Environment-friendly defoaming masterbatch particles for rubber, and preparing and packaging methods thereof

A technology of colloidal particles and masterbatch, which is applied in the direction of fibrous filler, dyed low-molecular organic compound treatment, dyed high-molecular organic compound treatment, etc., and can solve problems such as poor compatibility of rubber, odor, dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0096] The concrete steps that the present invention prepares defoamer calcium oxide masterbatch are as follows:

[0097] 1. Adopt ultra-fine technology and particle size control process to crush and control the particle size of calcium oxide. The crushing of calcium oxide can be realized by ball mill or jet mill, and the average particle size of the powder is strictly controlled to be 0-30 μm. The particle size is below 40-65 μm.

[0098] 2. Add the pulverized calcium oxide into the internal mixer quickly, and add the components including high polymer carrier masterbatch, plasticizer, stabilizer, processing oil, resin, and coupling agent in a certain proportion in sequence.

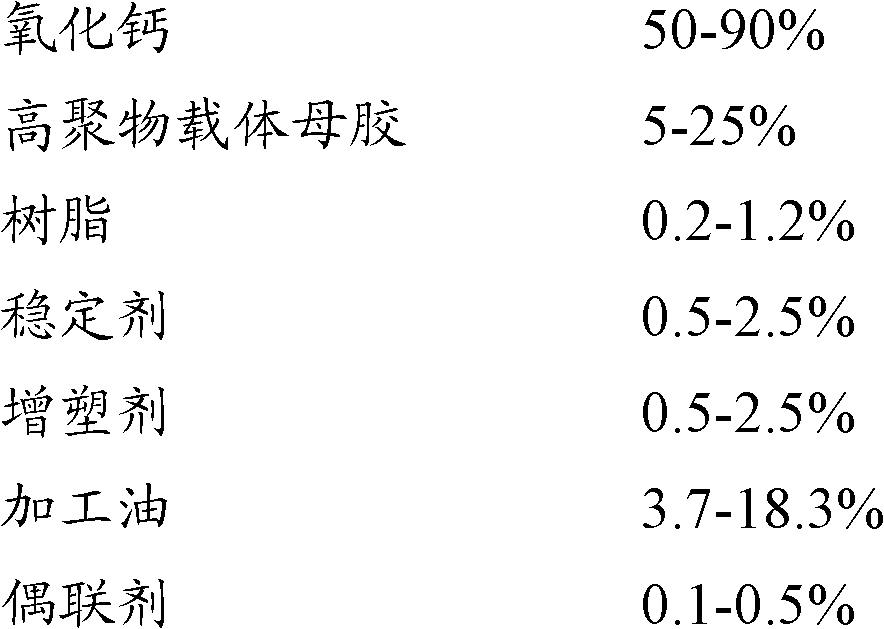

[0099] (1) The sum of the proportions of each component is 100%, and the formula ratio (mass / weight percentage) is specifically:

[0100]

[0101] (2) Requirements for each composite component:

[0102] Rubber: one or several mixtures of EPDM rubber, EPDM rubber, styrene-butadiene rubber, and nitril...

Embodiment 1

[0117] Weigh 2kg of calcium oxide powder (purchased from Lianyungang Jingsheng New Material Co., Ltd., purity 97%) and put it into a 5L airtight ball mill, grind for 3 hours, take 0.5g for particle size test, the result is: the average particle size is 8.968 μm, All particle diameters are 35 μm or less.

[0118] Mix 250g of nitrile rubber (purchased from Zhenjiang Nandi Chemical Co., Ltd., Jiangsu, China) with 12.5g of cable-grade EVA resin (purchased from DuPont), 25g of stearic acid, 15g of dioctyl phthalate, 3.25g of aromatic Oil (purchased from Hangzhou Refinery of Sinopec Group) was added to a 3.5L internal mixer and mixed for 2 minutes, the temperature rose to 60°C, and the speed was 60r / min; the crushed calcium oxide powder and dioctyl phthalate 10g , 15g of aromatic oil, 5g of fumaric acid was added into the internal mixer in 2 times and mixed with the high polymer carrier masterbatch of nitrile rubber for 3 minutes, and then thinly passed 6 times on the open mixer to ...

Embodiment 2

[0121] Weigh 2Kg of calcium oxide powder into a 5L closed ball mill, grind for 2 hours, the average particle size is 12.95 μm, and the total particle size is 63 μm or less.

[0122] Add 428g of EPDM rubber (purchased from Disman, the United States), 21g of cable-grade EVA resin (purchased from BASF), 43g of stearic acid, 25g of fatty acid alcohol ester mixture, and 103g of naphthenic oil in 3.5L Mix in an internal mixer at 60°C for 4 minutes at a speed of 65r / min;

[0123] Then add 2Kg of crushed calcium oxide powder and 18g of the mixture of fatty acid alcohol ester, 210g of naphthenic oil, 8.6g of the mixture of ethyl acrylate and fumaric acid, and add them to the internal mixer in 3 times and refine them with the rubber polymer carrier for 5 minutes , and then thin pass 6 times on the mill;

[0124] Put the rubber into the extruder, the heating temperature of the extruder is 60°C, the speed of the main machine is 100 rpm, the feeding speed is 60 rpm, pelletize, add 1% rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com