Water floating cable

A floating cable and cable connection technology, applied in the field of power cables, can solve the problems of poor waterproof performance and low tensile strength, and achieve the effects of increased friction, good tensile effect and prevention of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

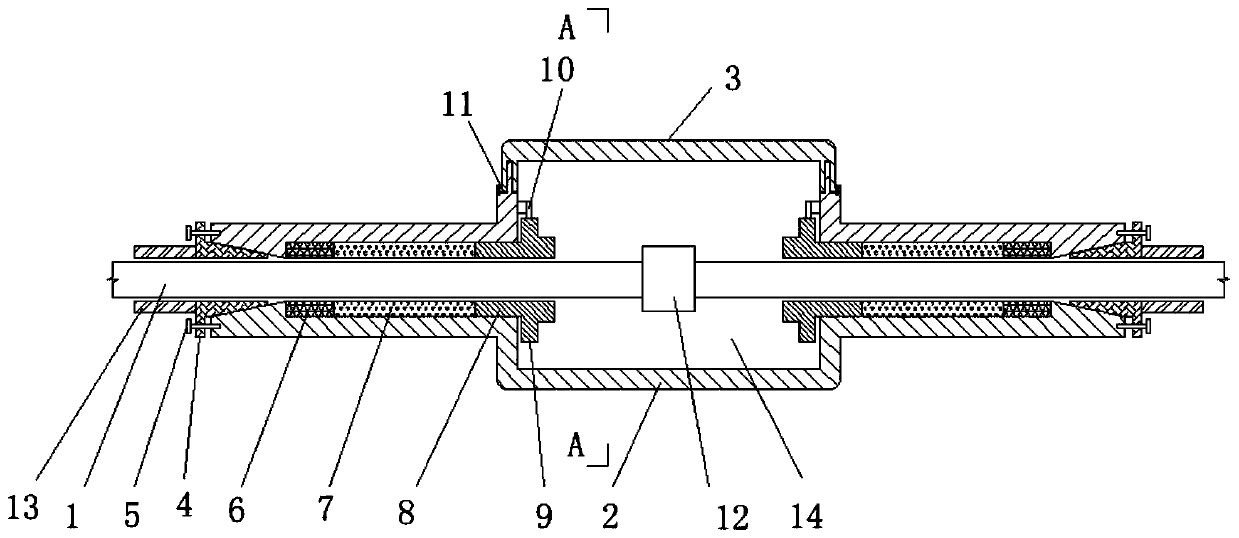

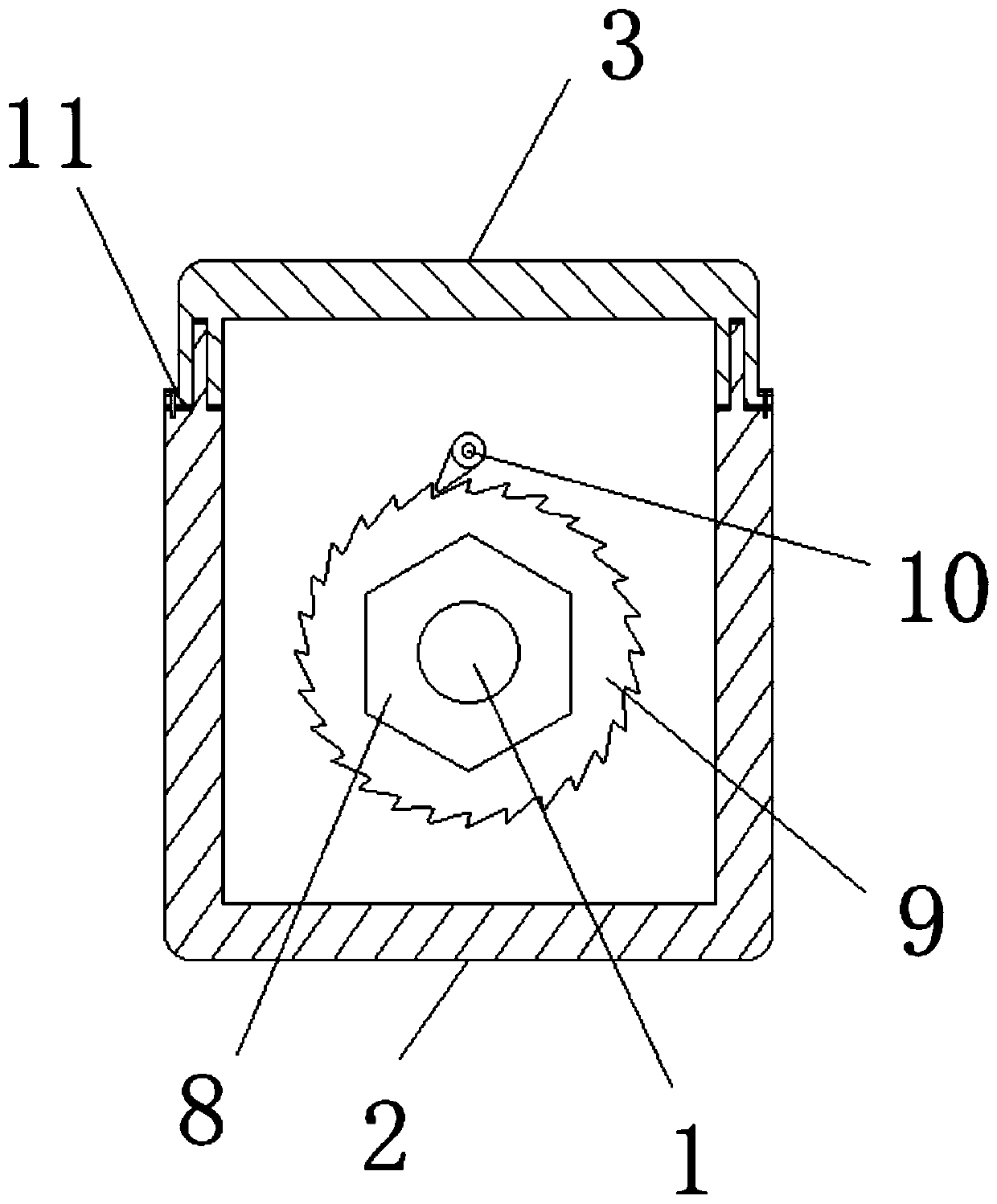

[0047]A floating cable on water includes a cable core, an insulating layer, a waterproof layer, a floating layer, and a floating cable connection device. The floating cable connection device includes a housing 2 and a top cover 3. In this embodiment, a sealing ring is provided between the housing 2 and the top cover 3 and connected by bolts. The casing 2 is integrally formed, and the casing 1 encloses a cable connection chamber 14 and a cable sealing part, and the cable sealing part is arranged on both sides of the cable connection chamber 14 . The cable sealing part is a cylindrical structure and communicates with the cable connection chamber 14 . The end of the cable sealing part away from the cable connection chamber 14 is connected with a tapered sealing block 4, the smaller side of the tapered sealing block 4 faces the cable connecting chamber 14, and the shape of the end of the cable sealing part is also set as a cone. The shape matches the shape of the conical sealing ...

Embodiment 2

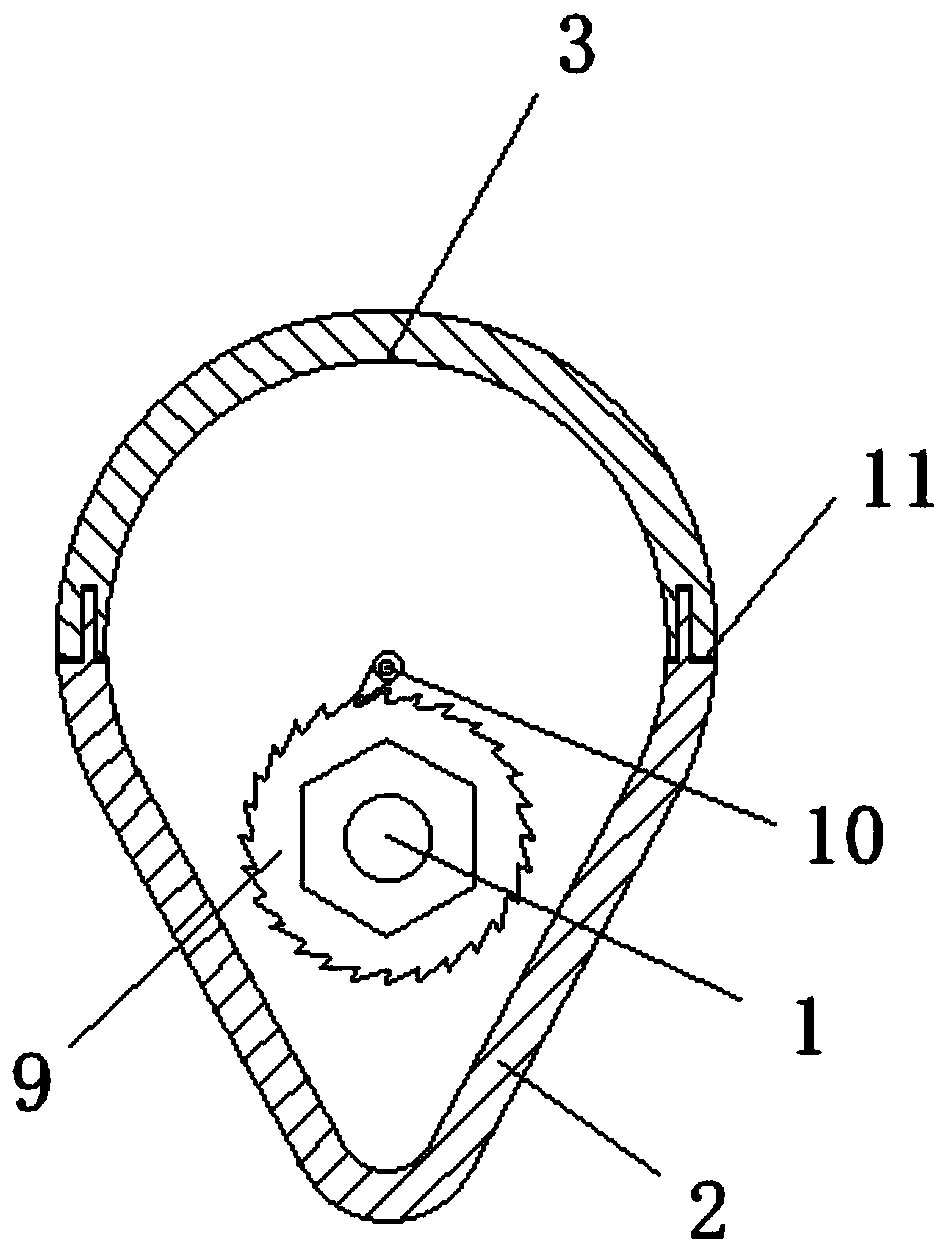

[0057] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that the upper part of the cable connection chamber 14 has an arc-shaped cross-section, the lower part has a V-shaped cross-section, the upper part is a top cover 3, and the lower part is a shell body 2, and the cable sealing part is provided in the lower part of the cable connection chamber 14. This arrangement can make the floating cable connection device float on the water surface, the top cover 3 is always above the water surface, and the top cover 3 is arc-shaped, no water can accumulate on it, and the weight can be reduced.

Embodiment 3

[0059] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that the cross-sectional shape of the cable connection chamber 14 is circular. Such arrangement can make the cable connection chamber 14 have the strongest compressive capacity when the floating cable 1 is in water, and is not easily deformed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com