Preparation method of high-performance magnesium alloy plate with double-phase structure

A dual-phase structure, magnesium alloy technology, applied in the field of high-performance magnesium alloy sheet preparation, can solve the problems of poor high-temperature mechanical properties and stability, low sheet yield, long rolling process, etc., to achieve higher mechanics and yield. High and shortened rolling process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

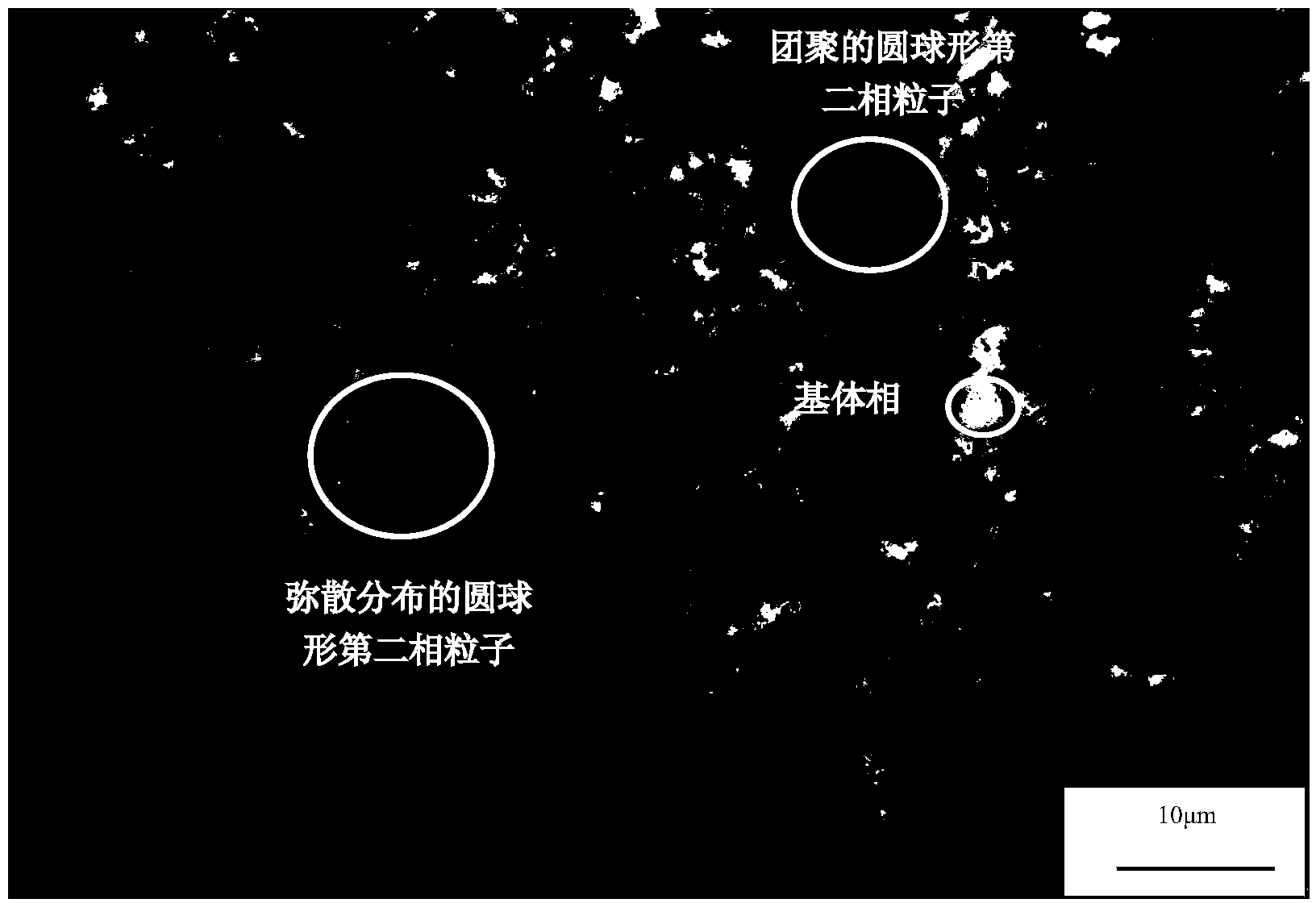

Embodiment 1

[0027] The preparation process of dual-phase high-performance Mg-13Al-4Zn-7Ca-1Mn-2Nd magnesium alloy rolling plate: industrial pure nitrogen is used as the atomizing gas of magnesium alloy, the atomizing gas pressure is about 0.6-0.9MPa, the melt The temperature is 760-830°C. After the alloy liquid is raised to about 800°C, it is sprayed. The deposited billet after spraying is subjected to hot extrusion pre-deformation. The extrusion ratio is about 9:1, and the extrusion temperature is 350°C. The billet is used as a hot-rolled billet. The deposited slab was heated before rolling at a temperature of 350°C and a holding time of 30 minutes. During the rolling process, the reduction in passes is between 5% and 15%, the rolling temperature is 300-400°C, and the temperature of the rolls is heated to about 200°C. After rolling, the structure of the magnesium alloy plate is uniform and fine, the grain size is between 5 and 10 μm, the tensile strength at room temperature is 435 MPa, ...

Embodiment 2

[0029]The preparation process of dual-phase high-performance Mg-5Al-4Zn-7Ca-1Mn-1Nd magnesium alloy rolled plate: industrial pure nitrogen is used as the atomizing gas of magnesium alloy, the atomizing gas pressure is about 0.6-0.9MPa, the melt The temperature is about 760-830°C. After the alloy liquid rises to about 800°C, it is sprayed. The deposited billet after spraying is subjected to hot extrusion pre-deformation. The extrusion ratio is about 16:1, and the extrusion temperature is 350°C. The compact is used as a hot-rolled billet. The deposited slab was heated before rolling at a temperature of 350°C and a holding time of 30 minutes. The reduction of the rolling pass is between 5% and 25%, the rolling temperature is 300-400°C, and the temperature of the roll is heated to about 200°C. After rolling, the structure of the magnesium alloy plate is uniform and fine, the grain size is between 5 and 10 μm, the tensile strength at room temperature is 386MPa, the yield strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com