Floating cable

A floating cable and inner sheath technology, applied in the direction of floating cables, insulated cables, cables, etc., can solve the problems of paralysis of conductive cores, difficult to meet the cable, difficult processing, etc., to meet the requirements of frequent bending without damage, convenient Processing and production, the effect of simple internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

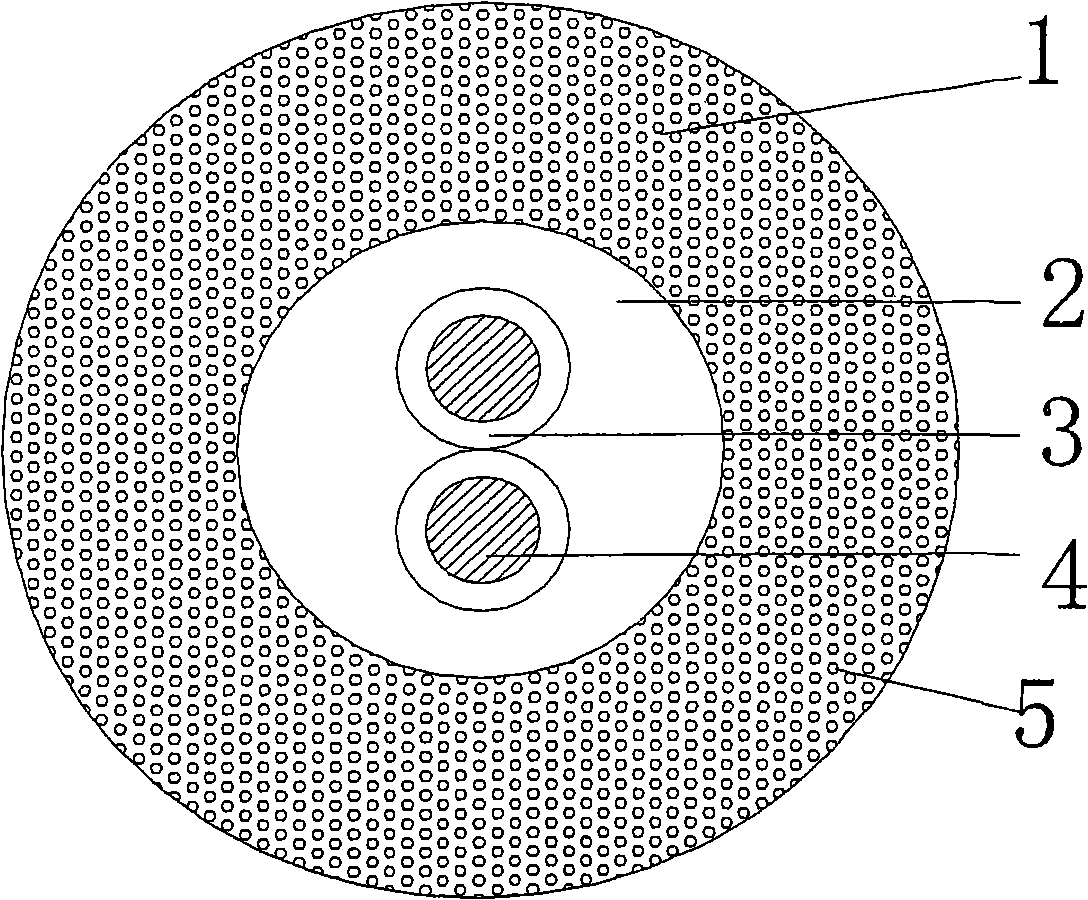

[0021] Please refer to the accompanying drawings in detail. From the profile of the cable structure, that is, the cross section, it can be clearly seen that the conductor 4 is located in the middle. 4 Select the tinned copper wire with a diameter of 0.05mm to twist itself into a bundled wire (also called a bundled wire), and then twist the twisted bundled wires to each other, so as to obtain a twisted wire that is a conductor. On the outside, the equipment commonly used in the wire and cable industry is used to cover polyolefin or polyethylene or polyvinyl chloride material on the outside of the conductor 4 to form a coating insulating sheath 3. In this example, polyvinyl chloride is used, and the thickness of the insulating sheath 3 is controlled at 0.2 ~ 2mm. In this example it is 0.2mm. More specifically, the insulating sheath 3 is extruded outside the conductor 4 shown in the figure to wrap the inner sheath 2. The material of the inner sheath 2 is thermoplastic elastomer T...

Embodiment 2

[0023] The diagram is omitted, only the number of conductors 4 is changed to 5, the material constituting the conductors is changed to an annealed bare copper wire with a diameter of 0.2 mm, the insulating sheath 3 is changed to polyolefin, and the thickness of the insulating sheath 3 is changed to 1 mm. The thickness of cover 2 is changed to 1 mm, the weight ratio of thermoplastic elastomer (TPE): foaming agent: lubricating oil is changed to 100: 1.2: 1.5, and the main component of thermoplastic elastomer (TPE) is changed to styrene block copolymer (SBS), the thickness of outer sheath 1 is changed into 2.5mm, and all the other are all the same as the description to embodiment 1.

Embodiment 3

[0025] The diagram is omitted, only the number of conductor 4 is changed to 1, the material constituting the conductor is changed to an annealed bare copper wire with a diameter of 0.5mm, the insulating sheath 3 is changed to polyethylene, and the thickness of the insulating sheath 3 is changed to 2mm. The thickness of cover 2 is changed to 2 mm, the weight ratio of thermoplastic elastomer (TPE): foaming agent: lubricating oil is changed to 100: 1.5: 2, the thickness of outer sheath 1 is changed to 5 mm, and the rest are the same as in Example 1 description of.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com