Patents

Literature

362results about How to "Control mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

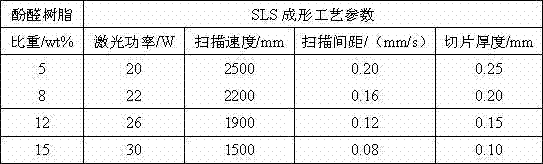

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

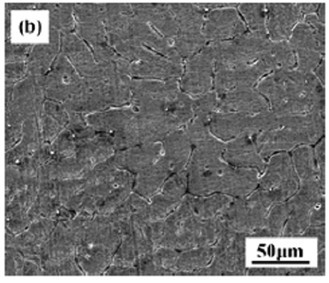

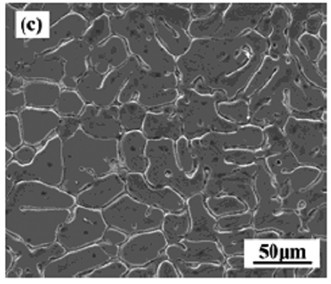

High-entropy alloy with dispersion nano-sized precipitate strengthening effect and preparing method thereof

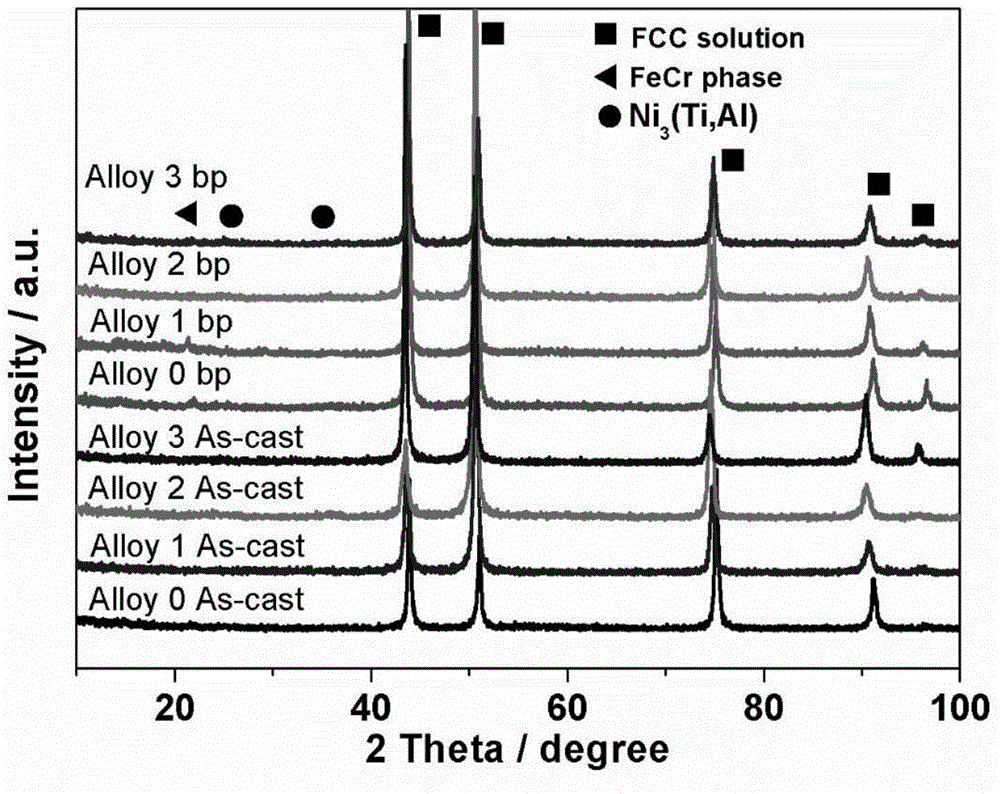

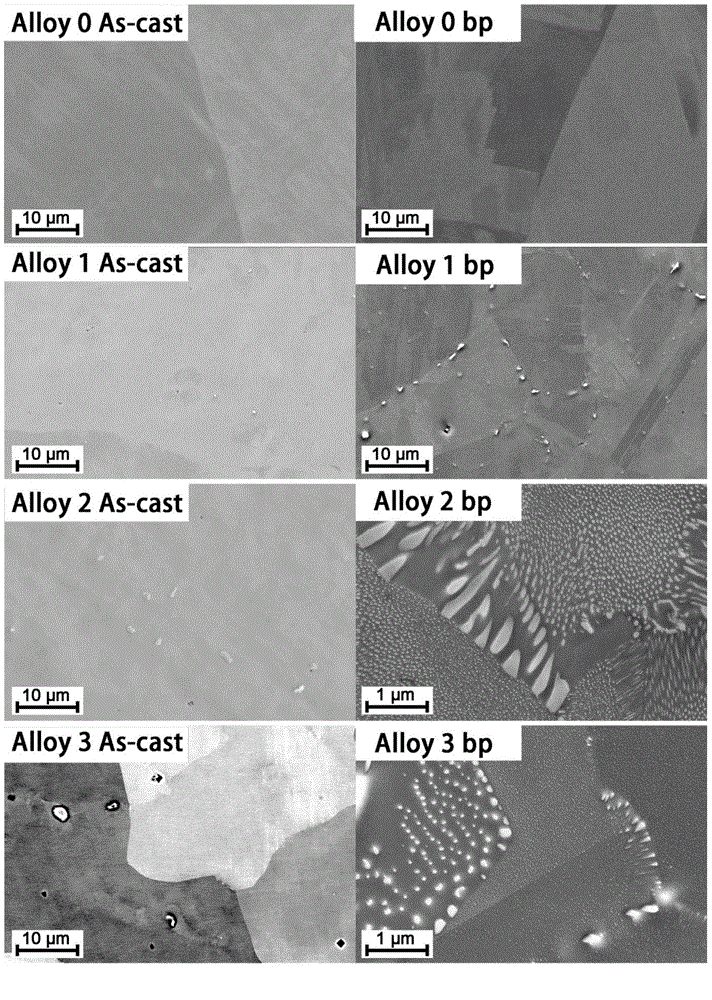

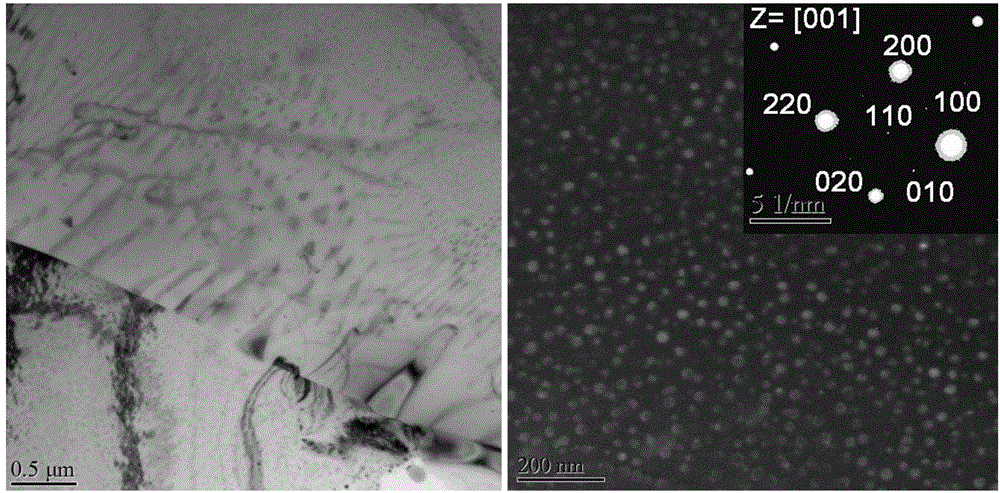

ActiveCN104694808AWide range of ingredientsControl mechanical propertiesElectric arc furnaceHigh entropy alloys

The invention discloses high-entropy alloy with the dispersion nano-sized precipitate strengthening effect and a preparing method thereof. The method comprises the steps of removing oxidized skin of a metal material, and then conducting weighing and burdening accurately according to a ratio; conducing smelting in an electric-arc furnace in an argon shield atmosphere of titanium absorbed oxygen to obtain an initial high-entropy alloy ingot, and conducting cold rolling, wherein rolling reduction is 20-50%; placing the ingot in a heat treatment furnace with a temperature ranging from 900 DEG C to 1000 DEG C for heat preservation for 0.5-2 hours, and conducting quenching; placing the ingot in a heat treatment furnace with a temperature ranging from 700 DEG C to 800 DEG C for heat preservation for 2-18 hours, and conducting quenching. By means of precipitation strength, on the premise that high plasticity is kept, yield strength and tensile strength are improved greatly. The room-temperature tensile strength of (FeCoNiCr)94Ti2Al4 in the final state reaches 1094 MPa, plastic elongation is 35%, work hardening effect is remarkable, comprehensive room-temperature mechanical property is prominent, high-temperature tensile strength can reach 400 MPa at the temperature of 800 DEG C and strain rate of 10<-3>, steady creep rate is smaller than or equal to 10<-8> under the stress of 100 MPa and at the temperature of 750 DEG C, and high-temperature tensile strength and creep mechanical property are excellent.

Owner:UNIV OF SCI & TECH BEIJING

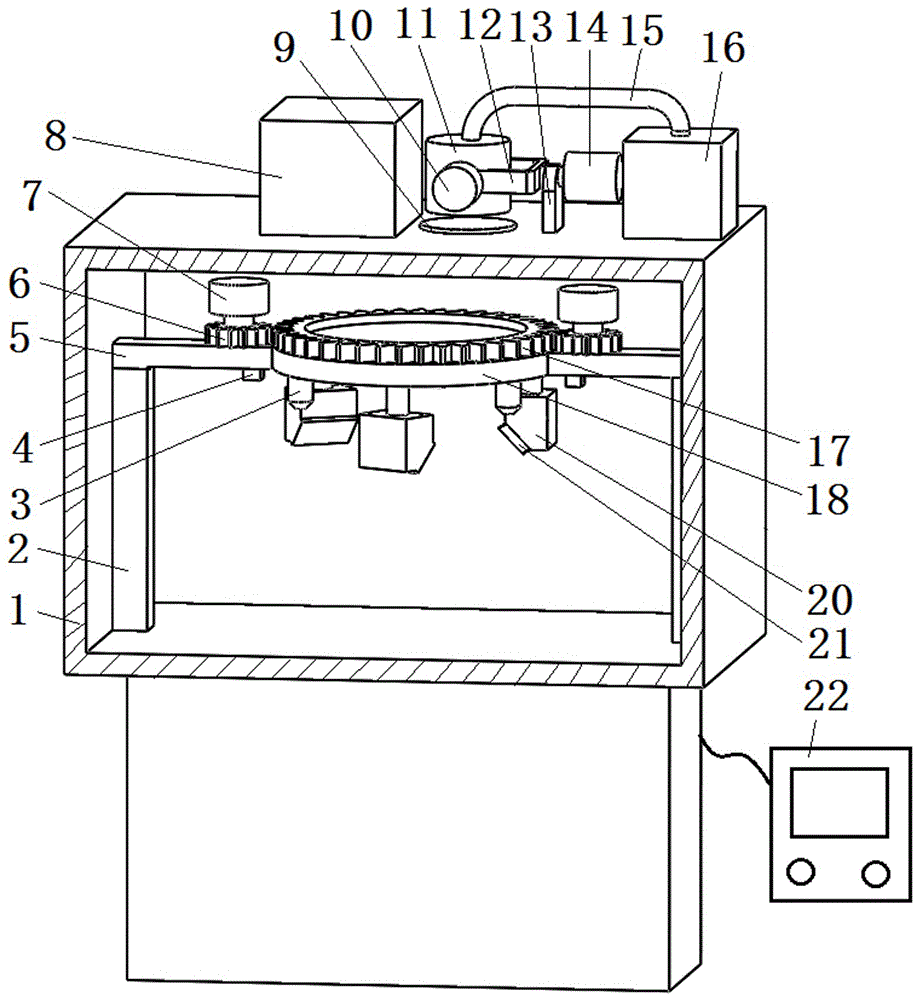

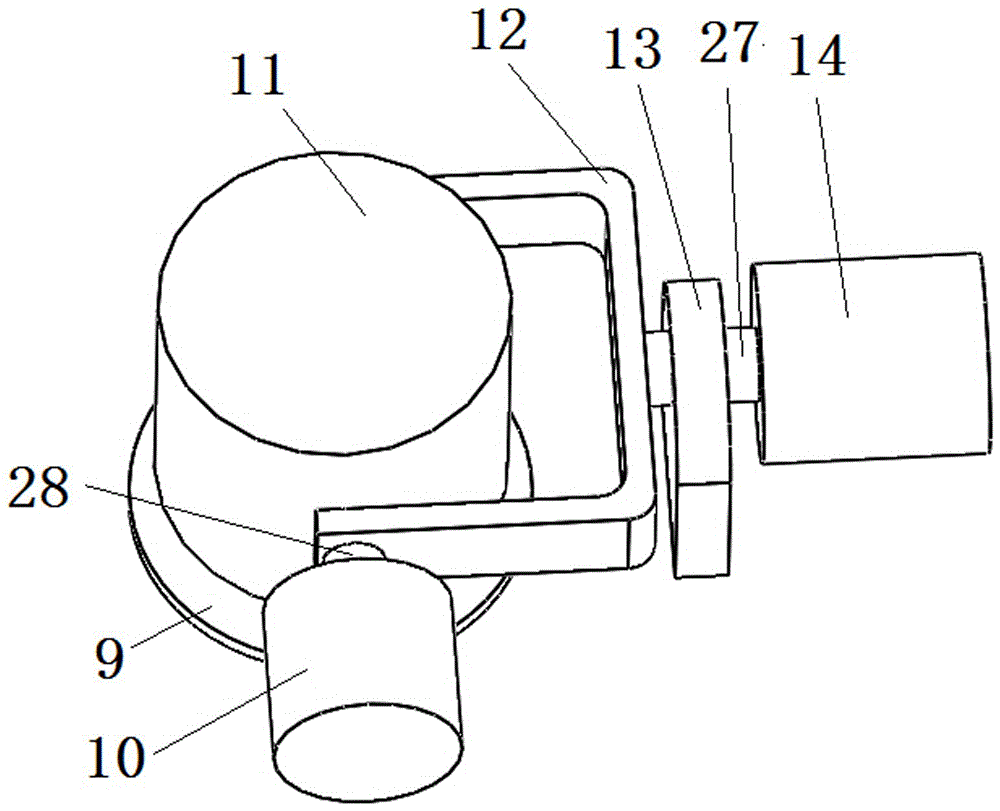

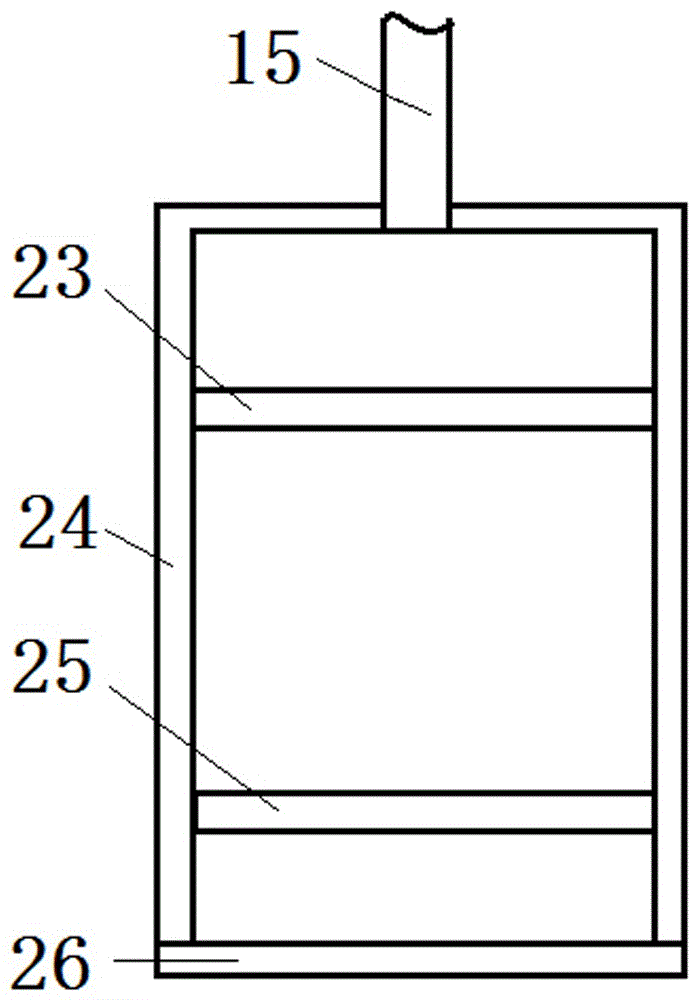

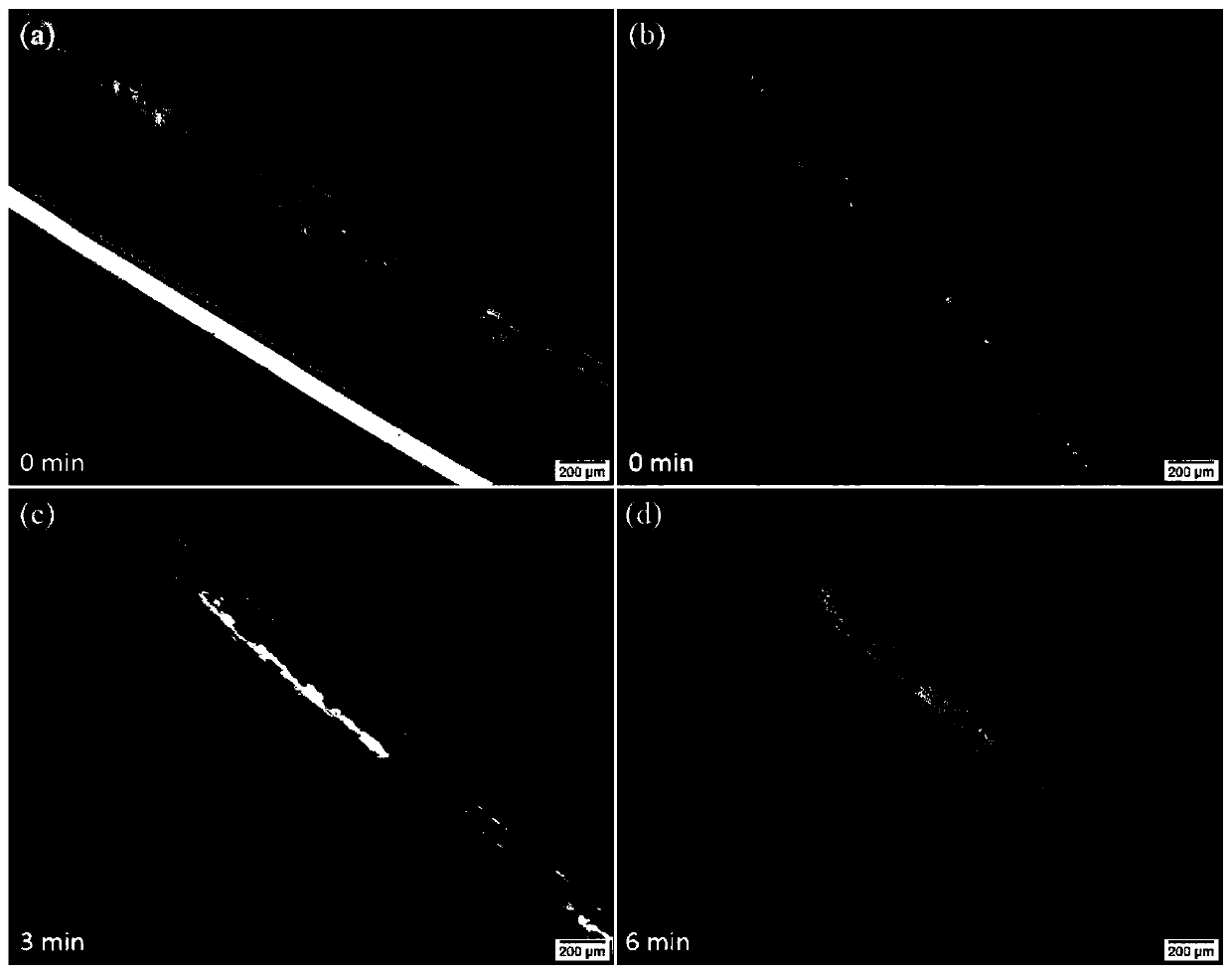

Selective laser melting forming molten bath real-time monitoring device and monitoring method

ActiveCN106363171AImprove yieldEasy to controlAdditive manufacturing apparatusIncreasing energy efficiencyForming processesPulsed laser

The invention relates to a selective laser melting forming molten bath real-time monitoring device and a monitoring method, and belongs to the technical field of 3D printing additive manufacturing. The selective laser melting forming molten bath real-time monitoring device and the monitoring method can monitor the molten bath temperature, the shape and the area in the SLM forming process in real time, conduct online assessment on the forming precision and the laser power and feed back the result. According to the adopted technical scheme, a melting forming laser system and a pulsed laser are arranged on the top of a forming cavity, a piece of transparent glass is arranged in the center of the top of the forming cavity, a laser lens tube is arranged above the transparent glass, and the pulsed laser is connected with the laser lens tube through an optical fiber. A lifting frame is arranged in the forming cavity, lifting mechanisms are arranged on the two sides of the lifting frame, and cameras are arranged at the bottom of the lifting frame in the mode of different angles. The melting forming laser system, the pulsed laser, the lifting mechanisms and the cameras are connected with a master control system. The selective laser melting forming molten bath real-time monitoring device and the monitoring method are widely used for real-time monitoring of a selective laser melting forming molten bath.

Owner:山西阳宸中北科技有限公司

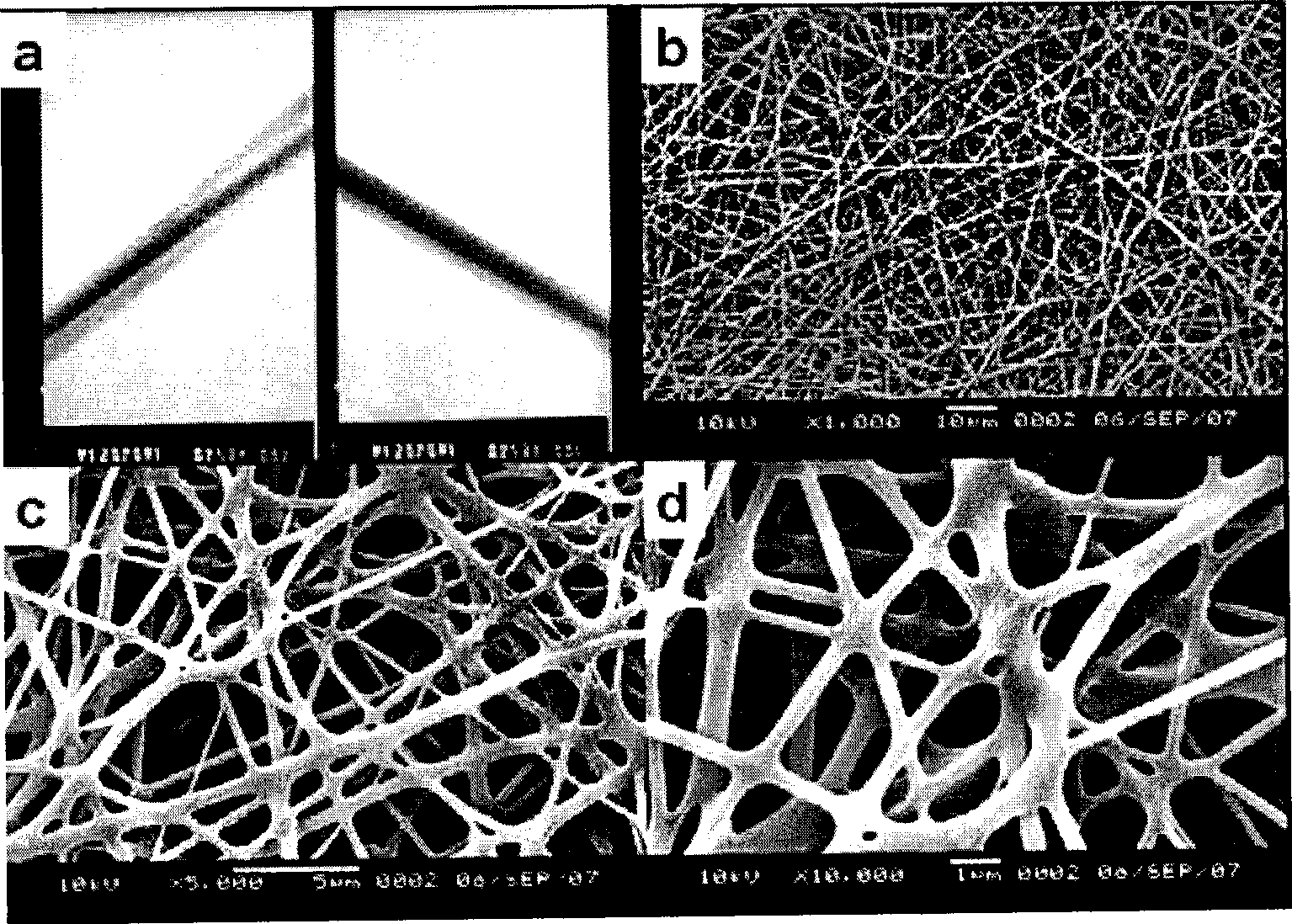

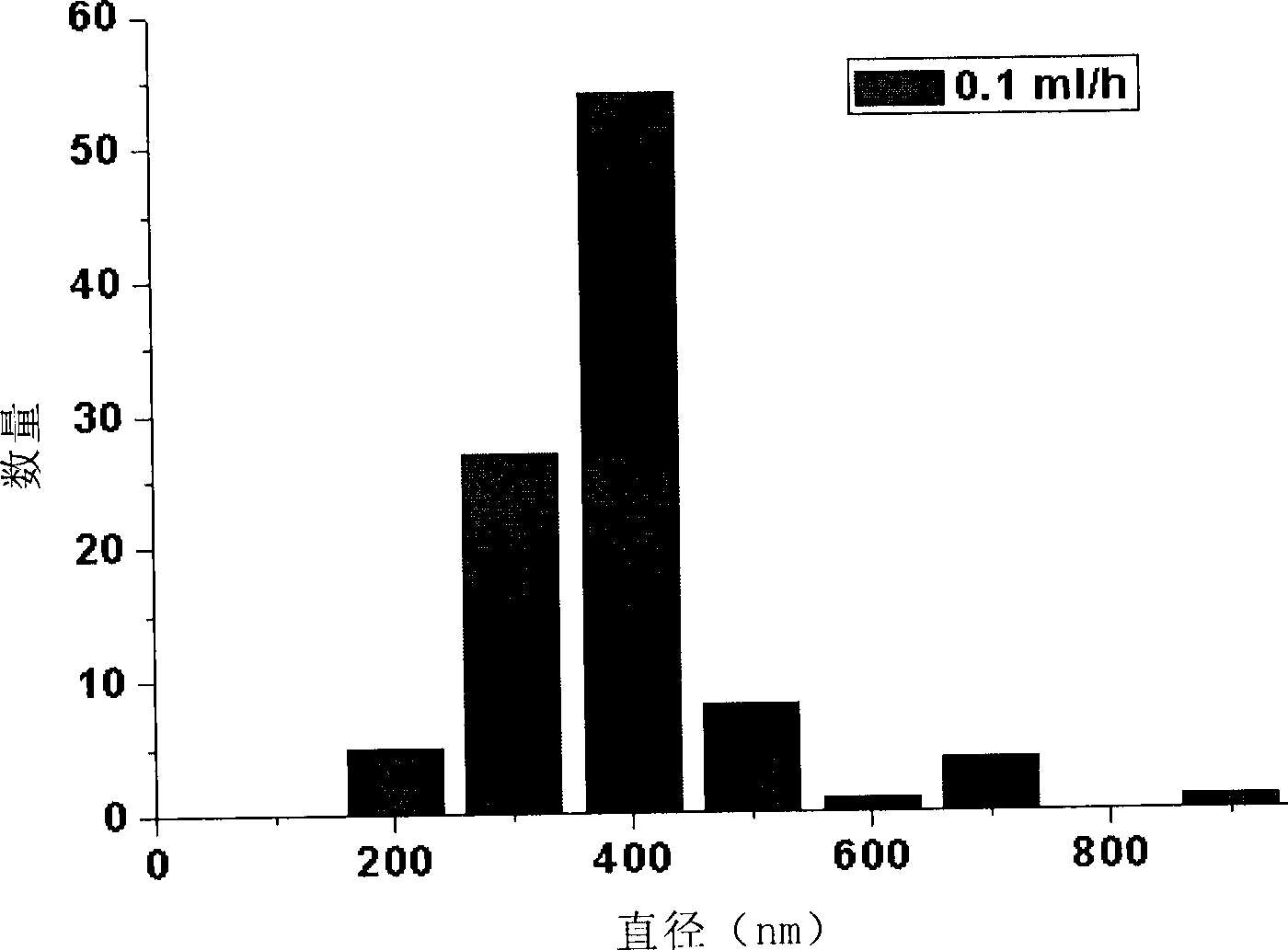

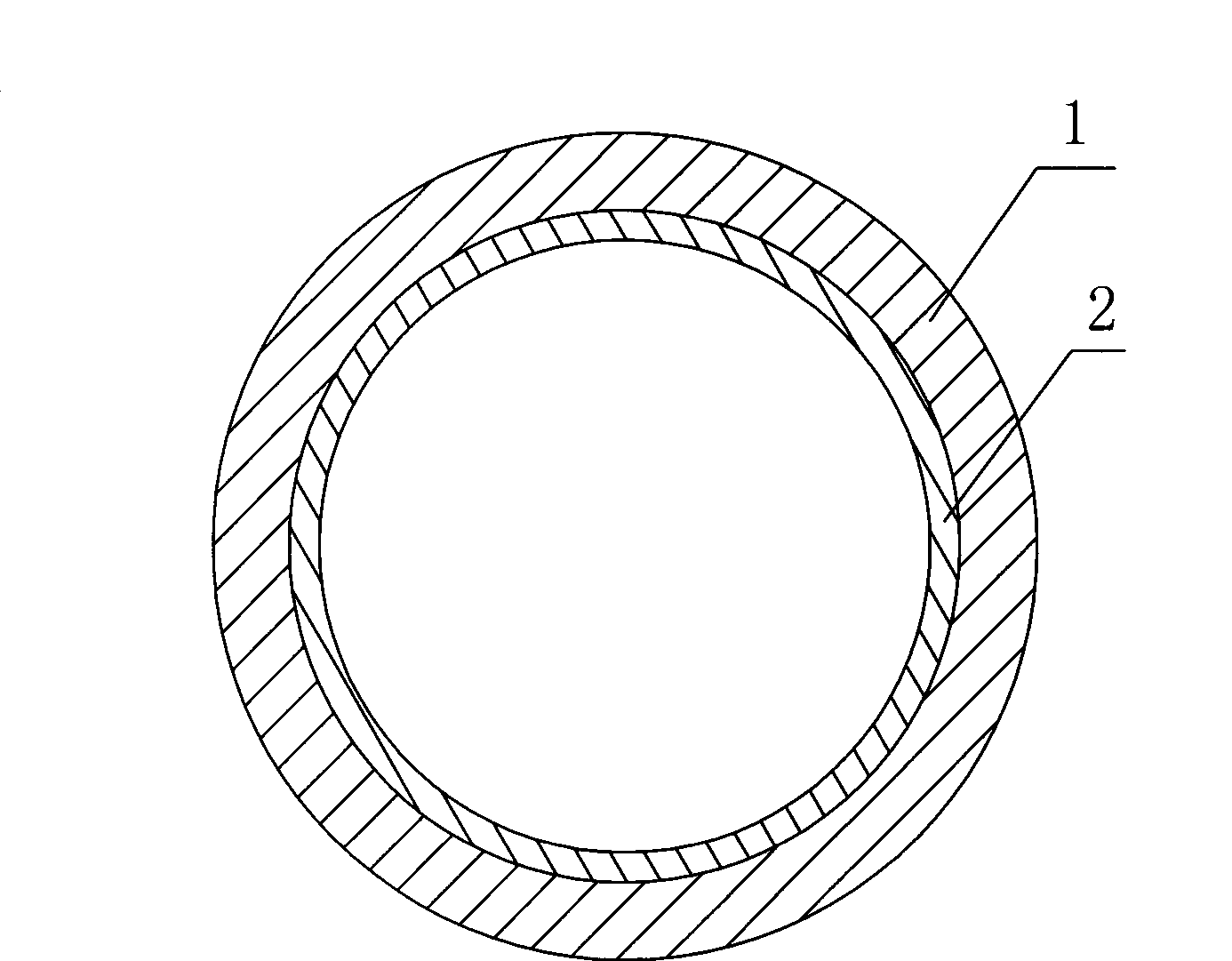

Nerve catheter as well as preparation method and application thereof

InactiveCN101439205APromote regenerationHigh porosityFilament/thread formingCatheterMedicineActive component

The invention discloses a nerve duct and a preparation method as well as use thereof. The nerve duct is composed of 'shell-core' structured nanofiber, a core layer of the 'shell-core' structured nanofiber contains a biological active component, and a shell layer of the 'shell-core' structured nanofiber contains a biodegradable material; the inside diameter of the nerve duct is 0.5-5.0mm, and the outside diameter thereof is 1.0-6.0mm; the biological active component is a neurotrophic factor; and the biodegradable material is selected from one or more than one of the following components: polylactic-co-glycolic acid (PLGA), poly(lactic acid-caprolactone copolymer) (P (LLA-CL)) and poly(3-hydroxybutyrate) (PHB) or polyphosphoester (PPE).

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

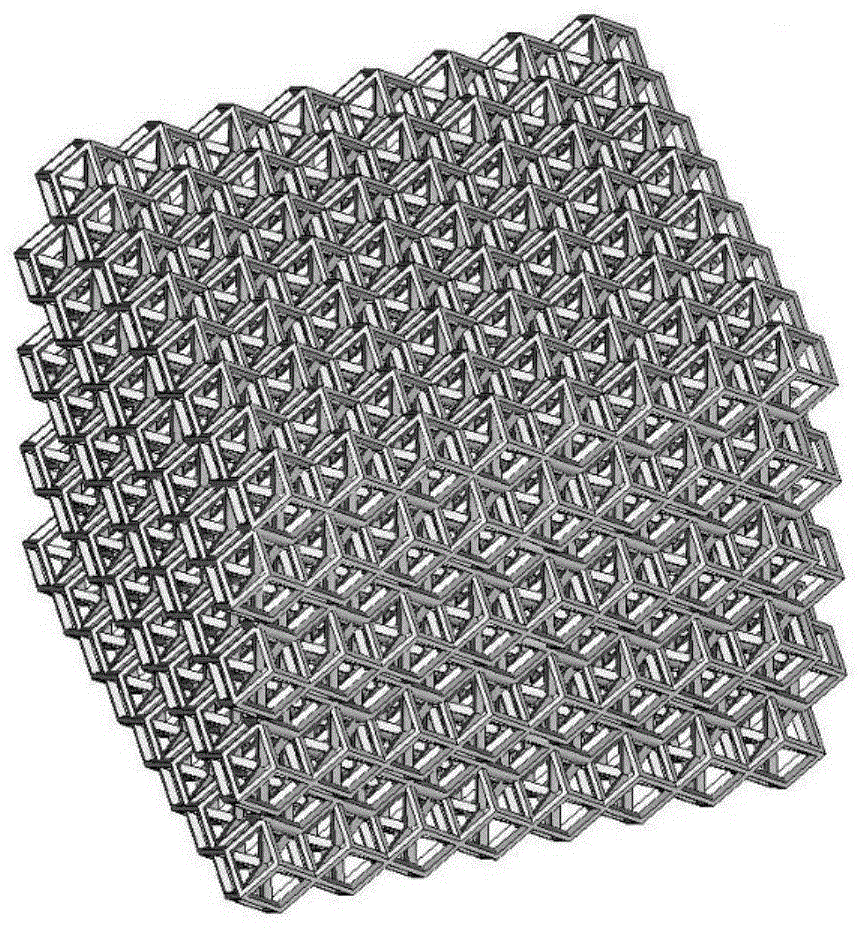

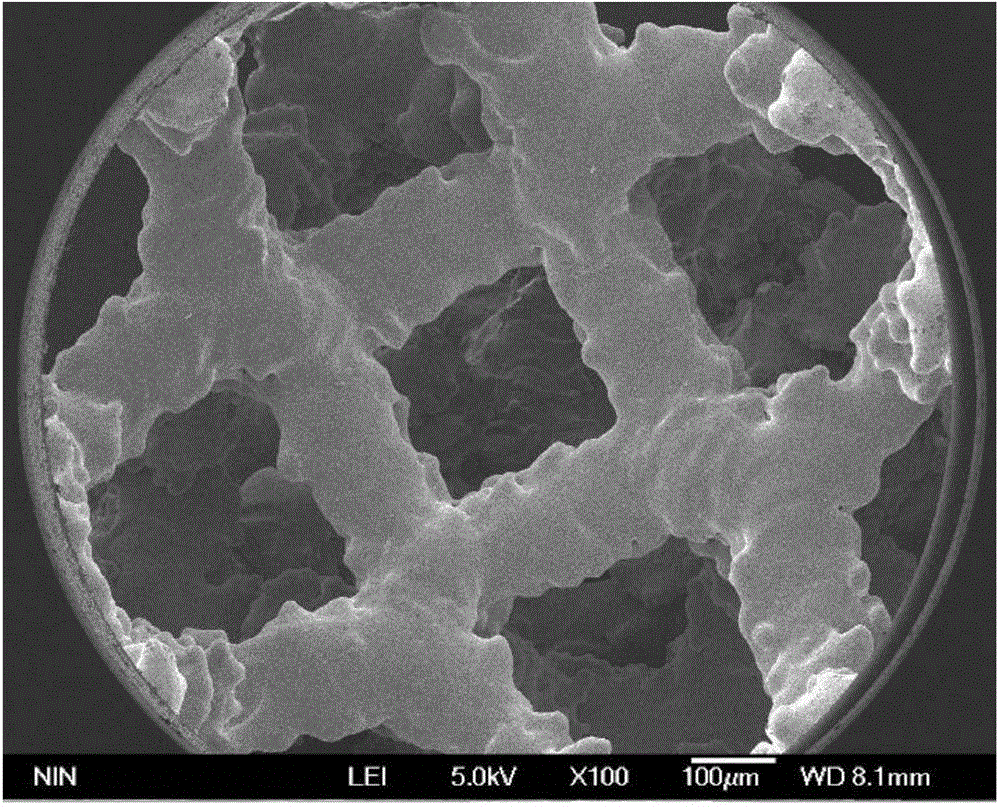

High-strength small-bore metal bone trabecula and preparation method of same

InactiveCN104887351AHigh strengthImprove uniformityAdditive manufacturing apparatusBone implantStructure of the EarthHigh intensity

The invention provides a high-strength small-bore metal bone trabecula and a preparation method of the same. The high-strength small-bore metal bone trabecula is made through overlapping of a plurality of basic units, wherein the basic unit has seamed edges and is solid, other parts have a hollow polyhedral structure, one face of one basic unit coincides with one face of an adjacent basic unit, and reinforced bars are disposed inside the basic unit. The invention also provides a method to prepare the metal bone trabecula, which comprises the steps: 1. modeling is completed; 2. sectioning is completed; 3. a base plate is pre-heated; 4. powder is pre-heated; 5. areas are selected for melting and scanning; 6. the fourth and the fifth steps are repeated to obtain a 3D printing part; 7. residual powder is removed; and 8. electrochemical corrosion is carried out to obtain the high-strength small-bore metal bone trabecula. The high-strength small-bore metal bone trabecula provided by the invention has compression strength of 60 MPa-90 MPa, and effective aperture of 100 mum-150 mum, wherein the aperture is reduced by over 50% and the compression strength increases by over 20% in comparison with those of a conventional 3D printing porous material. The high-strength small-bore metal bone trabecula provided by the invention is more beneficial for bone in-growth and cell growth.

Owner:西安赛隆增材技术股份有限公司

Method for performing three-dimensional printing on biological ceramic bracket based on light-cured molding, and application

ActiveCN107296985AIncreased intensityHigh precisionAdditive manufacturing apparatusTissue regenerationThree Dimensional SizeRepair material

Owner:GUANGDONG UNIV OF TECH

Composite enhanced through coupling of flaky and linear thermal conductive materials and preparation method

The invention provides a composite enhanced through coupling of flaky and linear thermal conductive materials. The composite is obtained through compounding a porous flaky thermal conductive material, a linear thermal conductive material and a basis material, wherein the thermal conductive materials are at least one selected from graphite, diamond, graphene, carbon nanotubes, graphene coated diamond and carbon nanotube coated diamond; the basis material is a metal or a polymer; and high-thermal conductivity particles can be added in the basis material. According to the invention, the metal based or polymer based composite enhanced through coupling of the porous flaky thermal conductive material and the linear thermal conductive material has relatively high thermal conductivity in the direction parallel to the heat flux direction and the direction vertical to the heat flux direction, the industrial production can be achieved, and the application prospect is wide.

Owner:CENT SOUTH UNIV

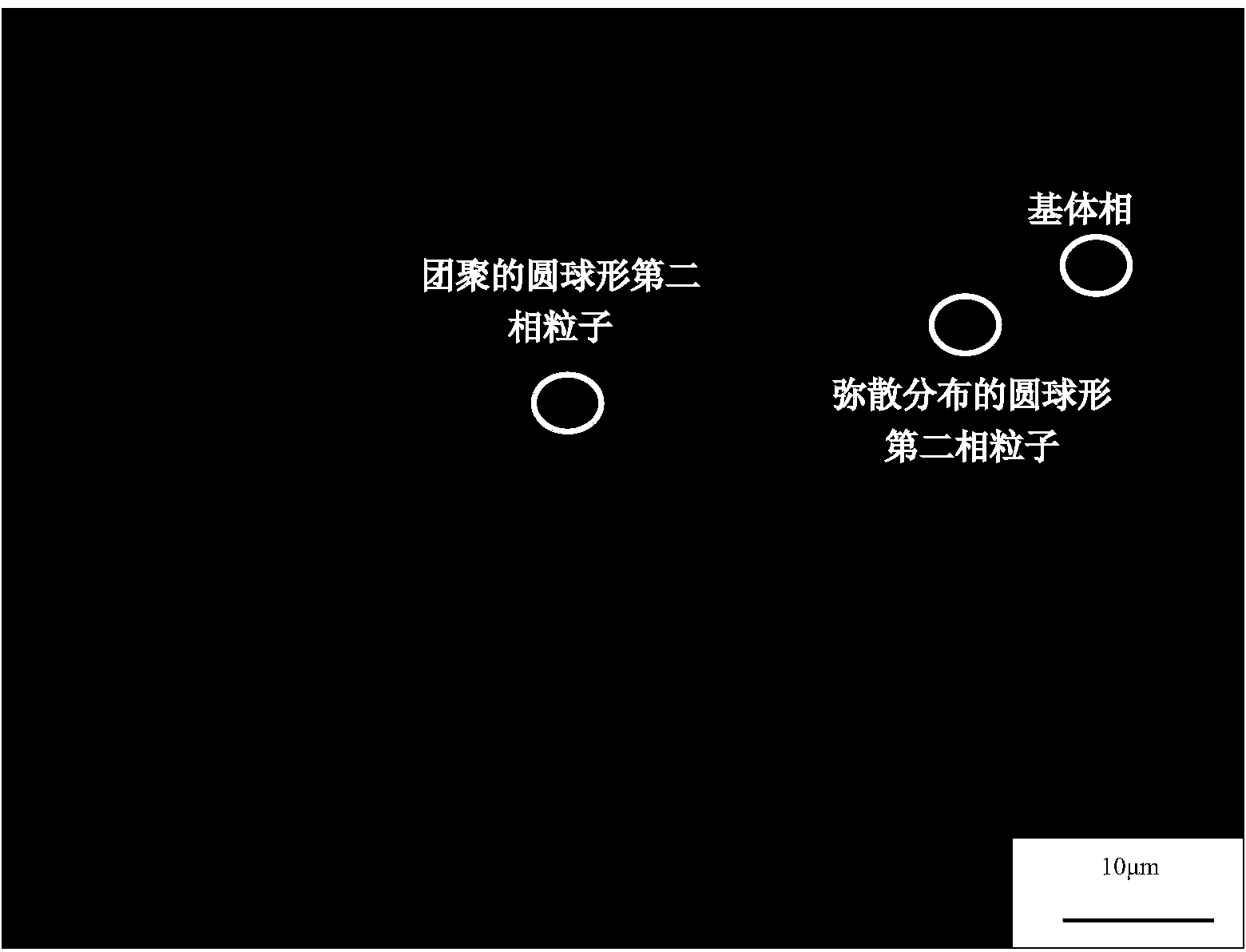

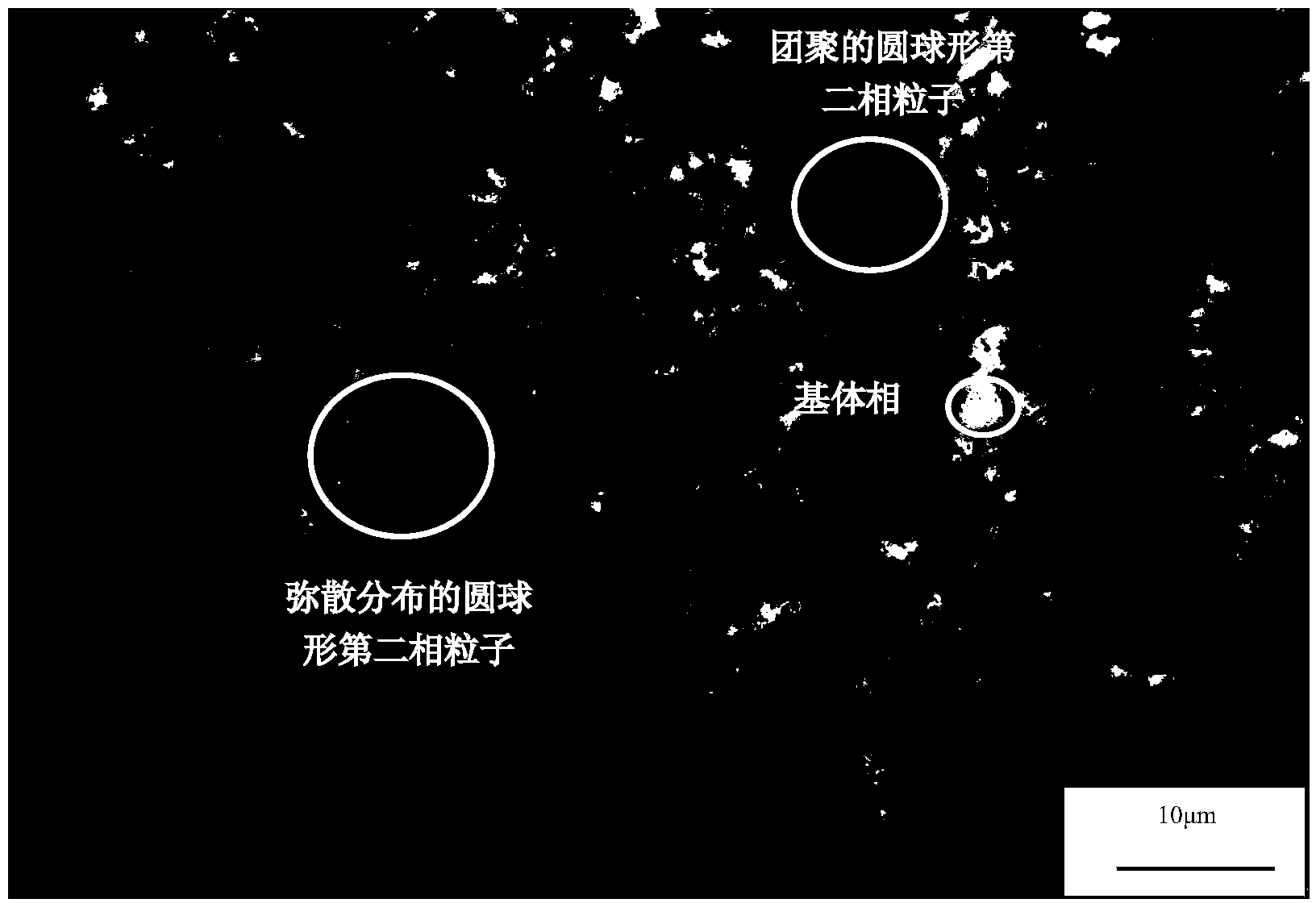

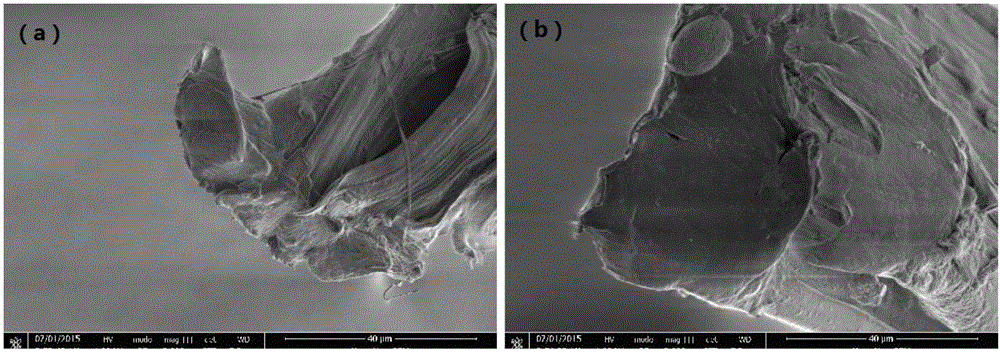

Preparation method of high-performance magnesium alloy plate with double-phase structure

The invention belongs to the technical field of non-ferrous metal magnesium alloy preparation and processing, and particularly relates to a preparation method of a high-performance magnesium alloy plate with a double-phase structure. In the method provided by the invention, a virgin alloy blank of a double-phase microstructure magnesium alloy is prepared by a spray deposition or quick-flow powder preparation or powder metallurgy process; the virgin alloy blank of the double-phase microstructure magnesium alloy is subjected to extrusion, forging, rolling and stamping 'pre-deformation' to form a pre-deformed blank with a 'double-phase texture'; and the pre-deformed blank is subjected to hot rolling or cold rolling to obtain the finished product. The magnesium alloy provided by the invention has the characteristics of 'double-phase structure' (consisting of fine alpha-Mg matrix phase and stable fine second-phase particles) and 'double-phase texture', and a magnesium alloy plate with good comprehensive performance can be obtained.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Graphene/UHMWPE composite fiber and preparation method and application thereof

ActiveCN106222780AGood dispersionEasy secondary dispersionMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberCvd graphene

The invention discloses a graphene / UHMWPE composite fiber and a preparation method thereof. In the composite fiber, the content of graphene is 0.05-5 wt% of that of UHMWPE. The preparation method comprises: pre-dispersing graphene in a solvent to form a uniform graphene dispersion liquid, fully dissolving UHMWPE powder in a solvent in a heating condition, fully mixing the obtained solution with the obtained graphene dispersion liquid, spinning the fully-mixed UHMWPE / graphene mixed solution through a gel-spinning method, and performing solvent extraction and drawing to obtain the graphene / UHMWPE composite fiber. The prepared graphene / UHMWPE composite fiber is obviously improved in the mechanical strength. The tensile strength can reach 29 cN / dtex, and the tensile modulus can reach 1300 cN / dtex. Through changing the addition ratio of graphene and UHMWPE powder, the size of graphene and different dispersion processes, the mechanical property of the composite fiber can be regulated.

Owner:南通恒尚新材料科技有限公司 +1

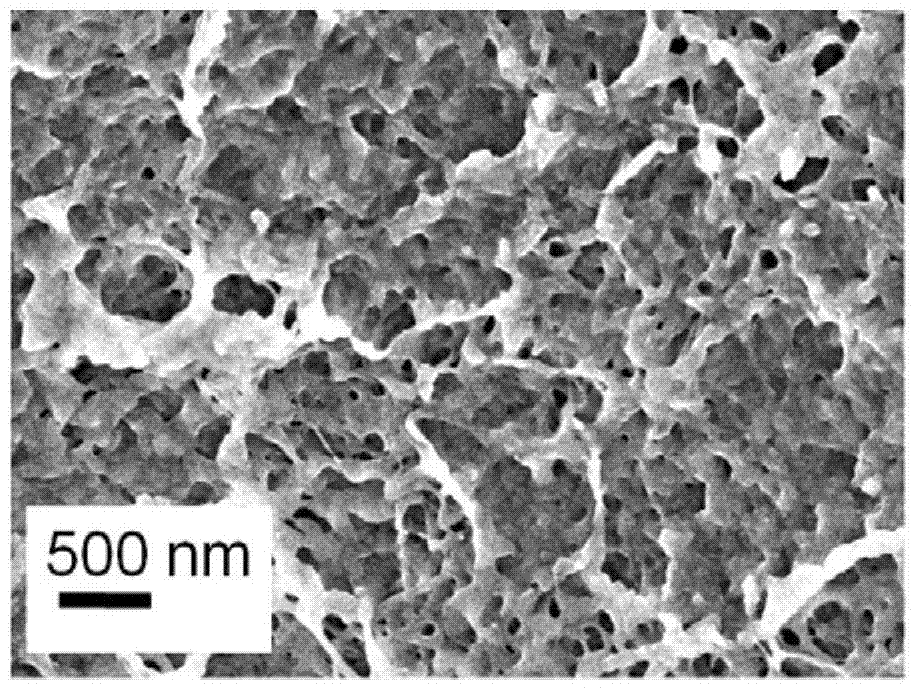

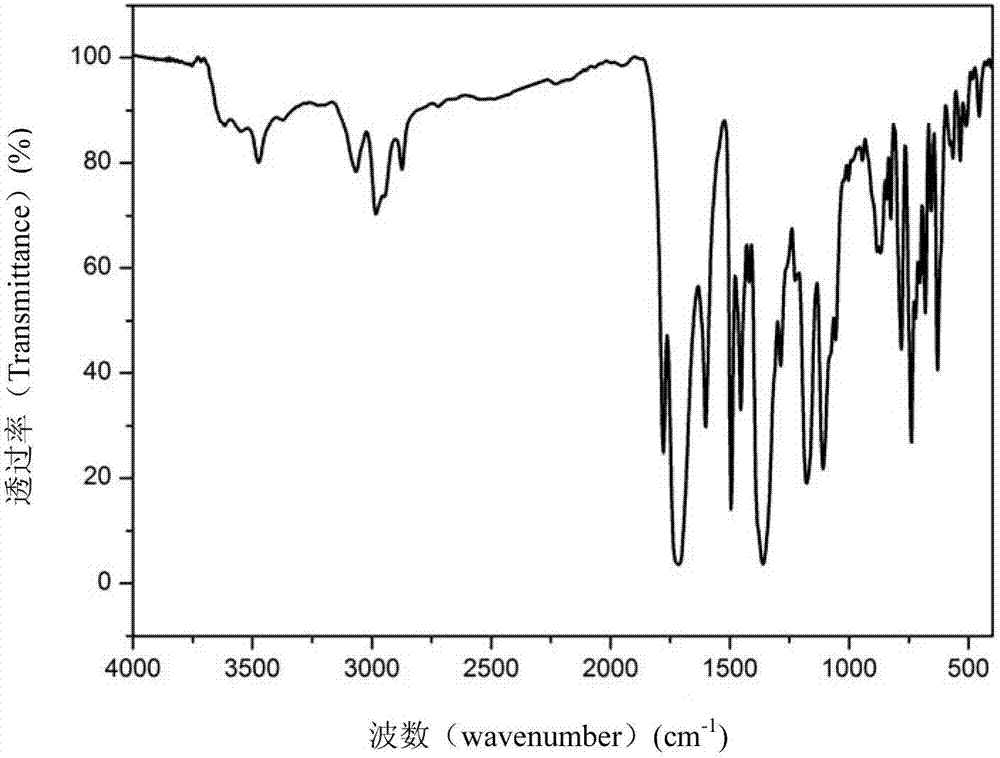

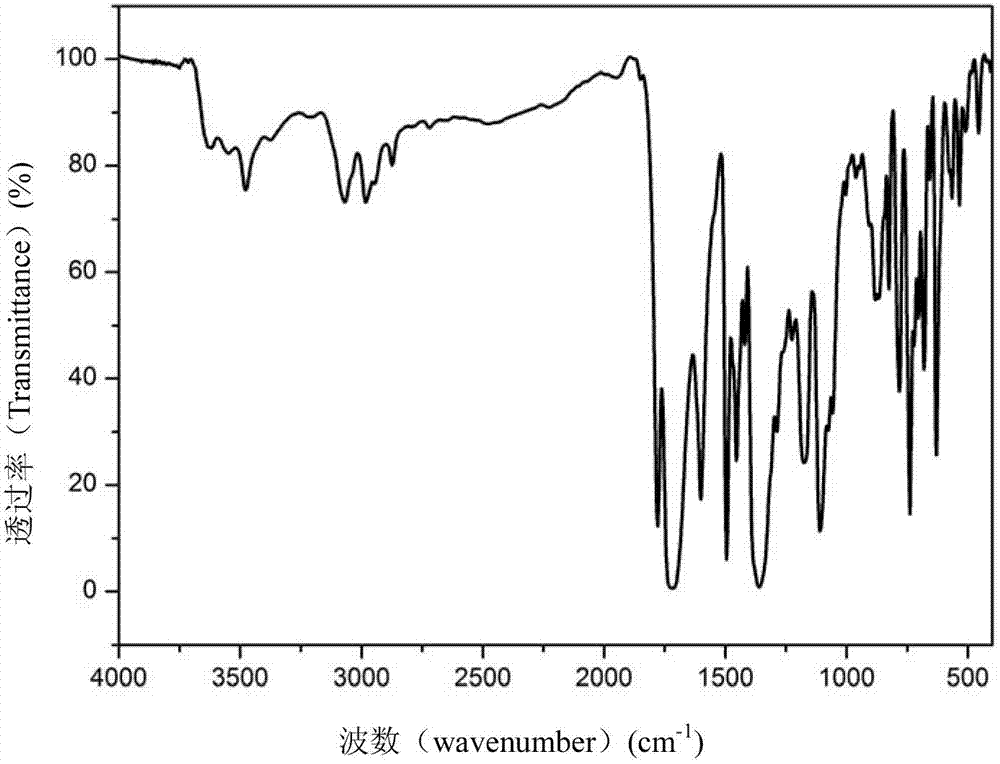

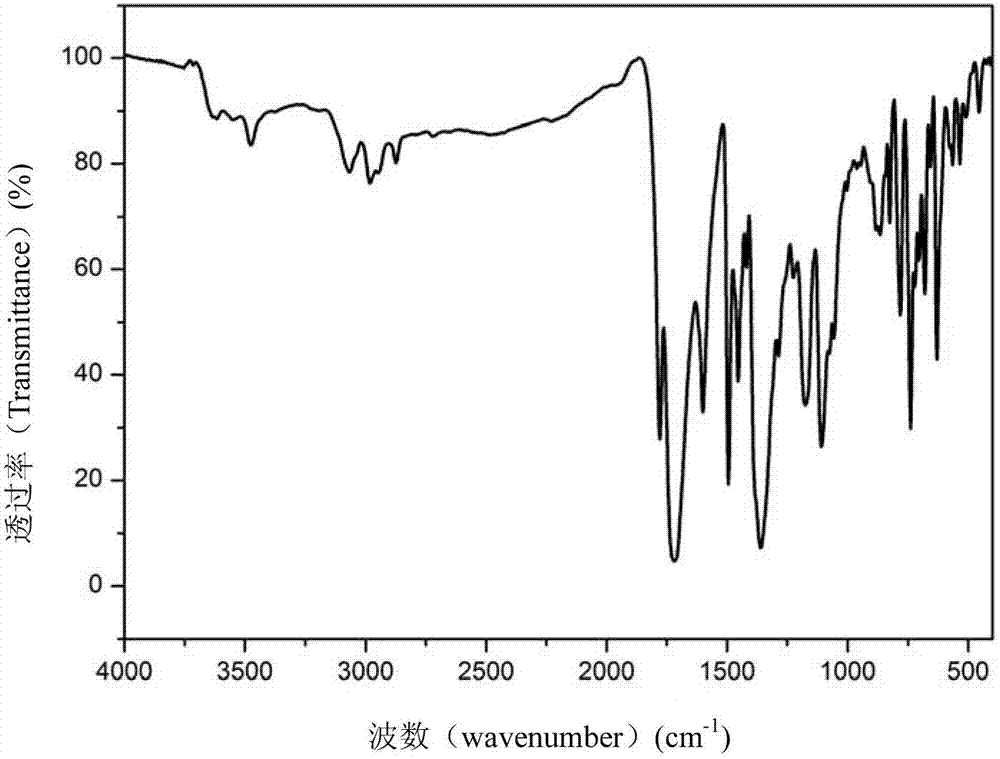

Preparation method of phenolic resin aerogel

ActiveCN103709346AStructural regulationControl mechanical propertiesOther chemical processesCarbon preparation/purificationAnhydrous ethanolOrganic solvent

The invention discloses a preparation method of phenolic resin aerogel. The preparation method is characterized in that chitosan, one or more acid, one or more filling materials, one or more phenols, one or more aldehydes, and water or a water-anhydrous ethanol mixture are mixed; the mixture undergoes a hydrothermal reaction to produce phenolic resin organogel; the phenolic resin organogel is immersed in an organic solvent for replacement; and the replacement product is subjected to supercritical CO2 drying so that the phenolic resin aerogel is obtained. The preparation method has simple processes and safe and reliable reactions and realizes adjustment of a structure and mechanical properties of the phenolic resin organogel. The structure and density of the phenolic resin aerogel obtained by drying and porosity and a specific surface area of the derivative porous carbon material obtained by carbonization of the phenolic resin aerogel are adjusted and controlled well.

Owner:UNIV OF SCI & TECH OF CHINA

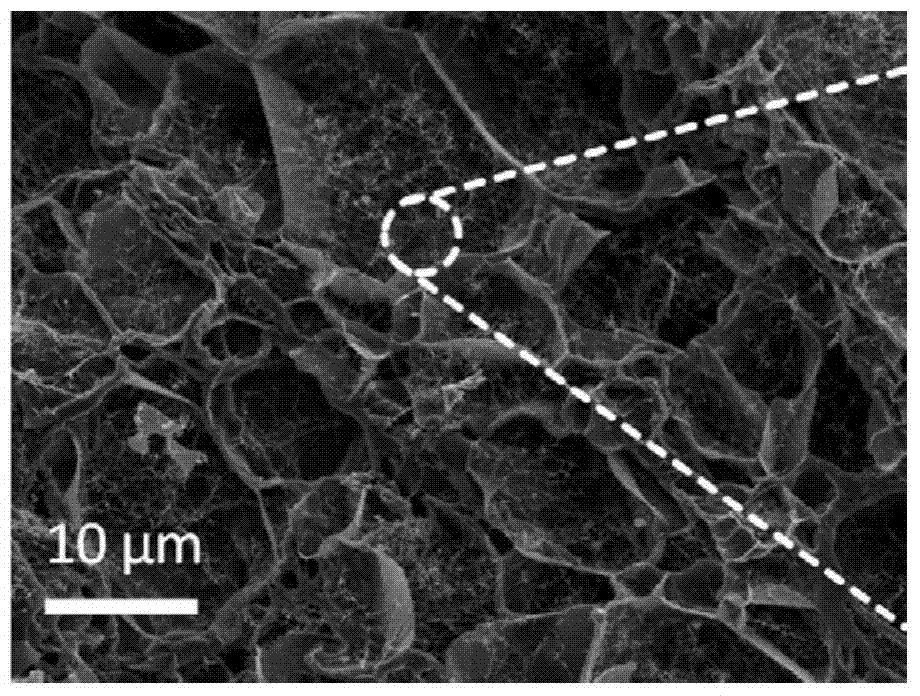

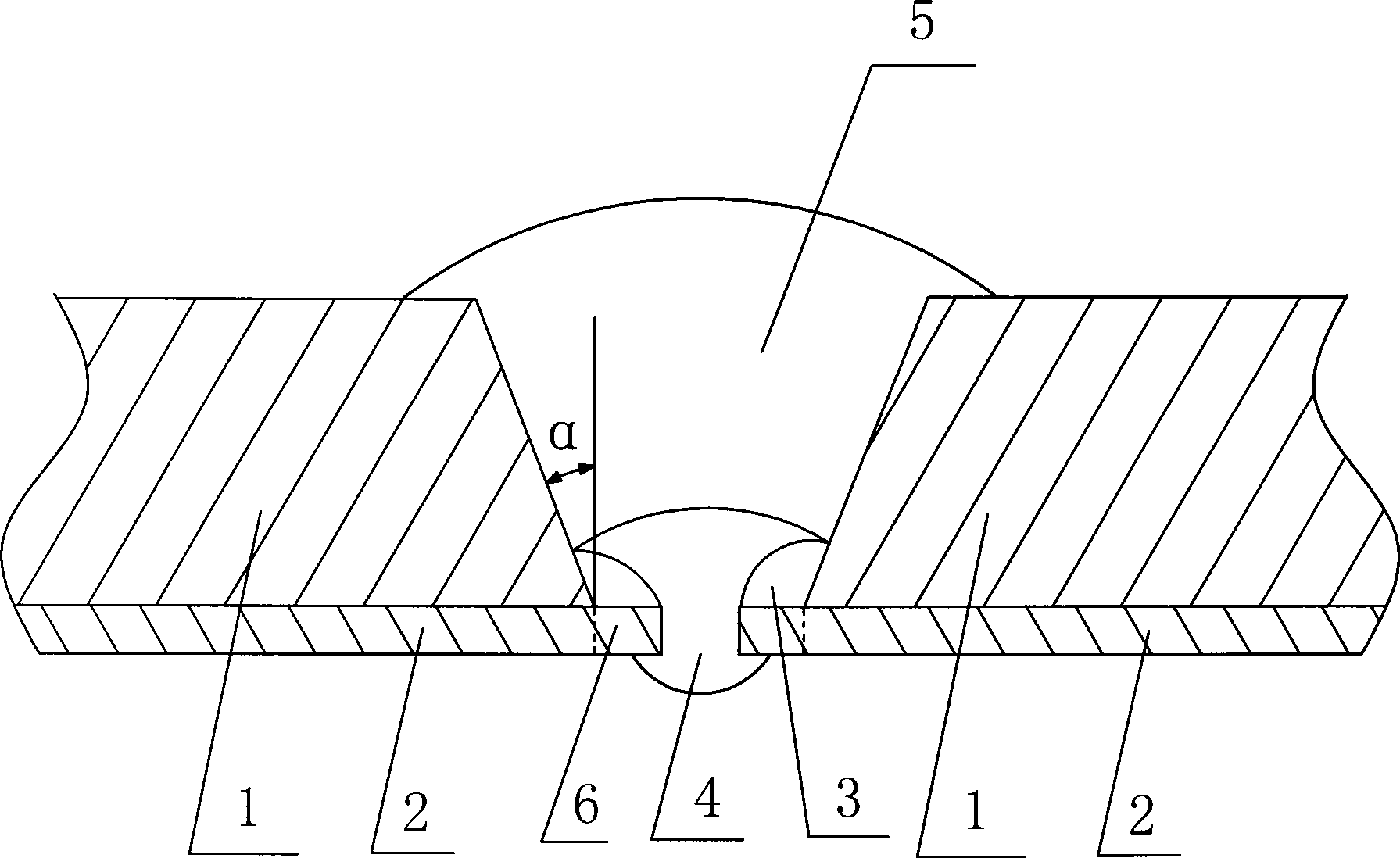

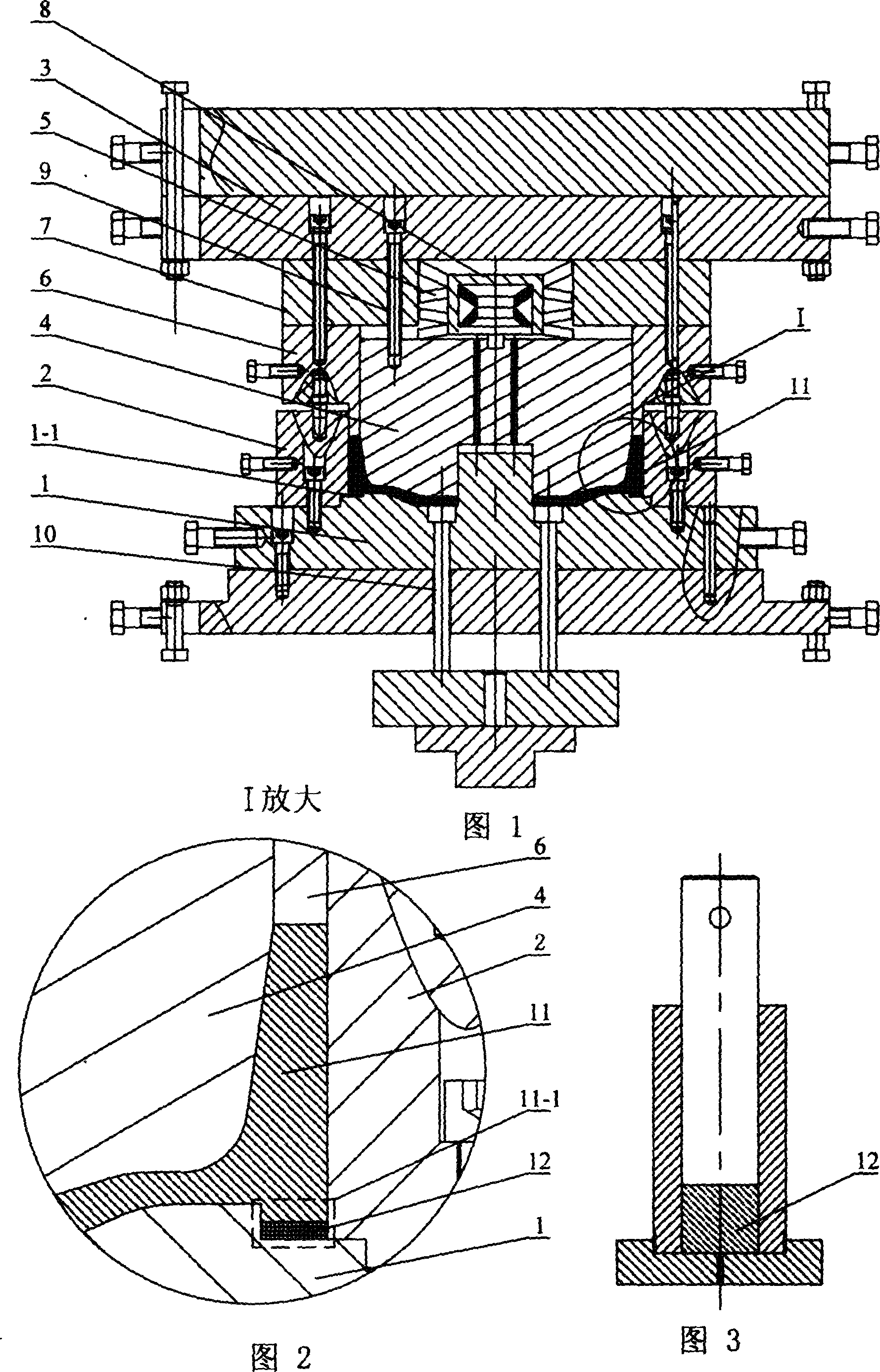

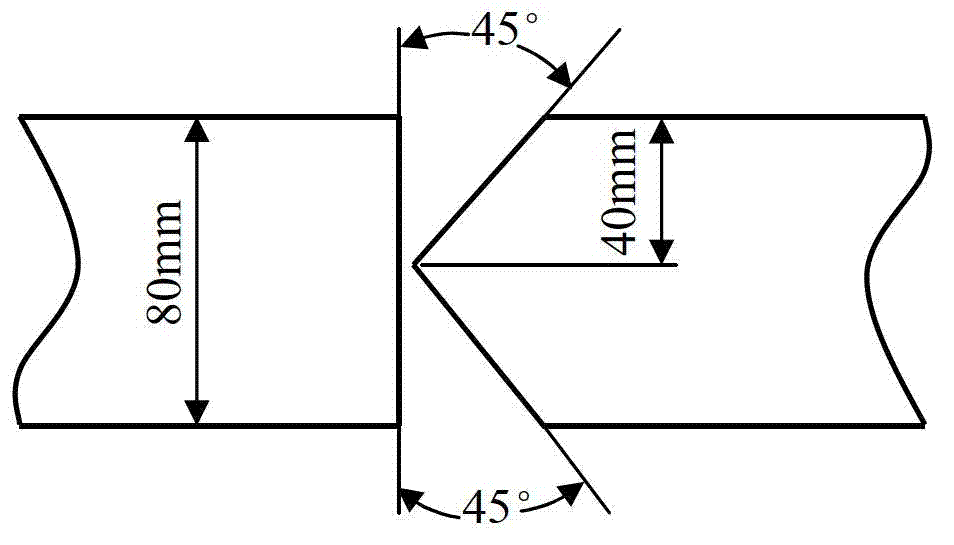

Girth welding method of duplex stainless steel bimetal composite pipe

InactiveCN101362249ASimple welding processExcellent weld mechanical properties and corrosion resistanceArc welding apparatusWelding/soldering/cutting articlesCarbon steelDouble phase

The invention discloses a method for girth welding for double-phase stainless steel bimetal composite tubes. The method comprises the following steps of: firstly, groove processing: the double-phase stainless steel bimetal composite tube consists of a double-phase stainless steel lining tube and a carbon steel base tube, the welding surface of the base tube is processed into a V-shaped groove at an angle of 45-55 degree, and the lining tube is 2-3 mm longer than the base tube; secondly, caulk welding: the connection ports between the base tube and the lining tube are welded through argon tungsten-arc welding, double-phase stainless steel welding wires are adopted, and the welding current is 65-80 A; thirdly, backing welding: the connection ports of lining tube are welded through argon tungsten-arc welding, double-phase stainless steel welding wires are adopted, and the welding current is 60-90 A; fourthly, base tube welding: the connection ports of the base tube are welded through arc welding, and double-phase stainless steel welding wires are adopted. The procedures and the steps are simple, the used welding material is in a small amount, the welding qualification rate is high, the welding defect can be reduced or avoided, and the production efficiency can be greatly improved.

Owner:XIAN SUNWARD AEROSPACE MATERIAL

Medical degradable and absorbable Mg-Sr system magnesium alloy implant and preparation method thereof

InactiveCN102580143APromote osteogenesisInhibit bone resorptionCoatingsProsthesisYttriumImplant material

The invention relates to a medical degradable and absorbable Mg-Sr system magnesium alloy implant and a preparation method thereof. The medical implant is made of Mg-Sr system alloy, and the Mg-Sr system alloy comprises the following elements in percentage by weight: 0 to 5 percent of strontium (except for 0 percent), a small amount of trace elements, namely one or more of manganese, zirconium, stannum, rare earth and yttrium and the balance of magnesium, wherein the total content of the trace elements is less than 3 percent. In-vivo and in-vitro experiments prove that the Mg-Sr system magnesium alloy implant does not have toxicity, has high histocompatibility, and is a reliable biological medical implant material.

Owner:浙江海圣医疗器械股份有限公司

Microbolometer and preparation method thereof

InactiveCN101774530AImprove performanceReduce residual stressTelevision system detailsNanostructure manufactureComposite filmControl layer

The invention relates to a microbolometer, which comprises a microbridge structure, wherein a thermosensitive resistance material and an infrared absorption material layer in the microbridge structure are of a carbon nanometer tube-amorphous silicon composite film, the carbon nano tube-amorphous silicon composite film is formed by compounding an one-dimension carbon nano-tube and a two-dimensional amorphous silicon film, and the microbridge structure is of a three-layer sandwich structure; the most bottom layer is of a amorphous silicon nitride film which is used as a supporting and insulation material of the microbridge; the intermediate layer is of one layer or multiple layers of carbon nano-tube-amorphous composite film, the stress is opposite to the nature of the bottom layer silicon nitride film, and the carbon nano-tube-amorphous composite film is used as the thermosensitive layer and the infrared absorption layer of the microbolometer; and the surface layer is of an amorphous silicon nitride film, the stress of the amorphous silicon nitride film is opposite to the nature of the intermediate carbon nano-tube-amorphous composite film, and the amorphous silicon nitride film is used as a passivation layer of the inforared sensing film and a control layer of the stress. The microbolometer and the preparation method can overcome the weaknesses of the prior art, improves the working performance of the part, reduces the cost of the raw material and are applicable to the industrialized mass production.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

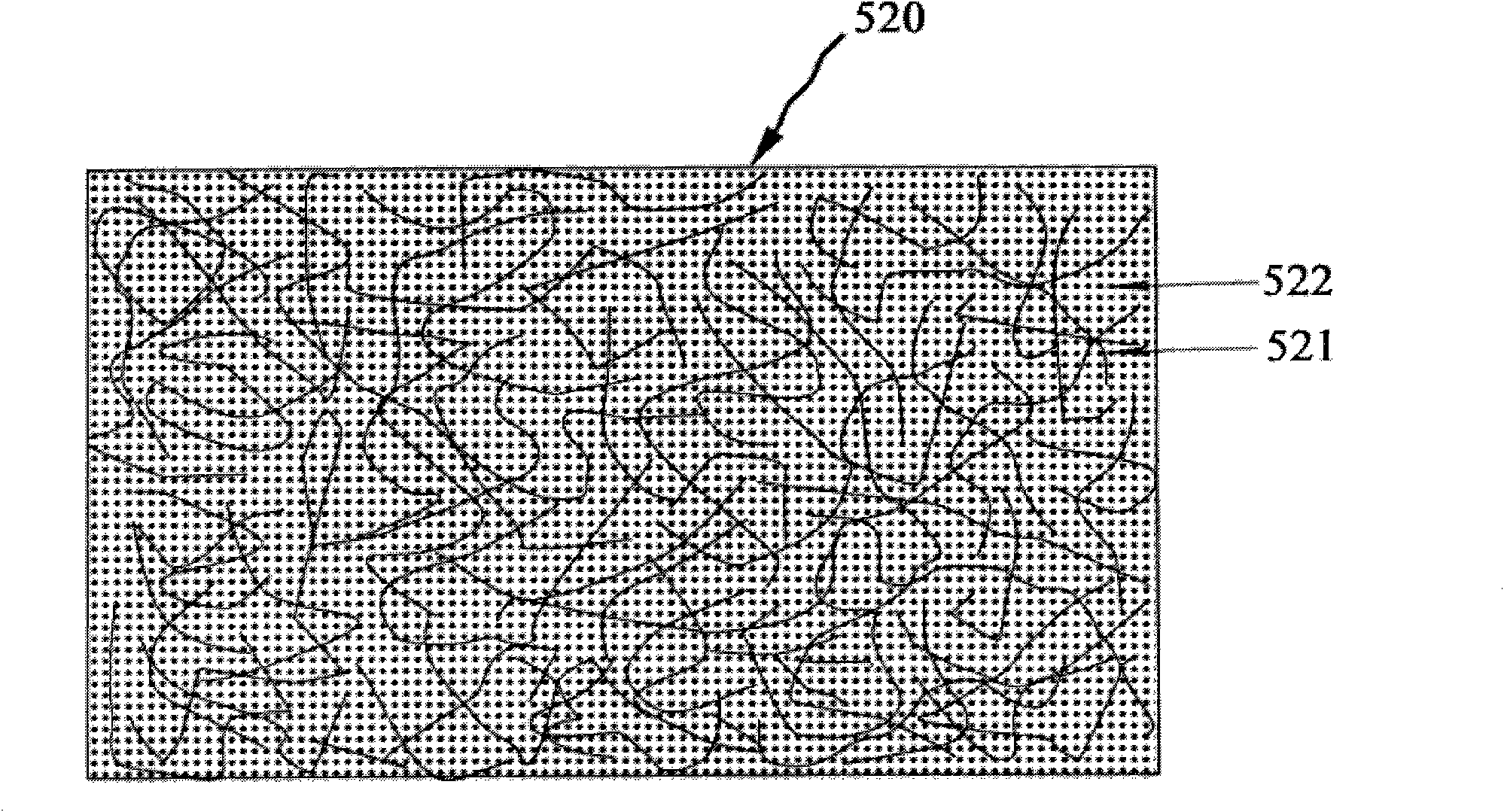

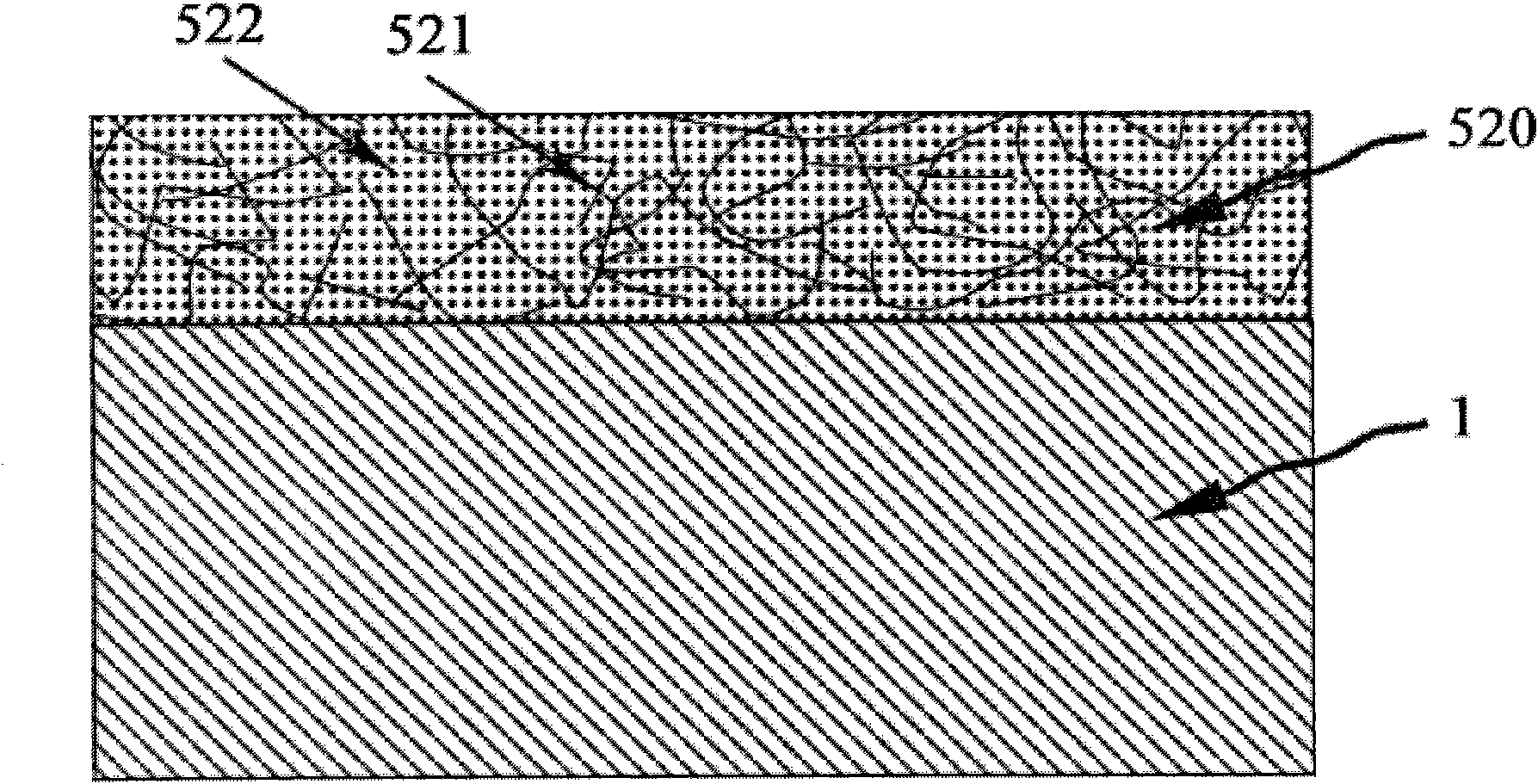

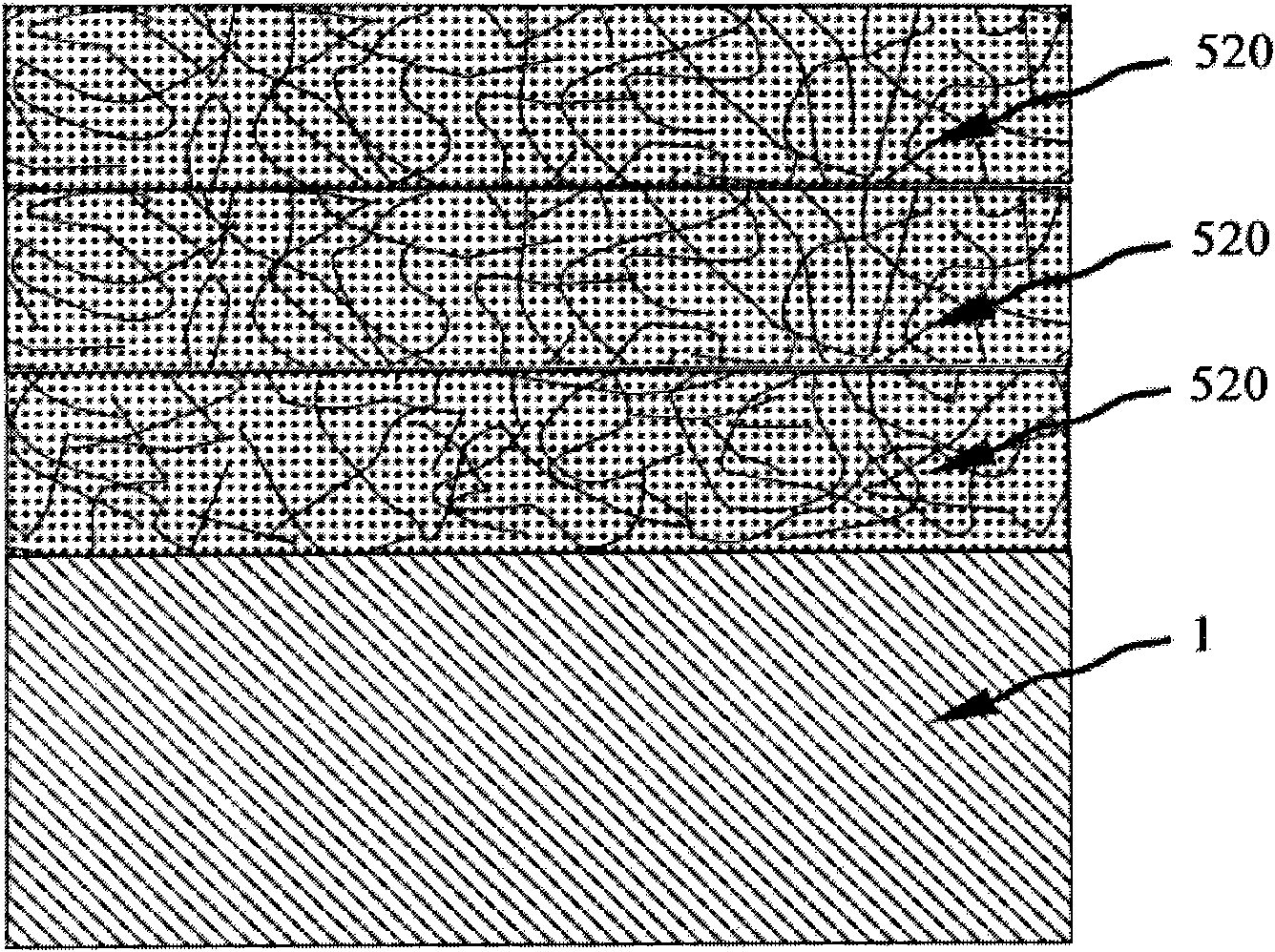

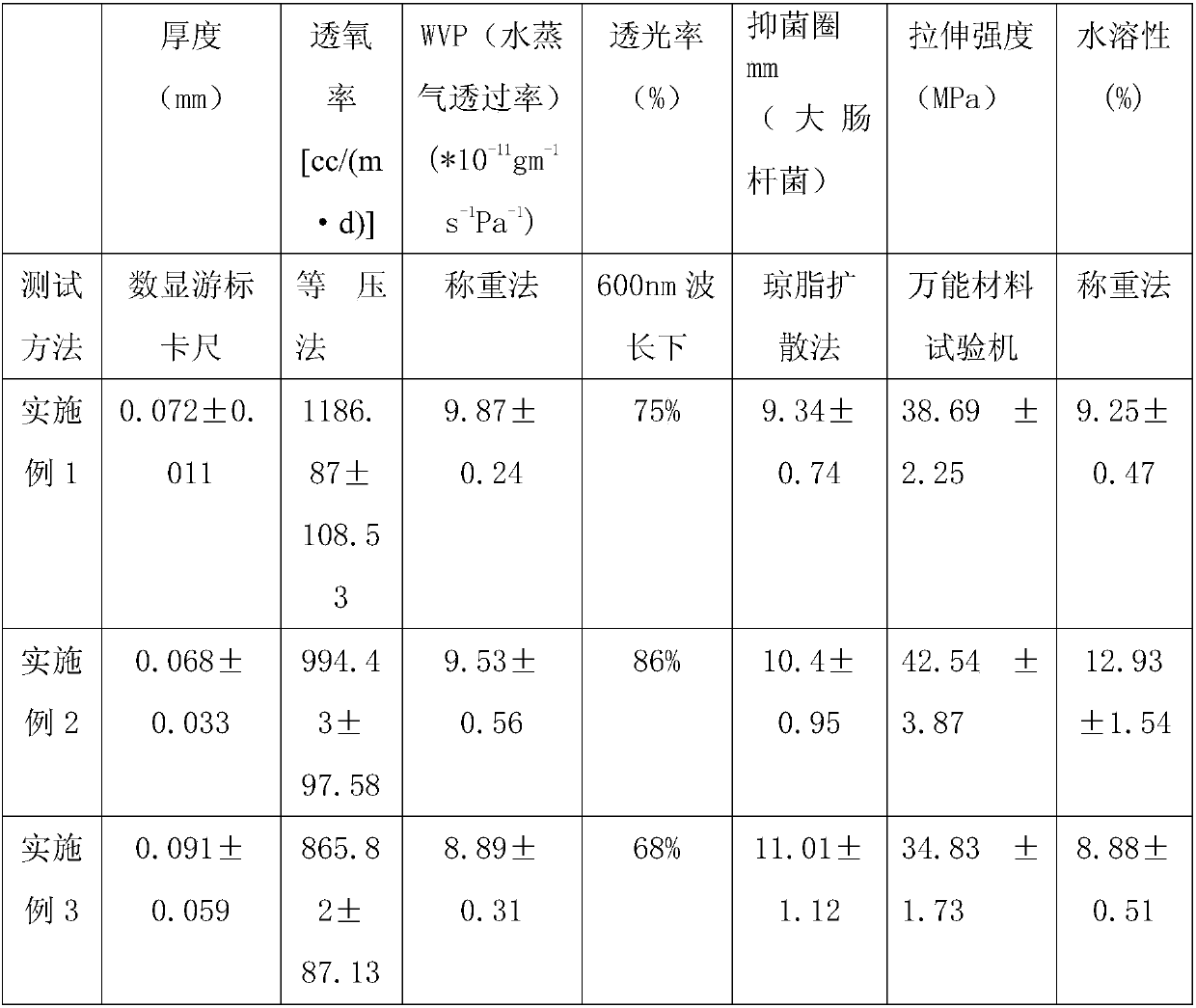

Sodium alginate-chitosan double-layer edible membrane as well as preparation method and application thereof

InactiveCN107840981AImprove food safetyExtensive sources of raw materialsFlexible coversWrappersChemistryFruits and vegetables

The invention discloses a sodium alginate-chitosan double-layer edible membrane as well as a preparation method and an application thereof. The sodium alginate-chitosan double-layer edible membrane isprepared from a sodium alginate membrane and a chitosan membrane through cross-linking compounding. The sodium alginate-chitosan double-layer edible membrane is prepared from a safe and non-toxic material, wide in raw material source, low in production cost and good in membrane forming property, the eating security of an edible inner packaging membrane is improved, through synergetic promotion ofthe components, the air permeability of the membrane is remarkably degraded, the oxygen permeation rate of the membrane is remarkably reduced, the tension property and the transparency of the membrane are remarkably improved, and the membrane is easy to degrade; due to addition of a natural antibacterial agent, microorganism pollution can be very well prevented; the thickness of the membrane canbe controlled by changing the proportioning of the sodium alginate to the chitosan, and then the mechanical properties, the dissolution degree and the antibacterial agent release speed of the membraneare controlled; and the membrane is simple in preparation step, and by adopting the preservative membrane made from the membrane disclosed by the invention, moisture loss and microorganism pollutionin the transportation, storage and processing process of fruits and vegetables can be reduced.

Owner:HAINAN NORMAL UNIVERSITY

High temperature-resistant anti-compression cross-linking polyimide foam material and preparation method and application thereof

The invention discloses a novel high temperature-resistant anti-compression cross-linking polyimide foam material, a precursor and a preparation method and an application thereof. The structural formula of the cross-linking polyimide foam material precursor is shown as a formula I. The preparation method comprises the following steps: mixing organic tetracarboxylic dianhydride or malonate ester of organic tetracid, norbornene mono acid monoester and aromatic diamine mixture in organic solvent to form a polyimide precursor resin solution, removing part solvent, drying and grinding to obtain precursor powder, and heating the precursor powder to 300-400 DEG C and foaming to obtain the cross-linking polyimide foam. The method has the characteristics of simple process and low forming temperature, and the obtained foam material is high in temperature resistance, strength and toughness and low in compression deformation at high temperature. The material can be applied to preparing high temperature-resistant sandwich materials, high temperature-resistant thermal insulation materials, high temperature-resistant damping materials and high temperature-resistant wave-transmitting materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

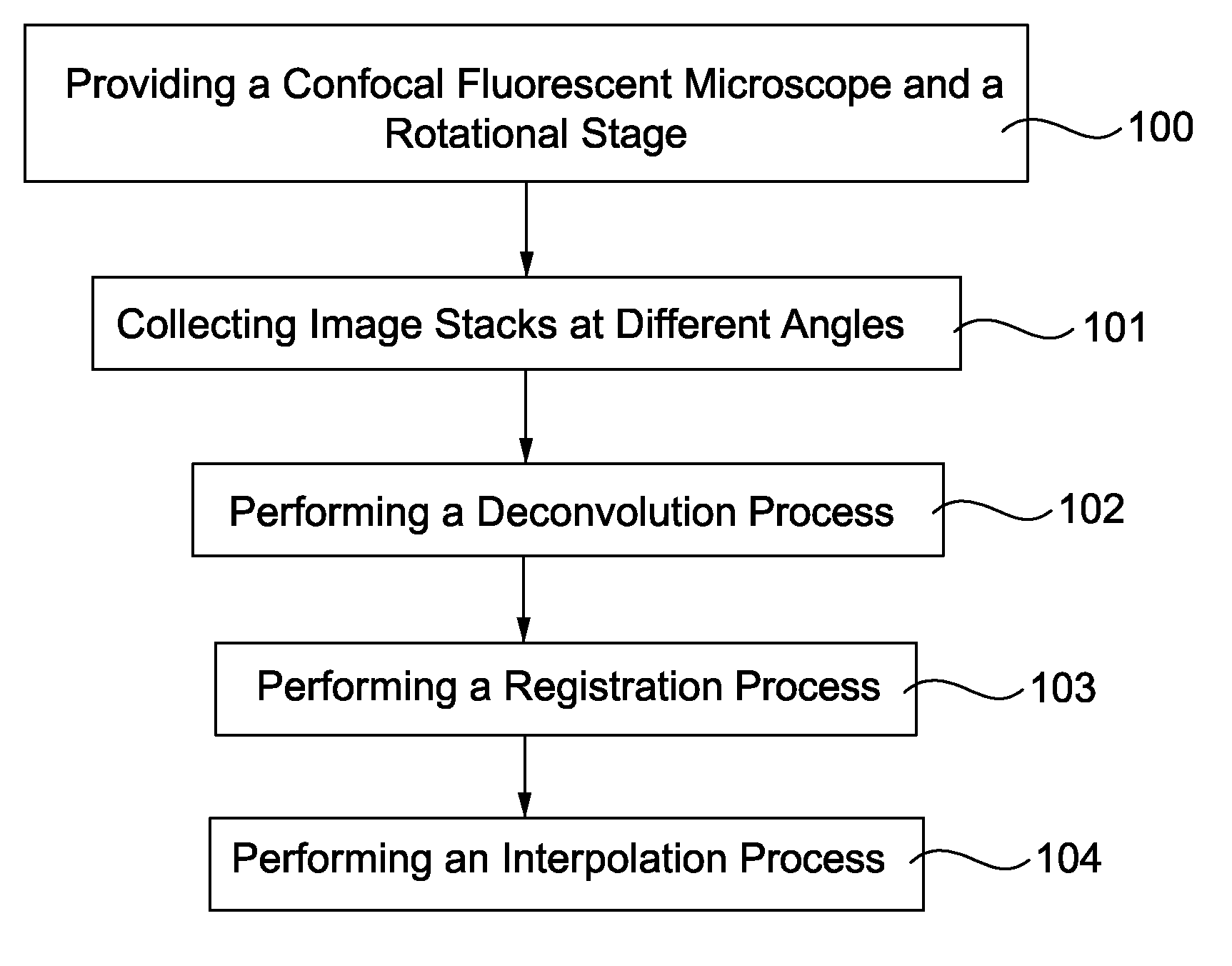

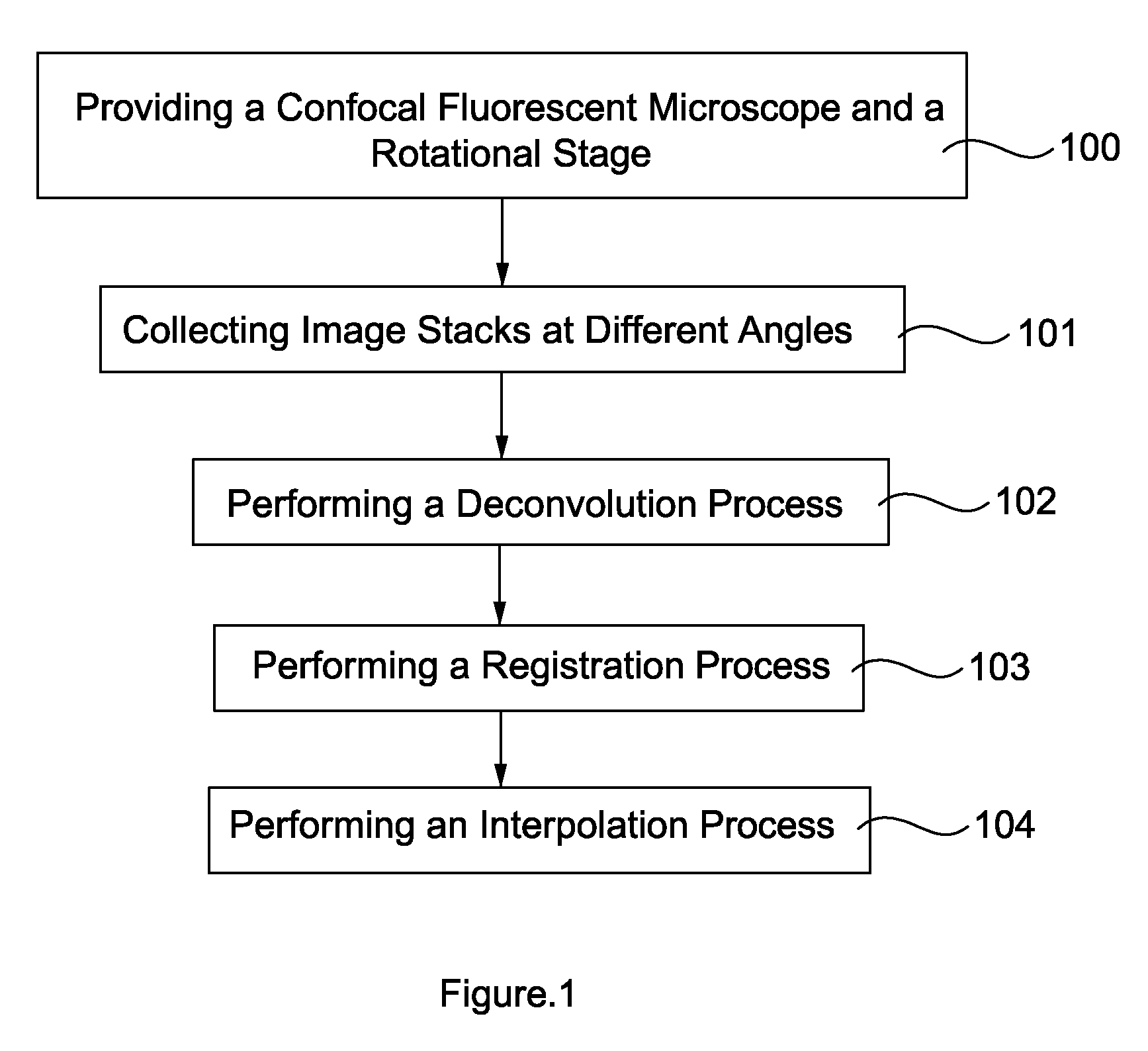

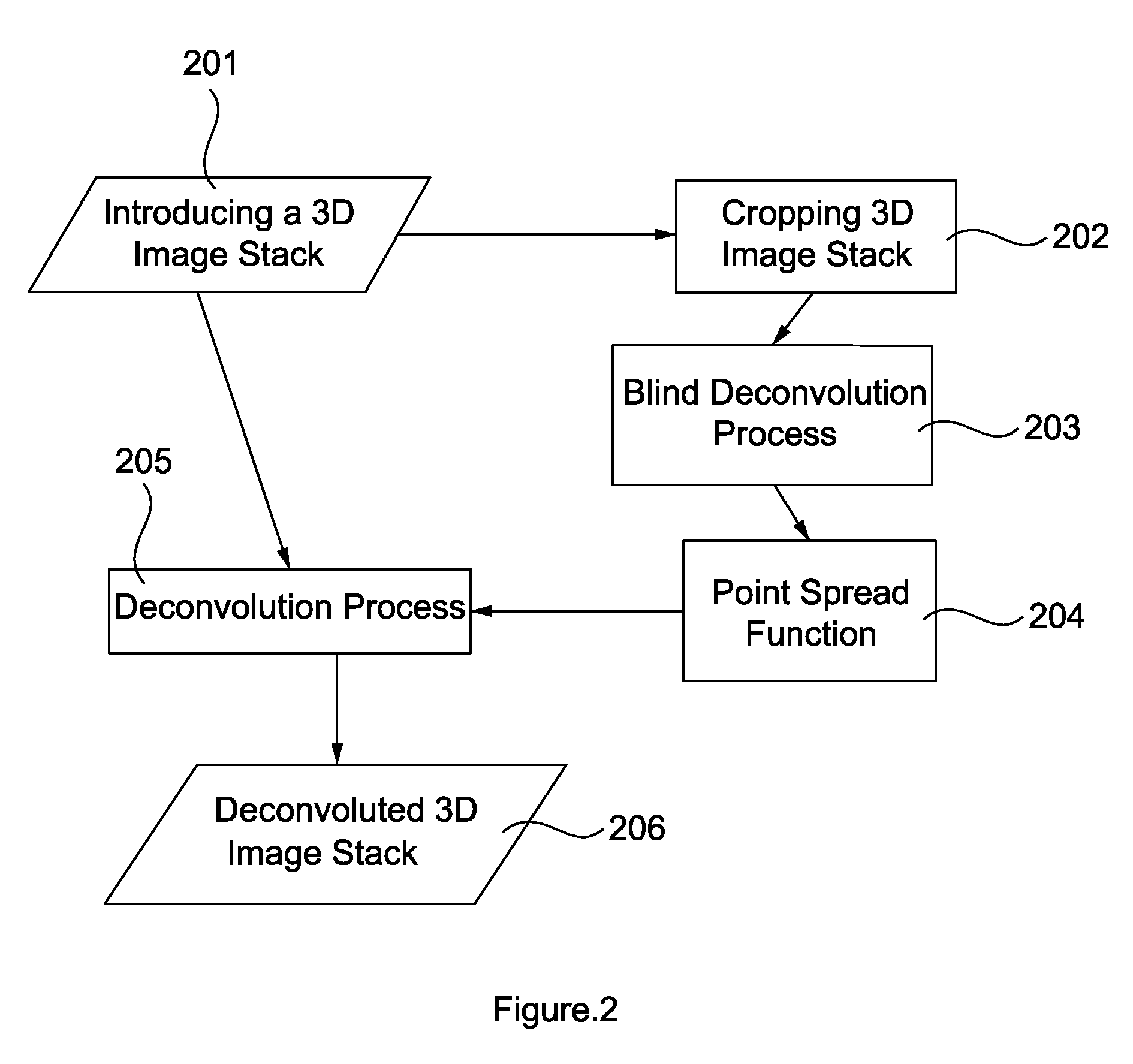

Method of Enhancing 3D Image Information Density

ActiveUS20120194646A1Enhancing D image information densityPoor resolutionGeometric image transformationMicroscopes3d imageFluorescence

A method of enhancing 3D image information density, comprising providing a confocal fluorescent microscope and a rotational stage. 3D image samples at different angles are collected. A deconvolution process of the 3D image samples by a processing unit is performed. A registration process of the deconvoluted 3D image samples by the processing unit is performed. An interpolation process of the registered 3D image samples by the processing unit is performed to output a 3D image in high resolution.

Owner:NATIONAL TSING HUA UNIVERSITY

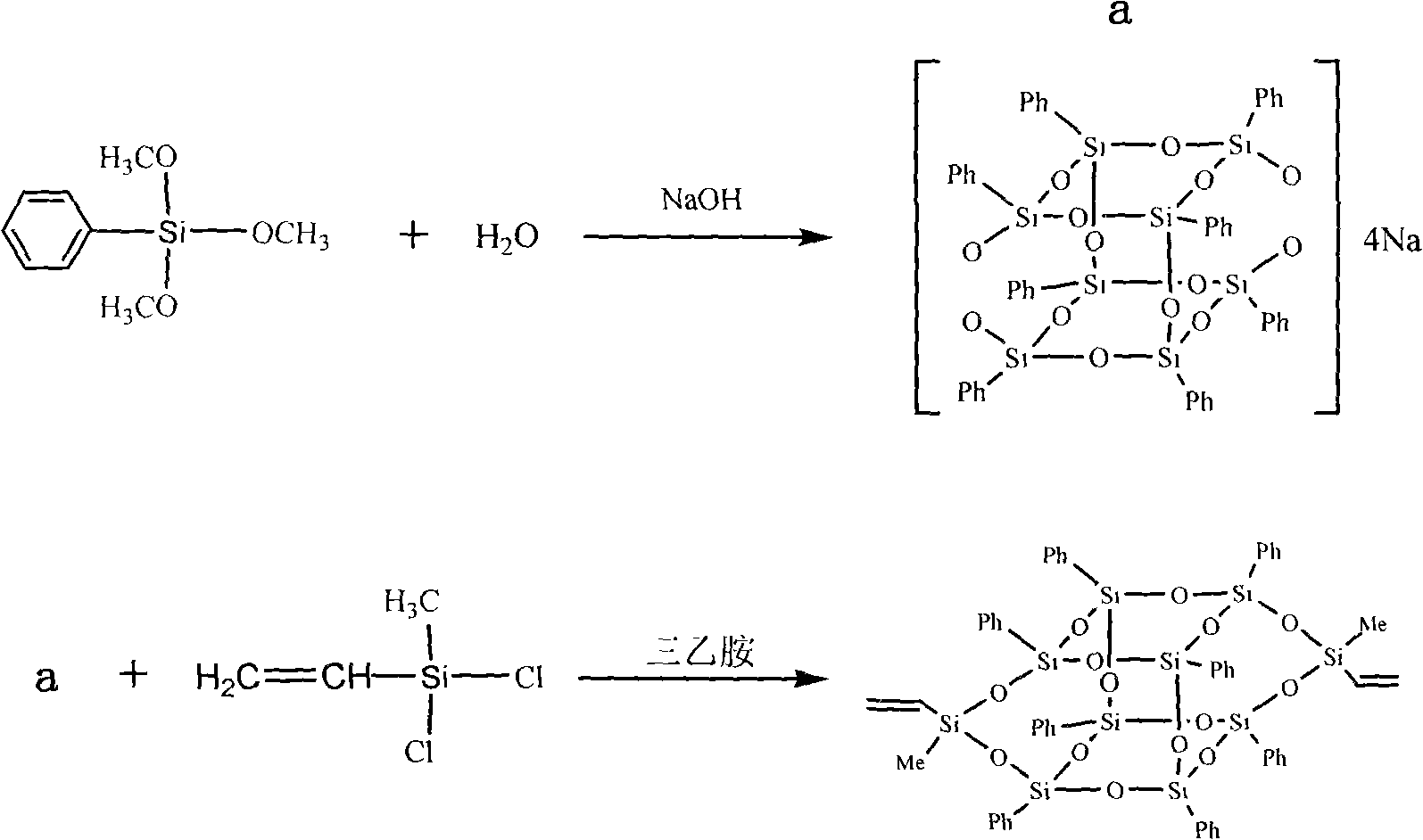

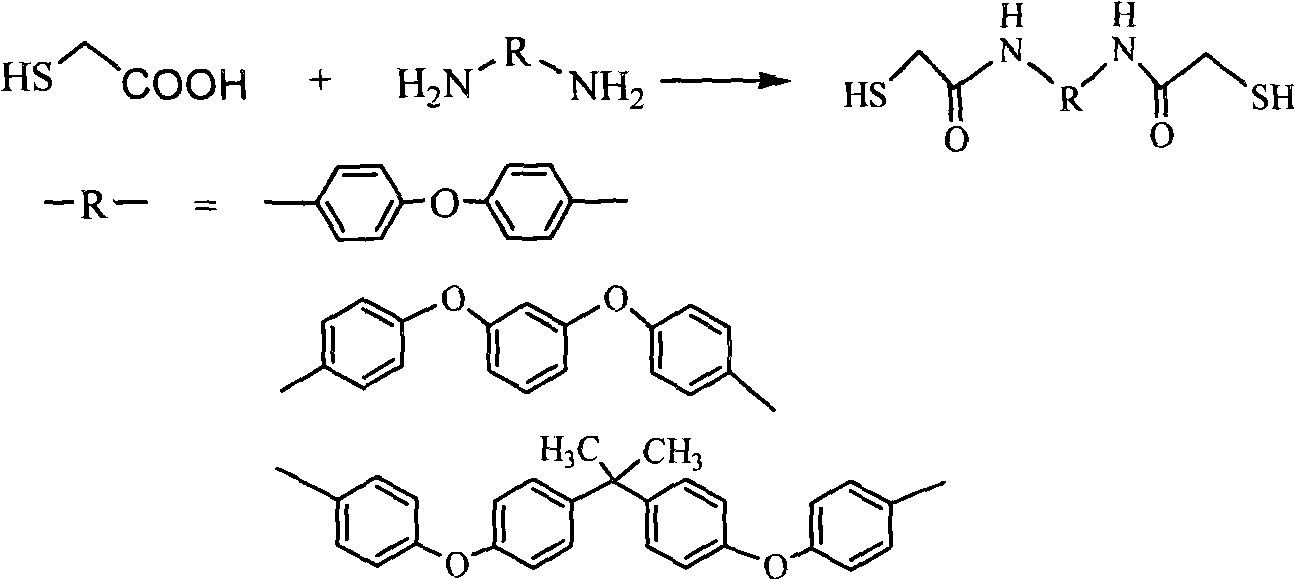

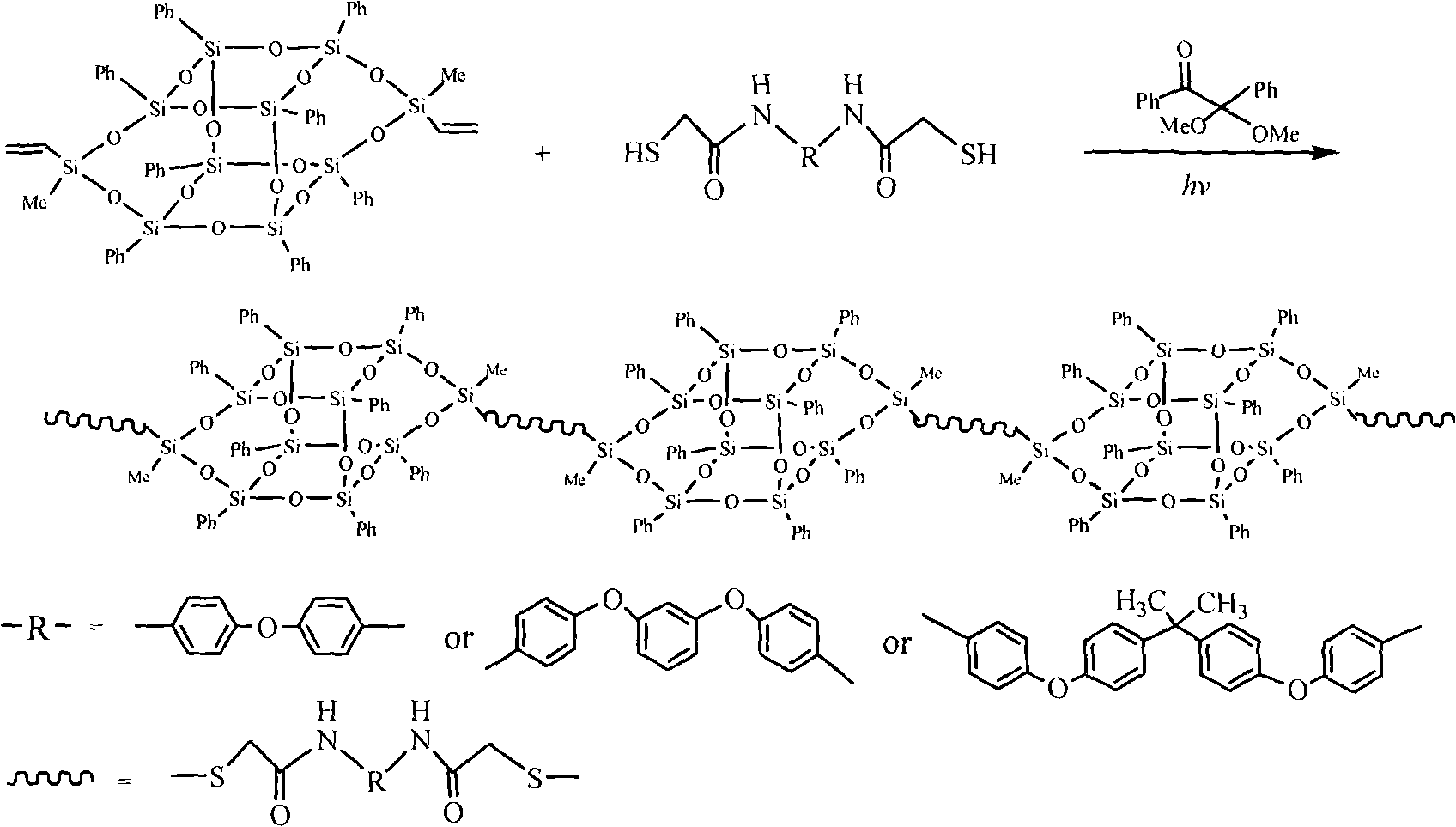

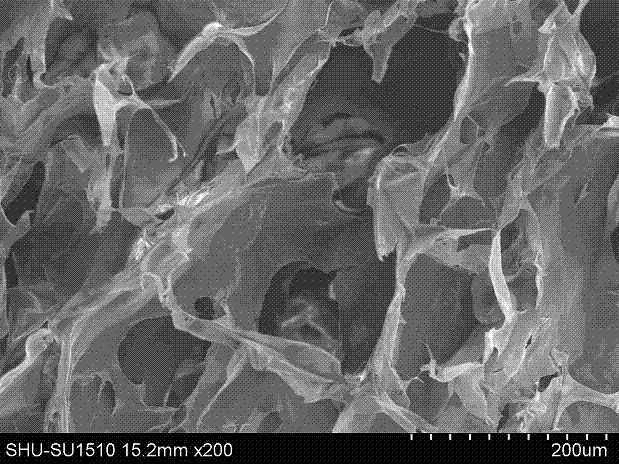

Accurate structure POSS hybridization low dielectric material preparation

InactiveCN101348568AMild reaction conditionsUniform and Orderly ConnectedPlastic/resin/waxes insulatorsPorosityChemical synthesis

The invention relates to a preparation method for a finely structured POSS hybridization low dielectric material. The method takes a POSS monomer containing an active group and dual functional group organic micromolecules capable of having a click chemical reaction as the precursor of the finely structured hybridization low dielectric material, and makes use of an environmentally friendly click chemical synthesis method to connect the finely structured POSS molecules and the organic micromolecules onto the low dielectric material structure orderly. Through changing the composition, structure and performance of the organic molecular chain connected with POSS, the method realizes the adjustment and control of the structure, porosity, thermal property, mechanical property and dielectric constant of the finely structured hybridization low dielectric material.

Owner:DONGHUA UNIV

Polylactic acid and electron beam radiation modifying method for copolymer composite material thereof

The invention relates to a modification method of the electron beam radiation for polylactic acid and the copolymer composite of polylactic acid, which comprises: firstly, the polylactic acid or the copolymer of polylactic acid, the fillers and the cross-bonding agent are mixed homogenously at the ambient temperature to prepare the composite; secondly, the composite is processed to a product which is put in nitrogen or vacuum environment; at last, the product is radiated by an electron beam and the radiation dose is 10 to 180kGy. The ratio of the fillers and the polylactic acid or the ratio of the fillers and the copolymer of polylactic acid is 5:100 to 60:100; the ratio of the cross-bonding agent and the polylactic acid or the ratio of the cross-bonding agent and the copolymer of polylactic acid is 0.5:100 to 10:100.

Owner:SICHUAN UNIV

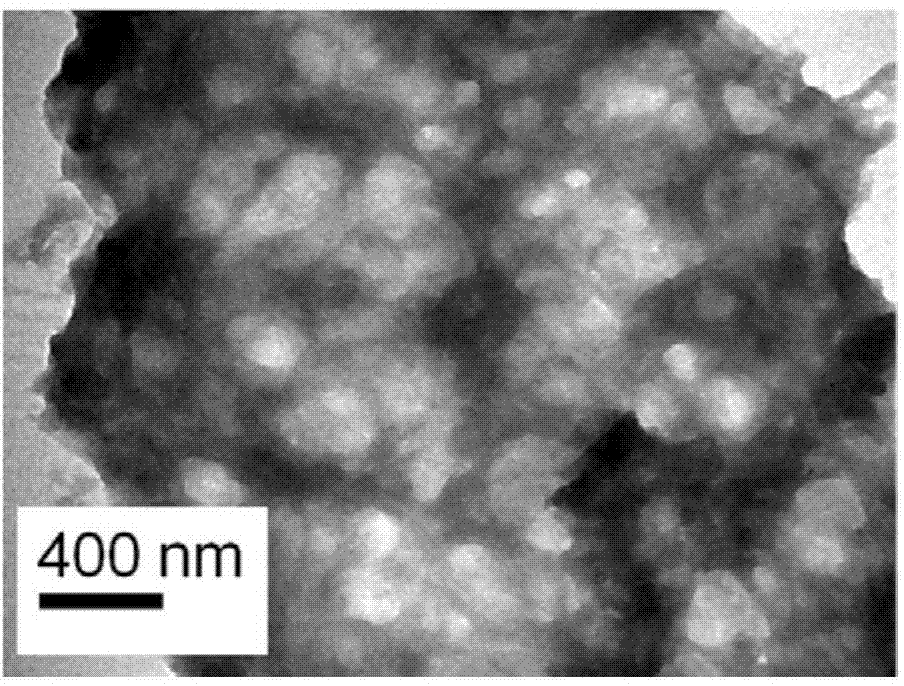

Superhigh-thermal-conductivity continuous diamond skeleton reinforced composite material and preparation method

ActiveCN105695831AHigh thermal conductivityImprove mechanical propertiesChemical vapor deposition coatingHeat conductingGas phase

The invention provides a superhigh-thermal-conductivity continuous diamond skeleton reinforced composite material and a preparation method. The composite material is composed of a continuous diamond reinforced body and a base material. The continuous diamond reinforced body is prepared by depositing diamond films or diamond compound films on diamond particle preforms through a CVD method. The diamond compound films are graphene-wrapped diamond films or carbon-nanotube-wrapped diamond films. The base material is made of metal or polymer. Diamond powder is prepared into the performs, then the diamond films deposit on the surfaces of the performs through the CVD method, the diamond films are formed at the contact positions of adjacent diamond particles, and accordingly continuous heat conducting channels are formed between the isolated diamond particles. The deposited diamond films can serve as heat conducting bridges between the diamond particles, so that the dispersed diamond particles form a connection structure, accordingly high heat conductivity of diamond is fully used by the composite material, and the heat conductivity of the composite material is greatly improved.

Owner:CENT SOUTH UNIV

Cartilage tissue engineering scaffold material and preparation method thereof

InactiveCN103638562AControl mechanical propertiesControl degradabilityProsthesisSide chainBone tissue engineering

The invention discloses a cartilage tissue engineering scaffold material and a preparation method thereof. The scaffold material is a three-dimensional porous structure formed by using sodium alginate and chitosan as a base material, and enabling the carboxyl on a side chain of the sodium alginate activated by activation cross-linking agent to react with amino group of chitosan, wherein molar ratio of the sodium alginate carboxyl to the chitosan amino group is (3:7)-(7:3), and the final product only contains two components, sodium alginate and chitosan. The three-dimensional porous scaffold provided by the invention has good biocompatibility, and is suitable for the cartilage tissue engineering.

Owner:SHANGHAI UNIV

Polymeric film or coating comprising hemicelulose

ActiveUS20060173104A1Control mechanical propertiesAdvantage for environmentPaper coatingCellulose adhesivesOligomerPlasticizer

A film-forming composition and a polymeric film or coating comprising hemicellulose, having a molecular weight of less than 50 000 g / mol, and at least one component selected from the group consisting of plasticizers, cellulose and a synthetic oligomer or polymer is disclosed. The use of said film or coating as an oxygen barrier is also disclosed. Further, a method for the manufacture of said polymeric film or coating is disclosed, as well as a method for improving the film-forming properties of hemicellulose having a molecular weight of less than 50 000 g / mol.

Owner:SEELUTION AB

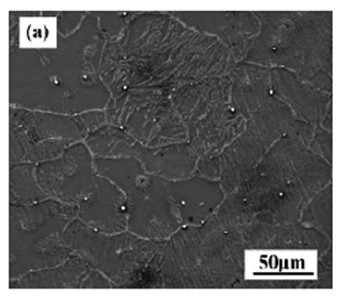

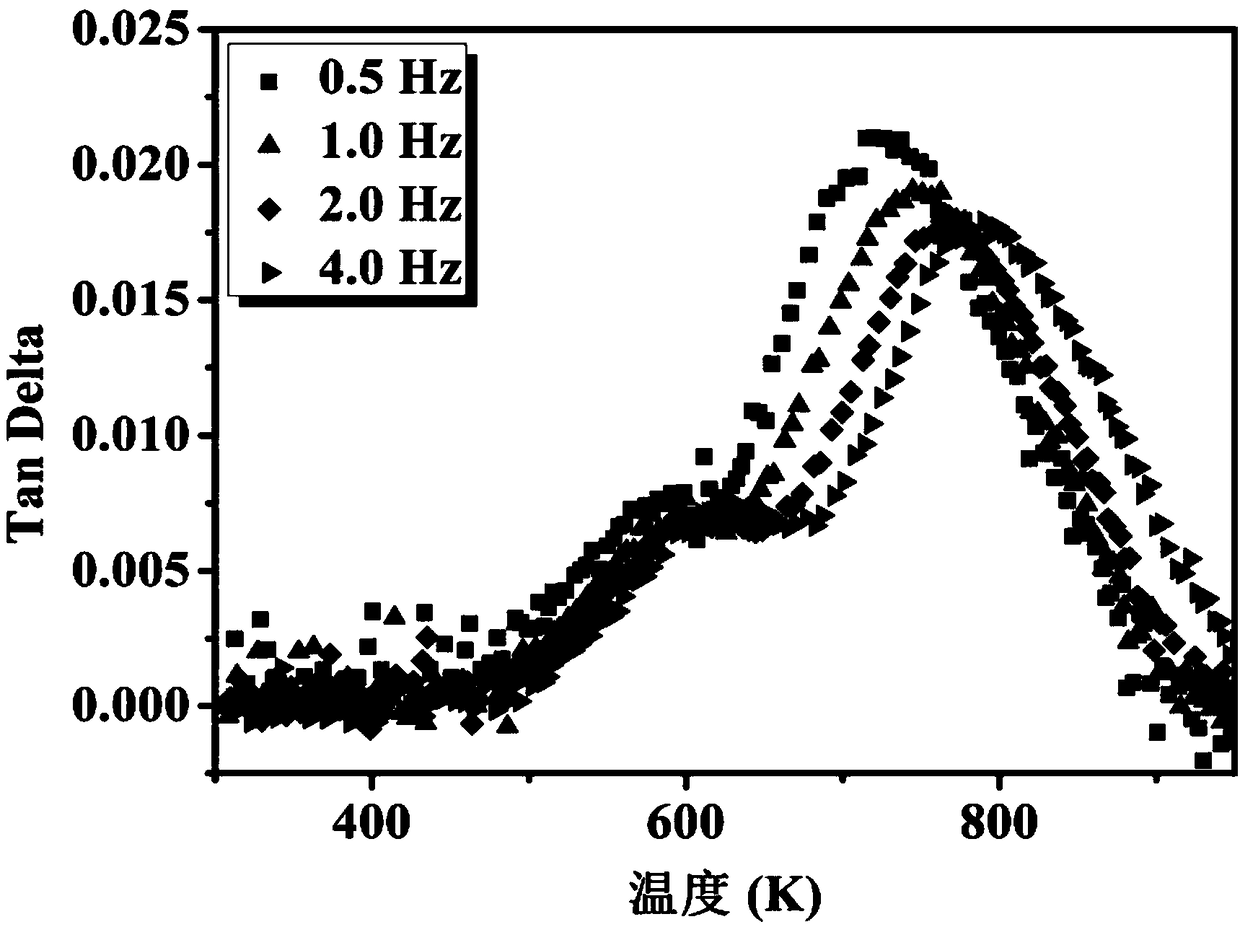

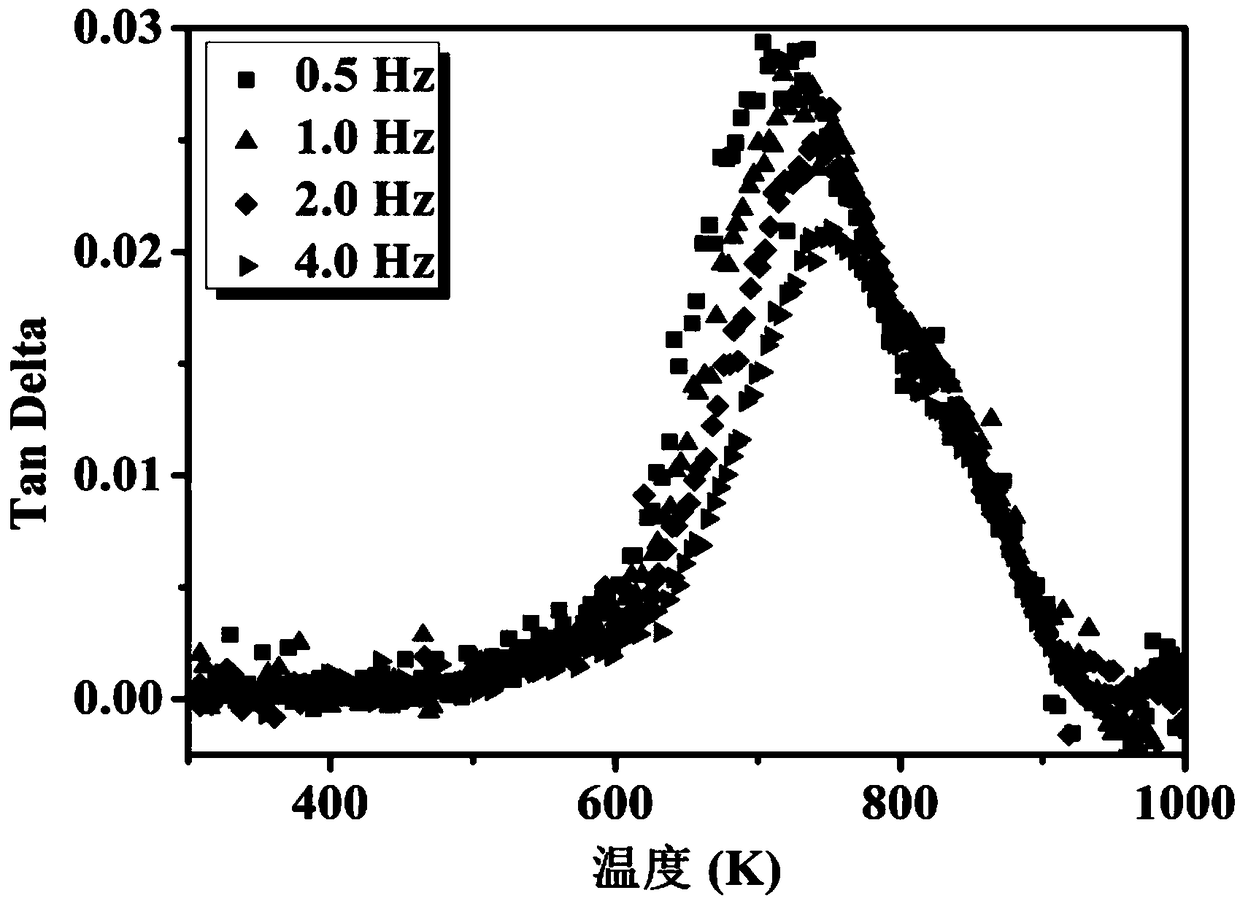

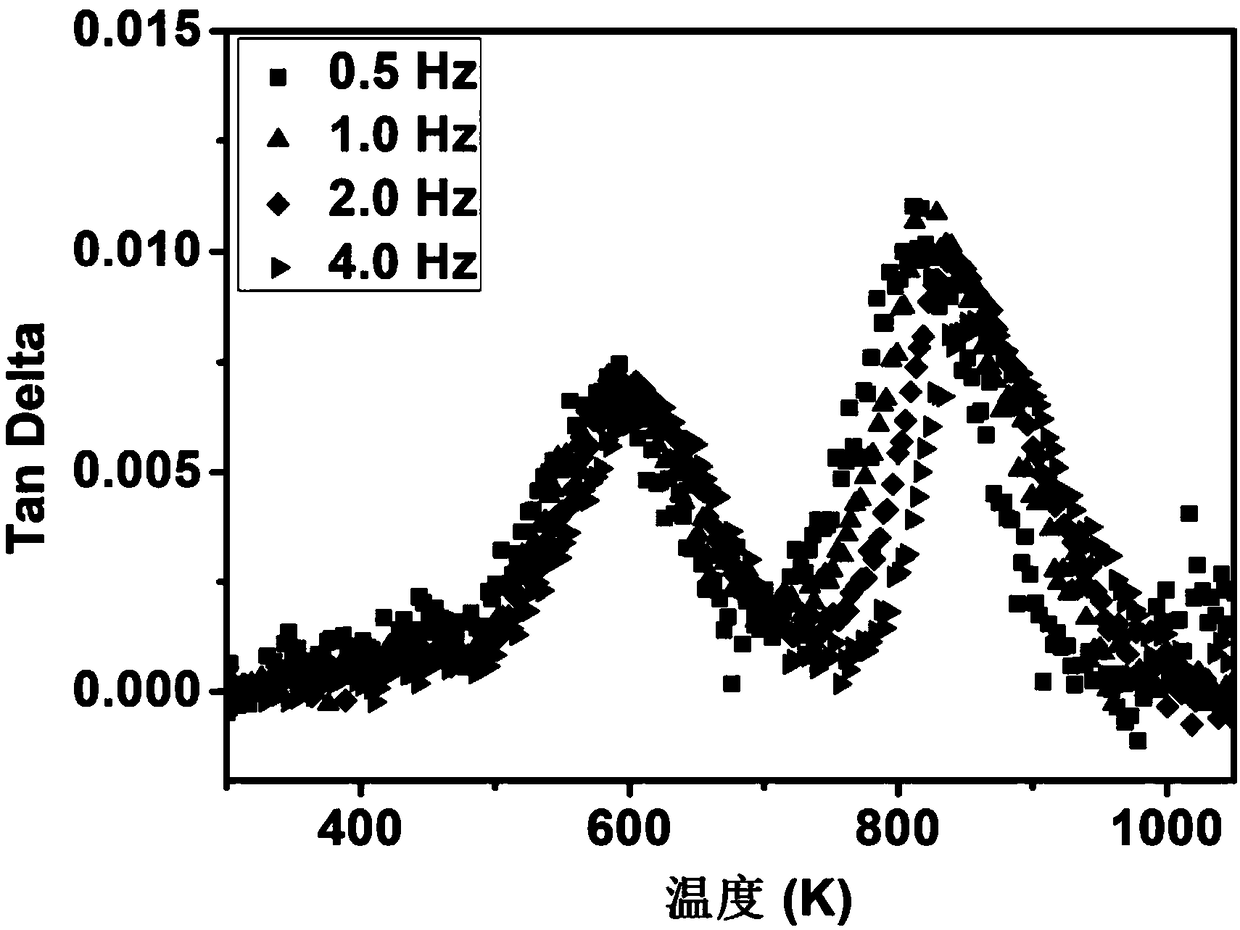

High temperature and high damping high entropy alloy and preparation method thereof

ActiveCN109338200AThe scope of application of large ingredientsBroad preparation conditionsElectric arc furnaceHigh entropy alloys

The invention relates to a high temperature and high damping high entropy alloy and a preparation method thereof. Due to the microalloying oxygen or nitrogen elements of a refractory high-entropy alloy matrix and utilizing high thermal stability of a high-entropy alloy matrix, the high temperature and damping capacity of the high entropy alloy is achieved. The process is as follows: the metal materials Ta, Nb, Hf, Zr, Ti, Mo, V, W, Al, etc. are subjected to mechanical removal of oxidized scale, and are weighted by the molar ratio; other added elements are mechanically scaled, ultrasonically cleaned or pickled, and weighted by the molar ratio; the oxygen element is added in the form of an oxide, and the nitrogen element is added in the form of a nitride; and the alloy is obtained by vacuumcasting or casting equipment through smelting in a non-consumable vacuum electric arc furnace or a cold crucible suspension furnace. The high temperature and high damping high entropy alloy and the preparation method thereof utilize the high structural stability of the high-entropy alloy, and significantly improves the high temperature damping performance and mechanical property of the alloy by small atom microalloying.

Owner:UNIV OF SCI & TECH BEIJING

Model and method for liquid state formation of aluminium hub disc for special vehicle

InactiveCN1887474AImprove performanceMeet the needs of local wear resistanceExtrusion diesForging/hammering/pressing machinesLiquid stateWear resistant

The present invention relates to material forming technology, and is especially mold and method for liquid state formation of aluminum hub disc for special vehicle. The mold includes a lower mold, a female mold casing, an upper mold, an inner male mold and an outer male mold. The corresponding forming process includes the steps of: making wear resistant reinforcing body, setting the reinforcing body inside the mold, pouring aluminum alloy liquid, and extruding. The mold has simple structure, the forming process is simple and high in efficiency, and the product has high performance.

Owner:HARBIN INST OF TECH

Submerged arc welding method for K-shaped groove of 80mm extra-thick steel plate with excellent plate shape after welding

InactiveCN102922103AReduce peak residual stressOffset deformationArc welding apparatusWorkpiece edge portionsResidual deformationMixed gas

Owner:NANJING IRON & STEEL CO LTD

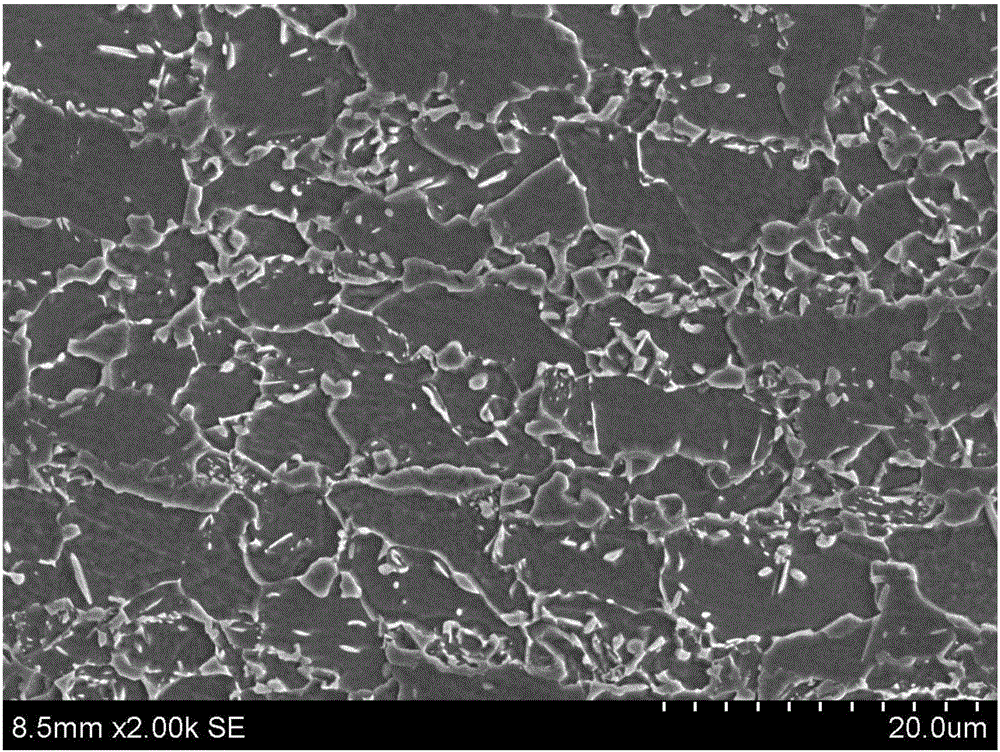

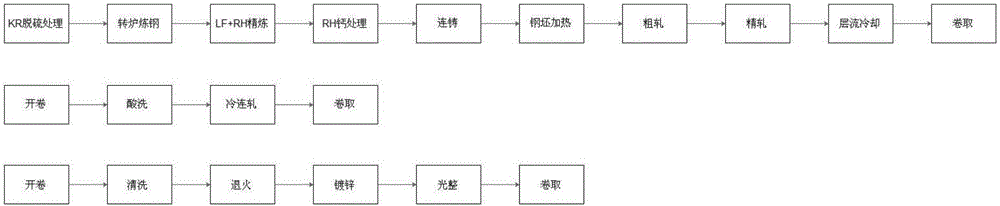

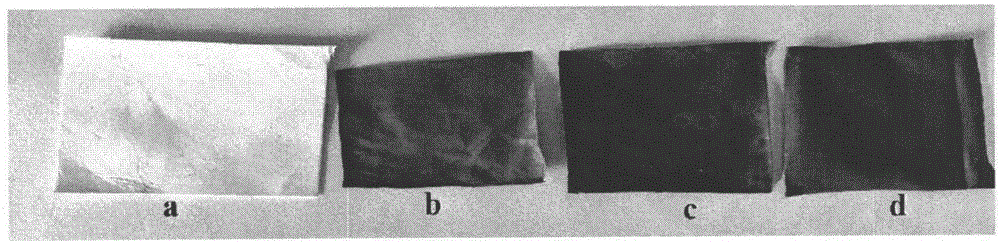

Zinc-plated double-phase steel and production method thereof

The invention belongs to the technical field of cold rolled steel and discloses zinc-plated double-phase steel and a production method of the zinc-plated double-phase steel. The zinc-plated double-phase steel comprises, by weight percentage, 0.085%-0.115% of C, 0.15%-0.24% of Si, 1.45%-1.55% of Mn, not larger than 0.015% of P, not larger than 0.005% of S, 0.025%-0.065% of Alt, 0.14%-0.24% of Cr, 0.24%-0.29% of Mo, not larger than 0.006% of N and the balance Fe and other inevitable impurities. The production method includes the steps of KR desulfuration, converter steelmaking, LF+RH refining treatment, RH calcium treatment, continuous steel casing, billet heating, rough rolling, finish rolling, laminar cooling and winding; unwinding, acid pickling, cold continuous rolling and winding; and unwinding, cleaning, annealing, zinc plating, finishing and winding. Through composition design and process control, the zinc-plated double-phase steel is suitable for annealing production lines having the rapid cooling segment or not.

Owner:SHOUGANG CORPORATION

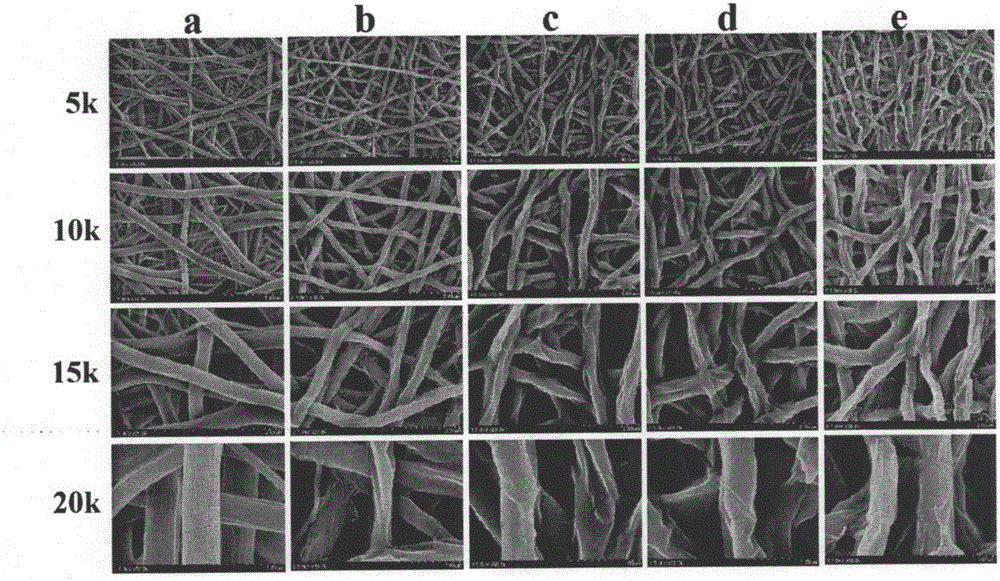

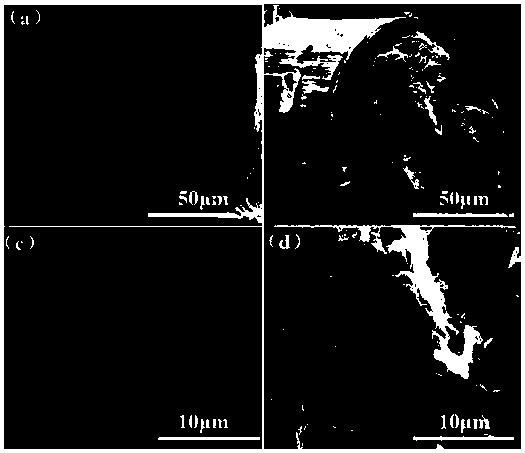

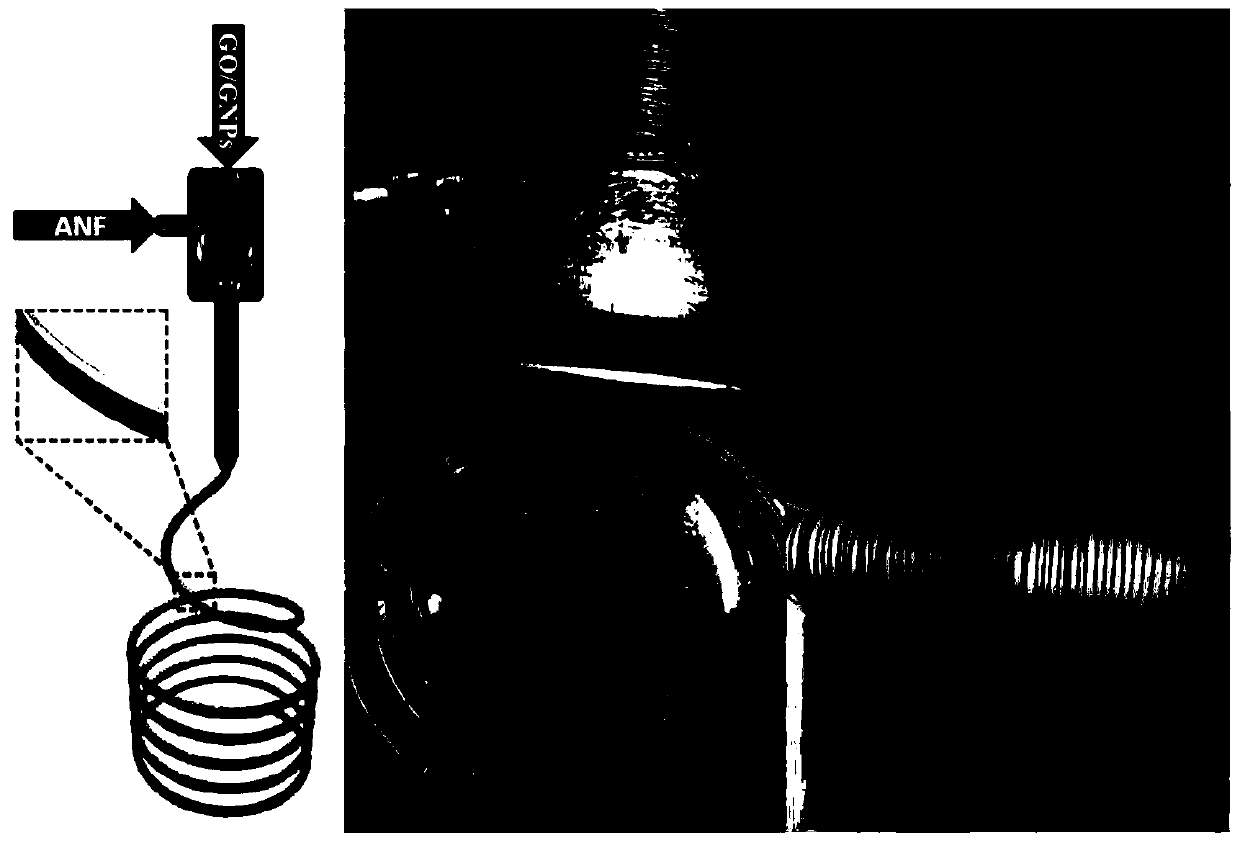

Method for preparing conductive composite nanofiber nervous tissue engineering scaffold based on graphene

InactiveCN106400312AExcellent physical and chemical propertiesGood biocompatibilityElectro-spinningNon-woven fabricsFiberDissolution

The invention provides a method for preparing a conductive composite nanofiber nervous tissue engineering scaffold based on graphene. The method includes the following steps: a step 1, dissolving tussur silk fibroin and poly (lactic acid)-poly caprolactone in a solvent with stirring till complete dissolution of the tussur silk fibroin and the poly (lactic acid)-poly caprolactone so as to acquiring a spinning solution; a step 2, performing electrostatic spinning on the spinning solution obtained from the step 1 so as to acquire a nanofiber membrane, performing steam fumigation treatment by using ethyl alcohol, and performing drying so as to acquire tussur silk fibroin / poly (lactic acid)-poly caprolactone composite nanofibers; and a step 3, dipping the tussur silk fibroin / poly (lactic acid)-poly caprolactone composite nanofiber scaffold material obtained from the step 2 in a graphene oxide dispersion liquid, taking out the tussur silk fibroin / poly (lactic acid)-poly caprolactone composite nanofiber scaffold material, cleaning the tussur silk fibroin / poly (lactic acid)-poly caprolactone composite nanofiber scaffold material, soaking the tussur silk fibroin / poly (lactic acid)-poly caprolactone composite nanofiber scaffold material in an ascorbic acid solution, taking out the tussur silk fibroin / poly (lactic acid)-poly caprolactone composite nanofiber scaffold material, and cleaning the tussur silk fibroin / poly (lactic acid)-poly caprolactone composite nanofiber scaffold material so as to acquiring the conductive composite nanofiber nervous tissue engineering scaffold based on the graphene. The method is simple to operate, is excellent in repeatability, and can provide a new thought for nerve defect repairing.

Owner:DONGHUA UNIV

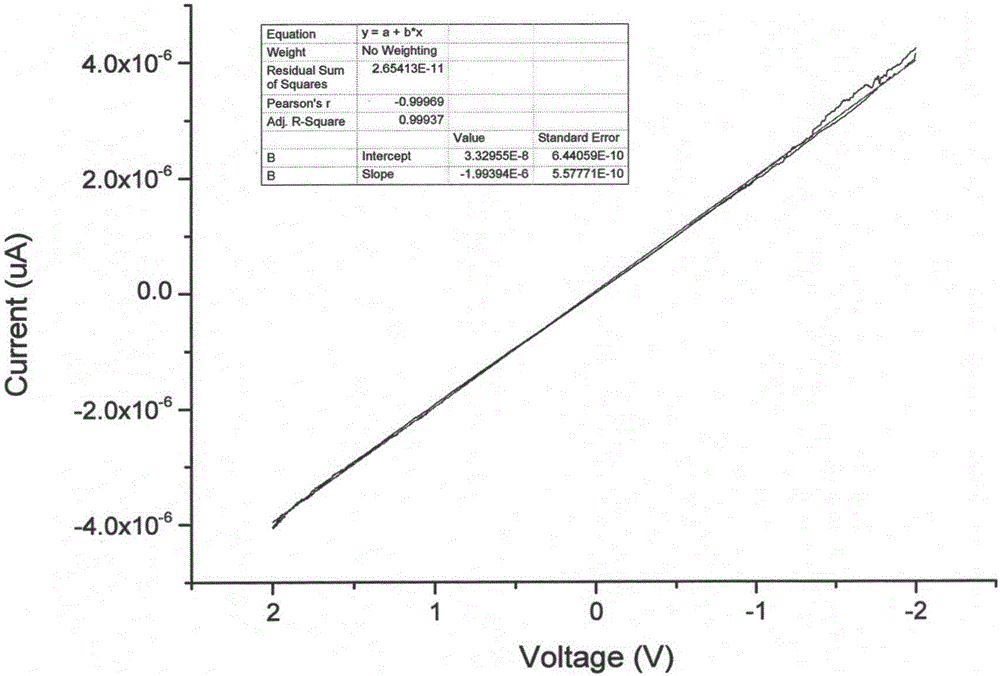

Flexible conductive fiber with sheath-core structure and preparation method thereof

ActiveCN109811426AImprove conductivityImprove mechanical propertiesFilament/thread formingConjugated synthetic polymer artificial filamentsNanofiberGraphene

The invention belongs to the technical field of flexible conductive fibers for wearable electronic devices and preparation thereof, specifically relates to a conductive coaxial nanofiber with a sheath-core structure of an aramid fiber or a polyamide fiber coating a reduced graphene oxide and a preparation method thereof, and provides a preparation method of a conductive fiber with a sheath-core structure. The preparation method of the conductive fiber with the sheath-core structure comprises the steps that (1), a core layer spinning solution is prepared; (2) a sheath layer spinning solution isprepared; (3) a coaxial fiber is prepared; and (4), high-temperature thermal reduction is conducted, specifically, the coaxial fiber obtained in the step (3) is subjected to the high-temperature thermal reduction to obtain a conductive coaxial nanofiber, that is, the conductive fiber with the sheath-core structure. According to the preparation method of the conductive fiber with the sheath-core structure, graphene oxide is used as the core layer material, and the high temperature resistant wet spinning polymer is used as the sheath layer material, thus reduction of the core layer graphene oxide through the high temperature thermal reduction can be realized, so that the obtained fiber has flexibility and also has the excellent electrical and mechanical properties.

Owner:SICHUAN UNIV

Biodegradable magnesium alloy blood vessel rack

The biodegradable magnesium alloy blood vessel rack consists of magnesium in 60-95 wt% and other metals, including RE, for the rest. Metal magnesium as the basic material has excellent tissue compatibility and blood compatibility, and the added other metal, including RE, elements raise and improve the comprehensive performance, especially mechanical strength, plasticity, degradability and biocompatibility. The magnesium alloy blood vessel rack has tensile strength of 200-300 MPa, elastic module of 10-50 GPa, elongation at break of 2-10%and degrading half life of 6-18 weeks. Most of the degraded metal ions are drained through renal tubules while small part being utilized by human body.

Owner:LIAONING YINYI BIOTECH CO LTD

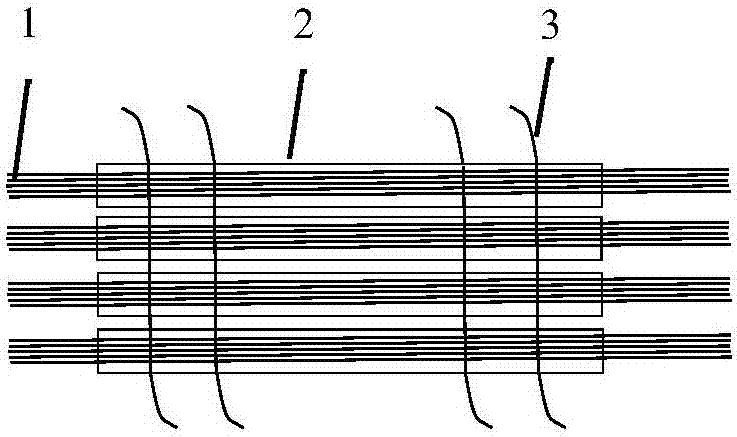

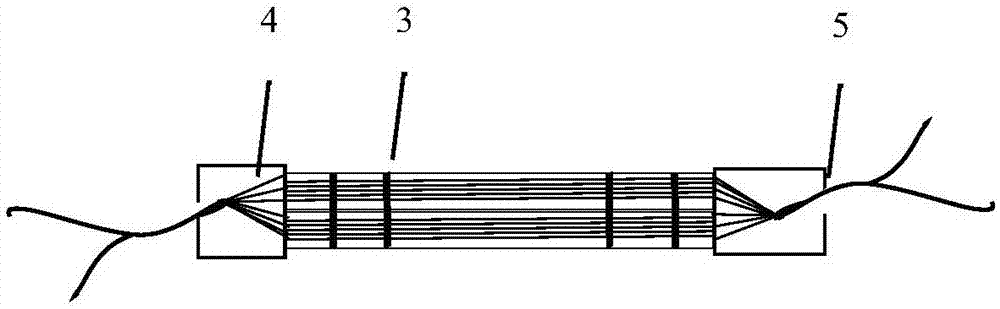

Regenerative implant of cruciate ligament and preparation method and application thereof

The invention relates to a regenerative implant of a cruciate ligament and a preparation method and application thereof. A surgical suture-shaped structure made of a degradable high molecule polymerization material is used as an initial mechanical support structure; a membrane-shaped structure made of a composite electrostatic spinning timbering material is used as a core structure for tissue remodeling and regeneration to be tightly wrapped in a winding mode on the initial mechanical support structure so as to form ligament regeneration elements; the multiple ligament regeneration elements form a ligament regeneration element set which is the regenerative implant of the ligament. The results of a goat animal experiment confirms that the implant is completely degraded within 52 weeks after being implanted to an organism, is induced to form an autogenous ligament tissue in the cavity of a knee joint, and induces the bone tunnel interface of a tibia and a femur to form tendon-bone healing; the maximum pulling force of the regenerated ligament is 20-60% that of a normal ligament tissue within 12 months after the implant is implanted to the organism.

Owner:SHANGHAI P & P BIOTECH

Preparation of acrylic ester mixed polymer urea slow release coating agent

ActiveCN101353283AImprove film forming performanceImprove membrane stabilityFertilizer mixturesWater soluble polymersUrea

The invention discloses a preparation method of a urea slow-release film coating agent of an acrylic ester mixed polymer, which comprises the following steps: the preparation of the acrylic ester mixed polymer, the preparation of water-soluble polymer water solution and the preparation of the slow-release film coating agent of the acrylic ester mixed polymer. The preparation method takes water as a polymerization medium, polymer emulsion prepared by segmentation emulsion polymerization effectively controls water resistance and mechanical properties of slow-release materials, and the polymer emulsion is added with the water-soluble polymer material to improve the film forming capacity of the emulsion and the stability of the film material. The method has the advantages that no organic solvent is adopted during the production process, no waste gas and waste liquid is produced, and the slow-release film coating material obtained has good film forming effect, excellent slow-release function and good water solubility, therefore, the slow-release film coating agent is an ideal environment-friendly film coating material.

Owner:CNOOC FUDAO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com