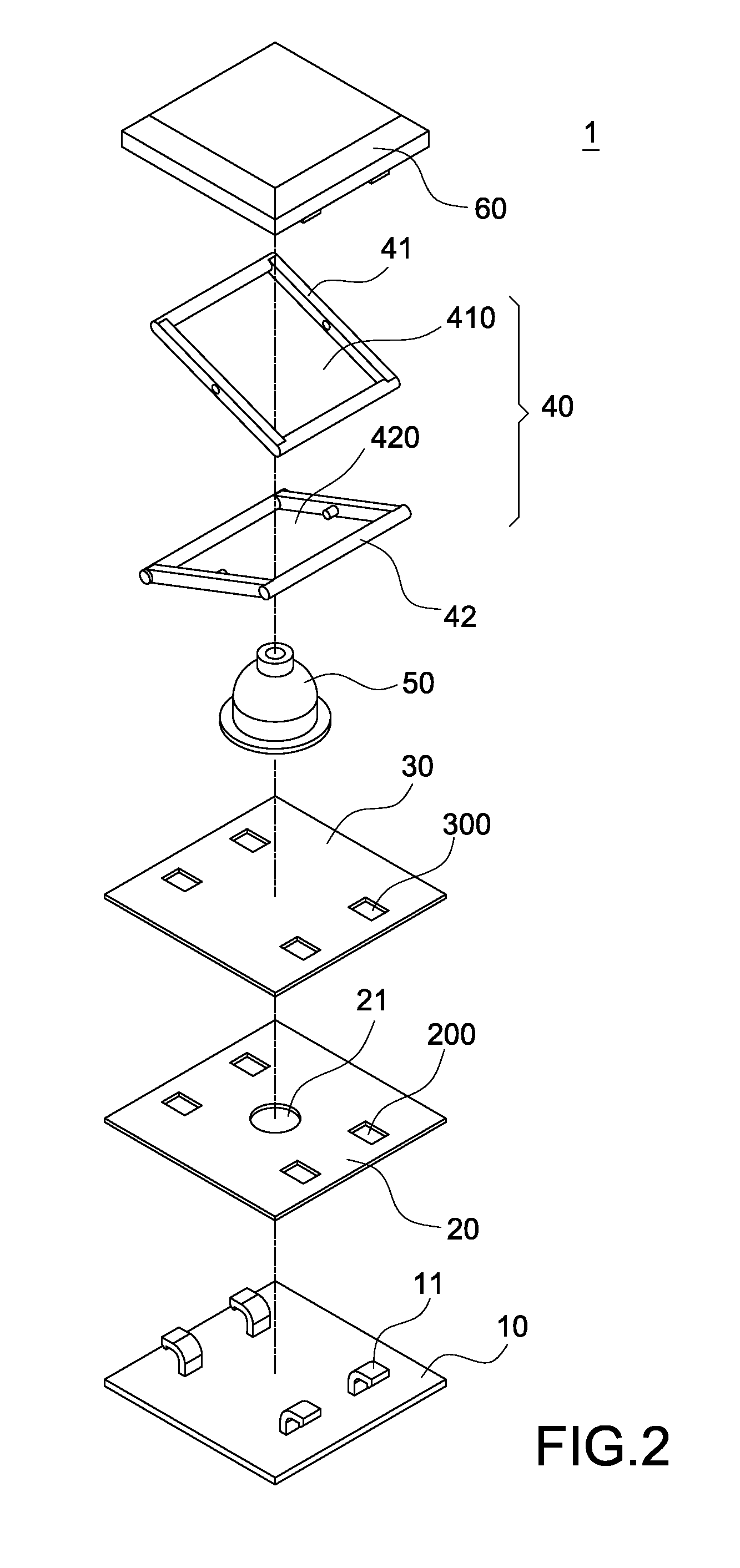

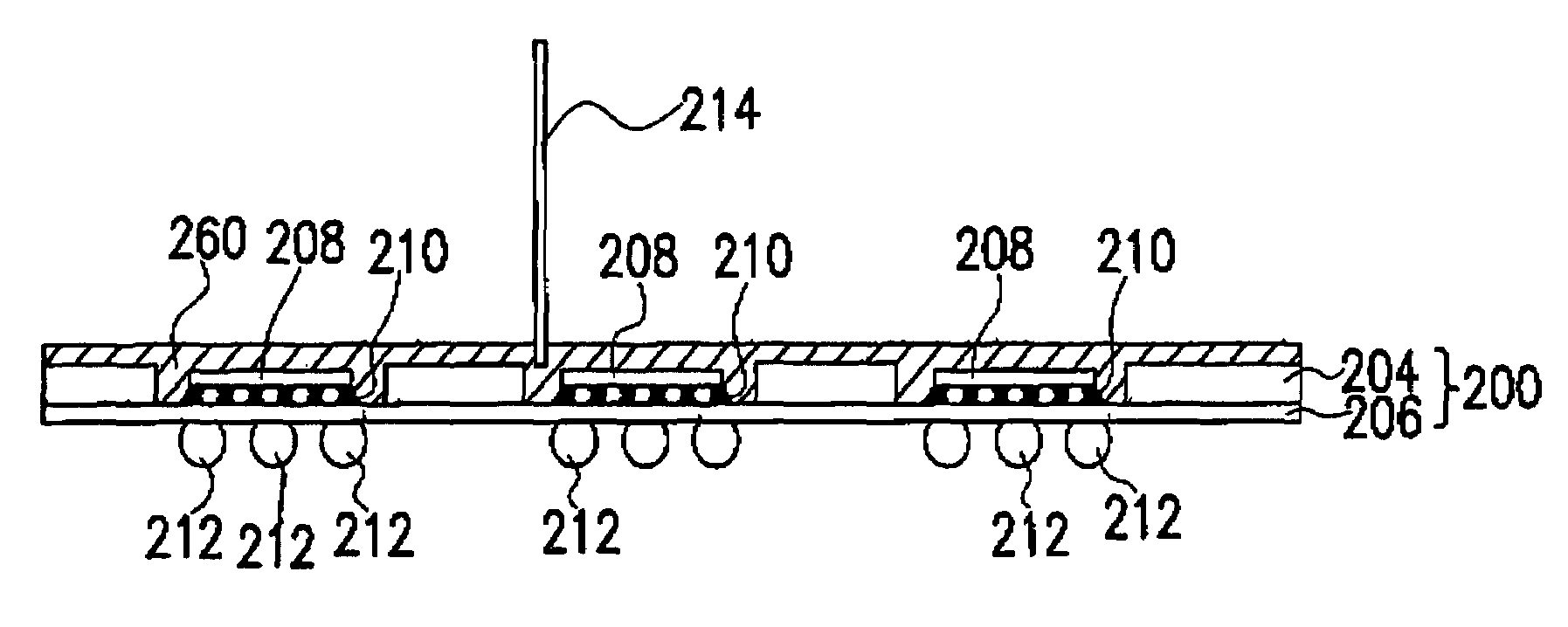

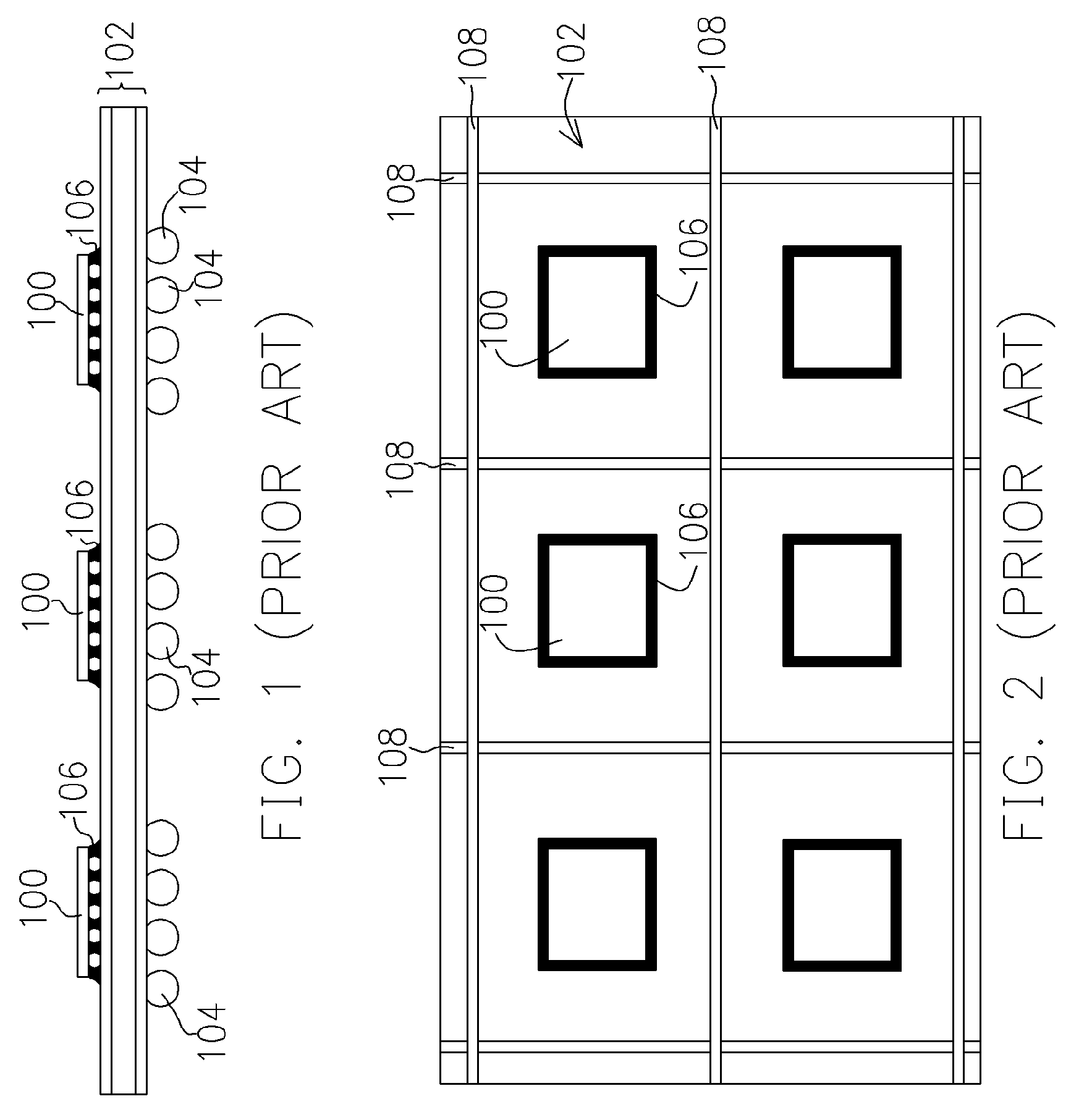

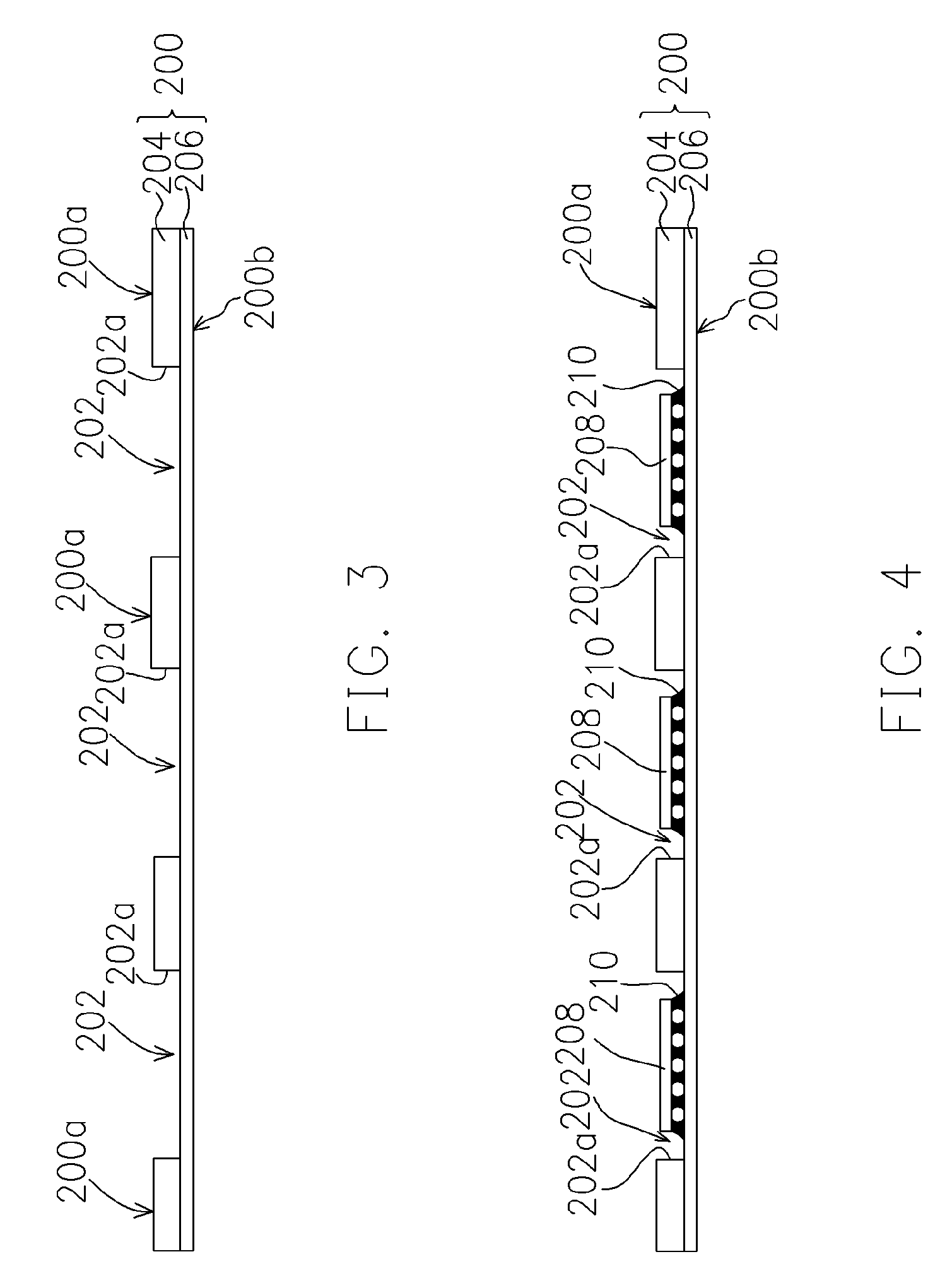

[method of fabricating flip chip ball grid array package]

ActiveUS20050019981A1Reduce thicknessAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesSolder ballEngineering

A method of fabricating a flip chip ball grid array (FC-BGA) package is provided. First, a substrate including a first surface and a second surface is provided, wherein the first surface includes a plurality of cavities. Then, a plurality of flip chips is adhered in the cavities of the substrate. Thereafter, an underfill filling step is performed to fill an underfill between the substrate the flip chips. Then, a ball placement step is performed to attach a plurality of solder balls to a second surface of the substrate. Thereafter, the substrate is divided to separate a portion of the substrate adhering to the flip chips from a sidewall of the cavities.

Owner:ADVANCED SEMICON ENG INC

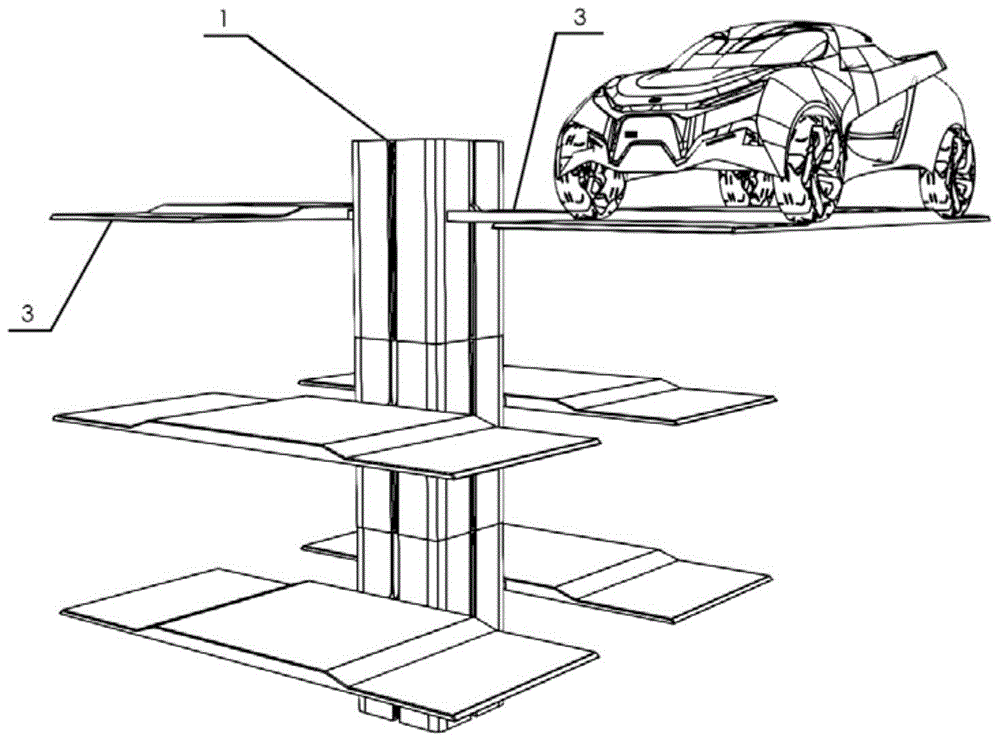

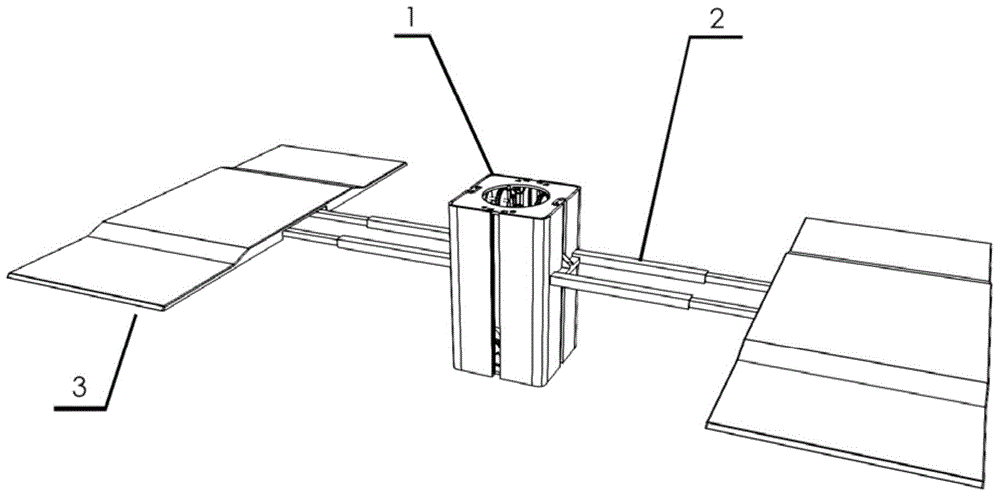

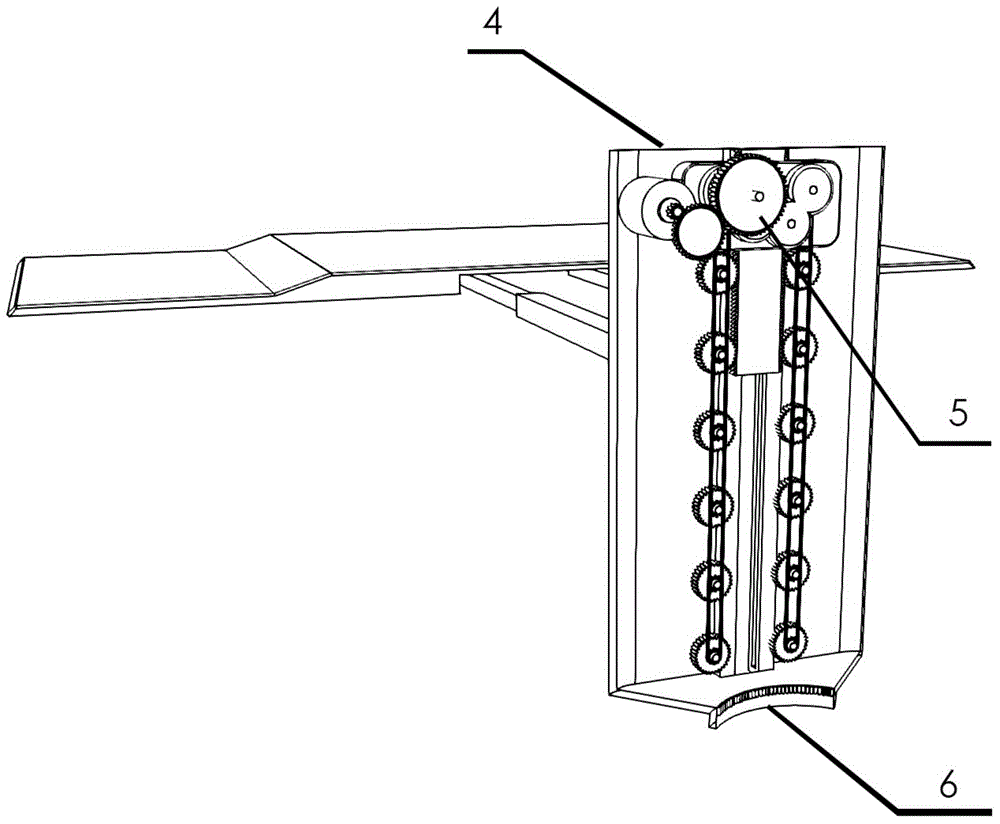

Three-dimensional parking device

InactiveCN104453298AEfficient use ofOptimize volumeRoof covering using slabs/sheetsRoof covering using tiles/slatesElectric machineryParking space

The invention discloses a three-dimensional parking device which comprises a support pillar, parking plate connecting rods, parking plates, a horizontal linkage gear mechanism, a power motor and a rotating power transmission and clutch, wherein the support pillar is provided with lift guide rails; the power motor is connected with the parking plate connecting rods through the horizontal linkage gear mechanism and the rotating power transmission and clutch and is further connected with the parking plates through the parking plate connecting rods. The vertical parking device occupies less floor, and is convenient for parking, easy to maintain, stable and reliable, low in cost, and suitable for application in urban areas.

Owner:CHINA NAT CHEM CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[method of fabricating flip chip ball grid array package] [method of fabricating flip chip ball grid array package]](https://images-eureka.patsnap.com/patent_img/ecebbe79-caa6-489d-a6d9-4f3fe30d273e/US20050019981A1-20050127-D00000.png)

![[method of fabricating flip chip ball grid array package] [method of fabricating flip chip ball grid array package]](https://images-eureka.patsnap.com/patent_img/ecebbe79-caa6-489d-a6d9-4f3fe30d273e/US20050019981A1-20050127-D00001.png)

![[method of fabricating flip chip ball grid array package] [method of fabricating flip chip ball grid array package]](https://images-eureka.patsnap.com/patent_img/ecebbe79-caa6-489d-a6d9-4f3fe30d273e/US20050019981A1-20050127-D00002.png)