Thin-layer antirust oil and preparation method thereof

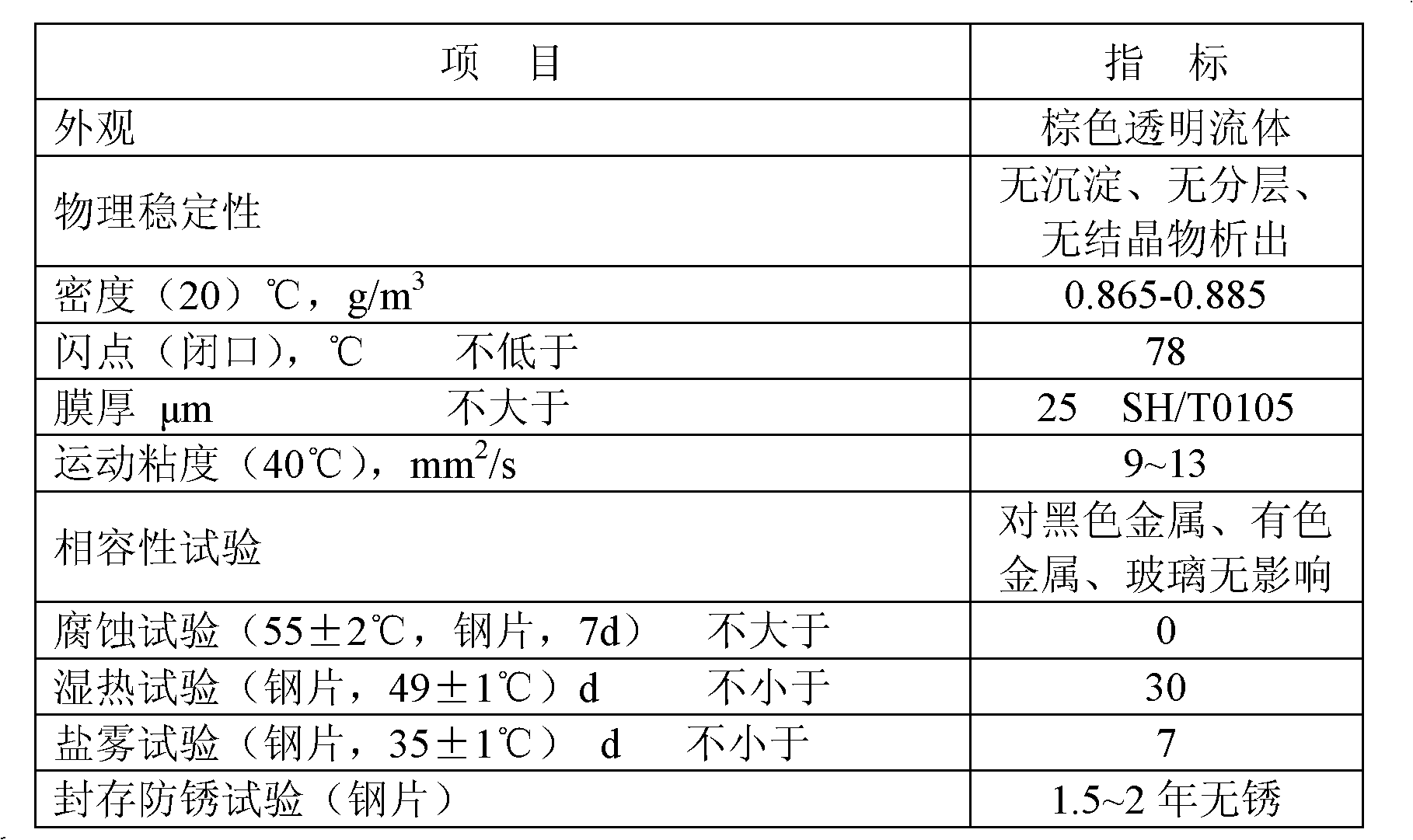

A rust-proof oil, thin-layer technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of unsatisfactory damp heat and salt spray test, short rust-proof period of rust-proof oil, easy to stick to hands, etc. The effects of damp heat and salt spray resistance, simple production process and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Based on light refined oils. In the production process, first add 66.37kg of light refined oil into the reaction kettle and stir; then add 10kg of anti-rust compound agent 1, 10kg of anti-rust compound agent 2, 12kg of anti-rust compound agent 3 and continue stirring for 25-35 minutes; Add 0.08 kg of stearic acid, 0.5 kg of anti-oxidant compound agent and 0.05 kg of anti-rust compound agent 4 in sequence, and continue stirring for 25-35 minutes; finally add 1 kg of surfactant and continue stirring for 80-120 minutes to obtain a thin layer of anti-rust oil.

Embodiment 2

[0031] Based on light refined oils. In the production process, first add 65kg of light refined oil into the reaction kettle and stir; then add 9.5kg of anti-rust compound agent 1, 11kg of anti-rust compound agent 2, and 13kg of anti-rust compound agent 3 and continue stirring for 25-35 minutes; Add 0.06kg of stearic acid, 0.6kg of anti-oxidant compound agent and 0.04kg of anti-rust compound agent 4 in sequence, and continue to stir for 25-35 minutes; finally add 0.8kg of surfactant and continue to stir for 80-120 minutes to obtain a thin layer of anti-rust oil.

Embodiment 3

[0033] Based on light refined oils. In the production process, first add 67kg of light refined oil into the reaction kettle and stir; then add 11kg of anti-rust compound agent 1, 9kg of anti-rust compound agent 2, 11.2kg of anti-rust compound agent 3 and continue stirring for 25-35 minutes; Add 0.1 kg of stearic acid, 0.42 kg of anti-oxidant compound and 0.08 kg of anti-rust compound 4 in sequence, and continue to stir for 25-35 minutes; finally add 1.2 kg of surfactant and continue to stir for 80-120 minutes to obtain a thin layer of anti-rust oil.

[0034] In the embodiment of the present invention, the light refined oil is No. 5 white oil, which is a commercially available product and purchased from Ningbo Zhenhai Oil Refinery. The surfactant is Span-80. The antirust composite agent 1 is a mixture of barium petroleum sulfonate and No. 5 machine oil, wherein the barium petroleum sulfonate accounts for 40% of the total weight of the mixture, and No. 5 machine oil accounts fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com