Cable migrating and moving in water

A cable and cable structure technology, applied in the direction of floating cables, etc., can solve problems such as oversize, large resistance, and increased cable weight, and achieve the effects of low cost, light weight, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

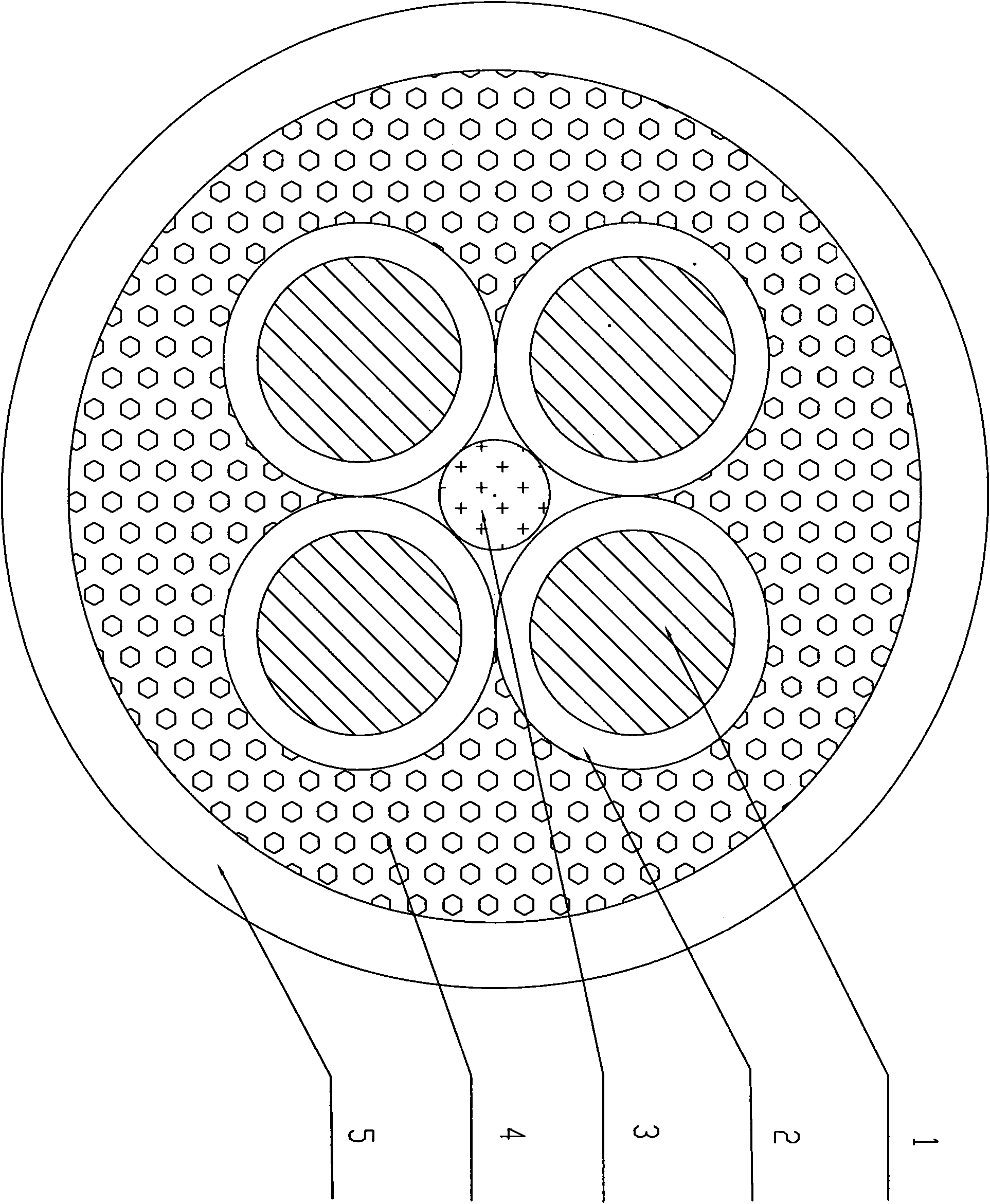

[0016] Please refer to the attached drawing for details. The conductor 1 is made of multiple "copper-clad aluminum wires" thin monofilament bundles or tubes, and multiple twists. The insulating layer 2 is coated and dried with polyimide paint, and the center is filled with 3 "Polypropylene tearing film" is used, which is put in when the insulated core is cabled. The inner sheath 4 is extruded from foamed polyethylene plastic, and the outer sheath 5 is extruded from blue chlorinated polyethylene. become. The number of cores of the insulated wire cores in this embodiment is 4 cores.

Embodiment 2

[0018] Change conductor 1 in Embodiment 1 to "aluminum-clad copper wire" or "copper-clad aluminum-clad copper wire" or "aluminum-clad steel wire" or "aluminum alloy wire" or "aluminum wire" or "copper wire" or strip Any thin monofilament of the plated "copper wire" is twisted to form a conductor, and the rest are the same as the description of "Embodiment 1".

Embodiment 3

[0020] Adopt any kind of fine monofilament twisted conductor in embodiment 1 and embodiment 2, change the insulating layer 2 in embodiment 1 into "acetal paint" or "polyester paint" or "polyurethane paint" or "Polyesterimide paint" or "polyamideimide paint" is coated and dried, or extruded from cross-linked polyethylene, polyethylene, and polyvinyl chloride, and the rest are the same as "Example 1" The instructions are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com