Bending-resistant highly-flexible floating cable and manufacturing method thereof

A floating cable, flexible technology, used in cable/conductor manufacturing, floating cable, bendable cable, etc., can solve the problems of floating cable inflexibility, large bending radius of curvature, poor flexibility, etc., to achieve good waterproof and elastic Good recovery performance and improved flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

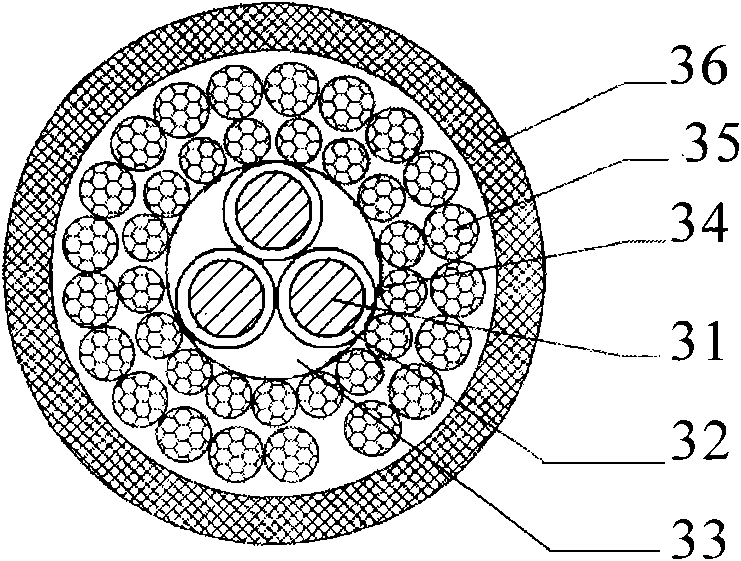

[0052] see Figure 4 , the present invention proposes a flexure-resistant and highly flexible floating cable, which includes a core group 5 , a wrapping layer 6 , a filler 7 , a floating core group 8 , and an outer cladding layer 9 .

[0053] The wire core set 5 includes a conductor 52 and an insulating layer 54 .

[0054] The conductor 52 is formed by twisting tinned annealed copper wires.

[0055] The insulating layer 54 covers the outside of the conductor 52 and is made of hydrogenated styrene-butadiene-styrene block copolymer (SEBS) thermoplastic elastomer, which is excellent in flexibility and resilience.

[0056] The wrapping layer 6 is wound outside the core set 5 .

[0057] The filler 7 is filled between the wire cores and between the wrapping layer 6 and the wire core group 5 .

[0058] The floating core group 8 is wrapped on the outside of the wrapping layer 6. The floating core group 8 is a foam layer made of hydrogenated styrene-butadiene-styrene block copolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com