Patents

Literature

120results about "Floating cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

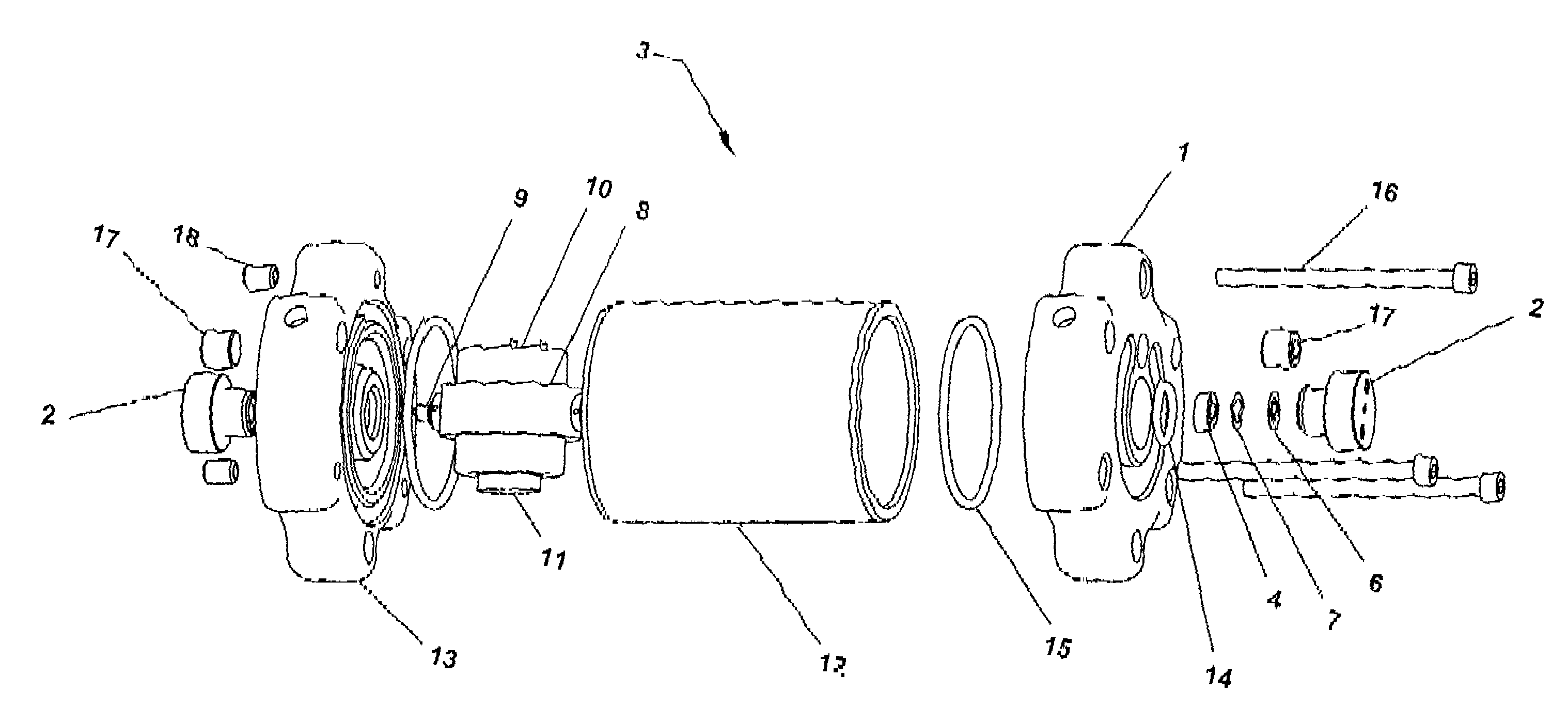

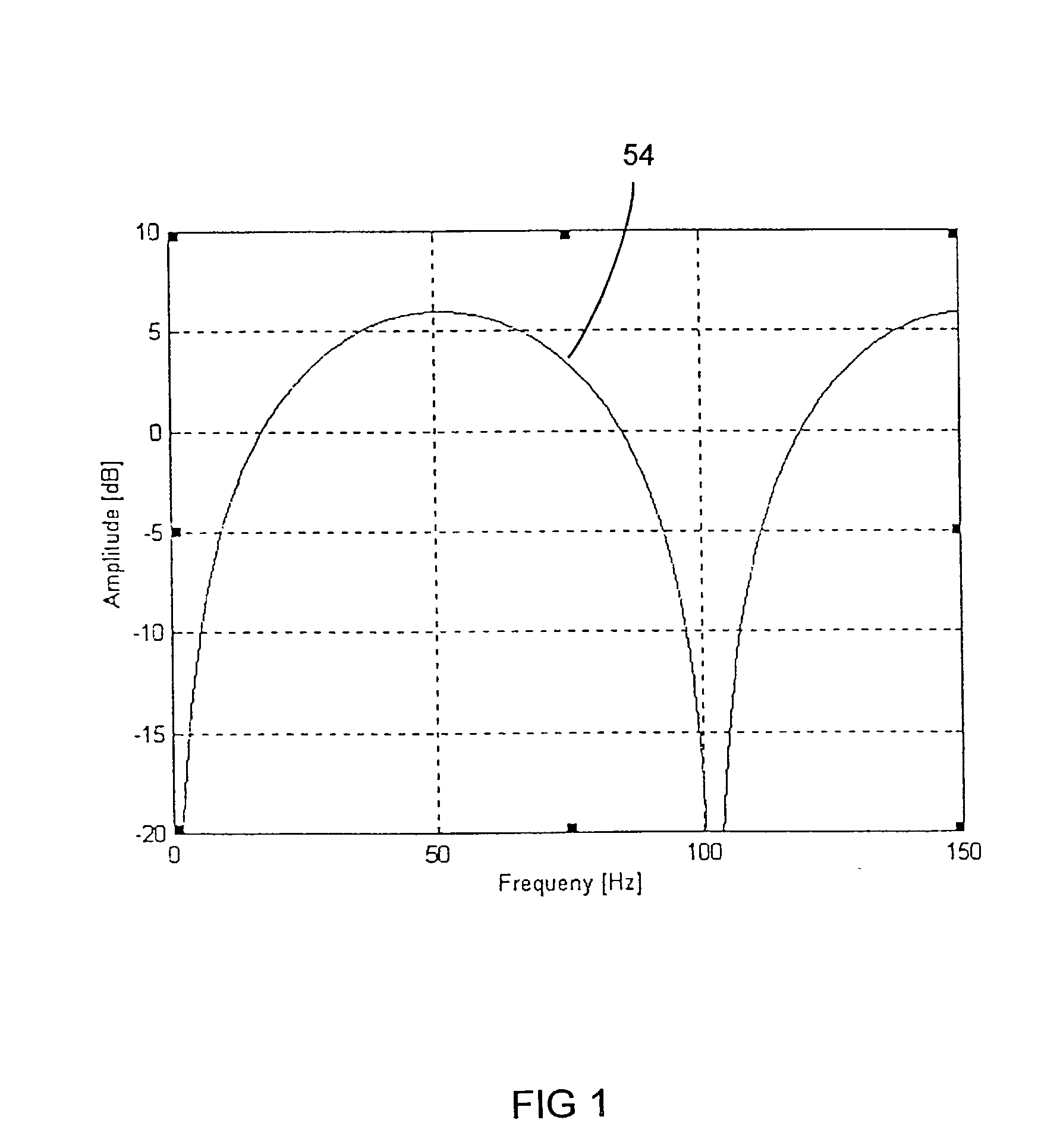

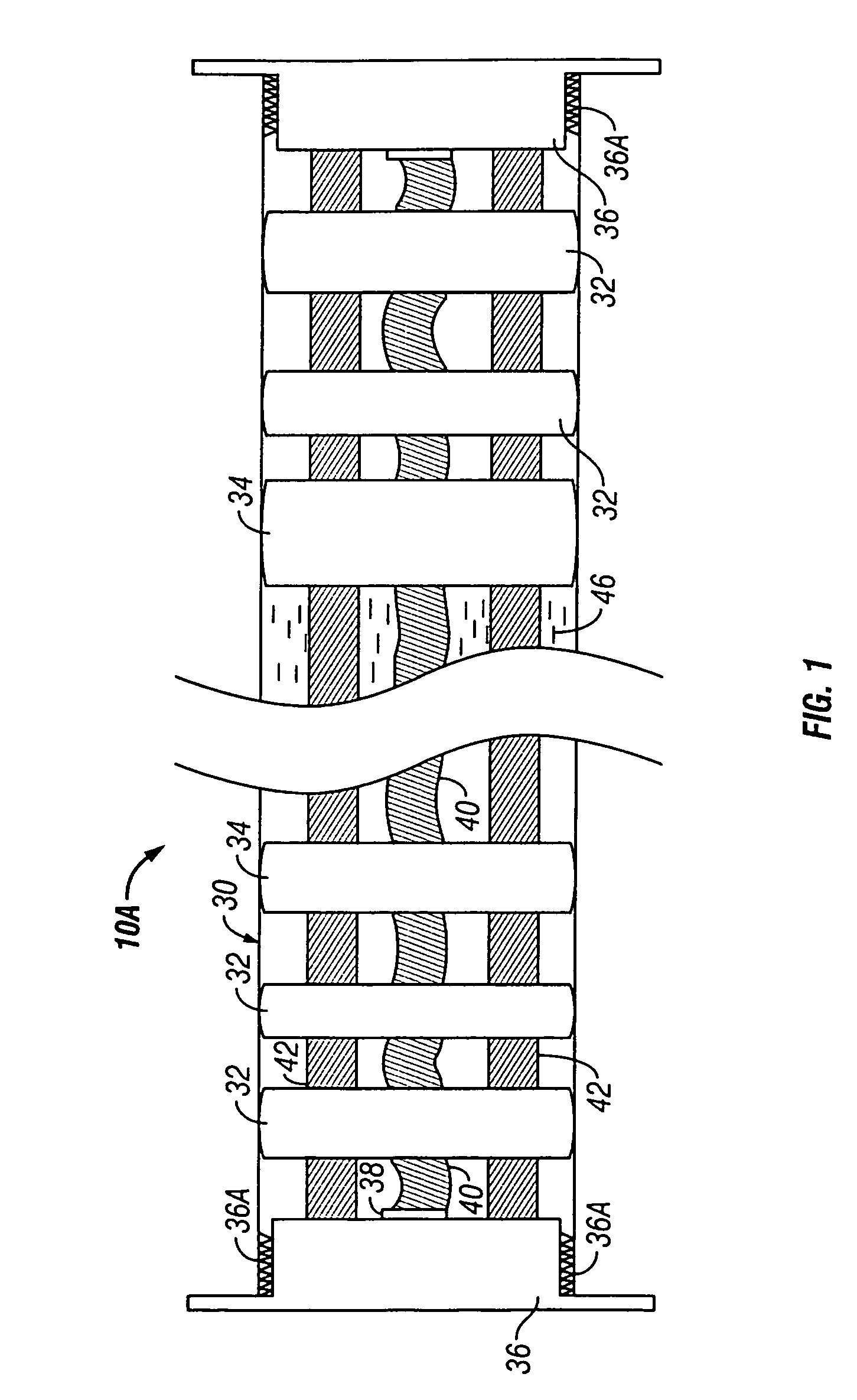

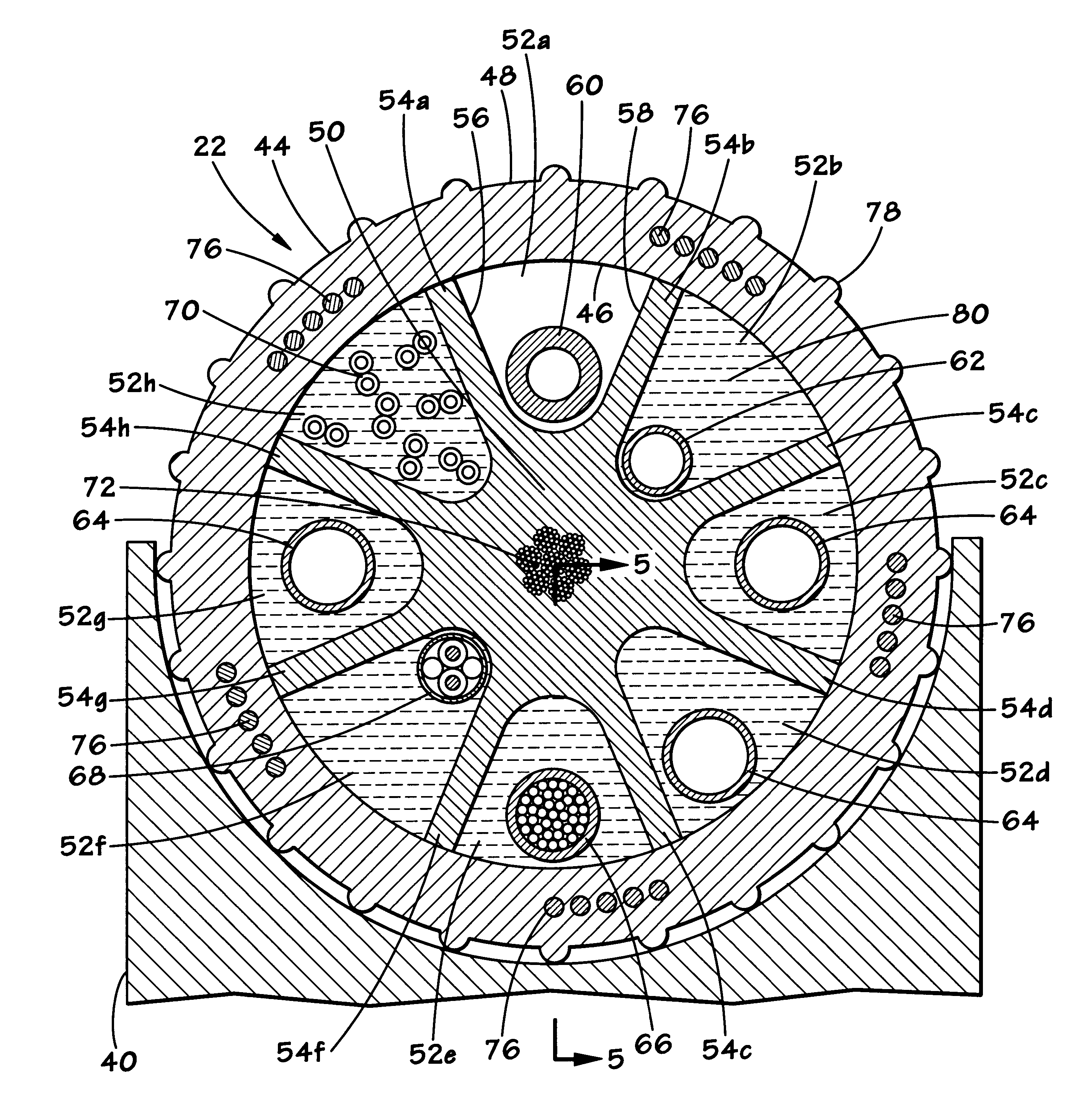

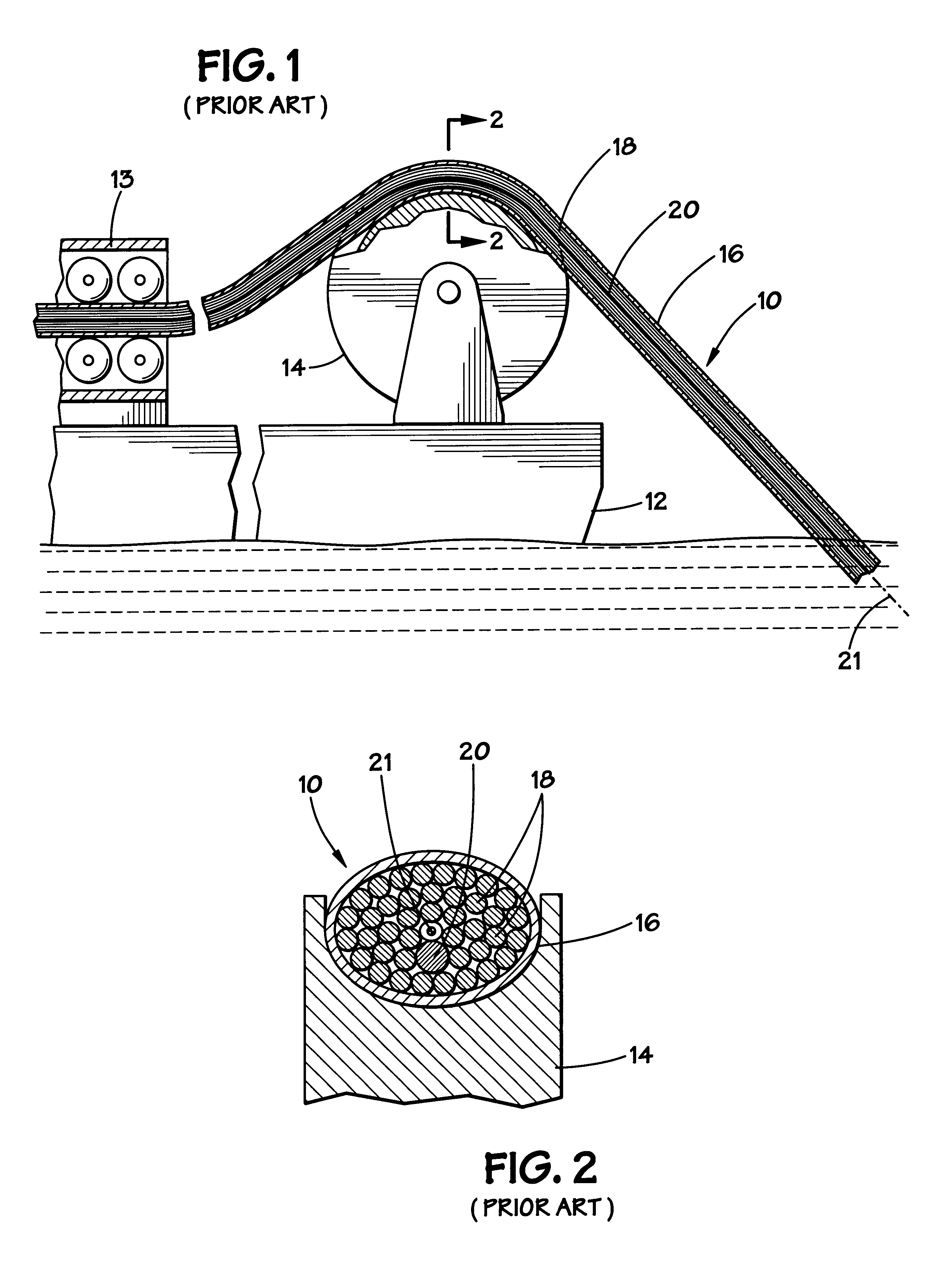

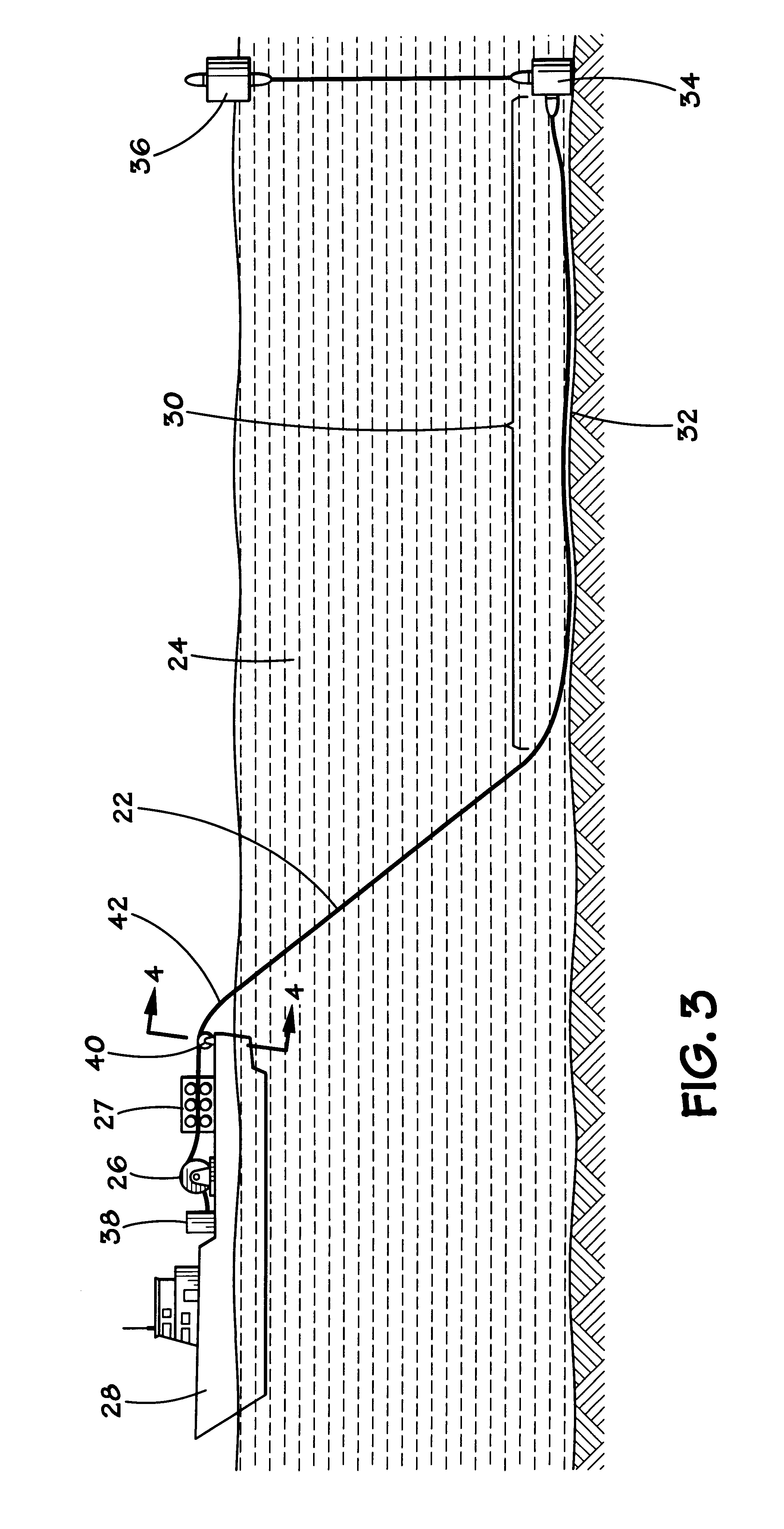

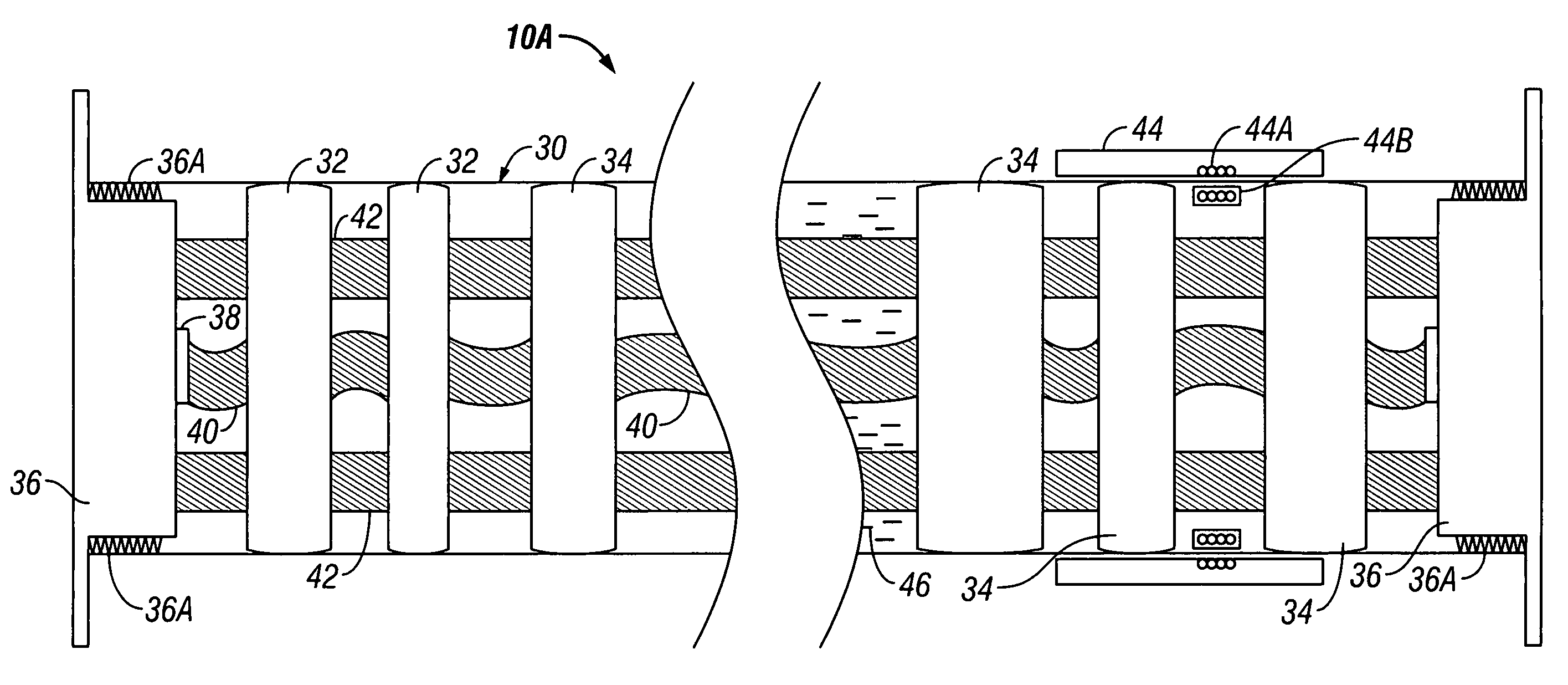

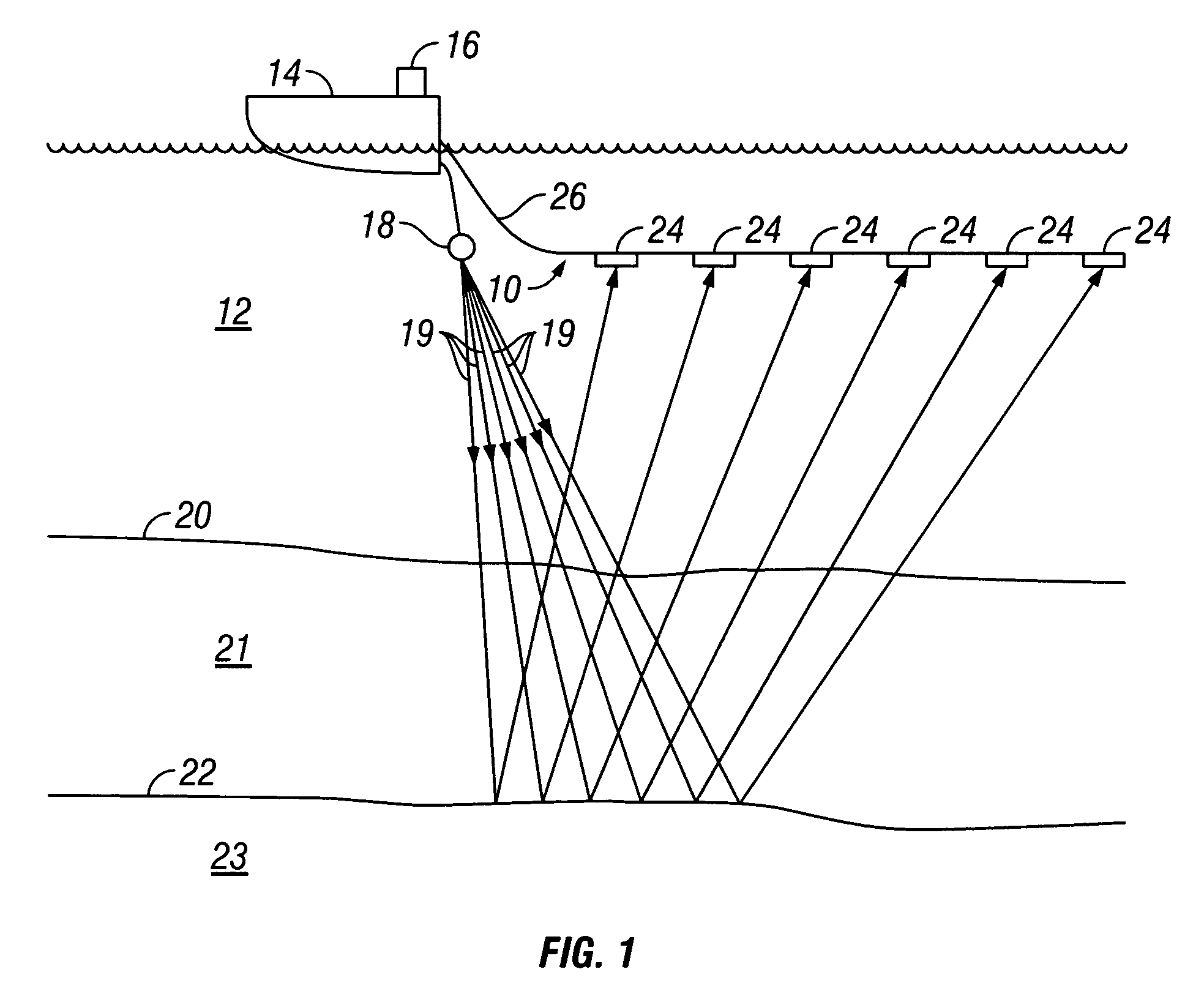

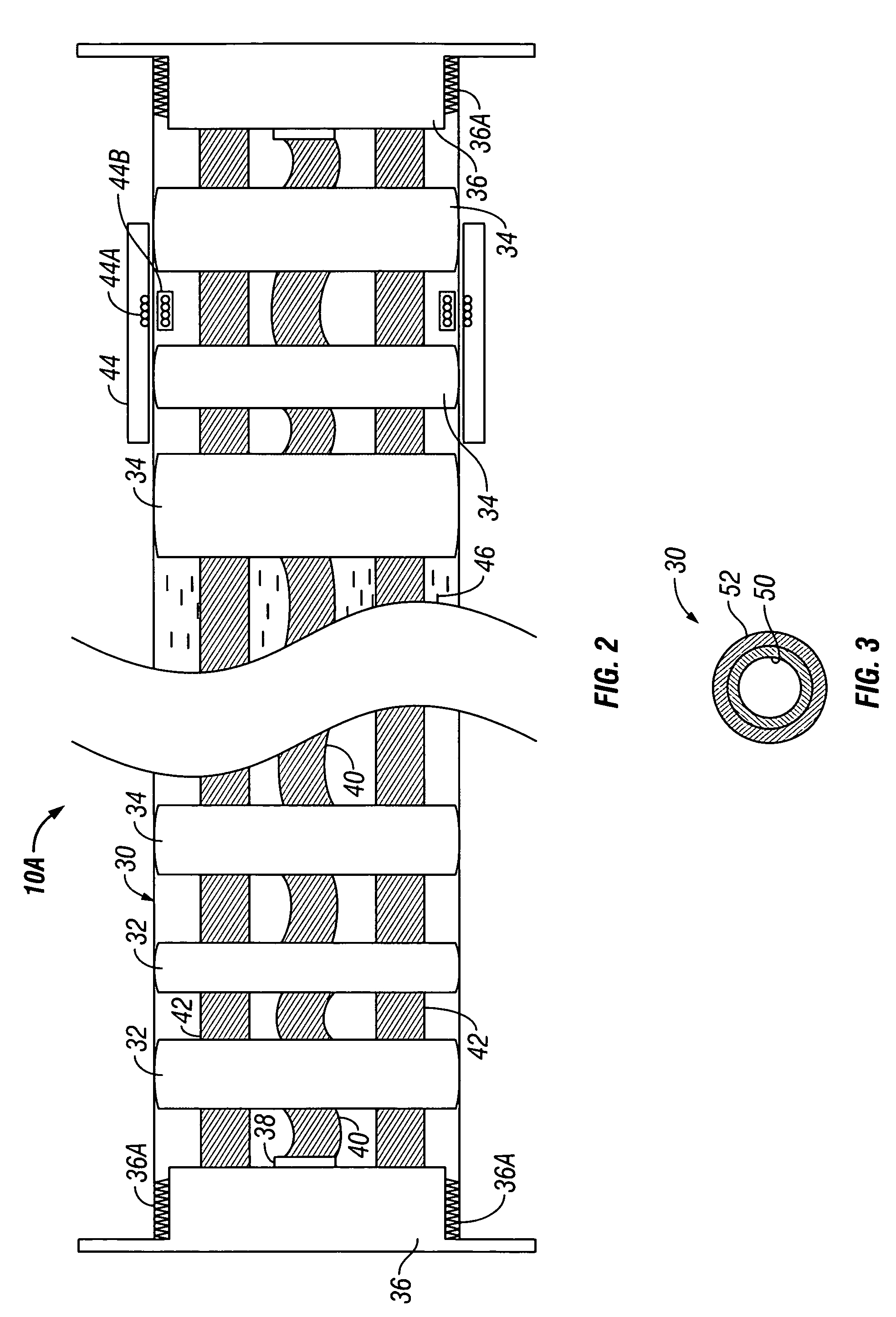

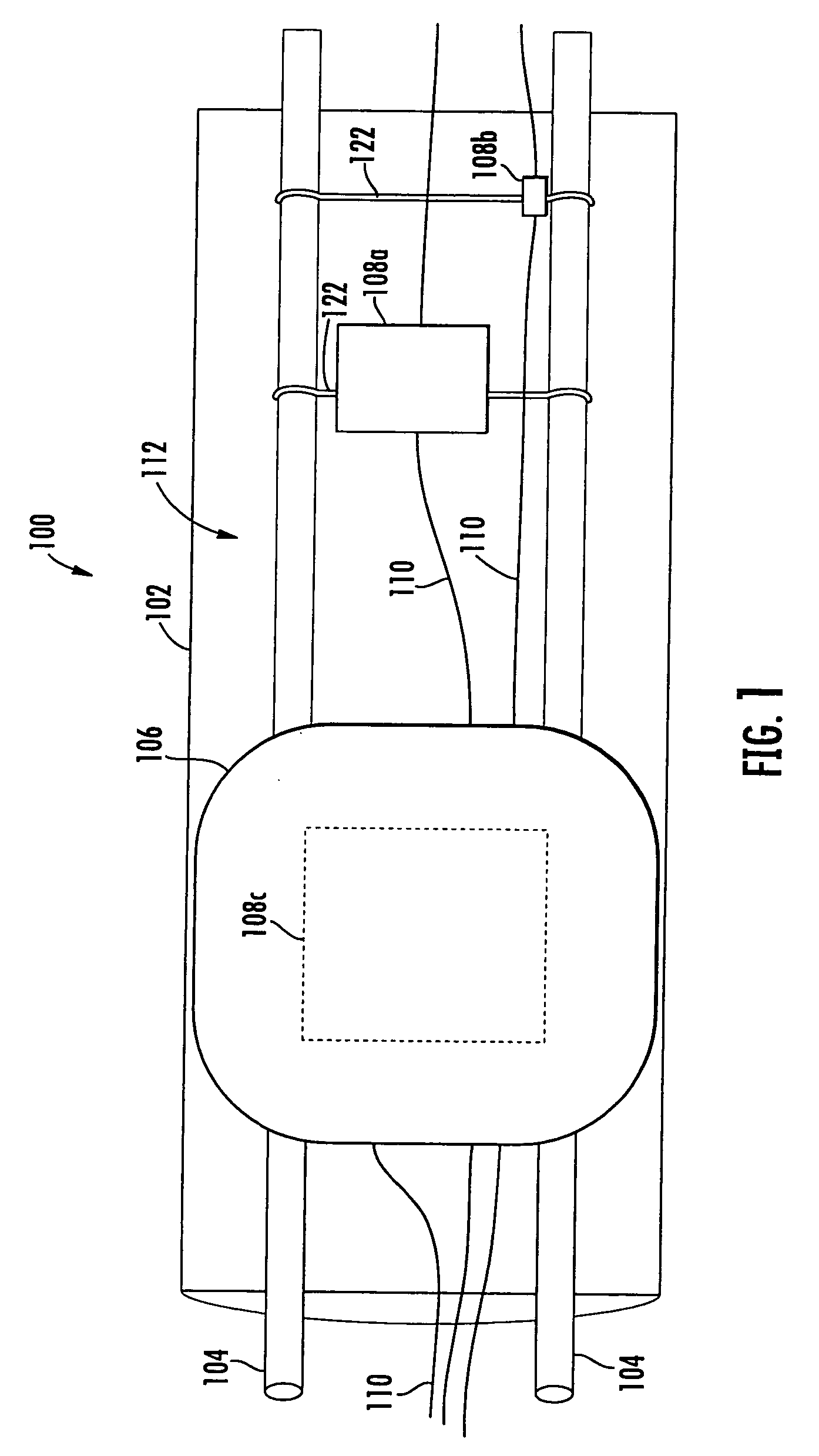

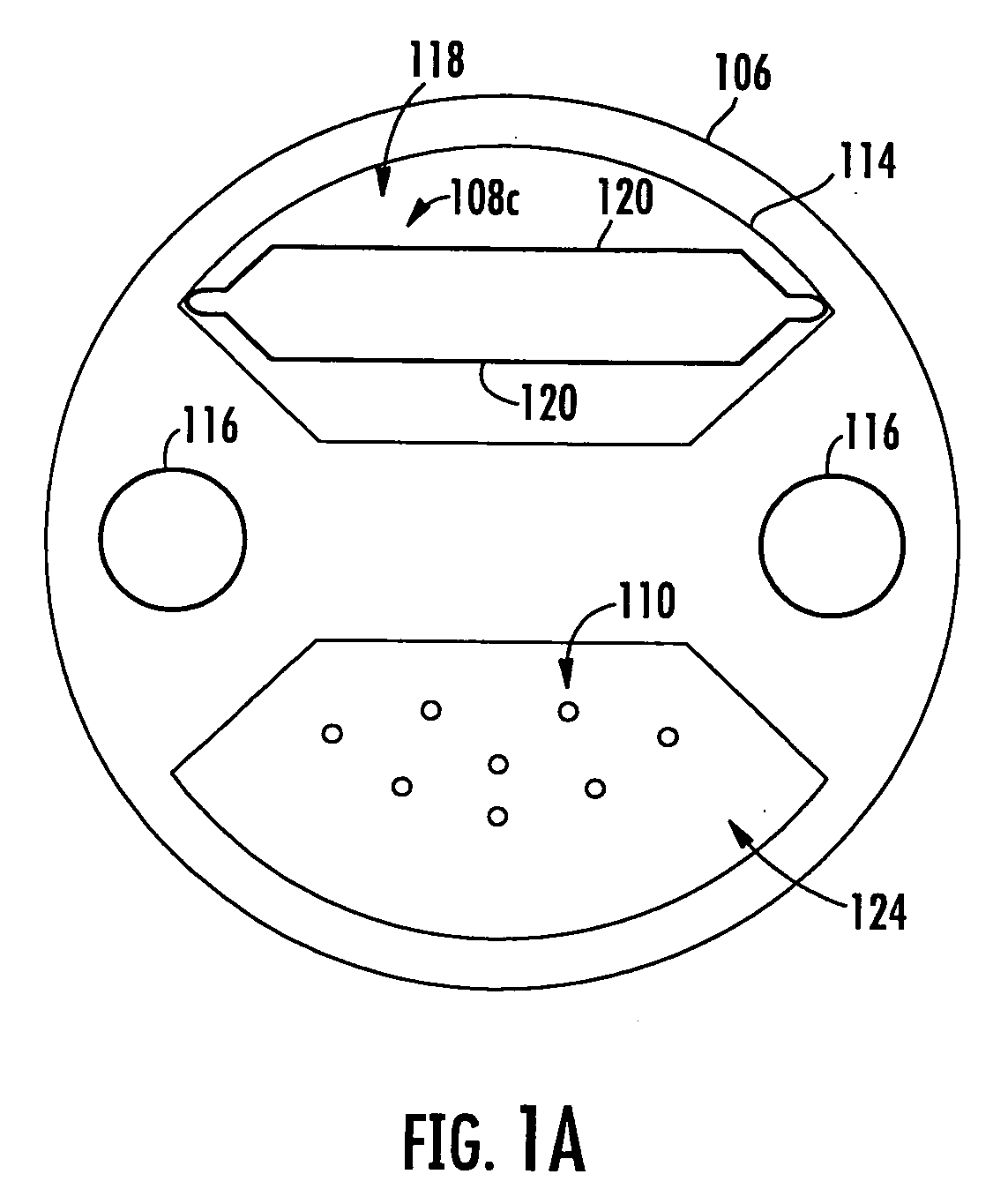

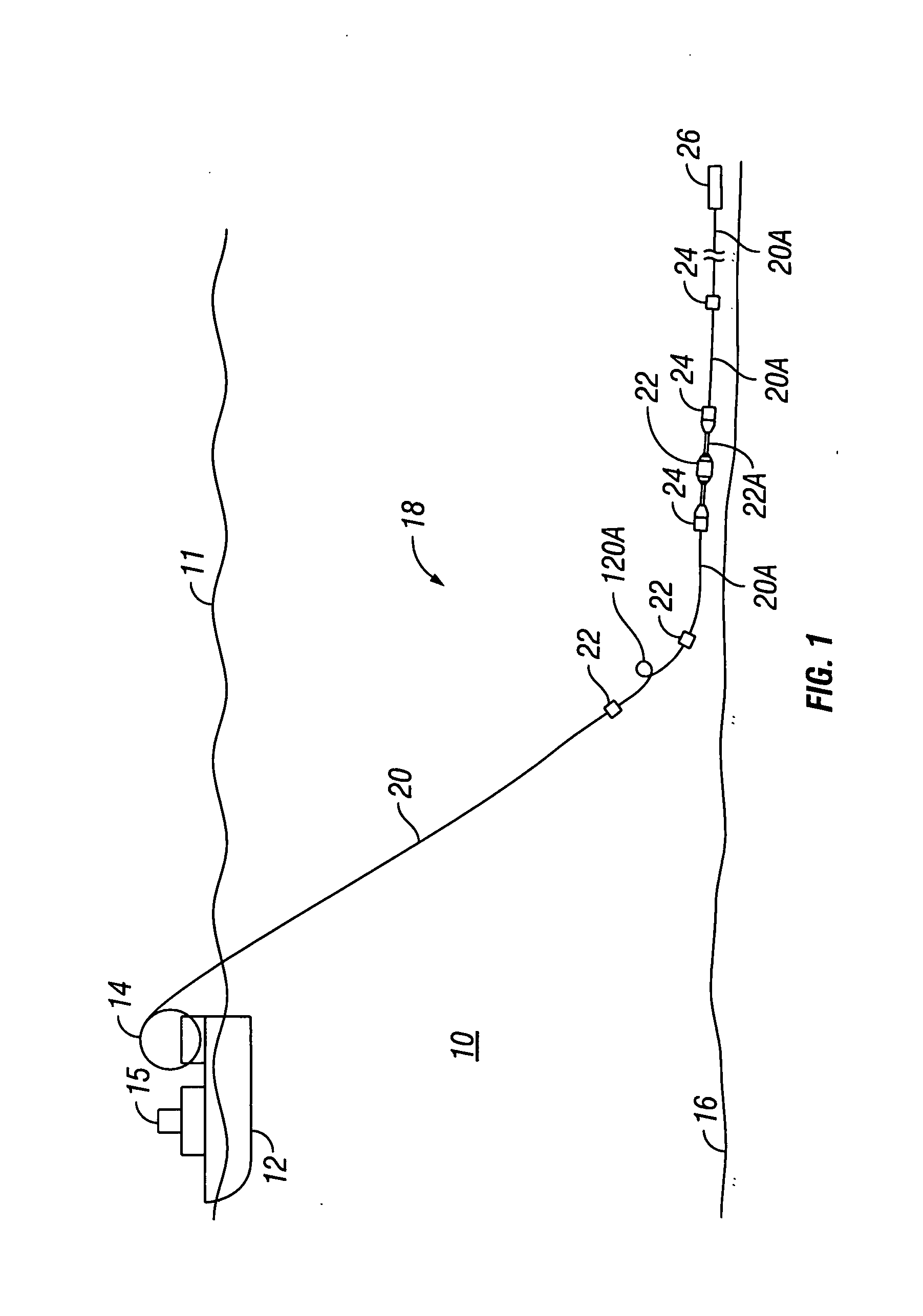

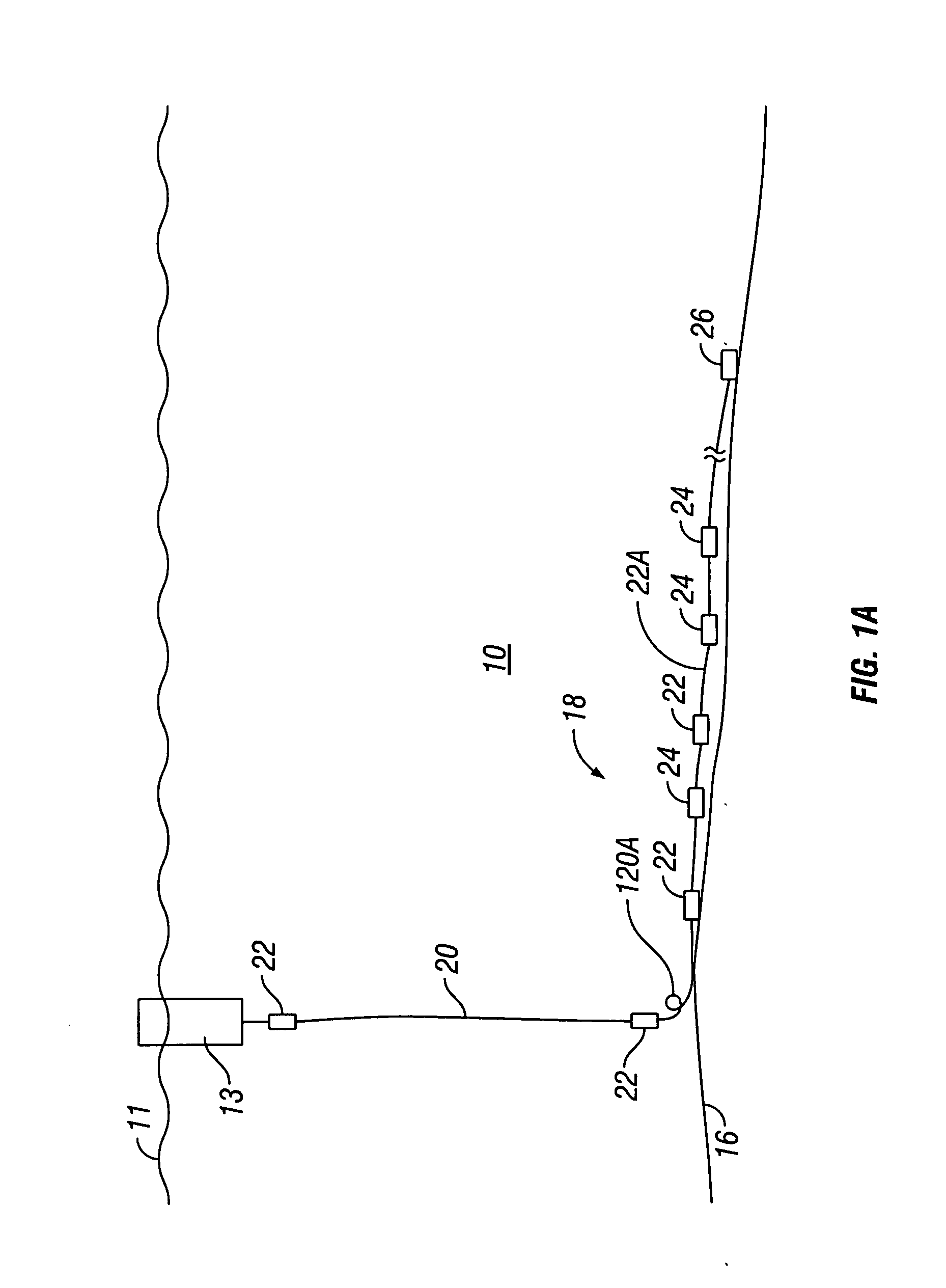

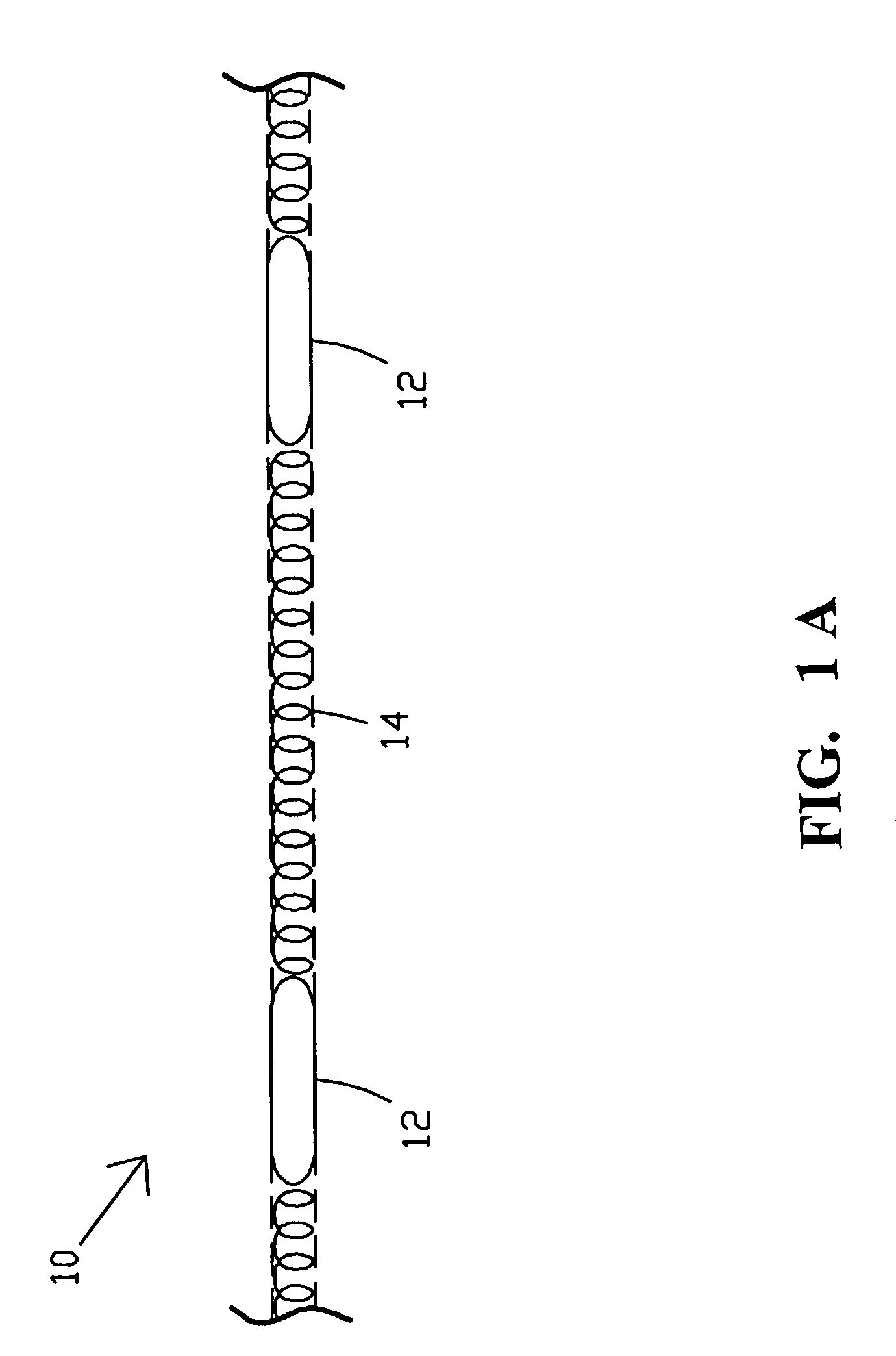

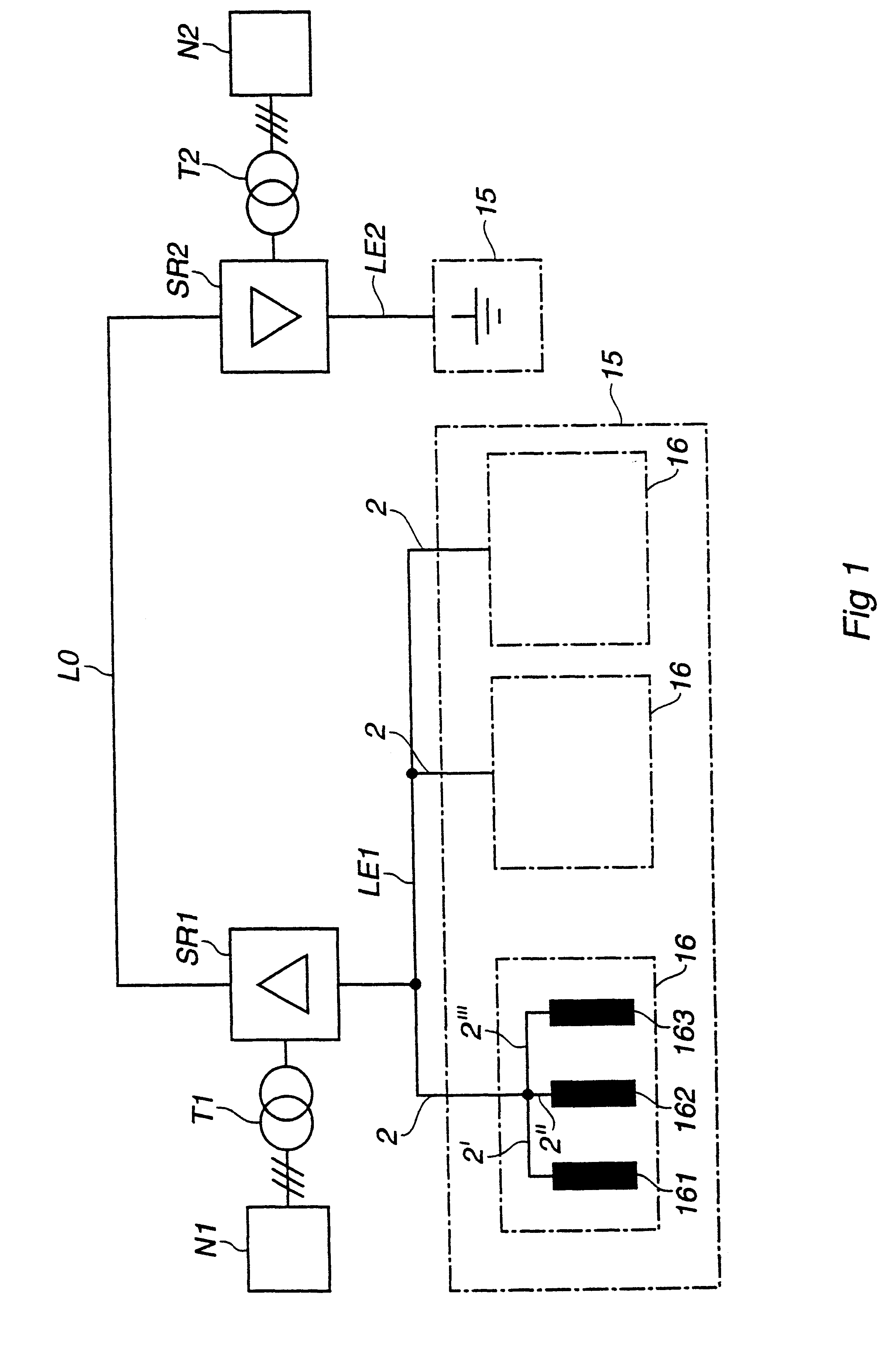

Apparatus and methods for multicomponent marine geophysical data gathering

InactiveUS7239577B2Subsonic/sonic/ultrasonic wave measurementFloating cablesGeophoneCubic metre per second

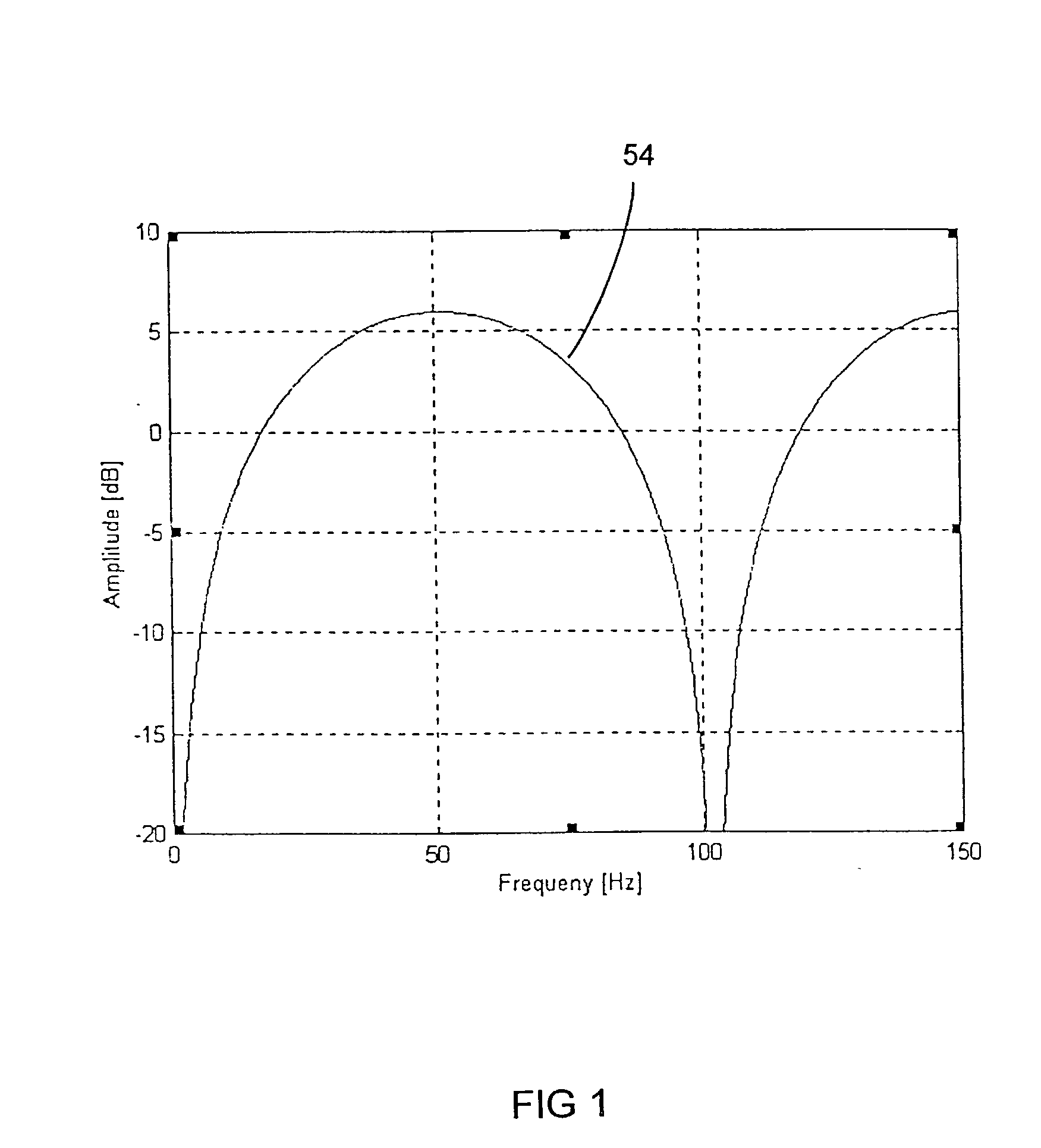

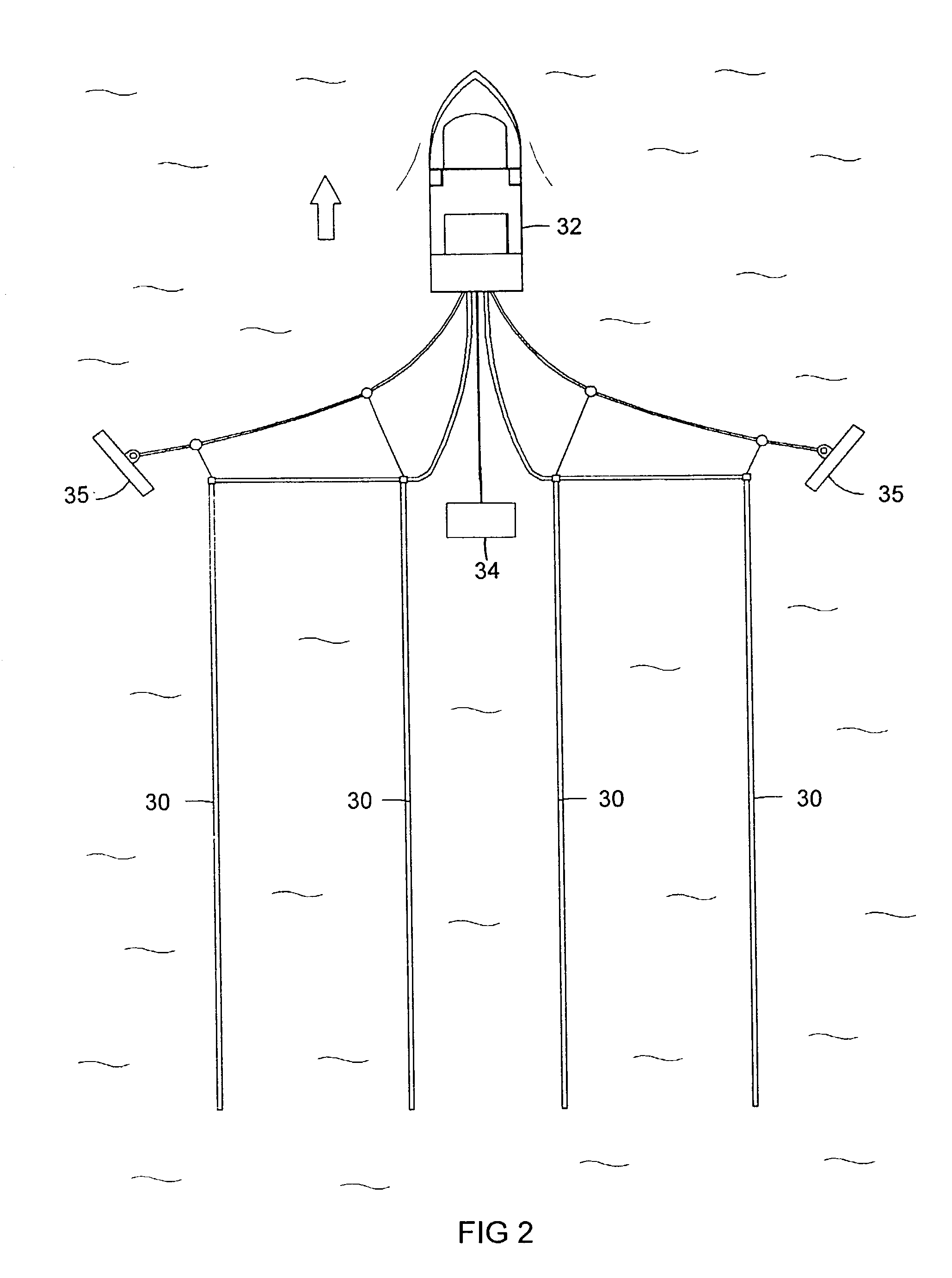

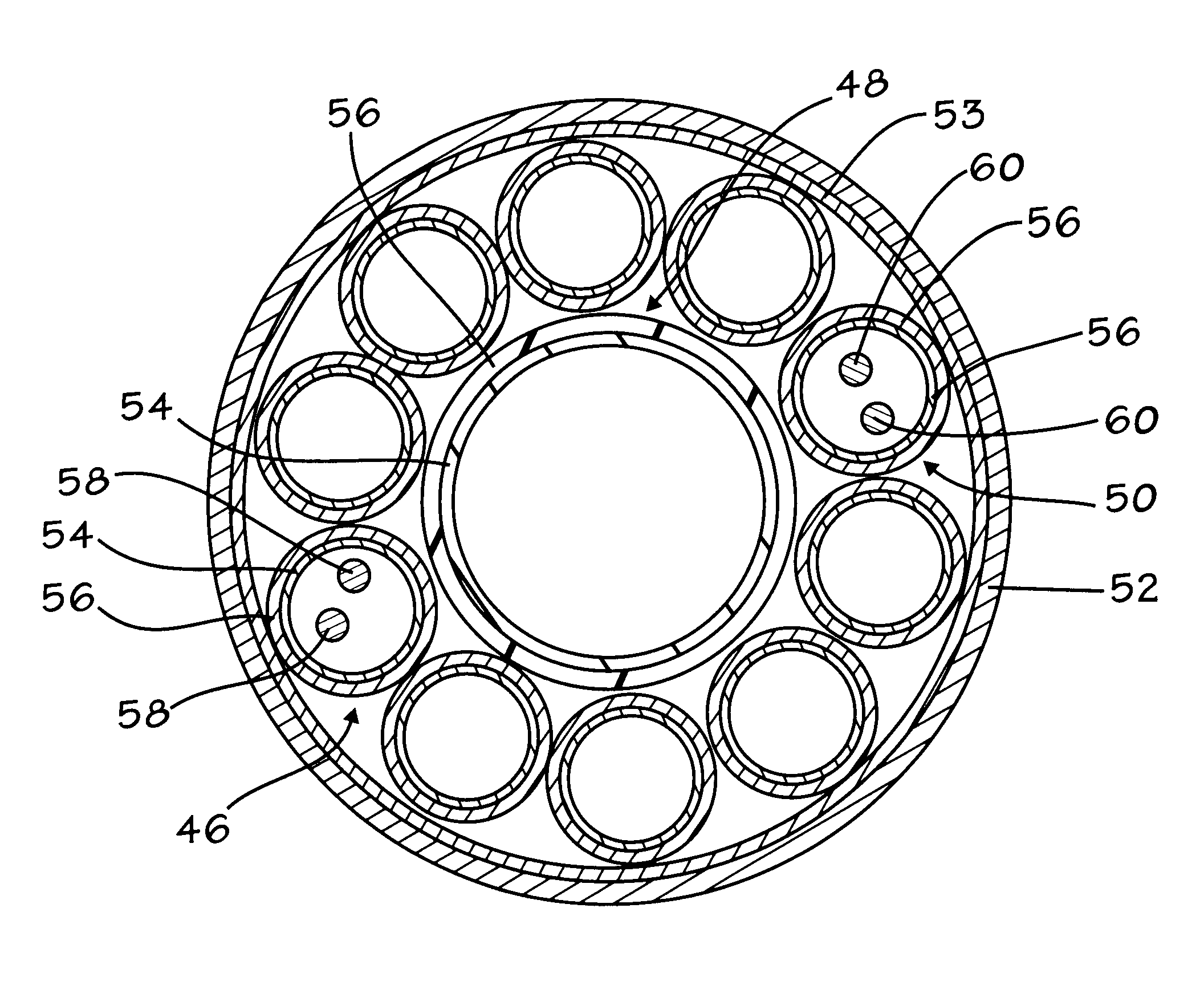

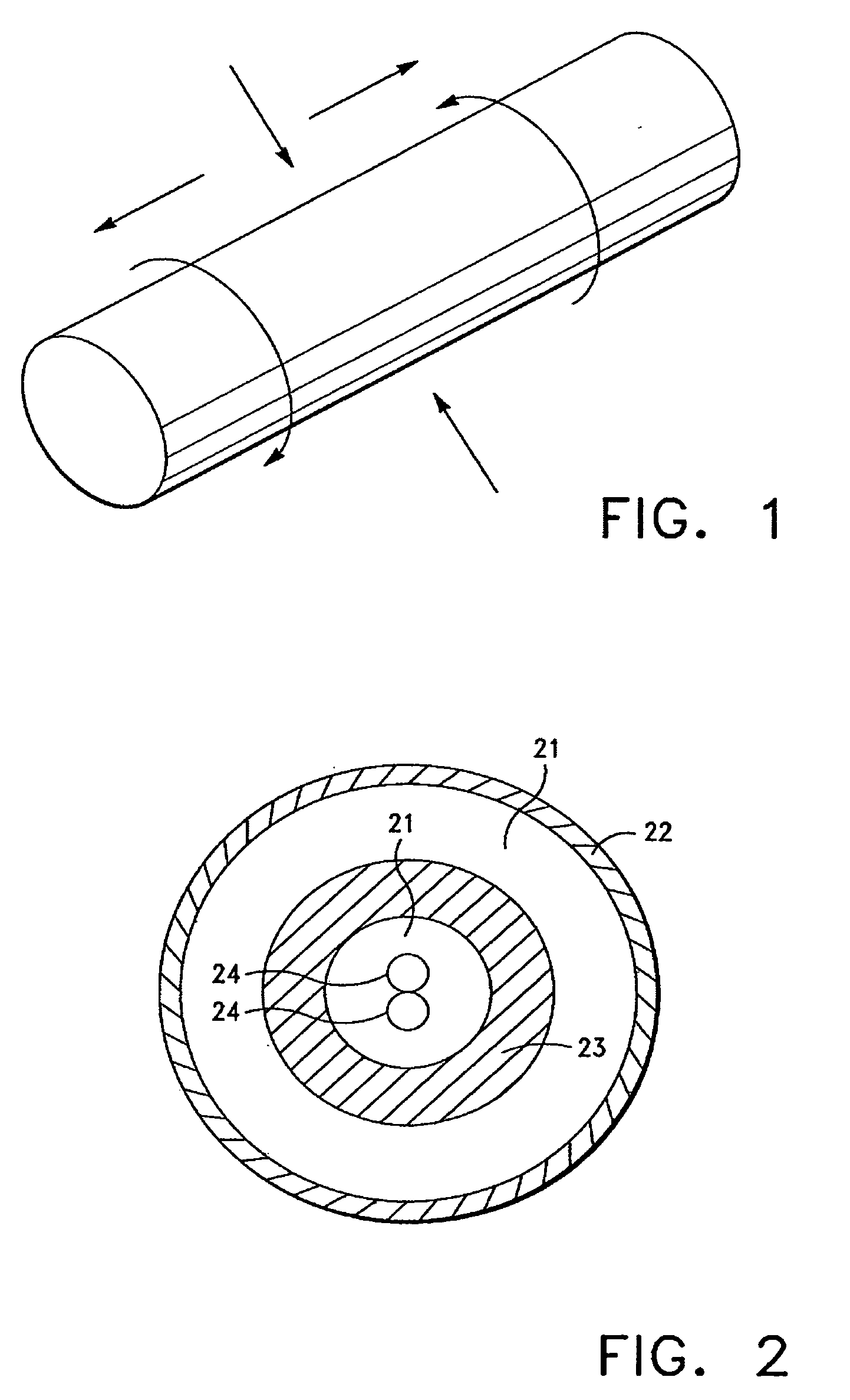

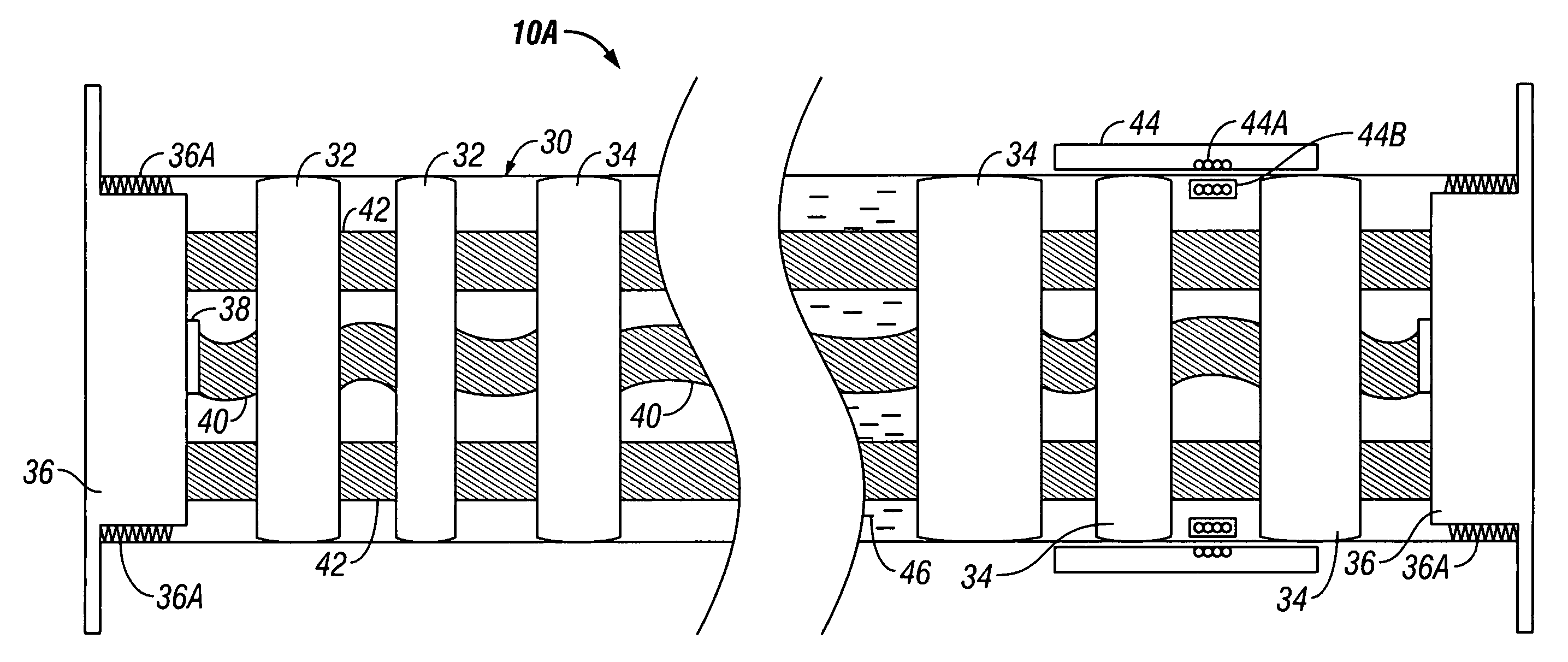

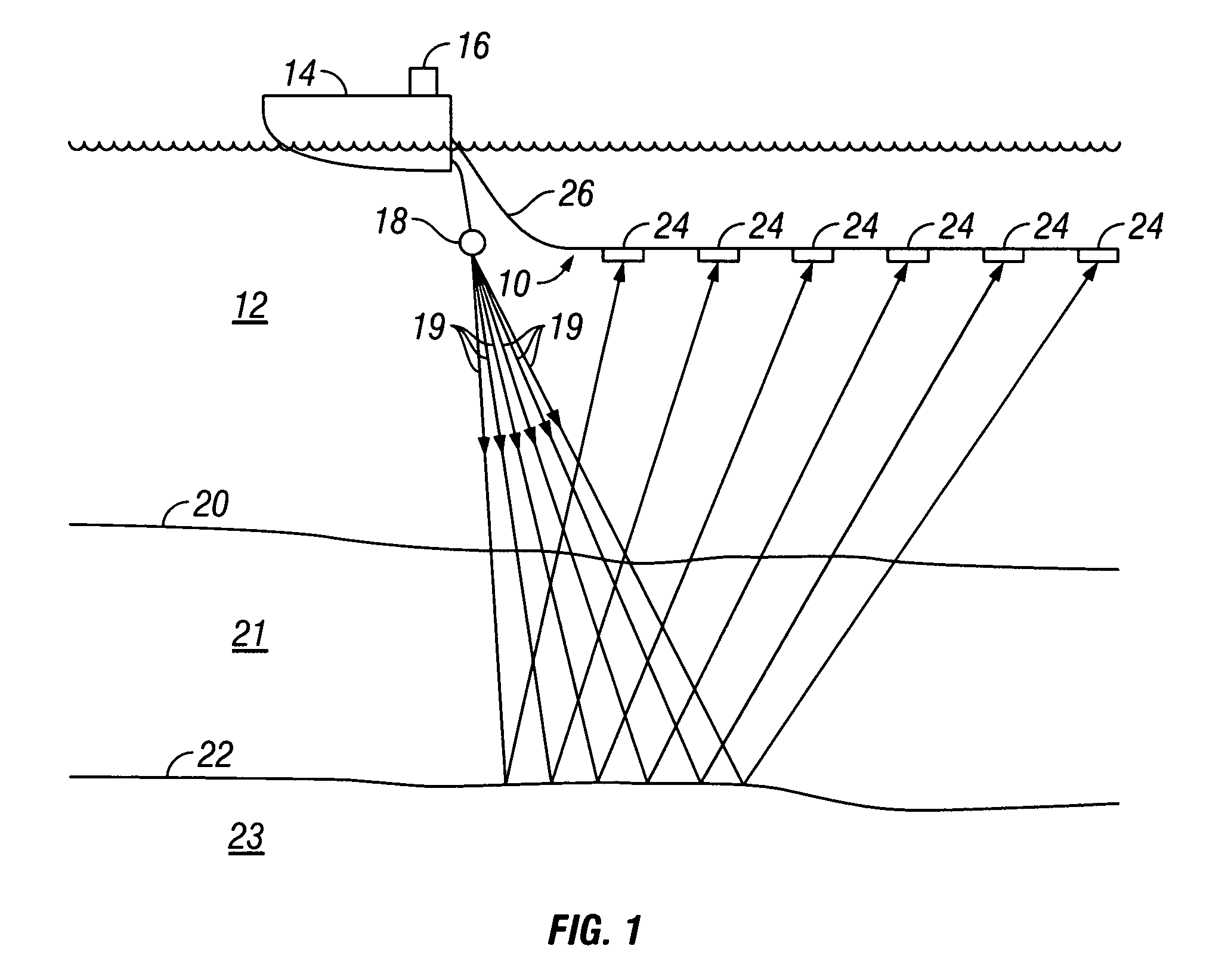

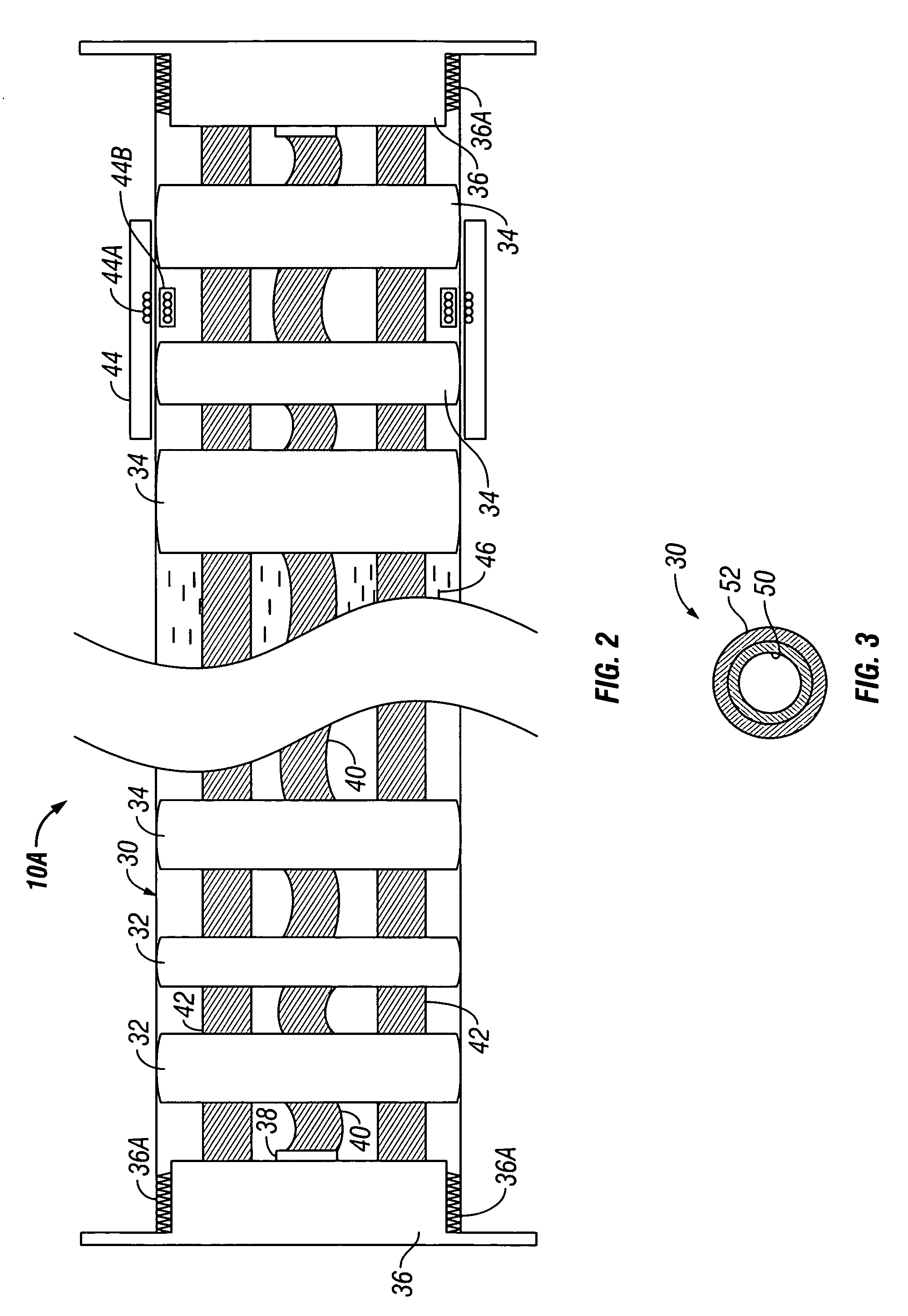

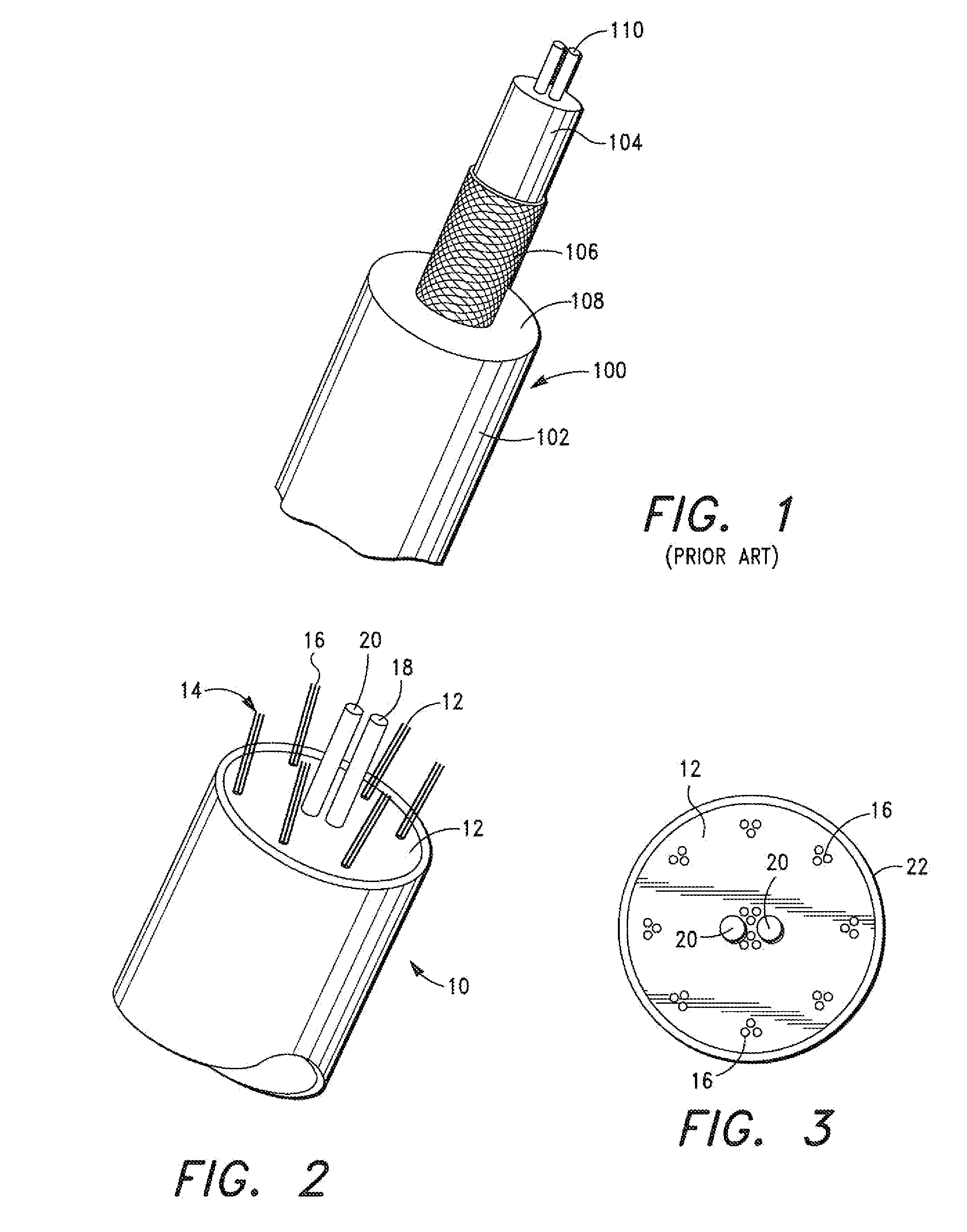

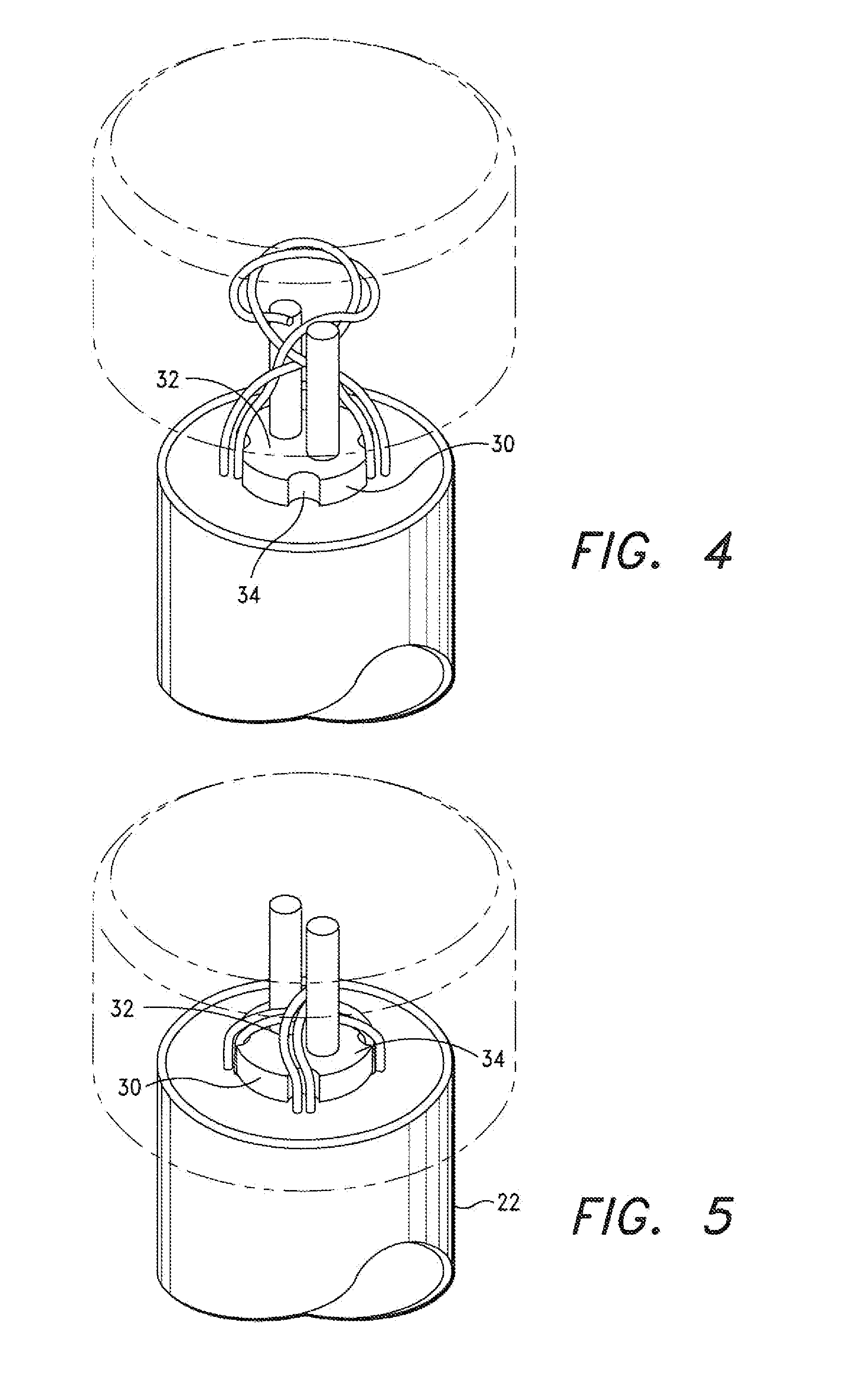

In one embodiment the invention comprises a particle velocity sensor that includes a housing with a geophone mounted in the housing. A fluid that substantially surrounds the geophone is included within the housing. The particle velocity sensor has an acoustic impedance within the range of about 750,000 Newton seconds per cubic meter (Ns / m3) to about 3,000,000 Newton seconds per cubic meter (Ns / m3). In another embodiment the invention comprises method of geophysical exploration in which a seismic signal is generated in a body of water and detected with a plurality of co-located particle velocity sensors and pressure gradient sensors positioned within a seismic cable. The output signal of either or both of the particle velocity sensors or the pressure gradient sensors is modified to substantially equalize the output signals from the particle velocity sensors and the pressure gradient sensors. The output signals from particle velocity sensors and pressure gradient sensors are then combined.

Owner:PGS AMERICA INC

Apparatus and methods for multicomponent marine geophysical data gathering

InactiveUS20040042341A1Subsonic/sonic/ultrasonic wave measurementFloating cablesGeophoneCubic metre per second

In one embodiment the invention comprises a particle velocity sensor that includes a housing with a geophone mounted in the housing. A fluid that substantially surrounds the geophone is included within the housing. The particle velocity sensor has an acoustic impedance within the range of about 750,000 Newton seconds per cubic meter (Ns / m<3>) to about 3,000,000 Newton seconds per cubic meter (Ns / m<3>). In another embodiment the invention comprises method of geophysical exploration in which a seismic signal is generated in a body of water and detected with a plurality of co-located particle velocity sensors and pressure gradient sensors positioned within a seismic cable. The output signal of either or both of the particle velocity sensors or the pressure gradient sensors is modified to substantially equalize the output signals from the particle velocity sensors and the pressure gradient sensors. The output signals from particle velocity sensors and pressure gradient sensors are then combined.

Owner:PGS AMERICA INC

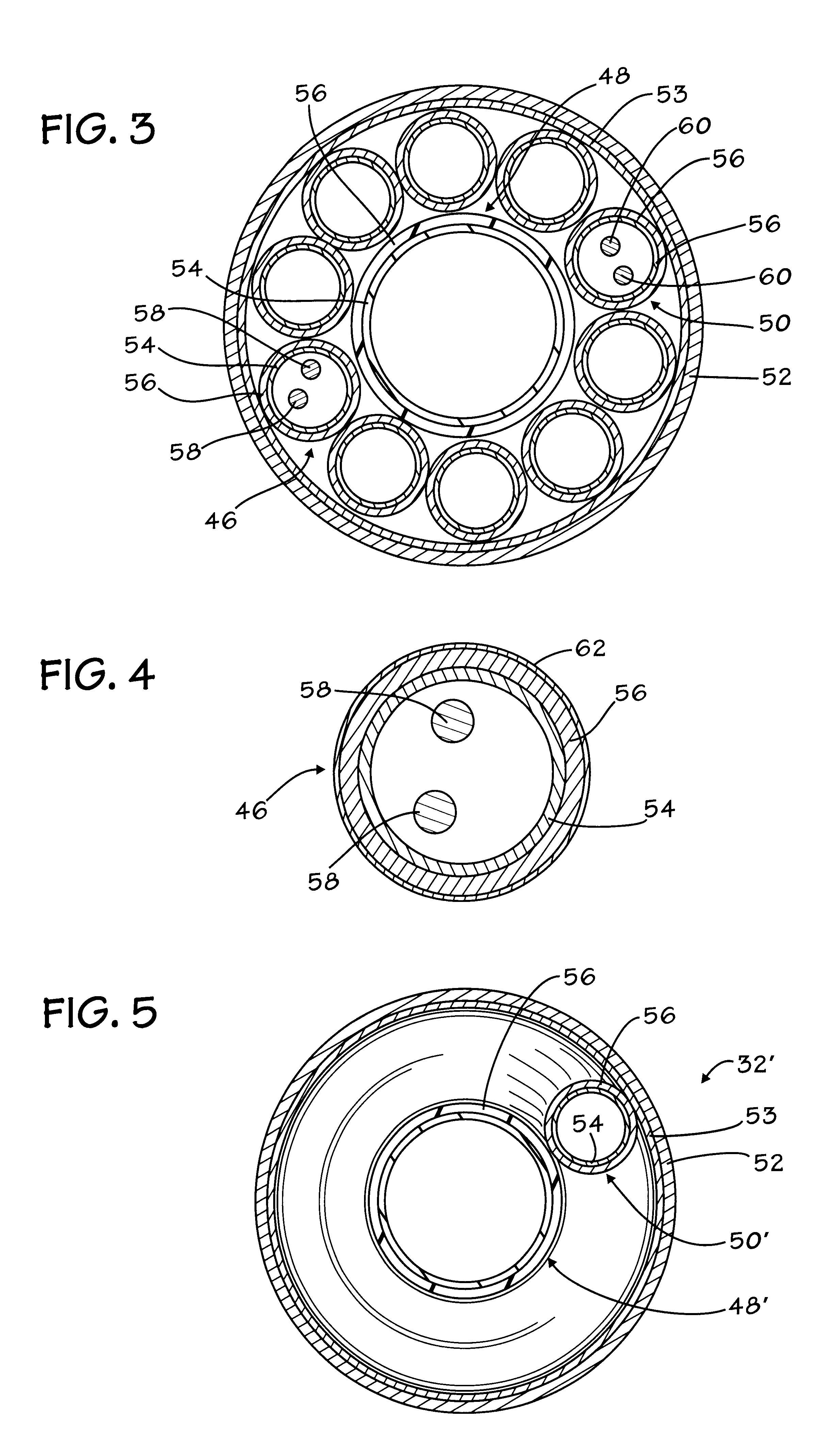

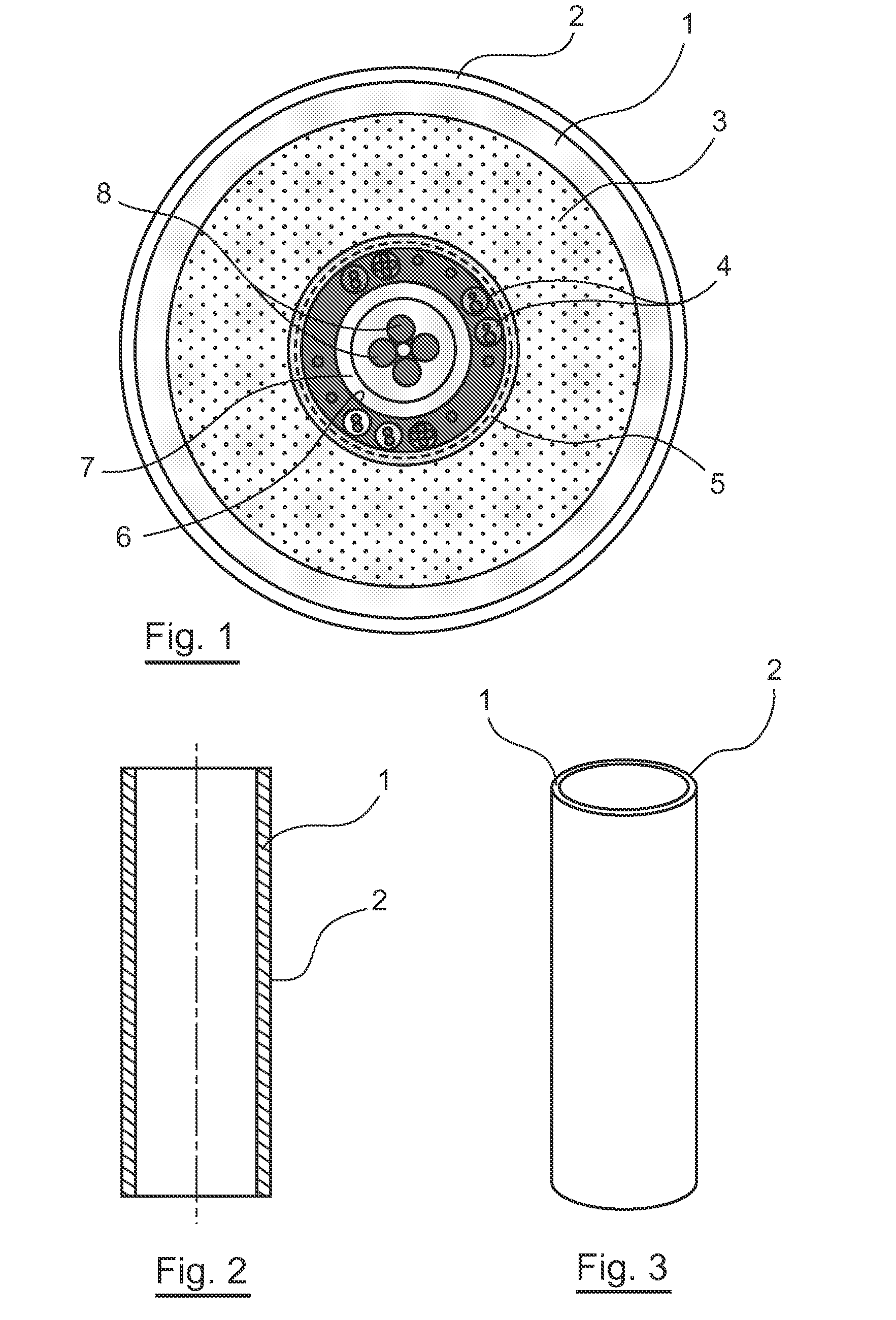

Marine umbilical

Various embodiments of an umbilical are provided. In one aspect, an umbilical is provided that includes a first tube, a second tube positioned in the first tube and a plurality of third tubes positioned in the first tube. Each of the plurality of third tubes has an inner polymer sleeve and an outer sleeve of carbon fibers in an epoxy matrix positioned around the polymer sleeve. The composite tubes yield a lighter umbilical that is easier to handle than a comparably sized conventional umbilical incorporating steel inner tubing and is more tolerant of dynamic bending and hydrostatic pressure loading.

Owner:MARINE INNOVATIONS

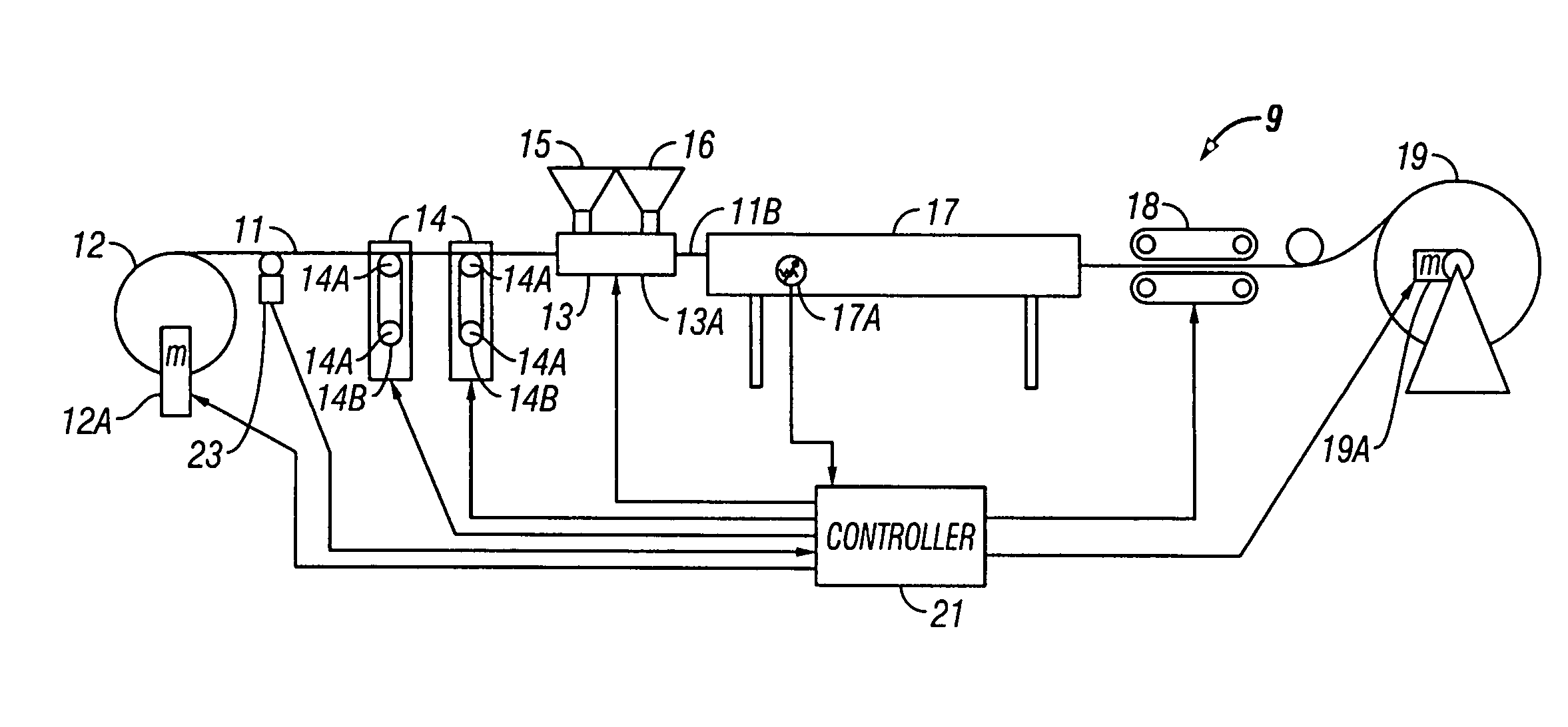

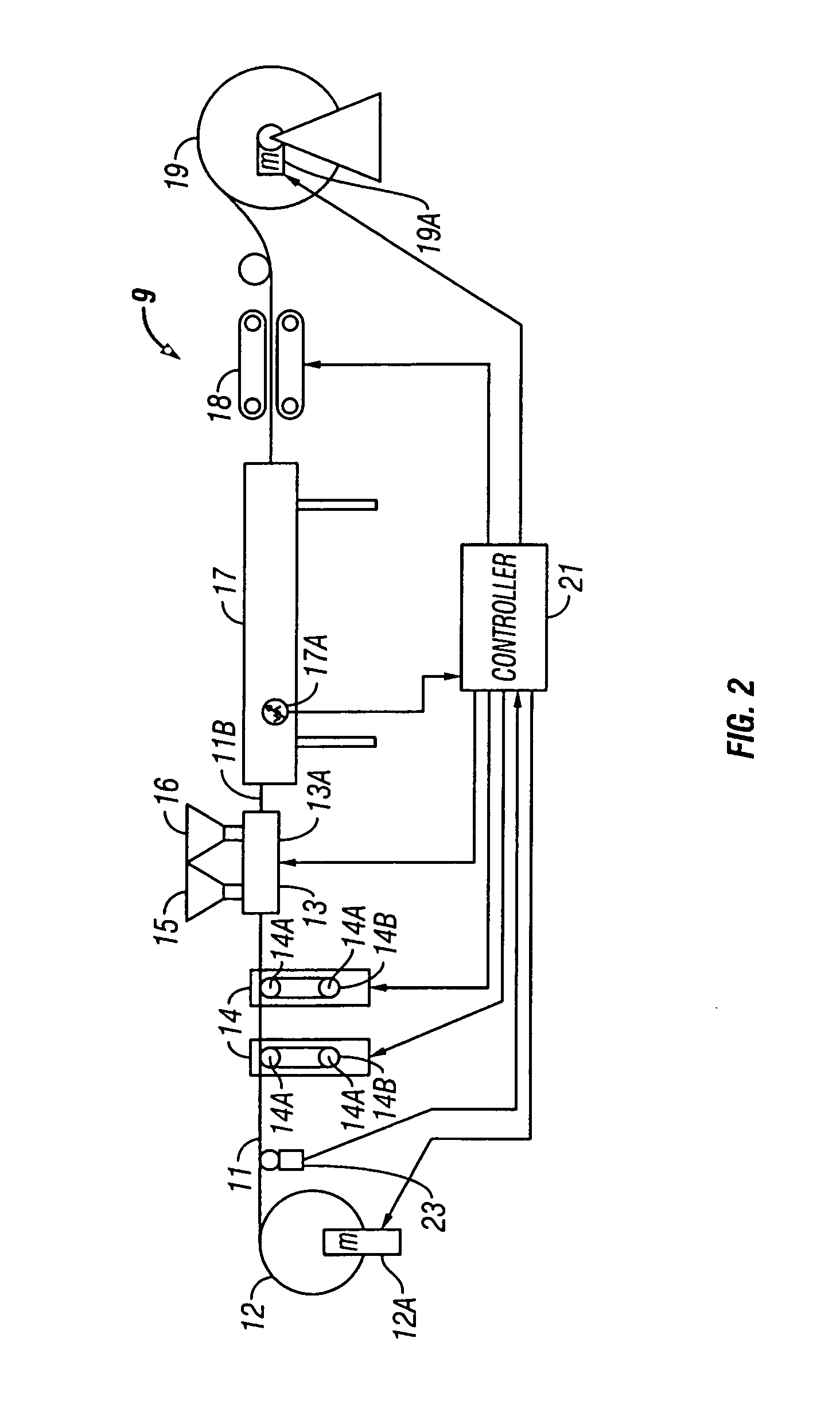

Method and system for making marine seismic streamers

An apparatus for making a marine seismic streamer includes a conveyor for transporting assembled mechanical harness from a storage device therefor to a storage device for storing completed marine streamer. The apparatus includes a first extruder for filling the harness with a void fill material and a second extruder for depositing jacketing material onto the filled harness both extruders being intermediate the two storage devices. A means for changing state of the void filling material is disposed proximate an outlet of the first extruder. In one embodiment, the means for changing state includes a radiation source.

Owner:PGS GEOPHYSICAL AS

Variable buoyancy cable

A variable buoyancy cable is provided. In one aspect, the variable buoyancy cable includes a flexible sleeve that has an inner wall and an outer wall. A core is positioned in the sleeve and has a longitudinally disposed external channel with opposing first and second sidewalls. The channel and the inner wall of the flexible sleeve define a fluid passage for receiving a fluid to affect the buoyancy of the variable buoyancy cable. A slackened utility line is positioned in the channel and a fluid supply is coupled to the flexible sleeve and is operable to move fluid into and out of the fluid passage to selectively affect the buoyancy of the variable buoyancy cable. The core protects utility lines in the cable from damage due to ambient pressure and / or bending during deployment and retrieval. The buoyancy may be varied to suit various water conditions and mission requirements.

Owner:MARINE INNOVATIONS

Seismic streamer formed of sections comprising a main sheath covered with an external sheath formed using a thermoplastic material loaded with a biocide material

ActiveUS20100020644A1Reduce weightOvercome disadvantagesFloating cablesSeismic signal receiversBiomedical engineeringThermoplastic materials

Described herein is a seismic streamer formed of sections including a main sheath covered with an external sheath, wherein said external sheath is formed using a thermoplastic material loaded with a biocide material.

Owner:SERCEL INC

System and method for using copper coating to prevent marine growth on towed geophysical equipment

A system comprises towed marine seismic equipment marine seismic equipment, adapted for towing through a body of water; and a coating of copper particles covering the marine seismic equipment to protect from marine growth. A method comprises towing marine seismic equipment having a coating of copper particles thereon to protect from marine growth.

Owner:PGS GEOPHYSICAL AS

Sensor streamer having two-layer jacket

Owner:PGS GEOPHYSICAL AS

Streamer cable with enhanced properties

The present invention relates to streamer cables. One embodiment of the present invention relates to a method for preparing a streamer cable. The method may comprise retrofitting the streamer cable with a solid void-filler material, where the streamer cable was configured as a liquid-filled streamer cable. The retrofitting may comprise introducing a void-filler material into the streamer cable when the void-filler material is in a liquid state and curing or otherwise solidifying the void-filler material to a solid state. In another embodiment, the present invention relates to a streamer cable comprising an outer skin and at least one sensor positioned within the outer skin. The streamer cable may also comprise a solid void-filler material positioned between the outer skin and the at least one sensor, wherein the solid void-filler material is coupled to the at least one sensor.

Owner:TELEDYNE INSTR INC

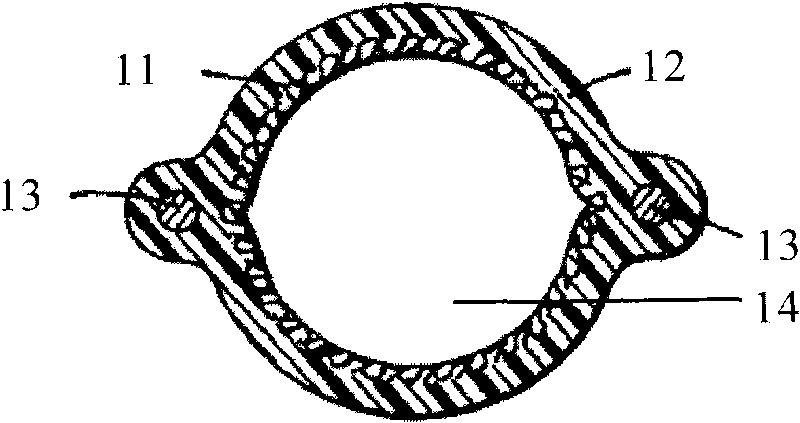

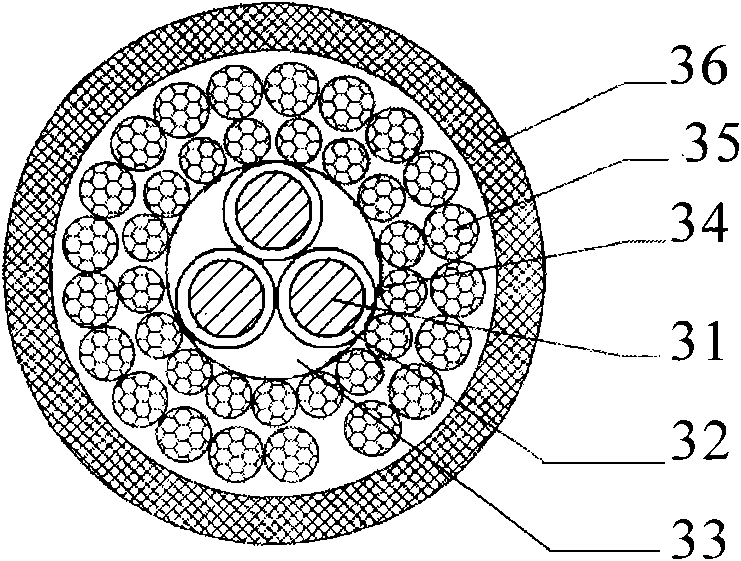

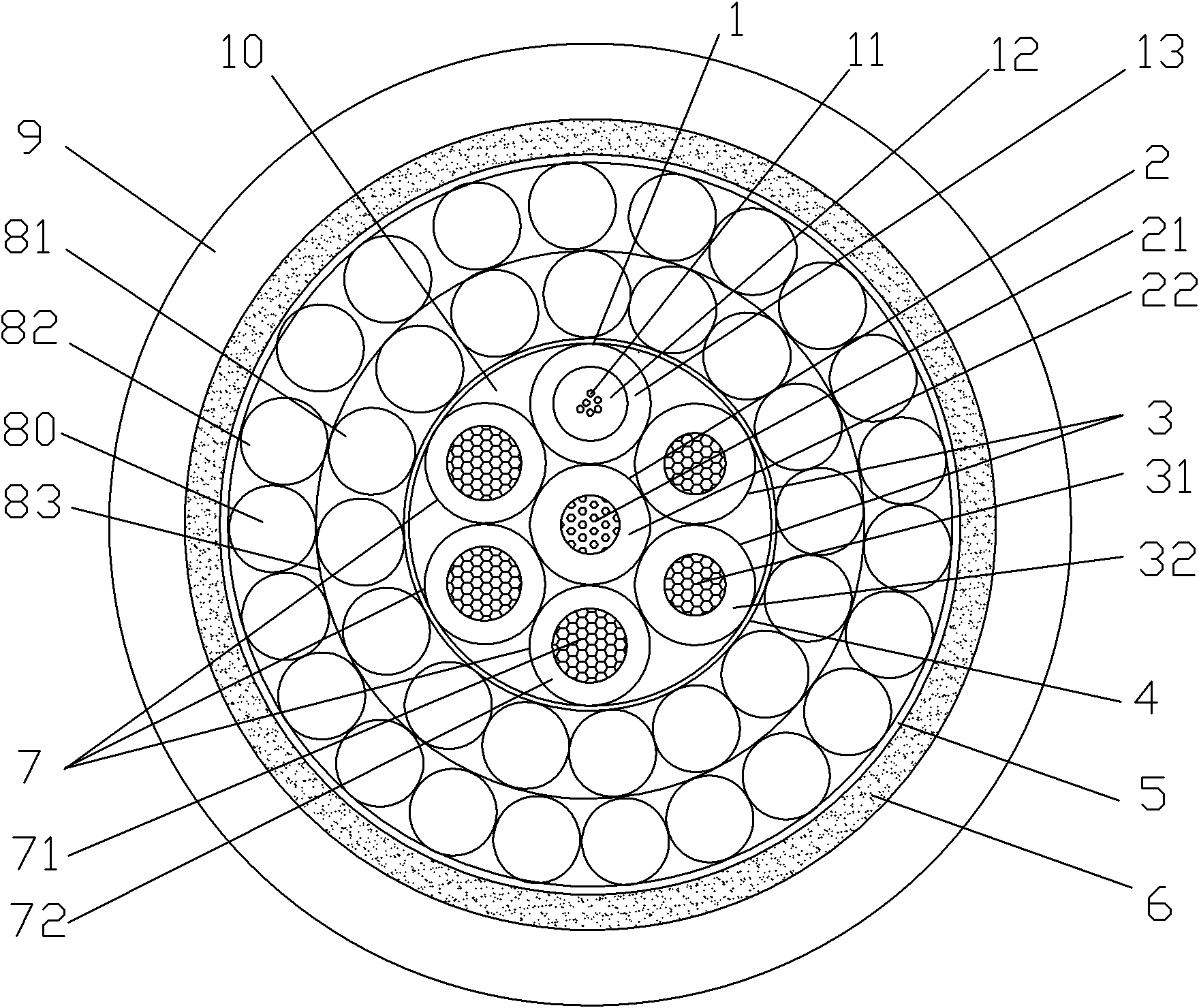

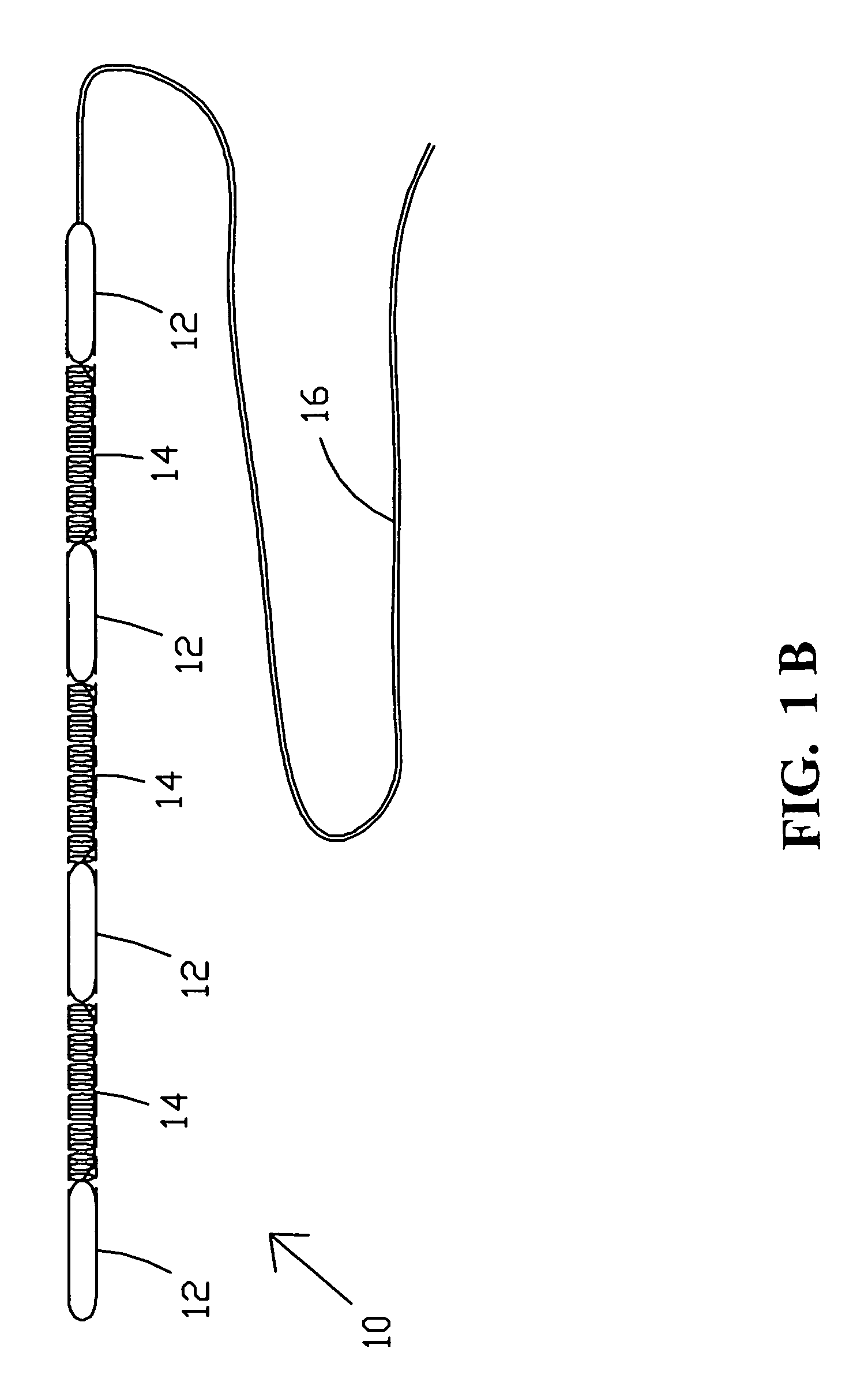

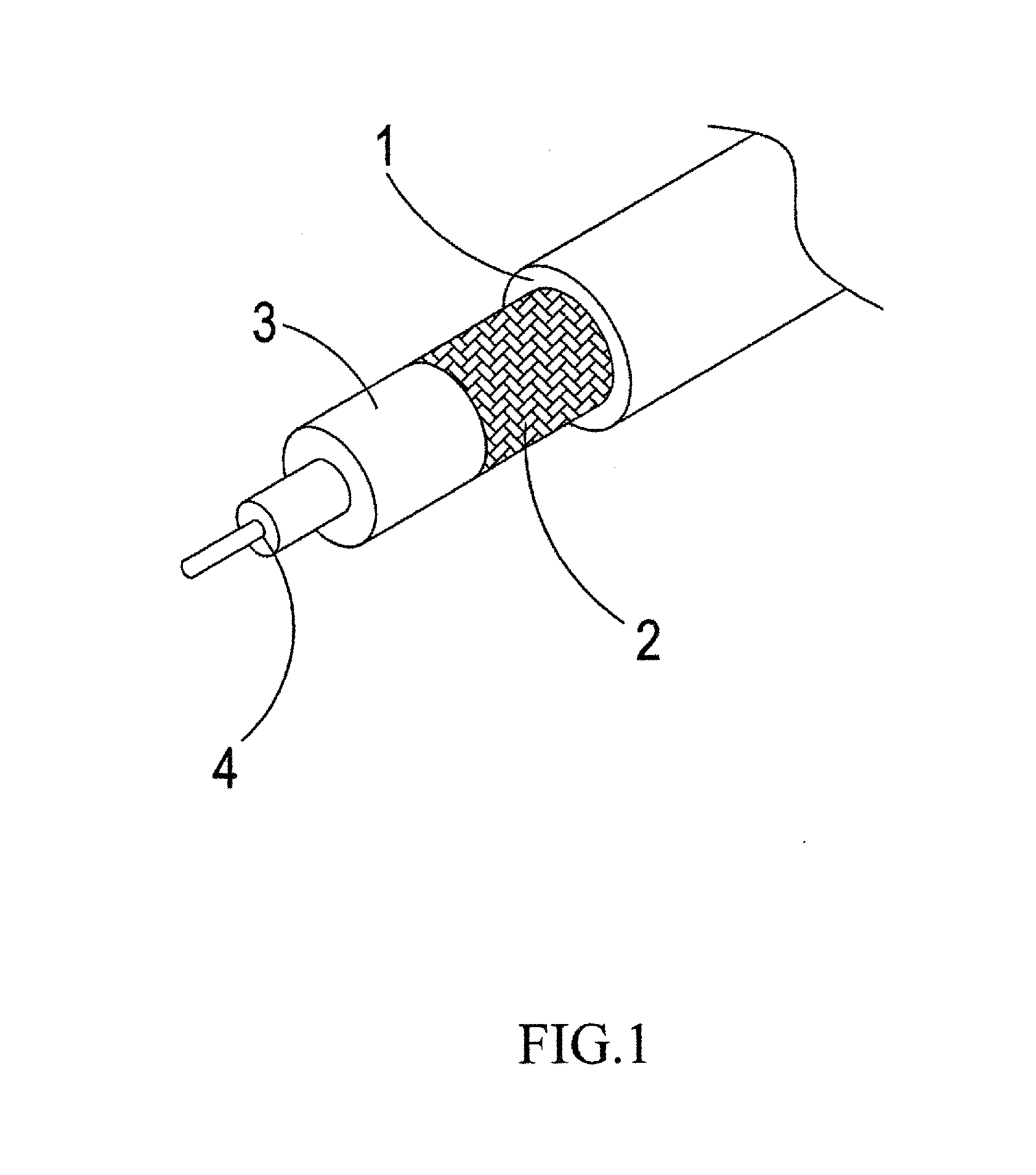

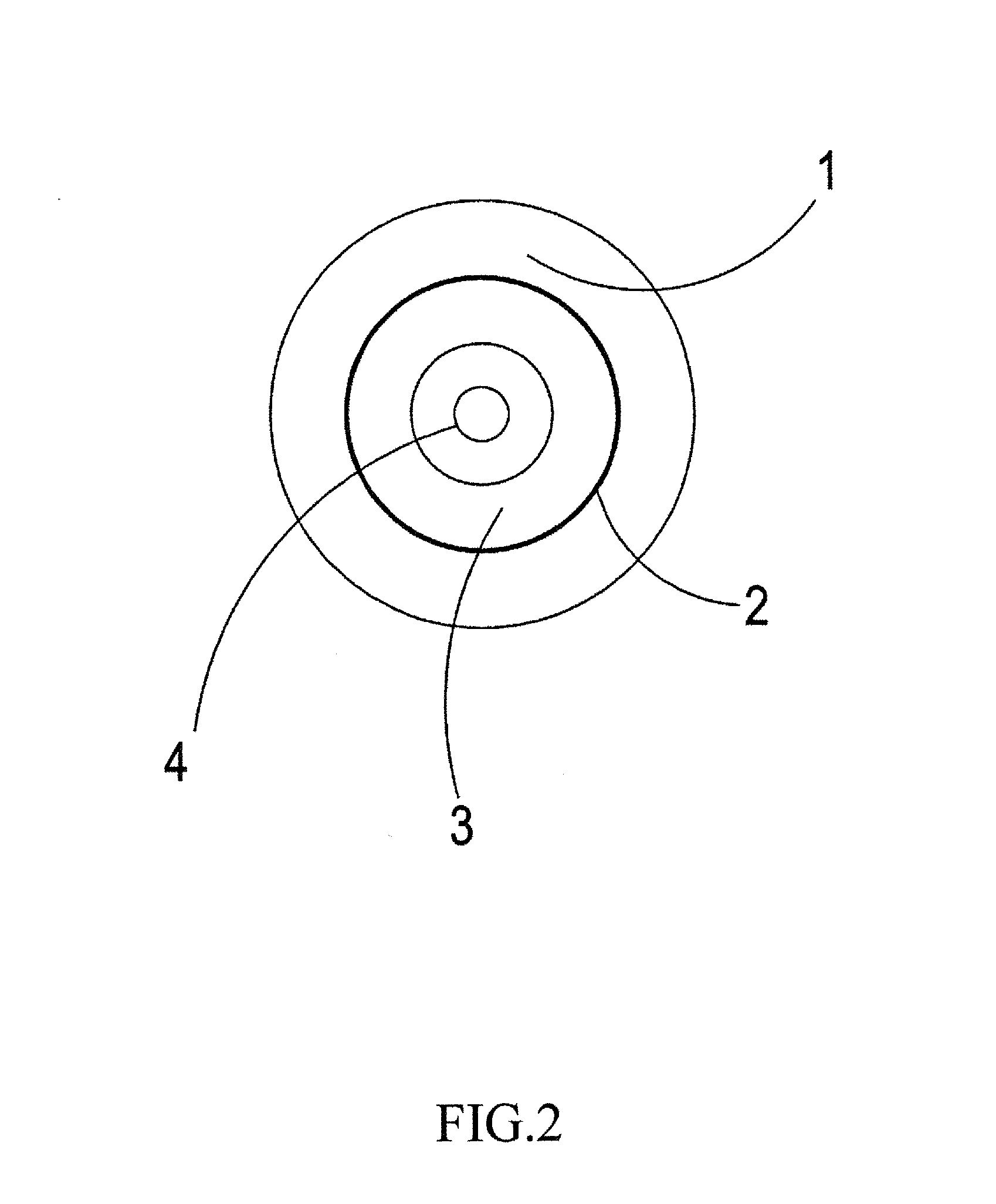

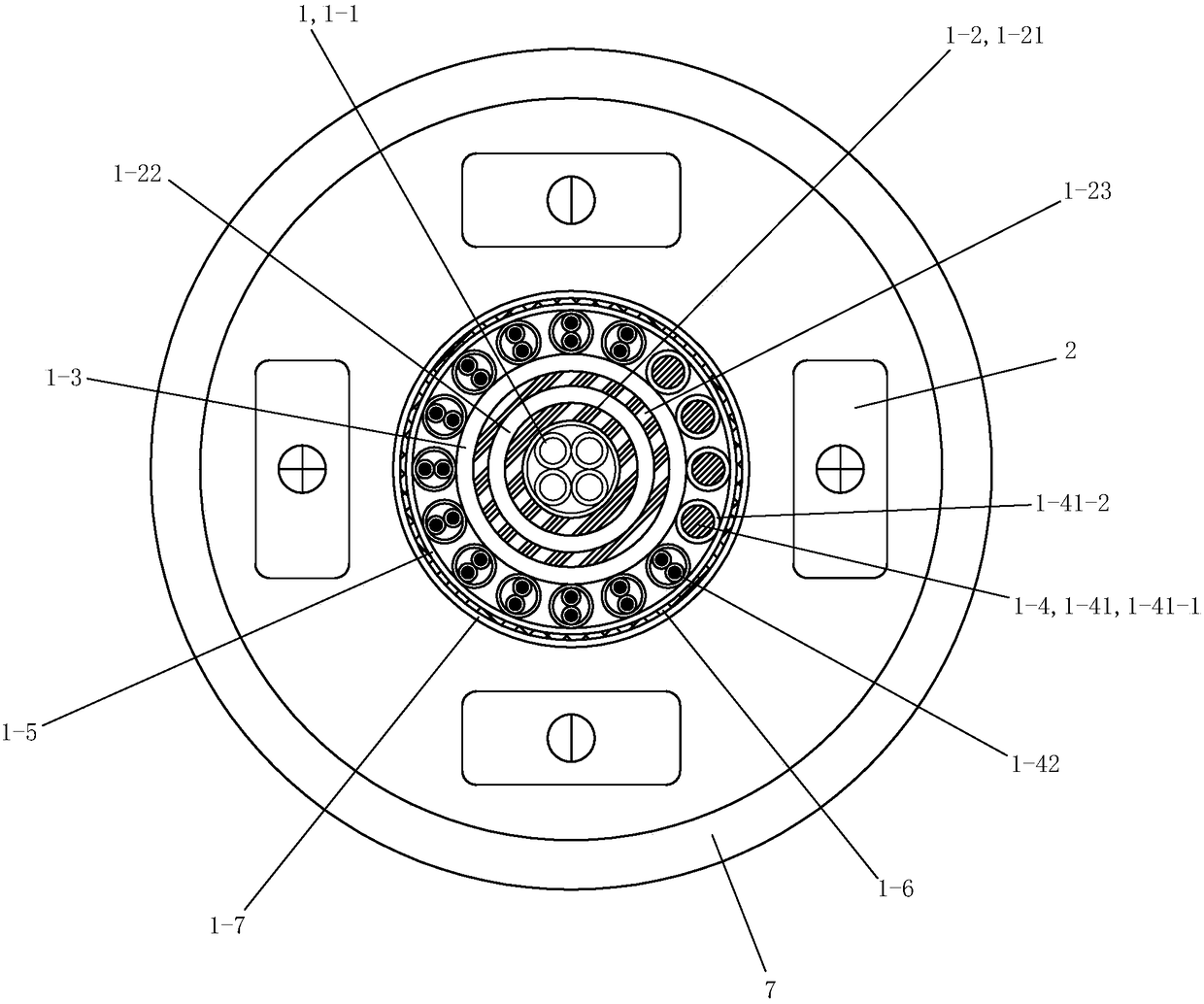

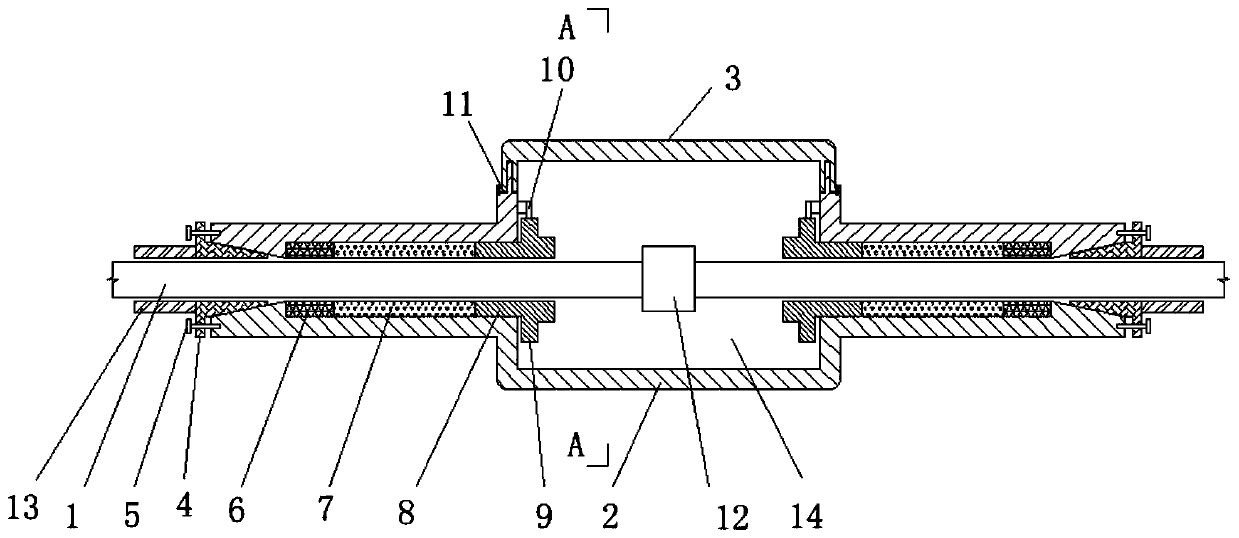

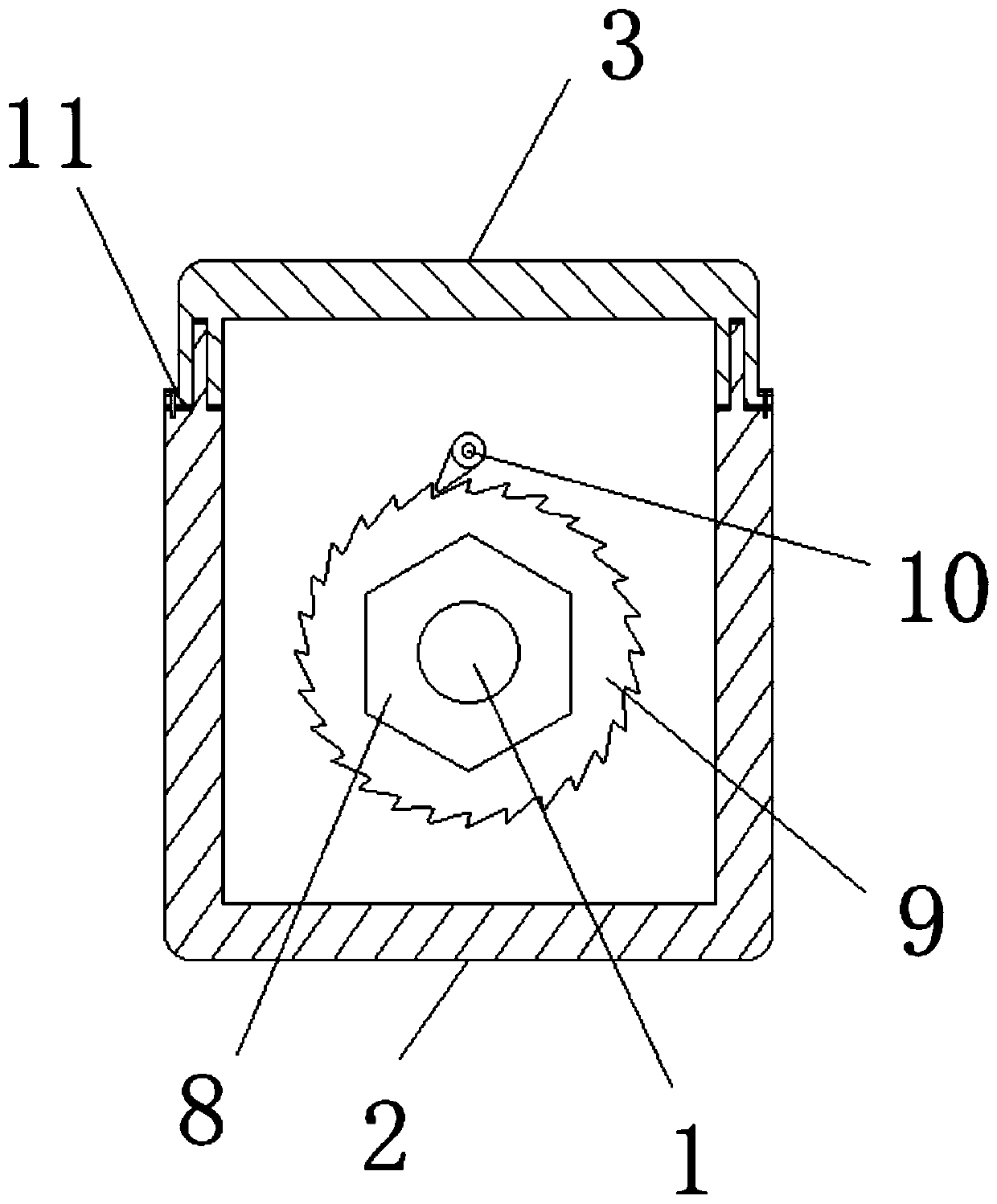

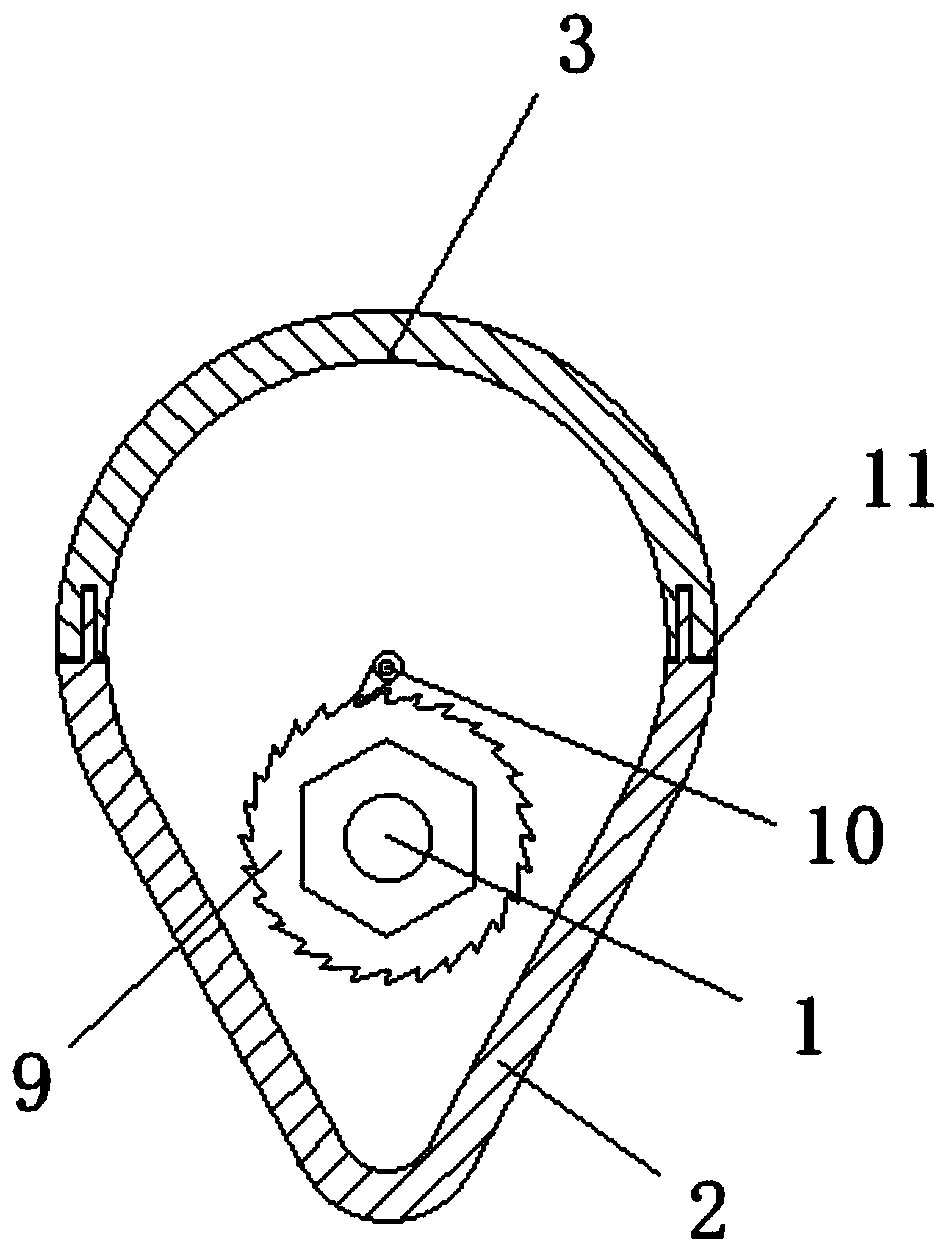

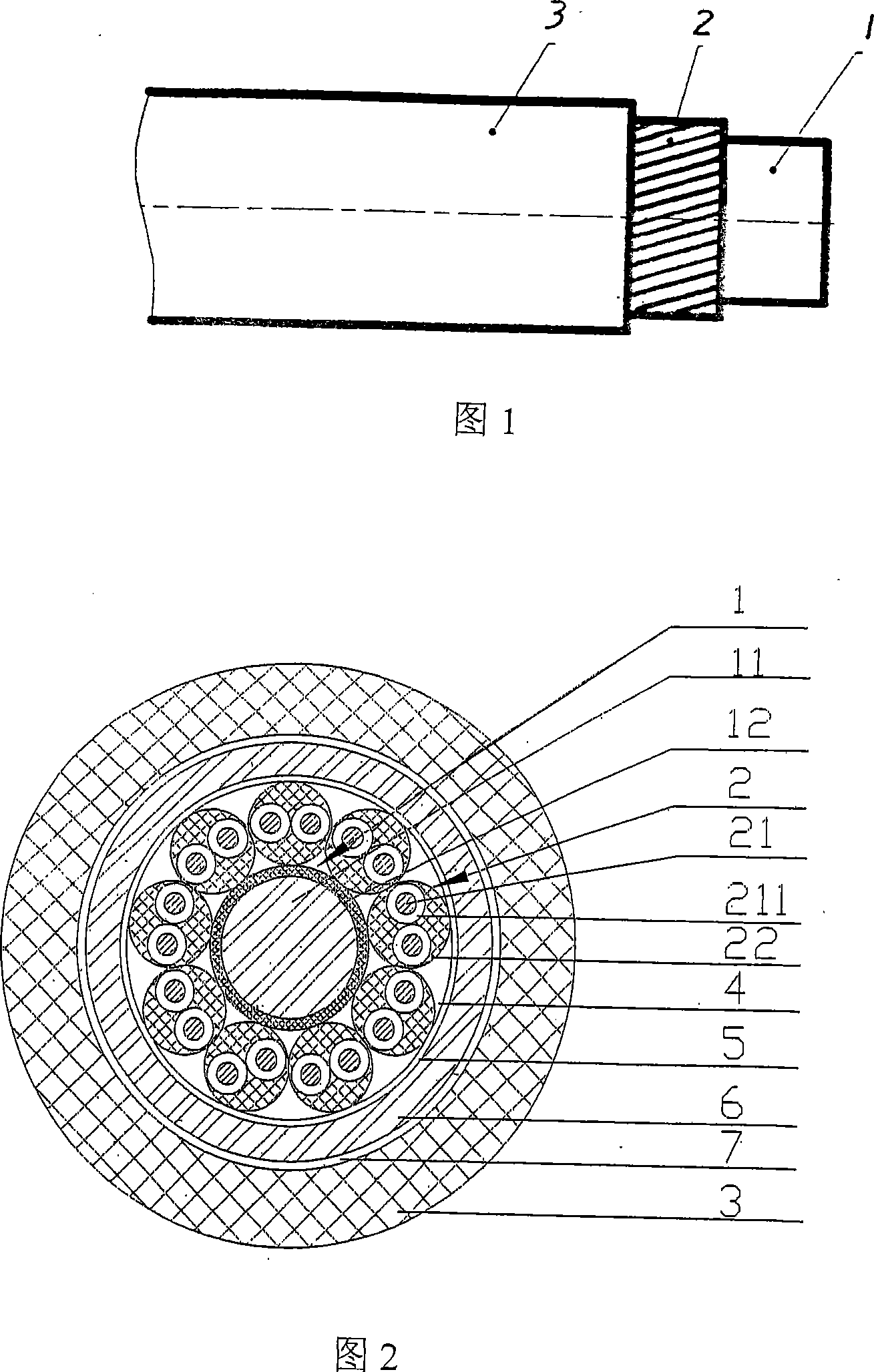

Bending-resistant highly-flexible floating cable and manufacturing method thereof

InactiveCN101710501AHigh mechanical strengthReduce wearPlastic/resin/waxes insulatorsFloating cablesElectrical conductorThermoplastic elastomer

A bending-resistant highly-flexible floating cable comprises a wire core group, a winding package layer, a floating core group and an outer coating layer. Each wire core comprises a conductor and an insulating layer which coats the outside of the conductor. The insulating layer is made of the thermoplastic elastomer of the hydrogenated styrene-butadiene-styrene block copolymer. The winding package layer winds the outside of the wire core group. The floating core group coats the outside of the winding package layer, is a foaming layer and is made of the thermoplastic elastomer of the hydrogenated styrene-butadiene-styrene block copolymer. The outer coating layer coats the outside of the floating core group and is made of the modified thermoplastic polyurethane elastomer (TPU) or modified nylon. The invention also provides a manufacturing method, material formula and a preparation process of the cable. The floating cable has good bending endurance performance, good flexibility and small radius of bending curvature, is easy to operation and suitable for frequent bending and is frequently used by deploying and retracting.

Owner:SHENZHEN POLYTECHNIC +1

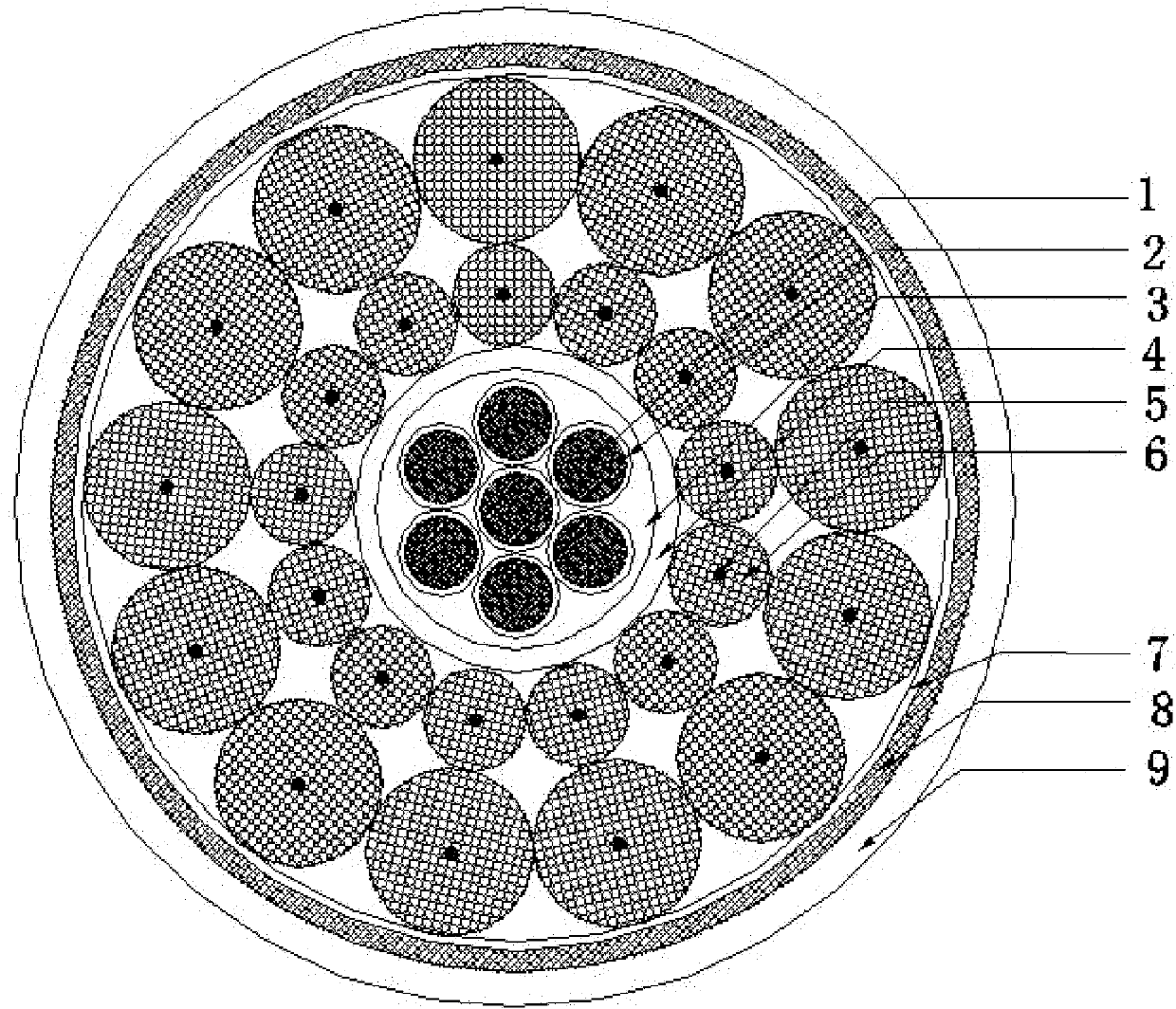

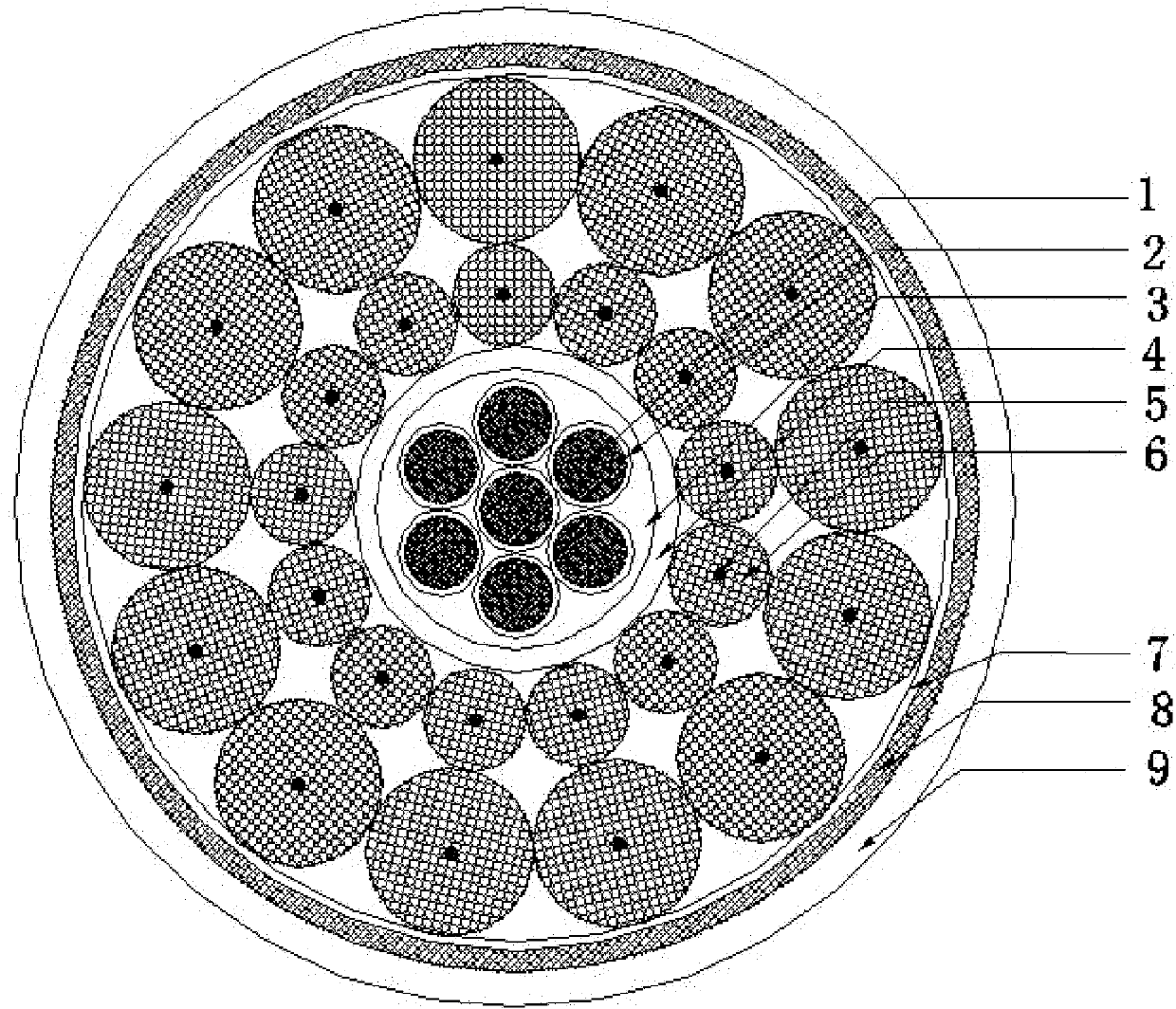

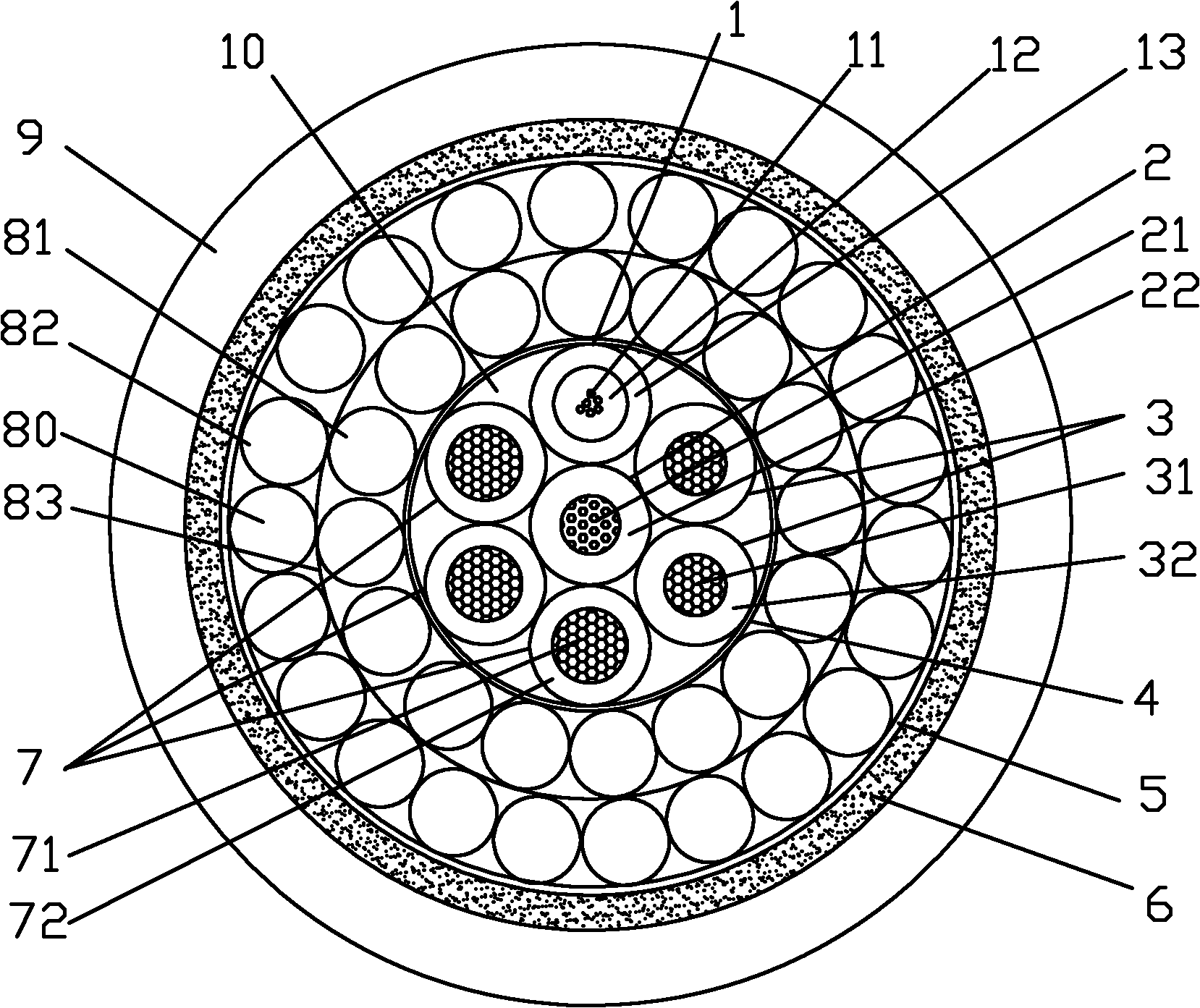

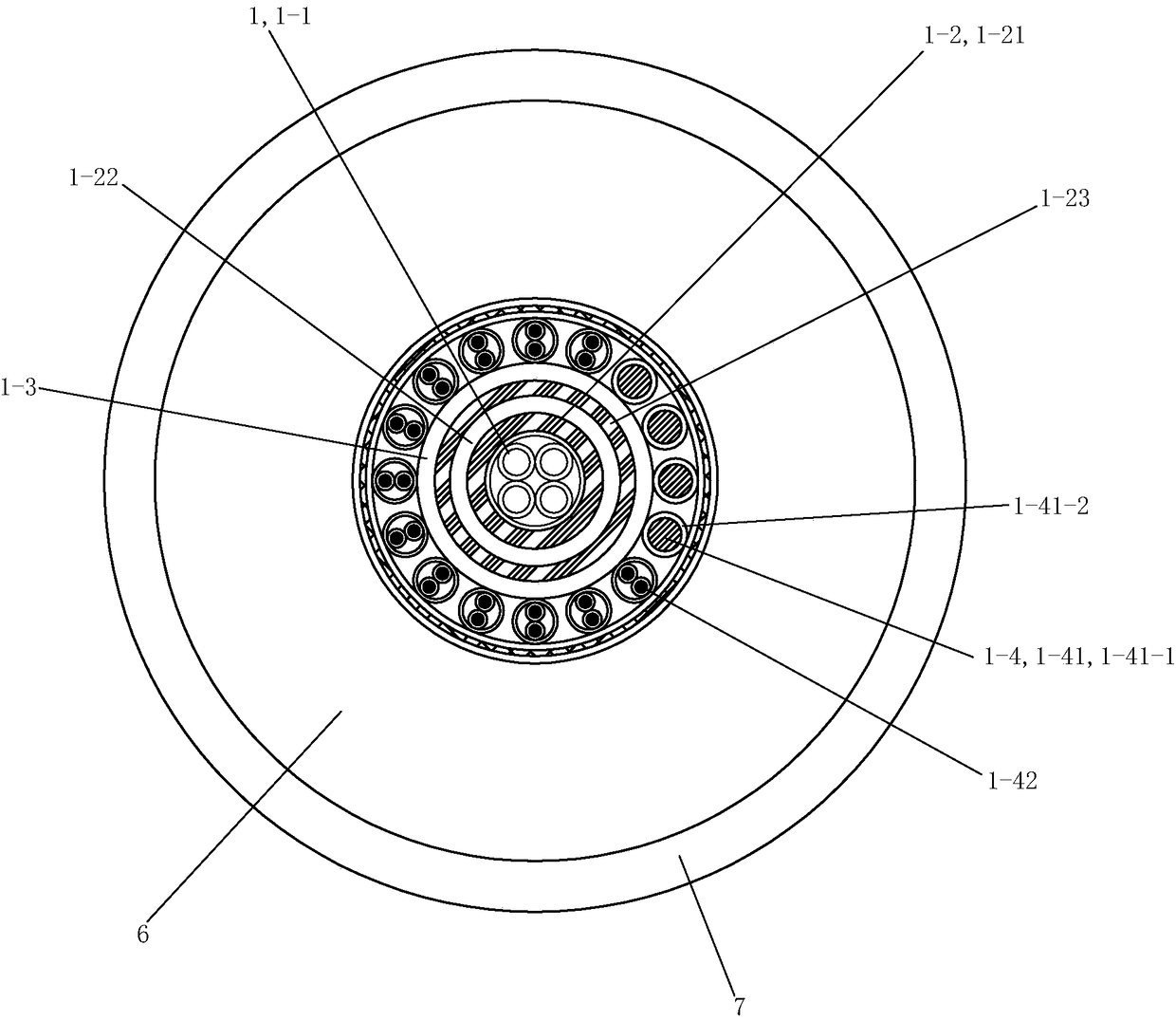

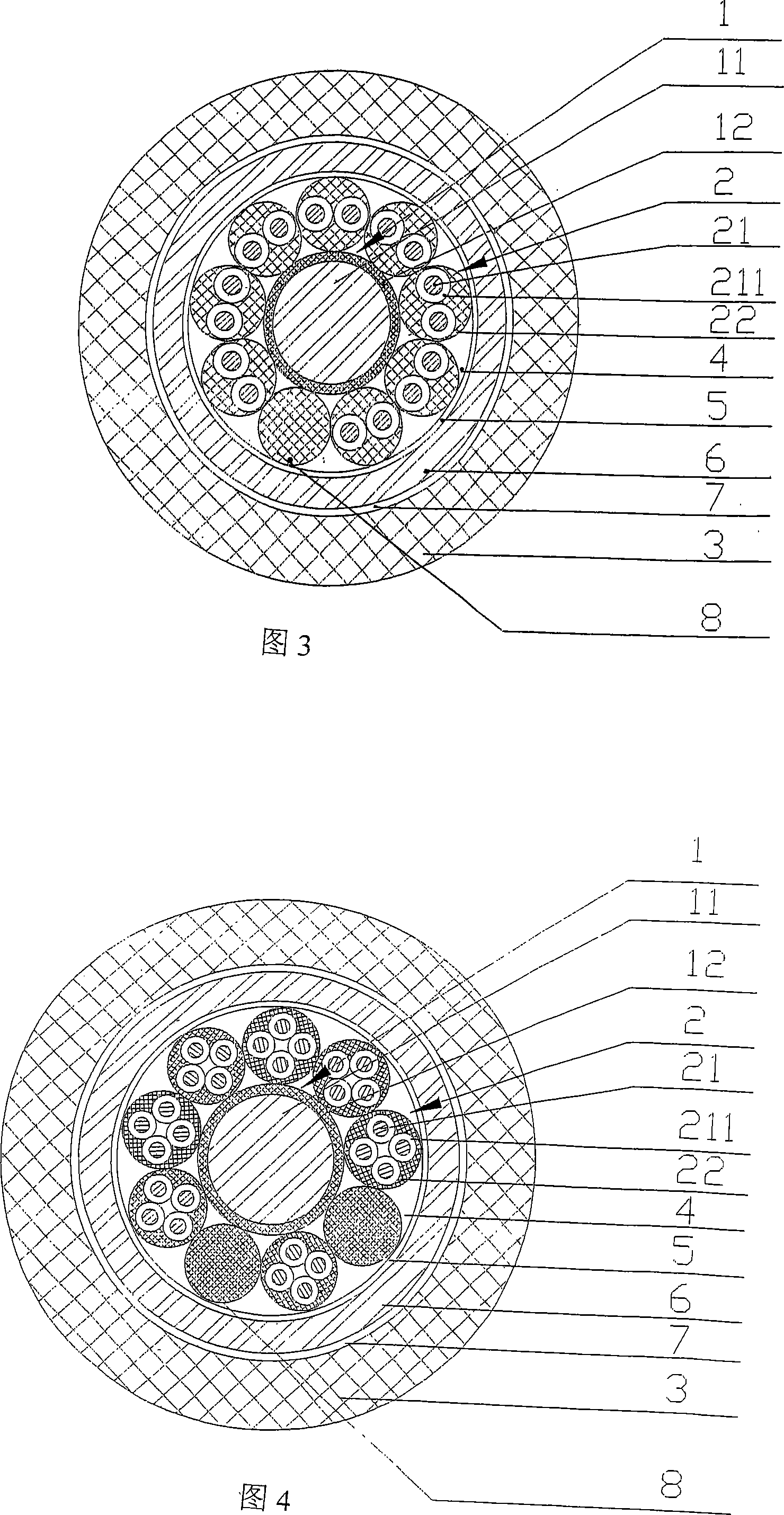

Offshore floating wind power generation cable

ActiveCN101996708AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFloating cablesPolyolefinElectrical conductor

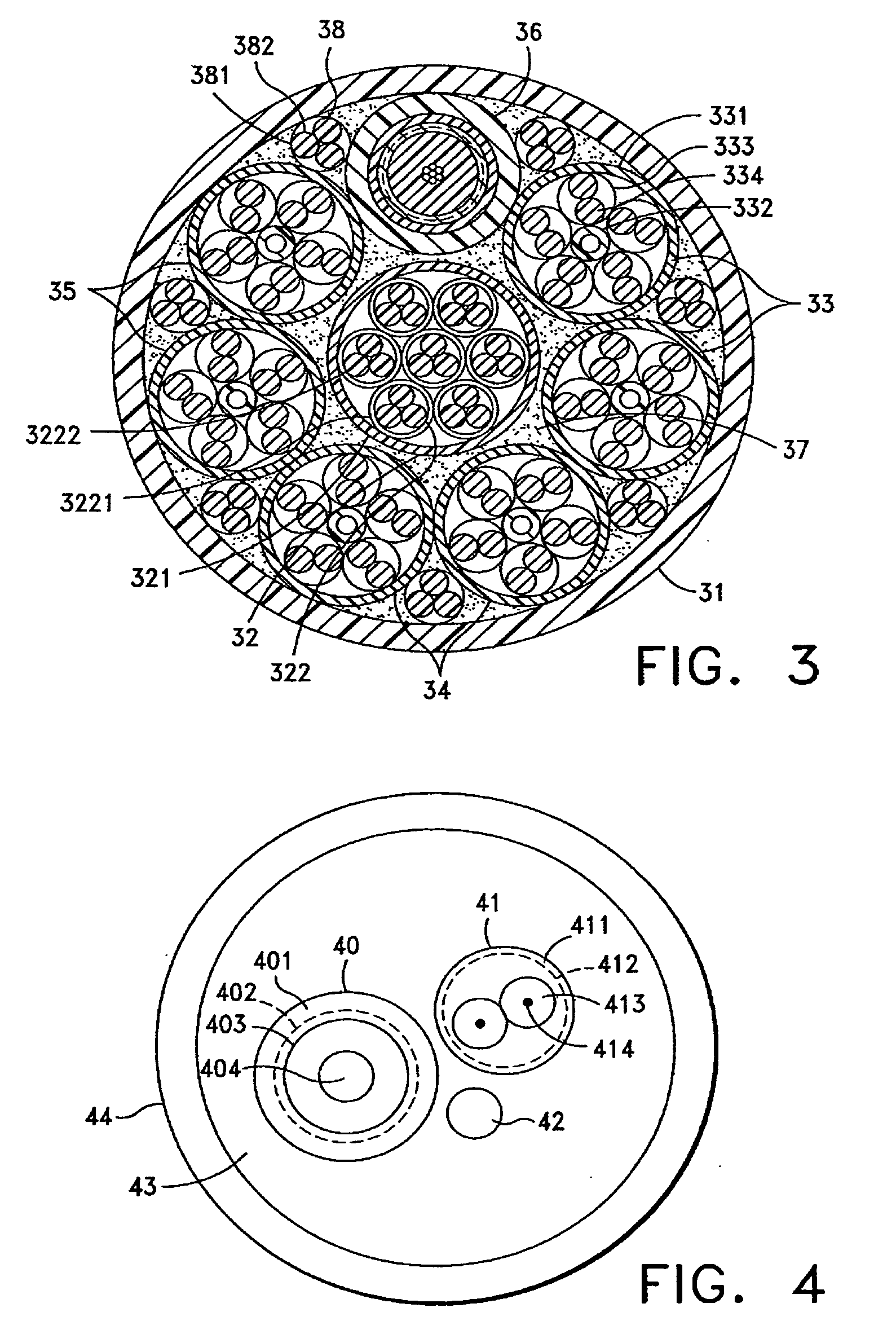

The invention discloses an offshore floating wind power generation cable, which comprises conductors, insulating layers, an inner lining layer, an inner protection layer, tensile components, floating components, a waterproof layer, protective layers and an outer sheath, wherein the conductor is coated with the insulating layer by way of extrusion so as to form insulating wire cores, and a plurality of insulating wire cores are stranded into a cable core; the cable core is respectively coated with the inner lining layer and the inner protection layer by way of extrusion; two protective layers are wound outside the inner protection layer, each protective layer consists of a plurality of protective elements which are arranged in the shape of circle, and each protective element is formed by coating the tensile component with the floating component by way of extrusion; the two protective layers are respectively coated with the waterproof layer, the protective layer and the outer sheath by way of outward extrusion; the insulating layers and the inner lining layer are made of thermoplastic elastomeric materials by way of extrusion; and the insulating layer is made of thermoplastic polyolefin (TPO) materials in thermoplastic elastomer (TPE), and the inner lining layer is made of toughened polystyrene (TPS) materials in TPE. The wind power generation cable of the invention has the advantages of low temperature resistance, bending resistance, torsion resistance, abrasion resistance, water blocking, corrosion resistance, weather fastness, high tensile strength, and capability of effectively preventing the damages of stormy waves and other floaters over the sea to the cables.

Owner:FAR EAST CABLE +2

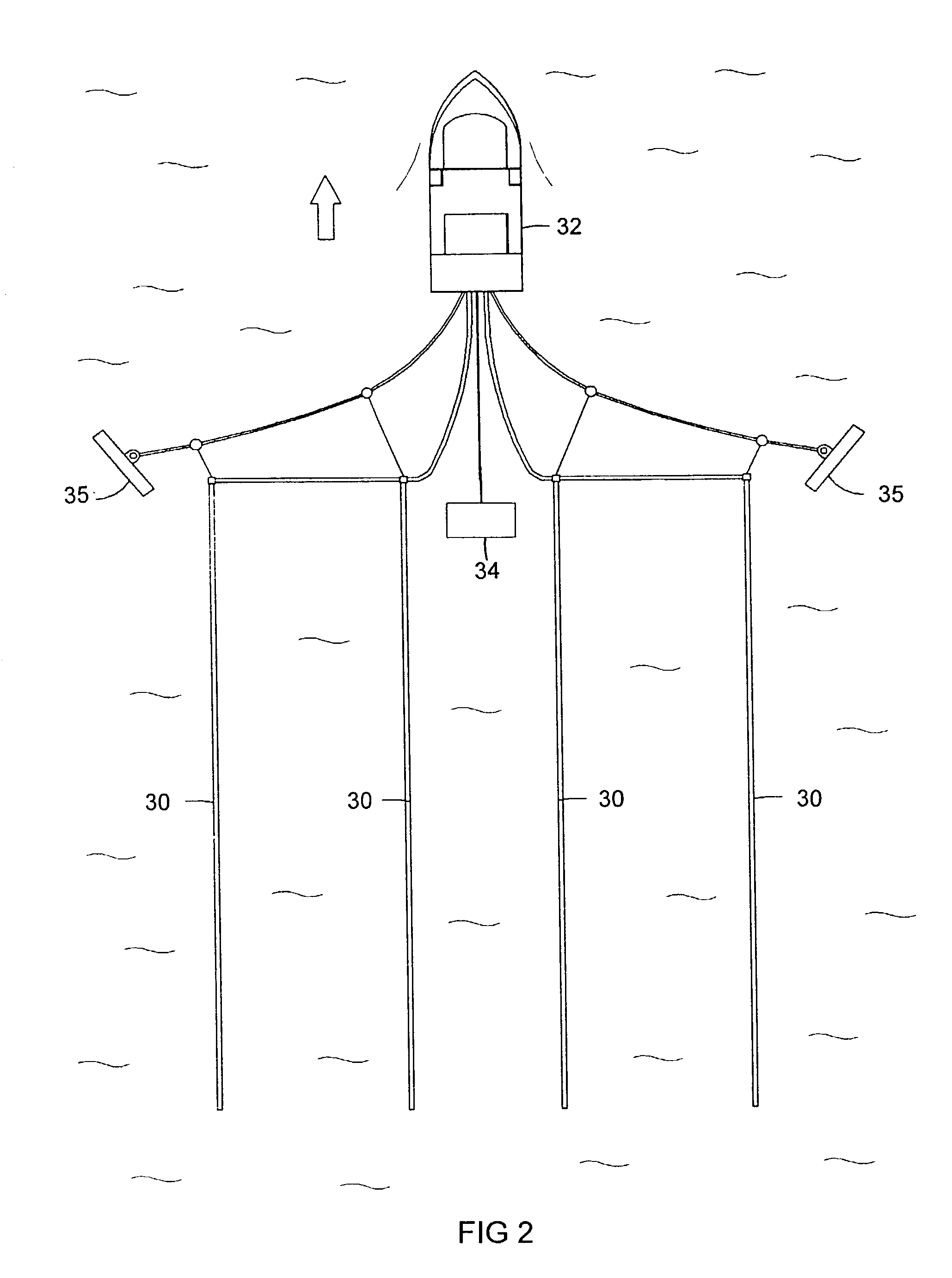

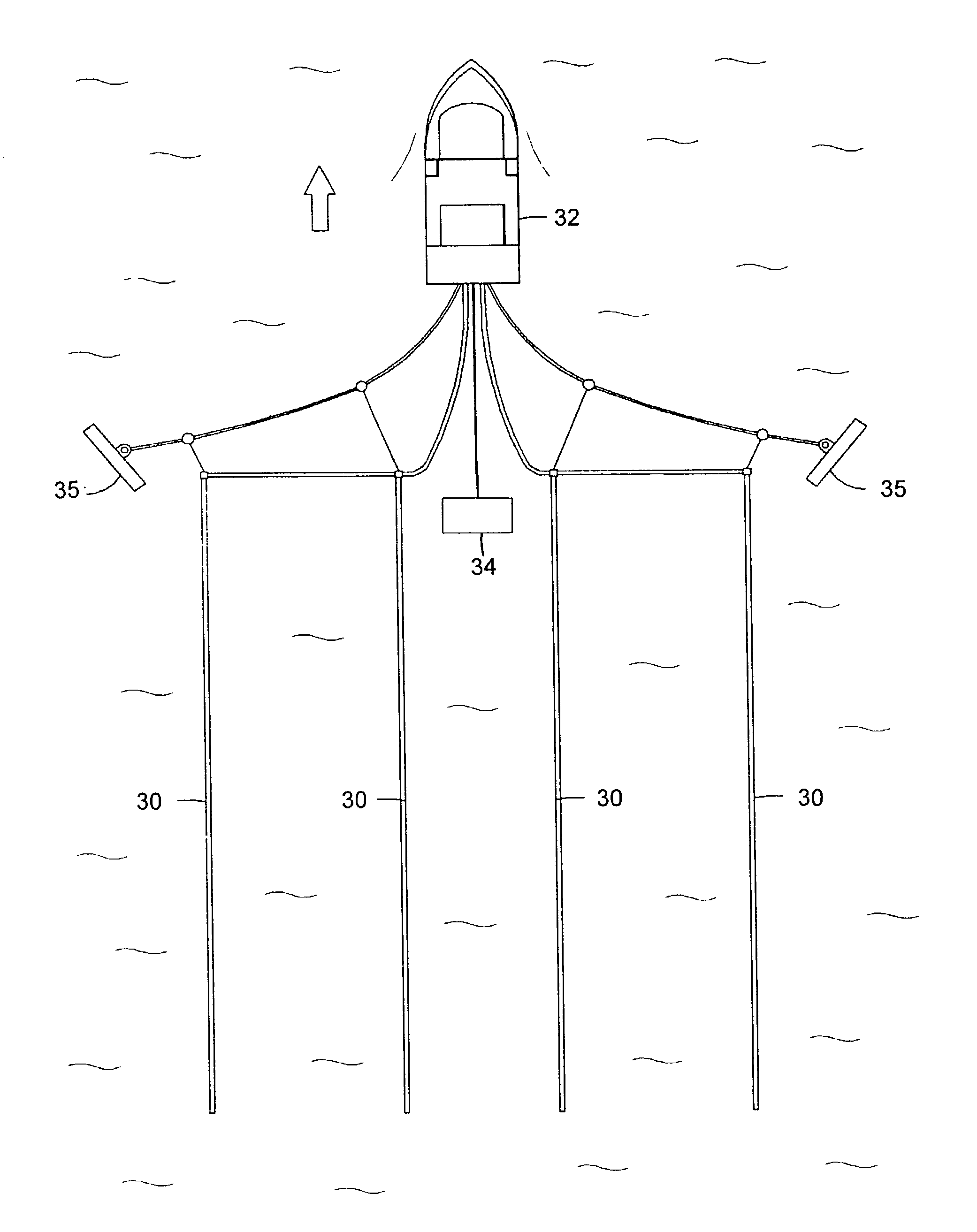

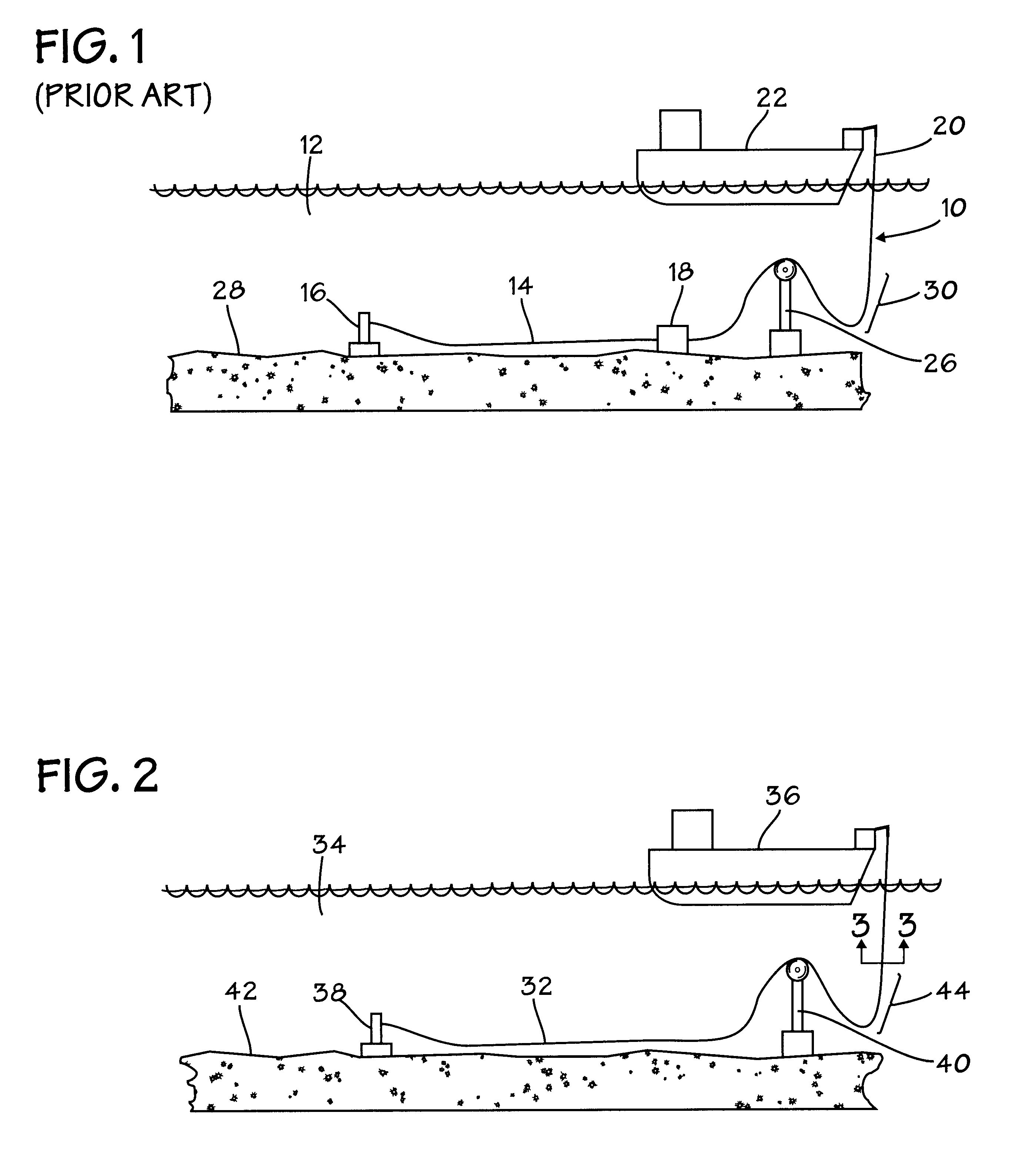

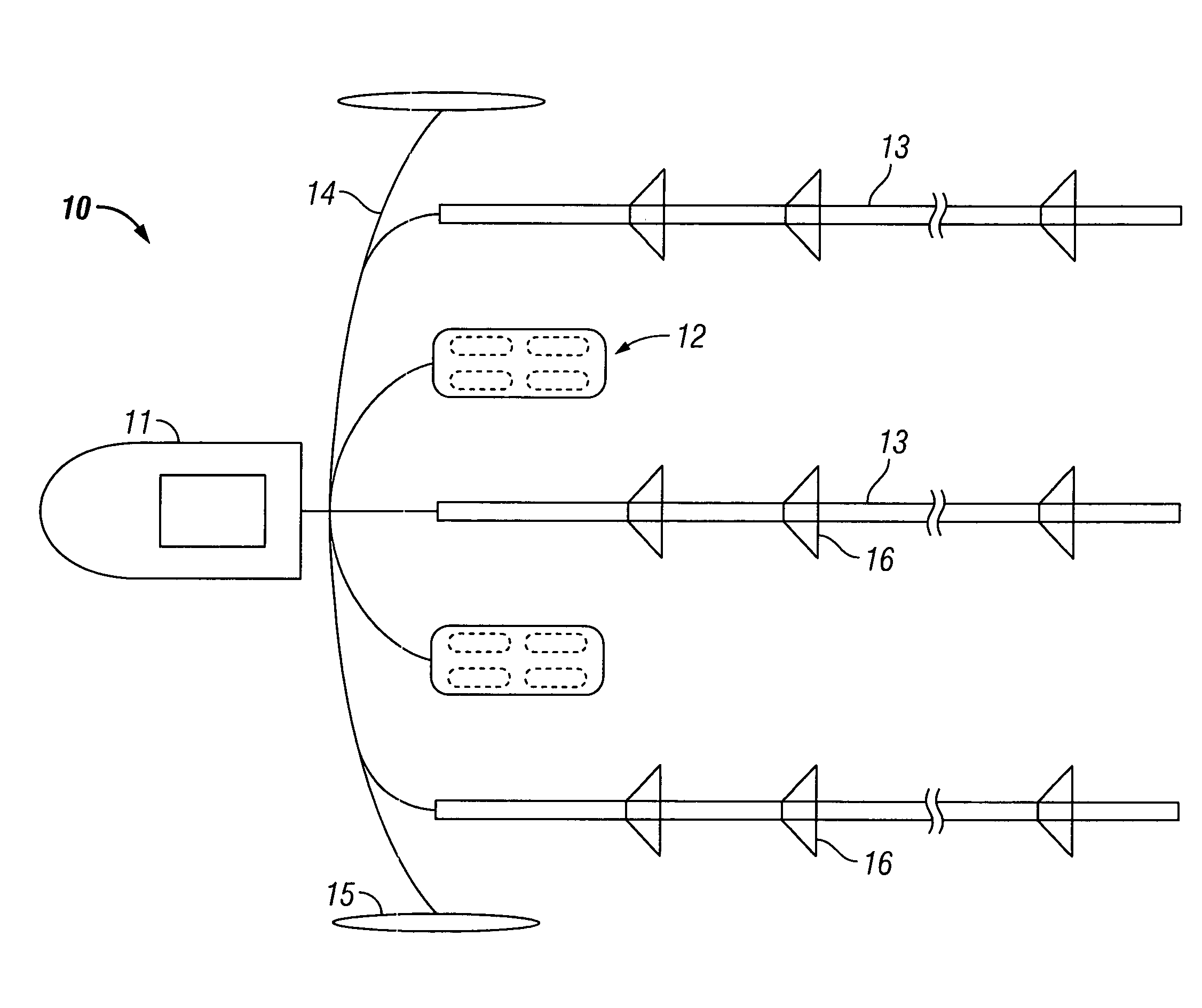

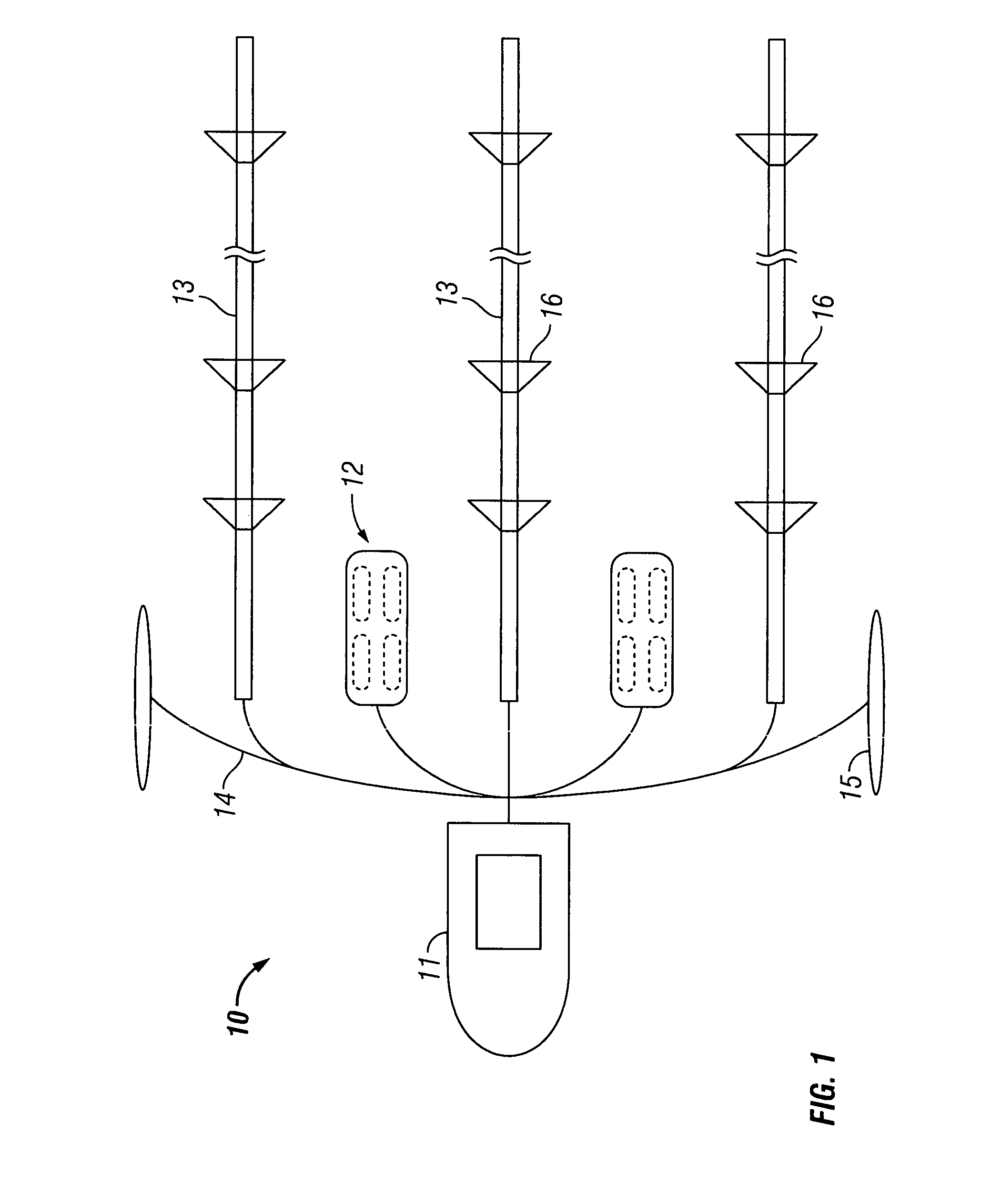

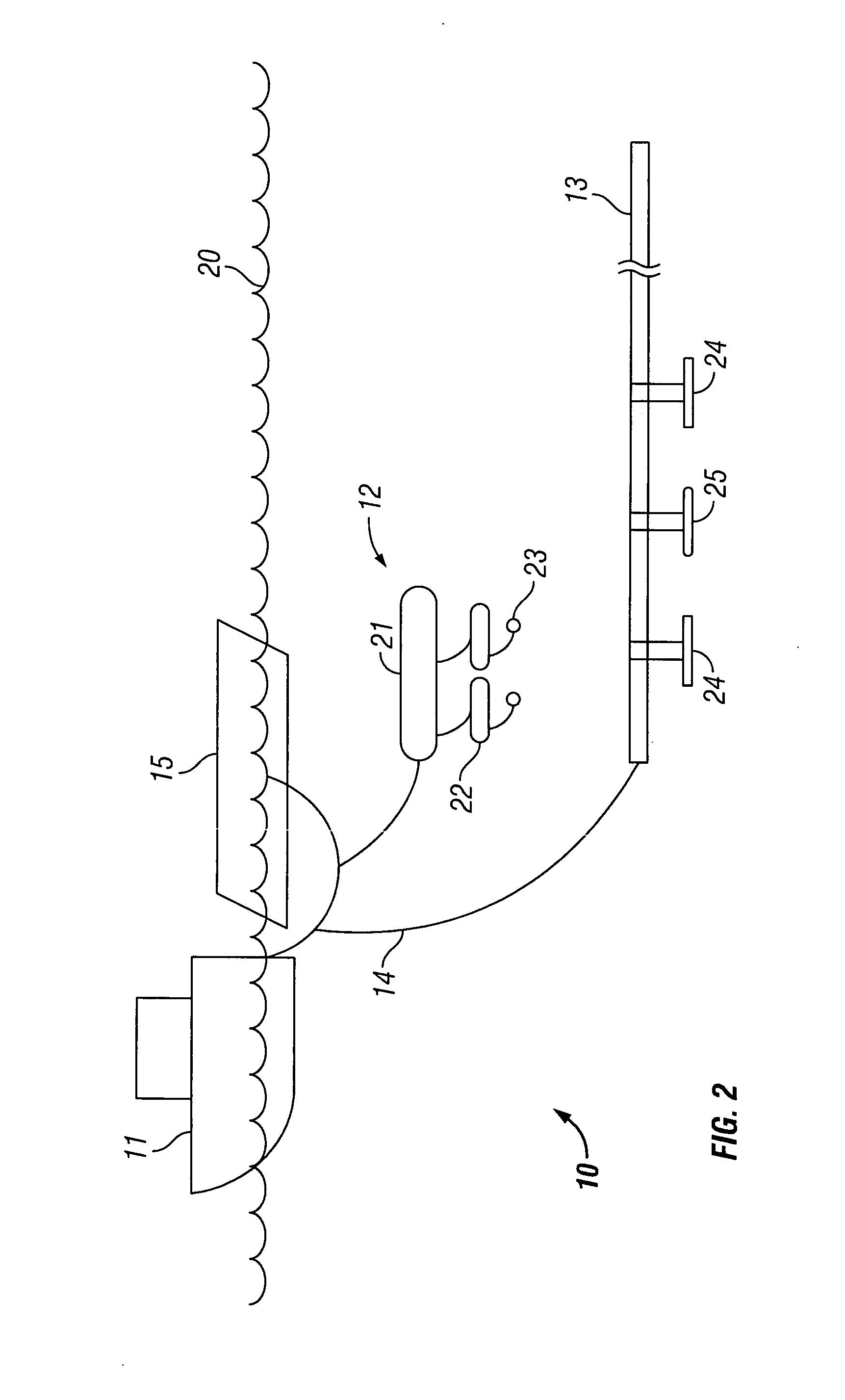

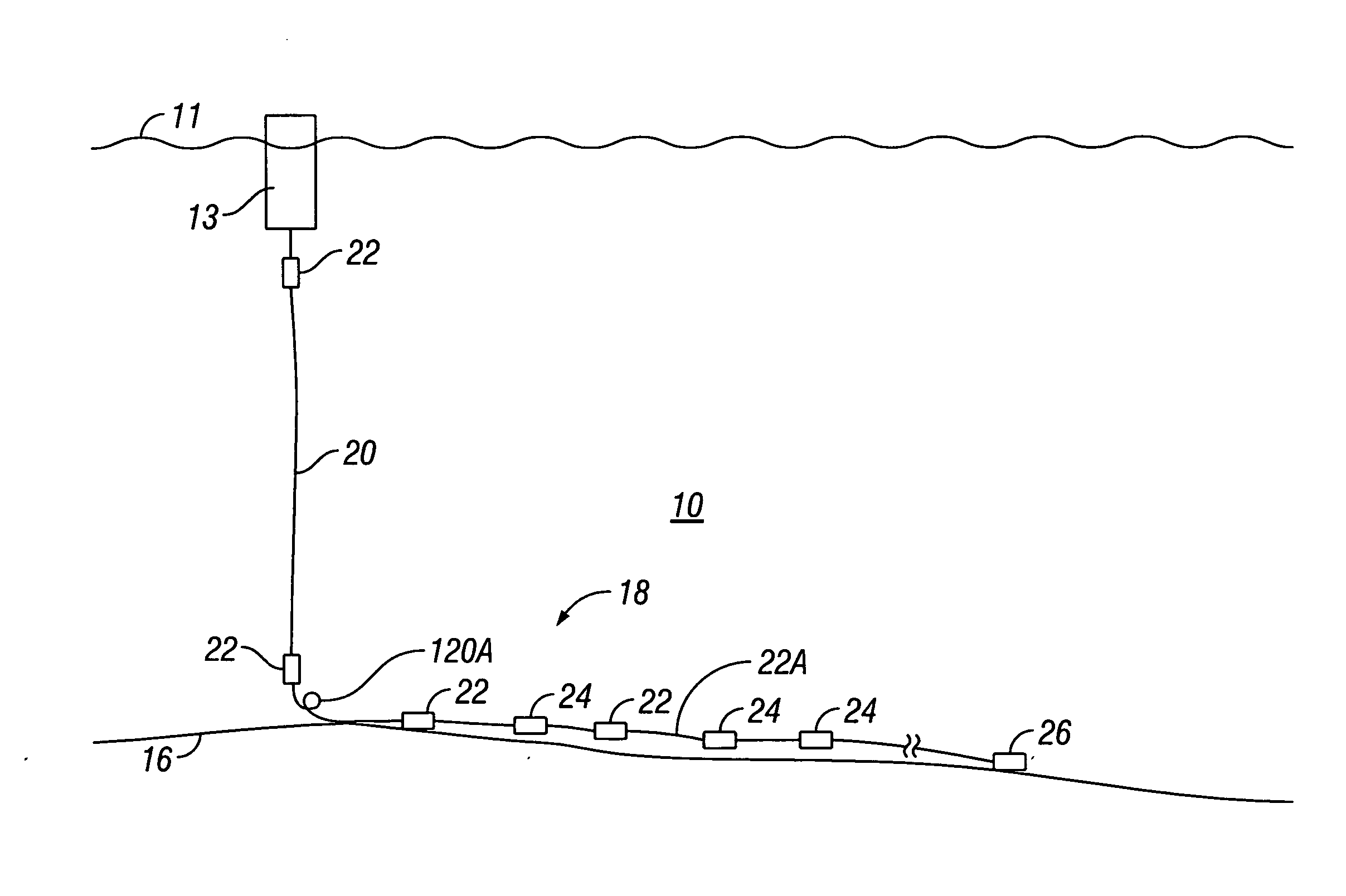

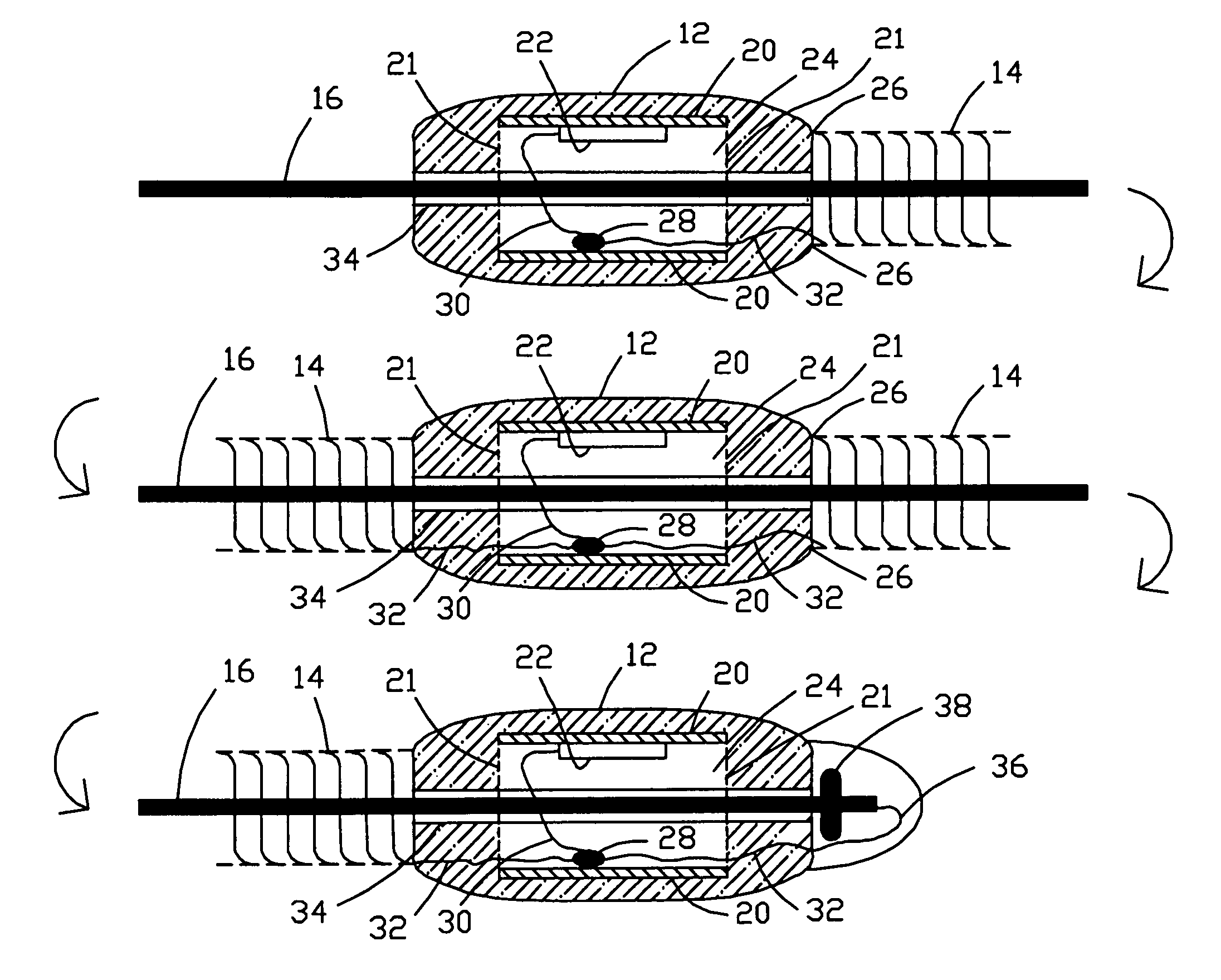

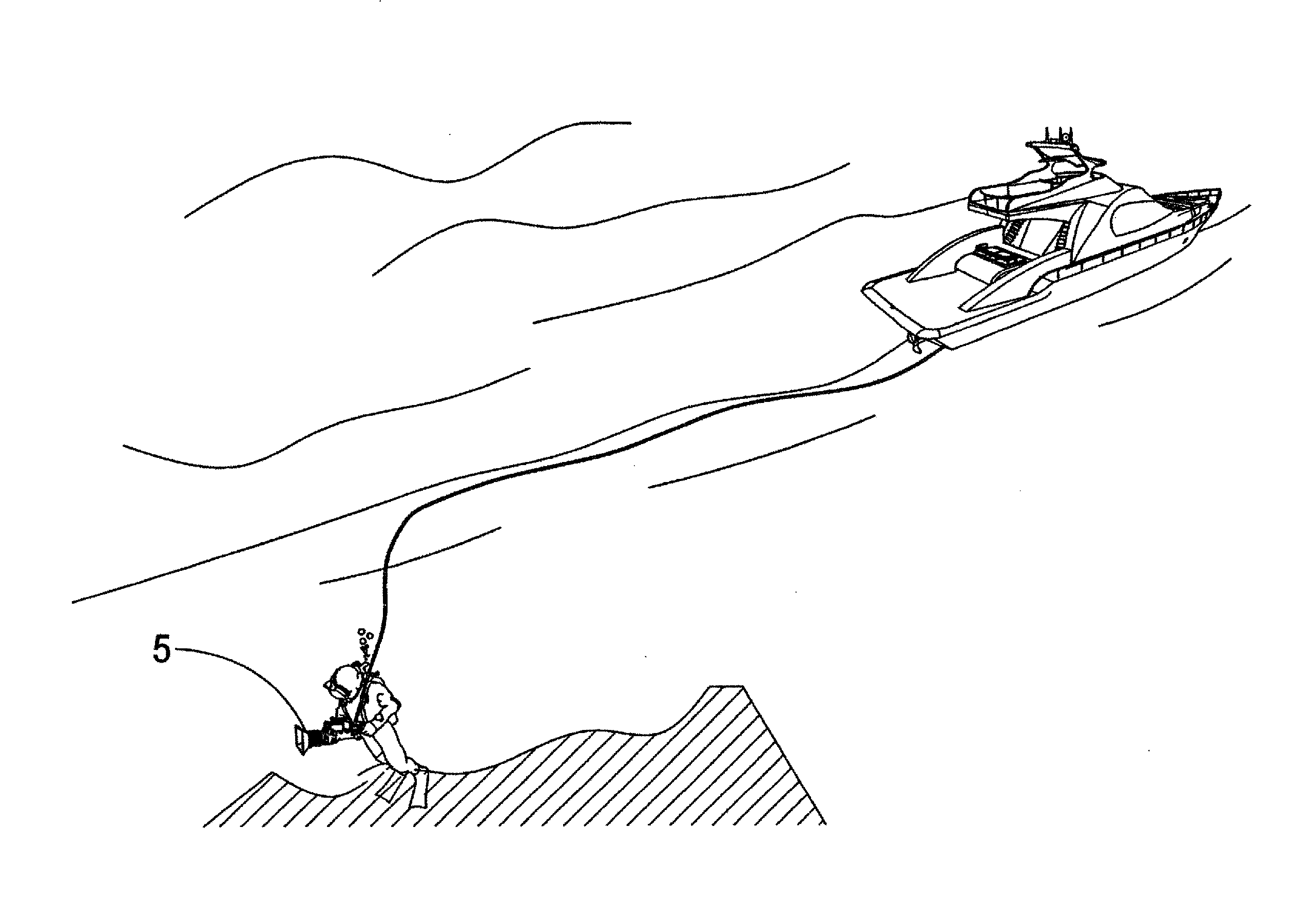

Ocean bottom seismic sensor cable system including torque-relieveing swivel

An ocean bottom cable system includes a sensor cable configured to be extended from a vessel to the bottom of the body of water. The sensor cable includes a plurality of seismic sensor units at spaced apart locations. A lead in cable is coupled at a to at least one of the vessel and a buoy, and to an aft lead in cable segment. The segment includes a cable loop to compensate water-caused motion of the lead in cable substantially without moving the sensor units. A first swivel is disposed between a forward end of the sensor cable and an aft end of the aft lead in cable segment. The first swivel enables relative rotation between the sensor cable and the segment. At least a second swivel is disposed between the second end of the lead in cable and a forward end of the aft lead in segment.

Owner:PGS GEOPHYSICAL AS

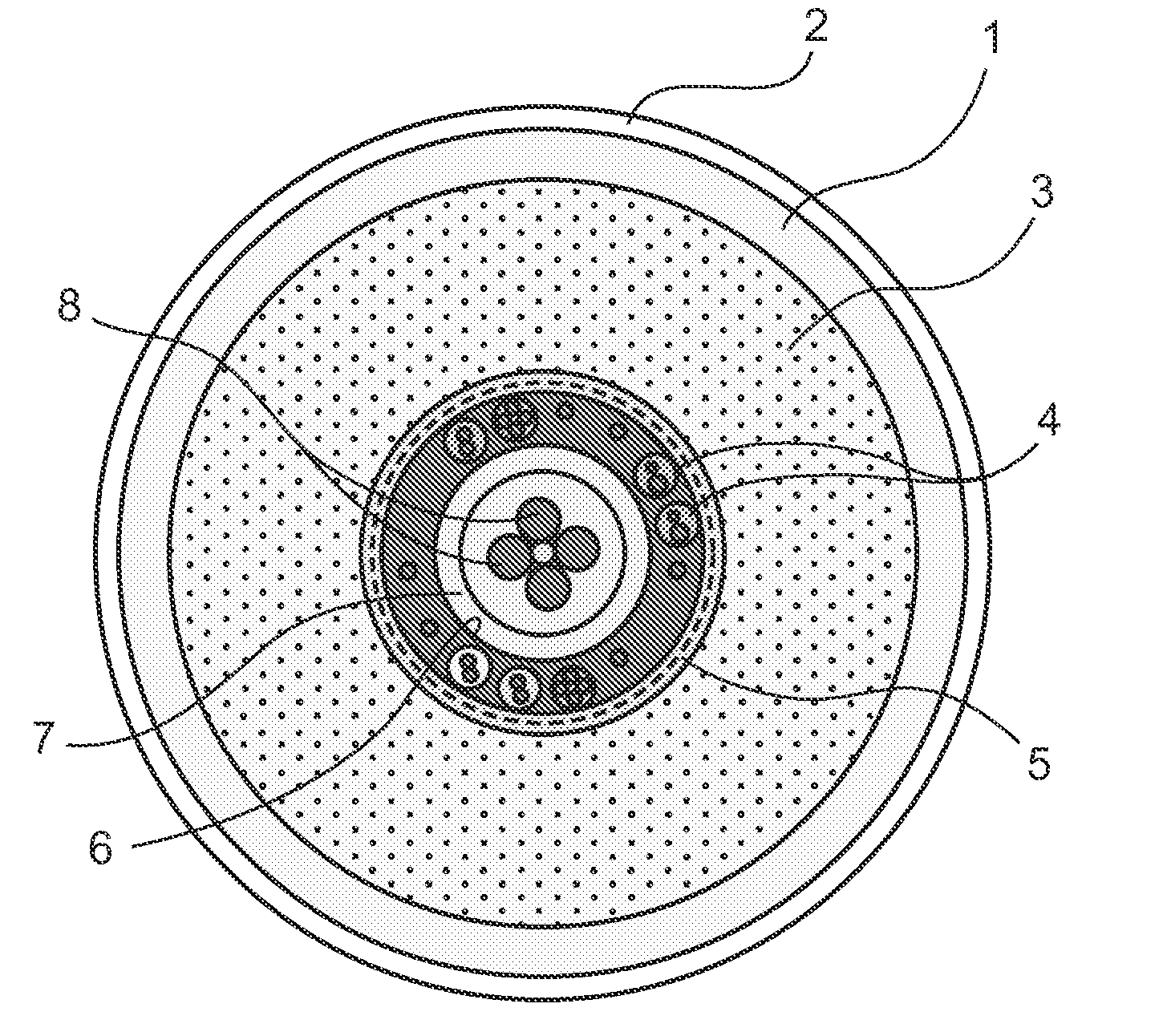

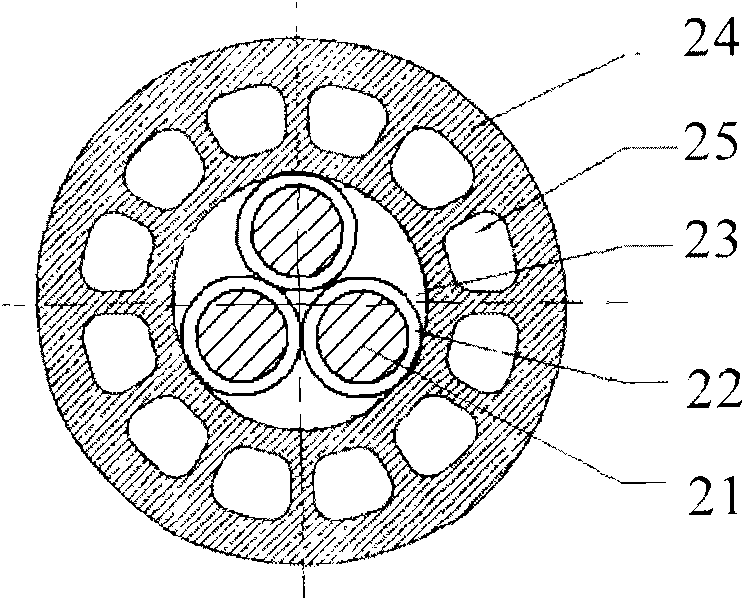

Buoyancy controllable optoelectrical composite cable

InactiveCN101866720AReasonable and flexible control of buoyancyGuaranteed tensile strength requirementsCommunication cablesFloating cablesCoaxial cableUnderwater

The invention relates to a buoyancy controllable optoelectrical composite cable comprising a cable core and a sheath, wherein the sheath is sleeved outside the cable core, the cable core comprises a reinforcing core, more than one optic bundle tube and a power lead, wherein the optic bundle tubes are twisted around the reinforcing core and comprise a loose tube, optical fibers arranged in the loose tube and filling fiber paste. The buoyancy controllable optoelectrical composite cable is characterized in that more than one buoyancy control unit twisting layer is additionally arranged in the sheath, a buoyancy control unit is a physical foamed plastic filling rope or a hollow plastic tube, the reinforcing core is formed by covering a plastic cushion layer by aramid fiber, the sheath mainly comprises a first water-blocking taping layer, two buoyancy control unit twisting layers, a second water-blocking taping layer, an aramid fiber reinforcing layer and an outer polyurethane sheath which are coated on the cable core sequentially, and a copper core signal wire and / or a coaxial cable signal wire are / is arranged in the cable core. The invention has the advantages of reasonably and flexibly controlling the buoyancy of an optoelectrical composite cable, satisfying special application requirements of operation positioned on a water surface or underwater and obviously improving the tension intensity.

Owner:天津立孚光电科技股份有限公司

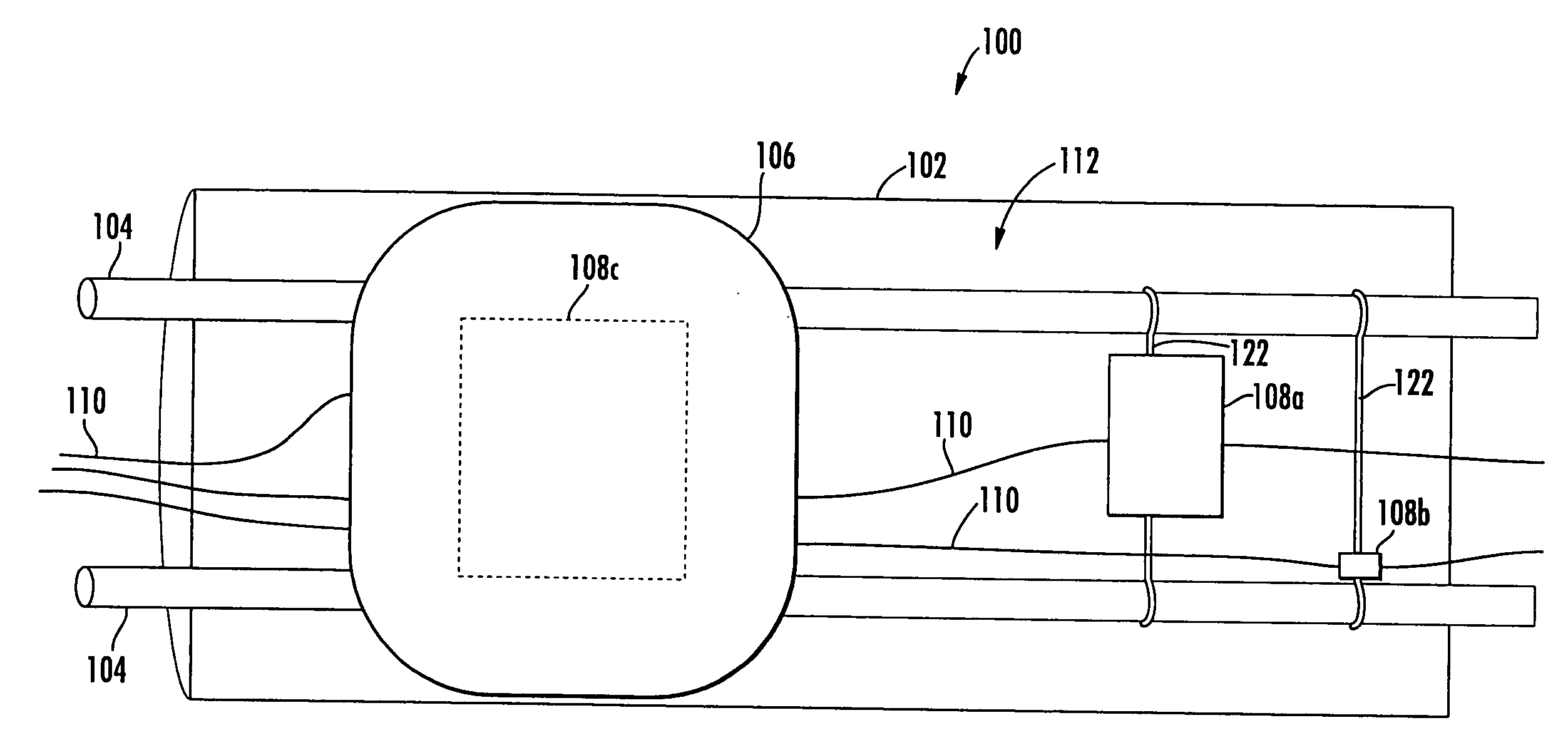

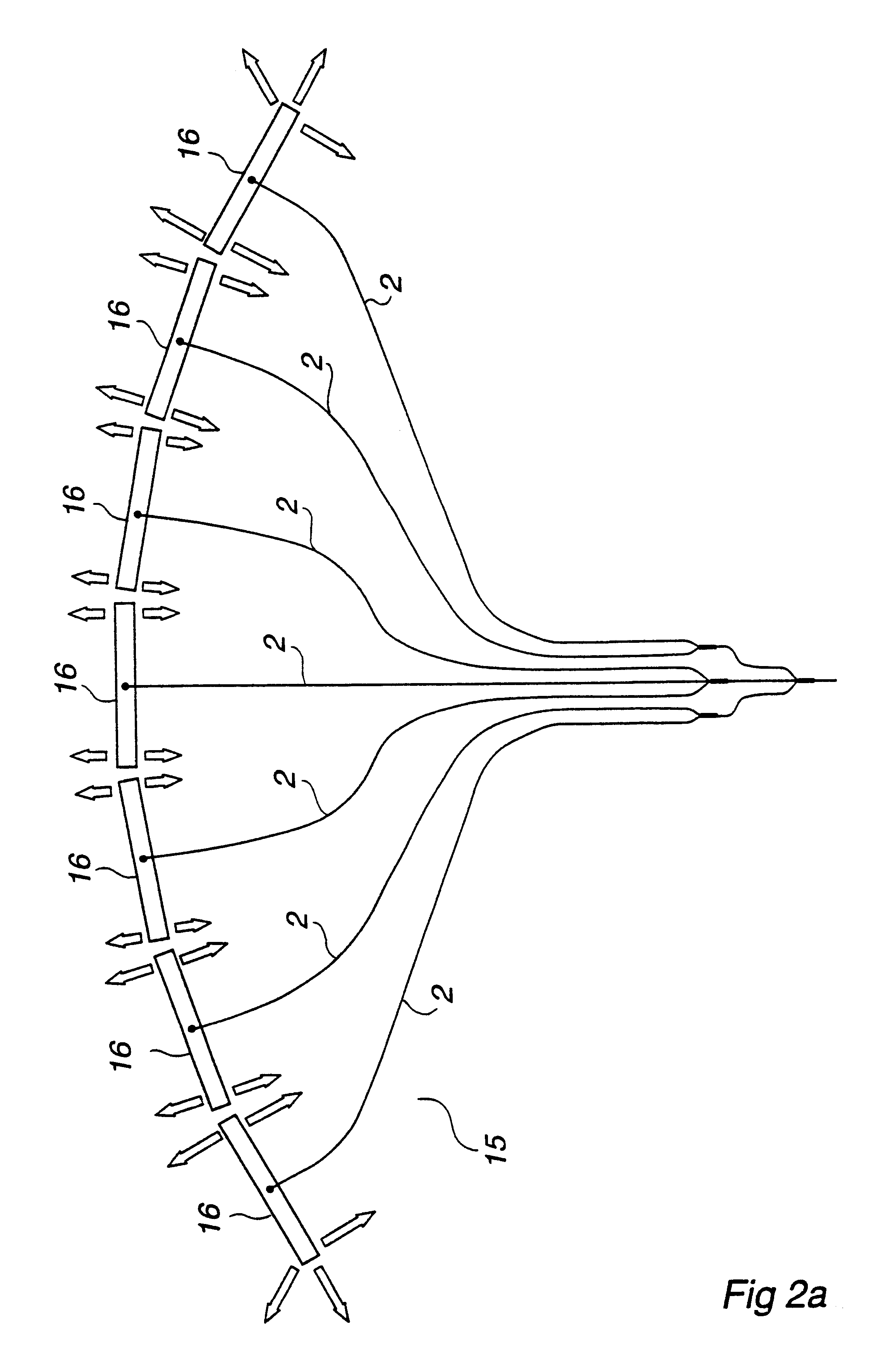

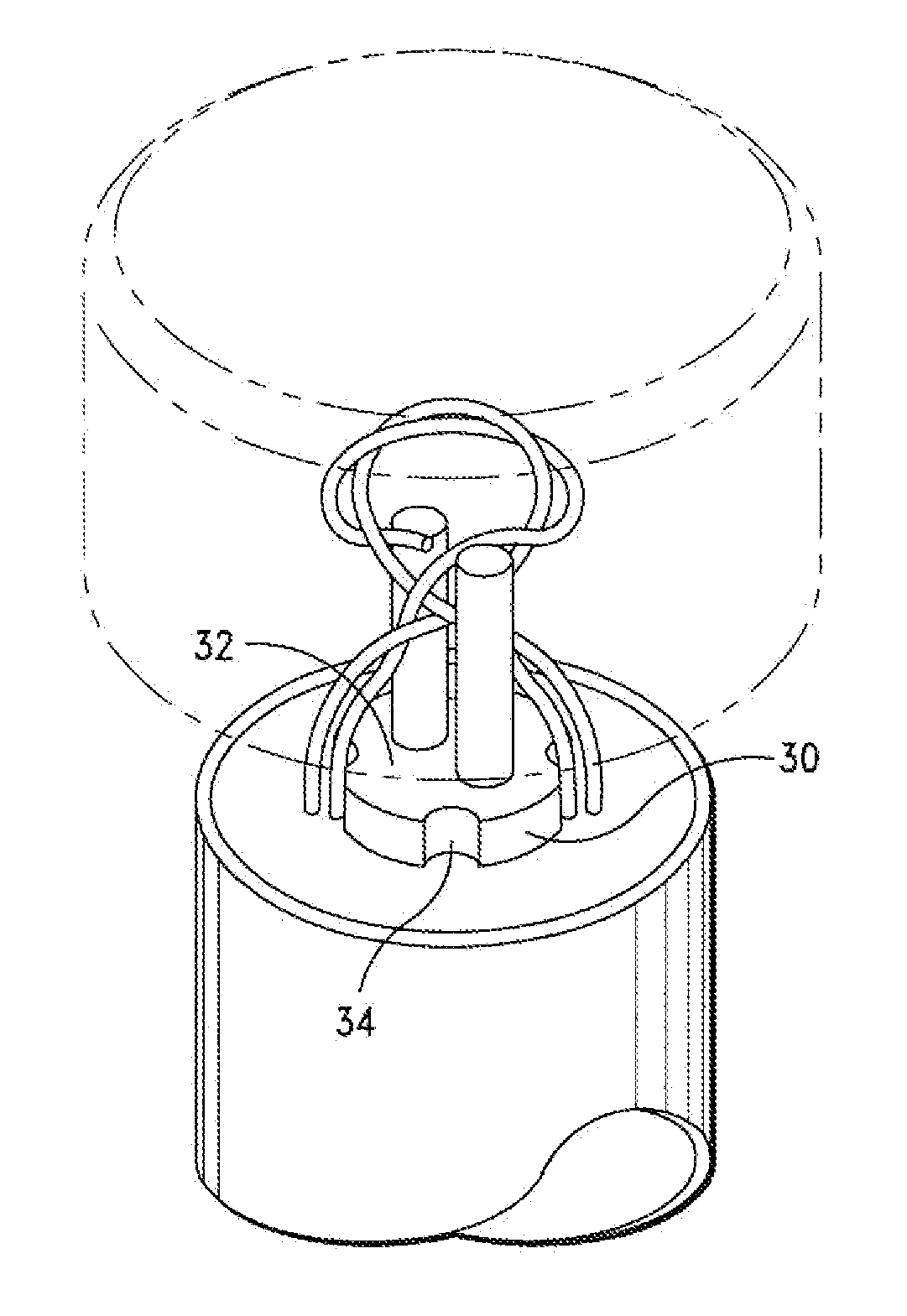

Subsurface deployable antenna array

InactiveUS8179327B1Compactly stowedAntenna supports/mountingsAntenna adaptation in movable bodiesAntenna arrayElectrical wiring

A subsurface deployable antenna array is provided which expands upon deployment and contracts for storage to provide an antenna array that can be stored in a comparatively compact space. Electronically interconnected antenna modules are connected by expandable / contractable connectors. A helically-organized bundle of optical cables and electrical wiring are utilized in the expandable / contractable connectors. Mechanical, electrical, or hydraulic means may be utilized to control the spacing between the antenna modules.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

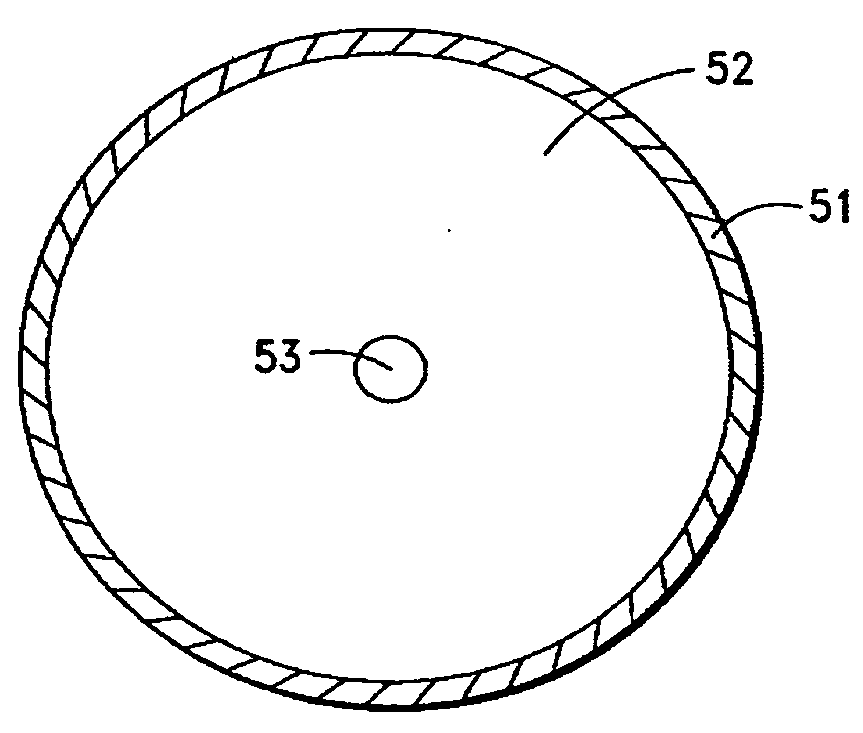

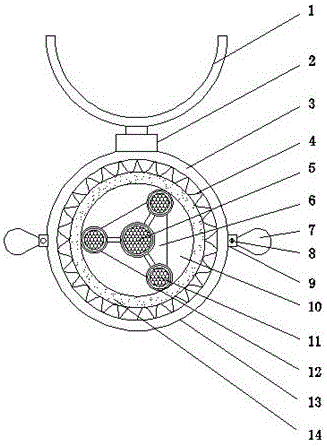

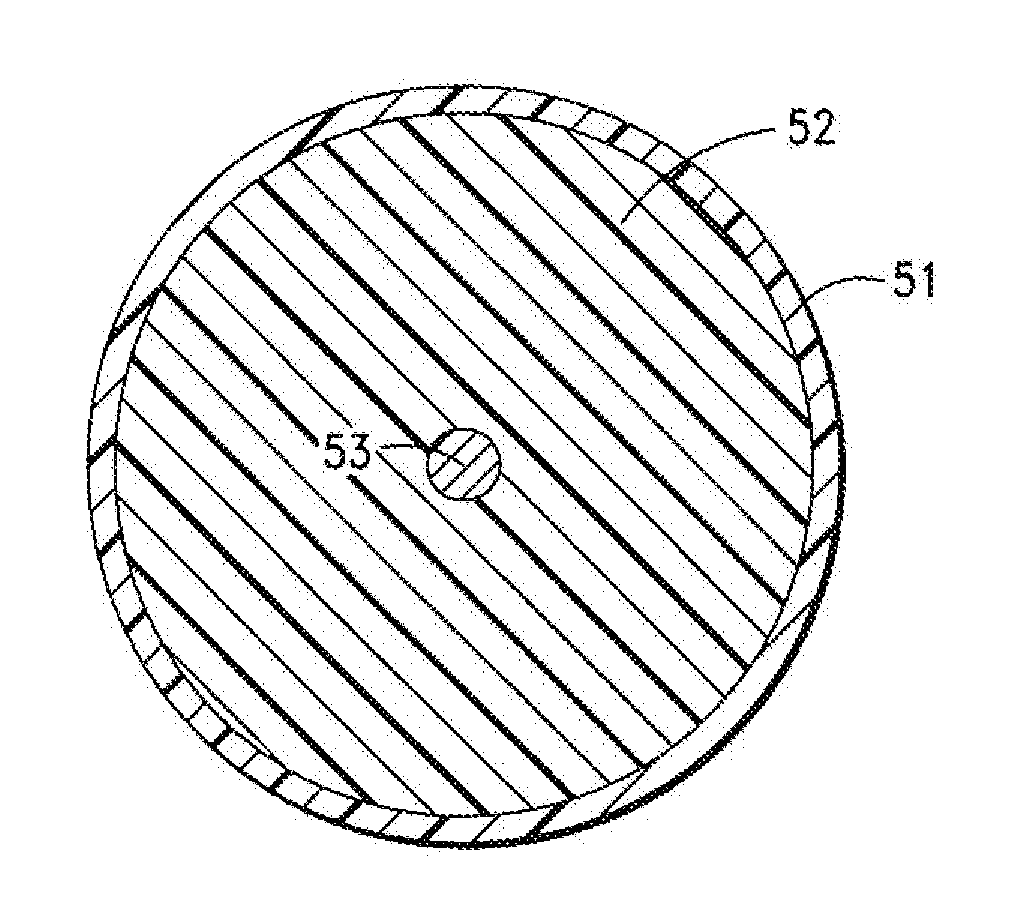

Floating cable

ActiveCN101299355ASimple internal structureIncrease productivityPlastic/resin/waxes insulatorsFloating cablesFoaming agentElectrical conductor

A floadting cable includes a conductor coated with the insulated sheath, an inner sheath and an outer sheath, wherein the inner sheath is made of the thermoplastic elastomer coated on the insulation sheath of the conductor; the outer sheath is made of the mixtures of the thermoplastic elastomer, the foaming agent and the lubricant, which are coated on the outside of the inner sheath in definite amounts by weight after being mixed to form the foaming layer, and foaming micropores are formed in the foaming layer. The cable has the advantages of floating on the water because the global density of the cable is smaller than 1, which is convenient to maintain; providing with excellent global density and the frequent bending tolerance; mixing the foaming agent into the outer sheath, wherein airtight foaming micropores are formed in the outer sheath to constitute the foaming layer in the extruding process; the foaming layer adopts the conventional extruding device in the cable industry to coat on the outside of the inner sheath, which not only leads the inner structure of the floating cable with simple structure, but also is convenient to process with high production efficiency, which is suitable for the industrialization volume production.

Owner:SUZHOU CABLEPLUS PHOTOELECTRIC TECH

Electrically conductive buoyant cable

InactiveUS20080296040A1Increase buoyancyGreat resistance to tensile stressFloating cablesInsulated conductorsElectrical conductorFilling materials

Disclosed herein is an electrically conductive buoyant cable. The cable includes an electrical conductor member having at least one electrical conductor. The cable also includes a filler layer that consists of buoyant materials with relative density lower than 1. The filler layer surrounds and encloses the electrical conductor member. The invention includes a jacket, which, in one embodiment, contains a small quantity of filler material or no filler material. The jacket surrounds the filler layer. In one embodiment, the filler layer and the jacket are made of the same material.

Owner:SMARTPOOL

Cable migrating and moving in water

The invention relates to a cable migrating and moving in water, which belongs to the technical field of electromechanical products. In order to meet the special requirements on wiring for an electrical installation working underwater, the invention provides a cable which cannot be enwound and wringed by self, cannot be daggled in a pool bottom and is basically parallel with the pool bottom surface when migrating and moving in water, and has an outer diameter not more than 15 millimeters. The cable comprises a conductor, an insulting layer, a cable core center padding, an inner protective layer and an outer protective layer. The cable is characterized in that the thickness of the inner protective layer made of foamed plastic is less than 3 millimeters, and the outer diameter of the cable is not more than 15 millimeters. The cable is used for connecting the electrical installation working underwater and supplying power for the same. The cable is soft with hardness, has elastic resilience and cannot be enwound and wringed by self when migrating and moving disorderly under water along with the electric installation, the inner protective layer is made of the foamed plastic so that the cable has light weight and the function of blocking water, is suitable for horizontal operations, cannot be daggled in the pool bottom and is basically parallel with the pool bottom surface in work, and has small outer diameter size, simple structure and low cost, and the manufacturing process and devices are general process and devices.

Owner:刘斌恒

Sensor streamer having two-layer jacket

Owner:PGS GEOPHYSICAL AS

High-voltage shielding flexible cable

The invention discloses a manufacturing process for a high-voltage shielding flexible cable. Cable insulation adopts a three-layer coextrusion mode. A certain amount of specific substance such as meltable polytetrafluoroethylene is added into the formula of a sheath, so that a conductor shielding layer is prevented from entering a conductor gap, surface finish of the cable is guaranteed, and salt crust on the surface of the cable jacket is avoided.

Owner:成都亨通光通信有限公司

Cable Structure for Underwater Equipment

InactiveUS20140126865A1Cable structureAvoid excessPlastic/resin/waxes insulatorsCommunication cablesBuoyancyPetroleum engineering

A cable structure for underwater equipment is disclosed, which comprises a waterproof layer, a tension-resistant layer, a buoyant layer, and a communication thread. The tension-resistant layer is enveloped in the waterproof layer. The buoyant layer is enveloped in the tension-resistant layer. The communication thread is enveloped in the buoyant layer. In use, the waterproof layer can protect the communication thread from contacting with water. The tension-resistant layer can enhance the tensile strength of the cable structure, so that the cable structure can be protected from damages upon being pulled. The buoyant layer can provide buoyancy for the cable structure, so that the cable structure can avoid excessive cable being submerged in the water, so that entwining or entangling of the submerged cable section can be prevented. Accordingly, the present invention is a useful contrivance that can avoid cable entanglement and has a tension-resistant capability.

Owner:YOU FENG +1

Cable for water floating ship

InactiveCN102339660ASoftImprove bending performanceClimate change adaptationFloating cablesFiberThermoplastic elastomer

The invention relates to a cable. A cable for a water floating ship comprises an outer insulating layer, an inner insulating layer and cable cores, wherein a waterproof layer is arranged between the outer insulating layer and the inner insulating layer; a fiber woven layer is arranged between the inner insulating layer and cable cores; the number of the cable cores is at least two; the outer insulating layer is extruded by a foaming thermoplastic elastomer and is flat; and the inner insulating layer is an insulating layer containing fluoroplastic. According to the technical scheme, the cable for the water floating ship can be floated on the water surface and has the advantages of high flexibility and bendability, high water-blocking performance, ideal mechanical strength and the like.

Owner:上海永进电缆(集团)有限公司

Anti-compression suspension cable

InactiveCN106340345AStrong extrusion resistanceSo as not to damageFloating cablesInsulated conductorsElectrical conductorIsoetes triquetra

The invention provides the following technical proposal of an anti-compression suspension cable comprising a primary conductor, air bags, secondary conductors and a cable main body. The top end of the cable main body is connected with a clamping slot through a fixing block; both sides of the cable main body are provided with air charging pipes. One end of each air charging pipe is provided with an air valve. One side of each air charging pipe is provided with an air bag. The central position inside the cable main body is provided with an equilateral triangle shaped anti-tensile core. And the three corners of the equilateral triangle shaped anti-tensile core are provided with the secondary conductors. The central position of the equilateral triangle shaped anti-tensile core is penetrated by the primary conductor. The surface of the equilateral triangle shaped anti-tensile core is coated with a spinning layer. According to the invention, the anti-compression suspension cable is provided with a rubber buffer layer, enabling the cable to have a better anti-extrusion capability. At the same time, even extruded, irreversible deformation does not occur to the cable, nor does the damage. Therefore, the service lifetime of the cable is lengthened.

Owner:LEIYANG XINGYU WIRE & CABLE CO LTD

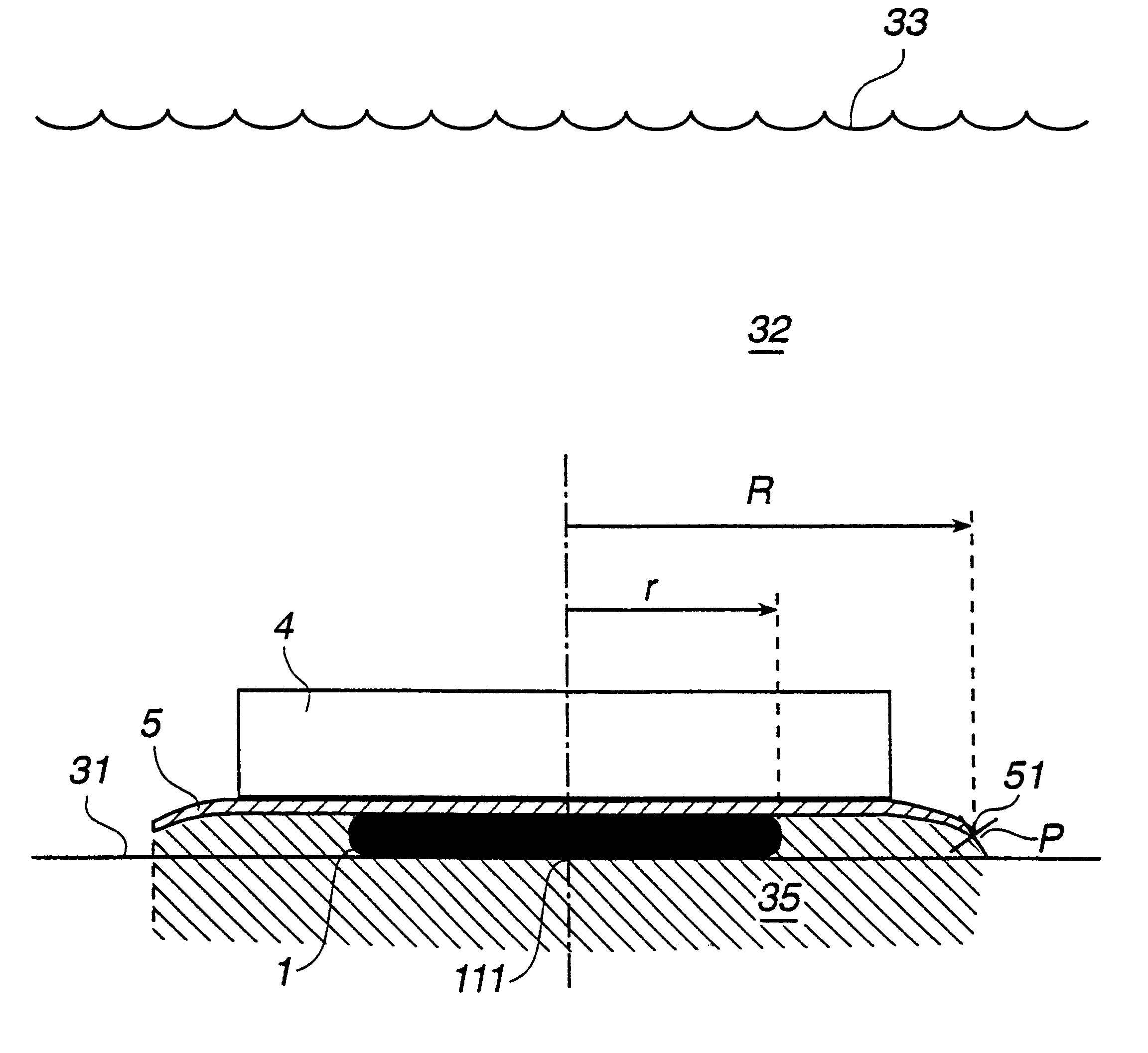

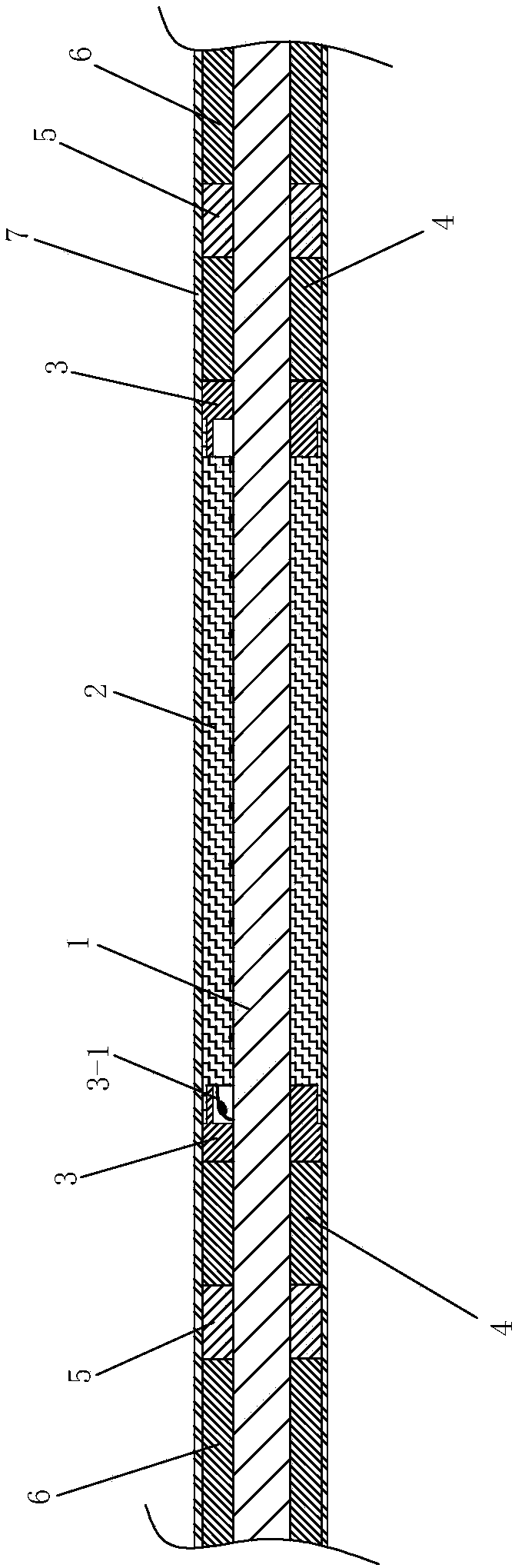

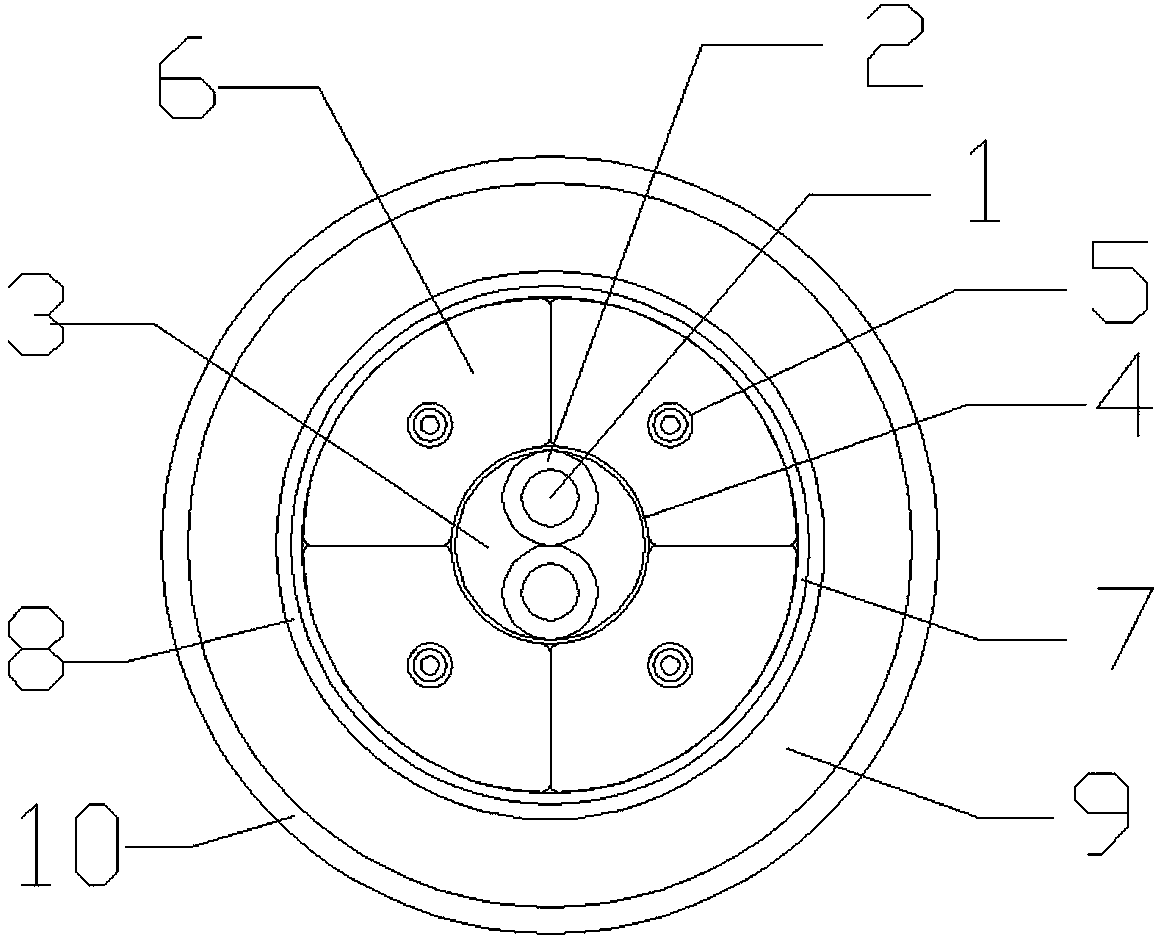

Sea electrode for a high voltage direct current transmission system

InactiveUS6242688B1Cable installations on groundConnections to liquidElectrical field strengthConductive materials

A sea electrode (15) for grounding of a high voltage direct current transmission system comprises an electrically conducting electrode body (1) for connection to the transmission system and at least one ballast (4) located above the electrode. The electrode further comprises a layer (5) of an electrically non-conducting material, located above the electrode body and extending over it, so as to influence the maximum electrical field strength not to exceed a desired level at a point (P) at the edge of the non-conducting layer and thereby also in the sea water outside a zone (35) located below the non-conducting layer and in a vertical direction limited by the edge of the non-conducting layer.

Owner:ABB (SCHWEIZ) AG

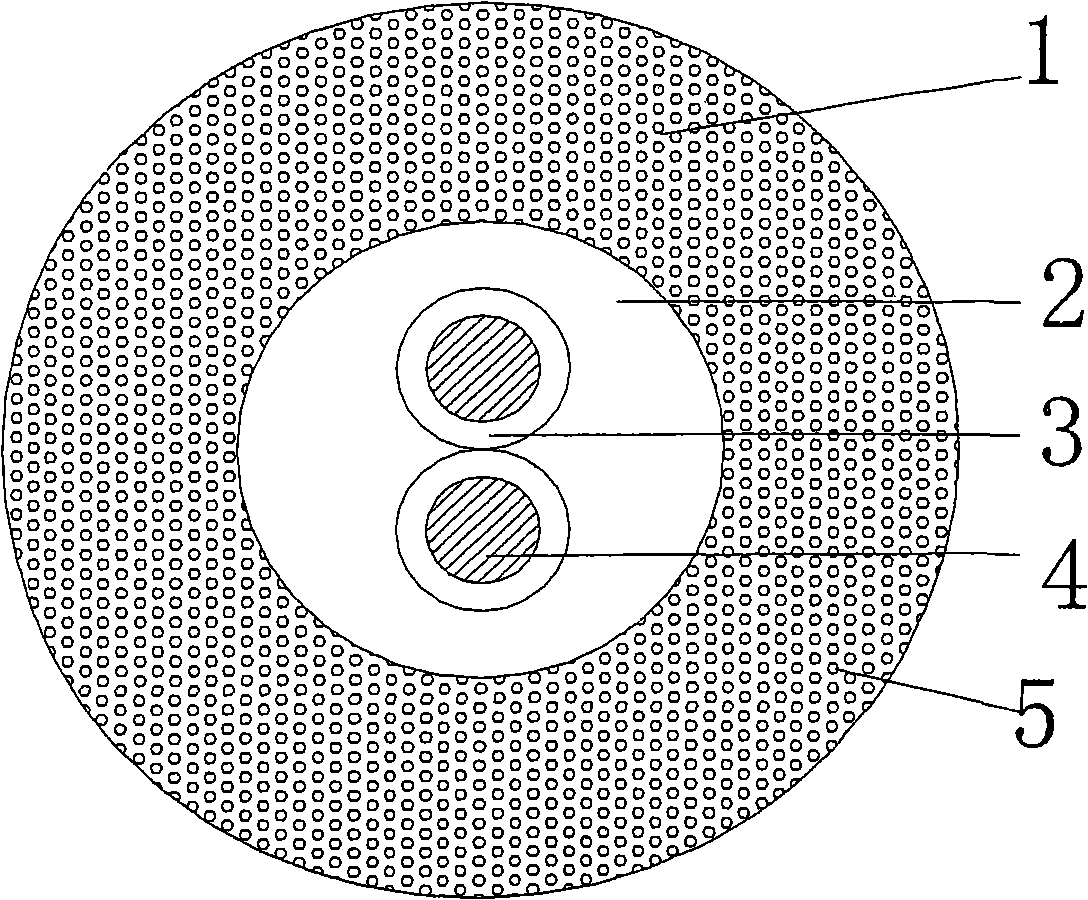

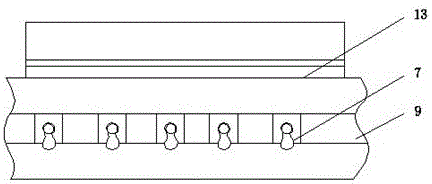

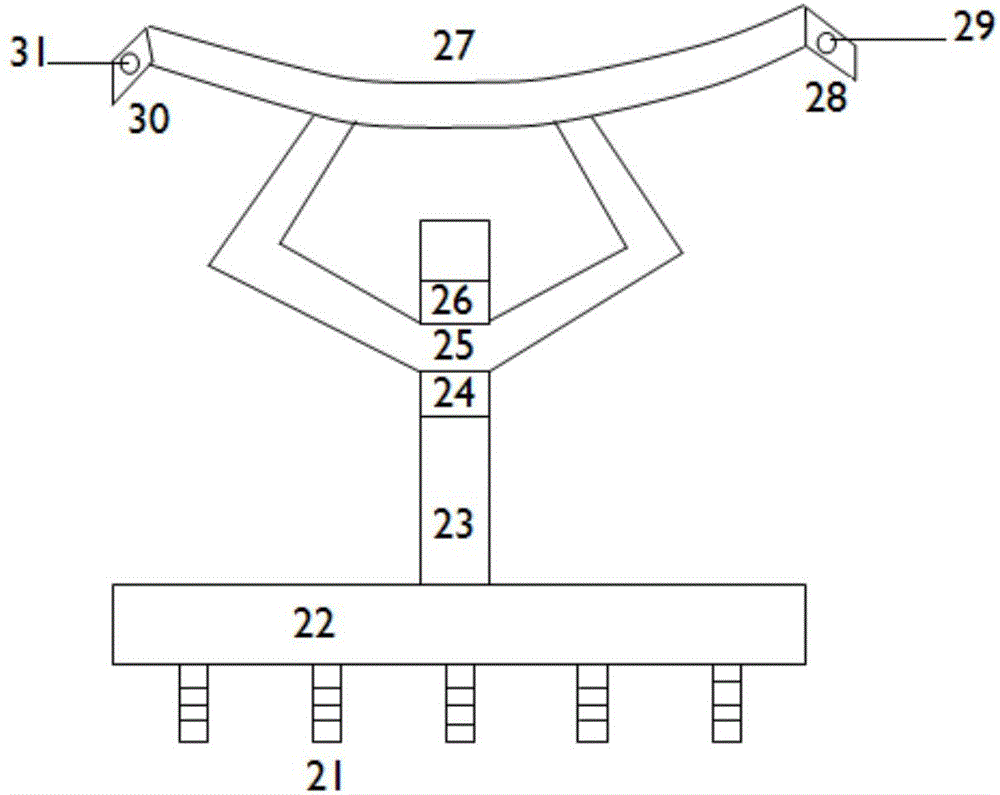

Solid towline with good dragging performance for marine seismic exploration

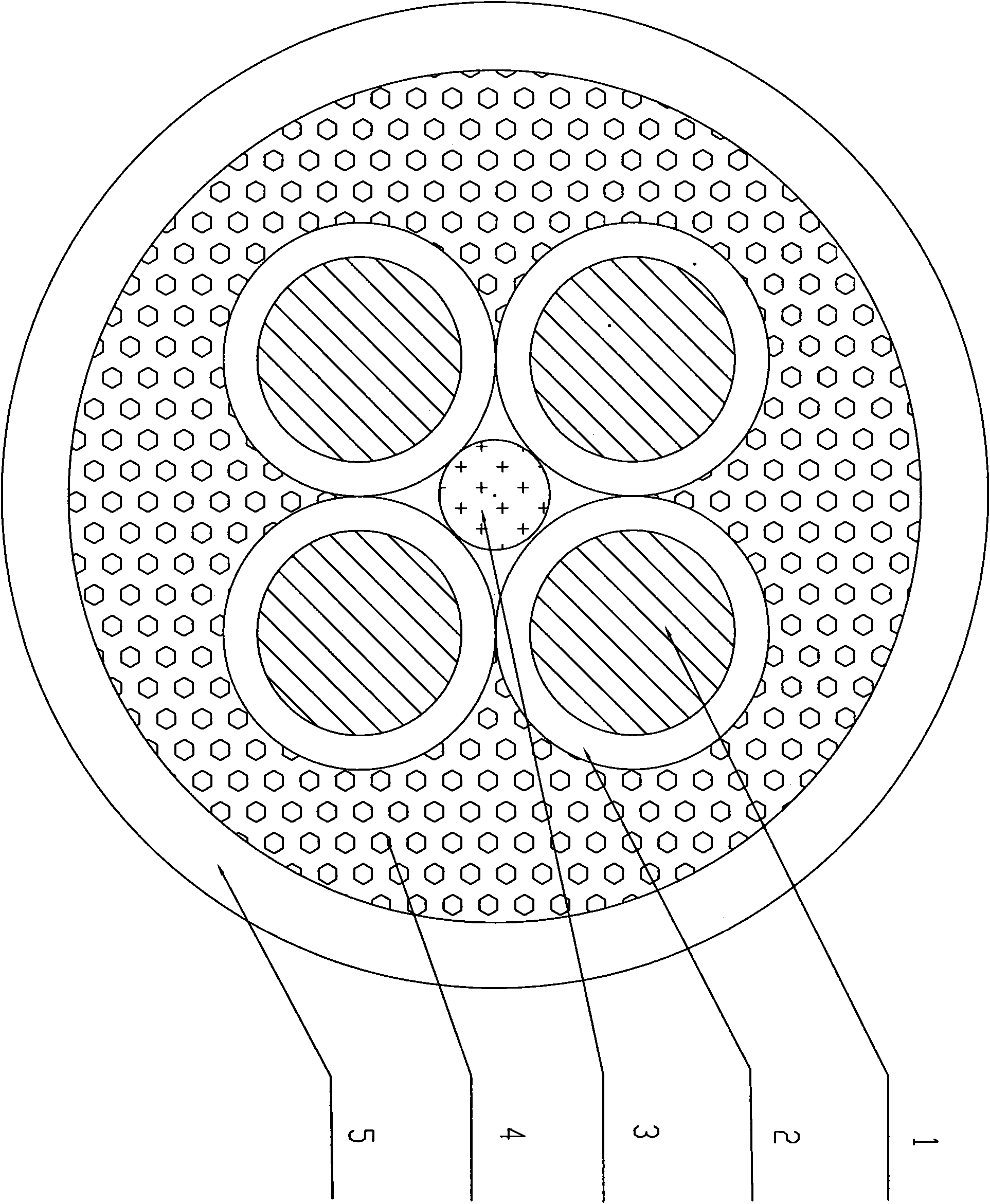

InactiveCN108447591AMaintain pressure resistanceWith impact resistanceNon-insulated conductorsFloating cablesYarnRubber material

The invention discloses a solid towline with good dragging performance for marine seismic exploration. The solid towline is characterized in that the solid towline comprises a main cable, hydrophones,buoyancy sleeves and an outer sheath. The hydrophones are fixedly arranged on the main cable with an equal interval. The hydrophones are electrically connected to corresponding wire cores in the maincable. Each of the buoyancy sleeves is made of a foamed polyethylene material, and foamed polyethylene is extruded on the main cable. The main cable includes the transmission wire cores, a tensile fiber layer and a conductive wire layer. The tensile fiber layer is formed by weaving aramid yarn and / or polyester yarn outside the transmission wire cores. The conductive wire layer includes a set of power lines and a set of signal lines. The power lines and the signal lines are orderly arranged with an equal interval along the circumferential direction of the main cable outside the tensile fiber layer to form the corresponding wire layer. The buoyancy sleeves are fixedly arranged on the main cable with an equal interval, and each of the buoyancy sleeves is between two adjacent hydrophones. Theouter sheath is made of a thermoplastic polyurethane elastomer rubber material and is extruded outside the hydrophones, positioning ends and the buoyancy sleeves, and the outer sheath is seamlessly bonded to the hydrophones.

Owner:CHANGZHOU MARINE CABLE

Water floating cable

ActiveCN110932222AAvoid breakingImprove waterproof performanceFloating cablesCable junctionsPower cableMechanical equipment

The invention belongs to the technical field of power cables, and particularly relates to a water floating cable. The problems of poor waterproof performance and low tensile strength of the connectionpart of the water floating cable in the prior art are solved. The technical scheme of the invention is as follows: the method comprises the following steps: the cable comprises a cable core, an insulating layer, a waterproof layer and a floating layer and also comprises a floating cable connecting device; the floating cable connecting device comprises a shell and a top cover, the shell is connected with the top cover in a sealed mode; a cable connecting chamber and cable sealing parts arranged on the two sides of the cable connecting chamber are defined by the shell; the cable sealing part isof a cylindrical structure; the end, away from the cable connecting chamber, of the cable sealing part is connected with a conical sealing block, the cable sealing part matches the conical sealing block in shape, and the conical sealing block is connected with the end face of the shell through a fastening bolt. The waterproof performance and the tensile strength of the connection part of the water floating cable are improved, the cable is prevented from being snapped or leaking electricity, and the cable is suitable for supplying power and communicating with mechanical equipment.

Owner:CHENGDU CHUANLAN CABLE

Electrically conductive buoyant cable

InactiveUS20130062092A1Increase buoyancyGood flexibilityFloating cablesInsulated conductorsFiberElectrical conductor

Disclosed herein is an electrically conductive buoyant cable. The cable includes an electrical conductor member having at least one pair of electrical conductors. The electrical conductors are embedded into a core member. The core member defines a filler layer. A reinforcing member is similarly embedded into the core. The reinforcing member includes strands of reinforcing fibers. The reinforcing members are grouped to support the electrical conductor and prevent delamination. A skin member surrounds the core member and encapsulates the members and prevents water penetration. A tie down member secures each end of the cable while an end cap is fitted over the tie down member. The end cap is sized and shaped for compatible engagement with the desired movable device and a power source.

Owner:SMARTPOOL

Power equipment

The invention relates to power equipment, which comprises a body and an auxiliary structure, wherein the body comprises a cable; the cable is of a multi-layer structure and sequentially comprises a wire, an insulating film, a first filling layer, a first armor layer, a second filling layer, an insect-proof copper strip, a third filling layer, a second armor layer, an anticorrosive coating and an outer sheath layer from inside to outside; and the auxiliary structure at least comprises an auxiliary structure I and an auxiliary structure II. The power equipment is compact in structure, has the advantages of being solid, anticorrosive and durable, and has a wide market prospect.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD SUQIAN POWER SUPPLY BRANCH +2

Floatage signal cable for ocean operation

ActiveCN101145414ALow densityHigh mechanical strengthRubber insulatorsPlastic/resin/waxes insulatorsOcean bottomElectrical conductor

Owner:JIANGSU ZHONGLI GRP CO LTD +3

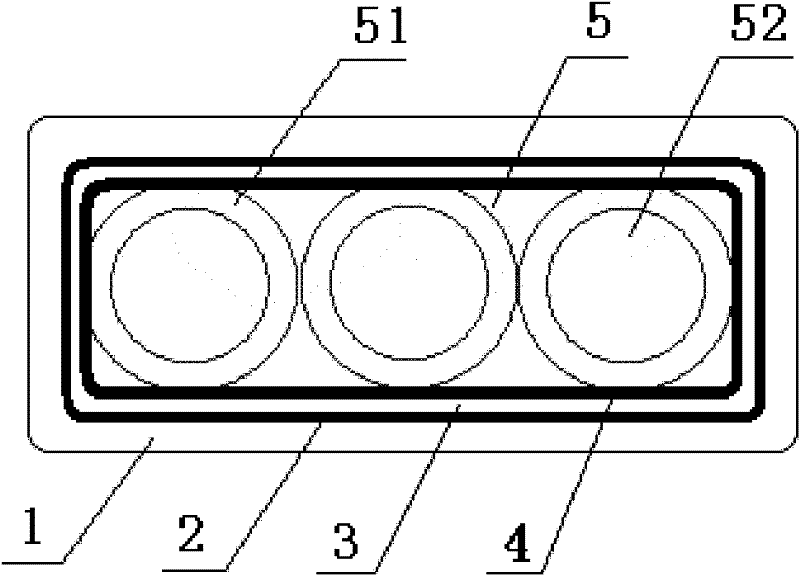

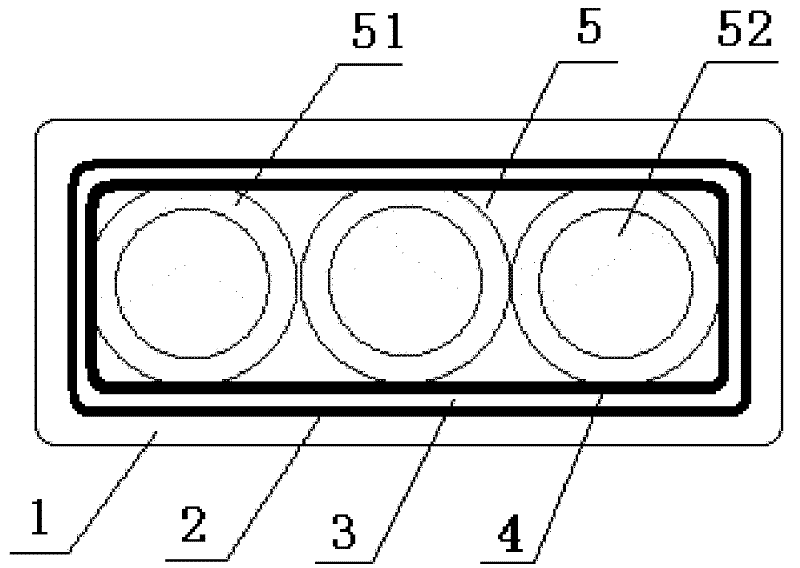

Traveling floating cable for offshore platforms

PendingCN110098003AImprove mechanical propertiesImprove conductivityRubber insulatorsPlastic/resin/waxes insulatorsCopper conductorFiber

The invention discloses a traveling floating cable for offshore platforms, which comprises tin-plated copper conductors. Each tin-plated copper conductor is coated with a cross-linked polyethylene insulating layer. The cross-linked polyethylene insulating layers are coated with a carbon fiber braided shielding layer. A high-strength tensile filling layer is arranged between the cross-linked polyethylene insulating material and the carbon fiber braided shielding layer. The carbon fiber braided shielding layer is coated with a foamed polyethylene filling layer wrapping several control line cores. The foamed polyethylene filling layer is coated with a Kevlar fiber braided strengthening layer. A medium-density polyethylene inner sheath is arranged by extrusion outside the Kevlar fiber braidedstrengthening layer. A foamed polyethylene sheath is arranged by extrusion outside the medium-density polyethylene inner sheath. A medium-density polyethylene outer sheath is arranged by extrusion outside the foamed polyethylene sheath. Compared with traditional cables, the traveling floating cable for offshore platforms in the invention has the advantages of wind-resistant, waterproof, wear-resistant, tensile, light and environment-friendly.

Owner:YUANCHENG CABLE CO LTD

Electrically conductive buoyant cable

InactiveUS20130319721A1Increase buoyancyGreat resistance to tensile stressFloating cablesInsulated conductorsElectrical conductorFilling materials

Disclosed herein is an electrically conductive buoyant cable. The cable includes an electrical conductor member having at least one electrical conductor. The cable also includes a filler layer that consists of buoyant materials with relative density lower than 1. The filler layer surrounds and encloses the electrical conductor member. The invention includes a jacket, which, in one embodiment, contains a small quantity of filler material or no filler material. The jacket surrounds the filler layer. In one embodiment, the filler layer and the jacket are made of the same material.

Owner:SMARTPOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com