Offshore floating wind power generation cable

A cable and floating element technology, applied in the field of cables for offshore floating wind power generation, can solve the problems of cable tensile strength, waterproof performance, corrosion resistance, poor flexibility and bending performance, small specific gravity, etc., and achieve salt spray resistance. Excellent, good mechanical properties, excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

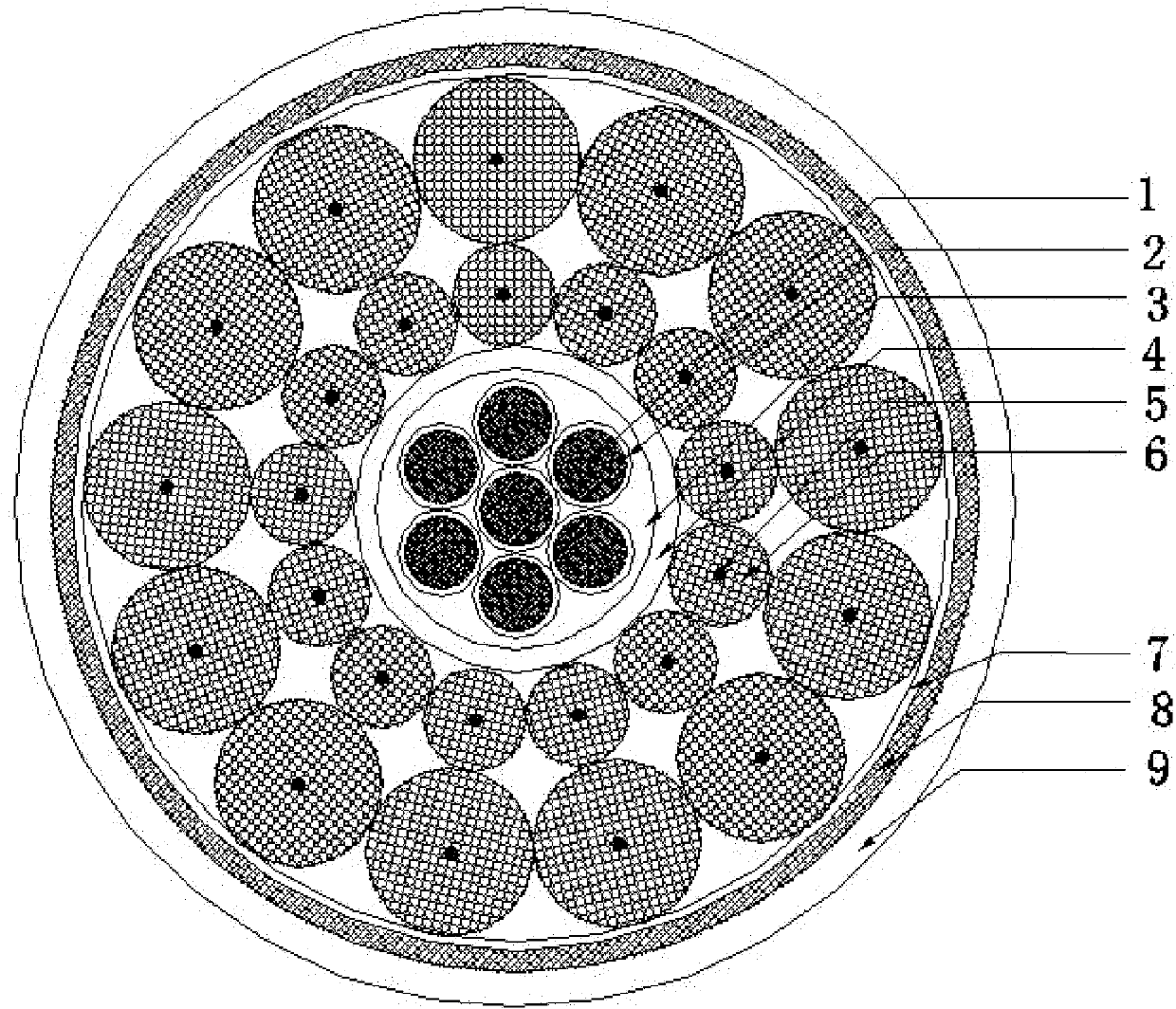

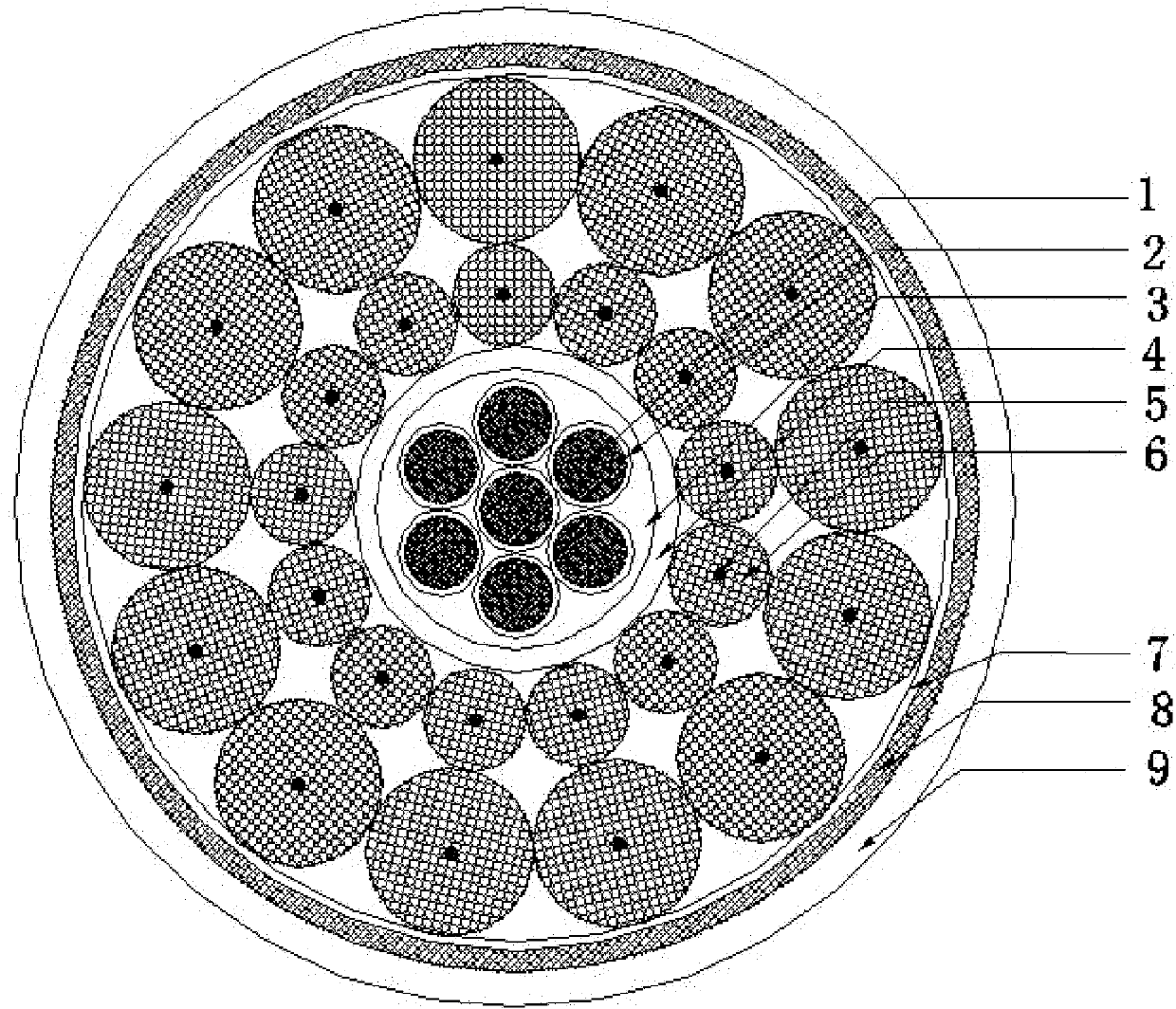

[0034] See figure 1 , This embodiment includes a conductor 1, an insulating layer 2, an inner lining layer 3, an inner sheath 4, a tensile element 5, a floating element 6, a water blocking layer 7, a protective layer 8 and an outer sheath 9.

[0035] Conductor 1 is extruded and covered with insulating layer 2 to form an insulated wire core, and multiple insulated wire cores are twisted into a cable core; conductor 1 is made of tinned annealed copper wire; the pitch ratio of the strand made of copper wire is 15 to 18 times; The inner and outer strands of the double strand are the same as the pitch diameter ratio, and the pitch diameter ratio is 8 to 9 times. The insulating layer 2 adopts TPO material in TPE.

[0036] The inner liner 3 and the inner sheath 4 are sequentially extruded outside the cable core. The inner lining layer 3 is made of TPS material in TPE, and talcum powder is filled between the inner lining layer 3 and the insulated wire core; the inner sheath layer 4 ...

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, except that the floating element 6 is made of polyurethane foam, and the protective layer 8 is made of antimagnetic metal fiber braided fiber braided layer.

Embodiment 3

[0042] This embodiment is basically the same as Embodiment 1, except that the floating element 6 is made of cross-linked polyolefin foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com