Patents

Literature

186results about How to "Strong anti-salt spray performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant, anti-corrosion and thermal-insulation coating and preparation technology thereof

ActiveCN104673063AReduce internal stressImprove high temperature resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentCross linker

The invention discloses a high-temperature-resistant, anti-corrosion and thermal-insulation coating which comprises components in parts by weight as follows: 45-60 parts of film-forming resin, 20-30 parts of a pigment and filler, 15-30 parts of an aid and 25-30 parts of a solvent. The invention further designs a preparation technology of the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The technology comprises steps as follows: firstly, mixing the film-forming resin with the pigment and the filler, sequentially adding an antifoaming agent, a leveling agent, a coupling agent, a crosslinking agent and a curing agent, and evenly stirring the mixture at the normal temperature to obtain the high-temperature-resistant, anti-corrosion and thermal-insulation coating. The coating has the advantages of environment-friendliness, low cost, high hardness, long service life, good heat resistance, good flexibility, good high-temperature resistance and the like.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Glass fibre reinforced nylon colorful heat insulation stripe for al-alloy door & window and method for preparing same

InactiveCN101307147ADifficult to disperseSolve easy discolorationDoors/windowsMasterbatchGlass fiber

The invention discloses a glass fiber reinforced nylon colored insulated strip used for an aluminum alloy door and window. The compositions by weight portion of the glass fiber reinforced nylon colored insulated strip are: 100 portions of nylon resin, 5 to 50 portions of glass fibers, 0 to 50 portions of inorganic filler, 5 to 25 portions of toughening agent, 0.3 to 5 portions of coupling agent, 0.3 to 5 portions of dispersing lubricant, 0.2 to 5 portions of antioxidant, 0.1 to 1 portion of light stabilizer, 0.1 to 1 portion of heat stabilizer and 2 to 10 portions of colored masterbatch. The invention also discloses a method for preparing the colored insulated strip. The glass fiber reinforced nylon colored insulated strip solves the problems that the masterbatch and the filler are difficult to disperse and nylon 66 is easy to change color during the processing procedure; the insulated strip products have various colors, superior performance and beautiful appearance; and the glass fiber reinforced nylon colored insulated strip realizes perfect matching with the window color, can achieve the beautility effect, meets and enlarges the demand of clients and the market, and is favorable for promotion, use and development of the glass fiber reinforced nylon 66 insulated strip.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

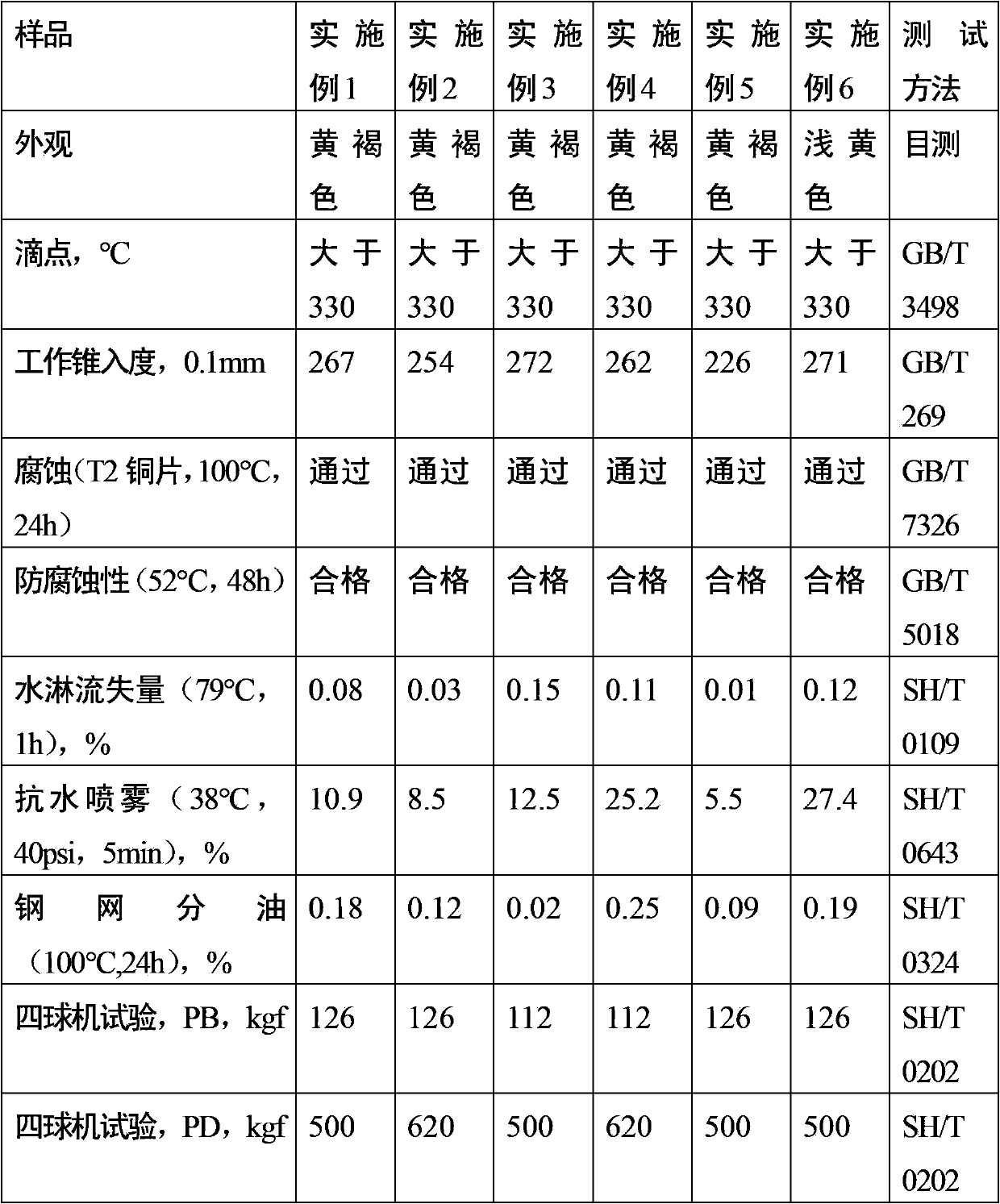

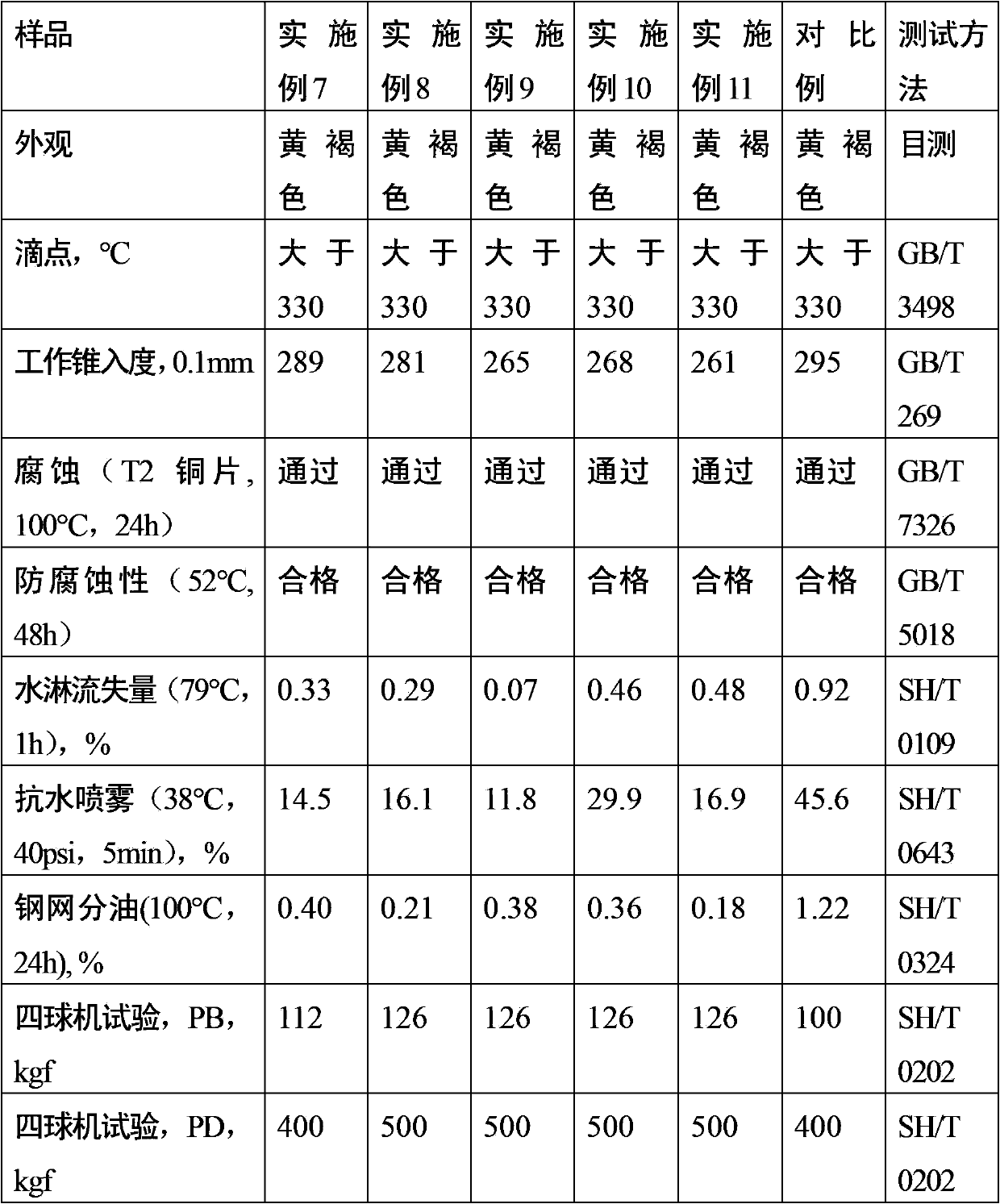

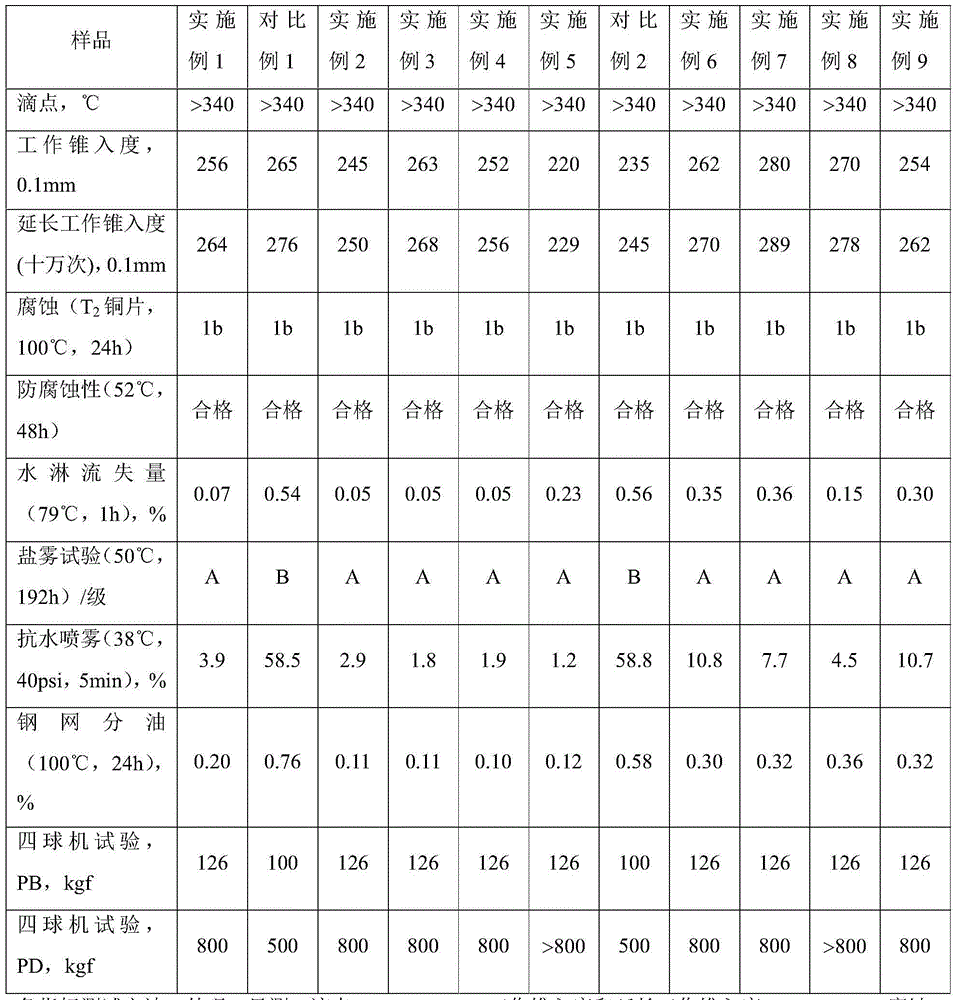

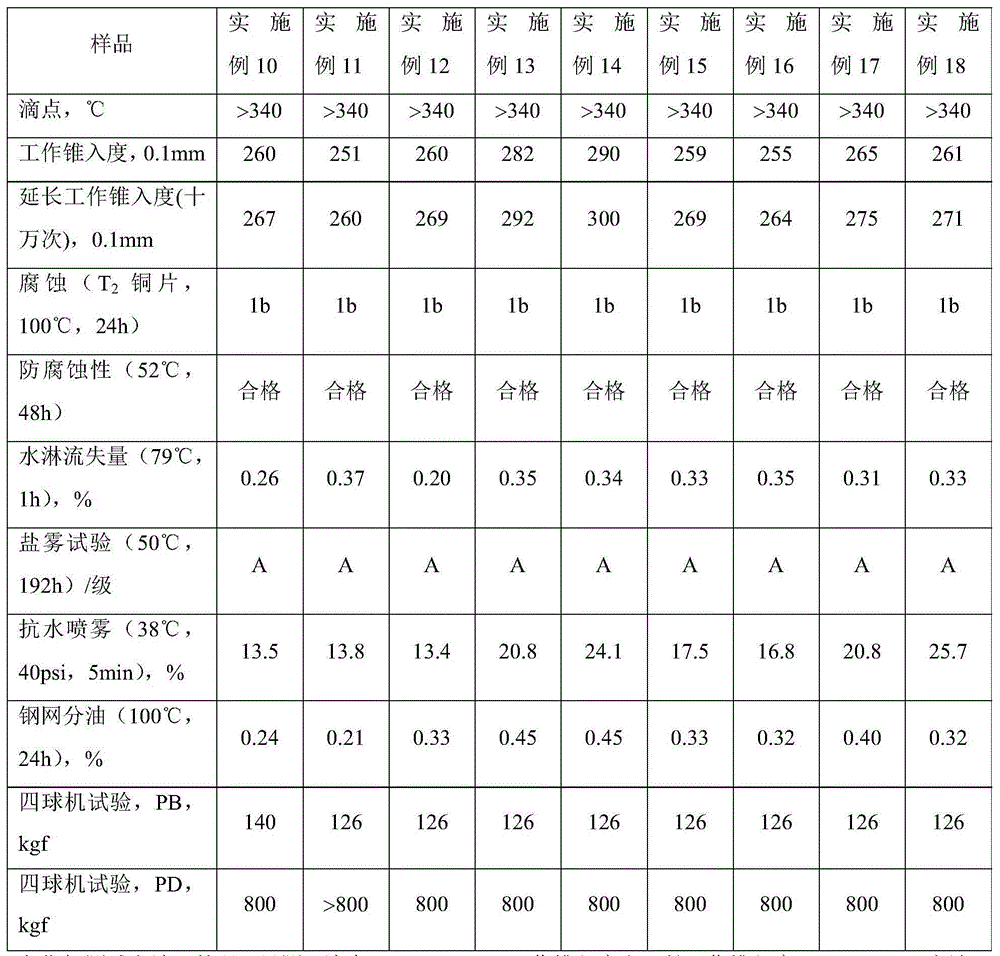

Composite calcium-sulfonate-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN102453599AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersCorrosionSulfonic acid

The invention discloses a composite calcium-sulfonate-based tetrapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 1-10% of higher fatty acid calcium; (3) 1-15% of small-molecule inorganic acid calcium or organic acid calcium; (4) 0.5-30% of tetrapolyurea; and (5) 10-80% of lubricating base oil. According to the lubricating grease, calcium petroleum sulfonate or synthesized calcium sulfonate is adopted as a raw material, and the lubricating oil contains a composite calcium thickening agent and a tetrapolyurea compound. The lubricating grease has excellent extreme pressure wear resistance, ultra-long lubricating life, good adhesion, water resistance, colloid stability, high dropping point, thermal stability, corrosion resistance, and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Universal metallic surface silanization treating agent, preparation and use thereof

InactiveCN101476118ALow costOvercome flammability and explosion hazardsMetallic material coating processesIonChemistry

The invention discloses a versatile metal surface silanization treating agent, a preparing method and an application thereof. The preparing method includes steps as follows: mixing an organic solvent with 5-20 volumes and an silane coupling agent with 5-20 volumes evenly for obtaining the silane main solution, injecting a pre-adjust PH value deionized water with 100 volumes into the silane main solution for obtaining composite mixing solution; controlling temperature of the composite mixing solution in 20-60 DEG C and hydrolysis during 0.5-12 hours; cooling to a room temperature, water phase is the metal surface silanization treating agent after the solution is layered; the organic phase can supply the silane coupling agent and uses repeatedly. The treating agent, the method and the application provided by the invention have advantages of lower cost, safe in utilization, simple manufacturing equipment, convenient for use and wide metal processing range, such as steel, galvanized steel, copper, zinc, aluminium, aluminium alloy and magnesium alloy. The method has better processing effect, strong ability of hydrolytic resistance, washing resistance and salt mist resistance, longer protective period for metal, and increases and enhances fact application value of the silanization treating technique, helps the development of the metal surface silanization treating technique industrialization.

Owner:HUNAN UNIV

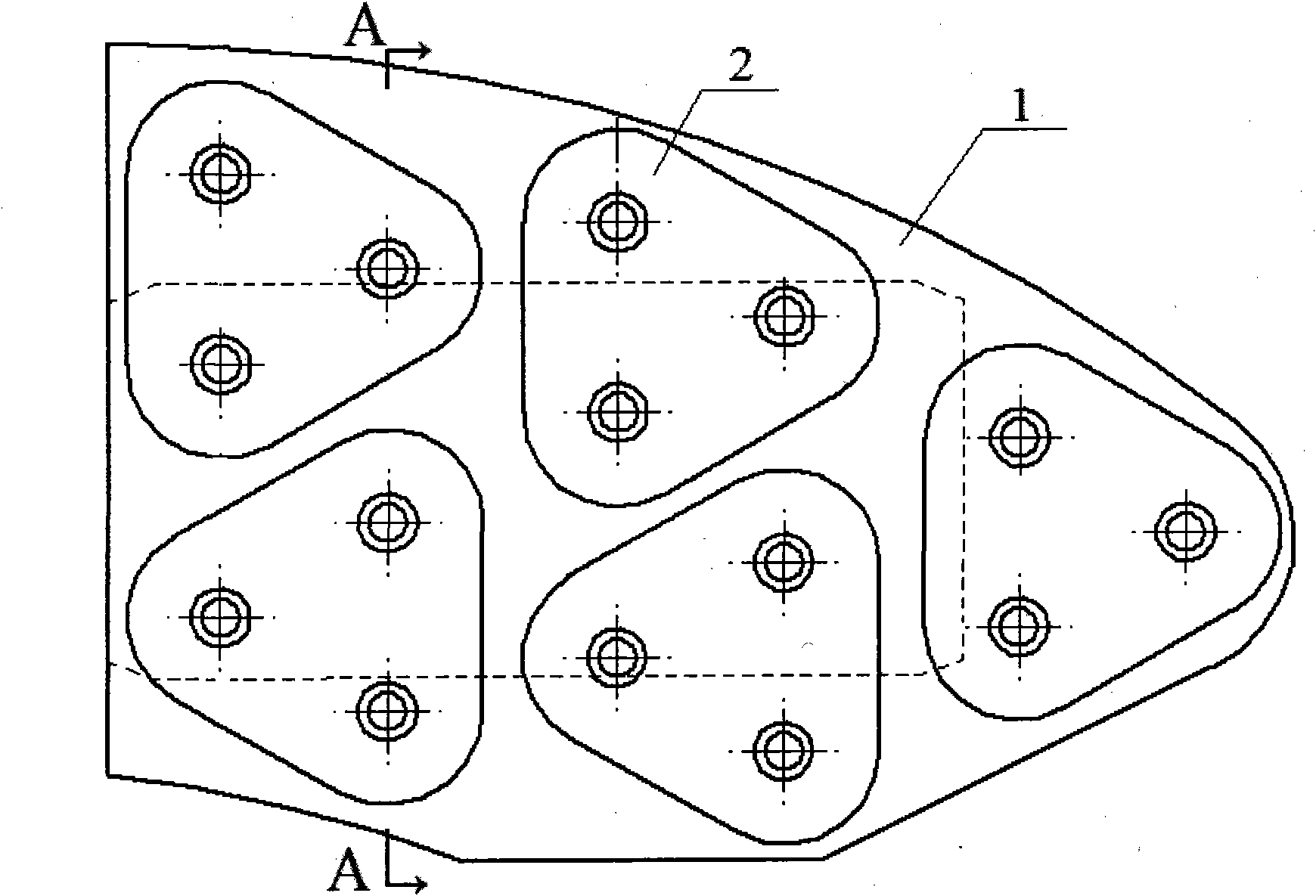

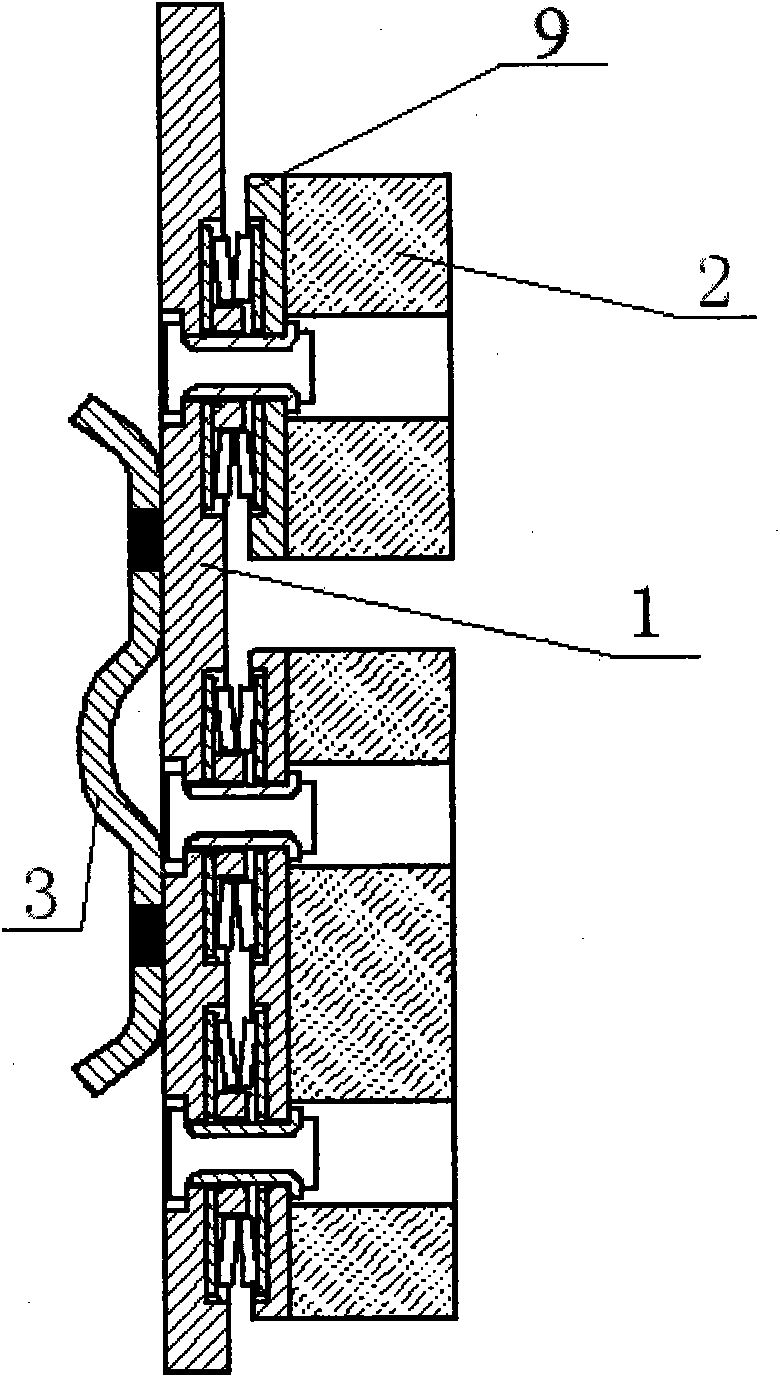

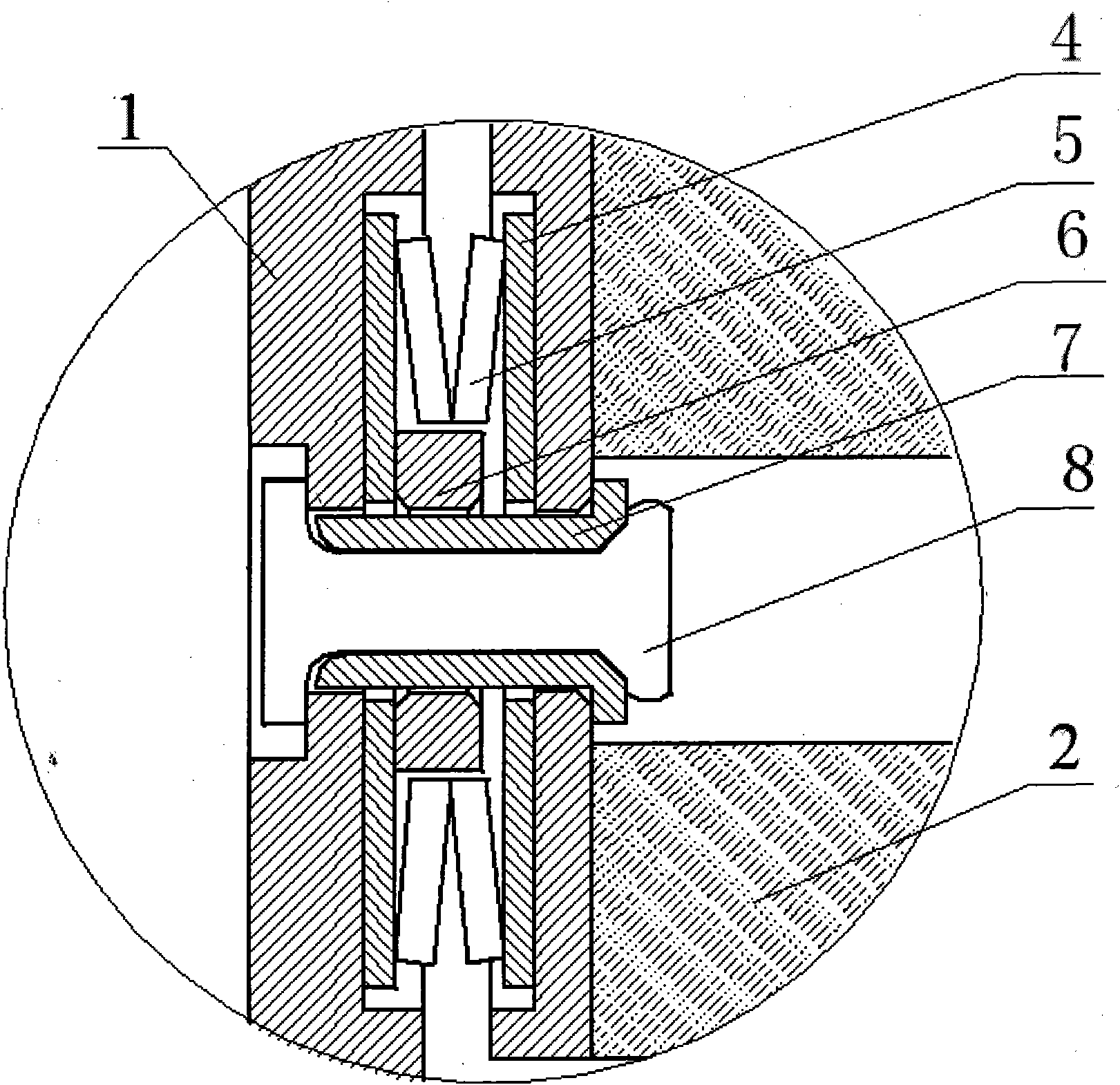

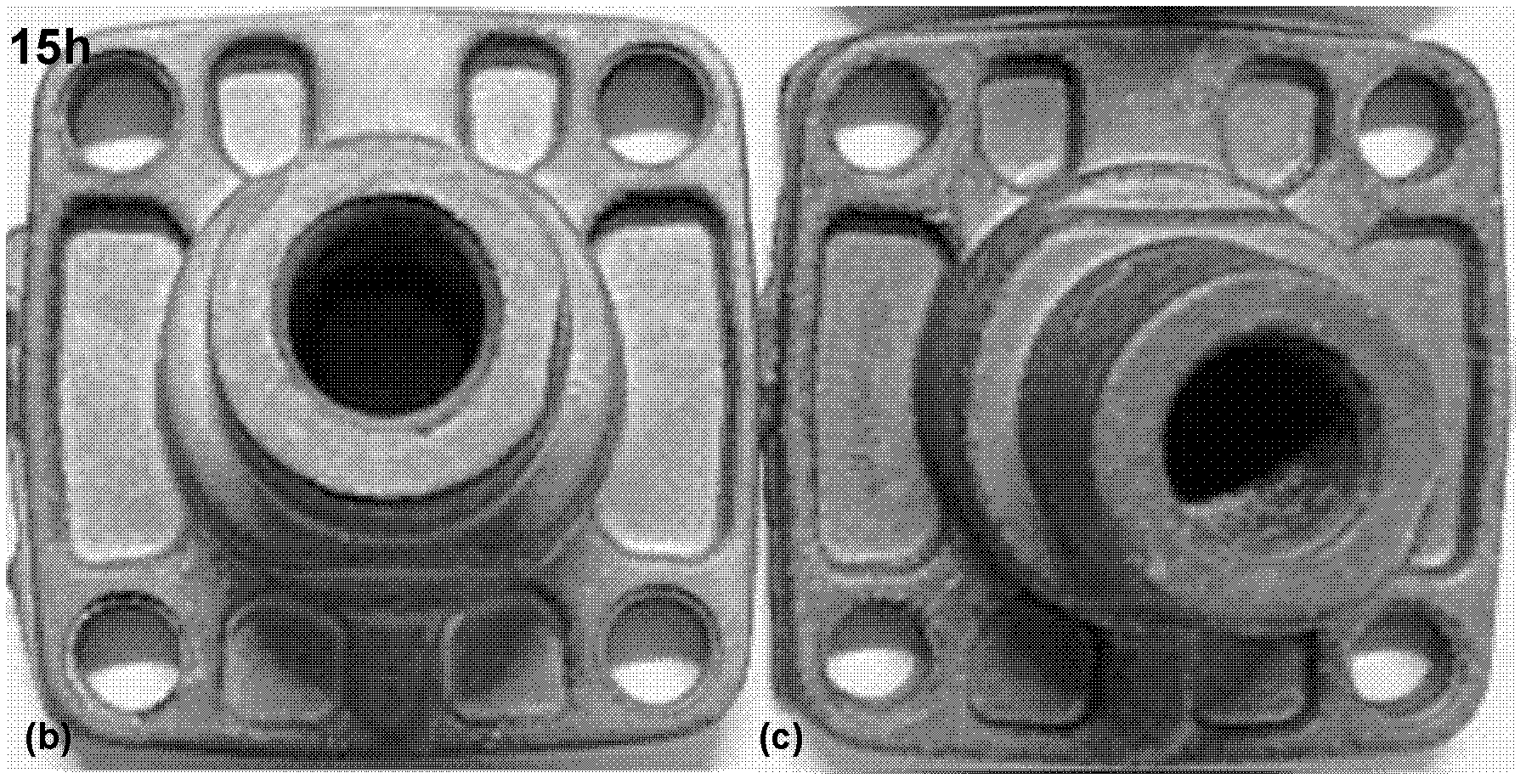

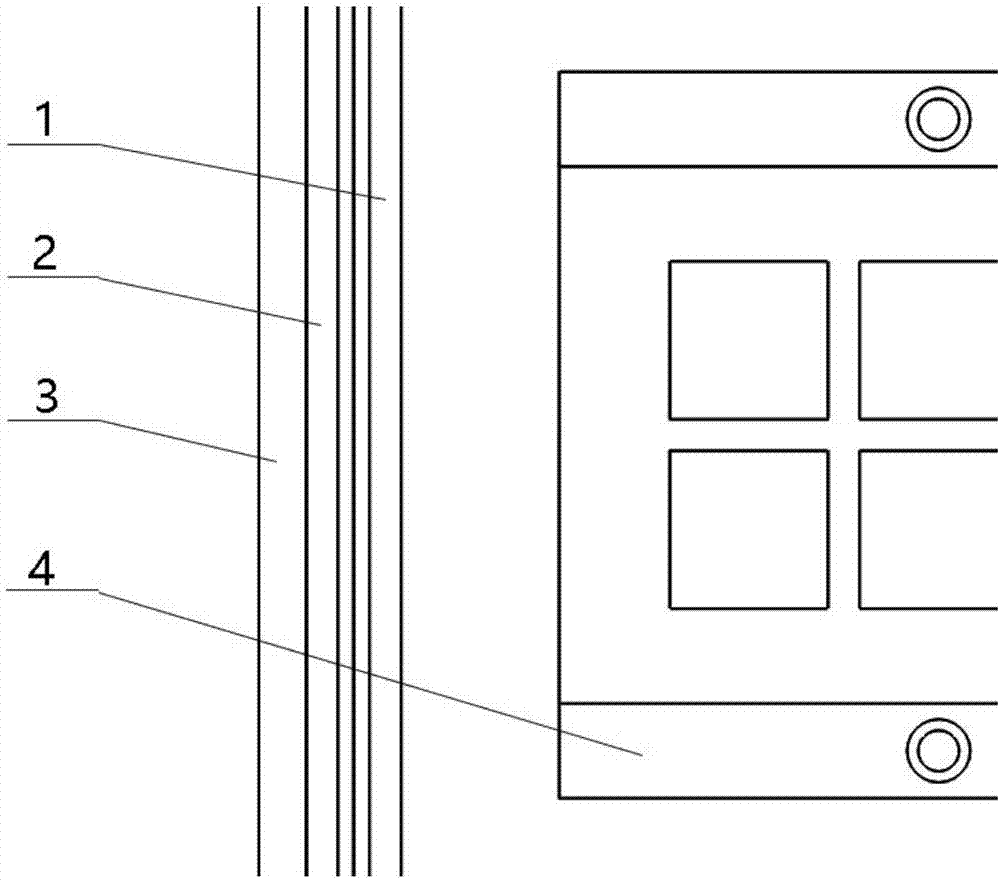

High-speed brake lining with elastic structure

ActiveCN102107665AHigh mechanical strengthReduce wearBrakes for specific applicationsEngineeringThermal stability

The invention provides an elastic high-speed brake lining, consisting of a steel backing (1), a brake block (2), a dovetail plate (3), a gasket (4), a disk spring (5), a guide sleeve (6), a bushing (7) and a rivet (8). The elastic structure high-speed brake lining provided by the invention has the advantages of high mechanical strength, small wearing capacity, stable friction performance, good thermal stability, good heat conductive performance, high dynamic moment and static moment, no noise, seawater corrosion resistance, sand wind prevention, excellent salt mist resistance and the like. Due to the elastic structure, the brake block of the high-speed brake lining is protected from eccentric wear caused by insufficient contact of the brake block of the high-speed brake lining and the surface of a brake disc, so that a high-speed train can brake smoothly, and the braking distance is short.

Owner:贵州新安航空机械有限责任公司

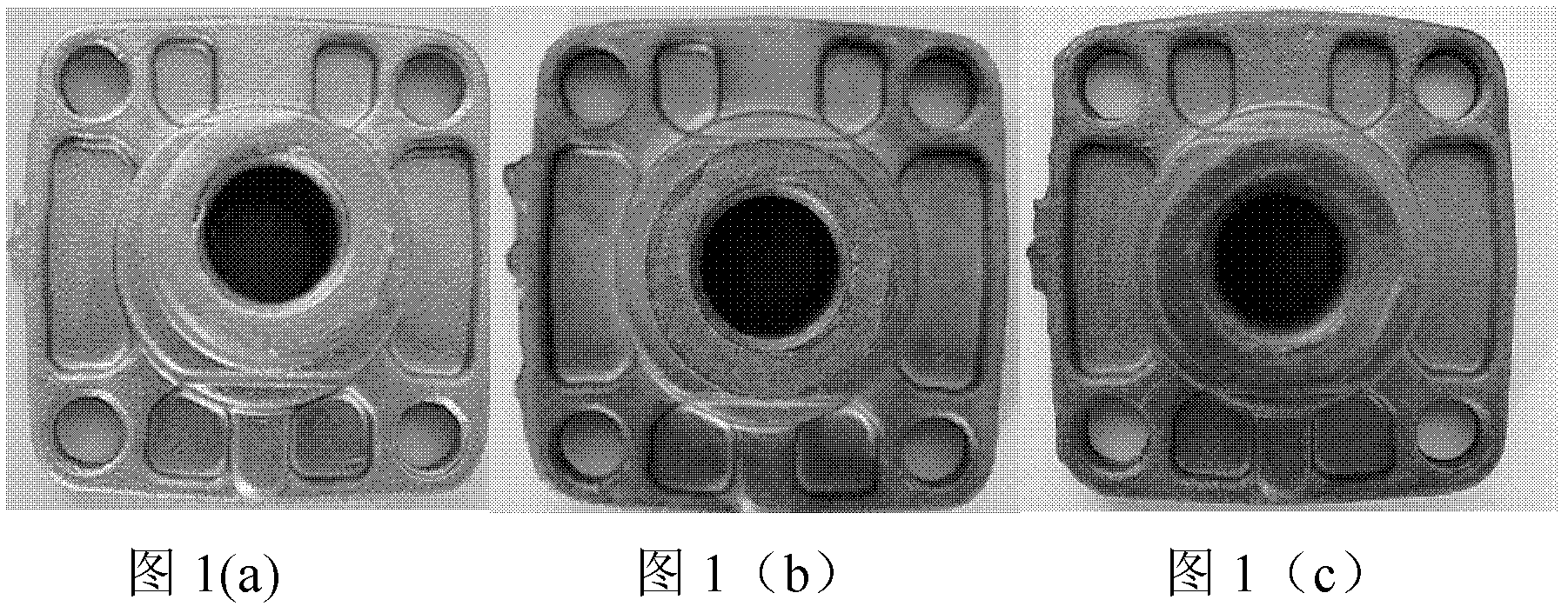

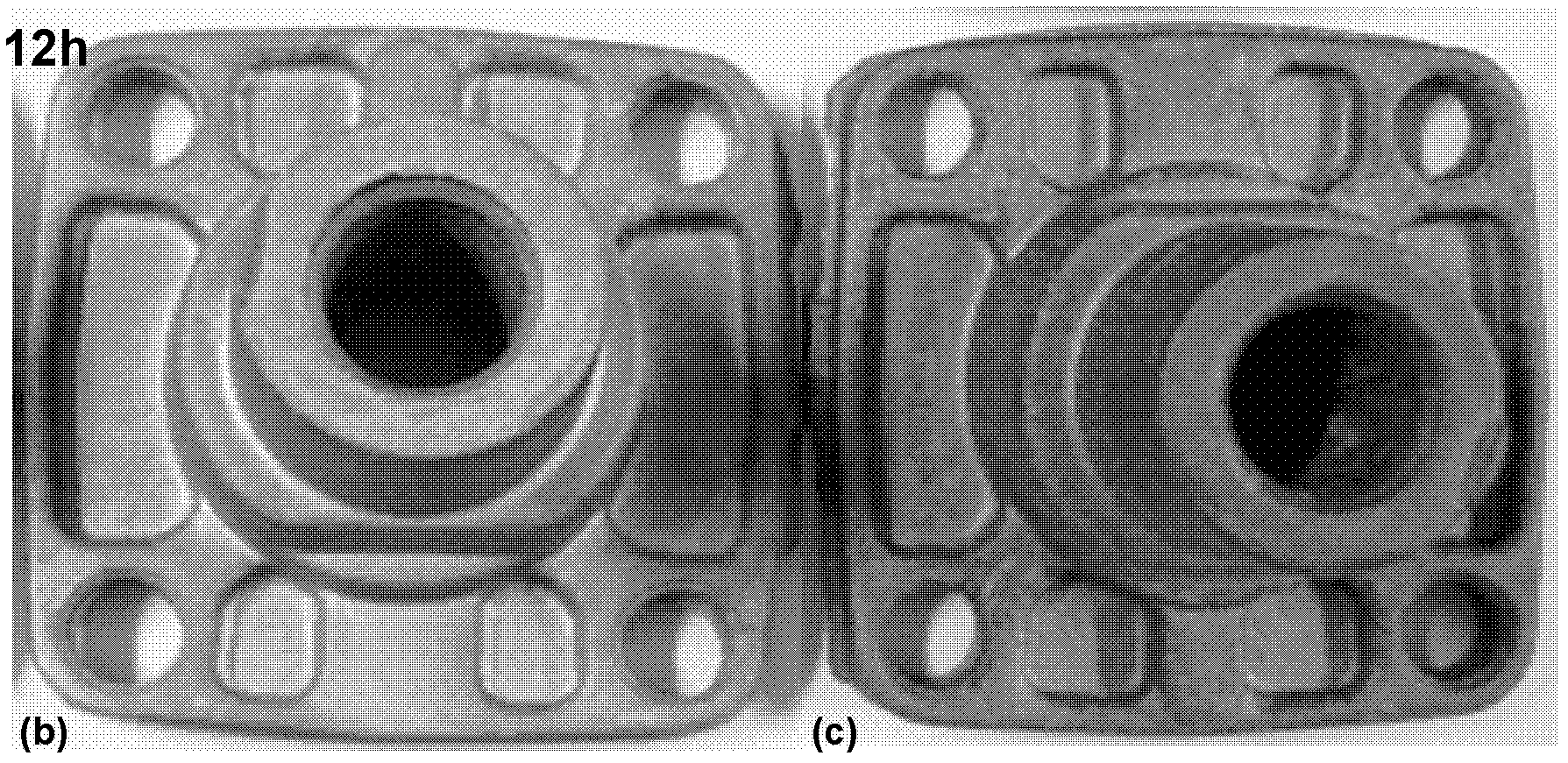

Chromium-free rare-earth environment-friendly chemical conversion treatment method of die casting aluminium alloy part

InactiveCN102212812AImproved salt spray resistanceImprove corrosion resistanceMetallic material coating processesHuman healthHexavalent chromium

The invention relates to a chromium-free environment-friendly chemical conversion treatment process of a die casting aluminium alloy part, comprising the steps of: surface sand-blasting treatment of the die casting aluminium alloy part, surface pre-treatment of the die casting aluminium alloy part, preparation of a chromium-free environment-friendly conversion solution, chemical conversion treatment, and sealing treatment after the chemical conversion treatment. One composition of a chemical conversion coating layer is oxide of tetravalent cerium. The chemical conversion coating layer is uniform and tawny with the thickness about 2 mum. The chemical conversion coating layer prepared with the method has an excellent corrosion resisting property, is on a par with a trivalent chromium chemical conversion coating, and has high binding strength with a matrix. Products or discharges after the chemical conversion treatment do not contain hexavalent chromium, which is harmful to the environment and human health.

Owner:UNIV OF SCI & TECH BEIJING +1

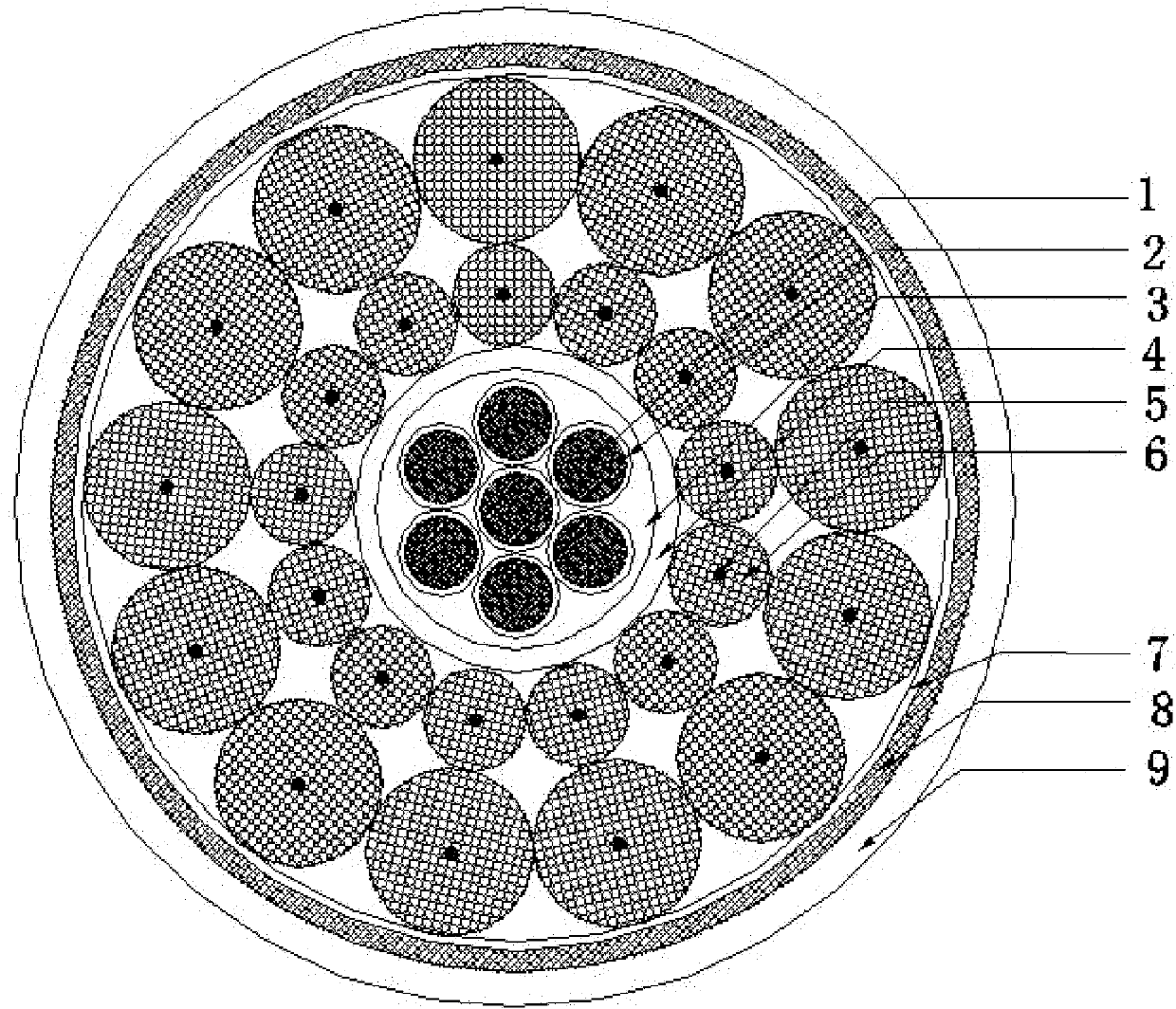

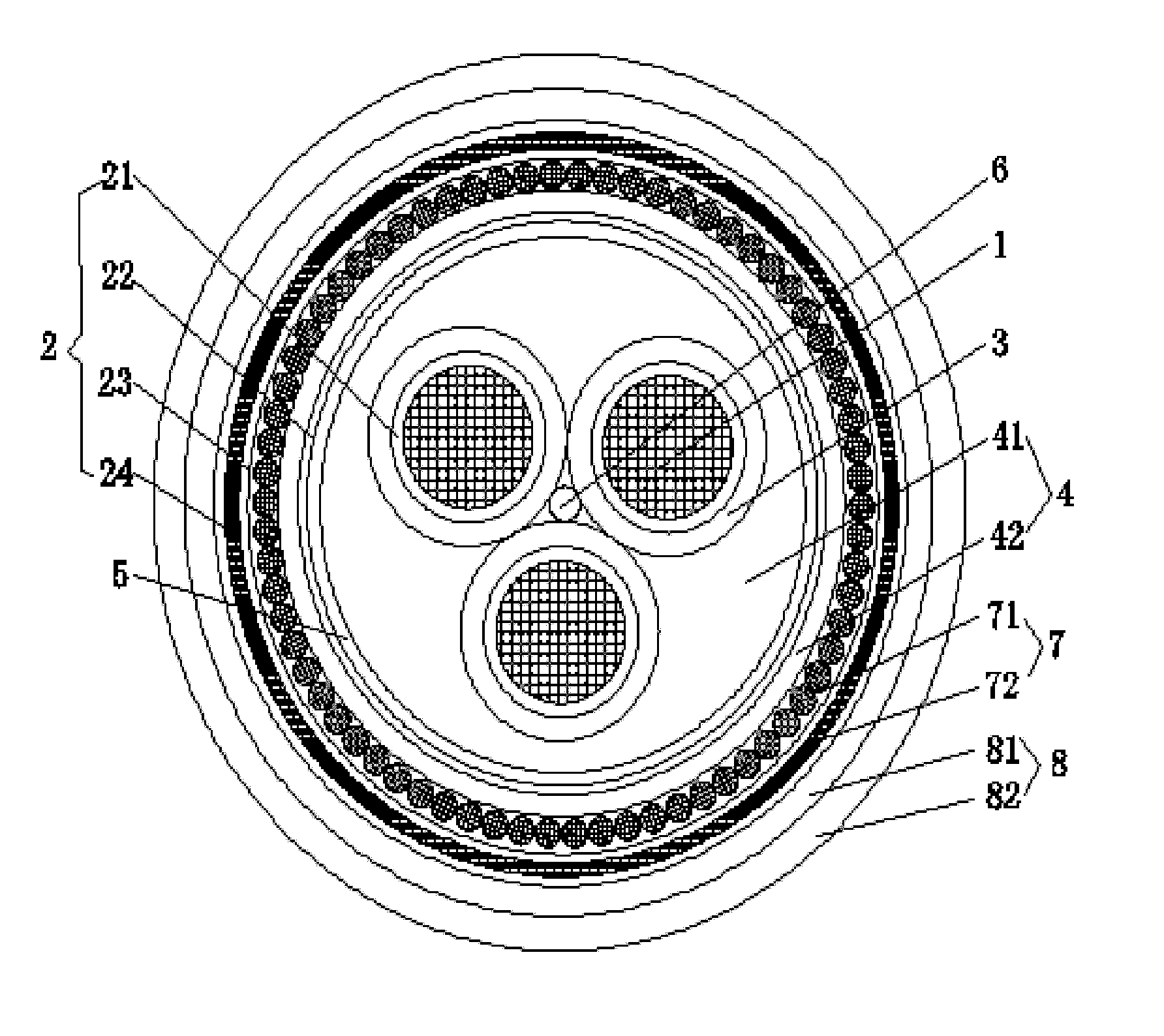

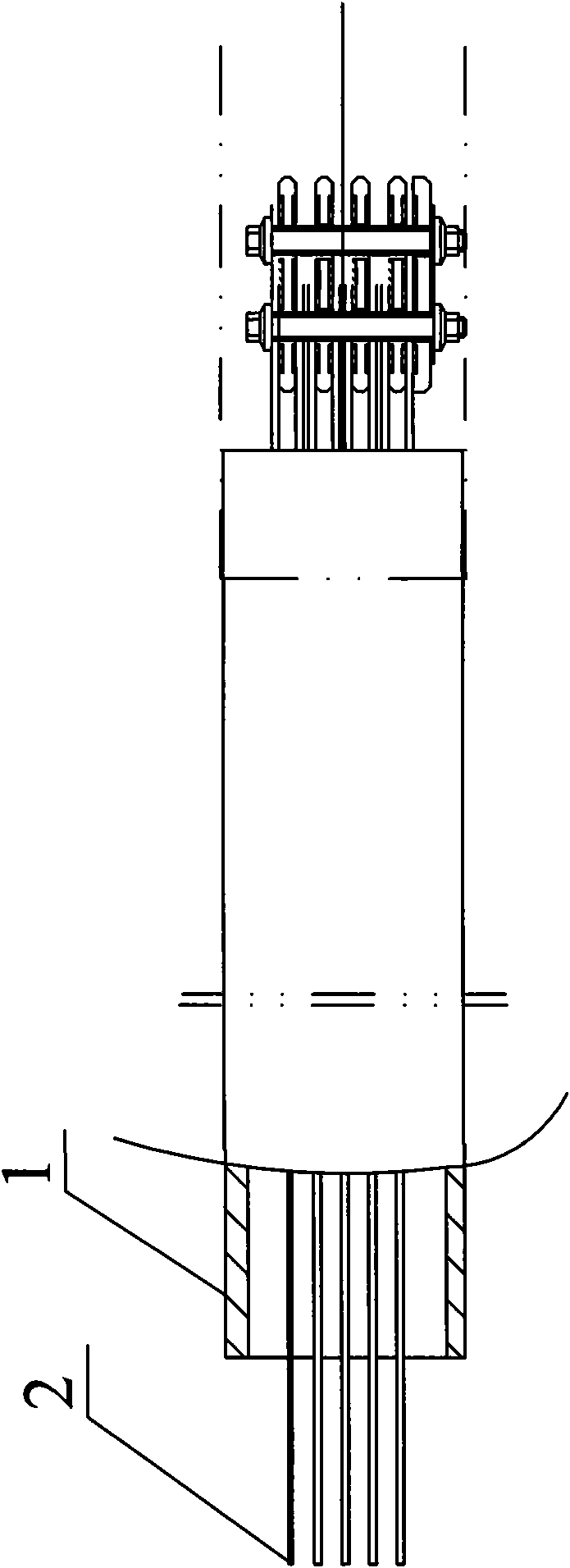

Offshore floating wind power generation cable

ActiveCN101996708AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFloating cablesPolyolefinElectrical conductor

The invention discloses an offshore floating wind power generation cable, which comprises conductors, insulating layers, an inner lining layer, an inner protection layer, tensile components, floating components, a waterproof layer, protective layers and an outer sheath, wherein the conductor is coated with the insulating layer by way of extrusion so as to form insulating wire cores, and a plurality of insulating wire cores are stranded into a cable core; the cable core is respectively coated with the inner lining layer and the inner protection layer by way of extrusion; two protective layers are wound outside the inner protection layer, each protective layer consists of a plurality of protective elements which are arranged in the shape of circle, and each protective element is formed by coating the tensile component with the floating component by way of extrusion; the two protective layers are respectively coated with the waterproof layer, the protective layer and the outer sheath by way of outward extrusion; the insulating layers and the inner lining layer are made of thermoplastic elastomeric materials by way of extrusion; and the insulating layer is made of thermoplastic polyolefin (TPO) materials in thermoplastic elastomer (TPE), and the inner lining layer is made of toughened polystyrene (TPS) materials in TPE. The wind power generation cable of the invention has the advantages of low temperature resistance, bending resistance, torsion resistance, abrasion resistance, water blocking, corrosion resistance, weather fastness, high tensile strength, and capability of effectively preventing the damages of stormy waves and other floaters over the sea to the cables.

Owner:FAR EAST CABLE +2

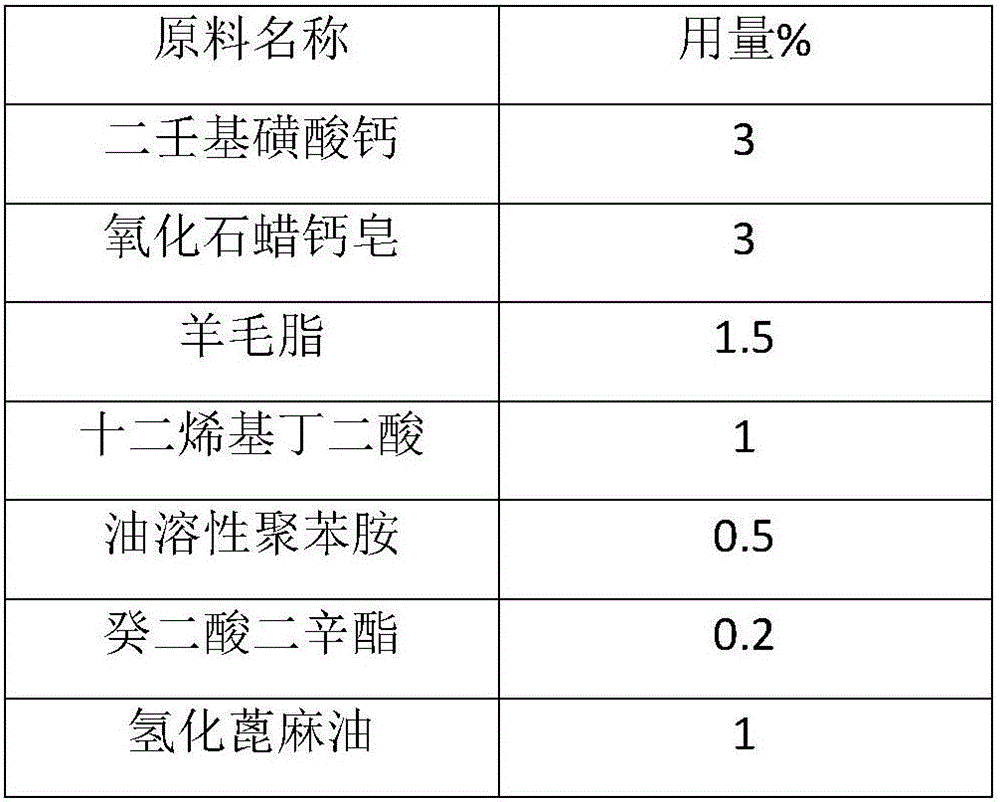

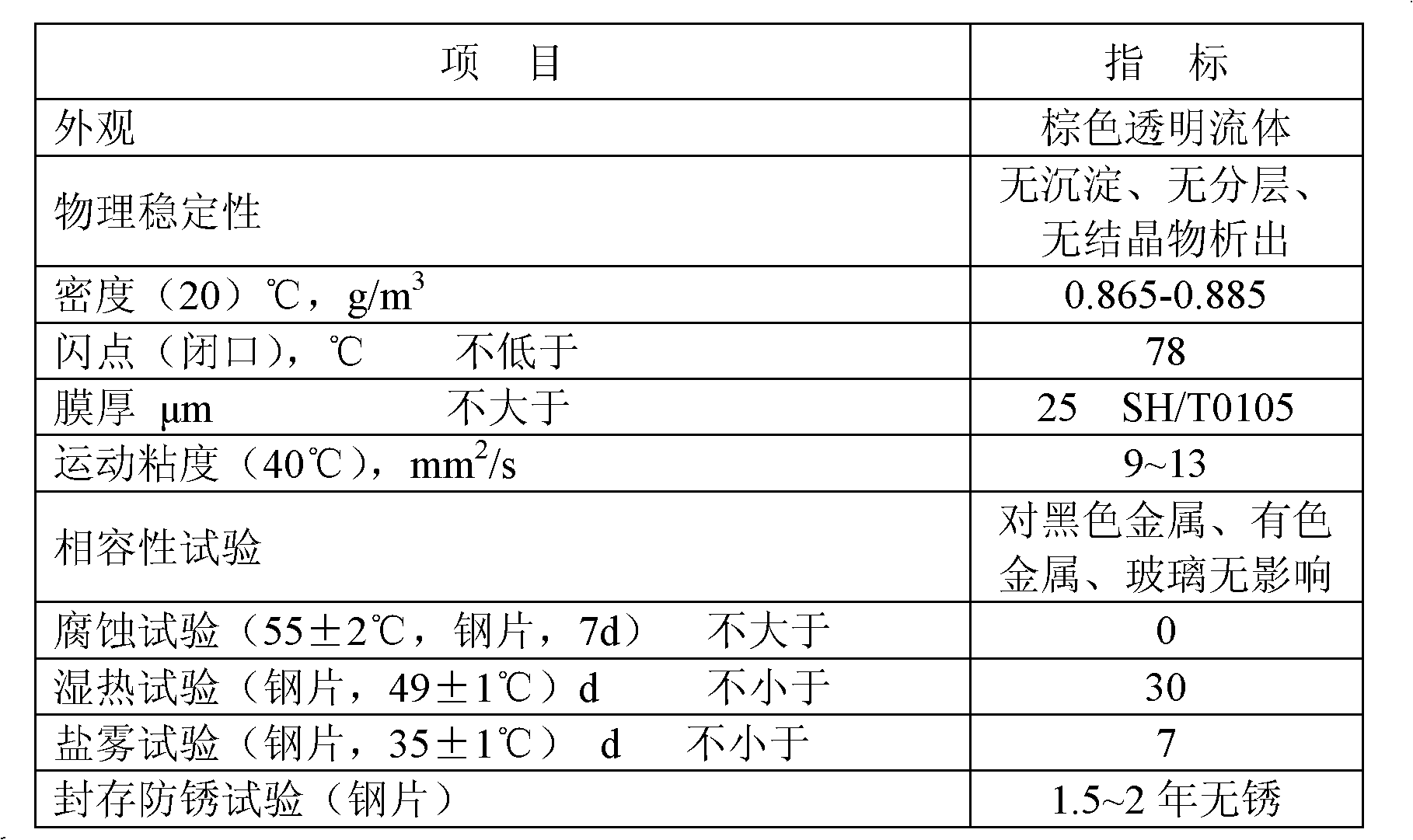

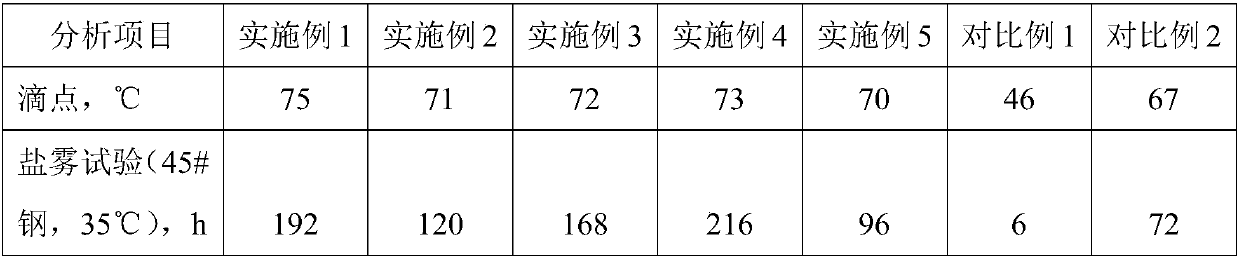

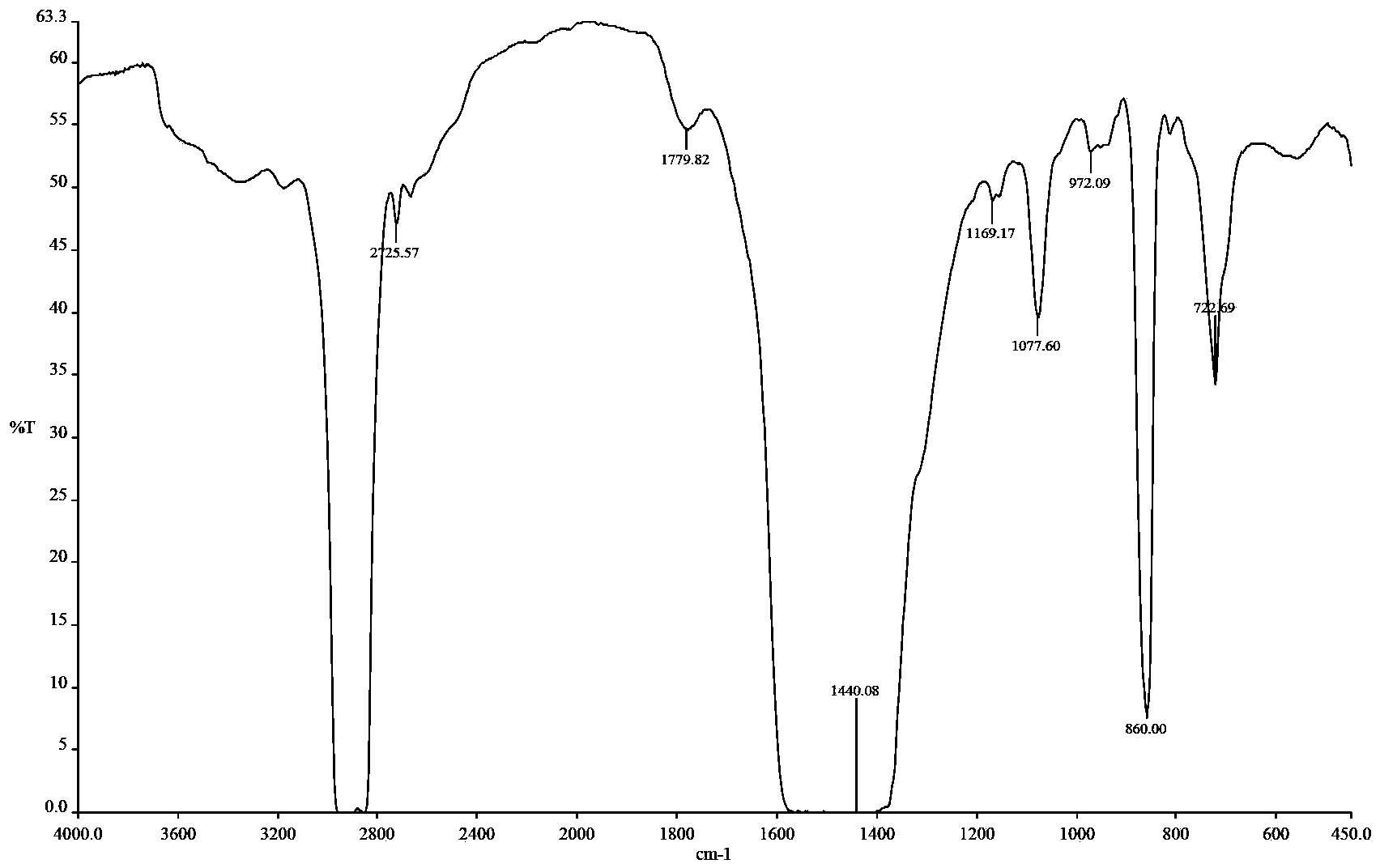

Solvent type thixotropic anti-rust oil and preparation method thereof

InactiveCN106221880ALess overall consumptionImprove thixotropyLubricant compositionFilm-forming agentSolvent

The invention relates to anti-rust oil for steel corrosion protection and a preparation method of anti-rust oil, in particular to solvent type thixotropic anti-rust oil and a preparation method thereof and belongs to the field of metal protection. The solvent type thixotropic anti-rust oil is prepared from components including, by weight, 5-30% of an anti-rust agent, 0.1-5% of a thixotropic agent, 0.1-5% of a film-forming agent, 0.1-3% of a coalescing agent, 5-20% of the base oil and the balance of dearomatization solvent oil. The thixotropic agent is combined with oil-soluble polyaniline, so that good salt fog resistance of the anti-rust oil is achieved, and time for salt fog can reach more than 400 hours.

Owner:NANJING KERUN NEW MATERIAL TECH

Compsn. of rust inhibiting lubricant special for chain

InactiveCN1415713AGood rust resistanceExcellent extreme pressure and wear resistanceAdditivesEnvironmental chemistryP-Cresol

A composite antirust hebricant for chain contains sulfonate as antirust agent, olefine butanedioic acid type antirust agent, dialkyldithiophosphate-formaldehyde-lipoamin condensate, plant oil, phenyltriazole lipoamine salt, polyisobutylene, vaseline, 2,6-ditert-butyl p-cresol, and basic oil. Its advantages are excellent resistance to rust, salt fog and abrasion, high adhesive, and good water displacing nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

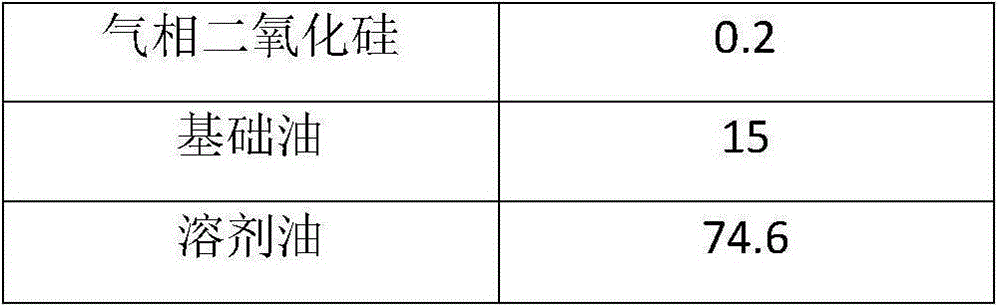

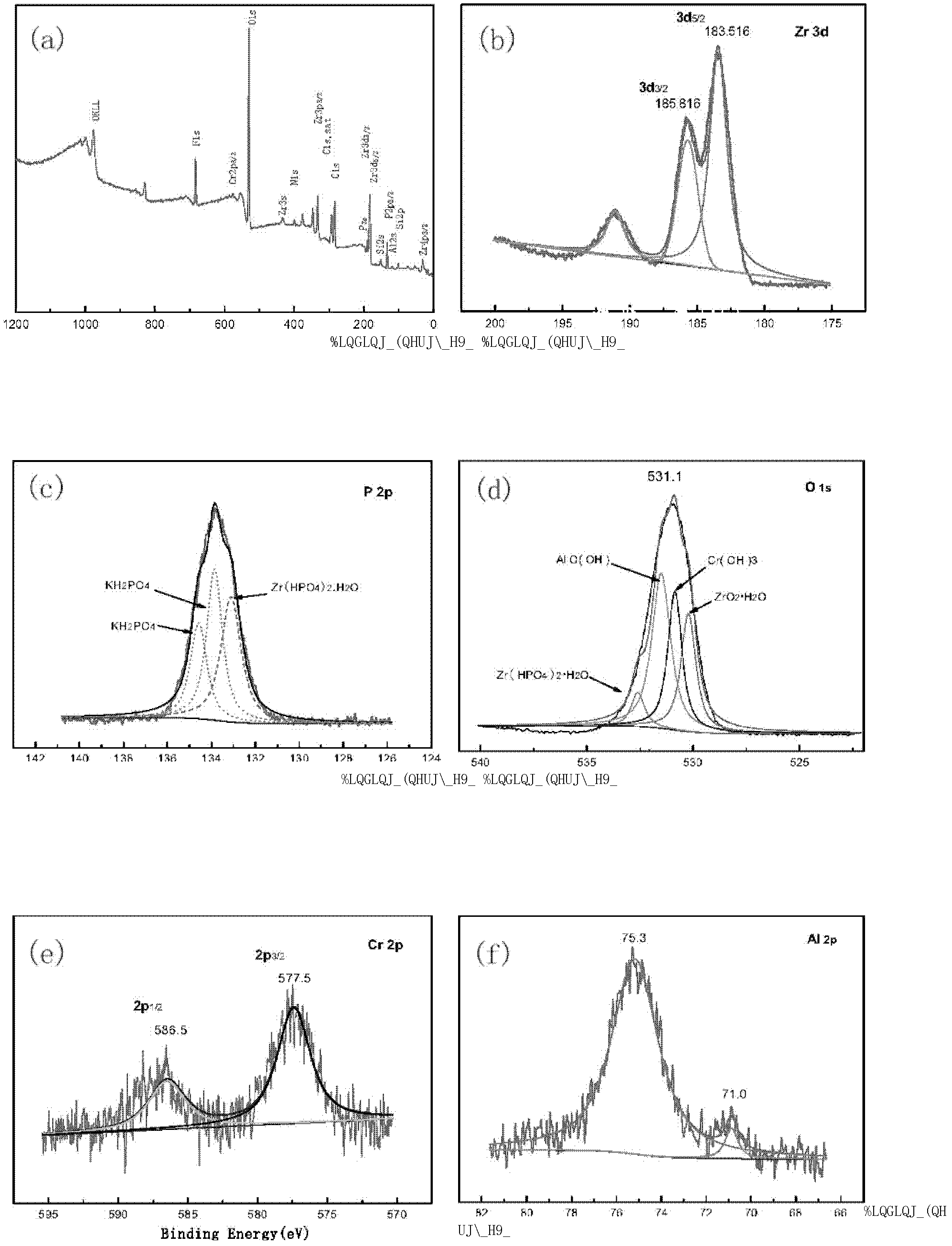

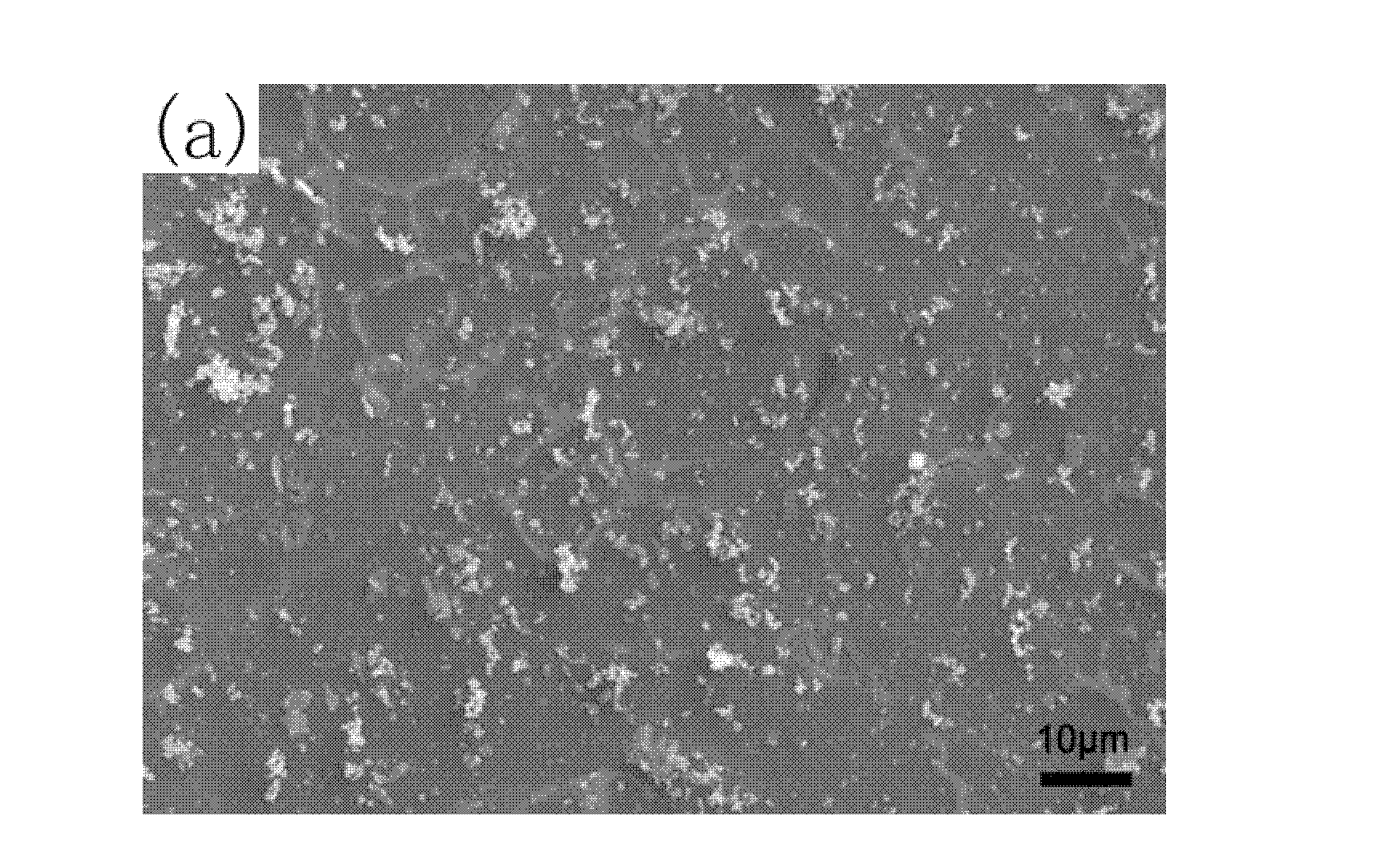

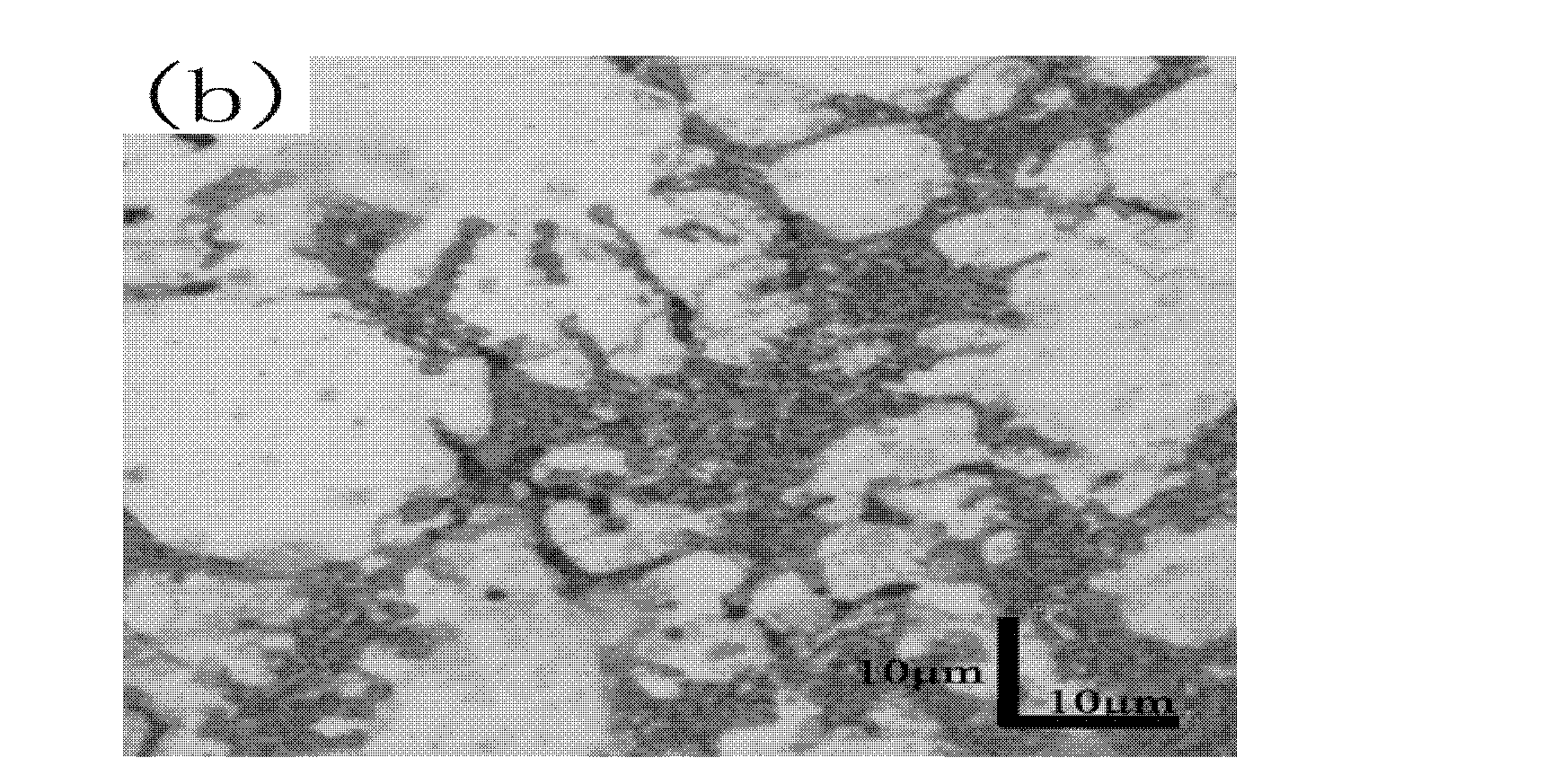

Zirconium salt chemical conversion treatment method for surface of die-casting aluminum alloy

InactiveCN102534592AStrong anti-salt spray performanceImprove corrosion resistanceMetallic material coating processesChromium CompoundsActive agent

The invention belongs to the field of metallic materials and relates to a chemical conversion solution and a treatment method for the surface of a die-casting aluminum alloy. The conversion solution is formed by compounding an A ingredient and a B ingredient, the A ingredient consists of a zirconium salt, a surfactant and a trivalent chromium salt; the B ingredient consists of a complexing agent and a film-forming accelerant; in the A ingredient, the content of the zirconium salt is 5-60 g / L, the content of the surfactant is 2-10 g / L, and the content of the trivalent chromium salt is 5-50 g / L; in the B ingredient, the content of the complexing agent is 4-20 g / L, and the content of the film-forming accelerant is 2-15 g / L; and the method comprises the pretreatment on the surface of the die-casting aluminum alloy and the zirconium salt chemical conversion treatment. A chemical conversion coating contains zirconium phosphate compounds and a small amount of trivalent chromium compounds, wherein the coating has uniform light blue and the thickness of about 0.5-1 micron. The zirconium salt chemical conversion coating prepared by the method has excellent corrosion resistance, the bonding strength between the coating and a substrate is high, the product, the waste water and the waste liquor obtained after the chemical conversion treatment do not contain hexavalent chrome which is harmful to the environment and the health of human bodies.

Owner:UNIV OF SCI & TECH BEIJING

Calcium-sulfonate-based hexapolyurea lubricating grease and preparation method thereof

ActiveCN102417856AGood extreme pressure and anti-wear propertiesImprove adhesionThickenersHeat stabilityLubrication

The invention provides a calcium-sulfonate-based hexapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of, by weight: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 0.5-30% of hexapolyurea; and (3) 10-80% of lubrication base oil. According to the invention, Newtonian fluid calcium sulfonate is converted and is subject to a reaction with diisocyanate, diamine and monoamine, such that the calcium-sulfonate-based hexapolyurea lubricating grease is obtained, the lubricating grease provided by the invention has excellent extreme pressure anti-wear capacity, ultra-long lubricating life, good adhesion, good water resistance, good colloid stability, high dropping point, good heat stability, good corrosion resistance, good salt spray resistance, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy corrosion-resistant paint for industry and preparation method thereof

InactiveCN104212324AImprove corrosion resistanceStrong anti-salt spray performanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolyamideFirming agent

The invention discloses heavy corrosion-resistant paint for industry. The heavy corrosion-resistant paint comprises the following components in parts by weight: 10-30 parts of epoxy resin, 25-45 parts of polyurethane, 2-15 parts of solvent, 2-4 parts of modified amino silicon oil, 1-5 parts of polysiloxane, 1-3 parts of chlorinated paraffin, 1-3 parts of sodium polycarboxylate, 5-10 parts of polyamide, 8-15 parts of D9050 modified aromatic resin epoxy curing agent and 13-17 parts of additive; the additive comprises the following components in parts by mass: 10-15 parts of dispersing agent, 5-10 parts of thickening agent, 5-10 parts of film-forming additive, 1-5 parts of PH adjusting agent, 5-10 parts of silane coupling agent, 2-6 parts of delustering agent and 1-6 parts of defoaming agent. The heavy corrosion-resistant paint disclosed by the invention has strong corrosion-resistant property and anti-salt-mist property and can be firmly adsorbed on the surface of metal so as to have good corrosion-resistant and anti-rusting property; and the heavy corrosion-resistant paint has the advantages that the corrosion-resistant time is long, the raw materials are easily obtained, the production process is simple, the construction is convenient, the operation is easy, the drying speed is high, the construction period is short and the demolding is not needed in the following processing procedure. The invention also discloses a method for preparing the heavy corrosion-resistant paint for industry.

Owner:JIANGSU MARINE VICTORY COATING

Composite calcium naphthenate-based lubricating grease and preparation method therefor

ActiveCN103627496AGood extreme pressure and anti-wear propertiesLong lubrication lifeLubricant compositionHeat stabilityBase oil

The invention provides a kind of composite calcium naphthenate-based lubricating grease and a preparation method therefor. With the weight of the lubricating grease as a reference, the lubricating grease comprises the following ingredients: 10%-70% of non-Newtonian calcium naphthenate, 1%-10% of calcium salts of high fatty acids, 1%-15% of calcium salts of micromolecule inorganic acids or fatty acids and 10%-80% of lubrication base oil. The lubricating grease employs petroleum calcium naphthenate or synthesized calcium naphthenate as a raw material, and contains composite calcium densifiers. The lubricating grease has good anti-water-spray properties and anti-water spray loss properties, and has good performances of adhesion, extreme pressure antiwear property, colloid stability, high dropping point, heat stability, anti-corrosion and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thin-layer antirust oil and preparation method thereof

ActiveCN102041149ASimple production processReduce process costLubricant compositionChemistryThin layer

The invention discloses thin-layer antirust oil. The oil contains 65-67wt% of lightweight refined oil, 9-11wt% of antirust compounding agent 1, 9-11wt% of antirust compounding agent 2, 10-14wt% of antirust compounding agent 3, 0.02-0.08wt% of antirust compounding agent 4, 0.06-0.1wt% of stearic acid, 0.4-0.6wt% of antioxidation compounding agent and 0.8-1.2wt% of surfactant. A preparation method of the thin-layer antirust oil comprises the following steps: adding the lightweight refined oil to a reactor and stirring the lightweight refined oil; adding the antirust compounding agent 1, the antirust compounding agent 2 and the antirust compounding agent 3 to the reactor in sequence and continuously stirring the mixture for 25-35 minutes; then adding the stearic acid, the antioxidant and theantirust compounding agent 4 to the reactor in sequence and continuously stirring the mixture for 25-35 minutes; and then adding the surfactant to the reactor and continuously stirring the mixture for 80-120 minutes, thus obtaining the thin-layer antirust oil. The thin-layer antirust oil has the following advantages: the production process of the antirust oil is simple; the antirust oil is non-toxic and harmless, has excellent moisture and heat resistance and salt mist resistance and can be sprayed, brushed or dipped on the parts; and the antirust oil has thin coating, so the parts with the antirust oil can be assembled without cleaning the antirust oil.

Owner:上海锦海特种润滑油厂

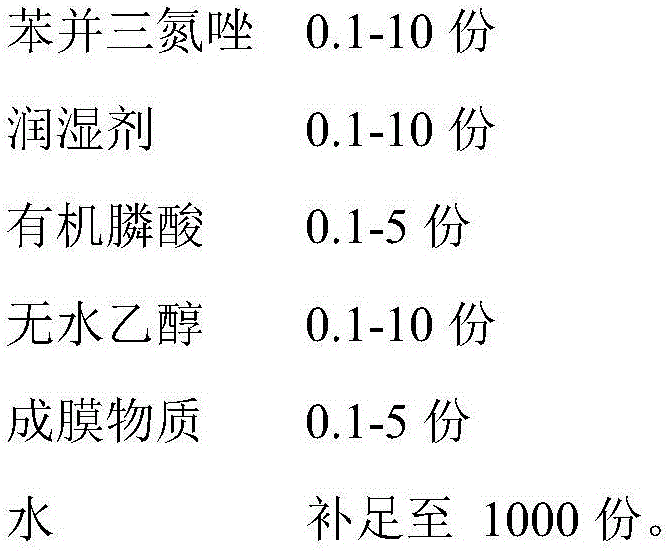

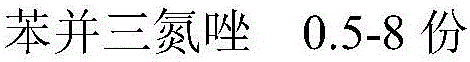

Copper material passivator, preparation and application thereof

InactiveCN106148934AImprove corrosion resistanceNon-toxicMetallic material coating processesBenzeneAlcohol

The invention relates to the technical field of surface passivating treatment, in particular to a copper material passivator, preparation and application thereof. The copper material passivator comprises 0.1 to 10 parts by weight of benzotriazole (BTA), 0.1 to 10 parts by weight of a wetting agent, 0.1 to 5 parts by weight of organic phosphonic acid, 0.1 to 10 parts by weight of absolute ethyl alcohol and 0.1 to 5 parts by weight of film forming matters, and water is supplemented till the weight part of all the components is 1000 parts. A preparation method comprises the steps of putting BTA and absolute ethyl alcohol into water, and stirring and mixing to promote dissolution of BTA, so as to obtain a colorless and transparent solution; and then, sequentially adding the wetting agent, organic phosphonic acid and the film forming matters, stirring and mixing, and finally, adding the remaining water, so as to obtain the uniformly mixed copper material passivator. According to the copper material passivator, the high molecular resin film forming matters are introduced and exert a synergistic function with BTA; through a drying procedure, a layer of compact passive film is quickly formed on the surface of a copper material, and excellent corrosion resistance is achieved; and the color of the passive film formed through the passivator does not change after the passive film is hung indoors for 180 days.

Owner:合肥普庆新材料科技有限公司

Method for processing waste leather into top-layer leather

ActiveCN105500804AGood weather resistanceImprove impact resistancePolyureas/polyurethane adhesivesSynthetic resin layered productsEngineeringPolyresin

The invention relates to the technical field of leather processing, in particular to a method for processing waste leather into top-layer leather. The method comprises steps as follows: selection: the waste leather produced after furniture production processing is selected for standby application; spraying of a hot-melt adhesive: the waste leather is laid flatly as one layer, and then a hot-melt adhesive material layer is sprayed on the waste leather; attachment of a resin film: the resin film is attached to the hot-melt adhesive material layer; attachment of cloth: a layer of cloth is attached to the resin film, and a finished leather product is prepared. The leather prepared with the method has good tensile strength and breaking resistance, and the added value of the finished leather product is high.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

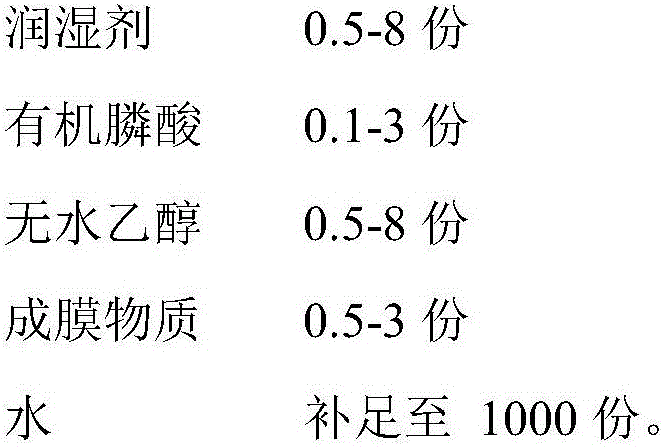

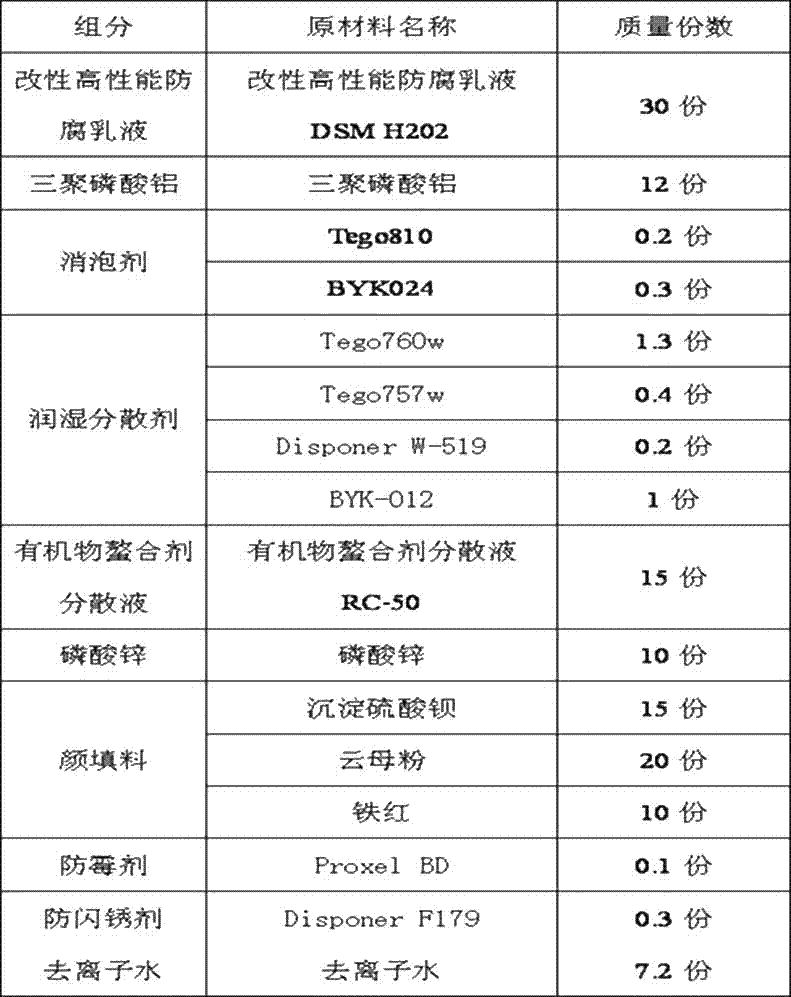

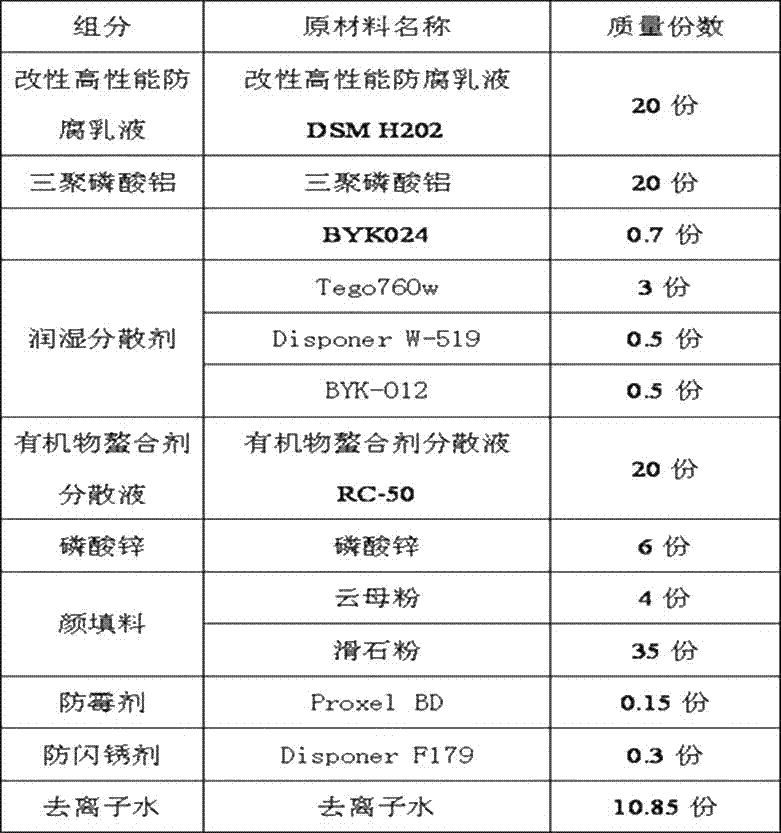

Long-acting waterborne over-rust corrosion protective coating and preparation method thereof

InactiveCN107312460AIncrease crosslink densityHigh film strengthFireproof paintsAnti-corrosive paintsWater basedTectorial membrane

The invention discloses a long-acting waterborne over-rust corrosion protective coating. The long-acting waterborne over-rust corrosion protective coating comprises the following components by weight: 20-35 parts of modified high-performance anti-corrosive emulsion, 10-20 parts of aluminum triphosphate, 6-12 parts of zinc phosphate, 0.1-0.8 part of defoamer, 2-4 parts of wetting dispersant, 10-20 parts of organic chelating agent dispersing agent, 37-45 parts of pigment and filler, 0.1-0.2 part of mildew preventive, 0.2-0.3 part of anti-flash-rust agent, and 7-12 parts of deionized water. The invention provides the long-acting waterborne over-rust corrosion protective coating, the rust is converted into a mode of a dense protective film within a short period of time by improving the crosslinking density and the strength of a film and promoting the rapid dispersing and chelating of the rust, so that the durability, the salt spray resistance and the adhesive force of the coating are improved obviously.

Owner:洛阳双瑞防腐工程技术有限公司

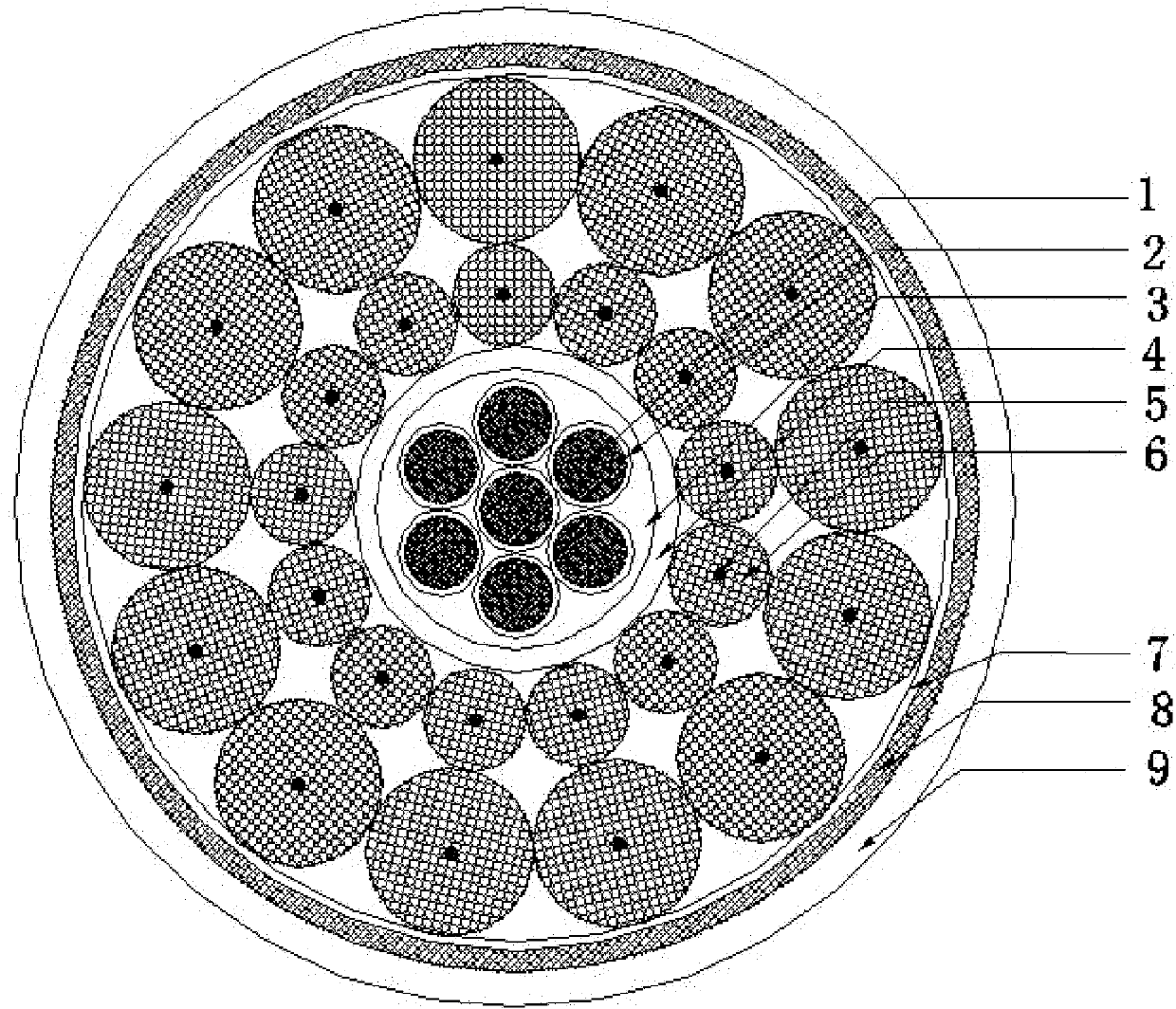

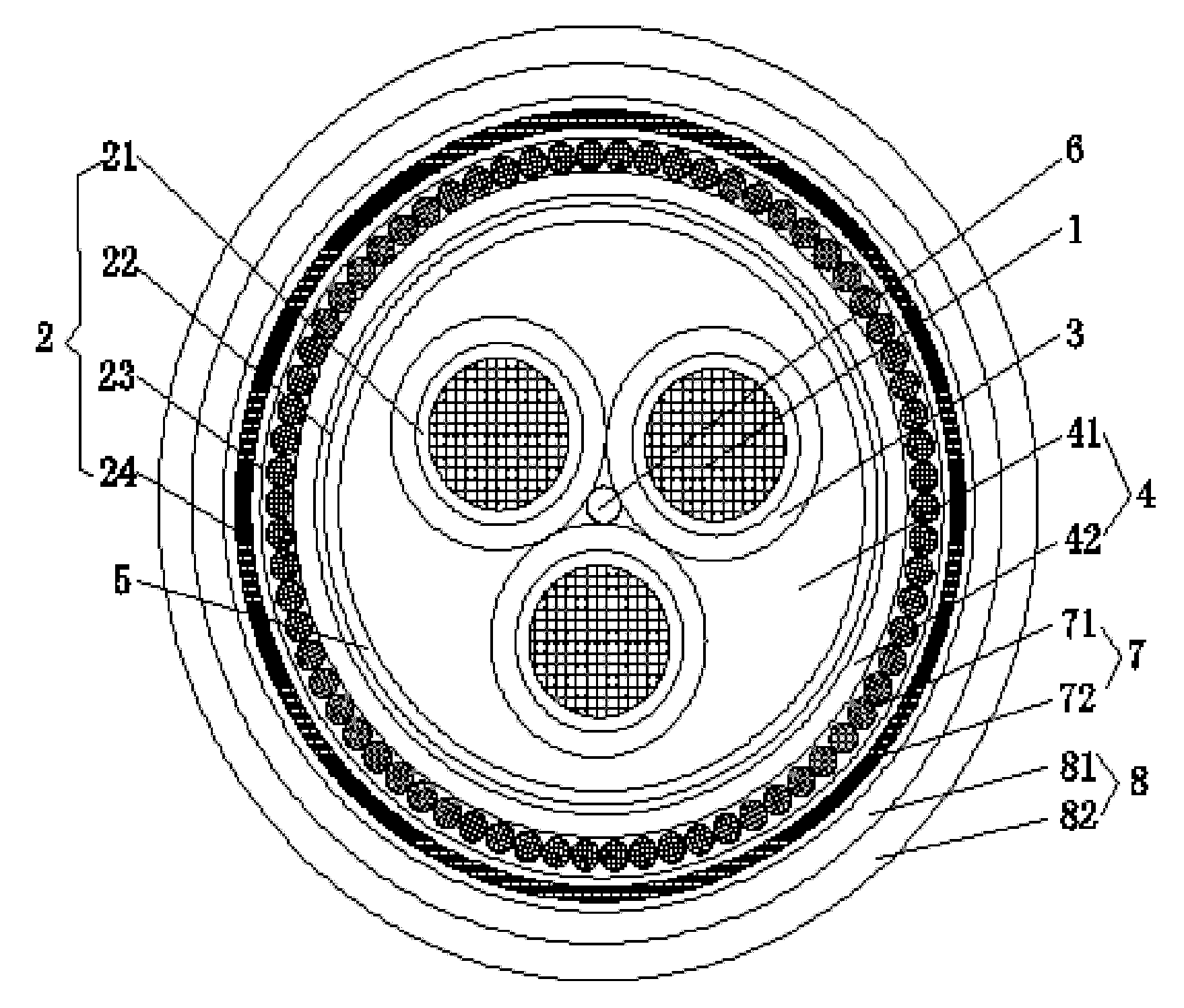

Cable for shallow sea wind power generation

ActiveCN101937738AImprove electrical performanceImprove mechanical propertiesNon-insulated conductorsFlexible cablesElectricityElectrical conductor

The invention discloses a cable for shallow sea wind power generation, which comprises a conductor, water-blocking tapes, an insulating layer and lining layers, wherein, the first water-blocking tape and the extruded insulating layer are wrapped sequentially outside the conductor to form insulating wire cores, and a plurality of insulating wire cores are twisted together to form a cable core; the first lining layer and the second water-blocking tape are wrapped sequentially outside the cable core; and the insulating layer and the first lining layer are formed by extruding a thermoplastic elastomer (TPE). In the invention, the insulating layer is made of a thermoplastic olefin (TPO) material in the TPE and the first lining layer is made of a thermoplastic starch (TPS) material in the TPE, wherein, the TPE has good electrical property, good mechanical property, excellent low-temperature bending property and excellent torsion resistance, high long-term working temperature up to 125 DEG C, better water resistance and excellent salt-fog resistance, and especially the TPE can still maintain good flexibility at -60 DEG C; and TPO has more excellent electrical property, and TPS has better water resistance than that of the TPO.

Owner:FAR EAST CABLE +2

Environmentally-friendly antirust oil for iron-based powder metallurgy parts and preparation method of antirust oil

ActiveCN110437917AImprove rust resistanceStrong anti-salt spray performanceLubricant compositionEnvironmental resistanceMetalworking

The invention belongs to the technical field of metal processing, and more particularly relates to environmentally-friendly antirust oil for iron-based powder metallurgy parts and a preparation methodof the antirust oil. The environmentally-friendly antirust oil for the iron-based powder metallurgy parts comprises the following components, in parts by weight: 60-90 parts of base oil, 3-20 parts of a barium-free sulfonate, 0.1-20 parts of a rust inhibitor, 0.5-10 parts of an auxiliary agent and 0.1-1 part of an antioxidant. According to the environmentally-friendly antirust oil for the iron-based powder metallurgy parts provided by the invention, the base oil, the barium-free sulfonate, the rust inhibitor, the auxiliary agent and the antioxidant are adopted for compounding to provide highantirust performance, different from a traditional antirust method of powder metallurgy which needs high-temperature cooking, the product provided by the invention is immersed at room temperature andcan be quickly penetrated into metal gaps to discharge moisture in pores and the metal surface out, after draining is performed, an oil film is thin and non-sticky, has good salt spray resistance andmeets the antirust requirements for sea export of products, and the product does not contain heavy metals such as barium and is safe and environmentally friendly.

Owner:GUANGZHOU LANDNOK CHEM TECH

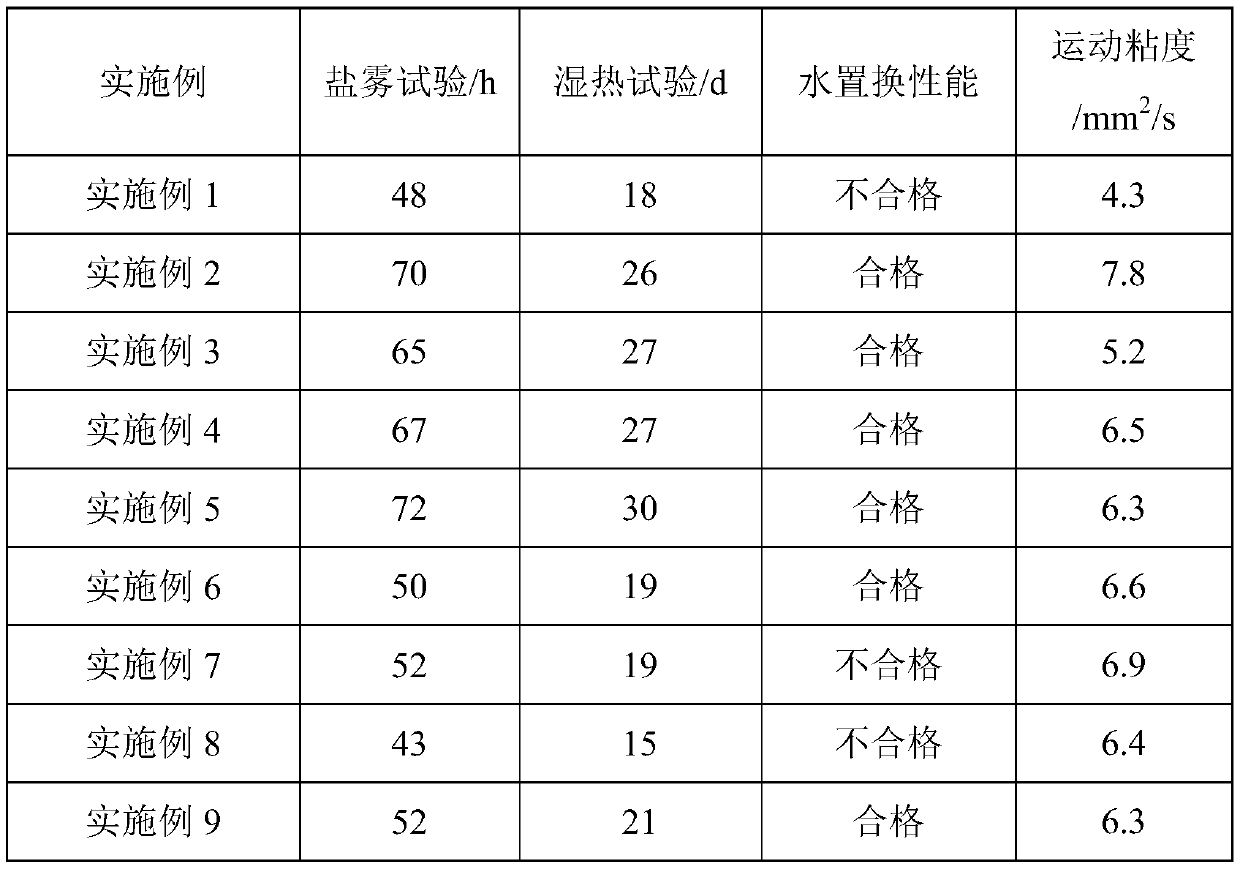

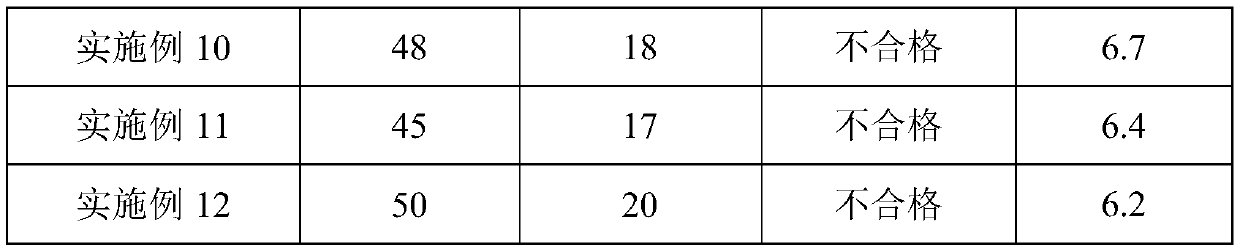

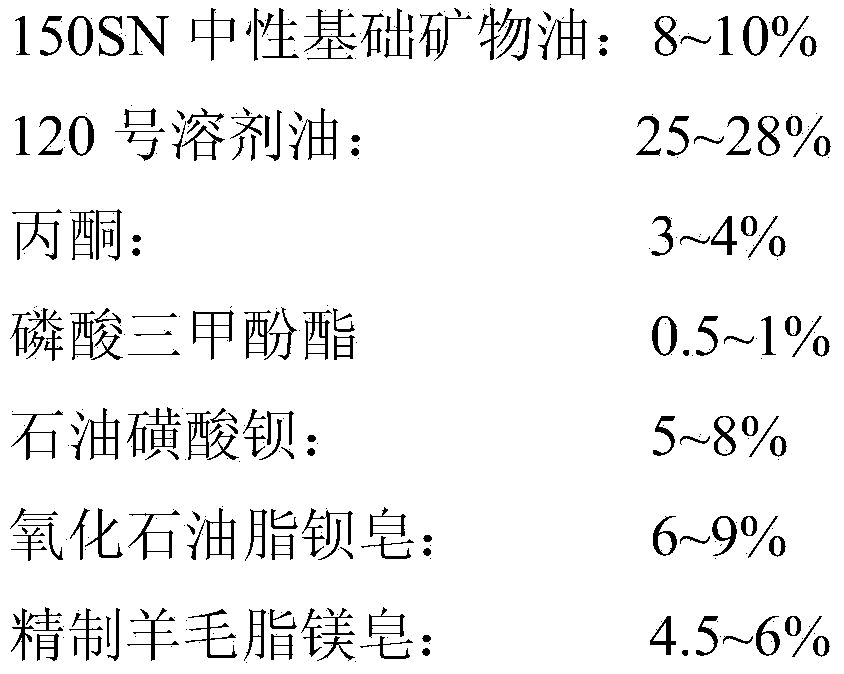

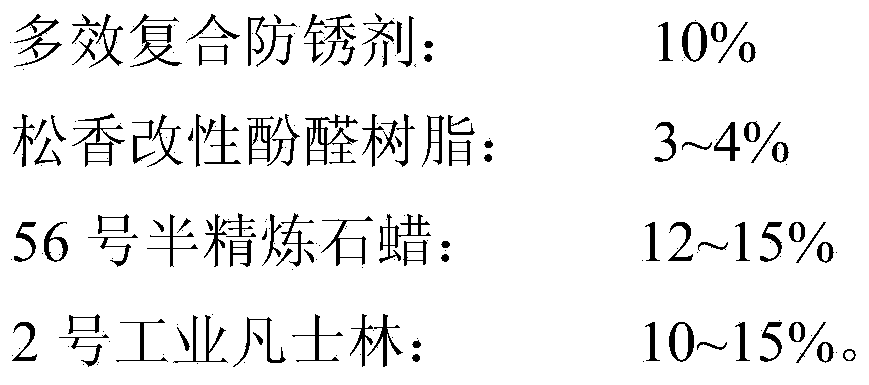

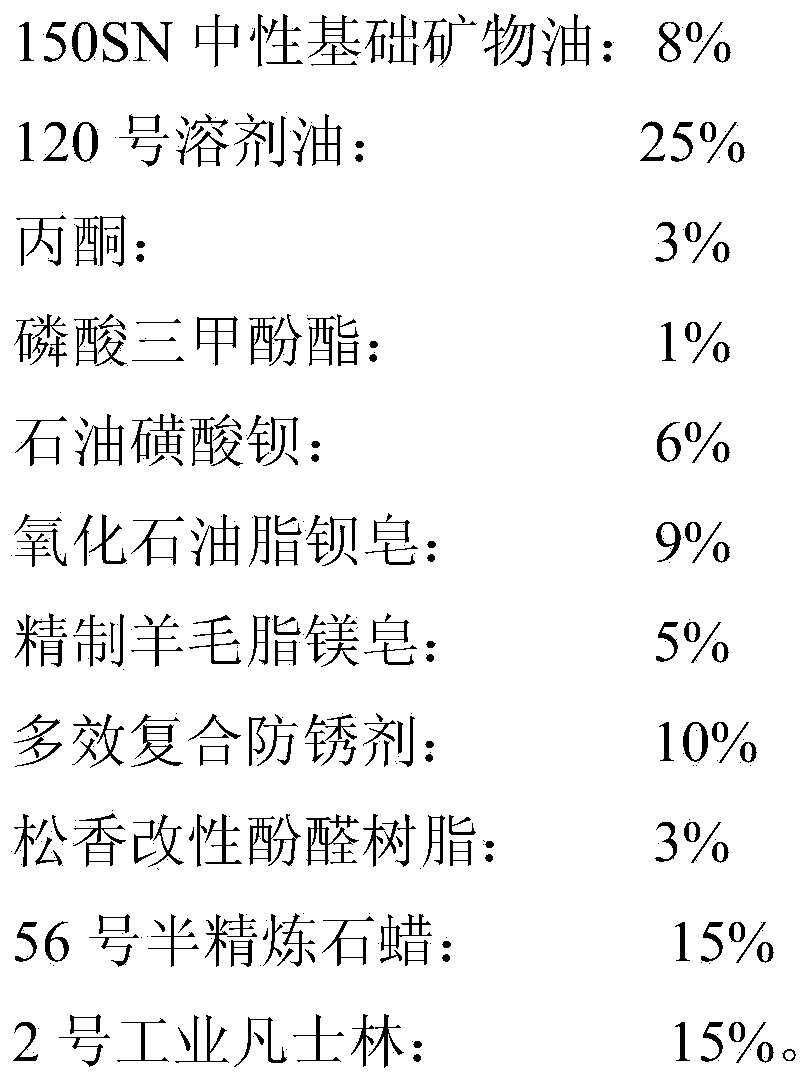

Brown high-build quick-drying antirust oil applicable to diesel engines of ships and warships and preparation method thereof

ActiveCN103540393AStrong adhesionImprove corrosion resistanceLubricant compositionParaffin waxLanolin

The invention discloses brown high-build quick-drying antirust oil applicable to diesel engines of ships and warships and a preparation method thereof. The black high-build quick-drying antirust oil applicable to the diesel engines of the ships and warships is prepared from 150SN neutral basic mineral oil, No.120 solvent oil, acetone, tricresyl phosphate, barium petroleum sulfonate, barium soap of petroleum ester oxide, refined lanolin magnesium soap, a multi-effect compound antirust agent, rosin modified phenolic resin, No.56 semi-refined paraffin wax and No.2 industrial Vaseline. The brown high-build quick-drying antirust oil can form a semi-hard membrane-like protective coating with strong compactness, good adhesive force and naturally quick-drying property on the surface of a material, is resistant to atmospheric corrosion and has excellent moisture resistance and salt mist resistance, and the rustproof life can be more than three years; the antirust effect is good, and the antirust quality technical requirement of a user on products in processes of production, manufacturing, transportation, storage and the like can be completely met.

Owner:广东中诚表面防护材料检验研究院有限公司

Metal antirust compound containing oil-soluble polyaniline and application thereof

InactiveCN103305317AGood solubility and dispersibilityStrong anti-rustAdditivesSolubilityFilm-forming agent

The invention relates to a metal antirust compound containing oil-soluble polyaniline and application thereof. The invention is characterized in that the antirust compound comprises, expressed in mass percentages, 5 to 30% of oil-soluble polyaniline, 10 to 40% of dodecenylsuccinic acid and 40 to 80% of barium petroleum sulfonate. When the antirust compound provided by the invention is added into a lubricant base oil or / and mineral spirit, the antirust compound has good dissolvability and realizes phase-free separation, a solution system is uniform and stable, a lubricant anti-rust oil, or a solvent dilution type anti-rust oil not containing a film forming agent or a hard-film anti-rust oil can be prepared, and the formed anti-rust oils have the advantages of a small total addition amount, low viscosity and a good antirust effect, in particular, protruding salt mist prevention performance; when the total addition amount of the antirust compound is within 9%, antirust periods of the prepared lubricant anti-rust oil, the solvent dilution type anti-rust oil not containing a film forming agent and the hard-film anti-rust oil under a salt mist condition are greater than 6 d, greater than 11 d and greater than 31 d, respectively, and antirust periods the above-mentioned anti-rust oils under damp and hot conditions are all greater than 60 d.

Owner:PETROCHINA CO LTD

Solid bus slot with high strength

InactiveCN101552441AThere will be no mutual "extended bite"Convenient thermal protectionBus-bar installationElectrical conductorHigh intensity

The invention discloses a solid bus slot with high strength which consists of a shell made of the composite materials, the composition of the composite materials and a preparation method thereof. By adopting the bus slot, as the shell of the bus slot made of the composite materials, the bus slot has good hydrolytic resistance and good anti-salt fog performance. The withstand voltage is as high as 5000V or more; and as the linear expansion coefficient of the composite materials are very close to the conductor, the situation of 'extended bite' with each other can not appear due to the mixed-assembled with a plurality of materials with different expansion coefficients, thus improving the insulation protection of the bus slot and having very high insulation performance. The mechanical strength of the bus slot made of the composite materials is high, which can withstand 15 Joules impact strength. The overload capability of the bus slot is strong, the anti inter-phase short circuit ability is good, the low temperature resistance is good, the protection grade can achieve IP68, and the use life is longer than that of the metal.

Owner:JIANGSU JIANGCHENG ELECTRIC

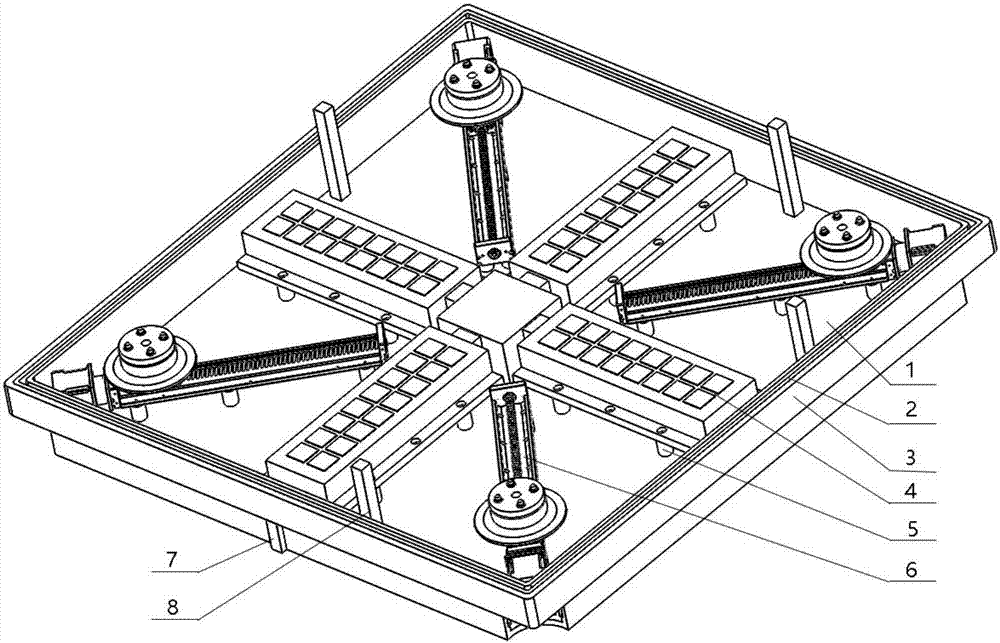

Small ship-borne unmanned helicopter landing assisting and mooring device

ActiveCN107539492ASave energyNo risk of adsorption failureAircraft landing aidsGround installationsOn boardSpray coating

The invention provides a small ship-borne unmanned helicopter landing assisting and mooring device. The small ship-borne unmanned helicopter landing assisting and mooring device comprises an electricpermanent magnetic chuck, a cushion block, an outer shielding body, an inner shielding body, a demagnetizating coil, a mechanical clamping device, a magnetic induction transducer and a photoelectric sensor. The small ship-borne unmanned helicopter landing assisting and mooring device achieves efficient landing assisting and mooring of an unmanned helicopter by matching of the electric permanent magnetic chuck, the mechanical clamping device and the photoelectric sensor. When the unmanned helicopter enters the detection range of the photoelectric sensor, the photoelectric sensor is triggered, and the electric permanent magnetic chuck is filled with magnetism. After the unmanned helicopter lands on a platform, the mechanical clamping device is started, when an unmanned helicopter landing gear triggers a pressure sensor in the mechanical clamping device, clamping is in place, the electric permanent magnetic chuck is degaussed, and landing assisting and mooring are completed. The small ship-borne unmanned helicopter landing assisting and mooring device adopts a magnetic shielding and degaussing system, and avoids the bad influence of a magnetic field on a hull and ship equipment, the structure is simple and compact, energy saving and environmental protection are achieved, the small ship-borne unmanned helicopter landing assisting and mooring device also has good environmental adaptability through salt spray proofing coating treatment.

Owner:SHANGHAI RONGJUN TECH

Environment-friendly anti-wear rust-proof chain lubricating grease

ActiveCN108048174AStrong anti-salt spray performanceStrong rust resistanceLubricant compositionAntioxidantHuman health

The invention relates to environment-friendly anti-wear rust-proof chain lubricating grease. The environment-friendly anti-wear rust-proof chain lubricating grease is prepared from, by weight, 20-85%of basic oil, 5-20% of tackifier, 5-35% of densifier, 0.1-5% of antioxidant, 5-30% of antirust agent, 0.1-1% of metal passivant and 0.1-5% of anti-wear extreme pressure reagent. The lubricating greasehas the high salt spray corrosion resistance, rust-proof performance and anti-wear extreme pressure performance, and the requirements for rust prevention, sea transportation and lubrication of a chain are met. Meanwhile, the lubricating grease contains no barium or phosphorus element, no harm is caused to the human health and environment, and the lubricating grease is safe and environmentally friendly to use.

Owner:SHANDONG NORTH ZITE SPECIAL OIL

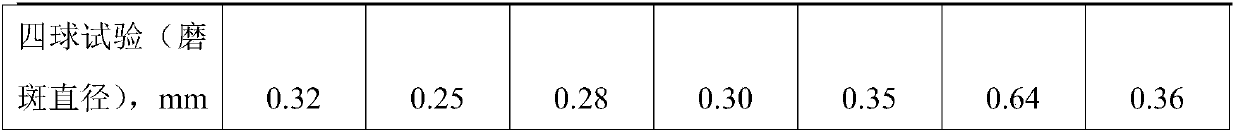

Composite calcium naphthenate-based lubricating grease and preparation method thereof

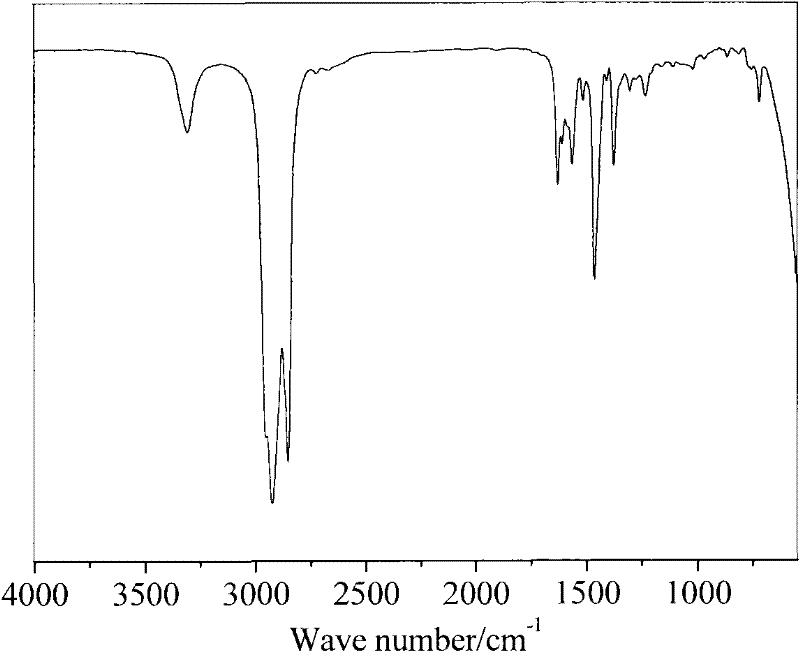

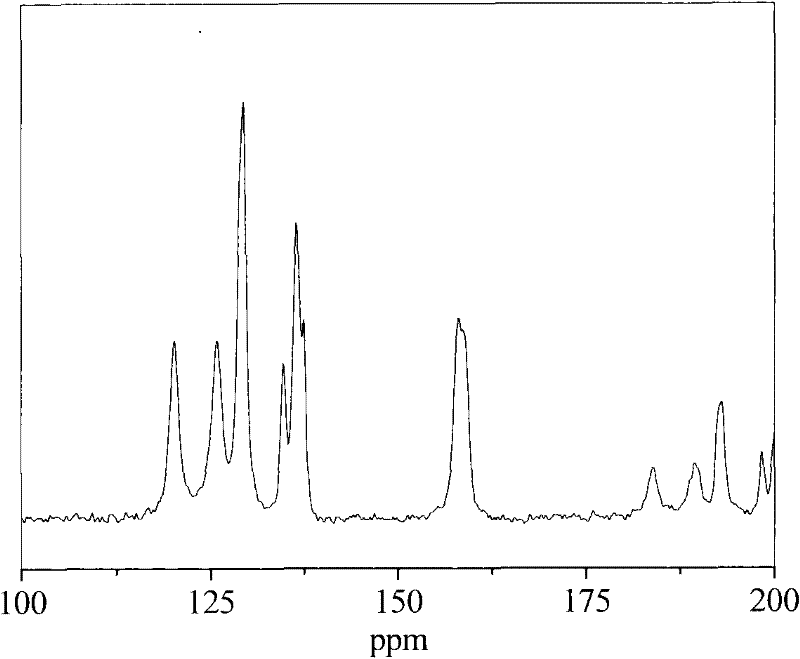

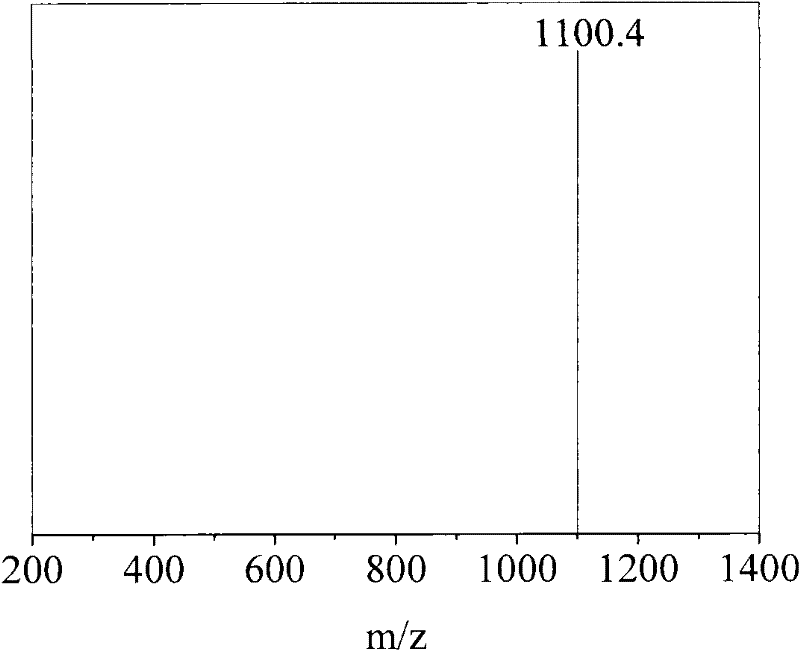

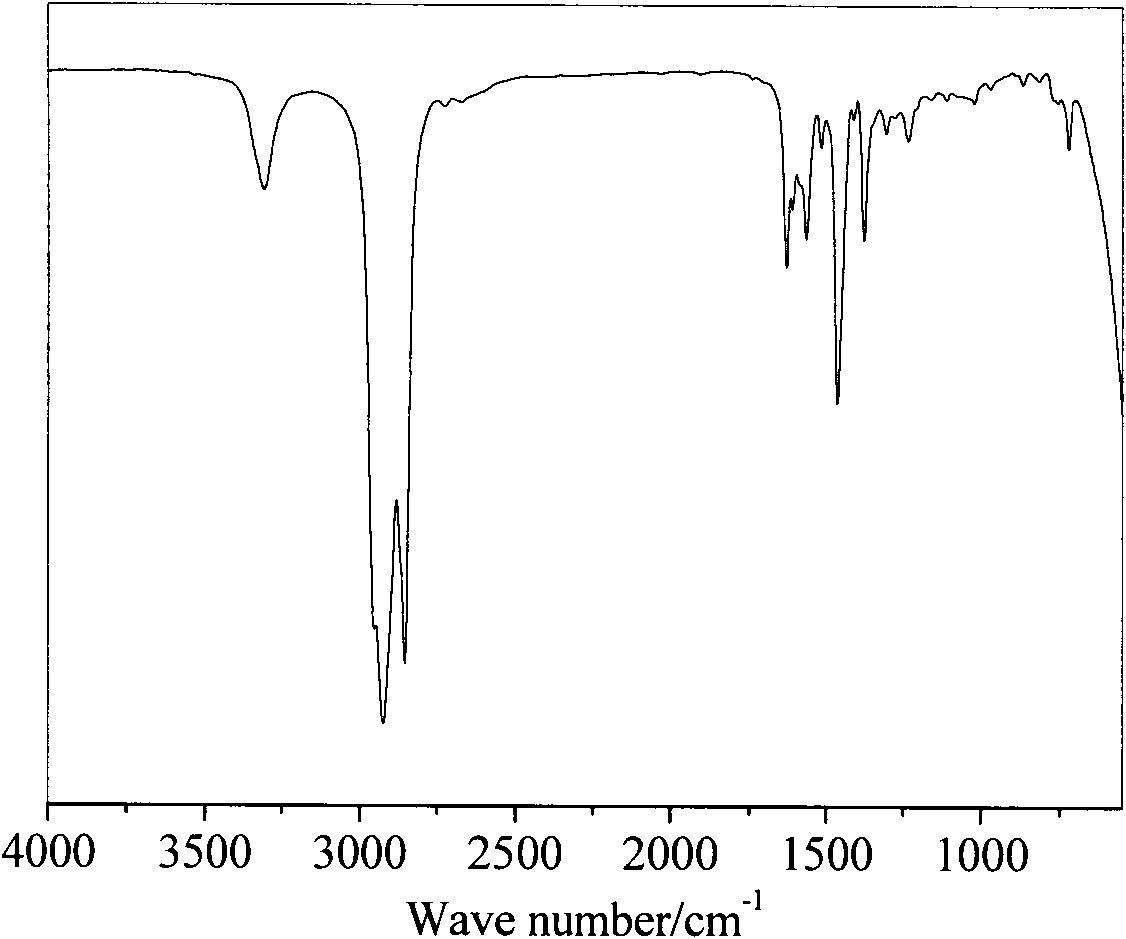

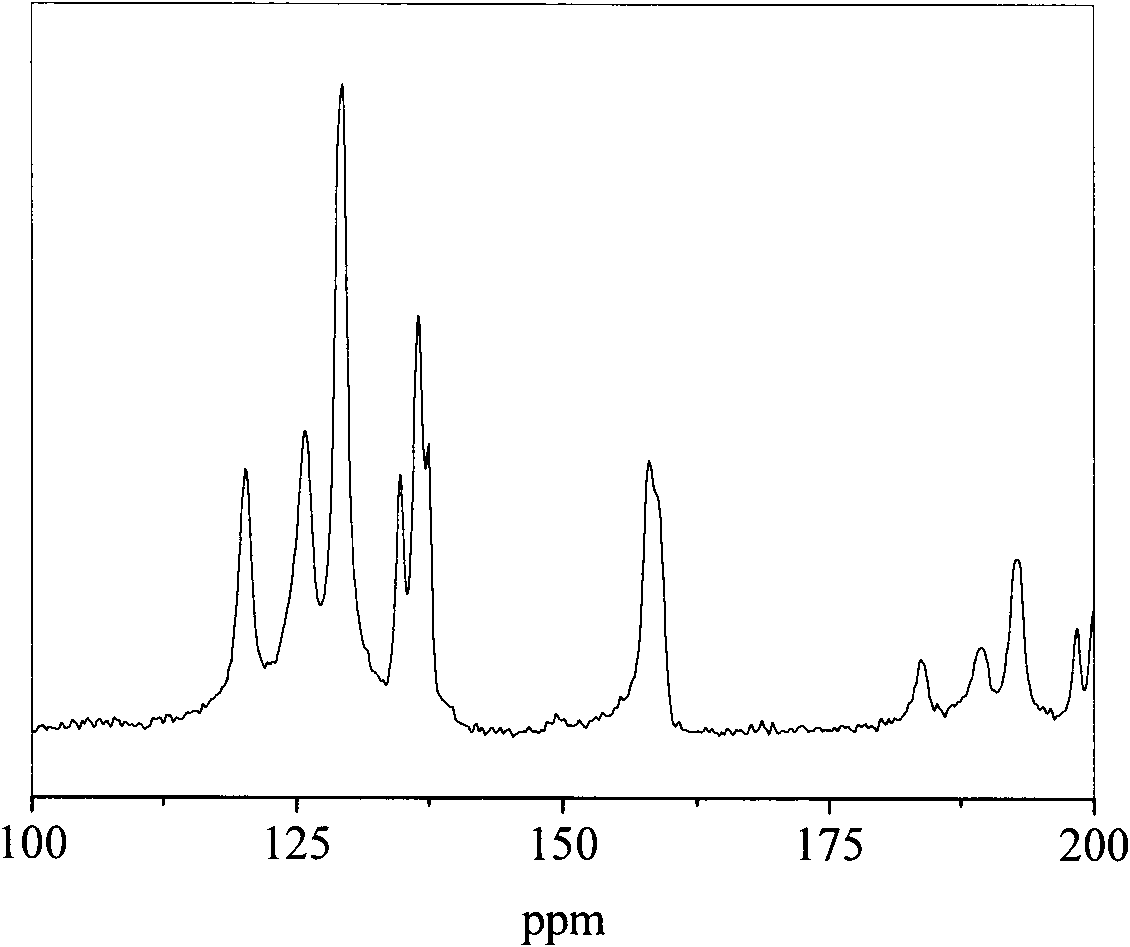

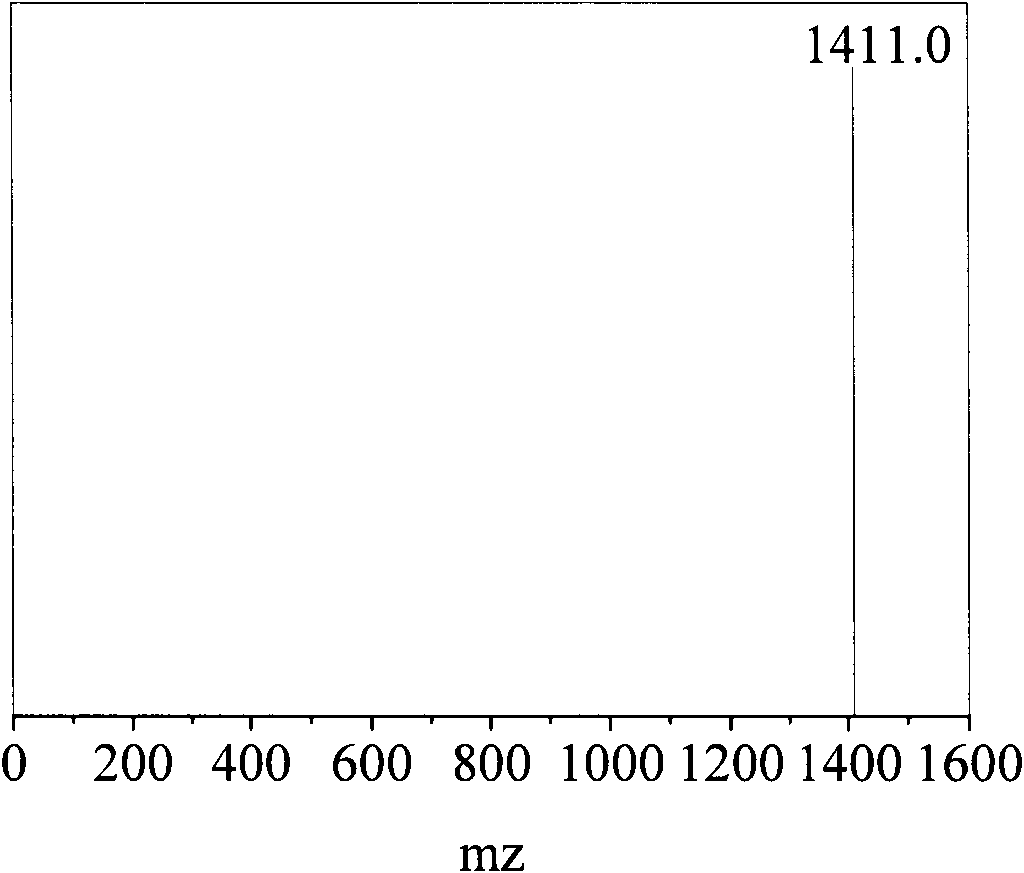

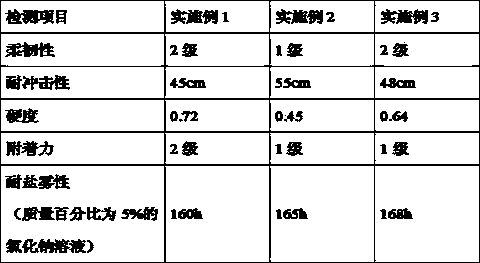

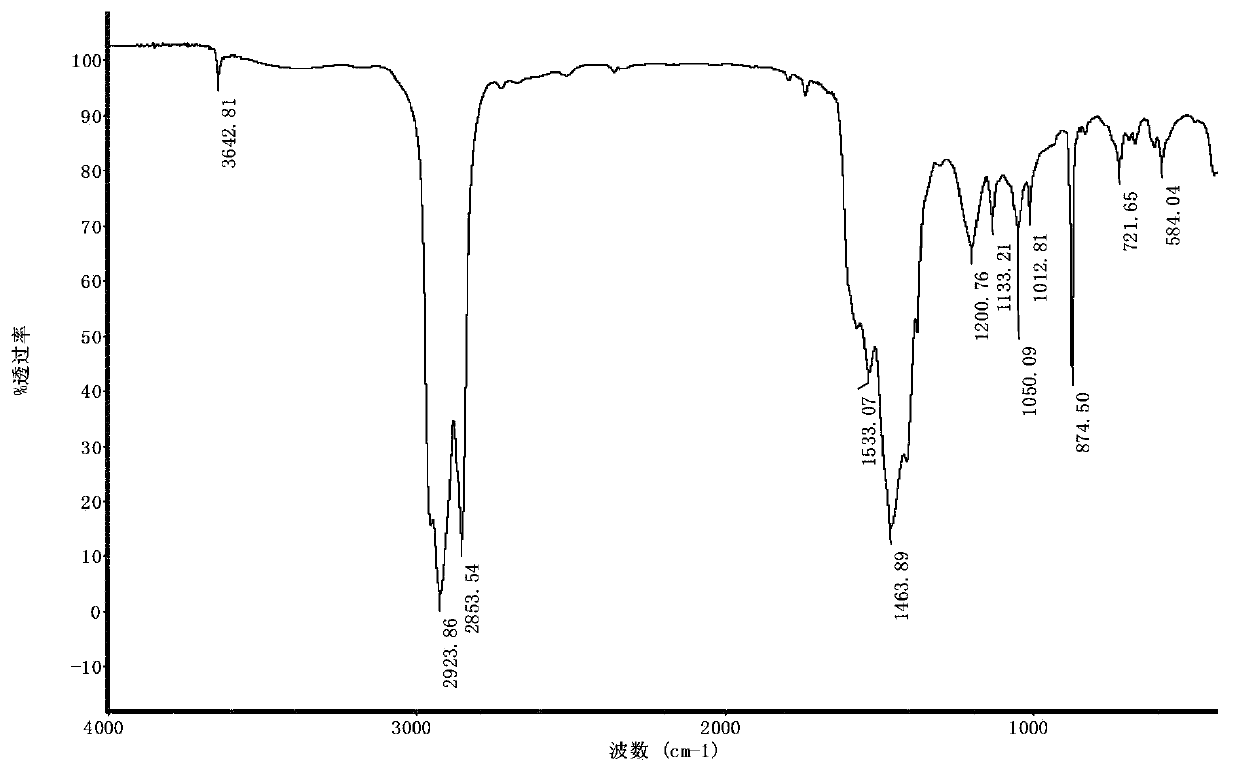

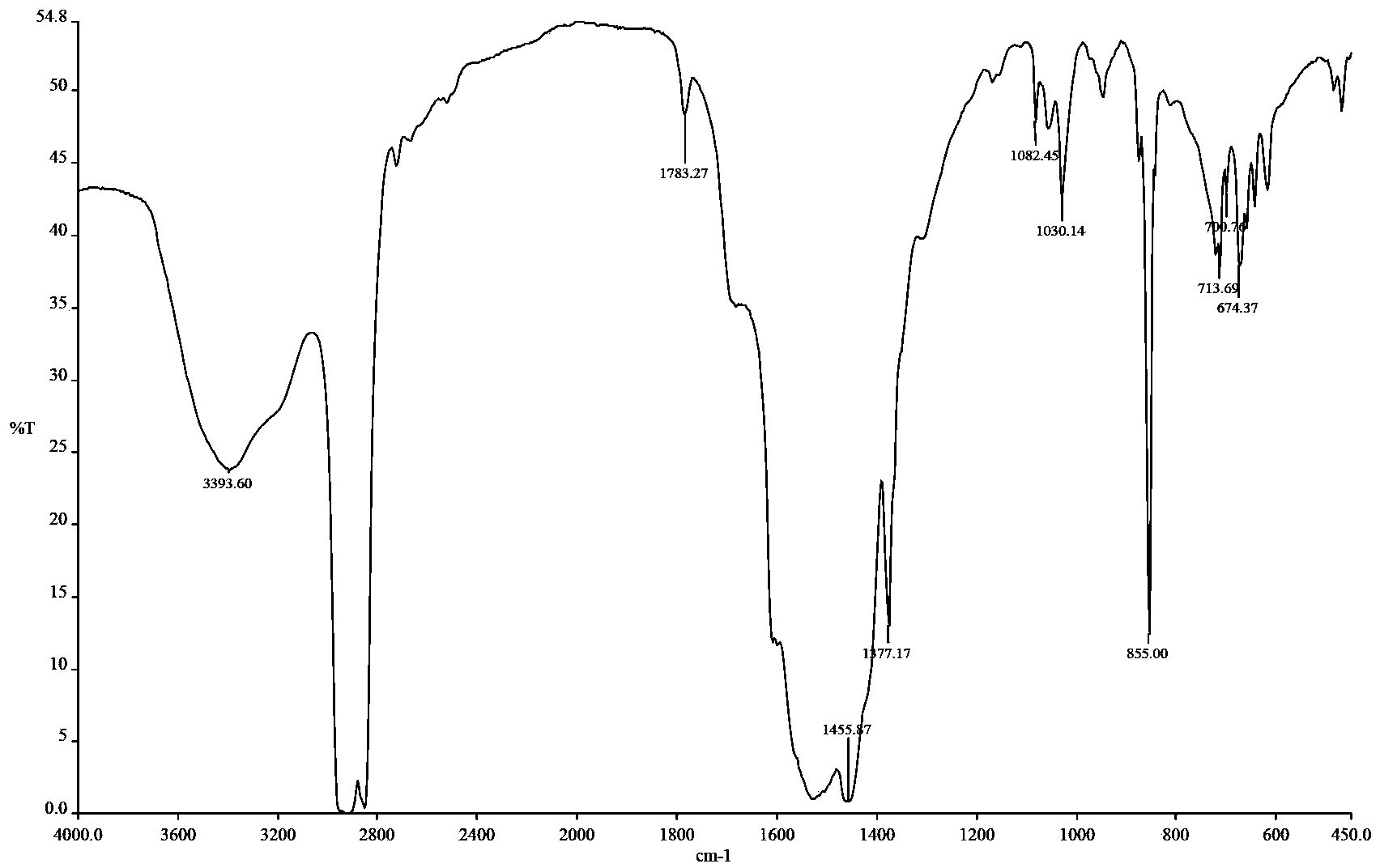

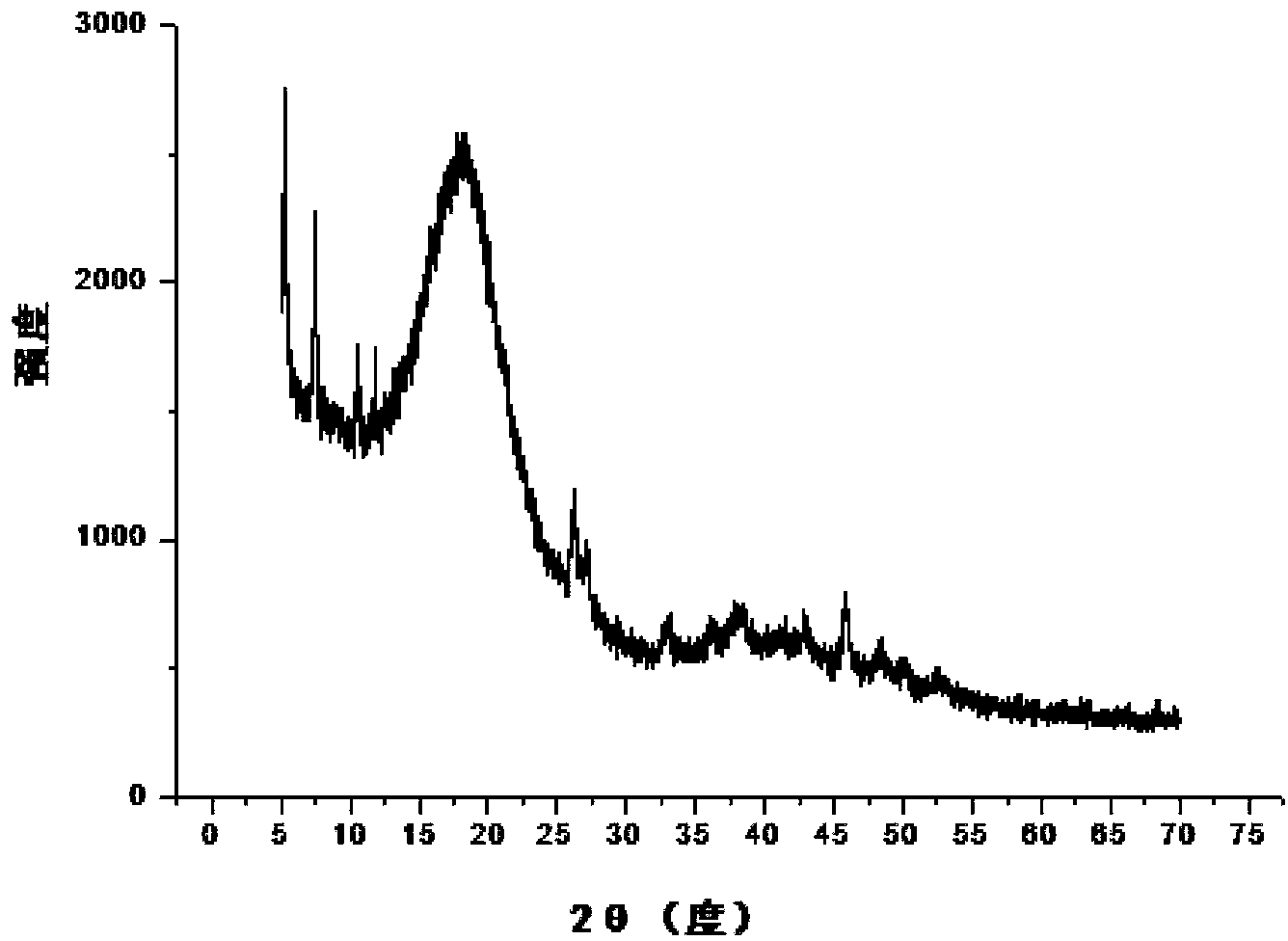

ActiveCN104293449AImprove corrosion resistanceStrong anti-salt spray performanceLubricant compositionSulfonateAragonite

The invention discloses composite calcium naphthenate-based lubricating grease which is characterized by including following components, on the basis of the weight of the lubricating grease, 20-70 wt% of non-Newtonian calcium naphthenate, 1-10 wt% of a calcium salt of a higher fatty acid and 25-70 wt% of a basic oil. An infrared spectrogram of the non-Newtonian calcium naphthenate has a characteristic absorption peak of aragonite-type calcium carbonate. The invention also discloses a preparation method of the composite calcium naphthenate-based lubricating grease and the composite calcium naphthenate-based lubricating grease prepared through the same. The composite calcium naphthenate-based lubricating grease has excellent anti-corrosion property and anti-salt fog property, and has performances comprising a high-temperature-resistant performance, a water-resistant performance, an adhesive performance, a colloid stability and the like, which are better than those of composite calcium sulfonate-based lubricating grease. The composite calcium naphthenate-based lubricating grease has a longer lubricating service life. The preparation method is simple, environmental-protective, low in cost and stable in product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

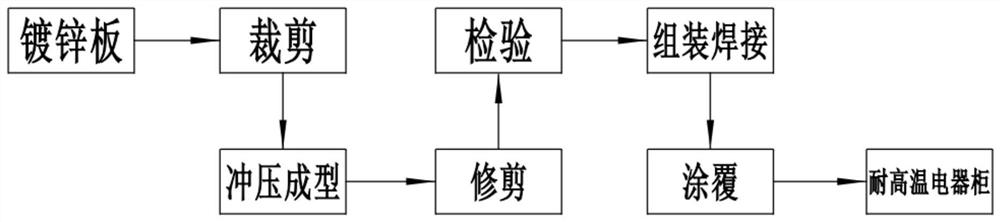

Machining method of electric appliance cabinet

PendingCN111687597AAvoid corrosionLow priceFireproof paintsCasings/cabinets/drawers detailsMachiningTop cap

The invention relates to the technical field of electric appliance cabinets, in particular to a machining method of an electric appliance cabinet. The method comprises the following steps of (1) selecting a galvanized plate as a material for manufacturing a cabinet body; (2) dividing the electric appliance cabinet into a door, a rear shell, a base and a top cover according to the shape of the electric appliance cabinet; (3) cutting the selected galvanized plate according to the preset size, and stamping the cut on a stamping machine and bending to be formed; (4) trimming flashes and burrs of the galvanized plate formed by stamping and bending and forming, and obtaining a semi-finished product of the electric appliance cabinet after the galvanized plate passes inspection; and (5) combiningand installing the qualified semi-finished electric appliance cabinet products, assembling the semi-finished electric appliance cabinet products into a complete electric appliance cabinet, and then carrying out welding and forming. The machining method has beneficial effects that the galvanized plate and the high-temperature-resistant coating are combined to process and manufacture the electric appliance cabinet, so that the electric appliance cabinet not only has good corrosion resistance, but also has good high-temperature resistance, and the service life of the electric appliance cabinet isprolonged.

Owner:南京天普机电产品制造有限公司

Compound calcium sulfonate-calcium naphthenate zirconium-based lubricating grease and preparation method thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

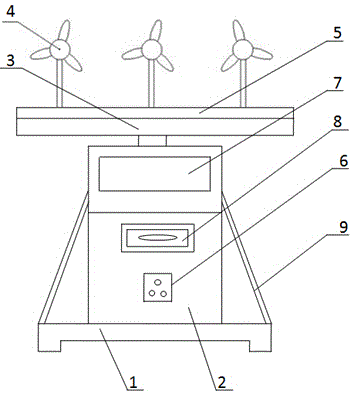

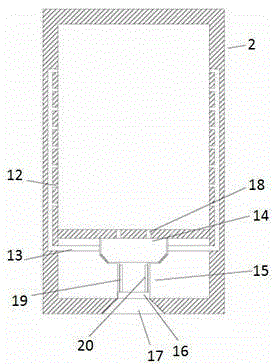

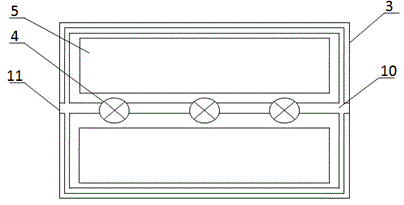

Anti-salt-fog automobile new-energy charging pile

PendingCN105356537AAvoid sun exposureAvoid scourBatteries circuit arrangementsElectric powerNew energyElectric vehicle

The invention provides an anti-salt-fog automobile new-energy charging pile. According to the charging pile, the solar energy and the wind energy can be utilized simultaneously to charge an electric vehicle, thereby saving the energy and meeting the new requirement of energy utilization in future. A gutter channel is formed in a sunshade platform, so that the sunlight exposure can be avoided and rain washing can be prevented and thus electronic elements in the charging pile body can be effectively protected. Besides, a salt-fog removing ventilation apparatus is also arranged, so that the ventilation and anti-salt-fog effect are good and the service life of the charging pile body is substantially prolonged.

Owner:JIANGSU JIUYU IND

Compressor for refrigeration system

InactiveCN108034288AHigh strengthReduce internal stressPositive displacement pump componentsPretreated surfacesEngineeringRefrigeration

The invention discloses a compressor for a refrigeration system. The compressor comprises a shell and a cylinder, wherein the cylinder is arranged in a shell; a through hole is formed in the side wallof the shell; a protective layer is arranged on the outer wall of the shell. A refrigeration device disclosed by the invention is simple and compact, and good in wear resistance effect, and a reinforcing process is simple and feasible; the reinforced refrigeration device is higher in wear resistance performance, and the service life of the refrigeration device is prolonged.

Owner:博维恩冷冻科技(苏州)有限公司

Long-acting water-based antirust agent and preparation method thereof

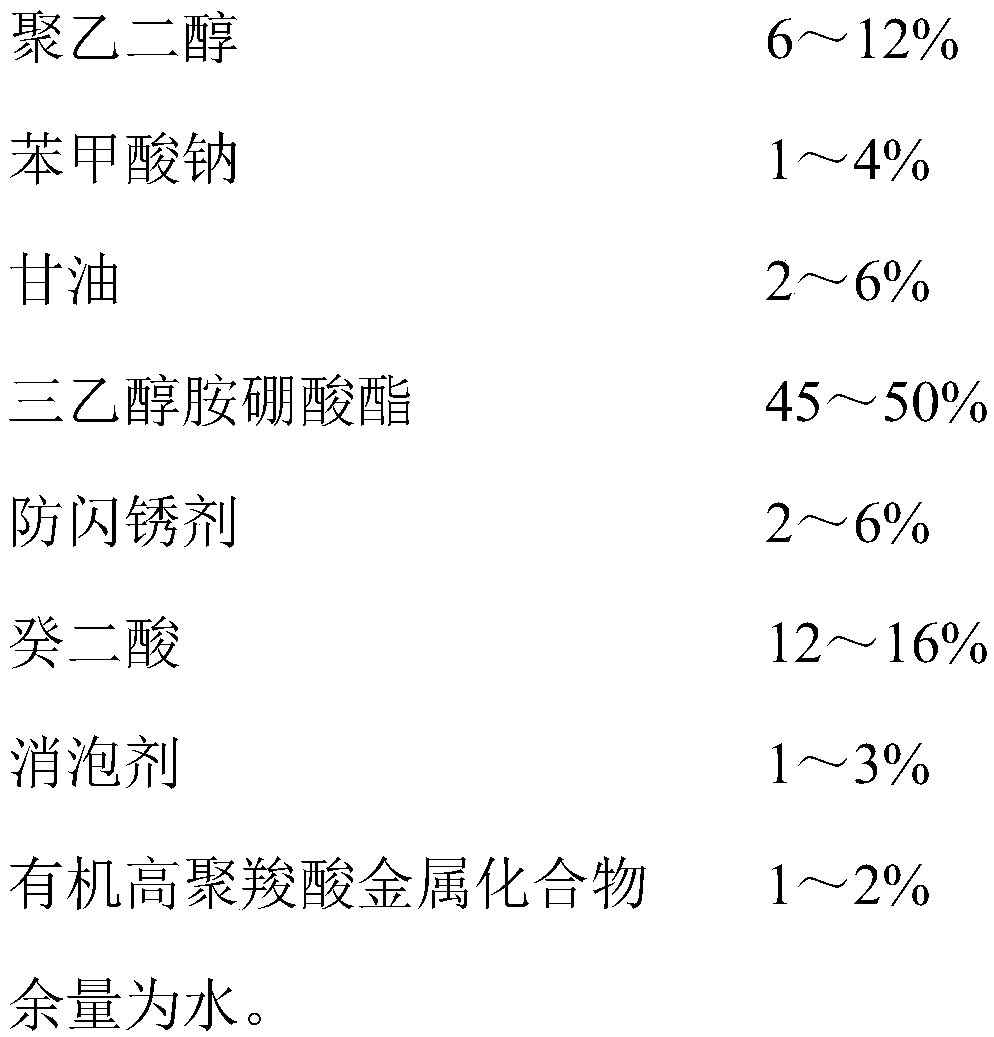

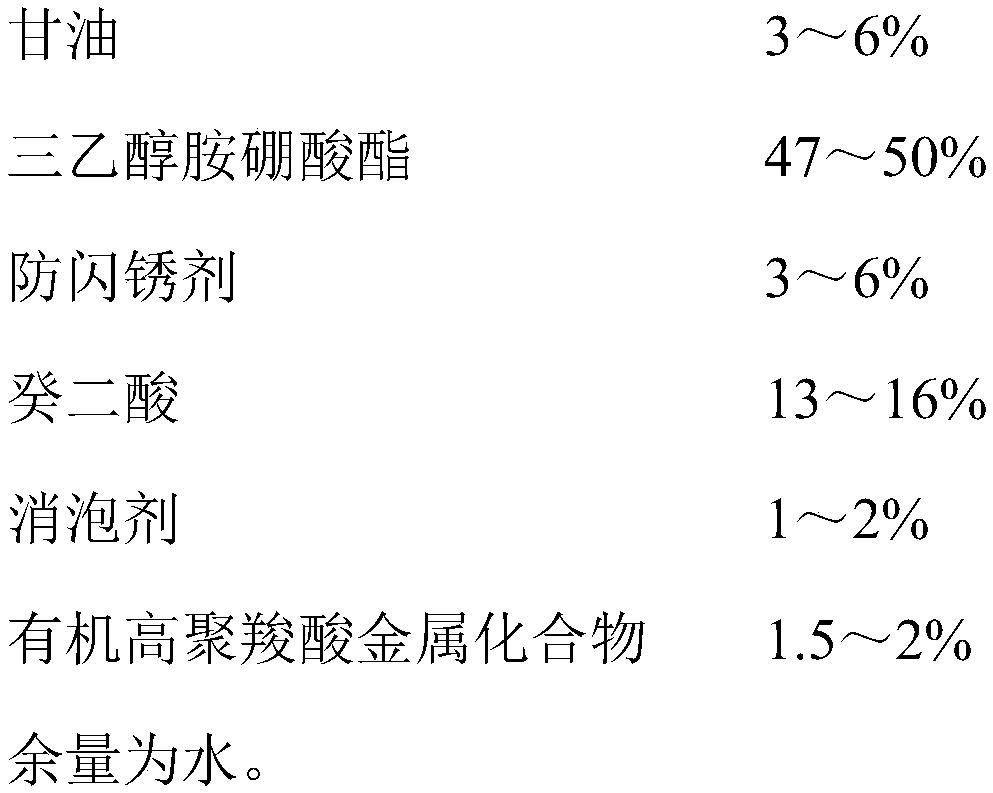

The invention provides a long-acting water-based antirust agent, and aims to overcome the defects in the prior art. The long-acting water-based antirust agent comprises the following components of, byweight, 6-12% of polyethylene glycol, 1-4% of sodium benzoate, 2-6% of glycerol, 45-50% of triethanolamine borate, 2-6% of an anti-flash rust remover, 12-16% of sebacic acid, 1-3% of a defoaming agent, 1-2% of an organic high-polycarboxylate metal compound and the balance water. The water-based antirust agent can be widely applied to rust prevention during procedures of steel materials, cast iron, mechanical parts, alloy steel product assemblies and materials, and the advantages of being long in rust prevention period, convenient to clean, good in stability, not prone to decomposition at a high temperature and long in indoor storage period are achieved.

Owner:青岛亚东精细化学品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com