Patents

Literature

232results about How to "Prevent water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

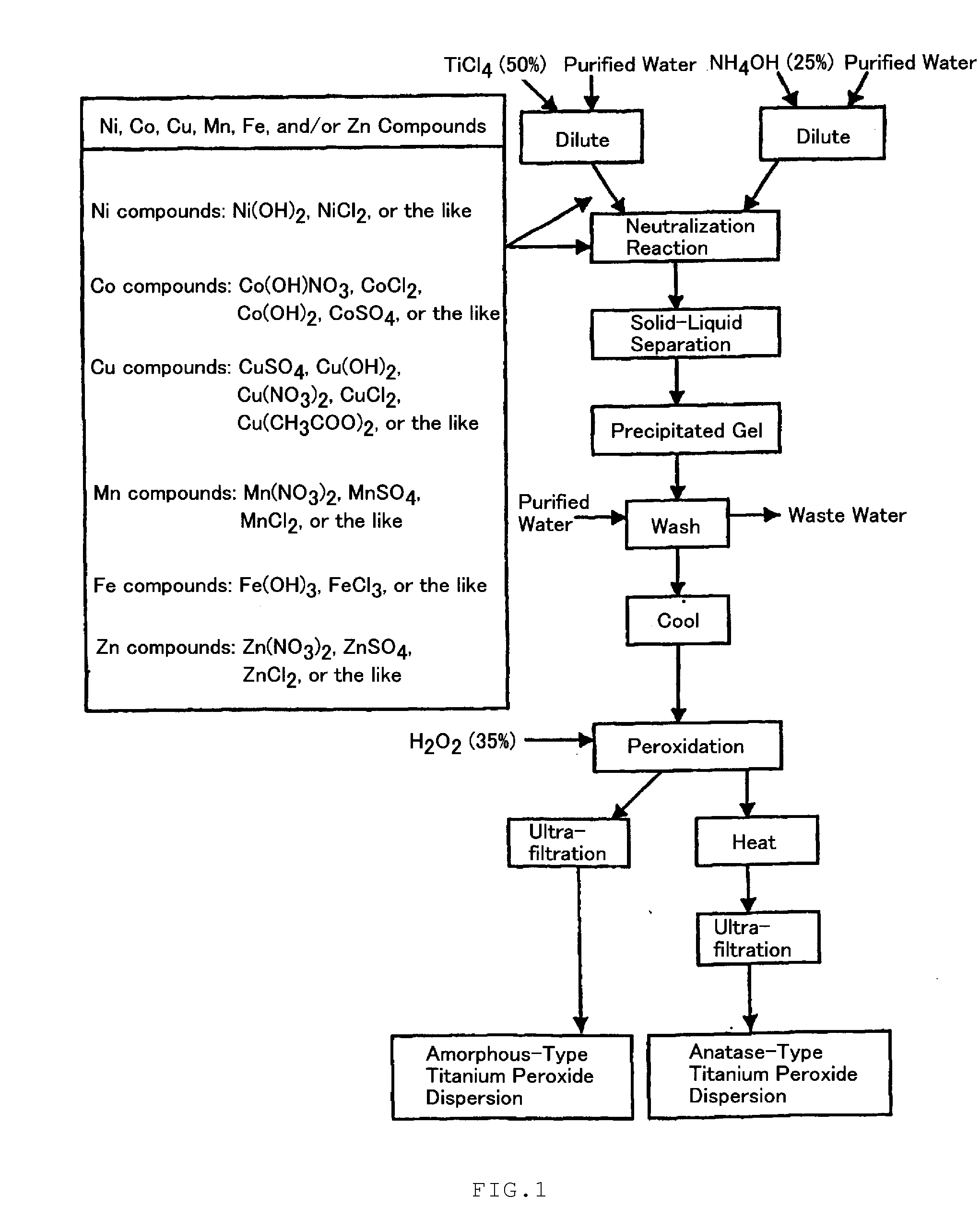

Conductive Copolymer, Conductive Copolymer Composition, Film and Opto-Electronic Device Using the Same

ActiveUS20080105854A1Avoid problemsReduce concentrationConductive materialSolid-state devicesConductive polymerOpto electronic

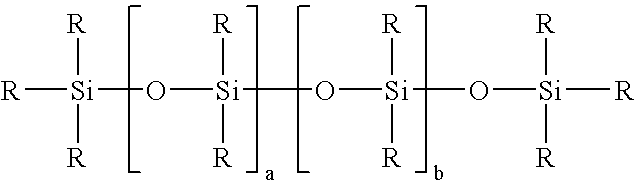

Disclosed herein is a conductive copolymer. The conductive copolymer can prevent water-absorbance, lower the concentration of polyacid contained in a molecule and exhibit superior film characteristics and excellent storage stability via a reduction in aggregation between molecules, as well as impart improved efficiency and lifetime to optoelectronic devices. The conductive copolymer includes a conductive polymer doped with a polyacid copolymer represented by Formula 1 below:Further disclosed are a conductive copolymer composition, a conductive copolymer composition film and an organic optoelectronic device, each including the conductive copolymer.

Owner:CHEIL IND INC

Antimicrobial coating composition and treated building construction materials therewith

InactiveUS20060035097A1Prevent water absorptionMinimize opportunityBiocideAntifouling/underwater paintsWater basedHalogen

The present invention concerns an antimicrobial composition, a process for making antimicrobial building construction surfaces, and building construction products treated with the composition on their surfaces. The water based antimicrobial composition disclosed comprises a water resistant polymer, at least three organic based antimicrobial agents, with at least one antimicrobial agent being halogen containing, and at least one antimicrobial agent being non-halogen containing. The composition is useful for treating the surfaces of building construction materials to make products that are highly resistant to microbial growth even in severe environments.

Owner:BATDORF VERNON H

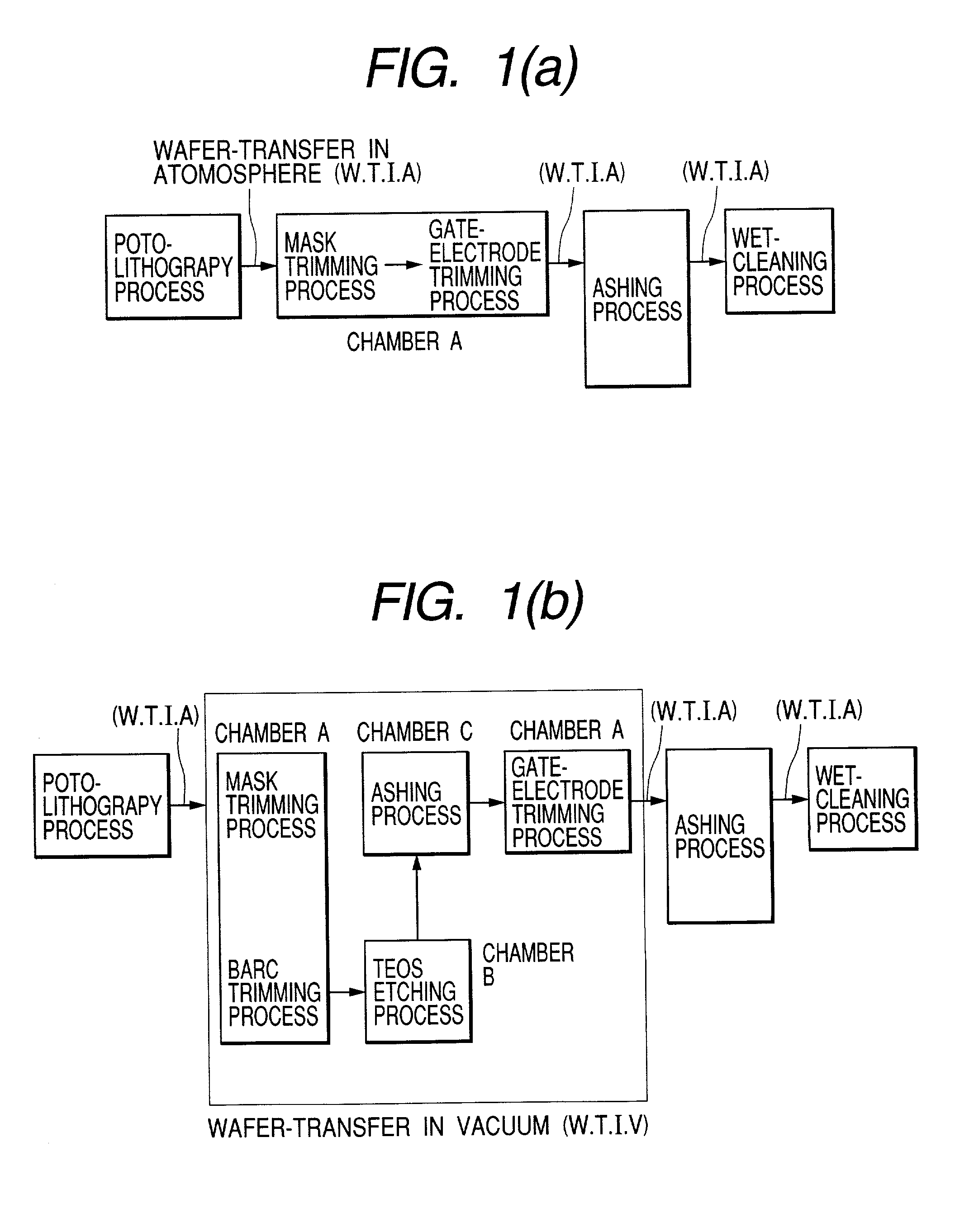

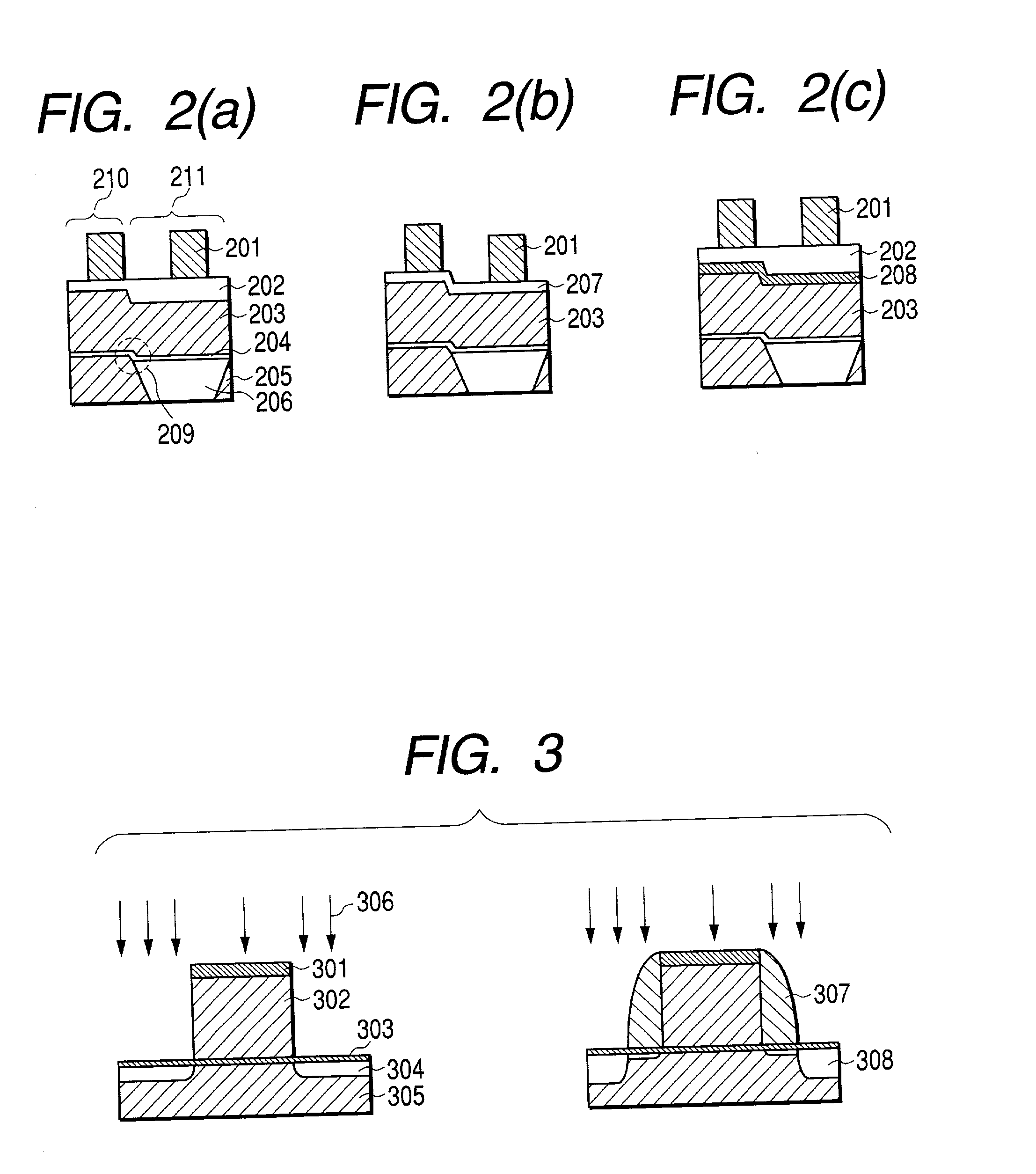

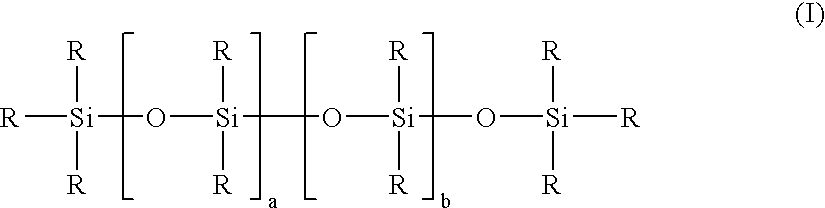

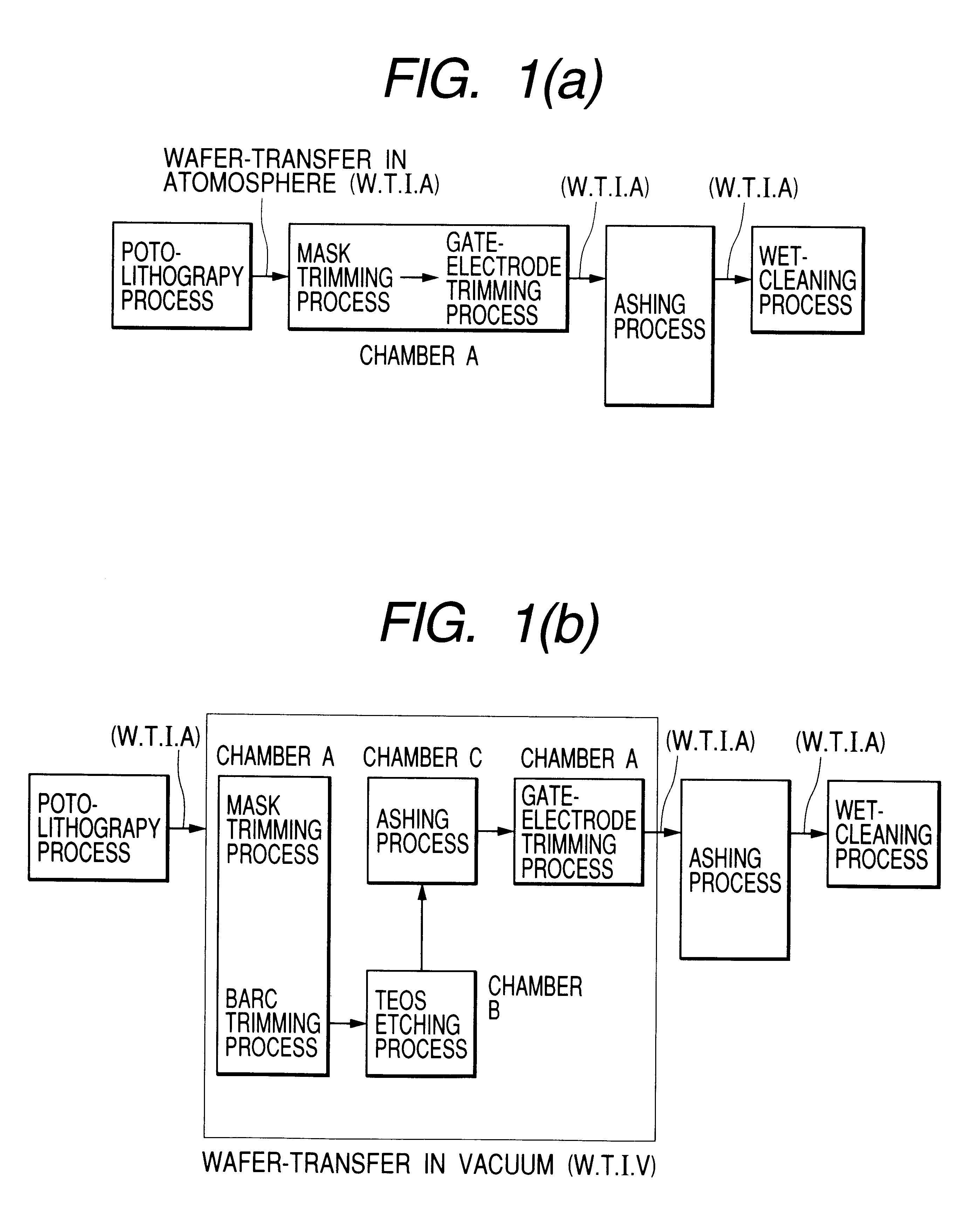

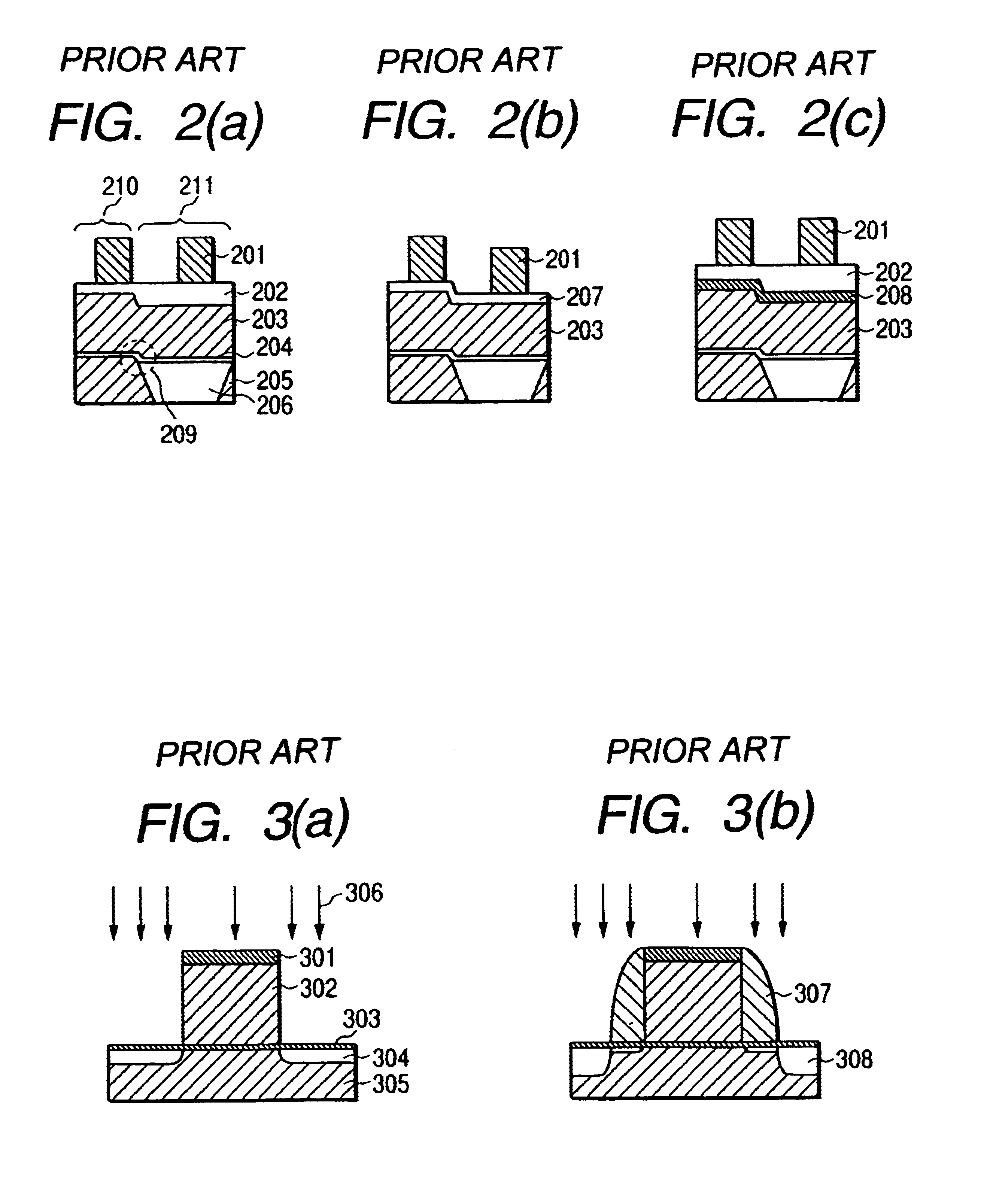

Method of manufacturing semiconductor devices

InactiveUS20030049876A1Reduce variationHigh precision machiningSemiconductor/solid-state device manufacturingSemiconductor devicesResistEngineering

A process for economical and efficient fabrication of gate electrodes no larger than 50 nm, which is beyond the limit of exposure, is characterized by gate-electrode trimming and mask trimming with high resist selectivity which are performed in combination. The process is also preferably characterized by performing trimming and drying cleaning in a vacuum environment and may also include steps of inspecting dimensions and contamination in a vacuum environment. The process can be implemented to provide the effects of forming a gate no longer than 50 nm (beyond the limit of exposure) without restrictions on the resist thickness; reducing contamination resulting from transfer of wafers from one step to next, thereby improving yields; preventing resist from hydrolysis by ArF laser, thereby reducing roughening which adversely affects the gate width; and ensuring stable yields despite variation in dimensions and contamination owing to the additional dry cleaning step and feed-forward control based on CD inspection and contamination inspection.

Owner:HITACHI LTD

Aqueous phospholipid-containing anti-frizz composition for hair

InactiveUS20080085254A1Avoid absorptionPrevent water absorptionCosmetic preparationsHair cosmeticsChemistryNonionic surfactant

The present invention is drawn to a composition and process for inhibiting hair from becoming frizzy when exposed to high and / or low humidity, the composition containing: (a) at least one phospholipid; (b) at least one nonionic surfactant; (c) at least one anionic silicone; (d) at least one water-insoluble material; (e) at least one cationic polymer; and (f) at least one film former, different from (e).

Owner:LOREAL SA

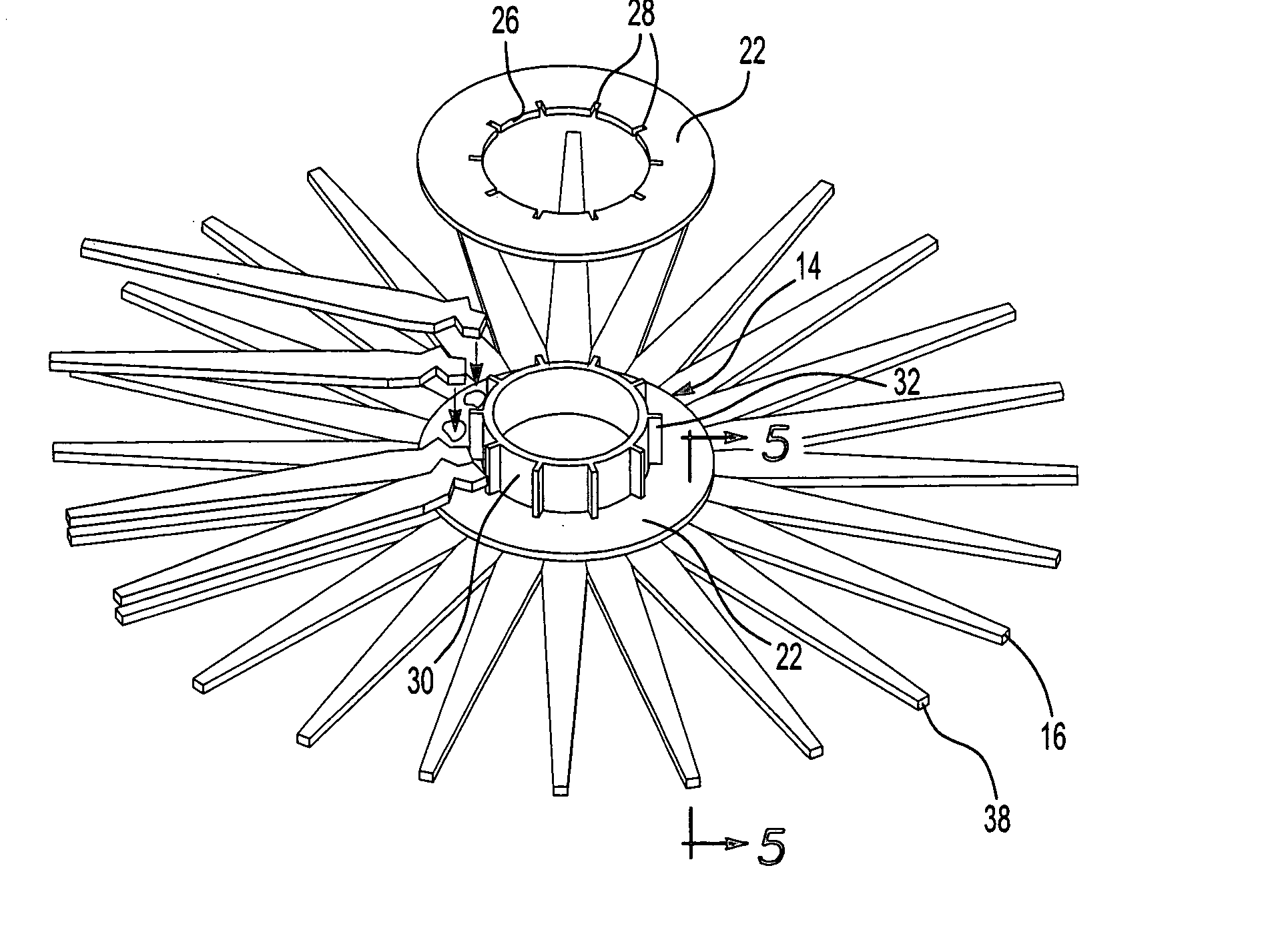

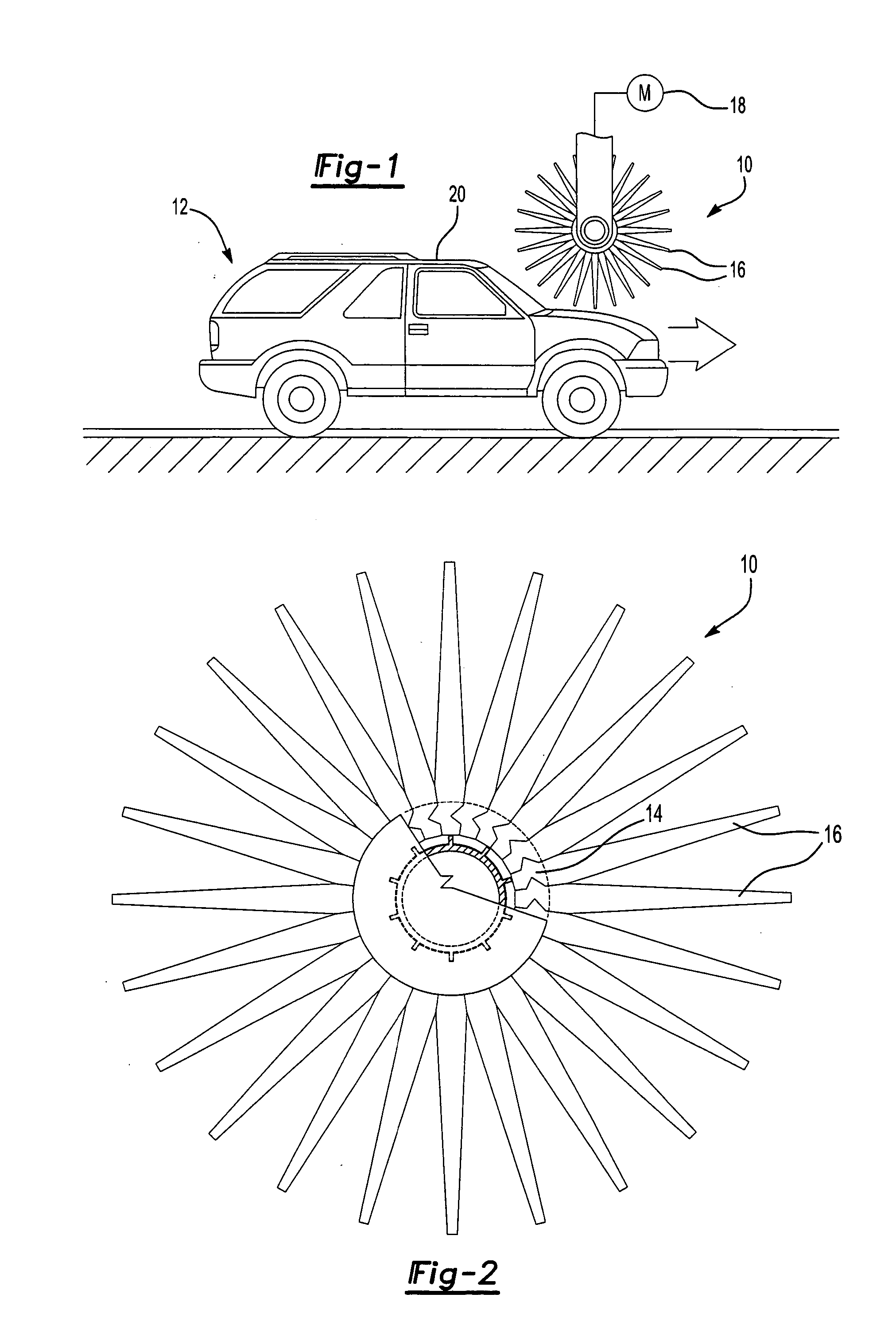

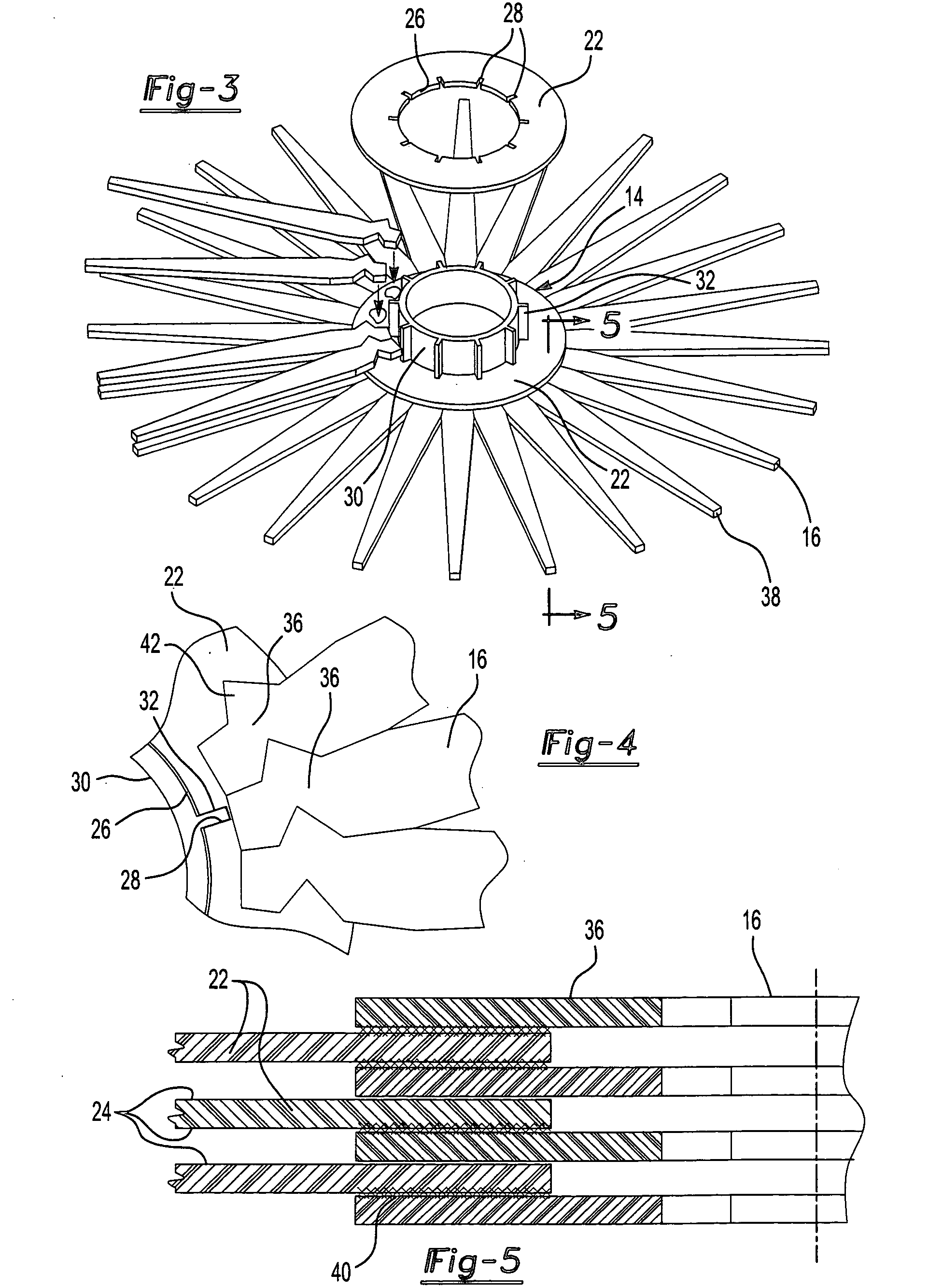

Carwash brush

InactiveUS20040200024A1Prevent water absorptionLiquid surface applicatorsBrush bodiesEngineeringElongated fingers

A carwash brush having a pair of annular hubs, each hub having a planar annular surface. A plurality of elongated fingers each have a first end sandwiched in between the hubs so that the fingers extend radially outwardly from the hubs and so that the second or outer ends of each finger are circumferentially spaced from each other. The first ends of the fingers are continuously bonded to the hubs. Preferably, both the hubs and the fingers are constructed of a closed-cell foam.

Owner:YAMIN THEODORE

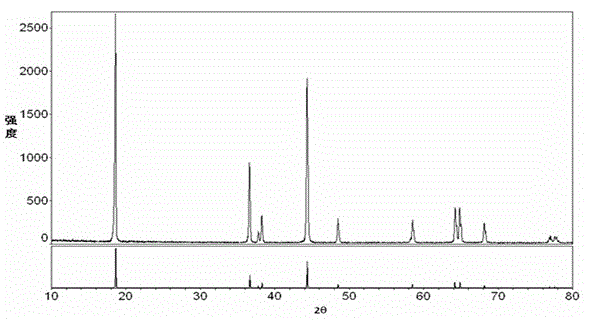

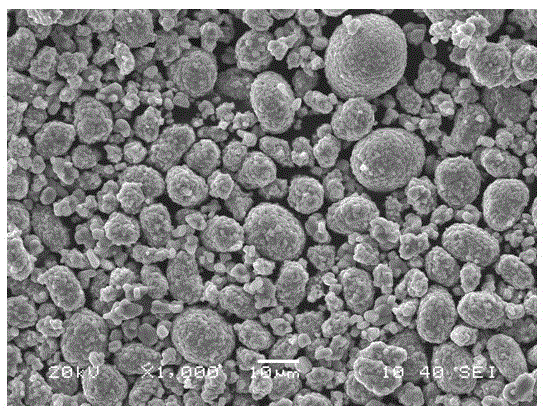

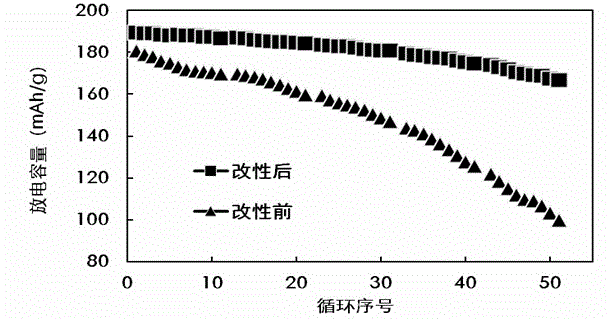

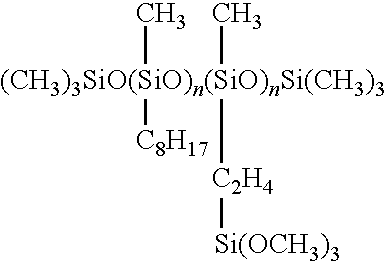

Positive electrode material of high-capacity dynamic-type nickel-rich lithium ion battery and preparation method thereof

ActiveCN103606671AStable structureImprove cycle performanceCell electrodesMaterials processingLithium-ion battery

The invention relates to a positive electrode material of a high-capacity dynamic-type nickel-rich lithium ion battery and a preparation method. The molecular formula of the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery is LiaNi1-x(MM')xO2.M''O, wherein a is equal to 0.9-1.2, x is more than or equal to 0 and less than or equal to 0.7, and M is at least one of Co, Mn and Al; M' is at least one of Co, Al, V, Mn, Zr, Mg, Ti, Cr, Zr, La, Ce, Pr, Nd, Nb, Mo, Y, Sr, Ba, B, Sr, Sn and Ta; M''O is a cladding layer, and M'' is Co and Al. The invention also relates to a preparation method for the positive electrode material of the high-capacity dynamic-type nickel-rich lithium ion battery. The material machining performance is excellent, the battery prepared by utilizing the material, the cycling performance and the high-voltage performance are excellent, the safety and stability in use can be realized, not only can the application performance requirement of a portable electronic device on the battery be met, but also the positive electrode material is applicable to the power battery.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

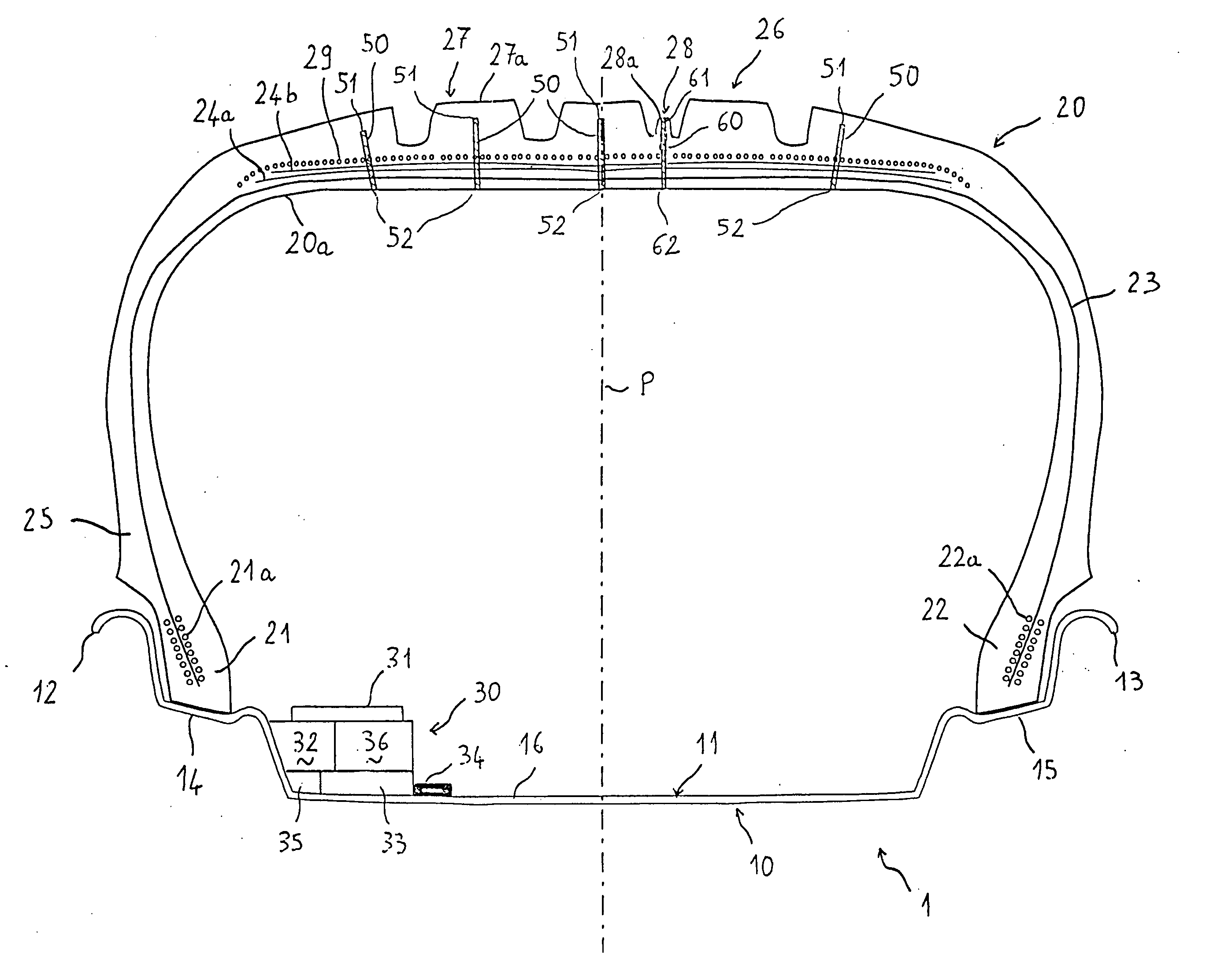

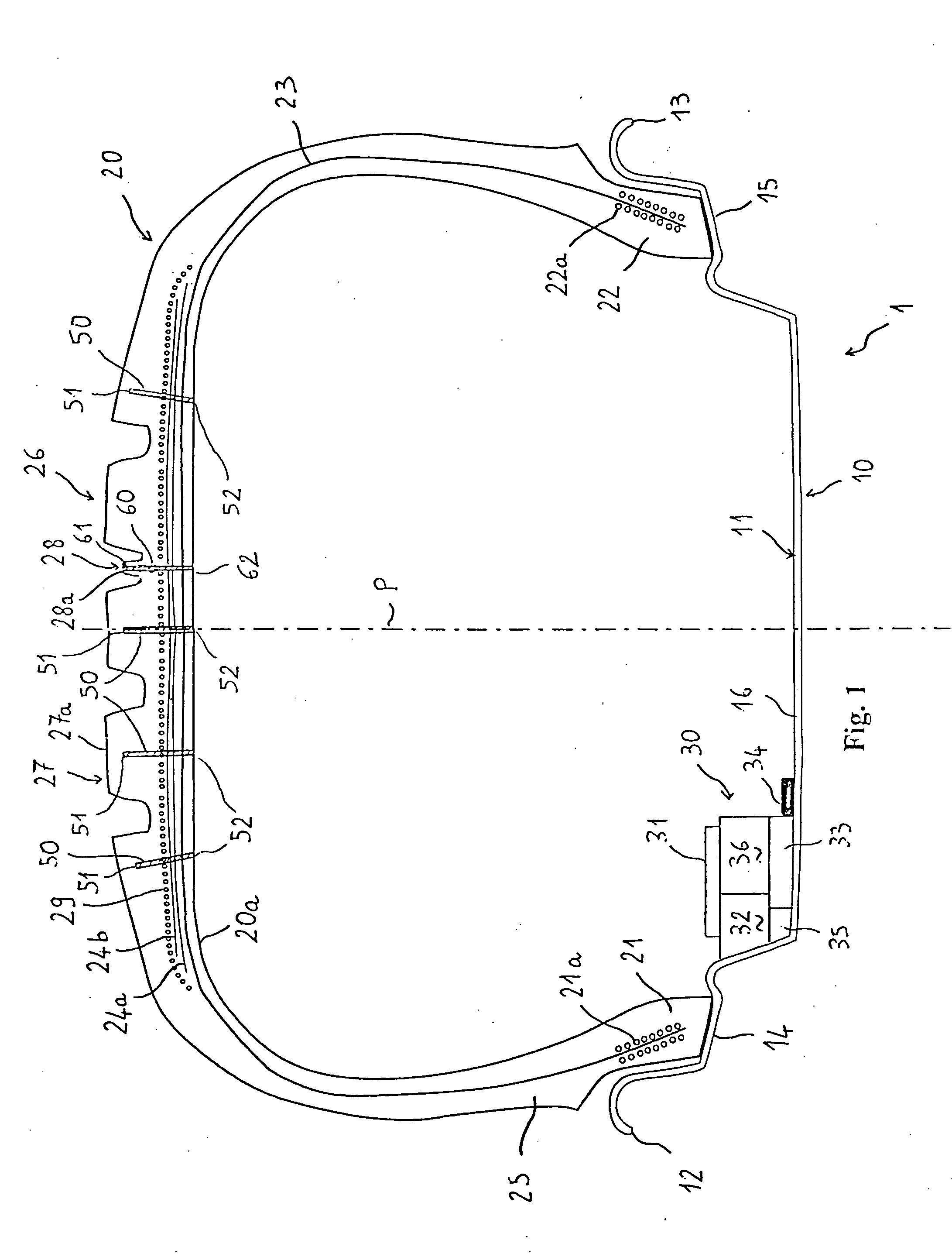

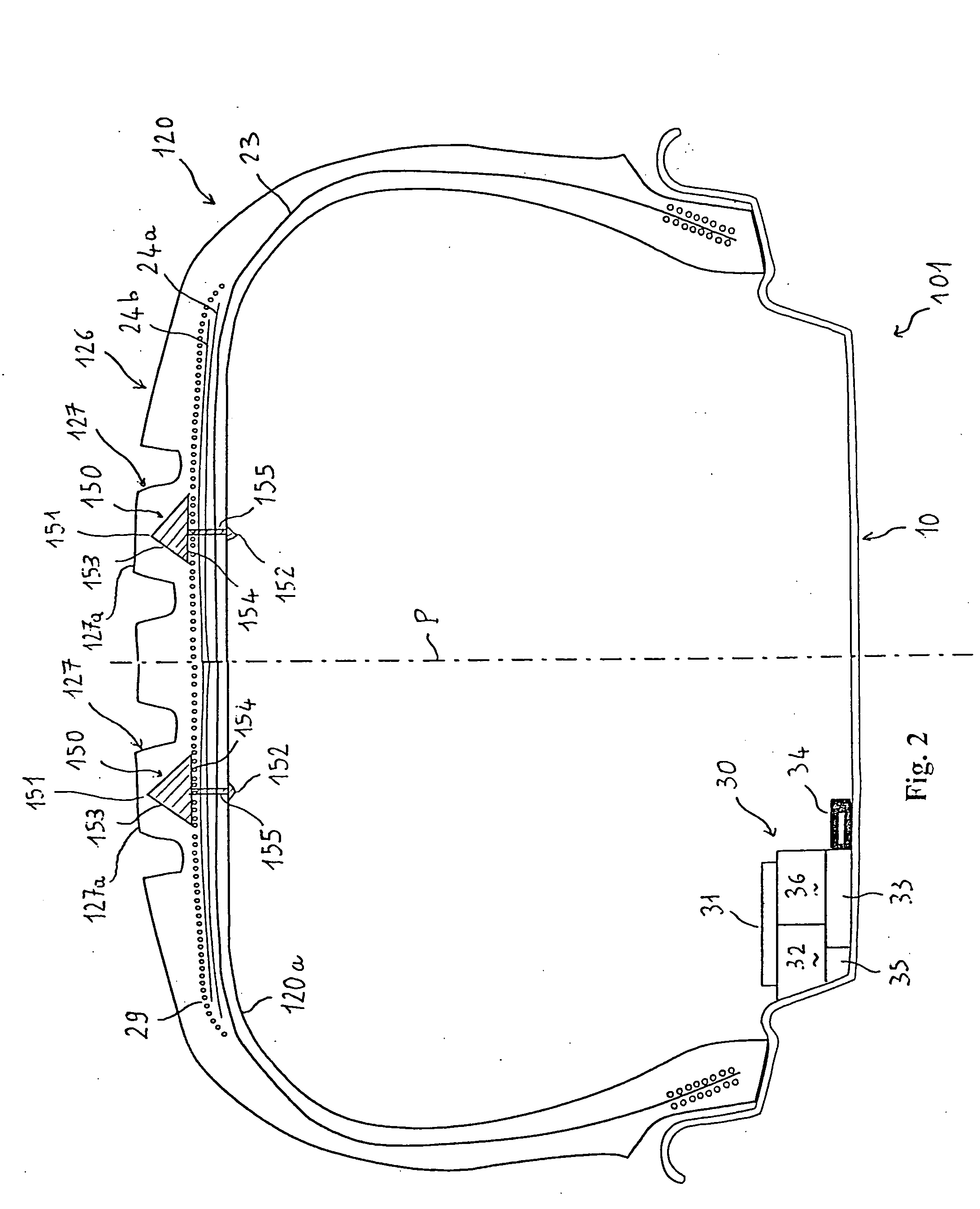

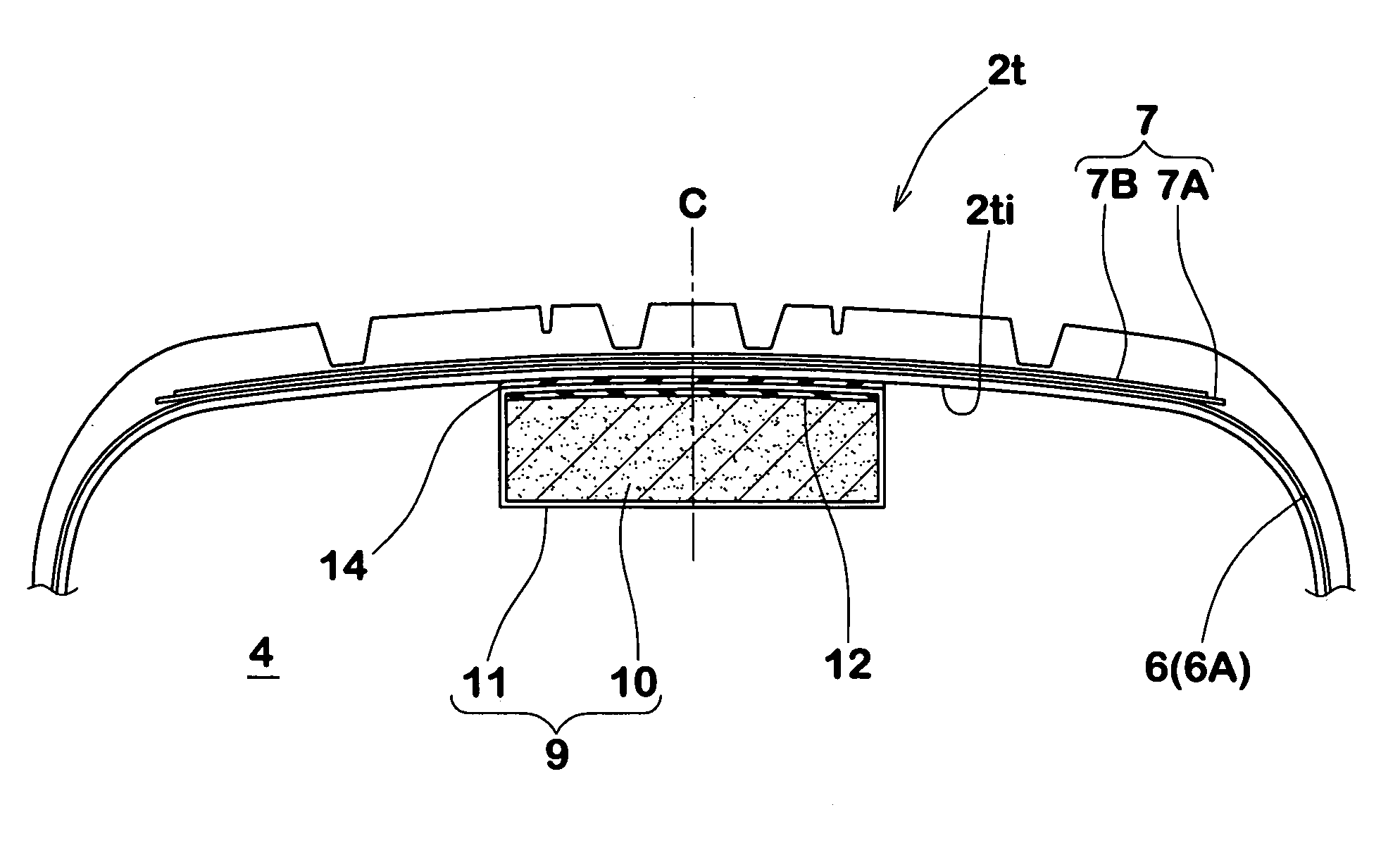

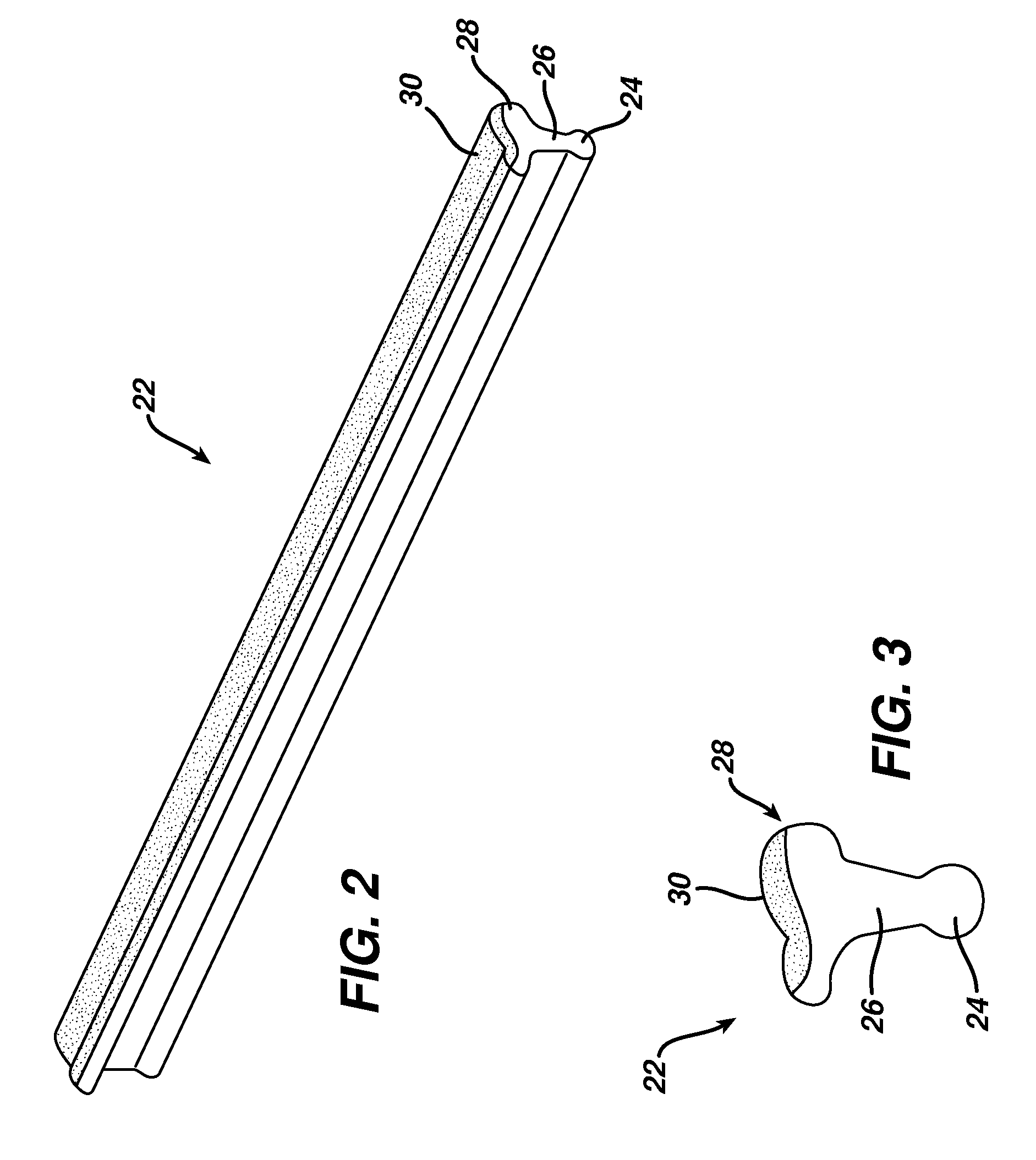

Method and systems for measuring wear on a tire

ActiveUS20050044943A1Improve the transfer coefficientLarge axial section areaMaterial analysis by optical meansUsing optical meansEngineeringElectromagnetic radiation

The present invention concerns a method of measuring the wear on at least one tire (20) mounted on a wheel (10) and comprising tread pattern elements (27, 28), and a tire (20), wheel (10), and a tire / wheel assembly (1) for implementing this method. According to the invention, the wear measurement method includes detecting electromagnetic energy transmitted through a transmission element disposed in at least one tire tread element to an internal space of the tire, the energy detected representative of a wear condition of the tread element or elements (27, 28). A tire (20) according to the invention comprises at least one device for transmitting electromagnetic radiation (50, 60), which device is disposed in at least one of tread element (27, 28) to conduct incident radiation striking the external surface to the tire (20) to the internal space, the transmission devices (50, 60) becoming exposed to the external surface upon a predetermined amount of wear of the tread element (27, 28).

Owner:MICHELIN RECH & TECH SA

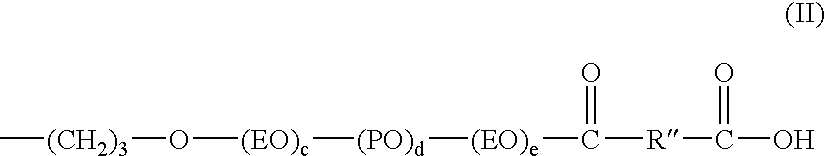

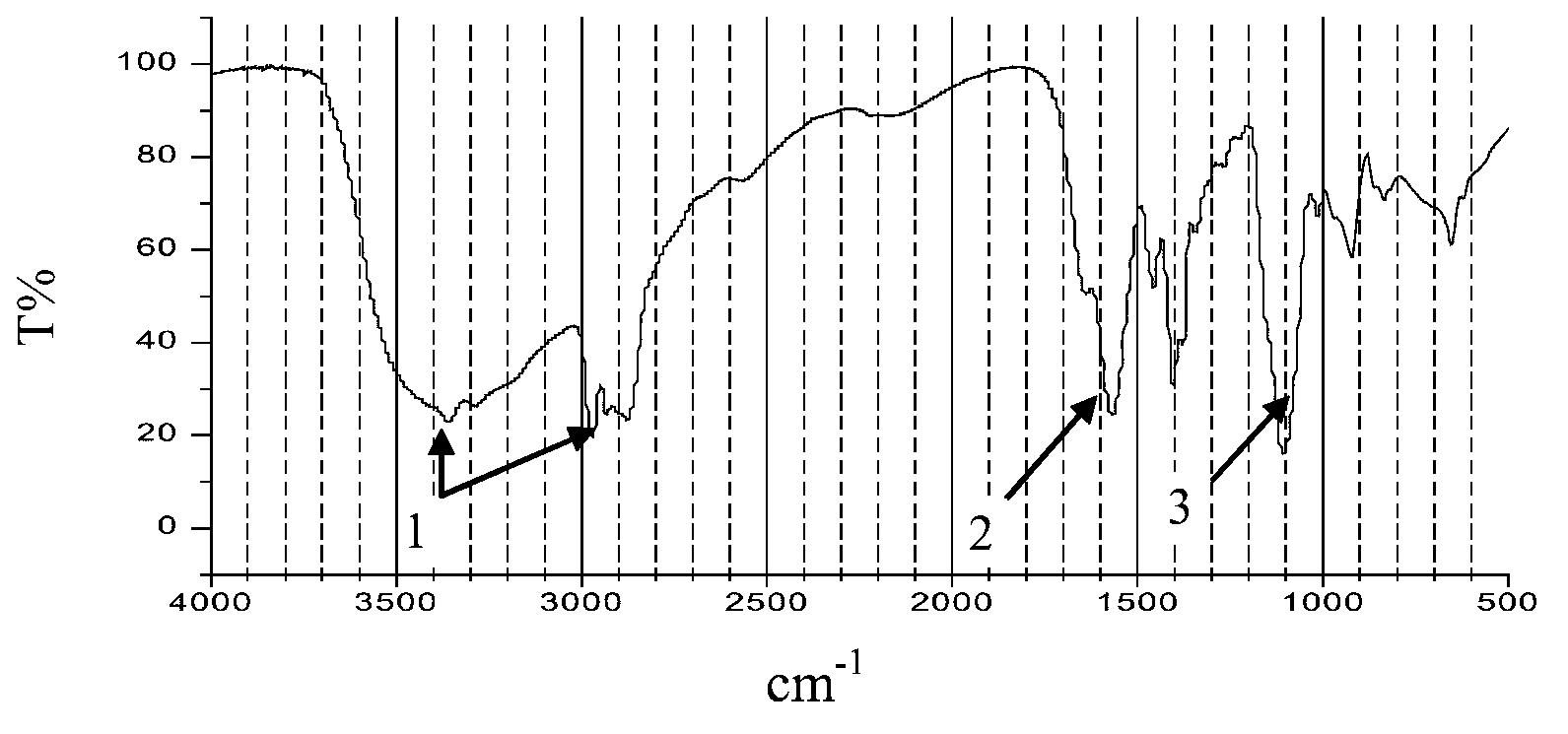

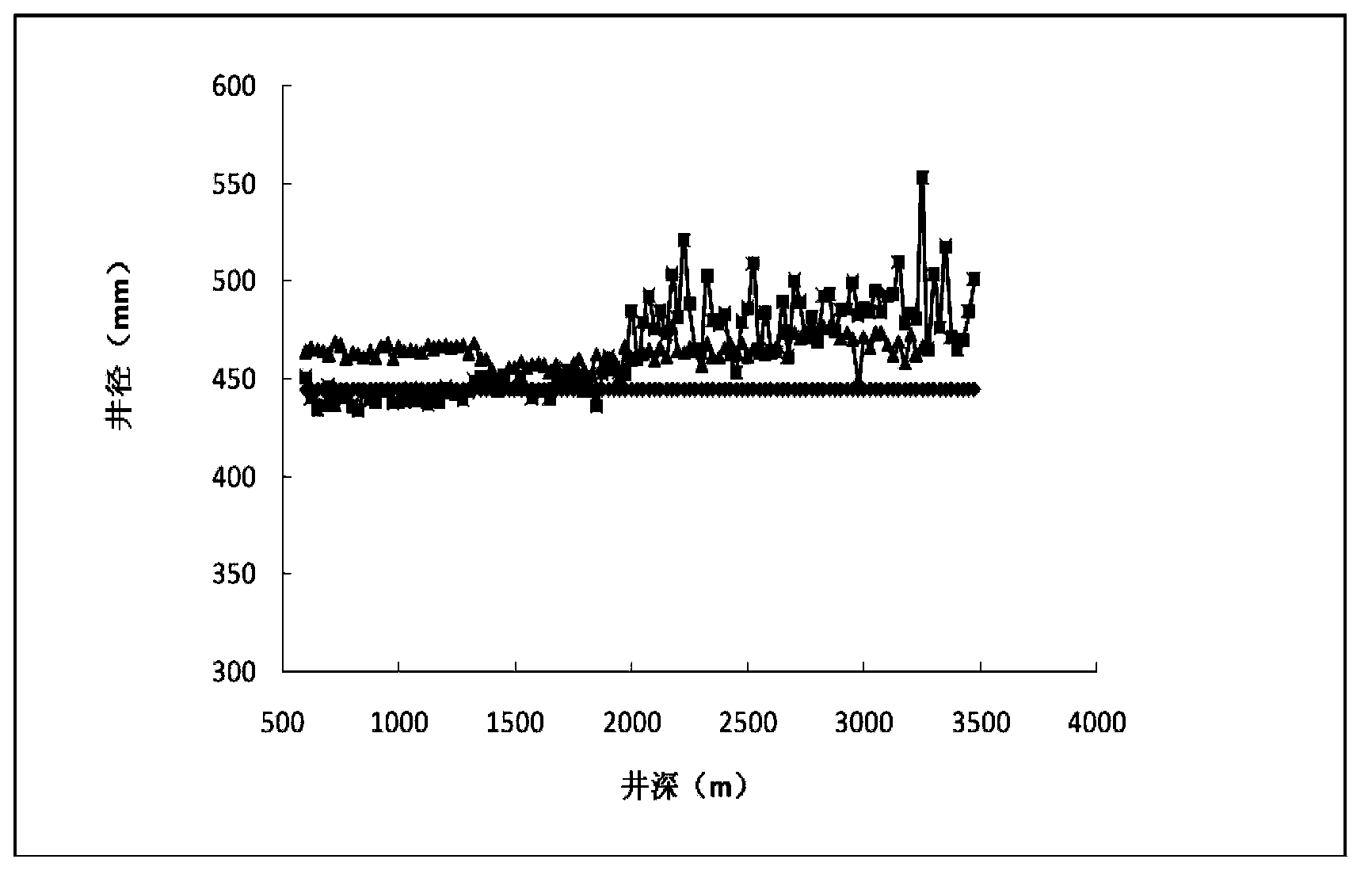

Strong-inhibition drilling fluid system

ActiveCN103013470AEnhanced inhibitory effectImprove stabilityDrilling compositionSlurryHigh pressure

The invention relates to a strong-inhibition drilling fluid system, comprising the following components by mass percent of 2.5-4.5% of bentonite slurry, 0.1-0.3% of alkaline regulator, 0.3-2.0% of shale inhibitor, 0.2-0.4% of metal ion polymer, 2.0-5.0% of walchowite, 2.0-5.0% of sulfomethal phenolaldehy resin, 1.0-3.0% of cation emulsified asphalt, 0.5-3.0% of lubricating agent, 0.2-0.8% of emulsifier, 2.0-8.0% of crude oil, and 1.0-3.0% of calcium carbonate superfine powder according to 100% of water. The compound in a general formula (I) is also provided; R1 is H or CH3; R2 is H, CH3 or C2H5; and X is an integer between 2 and 20 and applied to the shale inhibitor. The compound and the cation emulsified asphalt are applied to the drilling liquid system; the drilling liquid system is strong in shale inhibition; the shale recovery rate can be up to 90.33% and is improved by over 35.02% in comparison with that of water shale; the high temperature resistance can be up to 150 DEG C; the lubricating friction coefficients before and after aging respectively are smaller than 0.1; the strong-inhibition drilling fluid system is strong in capacity of resisting poor soil, salt and calcium contamination, strong in rejection capability, and good in blocking effect; the API (American petroleum institute) water loss of the drilling fluid is smaller than 4.5mL, and the HTHP (high temperature and high pressure) water loss is smaller than 12mL.

Owner:CHINA PETROLEUM & CHEM CORP

Aqueous polymaine-containing anti-frizz composition for hair

InactiveUS20080085258A1Avoid absorptionAbsorption lossCosmetic preparationsHair cosmeticsPolyamine CompoundWater insoluble

The present invention is drawn to a composition and process for inhibiting hair from becoming frizzy when exposed to high and / or low humidity, the composition containing: (a) at least one polyamine compound comprising at least three amino groups; (b) at least one nonionic surfactant; (c) at least one anionic silicone; (d) at least one water-insoluble material; (e) at least one cationic polymer; and (f) at least one film former, different from (e).

Owner:LOREAL SA

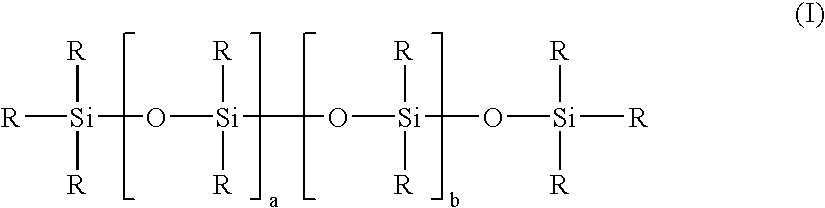

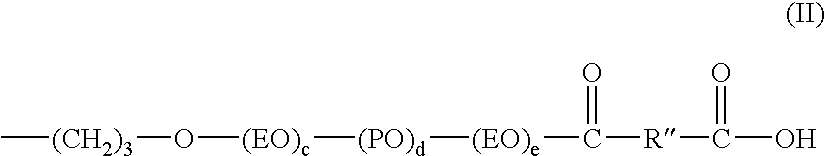

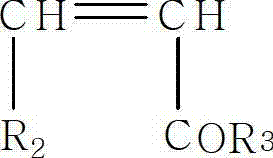

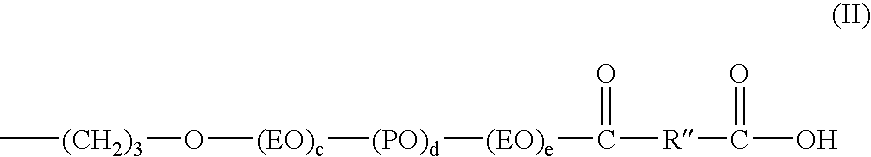

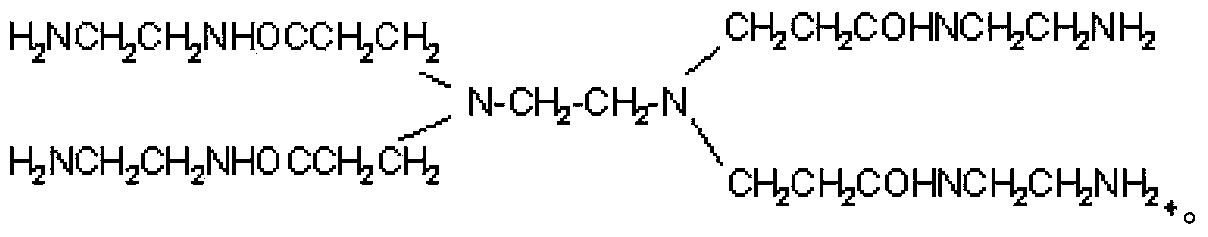

Clay-resistant polycarboxylate water reducer and preparation method thereof

The invention discloses a clay-resistant polycarboxylate water reducer and a preparation method of the clay-resistant polycarboxylate water reducer. The water reducer comprises the following components by weight: 35-45% of unsaturated polyoxyethylene ether monomer I, 40-50% of unsaturated polyoxyethylene ether monomers II, 10-20% of unsaturated monocarboxylic acid and derivative monomer of unsaturated monocarboxylic acid, 5-15% of unsaturated alkenyl sulphonate, and the like, wherein the unsaturated polyoxyethylene ether monomers I, the unsaturated polyoxyethylene ether monomers II, the unsaturated monocarboxylic acid and the derivative monomers of the unsaturated monocarboxylic acid, the unsaturated alkenyl sulphonate and the like are mixed and copolymerized, and then neutralized by polyethylene polyamine which is 0.5-2.0% of total monomer weight. The polyethylene oxide alkenyl short side chain of the water reducer can enhance the stability of the solvation water membrane layer on the surface of mineral fine powder particles in concrete; carboxyl groups and sulfonic groups generate electrostatic adsorption to prevent the adsorption and water absorption expansion rate of internal structures between clay layers; and polyethylene polyamine chains are adsorbed on the surfaces of clay particles to have shielding and scattering functions, therefore, the problem that the polycarboxylate water reducer and overlarge mud content in a concrete material are incompatible can be solved effectively.

Owner:北京榆构有限公司

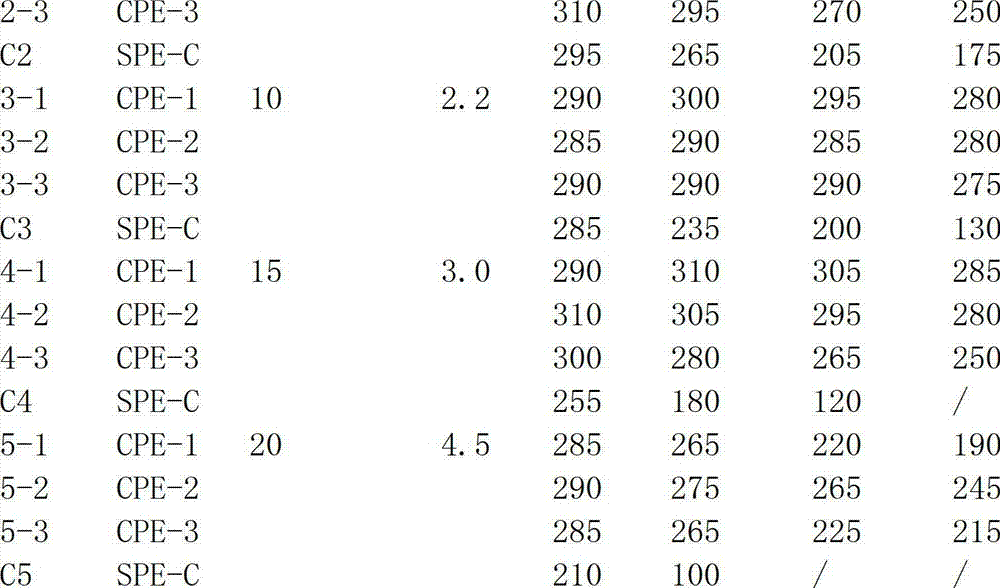

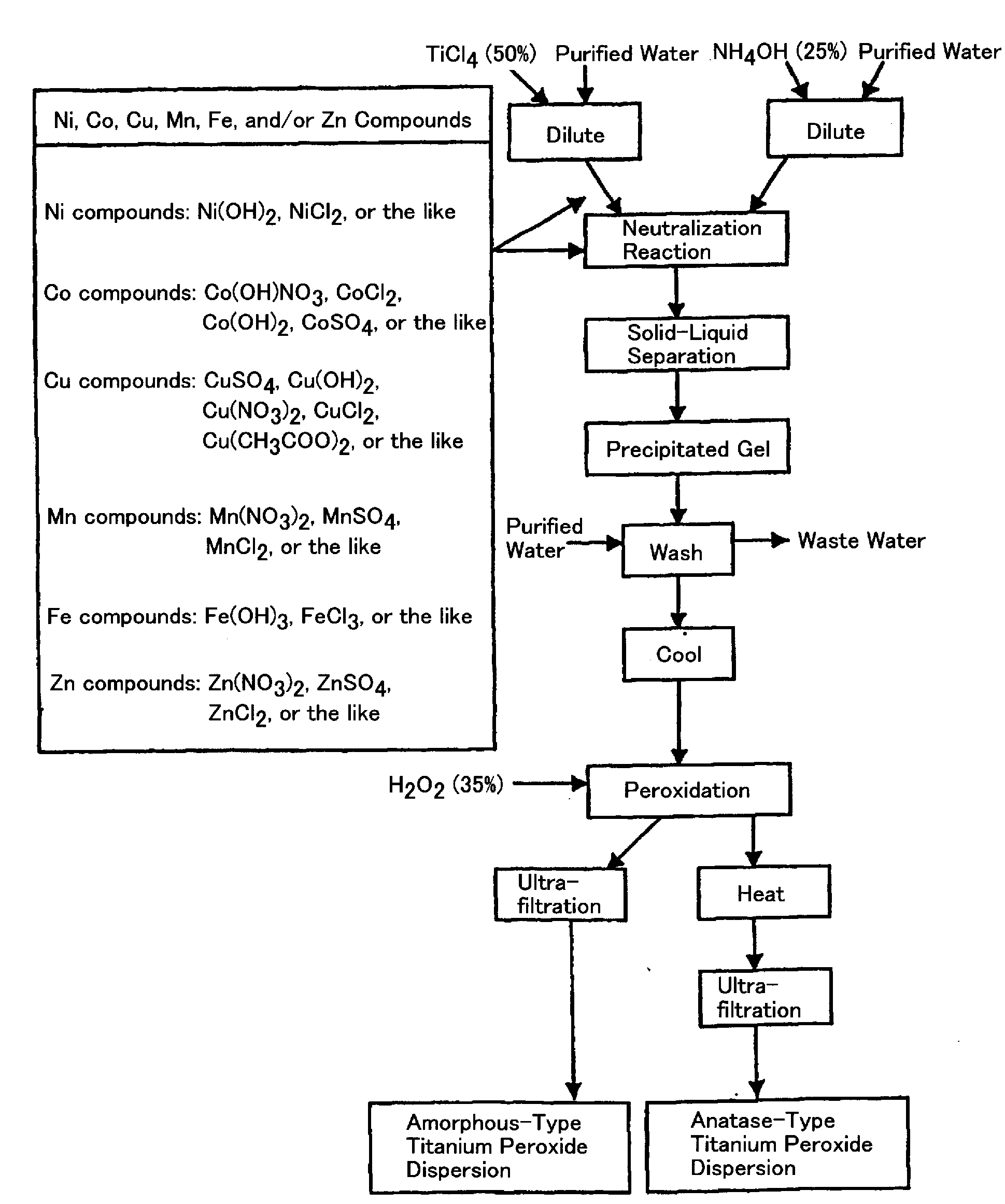

Solution Or Dispersion For Base Surface Treatment Containing Titanium Oxide Doped With Metal Element, Method Of Treating Base Surface With The Liquid, And Surface-Treated Material Obtained By the Method

InactiveUS20090211491A1Reduce fadingHard surfacePigmenting treatmentOther chemical processesSurface layerSilanes

A surface-treating agent for imparting both water repellency or unsusceptibility to water absorption and excellent antifouling properties to a surface of a material, especially a material for outdoor use; and a material whose surface has been treated with the surface-treating agent. A solution or dispersion which contains a water repellent or water absorption inhibitor, preferably a water repellent or water absorption inhibitor of the silane, siliconate, silicone, silicone / silane composite, and / or fluorochemical type, and a titanium oxide doped with at least one metal element selected from the group consisting of copper, manganese, nickel, cobalt, iron, and zinc, preferably an amorphous titanium oxide or an amorphous titanium oxide which has been peroxidized at least partly, is used to form, on a surface of a base material and / or in a surface layer thereof, a layer comprising the water repellent or water absorption inhibitor and the titanium oxide doped with at least one metal element selected from the group consisting of copper, manganese, nickel, cobalt, iron, and zinc.

Owner:DOW CORNING TORAY CO LTD

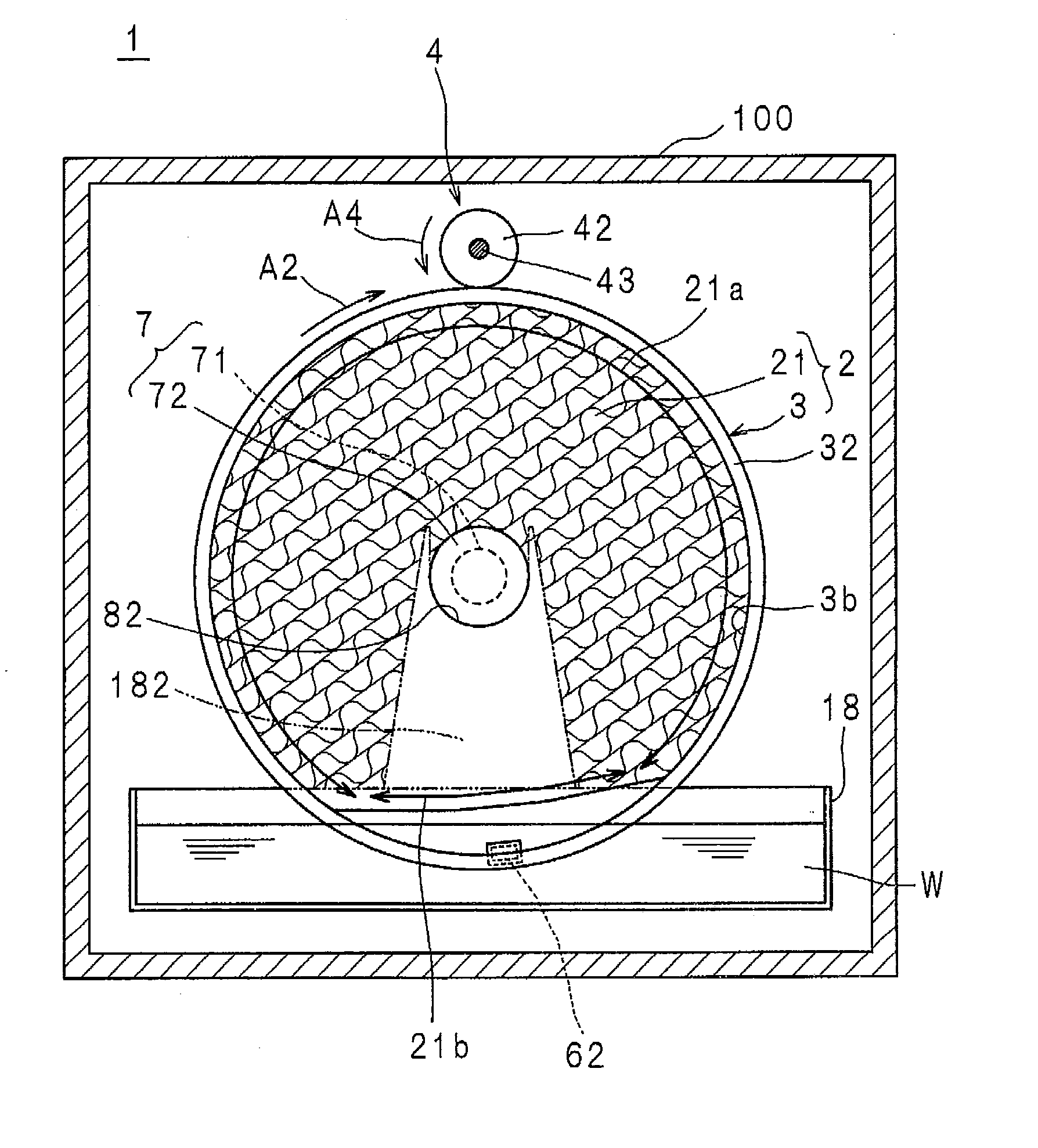

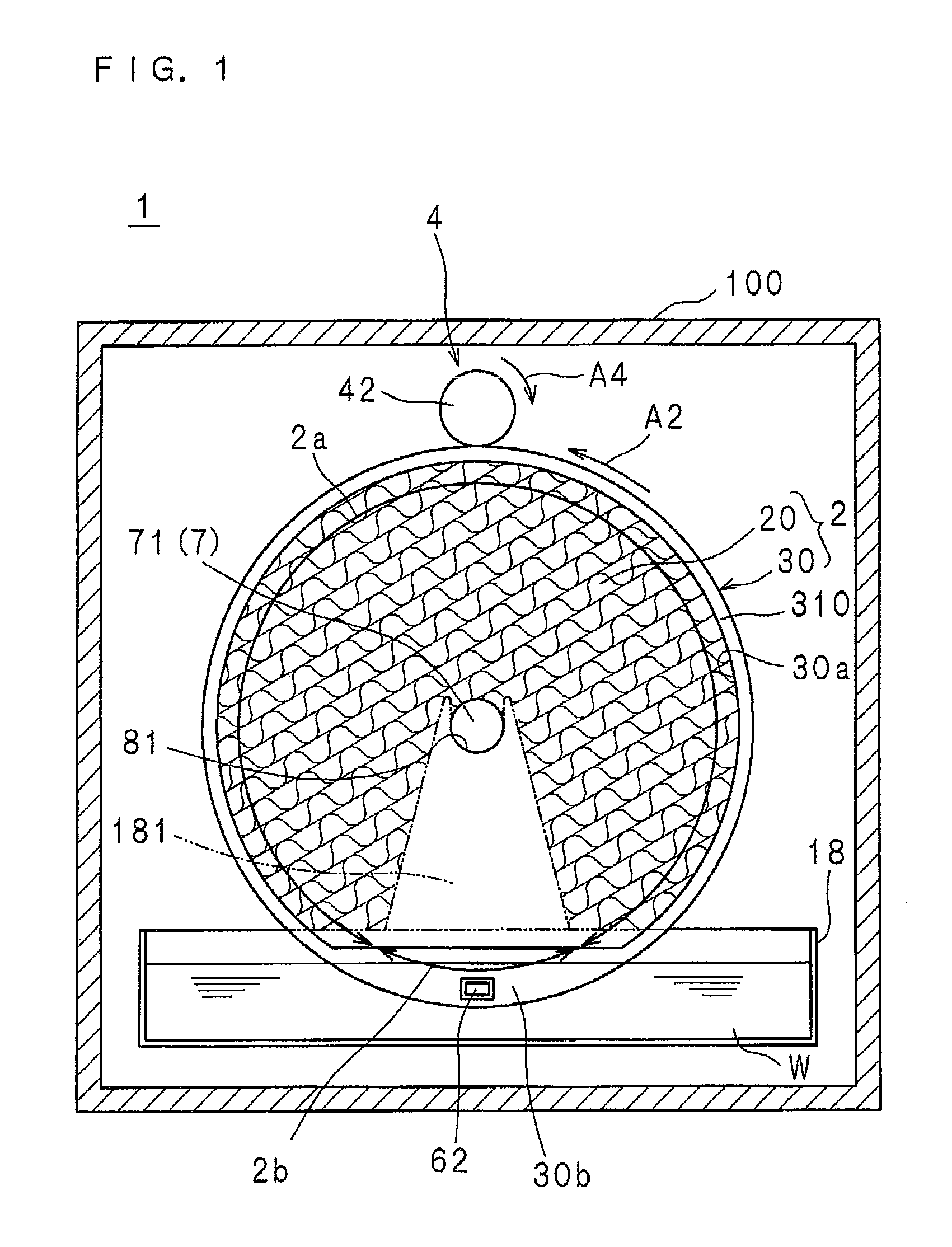

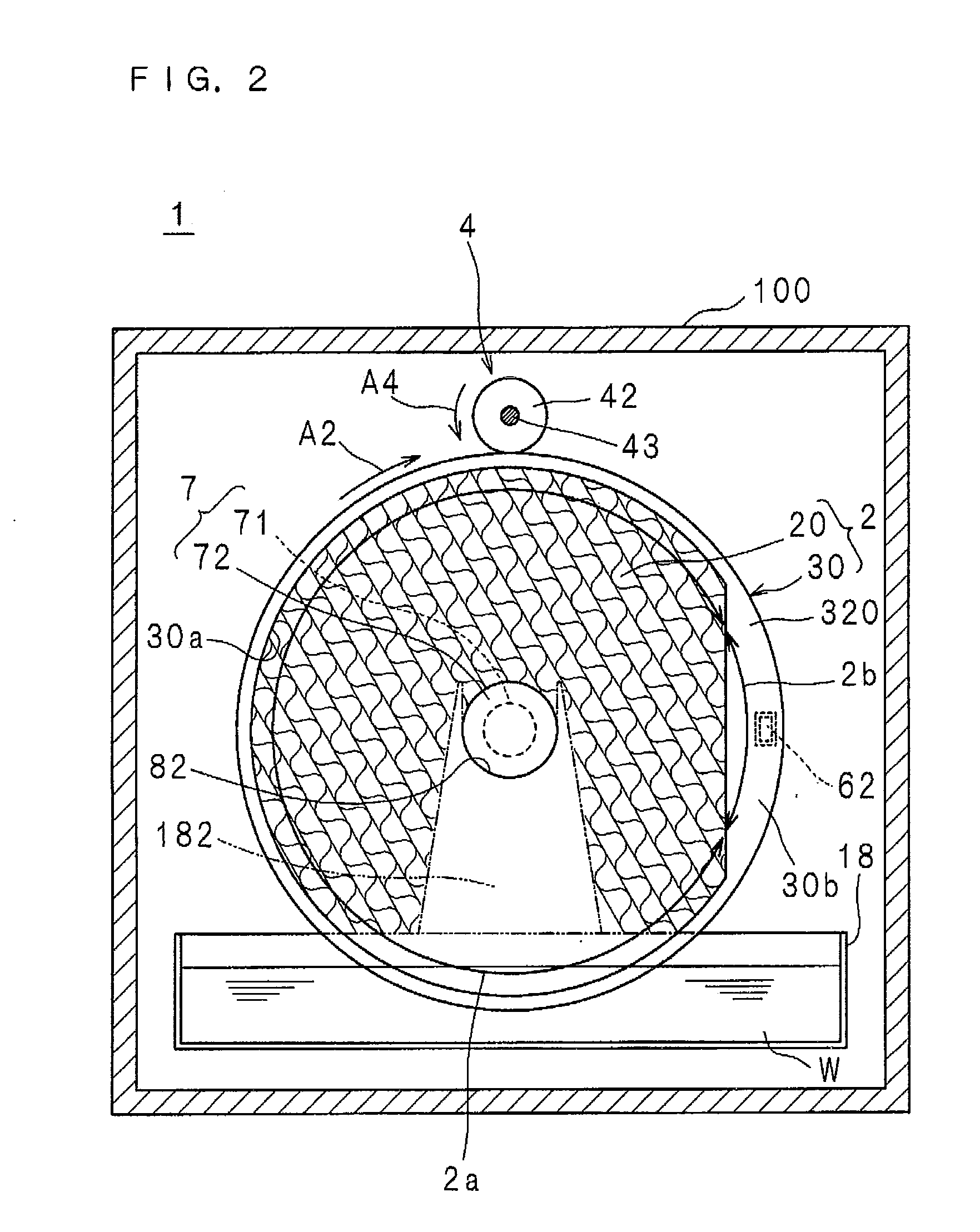

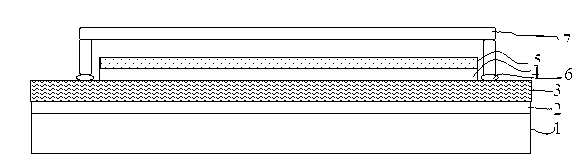

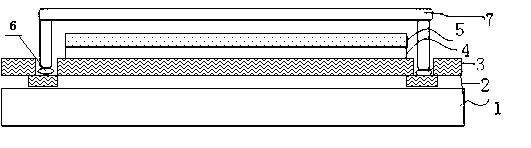

Humidifier, filter unit and rotation drive structure

ActiveUS20100201007A1Prevent water absorptionSimple structureLighting and heating apparatusMixing methodsAbsorption of waterWaste management

A disc-shaped filter unit including a filter main body having a water absorbability and a holder having a non water absorbability is disposed in a vertical orientation, with a part of a circumferential portion thereof immersed in water reserved in a water tank, and is rotated by a rotation drive mechanism in a circumferential direction. The filter unit has an absorptive region and a non-absorptive region arranged adjacent to each other in the circumferential direction. Therefore, in accordance with rotation of the filter unit in the circumferential direction, a state where the absorptive region is immersed and the filter main body of the filter unit absorbs water through a water-conduction hole and a state where the non-absorptive region is immersed and water absorption of the filter main body is prevented by a watertight section having a non water absorbability are continuously alternated.

Owner:SHARP KK

Method for preparing epoxy cross-linking modified paper wet-strengthening agent

The invention discloses a method for producing an epoxy crosslinking modified paper humidity intensifier. The alkaline cured humidity intensifier polyamide polyamine epoxy chloropropane resin is the mainstream product at present, but the PAE which is not cross-linked and modified is poor in the crosslinking degree and molecular weight and has poor retaining performance, and the humidity-intensifying effect of the paper can not reach the production requirement, and can result in the increase of the adsorptive organic halide in the wastewater. The invention adopts the dibasic acid and polybasic amine as the raw material to produce the intermediate of polyamide polyamine; a certain amount of polyamide polyamine intermediate, epoxy and epoxy chloropropane react under certain temperature until the product reaches a certain viscosity, then acid is added to terminate the reaction and obtain the epoxy crosslinking modified paper humidity intensifier. The method can reduce the consumption of the epoxy chloropropane and decrease the content of organochlorine in the waste; the retaining rate of the product is greatly improved; the product provided by the invention can not only improve the wet strength of the paper but also can increase the physical properties of the paper, such as the folding strength, tensile strength and dry strength and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Fireproof foam concrete door core plate and preparation method thereof

InactiveCN103089118ASmall shrinkagePrevents cracking and water absorptionFireproof doorsCeramicwareFilling materialsEmulsion

The invention relates to a fireproof foam concrete door core plate and a preparation method thereof. A foam concrete base plate of the door core plate is prepared from cement paste and foam used for concrete in a volume ratio of 1:(5-12); the cement paste comprises the following raw materials in part: 80 to 100 parts of Portland cement, 10 to 30 parts of filling material, 30 to 50 parts of water, 2 to 7 parts of EVA emulsion, 2 to 6 parts of waterproof agent, 0.5 to 1.0 part of water repellent, 1.5 to 2.5 parts of water reducing agent, and 1 to 3 parts of early strength agent; and the volume weight of the foam used for the concrete is 70g / L to 90g / L, and the foam is prepared by adding water into a high-quality foaming agent for foaming. The fireproof foam concrete door core plate has the advantages of light weight, high strength, low heat conductivity coefficient, good fireproof and waterproof performance, long service life and the like, the preparation process is simple, and the cost is low.

Owner:河南永立建材有限公司

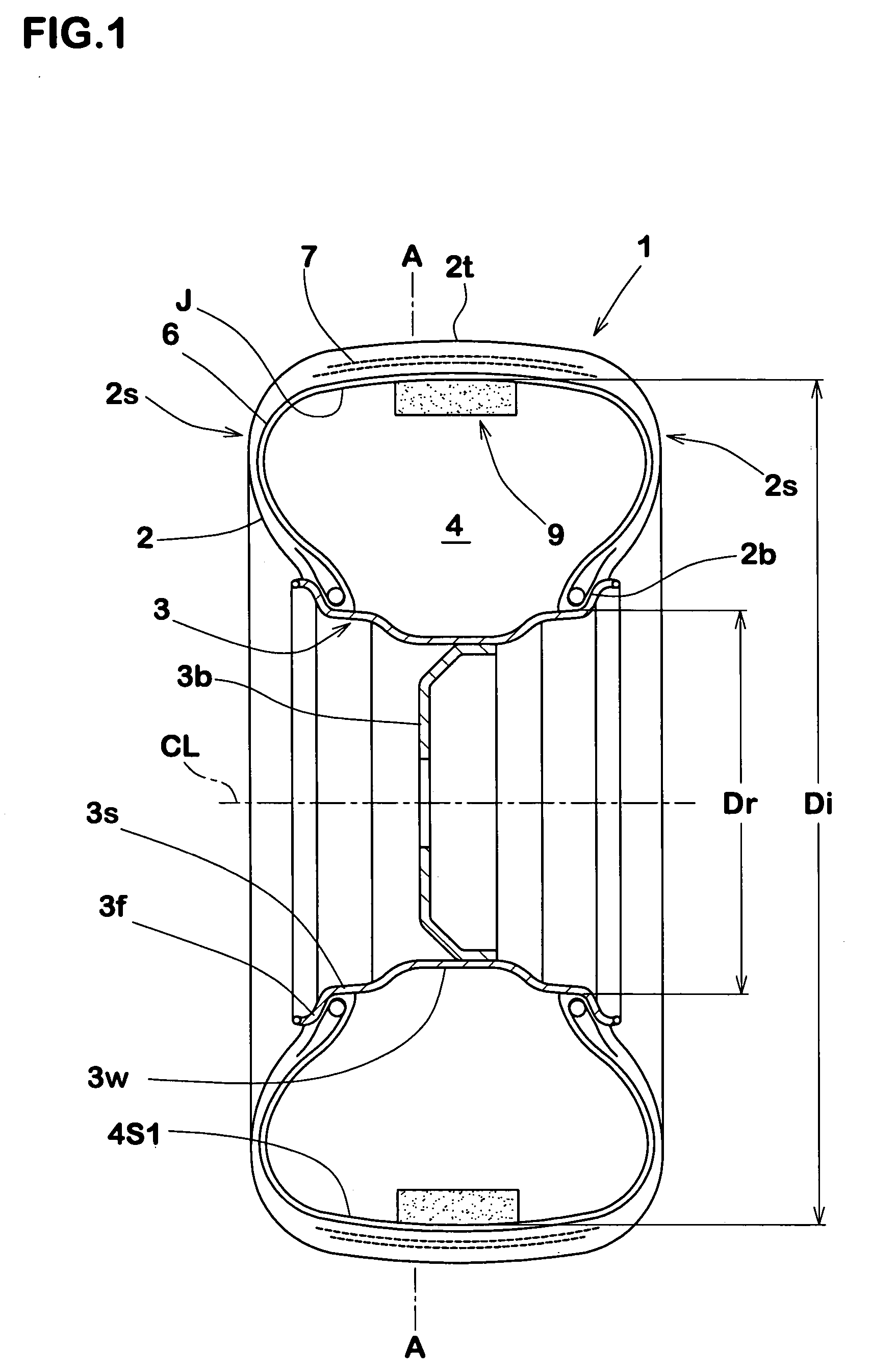

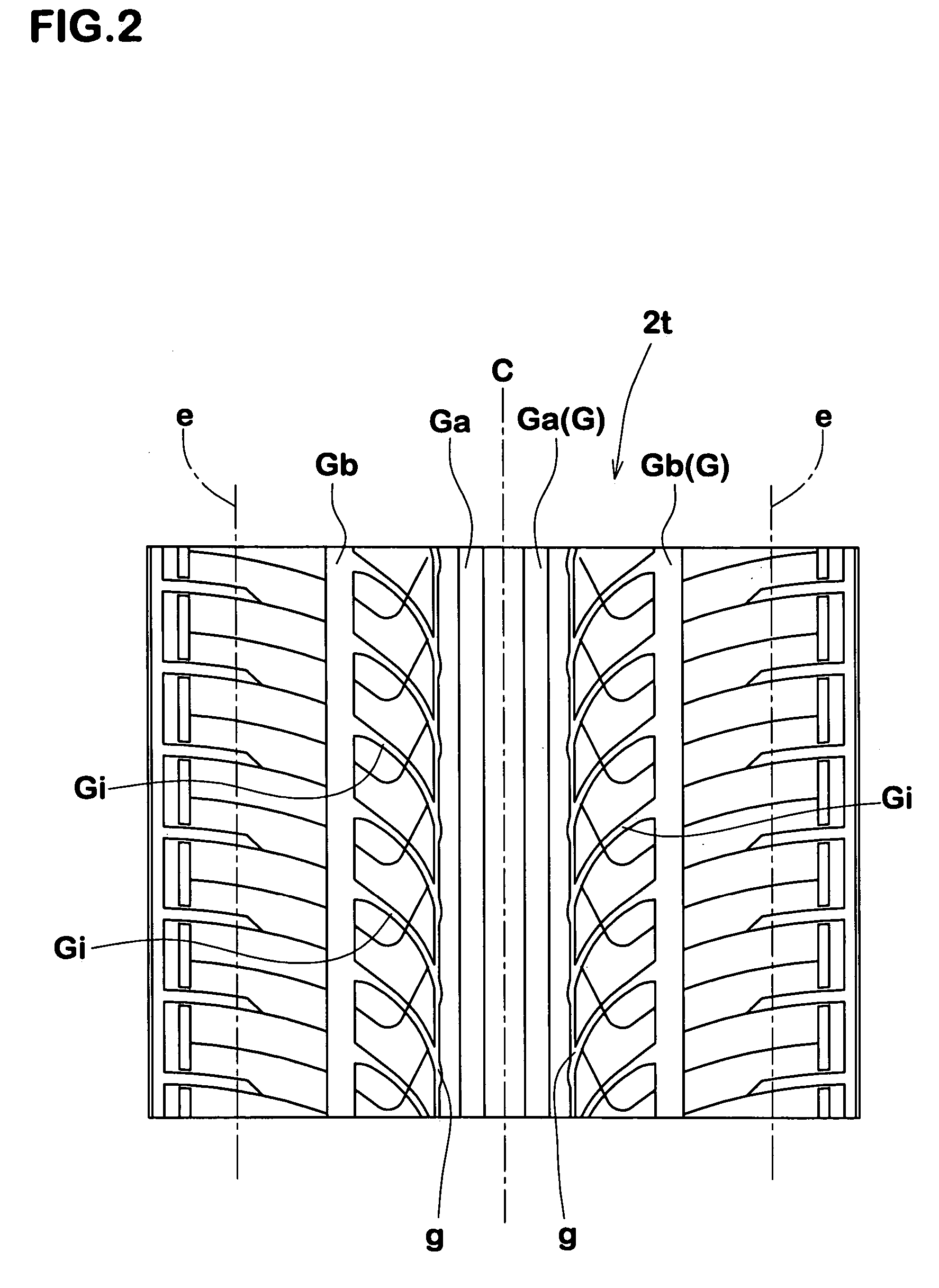

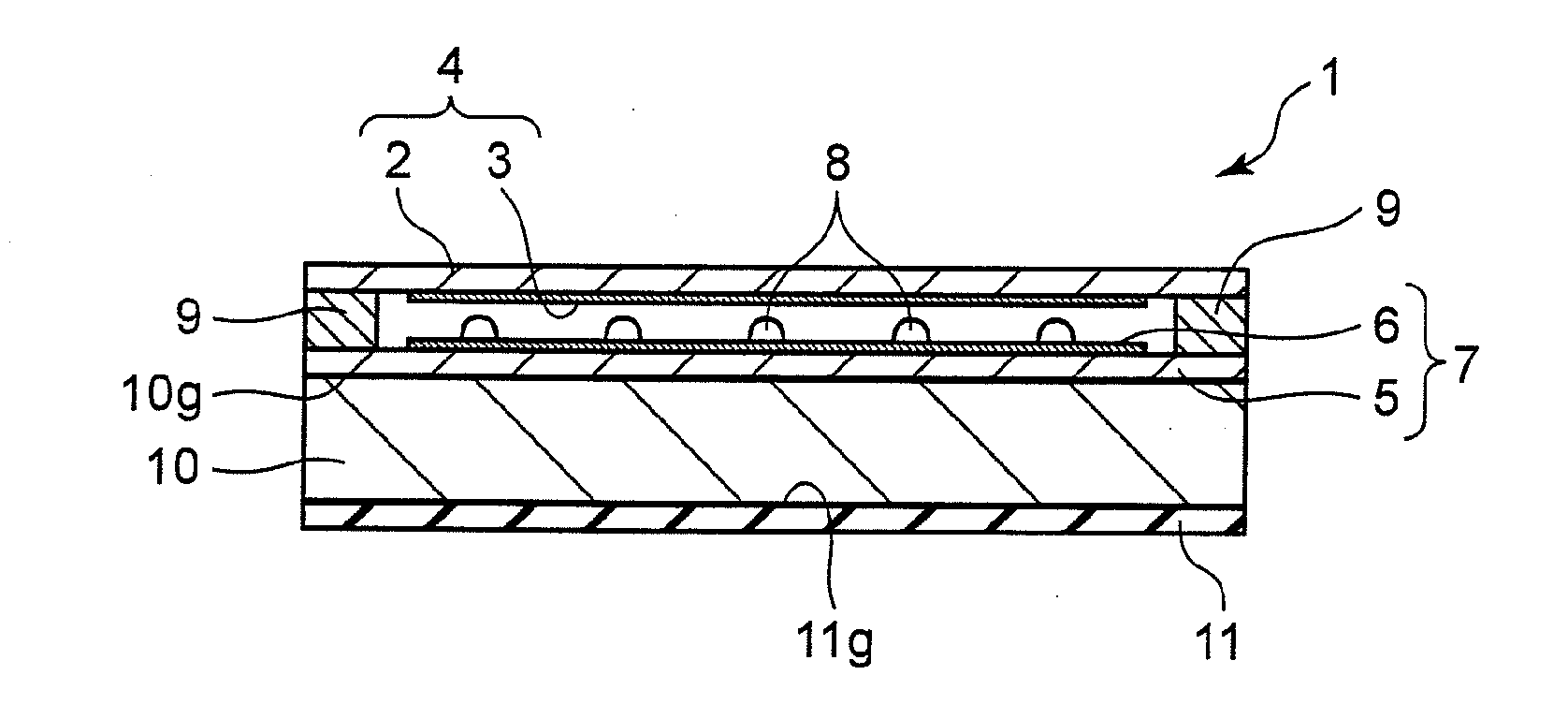

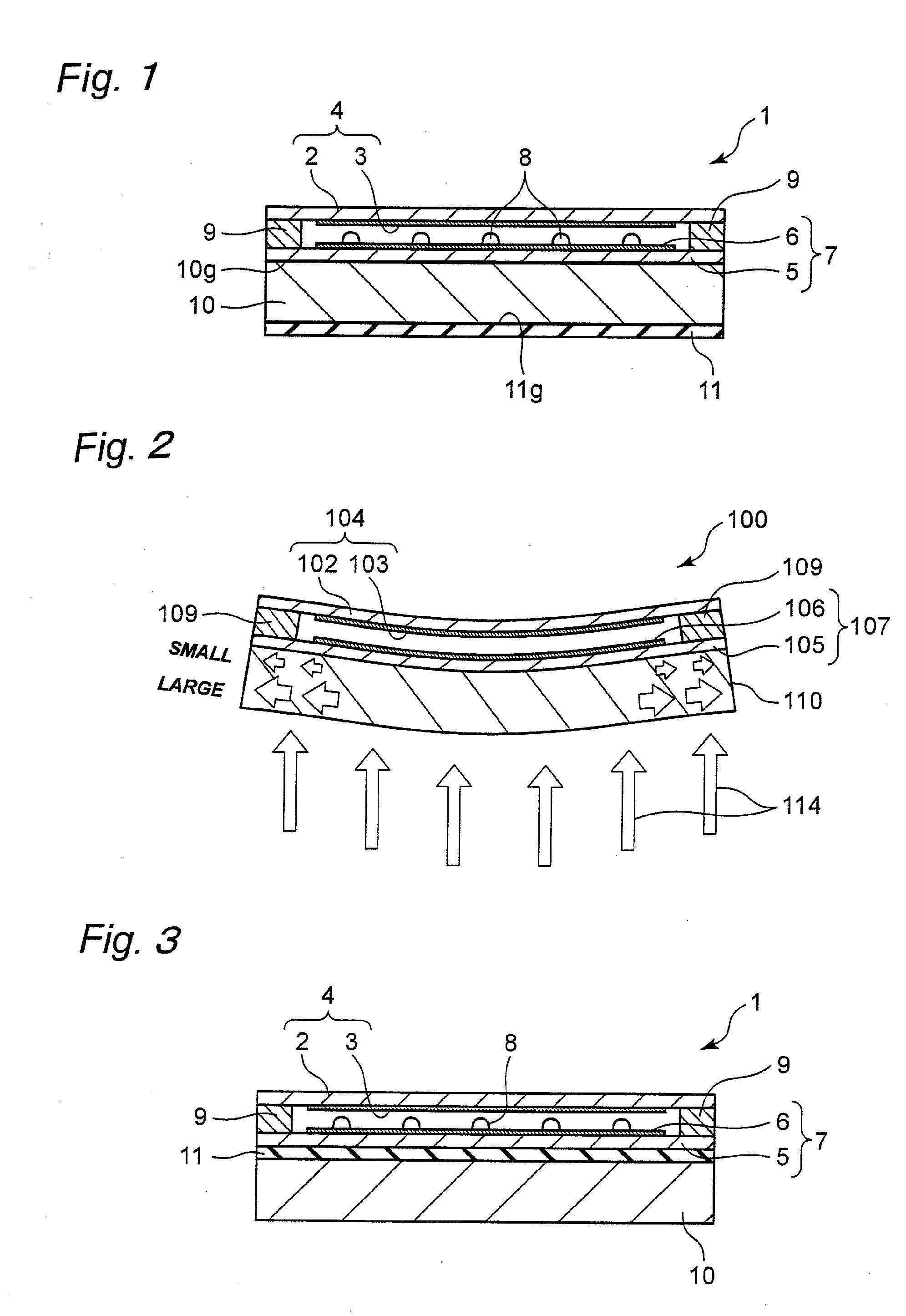

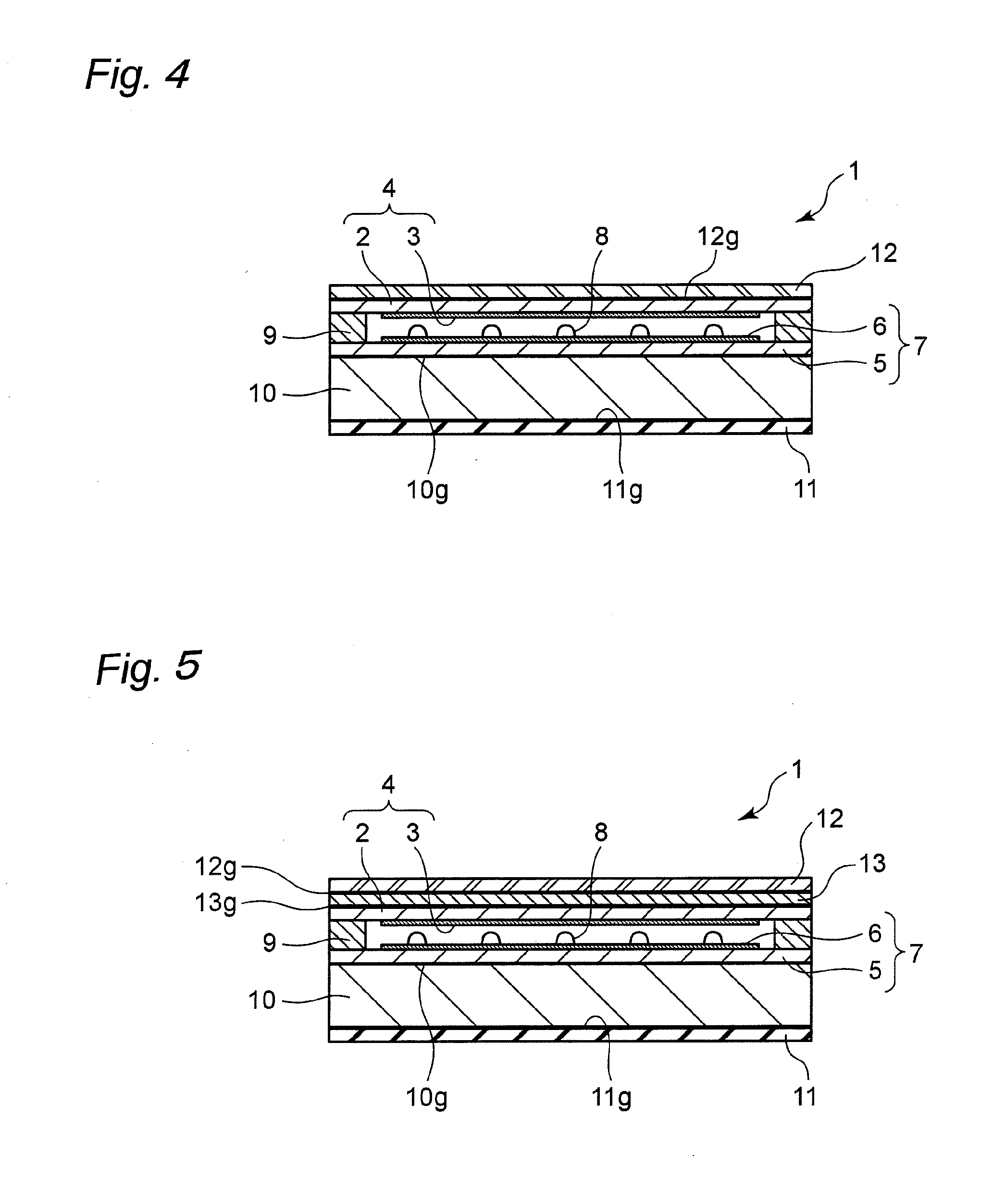

Pneumatic tire with noise damper

ActiveUS7188652B2Avoid thermal failureHigh speed conditions can be effectively preventedSpecial tyresInflatable tyresEngineeringCellular material

Owner:SUMITOMO RUBBER IND LTD

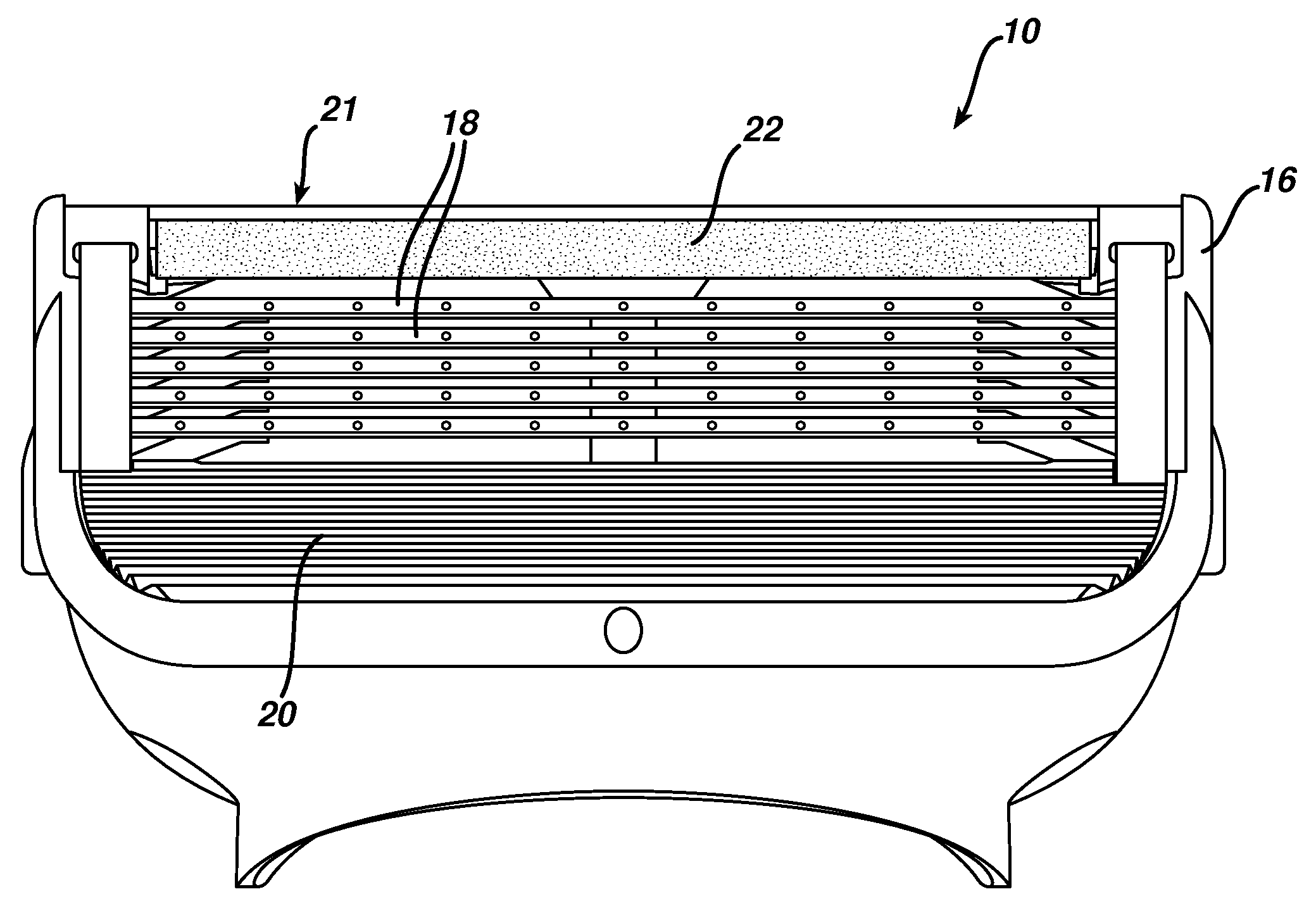

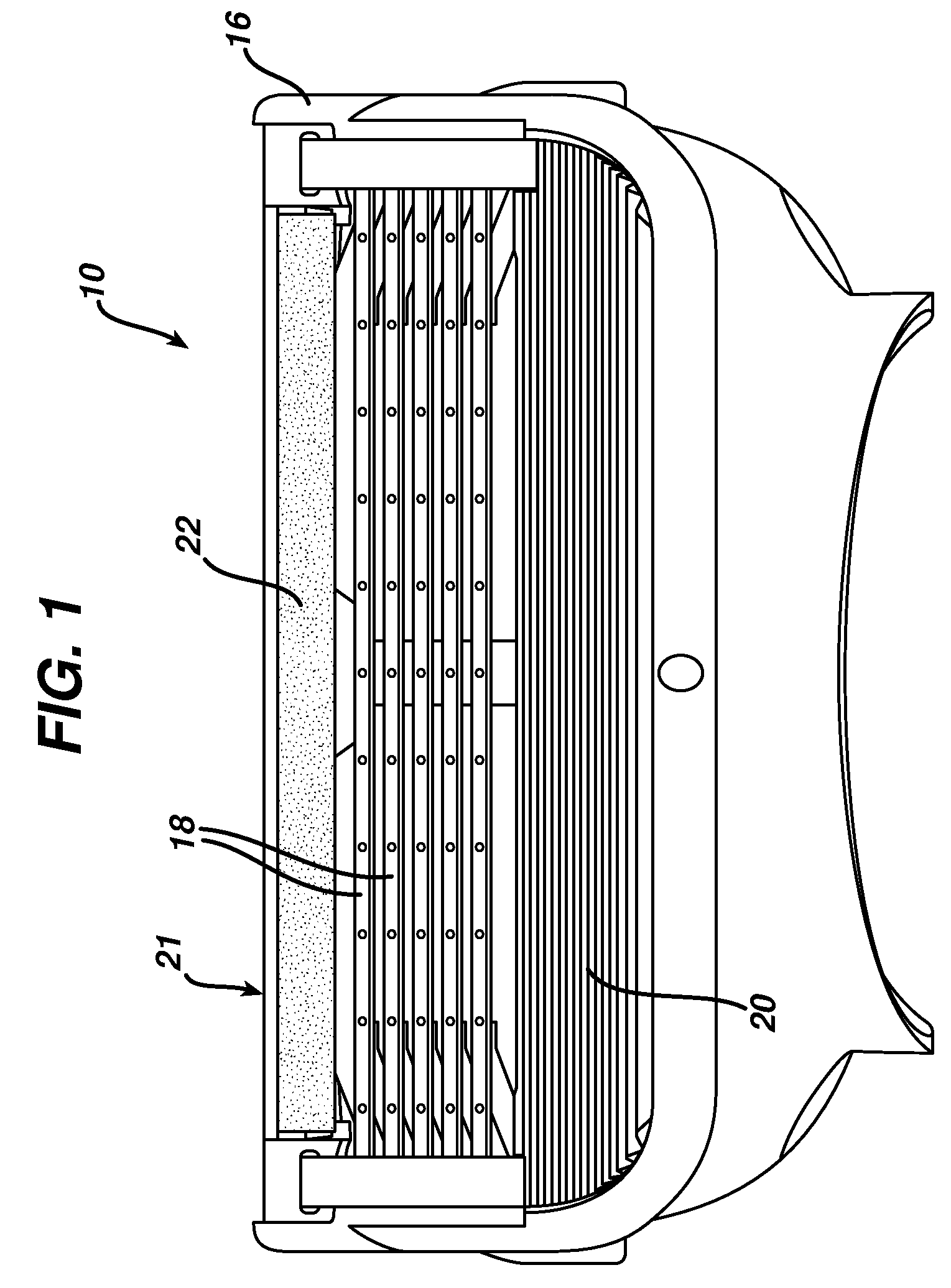

Wet shaving system including a mineral oil coated shaving aid

ActiveUS8236214B2Inhibit swellingPrevent water absorptionCosmetic preparationsToilet preparationsWater insolubleEngineering

A wet shaving system is disclosed including a blade member and a skin-engaging portion in proximity to said blade member, the skin-engaging portion comprising a solid polymeric shaving aid composite including an exposed portion containing a water-soluble shaving aid dispersed in a water-insoluble polymeric matrix, the water soluble shaving aid being coated with mineral oil.

Owner:THE GILLETTE CO

Touch input device and electronic apparatus

InactiveUS20110148800A1Improve moisture resistancePrevent excessive expansionLayered product treatmentSynthetic resin layered productsWater vaporAcrylic resin

A touch input device of a resistance film system having a structure in which a plastic supporting plate, made from a polycarbonate resin or an acrylic resin, is bonded to the entire lower surface of a lower electrode film, with an adhesive material being interposed therebetween, is provided with a water-vapor barrier film that is superior in moisture dimensional stability and bonded to the entire surface of the plastic supporting plate on the side opposite to the surface thereof bonded to the lower electrode film with an adhesive material being interposed therebetween.

Owner:NISSHA PRINTING COMPANY

Aqueous fatty monoamine-containing anti-frizz composition for hair

InactiveUS20080085255A1Avoid absorptionPrevent water absorptionCosmetic preparationsHair cosmeticsWater insolublePolymer

The present invention is drawn to a composition and process for inhibiting hair from becoming frizzy when exposed to high and / or low humidity, the composition containing: (a) at least one fatty monoamine; (b) at least one nonionic surfactant; (c) at least one anionic silicone; (d) at least one water-insoluble material; (e) at least one cationic polymer; and (f) at least one film former, different from (e).

Owner:LOREAL SA

Method of preparing storage phosphors from dedicated precursors

InactiveUS20050186329A1Excellent and reproducible qualityPrevent water absorptionCoatingsSpecial surfacesGas phaseHigh energy

A method for producing CsX:Eu stimulable phosphors and screens or panels provided with said phosphors as powder phosphors or vapor deposited needle-shaped phosphors suitable for use in image forming methods for recording and reproducing images of objects made by high energy radiation, wherein said CsX:Eu stimulable phosphors are essentially free from oxygen in their crystal structure, and wherein X represents a halide selected from the group consisting of Br, Cl and combinations thereof, and wherein the method further makes use of starting compounds (precursors) or combinations of precursors for the synthesis of said CsX:Eu stimulable phosphors, said precursors (starting compounds) having as a composition CsxEuyX′x+αy, wherein the ratio of x to y exceeds a value of 0.25, wherein α>2 and wherein X′ is a halide selected from the group consisting of Cl, Br and I and combinations thereof; heating said mixture at a temperature above 450° C.; cooling said mixture, and optionally annealing and recovering said CsX:Eu phosphor.

Owner:T2PHARMA GMBH

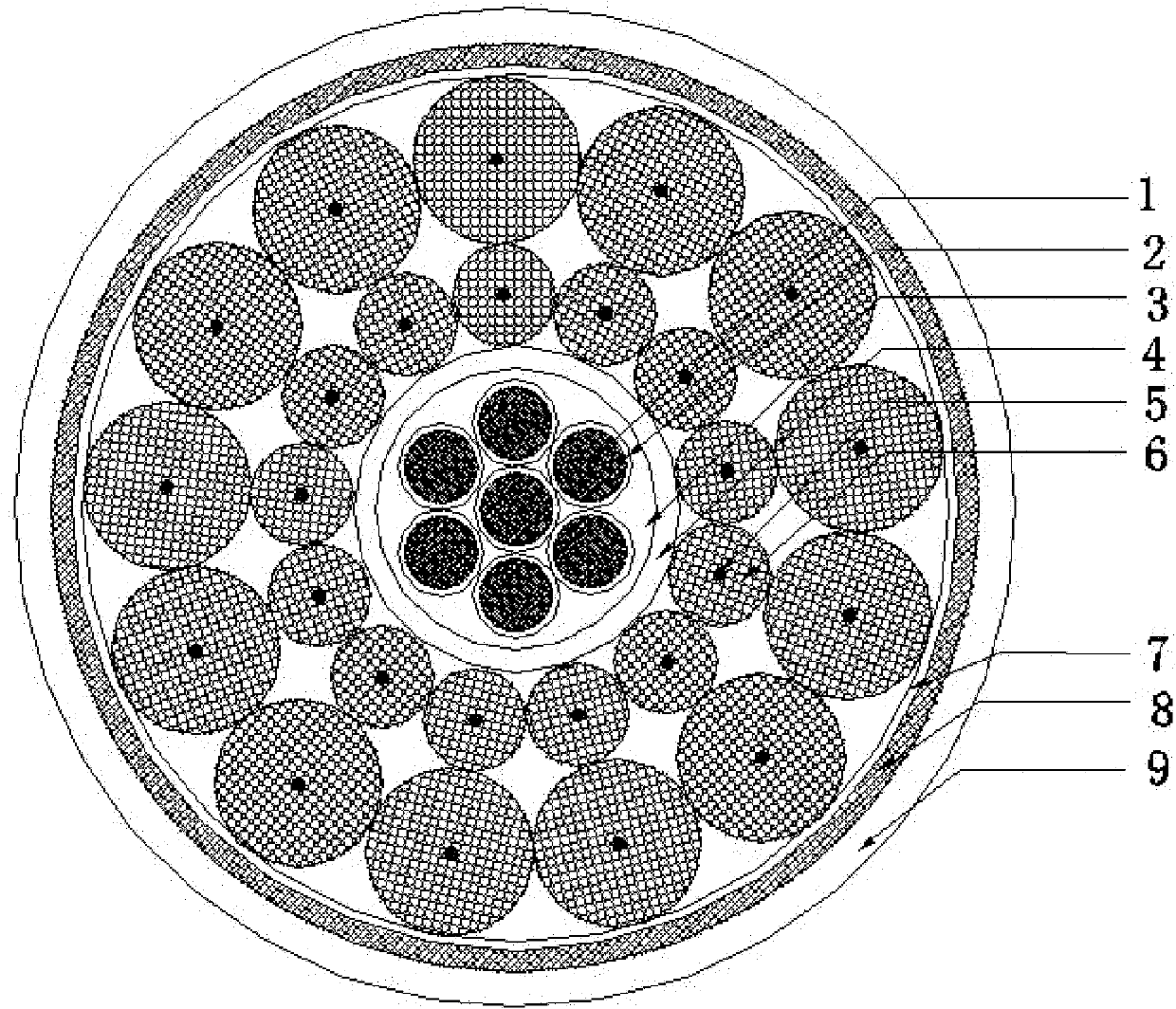

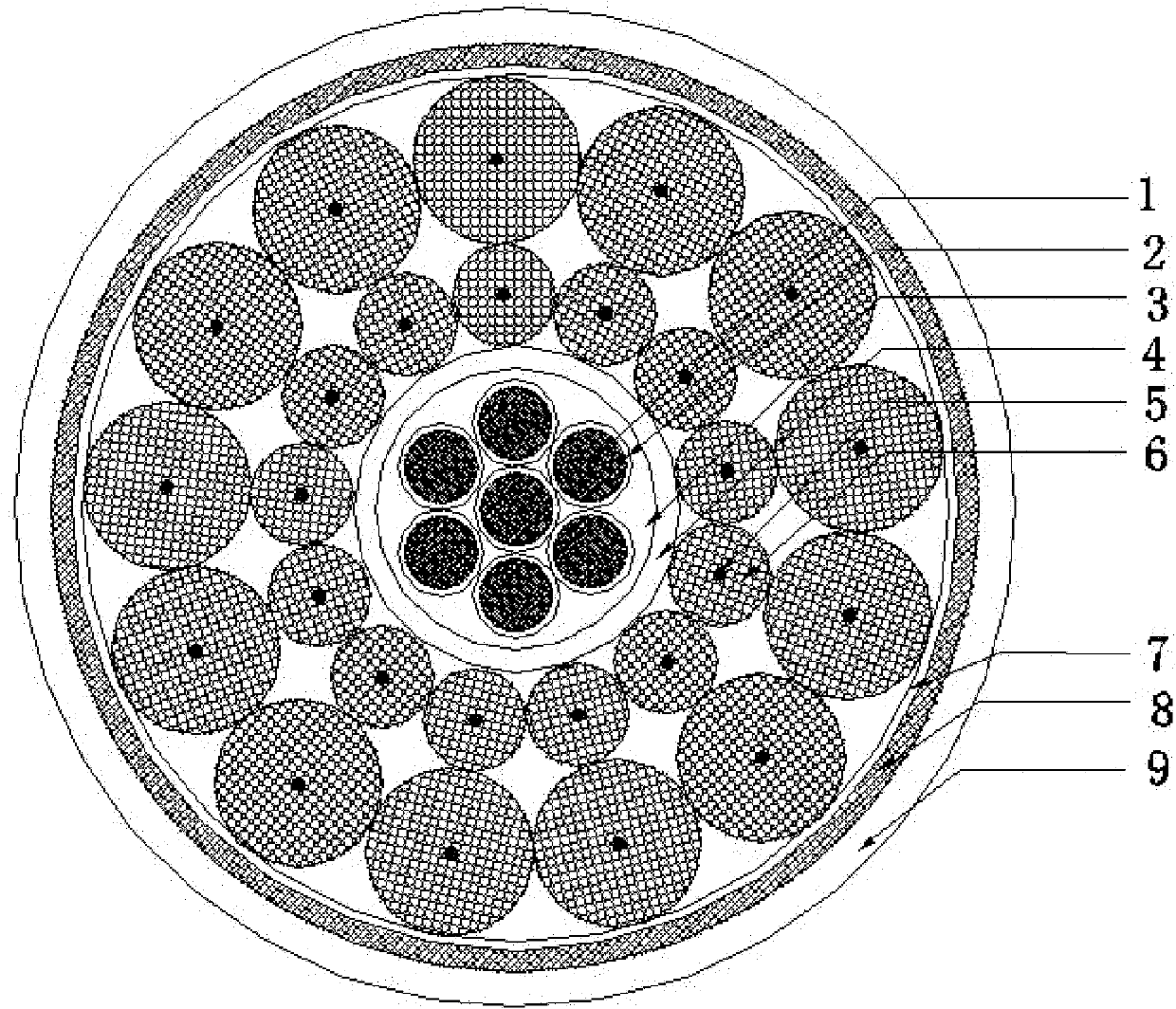

Offshore floating wind power generation cable

ActiveCN101996708AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFloating cablesPolyolefinElectrical conductor

The invention discloses an offshore floating wind power generation cable, which comprises conductors, insulating layers, an inner lining layer, an inner protection layer, tensile components, floating components, a waterproof layer, protective layers and an outer sheath, wherein the conductor is coated with the insulating layer by way of extrusion so as to form insulating wire cores, and a plurality of insulating wire cores are stranded into a cable core; the cable core is respectively coated with the inner lining layer and the inner protection layer by way of extrusion; two protective layers are wound outside the inner protection layer, each protective layer consists of a plurality of protective elements which are arranged in the shape of circle, and each protective element is formed by coating the tensile component with the floating component by way of extrusion; the two protective layers are respectively coated with the waterproof layer, the protective layer and the outer sheath by way of outward extrusion; the insulating layers and the inner lining layer are made of thermoplastic elastomeric materials by way of extrusion; and the insulating layer is made of thermoplastic polyolefin (TPO) materials in thermoplastic elastomer (TPE), and the inner lining layer is made of toughened polystyrene (TPS) materials in TPE. The wind power generation cable of the invention has the advantages of low temperature resistance, bending resistance, torsion resistance, abrasion resistance, water blocking, corrosion resistance, weather fastness, high tensile strength, and capability of effectively preventing the damages of stormy waves and other floaters over the sea to the cables.

Owner:FAR EAST CABLE +2

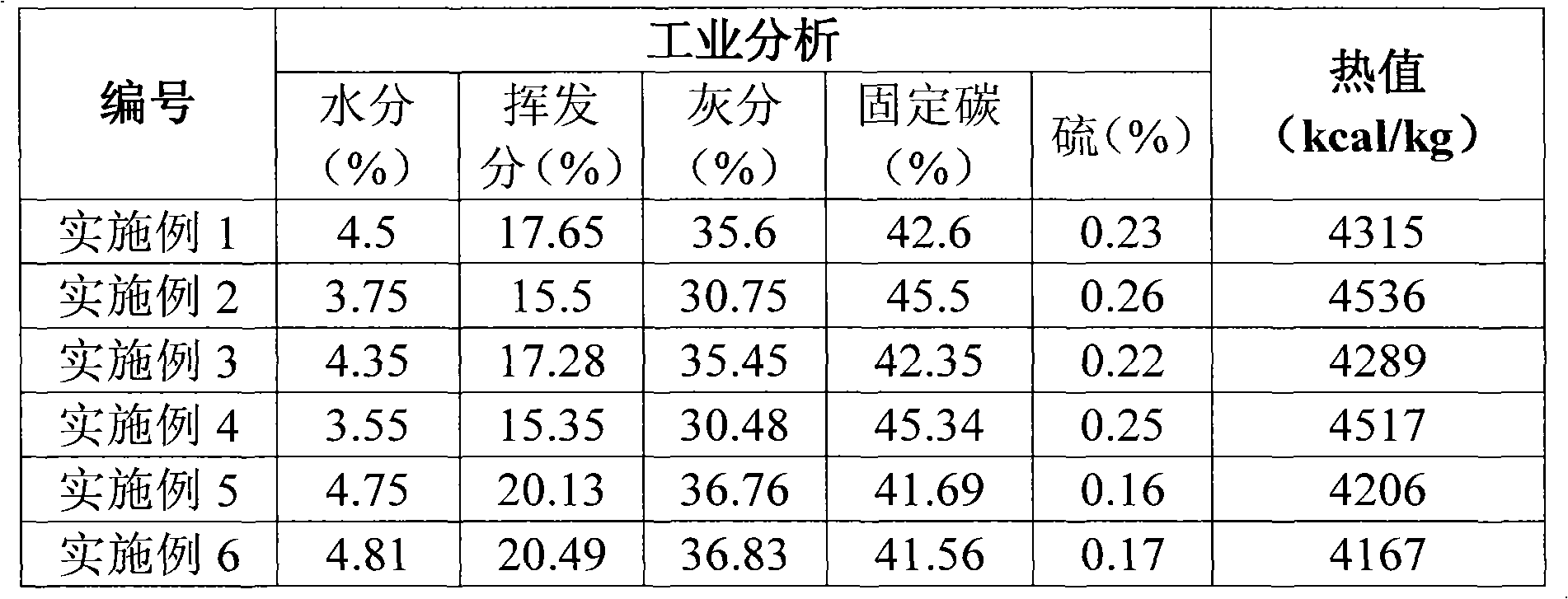

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

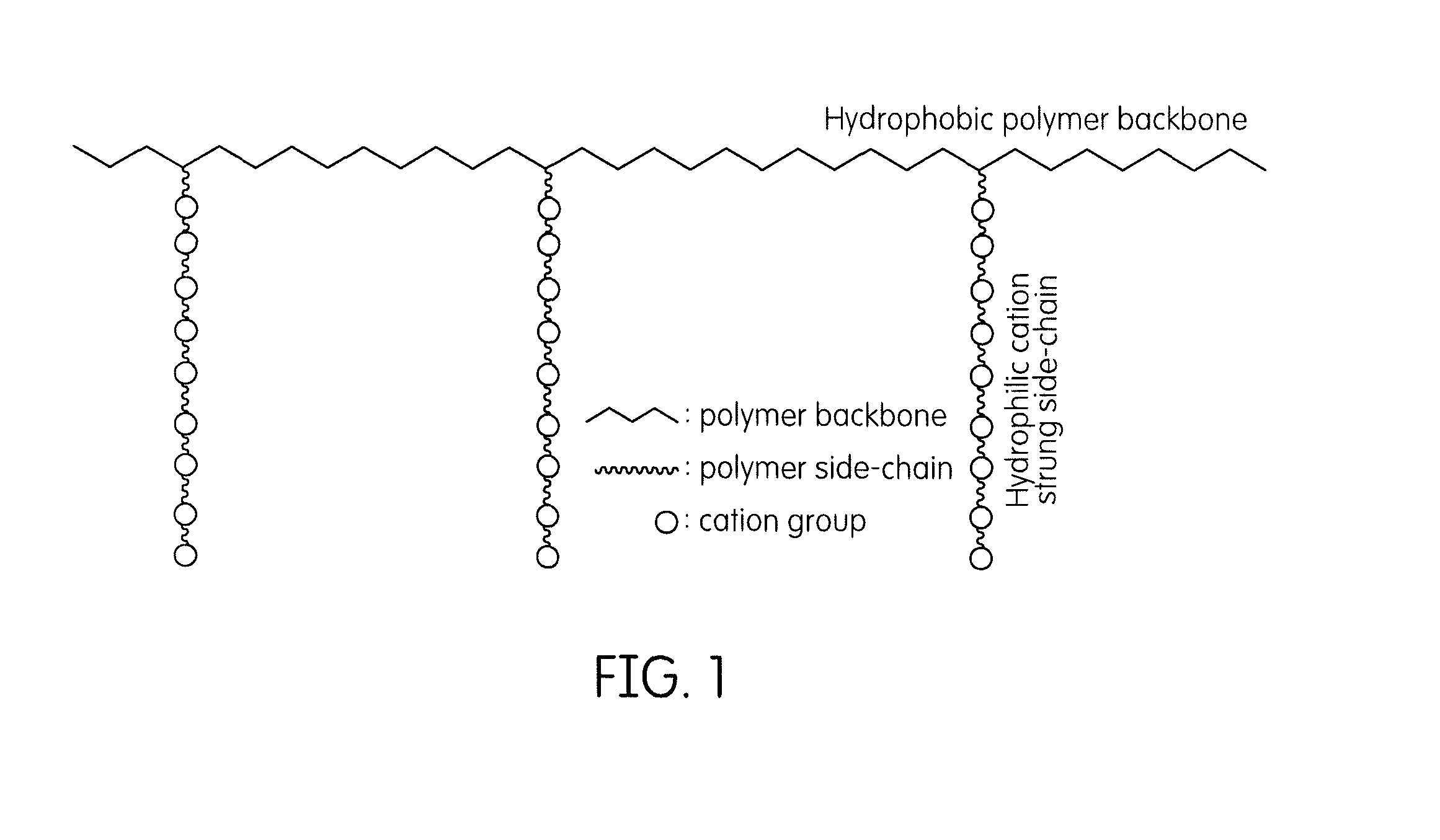

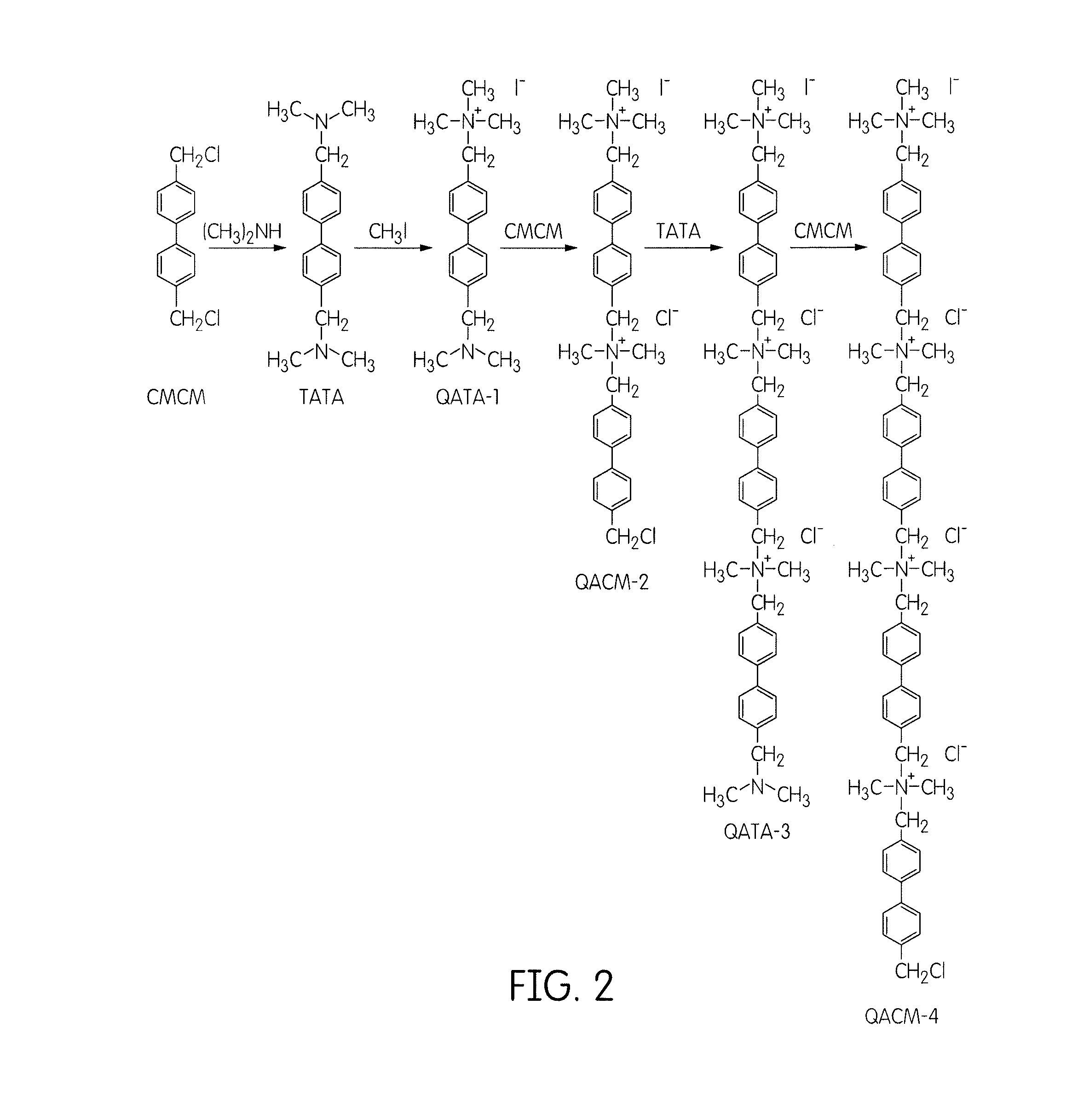

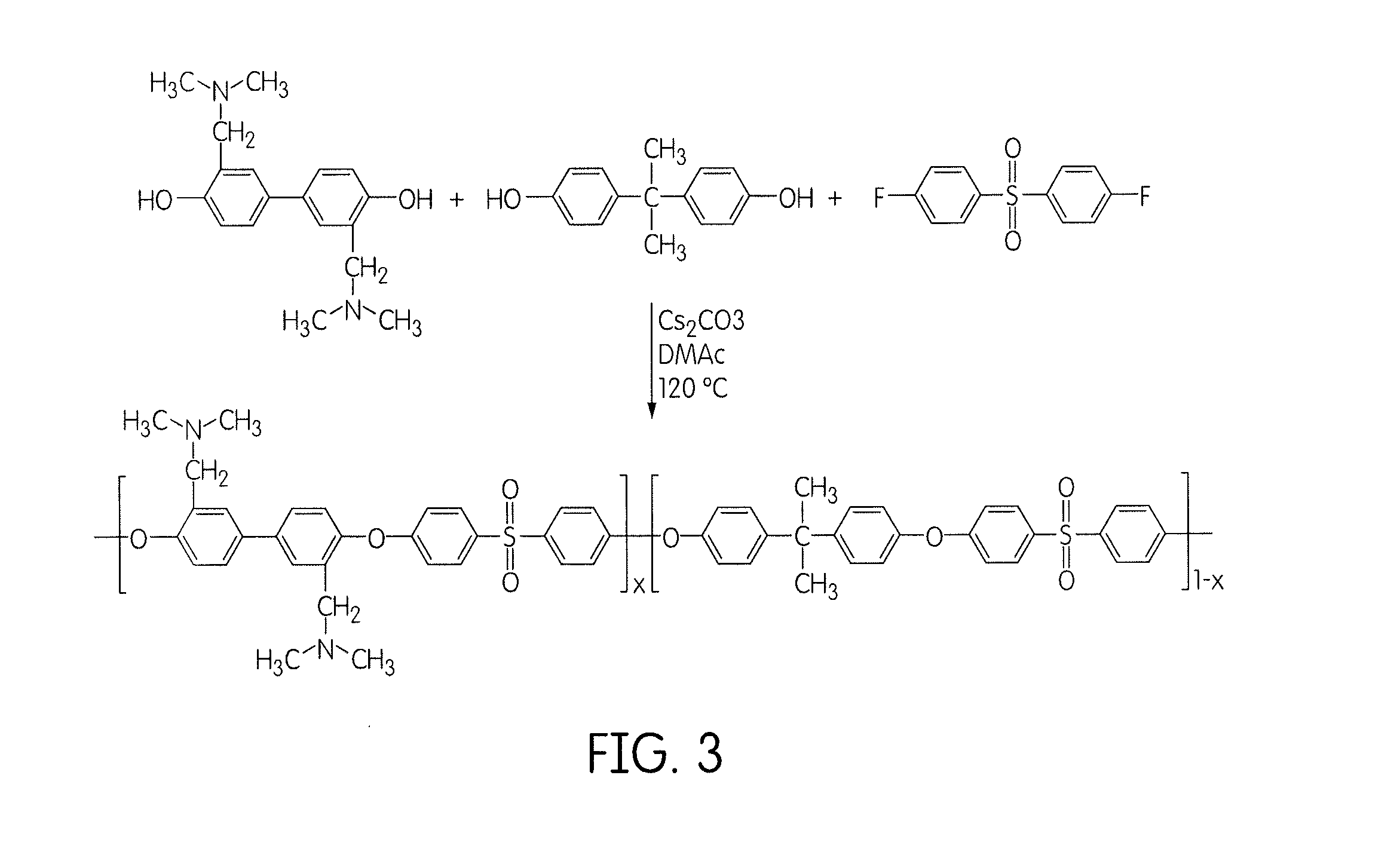

Cation-strung side chain polymers useful in hydroxide/anion exchange membranes

InactiveUS20140107237A1Prevent water absorptionEffectively overcomeMembranesSolid electrolytesElectrolysisSide chain

This invention provides a family of cation-strung polymers capable of forming membranes having exceptional hydroxide ionic conductivity as well as low water uptake and methods of making the same. The invention also provides for using these cation-strung polymers to manufacture membranes useful in HEMFC fuel cells and other devices such as electrolysis, solar hydrogen generation, redox flow battery, dialysis, reverse osmosis, forward osmosis, pervaporation, ion exchange, sensor, and gas separation.

Owner:UNIVERSITY OF DELAWARE

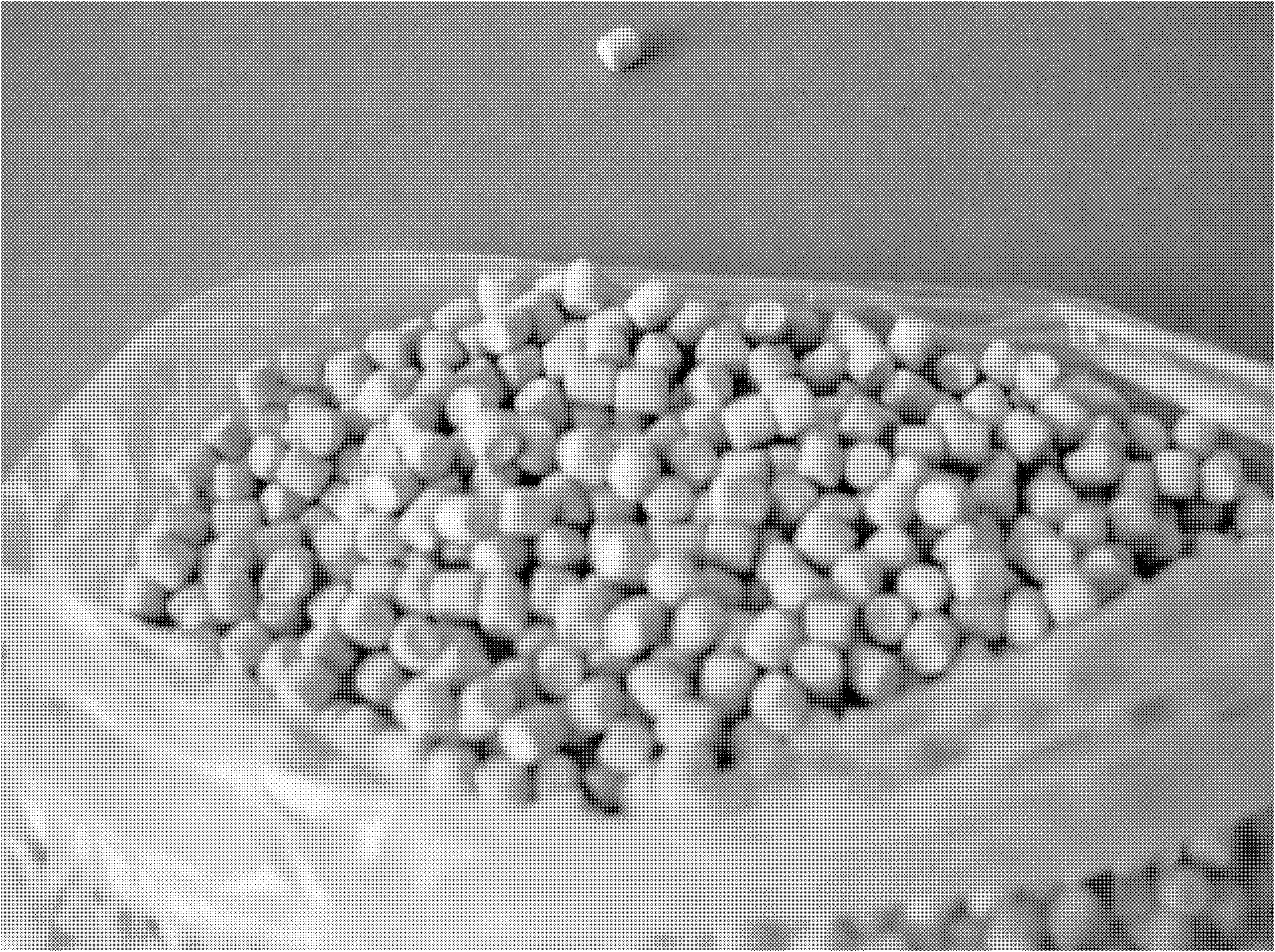

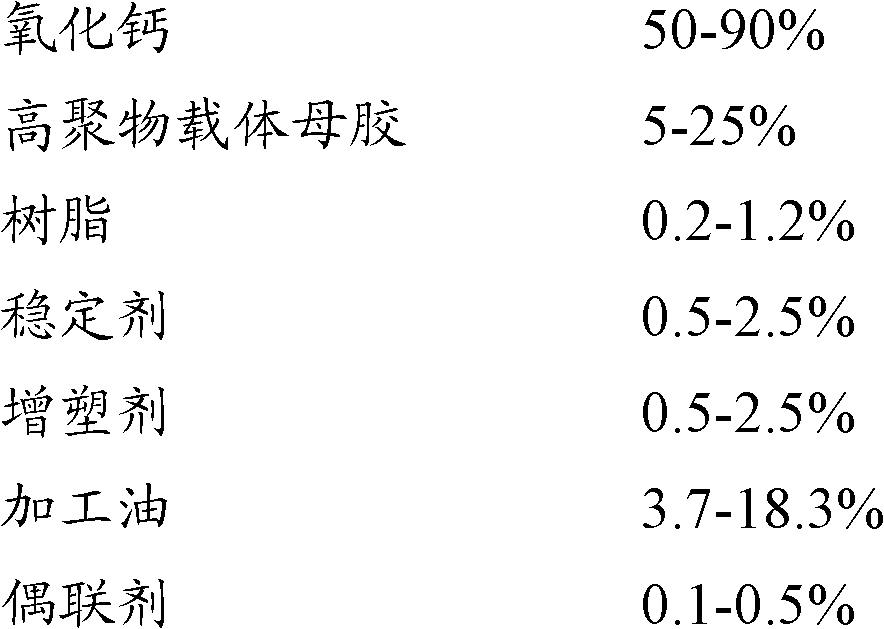

Environment-friendly defoaming masterbatch particles for rubber, and preparing and packaging methods thereof

ActiveCN102127247ALarge specific surface areaGood dispersionPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsMasterbatchProcedure Agents

The invention provides a calcium oxide-containing micelle composition, which comprises masterbatch at least comprising one of natural rubber, synthetic rubber and a mixture thereof, calcium oxide, a coupling agent, and a processing aid comprising at least one of processing oil, a plasticizer and a stabilizing agent. The calcium oxide-containing pre-dispersed materbatch particles overcome the defects of dust, odor, low compatibility with rubber, nonuniform dispersion and the like in the conventional method that calcium oxide powder is directly used as a defoaming agent in rubber, and are environment-friendly. Meanwhile, the invention also provides methods for preparing and storing the calcium oxide-containing micelle composition.

Owner:河南利源精细材料有限公司

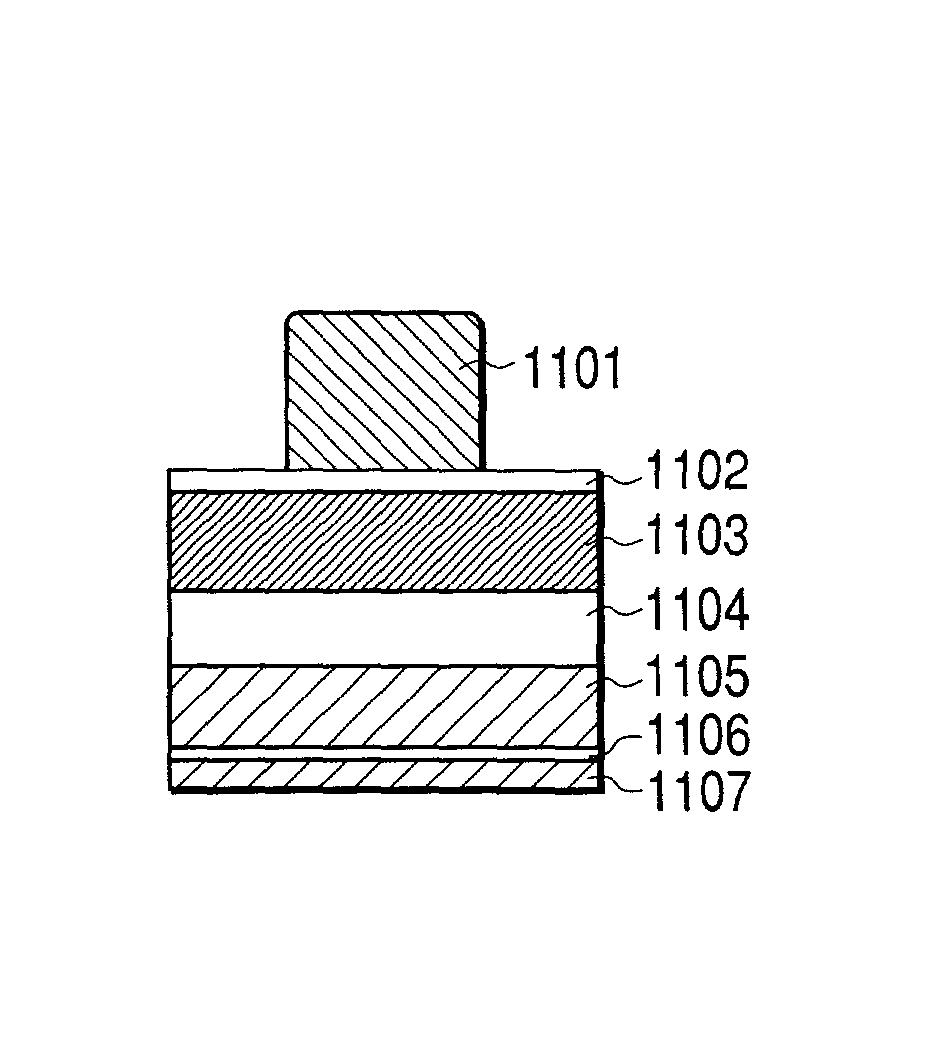

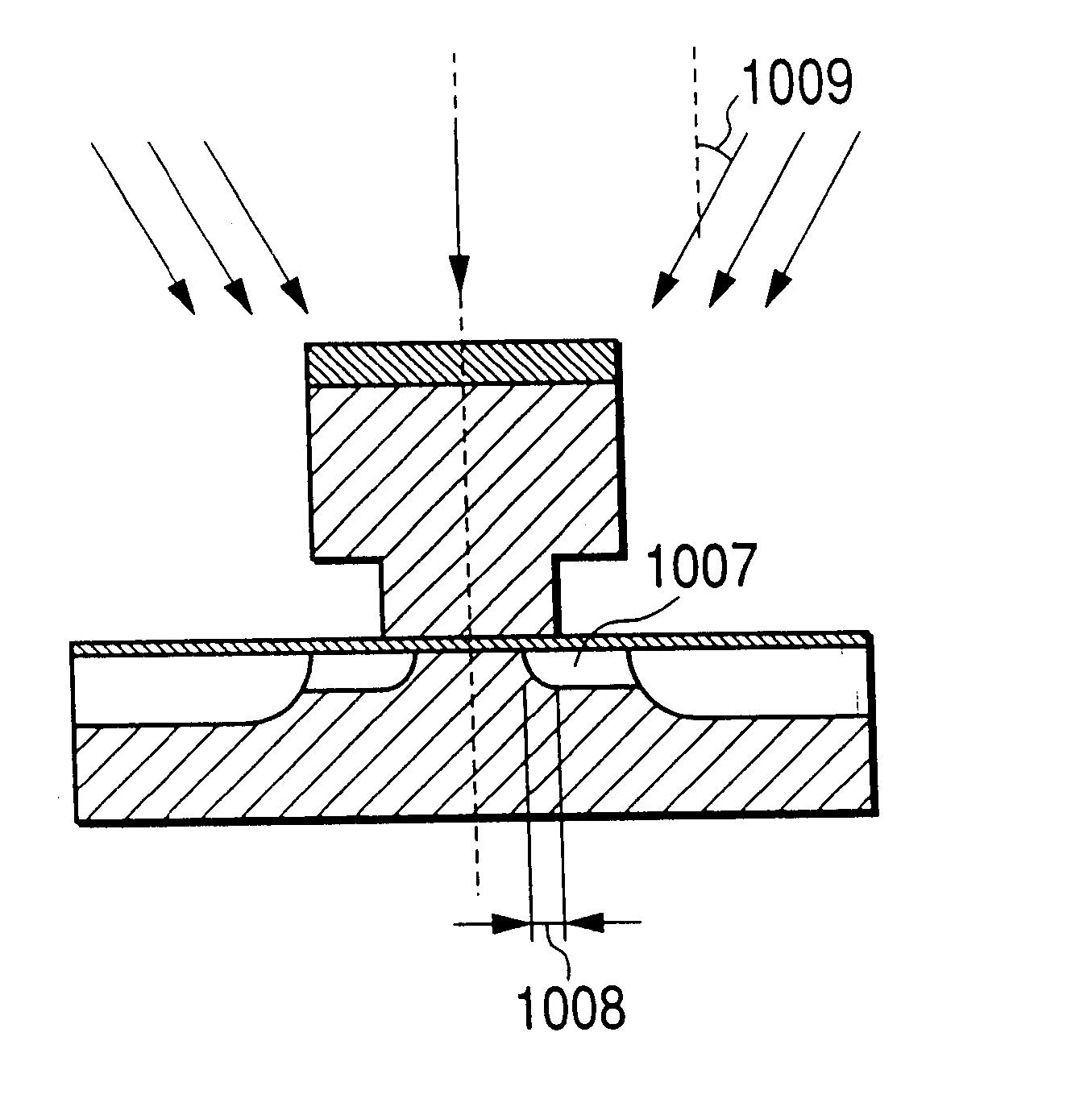

Method of manufacturing semiconductor devices

InactiveUS6673685B2Resist selectivityReduce variationSemiconductor/solid-state device manufacturingSemiconductor devicesResistEngineering

A process for economical and efficient fabrication of gate electrodes no larger than 50 nm, which is beyond the limit of exposure, is characterized by gate-electrode trimming and mask trimming with high resist selectivity which are performed in combination. The process is also preferably characterized by performing trimming and drying cleaning in a vacuum environment and may also include steps of inspecting dimensions and contamination in a vacuum environment. The process can be implemented to provide the effects of forming a gate no longer than 50 nm (beyond the limit of exposure) without restrictions on the resist thickness; reducing contamination resulting from transfer of wafers from one step to next, thereby improving yields; preventing resist from hydrolysis by ArF laser, thereby reducing roughening which adversely affects the gate width; and ensuring stable yields despite variation in dimensions and contamination owing to the additional dry cleaning step and feed-forward control based on CD inspection and contamination inspection.

Owner:HITACHI LTD

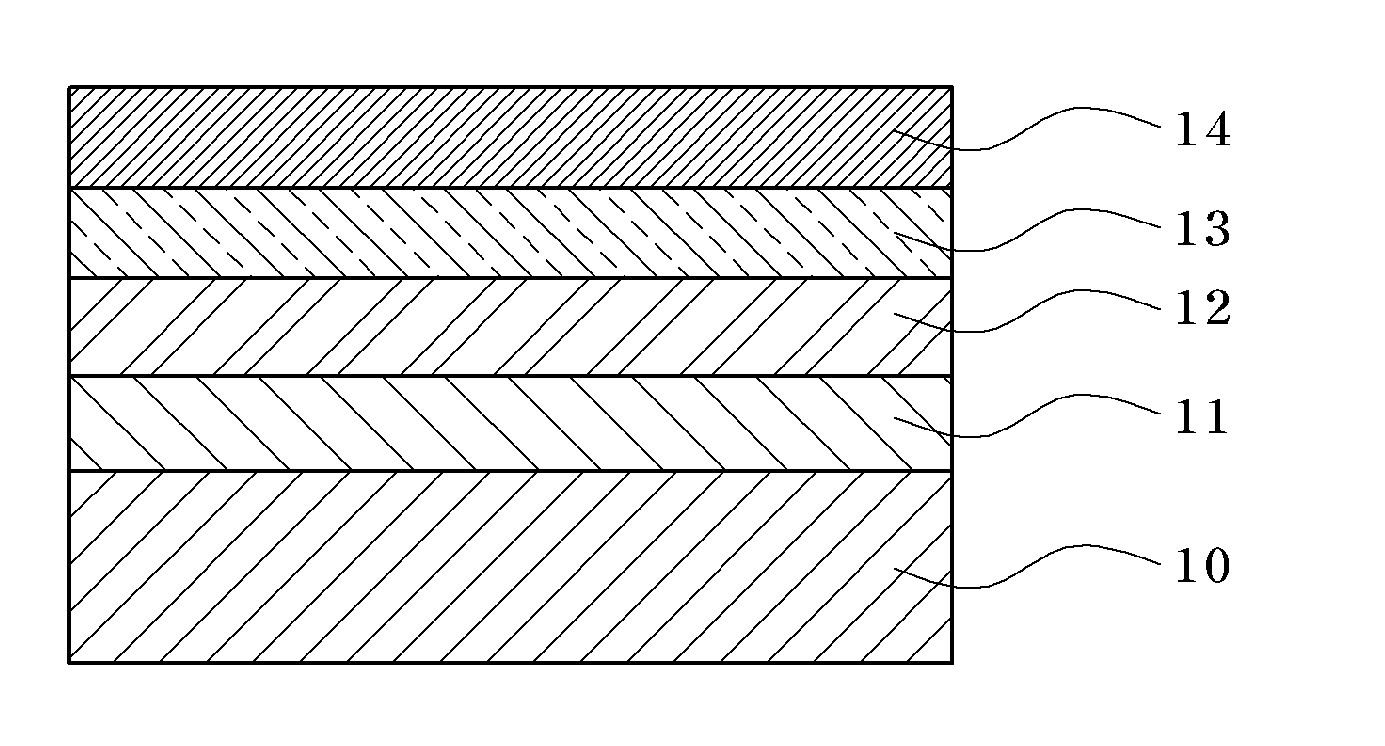

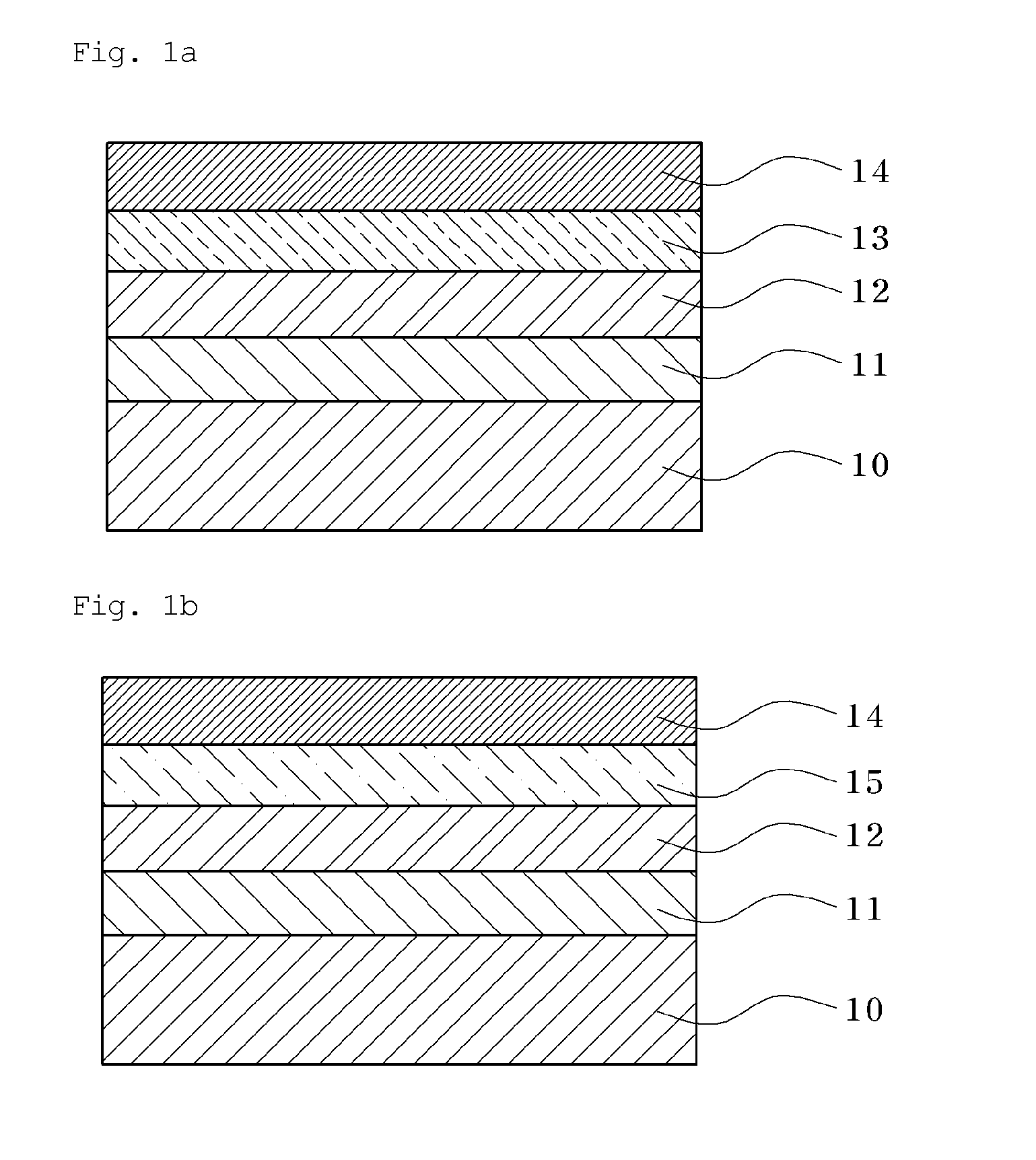

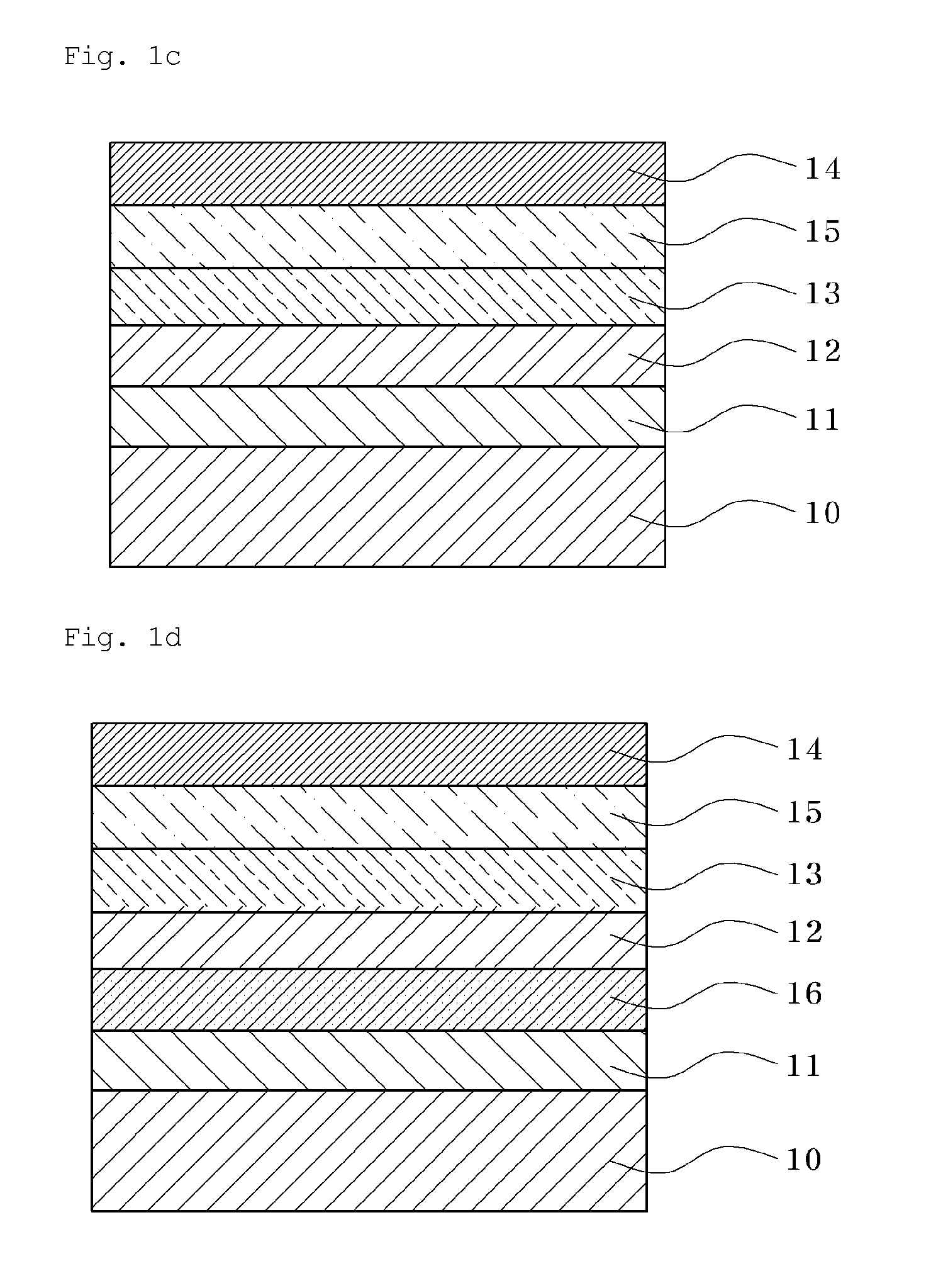

Preparation method for high-refractivity scattering layer and preparation method for organic light-emitting diode (OLED) with high luminous efficiency

ActiveCN102709489AEasy to operateGood flatnessSolid-state devicesSemiconductor/solid-state device manufacturingChemistryPhotoresist

The invention discloses a preparation method for a high-refractivity scattering layer and a preparation method for an organic light-emitting diode (OLED) with high luminous efficiency. The preparation method for the high-refractivity scattering layer comprises the following steps of: S1, preparing grinding dispersion, wherein the grinding dispersion comprises 10 to 60 mass percent of high-refractivity scattering particle, a dispersing agent of which the mass is 1 to 60 percent based on the mass of the high-refractivity scattering particles, 0 to 5 mass percent of anti-settling agent, 0 to 60 mass percent of photoresist and 20 to 89.9 mass percent of organic solvent; S2, filter-pressing the grinding dispersion prepared by the step S1 by using filter paper with filtering hole apertures of 0.8 to 1.2 mu m to obtain a film preparation solution; and S3, photoetching and spinning the film preparation solution prepared by the step S2 to obtain the high-refractivity scattering layer. When the high-refractivity scattering layer is arranged between a substrate and an electrode of the OLED with the high luminous efficiency, the luminous efficiency of the OLED can be greatly improved.

Owner:GUAN YEOLIGHT TECH CO LTD

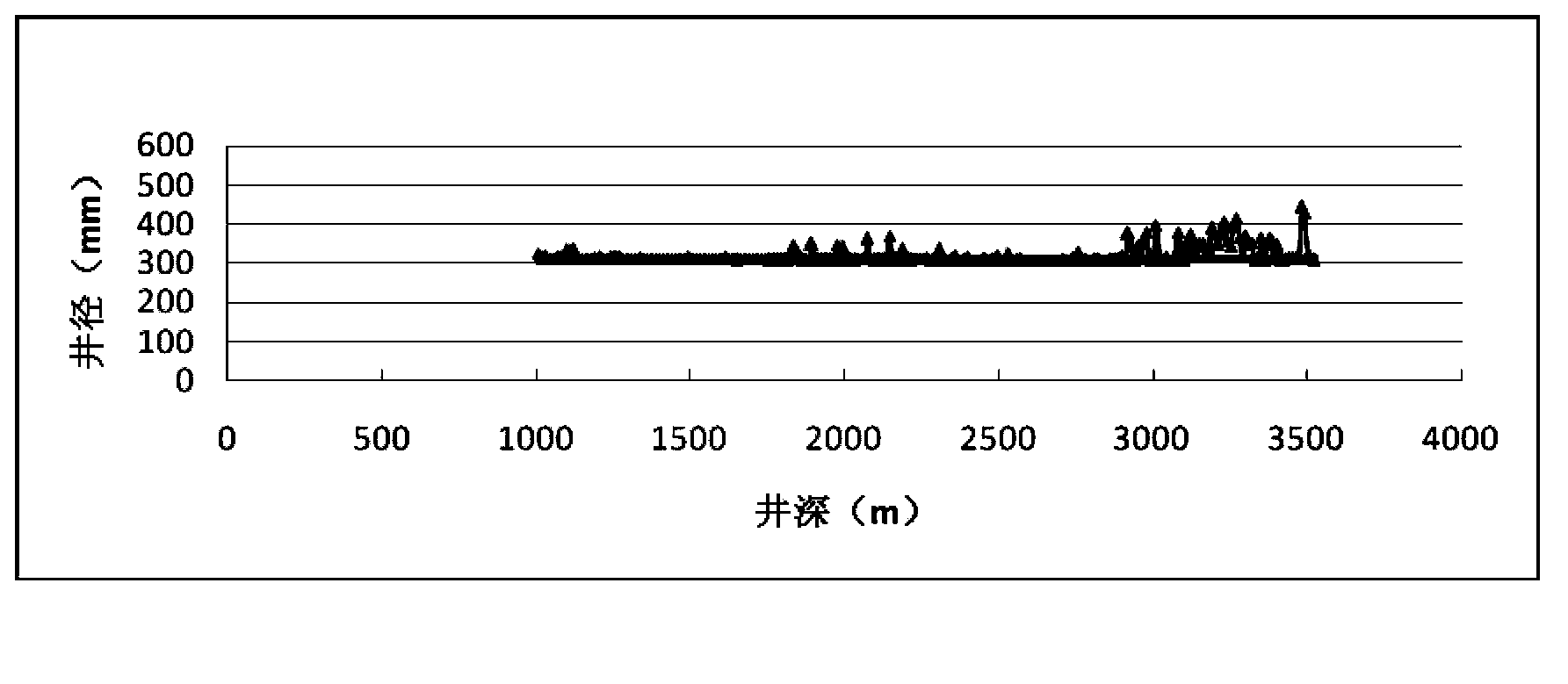

Dendritic multi-amino polymer drilling fluid used for mud rock well drilling

ActiveCN104130758AEnhanced inhibitory effectReduce plasticityDrilling compositionPotassiumWell drilling

The invention relates to a dendritic multi-amino polymer drilling fluid used for mud rock well drilling. The drilling fluid is characterized by consisting of a dendritic multi-amino polymer, drilling fluid bentonite, sodium carbonate, a polymer coating agent, potassium polyacrylate, a hydrolyzed polyacrylonitrile ammonium, a bit balling resistant lubricant and water. The dendritic multi-amino polymer drilling fluid can improve an inhibitive performance of the drilling fluid, can greatly improve the inhibitive performance on clay and drilled chips of the drilling fluid, can reduce plasticity of daub rock, can avoid water-absorption swelling and dispersing of the daub rock, can reduce friction resistance, can prevent bit balling, can increase a penetration rate and can ensure safety of a downhole operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for manufacturing porous nickel powder by electro-deposition of Ni-Al-Mg-Li alloy

The invention discloses a method for manufacturing porous nickel powder by electro-deposition of Ni-Al-Mg-Li alloy. The method includes that non-aqueous solution containing lithium salt is used as an electrolyte, metal nickel, metal aluminum and metal manganese are connected in parallel to be used as an anode, a metal titanium sheet is used as a cathode, and a rough Ni-Al-Mg-Li alloy product is prepared by means of electrochemical deposition; the rough Ni-Al-Mg-Li alloy product is subjected to high-energy ball milling, discharging, washing, filtering and drying to obtain Ni-Al-Mg-Li alloy powder; and the Ni-Al-Mg-Li alloy powder is subjected to acid treatment, washing, drying and grinding to obtain the porous nickel powder. The method has the advantages of simplicity in process, low energy consumption, equipment investment and production cost, zero pollution, high production efficiency and the like, the production benefit and the economical benefit can be effectively increased, and the method is beneficial to popularization and application.

Owner:NANJING UNIV OF TECH

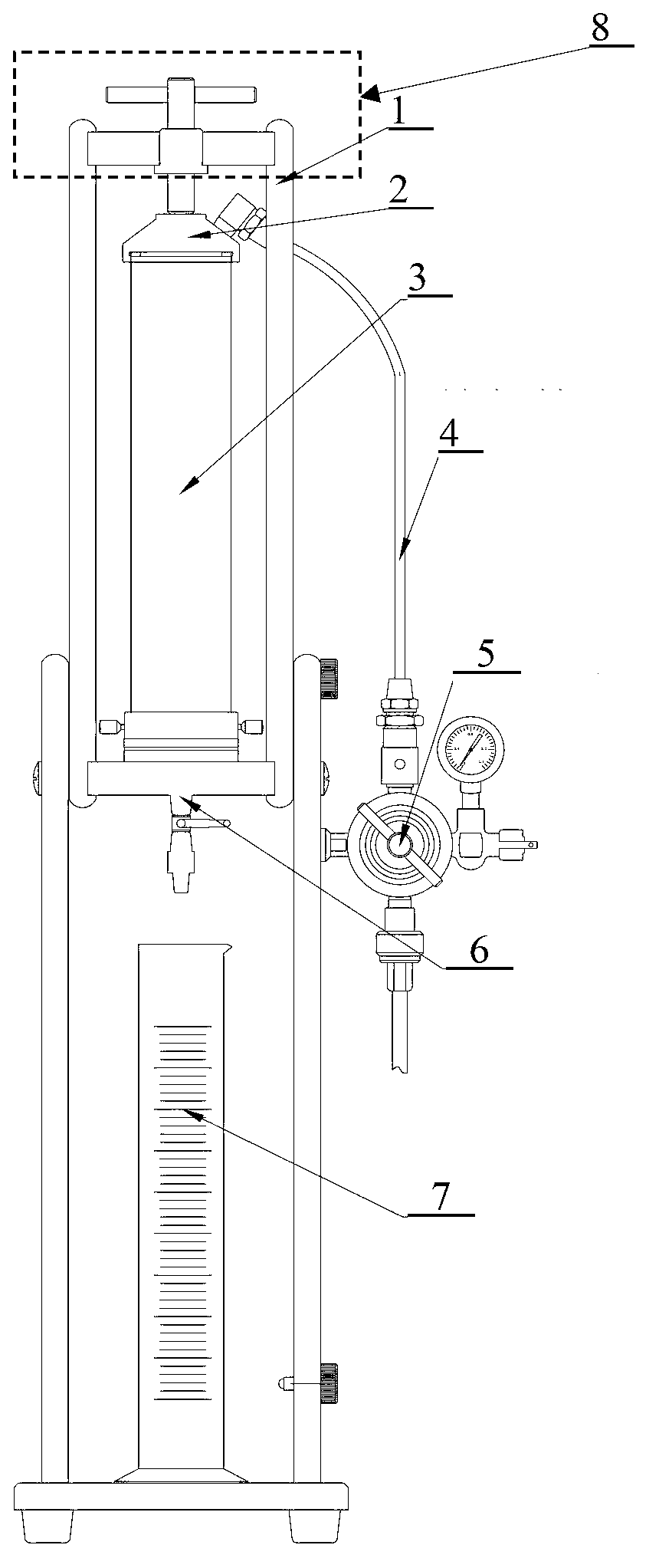

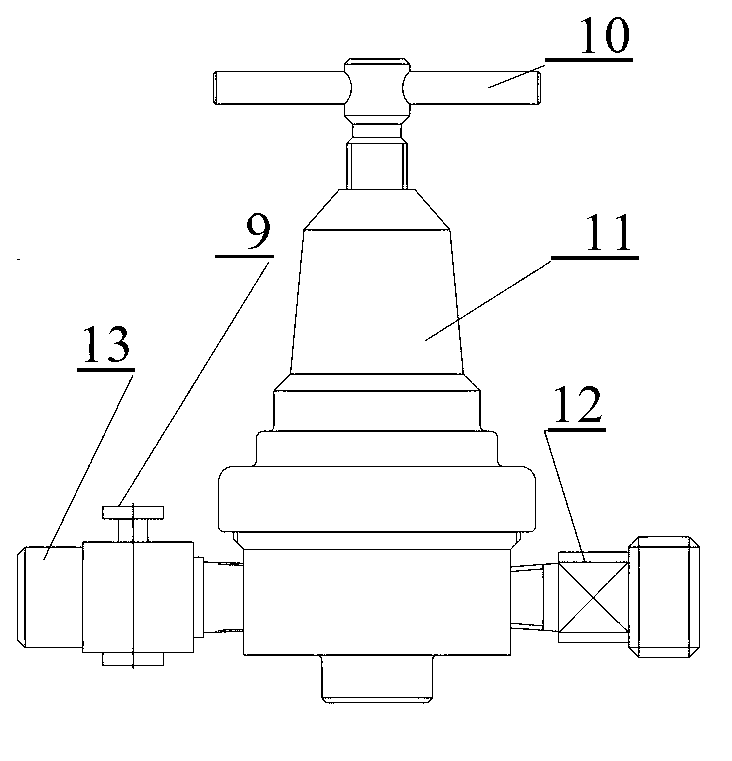

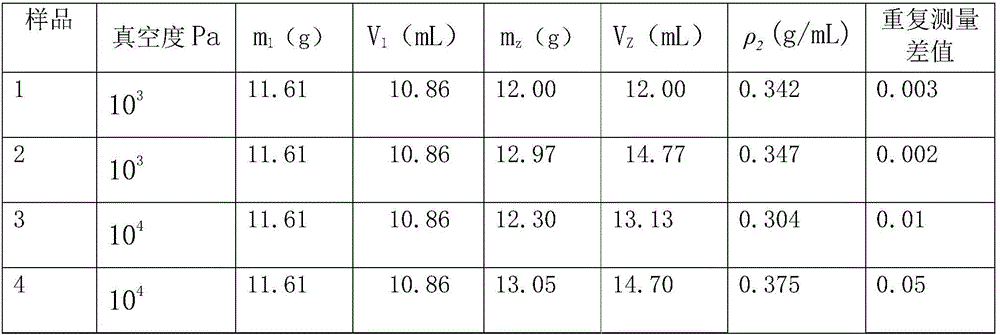

Method for determining density of cotton through water drainage technology

InactiveCN105865974APrevent water absorptionEasy to detectSpecific gravity measurementGraduated cylinderEngineering

The invention relates to a method for determining the density of cotton through a water drainage technology. The method comprises the following steps: respectively measuring the volume of a vacuum packaging bag and the volume of a vacuum packaging bag provided with cotton by using a measuring cylinder water drainage technology, calculating the mass and the volume of cotton through a differential technology, and calculating the density of the cotton. The vacuum packaging bag is waterproof, so water absorption of the cotton is avoided, detection is convenient, the measurement error is small, and the result is accurate; and the determination method is simple and understandable, and is simple to operate.

Owner:SHAANXI NORMAL UNIV

Preparation method of nutritious noodle

InactiveCN102366049AUniform moisturePrevent water absorptionDough treatmentFood preparationEconomic benefitsEngineering

The invention provides a preparation method of a nutritious noodle. The preparation method comprises the following steps: 1, putting flour and purified water in a dough kneading machine, carrying out dough kneading for 5-20min, adding vegetable powder to the dough kneading machine, continuously carrying out dough kneading for 5-20min, carrying out dough rest for 5-20min in a dough rest machine, and successively carrying out calendering, strip cutting, drying, and cutting processing to obtain finished products. According to the invention, the method that the vegetable powder is added after the flour is subjected to the dough kneading for a period of time is adopted to replace a traditional method that the dough kneading is carried out after the vegetable powder is mixed with the flour, and the change which produces unexpected positive effects allows the excess water absorption of the vegetable powder to be avoided, water in the dried noodle to be uniform, and the shelf life of the dried noodle to be prolonged. The shelf life of the vegetable noodle produced by the method of the invention is prolonged to one year, and the prepared noodle which is soft and tasty can be treated as an auxiliary food for the vegetable feeding of children. The method of the invention has the advantages of simple preparation, good economic benefit and high quality of the finished product.

Owner:宜垦(天津)农业制品有限公司

Method of preparing storage phosphors from dedicated precursors

ActiveUS20050181119A1Excellent and reproducible qualityPrevent water absorptionX-ray/infra-red processesCathode ray tubes/electron beam tubesGas phaseHigh energy

A method for producing CsX:Eu stimulable phosphors and screens or panels provided with said phosphors as powder phosphors or vapor deposited needle-shaped phosphors suitable for use in image forming methods for recording and reproducing images of objects made by high energy radiation, wherein said CsX:Eu stimulable phosphors are essentially free from oxygen in their crystal structure, and wherein X represents a halide selected from the group consisting of Br, Cl and combinations thereof, and wherein the method further comprises the steps of mixing CsX with a compound or combinations of precursor compounds having as a composition CsxEuyX′x+αy, wherein the ratio of x to y exceeds a value of 0.25, wherein α≧2 and wherein X′ is a halide selected from the group consisting of Cl, Br and I and combinations thereof; heating said mixture at a temperature above 450 ° C.; cooling said mixture, and optionally annealing and recovering said CsX:Eu phosphor.

Owner:AGFA NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com