Patents

Literature

87results about "Bearing bushes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

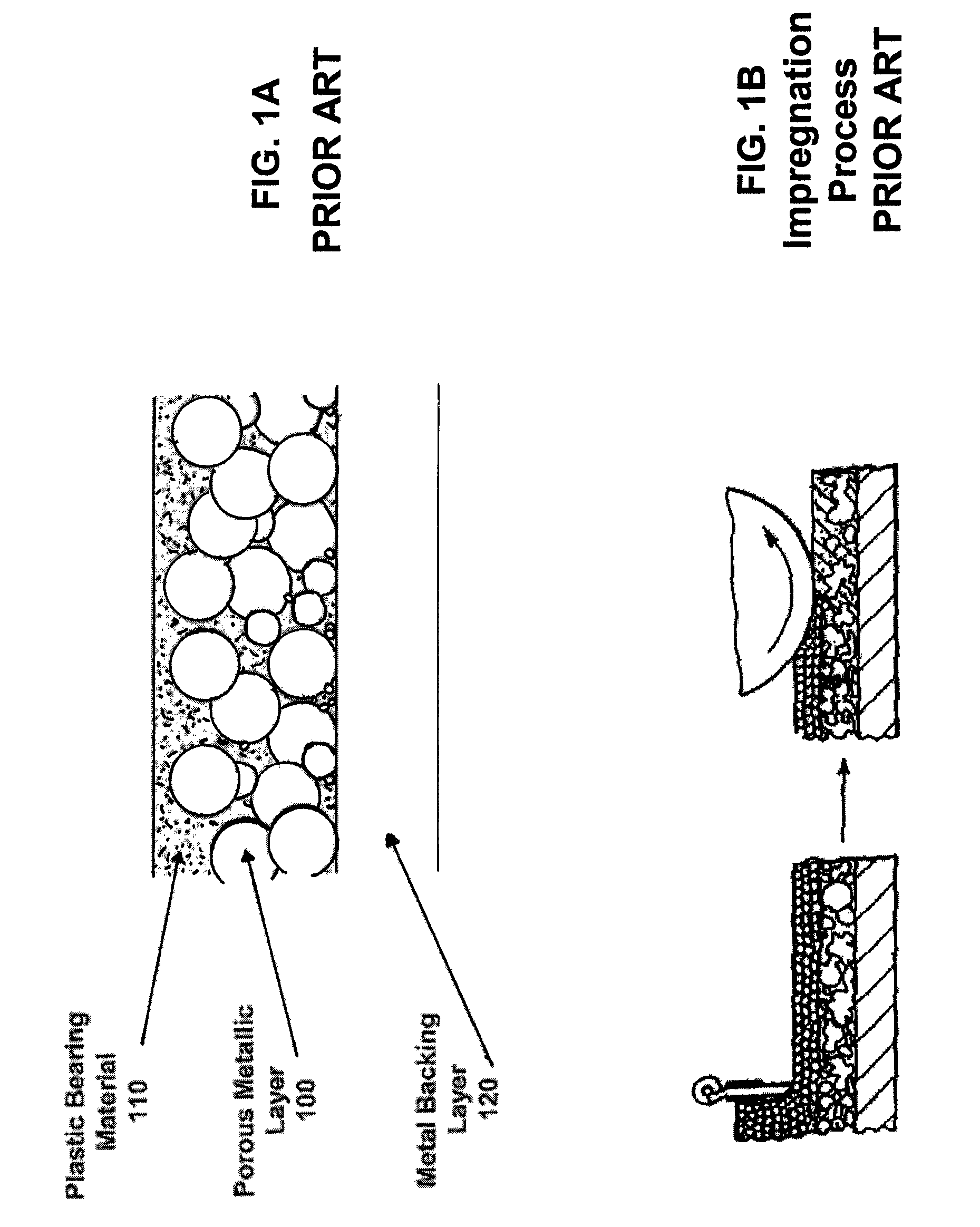

Lead-free bearing

A lead-free bearing includes a bronze matrix powder metal bearing layer bonded to a steel backing a fully densified. The bearing material has about 8 to 12% by weight tin, about 1 to less than 5% by weight bismuth, and about 0.03 to 0.08% by weight phosphorus, with the balance being copper. The tin is soluable in the copper to yield the bronze matrix, and the bismuth exists as finely dispersed, undissolved islands through the matrix. Such bearings exhibit physical properties comparable to or better than those of traditional bronze-lead bearings and improved wear in seizure properties.

Owner:CITIGROUP GLOBAL MARKETAB

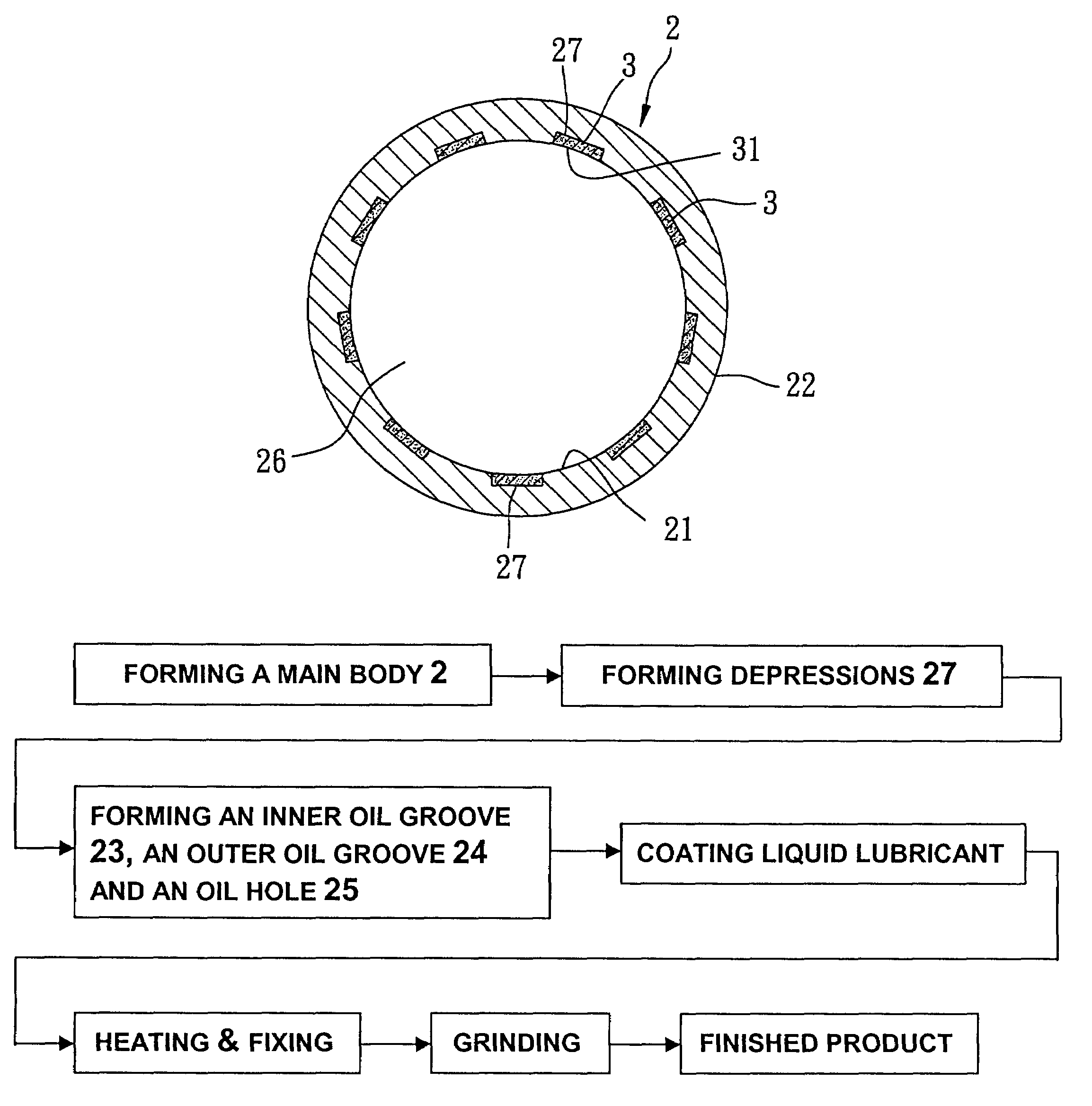

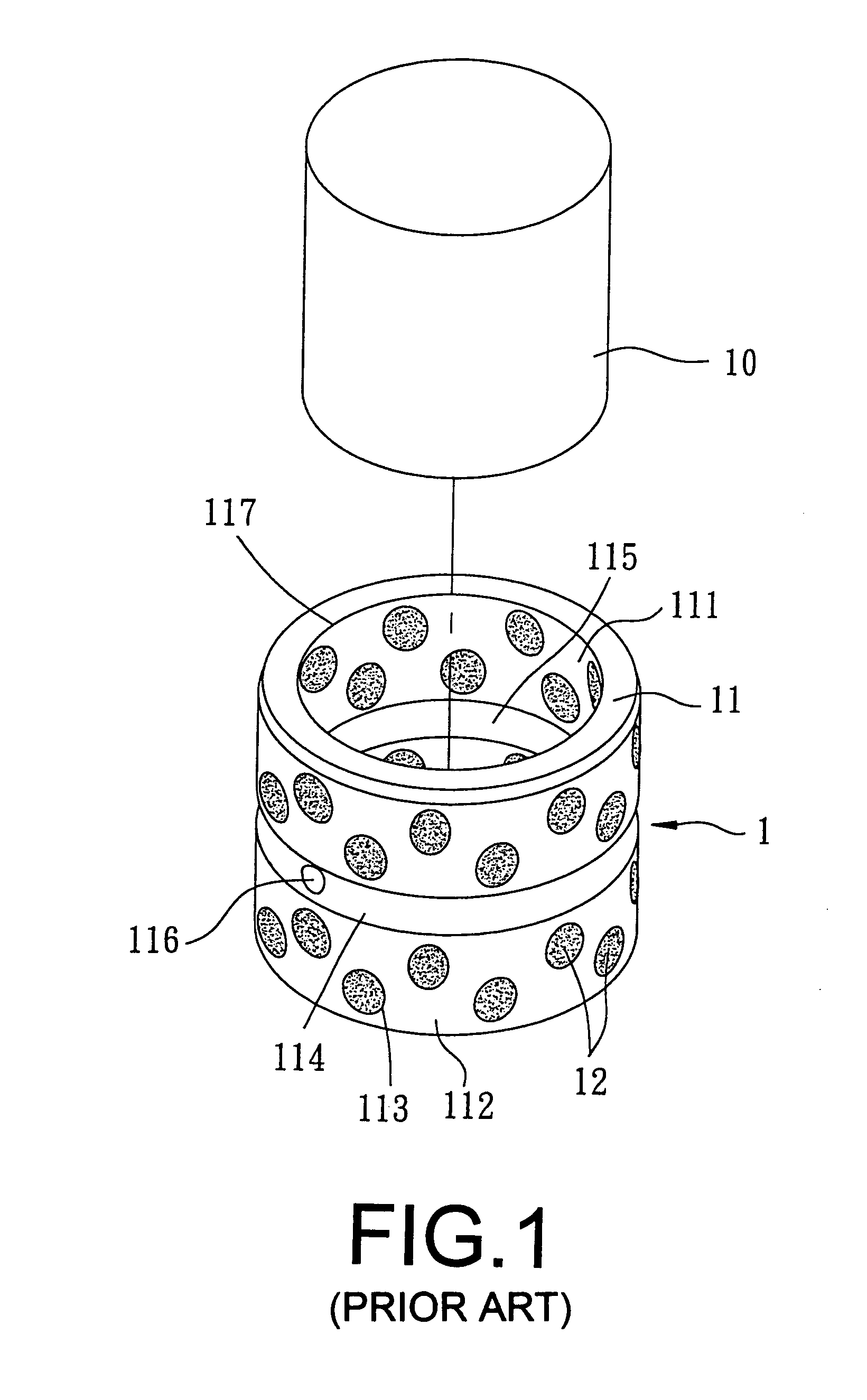

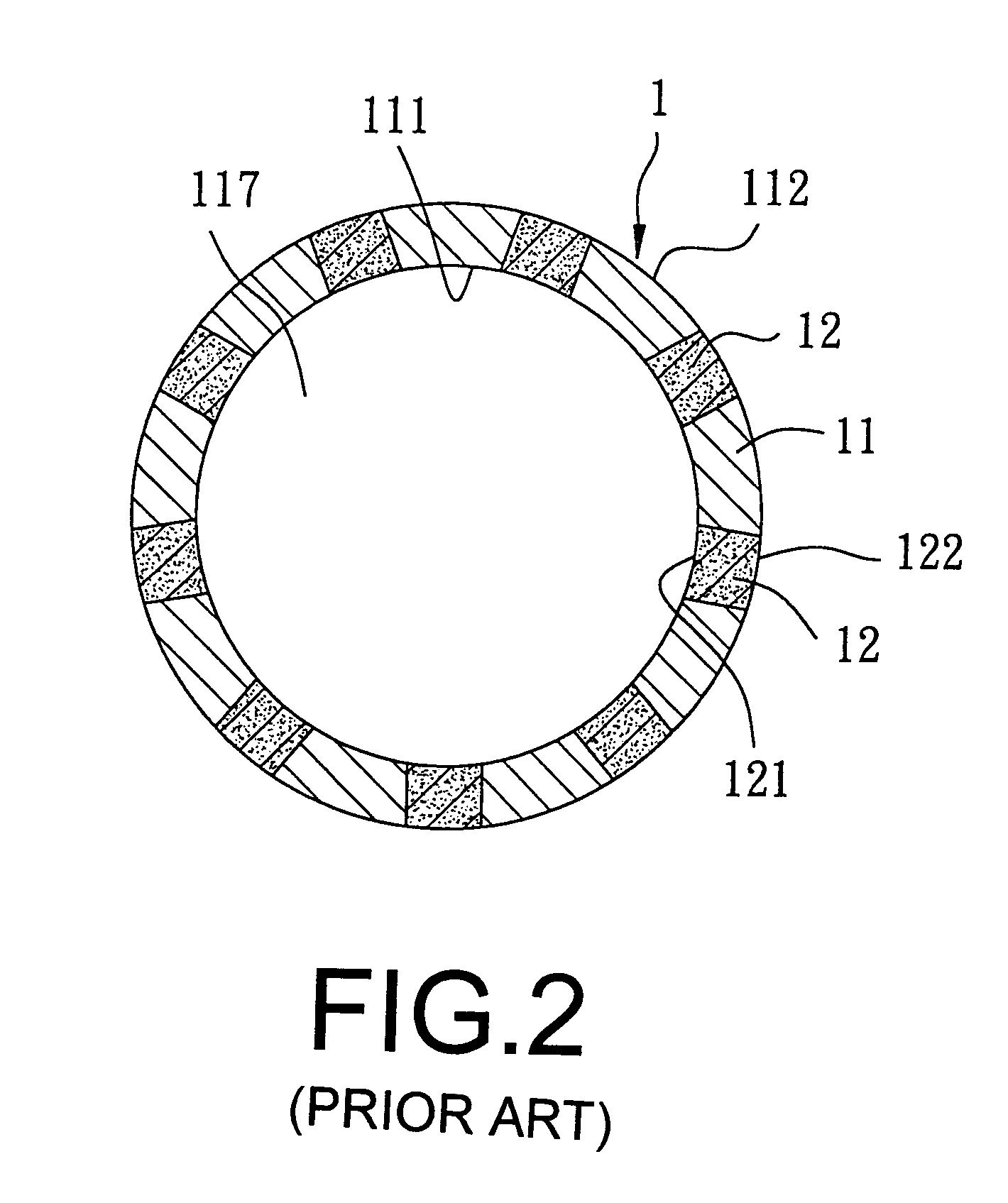

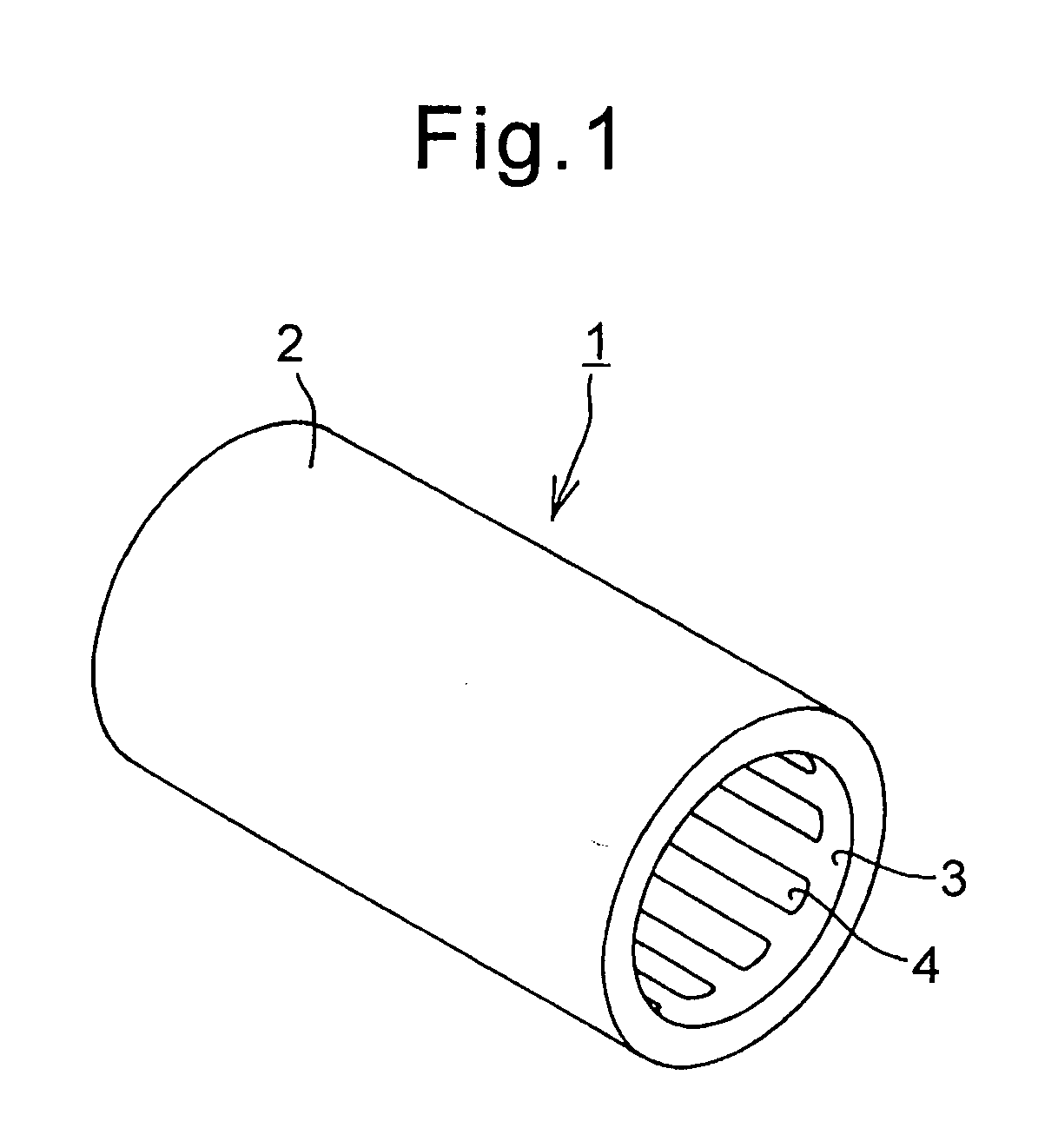

Self-lubricating bearing and method of producing the same

This invention relates to a self-lubricating bearing and a method of producing the same. The self-lubricating bearing includes a main body and a plurality of solid lubricant pieces. The main body has an inner annular wall surface, an outer annular wall surface, and a through hole defined by the inner annular wall surface. The solid lubricant pieces are embedded in a plurality of depressions of the inner annular wall surface by coating and grinding and each has a radial inside annular surface in a curve conforming to that of the inner annular wall surface. The forming of the depressions without radially penetrating through the outer annular wall surface to make the solid lubricant pieces embedded into the depressions with less amount by coating and grinding allows the self-lubricating bearing to reduce the material cost, and keep its structural strength and lubricating effect simultaneously.

Owner:LEE HU I LONG

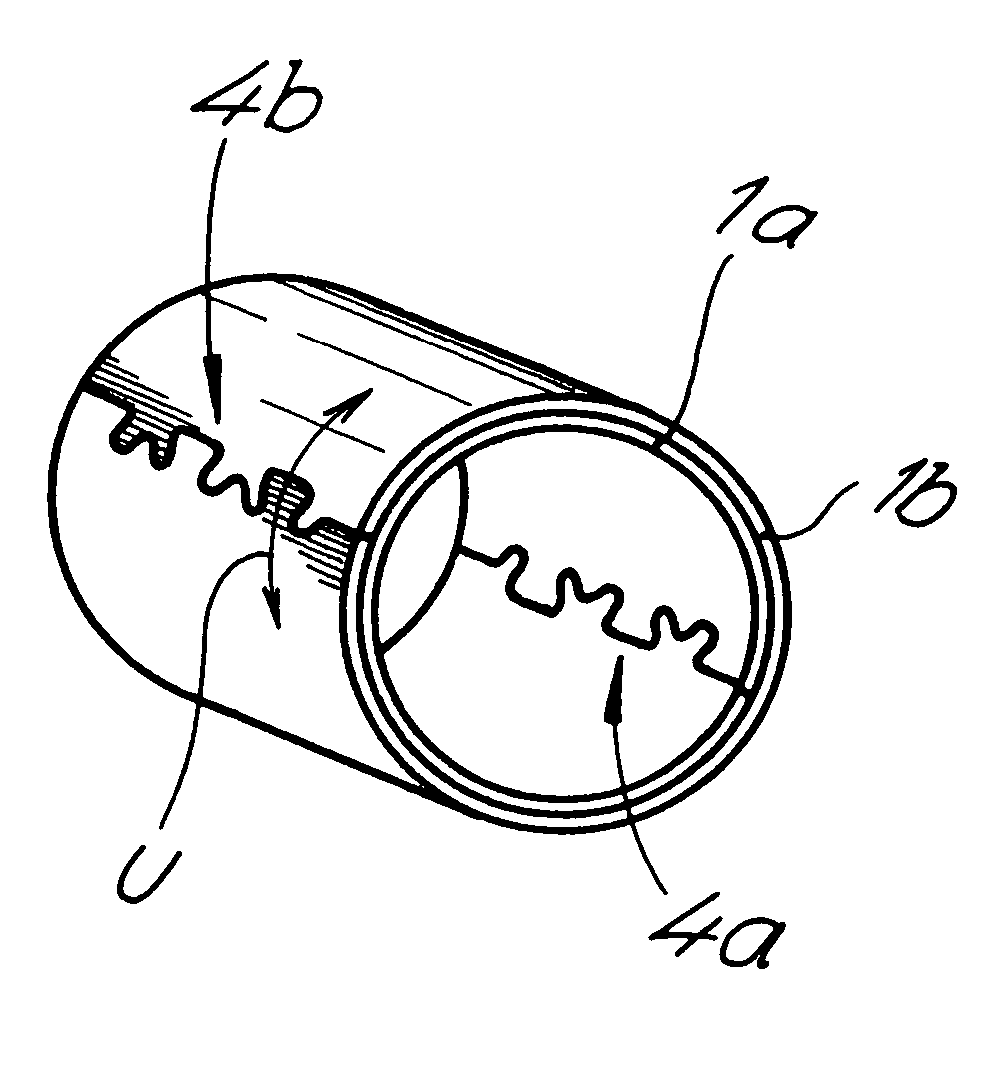

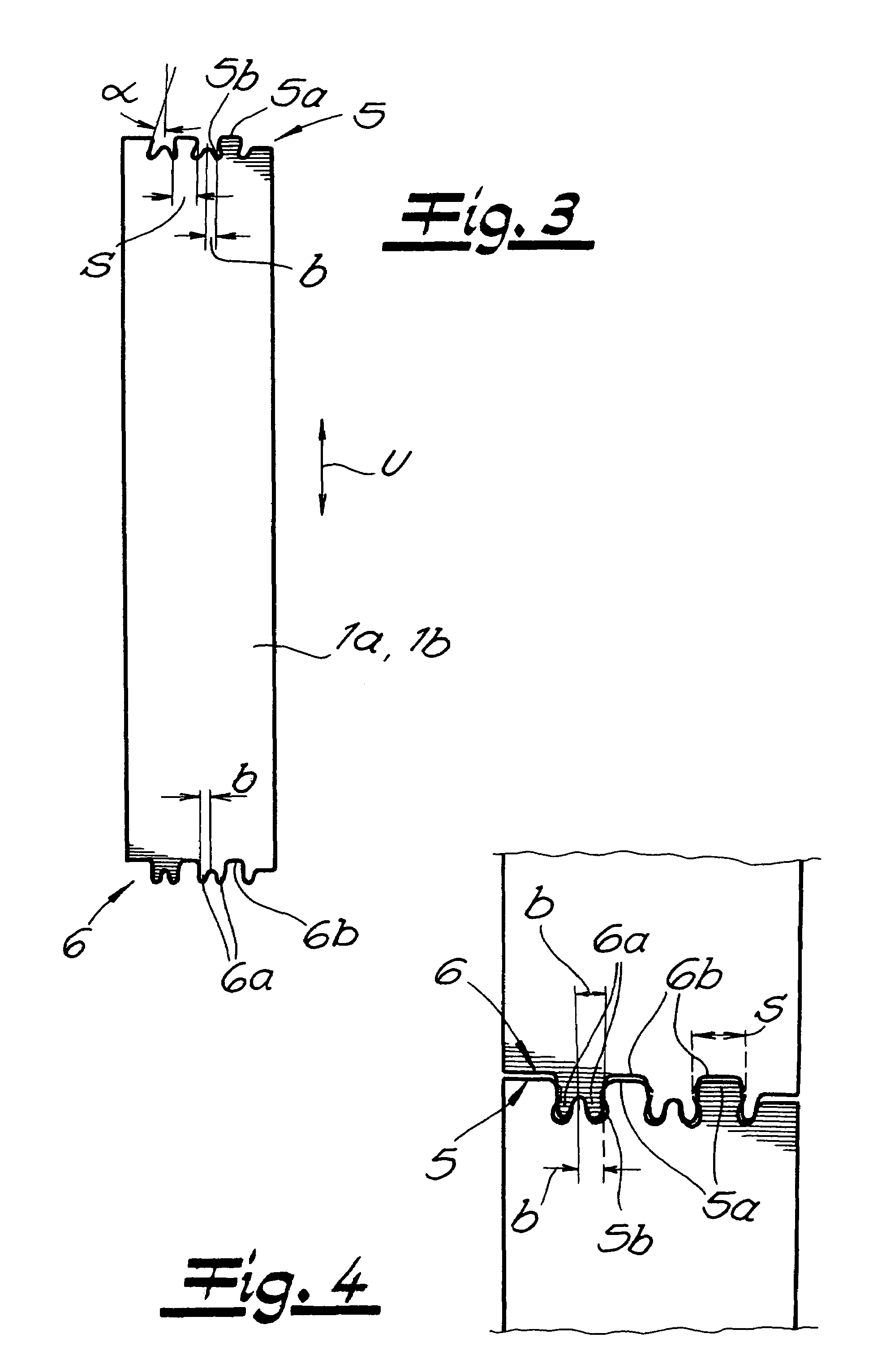

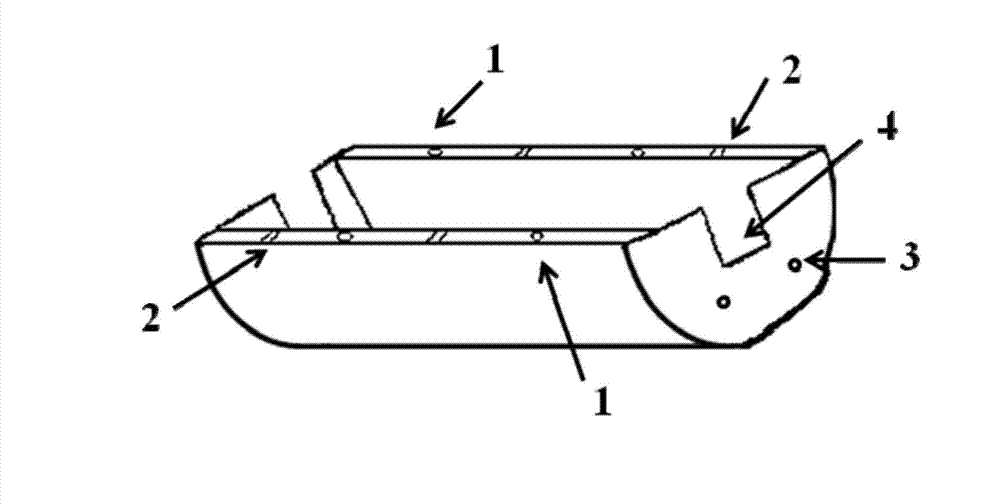

Bearing, particularly rubber bearing

A bearing, particularly a rubber bearing, has in its fundamental structure at least one bearing bushing and one rubber body surrounded by the bearing bushing. The bearing bushing has at least one longitudinal parting line having edge profiles that are complementary to one another, provided at adjacent longitudinal edges. The tines and tine recesses, respectively, engage into one another at the edge profiles which are complementary to one another. The tine along the one longitudinal edge, in each instance, dips into a related tine recess on the other longitudinal edge, essentially in the circumference direction of the bearing bushing in the course of production. During this process, the tine is plastically deformed by a predetermined measure, so that the tine and the related tine recess wedge into one another.

Owner:STABITEC STANZ BIEGETECHN

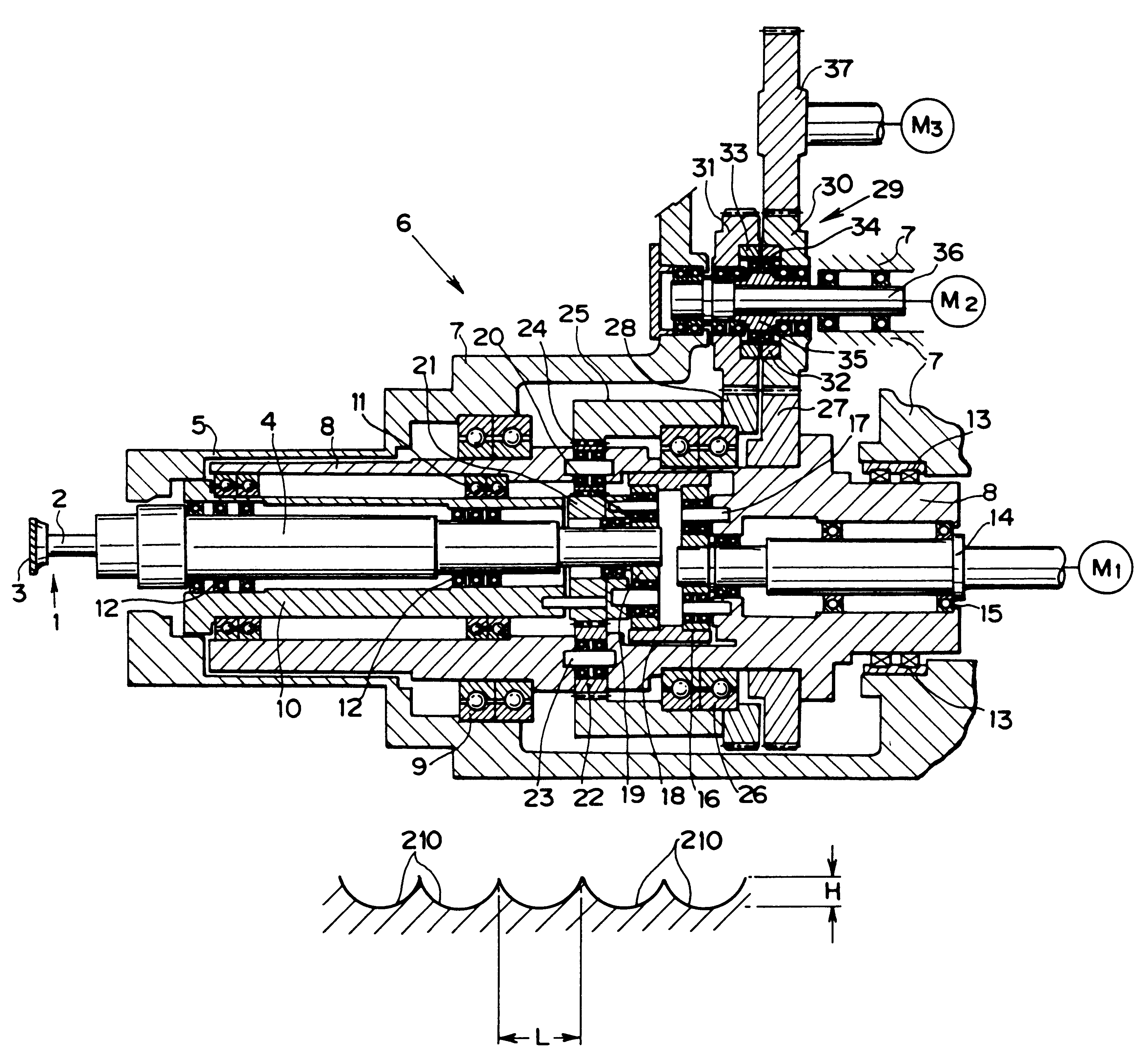

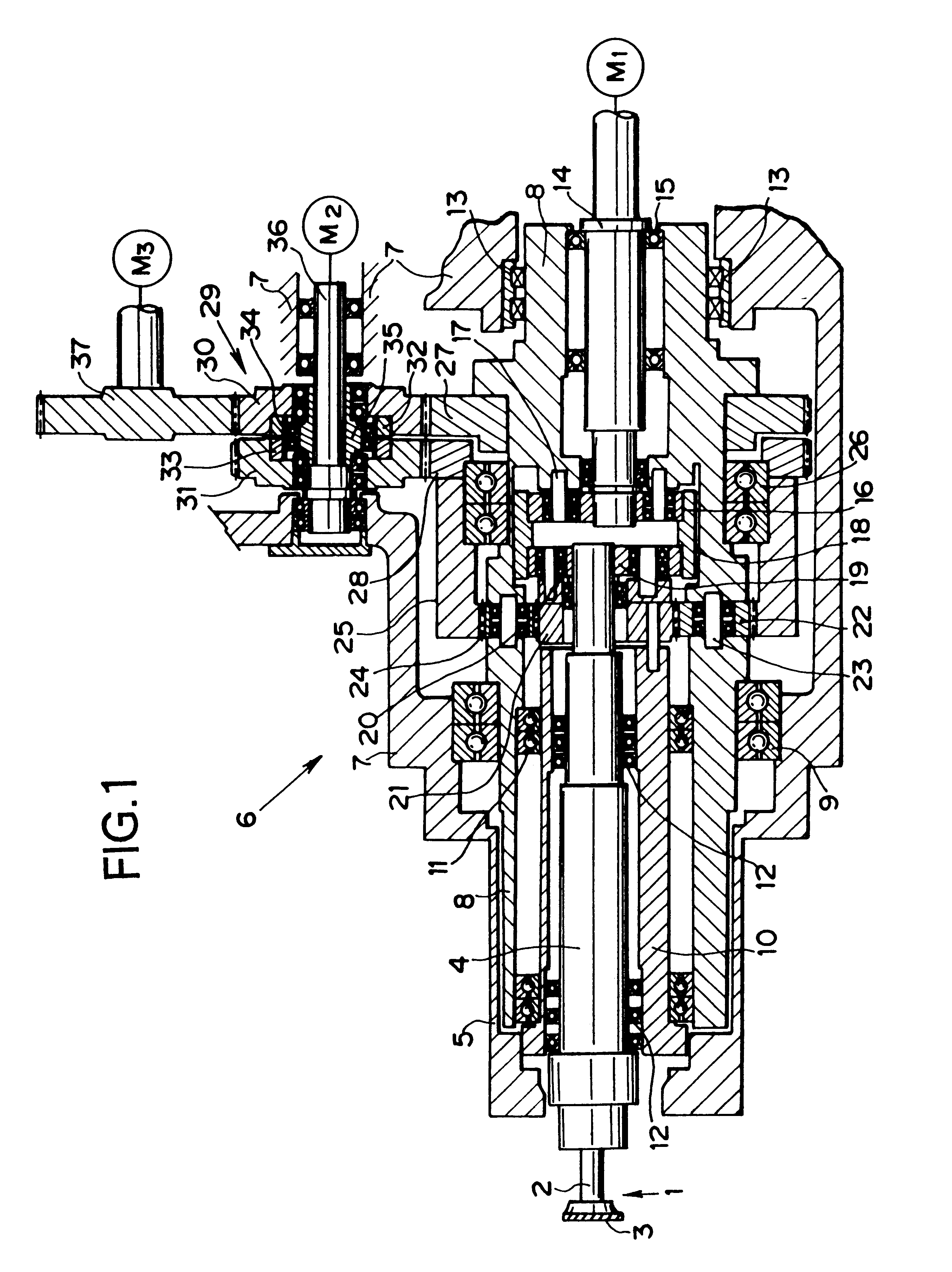

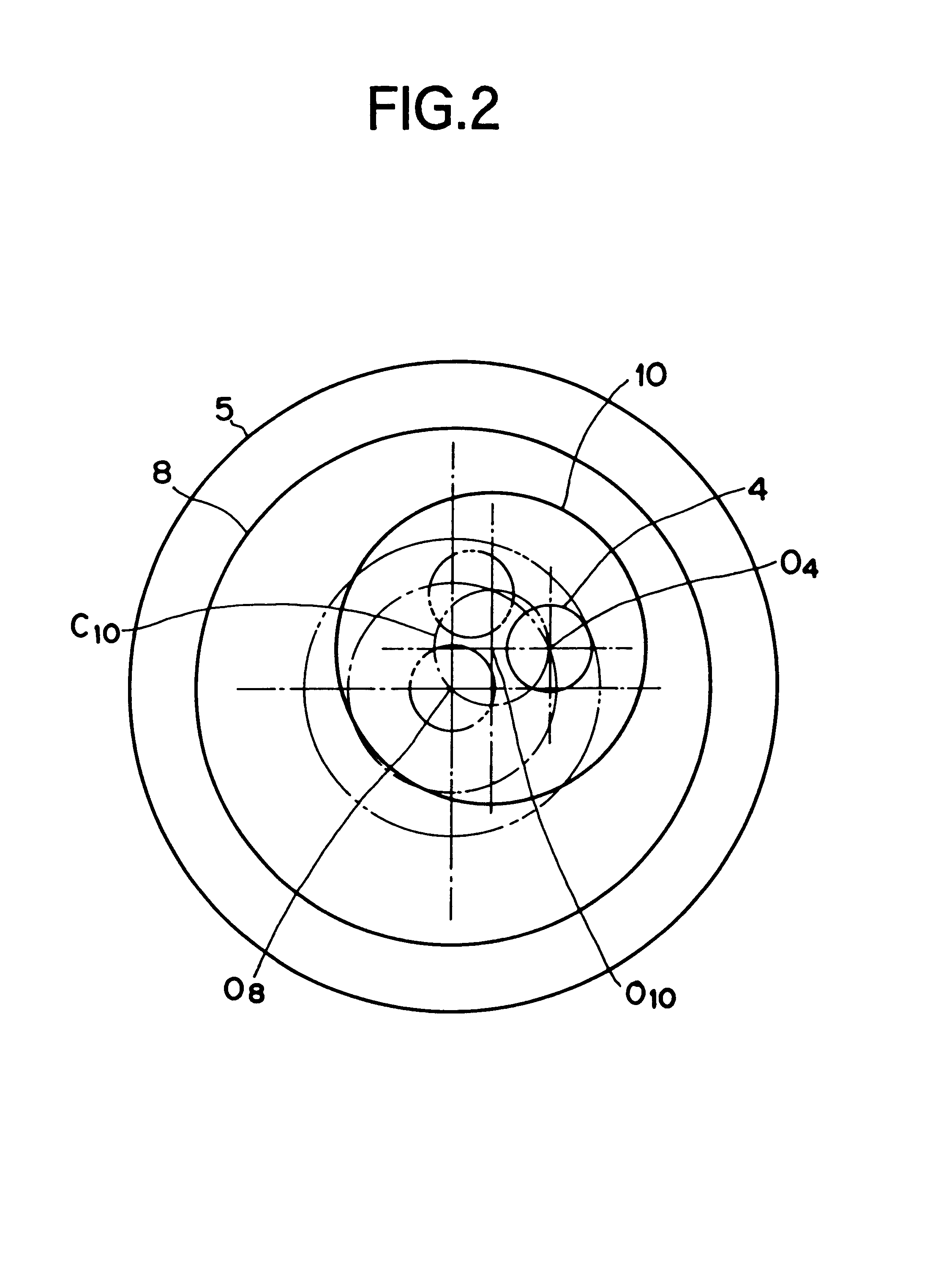

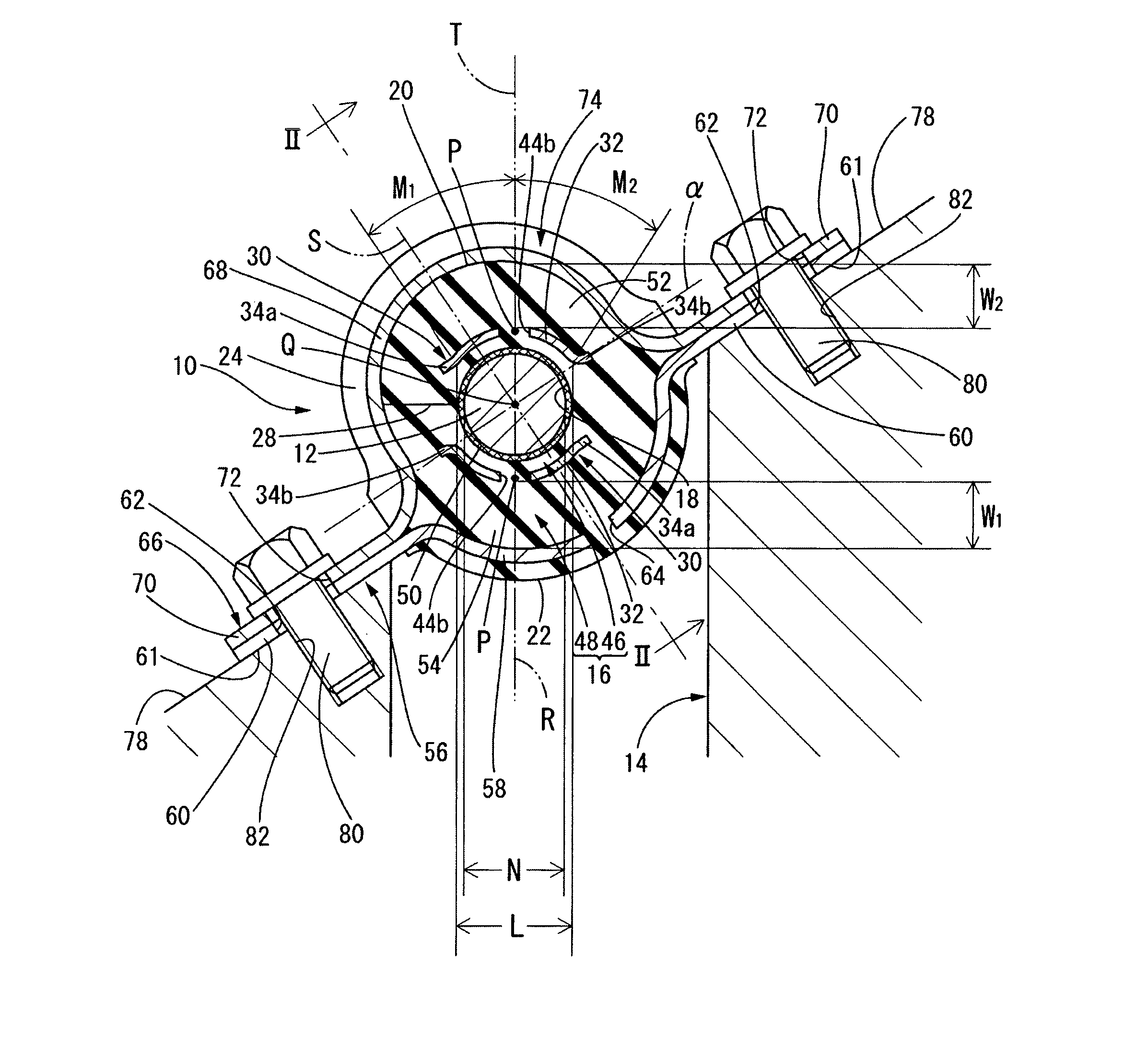

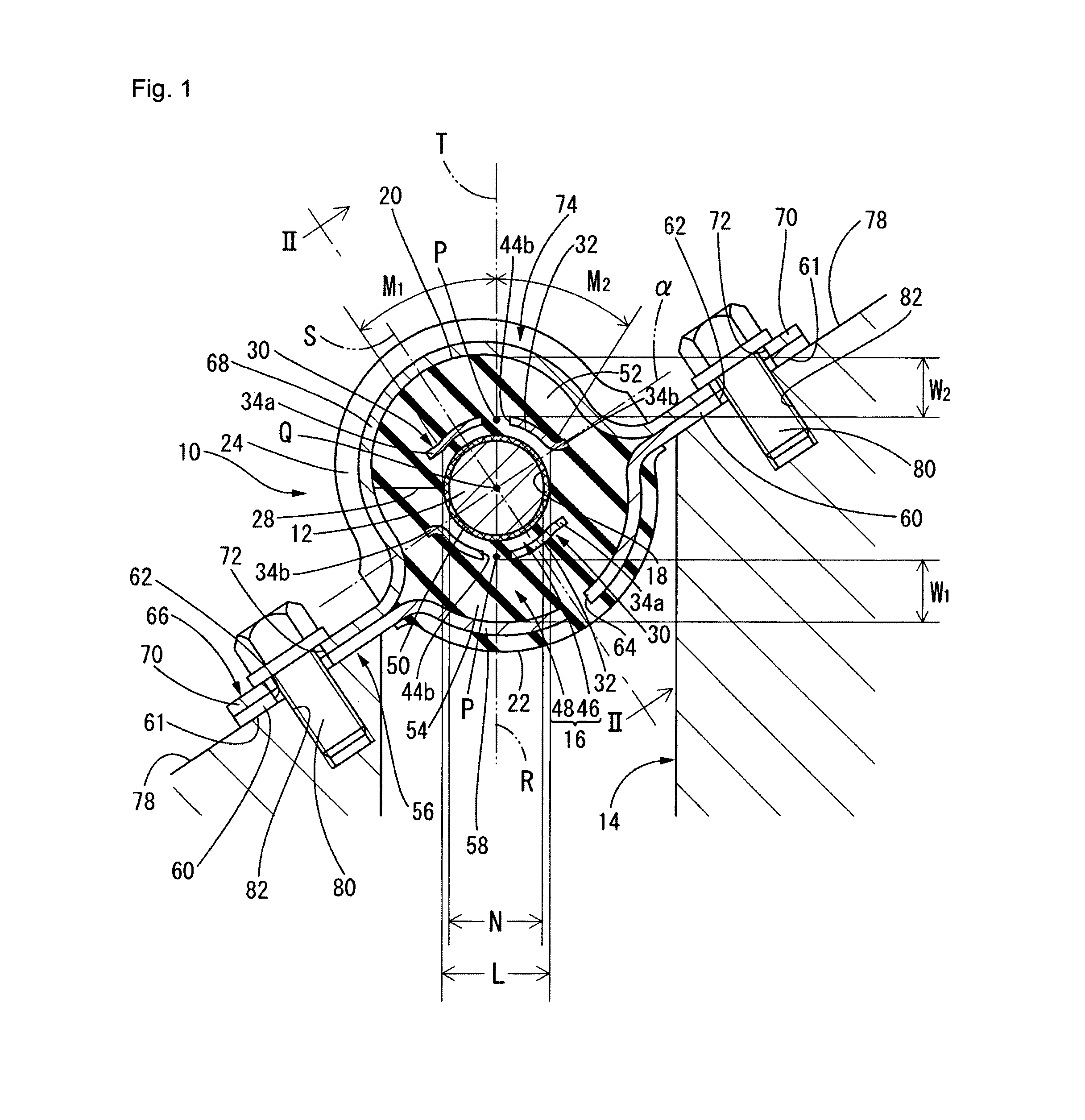

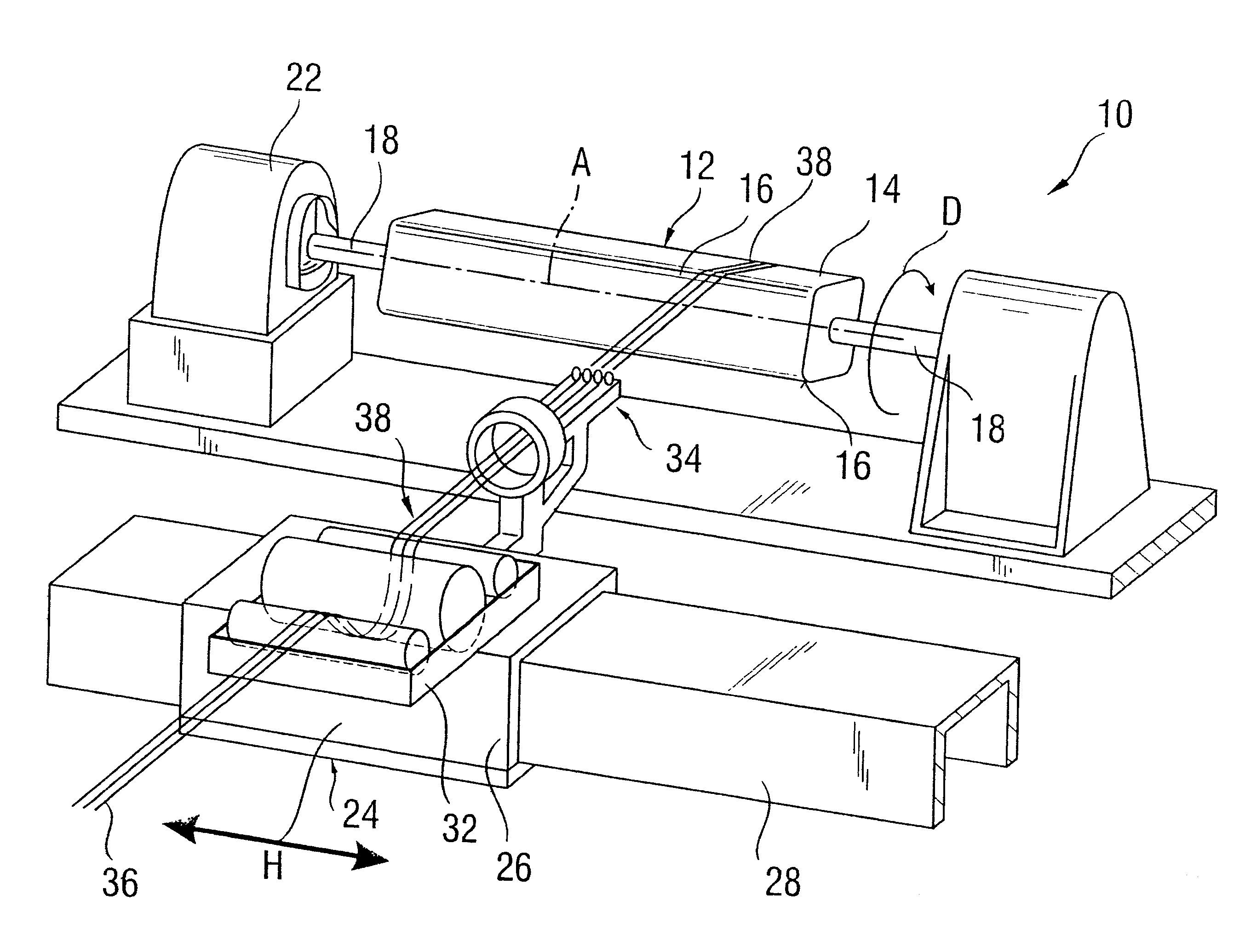

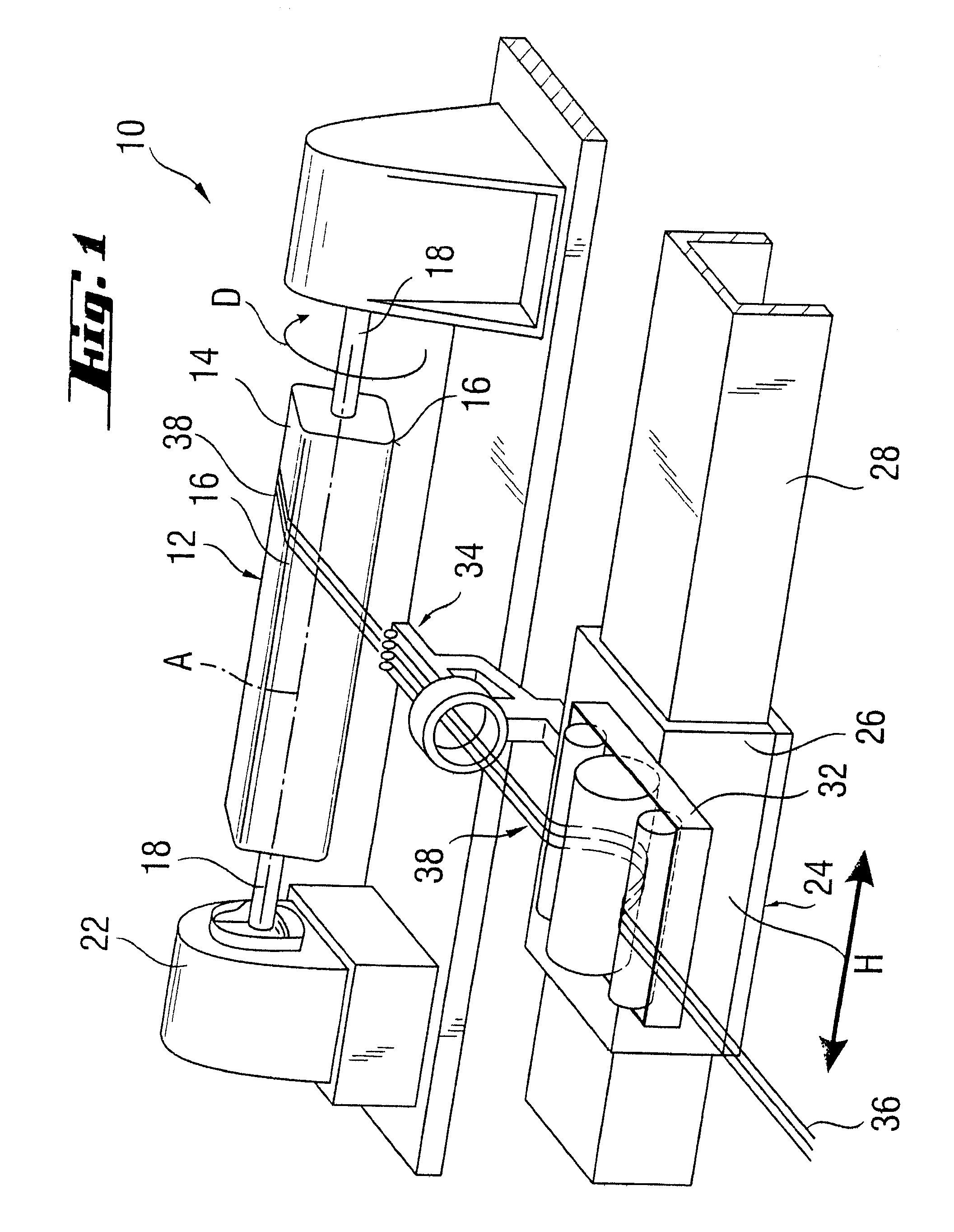

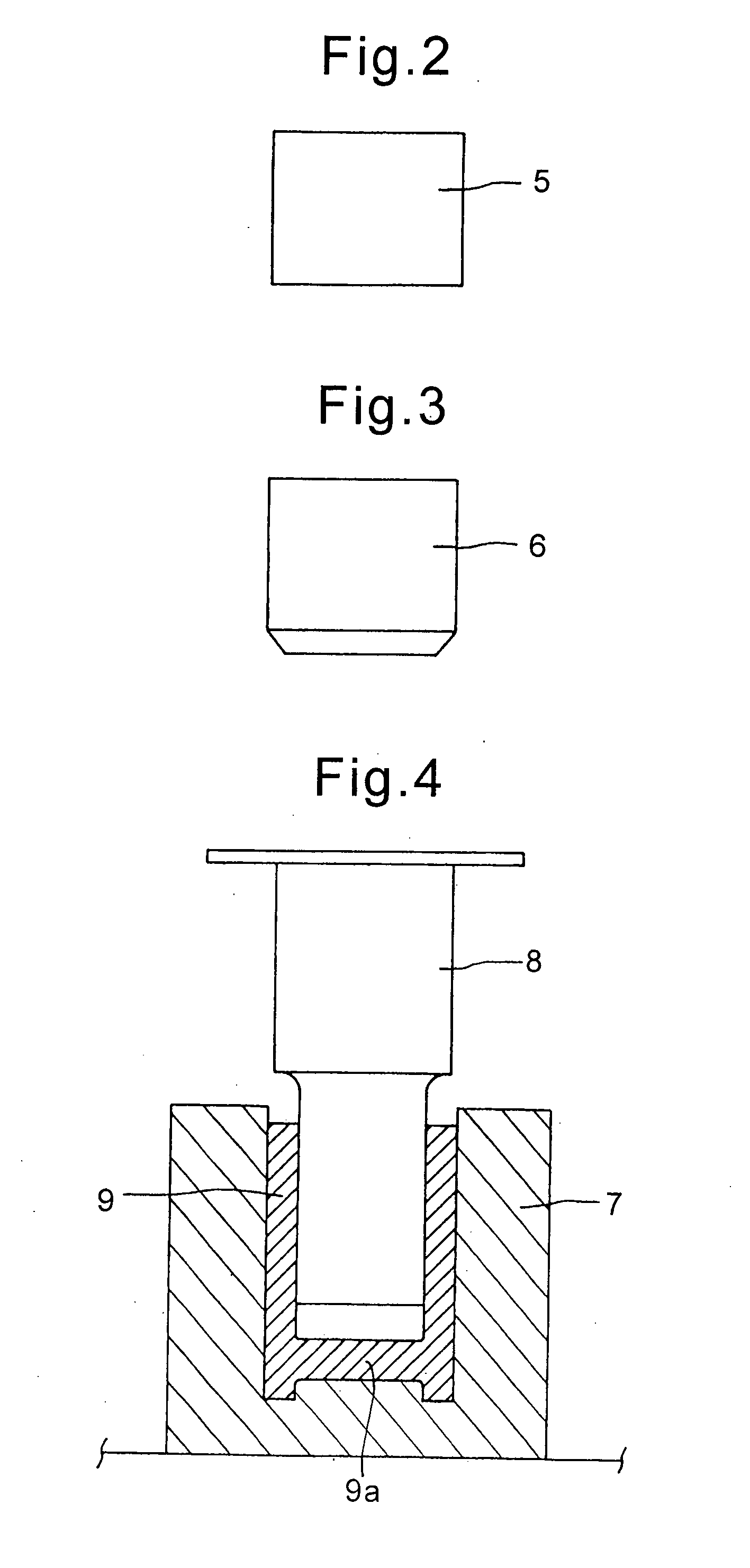

Machining apparatus and machining method

InactiveUS6840722B1Increased durabilityImprove efficiencyTurning machine accessoriesGrinding drivesEngineeringMachining

A machining apparatus for machining a workpiece by rotating and revolving either the workpiece or a tool 1 to contact with each other. The machining apparatus comprises rotation / revolution ratio setting motors M1 and M3 for setting a ratio of a number of rotations to a number of revolutions of the workpiece or the tool 1, to a numerical value having a fraction below a decimal point, by changing the number of revolutions. The workpiece is machined by setting the number of revolutions and the number of rotations at the ratio.

Owner:TOYOTA JIDOSHA KK

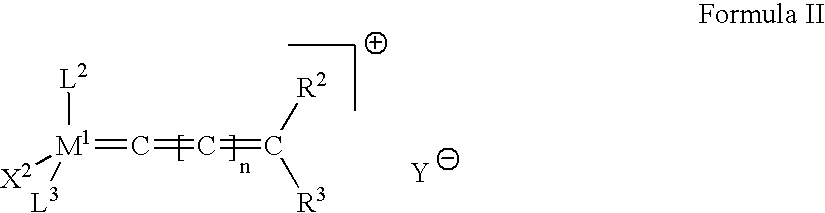

Process for the preparation of low molecular weight hydrogenated nitrile rubber

ActiveUS7381781B2Reduce molecular weightNarrow molecular weight distributionBearing bushesSpecial tyresPolymer scienceNitrile rubber

The present invention relates to a process for the production of hydrogenated nitrile rubber polymers having lower molecular weights and narrower molecular weight distributions than those known in the art in the absence of a co-(olefin).

Owner:LANXESS INC

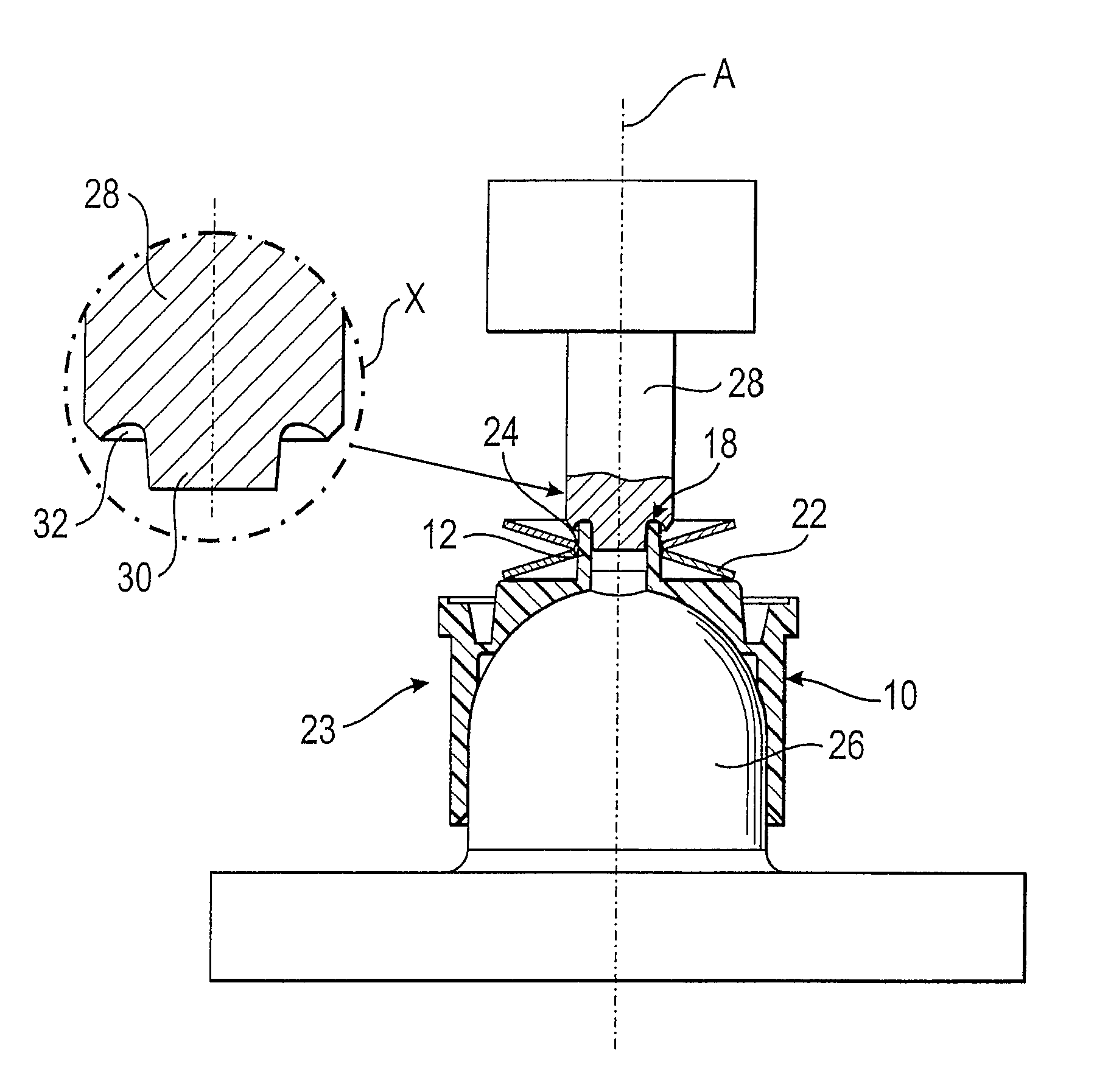

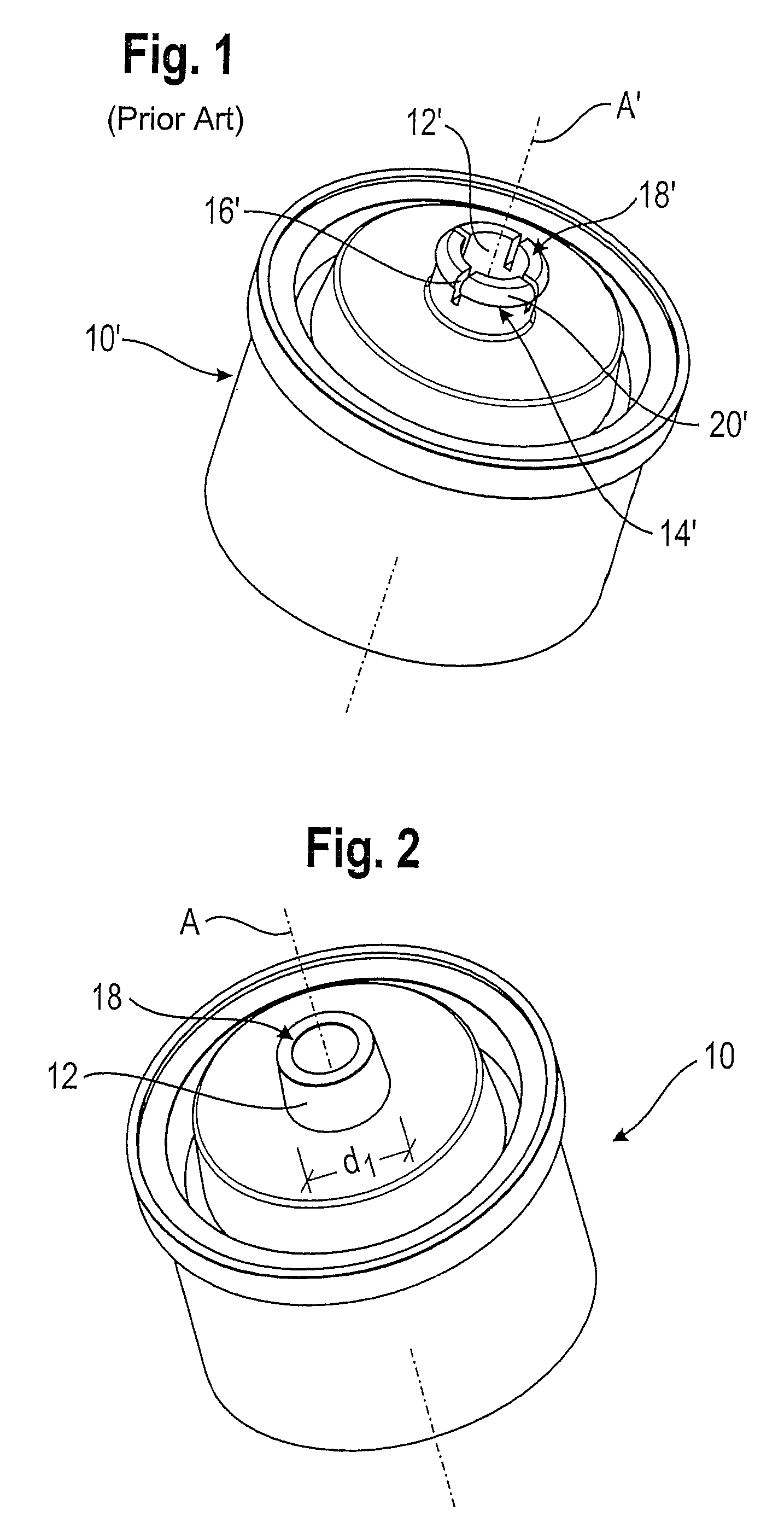

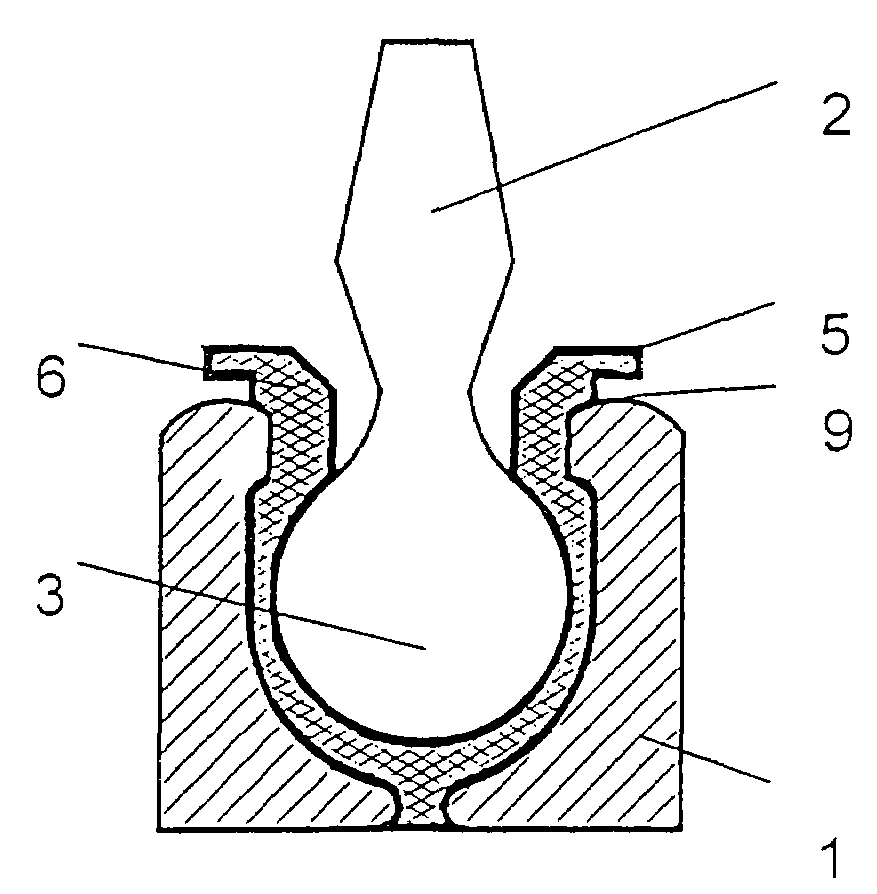

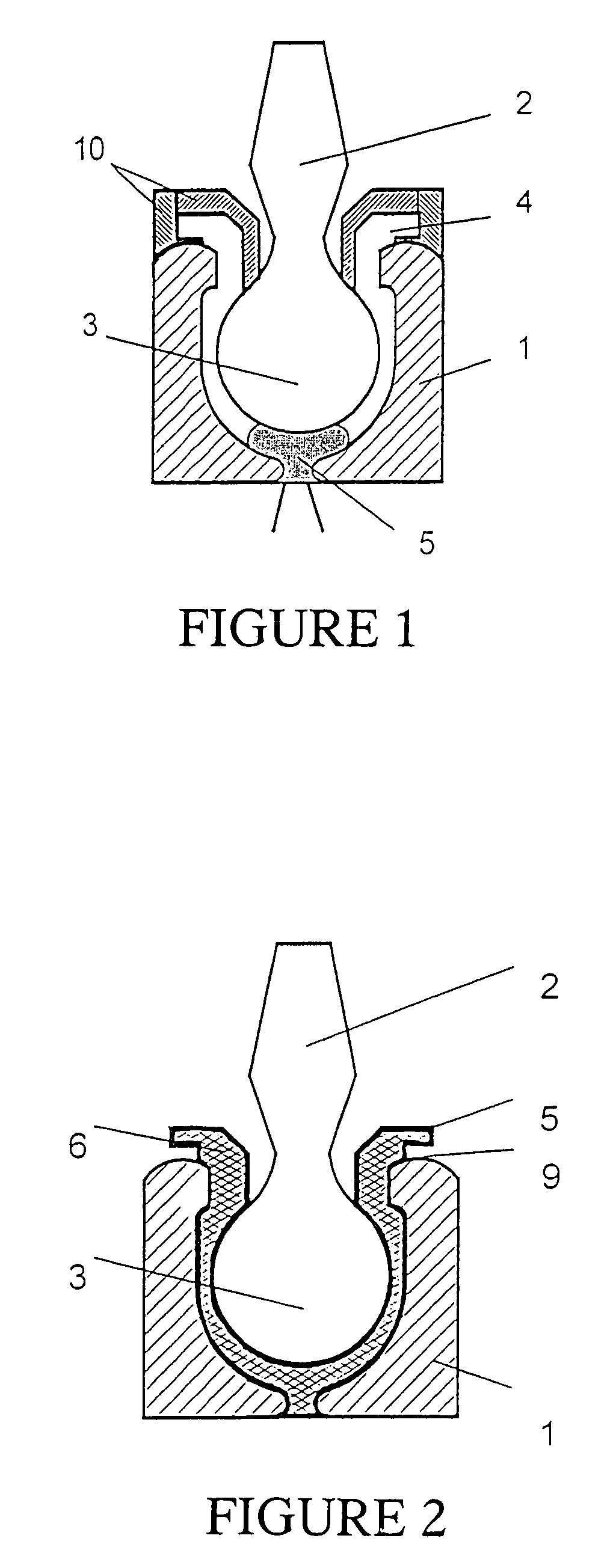

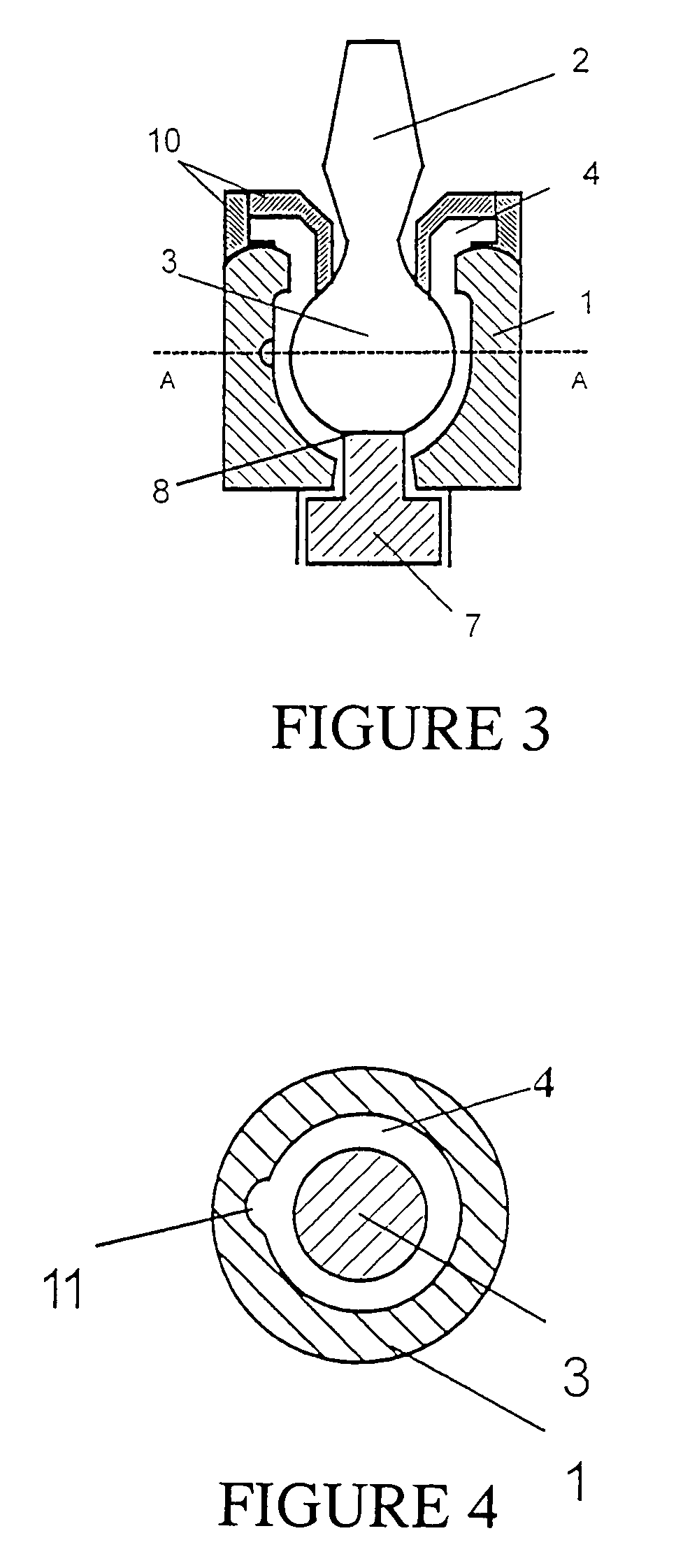

Method for manufacturing a bearing shell assembly, and bearing shell assembly for a ball joint

A method for manufacturing a bearing shell assembly for a ball joint includes the following steps: a) a bearing shell having a plastic extension is produced; b) a spring element is arranged in a region of the plastic extension; and c) the spring element is fastened to the bearing shell by deformation of the plastic extension. The invention further relates to a bearing shell assembly for a ball joint, including a bearing shell and a spring element, the spring element being non-detachably connected with the bearing shell.

Owner:THK RHYTHM AUTOMOTIVE GMBH

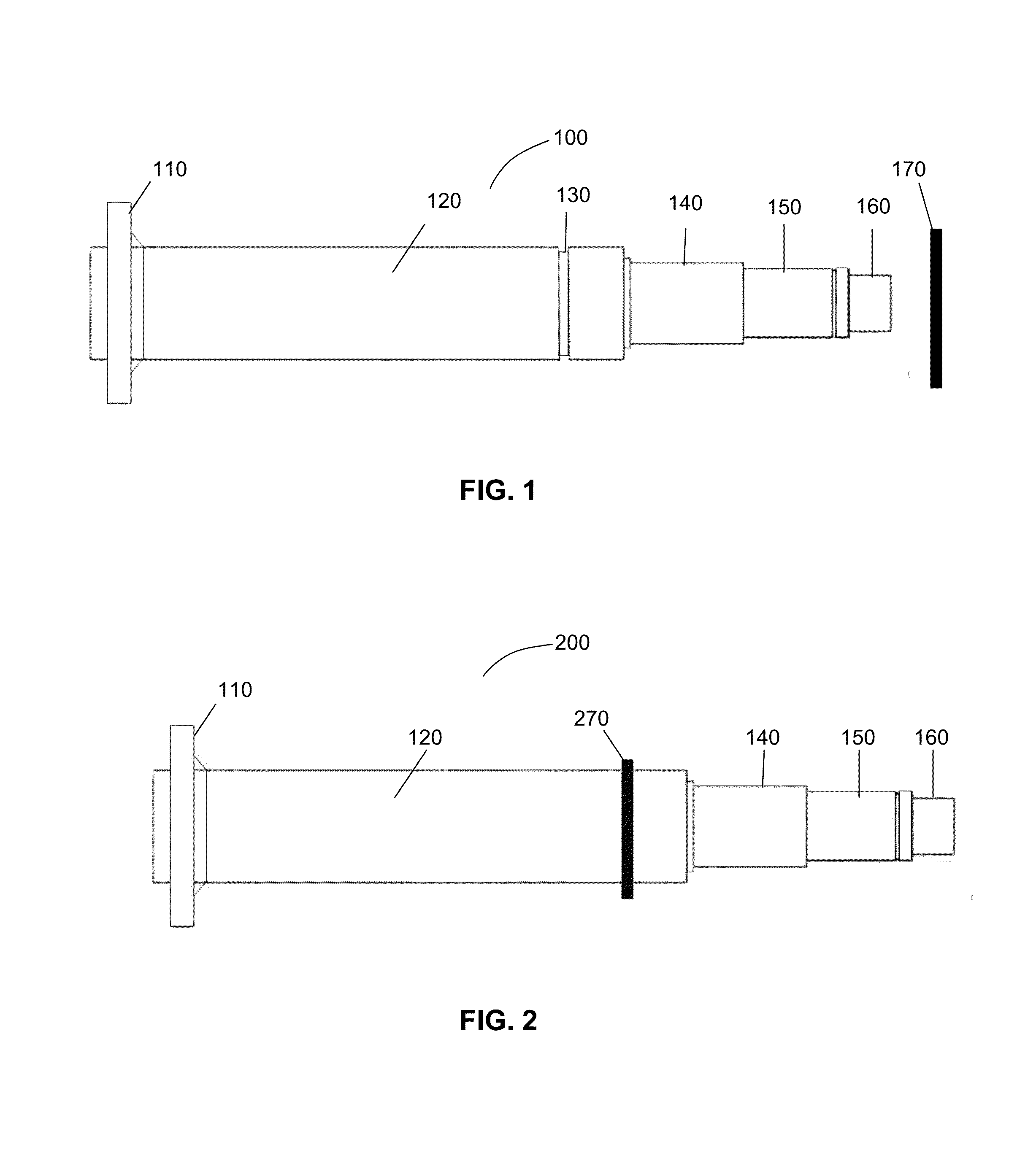

Electric bushing and a method of manufacturing an electric bushing

InactiveUS20090032283A1Increase elasticityBearing bushesMetal-working apparatusElectrical conductorGround plane

A bushing for electrical current and / or voltage through a grounded plane. A substantially rotationally symmetrical insulating body surrounds a central electrical conductor. The bushing includes a sealing member for gas / liquid sealing between the conductor and the insulator body. The bushing includes a compressible sealing element, which forms a gas / liquid seal, integrated with the insulating body, between the conductor and the insulating body. A method of manufacturing a bushing.

Owner:ABB POWER GRIDS SWITZERLAND AG

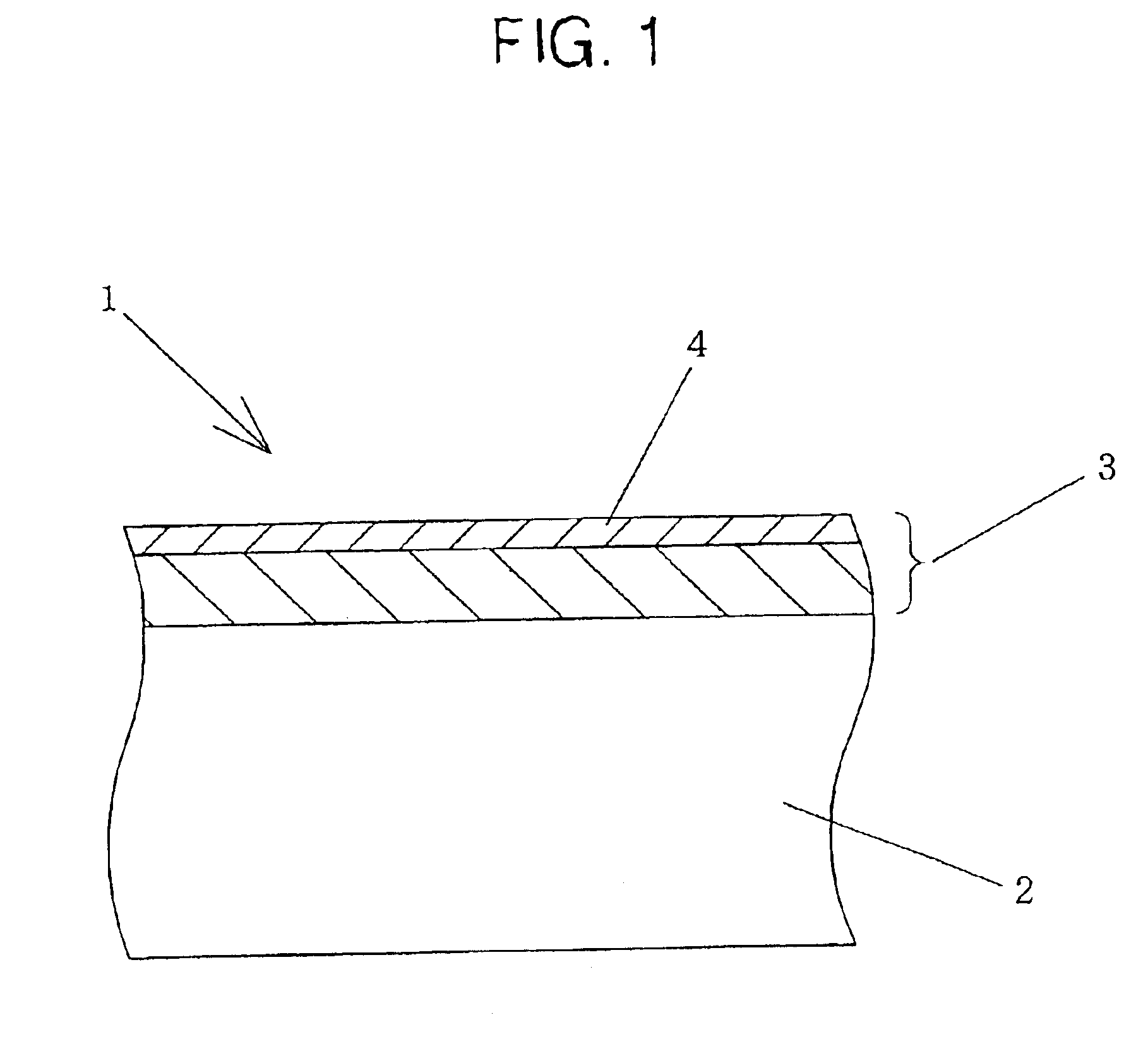

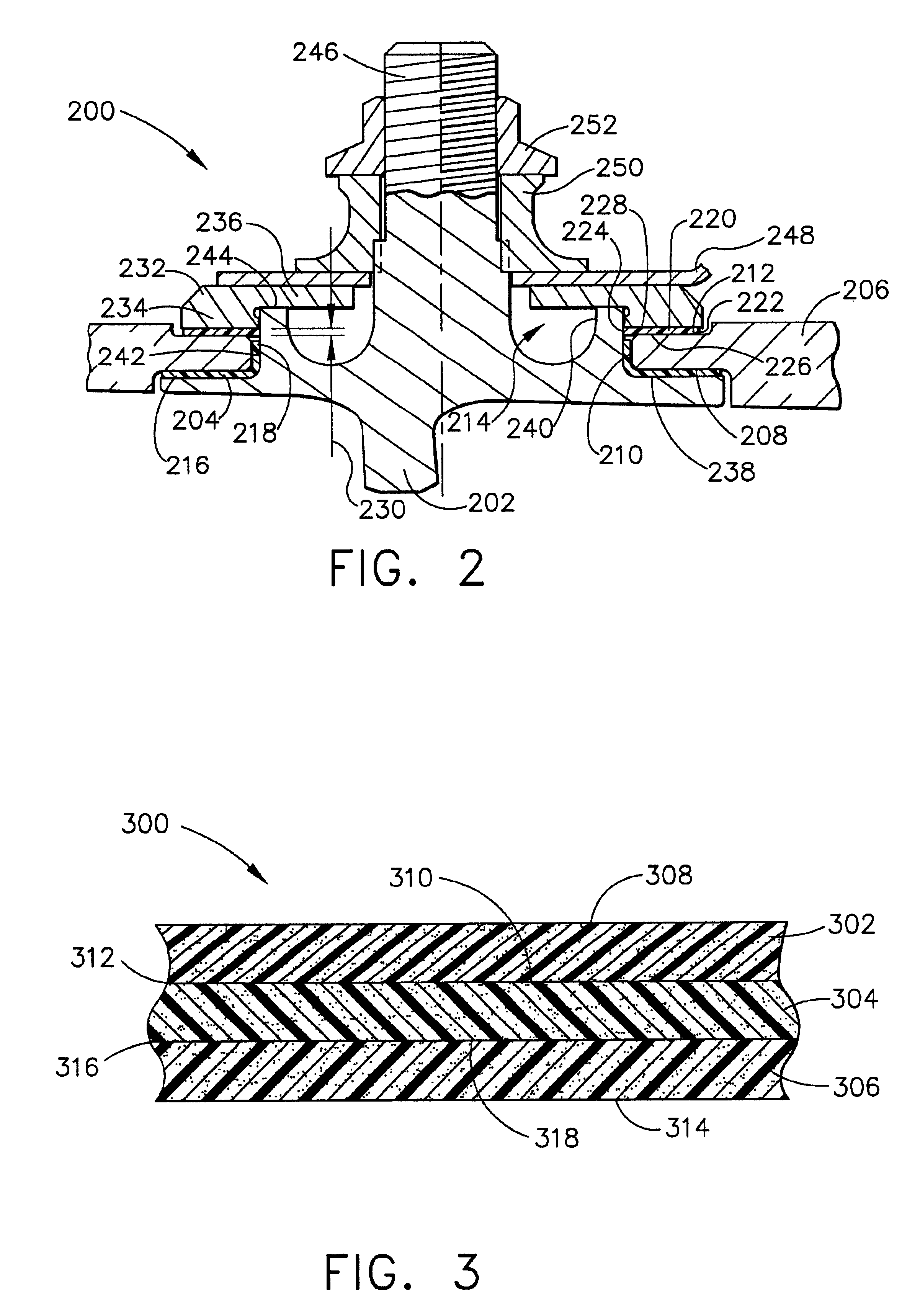

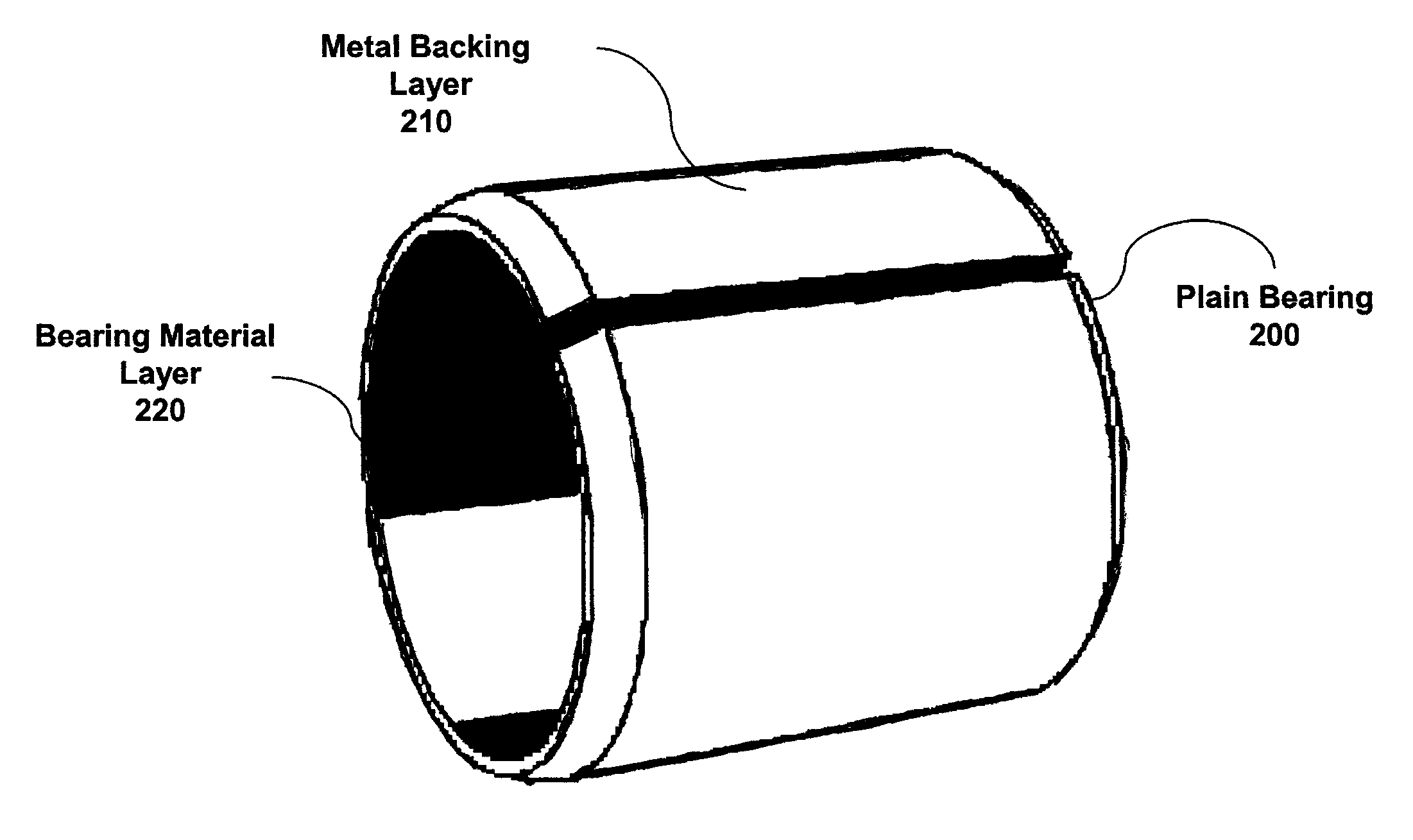

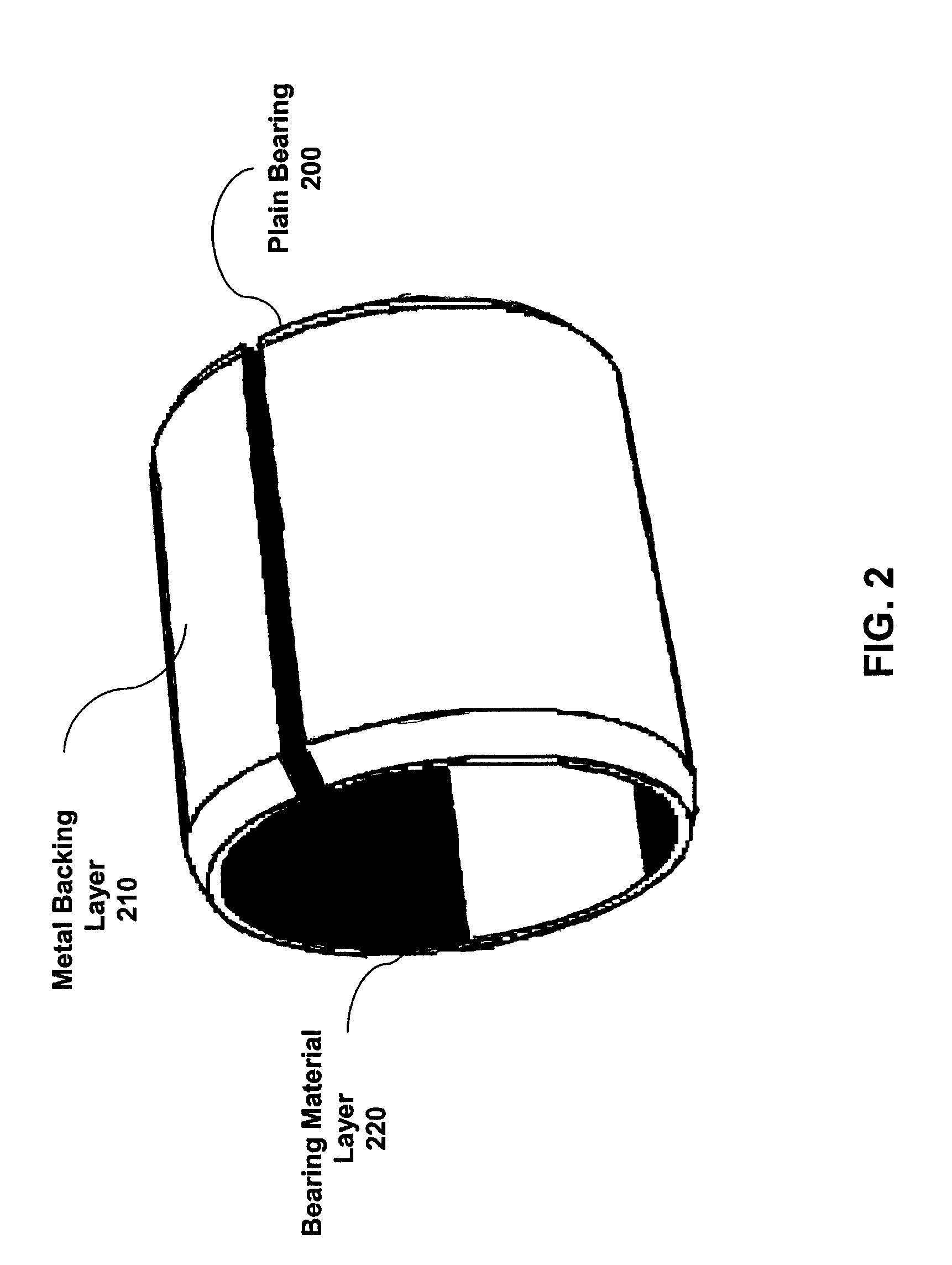

Plain bearing and process for producing the same

Owner:DAIDO METAL CO LTD

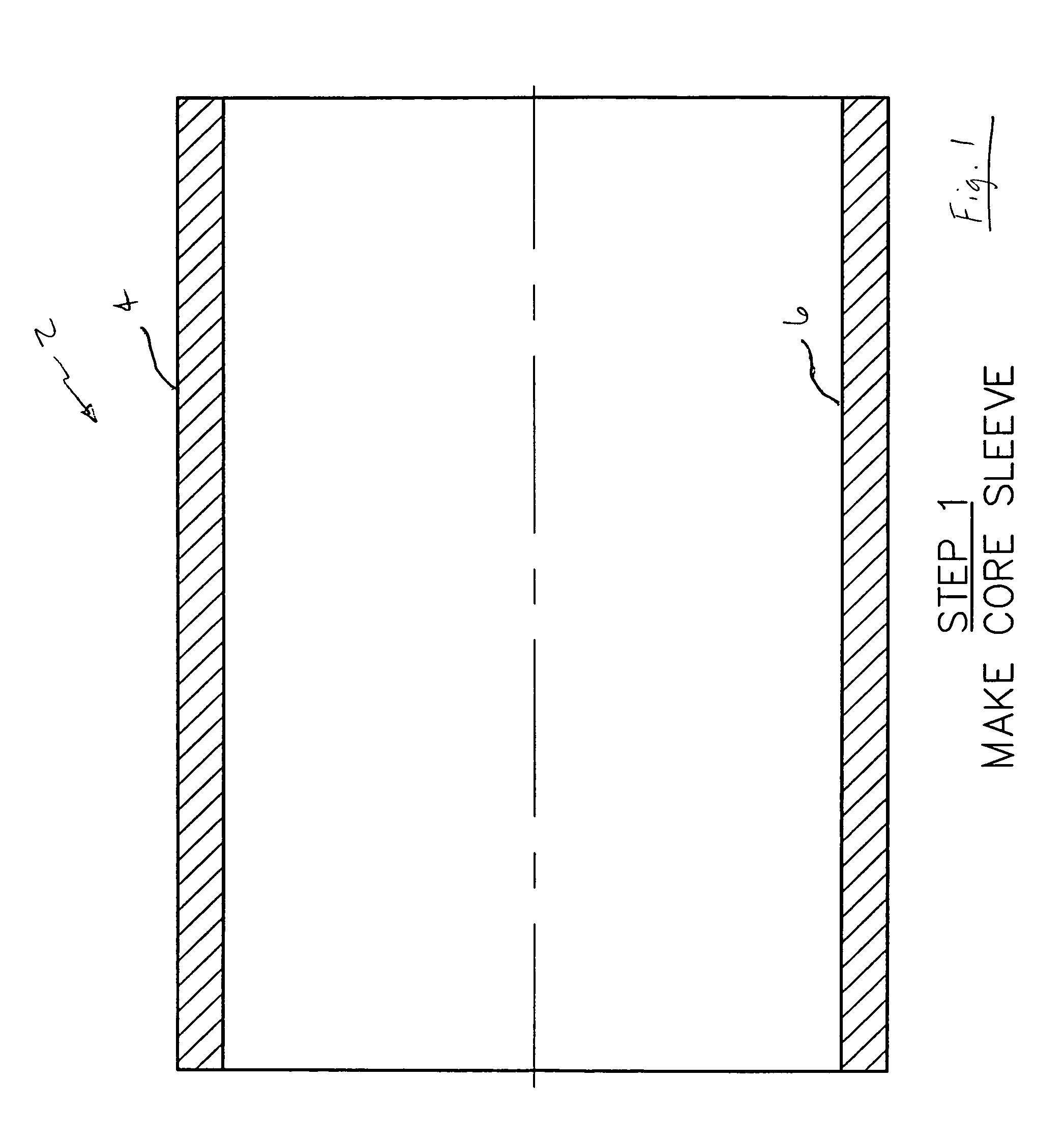

Method of making a guide bushing

InactiveUS6904680B2Uniform inner diameterBearing bushesMetal-working apparatusEngineeringMechanical engineering

A bushing utilizes a fabric reinforced thermoset composite sleeve incorporated within an outer shell in a construction enabling the sleeve to be press-fitted within the shell and held therein by a constriction in the shell bore which is embraced by the bearing liner. Following installation of the bearing sleeve, the sleeve bore may be reamed to provide a uniform inside diameter.

Owner:ANCHOR LAMINA AMERICA INC

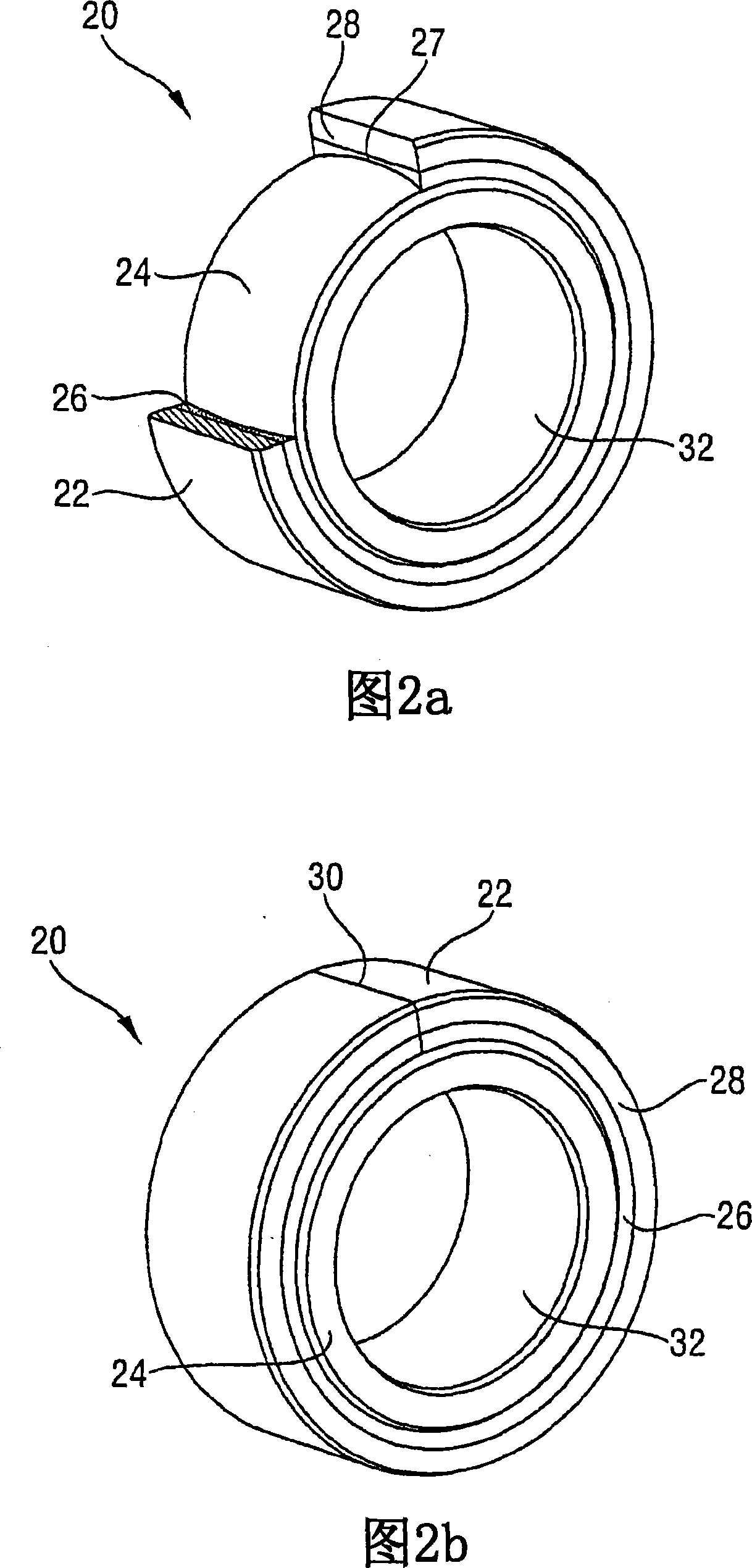

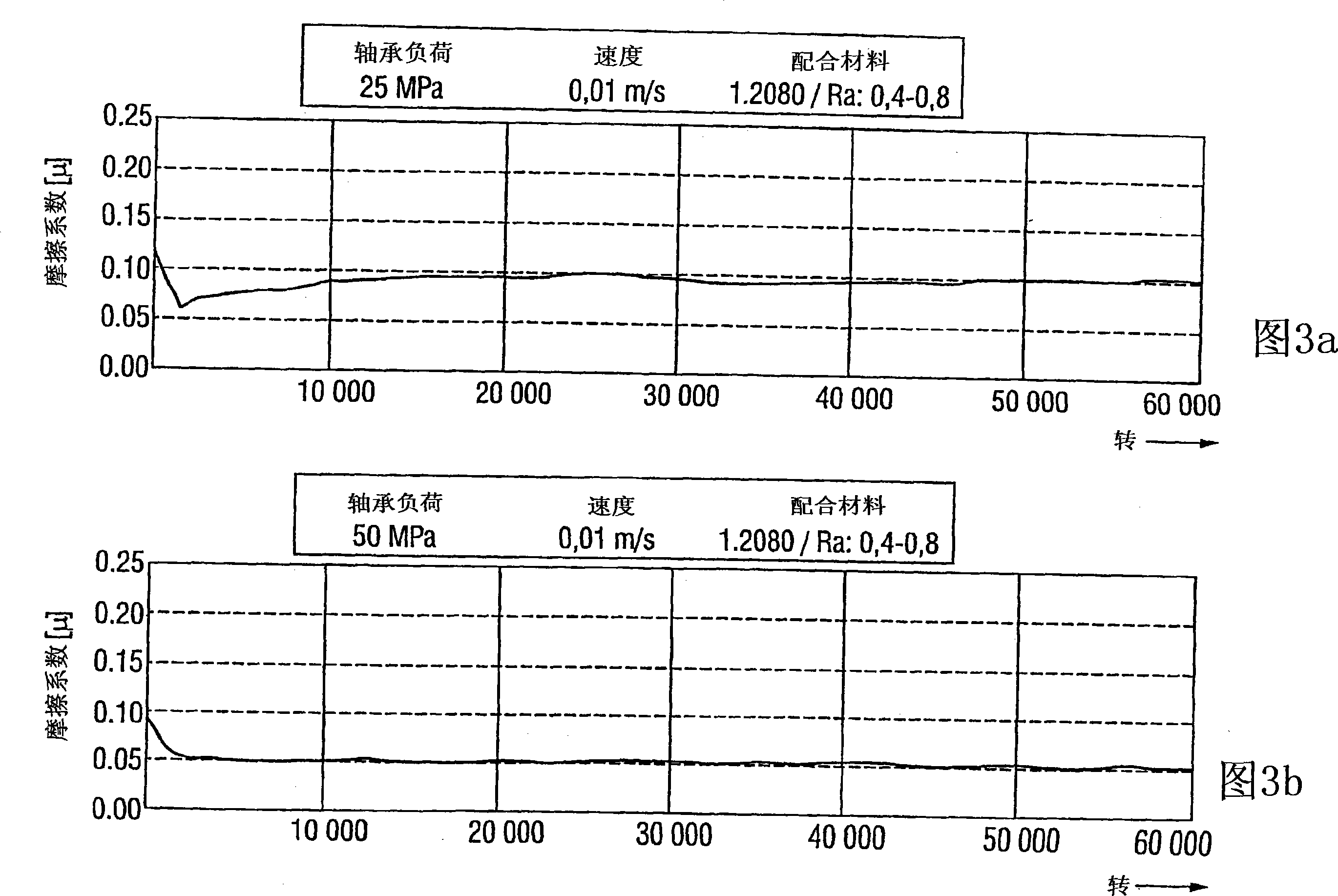

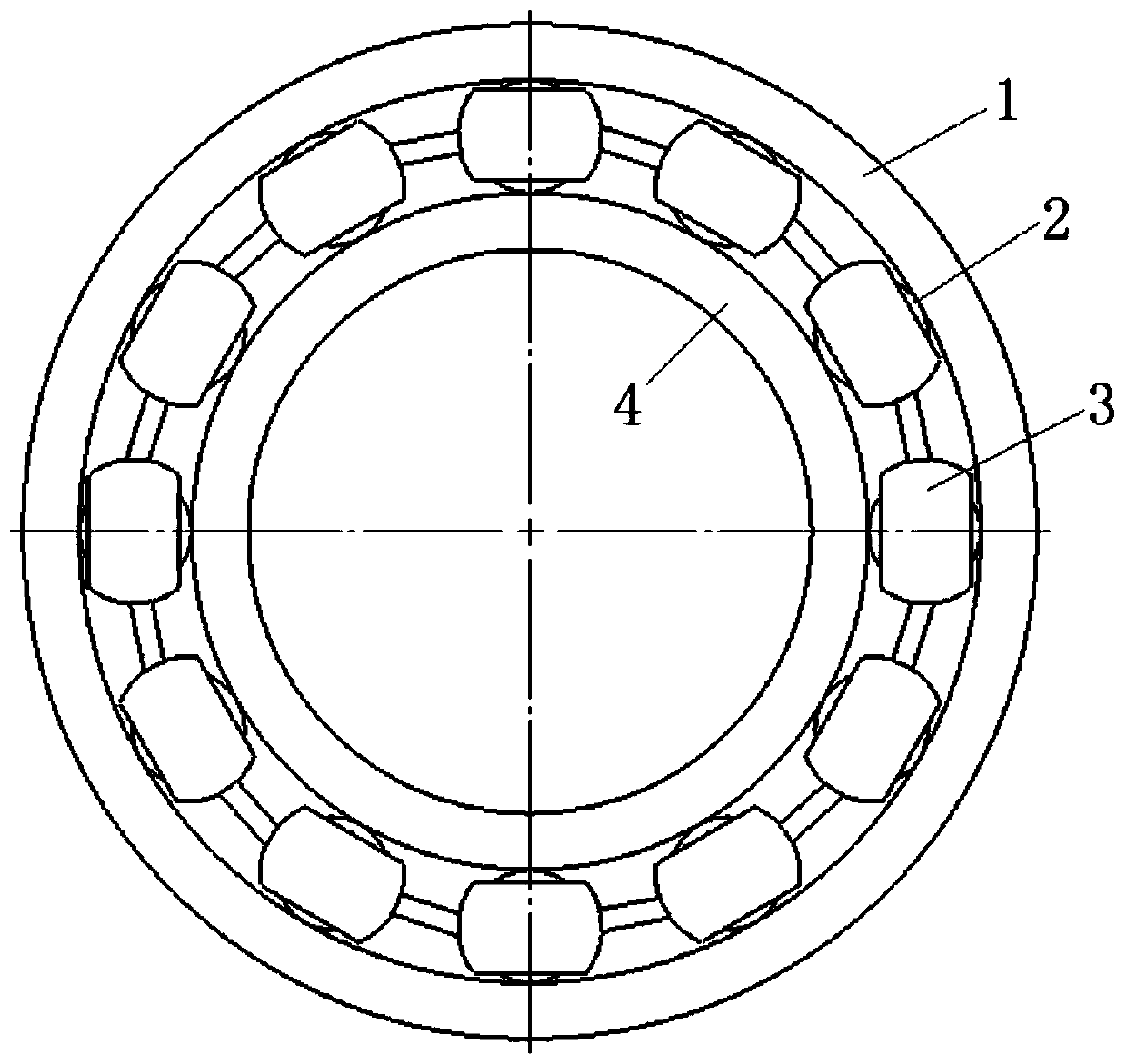

Pivot bearing with plastic outer ring and method for its manufacture

ActiveCN101144505AIncreased load-bearing capacityBearing bushesSynthetic resin layered productsEngineeringSynthetic resin

The invention relates to an outer ring of joint bearing with a built-in sliding layer and an exposed bearing layer, wherein the sliding layer and the bearing layer are composed of winding fiber composite material. The outer ring has only one dividing slot. The invention also relates to a joint axle with the said outer ring and manufacturing method thereof. A sliding and bearing layer formed by synthetic resin impregnation fiber are winded in turn along a winding mandrel and the winding body generated by the above step forms outer ring after hardening. The said sliding and bearing layer are winded along a cylindric winding mandrel, the outer ring has only one dividing slot and the shape of the material of sliding layer at the medial side is abraded to obtain an inner ring in which the partly spherical outline is used to house complementation.

Owner:FEDERAL MOGUL DEVA

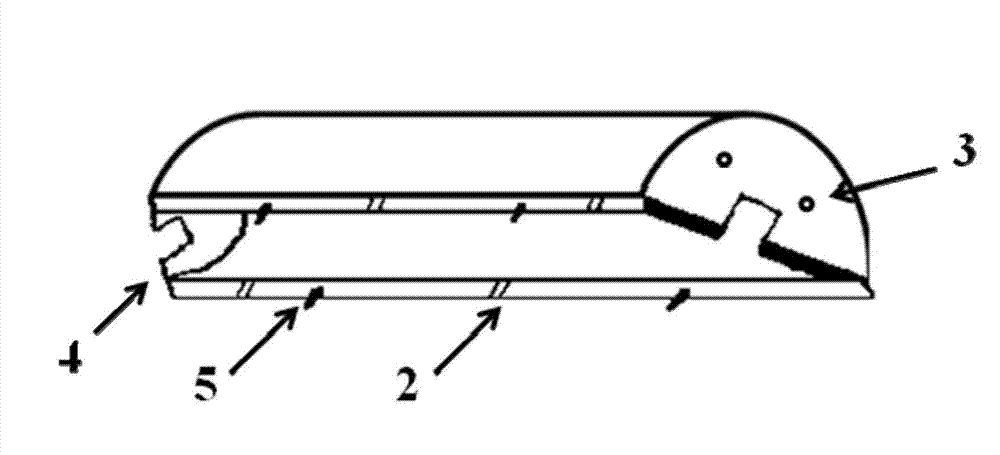

Stabilizer bushing for vehicle and method of producing the same

ActiveUS20120299261A1Improve ride comfort performanceSufficient operationTorsion springsBearing bushesMechanical engineeringProjection View

Semi-tubular portions of two partition members partitioning a bushing body into an outer rubber portion and an inner rubber portion are asymmetrically arranged with respect to a reference plane containing a central axis of the bushing body and parallel to two attachment surfaces of a bracket. In addition, each of the semi-tubular portions is configured to have a length equal to or larger than a diameter of a stabilizer bar, the length being from one end to the other end in a circumferential direction of the semi-tubular portion in a projection view obtained by projecting the semi-tubular portion to a horizontal surface in a vertical direction.

Owner:SUMITOMO RIKO CO LTD

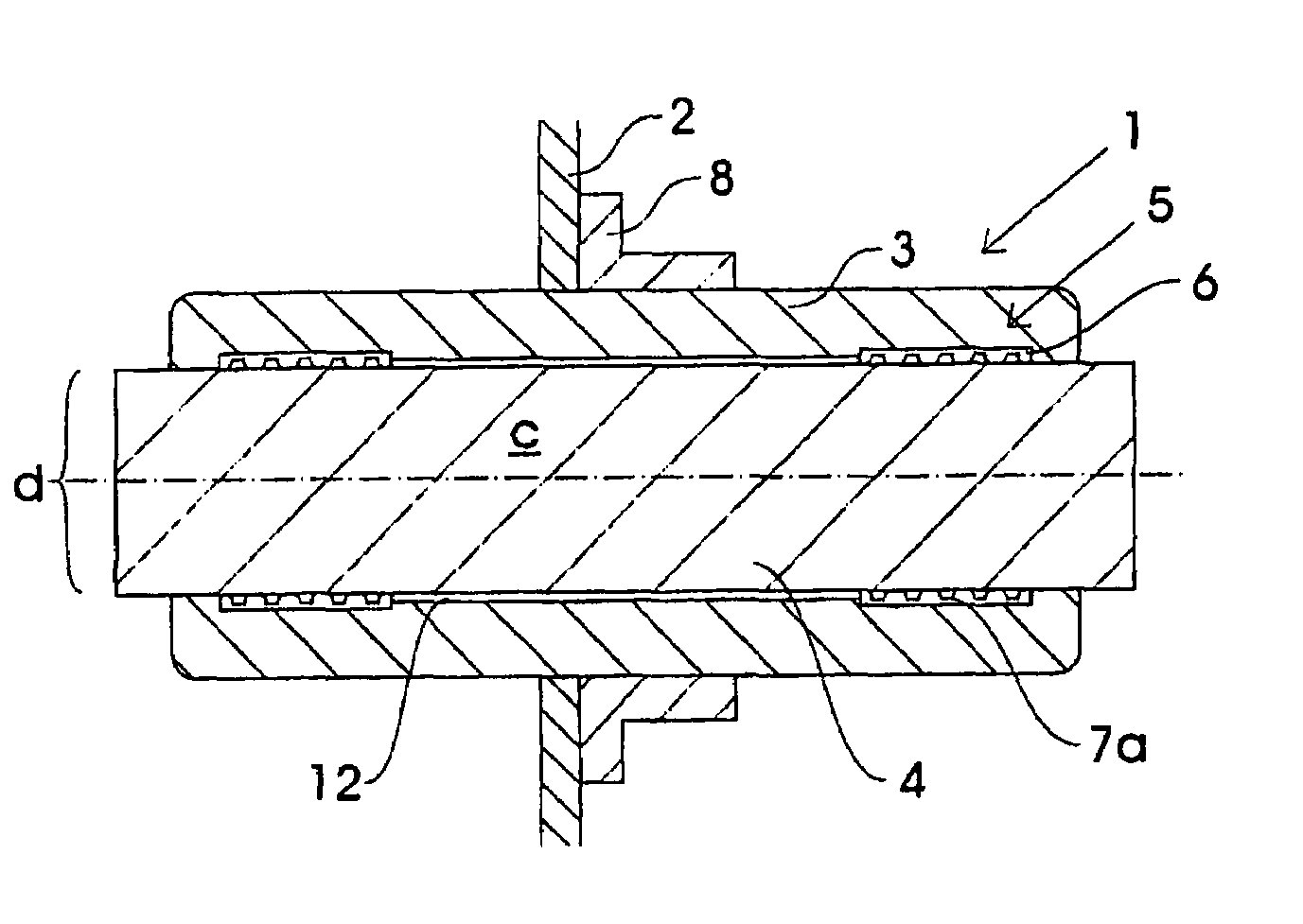

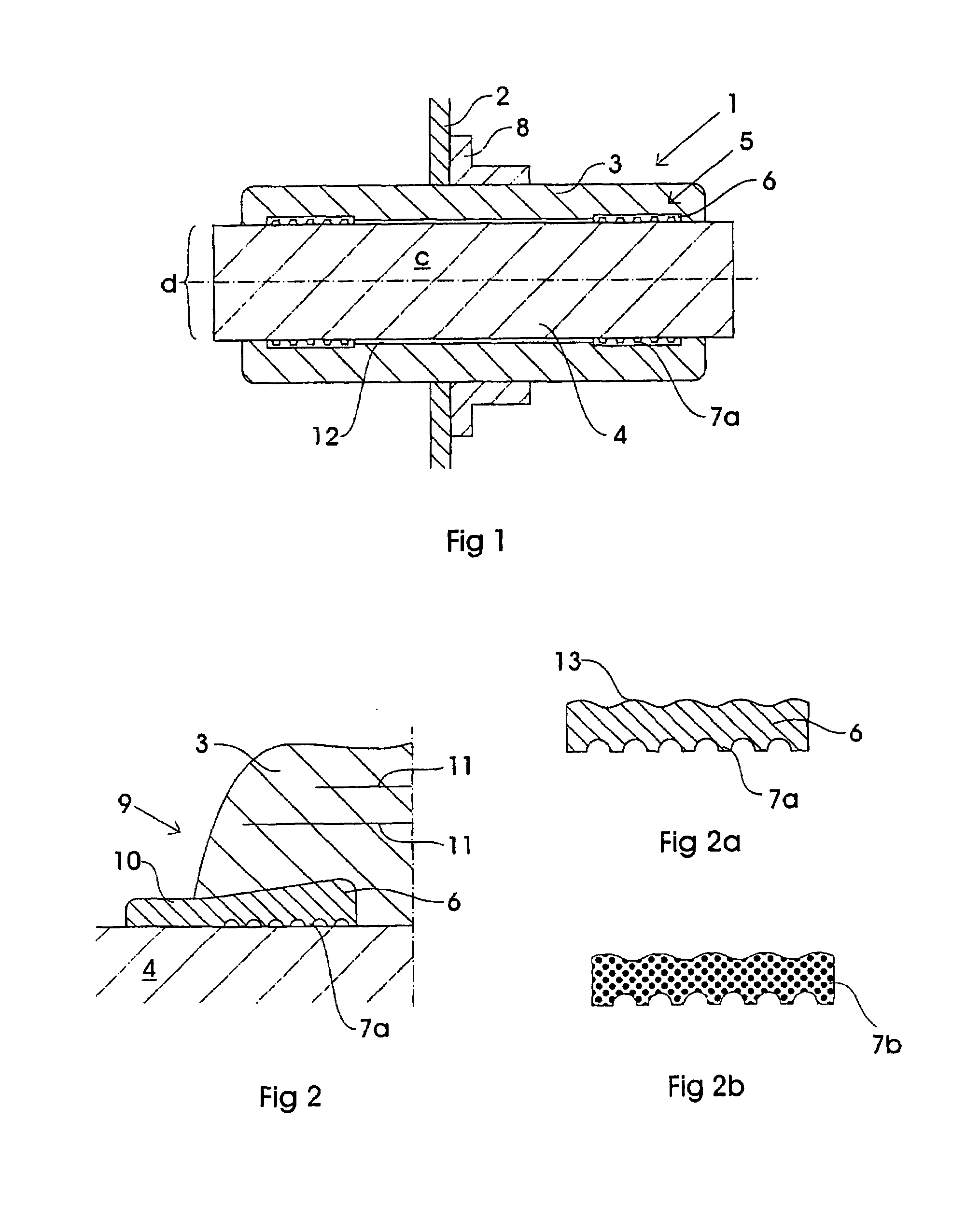

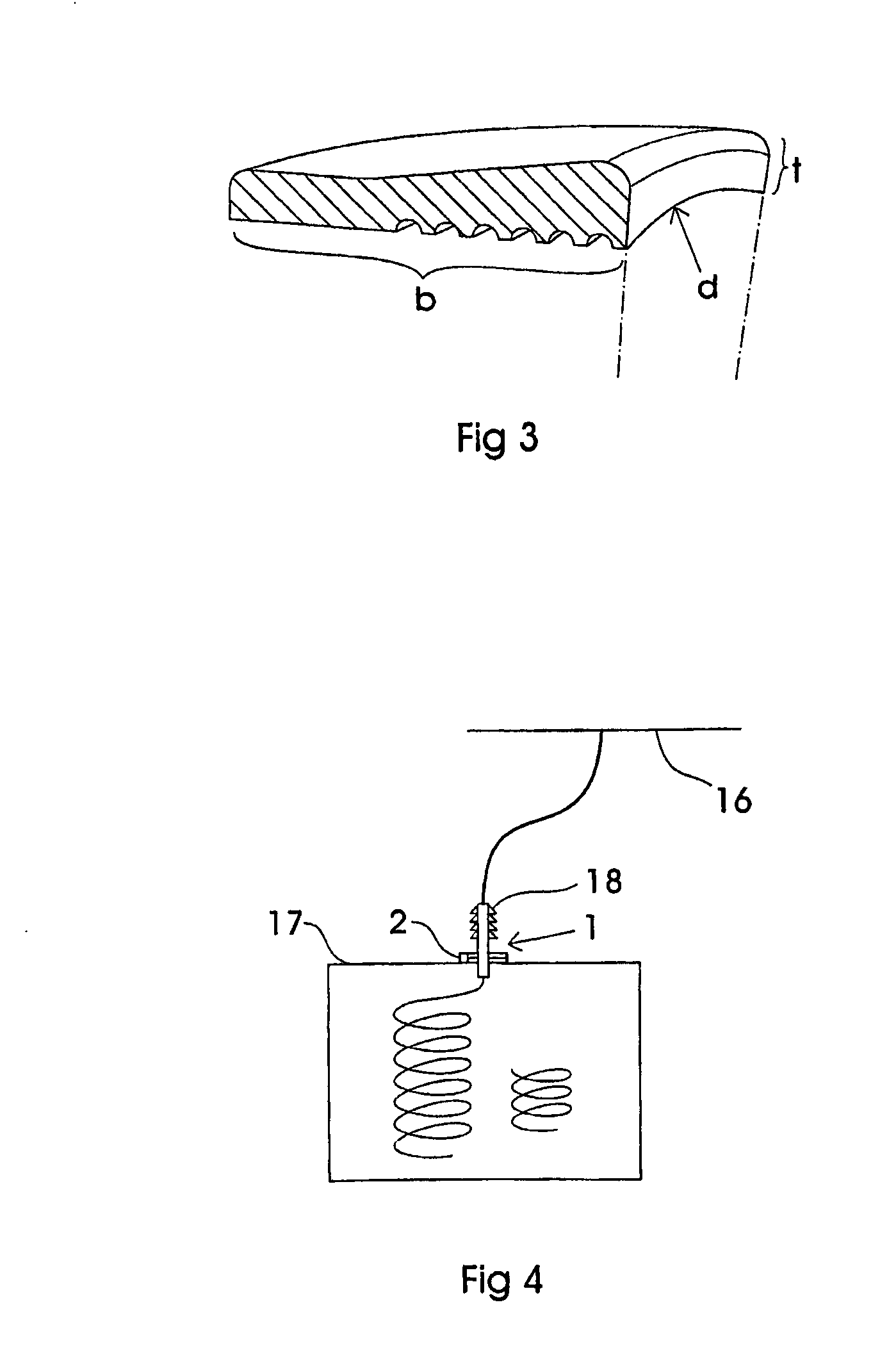

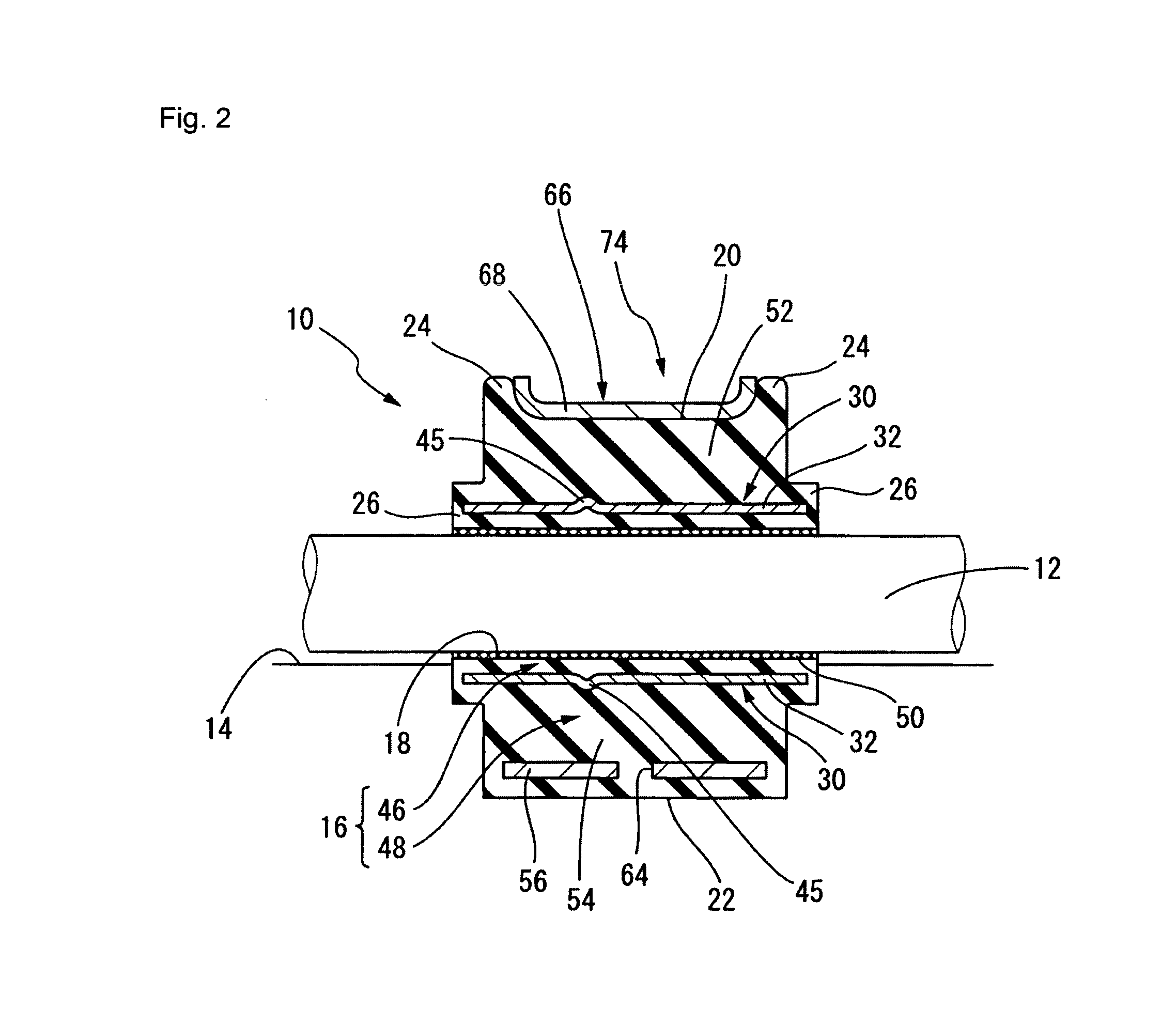

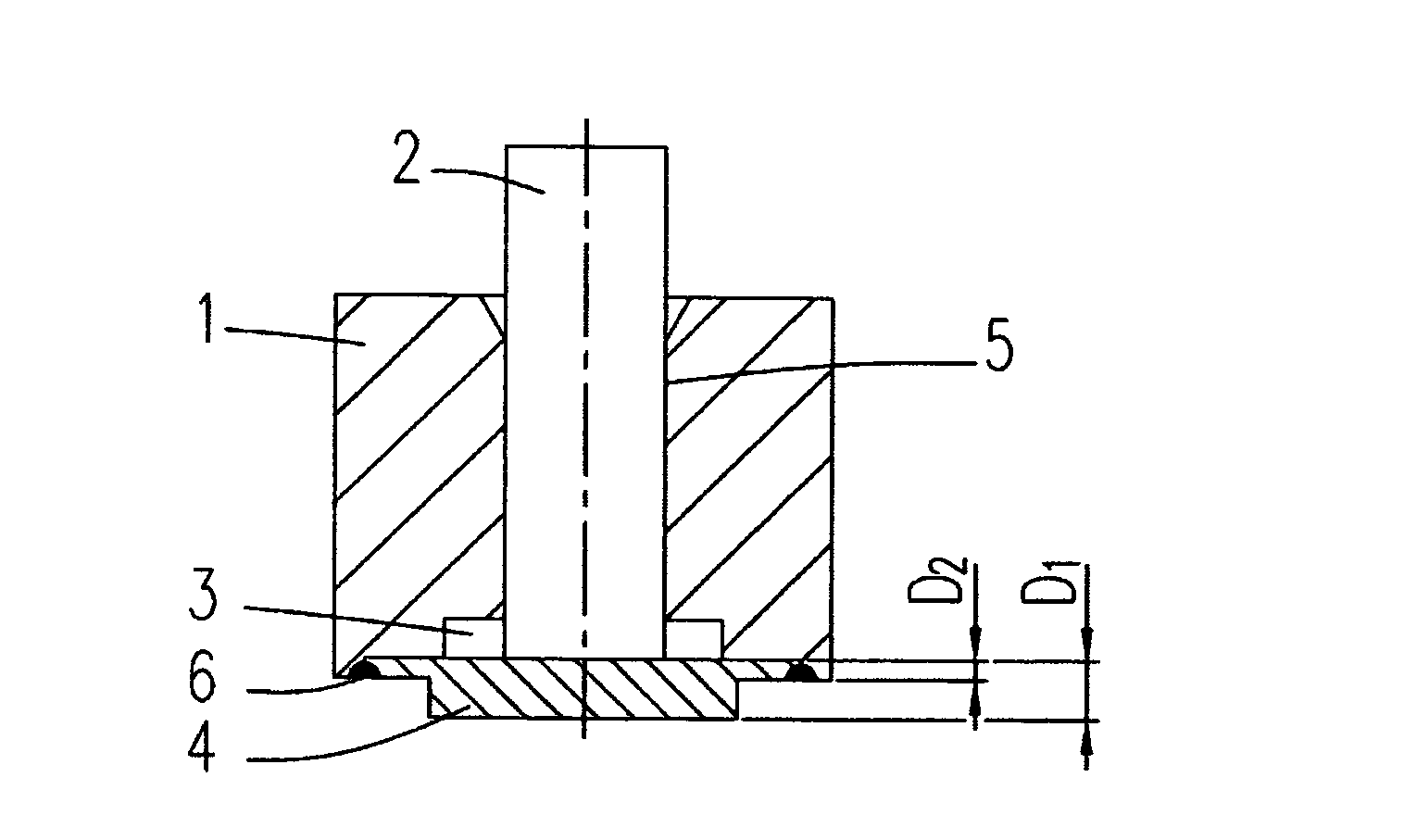

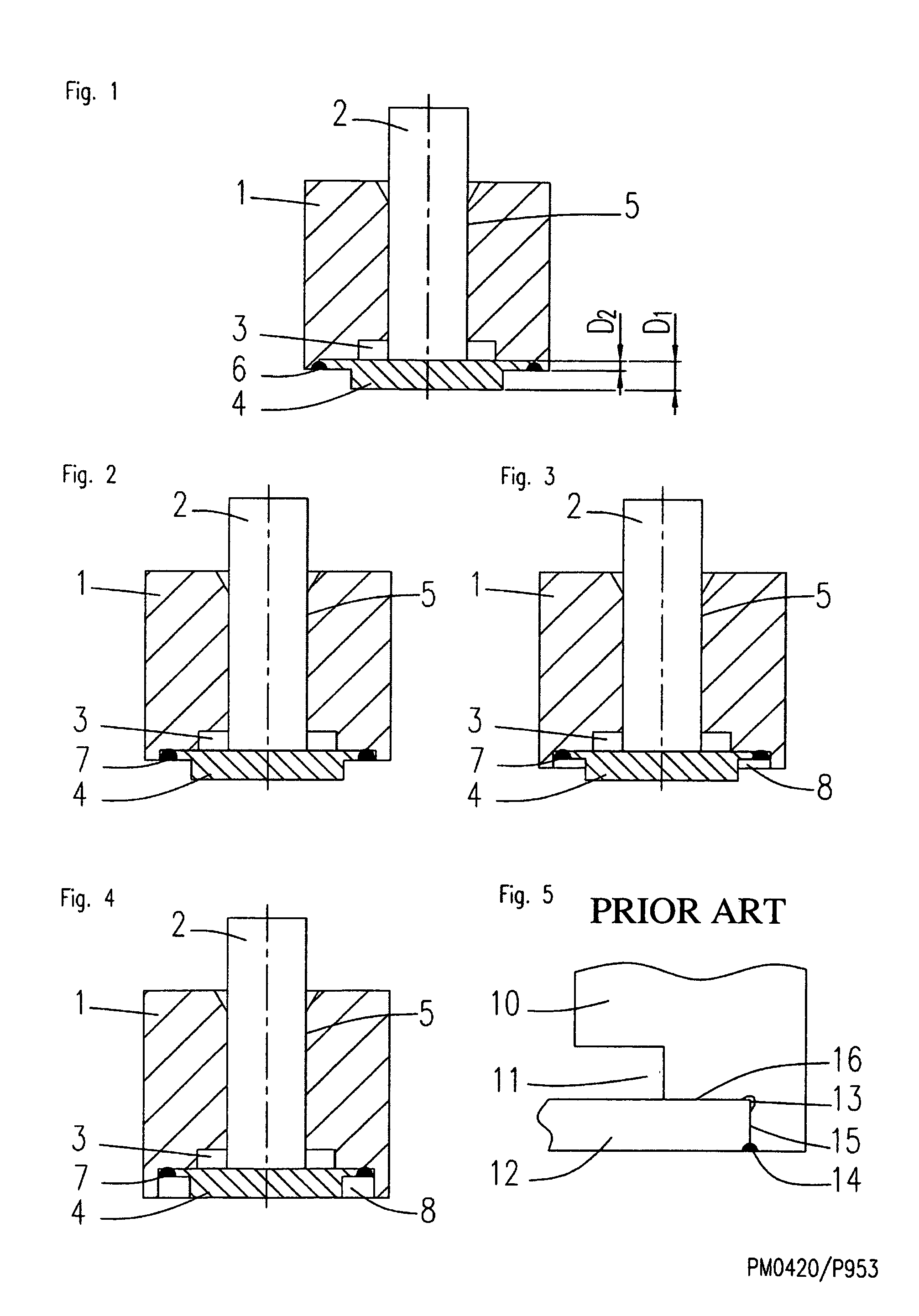

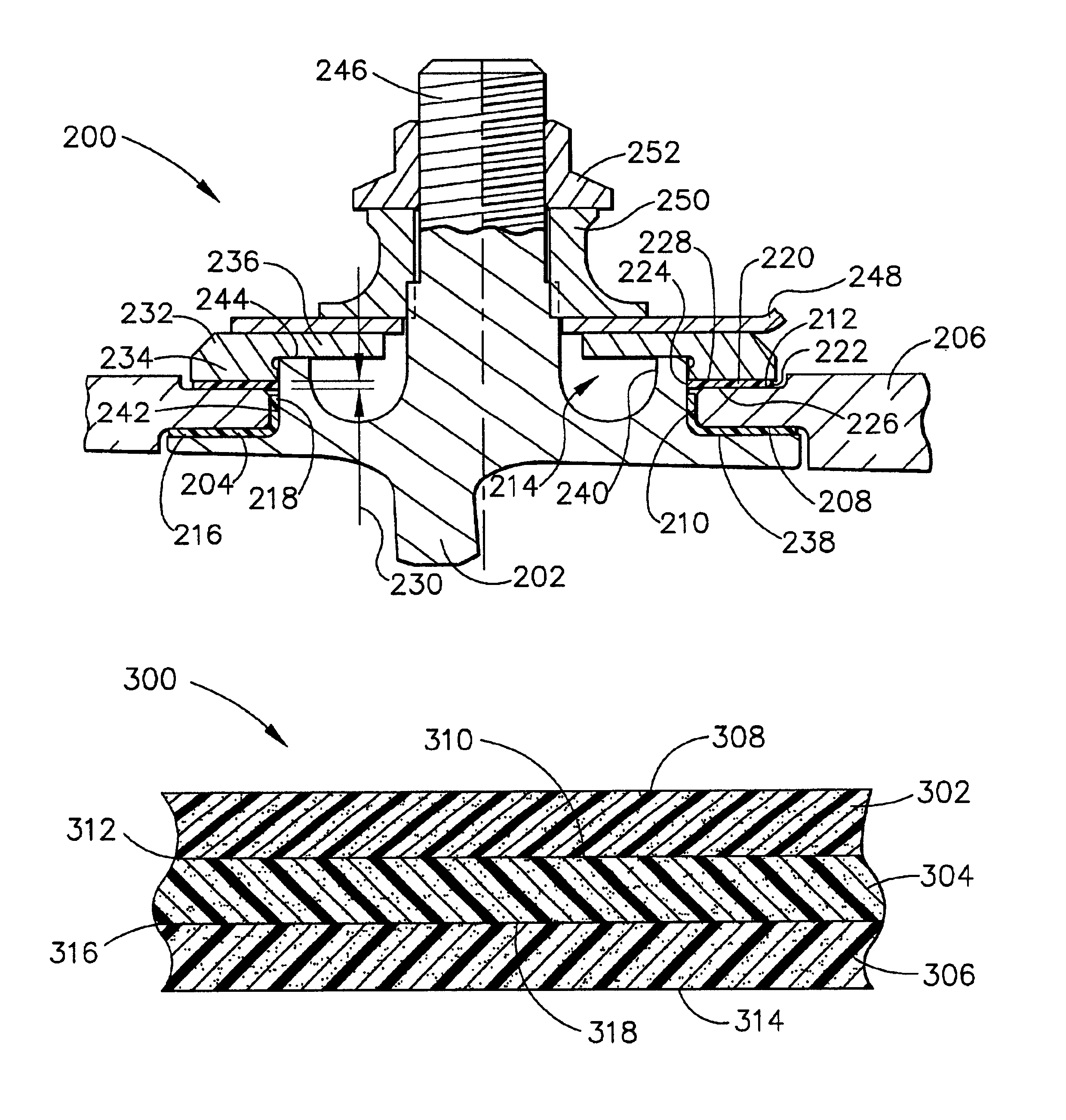

Fluid dynamic bearing system

The invention relates to a fluid dynamic bearing system particularly for the purpose of rotatably supporting a spindle motor, having a first bearing part that comprises a bearing sleeve, and a second bearing part that comprises a shaft, the two bearing parts being spaced apart from one another by a bearing gap and being rotatable with respect to each other, wherein the bearing sleeve is closed at one end by a counter plate that is accommodated in an annular recess in the bearing sleeve and connected to the bearing sleeve by a welded joint. According to the invention, a bearing system is provided in which the counter plate has a reduced thickness (D2) at its outer edge and is welded in the region of its reduced thickness (D2) to the bearing sleeve. The reduced thickness of the counter plate at the region of its outer edge means that the vertical gap between the bearing sleeve and the counter plate is made very much shorter, or is done away with altogether, so that no unwanted air can remain in the gap.

Owner:MINEBEA CO LTD

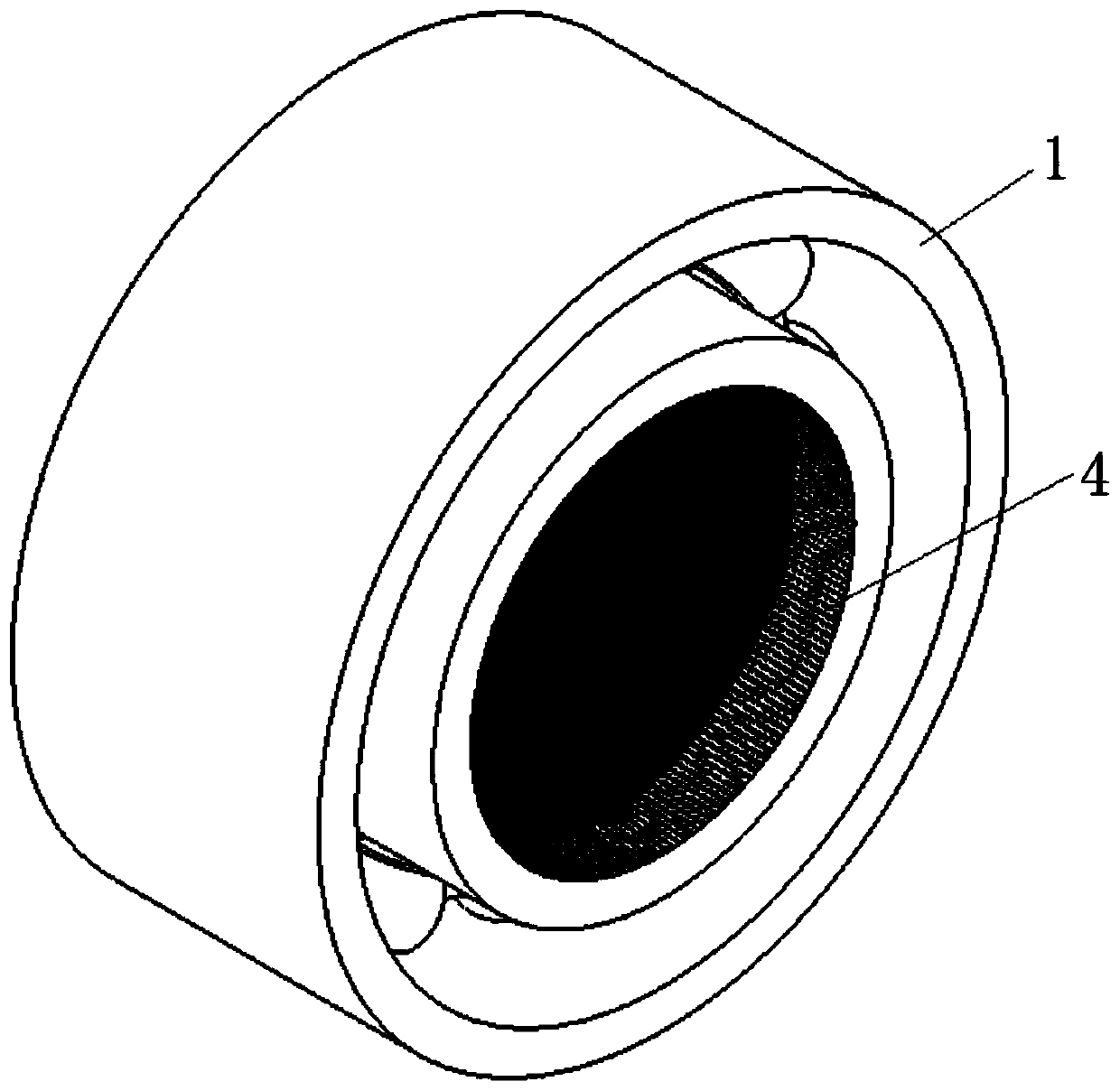

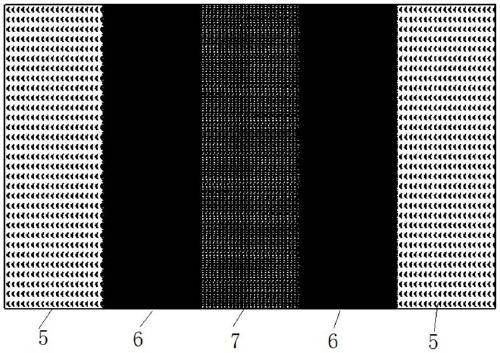

Bearing bush with functionally graded bionic texture as well as preparation method and water-lubricated bearing thereof

PendingCN111536161AImprove wettabilityImprove surface topographyBearing bushesBearing componentsHydrophobeMechanical engineering

The invention discloses a bearing bush with a functionally graded bionic texture as well as a preparation method and a water lubricated bearing thereof. The bearing bush is characterized in that the surface of the bearing bush is provided with the bionic texture capable of realizing functional gradient, and the bionic texture comprises a radial ridge-shaped hydrophilic surface texture imitating acommon nepenthes lip and a crescent hydrophobic surface texture imitating a waxy region. According to the bearing bush, antifriction between the bearing bush and two sliding surfaces on a shaft is realized, and a lubricant is directionally conveyed from the end part to the middle part, so that the lubricating state of the middle area of an inner ring bearing bush is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

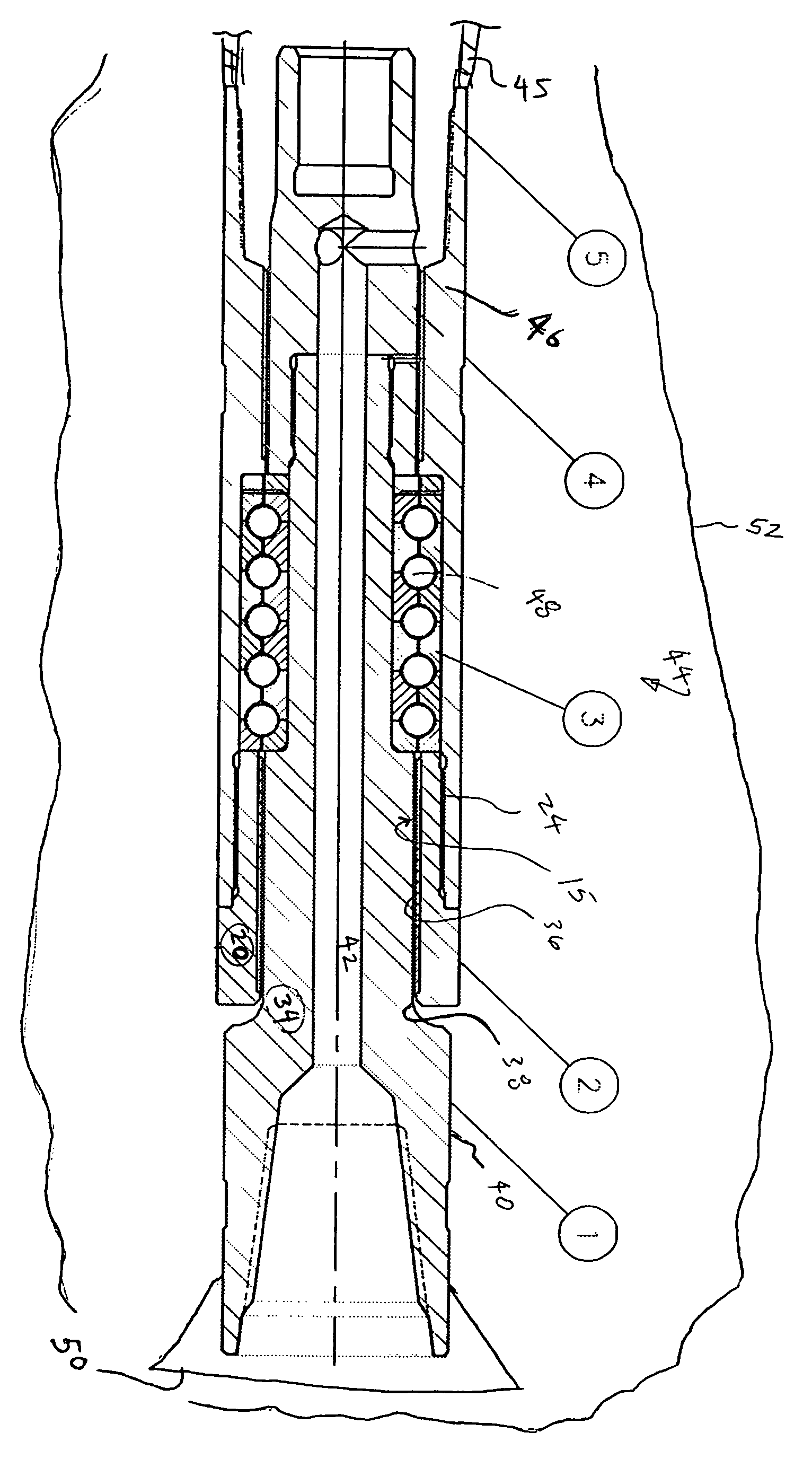

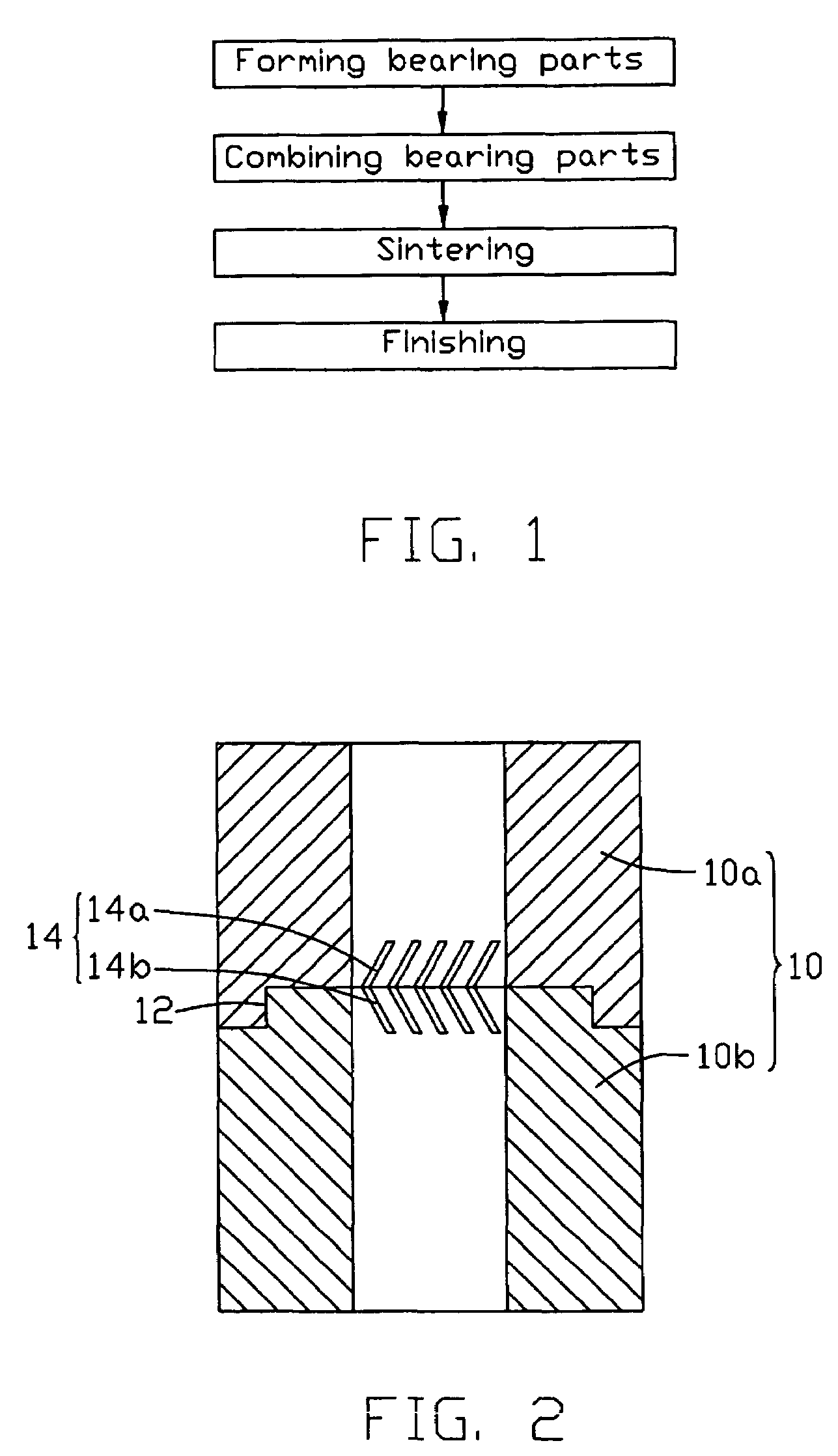

Process for manufacturing a bearing

InactiveUS7882638B2Strong and more ruggedEliminate needDrilling rodsShaftsEngineeringMechanical engineering

A process for manufacturing a bearing. The bearing may be used in a tool disposed within a bore hole. The process comprises providing a tubular sleeve and applying a hard facing material on the outer diameter of the tubular sleeve so that the hard facing material is fused onto the outer diameter, and thereafter applying a material layer on the outer diameter so that the material layer is fused onto the outer diameter. The method further includes machining the outer diameter so that a portion of the material layer is removed, and then machining the inner diameter so that only the hard facing material is left as an inner diameter. The method further includes machining the outer diameter and the inner diameter in order to form the bearing. In the most preferred embodiment, the method further includes placing the bearing into a housing, and inserting a mandrel into the bearing, and wherein a hard coating of the mandrel abuts the bearing. A mud motor for rotating a bit in a well bore is also disclosed.

Owner:RIVAL DOWNHOLE TOOLS LC

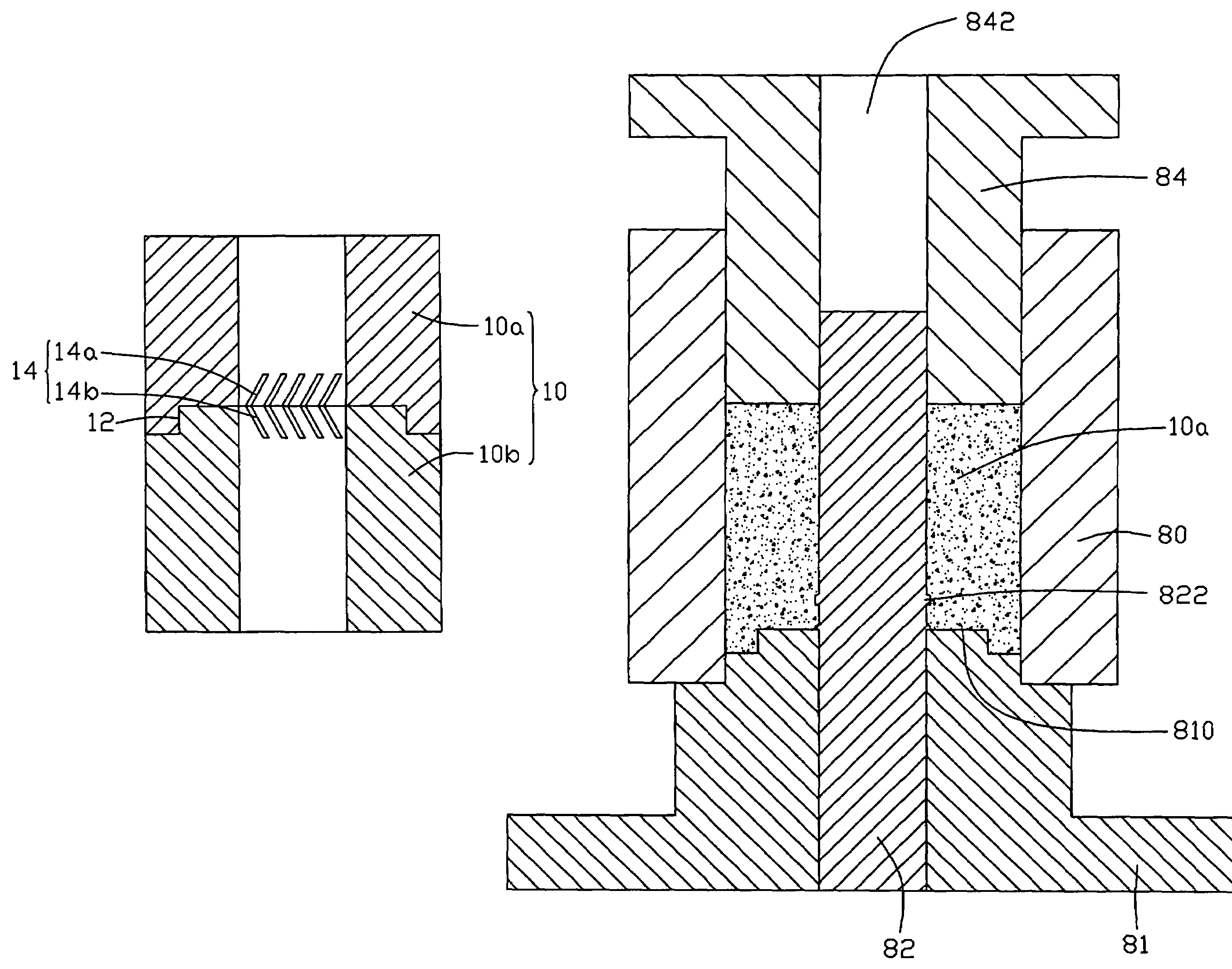

Two-component bearing shell for an injection-molded ball-and-socket joint

InactiveUS7195398B2Improve mechanical propertiesGood tribological material propertyRolling contact bearingsShaftsCore componentEngineering

The present invention pertains to a bearing shell for a ball-and-socket joint, wherein the bearing shell has a core component consisting of a first material, which is completely enclosed by a jacket component consisting of a second material.

Owner:ZF LEMFOERDER METALLWAREN AG

Manufacturing method of water lubricated bearing taking hard rubber as liner

ActiveCN102825814AImprove carrying capacityImprove mechanical propertiesBearing bushesEngineeringHardness

A manufacturing method of a water lubricated bearing taking hard rubber as a liner belongs to the field of a manufacturing method of a bearing. The problem that the existing manufacturing method of the rubber bearing is inapplicable for the water lubricated bearing taking the high-hardness rubber as the liner is solved. The method comprises the following steps of: mixing and milling the hard rubber by a double-roller mill, winding the mixed and milled hard rubber on a central spindle, arranging the mixed and milled hard rubber on a mold base, covering an upper cover of the mold on the mixed and milled hard rubber, arranging the mold on a vulcanizing machine, vulcanizing for 20-30min under the condition of 120 DEG C to 180 DEG C, opening the mold, de-molding, obtaining the water lubricated bearing lining blank product, performing machine finishing to the water lubricated bearing lining blank product, then arranging the product in a bearing sleeve, and obtaining the water lubricated bearing taking the hard rubber as the liner. Aiming at the defect that the hard rubber is hard to flow, a novel sleeve mold and the vulcanizing technique are used for preparing the water lubricated bearing; and the preparation method is simple, and high in efficiency, and is beneficial for mass production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

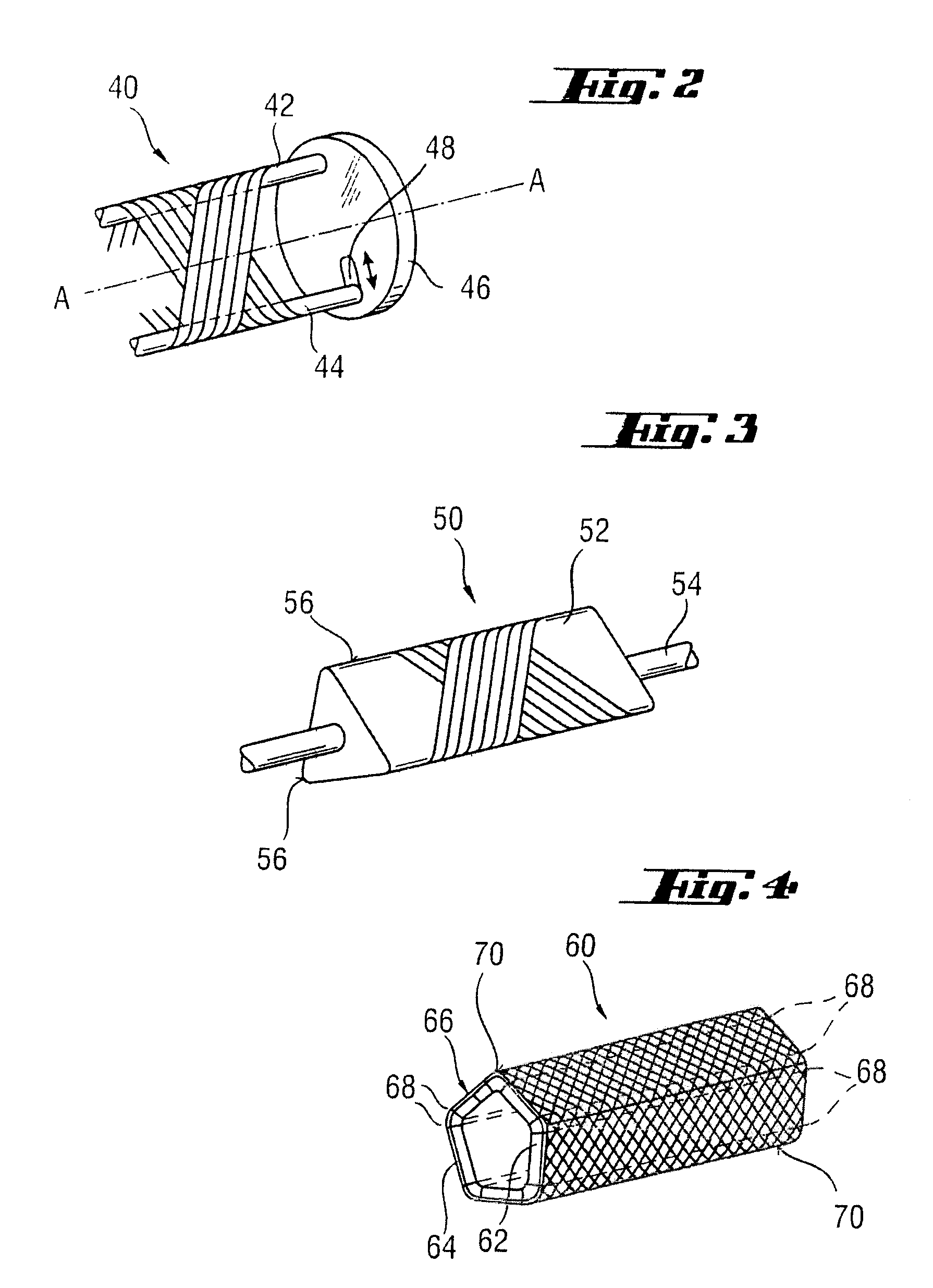

Sliding element procedure and device for its production

InactiveUS20080240634A1Low costEfficient productionLinear bearingsBearing bushesEngineeringConductor Coil

A method and a device is provided for producing a flat or arc-shaped sliding element with a very large radius of curvature. The sliding element has a sliding layer based on a fiber reinforced plastic with a plastic matrix and a reinforcing element containing at least one thread. The reinforcing element is deposited on a polygonal winding core by means of a guide with the addition of a synthetic resin forming the plastic matrix. The flat or arc-shaped segments formed between the edges are separated from the tubular, polygonal winding body thus formed after it has set.

Owner:FEDERAL MOGUL DEVA

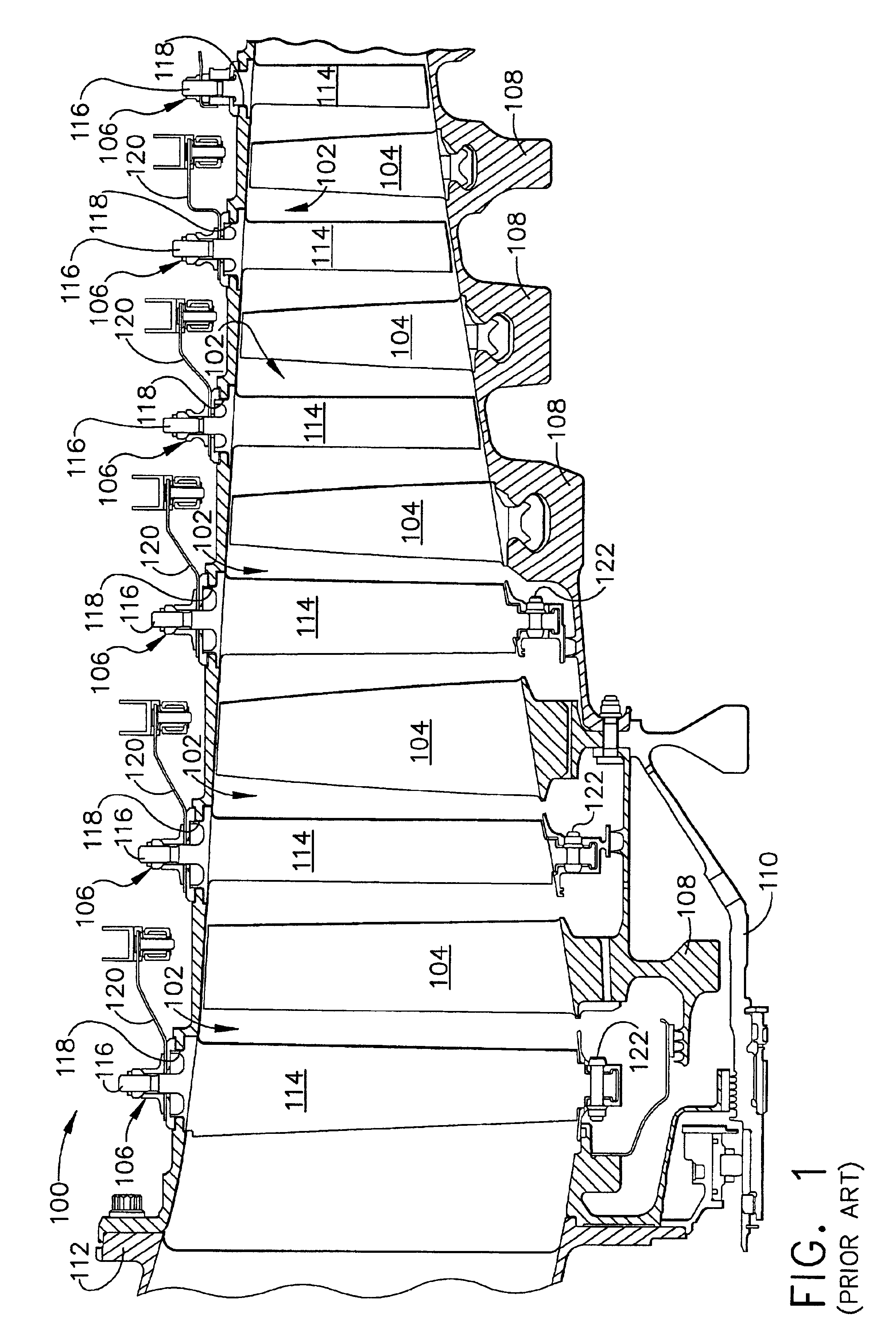

Method of manufacturing variable vane seal and washer materials

InactiveUS6915574B2Avoid contactDesirable performance characteristicEngine sealsPump componentsFiberGlass fiber

A multi-layer seal and washer that provide a seal between a vane stem and a casing in a turbine engine are disclosed. The seal and washer are fabricated from materials such as Teflon fibers and glass fibers and are impregnated with a polyimide resin. The seal and washer are durable and have a low coefficient of friction.

Owner:GENERAL ELECTRIC CO

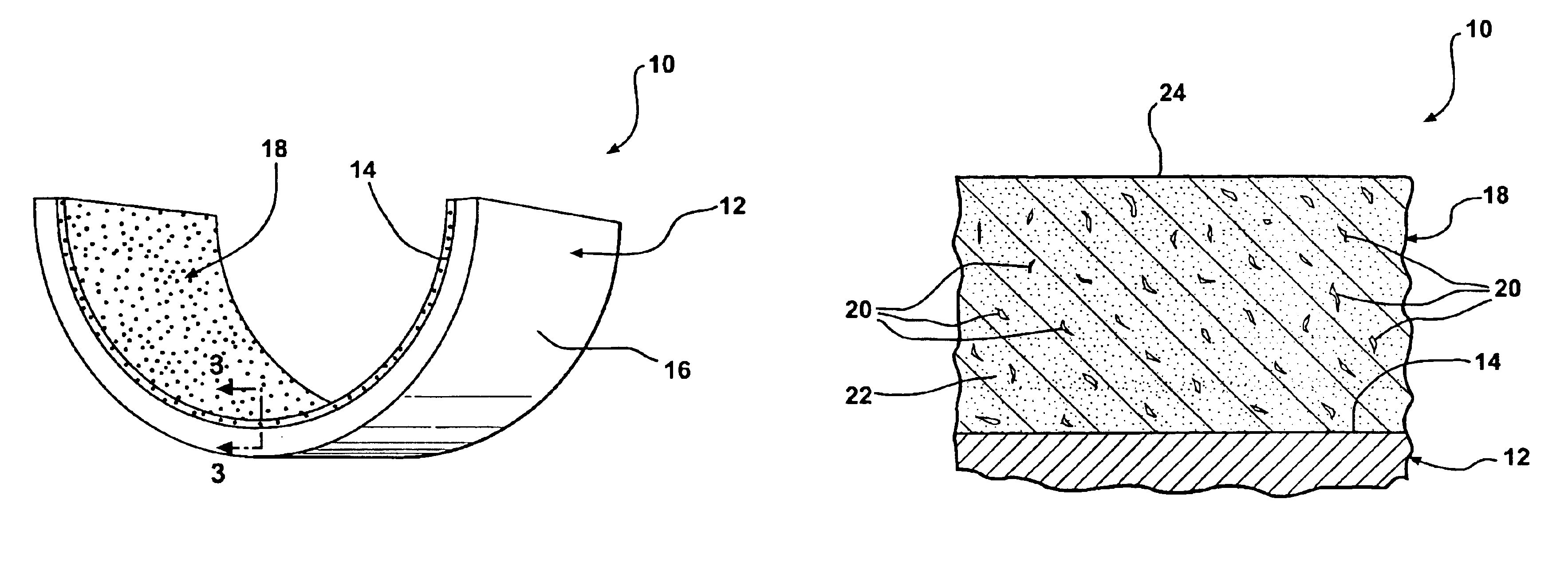

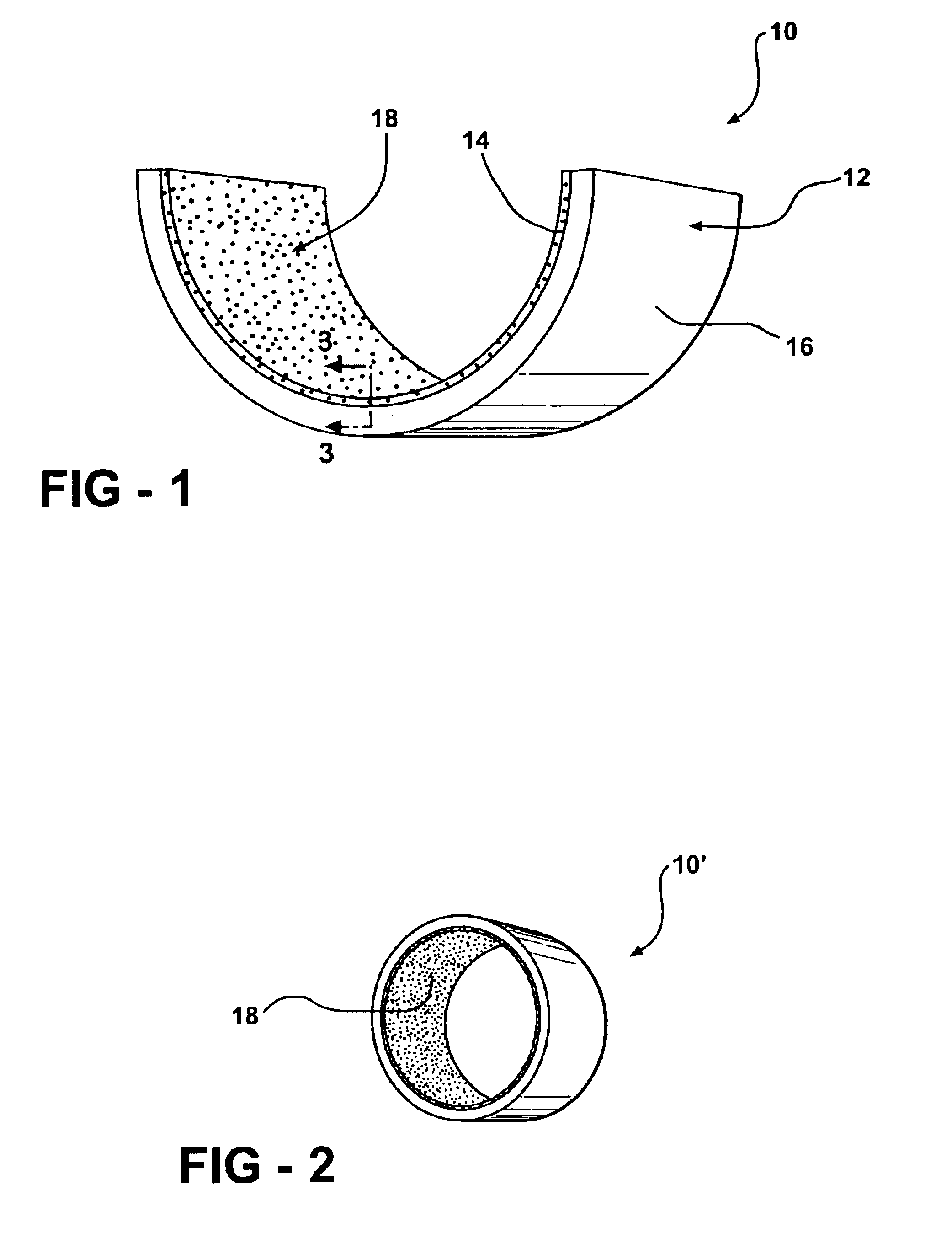

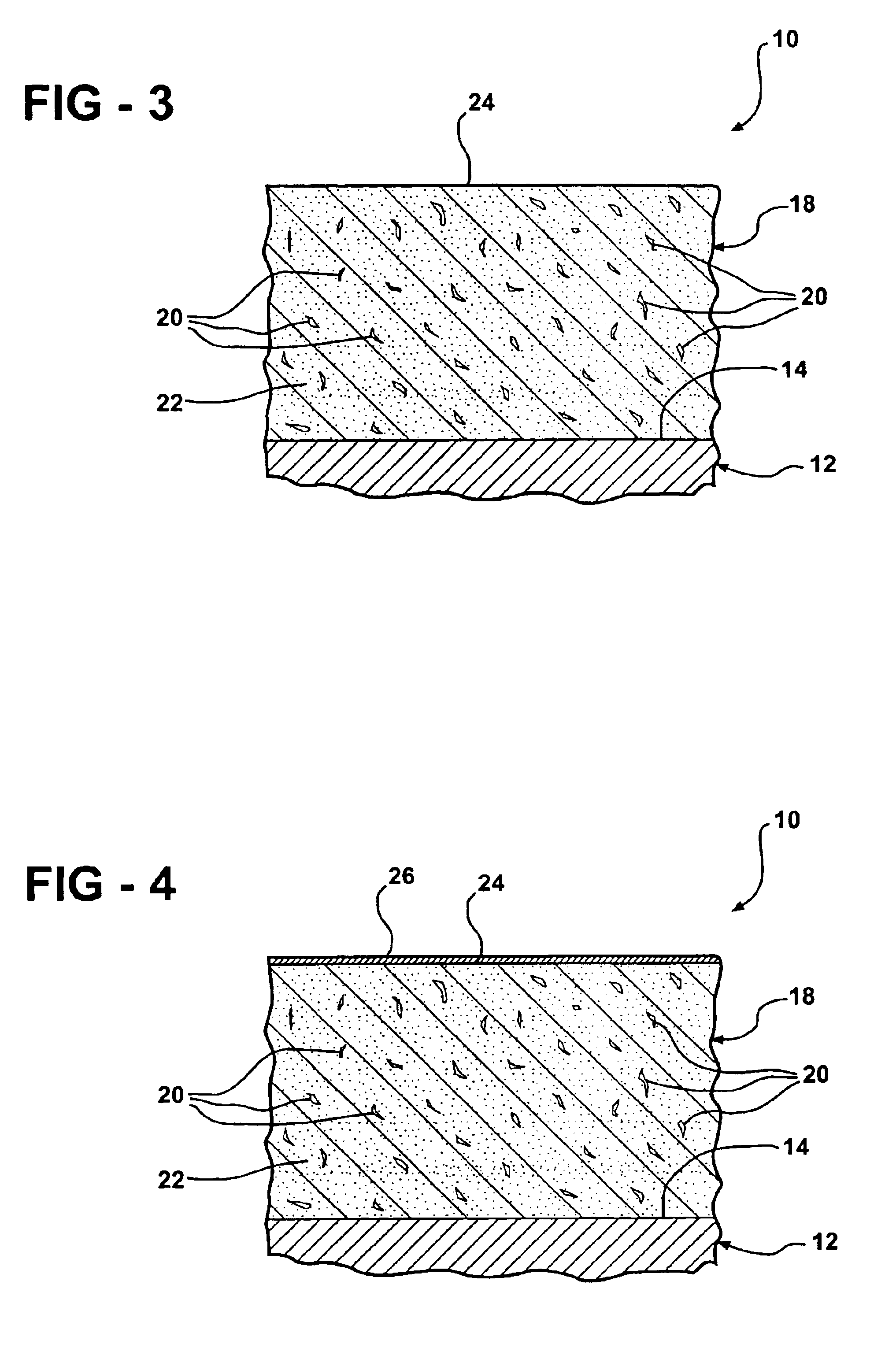

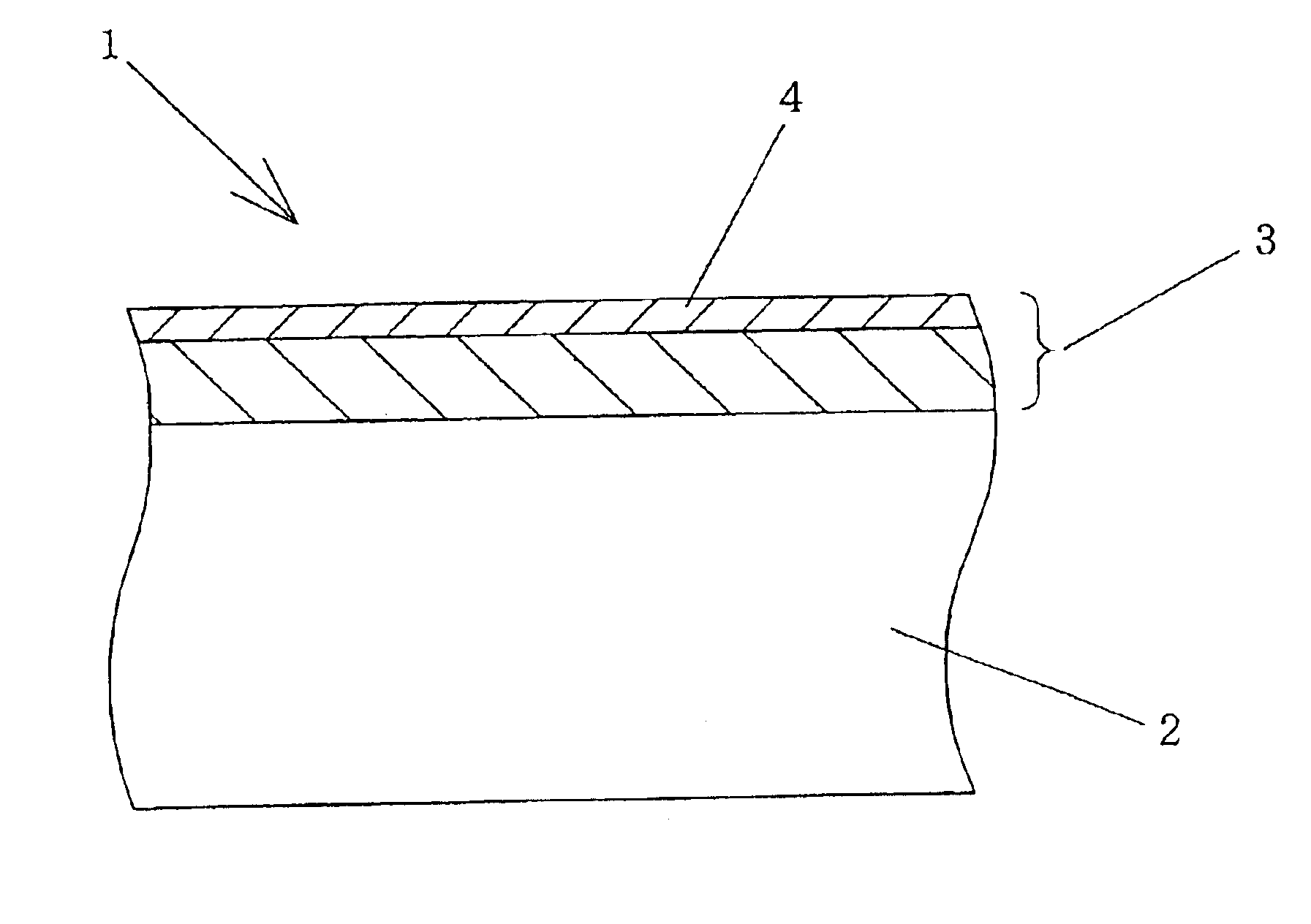

Metal-backed plain bearing

ActiveUS8931957B2Easy to operateSimilar of adhesionLiquid surface applicatorsBearing bushesResin matrixPliability

A bearing comprises a resin matrix filled with fluoropolymer, graphite, and other discrete particles of an additive material that is attached to a backing material. The specific selection and mix of fillers with the resin matrix provides the desired blend of bearing properties such as wear resistance, fatigue and erosion resistance and low friction whilst maintaining sufficient flexibility for being formed into flanged cylindrical geometries without detriment to the adherence of the lining to the backing. A method for manufacturing a bearing comprises depositing to a backing material a fluid polymer bearing material comprised of a resin matrix filled with fluoropolymer, various fillers, and discrete particles of an additive to form a continuous consolidated bearing material, and curing the lining material to bond the lining material onto the backing material.

Owner:GGB U S HOLDCO LLC

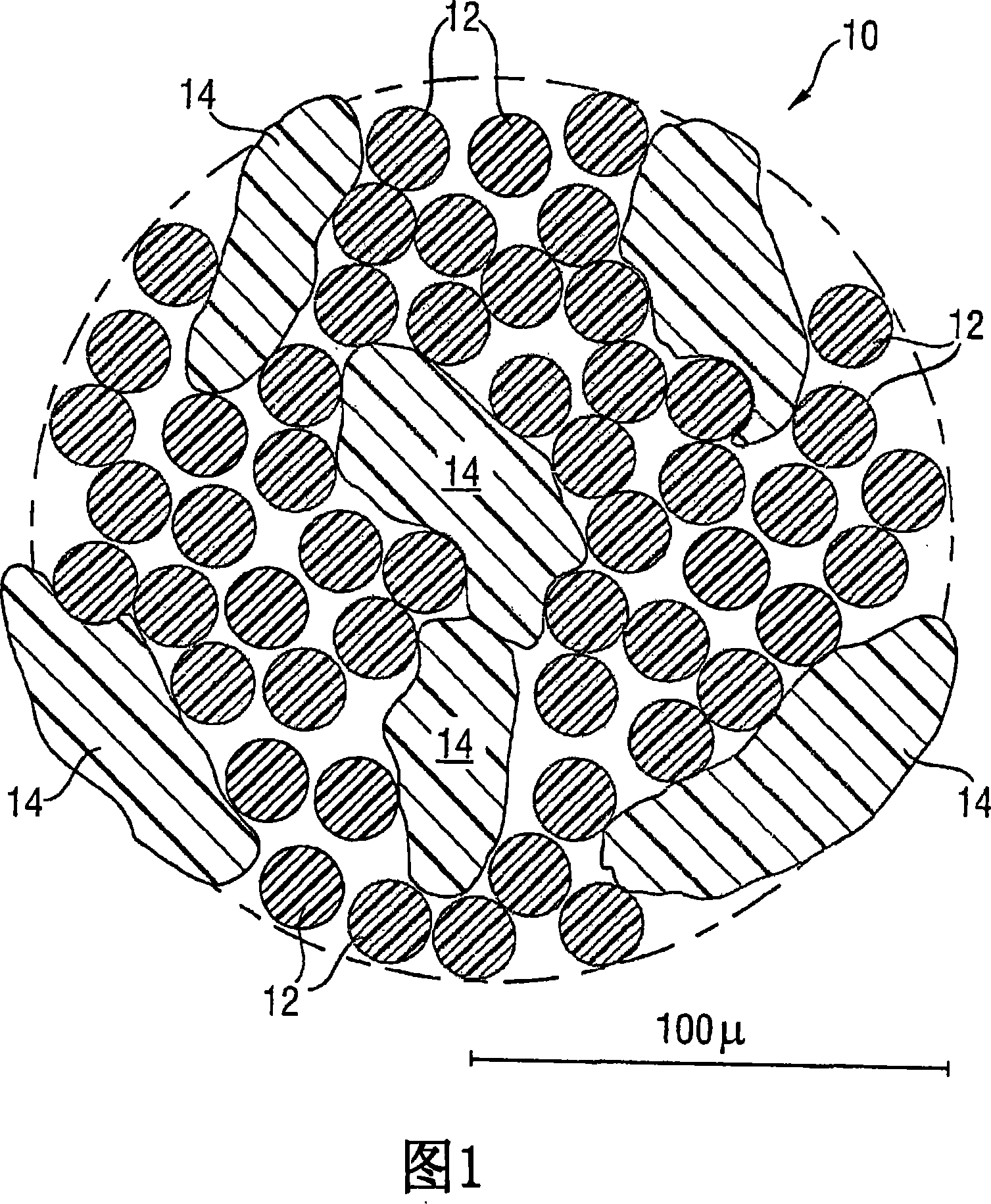

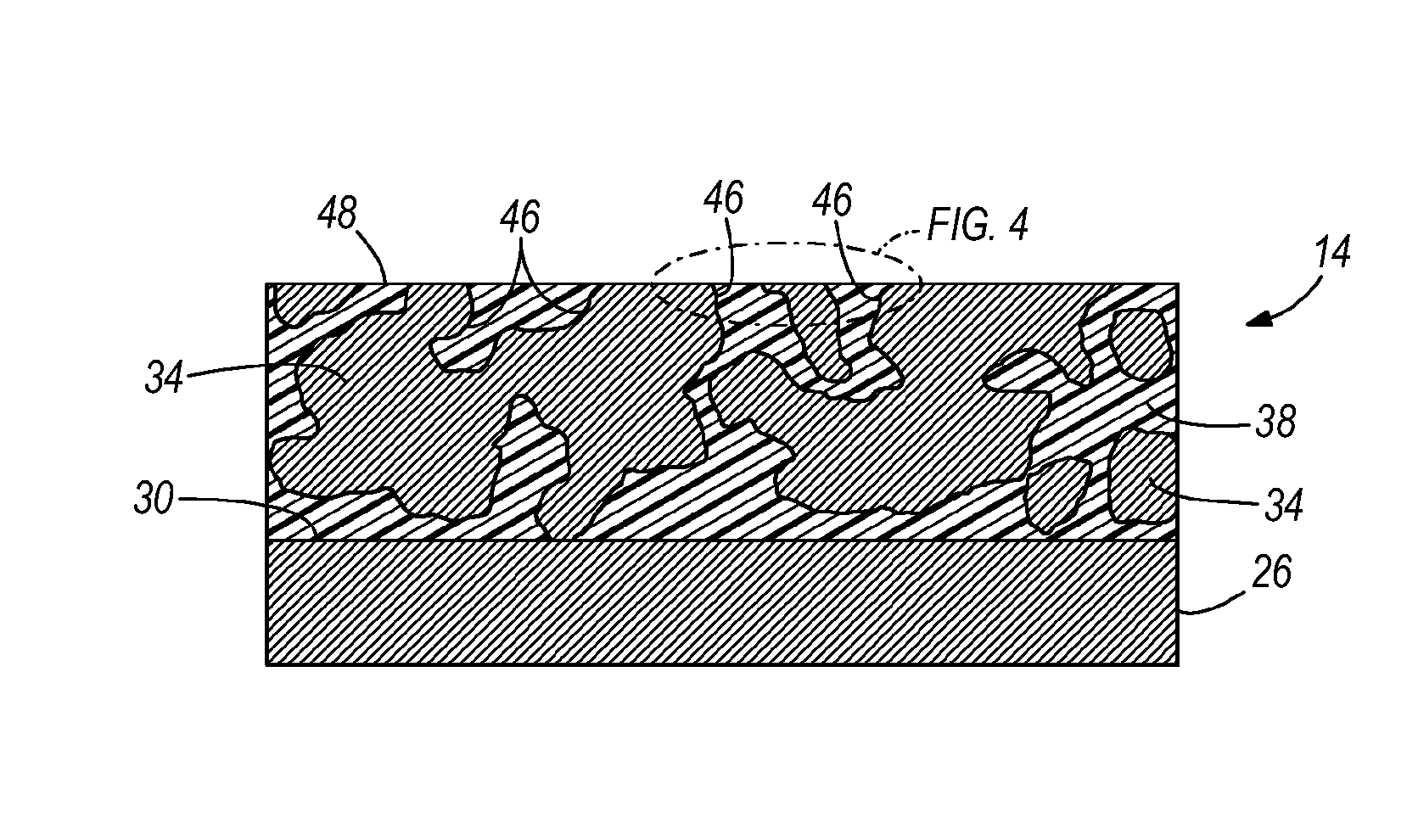

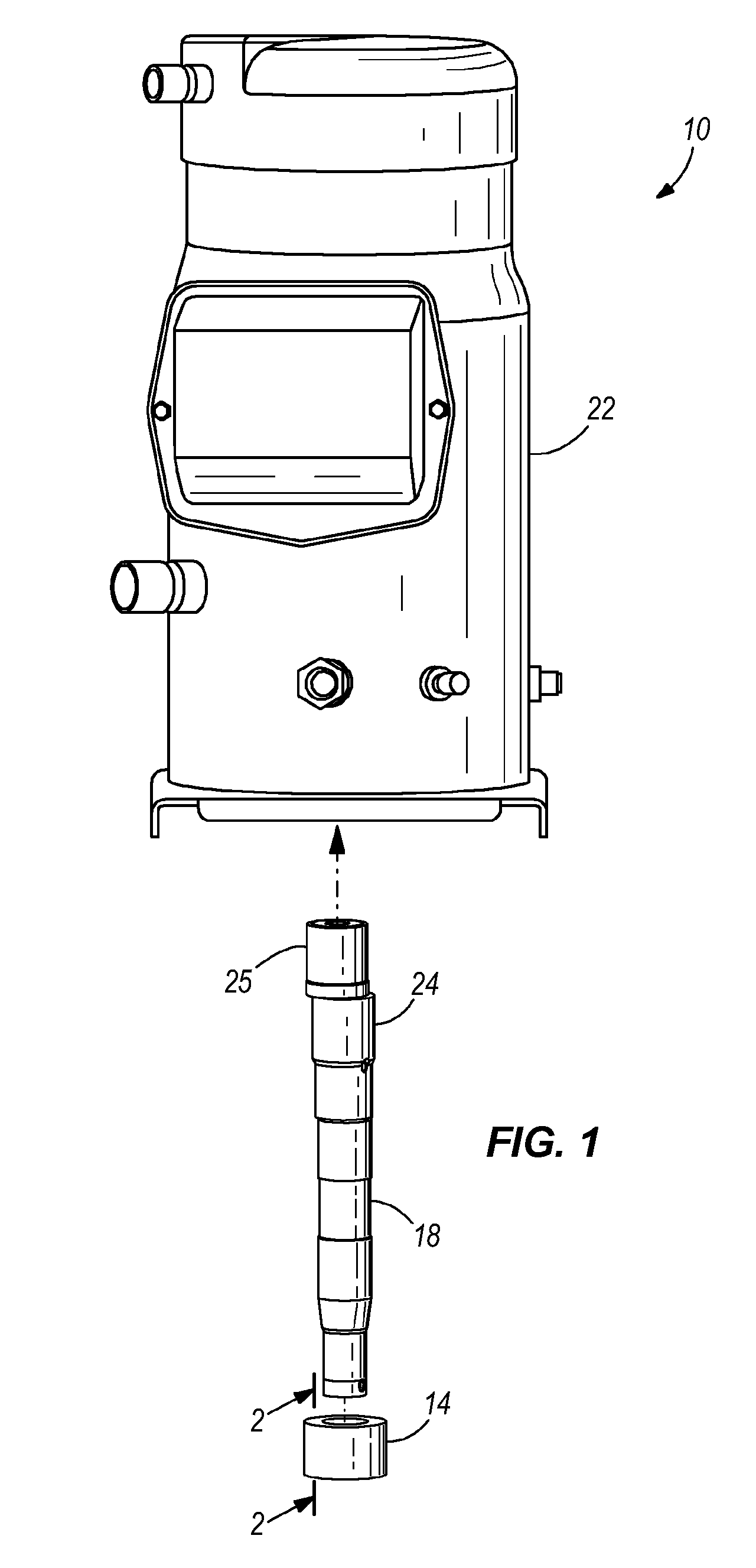

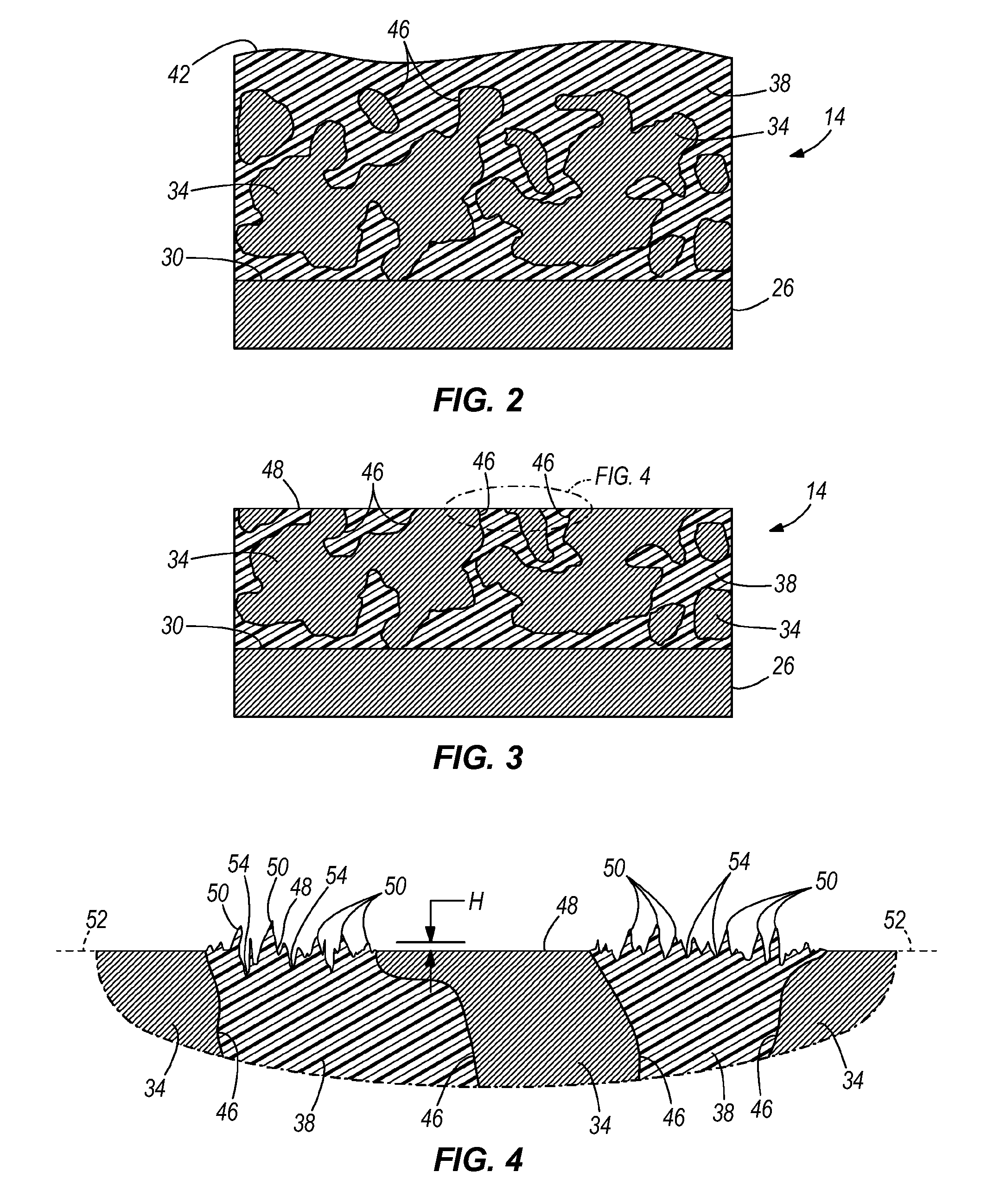

Composite metal-polymer bushing and crankshaft assembly

ActiveUS8613555B2Reduce wear rateRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeSurface finishMetal particle

An assembly includes a composite metal-polymer bushing having an outer metal layer with an inner surface, metal particles sintered to the inner surface, a polymer material between the metal particles, a finished interior surface collectively defined by the polymer material and exposed portions of the metal particles, a plurality of interstices formed between the metal particles and the polymer material, and a plurality of ridges defined by the polymer material that protrude above the metal particles. The ridges occupy at least about 8% of the area of a cylindrical reference surface nominally coinciding with the finished interior surface. The assembly also includes a crankshaft having a journal at least partially received within the bushing and supported by the finished interior surface. The journal is polished to a surface finish of about 0.1 microns or less to reduce a wear rate of the bushing.

Owner:TRANE INT INC

Method of making fluid dynamic bearing

Owner:HON HAI PRECISION IND CO LTD

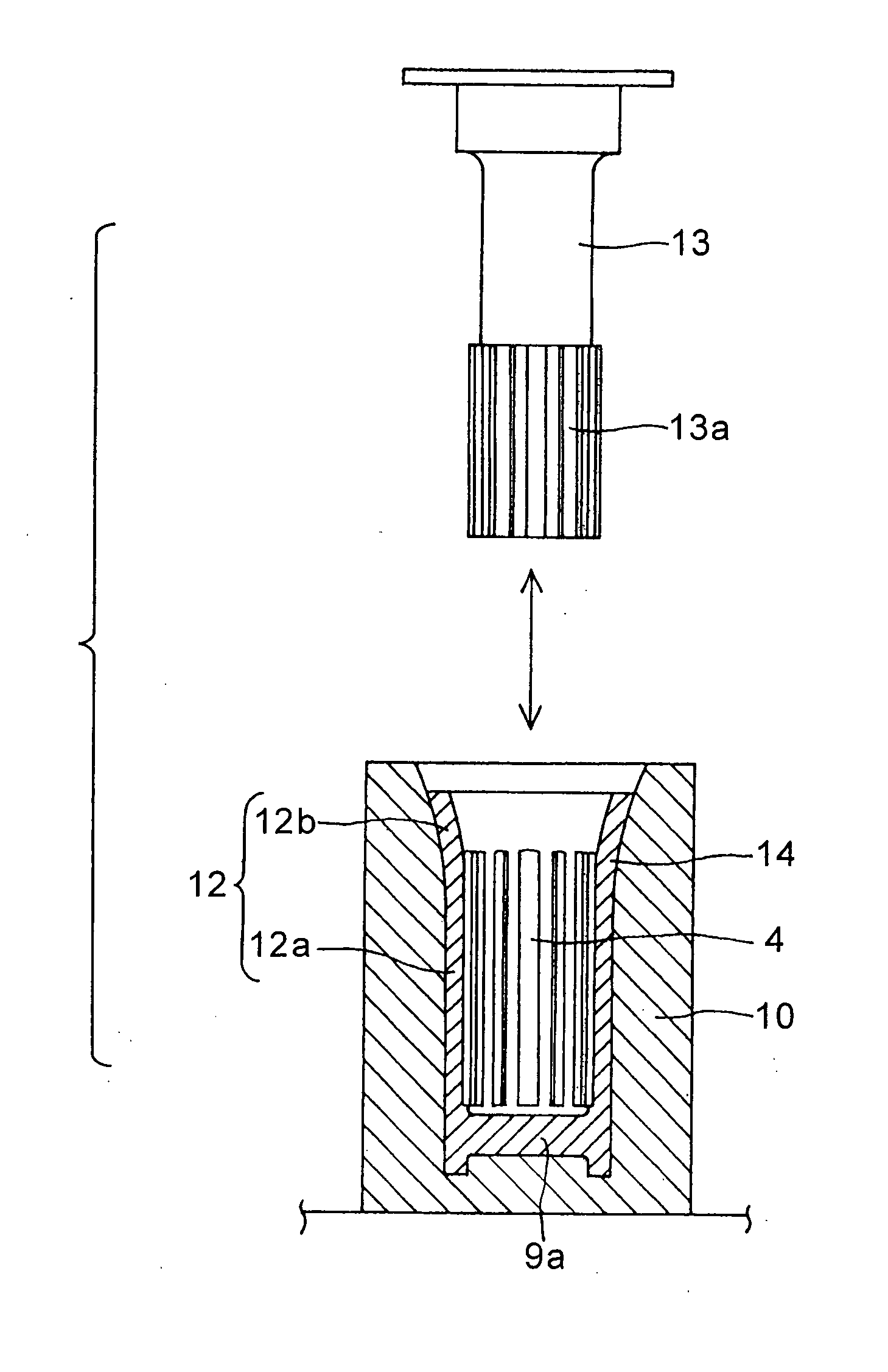

Method of manufacturing cylindrical bearing member

InactiveUS20060123630A1MaintainabilityImprove efficiencyBearing bushesMetal-working apparatusMaintainabilityEngineering

A small-bored cylindrical bearing member which can enhance the maintainability for a lubricating oil therein. The member has blind grooves in a seamless cylindrical central body portion of the interior hollow cylindrical surface of the bearing member. A method of manufacturing the cylindrical bearing member having blind grooves with blocked-in end portions extending in the longitudinal direction of the cylindrical portion and spaced from the ends of the member. The grooves can be easily formed in the central body portion of the inner circumferential cylindrical surface of the central body portion with the blocked-in ends spaced from the opposite ends of the seamless bearing member. The seamless member is first formed with a tapered or flared portion at one open end which is later narrowed into a round cylindrical form. Before narrowing the tapered or flared portion, the blind grooves are formed by a groove punch pushed through the open end into the central body cylindrical portion. After narrowing, the blind grooves have blocked end portions spaced from the opposite ends of the bearing in the longitudinal direction.

Owner:TSUBAKIMOTO CHAIN CO

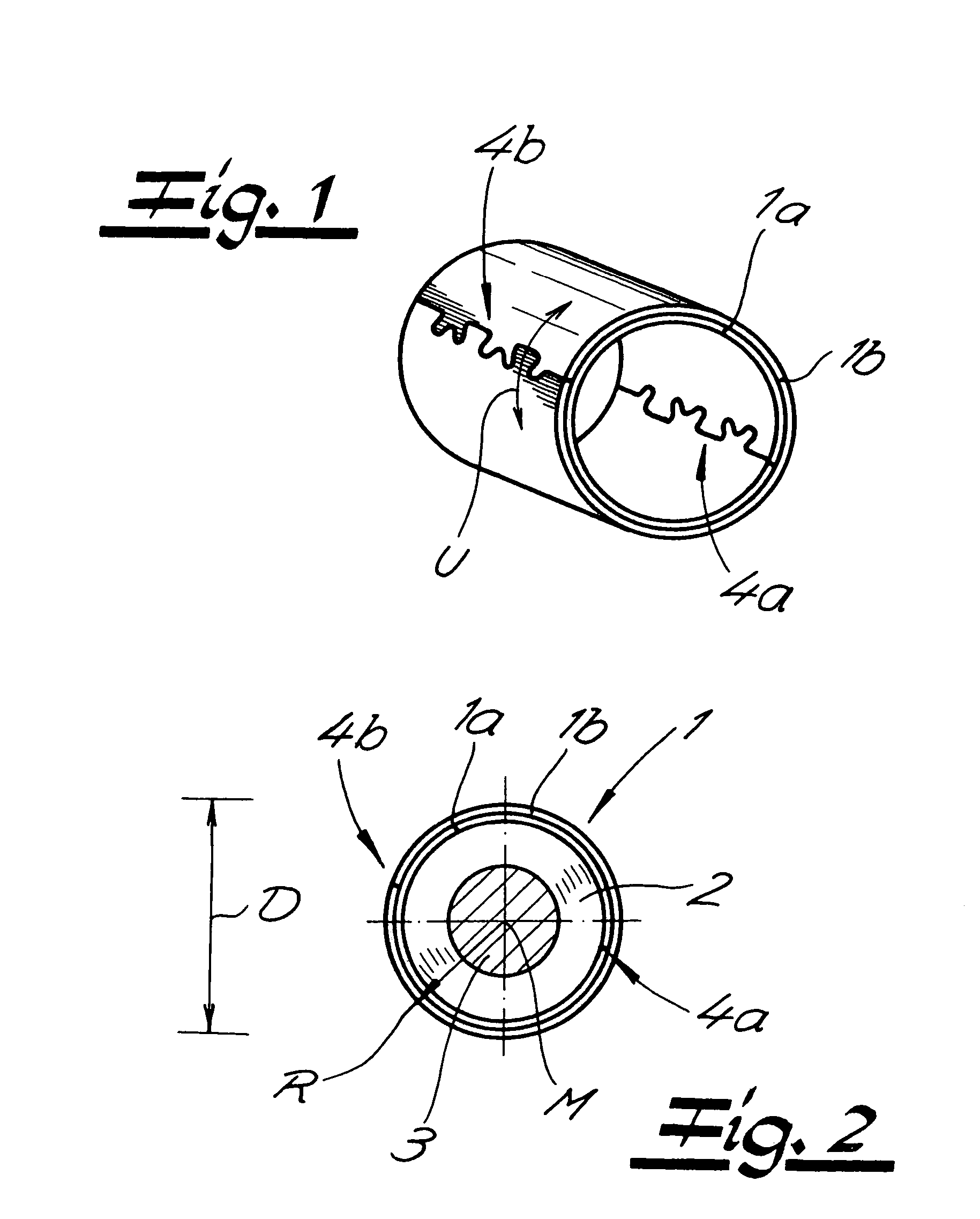

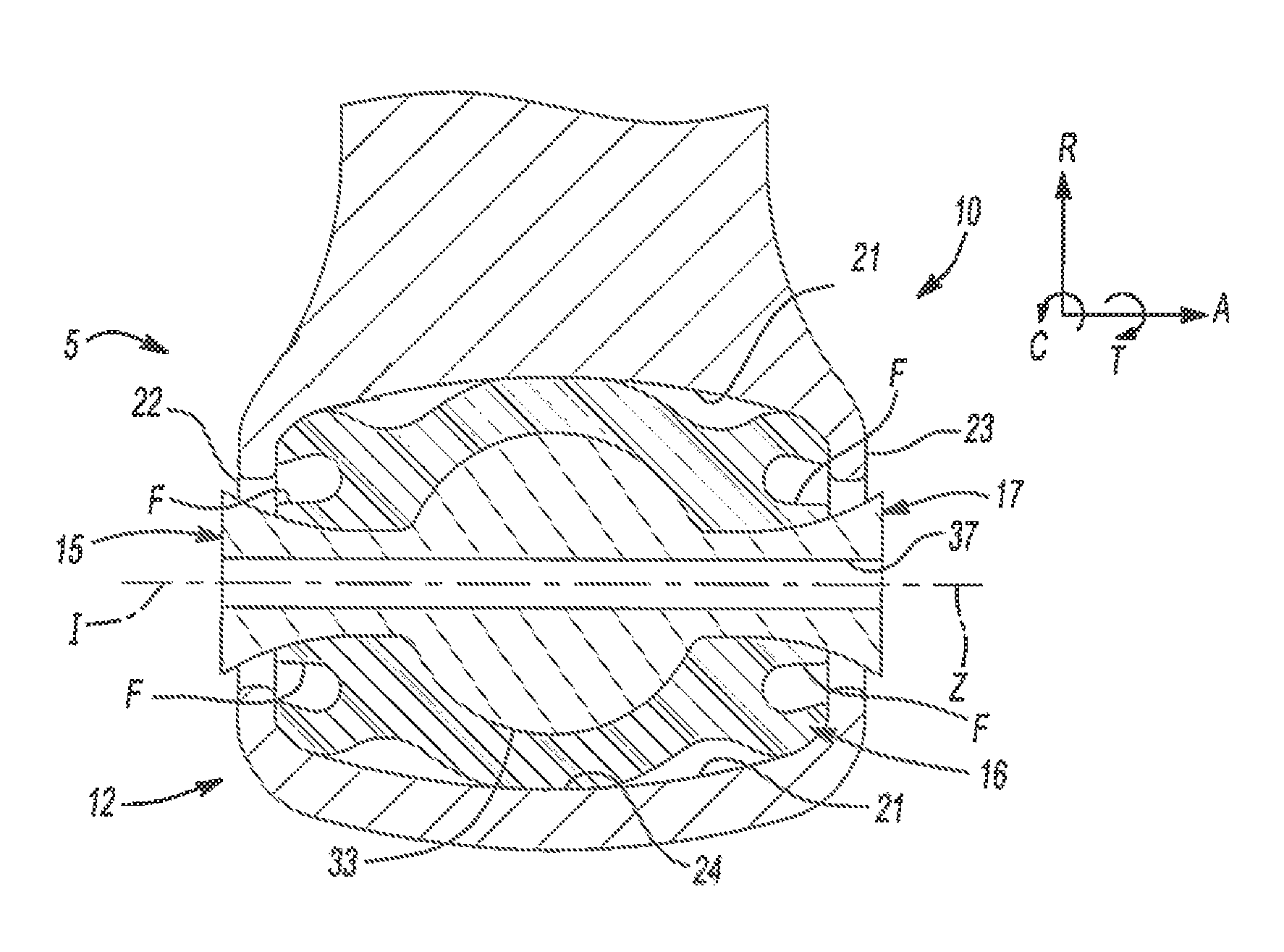

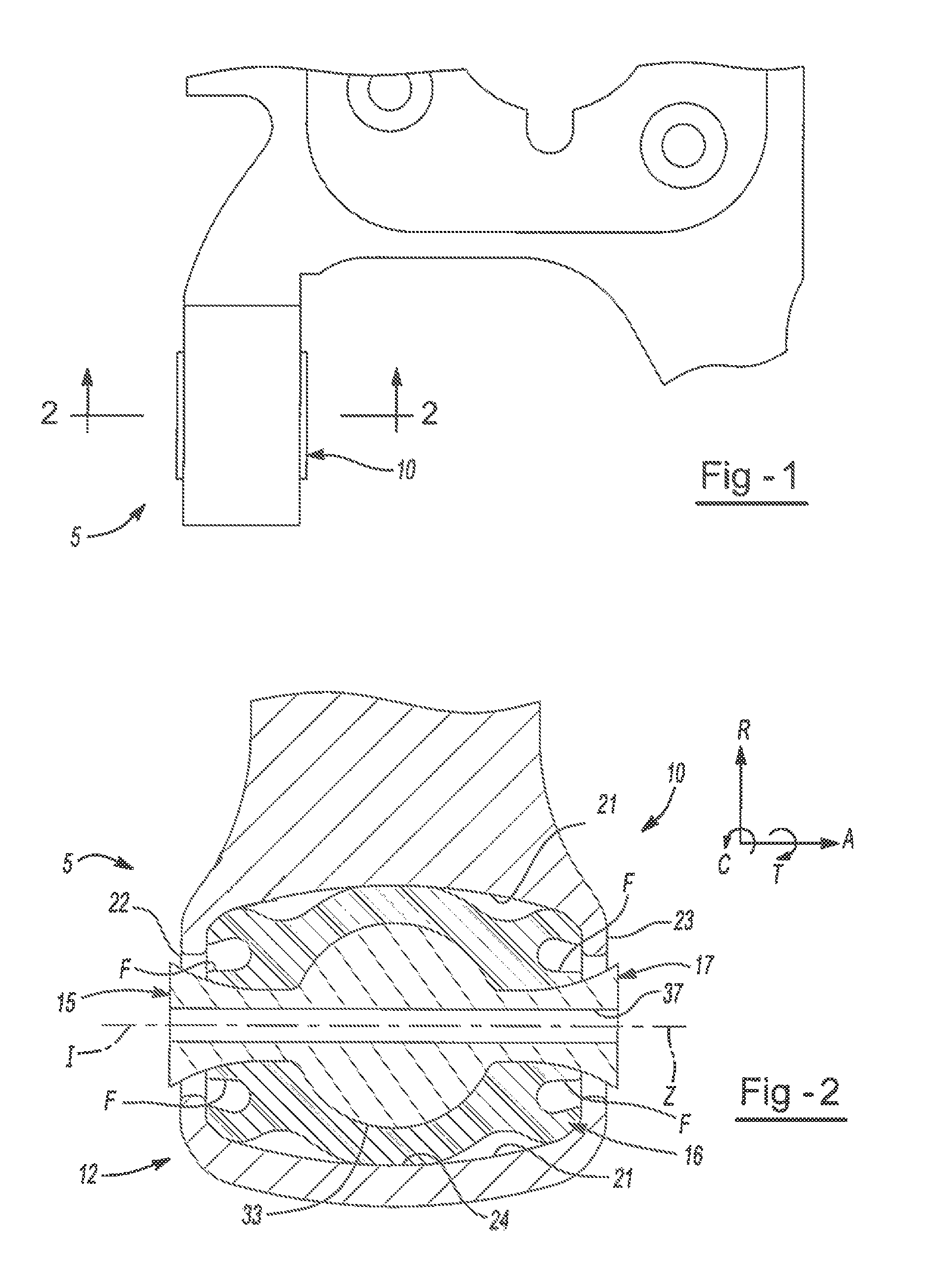

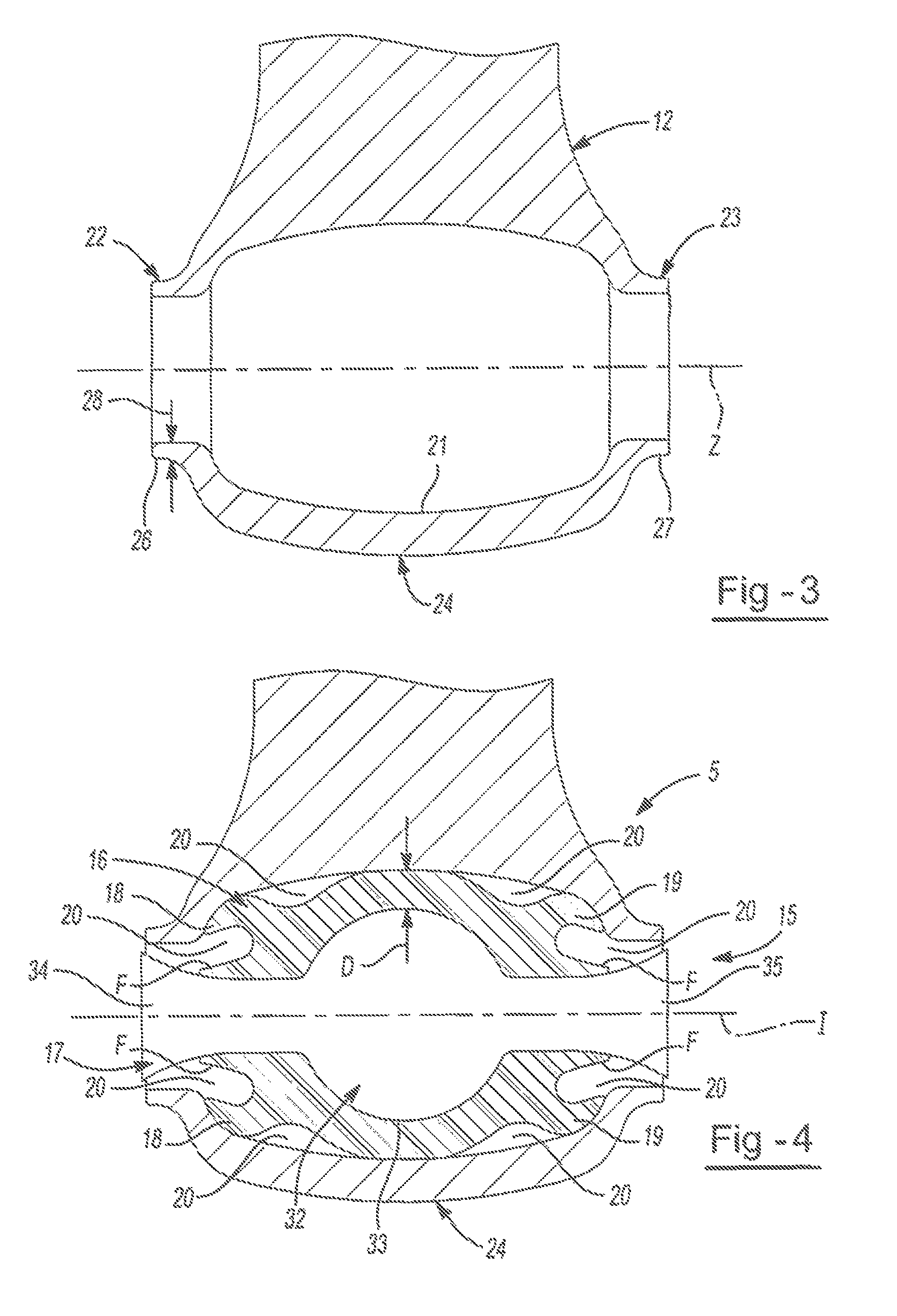

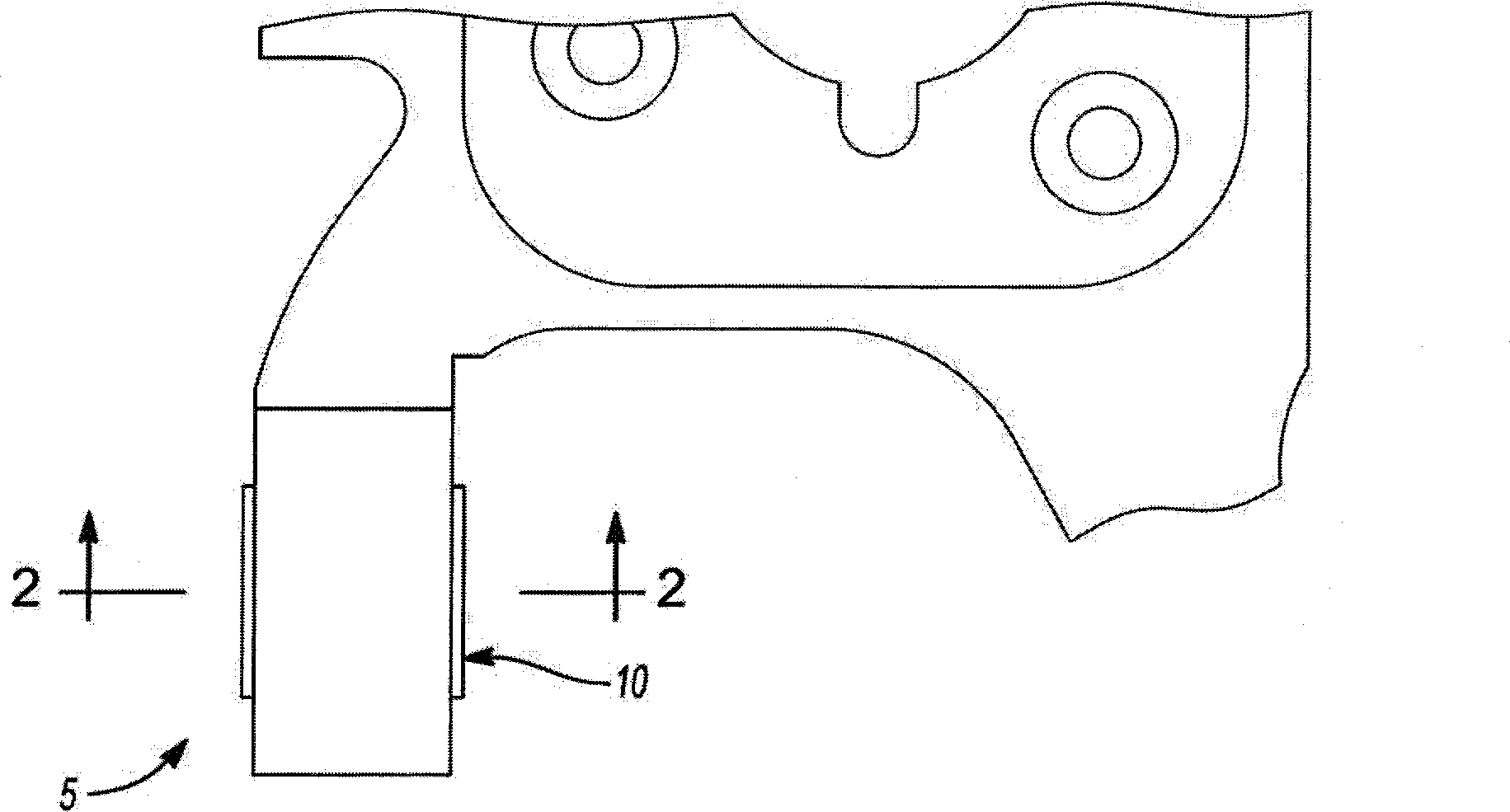

Knuckle and bushing assembly

InactiveUS9102211B2Improve axial stiffnessImproved torsionalBearing bushesResilient suspensionsElastomerHigh stiffness

A suspension coupling for use in a vehicle suspension system the suspension coupling including a knuckle and bushing assembly wherein the knuckle member is a cast aluminum piece having a passage for receiving a two-piece bushing having a formed, metal inner member and a molded, elastomeric outer member having extension members at each end. The bushing member is press-fit into the knuckle member and exhibits higher stiffness in the radial and axial directions and lower stiffness in the torsional and conical directions.

Owner:ALUDYNE NORTH AMERICA INC

Elastic metal-plastic bush and manufacturing method thereof

ActiveCN102979817AControl Mechanical PropertiesGuaranteed uniformity of elastic modulusFinal product manufactureBearing bushesResin-Based CompositeEngineering

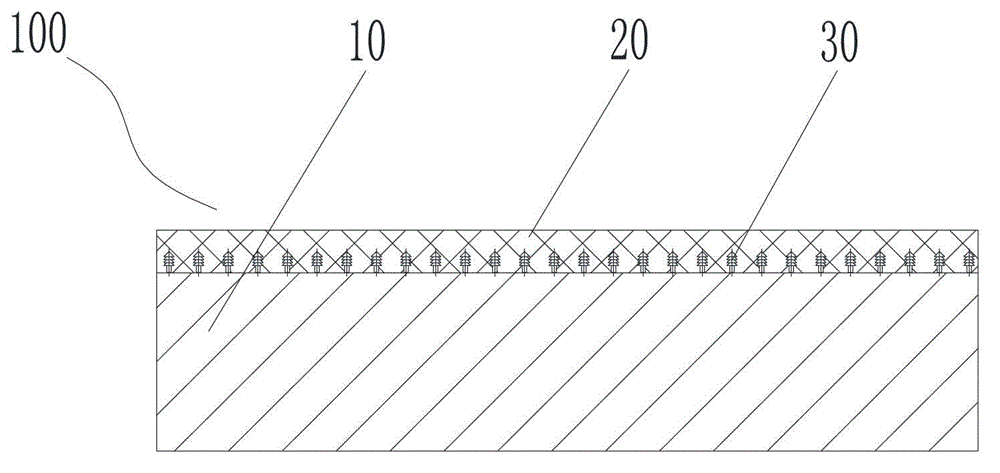

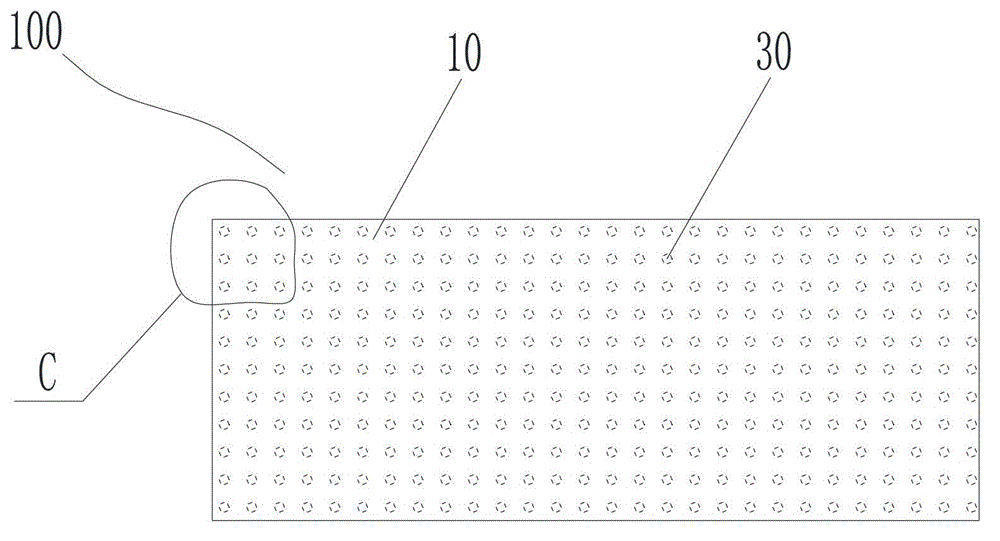

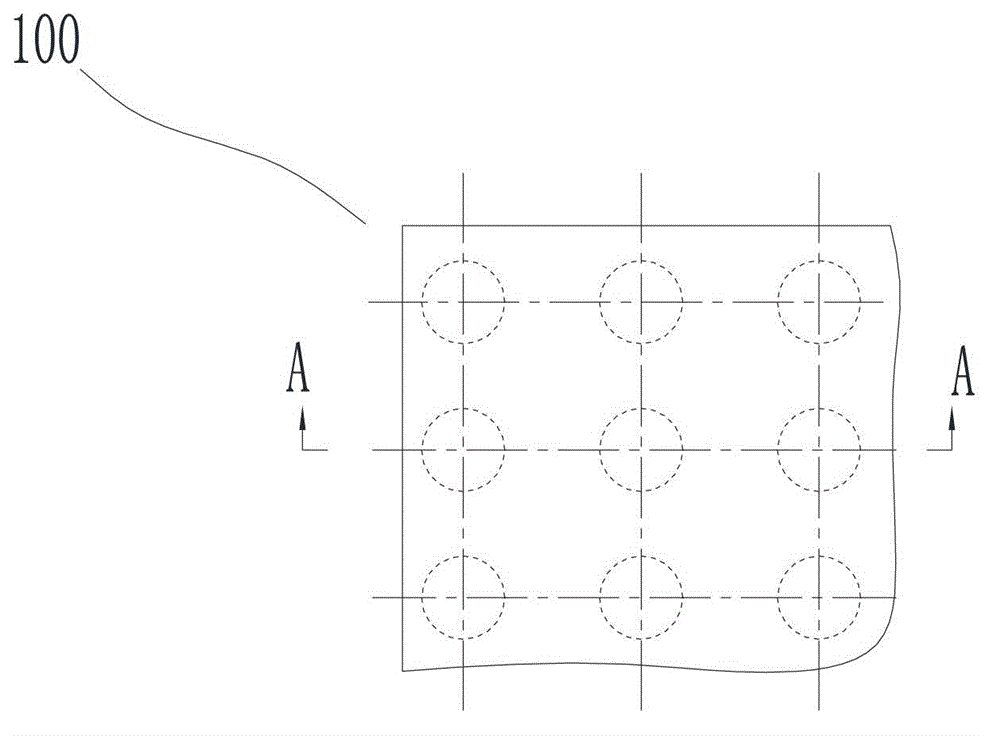

The invention provides an elastic metal-plastic bush and a manufacturing method thereof. The elastic metal-plastic bush comprises a bush base (10), a composite resin layer (20) and a plurality of connecting columns, wherein the composite resin layer (20) is fixed on a connecting surface of the bush base (10), each connecting column comprises a first end and a second end which are arranged oppositely, the second ends are fixedly connected with the connecting surface of the bush base (10), the height of the connecting columns is smaller than the thickness of the composite resin layer (20), and the bush base (10) and the composite resin layer (20) are fixed through the connecting columns. According to the elastic metal-plastic bush and the manufacturing method of the elastic metal-plastic bush, the bush base is connected with the composite resin layer through the connecting columns, so that the automation of the connection between the connecting columns and the bush base can be realized, the manufacturing efficiency of the composite resin layer can be increased, the automation of production is then realized, and the production efficiency is increased.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

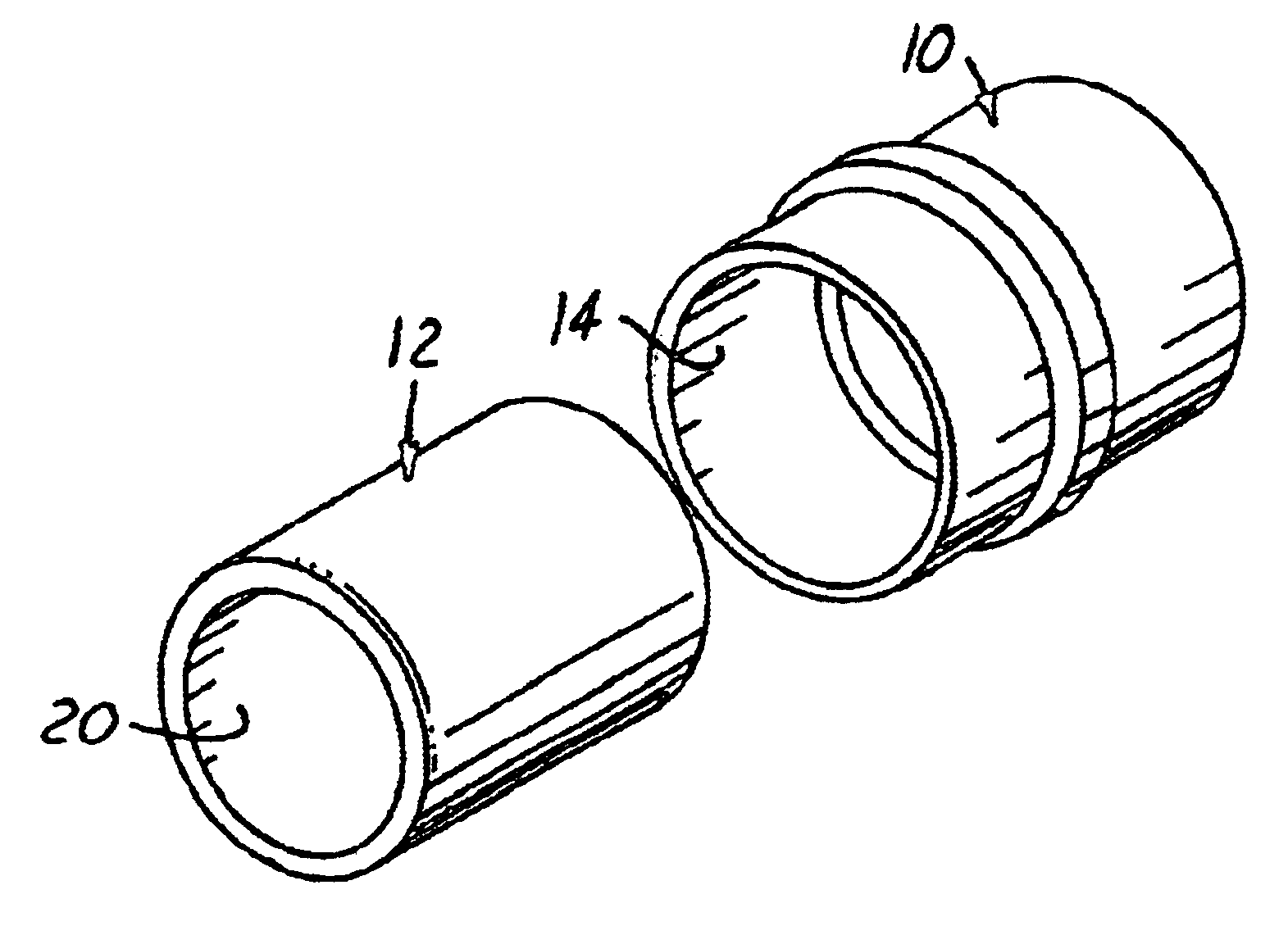

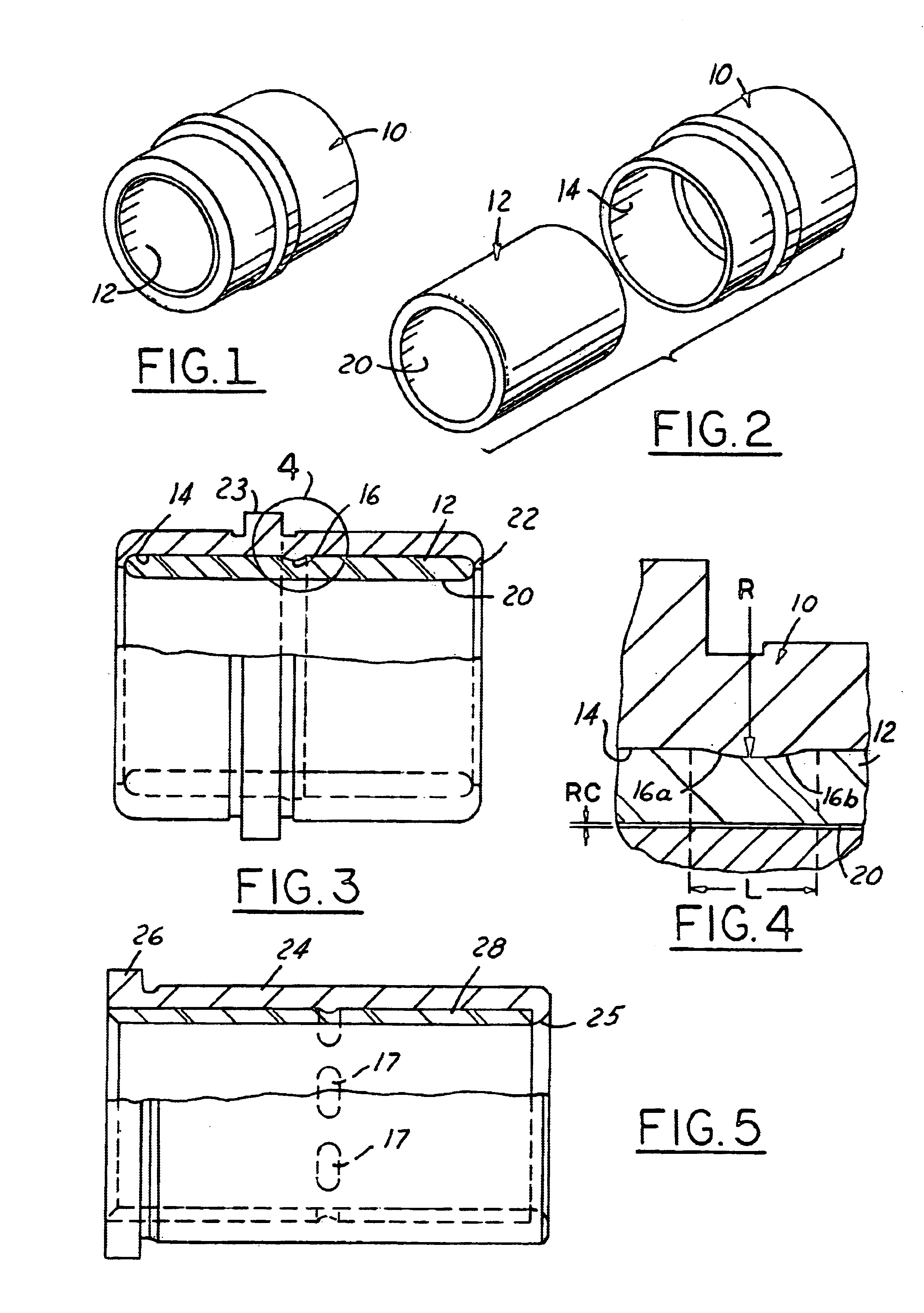

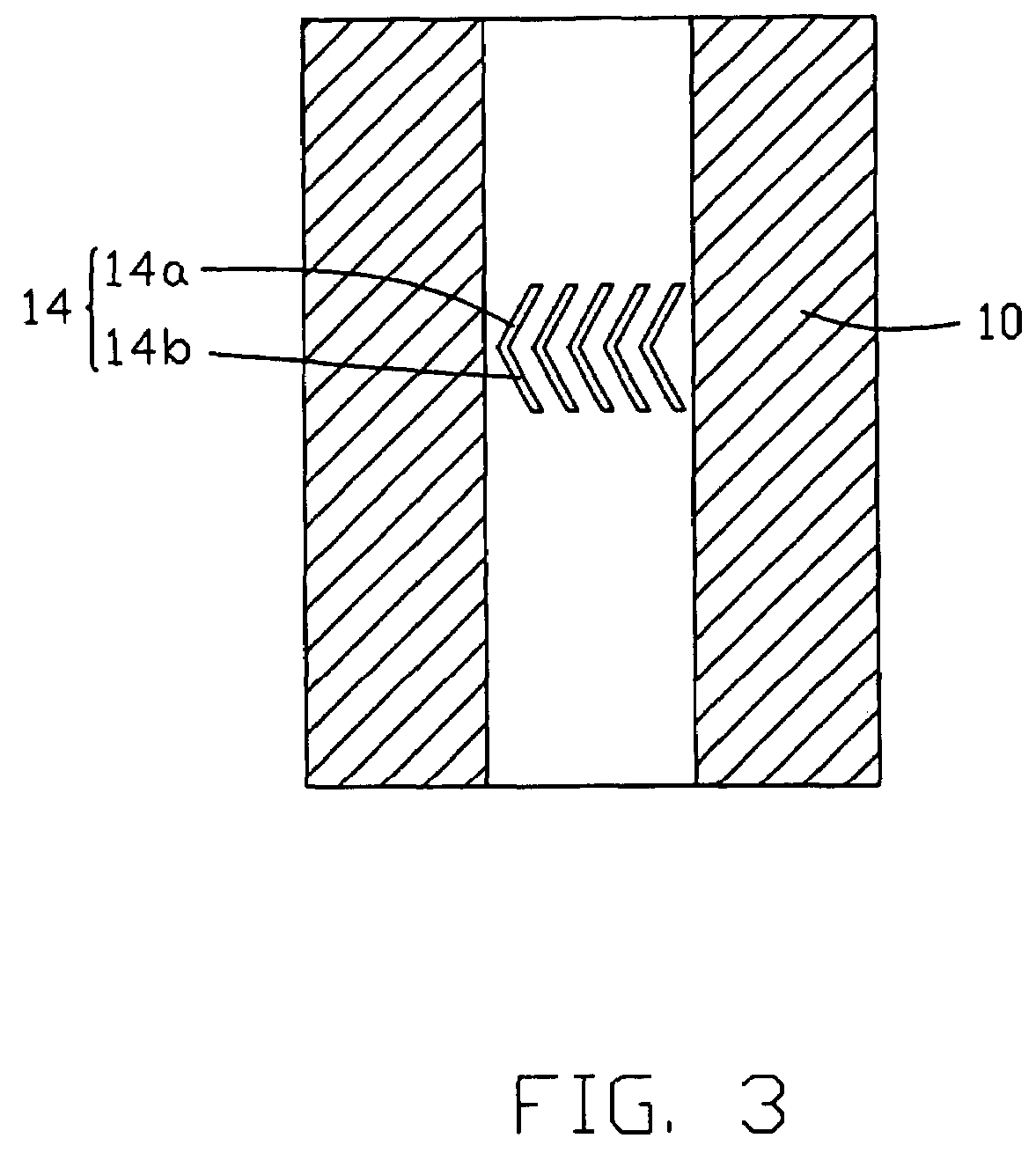

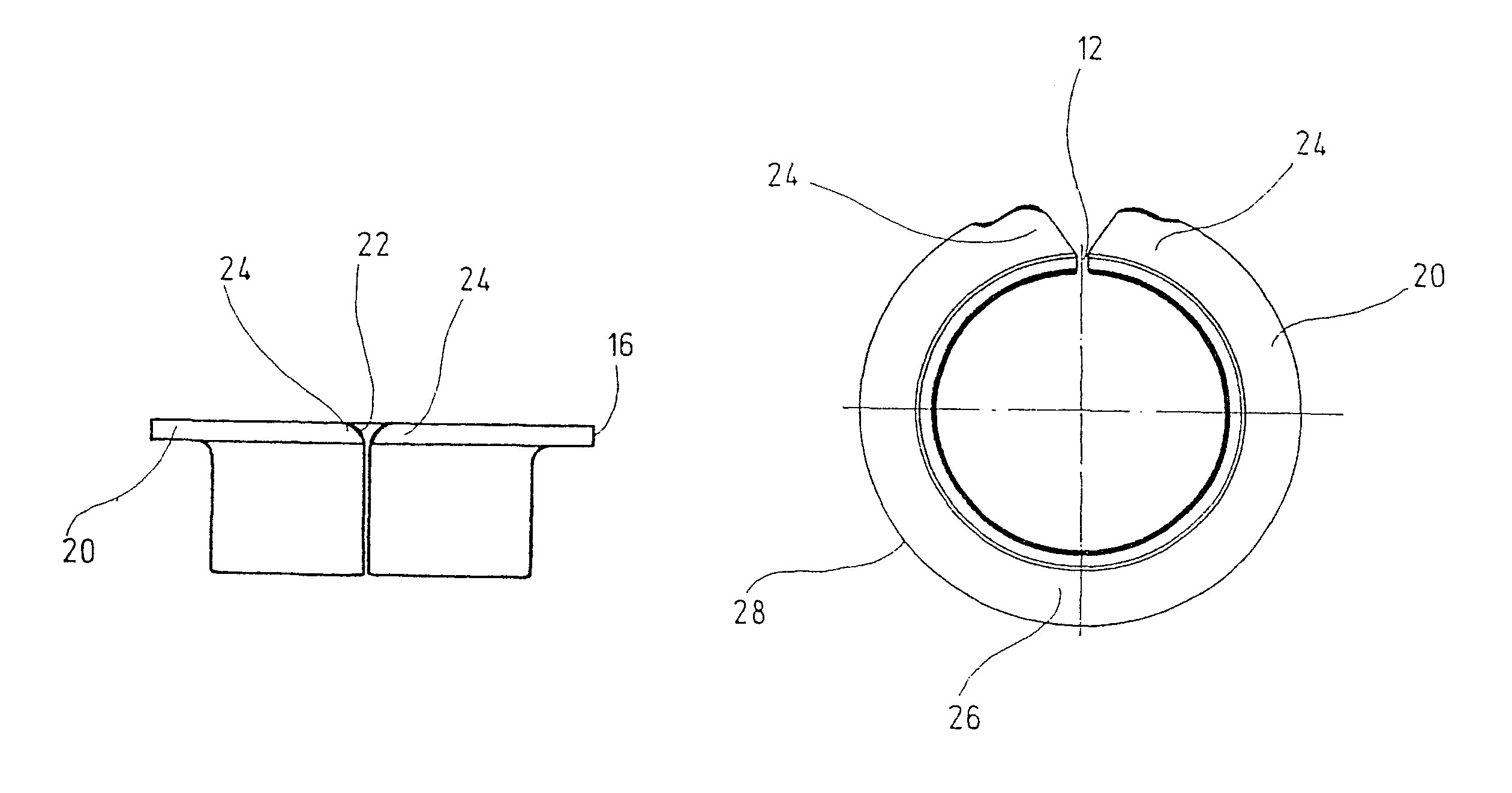

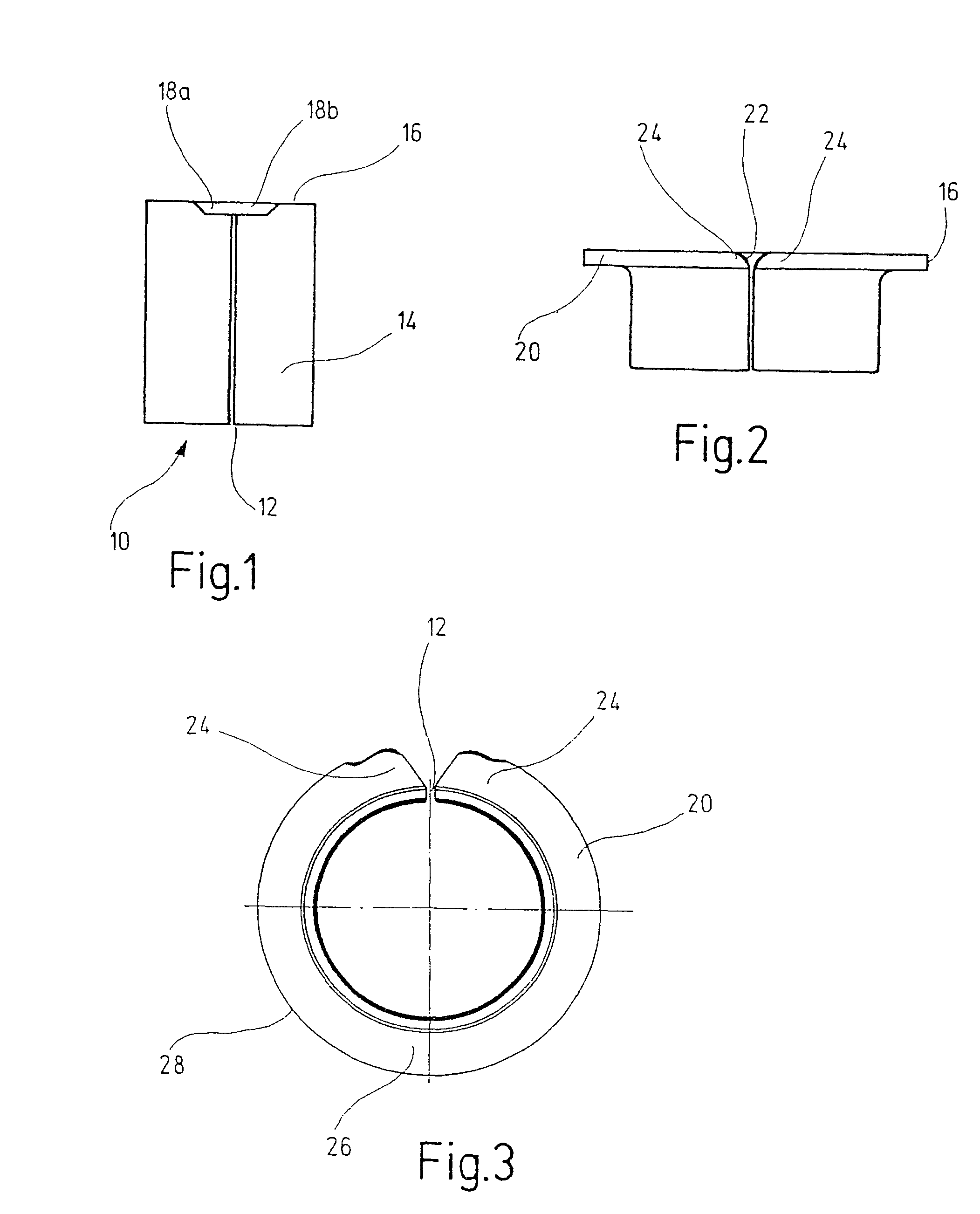

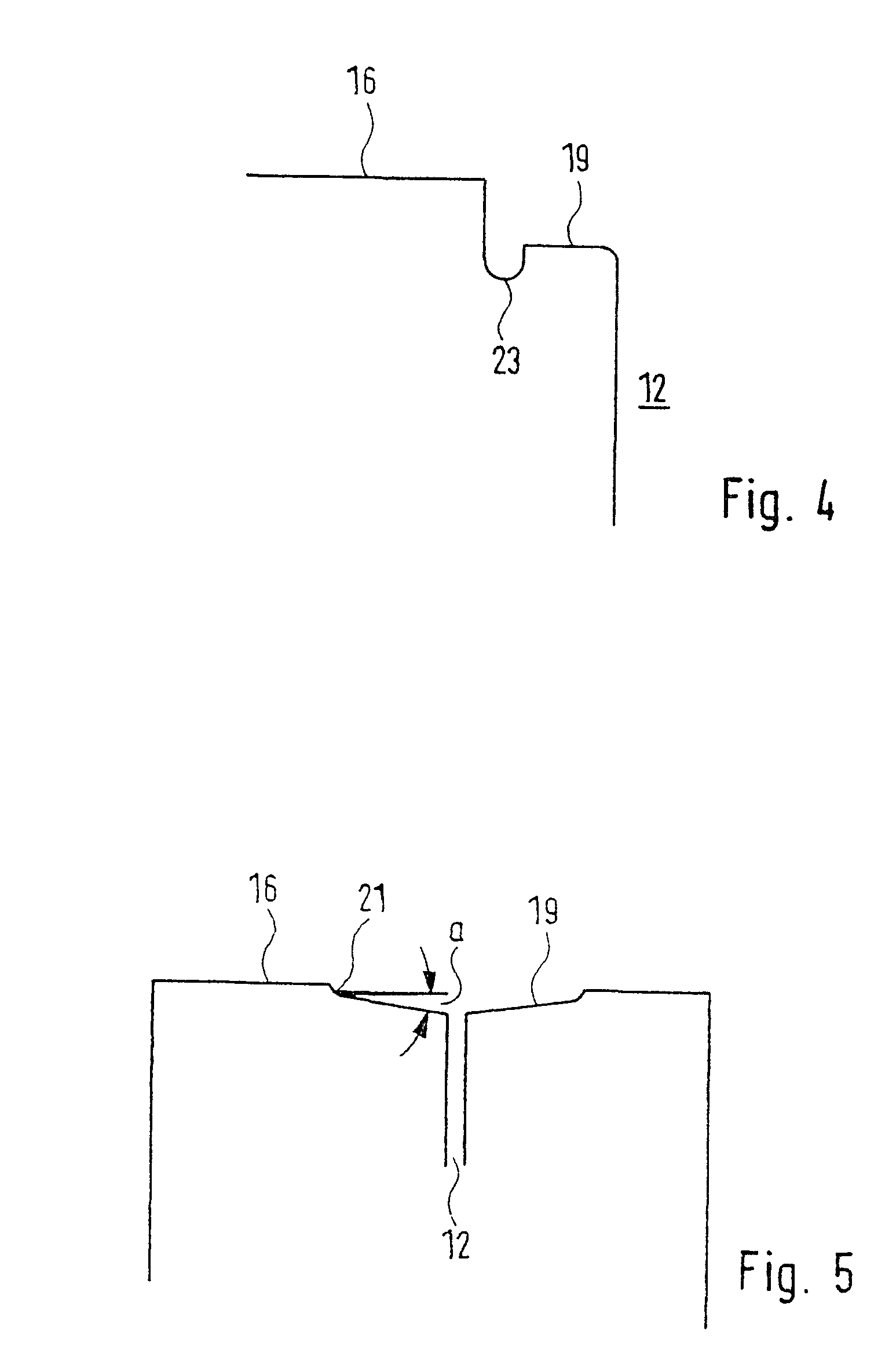

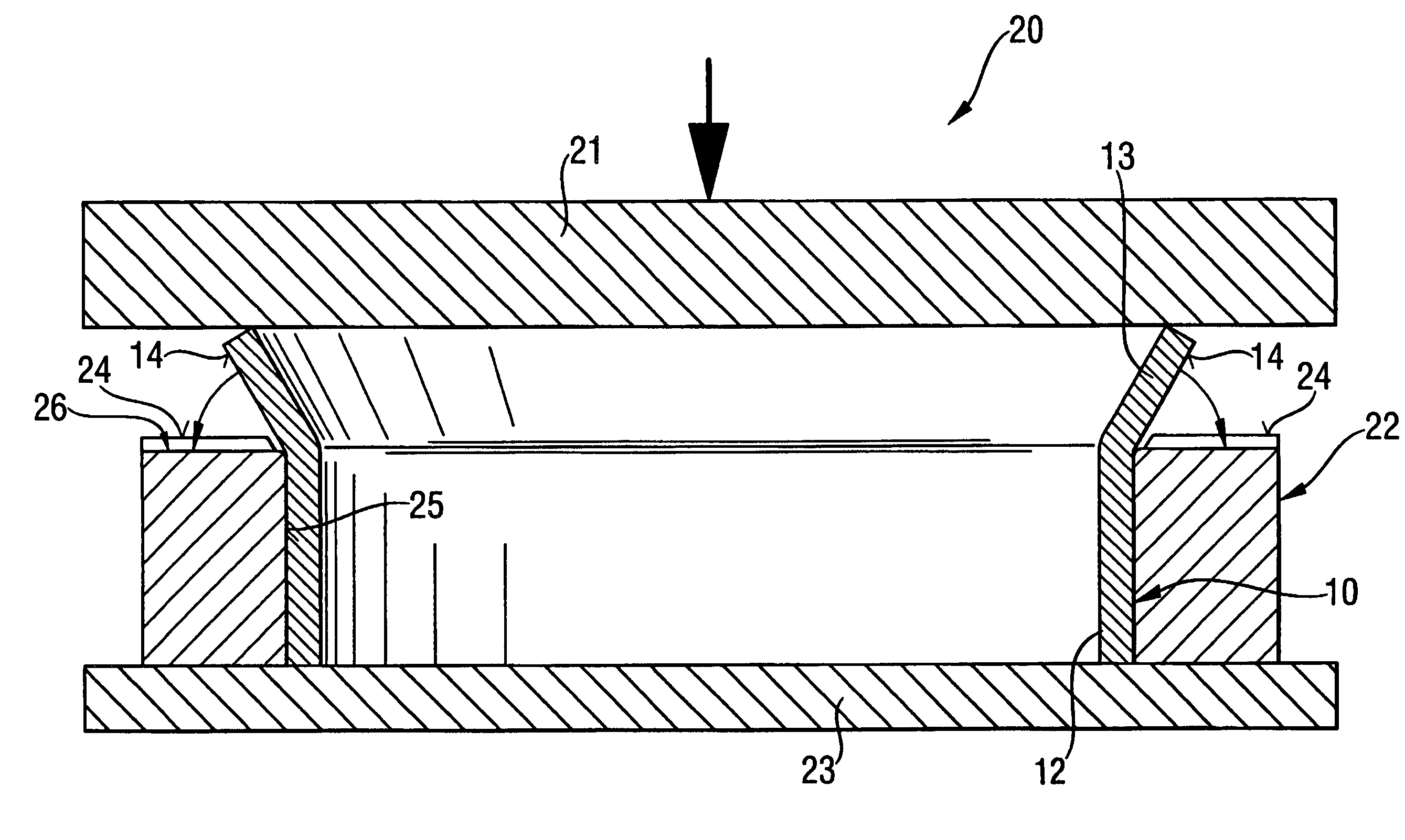

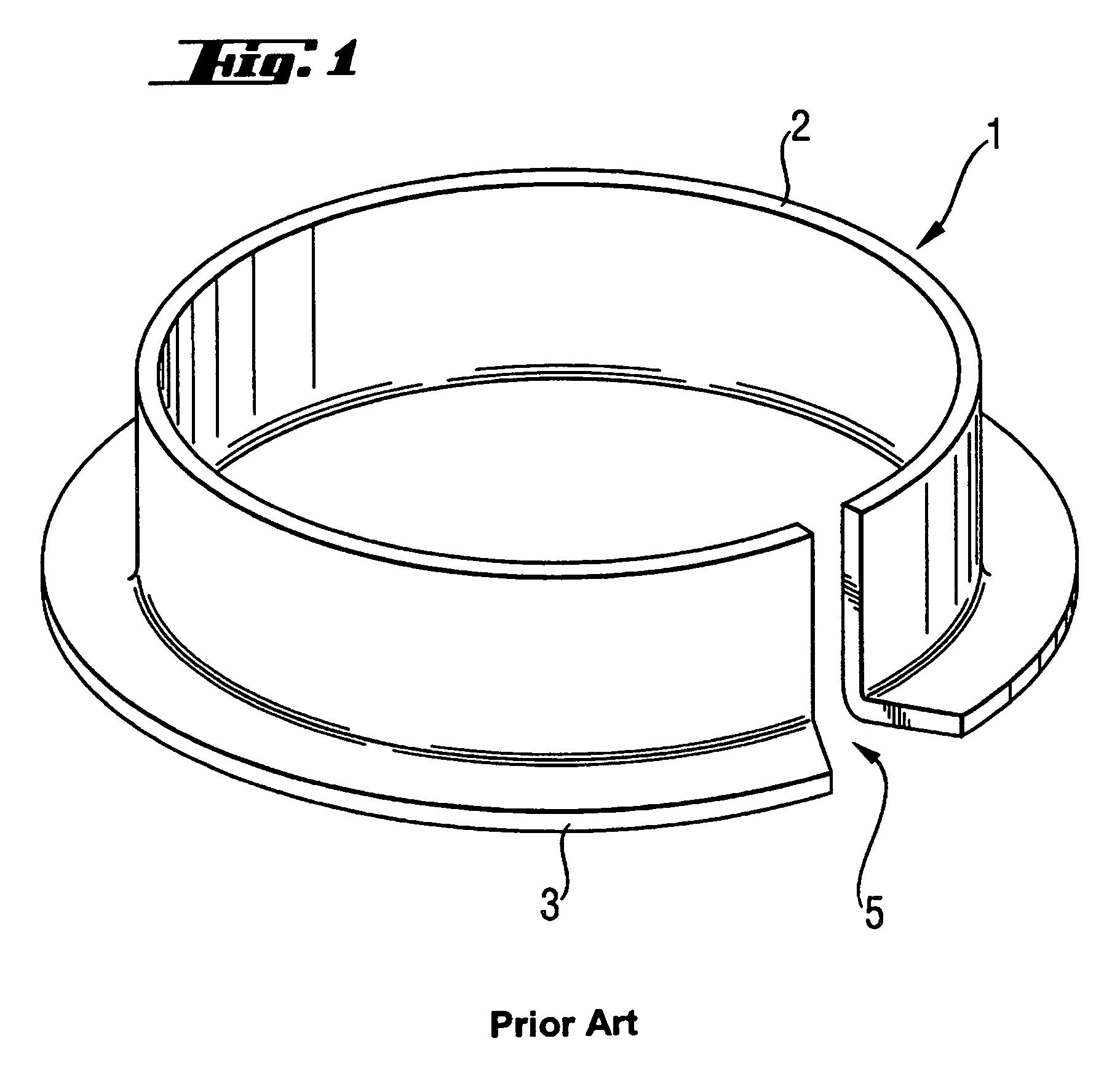

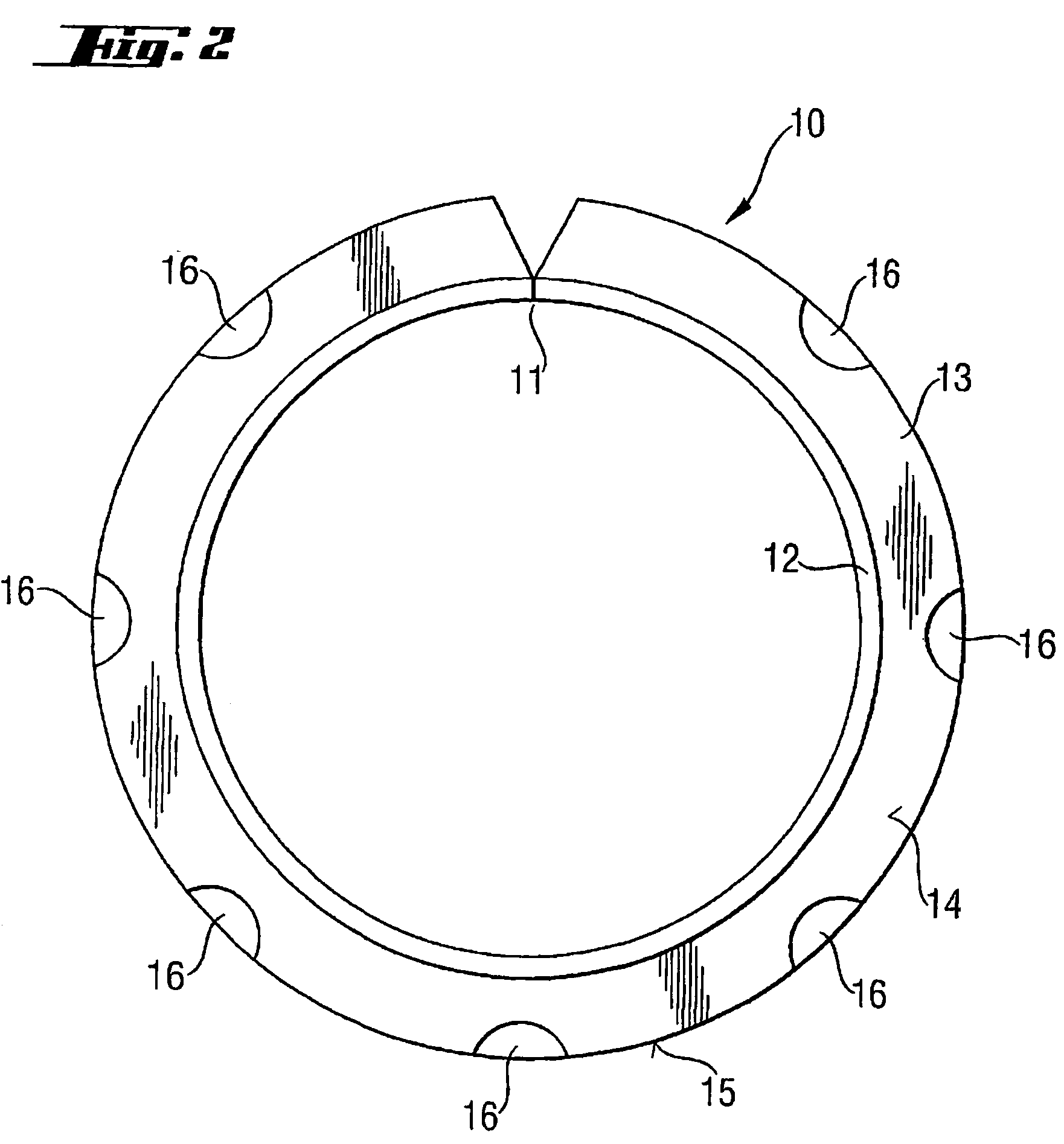

Flange sleeve and method for the production thereof

The invention relates to a method for the production of a flange sleeve (10) especially for a sliding bearing. A strip of material is cut into lengths corresponding to the later periphery of the flange sleeve. The strip section (14) thus arising is rolled to form a hollow cylindrical sleeve with an open butt joint (12) and a collar (20) is placed around one or two sides. The open butt joint is expanded in the region of the collar to form a V-shaped slit. One or several recesses (18a, 18b) are made in the region of the later open butt joint (12) on one or two of the longitudinal edges (16) of the strip section.

Owner:GLEITLAGER

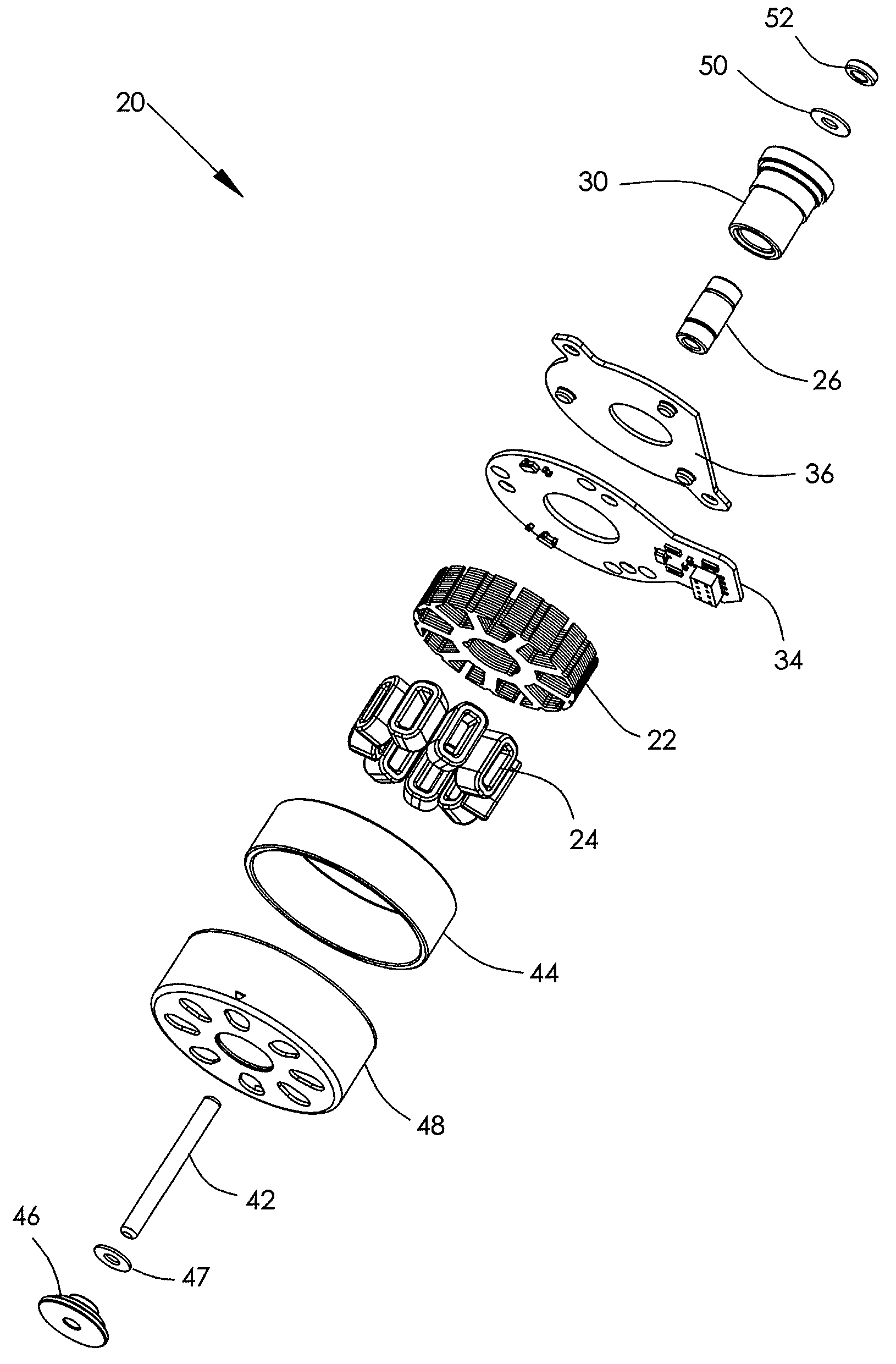

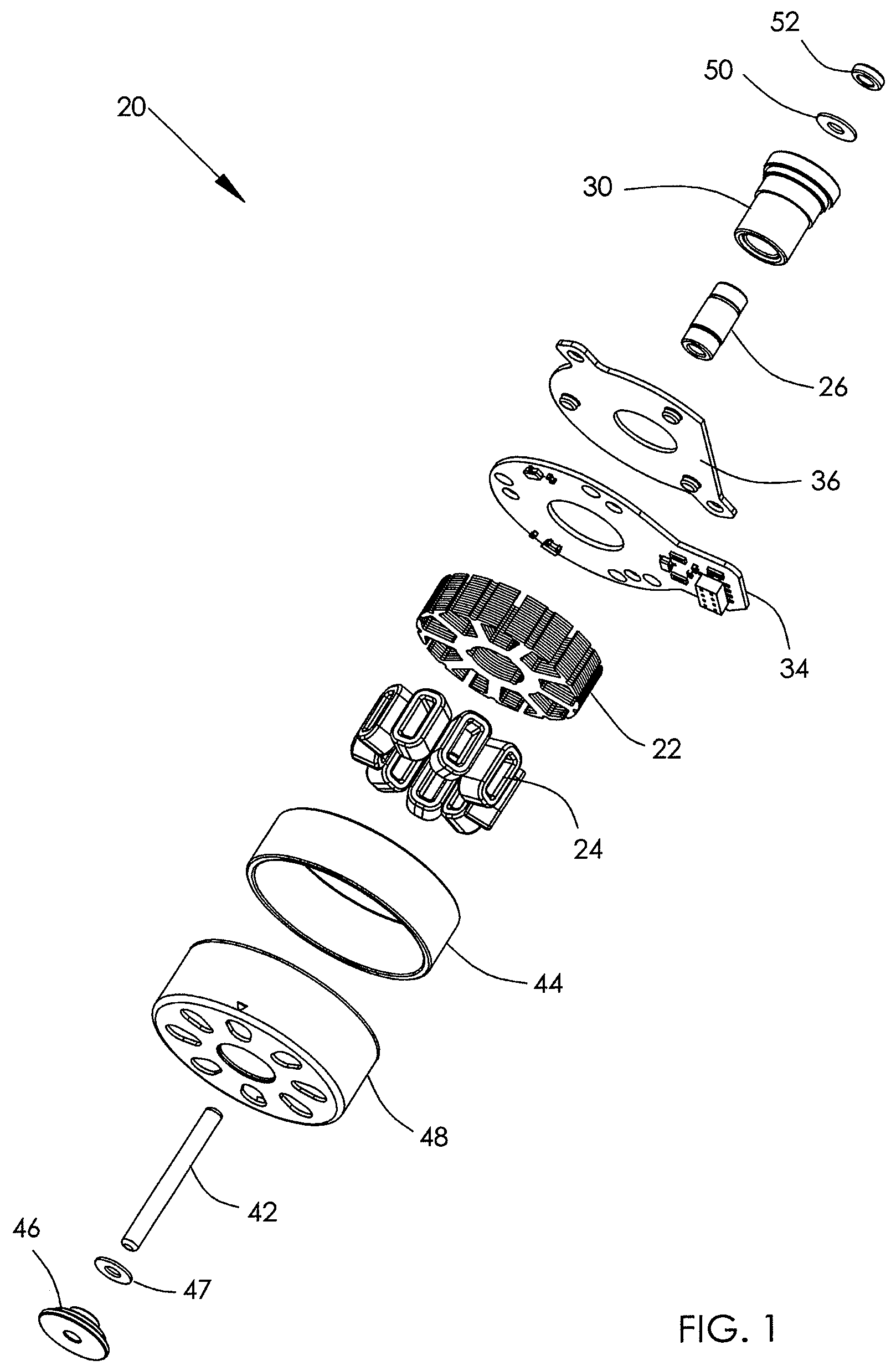

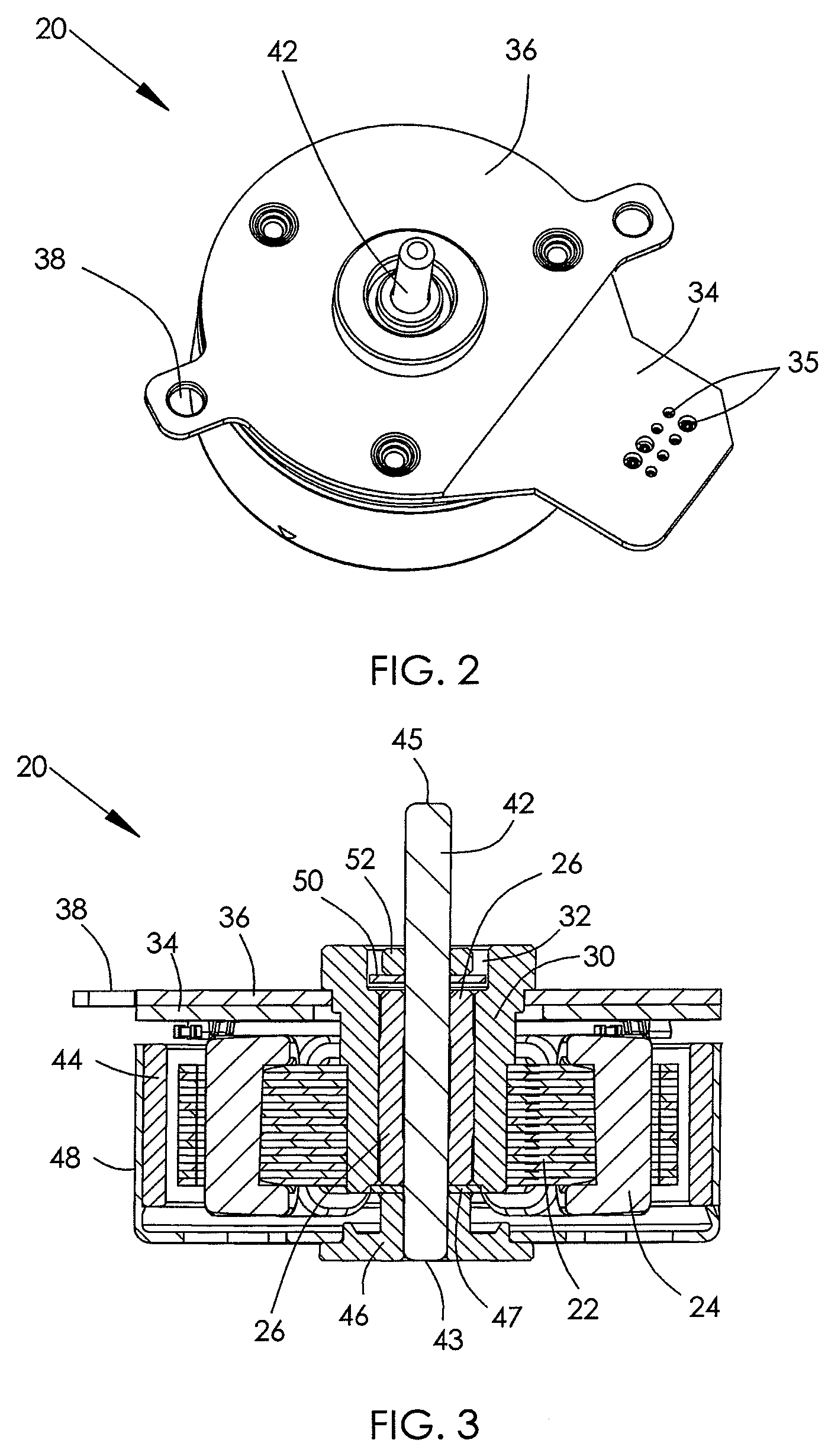

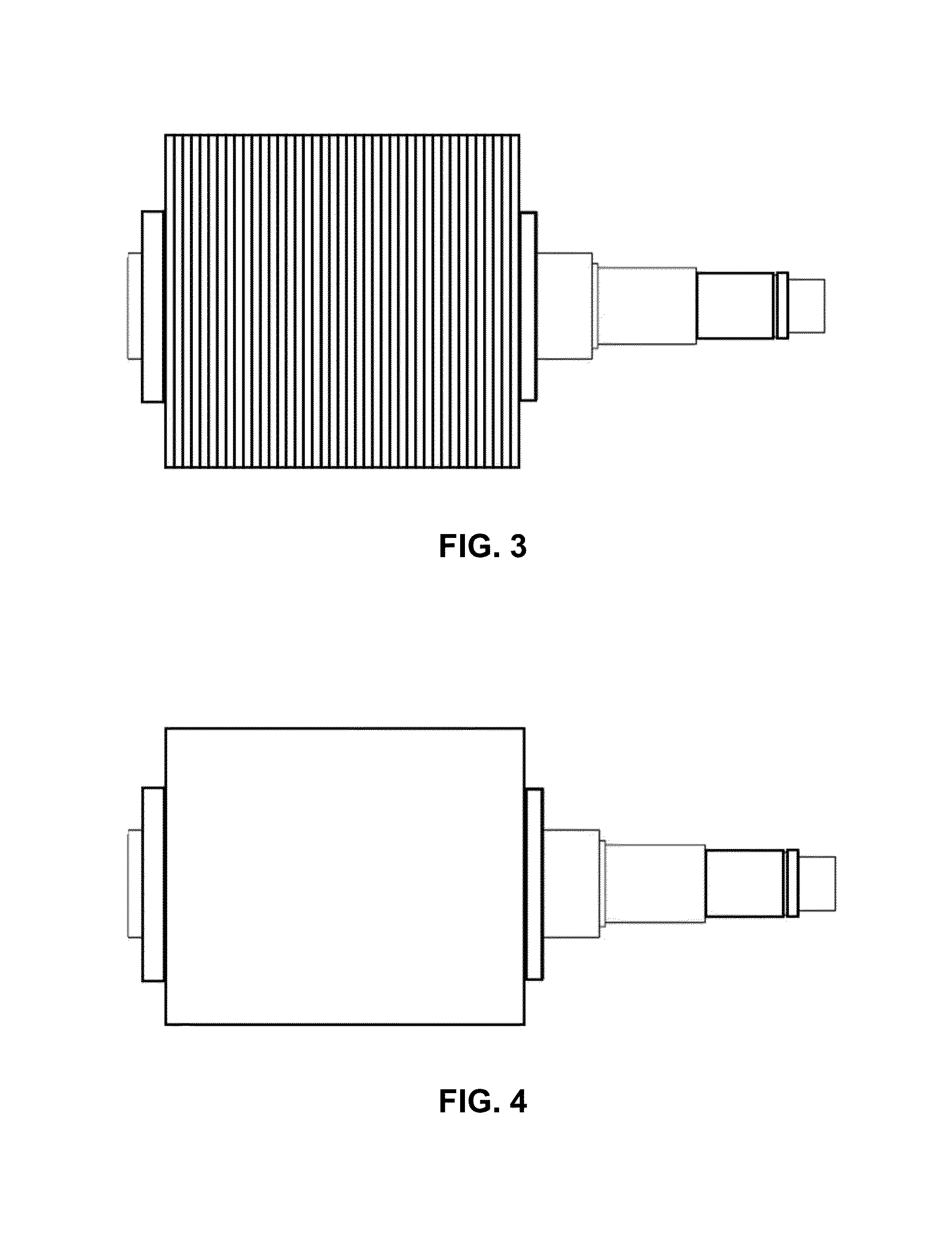

Brushless DC motor

A brushless direct current motor for use in a HVAC system, has a stator and a rotor rotatably mounted to the stator. The stator has a stator core, field windings wound on the stator core and a bushing. The rotor has a shaft rotatably supported by the bushing and adapted to connect with a valve adjuster of the HVAC system. The rotor also has at least one permanent magnet fixed with respect to the shaft. The bushing is a monolithic construction with two journal portions and one middle portion. The two journal portions support the shaft and are formed at respective axial ends of the middle portion. The middle portion has an inner diameter larger than an outer diameter of the shaft at portions corresponding to the middle portion, so as to form a gap between the middle portion and the shaft.

Owner:STACKPOLE INT POWDER METAL LTD

Flange sleeve, method for the production thereof and bending tool for producing flanges on a sleeve

InactiveUS7174765B2Great material displacementReduce in quantityShaftsBearing bushesMetal coatingEngineering

A flange sleeve comprising at lest one flange formed thereon, having no gap at the joint or having a controllably adjusted width of the gap at the joint. The flange has two crowding recesses at least in the metal coating thereof in at least two points distributed over the flange in the direction of the periphery. According to the method for producing the flange sleeves, the edge of the flange is bent. At least two crowding recesses in at least two points distributed over the flange in the direction of the periphery are made at least in the metal coating thereof, the recesses preferably being made by bending the edge of the sleeve. The invention also relates to a bending tool and a bending device.

Owner:FEDERAL MOGUL WIESBADEN

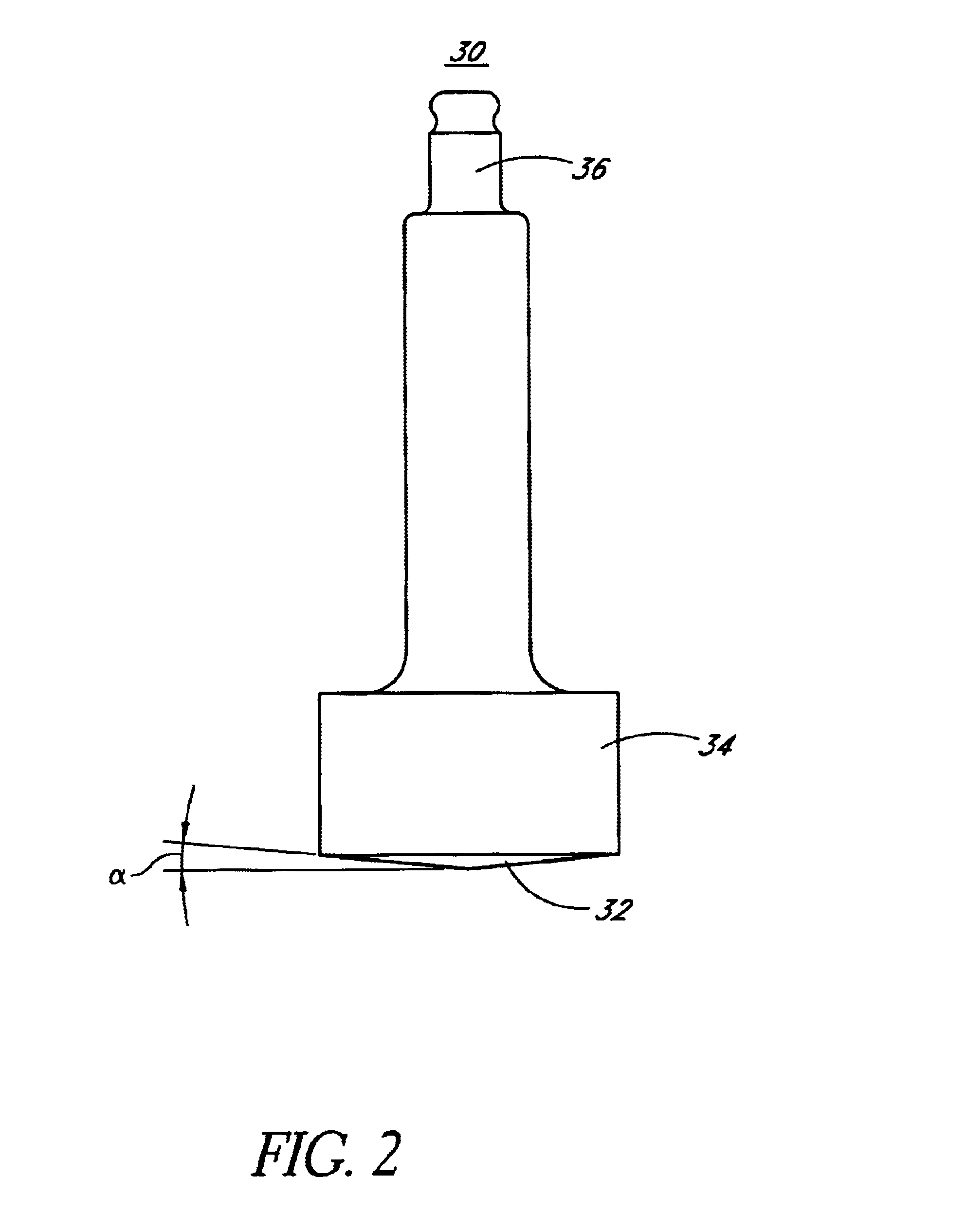

Method of producing vibration-isolating bushing

A method of producing a vibration-isolating bushing with which it is possible to secure a larger area of the edge surface of an inner cylinder than in the prior art method. In upsetting one extremity of the inner cylinder by cold plastic working, after a rubber elastomer is secured to the outer circumference of the inner cylinder by vulcanization molding, as a jig for pressing onto the edge surface of the inner cylinder, an upsetting jig whose top surface is flat is used and the top surface of the jig is pressed onto the edge surface of the inner cylinder while causing the jig to gyrate on a conical orbit centering the axis of the inner cylinder, whereby the outside diameter only of the extremity is enlarged while suppressing the enlarging of the inside diameter.

Owner:TOYO TIRE & RUBBER CO LTD

Methods of manufacturing a modular pulling roll

Methods for the preparation of a pulling roll including a sleeve (800) and / or a cartridge (1330) are disclosed. Also disclosed are methods for the change or repair of at least a portion of a heat resistant material of a pulling roll. Also disclosed are a sleeve and a cartridge for use with a pulling roll, each including a heat resistant material.

Owner:CORNING INC

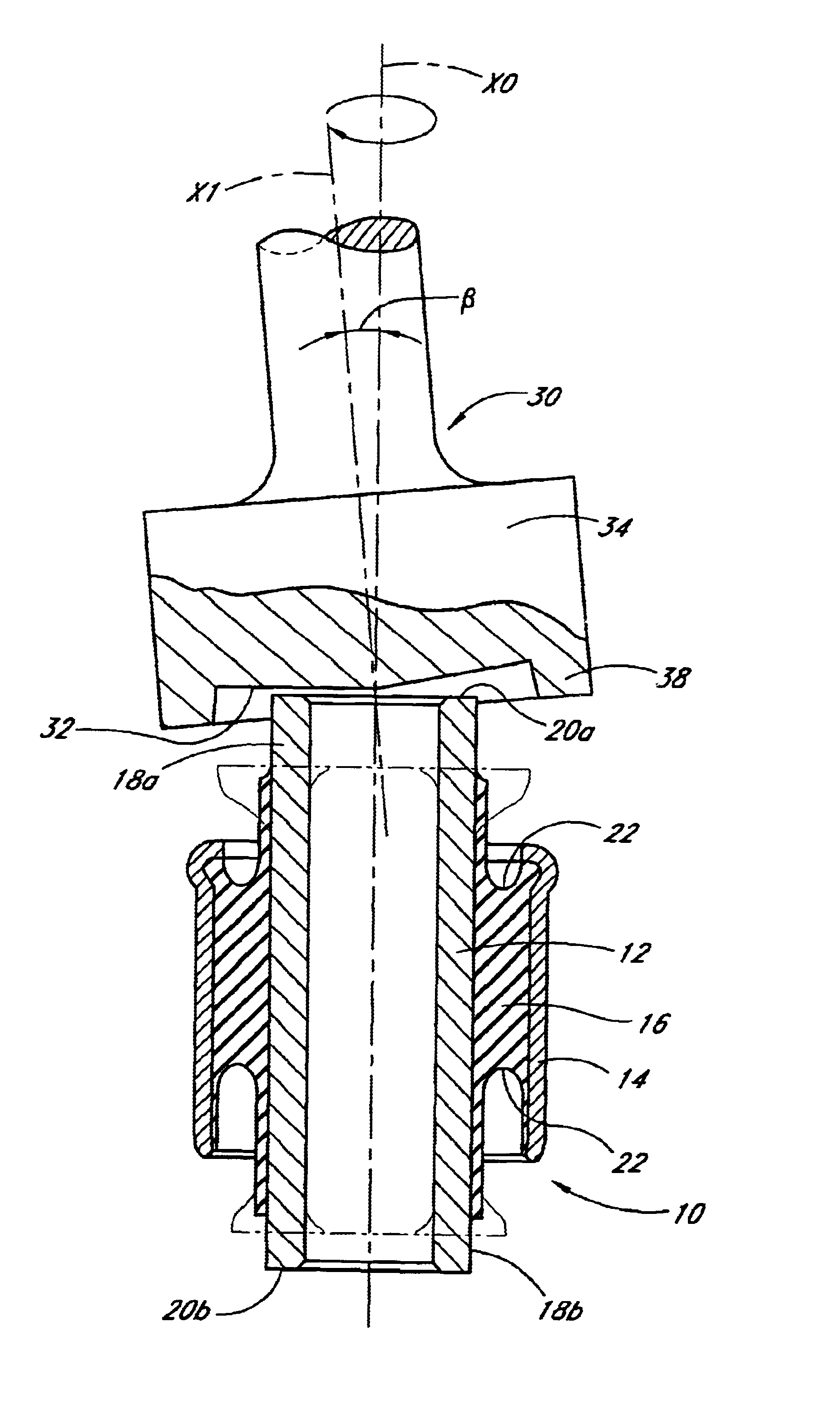

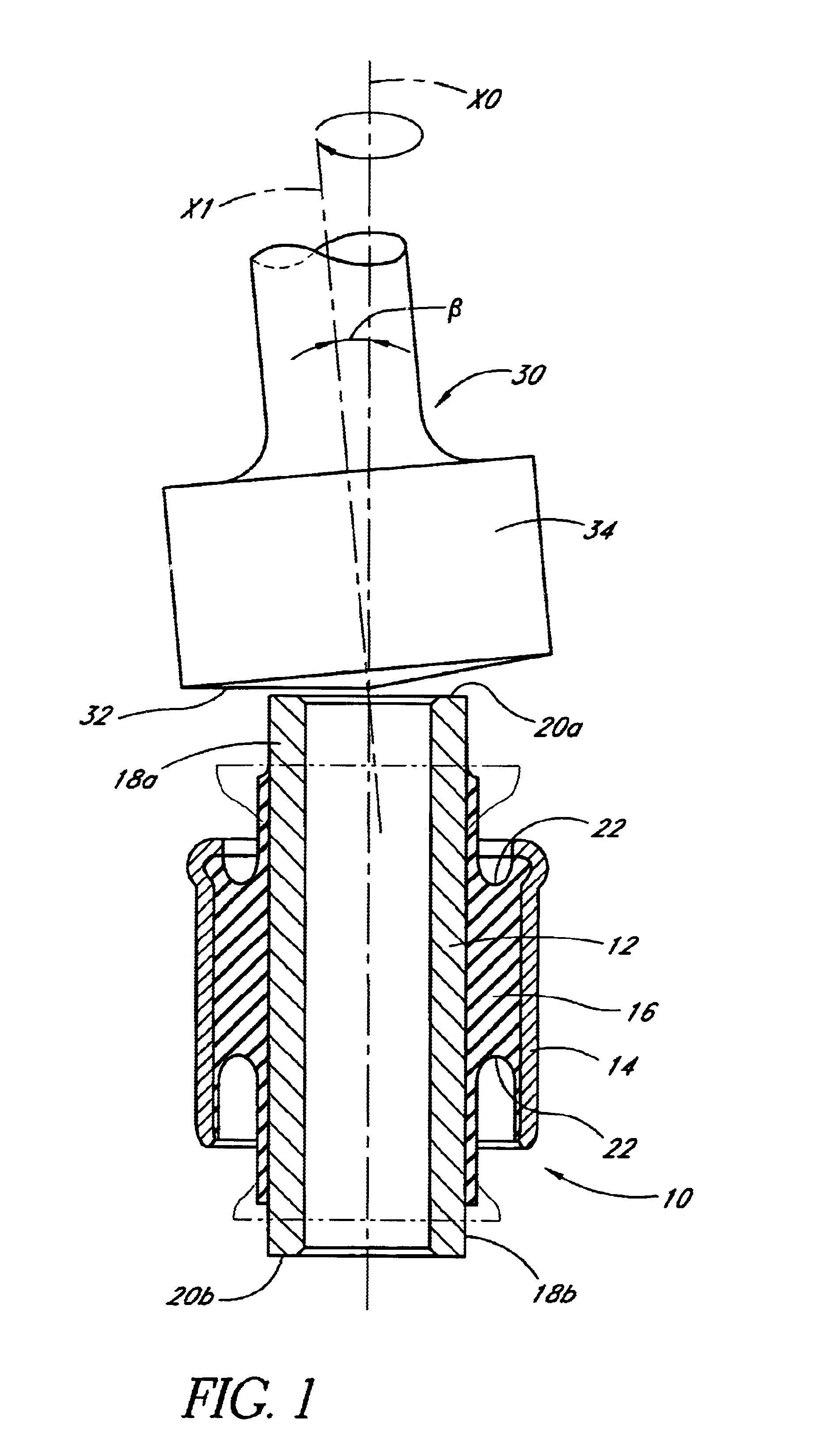

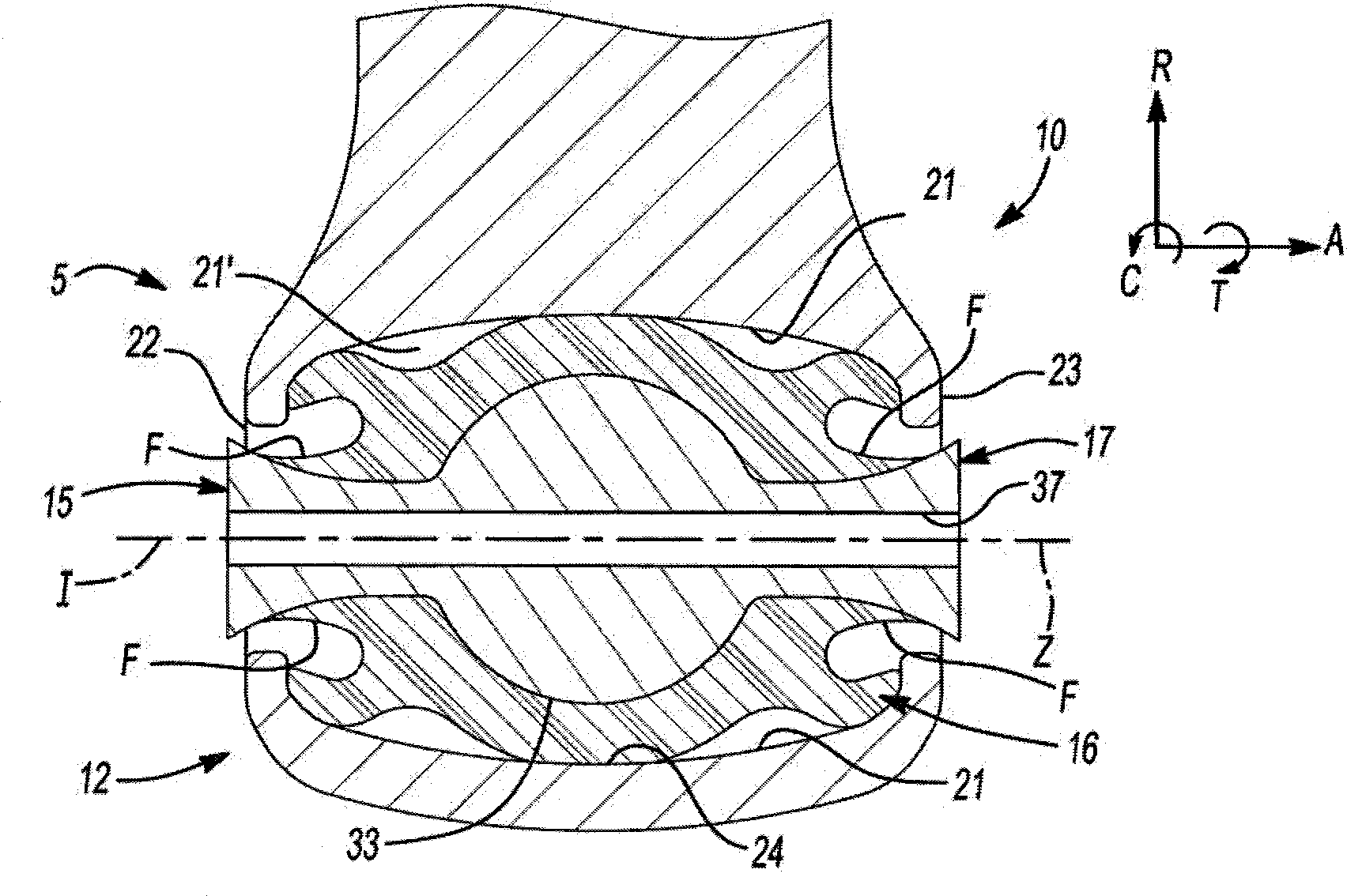

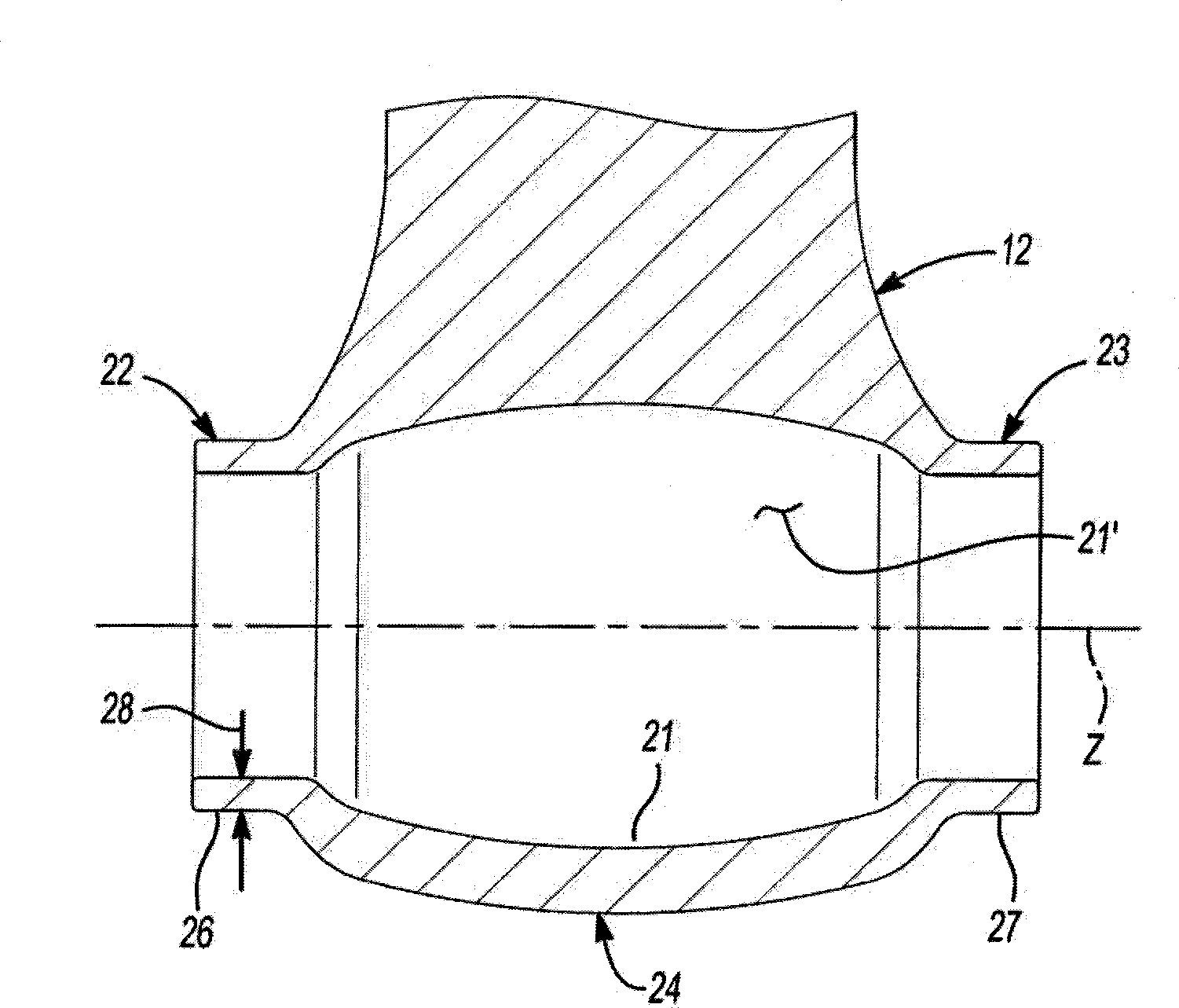

Knuckle and bushing assembly

A suspension coupling (5) for use in a vehicle suspension system the suspension coupling (5) including a knuckle and bushing assembly (10) wherein the knuckle member is a cast aluminum piece having a passage for receiving a two-piece bushing member (15) having a formed, metal inner member (17) and a molded, elastomeric outer member (16) having extension members (19) at each end. The bushing member (5) is press-fit into the knuckle member (12) and exhibits higher stiffness in the radial (R) and axial (A) directions and lower stiffness in the torsional (T) and conical (C) directions.

Owner:DIVERSIFIED MACHINE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com