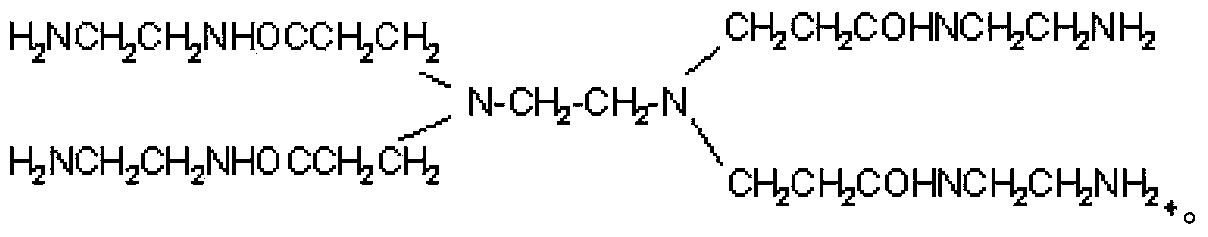

Dendritic multi-amino polymer drilling fluid used for mud rock well drilling

A drilling fluid and polymer technology, which is applied in the field of drilling fluids, can solve the problems such as the inability to completely solve the problems of reducing diameter and blocking of colloidal mudstone formations, failing to meet the environmental protection requirements of drilling engineering, and difficult to control the performance of drilling fluids, so as to avoid water absorption, expansion and dispersion. , Improve drilling efficiency and reduce reservoir damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

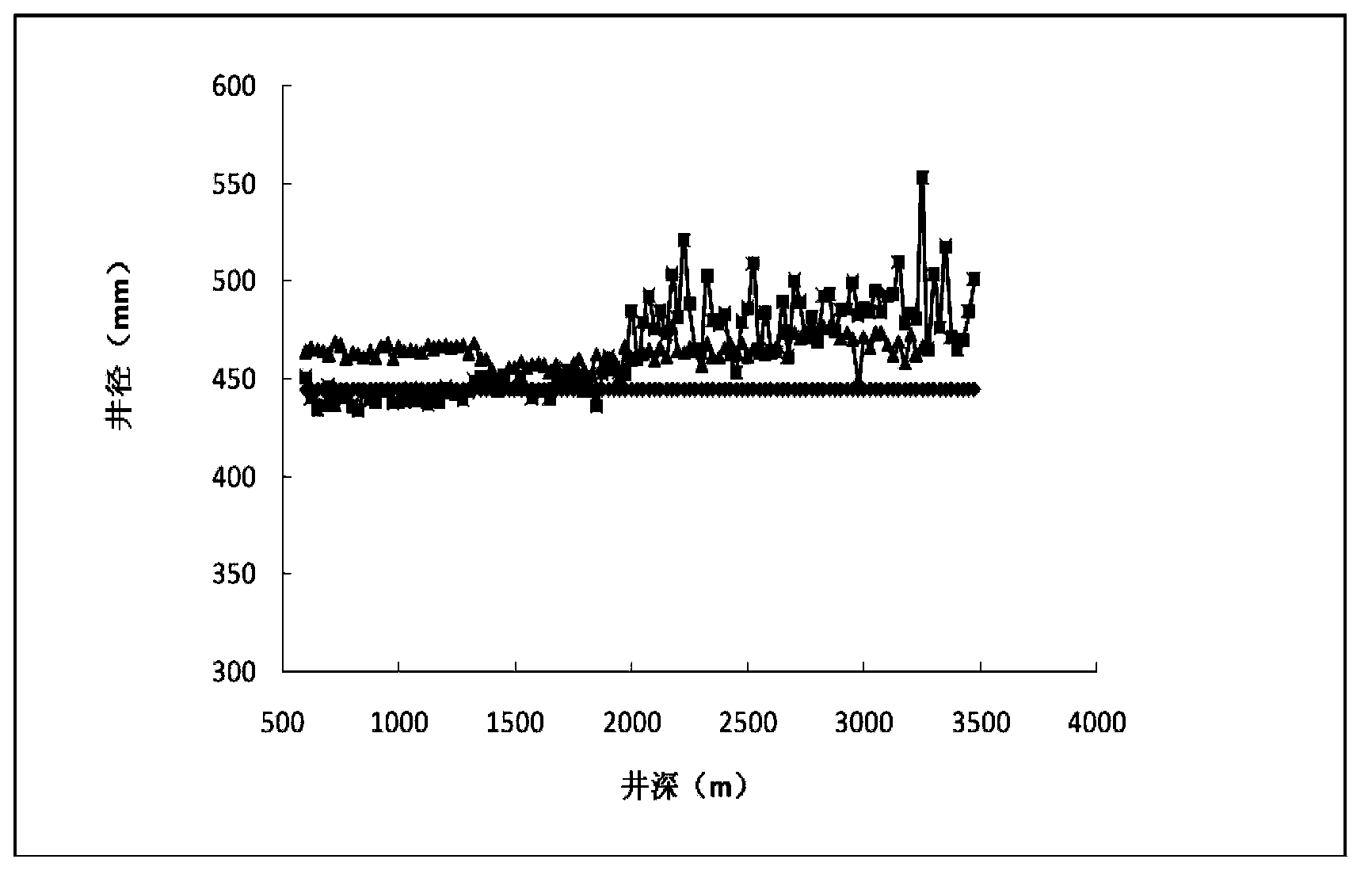

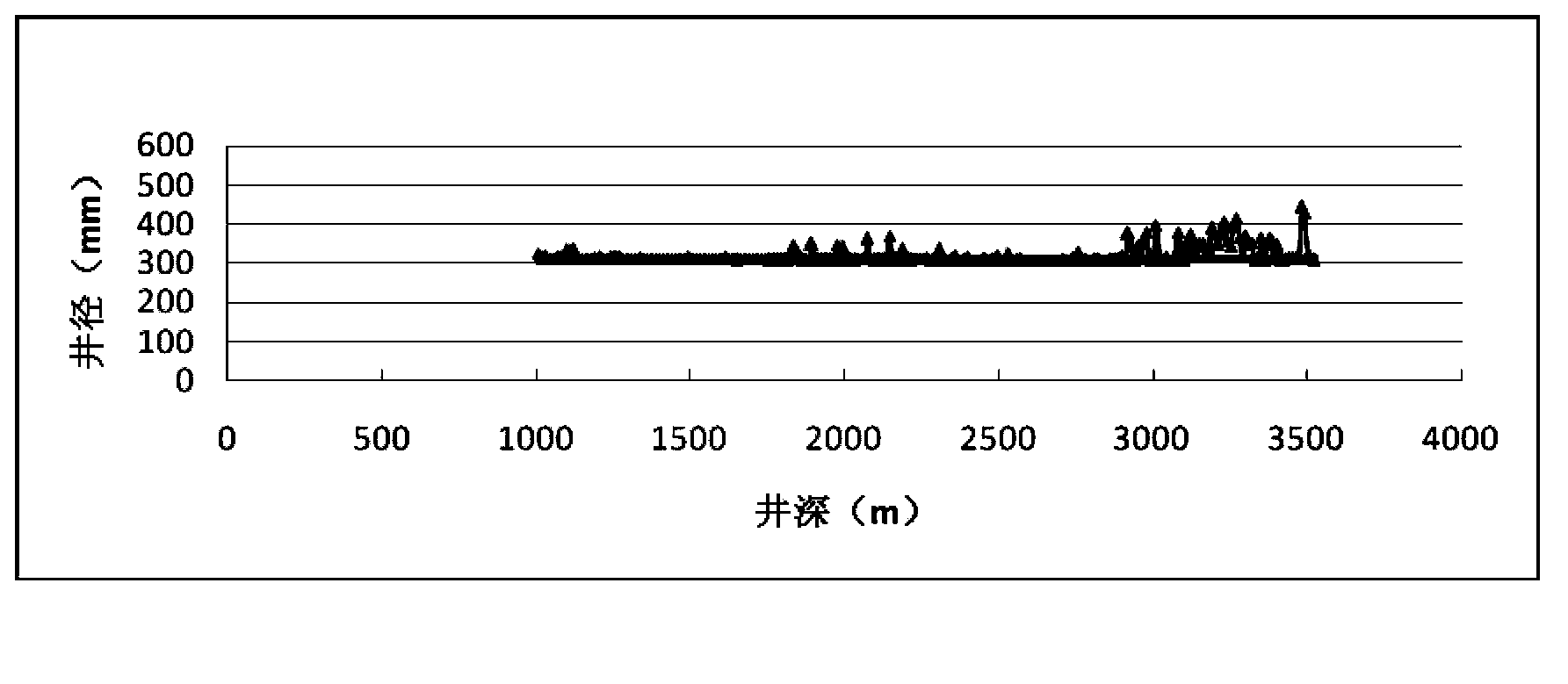

[0037] Example 1 Inhibition of Xuanhua Bentonite Slurry and Temperature Resistance Evaluation

[0038] Add 35% Xuanhua bentonite to the drilling fluid formula 1, put it into the aging tank and roll and age at different temperatures for 16 hours, and measure the rheology of the drilling fluid after cooling to room temperature. The data are shown in Table 1.

[0039] Drilling fluid formula 1: 10 parts by weight of dendritic polyamine-based polymer; 4 parts by weight of bentonite in drilling fluid; 2 parts by weight of soda ash; 2 parts by weight of polymer coating agent; 2 parts by weight of potassium polyacrylate; hydrolyzed polyacrylonitrile ammonium salt 15 parts by weight; 10 parts by weight of anti-mud bag lubricant; 1000 parts by weight of water.

[0040] Table 1 Inhibition of Xuanhua bentonite pulping and temperature resistance (the following is the mass fraction)

[0041] drilling fluid

Experimental conditions

PV

YP

Drilling fluid formula 1+35%...

Embodiment 2

[0045] Example 2 Shale Rolling Recovery Rate Determination Test

[0046] Refer to "Zhang Xiaohua, Luo Xingshu, et al., "Modern Mud Experimental Technology" to suppress the shale dispersion experiment (page 45).

[0047] Drilling fluid formula 1: 10 parts by weight of dendritic polyamine-based polymer; 4 parts by weight of bentonite in drilling fluid; 2 parts by weight of soda ash; 2 parts by weight of polymer coating agent; 2 parts by weight of potassium polyacrylate; hydrolyzed polyacrylonitrile ammonium salt 15 parts by weight; 10 parts by weight of anti-mud bag lubricant; 1000 parts by weight of water.

[0048] Organic amine strong inhibition anti-slump drilling fluid: organic amine inhibitor G319-FTJ 1.0%-2.0%, organic inhibitor 0.3%-0.5%, viscosifier 0.3%-0.5%, low viscosity polyanionic cellulose PAC-LV 0.3-0.5%, high viscosity polyanionic cellulose PAC-HV 0.3-0.6%, barite 0-3%, preservative 0.05-0.2%, defoamer 0.1-0.3%, and the balance is water. (Refer to the Chinese p...

Embodiment 3

[0059] Embodiment 3 biological toxicity evaluation

[0060] Detected by China Oceanic Administration Tianjin Marine Monitoring Center Station, the LC of the present invention 50 The value is 35000mg / L, which is a non-toxic product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com