Cases of electronic devices and mfg. methods

A technology for electronic devices and manufacturing methods, which are applied to electrical equipment casings/cabinets/drawers, electrical components, metal casings, etc., can solve problems such as insufficient structural strength and inability to meet the requirements of thin and light casings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

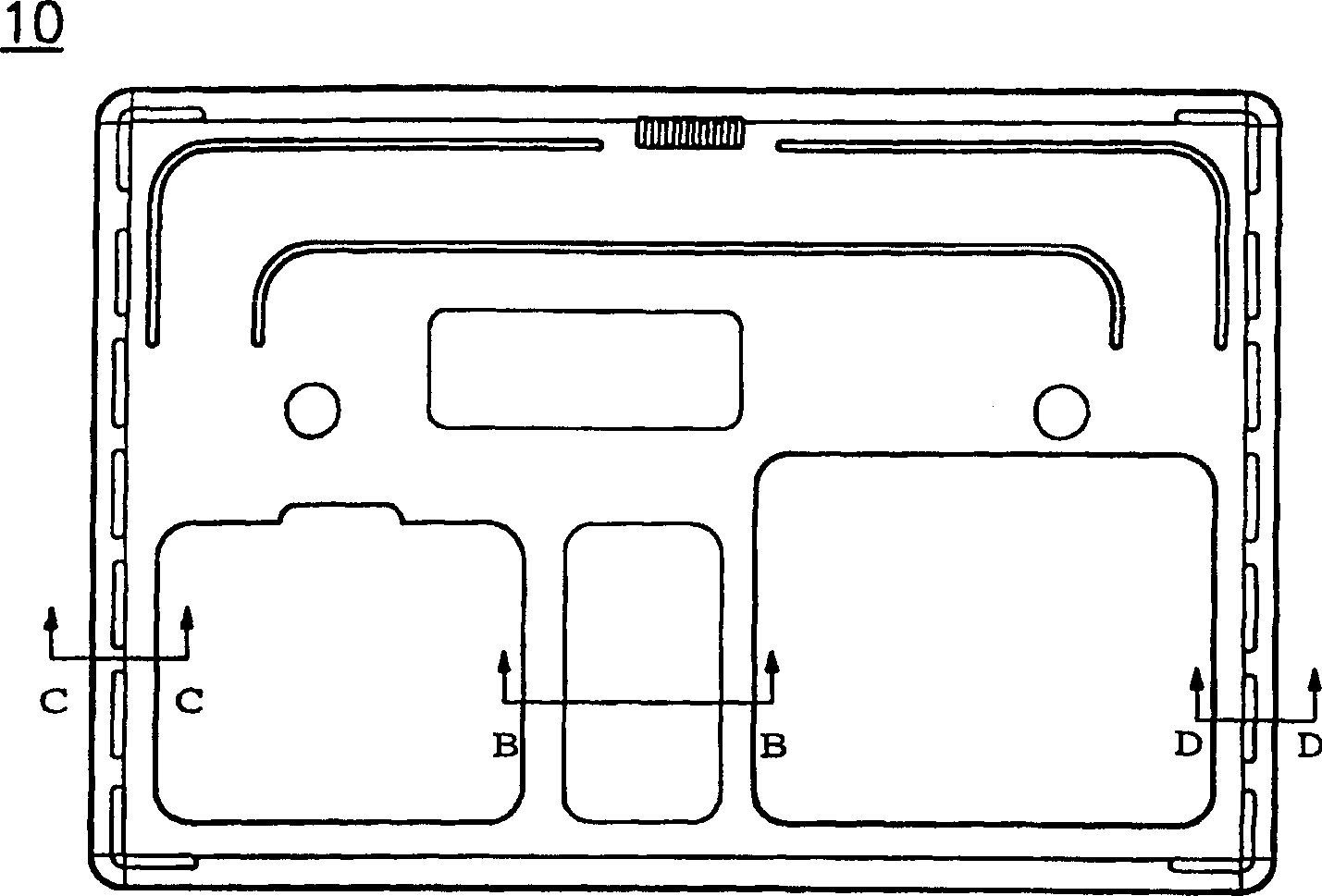

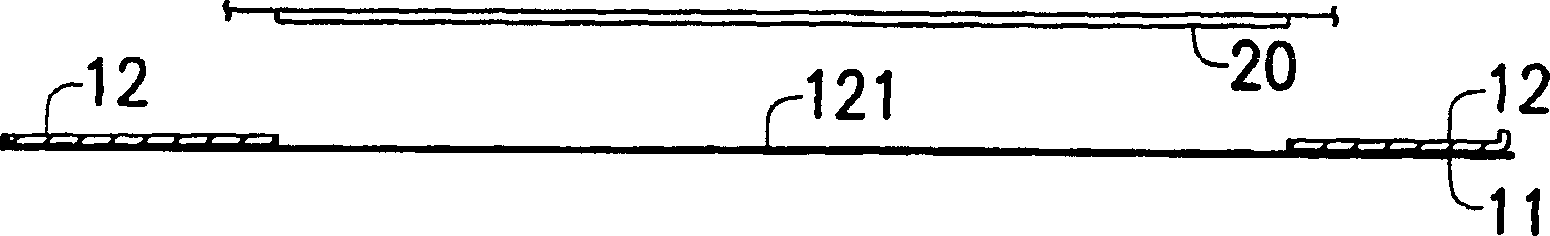

[0017] refer to figure 1 , a general electronic device 1, such as a notebook computer, has a casing 10 composed of different parts, Figure 2a A part of the housing 10 is shown, and through a section on the housing 10, such as Figure 2b , Figure 2c and Figure 2d As shown, it can be seen that the casing 10 of the present invention is formed by a first component 11 and a second component 12 .

[0018] refer to Figure 2b , the electronic device 1 has a plurality of elements 20 (only one is shown in the figure), and the second member 12 is disposed on the first member 11, and the second member 12 has a step portion 121 corresponding to the element 20, and the second The member 12 is closer to the element 20 than the first member 11 , and it should be noted that the number of step portions 121 formed corresponds to the number of elements 20 provided.

[0019] Moreover, the casing 10 further includes a glued portion 13 located between the first member 11 and the second memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com