Chromium-free rare-earth environment-friendly chemical conversion treatment method of die casting aluminium alloy part

A technology of chemical conversion treatment and casting aluminum alloy, which is applied in the direction of metal material coating process, etc., can solve the problems of poor corrosion resistance and anticorrosion effect not as good as profile aluminum alloy, and achieve the effect of improving salt spray resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

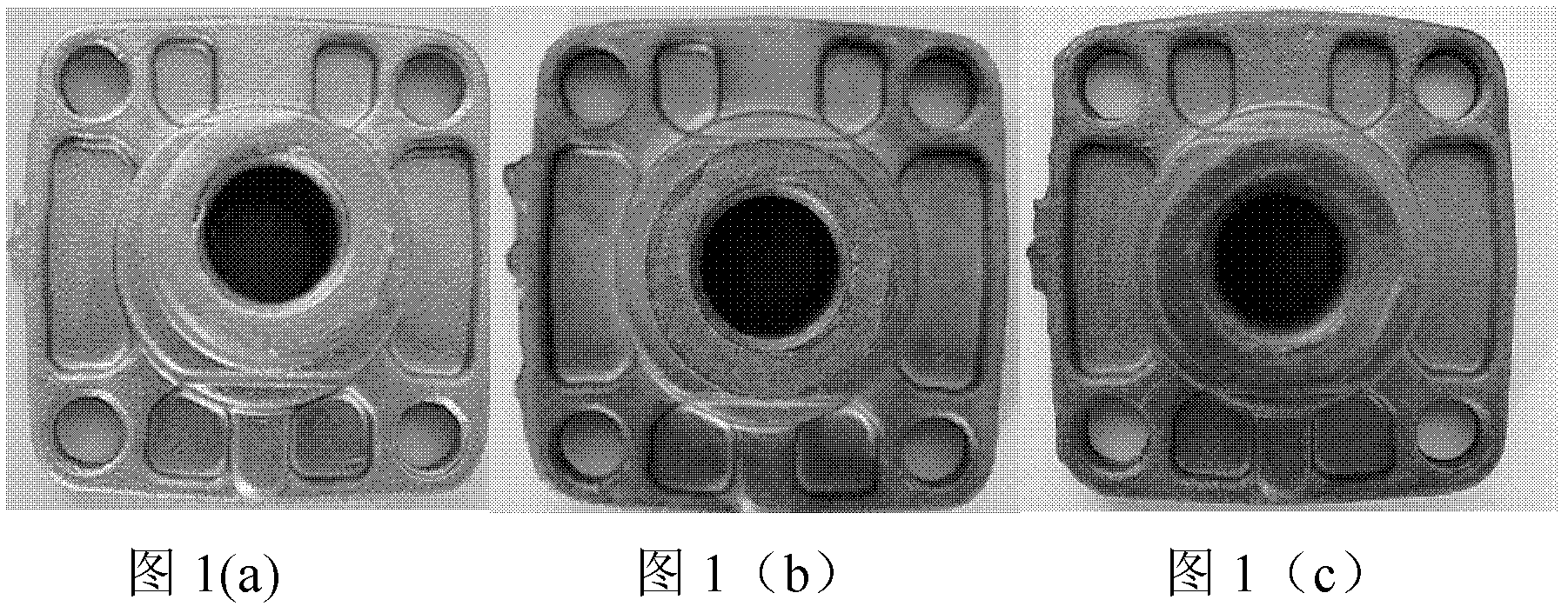

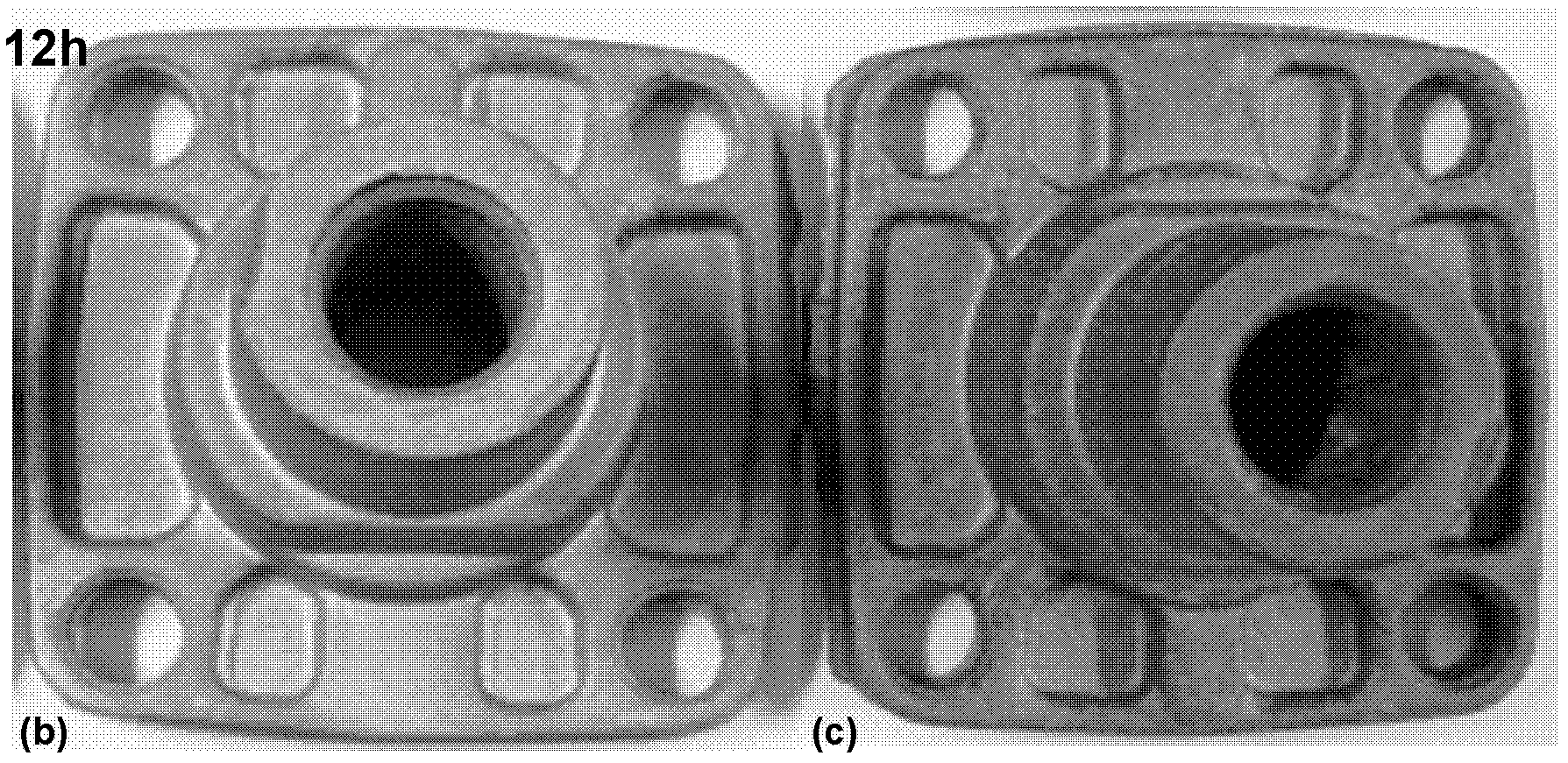

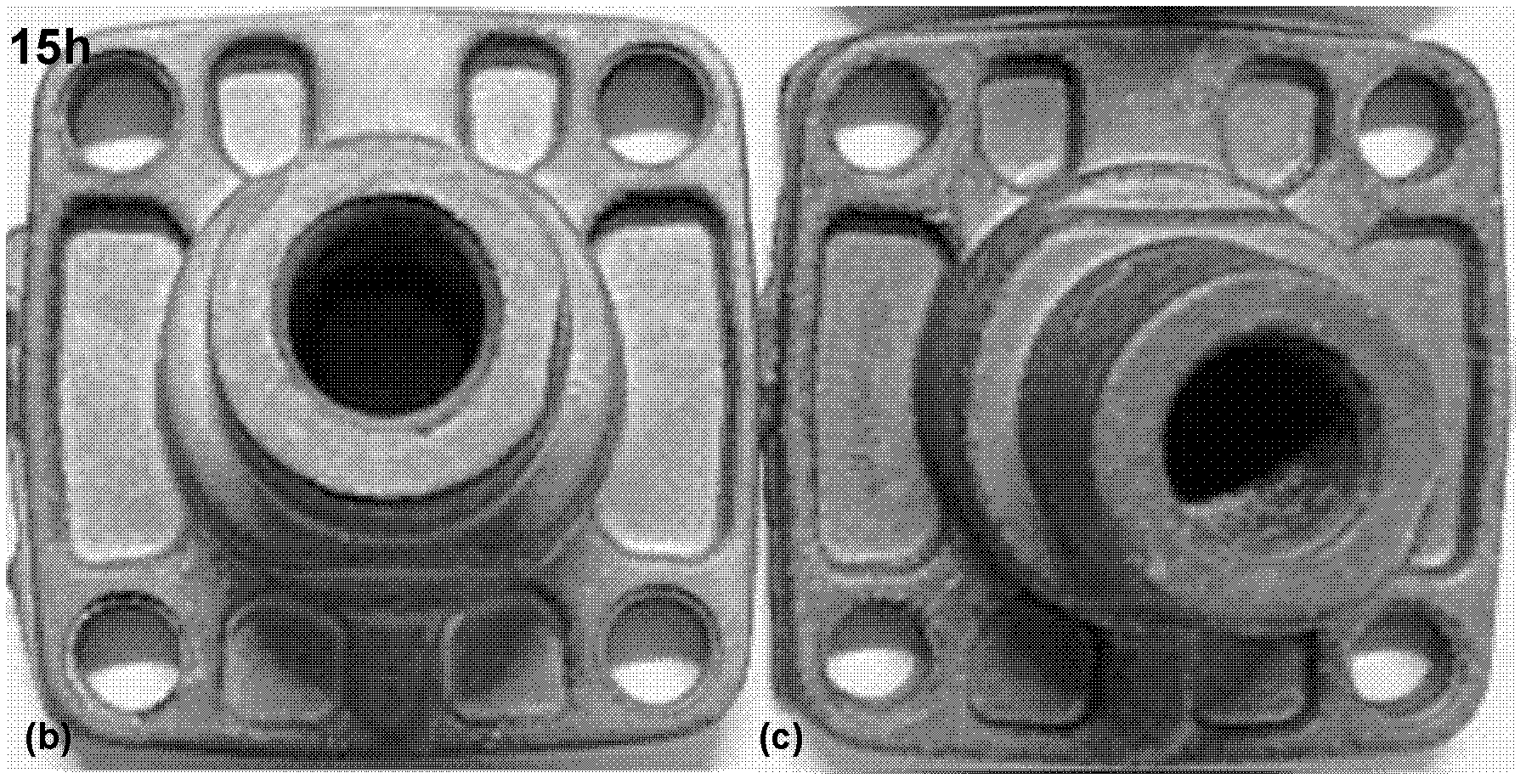

Image

Examples

Embodiment 1

[0033] Configure chemical conversion solution component A: cerium nitrate 10g / L, surfactant stearic acid 2g / L, activator potassium fluoride 4g / L; component B: potassium permanganate 5g / L, phosphoric acid 4g / L; When in use, prepare the two-component solutions of A and B at a volume ratio of 1:1, soak the pretreated die-casting aluminum alloy parts in the chemical conversion solution, convert them at 80°C for 6 minutes, and then deionized water Clean the parts, place them in deionized water at 90°C for 10 minutes, and finally dry them. The neutral salt spray resistance time of the chemical conversion coating obtained by testing the die-casting aluminum alloy parts is 2 hours.

Embodiment 2

[0035] Configuration chemical conversion solution component A: cerium nitrate 10g / L, surfactant lauric acid 2g / L, activator sodium fluoride 4g / L; component B: hydrogen peroxide 5g / L, tannic acid 4g / L; , the two-component solution of A and B is prepared at a volume ratio of 1:1, and the pretreated die-casting aluminum alloy parts are soaked in the chemical conversion solution, converted at 80 ° C for 6 minutes, and then cleaned with deionized water. The parts were sealed in deionized water at 90°C for 10 minutes, and finally dried. The neutral salt spray resistance time of the chemical conversion coating obtained by testing the die-casting aluminum alloy parts is 5 hours.

Embodiment 3

[0037] Configuration chemical conversion solution component A: cerium chloride 10g / L, surfactant sodium dodecylbenzenesulfonate 2g / L, activator potassium fluoride 2g / L; component B: potassium chlorate 1g / L, chloride Strontium 1g / L; when in use, prepare A and B two-component solutions with a volume ratio of 1:1, soak the pretreated die-casting aluminum alloy parts in the chemical conversion solution, and convert them at 60°C for 5 minutes , and then wash the parts with deionized water, put them in deionized water at 90°C for 5 minutes, and finally dry them. The neutral salt spray resistance time of the chemical conversion coating obtained by testing the die-casting aluminum alloy parts is 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com