Elastic metal-plastic bush and manufacturing method thereof

An elastic metal and manufacturing method technology, applied in the field of bearings, can solve the problems of large elastic modulus differences, difficult density control, and low operating efficiency of elastic metal and plastic tiles, achieve uniformity of elastic modulus, realize automatic production, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

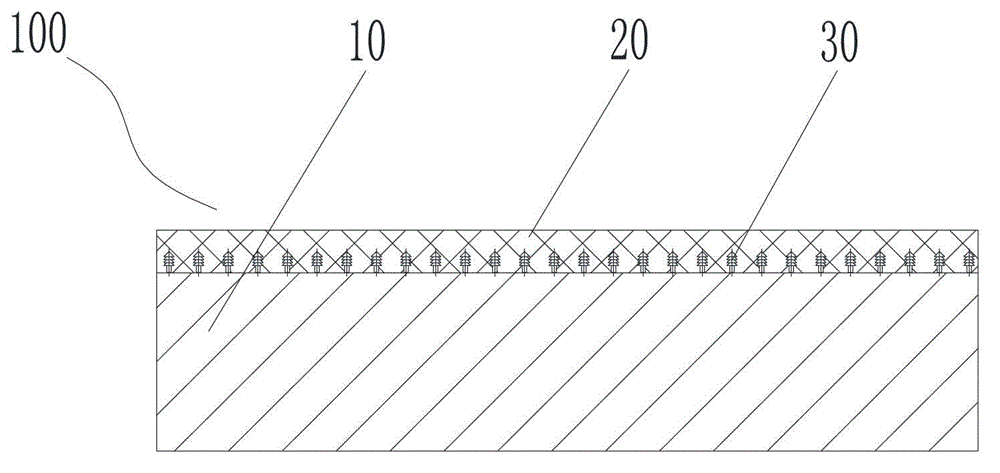

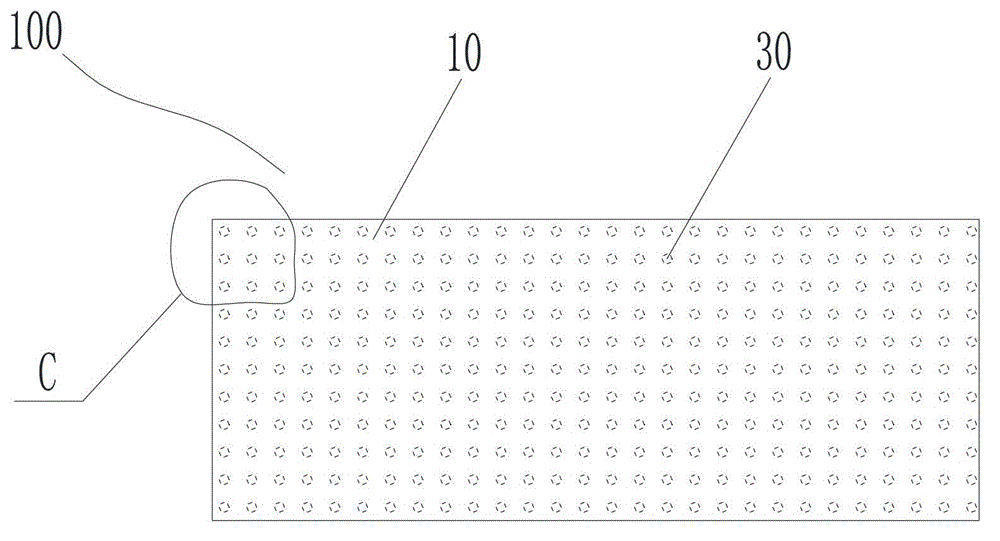

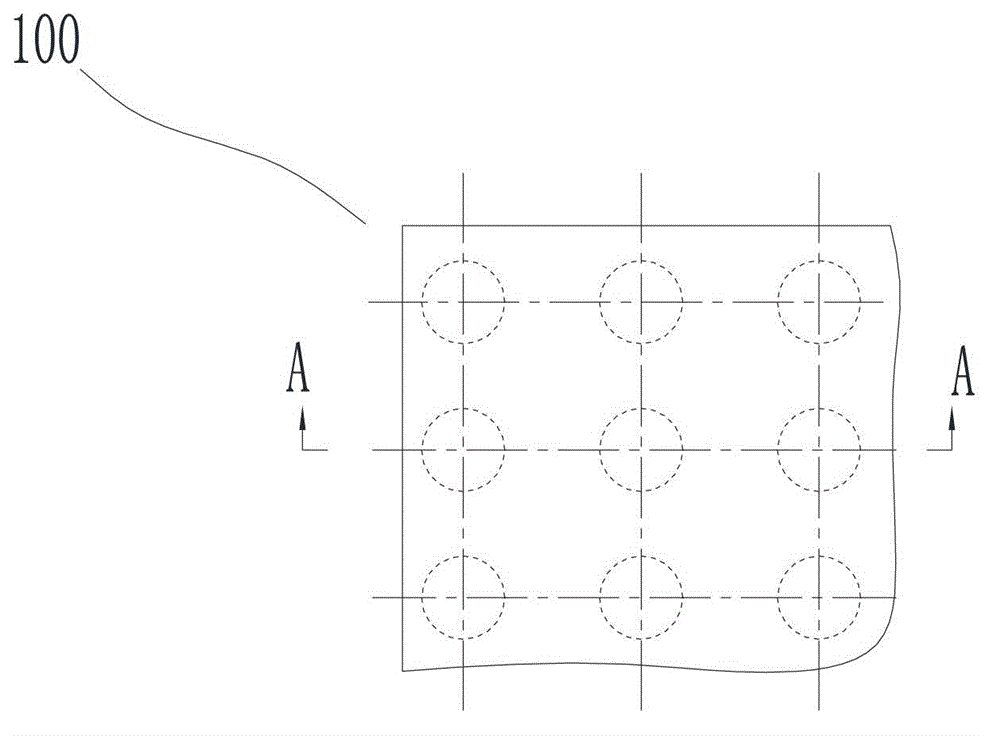

[0040] Such as Figures 1 to 5 The structure of the elastic metal plastic tile of the first embodiment is shown. The elastic metal-plastic tile 100 includes a tile base 10 , a composite resin layer 20 and a plurality of connecting columns 30 . The composite material resin layer 20 is fixed to the connection surface of the tile base 10 . The second end of the connection post 30 is fixedly connected to the connection surface of the tile base 10 , the height of the connection post 30 is smaller than the thickness of the composite material resin layer 20 , and the tile base 10 and the composite material resin layer 20 are fixed by a plurality of connection posts 30 .

[0041] Wherein, the connecting column 30 includes a guiding portion 31 and a main connecting portion 32 . The cross-sectional area of the guide portion 31 gradually increases from the top of the first end toward the second end. The main connection portion 32 is located between the guide portion 31 and the tile ...

no. 2 example

[0047] Image 6 It is a structural schematic diagram of the connecting column of the elastic metal-plastic tile according to the second embodiment of the present invention. In the second embodiment, the connecting column 40 includes a guiding portion 41 and a main connecting portion 42 formed of a cone. The main connection part 42 includes a circular post 421 having a diameter smaller than the maximum diameter of the guide part 41 and a toothed part 422 located between the guide part 41 and the post 421 .

[0048] In the second embodiment, the tooth-shaped portion 422 includes a plurality of circular connection cones arranged sequentially from the guide portion 41 toward the cylinder 421 . Wherein, each connecting frustum of the multiple connecting frustums has the same large cross-sectional end area and small cross-sectional end area, starting from the guide part 41, the large cross-sectional end face of the first connecting frustum among the multiple connecting frustums In...

no. 3 example

[0050] Figure 7 It is a structural schematic diagram of the connecting column of the elastic metal-plastic tile according to the third embodiment of the present invention. In the third embodiment, the connecting column 50 includes a guide portion 51 and a main connecting portion 52 formed of a cone. The main connecting part 52 includes a circular post 521 with a diameter equal to the maximum diameter of the guide part 51 and a toothed part 522 between the guide part 51 and the post 521 . The toothed portion 522 includes a plurality of annular teeth arranged at intervals in sequence. Preferably, the rim of the ring tooth is thinner than the root of the ring tooth. In a modified embodiment, since the dedendum of each annular tooth is relatively thick, there may be no space between each annular tooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com