Floatage signal cable for ocean operation

A signal cable and buoyancy technology, which is applied in the field of signal transmission, can solve problems such as cables, core paralysis, and damage to the core, and achieve the effects of preventing seawater invasion, reliable water blocking protection, and enhancing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

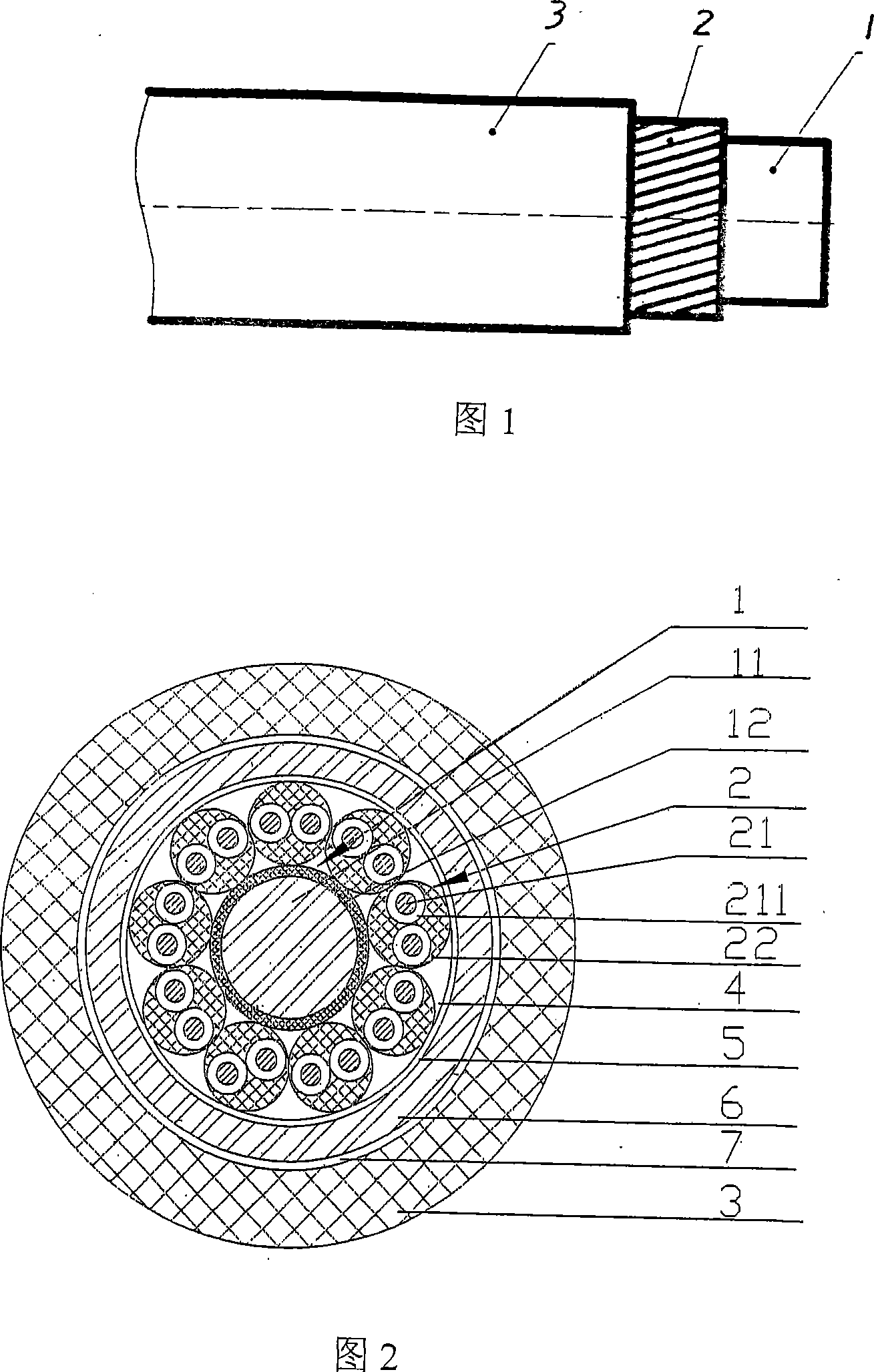

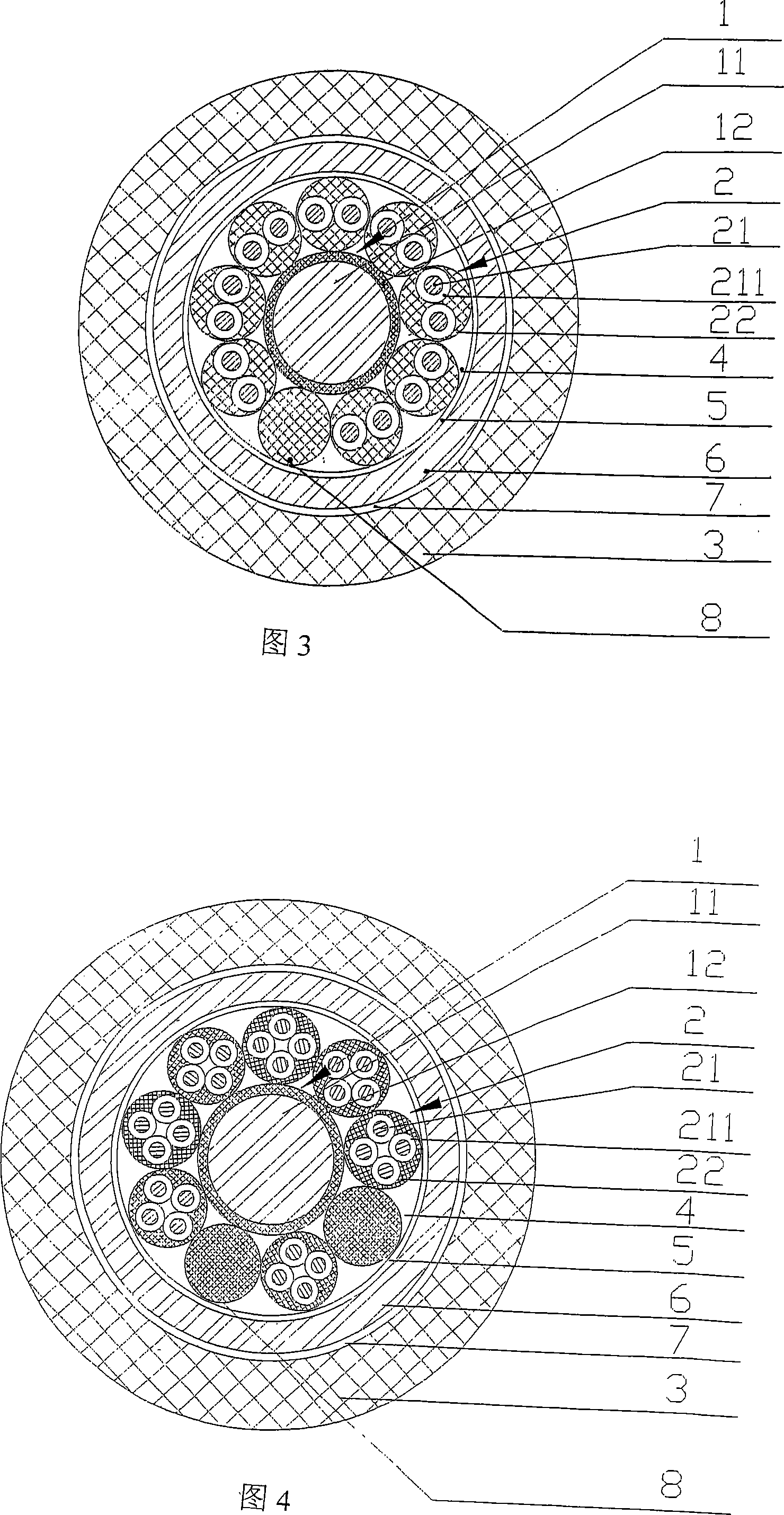

[0022] Please refer to FIG. 2 in detail. It can be clearly seen from the cross-section of the cable structure that the cross-sectional shape of the floating core 1 is a circular floating core 1. The diameter of the floating core 1 is 11.5mm, and the diameter of the floating core is 9.5mm. The fiber body 11 and the first extruded cladding layer 12 with a thickness of 1 mm are formed. As for the material of the fiber body 11, it is preferable and not absolutely limited to use aramid fibers with good strength, more specifically aramid fibers (also called aramid fibers). Kevlar), extruding polyethylene outside the fiber body 11 constitutes the first extruding layer 12, the positive meaning of the first extruding layer 12 can make the fiber body 11 round and round, and the more positive meaning is that it can ensure the follow-up the roundness of the cabling. The extrusion package mentioned here is in terms of the technical term of the processing equipment in the cable production i...

Embodiment 2

[0027] Please refer to FIG. 3, in this embodiment, the applicant provides 8 cores 2 and 1 filler 8, 8 cores 2 and a filler with a circular cross-sectional shape processed from polyethylene The objects 8 are closely arranged in a circle around the outside of the floating core 1 , and a tangential relationship is formed between the cores 2 and between the cores 2 and the filler 8 . It should be noted that when there is a filler 8, there are two quantitative relationships between the filler 8 and the wire core 2. One is that the two are equal, and the other is that the two are inversely proportional. The former is like 5 wires. Core 2 and 5 fillers 8; if the latter has more cores 2, there will be less filler 8, and vice versa. In this embodiment, the conductor 21 is a copper tow wire which is assembled (self-twisted) by 19 tinned copper wires with a diameter of 0.25 mm. The thickness of the fiber layer 6 is 4 mm, and the rest are the same as those described in Example 1. The re...

Embodiment 3

[0029] Please refer to FIG. 4 in detail, only the diameter of the floating core 1 is changed to 14.0mm, wherein the diameter of the fiber body 11 is 12.2mm, the thickness of the first extruded cladding layer 12 is 0.9mm, and the number of cores 2 is changed to 7 , The number of fillers 8 is 2, the material of the conductor 21 of the core 2 is changed to a single (1) annealed bare copper wire with a diameter of 1.0mm, and each core 2 is made of four conductors 21. Extruded insulation layer 211 composed of an insulating core and a second extrusion wrapping layer 22 after twisting the insulating core. The first wrapping layer 5 is made of non-woven fabric, and the second wrapping layer 7 is also made of non-woven fabric. The thickness of the layer 6 is changed to 5 mm, the material of the outer sheath 3 is polypropylene, and the thickness is 4.8-5.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com