Bearing bush with functionally graded bionic texture as well as preparation method and water-lubricated bearing thereof

A technology of bionic texture and functional gradient, applied in the direction of shafts and bearings, bearing components, bearing bushings, etc., to achieve the effects of optimizing friction and lubrication performance, improving wettability, and improving surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a bearing pad with a functionally graded bionic texture, and the surface is designed and arranged with a bionic texture capable of realizing functional gradient.

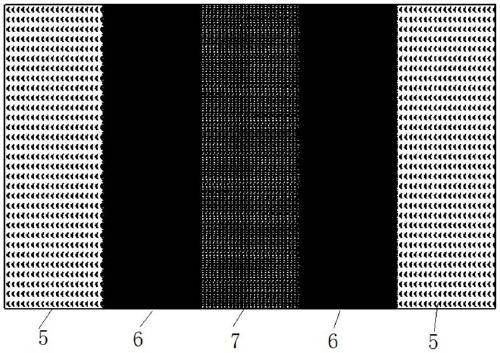

[0040] Such as Figures 2a-2g As shown, the biomimetic texture mainly refers to the surface texture of the lip and waxy area of Nepenthes. The hydrophobic surface texture is formed, and the parameter setting and structure optimization that are beneficial to the friction reduction and lubrication of the bearing are carried out.

[0041] The crescent-shaped hydrophobic surface texture 8 is arranged on the two ends 5 of the bearing bush to realize the directional transport of the lubricant from the end to the middle; the radial ridge-shaped hydrophilic surface texture is arranged on the middle part 6 of the bearing bush, It can facilitate the establishment of the hydrodynamic lubrication state in the middle area of the bearing pad where the lubricating water film pressure is the large...

Embodiment 2

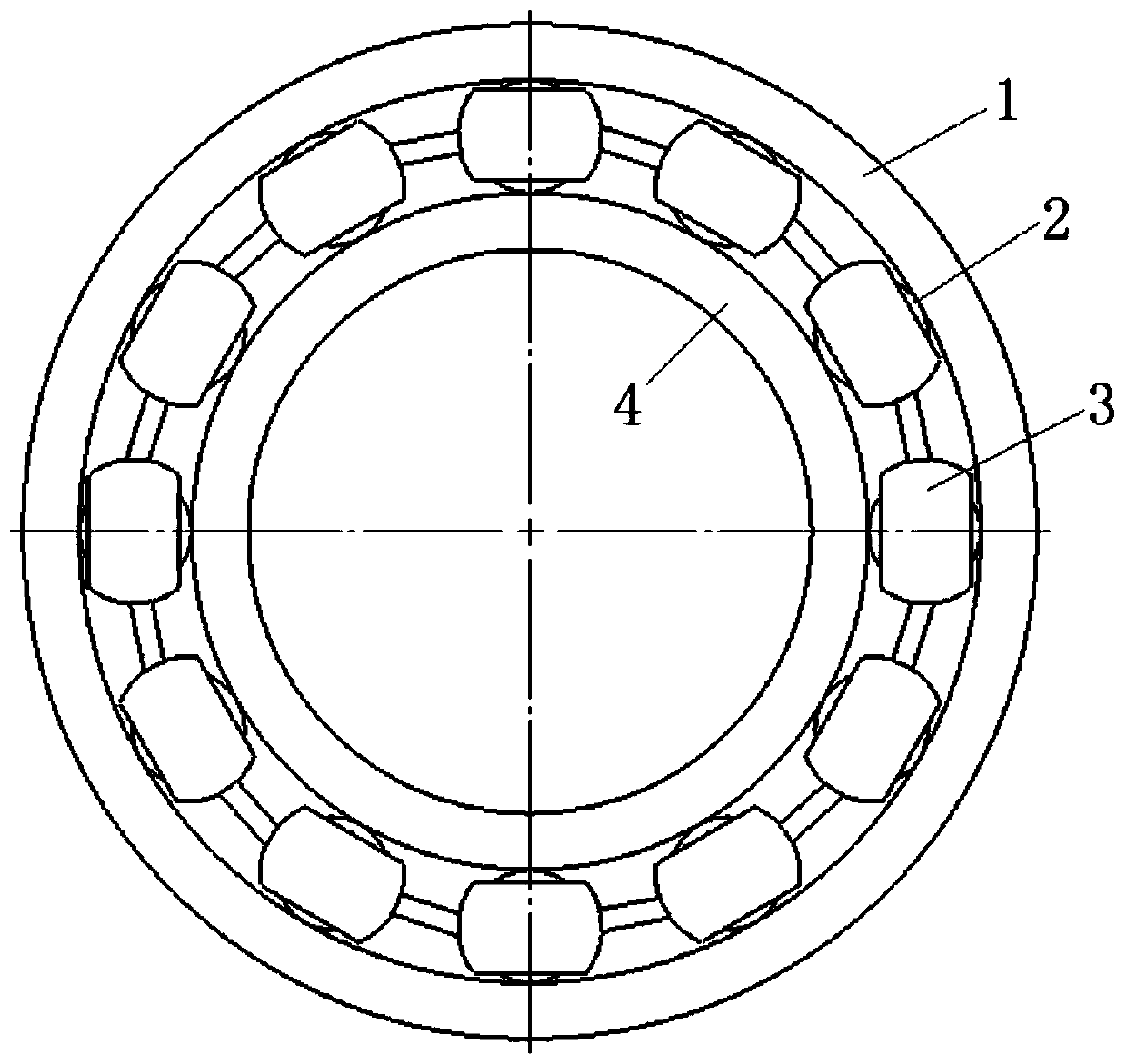

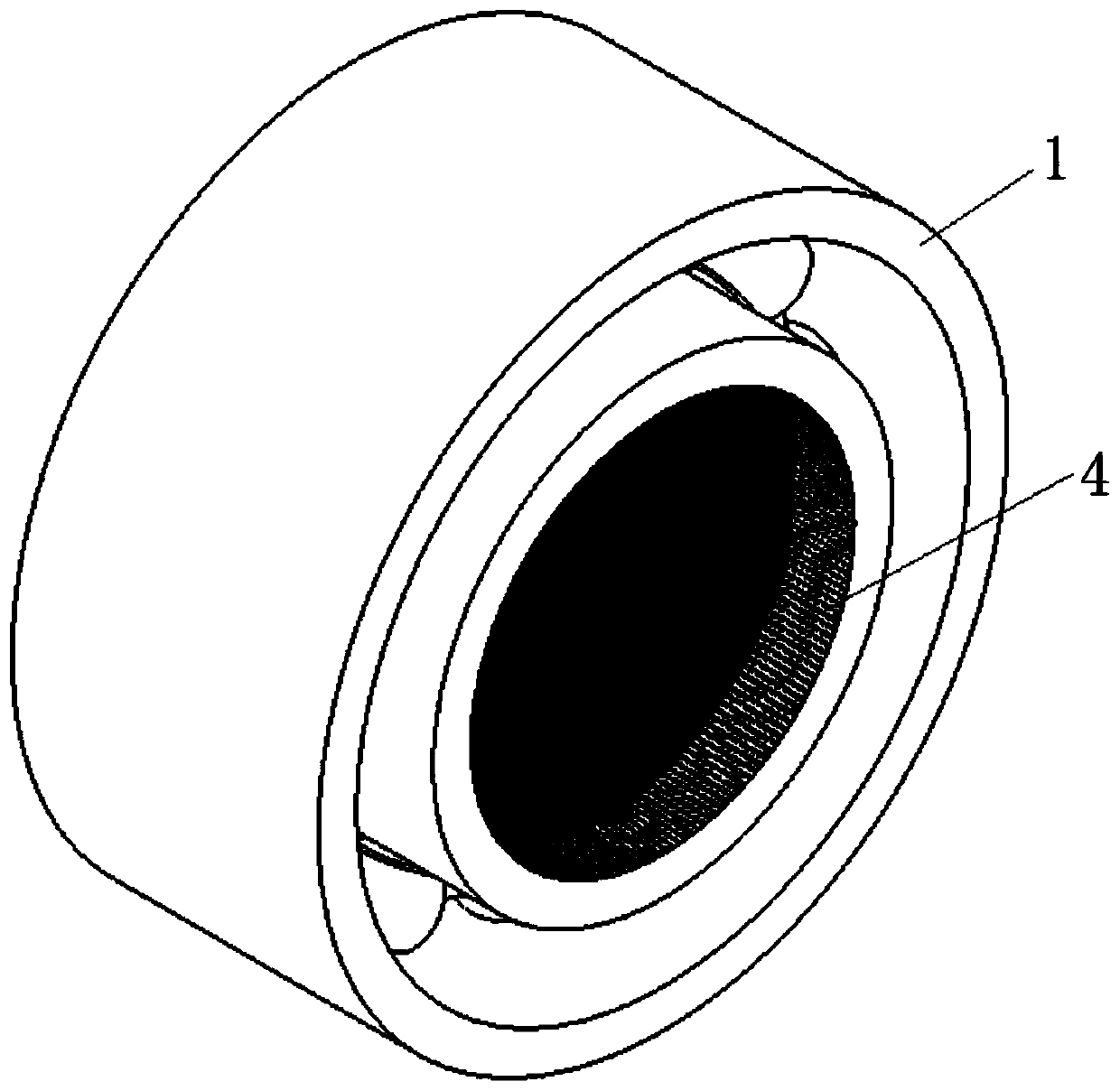

[0046] As shown in Figure 1, a water-lubricated bearing with a functionally graded bionic texture bearing pad in this embodiment has the same structure as a traditional sliding bearing, including an outer ring bushing 1, rolling elements 2 and retaining bearings from outside to inside. Frame 3, inner ring bearing 4; the surface of the inner ring bearing 4 is designed and arranged with a bionic texture that can realize functional gradient.

[0047] The bearing pad 4 of the inner ring adopts the bearing pad with a functionally graded bionic texture as described in Embodiment 1, and the specific structural design will not be repeated here.

Embodiment approach

[0049] This example provides a method for preparing a bearing with a functionally graded biomimetic texture, as a preferred implementation, including the following steps:

[0050] (1) Preparation and surface treatment of UHMWPE matrix material: Using a small laboratory injection molding machine, the UHMWPE powder material is heated, compressed, plasticized, injected, cooled, etc. to obtain a block-shaped workpiece of UHMWPE, and then cut into pieces , grinding, polishing and other steps to obtain a workpiece with a semicircular shape and a width of 1 / 5 of the actual width of the bearing.

[0051] (2) Micro-nano processing of bionic texture: using ultraviolet soft mold nanoimprinting equipment, after template processing, pattern transfer, substrate processing and other steps, the surface texture with shape and size parameters meeting the requirements is processed on the inner surface of the workpiece. The structures are respectively a crescent-shaped hydrophobic texture 8, a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com