Power equipment

A technology of power equipment and cables, which is applied in the direction of power cables, circuits, floating cables, etc., can solve the problems that the installation parts are difficult to deal with, and achieve the effect of changing styles, compact structure, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An electric device includes a main body and an auxiliary structure.

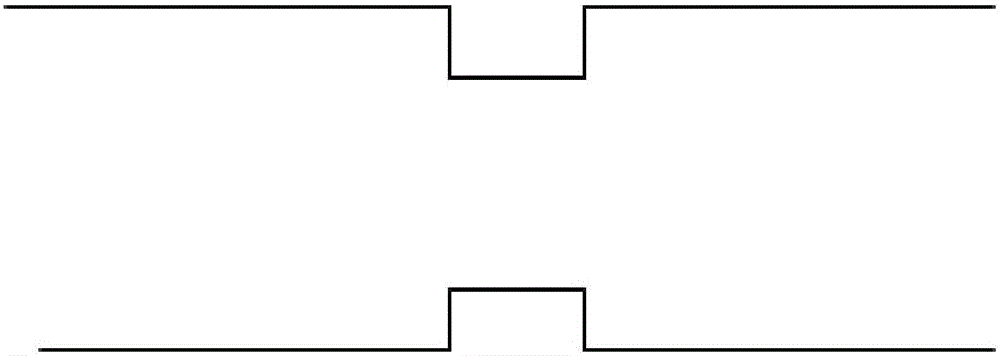

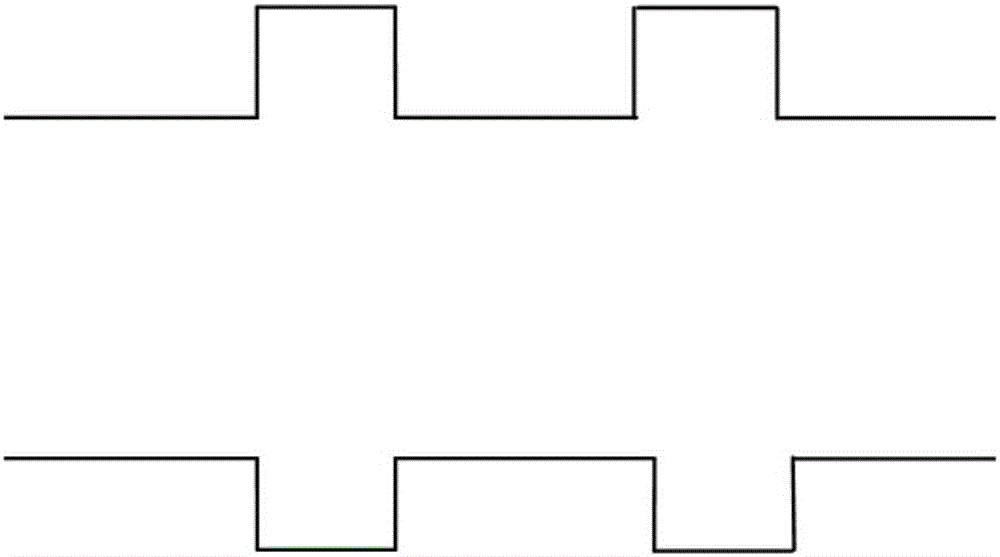

[0036] The body includes a cable; the cable is a multi-layer structure, which sequentially includes a wire, an insulating film, a first filling layer, a first armor layer, a second filling layer, an insect-proof copper tape, and a third filling layer from the inside to the outside , second armor layer, anti-corrosion coating, and outer sheath layer.

[0037] The fillers in the first filling layer and the second filling layer are waterproof and hydrogen-absorbing polyalphaolefins, which have excellent waterproof and hydrogen-absorbing properties, and have multi-layer protection effects on cables.

[0038] The third filling layer is an air-filled hollow layer, and the air-filled hollow layer can adjust the density of the cable, such as making the density greater than, less than or equal to the liquid density in the environment, so that the cable can be better stabilized in the environment , or suspend....

Embodiment 2

[0048] This embodiment is realized on the basis of the foregoing embodiment 1, and mainly introduces the preparation and production method of the cable.

[0049] The preparation and production method of the cable comprises the following steps:

[0050] (1) Conductor stranding, use conductor stranding equipment to strand, obtain conductor cores, conductor cores are reeled by variable diameter cabling machine;

[0051] (2) Extrude, input the wire core on the cable forming machine to the three-layer co-extrusion equipment, wrap the insulating film, obtain the insulated wire core, and pack;

[0052] (3) Forming the first filling layer. A first filling material is coated on the surface of the insulated wire core to form a first filling layer.

[0053] (4) Assembling the first armor layer;

[0054] (5) Forming the second filling layer. A second filling material is coated on the surface of the first armor layer to form a second filling layer.

Embodiment 3

[0063] This embodiment is realized on the basis of the foregoing embodiment 1 or 2, and mainly introduces auxiliary structures.

[0064] The auxiliary structure includes auxiliary structure 1; the function of auxiliary structure 1 is to fix and install the electric equipment, specifically a load-bearing structure compatible with cables and integrated pipes. In humid environments, such as lake bottoms, river bottoms, mud puddles, and seabeds, power cables can be arranged separately or integrated into special pipelines for unified arrangement.

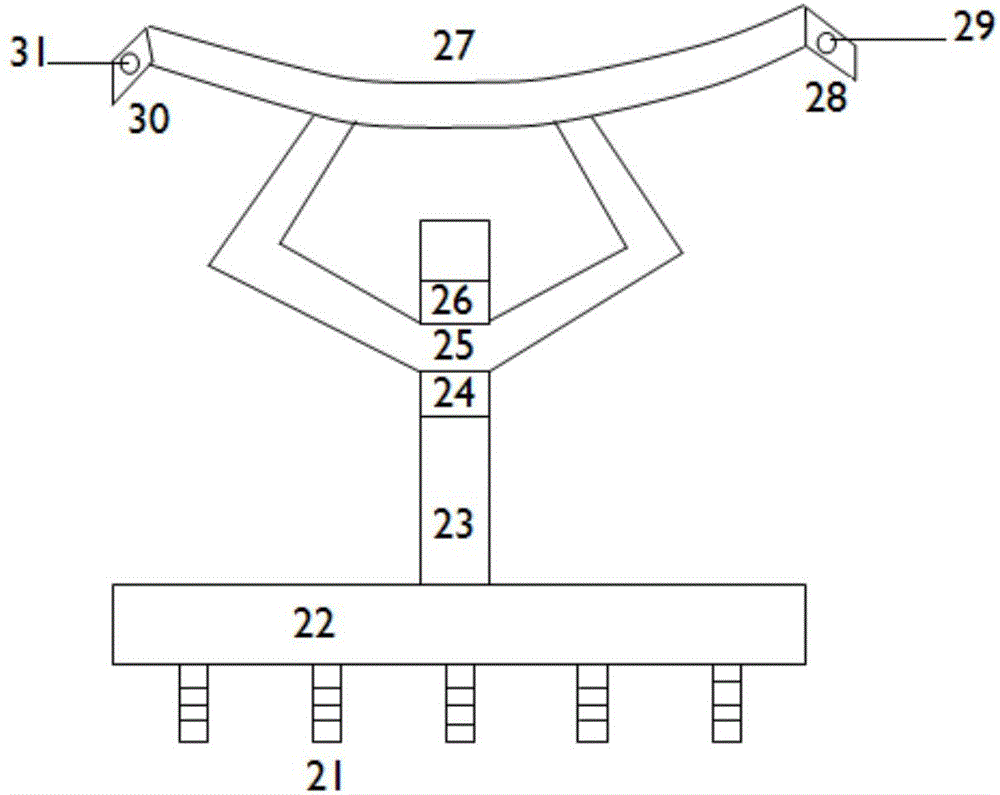

[0065] In order to facilitate the fixing of cables and their integrated pipes, a fixing seat was invented, such as image 3 As shown, the fixed seat includes a base (22), a first component and a second component.

[0066] like image 3 As shown, the bottom end of the base (22) is fixed on the support position such as the ground, the upper end of the base has a platform, and a stud (23) is vertically arranged above the platform, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com